Patents

Literature

45results about How to "Adjust the output speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

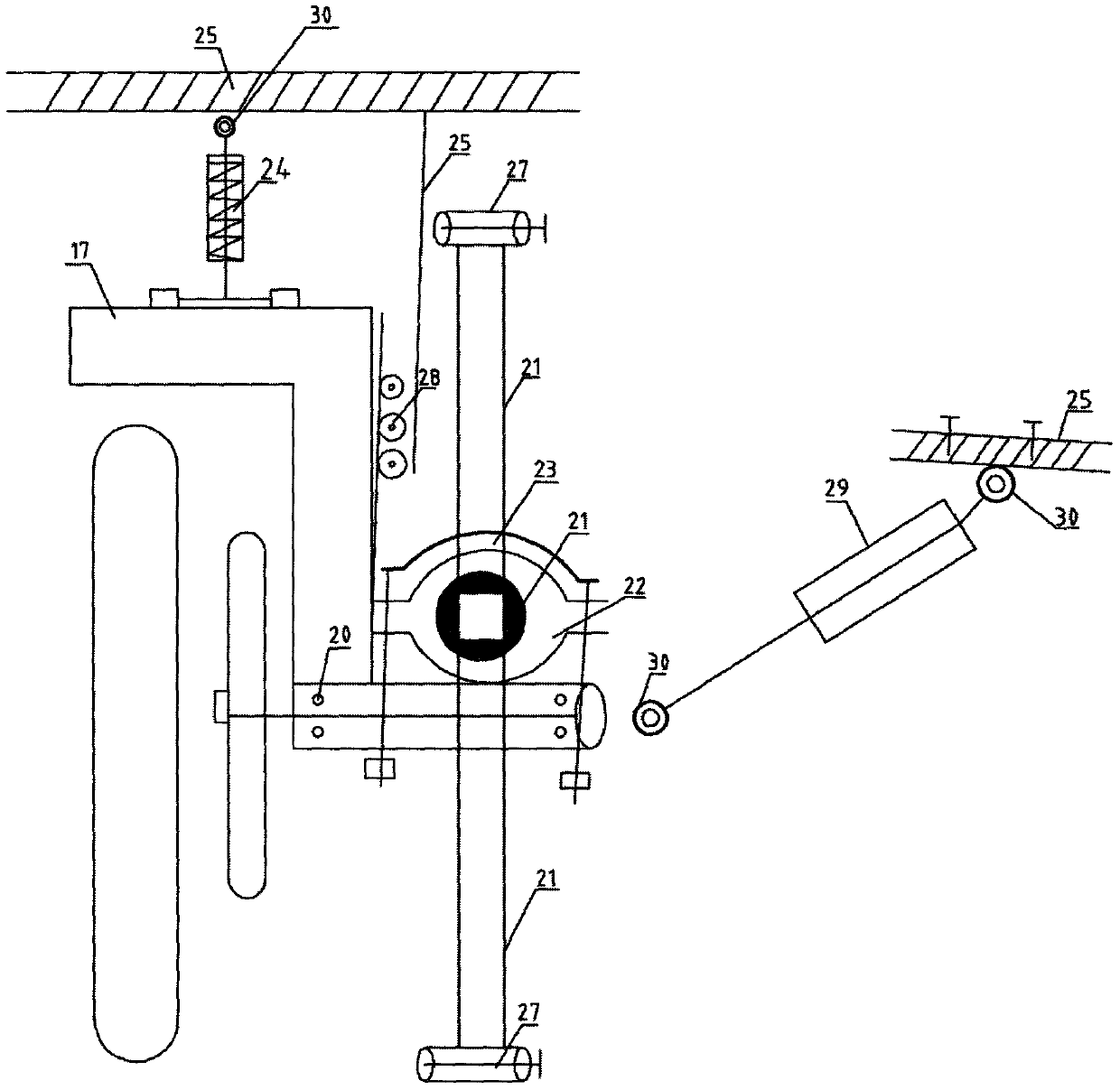

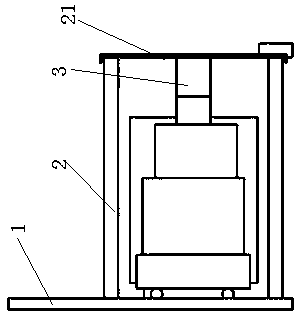

Novel plunger pump

InactiveCN107327382AMovement speed is stableExtended service lifeGearingPump controlReciprocating motionEngineering

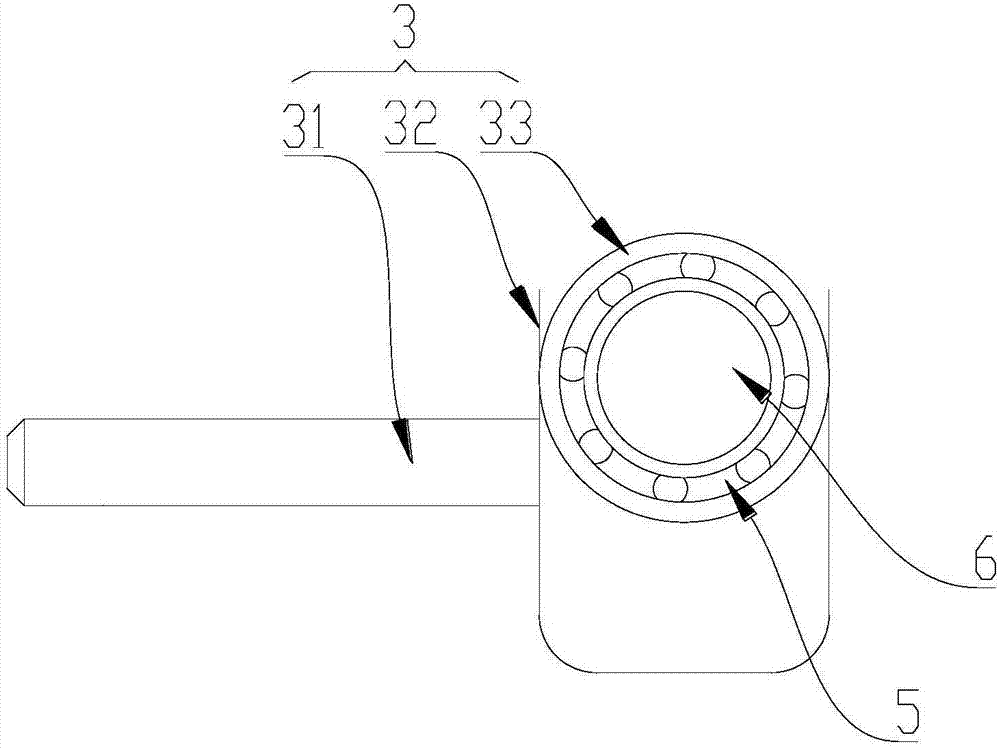

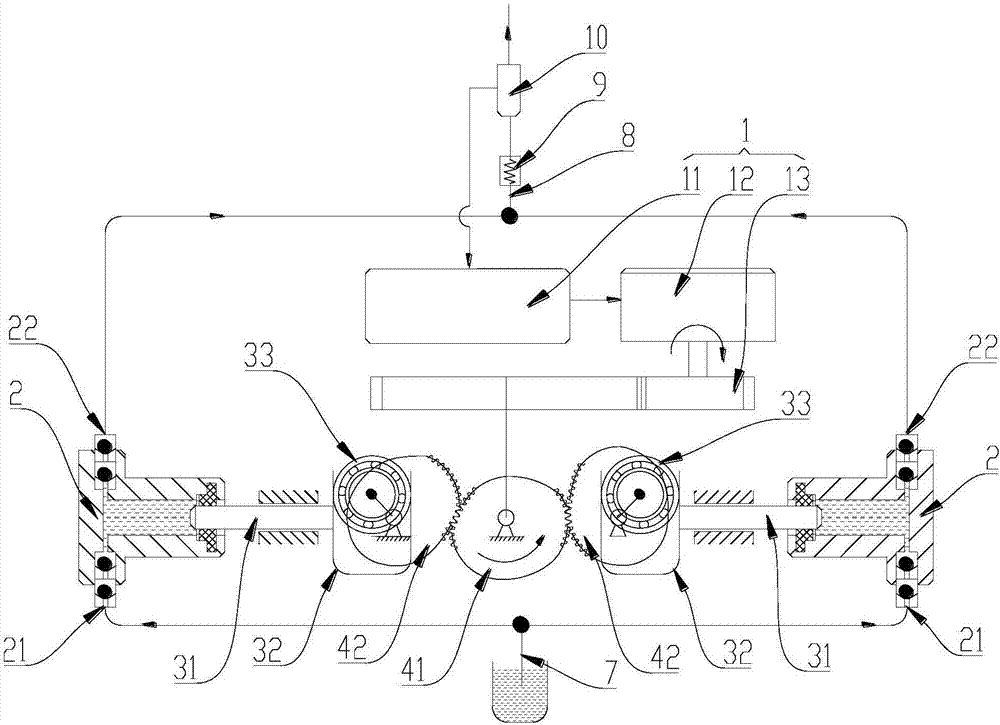

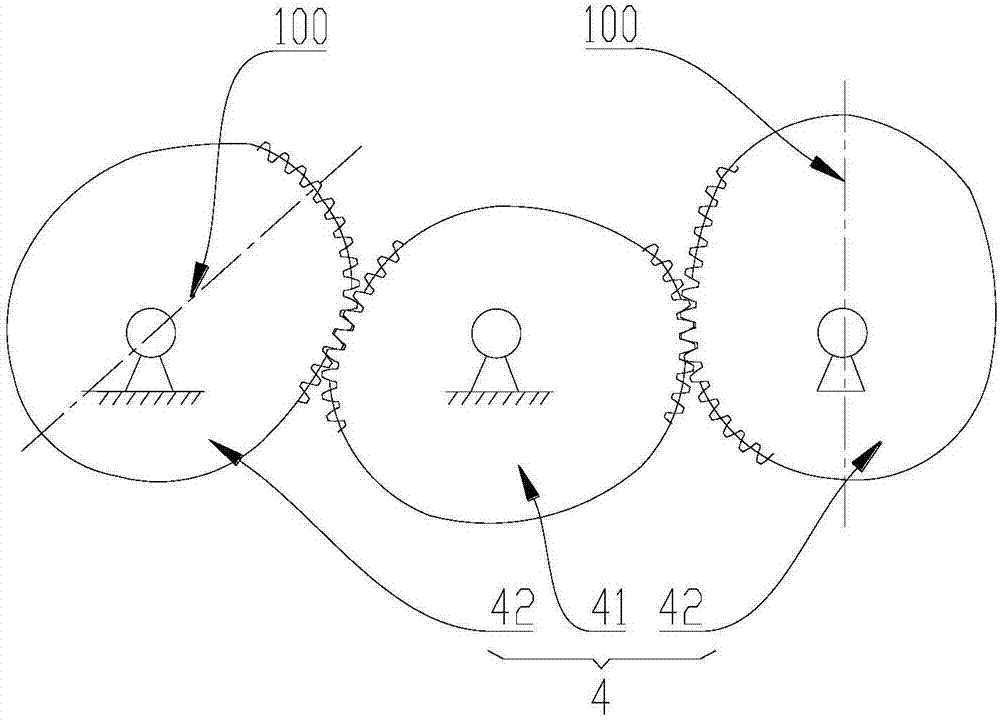

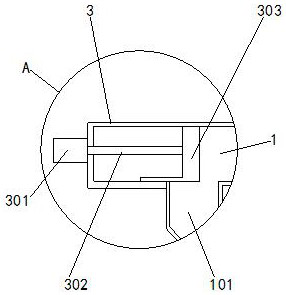

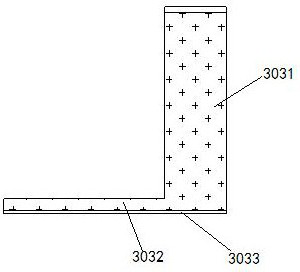

The present invention relates to a new type of plunger pump, which includes a driving device, a pump body, a power actuator assembly, and a power transmission assembly; the power actuator assembly includes a guide rod, a chute, and a swing plate that reciprocate in the pump body; The chute is fixedly mounted on one end of the guide rod protruding from the pump body, and the inner side of the chute has two parallel and opposite working planes, the working planes are perpendicular to the guide rod; The power transmission assembly includes an active non-circular gear and a passive non-circular gear meshing with each other, the passive non-circular gear is in transmission connection with the oscillating plate, the active non-circular gear is connected with the driving device, and is driven by the driving device its spinning. The plunger pump can realize the transmission of the sinusoidal mechanism, the pressure angle can be realized by the rotation of the chute and the oscillating disk, and the non-circular gear can realize the smooth movement speed of the guide rod. The equipment is driven by non-circular gears, which can greatly overcome many shortcomings of the cam mechanism, and has a long service life and is not easy to wear.

