Patents

Literature

302 results about "Capacitive displacement sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Capacitive displacement sensors "are non-contact devices capable of high-resolution measurement of the position and/or change of position of any conductive target". They are also able to measure the thickness or density of non-conductive materials. Capacitive displacement sensors are used in a wide variety of applications including semiconductor processing, assembly of precision equipment such as disk drives, precision thickness measurements, machine tool metrology and assembly line testing. These types of sensors can be found in machining and manufacturing facilities around the world.

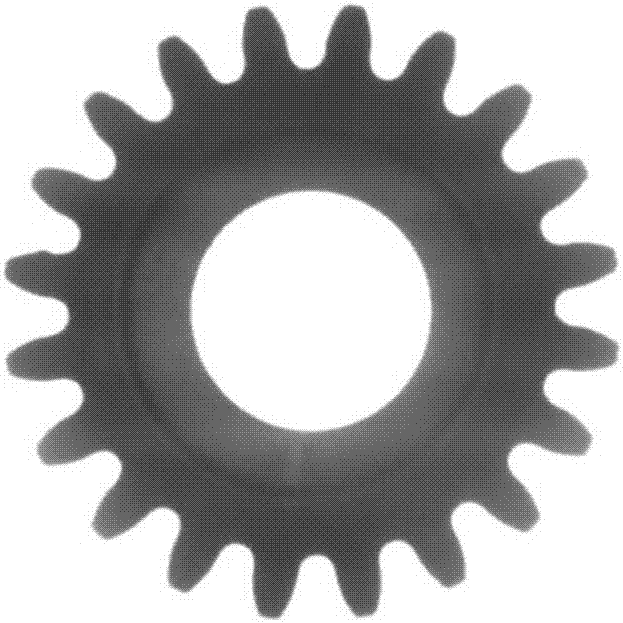

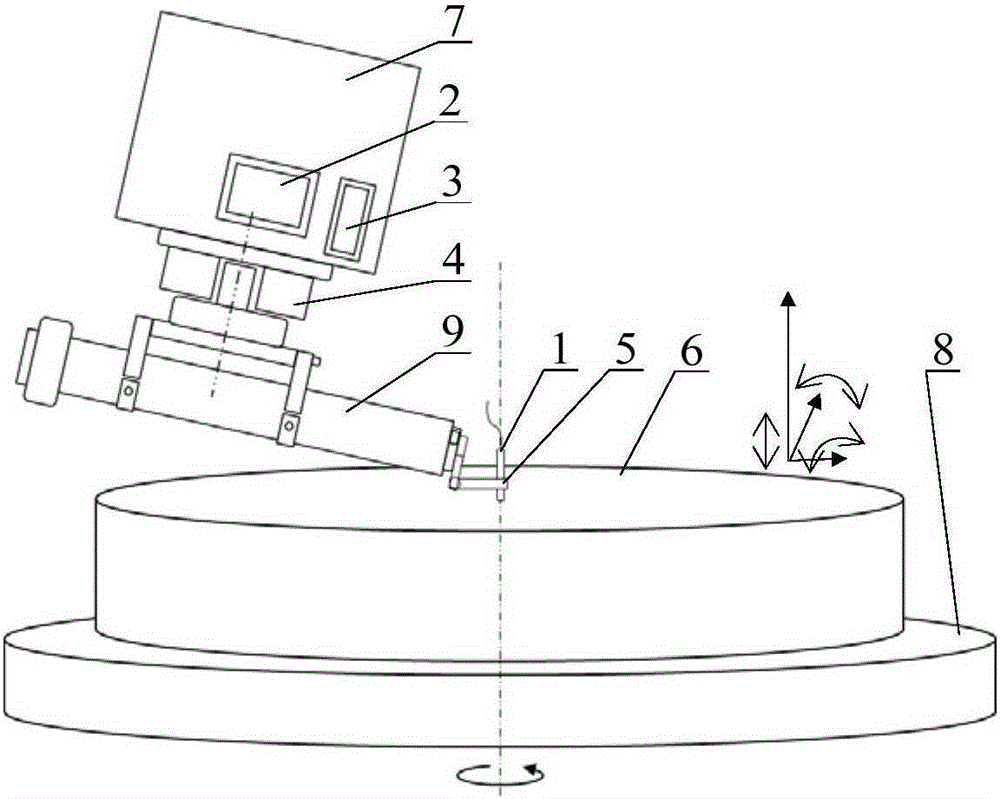

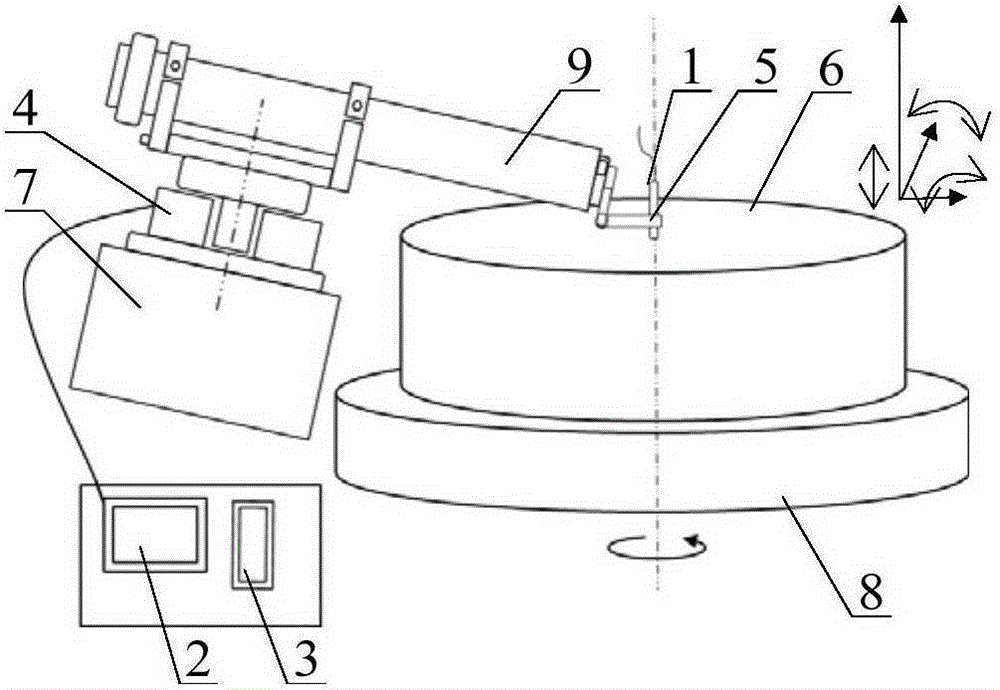

Gear measurement device based on laser displacement sensor and gear measurement method

ActiveCN105823435AHigh measurement accuracyEasy to measureUsing optical meansMeasurement deviceMeasurement point

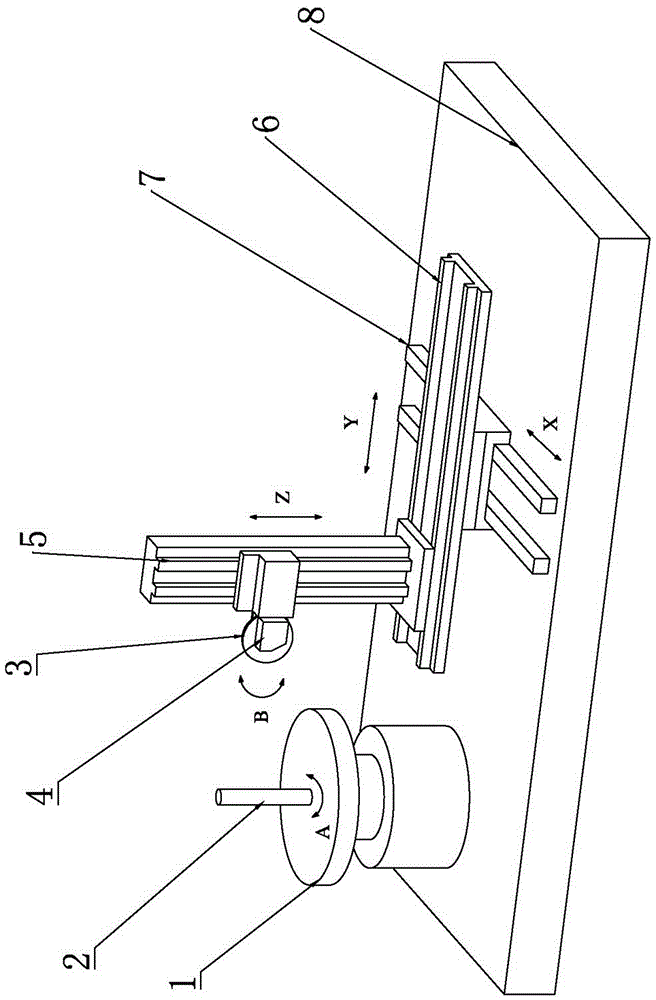

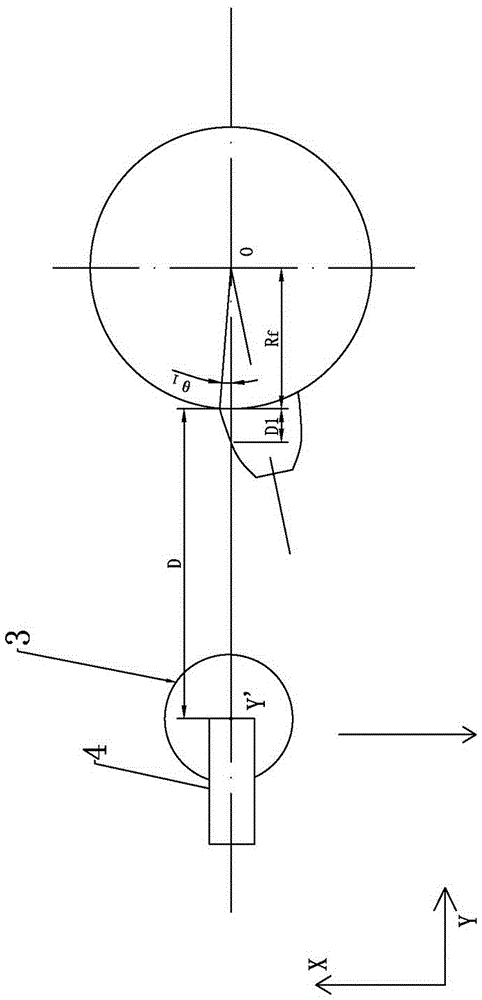

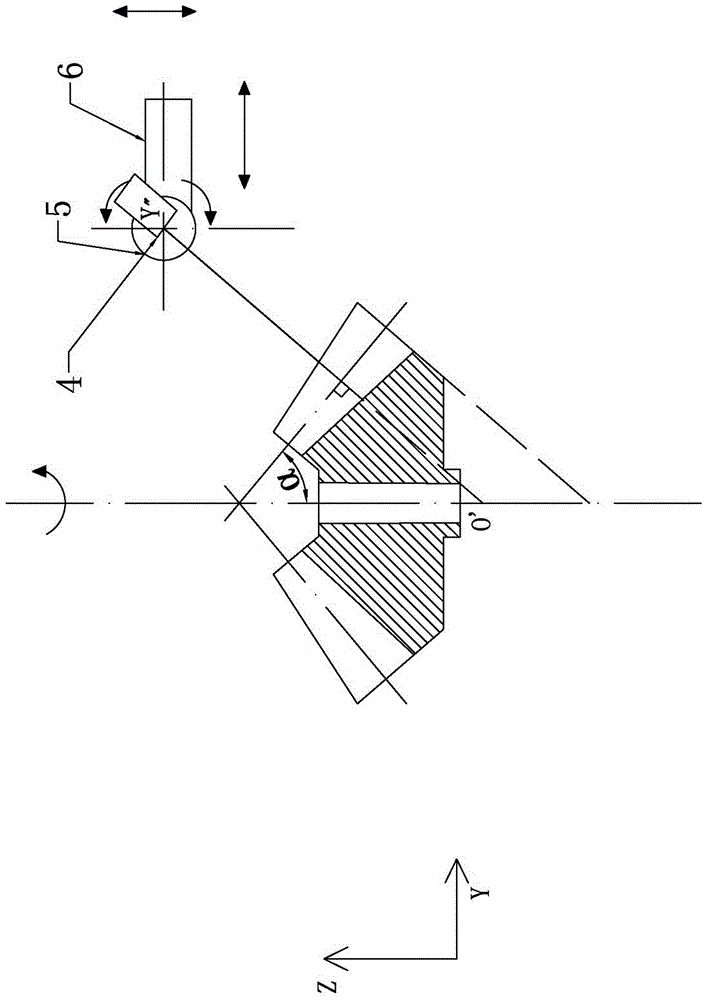

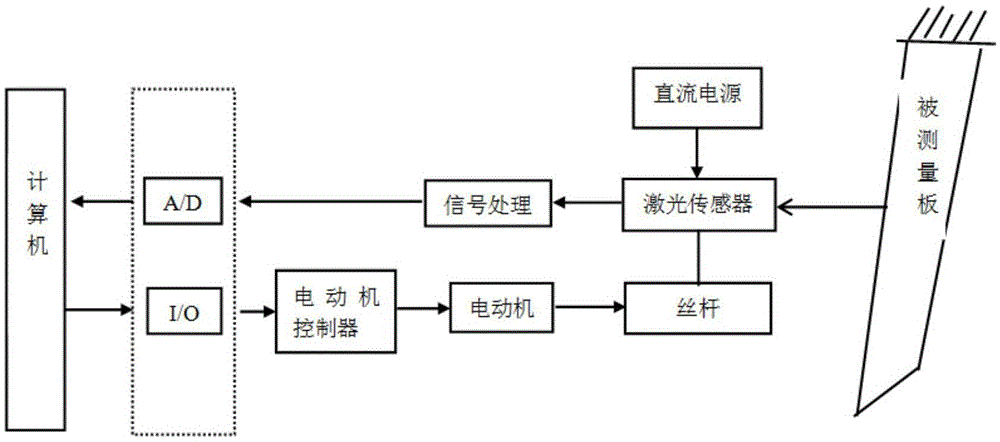

The invention relates to the technical field of gear measurement and especially relates to a gear measurement device based on a laser displacement sensor and a gear measurement method. The gear measurement device provided by the invention comprises a working table, wherein a work piece revolving table and a three-coordinate horizontal shifting device equipped with a rotatable measurement head are disposed on the working table; a zero marking spindle is disposed vertically on the work piece revolving table; the three-coordinate horizontal shifting device comprises an X-axis guide rail fixed on the working table; a Y-axis guide rail is disposed on the X-axis guide rail in a sliding manner; a Z-axis guide rail is disposed on the Y-axis guide rail in a sliding manner; a slide frame is disposed on the Z-axis guide rail in a sliding manner; and the rotatable laser displacement sensor is disposed on the slide frame. The gear measurement device provided by the invention is characterized in that the laser displacement sensor collects coordinate positions of each measurement point on a measured gear outline. In comparison with contact head measurement based on contact with a work piece, the device and the method provided by the invention have the advantages that measurement accuracy is high; a measurement head motion route does not need to be planned during the measurement; and measurement sources are simplified.

