Patents

Literature

324results about How to "No spillage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

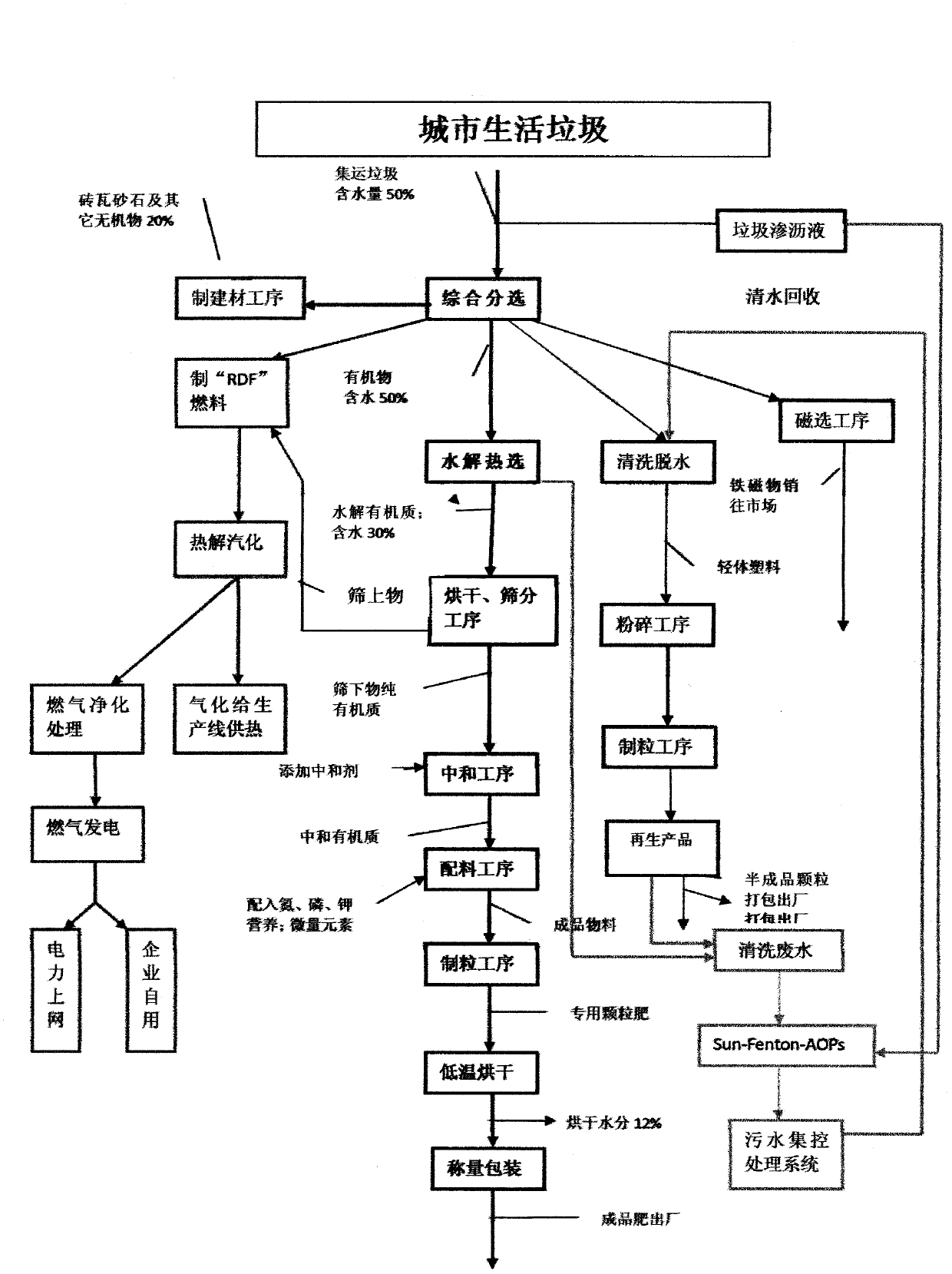

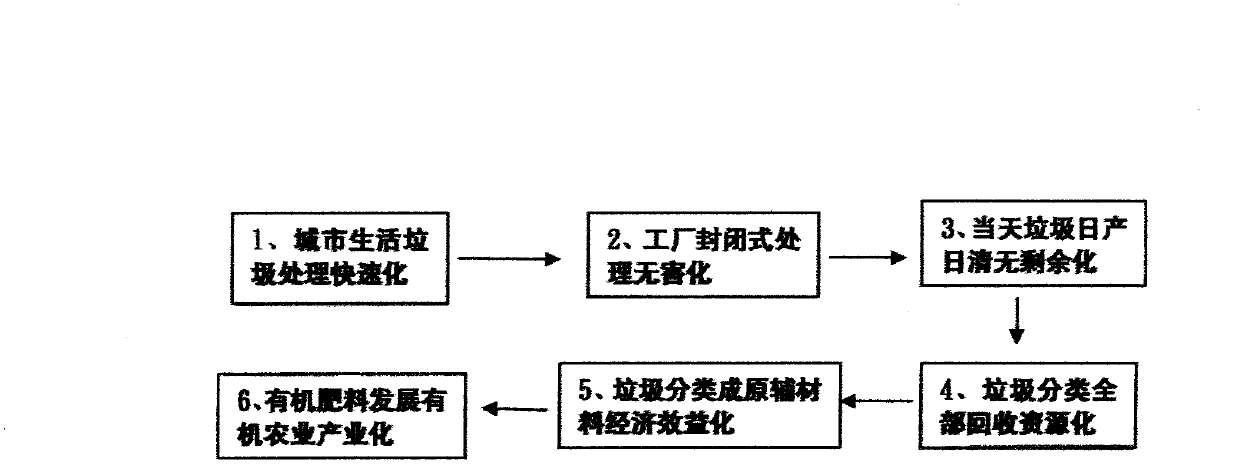

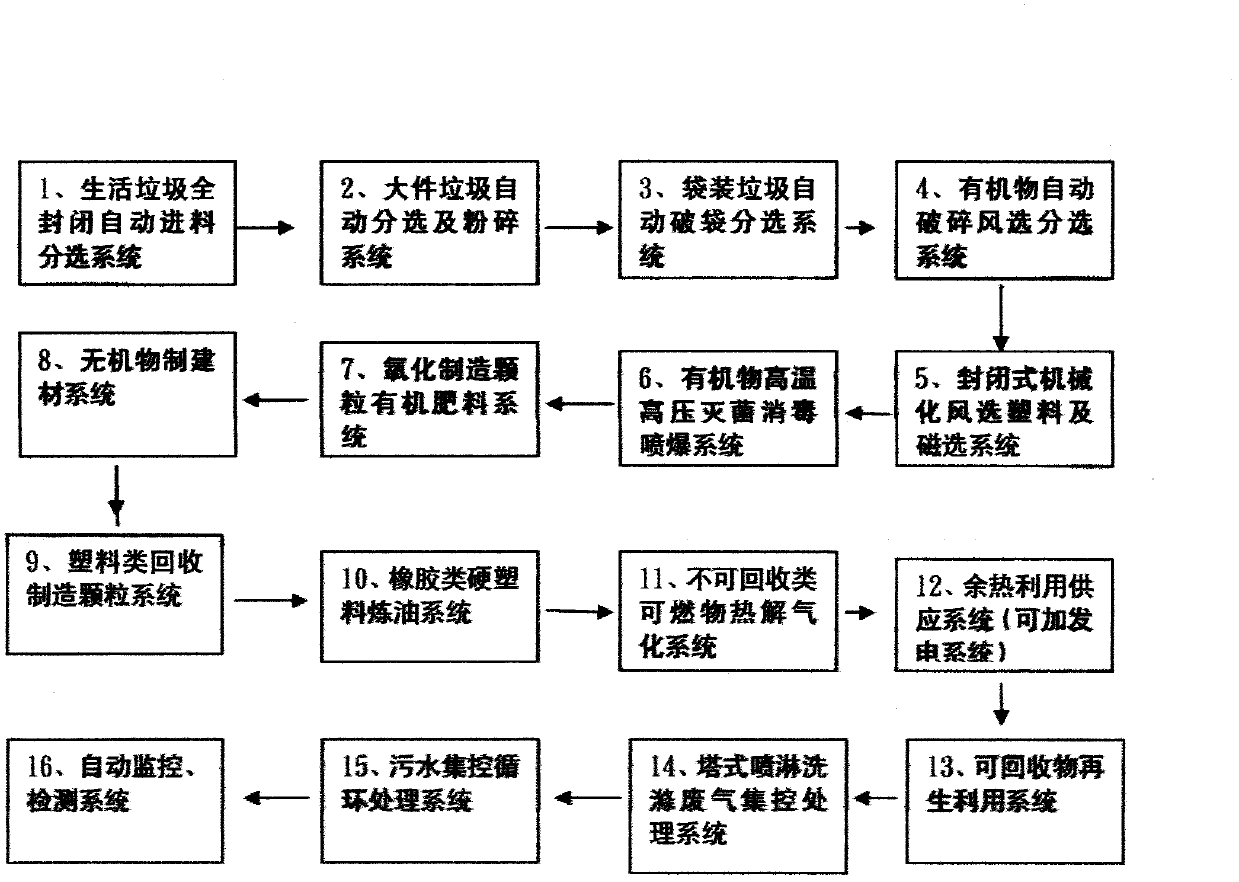

Municipal domestic waste resource recovery processing method with zero pollution, zero release and harmlessness

ActiveCN102327888ANo spillageNo pollution in the processSolid waste disposalResource utilizationSmall footprint

