Patents

Literature

118results about How to "Movement speed is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

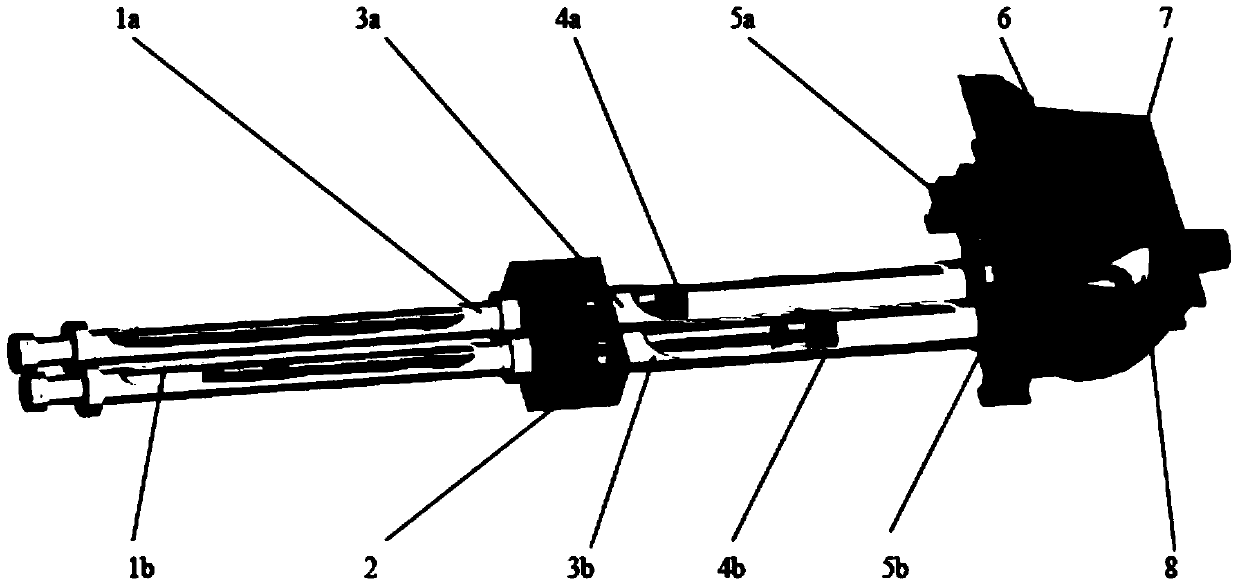

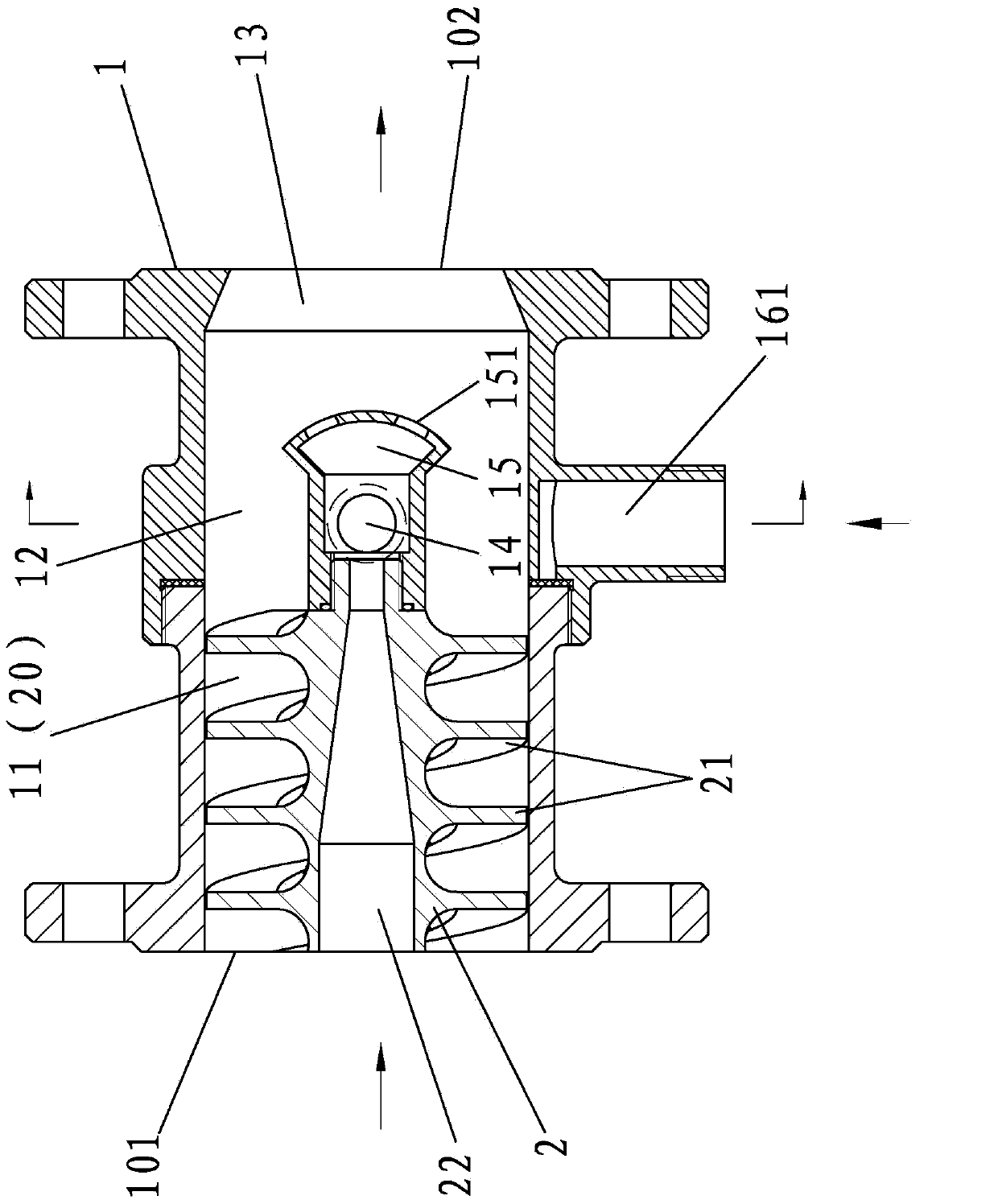

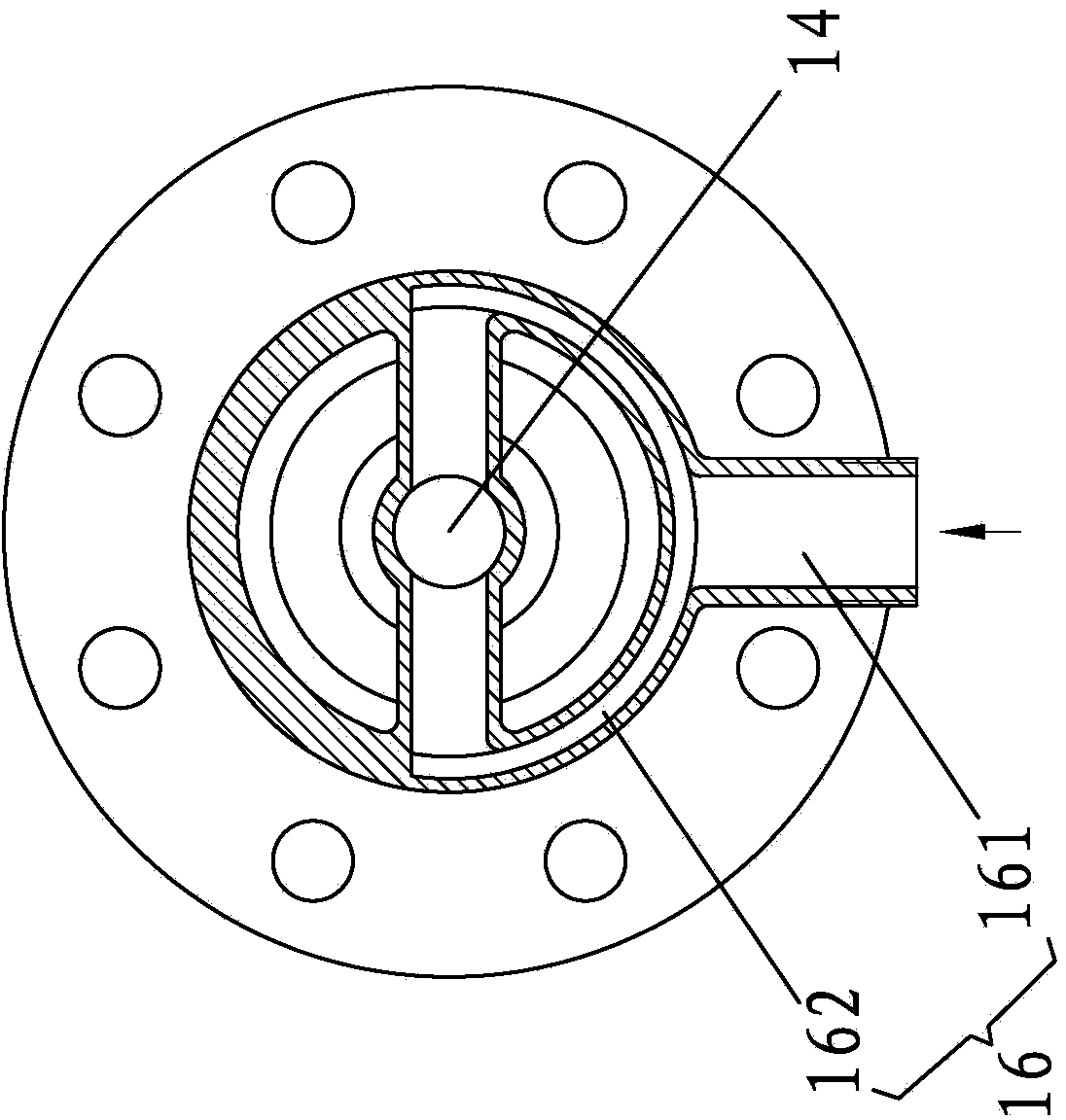

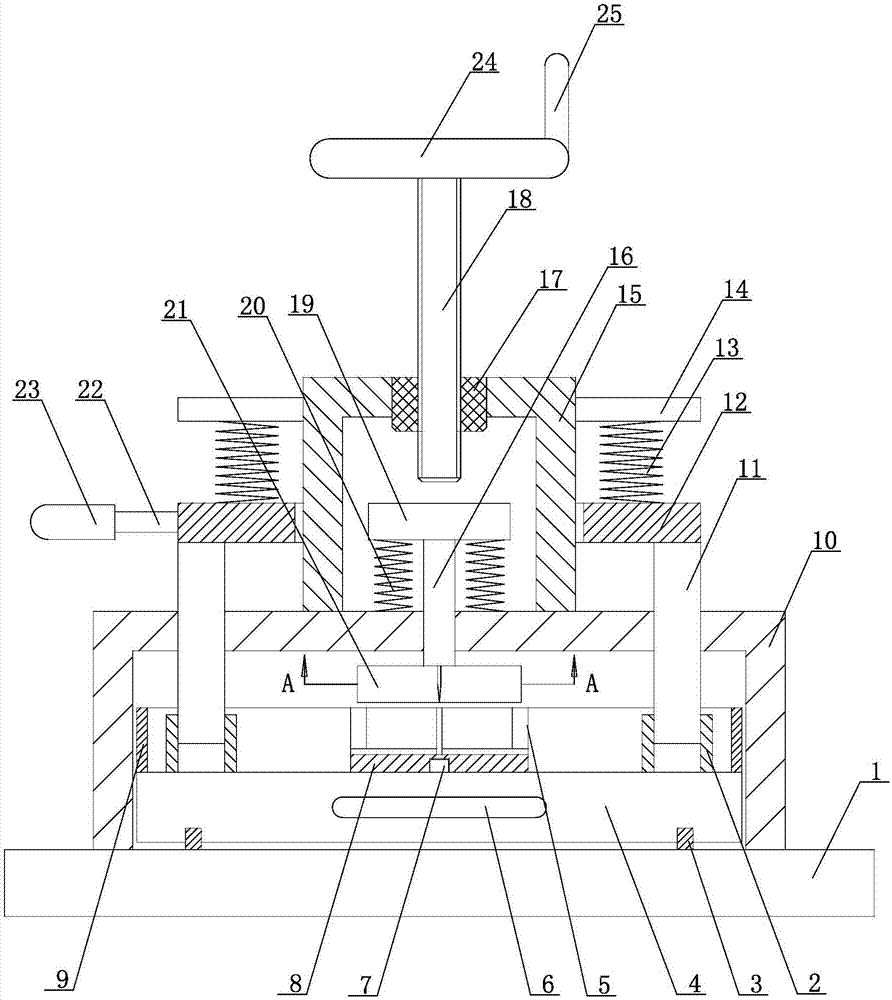

Device for measuring rotational inertia and friction moment of ball screw

InactiveCN103900813AReal-timeAchieve preservationMachine gearing/transmission testingStatic/dynamic balance measurementFriction torqueCoupling

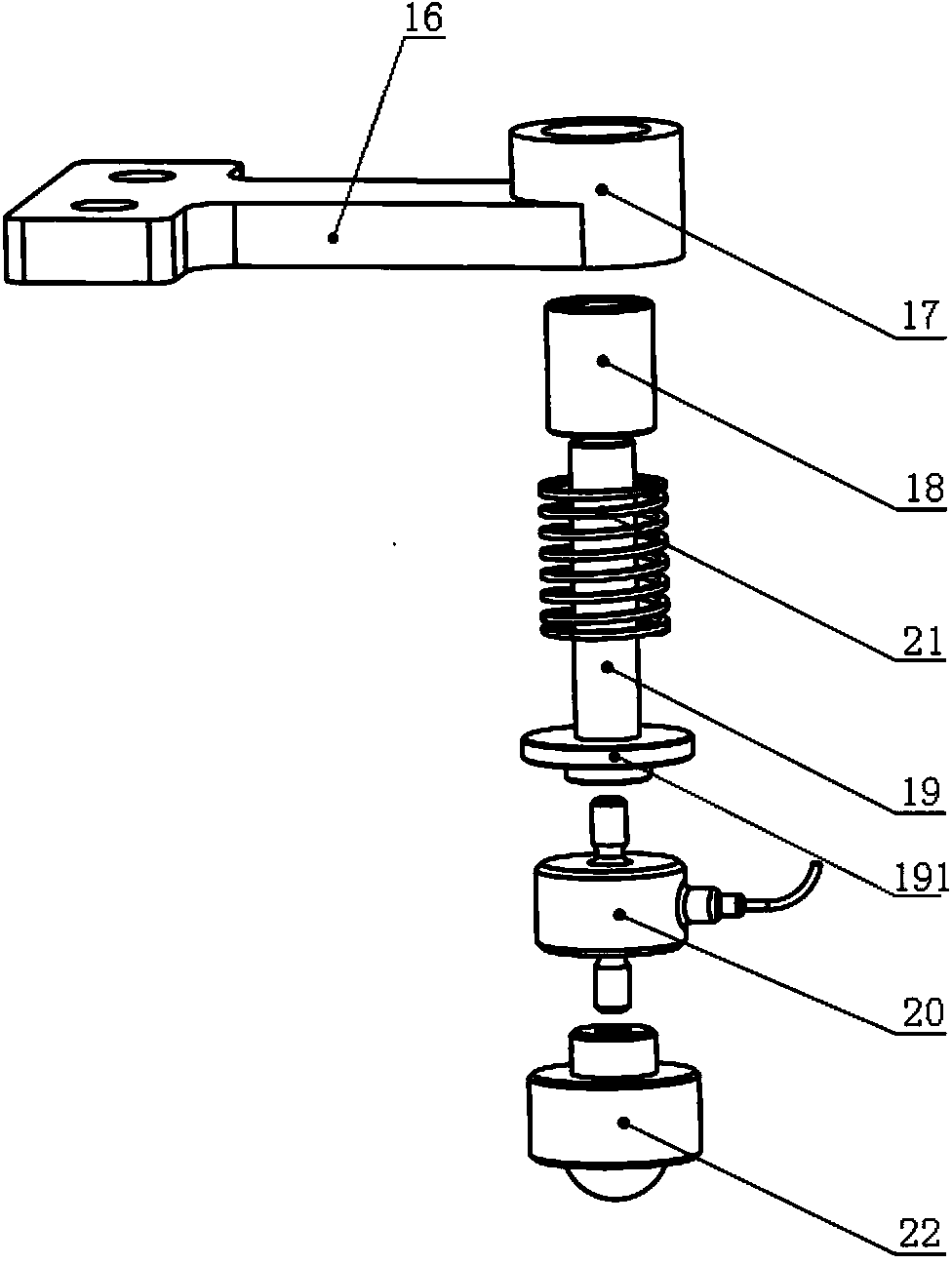

The invention relates to a device for measuring rotational inertia and friction moment of a ball screw. The device comprises a bottom plate, two linear guide rails, the ball screw, a torque sensor, a servo motor, a mobile platform and two friction moment measuring mechanisms. Each linear guide rail is provided with two sliding blocks. The two ends of the ball screw are supported by the part, located between the two linear guide rails, of the bottom plate in a rotary mode through a fixed supporting base and a floating supporting base. One end of the torque sensor is connected with the end, supported by the fixed supporting seat, of the ball screw through a coupler. An output shaft of the servo motor is connected with the torque sensor through a coupler. The two friction moment measuring mechanisms are arranged on the two sides of a screw nut base respectively. Each friction moment measuring mechanism comprises a cantilever. A connecting sleeve is arranged at the tail end of each cantilever. Each connecting sleeve is connected with a sliding bar through a vertical linear bearing. The other end of each sliding bar is connected with a pressure sensor. Each sliding bar is sleeved with a spring. The bottom of each pressure sensor is connected with a universal ball. The bottom of each universal ball makes contact with a linear slab which is parallel to the ball screw. The linear slabs are tightly connected to the bottom plate.

Owner:TSINGHUA UNIV

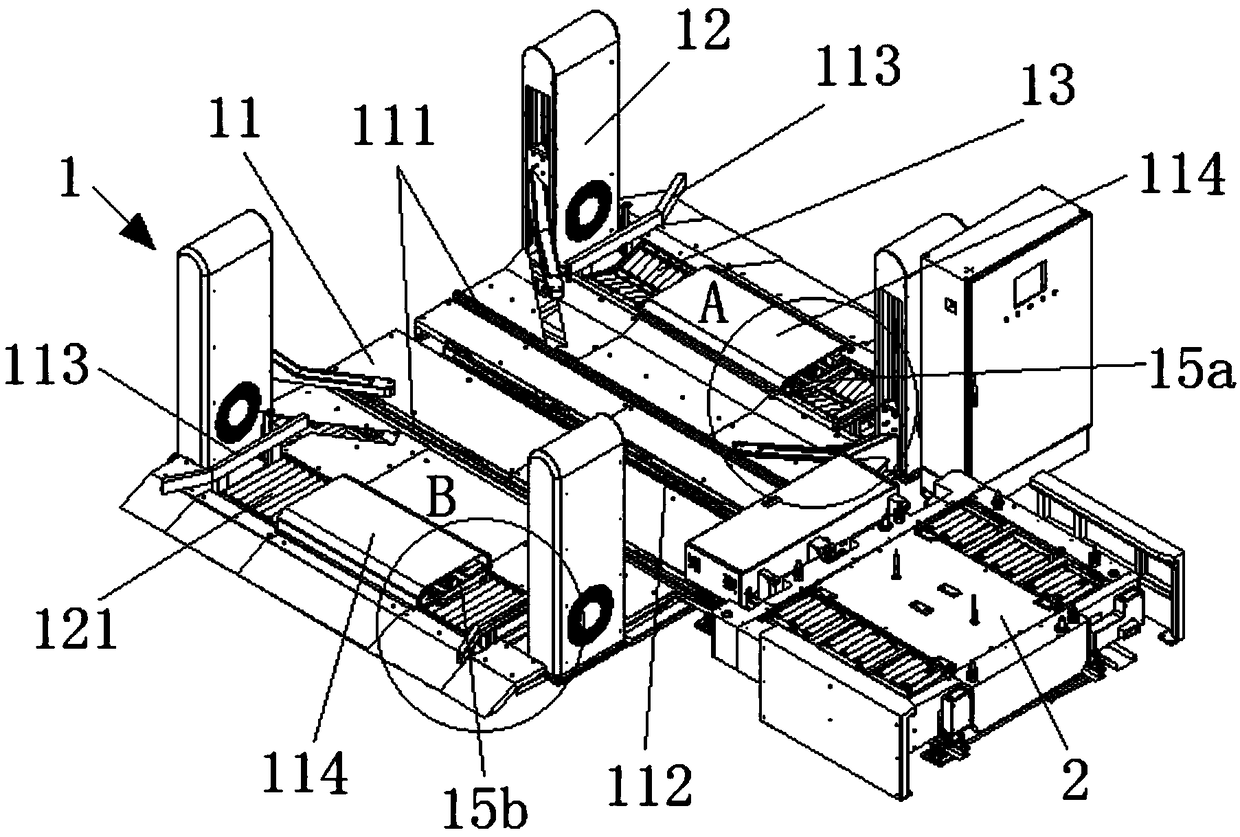

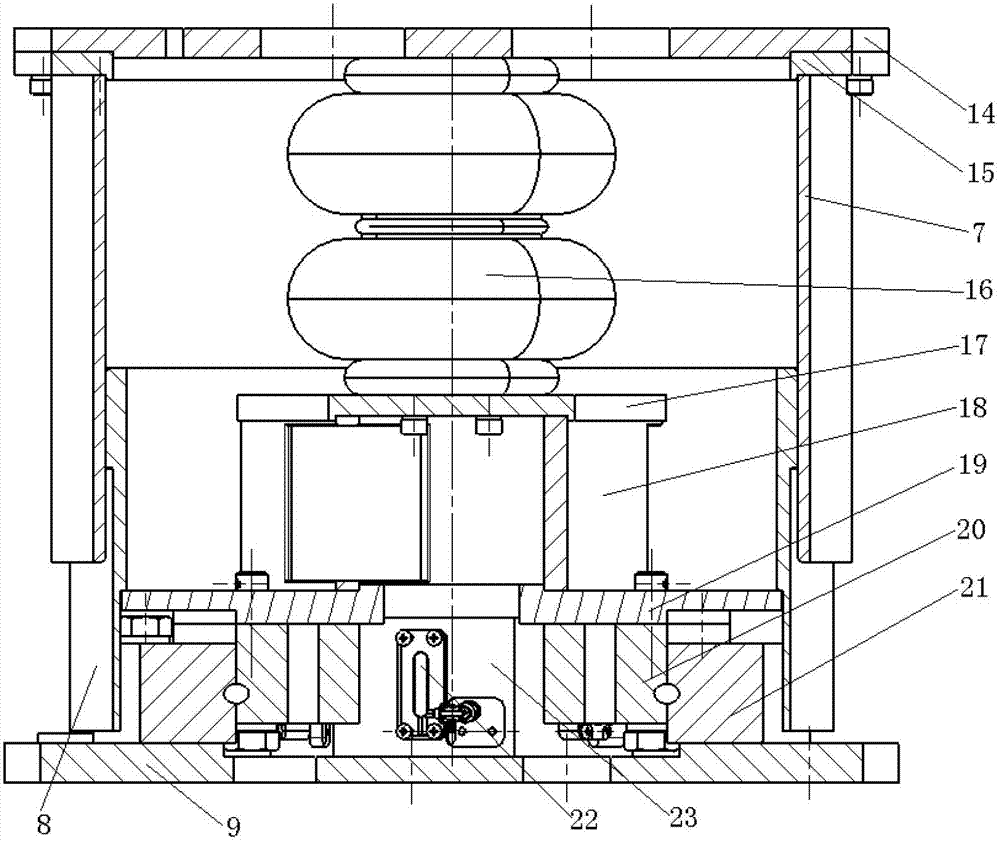

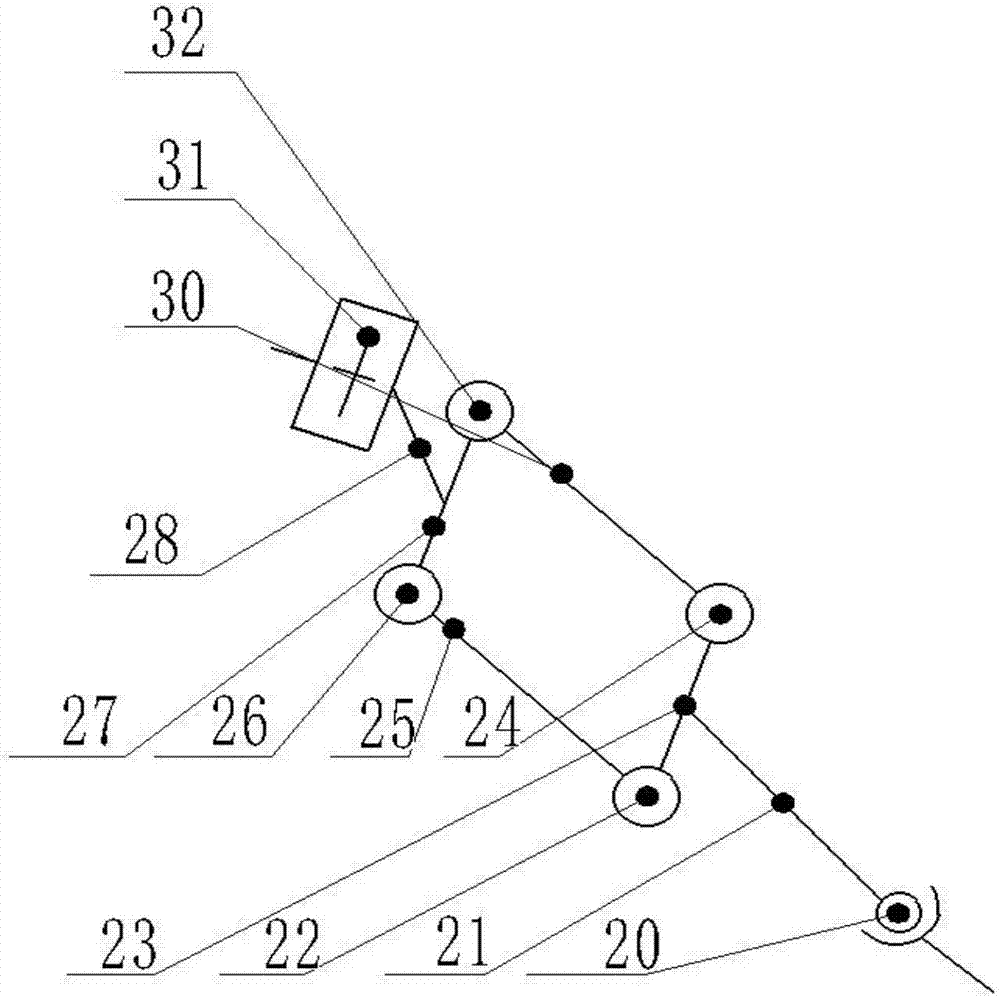

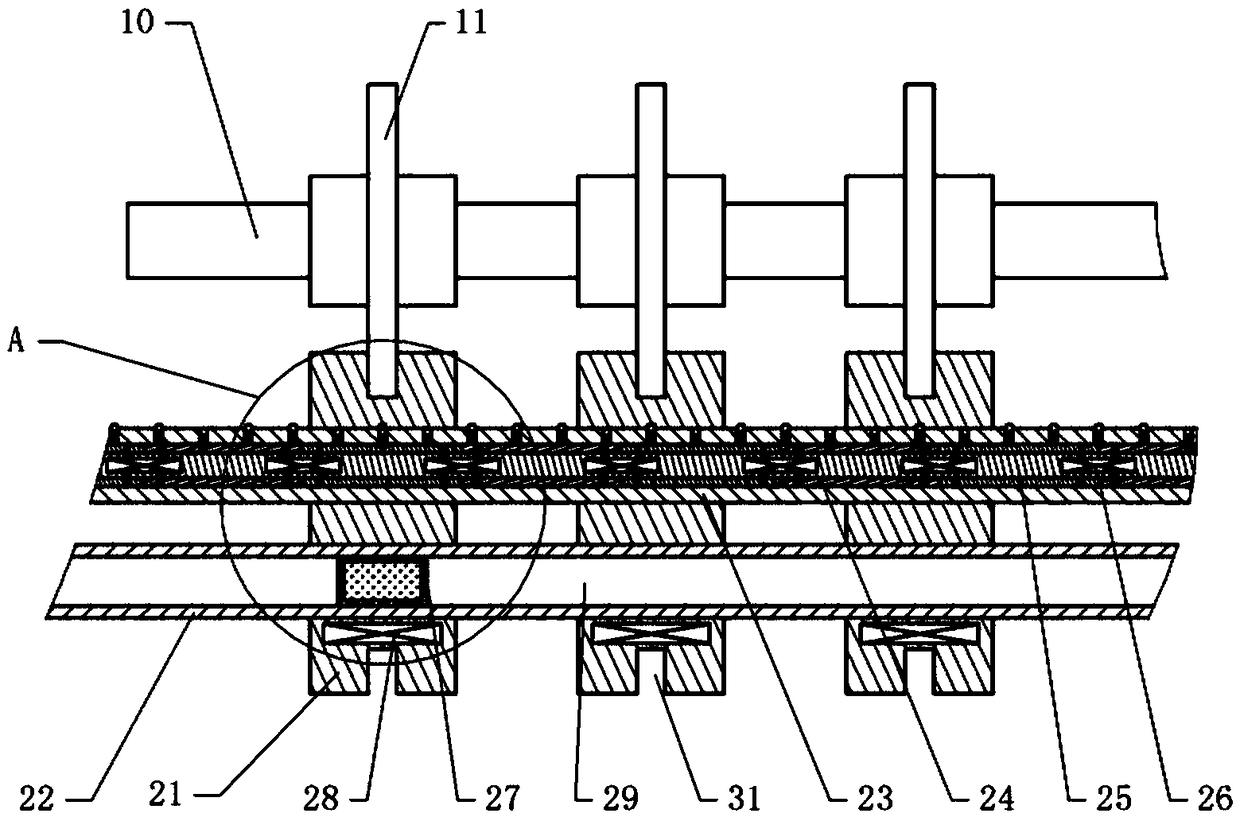

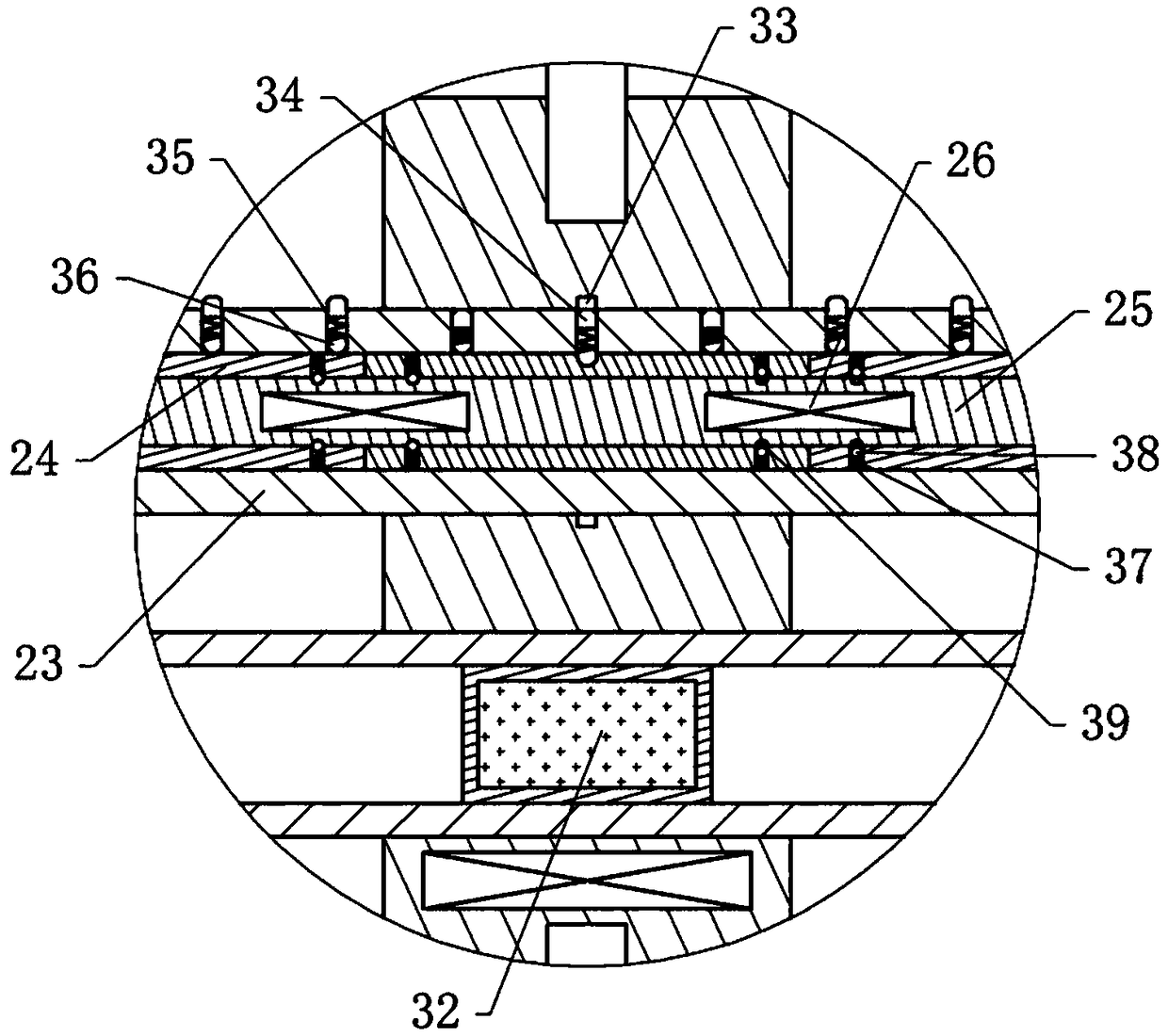

Floating type counterpoint vehicle-mounted storage battery automatic replacing station

