Patents

Literature

434results about How to "High movement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

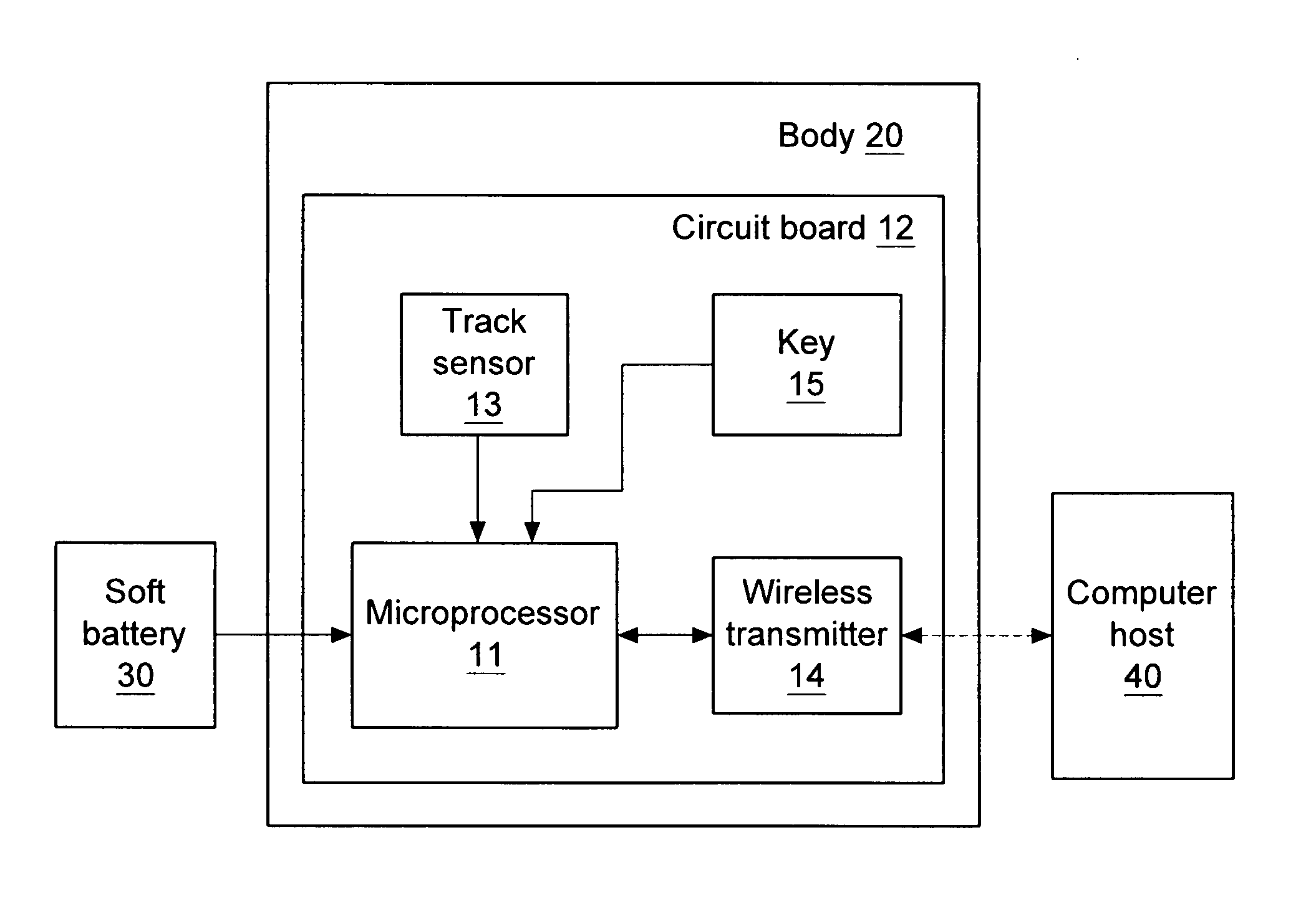

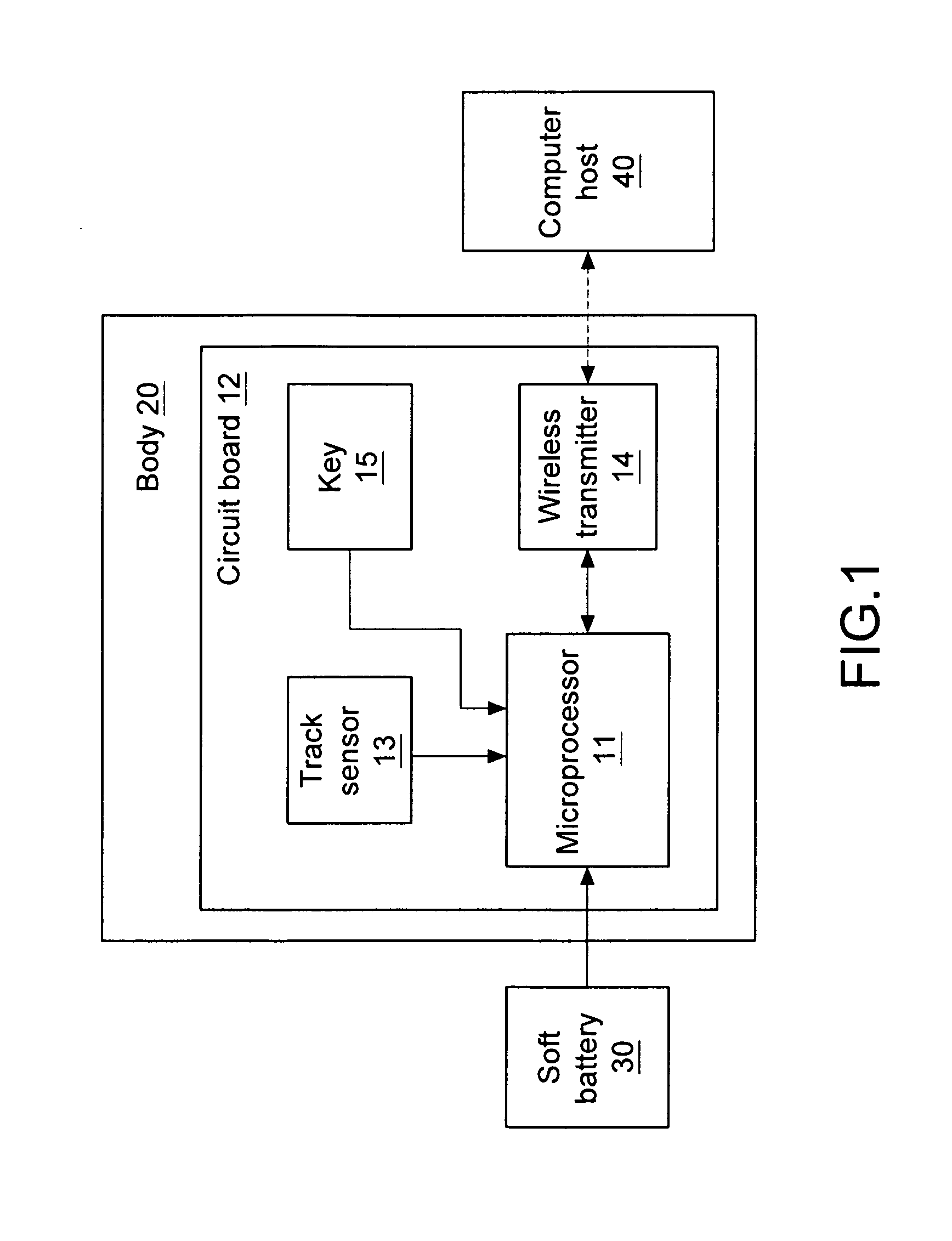

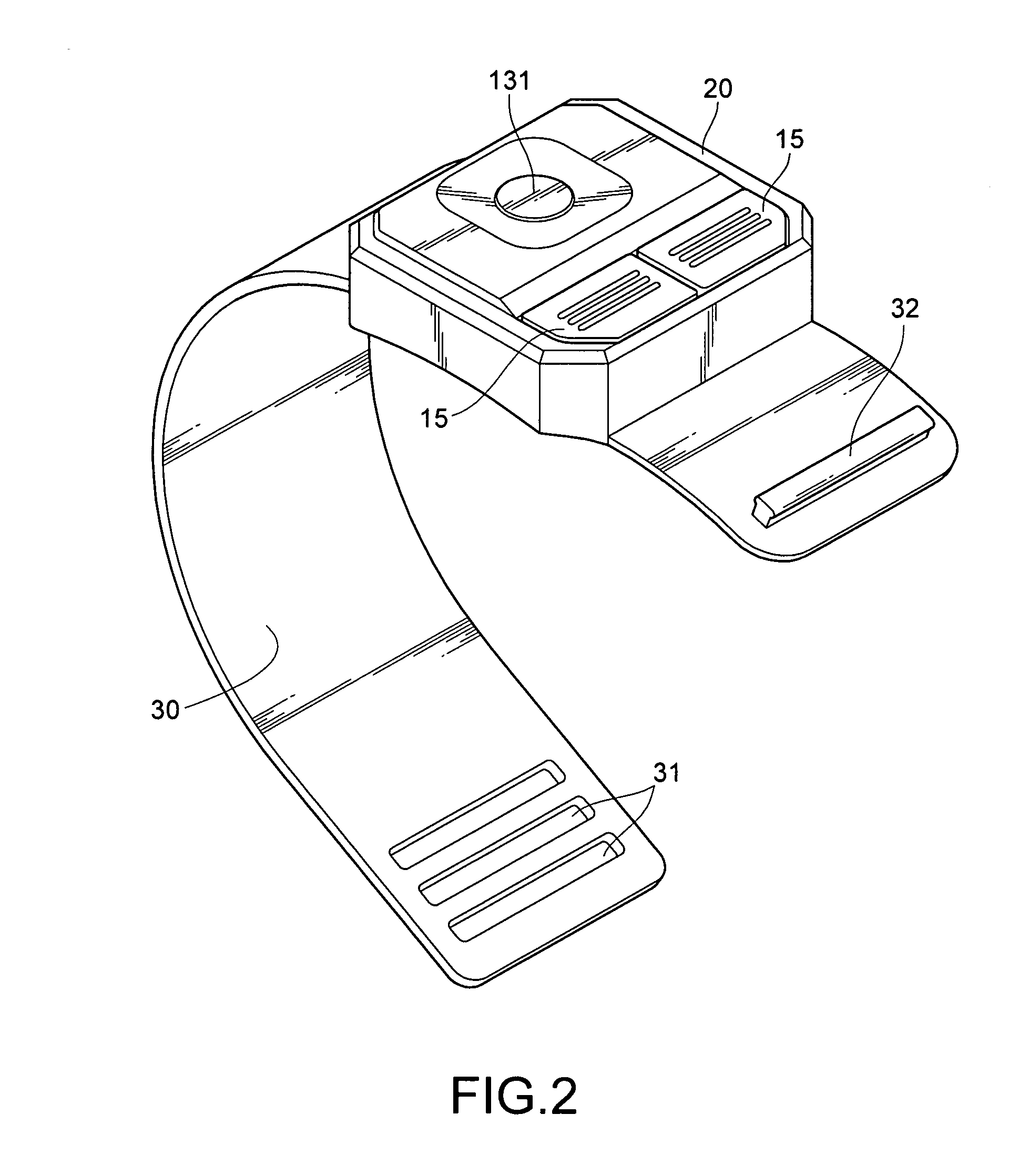

Wearable input device

InactiveUS20110090148A1High movement accuracyLarge manipulation areaCathode-ray tube indicatorsDetails for portable computersEngineeringInput device

A wearable input device includes a body and a soft battery. The body is connected to the soft battery to form a collar range, and the soft battery surrounds a hand of a user. The soft battery supplies an electric power to a finger-contact control module and a wireless transmitter in the body, such that the finger-contact control module senses a movement of an object (for example, a finger) on the body, and generates a control signal corresponding to a moving position of the object, and then the wireless transmitter transmits the control signal to a computer host, thus manipulating a cursor on an operating system frame of the computer host.

Owner:KYE SYST CORP

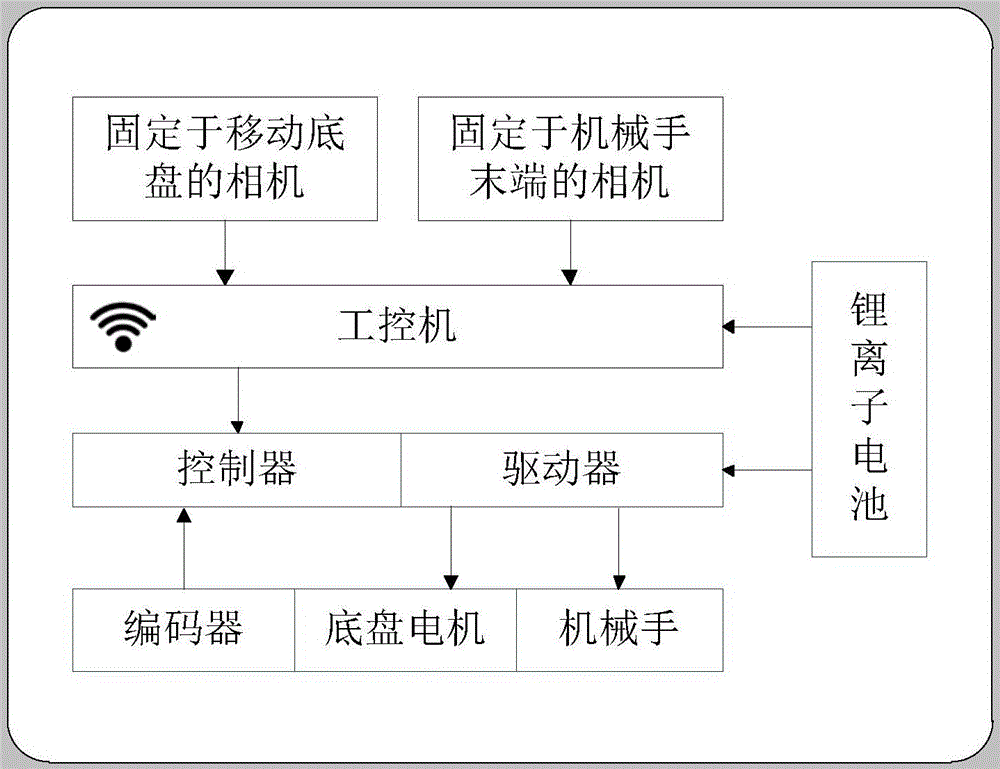

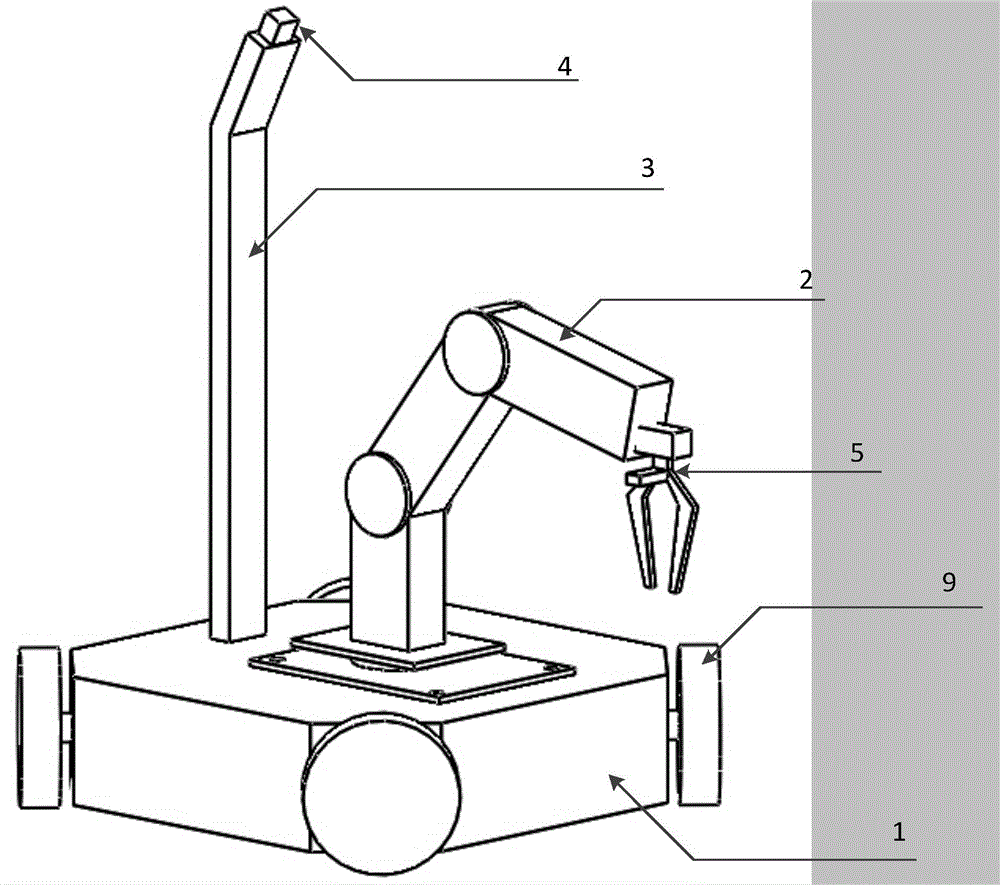

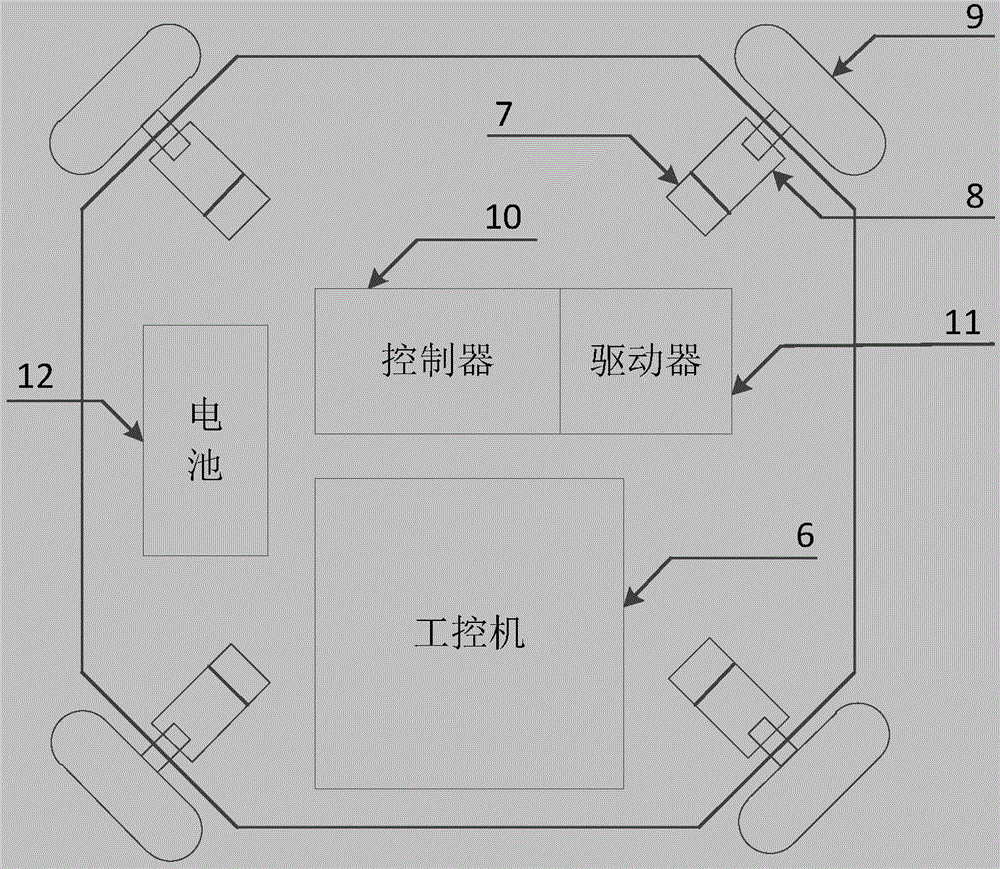

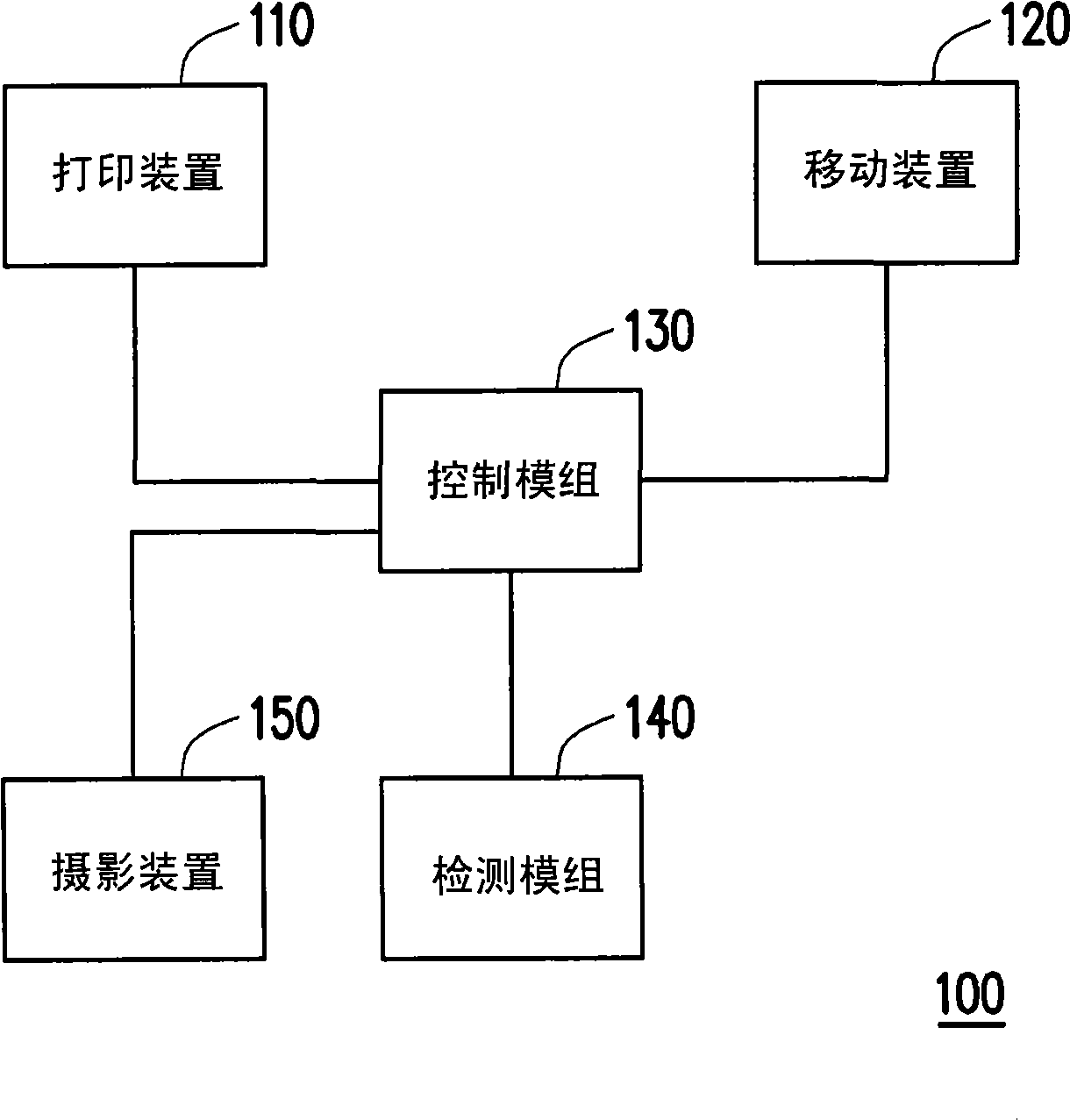

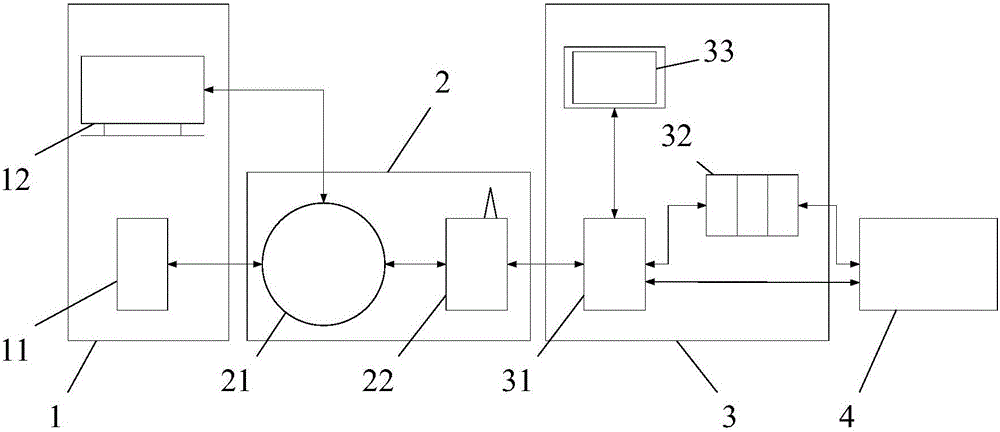

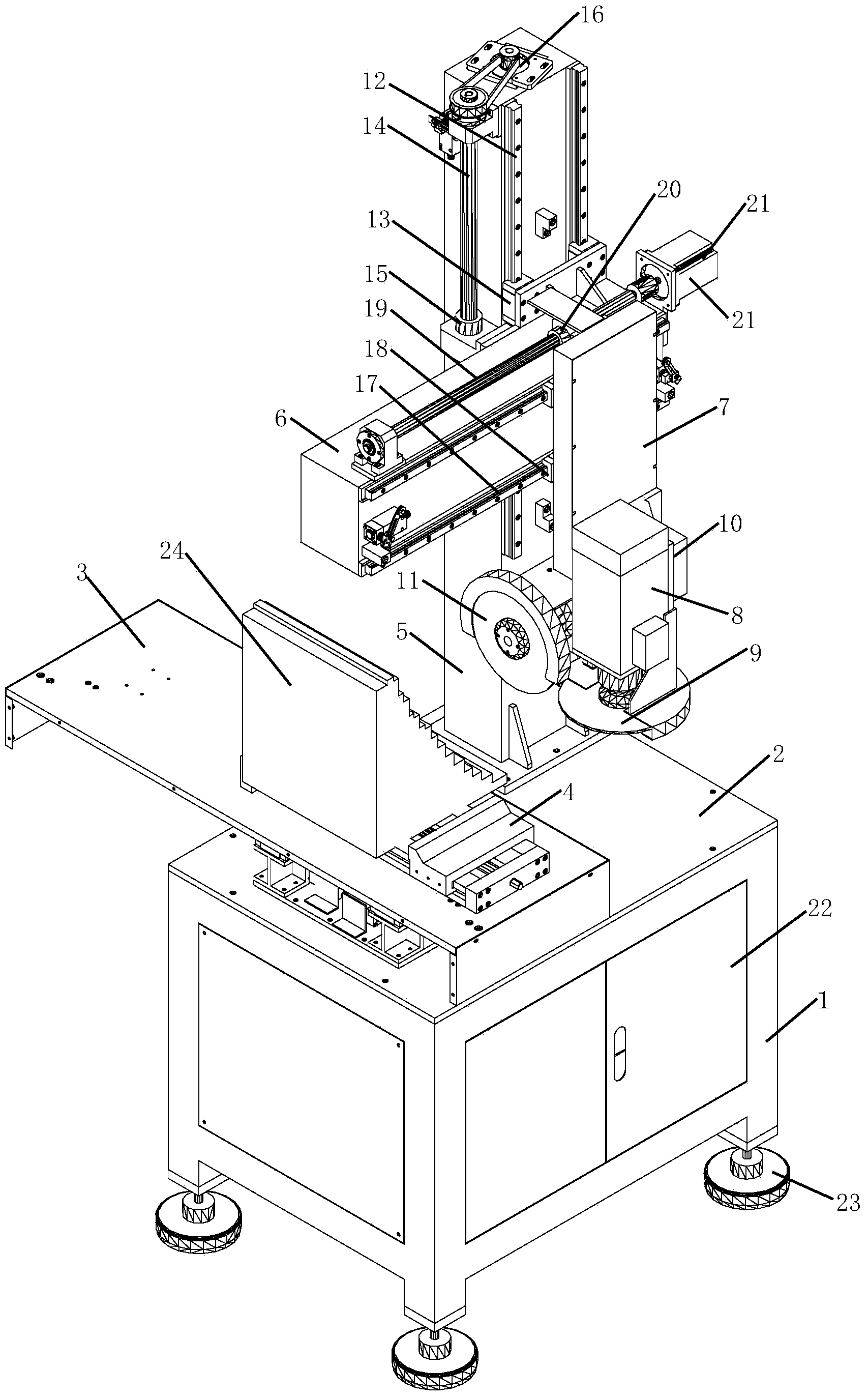

Mobile vision robot and measurement and control method thereof

InactiveCN106607907ARealize automatic controlHigh movement accuracyProgramme-controlled manipulatorMachine visionManipulator

The invention provides a mobile vision robot and a measurement and control method thereof. Positioning and state information of the mobile robot and a robot operating target is obtained through a machine vision detection method, and meanwhile, movement and other operation of the robot are controlled according to information provided by vision images; and the robot vision images are provided by two cameras, one camera is fixed to a mobile platform and used for acquiring images on the robot movement path, and the other camera is fixed to the tail end of a manipulator and used for acquiring detailed images of a manipulator operating target. According to the mobile vision robot and the measurement and control method thereof, the positioning and state information of the mobile robot and the specific target are calculated through an image distortion correcting and mode recognizing method according to the obtained image information, and then the robot is controlled to complete instructed action on a target object. Meanwhile, the invention provides a method for eliminating accumulative errors generated in the operating process of the robot through vision images. The mobile vision robot has the characteristics of high precision and high anti-interference capacity, complex environment support is not needed, and the mobile vision robot is suitable for various laboratories and factory environments.

Owner:XI AN JIAOTONG UNIV

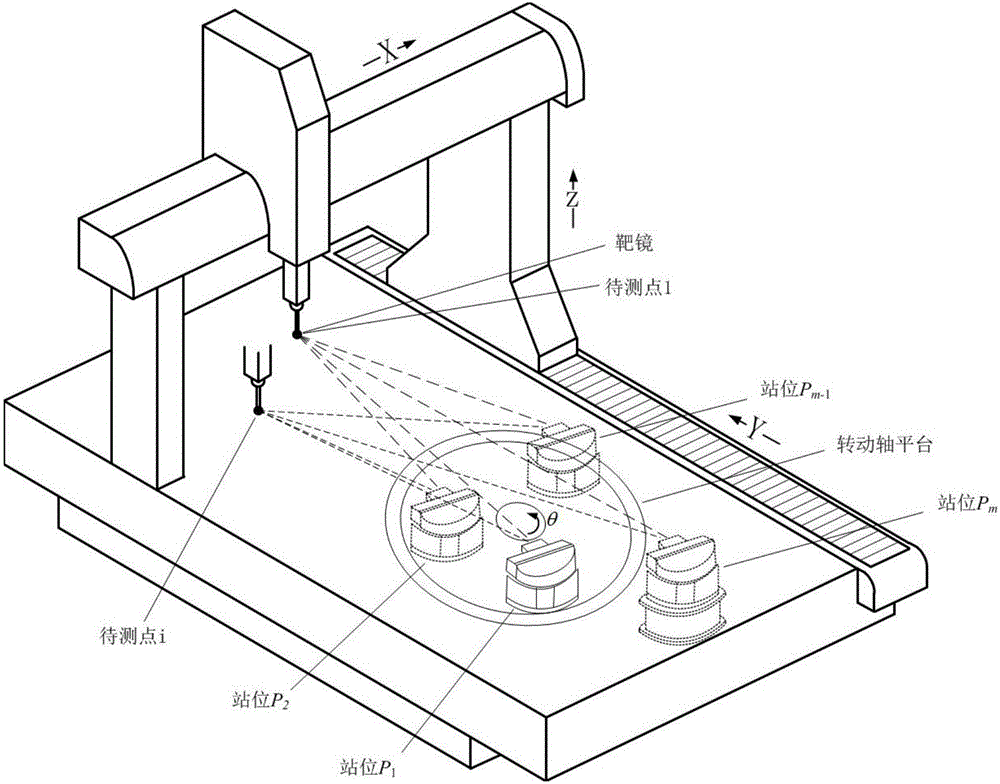

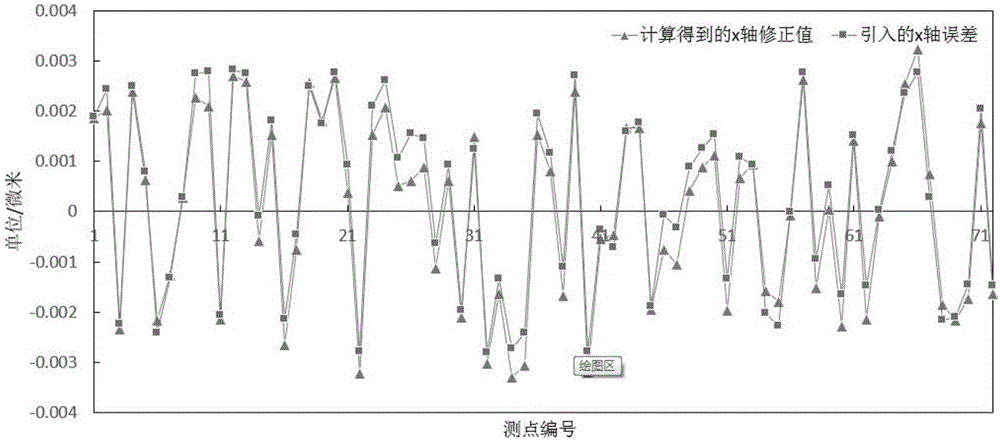

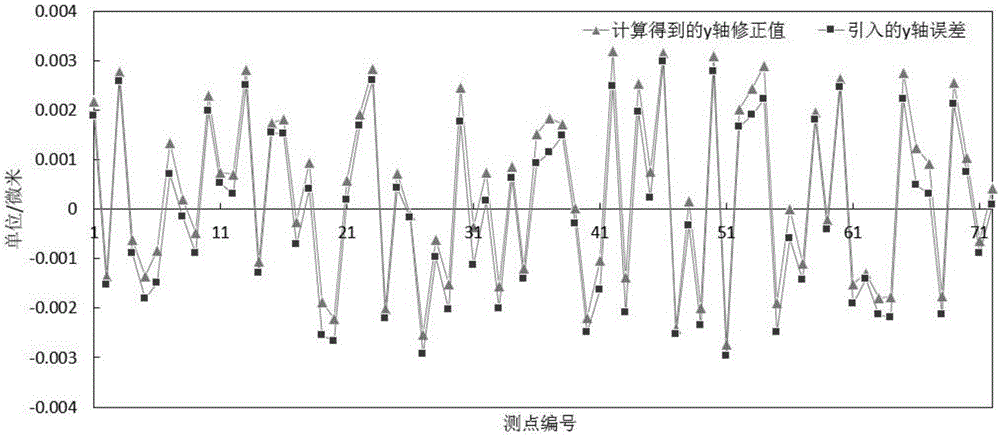

Four-shaft machine tool calibration method based on multi-station measurement of laser tracker

The invention discloses a four-shaft machine tool calibration method based on the multi-station measurement of a laser tracker, and belongs to the technical field of precise testing. The method comprises the steps: firstly determining the coordinates of measurement points in a movement space range of a four-shaft machine tool, moving a target lens to each measurement point during measurement, enabling the laser tracker to carry out transfer measurement on a rotating shaft platform along with a rotating shaft, and obtaining the relative interference length measurement value of each measurement point to an initial measurement point at different station; secondly solving the coordinates of each station and the distance between the corresponding station to the initial measurement point through employing a formula for the distance between two points, the principle of least squares and a laser tracker station solving optimization algorithm; thirdly enabling the coordinates of the measurement points, the coordinates of the stations and the distances from the corresponding stations to the initial measurement point as the initial values, and solving and obtaining the correction value of each measurement point in the directions of three moving shafts of the four-shaft machine tool through the expansion of the first-order Taylor series of an interference length measurement error equation; finally building the mapping relation between the coordinate information of the stations of the laser tracker and the angle of the rotating shaft through circle fitting, and achieving the high-precision measurement of an rotating angle error of the rotating shaft.