Owner:严大春

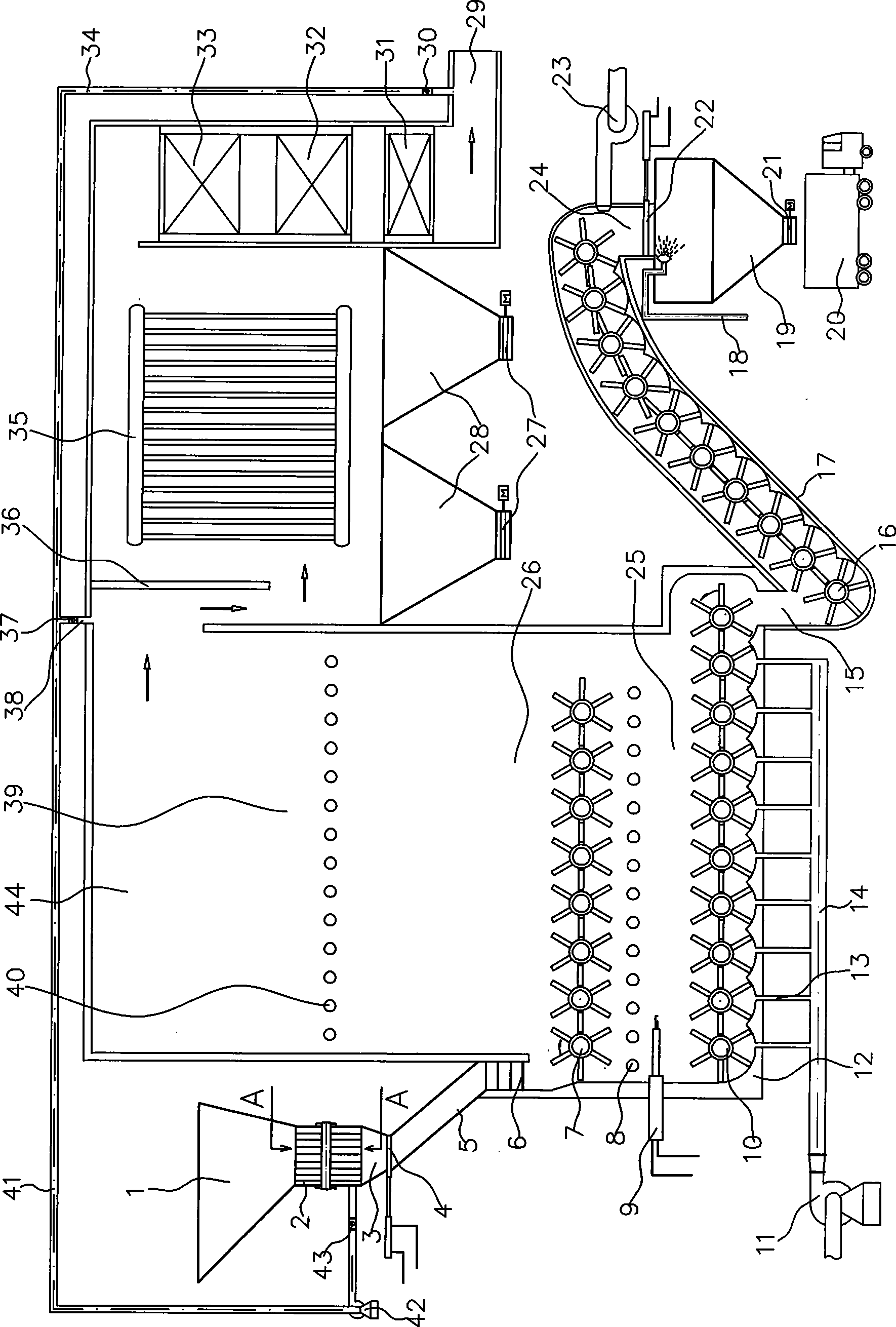

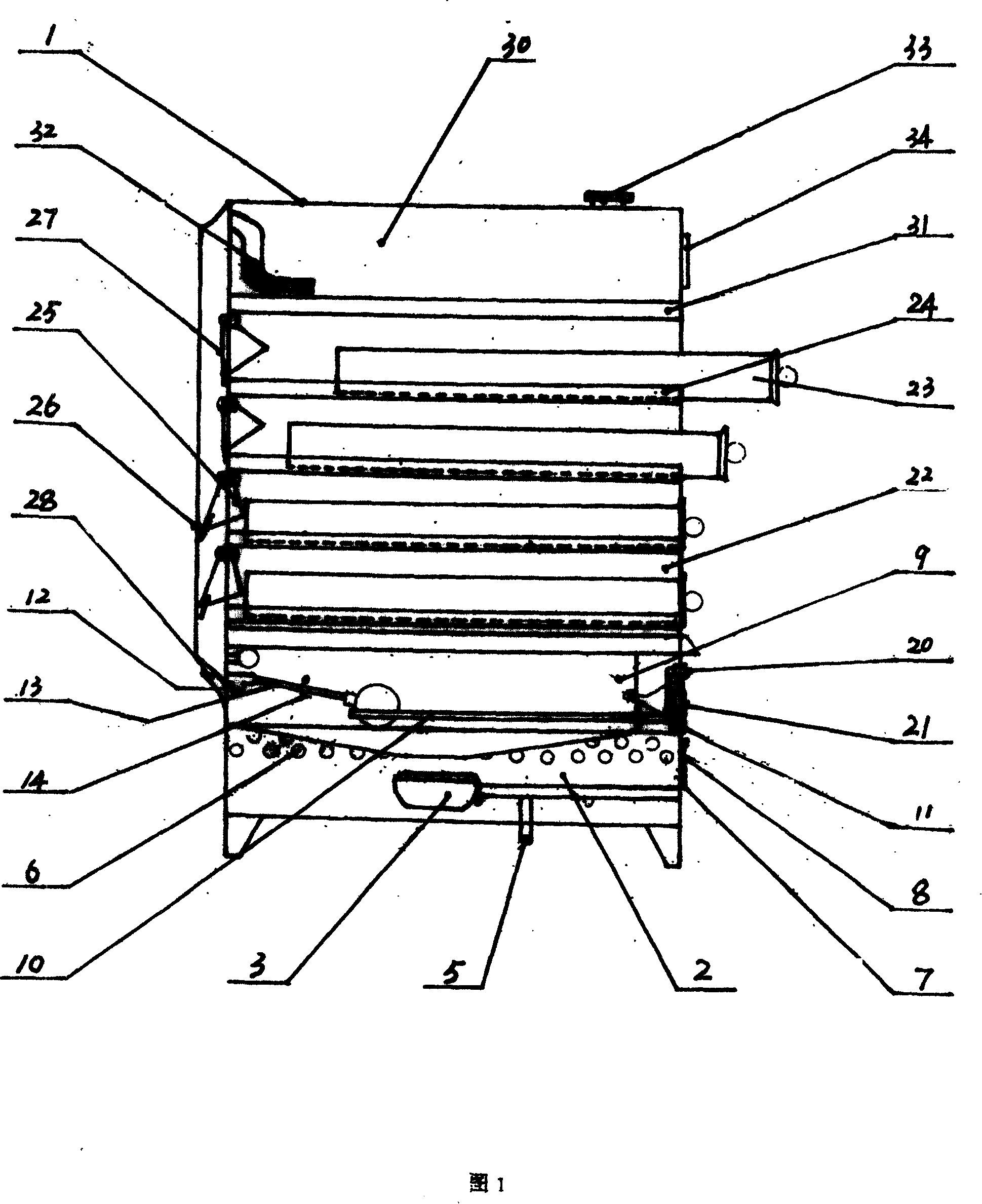

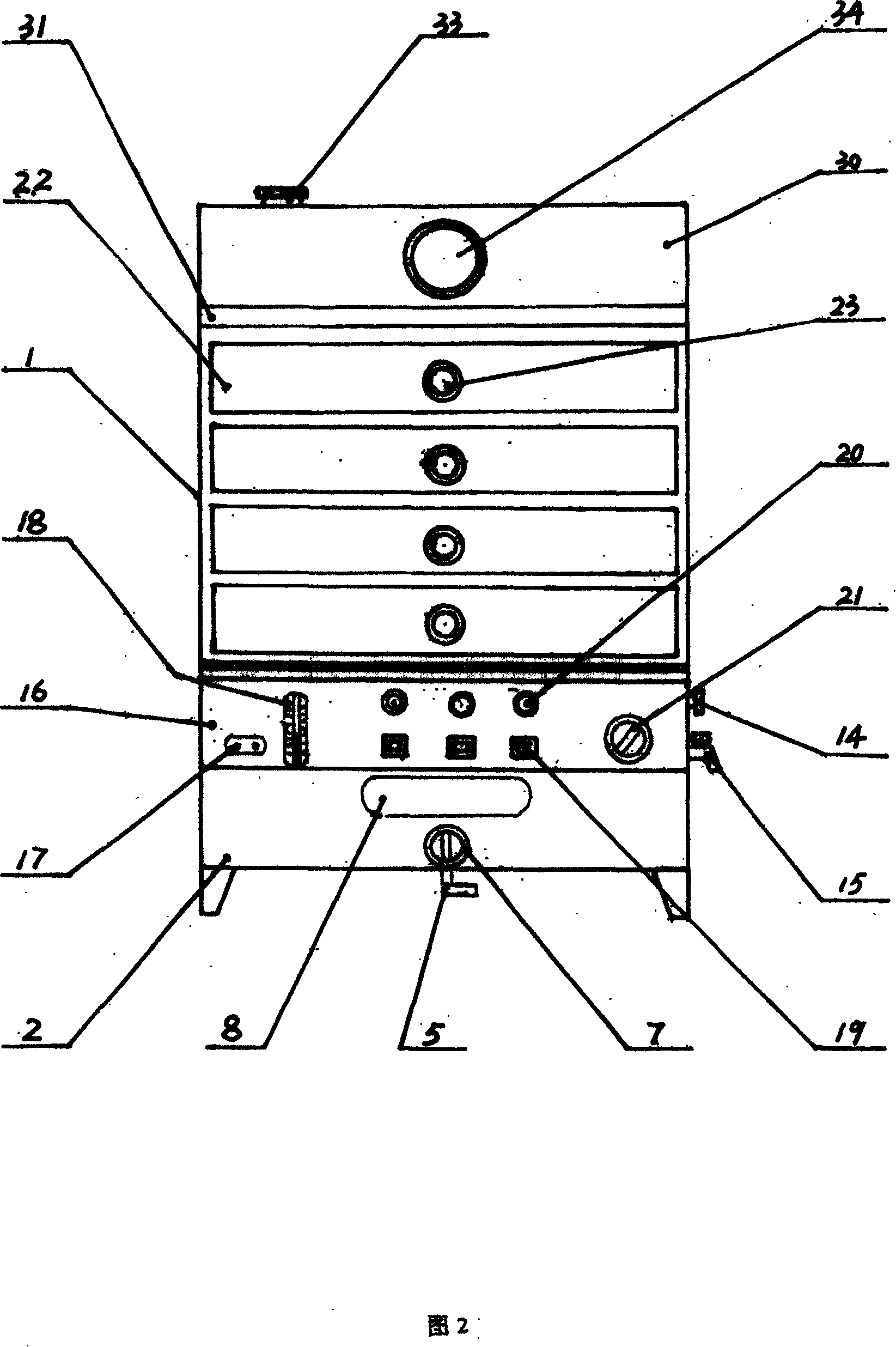

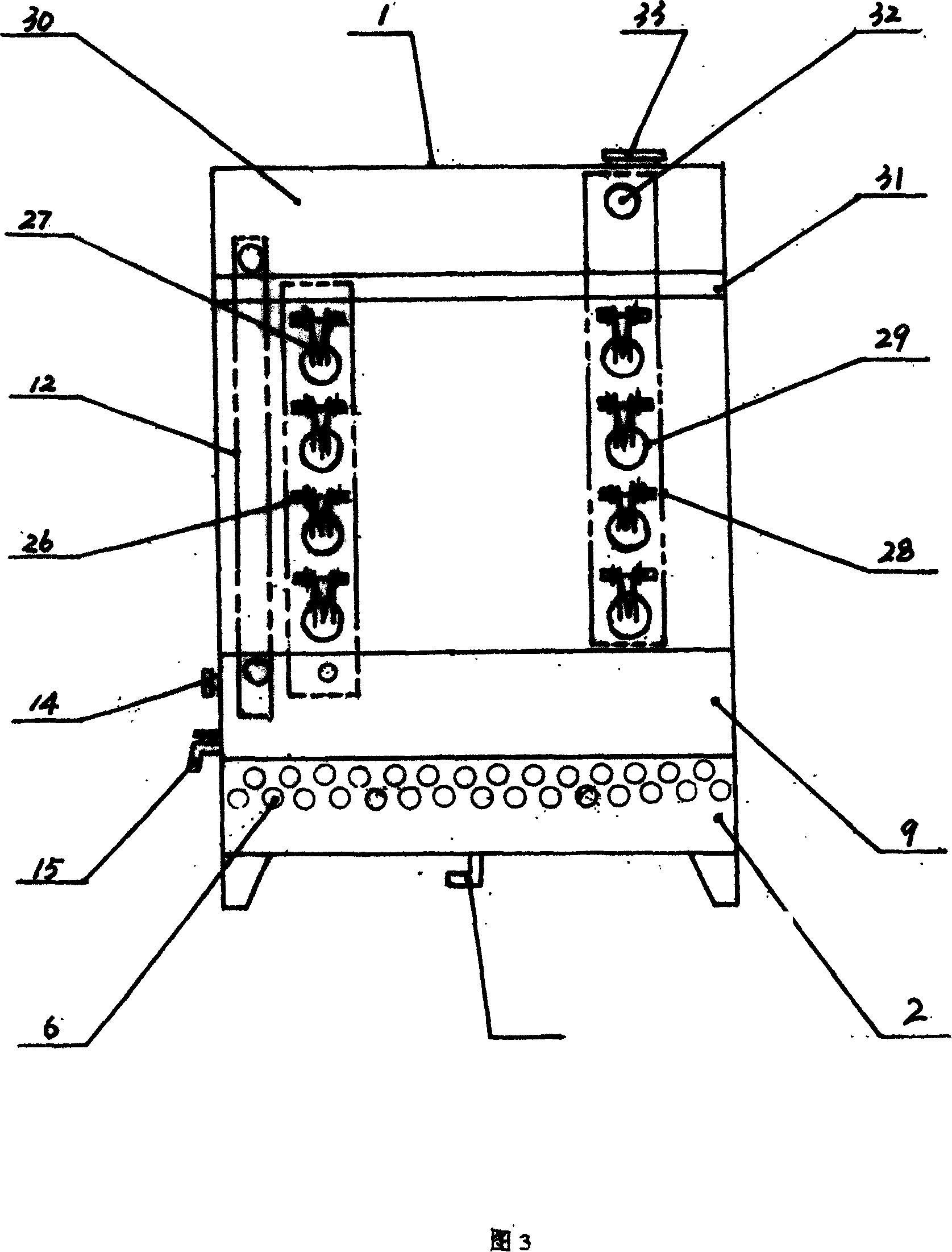

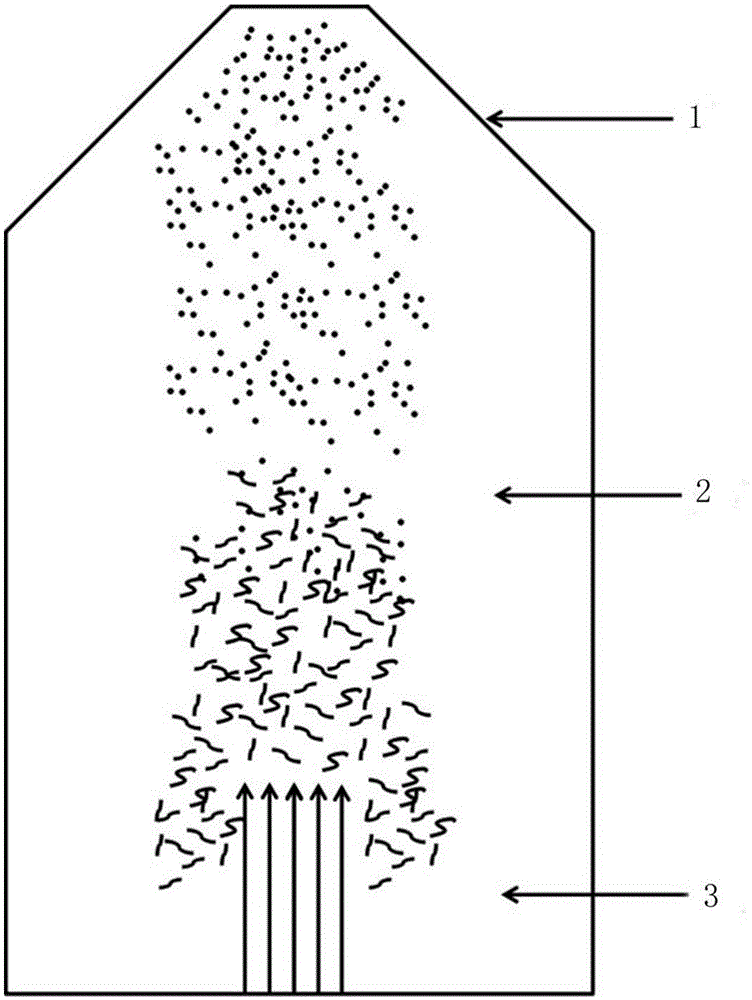

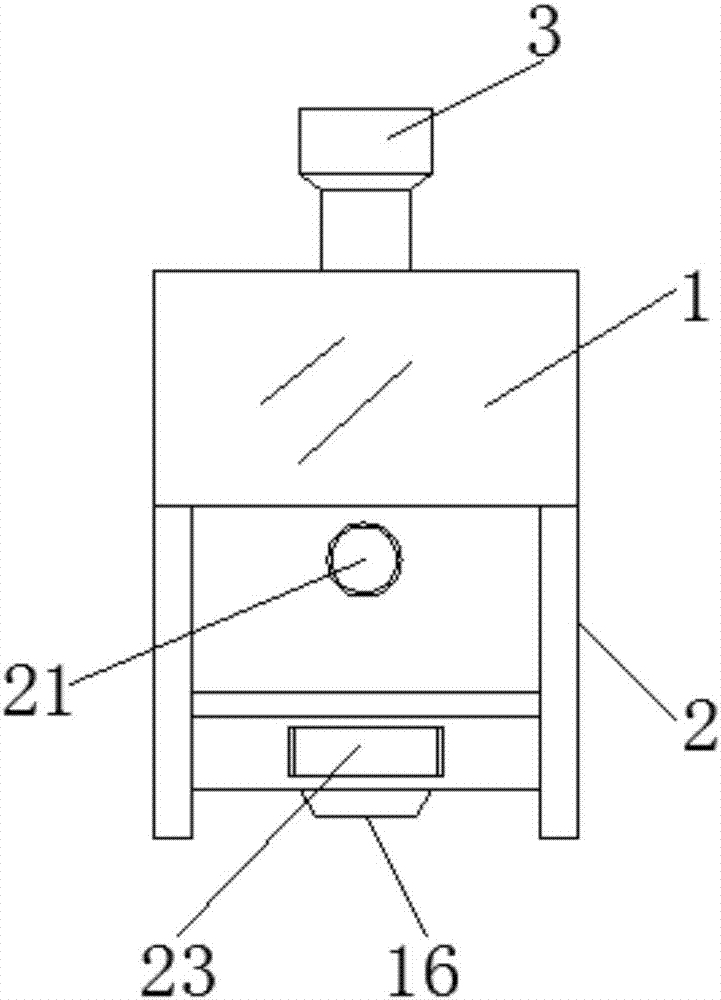

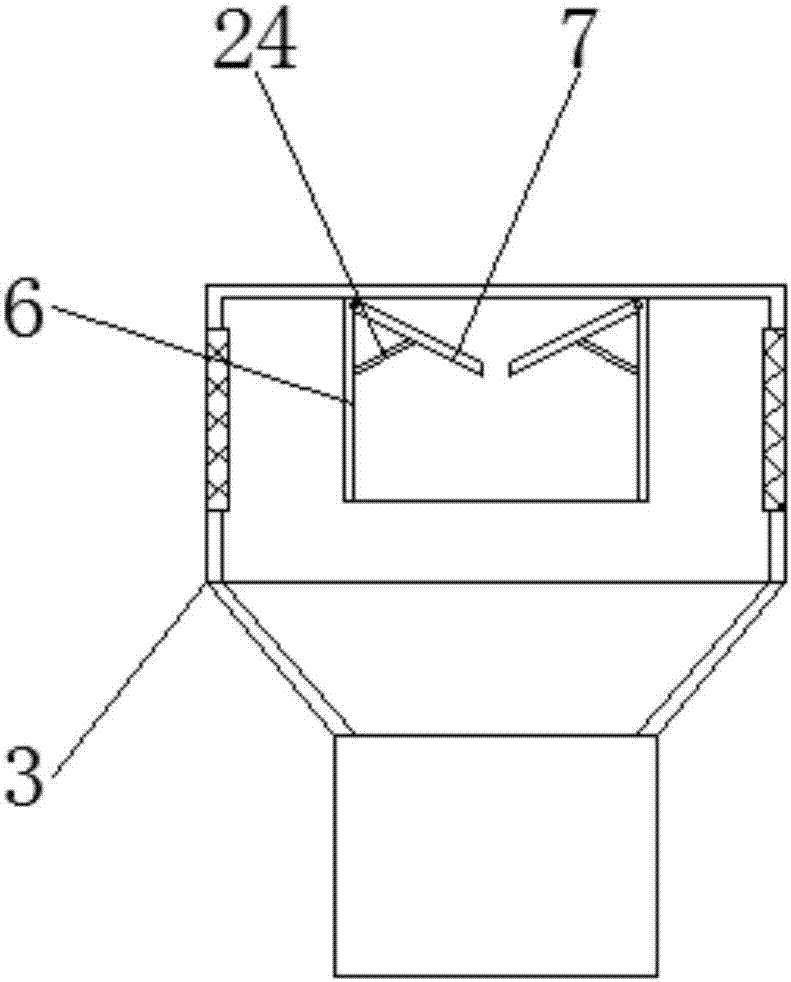

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

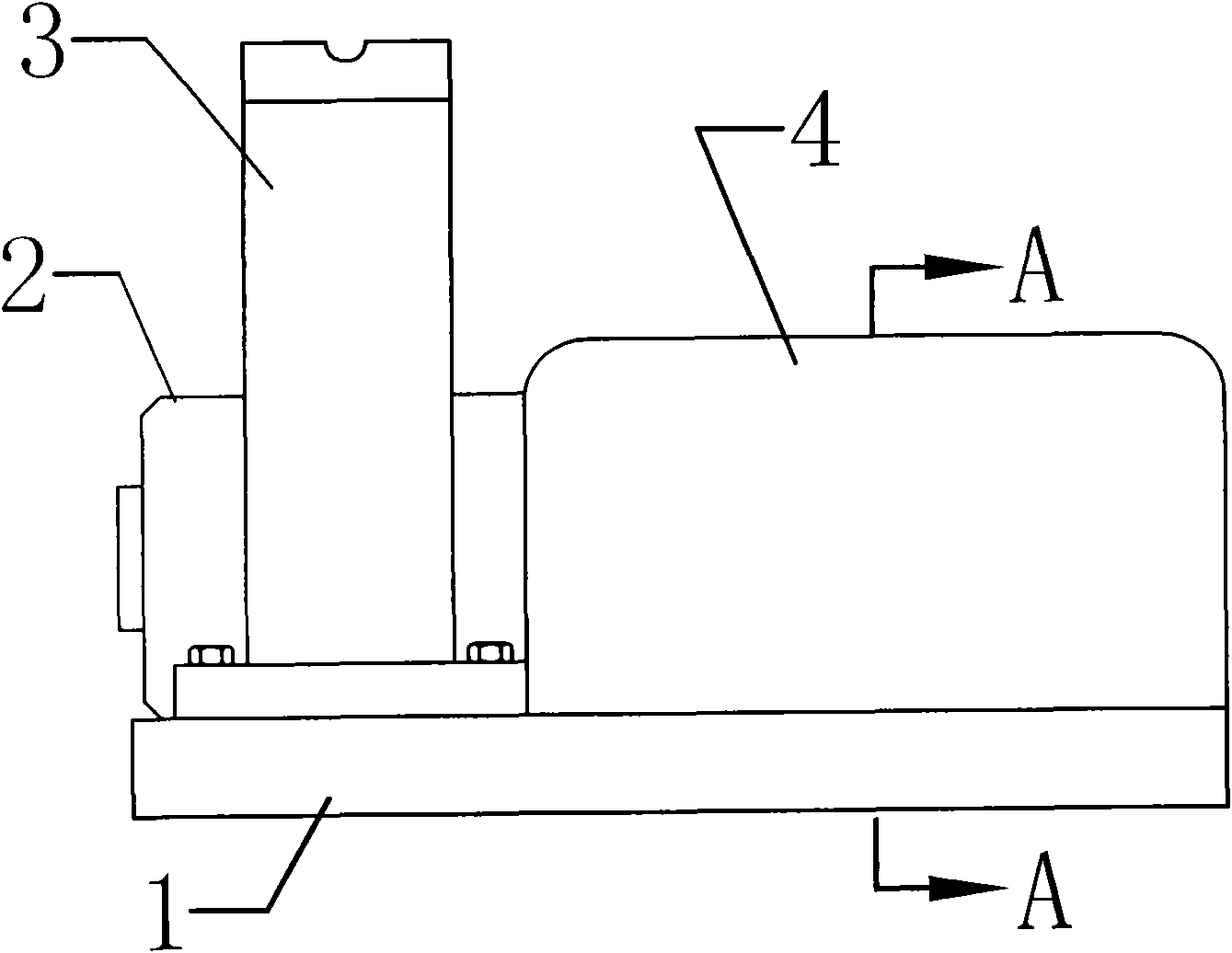

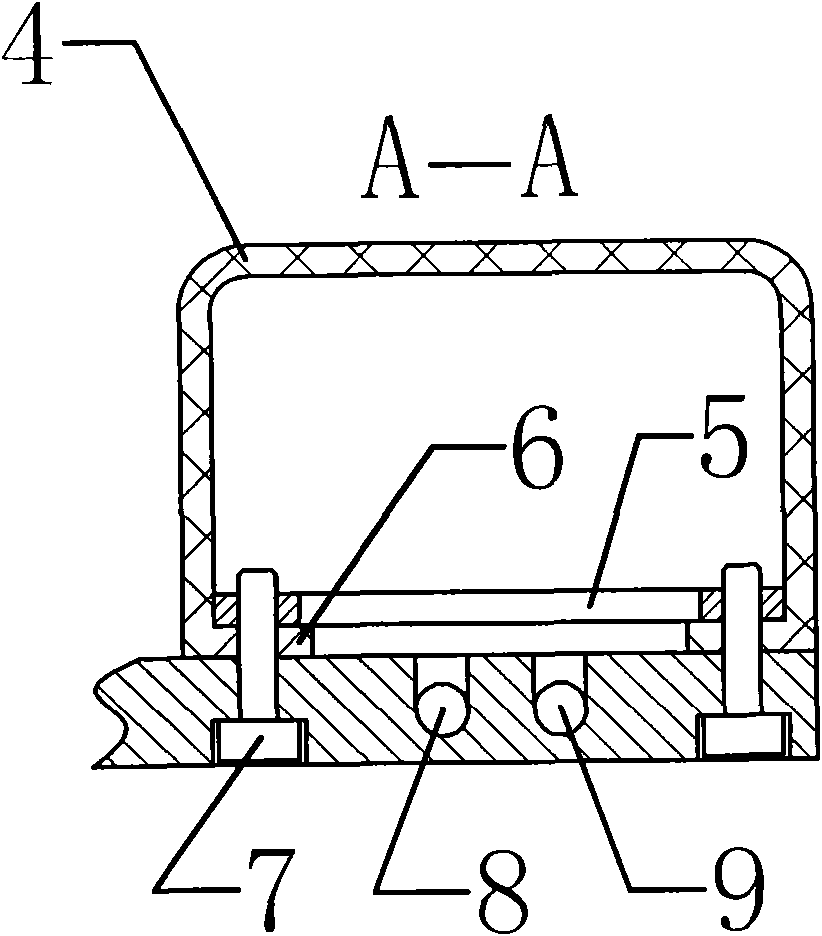

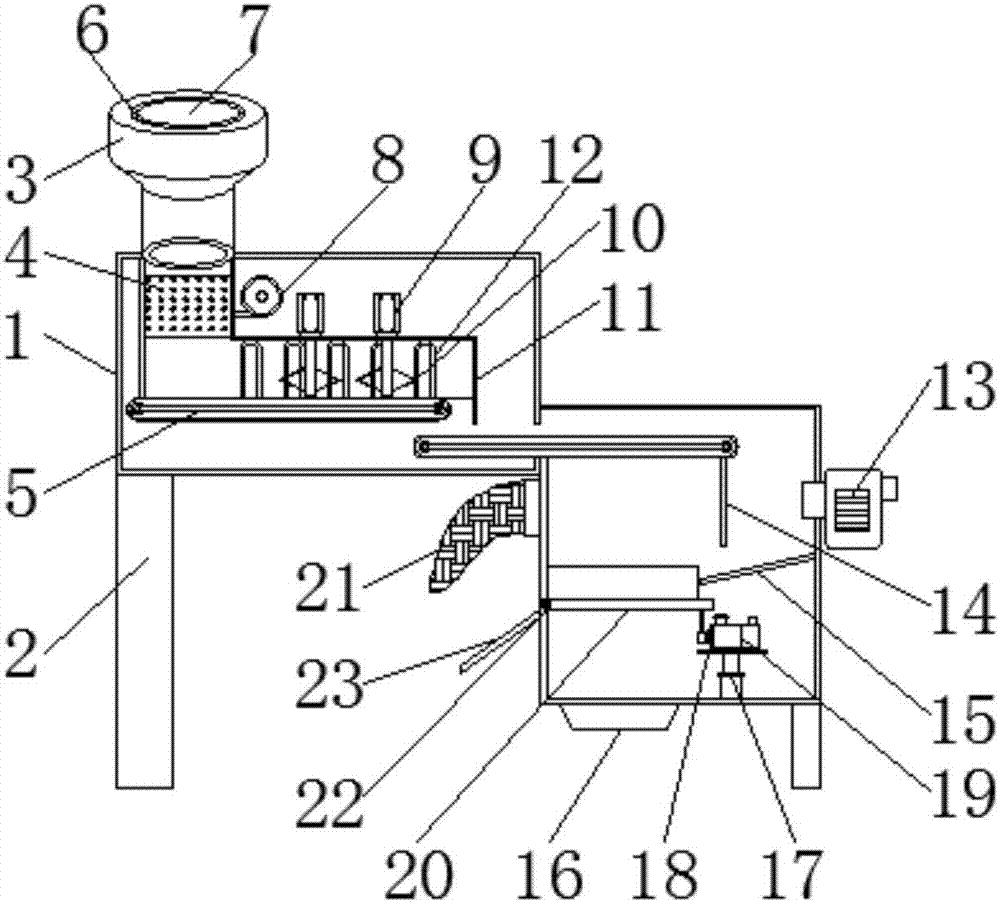

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

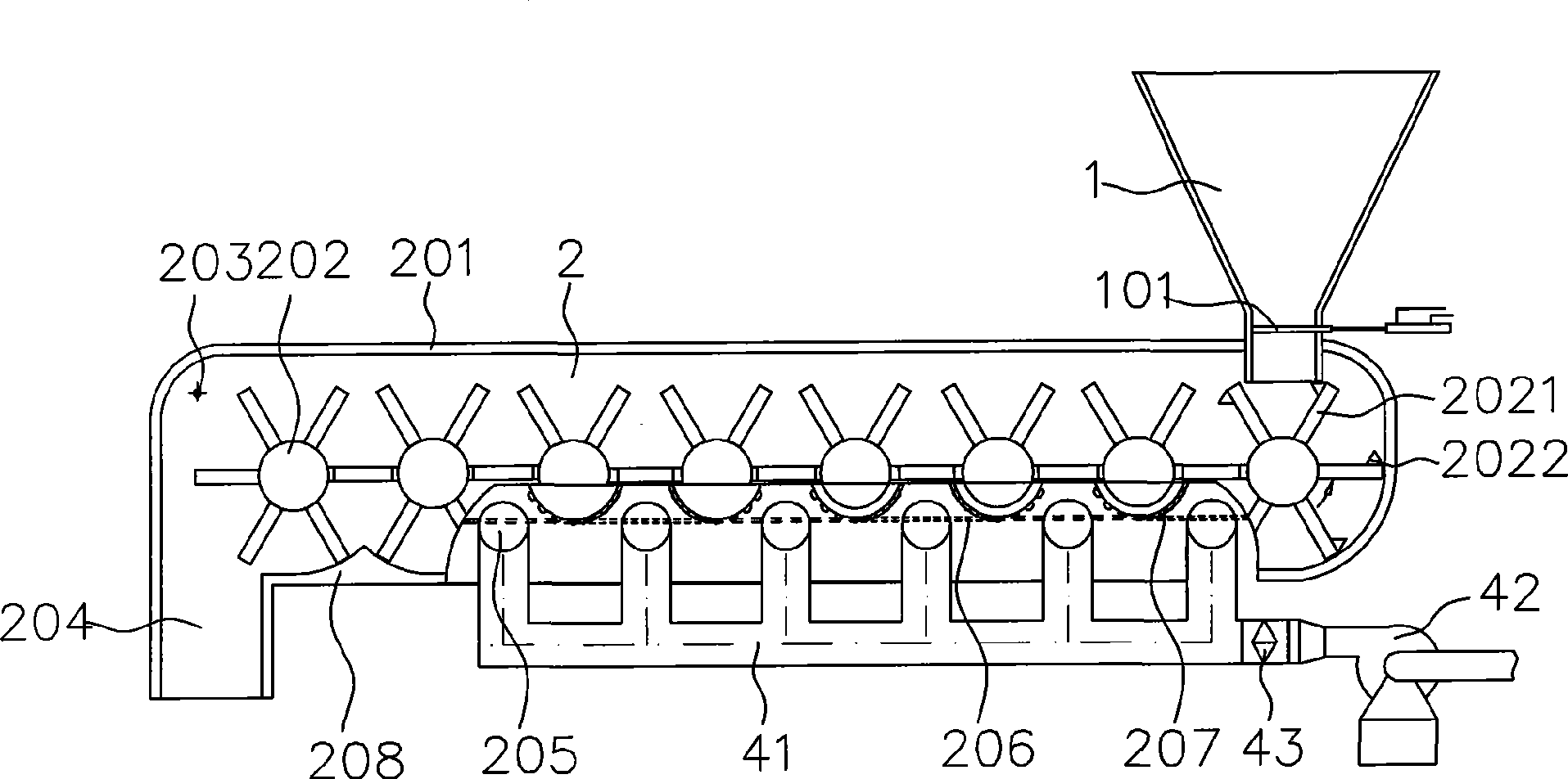

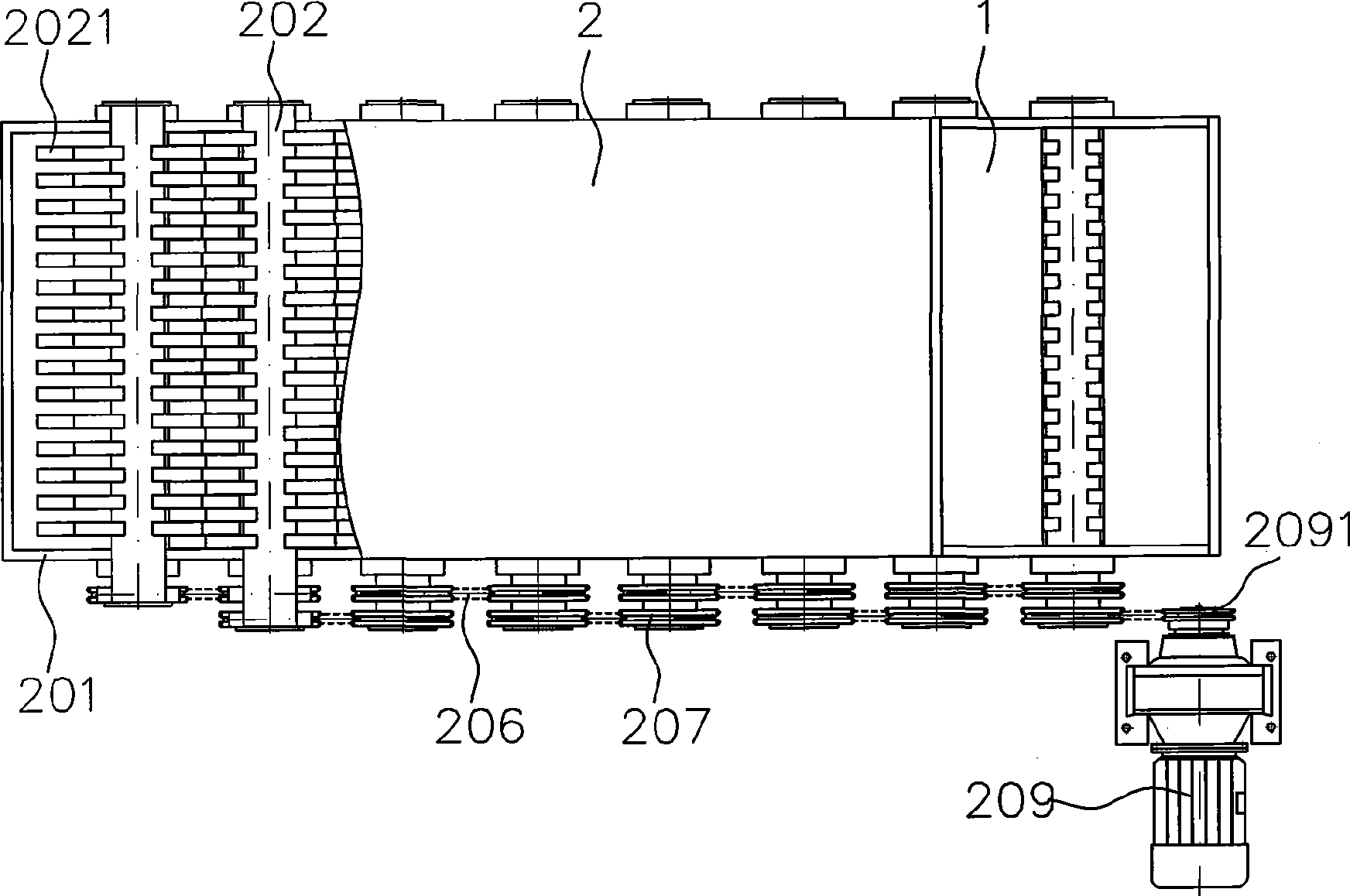

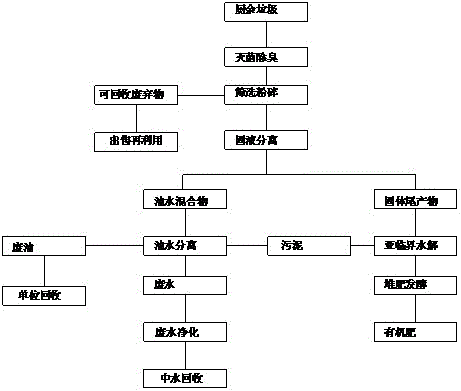

Kitchen garbage disposal method

InactiveCN102873078AStrong processing abilityHigh degree of resource utilizationSolid waste disposalPulverizerSewage

A kitchen garbage disposal method is characterized by including steps of 1, sterilizing, deodorizing, and adding hydrolyzing protease into kitchen waste; 2, screening and crushing the kitchen garbage, sorting wastes such as glass and ceramics which cannot be disposed from deodorized garbage automatically, crushing the residual waste by a crusher; 3, performing solid and liquid separation, separating suspended matters with thickness of 2mm at least and solids and squeezing to dewater to form a tailing product, and discharging oil water into an oil and water separator; 4, performing oil and water separation to separate heavy oil, light oil, sewage and sludge and the like in waste water of the kitchen garbage, feeding the separated oil, sewage and sludge into an oil storage barrel, a sewage treatment device and a sludge collection barrel respectively; 5, purifying sewage by details of feeding the separated sewage into a sewage purifying system which is provided with air flotation and reverse osmosis devices; and 6, treating the tailing solid products by details of hydrolyzing the tailing solid subcritically, subjecting dynamic fermentation to the tailing solid products for two to three days after subcritical hydrolysis treatment, and finally obtaining an organism modifier for soil.