Owner:YANGZHOU UNIV

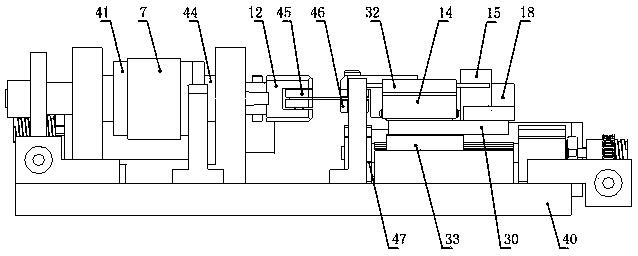

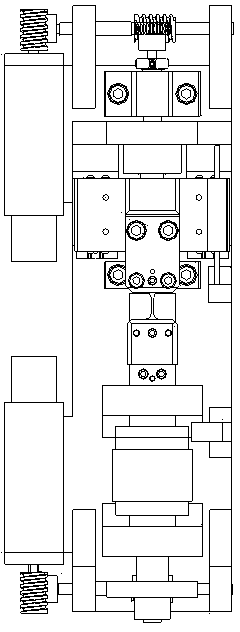

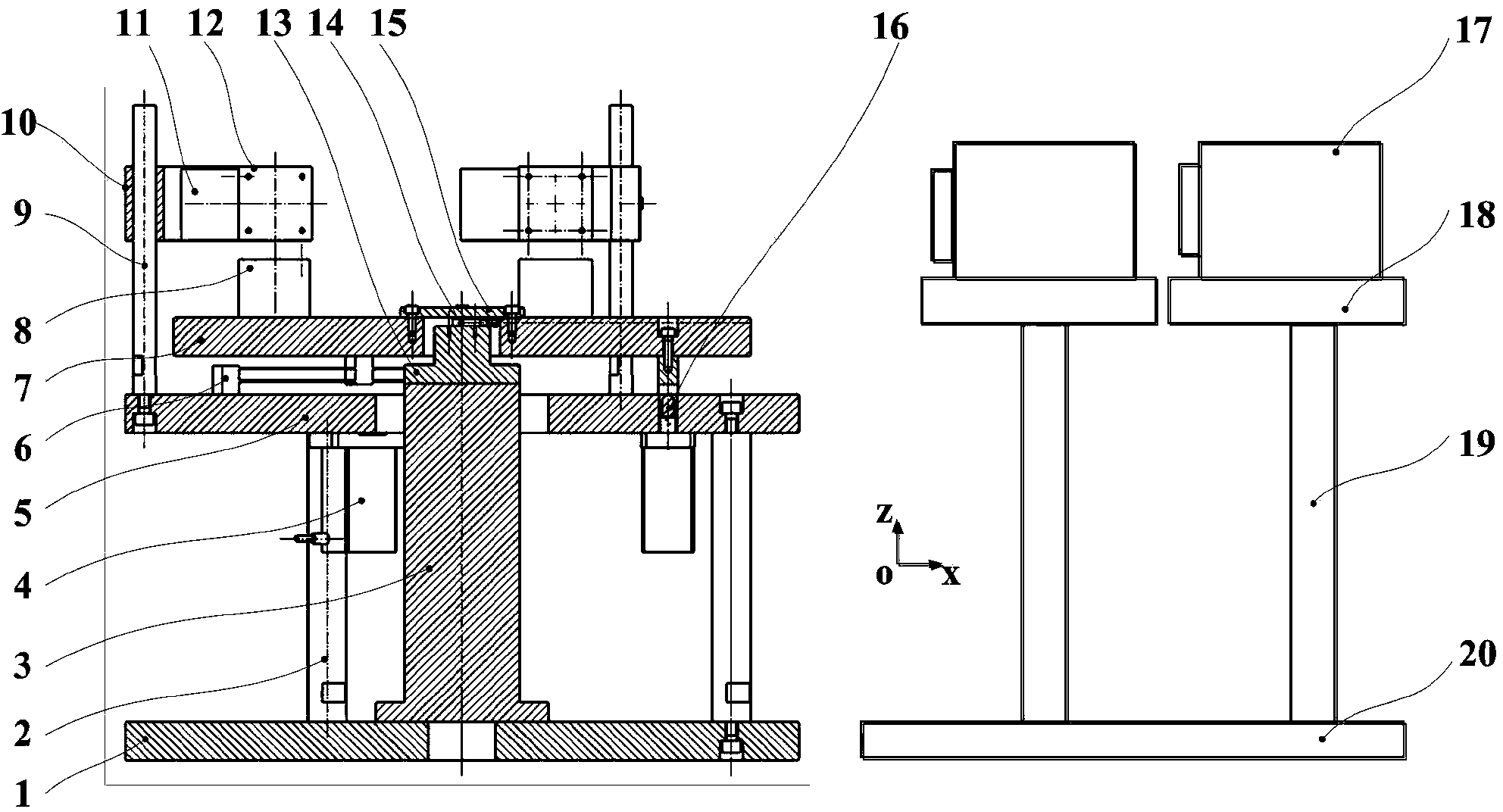

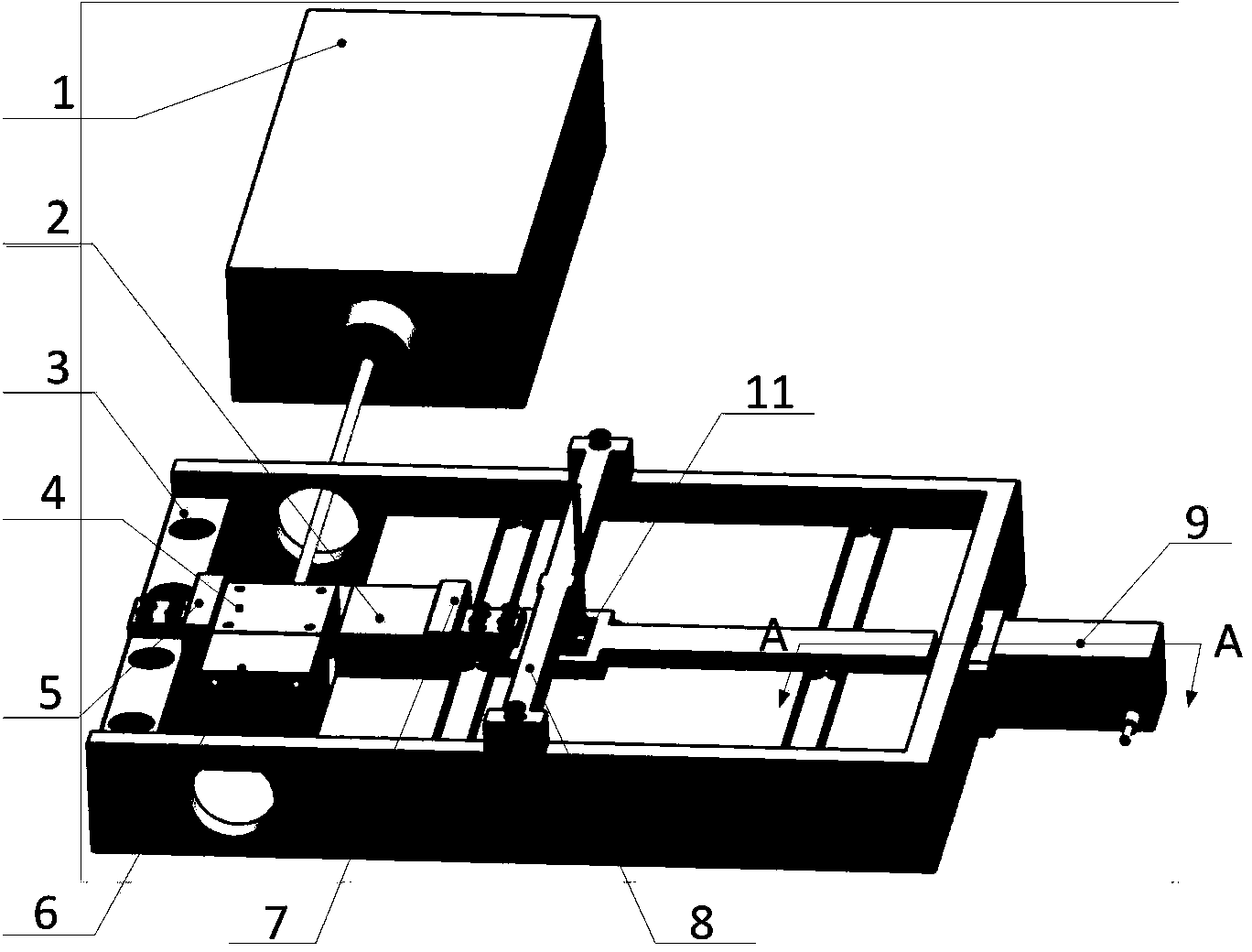

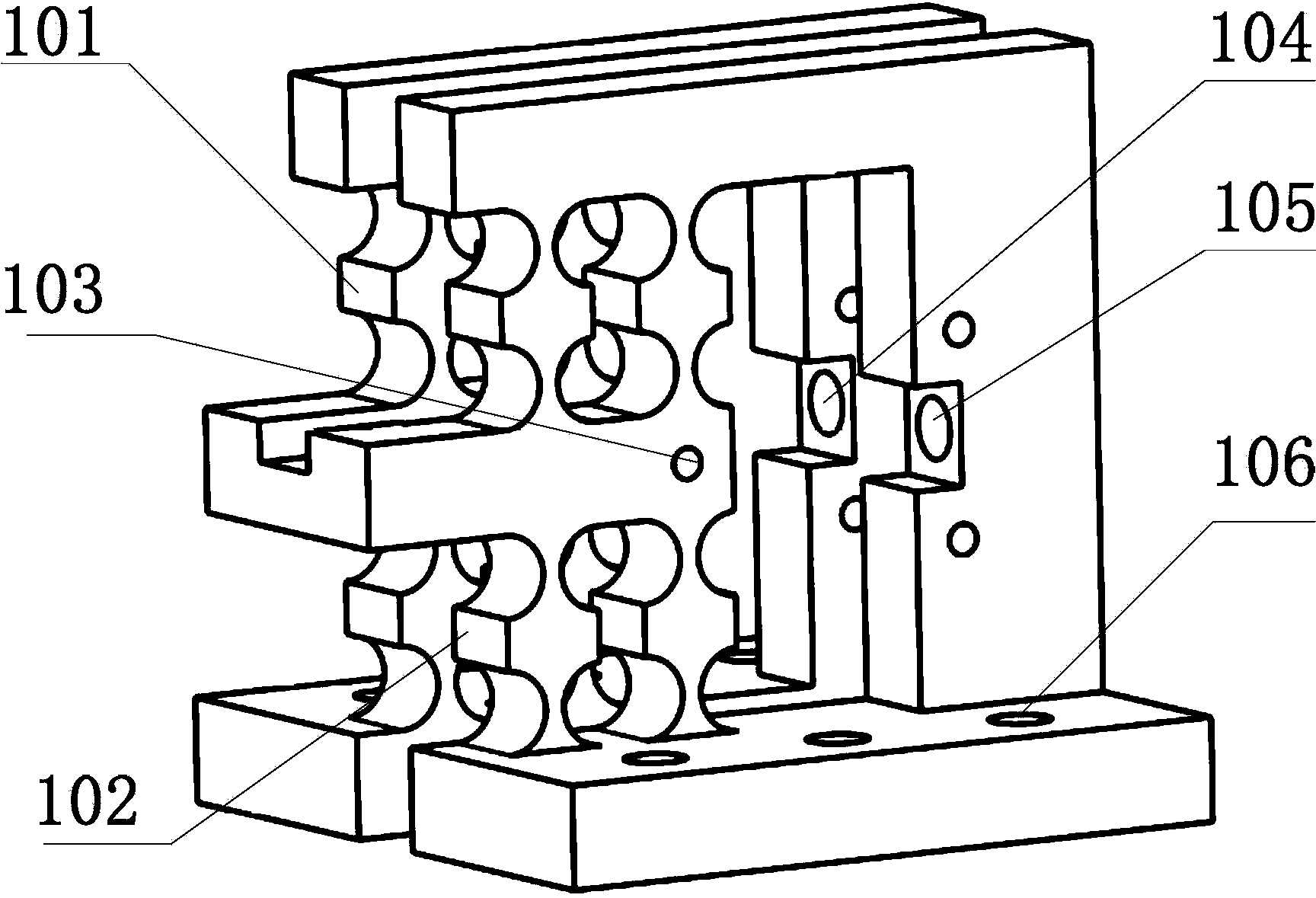

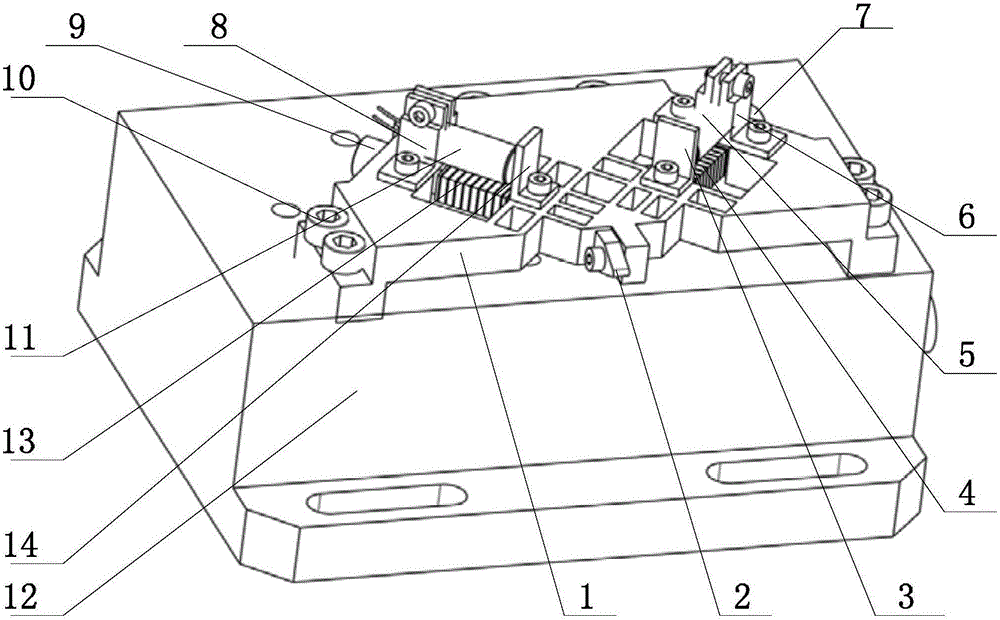

In-situ pull/press-torque combined load material micromechanics test platform

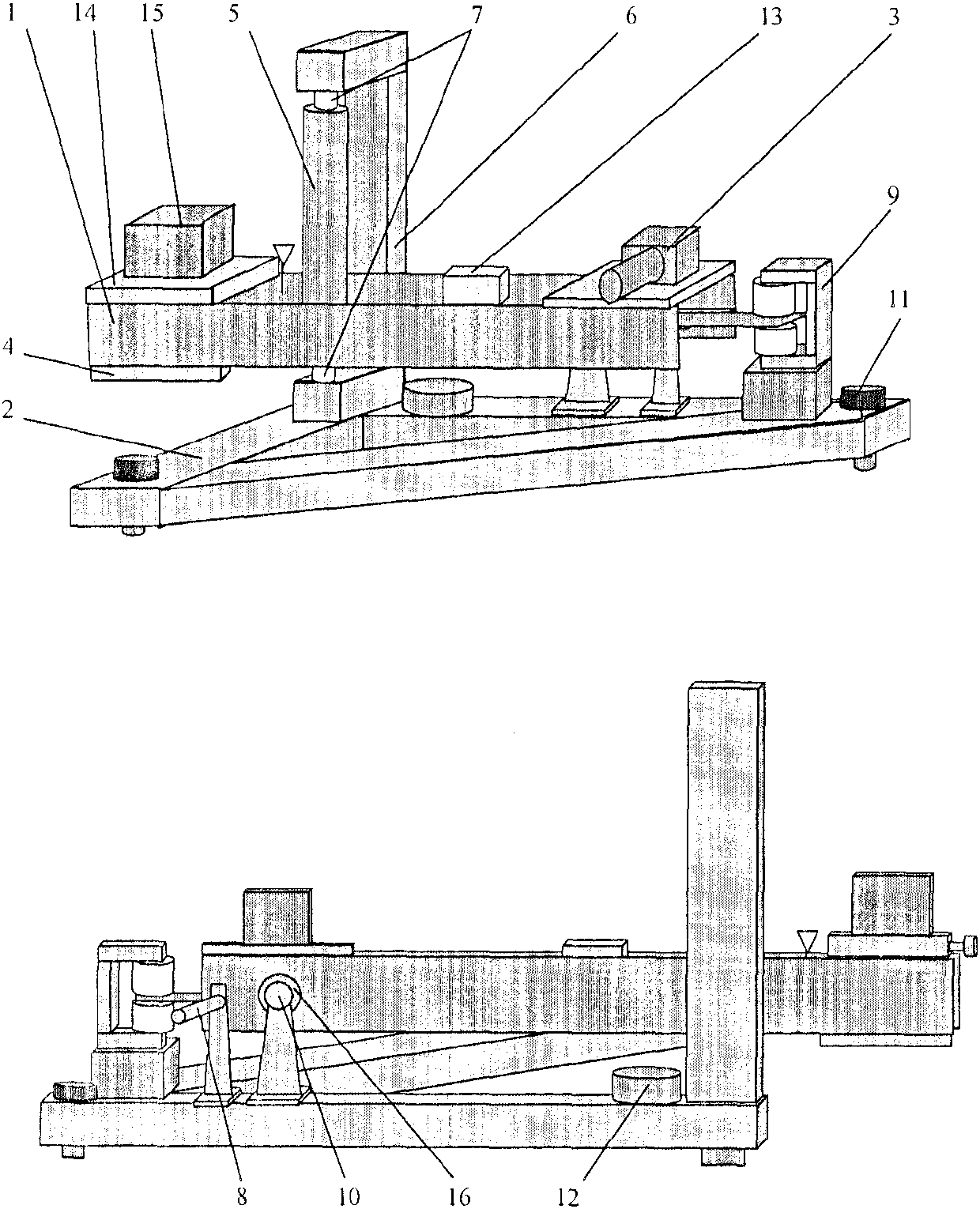

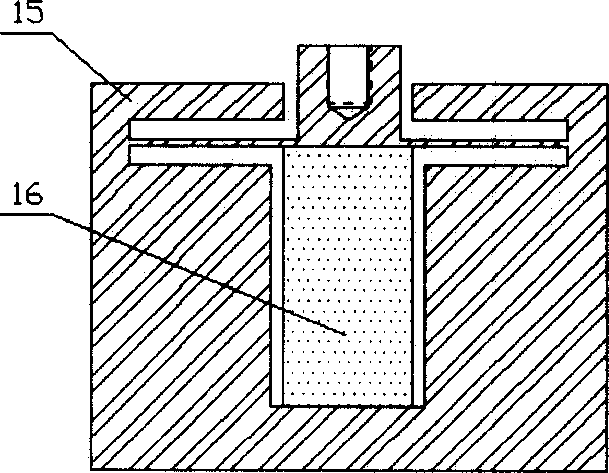

ActiveCN103528887AReduce volumeCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesMicro nanoGrating

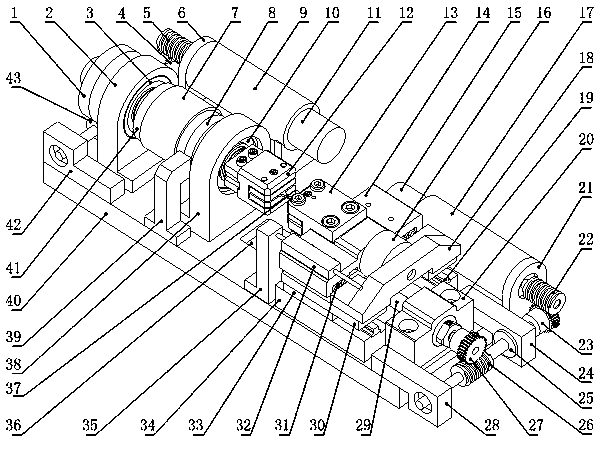

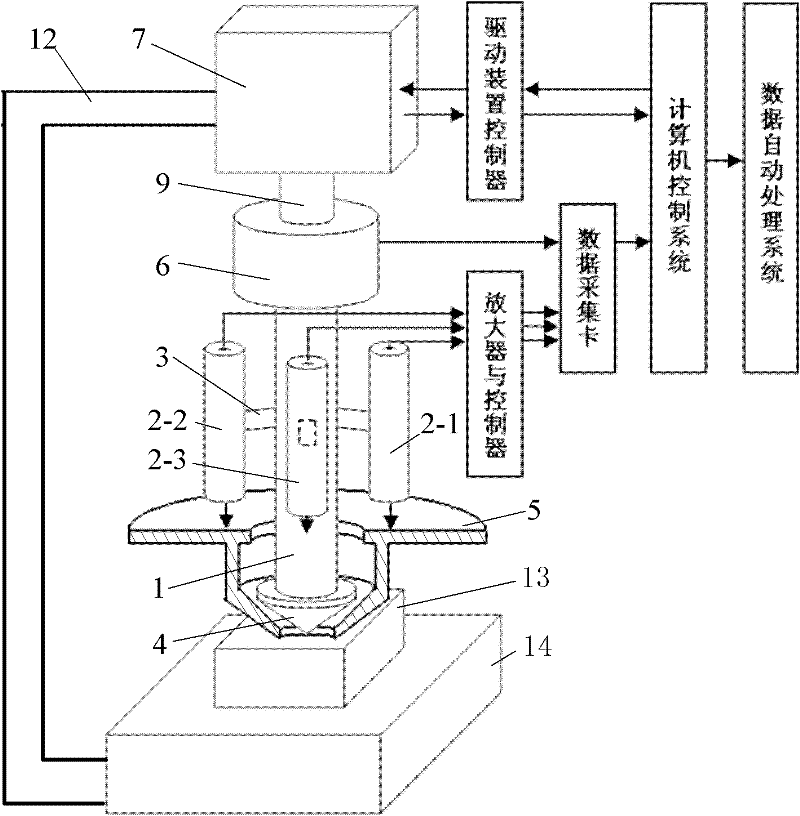

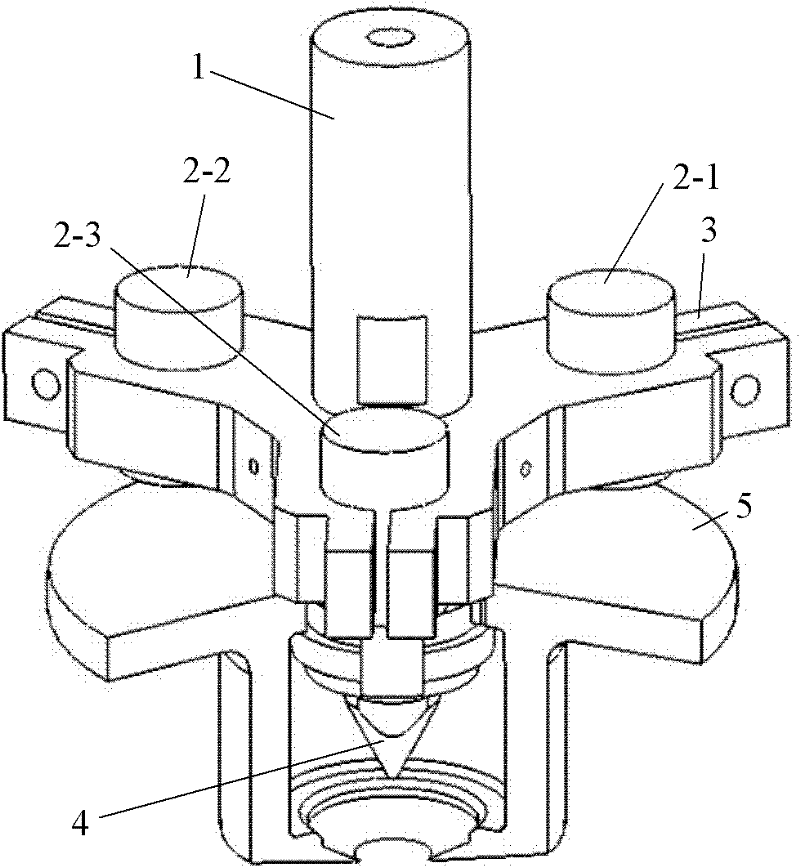

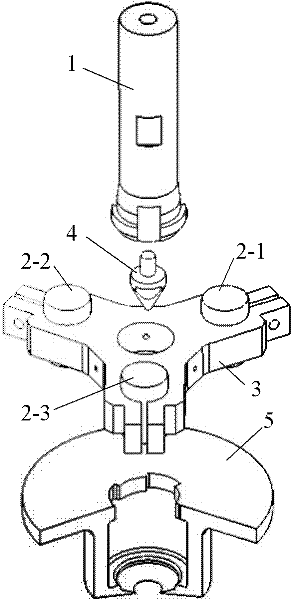

The invention relates to an in-situ pull / press-torque combined load material micromechanics test platform and belongs to the field of material mechanics tests. The in-situ pull / press-torque combined load material micromechanics test platform consists of a base, a precise loading unit, a detection control unit and a clamping and connecting unit, wherein the precise loading unit comprises a torque loading unit and a pull-press loading unit and can be used for realizing the independent and combined loading of pull-press loads and torque loads; aiming at the pull-press loads and the torque loads, the detection control unit respectively uses a pull pressure sensor and a torque sensor to perform load detection and is combined with a contact-type capacitance displacement sensor, a circular grating ruler and a photoelectric encoder so as to monitor and control a loading mechanism. The in-situ pull / press-torque combined load material micromechanics test platform is compact in structure, small in size and controllable in strain rate, and can be used for performing in-situ monitoring on microtexture structural changes, deformation damage mechanisms and performance evolution laws of a material under the action of the combined load, so that an effective test method for revealing the nanoscale mechanics characteristics and damage mechanisms of the material under an approximate service condition is provided.

Owner:JILIN UNIV

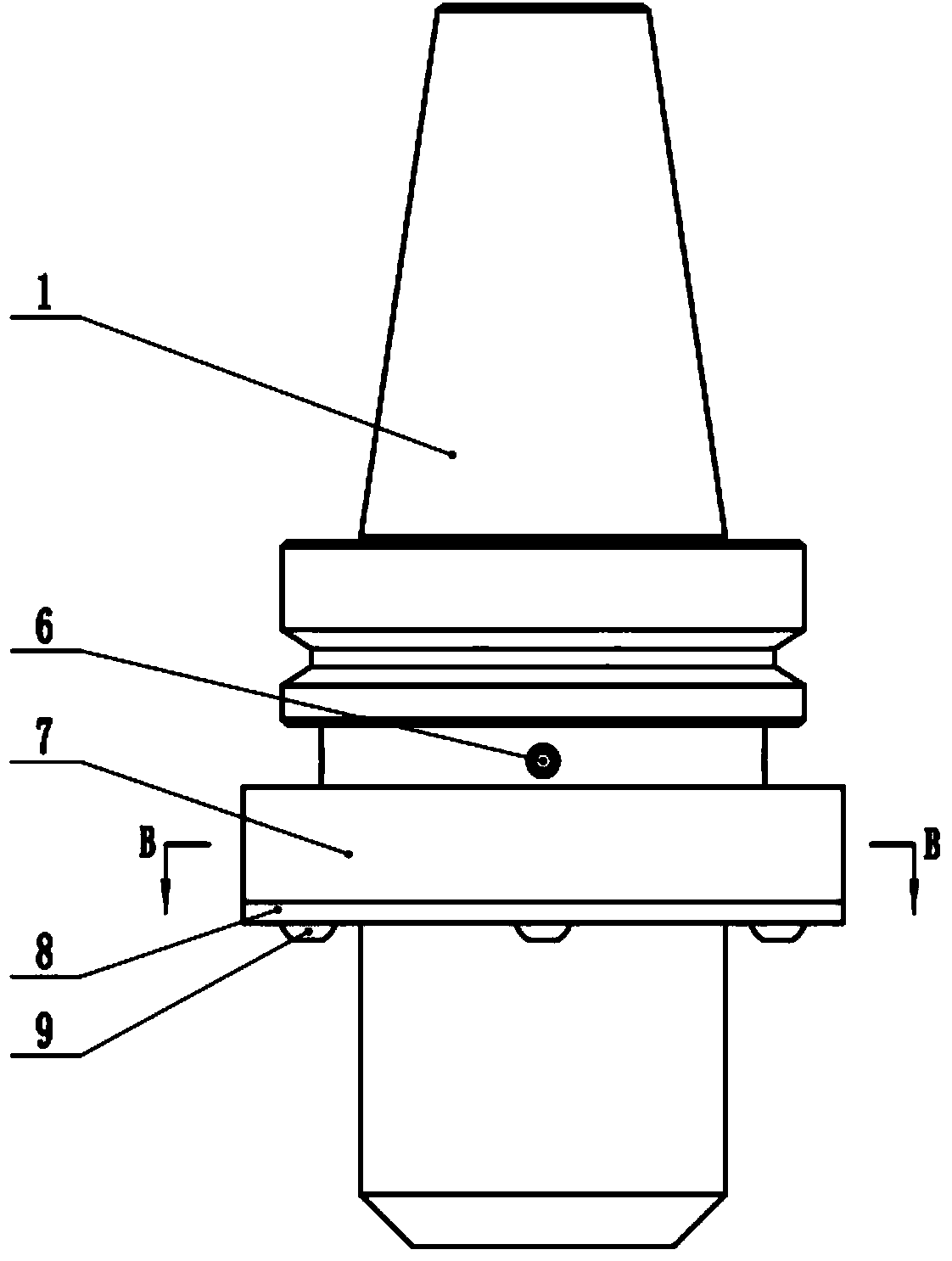

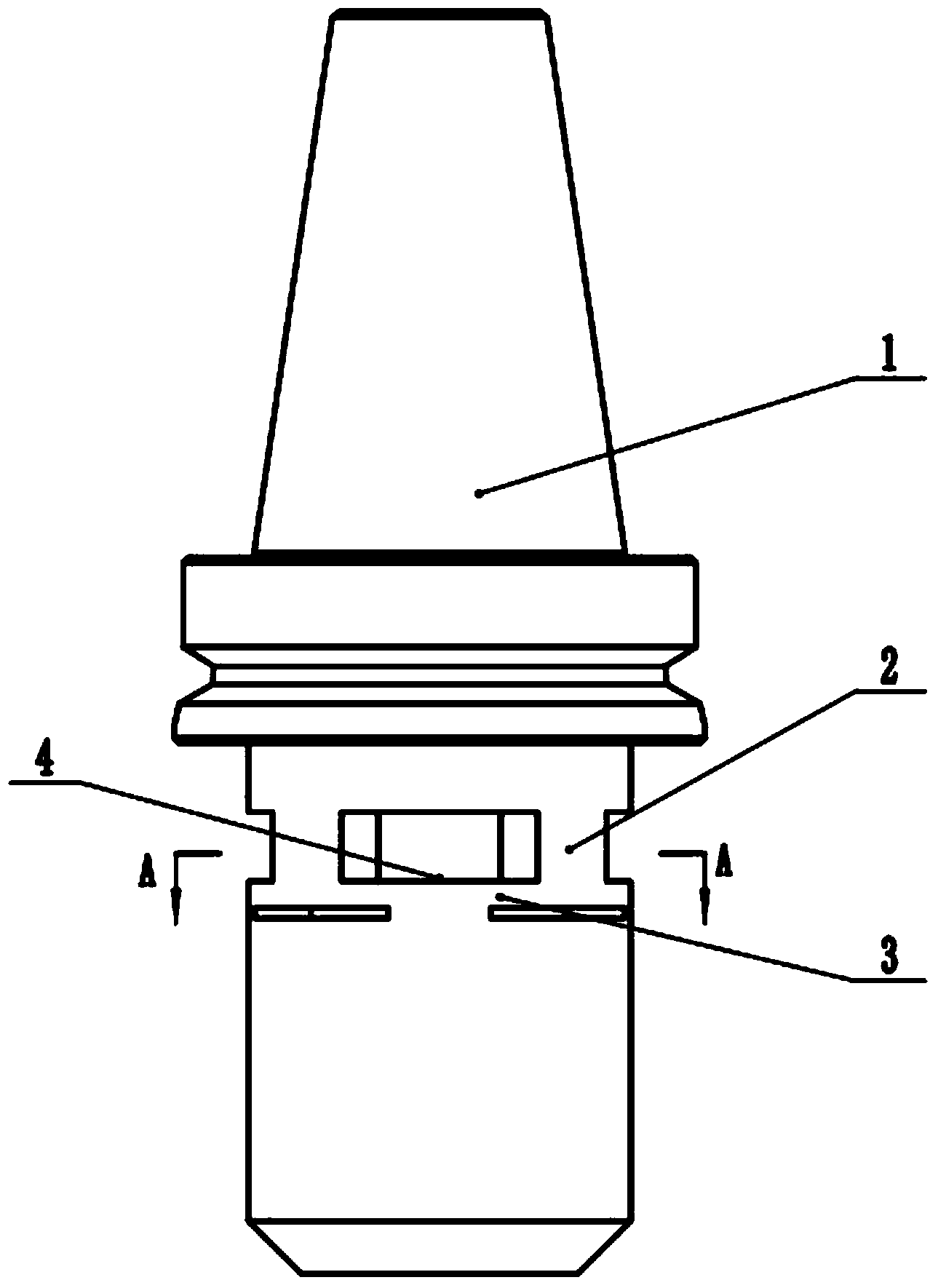

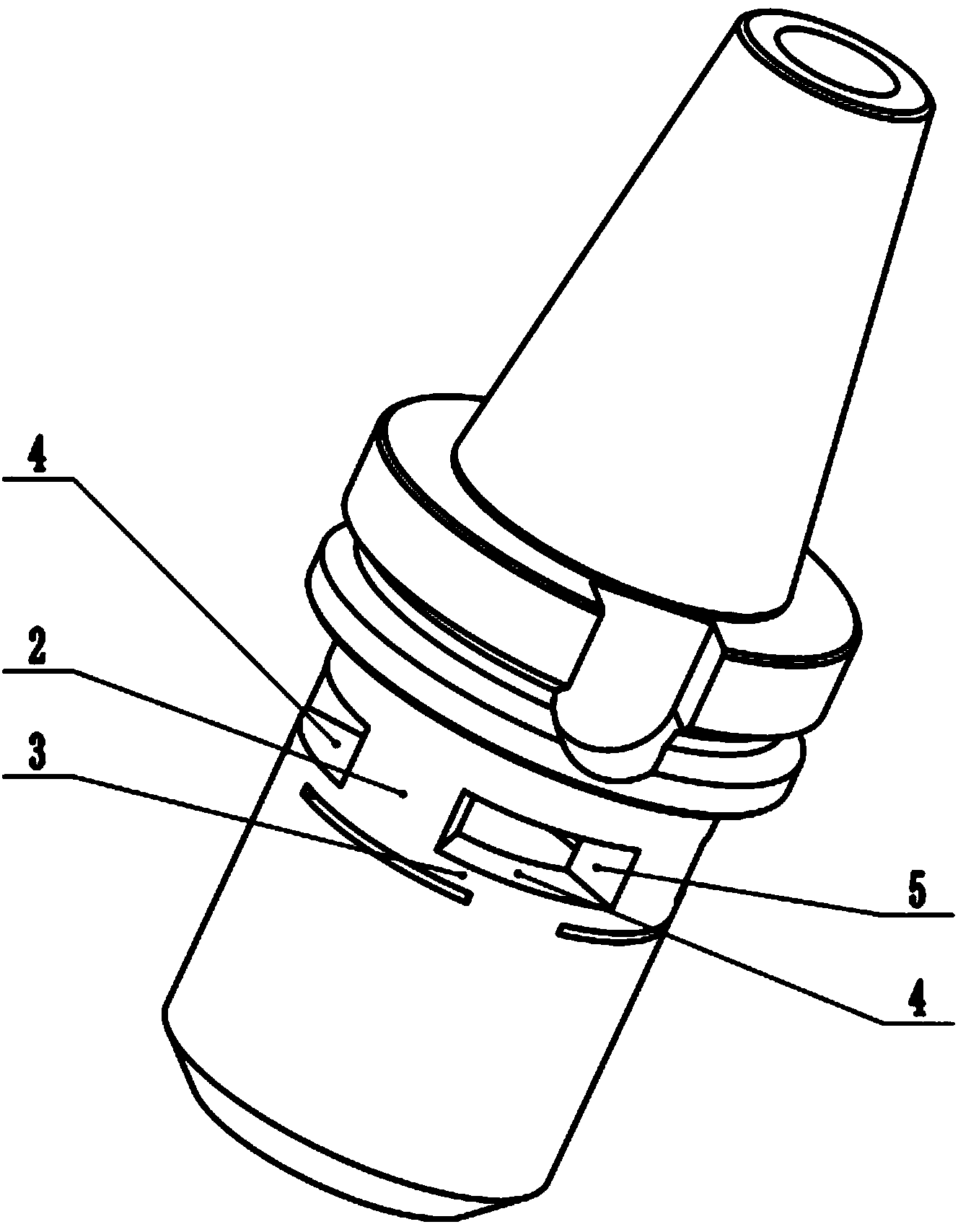

Capacitive intelligent knife handle system for detection of four-dimensional cutting force

ActiveCN104139322ADoes not affect installationDoes not affect normal useMeasurement/indication equipmentsMetal working apparatusRobot handComputer module

The invention discloses a capacitive intelligent knife handle system for detection of a four-dimensional cutting force. The capacitive intelligent knife handle system mainly comprises a standard knife handle, a capacitive displacement sensor, a lithium battery, a capacitive sensor detection circuit, a signal preprocessing and collecting unit, a signal wireless transmitting module, an outer packaging ring, a sealing cover and a fixing block, wherein a deformation rib structure is formed through grooving at a cylinder part of the lower end of the standard knife handle, the four-dimensional cutting force is computed by utilizing the deformation of a deformation rib, and the deformation is measured by the capacitive displacement sensor. The capacitive intelligent knife handle system for the detection of the four-dimensional cutting force, disclosed by the invention, has the advantages that the structure change of an original knife handle is smaller, the installation and the use of a knife and the catching of a mechanical hand are not influenced, the capacitive intelligent knife handle system has the advantages that the structure is simple, the applicability is strong and the like, the accuracy of detecting the deformation of the deformation rib by utilizing a high-accuracy capacitive micro displacement sensor is higher than the accuracy of detecting the deformation of the deformation rib by utilizing a strain type dynamometer, and the dynamic performance is better.

