Patents

Literature

223results about "Fire-tube steam boilers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

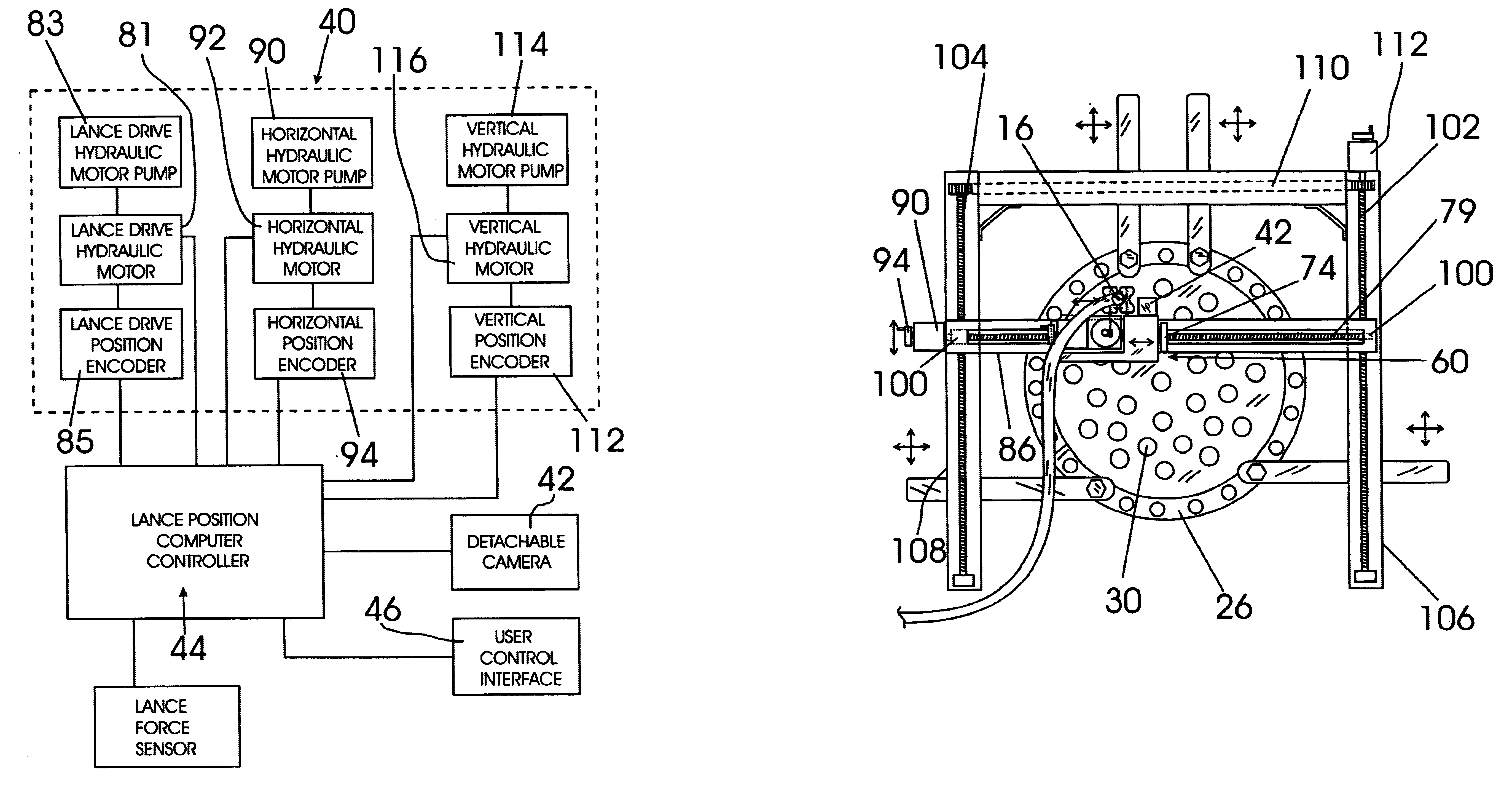

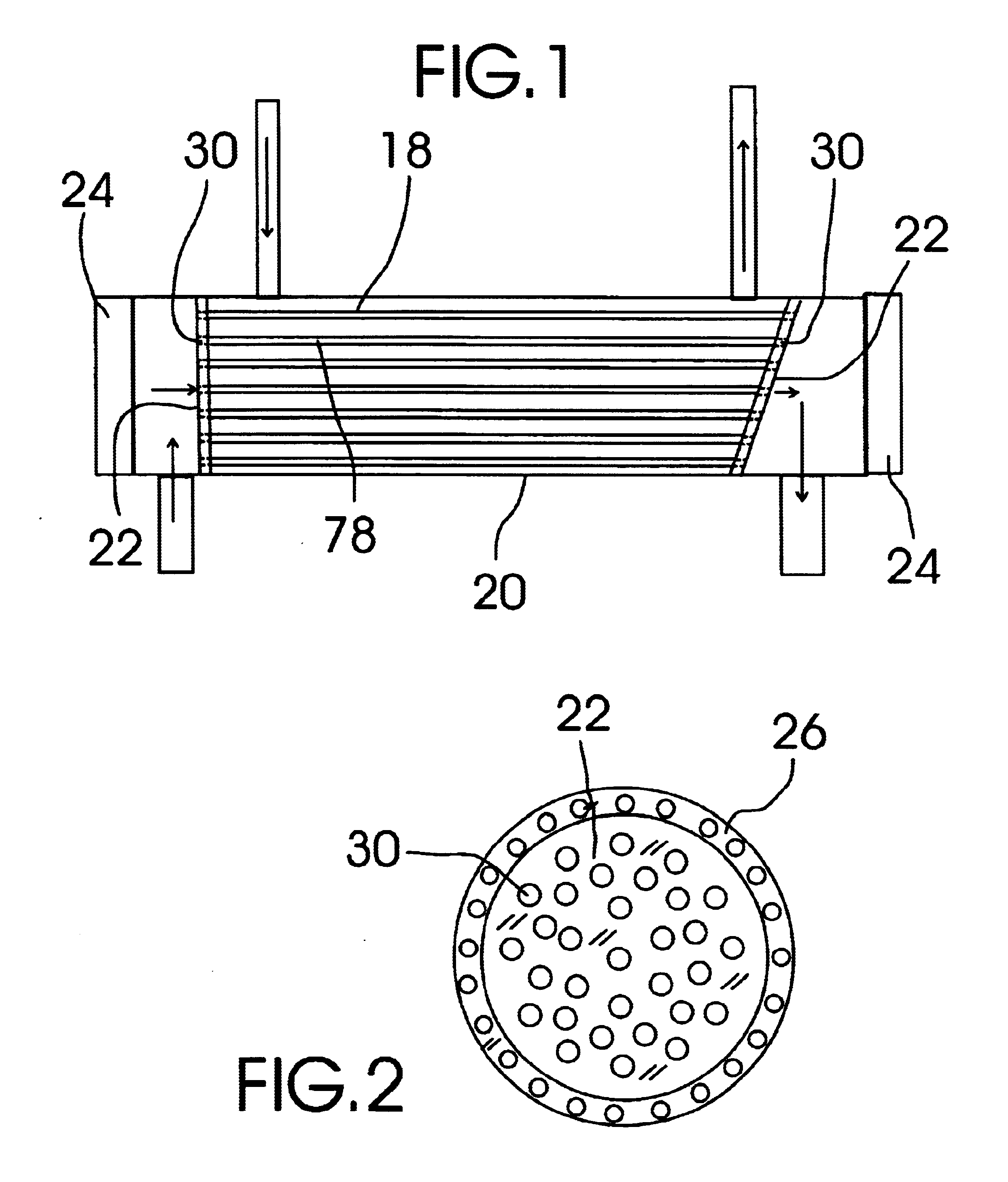

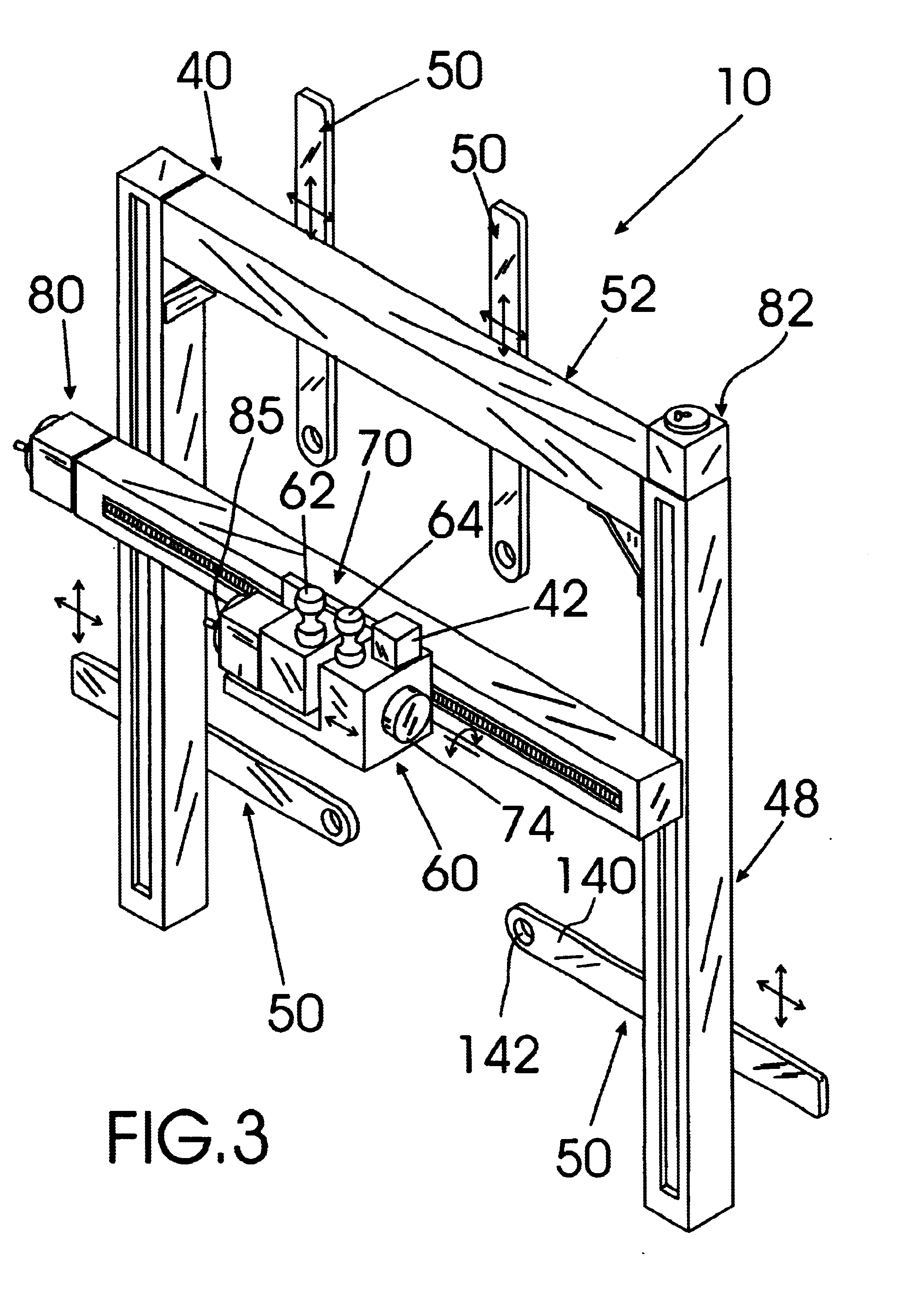

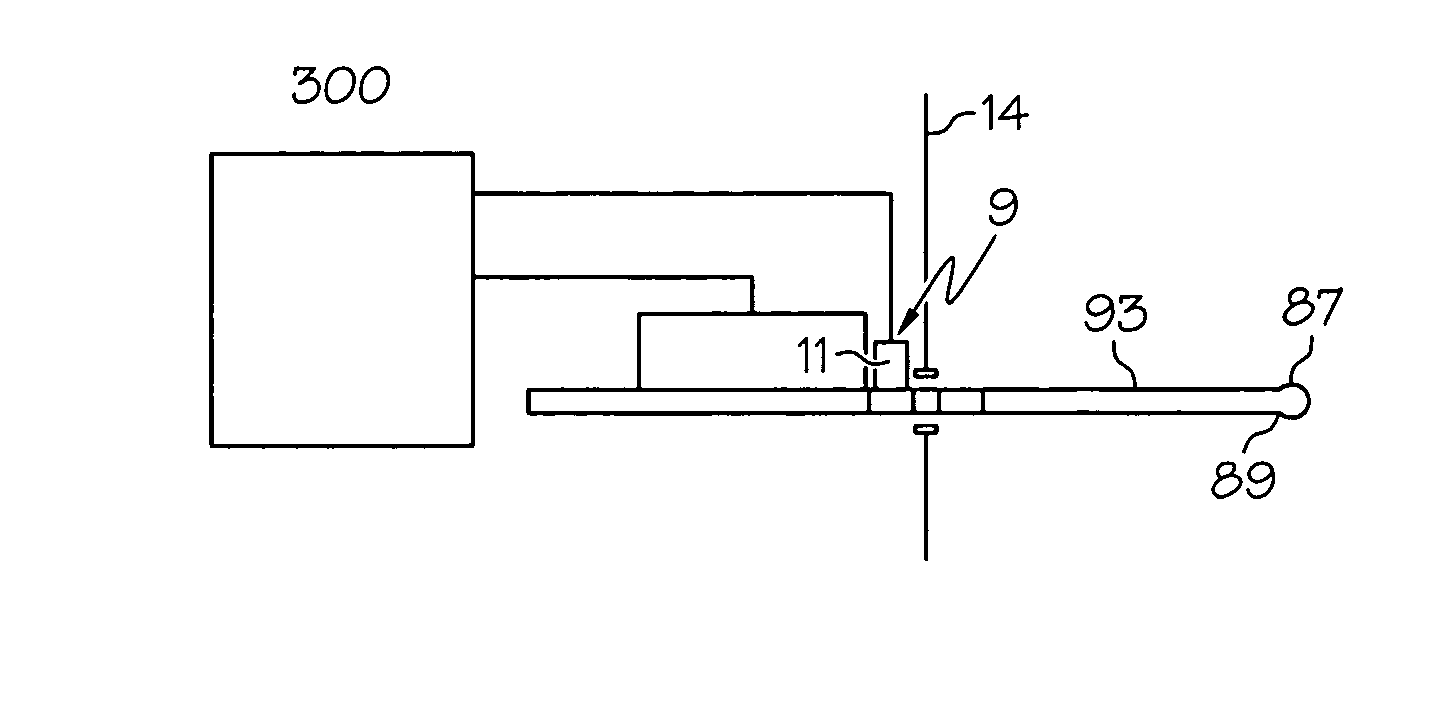

Heat exchanger exchange-tube cleaning lance positioning system

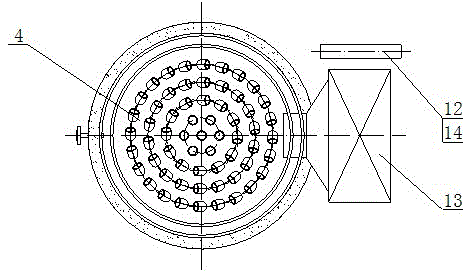

A heat exchanger exchange-tube cleaning lance positioning system that includes a three axis cleaning lance positioning mechanism that is attachable to the end of a heat exchanger and that is controlled by a lance position computer controller that determines the locations of each of the openings of the exchange-tubes of the heat exchanger by analyzing an image signal generated by a camera mounted to the three axis cleaning lance positioning mechanism and then positions a connected exchange tube cleaning lance into and through each of the exchange-tube passageways to clean the exchange-tube passageways automatically.

Owner:BALZER BRENT A

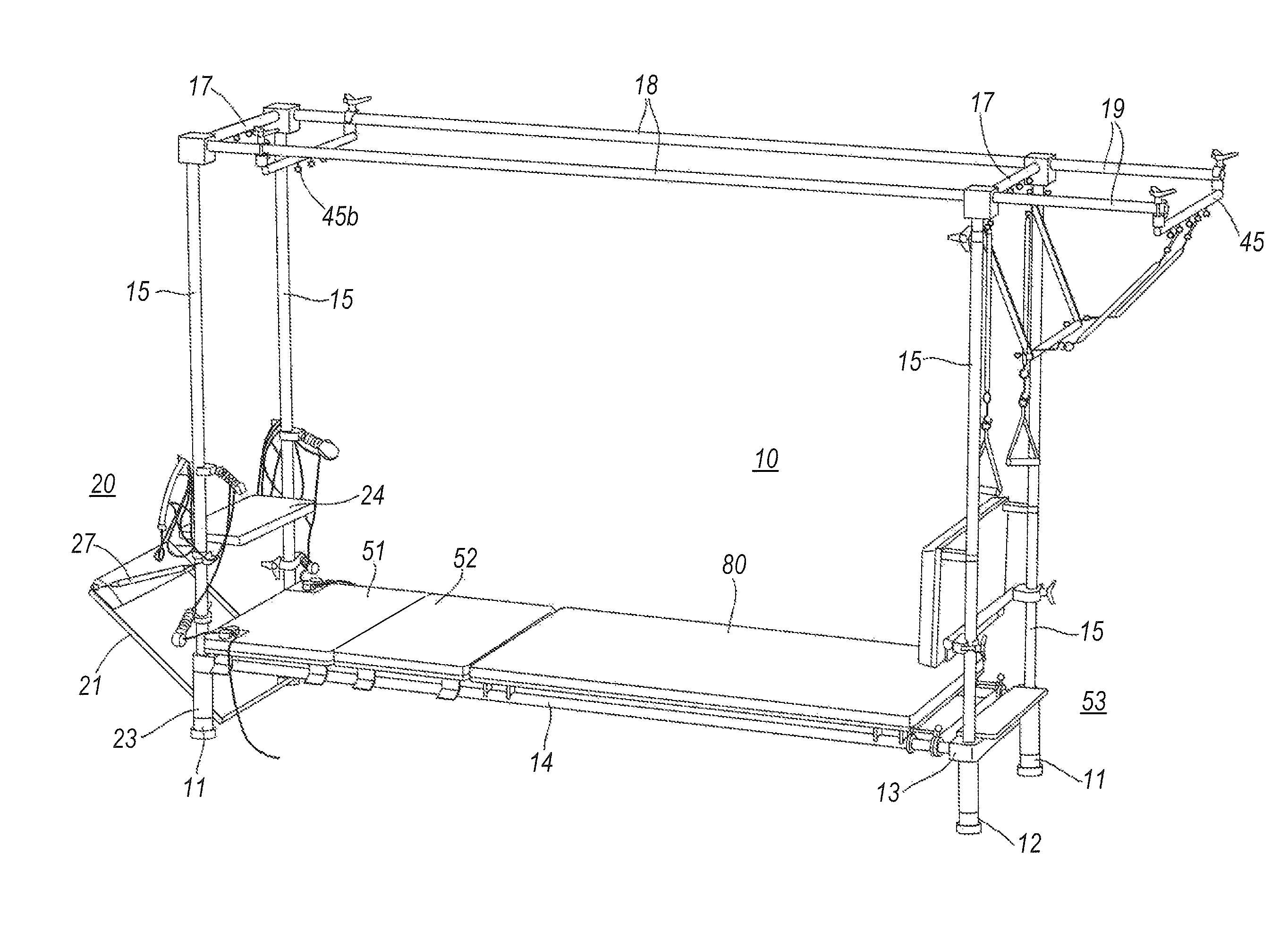

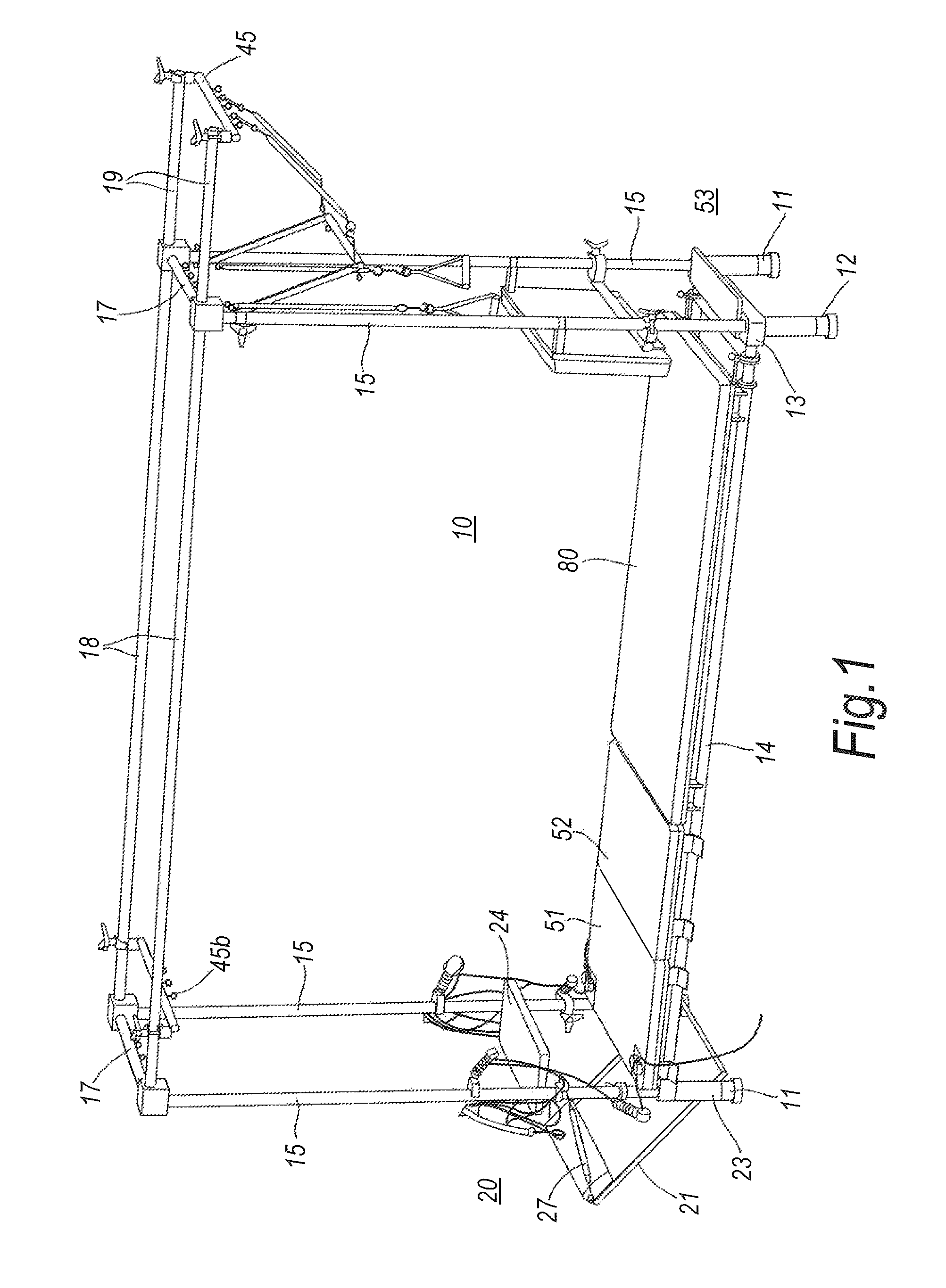

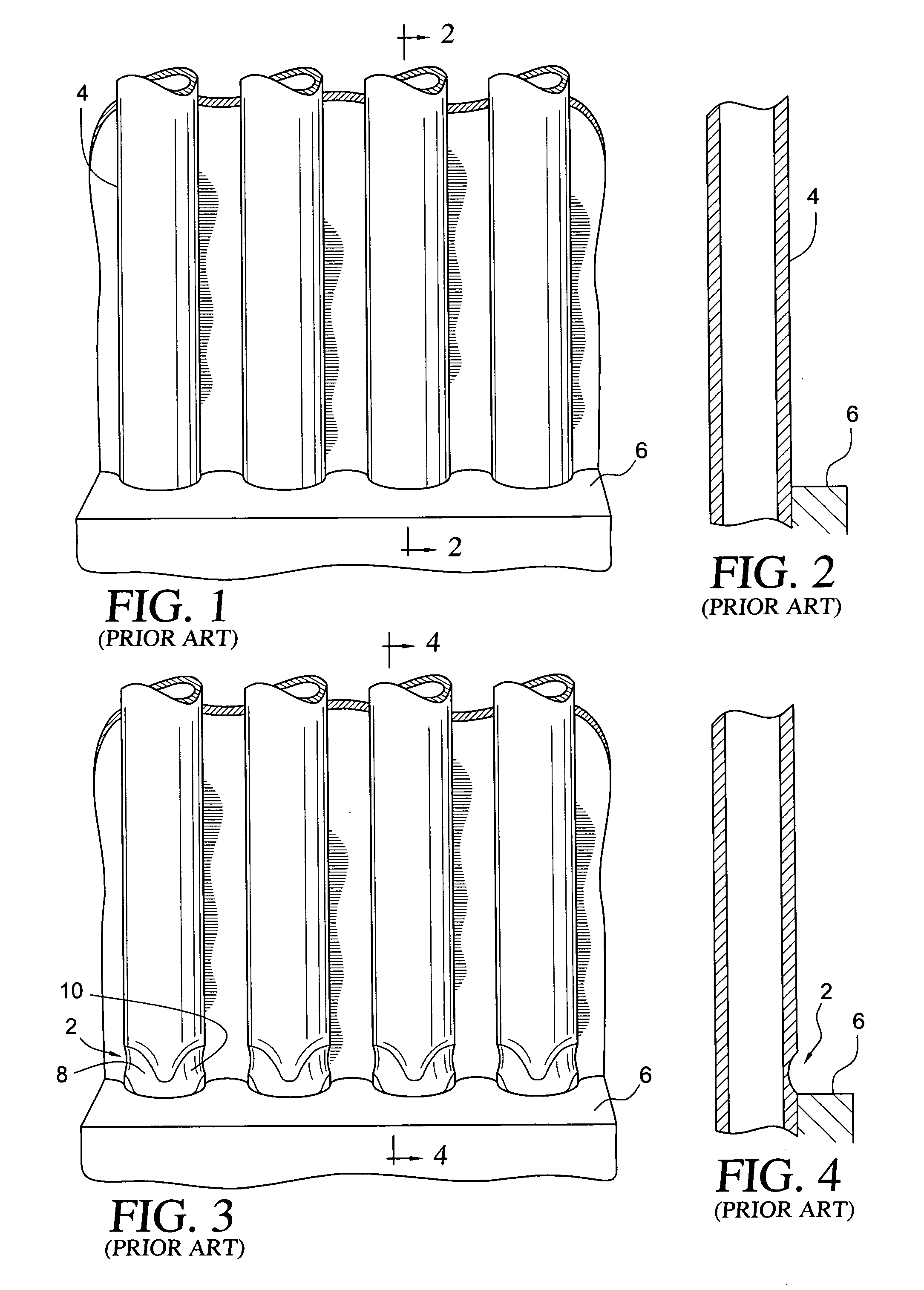

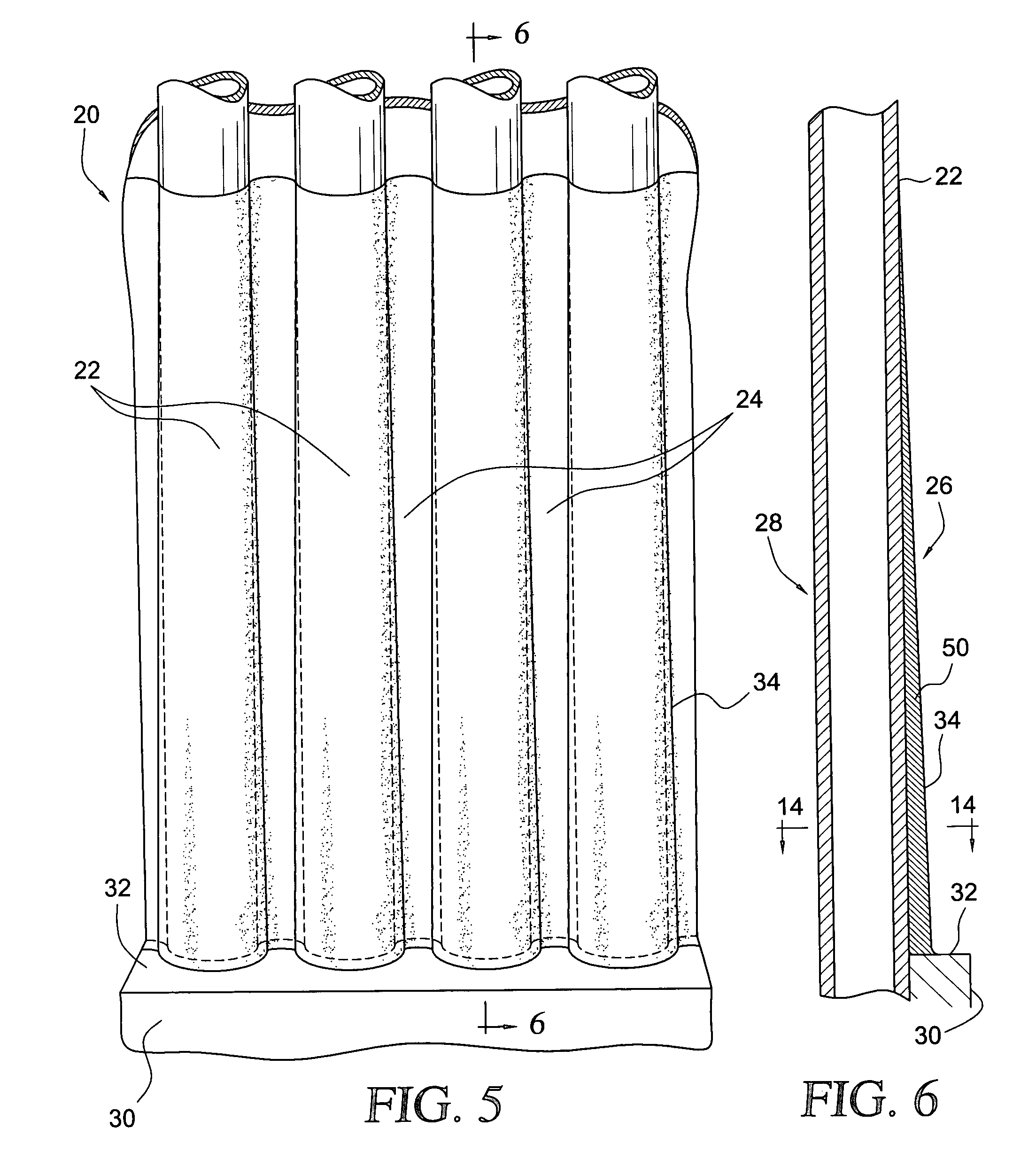

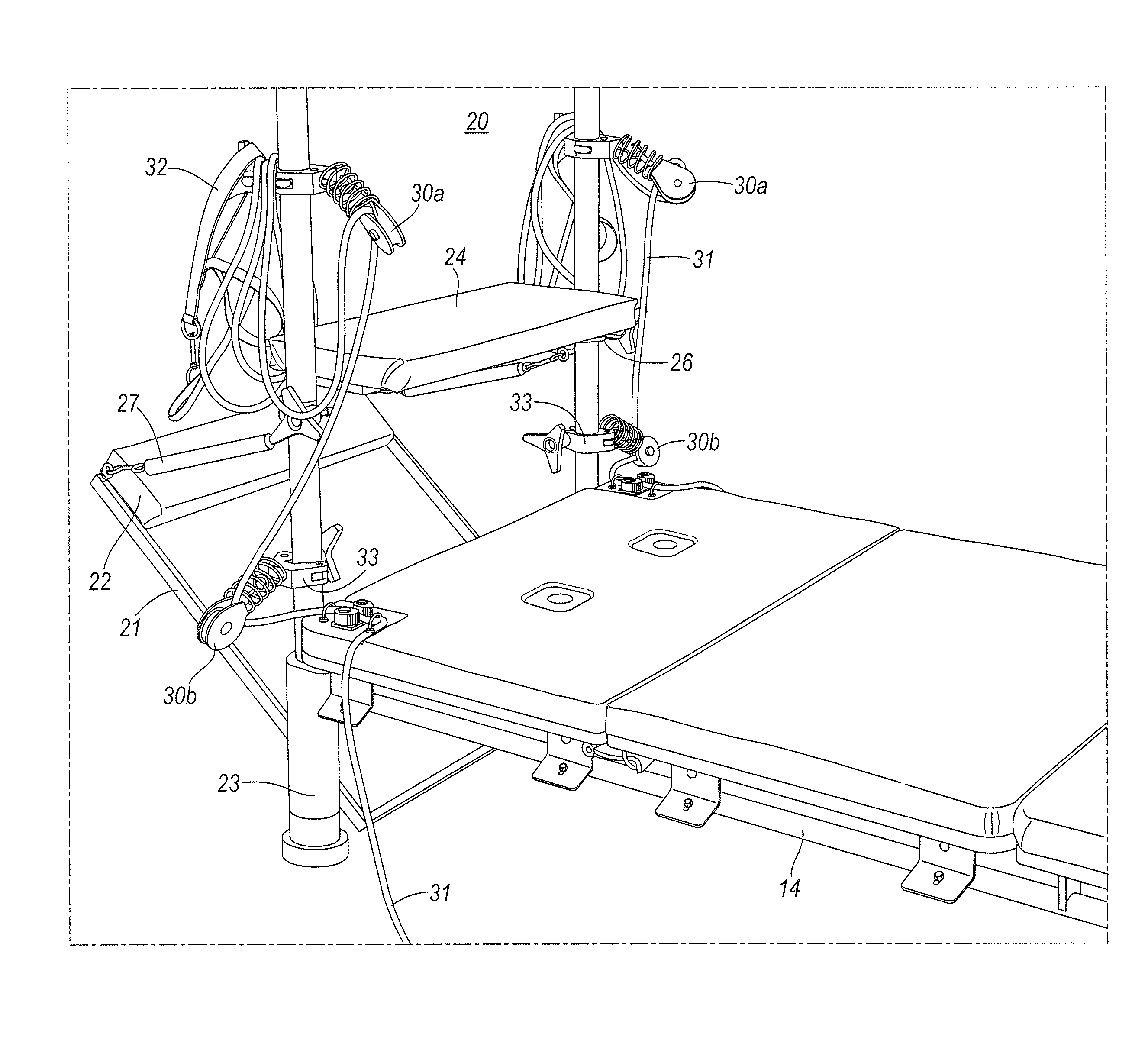

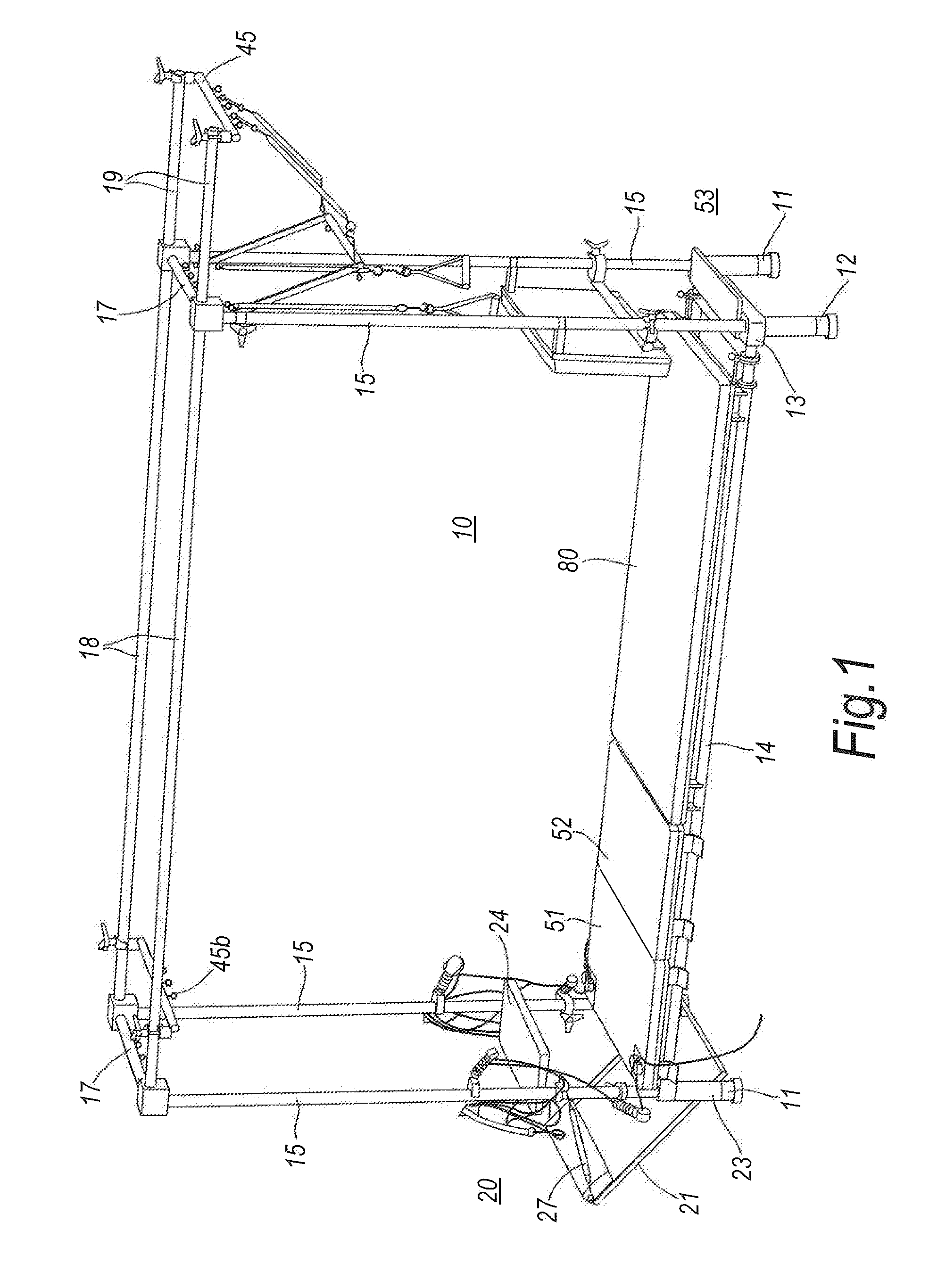

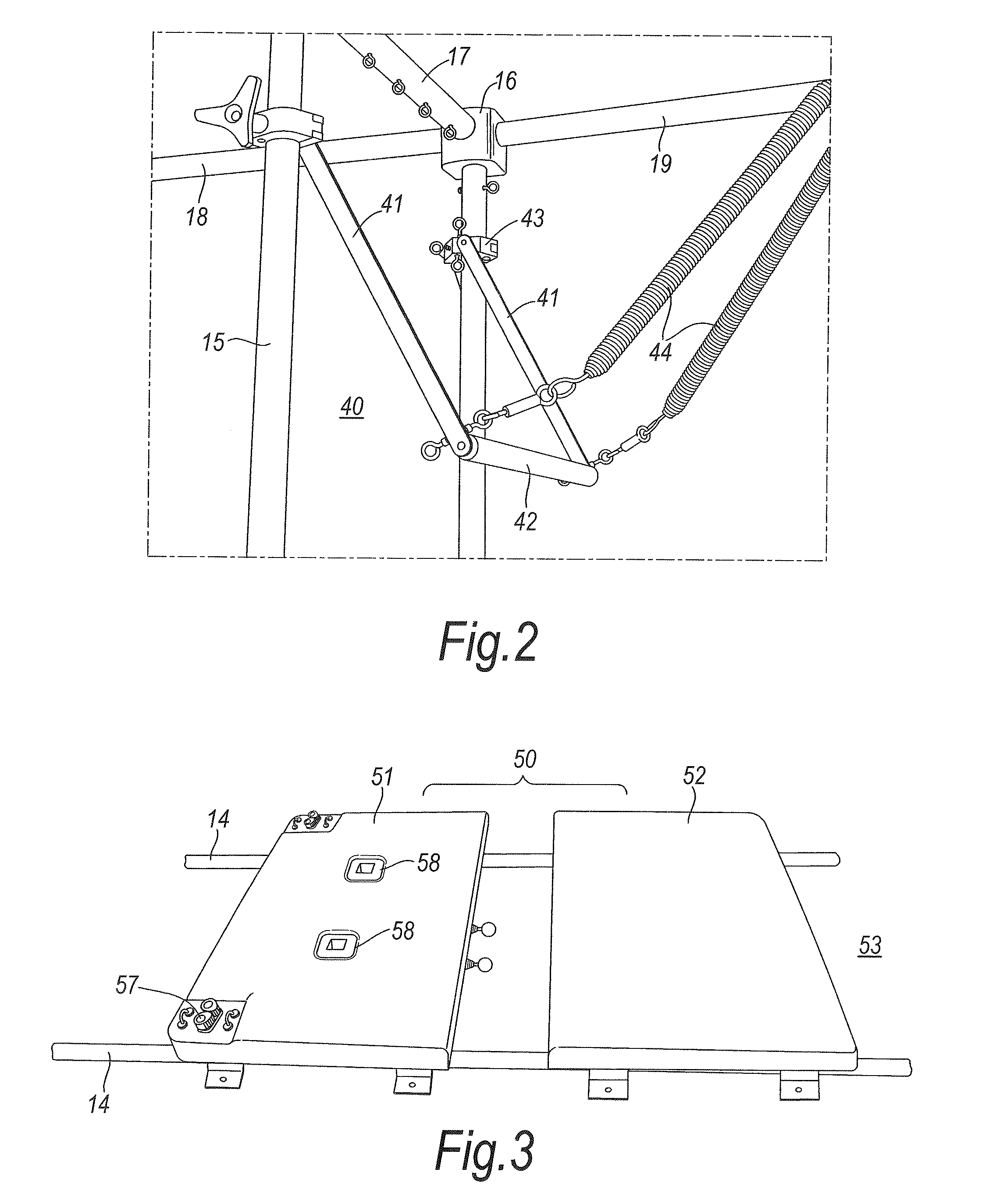

Exercise apparatus

ActiveUS7967736B2Reduce impactPrecise positioningResilient force resistorsFurnace-tube steam boilersEngineeringPhysical exercise

Apparatus suitable for pilates and other exercise comprises rails, supported on a box-like frame and an exercise carriage, mounted on the rails, wherein the carriage comprises a first carriage section and a second carriage section which sections can be (i) connected together to form a single exercise carriage which slides forwards and backwards on the rails, or (ii) disconnected to form two exercise carriages which independently slide forwards and backwards on the rails. The apparatus also has a seat with a spring-biased foot pedal and a spring-biased trapeze bar.