Owner:BEIJING UNIV OF TECH

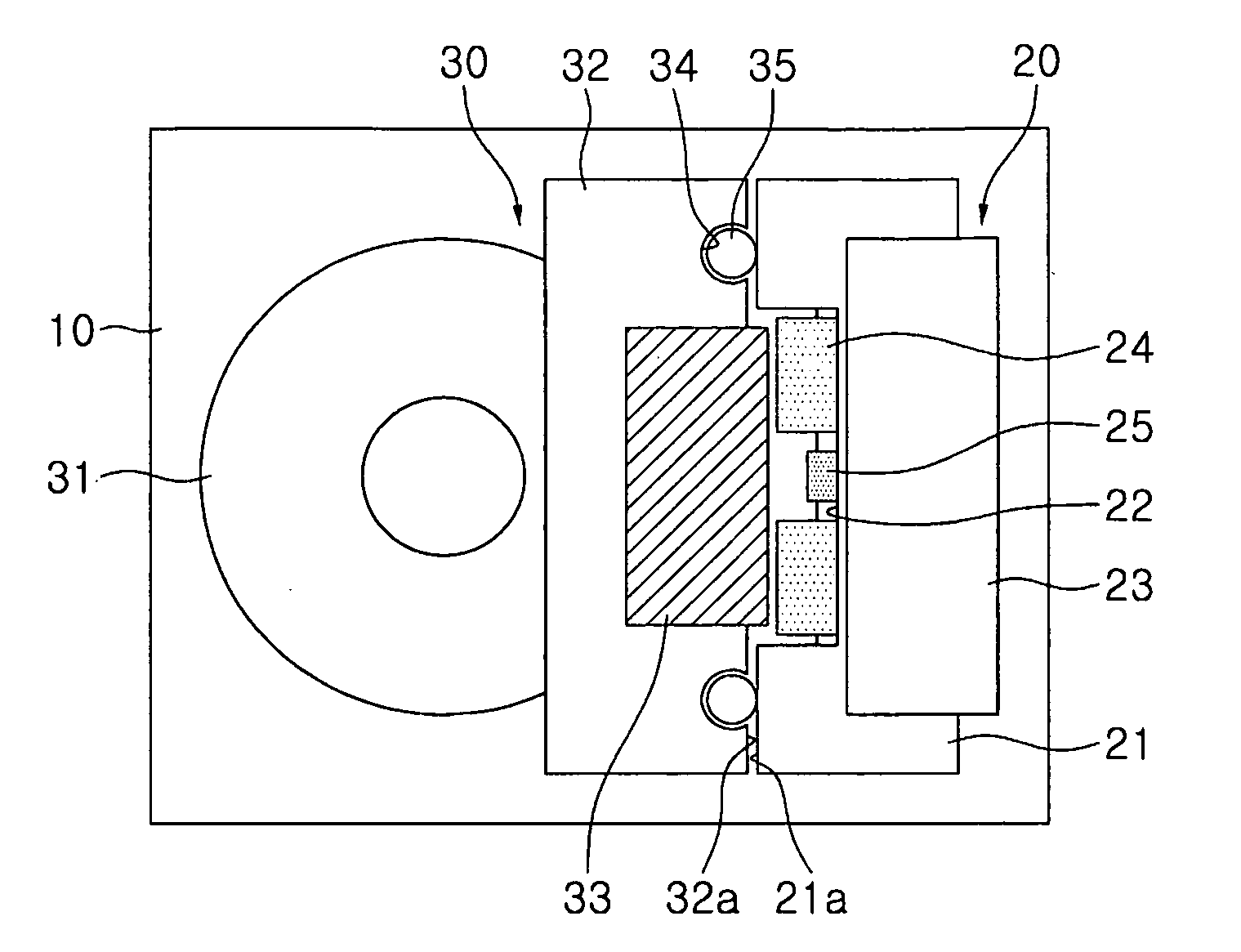

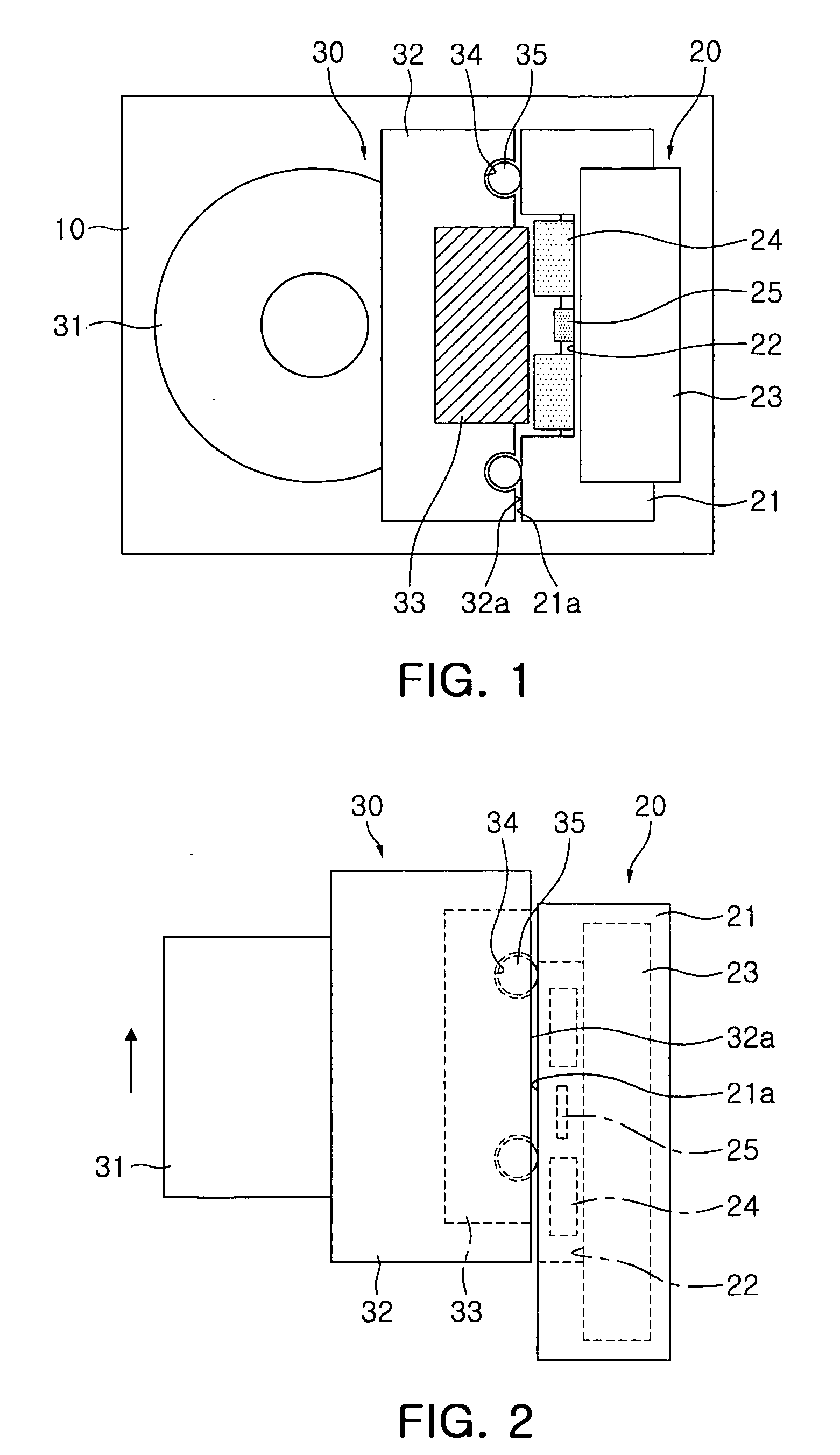

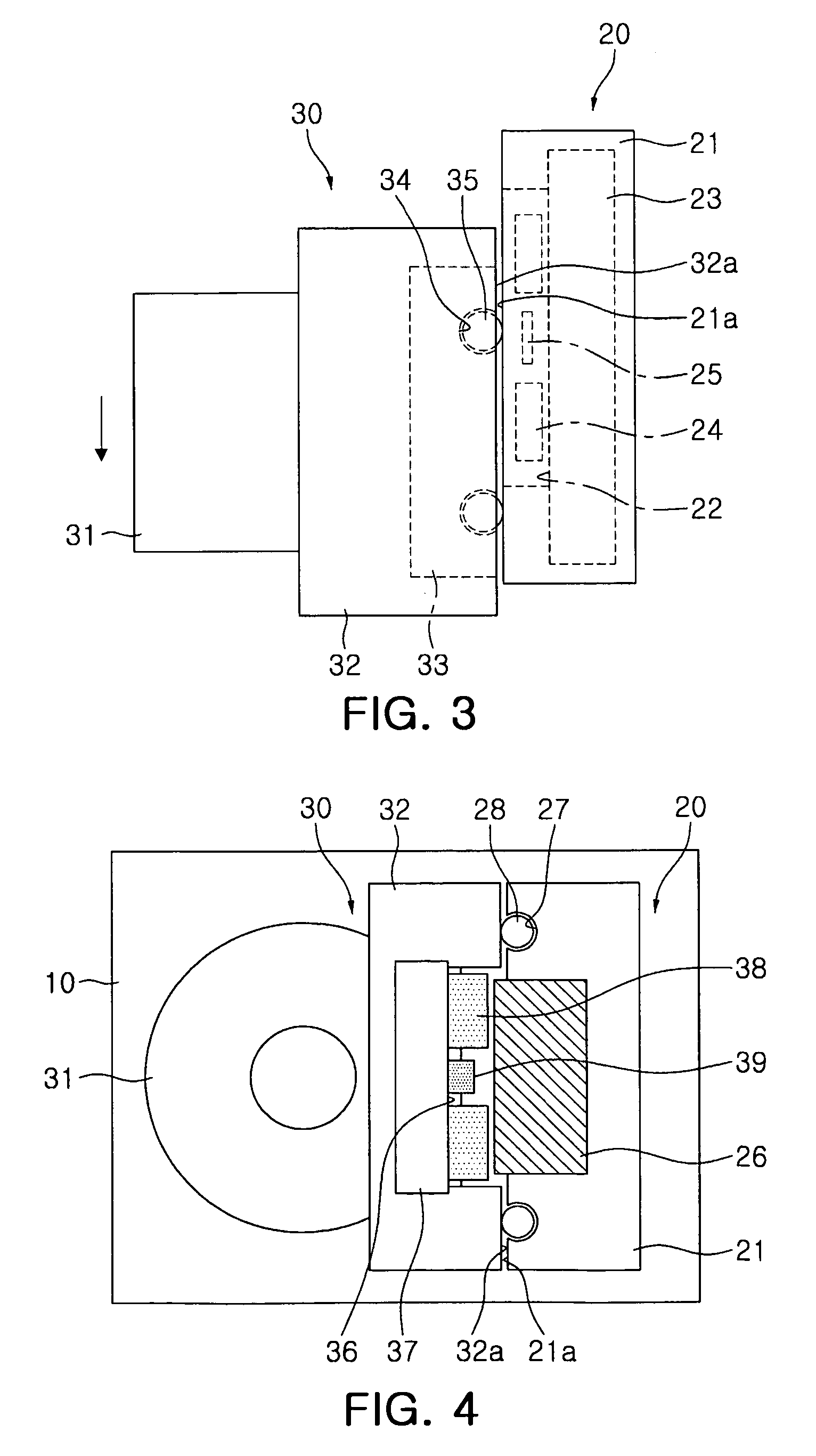

Camera module

ActiveUS20100053784A1High movement accuracyImprove driving reliabilityMountingsRadiation controlled devicesCamera lensOptical axis

A camera module according to an aspect of the invention may include: a housing; a fixed unit fixed to the inside of the housing; a lens barrel provided in the housing and having at least one lens; and a moving unit moved and supported by the fixed unit by a predetermined magnetic force, and moving the lens barrel along an optical axis, such that driving accuracy and reliability can be increased when performing auto focus or zoom.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

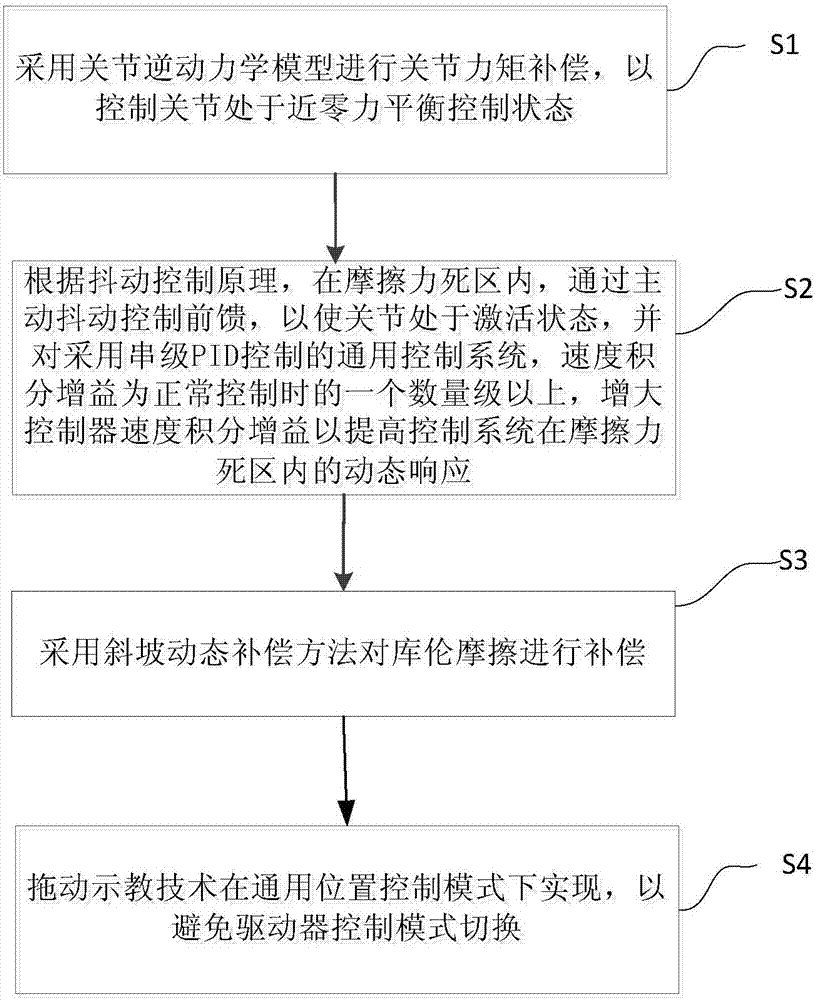

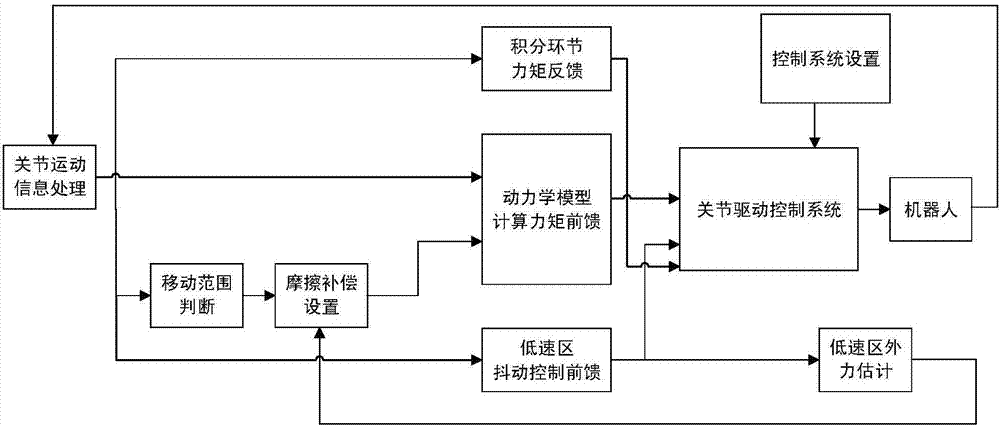

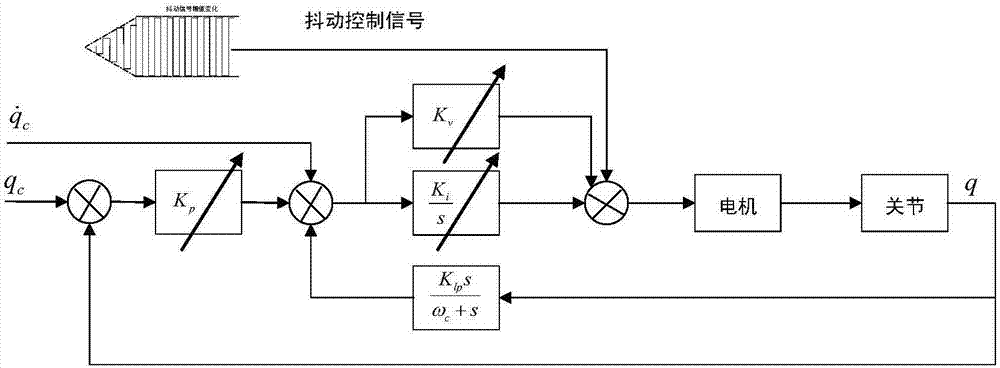

Industrial robot dragging teaching method without adopting torque sensor

The invention provides an industrial robot dragging teaching method without adopting a torque sensor. The method comprises the steps that a joint inverse dynamic model is adopted for joint moment compensation, so that a joint is controlled to be in a near-zero force balanced control state; according to a jitter control principle, feedforward is controlled through drive jitter within a dead zone of friction force, so that the joint is in an activated state, velocity integral grain of a universal control system adopting serial PID control is one order of magnitudes that of a system adopting normal control, and the controller velocity integral gain is increased to improve the dynamic response of the control system in the dead zone of the friction force; a slope dynamic compensation method is adopted for compensating coulomb friction; and a dragging teaching technology is achieved in a universal position control mode, so that switching of a control mode of a driver is avoided. According to the dragging teaching method adopted in the invention, the torque sensor is not needed, and the cost is low.