Owner:殷图源

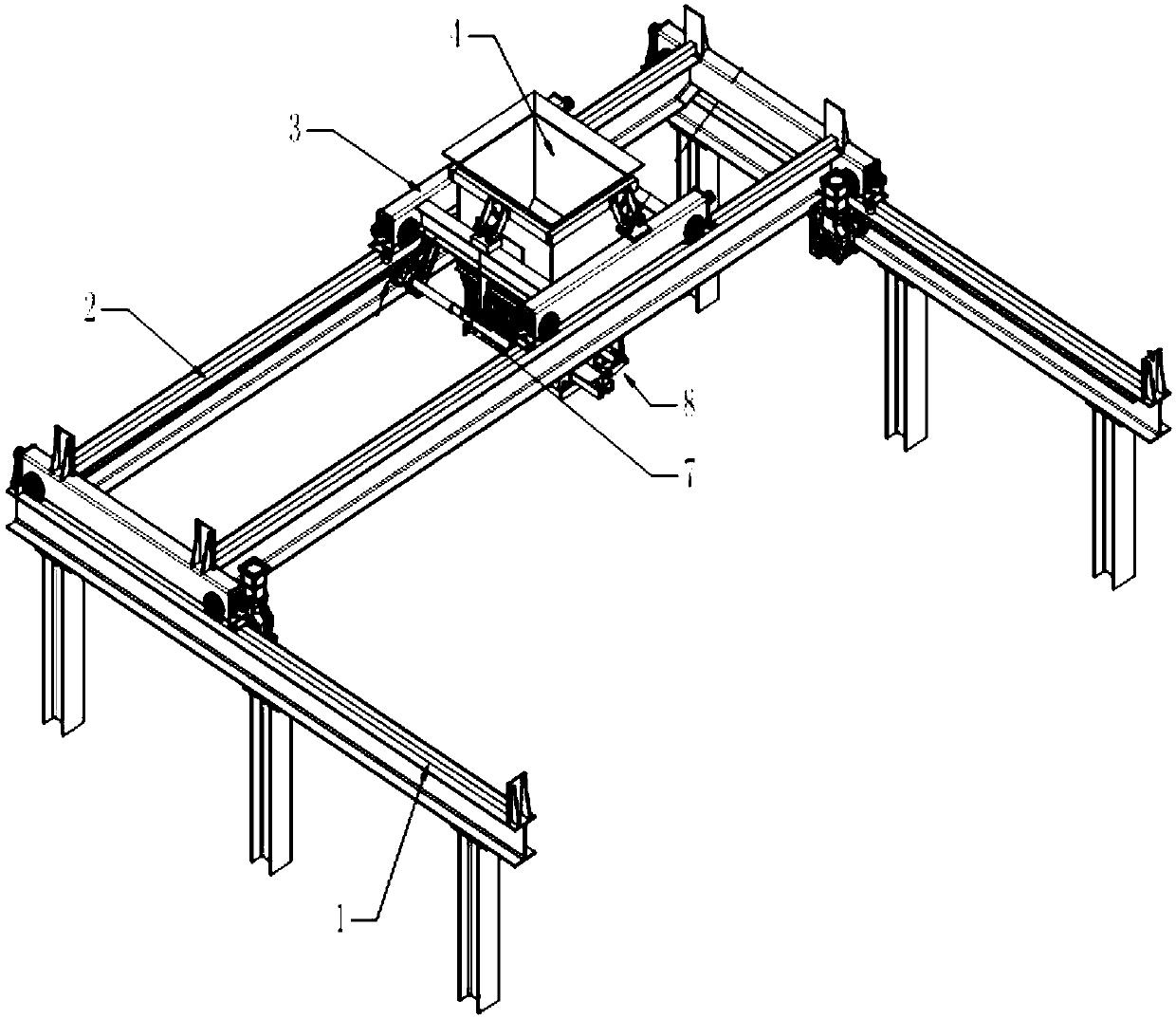

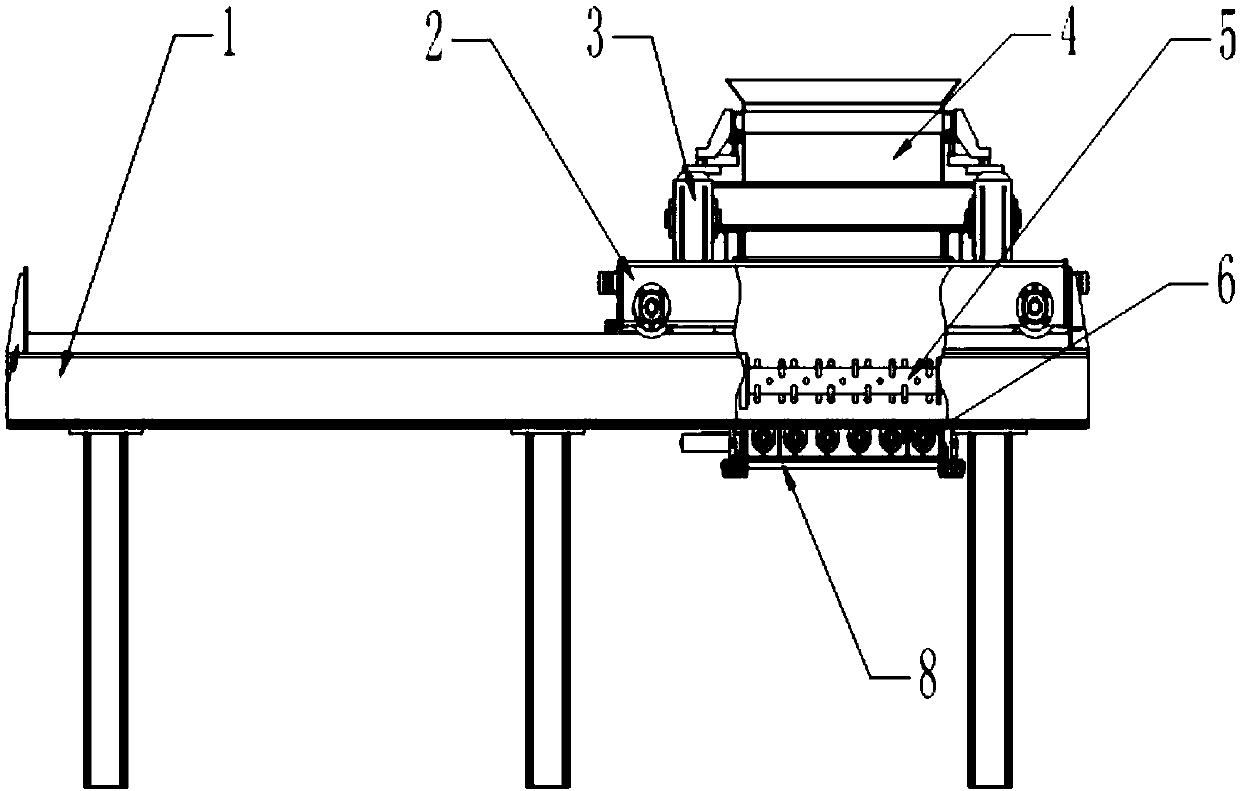

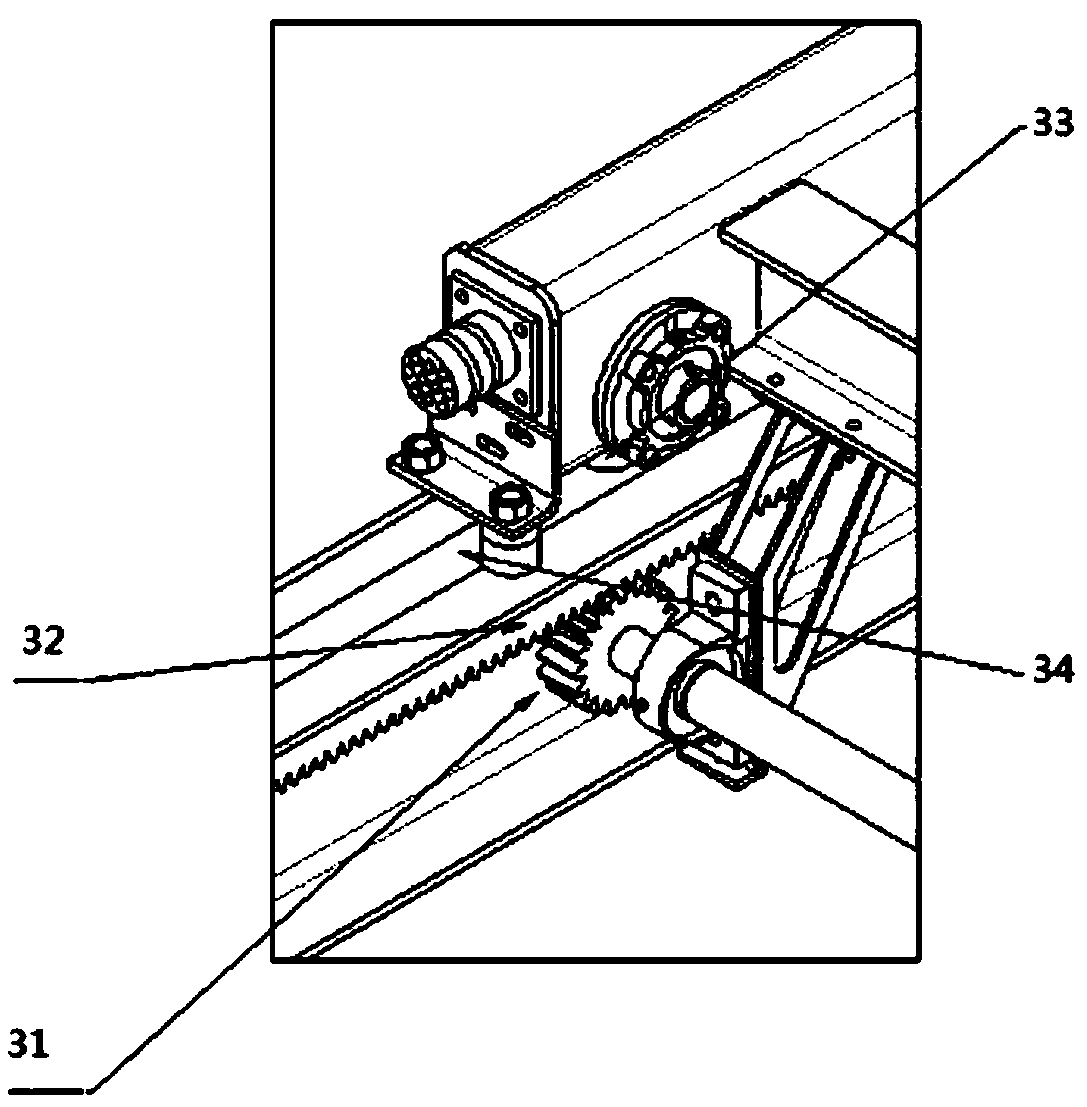

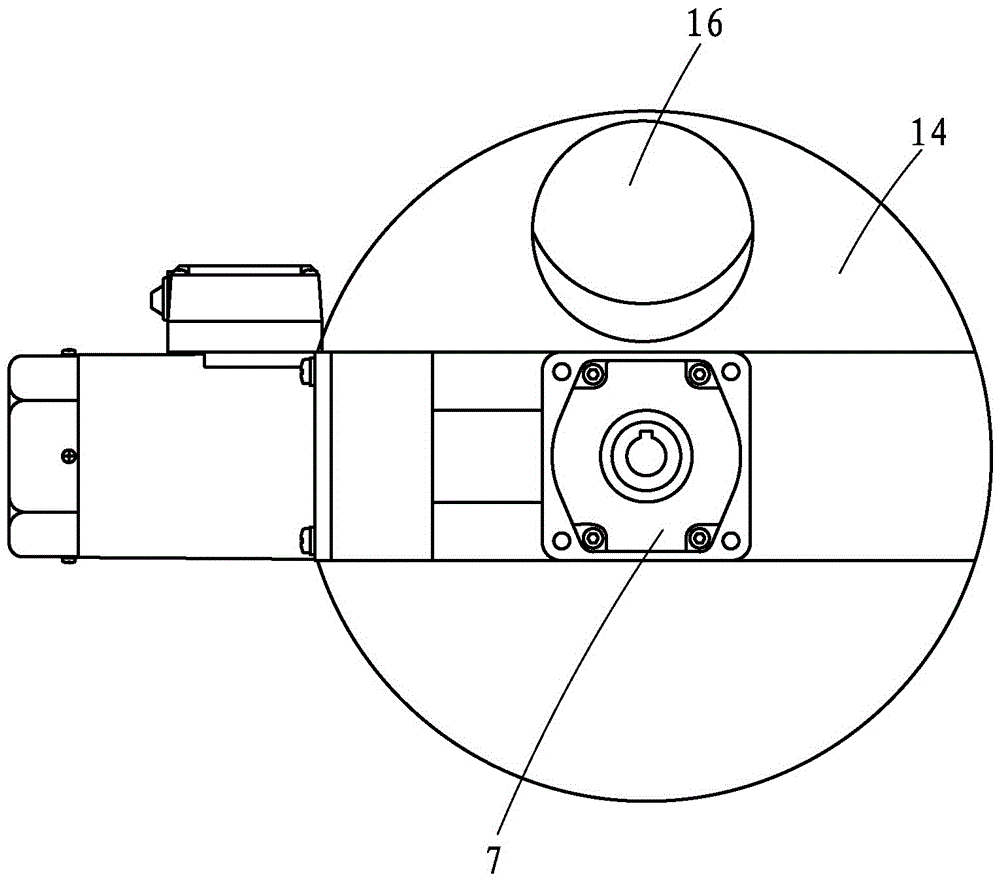

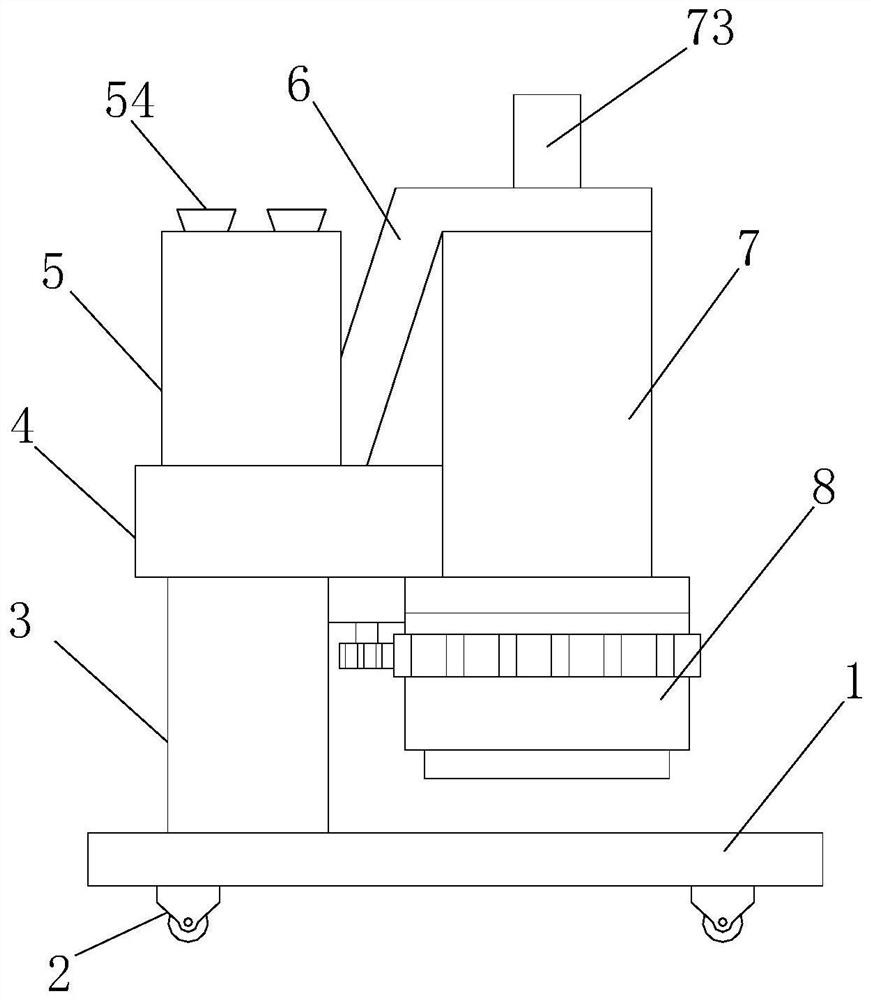

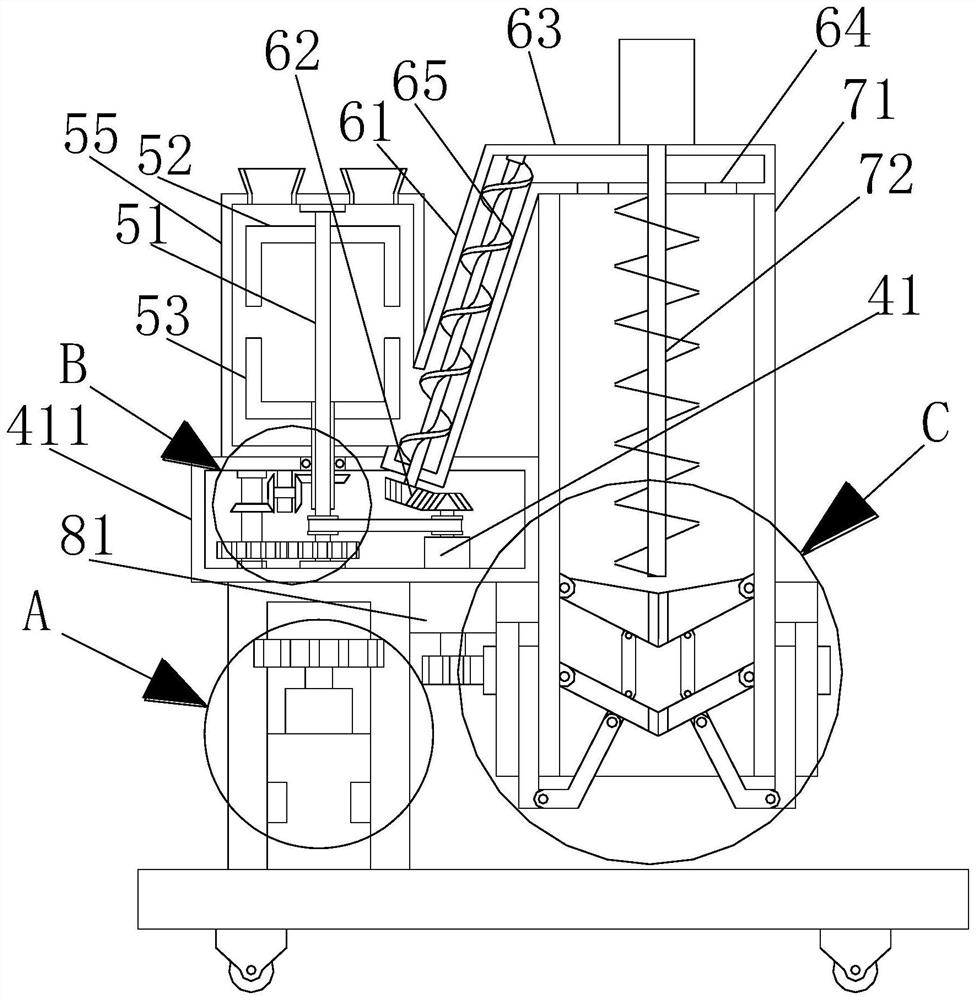

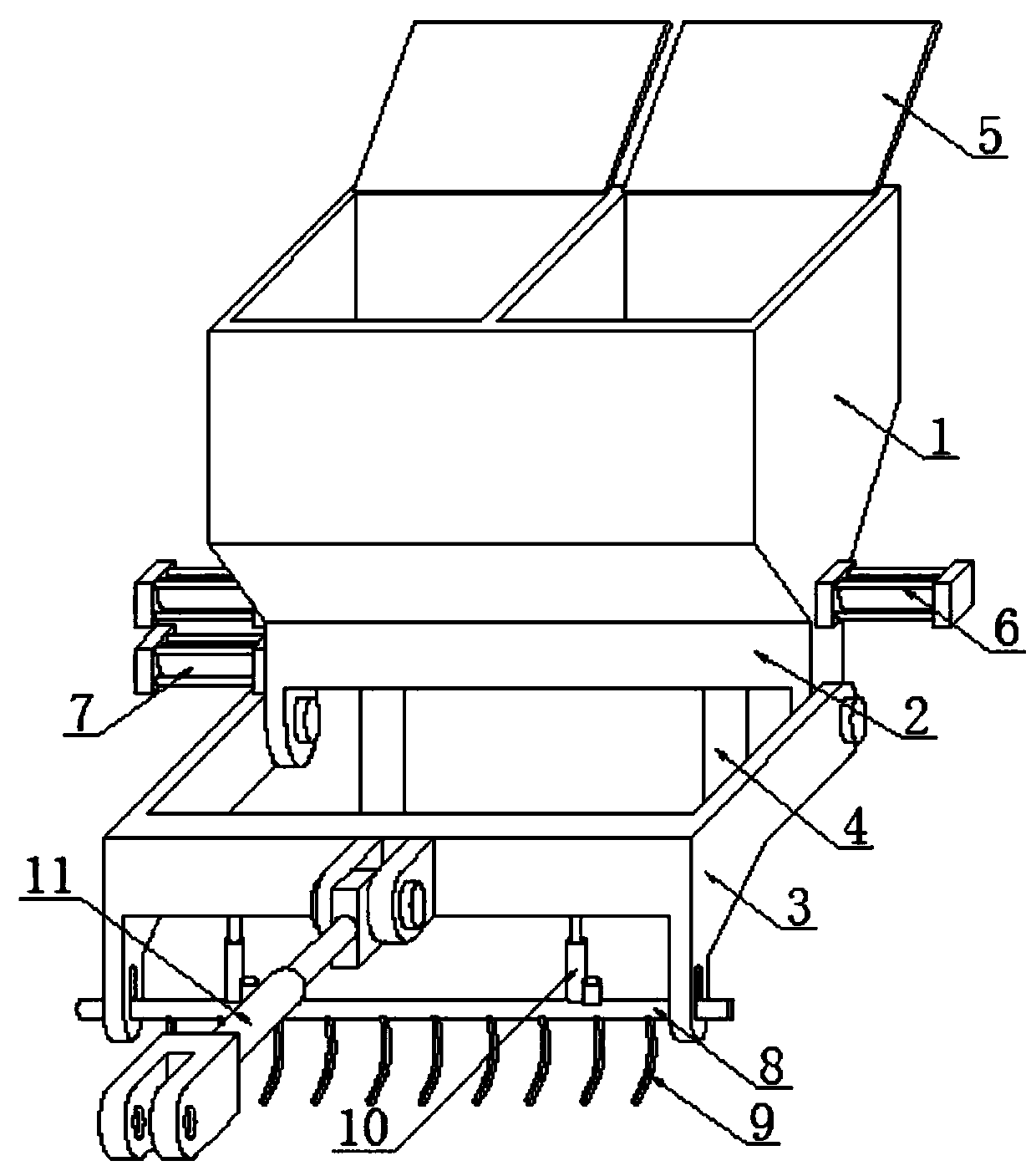

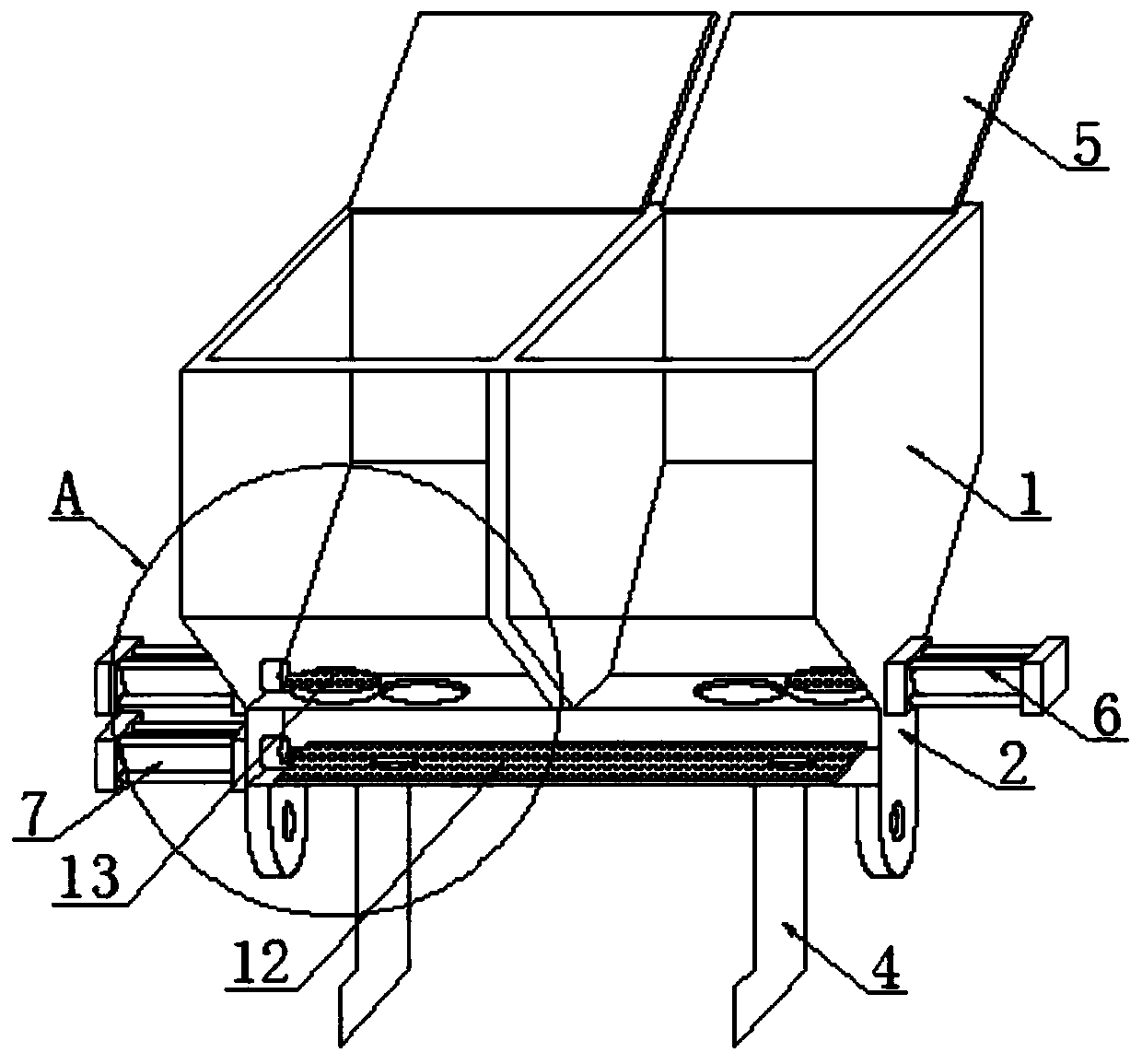

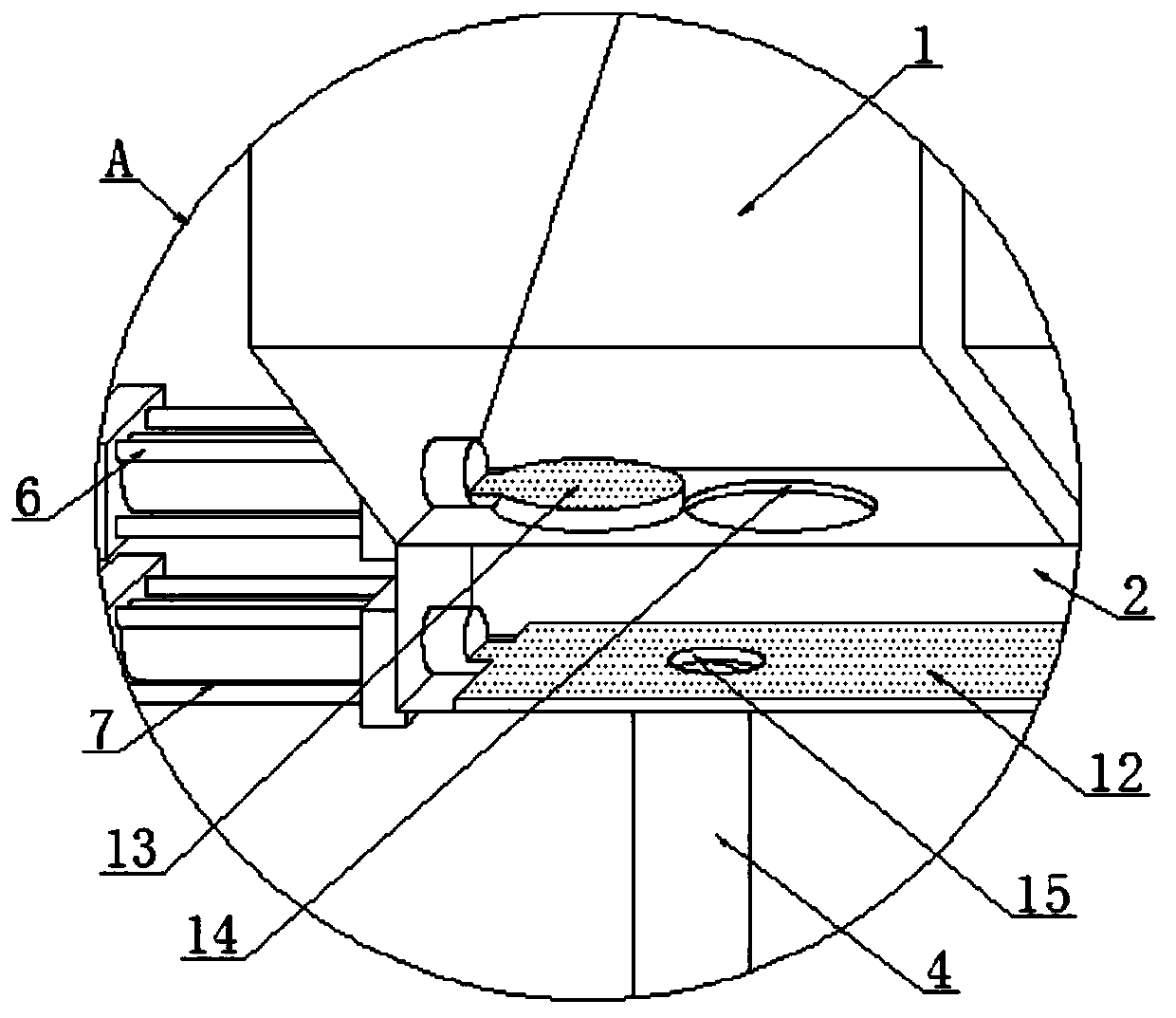

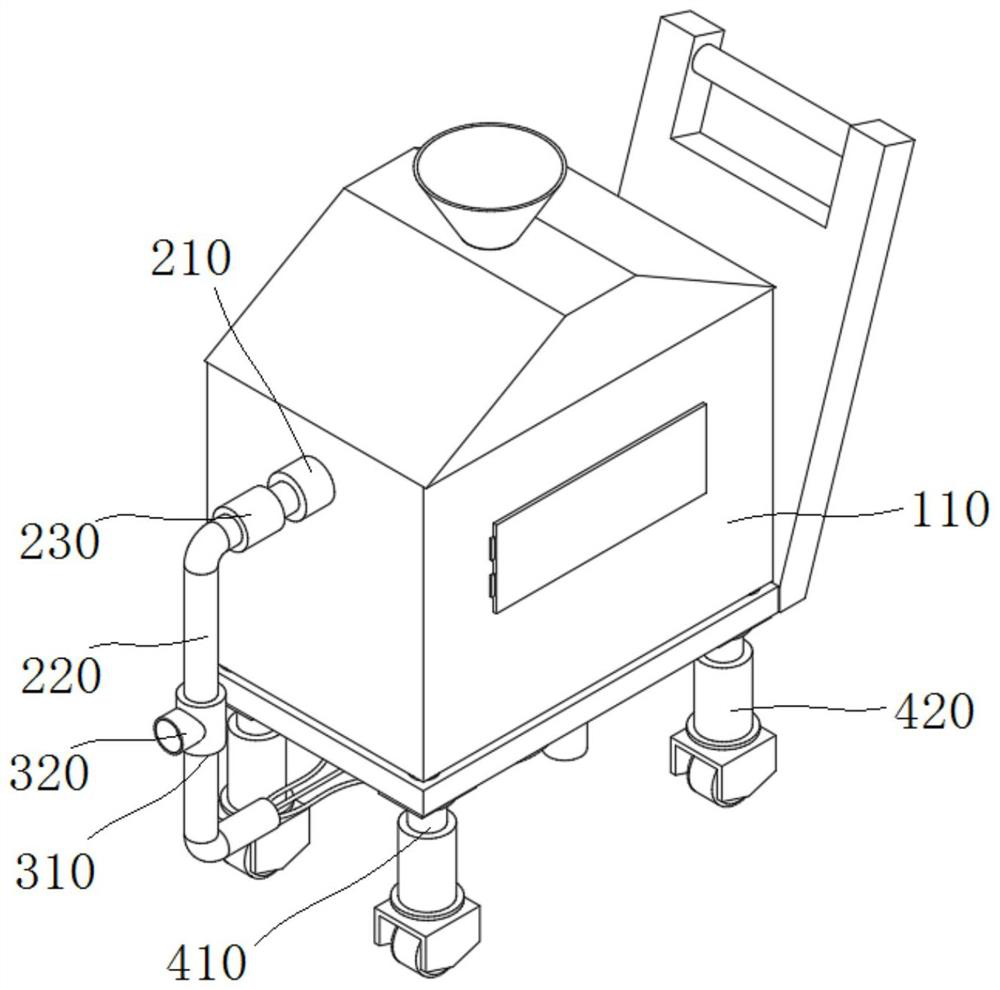

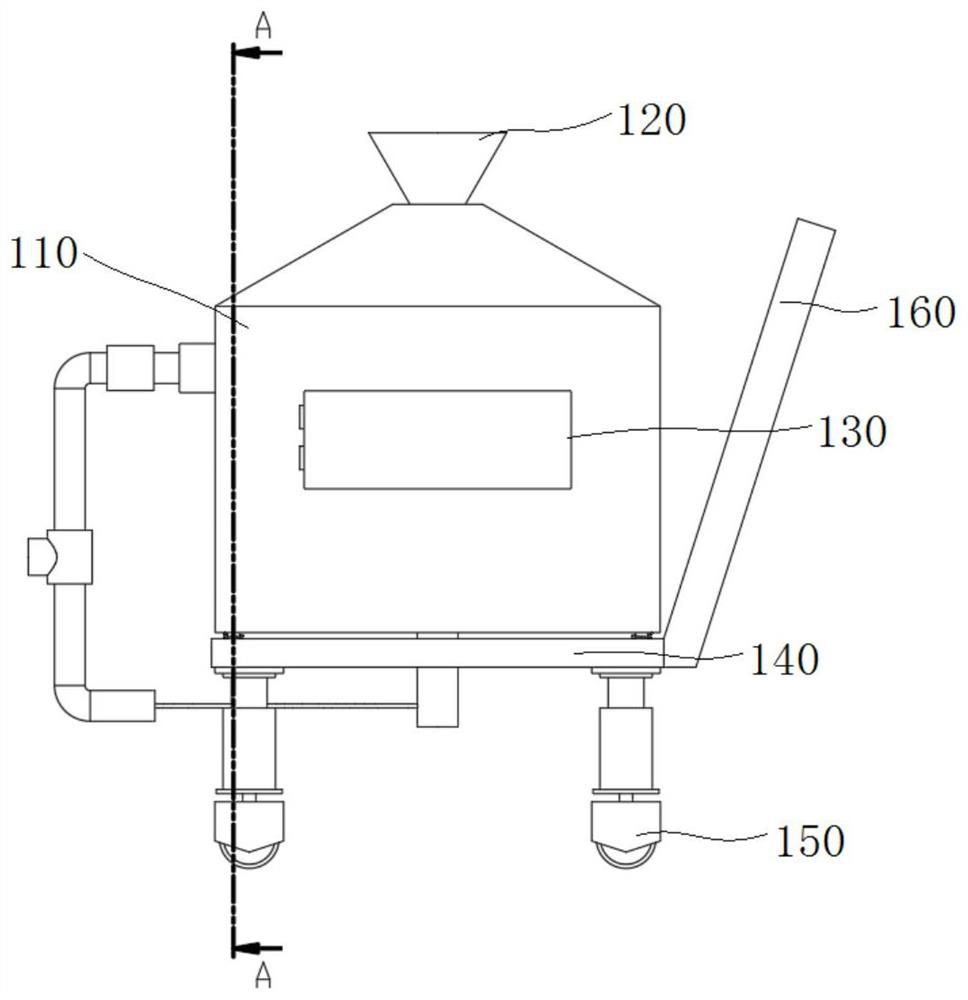

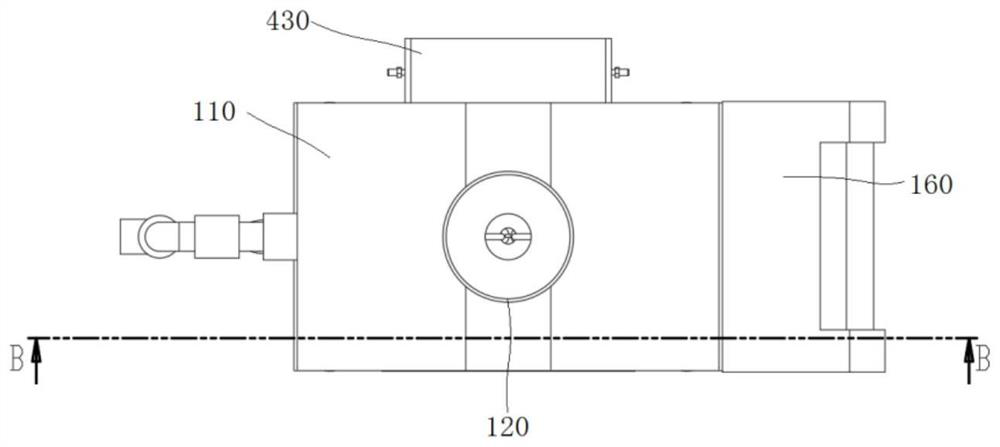

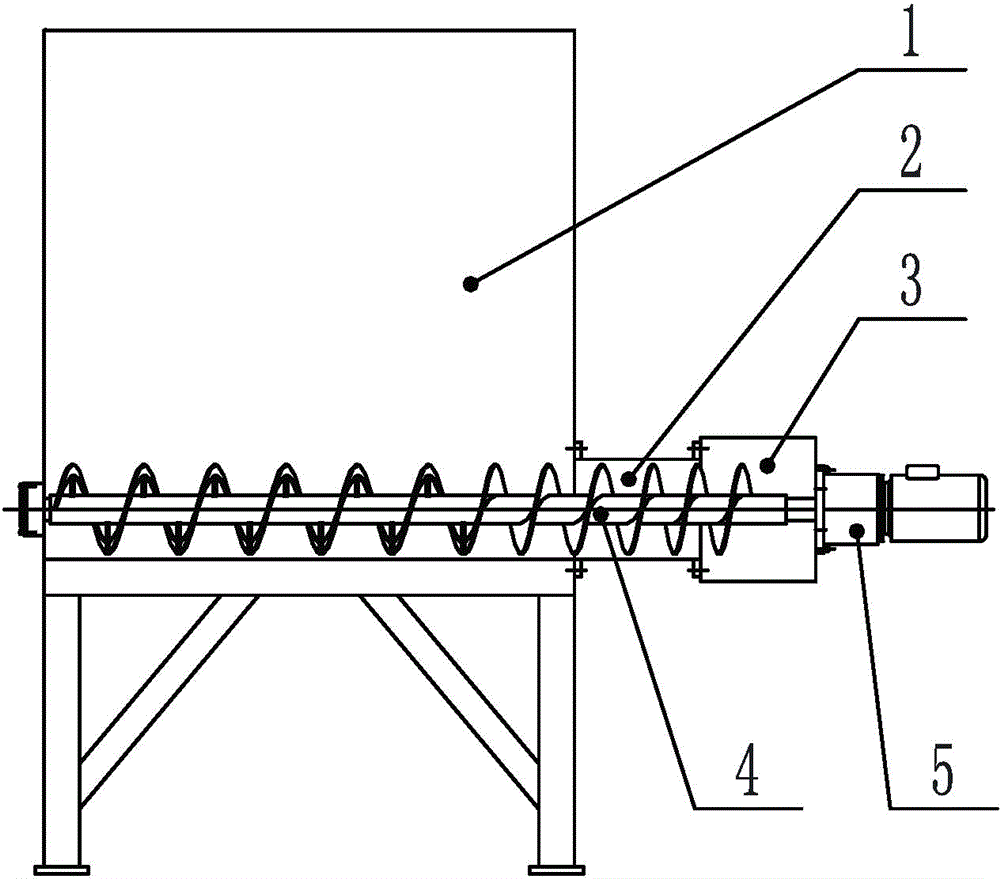

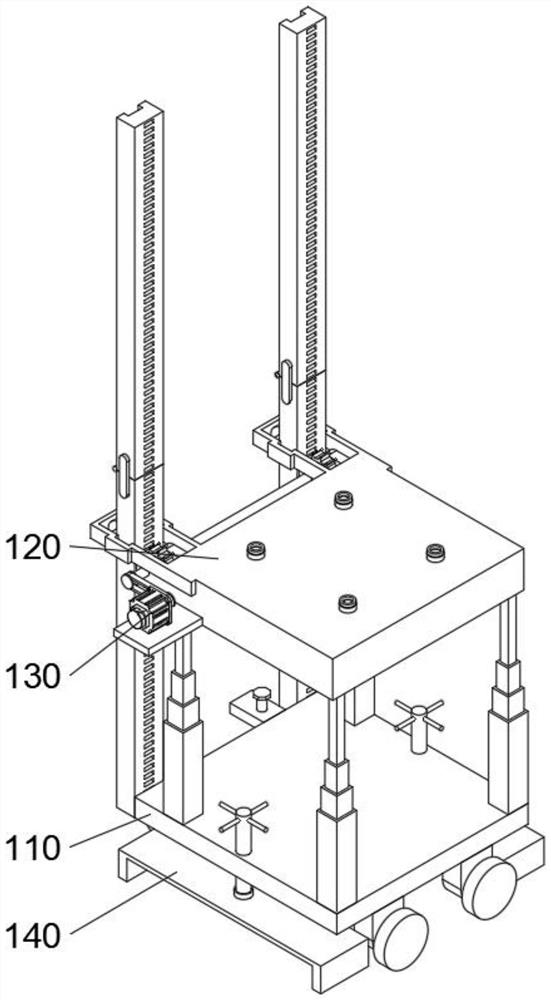

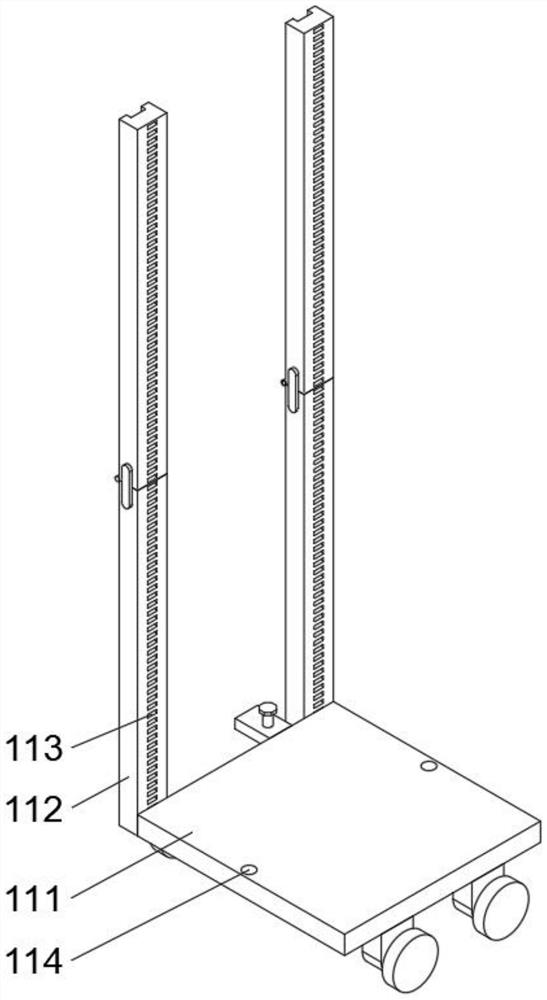

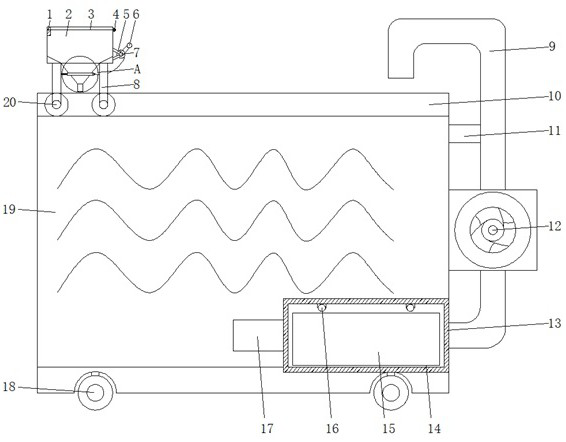

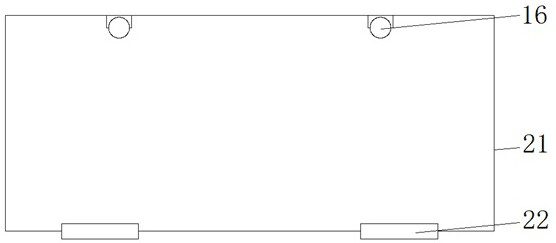

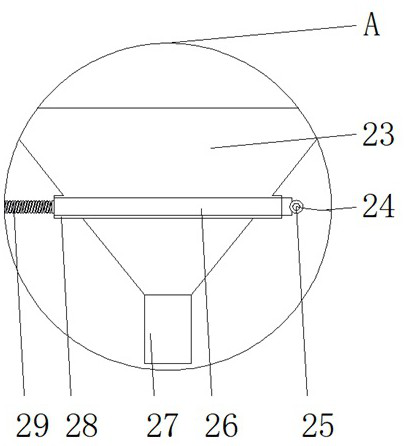

Concrete spreading experimental platform with functions of precise positioning and fine spreading

InactiveCN108678379AAccurate amount of fabricEasy to controlBuilding material handlingMicro motionEngineering

The invention belongs to the field of research and development of concrete member production equipment, and particularly relates to a concrete spreading experimental platform with functions of precisepositioning and fine spreading. According to the technical scheme, the concrete spreading experimental platform with the functions of precise positioning and fine spreading comprises a spreading system and a traveling system, wherein the spreading system comprises a hopper, a scattering device, a screw conveying device, gate assemblies and a bottom plate assembly; the traveling system comprises asteel-structure bracket, a large-vehicle micro-motion traveling device and a small-vehicle micro-motion traveling device, the large-vehicle micro-motion traveling device is mounted on the steel-structure bracket, the small-vehicle micro-motion traveling device is mounted on the large-vehicle micro-motion traveling device, and the spreading system is mounted on the small-vehicle micro-motion traveling device. Quantity and shape of the scattering device and the screw conveying device can be adjusted as required, the scattering device and the screw conveying device can be replaced as required, experimental study for factors affecting spreading precision and wear of core parts can be performed, and spreading compensation technique can be studied in real time according to change of spreading quantity.

