Patents

Literature

458results about "Electrostatic transducers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

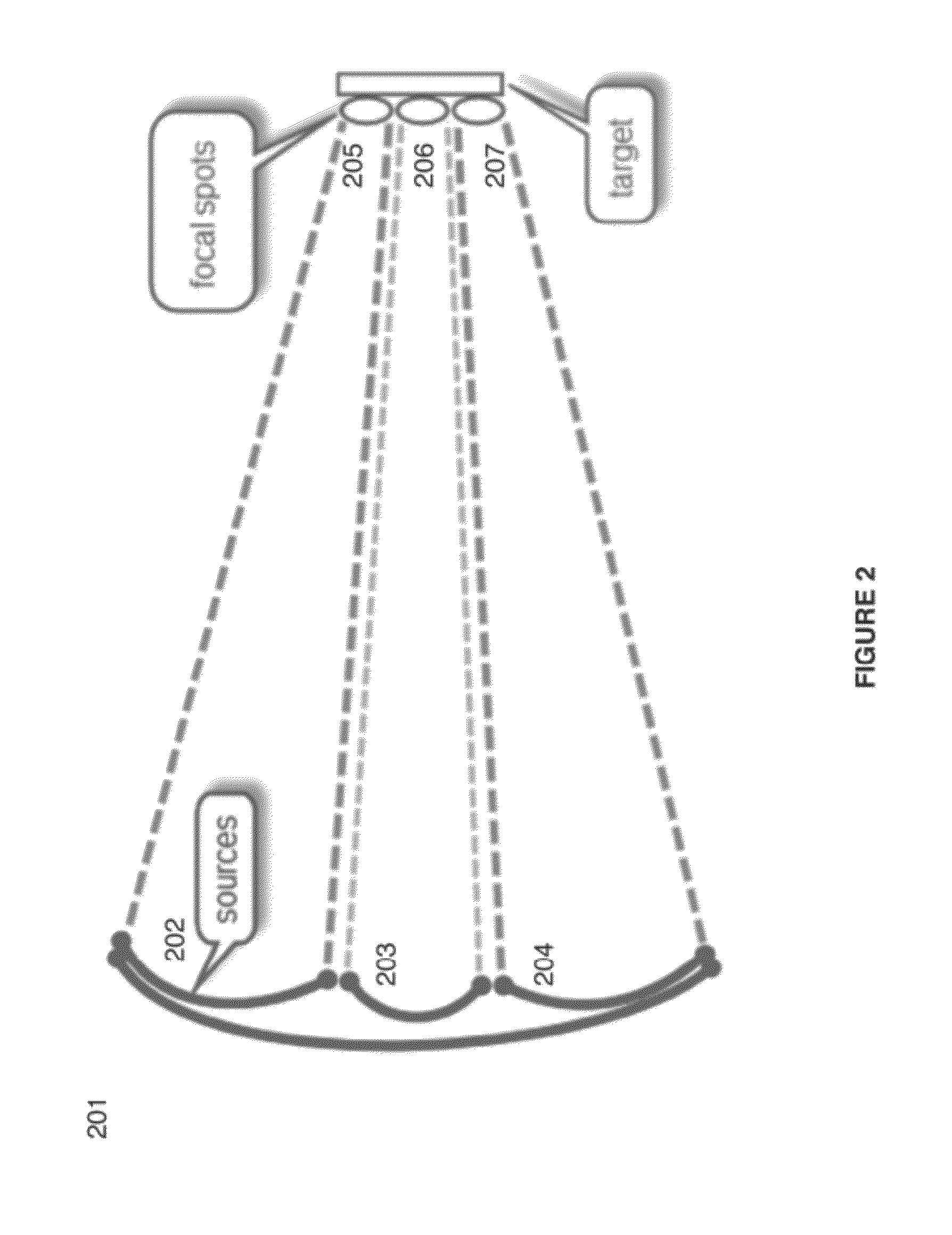

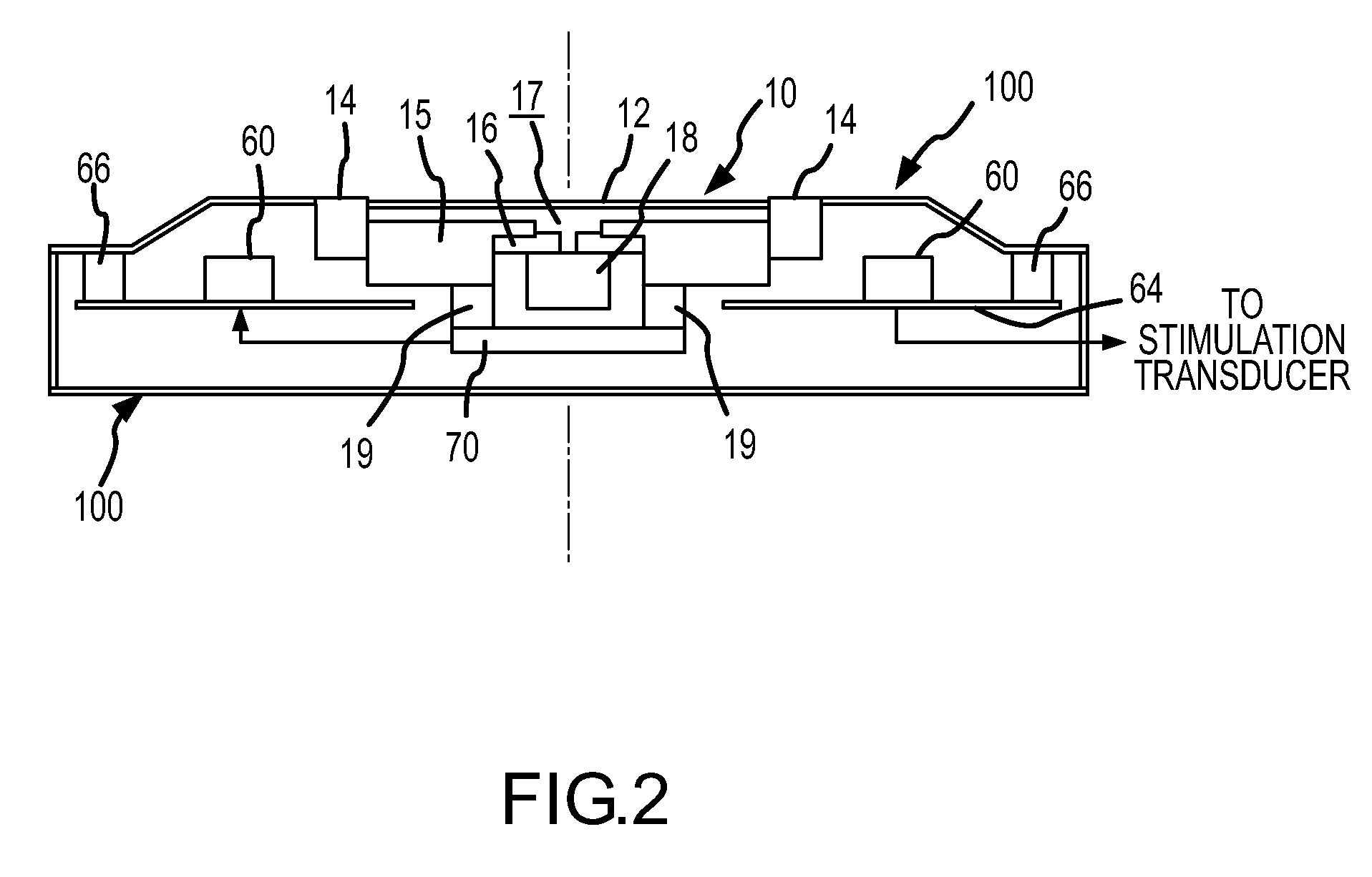

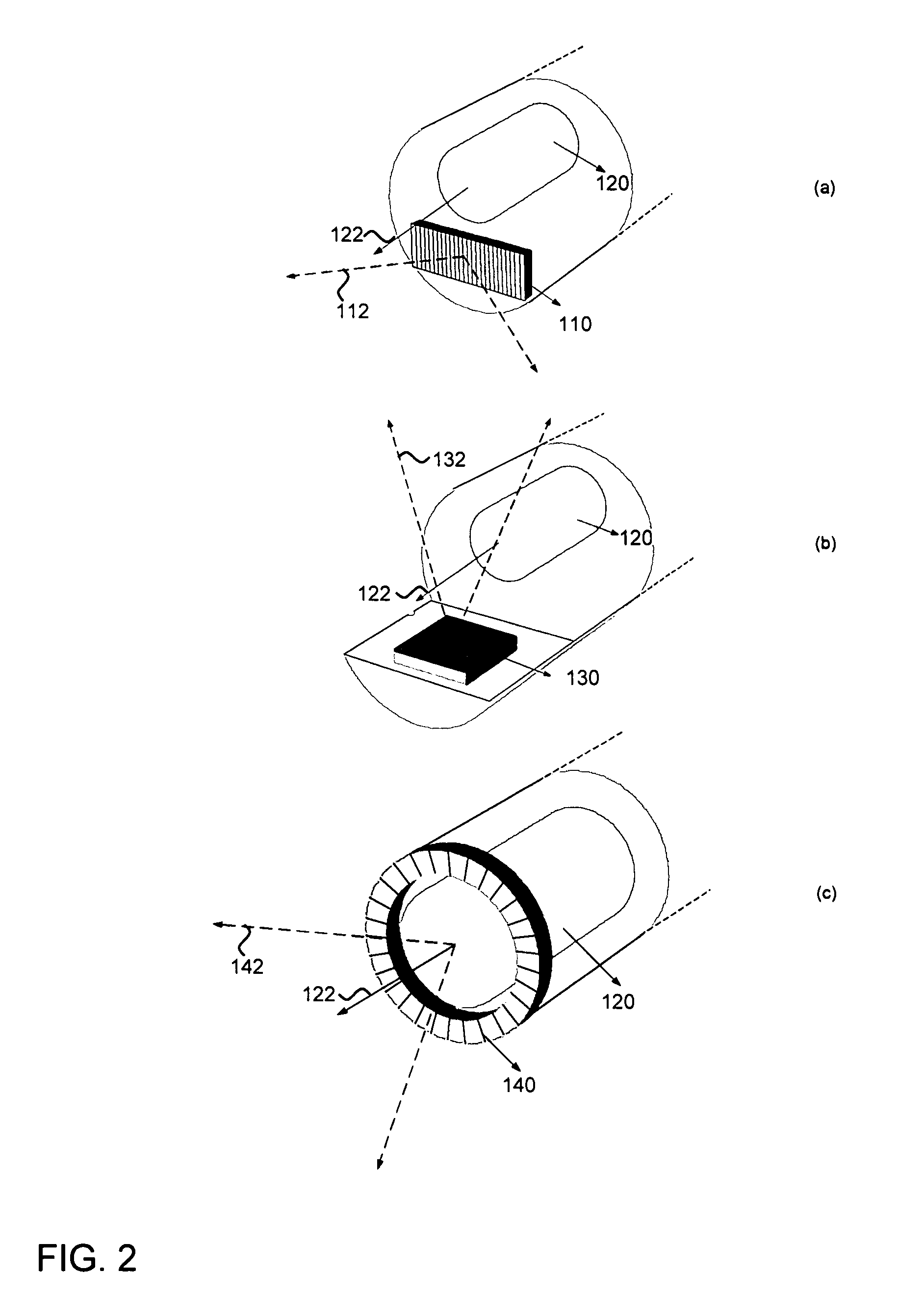

Sender communications for wireless power transfer

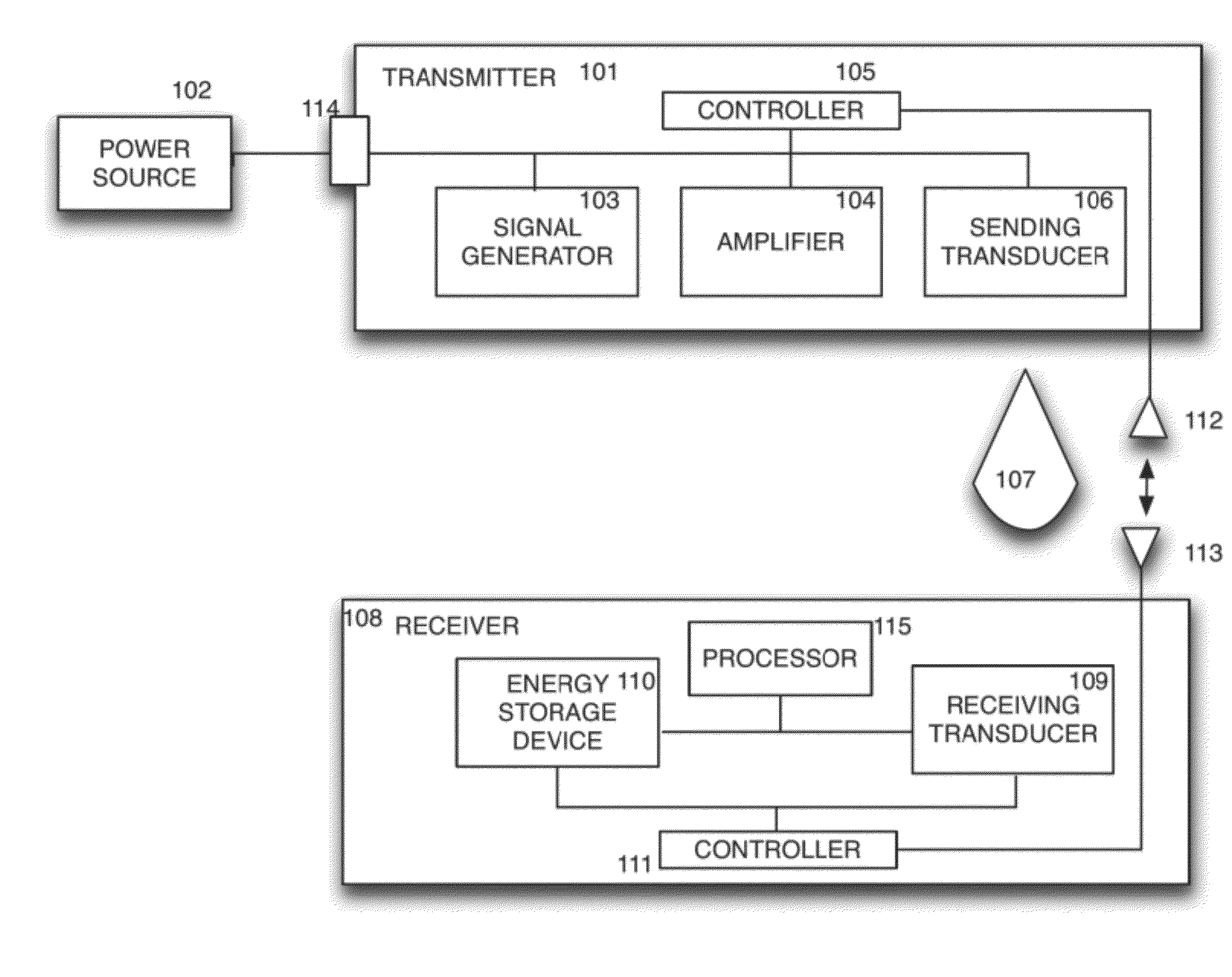

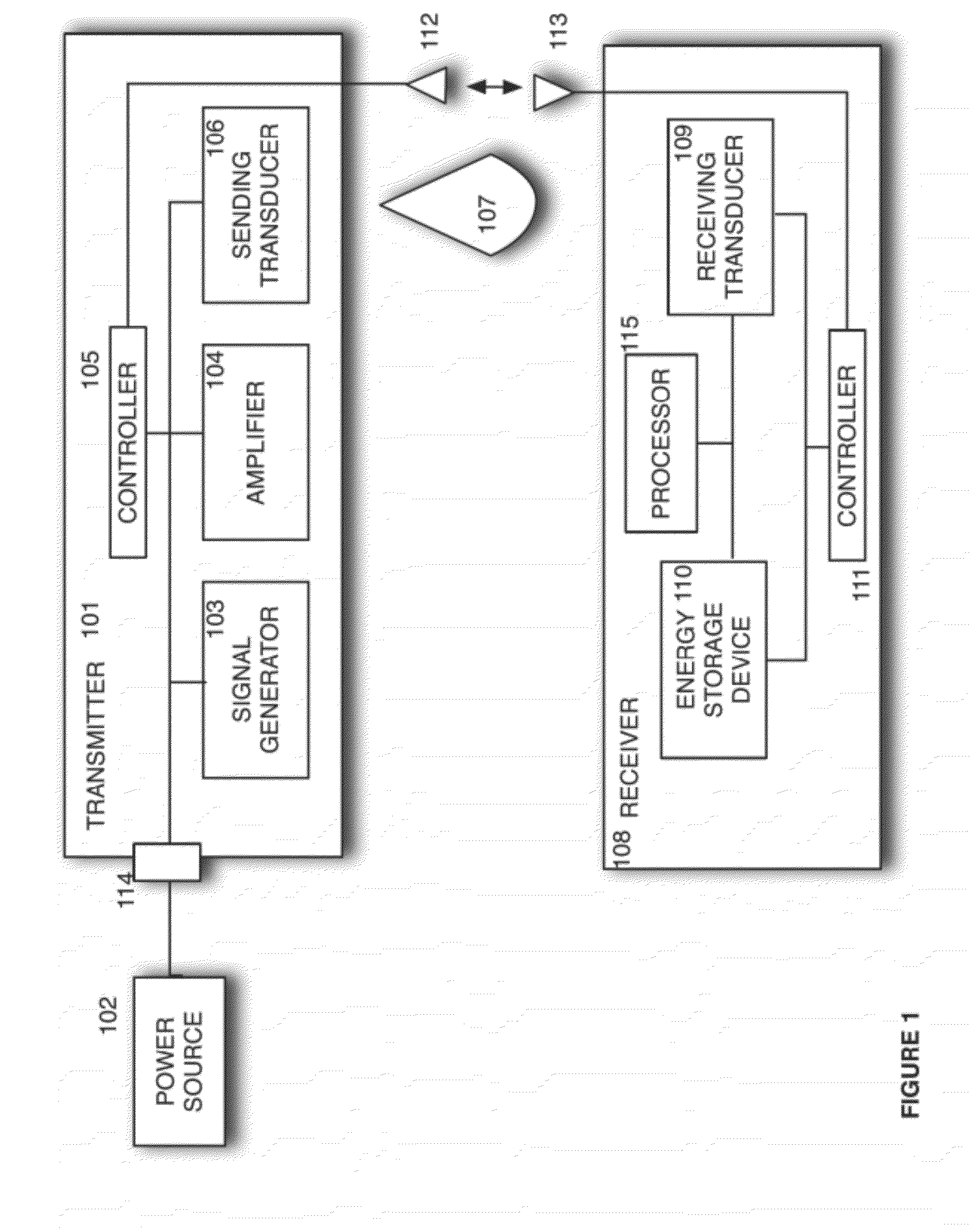

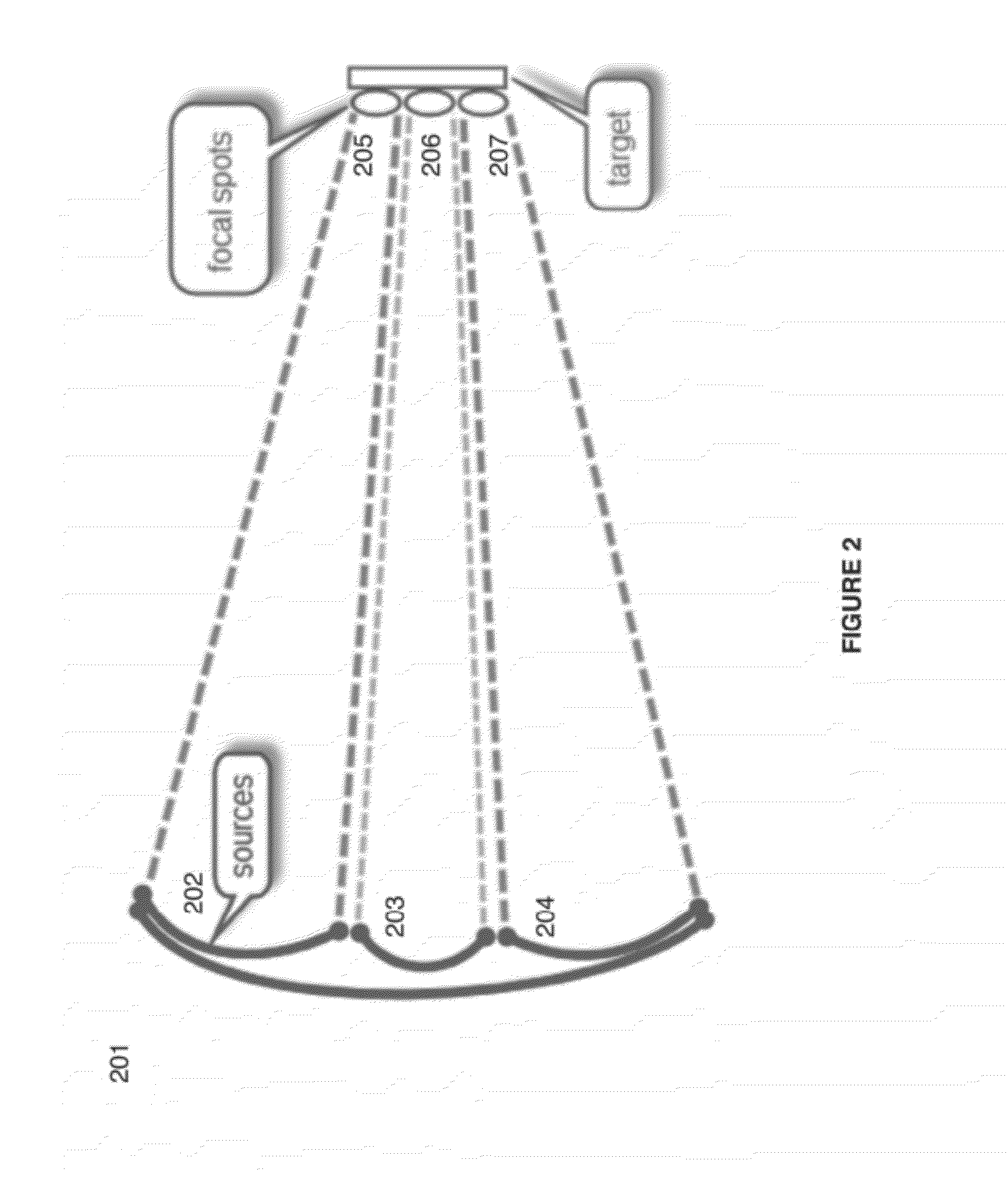

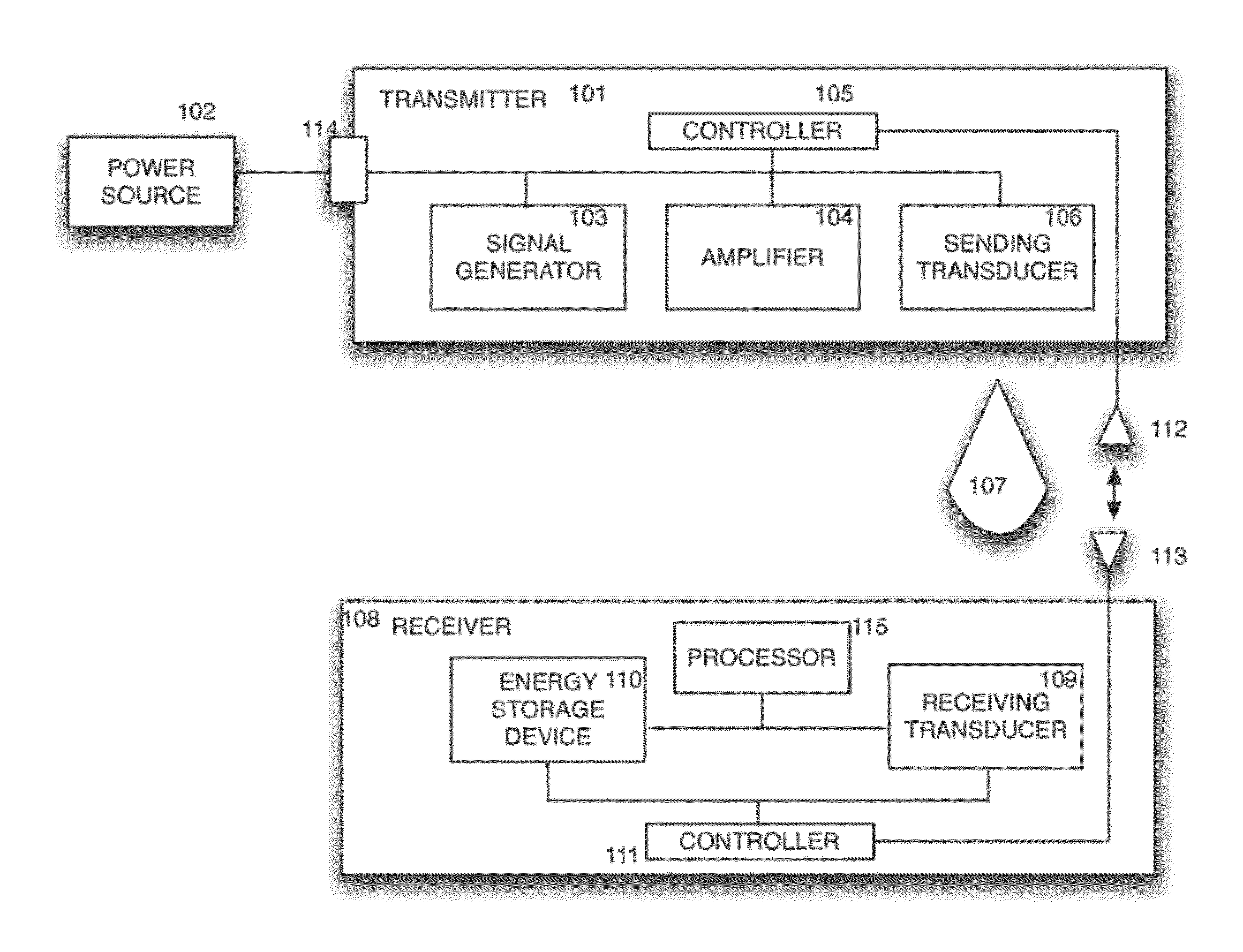

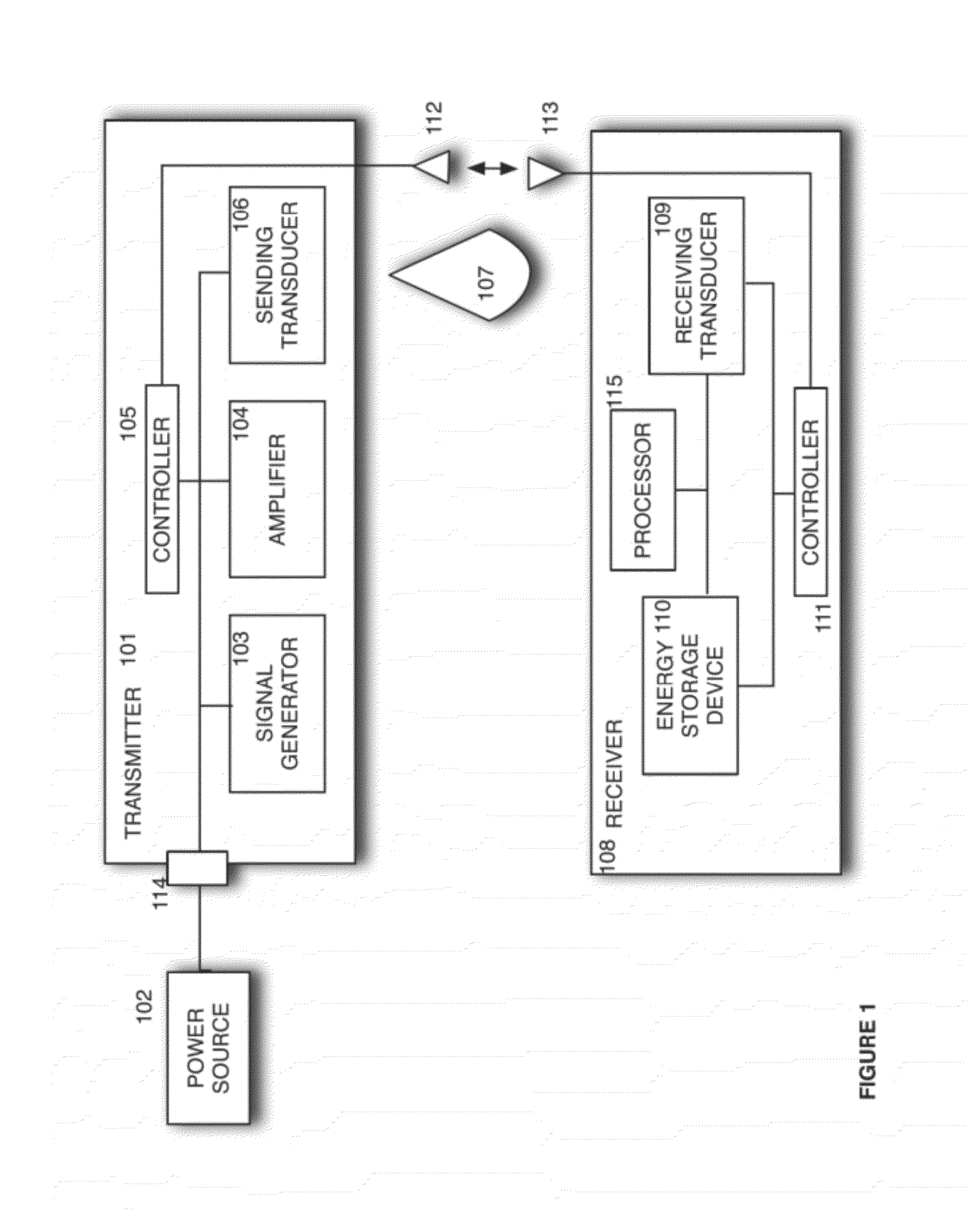

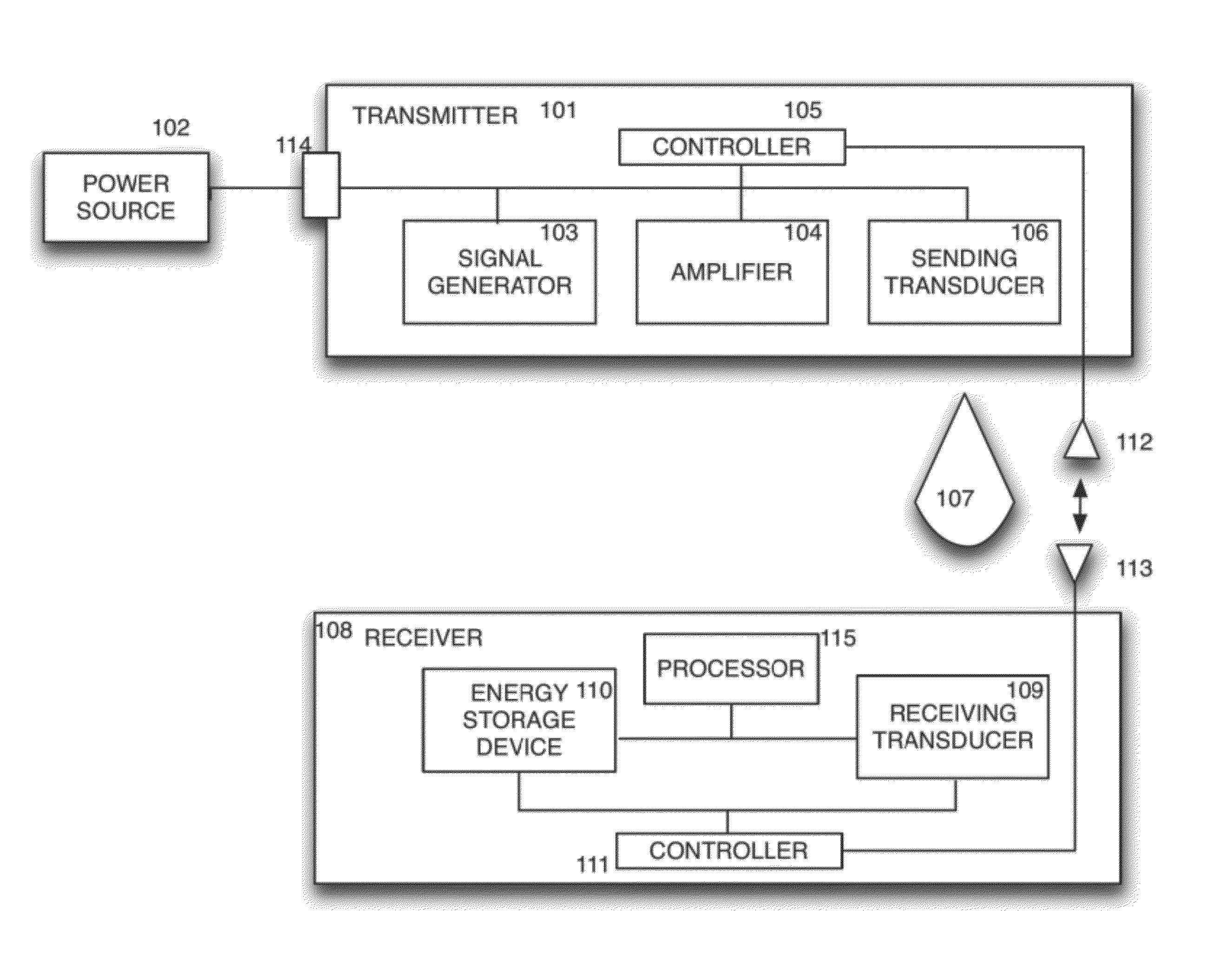

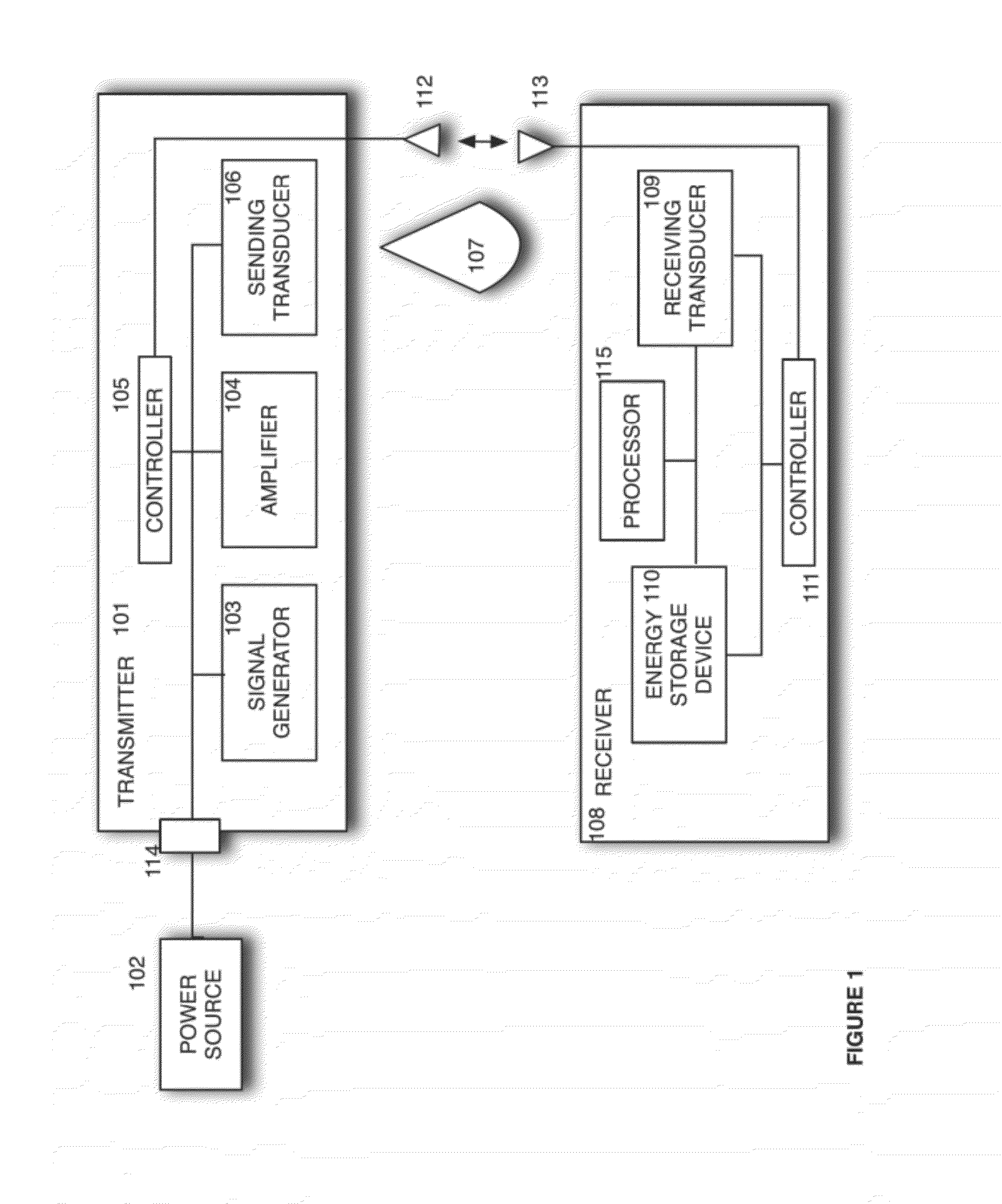

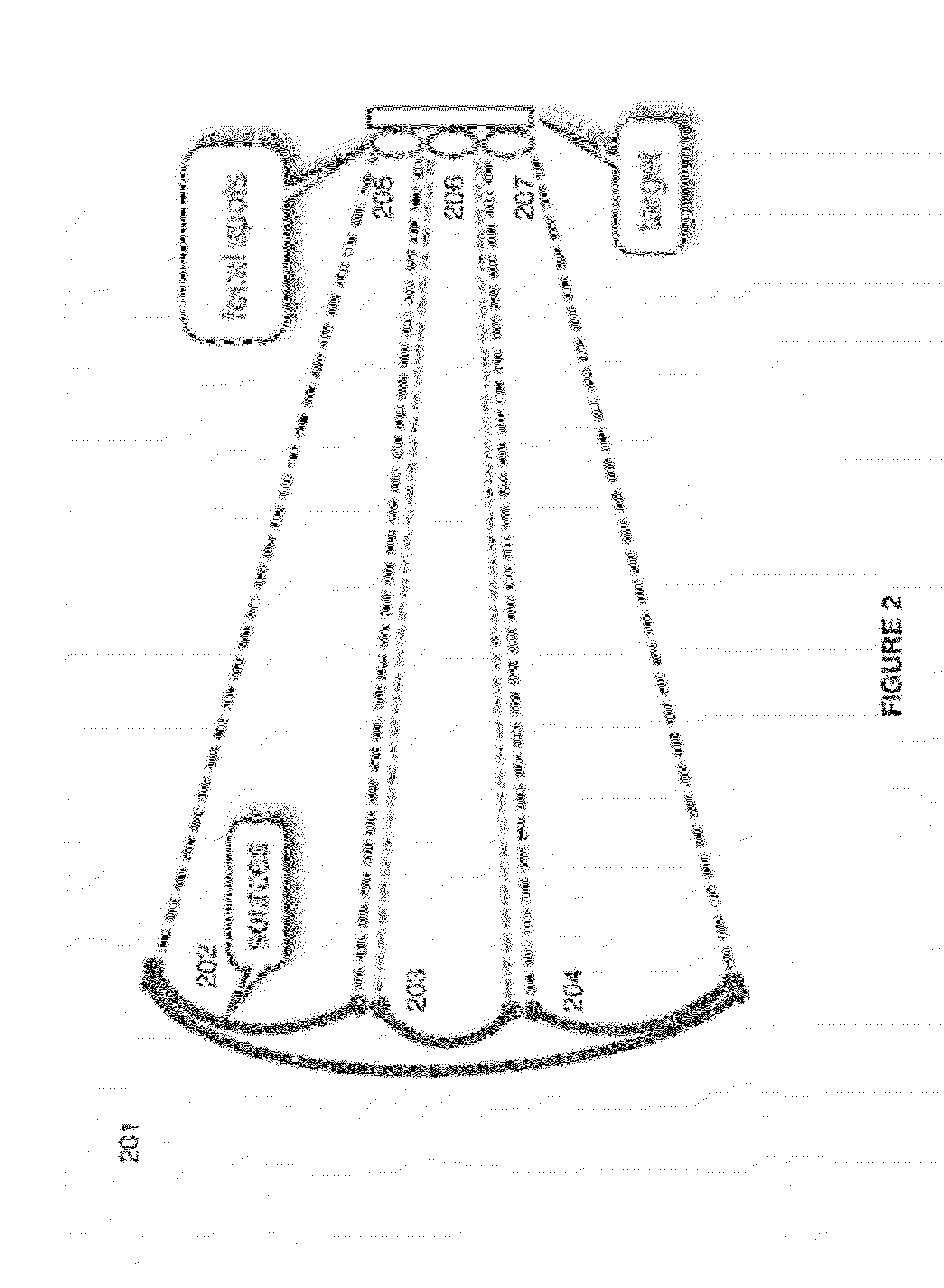

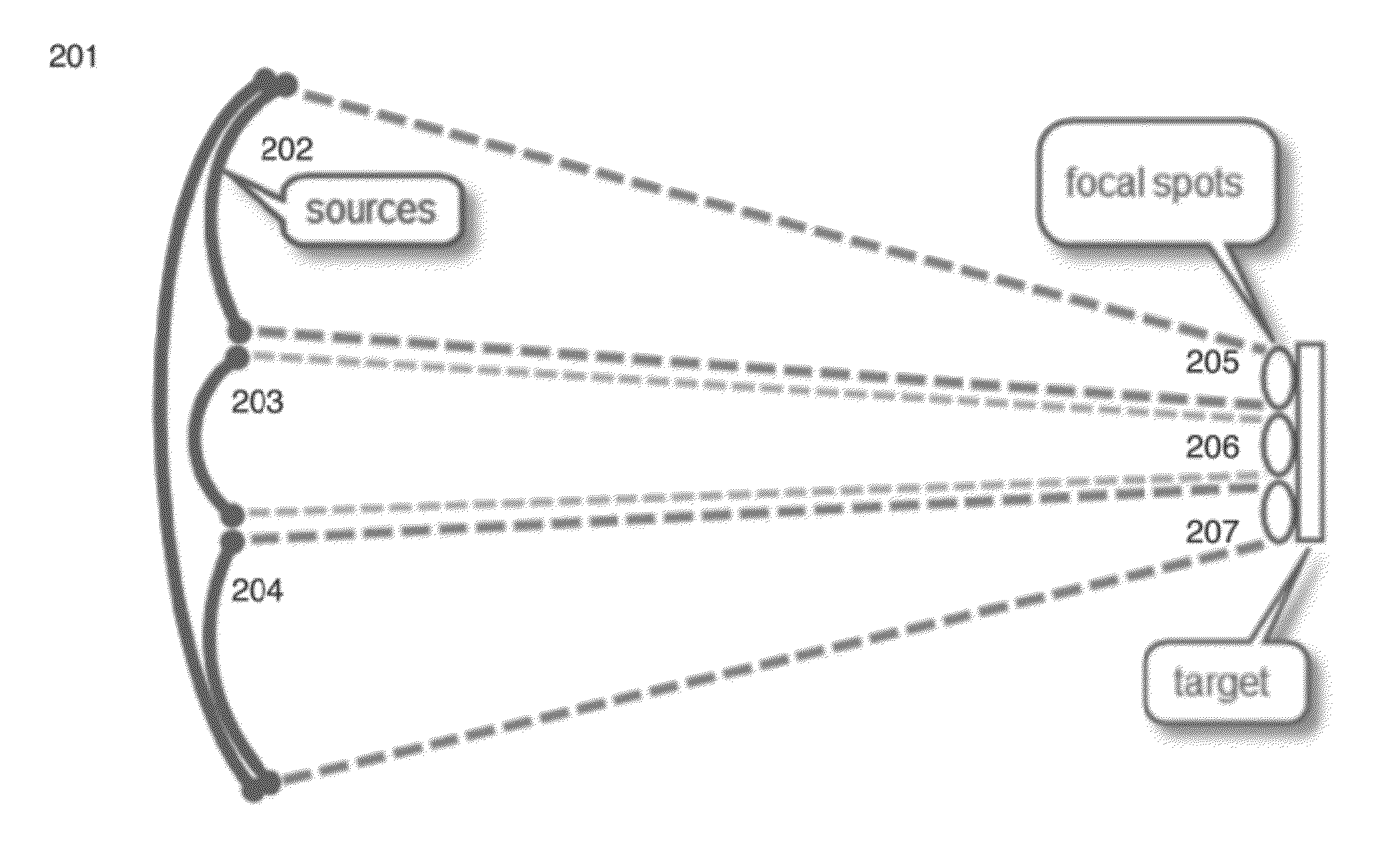

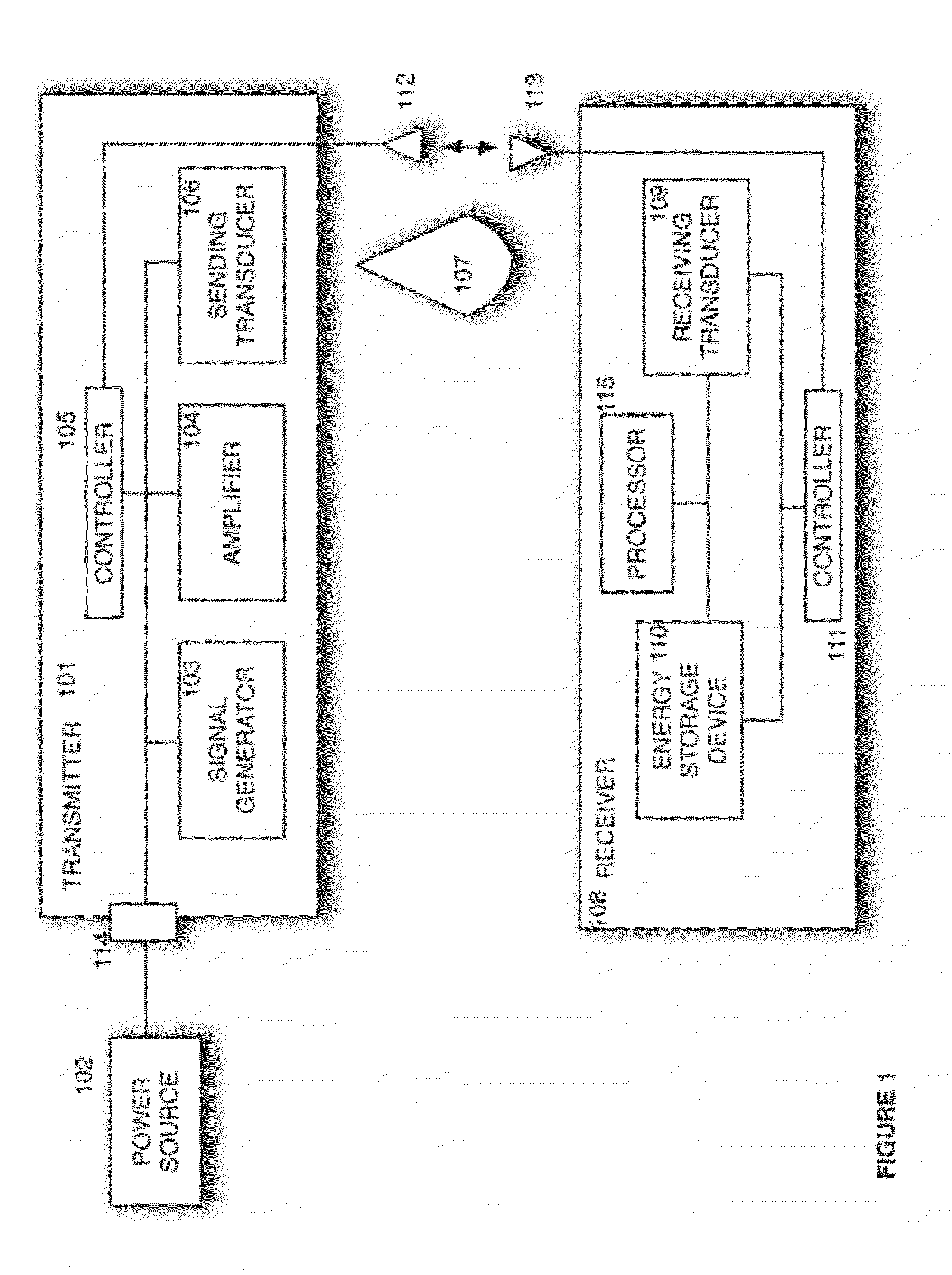

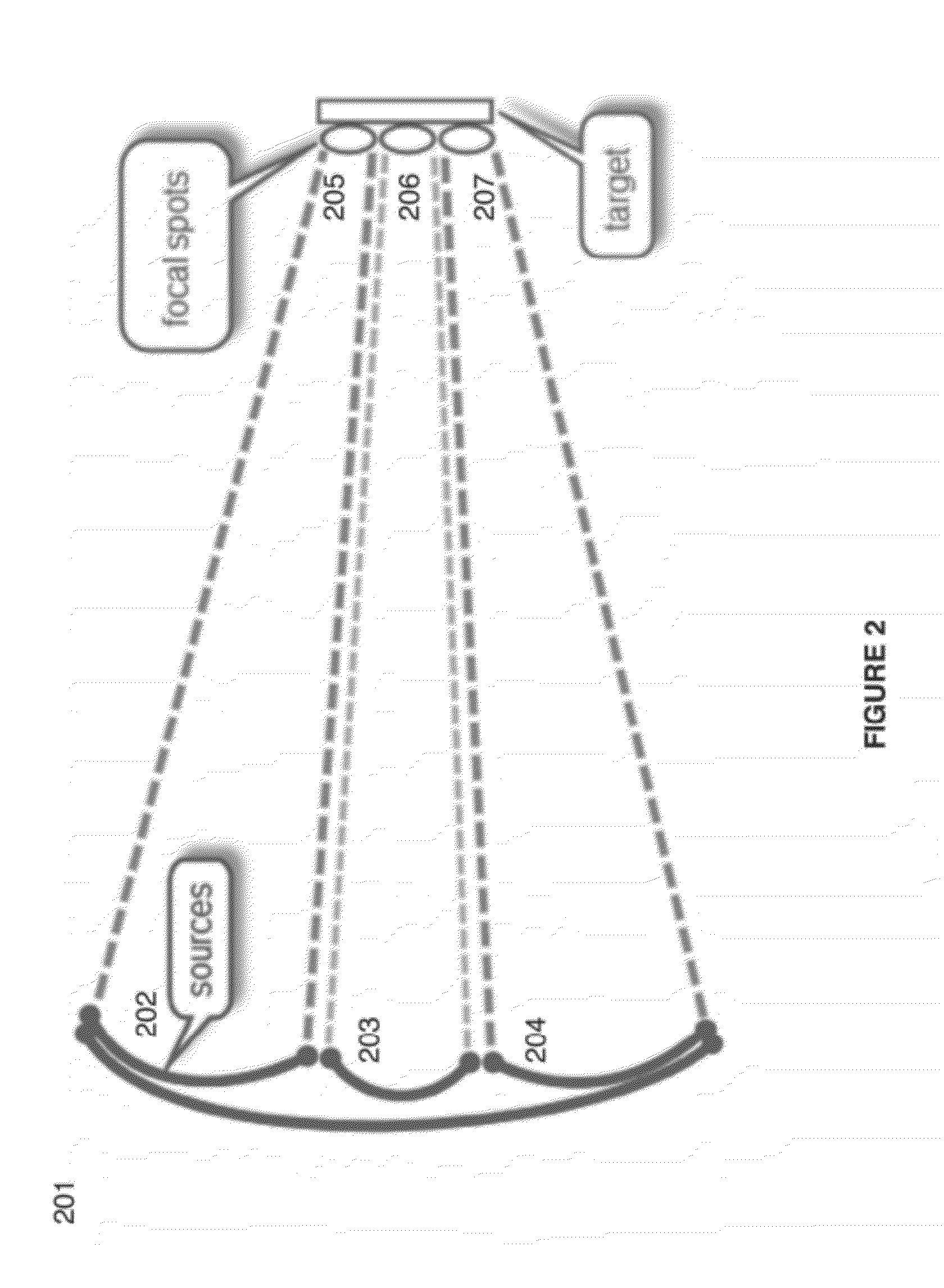

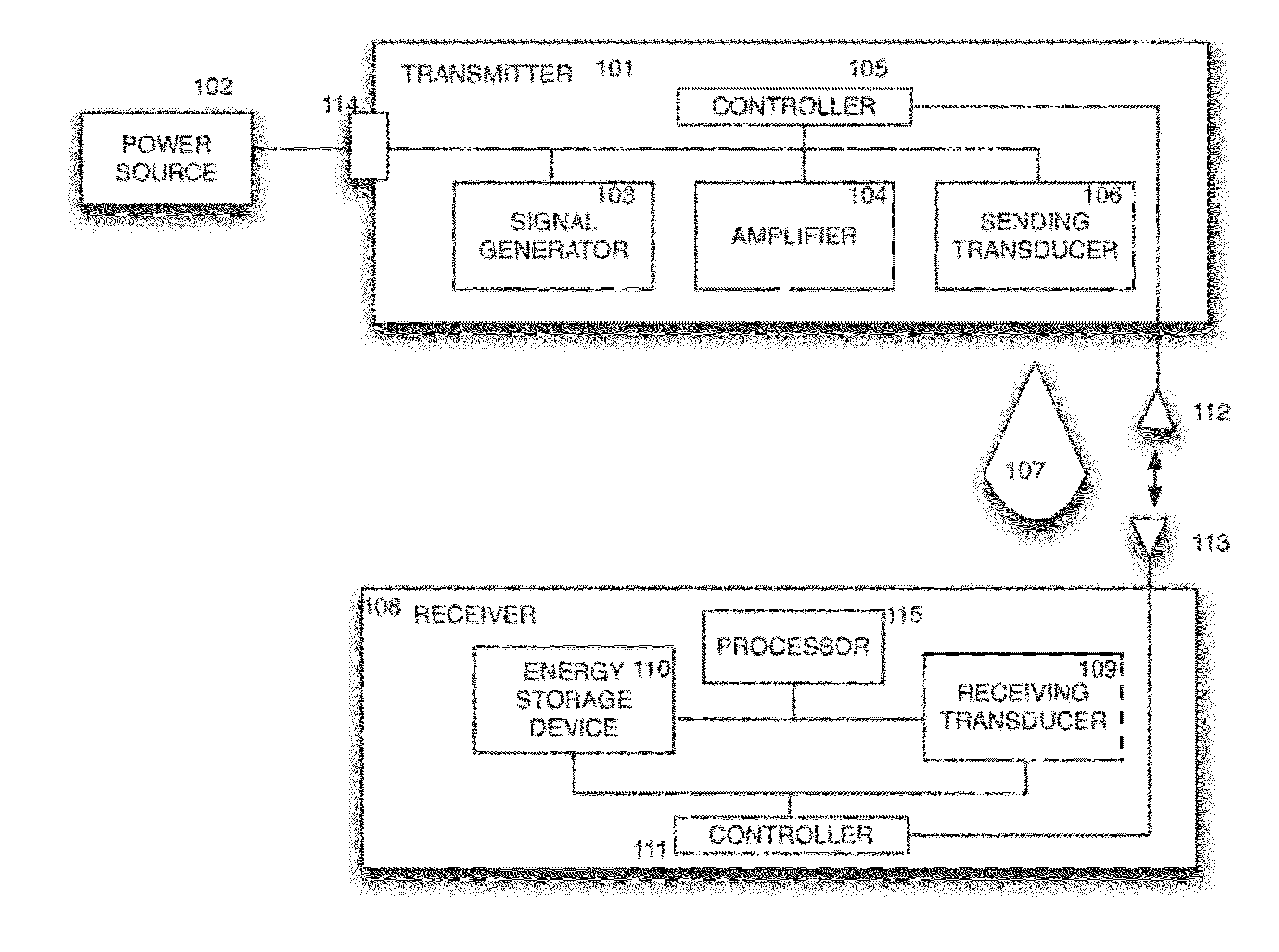

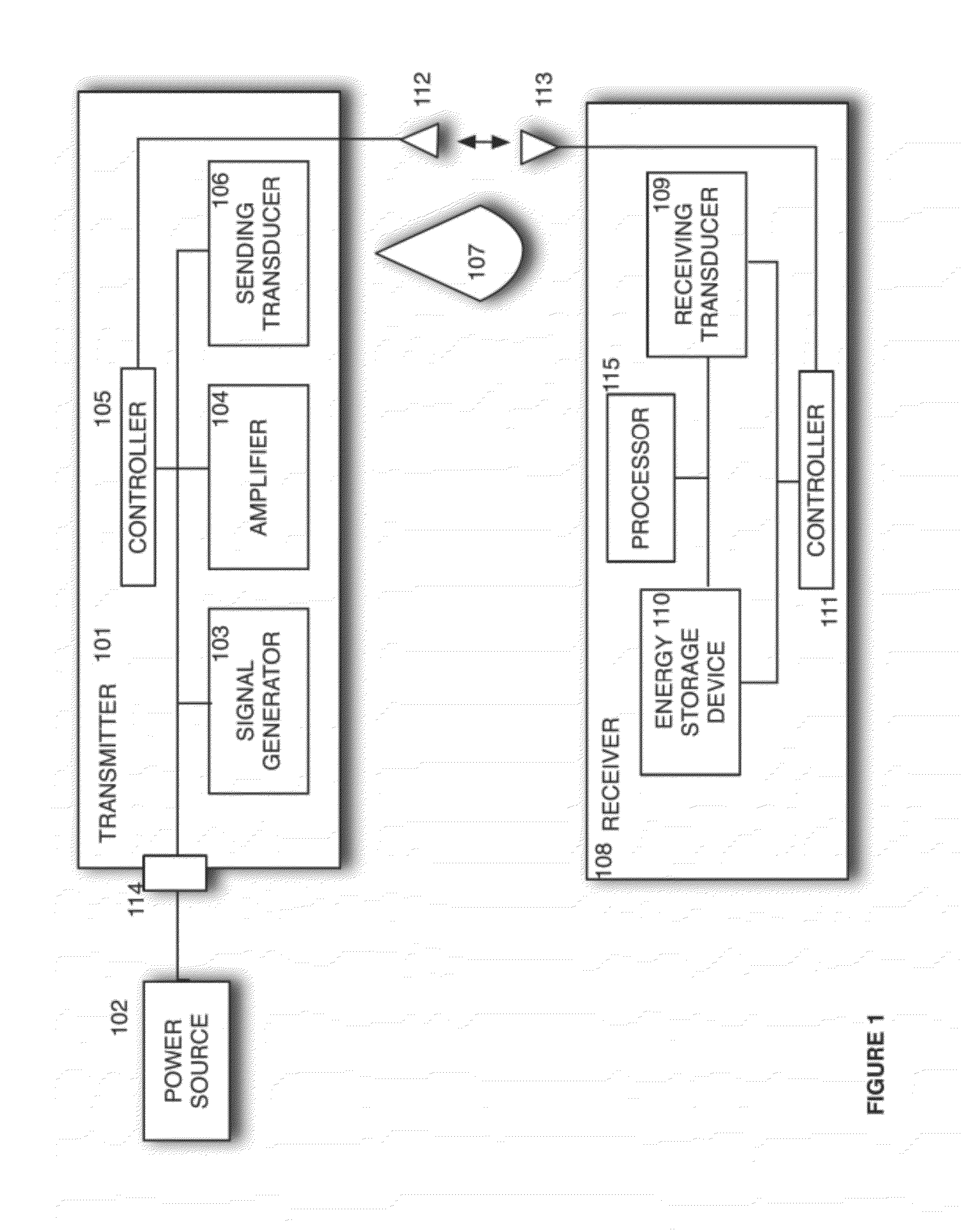

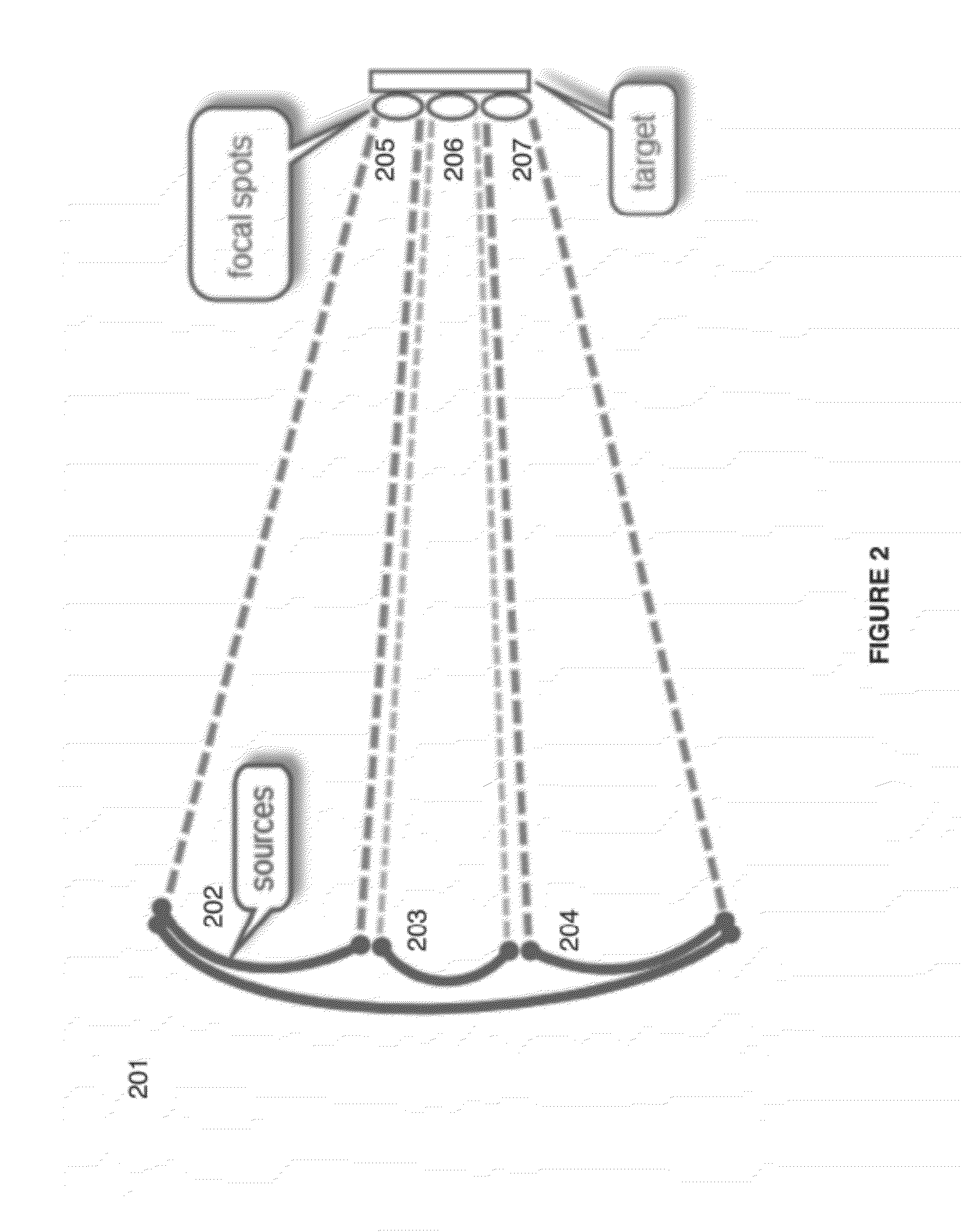

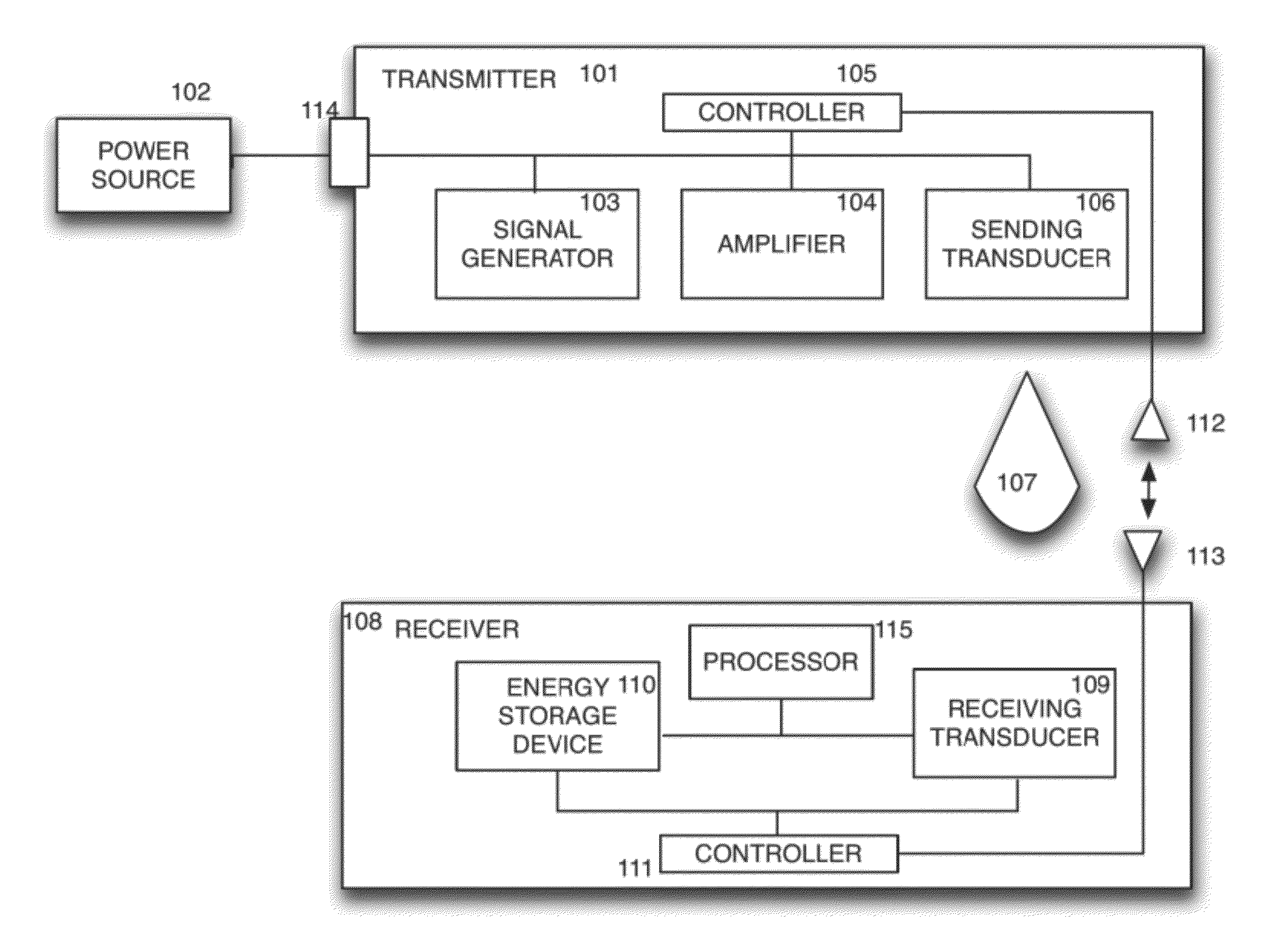

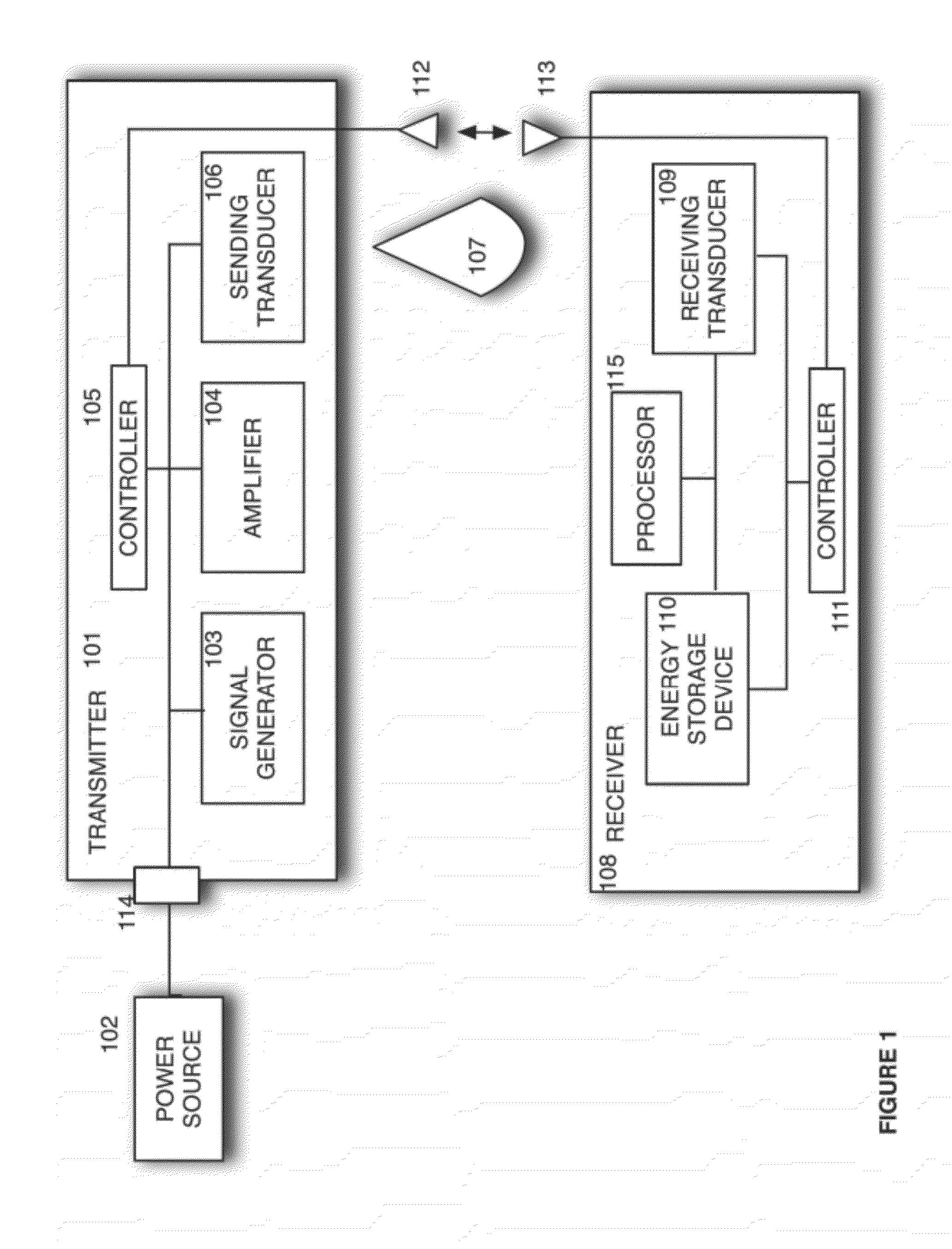

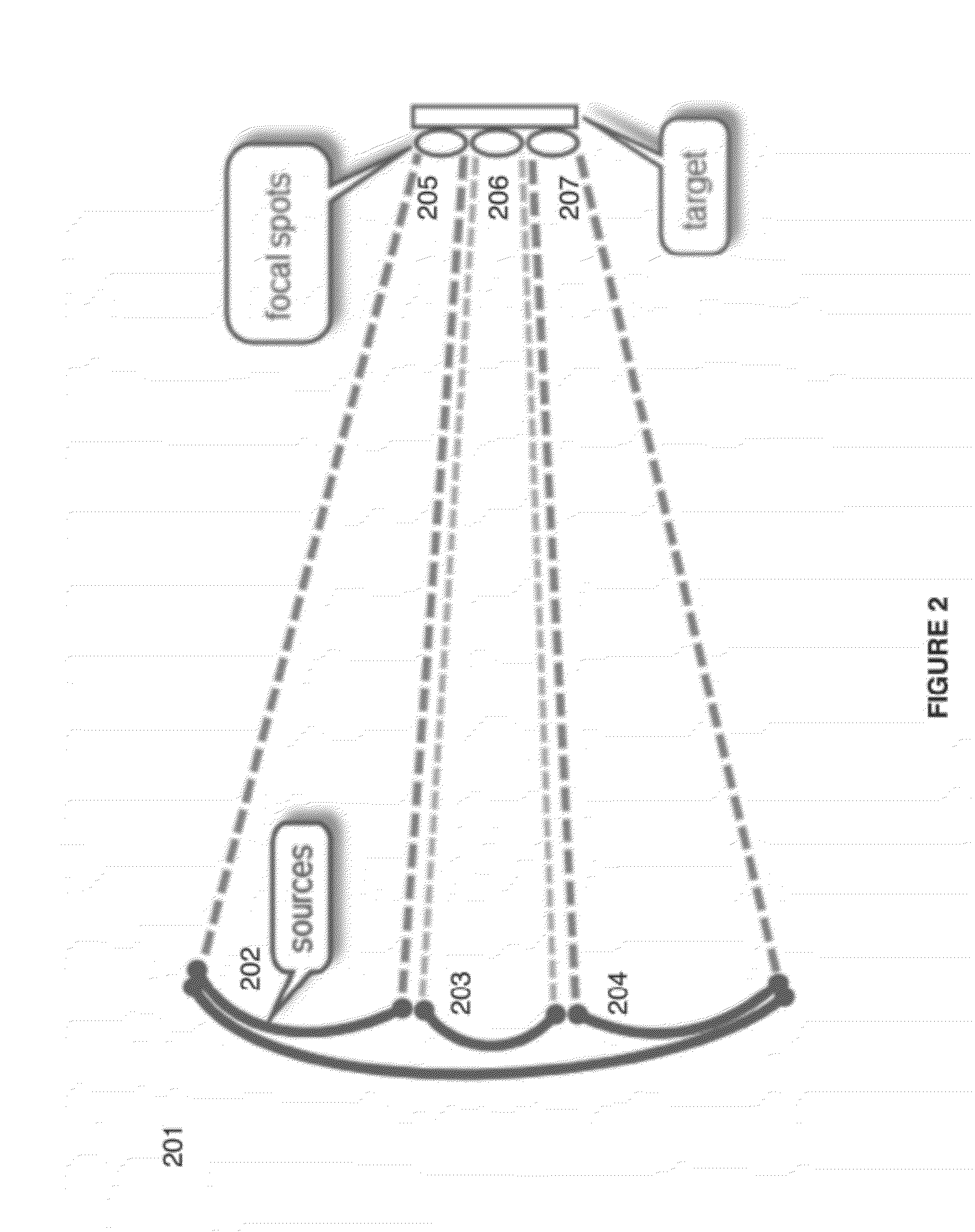

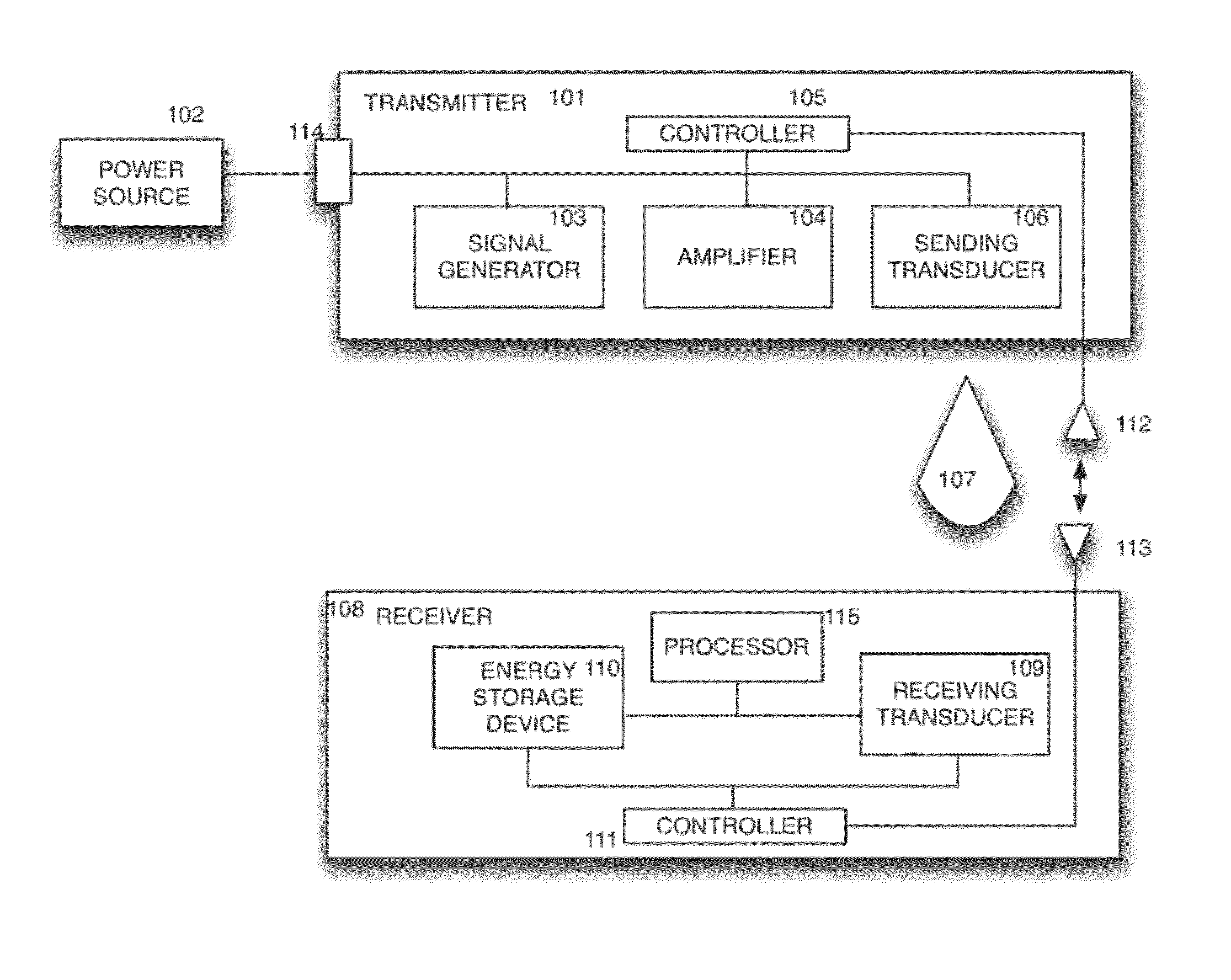

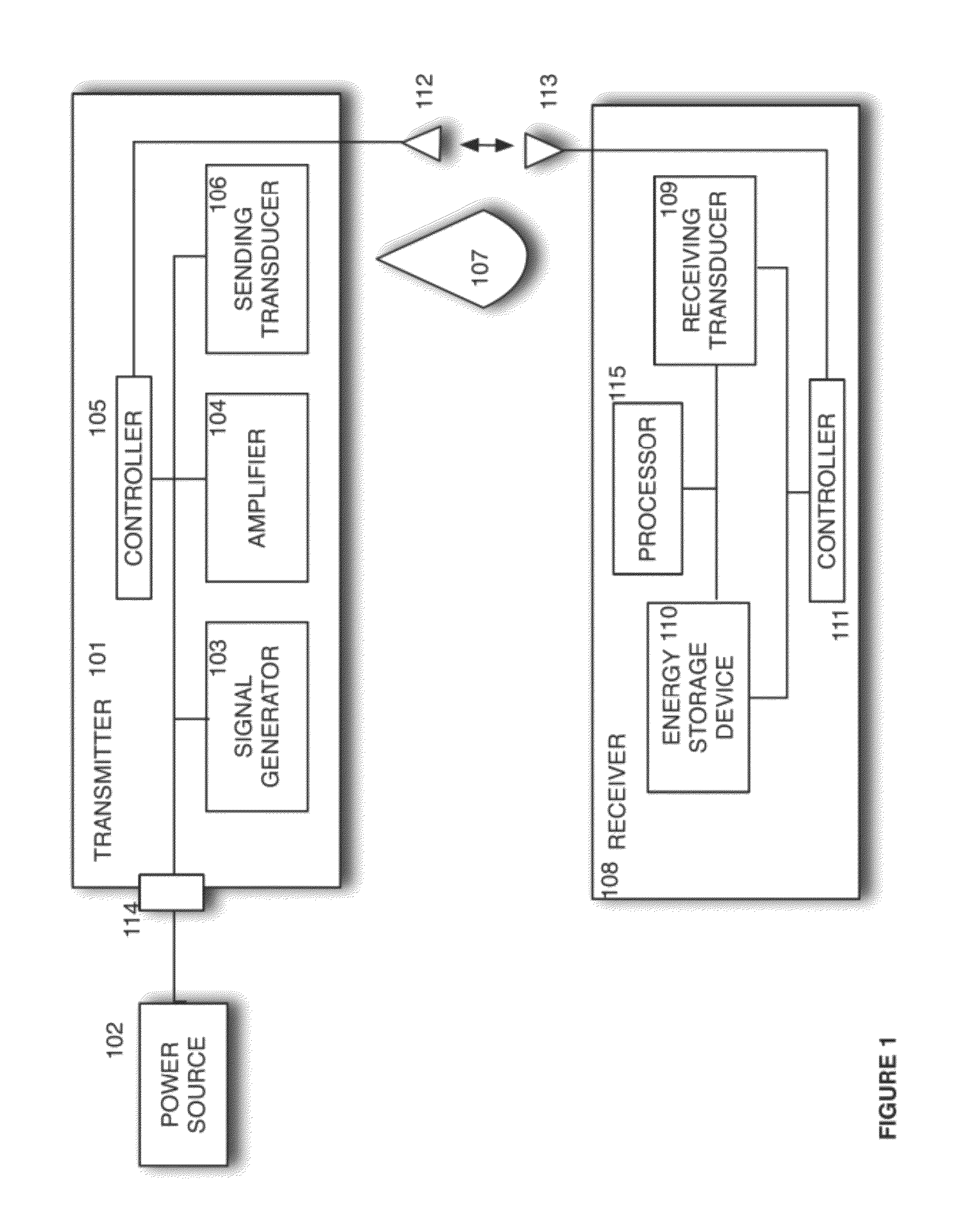

A signal generator generates an electrical signal that is sent to an amplifier, which increases the power of the signal using power from a power source. The amplified signal is fed to a sender transducer to generate ultrasonic waves that can be focused and sent to a receiver. The receiver transducer converts the ultrasonic waves back into electrical energy and stores it in an energy storage device, such as a battery, or uses the electrical energy to power a device. In this way, a device can be remotely charged or powered without having to be tethered to an electrical outlet.

Owner:UBEAM

Receiver controller for wireless power transfer

ActiveUS20120299542A1Electromagnetic wave systemTransducer detailsElectric power transmissionAudio power amplifier

A signal generator generates an electrical signal that is sent to an amplifier, which increases the power of the signal using power from a power source. The amplified signal is fed to a sender transducer to generate ultrasonic waves that can be focused and sent to a receiver. The receiver transducer converts the ultrasonic waves back into electrical energy and stores it in an energy storage device, such as a battery, or uses the electrical energy to power a device. In this way, a device can be remotely charged or powered without having to be tethered to an electrical outlet.

