Flexible connection element

A technology of connecting elements and connecting discs, which is applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve the problems of difficult to realize large displacement compensation and limited displacement compensation of flexible connecting elements, and achieve compact structure, disassembly Simple installation and optimized system layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

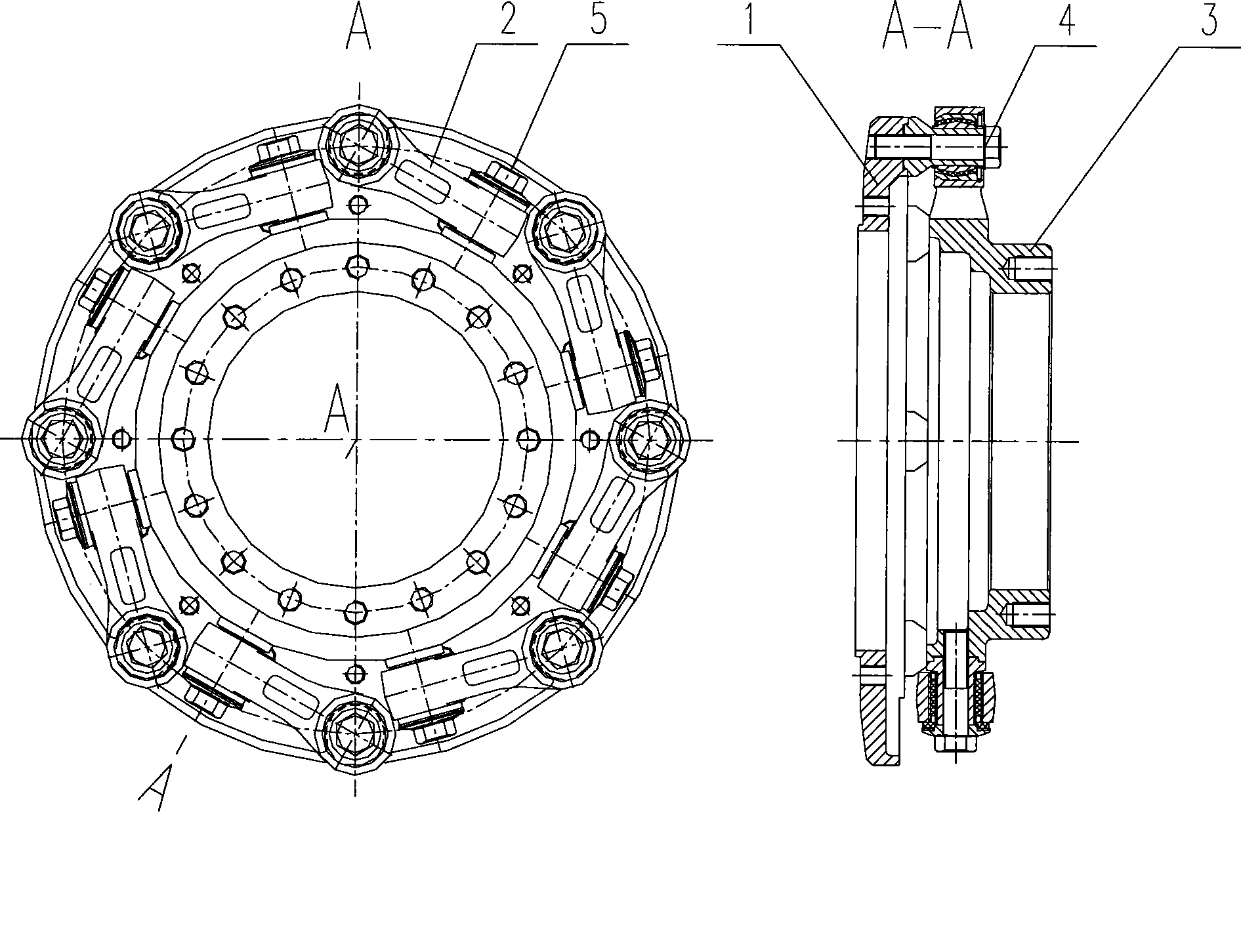

[0014] see figure 1 , In a specific embodiment of the present invention, the flexible coupling element is composed of a coupling disc 1, a rubber joint assembly 2, a short flange shaft 3, bolts I4 and bolts II5. The flange short shaft 3 is arranged on the end side of the coupling plate 1, and a plurality of rubber joint components 2 are evenly distributed on the end surface of the coupling plate 1, and one end thereof is fixedly connected to the coupling plate through a bolt I4, and the other end is connected to the coupling plate through a bolt II5. The short shaft of the flange is fixedly connected to form a rubber joint coupling.

