Intelligent laser engraving system based on industry 4.0

A laser engraving and intelligent technology, applied in transmission systems, signal transmission systems, general control systems, etc., can solve the problems of not having the ability to store and manage user information and order information, not having customized production capabilities, and difficult to grasp the production status in real time. , to achieve the effect of large engraving area, improving sales production efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below through the embodiments in conjunction with the accompanying drawings.

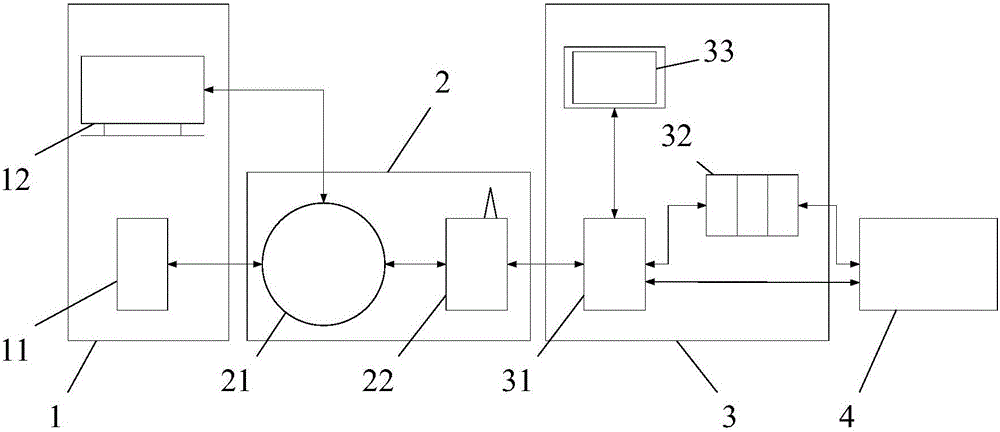

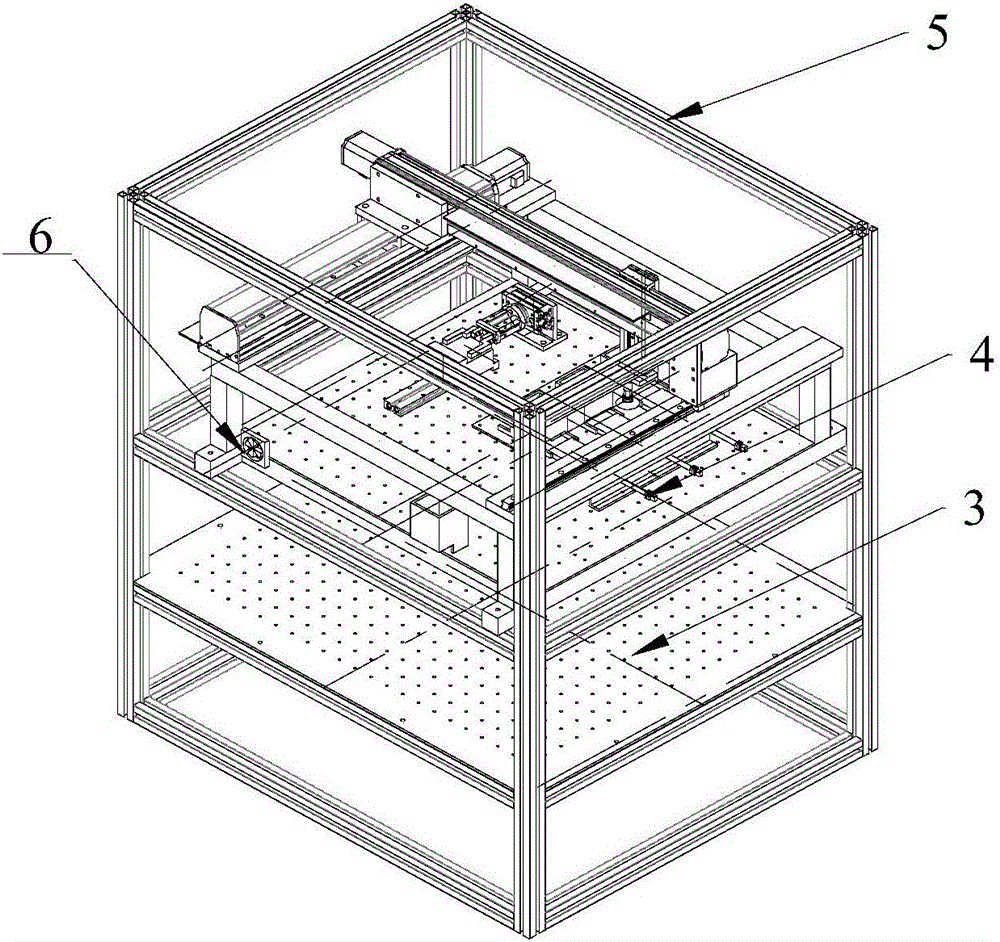

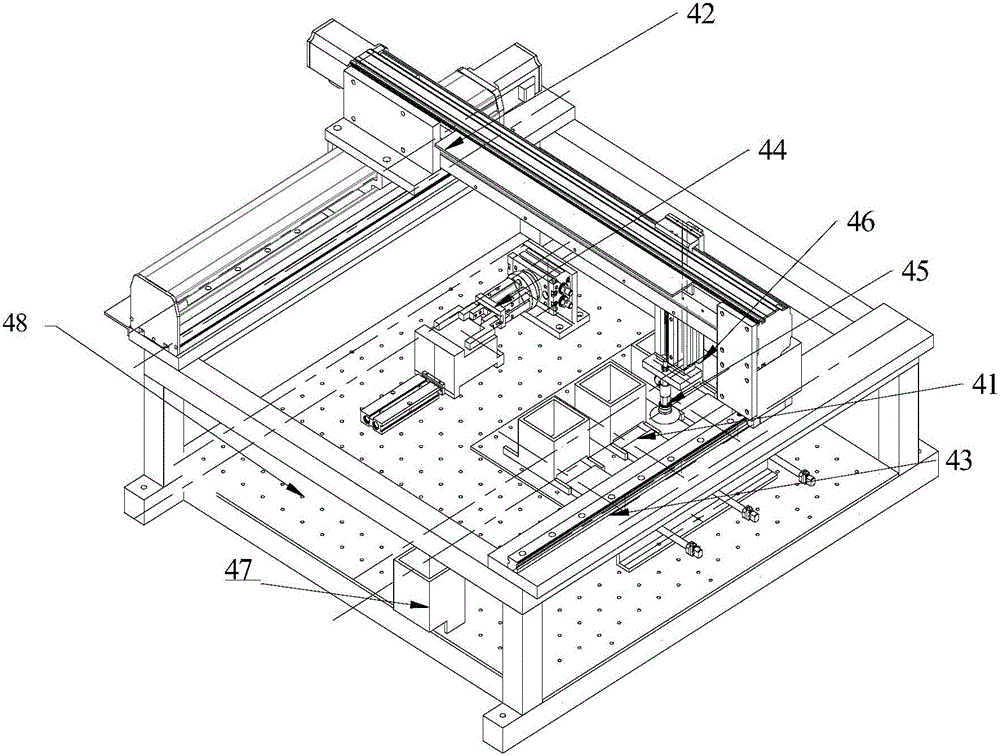

[0028] see Figure 1~4 , the embodiment of the present invention is provided with a user module 1, a communication module 2, an electrical control module 3 and a mechanical module 4;

[0029] Described user module 1 is provided with mobile client 11 and ERP management system 12;

[0030] The mobile phone client 11 is a webpage or mobile application for displaying products, and is used to provide preset engraving patterns for users to choose, allowing users to upload their own patterns, input a string of English character strings, select specific raw material colors, and have online Payment and online query function, first prompt the user to enter the necessary personal information, after the user purchases a pattern or uploads a pattern, selects the material color and enters an English character string, this module obtains user information and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com