Patents

Literature

217 results about "Laser triangulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

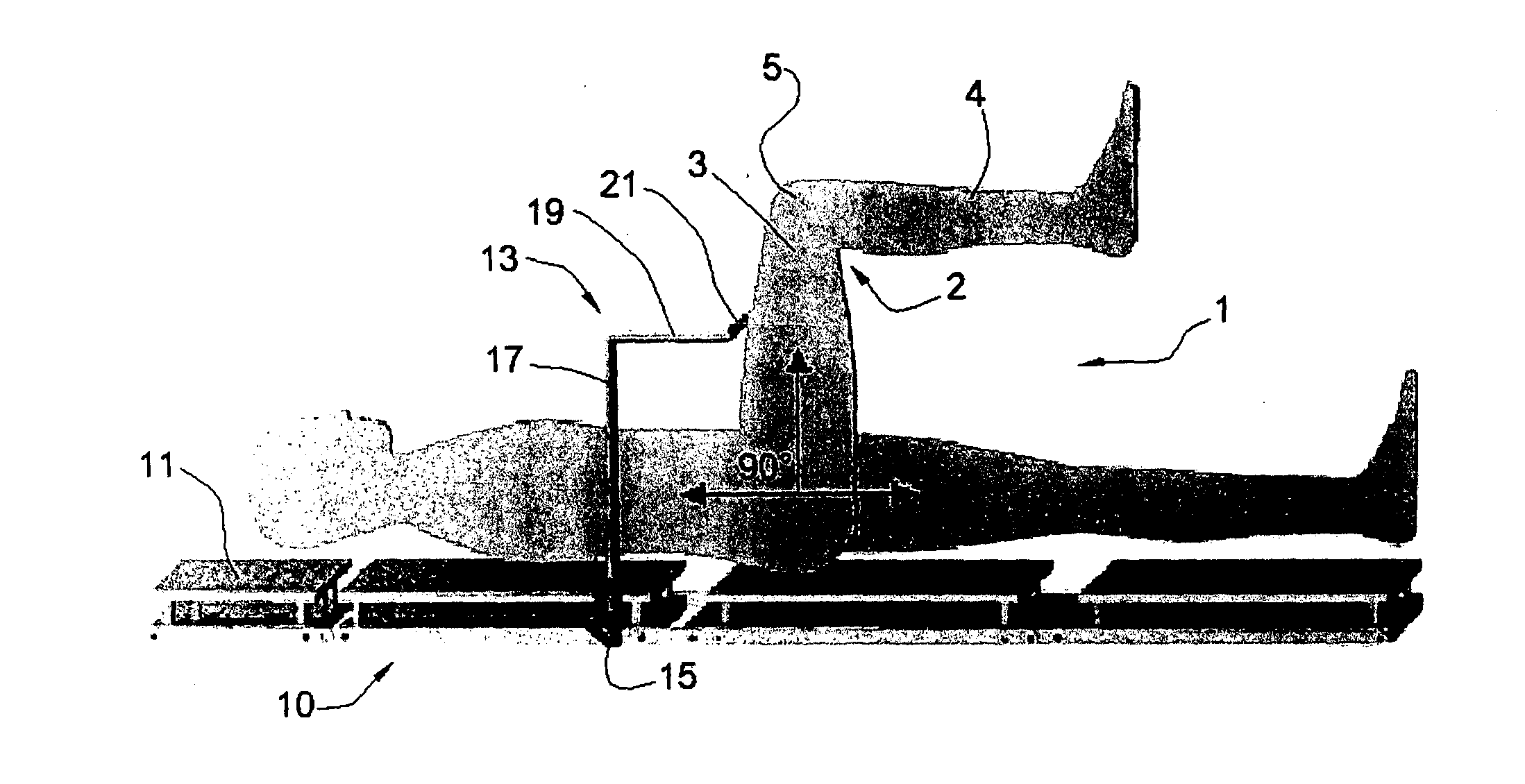

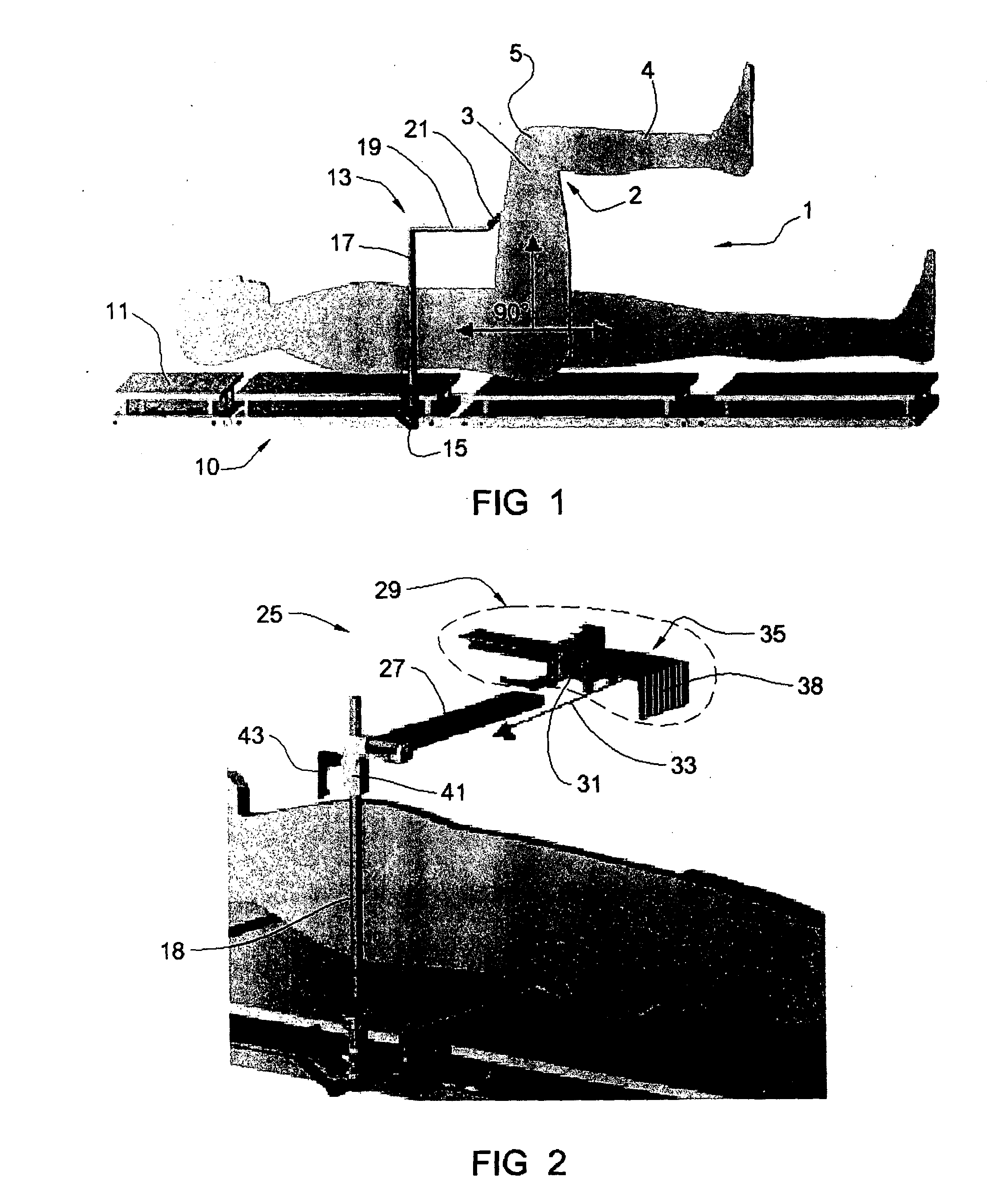

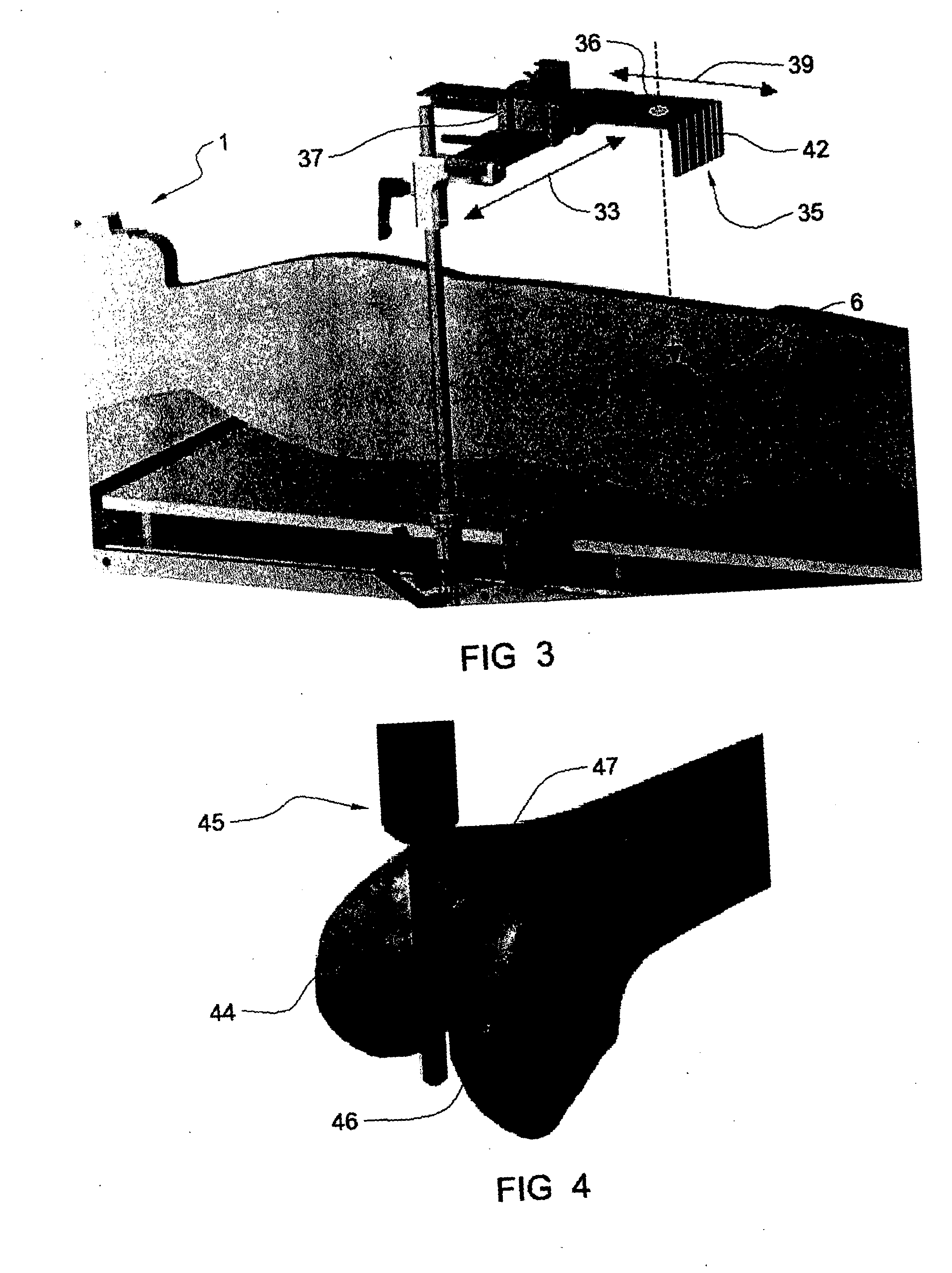

Laser triangulation of the femoral head for total knee arthroplasty alignment instruments and surgical method

InactiveUS20050070897A1Improve accuracyConsiderable morbidityDiagnostic recording/measuringSensorsArticular surfacesArticular surface

An Extramedullary system of alignment for total knee arthroplasties uses a small diode laser at the center of the knee adjustable to the longitudinal axis of the femur to triangulate the center of the femoral head. It utilizes a V-Frame positioning device that fits into the distal femoral intercondylar notch and is tangent to the articular surfaces of the notch. It is also parallel to the anterior femoral cortex by using a removal tongue flange that sits flat on the filed surface of the anterior cortex. This prepositions the Distal Femoral Resector Guide within a few degrees of the center of the femoral head. An adjustment knob on the V-Frame pivots the distal femoral resector guide to the exact center of the femoral head for that particular patient accomplishing fine adjustment of the longitudinal axis of the femur. There is only one position where the laser beam will go through the center of the target no matter where you position the leg and that is when the target's bulls-eye is exactly over the rotational center of the femoral head. Since the laser confirms this position, the surgeon is assured that the alignment is accurate. The Distal Femoral Resector Guide is then fixed to bone with fixation pins and the resection made with a power saw. The laser is moved to the target mount to act as a longitudinal “laser ruler” for the remainder of the operation.

Owner:PETERSEN THOMAS D

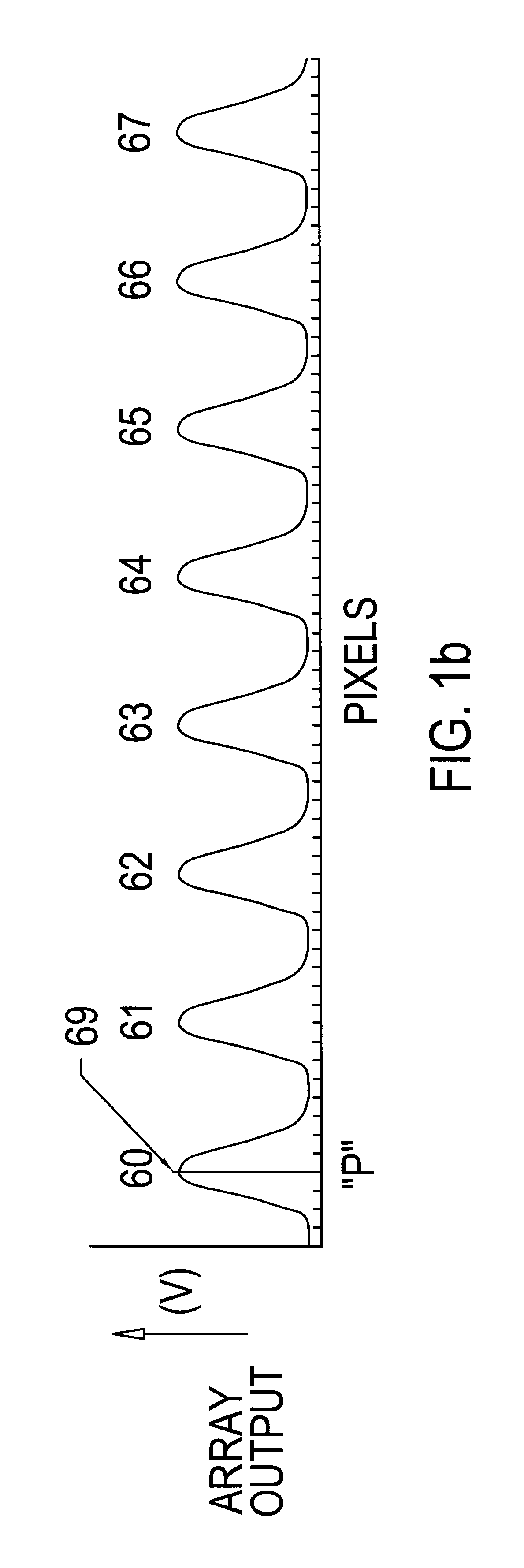

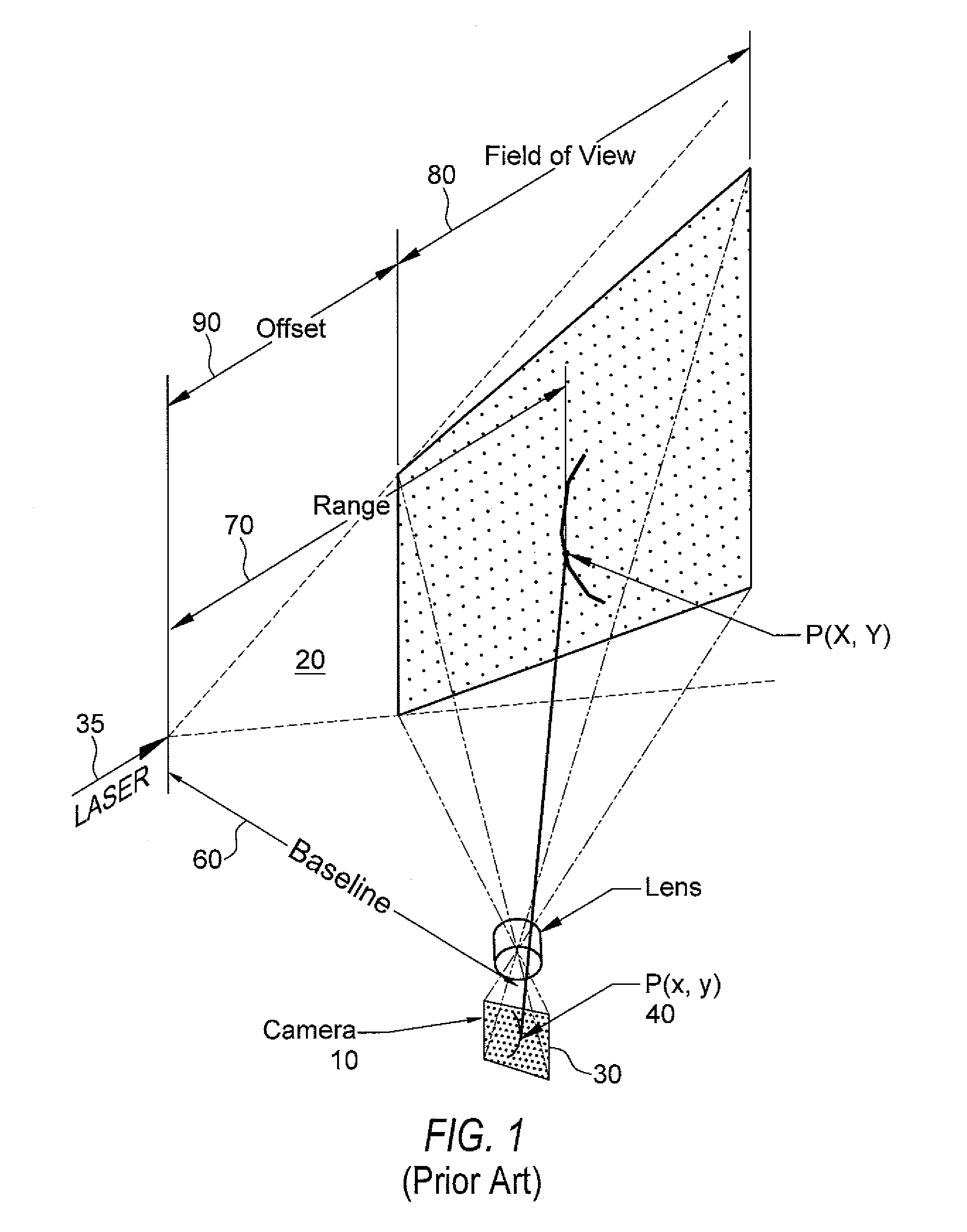

Laser triangulation system

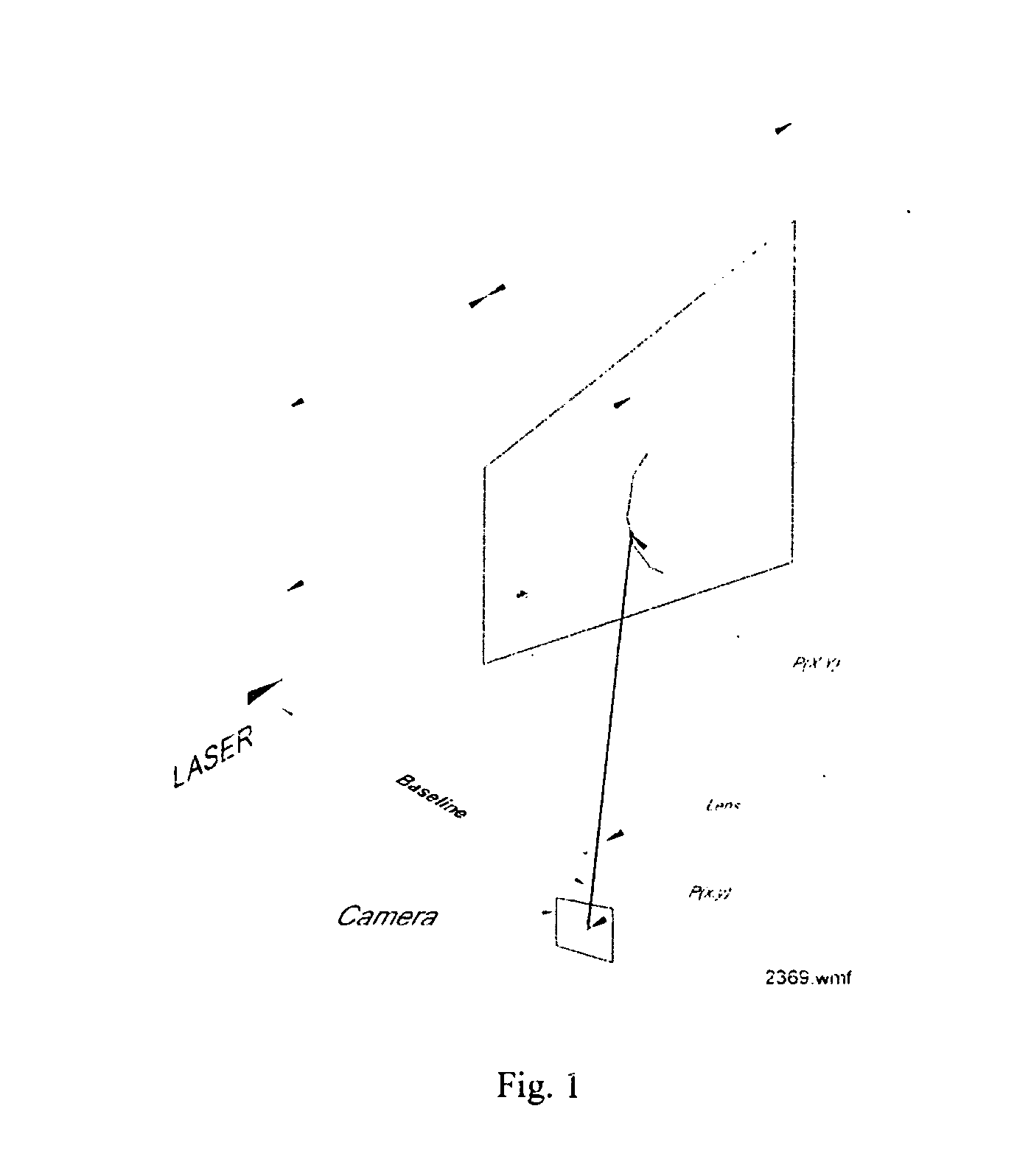

ActiveUS20050111009A1Not provideOptical rangefindersBeam/ray focussing/reflecting arrangementsPhotovoltaic detectorsPhotodetector

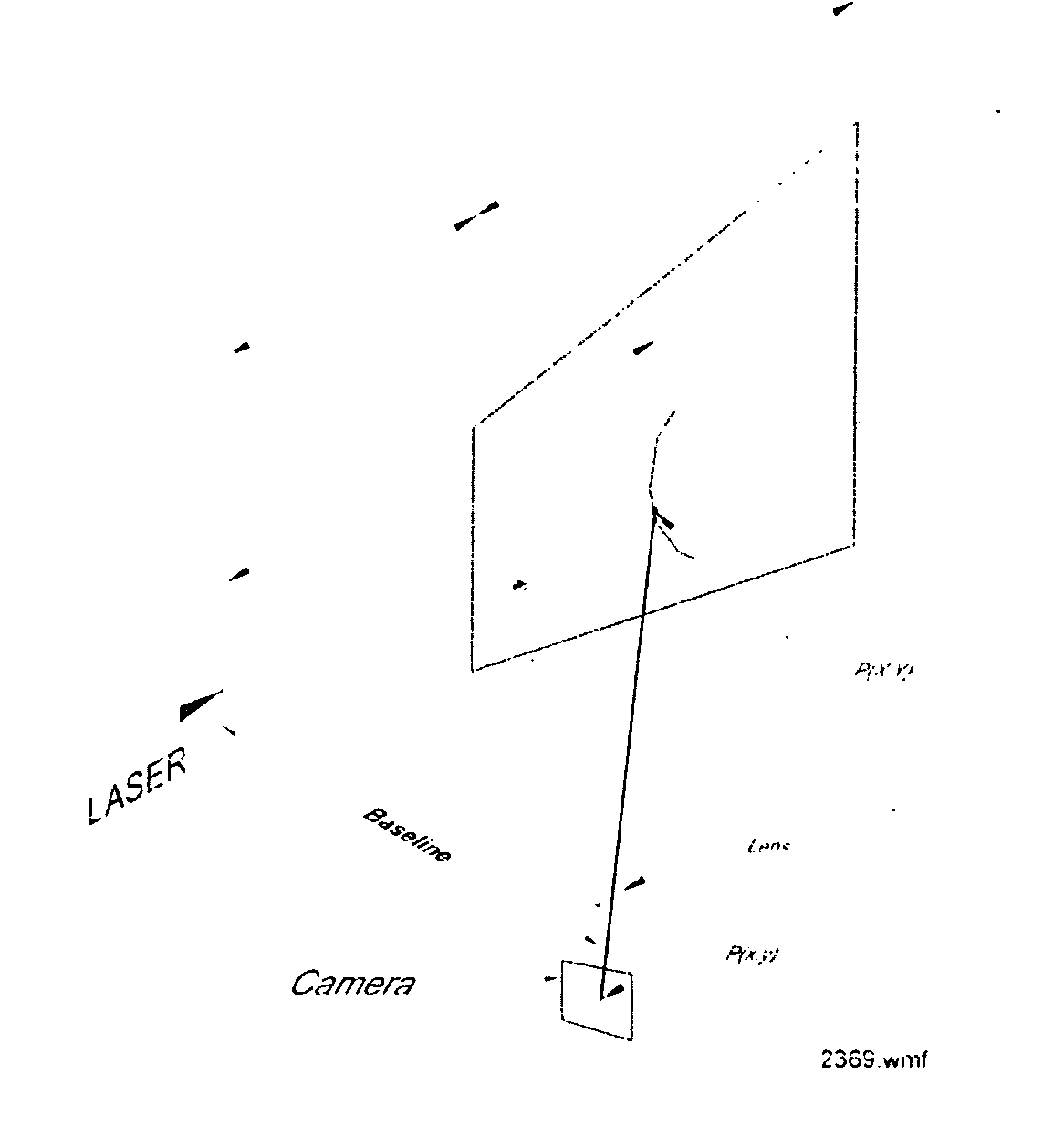

A method for measuring the range to multiple points on a surface by projecting a line of light onto the surface, imaging said line of light onto an XY photodetector array at an oblique angle, reading out the array one line at a time, computing the centroid of said line of light on each Y line across X columns as each line is read out of the array in onboard FPGA (Field Programmable Gate Array) or similar real time logic, computing quality factors for each computed centroid and encoding this as one or more bits in the centroid value, transmitting said tagged centroid to a local or remote data receiver, and computing the range to the surface for each point corresponding to each centroid using a previous calibration step.