Owner:ROKAE SHANDONG INTELLIGENT TECH CO LTD

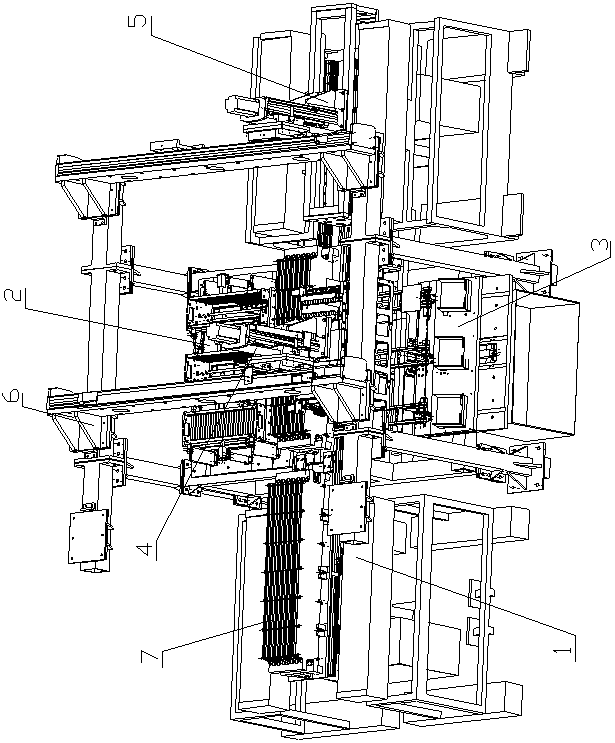

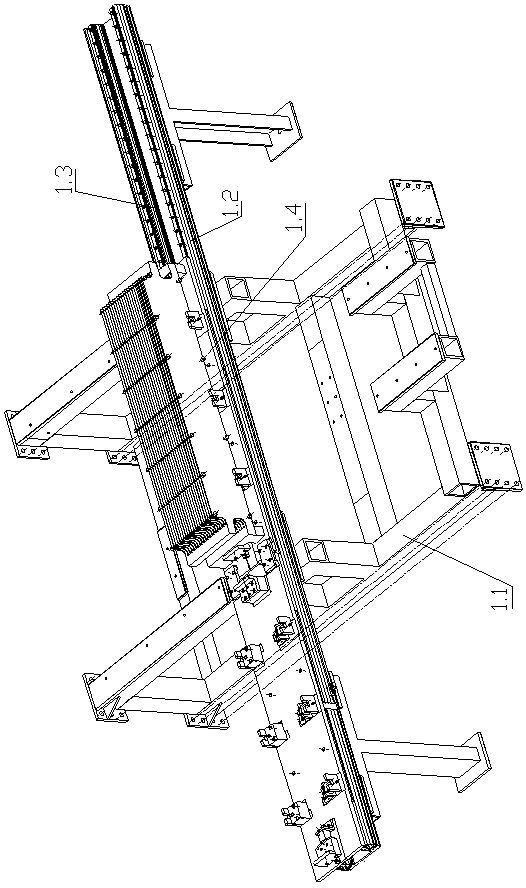

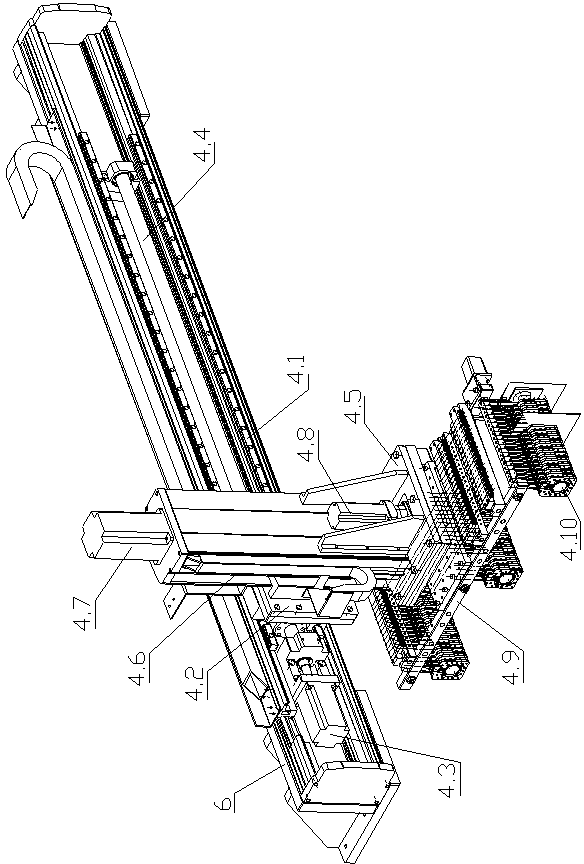

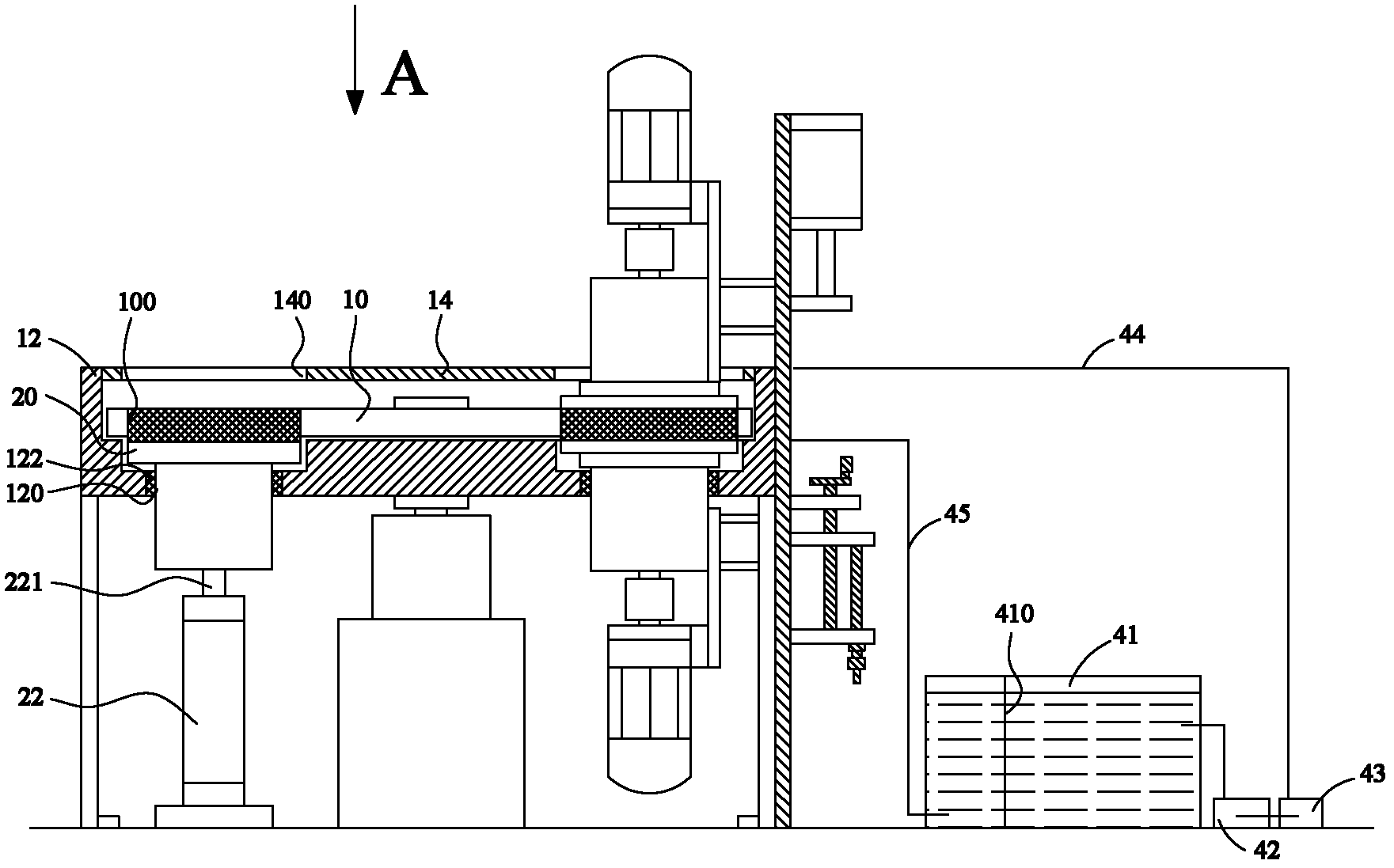

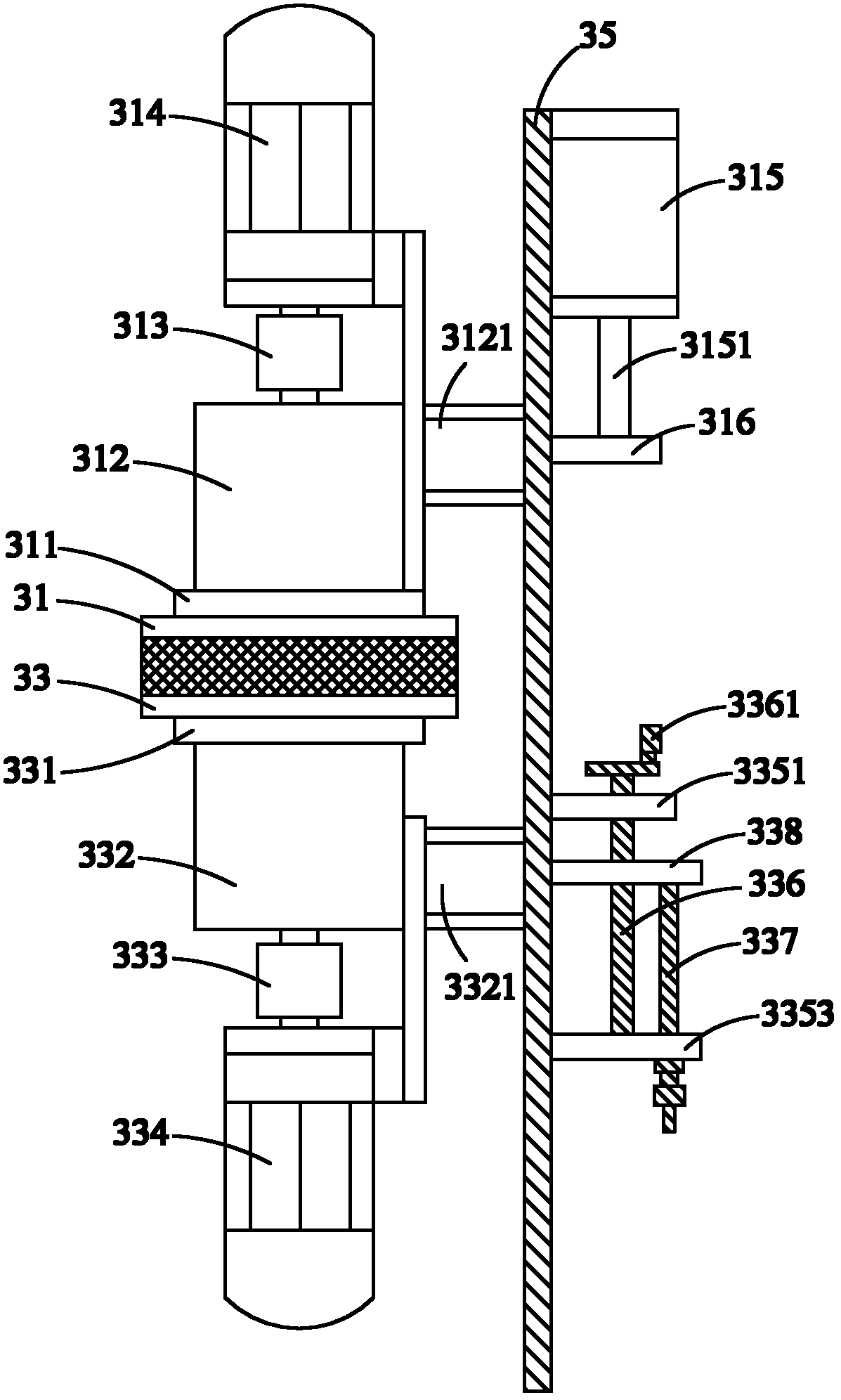

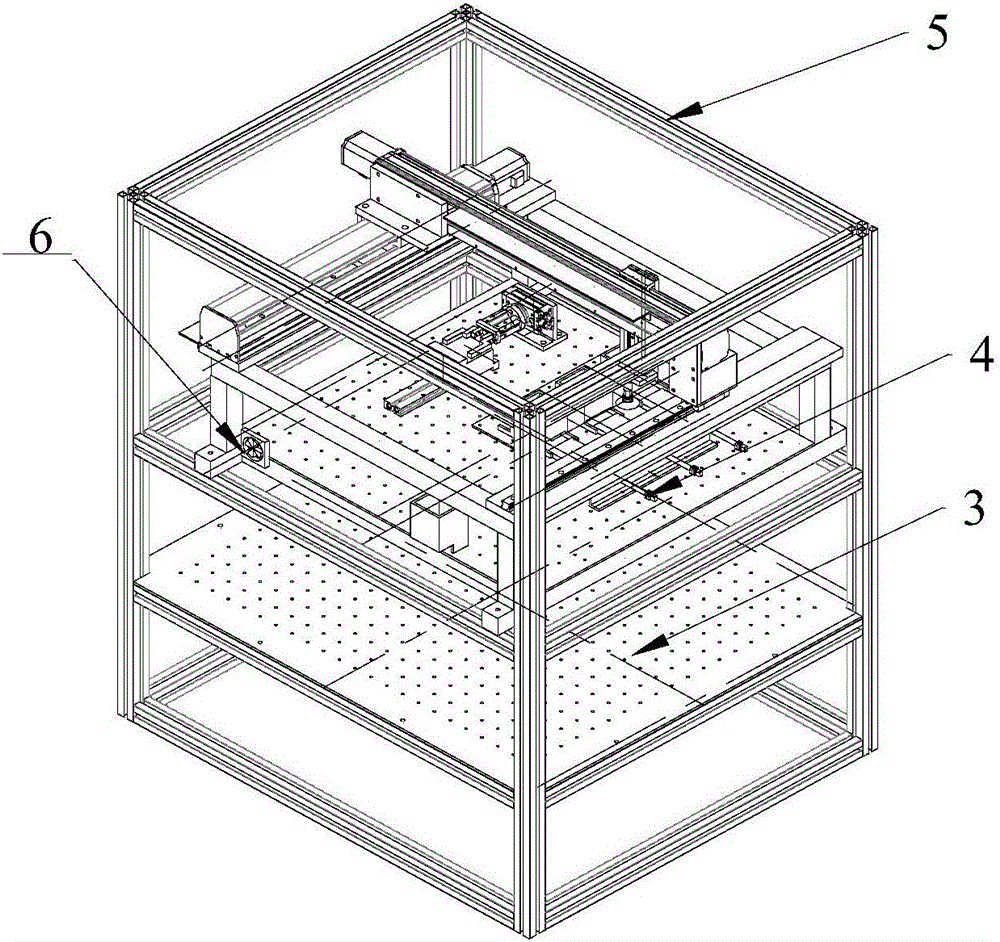

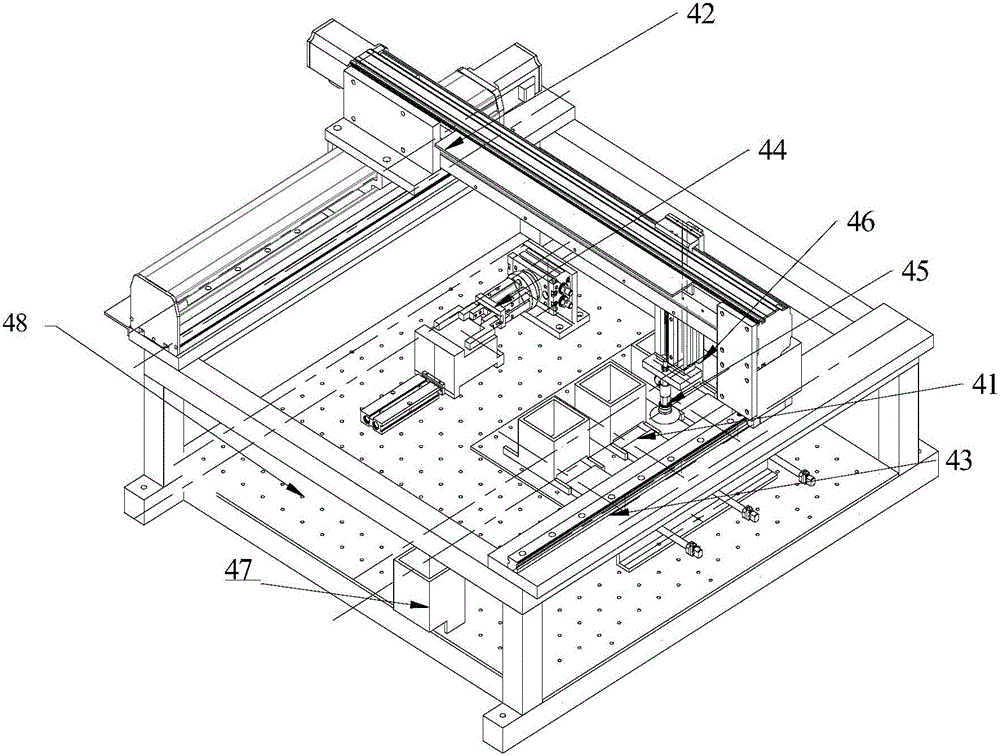

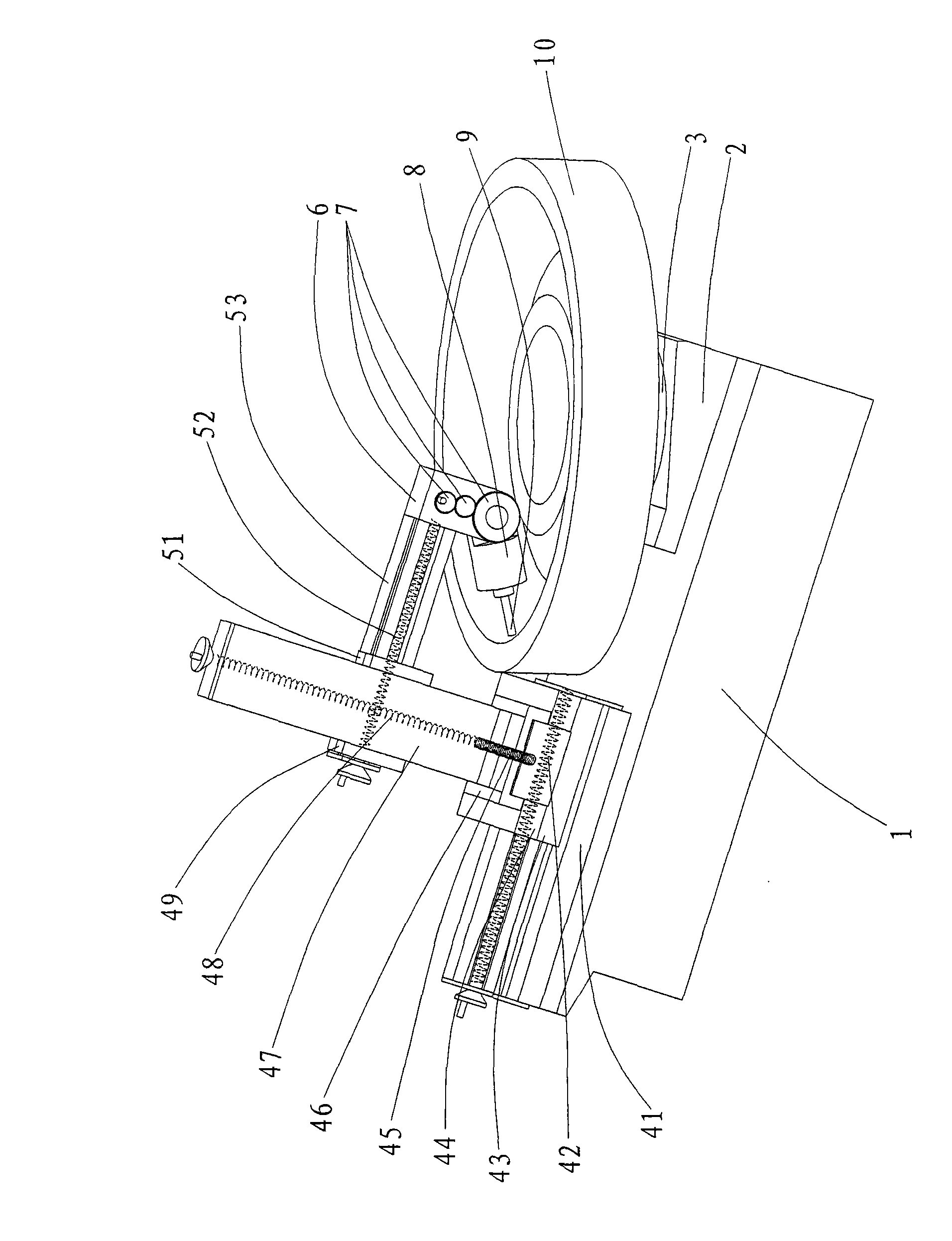

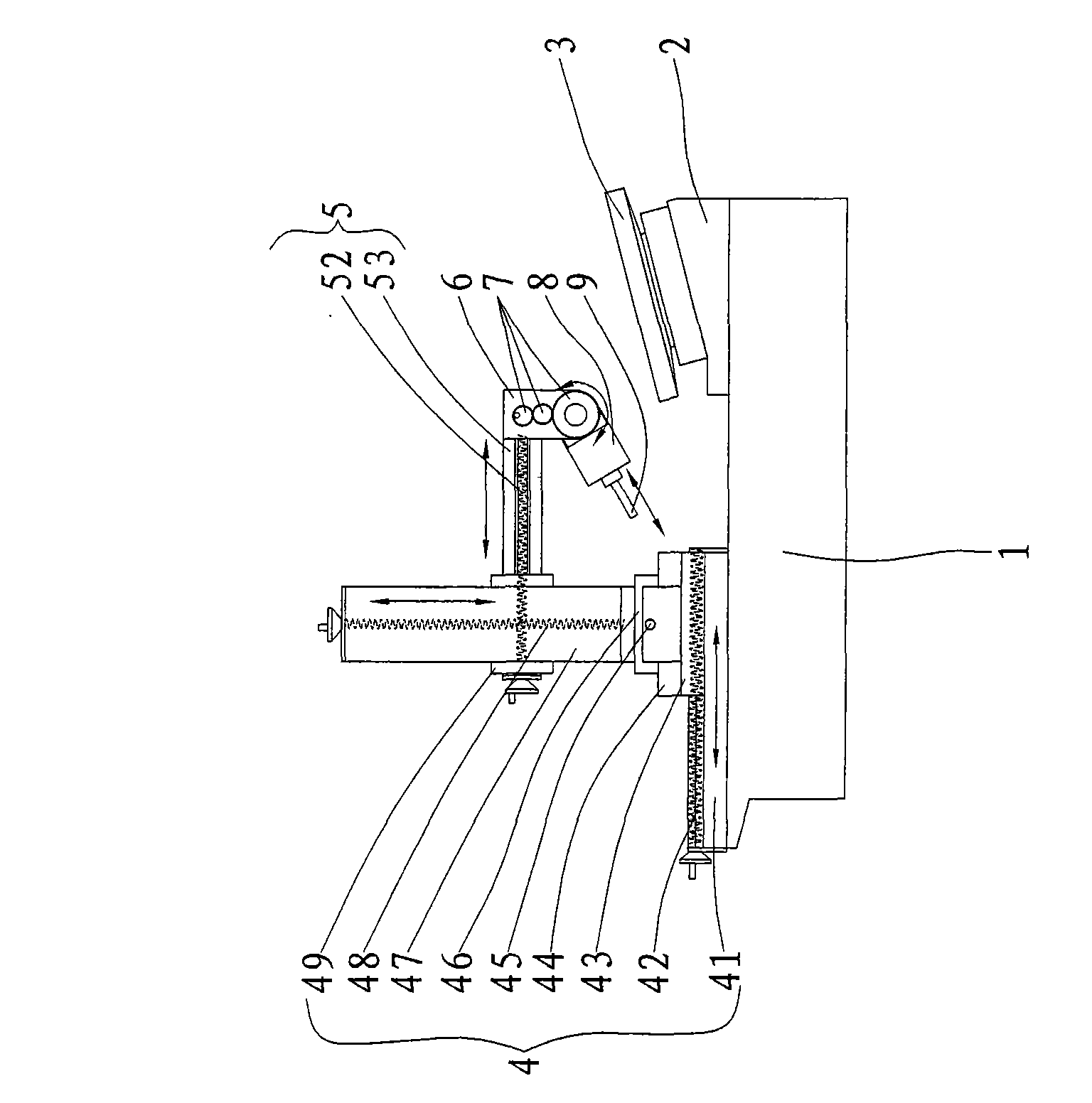

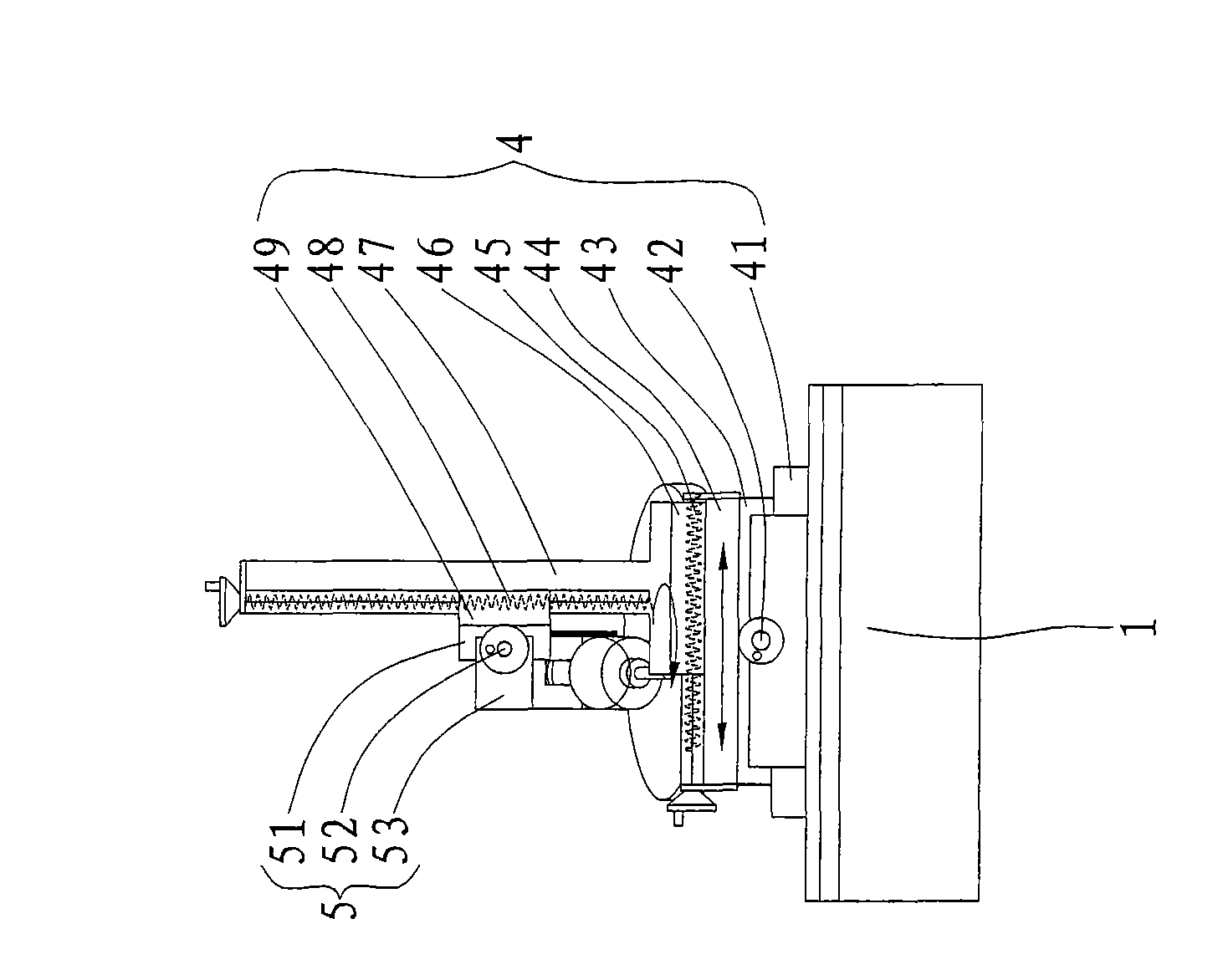

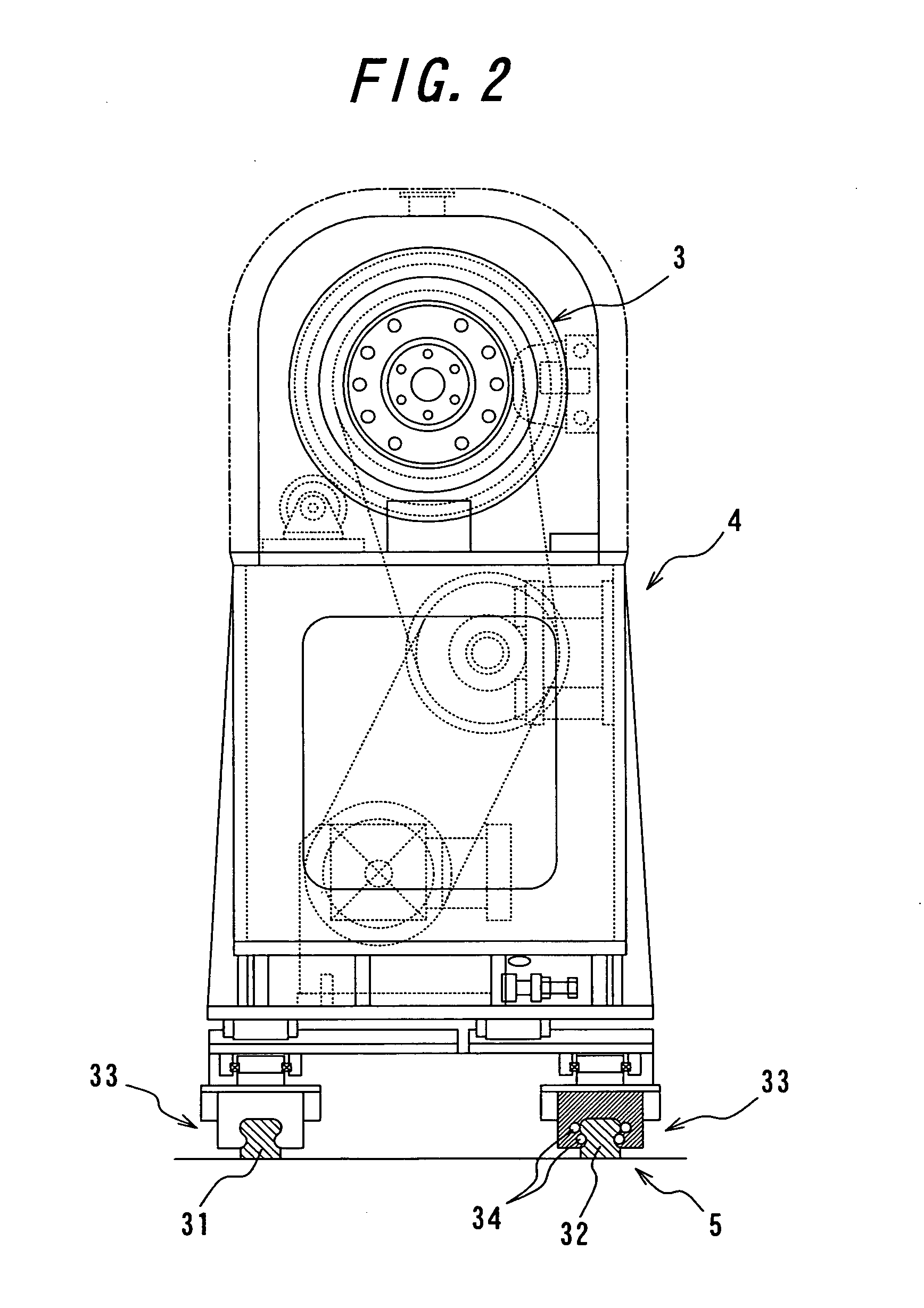

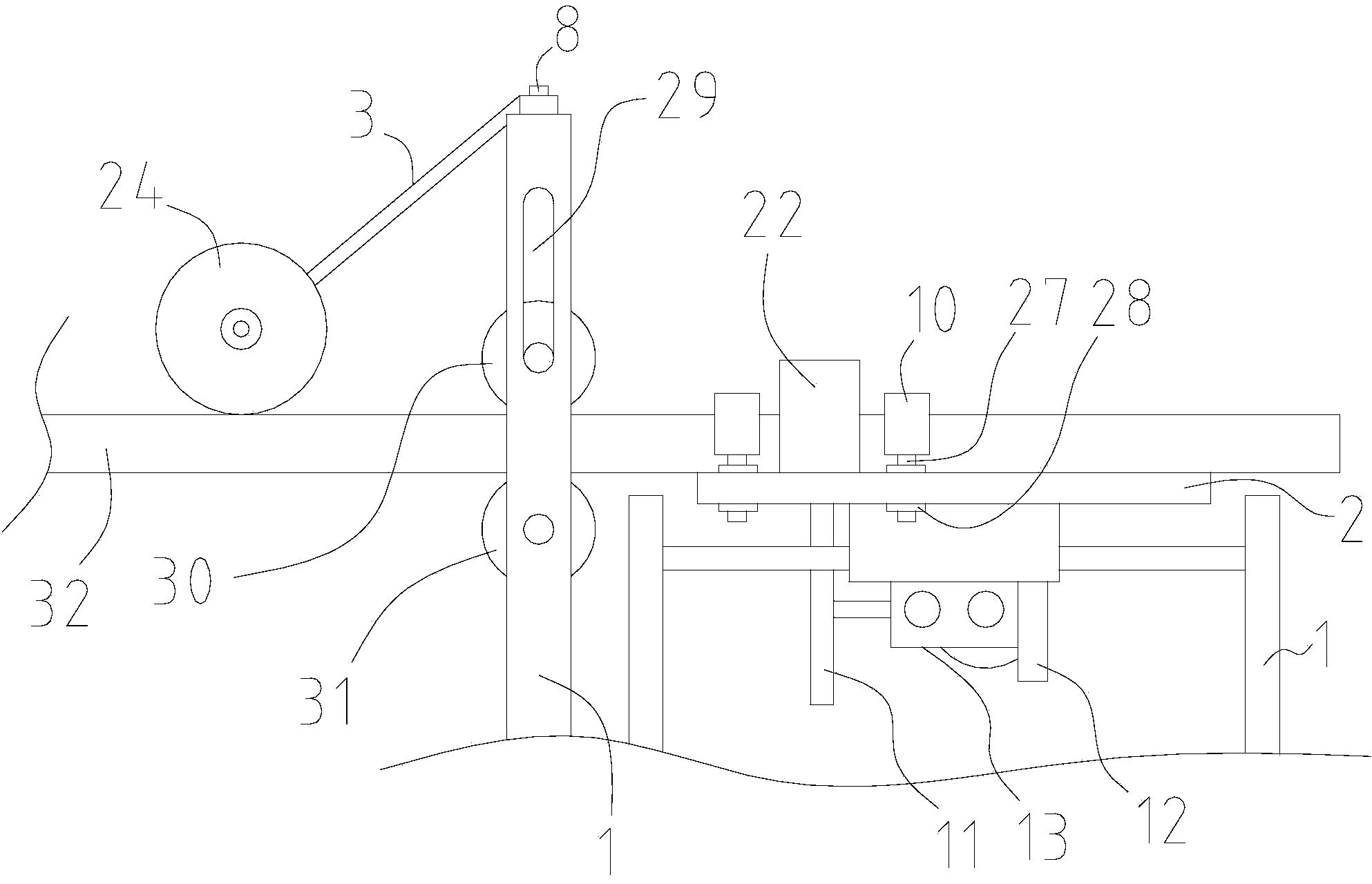

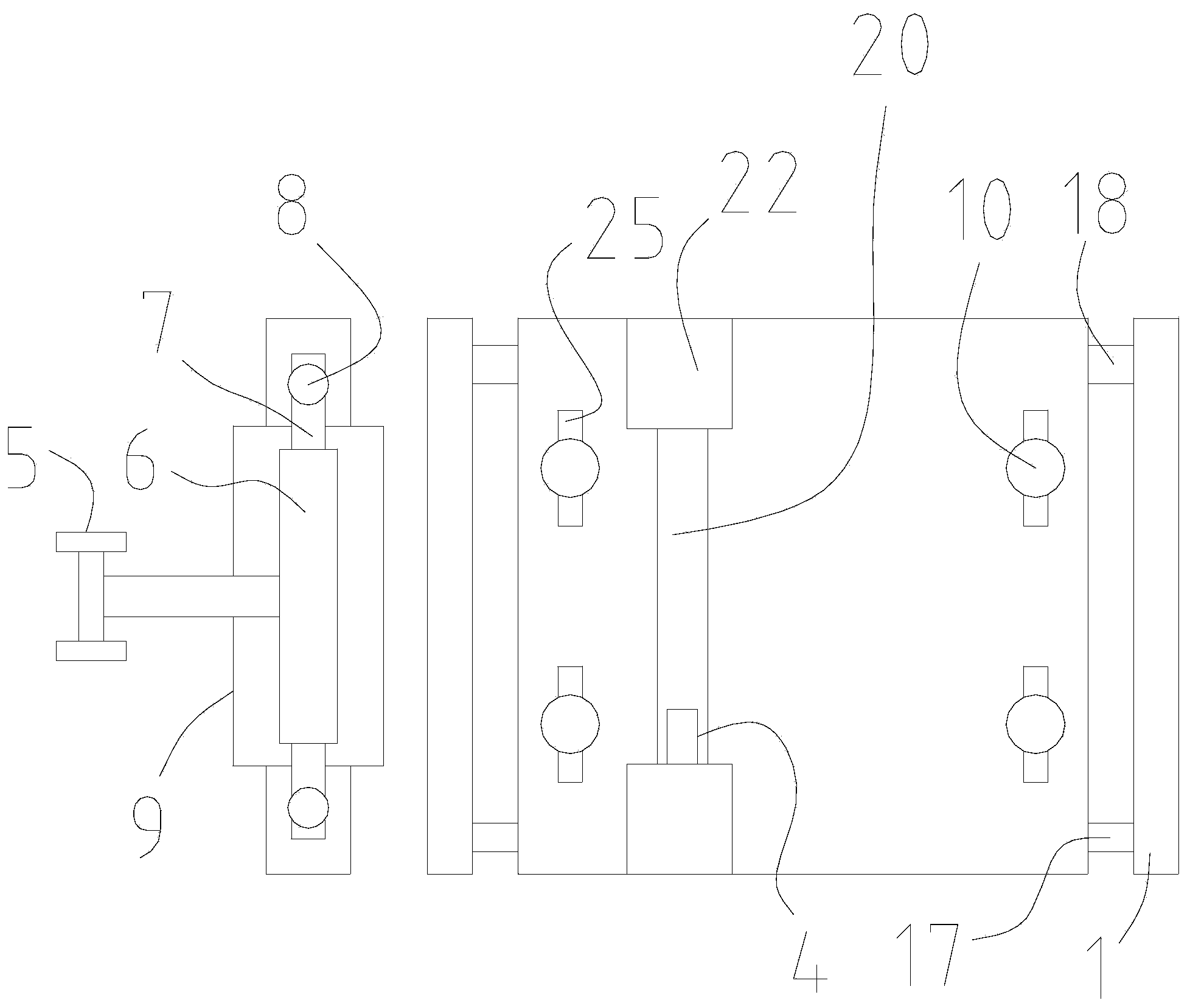

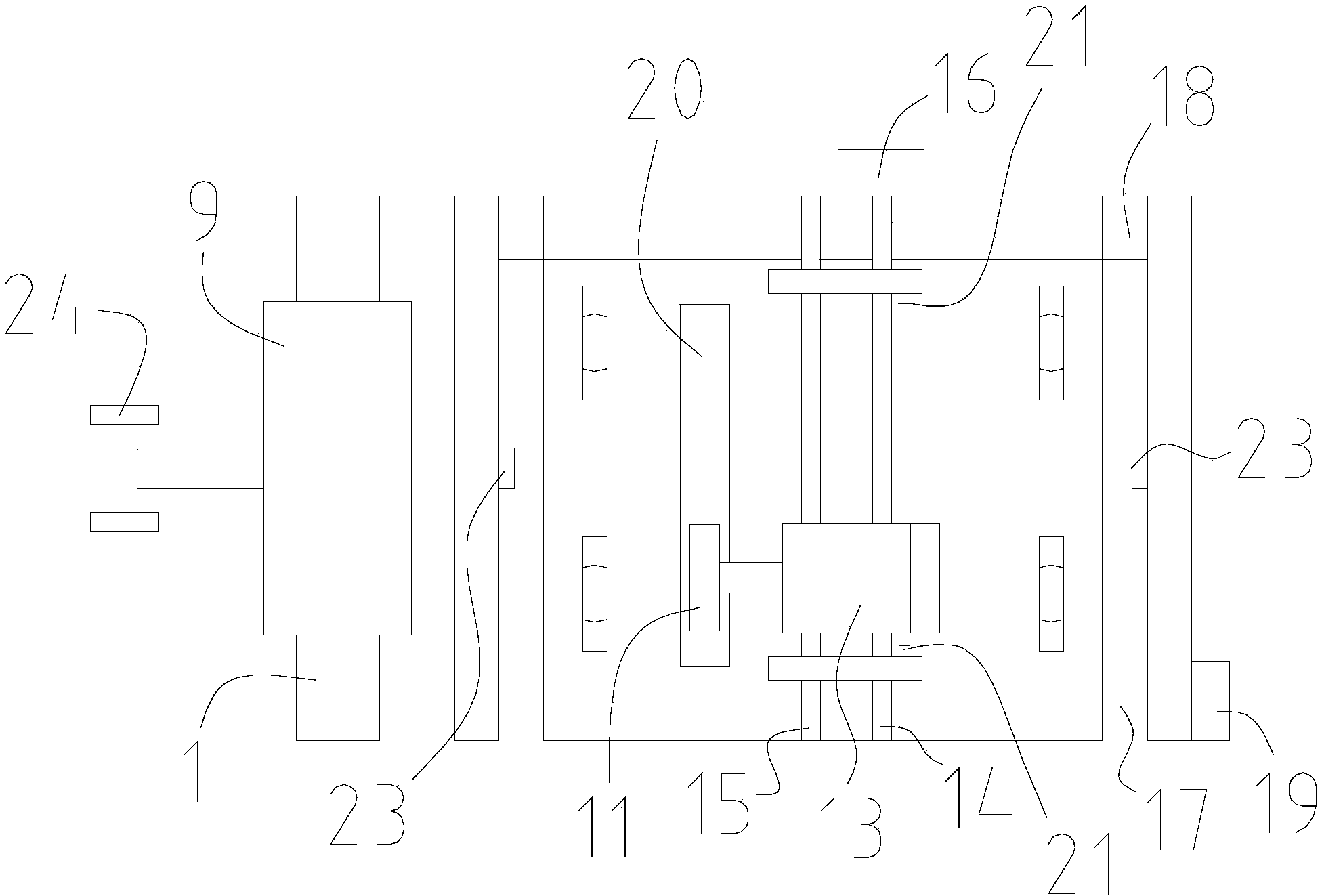

Pipe-type PECVD graphite boat assembling and disassembling piece system and process

ActiveCN104377154AReduce manufacturing costHigh movement accuracyFinal product manufactureSolid-state devicesLinear motionEngineering

The invention relates to a pipe-type PECVD graphite boat assembling and disassembling piece system. The system comprises a graphite boat delivery mechanism (1), a silicon slice feeding mechanism (2), a silicon slice discharging mechanism (3), a silicon slice grabbing and delivery mechanism (4) and a graphite boat assembling and disassembling mechanism (5), wherein the graphite boat delivery mechanism is used for carrying a graphite boat to move horizontally; the silicon slice feeding mechanism is used for taking silicon slices to be processed out of a flower basket; the silicon slice discharging mechanism is used for conducting overturning and discharging on the processed silicon slices; the silicon slice grabbing and delivery mechanism is used for absorbing the silicon slices and delivering the silicon slices in a linear motion mode; the graphite boat assembling and disassembling mechanism is used for assembling and disassembling the graphite boats. The pipe-type PECVD graphite boat assembling and disassembling piece system is precise to position and high in production efficiency.

