Arc cylinder pendulum type internal combustion engine

An internal combustion engine, pendulum technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as cylinder deviation, power consumption, noise, etc., and achieve the effect of increasing compression ratio, reducing noise, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

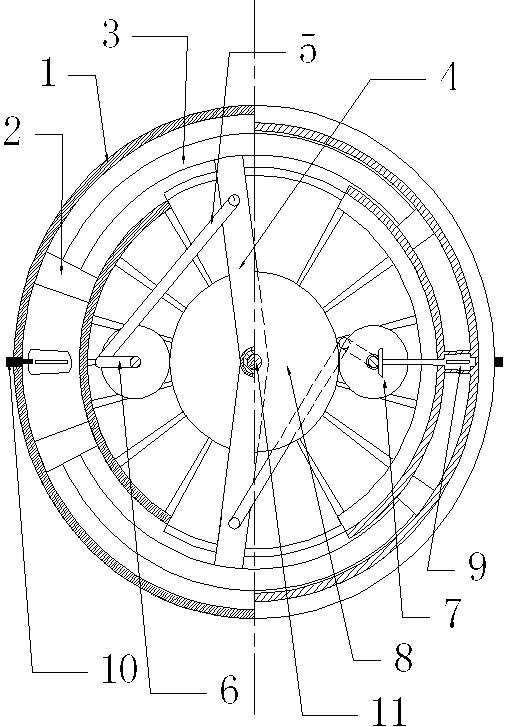

[0026] Embodiment 1: This embodiment is a four-stroke gasoline engine with two cylinders 1 . Below is the structure of a single cylinder 1:

[0027] like figure 1 , the whole of the cylinder 1 is circular, the cross section is circular, the casing at the central axis of the annular cylinder 1 is provided with a shaft sleeve, the main shaft 10 is installed in the shaft sleeve, and two swing rods 4 are symmetrically installed, each of which is One end of the swing rod 4 is sleeved on the shaft sleeve, and the other end extends into the cylinder 1 from the strip hole opened on the inner cylinder wall of the cylinder 1, and is installed in the middle of the arc-shaped connecting rod 3, and the two ends of the arc-shaped connecting rod 3 A piston 2 is installed, the cross section of the piston 2 is also circular, and a lap seal ring is installed on it to form a seal with the circular inner wall of the cylinder 1 . The two adjacent pistons 2 respectively installed on different ar...

Embodiment 2

[0035] Embodiment 2: Four swing rods 4 can also be installed in each cylinder 1. According to Embodiment 1, other corresponding mechanisms are set for each swing rod 4, so that four working chambers can be formed, and each working chamber can be simultaneously Do different strokes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com