Owner:3DM DEVICES

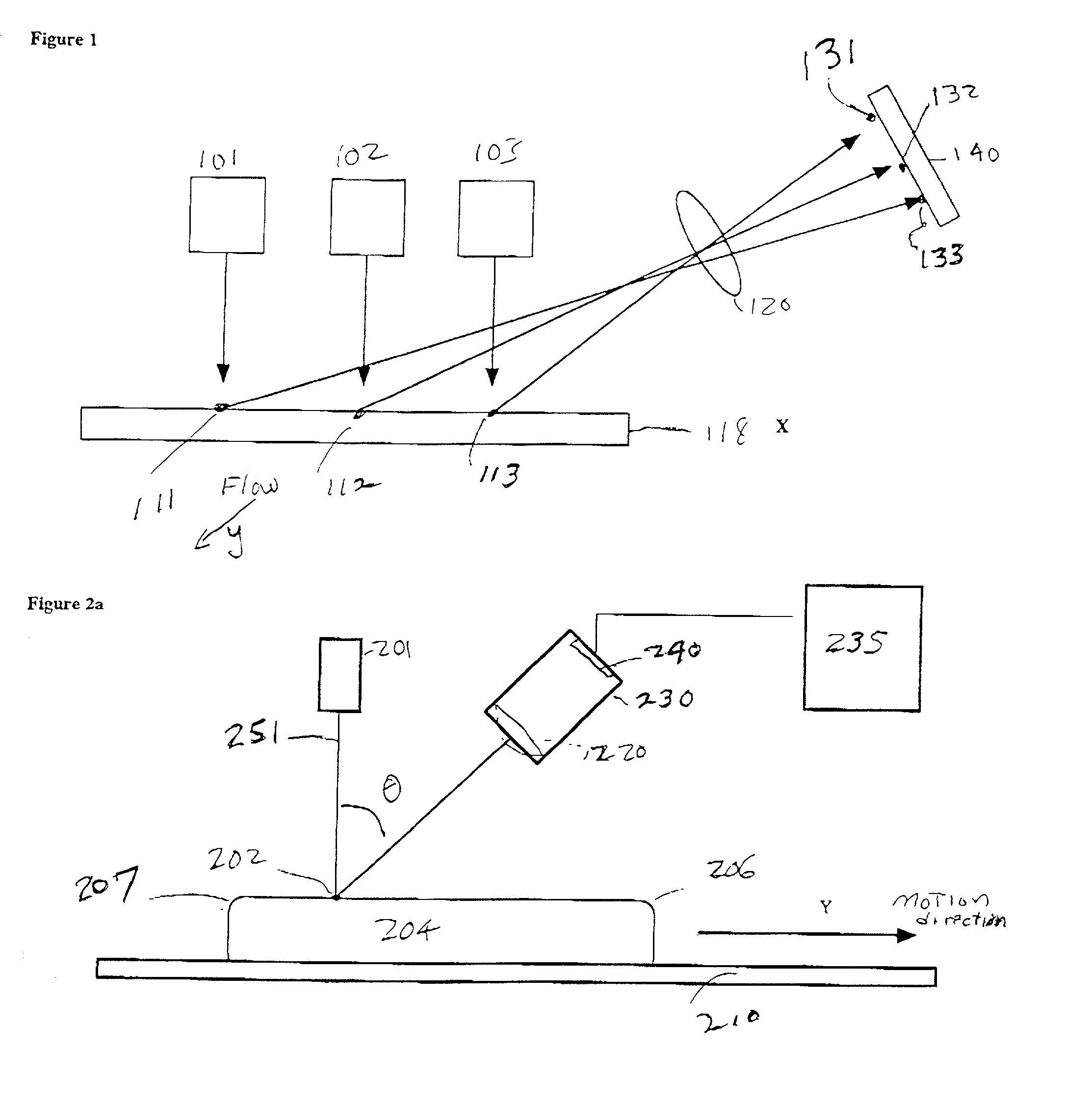

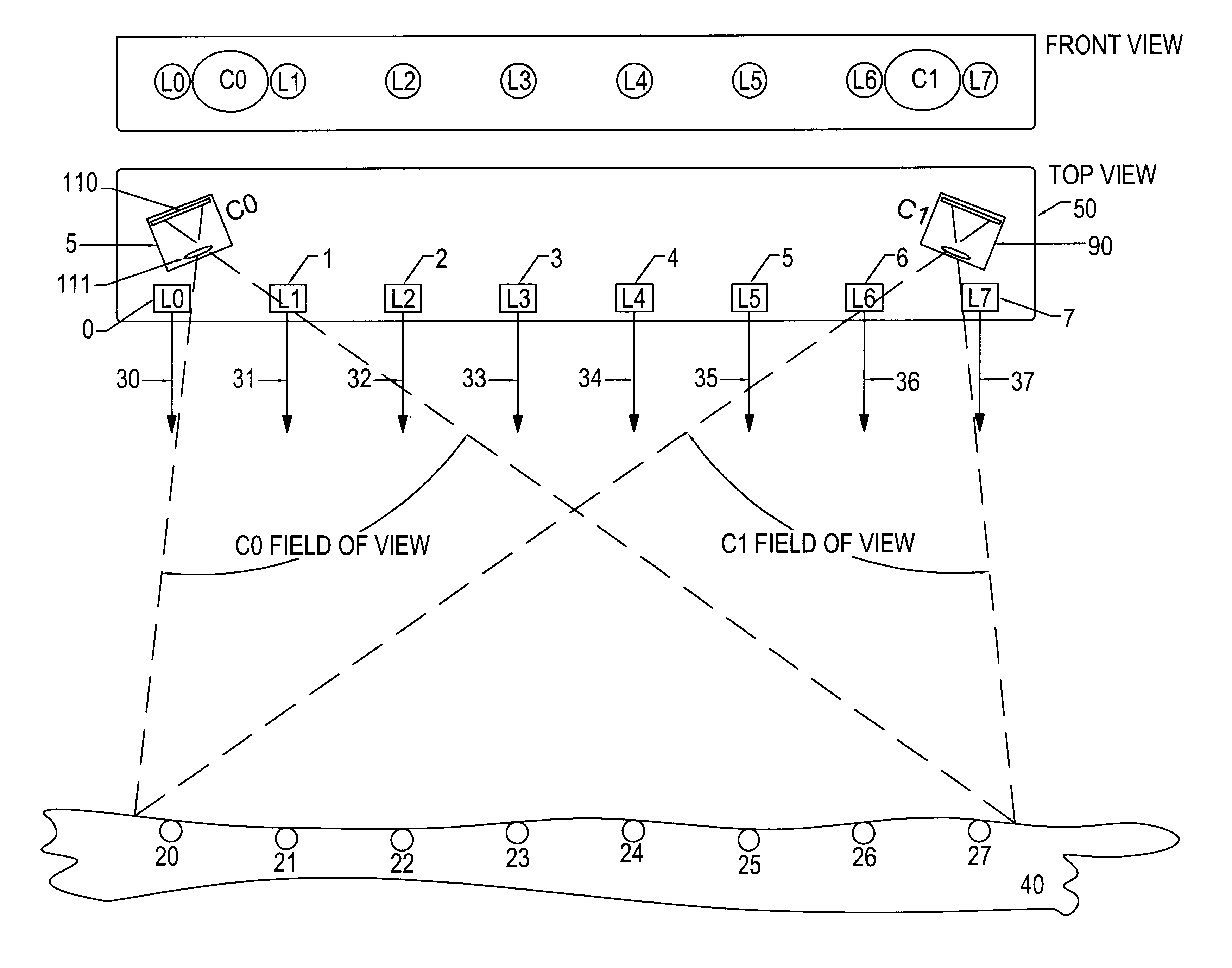

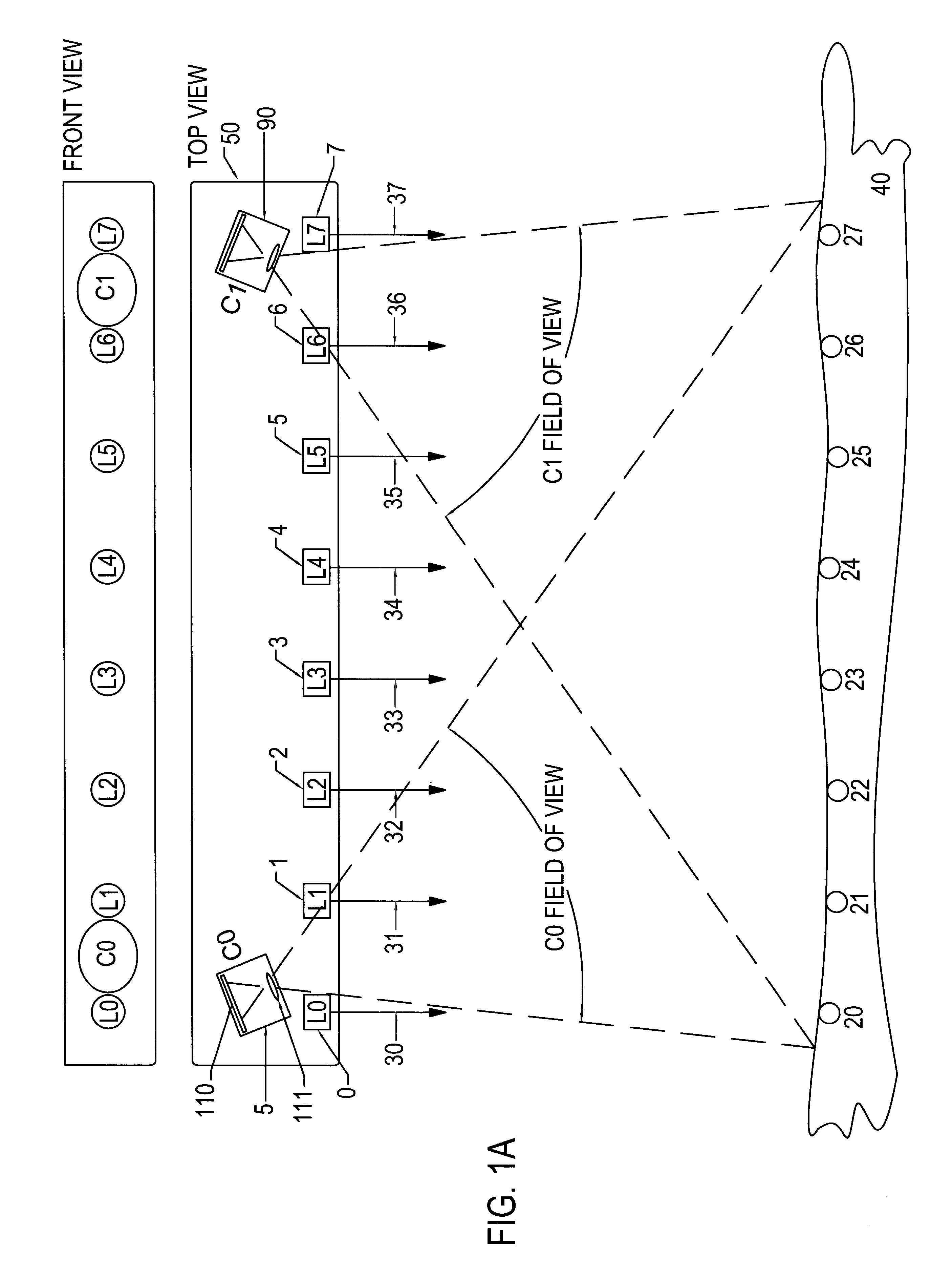

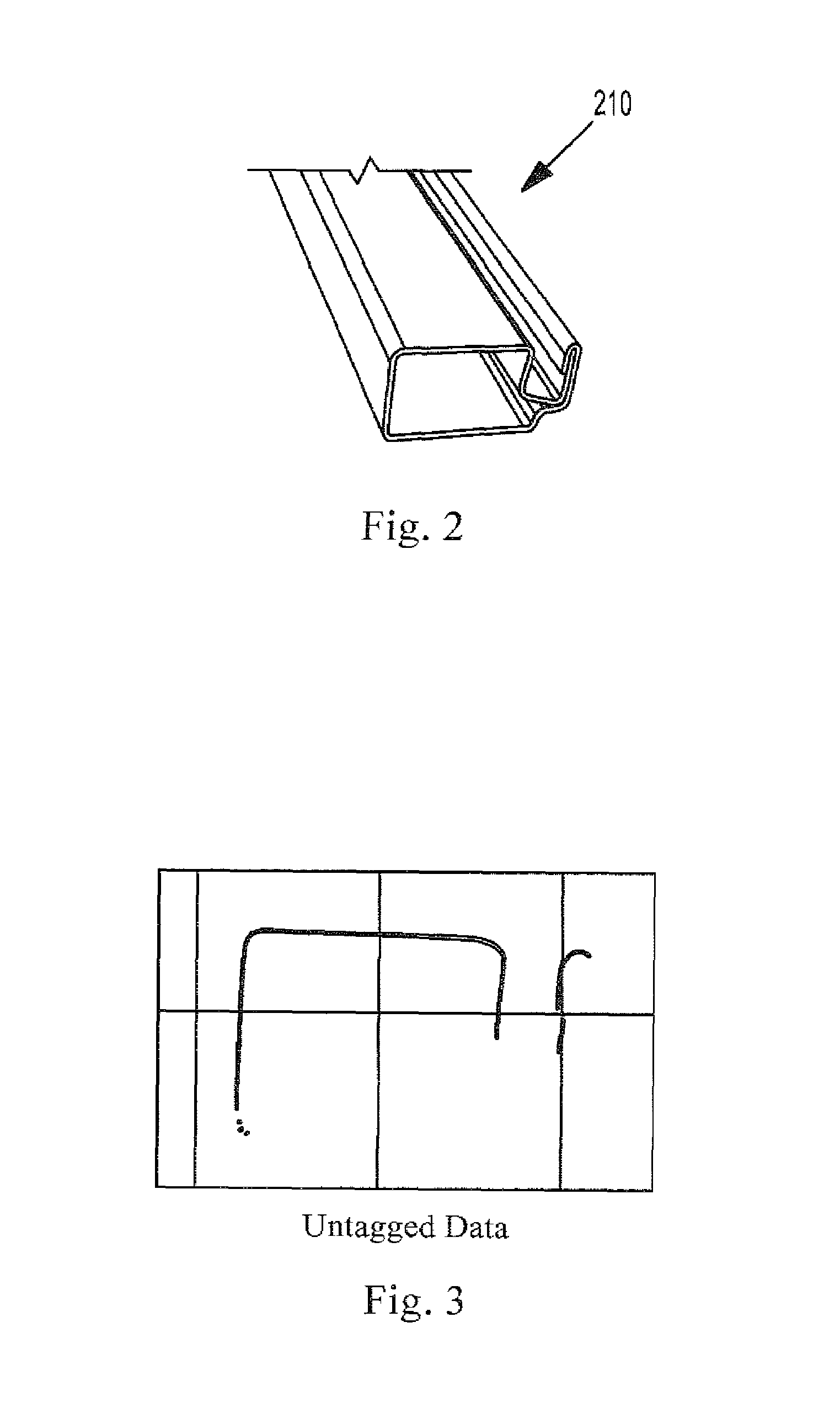

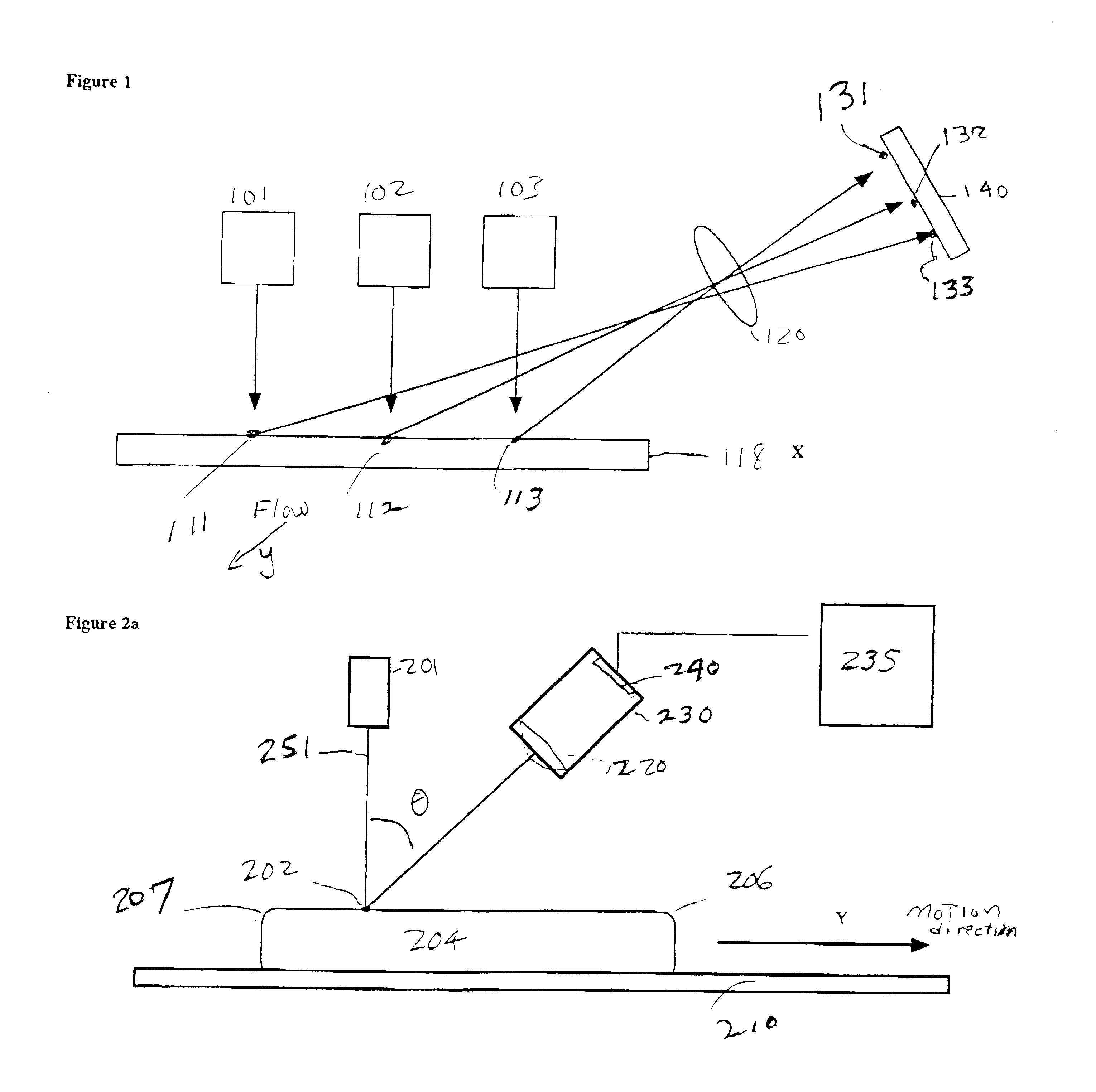

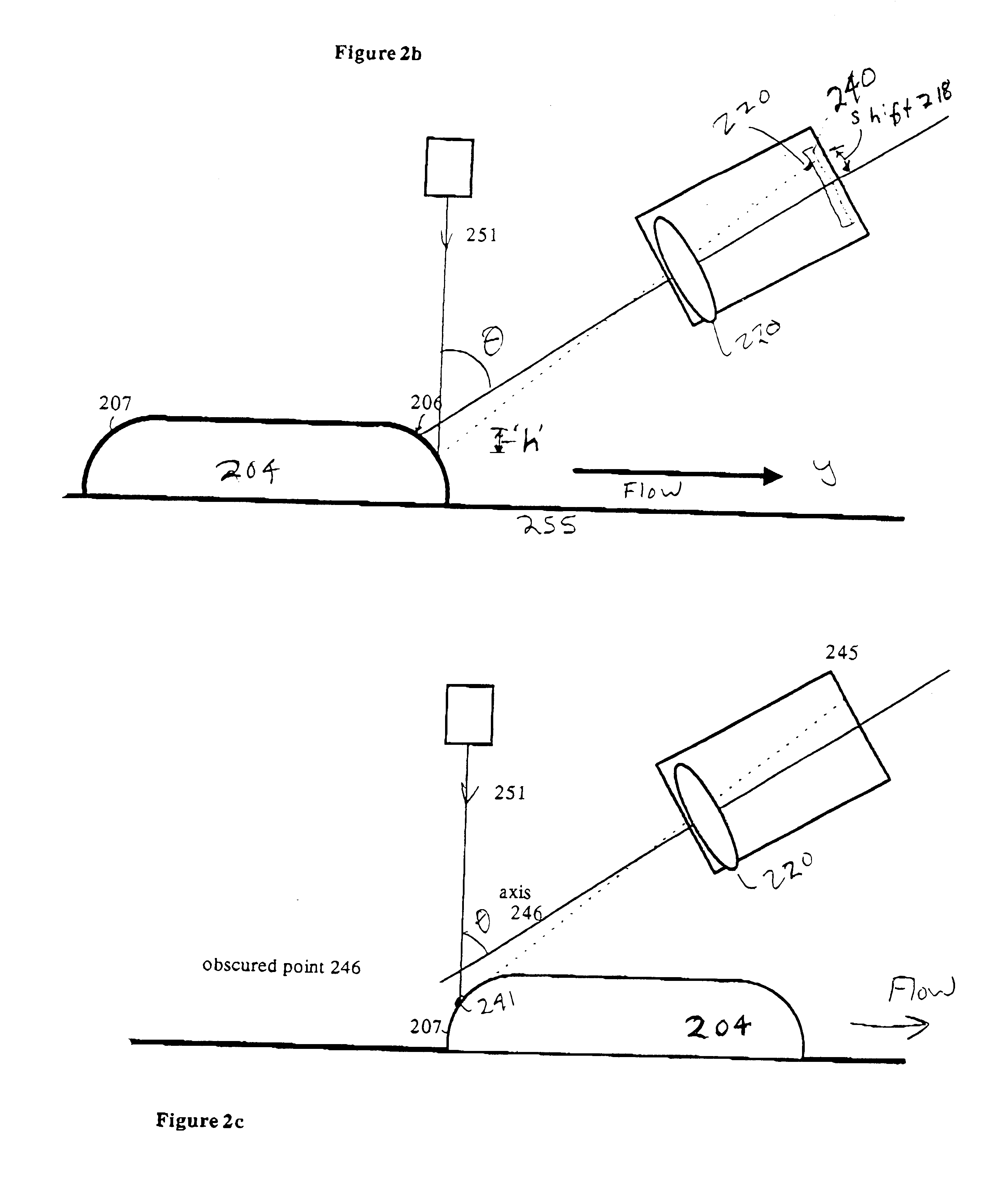

Method and apparatus for scanning lumber and other objects

InactiveUS20020024677A1Acceptable accuracyLow costInvestigating moving sheetsUsing optical meansElectro-optical sensorHigh velocity

Disclosed herein are TV Camera based and other electro-optical sensors and systems, providing affordable methods and apparatus for high speed determination of dimensions and other features of objects. Particular embodiments capable of fast and reliable acquisition of features of moving objects such as boards and wood products are disclosed. Preferred embodiments utilize laser triangulation range detection with at least two cameras viewing the same laser spot or line projected on the object.

Owner:LMI TECH

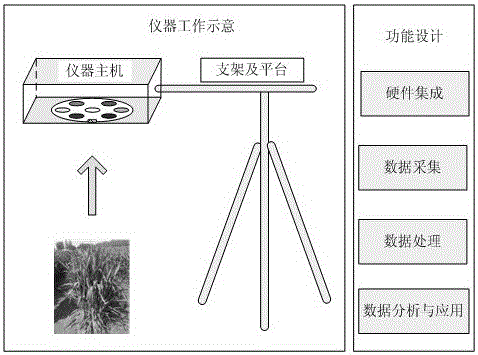

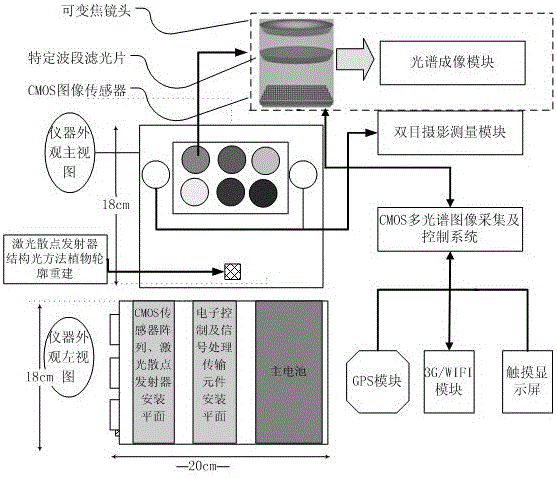

Portable crop parameter measurement and growth vigor intelligent analysis device and method

ActiveCN105675549AScattering properties measurementsColor/spectral properties measurementsLight spotData acquisition

The invention discloses a portable crop parameter measurement and growth vigor intelligent analysis device and method. The device comprises a spectral imaging module, a laser structured light scatter emitter, a binocular photography measurement module, an image acquisition control module, a data acquisition module, a data processing module, a data analysis and application module and a battery module. The device and the method provided by the invention realize fast automatic measurement of a crop canopy structure based on a structured light measurement technology of laser triangulation range-finding principle. A laser single-point light source is converted to a specific form to serve as a light source by an optical splitter to generate evenly spaced point-like projection light sources, and the generated light beams can irradiate a measured surface. When a multispectral image is acquired, the three-dimensional coordinate or spatial form of each light spot or light bar by a photogrammetry technology, and three-dimensional reconstruction of a crop canopy structure can be realized by a spatial interpolation technology.

Owner:WUHAN UNIV

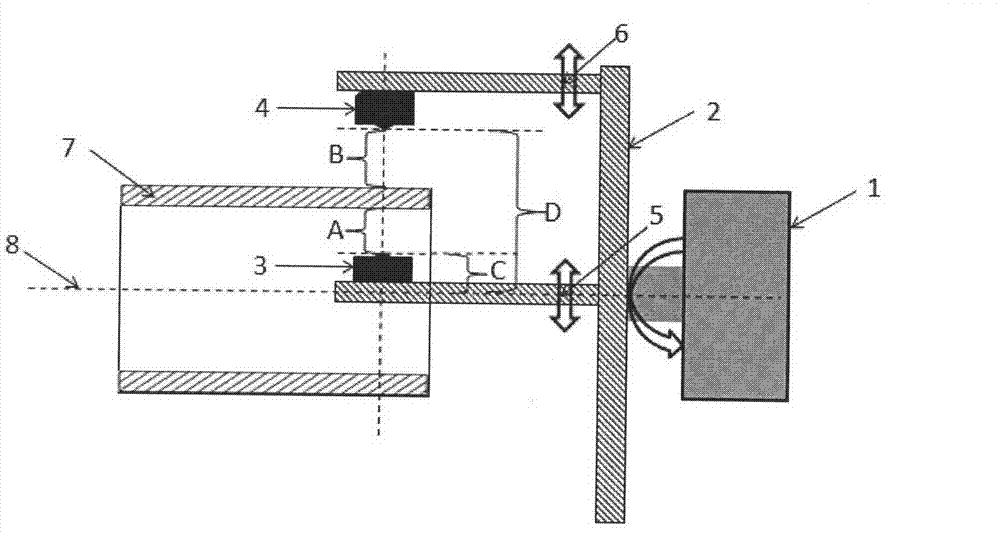

Three-dimensional object model reconstruction system and method based on laser images

InactiveCN103236076ASmall and convenientSimple structureImage analysis3D modellingPoint cloudMedicine

Disclosed is a three-dimensional object model reconstruction system and method based on laser images. The system comprises a computer, a single chip microcomputer, a stepping motor, a rotary cradle head, a laser device, a camera, a chessboard calibration plate and a three-legged support. The reconstruction process includes: according to a classical Zhang Zhengyou chessboard calibration method, acquiring calibrated images and generating camera parameters through a hardware system; and controlling the single chip microcomputer by the aid of software so as to control the stepping motor in real time, enabling the surface of a target object to be scanned by laser rays by 360 degrees, performing real-time shooting by the camera to obtain a target image, importing the target image into the computer to be used for selective acquisition of point cloud, obtaining a spatial three-dimensional coordinate of the point cloud by the aid of a laser triangulation measurement method, and reconstructing a three-dimensional model of the target object.

Owner:WUHAN UNIV

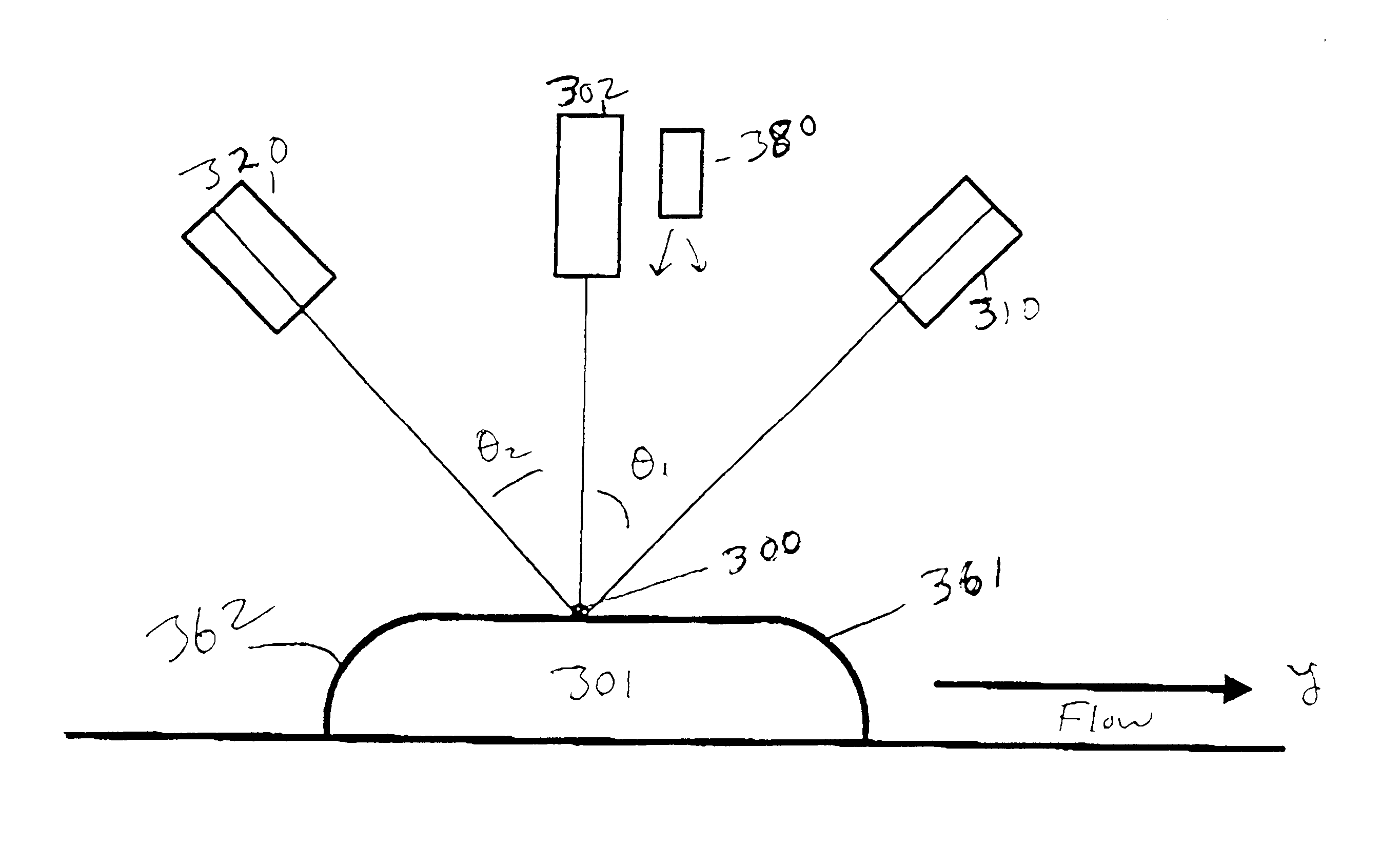

High speed laser triangulation measurements of shape and thickness

InactiveUS6466305B1Overcome ambiguityHigh possible operational speedOptical rangefindersInvestigating moving sheetsTriangulationLight beam

Owner:LMI TECH

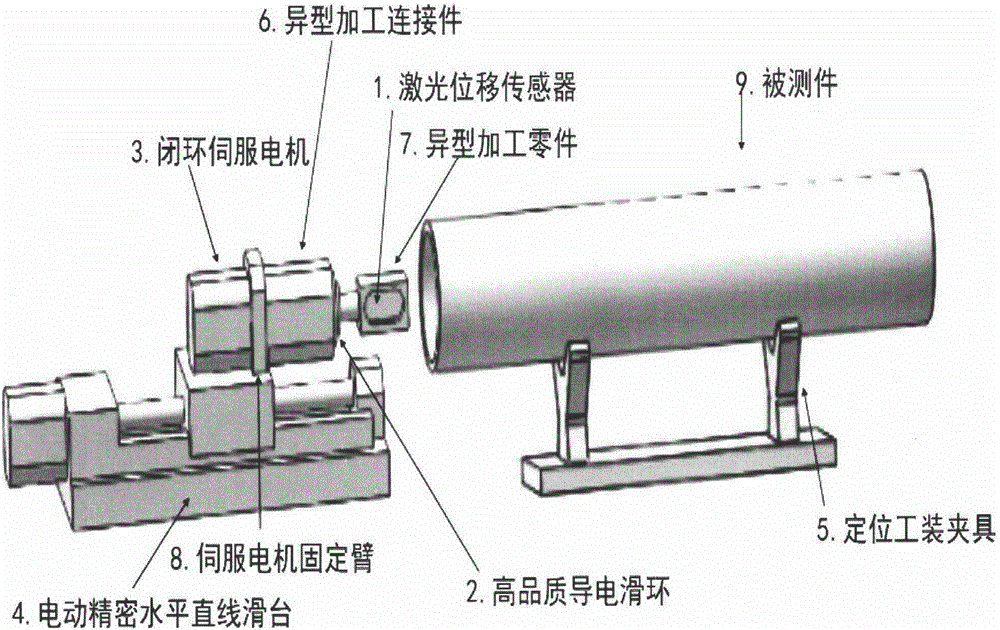

Method capable of automatically adjusting rotation radius and measuring inner diameter and outer diameter of pipe end of steel pipe

InactiveCN104729416AReduce alignment precision requirementsReduced alignment requirementsUsing optical meansLaser rangingEngineering

Provided is a method capable of automatically adjusting a rotation radius and measuring an inner diameter and an outer diameter of a pipe end of a steel pipe. The method is a measuring method which aims at a measuring device for the inner diameter and the outer diameter of the pipe end, wherein laser ranging probes rotate around the pipe end. According to the measuring method, by using the mode that the rotation radius is automatically adjusted during the rotation measuring process, the defect that a laser triangulation method ranging probe is limited in the measuring range is compensated, the requirement for the aligning precision between a rotating central axis and a steel pipe central axis of a rotating platform is greatly lowered, a dynamic range capable of measuring changes on a pipe diameter is enlarged, the equipment cost of an auxiliary machine is lowered, and the stability and the practicality of equipment are improved. Meanwhile, during the operation, aiming at steel pipes with different sizes, the positions of probe fixed arms do not need to be adjusted in advance, the operation procedure is reduced, and the maintenance cost is lowered.