Owner:UBEAM

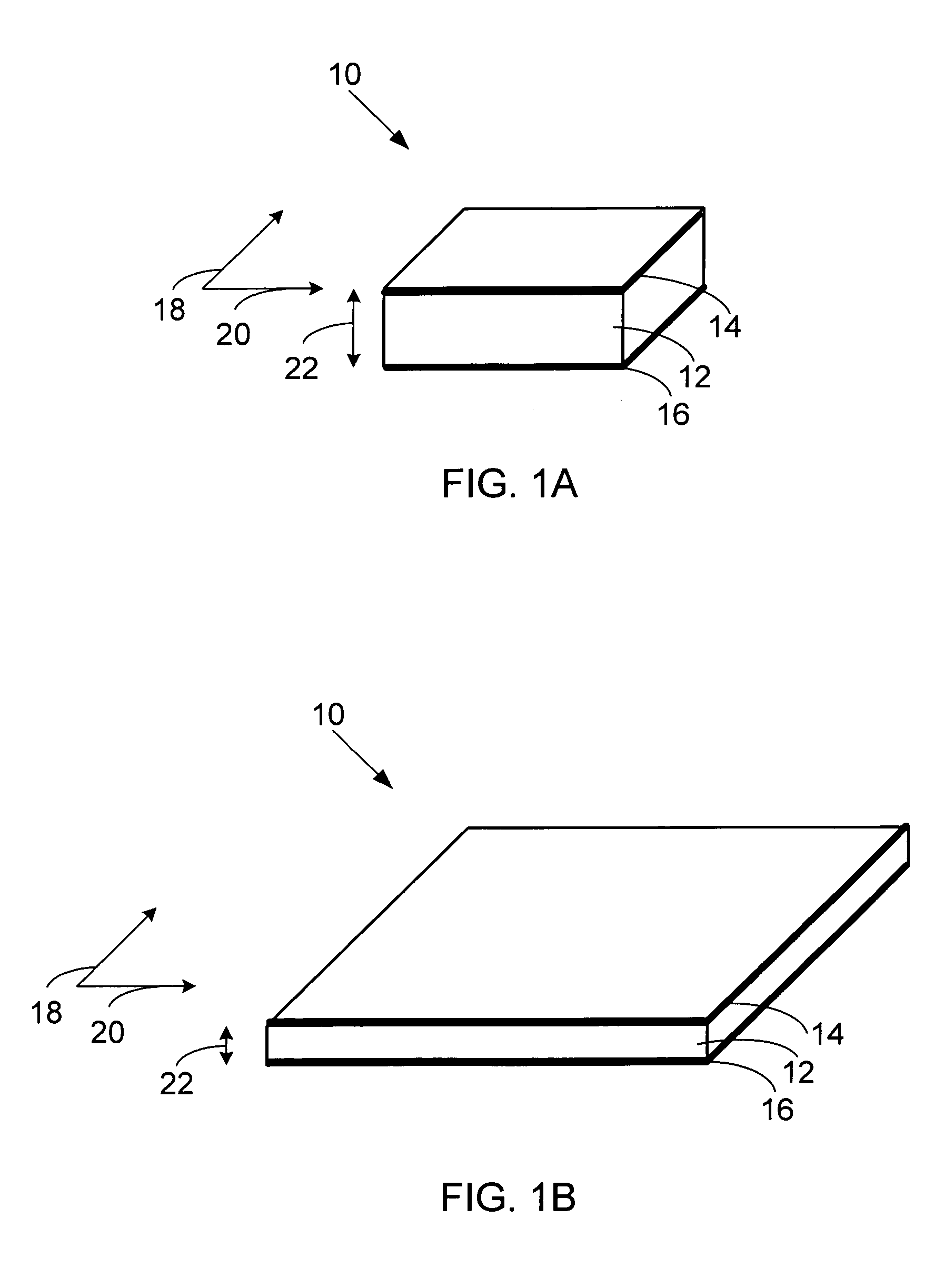

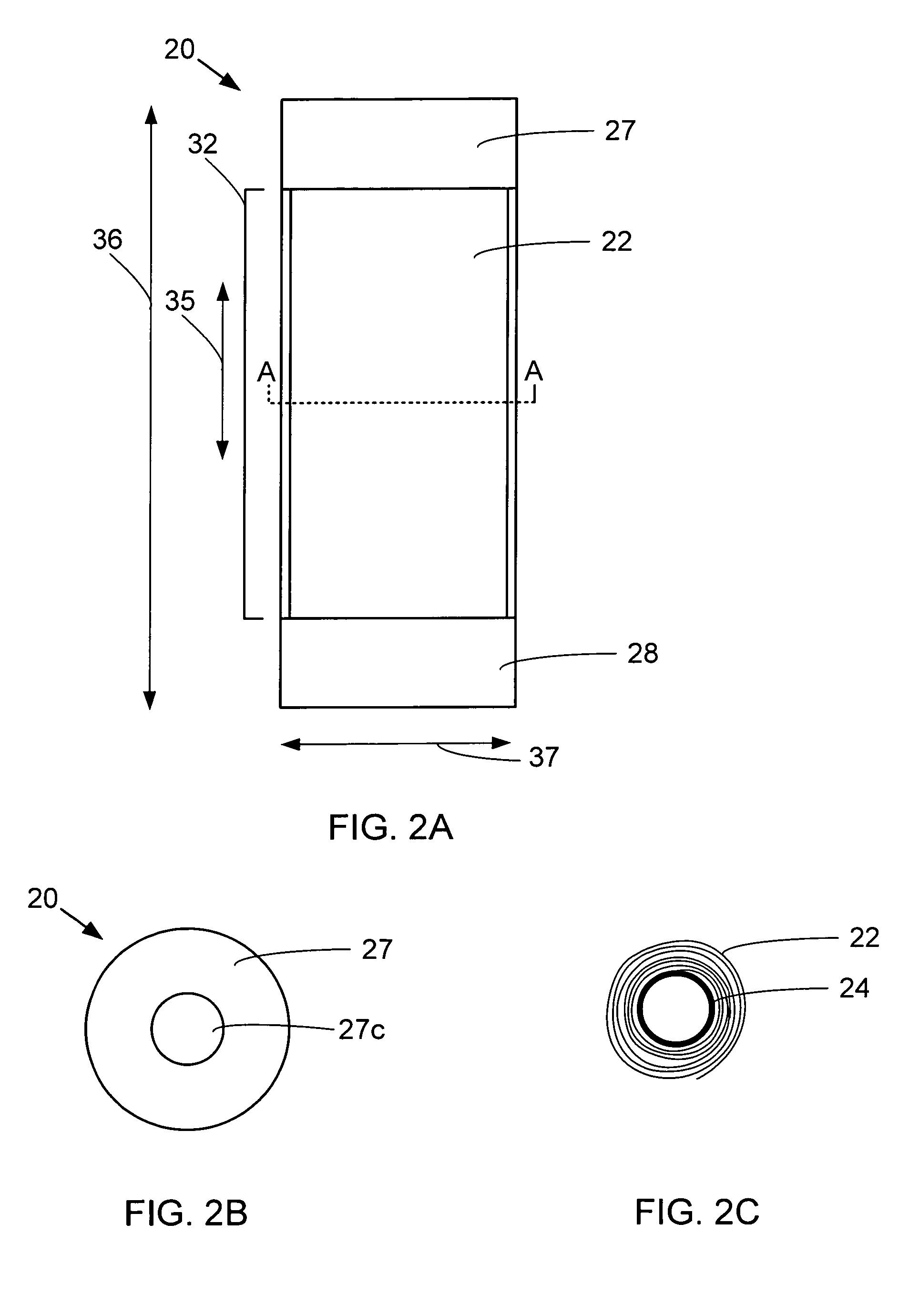

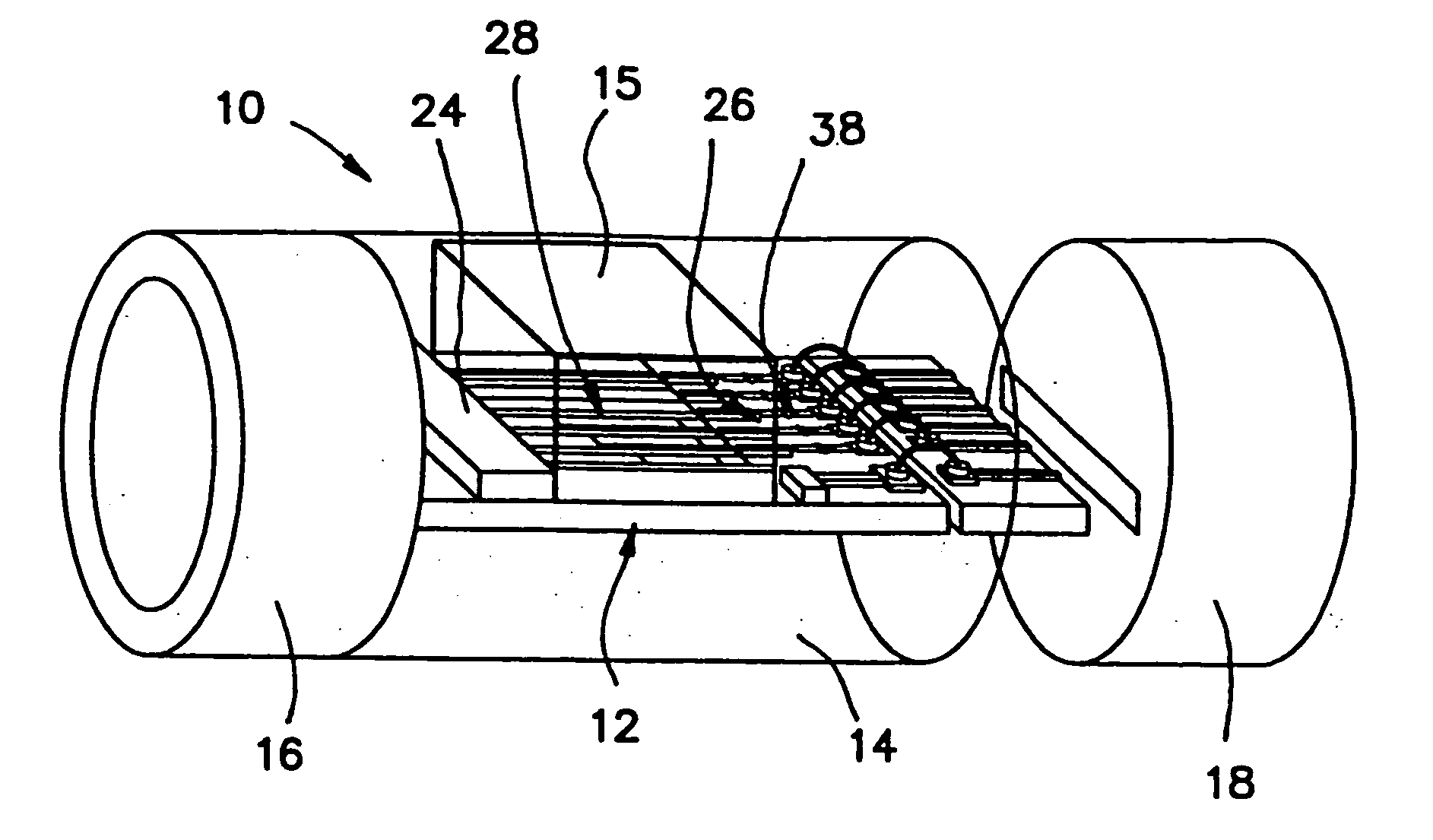

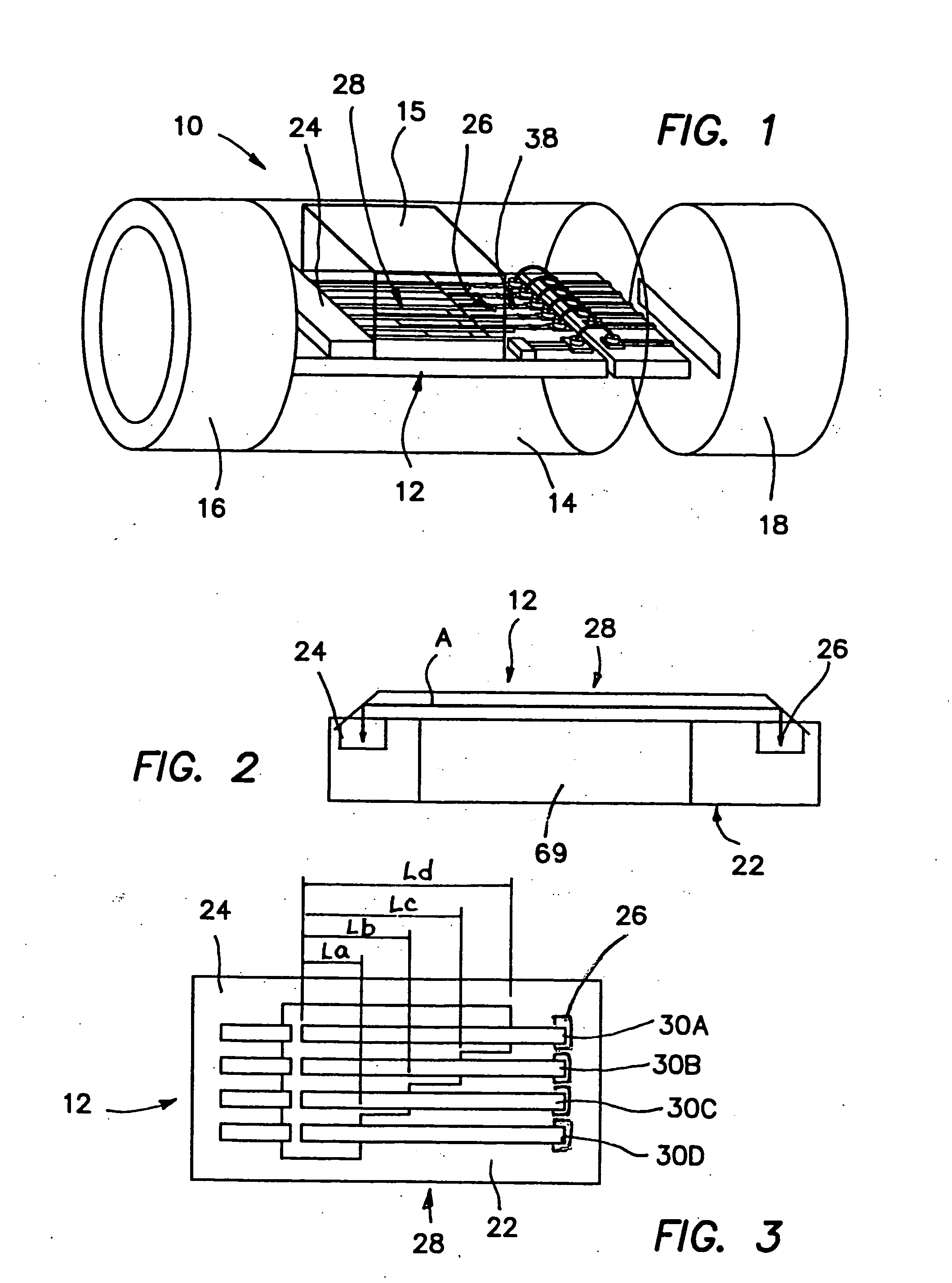

Sender transducer for wireless power transfer

ActiveUS20120300592A1Transducer detailsAngle modulation detailsElectric power transmissionAudio power amplifier

A signal generator generates an electrical signal that is sent to an amplifier, which increases the power of the signal using power from a power source. The amplified signal is fed to a sender transducer to generate ultrasonic waves that can be focused and sent to a receiver. The receiver transducer converts the ultrasonic waves back into electrical energy and stores it in an energy storage device, such as a battery, or uses the electrical energy to power a device. In this way, a device can be remotely charged or powered without having to be tethered to an electrical outlet.

Owner:UBEAM

Receiver transducer for wireless power transfer

InactiveUS20120300593A1Transducer detailsAngle modulation detailsElectric power transmissionAudio power amplifier

A signal generator generates an electrical signal that is sent to an amplifier, which increases the power of the signal using power from a power source. The amplified signal is fed to a sender transducer to generate ultrasonic waves that can be focused and sent to a receiver. The receiver transducer converts the ultrasonic waves back into electrical energy and stores it in an energy storage device, such as a battery, or uses the electrical energy to power a device. In this way, a device can be remotely charged or powered without having to be tethered to an electrical outlet.

Owner:UBEAM

Receiver communications for wireless power transfer

InactiveUS20120300588A1Transducer detailsAngle modulation detailsElectric power transmissionAudio power amplifier

A signal generator generates an electrical signal that is sent to an amplifier, which increases the power of the signal using power from a power source. The amplified signal is fed to a sender transducer to generate ultrasonic waves that can be focused and sent to a receiver. The receiver transducer converts the ultrasonic waves back into electrical energy and stores it in an energy storage device, such as a battery, or uses the electrical energy to power a device. In this way, a device can be remotely charged or powered without having to be tethered to an electrical outlet.

Owner:UBEAM

Sender controller for wireless power transfer

InactiveUS20120299541A1Electromagnetic wave systemTransducer detailsElectric power transmissionAudio power amplifier

A signal generator generates an electrical signal that is sent to an amplifier, which increases the power of the signal using power from a power source. The amplified signal is fed to a sender transducer to generate ultrasonic waves that can be focused and sent to a receiver. The receiver transducer converts the ultrasonic waves back into electrical energy and stores it in an energy storage device, such as a battery, or uses the electrical energy to power a device. In this way, a device can be remotely charged or powered without having to be tethered to an electrical outlet.

Owner:UBEAM

Receiver communications for wireless power transfer

InactiveUS9001622B2Transducer detailsAngle modulation detailsElectric power transmissionAudio power amplifier

A signal generator generates an electrical signal that is sent to an amplifier, which increases the power of the signal using power from a power source. The amplified signal is fed to a sender transducer to generate ultrasonic waves that can be focused and sent to a receiver. The receiver transducer converts the ultrasonic waves back into electrical energy and stores it in an energy storage device, such as a battery, or uses the electrical energy to power a device. In this way, a device can be remotely charged or powered without having to be tethered to an electrical outlet.

Owner:UBEAM

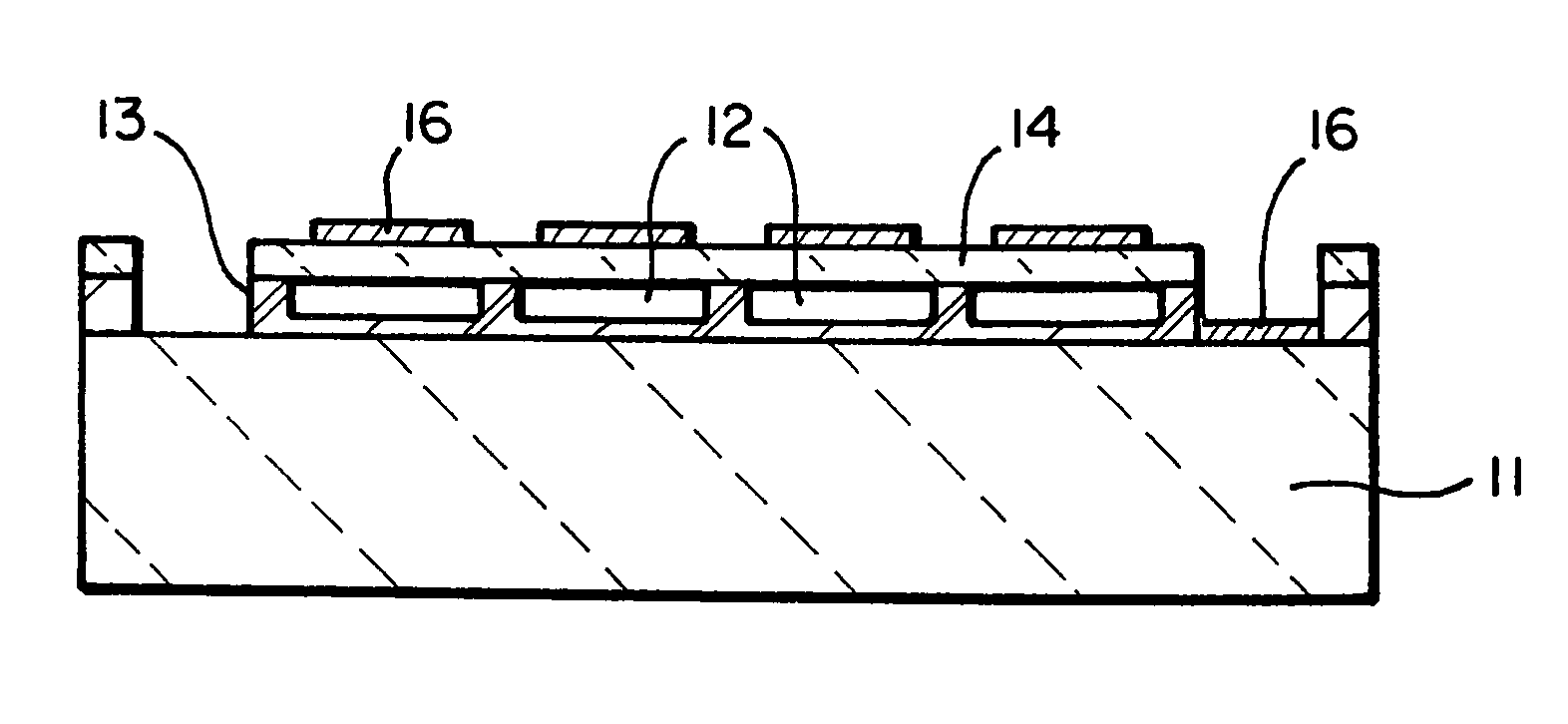

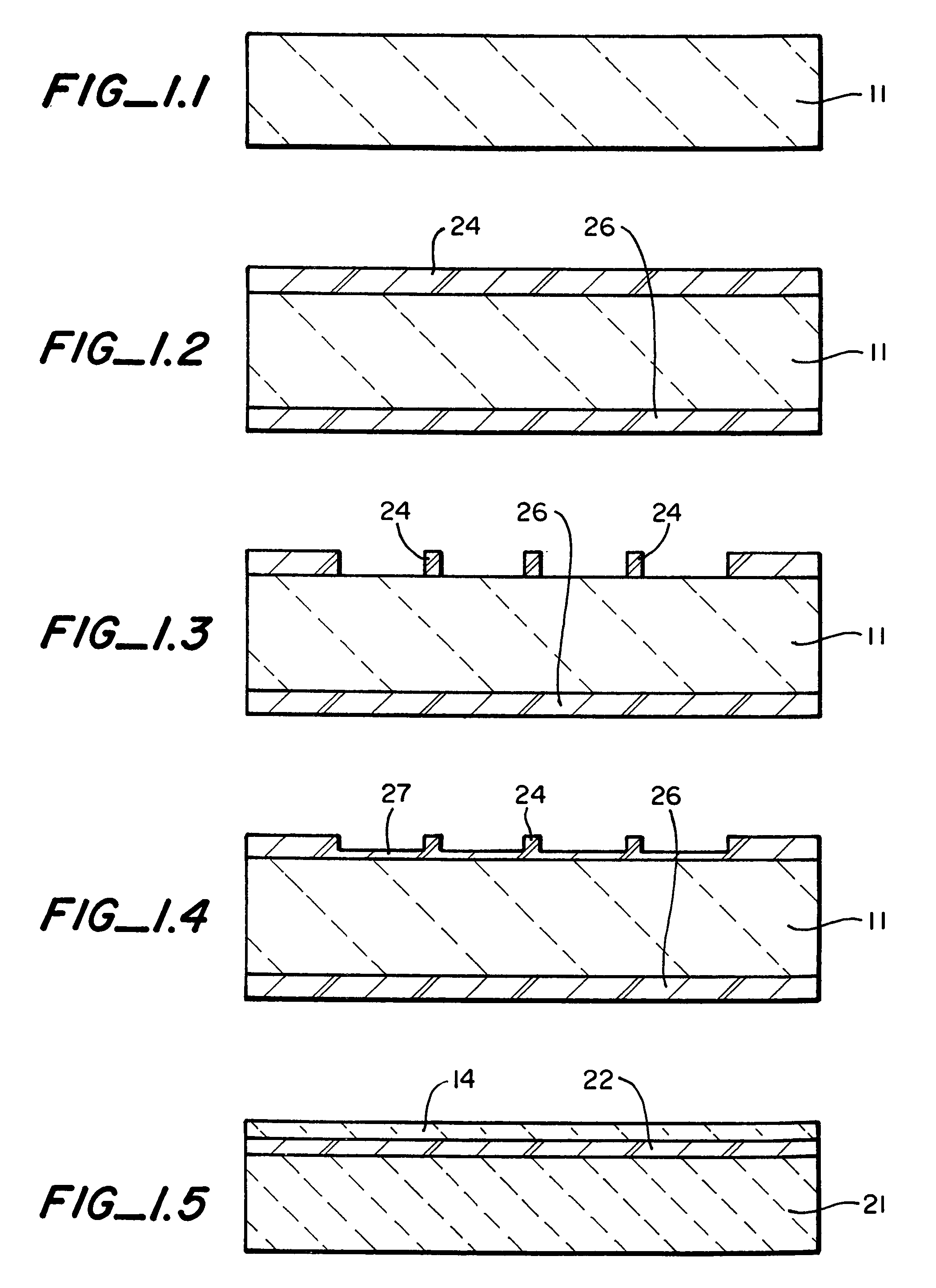

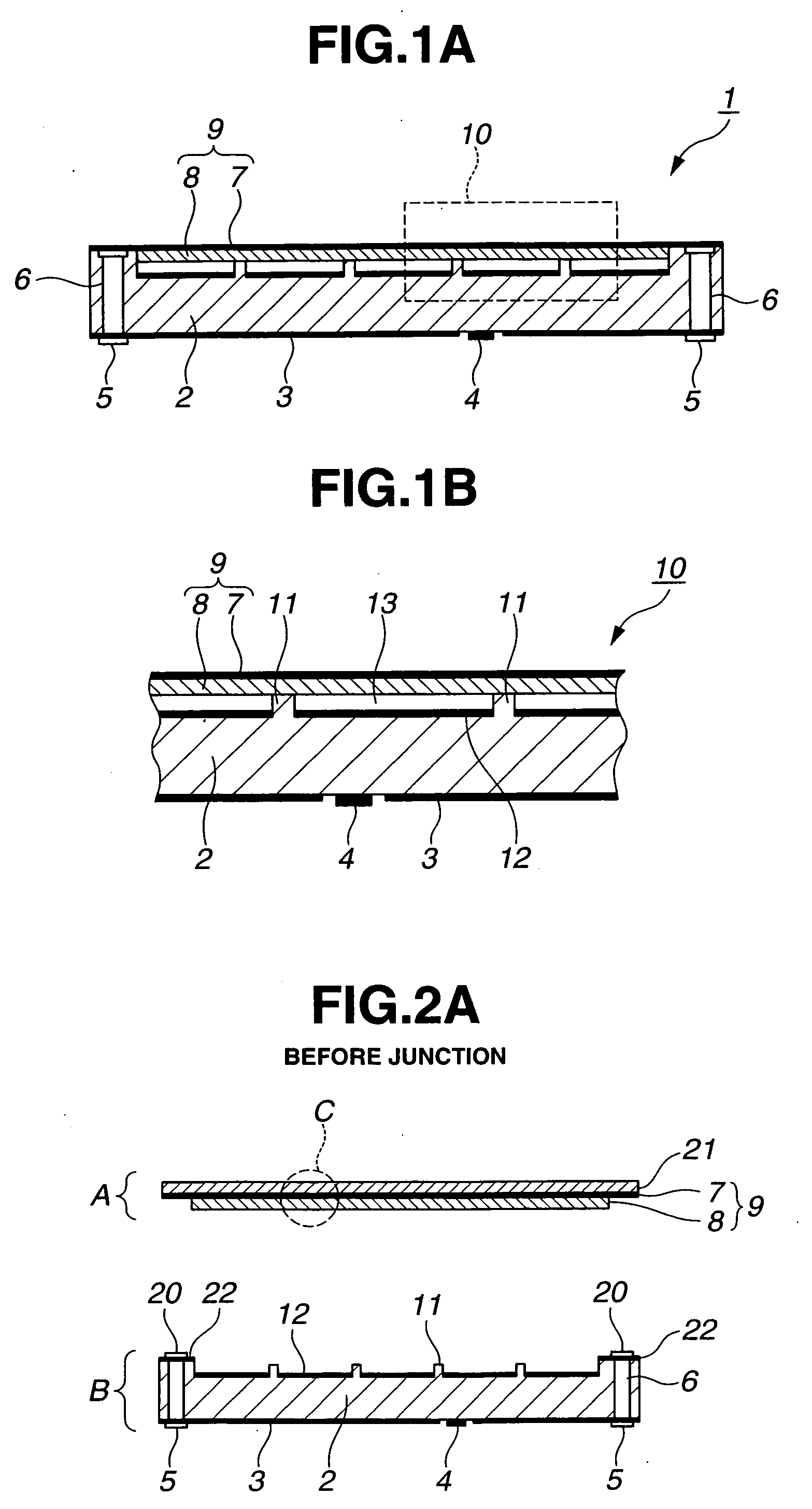

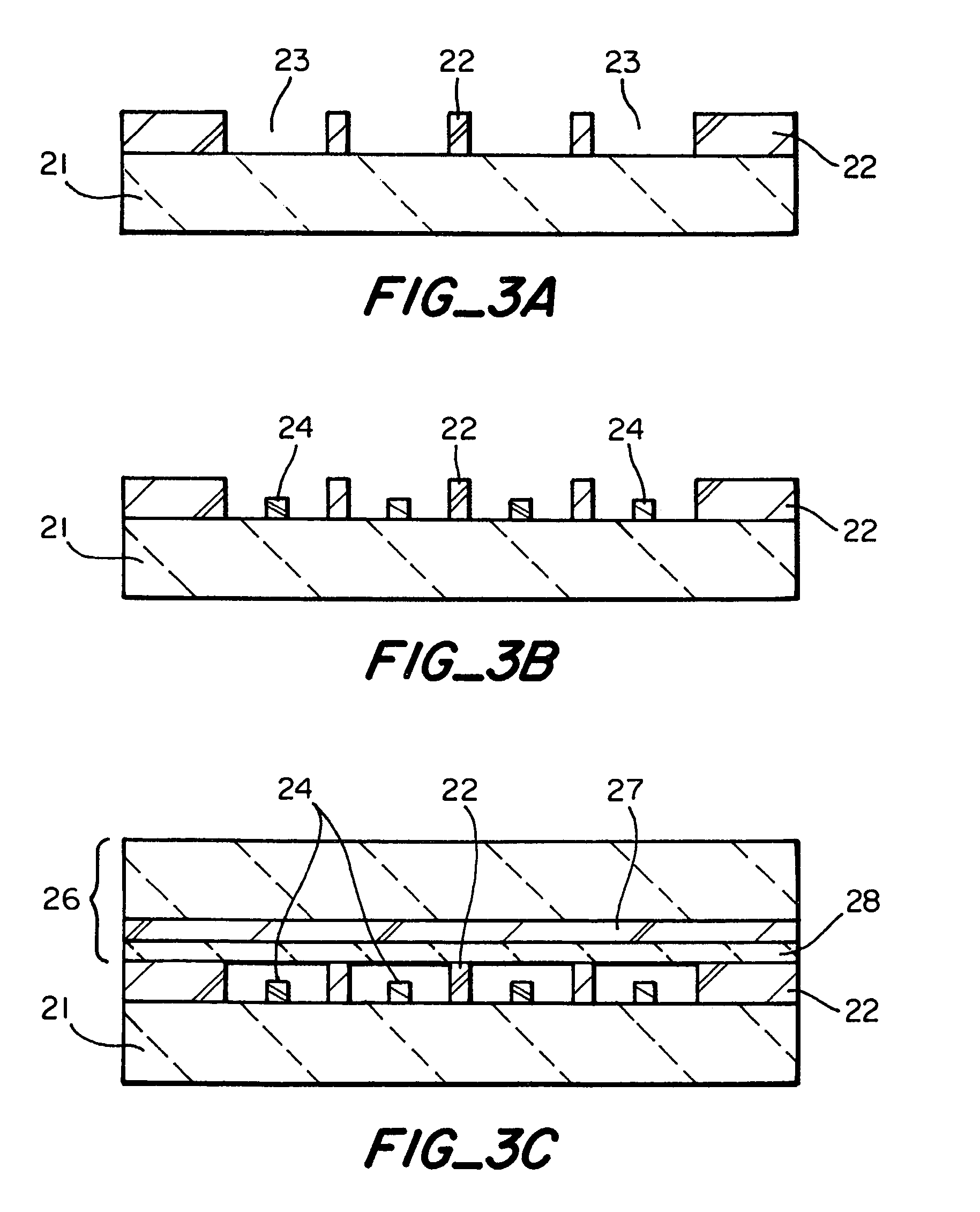

Micromachined ultrasonic transducers and method of fabrication

InactiveUS20040085858A1Decorative surface effectsSemiconductor/solid-state device manufacturingPMUTSilicon nitride

There is described a micromachined ultrasonic transducers (MUTS) and a method of fabrication. The membranes of the transducers are fusion bonded to cavities to form cells. The membranes are formed on a wafer of sacrificial material. This permits handling for fusions bonding. The sacrificial material is then removed to leave the membrane. Membranes of silicon, silicon nitride, etc. can be formed on the sacrificial material. Also described are cMUTs, pMUTs and mMUTs.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