Owner:HARBIN INST OF TECH

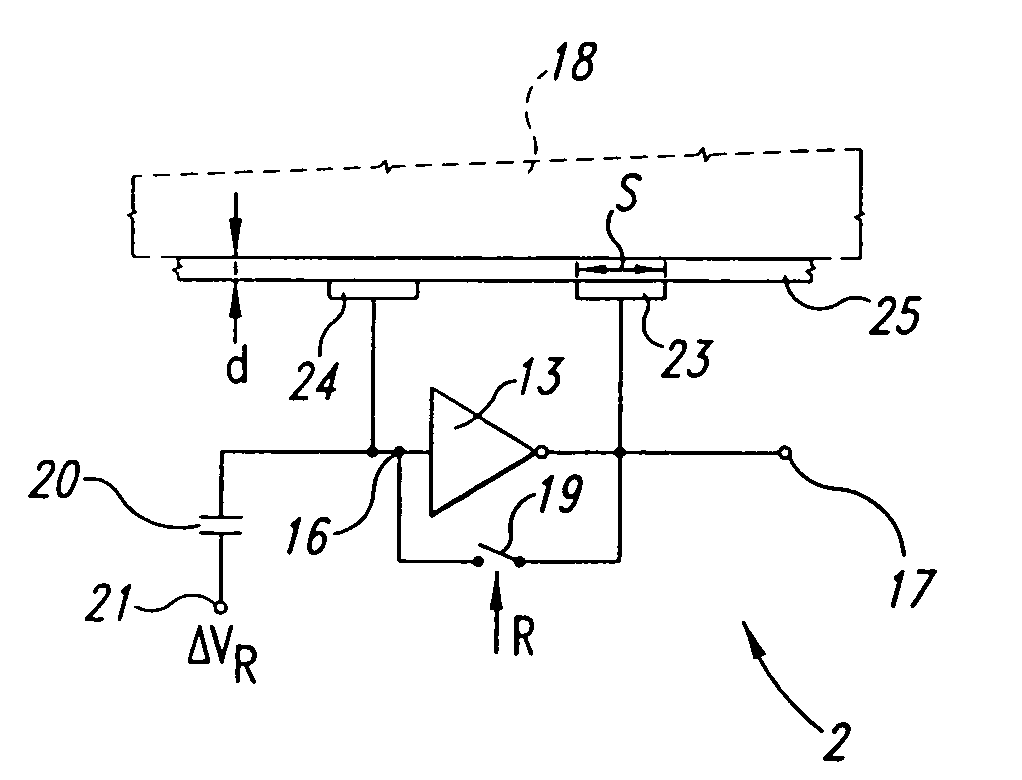

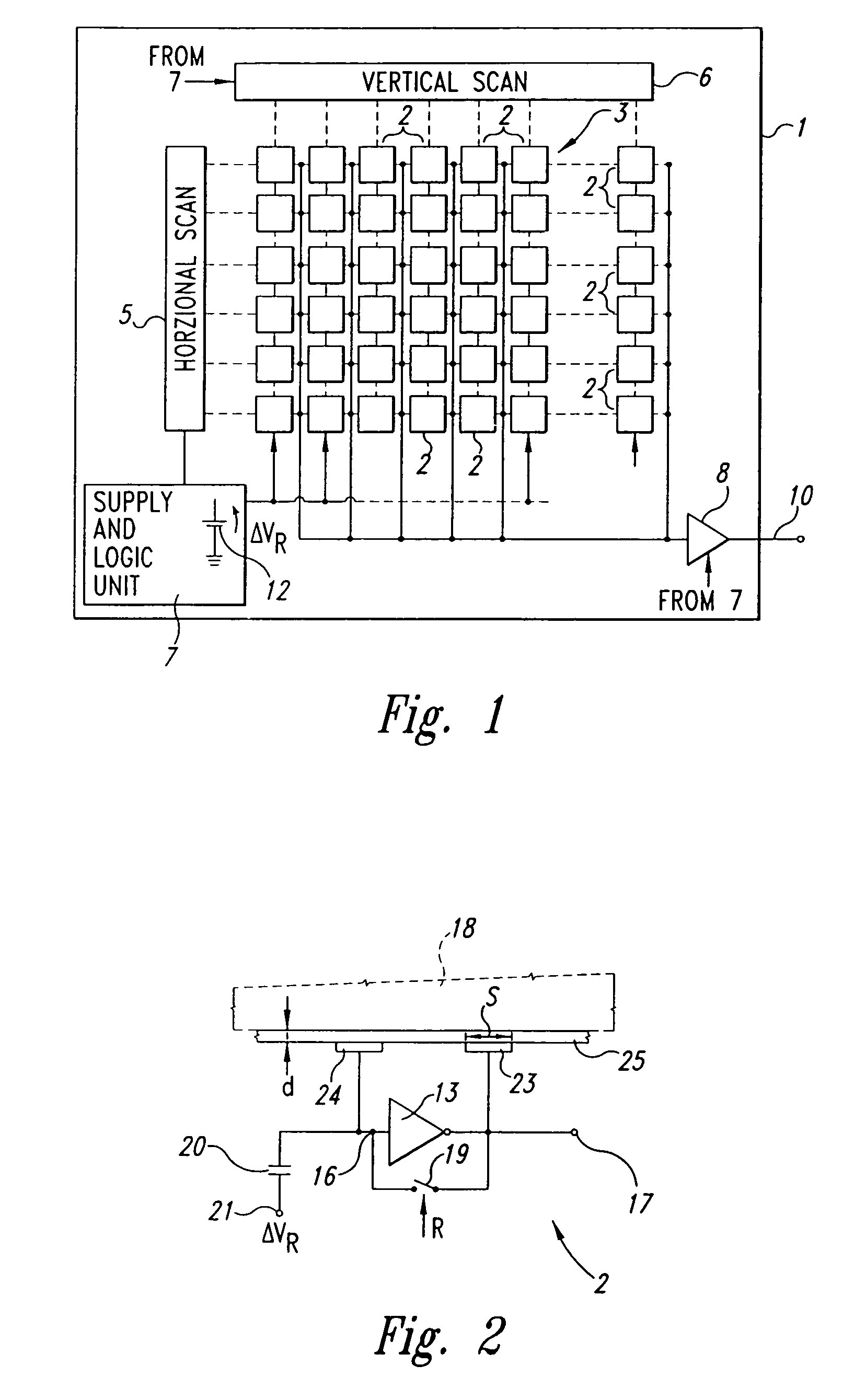

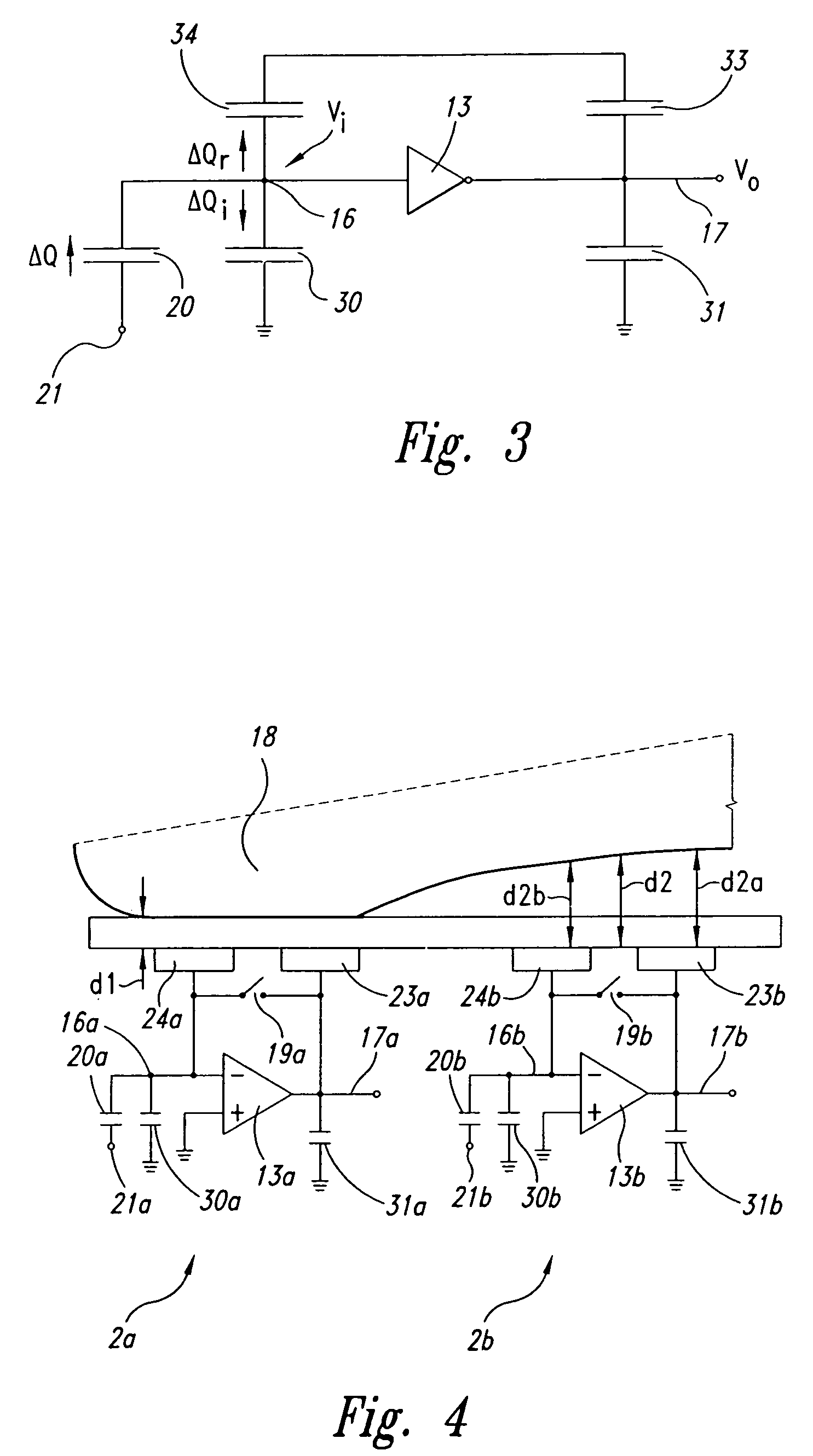

Capacitive distance sensor

InactiveUS6998855B2Prevent illegal useResistance/reactance/impedenceUsing electrical meansNegative feedbackSkin surface

A distance sensor has a capacitive element in turn having a first plate which is positioned facing a second plate whose distance is to be measured. In the case of fingerprinting, the second plate is defined directly by the skin surface of the finger being printed. The sensor includes an inverting amplifier, between the input and output of which the capacitive element is connected to form a negative feedback branch. By supplying an electric charge step to the input of the inverting amplifier, a voltage step directly proportional to the distance being measured is obtained at the output.

Owner:APPLE INC

A high-precision instrumented indenter and a method for calculating the indentation depth of a diamond indenter

InactiveCN102288500AElimination of influences on indentation depth measurementsGuaranteed accuracyElectric/magnetic depth measurementInvestigating material hardnessComputer control systemProbe type

Owner:ACADEMY OF ARMORED FORCES ENG PLA

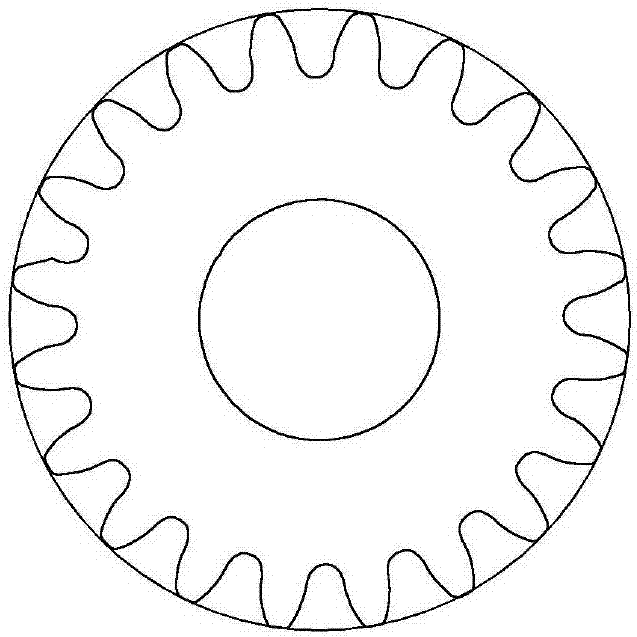

A gear measuring apparatus and measuring method based on active vision

InactiveCN107121093AHigh-resolutionSmall amount of calculationUsing optical meansMeasurement deviceEngineering

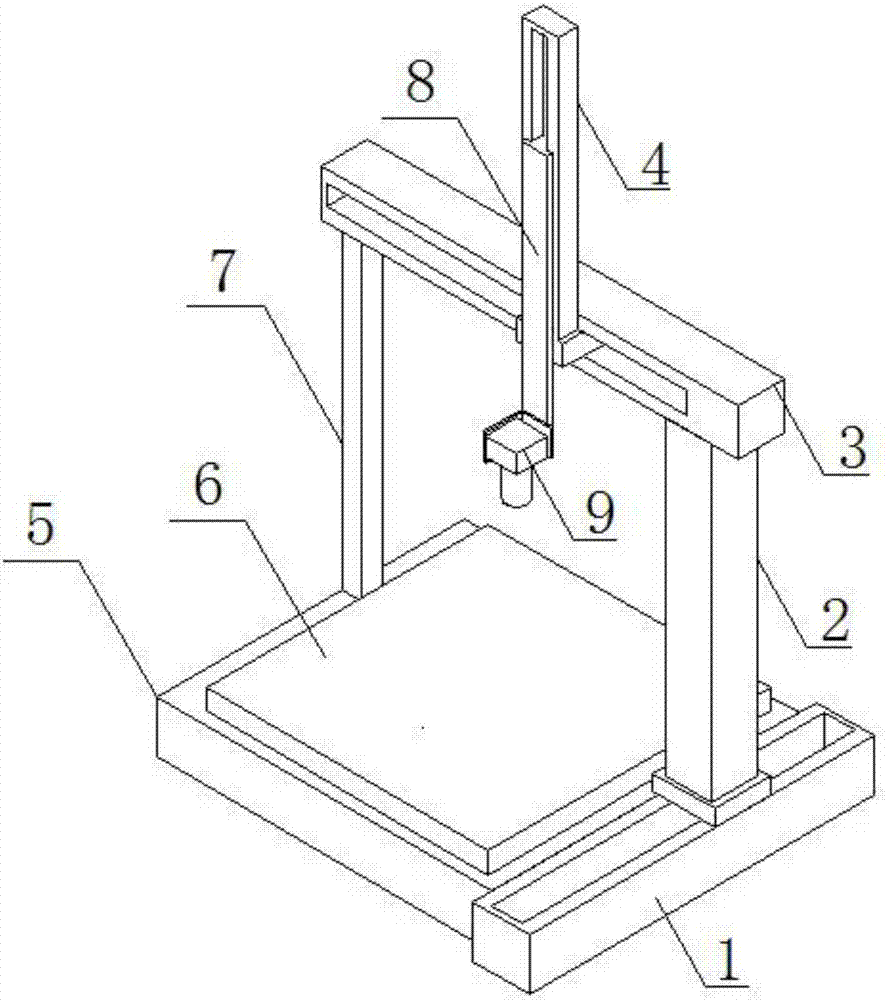

The invention relates to a gear measuring apparatus and measuring method based on active vision, and belongs to the technical field of high precision detection. The measuring apparatus comprises a base; a three-dimensional moving platform is arranged on the base; the three-dimensional moving platform comprises X, Y and Z axis guide rails which are perpendicular to each other; and a raster displacement sensor is arranged on the guide rail in each axis; the Z-axis guide rail is slidably provided with a carriage; an industrial camera and a lens which are connected are arranged on the carriage; an output end of the industrial camera is connected to a host computer; a background light source is fixed on the base; each displacement sensor is connected with a controller for calculating the positioning information of the three-dimensional moving platform; the controller is connected with the host computer; and the host computer realizes the motion control and positioning information acquisition of the three-dimensional platform through sending commands to the controller. The gear measuring apparatus and measuring method of the invention can effectively realize high-precision non-contact measurement of gears in the effective dimension scope of 50mm-500mm to reach an effect of reducing cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

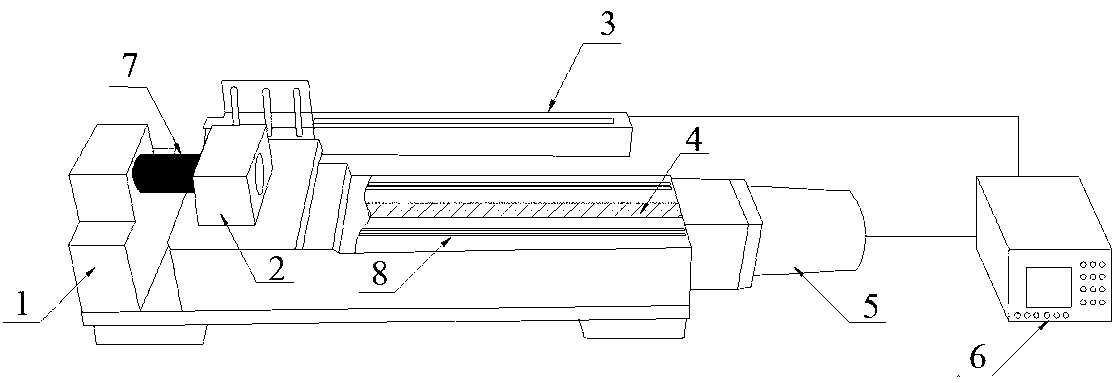

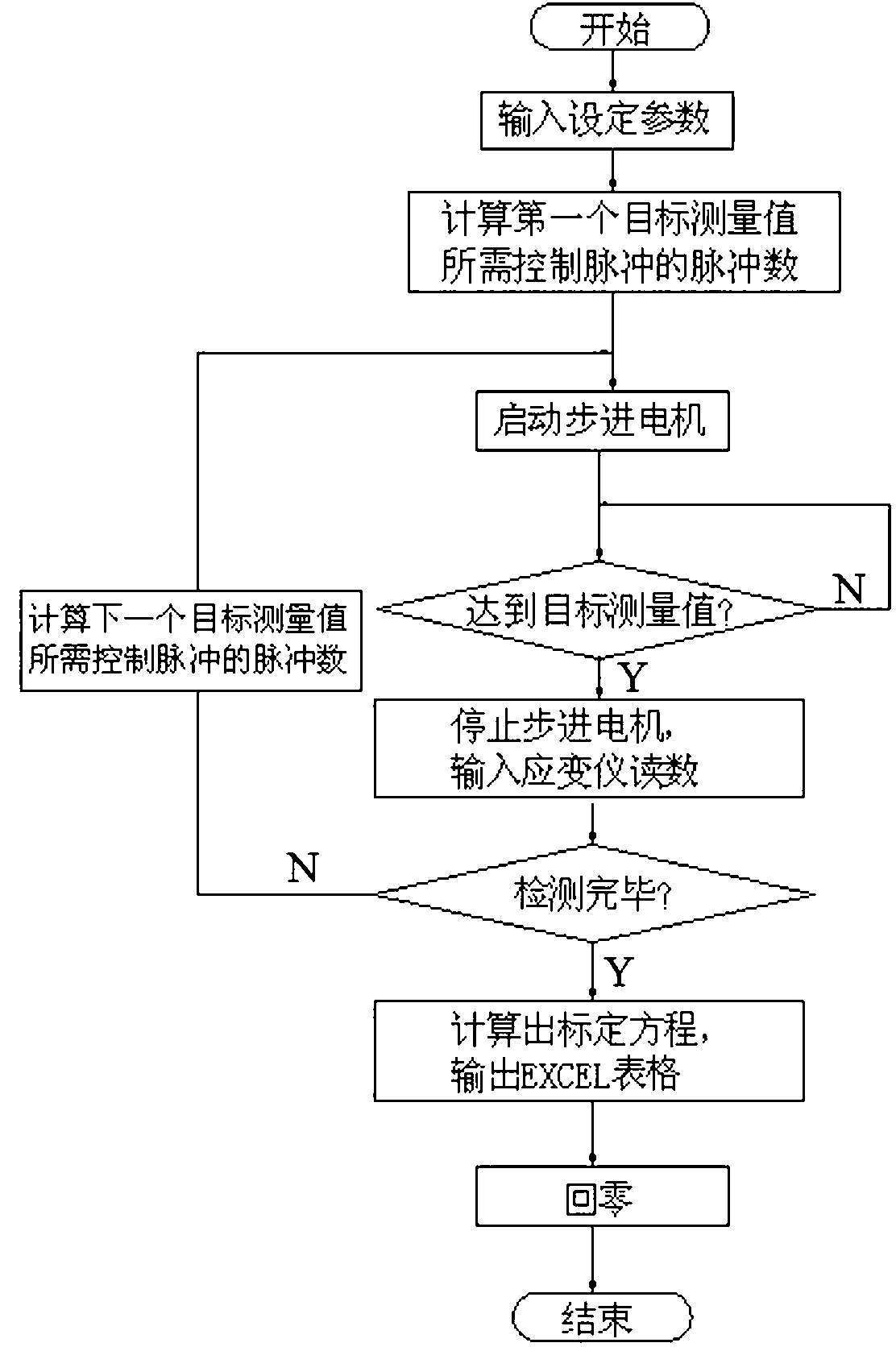

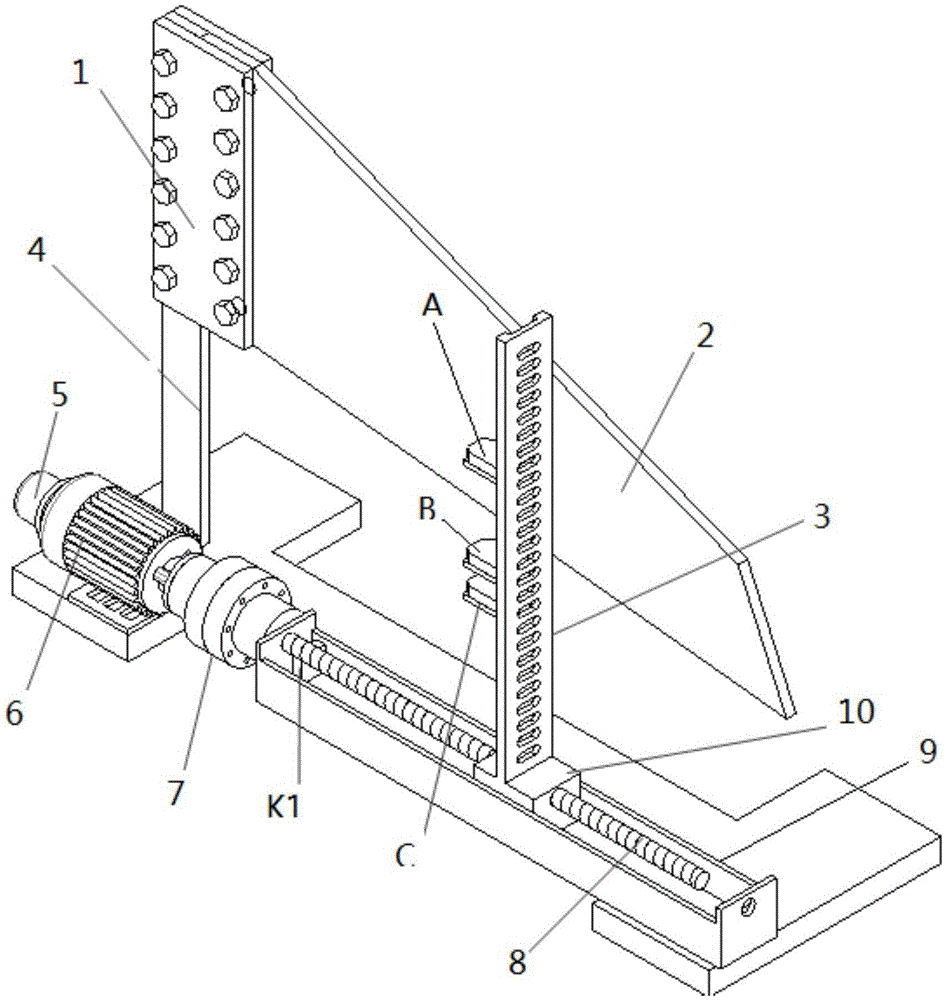

Automatic calibration device and calibration method for strain gauge

InactiveCN102927959AFully automatic calibrationFully automatic detectionMeasurement devicesContinuous measurementGrating

The invention provides an automatic calibration device and calibration method for a strain gauge. The automatic calibration device adopts a grating displacement sensor as a standard, a stepper motor for driving, a controller for controlling, reading and processing data, and a closed-loop system is completely adopted, so that full-automatic calibration and detection are realized for the strain gauge, wherein the output accuracy of the grating displacement sensor is 3 mum, so the detection accuracy is guaranteed; a horizontal base is provided with two V-shaped guide rails which are parallel to each other, so that a movable flame can not deflect or tilt when running with load, and the loading capacity and the application range can be improved; and a high-precision ball screw can be guaranteed to transfer enough torsion accurately during the movement process. With the adoption of the method, continuous measurement for multiple positions can be realized, the work efficiency of measurement can be improved, a calibration equation adopts a simple cubic equation, so that the calibration process is greatly simplified, a zero-returning step eliminates an accumulated error caused by long-term work of a controller, and further, the detection accuracy of the method is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

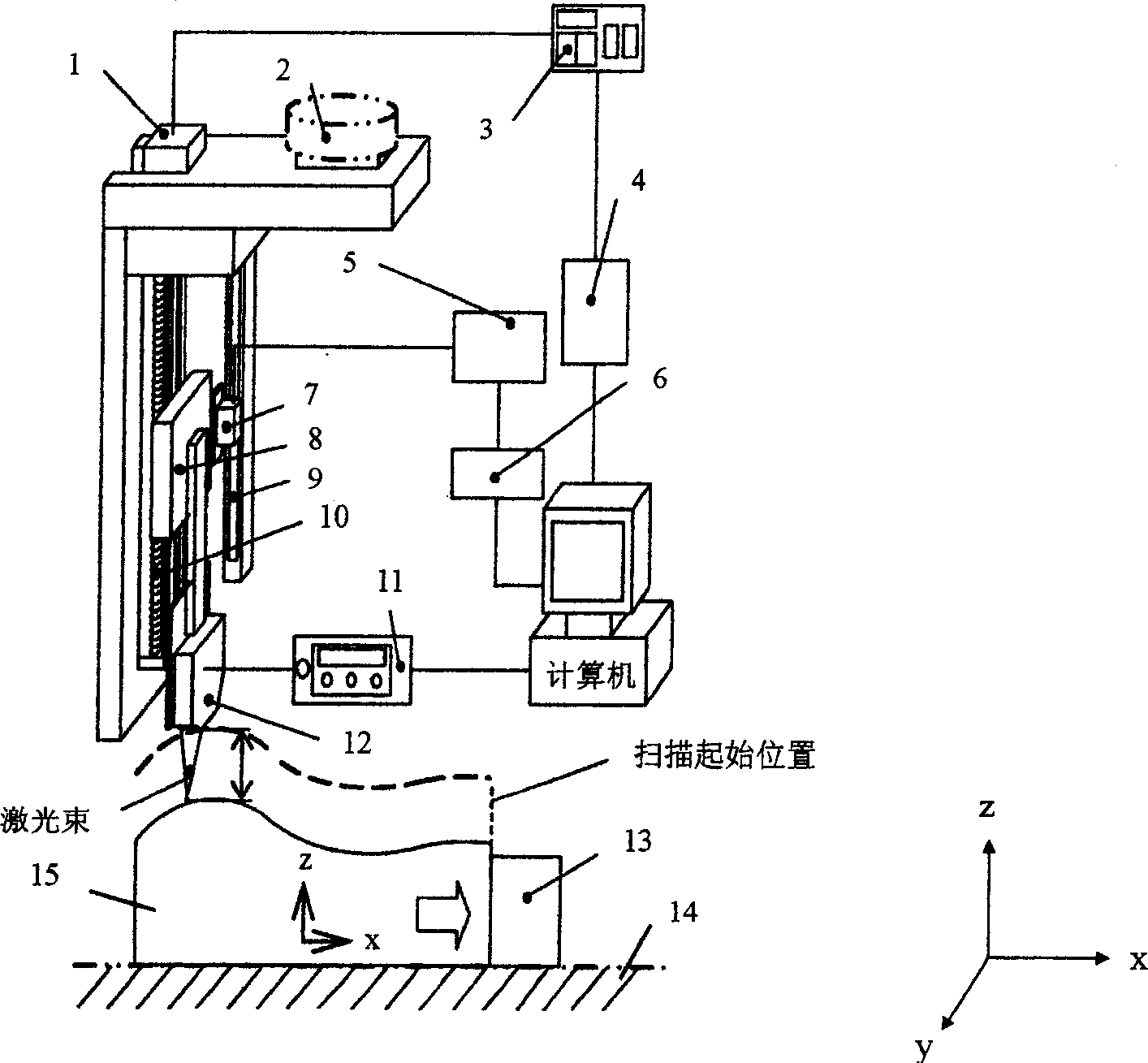

Wide range and high precision free curved surface measuring method

The wide range and high precision free curved surface measuring method includes setting the curved surface on one platform capable of shifting precisely in both X and Y directions, integrating laser displacement sensor and grating displacement sensor and linear coder, installing the laser displacement sensor onto one servo mechanism capable of moving in Z direction, obtaining the Z coordinates of the curved surface with the laser displacement sensor and grating displacement sensor and linear coder, and obtaining the X and Y coordinates with the precisely shifting platform. The present invention fuses several sensors, has the features of high efficiency, wide range and high precision in free curved surface measurement, and will find its wide application in manufacture technology.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

Calibration device for capacitance displacement sensor

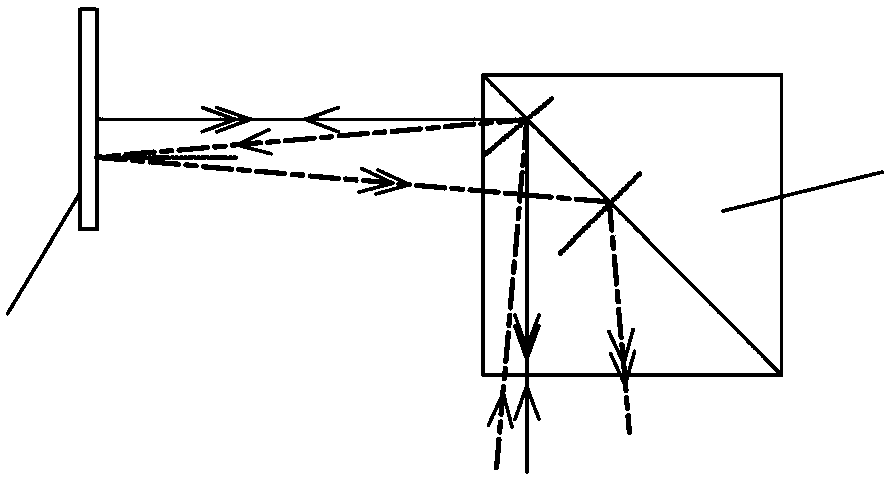

ActiveCN104075652ASimple and fast operationImprove the accuracy of assembly and adjustmentUsing electrical meansObservational errorBeam splitter

The invention discloses a calibration device of a capacitance displacement sensor, and belongs to the technical field of sensor calibration. The technical problem that a calibration device for a capacitance displacement sensor in the prior art is low in calibration precision is solved. The calibration device comprises a capacitance displacement mechanism and an interferometer mechanism. The capacitance displacement mechanism comprises a calibration table base, a calibration table supporting frame, a sensor supporting frame, a driver, a calibration table static platform, a hinge, a calibration table dynamic platform, a measurement angle reflecting mirror, a light guide element supporting frame, a light guide element fixing base, a reference angle reflecting mirror, a beam splitter mirror, a sensor fixing base, a capacitance sensor, a measured panel and a driver push rod. The interferometer mechanism comprises a single-axis laser interferometer, an interferometer adjusting base, an interferometer supporting frame and an interferometer base. According to the device, the parallelism depth precision of a sensing face and a measured face of the existing calibration device for the capacitance displacement sensor is improved when the sensor is mounted, measurement errors caused by adjustment are reduced, and the calibration precision of the sensor is improved.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

Calibration device for plate condenser displacement sensor

InactiveCN104048588AImprove work efficiencyImprove performanceUsing electrical meansOptical axisAcoustics

The invention discloses a calibration device for a plate condenser displacement sensor, and belongs to the technical field of sensor calibration. The calibration device aims to overcome the shortcomings that the calibration stroke of a calibration device in the prior art is small, continuous real-time calibration can not be achieved, and the sensor calibration precision is low. Light emitted by a laser interferometer enters a spectroscope after passing through a micrometric displacement adjustment mechanism, and the spectroscope is installed on the micrometric displacement adjustment mechanism. A reference reflector is connected with the spectroscope and located on the same straight line as the optical axis of the single-axis laser interferometer. A measurement reflector is installed at the left end of a guide mechanism of the micrometric displacement adjustment mechanism, and a light-passing hole of the measurement reflector is adjusted to be located on the same straight line as a light-passing hole of the spectroscope. A sensor surface to be measured is arranged at the front end of the guide mechanism. The plate condenser displacement sensor is installed in the middle of a sensor support, and the two ends of the sensor support are installed on bosses on the two sides of the micrometric displacement adjustment mechanism respectively. A driver push rod is installed at the left end of a driver and pushes the guide mechanism of the micrometric displacement adjustment mechanism.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