Owner:江苏方艾机器人有限公司

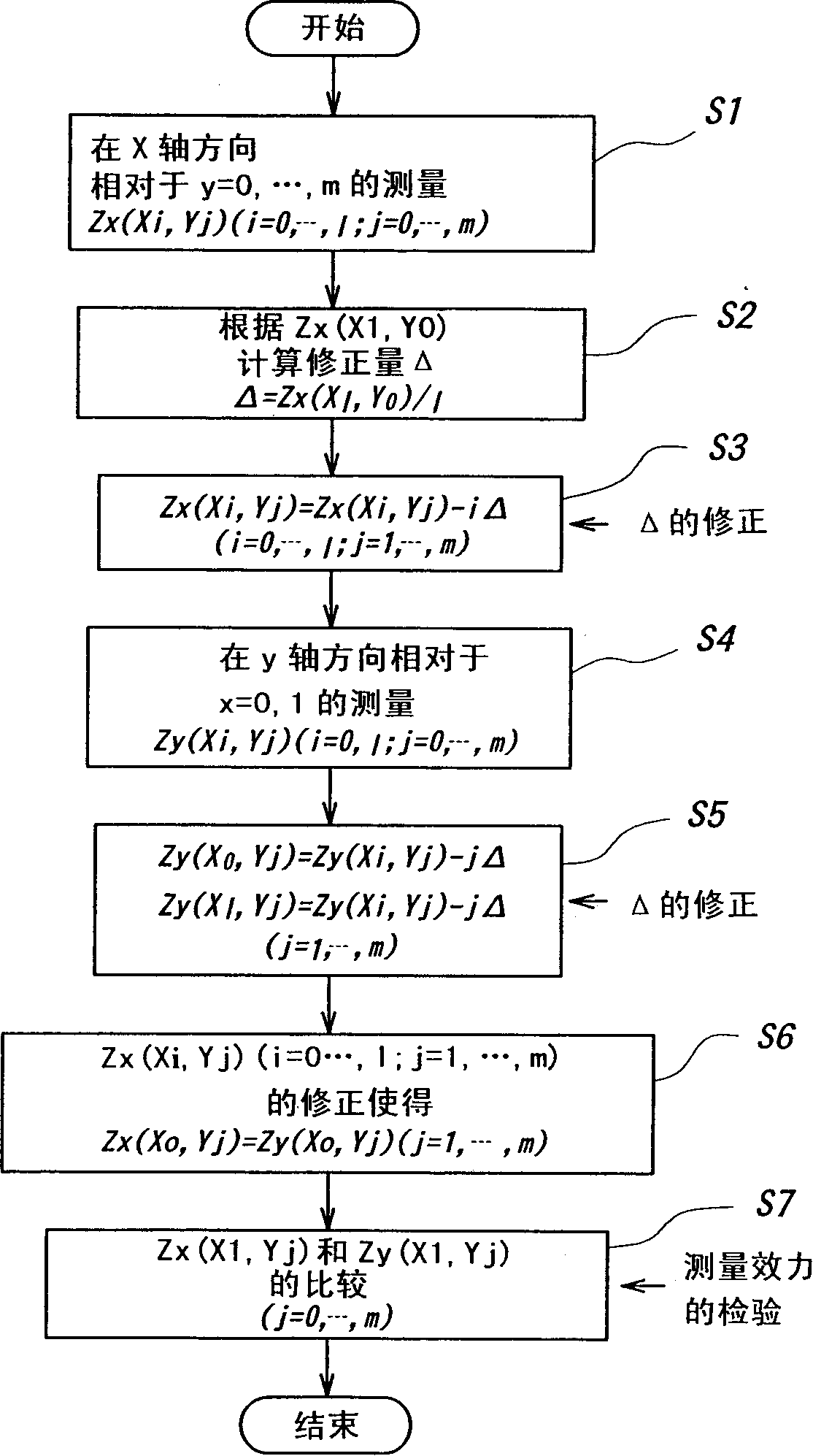

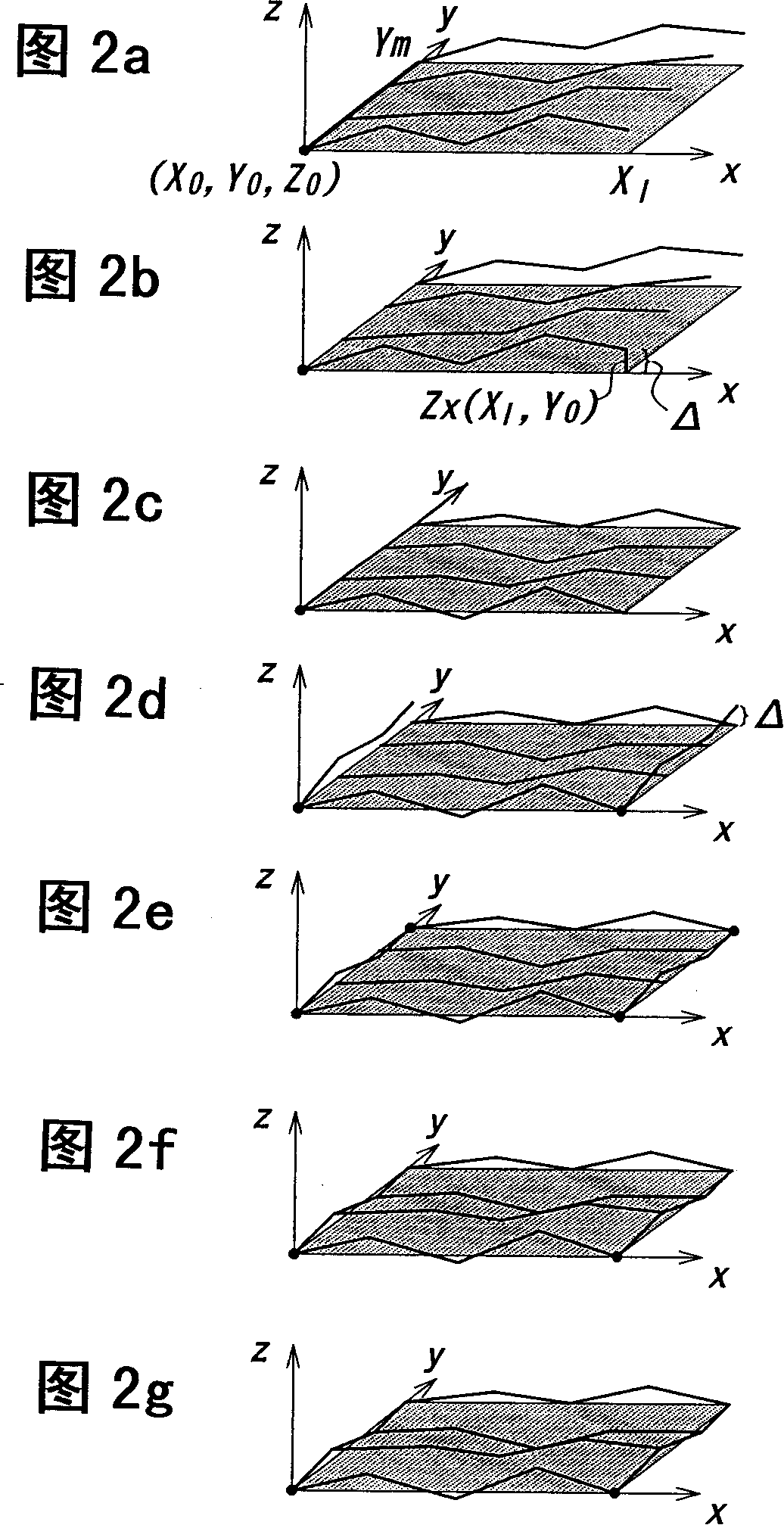

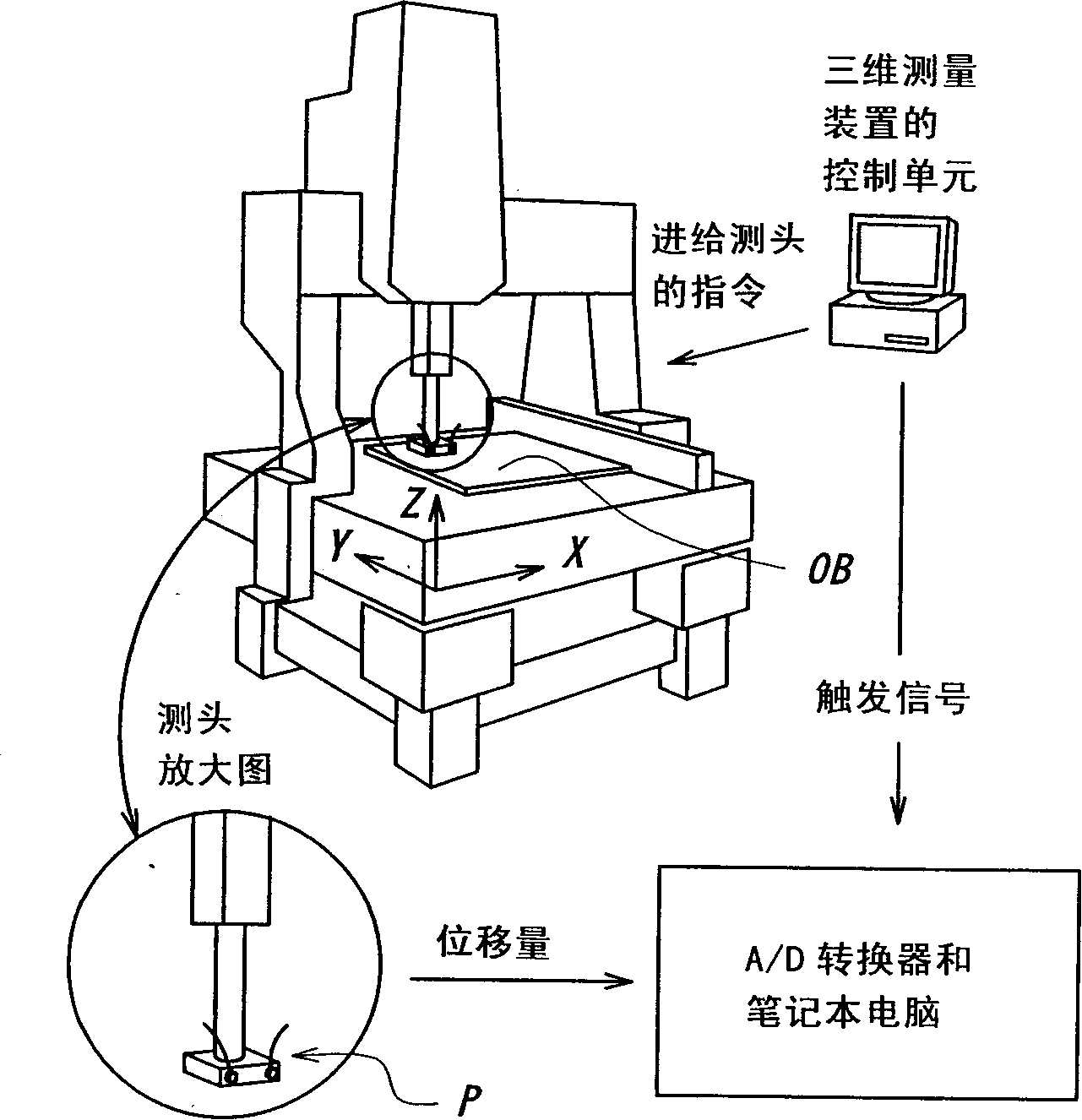

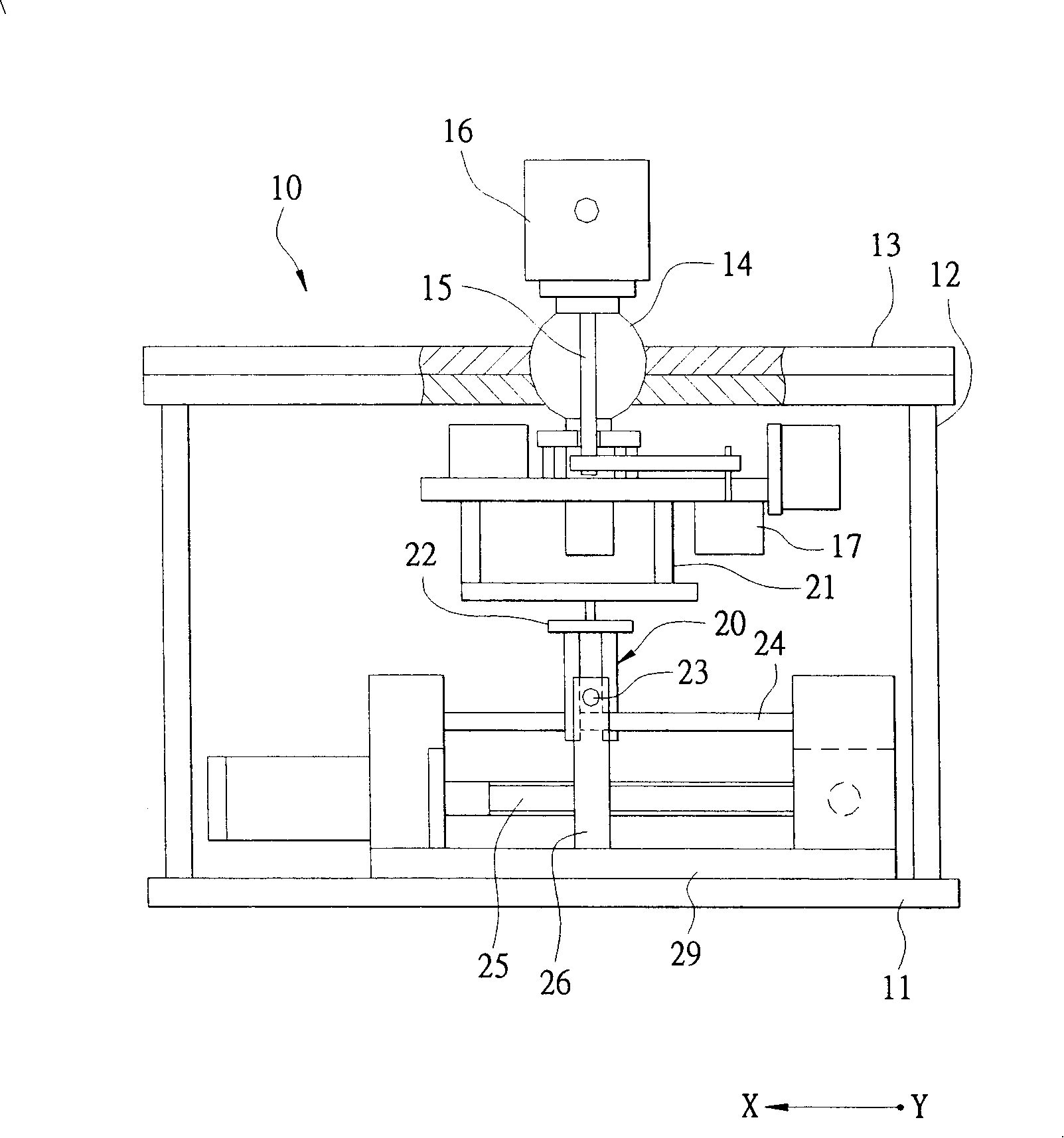

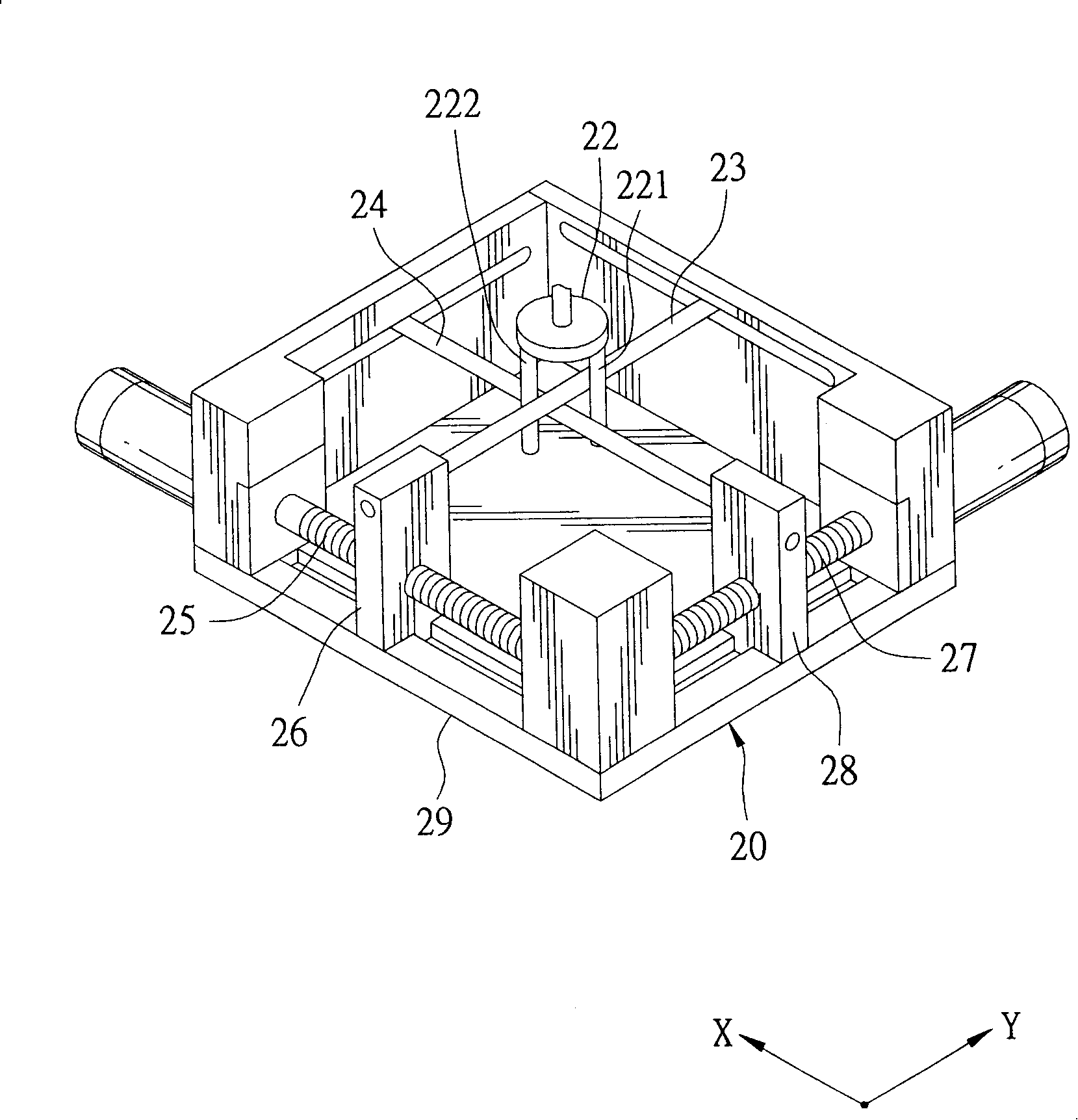

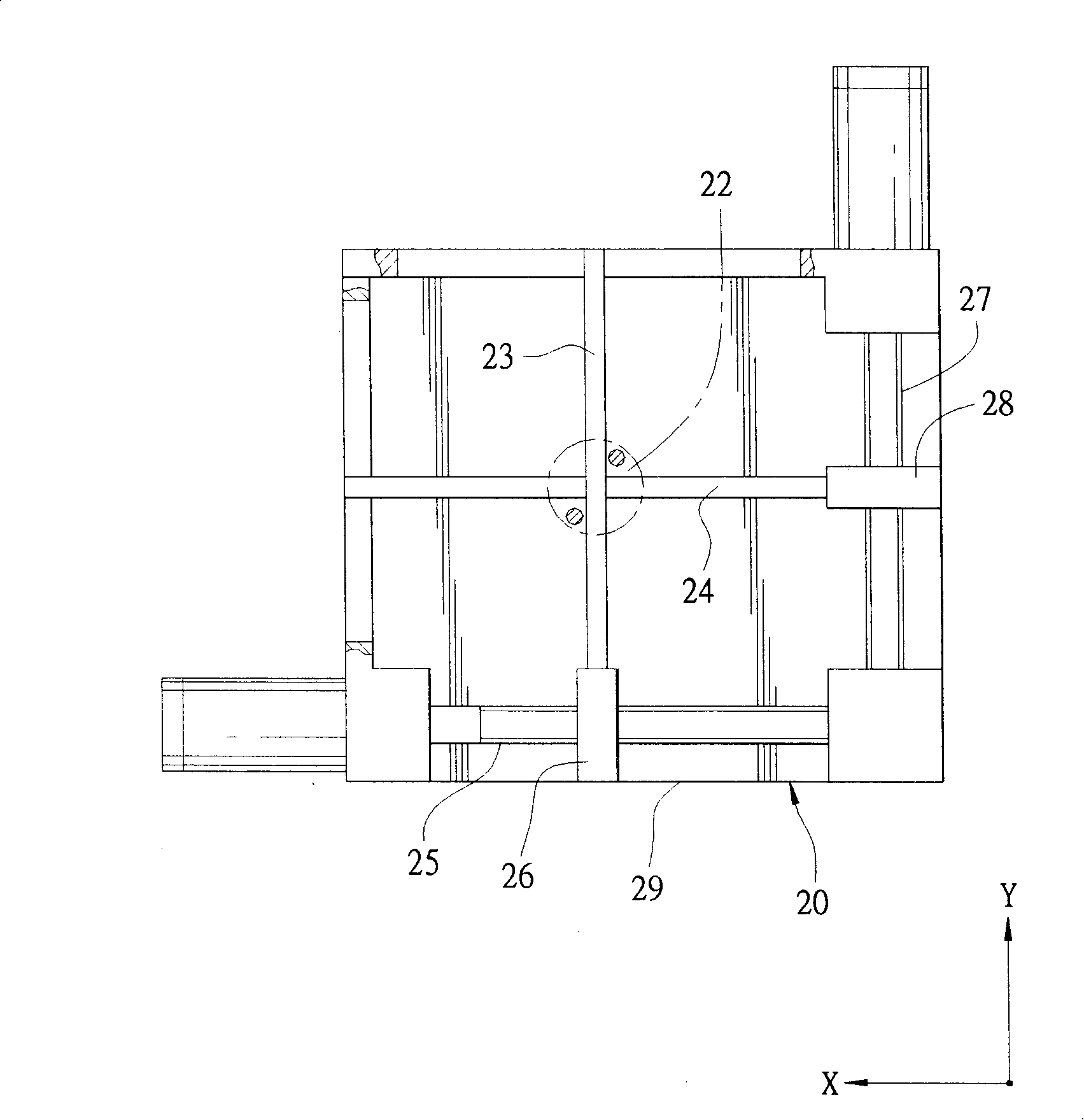

Positional error evaluation method for mobile device and movement accuracy improving method based on evaluation result

InactiveCN1392950AHigh measurement accuracyHigh movement accuracyProgramme-controlled manipulatorAutomatic control devicesPosition errorMobile device

In a mobile device for moving a mobile body in mutually orthogonal two- or three-axis directions, a positional error of the mobile body with respect to a direction orthogonal to preset two-axis directions out of the above two- or three-axis directions is used to determine, by using a sequential two-point method, a straightness error curve representing a change status along one-axis direction out of the above two-axis directions; the straightness error curve determining is repeated for the other one-axis direction out of the above two-axis directions.

Owner:CHUO UNIVERSITY

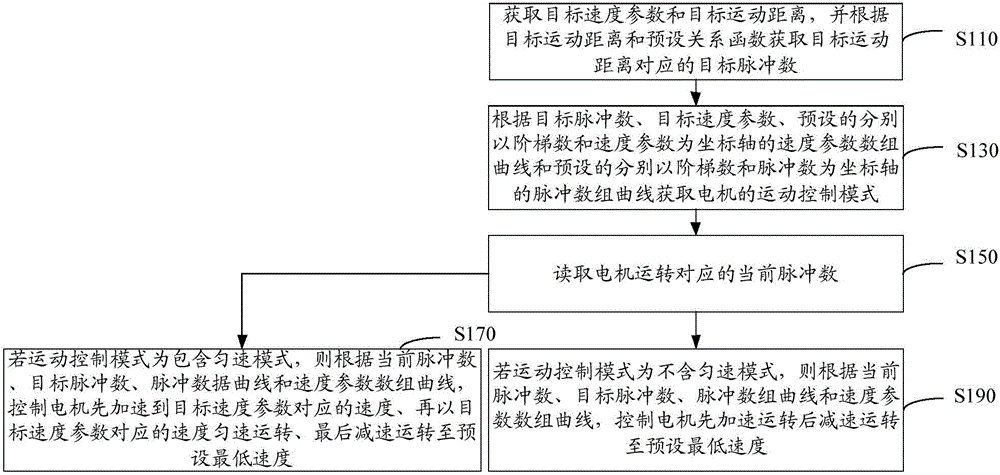

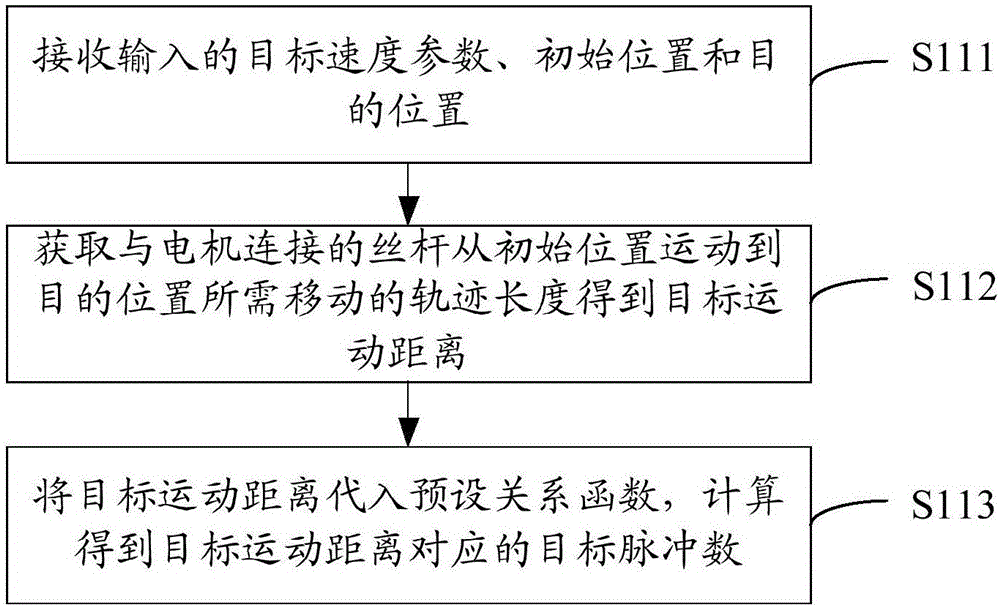

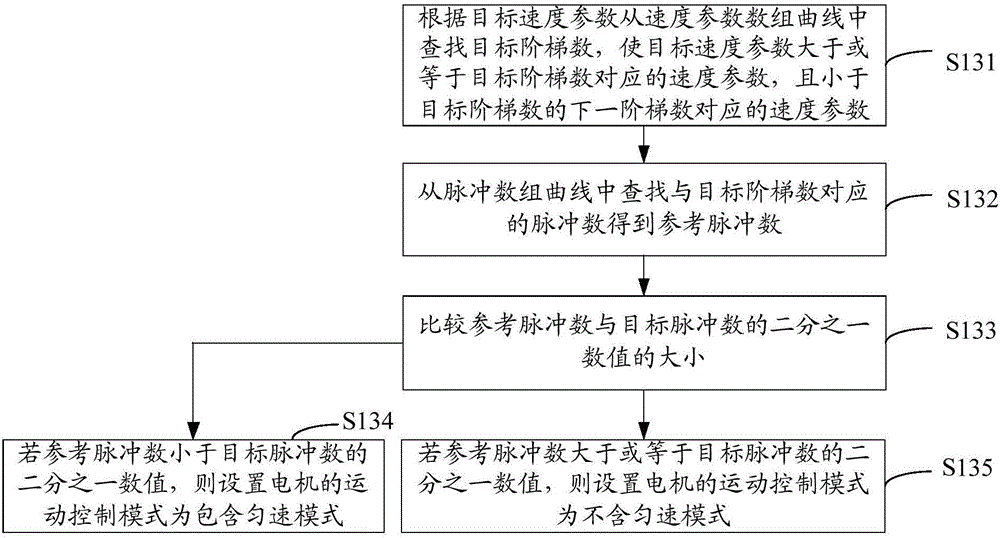

Motor acceleration and deceleration control method and three-dimensional pipette device

ActiveCN106787986ASimple controlEasy to implementSingle motor speed/torque controlDynamo-electric converter controlArray data structureLow speed

The invention relates to a motor acceleration and deceleration control method and a three-dimensional pipette device. The motor acceleration and deceleration control method comprises the following steps: a target speed parameter and a target moving distance are acquired, and a target pulse number is obtained according to the target moving distance and a preset relation function; a motion control mode of a motor is acquired according to the target pulse number, the target speed parameter, a preset speed parameter array curve and a pulse number array curve; the current pulse number corresponding to motor operation is read; if the motion control mode contains a constant speed mode, the motor is controlled to be accelerated to the speed corresponding to the target speed parameter, operate constantly at the speed corresponding to the target speed parameter and finally be decelerated to operate to a preset lowest speed; if the motion control mode does not contain the constant speed mode, the motor is controlled to perform accelerated operation and then perform decelerated operation to the preset lowest speed. Therefore, the control way is simple, easy to implement and high in precision.

Owner:GUANGDONG SHUNDE IND DESIGN INST GUANGDONG SHUNDE INNOVATIVE DESIGN INST

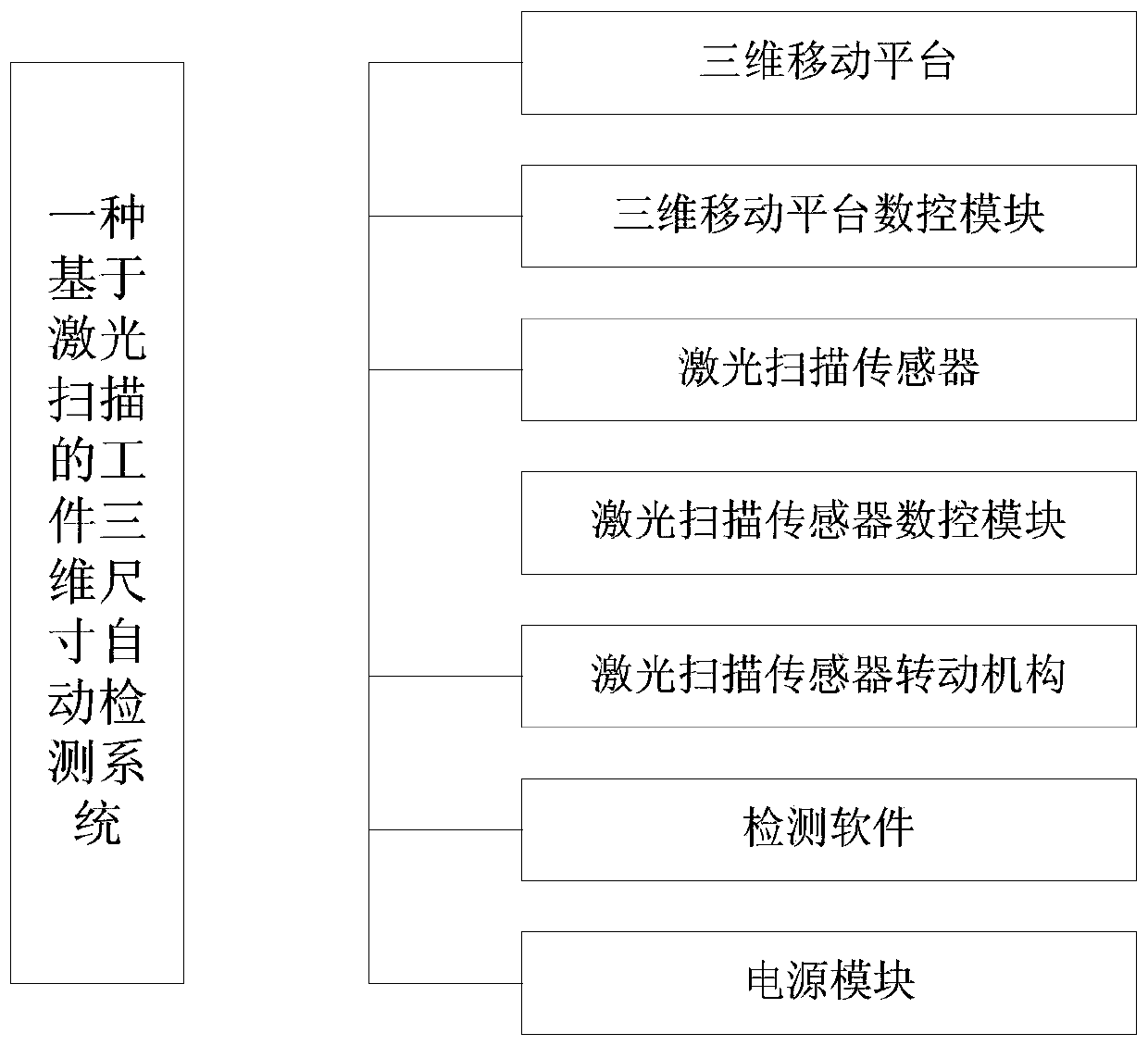

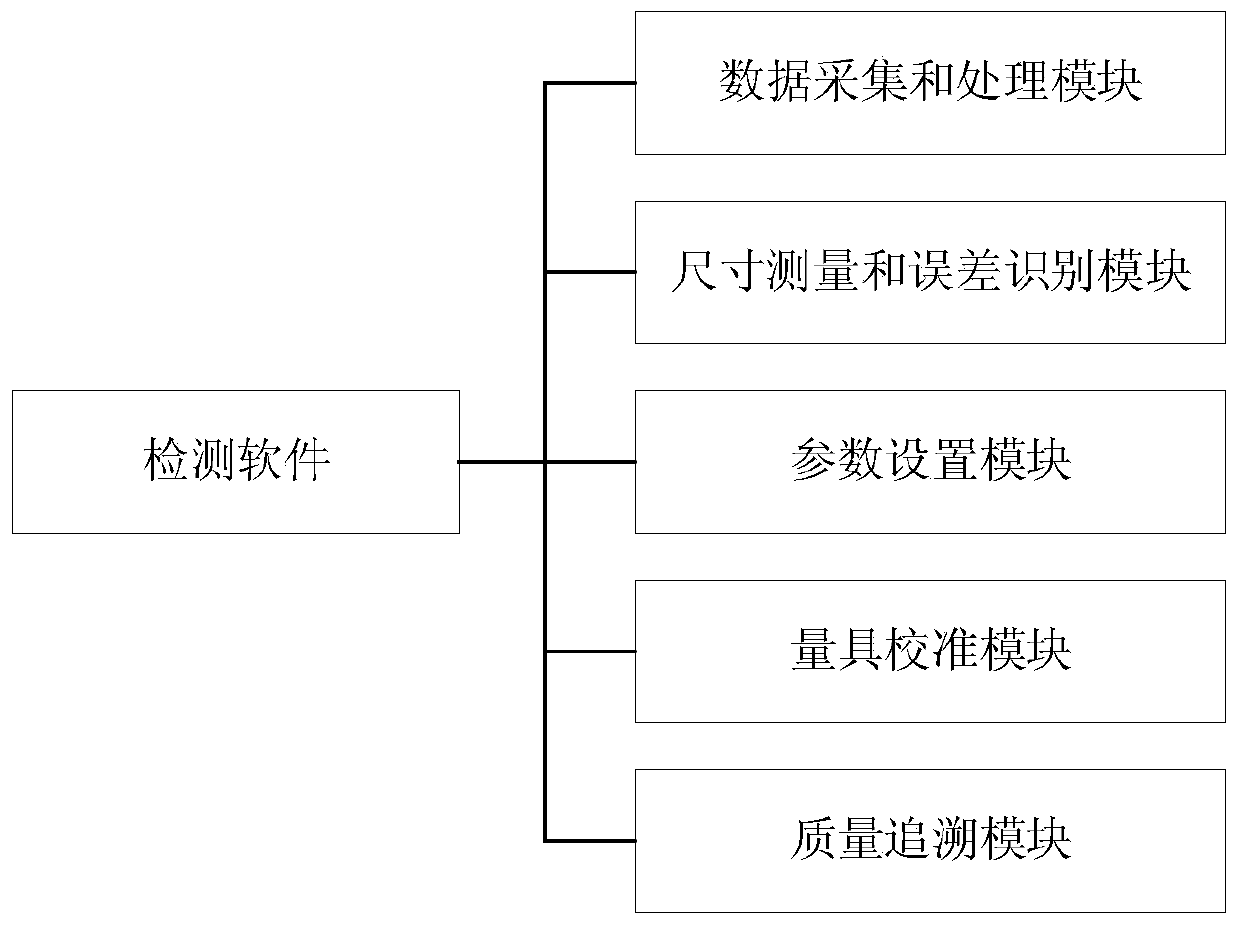

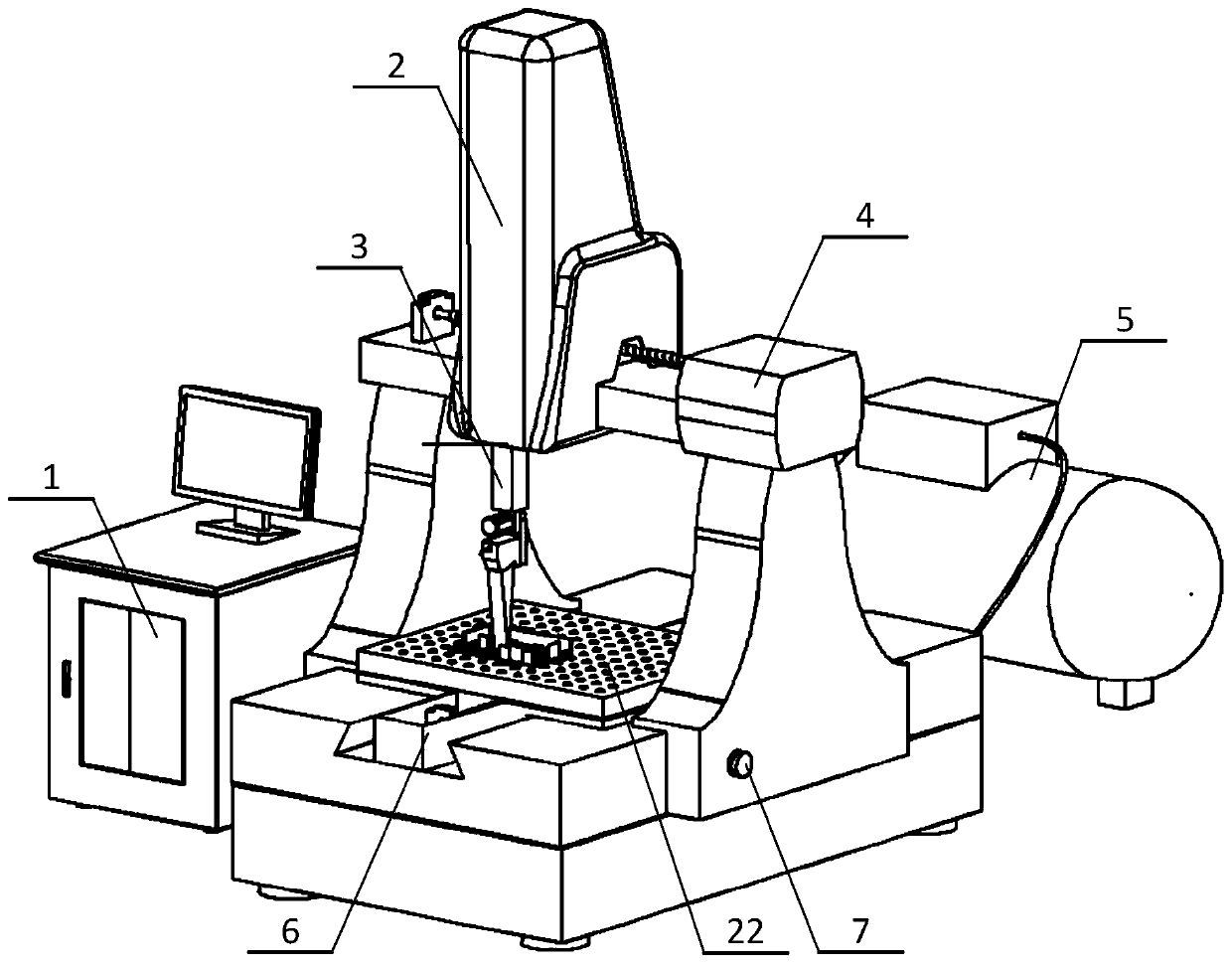

Workpiece three-dimensional dimensions automatic detection system and method based on laser scanning