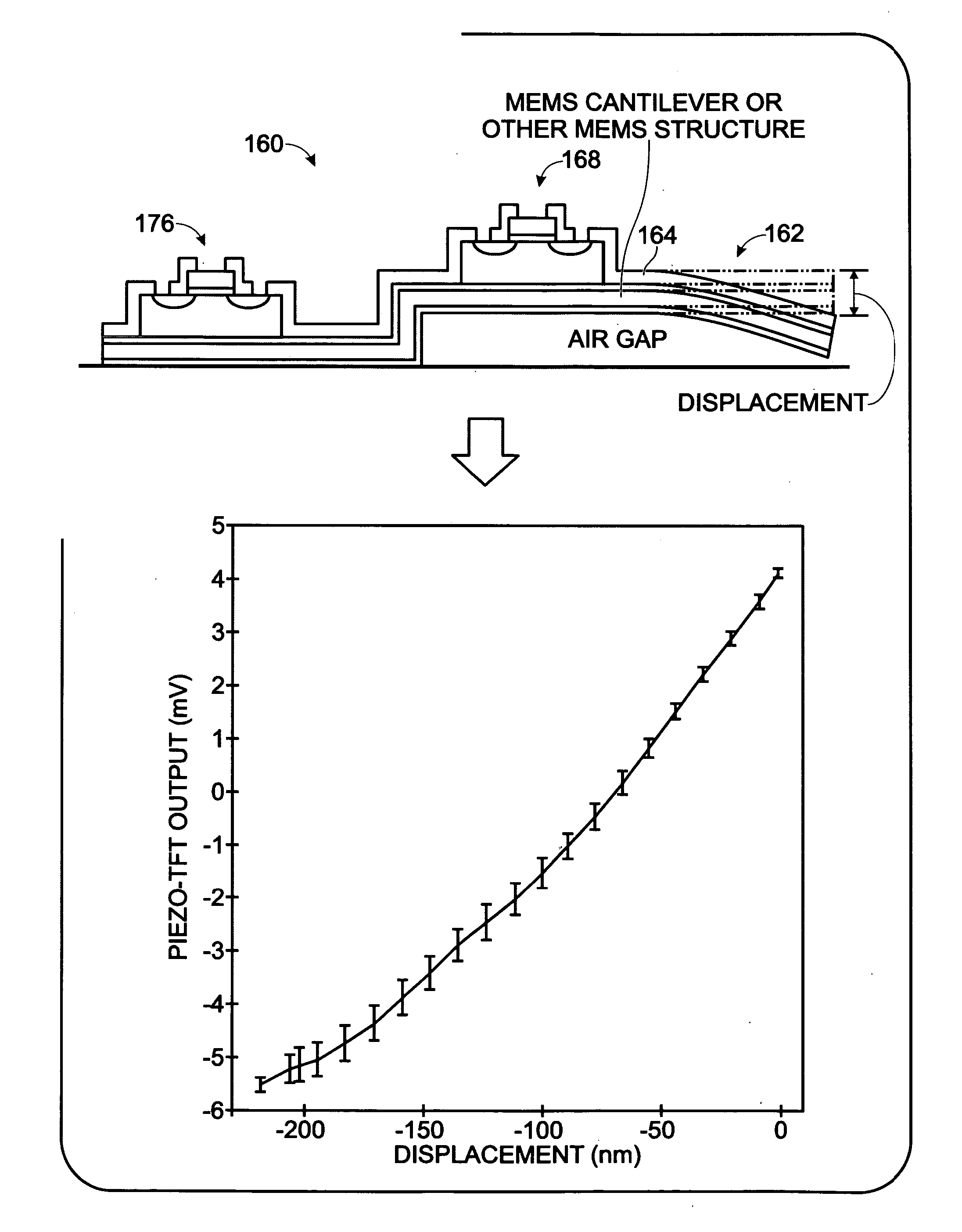

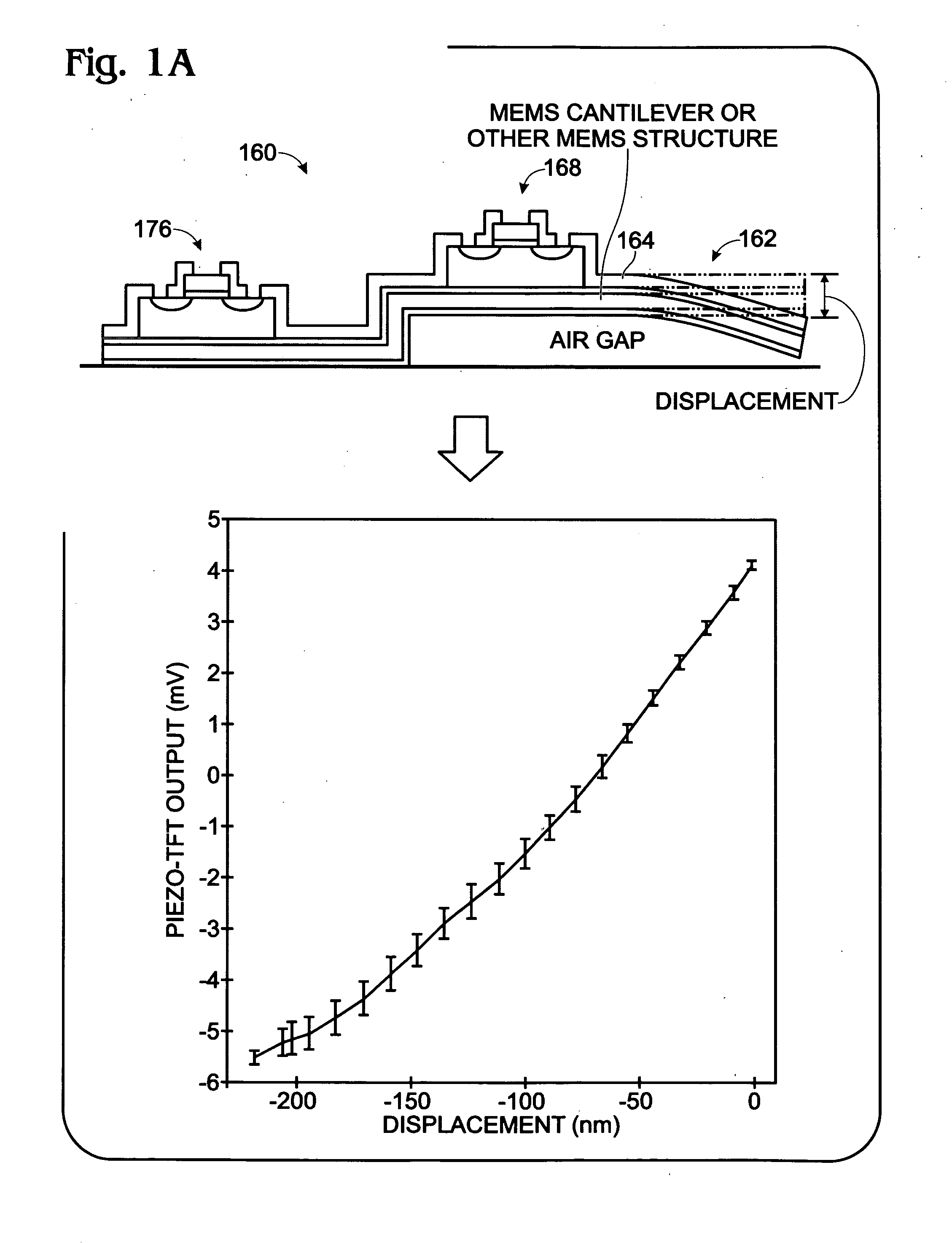

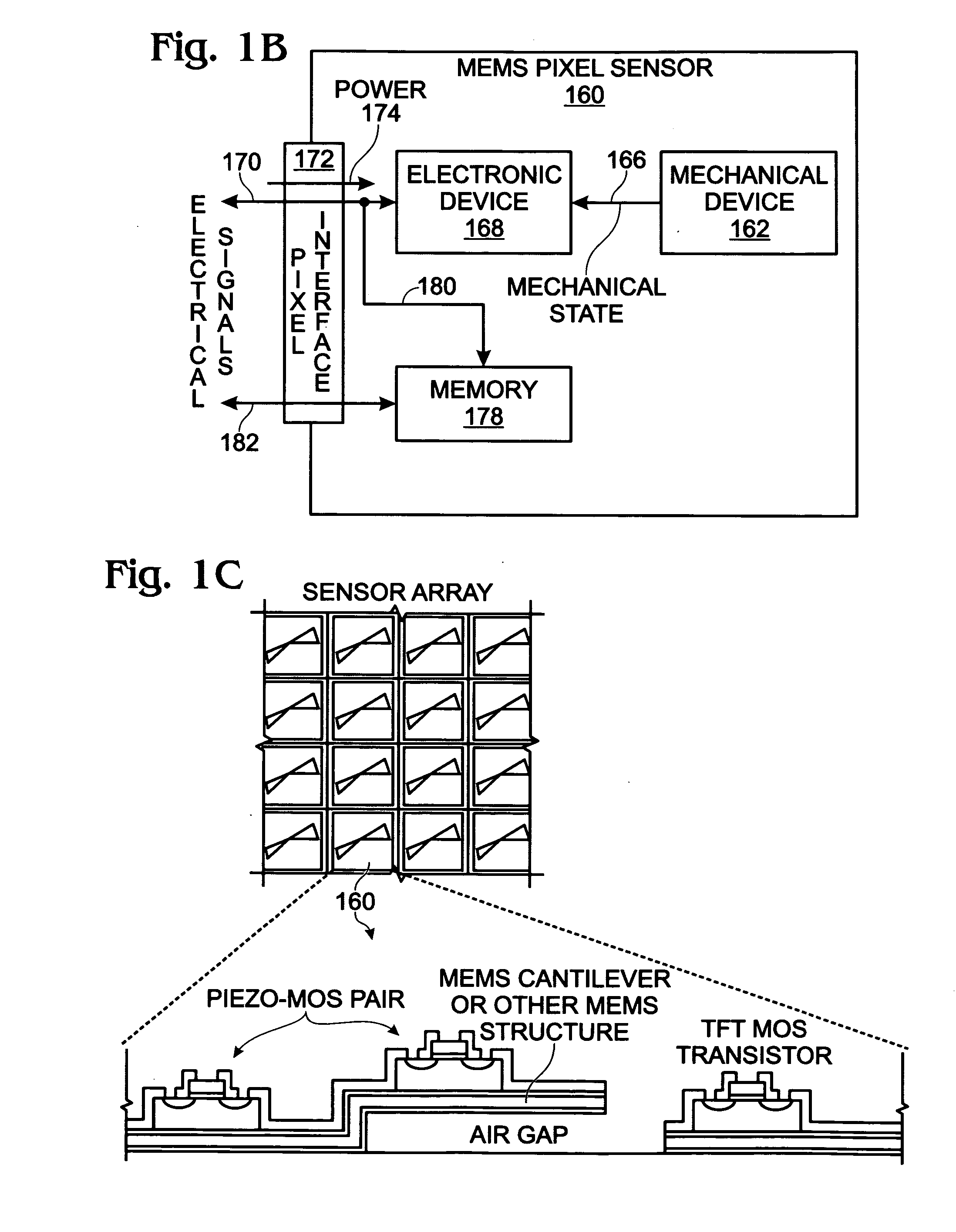

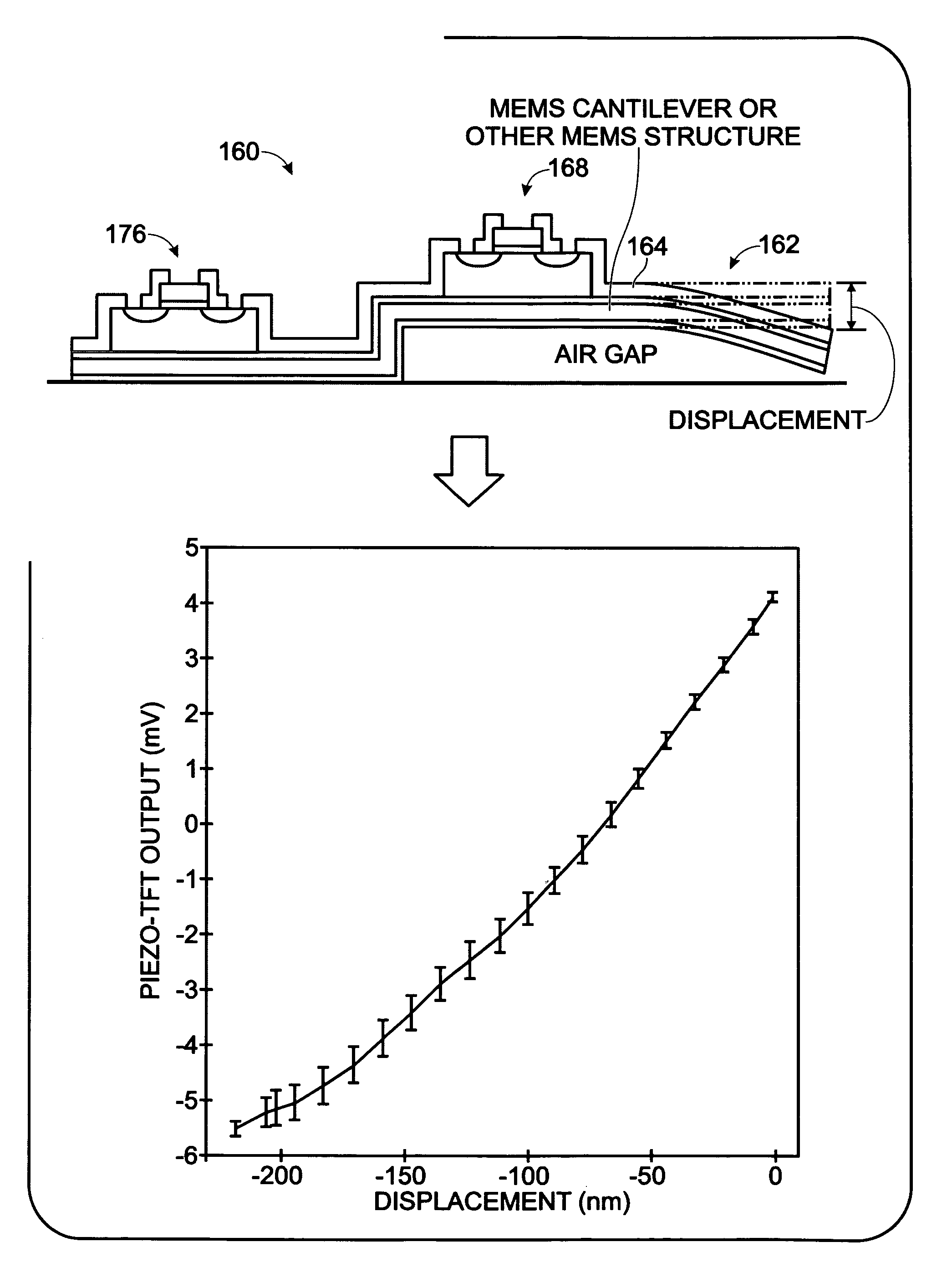

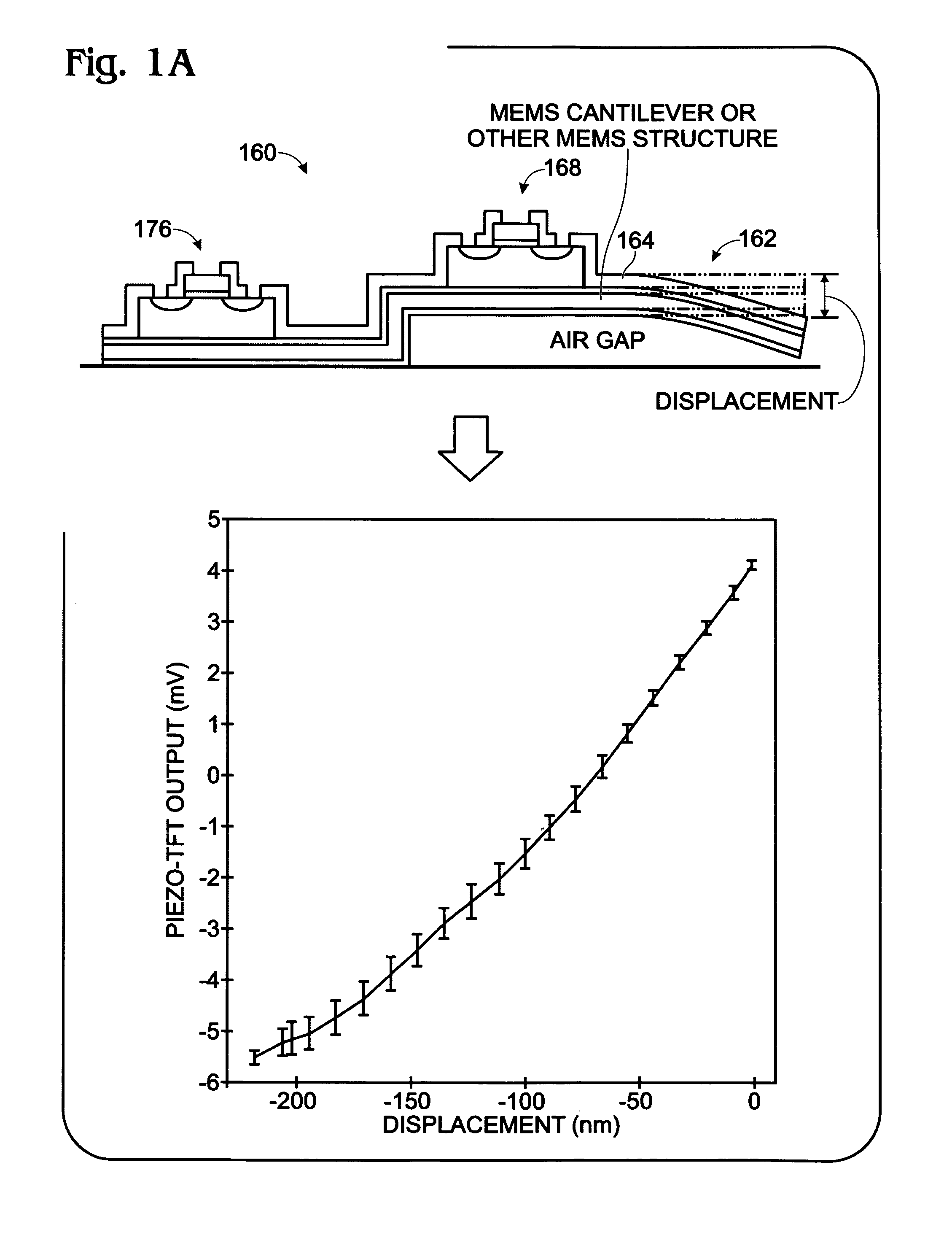

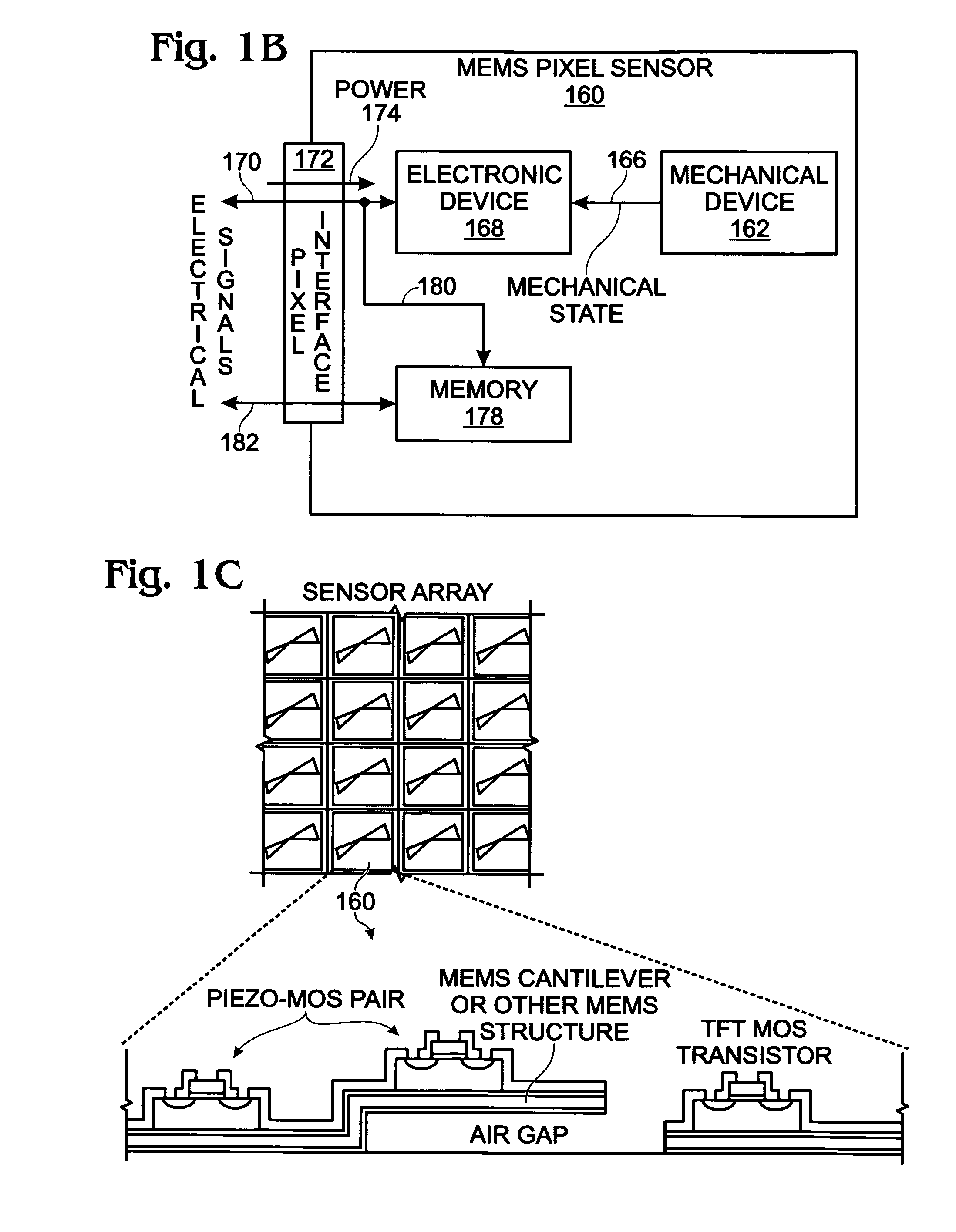

MEMS pixel sensor

InactiveUS20070023851A1Piezoelectric/electrostrictive microphonesSolid-state devicesBroadbandElectron

A MEMS pixel sensor is provided with a thin-film mechanical device having a mechanical body, with a mechanical state responsive to a proximate environment. A thin-film electronic device converts the mechanical state into electrical signals. A pixel interface supplies power to the electronic device and transceives electrical signals. The sensor is able to operate dynamically, in real-time. For example, if the mechanical device undergoes a sequence of mechanical states at a corresponding plurality of times, the electronic device is able to supply a sequence of electrical signals to the pixel interface that are responsive to the sequence of mechanical states, at the plurality of times. Each MEMS pixel sensor may include a number of mechanical devices, and corresponding electronic devices, to provide redundancy or to measure a broadband response range.

Owner:SHARP KK

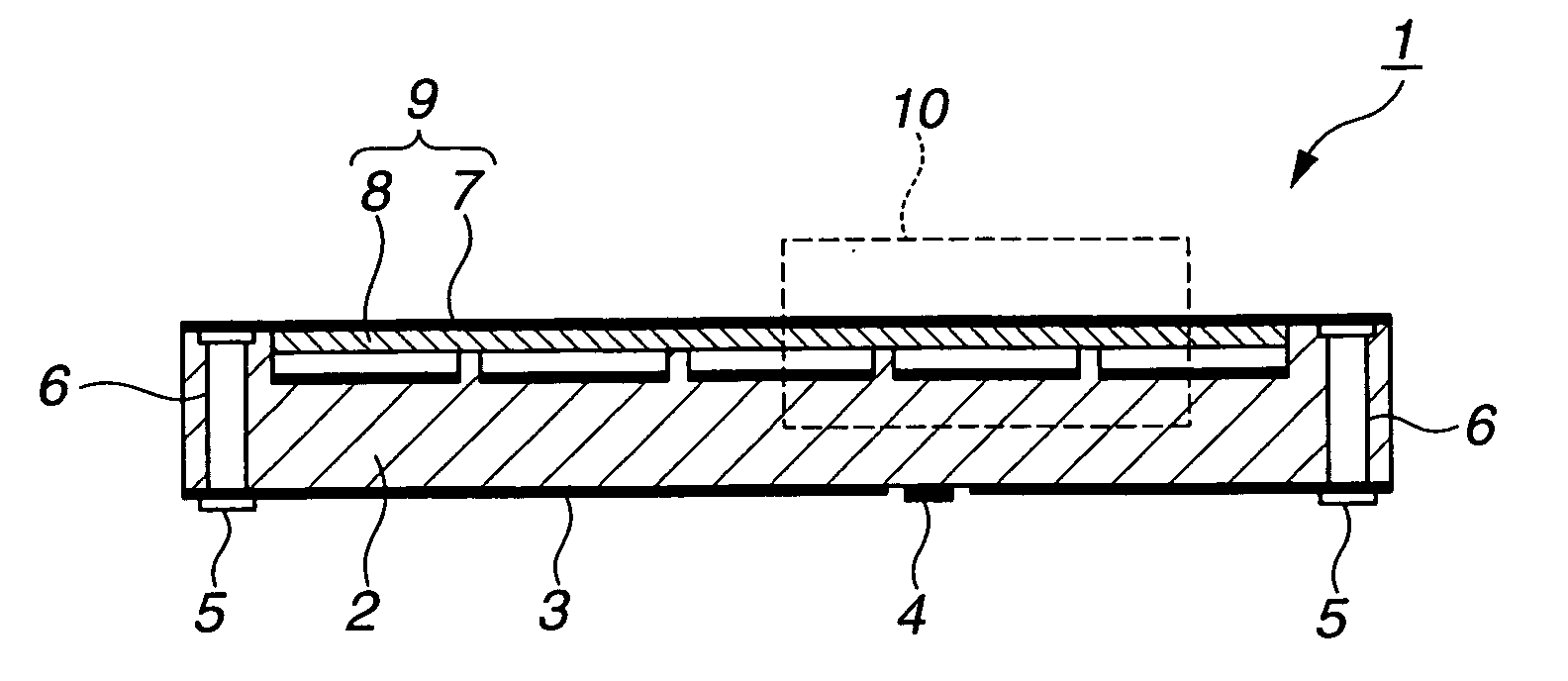

Capacitive ultrasonic transducer, production method thereof, and capacitive ultrasonic probe

InactiveUS20070164632A1Increase sound pressureSimple methodUltrasonic/sonic/infrasonic diagnosticsTransducer detailsSound pressureUltrasonic transmission

It becomes possible to obtain high sound pressure in a high frequency domain by a capacitive ultrasonic transducer which comprises a membrane on which one electrode is formed, a cavity constructed in its backface, and a substrate on which these are mounted and supported and on whose surface an electrode is provided, on a surface in an ultrasonic transmission and reception side, characterized in that the membrane comprises two or more layers, and at least one layer of them comprises a high dielectric constant film.

Owner:OLYMPUS CORP

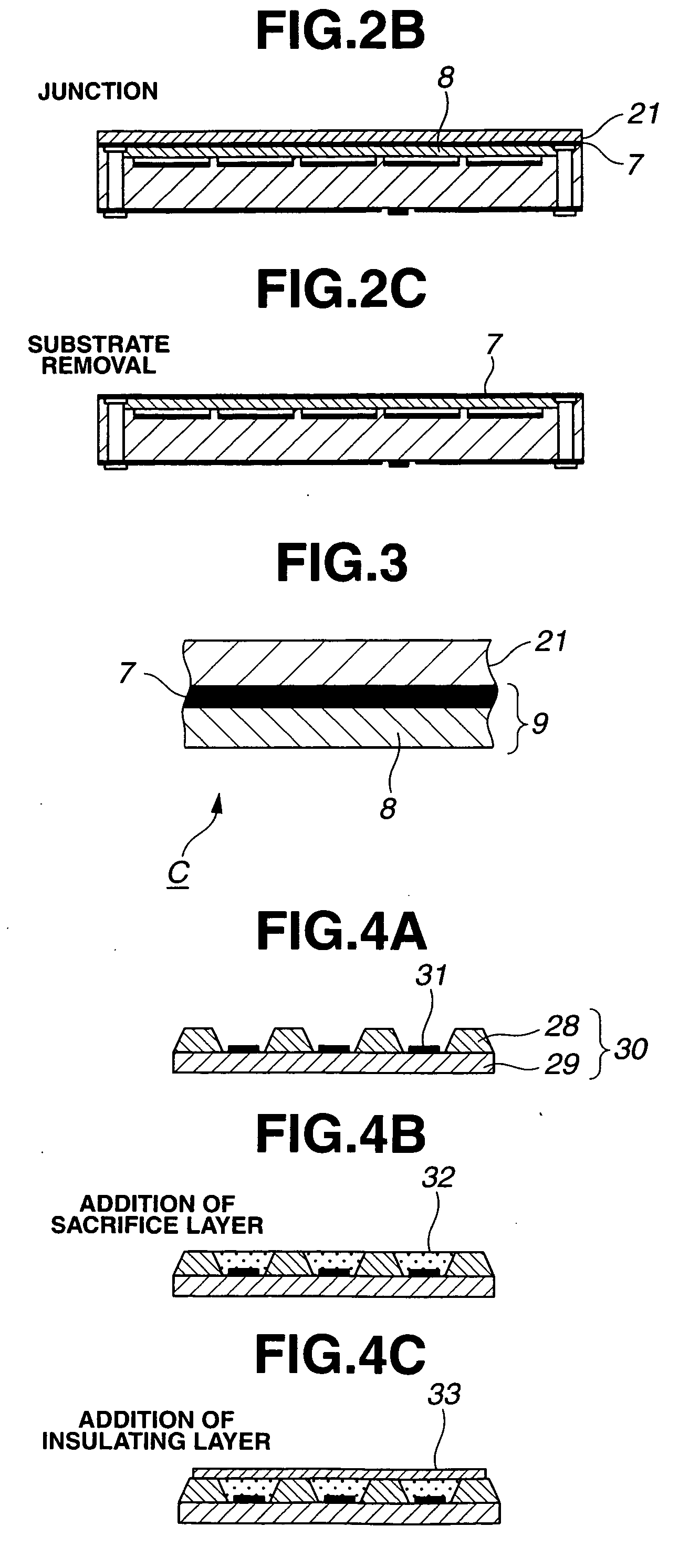

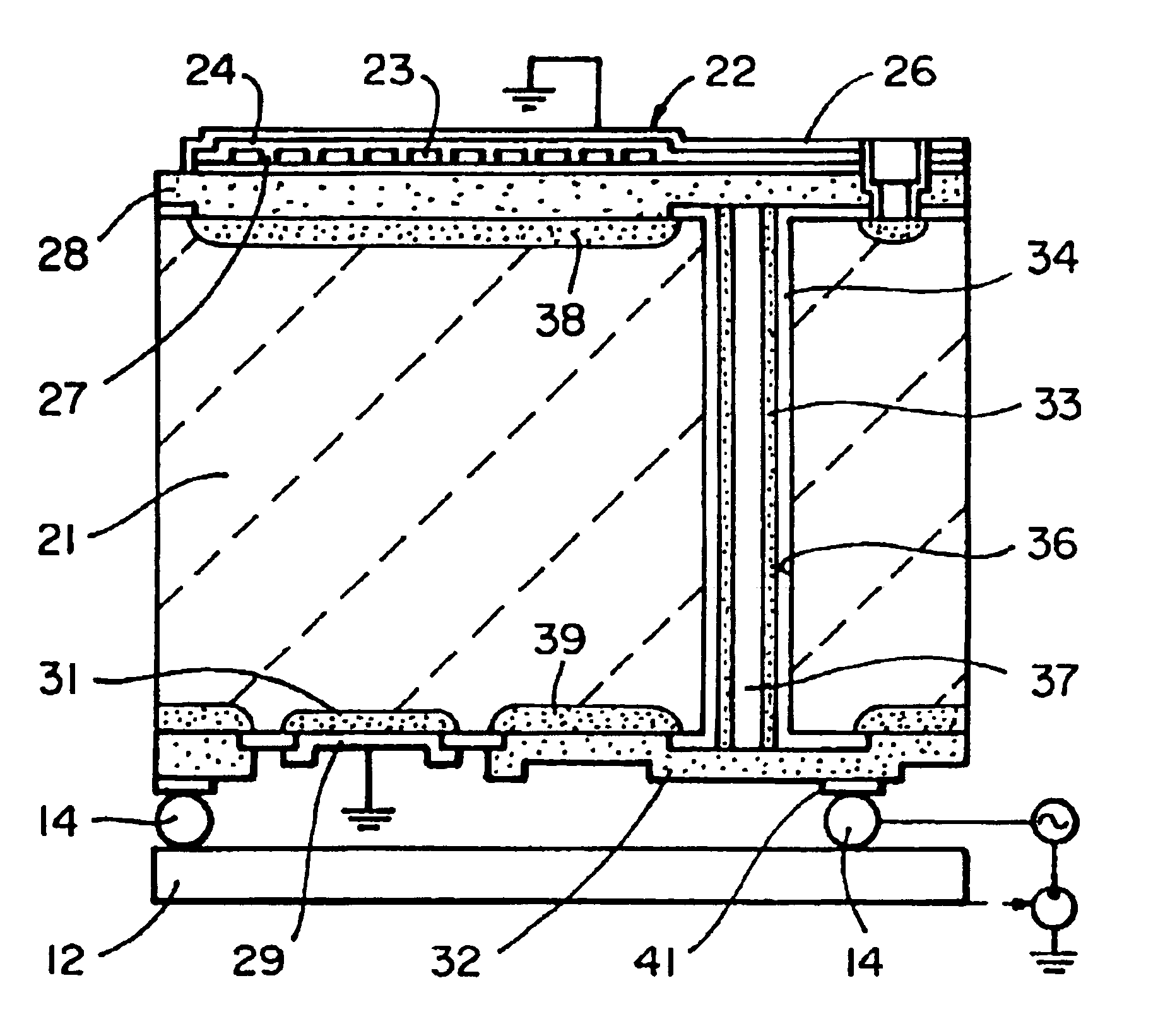

Hearing aid with large diaphragm microphone element including a printed circuit board

InactiveUS7003127B1Low costImprove performanceElectrostatic transducersHearing aids housingLow noiseElectrical connection

A disposable-type hearing aid uses a relatively large single diaphragm or a large single diaphragm subdivided into a plurality of smaller active diaphragm areas obtained using a grate-like back support plate with ridges which contact and divide the diaphragm into the several smaller active diaphragm areas. The diaphragm and a backplate are enclosed in a metal housing and are disposed proximal and parallel to a shell-like hearing aid enclosure having sound inlets. The metal housing is closed at an end opposite the sound inlets by a printed circuit board (PCB) forming an acoustical seal for a back volume of the microphone. The PCB also carries substantially all the electronic components for the hearing aid thereon. The PCB has a ground plane in contact with the housing whereby the PCB also acts as an EMI shield. An electrical connection is formed in various ways between the back support plate and the PCB during assembly of the metal housing and components with the PCB. Mass production of disposable hearing aids with large diaphragms and relatively low noise levels is thus possible using this invention.

Owner:HIMPP

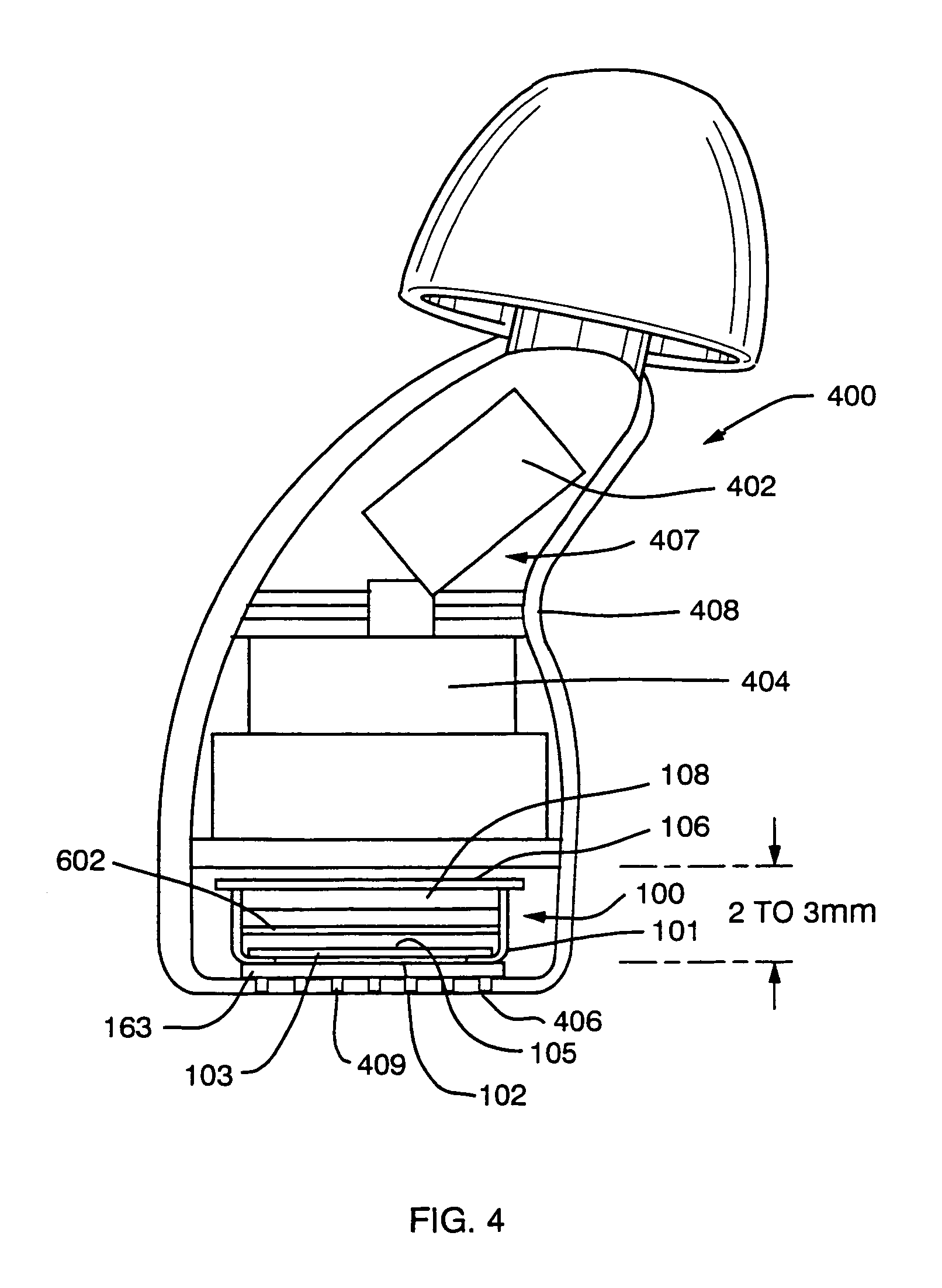

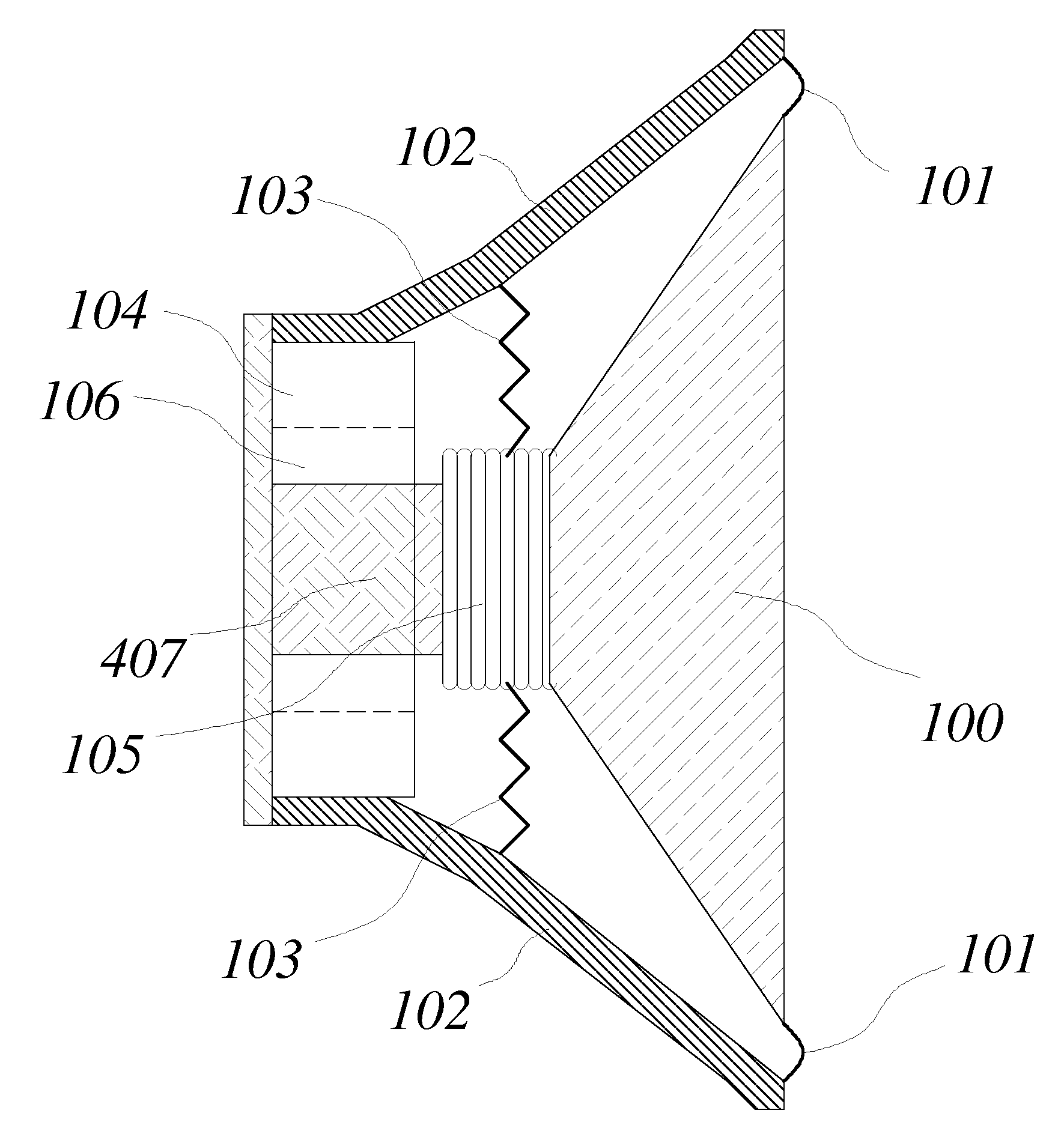

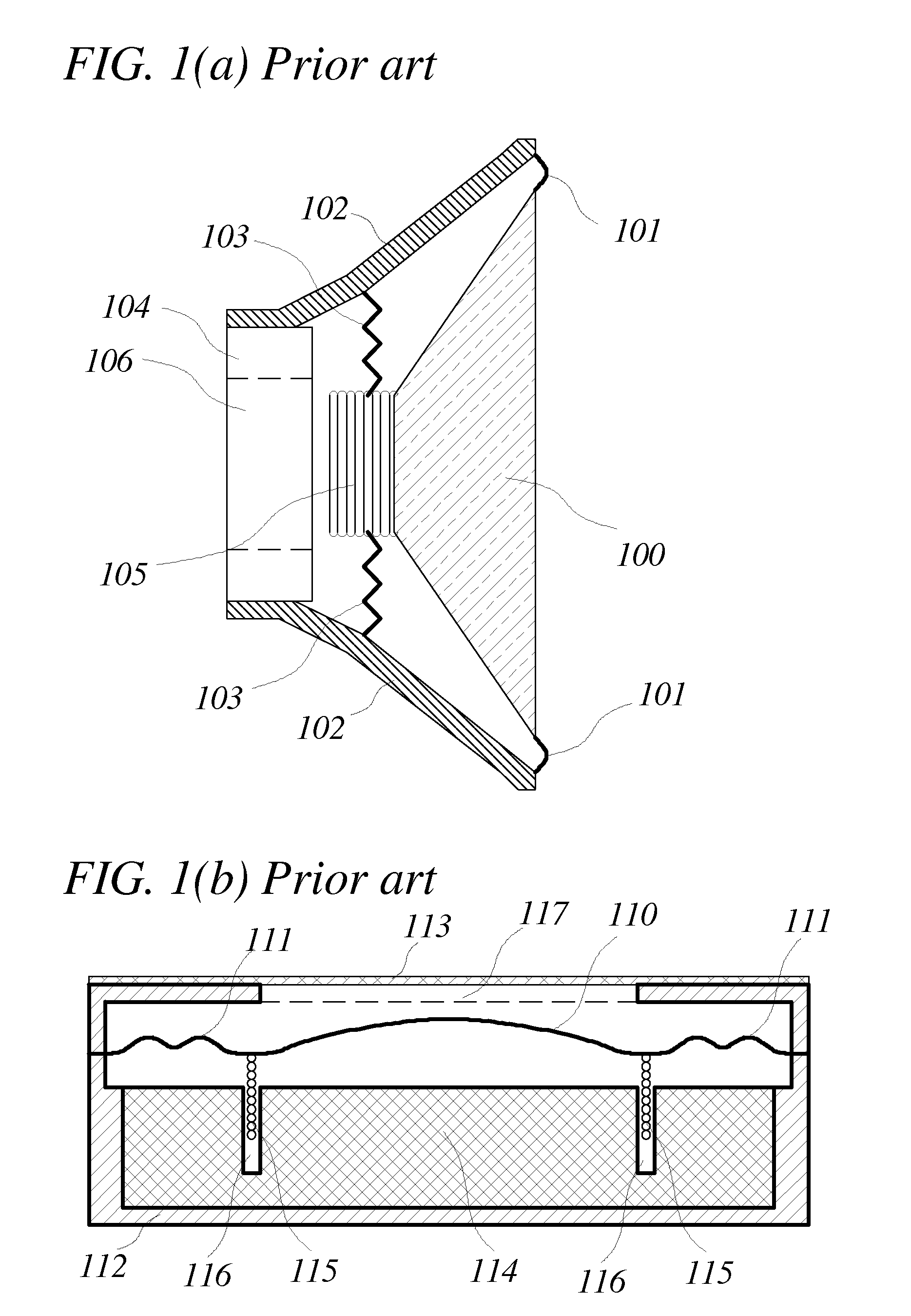

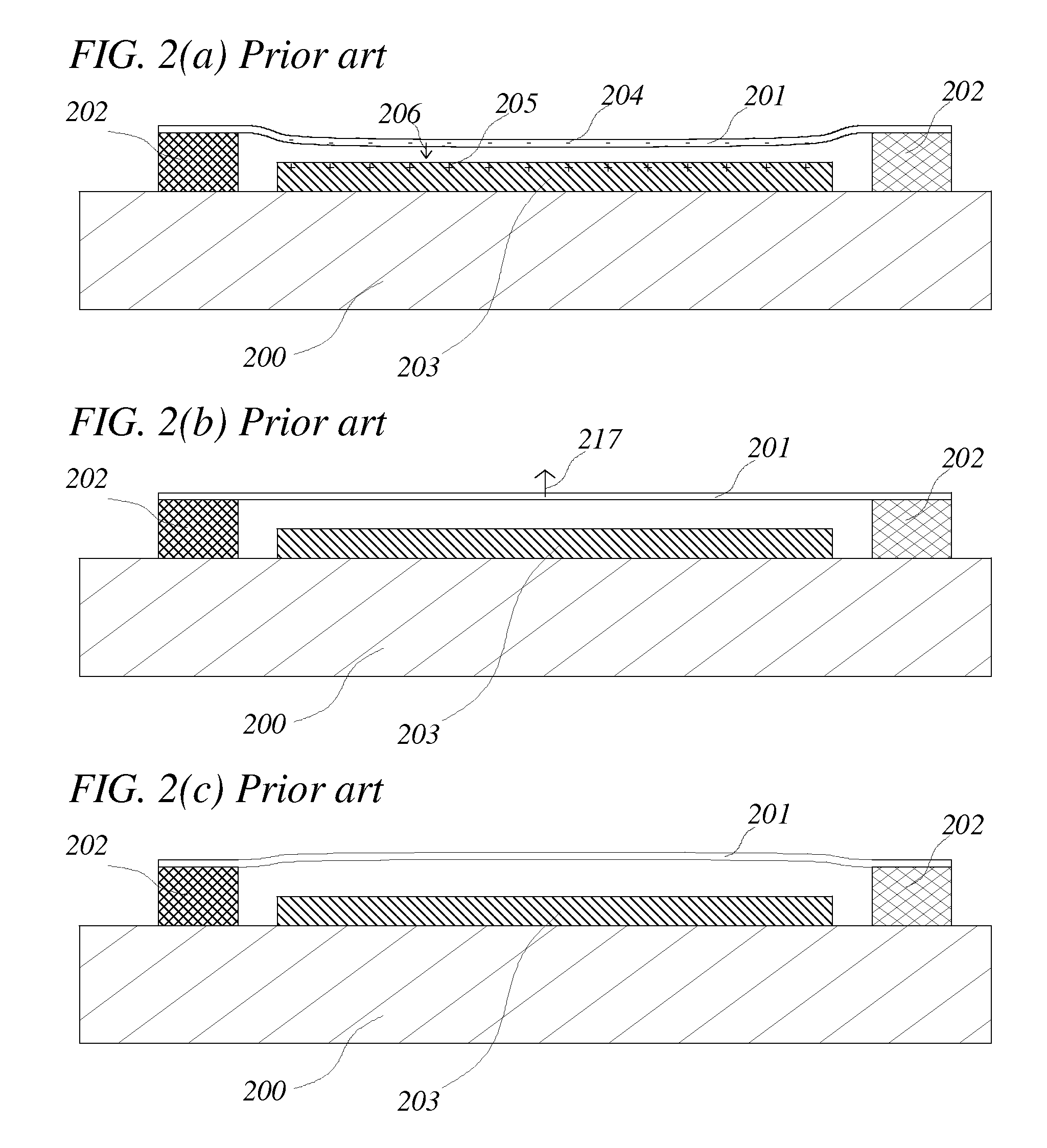

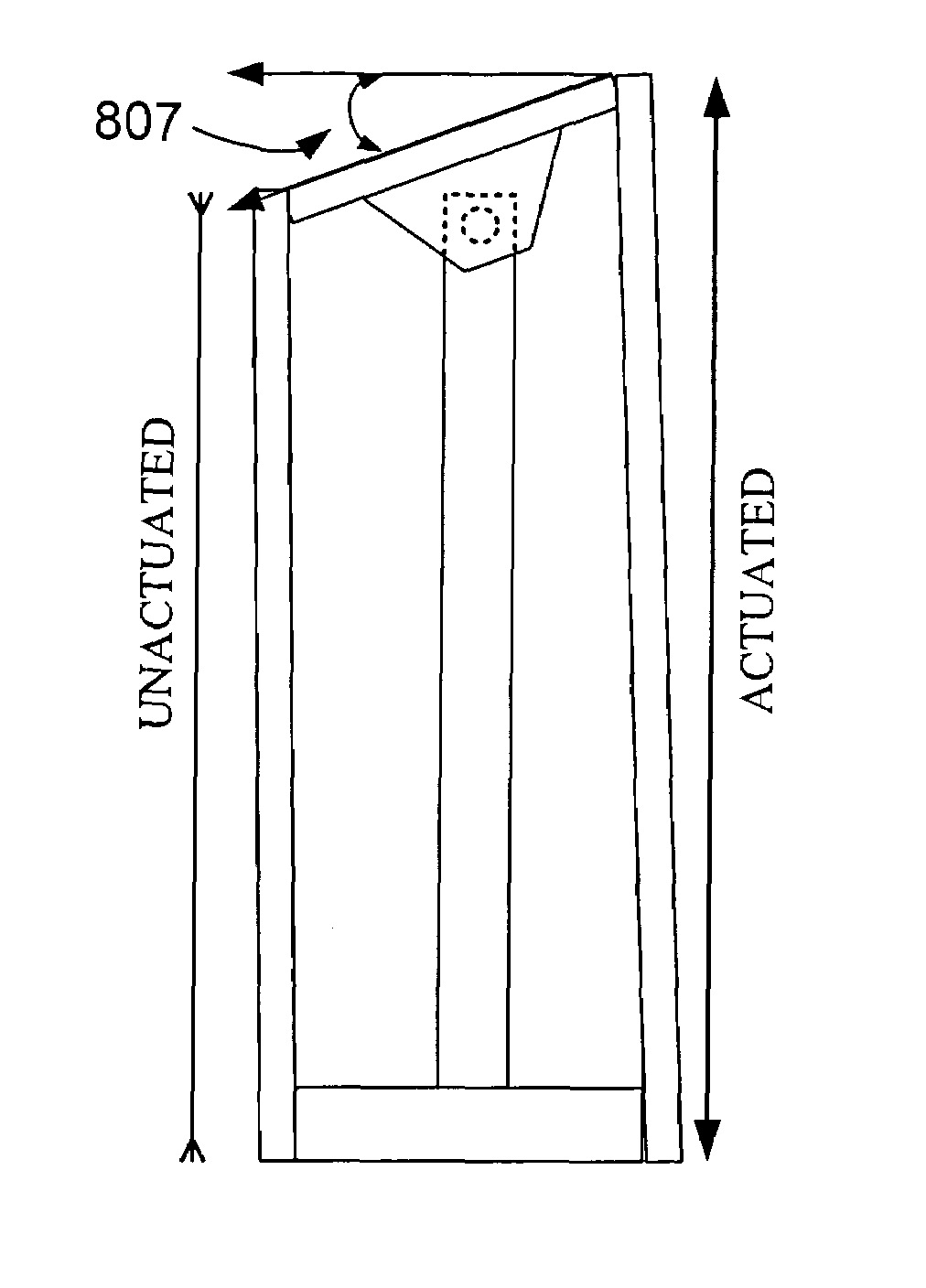

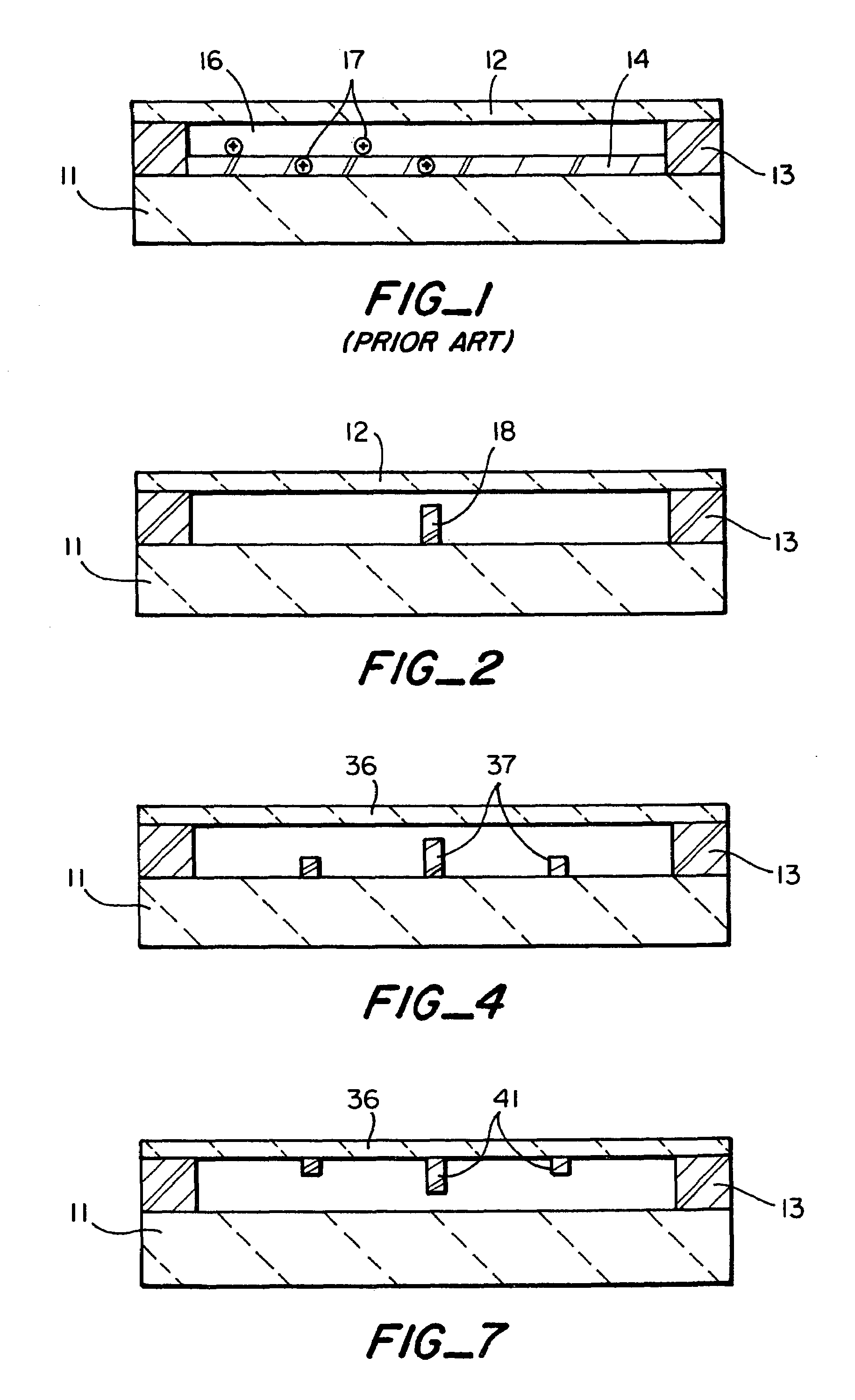

Precision audio speakers

InactiveUS20080037814A1Improve inertia distortionEfficient methodElectrostatic transducersFrequency/directions obtaining arrangementsSound generationLoudspeaker

The present invention is related to sound generating devices such as audio speakers. Prior art audio speakers typically have inertia related distortion. The present invention provides methods and structures to solve the inertia distortion problem by stop-and-forget mechanism using stoppers.