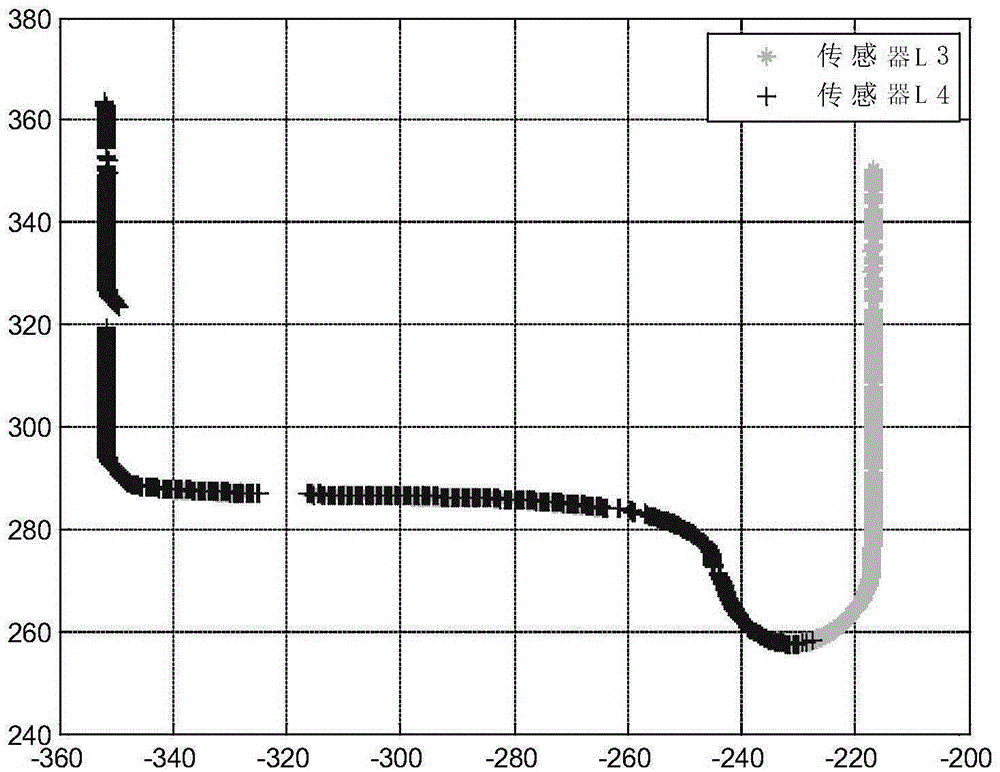

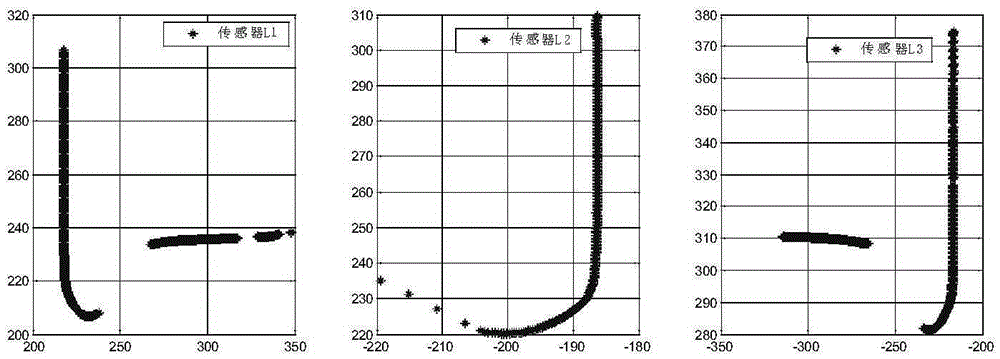

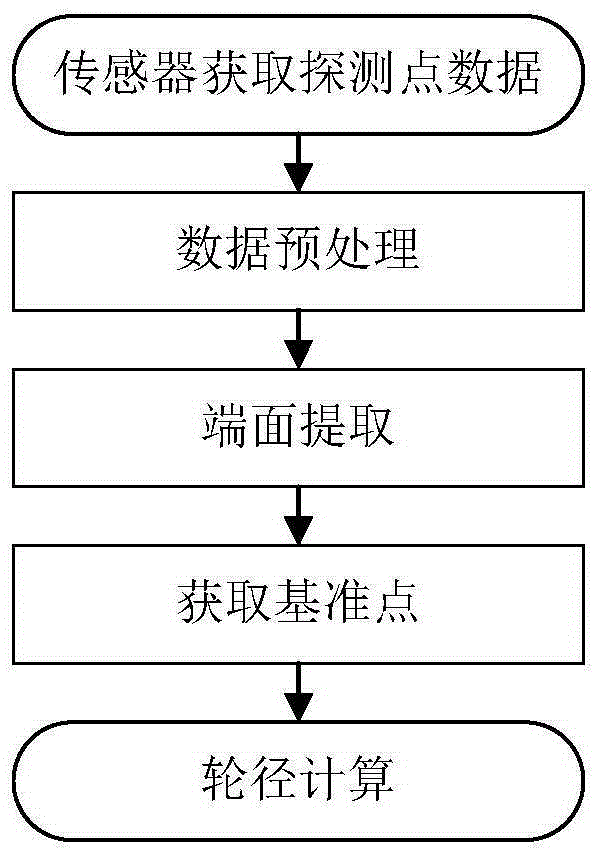

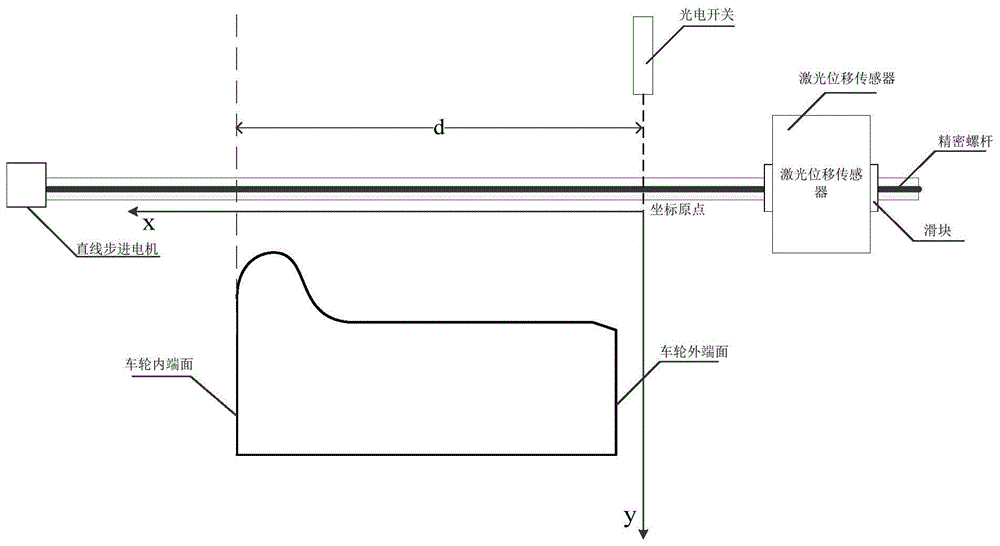

Online detection method for diameters of wheels of urban rail vehicle based on laser displacement sensors

InactiveCN105235713AGuaranteed operational safetyImprove detection efficiencyWheel-rims surveying/measuringContact typeEngineering

The invention discloses an online detection method for the diameters of wheels of an urban rail vehicle based on laser displacement sensors. The online detection method comprises the following steps: sequentially arranging a first laser displacement sensor, a second laser displacement sensor and a third laser displacement sensor on the inner side of a rail along the movement direction of a vehicle; setting a fourth laser displacement sensor on the outer side of the rail to be symmetrical to the third laser displacement sensor; carrying out coordinate conversion on detection point coordinates obtained by simultaneously detecting the wheels by the four laser displacement sensors; fusing the detection data, subjected to the coordinate conversion, of the third laser displacement sensor and the fourth laser displacement sensor on the same coordinate system to obtain a complete tread contour line; extracting a right end face of a tread according to the data subjected to the coordinate conversion and determining a transverse coordinate of the right end face of the tread; and after carrying out segmentation fitting on a tread curve, extracting tread standard point coordinates measured by the first laser displacement sensor, the second laser displacement sensor and the third laser displacement sensor respectively according to the transverse coordinate value of the right end face of the tread and obtaining the diameters of the wheels. According to the online detection method, structure arrangement is convenient, a system is stable and a measurement principle is simple; and high-precision online non-contact type measurement can be carried out.

Owner:NANJING UNIV OF SCI & TECH

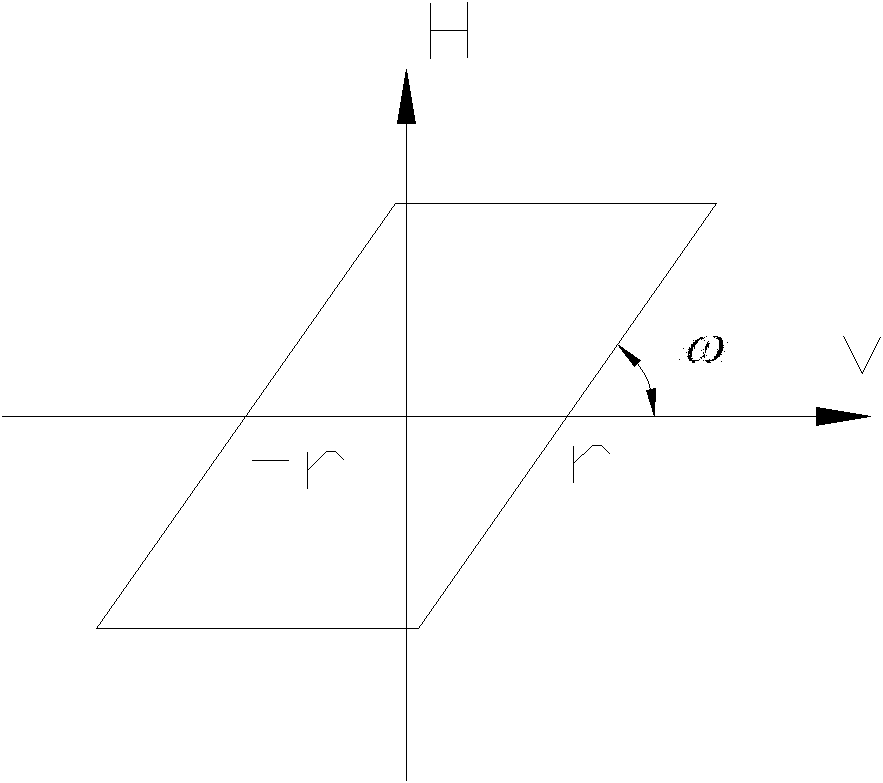

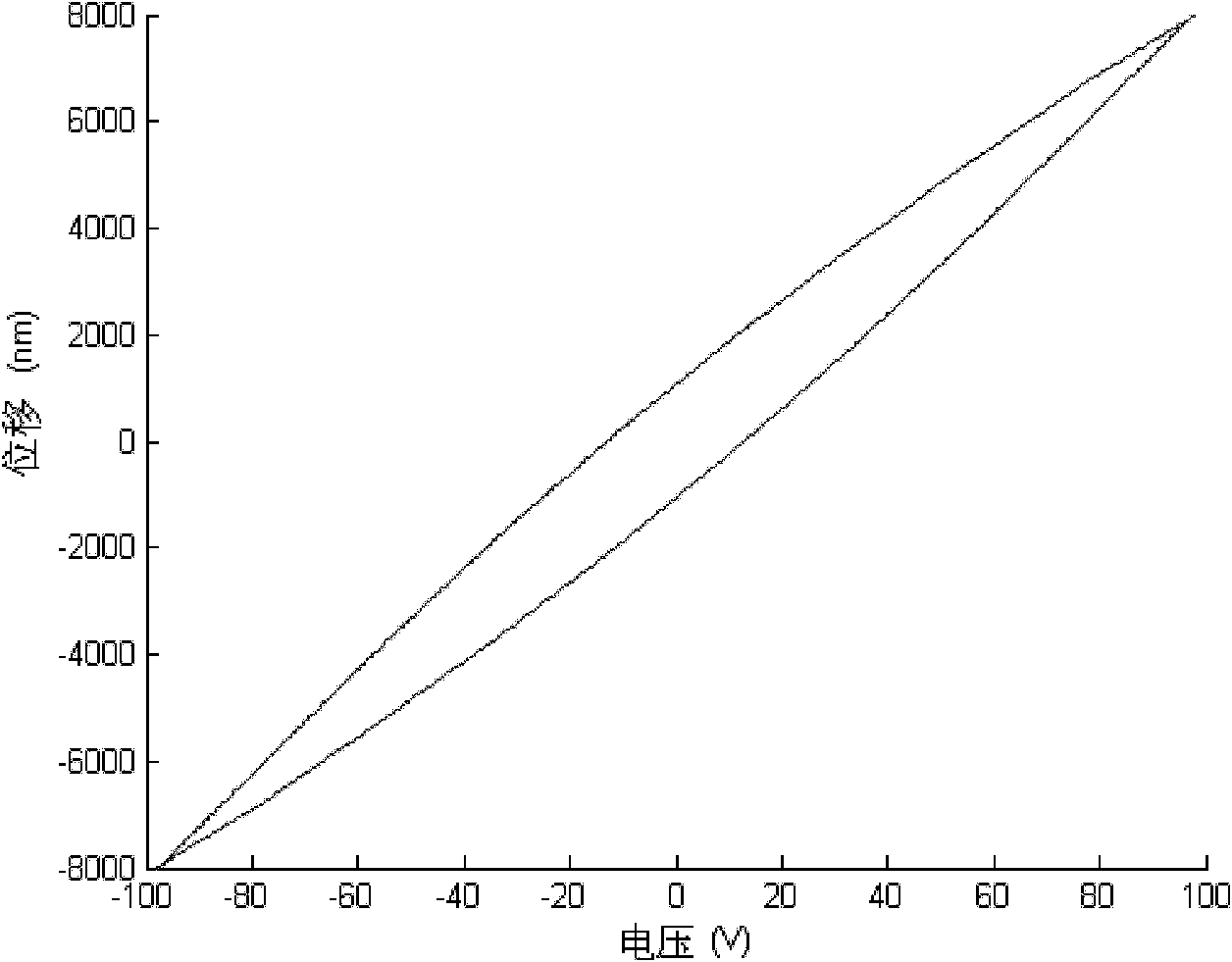

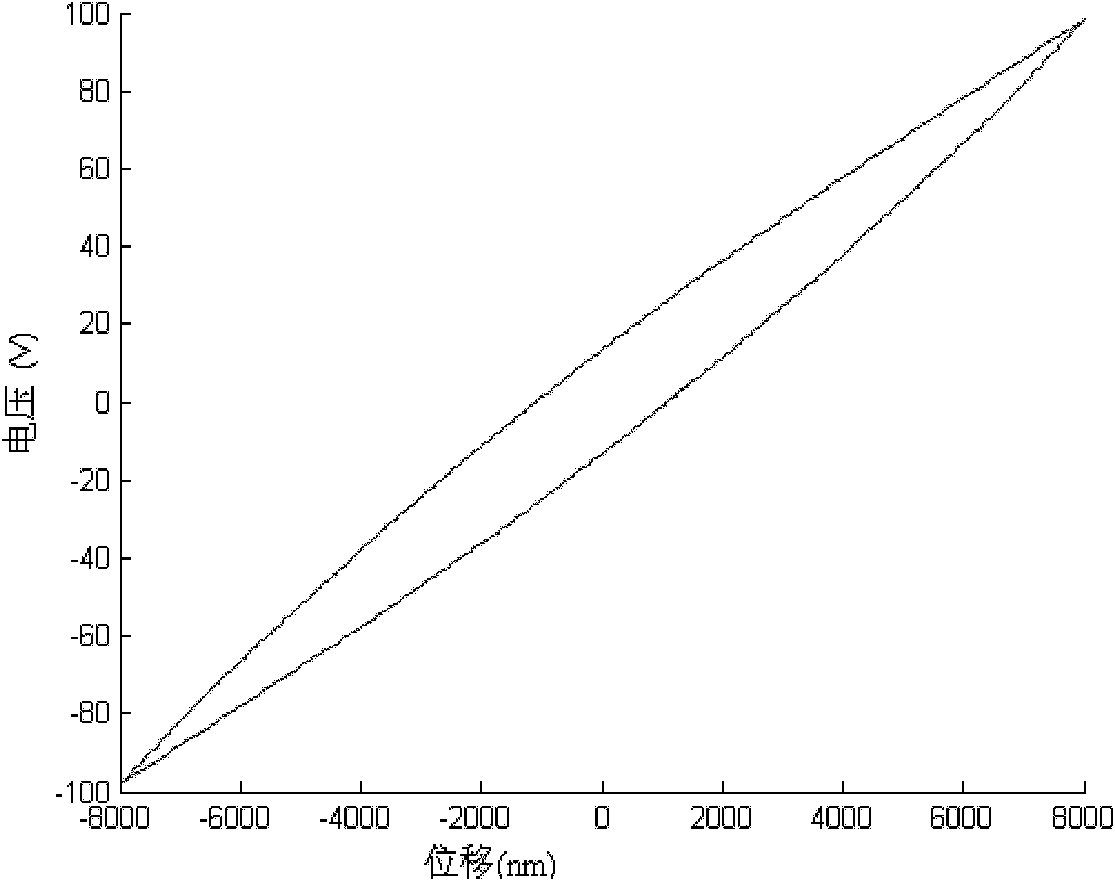

Model-based hysteresis feed-forward correction method of piezoelectric ceramic scanner

InactiveCN102486477AReal shapeImprove versatilityScanning probe techniquesSpecial data processing applicationsHysteresisElectricity

The invention relates to a model-based hysteresis feed-forward correction method of a piezoelectric ceramic scanner. The method comprises the following steps that: a capacitive displacement transducer is used to measure response data of a piezoelectric ceramic scanner under a linear input voltage; a mathematical model is established for hysteresis of the piezoelectric ceramic scanner; according to the response data obtained by the measurement, a mathematical model parameter is identified, and on the basis of the mathematical model parameter, a parameter of an inverse model is solved so as to establish the inverse model; and an output of the inverse model is used an input of the piezoelectric ceramic scanner as well as linear processing is carried out on the piezoelectric ceramic scanner, so that hysteresis feed-forward correction of the piezoelectric ceramic scanner is completed. According to the method provide in the invention, analytical inverse solution is obtained; and morphology of a scanning sample can be reflected really; and moreover, the method has advantages of good generality and high precision; therefore, the method has an important significance.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