ActiveCN108058688AAvoid chimera failureSmooth liftElectric propulsion mountingVehicular energy storageElectric vehiclePositioning system

The invention belongs to the technical field of vehicle maintenance, and relates to a floating type counterpoint vehicle-mounted storage battery automatic replacing station which comprises a vehicle positioning and lifting mechanism for positioning and lifting an electric vehicle and a battery locking and unlocking mechanism for positioning and replacing a vehicle-mounted storage battery. The battery locking and unlocking mechanism comprises an ejecting assembly, a positioning assembly arranged on the ejecting assembly and a plurality of locking and unlocking assemblies arranged on the positioning assembly. The ejecting assembly comprises a lifting table for fixing the positioning assembly. The positioning assembly comprises a floating support, and at least two positioning pins arranged onthe upper side of the floating support. The floating support is hung below a lifting table through four chains. The positioning assembly can float by means of the chains, the position of the vehicle-mounted storage battery can be automatically fine adjusted according to the actual conditions of a chassis when the vehicle-mounted storage battery is arranged on the electric vehicle chassis, and theembedment failure is avoided.

Owner:NIO CO LTD

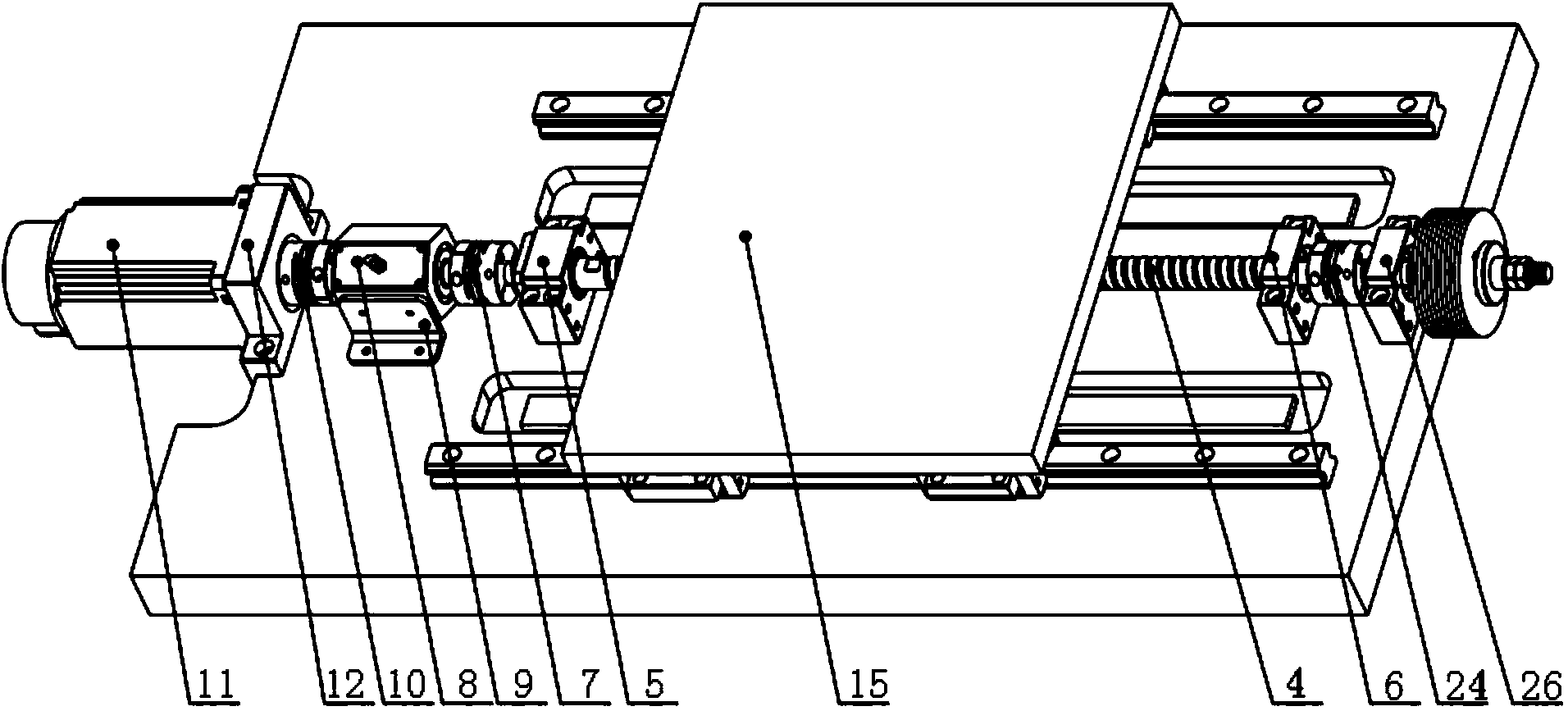

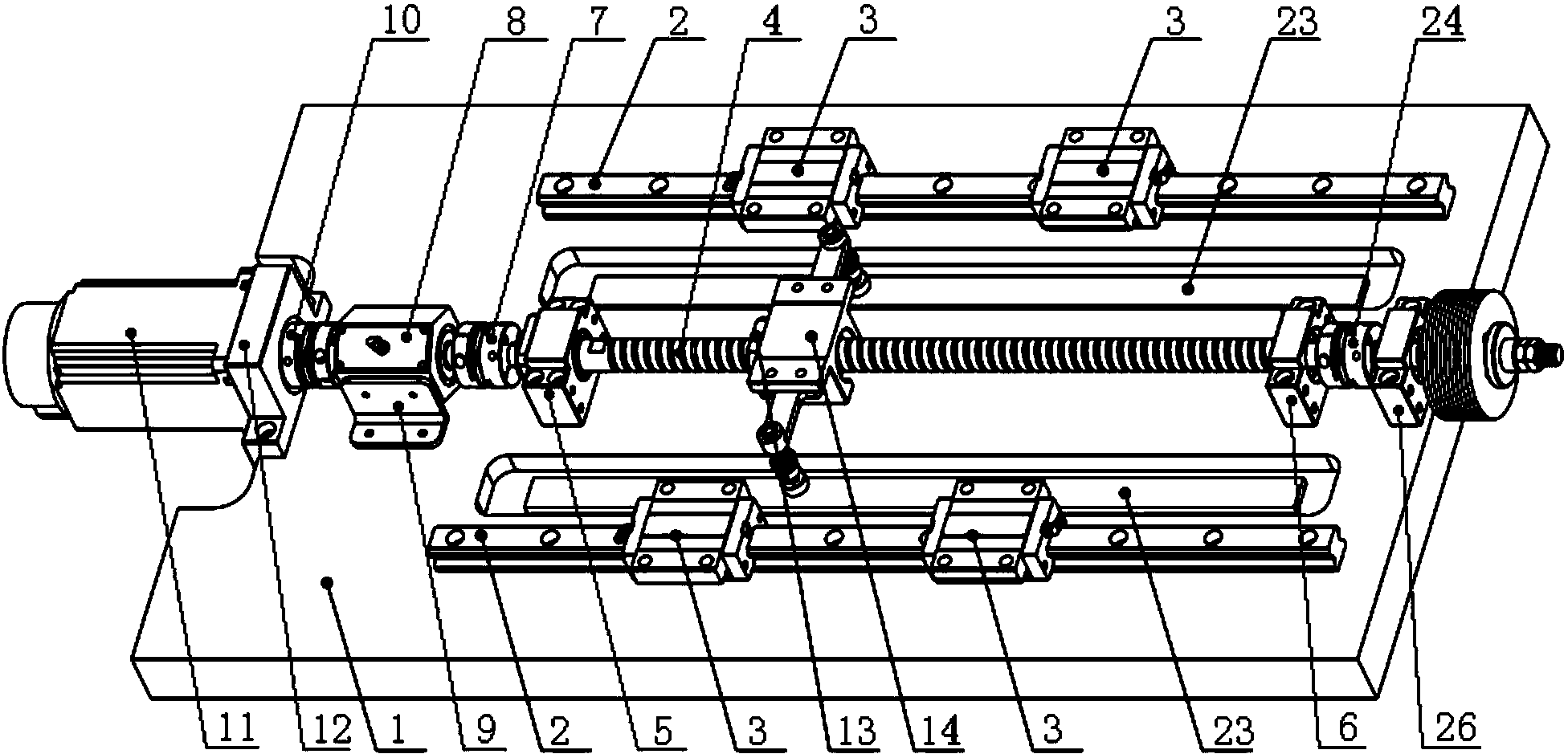

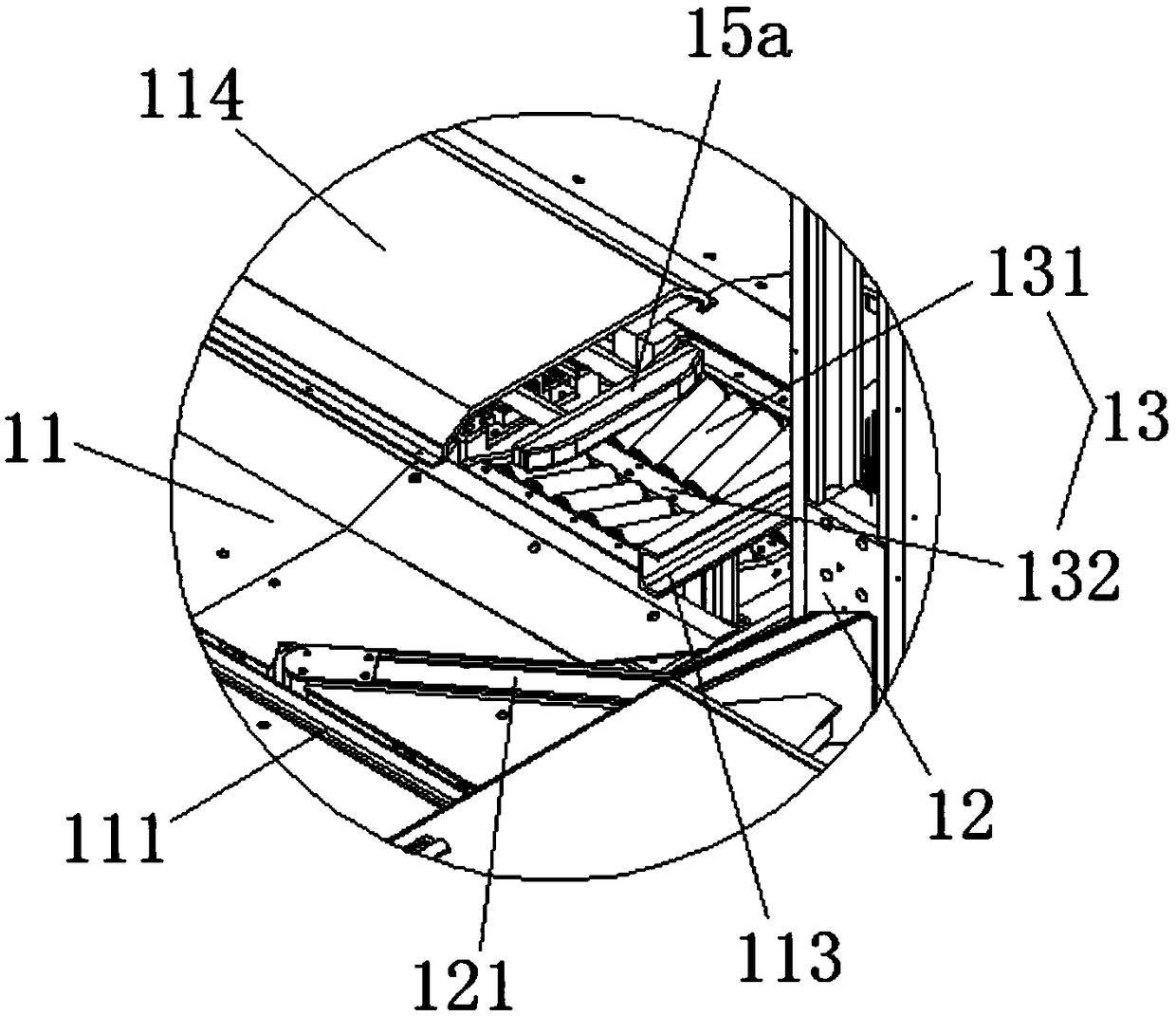

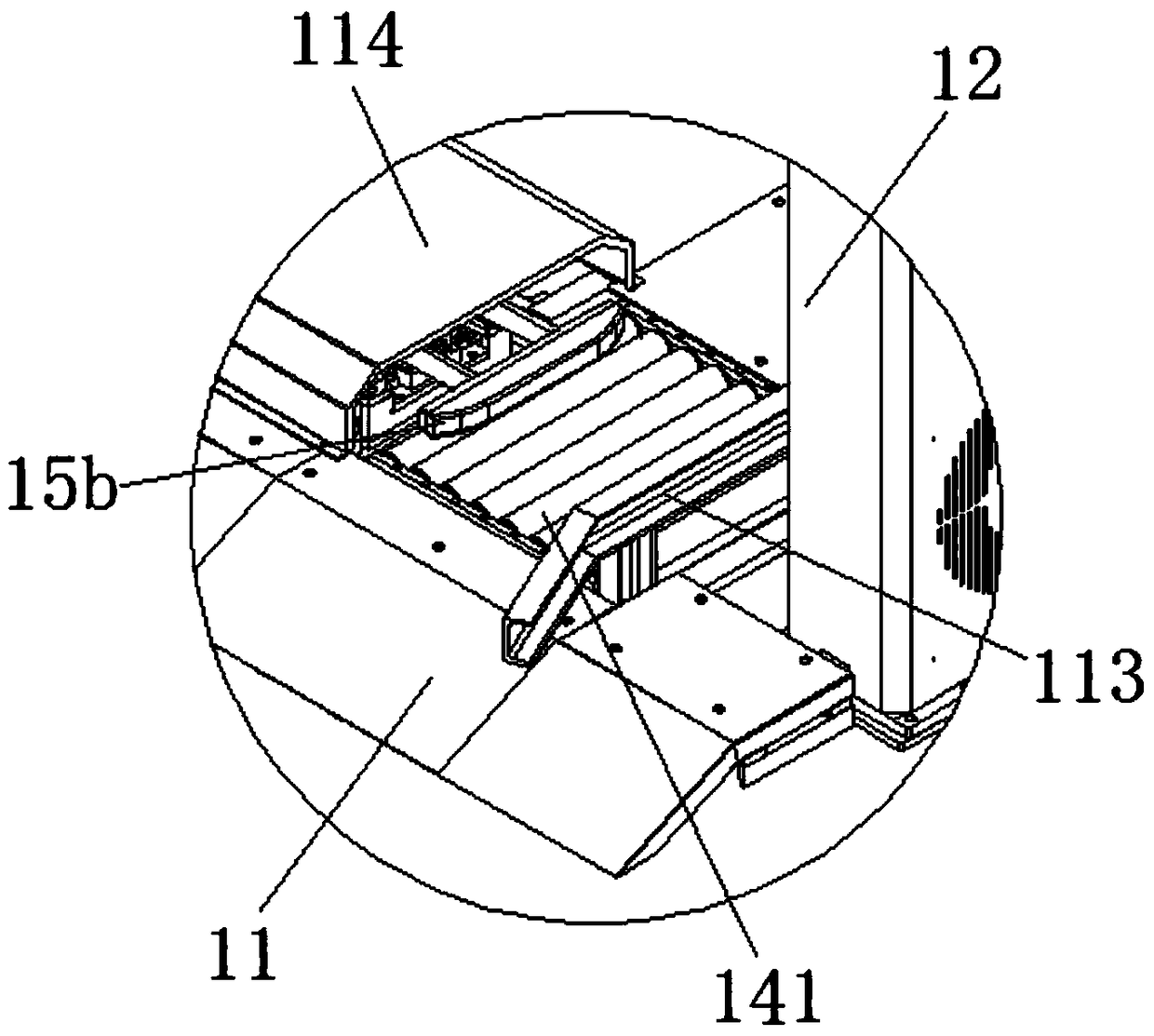

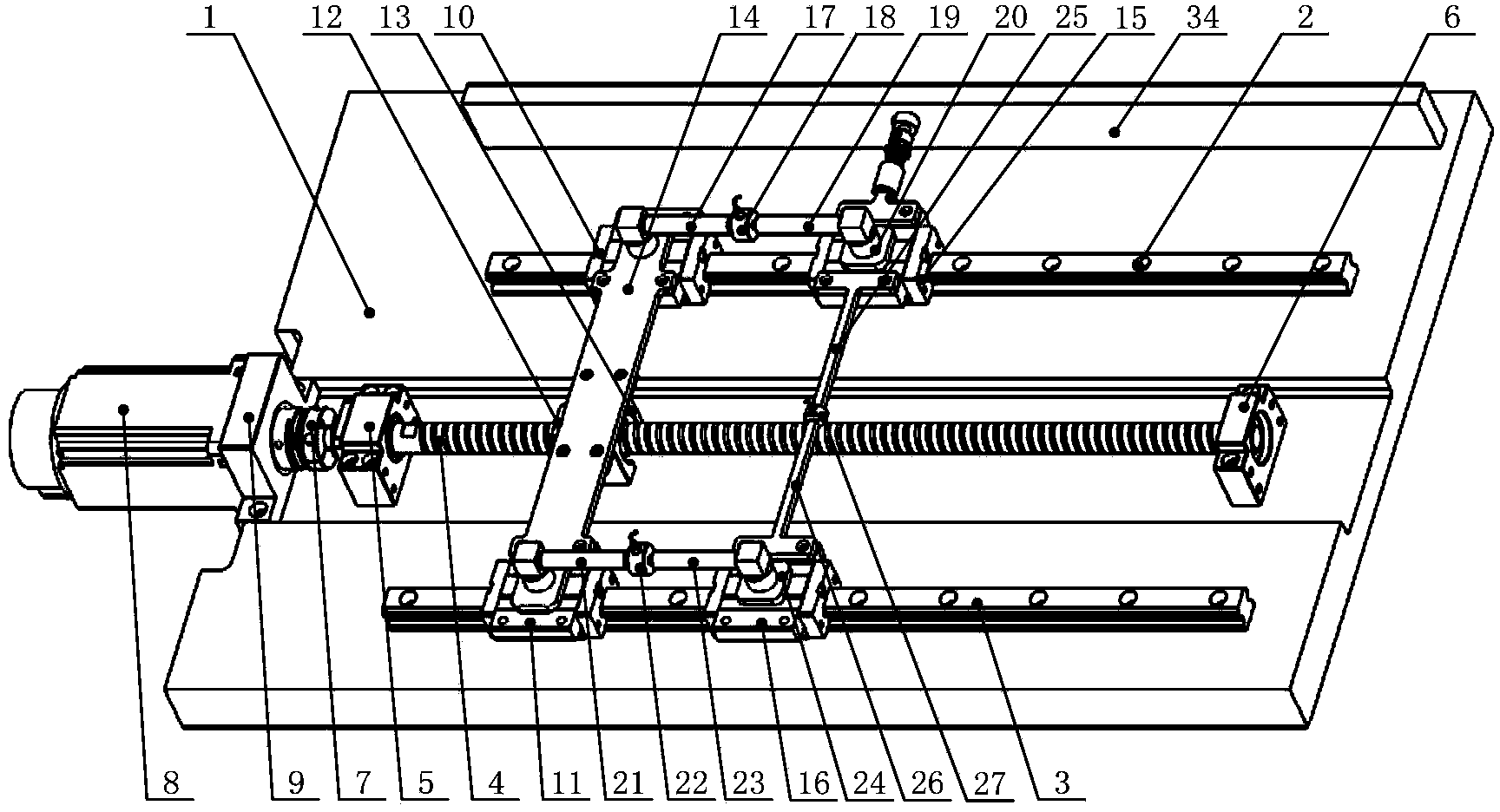

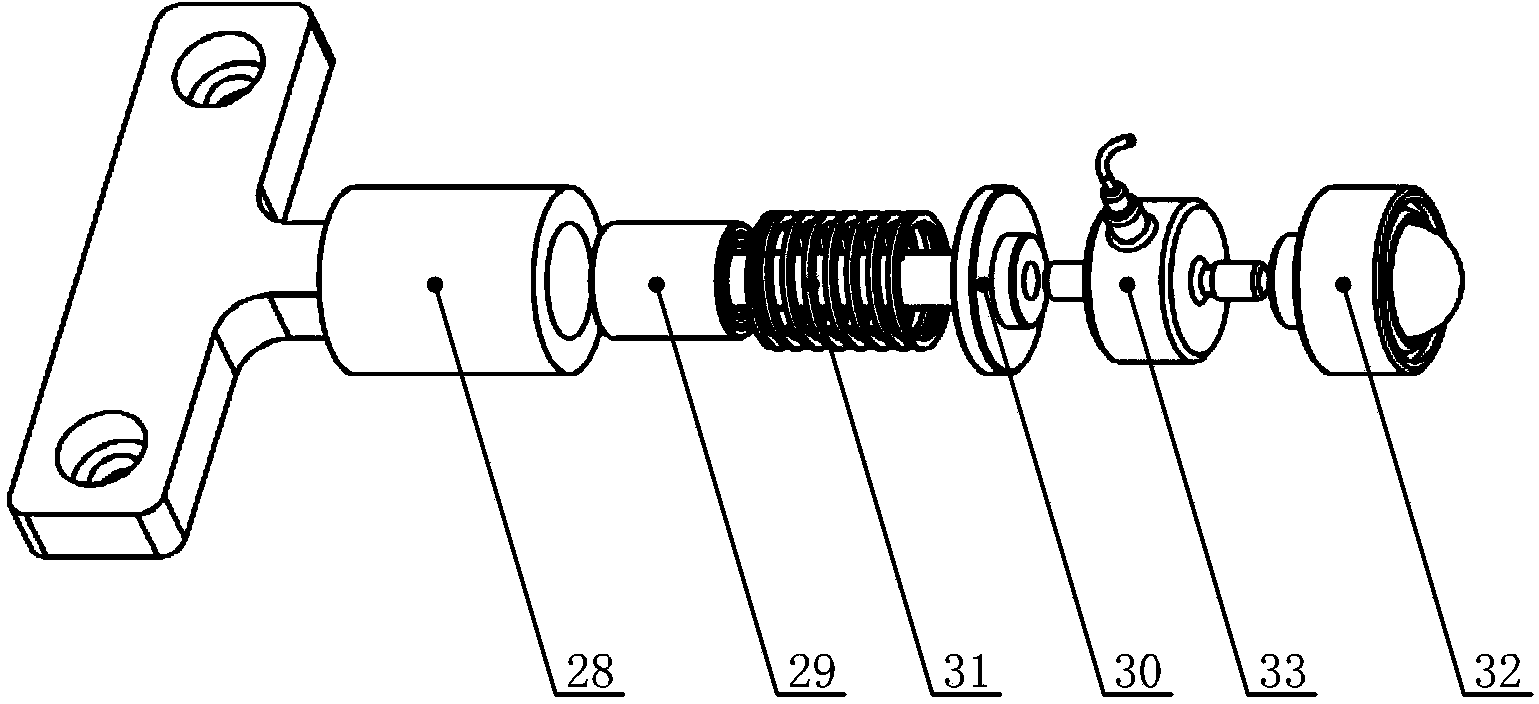

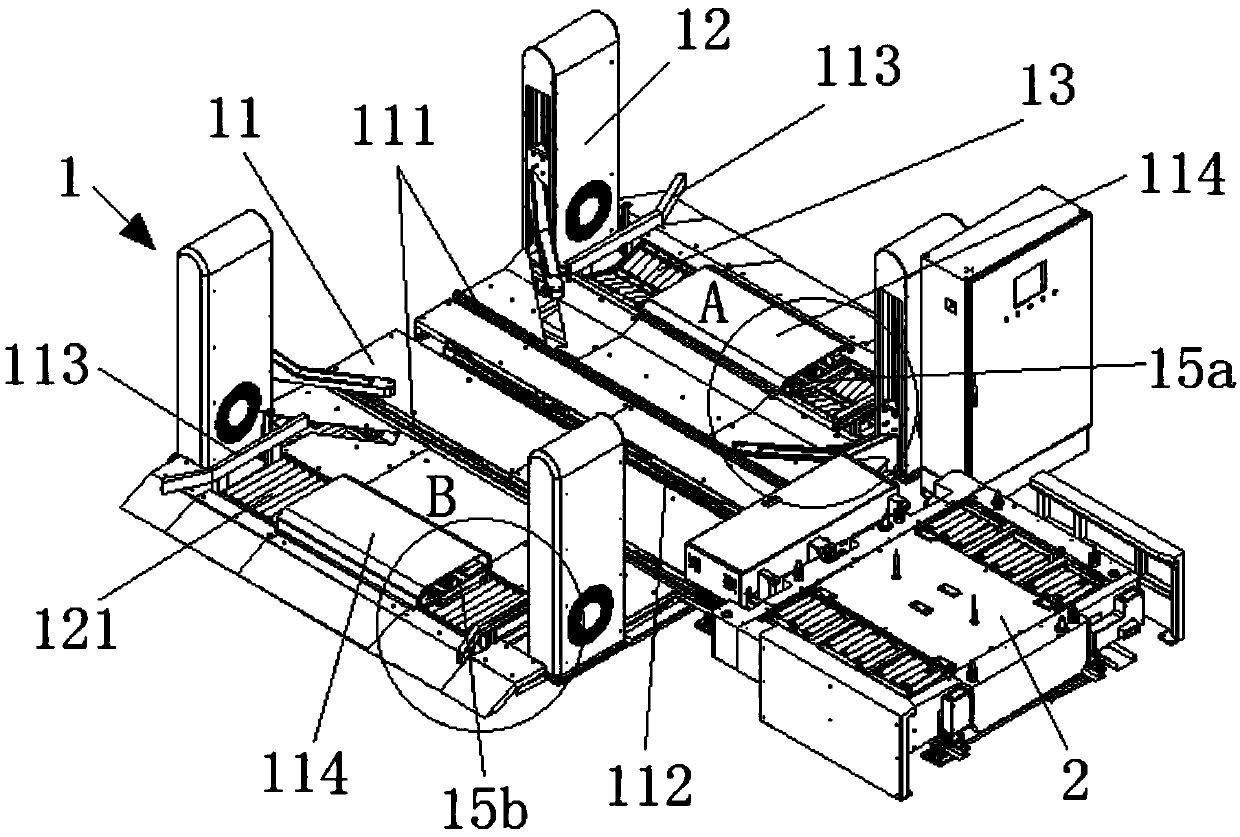

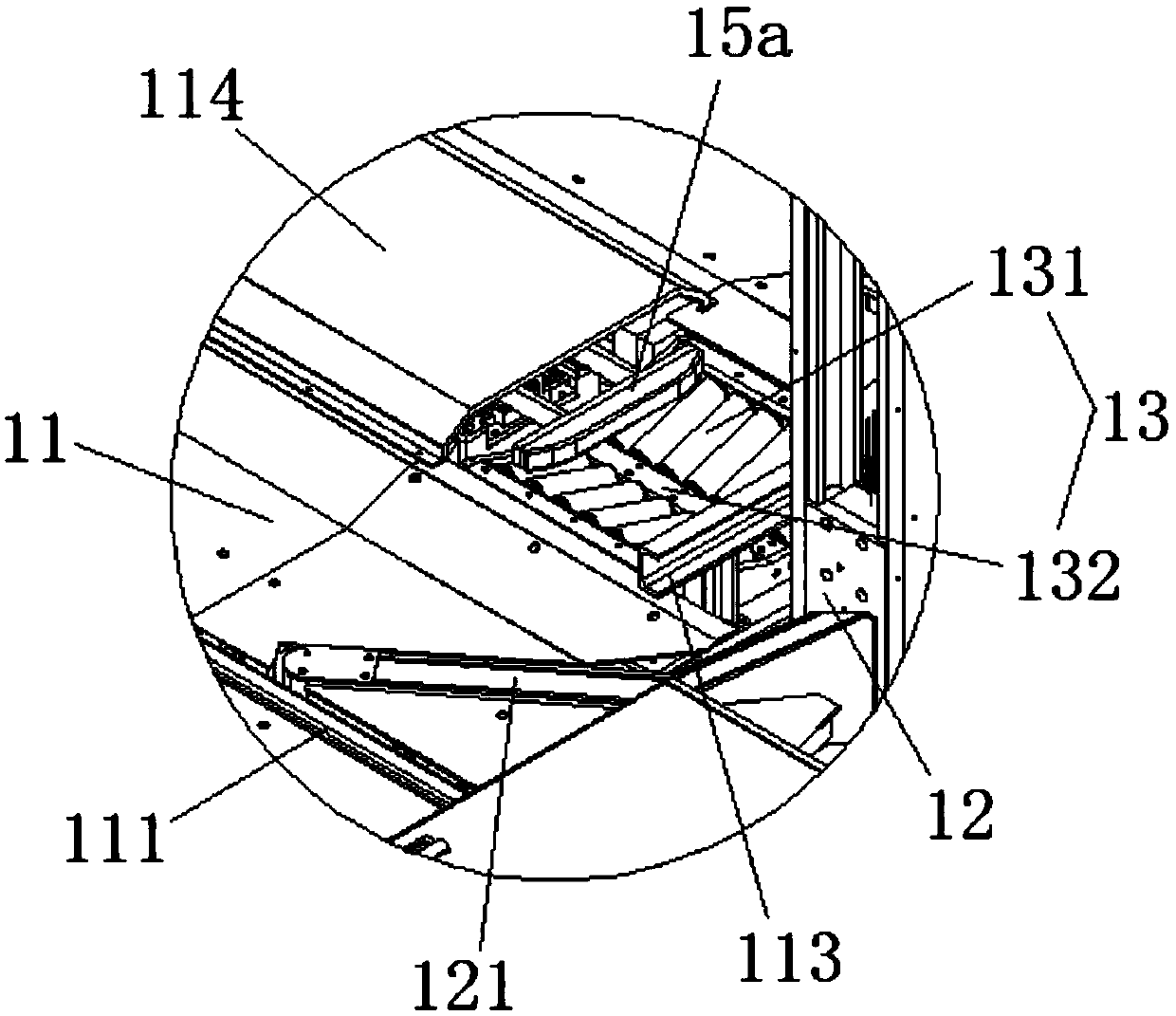

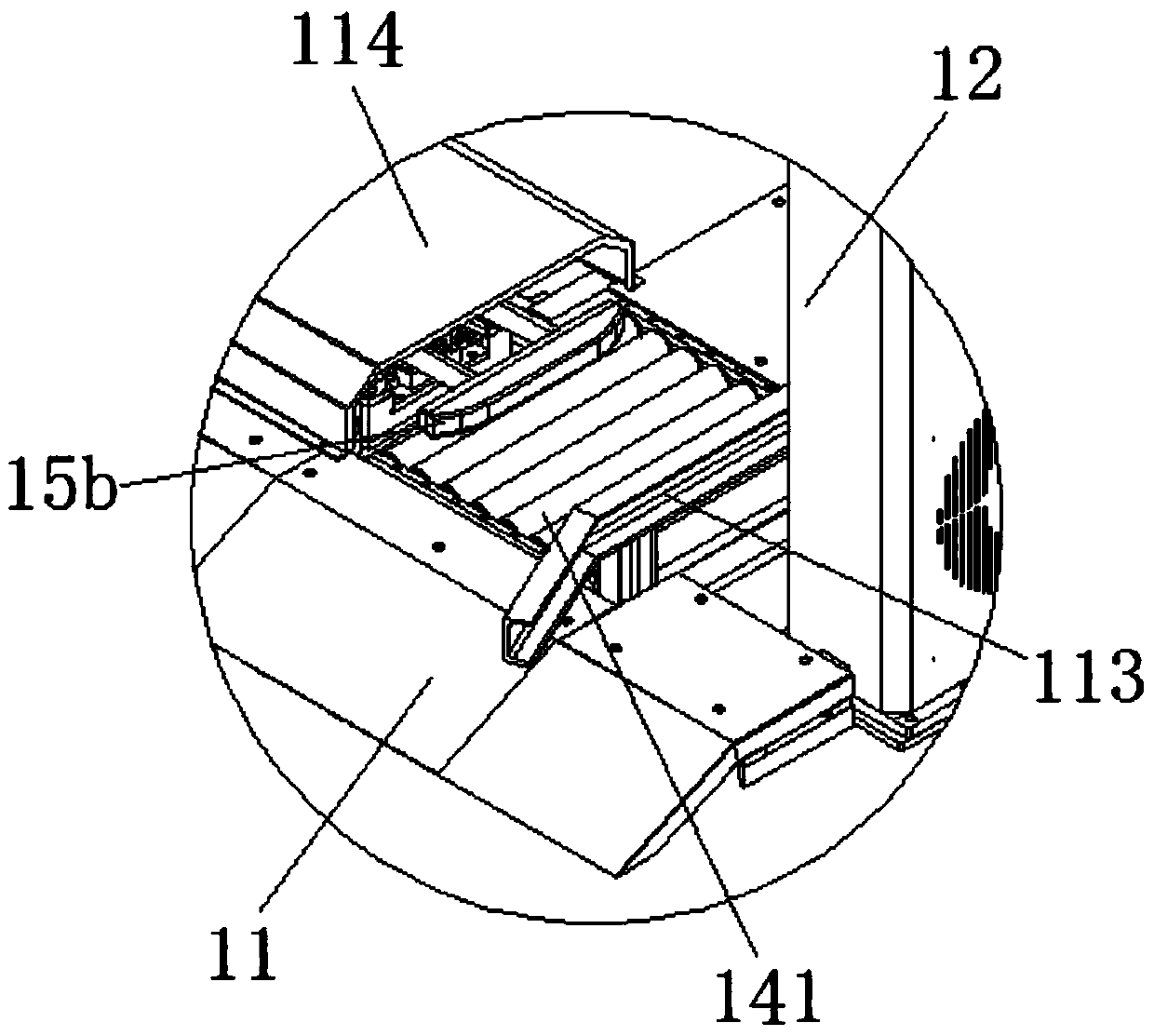

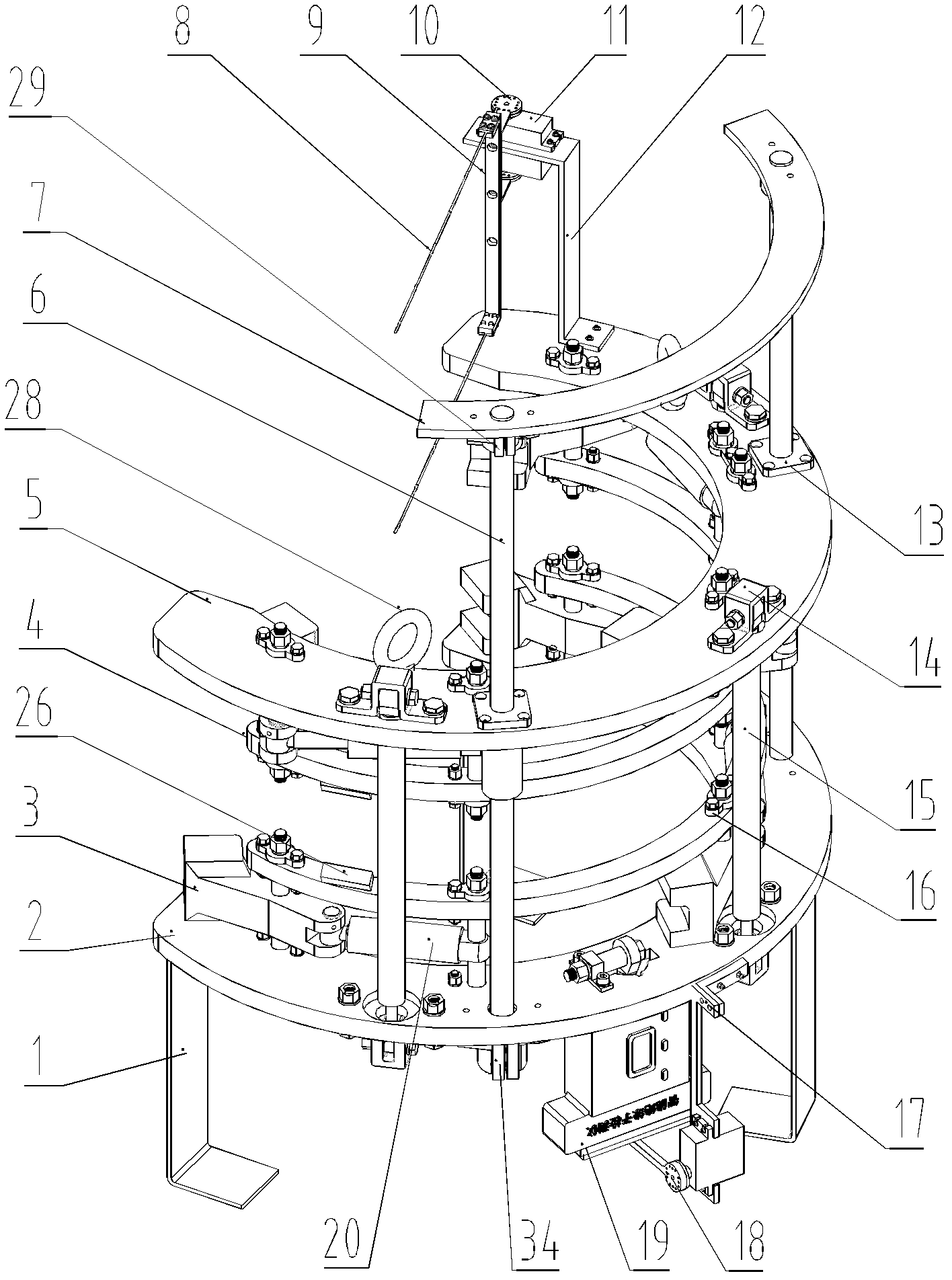

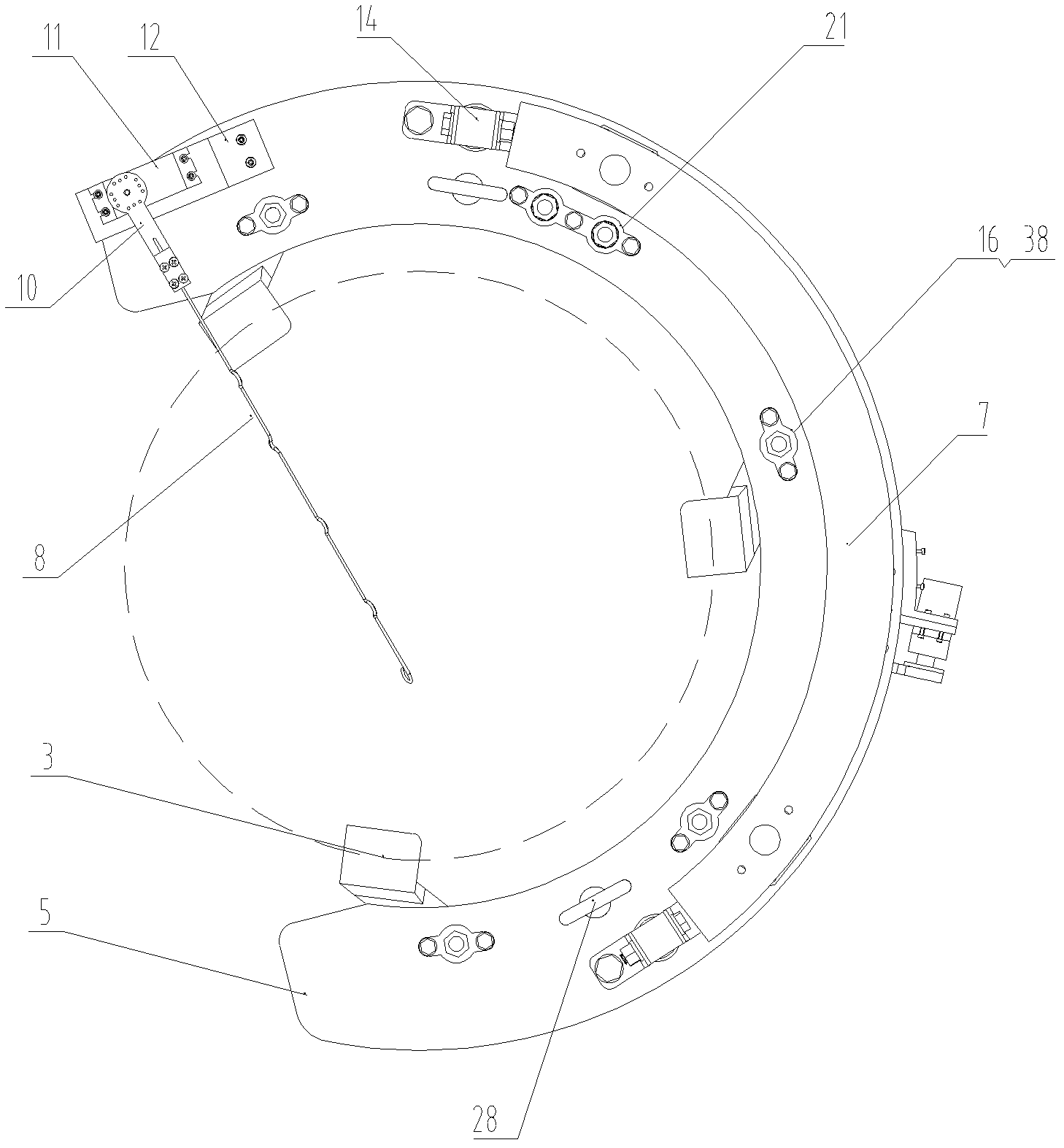

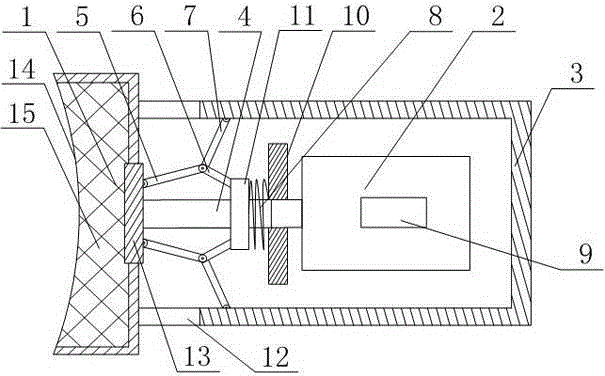

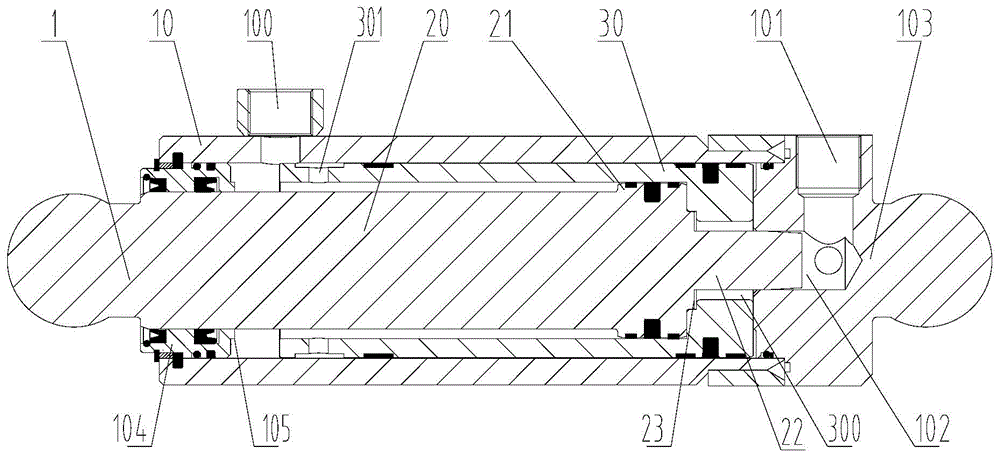