Owner:SHAU JENG JYE

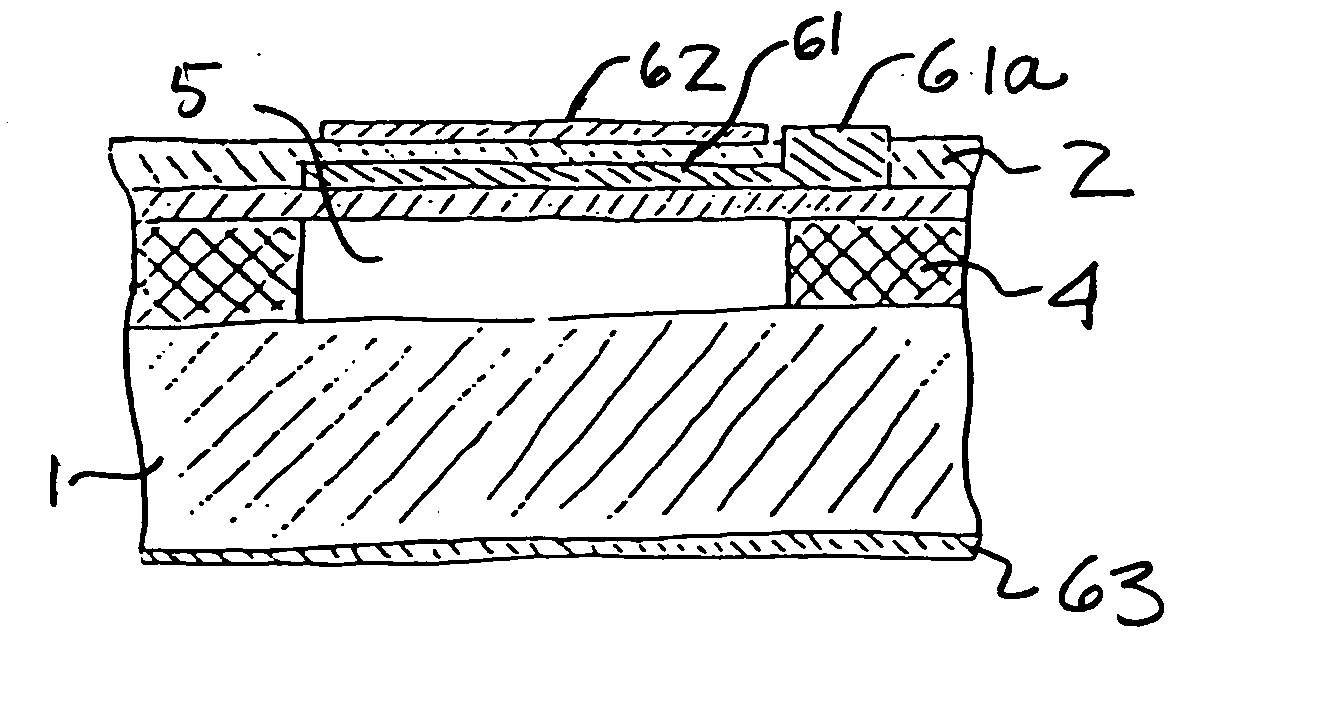

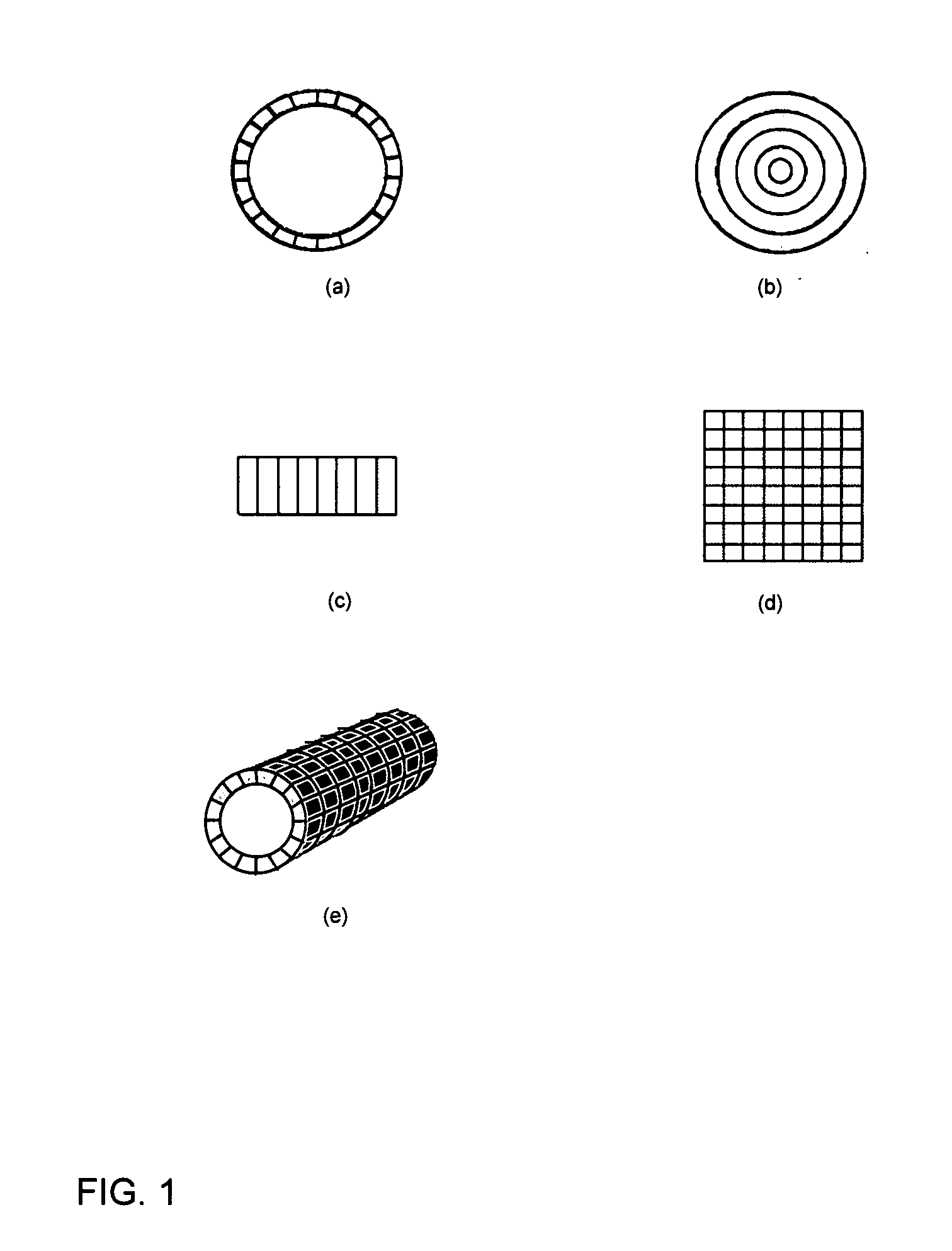

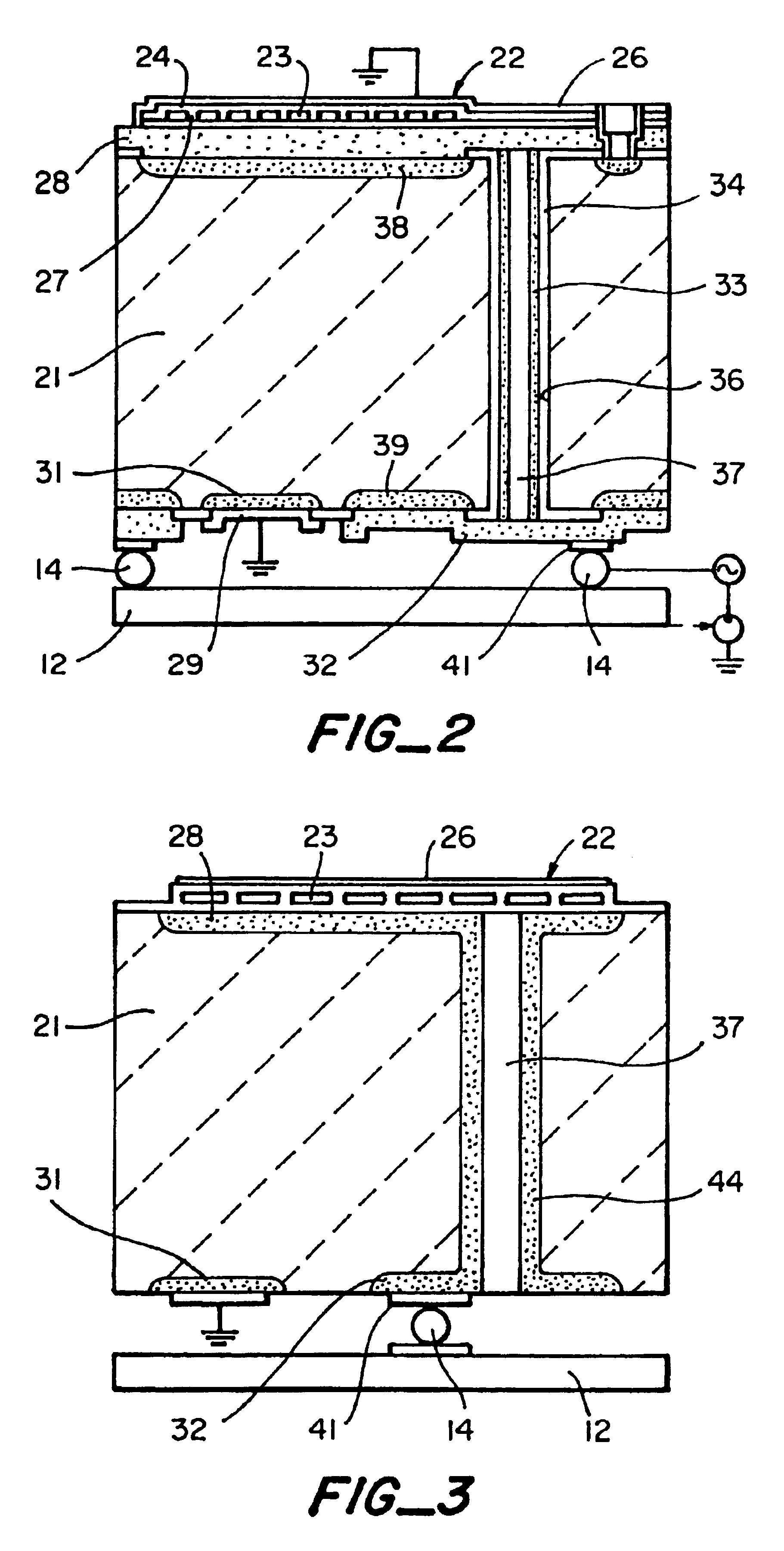

Direct wafer bonded 2-D CUMT array

ActiveUS20090122651A1Ultrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationCapacitanceCapacitive micromachined ultrasonic transducers

A capacitive micromachined ultrasonic transducer (CMUT) array connected to a separate electronic unit is provided. The CMUT array includes at least two active elements, a ground element at the array end, and a non-active element having isolation trenches disposed between the active and ground elements. The active element includes a doped first silicon layer, a doped second silicon layer, and a first insulating layer disposed there between. A cavity is in the first silicon layer having a cross section that includes vertical portions disposed at each end of a horizontal portion, and the vertical portion spans from the first insulating layer through the first silicon layer such that a portion of the first silicon layer is isolated by the first insulating layer and the cavity. A membrane layer on the first silicon layer spans the cavity. A bottom electrode is disposed on the bottom of the second silicon layer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

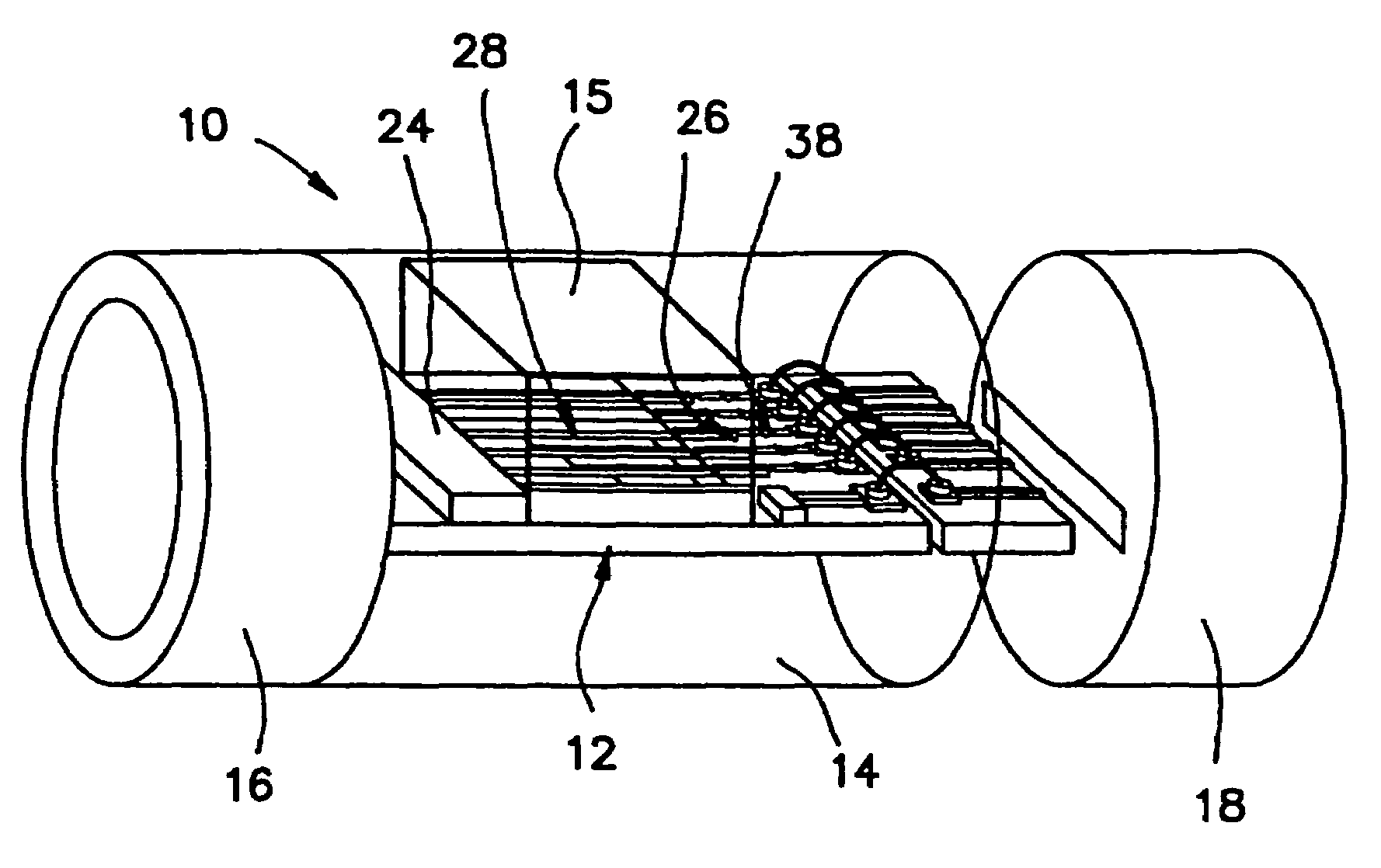

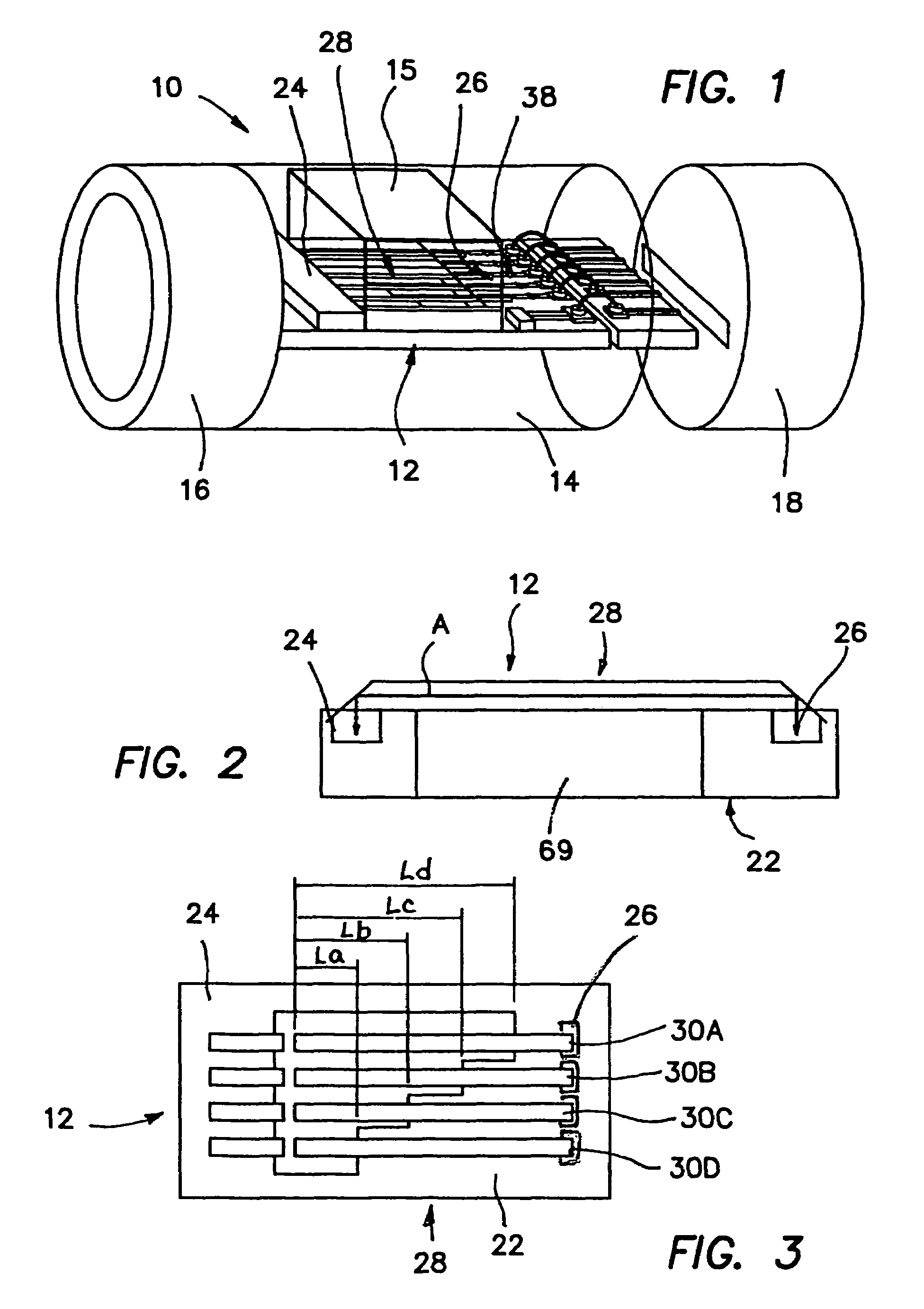

Rolled electroactive polymers

InactiveUS7233097B2Improves mechanical/electrical energy conversionImprove performancePiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsPolymer scienceMechanical energy

The invention describes rolled electroactive polymer devices. The invention also describes employment of these devices in a wide array of applications and methods for their fabrication. A rolled electroactive polymer device converts between electrical and mechanical energy; and includes a rolled electroactive polymer and at least two electrodes to provide the mechanical / electrical energy conversion. Prestrain is typically applied to the polymer. In one embodiment, a rolled electroactive polymer device employs a mechanism, such as a spring, that provides a force to prestrain the polymer. Since prestrain improves mechanical / electrical energy conversion for many electroactive polymers, the mechanism thus improves performance of the rolled electroactive polymer device.

Owner:SRI INTERNATIONAL

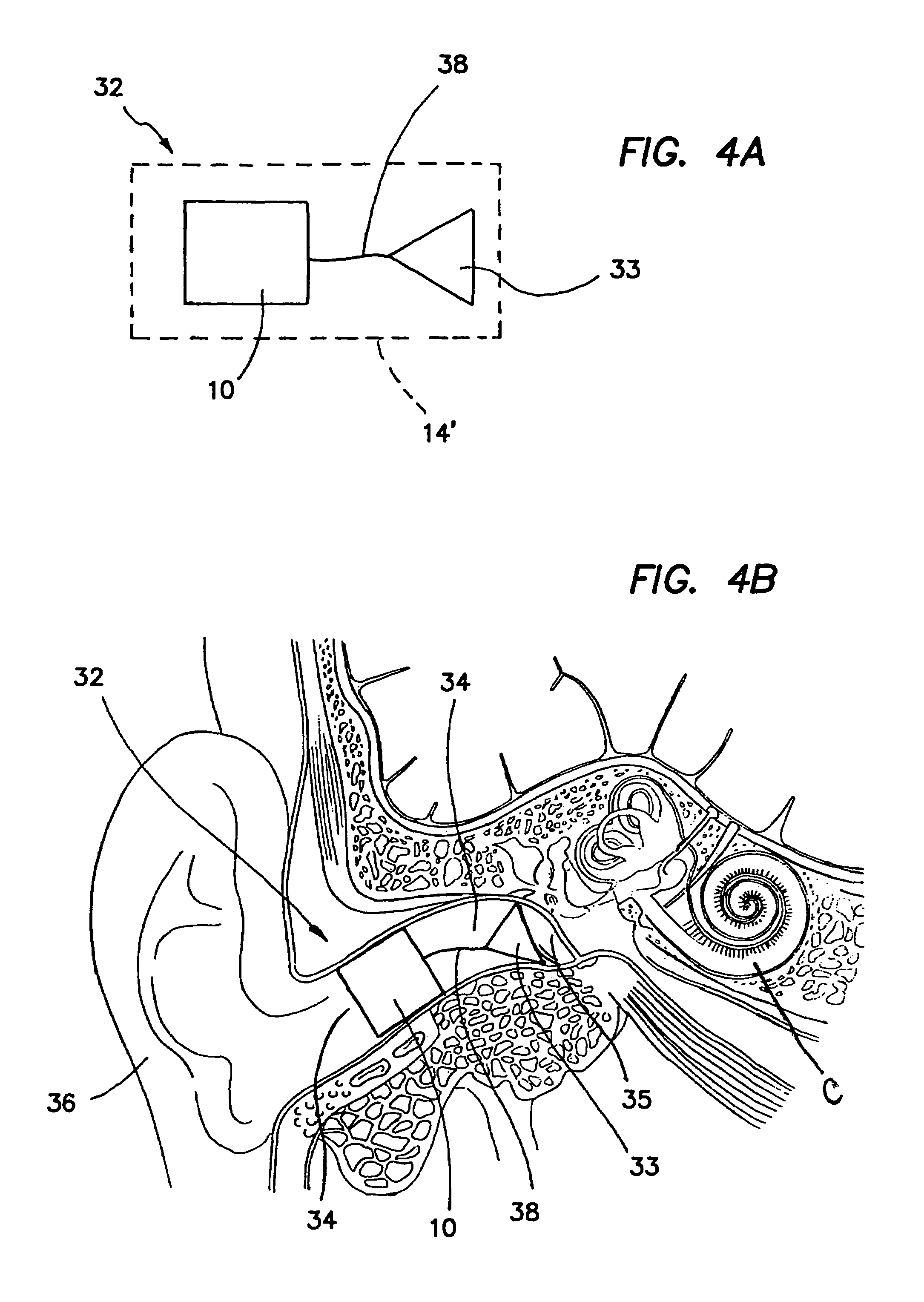

Optical waveguide vibration sensor for use in hearing aid

InactiveUS20060107744A1Improve hearingVibration measurement in solidsRecord carriersPolymer optical waveguideLoudspeaker

A directionally-sensitive device for detecting and processing vibration waves includes an array of polymeric optical waveguide resonators positioned between a light source, such as an LED array, and a light detector, such as a photodiode array. The resonators which are preferably oriented substantially perpendicularly with respect to incoming vibration waves, vibrate when a wave is detected, thus modulating light signals that are transmitted between the light source and the light detector. The light detector converts the modulated light into electrical signals which, in a preferred embodiment, are used to drive either the speaker of a hearing aid or the electrode array of a cochlear implant. The device is manufactured using a combination of traditional semiconductor processes and polymer microfabrication techniques.

Owner:RGT UNIV OF CALIFORNIA

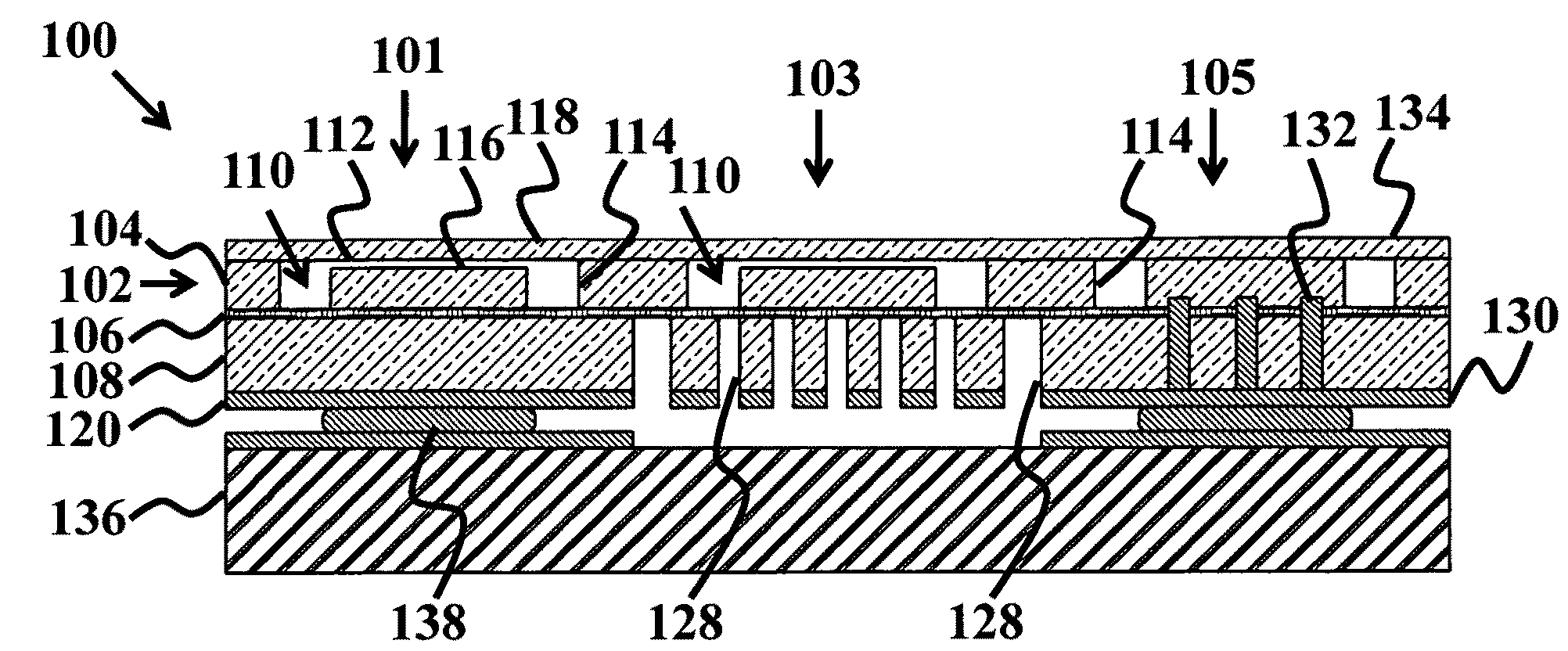

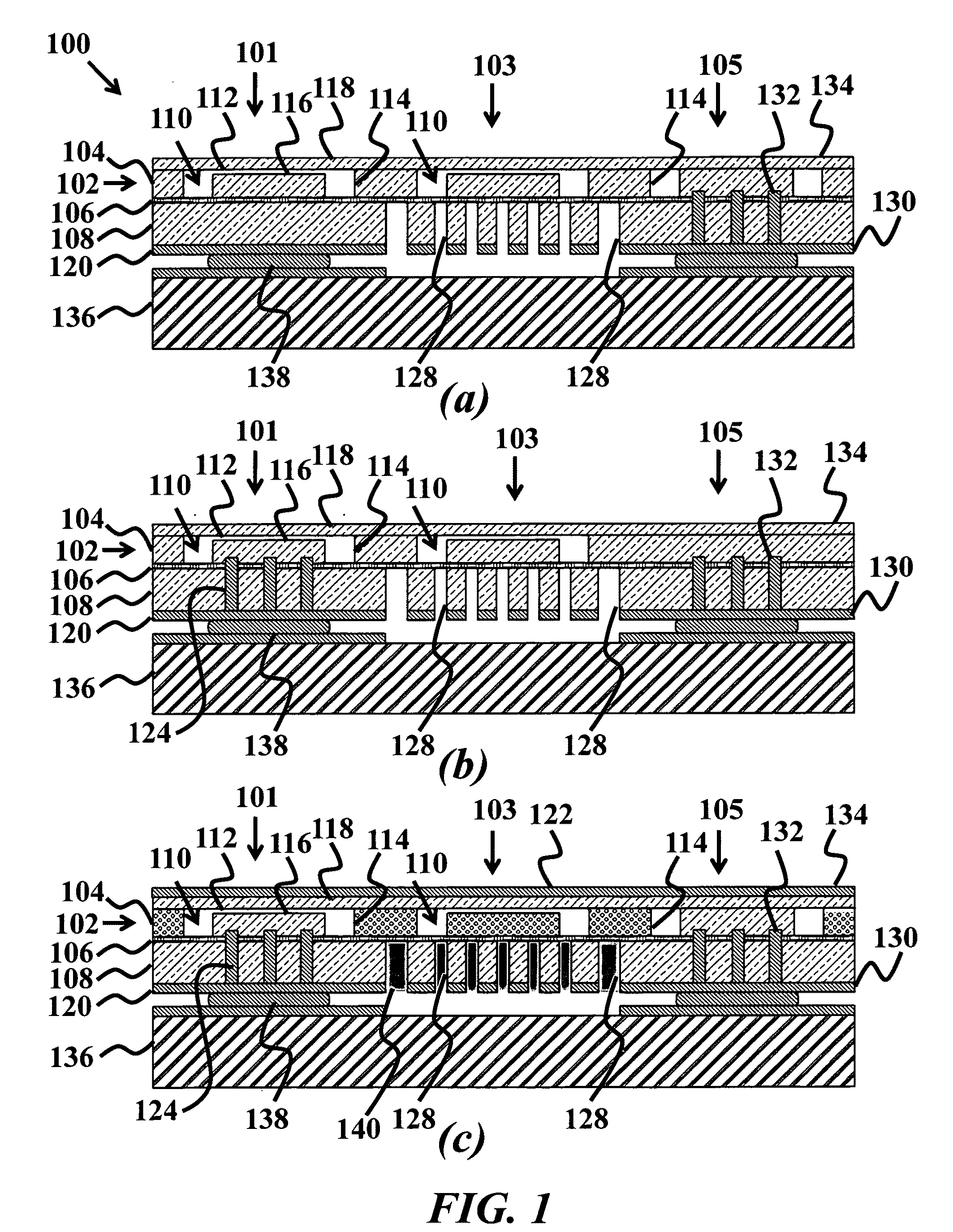

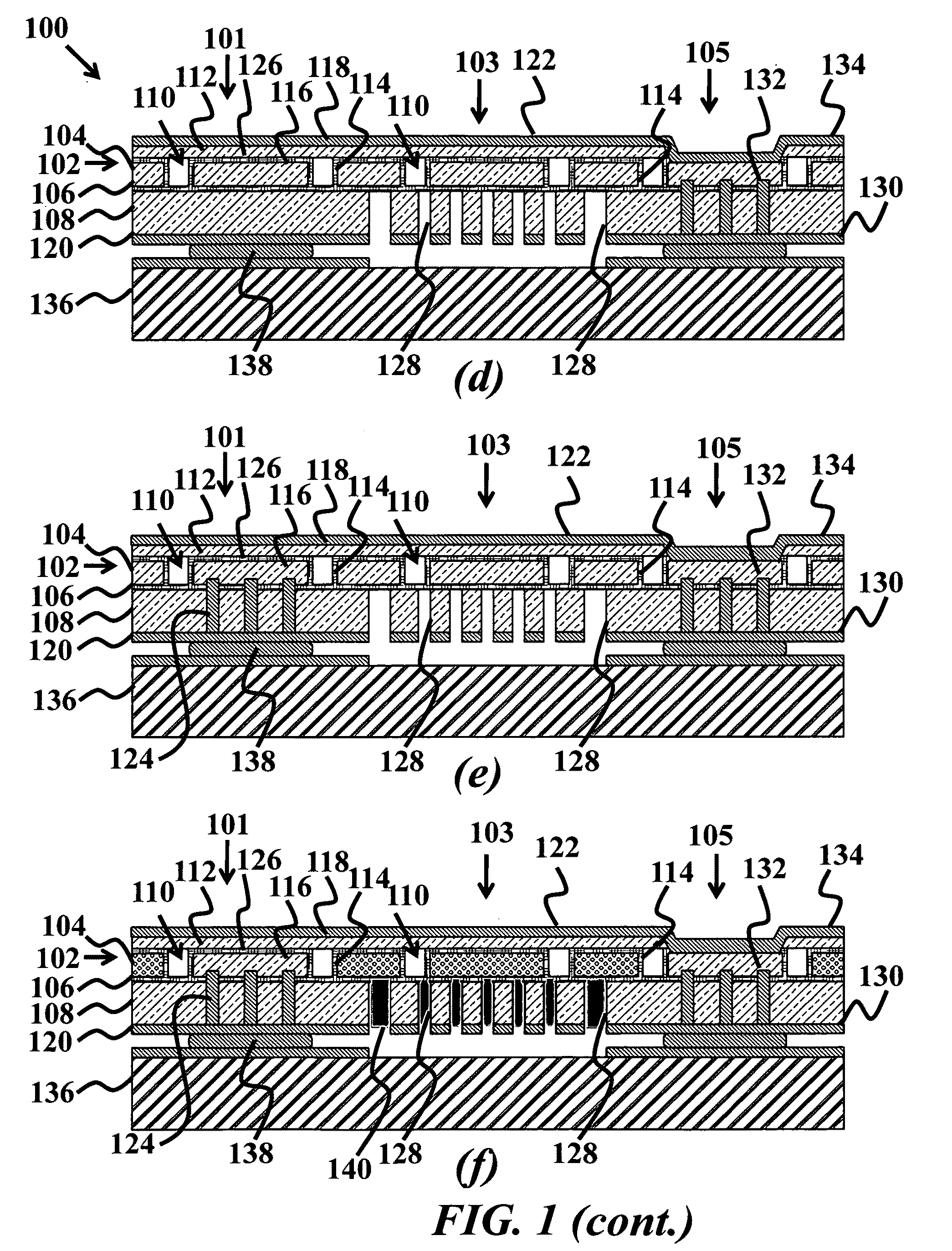

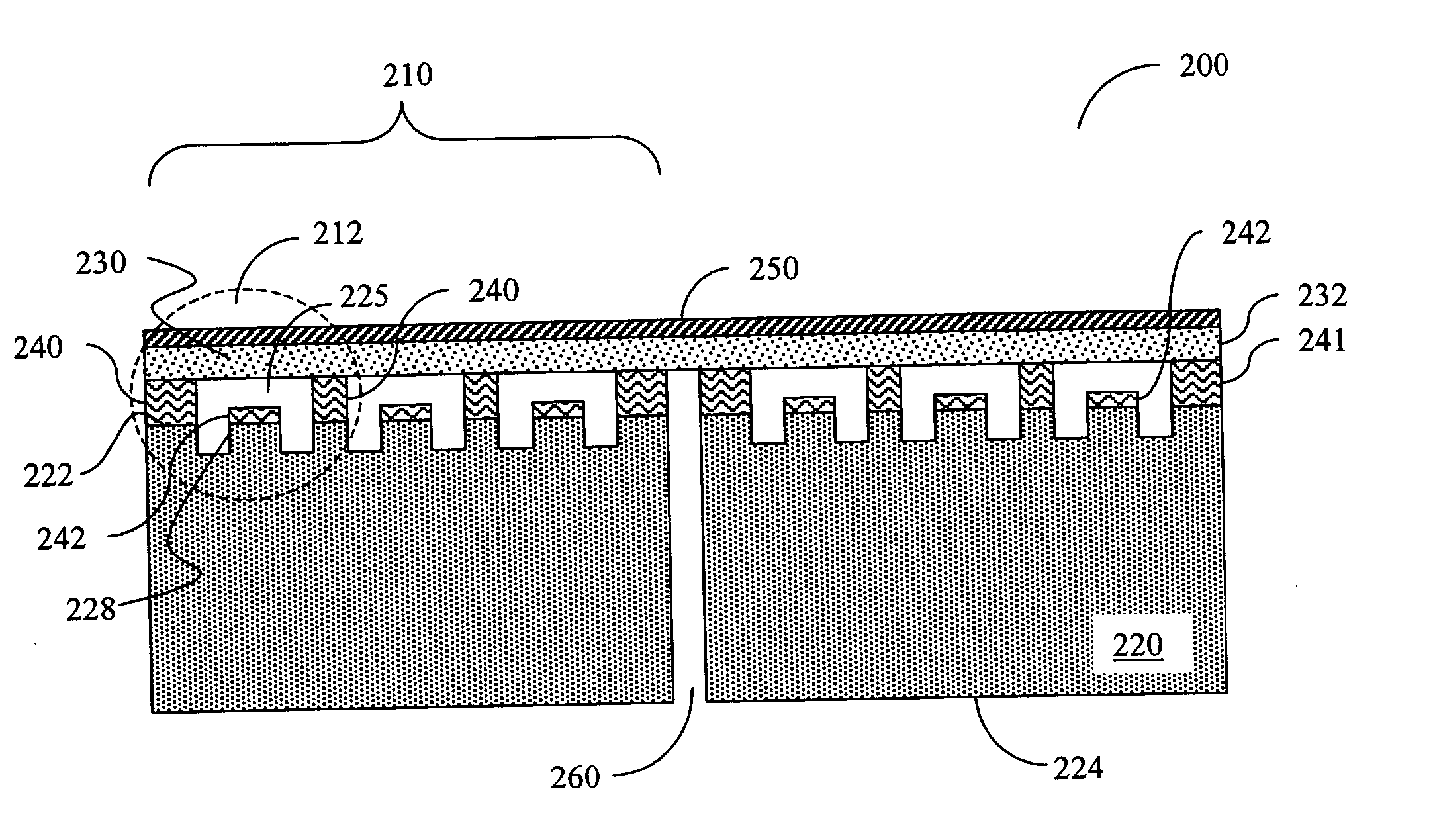

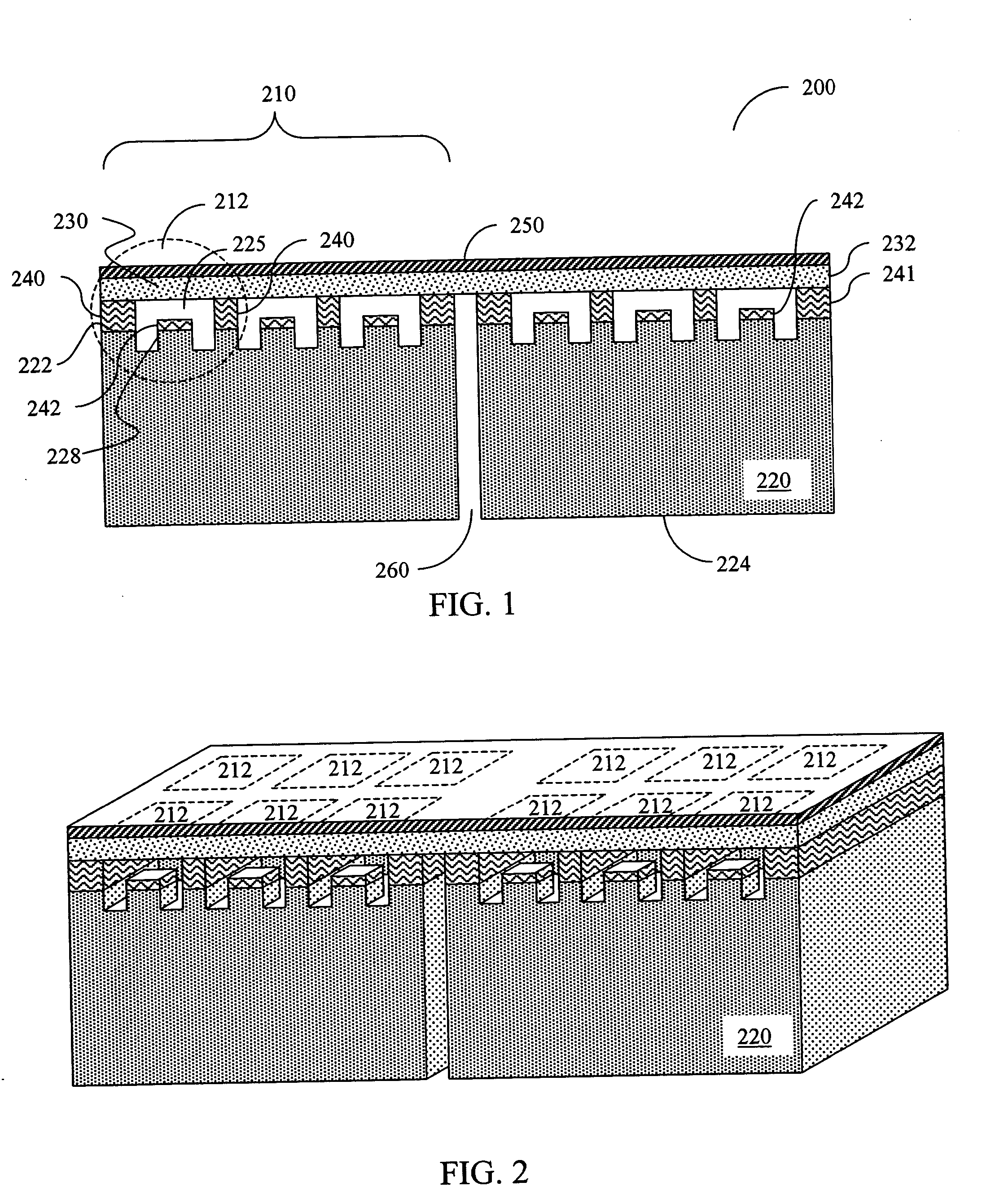

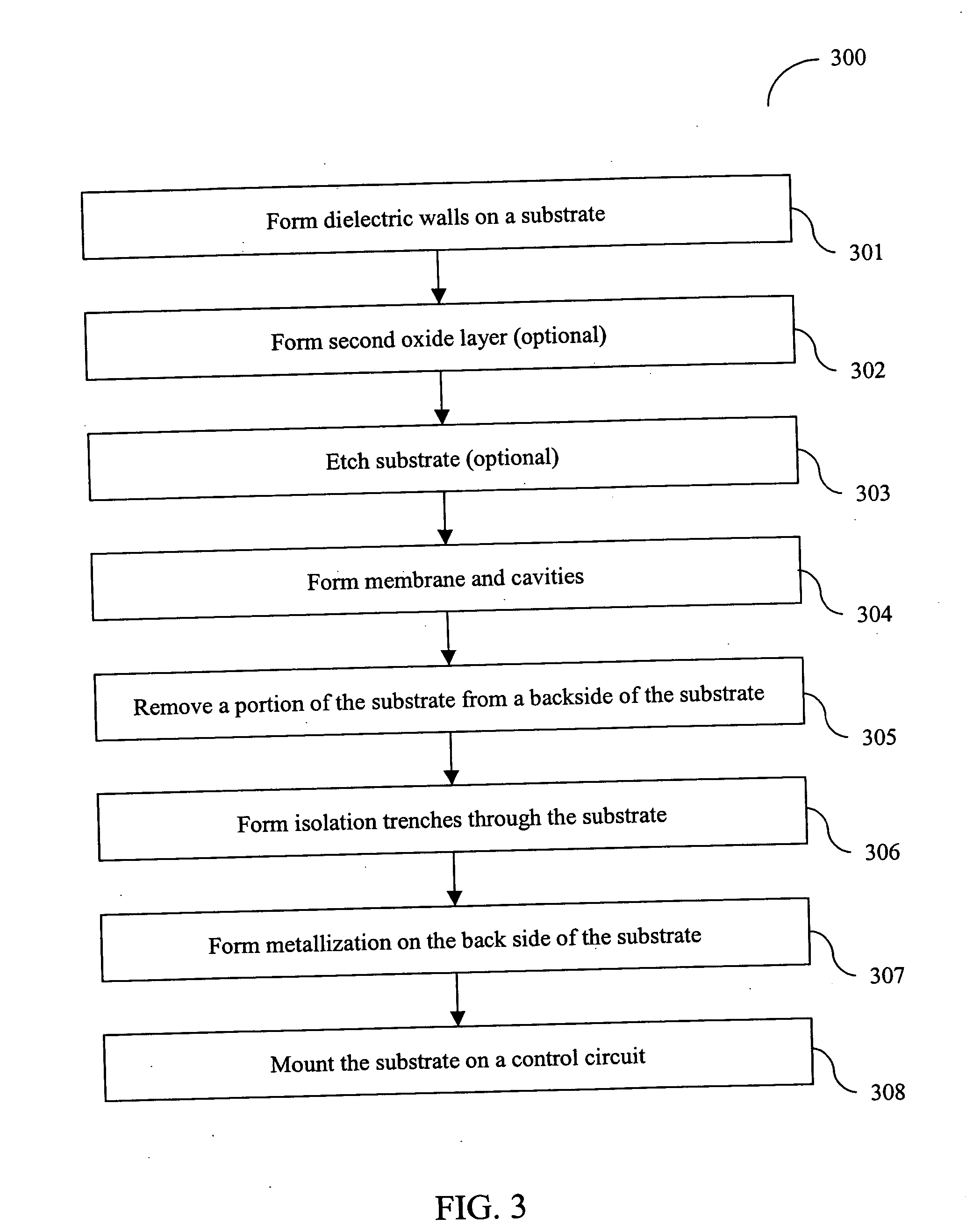

Capacitive micromachined ultrasonic transducer array with through-substrate electrical connection and method of fabricating same