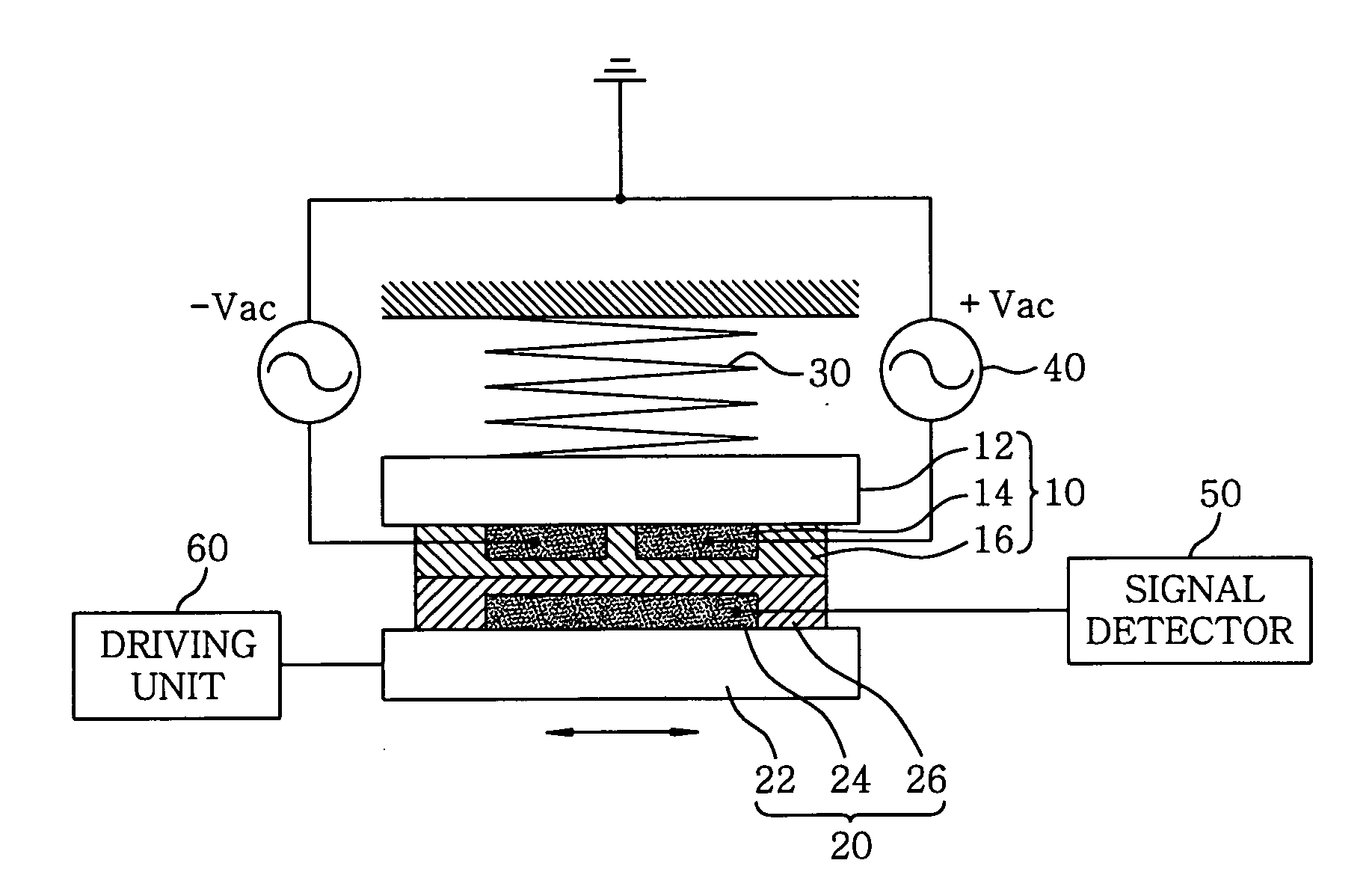

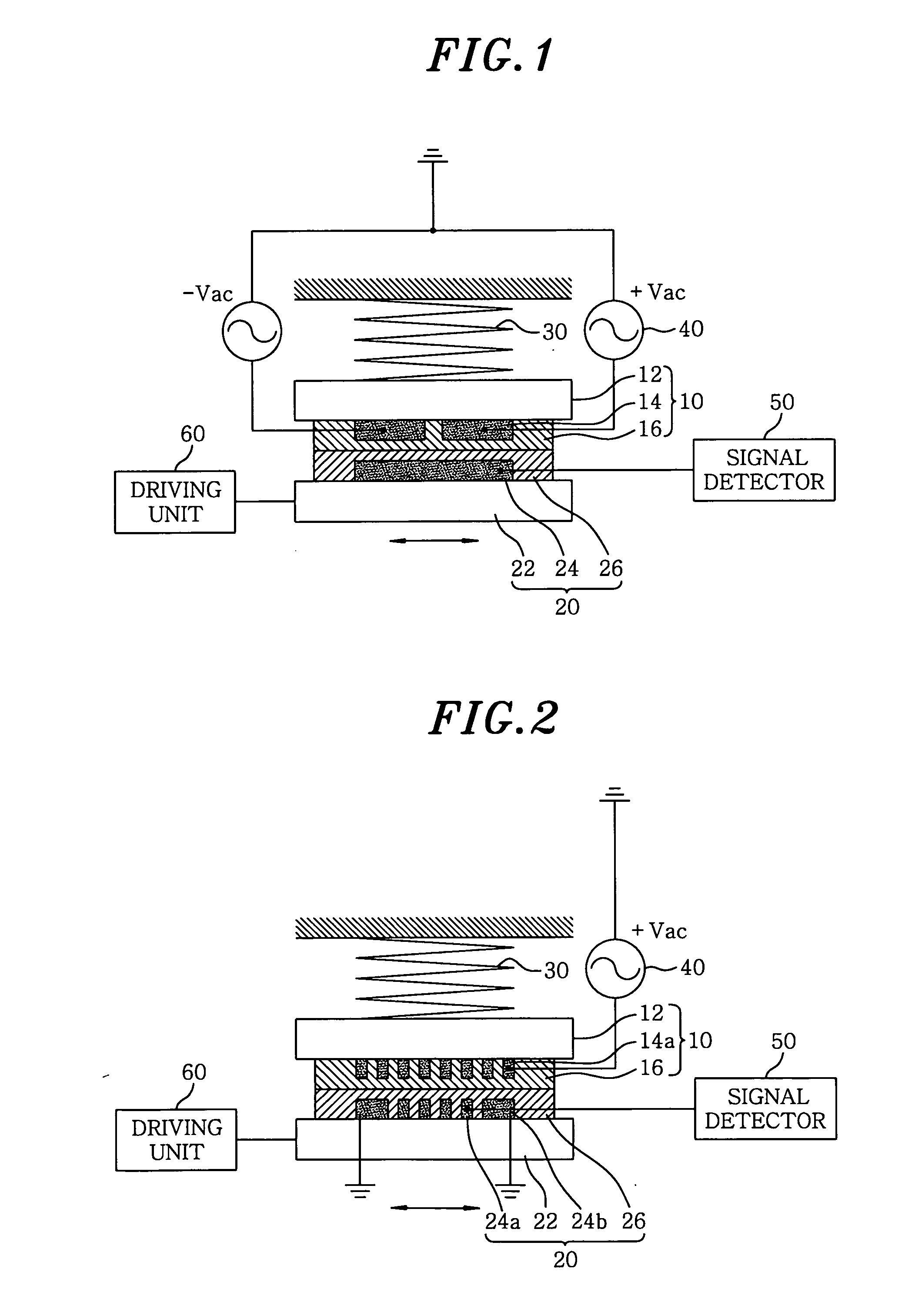

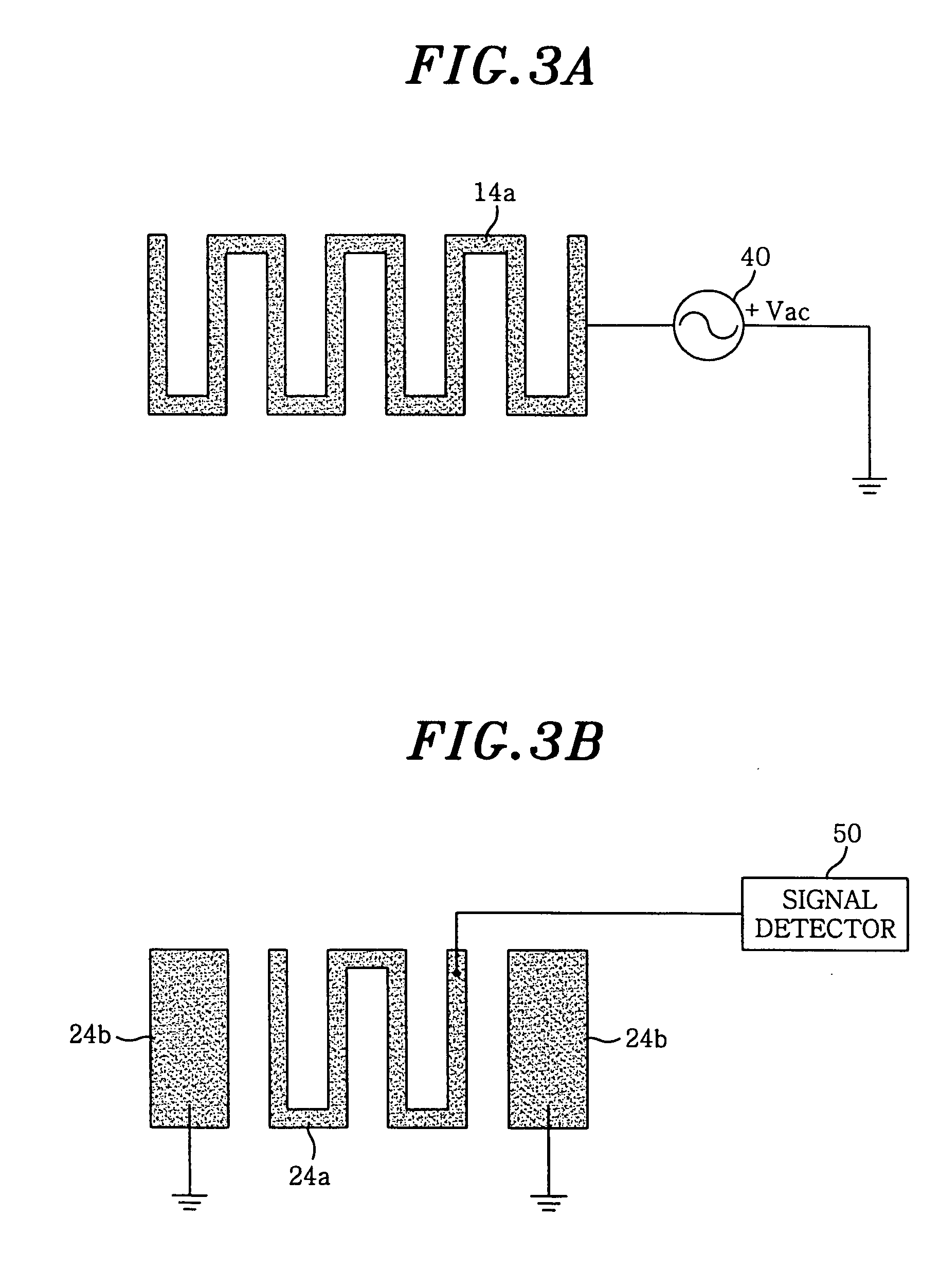

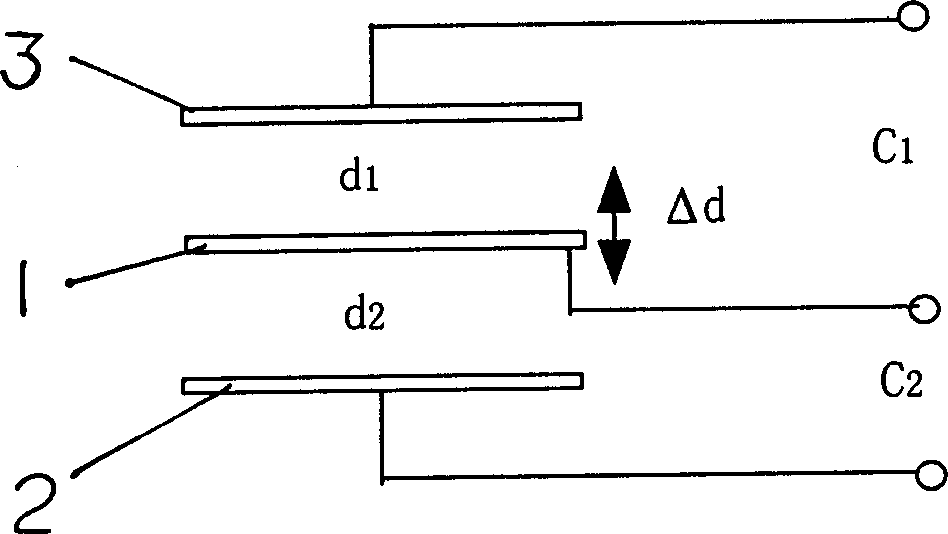

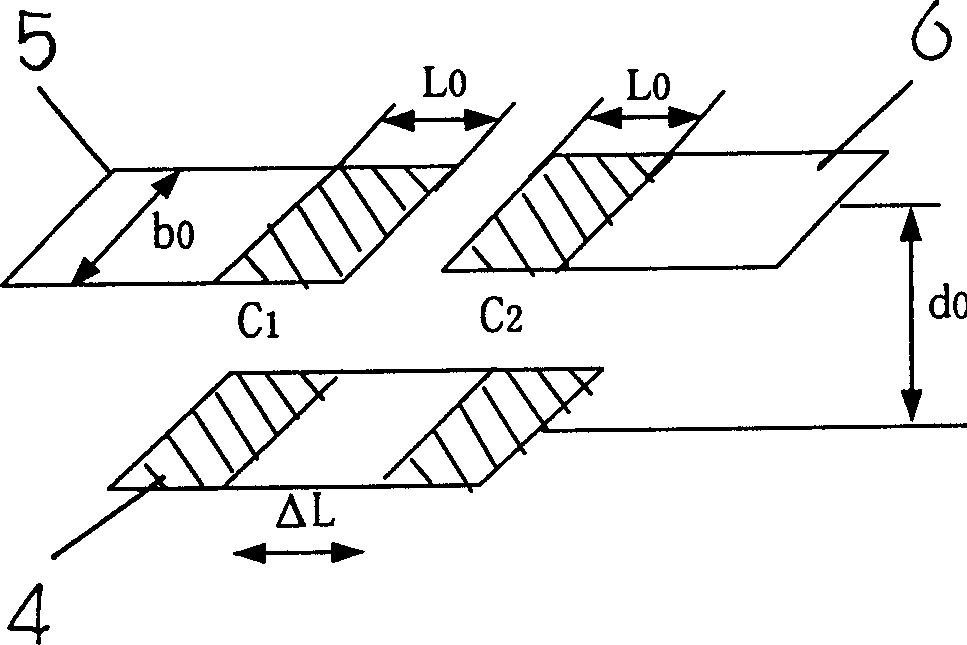

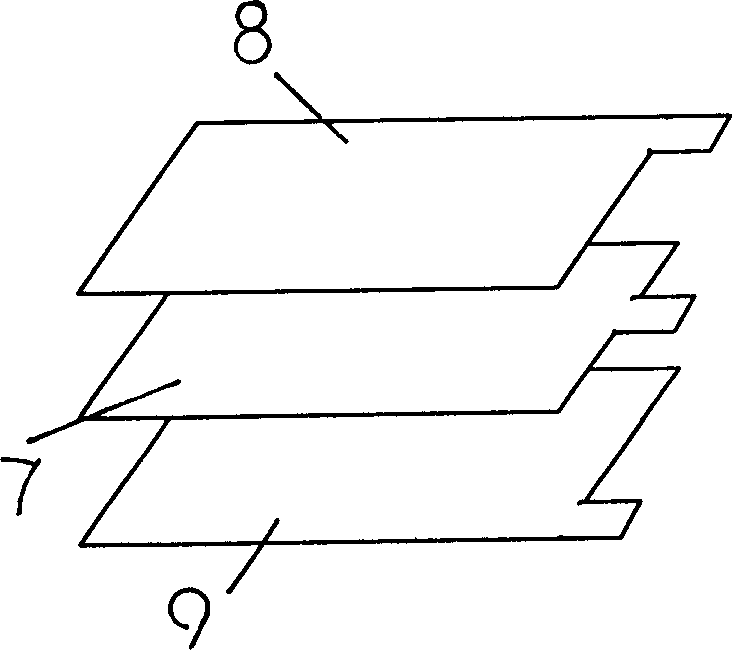

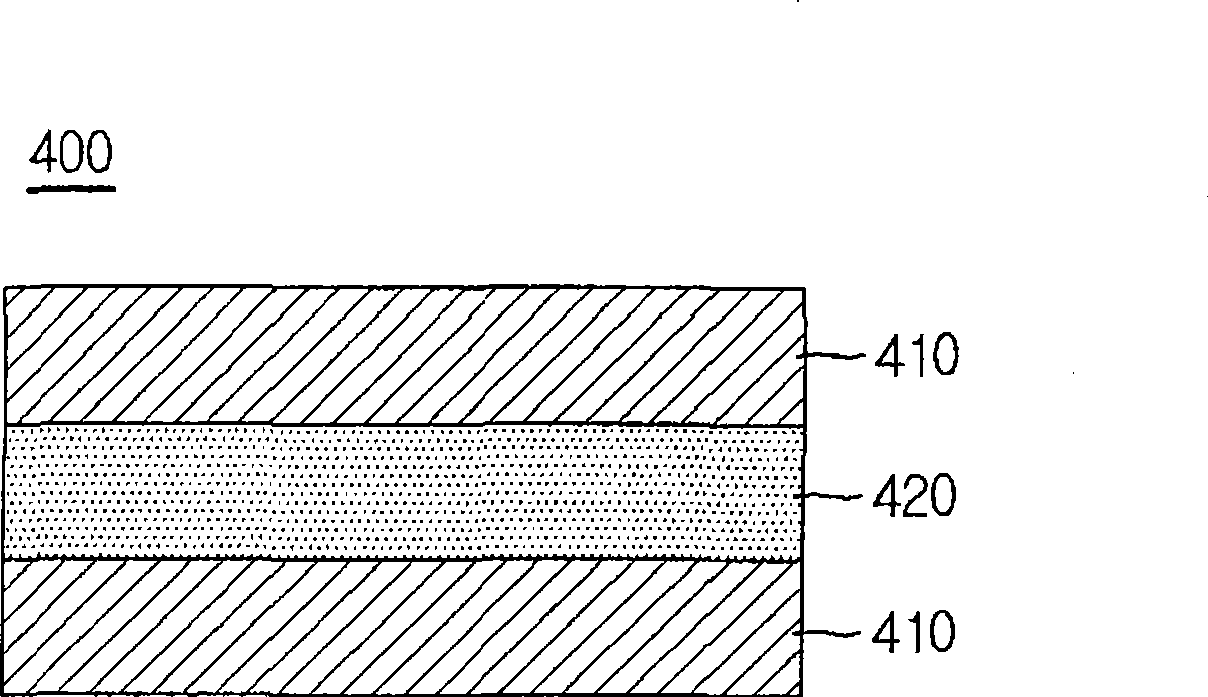

Contact-type electric capacitive displacement sensor

InactiveUS20070034013A1Reduce installation errorsSave installation spaceForce measurementUsing electrical meansElectrical conductorContact type

A contact-type electric capacitive displacement sensor includes a stationary element having a stationary plate, a stationary conductive pattern formed on the stationary plate and an insulation film coated on the stationary plate and a displaceable element having a displaceable plate, a displaceable conductive pattern formed on the displaceable plate and an insulation film coated on the displaceable plate. The stationary and the displaceable conductive patterns have a cyclic pattern of conductor to thereby produce a variation of capacitance therebetween when moving relative to each other.

Owner:MOON WONKYU

Active damping positioning device for dynamic gravity meter

ActiveCN104216024ASimple organizationLow priceGravitational wave measurementProportion integration differentiationGyroscope

The invention discloses an active damping positioning device of a dynamic gravity meter. The device at least comprises a damping coil, a PID (Proportion Integration Differentiation) controller and a shock insulation mechanism; an annular positioning groove is arranged in the bottom part of a tubular mass block; the damping coil is fixed into the positioning groove and positioned at one side of a detecting coil; the PID controller is positioned in the periphery of a gravity meter housing; the PID controller is respectively connected with a capacitive displacement sensor and the damping coil through communication lines; the shock insulation mechanism comprises a gyroscope stabilizing platform, a first super-long spring, a second super-long spring and a base frame; the gravity meter housing is fixedly mounted on the gyroscope stabilizing platform and positioned in the base frame; the upper surface of the gyroscope stabilizing platform is flexibly connected with the top part of the base frame through the first super-long spring and the second super-long spring. With the adoption of the device, a large damping coefficient can be obtained, thus a plurality of problems caused by air damping or liquid damping of the traditional dynamic gravity meter can be solved, the measuring precision of the dynamic gravity meter is improved, and the long-term stability is also improved.

Owner:INST OF GEODESY & GEOPHYSICS CHINESE ACADEMY OF SCI

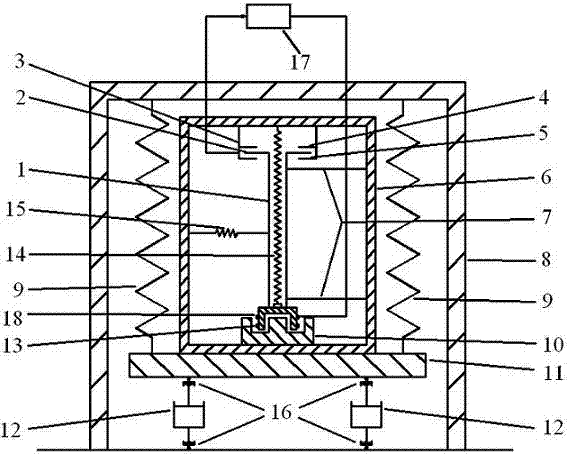

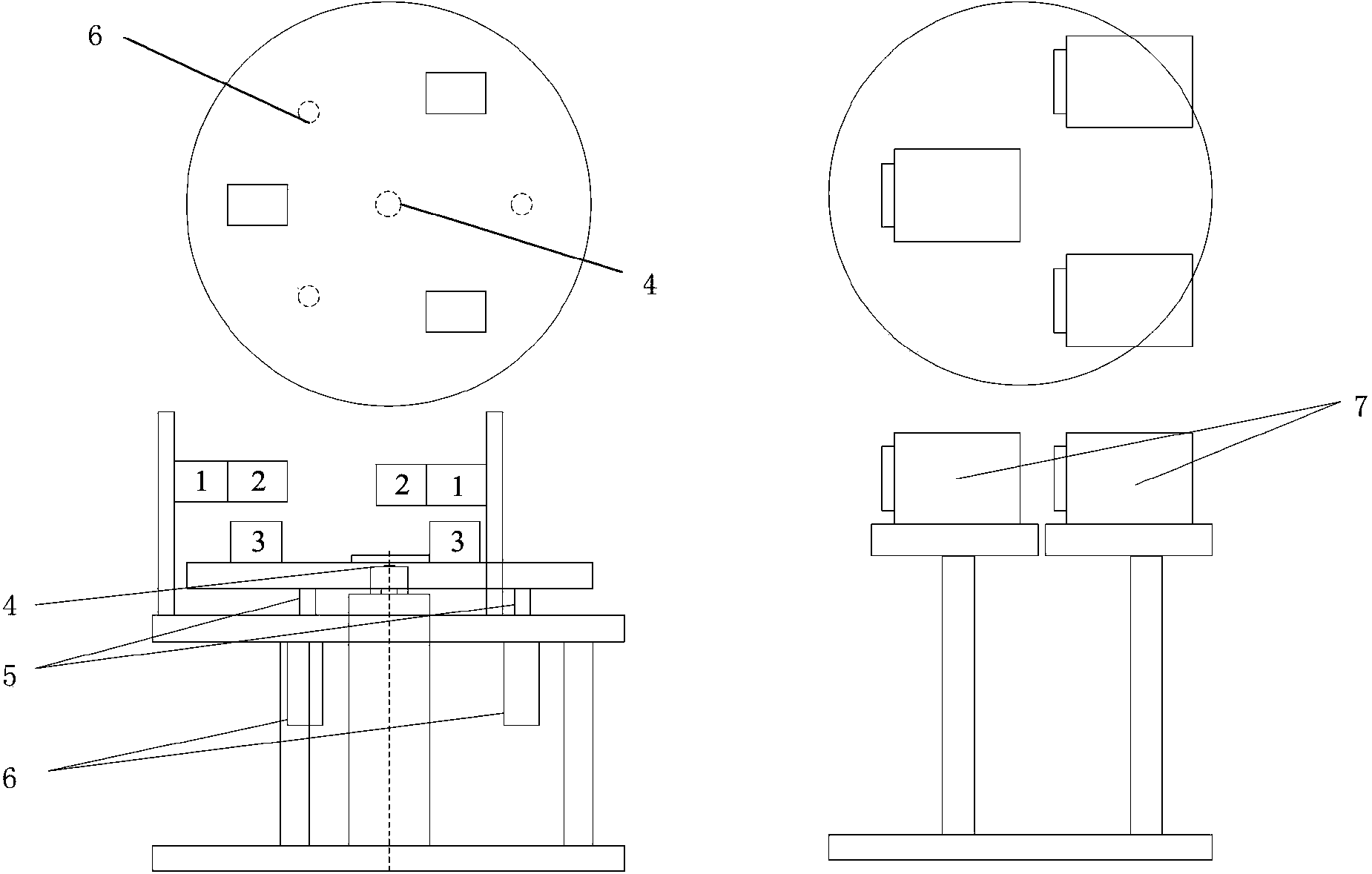

MDOF (multi-degree of freedom) differential capacitance displacement sensor calibration device

ActiveCN104654997AReduce the impactRealize multi-degree-of-freedom lattice value coefficient calibrationUsing electrical meansTemperature controlImage resolution

The invention discloses an MDOF (multi-degree of freedom) differential capacitance displacement sensor calibration device. The device comprises a differential capacitance displacement sensing module, a laser interferometry ranging module, a temperature control module and a data processing module, wherein the differential capacitance displacement sensing module comprises a mechanical sensitive probe and a differential capacitance sensing circuit; the mechanical sensitive probe comprises a movable polar plate, an MDOF micrometric displacement table, fixed polar plates and an insulating base; the laser interferometry ranging module comprises a laser, a shielding frame and N interference fringe units distributed in the translation DOF direction; the temperature control module is used for shielding disturbance of outside environment temperature; the laser interferometry ranging module measures displacement of the movable polar plate relative to the fixed polar plates, the differential capacitance displacement sensing module outputs a voltage signal, and a data acquisition and processing system processes data to obtain a scale coefficient when the movable polar plate moves to output voltage of the differential capacitance displacement sensing module in a translation DOF manner, so that the resolution level of the high-precision differential capacitance displacement sensing module with a micron-dimension range is accurately evaluated.

Owner:INST OF GEODESY & GEOPHYSICS CHINESE ACADEMY OF SCI

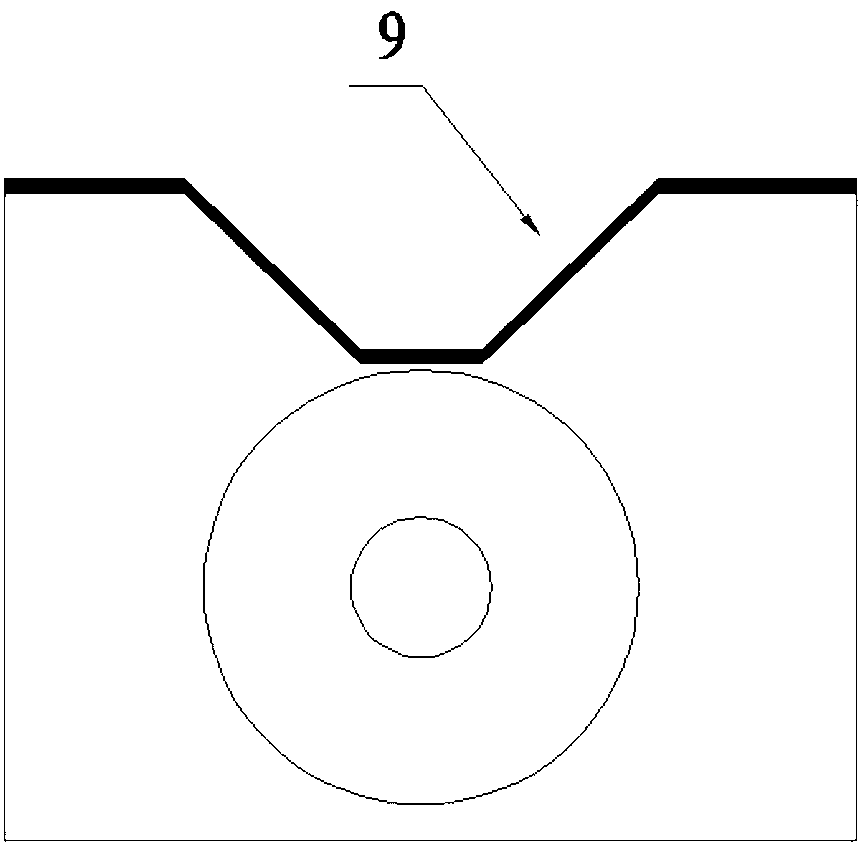

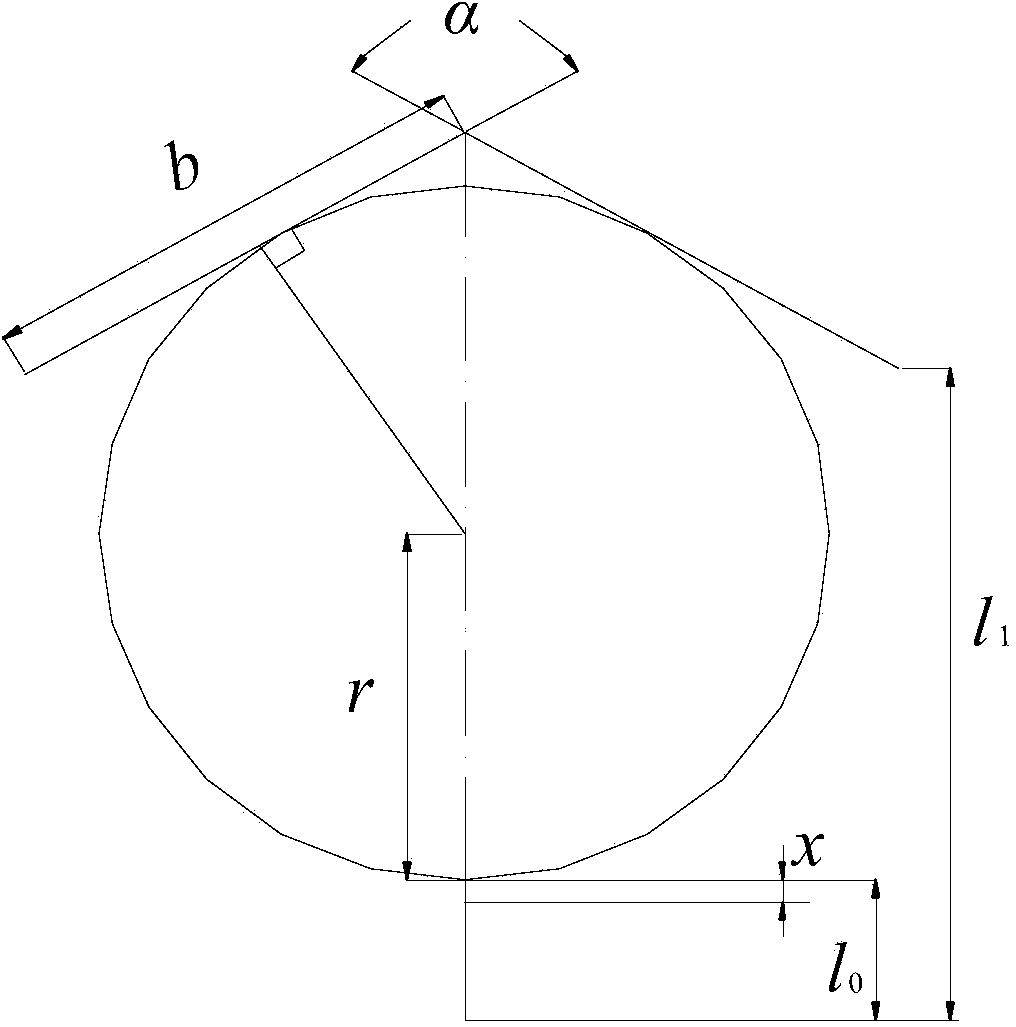

Precision measurement device for tree walk increment

ActiveCN104006784ALow surface requirementsLarge measuring rangeMeasurement devicesMeasurement deviceDiagonal

The invention discloses a precision measurement device for tree walk increment. The device can measure the diameter of a tree in real time and reduce errors. The measurement device comprises a support, a magnetic railing ruler, a sensor clamp, a micron-level displacement sensor and a signal transmission processing circuit. According to the support, the diameter is measured through a three-point method, and two parts are assembled to form a V-shaped body with an included angle ranging from 90 degrees to 150 degrees. With the combination of micron-level displacement sensor arranged at the coinciding position of diagonals of the V-shaped angle, measurement of the tree walk is achieved. The micron-level displacement sensor and the magnetic railing ruler conduct remote data transmission with an upper computer through the signal transmission processing circuit. By means of the precision measurement device for tree walk increment, the tree walk and the micro-change amount of the tree walk can be stably measured at the same time and in real time, and the measurement errors are reduced. The device applies small pressure on plants, and the device is simple in structure, convenient to use, light in weight, small in size and easy to carry.