Owner:SHENYANG JIANZHU UNIVERSITY

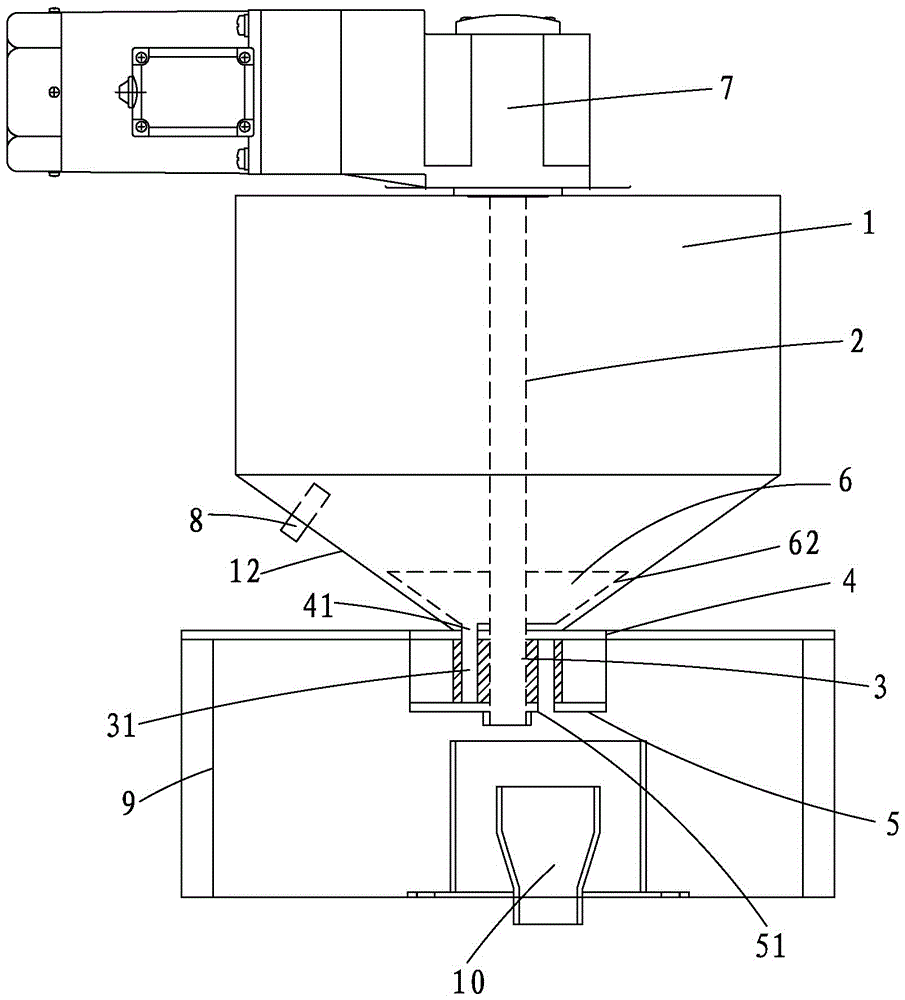

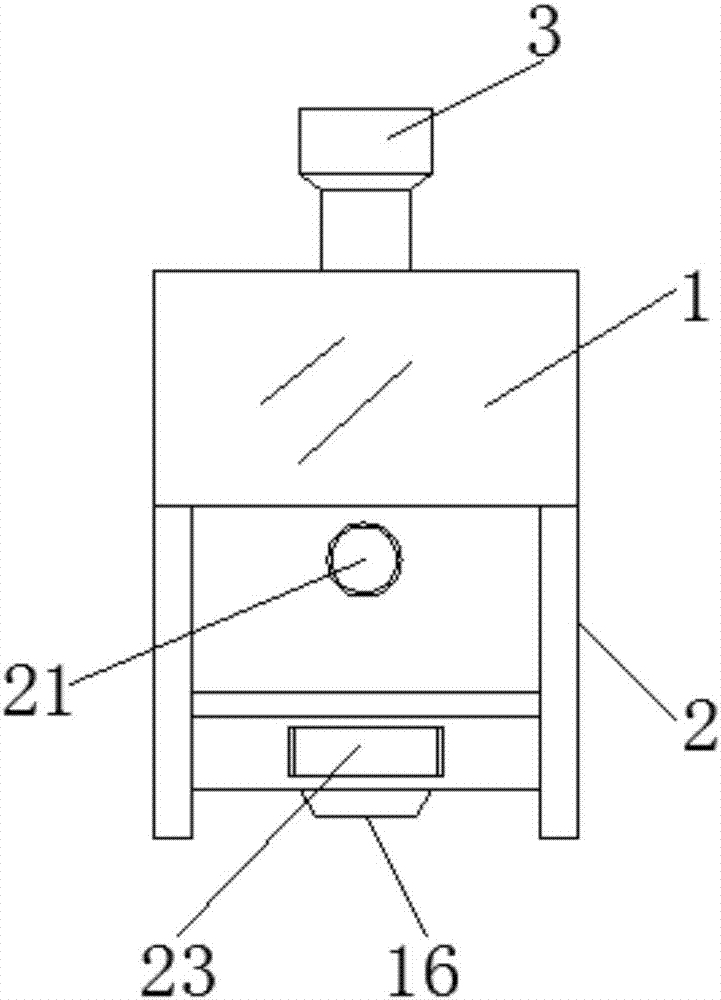

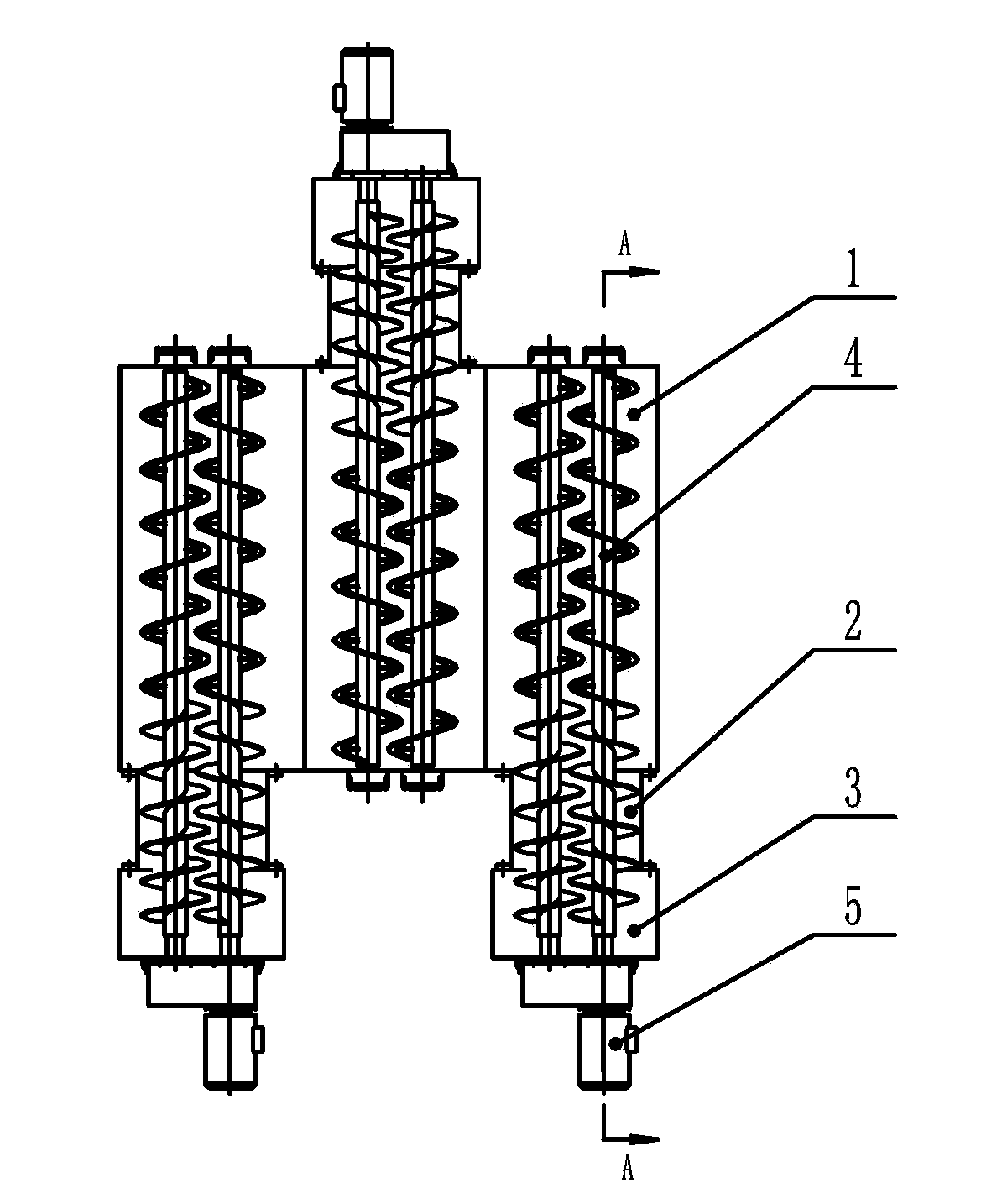

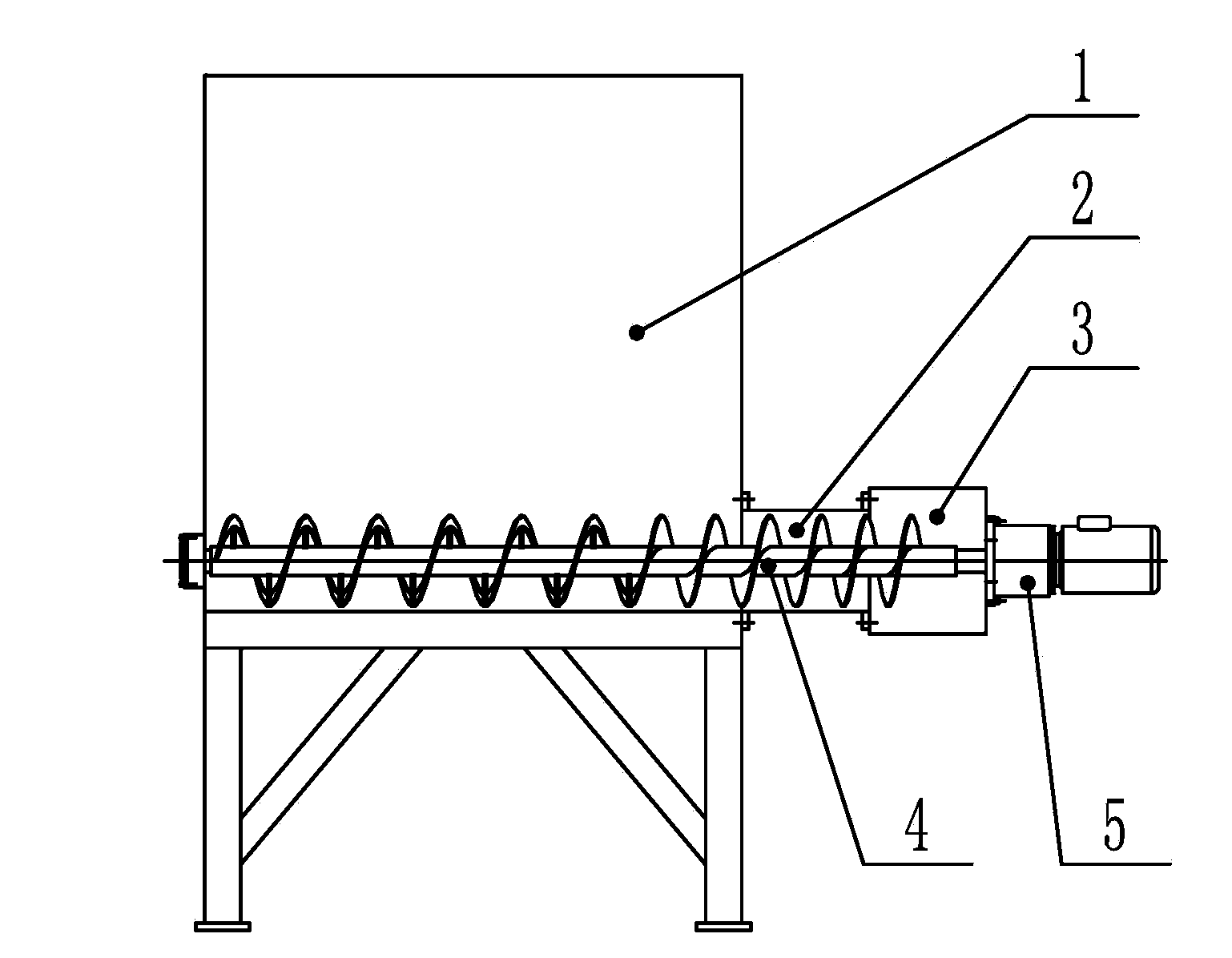

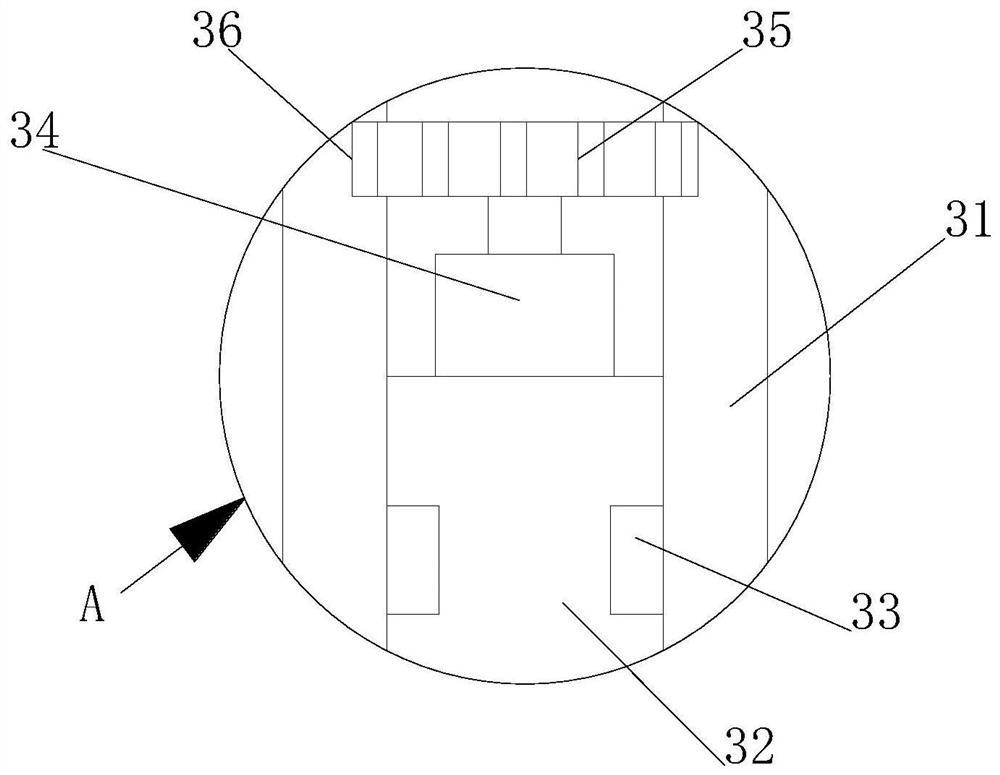

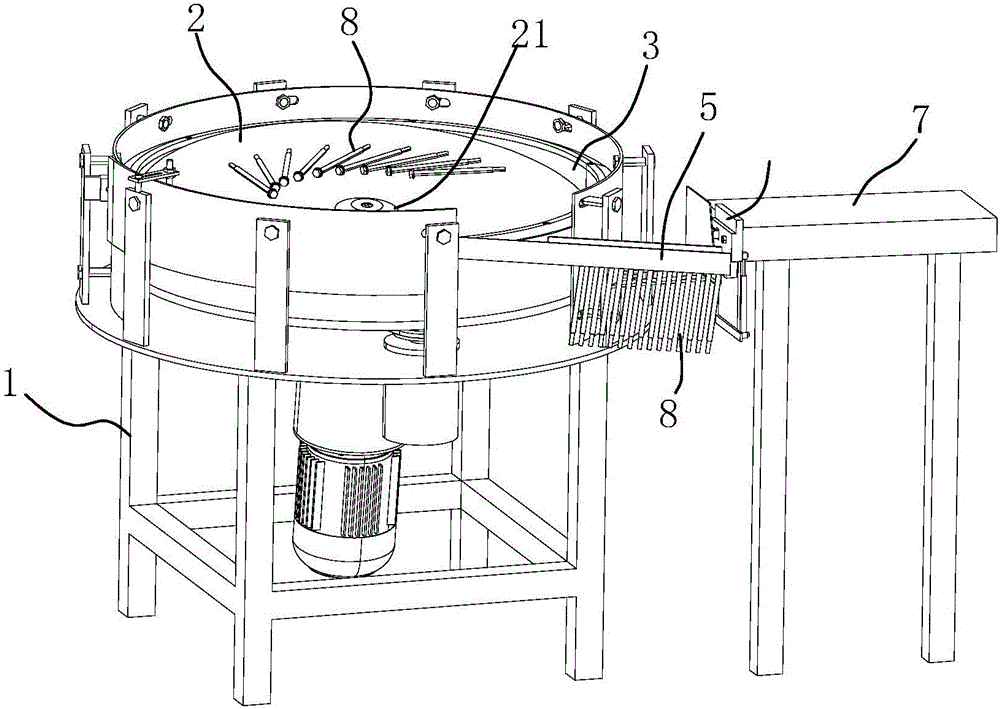

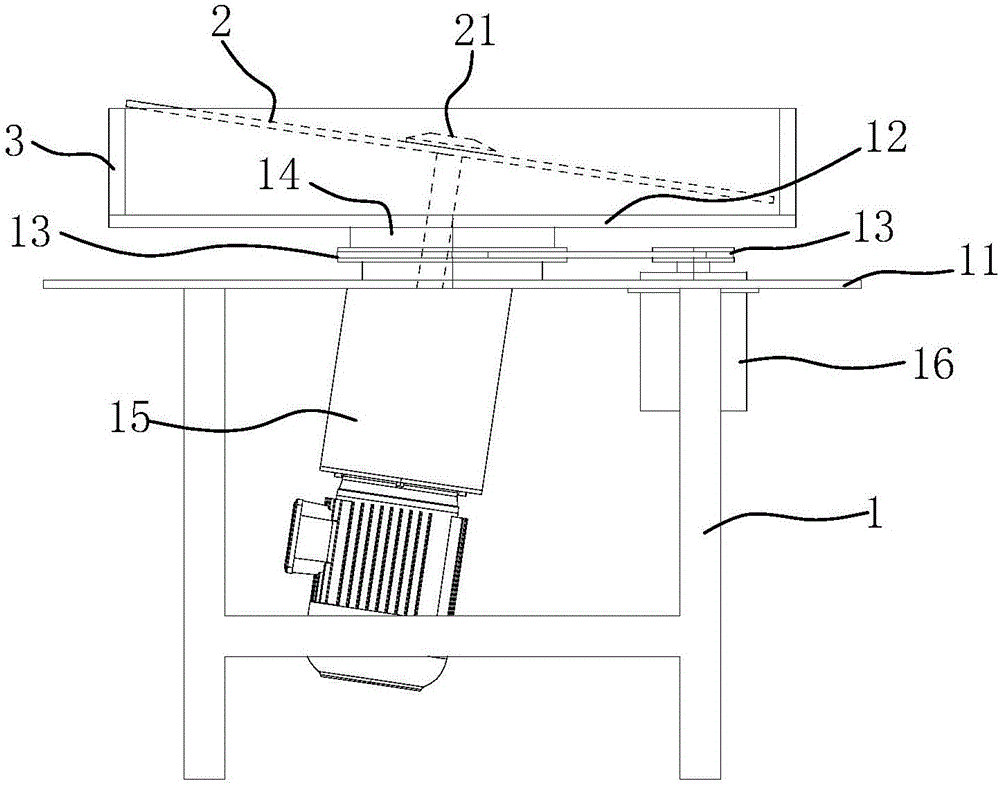

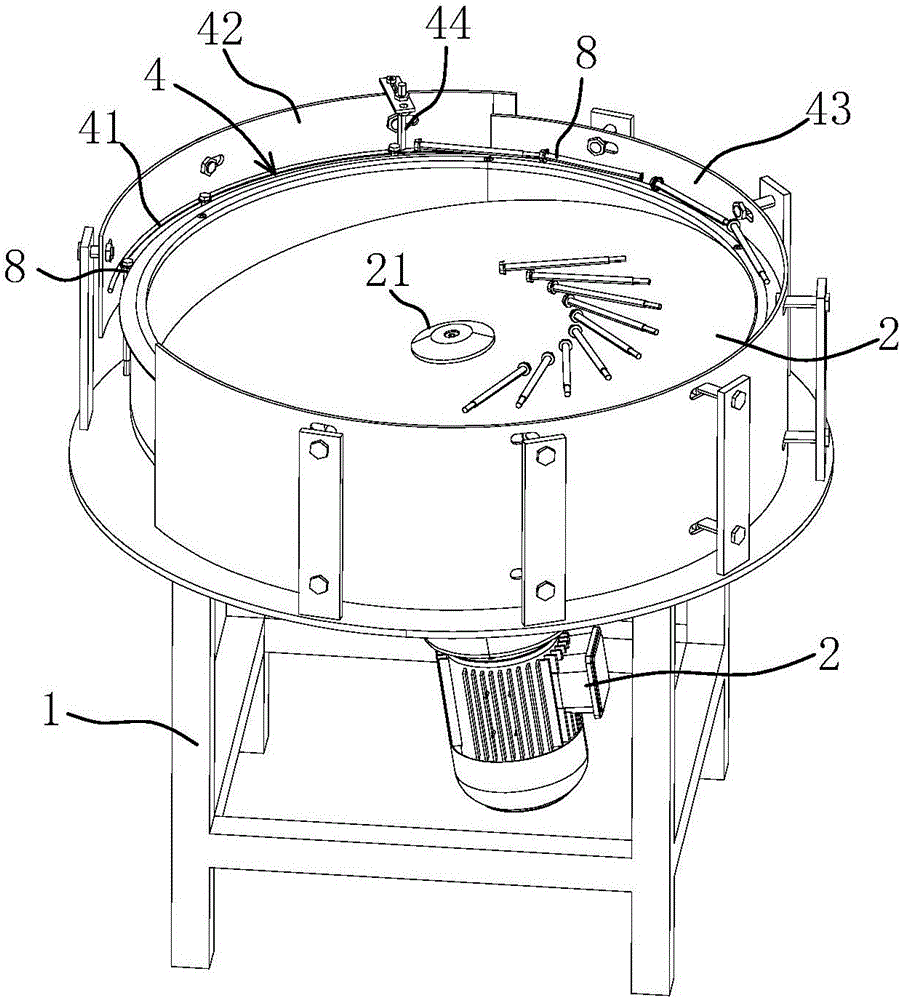

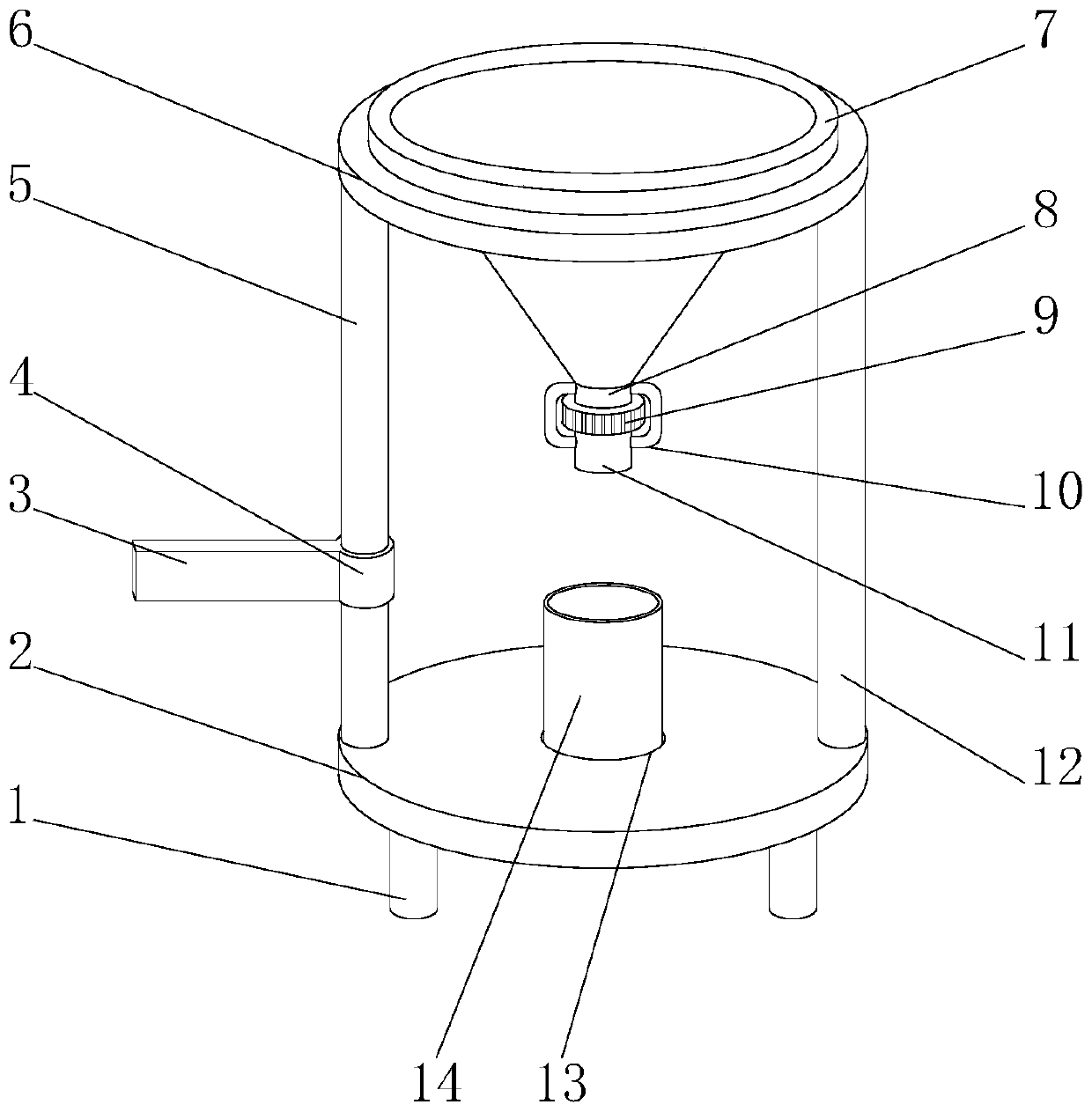

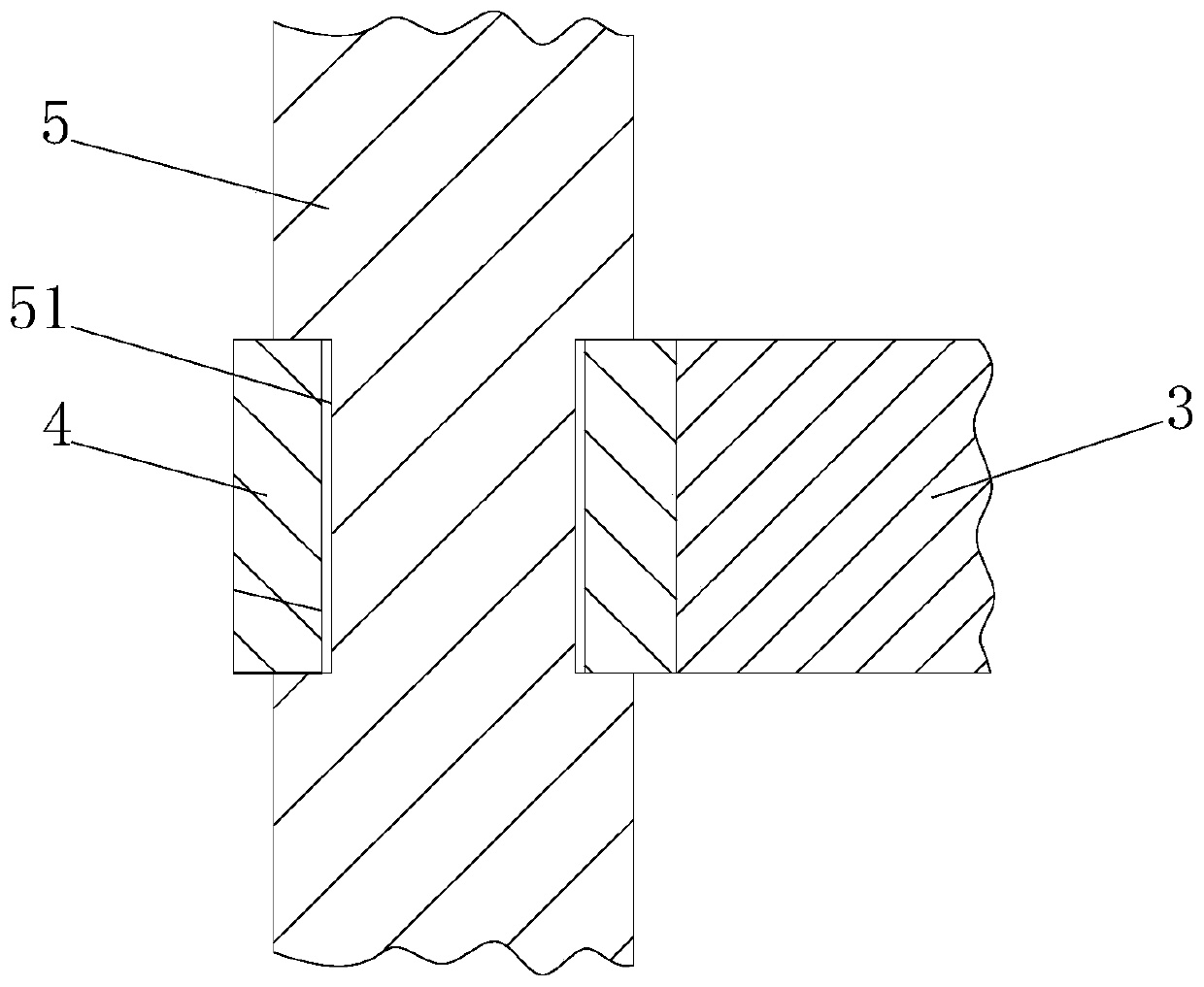

Continuous, quantitative and rotary feeder

InactiveCN106629126APrevent moisture from entering the material binPrevent moistureLoading/unloadingEngineeringMoisture

The invention provides a continuous, quantitative and rotary feeder which comprises a bin, a central shaft, a rotating block, an upper sealing plate and a lower sealing plate. The rotating block is provided with vertically through quantitative holes. The upper sealing plate is provided with a feeding port and is located at the bottom of the bin. The lower sealing plate is provided with a discharging port. The rotating block is arranged between the upper sealing plate and the lower sealing plate and is driven by the central driving shaft to rotate, and the quantitative holes are intermittently communicated with the feeding port or the discharging port in the rotating process of the rotating block. The phenomena of port blockage and material accumulation do not occur, the continuous, quantitative and rotary feeder can perform accurate feeding, effectively prevents moisture from entering the material bin, effectively prevents materials from being affected with damp and is simple in structure, convenient to manufacture, low in cost and low in failure rate.

Owner:吴云萍

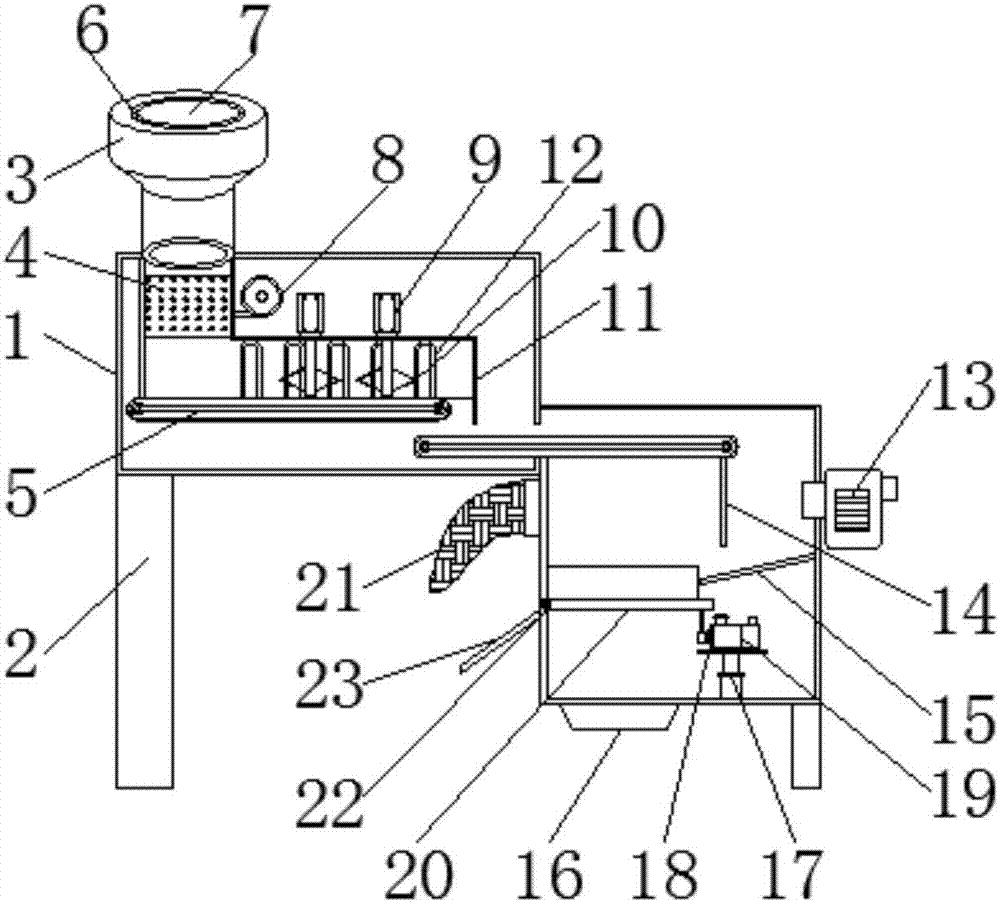

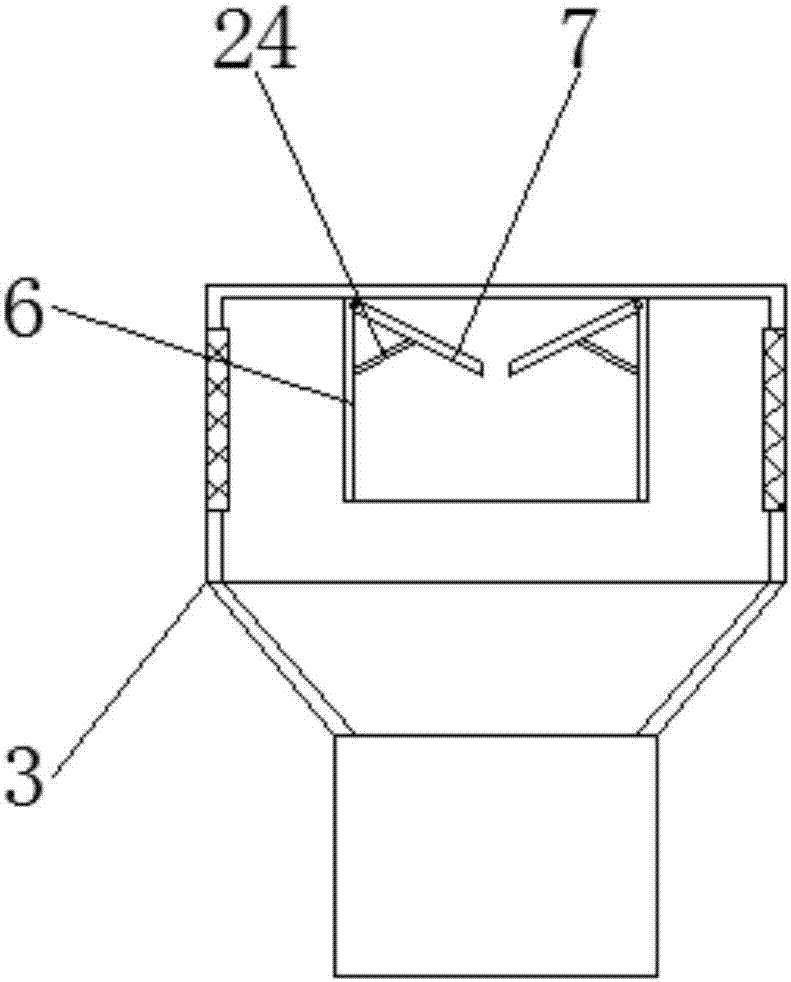

Tea drying and screening integrated machine

InactiveCN107497685ANo spillageAdjust the output speedSievingPre-extraction tea treatmentPulp and paper industryVibration motor

The invention relates to an integrated tea drying and screening machine, which includes a machine body, a motor and a second blower. Support legs are fixed at the lower end of the machine body, and a material inlet is installed at the upper end of the machine body, and an air outlet is installed at the lower end of the material inlet. , and the first blower is connected to the outside of the air outlet, the lower end of the windshield is fixed with a material guide plate, and the discharge end of the material guide plate is arranged above the mounting frame, the lower end of the body is equipped with a dust outlet, and the inside of the body is fixed There is an adjustment mechanism, a mounting frame is connected above the vibration motor, and one end of the mounting frame is connected to the body through a rotating shaft, a dust bag is installed on the outside of the body, and a discharge port is arranged below the dust bag, and the cover plate The inner lower end is connected by a telescopic mechanism partition, the upper end of the installation frame is fixed with a baffle plate, and the inner side of the installation frame is installed with a screening frame. The tea drying and screening integrated machine can continuously dry and screen tea leaves, effectively improving the working efficiency of the device.

Owner:薛迪宋

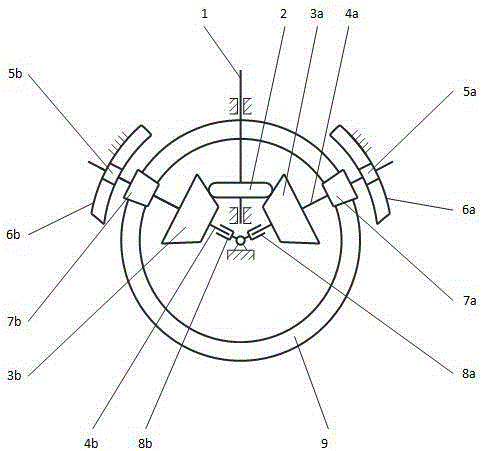

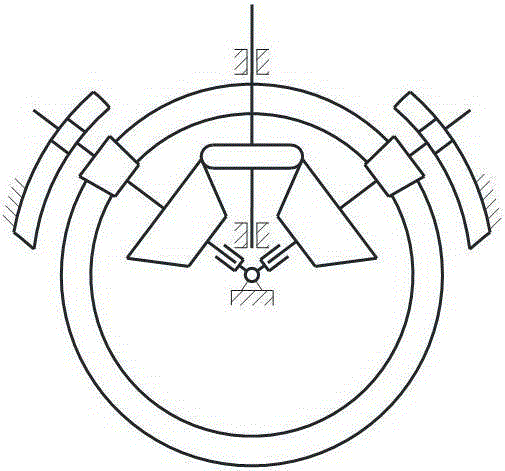

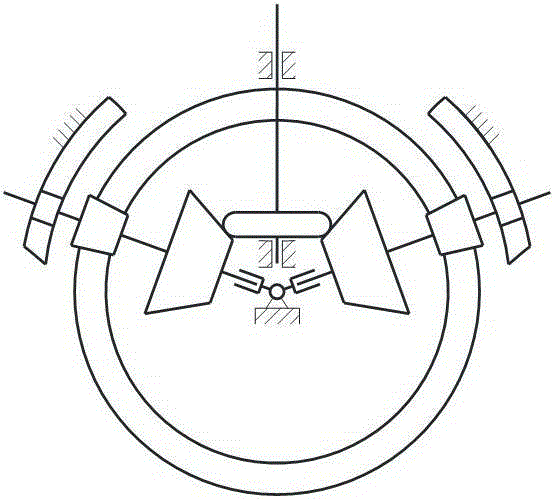

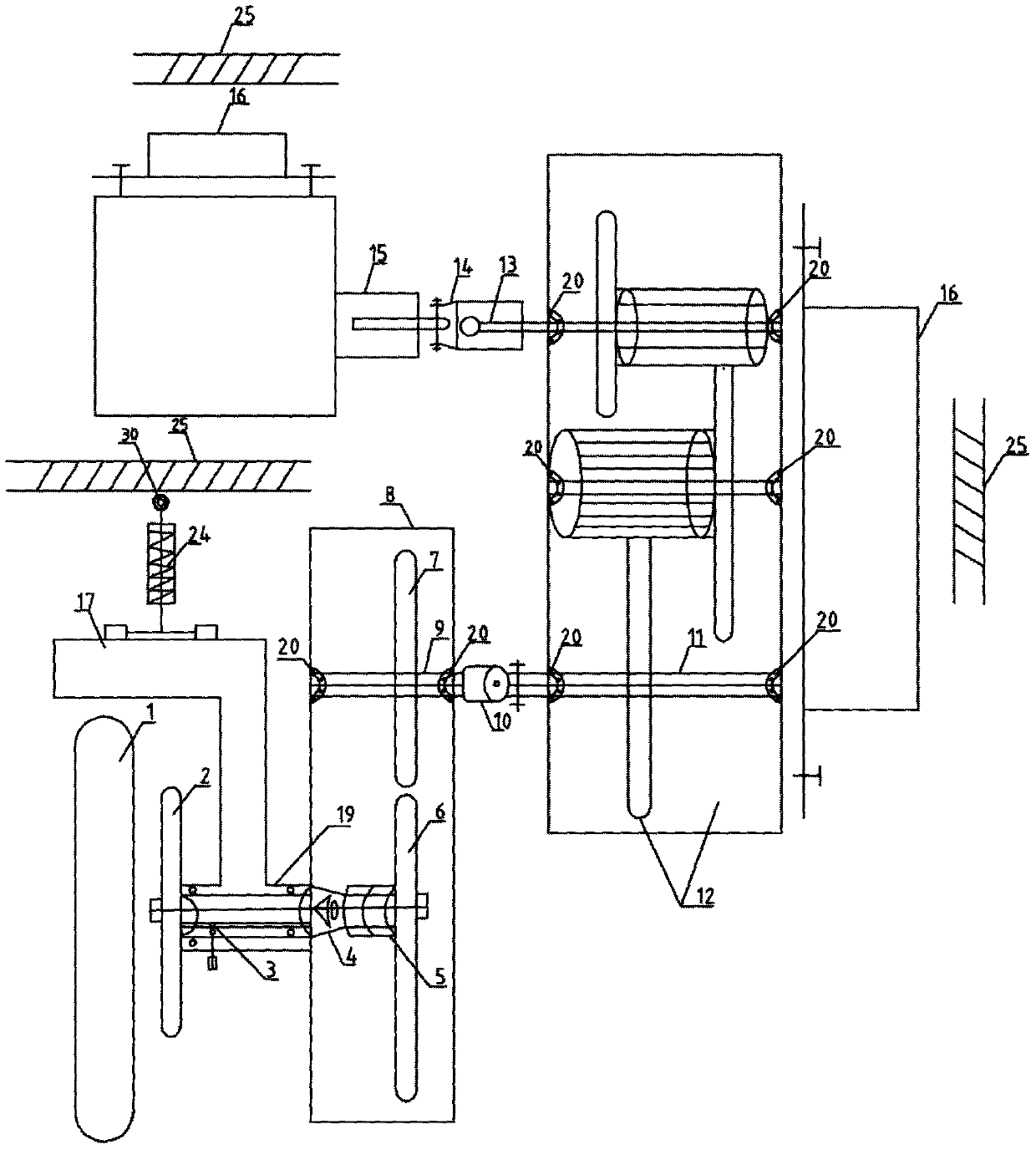

Self-rotation-free traction type stepless speed changer

ActiveCN105276110AEasy to manufactureImprove transmission efficiencyTransmission elementsMultiple ratio transmissionGear wheelMedial axis

The invention provides a self-rotation-free traction type stepless speed changer. The self-rotation-free traction type stepless speed changer mainly comprises an input shaft, a driving roller, a first intermediate shaft, a second intermediate shaft, a first swing bearing, a second swing bearing, a first driven cone disc, a second driven cone disc, a first small bevel gear, a second bevel gear, a first sliding block, a second sliding block, a first guide rail, a second guide rail and a large bevel gear, wherein power is input by the input shaft, is transmitted by the input shaft, the driving roller, the driven cone disc and the small bevel gear and is finally output by the large bevel gear. The self-rotation-free traction type stepless speed changer is characterized in that cone tops of the two driven cone discs, a cone top of a dividing cone of the large bevel gear and a cone top of a dividing cone of the small bevel gear are folded at the same point; generatrixes of the driving roller and the two driven cone discs are single curves. The traction type stepless speed changer is free of self rotation in the driving process and has the advantages of being simple in structure, easy to manufacture, small in number of parts and high in driving efficiency.