Owner:NANKAI UNIV

Laser triangulation system

ActiveUS7460250B2Optical rangefindersBeam/ray focussing/reflecting arrangementsPhotovoltaic detectorsPhotodetector

A method for measuring the range to multiple points on a surface by projecting a line of light onto the surface, imaging said line of light onto a photodetector, computing the centroid of said line of light, computing quality factors for each computed centroid and encoding the quality factors as one or more bits in the centroid value, transmitting said centroid value to a data receiver, and computing the range to the surface for each point corresponding to each centroid value.

Owner:3DM DEVICES

Method and apparatus for scanning lumber and other objects

InactiveUS6618155B2Acceptable accuracyLow costInvestigating moving sheetsOptically investigating flaws/contaminationElectro-optical sensorHigh velocity

Disclosed herein are TV Camera based and other electro-optical sensors and systems, providing affordable methods and apparatus for high speed determination of dimensions and other features of objects. Particular embodiments capable of fast and reliable acquisition of features of moving objects such as boards and wood products are disclosed. Preferred embodiments utilize laser triangulation range detection with at least two cameras viewing the same laser spot or line projected on the object.

Owner:LMI TECH

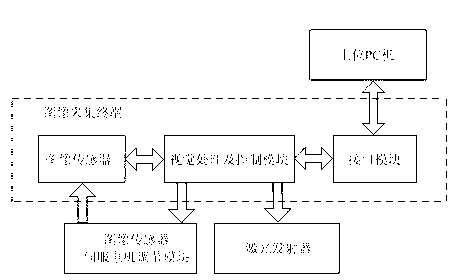

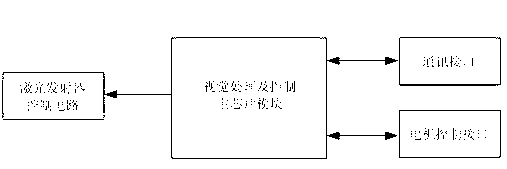

Fluorescent powder coating surface defect detecting system and method based on machine vision

InactiveCN103134785AThickness information richComprehensive quality inspectionOptically investigating flaws/contaminationUsing optical meansForeign matterVision processing

The invention provides a fluorescent powder coating surface defect detecting system and a detecting method based on machine vision. The system comprises a laser emitter, an image collecting terminal, an image sensor servo motor adjusting module, and an upper position personal computer (PC). The image collecting terminal comprises an image sensor, a vision processing and controlling module, and an interface module, wherein the image sensor, the vision processing and controlling module, and the interface module are connected in succession, the upper position PC is connected with the vision processing and controlling module through the interface module, the image sensor servo motor adjusting module is respectively connected with the vision processing and controlling module and the image sensor, and the laser emitter is connected with the vision handling and controlling module. A laser triangulation method is adopted to detect the defects that a fluorescent powder coating is too thick and too thin, and thickness is not even. The system collects fluorescent powder coating images which are coated to be compared with a standard image template, and therefore the defects that the fluorescent powder coating is irregular, stuck with glue and foreign matters and the like are detected. The system is simple in structure, low in cost, high in detection speed, and high in detection precision.

Owner:SOUTH CHINA UNIV OF TECH

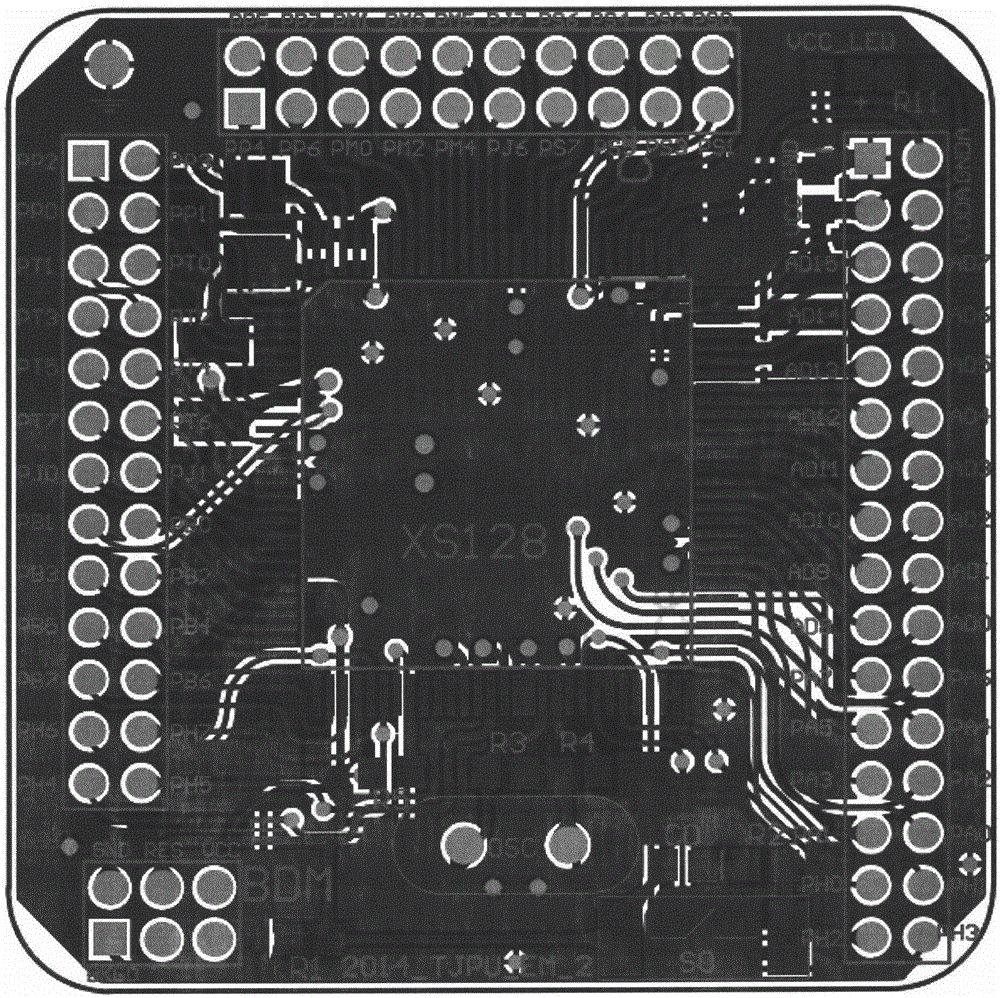

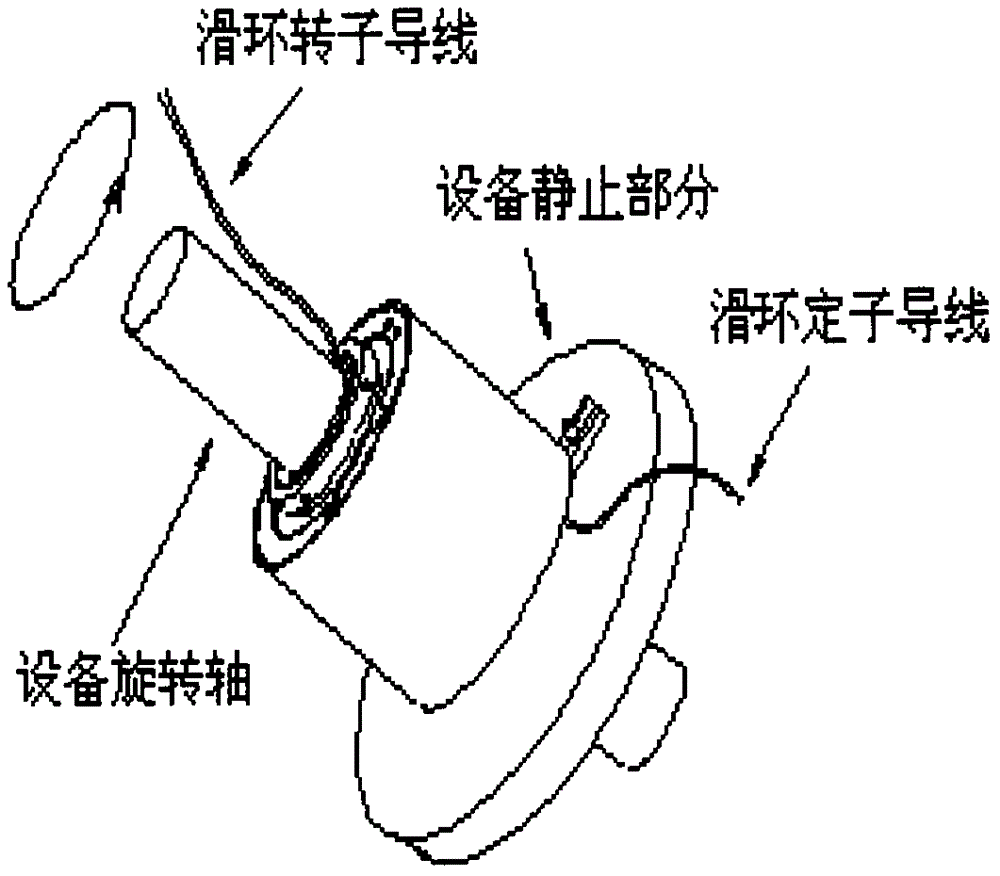

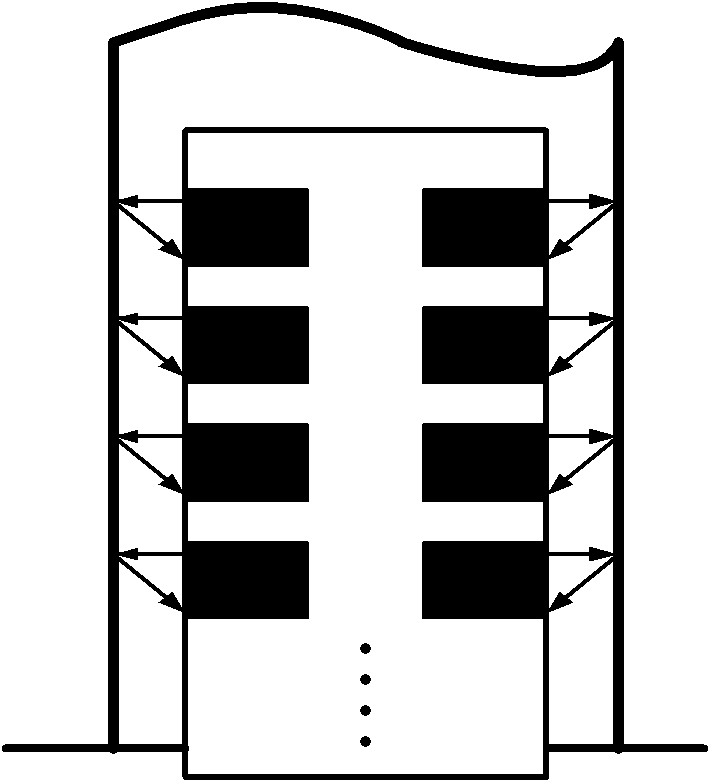

High-speed laser internal diameter detection system

InactiveCN106091961ARealize acquisitionEasy to detectUsing optical meansMeasurement pointElectric control

The invention belongs to the field of intelligent instruments and devices and relates to a high-speed laser internal diameter detection system. The good detection effect of laser on surfaces of objects such as metal is utilized, and relative coordinate information of the measurement point position of a detected internal diameter is obtained using a laser triangulation method. In order to ceaselessly, effectively and stably 360-degree collect various data required in internal diameter detection, a laser range finding probe is innovatively combined with a slip ring, so that the laser range finding probe can be directly connected to a motor and achieves 360-degree high-speed rotation. A high-precision electric control linear guide rail is utilized to achieve comprehensive acquisition of internal diameter data, thereby conducting high-precision internal diameter measurement. Through verification, the laser internal diameter detection method meets requirements of internal diameter nondestructive testing, a host computer platform is friendly, and correlated data can be fed back remotely and wirelessly. The measurement method provided by the method can be popularized into other high-precision dimension detection systems capable of reflecting object internal walls.

Owner:TIANJIN POLYTECHNIC UNIV

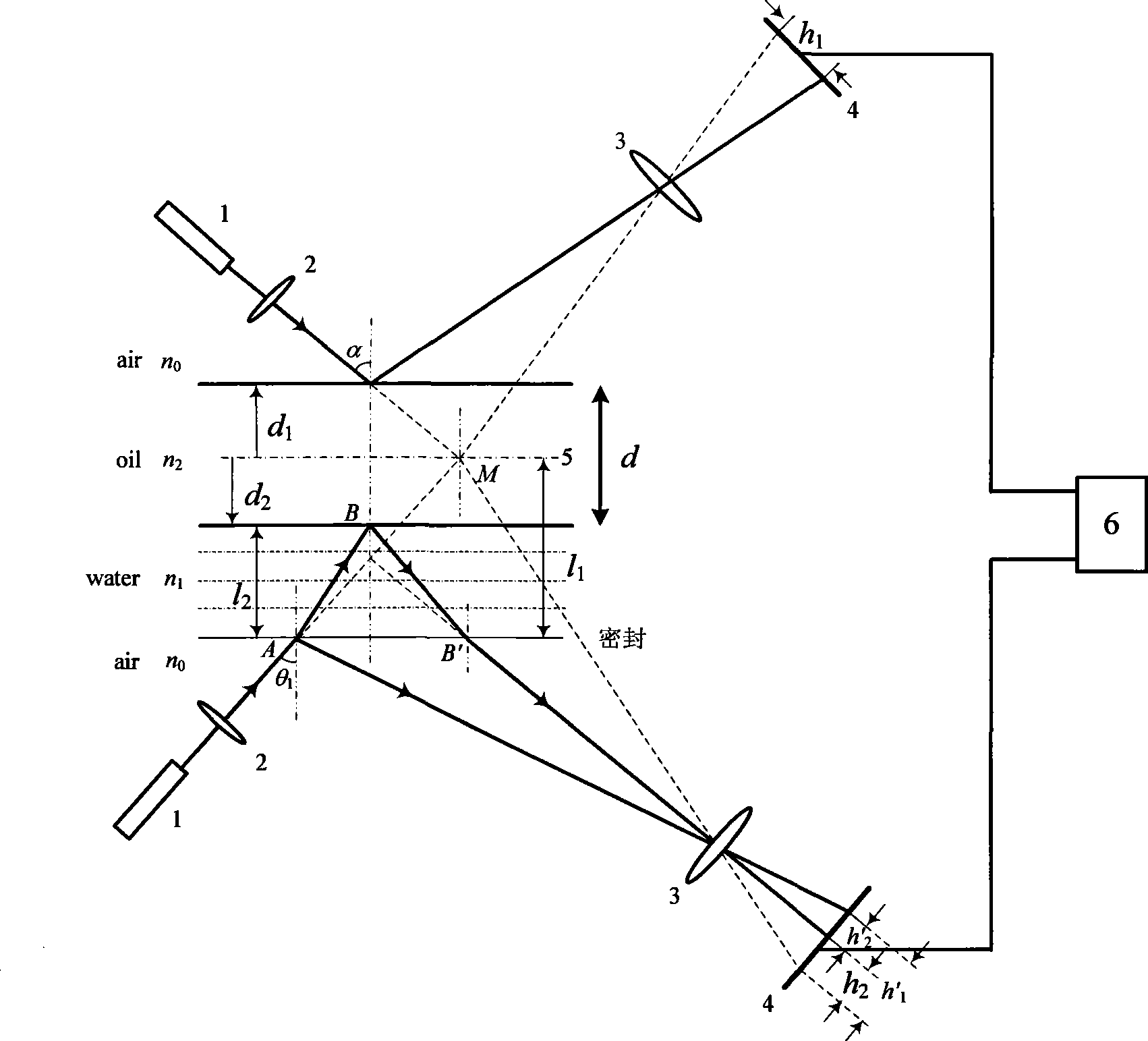

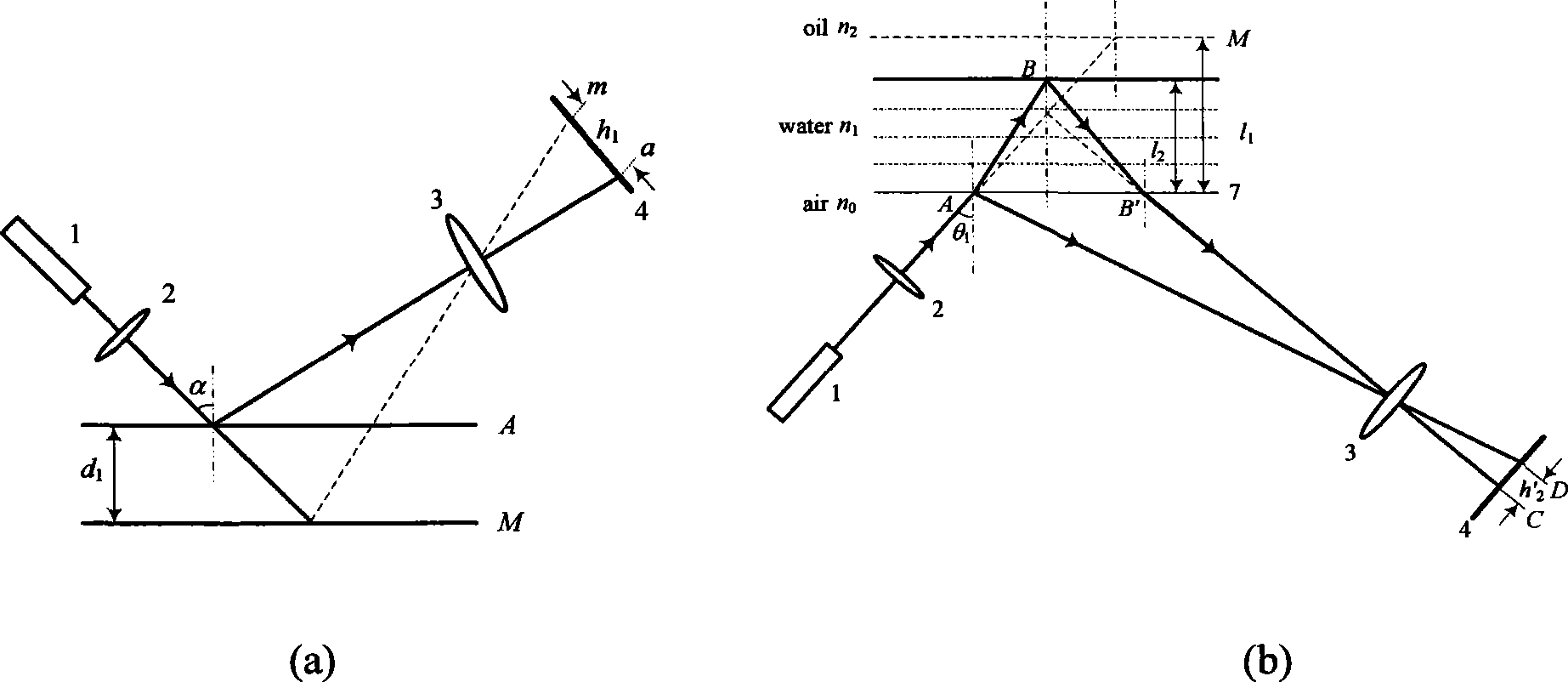

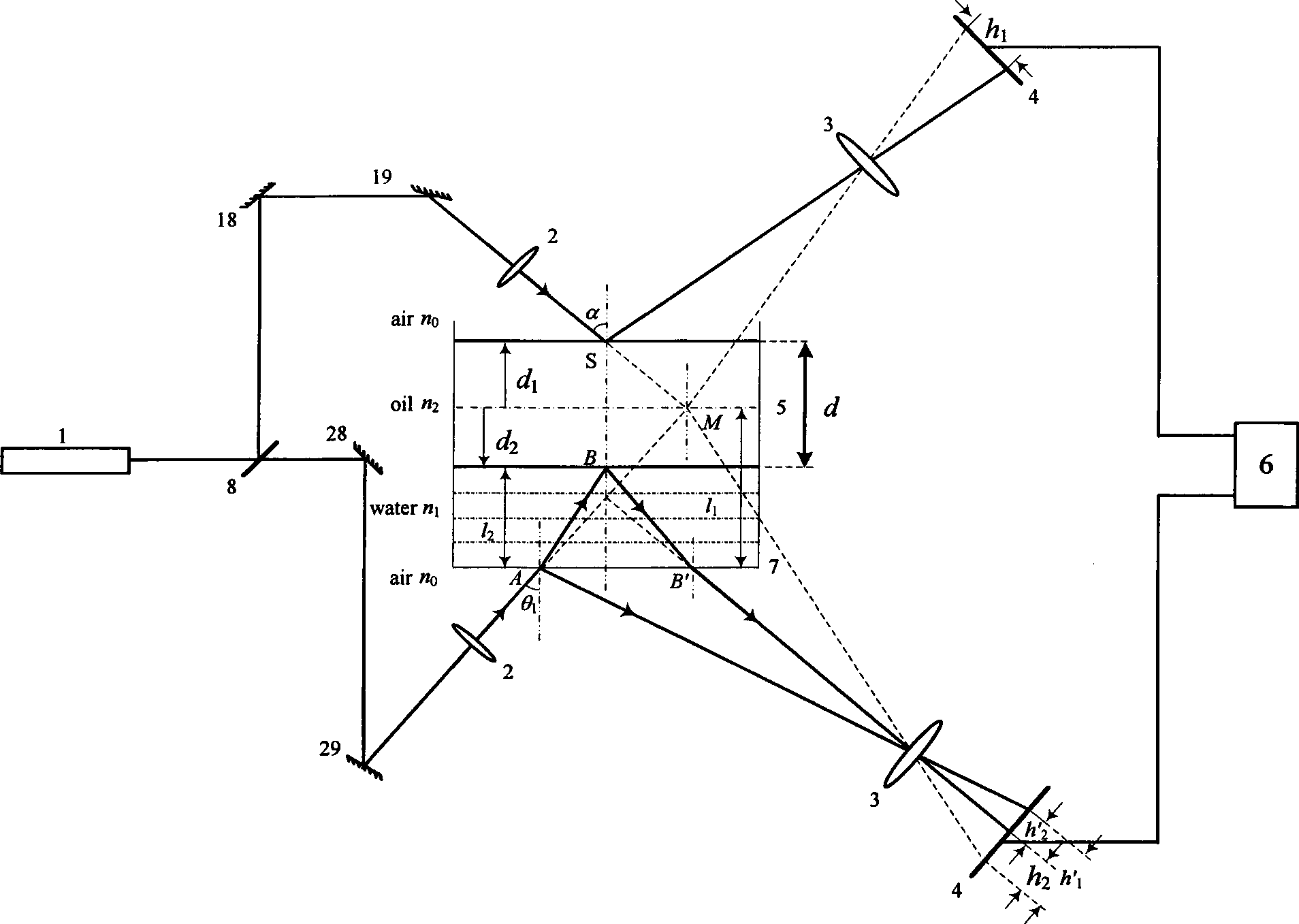

Method for measuring thickness of sea surface spilled oil film based on differential laser triangulation method

InactiveCN101532825AThe principle is simpleEasy to measureUsing optical meansAqueous solutionLaser beams

The invention relates to a method for measuring thickness of sea surface spilled oil film based on differential laser triangulation. The method uses dual laser triangulation ranging system, and laser beams emitted by two lasers are respectively irradiated to the upper and the lower surfaces of an oil film to be measured in any vertical direction; the off-plane displacements of the upper and the lower surfaces can be obtained simultaneously according to the size of image drift and configuration parameters of imaging system; the thickness of the measured oil film can be determined by subtracting; and the thickness distribution of oil film in spilled oil area can be obtained by multi-point sampling. The non-contact measuring method has the characteristics of simple theory, convenient measurement, low cost, high precision, small volume and the like, and can be applied to dynamic on-line measurement of oil film thickness at the surface of aqueous solution.

Owner:TIANJIN UNIV

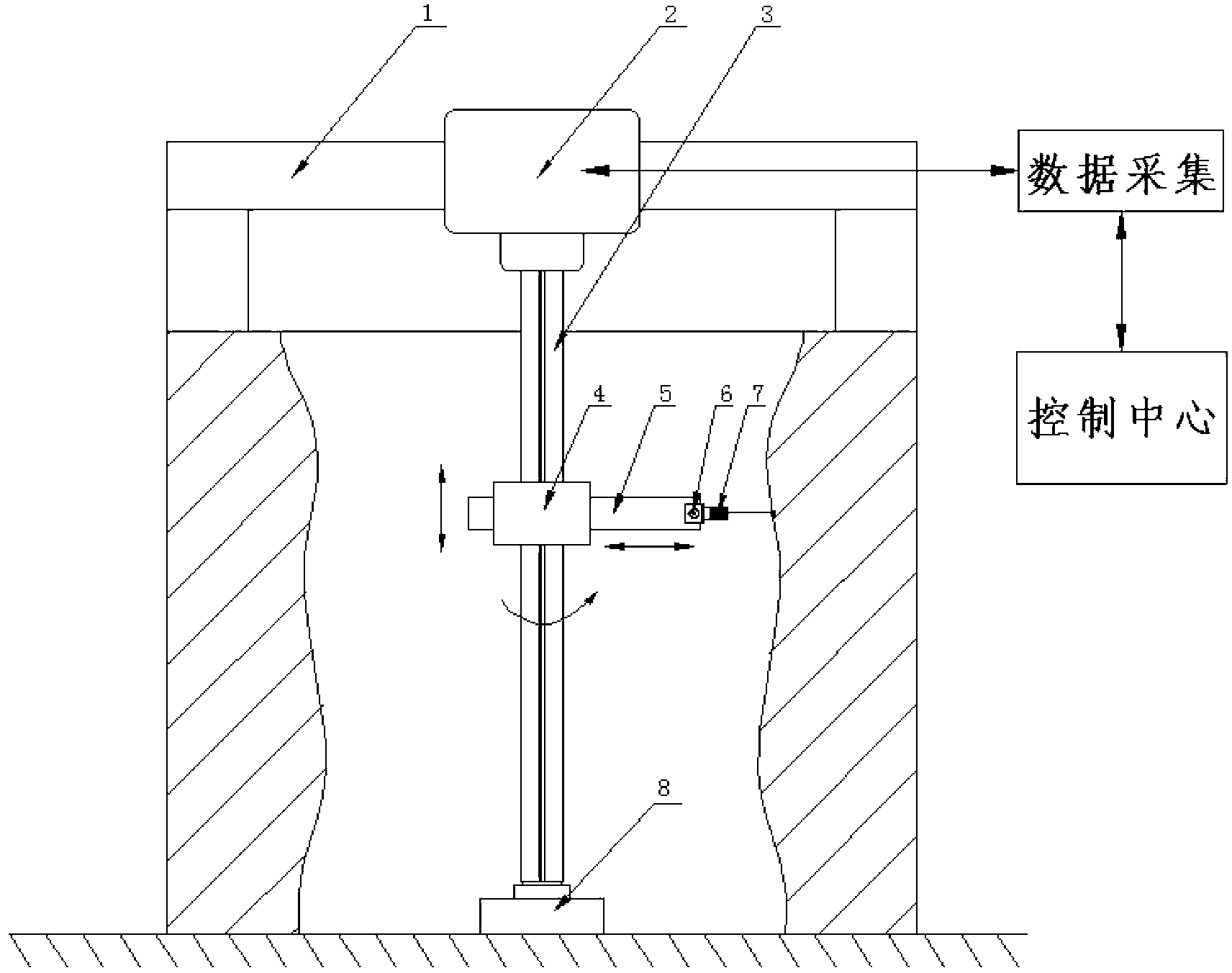

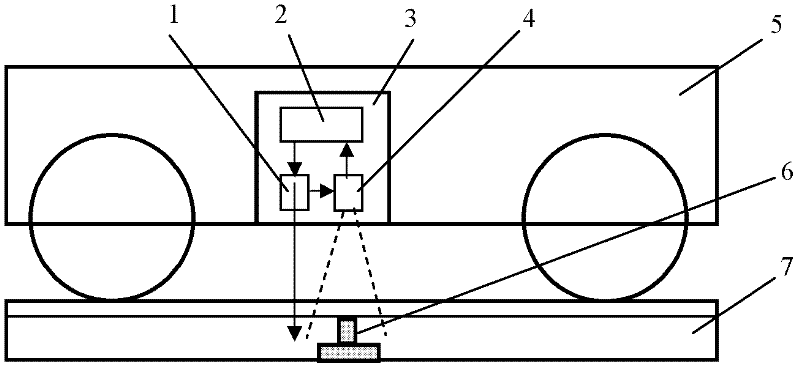

Field measuring device, system and method of inner wall size of large rotary workpiece

InactiveCN103307977AHigh measurement accuracyRealize on-site measurementUsing optical meansLeveling mechanismMeasurement device

The invention discloses a measuring device of the inner wall size of a large rotary workpiece. The device comprises a pedestal, a mounting frame, a rotary mechanism, a longitudinal moving mechanism, a transverse moving mechanism, a leveling mechanism and a laser displacement sensor, wherein the pedestal is used for supporting other parts of the device; the mounting frame is used for mounting the device on a workpiece to be measured; the rotary mechanism is arranged between the pedestal and the mounting frame and used for driving the laser displacement sensor to rotate on the horizontal plane; the longitudinal moving mechanism is used for adjusting the position of the laser displacement sensor in the vertical direction; the transverse moving mechanism is used for adjusting the distance of the laser displacement sensor relative to a workpiece measuring point in the horizontal direction; the leveling mechanism is used for adjusting the posture of the laser displacement sensor to enable laser beams emitted by the laser displacement sensor to horizontally illuminate the workpiece measuring point; and the laser displacement sensor is used for measuring the distance from the workpiece measuring point to the sensor. The invention also provides a measuring system and a measuring method based on the measuring device. The space coordinates of the measuring point are determined through laser triangulation theory, so that the measuring precision is high; and the measuring position can be automatically adjusted. The device, the system and the method are suitable for field measurement of various large rotary shell parts.