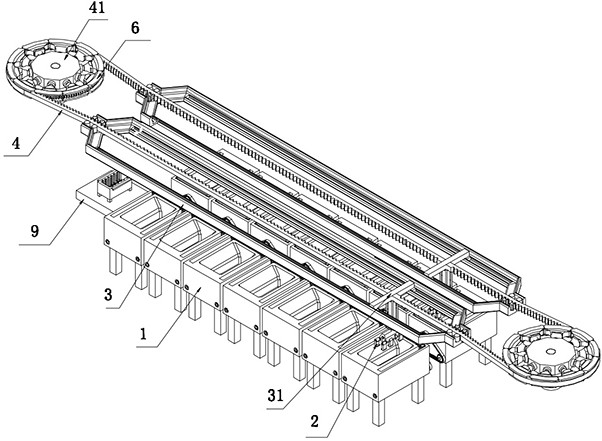

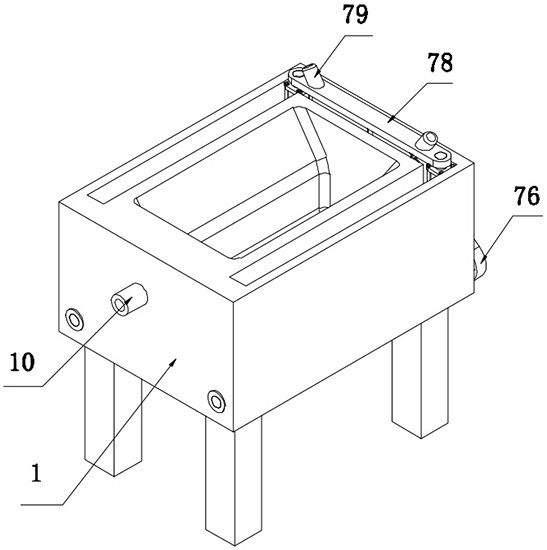

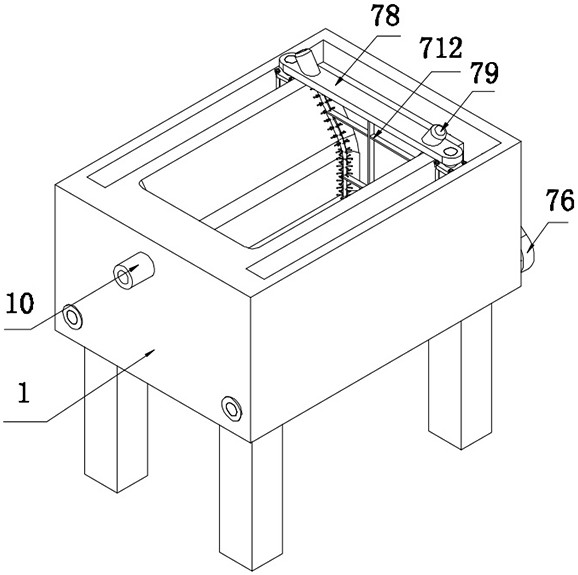

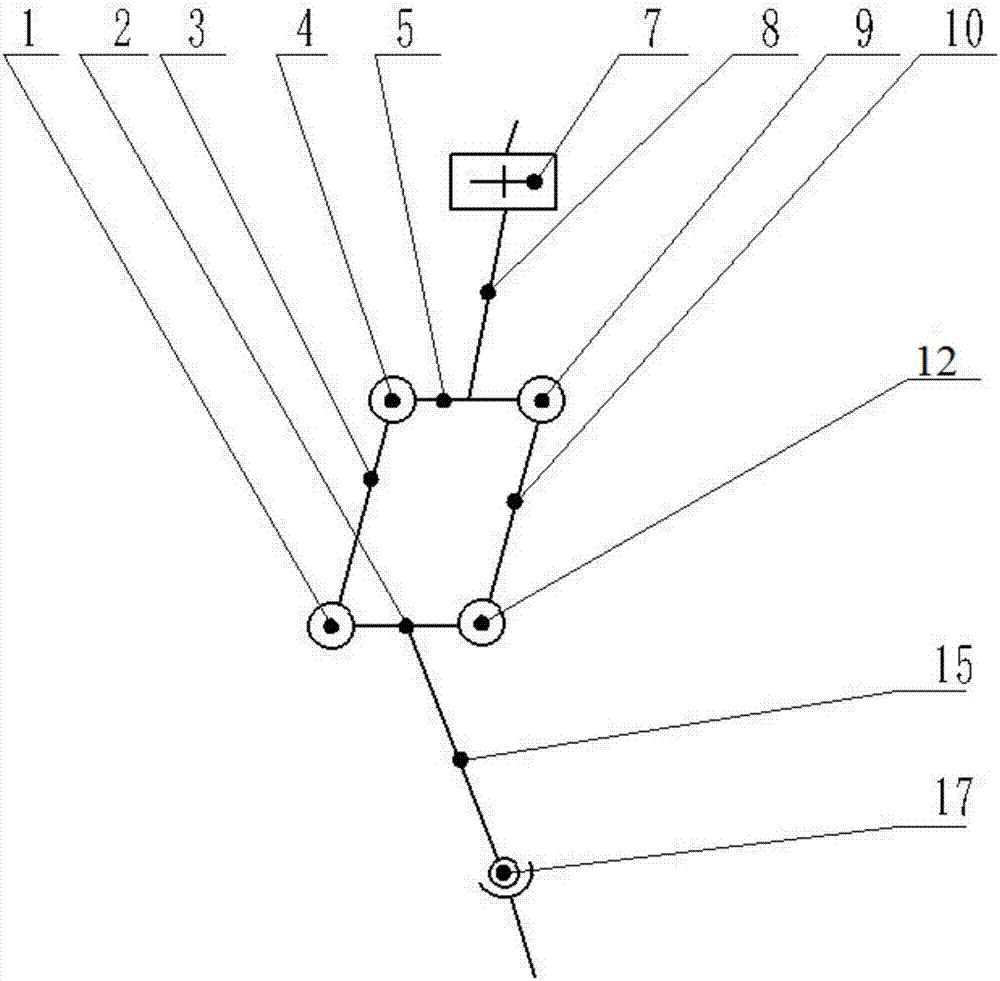

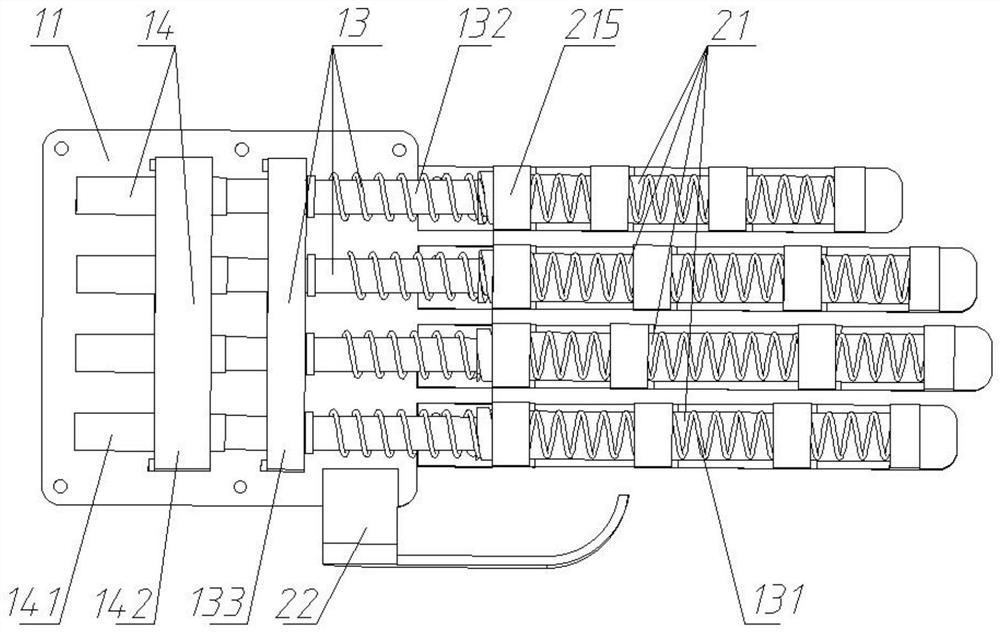

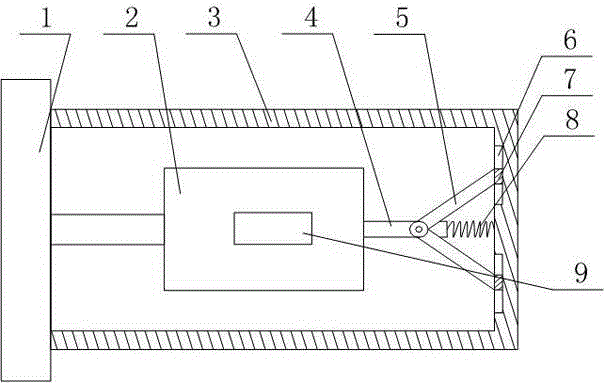

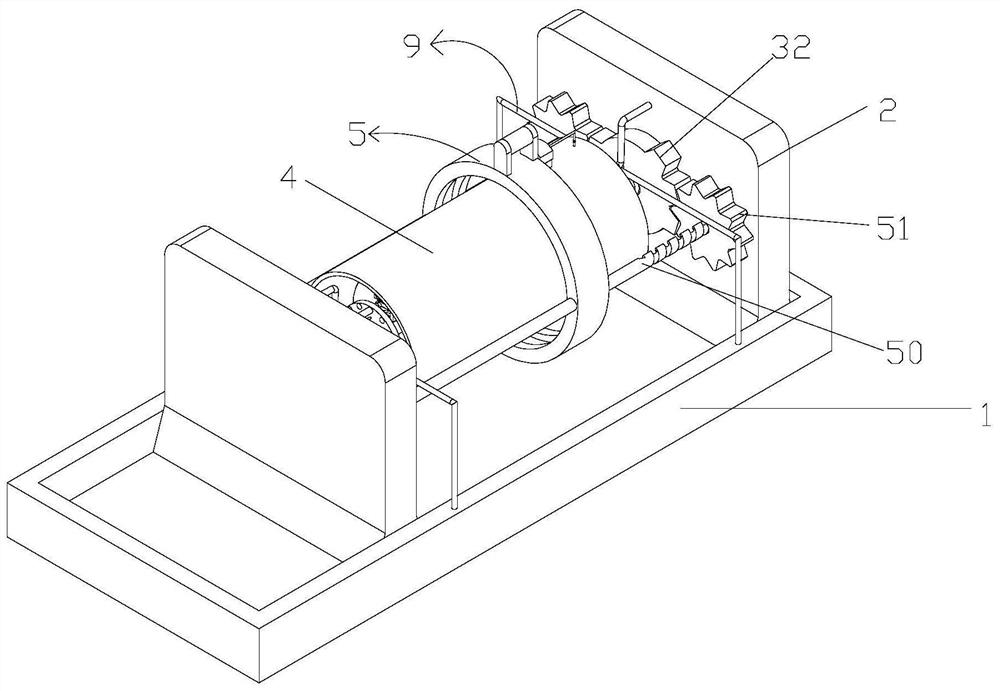

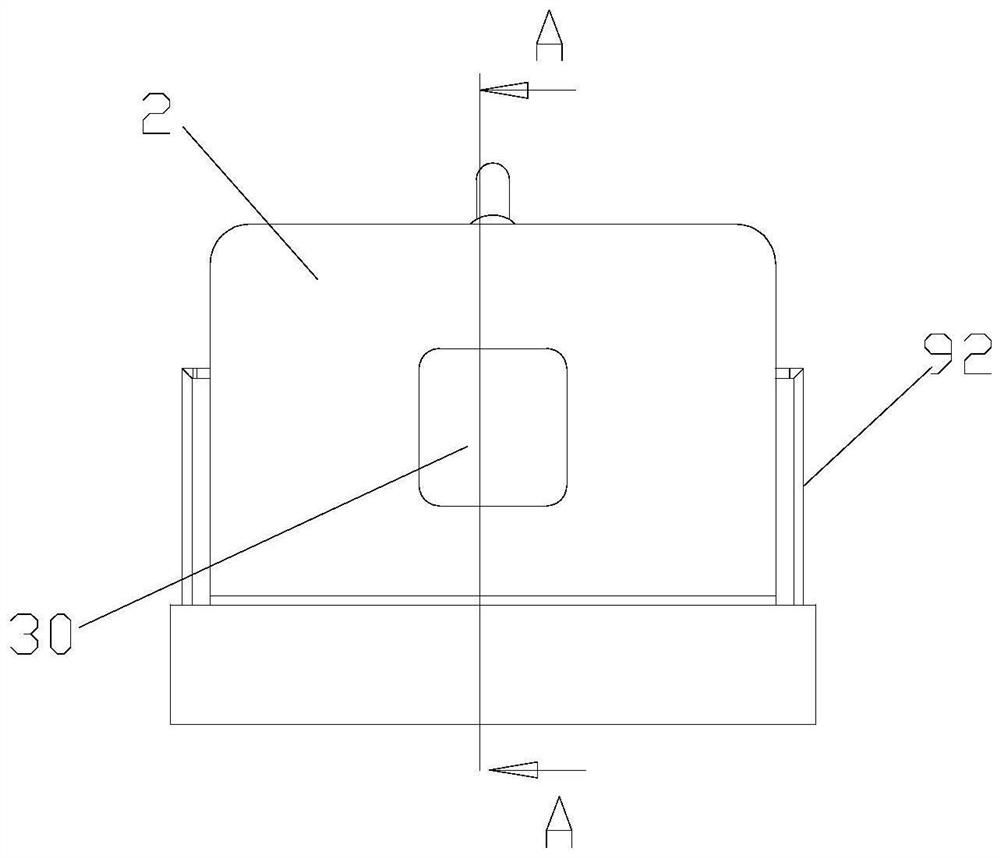

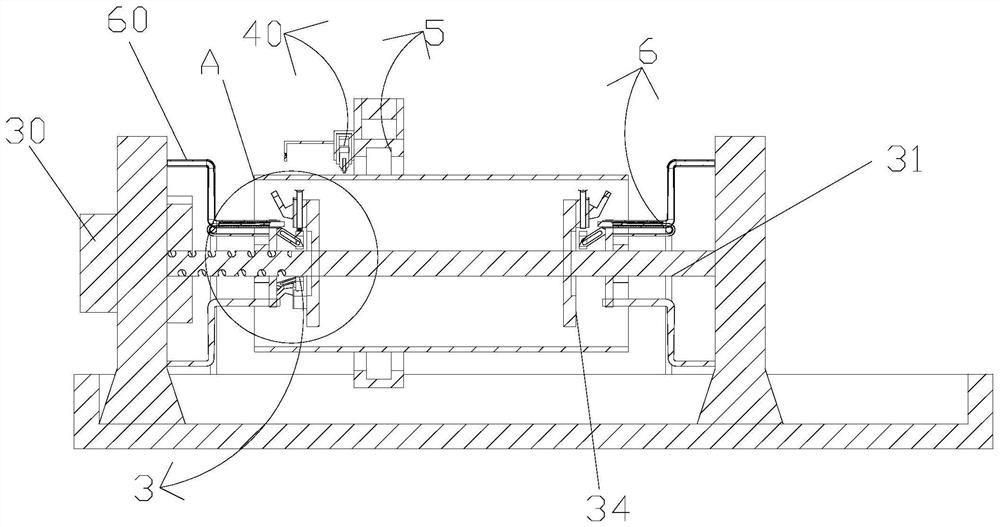

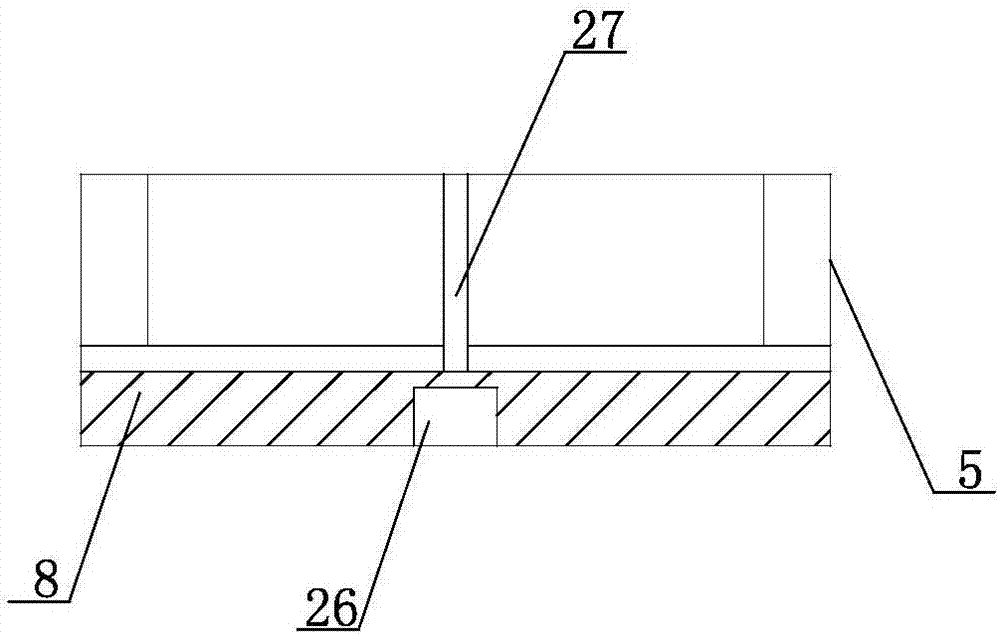

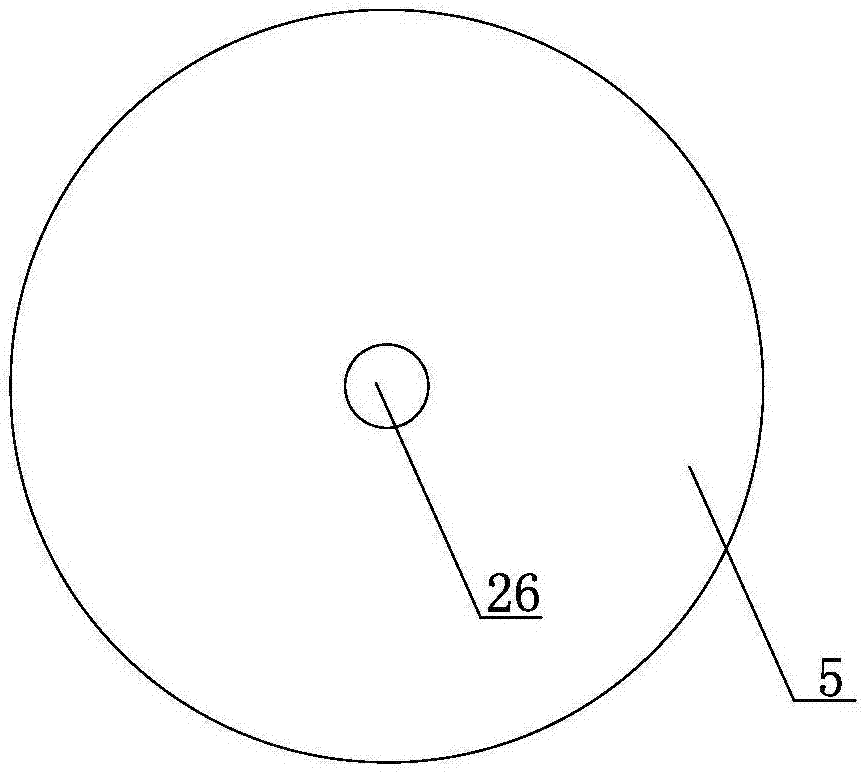

Device for comprehensively measuring linear guide rail friction force and manufacturing and mounting errors

InactiveCN103940471AEnabling Dynamic Friction MeasurementsMovement speed is stableMeasurement devicesMeasurement deviceEngineering

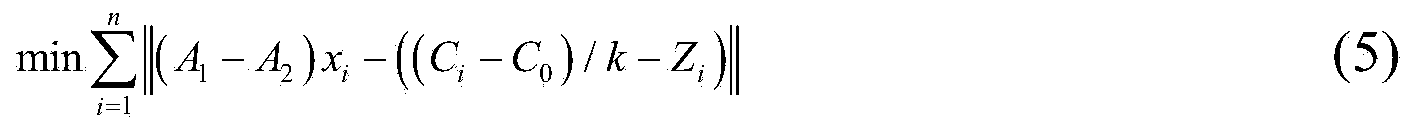

The invention discloses a device for comprehensively measuring linear guide rail friction force and manufacturing and mounting errors, and belongs the technical fields of measurement. The device for comprehensively measuring the linear guide rail friction force and the manufacturing and mounting errors mainly comprises a linear feeding system, a guide rail and sliding block friction force measuring device, a guide rail linearity error measuring device and a guide rail mounting parallelism error measuring device. The guide rail and sliding block friction force measuring device drives a sliding block to move through a servo motor to achieve measurement of the dynamic friction force of the sliding block at different running speed and under different loading effects, and the value of the friction force can be obtained by utilizing a pull pressure sensor. The guide rail mounting parallelism error measuring device converts parallelism errors among guide rails into internal stress of a connecting rod, and the values of the parallelism errors can be obtained through measurement of the pull pressure sensor. A standard straight gauge block is utilized by the guide rail linearity error measuring device as a reference of measurement, the linearity error of the guide rails is converted into changes of compression amount of a spring, a least square method is utilized for processing, measurement is convenient, and measurement accuracy is high.