Owner:CHINA JILIANG UNIV

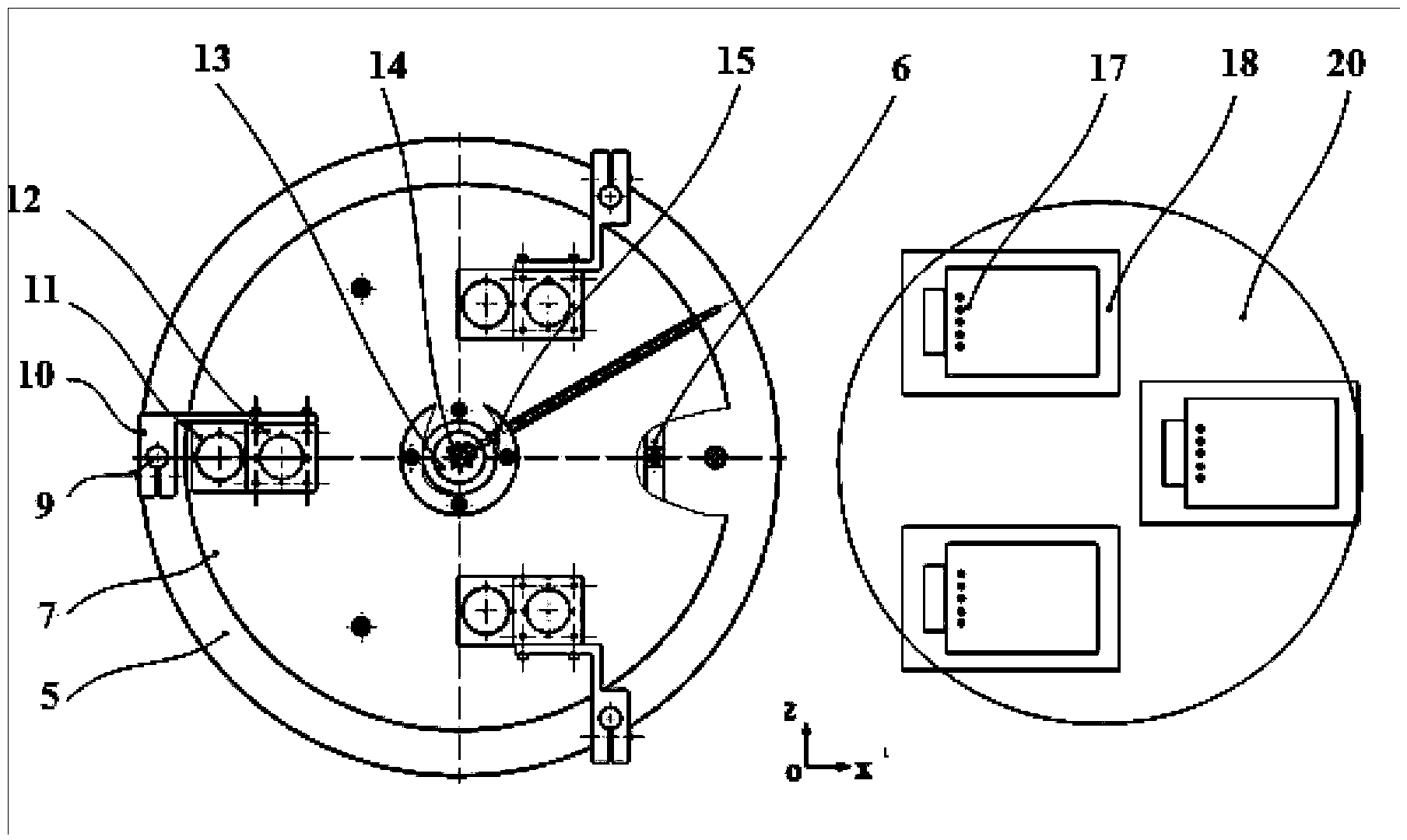

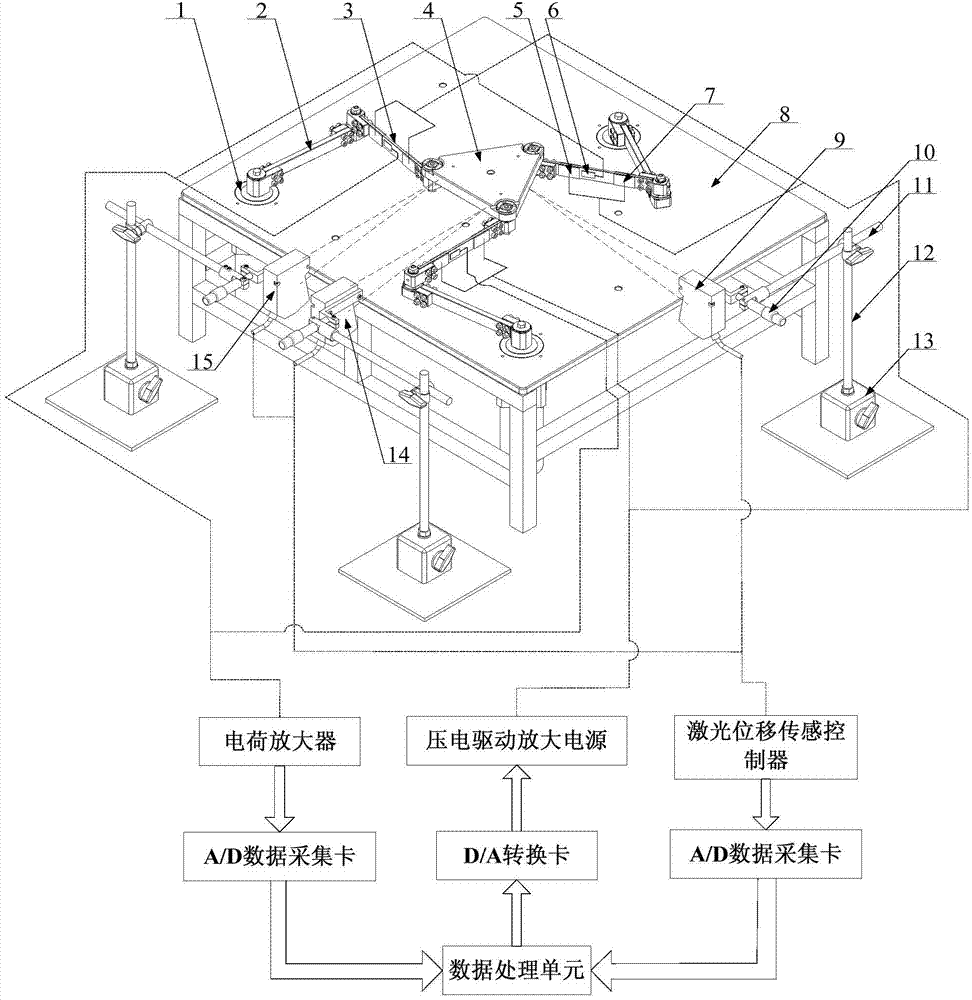

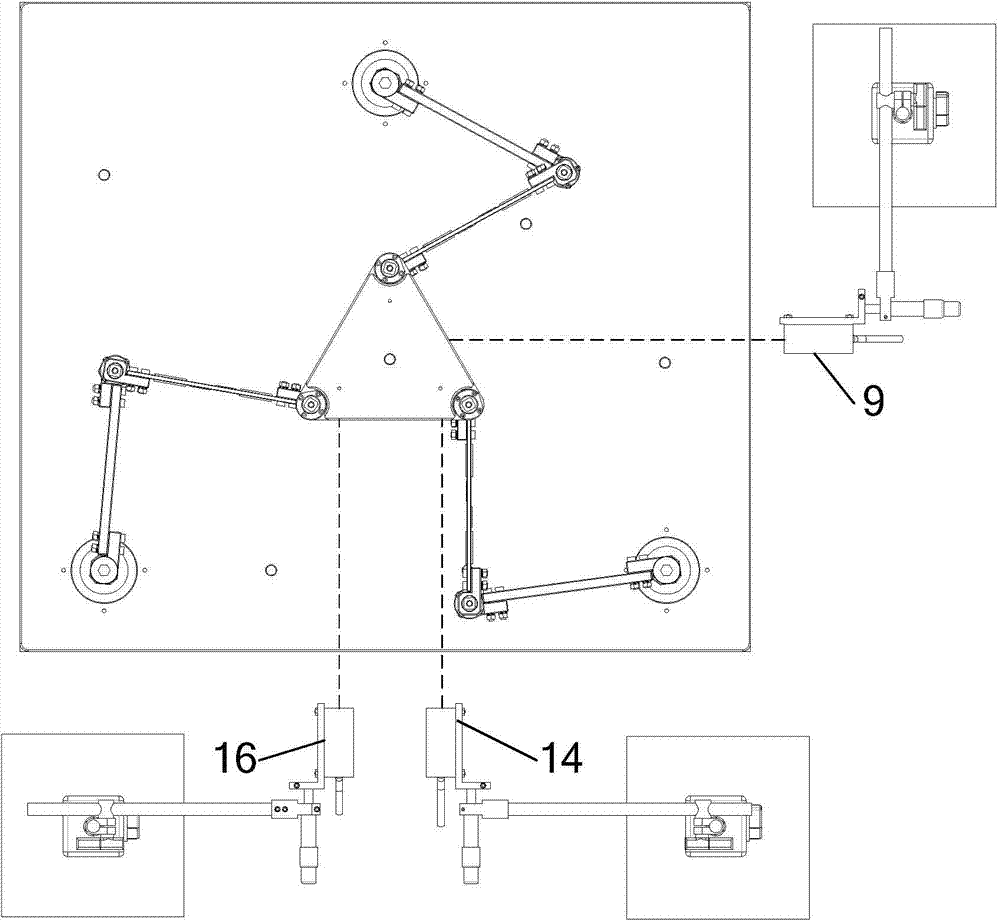

Laser displacement sensor based parallel platform vibration detection control device and method

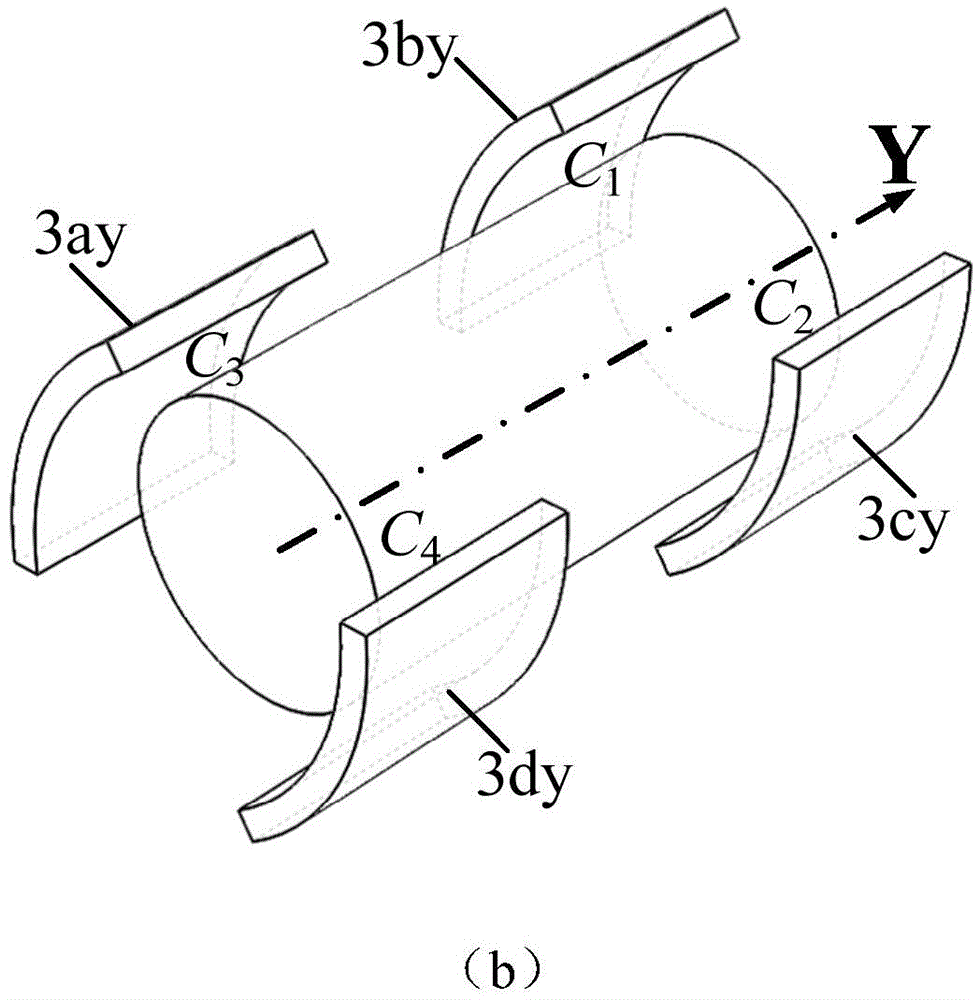

ActiveCN104760039ANo additional mass added to the structureNo added massProgramme-controlled manipulatorSubsonic/sonic/ultrasonic wave measurementElectricityVibration control

The invention discloses a laser displacement sensor based parallel platform vibration detection control device and method. The device comprises a parallel platform body unit, a vibration detection unit and a vibration control unit. The parallel platform body unit comprises a movable platform, a static platform and three parallel branches. Each parallel branch comprises a motor, a driving rod and a driven flexible rod which are connected successively. A plurality of piezoelectric ceramic piece drivers are pasted on the driven flexible rods. Three laser detection heads are arranged on the periphery of the static platform to be used for detecting the translation displacement and the rotation angle of the movable platform in the horizontal direction. The motors drive the driving rods and the driven flexible rods to locate the movable platform behind the target position, the movable platform has residual vibration, the laser detection head detects vibration signals of the movable platform, the vibration control unit applies the control quantity to the piezoelectric ceramic piece drivers, and accordingly, driving control over the residual vibration of the parallel platforms is achieved. The device and the method have the advantages of being high in measurement accuracy and sampling frequency and quick in dynamic response.

Owner:SOUTH CHINA UNIV OF TECH

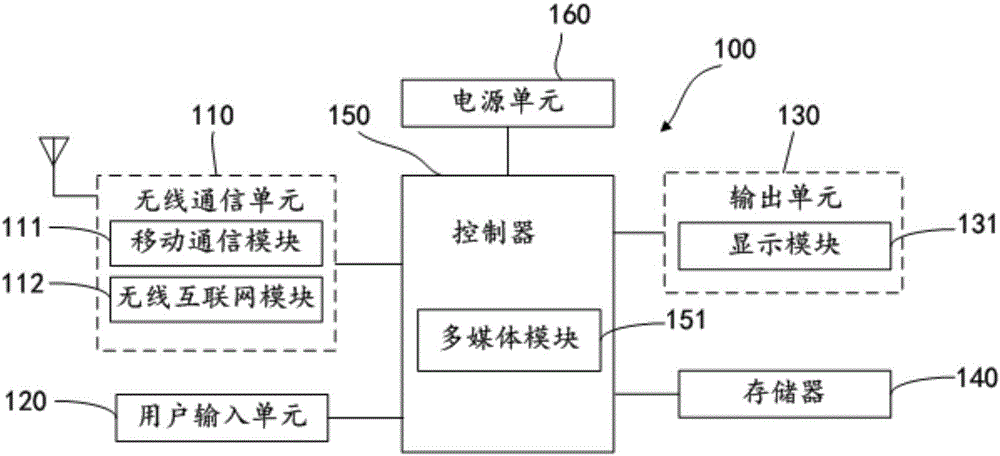

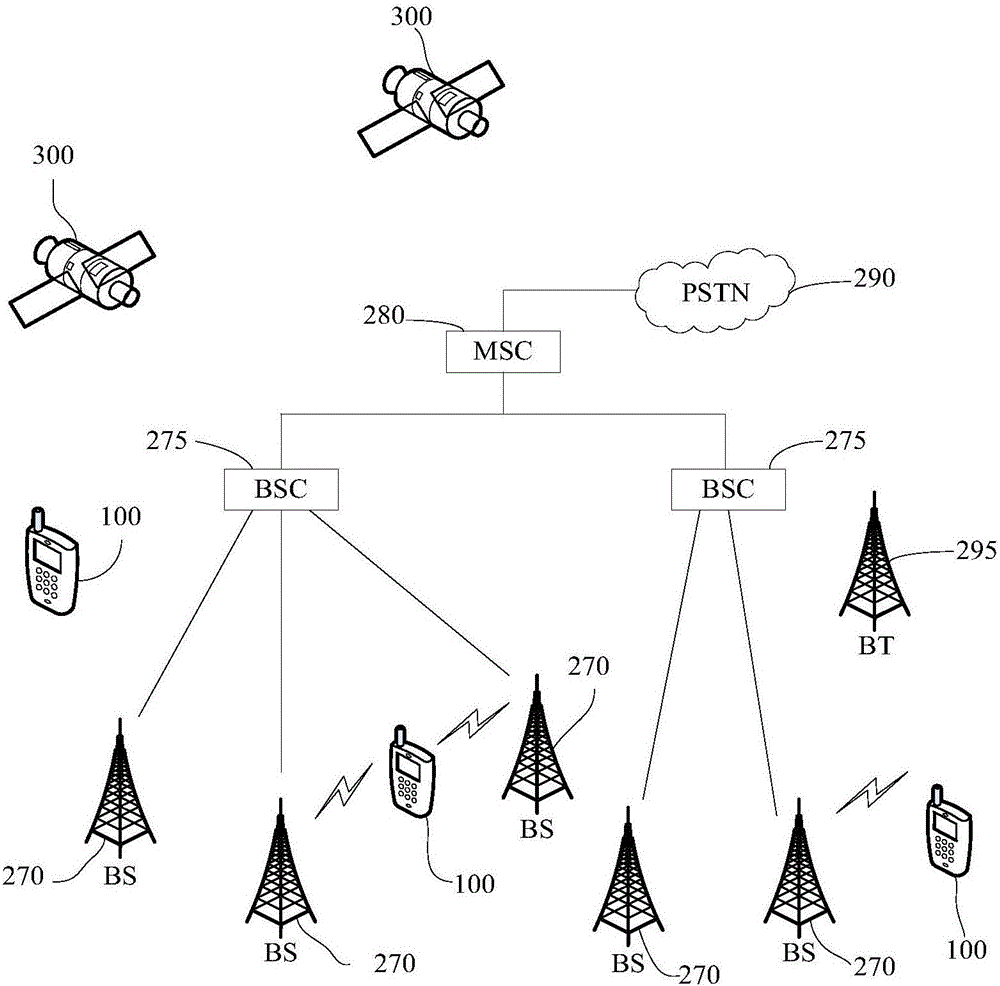

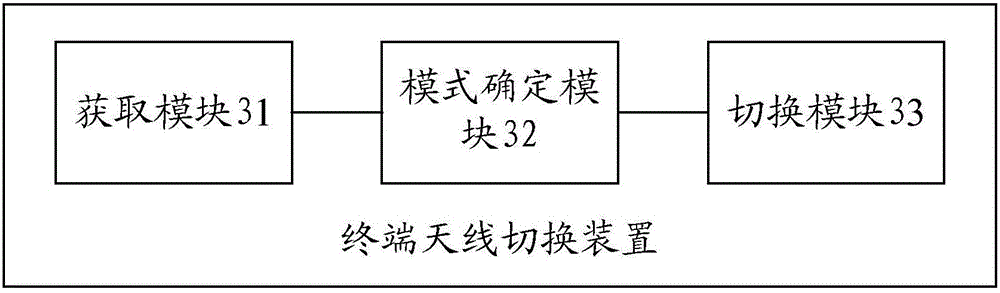

Terminal antenna switching device and terminal antenna switching method

InactiveCN106385474AImprove user experienceRealize automatic switchingTelephone set constructionsComputer terminalEngineering

