A sampling method for inspection of super pipe forgings used in nuclear power plants

A technology of super pipelines and nuclear power plants, applied in the field of nuclear steam supply systems of nuclear power plants, can solve problems such as difficult inspection of nozzle quality, difficult sampling of irregular sampling parts, and difficult mechanical processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that these embodiments are used to illustrate the basic principles, main features and advantages of the present invention, and the present invention is not limited by the scope of the following embodiments. The implementation conditions used in the examples can be further adjusted according to specific requirements, and the implementation conditions not specified are usually conditions in routine experiments.

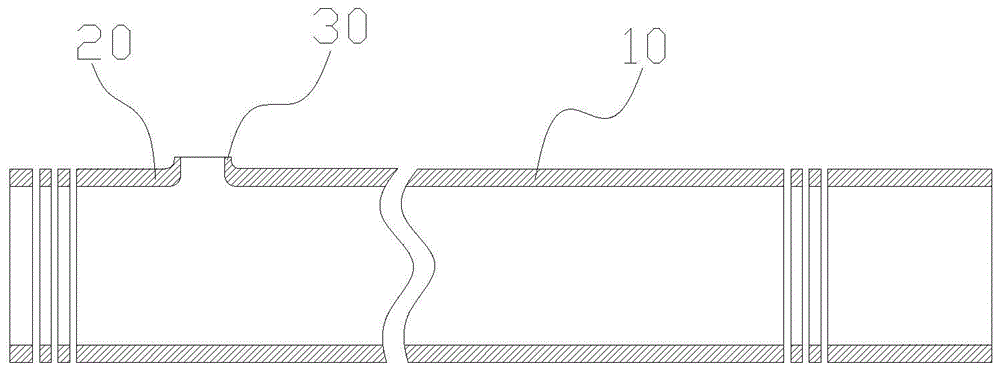

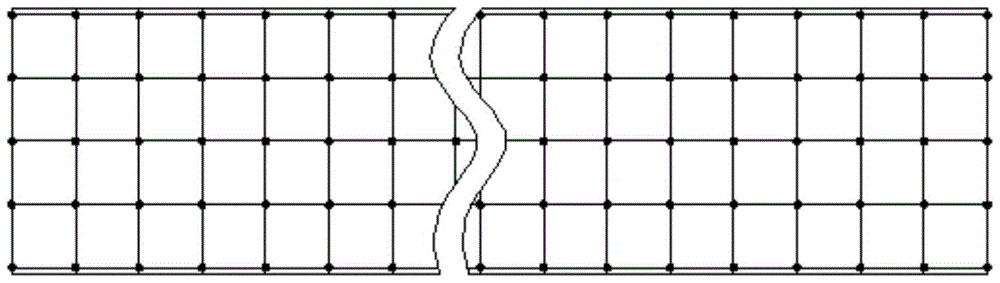

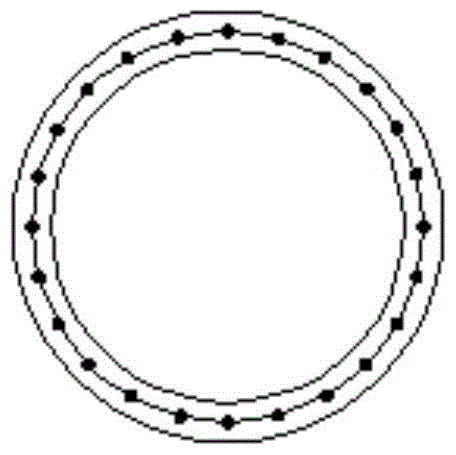

[0047] The invention provides a sampling method for inspection of super pipeline forgings for nuclear power plants, such as figure 1 Shown here is that the super pipeline forging of the present invention includes: a mother tube, a nozzle arranged on the mother tube, the nozzle is formed by heating, and the main size of the mother tube section 10 is: outer diameter D1 =810mm, inner diameter D2=718mm, wall thickness T=46, length L=4500mm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com