Owner:SICHUAN UNIV

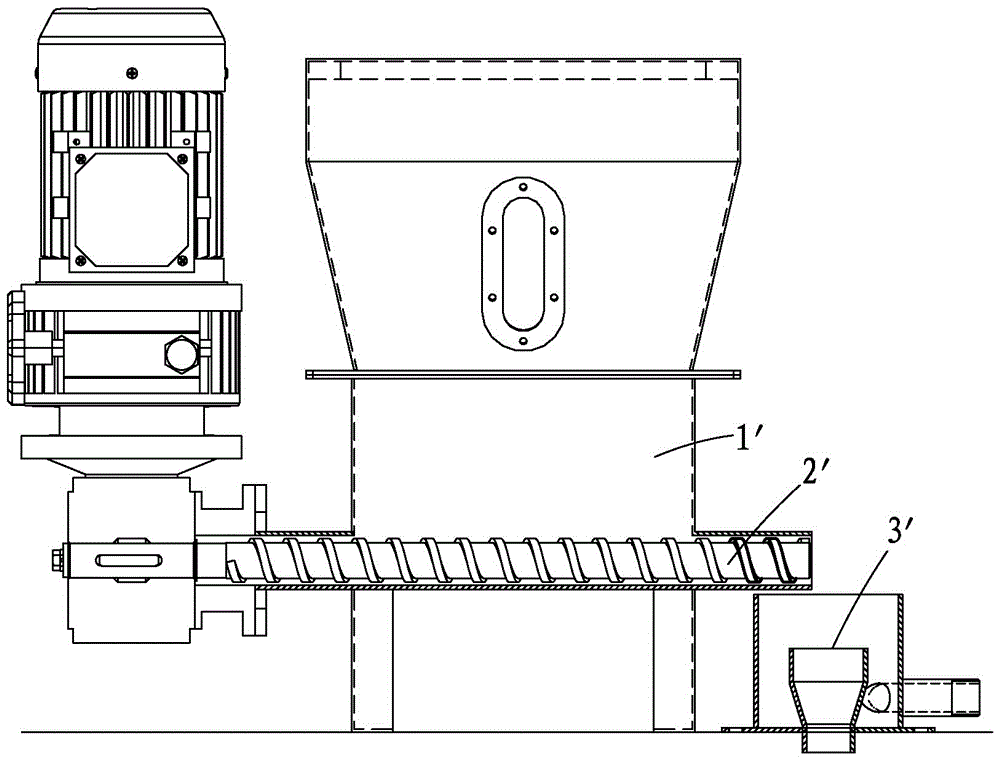

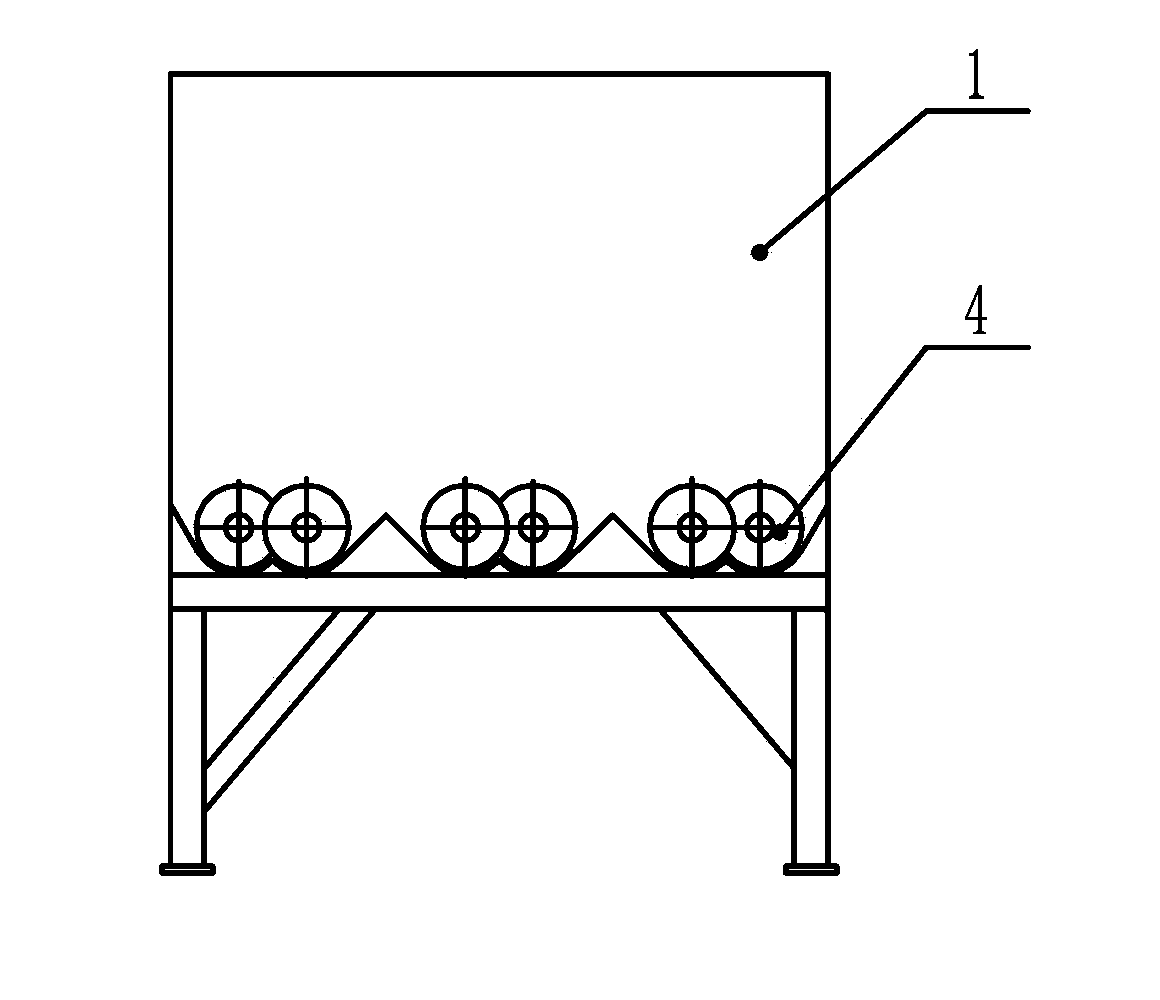

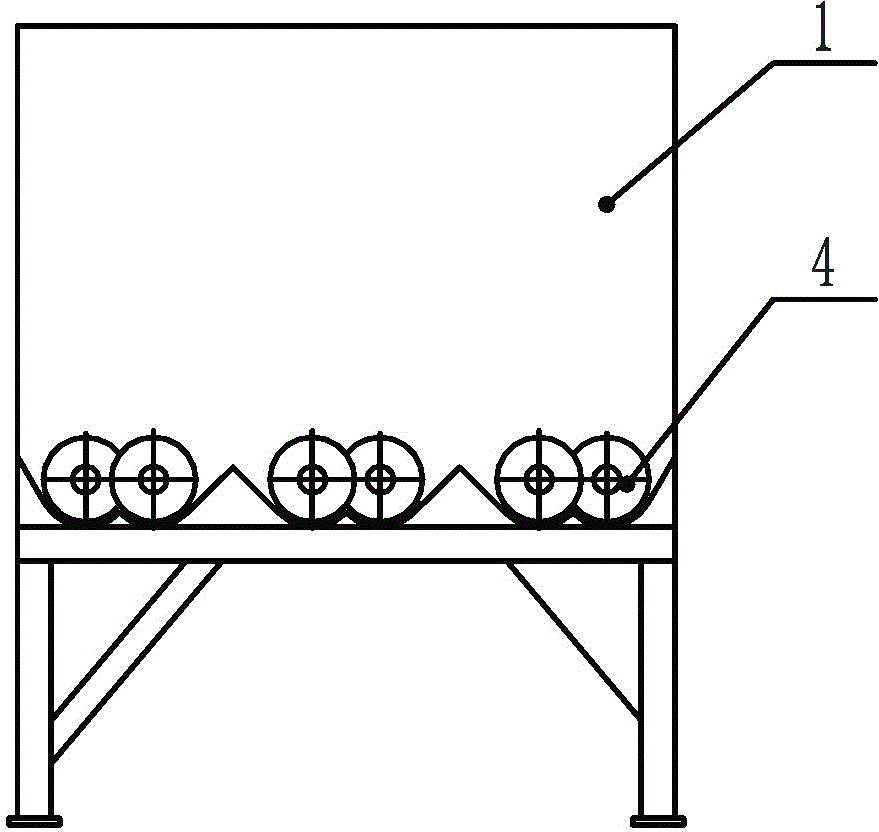

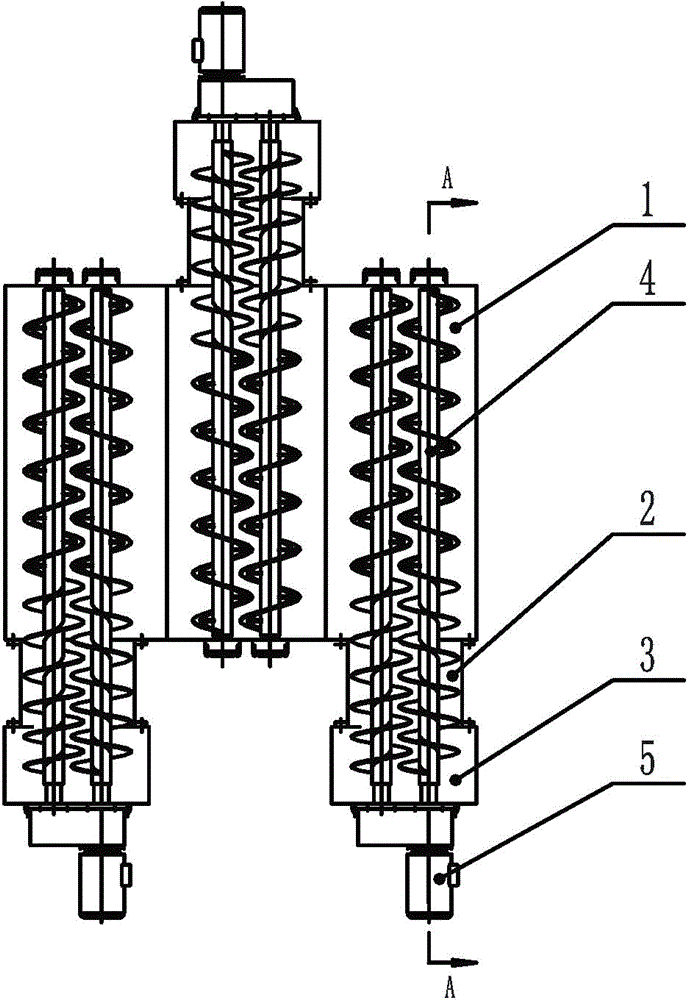

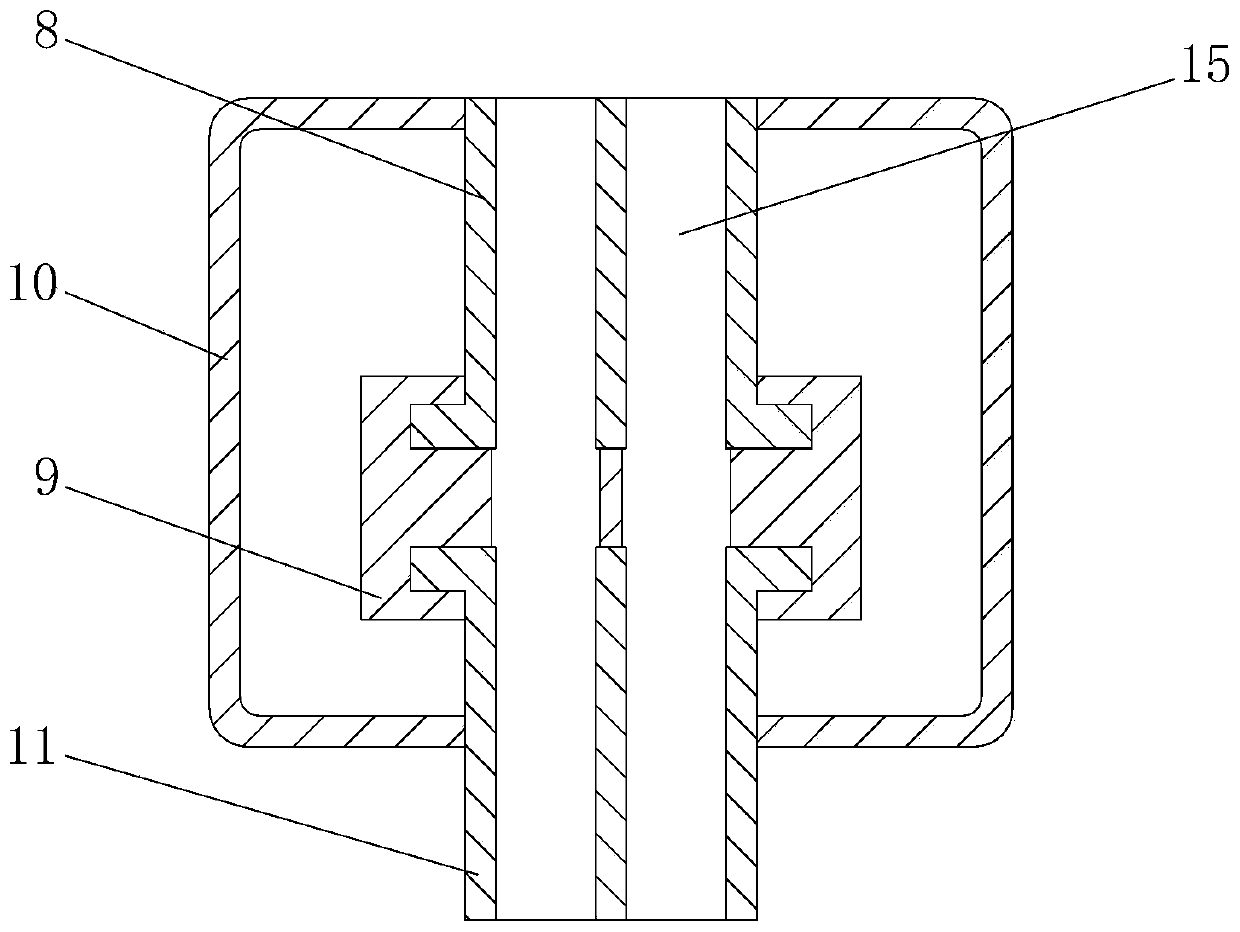

Caching feeding bin

ActiveCN103612924AAdjust the output speedPrevents reduction in feeding functionLarge containersLoading/unloadingWaste management

A caching feeding bin comprises a storage bin body, a discharge tube body, a discharge hopper, discharge spiral units and a discharge spiral unit drive mechanism. The discharge tube body is arranged on the side wall of the storage bin body. The discharge hopper is sequentially connected and communicated with the discharge tube body and the storage bin body. The discharge spiral units are arranged in the storage bin body, the discharge tube body and the discharge hopper and used for pushing materials in the storage bin body into the discharge hopper. The output end of the discharge spiral unit drive mechanism is connected with the discharge spiral units and drives the discharge spiral units to rotate. Due to the fact that the discharge speed of the materials is related to the rotating speed of the discharge spiral units, the constant discharge speed can be adjusted by controlling the rotating speed of the discharge spiral units.

Owner:光大清洁技术股份有限公司

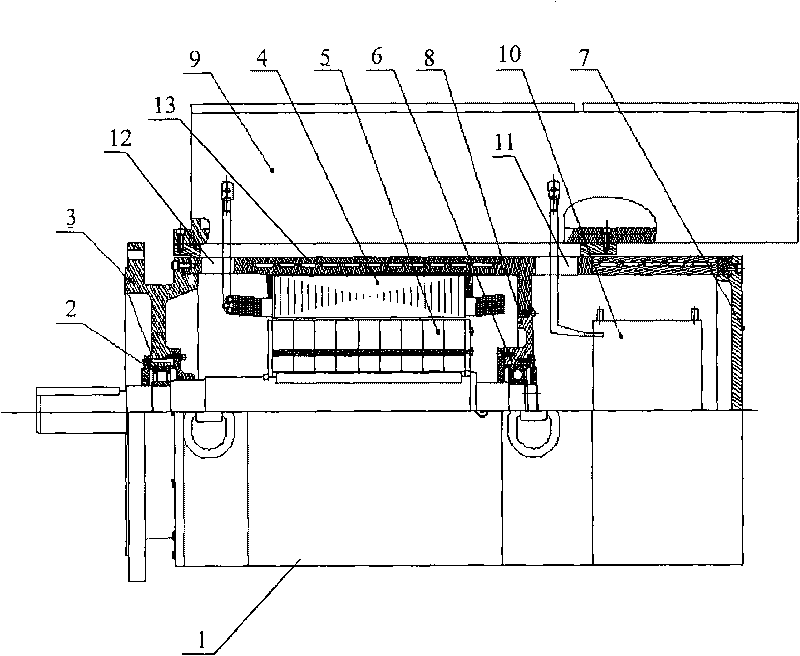

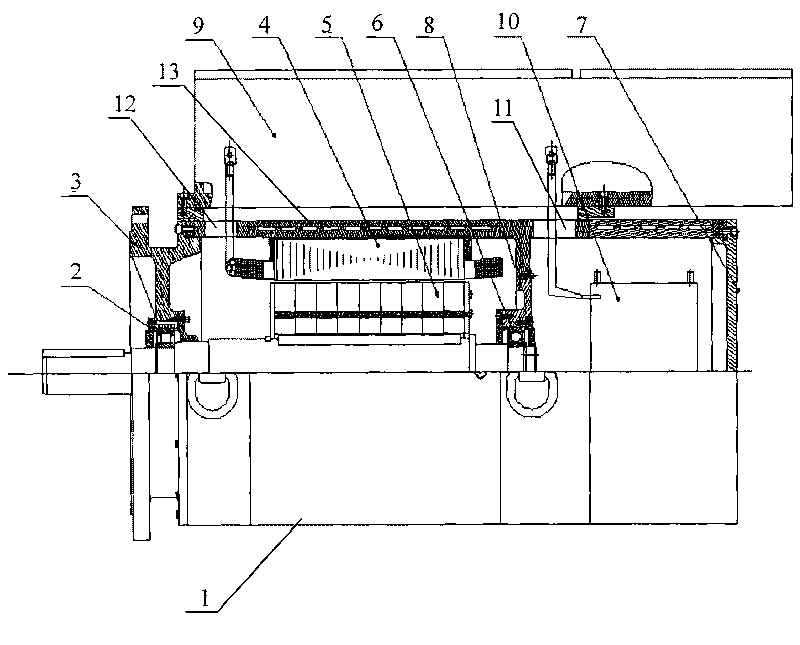

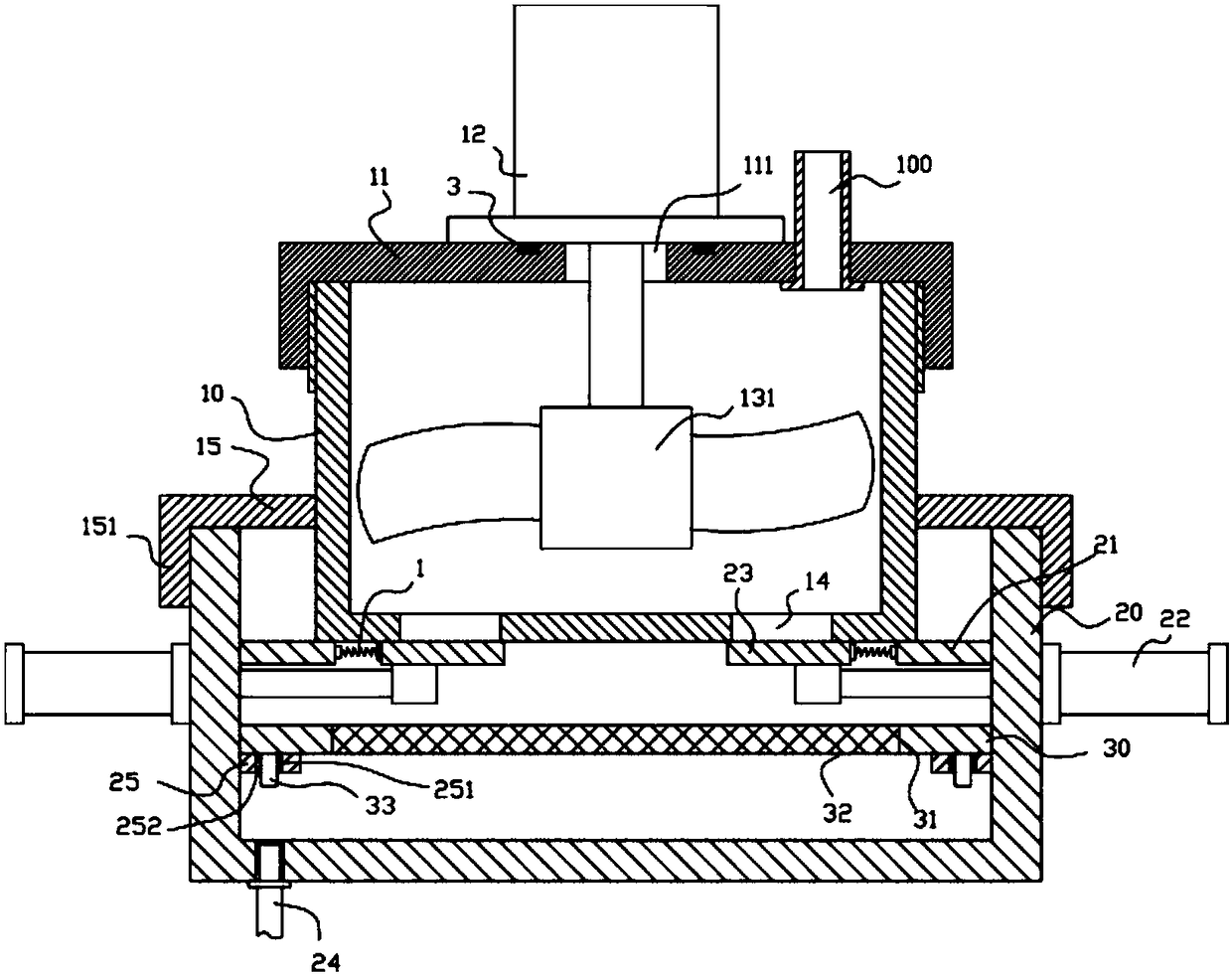

Frequency conversion motor and engineering machine with same

InactiveCN101710761AReduce in quantityCompact structureAssociation with control/drive circuitsCooling/ventillation arrangementFrequency changerFrequency conversion

The invention relates to a frequency conversion motor comprising a motor unit (1) and a frequency converter unit, wherein the motor unit (1) is provided with a drive end bearing (2), a drive end cover (3), a stator (4), a rotor (5), a non-drive end bearing (6) and a non-drive end cover (7); the frequency converter unit is integrated with the motor unit (1) into a whole, wherein a frequency conversion control cabinet (9) of the frequency converter unit is arranged on a bed designed into a part of the motor unit (1), and an incoming line reactor (10) of the frequency converter unit is arranged in the bed. Besides, the invention also relates to a coal planer with the frequency conversion motor.

Owner:三一集团有限公司北京分公司

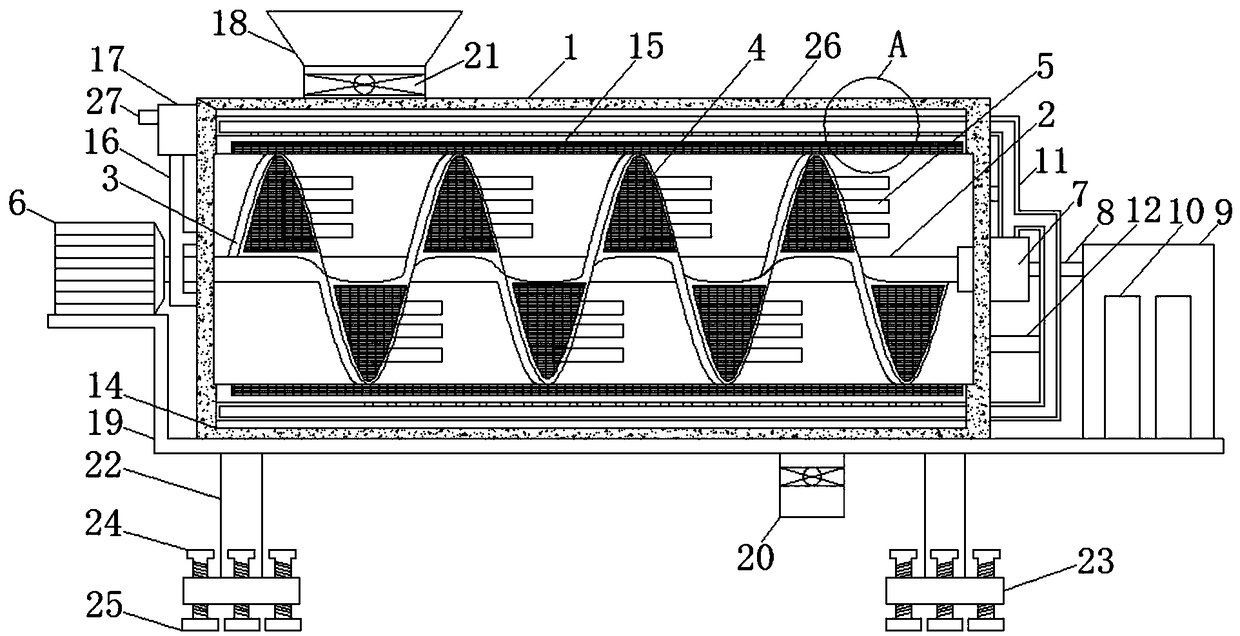

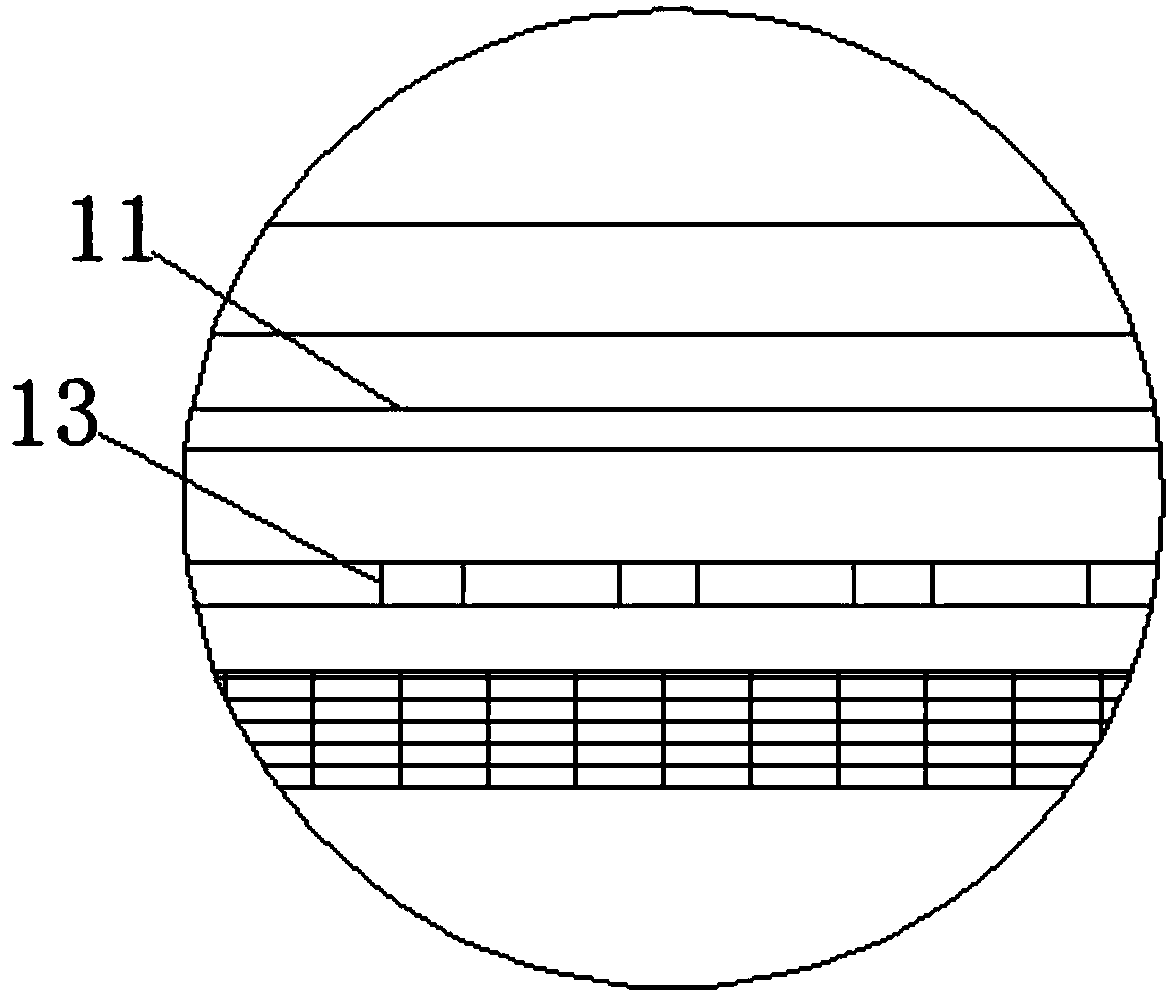

Air-blowing drier for production of attapulgite zearalenone adsorbing agent

InactiveCN108955170APull away quicklyEasy to pass throughDrying gas arrangementsDrying machines with non-progressive movementsSorbentSpiral blade

The invention discloses an air-blowing drier for production of an attapulgite zearalenone adsorbing agent. A spiral blade is fixedly connected to the outer side of a rotary roller, a first screen plate is connected with the middle of the spiral blade in a penetrating mode, a stirring plate is fixedly connected with the right side of the first screen plate, an air pump is fixedly connected with themiddle of the right side of a machine body, a first air inlet pipe communicates with the top of the air pump, the upper portion and the lower portion of the face, close to the right side of the machine body, of the first air inlet pipe communicate with second air inlet pipes, the opposite sides of two groove inner cavities are connected with a second screen plate in a penetrating mode, one end ofan air outlet pipe communicates with an exhaust fan, a feeding groove communicates with the left side of the top of the machine body, and a discharge groove is connected with the right side of the bottom of a supporting plate in a penetrating mode. By arranging the air pump, the first air inlet pipe, air inlet holes, the first screen plate, the exhaust fan, the spiral fan, the feeding groove, thedischarge groove, a valve, a bottom plate, a bolt and a gasket, the air-blowing drier for production of the attapulgite zearalenone adsorbing agent is high in practicability.

Owner:江苏伊居科技有限公司

Large mechanical mixing device for construction site

InactiveCN112546935APreliminary mixing wellAdjust the output speedTransportation and packagingRotary stirring mixersMechanical engineeringPhysics

Owner:湖州琦利智能装备科技有限公司

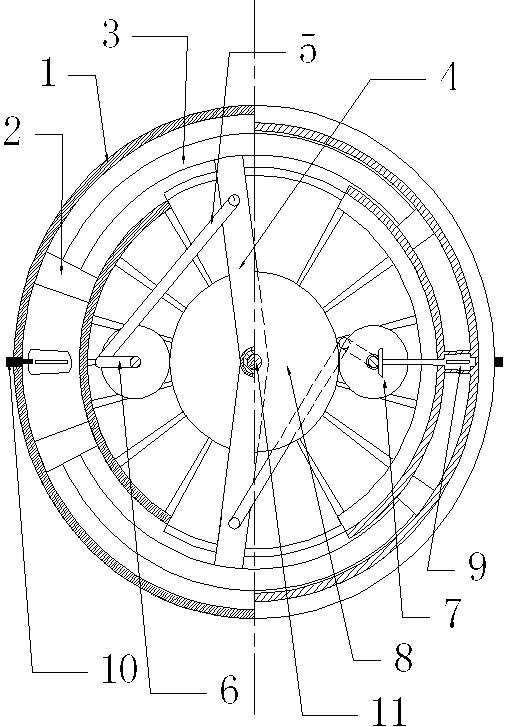

Arc cylinder pendulum type internal combustion engine

InactiveCN102840027ASolve the problem of eccentric cylinder idle forceIncrease inertiaInternal combustion piston enginesGearingEngineeringInternal combustion engine

The invention discloses an arc cylinder pendulum type internal combustion engine. The arc cylinder pendulum type internal combustion engine comprises an air cylinder (1) as well as pistons (2) and air valves (9) in the air cylinder (1), wherein the air cylinder (1) is annular; the pistons (2) are mounted at the two ends of each of arc-shaped connecting rods (3); the middle part of each of the arc-shaped connecting rods (3) is connected with a pendulum rod (4); the pendulum suspension point of the pendulum rod (4) is positioned in the center of the air cylinder (1); the pendulum rod (4) is connected with a crankshaft (6) through a connecting rod (5); working cavities are defined on the air cylinder (1) by the two adjacent pistons (2) respectively arranged on the different arc-shaped connecting rods (3); and the air valves (9) are arranged in the middle of the working cavities. A pendulum type structure is specially designed, so that the wall of the air cylinder is not additionally extruded by the pistons when power is transmitted to the crankshaft through the connecting rod due to the limitation of the pendulum rod, thereby solving the problem of an offset cylinder of the existing reciprocating internal combustion engine, noise and power consumption are reduced, power is increased, and the energy resources are saved.

Owner:GUIZHOU ACAD OF SCI

Mechanical device

InactiveCN111066434AEasy to controlImprove convenienceFertiliser distributersAgricultural engineeringStructural engineering

The invention discloses a mechanical device. The mechanical device comprises a fertilizer storing and applying structural member, wherein a fertilizer evening box is welded to the lower end of the fertilizer storing and applying structural member, a first cylinder is mounted on the external surface of the lower end of one side of the fertilizer storing and applying structural member, and a secondcylinder is mounted on the external surface of one side of the fertilizer evening box; an anti-winding structural member is rotatably connected to the external surface of the lower end of the fertilizer evening box, and fertilizer applying rods are mounted on the lower surface of the fertilizer evening box in a penetrating manner; a pull rod is mounted on the front surface of the anti-winding structural member, and an anti-winding connecting sliding rod is connected to the inner side of the lower end of the anti-winding structural member in a sliding manner; and cover boards are rotatably connected to the upper surface of the fertilizer storing and applying structural member. According to the mechanical device disclosed by the invention, two kinds of fertilizers can be placed at the same time, selective fertilizer application can be performed, and the discharging speed can be quickly and conveniently adjusted; and the anti-winding structural member is arranged, and electrical adjustment of the discharging speed is realized. The mechanical device disclosed by the invention is simple in structure and small in volume.

Owner:JIASHAN LUOJIA FURNITURE CO LTD

Centrifugal feeding machine

The invention discloses a centrifugal feeding machine. The problems that in the current screw feeding process, the noise is high, and the machining positions are inconvenient due to the vertical feeding mode are solved. The centrifugal feeding machine is characterized by comprising a machine frame; an inner turnplate is arranged on the machine frame; the inner turnplate is driven by a first driving device to rotate around the circle center; an outer turnplate which is driven by a second driving device to rotate around the circle center is arranged on the periphery of the inner turnplate; a discharging rail is arranged on the outer side of the outer turnplate; and a clamping piece is arranged between the tail end of a pending rail and a straight feeding channel and used for rotating vertically placed workpieces in the pending rail by 90 degrees and sequentially feeding the workpieces into the straight feeding channel. In this way, discharging of parts can be achieved through the centrifugal force, noise in the feeding process is reduced, in addition, finally, sequential transverse feeding can be achieved, and convenience is provided for subsequent machining.