Owner:ZHEJIANG AIKELE ENVIRONMENTAL PROTECTION

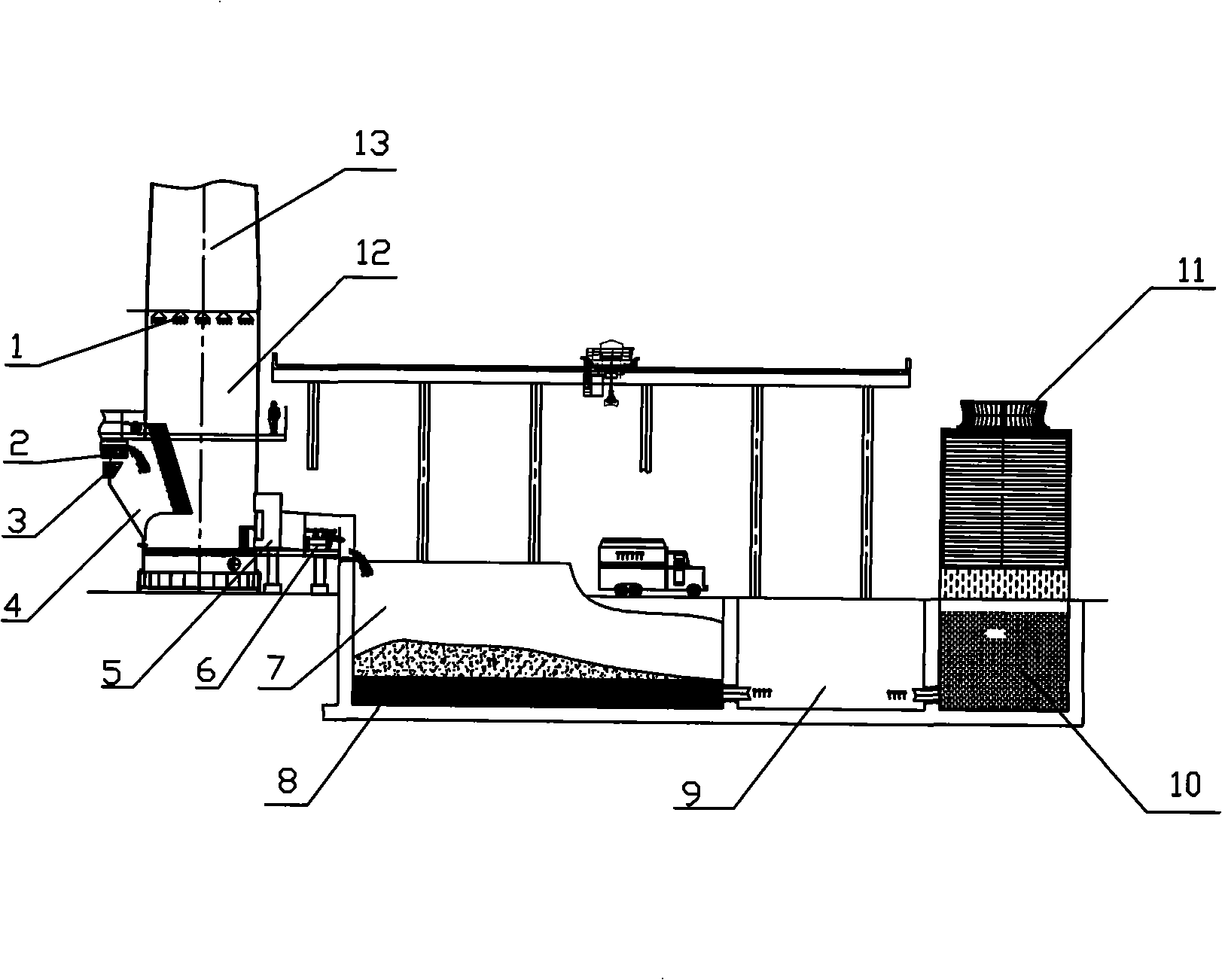

Environment-friendly type bottom filter process blast furnace slag treatment device and treatment method

The invention discloses an environment-friendly blast furnace slag treatment device based on bottom filter process and a treatment method thereof. The treatment device comprises a water slag granulation pool. The water slag granulation pool comprises a granulation pool entrance unit and a granulation pool exit unit. The granulation pool entrance unit is provided thereon with a granulator. The water slag granulation pool is provided inside with a granulation pool condensation / spray device. The granulation pool exit unit is connected with a filter tank. The downstream of the filter tank is connected with a cooling tower via an upper tower pump. The invention realizes energy conversation, discharge reduction and safe production, overcomes the problem of large occupied area of the conventional bottom filter process, and reduces the costs for construction and operation.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

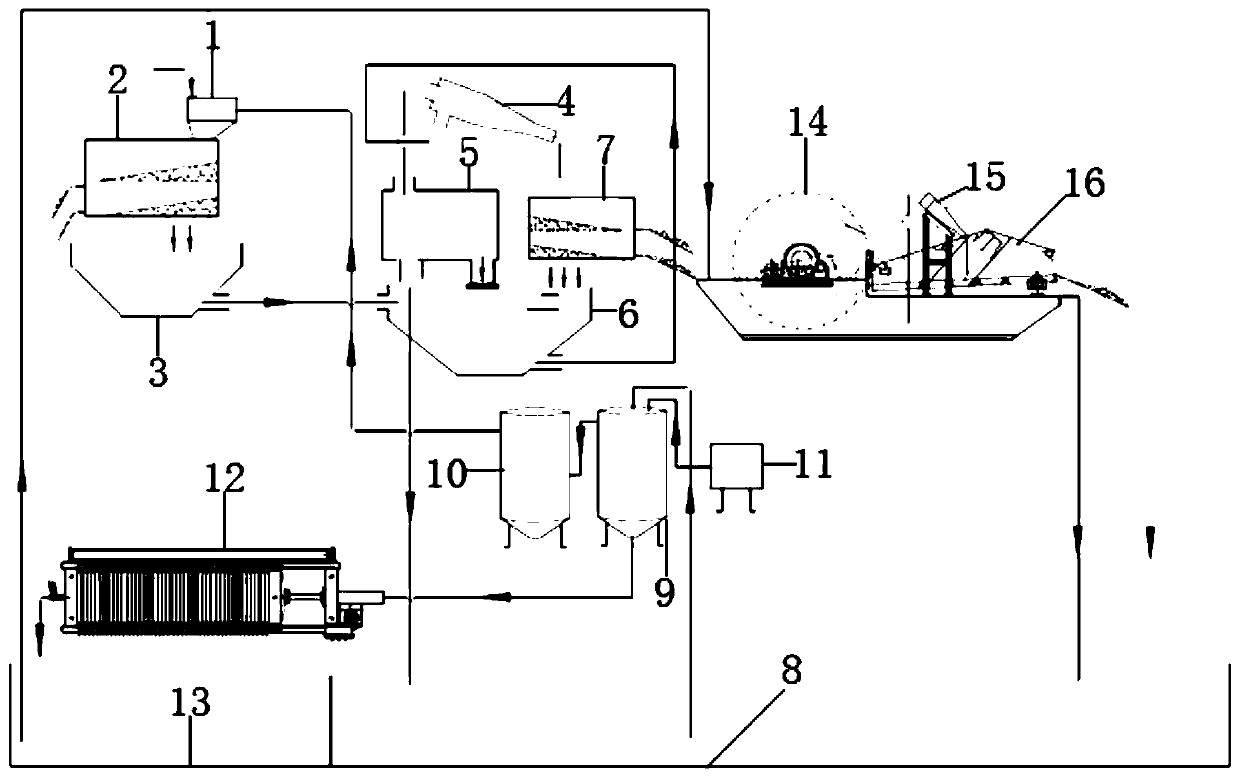

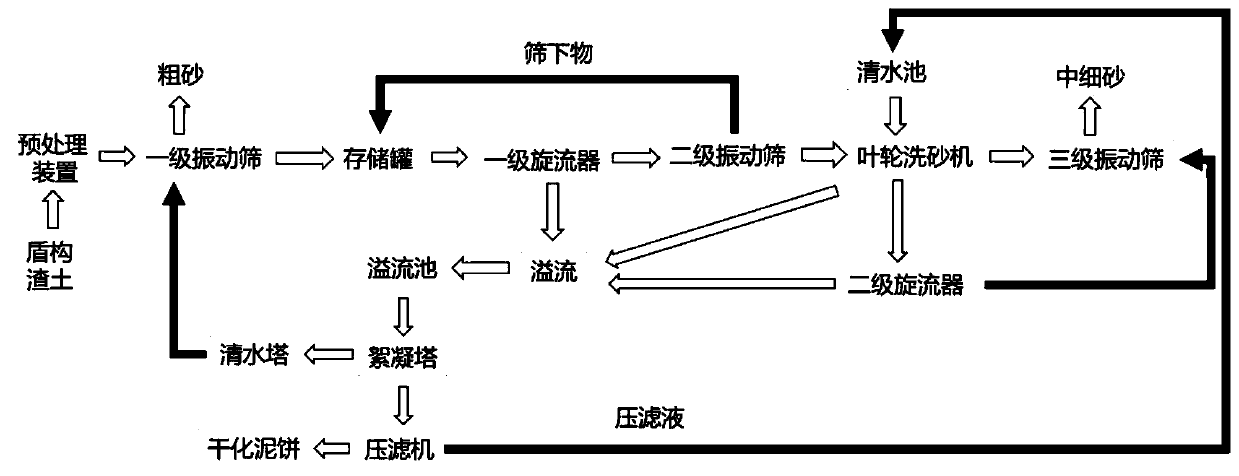

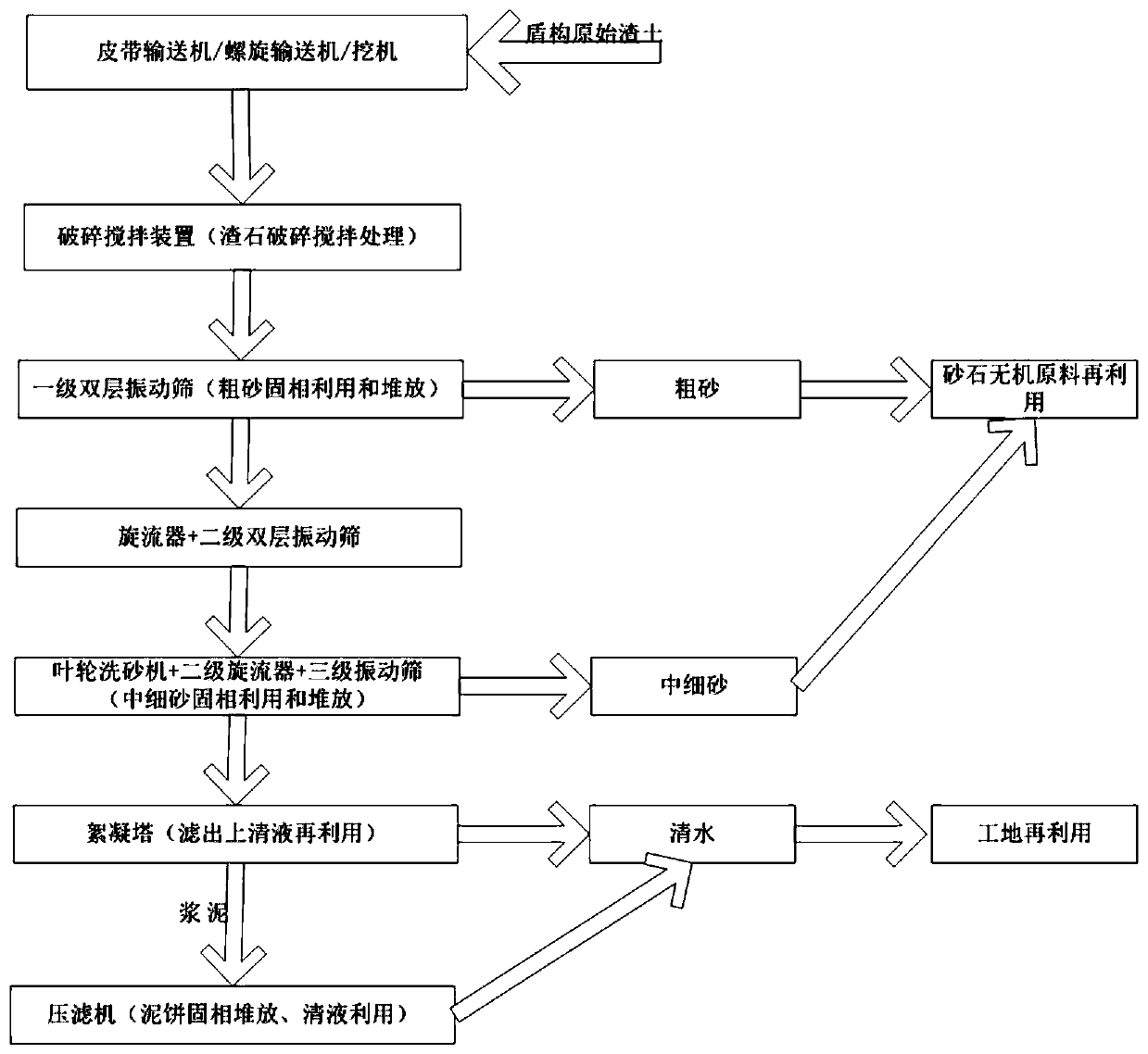

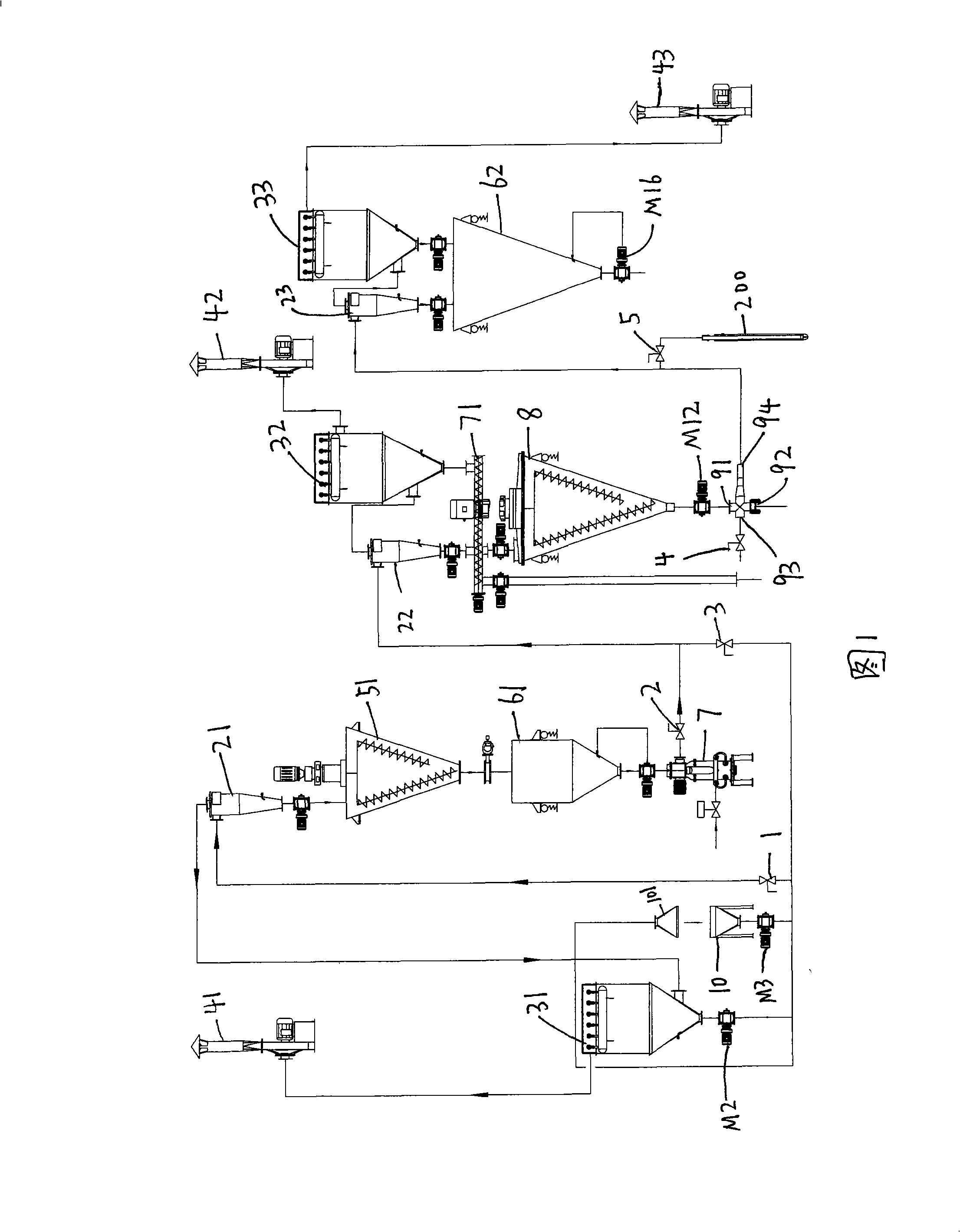

Shield construction muck treatment system and method

ActiveCN110303033AAchieve graded solid-liquid separationReduce transport volumeSievingConstruction waste recoveryEngineeringSlurry

The invention relates to the technical field of shield construction muck treatment, in particular to a shield construction muck treatment system and method. The muck generated by shield construction is crushed and stirred by a crushing and stirring device and then enters a primary-stage double-layer vibrating screen, oversize products are discharged out of the system, undersize products enter a sieve cone tank, the sieve cone tank is connected with a swirler through a pump, an intermediate tank is connected to an overflow port of the swirler, a discharge port of the intermediate tank is connected to an overflow tank through a pipeline, the slurry in the overflow tank is pumped to a flocculation tower through a pump, the flocculation tower is connected with an automatic dosing device, a flocculation medicament is pumped into the flocculation tower, the slurry in the flocculation tower is pumped to a filter press through a pump, drying mud cake treatment is carried out through the filterpress, the treated clear water flows into a clear water tank for reutilization, the dried mud cake is discharged out of the system, so that classified solid-liquid separation of different particle size components and water in the shield muck is realized, reutilization of inorganic raw materials and water resources of the shield muck is formed, and huge economic benefits are generated while the social resources are saved.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

Anti-cold Chinese medicine sterilizing fumet and fumigation stove

InactiveCN1554243ARelieve respiratory secretionsEliminate bad breathBiocideAnimal repellantsIndoor airMedicine

The present invention relates to Chinese medicine product for sterilizing and preventing diseases. The fumigation stove consists of fumigation chamber with electrothermal roastig board in the lower part, filter with upper fume outlet holes and material feeding opening and four claw support inside the outer casing. The casing is vase-shaped or in other decorative form. The fumet has moxa as main component and contains also eight kinds of Chinese medicinal materials, including basket kern, agastache, calamus, etc. The present invention is used in purifying and aromatizing indoor air, especially in disease spreading period. The medicated air has obvious effect of killing bacteria and inhibiting virus.

Owner:张留印

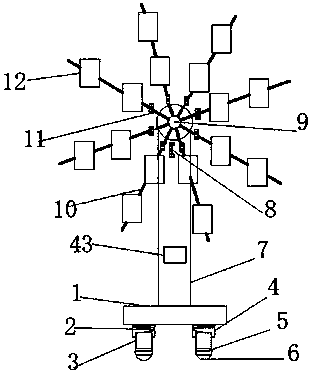

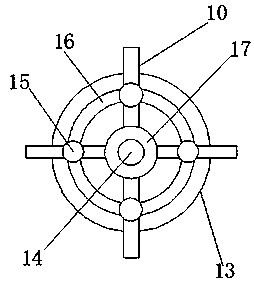

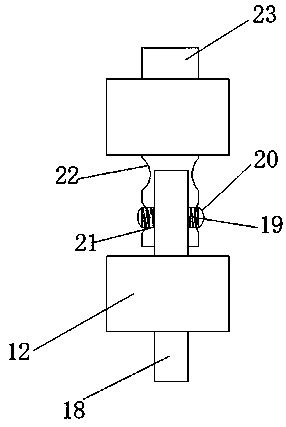

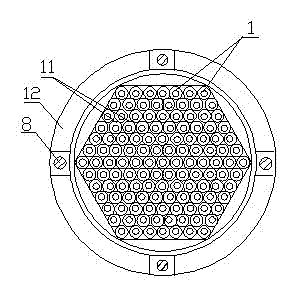

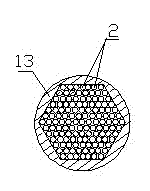

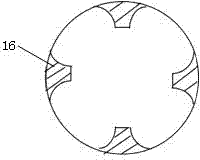

Non-flour dust overflow environment friendly intelligent fluidized bed airflow ultramicro crushing apparatus

The present invention discloses a no-dust-outflow, environment friendly and intelligent fluidized bed airflow micron ultra shifter, which mainly consists of a first cyclone separating device, a second cyclone separating device and a third cyclone separating device, a first pulsed jet cloth filter, a second pulsed jet cloth filter and a third pulsed jet cloth filter, a first draught fan, a second draught fan and a third draught fan, a first mixer communication, a disintegrator, a first weighing barrel and a second weighing barrel, a weighing mixer, a spiral feeder, a four-way valve and a suction pipe. All equipment of the whole device is sealed and connected. The machine is under completely closed negative-pressure operation; the feeding process includes an air draft hood, a PLC control and a touch screen button; the whole production line can achieve three functions (that is, packaging after grinding, mixed packaging and pure packaging); all the equipment adopts soft connection; no dust blowing can effectively ensure no dust outflow in the work process; therefore, the micron ultra shifter of the present invention is suitable for processing toxic materials to human body such as pesticide industry.

Owner:MIYOU GROUP

Double energy-source environmental protection energy-saving steam box

The present invention relates to a double energy source environment-protecting energy-saving cooking cabinet for cooking food. Said cooking cabinet includes the following several portions: gas range, steamer, electric heater, steam tube, water inlet tube and foat valve. Besides, said invention also provides its working principle and its concrete operation method.

Owner:刘伟

Gel-state electronic cigarette liquid and preparation method thereof

The invention relates to gel-state electronic cigarette liquid and a preparation method thereof. The gel-state electronic cigarette liquid comprises, by mass percentage, 1-17% of vegetable gelatin, 15-43% of atomizing agent, 2-20% of edible essence and 20-60% of pure water. The preparation method includes: adding the vegetable gelatin and the pure water according to the mass percentage, and heating to melt into gelatin liquid; adding the tobacco essence and the atomizing agent into the gelatin liquid, evenly mixing and stirring, and cooling to obtain the gel-state electronic cigarette liquid.The gel-state electronic cigarette liquid has the advantages that the solid and liquid states of the gel-state electronic cigarette liquid can be changed along with temperature, and the gel-state electronic cigarette liquid is good in tobacco tar liquefying condition, safe and reliable.