Owner:HUAZHONG UNIV OF SCI & TECH

System and method for detecting deficiency of railway fasteners on basis of laser and vision

InactiveCN102556116AMeet speed requirementsFast detectionPosition fixationRailway auxillary equipmentTriangulationEngineering

The invention discloses a system and a method for detecting deficiency of railway fasteners on the basis of laser and vision. The system comprises a laser positioning system, a vision identification system and a control center which are all arranged in a detector below a train body and rightly align to the upper side of the areas where the railway fasteners are located. The laser positioning system and the vision identification system are disposed front to back in a staggered manner along the running direction of the train, and the distance between the laser positioning system and the vision identification system is kept constant. The laser positioning system detects and positions the fasteners, sends out synchronous signals and triggers the vision identification system to work. The laser positioning system completes triangulation ranging measurement by utilizing a one-dimension array formed by high-speed semi-conductor photoelectric tubes to substitute for a linear array CCD (charge coupled device) in a common laser triangulation ranging sensor. By the aid of the system and the method for detecting deficiency of the railway fasteners on the basis of laser and vision, contradiction between detection accuracy and high running speed of the train is overcome effectively, and high-speed detection and identification for the railway fasteners are realized.

Owner:SHANGHAI JIAO TONG UNIV +1

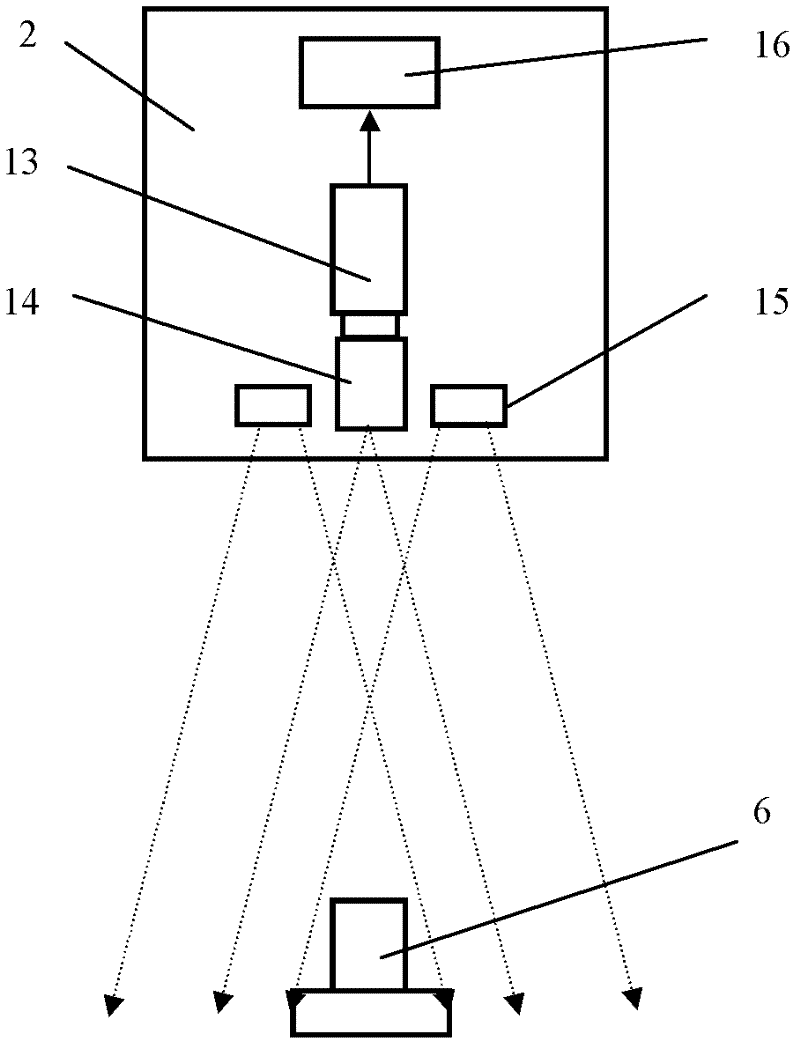

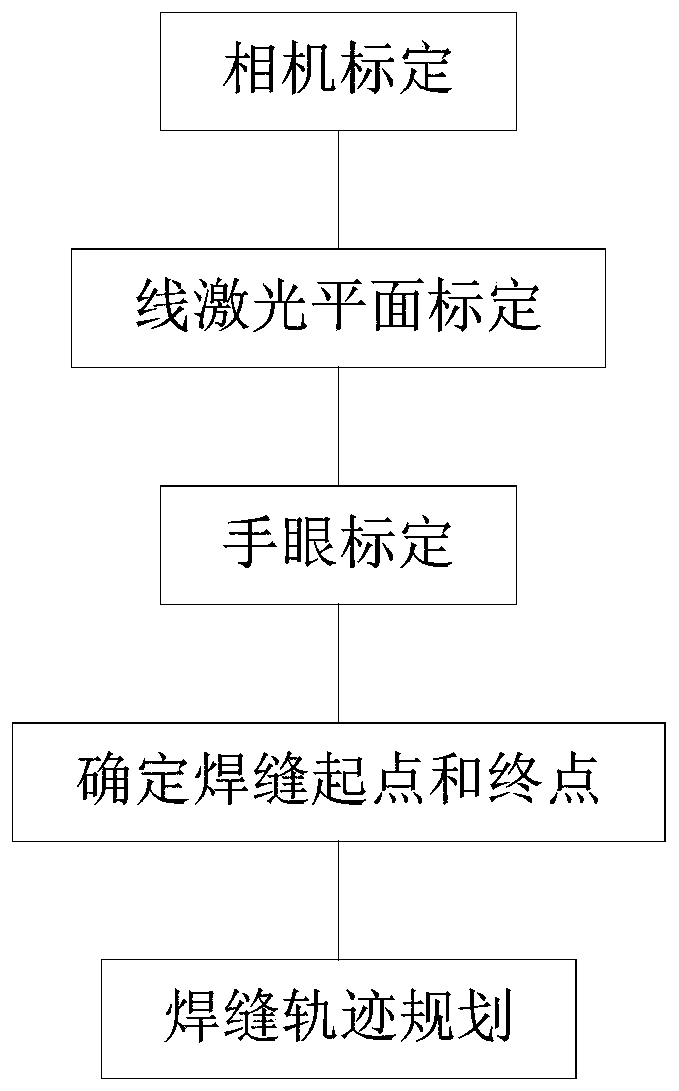

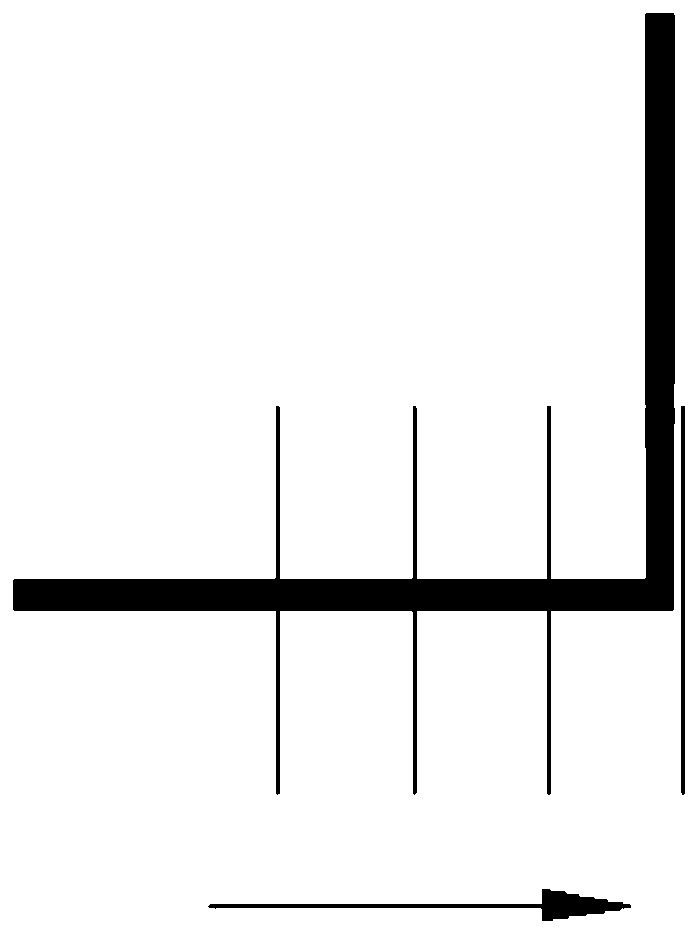

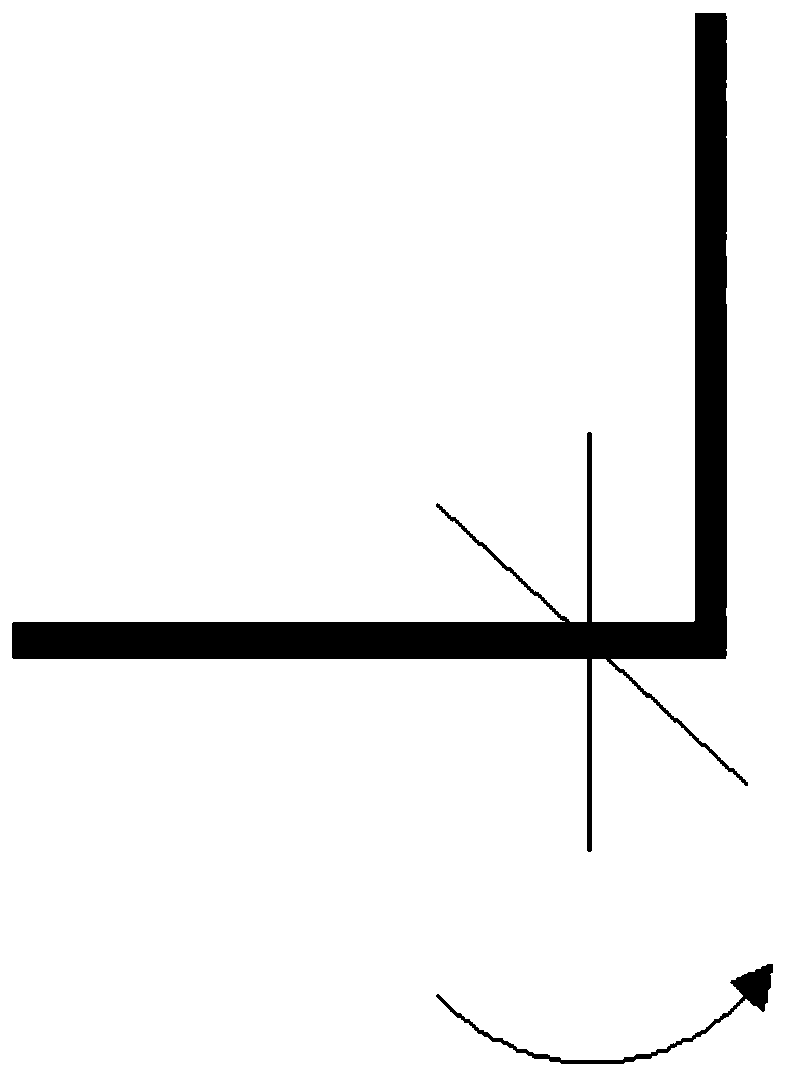

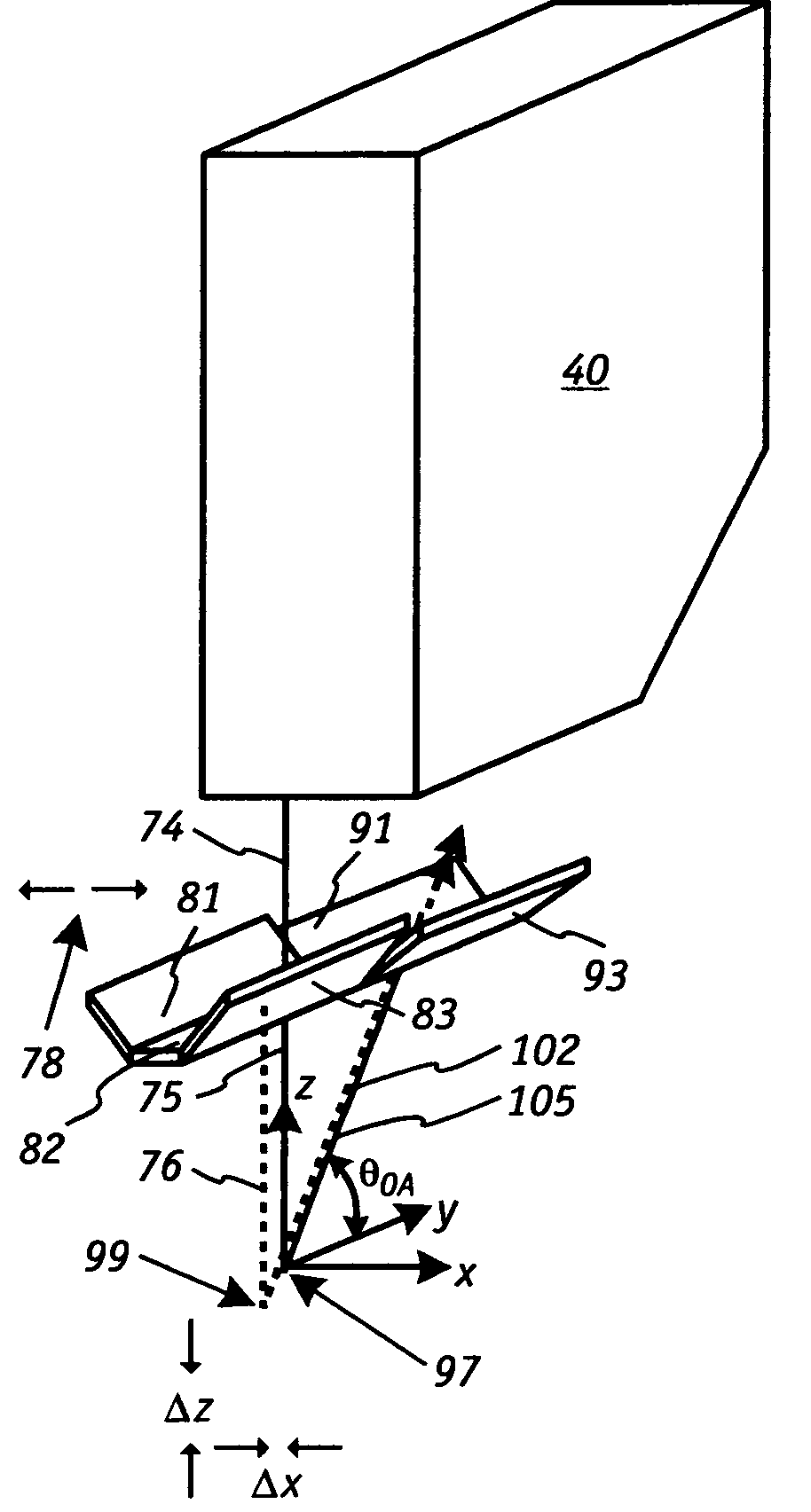

Intelligent three-dimensional autonomous weld joint tracing method

InactiveCN110245599ATrace implementationTracking and solvingImage enhancementProgramme-controlled manipulatorAcute angleHand eye calibration

The invention belongs to the technical field of automatic welding, and provides an intelligent three-dimensional weld joint autonomous tracking method which comprises the following steps: S1, camera calibration: a camera shoots and acquires image information of calibration plates at different spatial positions, establishes a corresponding equation set according to the shot image information, and obtains an internal parameter matrix and an external parameter matrix through analysis; s2, line laser plane calibration; s3, hand-eye calibration; s4, determination of a welding seam starting point and a welding seam ending point; and s5, welding seam track planning. According to the intelligent three-dimensional autonomous welding seam tracing method, any type of weld grooves is identified by utilizing an image algorithm; a linear laser triangulation method and a vision and robot calibration algorithm are adopted to autonomously plan a motion path, so that autonomous tracking of a welding line in any three-dimensional space is realized, three-dimensional orientation information of a welding line groove is obtained, and tracking of a right-angle or acute-angle inflection point is realized in a self-adaptive pre-swing manner.

Owner:深圳市超准视觉科技有限公司

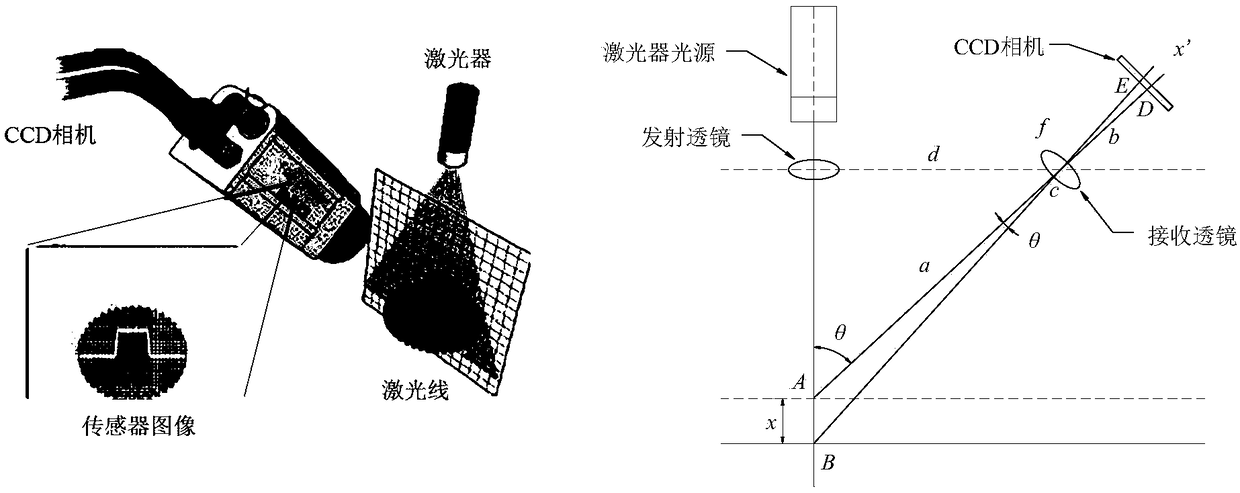

Laser triangulation sensor

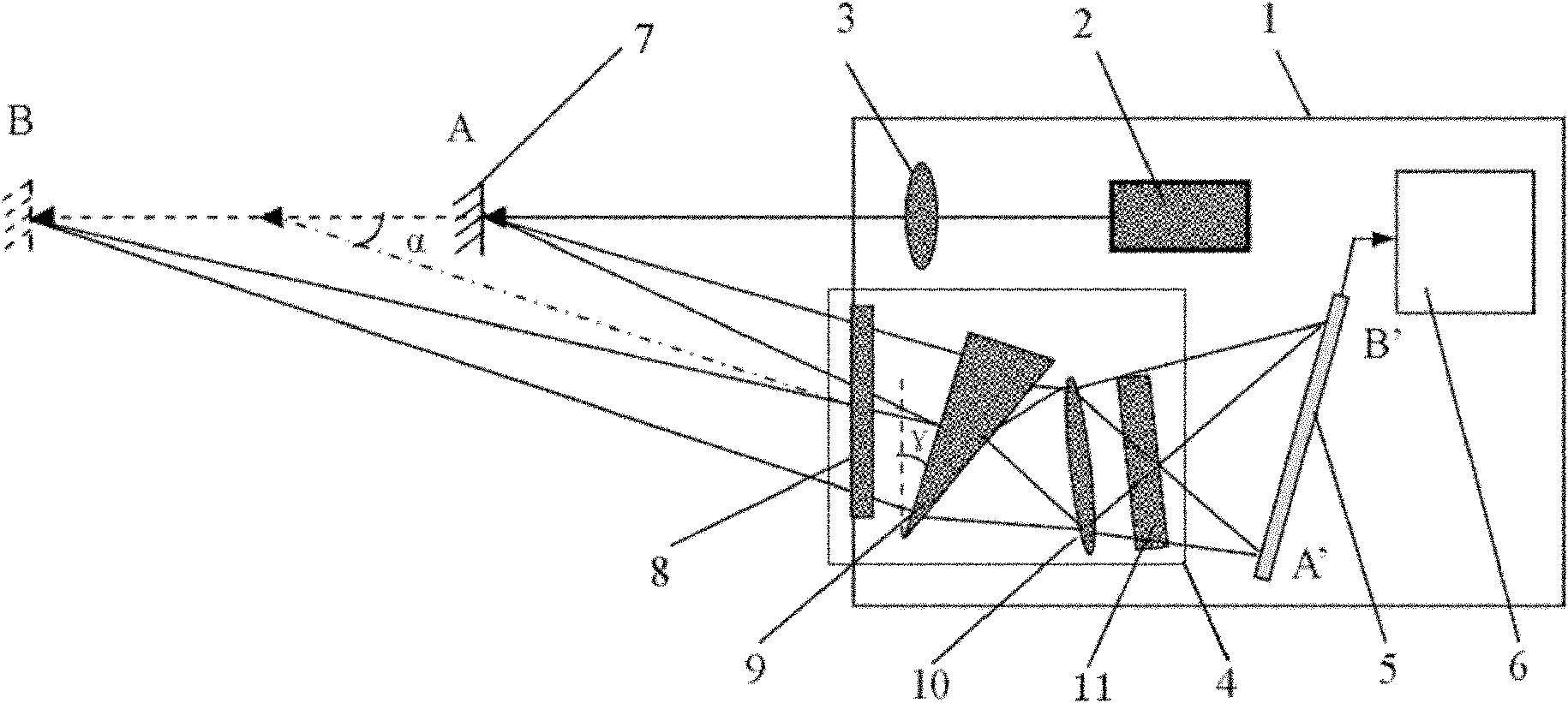

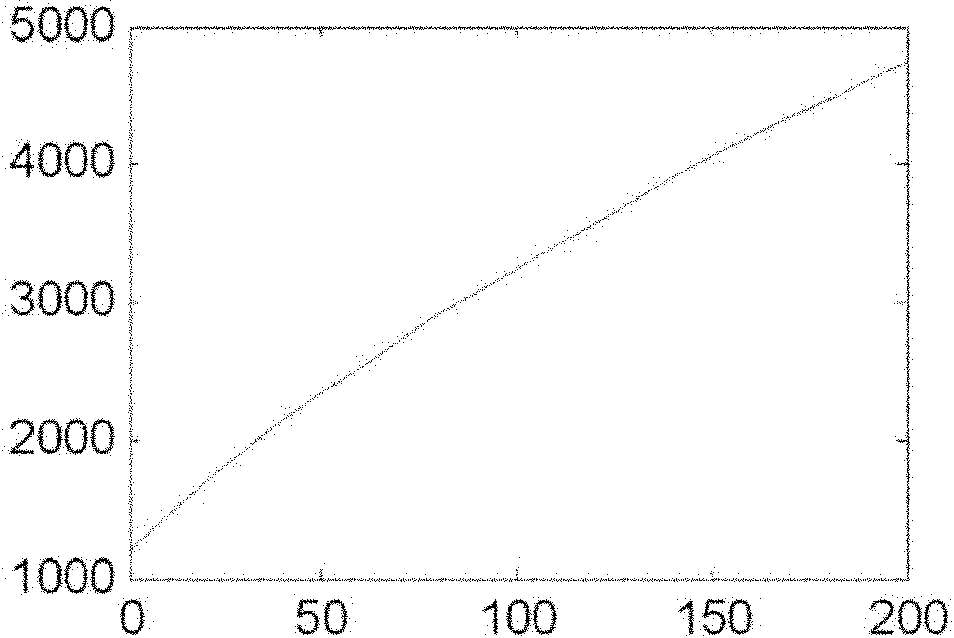

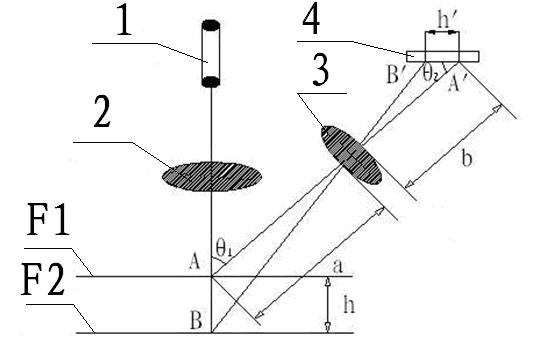

ActiveCN102147234AAdd nonlinearityImprove image qualityUsing optical meansOptoelectronicsOptical measurements

The invention discloses a laser triangulation sensor in the technical field of optical measurement. The laser triangulation sensor comprises a laser, a transmitting lens group, a receiving lens group, a photosensitive device and a signal processing device, wherein the laser, the transmitting lens group and a measured target are linearly arranged at the transmitting end; the receiving lens group and the photosensitive device are arranged at the reflecting end; the receiving lens group and the photosensitive device are arranged at the same side of the laser and the transmitting lens group and are located in the same plane with the laser and the transmitting lens group; and the signal processing device is connected with the photosensitive device for receiving electric signals. In the invention, non-axisymmetrical lenses are added in the receiving lens group, so that nonlinearity of the laser triangulation sensor is corrected in principle, and the problem of nonuniform resolution is solved.