InactiveCN110645910AImprove detection efficiencyHigh movement accuracyUsing optical meansLaser scanningEngineering

The present invention provides a workpiece three-dimensional dimensions automatic detection system and method based on laser scanning. The system comprises a three-dimensional moving platform, a three-dimensional moving platform numerical control module, a laser scanning sensor, a laser scanning sensor numerical control module, a laser scanning sensor rotating mechanism, a power module and detection software, and belongs to the technical field of three-dimensional scanning and digital analysis. According to the system, the numerical control three-dimensional moving platform is used, so that total dynamic measurement is implemented, manual movement detection is replaced, and detection efficiency is improved; a pneumatic floating slideway is used, so that movement precision is improved; thelaser scanning sensor rotating mechanism is assembled on a Z-axis pneumatic floating slideway, so that deflexion of the laser scanning sensor can be implemented, and a workpiece is scanned from different angles; and a blue line sweeping laser scanning sensor is selected, so that anti-interference is strong, and measurement precision is high.

Owner:BEIJING INST OF CONTROL ENG

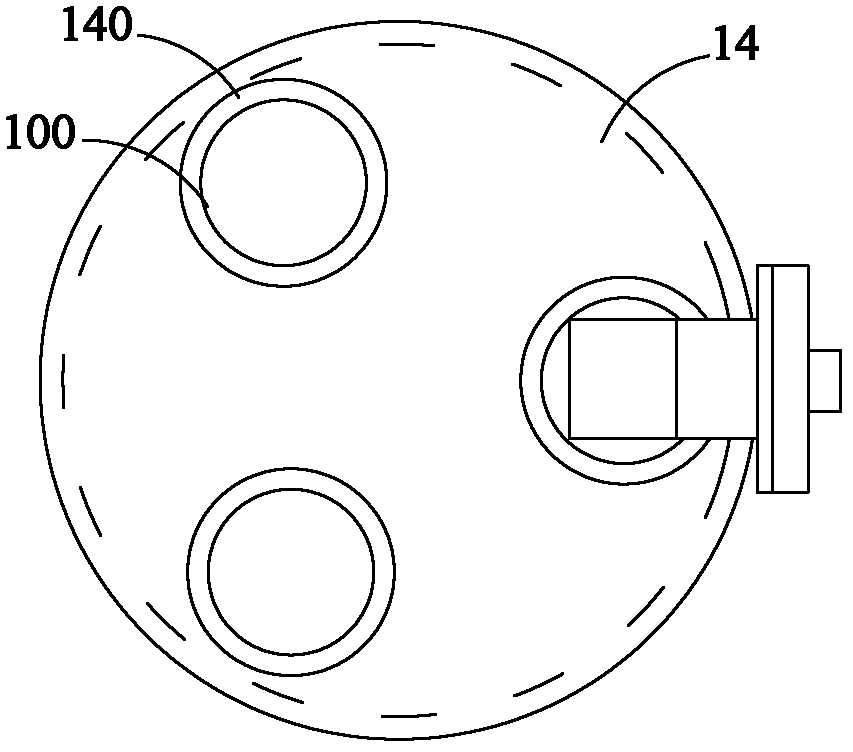

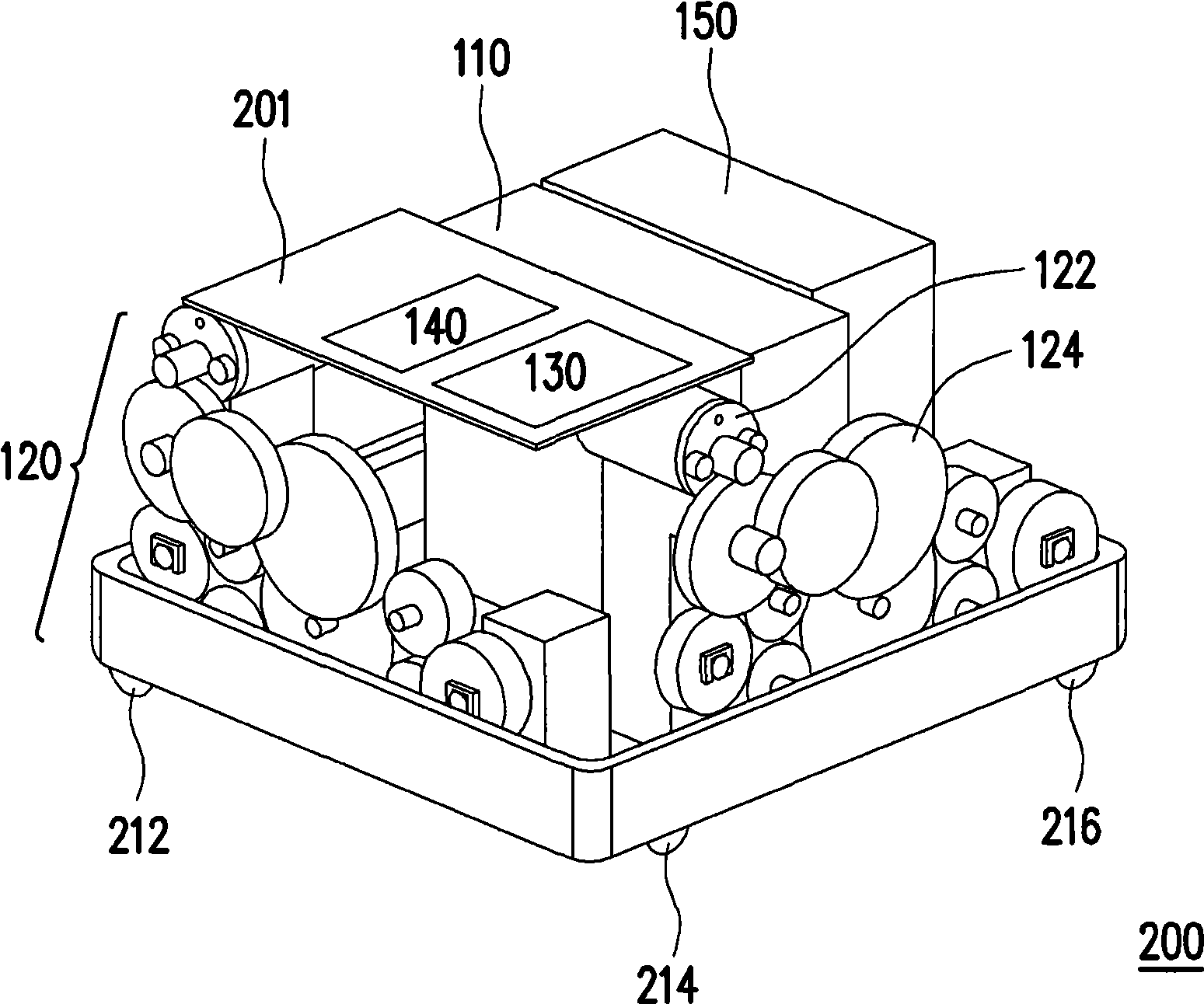

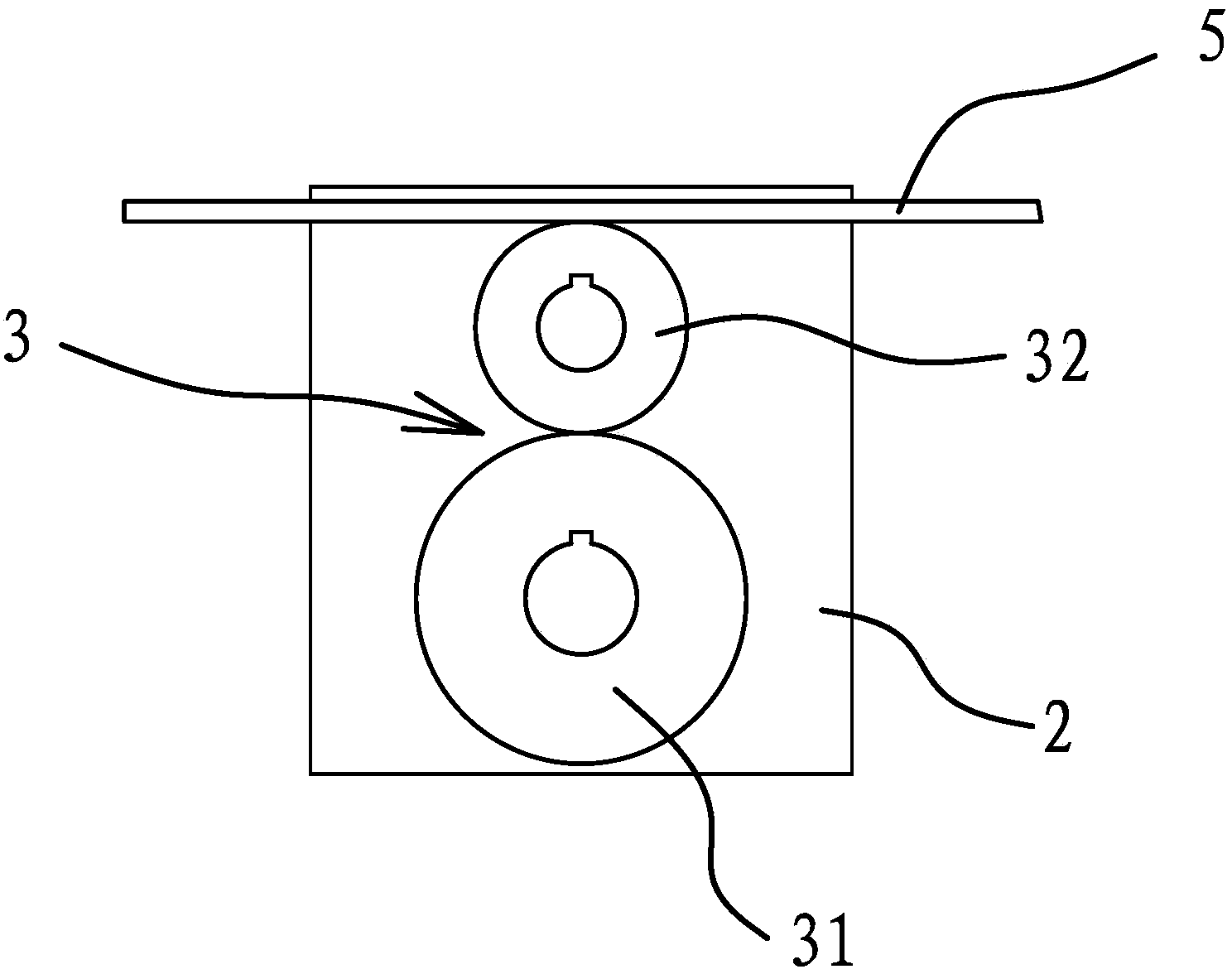

Two-sided automatic polishing machine

InactiveCN102626890AHigh movement accuracyImprove stabilityPlane surface grinding machinesEngineeringMechanical engineering

The invention discloses a two-sided automatic polishing machine, which comprises a horizontally arranged rotary table, an outer box, an upper abrasive wheel and a lower abrasive wheel, wherein the rotary table is provided with at least two through holes which are station holes; distances from the station holes to the center of the rotary table are the same; each station hole is used for transmitting a processing workpiece; the outer box is used for accommodating the rotary plate and is provided with an upwards opening; a through hole is arranged in a bottom face of the outer box; the upper abrasive wheel and the lower abrasive wheel are respectively arranged above and below the rotary plate and are horizontally arranged; rotating directions of the upper abrasive wheel and the lower abrasive wheel are opposite; the upper abrasive wheel can be lifted up and down, the lower abrasive wheel penetrates through the through hole of the outer box when being used for polishing, so that the upper surface of the lower abrasive wheel and a base plate of the rotary plate are coplanar; and wheel faces of the upper abrasive wheel and the lower abrasive wheel pass through the station holes in the middle parts of the upper abrasive wheel and the lower abrasive wheel when being rotated after stretching into the rotary plate. The two-sided automatic polishing machine has the beneficial effects that a table board of a radiator can be efficiently polished, the production efficiency is high, and the problems that the production efficiency for the table board of the radiator is low, the product quality is instable, and the market competitiveness is weak are solved.

Owner:安徽祥博传热科技有限公司

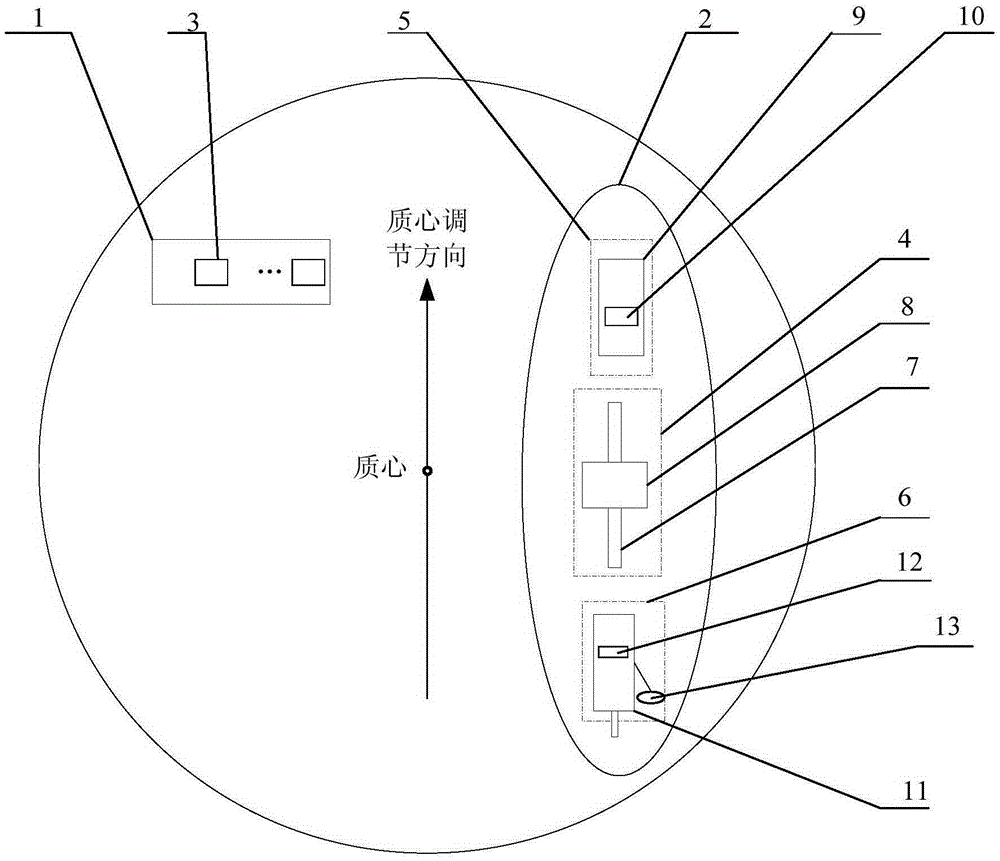

Mass center adjustment system of air-floating motion simulator

The invention relates to a mass center adjustment system of an air-floating motion simulator, which comprises a fixed counterweight unit, an adjustable counterweight unit, a first level gauge, a second level gauge and three gravity sensors, and is characterized in that the fixed counterweight unit comprises a plurality of counterweight blocks which are different in weight; the adjustable counterweight unit comprises a manual rough adjustment counterweight unit, a manual fine adjustment counterweight unit and an electrically controlled fine adjustment counterweight unit. According to the invention, under assistance of the first level gauge, the second level gauge and the three gravity sensors, mass centers of a translation platform and an attitude platform of the air-floating motion simulator can be gradually adjusted to a gyration center through three-level adjustment, that is, manual rough adjustment, manual fine adjustment and electrically controlled fine adjustment, of the fixed counterweight unit and the adjustable counterweight unit, thereby not only increasing the capacity and the range of mass center adjustment, but also improving the precision of mass center adjustment, greatly reducing the difficulty in mass center adjustment, and greatly shortening the time of mass center adjustment.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

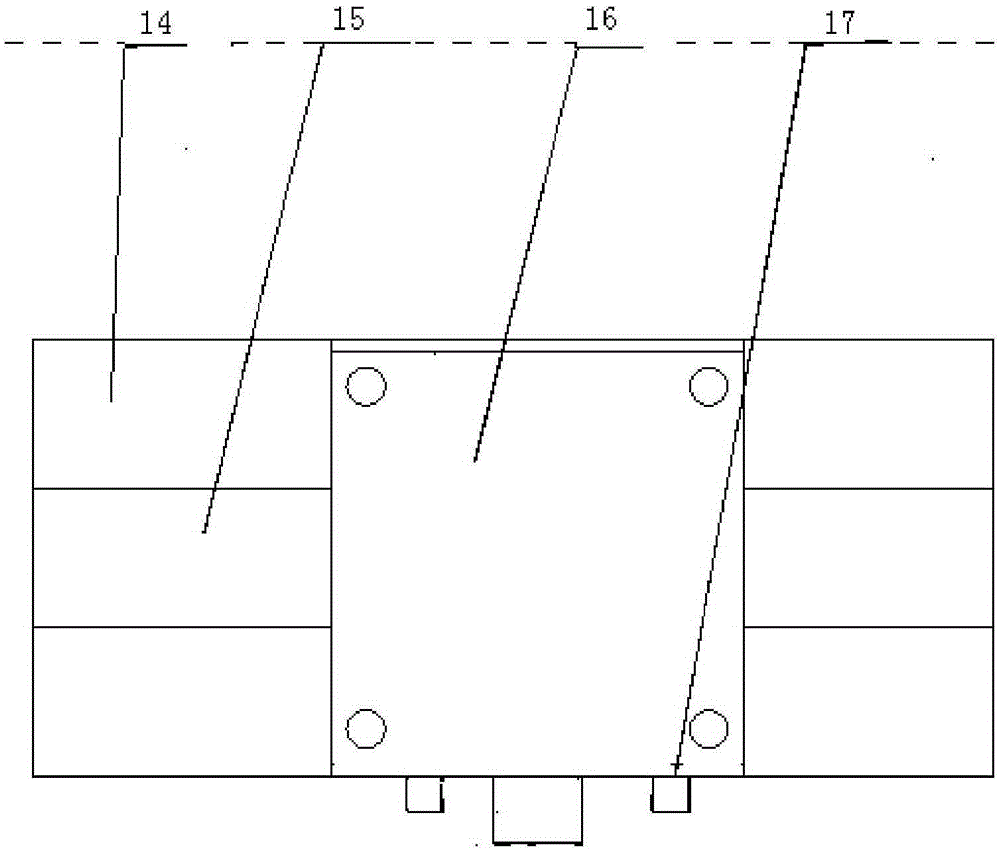

Dip angle regulating device

InactiveCN101187720AAchieve the purpose of the inventionIndependent adjustment of usage characteristicsSurveying instrumentsMountingsEngineeringMechanical engineering

Owner:ASIA OPTICAL CO INC

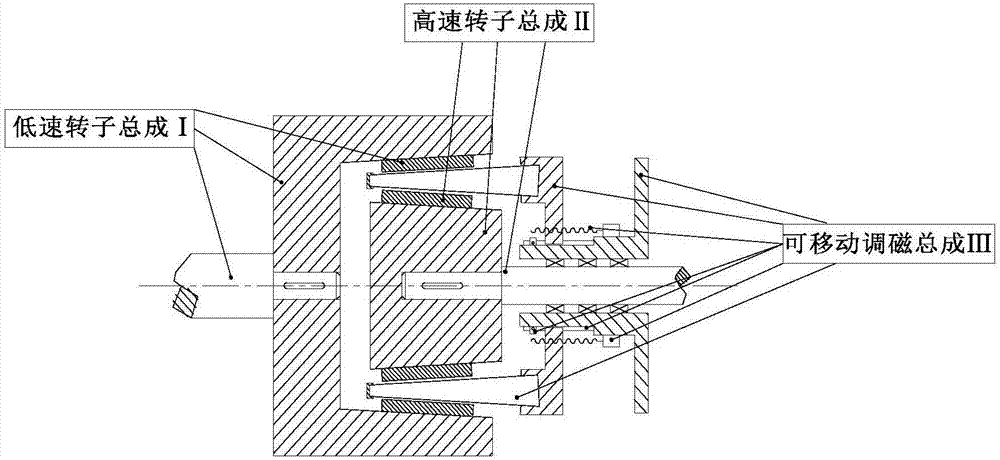

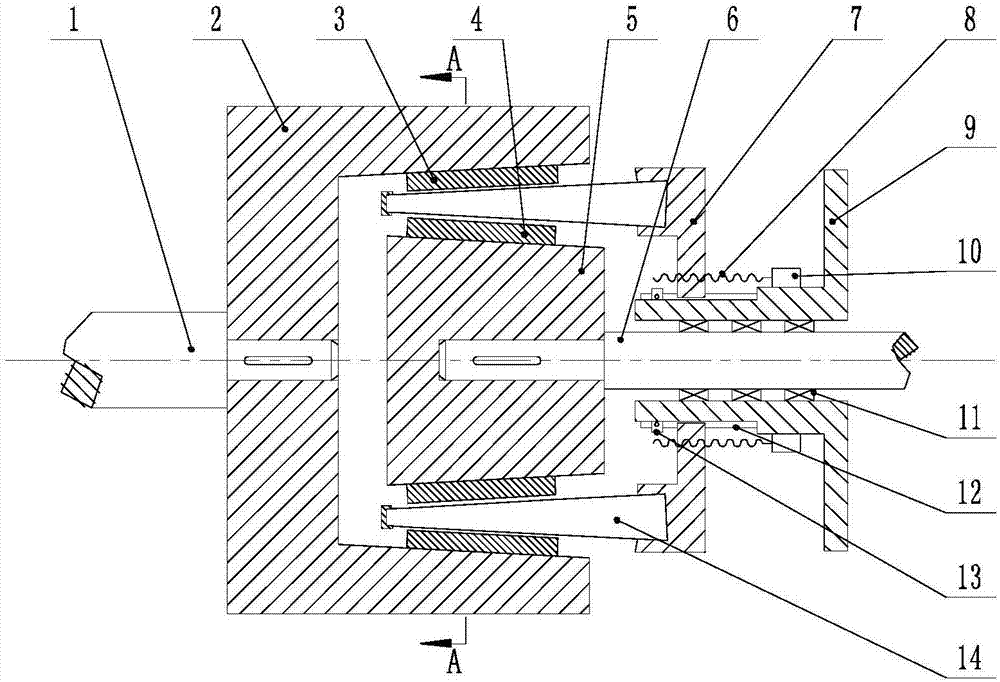

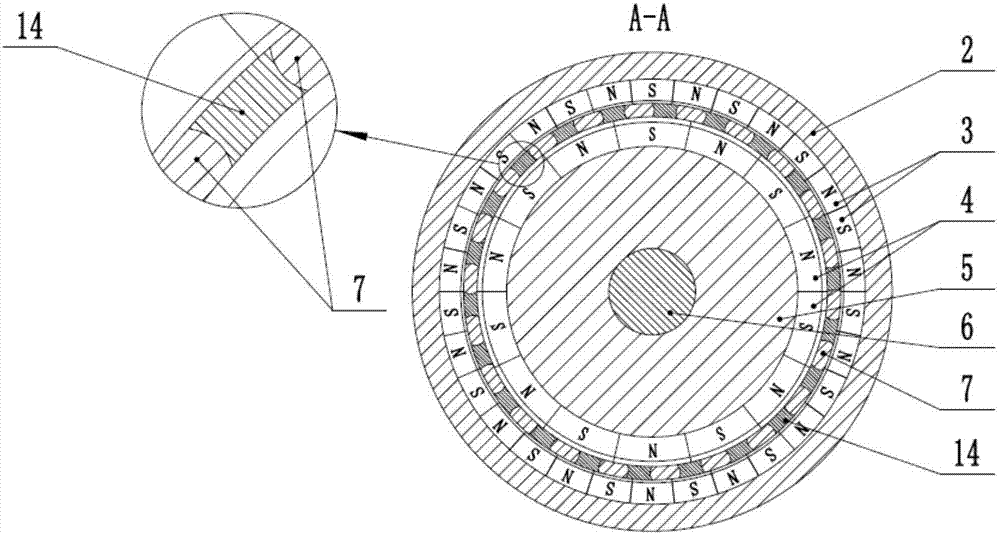

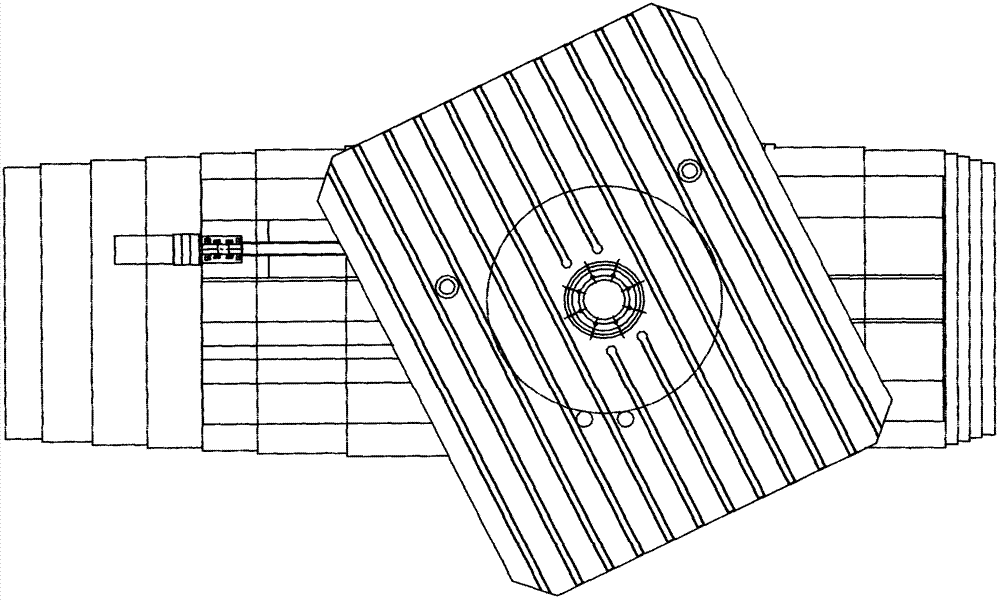

Air gap-adjustable magnetic gear with side positive rotating magnetic adjusting device

ActiveCN107425697AReduce eddy current lossImprove structural strengthPermanent-magnet clutches/brakesMagnetic tension forceTorque density

The invention relates to the technical field of transmission in mechanical engineering, in particular to an air gap-adjustable magnetic gear with a side positive rotating magnetic adjusting device. The air gap-adjustable magnetic gear comprises a low-speed rotor assembly, a high-speed rotor assembly and a mobile magnetic adjusting assembly. The air gap-adjustable magnetic gear is characterized in that a servo motor is connected with a support frame through a lead screw, and the servo motor moves to drive the lead screw to move to achieve axial movement of the support frame; an outer rotor permanent magnet and an inner rotor permanent magnet are both obliquely arranged, and the magnetic adjusting device is formed by stacking side positive rotating type magnetic adjusting pole pieces and arranged in a clamp groove formed in the support frame in a clamped mode; and the magnetic adjusting device is driven by axial movement of the support frame to move axially to achieve the purpose of changing the size of an inner air gap and an outer air gap, and the upper surface and the lower surface of the magnetic adjusting device are parallel to the surface of the outer rotor permanent magnet and the surface of the inner rotor permanent magnet respectively, so that the inner air gap and the outer air gap change uniformly. According to the air gap-adjustable magnetic gear, by changing the size of the inner gap and the outer gap, the purposes of improving the transmission efficiency and increasing the torque density are achieved.