InactiveUS20060075818A1Improve utilization efficiencyImprove device performanceMaterial analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementCapacitanceCapacitive micromachined ultrasonic transducers

The embodiments of the present invention provide a CMUT array and method of fabricating the same. The CMUT array has CMUT elements individually or respectively addressable from a backside of a substrate on which the CMUT array is fabricated. In one embodiment, a CMUT array is formed on a front side of a very high conductivity silicon substrate. Through wafer trenches are etched into the substrate from the backside of the substrate to electrically isolate individual CMUT elements formed on the front side of the substrate. Electrodes are formed on the backside of the substrate to individually address the CMUT elements through the substrate.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

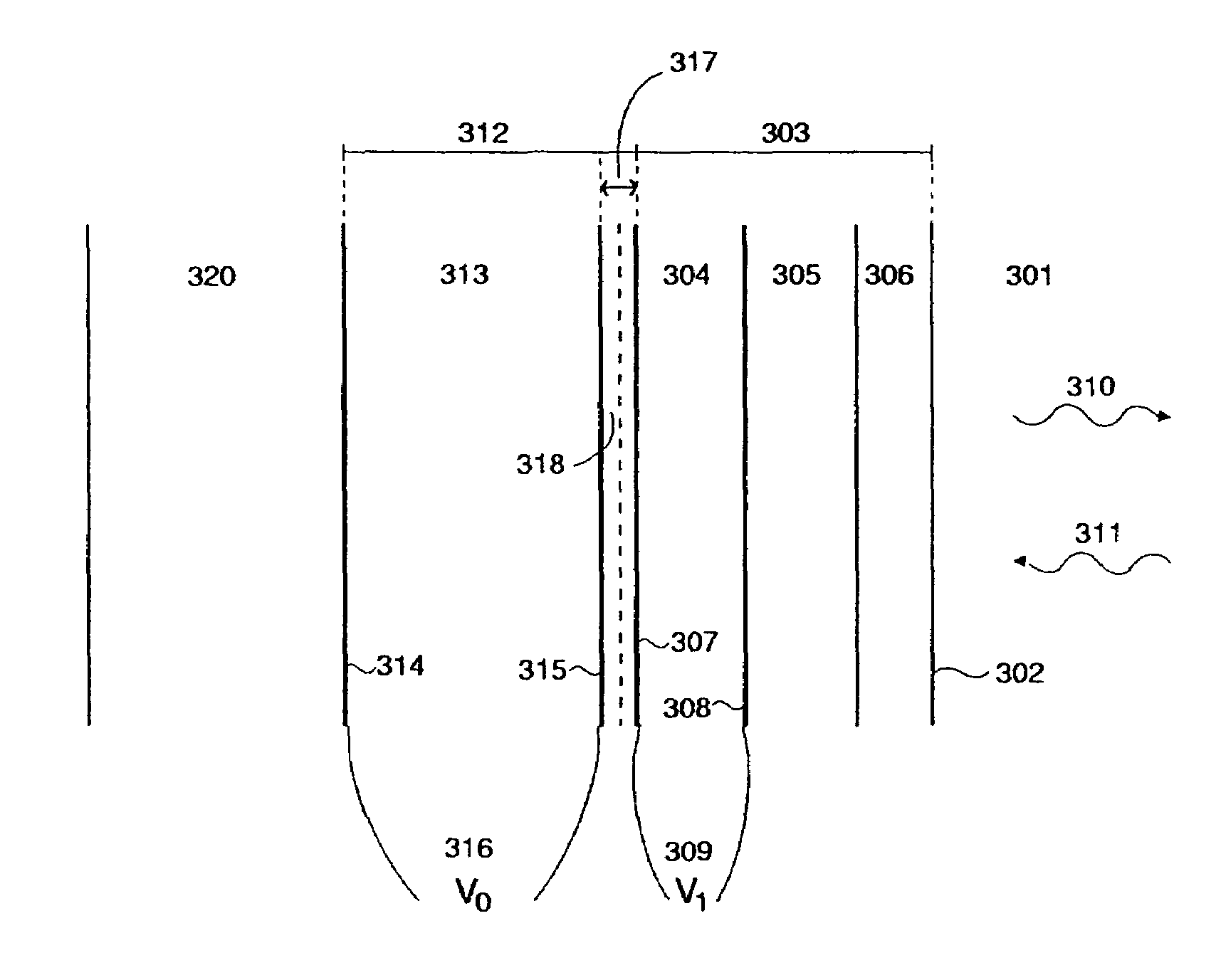

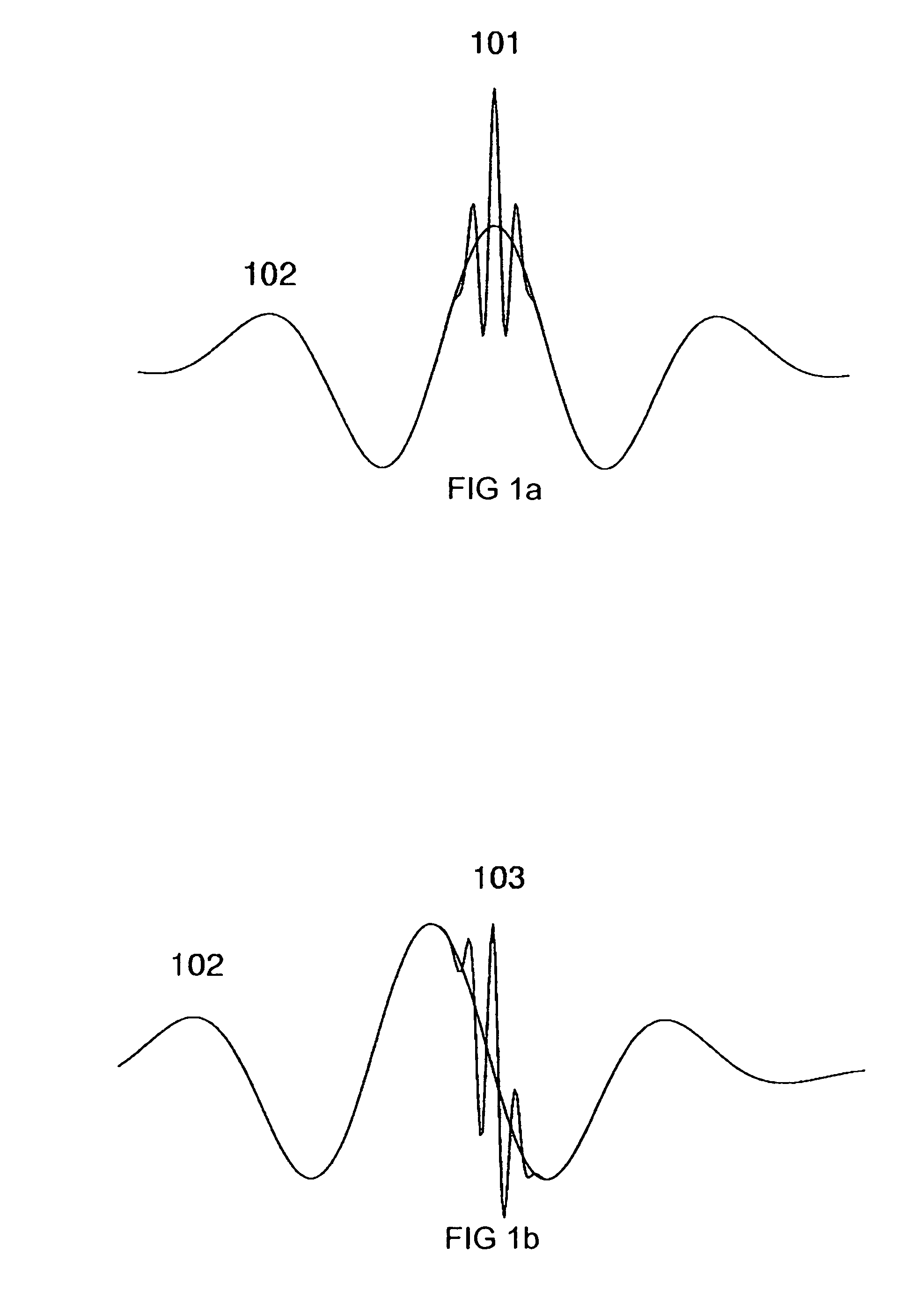

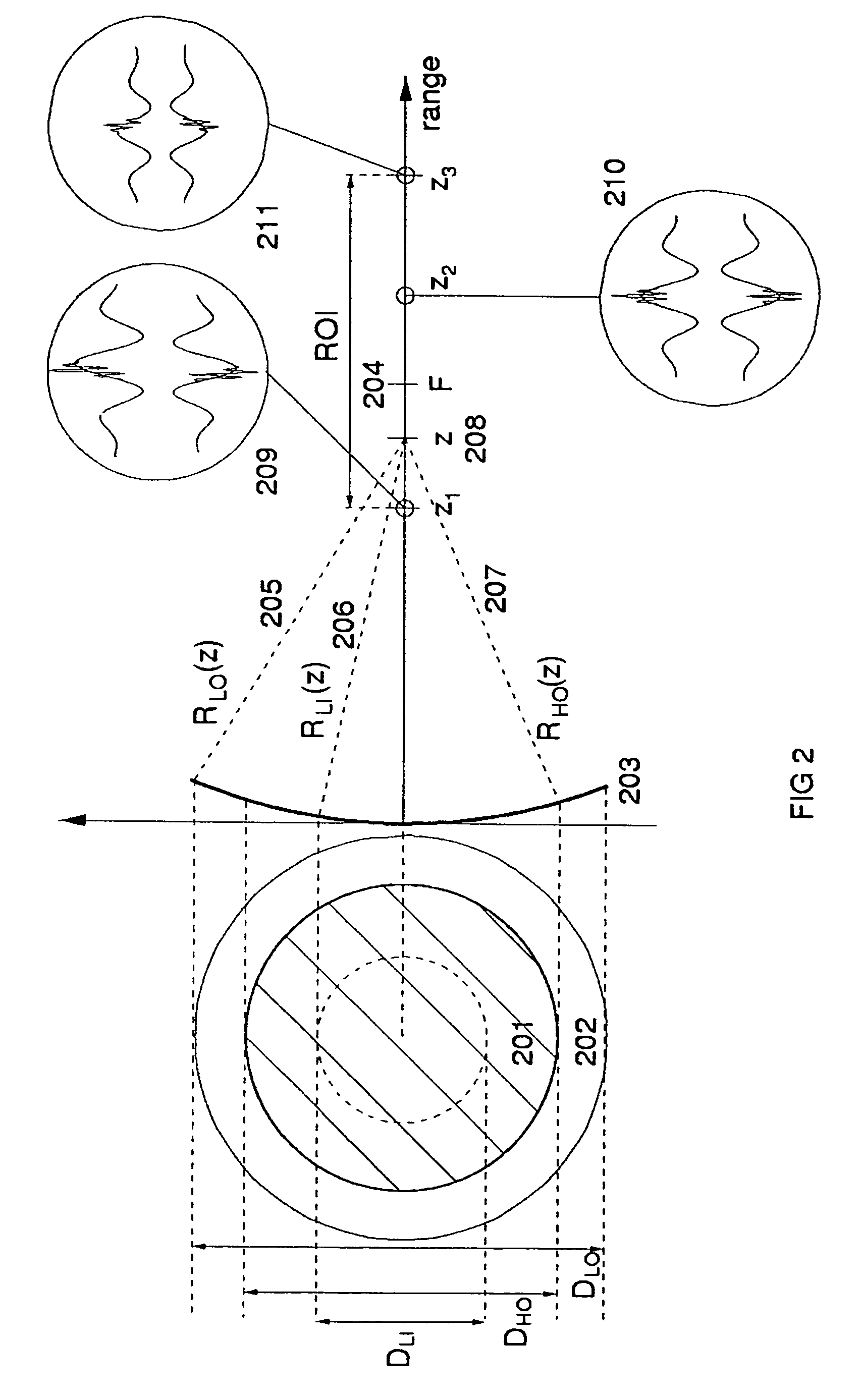

Dual frequency band ultrasound transducer arrays

ActiveUS7727156B2Ultrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesSonificationArray aperture

Owner:ANGELSEN BJORN A J +4

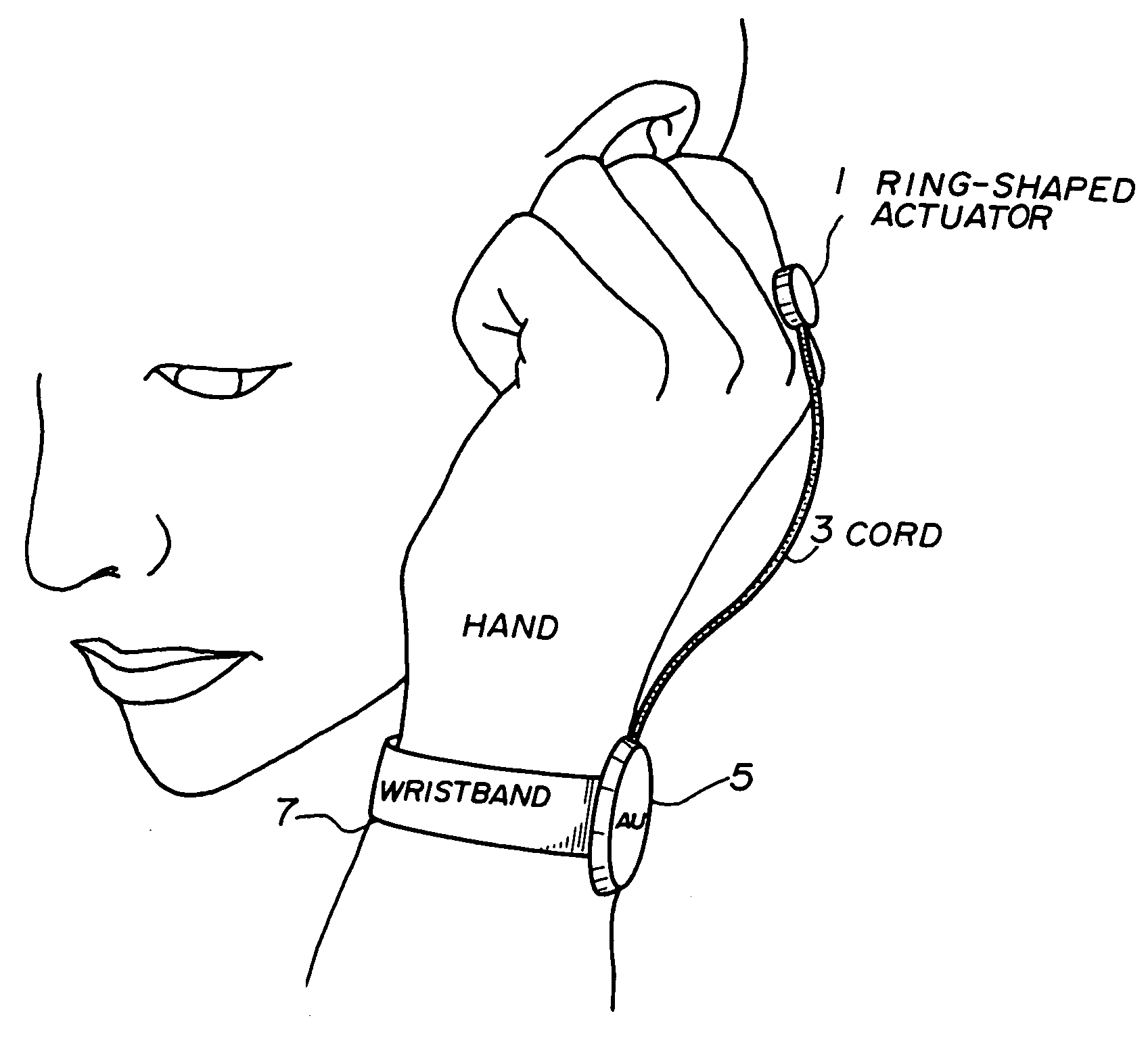

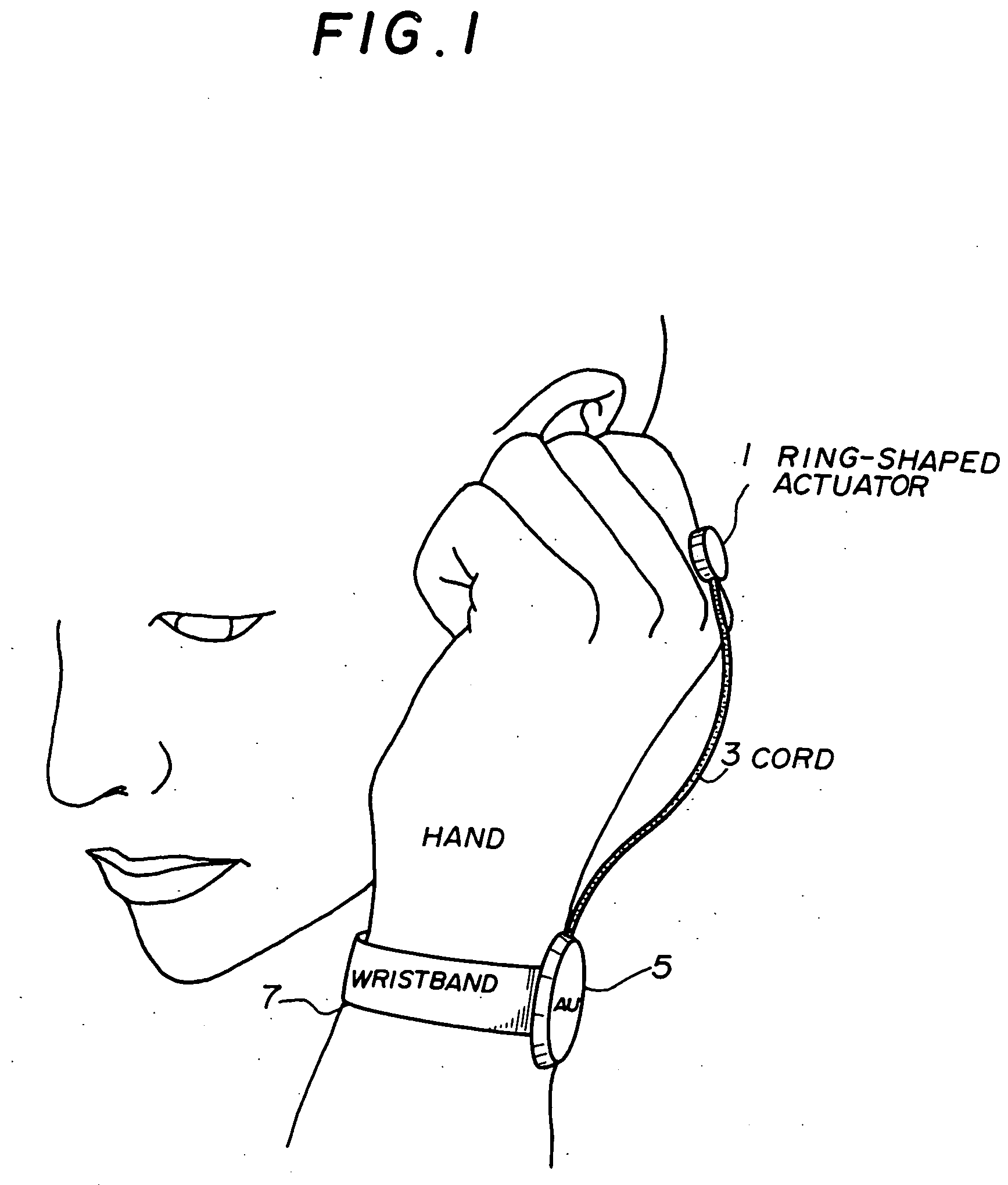

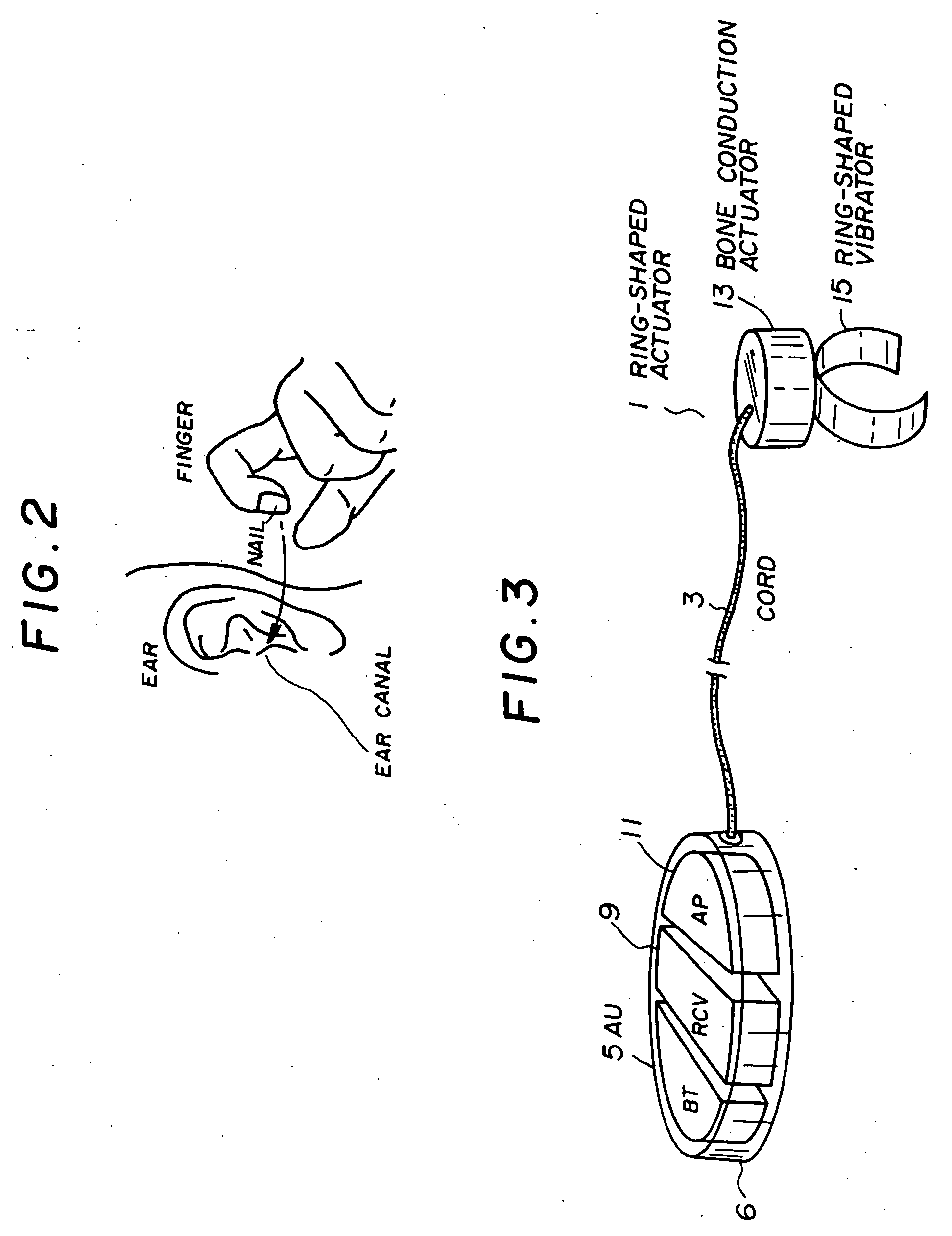

Wearable communication device

InactiveUS20050207599A1Easy to operateImprove usabilityTime indicationDigital data processing detailsBone conduction hearingActuator

A wearable communication device includes a bone conduction actuator which is applicable for being in contact with a user's wrist, hand, back of the hand, finger or nail in order to transmit voice signals. The user inserts the user's finger into the user's ear canal, or touches the user's finger to a part near the user's ear, or puts the user's fingertip or nail on the user's ear canal so as to block the user's ear canal when the user uses the wearable communication device. Also, the wearable command input device includes a first part for detecting shock or acceleration which arises when the user taps the user's fingertip on the surface of an object or when the user taps the fingertips mutually and which is transmitted through the user's finger, a second part for detecting specific frequency components which are included in signals from the first part and for detecting the presence or the absence of the tap of the finger of the user, and a part for determining and executing commands based on series of signals output from the second part.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

MEMS pixel sensor

InactiveUS7425749B2Piezoelectric/electrostrictive microphonesAcceleration measurement using interia forcesBroadbandEngineering

A MEMS pixel sensor is provided with a thin-film mechanical device having a mechanical body, with a mechanical state responsive to a proximate environment. A thin-film electronic device converts the mechanical state into electrical signals. A pixel interface supplies power to the electronic device and transceives electrical signals. The sensor is able to operate dynamically, in real-time. For example, if the mechanical device undergoes a sequence of mechanical states at a corresponding plurality of times, the electronic device is able to supply a sequence of electrical signals to the pixel interface that are responsive to the sequence of mechanical states, at the plurality of times. Each MEMS pixel sensor may include a number of mechanical devices, and corresponding electronic devices, to provide redundancy or to measure a broadband response range.

Owner:SHARP KK

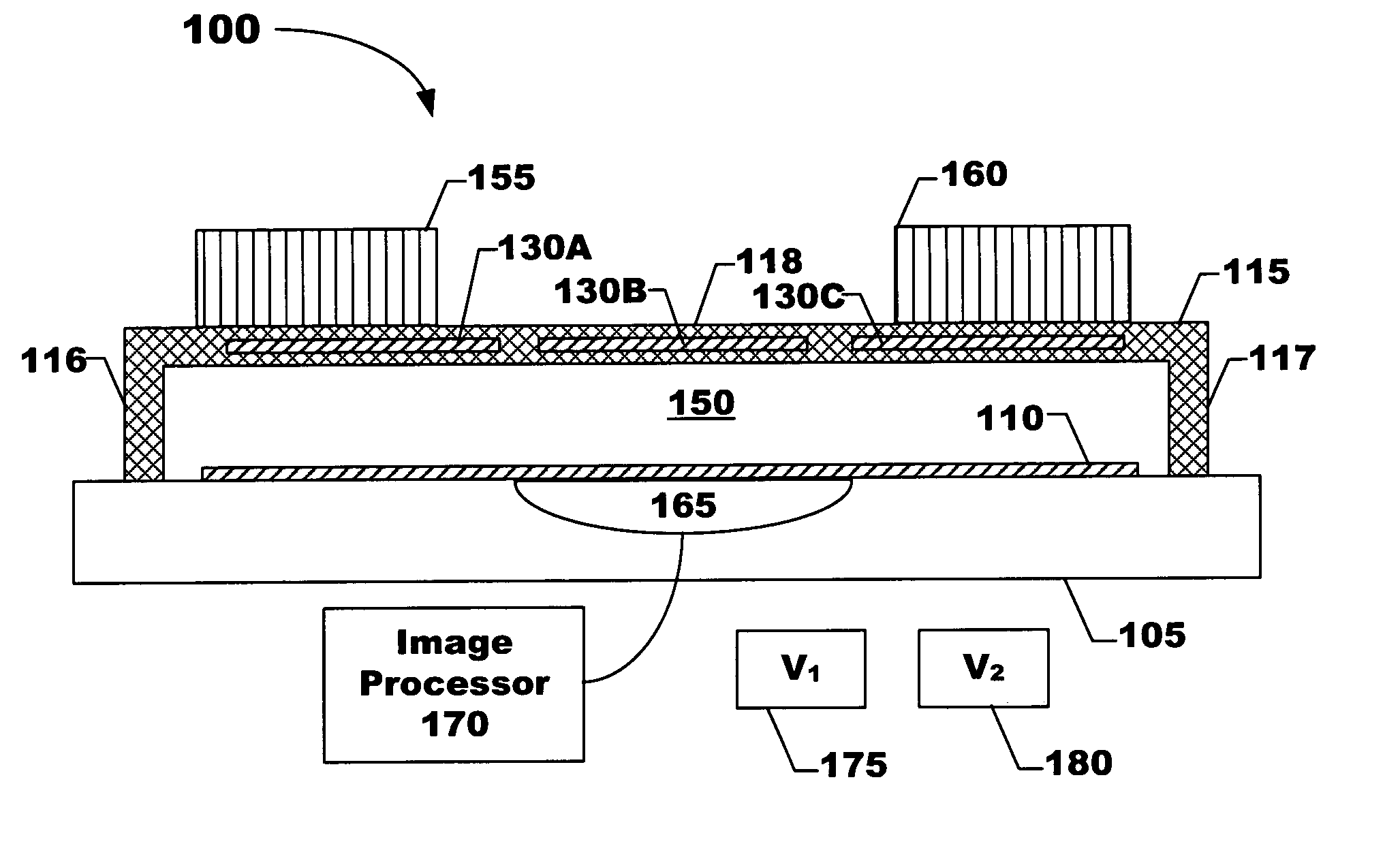

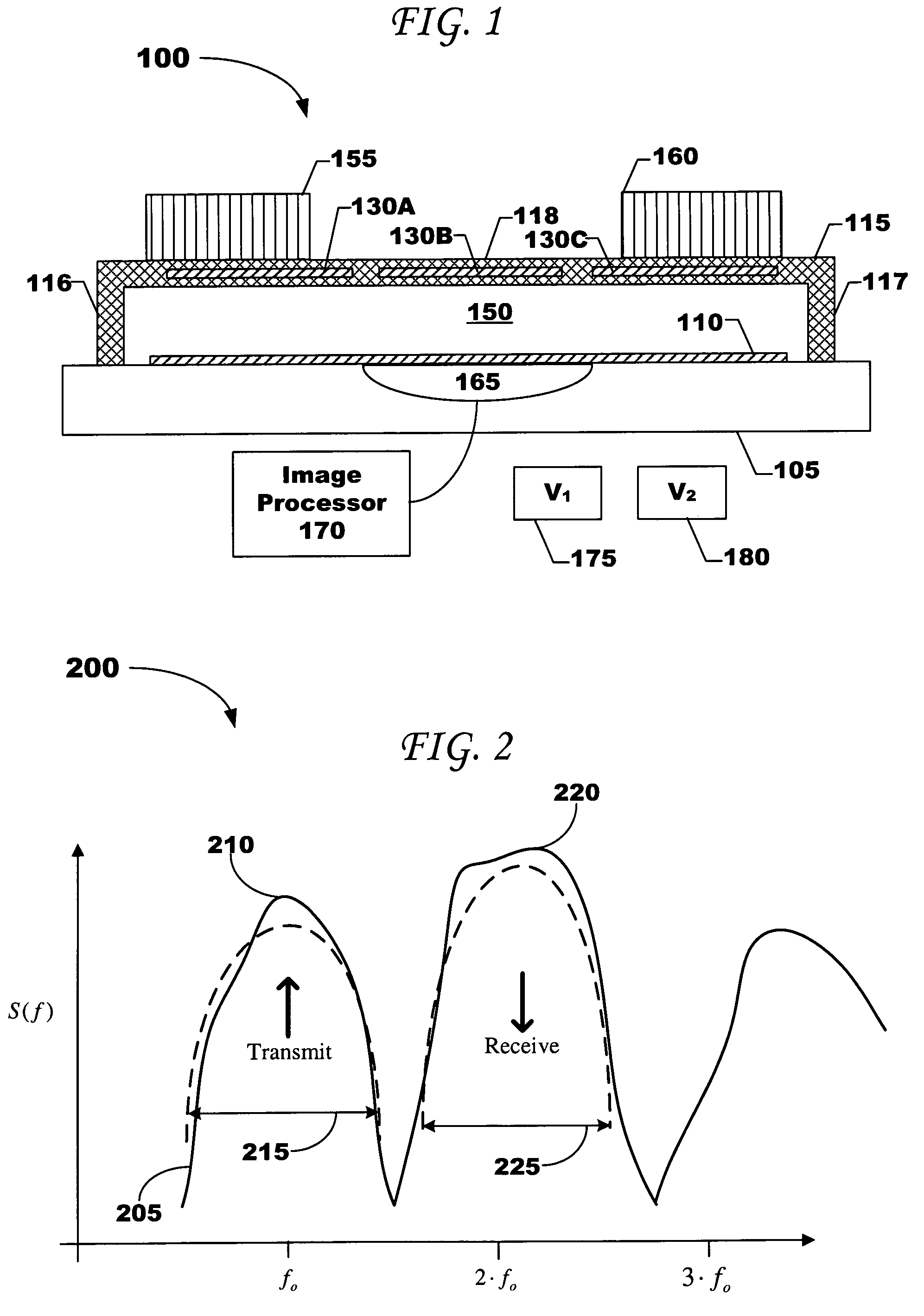

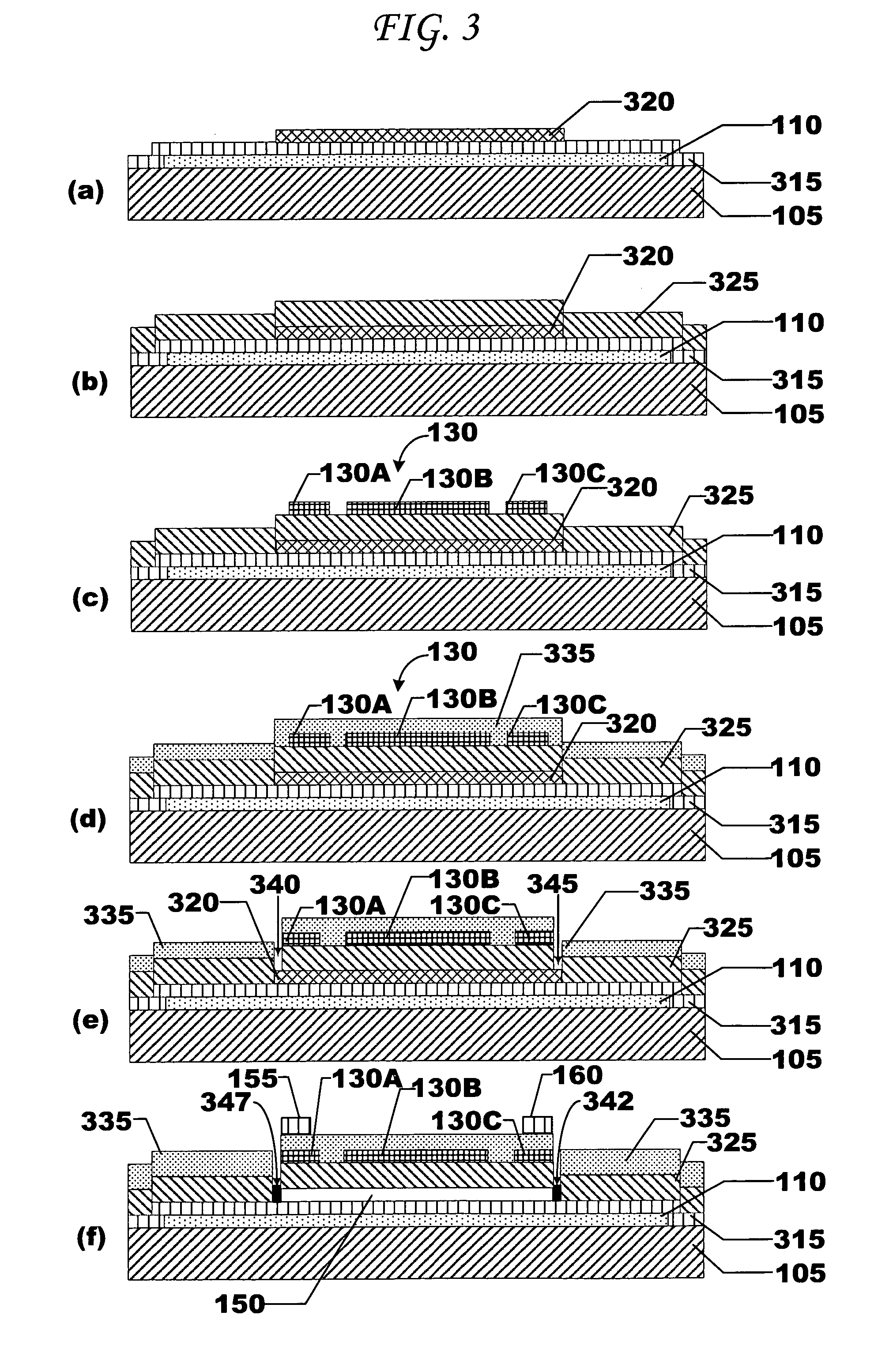

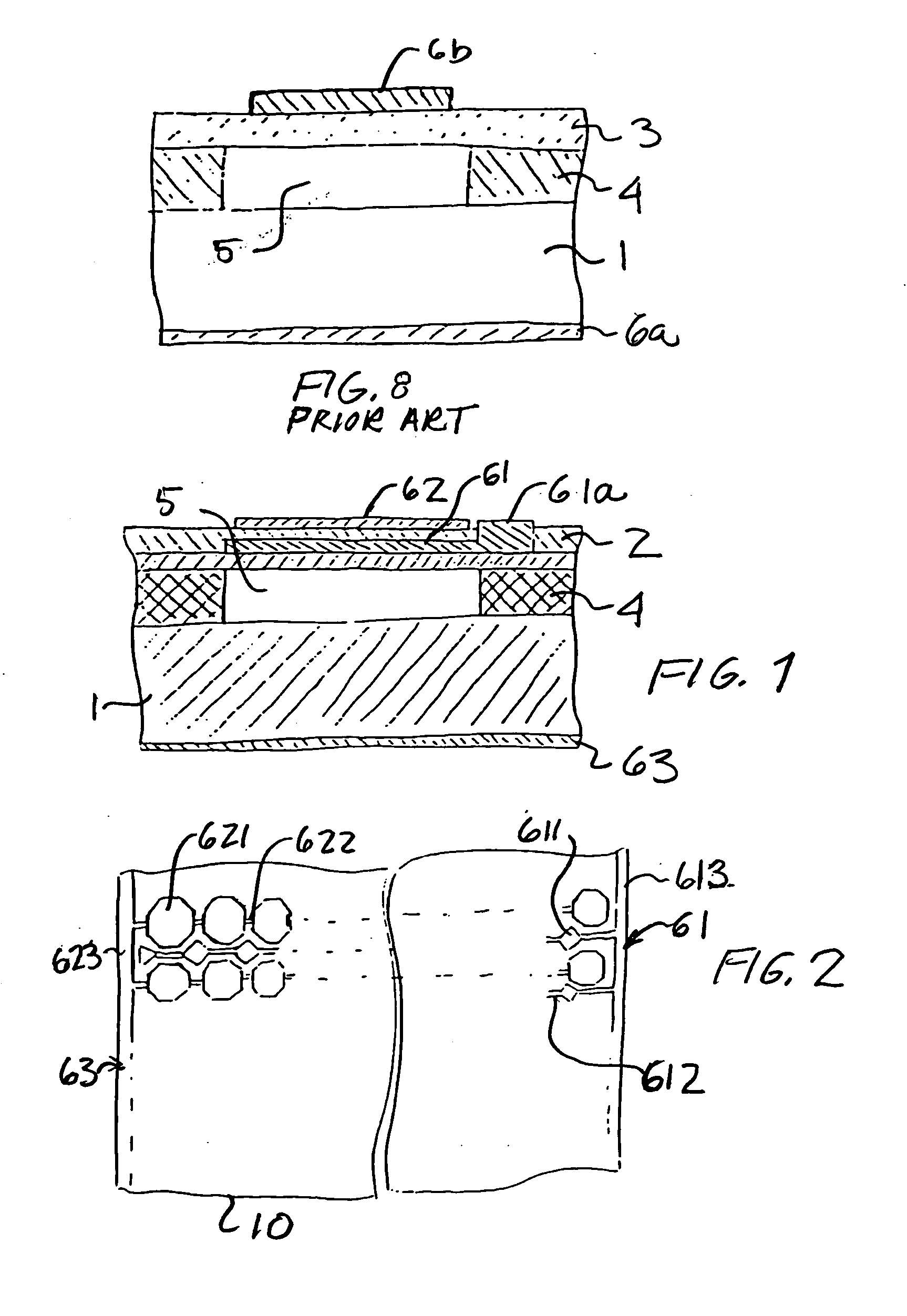

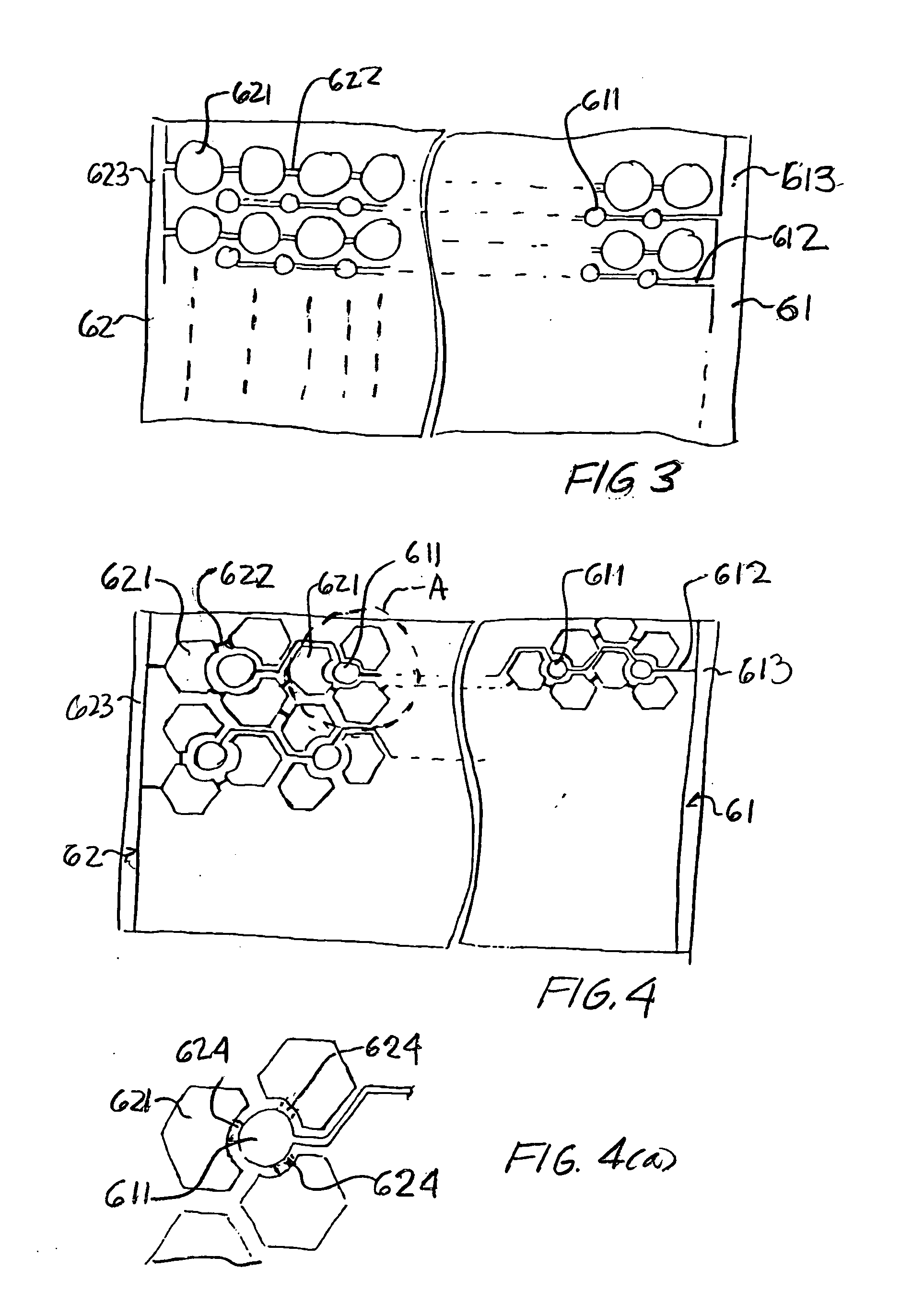

Harmonic cMUT devices and fabrication methods

InactiveUS7612483B2Reduce parasitic capacitanceImprove electrical performancePiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationCapacitive micromachined ultrasonic transducersHarmonic

Harmonic capacitive micromachined ultrasonic transducer (“cMUT”) devices and fabrication methods are provided. In a preferred embodiment, a harmonic cMUT device generally comprises a membrane having a non-uniform mass distribution. A mass load positioned along the membrane can be utilized to alter the mass distribution of the membrane. The mass load can be a part of the membrane and formed of the same material or a different material as the membrane. The mass load can be positioned to correspond with a vibration mode of the membrane, and also to adjust or shift a vibration mode of the membrane. The mass load can also be positioned at predetermined locations along the membrane to control the harmonic vibrations of the membrane. A cMUT can also comprise a cavity defined by the membrane, a first electrode proximate the membrane, and a second electrode proximate a substrate. Other embodiments are also claimed and described.