Owner:TSINGHUA UNIV

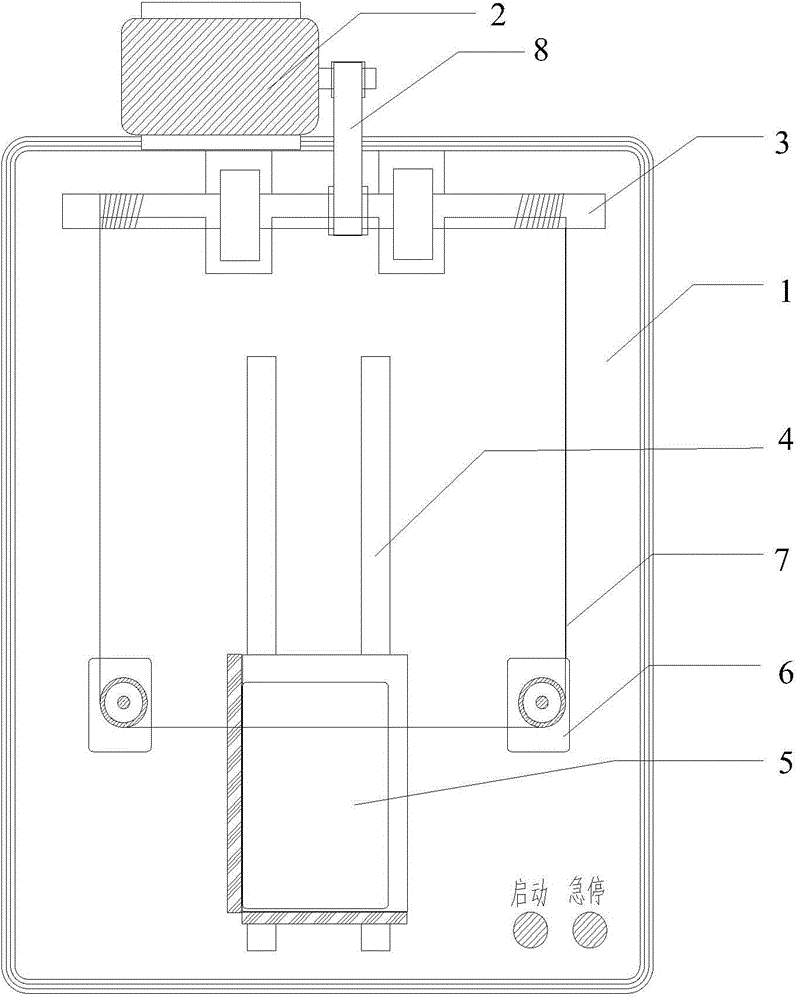

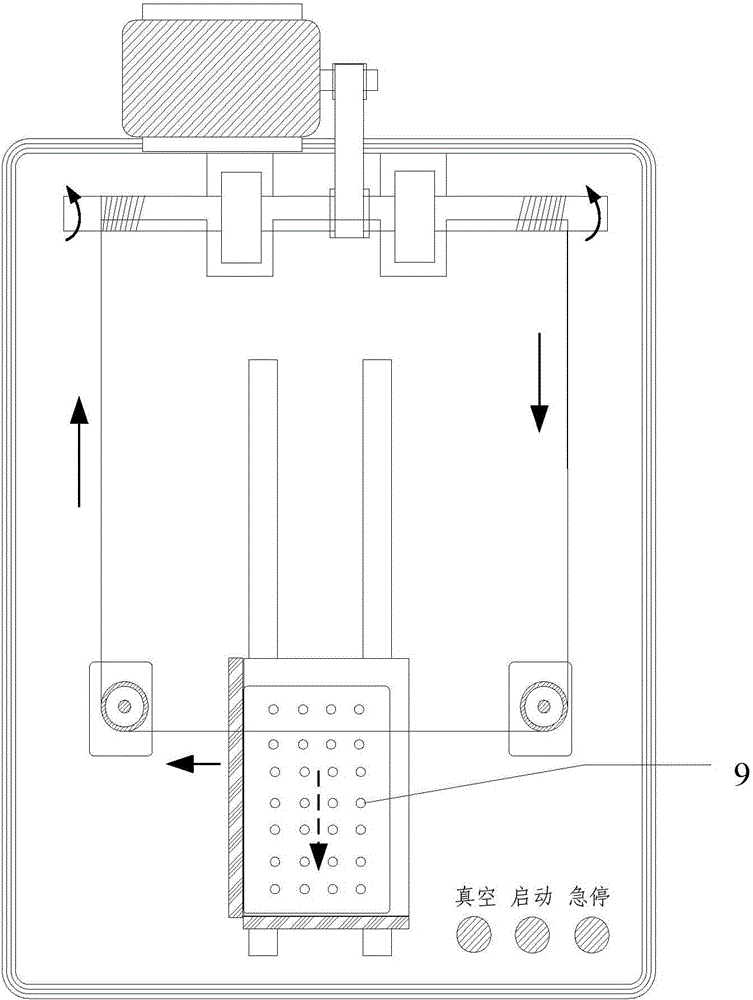

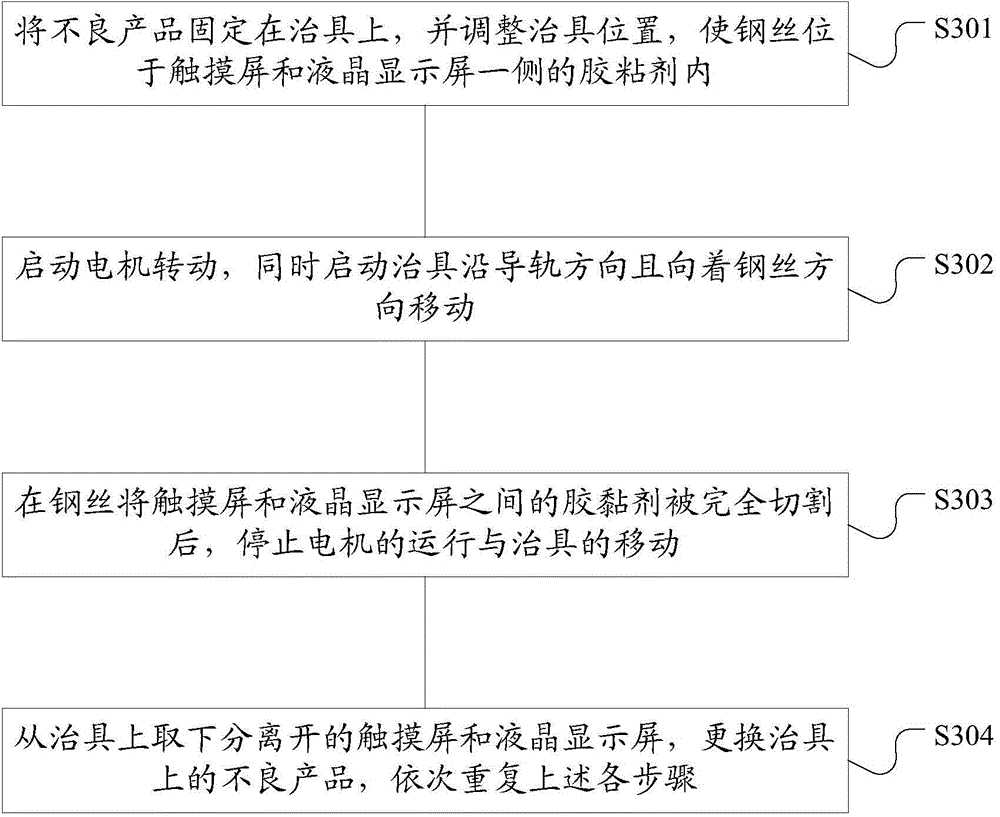

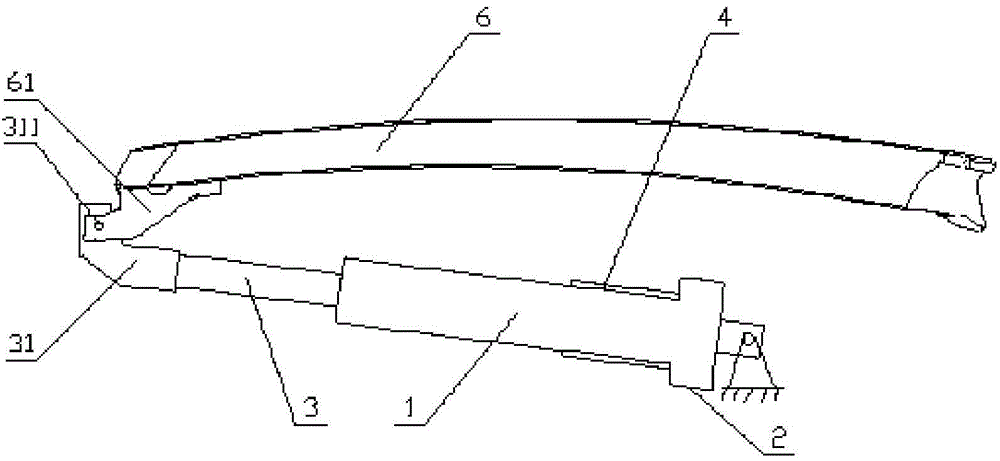

Disassembling device and disassembling method for touch screen and liquid crystal display screen

ActiveCN103552107AMovement speed is stableNo change in cutting forceMetal working apparatusBobbinLiquid-crystal display

The invention provides a disassembling device and a disassembling method for a touch screen and a liquid crystal display screen. The disassembling device comprises a working platform, a motor, a bobbin, a steel wire, a rotor, a guide rail and a jig. The invention further correspondingly provides a use method of the disassembling device. The disassembling method comprises the following steps: fixing a defect product on the jig; starting the motor; driving the bobbin to rotate under the rotating action of the motor; winding the steel wire at one end of the bobbin while releasing at the other end; driving the steel wire between the rotor and the bobbin to walk continuously; meanwhile, moving the jig towards the steel wire along the guide rail, so that the steel wire can be used for cutting an adhesive between the touch screen and the liquid crystal display screen on the jig, and the touch screen is separated from the liquid crystal display screen. The disassembling device provided by the invention is automatic mechanical equipment, and the rotating speed of the motor and the moving speed of the jig are uniform, so that the moving speed of the steel wire is kept stable, and the yields of the disassembled touch screen and liquid crystal display screen are increased relatively.