Owner:重庆雨力机械有限公司

Self-propelled printer having orientation adjusting device and method for setting coordinate

InactiveCN101544132AHigh movement accuracyAccurate printingTypewritersOther printing apparatusComputer science

Owner:KINPO ELECTRONICS

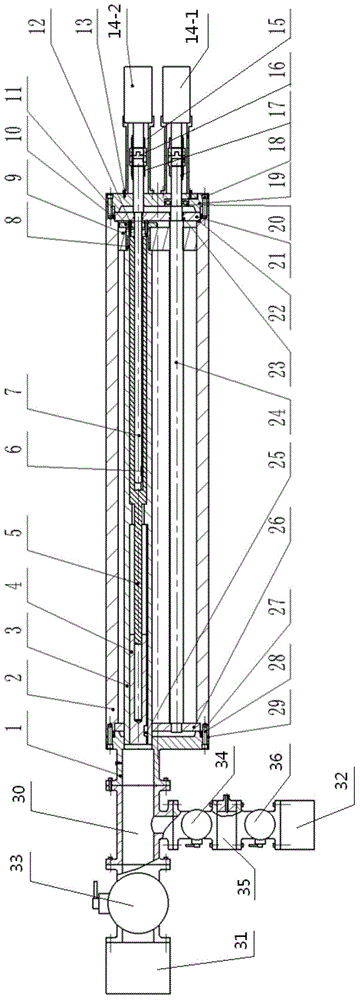

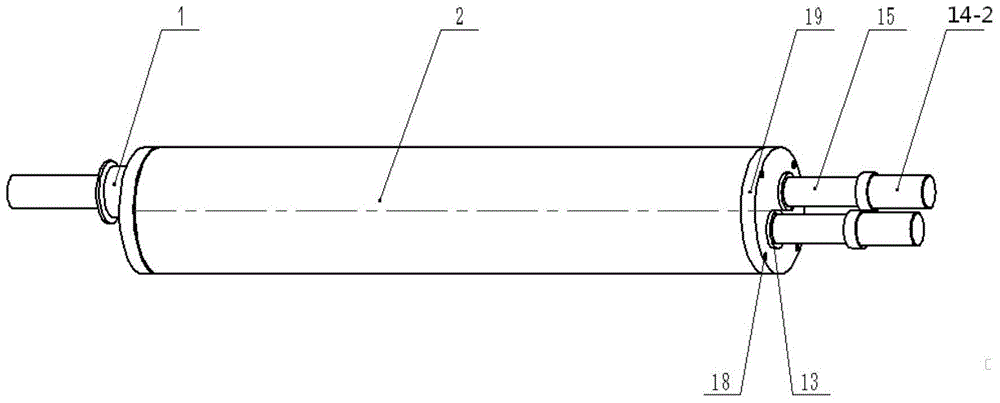

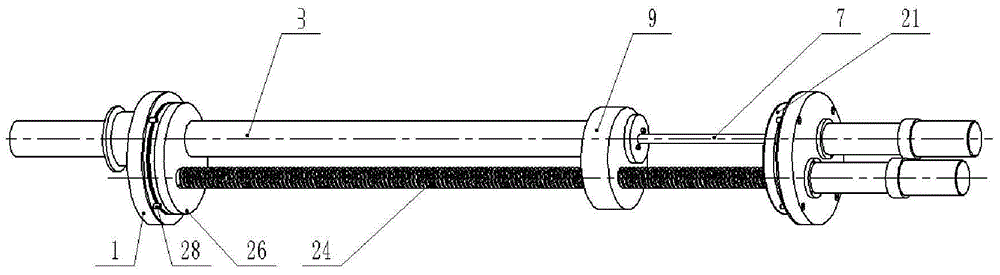

Pressure-maintained transferring system for deep sea microbes

InactiveCN105039146AIncrease profitSimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsManufacturing cost reductionTransfer system

The invention discloses a pressure-maintained transferring system for deep sea microbes. The pressure-maintained transferring system comprises a connection unit with a valve, a pressure-maintaining barrel communicated with the connection unit and a sampling unit installed in the pressure-maintaining barrel. The sampling unit comprises: a sampling barrel, which is axially and movably installed and has an open end that may extend out from the pressure-maintaining barrel, penetrate the connection unit and then implement sampling; a piston, which is circumferentially fixed in the sampling barrel, capable of axial sliding and used for pushing a material in the sampling barrel out from the open end; a first driving mechanism, which comprises a first power supply, a screw rod and an axially slidable slide block in thread transmission with the screw rod; and a second driving mechanism, which comprises a second power supply, a sampling driving rod and an axially slidable sampling transfer rod in circumferential fixed connection with the sampling driving rod. According to the invention, parallel double-shaft driving arrangement is employed, so the interior structure of the pressure-maintaining barrel is simplified, the structure of the system is more compact, and manufacturing cost is reduced; and axial movement power is transmitted through thread transmission, so stability, reliability and high movement precision are realized.

Owner:ZHEJIANG UNIV

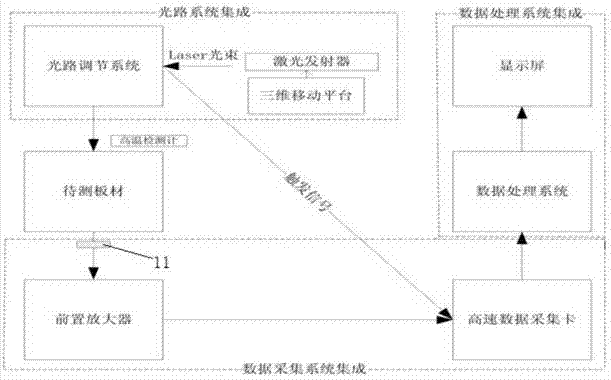

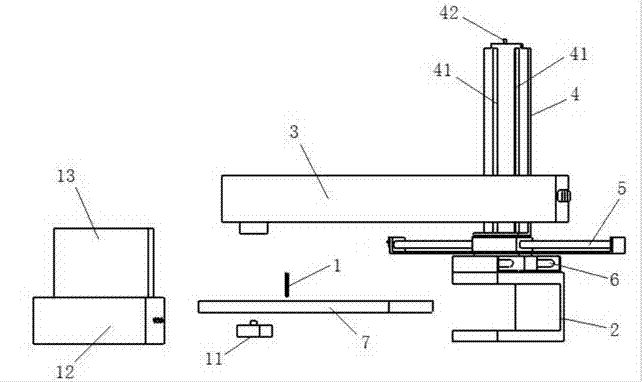

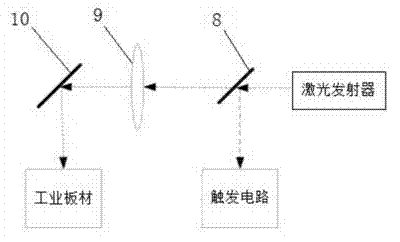

Sheet thickness online measurement system based on laser ultrasound

ActiveCN104729435AHigh movement accuracyRealize real-time online non-destructive testingUsing subsonic/sonic/ultrasonic vibration meansUsing optical meansLaser transmitterSonification

A sheet thickness online measurement system based on laser ultrasound comprises a light path system integration, a high-temperature detection meter, a data acquisition system integration and a data processing system integration, wherein the light path system integration comprises a U-shaped grounding frame, a three-dimensional mobile platform and a control cabinet integrating with a laser transmitter and a light path regulating system; the data acquisition system integration comprises a capacitive displacement sensor, a pre-amplifier and a high-speed data acquisition card, the capacitive displacement sensor is arranged at the first distance position below the alignment position of the bottom surface of a sheet, the data processing system integration converts bipolar signals having aliasing peak values and complex background noise into unipolar signals having clear peak values and low background noise, and therefore the time when longitudinal waves and transverse waves reach the alignment position of the bottom surface of the sheet first two times is accurately obtained, and the thickness of the sheet is calculated. The sheet thickness online measurement system has the advantages that the sheet thickness online measurement system is suitable for online measuring the thickness of the sheet under extreme environments such as high temperature, strong corrosion and high radiation, thickness measurement is accurate, and errors are small.

Owner:ZHEJIANG UNIV

Intelligent laser engraving system based on industry 4.0

ActiveCN105933449AHigh movement accuracyLarge carving areaTransmission systemsTransmissionThird generationThe Internet

The invention relates to an intelligent laser engraving system based on industry 4.0, relating to laser engraving equipment. A user module, a communication module, an electric control module and a mechanical module are arranged; the user module is provided with a mobile phone client side and an ERP management system; the ERP management system is connected to an internet and keeps real-time connection with a cloud server; the communication module is simultaneously connected to the user module and the electric control module; the communication module is provided with the cloud server and a 3G router; the electric control module is connected to the mechanical module; the electric control module is provided with a PLC, a servo driver and a HMI touch screen; and the mechanical module is provided with a warehouse entry area, a linear module, a linear guide rail, a processing station, a vacuum suction cup, a laser, a warehouse-out area and a load base. Personalized products can be customized according to requirements; manual operation is unnecessary from payment to order to processing completion; the production efficiency is high; the processing state can be monitored in real time more comprehensively; the movement precision is high; the engravable area is relatively large; and thus, the beauty of products is improved easily.

Owner:XIAMEN UNIV

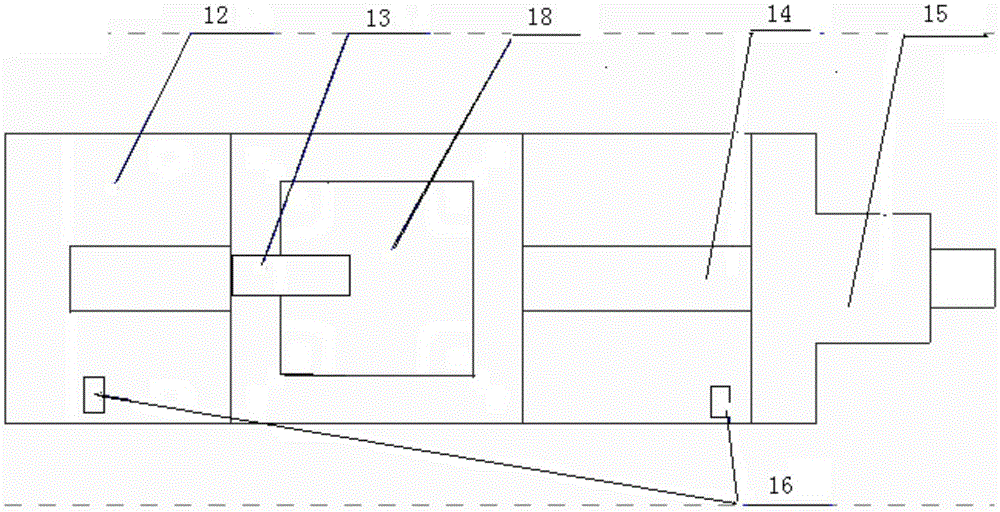

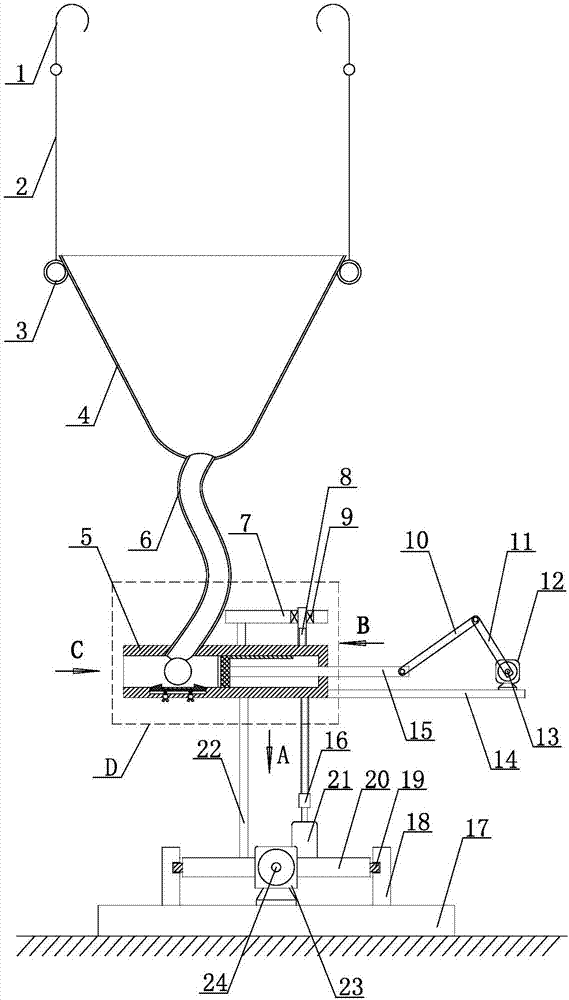

Multi-degree-of-freedom ping-pong automatic serving device

The invention discloses a multi-degree-of-freedom ping-pong automatic serving device. The device comprises a serving cylinder, a transverse driving structure and a vertical driving mechanism, wherein the transverse driving structure and the vertical driving mechanism are used for controlling the serving cylinder to move, and a serving motor fixing plate is fixedly arranged on the rear portion of the serving cylinder; a serving motor is arranged on the serving motor fixing plate, a serving spindle is arranged on the serving motor, and a crank is fixed on the serving spindle; a connecting rod is hinged to the top of the crank, and an elastic block is arranged in the serving cylinder; a piston rod is fixed at the rear end of the elastic block, the connecting rod is hinged to the piston rod, and a ball falling hole is formed in the top surface of the serving cylinder; a telescopic hose is arranged above the ball falling hole, a ball bin is arranged above the telescopic hose, and the top of the telescopic hose is connected with the bottom of the ball bin; the bottom of the telescopic hose is connected with the ball falling hole, and a suspension mechanism is arranged on the ball bin; a ball baffle is fixed on the top of the rear end face of the elastic block. The device has the advantages that the structure is simple and the automation degree is high.

Owner:济南富安机械设计有限公司

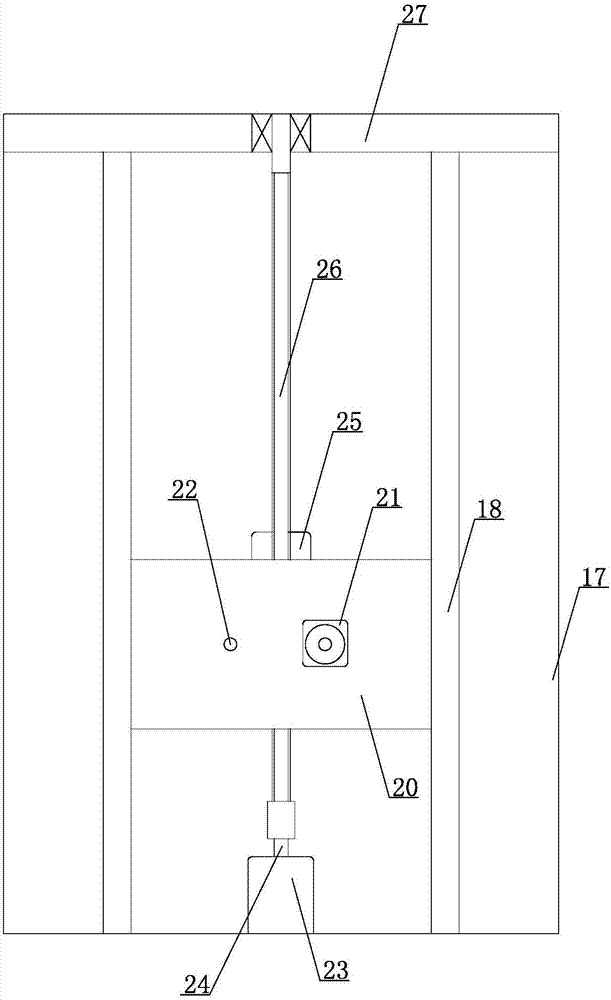

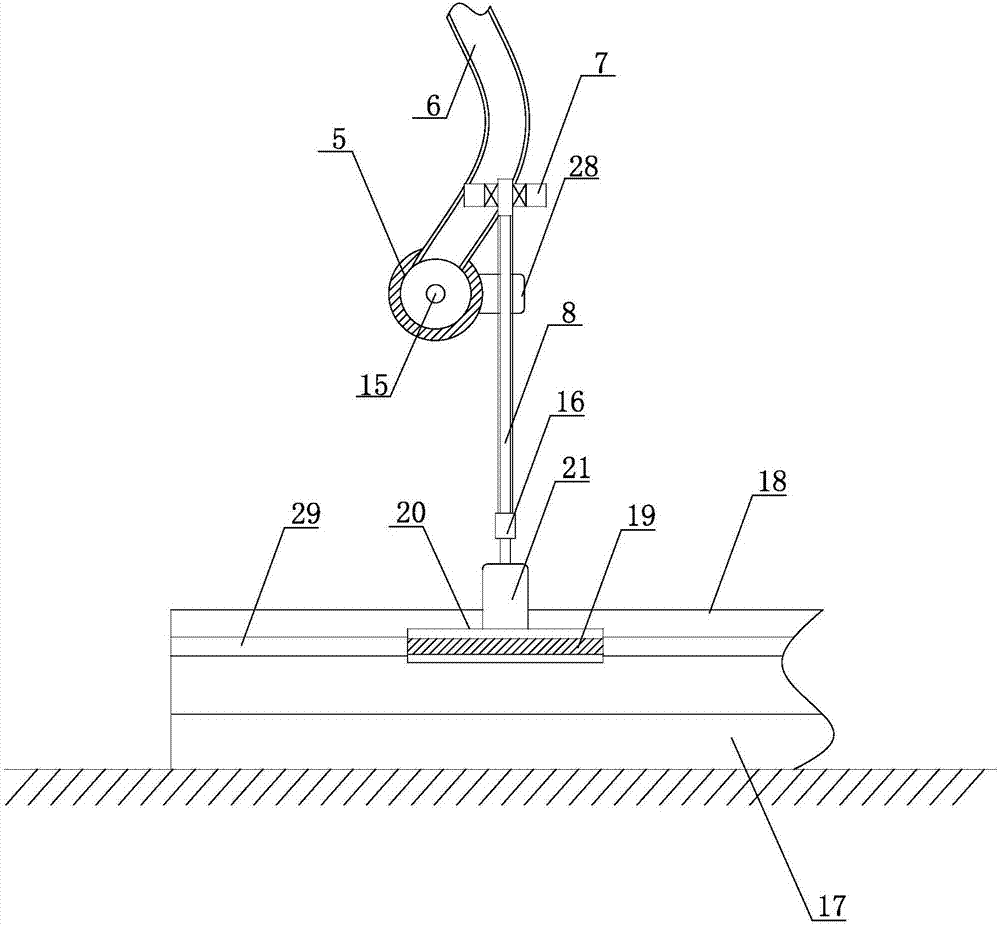

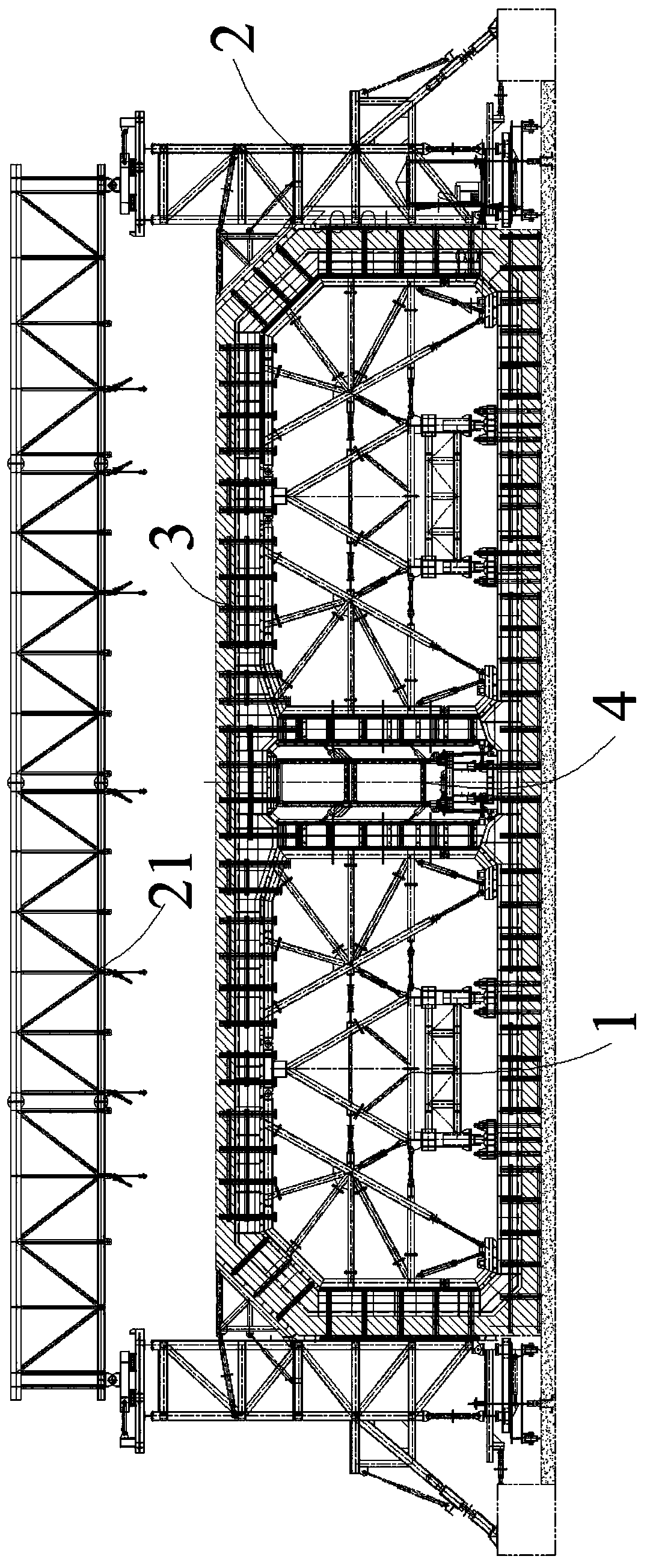

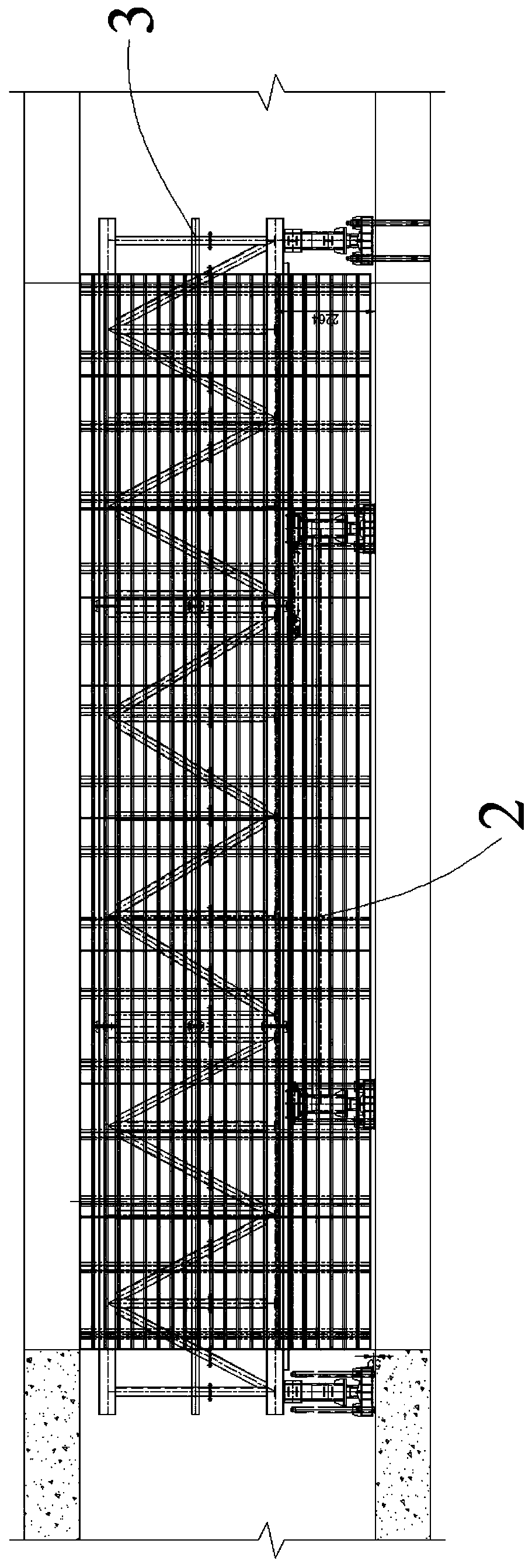

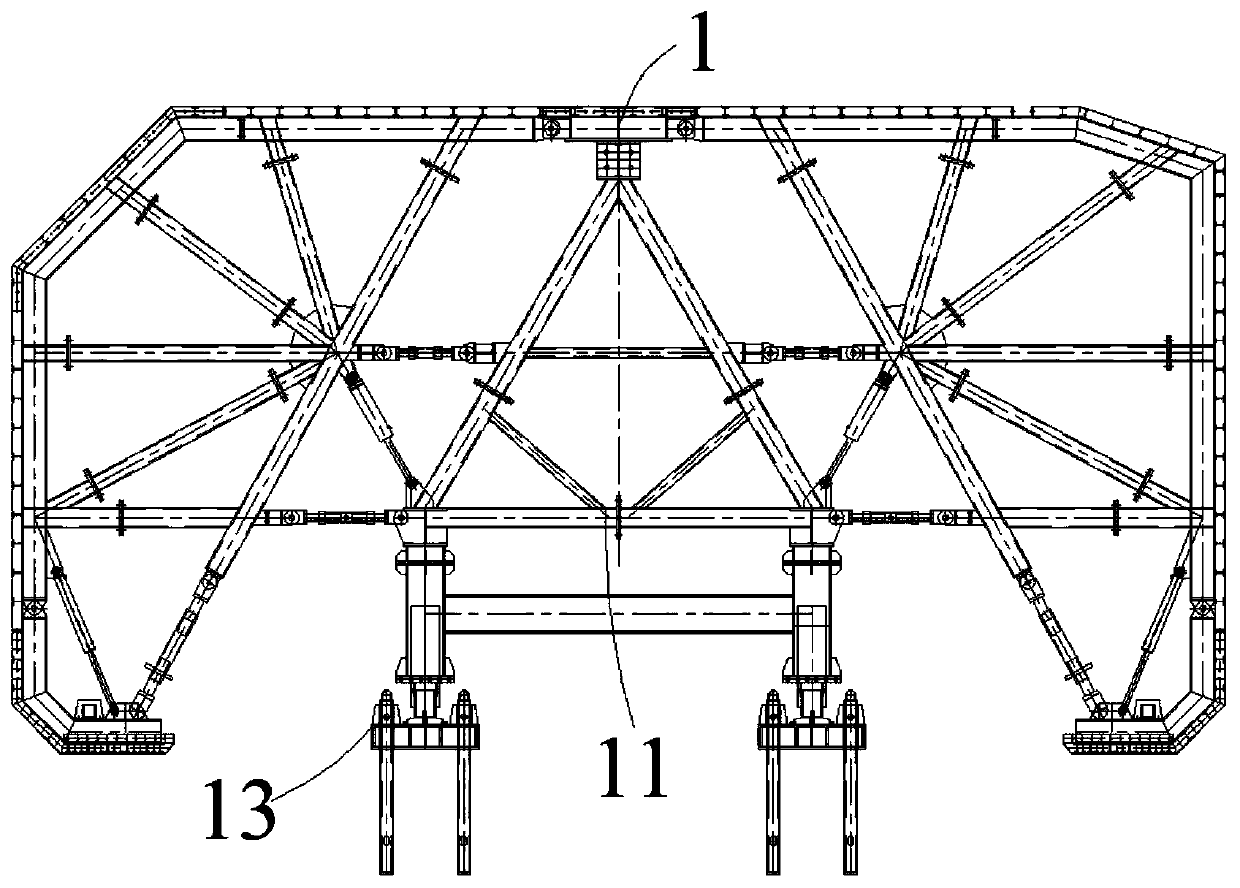

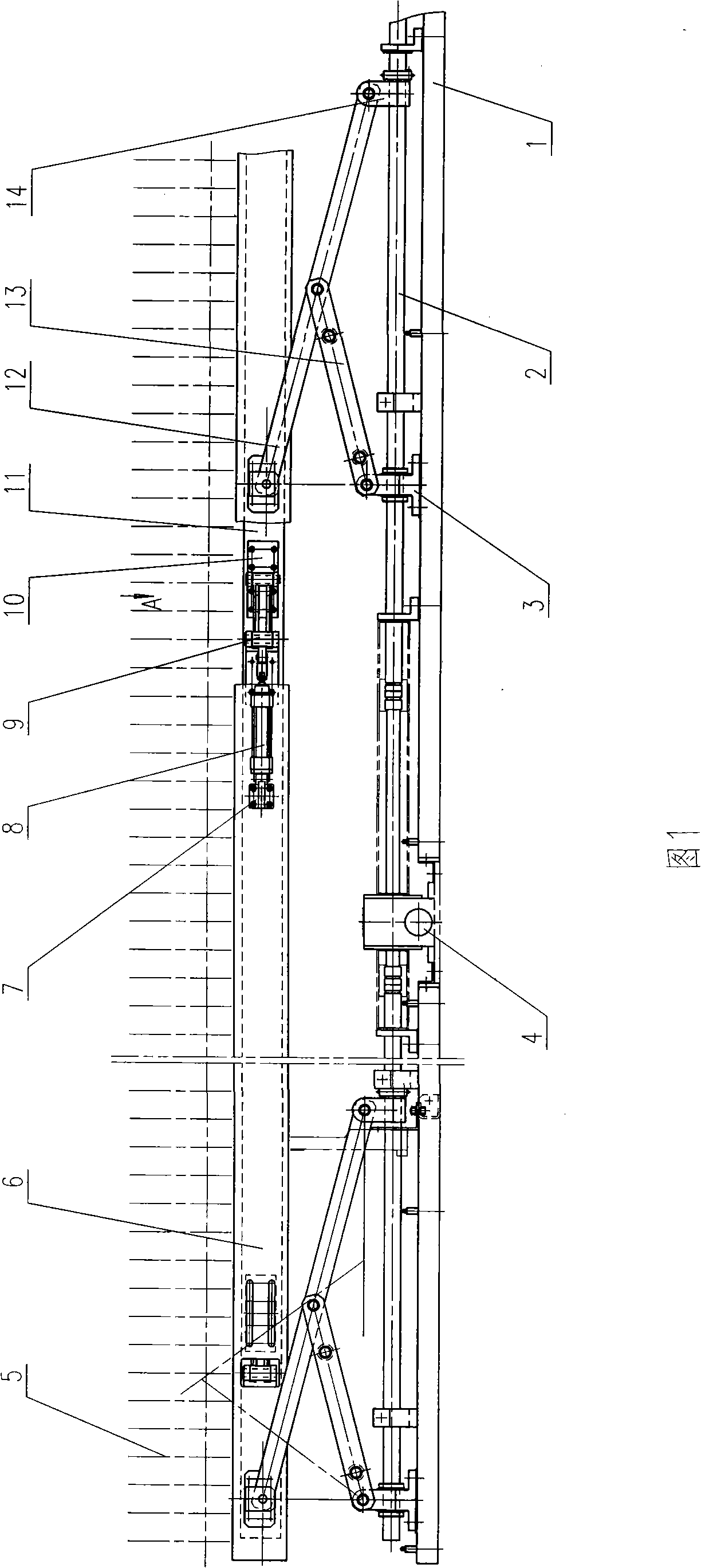

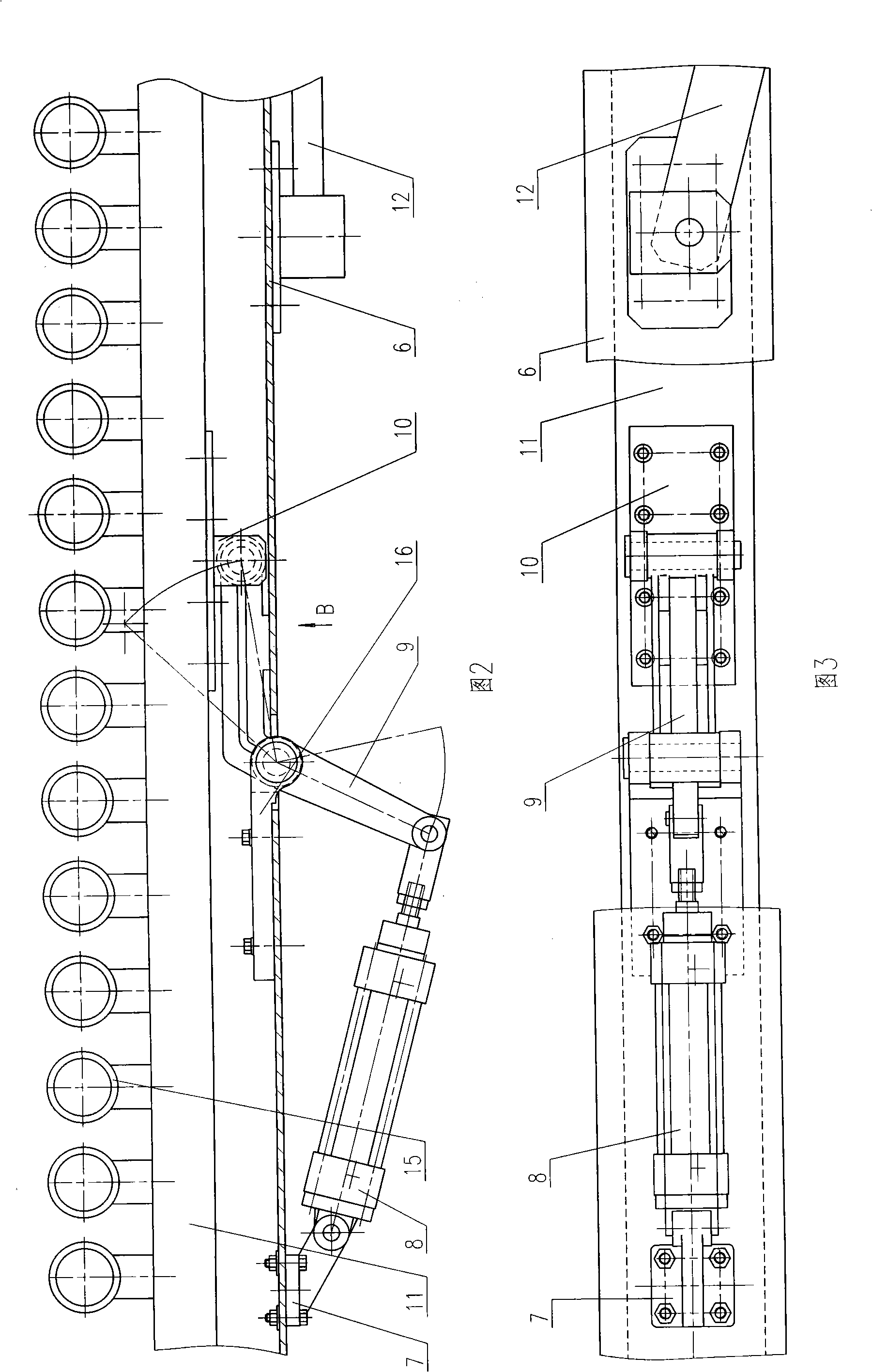

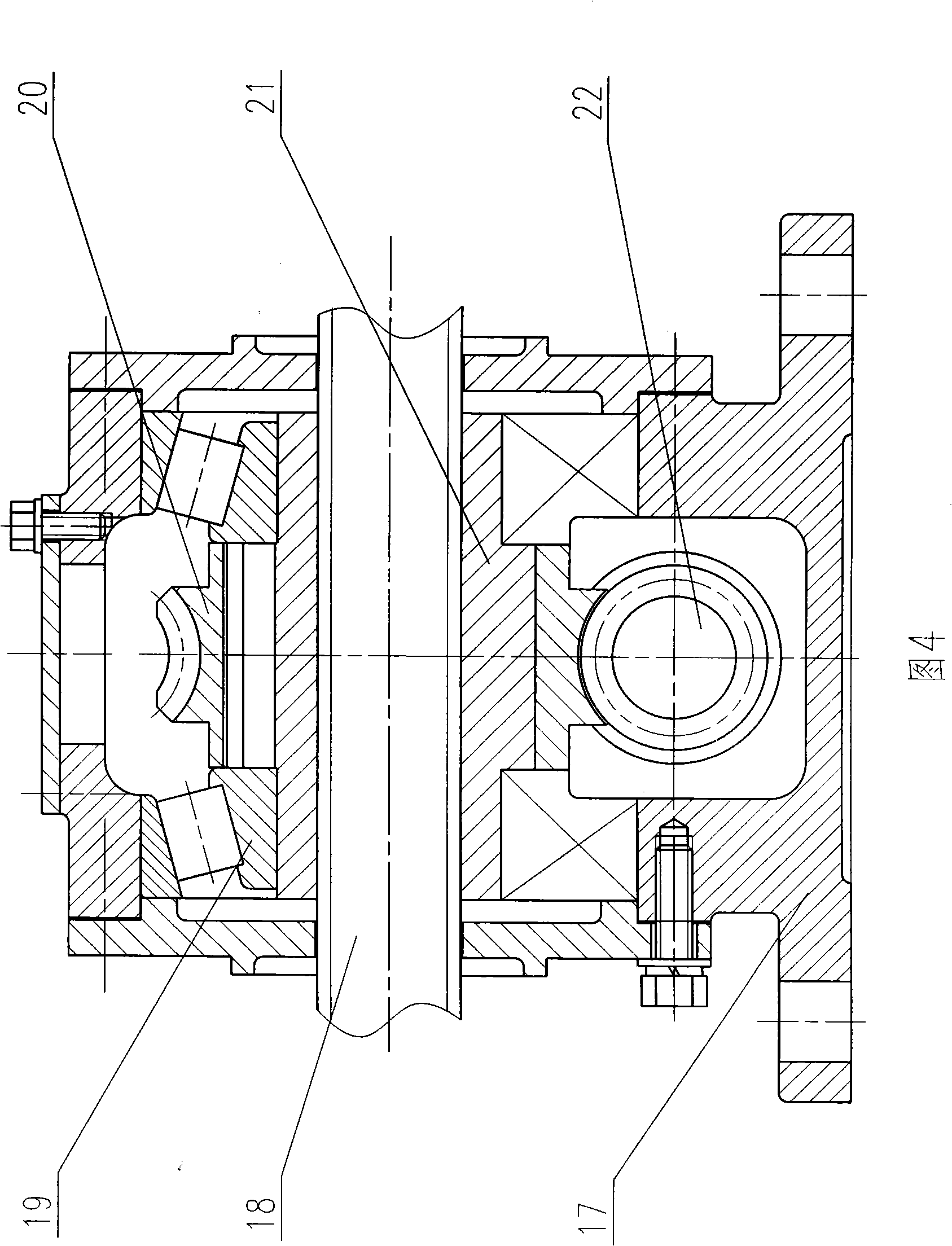

Dry dock sequential method full-section integral immersed tube prefabrication formwork system

PendingCN110076889AEasy to adjustSimple travel adjustmentDischarging arrangementMouldsSequential methodEngineering

The invention relates to the technical field of immersed tube prefabrication construction, in particular to a dry dock sequential method full-section integral immersed tube prefabrication formwork system. The system comprises an inner mold system, an outer mold system and an end mold system, wherein the inner mold system is located on the inner side of an immersed tube casting space and is connected with the outer mold system located outside the immersed tube casting space into a whole through the end mold system positioned at the longitudinal end part of the immersed tube casting space, the lower end of the inner mold system is provided with an inner mold travelling support device which is used for carrying out longitudinal, transverse and vertical position adjustment on the inner mold system, and the outer mold system is an outer side formwork structure capable of being adjusted in the longitudinal direction, the transverse direction and the vertical position. The immersed tube prefabrication method has the advantages of being accurate in position adjusting, less in main body structure damage and capable of operating all weather, so that the technical problems of sequential prefabrication, adjacent operation, compact space, longitudinal long-distance travel of an ultra-large super-heavy formwork is long, being prone to deviation and the like which occur to a sequential methodare solved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

Integral doffing device of ring spinning frame

The invention relates to an integral doffing device for a ring throstle, comprising a lifting beam and a lifting connecting rod mechanism which is hinged with the lifting beam, wherein, an inlet and outlet swinging arm is hinged on the lifting beam; one end of the inlet and outlet swinging arm is hinged with a beam of a yarn holding device, and at least one inlet and outlet cylinder is hinged between the other end of the inlet and outlet swinging arm and the lifting beam; the lifting connecting rod mechanism at least comprises two lifting connecting rods; a lifting swing stem is hinged on each lifting connecting rod; one end of the lifting connecting rod is hinged to the lifting beam and the other end of the lifting connecting rod is hinged with a lifting tension rod; and two inlet and outlet swinging arms are at least hinged on the lifting beam, and one inlet and outlet swinging arm is a bended swing stem. The doffing device has a compact structure, is convenient to operate and use, not only can be matched with a novel ring throstle but also is suitable for modifying a prior ring throstle, and has wide use range and strong applicability.

