Parallel vibrating screen used for separating maggots from culture medium mixture

A vibrating sieve and culture medium technology, which is applied in the direction of solid separation, sieve, grid, etc., can solve the problem of lack of rapid and controllable separation technology for mature fly maggots and livestock and poultry manure culture medium, low degree of mechanization and automation, and industrialization Low-level problems, to achieve high rigidity, overcome instantaneous stiffness, and light overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

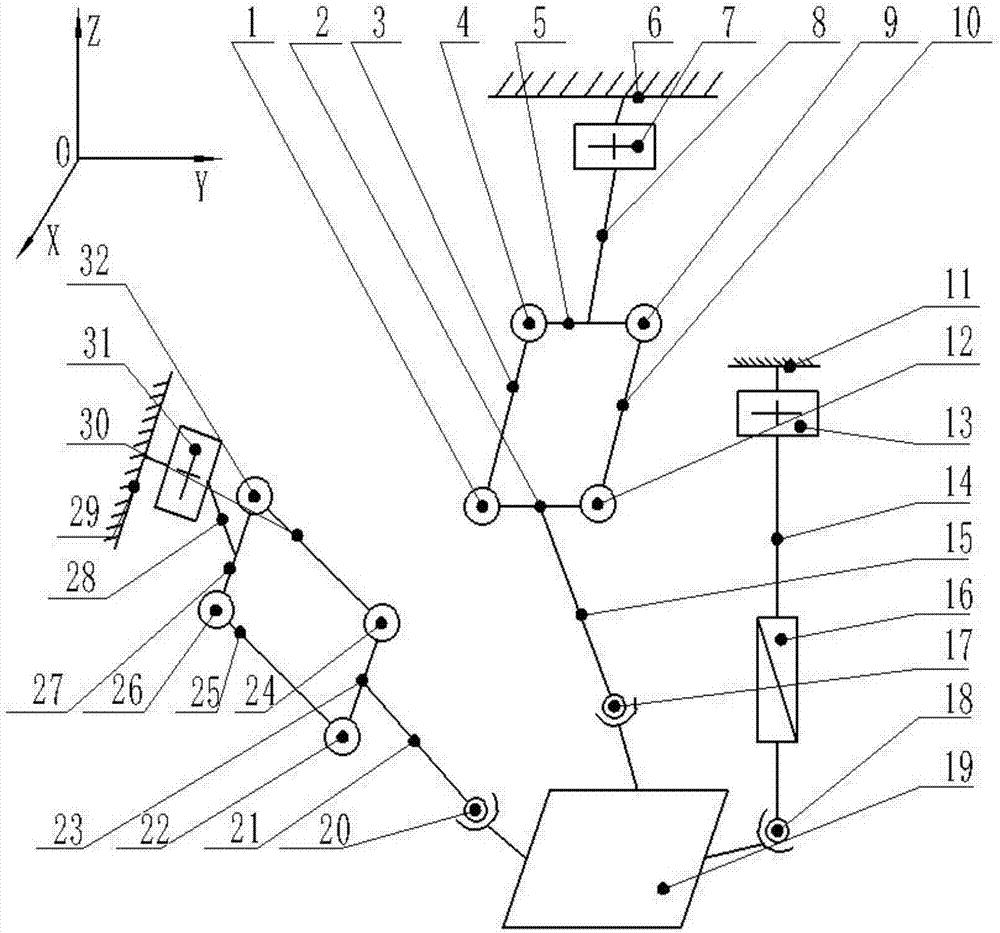

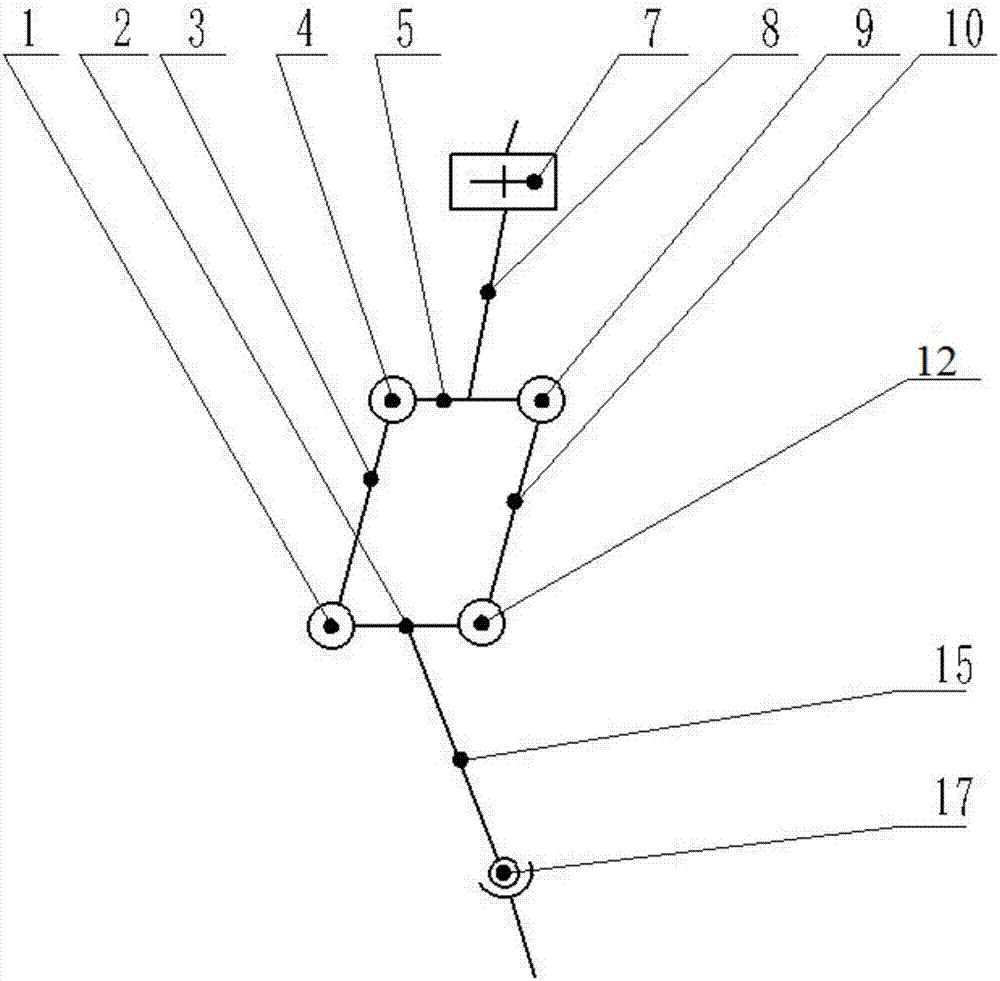

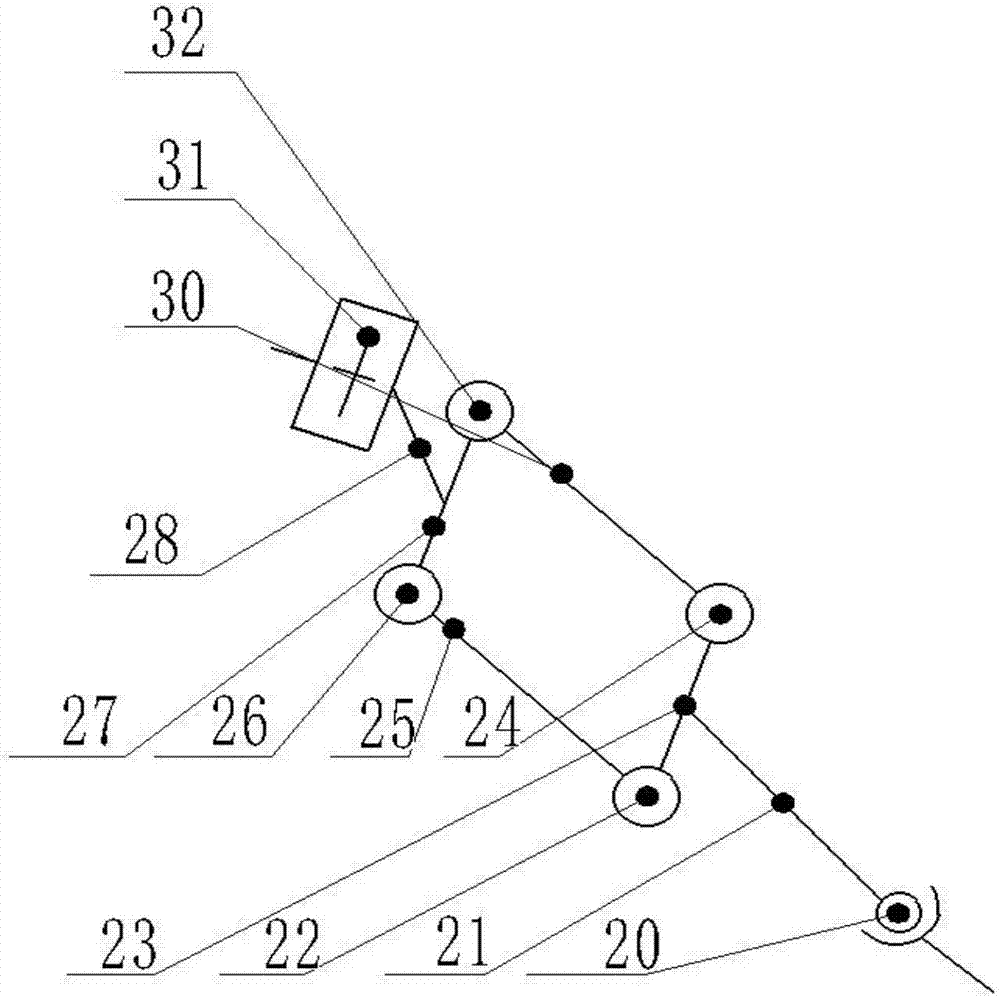

[0025]For a further understanding of the present invention, the present invention is further described in place in conjunction with the accompanying drawings: the technical realization of the present invention is achieved through the following scheme: a parallel vibrating screen used for separating fly maggots from medium mixtures, the parallel vibrating screen Including the static platform, the first branch chain, the second branch chain, the third branch chain and the screen frame; Parallel to the axis of the guide rail of the static platform; the kinematic ball pair at the end of the first branch chain, the second branch chain and the third branch chain are all connected to the screen frame; the screen frame is located directly below the plane where the static platform is located , and the installation axis of the third branch chain is vertical to the plane where the static platform is located. During the initial installation, the plane where the static platform is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com