Owner:常州高晟传感技术有限公司

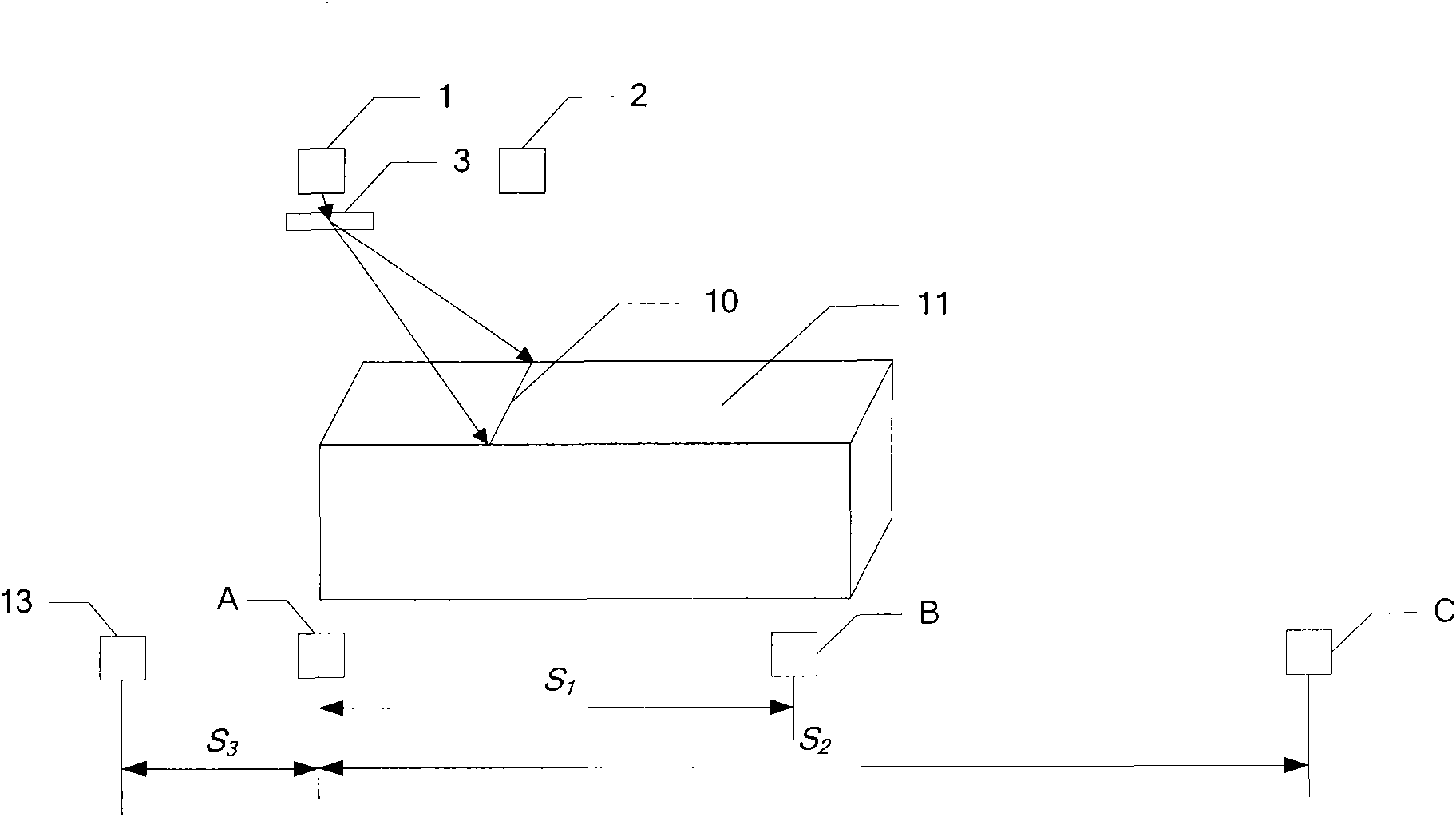

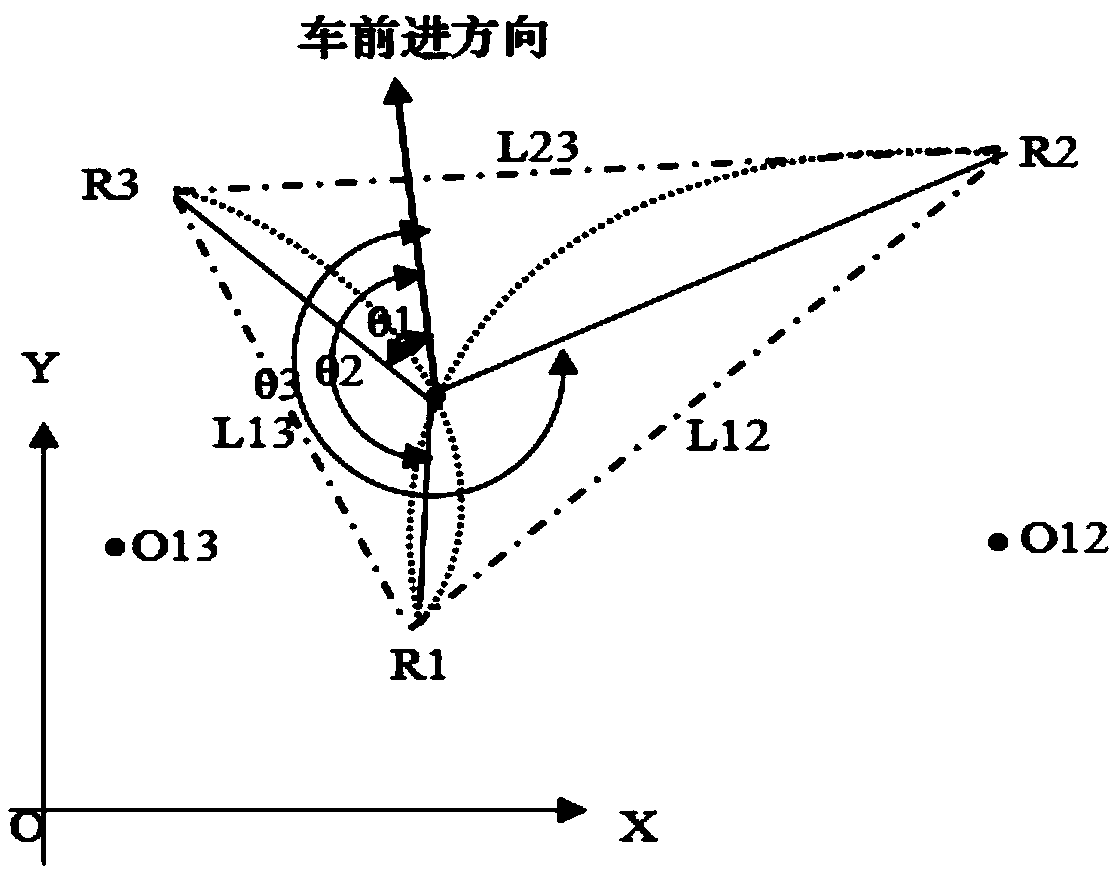

Truck volumetric measurement method based on laser triangulation

The invention discloses a truck volumetric measurement method based on laser triangulation, comprising the following steps: three measuring points are arranged in sequence along the vehicle travelling direction on a vehicle travelling channel; each measuring point is provided with a sensing device for sensing arrival and departure of the measured vehicle; a sensing device for acquiring car axle quantity of the measured vehicle is arranged at a set position in front of a first measuring point; the four sensing devices are used for acquiring length of the measured vehicle; a laser device and a video camera are arranged above the center line of the vehicle travelling channel; a cylindrical lens which causes laser beams to irradiate on a horizontal plane so as to form laser bars is additionally arranged in front of the laser device; length and position of the laser bars on vehicle roof, which are shoot by the camera video are used for acquiring width and height of the measured vehicle so as to work out volume of the measured vehicle. The method disclosed by the invention has advantages of practicability and reliability and can reduce costs for measuring the volume of trucks.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

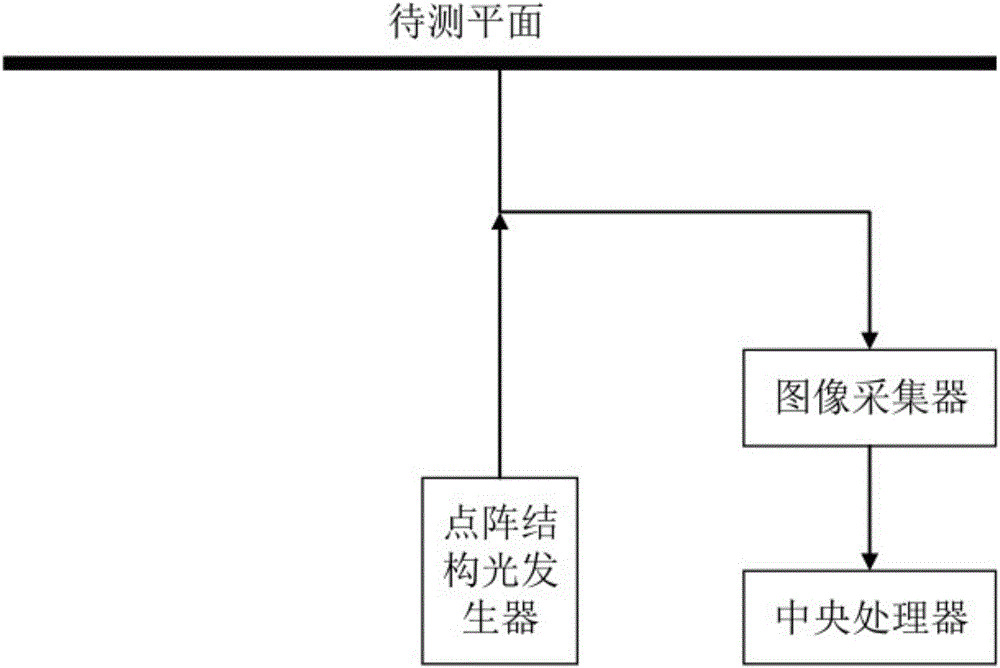

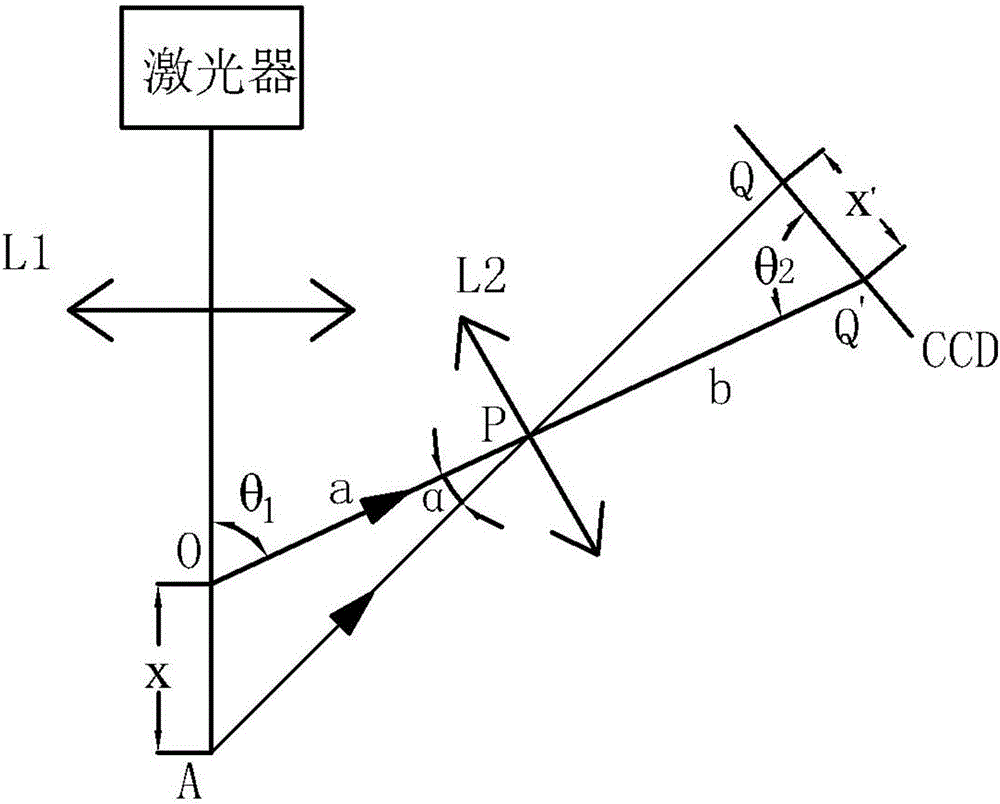

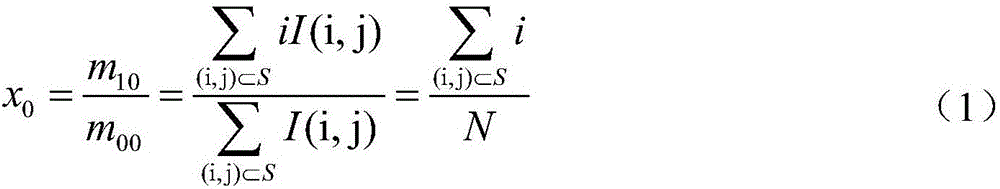

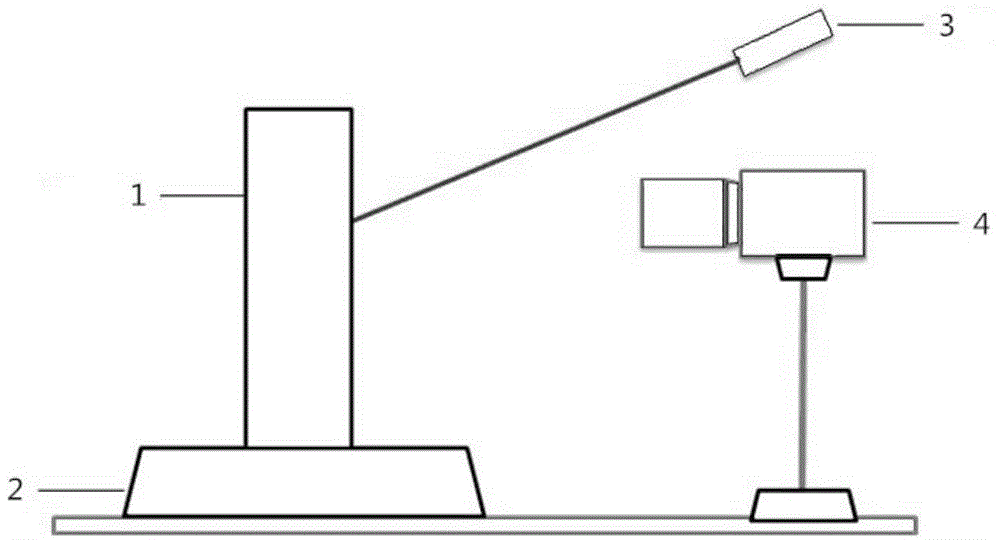

Method for measuring planeness through lattice structure light

The invention discloses a method for measuring planeness through lattice structure light. The method provided by the invention can simply, conveniently and quickly accomplishes medium precision measurement of the planeness through applying principles of the lattice structure light and a laser triangulation method. The method comprises the steps of firstly, through theoretical calculation, obtaining a world coordinate of each light spot of the lattice structure light on an ideal plane; then adopting an image collector calibration method for transforming coordinates to obtain corresponding image coordinates; acquiring images through a camera so as to accomplish transformation from the world coordinates of light spots on each plane to be measured to image coordinates; through operation, obtaining a difference value between the two image coordinates corresponding to each light spot; applying the principle of the laser triangulation method for carrying out coordinate transformation once again, and obtaining physics displacement corresponding to the image coordination difference value; processing the physics displacement of each light spot to obtain the planeness of the plane to be measured.

Owner:浙江四点灵机器人股份有限公司

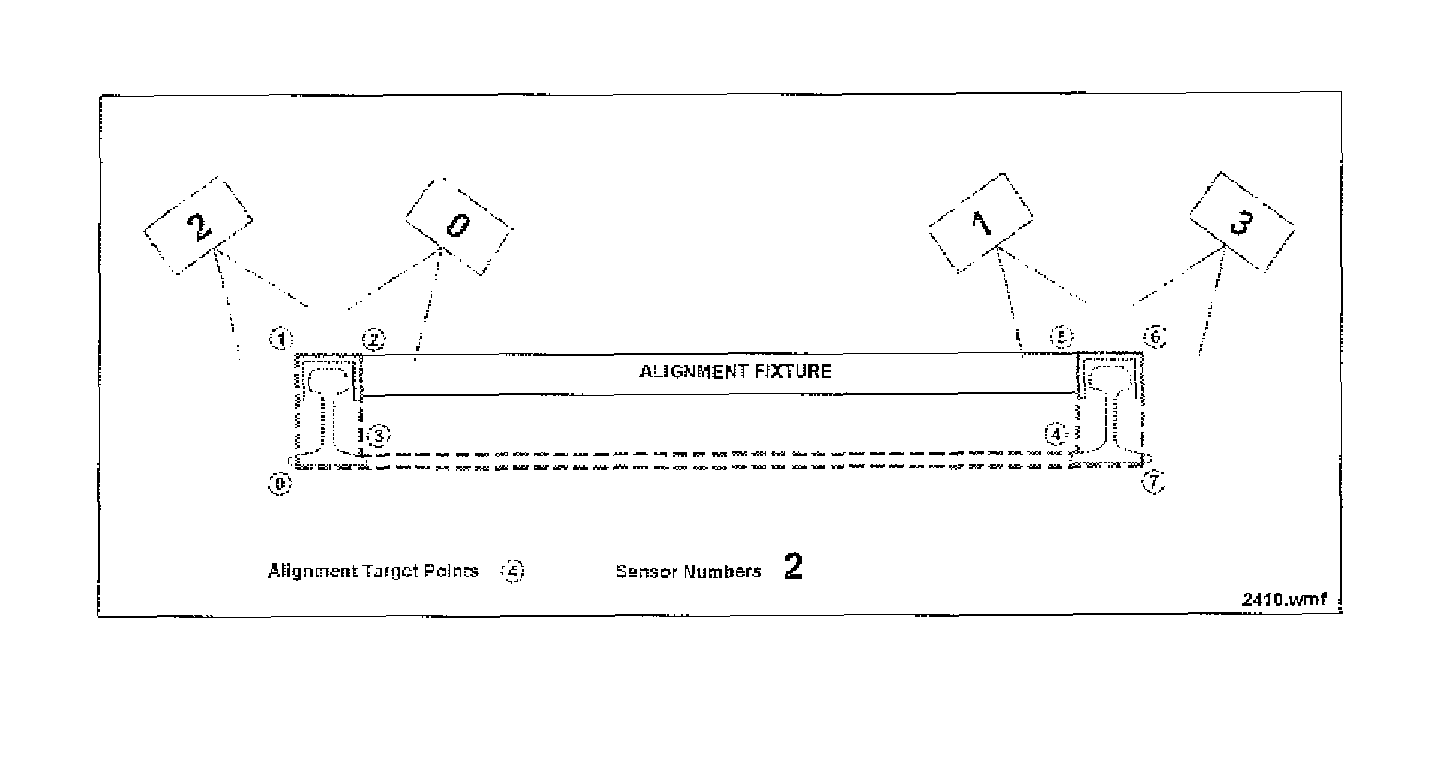

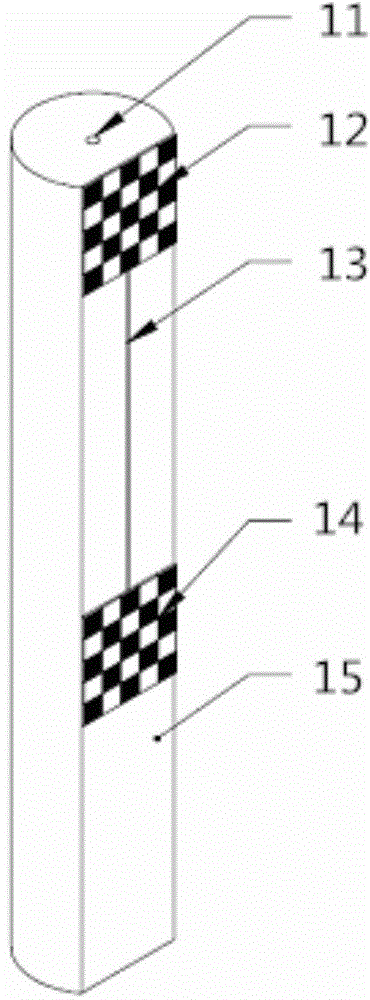

Apparatus and method for calibration of laser triangulation system

Disclosed in the invention is an apparatus for calibration of a laser triangulation system. The apparatus comprises a rotating platform, a top pin and a calibration cylinder; the calibration cylinder is fixedly arranged above the rotating platform; and the top pin is compressed at the upper surface of the calibration cylinder. In addition, the invention also discloses a calibration method for using the calibration apparatus. The calibration cylinder with a slit and checkerboard calibration boards is used as a tool; and on the basis of six steps, a slit image, a calibration board image and a laser image are collected and calculated in real time and whether the system calibration meets the preset requirement is determined. And at last, an imaging plane of a camera is in parallel with a reference plane; and an intersecting line of the laser and the reference plane is intersected with and is perpendicular to an optical axis of a lens. The provided method is simple and effective and can be mastered by an operator easily. Moreover, the adjustment precision is high; accuracy of the laser triangulation system can be effectively ensured; and thus the method and the apparatus have the good application prospects in the non-contact three-dimensional high-precision measurement field.