Owner:NUBIA TECHNOLOGY CO LTD

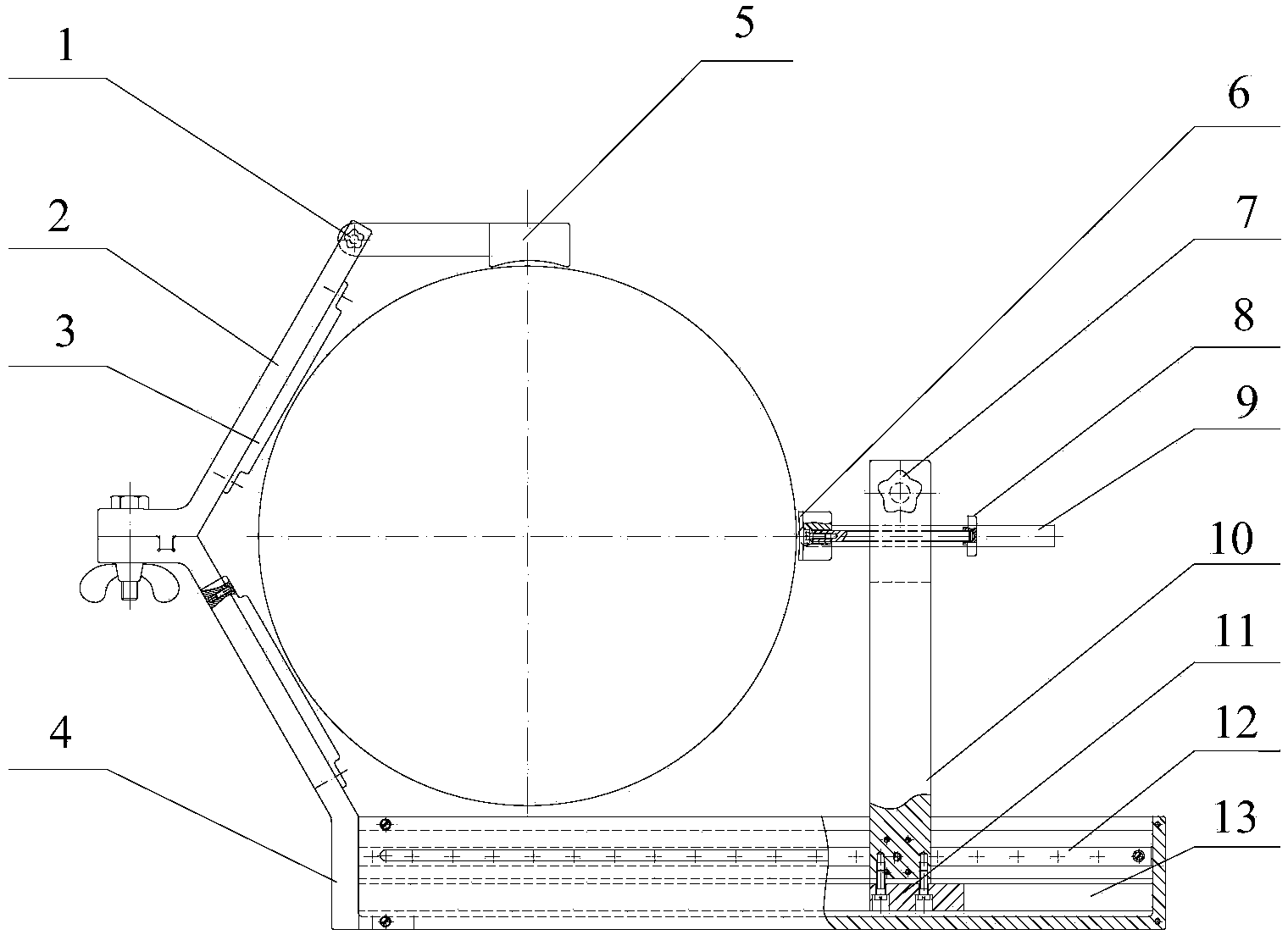

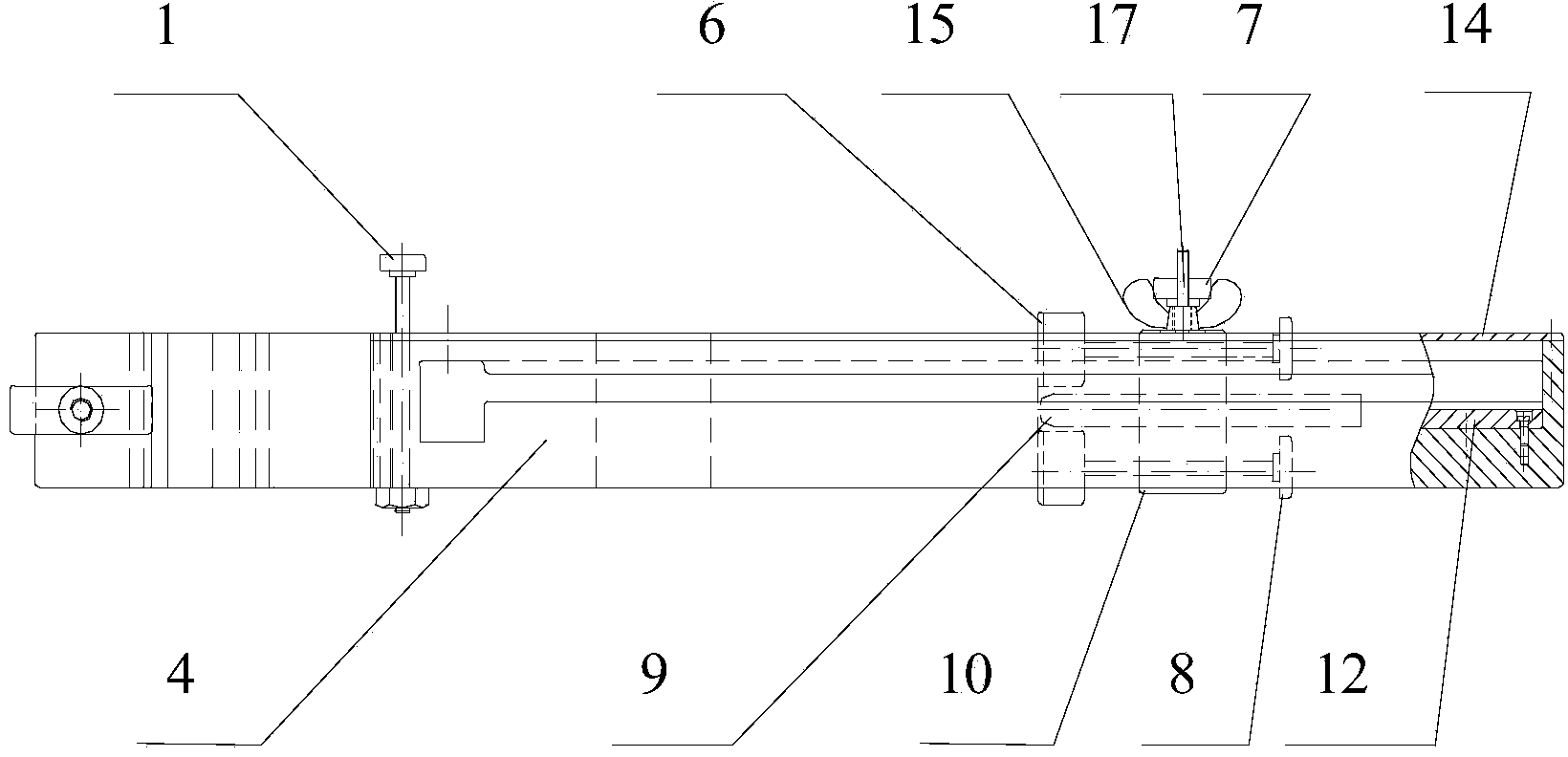

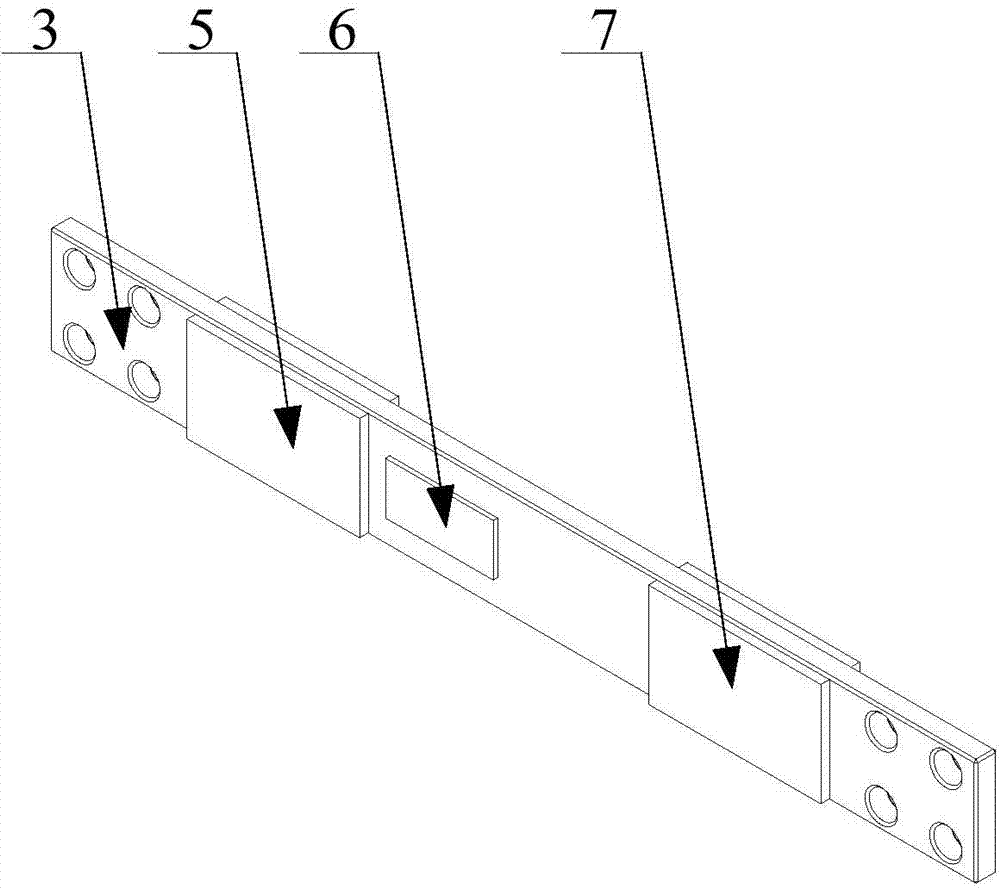

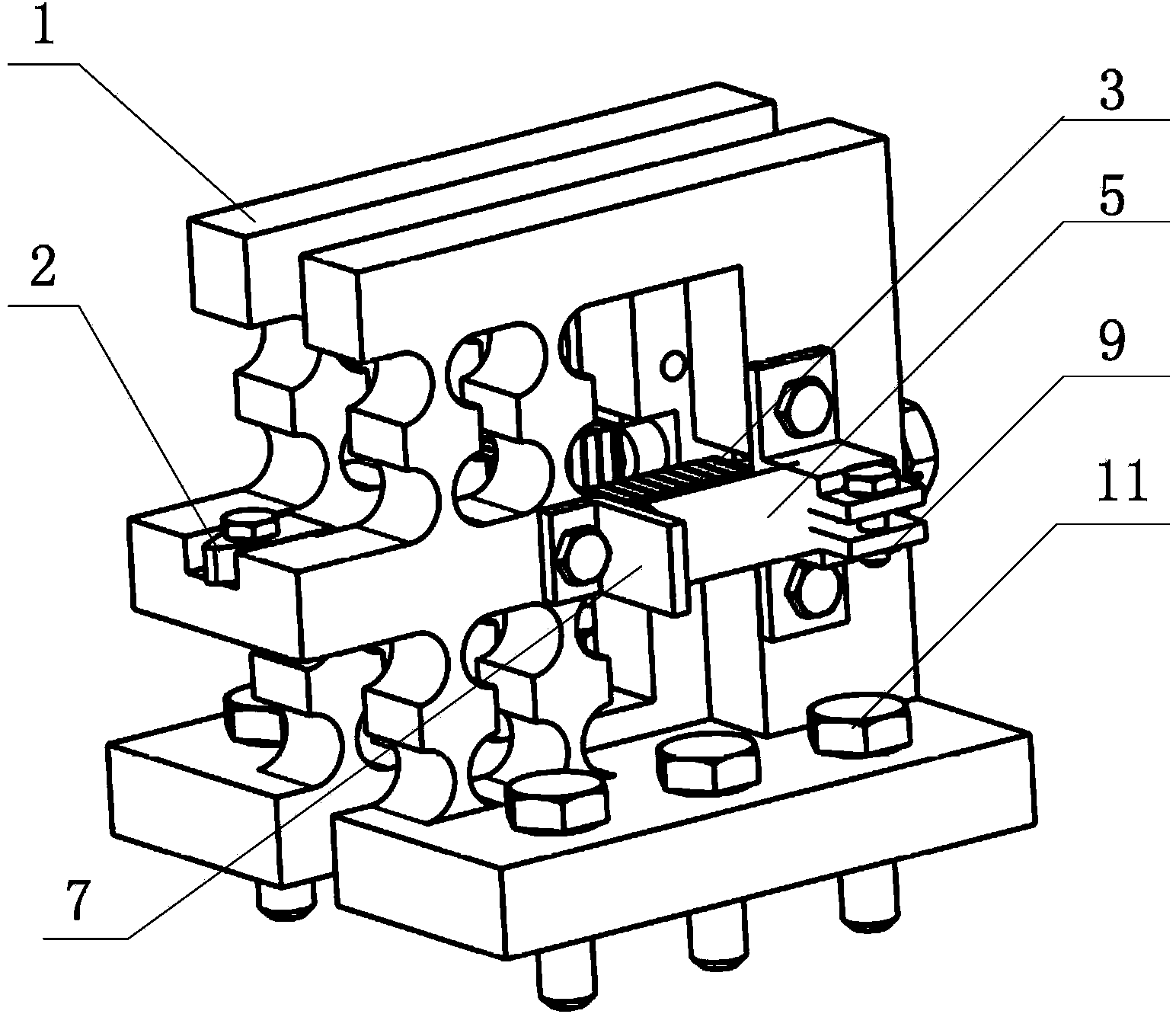

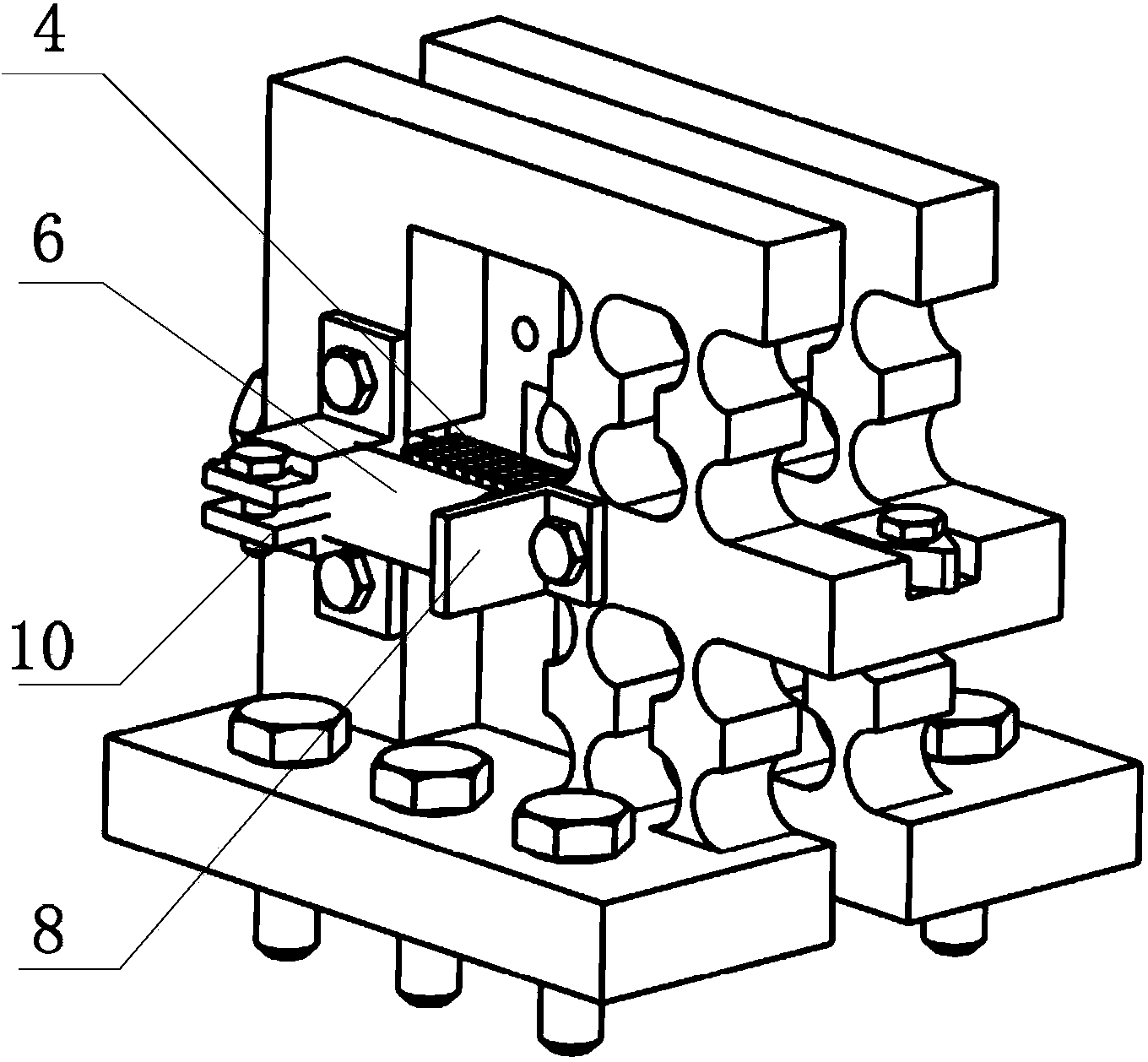

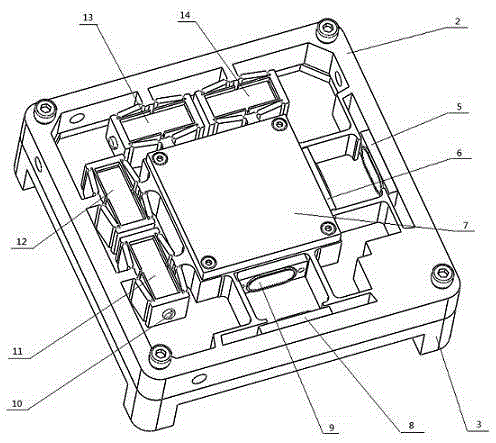

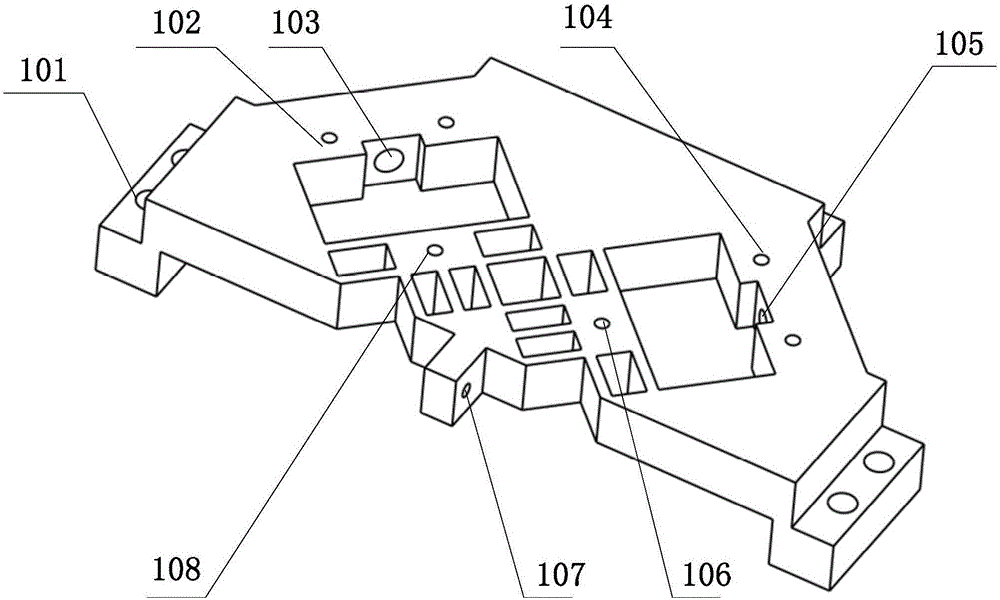

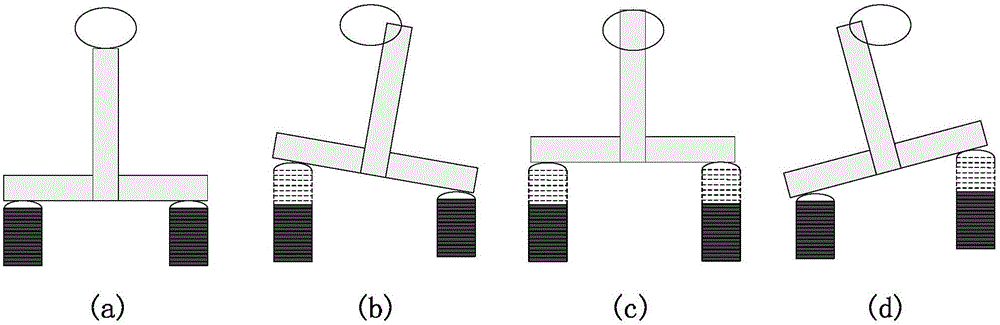

Hinge parallel type elliptical vibration cutting flexible device

ActiveCN103611947ALight in massEasy to realize high-frequency processingDriving apparatusOrbitMachine tool

The invention relates to a hinge parallel type elliptical vibration cutting flexible device and belongs to the technical fields of ultra-precision cutting and machining of complex optical parts hard to cut. A first piezoelectric stack and a second piezoelectric stack are respectively mounted in a first hole and a second hole of an integrated flexible hinge through pretightening screws. A first displacement measuring retaining plate and a second displacement measuring retaining plate are respectively fixedly connected with two displacement measuring retaining plate mounting holes of the integrated flexible hinge through fastening screws. A first capacitive displacement sensor and a second capacitive displacement sensor are respectively correspondingly mounted on a first displacement sensor clamp seat and a second displacement sensor clamp seat. A diamond cutter is fixedly connected with the groove at the front end of the integrated flexible hinge. The hinge parallel type elliptical vibration cutting flexible device has the advantages that the elliptical orbit of a diamond cutter point in a space can be achieved precisely, parameter adjusting range is large, the flexible device can be mounted on optional machine tools, and certain universality is achieved.

Owner:苏州迈智诺智能装备科技有限公司

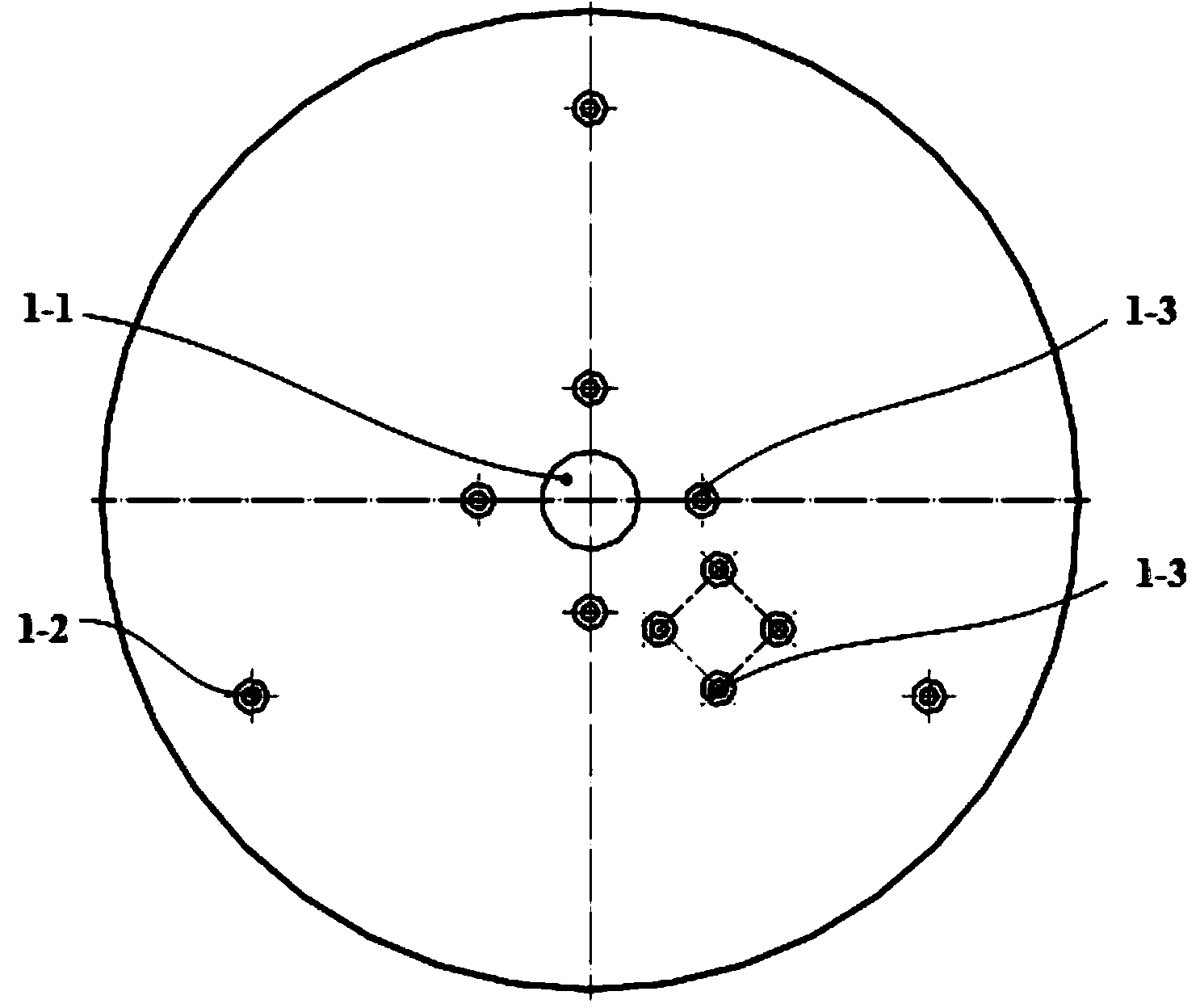

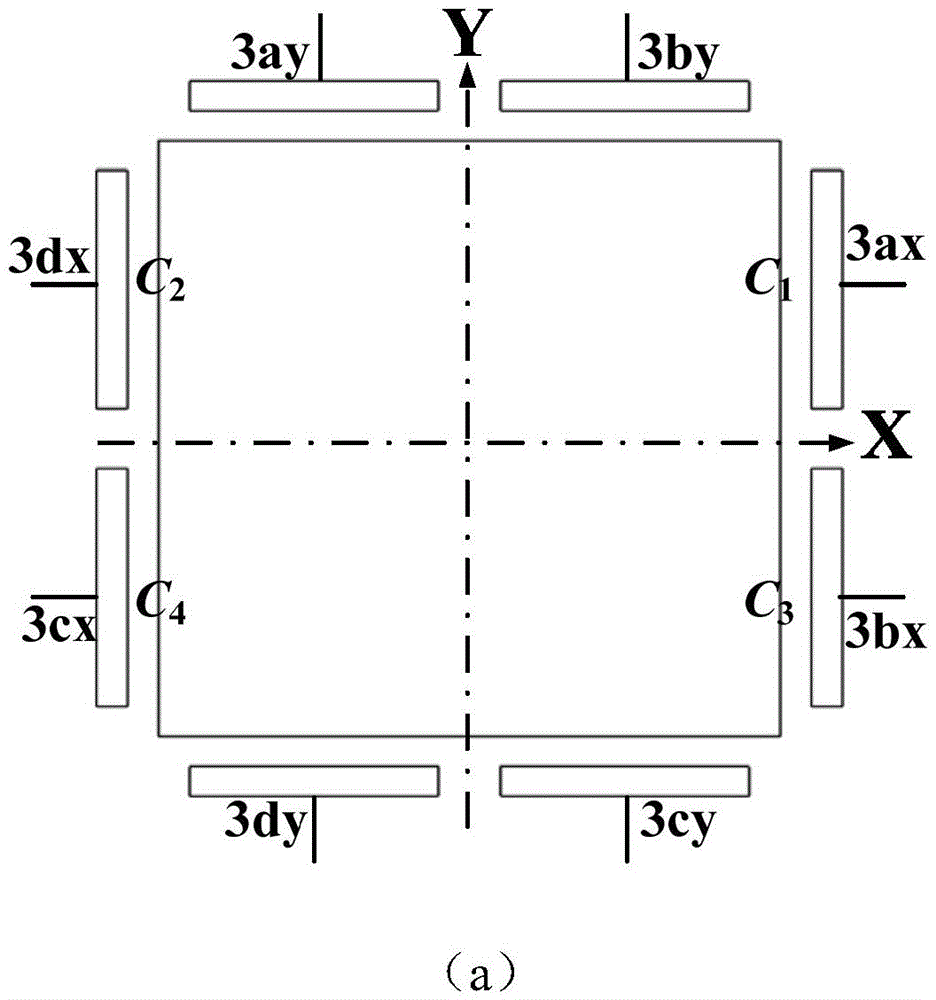

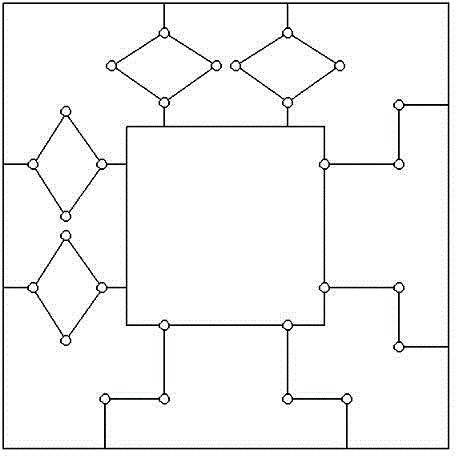

Multi-freedom degree capatitance displacement sensor

InactiveCN1651853ARealize measurementLow costUsing electrical meansConverting sensor output electrically/magneticallyTransducerEngineering

The present invention relates to a multi-freedom capacitance motion transducer. It is formed from movable plate and fixed plate, the movable plate is positioned in the centre, and is double-face plate; two fixed plates are respectively positioned at two sides of the movable plate, and one side relative to movable plate is single-face plate. It is characterized by that every electrode surface of the movable plate and two fixed plates is equipped with independently arranged four plate electrodes, all the plate electrodes are identical in form and size. Said invention also provides their position distributed mode. Said invention can be used in multi-freedom micrometion working table, and can obtain multi-freedom micromotion information.

Owner:HEFEI UNIV OF TECH

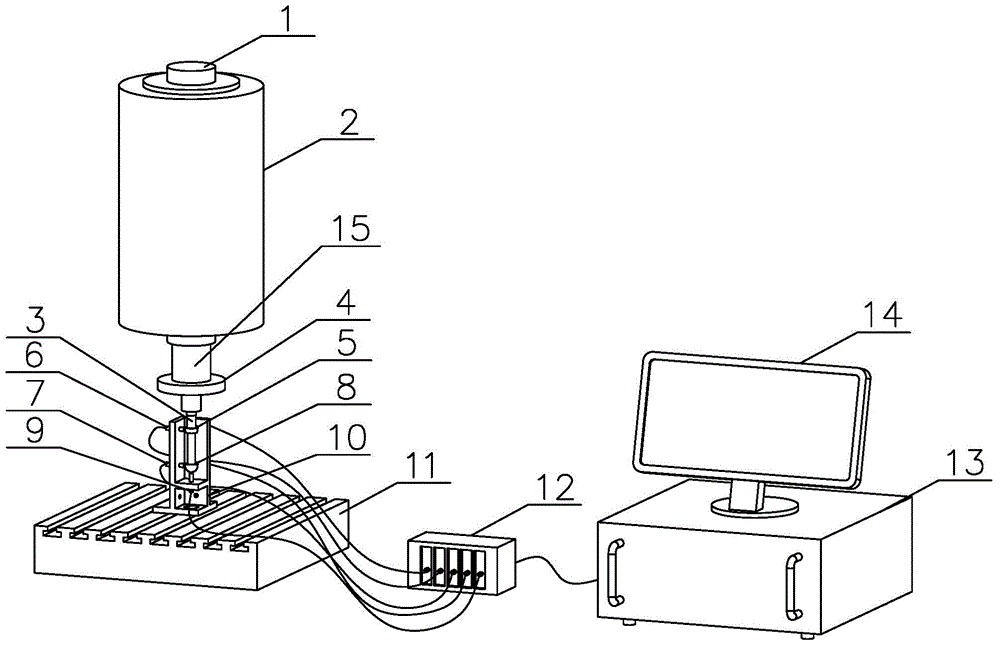

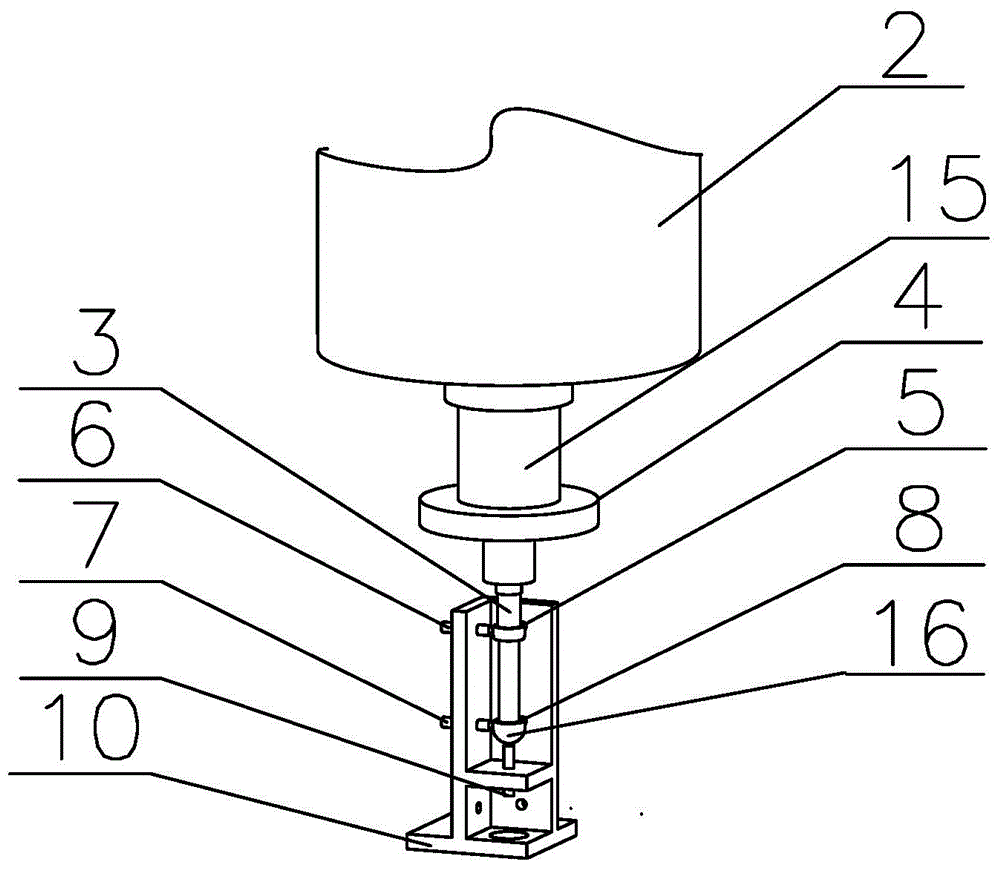

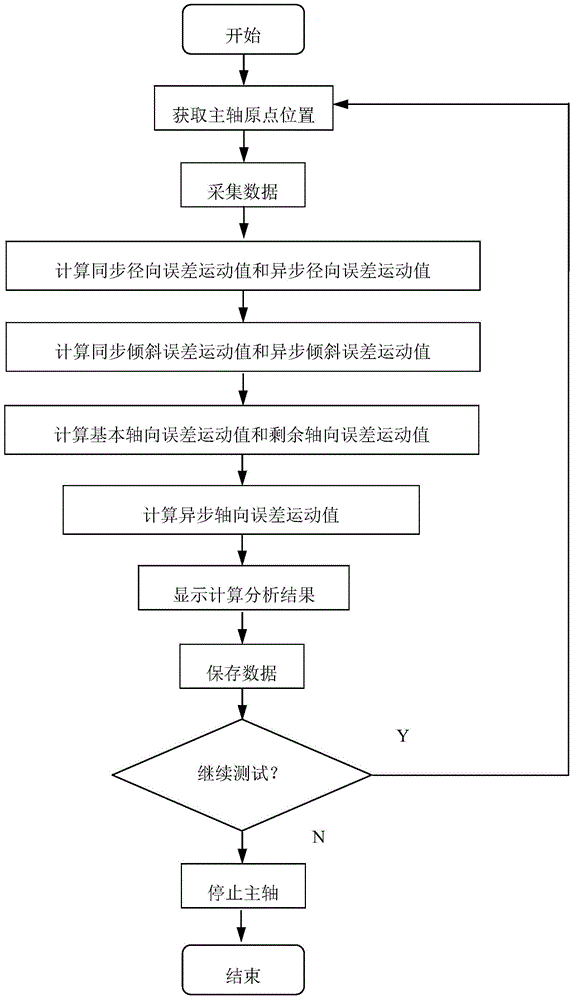

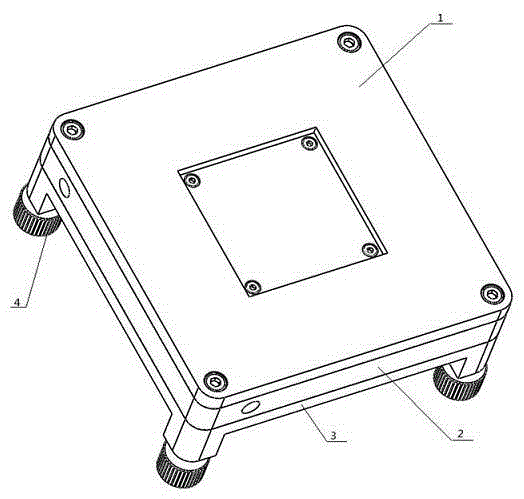

Testing system and testing method for dynamic rotation precision of main shaft

InactiveCN104482849AFlexible and simple system buildingRealize acquisitionUsing electrical meansSystem integrationData acquisition

The invention relates to a testing system and a testing method for dynamic rotation precision of a main shaft. The system adopts the scheme that a worktable is provided with a data acquisition mechanism which is connected with a rotary output shaft of the main shaft through a clamp, the data output end of the data acquisition mechanism is connected with an industrial personal computer through a sensor driving unit, and the main shaft is provided with a coder which is connected with the upper end of the rotary output shaft. The method comprises the following steps: preheating a to-be-tested shaft; acquiring and recording the initial position where data treatment is carried out on the to-be-tested shaft; collecting displacement data of a relative radial capacitive displacement sensor in the rotation process of the to-be-tested shaft and displacement data measured by an axial capacitive displacement sensor and storing the data; calculating a synchronous radial error motion value and an asynchronous radial error motion value; calculating a synchronous heeling error motion value and an asynchronous heeling error motion value; calculating a basic axial error motion value, a residual axial error motion value and an asynchronous radial error motion value; storing the data. All-around system integration is realized by using high-performance modular hardware, so that the dynamic rotation precision of the main shaft is tested.

