Wide range and high precision free curved surface measuring method

A measurement method and high-precision technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of difficult calibration, low precision, inability to combine large range and high precision, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

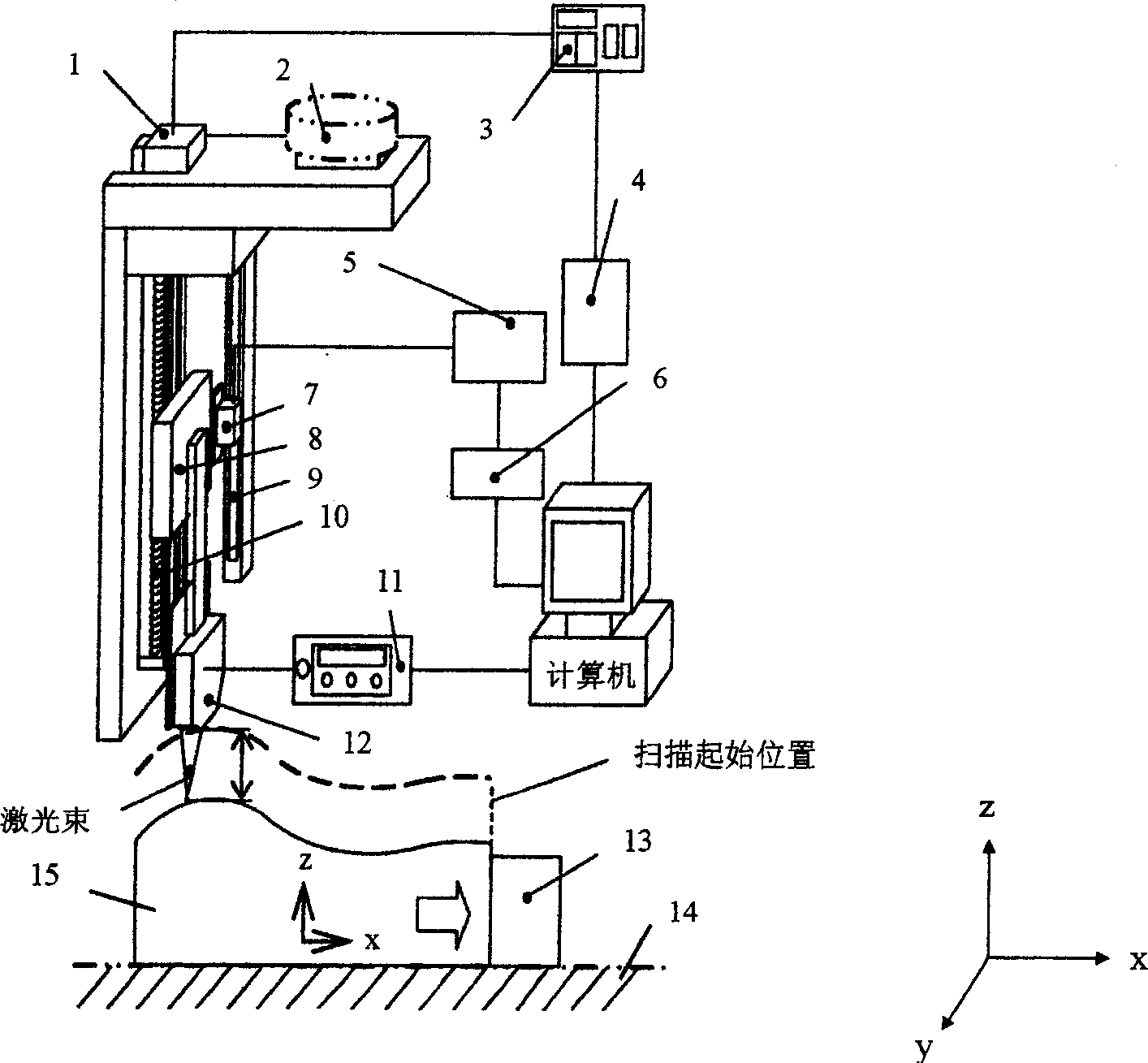

[0014] In the figure 1. Servo motor, 2. Machine tool spindle, 3. Motor driver, 4. Motor motion control board, 5. Amplifier, 6. Counter, 7. Linear encoder or grating sensor, 8. Linear feed platform, 9. Scale, 10, ball screw, 11, amplifier, 12, laser displacement sensor, 13, initial position stopper, 14, platform capable of precise movement in X direction and Y direction, 15, curved surface to be measured.

[0015] A high-precision measurement method for realizing a large-scale free-form surface, comprising the following steps:

[0016] (1) Place the measured curved surface 15 on a platform 14 that can be moved precisely in the X and Y directions;

[0017] (2) Install the laser displacement sensor 12 on the linear feed platform 8 driven by the ball screw 10 parallel to the main shaft of the machine tool 2 to form a Z-direction linear movement mechanism. The servo motor 1 controls the displacement of the linear movement mechanism, and the linear encoder Or the grating sensor 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com