Owner:DONGTAI TEXTILE MASCH CO LTD

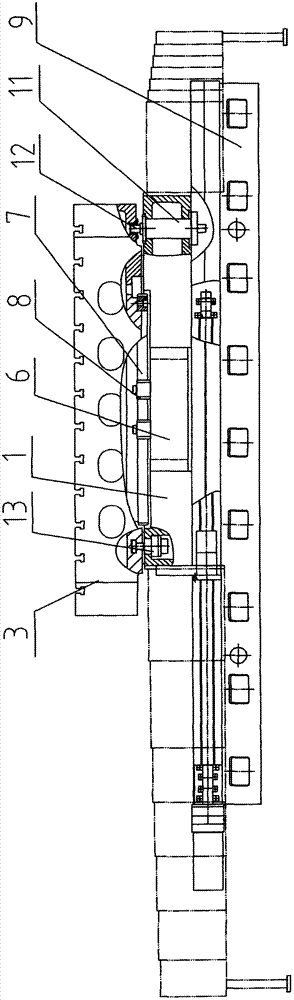

Electric spark processing equipment

InactiveCN101579760AImprove machining accuracyHigh movement accuracyElectrical-based auxillary apparatusRotation - actionGear wheel

The invention discloses an electric spark processing equipment, which mainly consists of a base, an inclination block, a rotary disc, a three-dimensional moving mechanism, a crossbeam mechanism, a steering block, a discharging head, a discharging head steering gear and an electrode. The discharging head with the electrode is articulated on the steering block; the steering block is fixed at the external end of the crossbeam; the crossbeam is connected with the three-dimensional moving mechanism by a crossbeam guide screw and a crossbeam sliding block; the discharging head is arranged on the three-dimensional moving mechanism by the crossbeam; a die is arranged on the rotary disc which drives the die to rotate and the processing of the discharging head on the die cavity is realized by the movement of the three-dimensional moving mechanism in X direction, Y direction and Z direction. As a mechanical transmission mechanism only provides the rotation action of the die, the movement in X direction, Y direction and Z direction is realized by the three-dimensional moving mechanism; therefore, the mechanical transmission mechanism has higher moving precision and the processing precision of the die is higher.

Owner:XIAMEN SHENGJENG MACHINERY

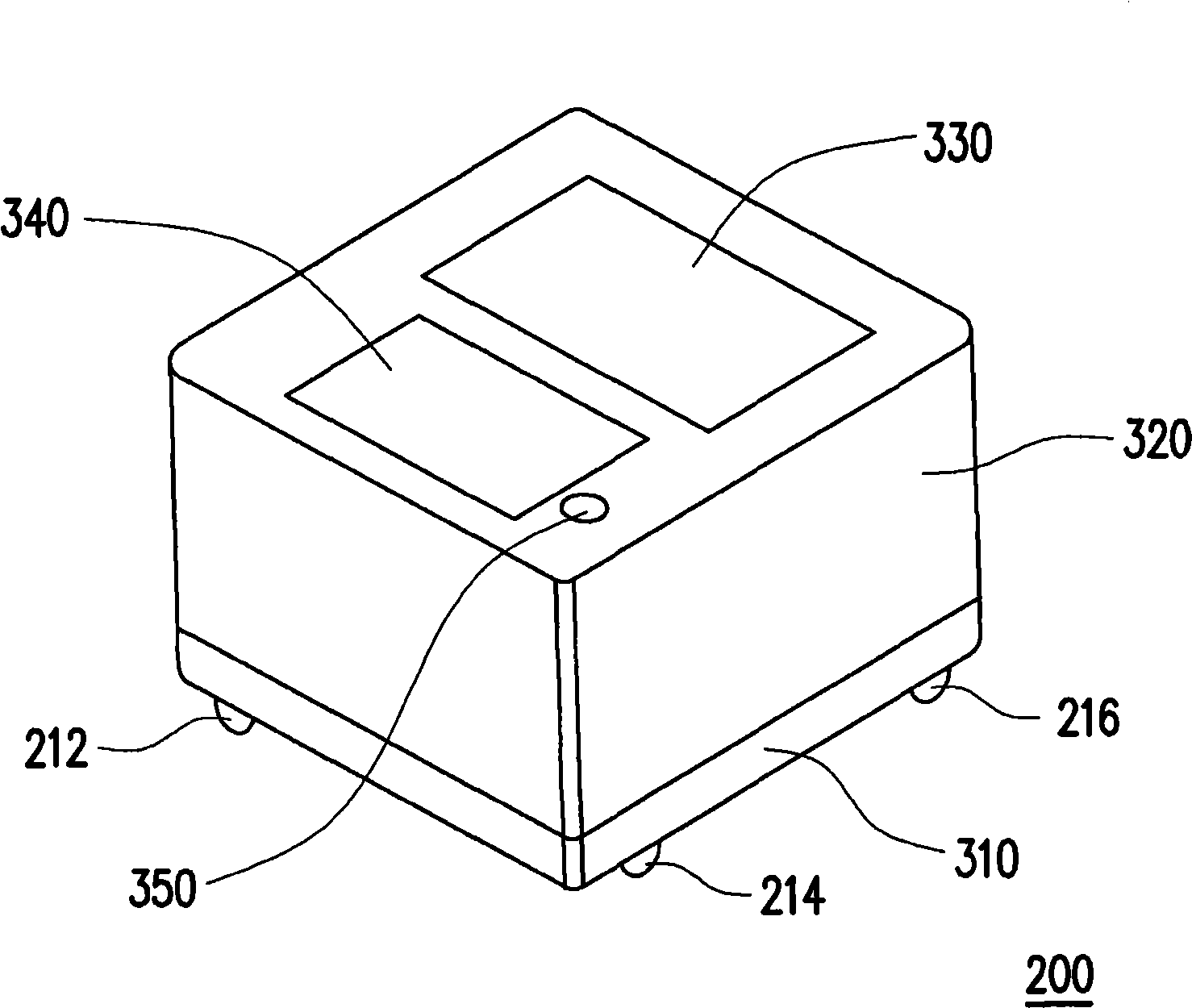

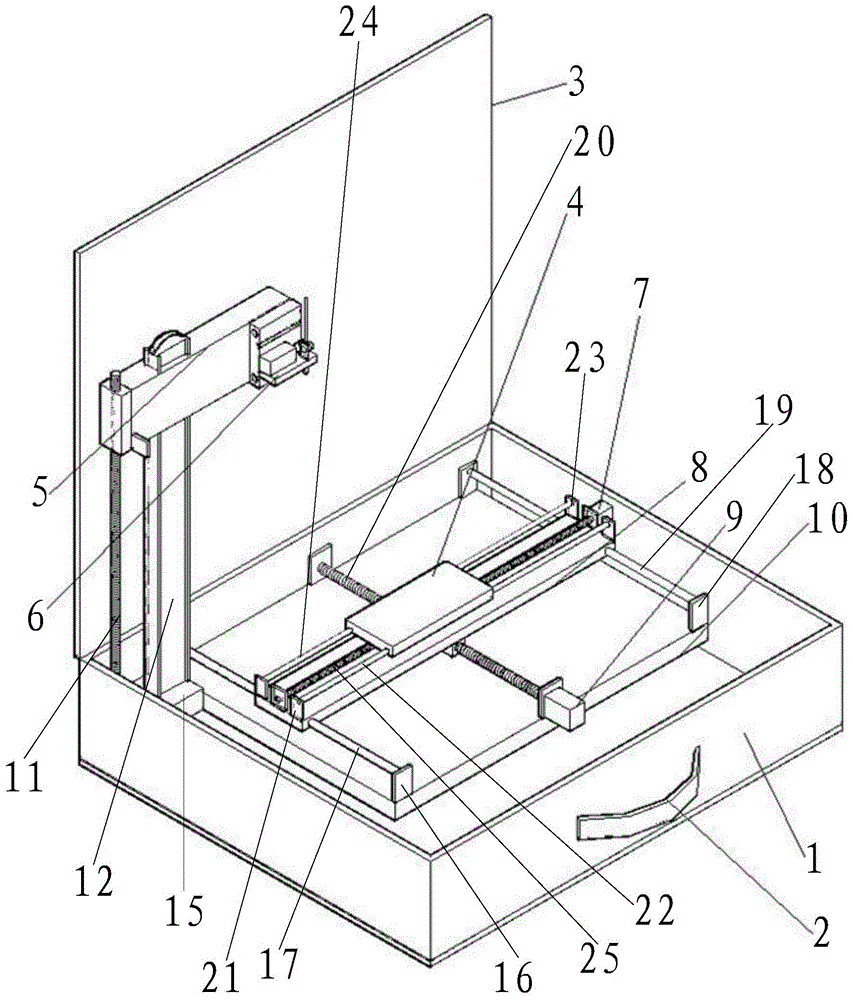

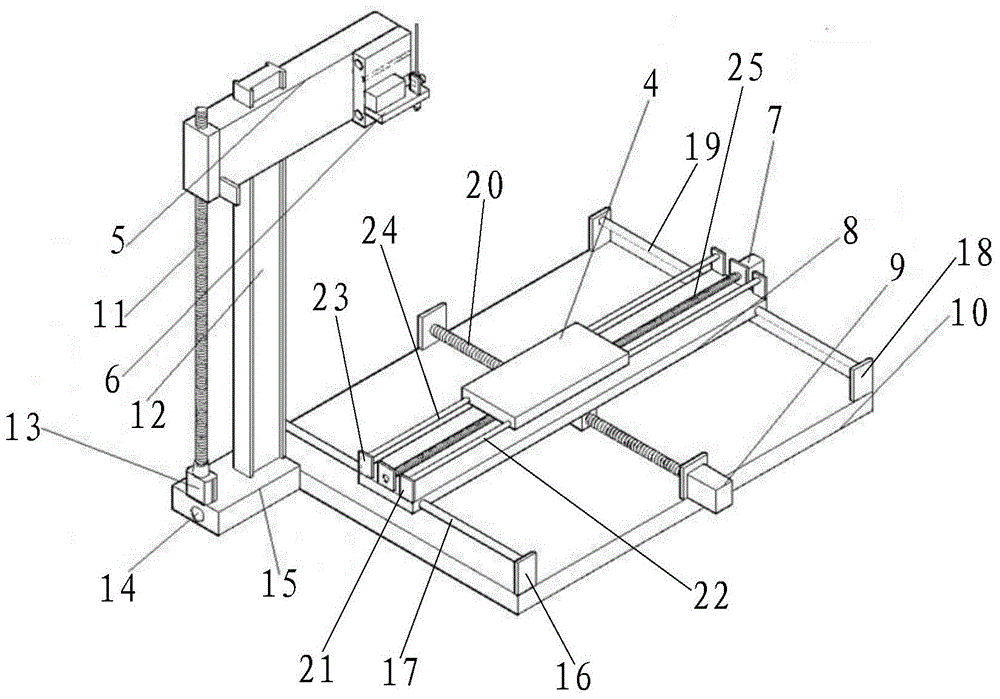

Portable small 3D printer

The invention discloses a portable small 3D printer which comprises a box body, a case cover and a handle, wherein a 3D printing mechanism is placed in the box body and comprises a bottom plate; a first light rod and a second light rod are connected to the top of the bottom plate, a mobile plate is connected between the first light rod and the second light rod, and a Y-axis mobile motor and a Y-axis transmission lead screw pair are mounted on the bottom plate; a third light rod and a fourth light rod are connected to the top of the mobile plate, a printing platform is connected between the third light rod and the fourth light rod, and an X-axis mobile motor and an X-axis transmission lead screw pair are mounted on the mobile plate; a hinging block is hinged to the side face of the bottom plate, a lifting bracket is arranged above the hinging block, a Z-axis lifting motor and a lifting guide rail are mounted on the top of the hinging block, the Z-axis lifting motor is connected with a lifting lead screw, the lifting guide rail and the lifting lead screw pass through the lifting bracket, and a printing head is mounted on the lifting bracket. The portable small 3D printer disclosed by the invention is compact in structure, small in size, convenient to carry and convey, high in mobile precision in all directions and strong in practicality.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

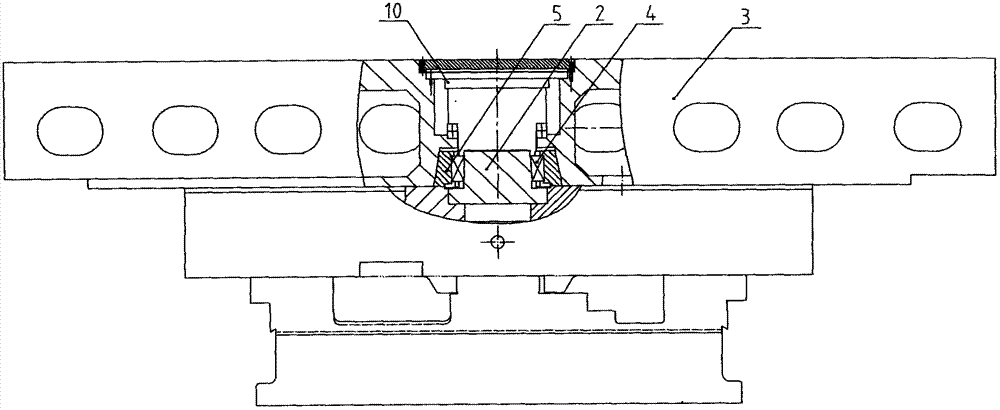

Rotary table for numerical control floor type boring miller

InactiveCN102773719AGuaranteed positioningGuaranteed positionLarge fixed membersNumerical controlGear wheel

The invention relates to a rotary table for a numerical control floor type boring miller. The rotary table comprises a rotary slide base, and a core shaft and a table top which are installed on the rotary slide base. The table top is installed on the rotary slide base through the core shaft; the rotary slide base is connected with a lead screw transmission mechanism used for driving the rotary slide base to move; a double-gear anti-backlash rotary mechanism is arranged between the rotary slide base and the table top, and is used for driving the table top to rotate; a rotary centering mechanism is arranged at the center of the table top, and comprises a two-line tapered roller bearing and a taper sleeve sheathed on the two-line tapered roller bearing; and the two-line tapered roller bearing is sheathed on the core shaft. The rotary table has the advantages that a backlash does not exist when the rotary slide base moves, so that the movement accuracy is high; and the backlash does not exist when the table top rotates, the rotary centering mechanism can guarantee the good centering performance of the rotary table when the load is large, the problem of rotary eccentricity is effectively solved, and the rotary table is positioned through a positioning air cylinder, so that the positioning performance of the table top is further guaranteed.

Owner:QINGDAO HUITENG MACHINERY EQUIP

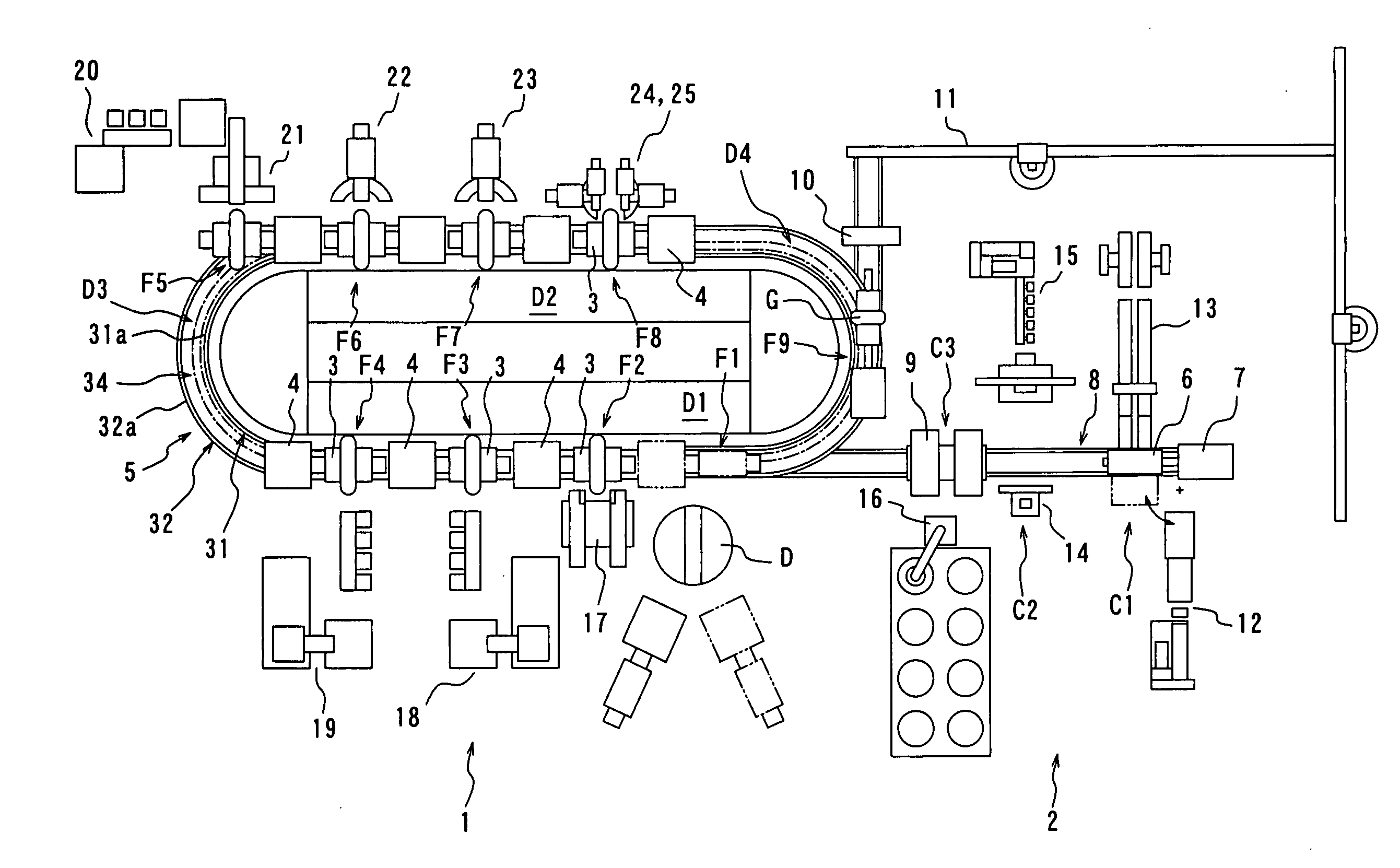

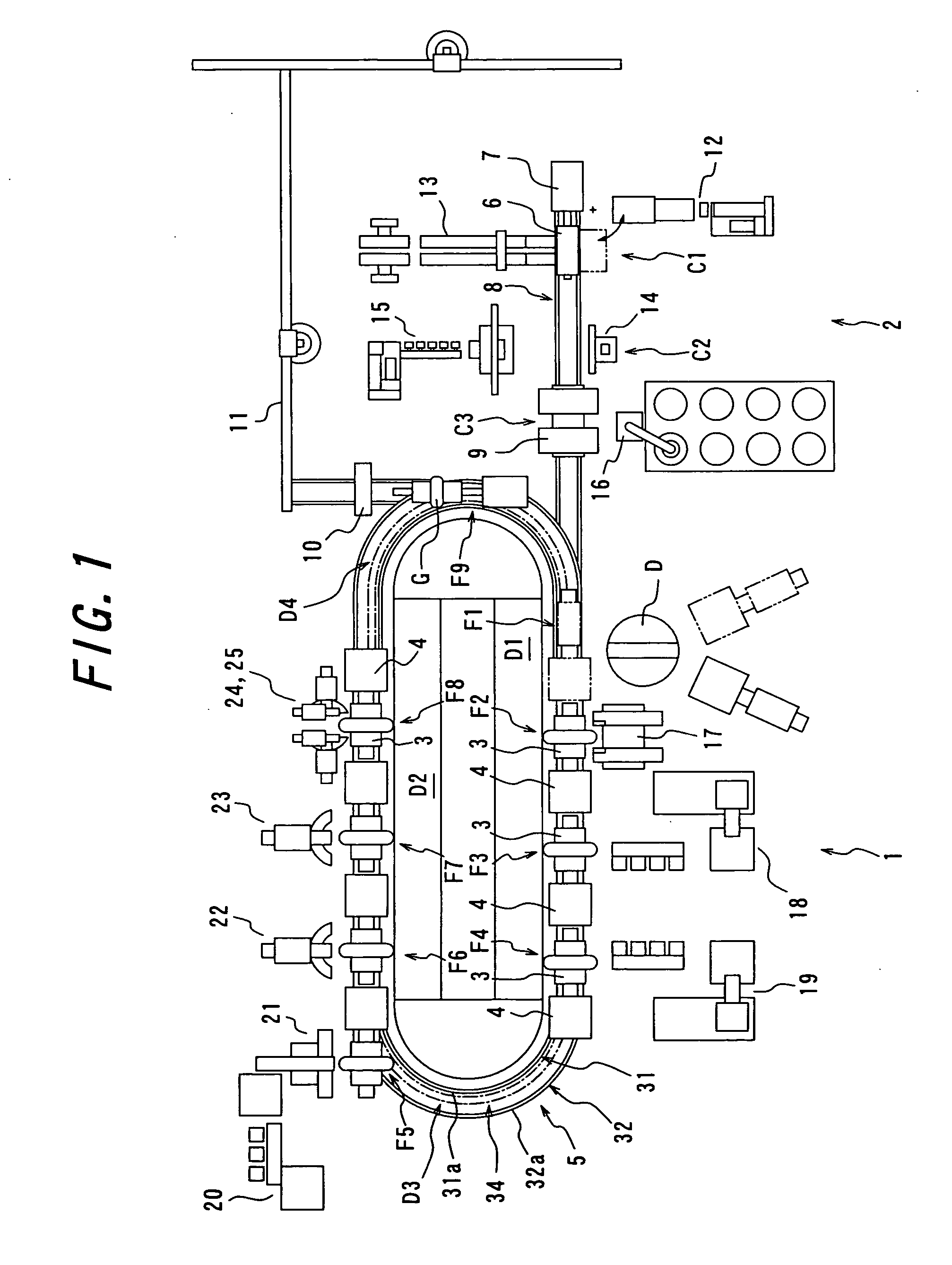

Method and Device for Pivotably Driving Carriage and Tire Building System Using Same

InactiveUS20070295442A1Improve accuracy of movementEasily spaceTyresRope railwaysEngineeringMechanical engineering

The present invention is aimed to simplify a configuration of a device and to reduce installation and running cost. A carriage is driven on a curved potions 31a, 32a of an oval-shaped endless moving path 5 under a guide of rails 31, 32. The carriage positioned on the ground side is engaged with a carrier 37 driven along the curved portions 31a, 32a. The carriage is towed over the entire length of the curved portion by the carrier 37.

Owner:BRIDGESTONE CORP

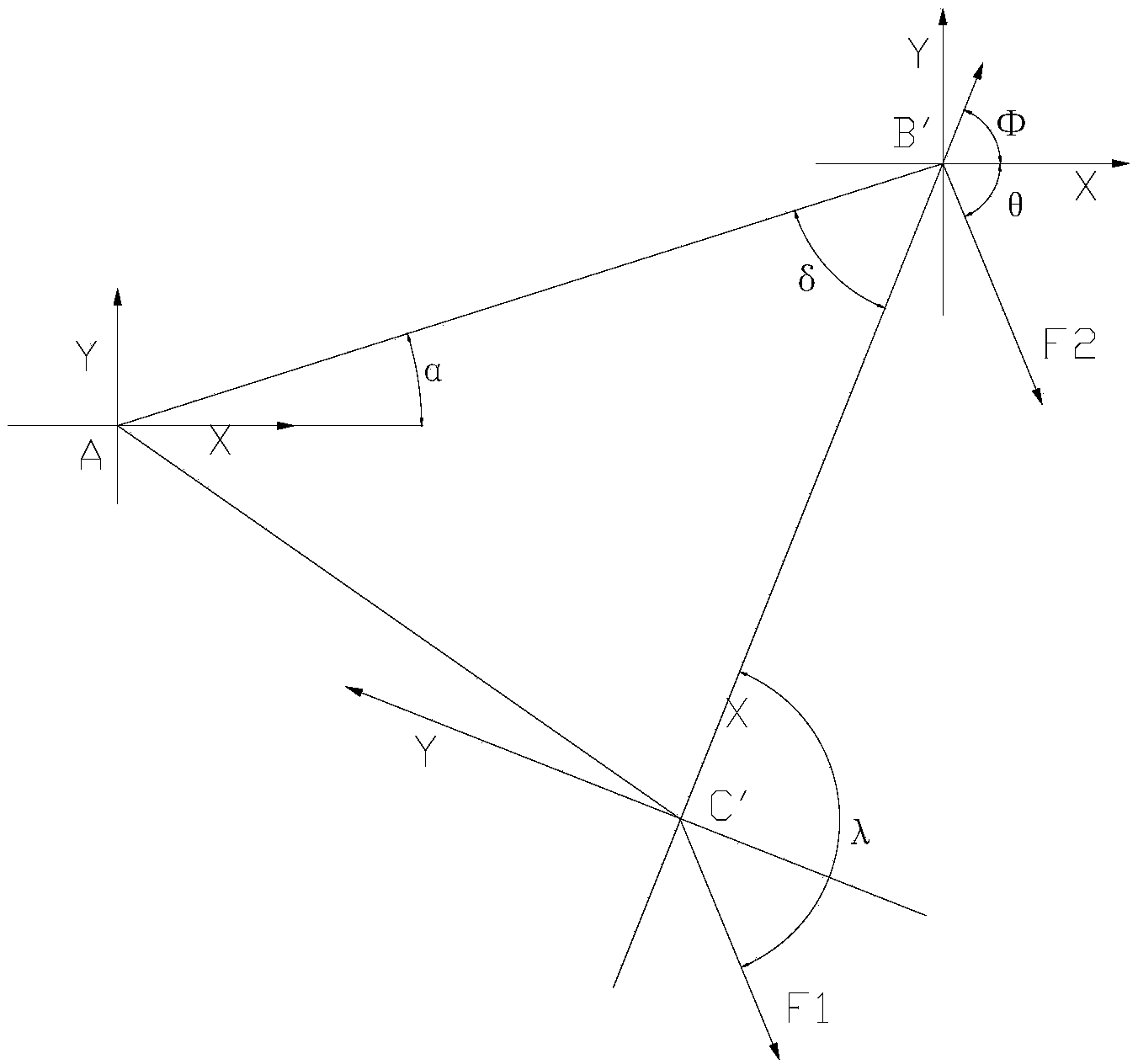

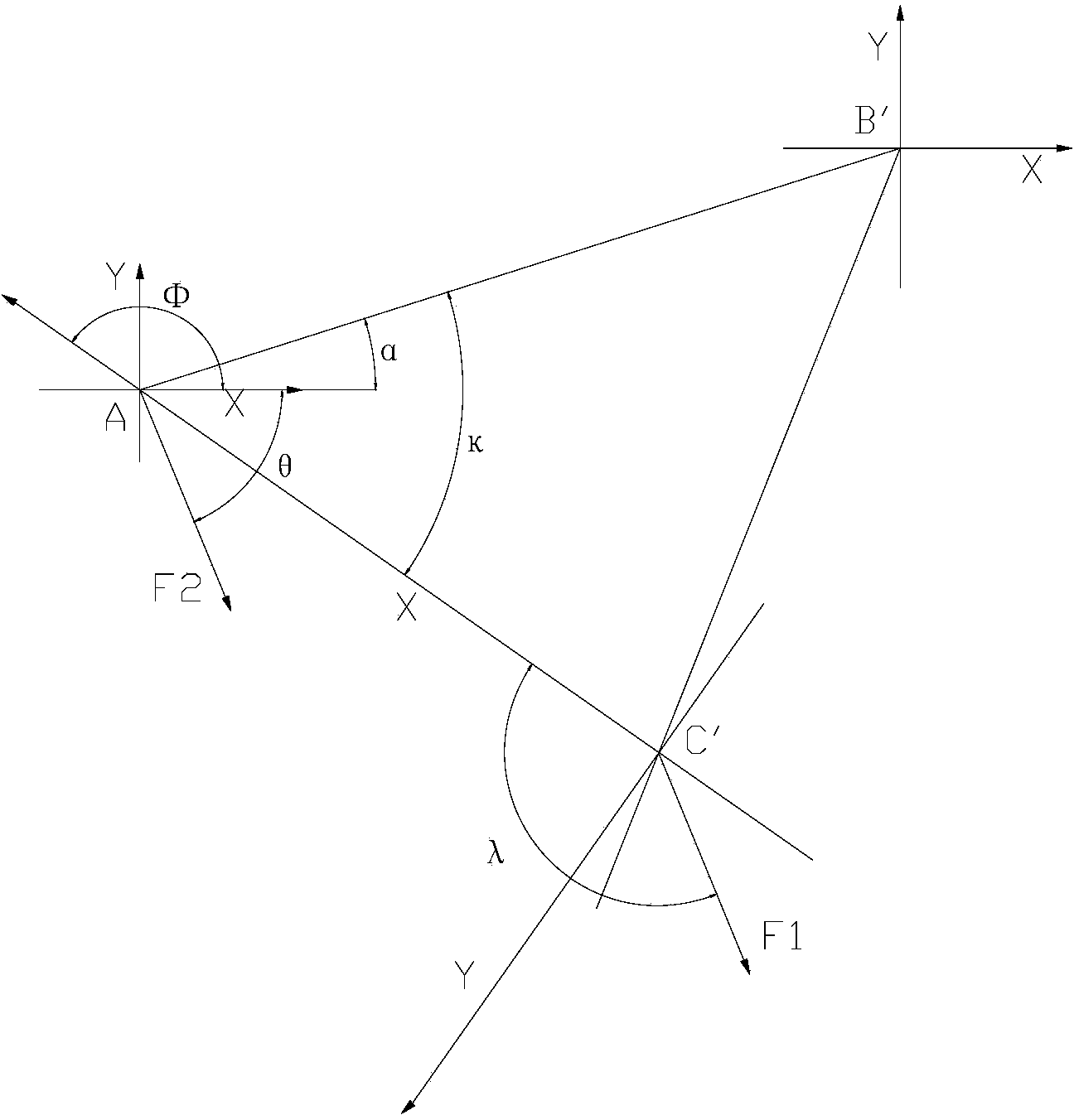

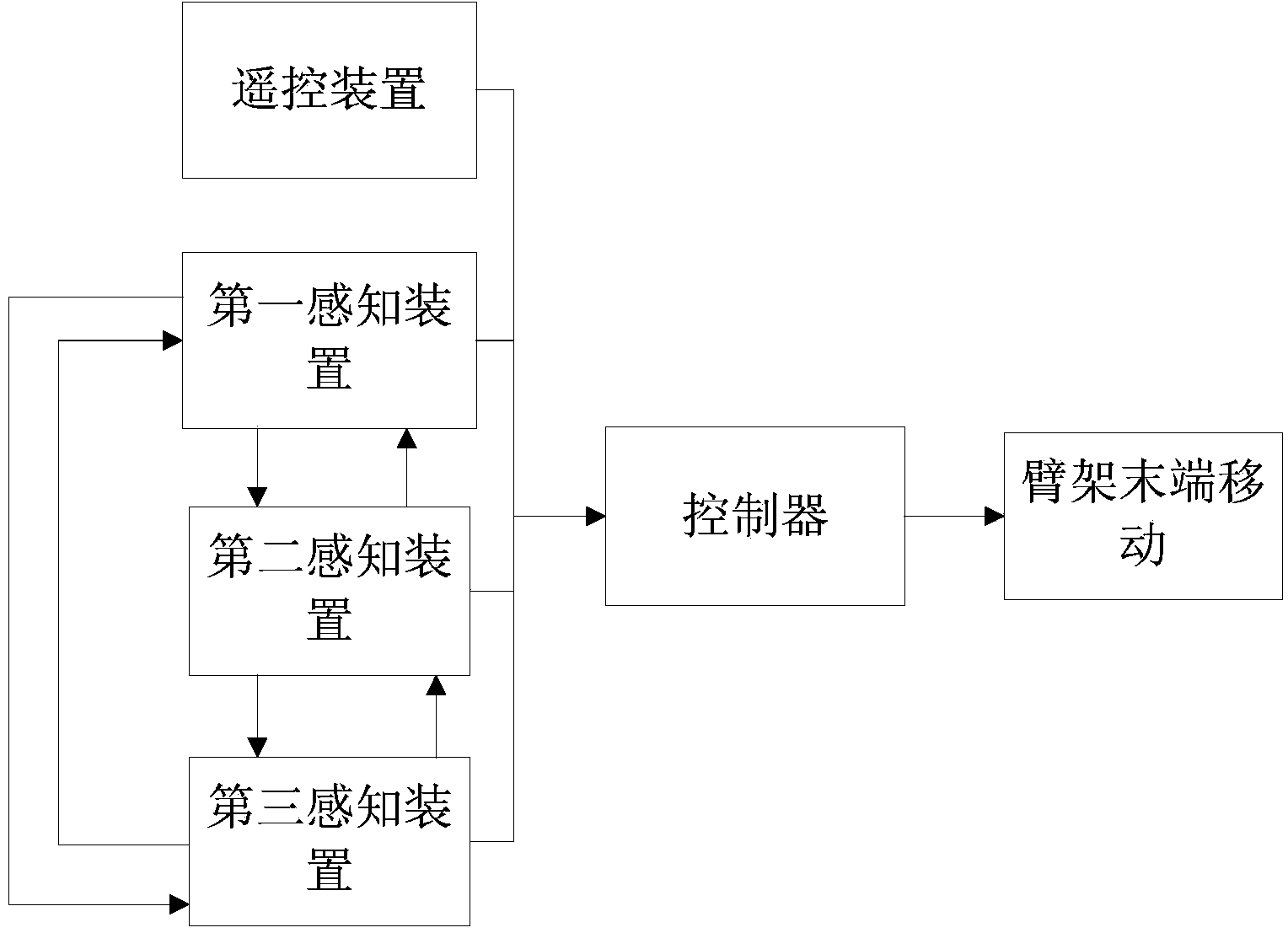

Placing boom control method, placing boom control device, concrete pump truck and material distributing machine