Owner:SHANGHAI JIAO TONG UNIV +1

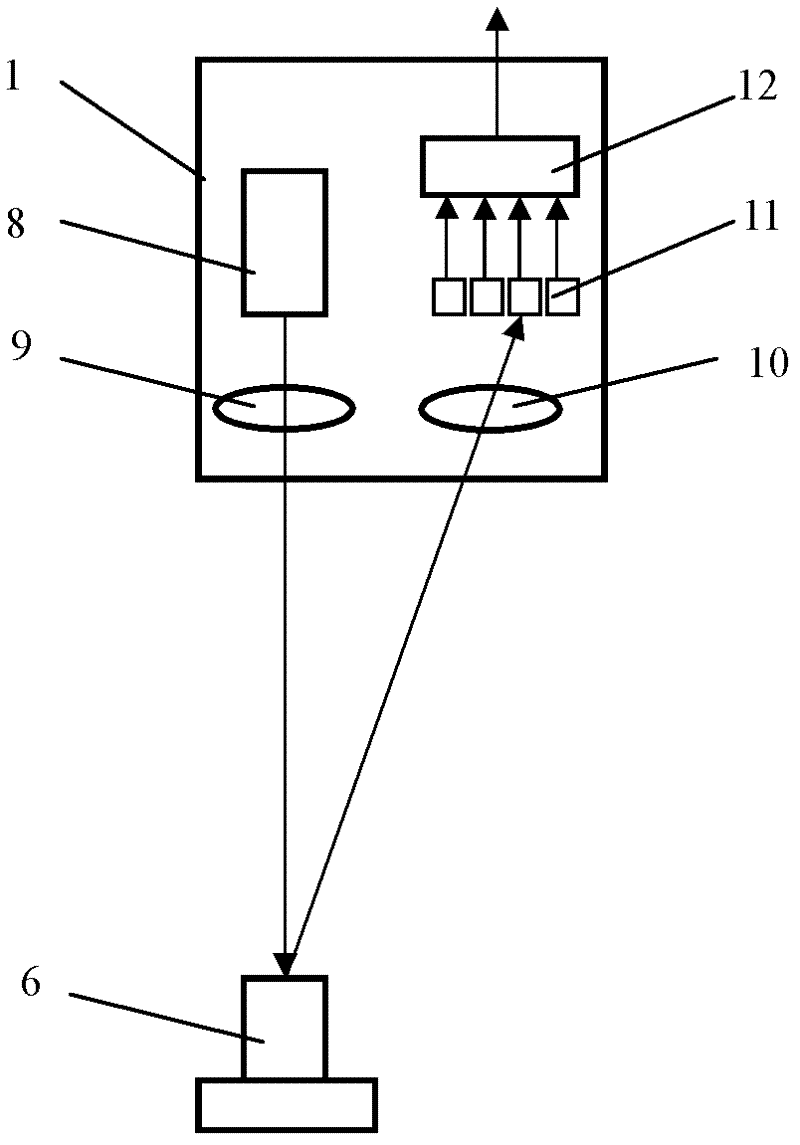

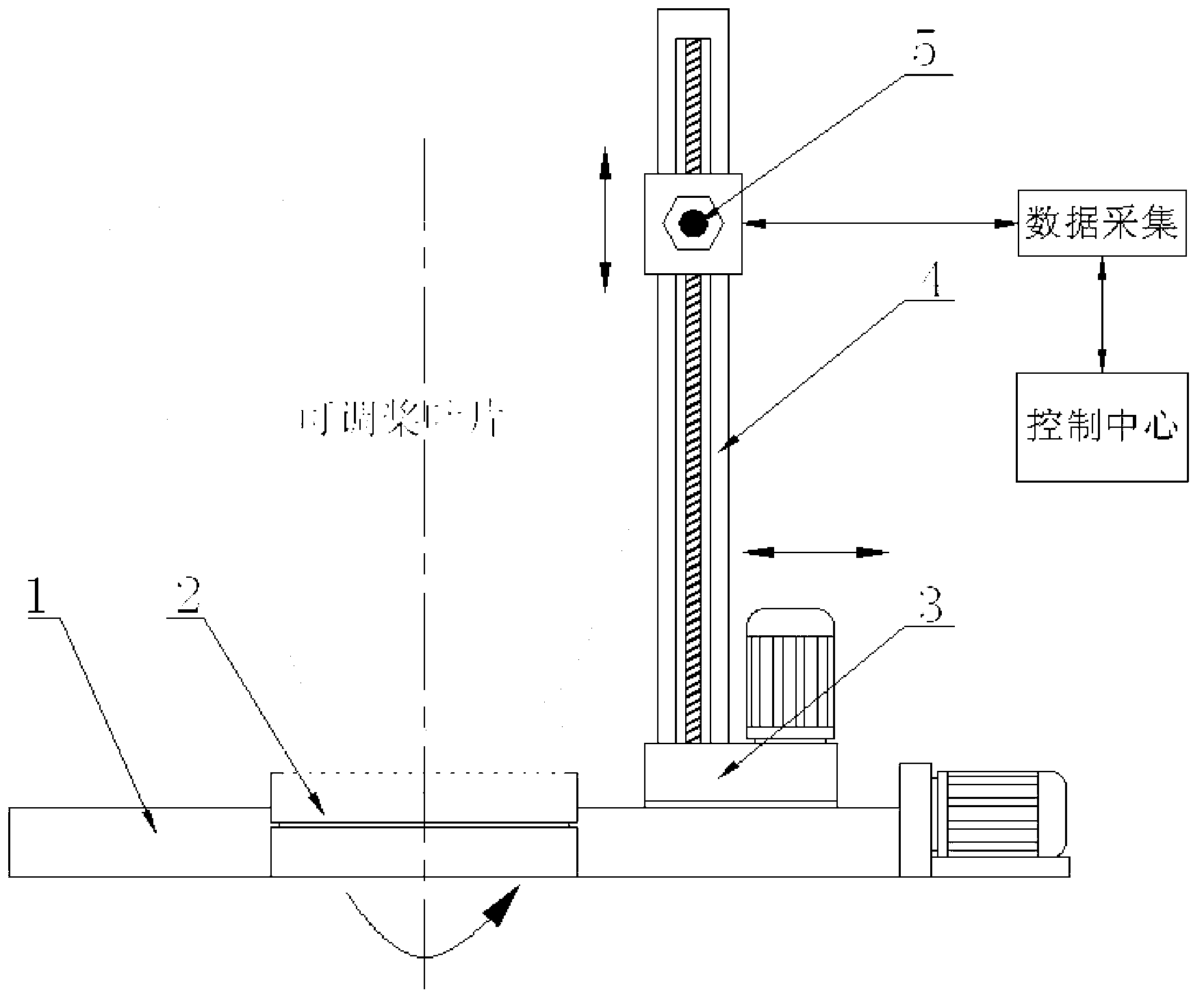

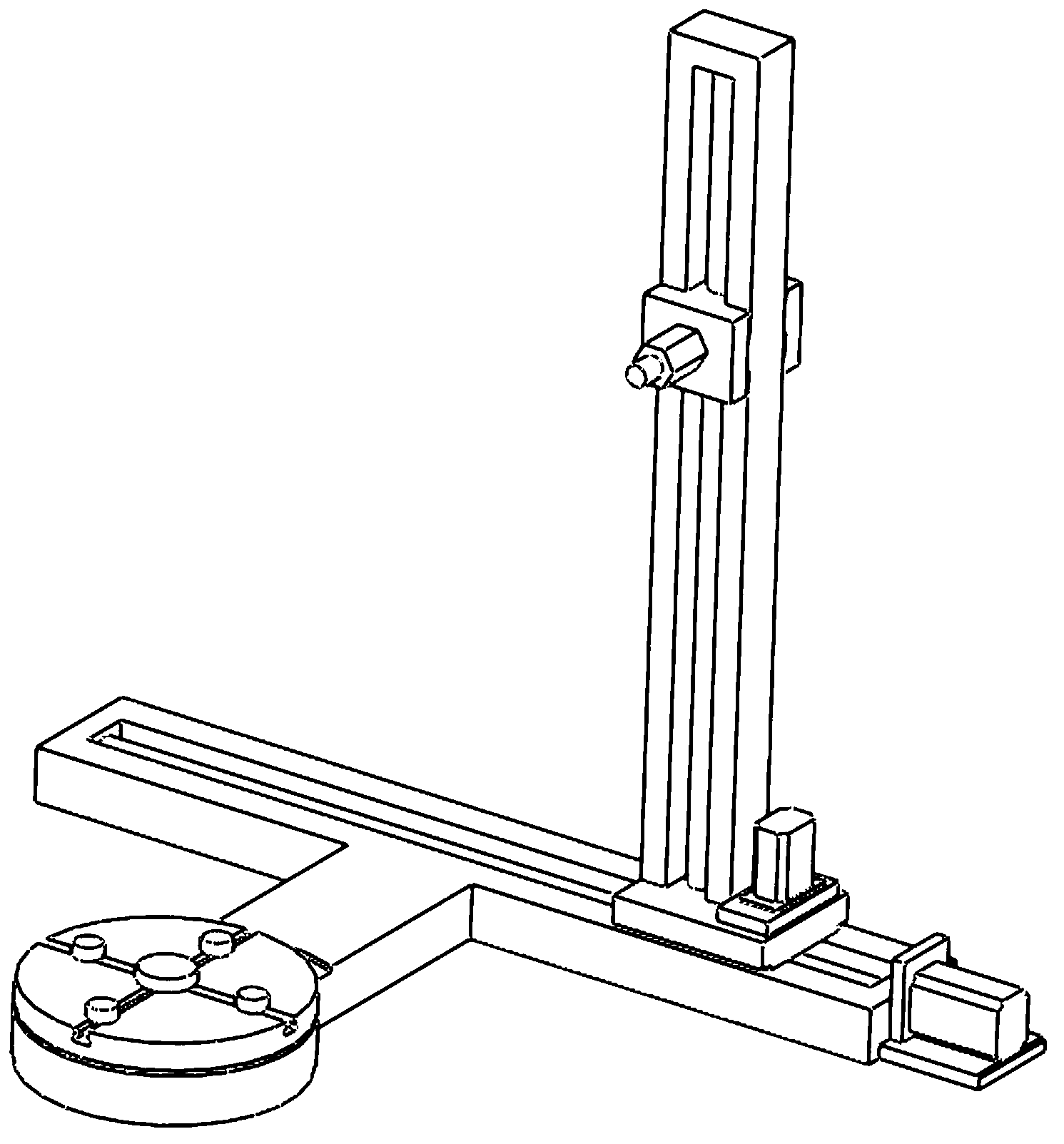

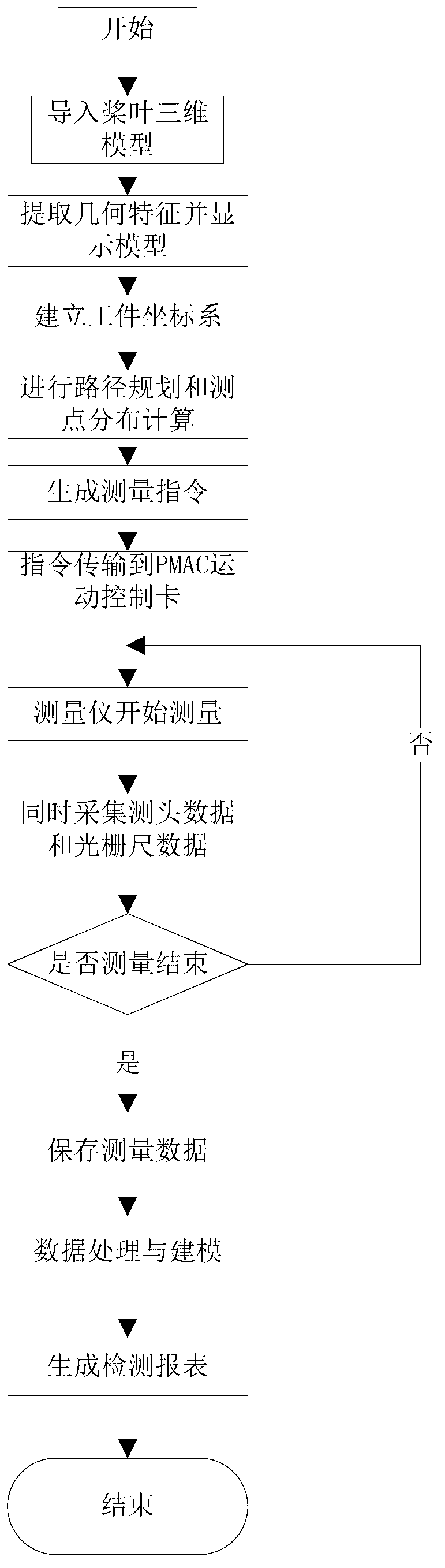

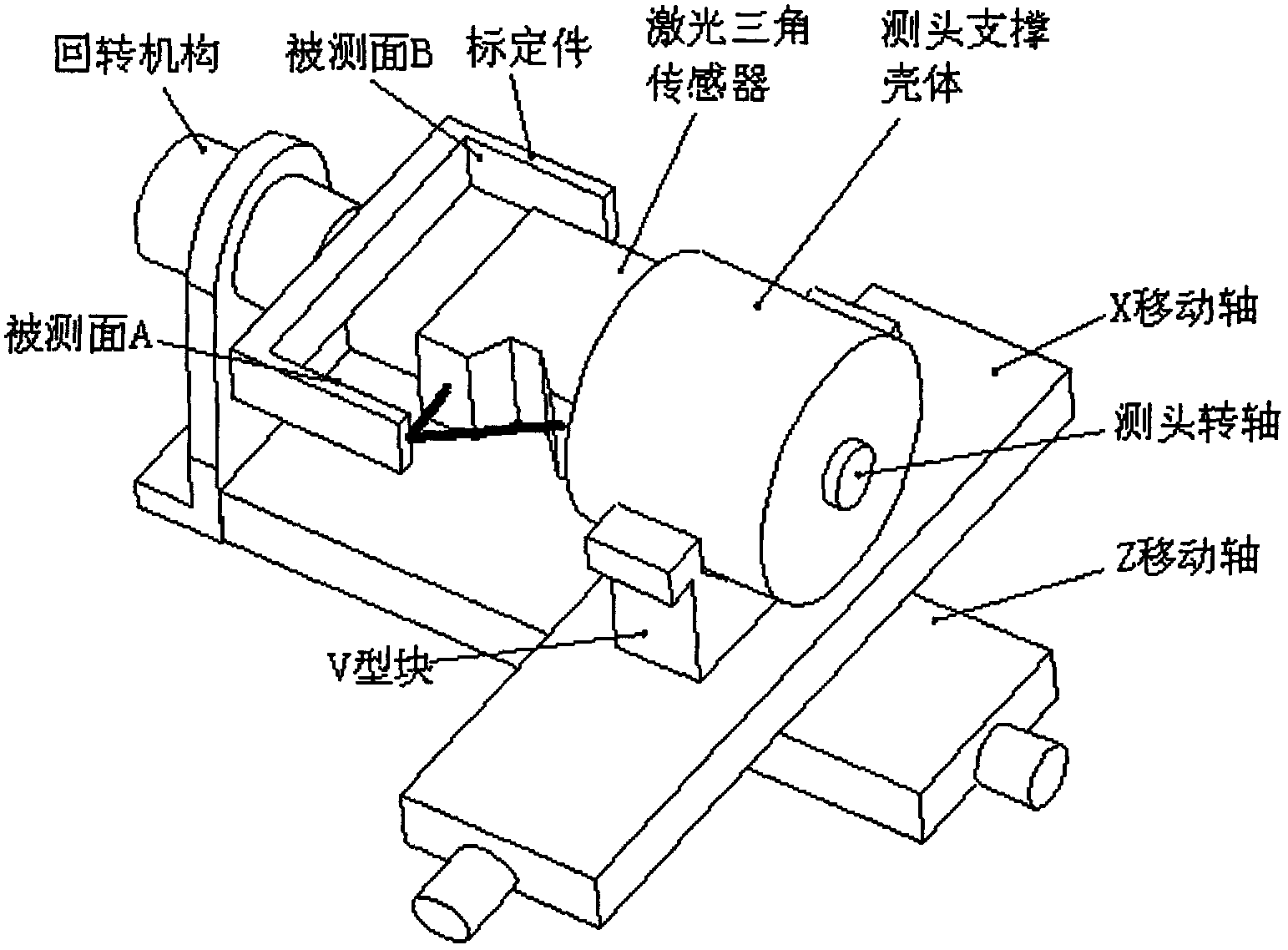

Laser measuring device, laser measuring system and laser measuring method for adjustable paddle blade

ActiveCN103307984ASimple structureEasy to controlUsing optical meansMeasurement deviceOptoelectronics

The invention discloses a laser measuring device for an adjustable paddle blade. The laser measuring device comprises a base, a rotary table, a laser displacement sensor, a transverse moving mechanism and a longitudinal moving mechanism, wherein the base is used for supporting other parts of the measuring device; the rotary table is arranged on the base and used for placing and rotating the adjustable paddle blade to be measured; the transverse moving mechanism is used for adjusting the position, corresponding to a measuring point on the adjustable paddle blade, of the laser displacement sensor in the horizontal direction; the longitudinal moving mechanism is used for adjusting the position, corresponding to the measuring point on the adjustable paddle blade, of the laser displacement sensor in the vertical direction; and the laser displacement sensor is used for collecting the distance between the measuring point on the adjustable paddle blade and the laser displacement sensor. The invention provides a laser measuring system and a laser measuring method for the adjustable paddle blade. With the principle of laser triangulation, the space coordinates of the measuring point are obtained, full automatic measurement of the adjustable paddle blade is realized, and the measurement precision and efficiency are effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

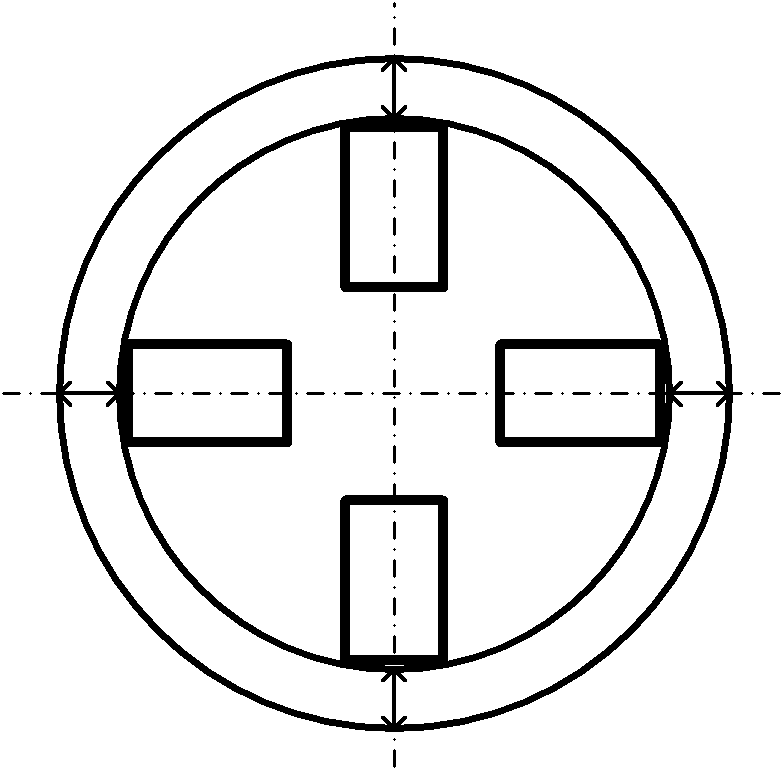

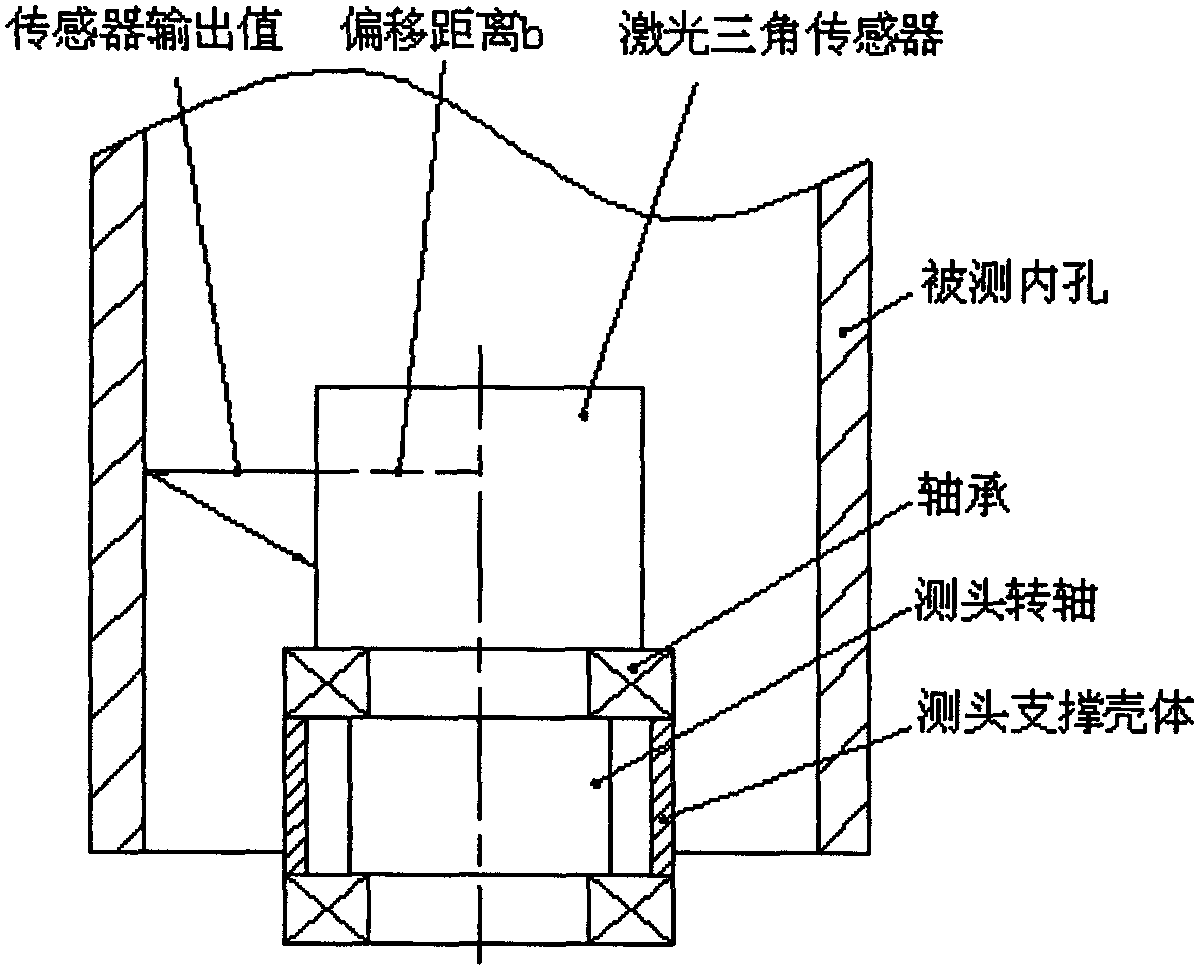

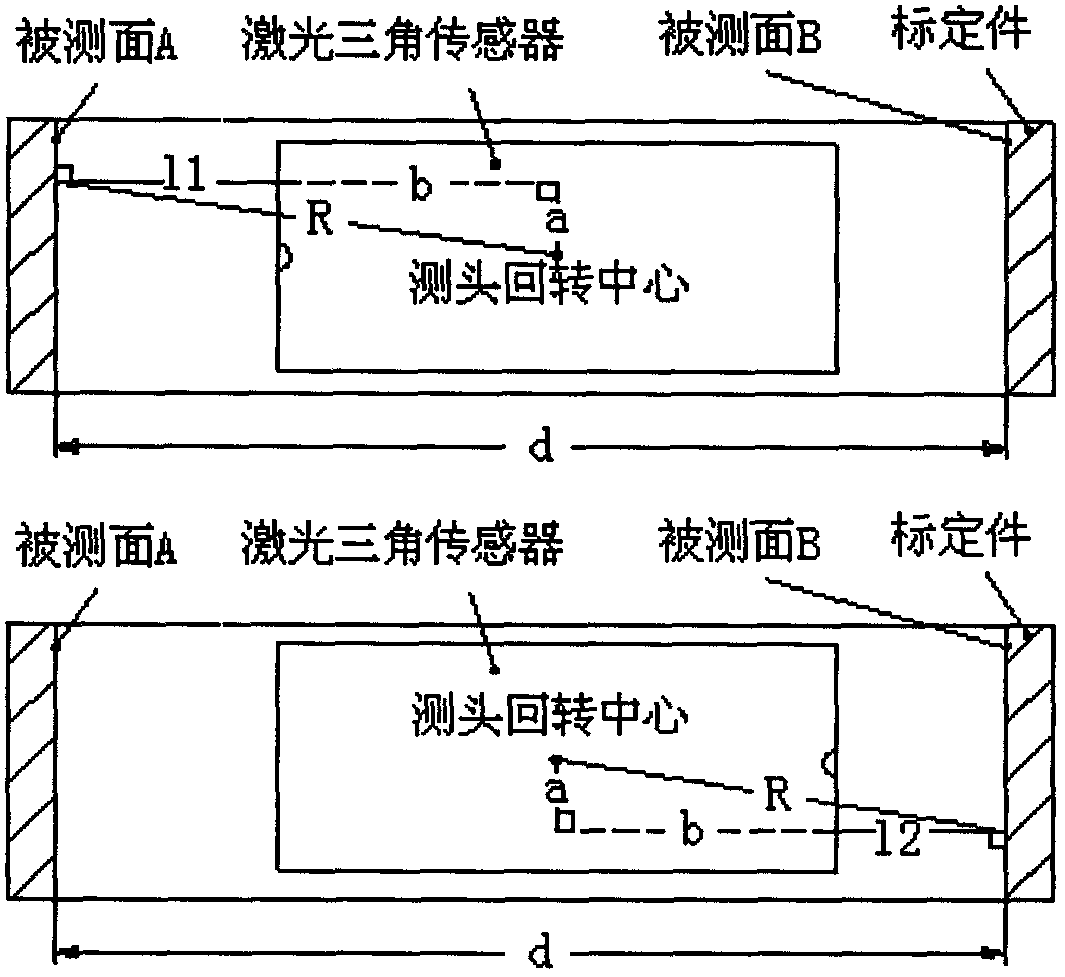

Method for precisely measuring inner diameter of multi-direction shaft hole based on laser triangulation method

InactiveCN101788272ASolve the problem of small measurement gapReduce the radial dimension of the measuring rodUsing optical meansPosition toleranceSize measurement

The invention discloses a method for precisely measuring the inner diameter of a multi-direction shaft hole based on a laser triangulation method. A measuring rod extends to the shaft hole to measure the inner diameter of the shaft hole, at least one measuring section is distributed on the measuring rod, at least two measuring heads are distributed on each measuring section, and each measuring head is a measuring member based on the measuring principle of the laser triangulation method. By applying the measuring principle of the laser triangulation method, the invention solves the problem of small measuring gap of the traditional measuring method and accomplishes the precise measurement under the condition of a large gap. A light source for measuring in the invention adopts the light transmission mode of an optical fiber so that the method greatly reduces the radial size of the measuring rod, lowers heat productivity and has obvious superiority in the size measurement of small hole diameters. The invention can accomplish the measurement of the multi-radial direction diameter size and the form and position tolerance of the shaft hole, has the advantages of high measuring efficiency and high speed and precision and can realize high-automation on-line measurement of products.