Owner:DSILVA LTD

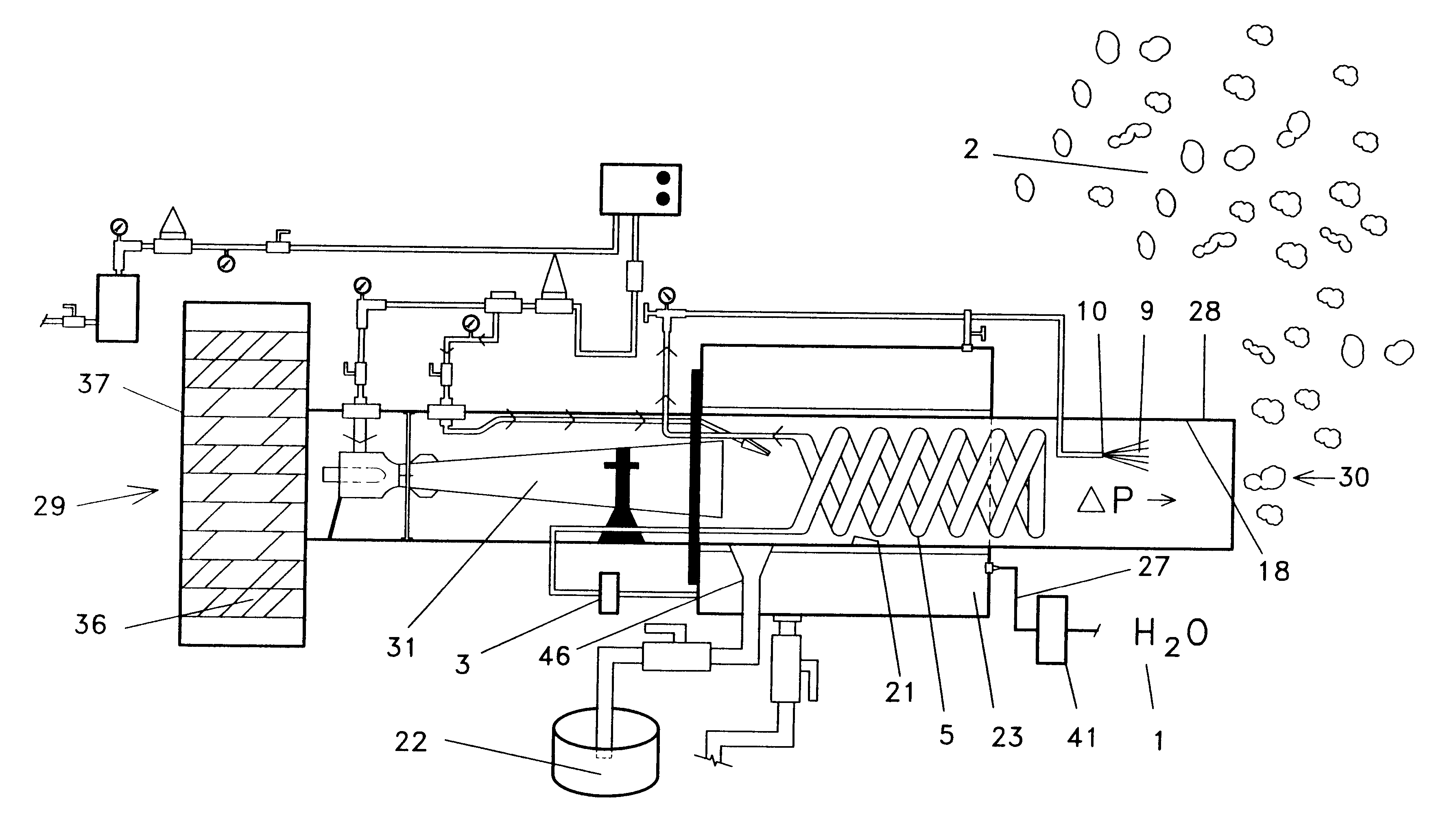

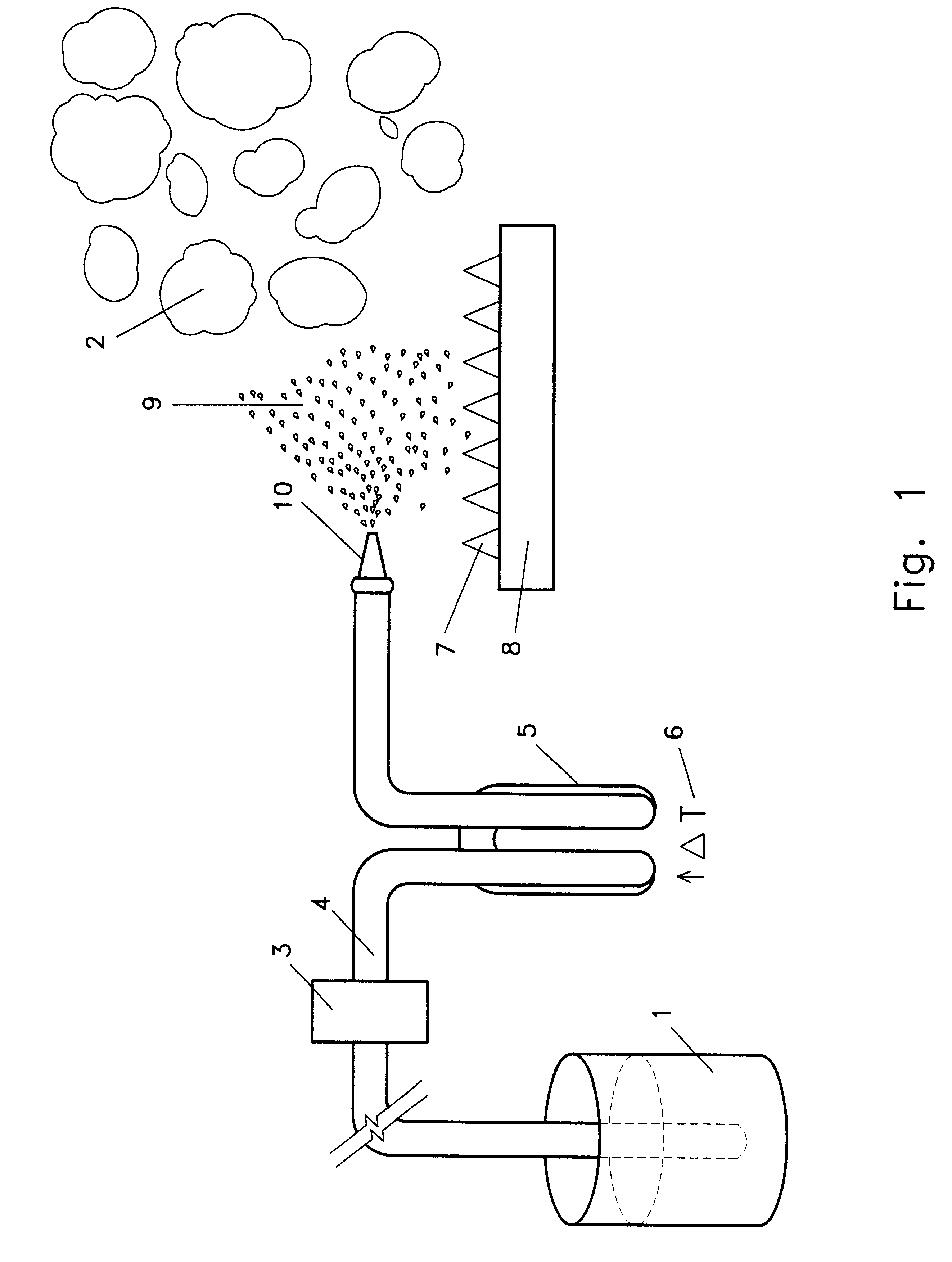

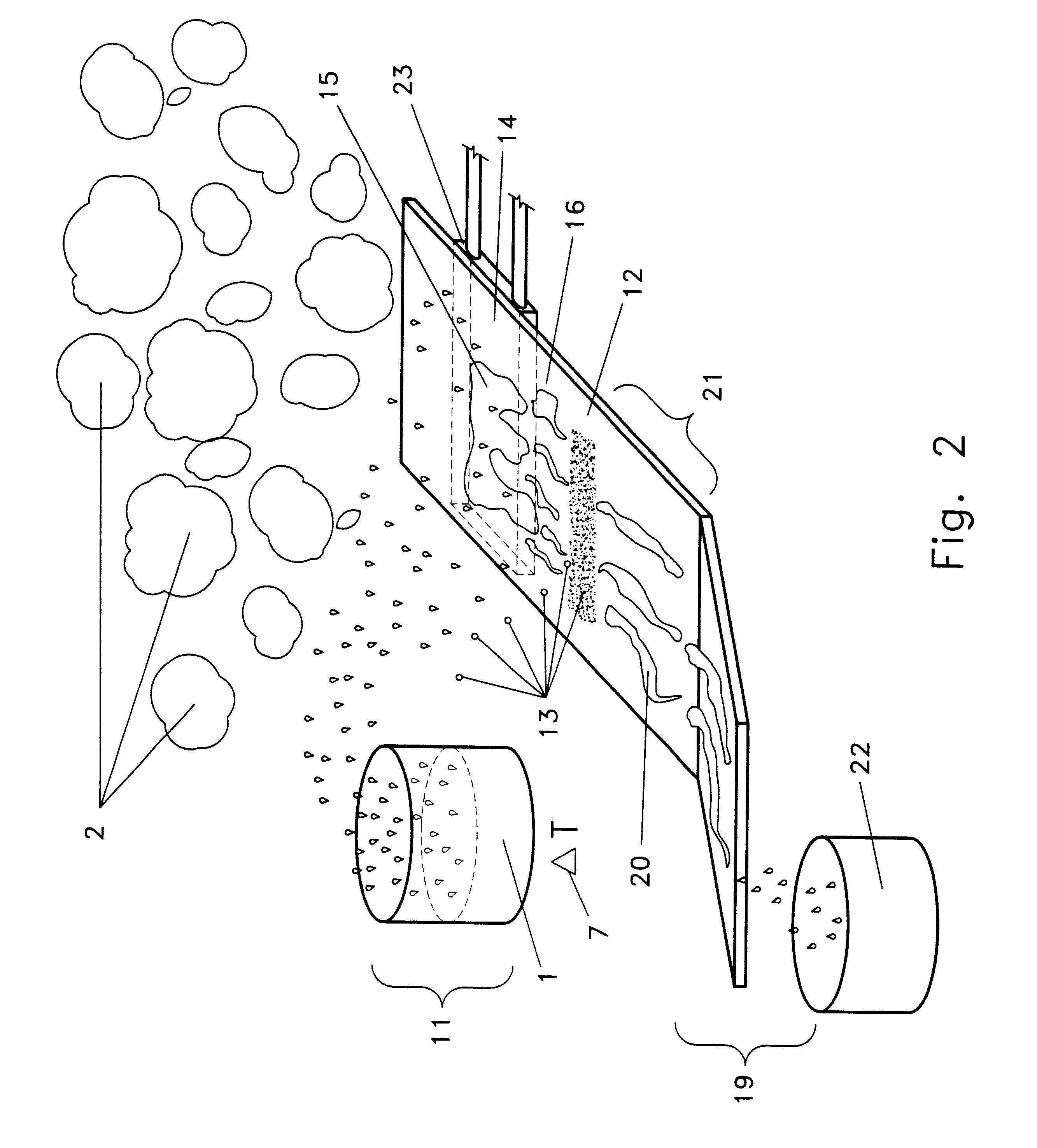

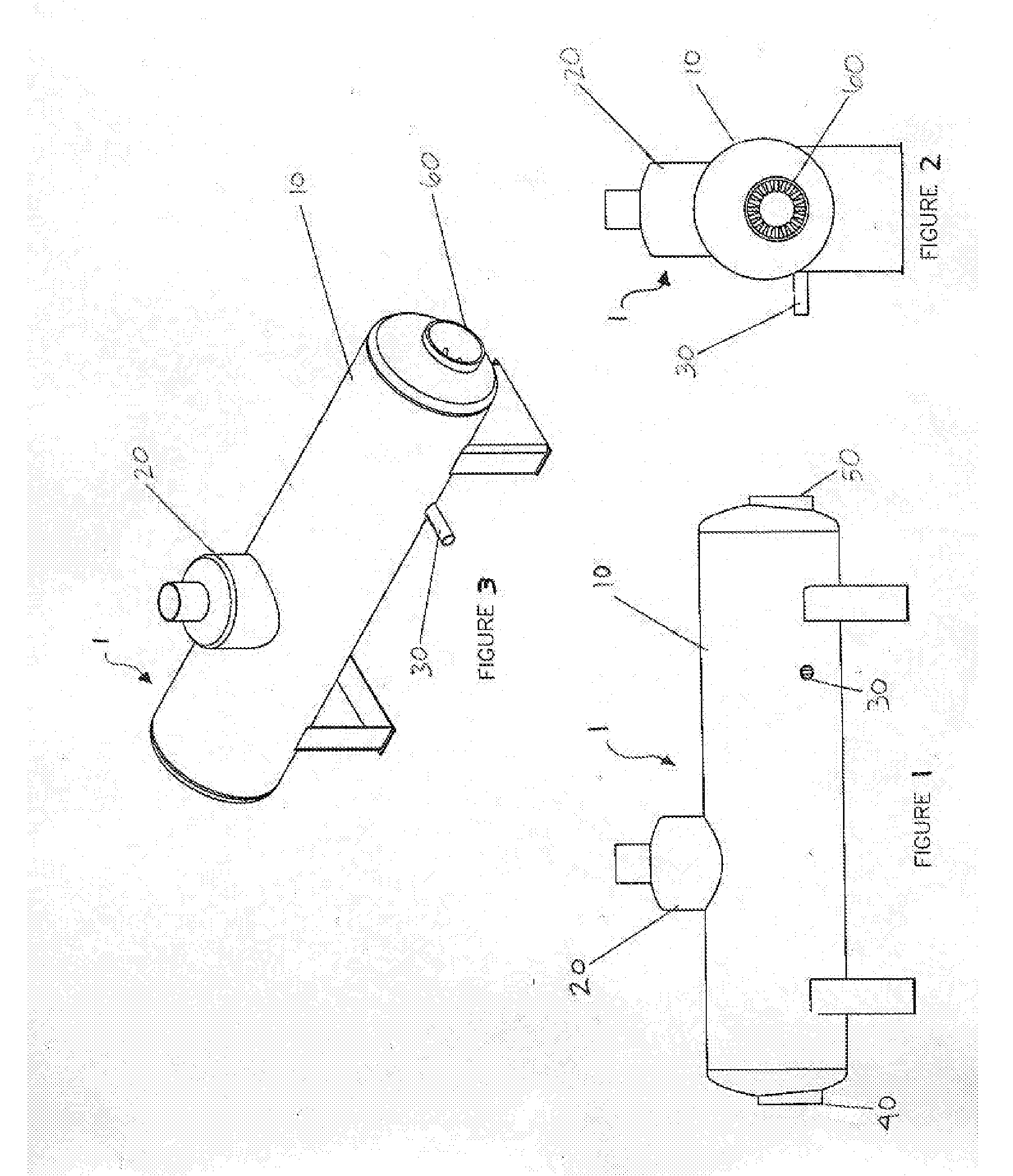

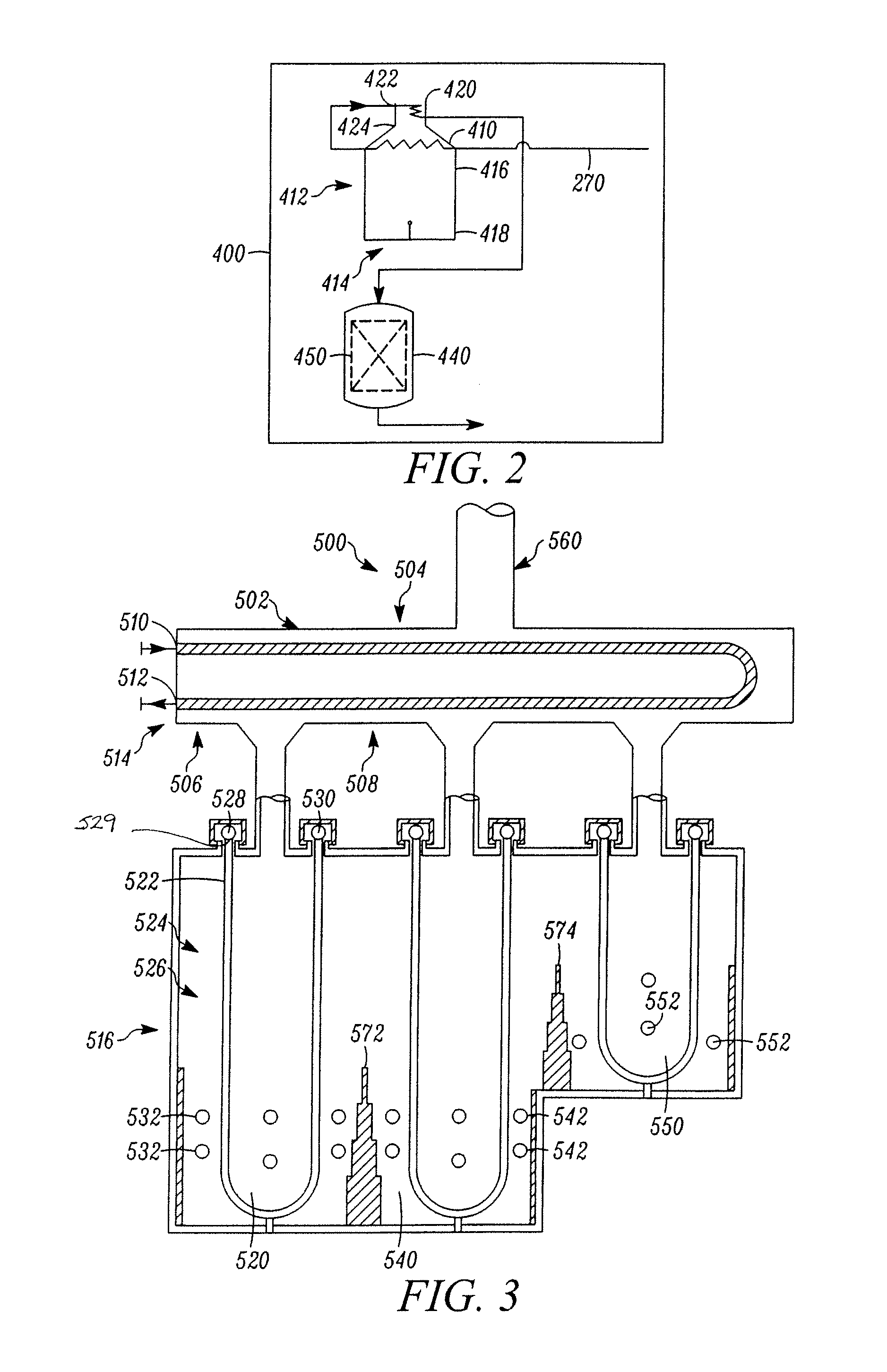

Accelerated water evaporation system

InactiveUS6637379B2Lower the volumeCost effectiveCombustion enginesFlash steam boilersGas to liquidsEvaporation

A liquid to gas converter to convert liquids (1) to gas (2) that can include a liquid pressurization element (3), a liquid preheating element (5), and a nozzle (10) to disperse liquids into energy (7) generated by an energy source (8). The gas to liquid converter can be located inside an enclosure (17) and substances dissolved in the liquid can accumulate as solids (13) on deposition surface (12) of the enclosure as the liquid (1) converts to gas Cis (2). Condensation of a portion of the gas (2) generated can be combined with the solids (13) for continuous removal of such solids (13) from the enclosure (17). A gas expansion compensator can generate a pressure gradient (24) to move the volume of gas generated from the liquid from the enclosure (17).