Owner:云南拓宝科技有限公司

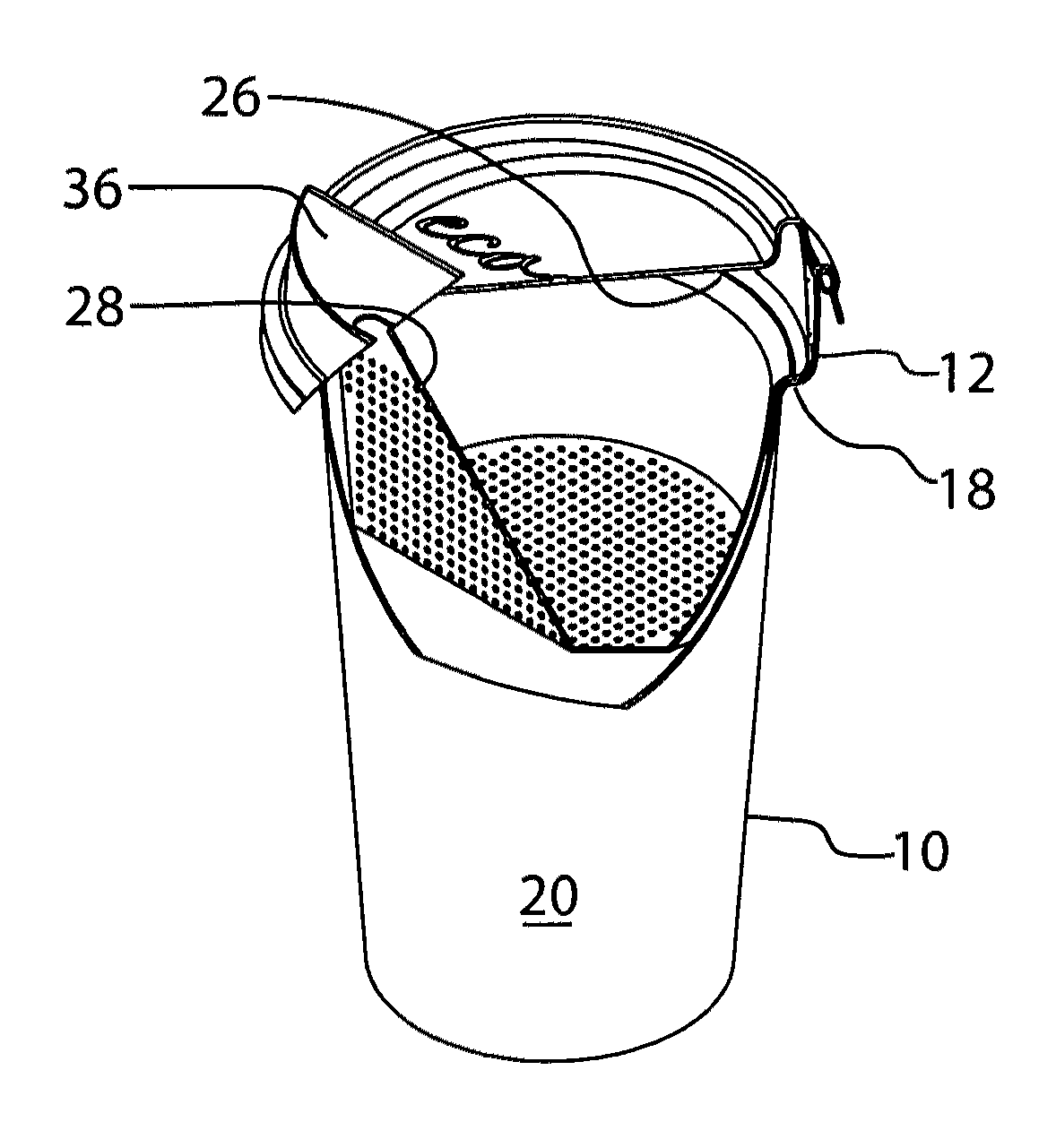

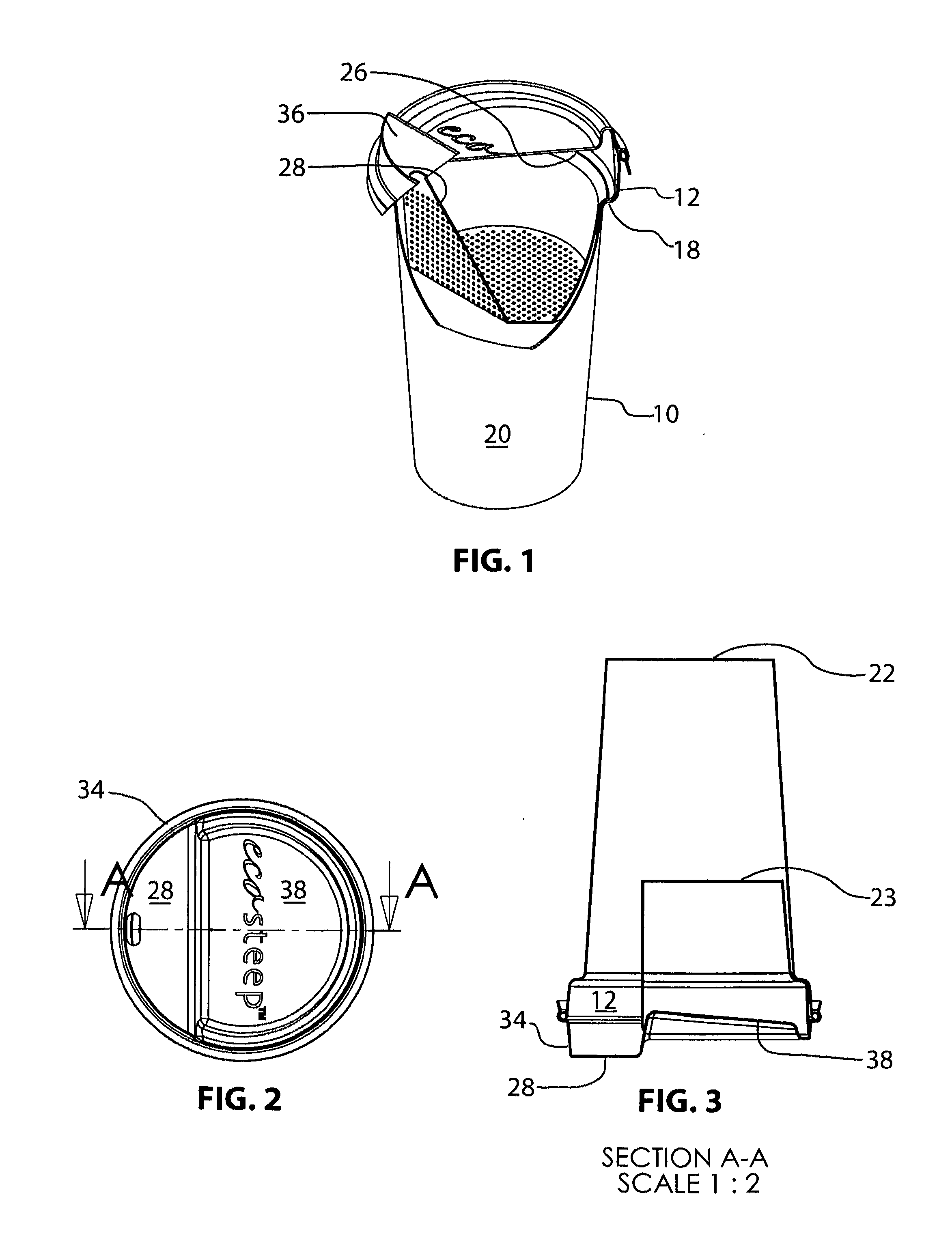

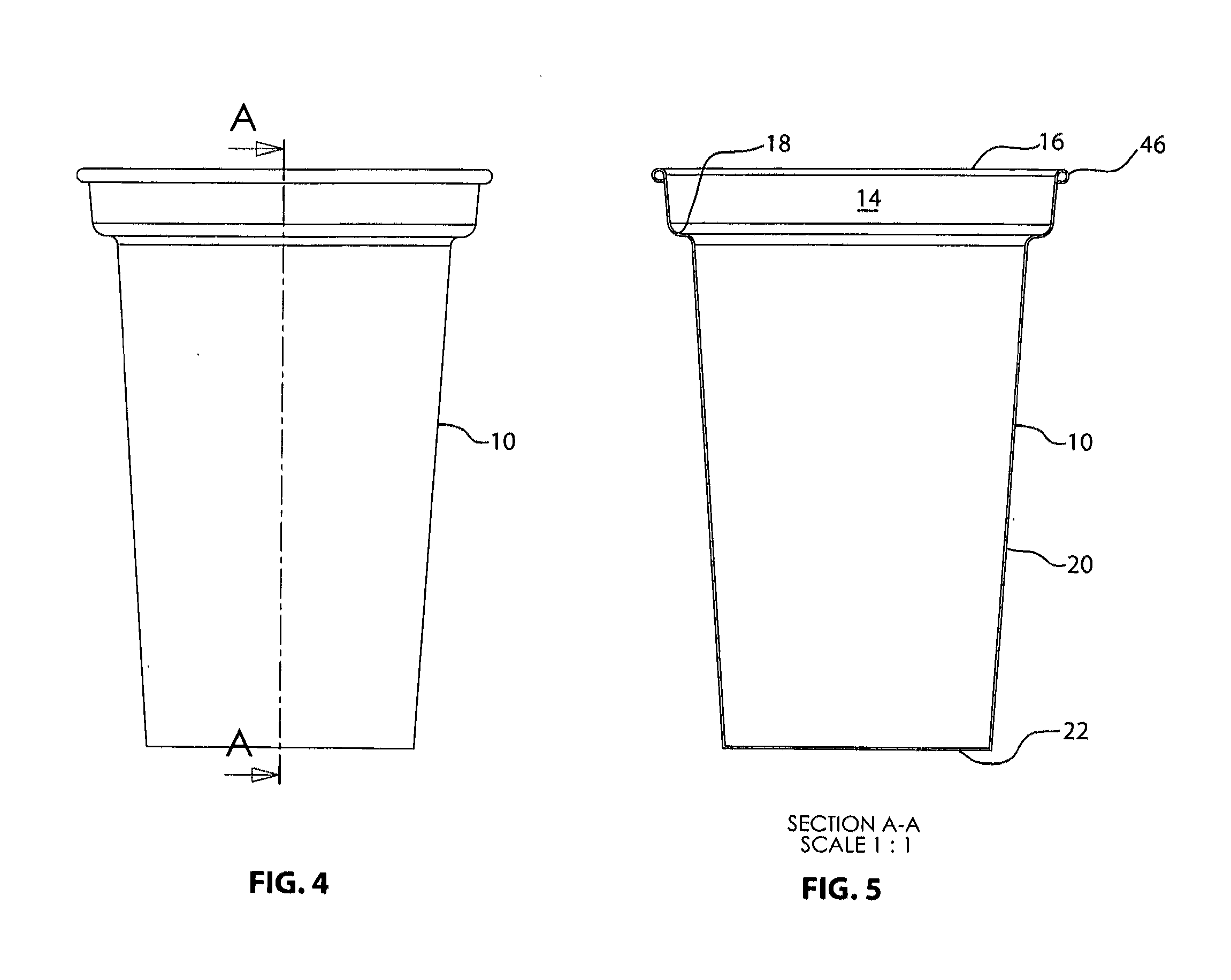

Tea steeping assembly

InactiveUS20120174795A1Easy to handleSystem securityFlexible coversWrappersSteepingLocking mechanism

A system and process for steeping tea in a vessel is disclosed. The present invention incorporates the use of an infusing filter seated on or within a vessel and a lid or retaining mechanism to steep tea in water. The vessel has an retaining ledge that supports a mating infuser placed inside. The infuser seats in a stationery position on the mating ledge inside the vessel, offset from the center of the vessel, to allow for stirring, pouring or drinking of the resulting beverage without introducing the infusible material into the resulting steeped beverage product. The infuser comprises a filter element that holds the infusible material and allows contact with the water. The infusing filter is retained in its seated position in the cup, ether by a lid or positive locking mechanism that allows for the safe and convenient portage of the tea steeping assembly. The tea steeping assembly introduces a system that has the ability to produce a beverage product in a process that is entirely biodegradable and compostable.

Owner:USPENSKI MARIA +1

Flexible heat conduction/heat storage double-function composite material, method for manufacturing same and application of flexible heat conduction/heat storage double-function composite material

ActiveCN105623619AGood cooling effectHigh thermal conductivityHeat-exchange elementsCooling/ventilation/heating modificationsThermal conductivityResponse capacity

The invention discloses a flexible heat conduction / heat storage double-function composite material. The flexible heat conduction / heat storage double-function composite material is characterized in that (1-40wt% of) phase-change heat storage material particles are uniformly dispersed in matrixes, and the matrixes comprise (60-99wt% of) high-heat-conduction materials and are of three-dimensional stereoscopic network structures. The invention further discloses a method for preparing the flexible heat conduction / heat storage double-function composite material and application of the flexible heat conduction / heat storage double-function composite material. The flexible heat conduction / heat storage double-function composite material, the method and the application have the advantages that the flexible heat conduction / heat storage double-function composite material has a phase-change heat storage function with quick response capacity and is extremely high in heat conductivity (20-200 W / mK), accordingly, heat can be quickly transferred, heat of high-heat-production components such as chips and screens can be effectively conducted / absorbed, the hot-spot temperatures can be lowered, the service life of electronic equipment can be prolonged, the flexible heat-conduction / heat storage double-function composite material is free of leakage and high in flexibility and can be widely applied to electronic equipment such as intelligent mobile phones with strict requirements on structure spaces, and the like.

Owner:XIAOMO THERMAL MANAGEMENT MATERIALS TECH SHENZHEN CO LTD

Converter steel slag treatment device and method

ActiveCN107287368AEasy to separateReduce moisture contentRecycling and recovery technologiesCooling towerSlag

The invention relates to a converter steel slag treatment device which comprises a crown block, a slag ladle, a chute, a forklift, a steel slag pool, a bottom filtering pool, a water pump house, a water storage tank, a cooling tower, a bridge-type grab crane, a chimney, a hydraulic roller couple, nozzles, a granulating room and a condensate water tank, wherein a lifting hook of the crown block is connected with the slag ladle, the outlet of the slag ladle is connected with the inlet of the chute, and the outlet of the chute is connected with the upper part of the hydraulic roller couple; nozzles a are symmetrically arranged on the two sides of the upper part and the two sides of the lower part of the hydraulic roller couple, and the hydraulic roller couple and the nozzles a are all arranged in the granulating room; the steel slag pool is arranged at the lower part of the granulating room, and the forklift is arranged on the outer side of the lower part of the granulating room. The invention further discloses a converter steel slag treatment method. The flow of the method is as follows: steel slag dumping, steel slag crushing, steel slag granulating, slag washing water filtering and vapor condensation recovery. The converter steel slag treatment device has the advantages of high slag treatment efficiency, compact occupied area, energy conservation, environment protection and no pollution, adapts the fast-paced production mode of a converter, is good for magnetic separation extracting of grain steel and comprehensive application of grain slag, and has remarkable economical benefit.

Owner:北京中冶设备研究设计总院有限公司

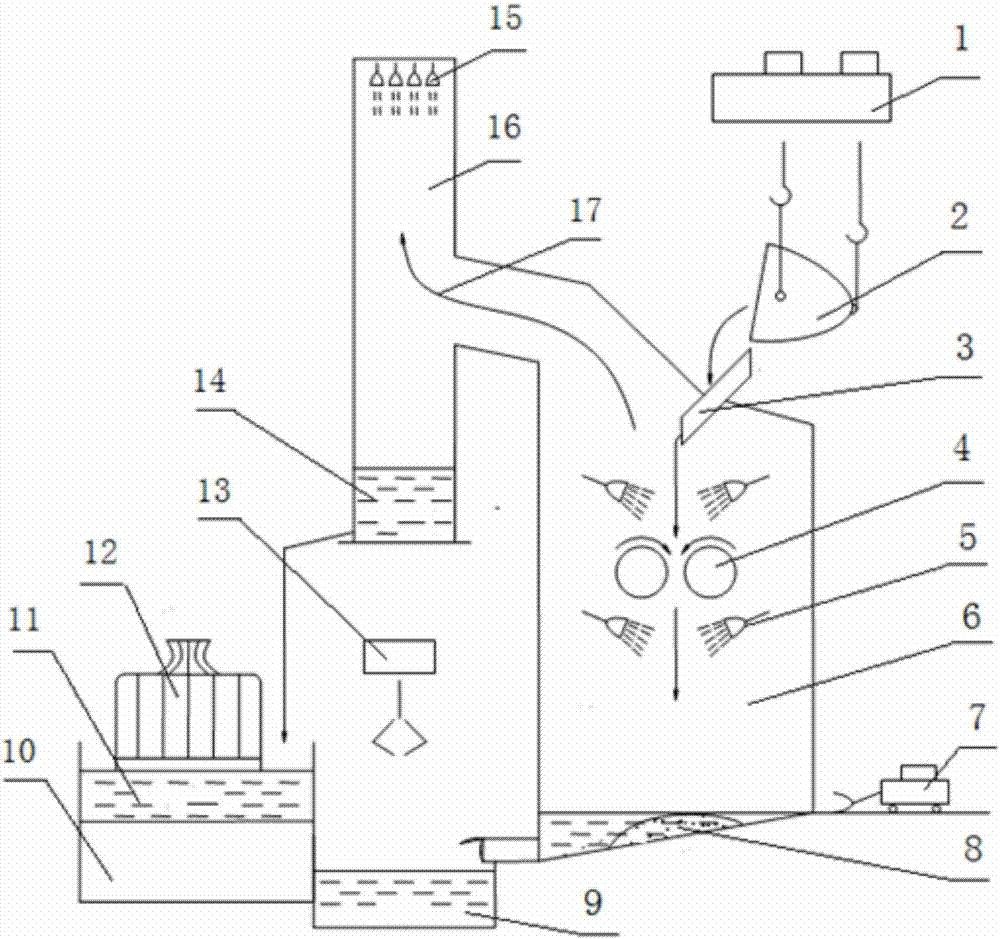

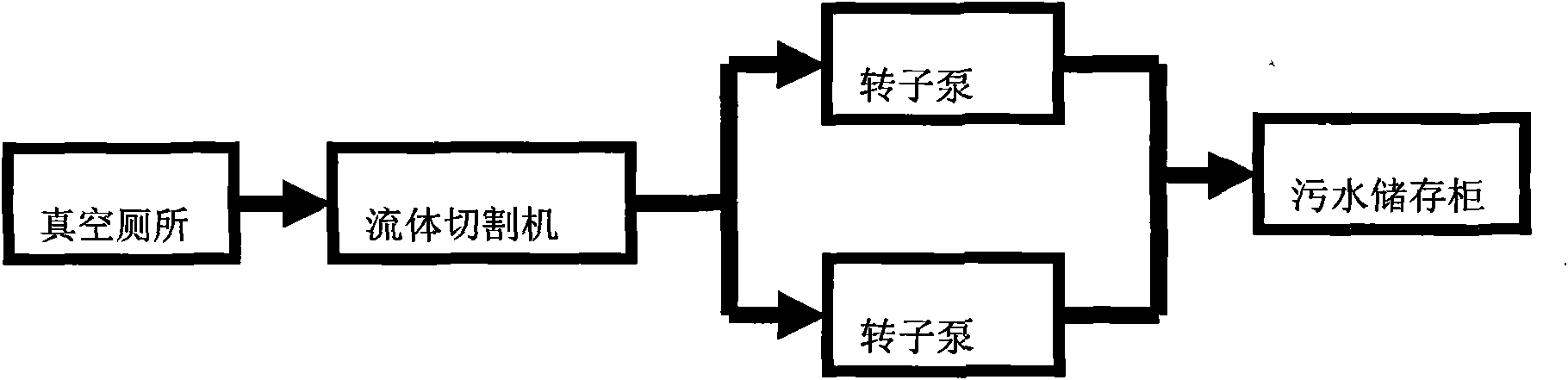

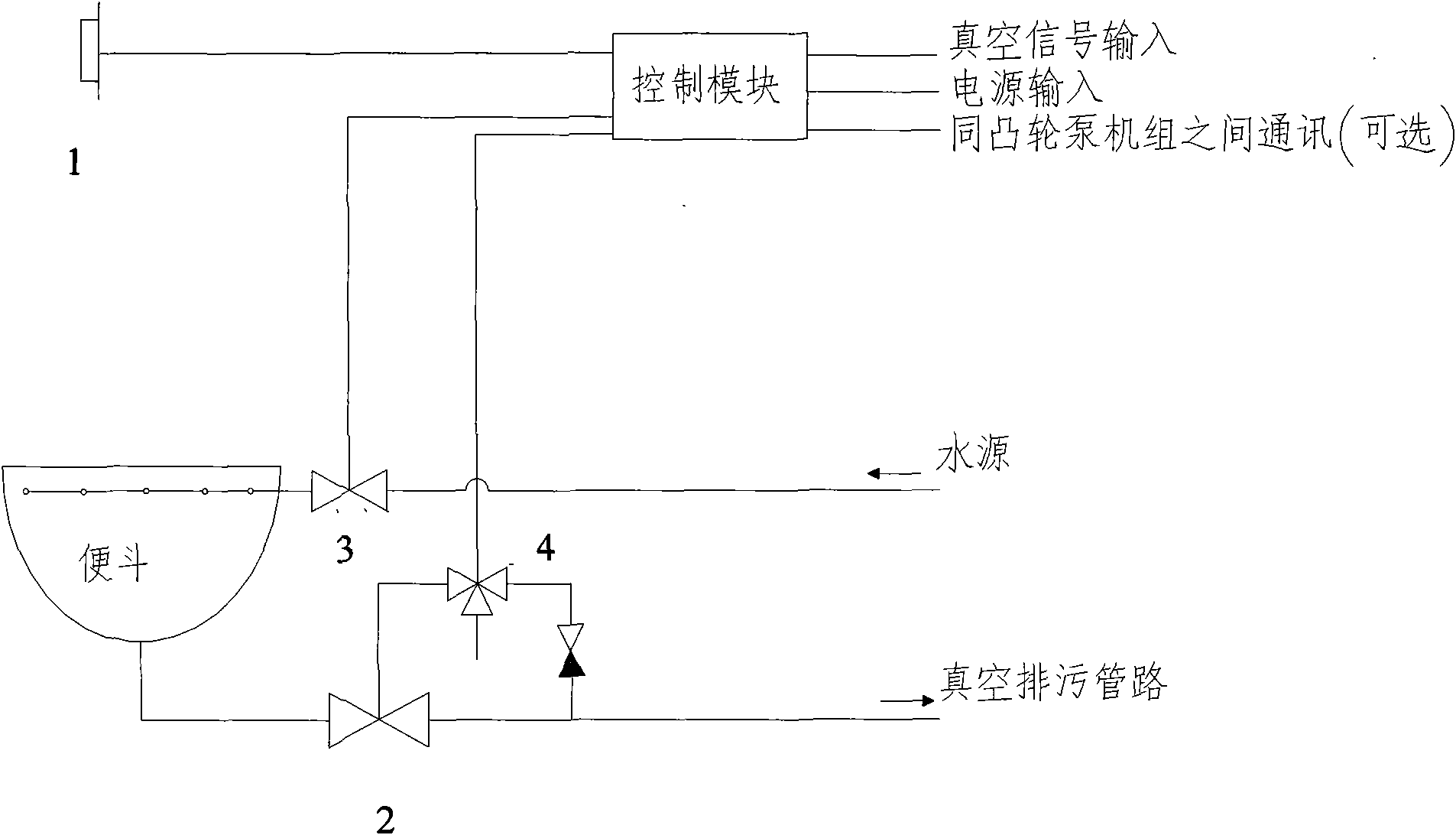

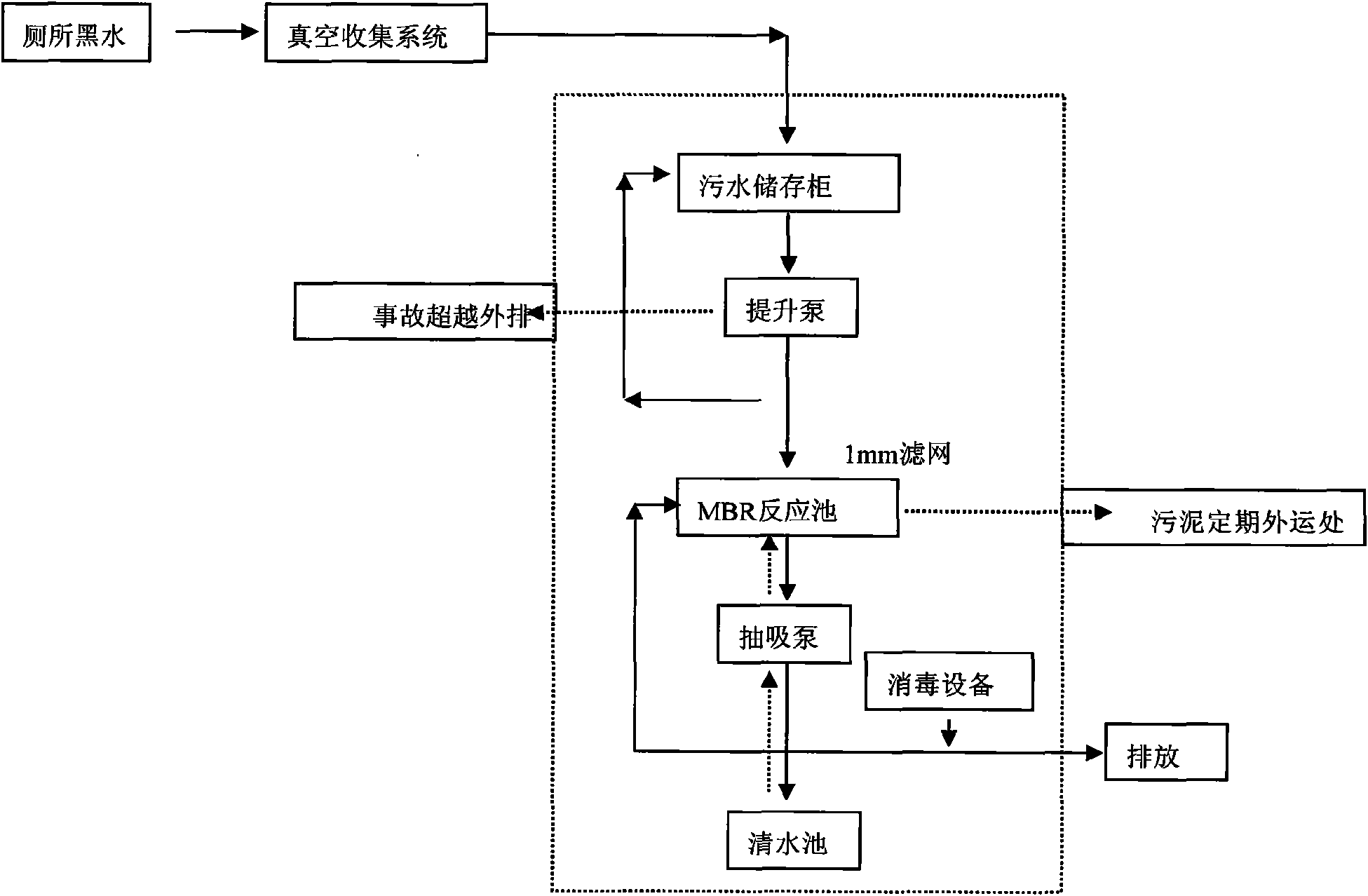

Marine domestic sewage treatment process and vacuum discharge and treatment system

ActiveCN101618927AReduce the amount of flushing waterSmall diameterAuxillariesWater/sewage treatment bu osmosis/dialysisCollection systemWater quality

The invention discloses a marine domestic sewage treatment process belonging to the technical field of sewage treatment and discharge. The marine domestic sewage treatment process comprises the following steps: (1) collecting sewage by a vacuum collection system, and achieving the discharge and transport by utilizing the pressure difference inside and outside the system; (2) crushing and thinning large granular suspended matters by a crushing pump, filtering by a grid and then conveying into a sewage tank; (3) conveying to a fur collector by the pump to remove furs and small granular suspended matters; and (4) degrading by aerobic bio-degradable bacteria, filtering by multiple groups of hollow micropore membrane reactors, then discharging into a sterilizing device, and finally discharging to the outside. The invention further discloses a marine domestic sewage vacuum discharge and treatment system. The invention has simple treatment process, not only saves space and water, has compact arrangement, safety and sanitation as well as easy maintenance, but also decreases the influence of the swing of a marine body on the water quality, and has high pollutant degradation efficiency and directly-reused discharged water.

Owner:SHENZHEN JINRUN IND

Traditional Chinese medicinal material saving equipment with good ventilation effect

InactiveCN109229792AMobile function is goodSolve the inconvenience of movingContainers preventing decayShock-sensitive articlesEngineeringChinese herbology

The invention discloses traditional Chinese medicinal equipment with a good ventilation effect, and belongs to the technical field of traditional Chinese medicine saving. According to the equipment, the interiors of the left and right side faces of a box body are provided with a micro fan and a ventilation port, wherein the micro fan is electrically connected with a control panel, an instruction is sent by the control panel to switch on the micro fan when temperature reduction ventilation is needed by medicinal materials to ventilate the medicinal materials, drying agent filling layers are arranged on both upper and lower ends of the box body, drying devices or other additives preventing mosquitoes and insects can fill the filling layers to ensure the dryness and completeness of the medicinal materials, the medicinal materials in the box body can be conveniently taken out, a limiting device is not arranged, and therefore the scattering of the medicinal materials caused by the sliding out of frame bodies of medicine drawers in the box body is ensured to be prevented when medicinal materials are taken out.