Owner:金龙机电(杭州)有限公司

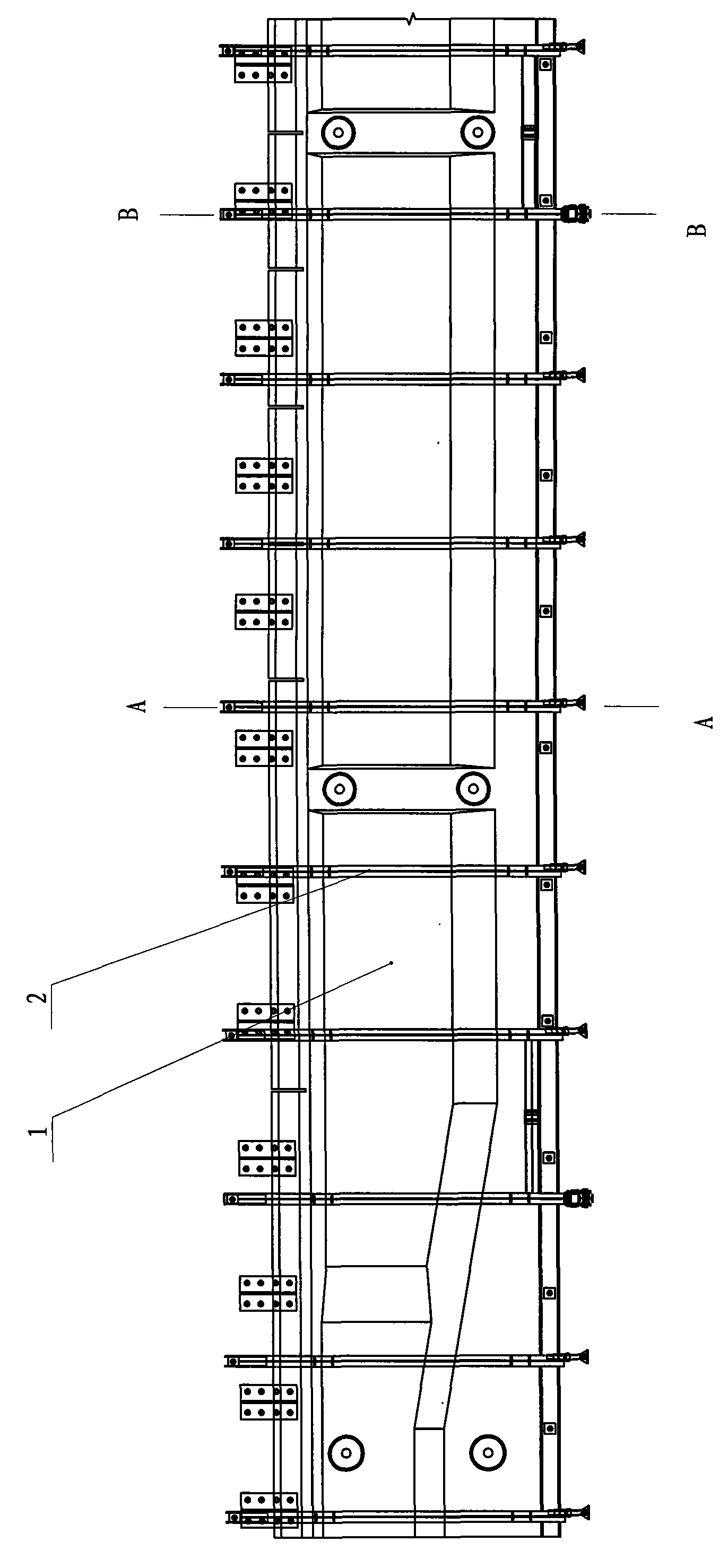

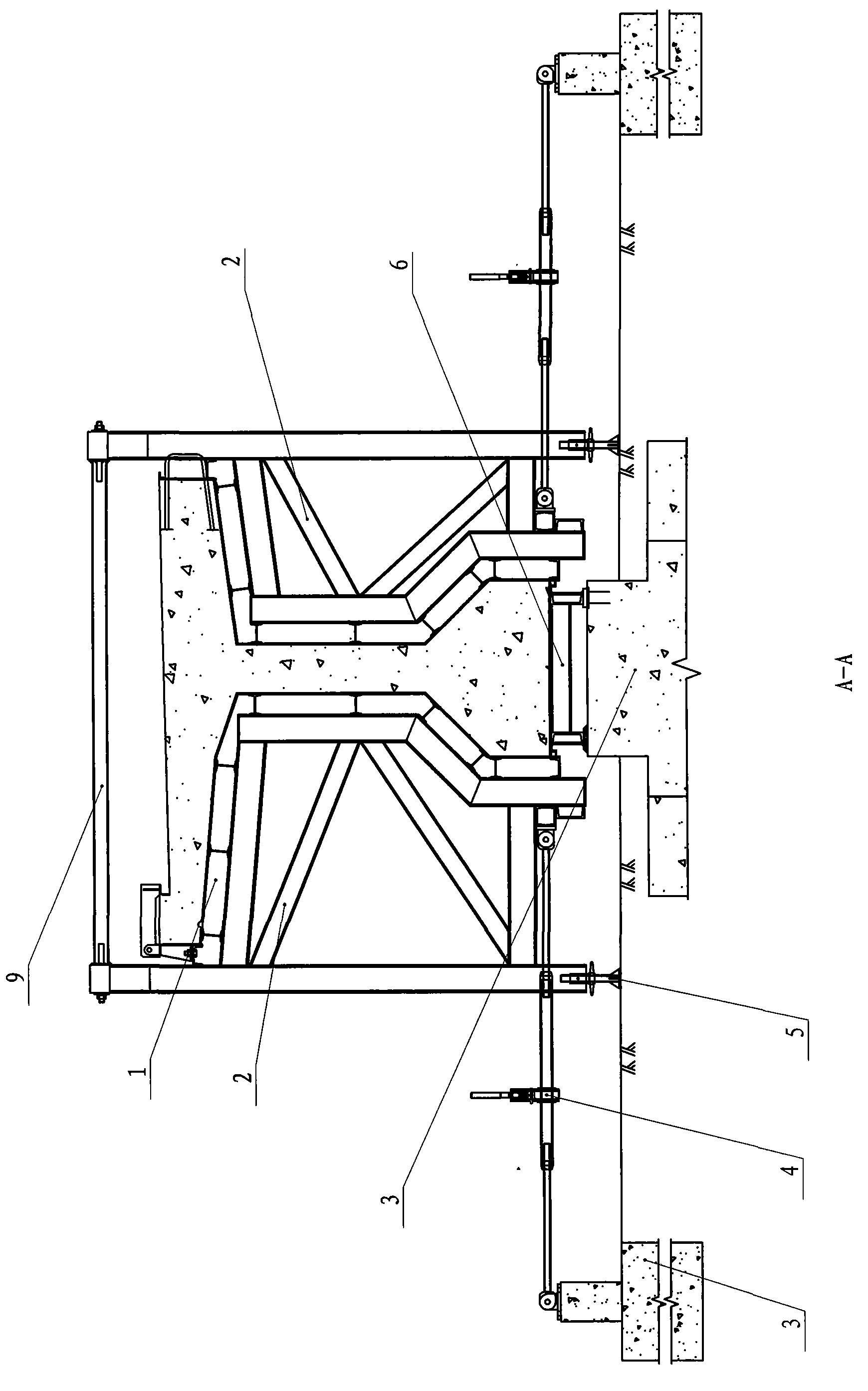

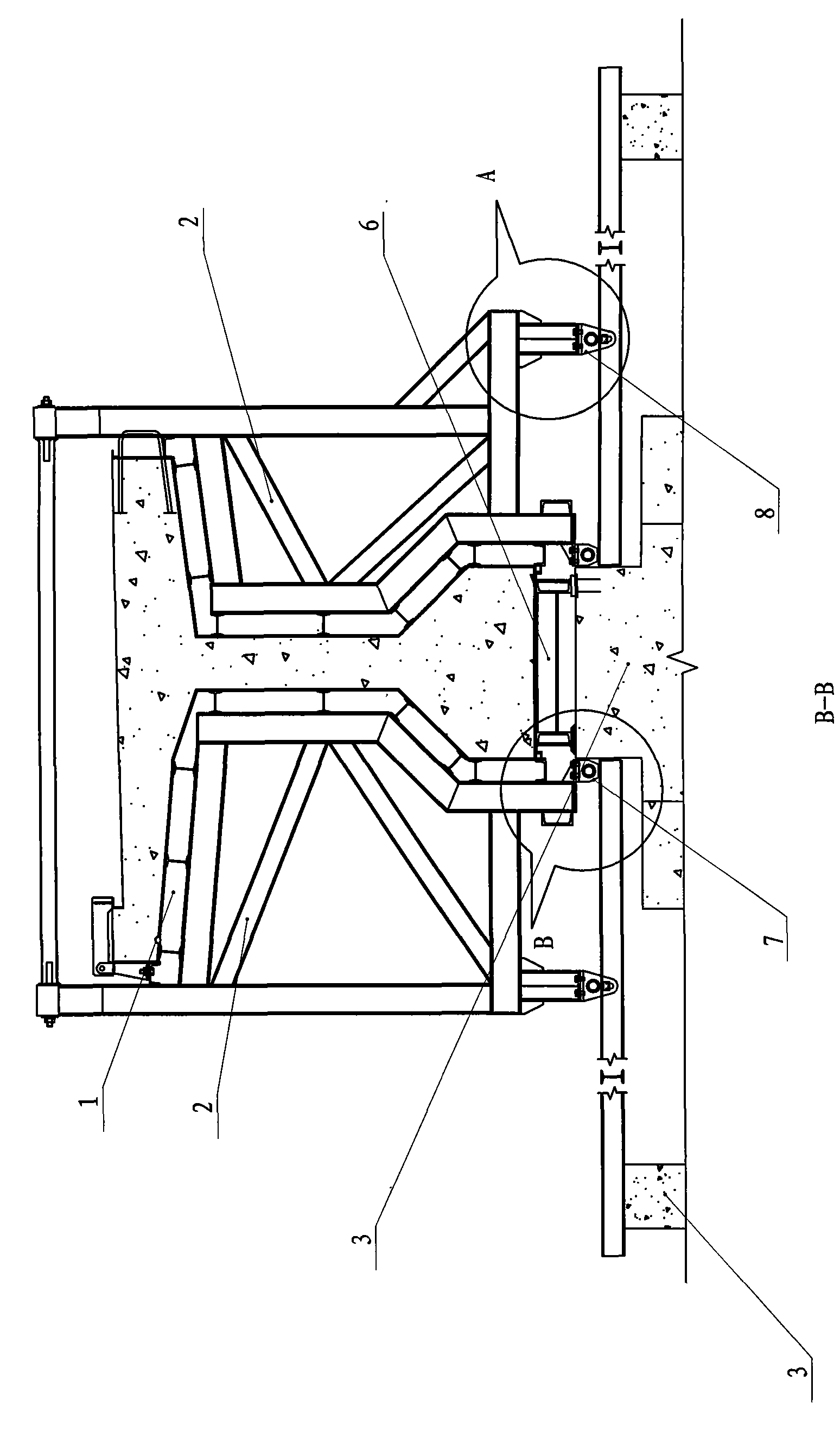

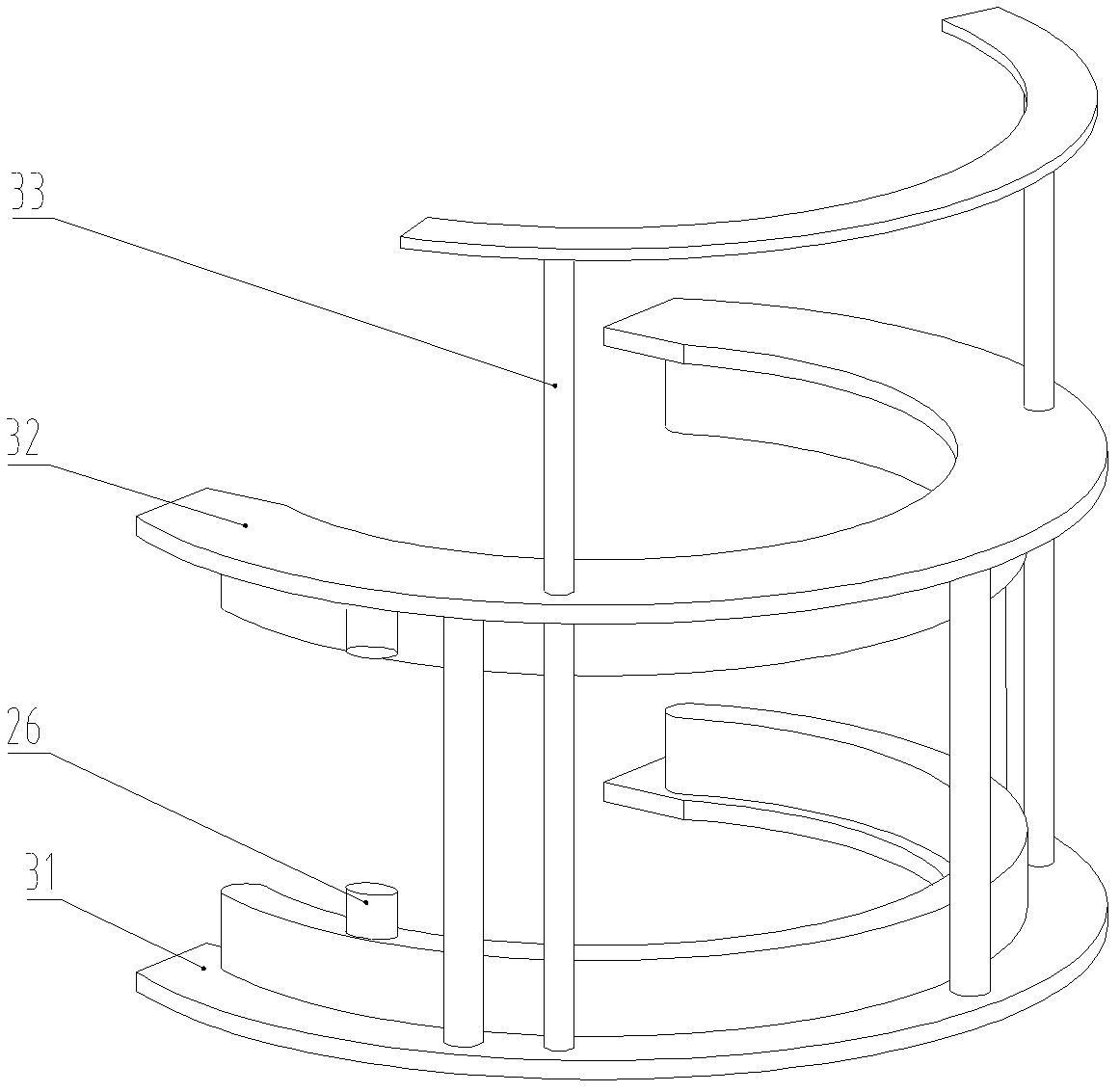

Template system capable of internally erecting and detaching mould

The invention relates to a template system capable of internally erecting and detaching a mould, which comprises a pedestal, a template and a bracket thereof. The template comprises two side templates and a bottom template; the bottom template is fixed on the pedestal; the bottom template and the two side templates are moveably connected through bolts; the upper parts of the two side templates are provided with transverse pull rods; the outsides of brackets of the two side templates are provided with a plurality of transverse parallel guide rails; the lower parts of the brackets on two sides are provided with rail wheel devices matched with the guide rails; and the lower parts of the brackets of the two side templates are connected with a plurality of bracket driving devices which can drive the brackets on two sides to move on the guide rails. The template system can realize the integral erecting and detaching of the templates, reduce the time and labor force input occupied in the erecting and detaching process, improve the production efficiency and save the cost.

Owner:CHINA RAILWAY 22ND BUREAU GROUP +1

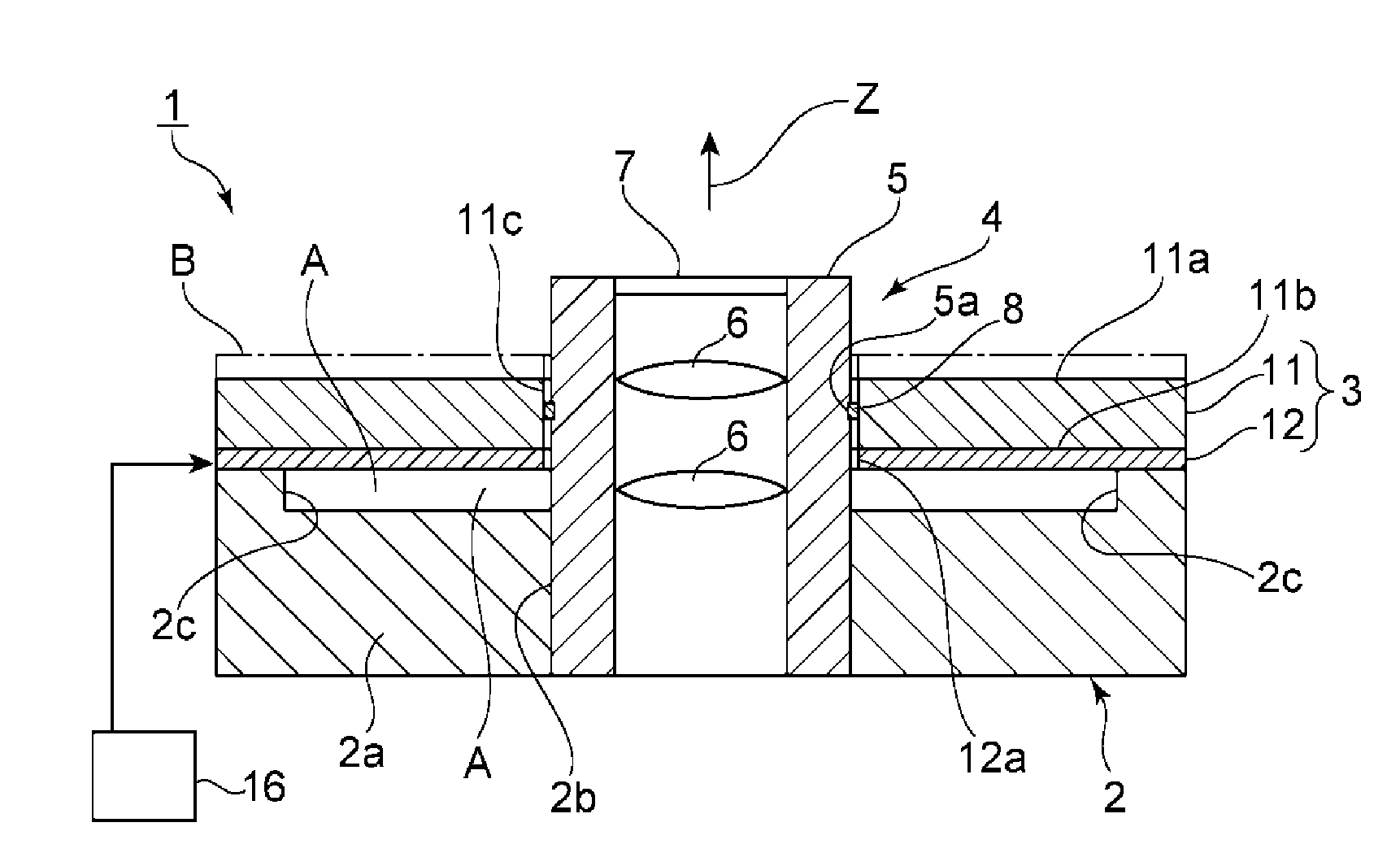

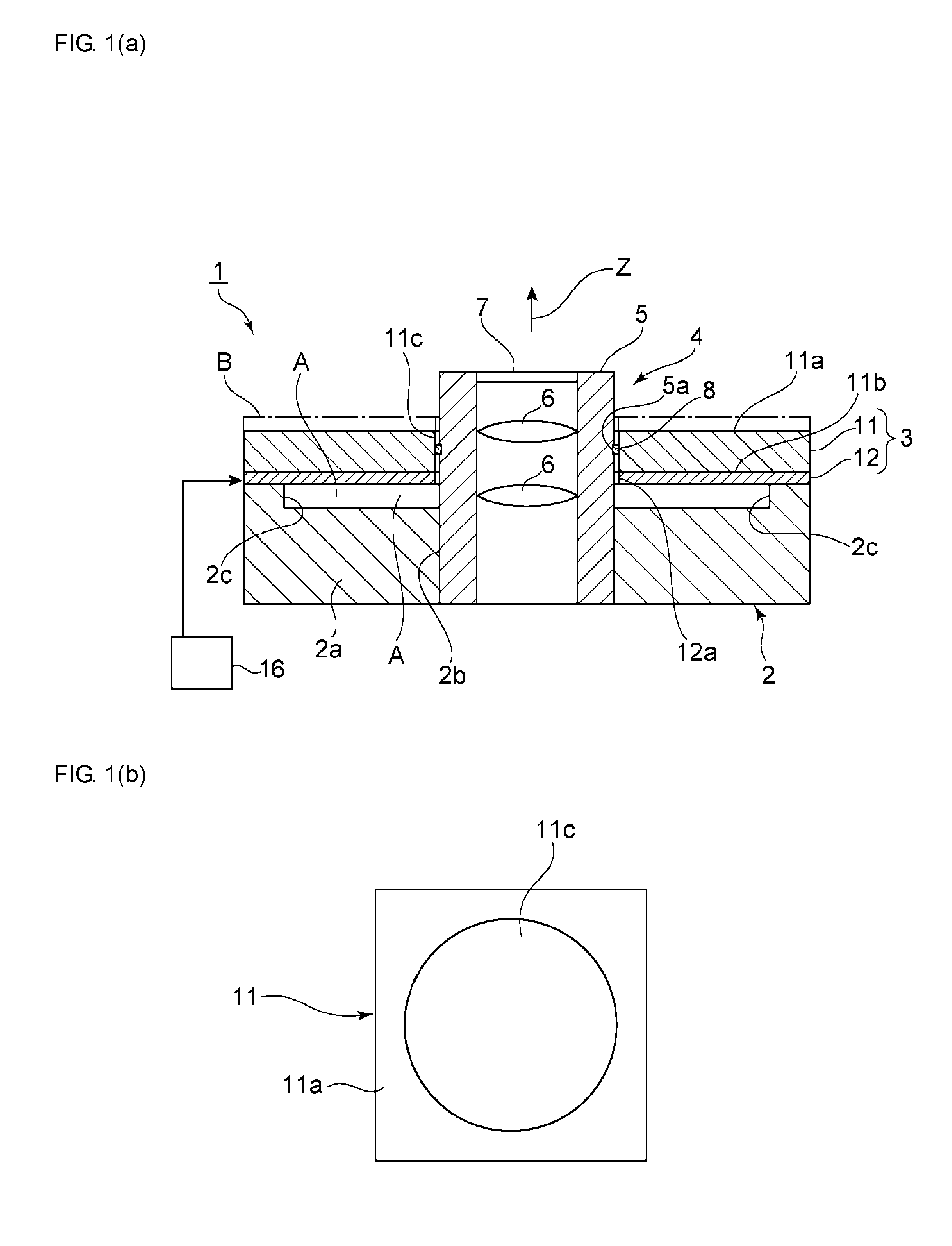

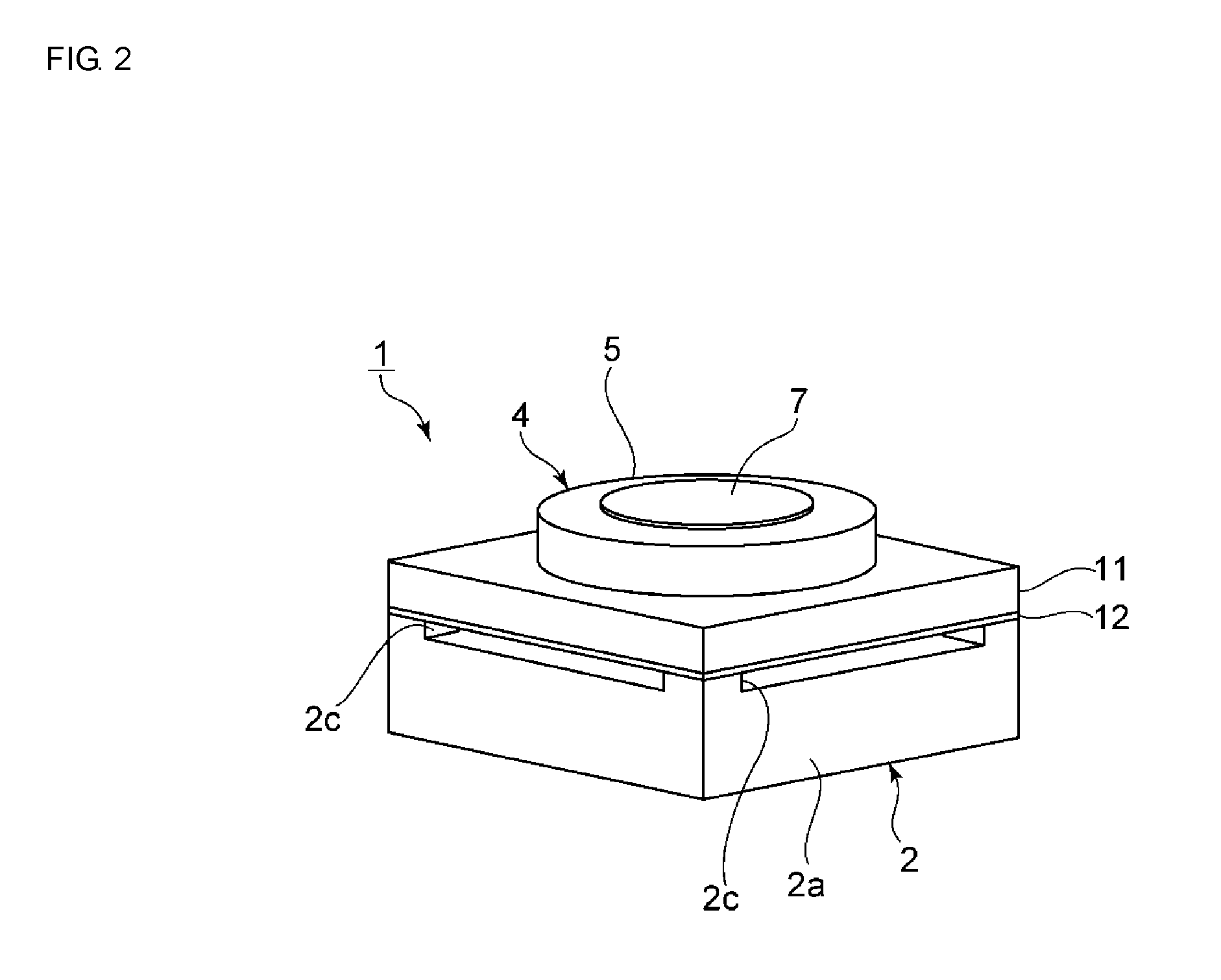

Driving device

ActiveUS20160268928A1Movement speed is stablePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsElastomerEngineering

A driving device that causes a movable body to move stably with minimal backward movement. The driving device includes a plate-shaped driving unit with an elastic body and a piezoelectric element joined to a main surface of the elastic body. Moreover, the movable body is disposed into a cavity of the elastic body and is moved by being pitch fed when the driving unit is driven. The driving unit vibrates with flexural vibration and one more other vibration modes or with vibration of a coupled mode in which the flexural vibration and the other vibration mode are coupled with each other.

Owner:MURATA MFG CO LTD

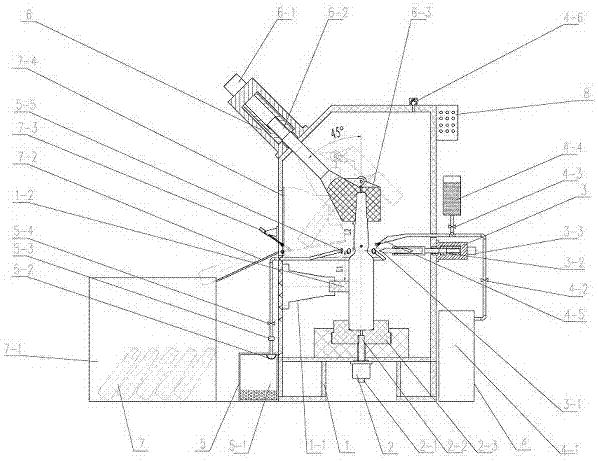

Sterile opening method and device of medical ampoule bottle

InactiveCN106946203ANo pollution in the processReduce generationOpening closed containersBottle/container closureAutomatic controlPharmacy medicine

The invention discloses a sterile opening method and device of a medical ampoule bottle. The device is composed of a sealing box body, a clamping and rotating mechanism, a sawing mechanism, a cleaning and disinfecting mechanism, a chip removing mechanism, a breakoff mechanism, a waste collecting mechanism and an electric control system. By means of reasonable depth and length sawing, liquid gas disinfecting and outward-pulling breakoff on the ampoule bottle, negative pressure lower than the pressure in the ampoule bottle is generated outside the ampoule bottle, and fewest glass chips are generated by the ampoule bottle in the breakoff process, and the glass chips directionally flow towards the outer portion of the ampoule bottle to be collected by the chip removing mechanism and cannot fall into the ampoule bottle. After breakoff of the ampoule bottle is finished, the ampoule bottle is inflated with sterile nitrogen, medicines are free of pollution, and a broken-off bottle head is automatically recycled. According to the sterile opening method and device, the process of clamping, sawing, chip removing, cleaning, disinfecting, breakoff and gas inflation is automatically completed, manual operation is not needed, and operation damage is avoided; liquid gas spraying disinfecting is carried out, and pollution of scrubbing absorbent cotton residues on medicines is avoided. Full-automatic control, safety, reliability and environment protection are achieved.

Owner:郇晶晶

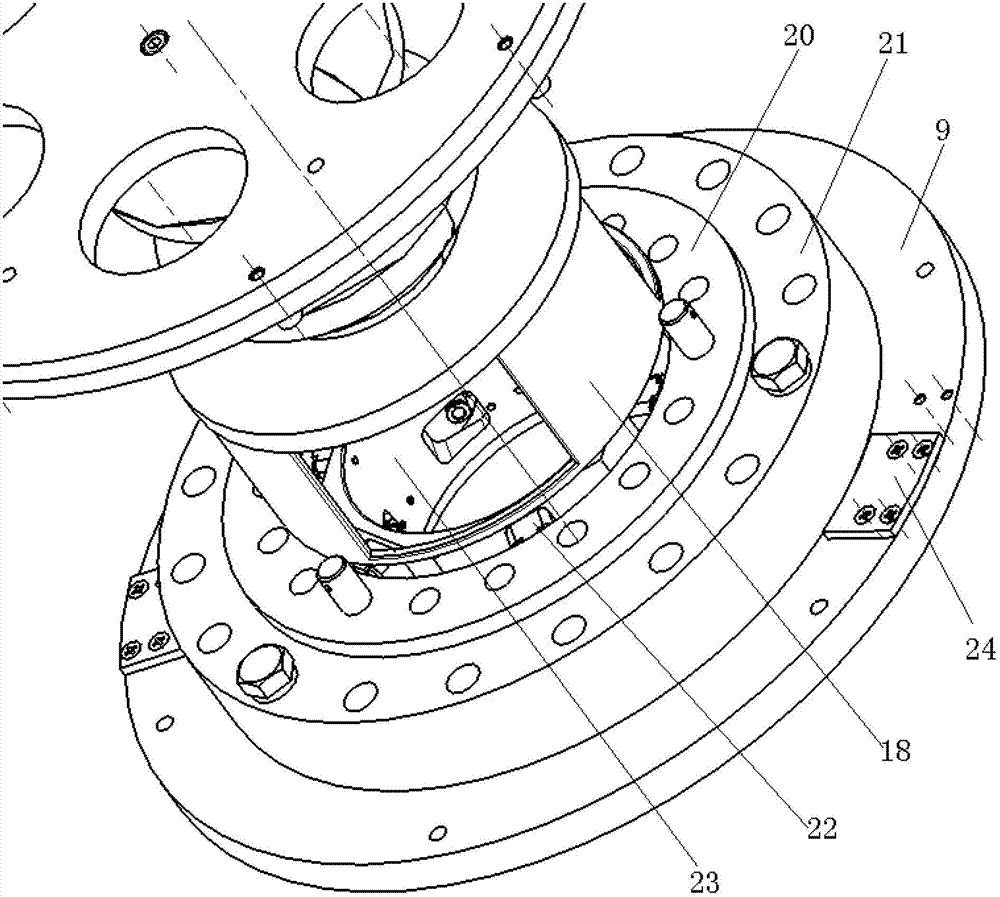

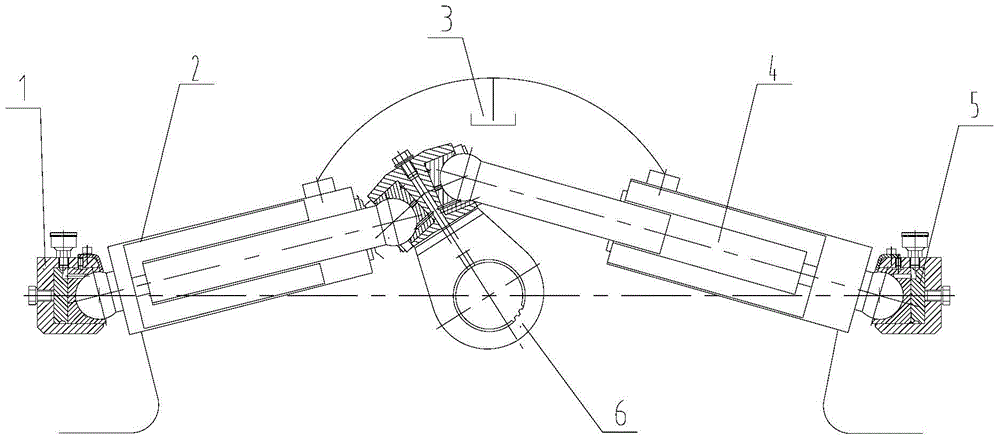

Swing mechanism and concrete pumping device

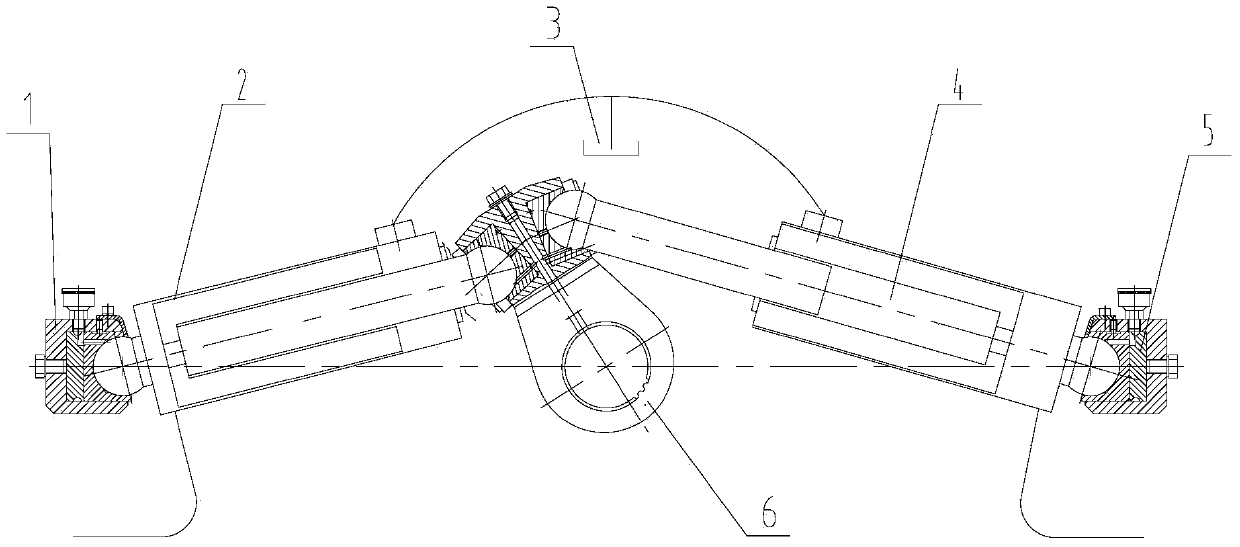

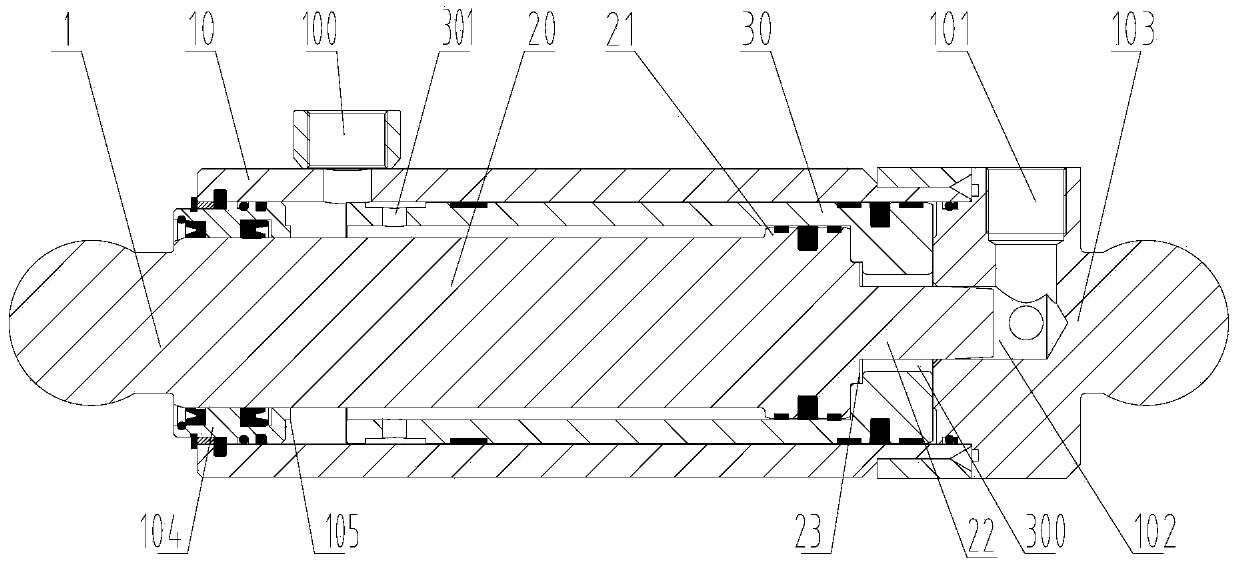

ActiveCN103470555AFast changeover timeReduce changeover timeServomotorsPumpsReverse timeMechanical engineering

The invention discloses a swing mechanism. The swing mechanism is used for driving a distributing valve of a concrete pumping device to swing and comprises a swing arm for driving the distributing valve and two hydraulic oil cylinders for driving the swing arm to swing from side to side. Ends of the two hydraulic oil cylinders are respectively connected with the left side and the right side of the swing arm, and the hydraulic oil cylinders are two-stage hydraulic oil cylinders. The invention further discloses the concrete pumping device comprising the swing mechanism. According to the swing mechanism and the concrete pumping device with the swing mechanism, the reversing speed is quick, impact is small, reversing time of the swing mechanism is close to reversing time of a main oil cylinder of the concrete pumping device, and pumping continuity is greatly improved.

