Alcohol-based fuel steam boiler

A steam boiler and alcohol-based fuel technology, applied in the field of boilers, can solve the problems of long start-up and shutdown time, unreasonable mixing ratio of oxygen supply and fuel, short flame length, etc., to shorten the start-up and shutdown time Effects that require time, enhance disturbance and residence time, and improve heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

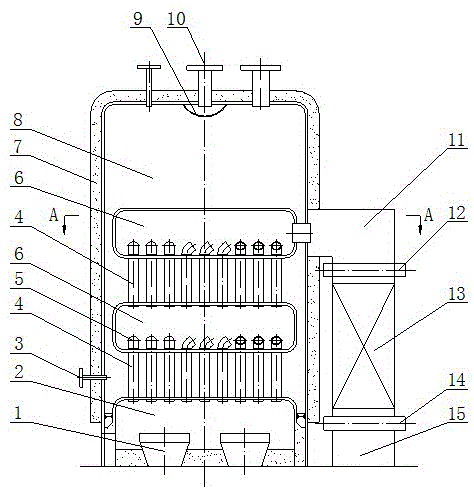

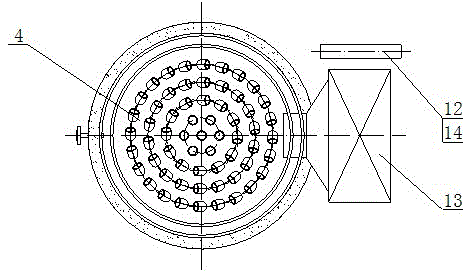

[0026] The invention discloses an alcohol-based fuel steam boiler. The alcohol-based fuel steam boiler can utilize the characteristics of alcohol-based fuel combustion and discharge, and by changing the combustion and heating mode of the traditional steam boiler, reducing the water volume of the boiler body to the greatest extent and increasing the heating area, Ensure high combustion efficiency and transform into effective heat utilization rate, realize high efficiency and energy saving of clean alcohol-based fuel steam boilers, so as to save costs for users, protect the environment, and achieve the purpose of saving energy and reducing consumption.

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com