Owner:NINGBO ZHUOCHENG AUTOMATION EQUIP

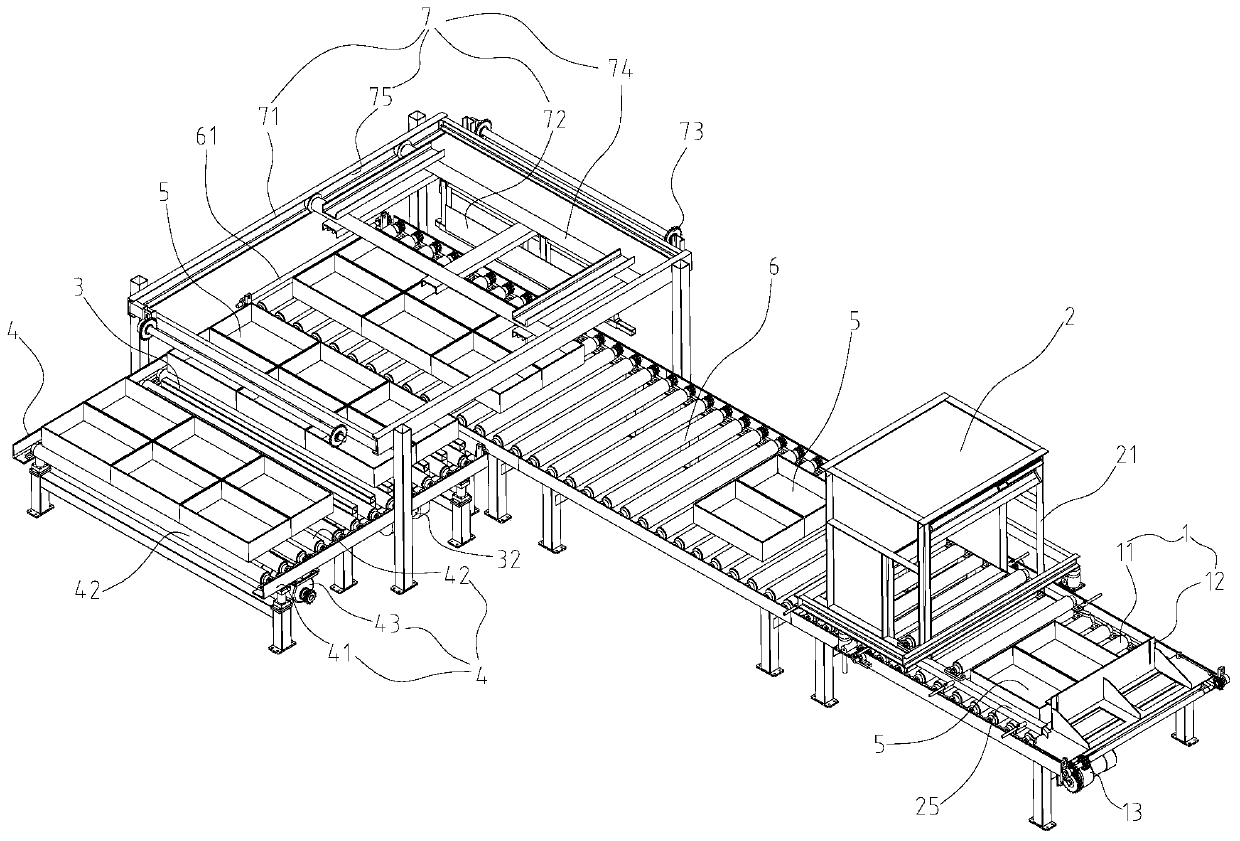

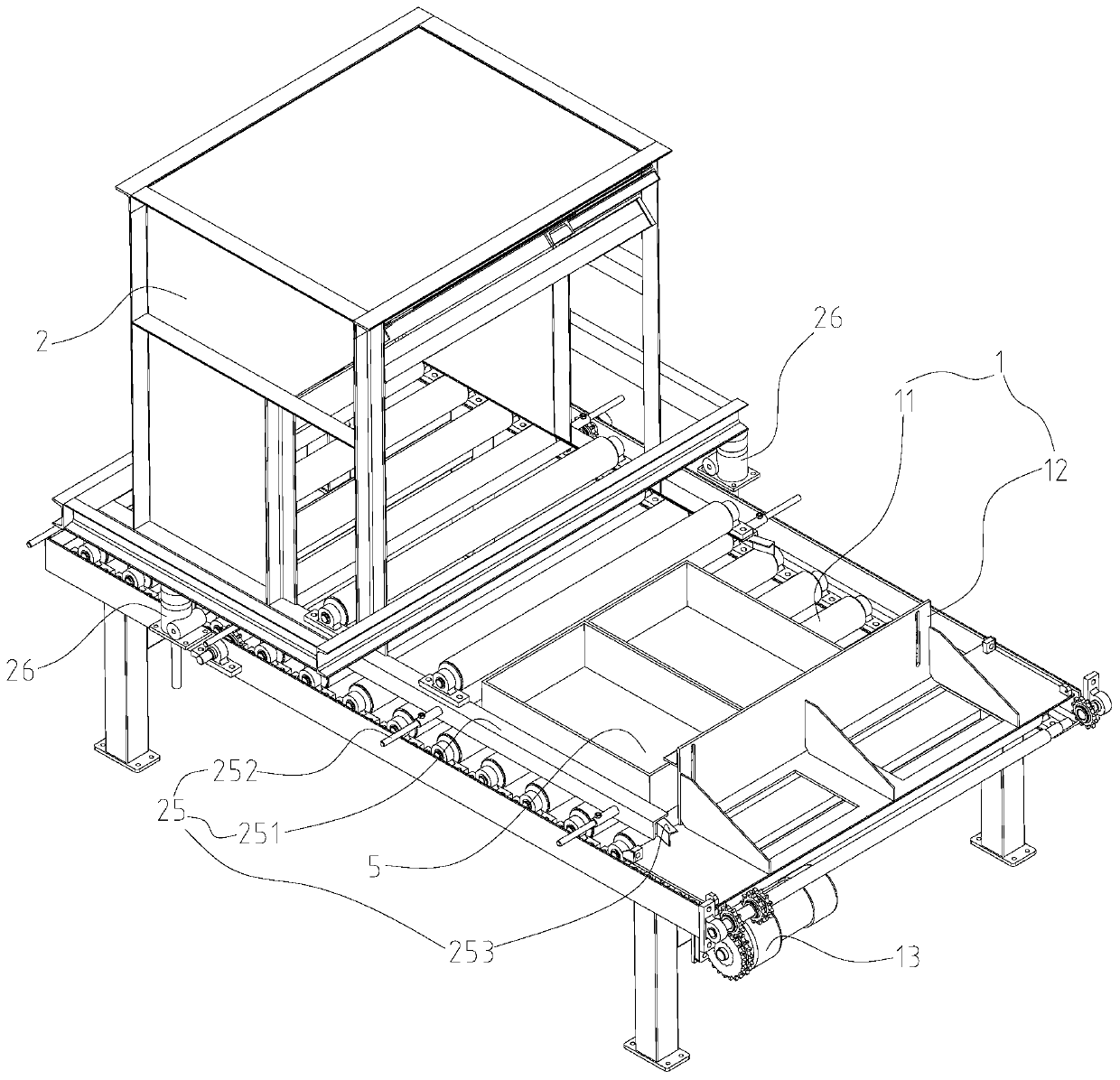

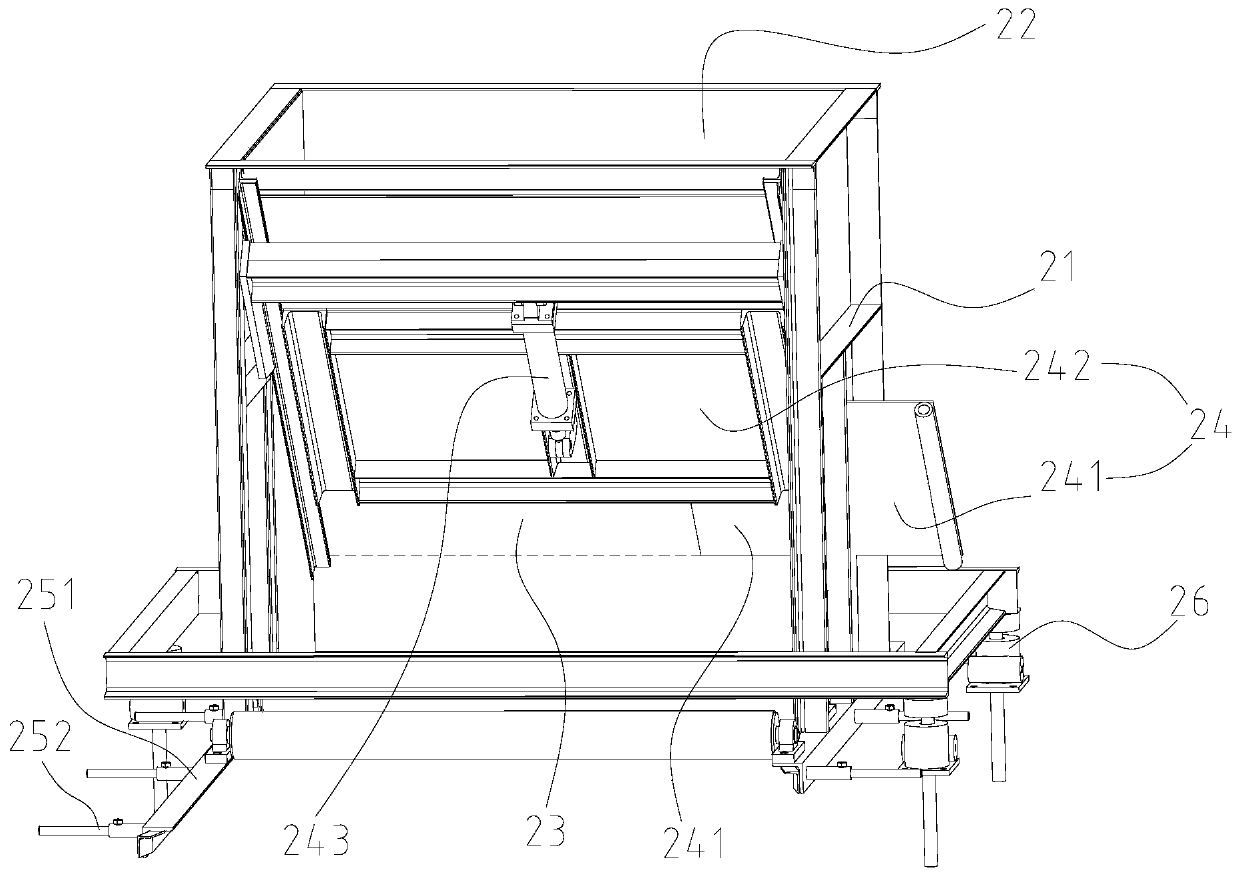

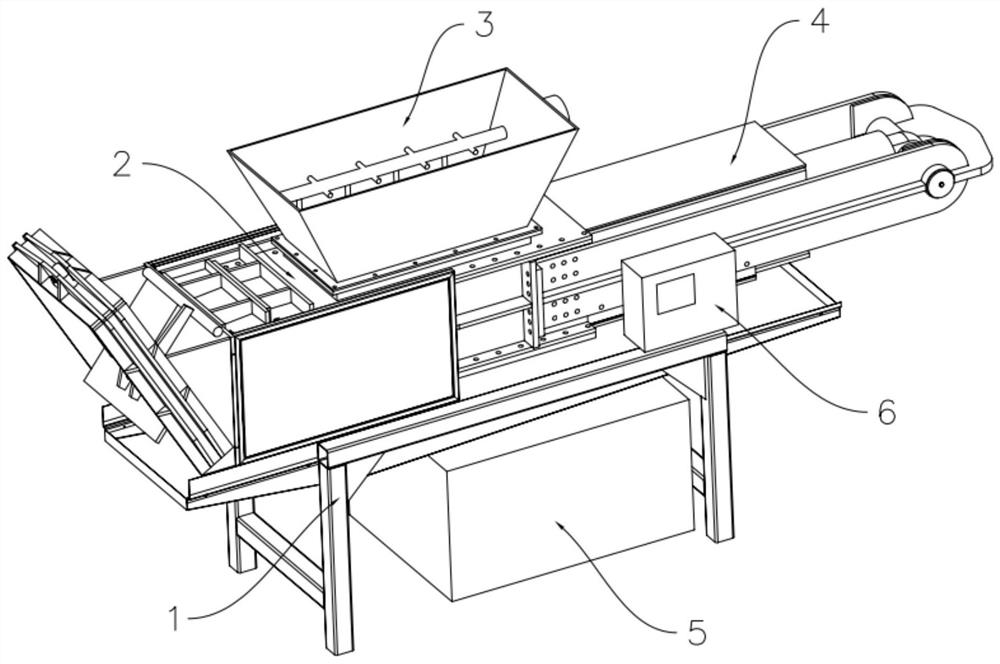

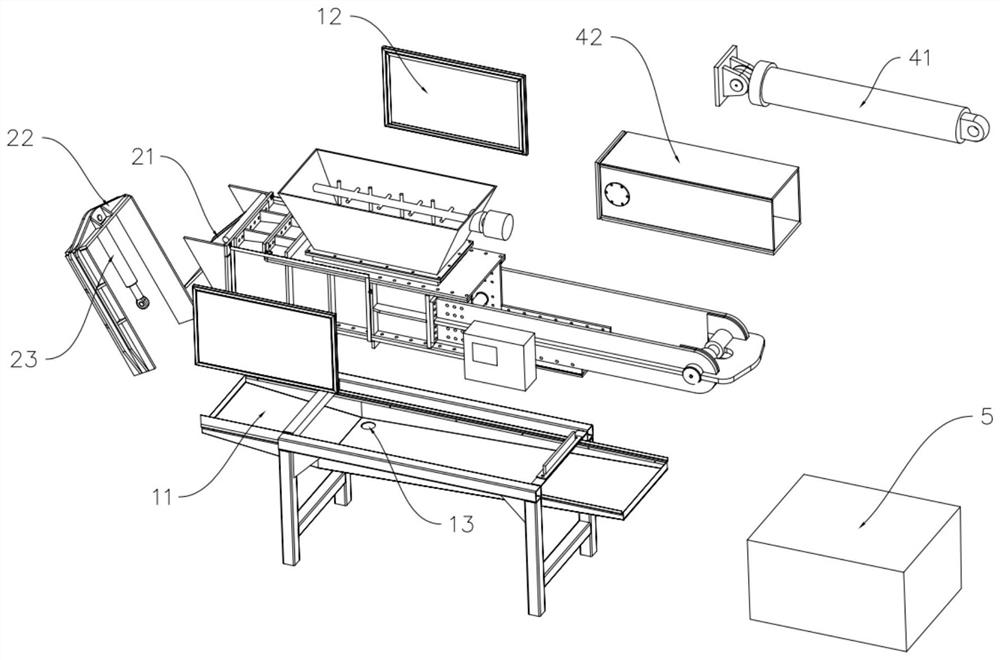

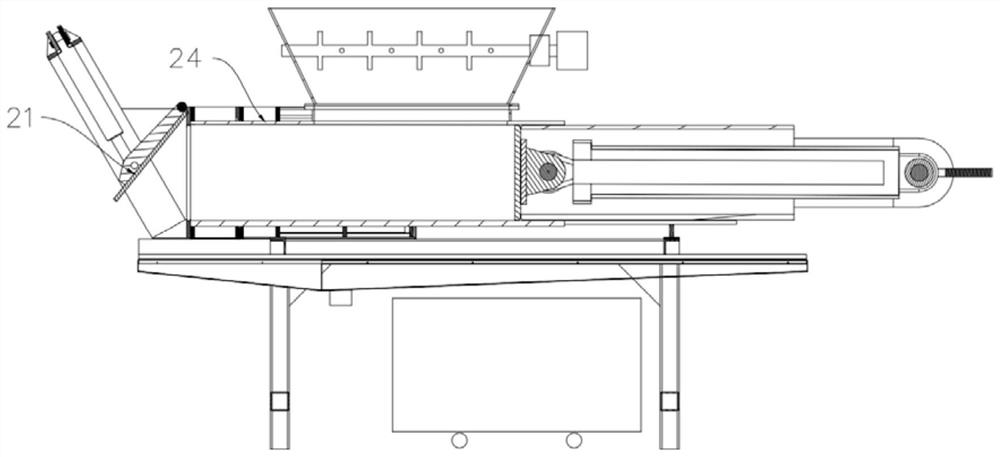

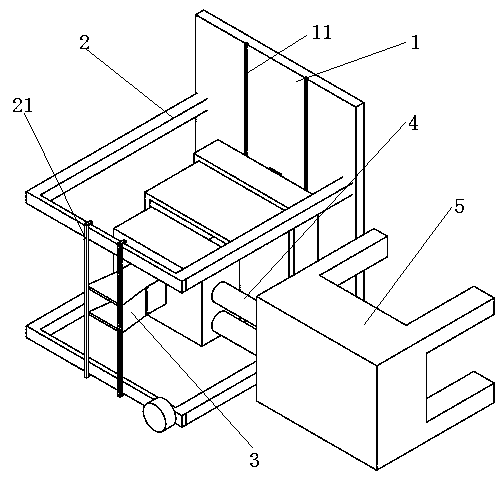

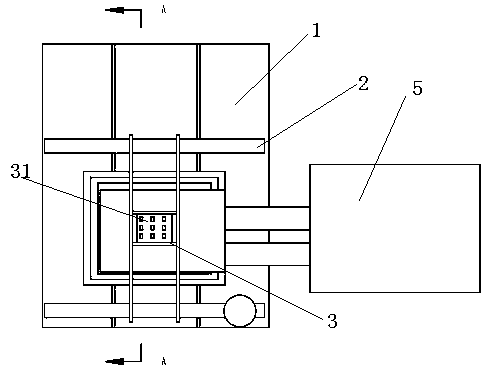

Precast concrete material distributing machine

PendingCN110466047AHigh degree of automationReduce the number of operatorsCeramic shaping plantsFeeding arrangmentsPrecast concreteAutomation

The invention provides a precast concrete material distributing machine and relates to the technical field of concrete pouring equipment. The precast concrete material distributing machine mainly solves the technical problems that in the prior art, the concrete manufacturing process has low automation degree and needs multiple people to work collaboratively. The precast concrete material distributing machine comprises a mold pushing device, a feeding device, vibration devices and a vehicle-loading device. The feeding device is located on the mold pushing device, and the mold pushing device canpush molds under the feeding device. The mold pushing device is connected to the vibration devices so that the molds can be transferred to the vibration devices after being filled. The vibration devices are connected to the vehicle-loading device, and the vehicle-loading device transfers and / or loads the molds on the vibration devices. By the adoption of the precast concrete material distributingmachine, the automation degree of the production process of precast concrete can be effectively increased, and the different product quality caused by the difference in the degree of operation and / orthe operation precision of operators is avoided; and on the other hand, the number of operators can be reduced from 6 to 7 people to 1 to 2 people, and thus the personnel cost is reduced.

Owner:久石(山东)智能设备有限公司

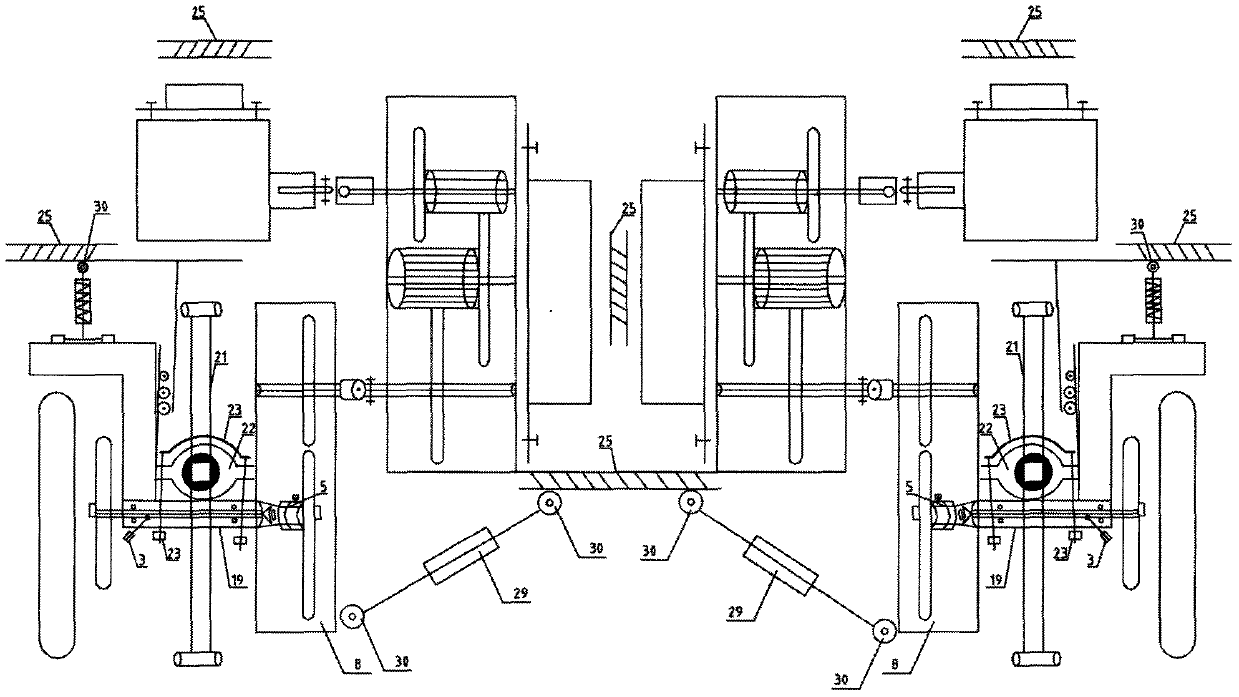

Wheel stabilization structure capable of generating power by utilizing integrated kinetic energy in vehicle running

PendingCN107933305APrevent reversalImprove stabilityAuxillary drivesInterconnection systemsElectric vehicleKinetic energy

The utility model relates to a structure for generating electricity and wheel stability by utilizing comprehensive kinetic energy during running of a vehicle. It relates to the technical field of energy saving and consumption reduction of electric or electric hybrid vehicles and the structure of a driving system. The invention discloses a structure utilizing comprehensive kinetic energy for power generation and wheel stabilization during vehicle running. The coupling is connected with the variable speed torque commutator and the generator, and the force arm type Z-shaped bracket is hinged to connect the spring steel plate assembly, the coil spring shock absorber and the double-acting cylinder type hydraulic wheelbase limit stabilizer bar to make the The left and right supports each constitute four hinged rotation points so that the center of gravity of the vehicle can be self-corrected. By using the comprehensive kinetic energy generated by the vehicle to generate electricity for the battery to continuously pressurize and increase the flow, it can provide sustainable power for increasing the cruising range of the electric vehicle. The above structure can solve the problem of making the electric vehicle When the car is running and generating electricity, the fusion of the vehicle's driving system and the power generation system.

Owner:杨晓东

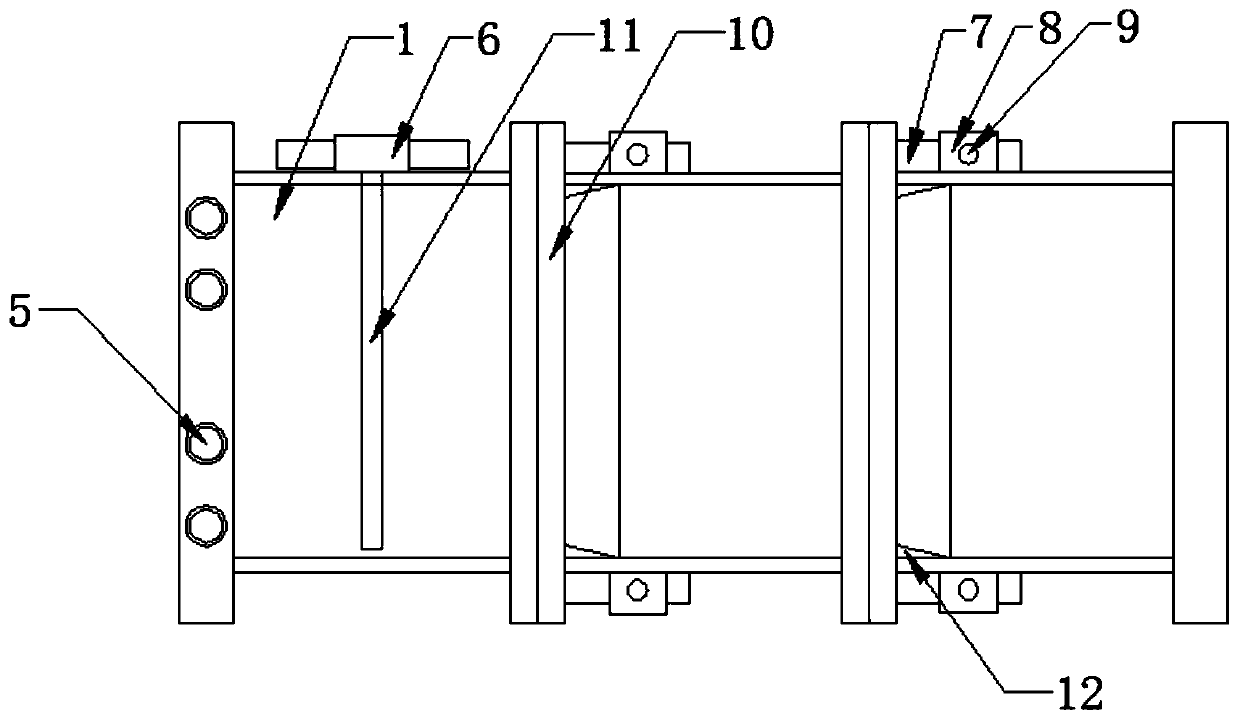

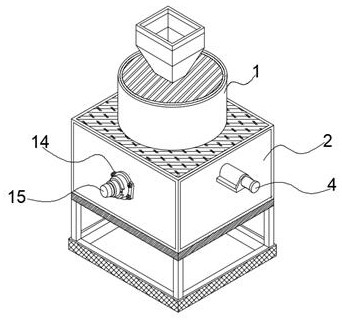

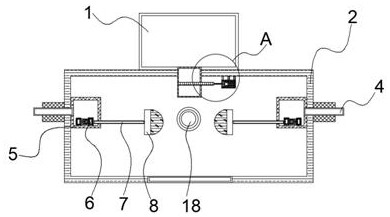

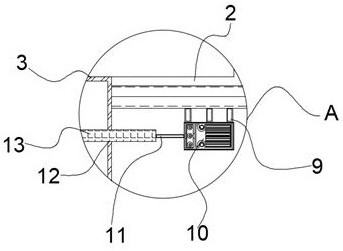

Automatic hydraulic garbage dehydrator

PendingCN112944817AReduce wasteFlexible useDrying solid materials without heatDrying chambers/containersHydraulic ramProcess engineering

The invention relates to the field of household garbage treatment devices, in particular to an automatic hydraulic garbage dehydrator which comprises a rack. A water tank is arranged on the rack, a drainage hole is formed in the water tank, a compression bin with two open ends and a hydraulic oil cylinder are arranged above the rack, and the hydraulic oil cylinder is communicated with the rear end of the compression bin. A movable baffle is arranged at the front end of the compression bin and rotatably connected to the upper portion of an opening in the front end of the compression bin, the water tank is arranged below the compression bin, the upper portion of the compression bin is communicated with a feeding bin, and the feeding bin is in a funnel shape. A hydraulic station is further arranged below the rack and used for providing working power for the hydraulic oil cylinder, and a PLC control cabinet is further arranged on the outer side of the rack and used for controlling the operation of all elements of the hydraulic garbage dehydrator. The reciprocating type automatic hydraulic garbage dehydrator capable of achieving efficient dehydration is provided so as to solve the problems that in the prior art, the solid matter dehydration capacity is low, and the dehydration efficiency is poor.