Owner:RESOURCE WEST

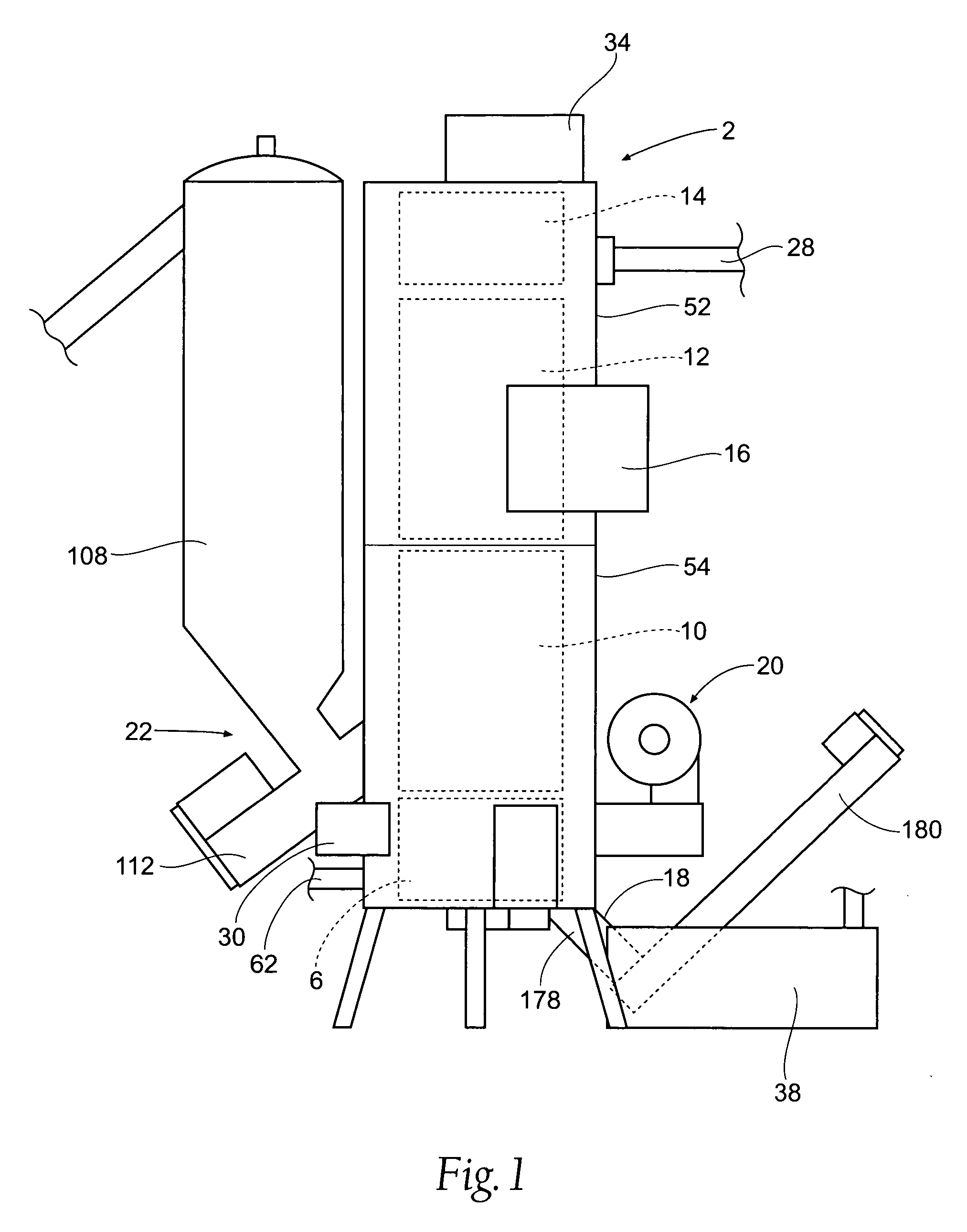

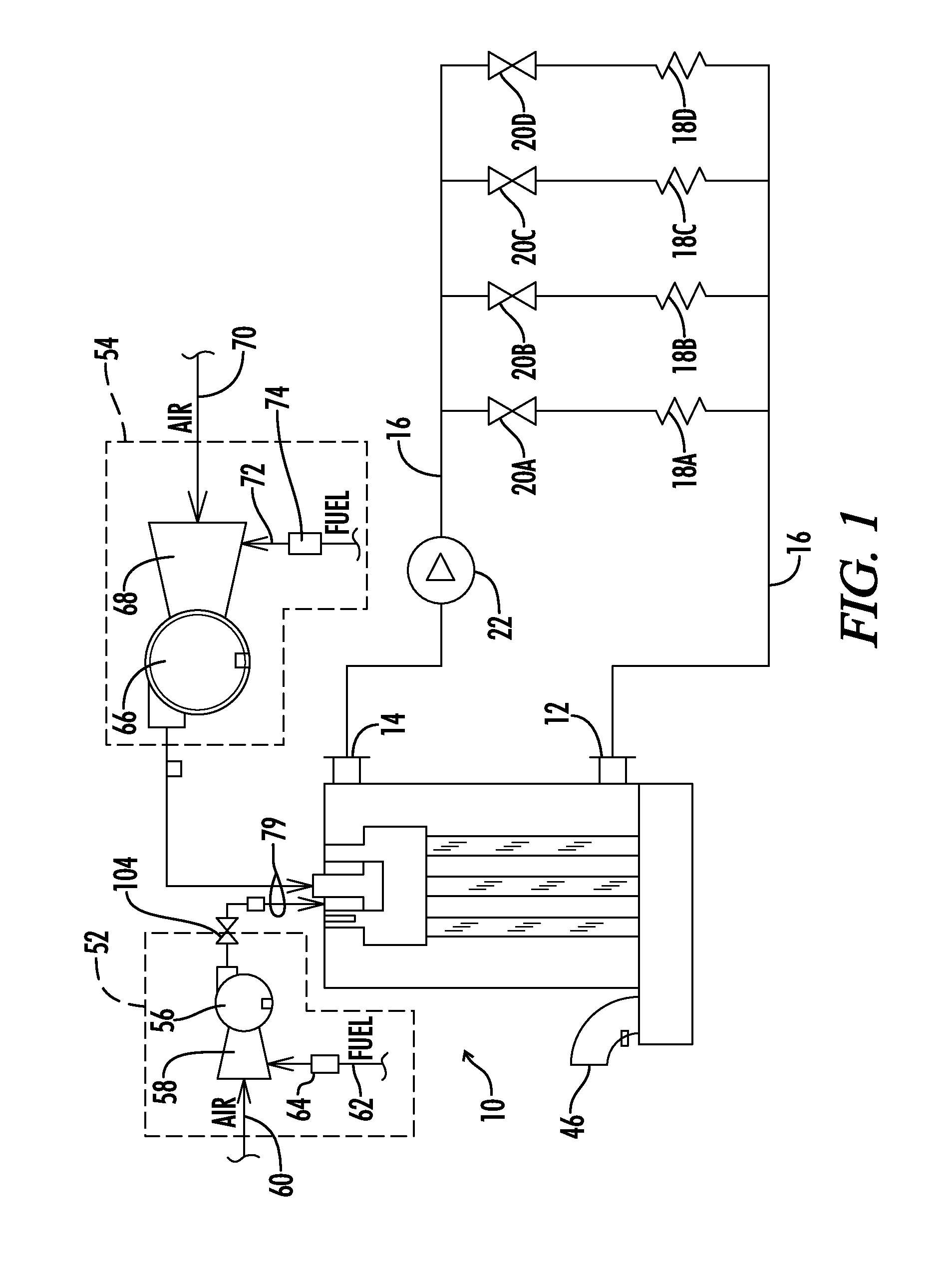

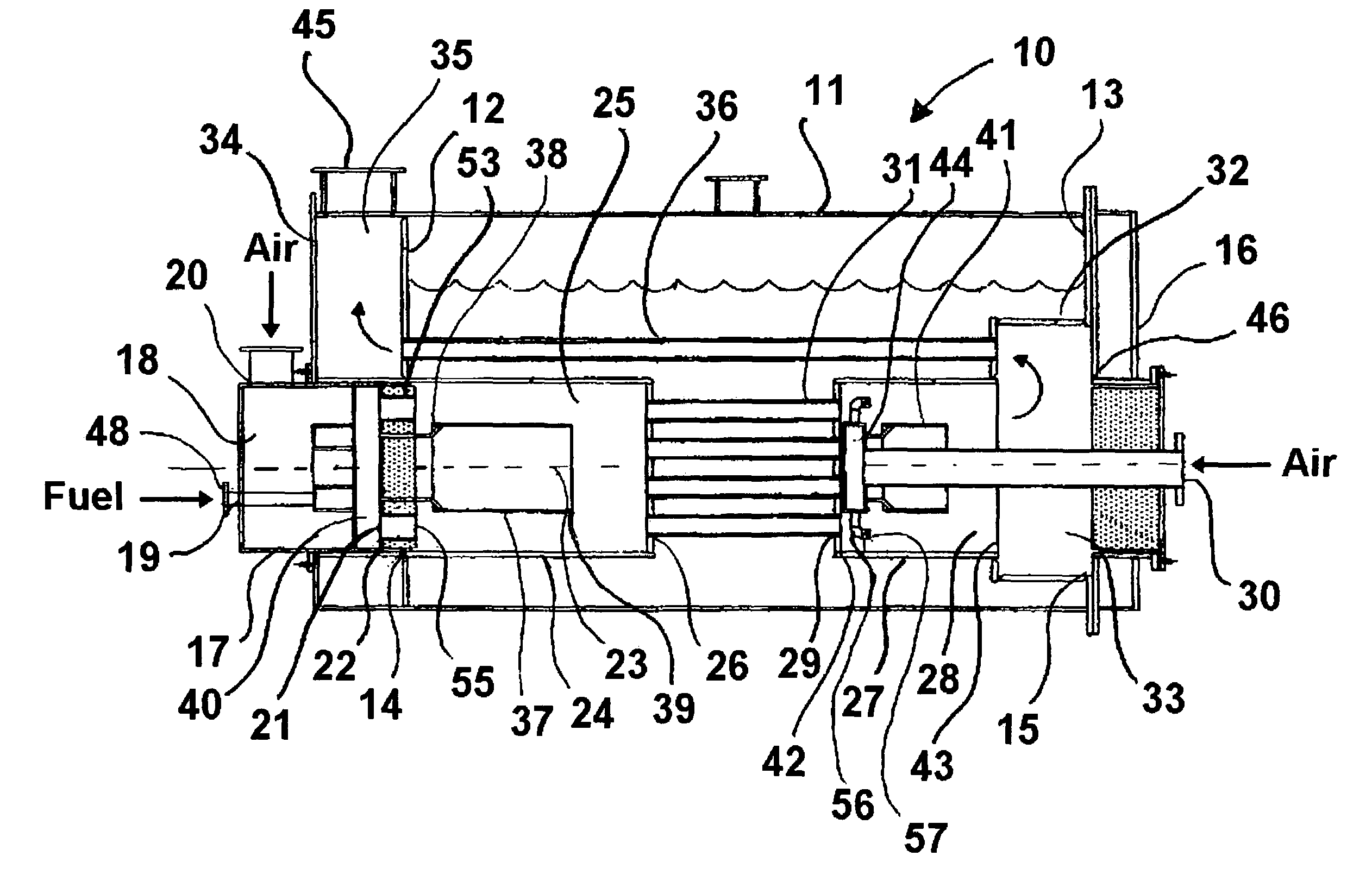

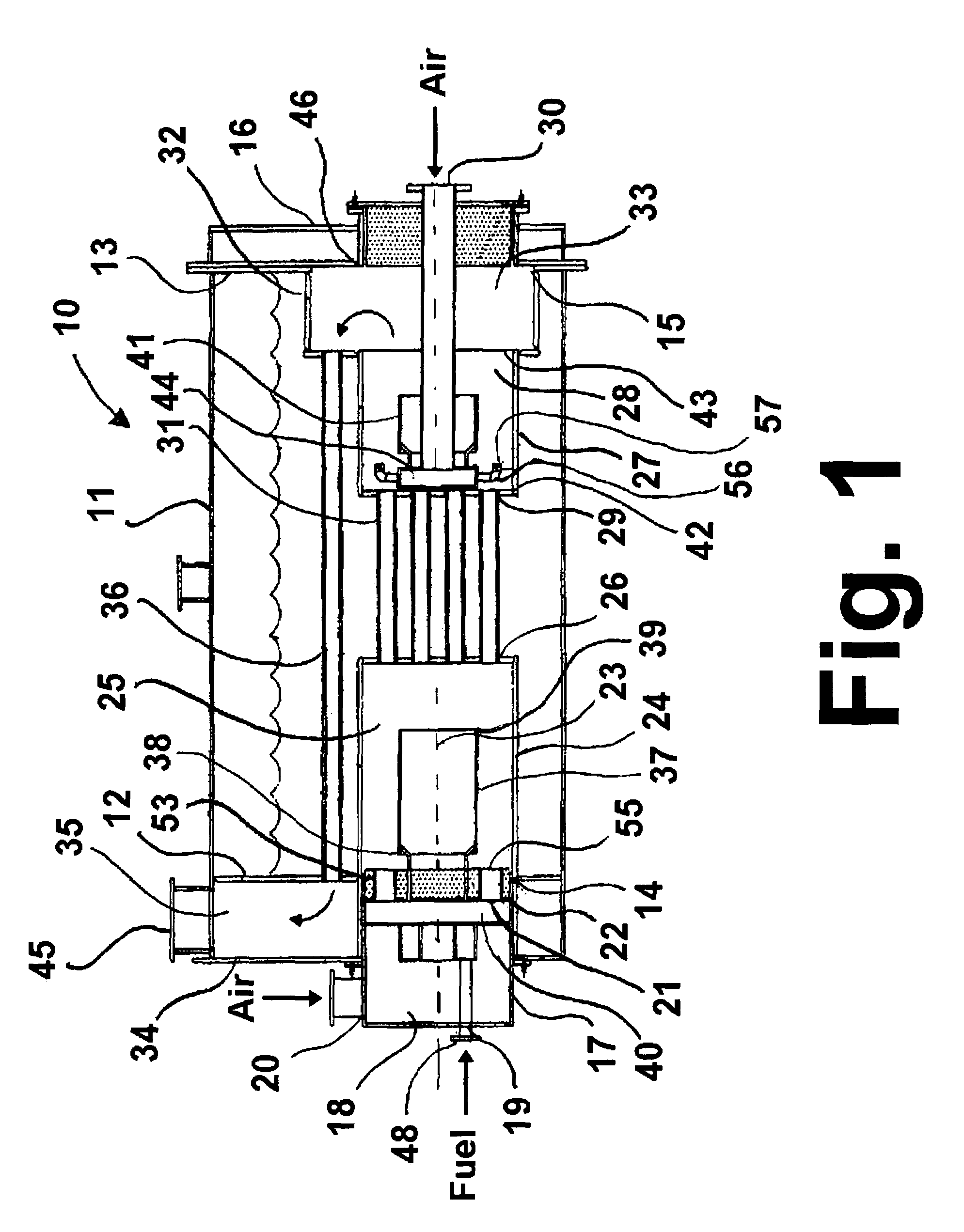

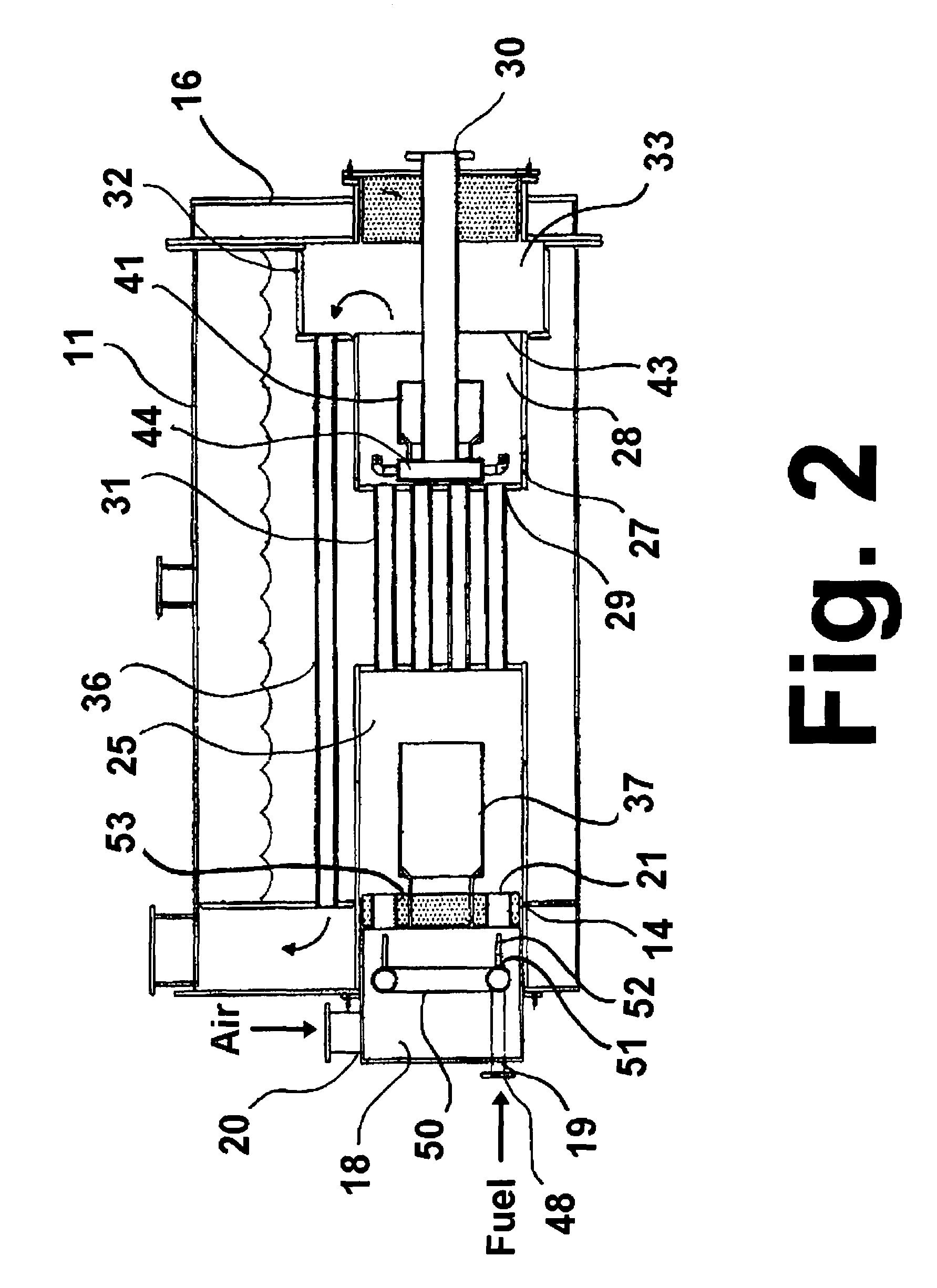

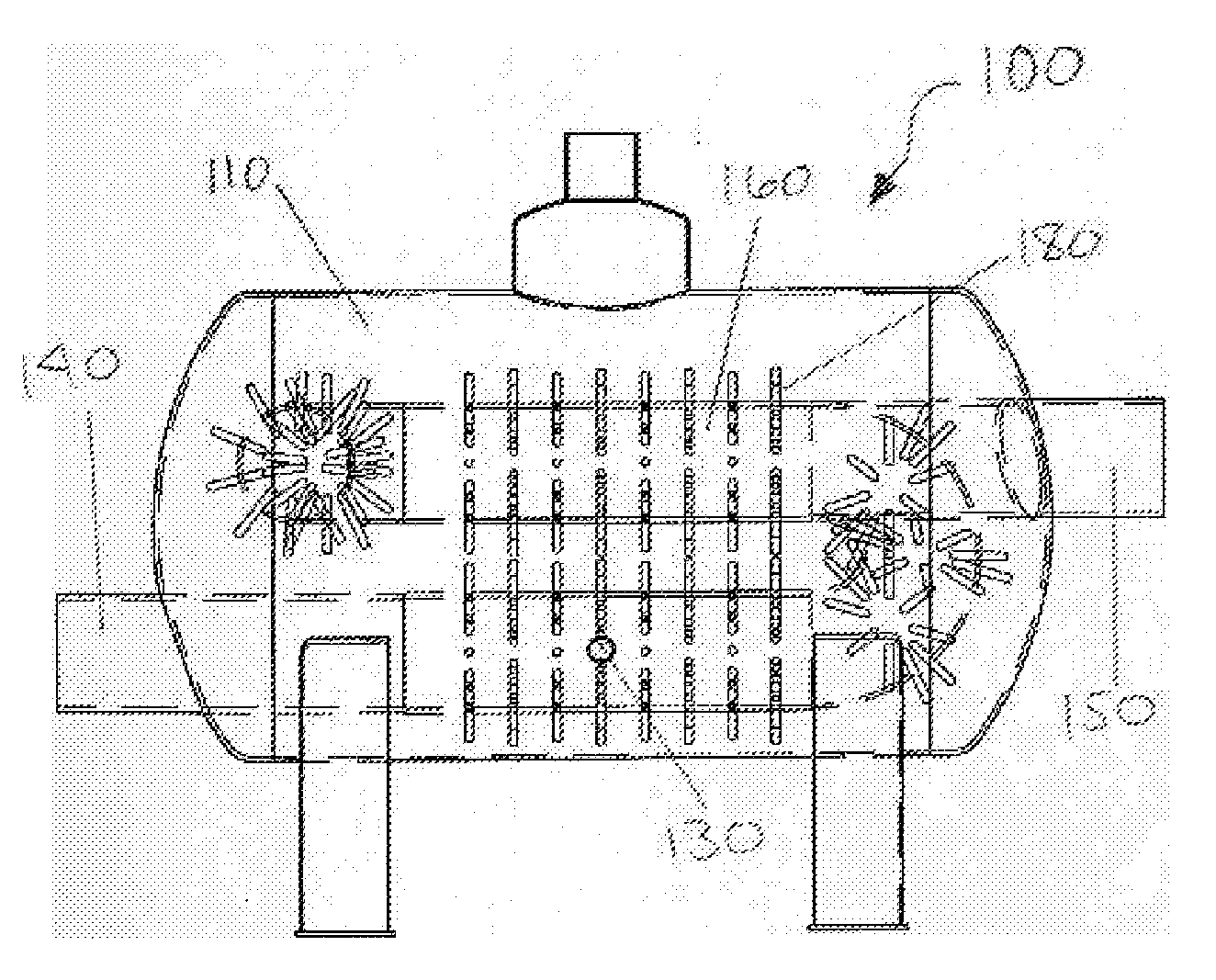

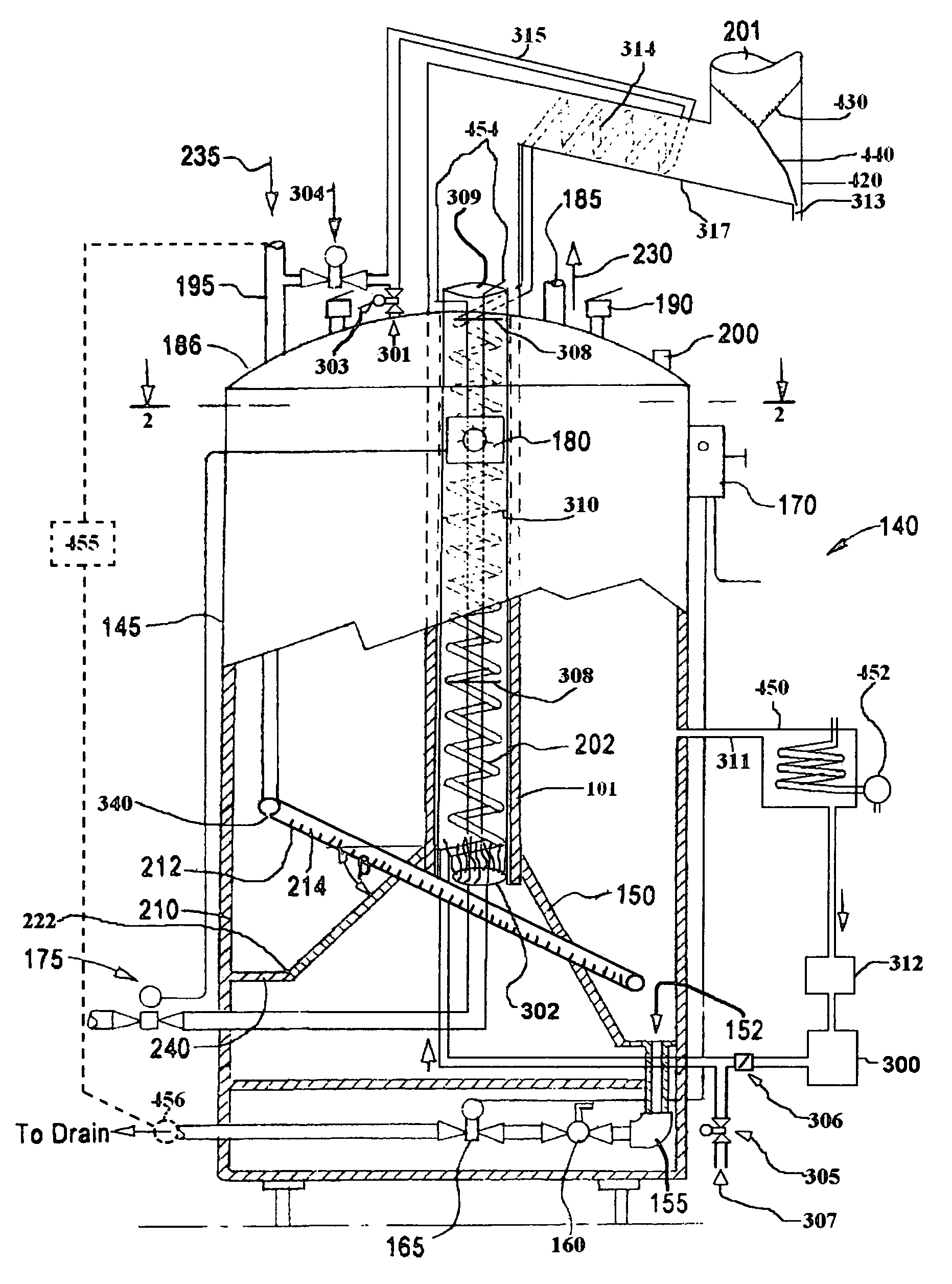

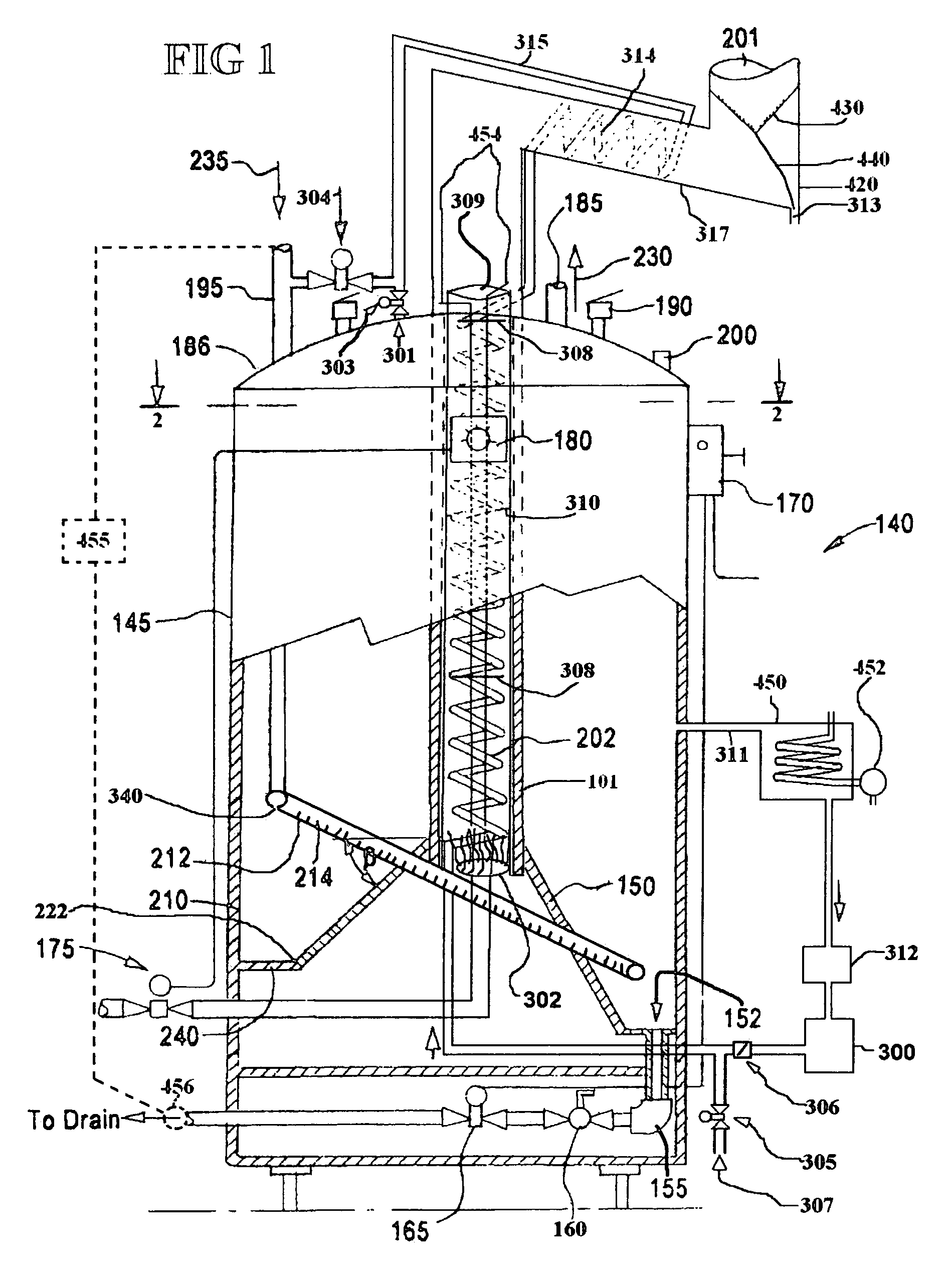

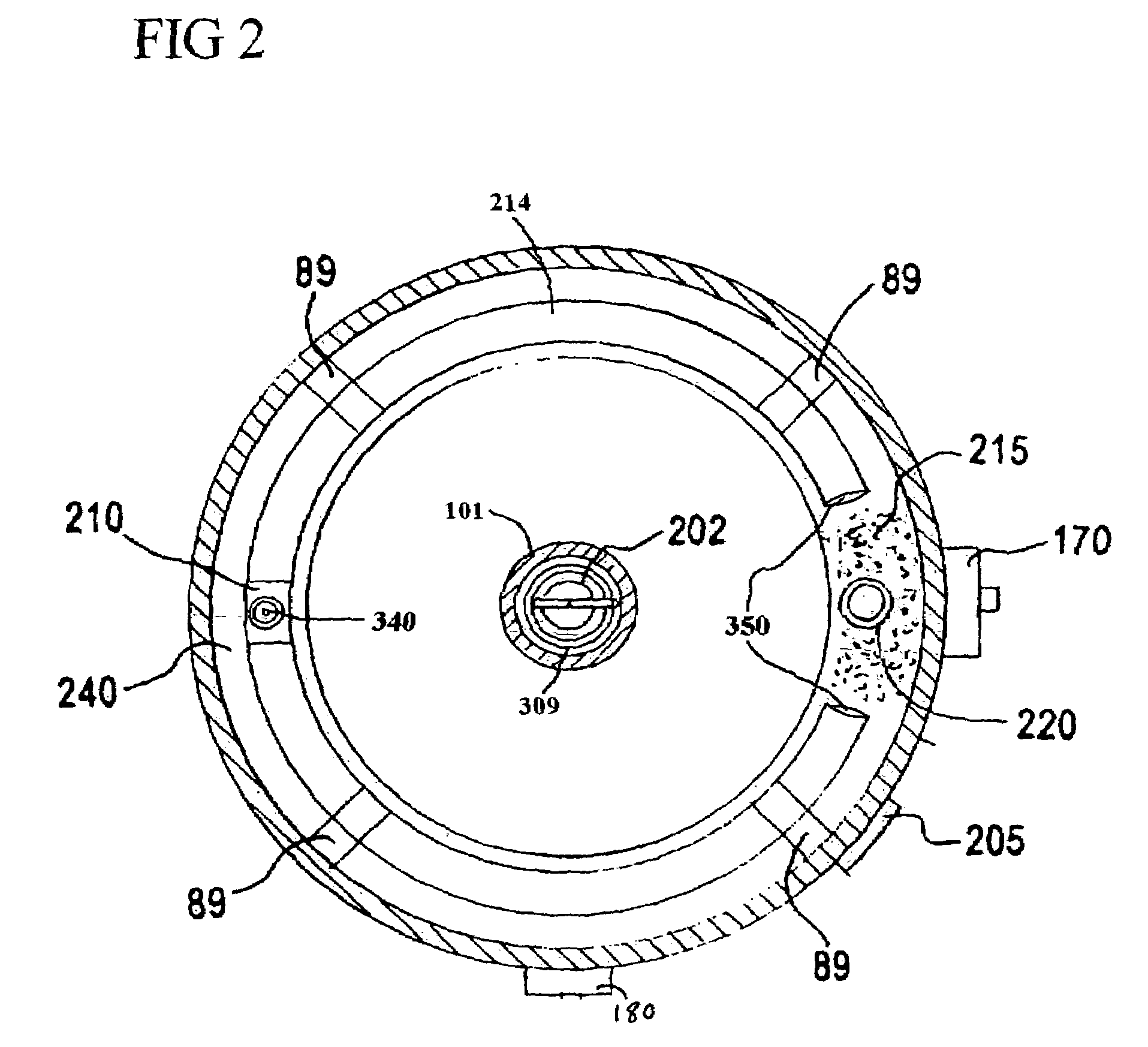

Granular biomass burning heating system

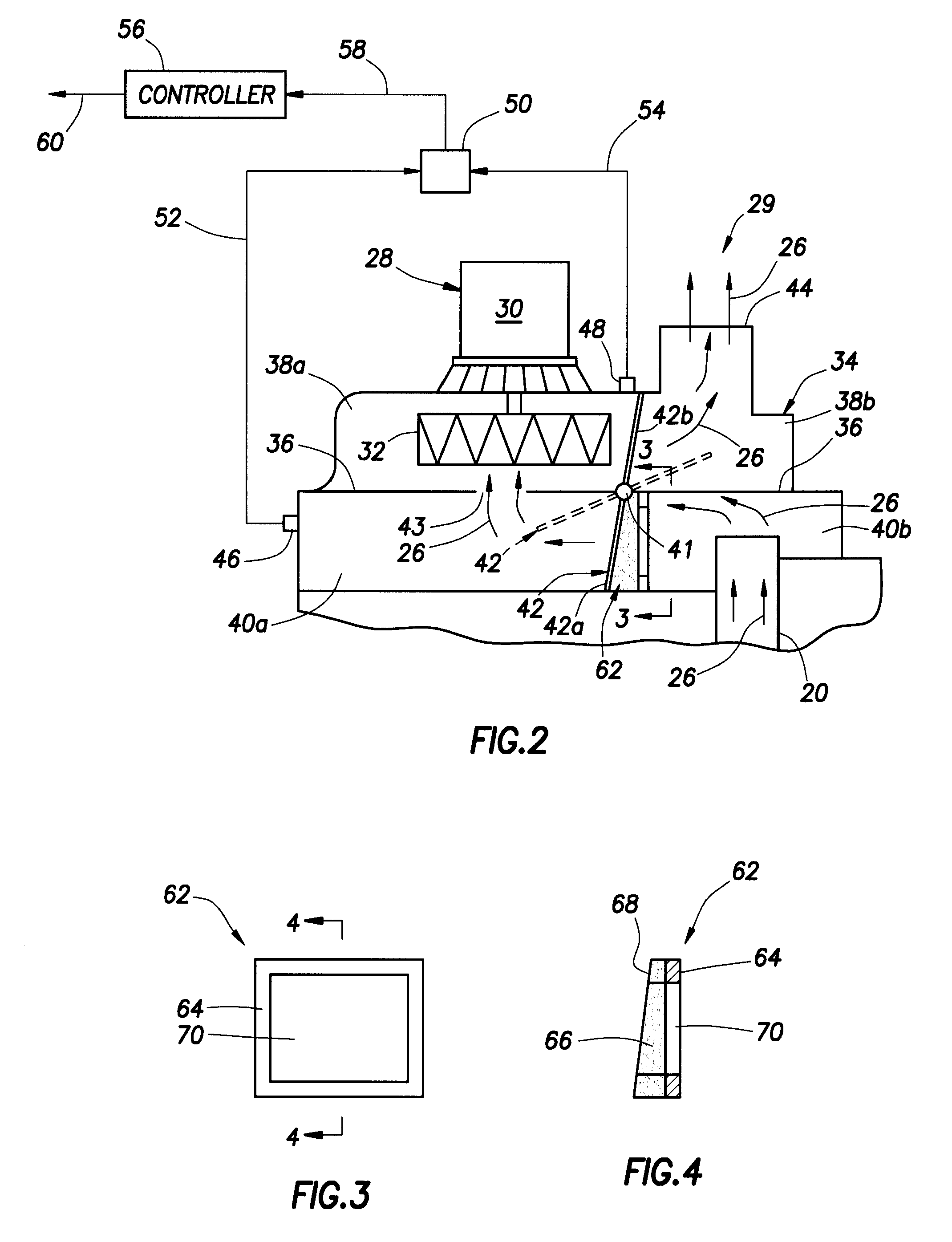

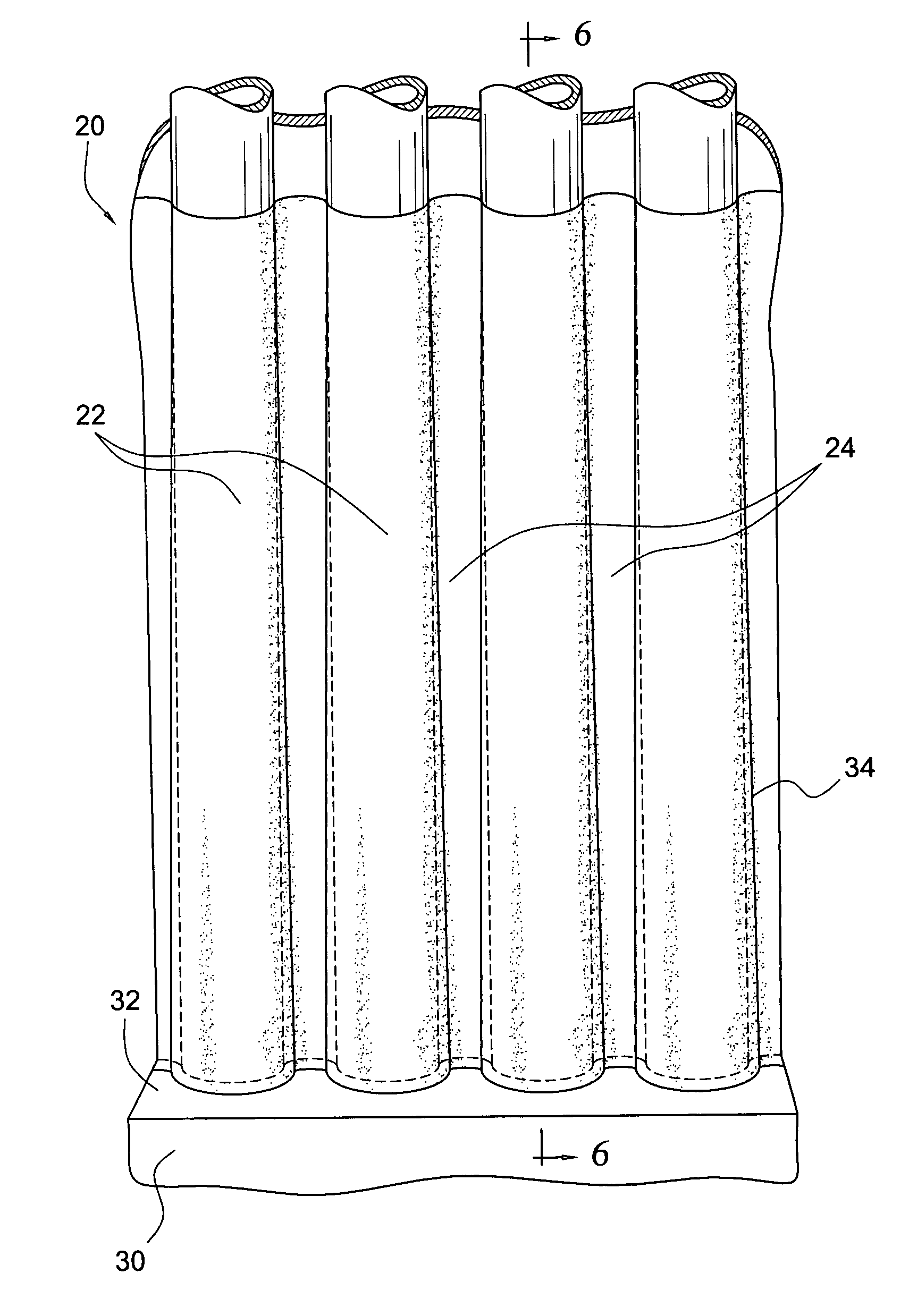

InactiveUS20070137538A1Improve unit efficiencyReduce lag timeAir supply regulationStirring devicesInformation controlProcess engineering

A granular biomass burning furnace for use with any appropriate granular biomass, such as grains, cherry pits, etc. The furnace includes a three stage heat exchanger, a fuel injector, a fuel stirrer, an ash ejector, a wash down system, a three stage air inducer, a fuel igniter, and supporting components. The unit includes a computer controller which controls all aspects of the operation of the unit based on information from sensors located throughout the unit. The unit includes a smart logic thermal controller to adjust the output heat of the unit via a variable speed air inducer. The three stage heat exchanger system includes a spiral water jacket surrounding the burn pot, a plurality of heat exchanger baffles in the unit, and a fine finned heat exchanger at the top of the unit. The air inducer provides air to the burn pot from three directions to promote complete combustion.

Owner:STERR KEVIN K

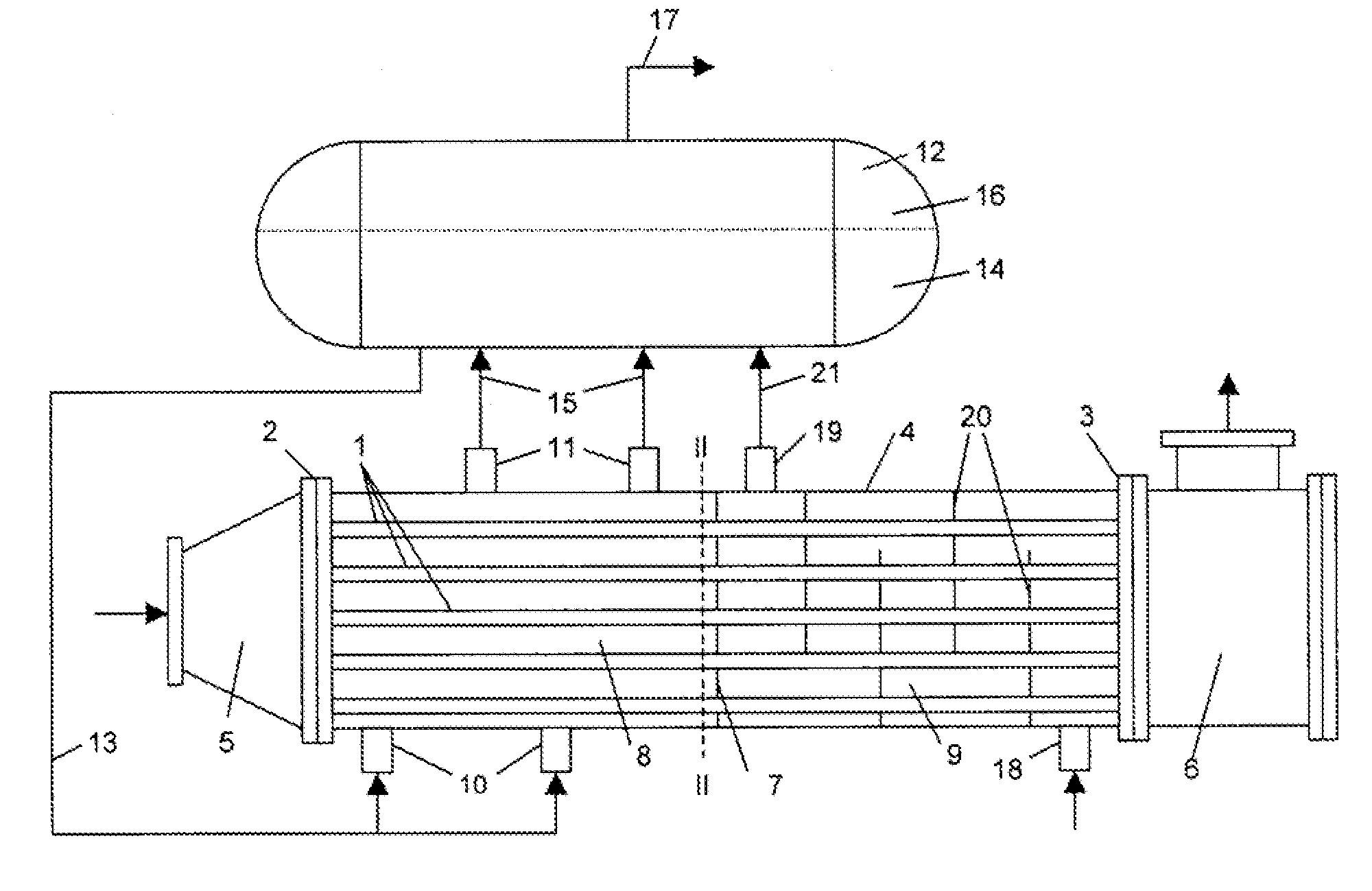

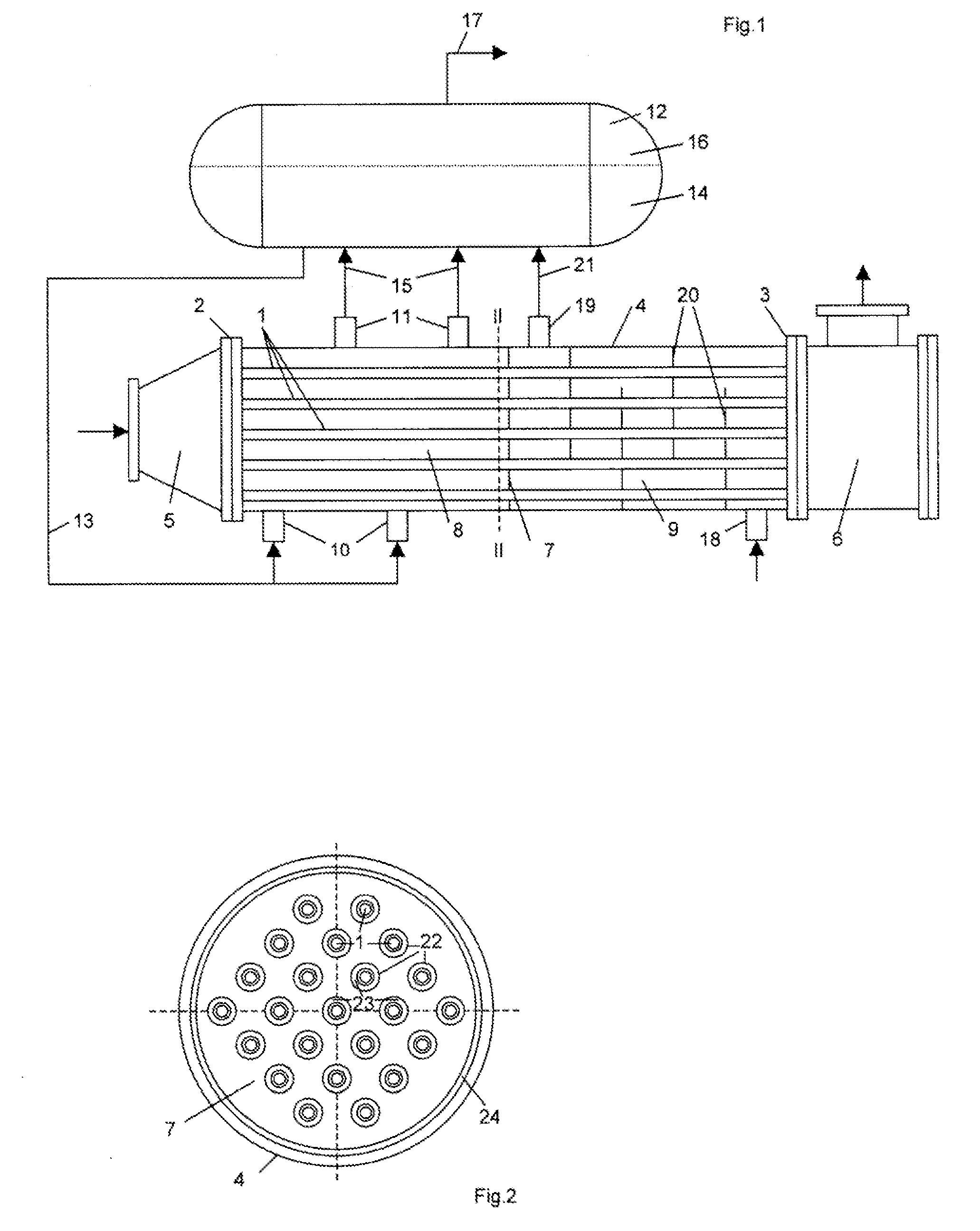

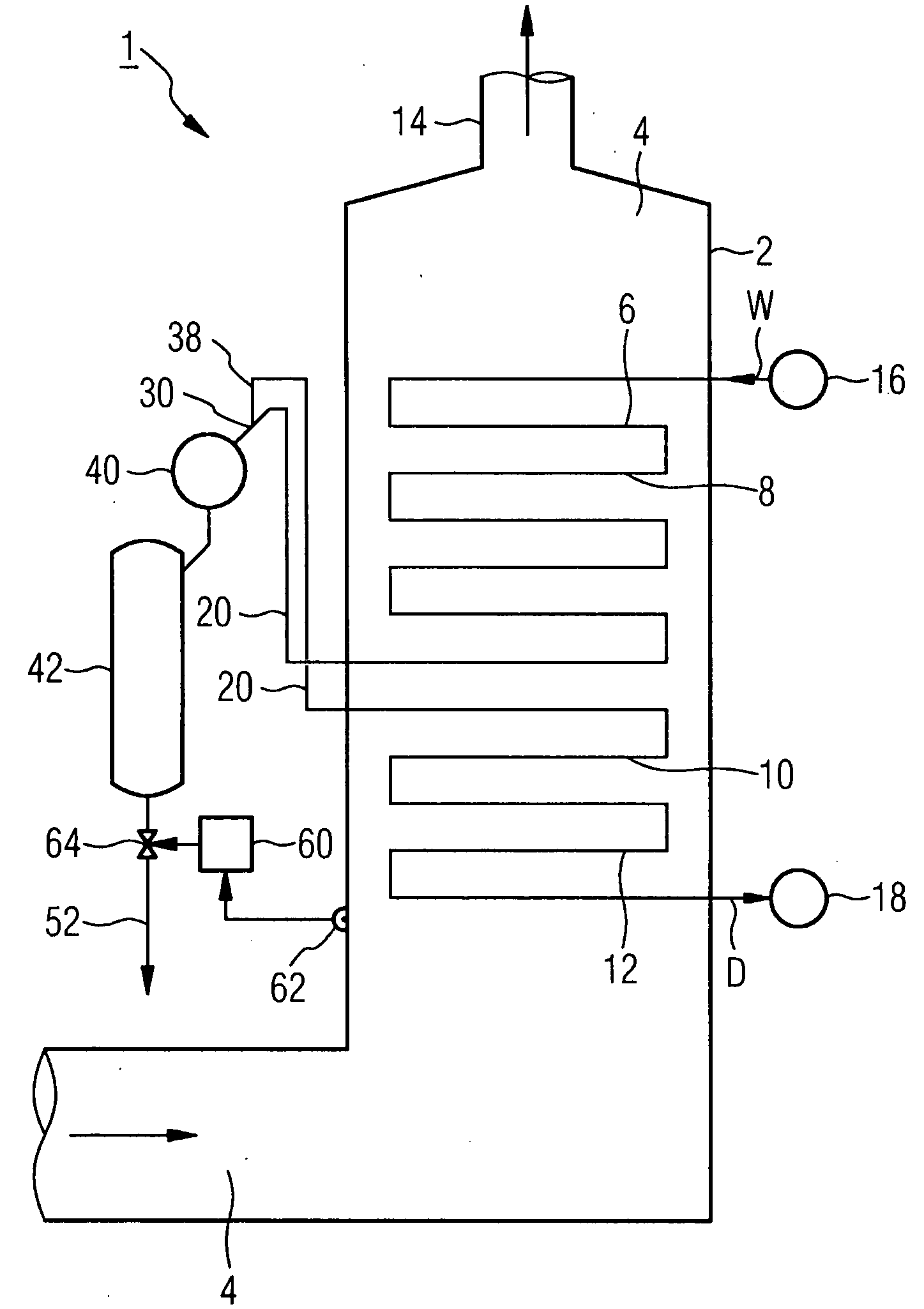

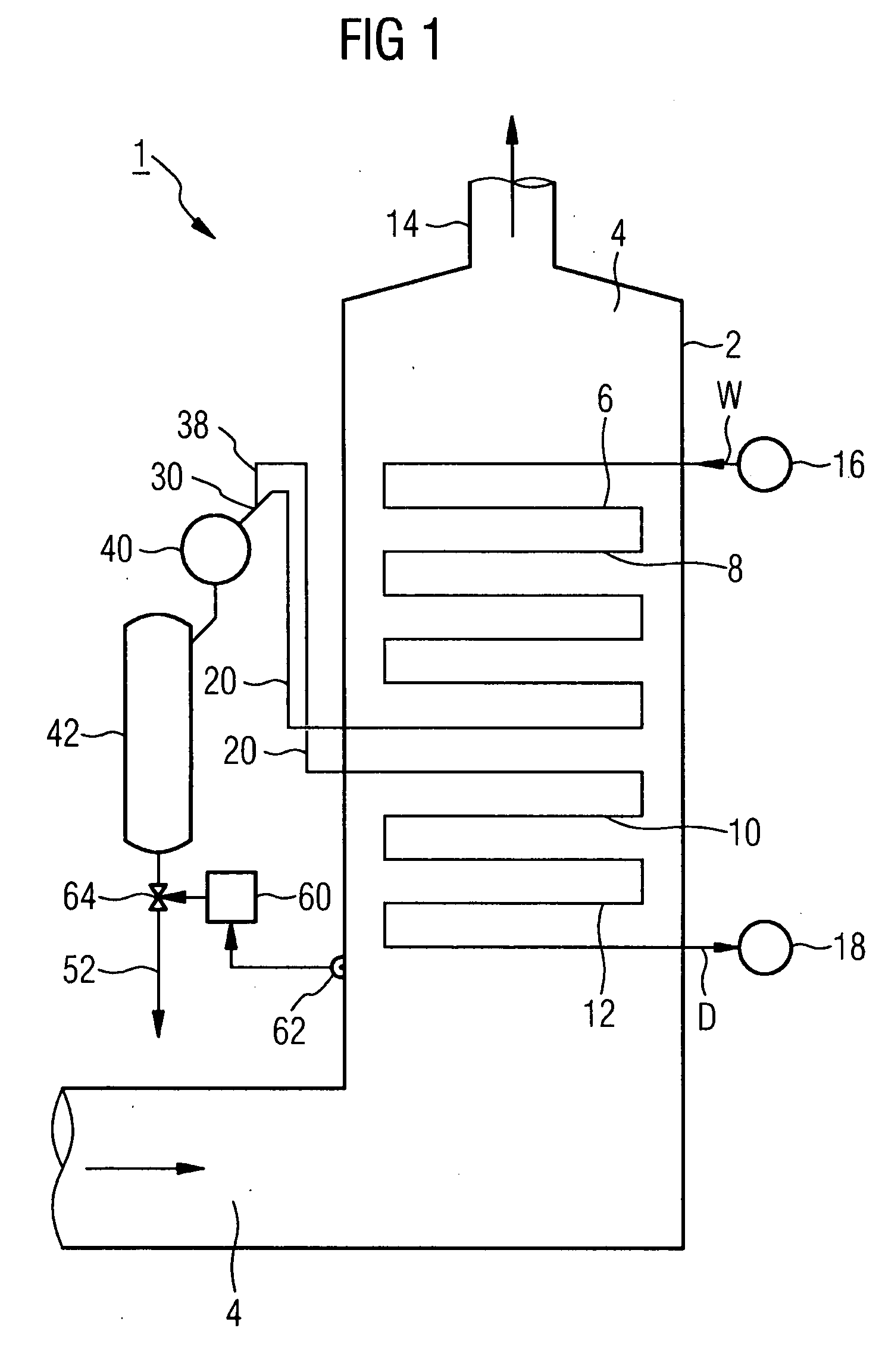

Heat exchanger for cooling reaction gas

ActiveUS20080121383A1Improve cooling effectSimple structureSteam generation heating methodsHeat exchanger casingsPlate heat exchangerNuclear engineering

A heat exchanger for cooling reaction gas, wherein the respective ends of heat exchanger tubes, through which the reaction gas flows, are inserted in a respective tube plate and are surrounded by a jacket, at the two ends of which are provided a respective end chamber that is partially delimited by one of the tube plates and serves for the supply and withdrawal of the reaction gas; water, as cooling agent, flows through the inner chamber of the heat exchanger that is surrounded by the jacket and that is divided by a partition, extending perpendicular to the heat exchanger tubes, which extend through it, into two partial chambers disposed one after the other in the direction of flow of the reaction gas, each partial chamber being provided with its own supply connectors and outlet connectors for the cooling agent; boiling water flows through the partial chamber that is disposed on the inlet side for reaction gas and that is connected via a supply line and withdrawal lines with a water / steam drum; feed water flows through the partial chamber that is disposed on the outlet side for the reaction gas and that is connected via a withdrawal line with the water / steam drum. The partition between the two partial chambers permits the passage of the cooling agent that flows in the inner chamber of the heat exchanger.

