Method for measuring thickness of sea surface spilled oil film based on differential laser triangulation method

A technology of laser triangulation and oil film thickness, applied in the direction of measuring devices, optical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

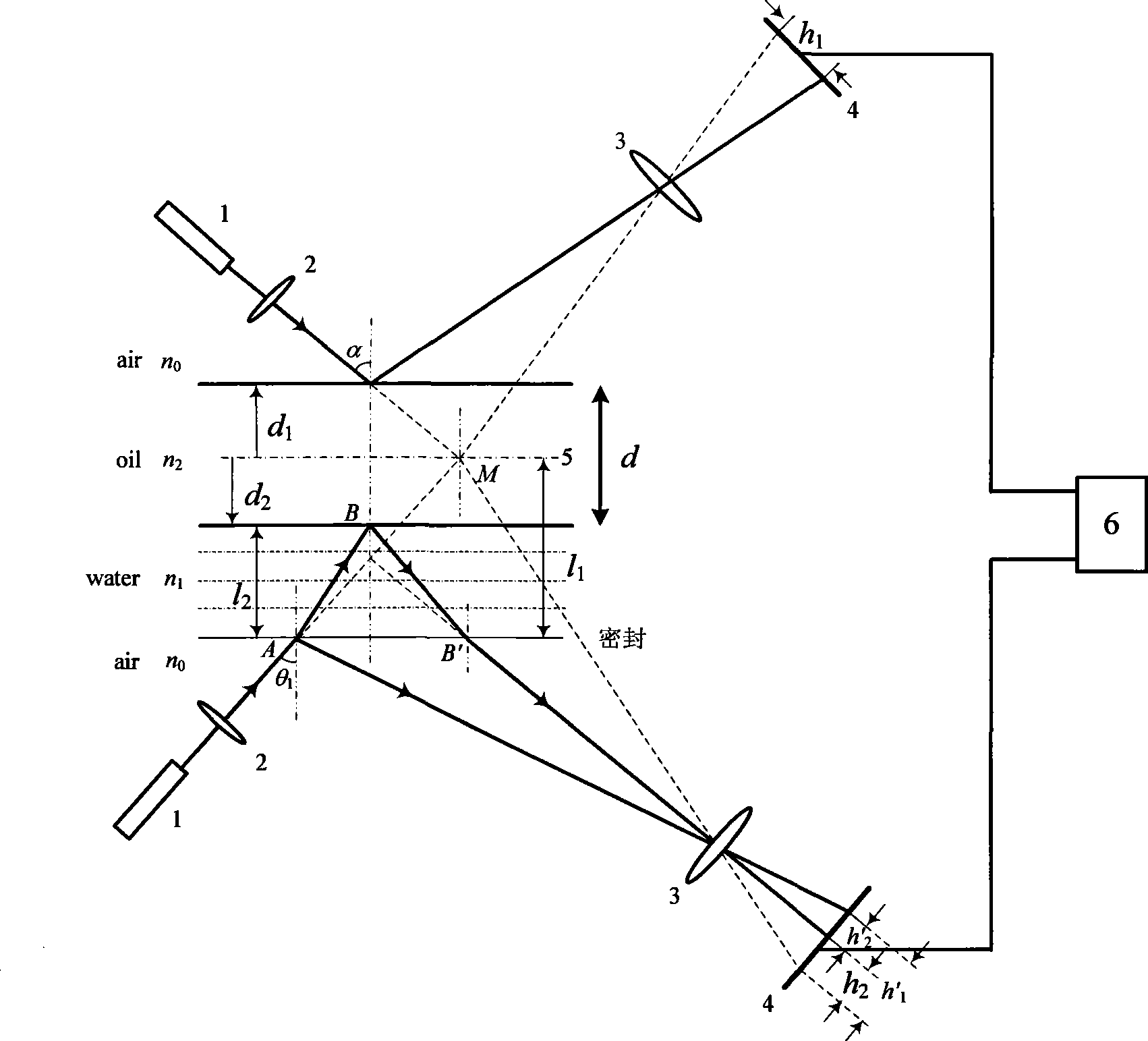

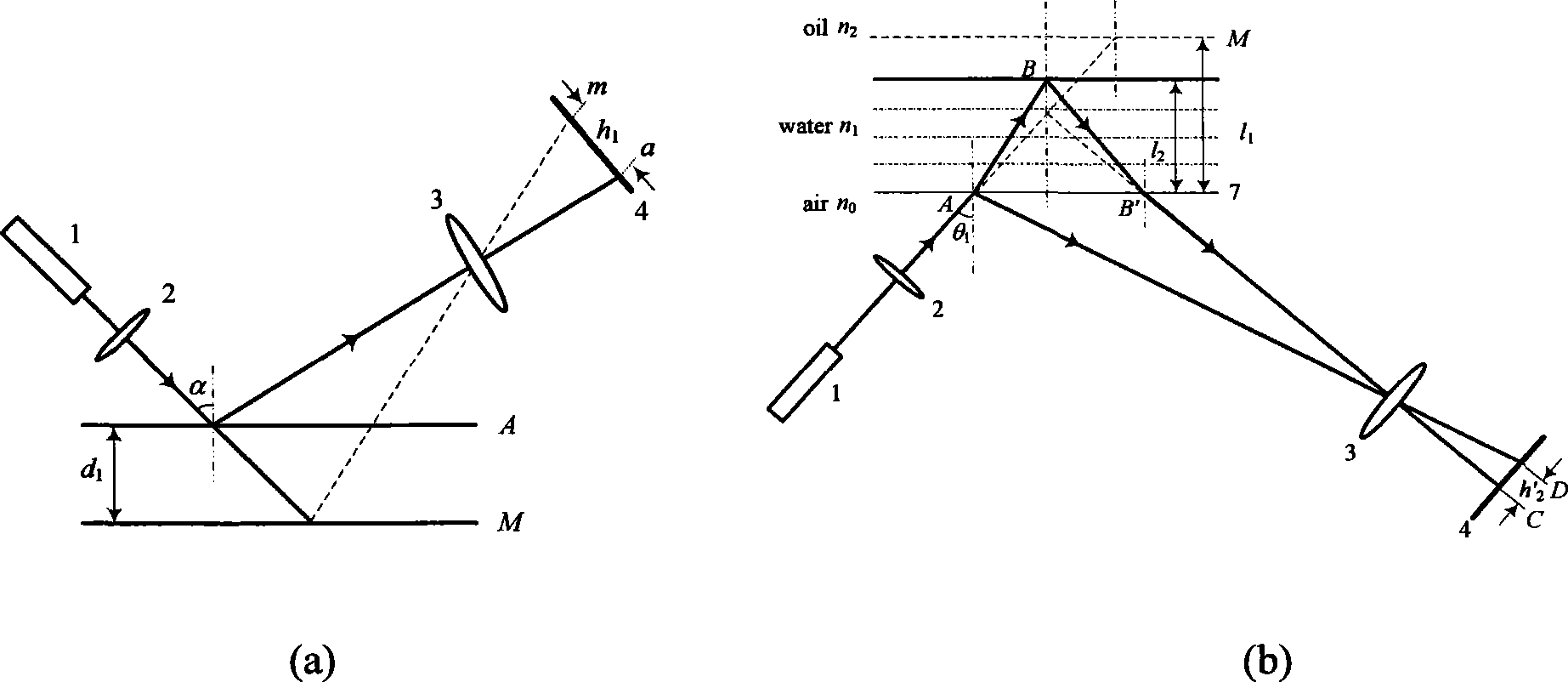

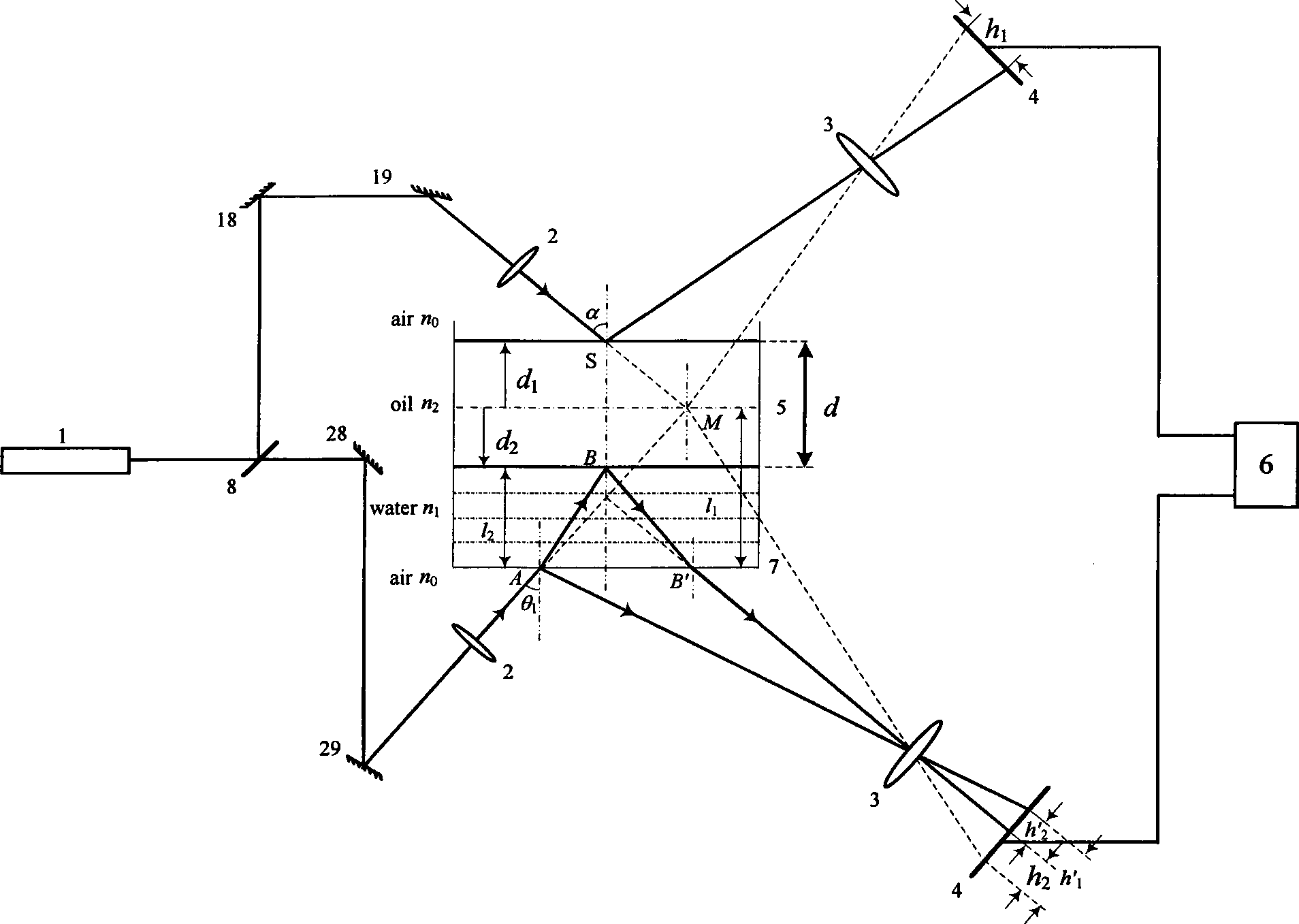

[0044] Below to image 3 The shown experimental light path is taken as an example to illustrate the specific measurement process of the measurement method of the present invention;

[0045] ① Optical path system construction

[0046] to build image 3 In the shown symmetrical oblique laser triangulation ranging system, the light source part of the system includes a laser 1 , a converging lens 2 , a beam splitter 3 , and mirrors 18 , 19 , 28 , and 29 . The laser 1 is a He-Ne laser with a wavelength λ=632.8nm, and the converging lens 2 is a converging lens with a focal length f=300mm. The receiving (imaging) system is composed of an imaging lens 3 , a detector CCD 4 and a data acquisition and processing module 6 . The imaging lens 3 is an imaging lens with f=250mm, the detector CCD 4 is an area array CCD, and the data acquisition and processing module 6 includes an image acquisition card and a computer. The sample pool 7 is a transparent glass pool without a cover, water is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com