Owner:JILIN UNIV FIRST HOSPITAL

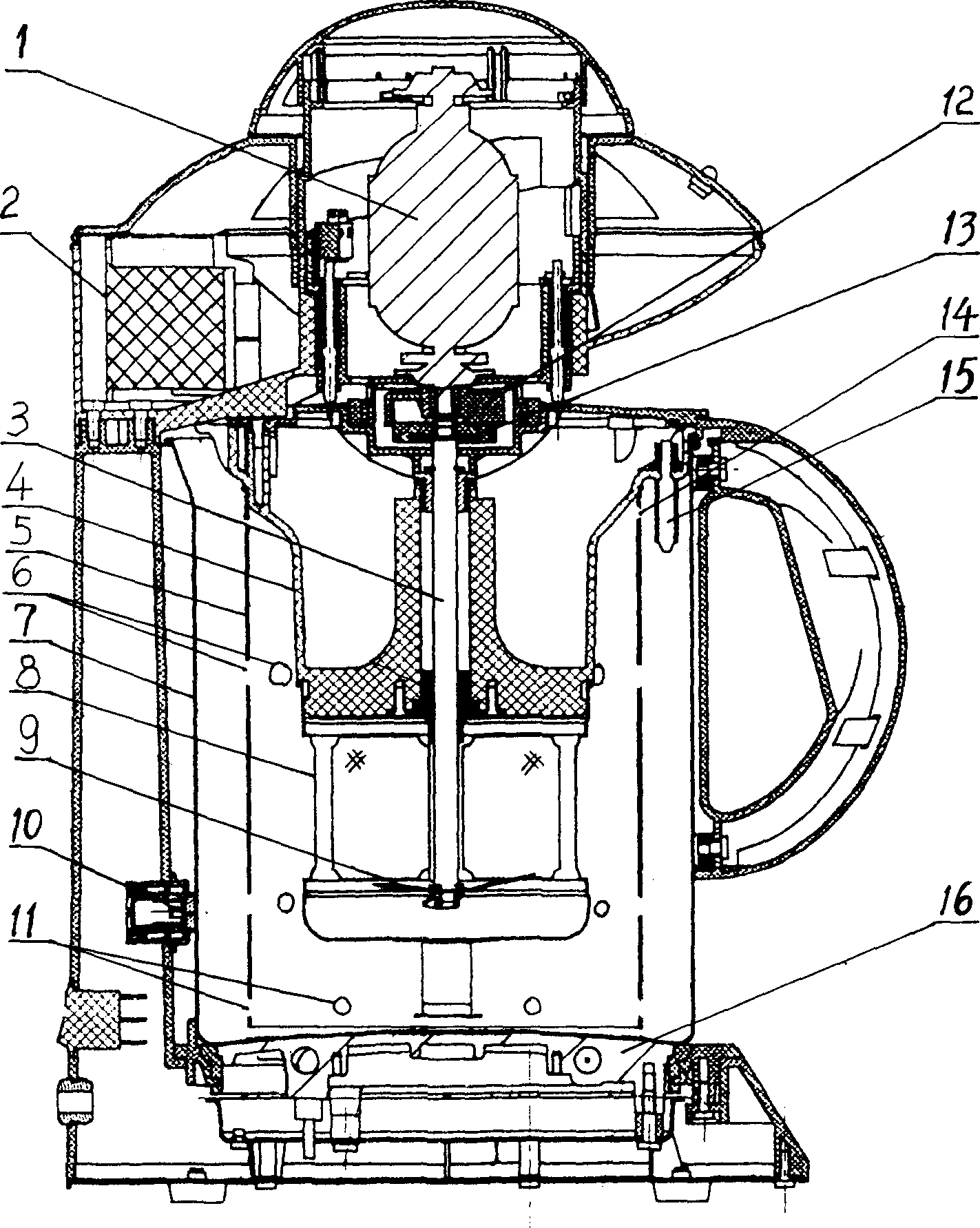

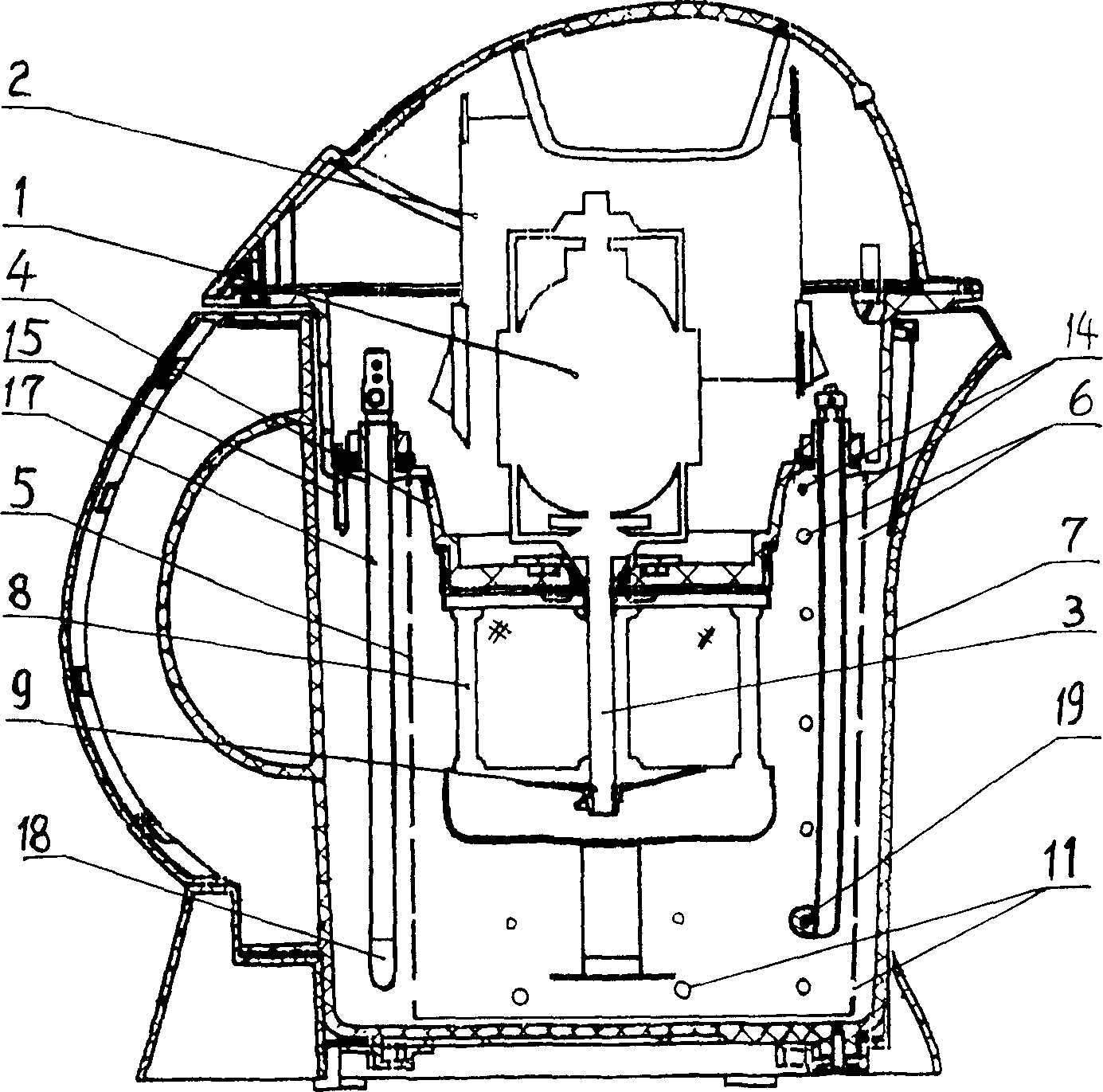

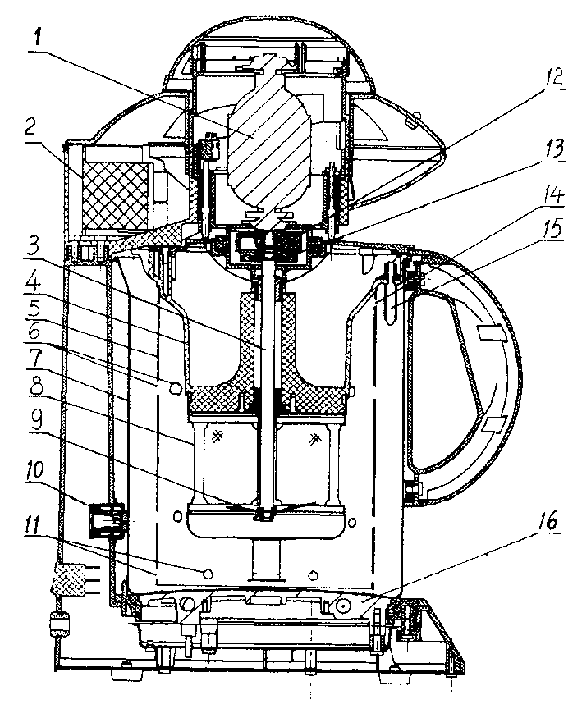

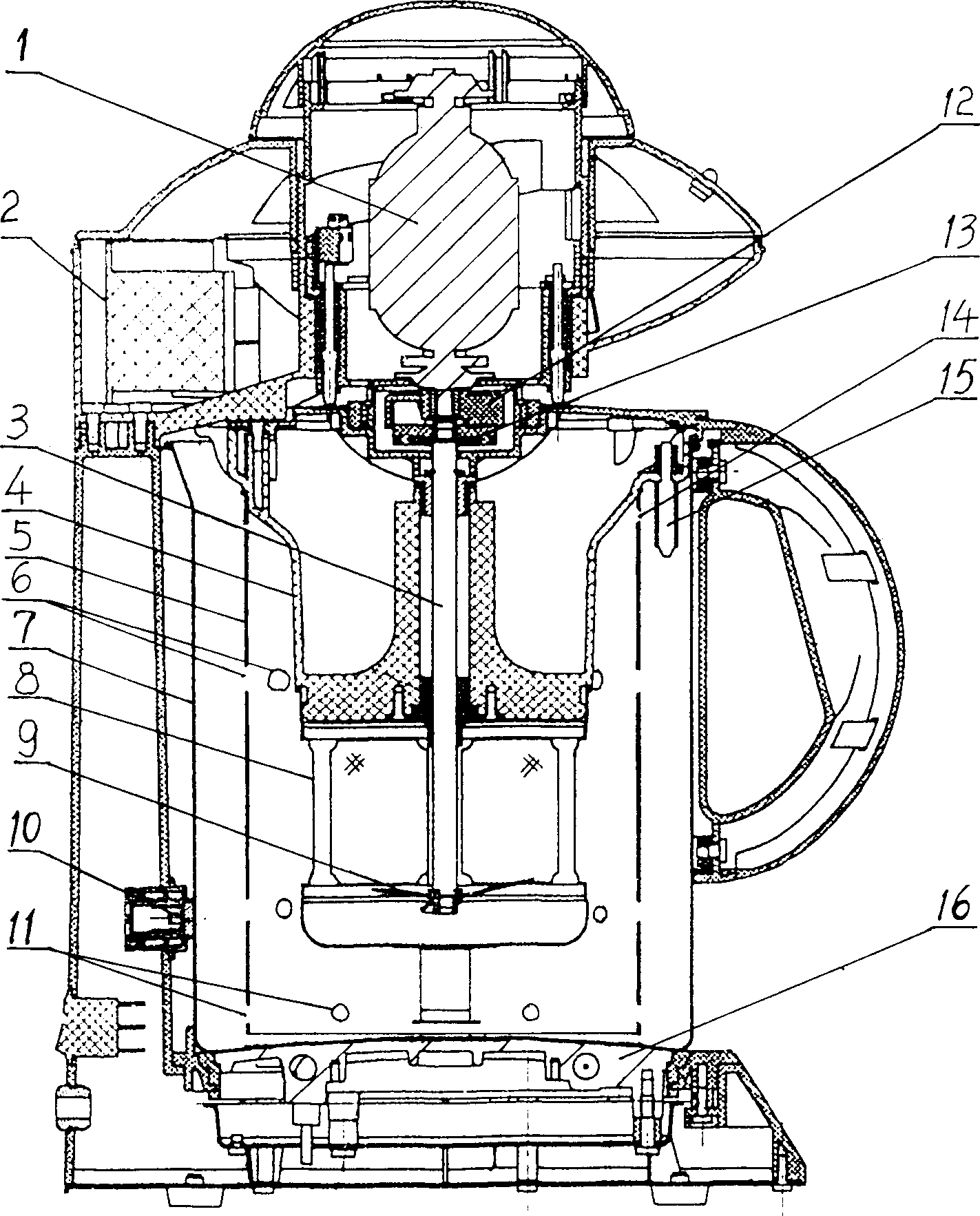

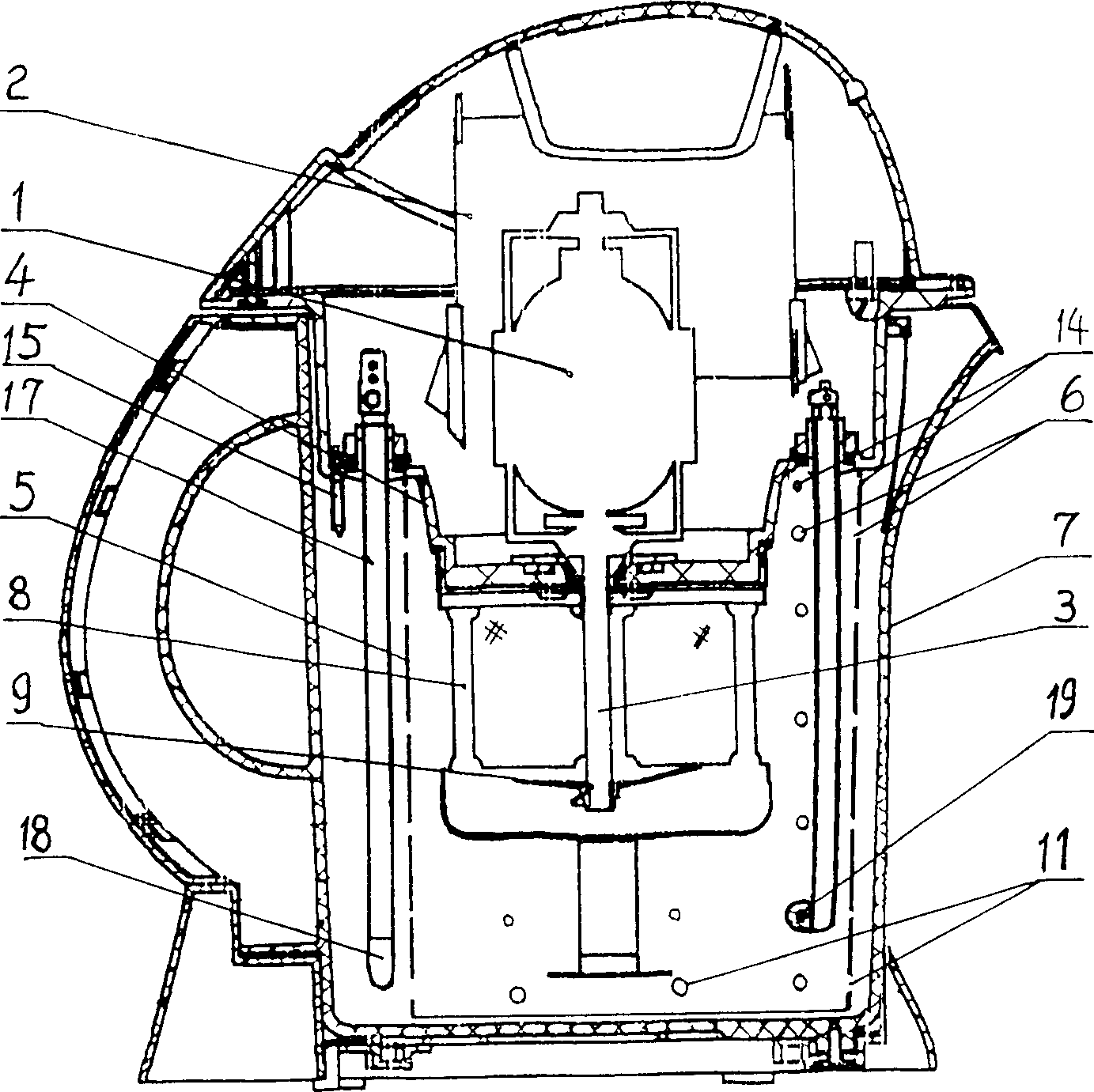

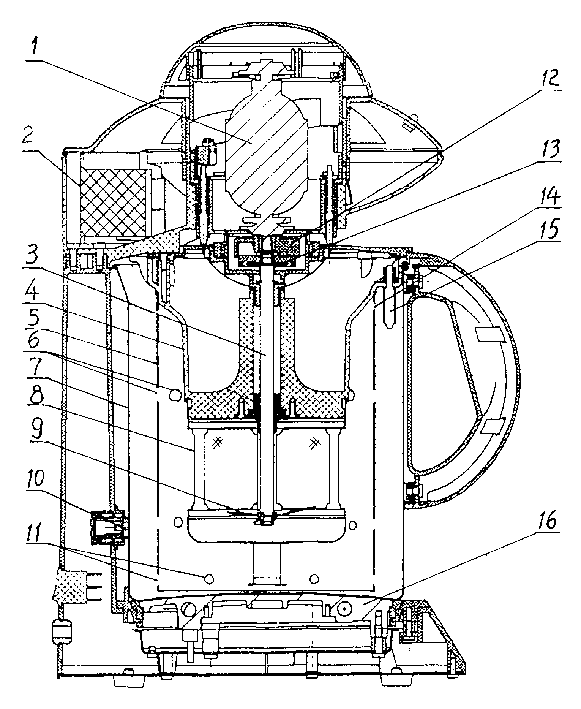

Heating method and heating device of soy milk and its application on soy milk machine

InactiveCN1426723AHigh degree of thermal expansionReduce temperature shrinkageBeverage vesselsEngineeringHigh pressure

A method and its device for heating soybean milk are disclosed, and can be used for domestic soybean milk maker. Its heater is composed of external cylinder and its cover and internal cylinder whose top is fastened to the inner surface of the said cover and whose side wall is perforated. When soybean milk is boiling, a slightly higher pressure is formed at upper part of internal cylinder to make the hot milk flow into the external cylinder through the holes. It is circulated between internal and external cylinders at 100-105 deg.C for 4-10 min for emulsifying it well.

Owner:JOYOUNG CO LTD

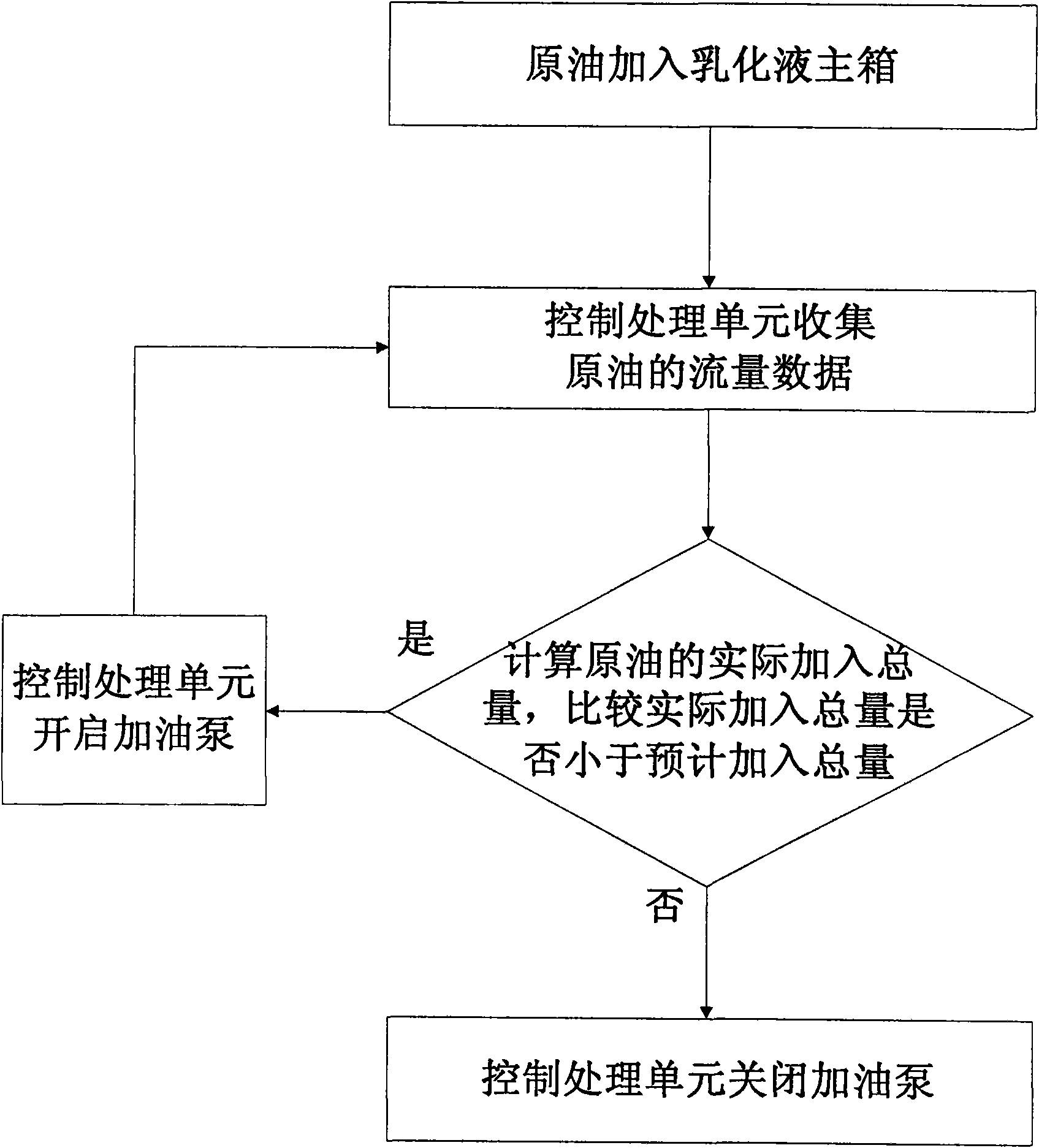

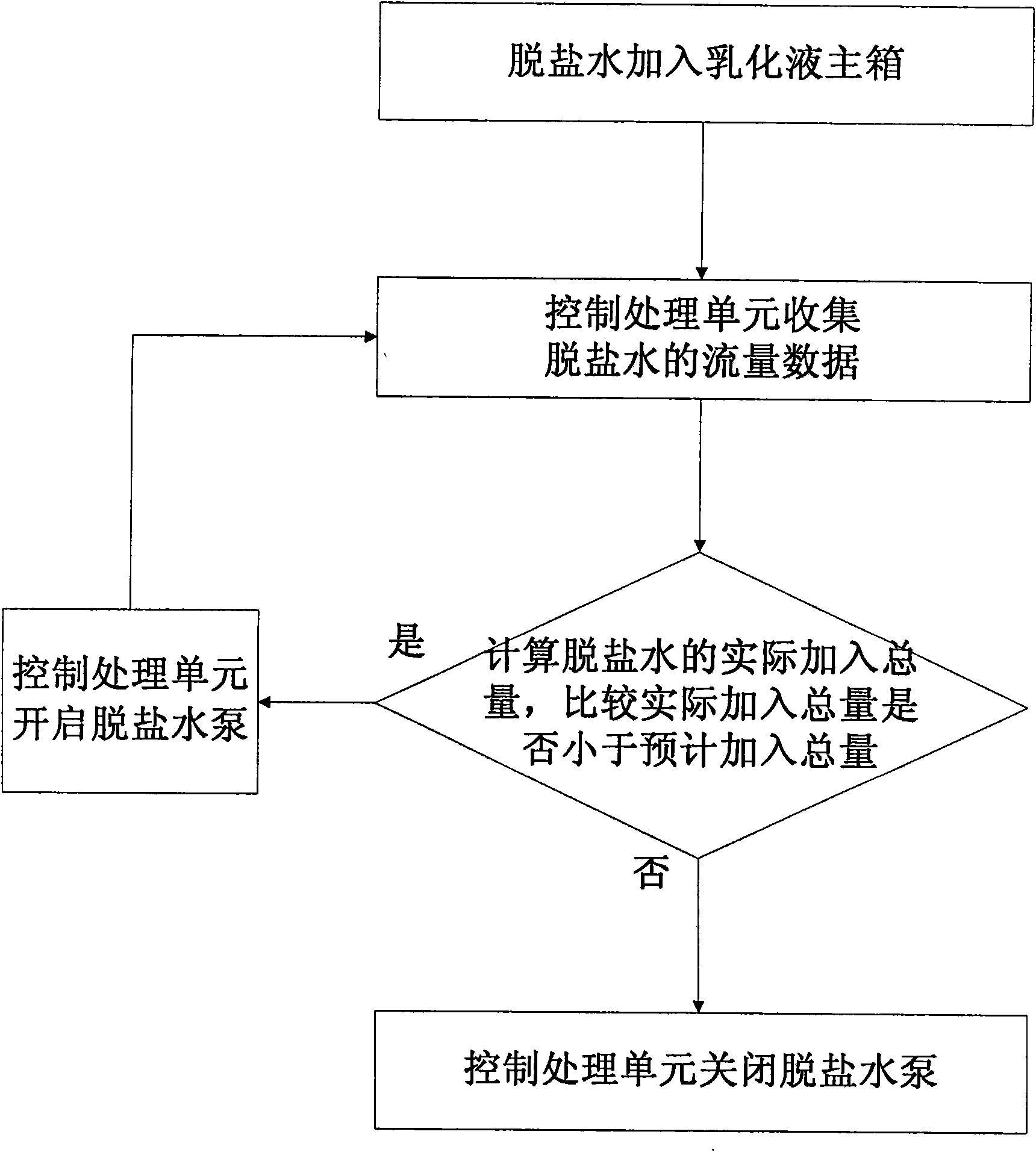

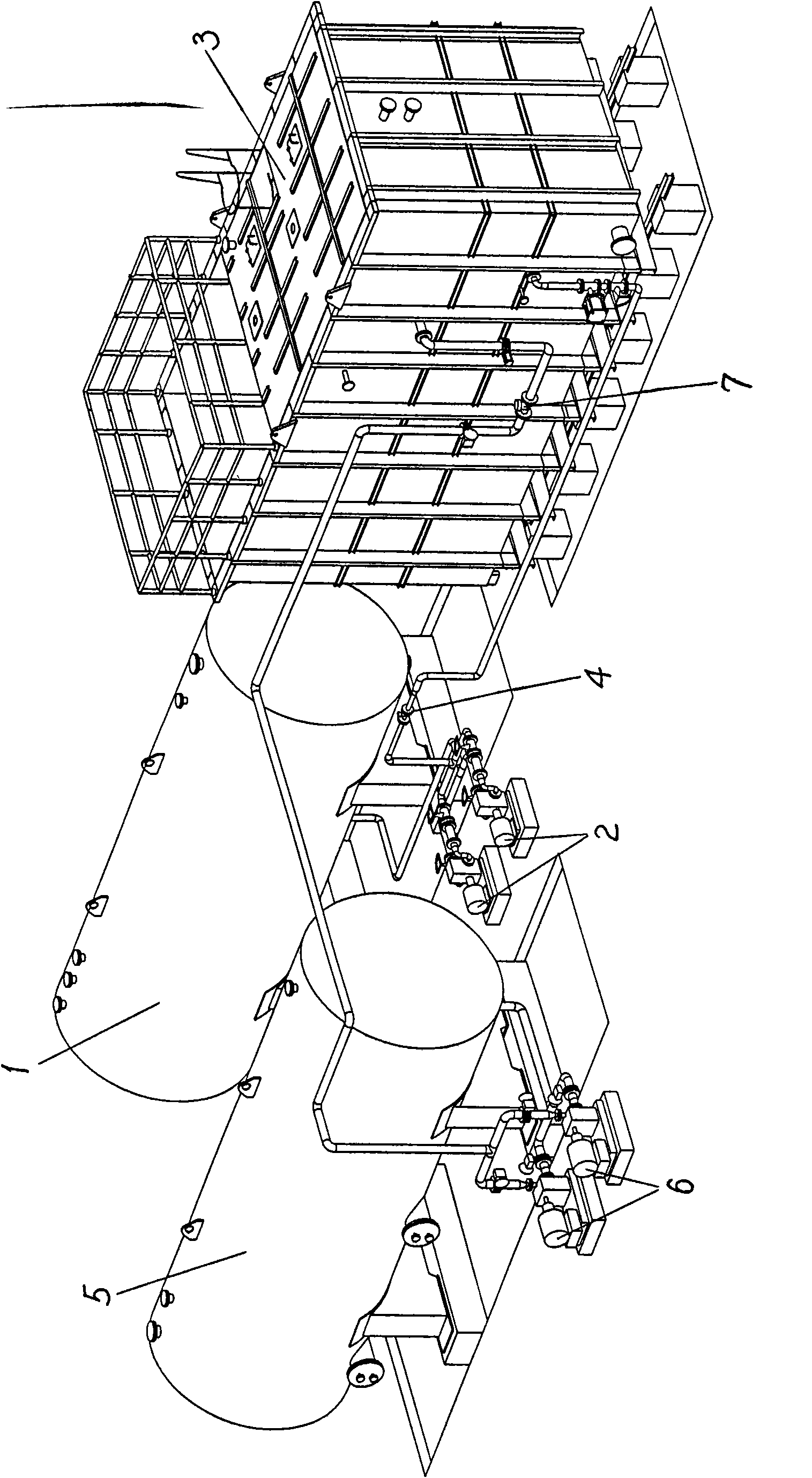

Method for compounding concentration of emulsion used for rolling mill and compounding device

