System and method for detecting deficiency of railway fasteners on basis of laser and vision

A railway fastener and detection system technology, which is applied to railway car body components, radio wave measurement systems, railway vehicle shape measuring devices, etc., can solve the problems of fastener missing detection technology, railway fastener missing high-speed detection system, etc., to achieve Achieve high-speed identification and detection, reduce the amount of processed information, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

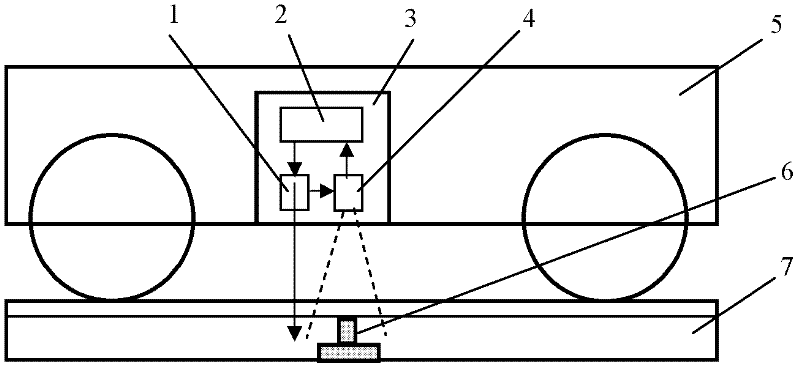

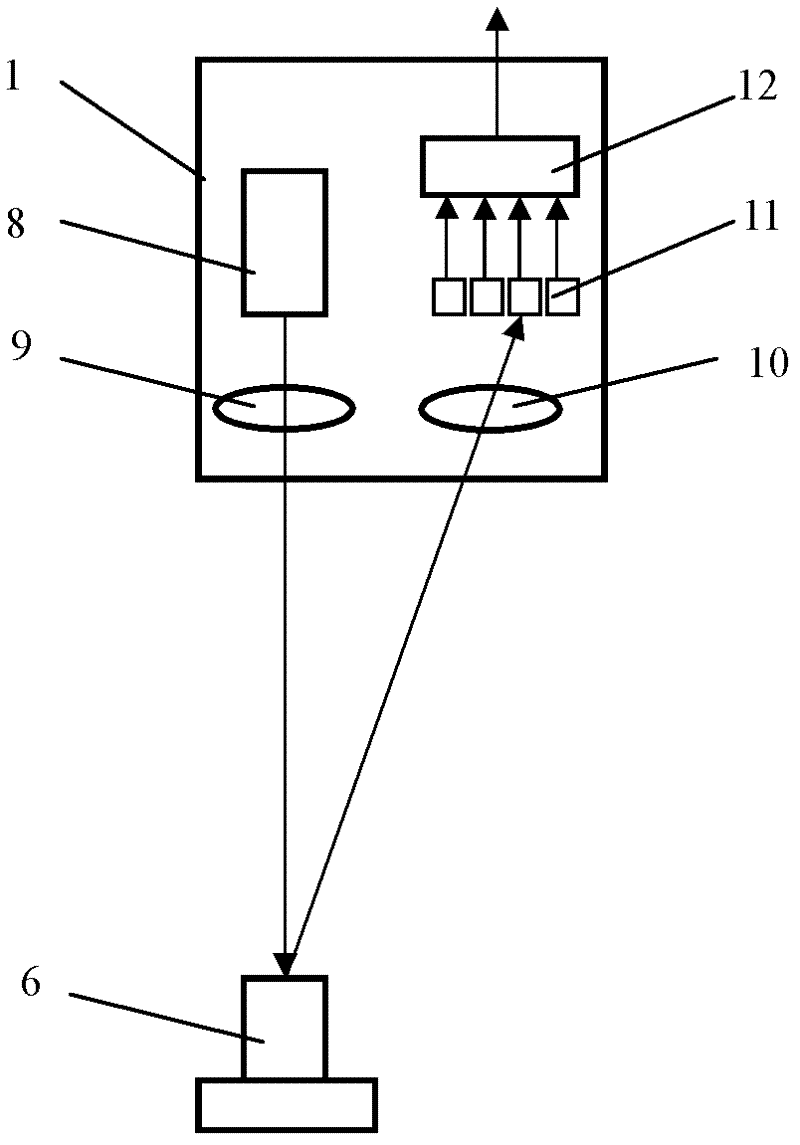

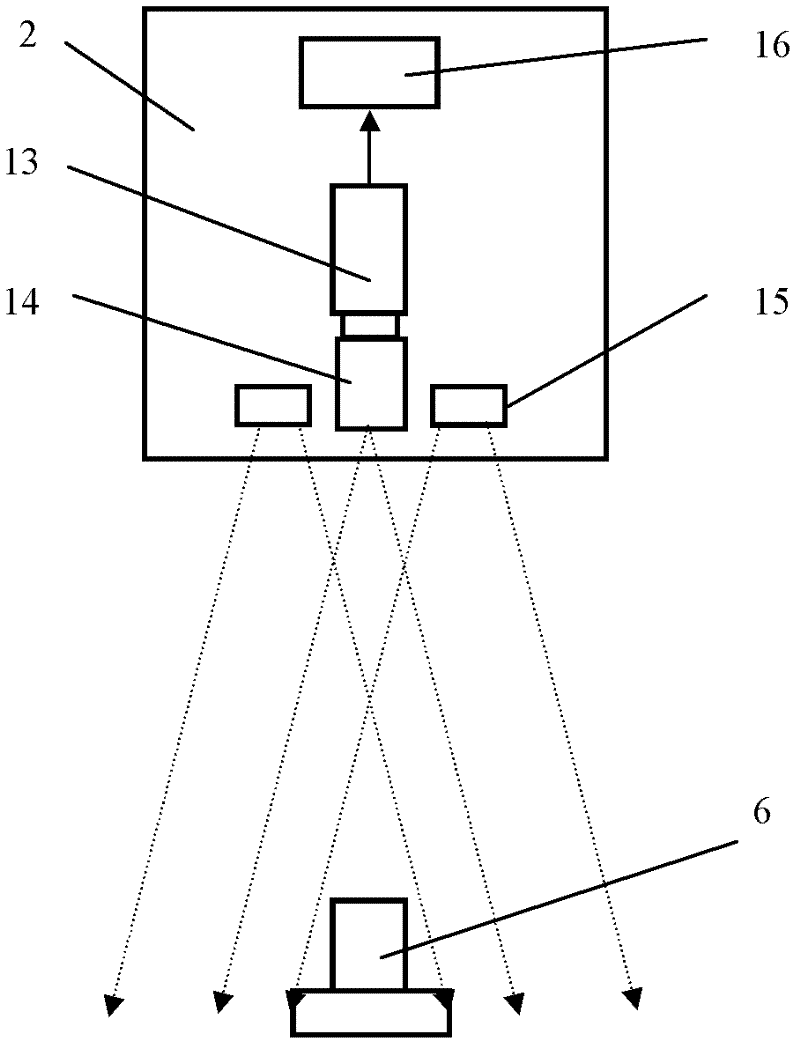

[0036] This embodiment provides a high-speed detection system for railway fasteners, the composition principle is as follows figure 1As shown, the detection system is mainly divided into three parts: laser positioning system 1, control center 2 and visual recognition system 4, the three components are located inside the detector 3, and the detector 3 is placed under the car body, facing the fastener 6 directly above the area. The laser positioning system 1 and the visual recognition system 4 are arranged staggered forward and backward along the direction of train running, the laser positioning system 1 is in front, and the visual recognition system 4 is behind, and the distance between them is constant. During the running of the train, when the detector 3 reaches the top of the area where the fastener 6 is located, the laser positioning system 1 automatically detects and locates the position of the fastener 6, and sends a synchronization signal to trigger the visual recognitio...

Embodiment 2

[0046] This embodiment provides a high-speed detection method for missing railway fasteners, and the implementation process is as follows:

[0047] Under the control of the control center 2, the laser positioning system 1 turns on the semiconductor laser 8, and the visual recognition system 4 turns on the illumination light source 15;

[0048] a) The laser positioning system 1 continuously collects the height information of the area where the fastener 6 is located. When it reaches the location of the fastener 6, the photoelectric array 11 generates a corresponding electrical signal due to the change in the height of the fastener 6, which is generated after passing through the photoelectric processing circuit 12. The synchronization signal is sent directly to the visual recognition system 4;

[0049] b) After the visual recognition system 4 receives the synchronization signal from the laser positioning system 1, it directly triggers the action of the high-speed industrial camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com