Owner:BORSIG AG

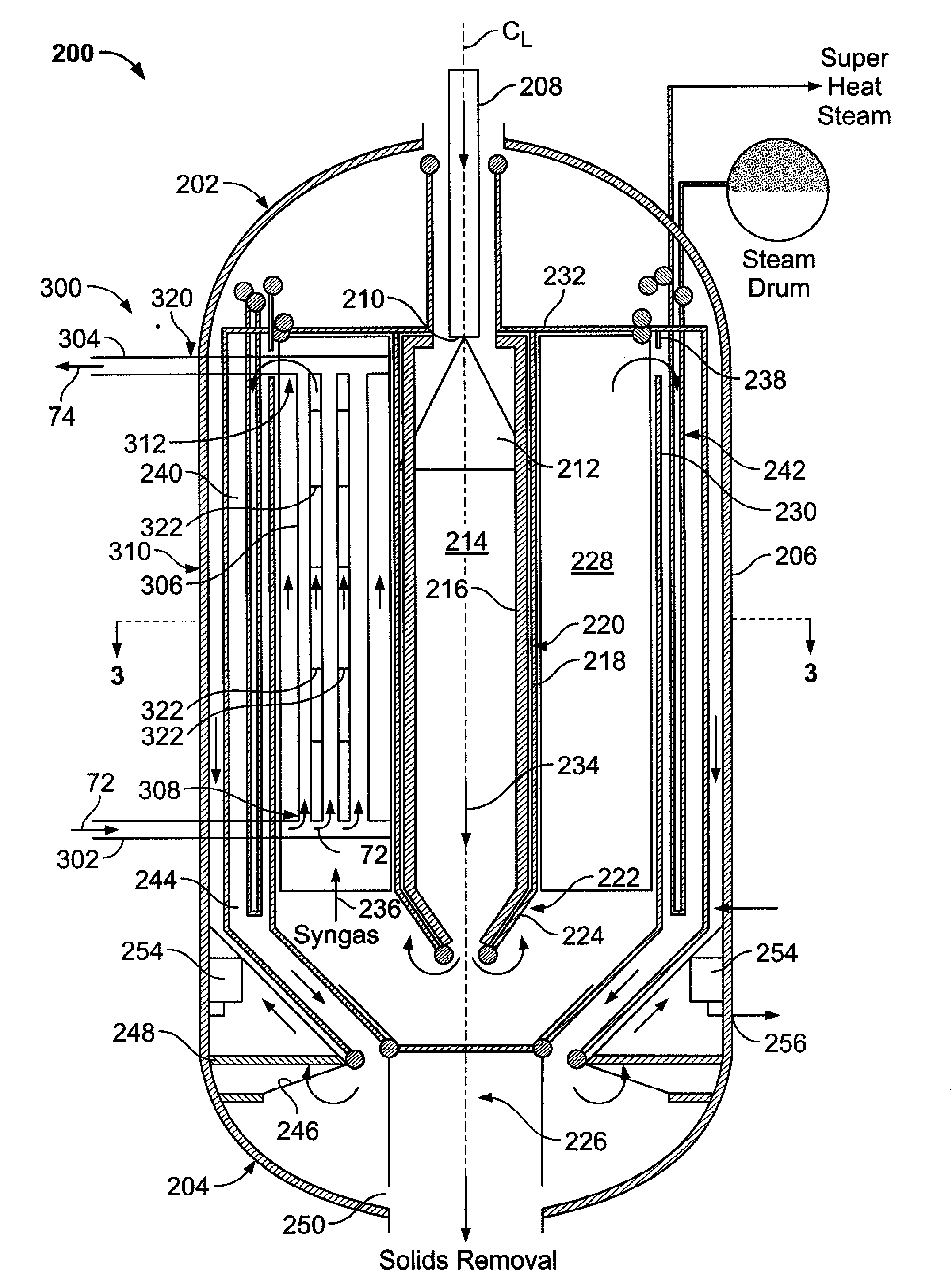

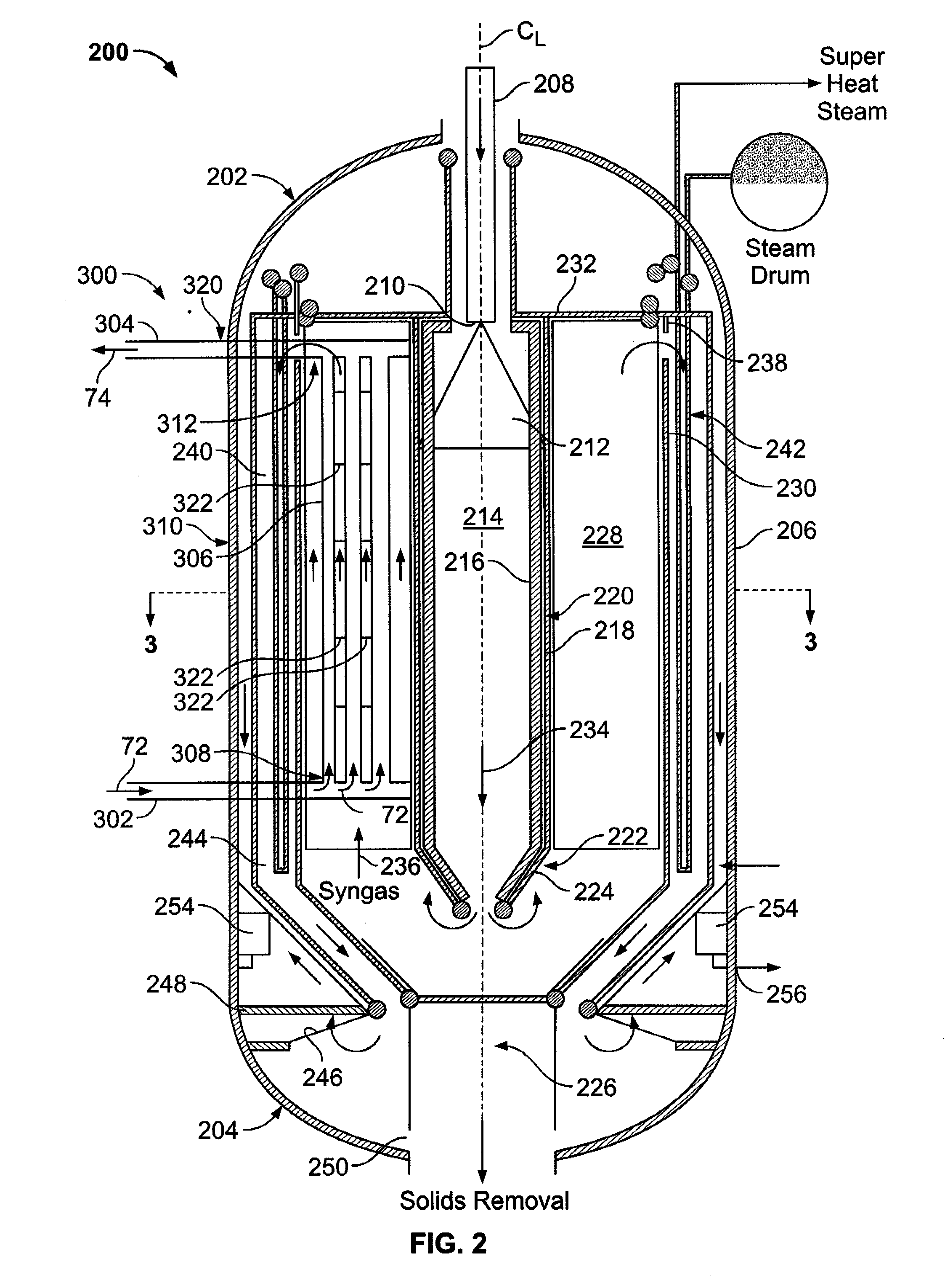

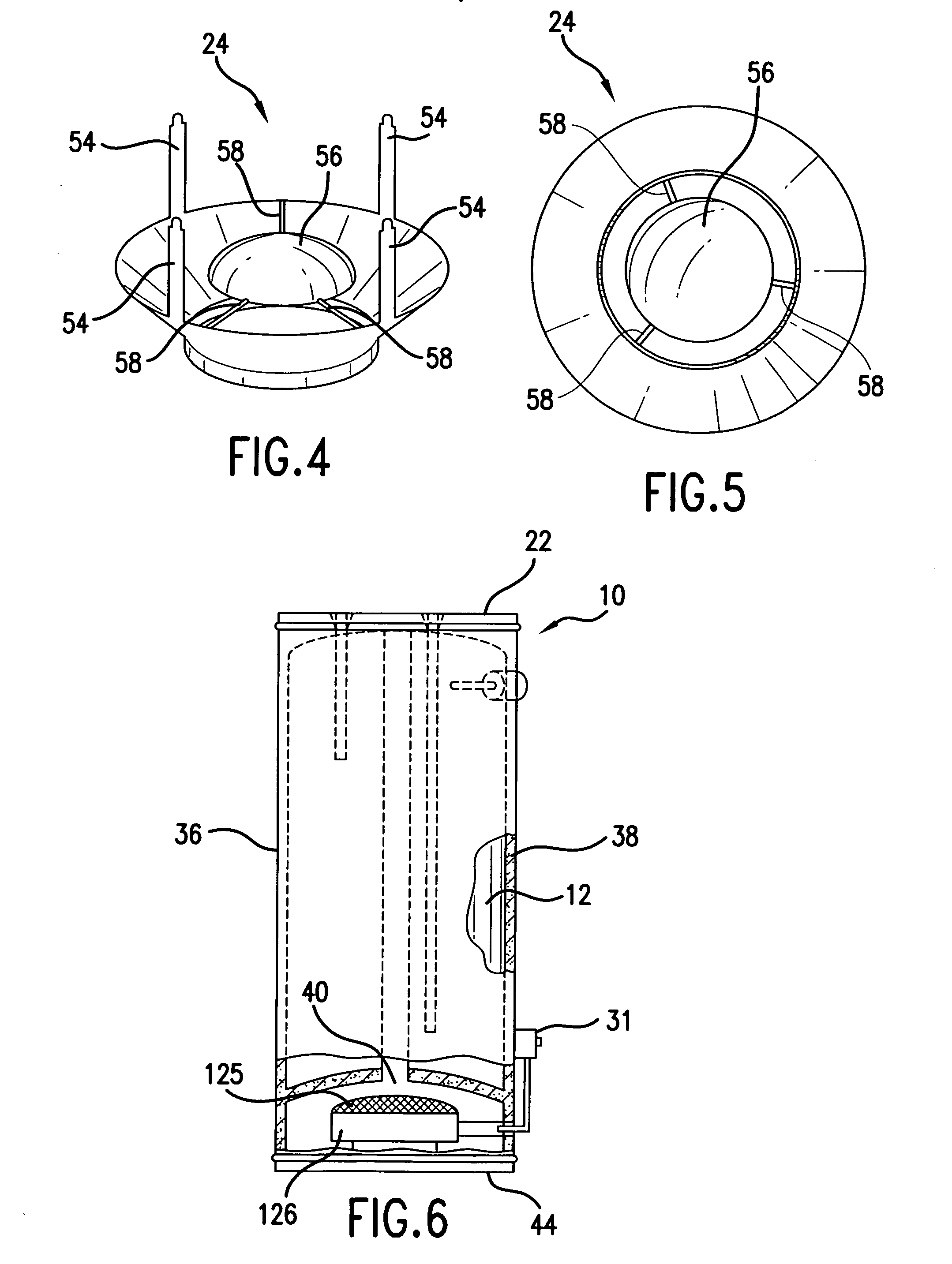

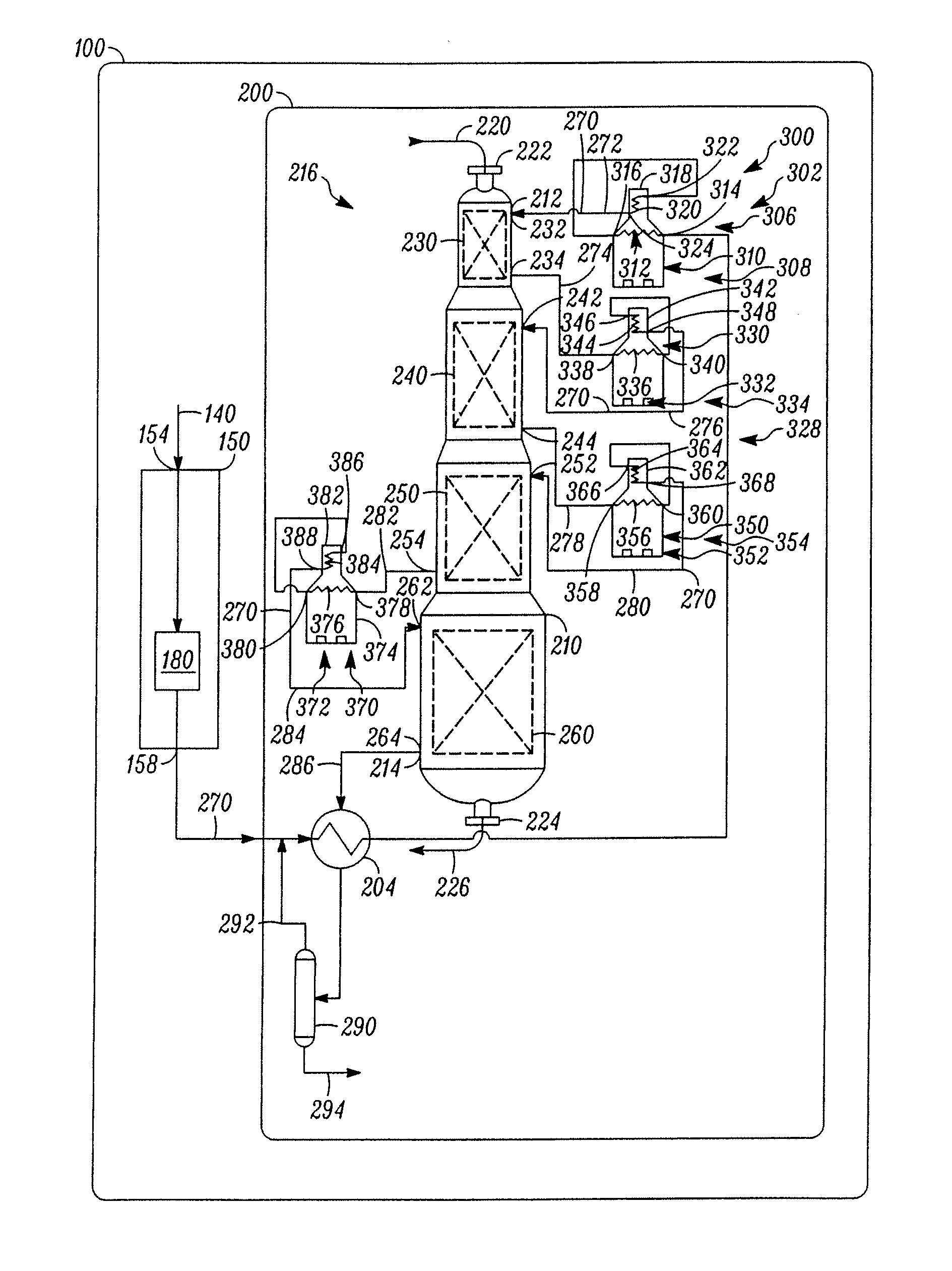

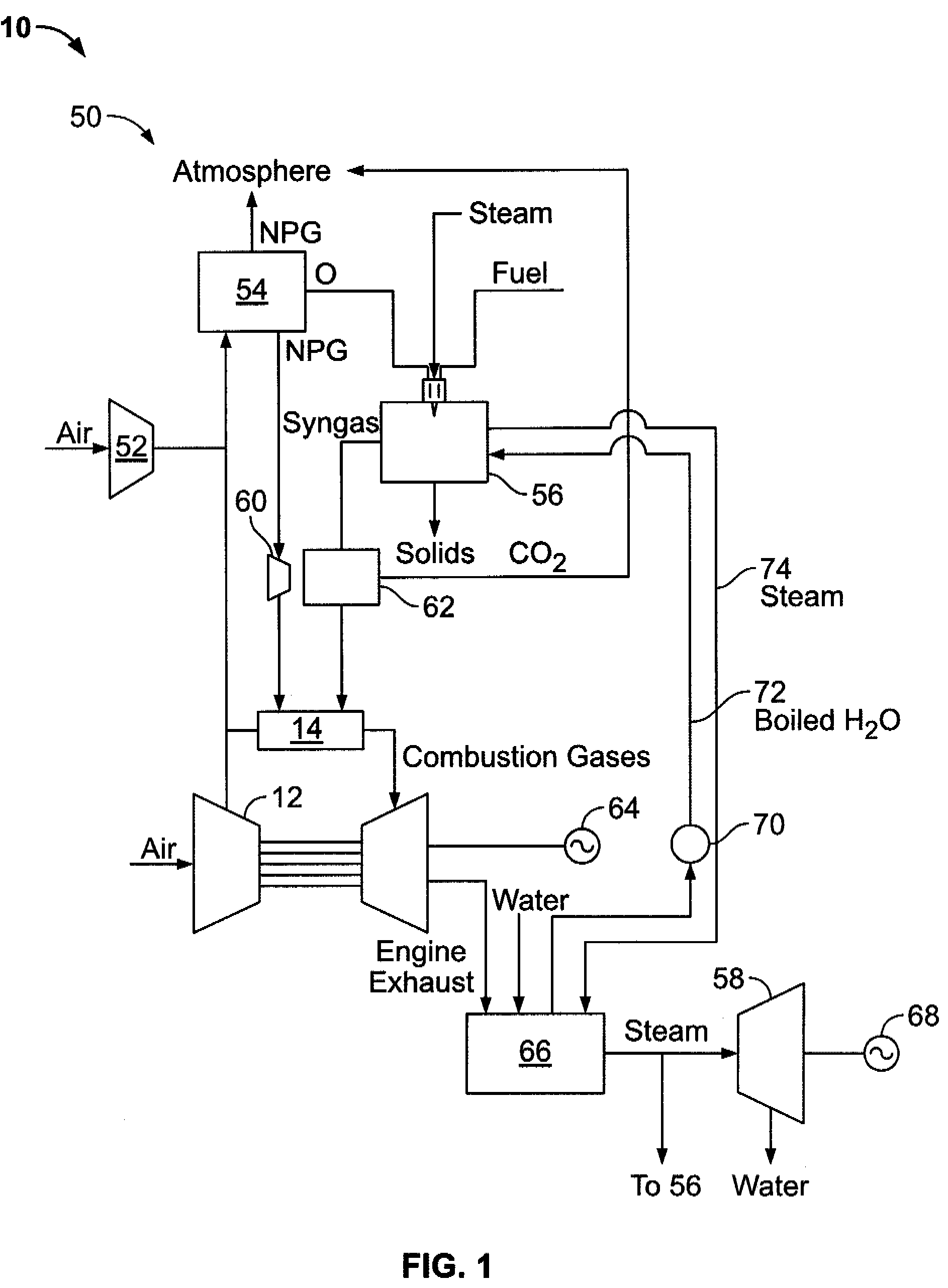

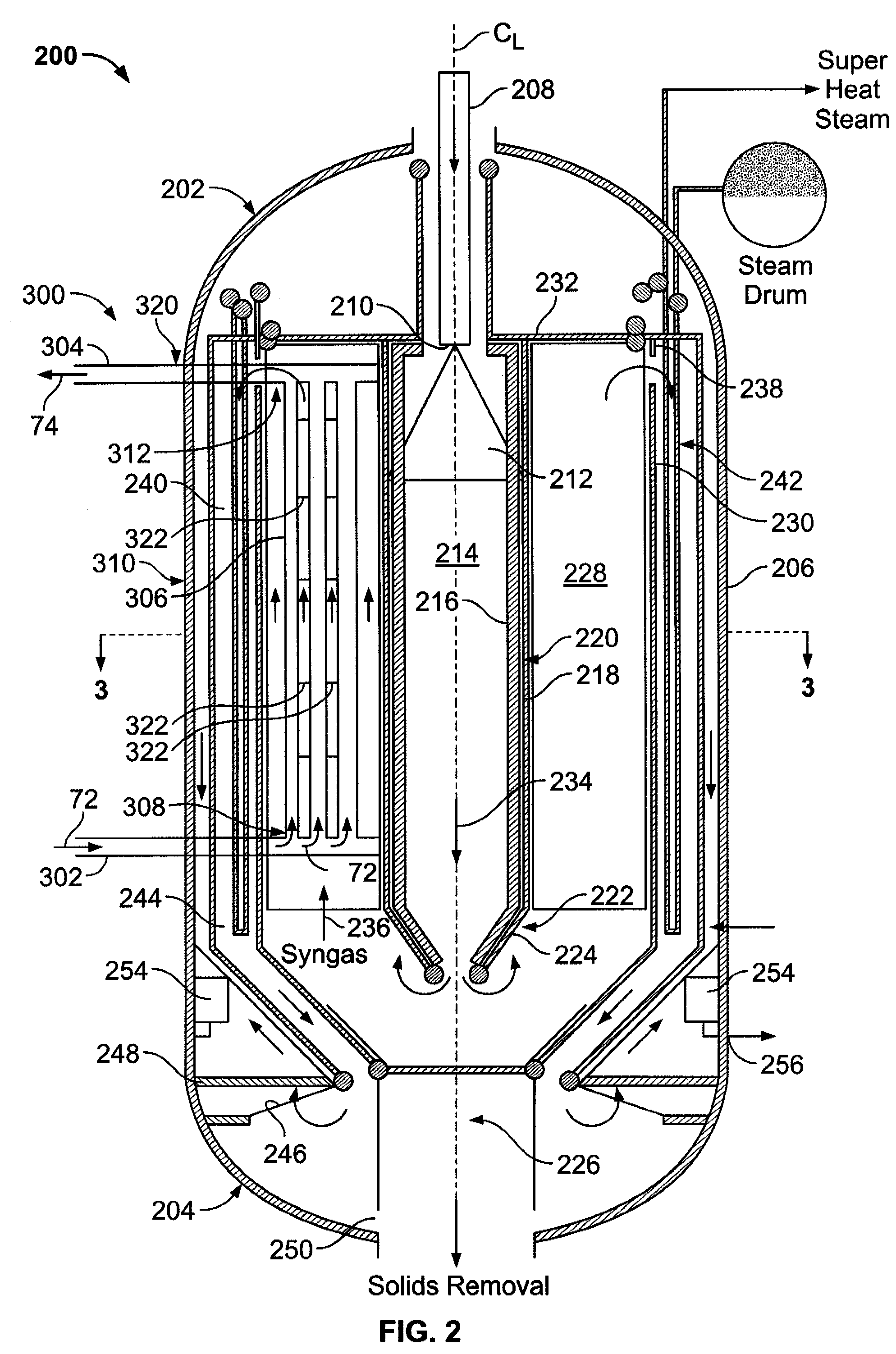

Methods and apparatus to facilitate cooling syngas in a gasifier

ActiveUS20080175770A1Improve heat transfer performanceMuffle furnacesGasifier mechanical detailsSyngasEngineering

A method of cooling syngas in a gasifier is provided. The method includes channeling cooling fluid through at least one platen that extends at least partially through a reaction zone of the gasifier, and circulating reactant fluid around the at least one platen to facilitate heat transfer from the reactant fluid to the cooling fluid.

Owner:AIR PROD & CHEM INC

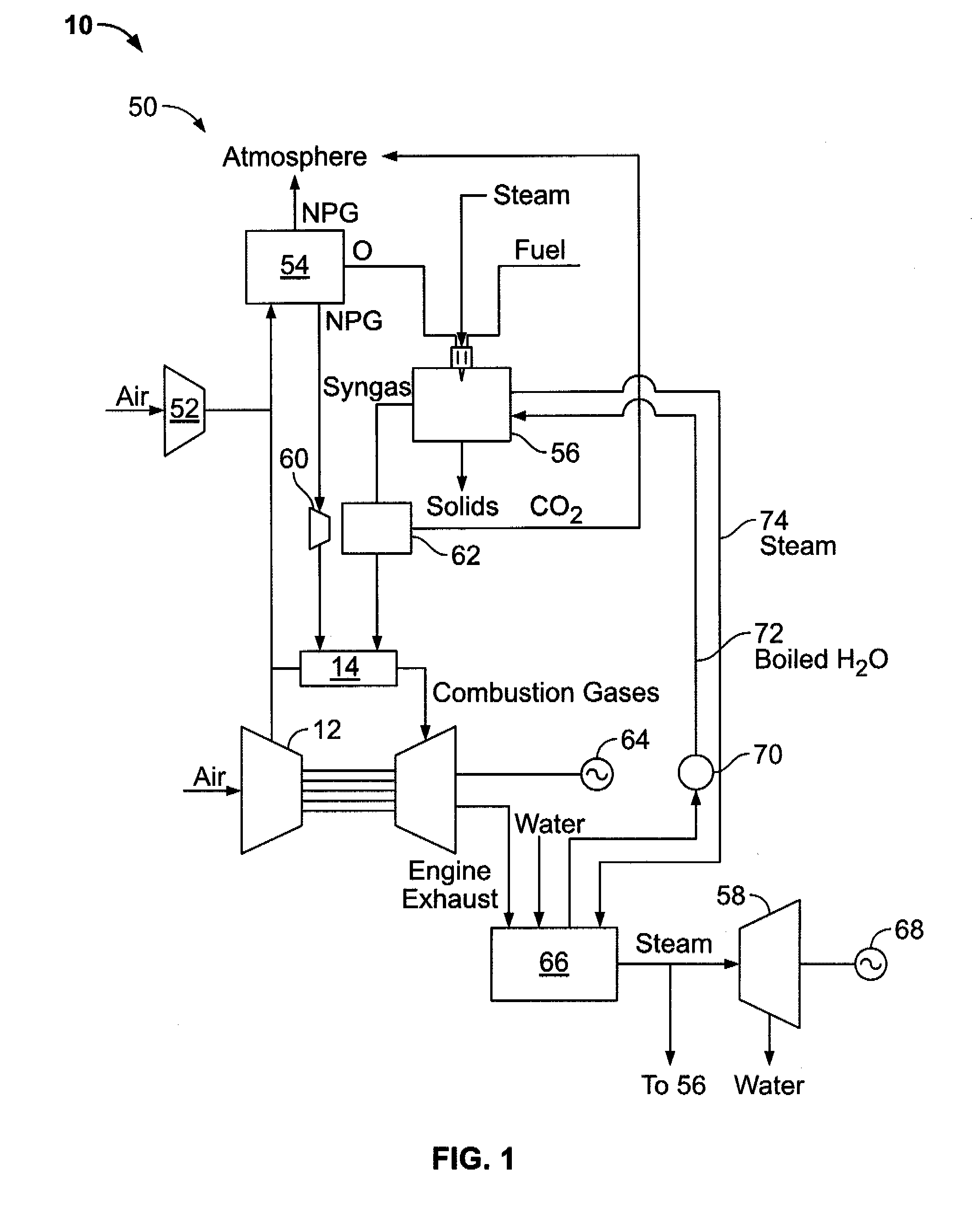

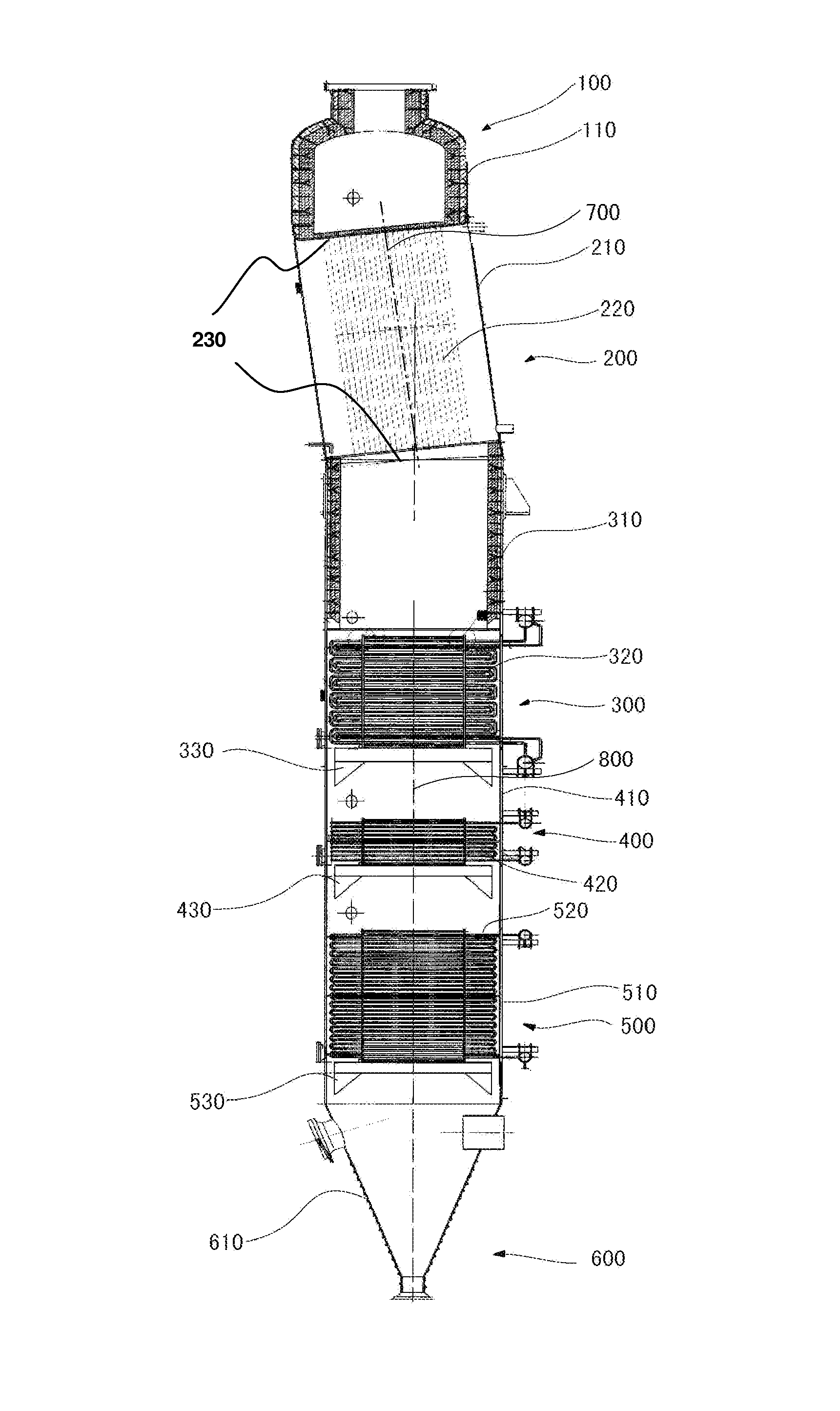

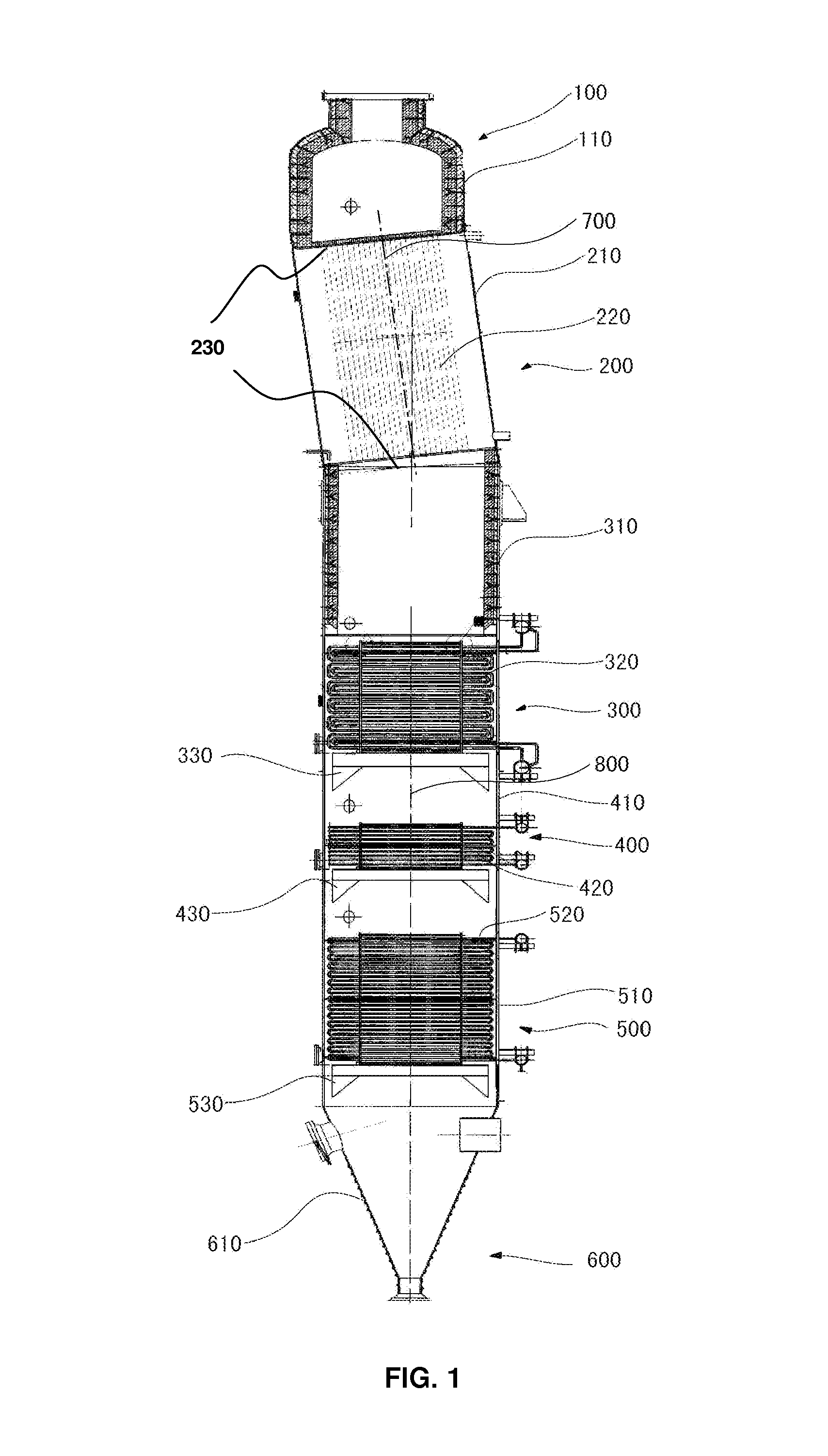

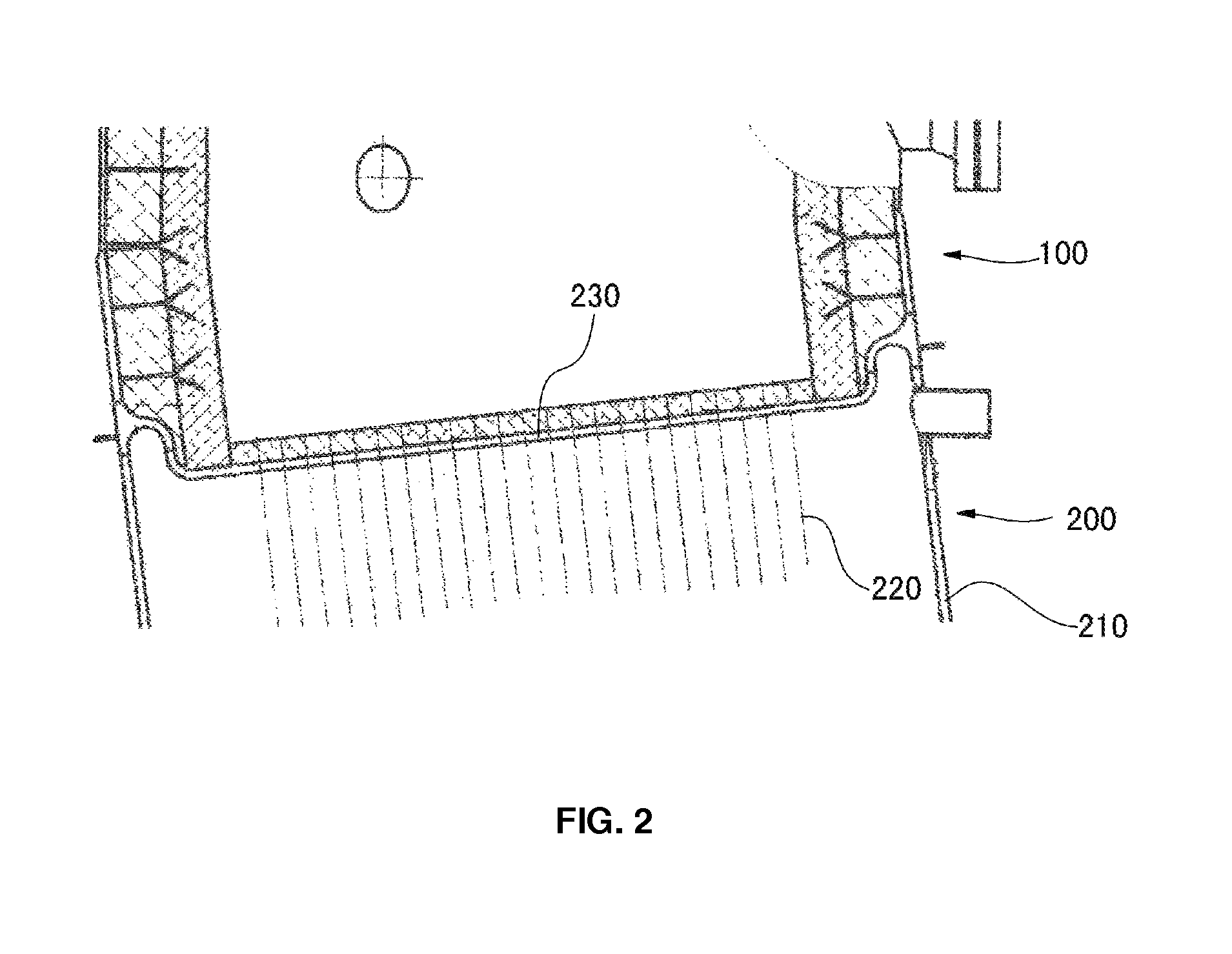

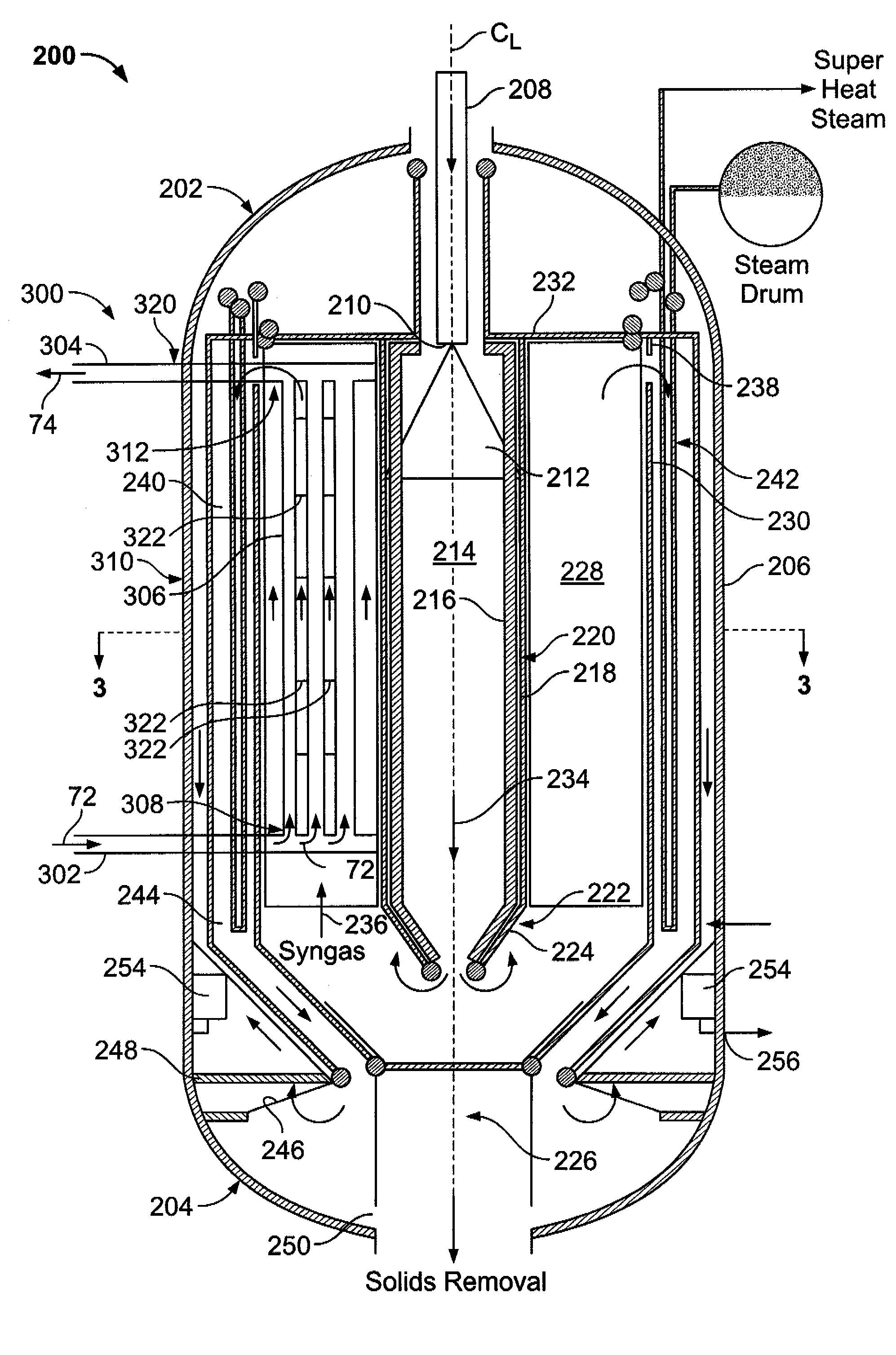

HRSG for fluidized gasification

ActiveUS9103234B2Reduce wearSaving space occupiedInternal combustion piston enginesEnergy inputSyngasFluidized bed