InactiveCN101574633AConcentration is easy to controlHigh precisionMixing methodsMixer accessoriesEmulsionSalt water

The invention relates to a method for compounding concentration of emulsion used for a rolling mill, wherein the process of adopting crude oil to prepare the emulsion is realized by flow-controlled adding process of crude oil and the process of adopting desalted water to prepare the emulsion is realized by flow-controlled adding process of desalted water. The crude oil is transferred to an emulsion main tank from a crude oil tank through a dispensing pump and a flow meter is adopted to monitor flow data of the crude oil and the flow data is sent to a control processing unit; and the desalted water is transferred to the emulsion main tank from a desalted water tank through a desalted-water pump and a flow meter is adopted to monitor the flow data of the desalted water and the flow data is sent to a control processing unit. The compounding device comprises the crude-oil tank, the dispensing pump, the desalted water tank, the desalted water pump, the emulsion main tank, two flow meters and two control processing units. With the invention, the concentration of the emulsion can be easily controlled and the precision is high; the operation is simple, convenient and feasible and the maintenance is convenient; both contamination and waste can be reduced; the manufacturing cost can be reduced; and the lubricating effect of the emulsion is good and the service life of rollers can be prolonged.

Owner:BAOSTEEL ENG & TECH GRP

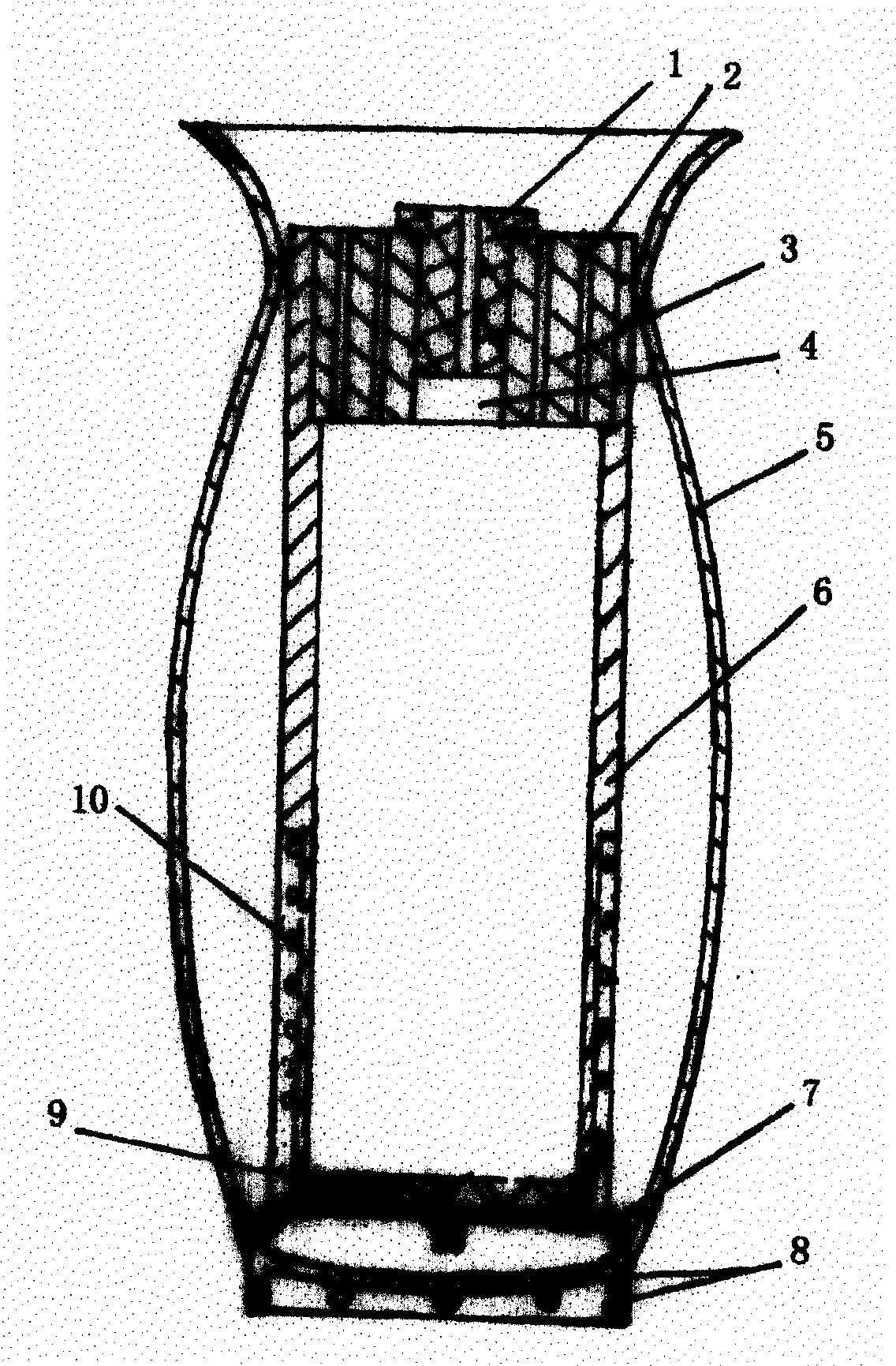

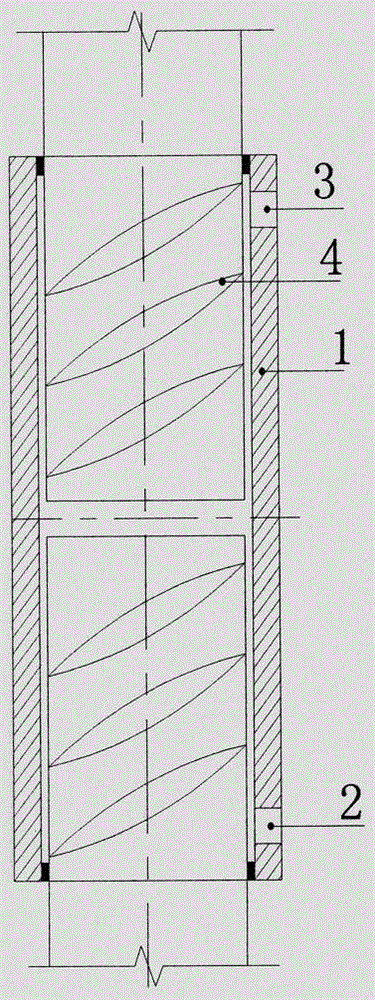

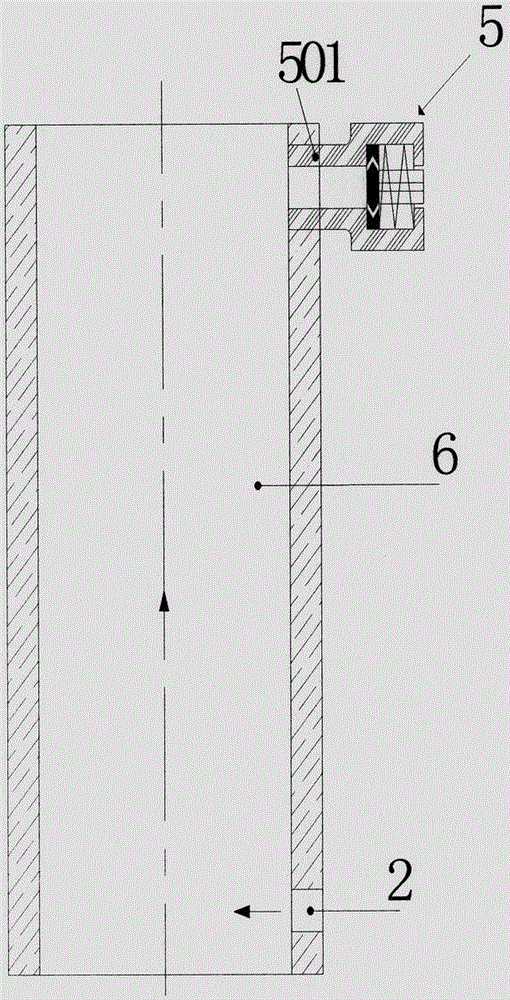

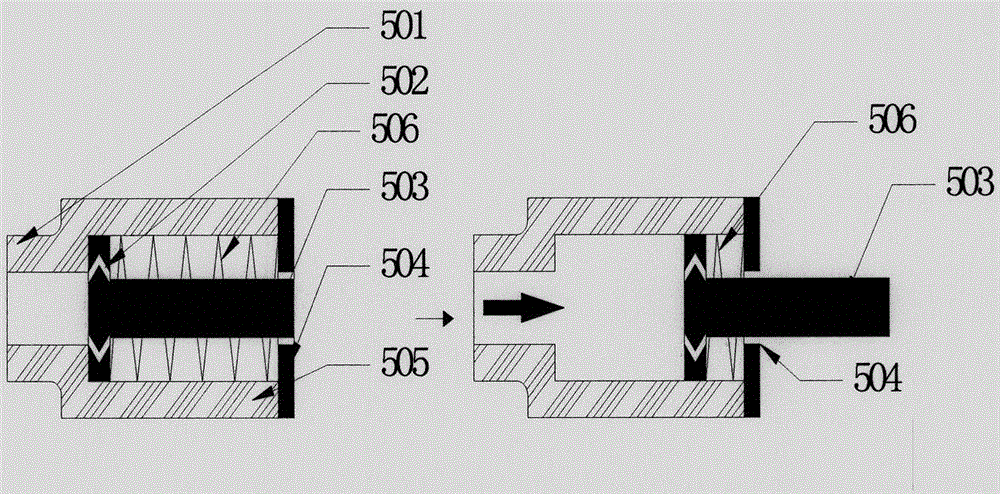

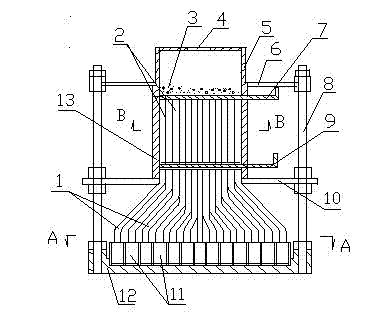

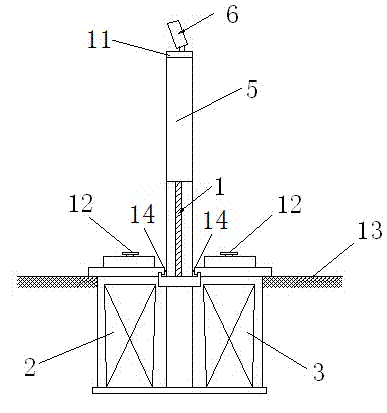

Blocking valve, grouting sleeve and prefabricated component connecting method

PendingCN105781022AImprove grout qualityHigh strengthBuilding reinforcementsLift valveAgricultural engineeringBlocked valves

The invention provides a blocking valve, a grouting sleeve and a prefabricated component connecting method. The steel bar connection grouting sleeve has a sealed space, and can be automatically sealed after grouting, and the grouting degree can be observed in a grouting process. Compared with an existing open sleeve, the grouting sleeve has the advantages that higher pressure can be born in the grouting process, the grouting sleeve can be automatically sealed after grouting, and the grout fullness of the sealed space can be observed in the grouting process, thereby monitoring the grouting quality of the grouting sleeve. The blocking valve, the grouting sleeve and the prefabricated component connecting method can be widely applied to a grouting sleeve connection process in the technical field of building construction.

Owner:BEIJING JIEYANTE ENG TECH

Heating method of soy milk and its application on soy milk machine

InactiveCN1160013CHigh degree of thermal expansionReduce temperature shrinkageBeverage vesselsEngineeringHigh pressure

A method and its device for heating soybean milk are disclosed, and can be used for domestic soybean milk maker. Its heater is composed of external cylinder and its cover and internal cylinder whose top is fastened to the inner surface of the said cover and whose side wall is perforated. When soybean milk is boiling, a slightly higher pressure is formed at upper part of internal cylinder to make the hot milk flow into the external cylinder through the holes. It is circulated between internal and external cylinders at 100-105 deg.C for 4-10 min for emulsifying it well.

Owner:JOYOUNG CO LTD

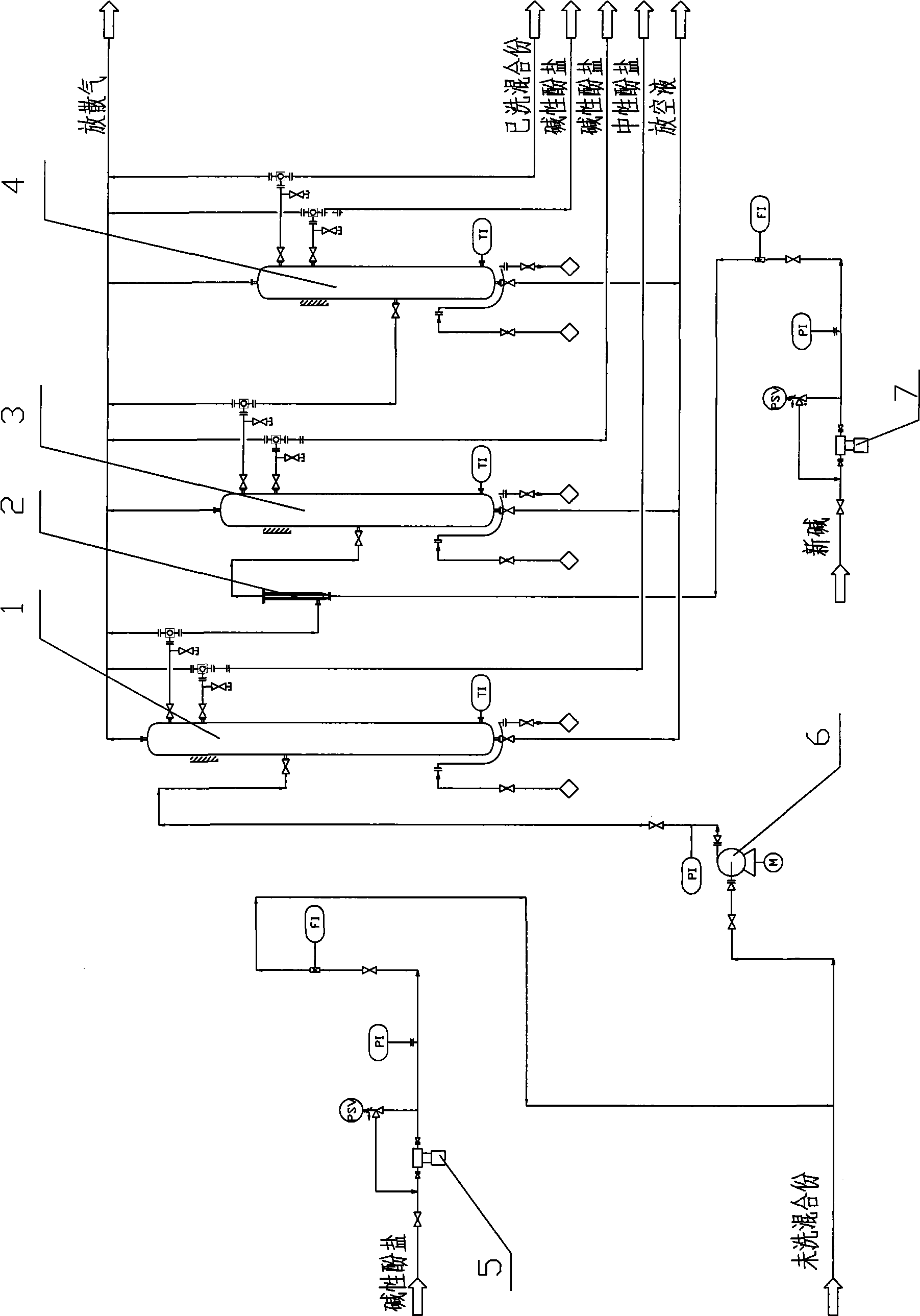

Distillate dephenolizing process and apparatus thereof

The invention relates to a distillate dephenolizing process for the middle production procedure of a coal tar processing device. The technical process comprises the following steps: using a dephenolizing washer pump to pump out the unwashed mixed part which comes from a tar distillation plant so as to be mixed evenly and react with basic phenate together in the dephenolizing washer pump; putting the mixed solution into a primary dephenolizing tower to be kept stand and separated into a mixed part and neutral sodium phenolate, wherein the mixed part enters a secondary dephenolizing tower through a mixing nozzle; and in order to further remove phenols in the mixed part, using 10 to 12 percent diluted alkaline to perform secondary dephenolizing on the mixed solution before the mixed part enters the secondary dephenolizing tower. The mixture is kept stand and separated into the basic phenate and a washed mixed part in the secondary dephenolizing tower, the washed mixed part flows into a phenate removing tower automatically and is kept stand and separated out the residual basic phenate in the phenate removing tower, then the basic phenate flows into a basic phenate groove, and finally the washed mixed part enters a industrial naphthalene distillation plant for further processing. The process can reduce the environmental pollution, save energy resources and improve the efficiency.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

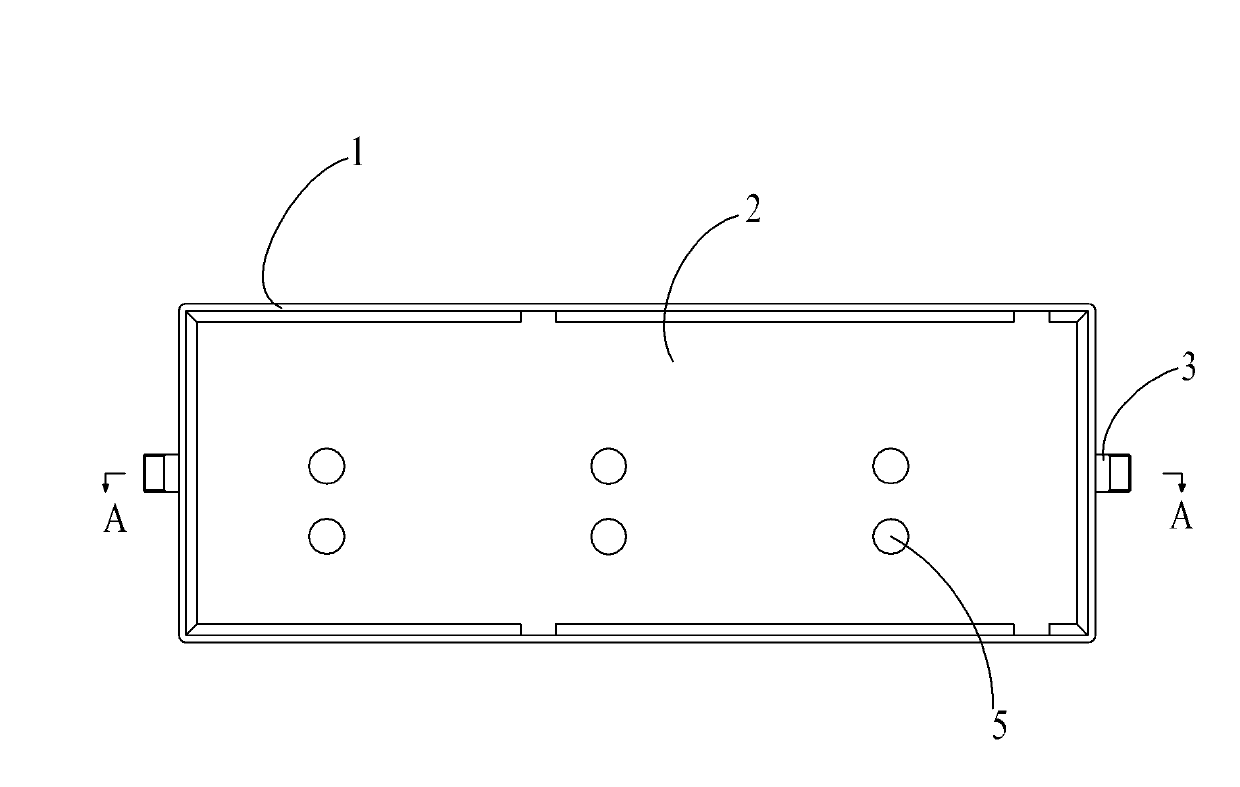

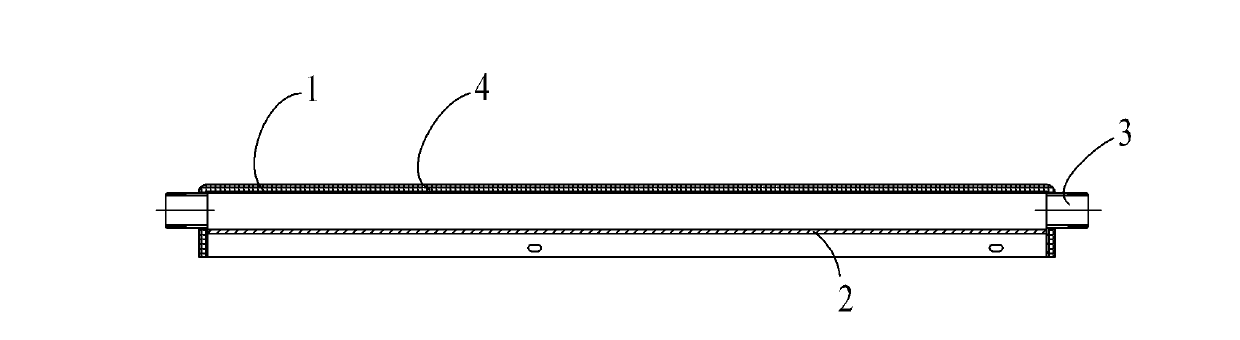

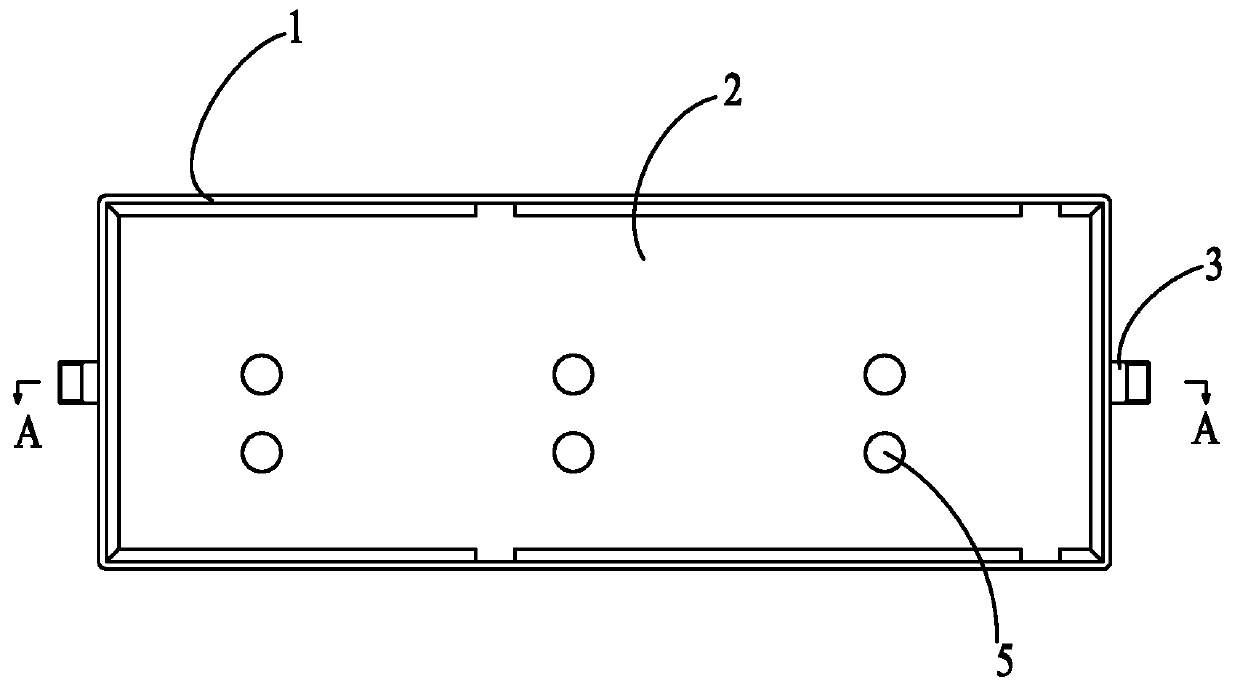

Defrosting pan for fan coil of ship

InactiveCN102434954AReduce internal water accumulationSimple and compact structureCondensate preventionCondensed waterEngineering

The invention relates to a defrosting pan for a fan coil of a ship. The defrosting pan comprises a defrosting pan body, wherein the two ends of the defrosting pan body are provided with condensation drainage joints; a water eliminator is covered above the defrosting pan body; the shape of the water eliminator is matched with the defrosting pan body; and the water eliminator is provided with a plurality of water inlet holes which are communicated with a cavity in the defrosting pan body. Under the condition that the fan coil cannot be kept in the horizontal state, condensed water can be drained from one of the condensation drainage joints at the two ends of the defrosting pan body, so that water accumulated inside the cavity of the defrosting pan is reduced effectively; under the condition that the fan coil swings and condensed water in the cavity of the defrosting pan cannot be drained smoothly, swinging condensed water is blocked by the water eliminator at the upper end of the defrosting pan body and is kept in the defrosting pan body, so that leakage is prevented; the defrosting pan has a simple and compact structure; and condensed water in a fan coil unit can be drained smoothly in the running and parking processes of the ship, and leakage of the condensed water can be prevented effectively when the ship swings.