Owner:TIANJIN UNIV

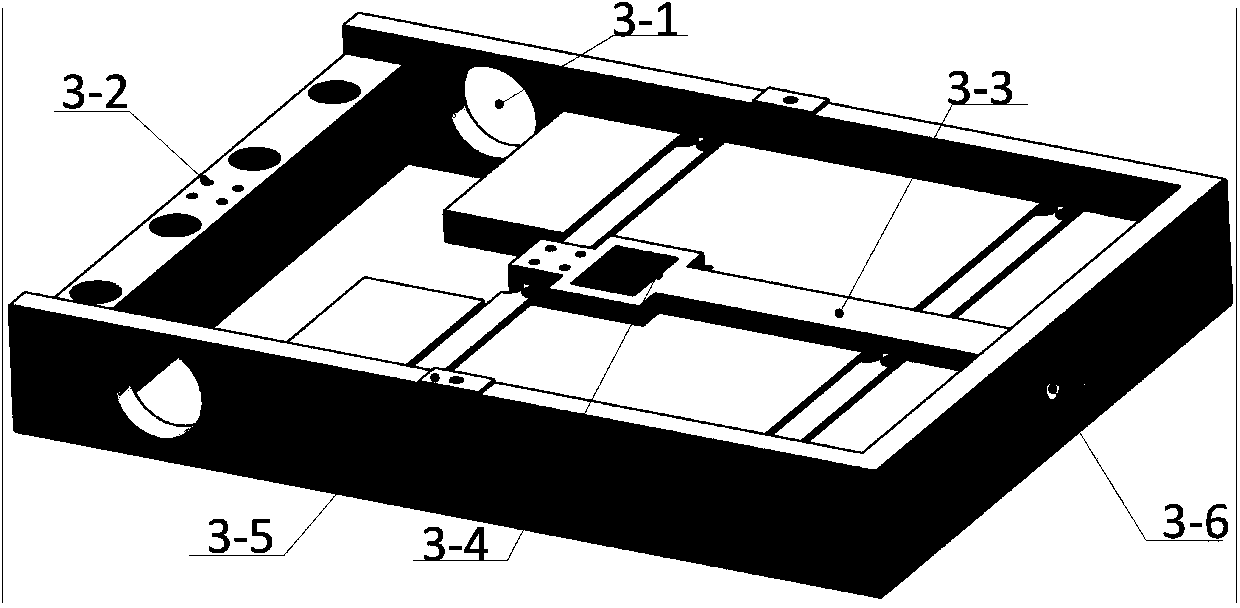

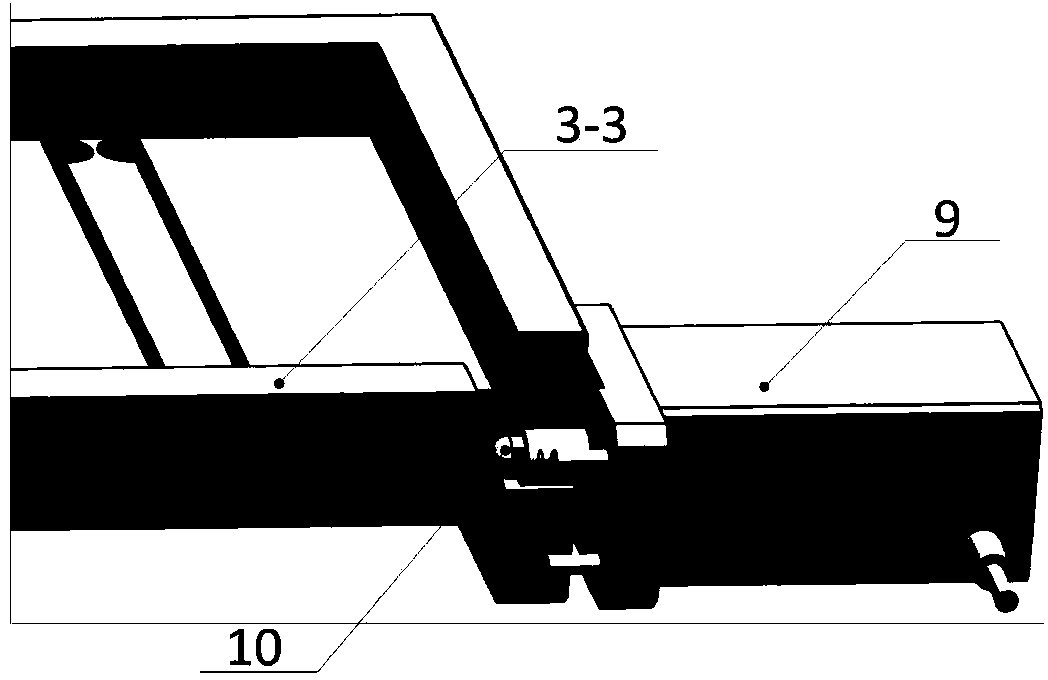

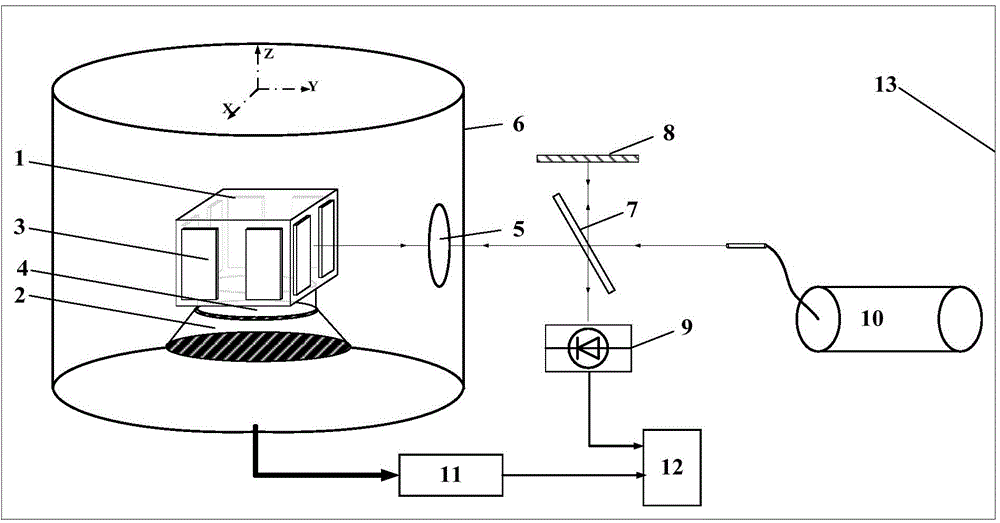

Large-stroke quick-response X-Y micro-motion workbench with double displacement magnification

ActiveCN105006254AIncrease load carrying capacityImprove responsivenessInstrumental componentsMicro nanoDisplacement mapping

The invention relates to a large-stroke quick-response X-Y micro-motion workbench with double displacement magnification. The workbench comprises a pedestal, a motion platform, a top cap, leveling screws, piezoelectric ceramics, an object stage, capacitive displacement sensors, and the like, wherein the pedestal, the motion platform, and the top cap are fixed through screws; the piezoelectric ceramics are installed in displacement magnifying mechanisms and are tightly locked by screws; and the capacitive displacement sensors are installed between the object stage and rounding straight-beam flexible hinges. Improved parallelogram displacement magnifying mechanisms applicable to micro-nano structures are adopted in the workbench; joint parts of the mechanisms are connected by round flexible hinges; and the stiffness of the mechanisms determine the loading capability and quick response of the displacement magnifying mechanism. Two displacement magnifying mechanisms are connected in parallel, so that output force and output displacement are doubled, and displacement coupling of the object stage is reduced. A symmetrical structure is adopted in the micro-motion workbench to provide the workbench with relatively high bandwidth and repeated accuracy. A combination structure of rounding straight-beam and parallel-board flexible hinges is adopted, so that the micro-motion workbench is good in unidirectional displacement.

Owner:NORTHEASTERN UNIV

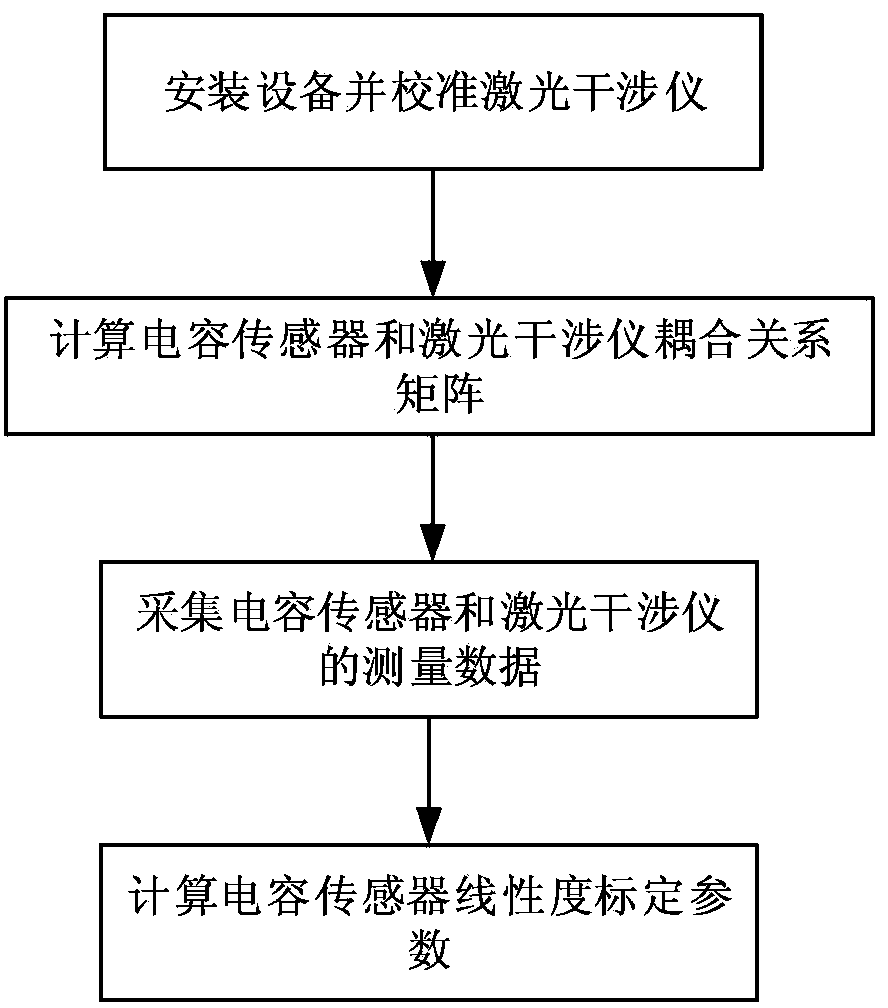

Linearity calibration method for capacitive displacement sensor

The invention belongs to the technical field of displacement measurement and provides a linearity calibration method for a capacitive displacement sensor. The problem that the measurement precision of the capacitive displacement sensor cannot meet the locating precision requirement of a micrometric displacement adjusting mechanism is solved. The calibration method comprises the following steps: installing devices on a calibration structure, adjusting and calibrating a light path of a laser interferometer, calculating a control decoupling matrix, adopting a PID control strategy to make a driver move in the measurement range of the sensor to collect measurement data, and calculating calibration parameters. By means of the linearity calibration method for the capacitive displacement sensor, the linearity of the capacitive displacement sensor is calibrated, and the linearity of the capacitive displacement sensor can be improved by nearly one order of magnitude, so that the precision index of the calibrated capacitive displacement sensor meets the requirement for high locating precision. The calibrating process of the linearity calibration method for the capacitive displacement sensor can be achieved through software, and the advantages of being simple, convenient and high in automation degree are achieved. Meanwhile, the method can also be applied to calibration of the linearity of other non-contact displacement sensors except other than the capacitive displacement sensor.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

High-precision and wide-range micro-thrust measurement system

ActiveCN111373875BContinuityCompatible with pulsed thrust measurementsApparatus for force/torque/work measurementUltrasound attenuationClosed loop

The invention relates to a micro-thrust measurement technology based on a thrust platform, and its purpose is to design a universal wide-range thrust measurement research platform. The thrust platform adopts a torsion balance scheme based on a flexible pivot, including: platform structure, leveling mechanism, trim mechanism, flexible pivot, capacitive displacement sensor, calibration and force coil, damper, etc. The system has two working modes: open loop and closed loop. When working in open loop, the beam starts to rotate under the action of continuous (or pulse) thrust, and as the rotation angle gradually increases, the elastic restoring force also increases accordingly. Under the attenuation of damping, the final rotation angle will tend to a (quasi) steady state new equilibrium position. The thrust is obtained by measuring the angular displacement of the beam. In closed-loop operation, the thrust is balanced by introducing a counterbalance force generated by the force applicator. The invention has the advantages of high measurement precision, wide measuring range, strong versatility and the like.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

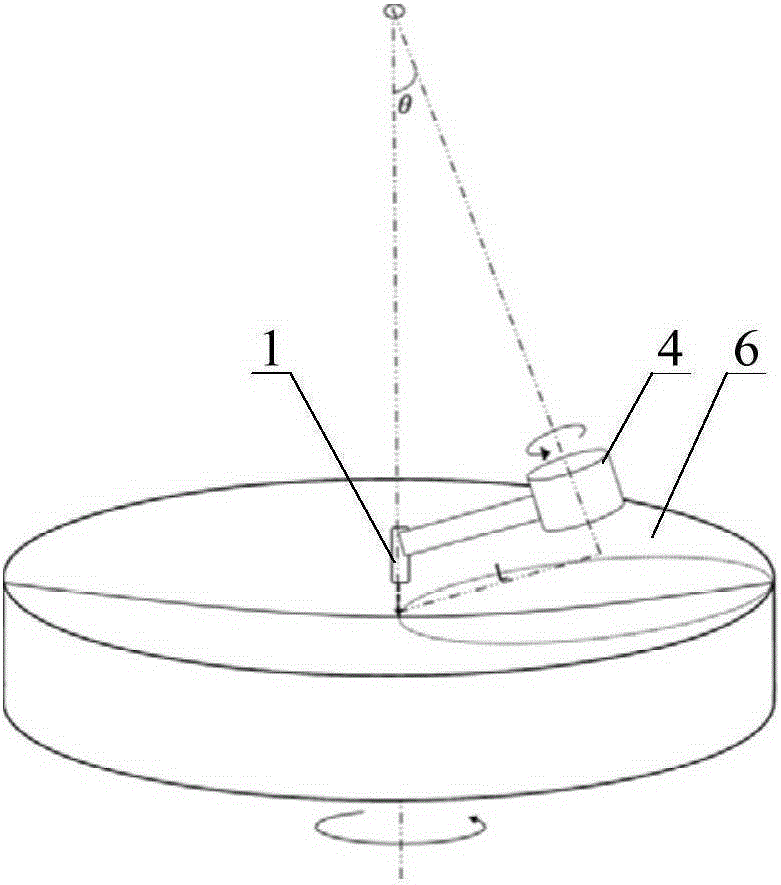

Swing arm profiler based on capacitive displacement sensor and alignment method thereof

ActiveCN105300270AHigh measurement accuracyImprove stabilityOptical surface grinding machinesGrinding feed controlEngineeringMeasurement precision

The invention provides a swing arm profiler based on a capacitive displacement sensor and an alignment method thereof, which belongs to the field of optical element surface shape detection. The problem that the swing arm profiler cannot meet the need of high-precision detection in the prior art is solved. According to the invention, a measuring arm and an air flotation turntable are fixedly connected; the probe of the capacitive displacement sensor is arranged on one end of the measuring arm through a probe chucking device; a counterweight is arranged on the other end; a signal acquisition card acquires the angle signal of the air flotation turntable; and a control unit controls the capacitive displacement sensor and the signal acquisition card to acquire a signal at the same time. According to the invention, the high-precision capacitive displacement sensor is used; the action distance is zero; high-precision swing arm profile detection is realized; compared with a traditional swing arm profiler, the swing arm profiler has the advantages of higher measurement precision and better stability; the invention further provides the alignment method of the swing arm profiler based on the capacitive displacement sensor; and the dangerous problem that the swing arm profiler collides with an element when the swing arm profiler is aligned and measured is effectively solved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Irregular flexible structure vibration measurement system based on multiple laser displacement sensors

InactiveCN105606197AMonitor VibrationDoes not affect intrinsic propertiesSubsonic/sonic/ultrasonic wave measurementUsing optical meansJet aeroplaneVibration measurement

The invention discloses an irregular flexible structure vibration measurement system based on multiple laser displacement sensors. The system comprises a base, a clamping apparatus, a measurement mechanism and a processor. The measurement mechanism is mainly composed of three laser displacement sensors A, B and C and a driving assembly; the type of current vibration and displacement caused by various vibration types are determined according to displacement of each laser displacement sensor at each measurement point, whether bending vibration is generated is determined; whether torsional vibration is generated is determined; and if the vibration is neither the bending vibration nor the torsional vibration, the current vibration is identified as bending and torsion composite vibration. The system provided by the invention has the advantage of realizing synchronous measurement of bending and torsional vibration displacement of irregular plate-shaped irregular flexible structure similar to an airplane wing.

Owner:NINGBO UNIV

Position detection equipment and method for detecting jet hole of coater and light spot of laser displacement sensor

ActiveCN101444773AImprove accuracyAdjustable measurement positionLiquid surface applicatorsSpraying apparatusLocation detectionLight spot

The present invention discloses position detection equipment and a position detection method for a coater, capable of detecting the position of a light spot of a laser displacement sensor of the coater and a discharge hole of a nozzle. The position detection equipment includes a head support member for supporting a head unit equipped with a nozzle and a laser displacement sensor, a camera locating facing the nozzle and the laser displacement sensor, and a transmittivity variable member arranged among the nozzle, the laser displacement sensor and the camera,transferring from a first state to a second state or inversely. Under the first state, a laser beam is capable of being transmitted through the transmittivity variable member and projecting the torque of the nozzle; under the second state, the laser beam is reflected and imaged on the transmittivity variable member.

Owner:TOP ENG CO LTD

Bi-piezoelectric vertical elliptical vibration cutting device suitable for vertical type excircle machining

The invention relates to a bi-piezoelectric vertical elliptical vibration cutting device suitable for vertical type excircle machining, and belongs to the technical field of micro-nano and ultra-precision manufacturing and processing of complex optical elements of difficult-to-process materials. A series connection integrated flexible hinge substrate is connected with two piezoelectric stacks respectively; a displacement measurement baffle is installed on the series connection integrated flexible hinge substrate; a capacitive displacement sensor is installed on a displacement sensor holder; the displacement sensor holder is installed on the series connection integrated flexible hinge substrate; and a diamond cutter is installed at the front end of the series connection integrated flexible hinge substrate through tightening screws. The bi-piezoelectric vertical elliptical vibration cutting device has the advantages as follows: the structure is novel; the series connection integrated flexible hinge substrate is formed by one-time processing; the whole structure is simple relatively; the device is easy to manufacture; and errors caused by assembly are reduced to a great extent. The bi-piezoelectric vertical elliptical vibration cutting device is small in size and low in mass and can realize high-frequency elliptical vibration cutting easily.

Owner:CHANGCHUN UNIV OF TECH

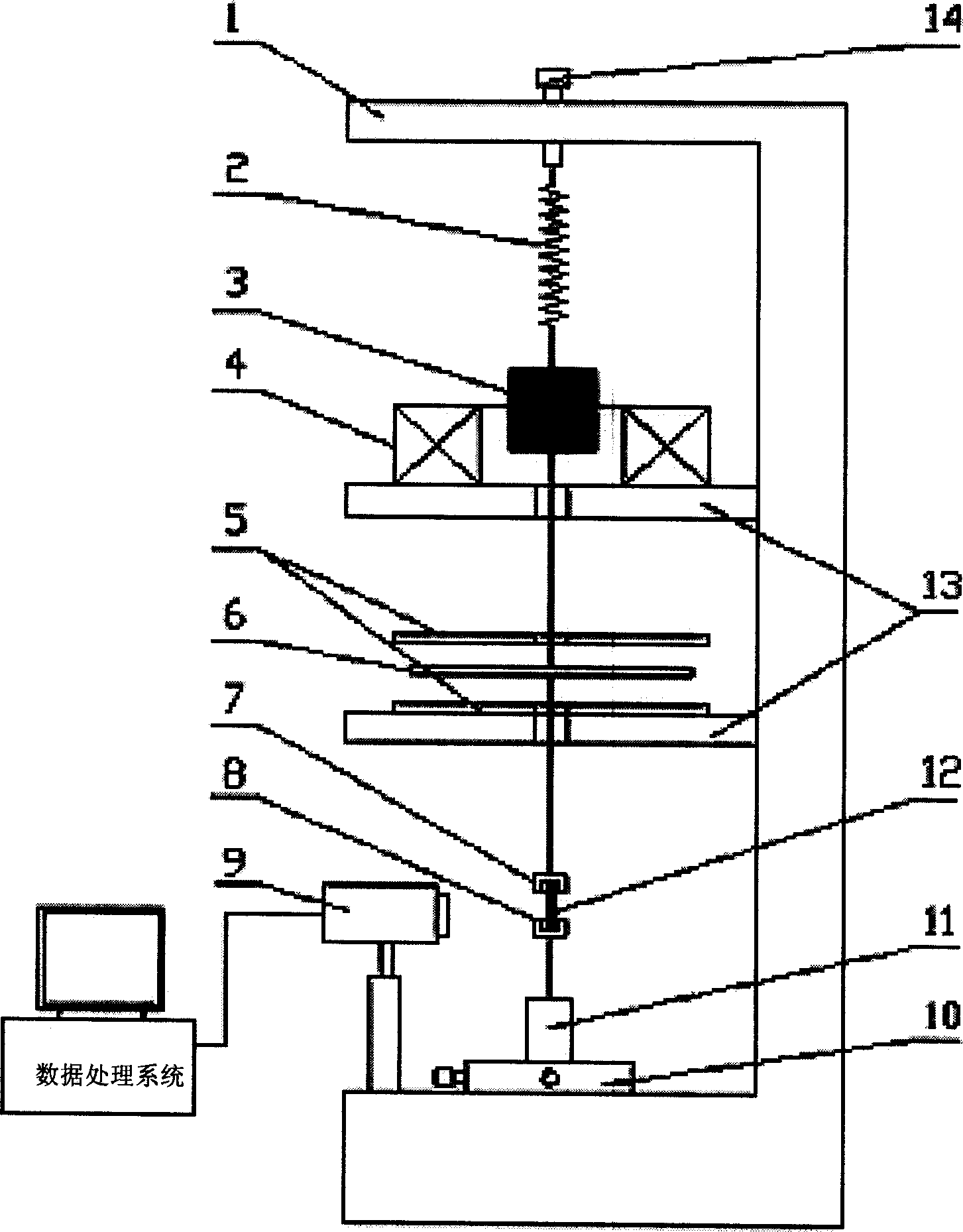

Suspension type static and dynamic material testing machine of tiny tensile

InactiveCN1696643AHigh measurement accuracyHigh sensitivityMaterial strength using tensile/compressive forcesUsing optical meansResearch ObjectMaterials testing

A microforce tensile tester of static and dynamic state in suspension type for testing lower - dimensional material is composed of base, flexible spring of low rigidity, electromagnetic force driving unit, capacity displacement transducer, piezoelectric displacement driver, noncontact optical measuring unit, top and bottom holding device for specimen, three - dimensional accurate translation table and three - dimensional translation regulating device. It has two loading and strain measuring modes for different object and purpose.

Owner:TSINGHUA UNIV

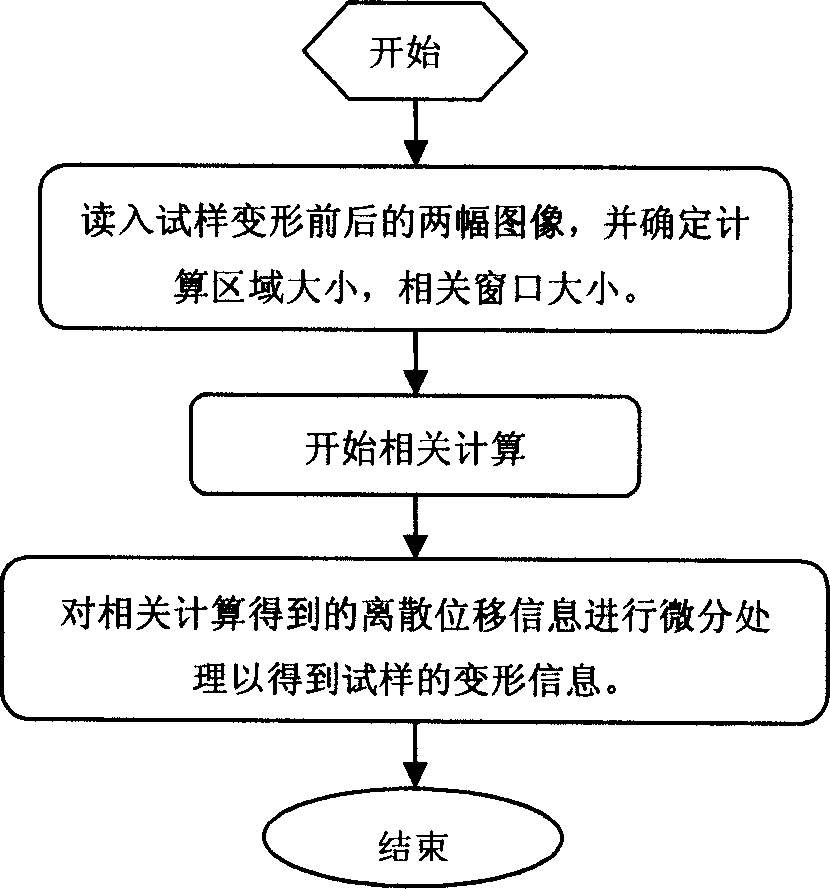

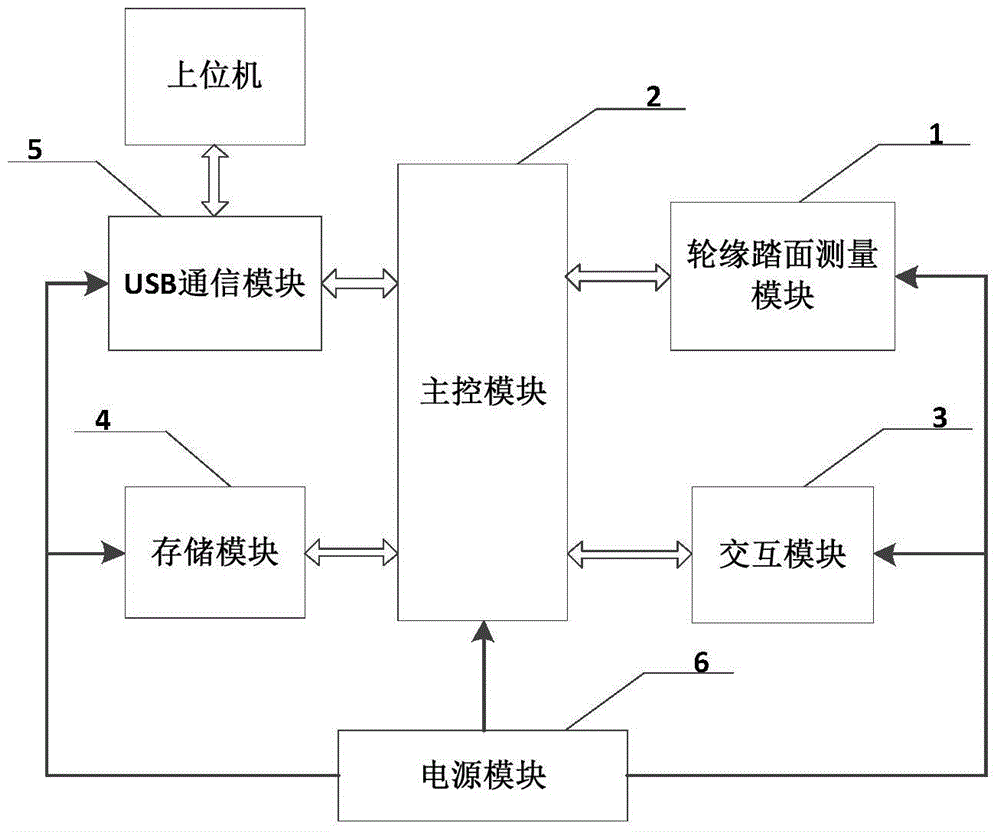

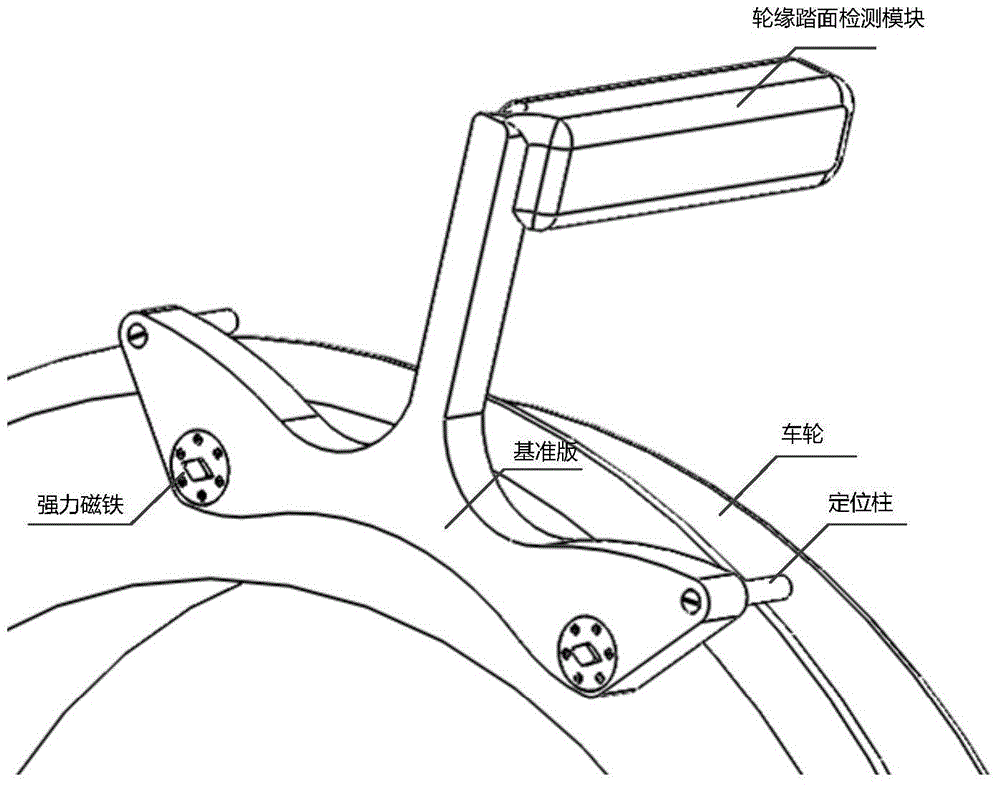

Device and method for measuring urban rail wheel parameters based on laser displacement sensor

InactiveCN105043248AImplement storageRealize transmissionUsing optical meansMeasurement deviceCurve fitting

The invention discloses a device and a method for measuring urban rail wheel parameters based on a laser displacement sensor. The device comprises a wheel flange and tread measurement module, an ARM embedded main control module, an interaction module, a data storage module, a USB communication module and a power supply module. The wheel flange and tread measurement module detects the coordinate of a wheel tread by means of a laser displacement sensor. The ARM embedded main control module conducts the curve-fitting treatment on the detected coordinate of the wheel tread so as to obtain the profile curve of a wheel. After that, the ARM embedded main control module figures out the height of a wheel flange, the thickness of the wheel flange, the diameter of the wheel and other wheel parameters based on the geometrical relationship thereof. The interaction module displays the profile curve of the wheel and wheel parameters. The data storage module stores measurement data and wheel parameters. A host computer acquires wheel parameters to further analyze the wheel parameters through the USB communication module. The power supply module powers up the entire device. According to the technical scheme of the invention, the device can measuring urban rail wheel parameters in the wheel non-dropping condition, thus having the advantages of convenience, high speed, high accuracy, simplicity and practicability.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com