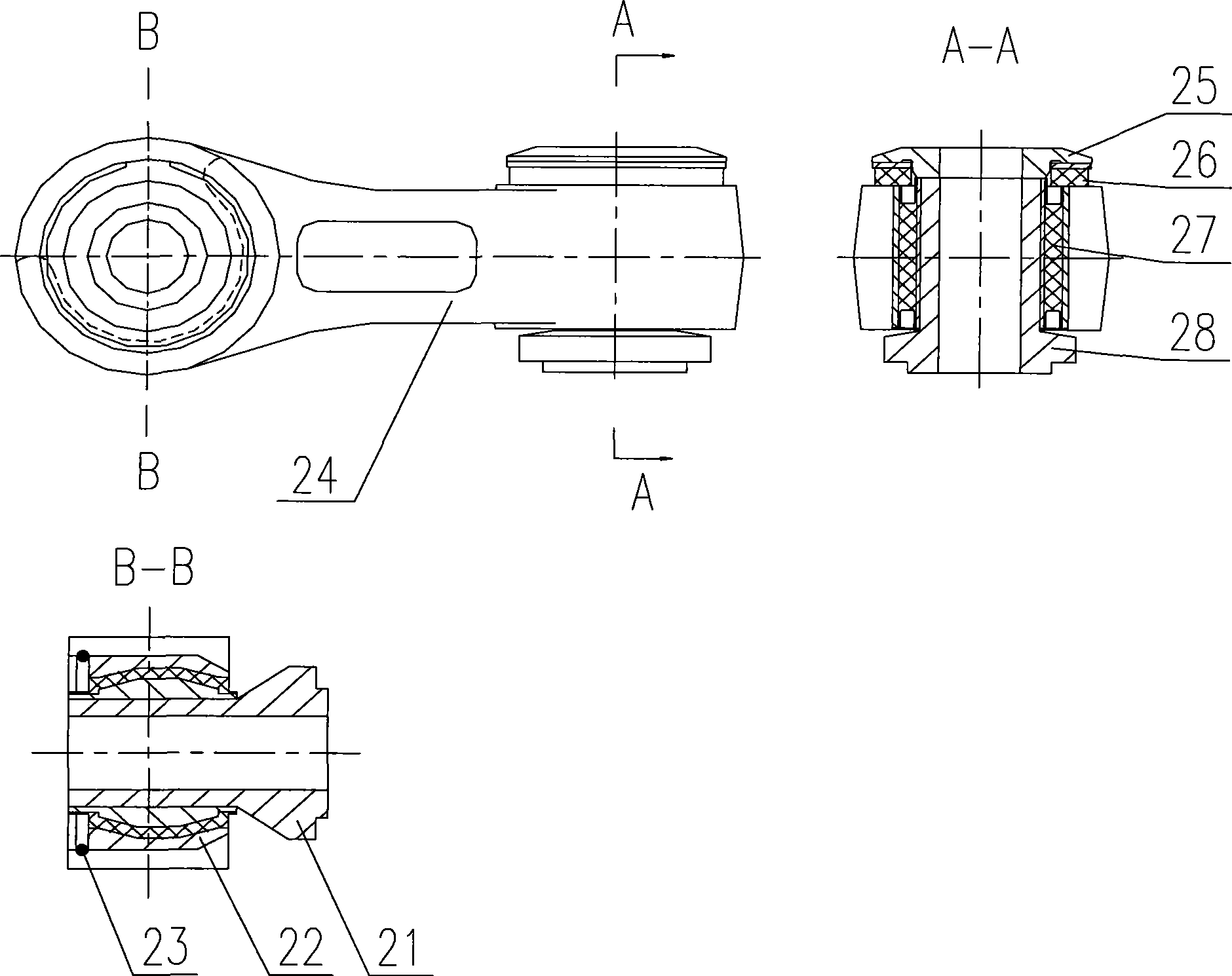

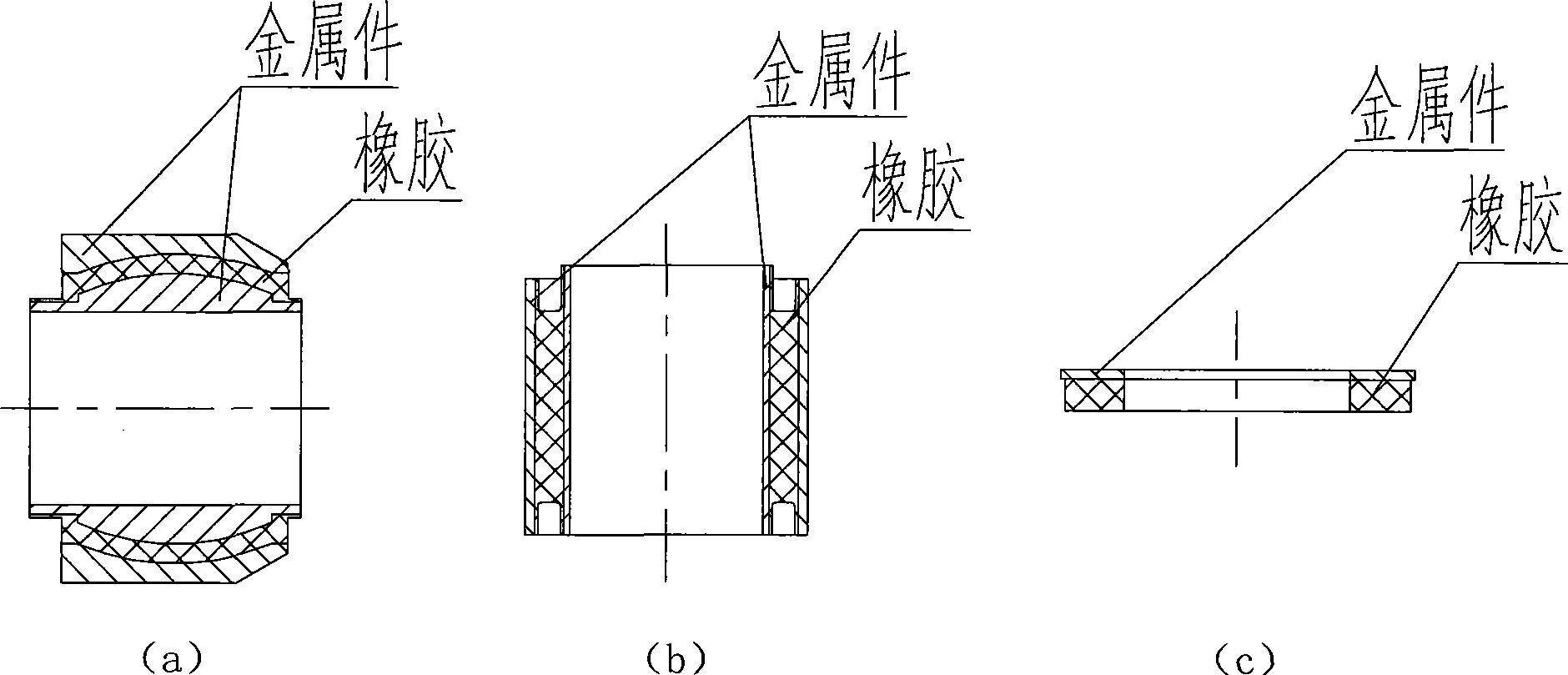

[0015] The structure of the rubber joint assembly 2, such as figure 2 shown. It includes pin sleeve I21, spherical rubber joint 22, stop ring 23, connecting rod 24, gland 25, washer 26, cylindrical rubber joint 27, pin sleeve II28. Wherein, spherical rubber joint 22 (see image 3 a), cylindrical rubber joint 27 (see image 3 b), washer 26 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com