Owner:GAS TECH INST

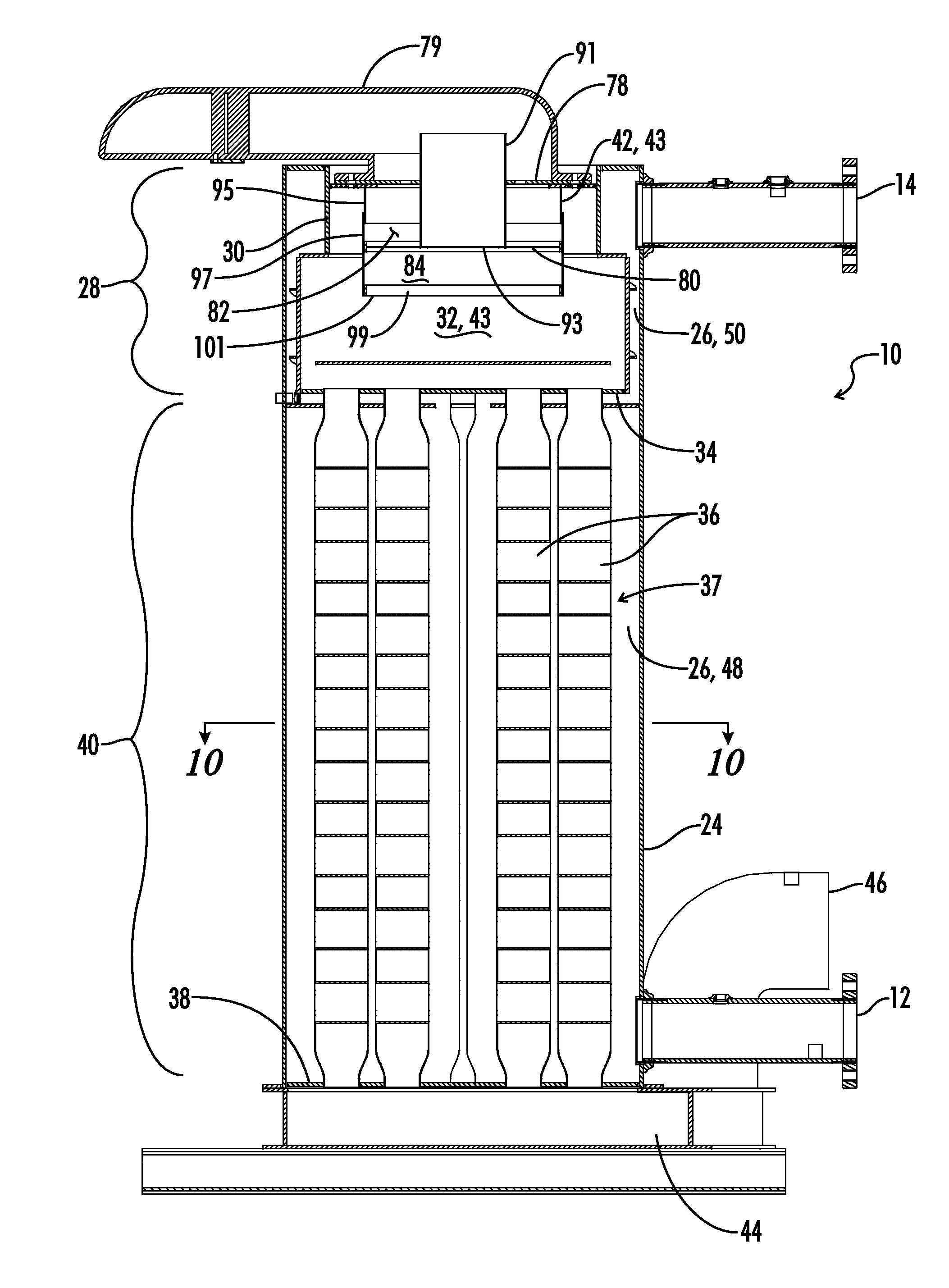

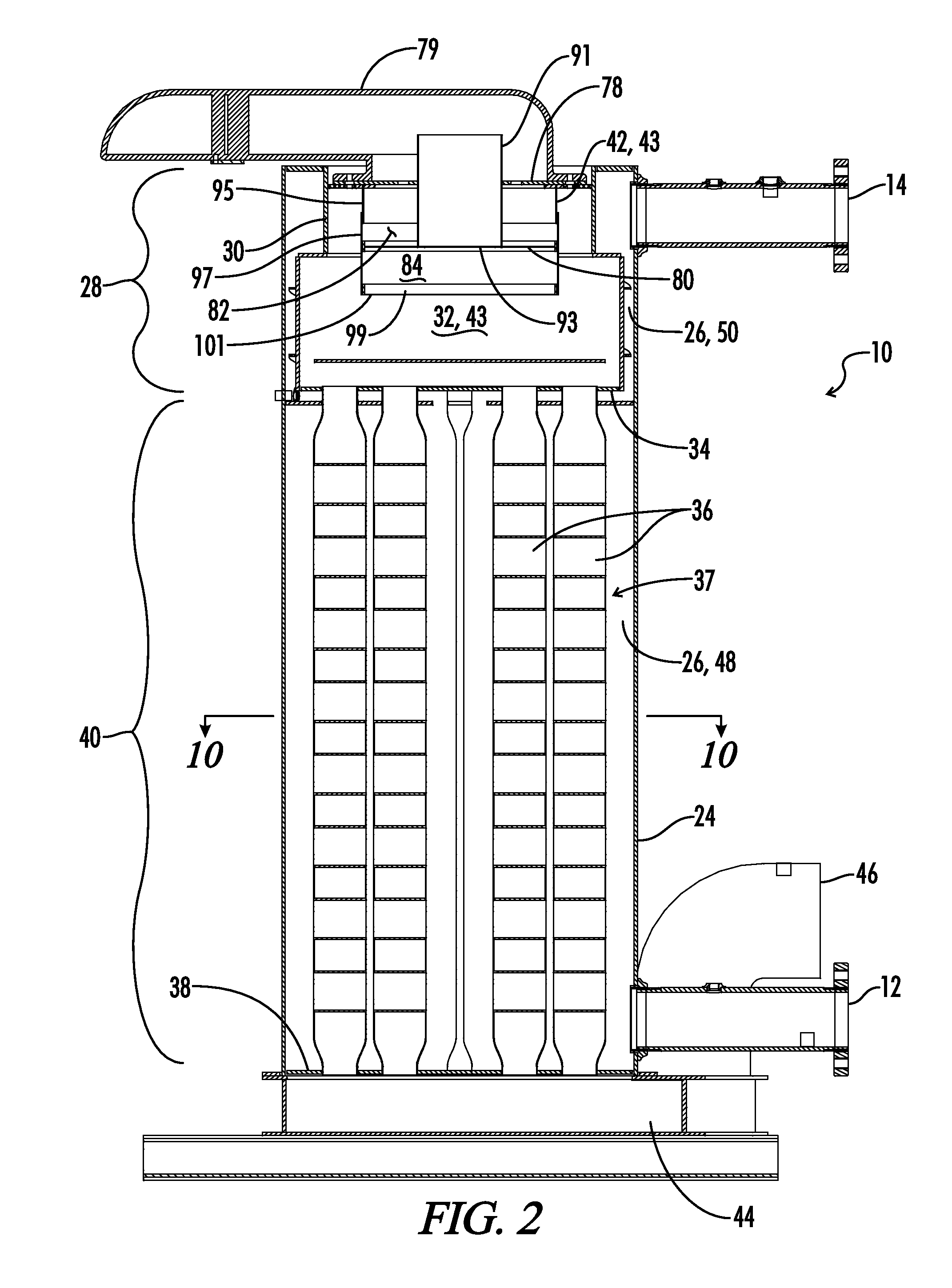

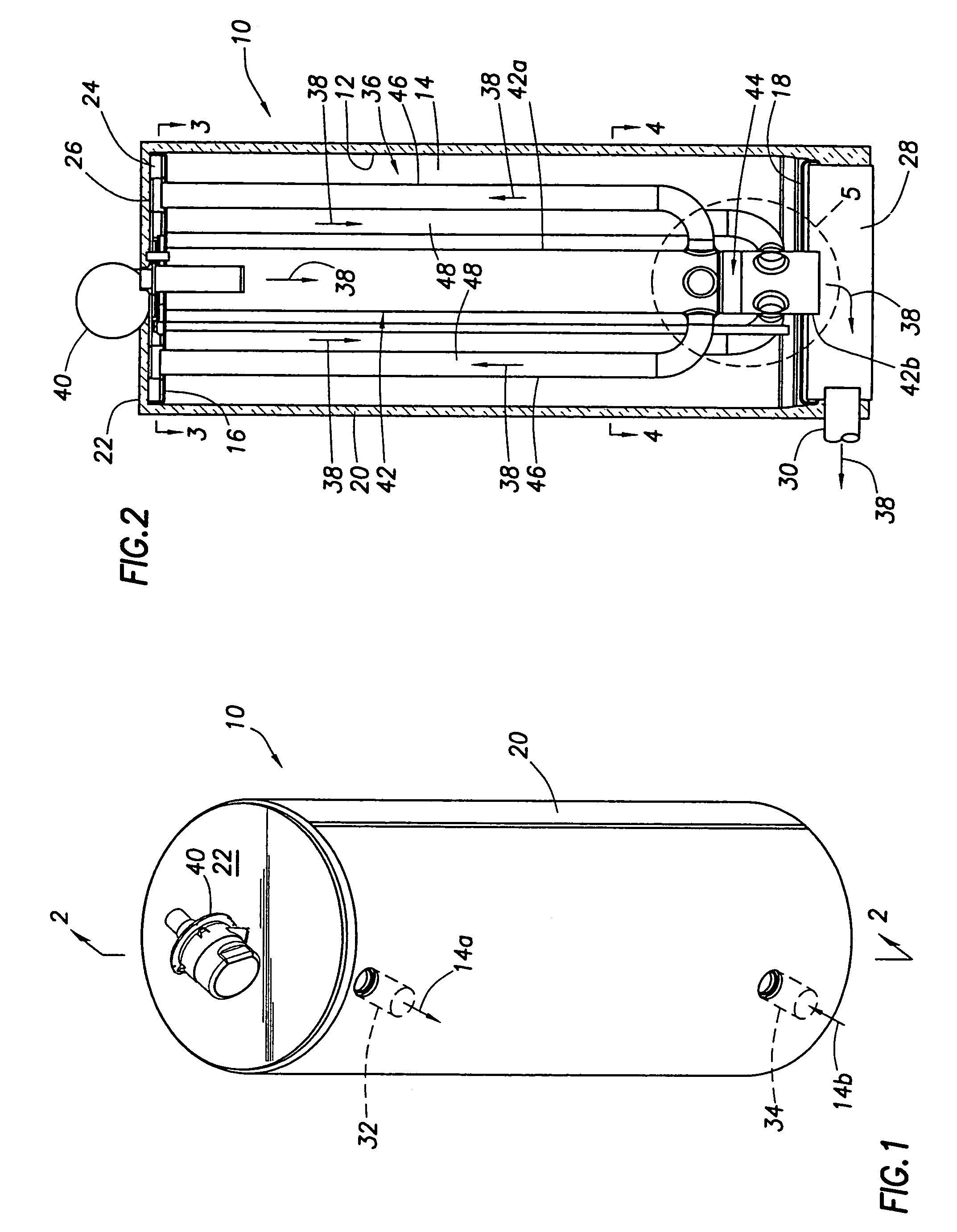

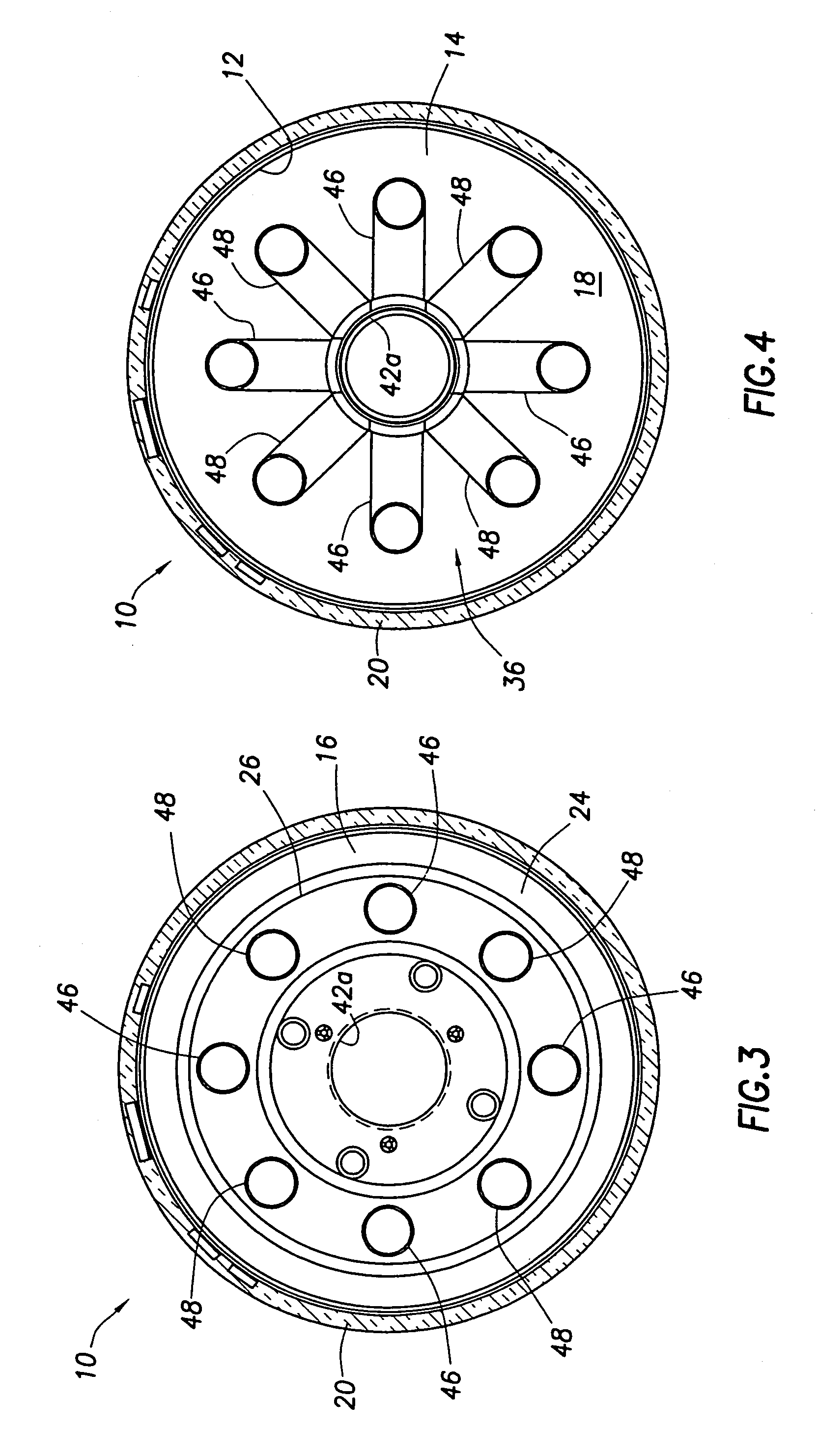

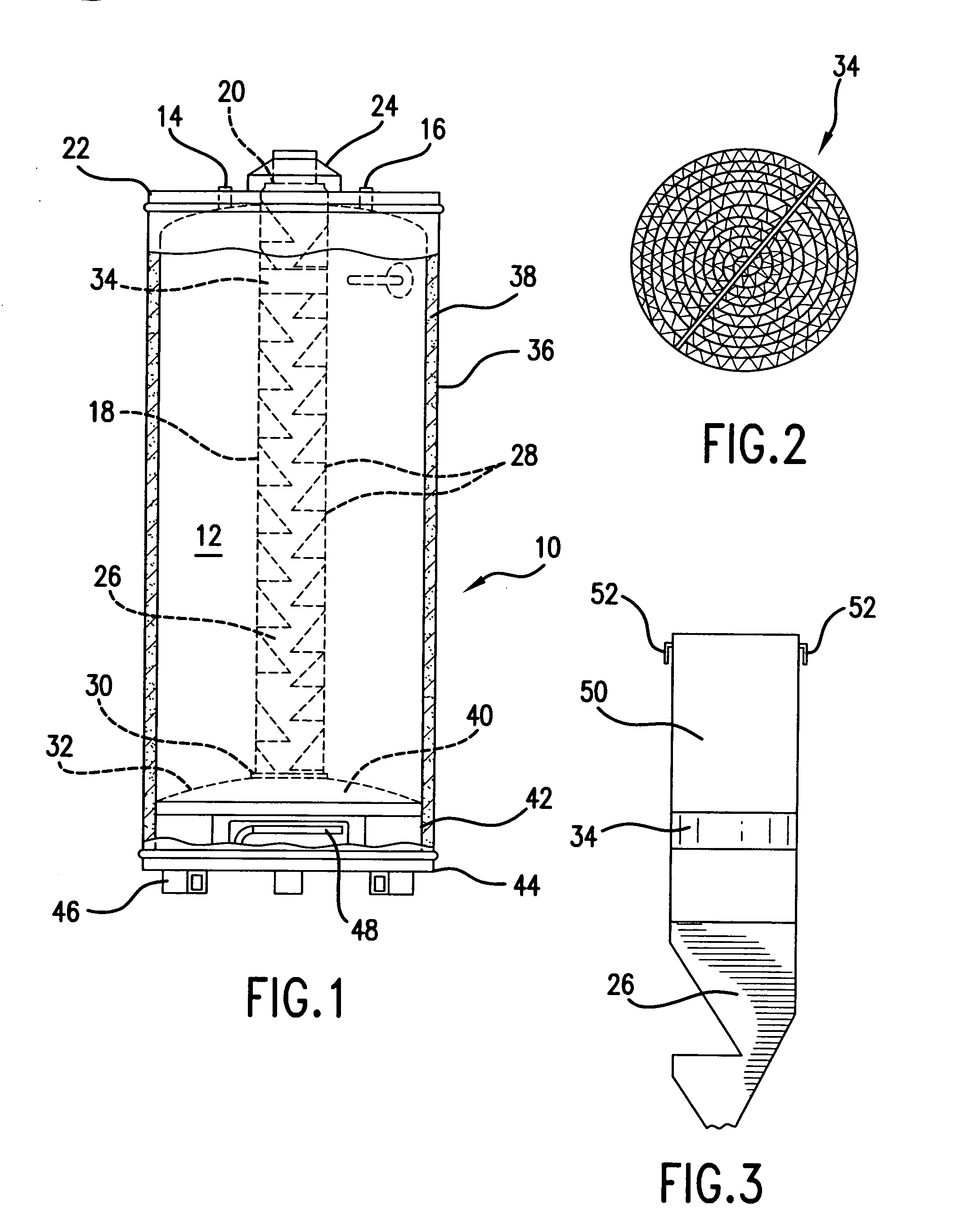

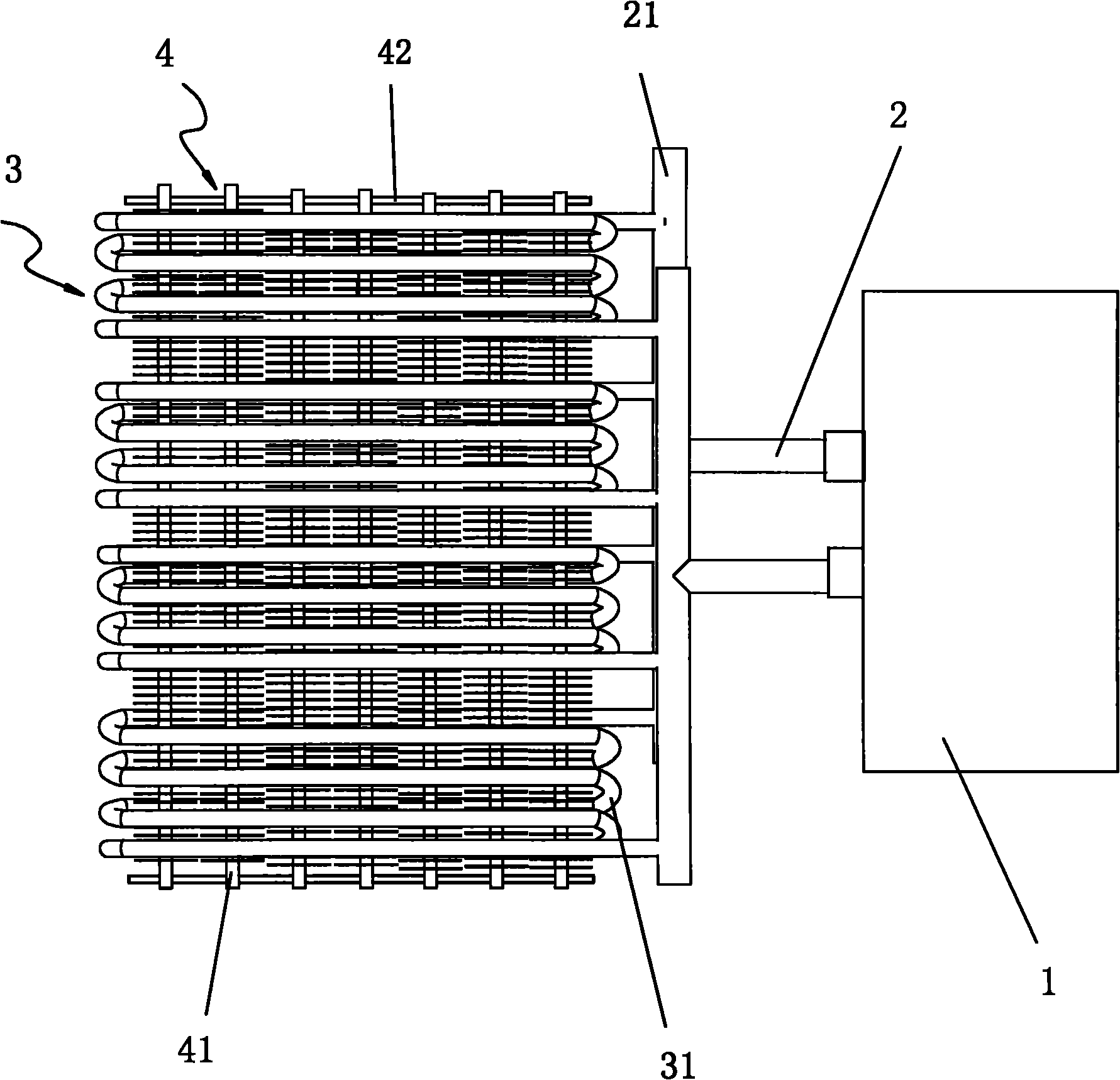

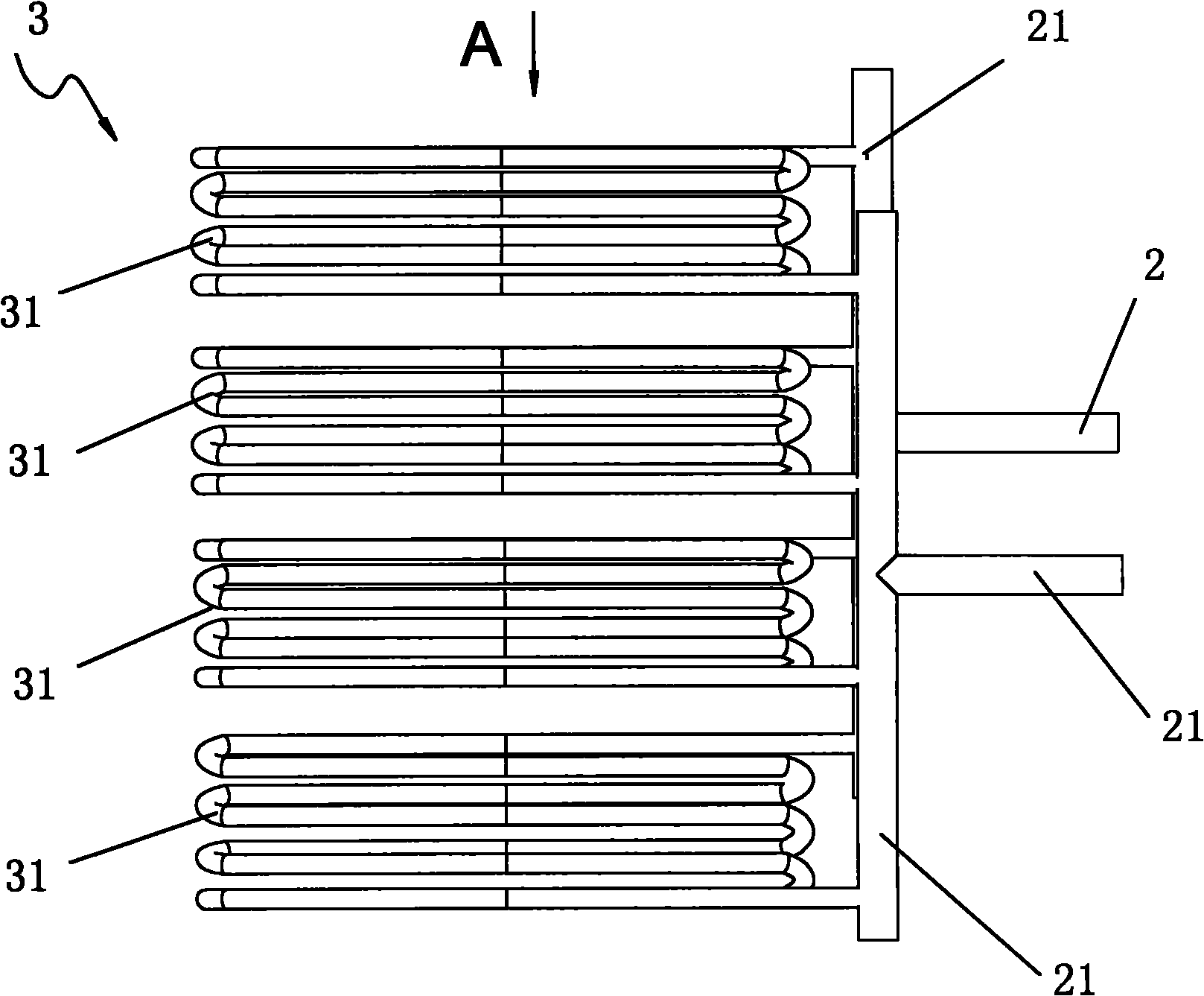

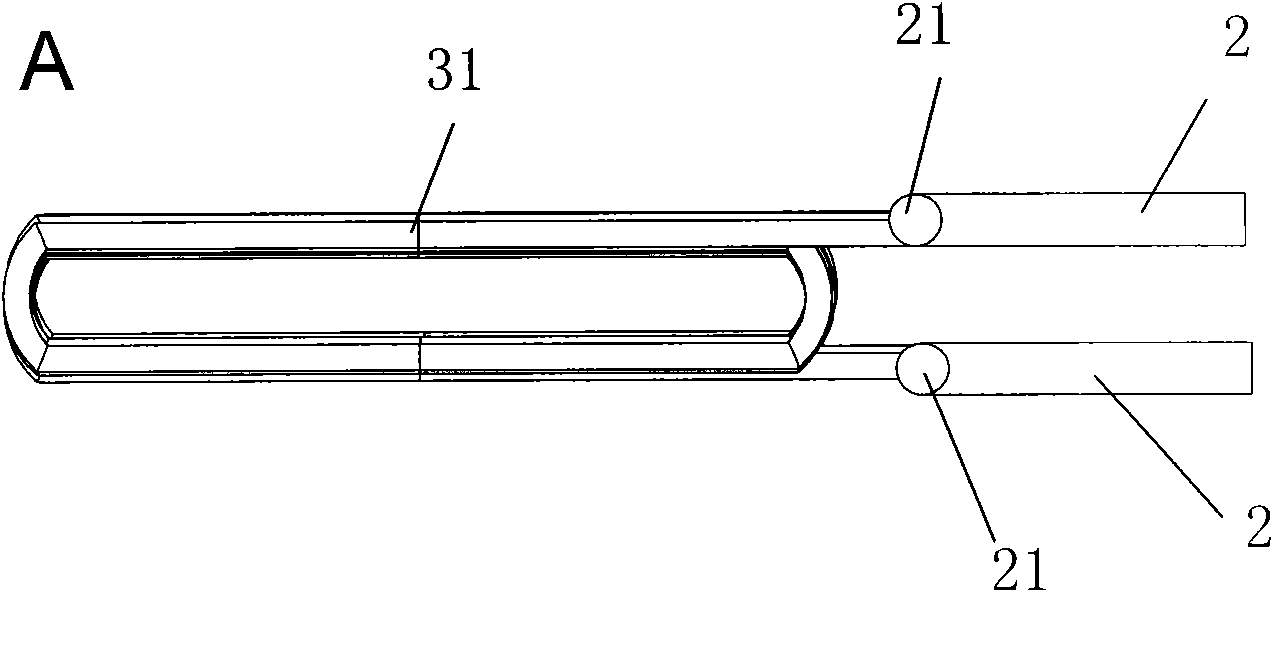

Fire Tube Heater

ActiveUS20110146594A1Stationary conduit assembliesHeat exchanger casingsCombustorMechanical engineering

A fire tube heater apparatus includes a shell, with a tube bundle received in the shell and a burner section communicated with the tube bundle. The tubes in the tube bundle have circular inlet and outlet end portions with a flattened, serpentine intermediate portion. The intermediate portion has a width greater than the inlet outside diameter and a tube thickness transverse to the width less than the inlet outside diameter.

Owner:LOCHINVAR

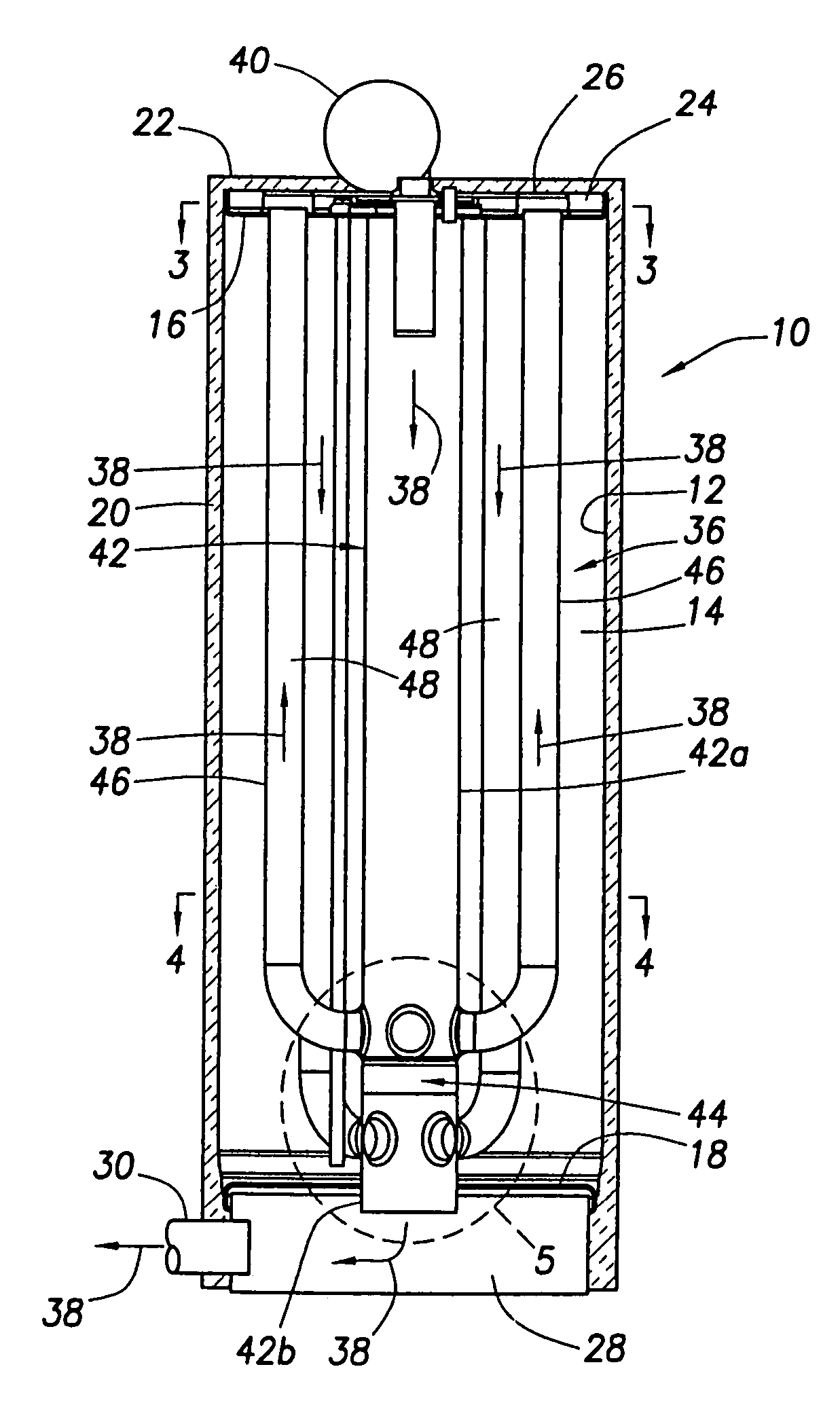

High efficiency, wet-base, downfired multi-pass water heater

A fuel-fired water heater has a three-pass condensing type heat exchanger disposed within its tank and having a central vertical first pass flue pipe separated into upper and lower portions by an internal dividing structure. Respectively coupled to the upper and lower first pass flue pipe portions are circumferentially spaced series of vertical second and third pass flue pipes which circumscribe the central flue pipe within the tank. During firing of the water heater, combustion gases from a power burner are sequentially forced downwardly through the upper portion of the first pass flue pipe, upwardly through the second pass flue pipes to an upper plenum external to the tank, and then downwardly through the third pass flue pipes and the lower central pipe portion into a bottom plenum external to the tank for discharge from the water heater.

Owner:RHEEM MFG CO

Fuel-fired, power vented high efficiency water heater apparatus

ActiveUS20090211540A1Improve energy efficiencyAvoid flowFurnace-tube steam boilersWater heatersCombustionFlue

A fuel-fired water heater has a draft inducer fan assembly with a housing having an inlet for receiving hot combustion gases discharged from the water heater, and an outlet for discharging the combustion gases. A normally closed damper member within the housing is openable by fluid pressure force created by operation of a draft inducer fan portion of the assembly. With the damper in its open position the fan exhausts the received combustion gases through a housing outlet. When the damper closes it prevents convective outflow through the housing outlet of flue-heated air. In alternate embodiments of the assembly the fan is operative to also draw in dilution air that cools the fan motor and the discharged combustion gases, with the assembly having an internal configuration preventing convective outflow of flue-heated air through the housing dilution air inlet during standby periods of the water heater.

Owner:RHEEM MFG CO

Preventing tube failure in boilers

ActiveUS20080163792A1Increasing side wall thickness of tubeReduce erosionFluidized bed combustionMolten spray coatingFluidized bedAlloy coating

The erosion-prone sections of the tubes in a circulating fluidized bed boiler are provided with a locally thickened sidewall without forming discontinuities on the outer surface of the tubes. This can be accomplished, for example, by replacing the erosion prone portion of the tube with a section having a smaller inside diameter, but the same outside diameter, or by replacing the erosion prone portion of the tube with a section having a thicker sidewall, but the same inside diameter, and smoothing over the outside discontinuity with an alloy coating. A useful alloy coating is also disclosed which can be used for this and other applications.

Owner:INTEGRATED GLOBAL SERVICES

Super low NOx, high efficiency, compact firetube boiler

ActiveUS6971336B1Reduce nitrogen oxide emissionsReducing NO<sub>Furnace-tube steam boilersCombustion enginesCombustion chamberBoiler furnace

A firetube boiler furnace having two combustion sections and an in-line intermediate tubular heat transfer section between the two combustion sections and integral to the pressure vessel. This design provides a staged oxidant combustion apparatus with separate in-line combustion chambers for fuel-rich primary combustion and fuel-lean secondary combustion and sufficient cooling of the combustion products from the primary combustion such that when the secondary combustion oxidant is added in the secondary combustion stage, the NOx formation is less than 5 ppmv at 3% O2.

Owner:GAS TECH INST

Exercise Apparatus

ActiveUS20100323857A1Improve instabilityReduce impactResilient force resistorsFurnace-tube steam boilersPhysical medicine and rehabilitationEngineering

Apparatus suitable for pilates and other exercise comprises rails, supported on a box-like frame and an exercise carriage, mounted on the rails, wherein the carriage comprises a first carriage section and a second carriage section which sections can be (i) connected together to form a single exercise carriage which slides forwards and backwards on the rails, or (ii) disconnected to form two exercise carriages which independently slide forwards and backwards on the rails. The apparatus also has a seat with a spring-biased foot pedal and a spring-biased trapeze bar.

Owner:DSILVA LTD

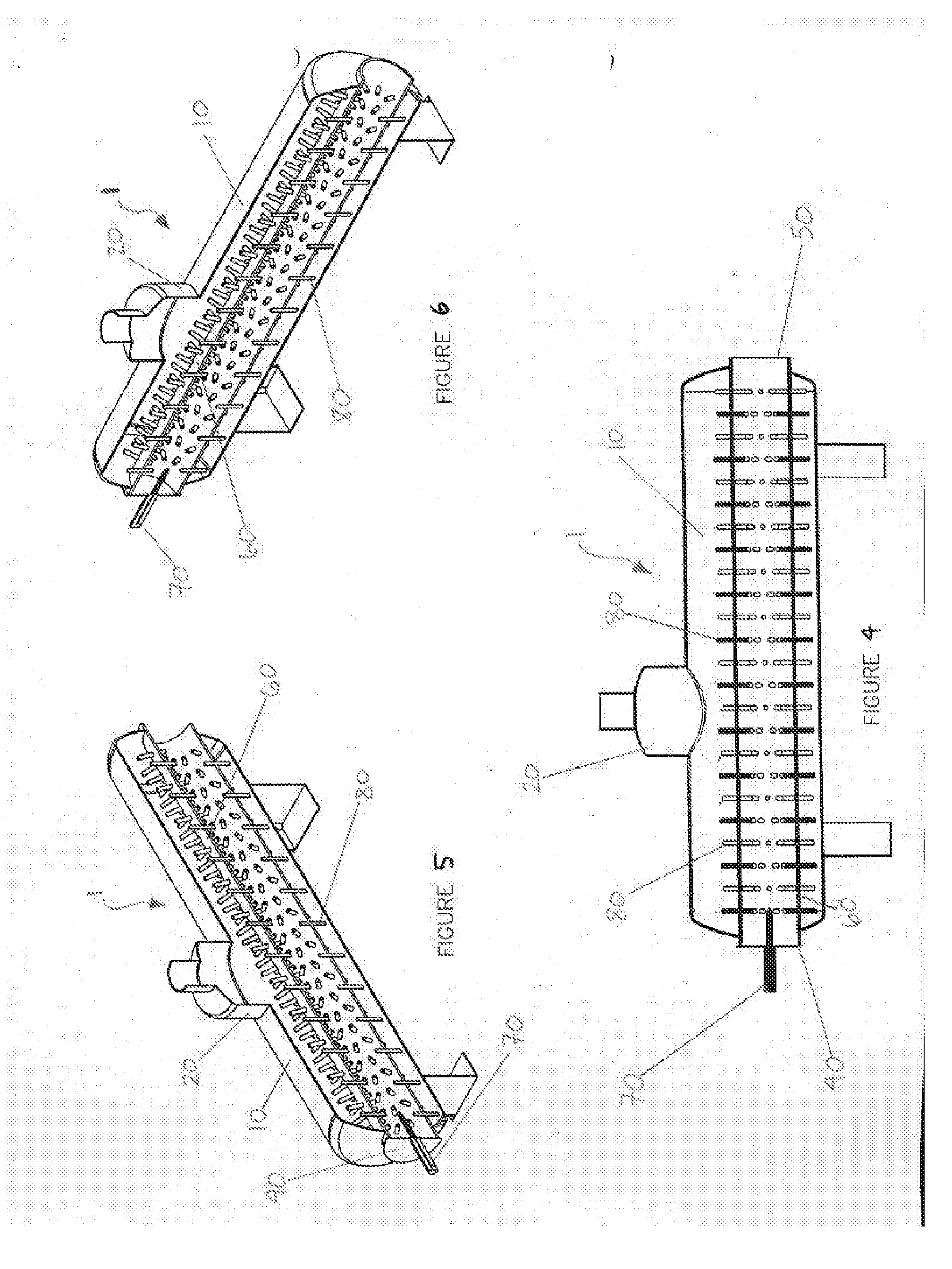

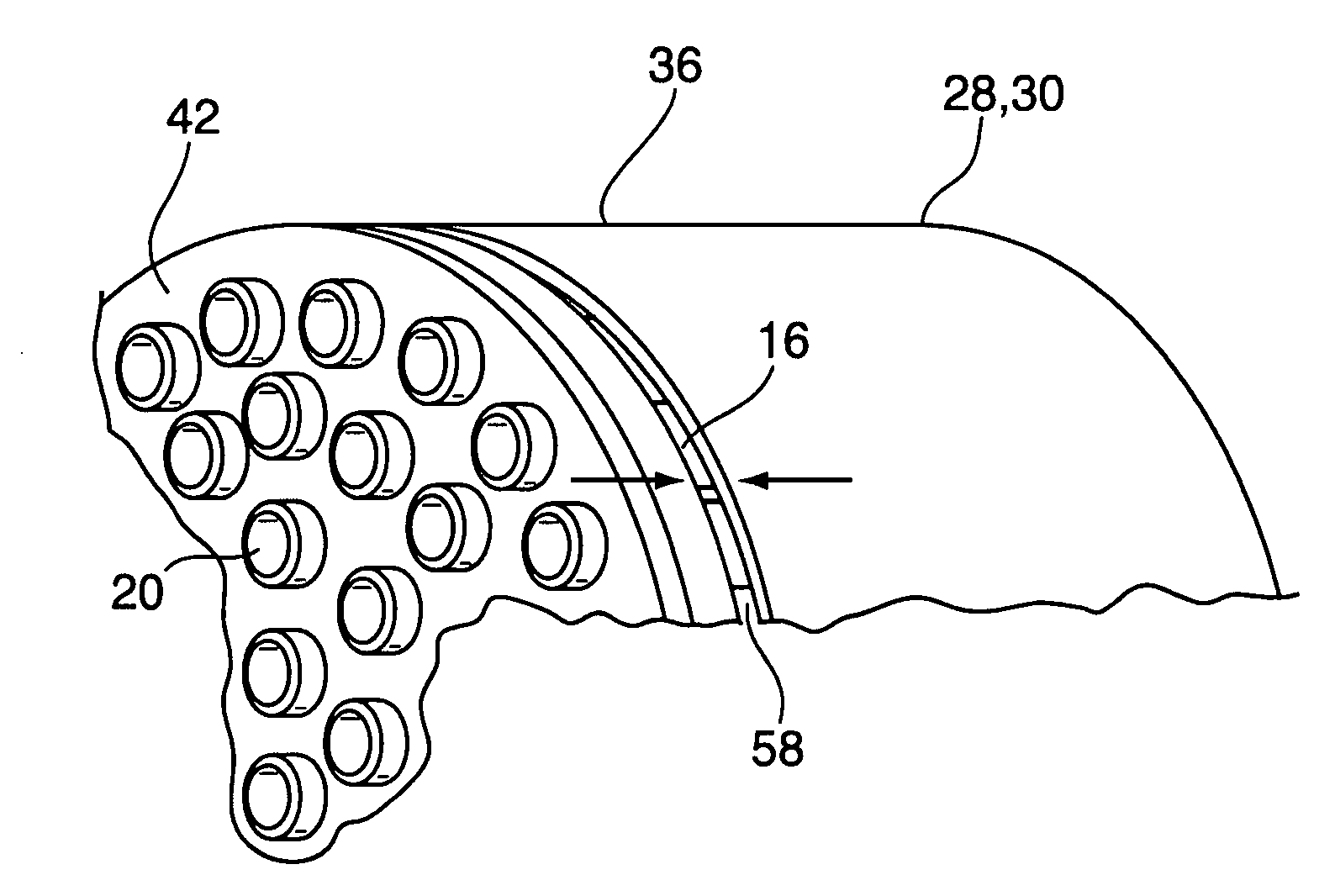

High-efficiency enhanced boiler

ActiveUS20070199688A1Increase surface areaEnhancing convection/conduction coupleStationary tubular conduit assembliesFire-tube steam boilersEngineeringConvection

In devices known in the art, “conventional firetube” and “waste heat recovery” boilers each require many small tubes making successive passes within the boiler. In one embodiment of the invention, however, an enhanced conduit replaces numerous conventional small tubes. In some embodiments, the enhanced conduit incorporates a plurality of fins, each of which extends through a wall of the conduit. In other embodiments, the enhanced conduit incorporates a plurality of tubes along its outer surface, through which a heat transfer medium flows. Both designs enhance the heat transfer relationship between the hot fluid and the heat transfer medium by providing a continuous heat transfer relationship with the heat transfer medium, increasing the surface area involved in the heat transfer relationship and enhancing convection / conduction couples. For some applications, all of the tube banks of other devices in the art can be replaced by one continuous enhanced conduit.

