A Sampling Method for Inspection of Water Chamber Head Forgings of Reactor Steam Generator

A technology of steam generator and water chamber head, applied in the direction of sampling device, etc., can solve the problems of difficult hardening, difficult to ensure the internal quality of forgings, easy to produce deformation, etc., and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that these embodiments are used to illustrate the basic principles, main features and advantages of the present invention, and the present invention is not limited by the scope of the following embodiments. The implementation conditions used in the examples can be further adjusted according to specific requirements, and the unspecified implementation conditions are usually the conditions in routine experiments.

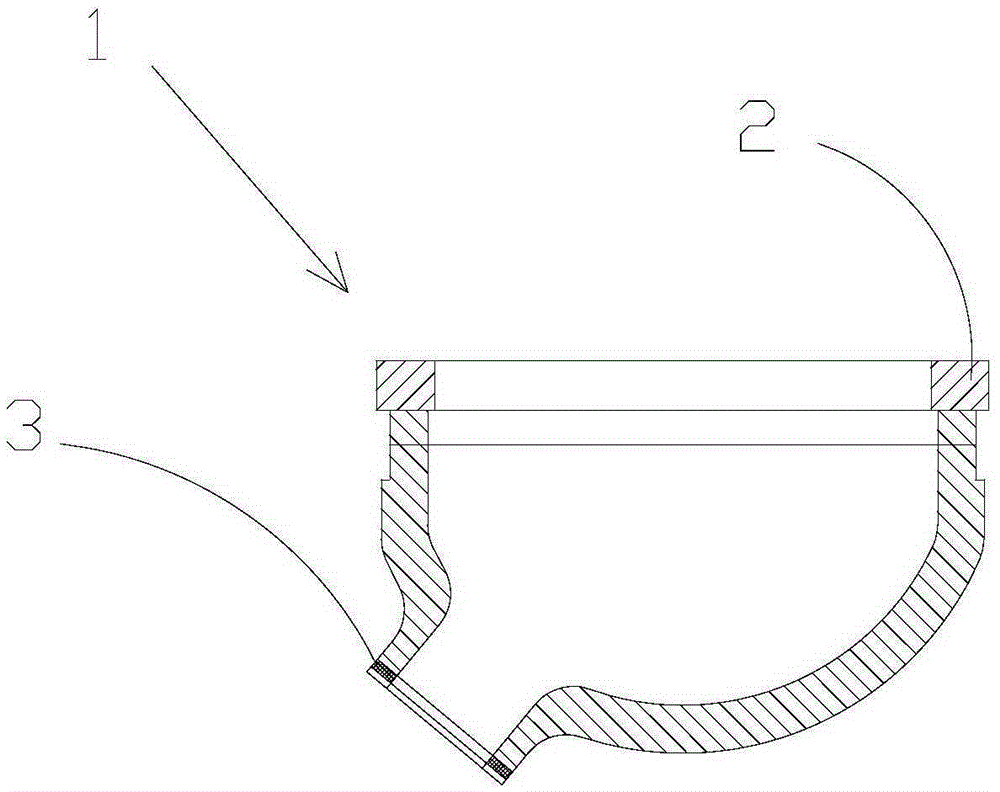

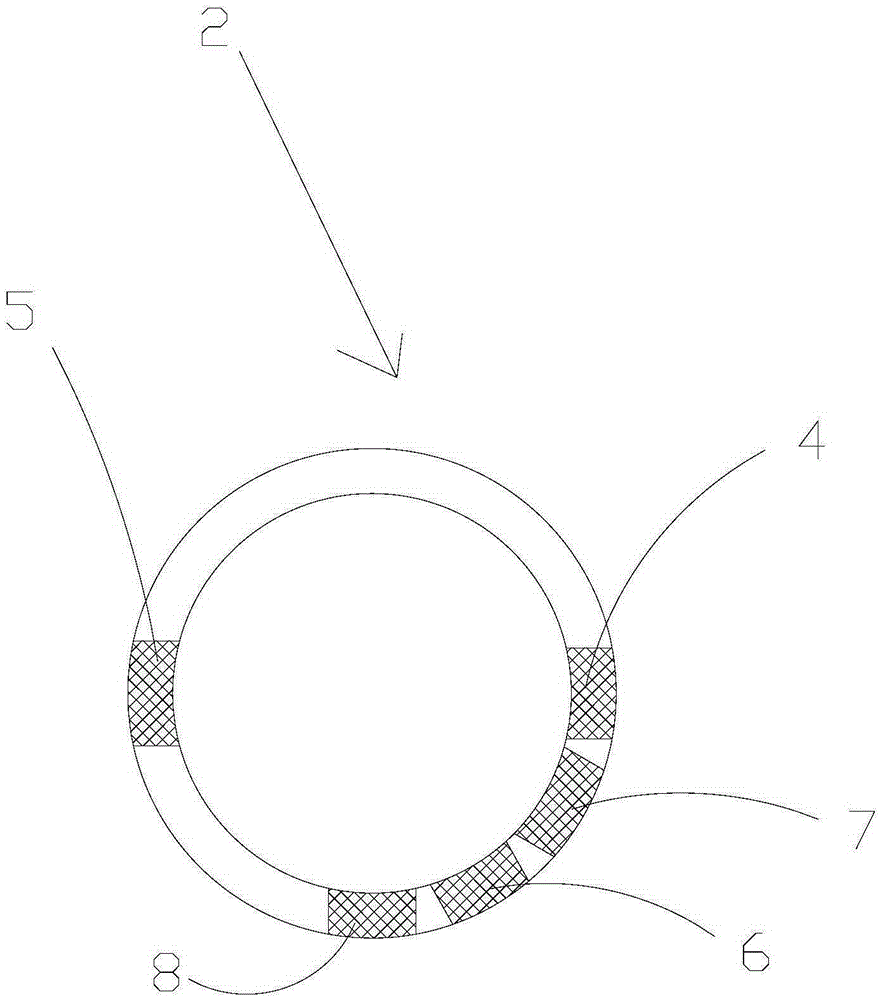

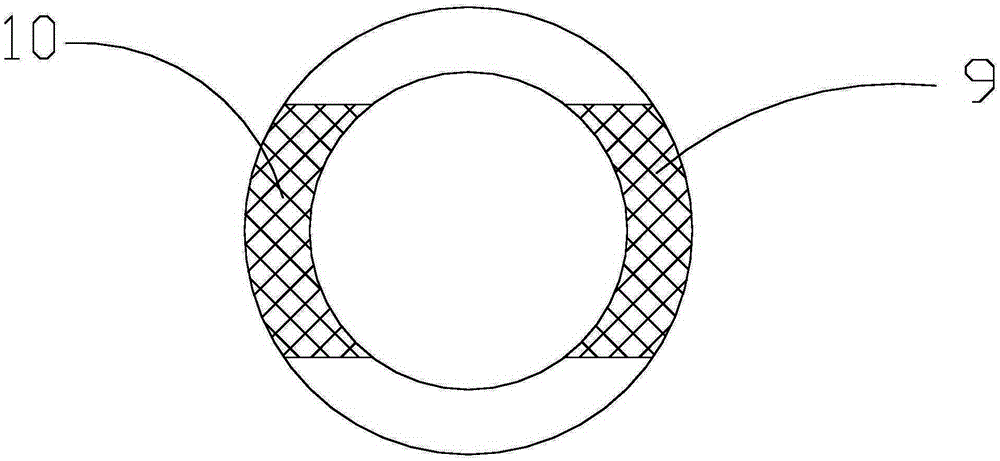

[0046] The water chamber head 1 comprises: a head body, a nozzle end, and an inclined nozzle, the nozzle end has a first sample ring 2, and the inclined nozzle has a second sample ring 3, and the water chamber The head 1 is the bottom head, the outer diameter D1 of the nozzle end of the water chamber head 1 is 3500-4000mm, the inner diameter D2 is 3000-3100mm, the outer diameter D3 of the inclined nozzle is 1000-1100mm, and the inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com