Owner:福建龙迪环保设备科技有限公司

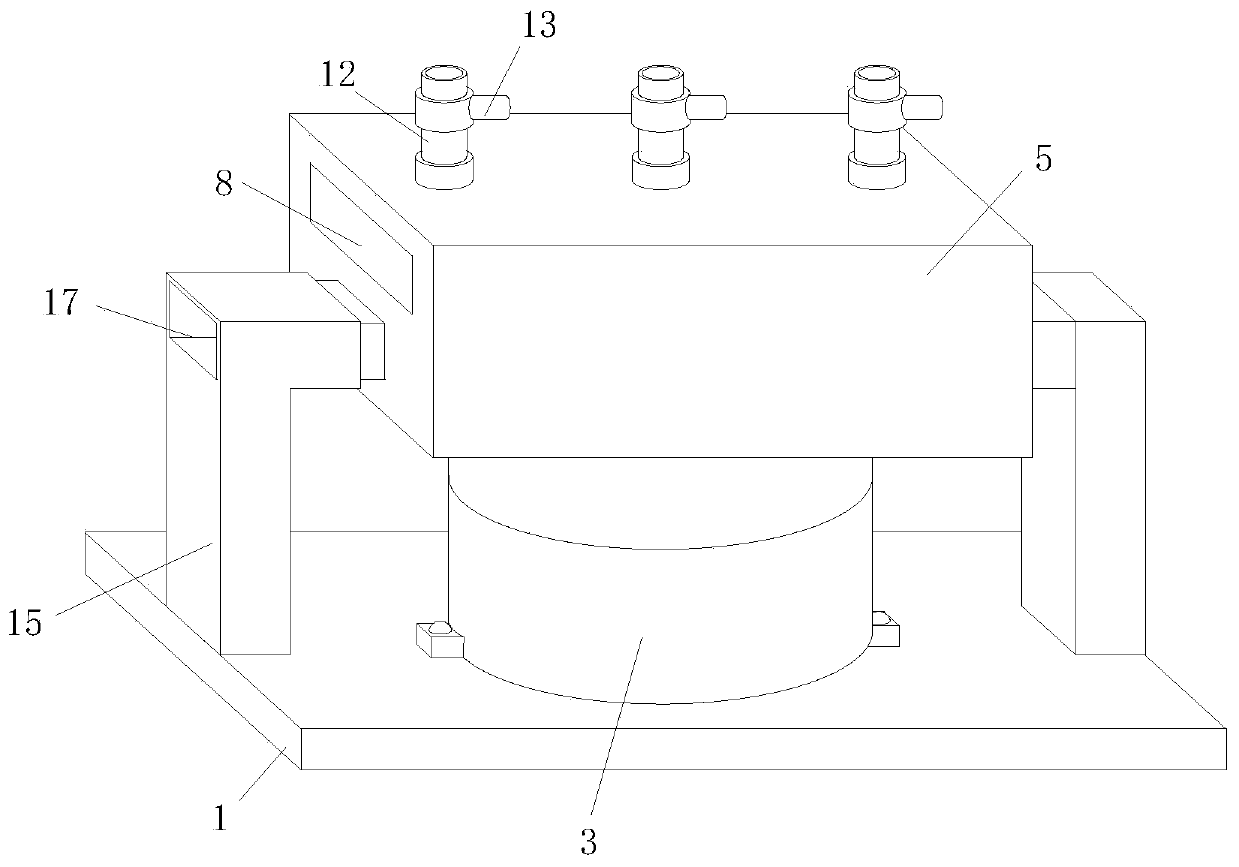

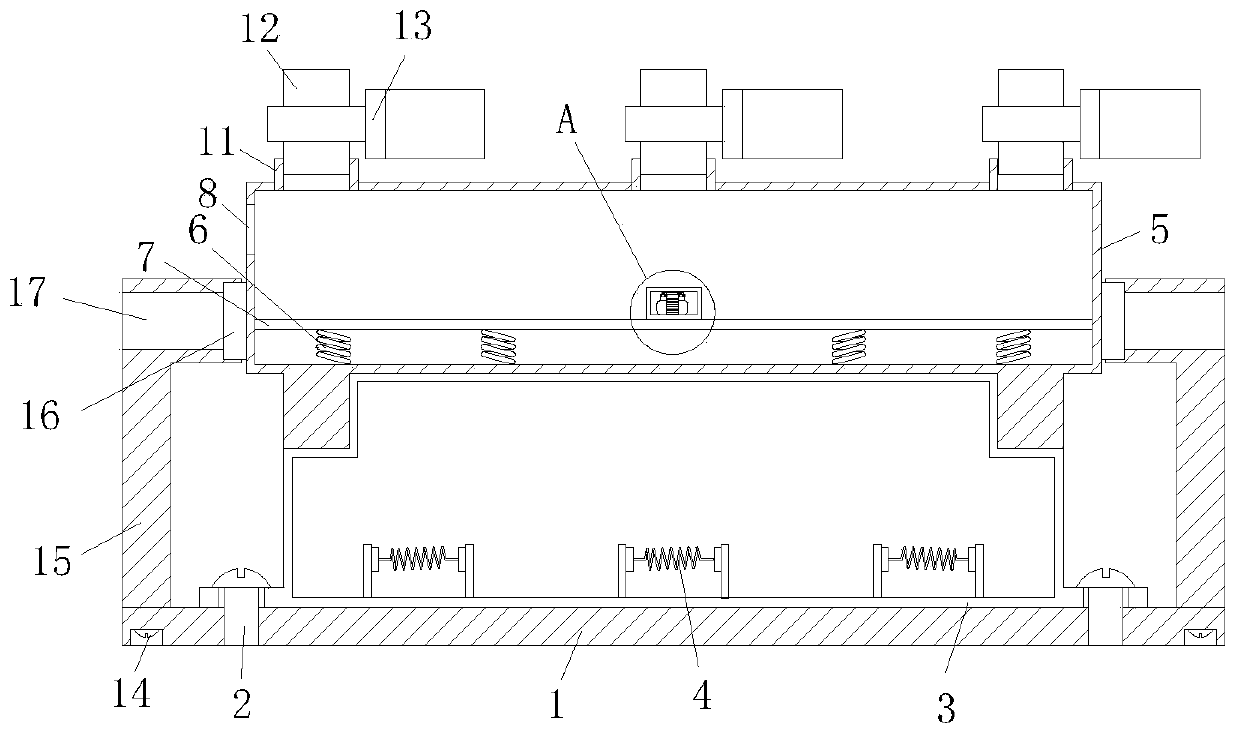

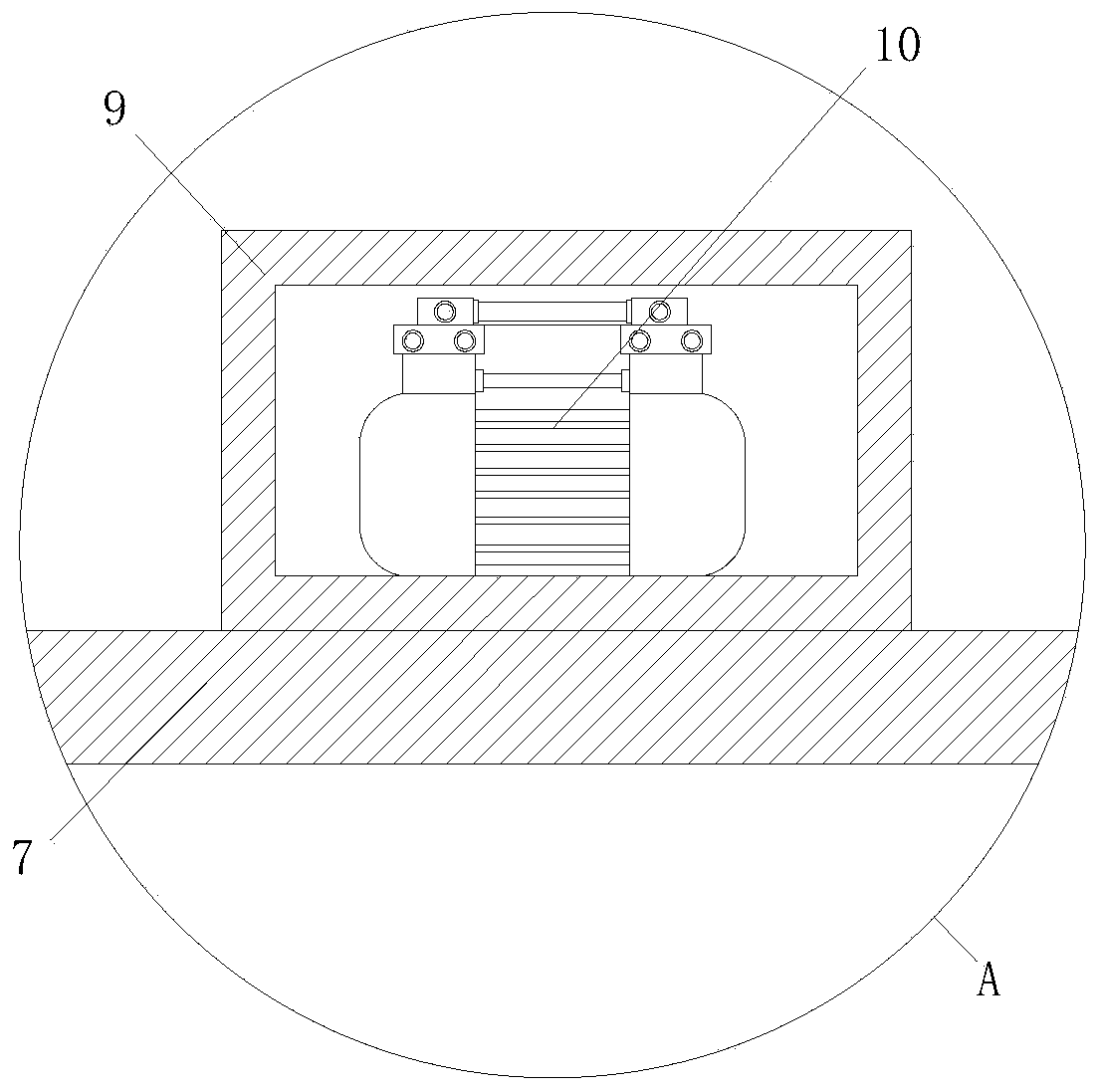

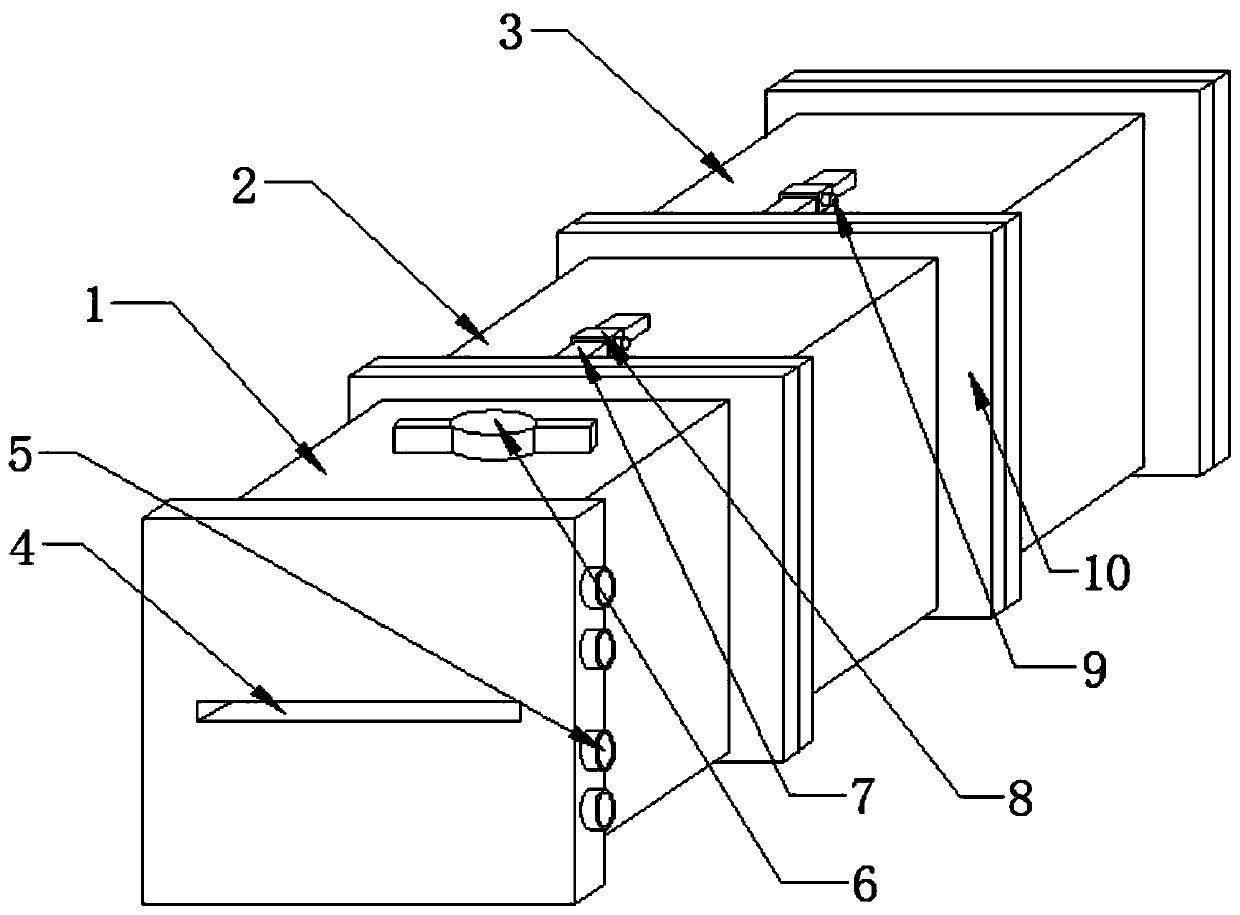

OLED evaporation source convenient to assemble

ActiveCN110670025APrevent affecting processing speedIncrease heating speedSolid-state devicesVacuum evaporation coatingElectric machineRefrigeration

The invention discloses an OLED evaporation source convenient to assemble. The OLED evaporation source comprises a bottom plate, a first screw, a heating box, a heating wire, an evaporation vessel, aspring, a vibration plate, a sealing door, a heat insulation case, a vibration motor, a threaded sleeve, a discharge pipe, an electric valve, a second screw, a support, a semiconductor refrigeration piece and a heat dissipation opening. According to the OLED evaporation source convenient to assemble, the vibration plate is arranged on the inner wall of the bottom of the evaporation vessel, the vibration plate vibrates under the driving of the vibration motor, the heating speed and the cooling speed can be effectively increased, and the coating efficiency is increased; the electric valve is installed on the surface of the plurality of discharging pipes in a communicating mode so that the steam discharging speed can be effectively adjusted, the control is more humanized in control, and the convenience in the processing process is also increased to a certain extent; and when refrigeration is needed, the heating wire is turned off and the semiconductor refrigerating sheet is opened, the refrigeration can be effectively carried out so that heating evaporation can be rapidly stopped, and the device is simple in structure, convenient to use and suitable for popularization and application.

Owner:江苏实为半导体科技有限公司

Agricultural mechanical fertilization device and method

PendingCN114679942AReduce air pressureIncrease air pressureFertiliser distributersAgricultural scienceAgricultural engineering

The invention discloses an agricultural mechanized fertilization device and method, and relates to the field of fertilization devices. The device comprises a material storage box, a drying assembly arranged in the material storage box and a pressure reduction assembly arranged on the material storage box; the drying assembly is used for drying fertilizer in the storage box, the pressure reducing assembly comprises a transfer pipe, a pressure reducing pipe, a pressure reducing valve and a soft air pipe, a plurality of discharging pipes are arranged in the storage box and are in a linear array, an inner cavity is divided into a small cavity and a large cavity, the small cavity is located above the large cavity, two air bags are arranged on the inner wall of the large cavity, and the air bags are arranged in the middle of the storage box. And the discharging speed and the discharging amount are adjusted.

Owner:HENAN UNIVERSITY

buffer feed bin

ActiveCN103612924BAdjust the output speedPrevents reduction in feeding functionLarge containersLoading/unloadingEngineeringWaste management

A caching feeding bin comprises a storage bin body, a discharge tube body, a discharge hopper, discharge spiral units and a discharge spiral unit drive mechanism. The discharge tube body is arranged on the side wall of the storage bin body. The discharge hopper is sequentially connected and communicated with the discharge tube body and the storage bin body. The discharge spiral units are arranged in the storage bin body, the discharge tube body and the discharge hopper and used for pushing materials in the storage bin body into the discharge hopper. The output end of the discharge spiral unit drive mechanism is connected with the discharge spiral units and drives the discharge spiral units to rotate. Due to the fact that the discharge speed of the materials is related to the rotating speed of the discharge spiral units, the constant discharge speed can be adjusted by controlling the rotating speed of the discharge spiral units.

Owner:光大清洁技术股份有限公司

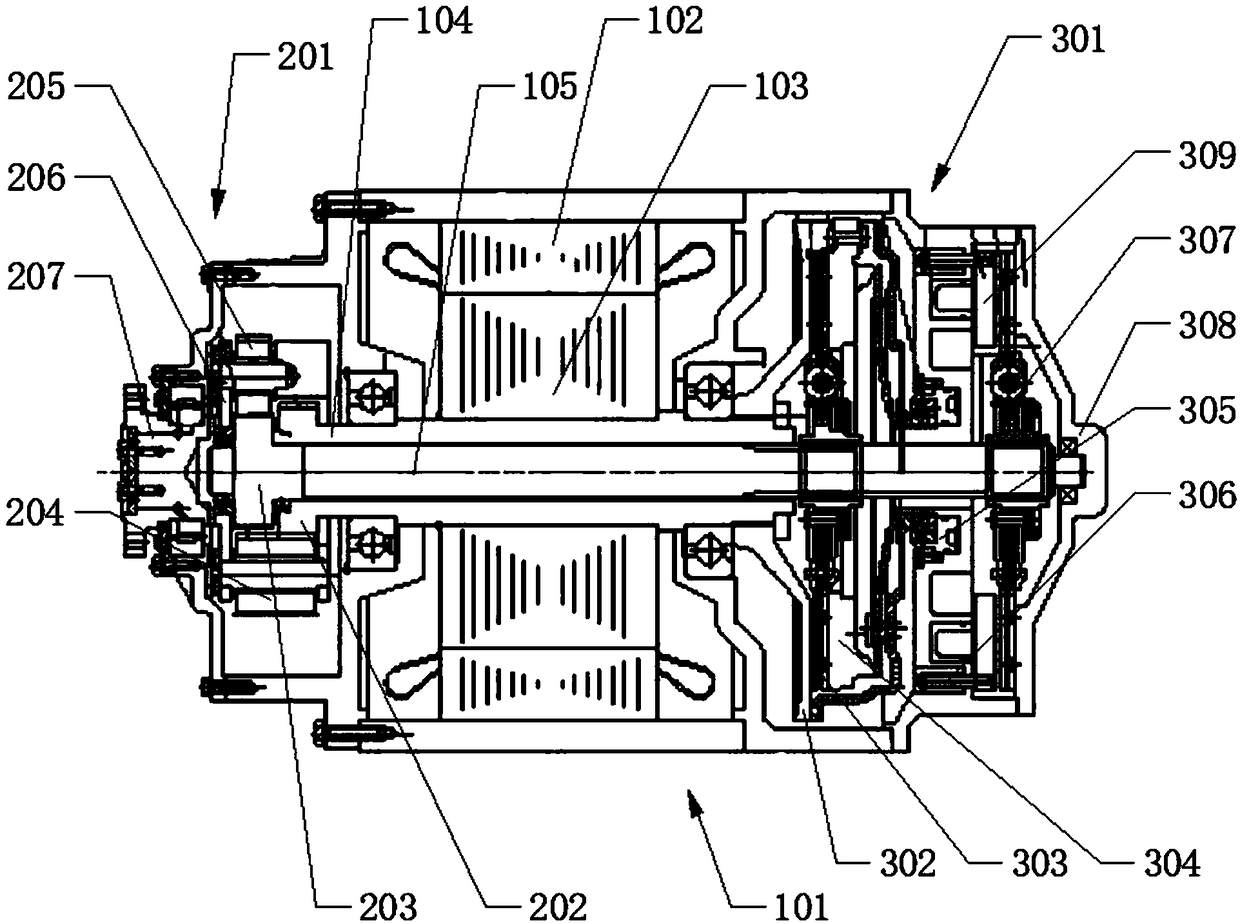

Integrated power device of electric car

PendingCN108556607AAdjust the output speedElectric propulsion mountingControl devicesElectric machineEngineering

The invention discloses an integrated power device of an electric car. The integrated power device comprises a driving motor, a planetary transmission assembly and a shifting assembly. The driving motor comprises a stator, a rotor, an outer rotor shaft and an inner rotor shaft. The planetary transmission assembly is arranged at one end of the driving motor, and comprises an outer sun gear, an inner sun gear, a long planet gear, a short planet gear, a planet carrier and an output flange. The shifting assembly is arranged at the other end of the driving motor, and comprises a fly wheel, a clutchdriven sheet, a press plate, a separation bearing, a braking piston, a braking friction plate and an end cover towards the other end along the driving motor. A planetary transmission and the shiftingassembly are arranged at two sides of the driving motor respectively, and accordingly, transmission oil is prevented from flowing to a brake shoe and a clutch plate of the shifting assembly during seepage; the separation bearing and the braking piston are driven to be attached to the braking friction plate or the clutch driven sheet, so that start and stop as well as the rotation mode of the planetary transmission assembly are controlled, and output speed of the motor is adjusted.

Owner:FUJIAN WANRUN NEW ENERGY TECH

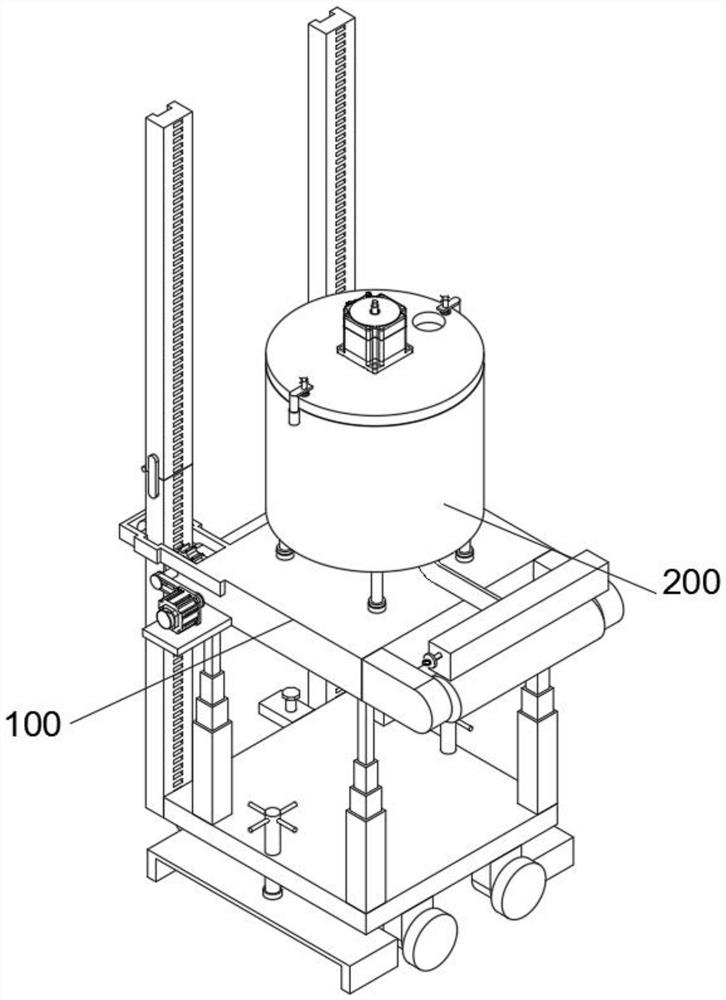

Gluing device for building decoration engineering construction

ActiveCN112663907ASolve the problem of easy falling from the stoolImprove gluing efficiencyBuilding constructionsArchitectural engineeringStructural engineering

The invention provides a gluing device for building decoration engineering construction. The gluing device comprises a lifting device and a glue brushing device installed above the lifting device, the lifting device at least comprises an installation mechanism, the installation mechanism comprises an installation plate, a second bearing plate is integrally formed on one side of a first bearing plate, and a rotating hole is formed in the other side of the first bearing plate. Through the arranged lifting device, the glue brushing mechanism can be driven to slide up and down back and forth on the wall surface, so that the high wall surface can be glued, and the problems that an existing gluing device is composed of simple rotating rollers, a worker generally steps on a stool when gluing the high wall surface, the worker needs to slide the gluing device with the arm during gluing, and consequently, the worker is prone to falling off from the stool are solved.

Owner:广东满大装饰工程有限公司

Plastic injection mold

The invention relates to a plastic injection mold. The plastic injection mold comprises a bottom plate, a support, an injection molding mechanism and a material collecting bin, wherein the support isarranged on the bottom plate, a idler wheel is arranged at the bottom of the injection molding mechanism, two parallel guide rails are arranged at the top of the support, a guide groove is formed in the position, corresponding to the idler wheel, of the bottom plate, the material collecting bin is arranged on the left side of the injection molding mechanism, the material collecting bin is used forcollecting plastic parts after injection molding, a feeding hopper is arranged at the top of the injection molding mechanism, and the upper part of the feeding hopper is slidably mounted on the guiderails; and the feeding hopper is of a V-shaped structure with a wide upper part and a narrow lower part, a feeding hopper discharging plate in the middle of the feeding hopper is provided with discharging holes which are larger than the size of plastic particles, a filter plate is slidably arranged at the bottom of the feeding hopper discharging plate, and the filter plate is provided with filterholes which are not smaller than the size of the discharging holes at the positions, corresponding to the discharging holes. According to the plastic injection mold, the filter plate is slid in a left-right mode, so that overlapping areas of the discharging holes and the filter holes are changed, discharging speed of a discharging hopper is adjusted, and accurate injection molding processing is achieved.

Owner:CIXI JINGCHENG MOLD

Aquaculture box

InactiveCN112106717AAdjust the output speedTo achieve the effect of leaching out the feedClimate change adaptationPisciculture and aquariaElectric machineryEnvironmental geology

The invention relates to an aquaculture box. A pulley groove is formed in the top end of the aquaculture box, a cavity structure is adopted in the pulley groove, a pulley is movably placed in the pulley groove, a leaking opening is formed in the bottom end of the interior of a discharging box, a discharging opening is formed in the lower end of the leaking opening, and limiting plate groove openings are formed in the two sides of the leaking opening; a limiting plate is inserted into each limiting plate groove opening, a spring is connected to one end of each limiting plate, a pull ring is welded to the other end of each limiting plate, the pull rings are connected with a winding disc through pull wires, a handle is installed at one side of the winding disc, a filtering groove is formed inthe bottom end of the interior of the aquaculture box, and a baffle is installed on the outer surface of the filtering groove; and a filtering box is placed in the filtering groove, one side of the filtering groove is connected with the input end of a water pump through a water conveying pipe, and a water conveying pipe is installed at the output end of the water pump to the aquaculture box. According to the aquaculture box, the movable discharging box is adopted to quantitatively move and scatter, a motor pumps internal water for circulation, filtering is performed, and circulation pollutionis prevented.