Owner:OKONSKI SR JOHN E +1

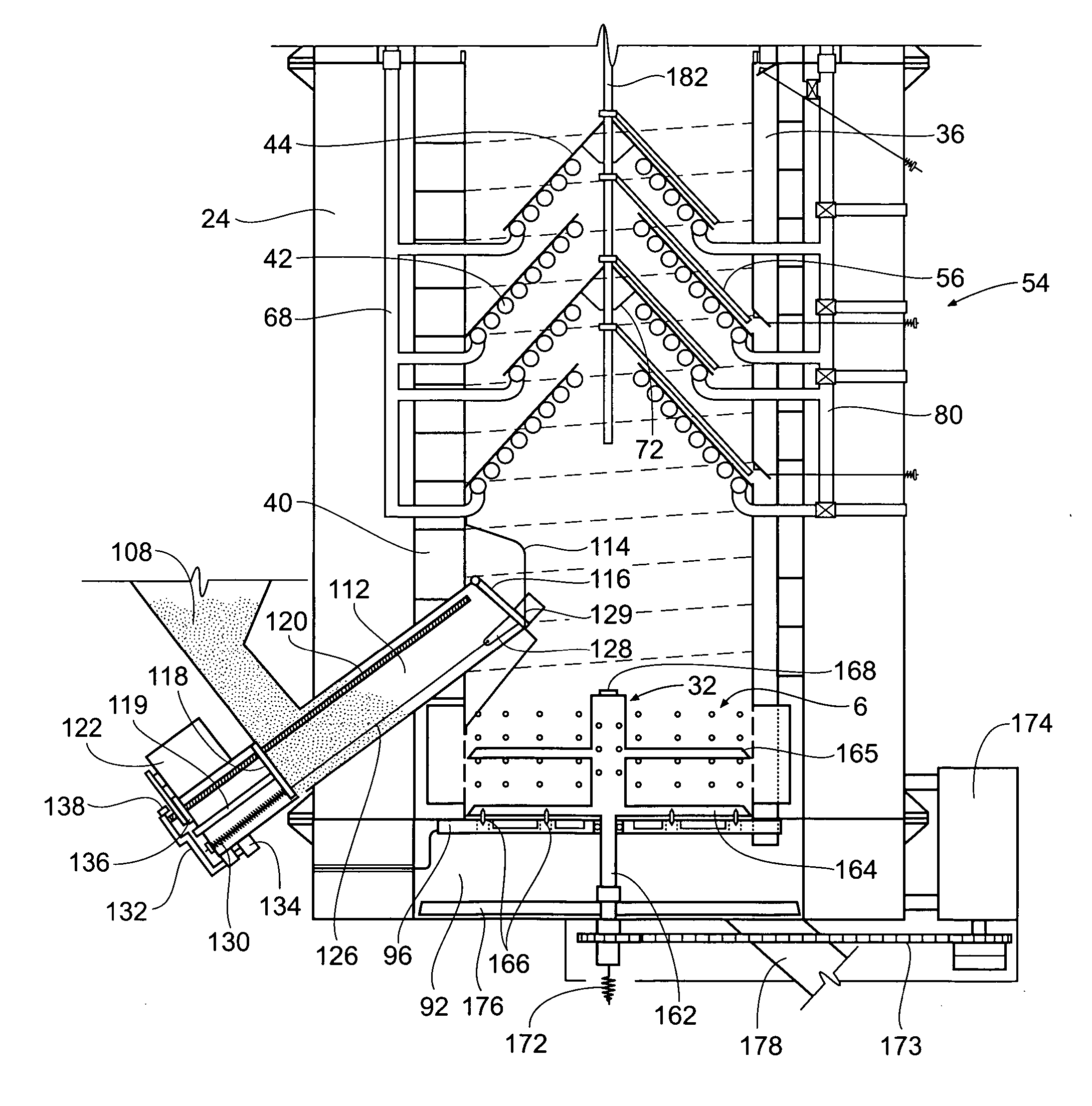

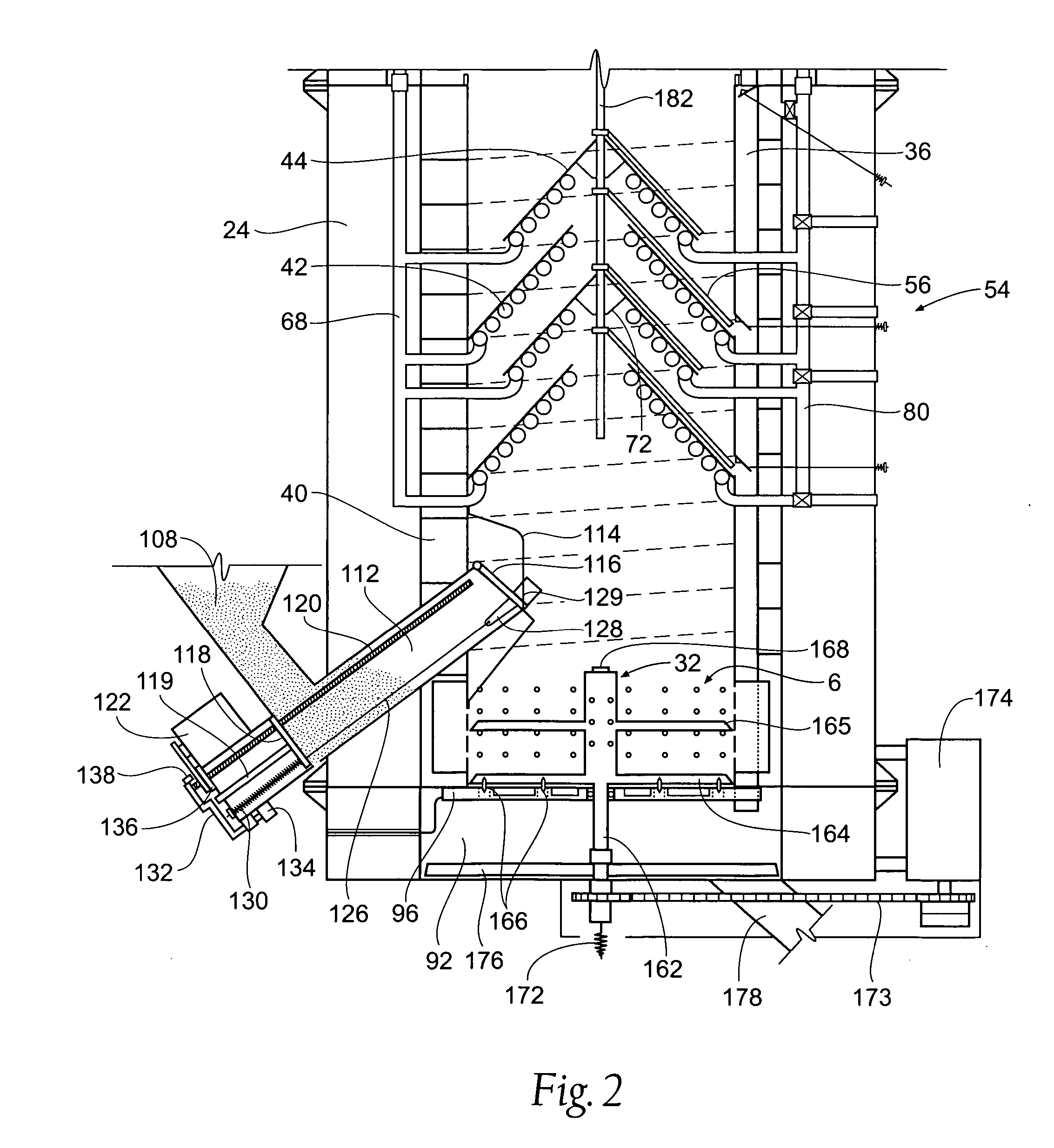

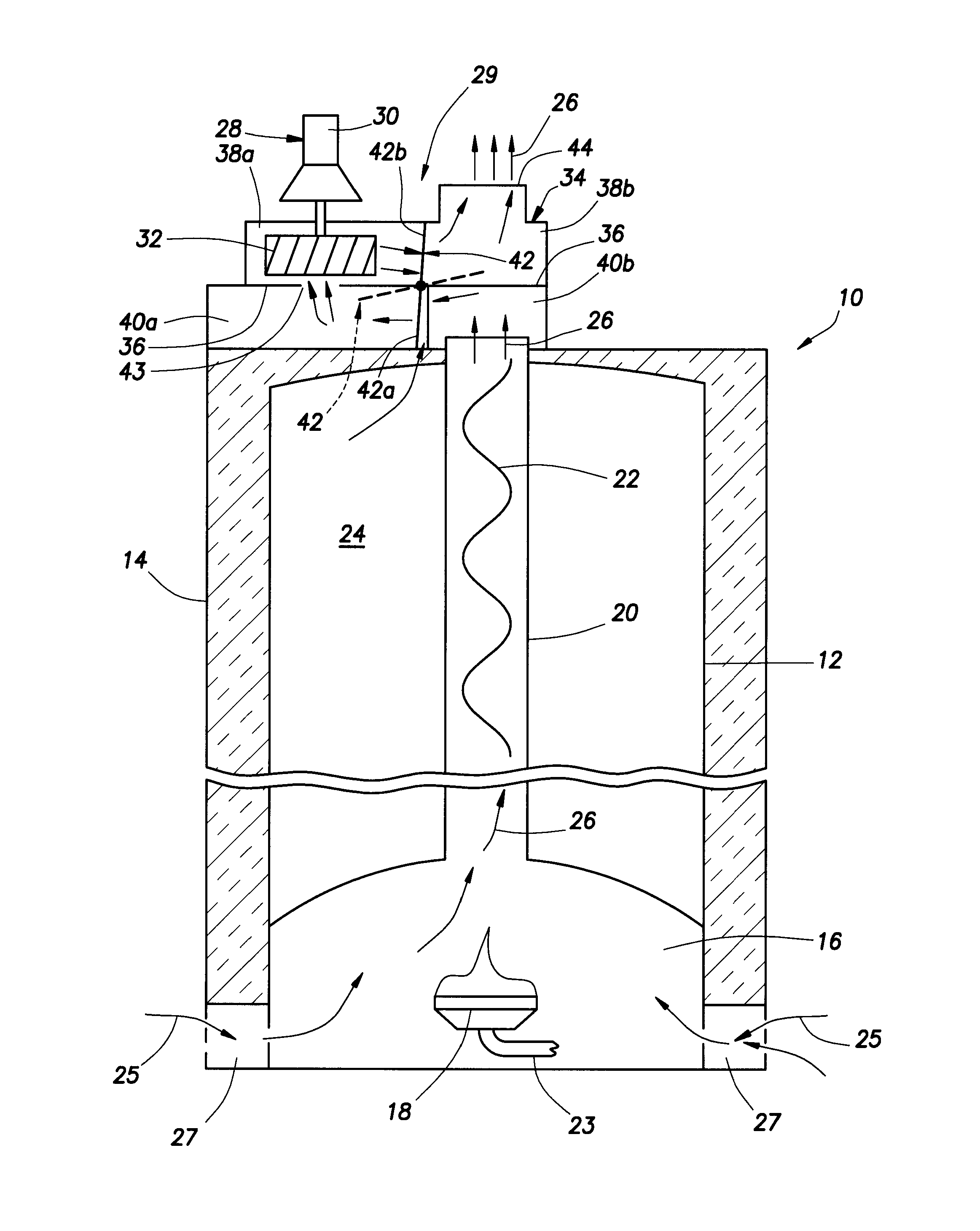

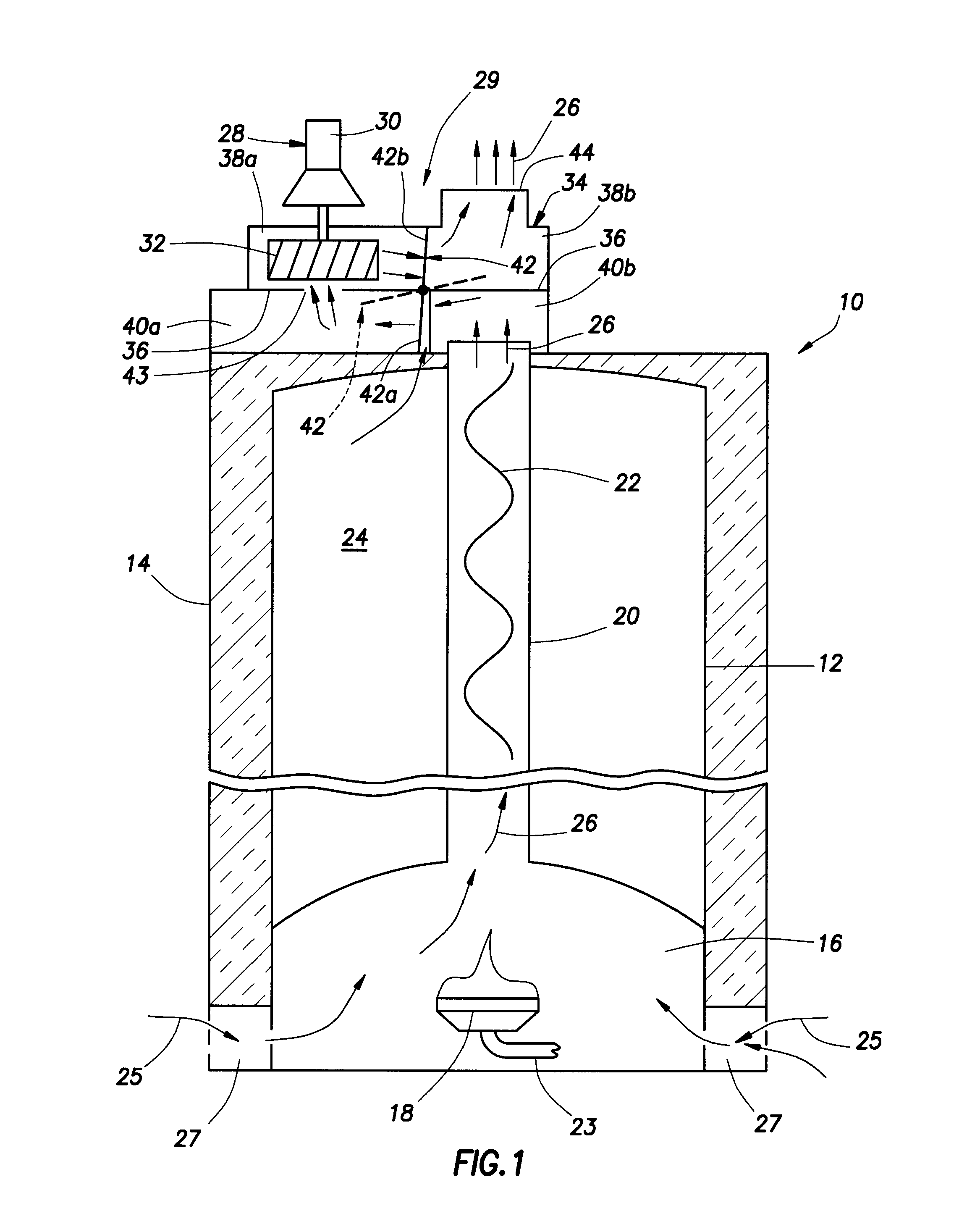

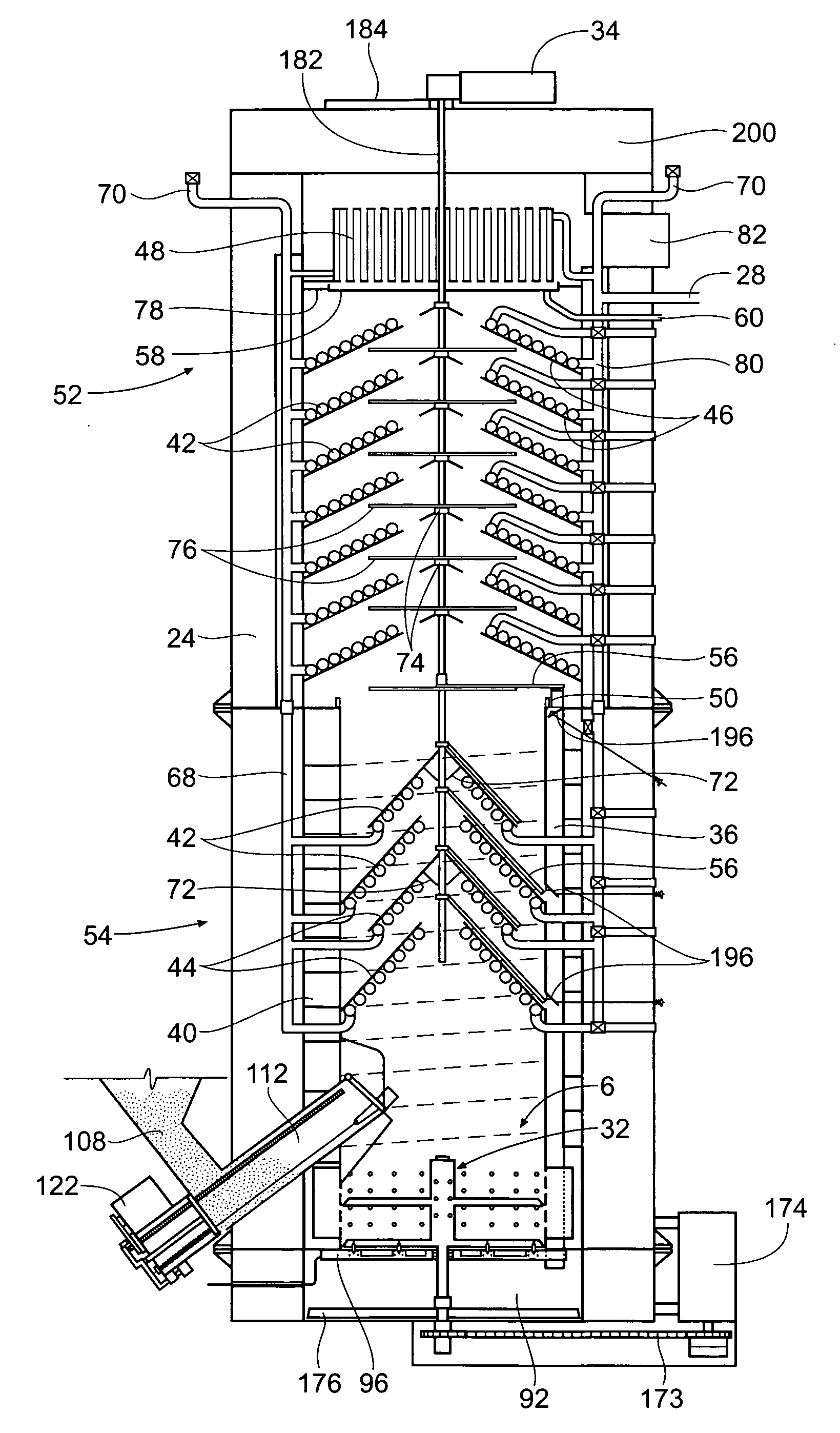

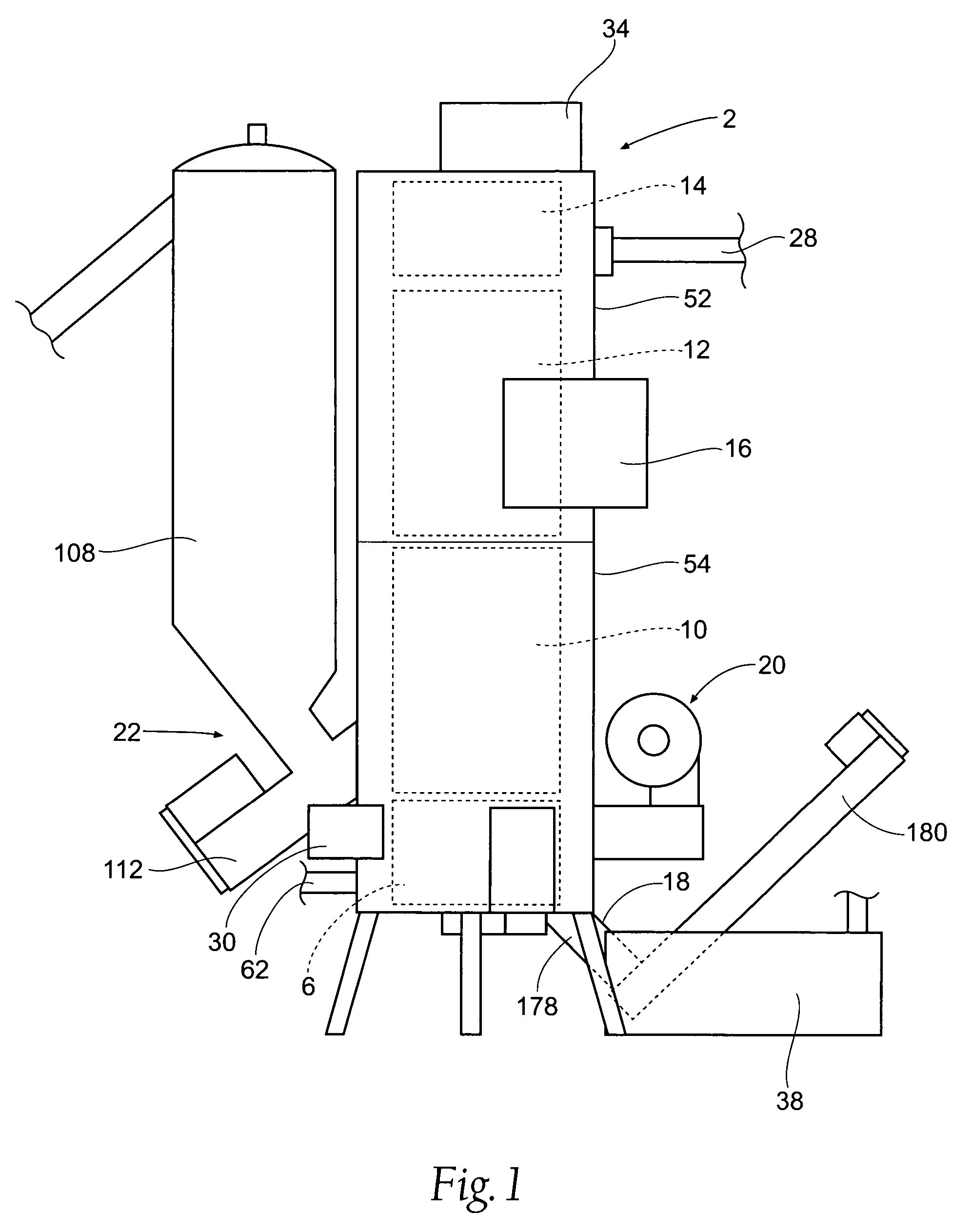

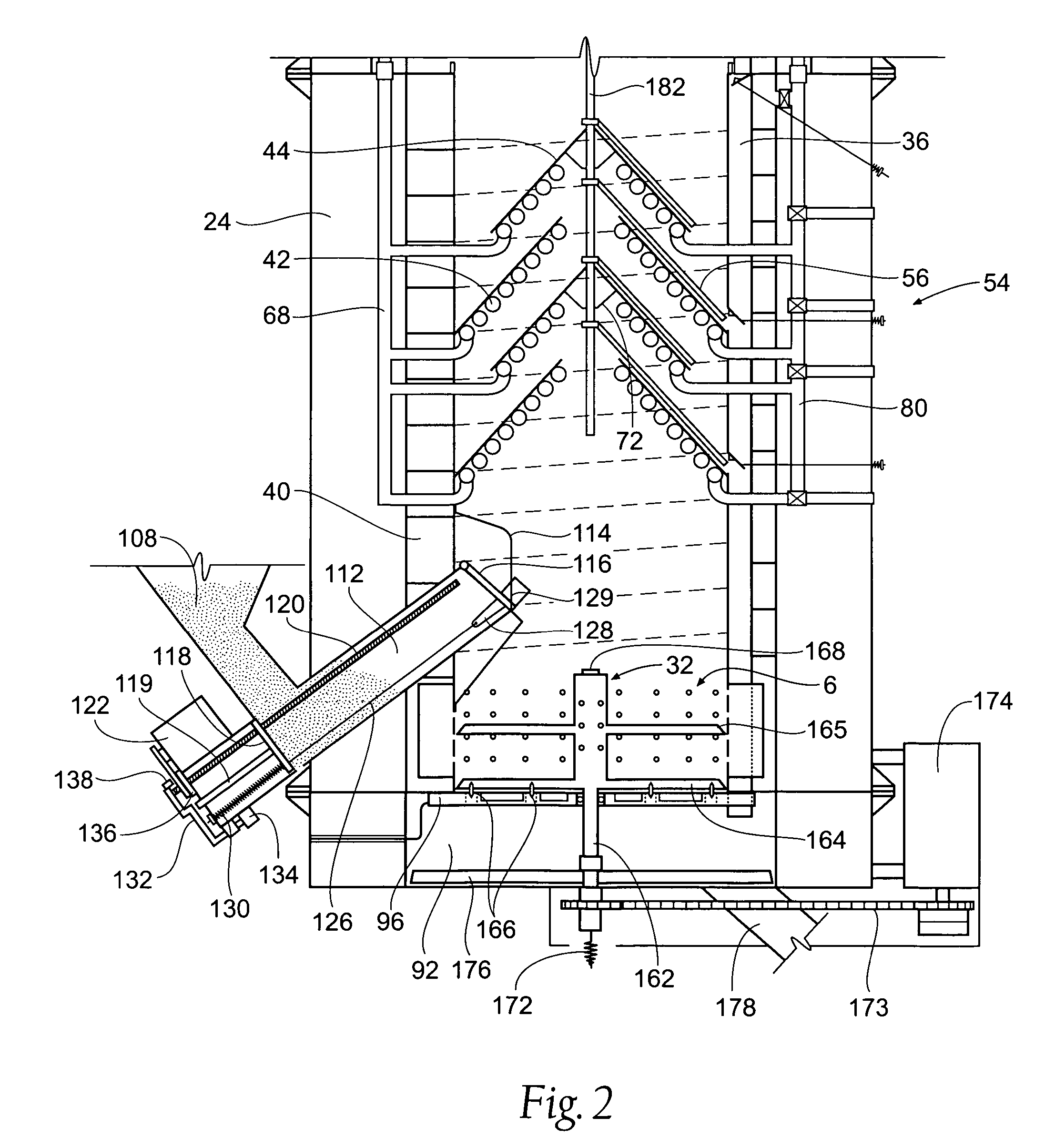

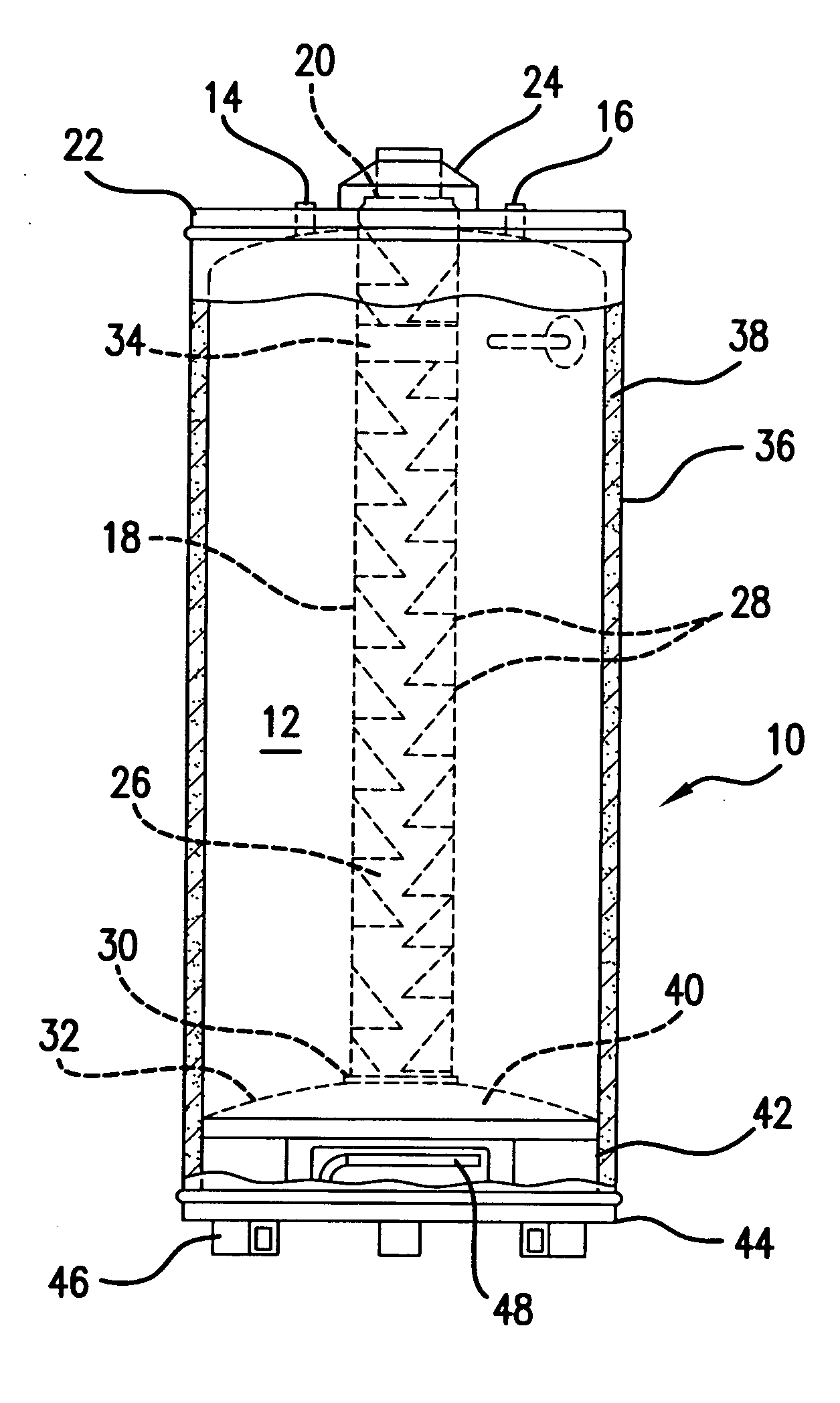

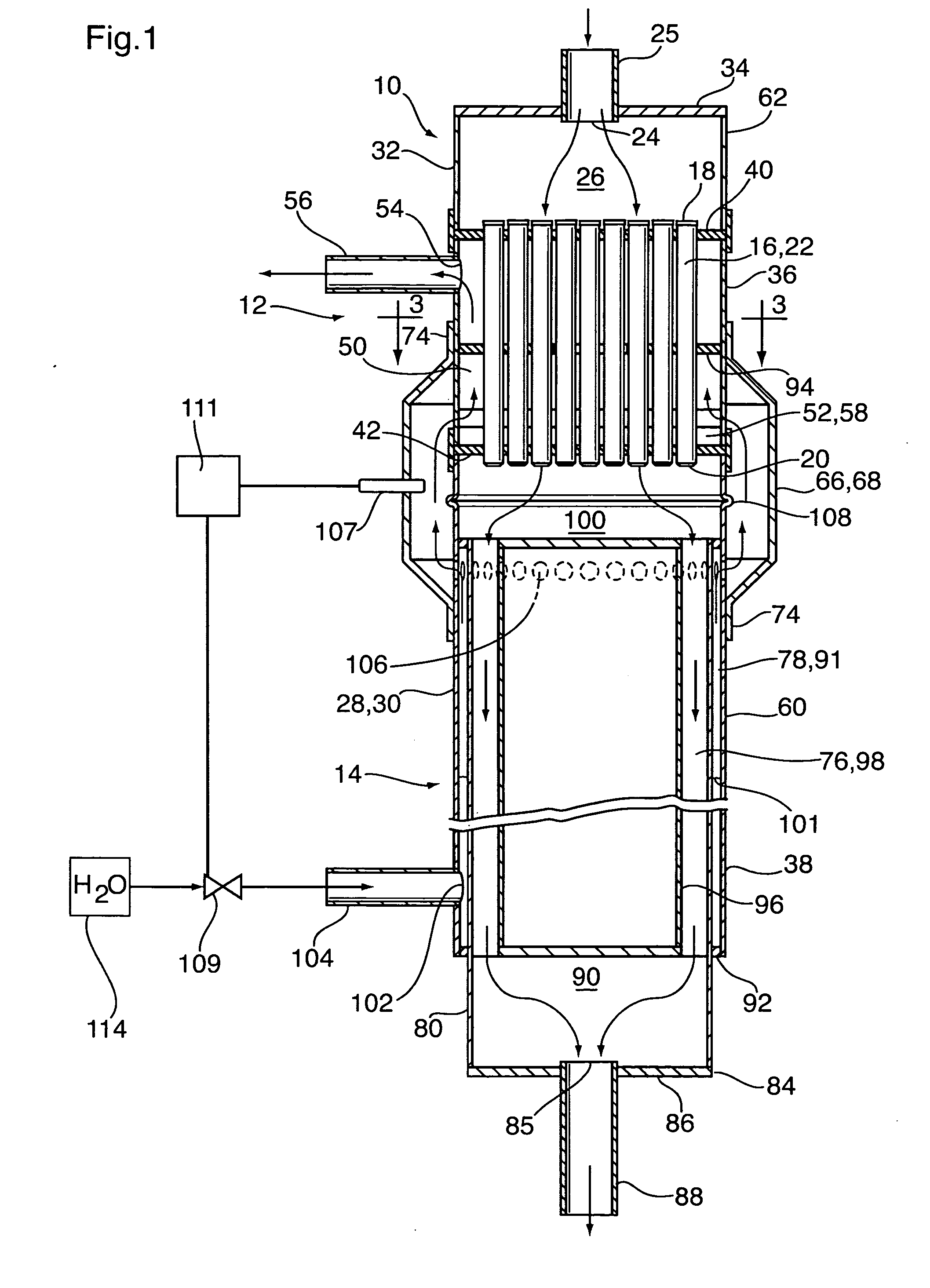

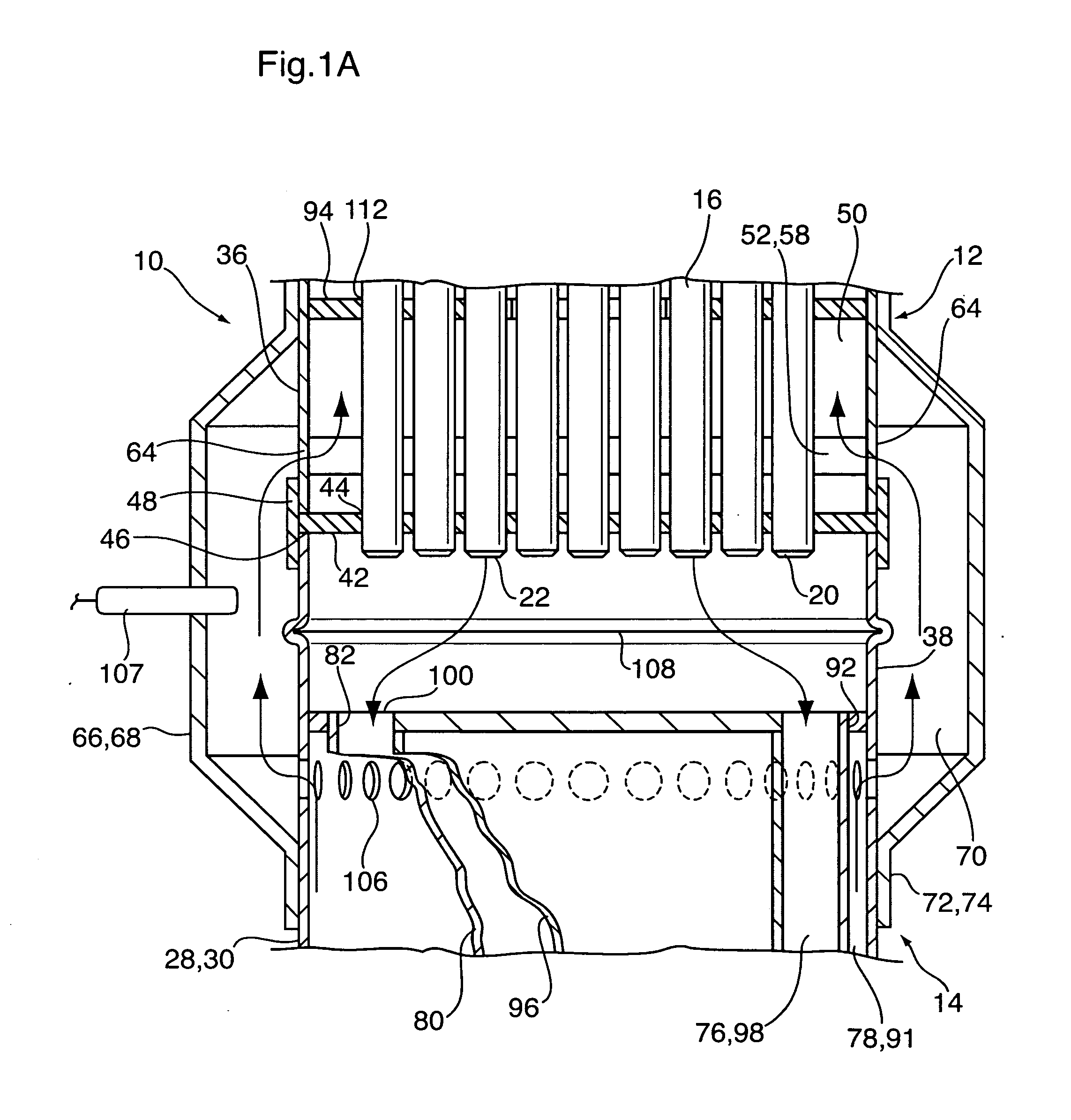

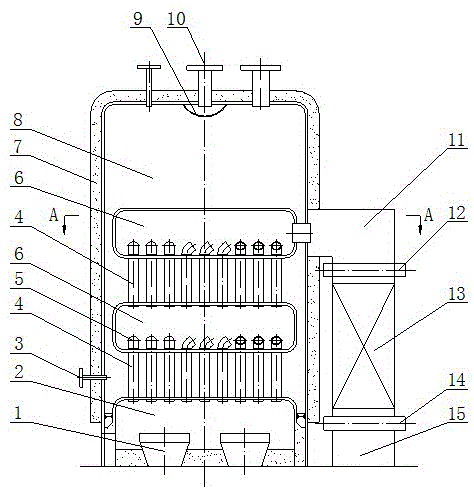

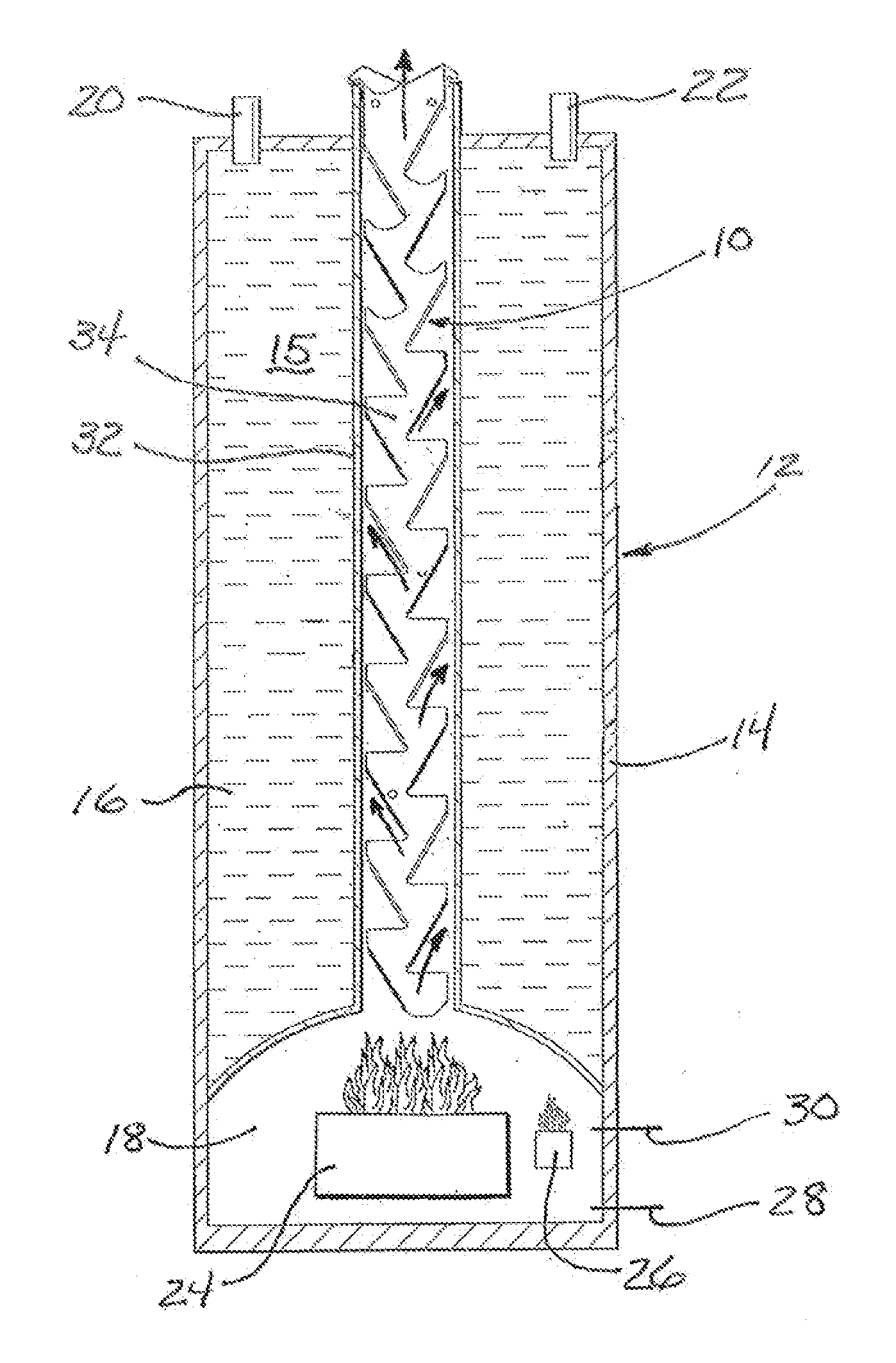

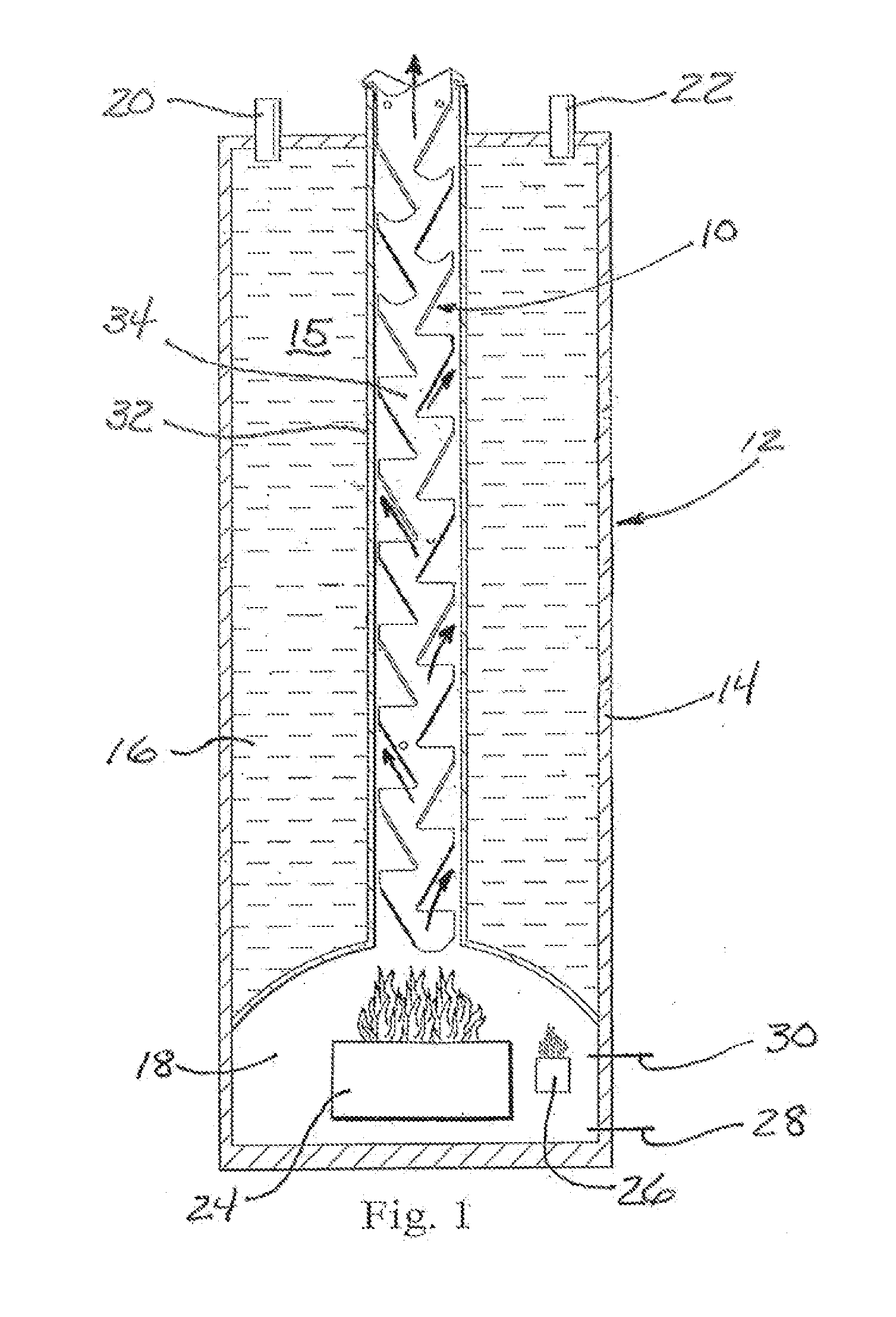

Granular biomass burning heating system

InactiveUS7621227B2Minimize back burningImprove unit efficiencyAir supply regulationStirring devicesCombustionThree stage

A granular biomass burning furnace for use with any appropriate granular biomass, such as grains, cherry pits, etc. The furnace includes a three stage heat exchanger, a fuel injector, a fuel stirrer, an ash ejector, a wash down system, a three stage air inducer, a fuel igniter, and supporting components. The unit includes a computer controller which controls all aspects of the operation of the unit based on information from sensors located throughout the unit. The unit includes a smart logic thermal controller to adjust the output heat of the unit via a variable speed air inducer. The three stage heat exchanger system includes a spiral water jacket surrounding the burn pot, a plurality of heat exchanger baffles in the unit, and a fine finned heat exchanger at the top of the unit. The air inducer provides air to the burn pot from three directions to promote complete combustion.