Owner:SANY AUTOMOBILE MFG CO LTD

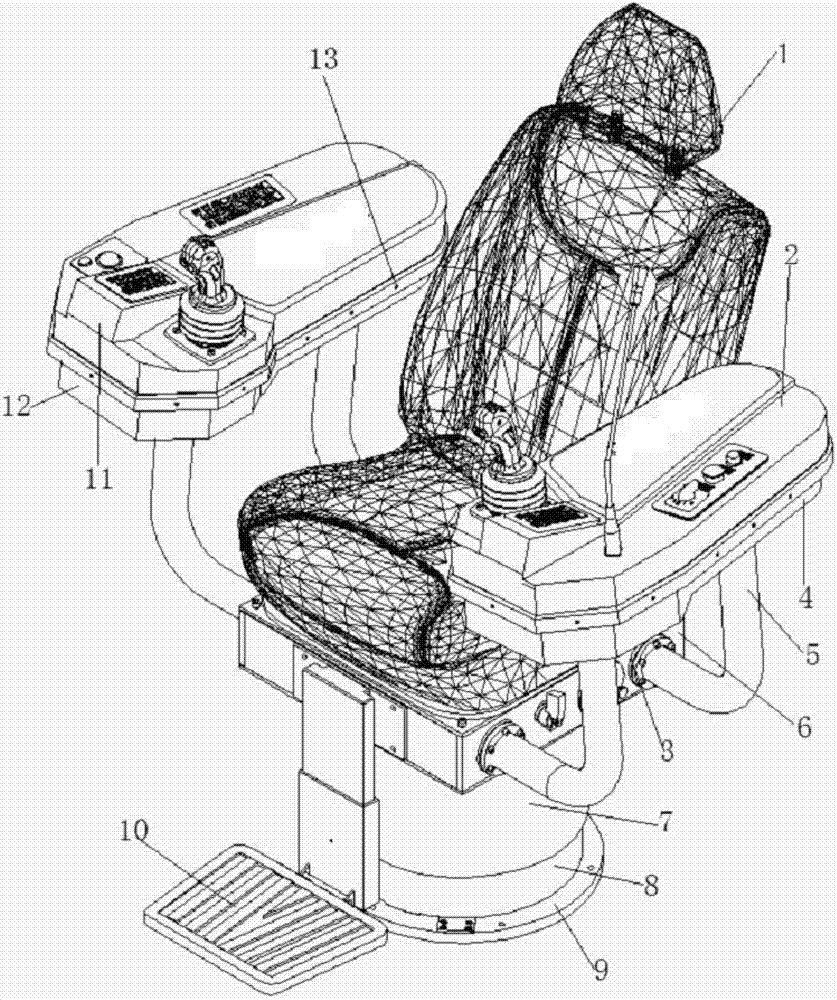

Driller operating seat of driller room of petroleum drilling machine

ActiveCN103192745ASmooth up and down motionMovement speed is stableMovable seatsHydraulic cylinderLocking mechanism

The invention discloses a driller operating seat of a driller room of a petroleum drilling machine. The driller operating seat comprises a rotating part, a lifting part, a seat and a box body. The rotating part adopts the structure that a bearing outer ring of a turnplate is fixedly mounted on the upper surface of a seat fixing plate; a mounting cylinder is fixedly mounted at the axis position of the seat fixing plate; a plurality of diaphragm type clamping cylinders are mounted on the mounting cylinder circumferentially and uniformly; the outer circumferences of the diaphragm type clamping cylinders are contacted with a bearing inner ring of the turnplate; a rotating limiting plate is arranged on the seat fixing plate; and a convex block corresponding to the rotating limiting plate is arranged on the lower edge of the bearing inner ring of the turnplate. The driller operating seat of the driller room solves the problems that a hydraulic cylinder leaks oil during lifting, an air cylinder is locked unreliably during lifting, the upper box body of the handrail operating box cannot be fixed reliably after being opened, upper and lower box bodies are sealed unreliably, the cable trend is influenced by excessive up-and-down motion guide rods and a rotating locking mechanism is not provided in the conventional products.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

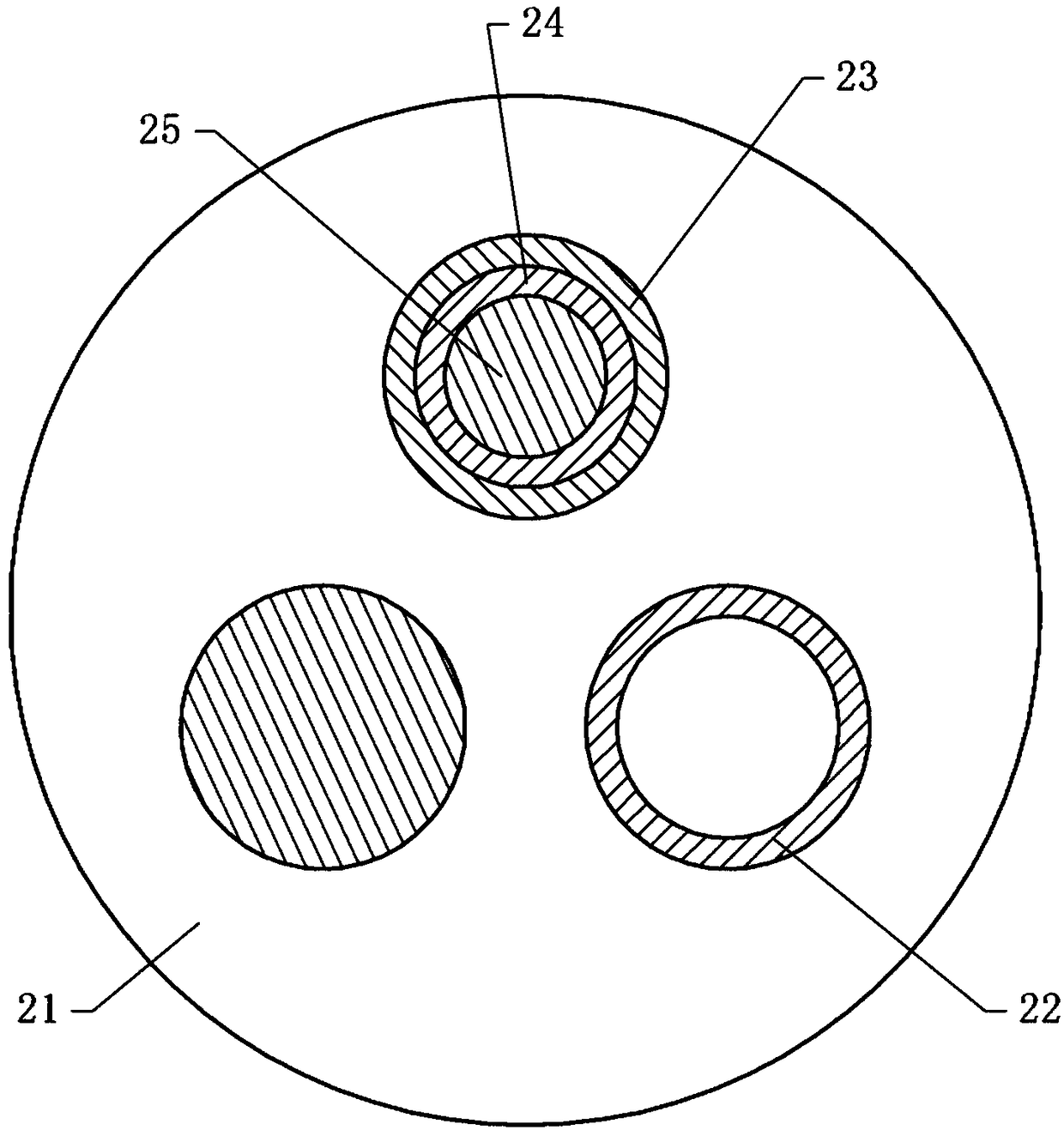

New method for preparing copper-aluminum composite pipe

InactiveCN101530870AMovement speed is stableAvoid wrinklesArc welding apparatusLaser beam welding apparatusRoom temperatureAluminum metal

The invention provides a new method for preparing a copper-aluminum composite pipe. The method comprises the following steps of winding a rolled internal layer copper or aluminum metal band into a metal circular pipe under the traction action of a guide wheel and the extrusion action of a forming roller; forming an internal layer metal pipe by welding a longitudinal seam; winding and cladding an external layer aluminum or copper metal band around the internal layer metal pipe by the same method; forming a copper-aluminum composite pipe blank by welding the longitudinal seam; and obtaining the copper-aluminum composite pipe with needed size through drawing and heat treatment. The adopted method ensures that the preparation of the copper-aluminum composite pipe can be conducted all at room temperature, multilayer composite of copper-aluminum-copper, and the like can be flexibly conducted, the preparation process is simple, and the requirement on the device is low. The speed at which the guide wheel moves forwards is controlled by a servo motor, thus ensuring the moving speed of the guide wheel to be stable and welding points of the longitudinal seam to be positioned in a same horizontal line, and preventing the phenomena that the composite pipe surface wrinkles, and the like. The method has great advantage in the preparation of the copper-aluminum composite pipe.

Owner:浙江恒飞控股有限公司

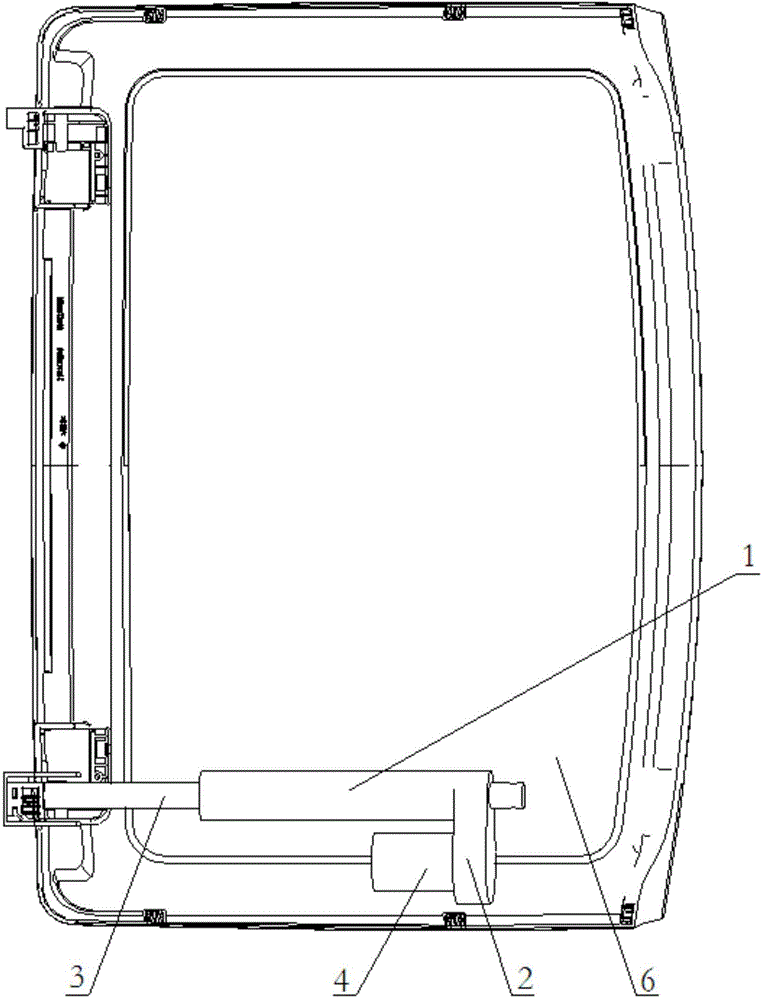

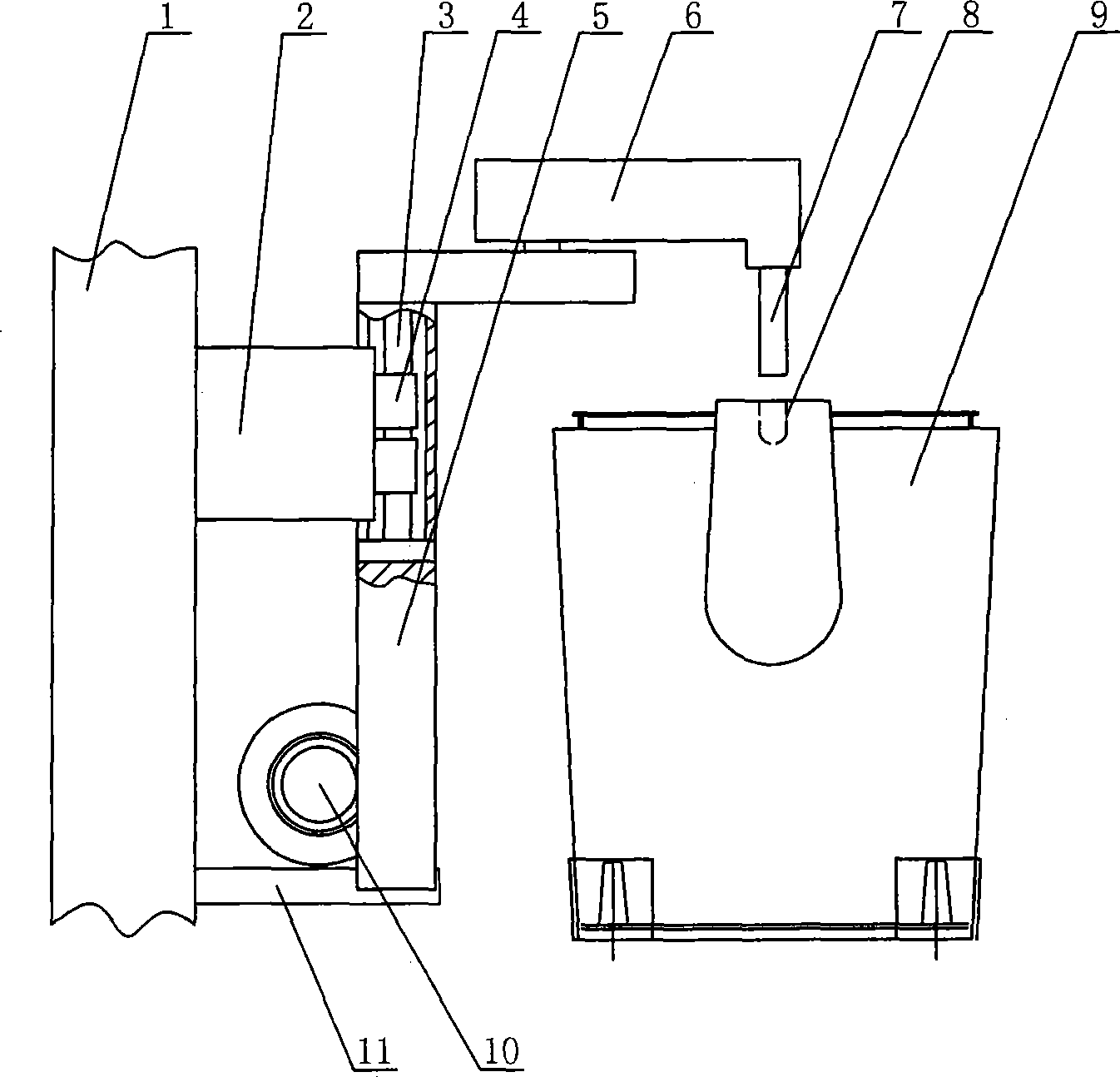

Opening and closing device of upper cover of washing machine and washing machine

ActiveCN104862929AMovement speed is stableGuaranteed stabilityOther washing machinesTextiles and paperMechanical engineeringTransmission ratio

The invention discloses an opening and closing device of an upper cover of a washing machine and the washing machine. The opening and closing device comprises a control device and a telescopic mechanism, wherein a lever is formed on the upper cover and can rotate around a rotating shaft, and the telescopic mechanism is connected with one end of the lever and can drive the lever to rotate under the control of the control device, so that the upper cover is opened and closed. According to the opening and closing device of the upper cover of the washing machine, the upper cover of the washing machine is opened and closed by the aid of a nut-screw transmission structure, the fixed transmission ratio can be set for the nut-screw transmission structure usually, so that the upper cover of the washing machine has the stable movement speed at any angle during opening or closing, and opening and closing stability and reliability of the upper cover are guaranteed.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

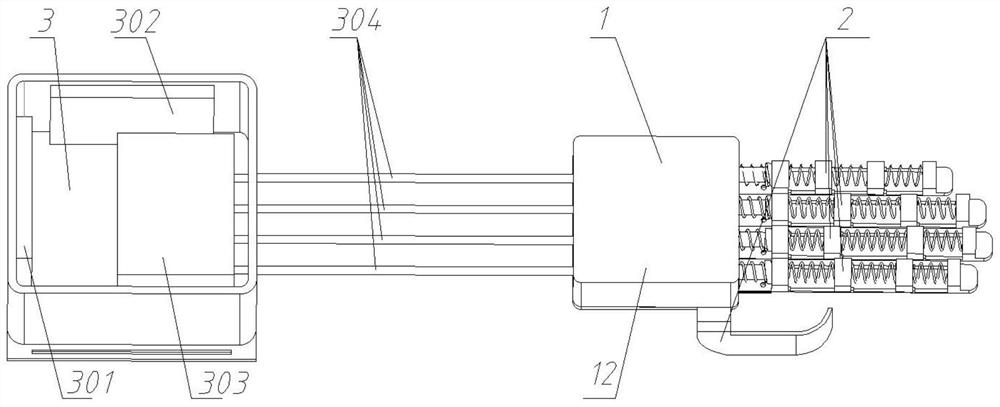

Accurate locking and unlocking automobile-mounted storage battery automatic exchange station

InactiveCN108032844ASmooth liftSmooth movementElectric propulsion mountingVehicle servicing/repairingElectric machineryMotion space

The invention belongs to the technical field of vehicle maintenance and relates to an accurate locking and unlocking automobile-mounted storage battery automatic exchange station. The station comprises an automobile locating and lifting mechanism used for locating and lifting an electric automobile and a battery locking and unlocking mechanism used for locating and replacing an automobile-mountedstorage battery. Each locking and unlocking component comprises a locking and unlocking motor and a screwdriver driven by the locking and unlocking motor and further comprises a connecting joint fixedto a main shaft of the locking and unlocking motor. Each screwdriver is provided with a handle part. Each connecting joint comprises a containing cavity used for containing the corresponding handle part. The inner section of each containing cavity is larger than the section of the corresponding handle part. Each of the two sides of each handle part is provided with a protruding lug. Each connecting joint is provided with two kidney-shaped holes formed in the axial direction. Each protruding lug is contained in the corresponding kidney-shaped hole, and each screwdriver cannot be separated fromthe corresponding connecting joint. Each containing cavity provides a small-range motion space for the corresponding screwdriver so that each locking and unlocking component can adapt to a target fixing screw, and the problem that all the locking and unlocking components cannot conduct locking and unlocking operation synchronously due to manufacturing errors of an automobile chassis or automobile-mounted storage battery fixing holes is solved.

Owner:NIO CO LTD

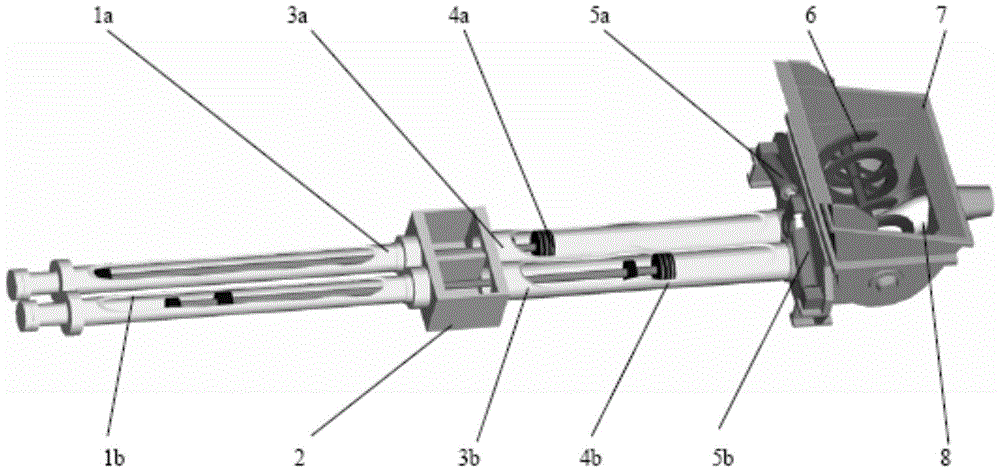

Detection robot for suspension porcelain insulator string

ActiveCN102621426AReduce wearLap firmlyProgramme-controlled manipulatorTransmission systemsRubber materialMechanical engineering

The invention discloses a detection robot for a suspension porcelain insulator string. The detection robot comprises a clamping mechanism, a lifting mechanism and a detecting mechanism, wherein the clamping mechanism comprises an upper clamping mechanism and a lower clamping mechanism, the lifting mechanism is arranged between the upper and the lower clamping mechanisms, and the detecting mechanism comprises a probe drive device which is arranged on the upper clamping mechanism and a detector triggering device which is arranged on the lower clamping mechanism; the upper and lower clamping mechanisms are respectively provided with a flexible insulation paw which is matched with the outer edge of an insulator shed; the clamping mechanism, the lifting mechanism and the detecting mechanism are connected with the controller respectively through a circuit. The robot is designed by adequately utilizing appearance characteristics of the suspension porcelain insulator string, and the clamping paws are respectively made of rubber materials, so that abrasion on the insulator is small, and short-circuited insulators are fewer; the robot has good safety and a good protective value and the insulators are simple to string, the movement speed is stable, accuracy in detection is realized, and the robot system can move along the direction of the suspension porcelain insulator string and can be electrified for detection.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

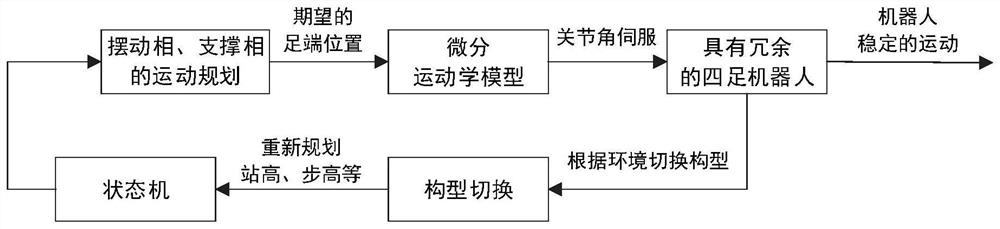

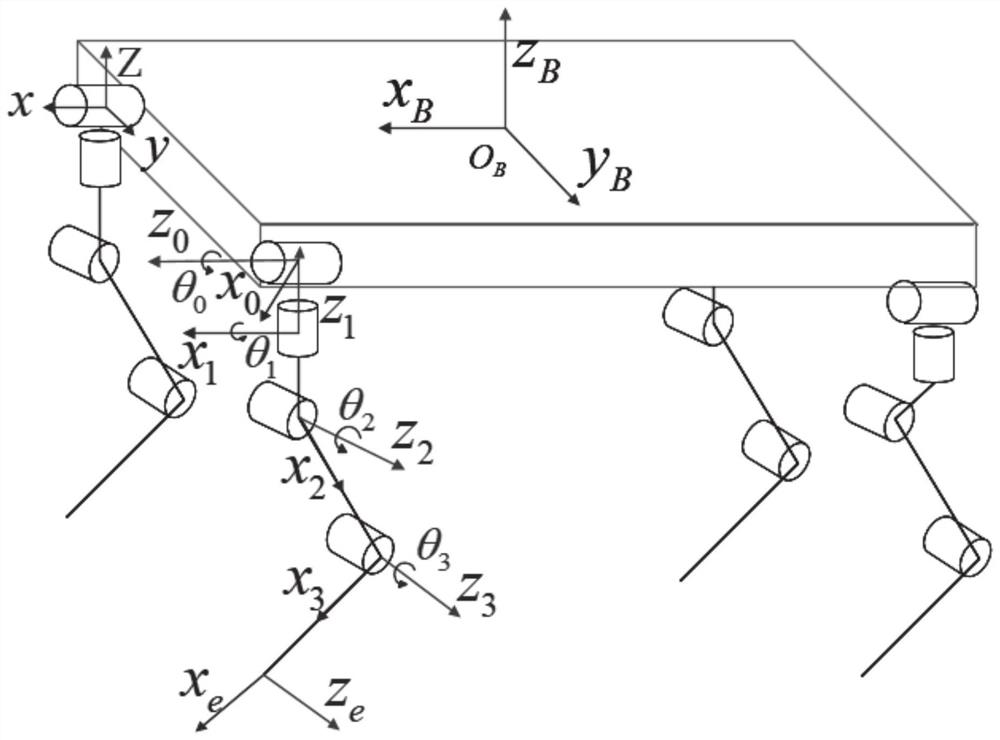

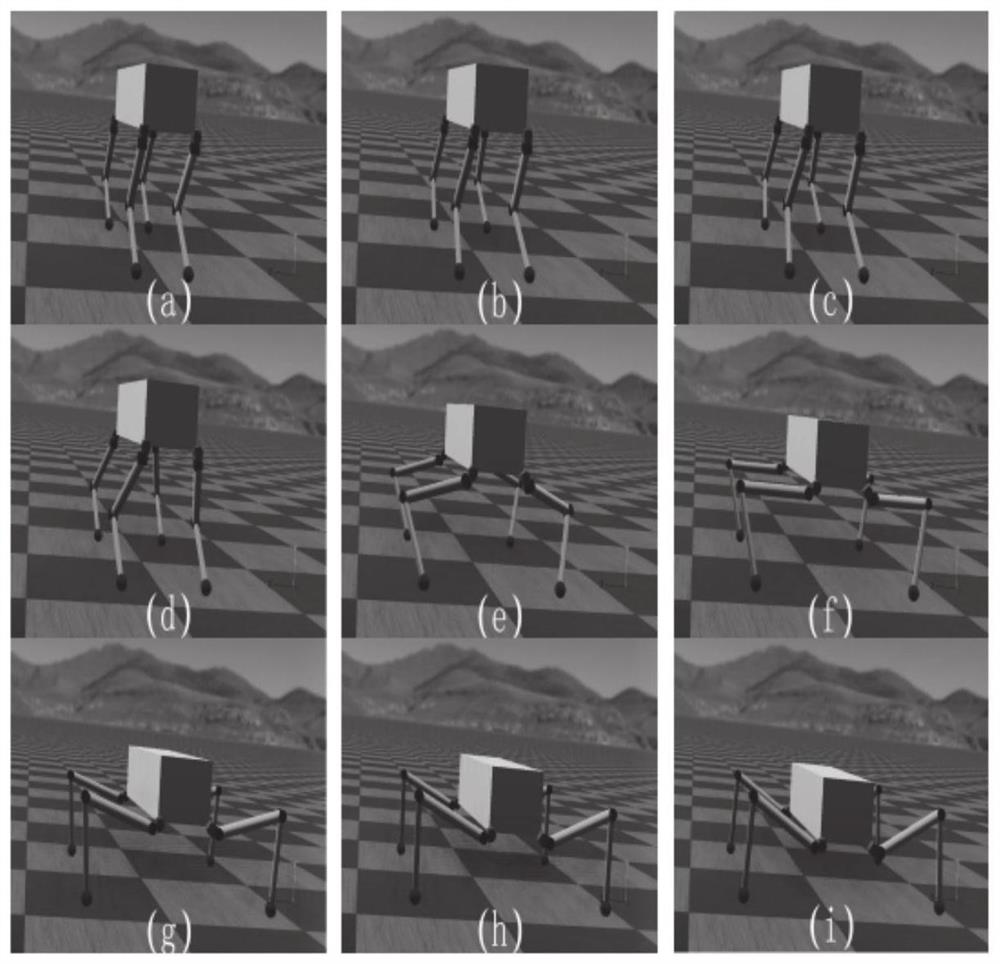

Configuration-variable quadruped robot motion control method and system

The invention discloses a configuration-variable quadruped robot motion control method and system. The method comprises the following steps that: the gait of a quadruped robot is planned; an integer programming model of the quadruped robot is established by taking the current joint position and speed of the robot as input based on differential kinematics of the robot; based on the redundant degreeof freedom, switching among various configurations of the robot is achieved; and the movement of the robot is planned based on a current configuration, and the expected foot end positions of a supporting phase and a swinging phase are planned. Therefore, all-directional movement of the quadruped robot under multiple configurations is achieved, and stability and adaptability are remarkably improved when the quadruped robot confronts complex terrains.

Owner:SHANDONG YOUBAOTE INTELLIGENT ROBOTICS CO LTD

Method for adjusting automobile seat headrest with protection function

InactiveCN105235561AAvoid harmImprove ride comfortVehicle seatsAutomobile safetyActive safety systems

The invention discloses a method for adjusting an automobile seat headrest with a protection function. The method comprises the following steps: firstly, a control module electrically connected with a cylinder is directly communicated with an automobile active safety system; when a distance of a vehicle behind to the present automobile is within a dangerous value range, the control module directly transmits a command to the cylinder so that an adjusting rod drives a head plate to move forwards, leading to that a supporting portion of the headrest gets close to the head of a passenger; in the movement process of the head plate, a fixed block is mounted on the adjusting rod and a connecting rod A, a connecting rod B and a connecting rod C are arranged on the fixed block, a bottom surface of the head plate and an inner sidewall of the frame, whereby the movement of the head plate is supported by the inner walls of the two sides of the frame and the fixed block simultaneously; when a distance of the vehicle behind to the present automobile is within a safe value range, the control module directly controls the cylinder to retract and the head plate directly falls into a rectangular groove so that the head of the passenger and the supporting portion of the head rest return, and therefore, synchronization of headrest protection and the automobile safety system is realized.