Owner:GEORGIA TECH RES CORP

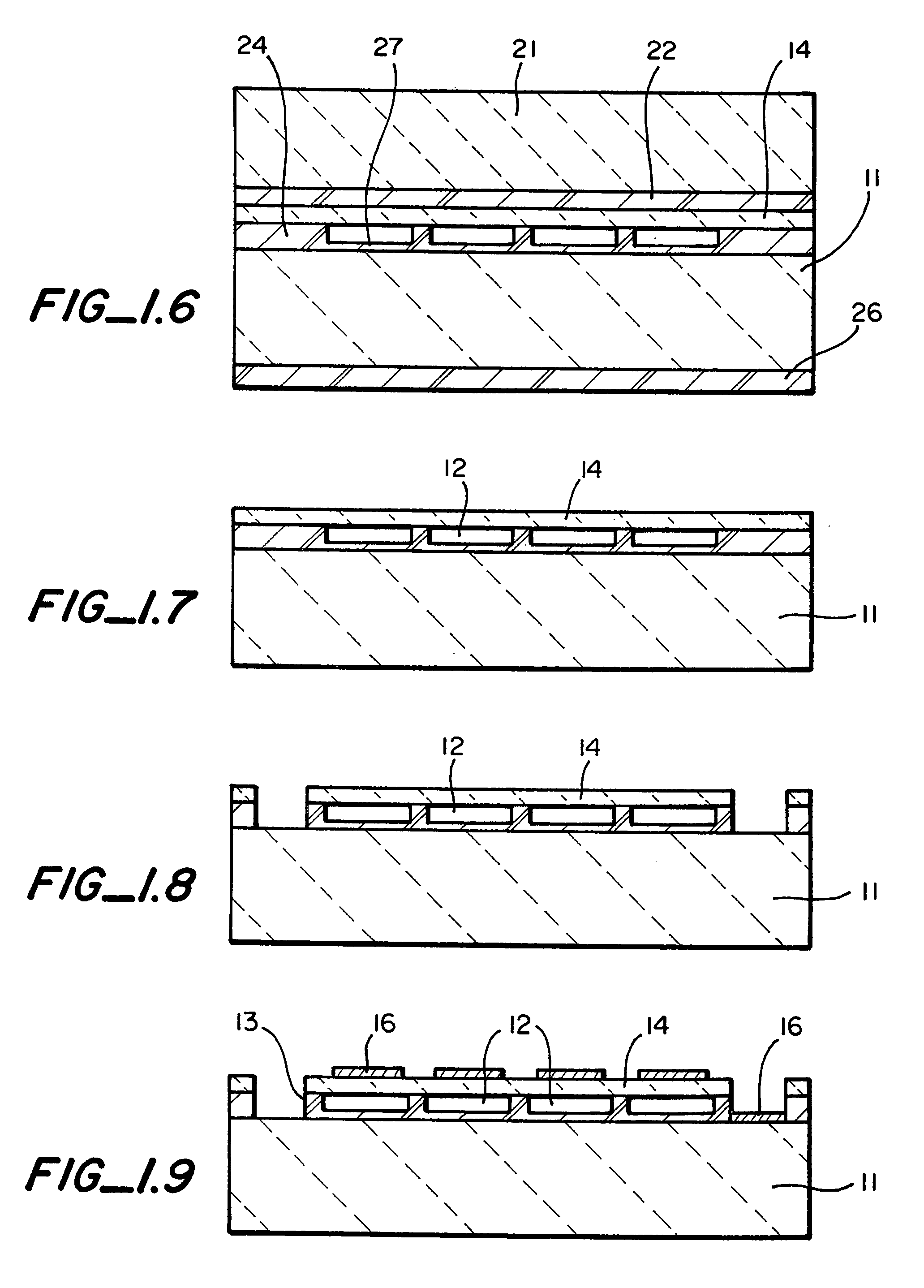

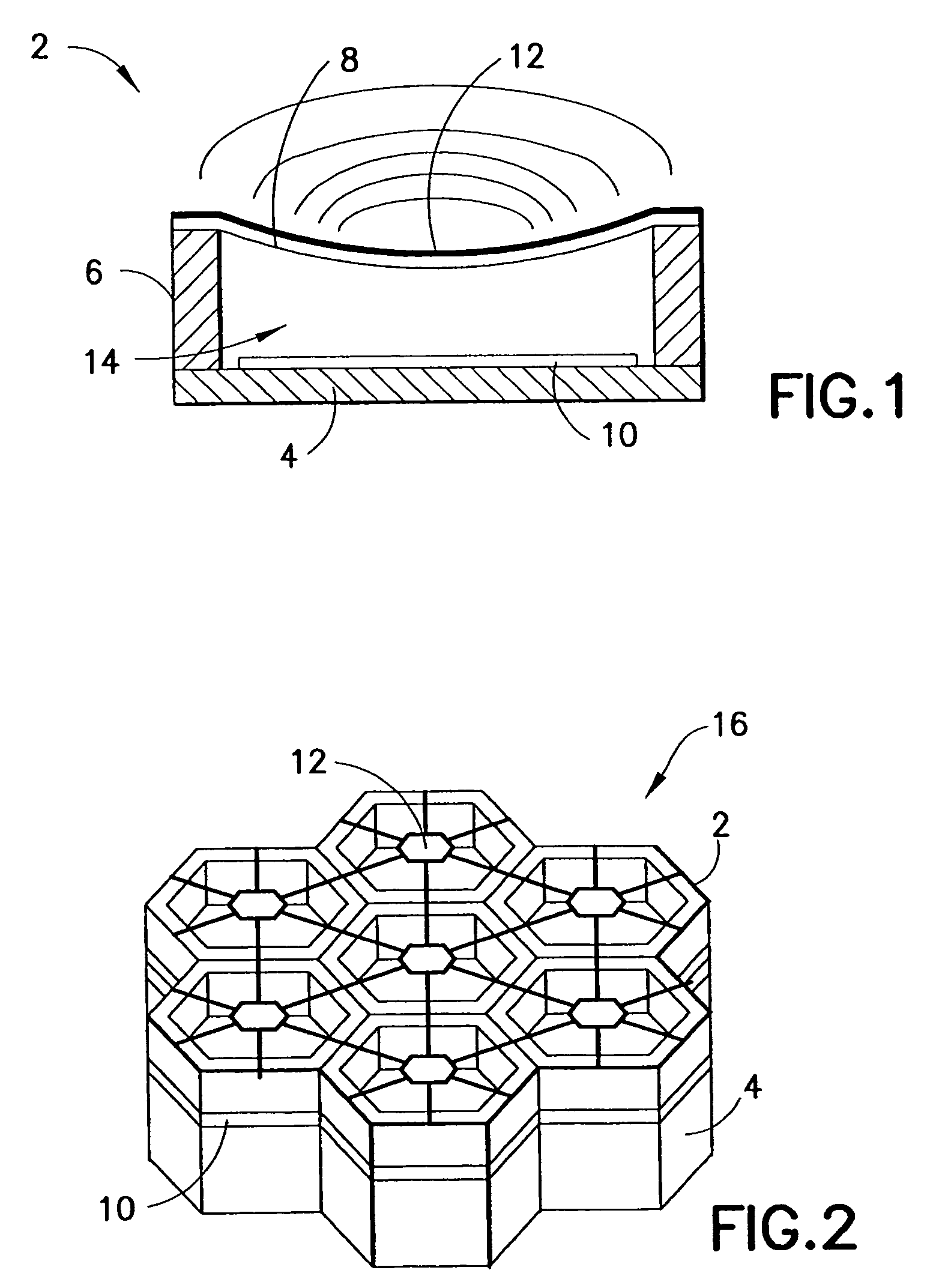

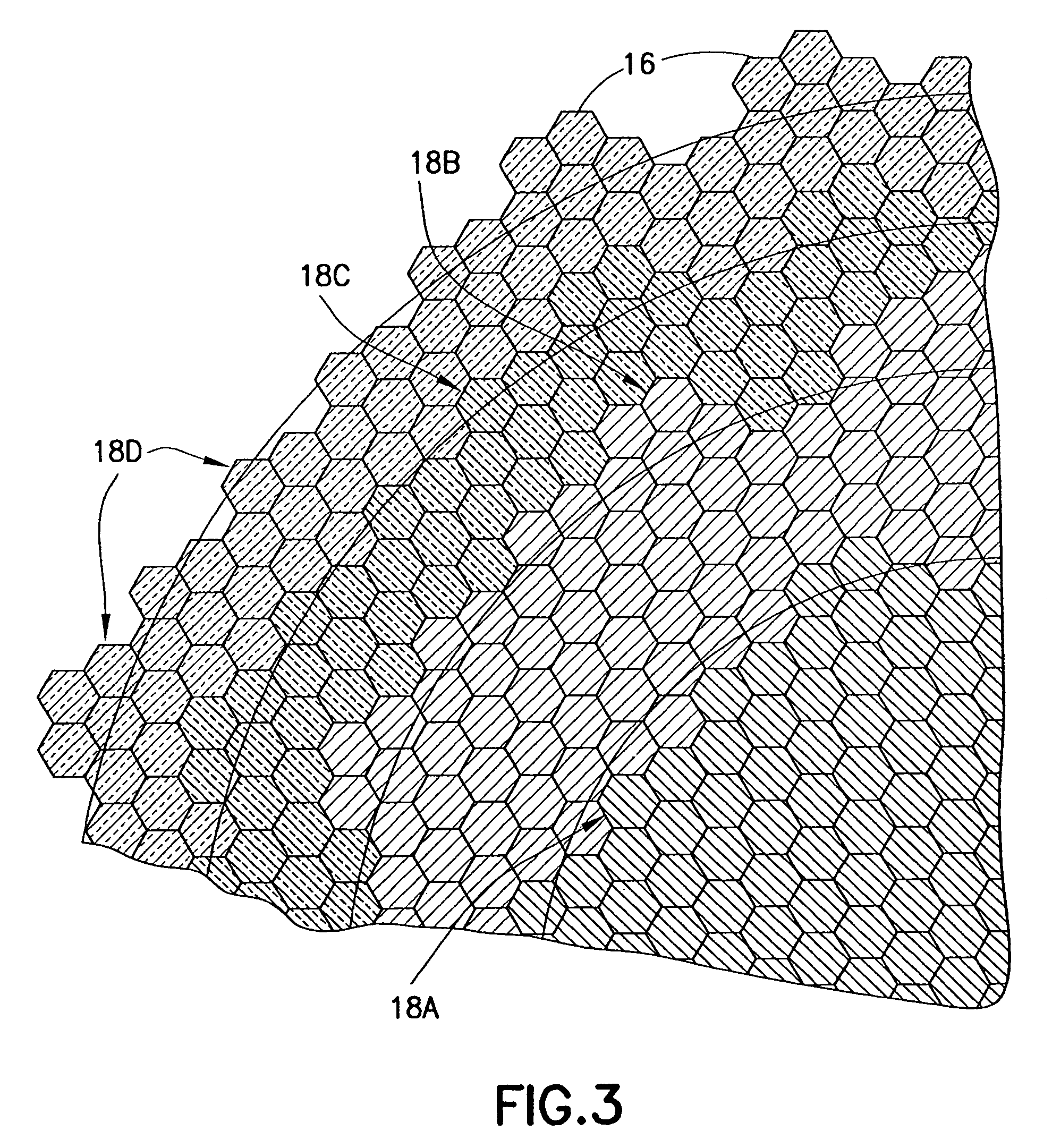

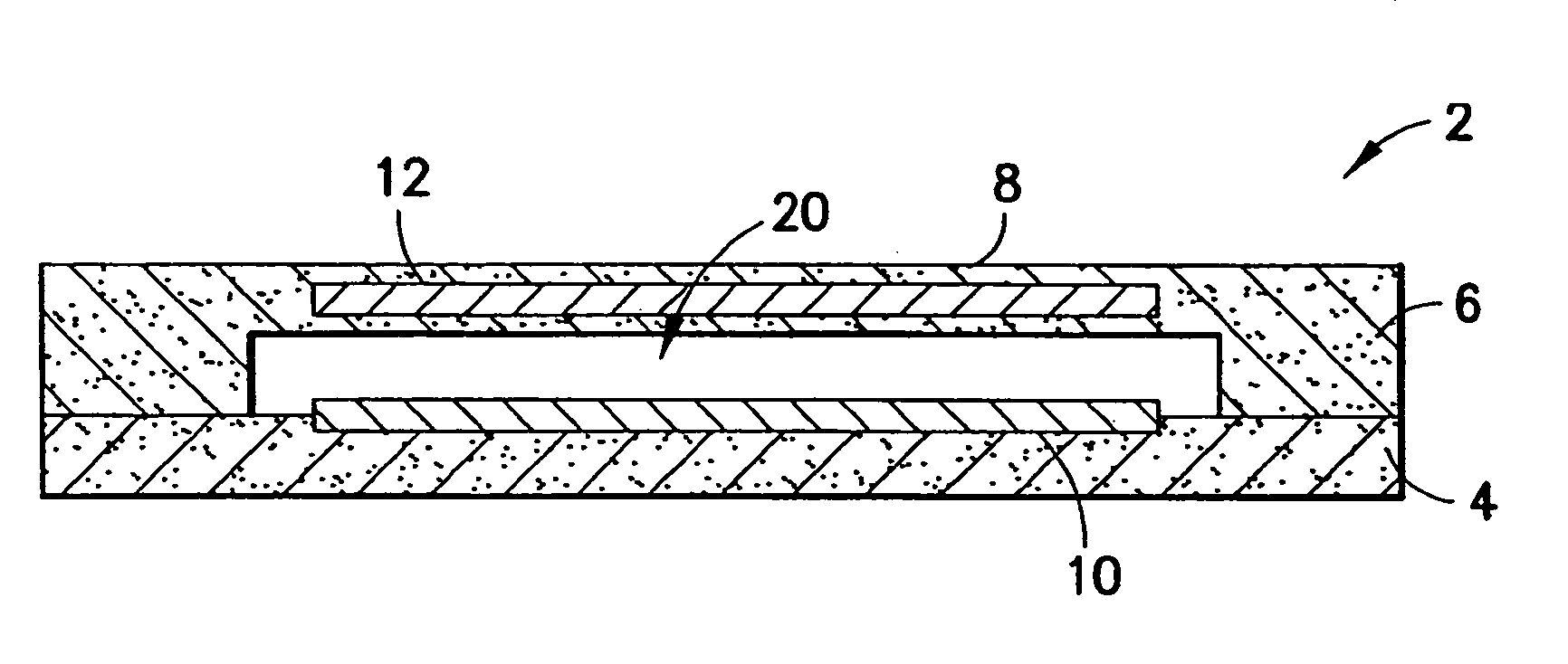

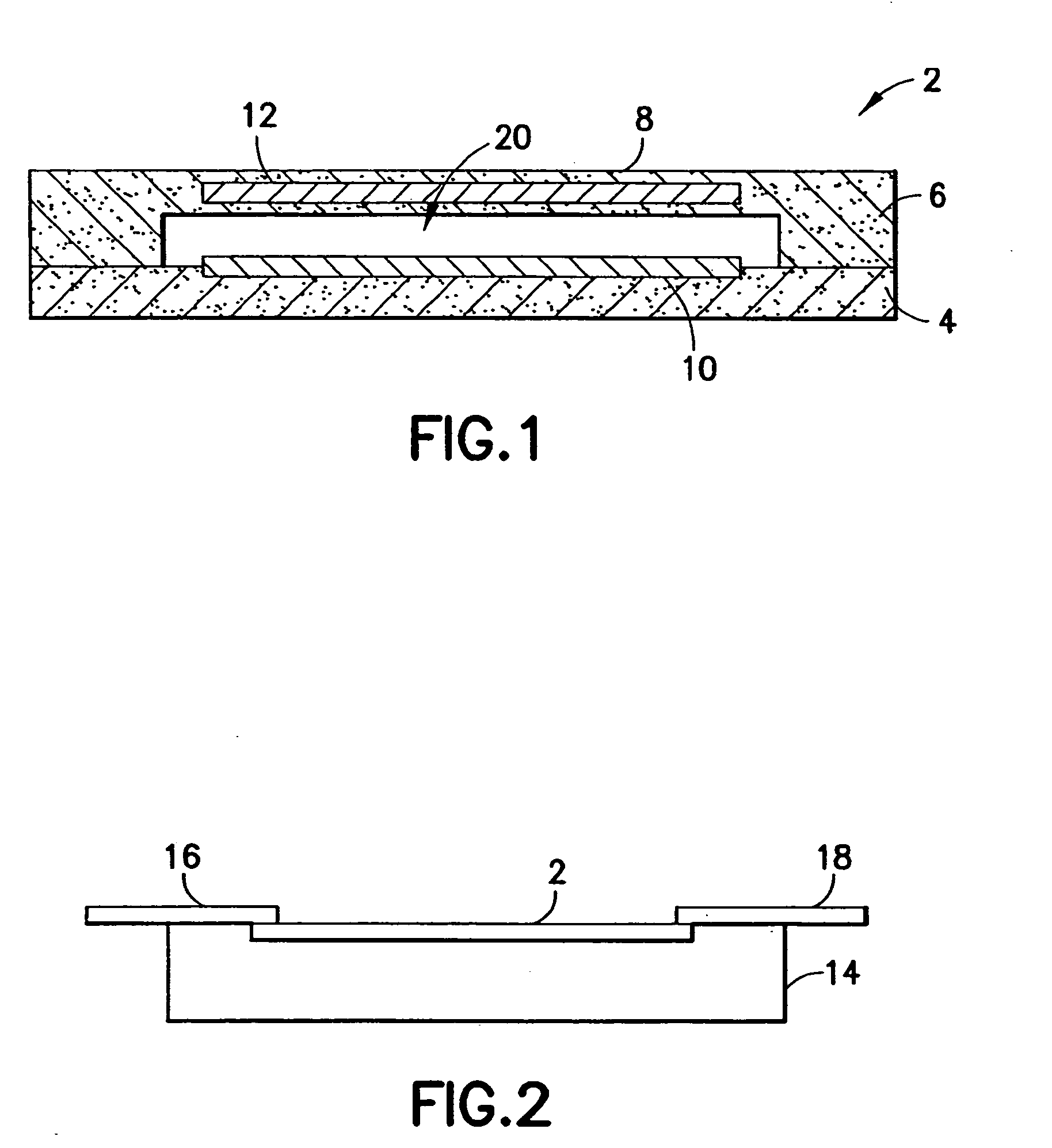

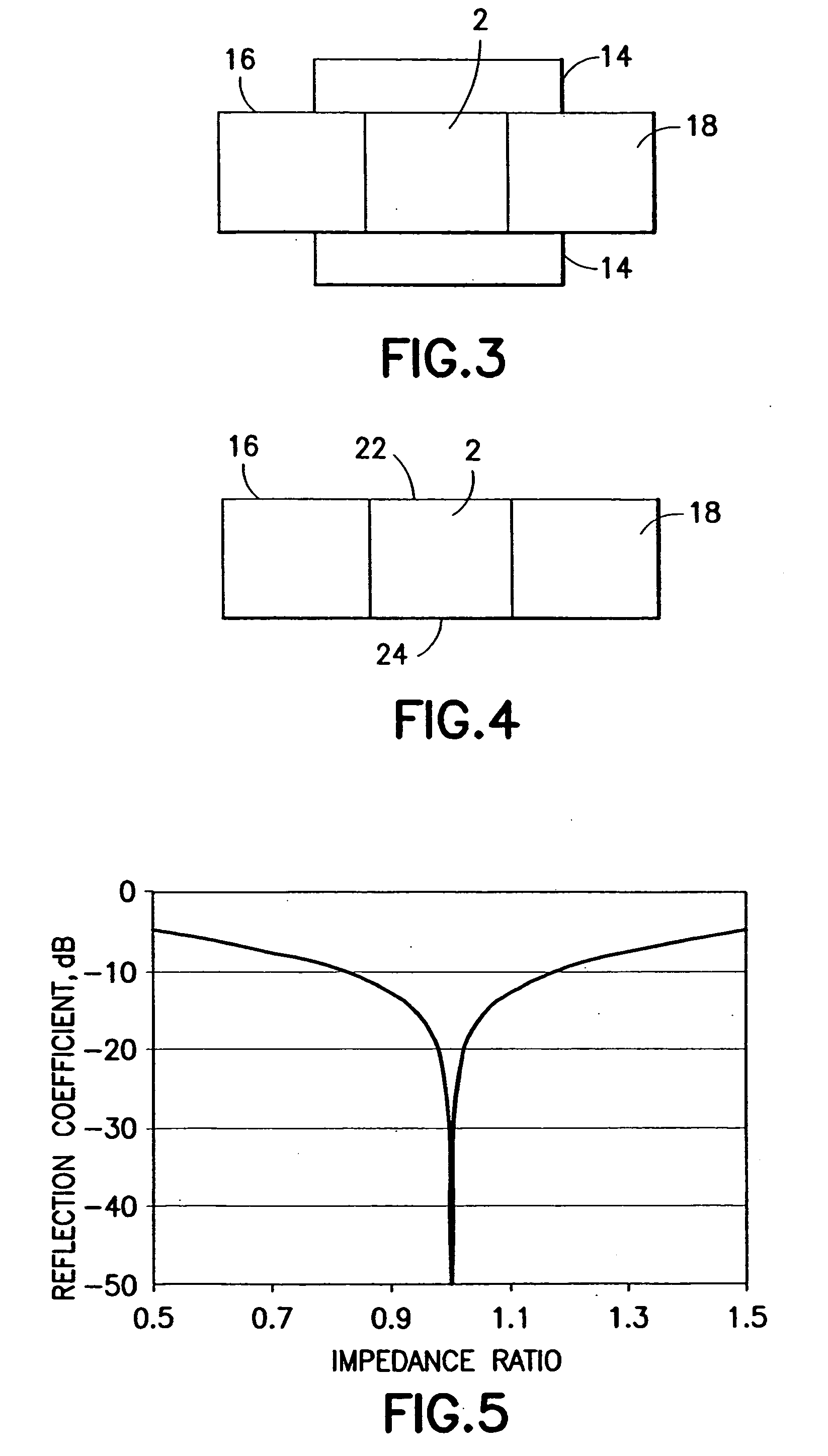

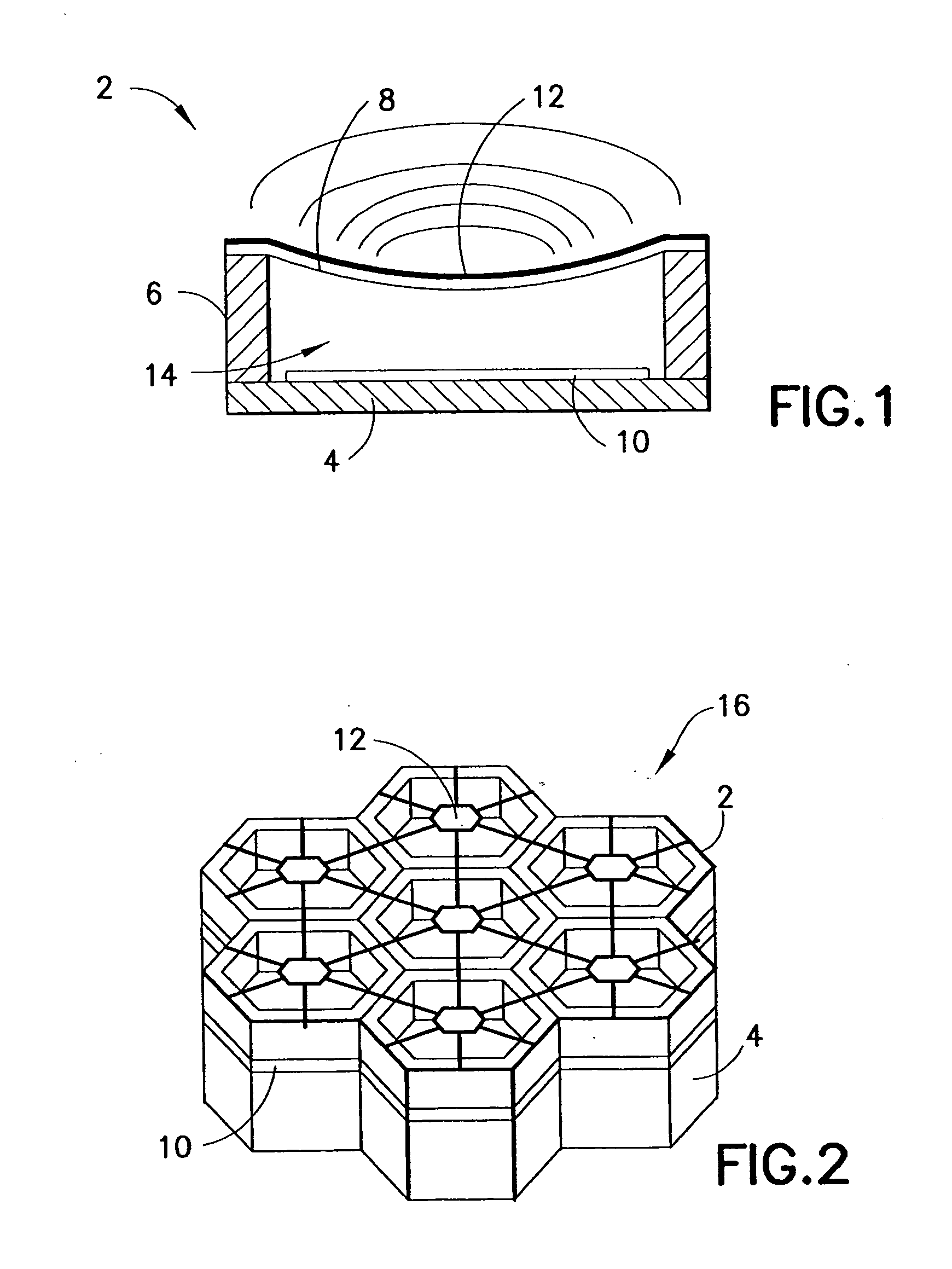

Electrostatic membranes for sensors, ultrasonic transducers incorporating such membranes, and manufacturing methods therefor

ActiveUS20060116585A1Maximize energy conversionEfficiently and effectively implementUltrasonic/sonic/infrasonic diagnosticsMechanical vibrations separationUltrasonic sensorTransducer

A micro-machined ultrasonic transducer substrate for immersion operation is formed by a particular arrangement of a plurality of micro-machined membranes that are supported on a silicon substrate. The membranes, together with the substrate, form surface microcavities that are vacuum sealed to provide electrostatic cells. The cells can operate at high frequency and can cover a broader bandwidth in comparison with conventional piezoelectric bulk transducers.

Owner:VERMON

Integrated interface electronics for reconfigurable sensor array

ActiveUS7257051B2Ultrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricitySensor array

Owner:GENERAL ELECTRIC CO

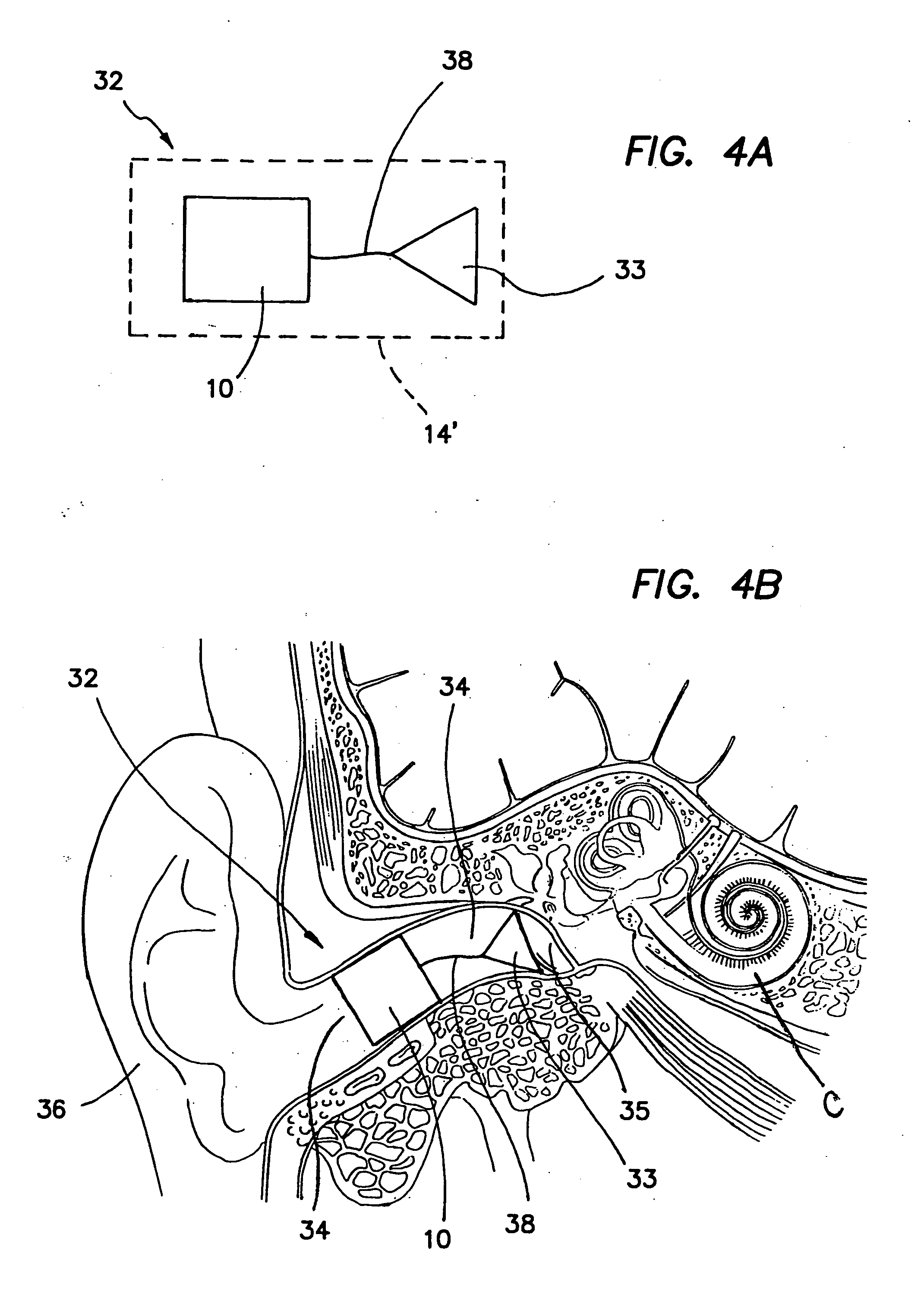

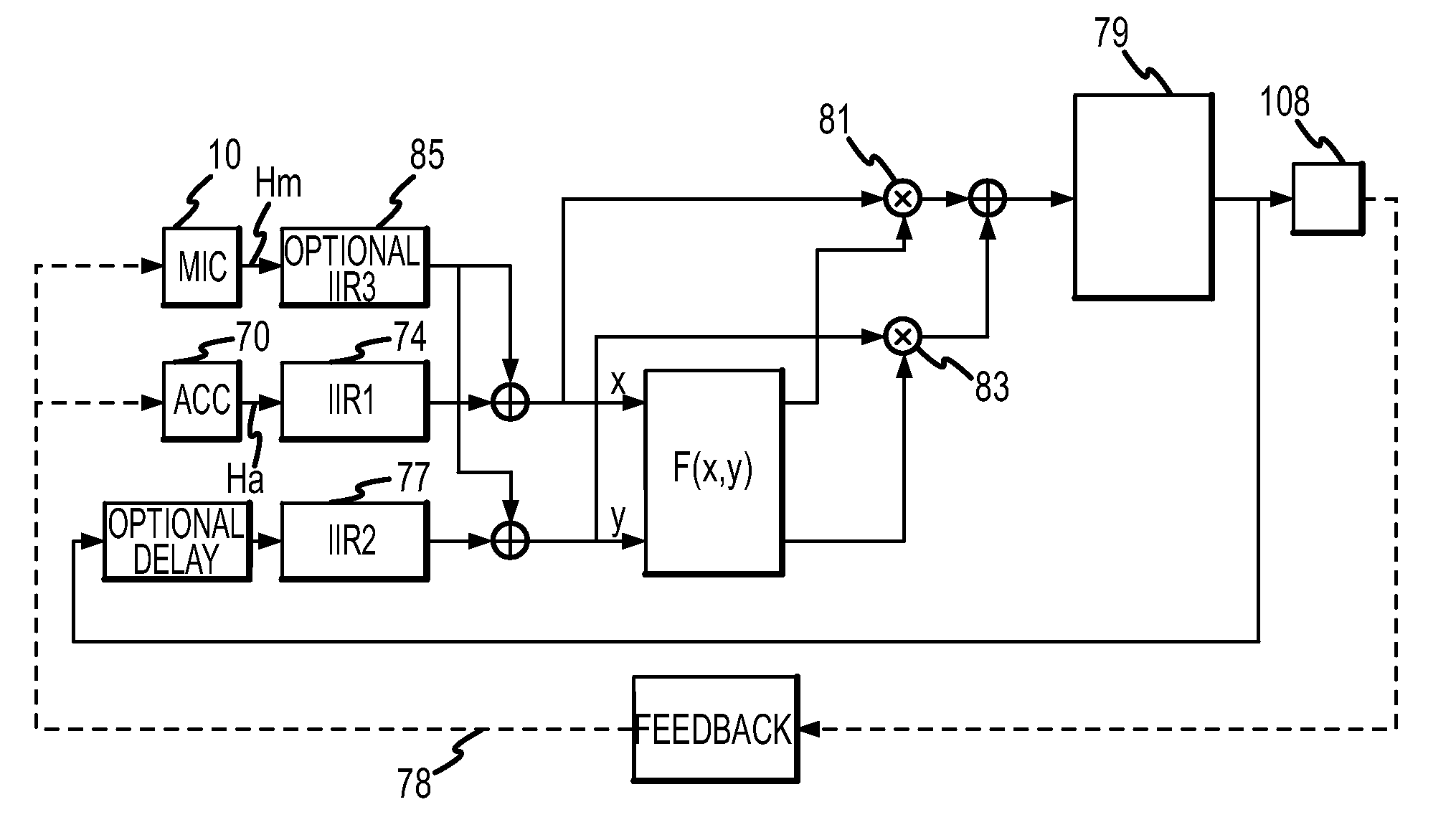

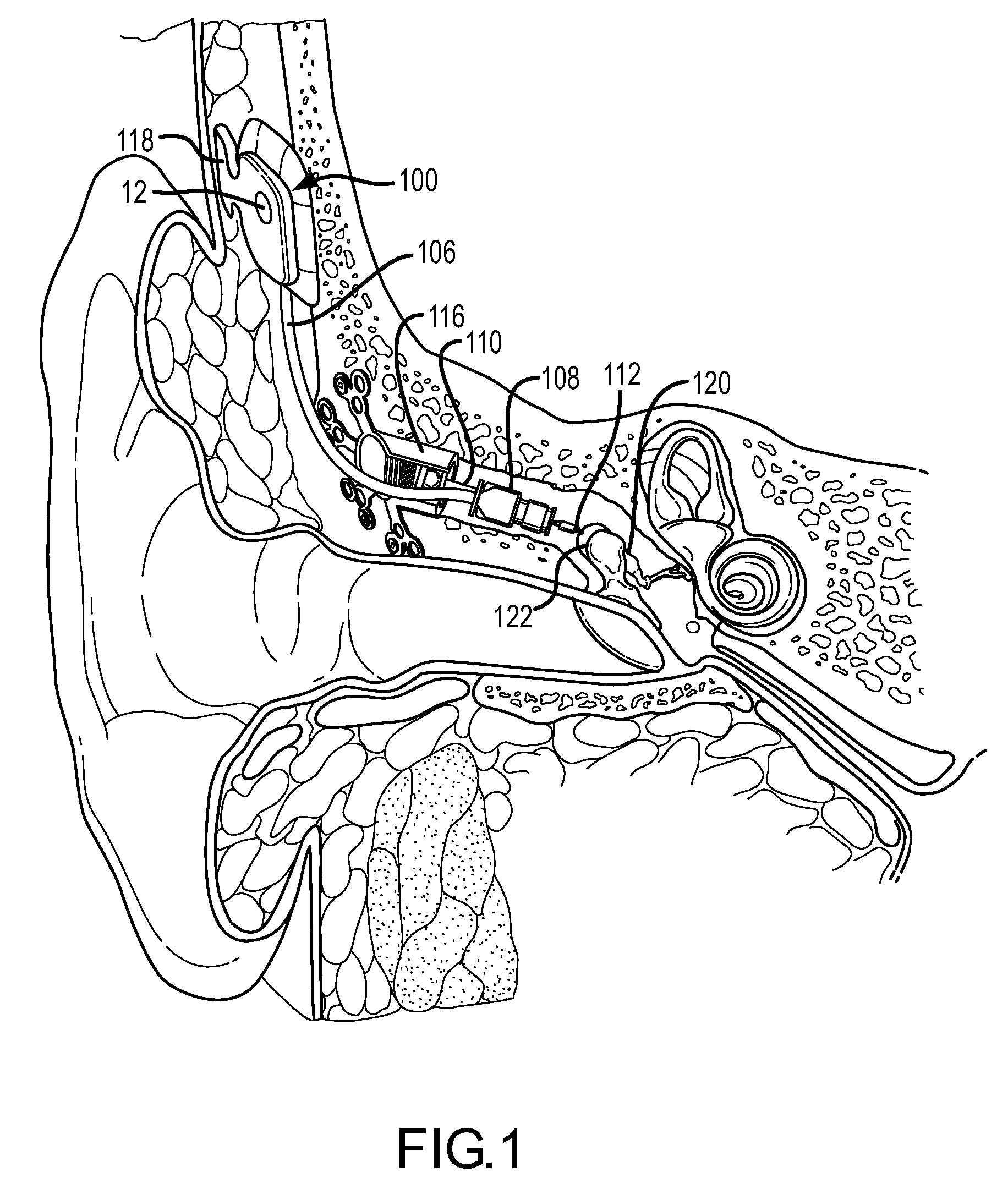

Dual feedback control system for implantable hearing instrument

InactiveUS7522738B2Easy to detectAccurate identificationImplantable hearing aidsElectrostatic transducersControl systemTransducer

Owner:COCHLEAR LIMITED

Optical waveguide vibration sensor for use in hearing aid

InactiveUS7444877B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesPolymer optical waveguideLoudspeaker

A directionally-sensitive device for detecting and processing vibration waves includes an array of polymeric optical waveguide resonators positioned between a light source, such as an LED array, and a light detector, such as a photodiode array. The resonators which are preferably oriented substantially perpendicularly with respect to incoming vibration waves, vibrate when a wave is detected, thus modulating light signals that are transmitted between the light source and the light detector. The light detector converts the modulated light into electrical signals which, in a preferred embodiment, are used to drive either the speaker of a hearing aid or the electrode array of a cochlear implant. The device is manufactured using a combination of traditional semiconductor processes and polymer microfabrication techniques.