Owner:TIANJIN UNIV

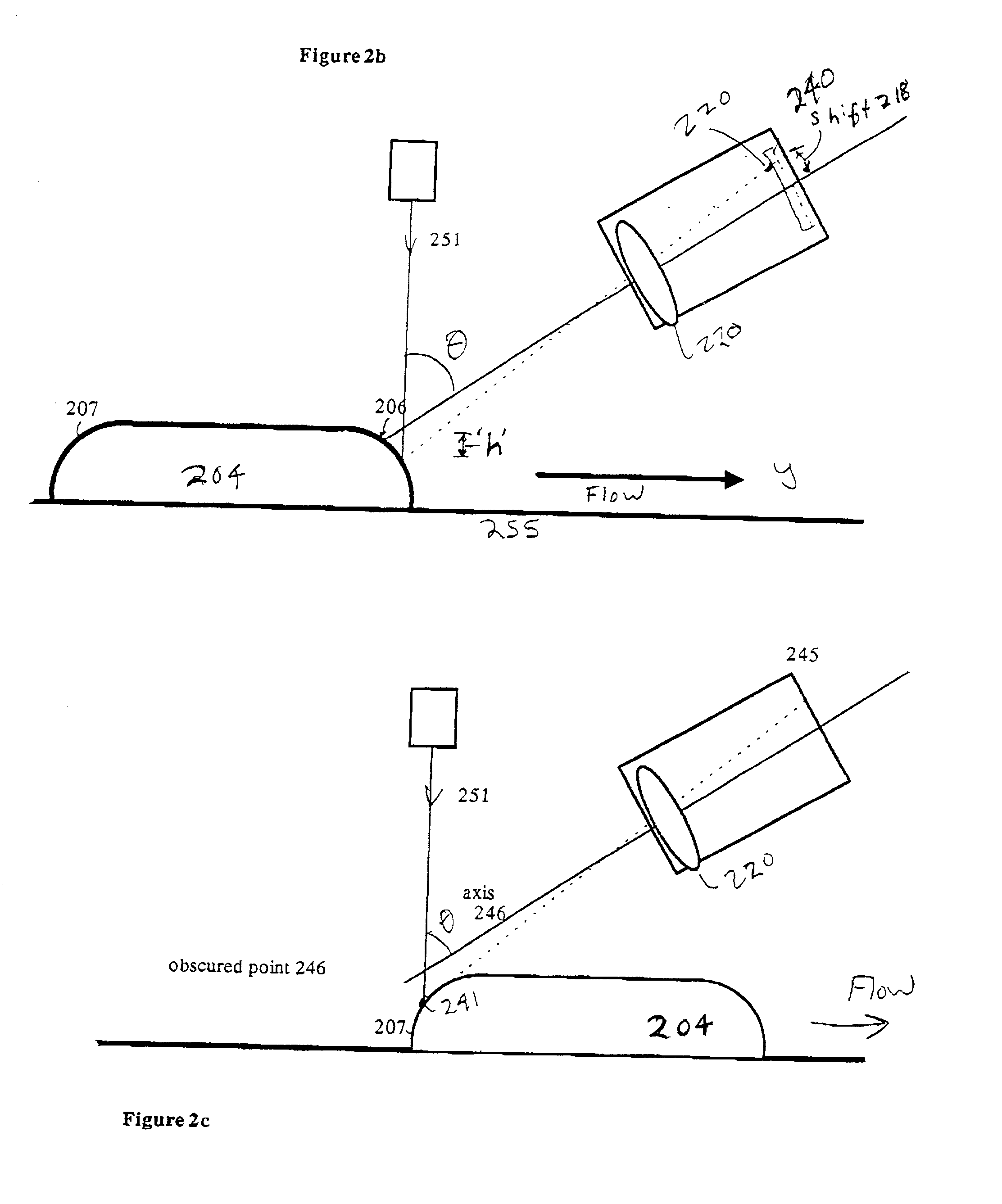

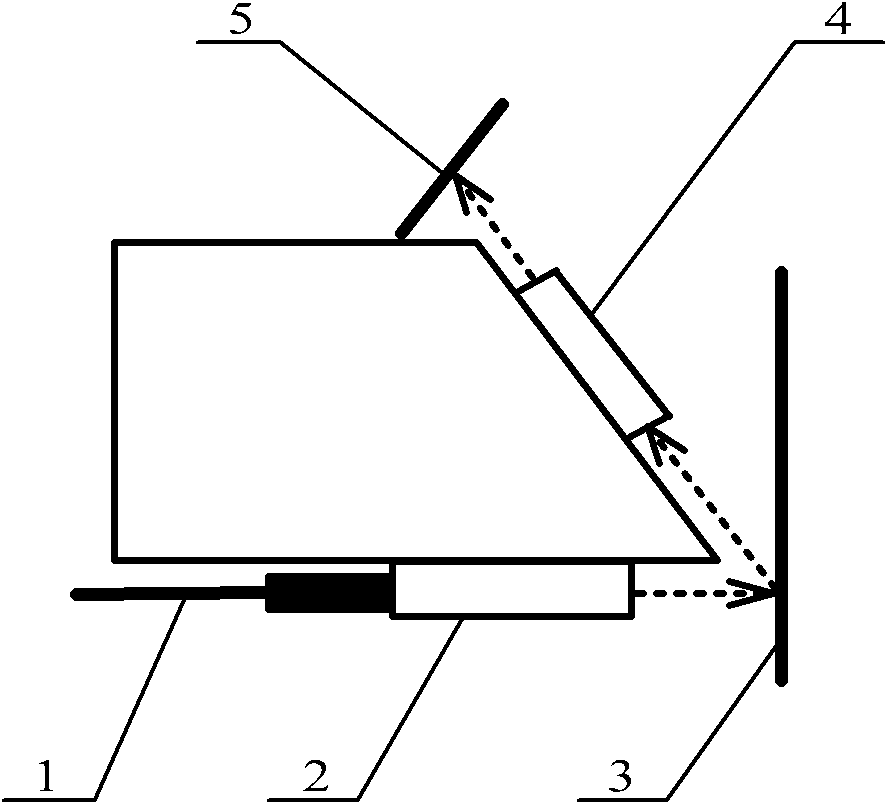

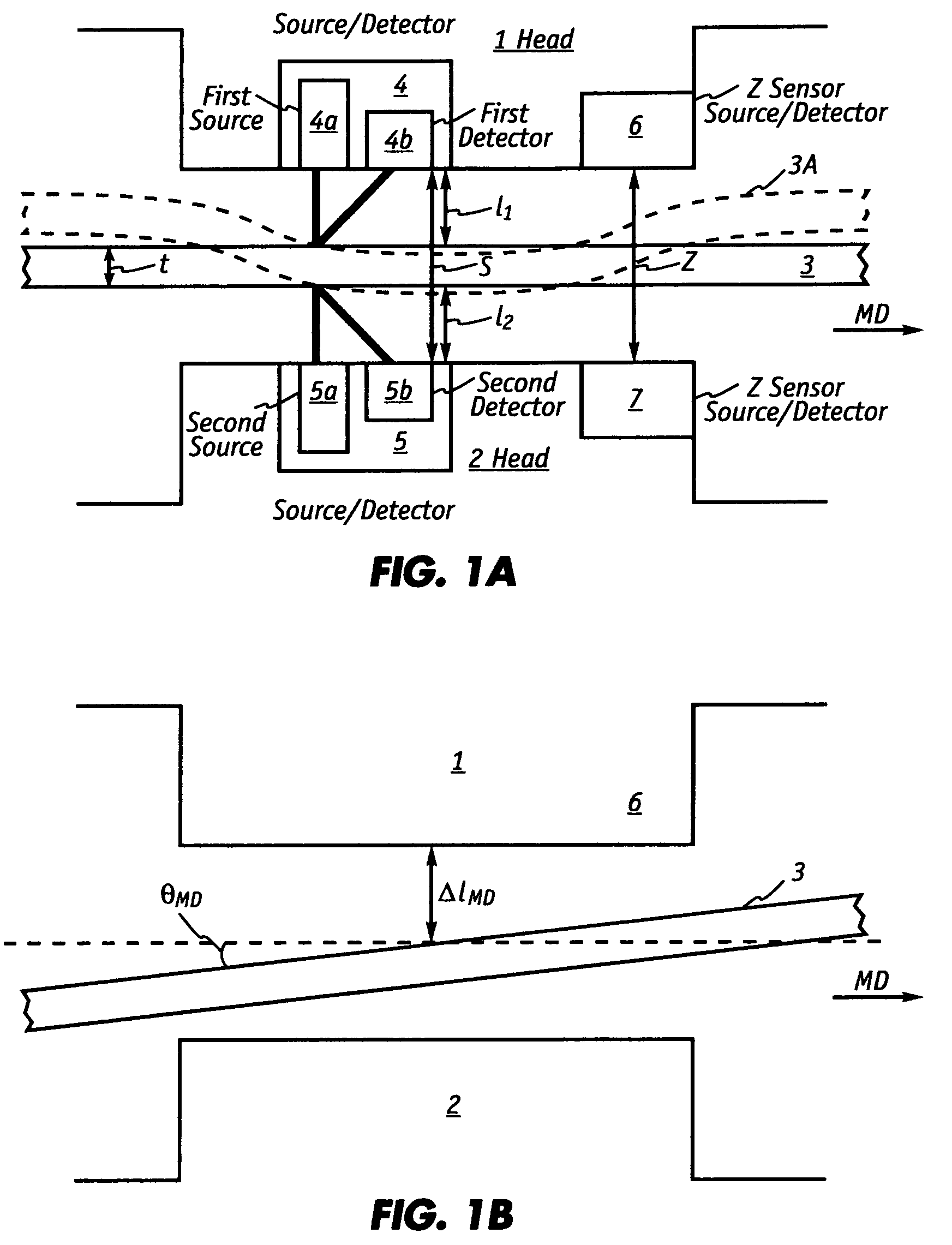

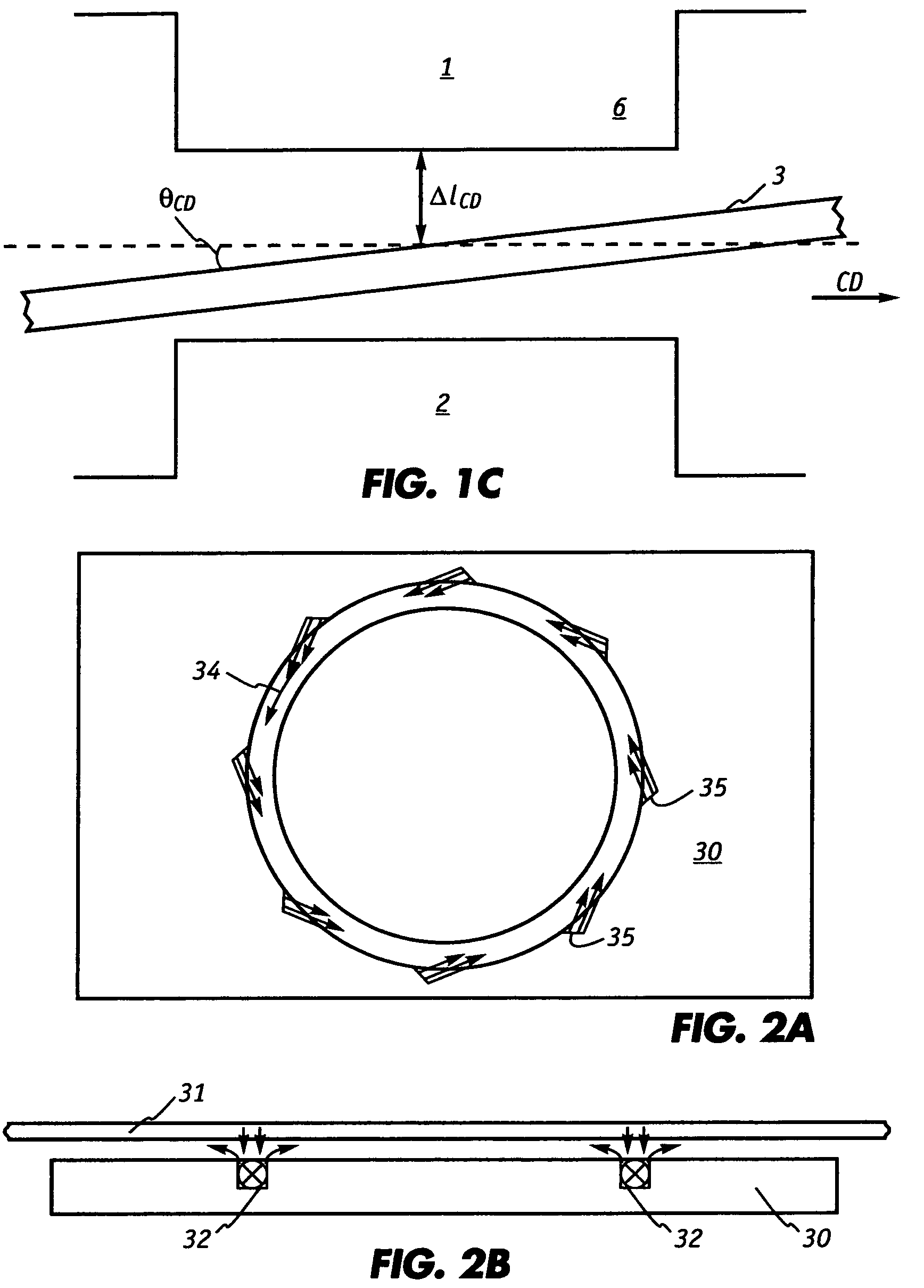

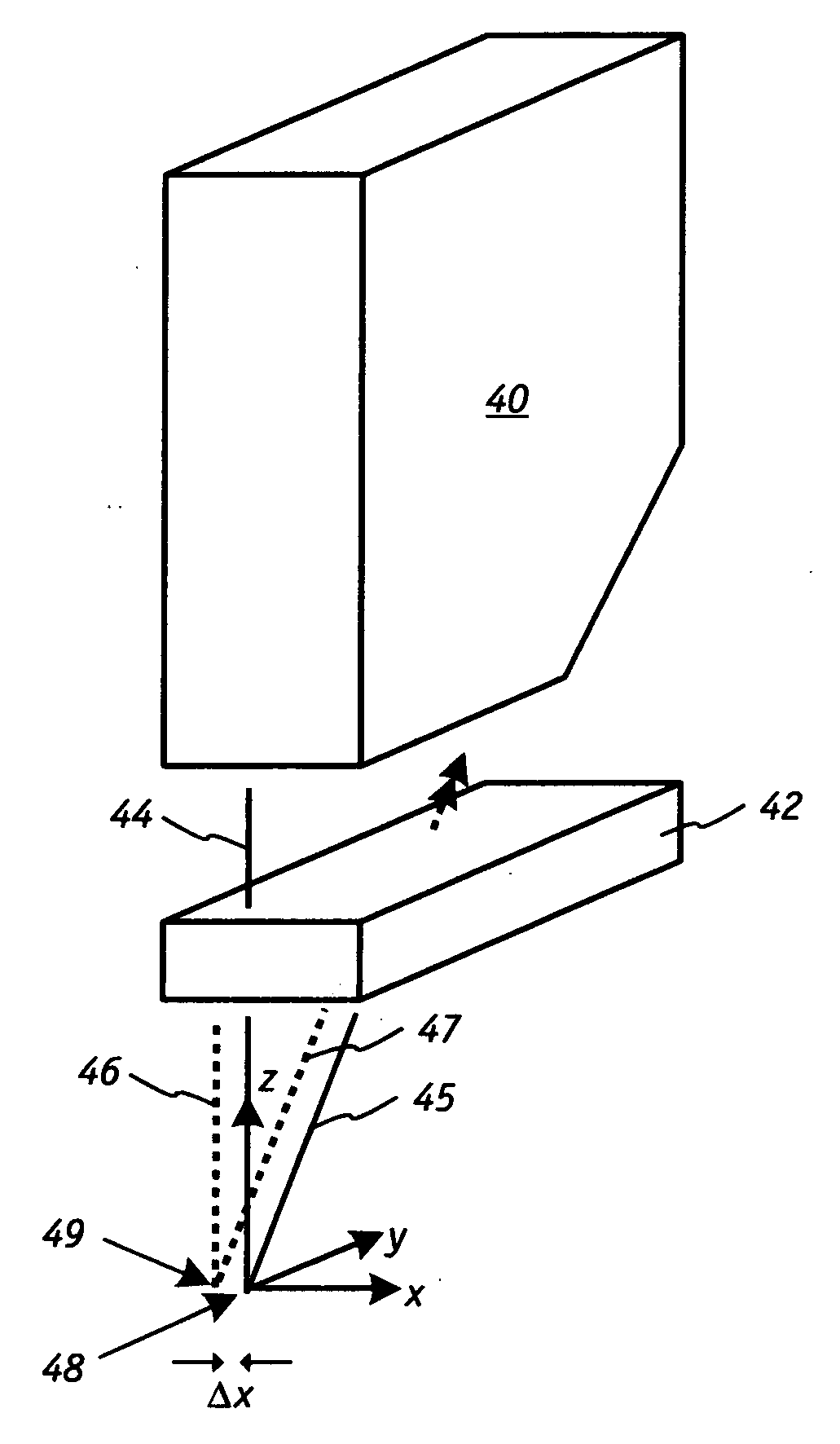

Optical translation of triangulation position measurement

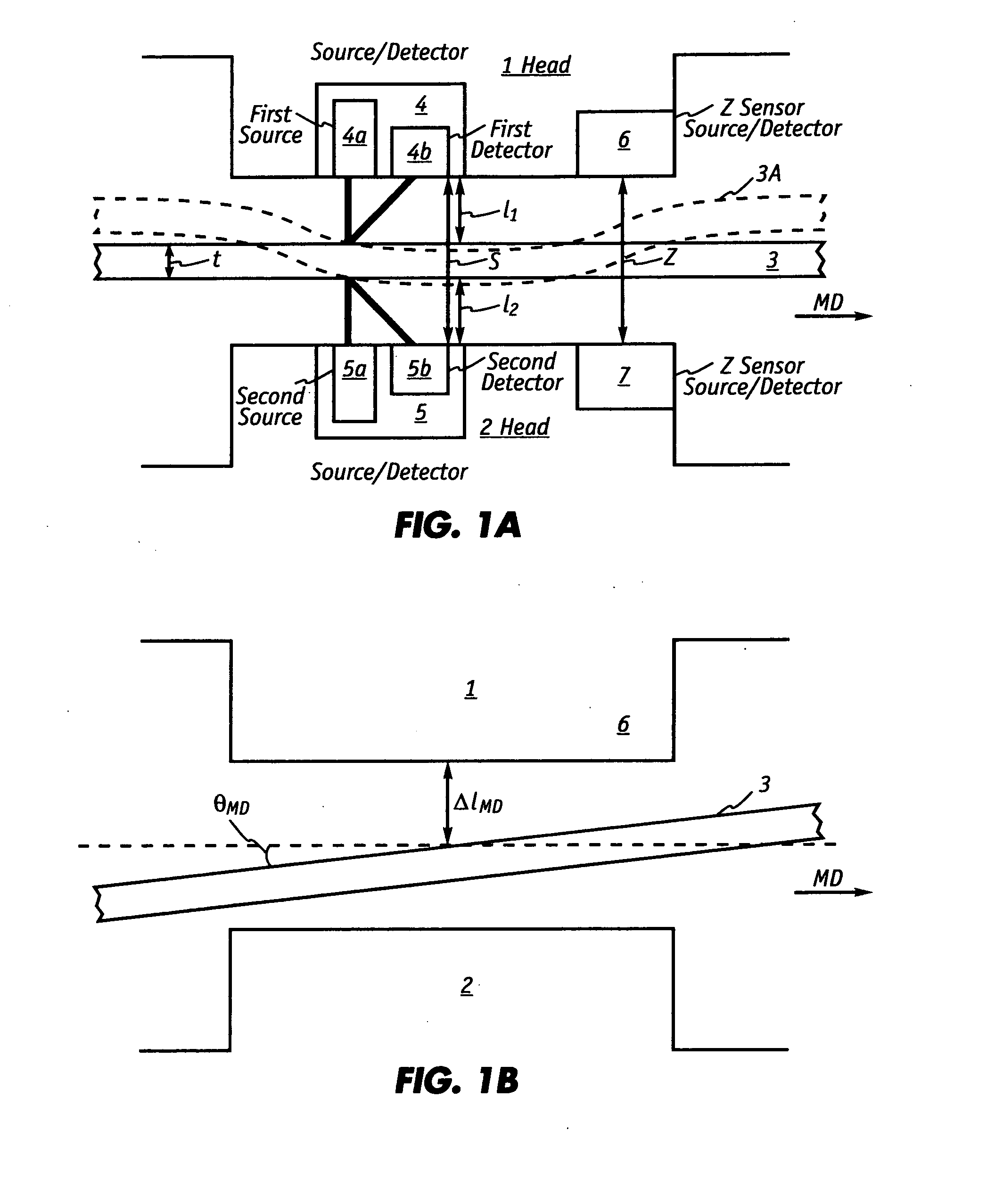

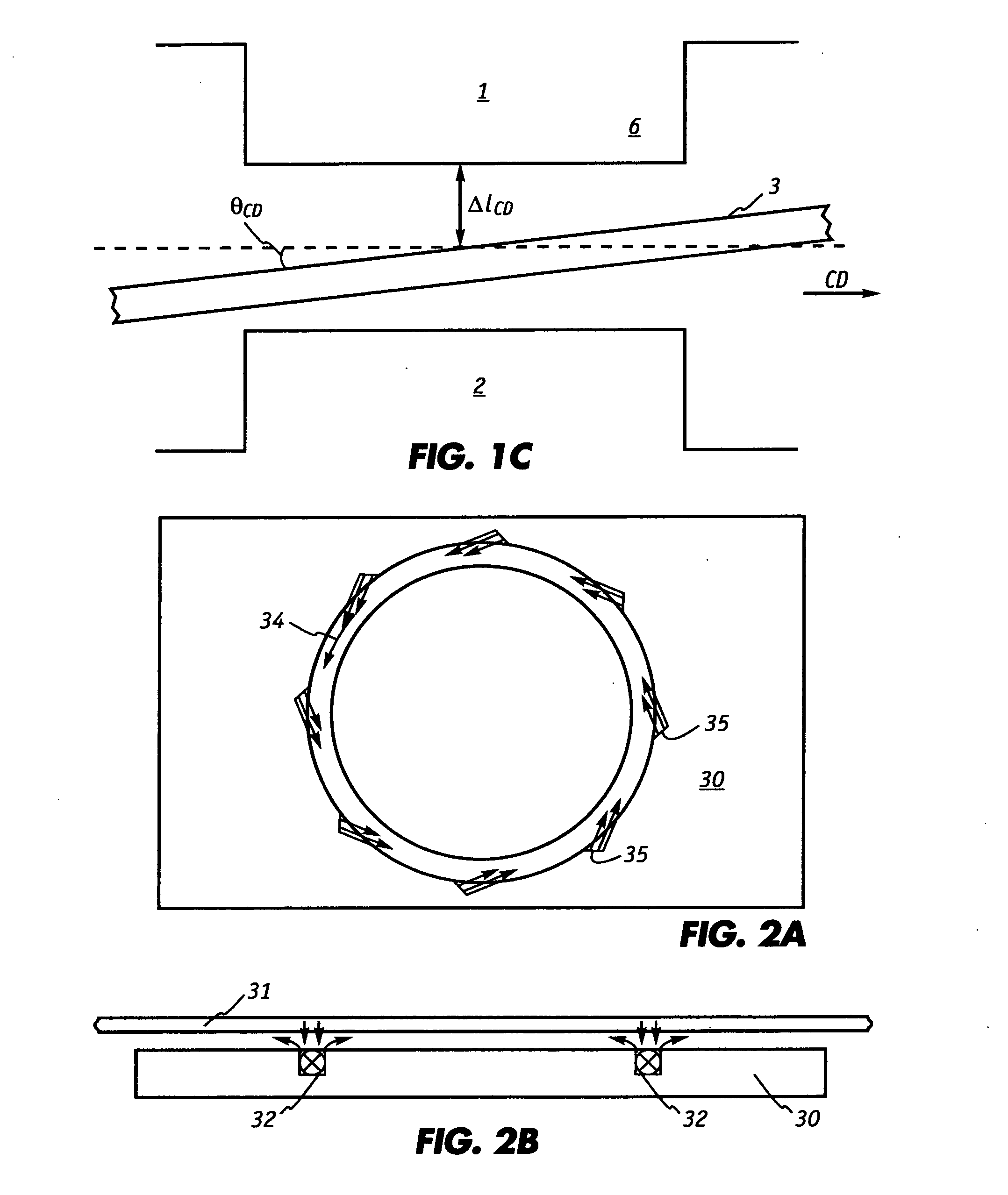

InactiveUS7528400B2Accurate thickness measurementOptical rangefindersInvestigating moving sheetsTriangulationRefractive index

An optical translation technique for moving the interrogation spot at which a triangulation system measures the displacement of a target is disclosed. In normal operation of the laser triangulation sensor, an incident laser beam is projected from a sensor head onto a surface of a web that is facing the sensor head. Radiation is reflected from the surface and detected by the sensor. The distance from the sensor head to the web surface is calculated by triangulation. With optical translation, both the incident ray path and the captured ray path are translated with a plurality of high refractive index geometries such that the nominal functioning of the triangulation sensor remains undisturbed. The optimal position on the sheet wherein the interrogation spot will be located can be ascertained.

Owner:HONEYWELL ASCA INC

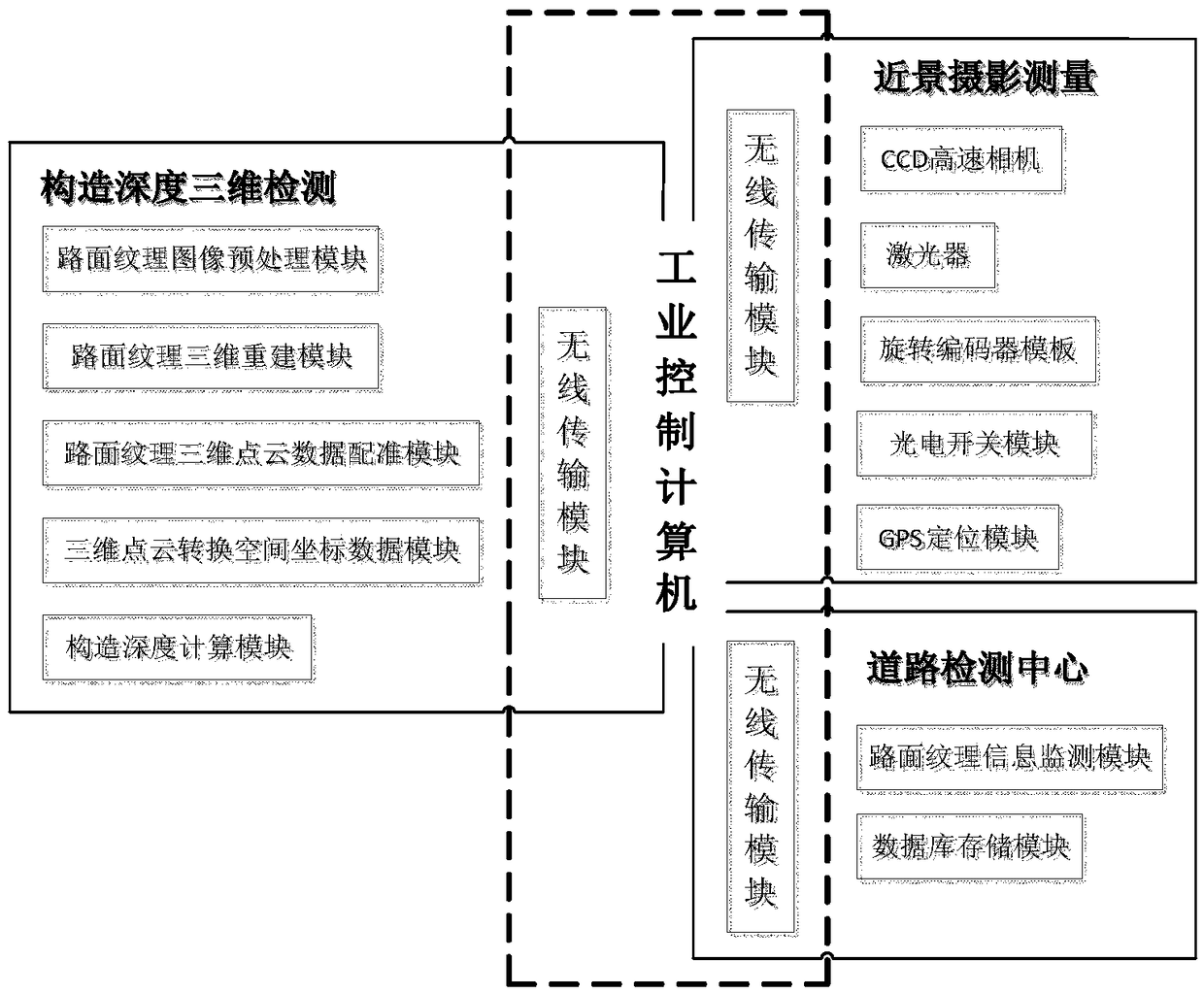

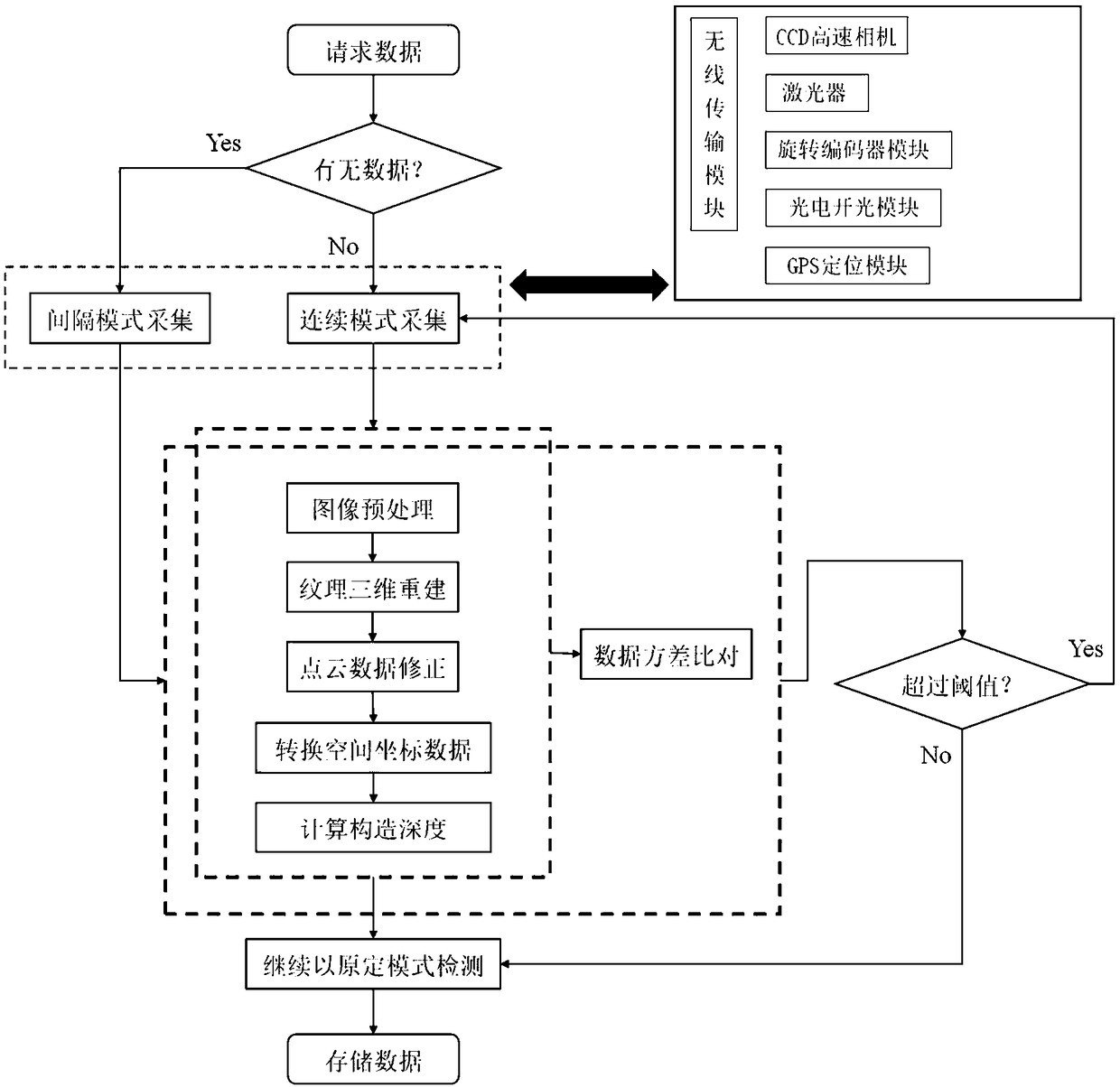

Real-time identification system and method of road surface textures for unmanned vehicle

InactiveCN108960060AAvoid influenceMake up for the shortcomings of human factorsImage analysisCharacter and pattern recognitionRoad surfaceEngineering

The invention provides a real-time identification system and method of road surface textures for an unmanned vehicle. The system is composed of a laser triangulation subsystem, a three-dimensional structure depth detection subsystem and a road detection center subsystem; and control and data transmission among the three subsystems are completed by an industrial control computer. According to the invention, with the laser triangulation technology, the asphalt pavement texture image is collected and thus road surface textures and data are collected automatically during the driving process of theunmanned vehicle; the three-dimensional structure depth detection subsystem analyzes and processes a collected pavement surface elevation and calculates a construction depth of an asphalt pavement texture of a measured point or a driving section. Therefore, the influence on the traffic flow by the traditional road detection is eliminated; and a defect of large impact of the human factor accordingto the traditional structural depth measurement method is overcome. The intelligent level is improved; the efficiency is enhanced. The real-time identification system and method has the guiding significance in driving strategy of unmanned vehicles.

Owner:SOUTHEAST UNIV

Inner bore measuring head inherent geometrical parameter calibration method based on laser triangulation

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

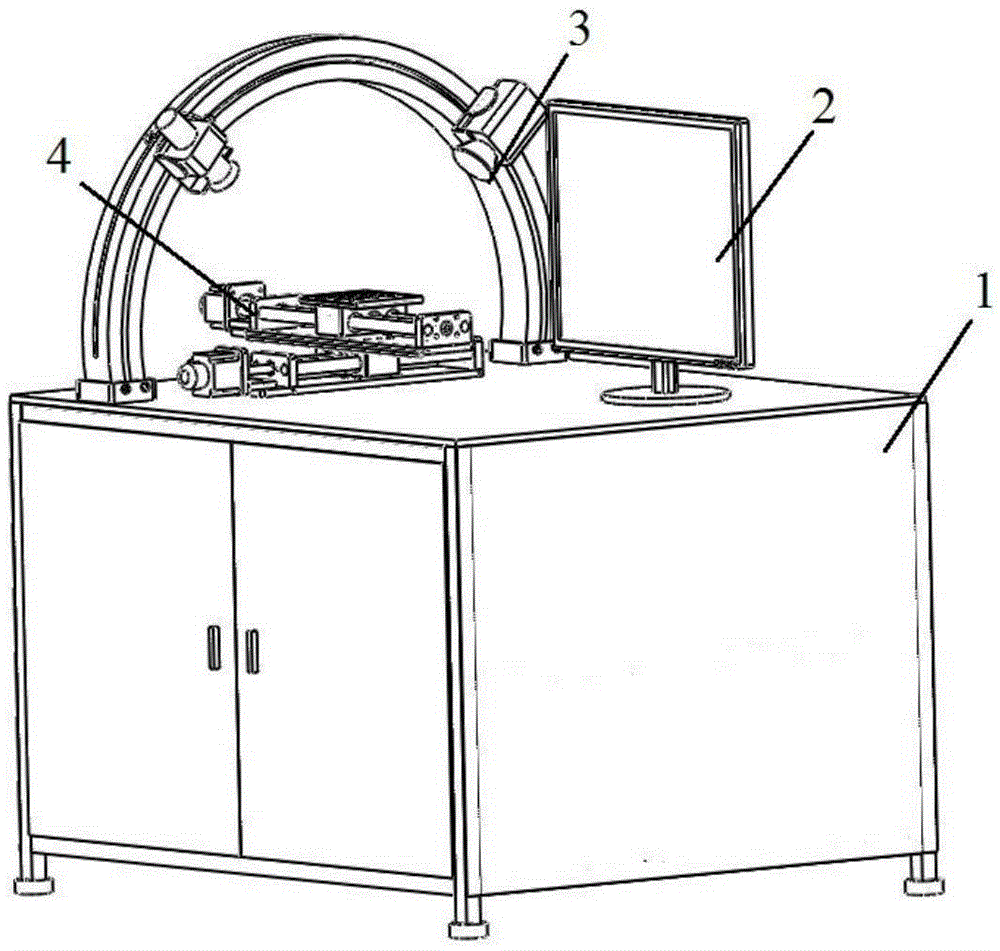

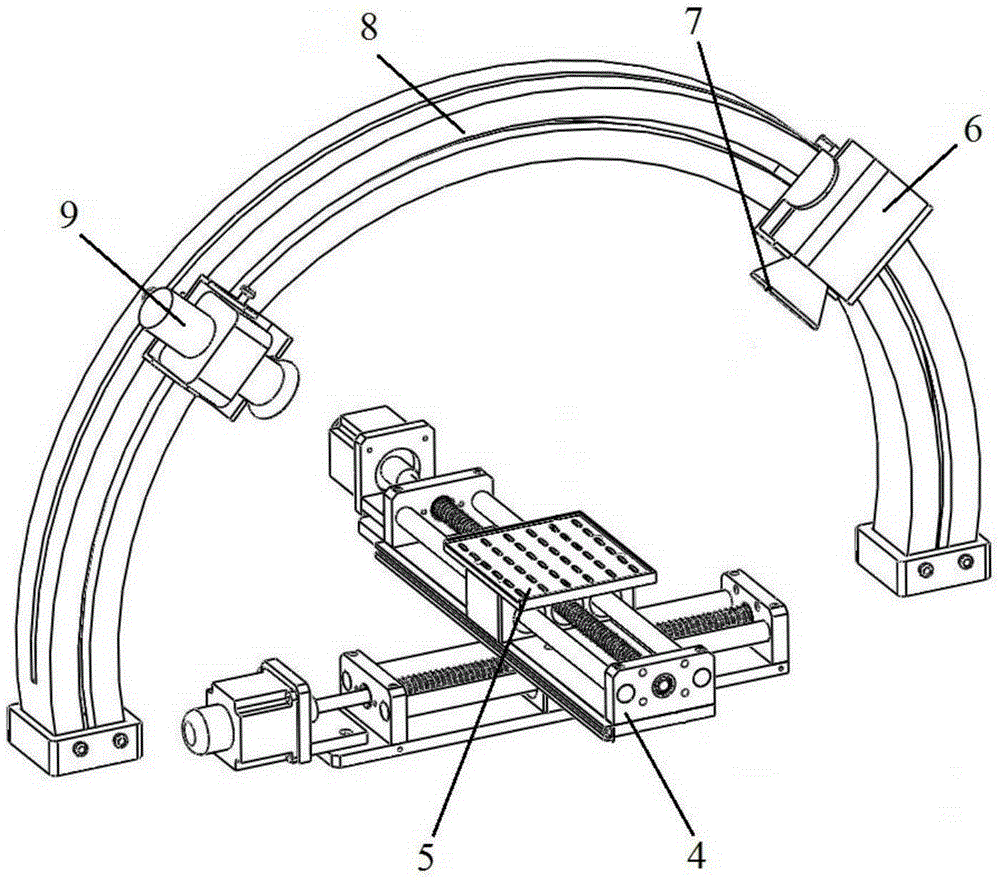

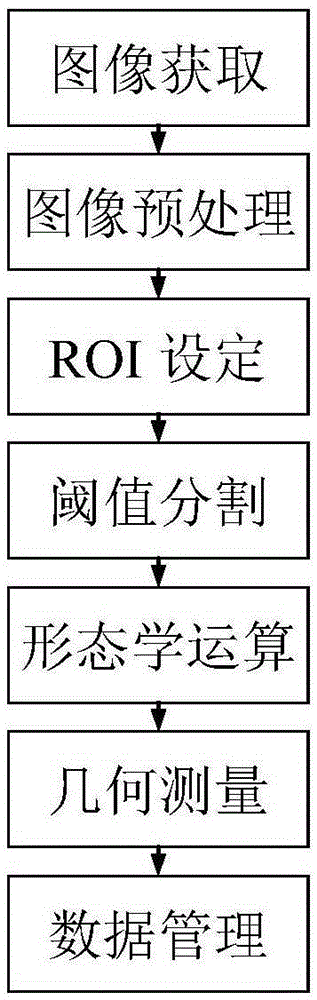

Visual detection method and system for pasting quality of FPC reinforcing pieces

ActiveCN105334231AImprove detection efficiencyHigh precisionImage enhancementImage analysisLaser transmitterEllipse

The invention discloses a visual detection method and system for the pasting quality of FPC reinforcing pieces. The visual detection system comprises a control cabinet, a display screen, an image collection device, a cross-shaped precision worktable and a tray. The image collection device comprises a camera, a lens, an arc-shaped rack and a laser transmitter. According to the visual detection method and system, the arc-shaped rack is adopted for simplifying the calibration process and reducing the influences of hardware equipment on image collection, Guass-Laplacian operators are utilized on the basis of a laser triangulation method, limit type threshold segmentation is introduced, and meanwhile morphological close operation is adopted for separating out the optical center areas of laser spots; the invariance of moment is utilized for performing ellipse fitting, variation of the center position of an ellipse is converted into variation of the thickness of the reinforcing pieces, and therefore observation is easier. By means of the visual detection method and system, the pasting quality of the reinforcing pieces is automatically detected, detection precision is high, detection efficiency is improved, working intensity is relieved, manual operation can be completely replaced, and the arc-shaped rack can also be applied to stereoscopic visional detection.

Owner:HUBEI UNIV OF TECH

Optical translation of triangulation position measurement

InactiveUS20070145307A1Accurate thickness measurementInvestigating moving sheetsUsing optical meansTriangulationRefractive index

An optical translation technique for moving the interrogation spot at which a triangulation system measures the displacement of a target is disclosed. In normal operation of the laser triangulation sensor, an incident laser beam is projected from a sensor head onto a surface of a web that is facing the sensor head. Radiation is reflected from the surface and detected by the sensor. The distance from the sensor head to the web surface is calculated by triangulation. With optical translation, both the incident ray path and the captured ray path are translated with a plurality of high refractive index geometries such that the nominal functioning of the triangulation sensor remains undisturbed. The optimal position on the sheet wherein the interrogation spot will be located can be ascertained.