Owner:WUXI TONGFANG ARTIFICIAL ENVIRONMENT

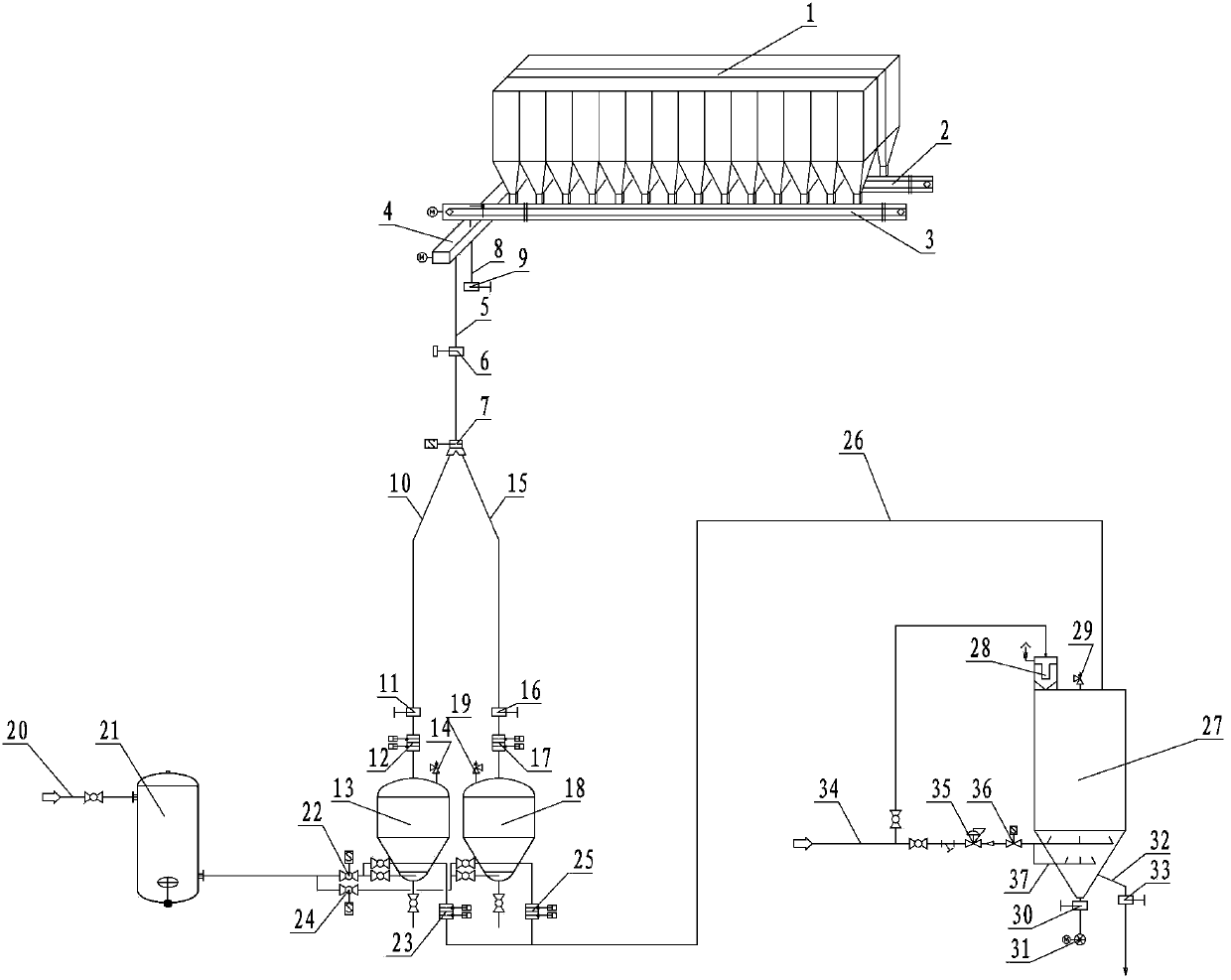

Pneumatic transmission method for dry dedusting of fine ash in converter gas

ActiveCN103388046AReduce the delivery linkLow failure rateManufacturing convertersNitrogenNitrogen gas

The invention relates to a pneumatic transmission method for dry dedusting of fine ash in converter gas, which comprises the following steps: S1, constructing a pneumatic transmission system for dry removal of dust and fine ash in converter gas; S2, material feeding: discharging ash into a first bin pump (13) or a second bin pump (18); S3, fluidizing: transporting nitrogen from a gas tank (20) into a first fluidizing device or a second fluidizing device; S4, conveying: conveying evenly fluidic gas ash mixture to a fine ash cabin (27) via a pneumatic conveying pipe (26); S5, blowing; and S6, transporting. The invention adopts a dry filter bag deduster with no spark discharge, which thoroughly solves the problem of easy explosion venting caused by a static deduster. By the method, conveying step of fine dust is minimized, and equipment failure rate is substantially reduced. Storage and transportation of ash in the fine ash cabin are not limited by site or distance.

Owner:WISDRI ENG & RES INC LTD

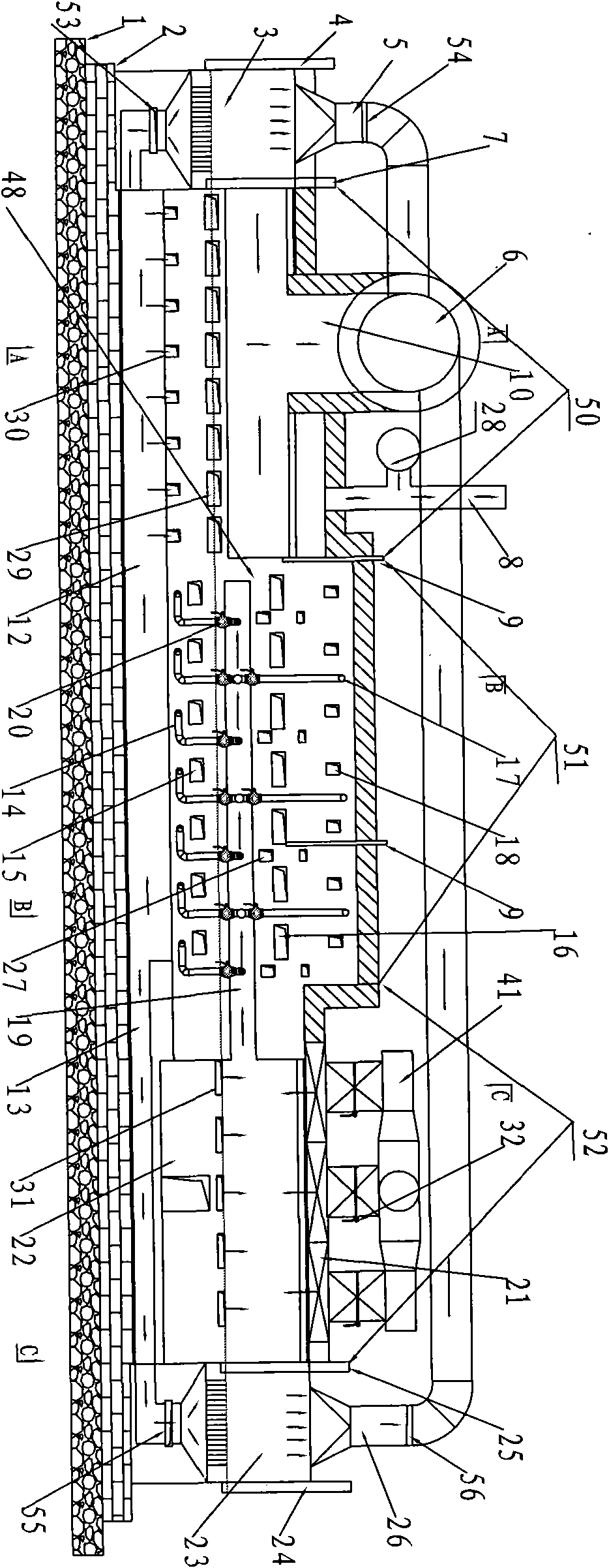

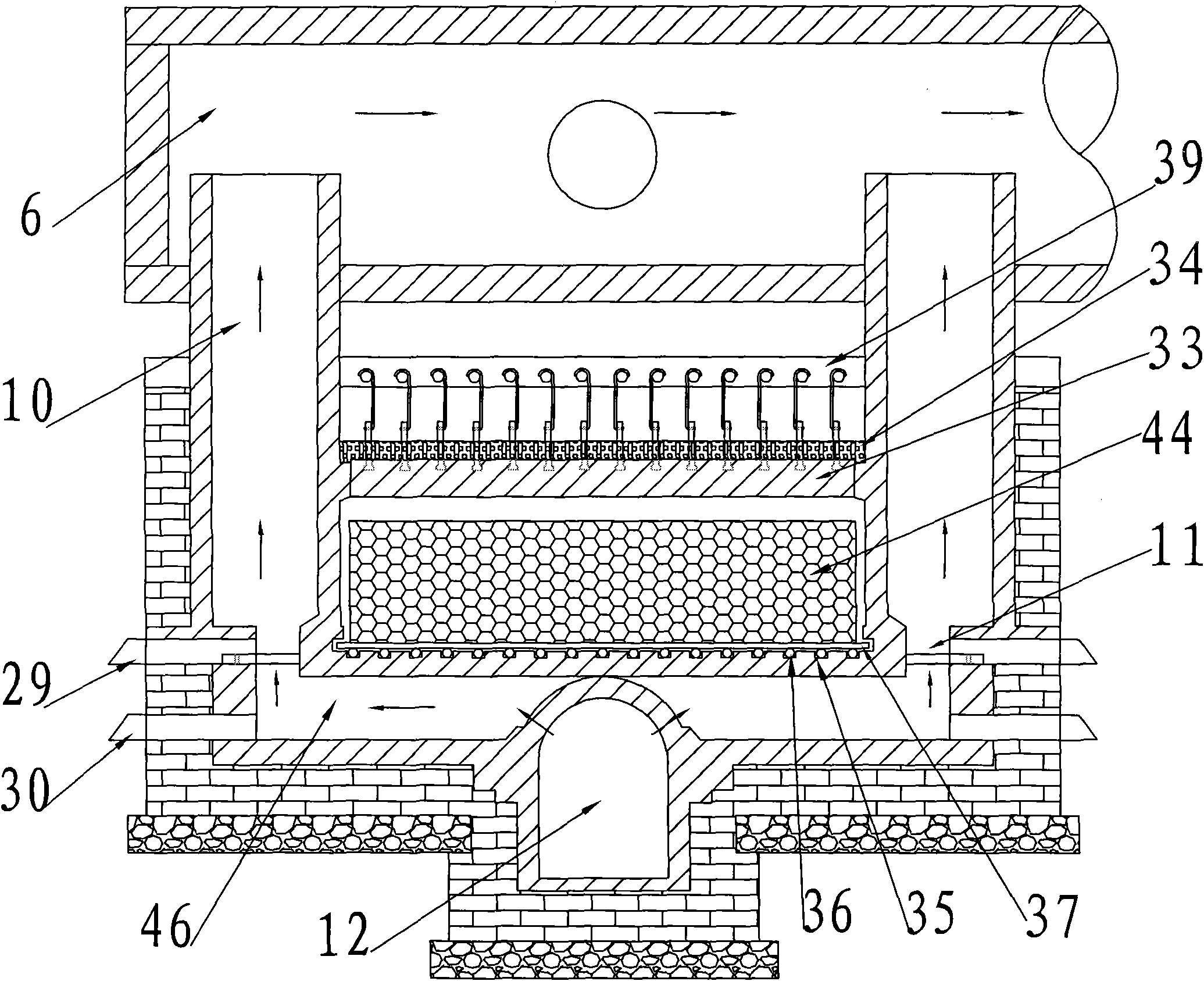

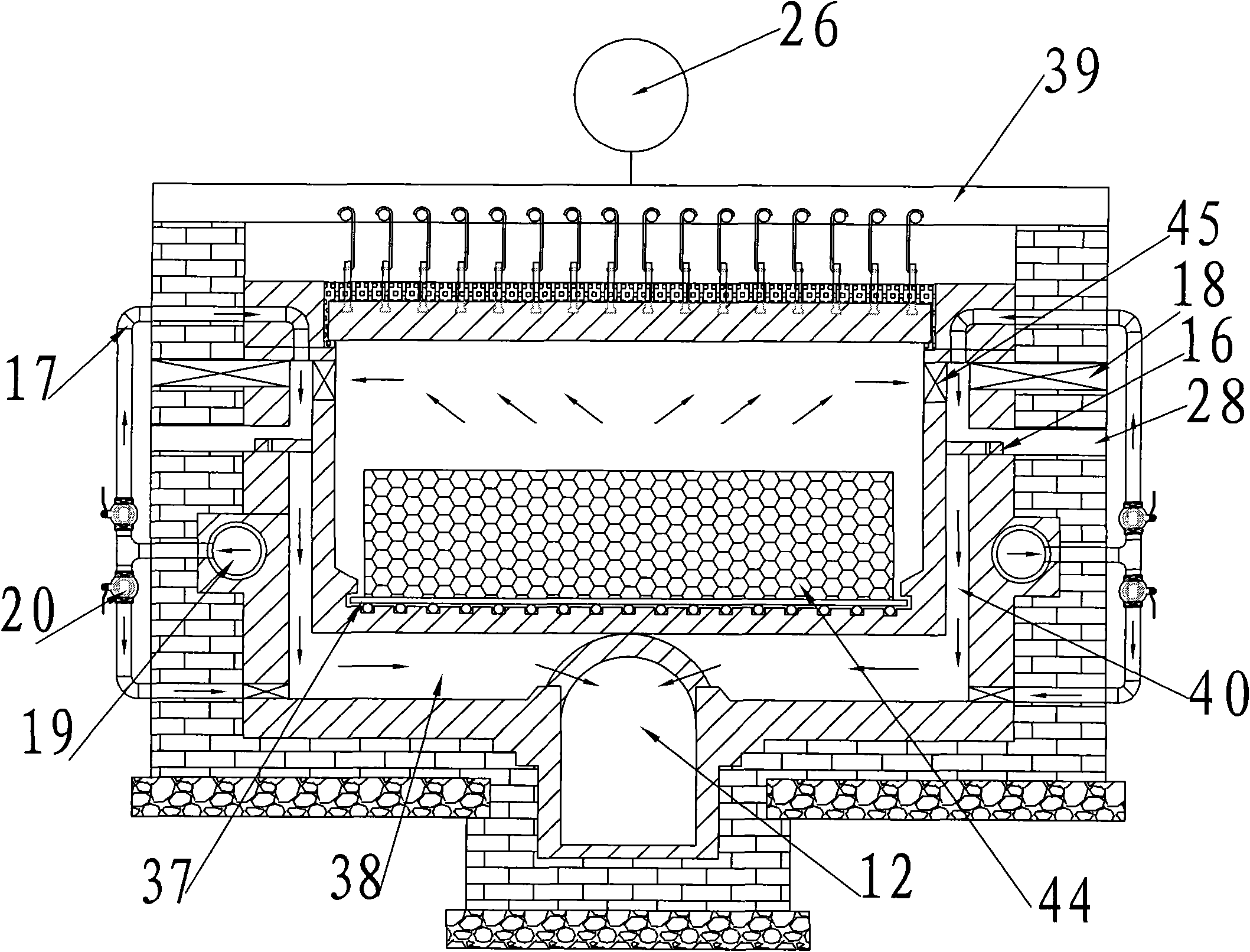

Movable slide bed tunnel type coke oven and use method thereof

InactiveCN101792676AReduce the amount of gasLow energy consumption for cokingMechanical conveying coke ovensHorizontal chamber coke ovensWater sourceFlue gas

The invention relates to a movable slide bed tunnel type coke oven and a use method thereof, and belongs to the field of coal processing and conversion and coking equipment. The coke oven comprises an oven body (48), a front sealing door (7) of the coke oven body, a back sealing door (25) of the coke oven body, a sub-flue (10), a bottom flue (12) and a main flue (6), and is characterized by comprising a coaling preparation chamber (3), a preheating section (50), a carbonization section (51), coke dry quenching section (52) and a coke outlet preparation chamber (23), each part has different structures, and the five parts are connected in series and communicated with each other; and a movable slide bed (37) of loading briquettes or tamping coal materials (44) sequentially pass through the five parts of the coke oven by intermittently moving on a slideway (35) of the slide bed, so that the coal materials are carbonized into coke. The produced coke has uniform specification, large lumpiness, good strength, high heat energy utilization rate, high degree of mechanization, and clean emission of flue gas, and the invention effectively protects atmosphere and water sources and realizes clean production.

Owner:GUIZHOU SUNNY CLEAN ENERGY TECH DEV

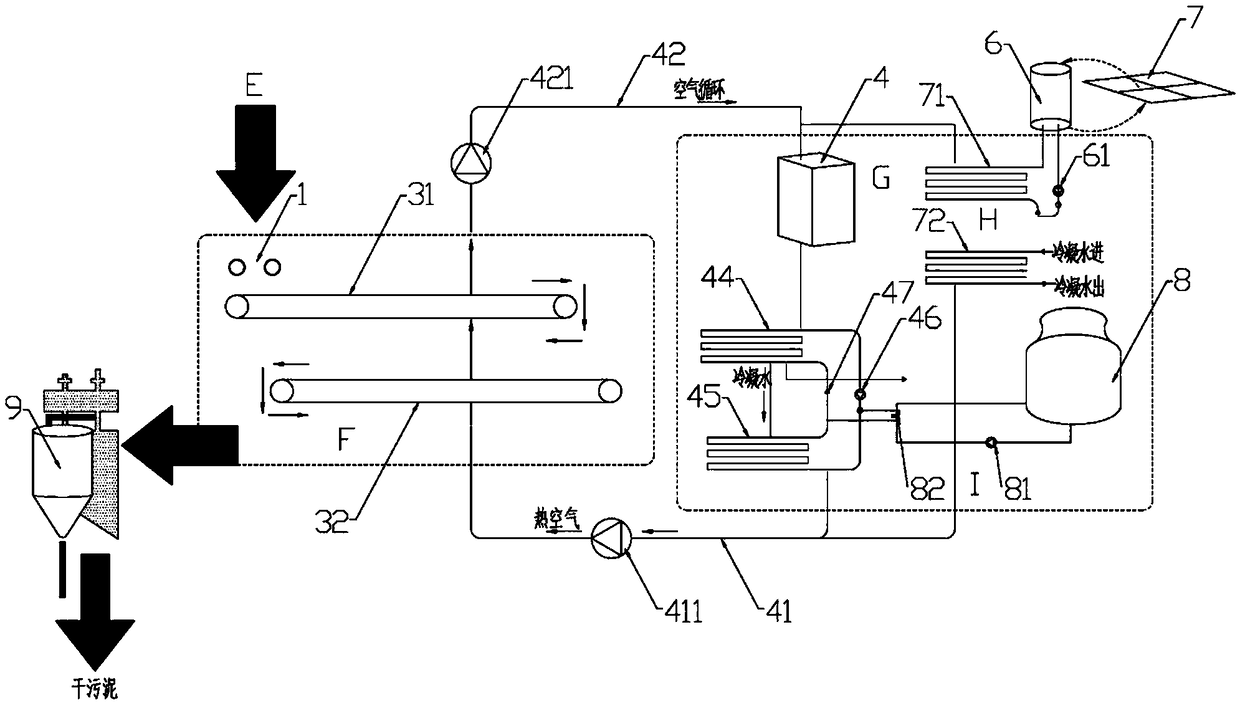

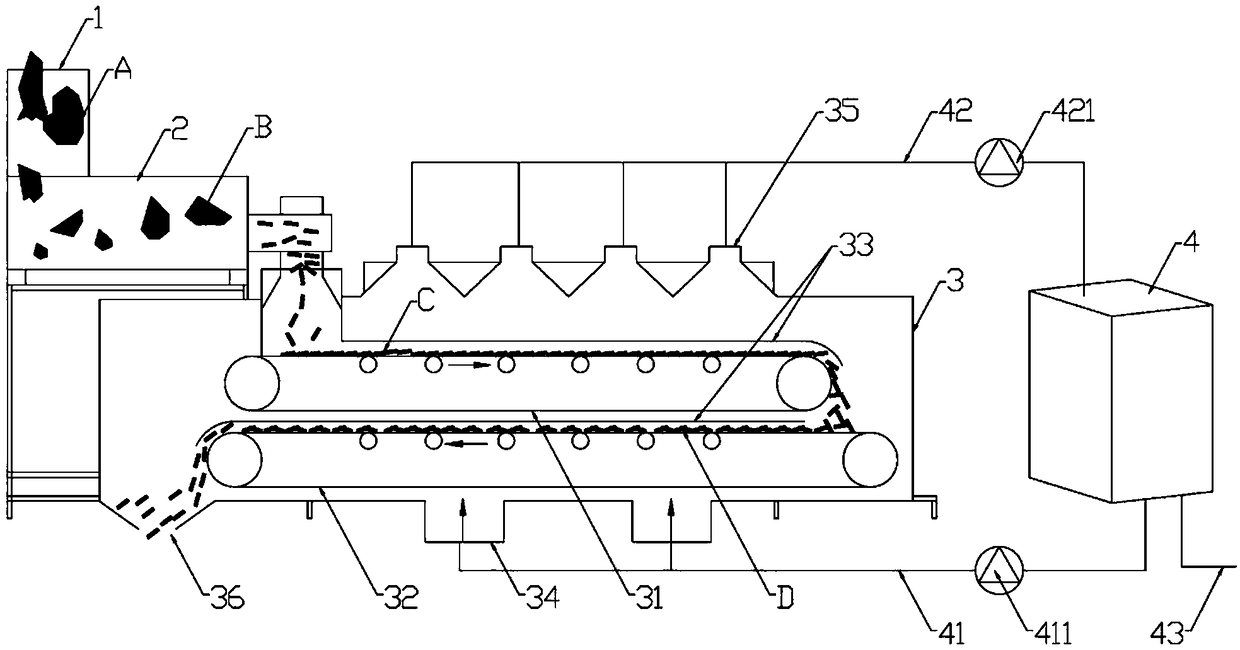

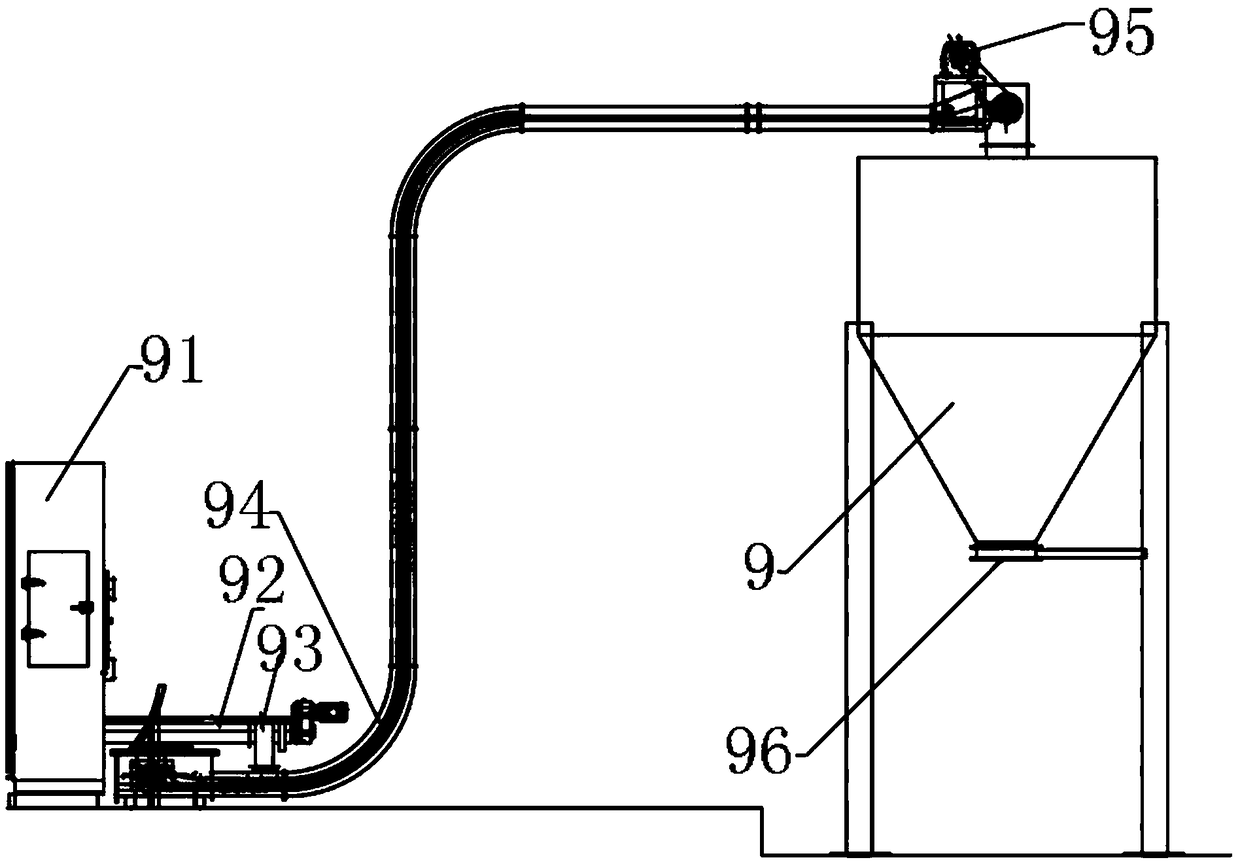

Energy-saving belt type sludge low-temperature drying device

PendingCN109399891ASystem operation is safe and reliableNo explosion hazardSludge treatment by de-watering/drying/thickeningHeat pumpSludge

The invention provides an energy-saving belt type sludge low-temperature drying device, and belongs to the technical field of sludge drying method processing devices. The drying device comprises a sludge feeding and forming zone, a drying zone, a heat pump heating zone, a clean energy heating zone, a circulating condensing zone and a discharging zone, wherein the drying zone is provided with a sludge outlet, and the sludge outlet is located at the end of the conveyor belt running direction. Dried sludge is delivered to the discharging zone through the sludge outlet and discharged. The drying device not only achieves continuous drying of the sludge, but also effectively uses the clean energy to achieve low-temperature low-energy drying of the sludge.