Owner:STERR KEVIN K

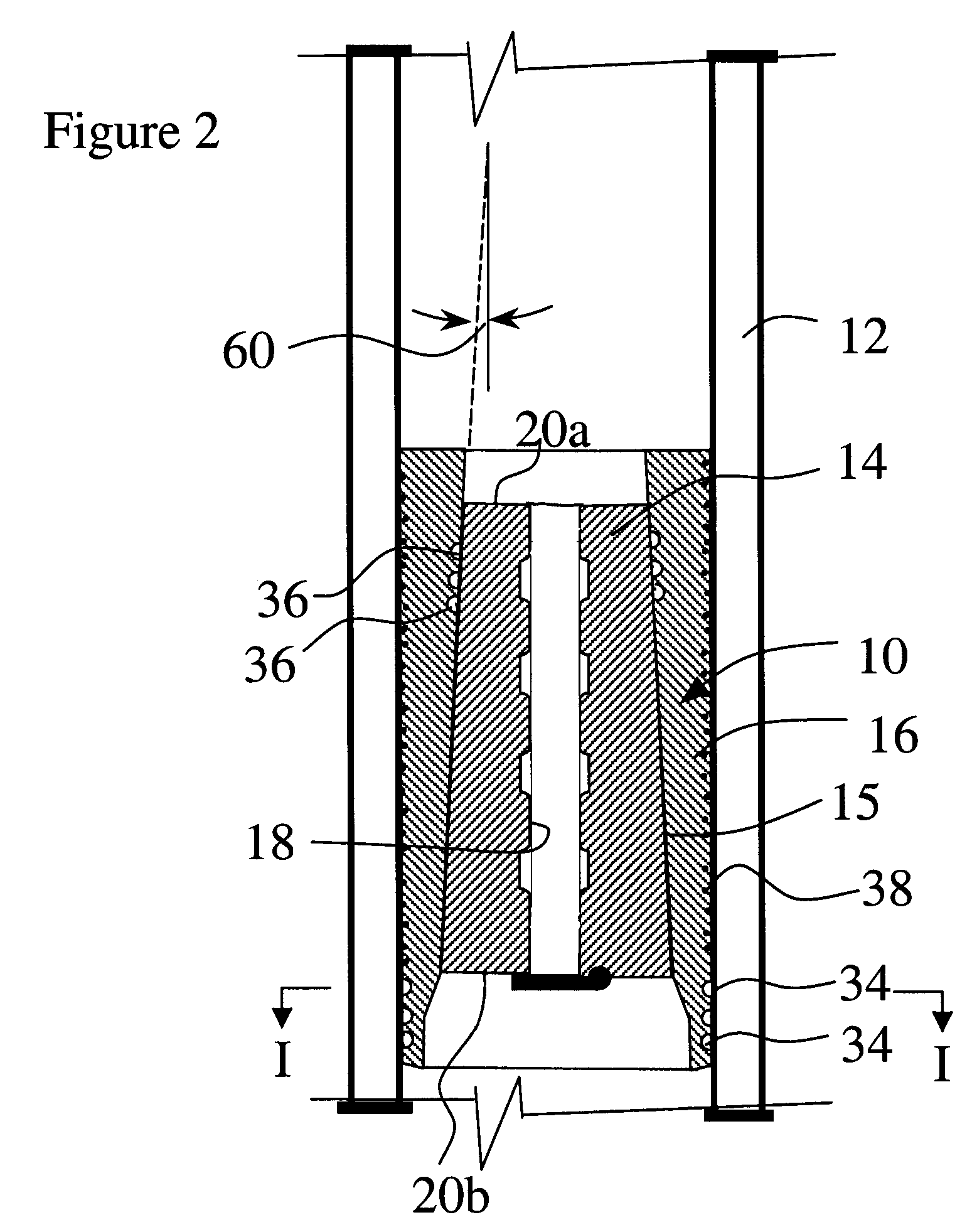

Cement float

A cement float for use in a wellbore tubing string includes: a mandrel having a bore extending from a first end to a second end including a fluid flow control device therein, and outer surfaces defining a tapering outer diameter from the first end to the second end; an outer lock sleeve having an outer surface and a sleeve bore therethrough, the outer lock sleeve retained at least about the outer surfaces of the mandrel surfaces and defining interfaces therebetween, the sleeve being expandable radially outwardly by driving the mandrel against the sleeve bore to place the cement float in anchoring position within the tubing string.

Owner:SCHLUMBERGER TECH CORP

Low CO water heater

InactiveUS20070186872A1Promote conversionReduce accumulationFluidized bed combustionFurnace-tube steam boilersForeign matterCombustor

A water heater including a water container, a combustion chamber adjacent the water heater, a burner associated with the combustion chamber and arranged to combust fuel to heat water in the water container, a flue having an upper portion and a lower portion operatively connected to the combustion chamber and extending through at least a portion of the water container, and a catalytic converter located in the upper portion of the flue. The water heater may also reduce NOx and CO emissions generated by a water heater having a radiant burner including activating the burner in response to the temperature of water in the water heater as needed, and substantially removing accumulated foreign matter on the burner by periodically activating the burner irrespective of the water temperature for a selected amount of time.

Owner:AMERICAN WATER HEATER

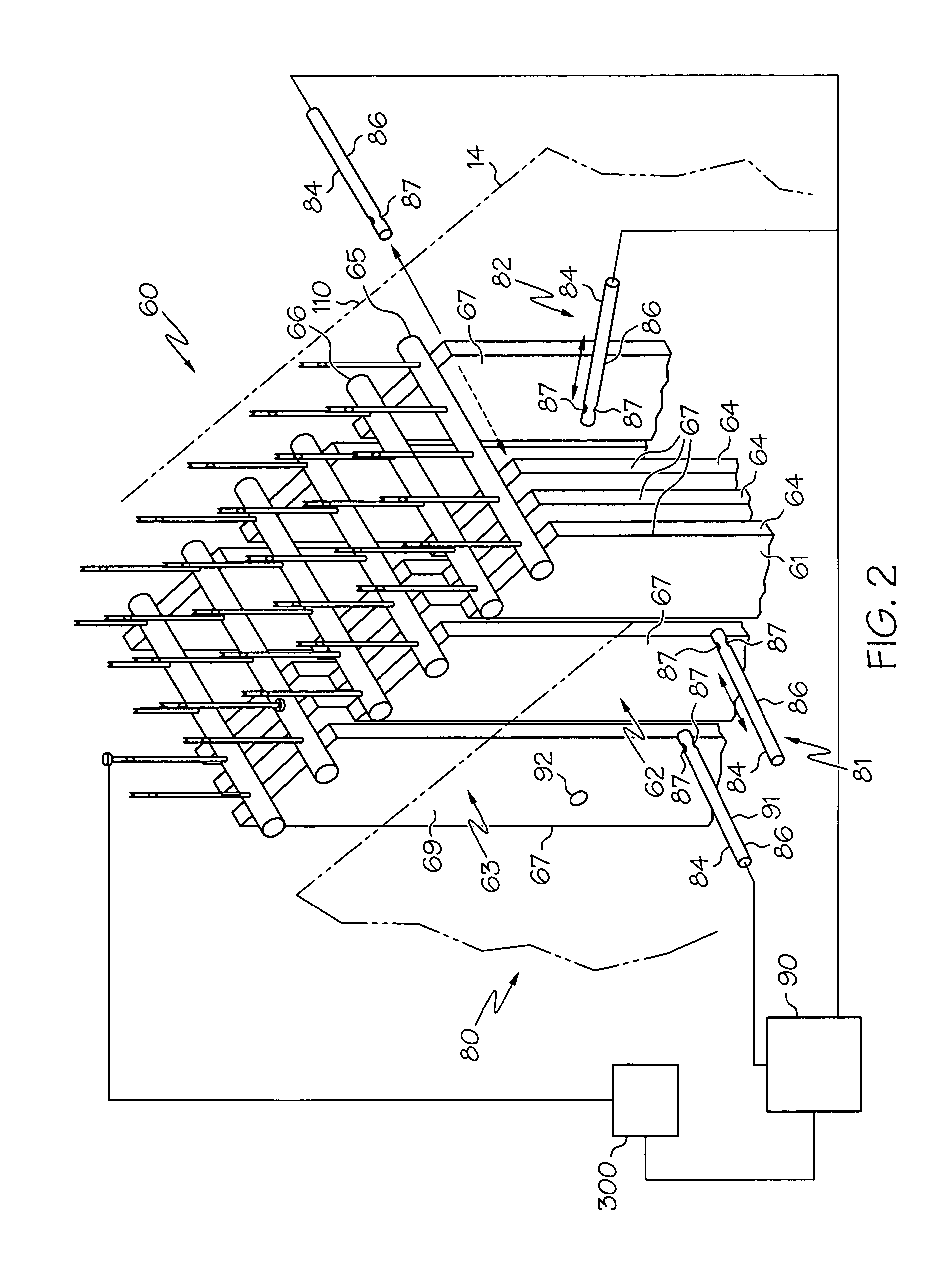

Fired heater for a hydrocarbon conversion process

ActiveUS8282814B2Low costShorten the timeThermal non-catalytic crackingRefining to change hydrocarbon structural skeletonEngineeringInlet manifold

One exemplary embodiment of the present invention can be a fired heater for a hydrocarbon conversion process. The fired heater includes inlet and outlet headers or manifolds, a set of heater tubes with each heater tube having an inlet and an outlet, at least one restriction orifice adjacent the inlet of at least one heater tube. The restriction orifice may be within the inlet manifold and adjacent the inlet of a heater tube, or between the inlet manifold and the inlet to the heater tube. A process may include passing a hydrocarbon stream through the fired heater described herein during the course of operating a hydrocarbon conversion process.

Owner:UOP LLC

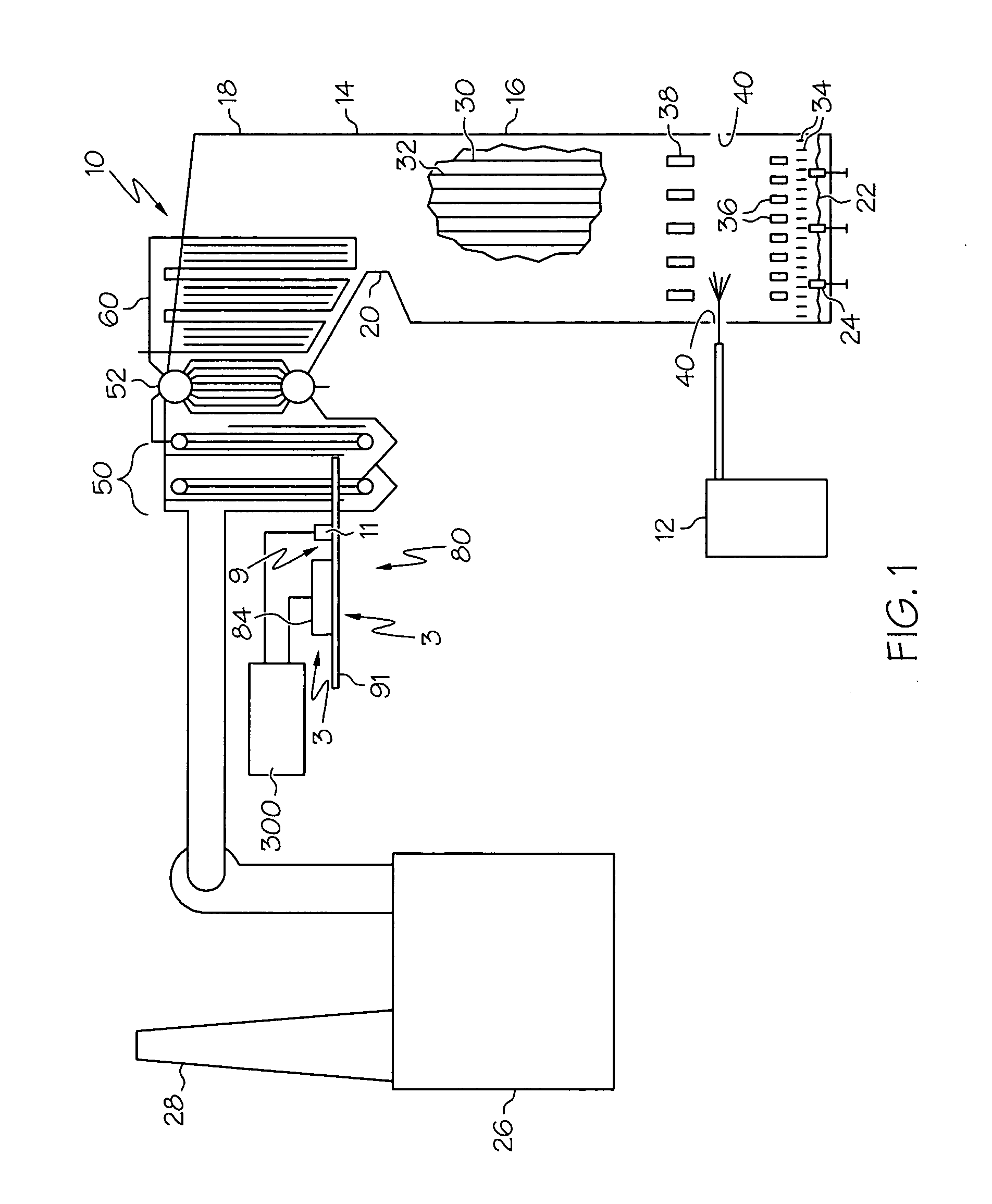

Controlling cooling flow in a sootblower based on lance tube temperature

A cleaning system and method for cleaning heat transfer surfaces in a boiler using a temperature measuring system for measuring and monitoring wall temperature of an annular wall of the tube of a lance of one or more sootblowers. Controlling a flow of steam or other fluid through the tube during the cooling portions of the strokes based on wall temperature measurements from the temperature measuring system. Infrared or thermocouple temperature measuring systems may be used. The steam or other fluid may be flowed at a default flowrate that may be substantially zero until the temperature measuring system indicates the wall temperature of the annular wall begins to exceed a predetermined temperature limit which may be the softening point of the annular wall. Then the steam or other fluid is flowed at a rate greater than the default flowrate.

Owner:INT PAPER CO

Heat Exchangers with Floating Headers

ActiveUS20140000845A1Safety devices for heat exchange apparatusHeat exchanger casingsWater-gas shift reactionEngineering

A heat exchanger is comprised of two heat exchanger sections, at least one of which is provided with a floating header to accommodate differential thermal expansion. The two heat exchanger sections are enclosed by an inner shell wall, and an external connecting passage is provided outside the inner shell wall, through which one of the fluids flows between the two heat exchanger sections. The external connecting passage is enclosed by an outer shell. The inner wall is provided with openings which communicate with the external connecting passage. The openings may be in the form of a substantially continuous gap or discrete openings. Specific examples of heat exchangers with this construction include a steam generator, a steam generator and combined catalytic converter, and a water gas shift reactor.