Owner:RGT UNIV OF CALIFORNIA

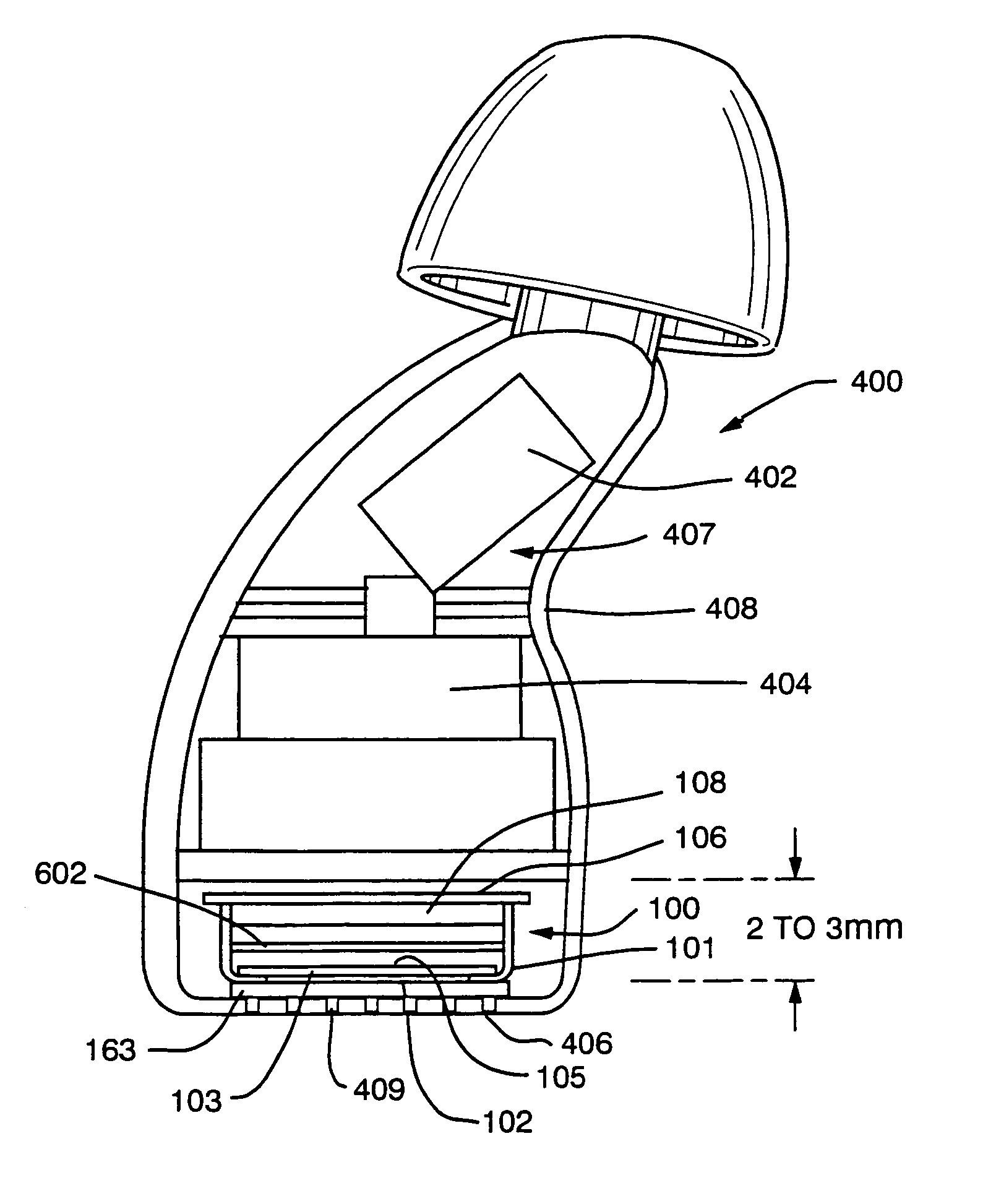

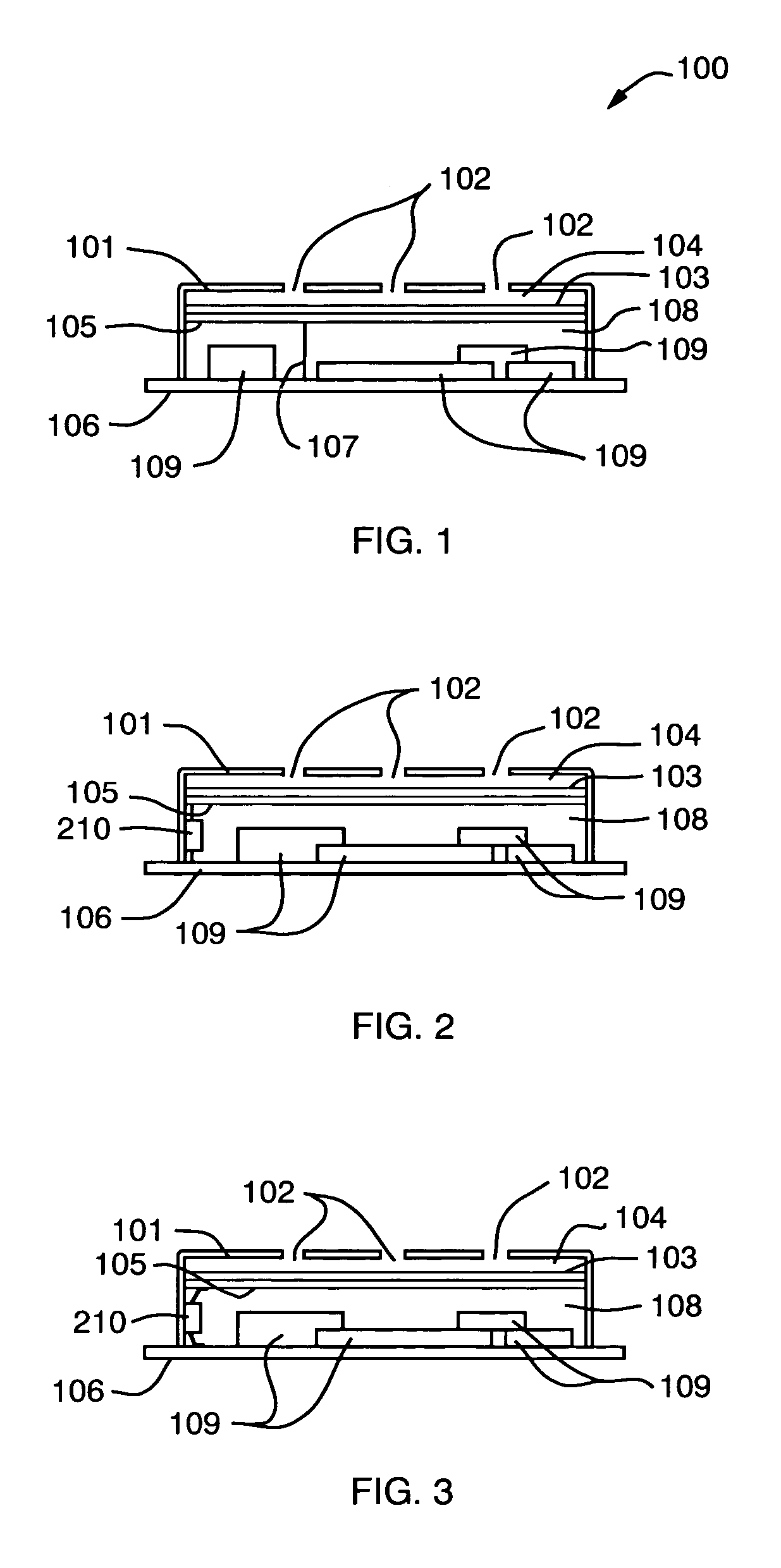

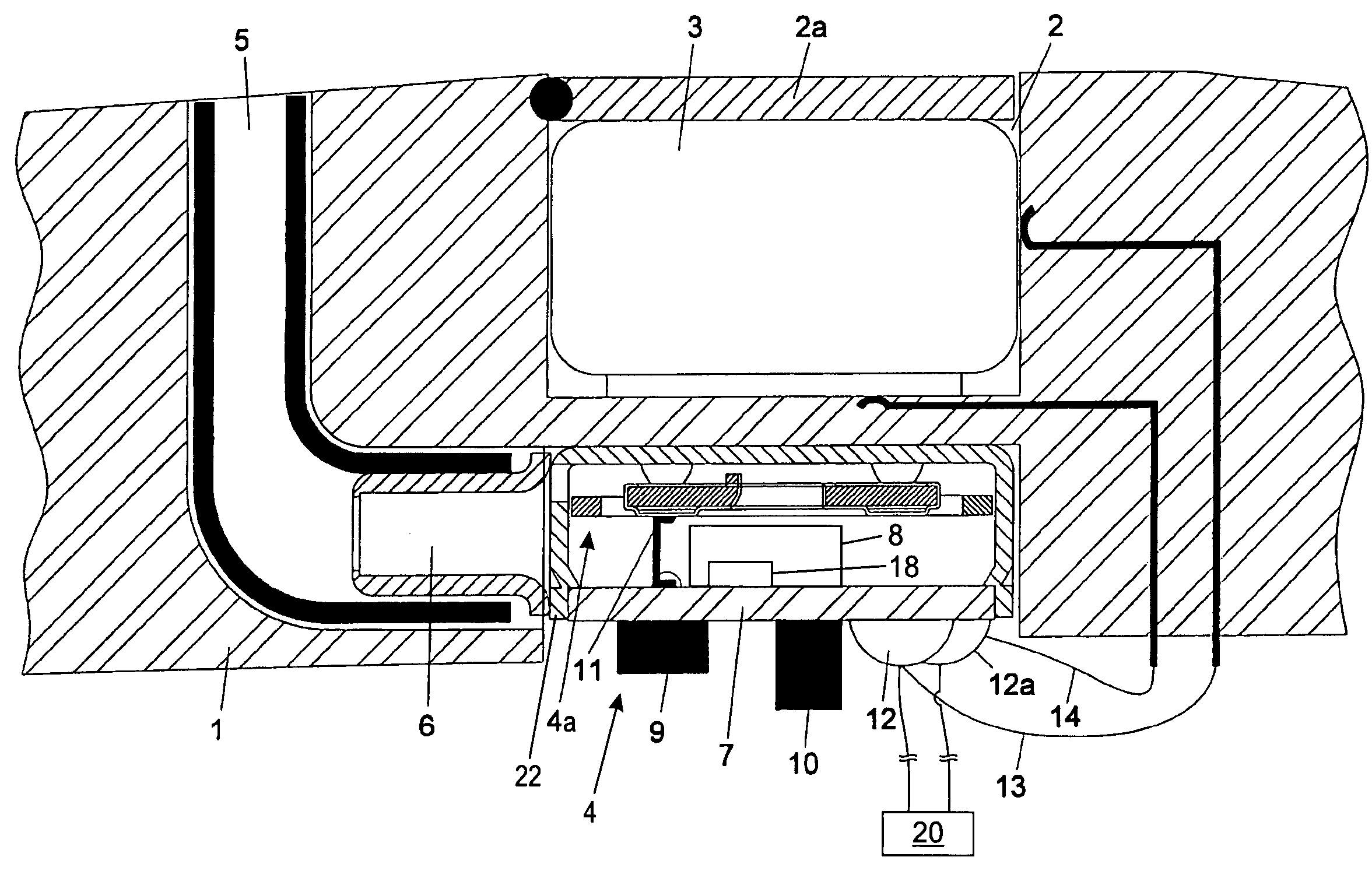

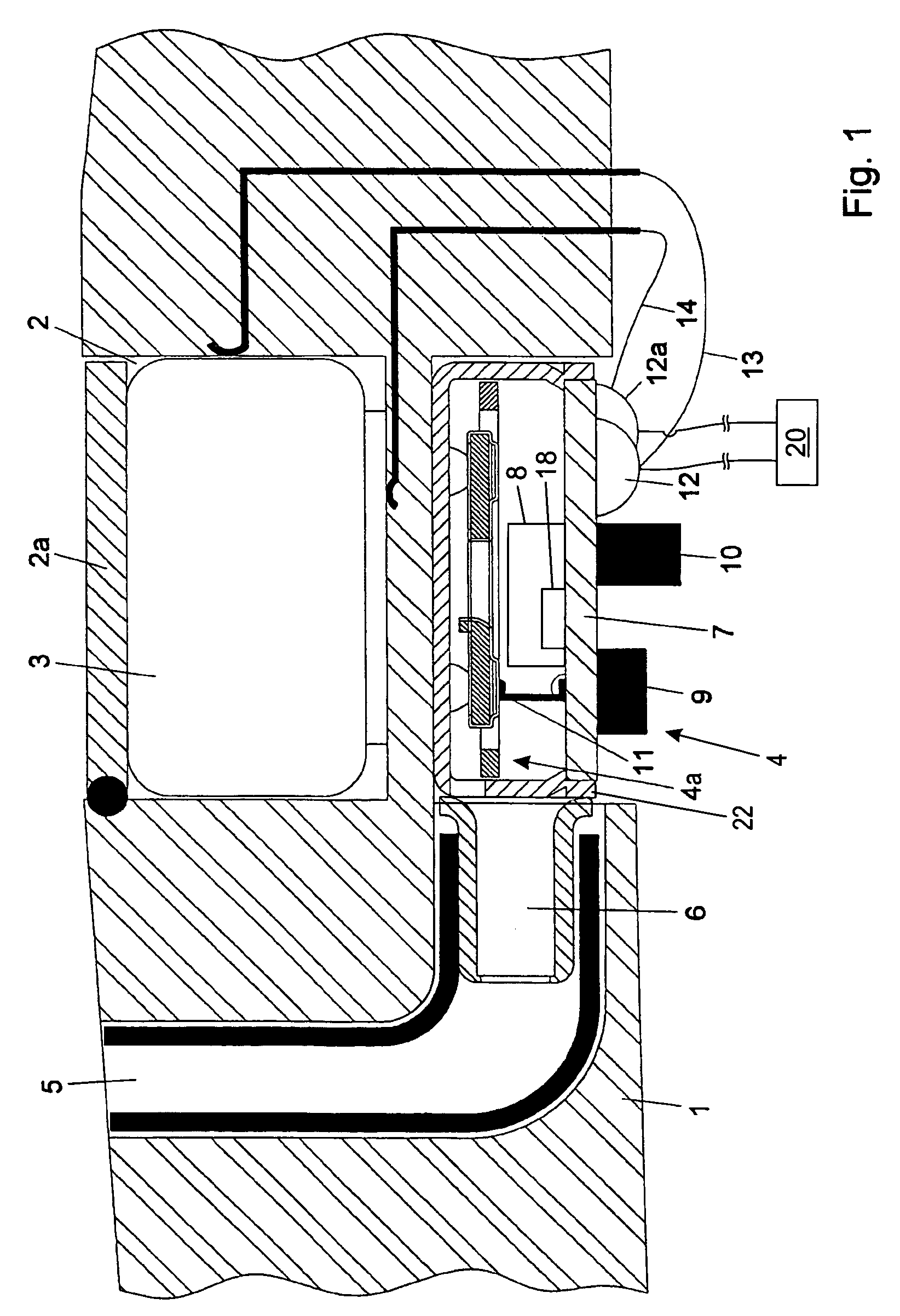

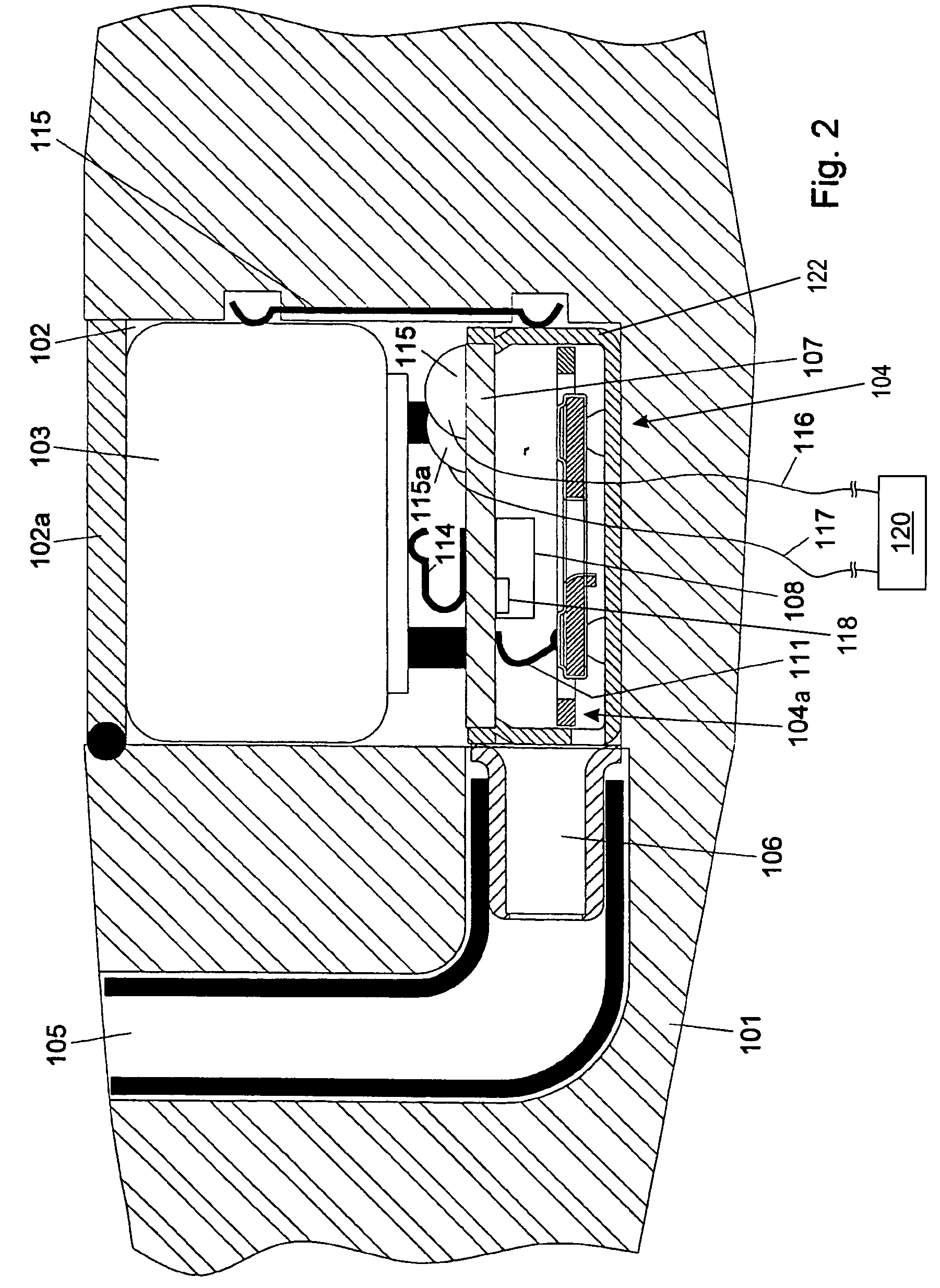

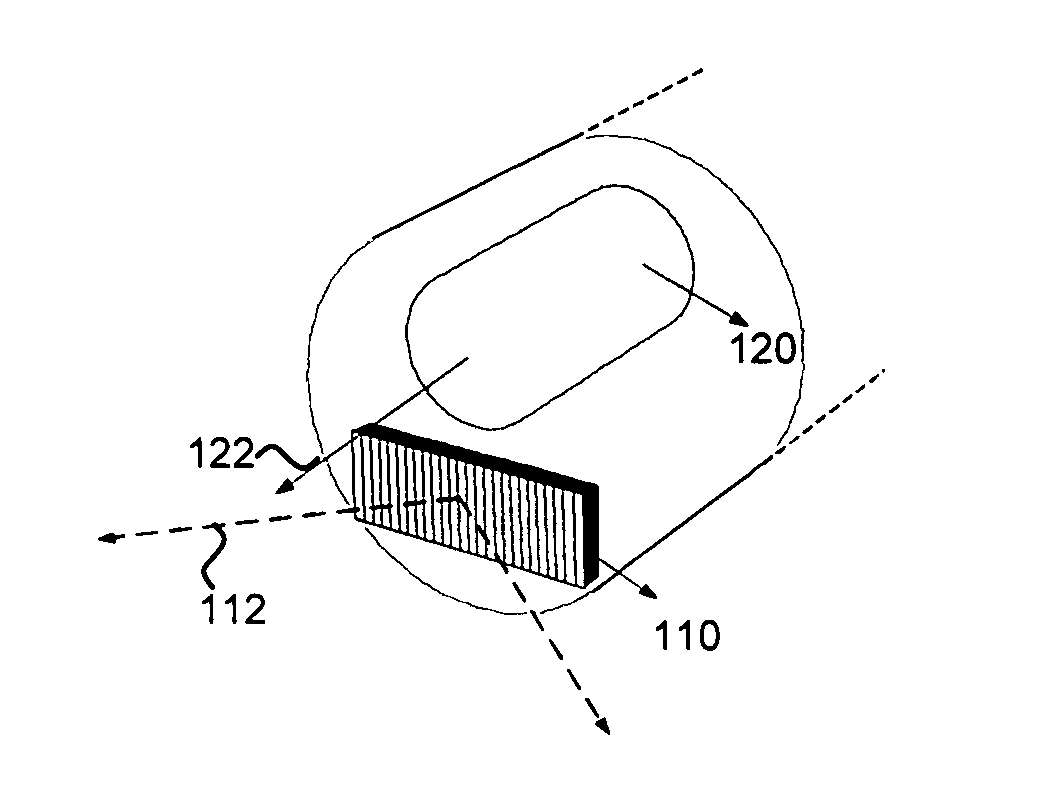

Microphone for a hearing aid

InactiveUS7292700B1Overcome disadvantagesElectrostatic transducersHearing aids housingAudio power amplifierTransducer

A microphone assembly having a housing, a transducer, and an electronic circuit. The housing has an opening, and the transducer is disposed within that opening. The electronic circuit covers the opening such that the transducer is surrounded by at least the electronic circuit and the housing. The electronic circuit includes a substrate and an amplifier for amplifying the electrical signal into an amplified electrical signal which is coupled to a connection means. The connection means provides a direct electrical connection between the electronic circuit and a receiver. The amplifier is mounted on the substrate and disposed on a side of the substrate of the electronic circuit facing the transducer. The receiver is disposed on a side opposite the side and outside the housing.

Owner:SONION NEDERLAND

Functional imaging using capacitive micromachined ultrasonic transducers

InactiveUS20070287912A1Increase working frequencyImprove imaging resolutionMaterial analysis using sonic/ultrasonic/infrasonic wavesDiagnostics using lightCapacitive micromachined ultrasonic transducersSonification

The present invention provides an apparatus for functional imaging of an object that is compact, sensitive, and provides real-time three-dimensional images. The apparatus includes a source of non-ultrasonic energy, where the source induces generation of ultrasonic waves within the object. The source can provide any type of non-ultrasonic energy, including but not limited to light, heat, microwaves, and other electromagnetic fields. Preferably, the source is a laser. The apparatus also includes a single capacitive micromachined ultrasonic transducer (CMUT) device or an array of CMUTs. In the case of a single CMUT element, it can be mechanically scanned to simulate an array of any geometry. Among the advantages of CMUTs are tremendous fabrication flexibility and a typically wider bandwidth. Transducer arrays with high operating frequencies and with nearly arbitrary geometries can be fabricated. A method of functional imaging using the apparatus is also provided.

Owner:BOARD OF TRUSTEES OF THE LELAND STANFORD JNIOR UNIV THE

Electrical through wafer interconnects

InactiveUS6836020B2Reduce capacitanceLower resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDepletion region

A wafer with through wafer interconnects. The wafer includes spaced through wafer vias which extend between the back side and front side of the wafer. A conductor within each of said vias connects to front and back side pads. Functions associated with said conductor and said pads provide a depletion region in the wafer between the pads and wafer or pads and conductor and the wafer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

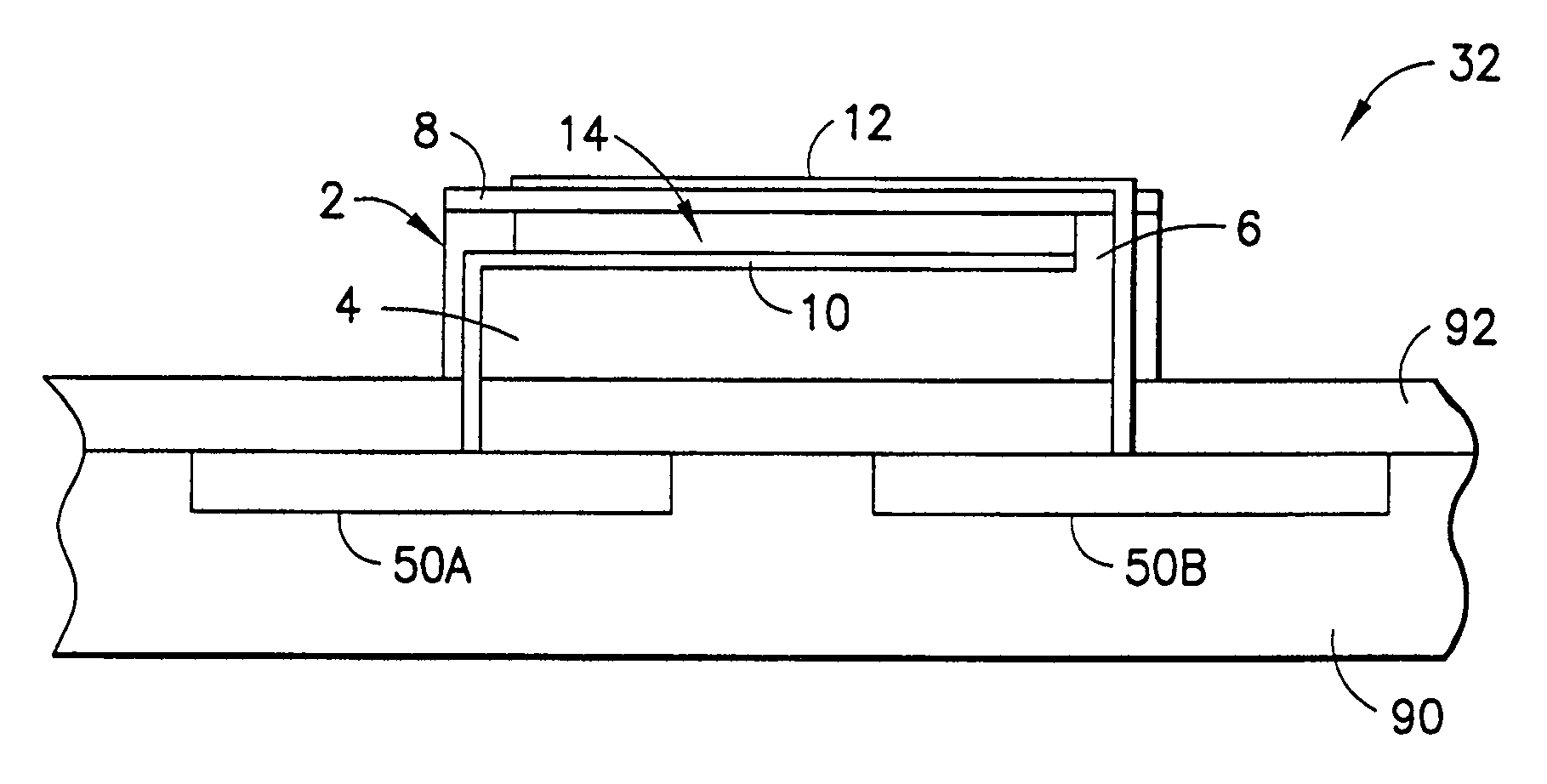

Method of manufacturing ultrasound transducer device having acoustic backing

InactiveUS20050046311A1Ultrasonic/sonic/infrasonic diagnosticsElectrical testingSonificationAcoustic energy

An ultrasonic transducer device comprising: an ultrasonic transducer array micromachined on a substrate; flexible electrical connections connected to the transducer array; and a body of acoustically attenuative material that supports the substrate and the flexible electrical connections. The acoustic backing material may contain additional features, such as tabs or notches, for use in positioning the transducer on fixtures during manufacturing or positioning the transducer within a housing during final assembly. Tabs or other features that are used only during manufacturing may be subsequently removed from the device. The MUT device itself may also be thinned so as to provide flexibility as desired. The backing material is preferably matched in acoustic impedance to the silicon wafer so as to prevent reflection at the interface of any acoustic energy propagating rearward, i.e., in the direction away from the device front surface. The backing material may also possess a high thermal conductivity to assist in removal of heat from the device.

Owner:GENERAL ELECTRIC CO

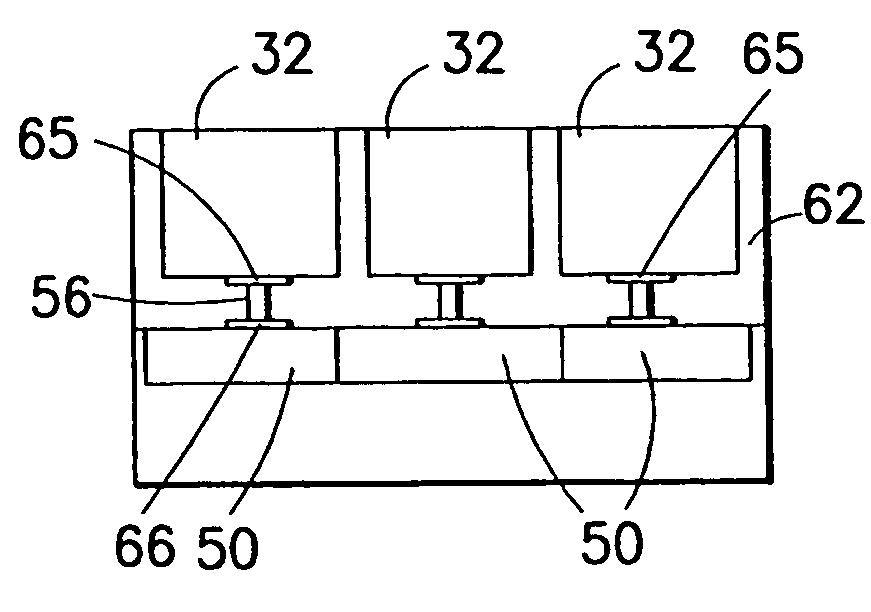

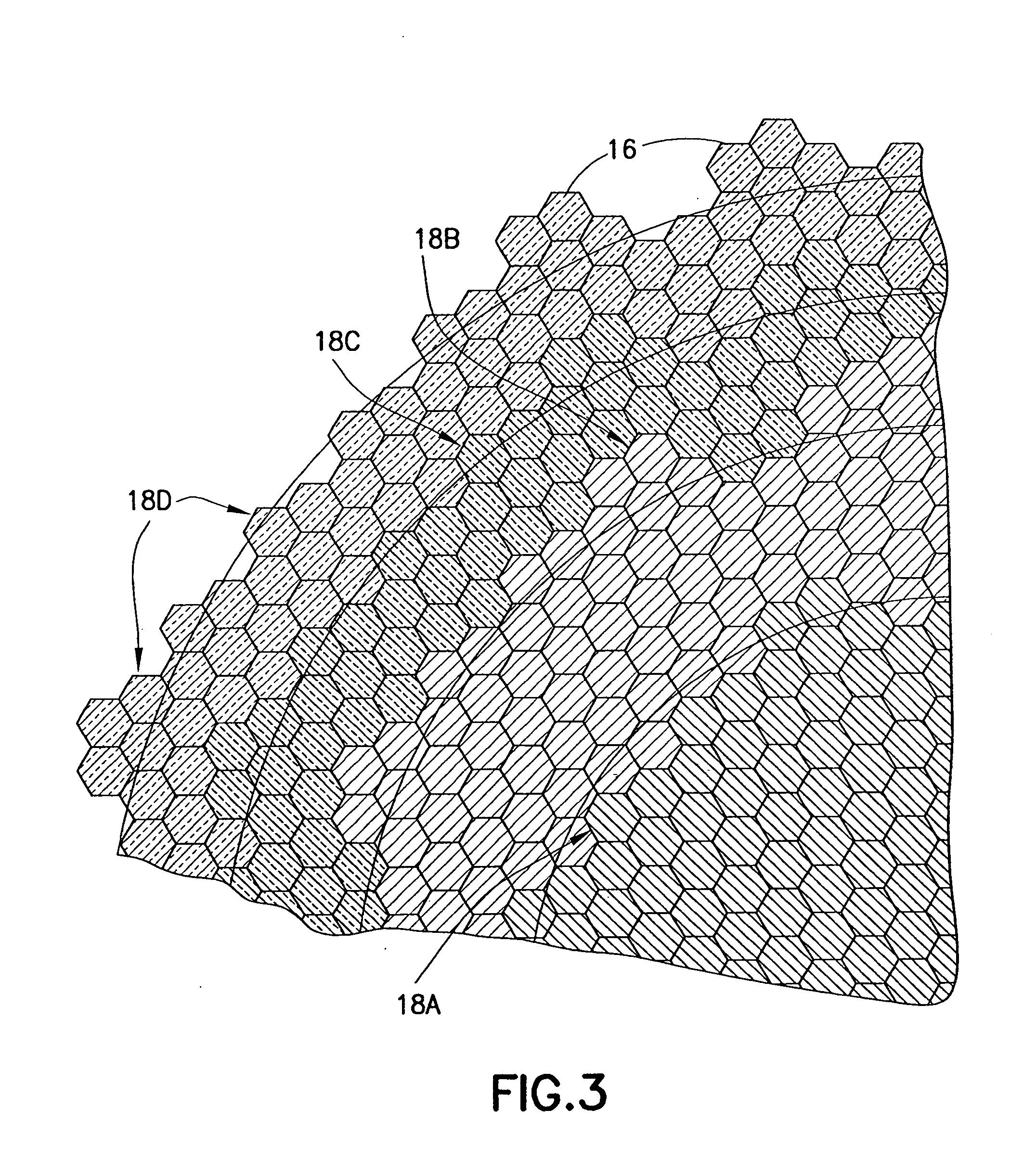

Integrated interface electronics for reconfigurable sensor array

ActiveUS20050094490A1Quickly reconfiguredUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricitySensor array

An integrated switch matrix for reconfiguring subelements of a mosaic sensor array to form elements. The configuration of the switch matrix is fully programmable. The switch matrix includes access switches that connect subelements to bus lines and matrix switches that connect subelements to subelements. Each subelement has a unit switch cell comprising at least one access switch, at least one matrix switch, a respective memory element for storing the future state of each switch, and a respective control circuit for each switch. The access and matrix switches are of a type having the ability to memorize control data representing the current switch state of the switch, which control data includes a data bit input to turn-on / off circuits incorporated in the control circuit. The sensor array and the switching matrix may be built in different strata of a co-integrated structure or they may be built on separate wafers that are electrically connected. If the sensors are arranged on a hexagonal grid, the unit switch cells may be arranged on either a hexagonal or rectangular grid.

Owner:GENERAL ELECTRIC CO

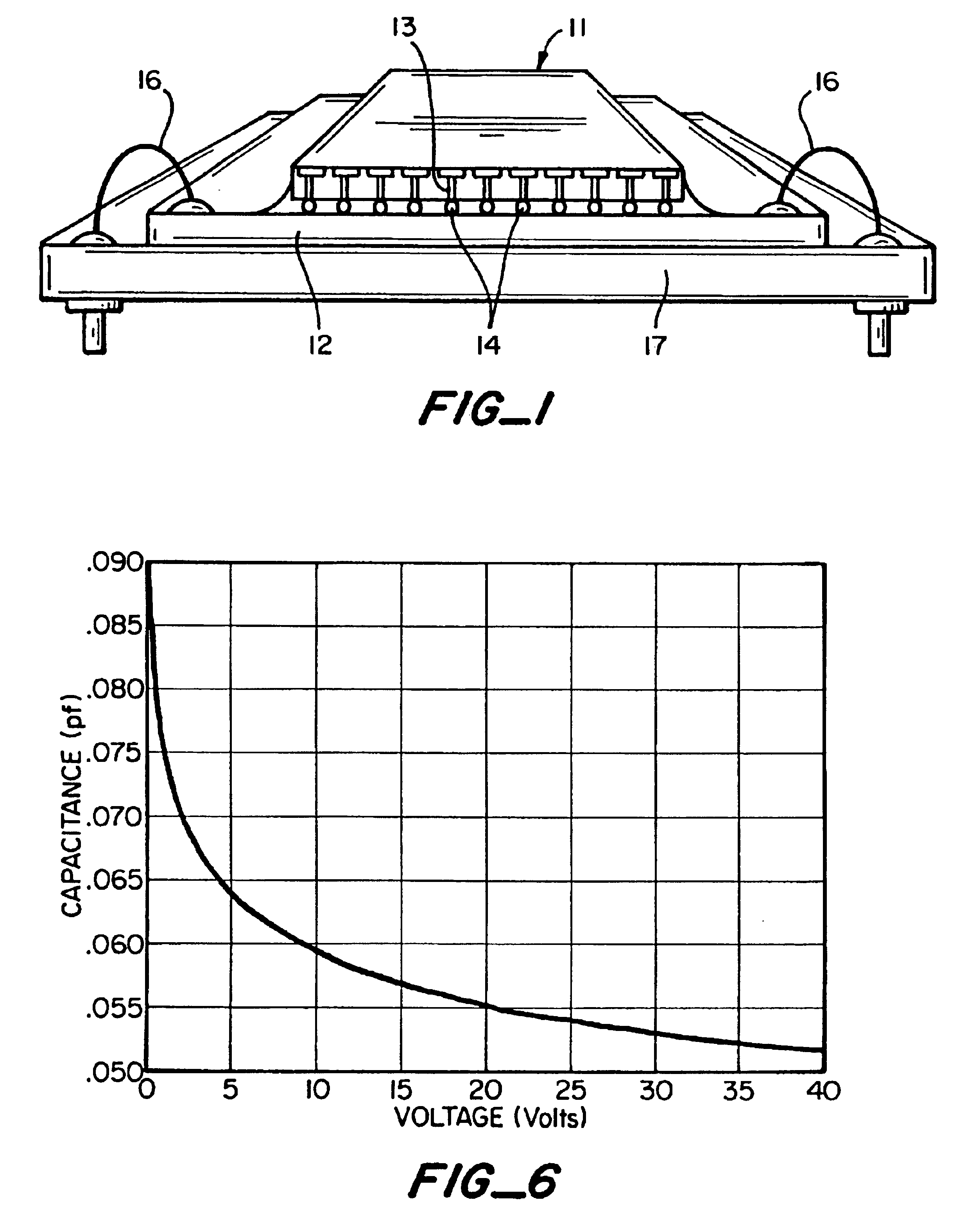

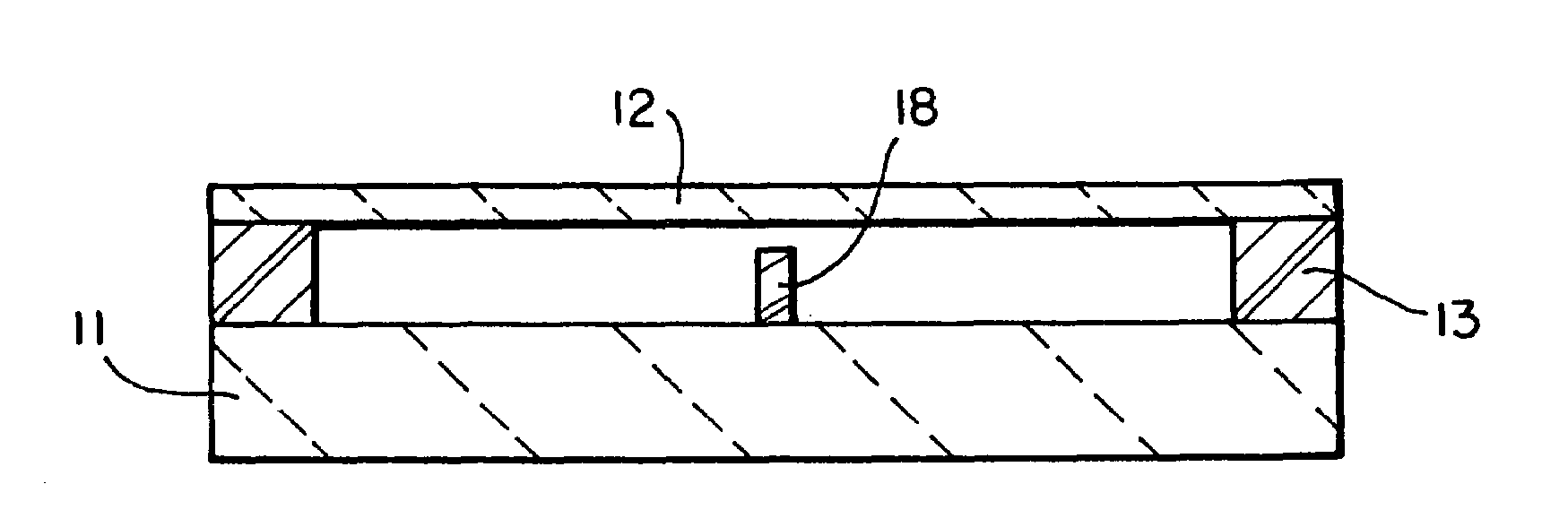

Capacitive ultrasonic transducers with isolation posts

InactiveUS7530952B2Resists deflectionMinimize the numberUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic sensorIsolation layer

A capacitive ultrasonic transducer is described which include one or more cells including a cavity defined by a membrane electrode supported spaced from a support electrode by insulating walls with a patterned isolation layer having isolation posts or areas located in said cavity to prevent the electrodes for coming into contact during operation of the transducer, and to minimize the accumulation of charge as compared to a non-patterned isolation layer for preventing contact of the electrodes during operation of the transducer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com