Owner:成都云科新能汽车技术有限公司

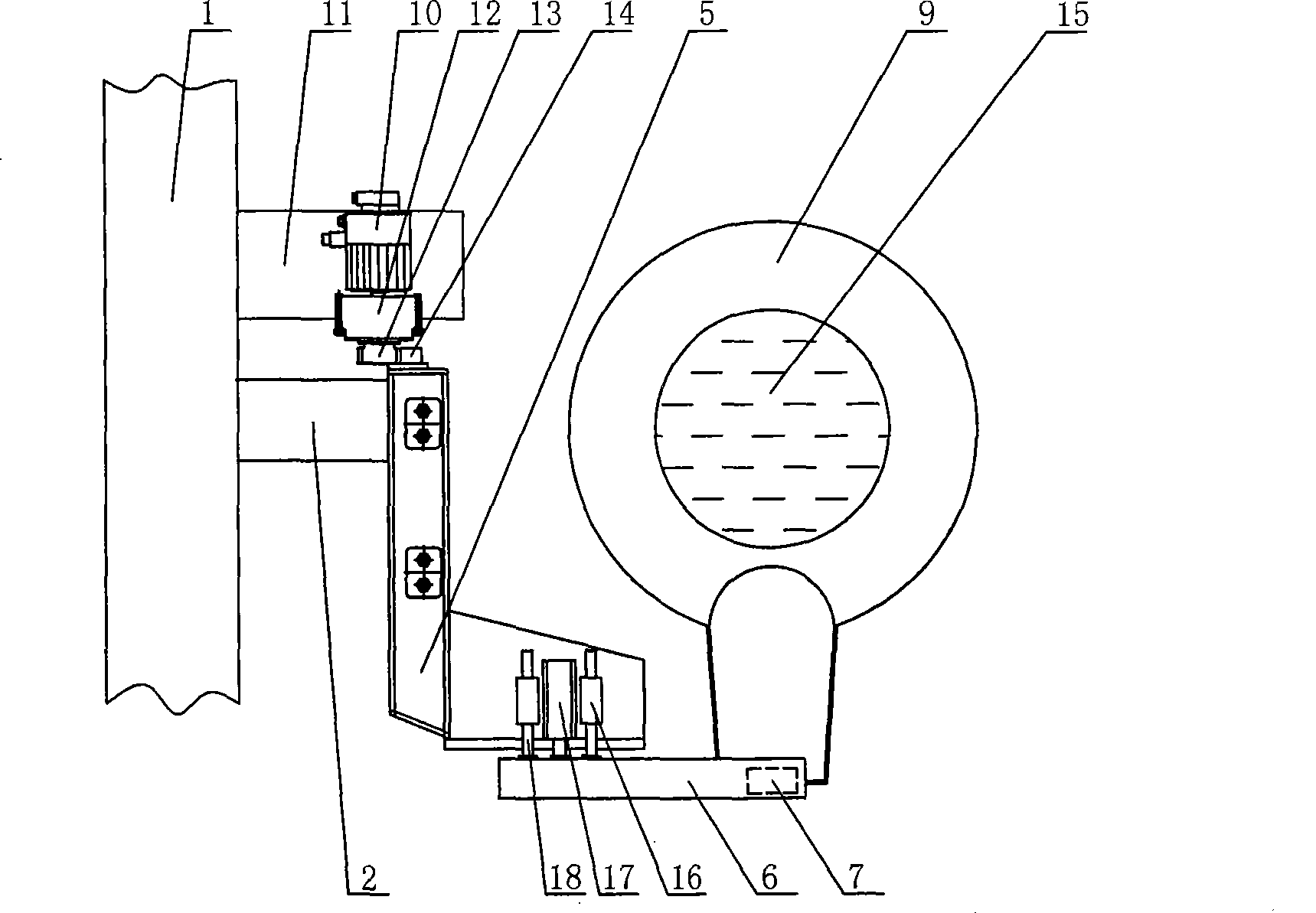

Pouring ladle with controlling mechanism of iron water flow

InactiveCN101433957AHigh degree of automationWith guided smoothingMelt-holding vesselsMotor driveControl signal

The invention relates to a casting ladle with a molten iron flow control mechanism. The casting ladle consists of a ladle frame and a ladle, wherein the ladle is provided with a ladle spout. The ladle frame is provided with a vertical beam vertically and glidingly. A horizontal beam is arranged on the upper end part of the vertical beam. The horizontal beam is vertically provided with a check block on one end corresponding to the ladle spout. A motor driving the vertical beam to do vertical movement is arranged on the ladle frame at a position corresponding to the bottom of the vertical beam. The casting ladle adopts a central control system to send a signal to a servo motor using gears and racks to realize the vertical movement of the vertical beam according to digital revolution given by a controller, realizes precise multi-point positioning displacement control with a digital control signal, and can cast stably and precisely compared with the prior pouring mode of casting ladle. The casting ladle is suitable to be used for casting castings which are complex in shape and light in mass and volume and is suitable for adjusting iron flow during mass product casting.

Owner:ZHIHENG TIANJIN IND

A swing mechanism and concrete pumping equipment

ActiveCN103470555BFast changeover timeReduce changeover timeServomotorsPumpsMaster cylinderEngineering

A wobbler mechanism is used for driving a distributing valve of a concrete pumping device to wobble, and comprises a wobbling arm (6) for driving the distributing valve, and two hydraulic oil cylinders (2, 4) for driving the wobbling arm (6) to wobble from side to side. One end of each of the two hydraulic oil cylinders (2, 4) is connected to left and right sides of the wobbling arm (6), and the hydraulic oil cylinders (2, 4) are two-stage hydraulic oil cylinders (2, 4). Also disclosed is a concrete pumping device having the wobbling mechanism. The wobbling mechanism and the concrete pumping device having the wobbling mechanism is fast in direction change and has a low impact, so that the direction change time of the wobbling mechanism is close to that of a master cylinder of the concrete pumping device, thereby greatly improving pumping continuity.

Owner:SANY AUTOMOBILE MFG CO LTD

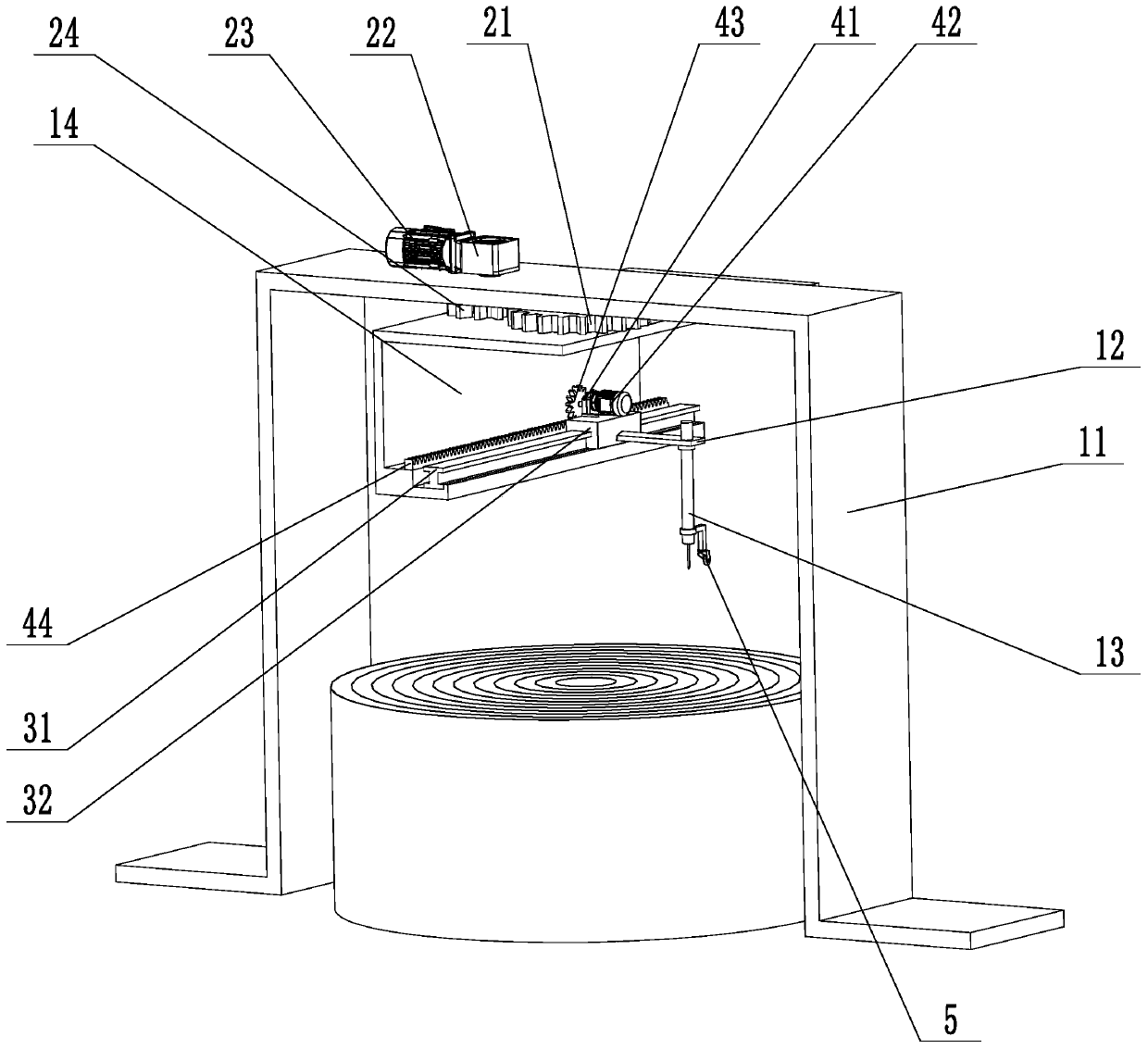

Spiral plate end surface welding device

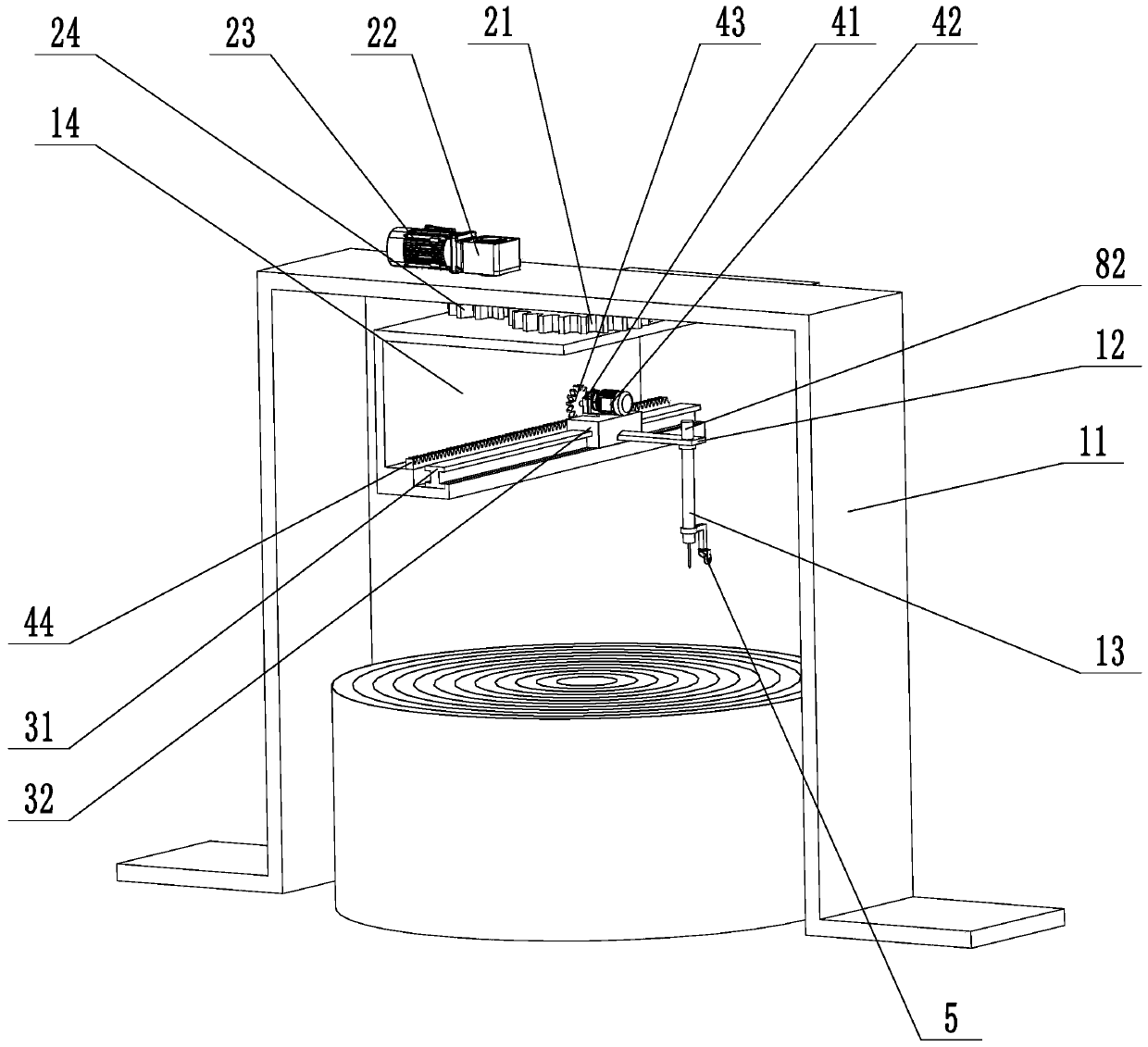

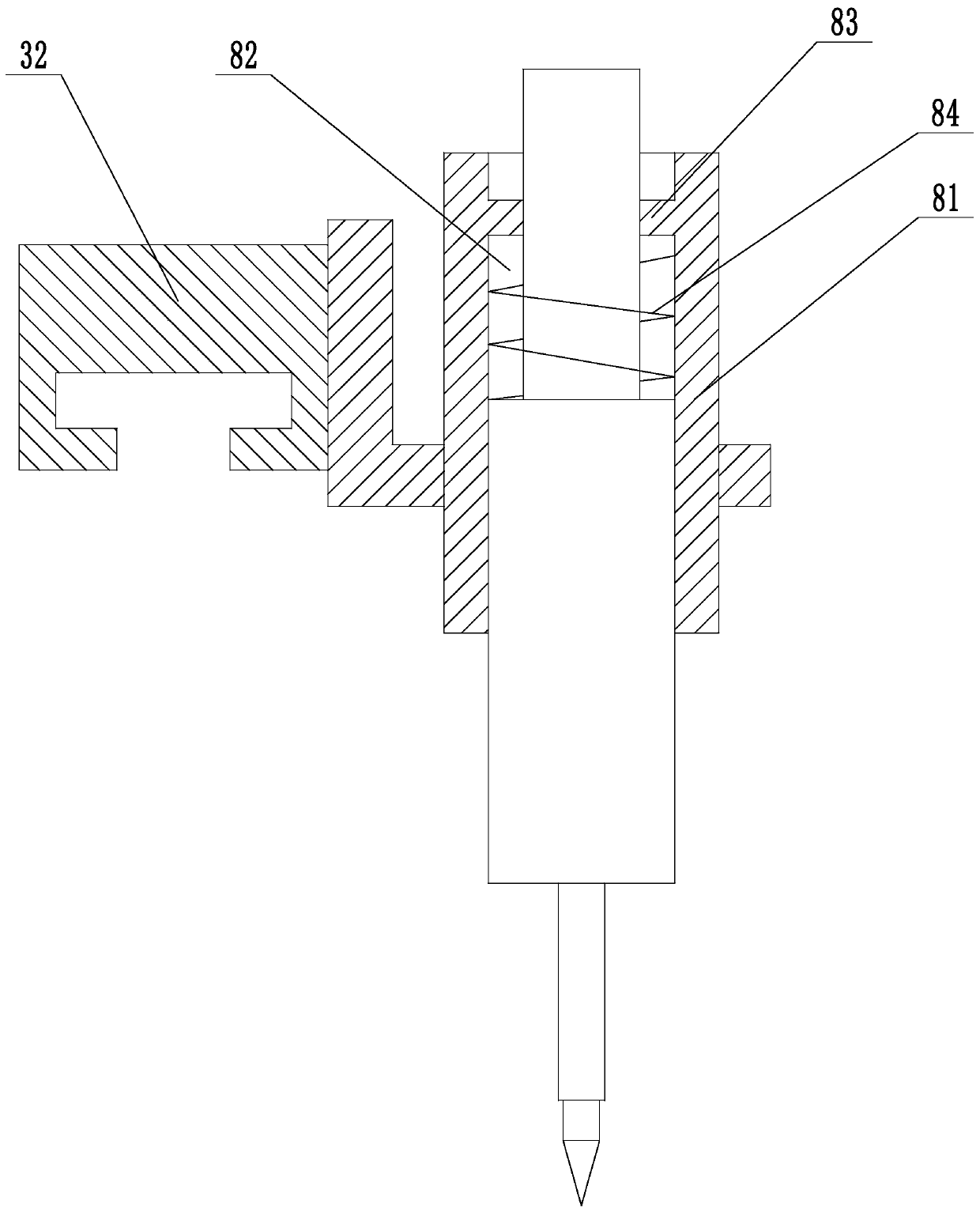

InactiveCN109894782ASmooth rotationHigh rotation accuracyWelding/cutting auxillary devicesAuxillary welding devicesGear wheelReducer

The invention relates to a spiral plate end surface welding device. The spiral plate end surface welding device comprises a portal frame, a rotating platform connected with the portal frame, a rotation driving device arranged on the portal frame and used for driving the rotating platform to rotate, a horizontal operating platform arranged on the rotating platform, a transverse linear module arranged on the horizontal operating platform, a welding gun arranged on the transverse linear module and a transverse driving device arranged on the transverse linear module and used for driving the transverse linear module to act, wherein a rotating bearing is arranged on the portal frame; the rotating platform is fixedly mounted on the rotating bearing; the rotation driving device comprises a rotating speed reducer arranged on the portal frame, a rotating servo motor connected with the rotating speed reducer and a rotating gear arranged on an output shaft of the rotating speed reducer. The spiralplate end surface welding device is used for welding spiral plates and has the characteristics of rapid welding speed, low welding cost and high operating efficiency.

Owner:河北华环化工设备制造有限公司

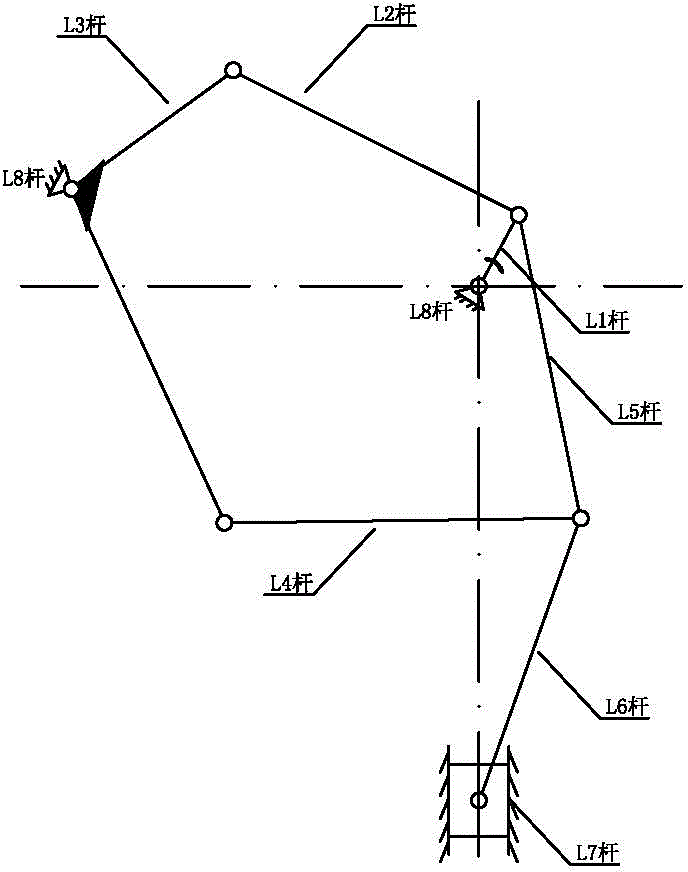

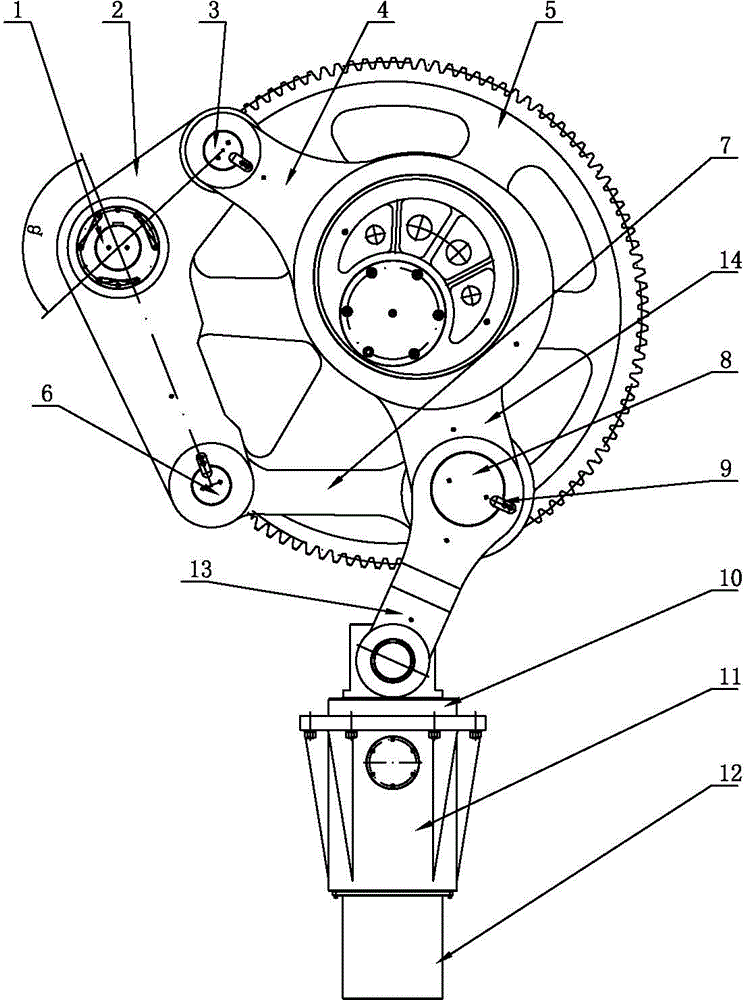

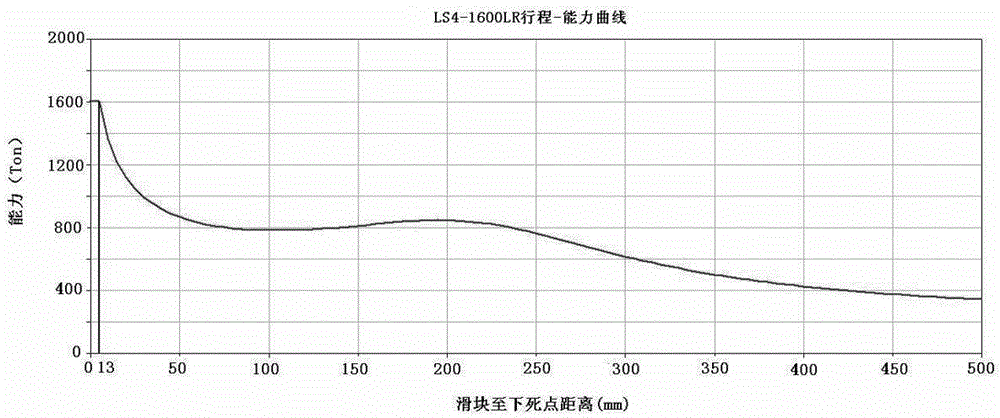

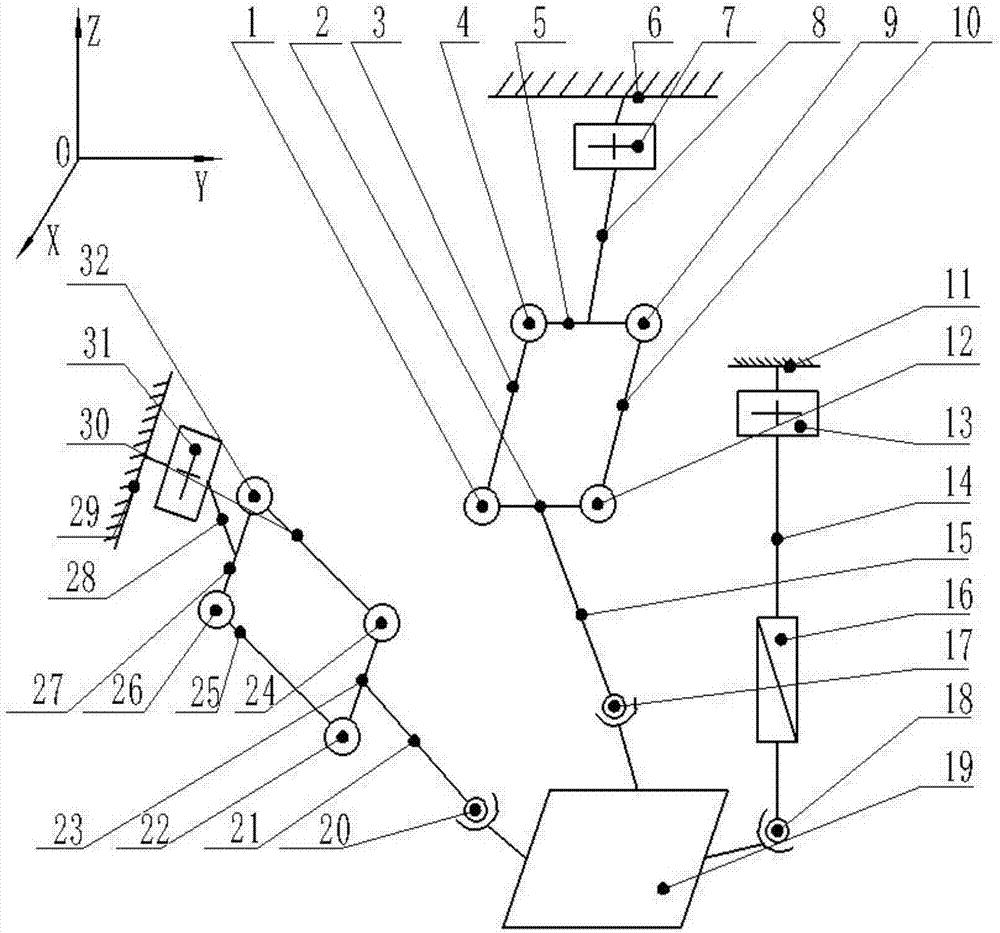

Transmission structure of multi-connecting-rod mechanical press

The invention discloses a transmission structure of a multi-connecting-rod mechanical press, which belongs to the field of presses. The transmission structure comprises an eccentric gear, an upper pull rod, an angular rocking rod, a lower pull rod, a crank connecting rod and a sliding block connecting rod, wherein one end of the upper pull rod and one end of the crank connecting rod are jointly hinged to the eccentric gear, the middle part of the angular rocking rod is hinged to a rack through a positioning shaft, the other end of the upper pull rod is hinged to the upper end of the angular rocking rod together through a first pin shaft, one end of the lower pull rod is hinged to the lower end of the angular rocking rod together through a second pin shaft, the other end of the lower pull rod, the other end of the crank connecting rod and the upper end of the sliding block connecting rod are hinged together through third pin shafts, the lower end of the sliding block connecting rod is hinged to a sliding block together, and the sliding block is arranged in a sliding sleeve. According to the transmission structure, all of the rods are reasonably matched in length and positions, so that the production efficiency is greatly improved, the service life of a mold is prolonged, and the transmission structure can be used in occasions with deep drawing heights.