Owner:DANA CANADA CORP

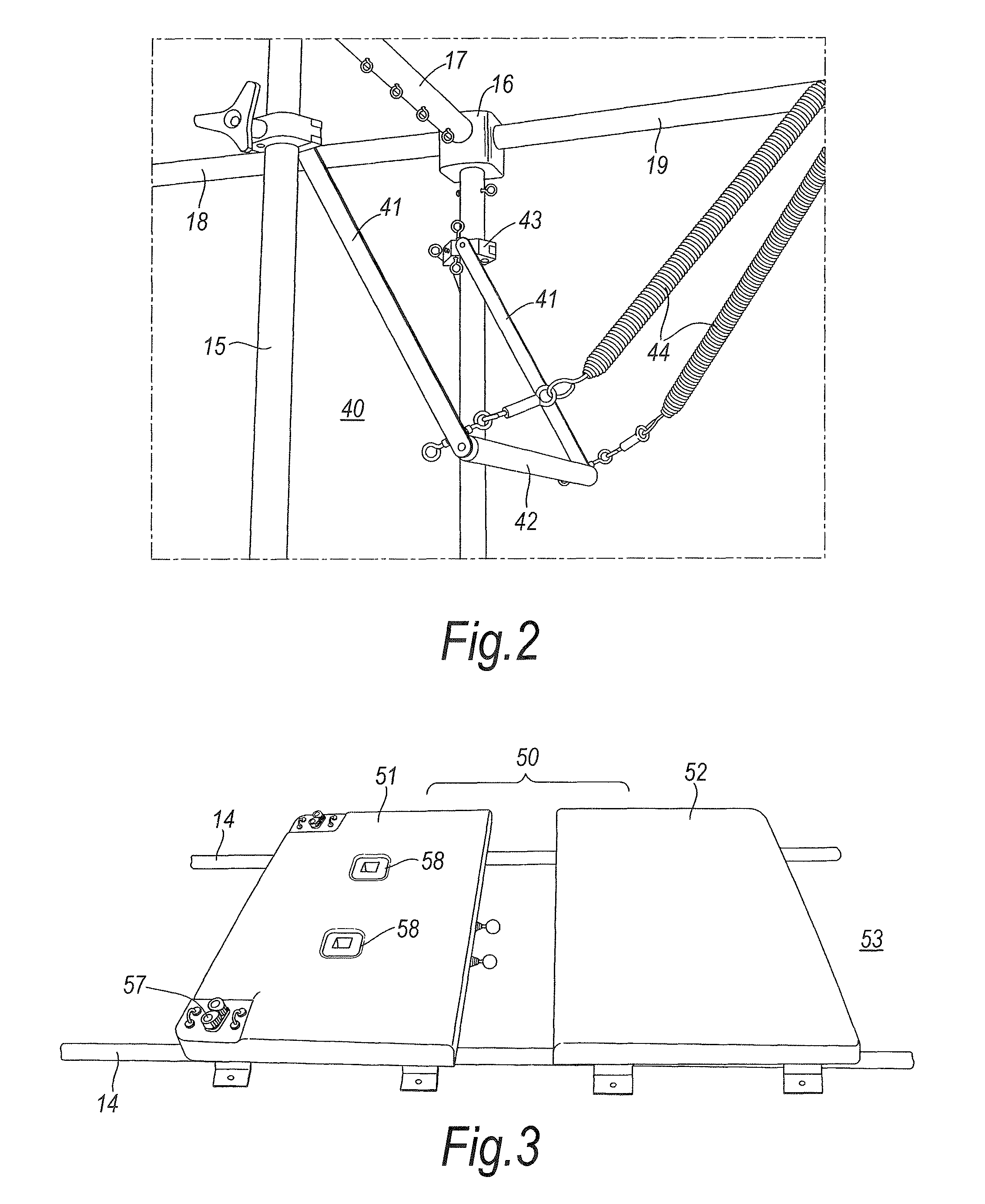

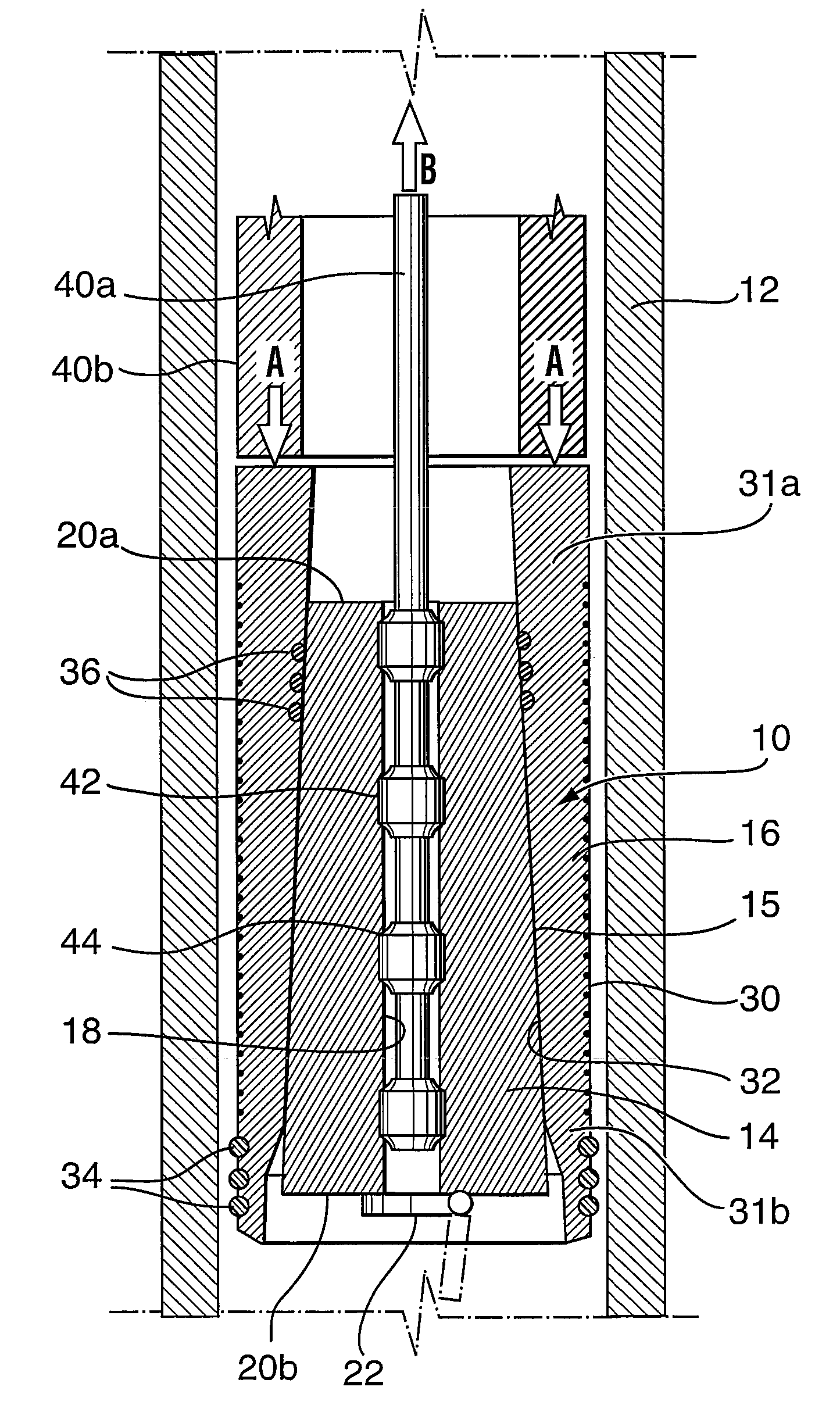

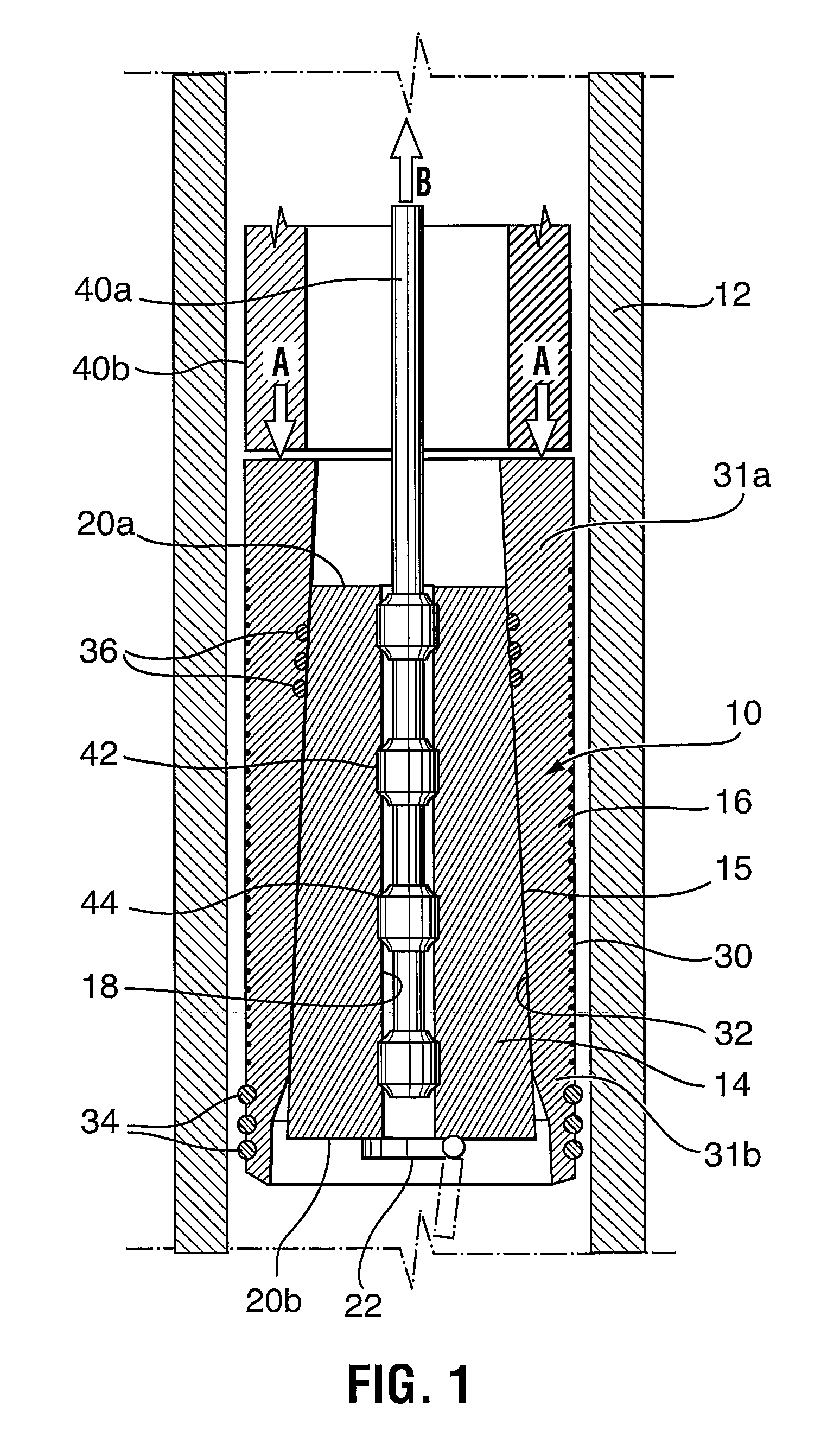

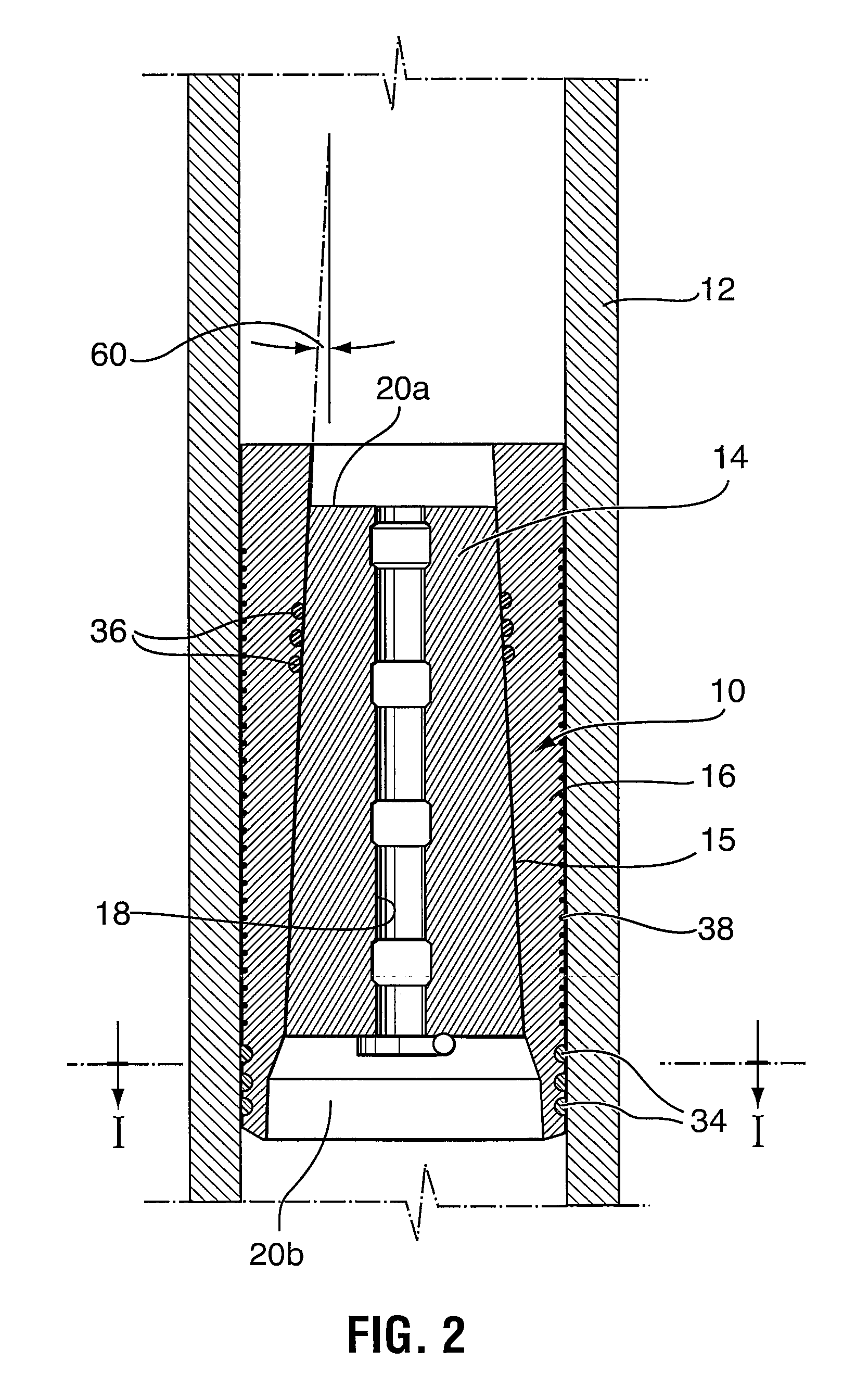

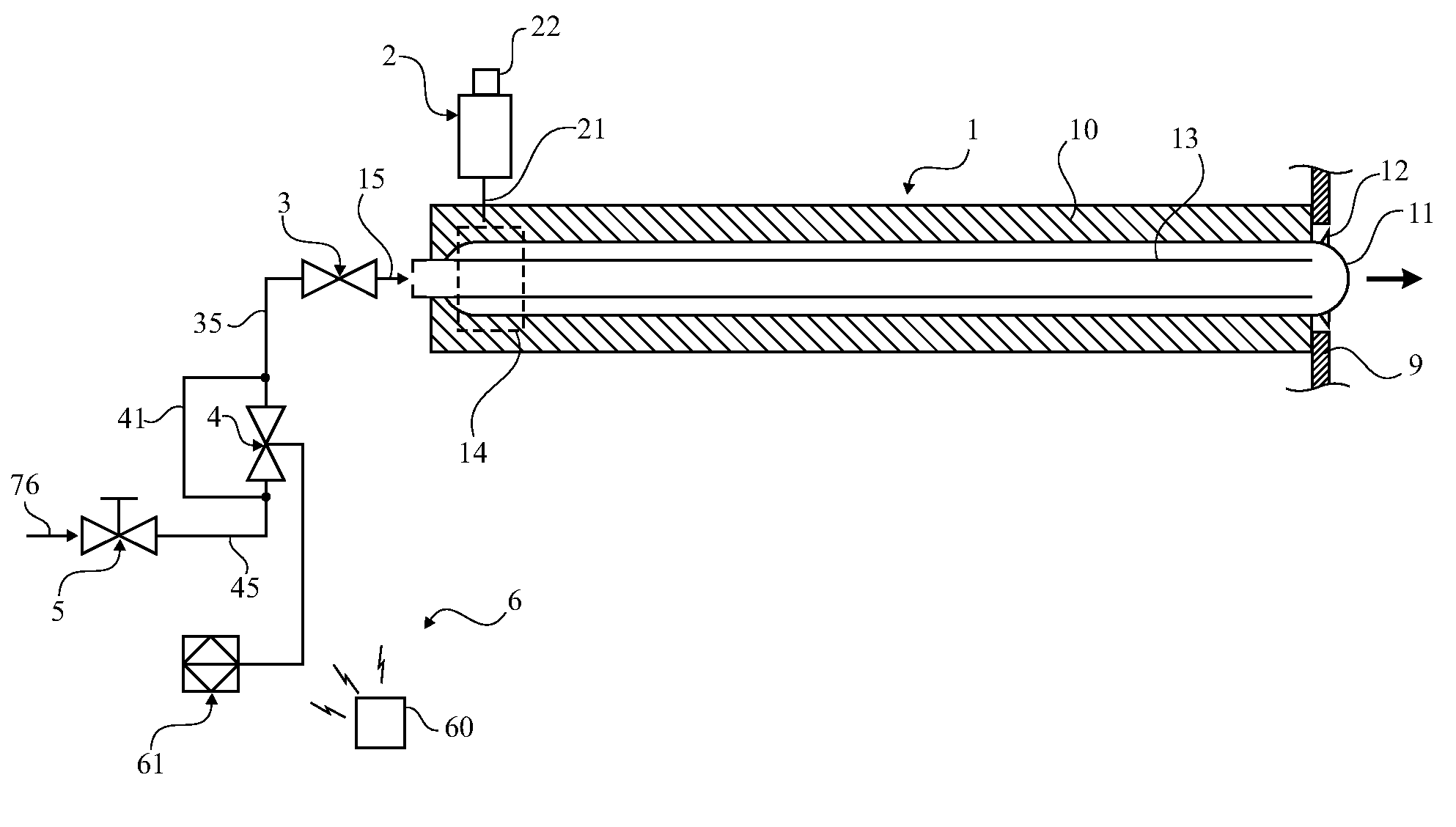

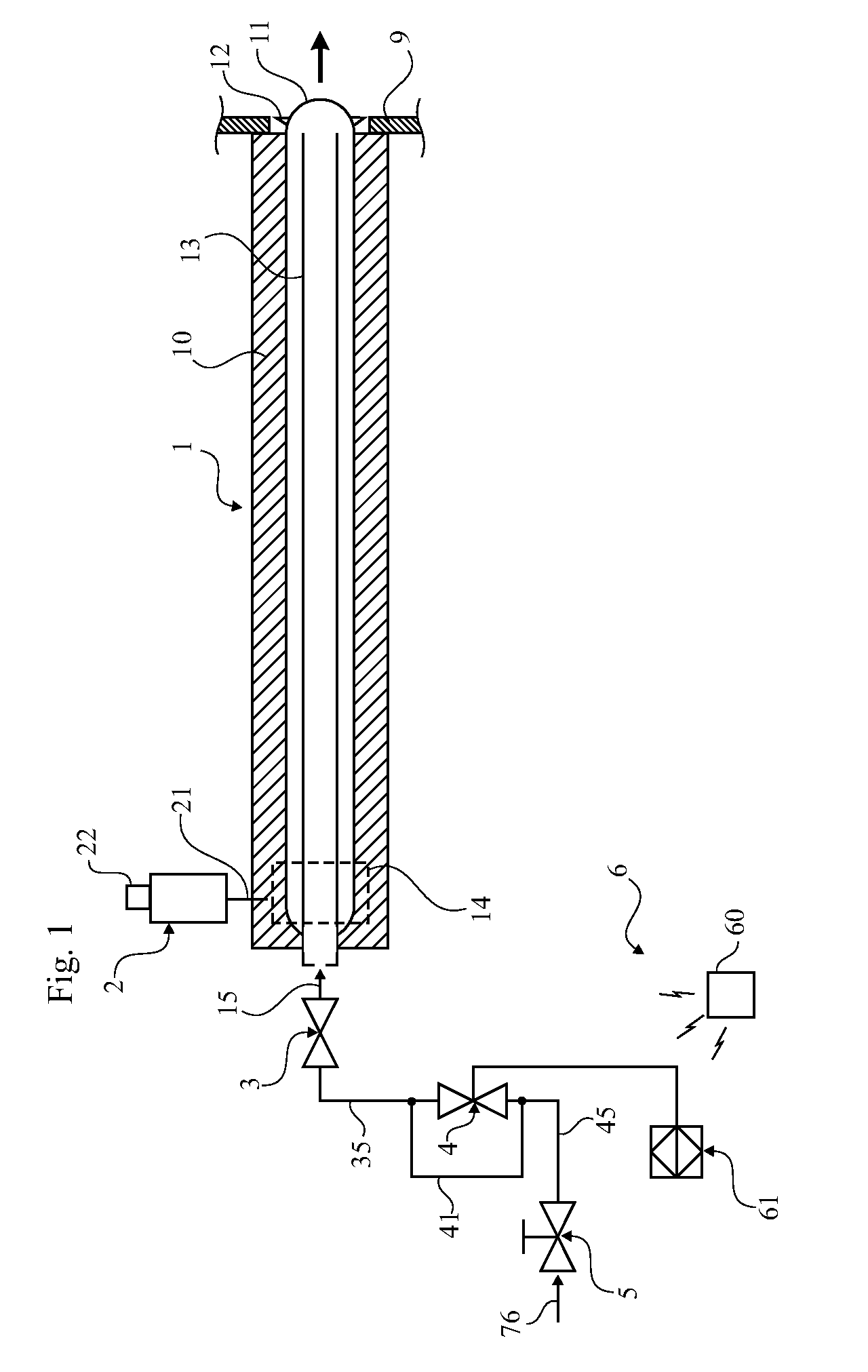

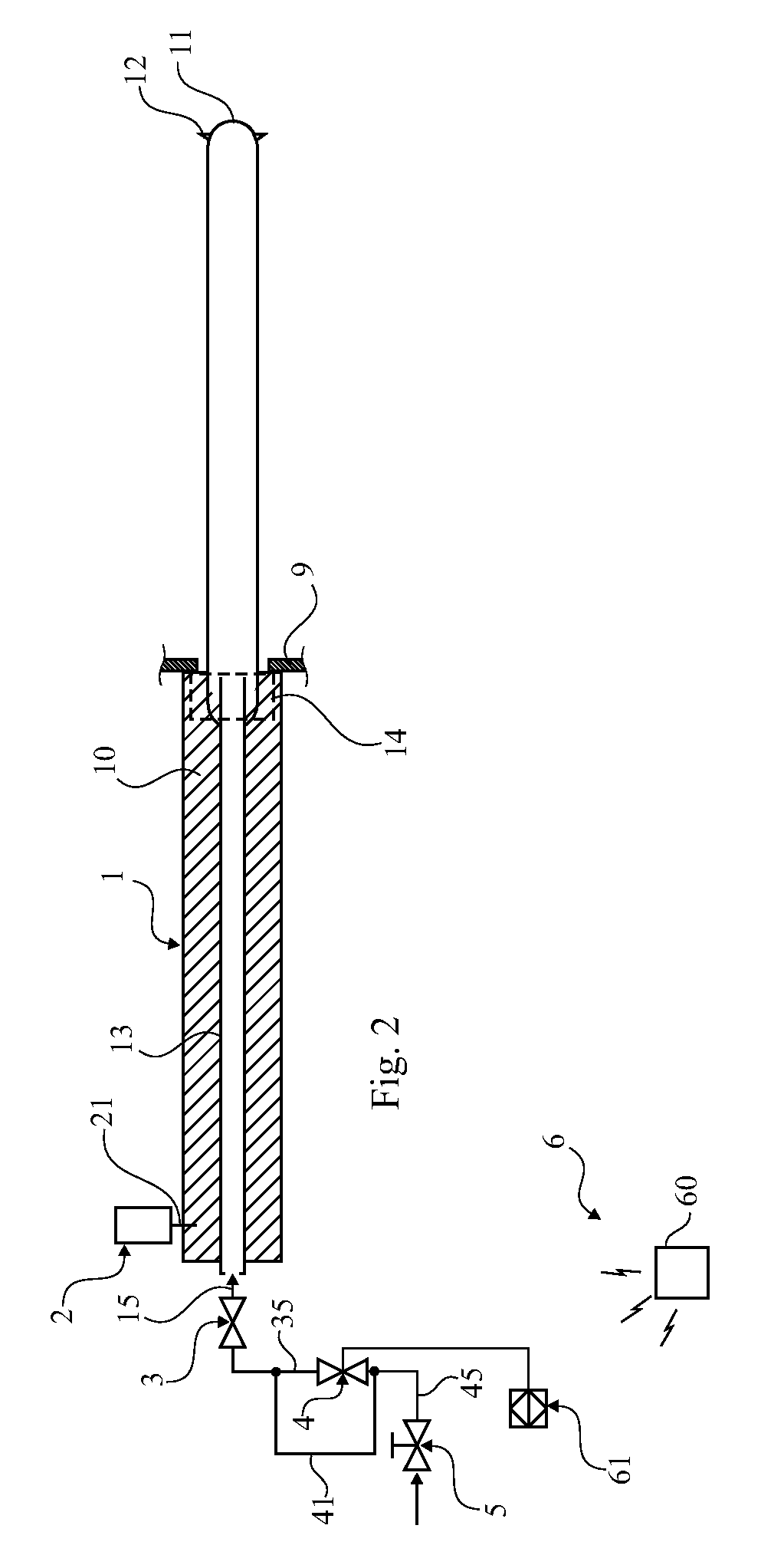

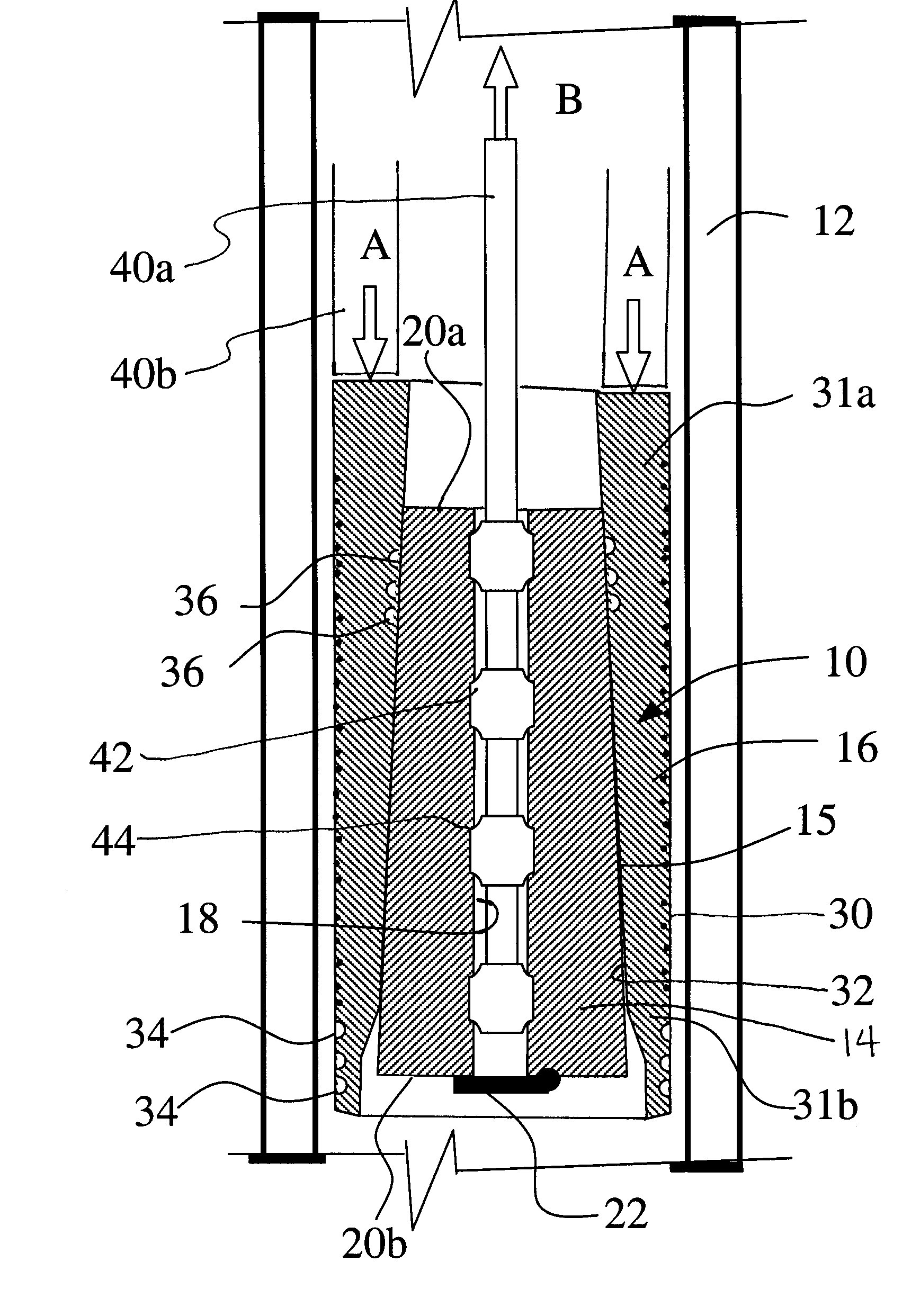

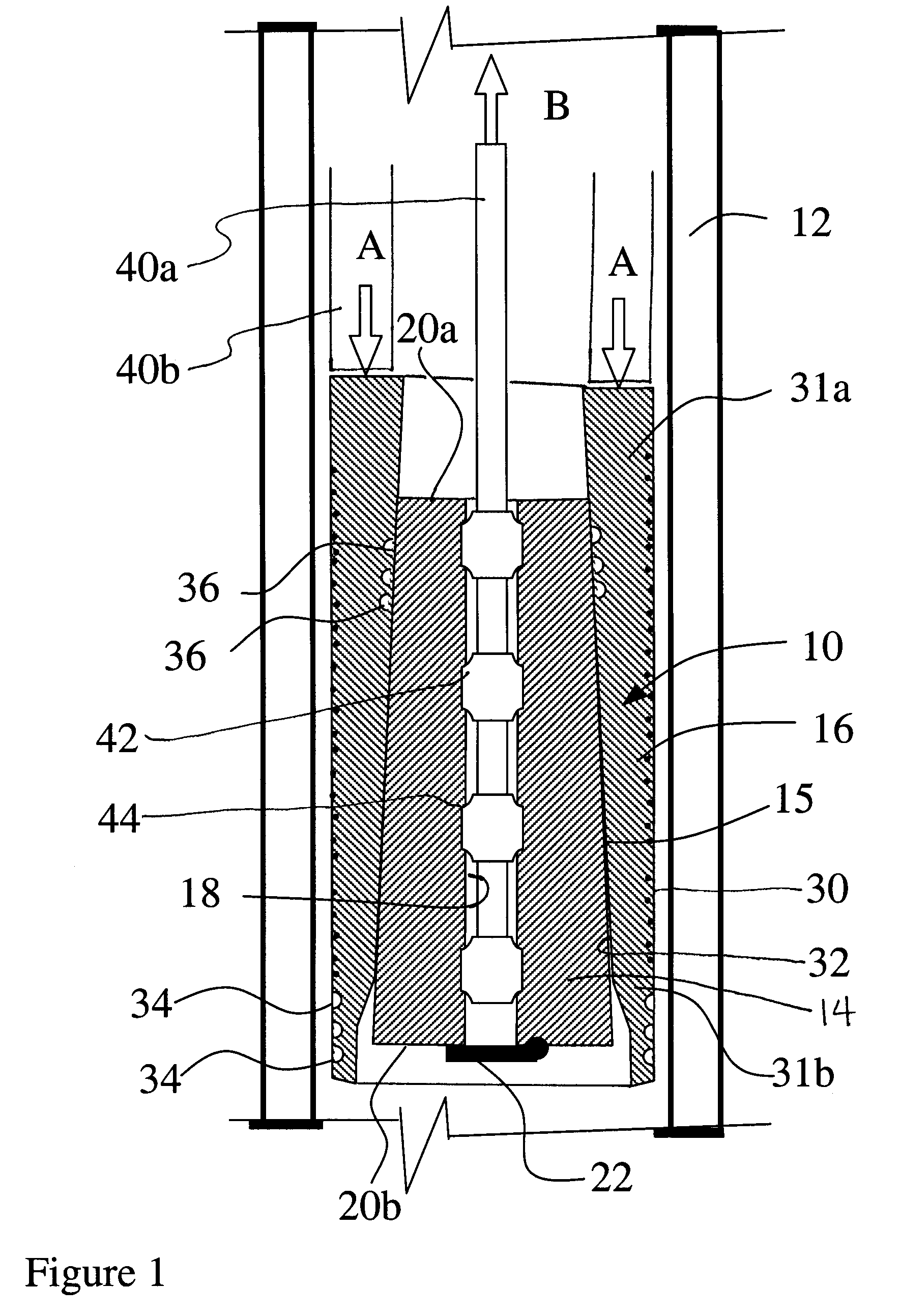

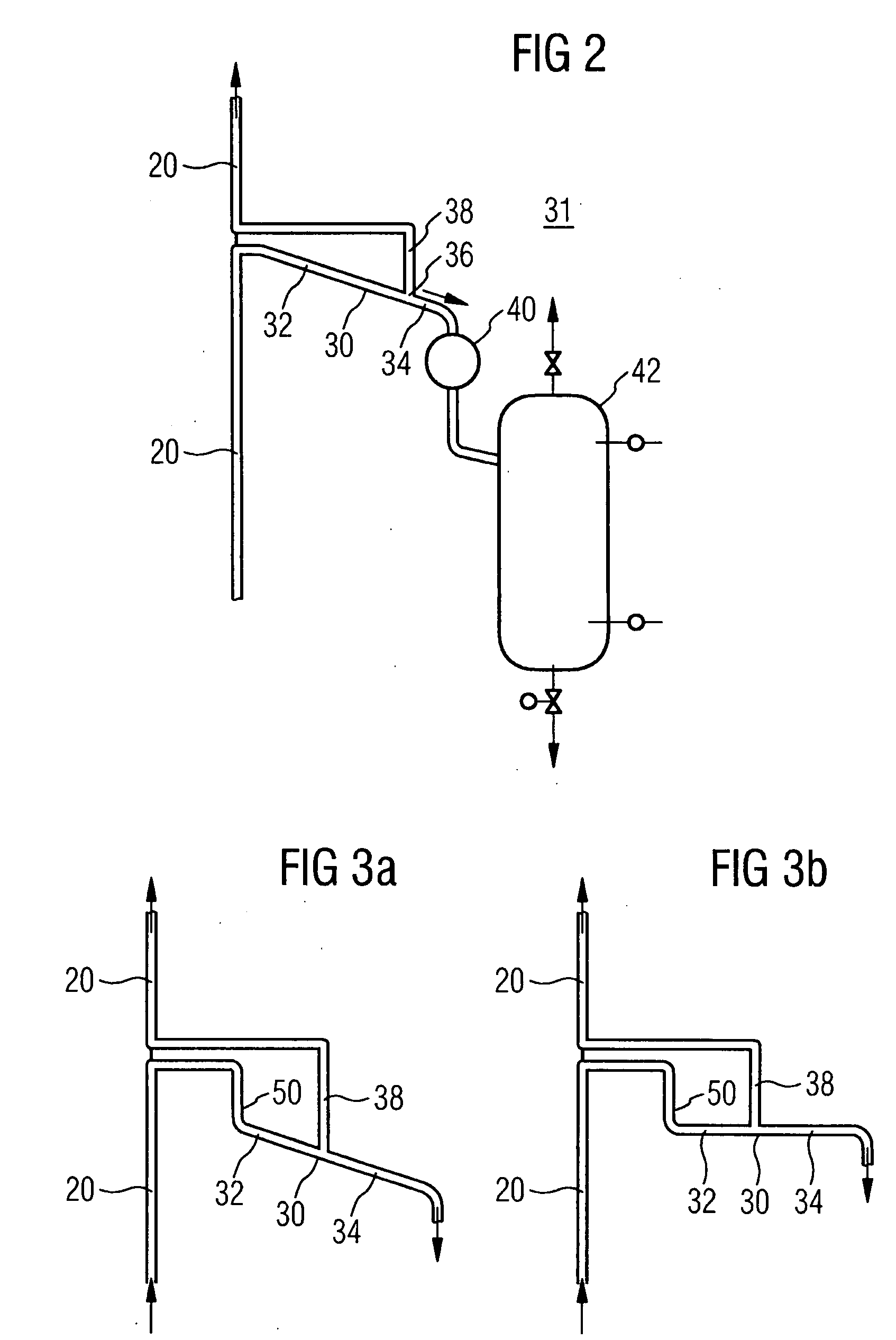

Method of rebuilding a sootblowing system of a recovery furnace, a sootblower for a recovery furnace, and a sootblowing system including a plurality of sootblowers

ActiveUS20100064470A1Reduce steam consumptionWithout reducing soot removal efficiencyMechanical cleaningPressure cleaningEngineeringFeeding tube

This invention relates to a method of rebuilding a sootblowing system of a recovery furnace, said sootblowing system including a plurality of sootblowers (1), and each sootblower (1) including a frame (10), a moveable carriage (14) supported by the frame (10), a motor (2) for moving the carriage (14), a lance tube (11) mounted on the carriage (14) to be insertable into and retractable from the recovery furnace (8), said lance tube (11) having at least one nozzle (12), and a steam feed tube (45, 35, 15) connected to the lance tube (11) for feeding sootblowing steam to be ejected through said at least one nozzle (12) into the recovery furnace, said steam feed tube (45, 35, 15) having a first valve (3) arranged to admit steam through said at least one nozzle (12) only when the carriage with the lance tube (11) is in an activated position, i.e. during retraction and introduction of the lance tube (11), wherein further providing means (4, 30) to arrange for controlled steam supply merely during a limited time period, e.g. merely during introduction.

Owner:SOOTTECH AB

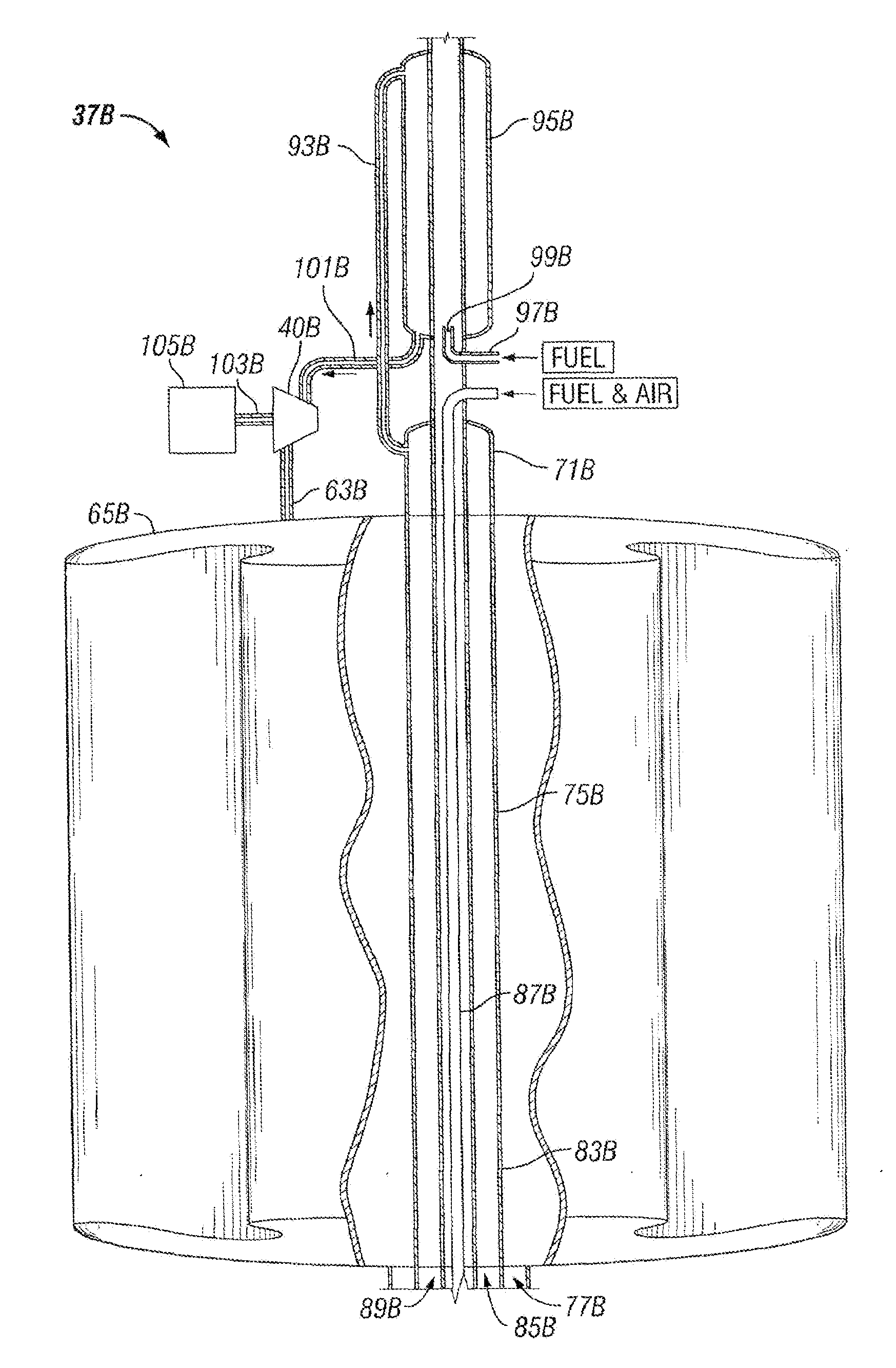

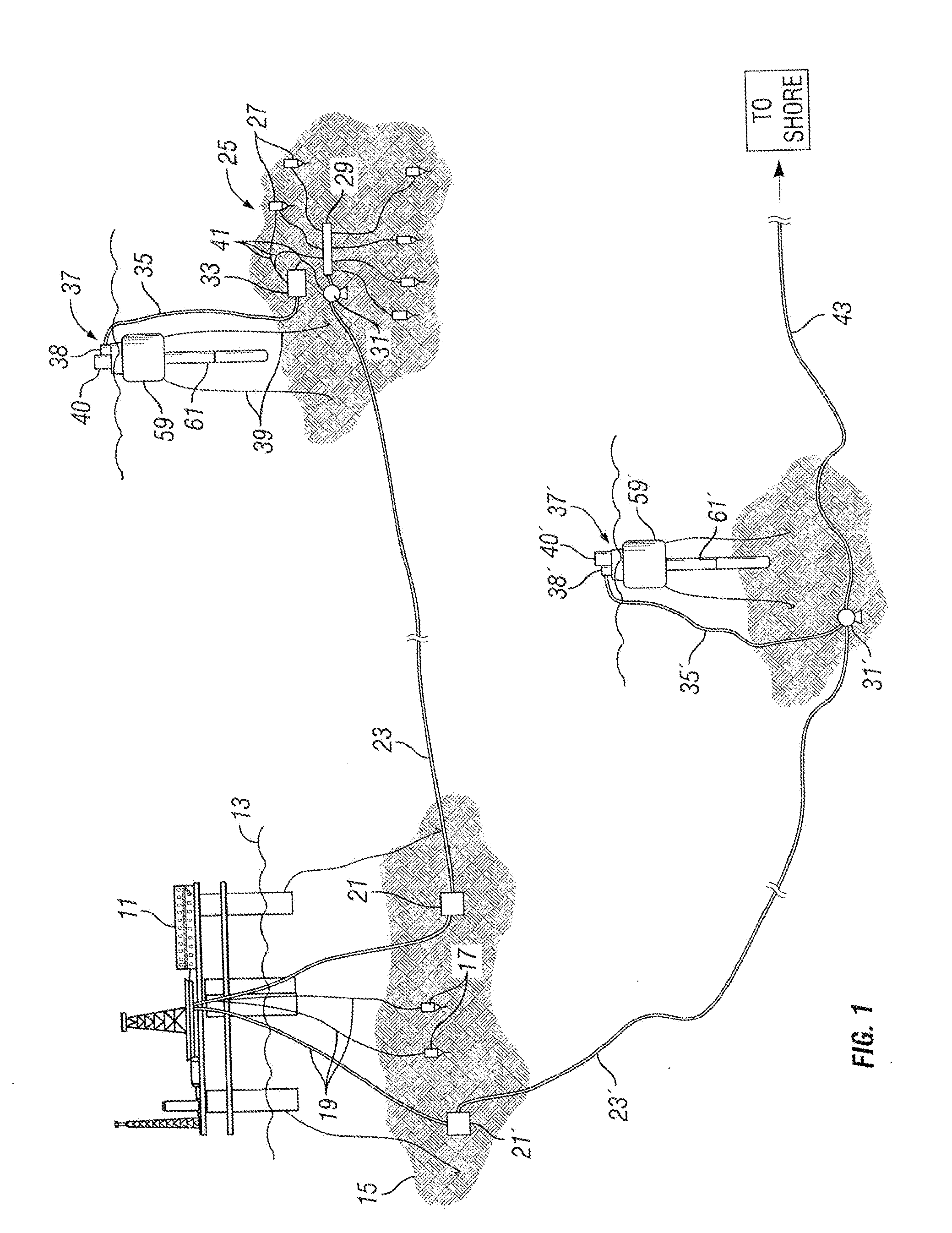

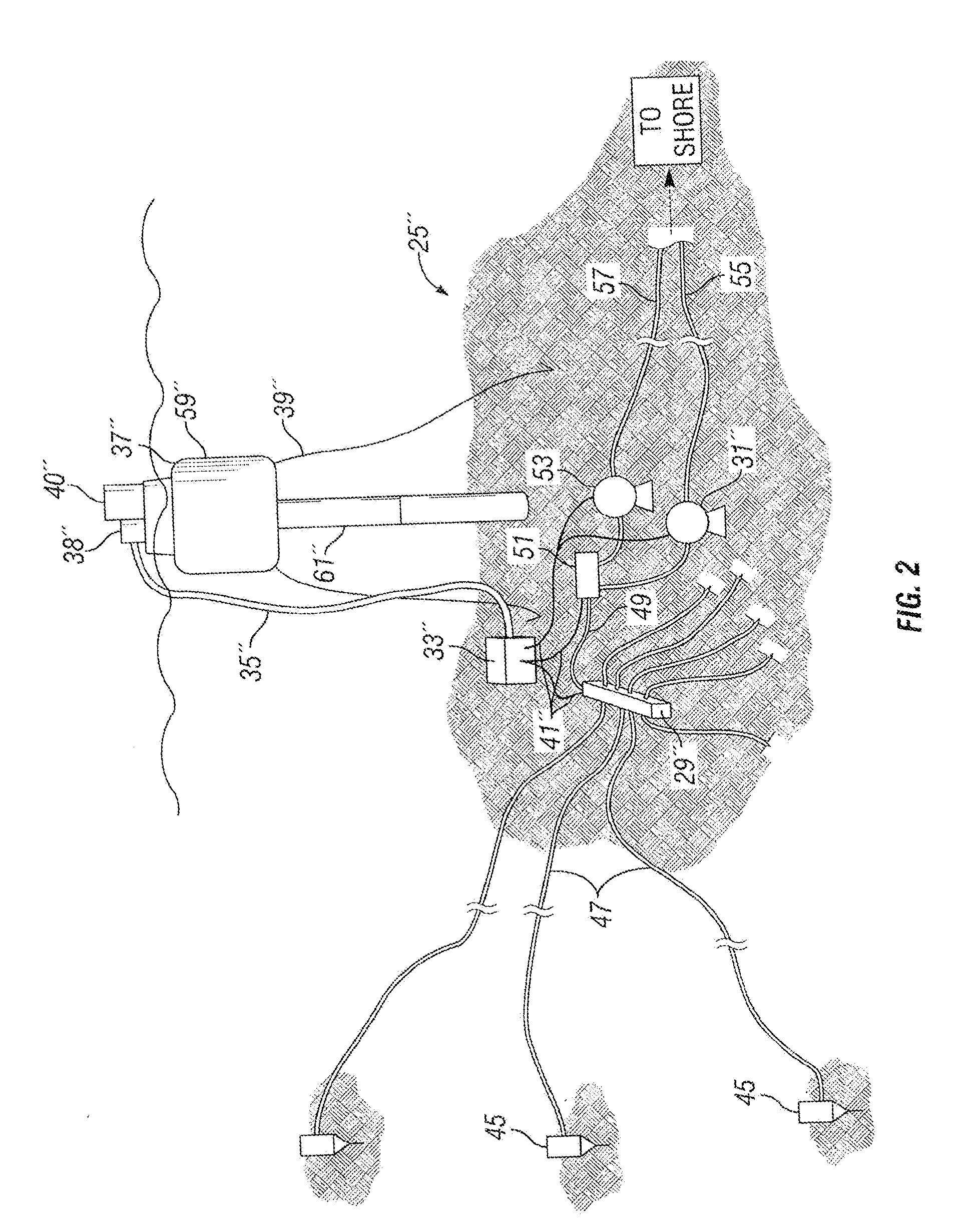

Remote power-generating assembly

InactiveUS20090152868A1Reduce spacingReduce weightFluid couplingsWaterborne vesselsTurbineElectric power

A remote power supply system associated with offshore hydrocarbon production and transportation operations includes an expansion turbine that generates power for the system. The remote power supply system also has a support structure that supports the expansion turbine. A cooling section is supported by the support structure, and is in fluid communication with the expansion turbine to receive the vapor therefrom and to condense it to liquid. A downcomer and boiler section is in fluid communication with the cooling section to receive the liquid condensed from the vapor. An ignition assembly is positioned toward a lower end portion of the downcomer and boiler section. The ignition assembly ignites a fuel and air mixture and causes the liquid received by the downcomer and boiler section from the cooling section to boil into vapor. A return passage conveys vapor from the downcomer and boiler section to the inlet of the expansion turbine.

Owner:CHEVROU USA INC

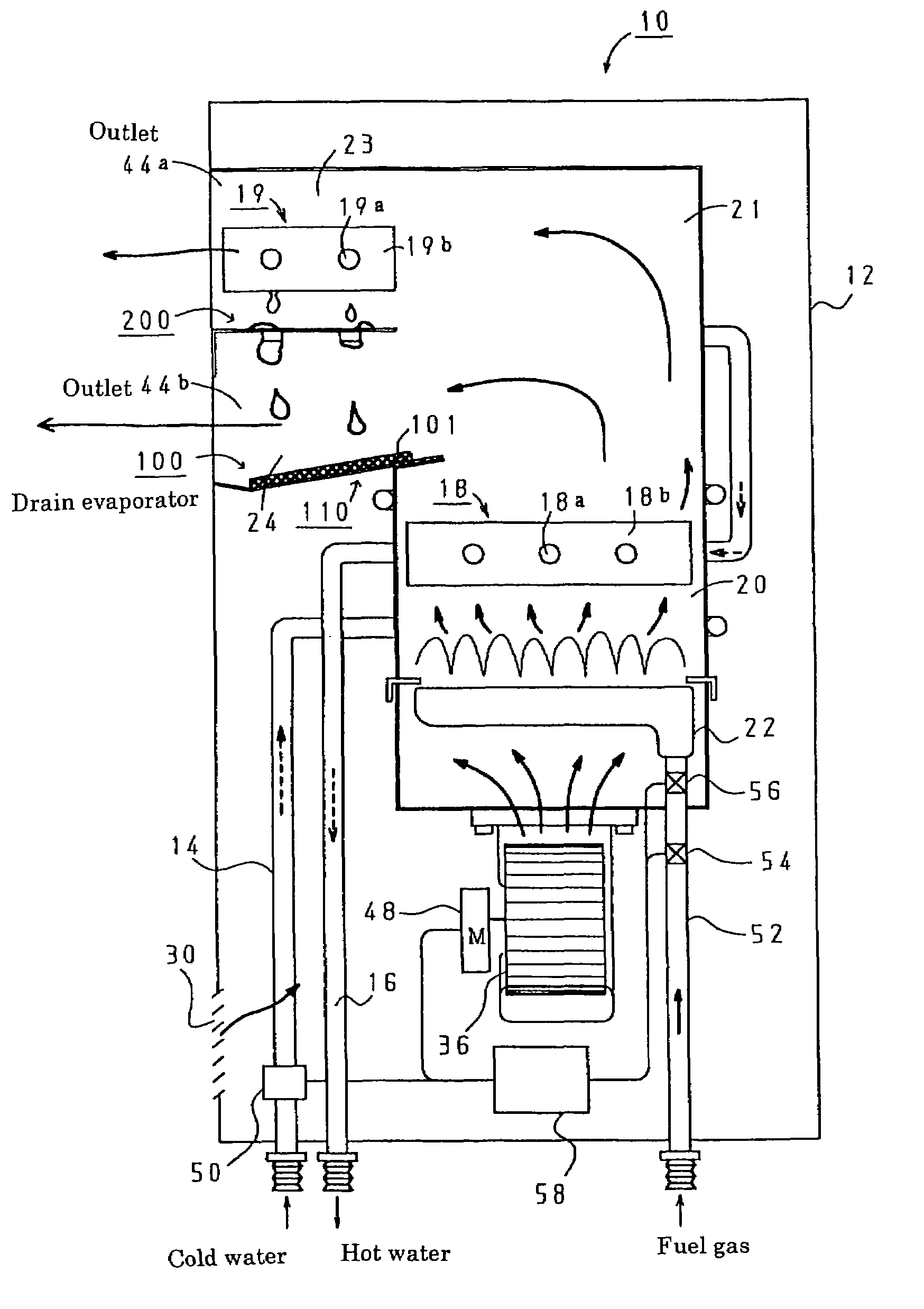

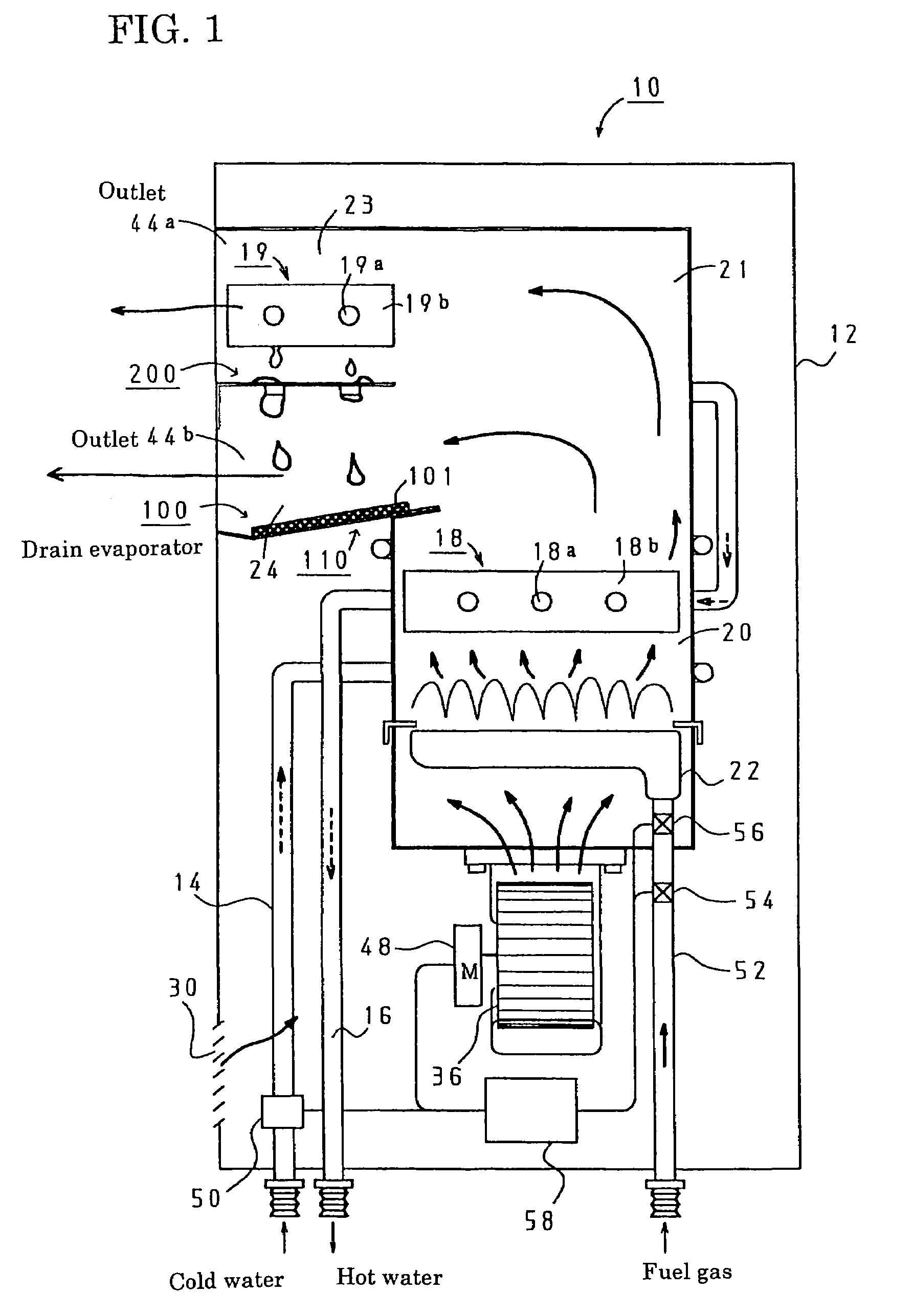

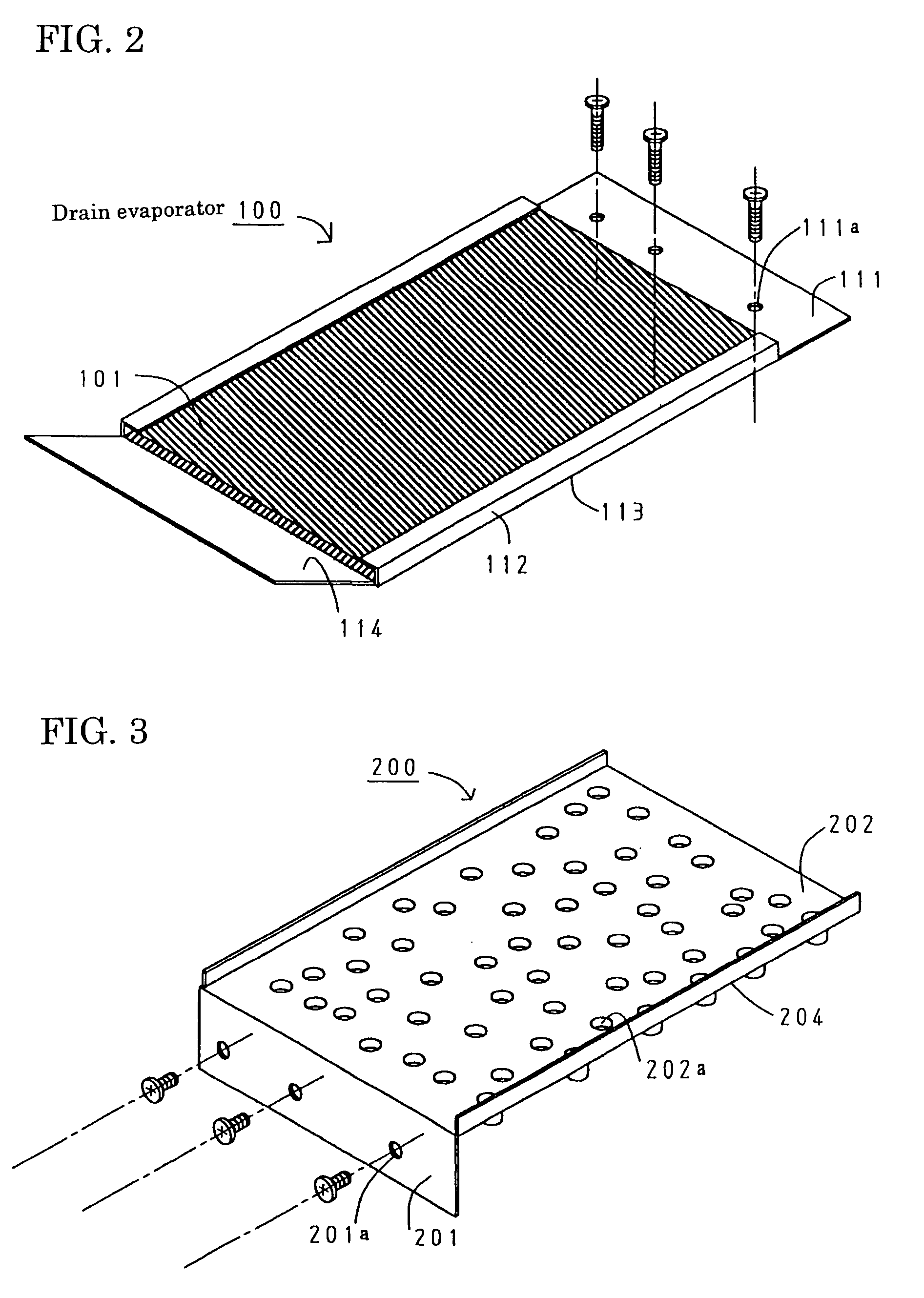

Water heater

InactiveUS6971335B2Efficient conductionEfficient evaporationFluidized bed combustionEnergy efficient heating/coolingExhaust fumesEngineering

A water heater is provided in which neutralization process of drain is not required and an excellent heat efficiency is achieved. A route of exhaust gas which is passing through the main heat exchanger 18 is divided into a first exhaust gas chamber 23 having a secondary heat exchanger 19 and a second exhaust gas chamber 24 having a drain evaporator. Because of this, hot exhaust gas which is passing through only the main heat exchanger 18 flows into both the secondary heat exchanger 19 and the drain evaporator 100. Therefore, in the secondary heat exchanger 19 exhaust gas heat can be efficiently recovered by utilizing the hot exhaust gas, and in the drain evaporator 100 drain can be evaporated efficiently by utilizing the hot exhaust gas.

Owner:PALOMA IND LTD

Methods and apparatus to facilitate cooling syngas in a gasifier

ActiveUS7749290B2Improve heat transfer performanceMuffle furnacesGasifier mechanical detailsSyngasEngineering

Owner:AIR PROD & CHEM INC

High efficiency tank type continuous flow and self cleaning water heater

InactiveUS7100541B2Reduce condensationAvoid overall overheatingFurnace-tube steam boilersWater heatersCombustorContinuous flow

A water heater comprising a closed tank having a water inlet for connection with a water supply, and a hot water outlet connected to the tank interior; a flue pipe extending vertically through the tank and having an upper portion for connection with a vent pipe; a cylinder having a lower end and upper open end with means for opening disposed within the flue pipe, and spaced from inner walls of the flue pipe, and extending substantially the length of the flue pipe; a burner disposed in a lower region of the cylinder and above the lower end thereof, such that combustion products from the burner rise through the cylinder; and a water conducing coil disposed within the cylinder connected with the interior of the tank.

Owner:FRASURE CHARLES J +3

Cement float

A cement float for use in a wellbore tubing string includes: a mandrel including a first end, a second end, a bore extending from the first end to the second end including a fluid flow control device therein and outer side surfaces defining a tapering outer diameter from the first end of the mandrel to the second end; an outer lock sleeve including an outer surface and a sleeve bore through the sleeve, the outer lock sleeve retained at least about the outer side surfaces of the mandrel with the mandrel extending through the sleeve bore, the sleeve bore having a taper to complement and be coactable with the tapering outer diameter of the mandrel outer side surfaces and the sleeve bore and the mandrel outer side surfaces defining interfacing surfaces therebetween, the sleeve being expandable radially outwardly by driving the mandrel against the taper of the sleeve bore to place the cement float in an anchored position in the tubing string with the outer lock sleeve wedged between the mandrel and the tubing string, the outer lock sleeve and the mandrel being formed over at least a portion of their interfacing surfaces to be frictionally and / or mechanically interactive to provide self locking against sliding movement therebetween that would dislodge the cement float from its anchored position. A method for setting the cement float is also disclosed.

Owner:SCHLUMBERGER TECH CORP

Steam Generator

ActiveUS20090071419A1Improve operational flexibilityShort reaction timeWater circulationSteam separation arrangementsElectric generatorEvaporator

The invention relates to a steam generator wherein a continuous heating panel of a generator, which is formed from a number of evaporator tubes, and an overheating panel, which is formed from a number of over-heating tubes which are arranged downstream from the evaporator tubes and on the flow side, are arranged in a heating gas channel. According to the invention, a water separating element is integrated into a number of over-flow tubes which are connected on the flow side of one of several evaporator tubes to one or several overheating tubes.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Method and device for heating flowing fluid as well as heating equipment applying same

ActiveCN101886843AImprove thermal efficiencyNo pollution in the processSteam generation heating methodsCoil arrangementsHigh frequency powerInductor

The invention relates to a method and a device for heating flowing fluid as well as heating equipment applying the same. In the method, a high-frequency induction coil is connected with a high-frequency power output end; the high-frequency induction coil is internally provided with a metal inductor electrically insulated with the high-frequency induction coil; and the high-frequency induction coil internally provided with the metal inductor is arranged in the flowing fluid and is used for heating the flowing fluid. The flowing fluid is heated by adopting the device of the invention, the invention has the advantages of energy saving, environment protection, high thermal efficiency, no pollution, low energy consumption, high heating speed and long service life. Because the flowing fluid medium can play a role of continuously cooling the metal inductor and the induction coil of a heating source, the heating device is kept a working state of long-term continuous heating.

Owner:佛山市南海超豪五金配件有限公司

Alcohol-based fuel steam boiler

ActiveCN104154519AReduce the amount of waterReduce consumptionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorAlcohol

The invention provides an alcohol-based fuel steam boiler. The alcohol-based fuel steam boiler comprises a barrel, a hearth, at least one set of middle heating tank and a tail flue. The hearth, the middle heating tanks and the tail flue are arranged in the barrel. The hearth is arranged at the lower portion of the barrel. One or more sets of burners are arranged in the hearth. The middle heating tanks are located above the hearth. The tail flue is arranged on the side edge of the barrel. The hearth is communicated with the middle heating tanks through smoke tubes. The middle heating tanks are communicated with the tail flue in the mode that a pipeline penetrates through the wall of the barrel. By means of the alcohol-based fuel steam boiler, water of a boiler body can be reduced to the maximum extent, the heating area is enlarged at the same time, high burning efficiency can be obtained and converted to the efficient heat utilization rate, the efficient and energy-saving operation of the pure-alcohol-based fuel steam boiler is achieved, the cost is lowered for users, environment is protected, and the purposes of saving energy and reducing consumption are achieved.

Owner:GUILIN GANLONG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

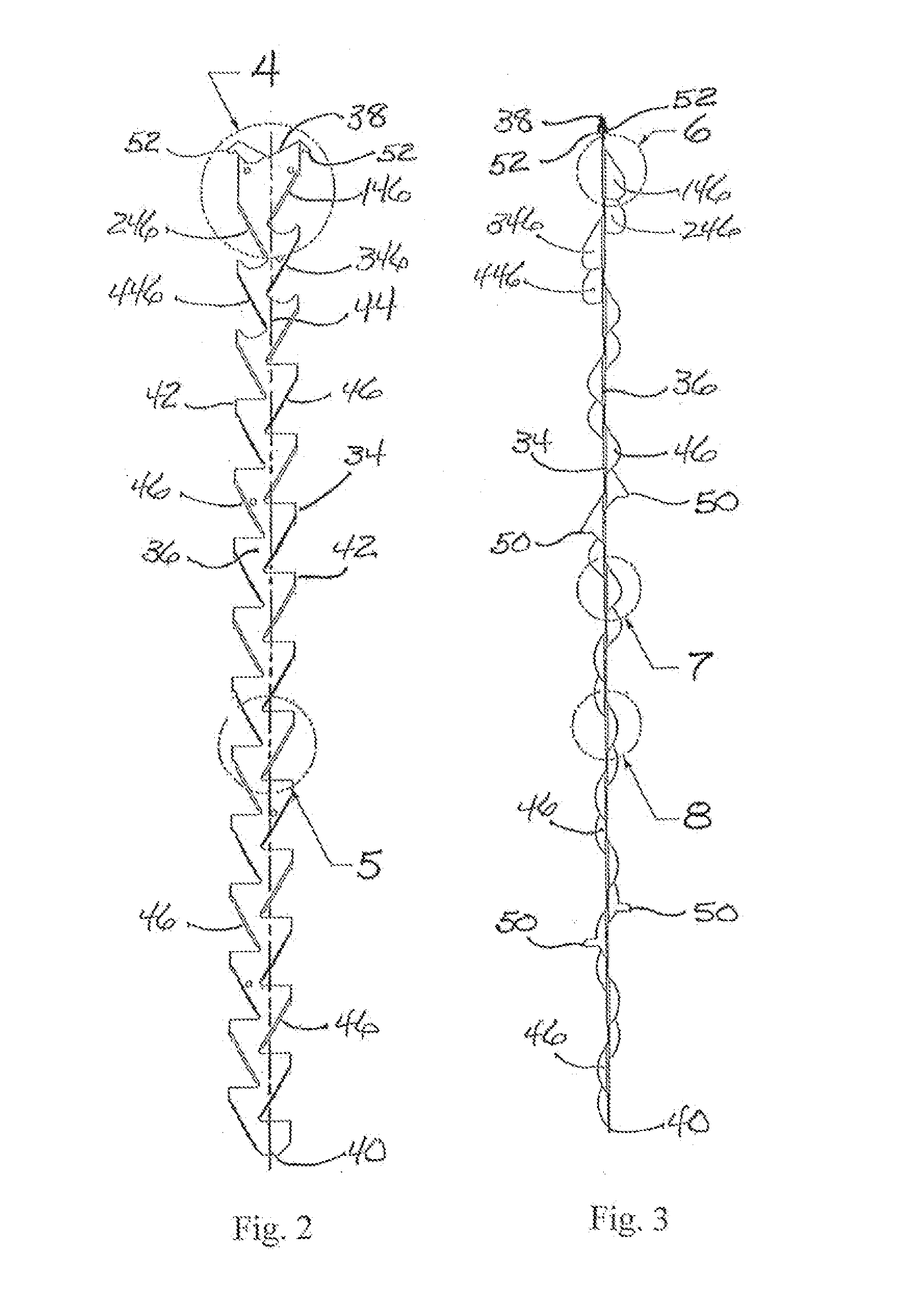

Heat transfer baffle arrangement for fuel-burning water heater

ActiveUS20160201944A1Improve heat transfer performanceExtended stayHeat storage plantsHeat exchanger casingsCombustionEngineering

A baffle arrangement disposed within the exhaust flue of a fuel-burning water heater promotes heat transfer from exhausted combustion by-products to the water storage chamber. The baffle arrangement has an elongate planar base and plural exhaust-directing fins spaced along opposite sides of the base. Each fin is a planar body extending perpendicularly from the base at an acute upward angle from a longitudinal centerline to a respective side of the base. The fins deflect combustion by-products laterally outwardly within the flue to promote heat transfer. The fins are of selected configurations generally increasing in surface area upwardly along the planar base for selectively controlling pressure drop within the exhaust flue. Hanger tabs project outwardly from the upper end of the base to suspend the baffle arrangement within the flue. The planar base, hanger tabs and exhaust-directing fins are formed integrally from a unitary body of sheet metal.

Owner:RHEEM MFG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com