ActiveCN103590606AEasy to controlReduce the difficulty of operationBuilding material handlingLoad-engaging elementsRemote controlCentre of rotation

The invention discloses a placing boom control method. The placing boom control method comprises the steps that a two-dimensional absolute coordinate system is established on the horizontal plane; a two-dimensional dynamic coordinate system is established on the horizontal plane, wherein the connection line between the original point of the two-dimensional absolute coordinate system and the original point of the two-dimensional dynamic coordinate system is an axis of the two-dimensional dynamic coordinate system, the original point of the two-dimensional absolute coordinate system is located on the rotating central point of a placing boom or the tail end point of the placing boom, and the original point of the two-dimensional dynamic coordinate system is located on a remote control device; the angles formed between the swinging direction of an operating hand shank of the remote control device and the coordinate axes of the two-dimensional dynamic coordinate system are obtained; the angle that the two-dimensional dynamic coordinate system rotates relative to the two-dimensional absolute coordinate system is obtained; through coordinate system conversion computation, the angles formed between the swinging direction of the operating hand shank of the remote control device and the coordinate axes of the two-dimensional absolute coordinate system are obtained to control the tail end of the placing loom to move. The invention further discloses a placing boom control device and a concrete pump truck. According to the placing boom control method, the placing boom control device, the concrete pump truck and a material distributing machine, the degree of intellectualization is high, operation difficulty of an operator is reduced, and moving accuracy and flexibility performance of the tail end of the placing loom are improved.

Owner:SANY AUTOMOBILE MFG CO LTD

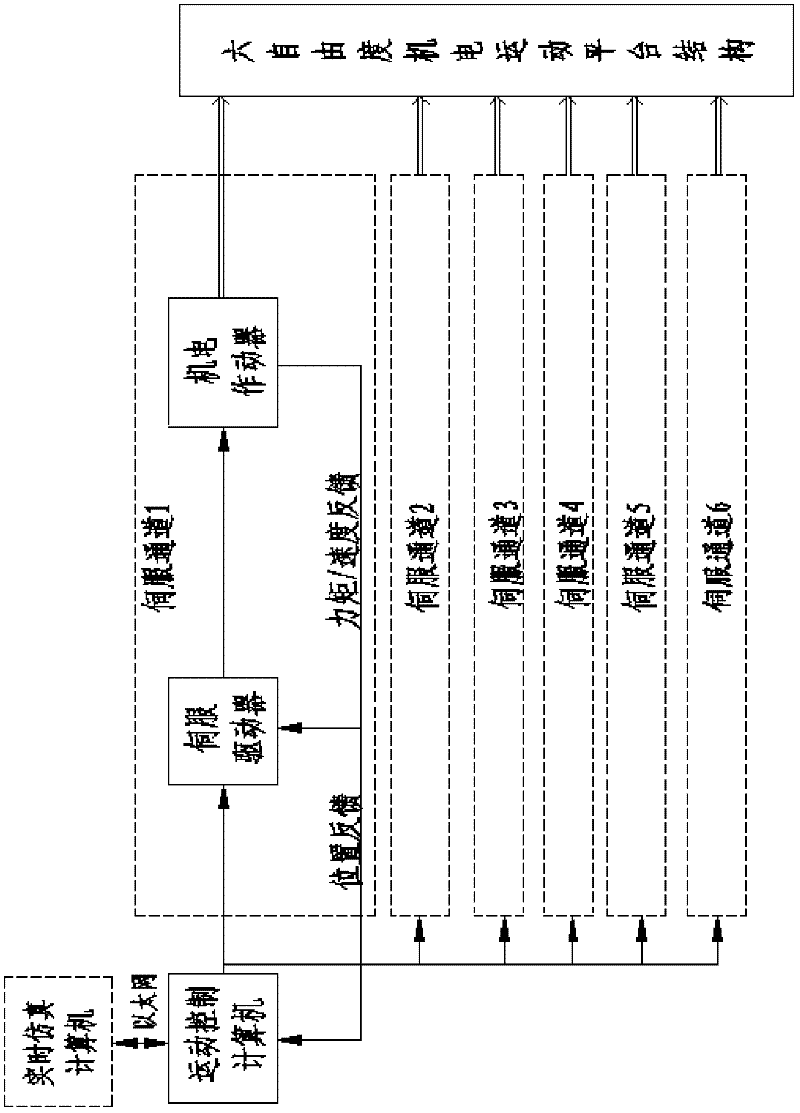

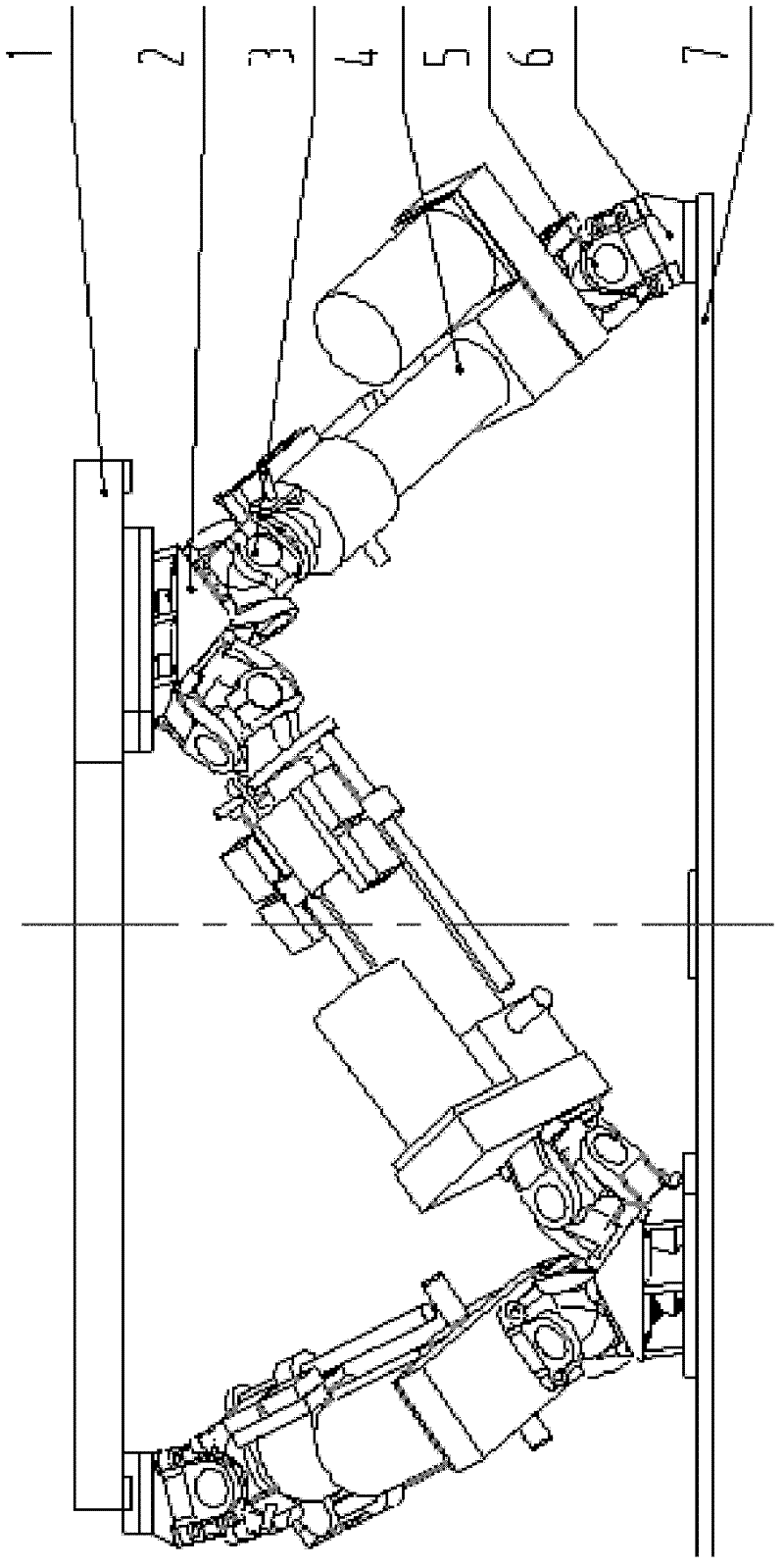

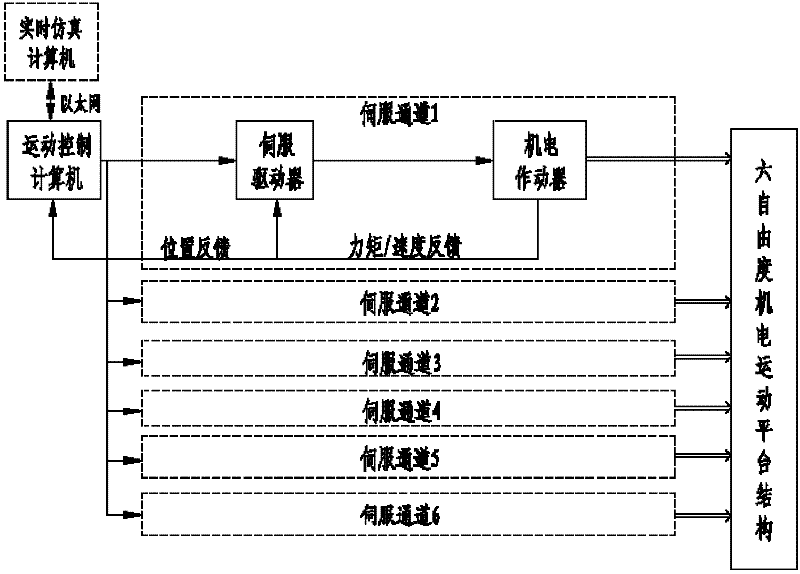

Six-DOF (degree of freedom) carrier dynamic simulator

InactiveCN102346978AHeavy loadHigh movement precisionCosmonautic condition simulationsSimulatorsClosed loopEngineering

The invention discloses a six-DOF (degree of freedom) carrier dynamic simulator. The dynamic simulator is composed of a real-time simulation computer and a movement control computer, a servo channel driver, a six-DOF electromechanical movement platform; each servo channel comprises a servo driver and an electromechanical actuator, the servo driver comprises a servo main loop frequency conversion power amplifying circuit module and a control loop circuit module, the electromechanical actuator is used for connecting a serve motor, a synchronous belt transmission box, a ball screw pair and a rotary encoder together. The six-DOF carrier dynamic simulator has the advantages that the modular structure is simple and compact, convenient for mounting, and simple in maintenance, the electromechanical cylinder improves the platform movement precision, a control scheme of a movement control card controls the position of each servo electromechanical cylinder, and greatly improves the precision and a limiting switch is built in to guarantee the ultimate safety; the full-digitalized closed loop servo control is used for guaranteeing the smooth transition of the movement and high simulation and reducing the dynamic drifting and distortion, the efficiency of the system is as high as 85%, and the application range of the simulator is wide.

Owner:LIM TEC BEIJING TRANSMISSION EQUIP

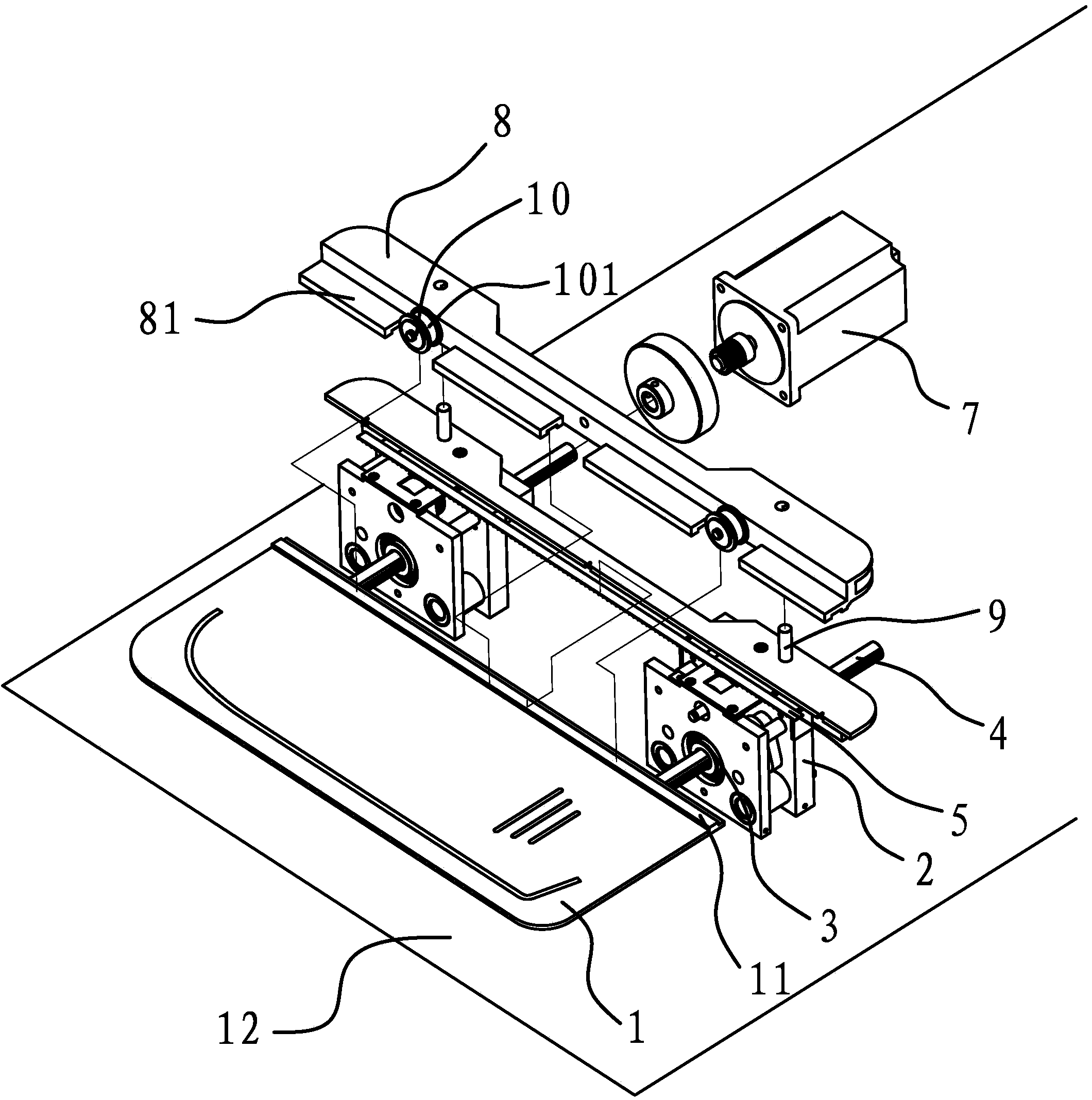

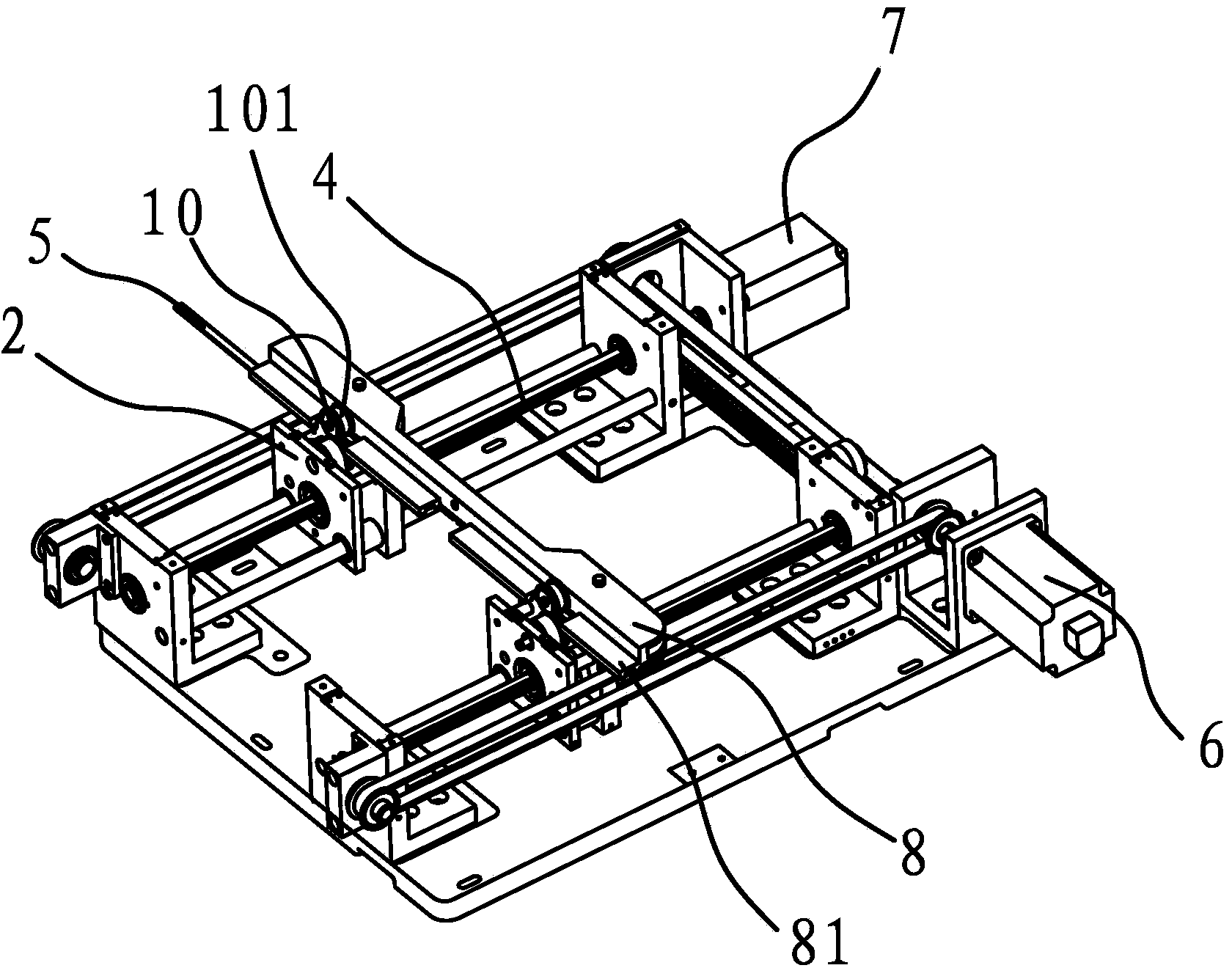

Template transmission mechanism for template-transporting sewing machine

ActiveCN103397484AEasy to moveMove fastWork-feeding meansSewing-machine control devicesGear driveDrive shaft

The invention provides a template transmission mechanism for a template-transporting sewing machine, belongs to the technical field of sewing machine manufacturing, and solves the problems of low template transmission speed, low production efficiency and the like of the conventional template transmission mechanism for the template-transporting sewing machine. The template of the template transmission mechanism for the template-transporting sewing machine is positioned at a worktable. The mechanism comprises a transmission seat, a transmission gear, a transmission shaft, a gear rack, a first drive piece and a second drive piece; the transmission gear is positioned in the transmission seat; both the first drive piece and the second drive piece are fixedly connected with the worktable; the first drive piece is connected with the transmission seat and can drive the transmission seat to move frontward and backward; the second drive piece is connected with one end of the transmission shaft; the other end of the transmission shaft is positioned in the transmission seat and is connected with the transmission gear; the gear rack is fixedly connected with the lower part of the template and is engaged with the transmission gear; and the template can translate leftward and rightward when the transmission gear drives the gear rack to translate. The template transmission mechanism for the template-transporting sewing machine has the advantages of high transmission stability, high transmission speed, high machining efficiency and the like.

Owner:ZHEJIANG ZOJE SEWING MACHINE

Belt material fixed length cutting device

ActiveCN104209581AImprove securityImprove stabilityMetal sawing devicesMetal sawing accessoriesEngineeringBolt connection

The invention relates to belt material production equipment, in particular to a belt material fixed length cutting device. The belt material fixed length cutting device provided by the invention is characterized in that a metering wheel is arranged on a machine frame through a sleeve, in addition, a fixing wheel matched with the sleeve is arranged on the machine frame, a fixing shaft is connected and arranged onto the machine frame through a screw bolt, the connection between the metering wheel and the machine frame is reliable, in addition, the structure is simple, the work stability performance of the metering wheel in the work process is improved, and the maintenance is convenient; in addition, a saw blade is moved through adopting a lead screw, when the saw blade moves in the concrete use process, the movement of the saw blade is stable, and in addition, the moving precision is high; through the arrangement of the lead screw, the moving tracks of the saw blade during the cutting and the resetting cannot be coincident, the interference of the saw blade with the belt materials during the resetting is prevented, the safety performance during the belt material cutting is improved, in addition, the saw blade cannot be easily damaged, and the service life of the saw blade is prolonged; further, through the arrangement of a protection cover, the safety performance during the belt material cutting is further improved.

Owner:湖州倍格曼新材料股份有限公司

Milling machine

ActiveCN104128650AEasy to adjustSimple structureFeeding apparatusOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses a milling machine. The milling machine comprises a pedestal; a workbench is arranged above the pedestal; the left side of the workbench is provided with a Y-axis sliding table capable of sliding along a Y-axis; a cushion block clamping device is mounted on the Y-axis sliding table; a Z-axis pillar is fixed on the workbench; the inner side surface of the Z-axis pillar is provided with an X-axis sliding table capable of sliding up and down along a Z-axis; the inner side surface of the X-axis sliding table is provided with a Z-axis sliding table capable of sliding along an X-axis; and the bottom of the Z-axis sliding table is provided with a first high-speed motor, a horizontal saw blade driven by the first high-speed motor, a second high-speed motor and a vertical saw blade driven by the second high-speed motor. The invention has the following beneficial effects: (1), the milling machine has a simple structure; (2) machining efficiency is high, the surface of a sawed step-like structure is smooth and free of burrs and has high fineness; (3) processing precision is improved; (4) the whole milling machine can be conveniently adjusted to be horizontal; and (5) control precision is high, and cost is low.

Owner:TAIAN XINJIE MACHINERY

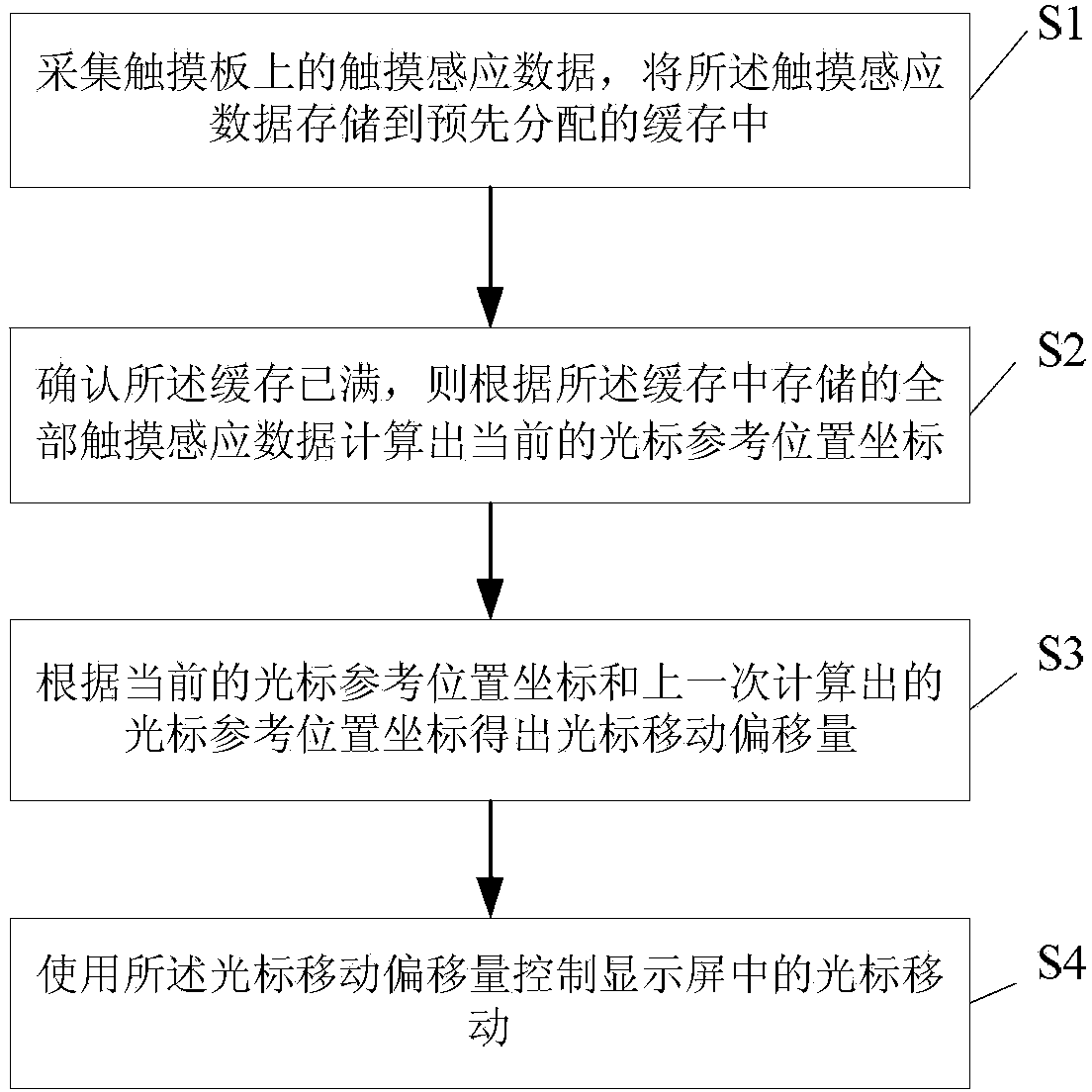

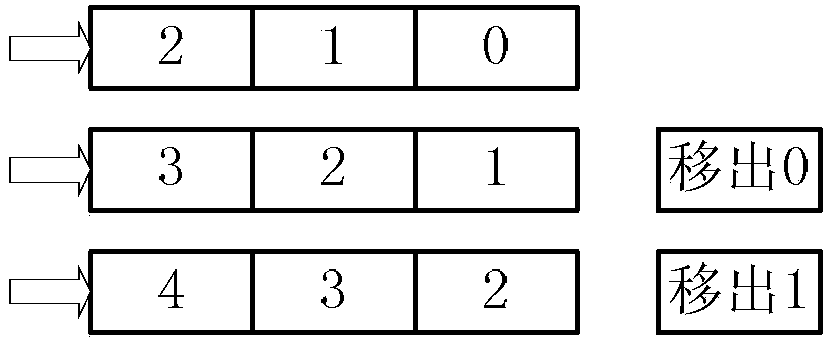

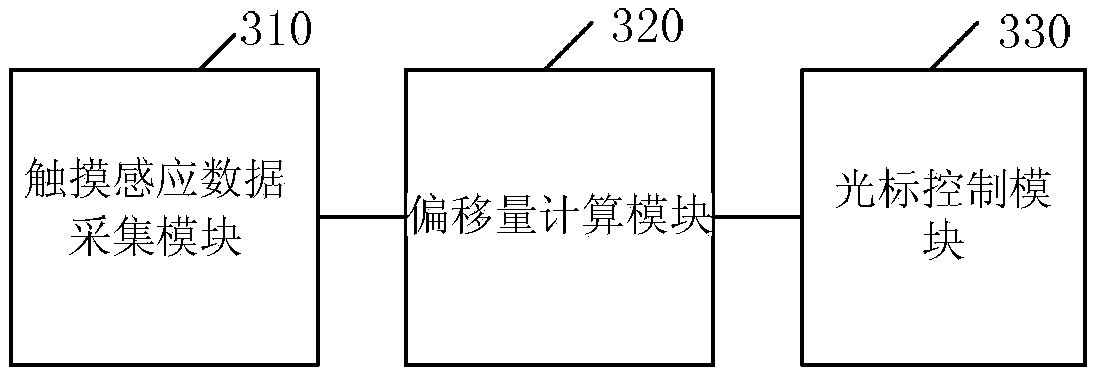

Cursor control method and device based on touch tablet

InactiveCN103353804AHigh movement accuracyLinear trajectory stabilityInput/output processes for data processingTouchpadData storing

The invention discloses a cursor control method and device based on a touch tablet. The method includes the steps that touch sensitive data on the touch tablet are collected and stored in a cache which is allocated in advance, wherein the touch sensitive data are position coordinates of touch sensitive cases in the touch tablet; whether the cache is full is detected, and if yes, current cursor reference position coordinates are calculated through a preset conversion rule according to all the touch sensitive data stored in the cache; the cursor moving offset of a display system is obtained according to the current cursor reference position coordinates and the cursor position coordinates calculated last time; the cursor moving offset is uploaded to the display system so that moving of a cursor in a display screen can be controlled according to the cursor moving offset. By means of the cursor control method and device based on the touch tablet, the DPI value when a user controls the cursor of the display screen to move through the touch tablet can adapt to the size of the display screen, and convenience is brought the user.

Owner:SHENZHEN RAPOO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com