Owner:YANGLI GRP CORP LTD

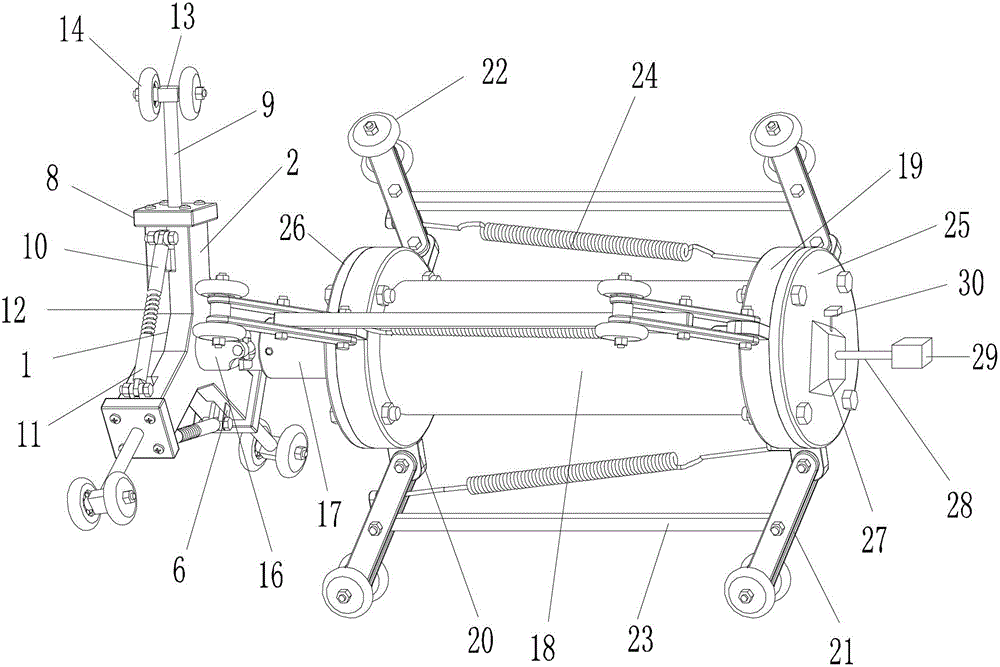

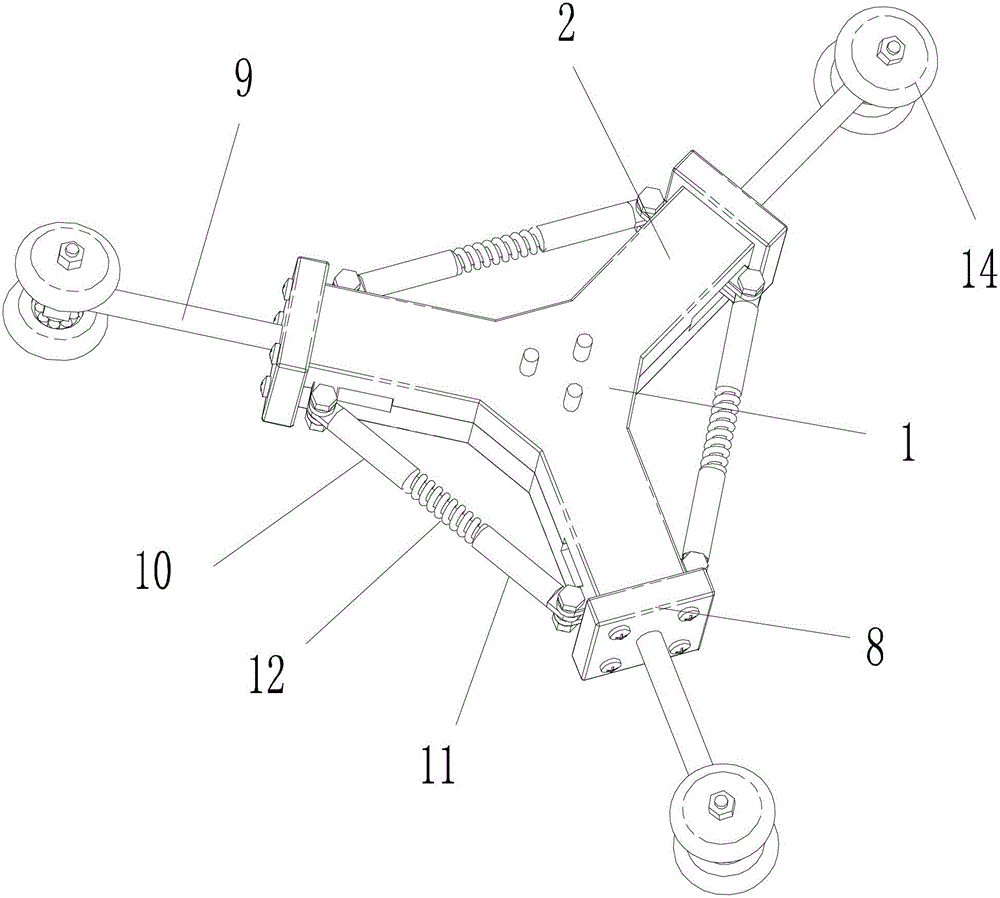

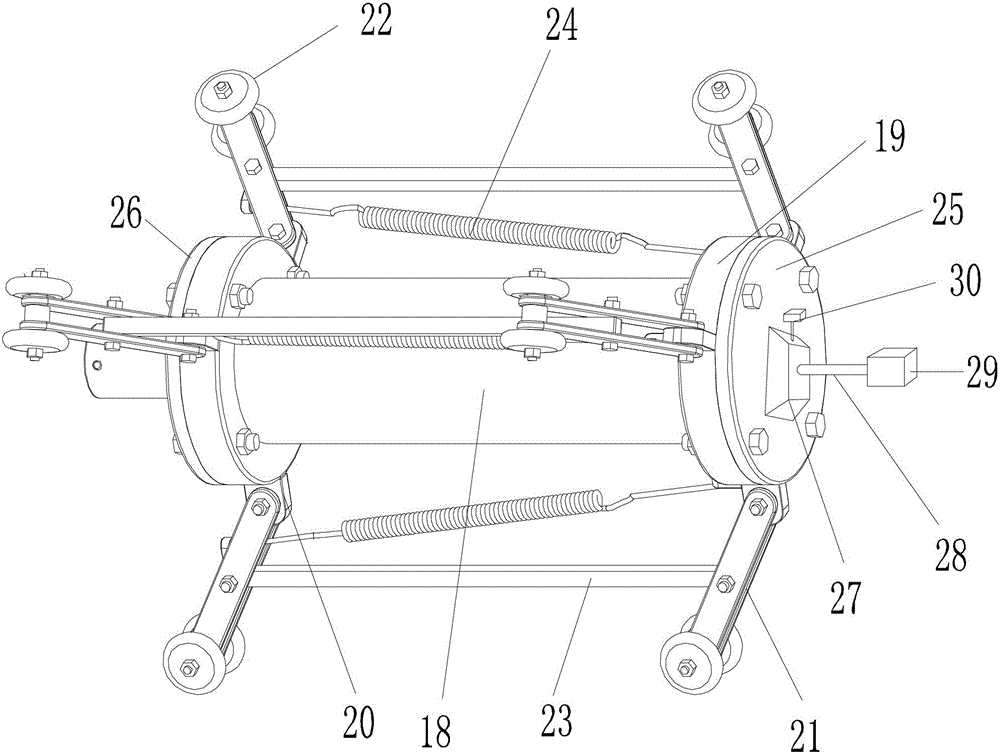

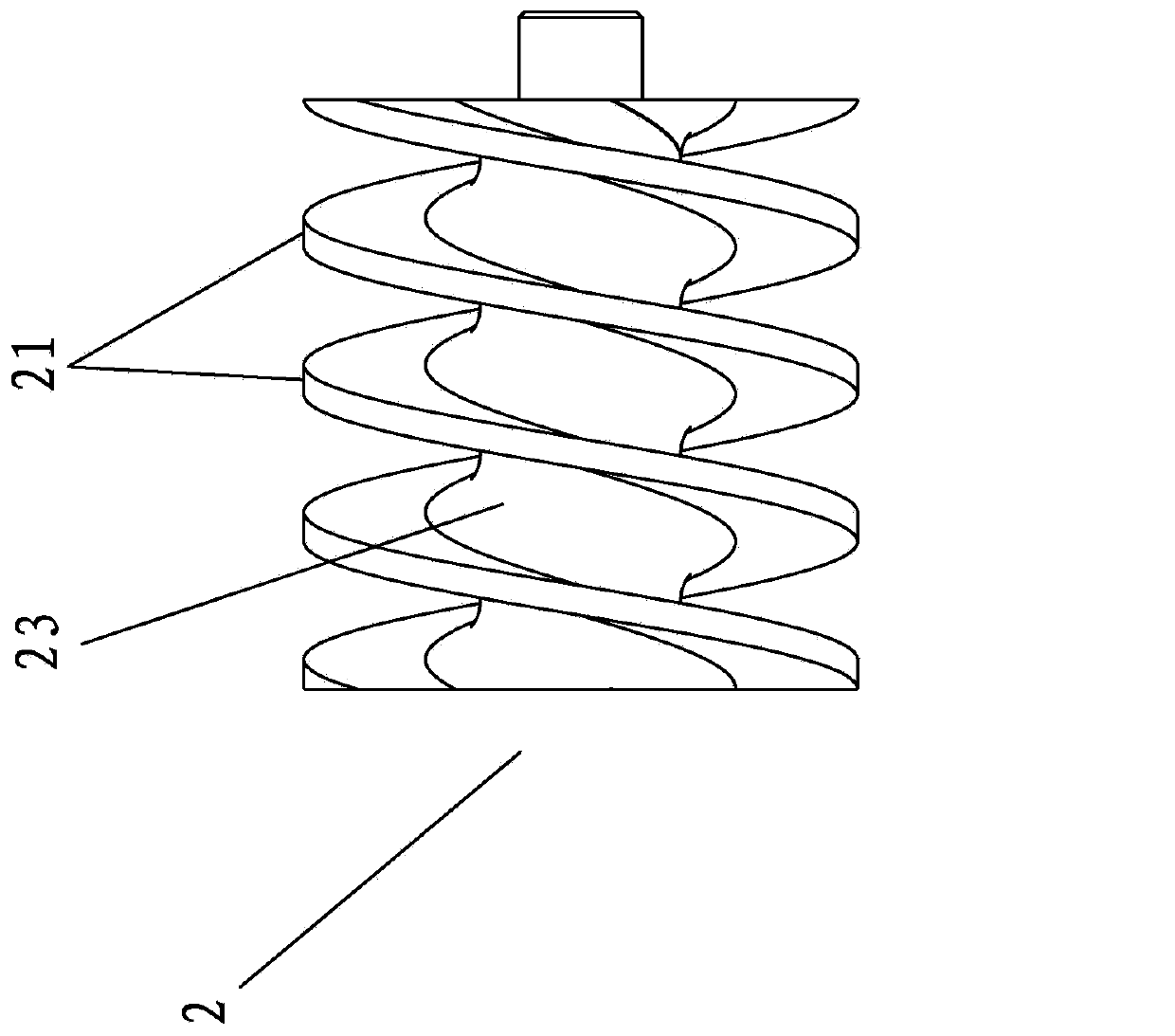

A screw-driven pipeline robot

The invention discloses a spiral driving pipeline robot. The spiral driving pipeline robot comprises a robot body and a remote control box which are connected with each other through an cable, the robot body comprises a driving mechanism, a walking mechanism and a control system, the driving mechanism comprises a driving wheel rack, driving wheels are mounted on the driving wheel rack, the walking mechanism comprises a walking body, and guide wheels are disposed on the walking body. According to the spiral driving pipeline robot, a spiral driving mode is utilized, the robot can specially work in an elongated pipeline that people can not reach so as to perform cleaning, detecting, wiring and the like, an artificial intelligence control technology is applied, and thereby, the walking process of the robot in the pipeline is smooth. Besides, the spiral driving pipeline robot is high in driving force and stable in moving speed, walking speed and angles of the robot can be changed with the change of working environment by the aid of remote control so as to be adapted to changeable conditions in the pipeline, and specific implementation of investigation, cleaning and the like in actual application is facilitated.

Owner:张瀚文

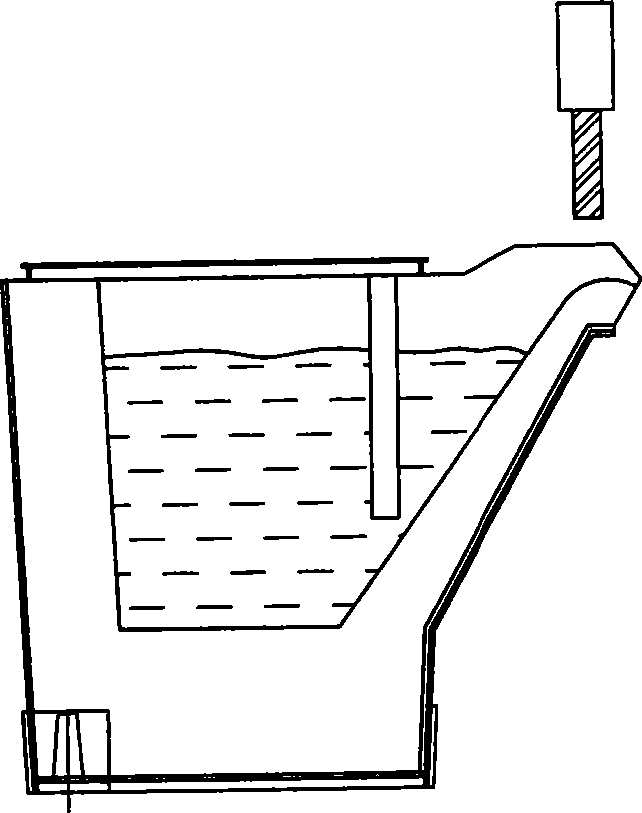

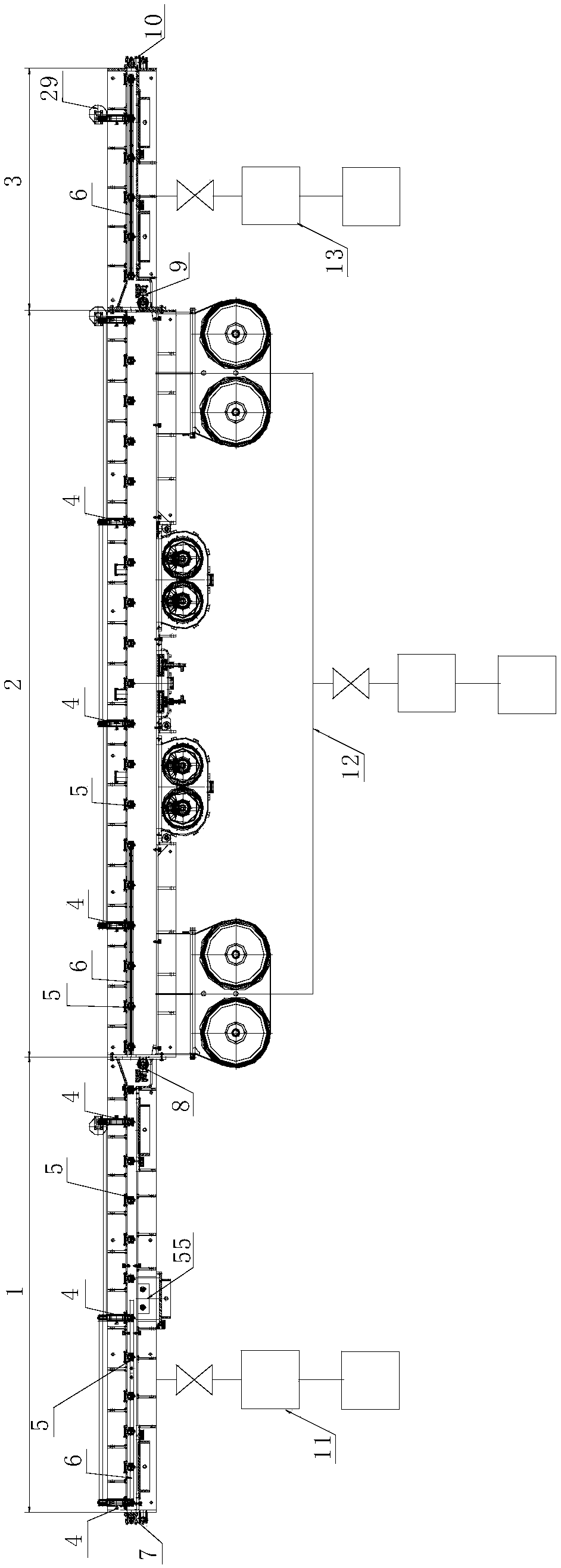

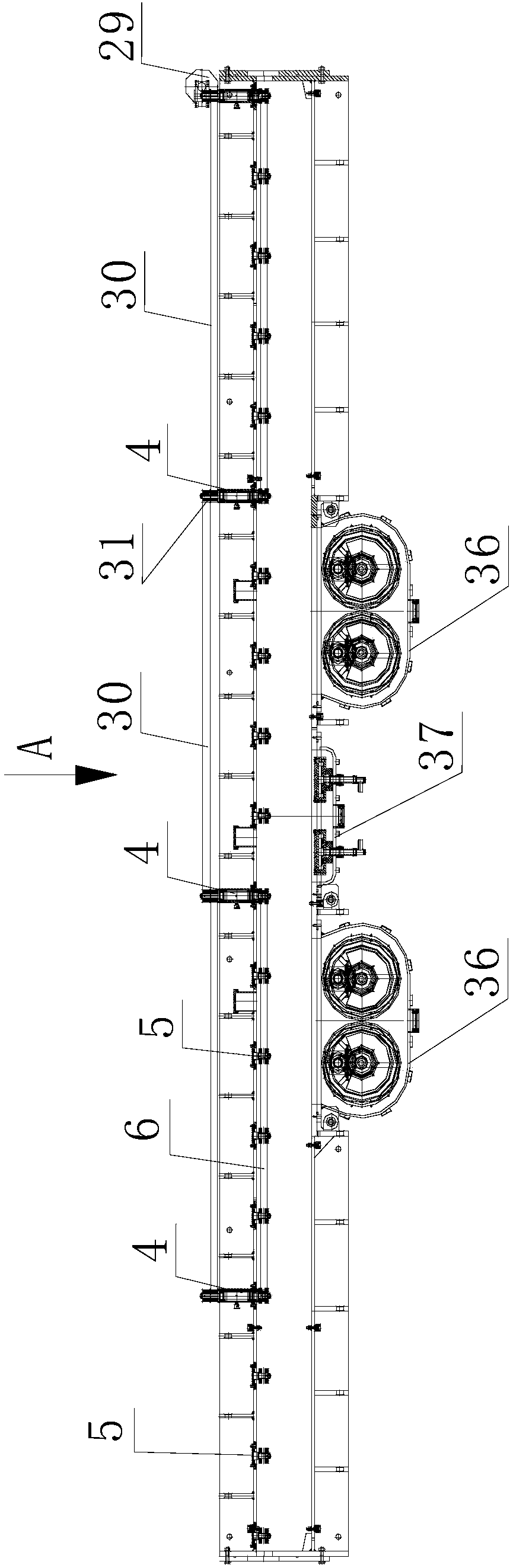

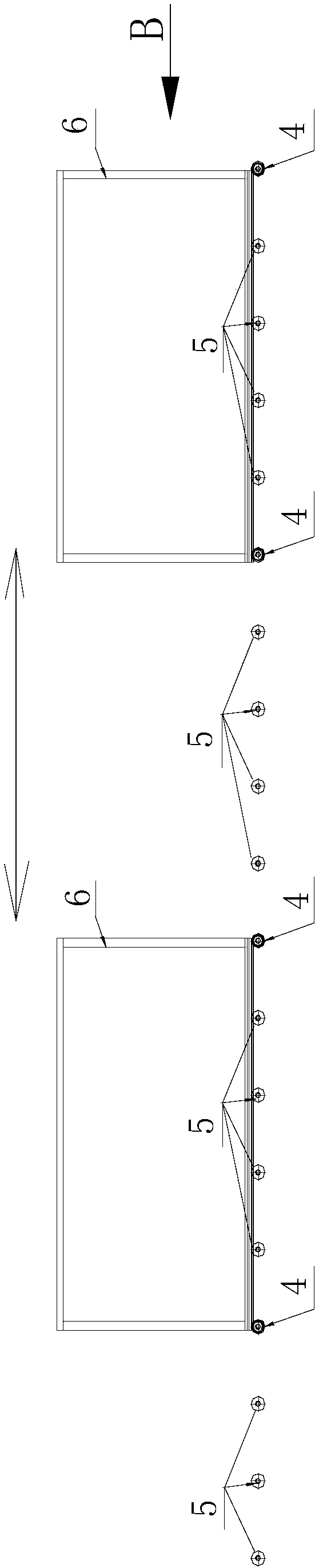

Semiconductor wafer groove type cleaning machine

ActiveCN114602873AHigh movement accuracyFast shippingFinal product manufactureHollow article cleaningEngineeringMachine

The invention belongs to the technical field of semiconductor production and manufacturing, and particularly relates to a semiconductor wafer groove type cleaning machine which comprises a cleaning groove and a mechanical arm used for taking a flower basket into the cleaning groove. The mechanical arm comprises a mechanical claw, the flower basket is taken into the cleaning tank through the mechanical claw to be cleaned, and a guiding and positioning mechanism is arranged above the mechanical arm. According to the groove type cleaning machine for the semiconductor wafer, by arranging the speed change mechanism, when the moving speed of the mechanical arm needs to be adjusted, meshing teeth are driven by stretching out and drawing back of the first air cylinder to make meshing movement with the synchronous belt, the synchronous belt is driven, and the moving speed of the synchronous belt and the mechanical arm is adjusted at the same time; and the moving speed of the manipulator is controlled, and the manipulator after speed regulation has the effect of uniform and stable moving speed.

Owner:ZHICHENG SEMICON EQUIP TECH (KUNSHAN) CO LTD

Parallel vibrating screen used for separating maggots from culture medium mixture

InactiveCN107413639AImprove screening efficiencyIncrease stiffnessSievingScreeningLivestockKinematic pair

The invention discloses a parallel vibrating screen used for separating maggots from culture medium mixture, and particularly relates to the field of maggot breeding industry by using solid livestock excrement. The parallel vibrating screen comprises a static platform, a first branch chain, a second branch chain, a third branch chain and a screening frame. Kinematic pair ball pairs of the tail ends of the first branch chain, the second branch chain and the third branch chain are connected with the screening frame. Power sources of all the branch chains are started simultaneously, and the three branch chains are driven to achieve translational vibration along an X axis, translational vibration along a Y axis and translational vibration along a Z axis of the screening frame. According to the maggot separating vibrating screen based on a parallel mechanism, defects of an existing maggot separating processing technology can be overcome, quick controllable separating of the maggots and solid livestock excrement particles is achieved, the screening efficiency of the vibrating screen is improved, the space volume of whole equipment is small, the rigidity is high, the screening performance is stable and reliable, and the practical significance for factory application is achieved.

Owner:JIANGSU UNIV

Spiral flow mixer for positive pressure metering injection type proportionally-mixing device

ActiveCN104190024AShock amplitude increasedMovement speed is stableFire rescuePositive pressureSpiral flow

The invention discloses a spiral flow mixer for a positive pressure metering injection type proportionally-mixing device. The spiral flow mixer comprises a mixer body and a continuous spiral deflector; a body cavity is formed in the mixer body, openings in two ends of the body cavity are a water inlet and a liquid outlet; the body cavity is axially divided into a spiral deflection chamber and a spiral flow chamber which are supported; a core body is arranged in the spiral flow chamber, the core body is internally provided with a crushing cavity and a spraying cavity which are arranged side by side along an axial direction and are communicated, and a foam liquid channel is arranged between the mixer body and the core body; the continuous spiral deflector is installed in the spiral deflection chamber in a matching manner, a double-spiral sheet is arranged at the outer wall of the continuous spiral deflector, the double-spiral sheet and the inner wall of the spiral deflection chamber form a spiral deflection channel, the continuous spiral deflector is internally provided with a Venturi effect channel, an inlet of the Venturi effect channel is communicated with the water inlet, and an outlet of the Venturi effect channel is communicated with the crushing cavity. According to the spiral flow mixer, by means of creative structure design, the purposes of highly and uniformly mixing and improving the fire extinguishing effect are achieved.

Owner:福建天广消防有限公司

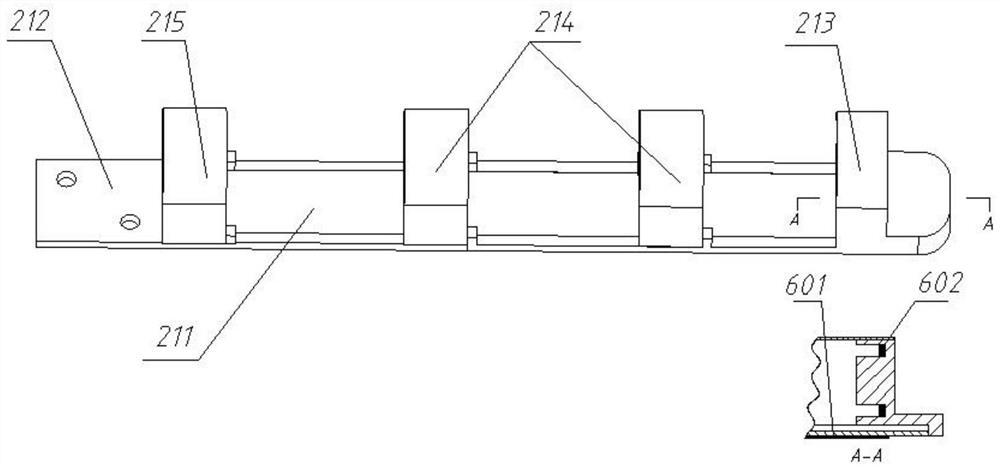

Novel hand exoskeleton rehabilitation device

InactiveCN112245221AImprove adaptabilityLarge bending angleChiropractic devicesHand partsElectric machinery

The invention relates to the field of hand rehabilitation robot research, and particularly relates to a novel hand exoskeleton rehabilitation mechanical arm which has flexible transmission and can beused for hand passive rehabilitation training. The device mainly comprises a palm part, a finger part, a control device and a detection device. The finger part and the palm part form a mechanical structure part of the whole device, a screw rod can be driven to rotate forwards and backwards through forward and backward rotation of a motor so as to control a spring to be disengaged from and insertedinto the screw rod, and therefore bending and straightening of fingers are achieved. The fingers can be bent and straightened fast many times through motor driving and spring piece bending, a plurality of training modes can be achieved, and the treatment effect is improved. Due to the fact that the soft spring piece structure is adopted, the device can conduct auxiliary movement with natural joint rotation of the fingers of a person as the constraint, and the device can adapt to the sizes of hands of different persons. The mechanical arm is provided with a pressure detection device and an angle detection device, and the safety of the whole device is improved. The novel hand exoskeleton rehabilitation device is portable, small in size, low in weight and high in cost performance, the application range of the device is widened, and the use burden on a patient is reduced. The novel hand exoskeleton rehabilitation device has important application value in the field of hand function recovery of stroke patients and high-strength continuous rehabilitation training.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Active headrest use method

InactiveCN105253043AHigh reliability factorIncrease the bearing rangeVehicle seatsDriving safetyCar driving

The invention discloses an active headrest use method. The use method comprises the following steps that a control module electrically connected with an air cylinder is communicated with an automobile active safety system; when a distance between a vehicle behind an automobile and the automobile is within a dangerous value range, the control module directly transmits an order to the air cylinder; an output end of the air cylinder extends and drives a head plate to move forward, so a supporting part of the headrest closes to a driver head; when a distance between the vehicle behind the automobile and the automobile is within a safe value range, the control module can directly control retraction of the air cylinder; and the output end of the air cylinder drives the head plate to move backward and the driver head and the supporting part of the headrest reset. Manual operation is unnecessary and synchronization between the headrest protection and the automobile safety system can be achieved and reliability coefficient of the automobile driving safety can be enhanced.

Owner:成都易默生汽车技术有限公司

Multi-film continuous coating device and method

InactiveCN108517504AReduce coating production costsReduce manufacturing costVacuum evaporation coatingSputtering coatingEngineeringFilm coating

The invention discloses a multi-film continuous coating device and method. The device comprises a surface treatment chamber, a multi-film coating chamber and a substrate outlet vacuum chamber which are connected in sequence; each chamber is provided with a workpiece reciprocating moving mechanism; and the workpiece reciprocating moving mechanisms are arranged below a substrate frame, a magnetic steering mechanism is arranged above the substrate frame, active drive supporting wheels and driven bearing wheels in the workpiece reciprocating moving mechanisms are arranged on a mounting support inthe vacuum chamber, the multiple driven bearing wheels are distributed between two adjacent active drive supporting wheels, and under driving of the active drive supporting wheels, the substrate framedoes reciprocated moving along the driven bearing wheels and the magnetic steering mechanism. The method comprises the steps that the workpiece reciprocating moving mechanisms drive the substrate frame and a workpiece to do reciprocated moving in the surface treatment chamber, and repeated surface roughening and cleaning treatment are achieved; reciprocated moving in the multi-film coating chamber is carried out, and multi-film coating is achieved; and finally, the workpiece is conveyed out from the substrate outlet vacuum chamber. The equipment structure can be effectively simplified, and the coating efficiency and the coating uniformity are improved.

Owner:ZHAOQING KERUN VACUUM EQUIP

Method for controlling wire rod routing in production process of copper-clad aluminum materials by clad-welding method

InactiveCN101530944AAvoid wrinkling and other problemsMovement speed is stableArc welding apparatusWire rodEngineering

The invention provides a method for controlling wire rod routing in the production process of copper-clad aluminum materials by a clad-welding method. The method comprises the following steps: in the production process of copper-clad aluminum wire rod, a copper strip, an aluminum wire and copper-clad aluminum wire blank moves forwards under the traction action of a guide wheel; when moving forwards, the copper strip gradually forms a circular copper pipe along the longitudinal direction under the extrusion of a plurality of pairs of forming rollers; a longitudinal seam of the circular copper pipe is continuously welded by argon arc welding; a servo motor controls the moving speed of the guide wheel to be matched with welding current of the argon arc welding so as to ensure the moving speed of the guide wheel to be stable and prevent the problems that the copper strip wrinkles, and the like; welding points on the longitudinal seam of the copper pipe is ensured to be positioned in a same horizontal line; and the servo motor controls the moving speed of the guide wheel to be matched with the welding current of the argon arc welding, thus avoiding loose welding or overwelding phenomenon caused by overhigh or overlow moving speed of the guide wheel when the welding current is fixed.

Owner:浙江恒飞控股有限公司

Automatic treatment equipment for PE pipe machining

ActiveCN111632960ARaise fundsStable speedHollow article cleaningPlastic recyclingGear wheelElectric machinery

The invention discloses automatic treatment equipment for PE pipe machining. The equipment comprises a tank body, supporting frames arranged on the left side and the right side of the tank body, moving devices arranged on one sides of the supporting frames, a PE pipe arranged on the moving devices and scraping mechanisms arranged on the front side and the rear side of the PE pipe, wherein the moving devices comprise motors, screws arranged on one sides of the motors, missing gears sleeving the screws, nuts sleeving the screws, guide devices arranged on the front sides and the rear sides of themissing gears, rotary discs arranged on the nuts and a plurality of supporting devices arranged on the rotary discs. According to the equipment, the moving devices drive the PE pipe to rotate, the scraping mechanisms are adopted for scraping an oxide layer on the surface of the PE pipe, the whole working process is easy to operate, labor force is greatly reduced, and the production efficiency ofthe PE pipe is improved.

Owner:山东斯玛特管道有限公司

Tablet cutting device

InactiveCN107252394AAchieve positioningSimple structureOral administration deviceMetal working apparatusEngineeringMechanical engineering

The invention discloses a tablet cutting device, which comprises a base, on which a cover is fixed, a drawer is inserted in the cover, the drawer includes a drawer seat, two slide rails are arranged on the upper surface of the base, and the bottom surface of the drawer is There are two slide grooves, the slide grooves are sleeved on the slide rails, a positioning pin is fixed on the drawer seat, and a stamping die is sleeved on the positioning pin. The stamping die includes a die base and a stamping cylinder fixed on the mold base. The stamping cylinder A stamping rod is inserted into the casing above the stamping rod. Several punching knives are evenly distributed on the lower end surface of the stamping rod. A top plate is fixed on the top of the stamping rod. Several supporting springs are evenly distributed between the top plate and the top surface of the casing. A cylindrical bracket is arranged on the top surface of the casing, a nut is fixed at the center of the bracket, a threaded rod matching the nut is inserted into the nut, and the threaded rod is located above the top plate. The beneficial effects obtained by the invention are: (1) simple structure; (2) high cutting precision and good cutting uniformity.

Owner:济南富安机械设计有限公司

Splitting machine cutter automatic adjusting device

The invention relates to cutter adjusting devices and particularly discloses a splitting machine cutter automatic adjusting device comprising a splitting shaft and a locating shaft. The splitting shaft and the locating shaft are each slidably connected with a plurality of cutters and locating blocks. The locating blocks are provided with annular grooves. The cutters are embedded into the annular grooves. The locating shaft comprises a guide rod, a hydraulic rod and a locating rod. A hydraulic cavity is formed in the hydraulic rod. A piston made of a permanent magnet is arranged in the hydraulic cavity. First electromagnets are arranged in the locating blocks. The locating rod comprises an outer sleeve, an inner rod and ring bodies arranged between the outer sleeve and the inner rod. The outer sleeve is provided with a locating hole. A locating column, balls and a compressed spring are arranged in the locating hole. Locating grooves are formed in the locating blocks. The ring bodies areprovided with spirally arranged hemispherical grooves. The balls can be embedded into the hemispherical grooves. A second electromagnet fixed to the inner rod is arranged between every two adjacent ring bodies. The ring bodies are provided with blind holes. Steel balls and tension springs are arranged in the blind holes. The steel balls and the bottoms of the blind holes are connected through thetension springs. The inner rod is provided with a driving groove. Adjusting of the cutter spaces can be simpler and more convenient through the splitting machine cutter automatic adjusting device.

Owner:重庆佑威电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com