Owner:江苏锡沂工业园投资开发有限公司

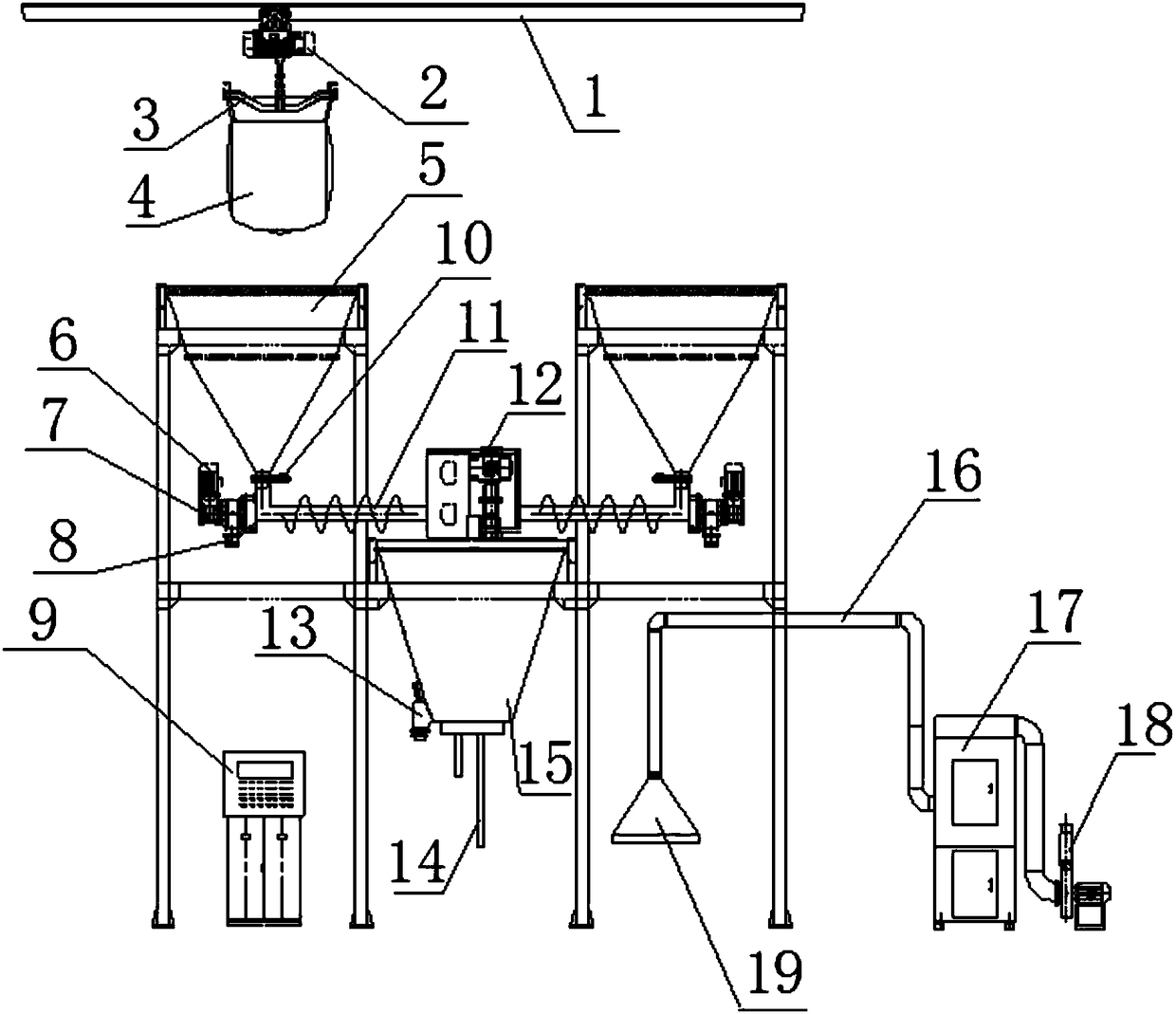

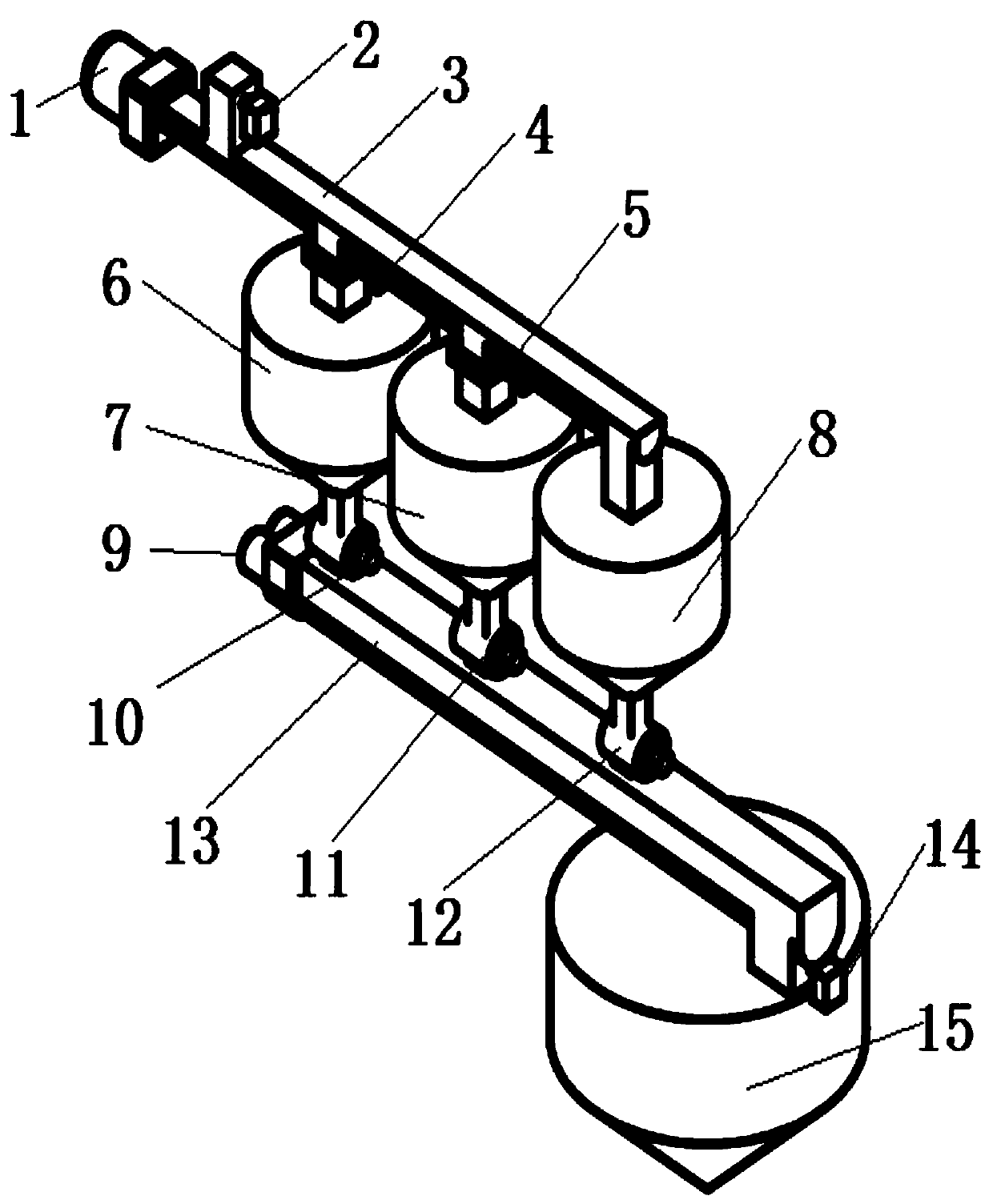

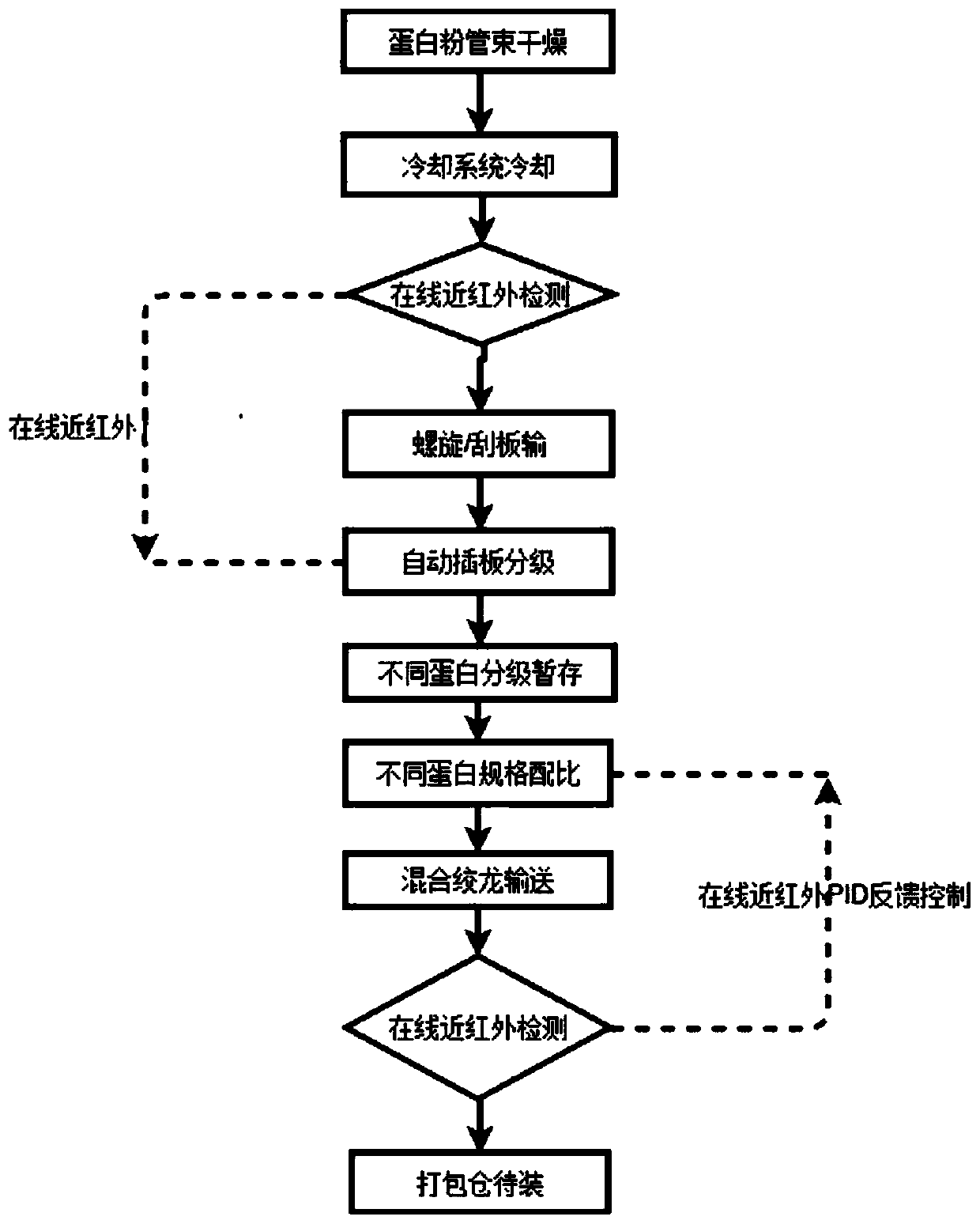

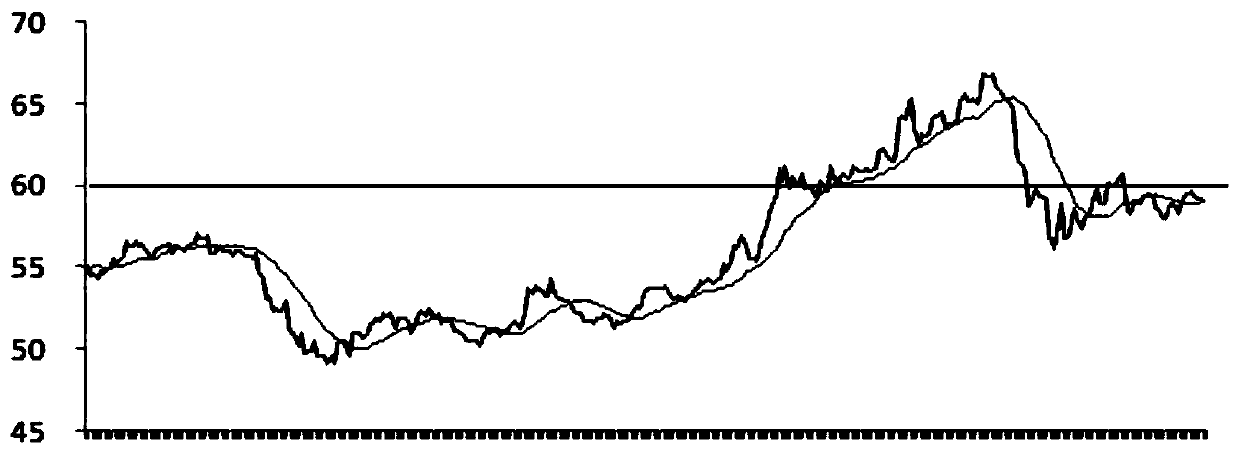

System and equipment for automatically grading and blending protein powder protein content

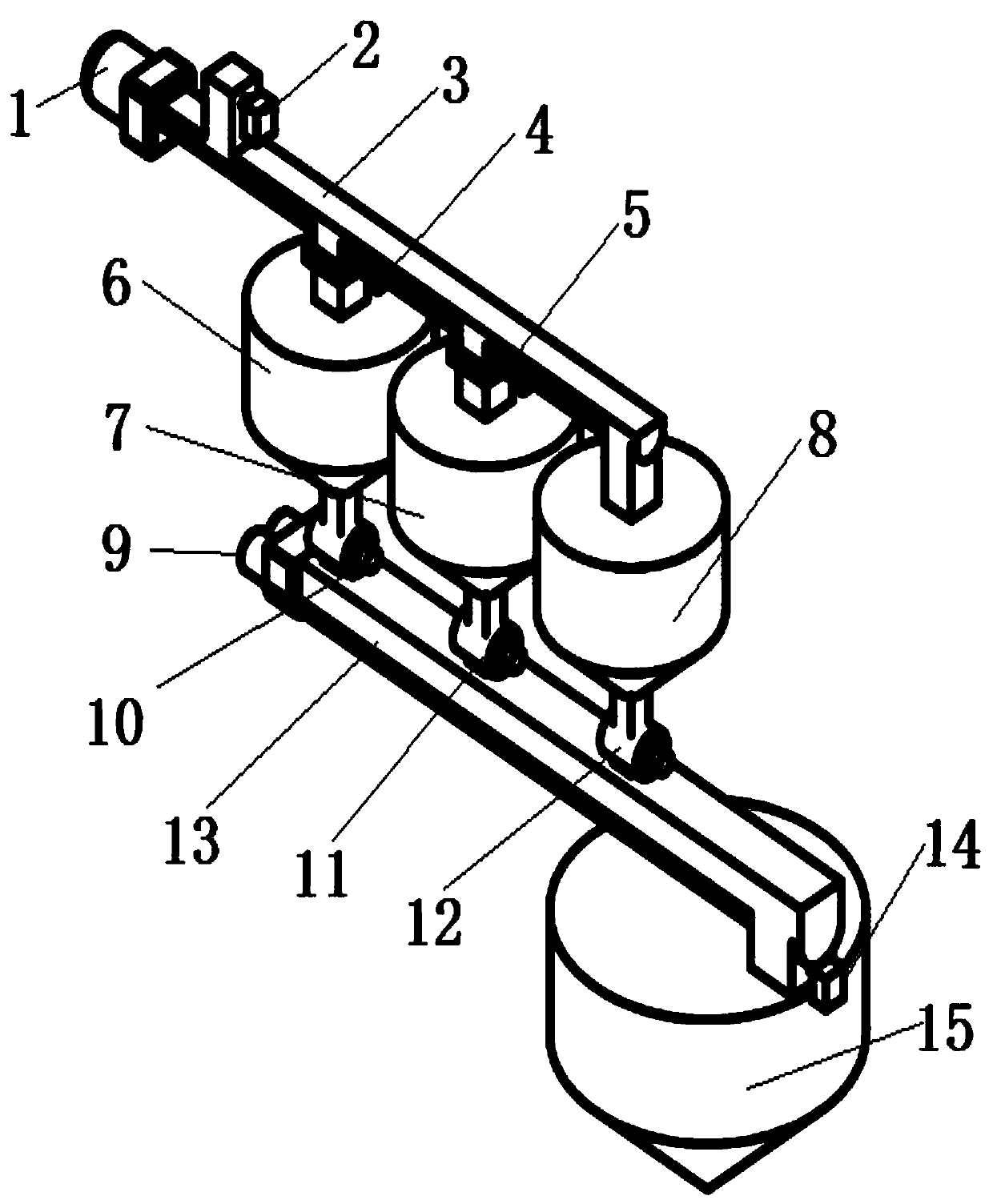

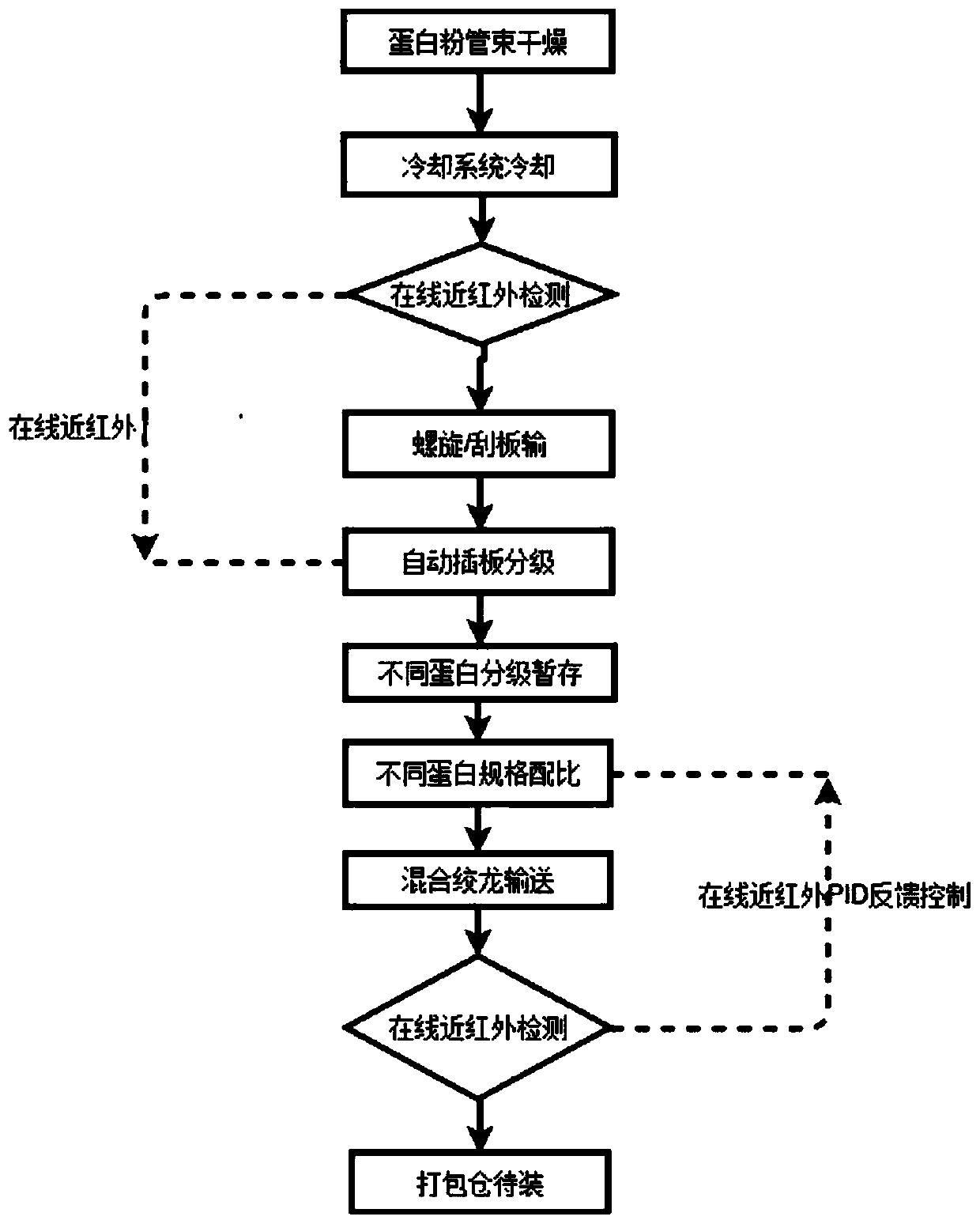

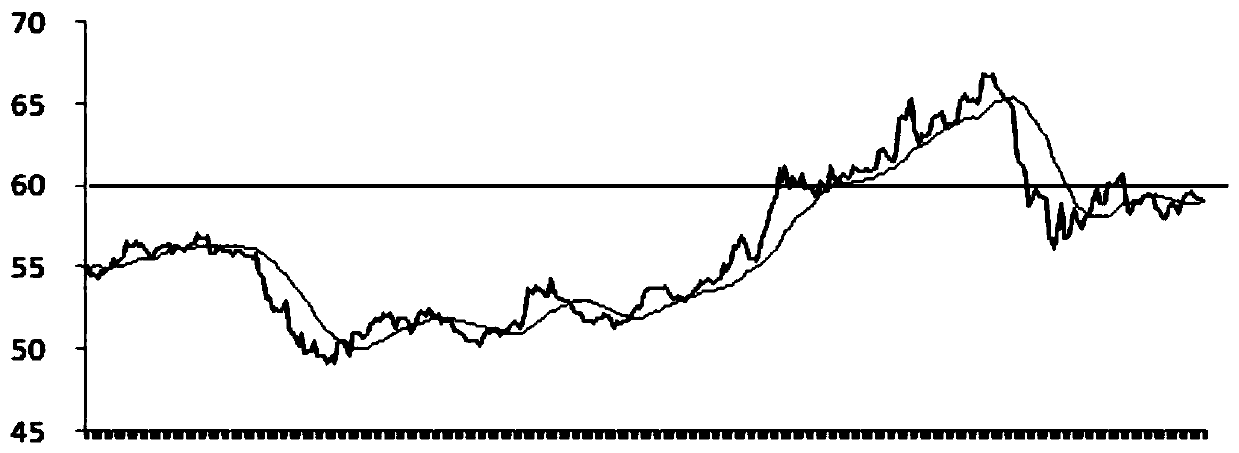

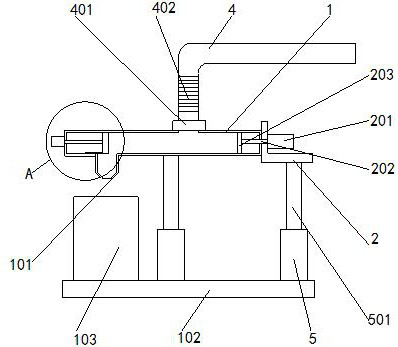

ActiveCN110302714AEfficient and accurate custom gradingComplete efficiently and accuratelyTransportation and packagingMixing methodsFeedback controlBiology

The invention belongs to the technical field of protein powder production, and provides a system and equipment for automatically grading and blending protein powder protein content. The system and equipment comprise: a grading detecting apparatus, a material conveying apparatus, a material buffering storage apparatus, an automatic proportioning apparatus, a material mixing apparatus, a ratio detecting apparatus and a control apparatus. Protein powder is detected by the grading detecting apparatus and transported to the material buffering storage apparatus by the material conveying apparatus, and then the blending of a protein powder with a set concentration is completed by the automatic proportioning apparatus and the material mixing apparatus. At least two of a protein can I, a protein can II and a protein can III are simultaneously opened to transport protein powder to the material mixing apparatus, and the control apparatus respectively adjusts a material discharge speed of a protein powder flow in each of the three protein cans into the material mixing apparatus by feedback control. The system and equipment have the advantages that production efficiency of the equipment is high, quickly grading and blending of the protein powder can be realized according to the protein content, and the protein content of a product is stable, and small in fluctuation.

Owner:北京中仪智控科技有限公司

Grouting device for cement pipe production

InactiveCN111975968AImprove grouting efficiencyAdjust outputFeeding arrangmentsAuxillary shaping apparatusClassical mechanicsMechanical engineering

The invention belongs to the technical field of cement pipes, in particular to a grouting device for cement pipe production. The grouting device comprises a grouting cylinder, wherein a bottom plate is arranged below the grouting cylinder, a cement pipe mold is installed on the upper end surface of the bottom plate, a discharging cylinder communicates with the left side of the lower end surface ofthe grouting cylinder, an adjusting cylinder communicates with the left side of the grouting cylinder, a second air cylinder is installed on the left side of the adjusting cylinder, a second connecting rod is detachably connected to the output end of the second air cylinder, the right end of the second connecting rod penetrates through the adjusting cylinder and extends into the adjusting cylinder, an adjusting block is installed on the right side of the second connecting rod, a first air cylinder is installed on the right side of an L-connecting frame, a pushing block is installed on the left side of a first connecting rod, and a pipeline communicates with the upper end of the connecting pipe. Thus, when the cement pipe mold is grouted, the discharge volume and discharge speed of the discharging cylinder are conveniently adjusted according to the diameter of the to-be-grouted cement pipe mold, and the grouting efficiency of the cement pipe molds with different diameters is improved.

Owner:新邵县永沣水泥制品有限公司

A food mixing and filtering device

The invention discloses a device for food stirring, filtering and feeding, the device for food stirring, filtering and feeding includes a stirring barrel body, the top of the stirring barrel body is fixed with a stirring cover, a material receiving barrel body is located below the stirring barrel body, the inner side wall of the upper part of the material receiving barrel body is provided with a supporting edge, the bottom surface of the stirring barrel body is pressed on the top surface of the supporting edge, both sides of a bottom plate of the stirring barrel body are provided with material dropping through holes, the outer side walls of a left side plate and a right side plate of the material receiving barrel body are fixedly provided with adjusting air cylinders, push rods of the adjusting air cylinders pass through the side plates of the material receiving barrel body and are fixedly provided with adjusting plates, the adjusting plates are pressed on the bottom surface of the stirring barrel body, and cover corresponding material dropping through holes, the push rods of the adjusting air cylinders are located below the supporting edge, and a filter board is arranged in the middle of the material receiving barrel body. A material can directly enter the material receiving barrel body after being stirred, then filtered by a filter net in the material receiving barrel body, and discharged by a discharge tube without repeated dumping, the production efficiency is greatly improved, at the same time, discharging speed can be adjusted, and material feeding requirements in subsequent processing can be met.

Owner:磐升瑞祥(山东)生物工程股份有限公司

Fracturing fluid proppant volume density tester

InactiveCN110542624AAdjust the output speedEasy to useSpecific gravity measurementTester deviceFracturing fluid

The invention discloses a fracturing fluid proppant volume density tester. The tester comprises support pins, a baseplate, a sweeping plate, a sleeve, a first joint pin, a groove, a top plate, a hopper, a first discharge pipe, a rotating disc, a connecting bended lever, a second discharge pipe, a second joint pin, a neck, a testing bucket and discharge holes; the discharge holes in the first discharge pipe, the rotating disc and the second discharge pipe can be mutually aligned when the rotation of the rotating disc is realized through the mutual cooperation of the first discharge pipe, the rotating disc and the second discharge pipe, thereby realizing the internal communication of the hopper and the second discharge pipe, and the discharge speed of the hopper can be regulated by regulating the rotating disc; when the testing bucket is clamped into the neck, the testing bucket can be located just below the second discharge pipe; after the internal of the testing bucket is covered withthe proppant, the sweeping plate is rotated again; since the bottom end of the sweeping plate is aligned with an upper surface of the testing bucket, the sweeping plate can flatly sweep the proppant in the testing bucket and the tester is comparatively simple in the use.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of automatic production equipment of high-performance instant glue powder

ActiveCN106040152BGuaranteed accuracyWith weighing functionTransportation and packagingMixer accessoriesEnvironmental qualityEngineering

The invention relates to an automatic production equipment for high-performance instant rubber powder, comprising two material bins and a reactor, the two material bins are respectively used to hold the main material and auxiliary materials, and the two material bins are respectively connected to the reactor through the feeding pipe. The reactor is connected with a stirrer, and the stirrer is used to mix and stir the main material and the auxiliary material and react to prepare the instant rubber powder. A discharge port for discharging the instant rubber powder is provided under the reactor. Compared with the prior art, the present invention has the functions of automatic loading, feeding, and separate weighing of main materials and auxiliary materials, which ensures the accuracy of the specific gravity of main materials and auxiliary materials. At the same time, the setting of reactor stirring and discharging structure can ensure the High-quality and high-performance instant gel powder, and a dust-absorbing structure can reduce the content of fine dust in the air and improve the environmental quality.

Owner:明辉大秦(上海)环保科技股份有限公司

Multi-section split type easy-to-split extrusion die for aluminum profiles

ActiveCN108856329BImprove sealingPrevent outflowExtrusion diesExtrusion control devicesEngineeringPipe

Owner:ANHUI JINYING ALUMINUM

Packaging material crushing and discharging device capable of controlling speed

The invention relates to the technical field of smashing and discharging devices, and discloses a speed-controllable packaging material smashing and discharging device which comprises a smashing device body, a dust removal box is fixedly connected to the bottom of the smashing device body, and a water pump is fixedly connected to the inner wall of a water tank. And one end of the spraying pipe is fixedly connected with a spraying head, the bottom of the support is fixedly connected with an air cylinder, and the inner wall of the sliding opening is slidably connected with a limiting plate. Compared with the prior art, the paper scrap crushing device has the following advantages and effects that a telescopic rod drives a limiting plate to slide in a sliding opening, so that the internal space of a discharging pipe can be controlled, the discharging speed of the crushing device body is adjusted, crushed paper scraps are wetted by water sprayed by a spray head in the falling process of falling into a dust removal box, the weight of the paper scraps is increased, and the dust removal effect is improved. The paper scraps are prevented from flying around when being discharged through the discharging opening in the bottom of the dust removal box, the dust removal effect is achieved, and the wetted paper scraps are convenient to collect.

Owner:徐州瑞杰机械科技有限公司

A system for automatically grading and adjusting the protein content of protein powder

ActiveCN110302714BEfficient and accurate custom gradingAdjust the output speedTransportation and packagingMixing methodsPROTEIN S HEERLENEngineering

The invention belongs to the technical field of protein powder production and provides a system for automatically grading and adjusting protein powder content. The system includes: a classification detection device, a material transmission device, a material buffer device, an automatic proportioning device, a material mixing device, a proportioning detection device and a control device. The protein powder is detected by the classification detection device and transported by the material transmission device After reaching the material buffer device, the automatic proportioning device and the material mixing device complete the preparation of protein powder with a set concentration; at least two of the protein tank I, protein tank II and protein tank III are simultaneously opened to mix with the material The protein powder is conveyed in the device, and the control device adjusts the output speed of the protein powder flow in the three protein tanks into the material mixing device through feedback control. The invention has the beneficial effects that: the system has high production efficiency, can realize fast grading and blending of protein powder according to the protein content, and the protein content of the product is stable and has little fluctuation.

Owner:北京中仪智控科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com