Owner:HONEYWELL ASCA INC

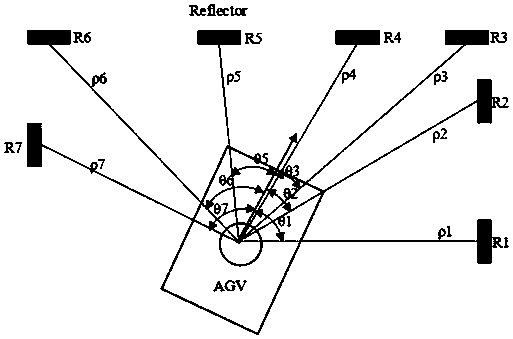

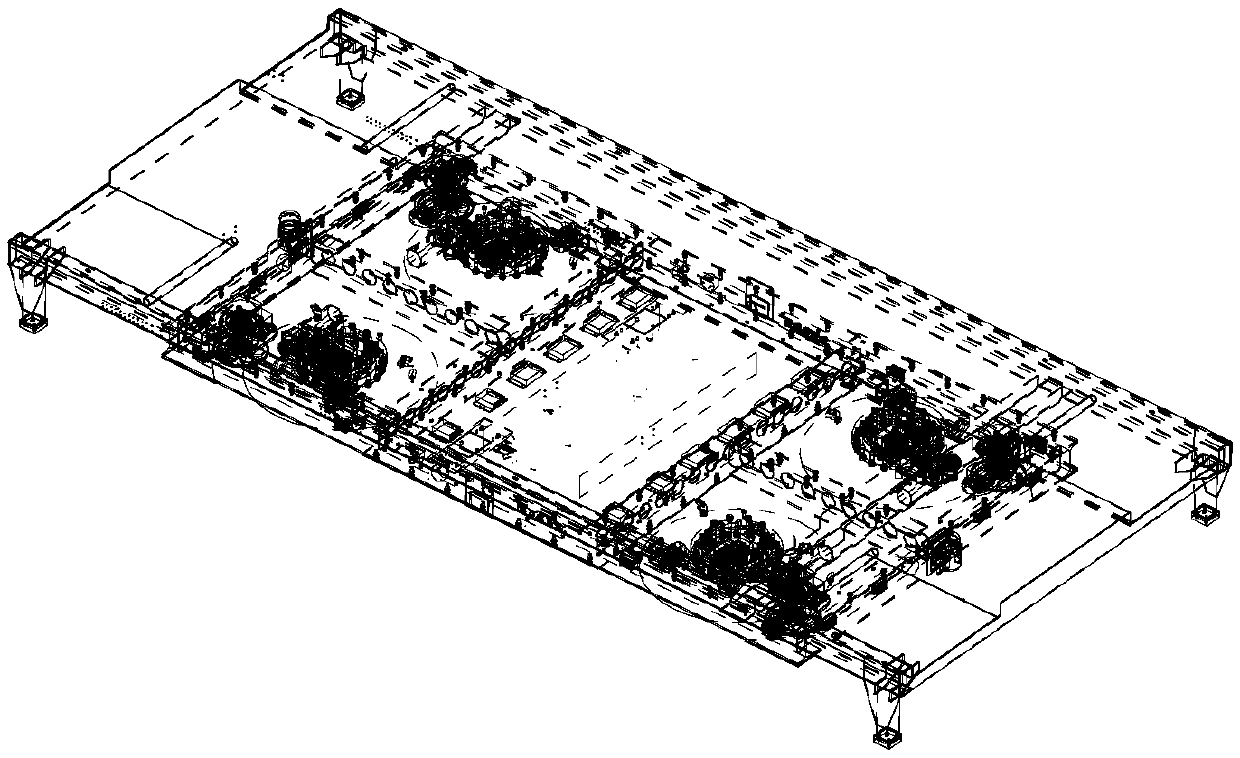

Improved graph optimization SLAM method

InactiveCN107741743AInstruments for road network navigationPosition/course control in two dimensionsAlgorithmEngineering

A traditional laser triangulation algorithm is high in location precision, and it is likely to be influenced by blocking of an obstacle to cause the phenomenon that AGV cannot be accurately located; the graph optimization SLAM algorithm ensures the precision and accuracy of map building through the method for building a map through front-end map building and rear-end optimization, and the integrity of map building is achieved through a closed-loop detection method. In the environment such as a garage which is less in feature, single in feature and symmetrical in feature height, the closed-loopdetection function cannot be well achieved, the phenomenon that the built map has multiple areas of overlap is caused, and the map cannot provide navigation and location. Accordingly, the method forconducting optimization by combining the laser triangulation algorithm with the SLAM algorithm is put forward, a reflector arranged in the environment in advance divides a large environment into countless small environments, and the small environments are numbered independently. The location can be conducted through laser triangulation in the small environments, after the environments are numberedin a regional mode, each area at which the AGV arrives can be detected, different areas have different numbers, and finally a graph optimization SLAM closed-loop detection signal is formed; in this way, the built map is high in precision.

Owner:SHENZHEN JINGZHI MACHINE

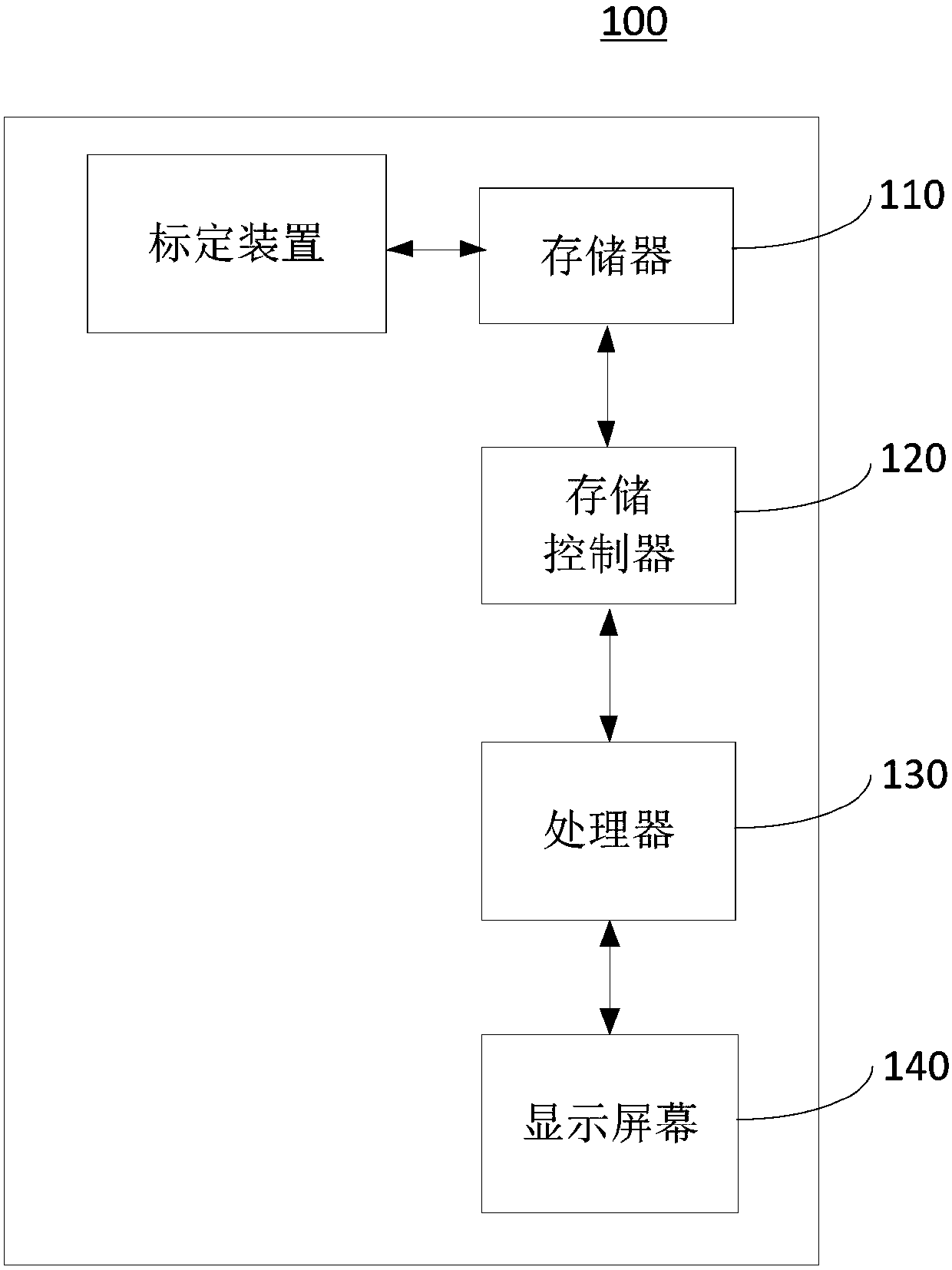

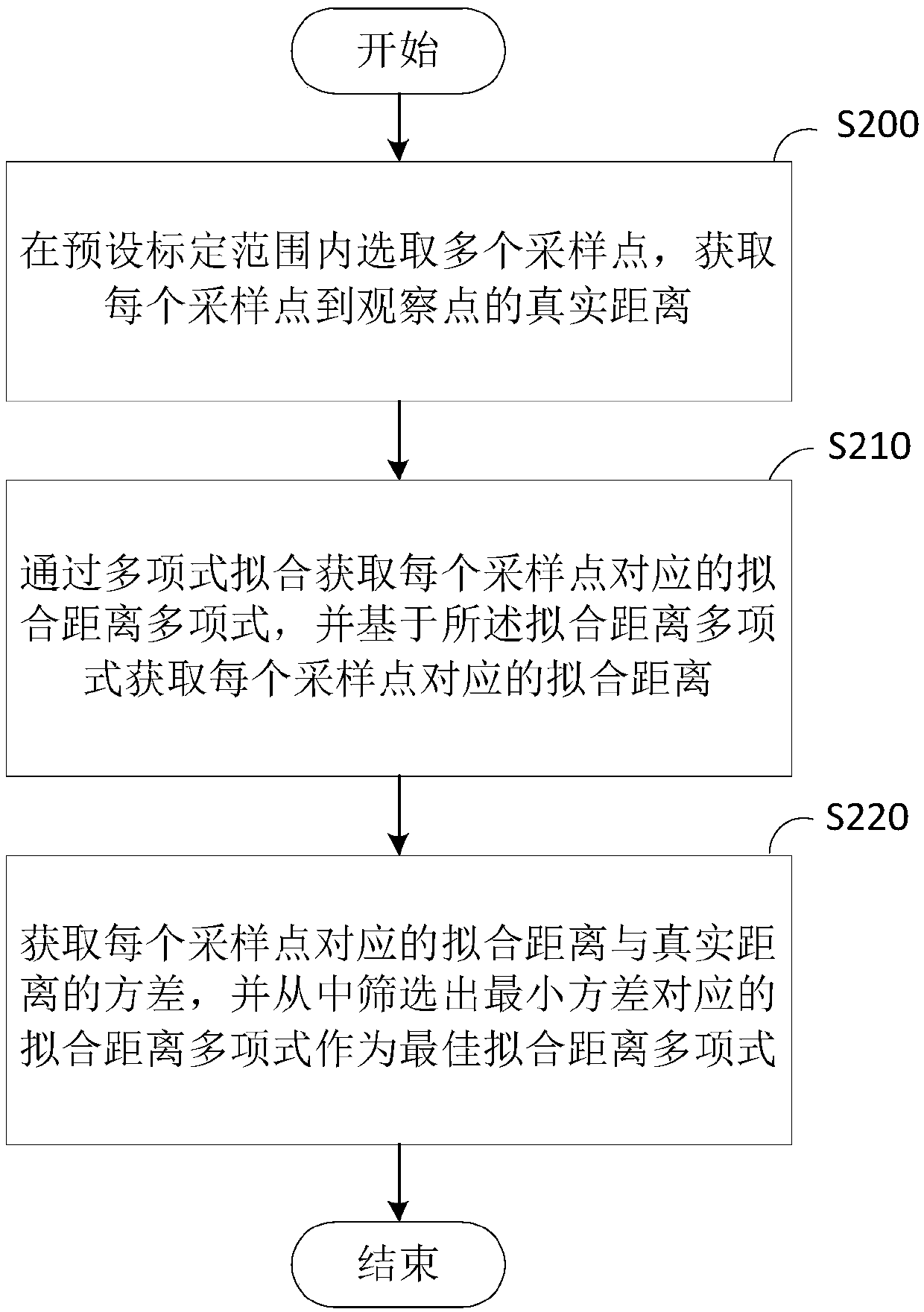

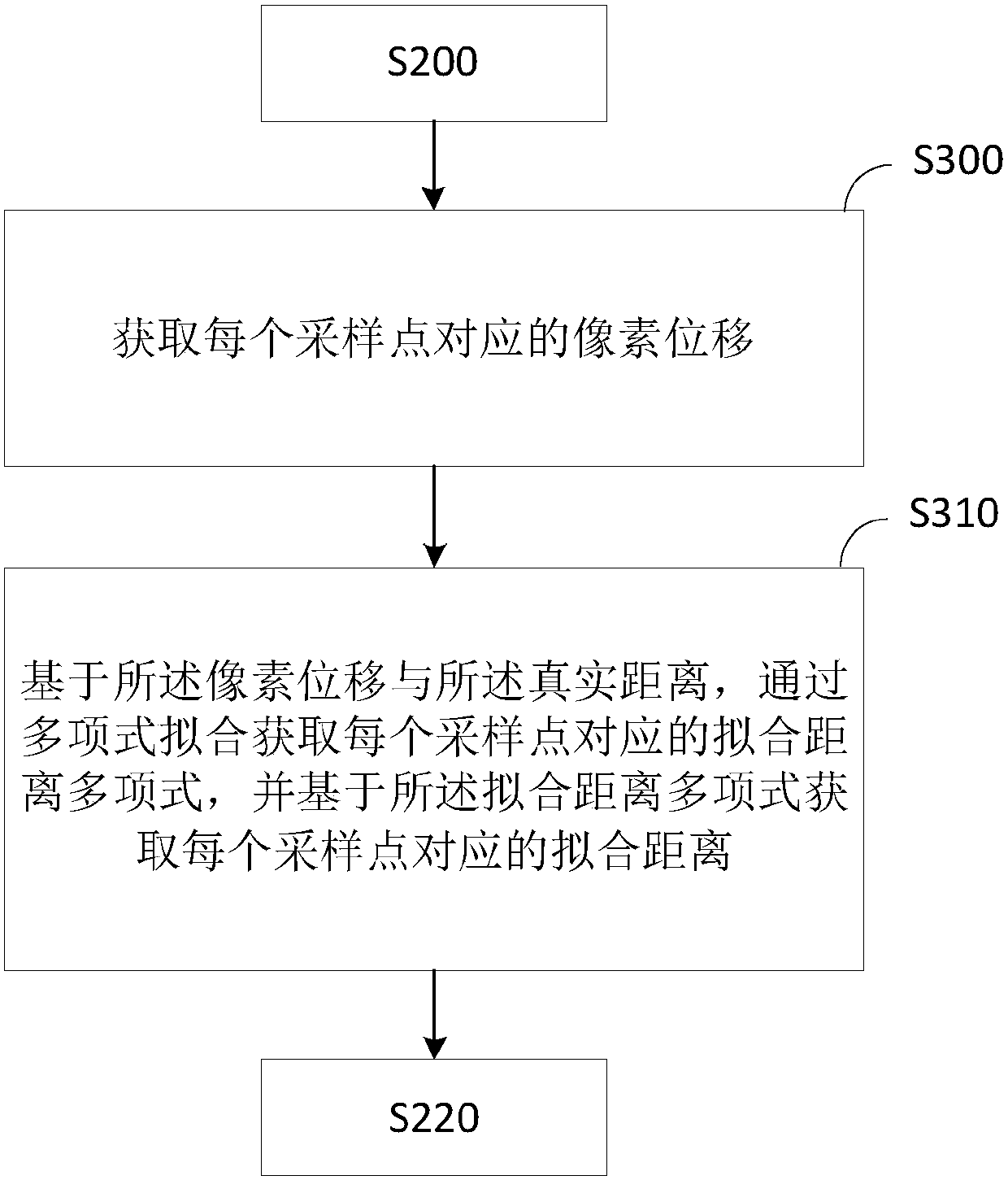

Calibration method and device

ActiveCN107861113AImprove generalization abilityRealistic ranging performanceWave based measurement systemsLaser rangingRadar

The invention provides a calibration method and device, and relates to the field of laser ranging. The calibration method comprises the steps of selecting a plurality of sampling points within a preset calibration range, and acquiring the actual distance between each sampling point and an observation point; acquiring a fitting distance polynomial corresponding to each sampling point through polynomial fitting, and acquiring the fitting distance corresponding to each sampling point based on the fitting distance polynomial; and acquiring the variance between the fitting distance corresponding toeach sampling point and the actual distance; and screening out the fitting distance polynomial corresponding to the minimum variance to serve as the optimal fitting distance polynomial. According tothe method and device provided by the invention, a plurality of fitting polynomials which are approximate to the actual value are created through polynomial fitting, then the most accurate function isscreened out through comparing the variance, targeted calibration can be provided for ranging radar with different performance parameters, the operation is convenient, the result is reliable, and themeasurement accuracy of laser triangulation ranging can be effectively improved.

Owner:SHEN ZHEN 3IROBOTICS CO LTD

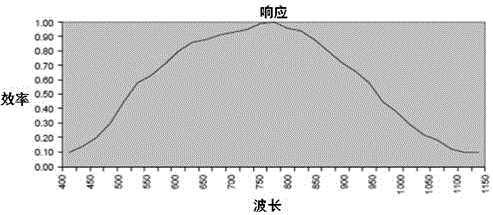

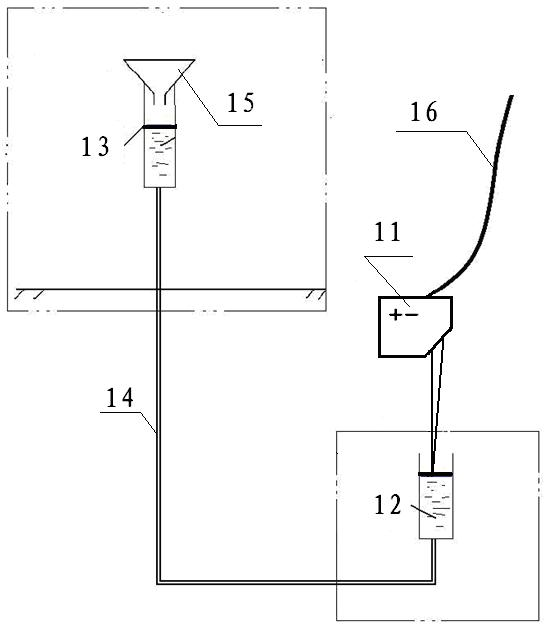

High-precision real-time laser triangulation method and triangulation device for liquid level

InactiveCN102419198AHigh sensitivityHigh precisionMachines/enginesLevel indicatorsSpectral responseMechanical engineering

The invention discloses a high-precision real-time laser triangulation method and a high-precision real-time laser triangulation device for a liquid level. The triangulation device comprises a laser triangulation displacement sensor, wherein the laser triangulation displacement sensor comprises a laser, a converging lens, a receiving objective and a charge coupled device (CCD); a laser beam emitted from the laser passes through the converging lens; the laser beam is refracted by a liquid surface; the laser beam is imaged on the CCD after passing through the receiving objective; the triangulation device also comprises an indoor liquid taking hopper, an indoor liquid taking test tube, an outdoor liquid taking test tube, a U-shaped tube and a signal line, wherein the indoor liquid taking hopper and the outdoor liquid taking test tube are fixedly arranged on a test worktable; the indoor liquid taking test tube is connected with the outdoor liquid taking test tube through the U-shaped tube; the laser triangulation displacement sensor is arranged above the outdoor liquid taking test tube; and the laser triangulation displacement sensor is electrically connected with an industrial personal computer through the signal line. The triangulation device has the advantages that: non-contact real-time liquid level measurement can be realized; and the sensitivity is high, the spectral response is wide, the dynamic range is wide, the linearity is high, the precision is high and the measurement range is wide.

Owner:CHANGCHUN UNIV OF SCI & TECH

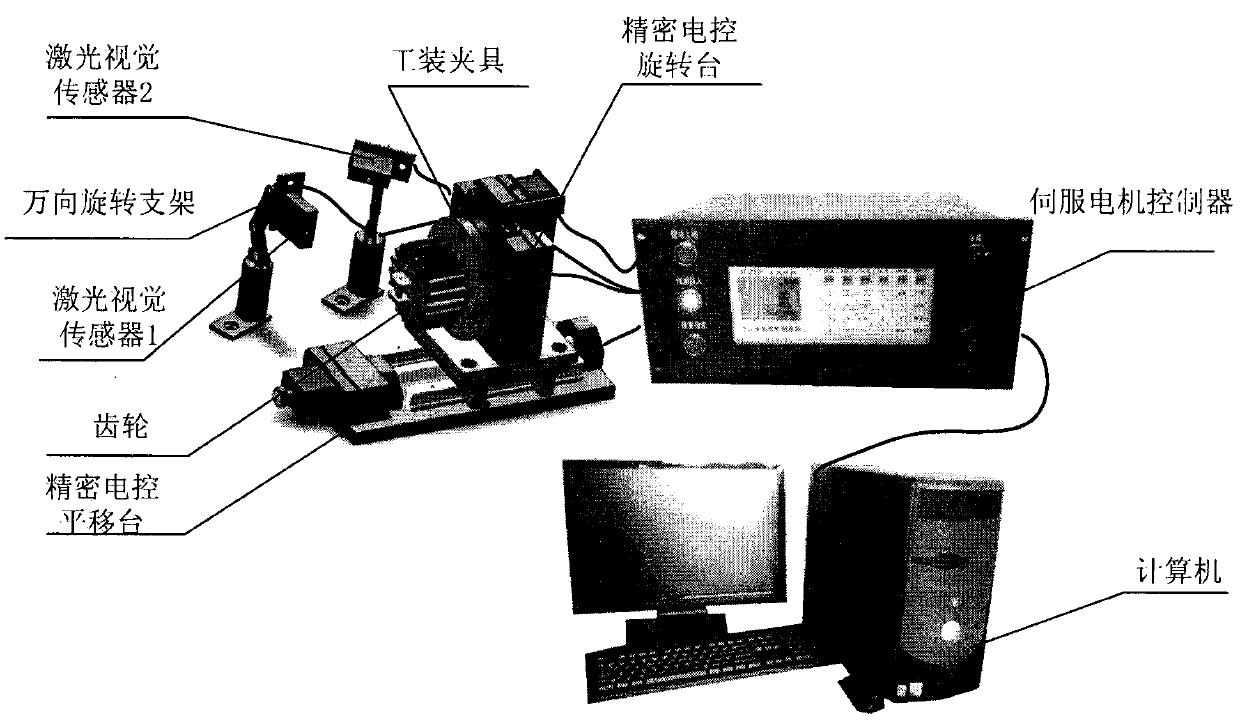

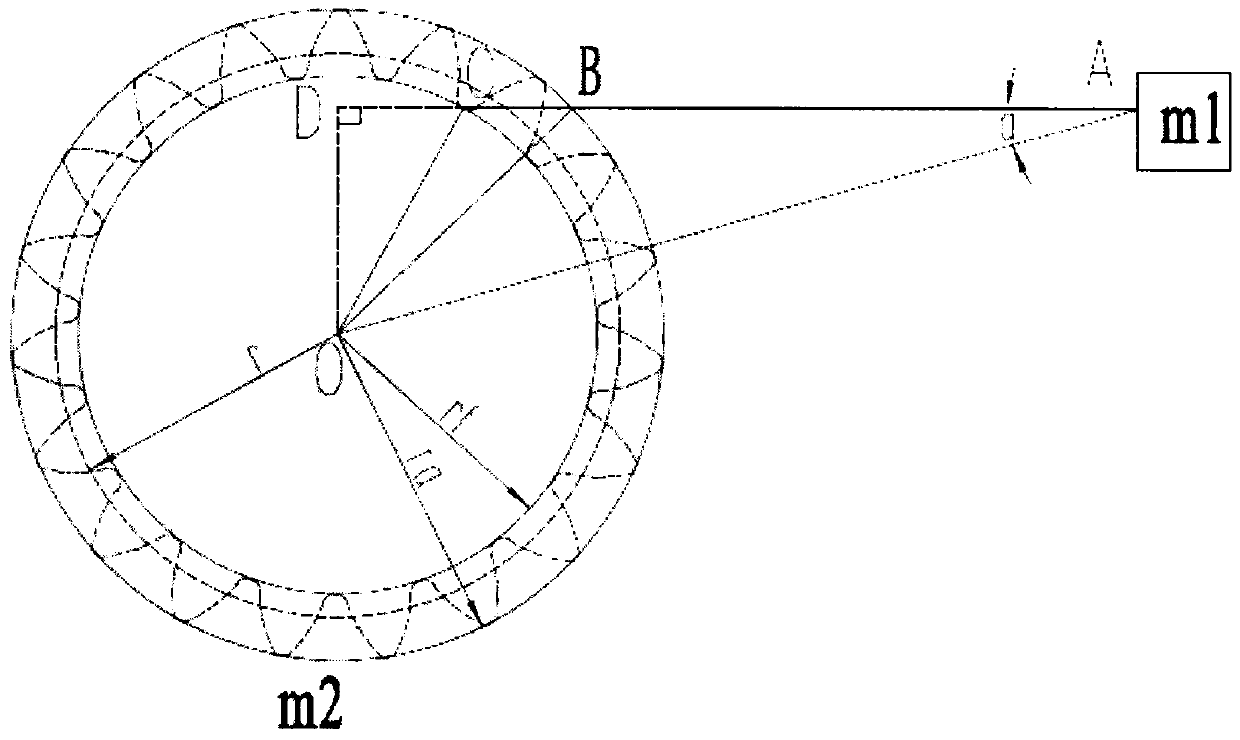

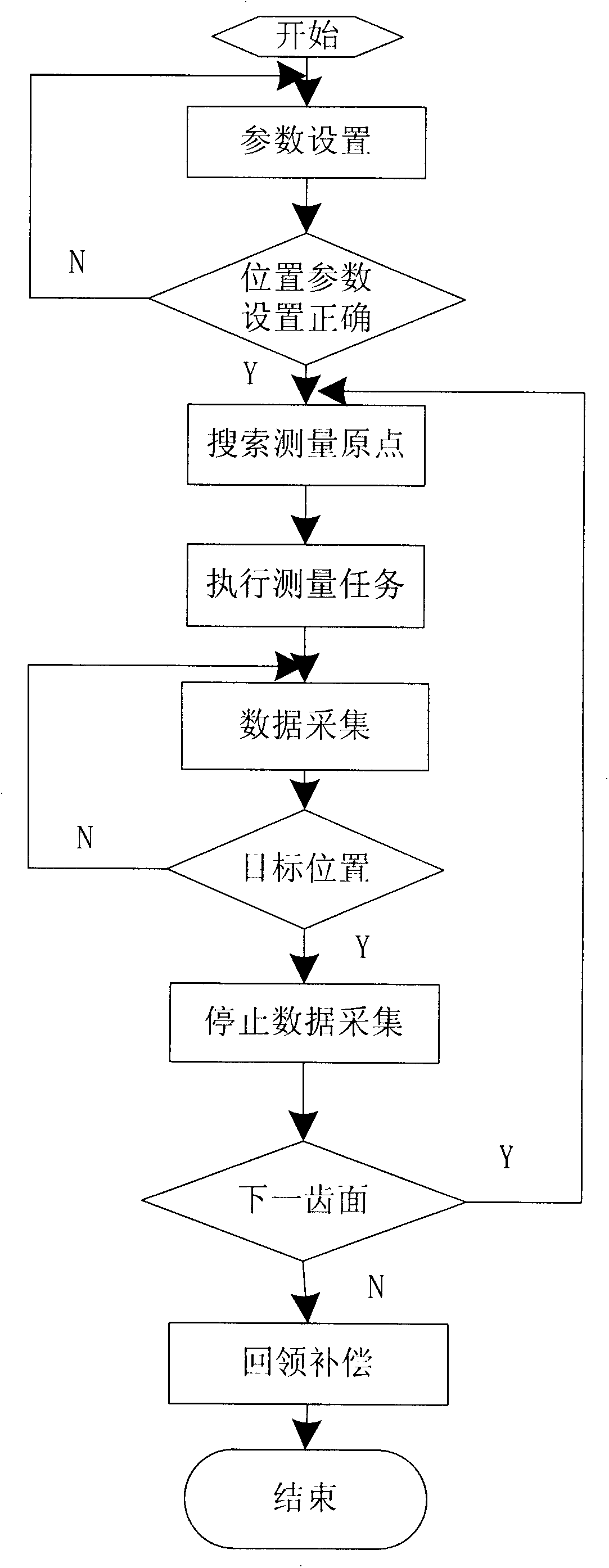

Non-contact type gear tooth direction measuring method of laser vision distance measurement

InactiveCN103363923AHigh precisionImprove the contact pressure, the disadvantage of large system errorUsing optical meansContact pressureEngineering

The invention belongs to the field of non-contact type measurement of a gear and relates to a gear tooth direction measuring method based on laser vision sensors. According to the gear tooth direction measuring method disclosed by the invention, the two laser vision sensors are used as main measuring tools and a grating ruler obtains data; the establishment of a system is finished by combining accurate positioning movement of a precise translation platform and a rotary platform with the control of upper computer software of a computer. A system position relation is calibrated and a corresponding algorithm is used for calculating a reference circle position relation of the sensors and a gear. And then, a laser triangulation distance measurement principle is used for measuring gear tooth direction data. According to the gear tooth direction measuring method disclosed by the invention, on the basis of a low software cost, a non-contact type measuring method is used for reducing a system error between a tested workpiece and a measuring system, caused by contact pressure, and a random error. Compared with other measuring methods, the gear tooth direction measuring method has the advantages of strong anti-interference capability, fast measuring speed, high precision, simplicity in operation method and the like. The gear tooth direction measuring method disclosed by the invention can also be used for measuring other workpieces with complicated surface shapes.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com