Fluorescent powder coating surface defect detecting system and method based on machine vision

A machine vision and defect detection technology, applied in the direction of optical testing defects/defects, fluorescence/phosphorescence, instruments, etc., can solve the problem of no coating thickness uniformity research, and achieve system cost savings, rich thickness information, and simple system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

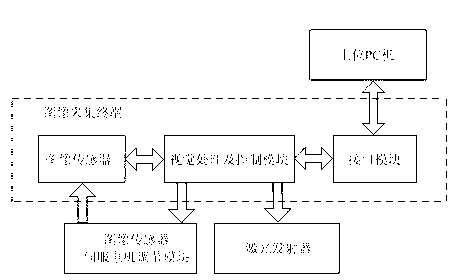

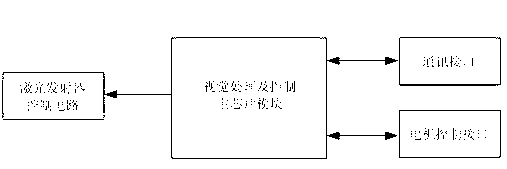

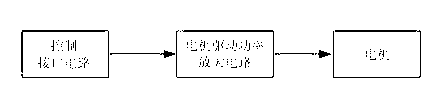

[0036] Such as figure 1 As shown, the phosphor coating surface defect detection system based on machine vision includes a laser transmitter, an image acquisition terminal, an image sensor servo motor adjustment module and a host PC. The image acquisition terminal includes an image sensor connected in sequence, visual processing and The control module and the interface module, the upper PC is connected with the vision processing and control module through the interface module, the image sensor servo motor adjustment module is connected with the vision processing and control module and the image sensor respectively, and the laser transmitter is connected with the vision processing and control module; The laser transmitter is used to emit laser light for measuring the thickness distribution of phosphor powder coating. The image sensor servo motor adjustment module is used to adjust the receiving angle of the image sensor. The image sensor is installed on the image sensor servo mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com