Owner:ZHEJIANG TIANXINGJIAN WATER SERVICE CO LTD

Quantitative explosive feeding device

The invention discloses a quantitative explosive feeding device which comprises a constant volume tube (2), an upper gate disc (7), a lower grate disc (9) and a uniform explosive distribution tube (1), wherein the upper gate disc (7) which is used for opening or closing the upper end of the constant volume tube is arranged between the upper end of the constant volume tube (2) and a hopper (5), the lower gate disc (9) which is used for closing or opening the lower end of the constant volume tube is arranged at the lower end of the constant volume tube, the uniform explosive distribution tube (1) is arranged below the lower gate disc, an orifice at the upper end of the uniform explosive distribution tube corresponds to an orifice at the lower end of the constant volume tube, and an orifice at the lower end of the uniform explosive distribution tube corresponds to a paper tube. The quantitative explosive feeding device has the beneficial effects of uniform explosive distribution, accurate quantification, quick blanking and directional feeding, also has capabilities of avoiding explosive scattering, causing small explosive waste, improving explosive feeding efficiency and lowering production cost of firecrackers and fireworks, and is beneficial to environmental protection. The quantitative explosive feeding device has the advantages of compact structure and convenience for production and maintenance, and is applicable to massive explosive feeding of various types of firecracker and firework paper tubes with different sizes; and in addition, since the explosive feeding operation is carried out in a closed environment, the production is safe and has high reliability.

Owner:JIANGXI JIALIAN TECH

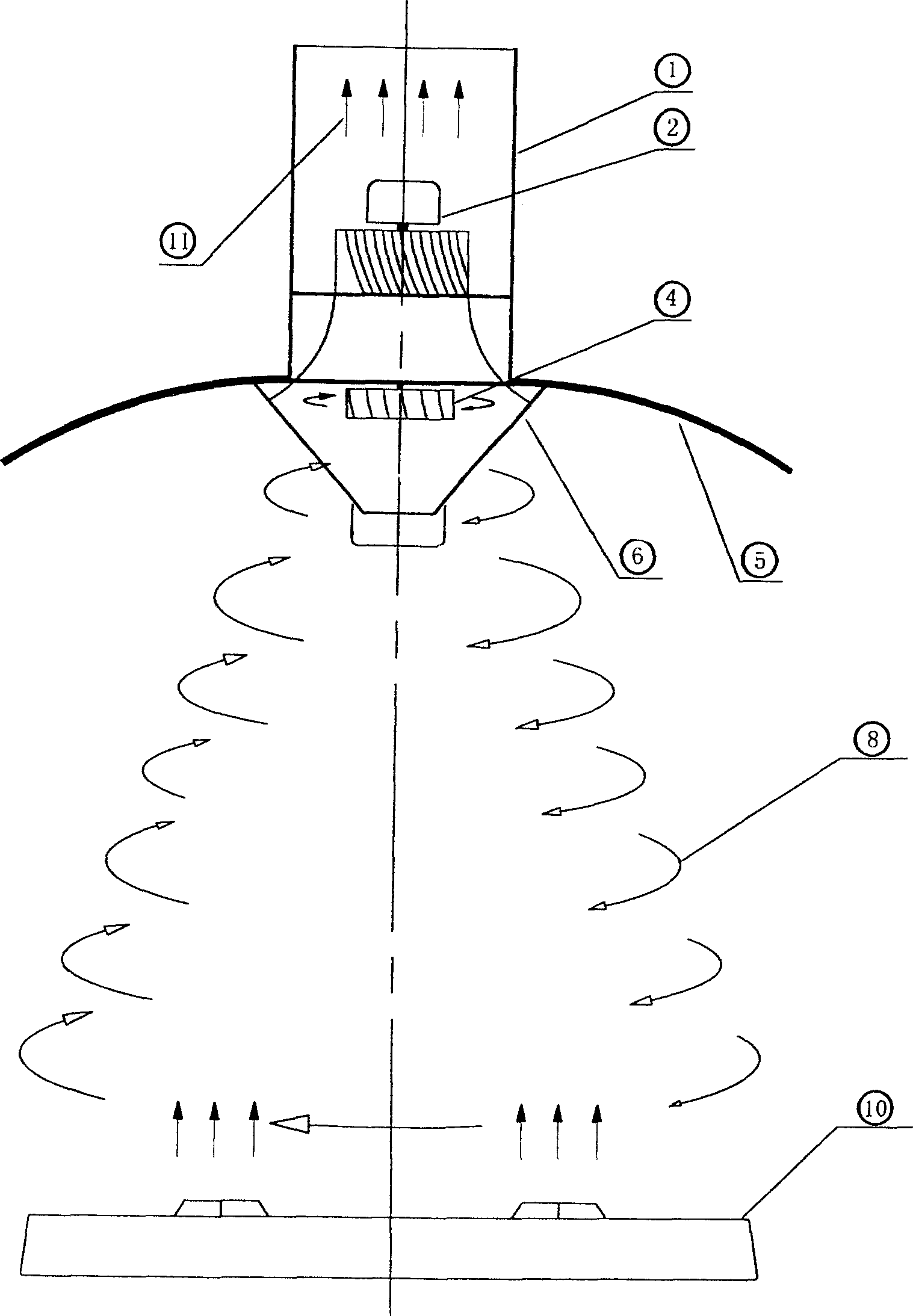

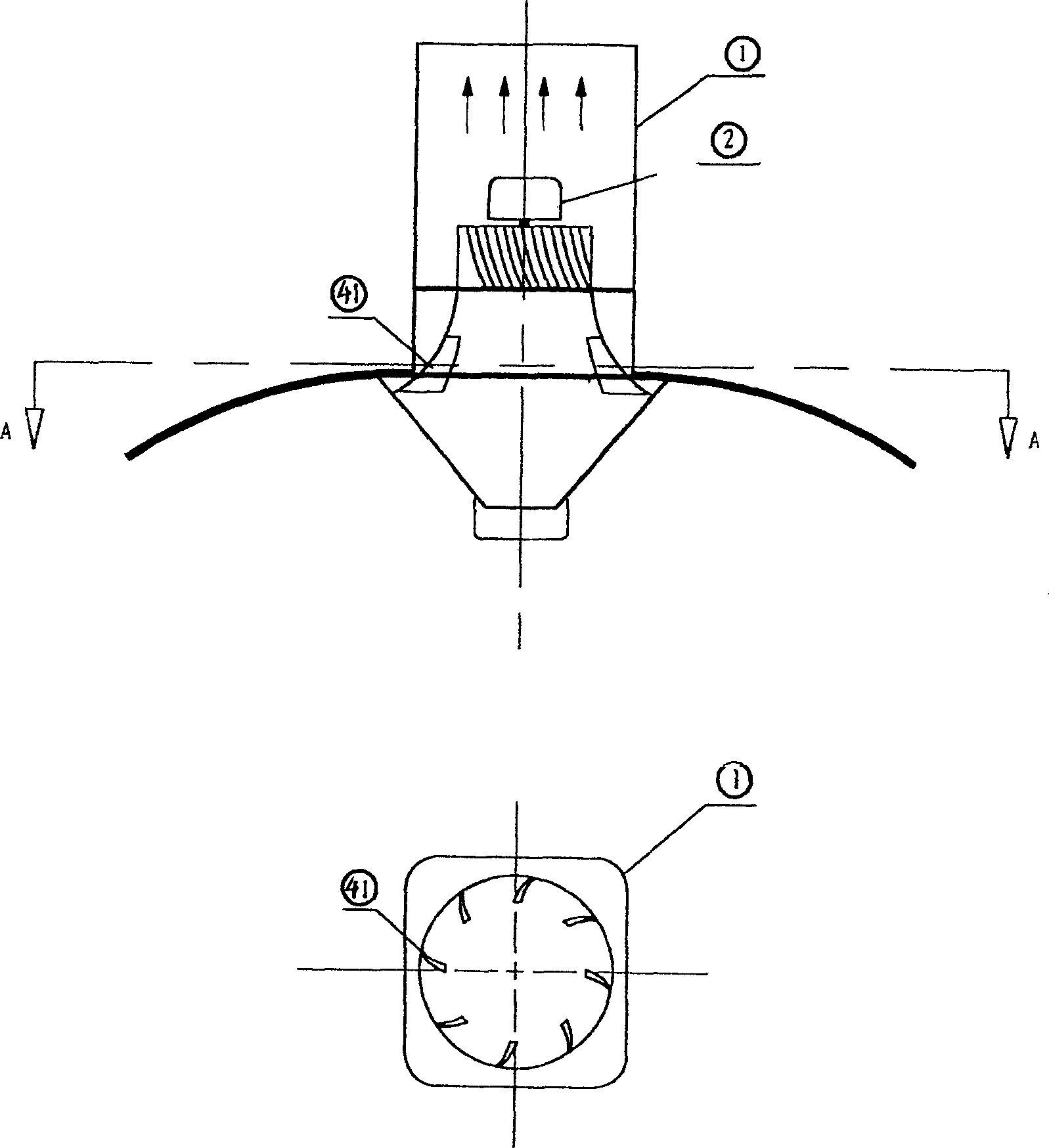

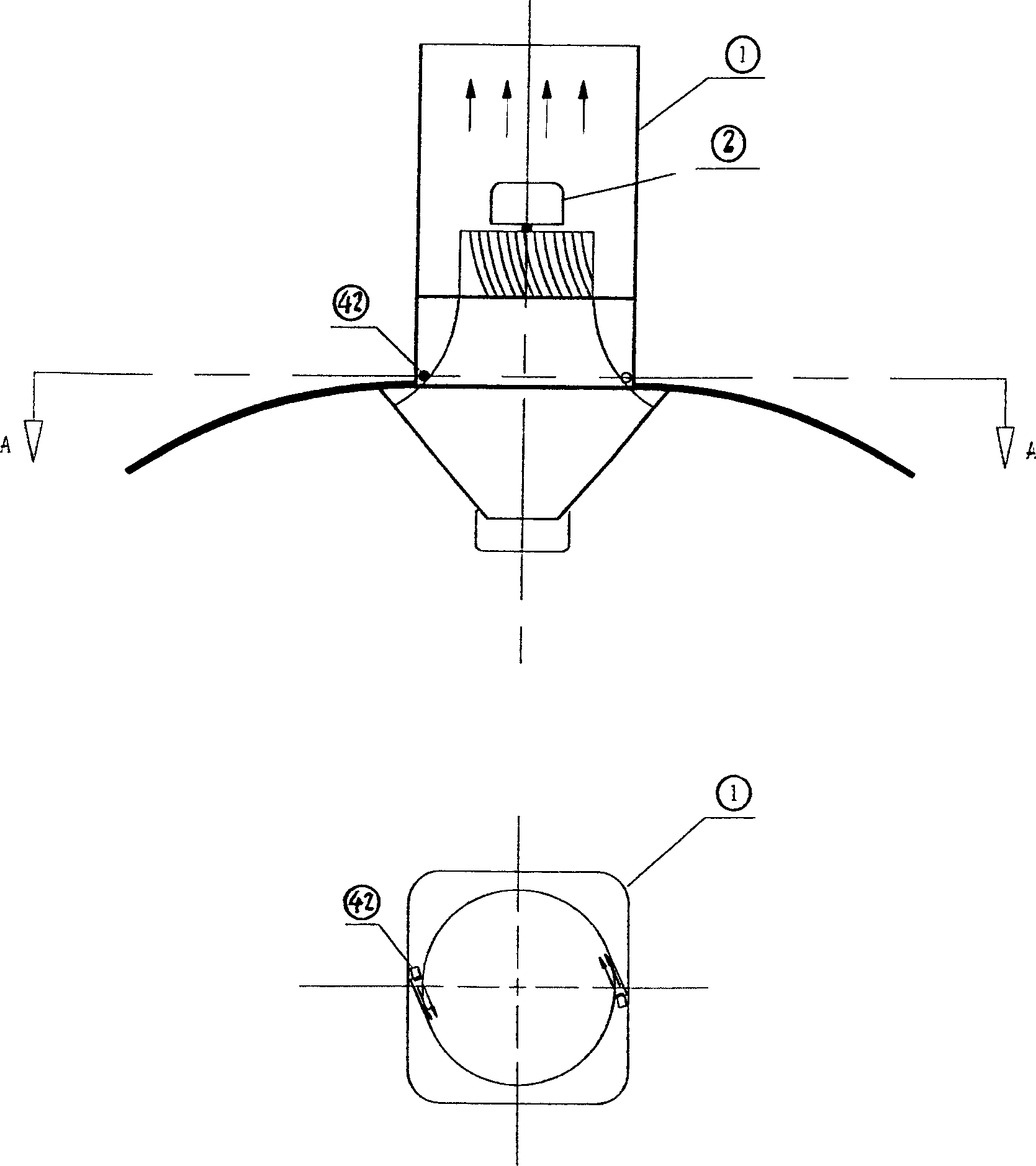

Oil smoke-expelling utensil capable of forming spirally- ascending air current

InactiveCN1828150AStrong upward impactReduce resistanceDomestic stoves or rangesLighting and heating apparatusCycloneEngineering

The invention relates to an oil smoke exhaust device for forming cyclone ascending airflow, which comprises a smoke collecting cover with a wind channel above and a oil collecting cover downward; the wind channel has a bracket with a motor as whorl motor; the wind inlet of said wind channel has a whorl generator which is the side-power wind blade at the middle of wind inlet of wind channel or the side-power wind blade near the wind inlet and the smoke collecting cover, or the side wind inlet motor between the wind inlet and the smoke collecting cover. The invention can fix the oil smoke and avoid overflow and realize oil smoke discharge.

Owner:吕才树

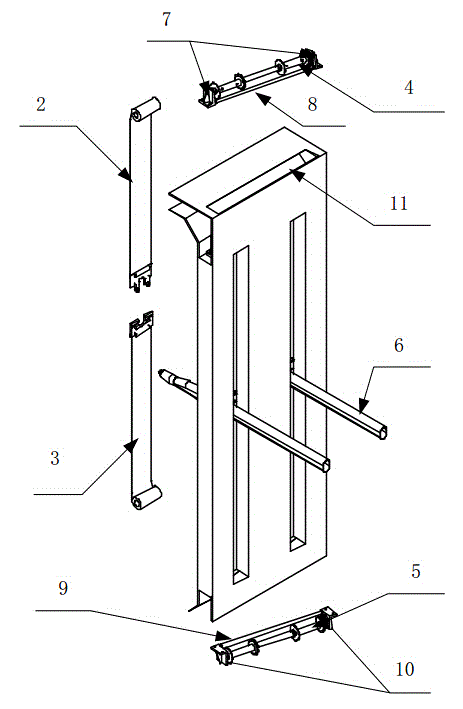

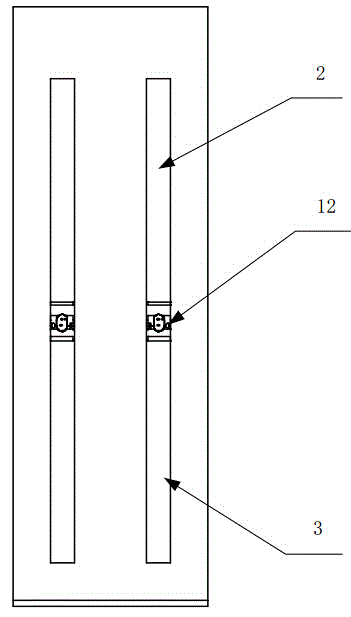

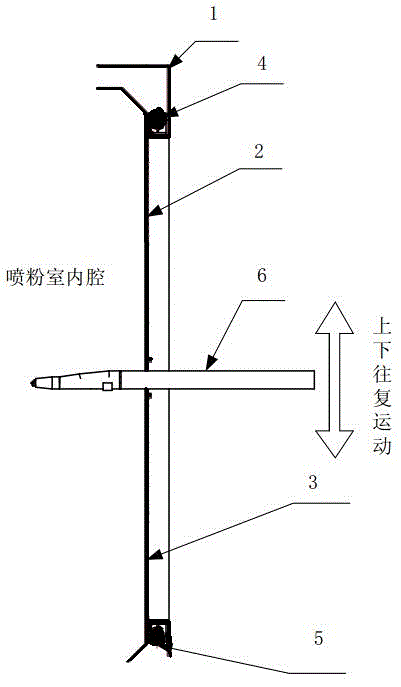

Pull curtain type full-closed overflowing-free spray gun mouth for electrostatic powder spraying booth

InactiveCN104437950AReduce energy consumptionReduce installed capacityLiquid surface applicatorsCoatingsEnvironmentally friendlyEngineering

The invention relates to a full-closed automatic spray gun mouth in the side of a powder spraying booth. In the electrostatic powder coating industry, a traditionally designed spray gun mouth in the side of a powder spraying booth is open during spray coating, and the power of a draught fan is very high in order not to overflow powder. In the process of clearing for color changing, the powder overflowing out of the automatic gun mouth will pollute the environment as well. According to the full-closed automatic spray gun mouth, two flexible belts (containing PU, PVC and the like) are adopted as pull curtains, and an upper flat belt and a lower flat belt are wound around rollers respectively, wherein coil springs (or clockwork springs or other energy storage mechanisms) are installed on the rollers; the flat belts reciprocate in the vertical direction along with a spray gun during spray coating and can close the spray gun mouth no matter where the spray gun moves. In the process of clearing for color changing, dust in the powder spraying booth will not overflow, and therefore pollution is reduced. In this way, the power of a motor can be lowered, so that pollution is further reduced. Accordingly, the spray gun mouth is a novel environmentally-friendly and energy-saving design for the powder spraying booth and is suitable for various powder spraying booths.

Owner:张洋

Oil supply structure of hydraulic electric jack

The invention provides an oil supply structure of a hydraulic electric jack, belonging to the technical field of jacks and solving the technical problems of easy oil leakage, easy pollution, short service life and the like existing in the oil supply structure of the traditional hydraulic electric jack. In the oil supply structure of the hydraulic electric jack, the hydraulic electric jack comprises a base and a lifting structure. The oil supply structure comprises an oil tank, an oil inlet channel and an oil outlet channel, wherein the oil tank is arranged on the base of the electric jack, one ends of the oil inlet channel and the oil outlet channel are communicated with the oil tank and the other ends are connected with the lifting structure of the hydraulic electric jack. The oil supply structure is characterized in that the oil tank is in a bag shape and is made of elastic materials. The invention has the advantages of more stable oil supply, difficult leakage of hydraulic oil, longer service life, and the like.

Owner:XINLEI COMPRESSOR CO LTD

Tea drying and screening integrated machine

InactiveCN107497685ANo spillageAdjust the output speedSievingPre-extraction tea treatmentPulp and paper industryVibration motor

The invention relates to an integrated tea drying and screening machine, which includes a machine body, a motor and a second blower. Support legs are fixed at the lower end of the machine body, and a material inlet is installed at the upper end of the machine body, and an air outlet is installed at the lower end of the material inlet. , and the first blower is connected to the outside of the air outlet, the lower end of the windshield is fixed with a material guide plate, and the discharge end of the material guide plate is arranged above the mounting frame, the lower end of the body is equipped with a dust outlet, and the inside of the body is fixed There is an adjustment mechanism, a mounting frame is connected above the vibration motor, and one end of the mounting frame is connected to the body through a rotating shaft, a dust bag is installed on the outside of the body, and a discharge port is arranged below the dust bag, and the cover plate The inner lower end is connected by a telescopic mechanism partition, the upper end of the installation frame is fixed with a baffle plate, and the inner side of the installation frame is installed with a screening frame. The tea drying and screening integrated machine can continuously dry and screen tea leaves, effectively improving the working efficiency of the device.

Owner:薛迪宋

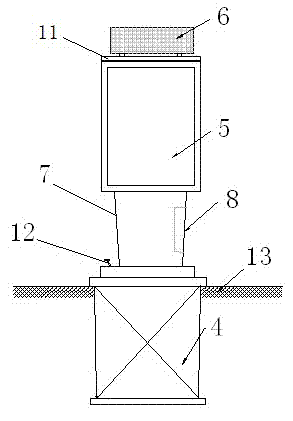

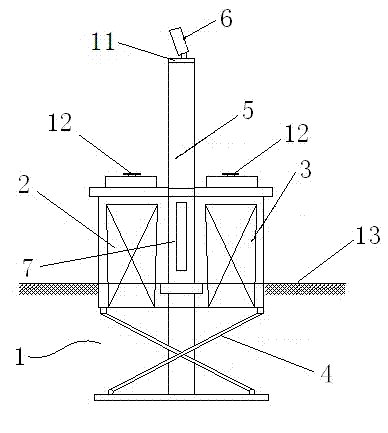

Embedded lift-type classification dustbin with advertising function

InactiveCN102963643AWith the concept of ecological and environmental protection classificationUnique shapeWaste collection and transferRefuse receptaclesTyping ClassificationEngineering

The invention discloses an embedded lift-type classification dustbin with an advertising function. The dustbin is characterized by comprising a lift mechanism, wherein a first waste container and a second waste container are arranged on two sides of the lift mechanism respectively, a lift bracket connected to the lift mechanism is arranged at the bottoms of the first waste container and the second waste container, an advertising lamp box is arranged above the lift mechanism, a solar panel is installed above the advertising lamp box, the power output end of the solar panel is connected to the power input end of the advertising lamp box, and a flashing board is arranged between the solar panel and the advertising lamp box. The embedded lift-type classification dustbin with the advertising function, provided by the invention, is designed in accordance with an eco-friendly idea, is rain-proof, unique in modeling, convenient for collecting wastes and suitable to be popularized and used in cities and towns with dense population, and has a wide application prospect.

Owner:陈江

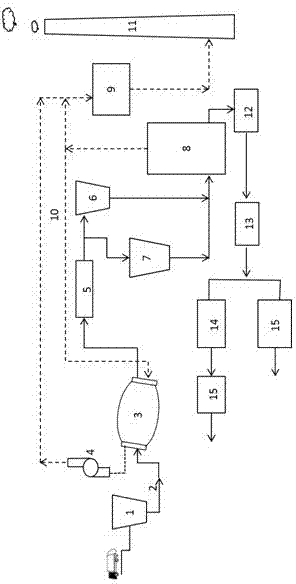

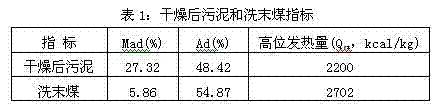

Comprehensive utilization method and comprehensive utilization system for biochemical sludge

ActiveCN102863137ARealize comprehensive utilizationEasy to handleSludge treatment by de-watering/drying/thickeningSilicaSludgeCoal

The invention discloses a comprehensive utilization method and a comprehensive utilization system for biochemical sludge. The method comprises the following processing steps: step (1) of centrifuging the biochemical sludge, rotating and drying in a rotary drier to obtain the dry sludge, wherein a drying medium is boiler exhaust gas; step (2) of grinding the dry sludge as boiler fuels or mixing the dry sludge with thermal coals as the boiler fuels; taking the boiler exhaust gas generated by burning as the drying medium in the step (1); step (3) of directly burning the dry sludge or burning the dry sludge with the thermal coals to generate ashes, filtering the ashes after melting with alkalis or water; adding acids in filtrate to precipitate, filtering to obtain precipitates and secondary filtrate; washing, drying and burning the precipitates to obtain white carbon blacks; adding the alkalis in the secondary filtrate to precipitate, filtering and collecting the precipitates, washing, drying and burning the precipitates to obtain iron oxide reds. The method can effectively process the sludge and reasonably utilize generated heats and products, so that the method has the advantages of good processing effects, energy conservation and environment protection.

Owner:KAILUAN ENERGY CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com