Patents

Literature

83 results about "PMUT" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piezoelectric Micromachined Ultrasonic Transducers (PMUT) are MEMS-based piezoelectric ultrasonic transducers. Unlike bulk piezoelectric transducers which use the thickness-mode motion of a plate of piezoelectric ceramic such as PZT or single-crystal PMN-PT, PMUT are based on the flexural motion of a thin membrane coupled with a thin piezoelectric film, such as PVDF. In comparison with bulk piezoelectric ultrasound transducers, PMUT can offer advantages such as increased bandwidth, flexible geometries, natural acoustic impedance match with water, reduced voltage requirements, mixing of different resonant frequencies and potential for integration with supporting electronic circuits especially for miniaturized high frequency applications.

Micromachined ultrasonic transducers and method of fabrication

InactiveUS20040085858A1Decorative surface effectsSemiconductor/solid-state device manufacturingPMUTSilicon nitride

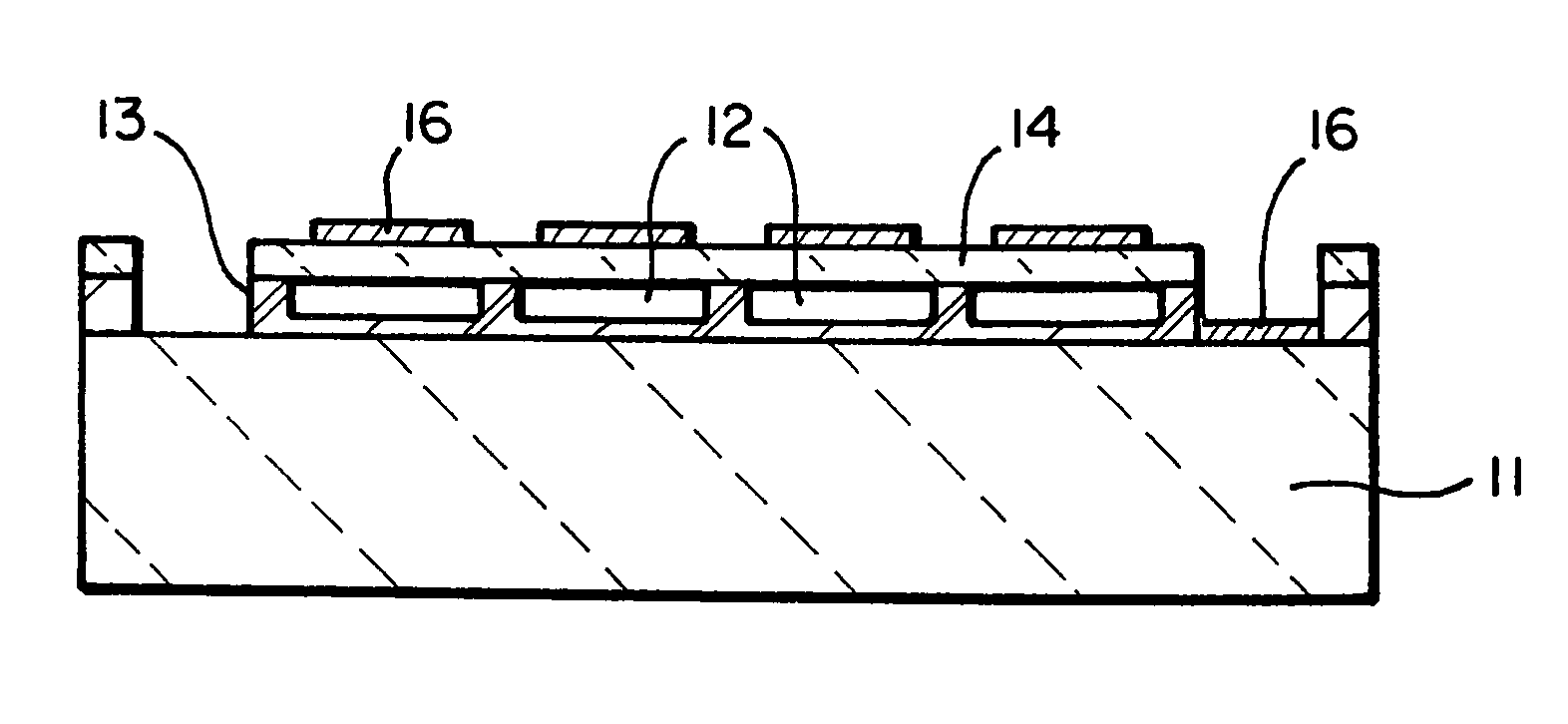

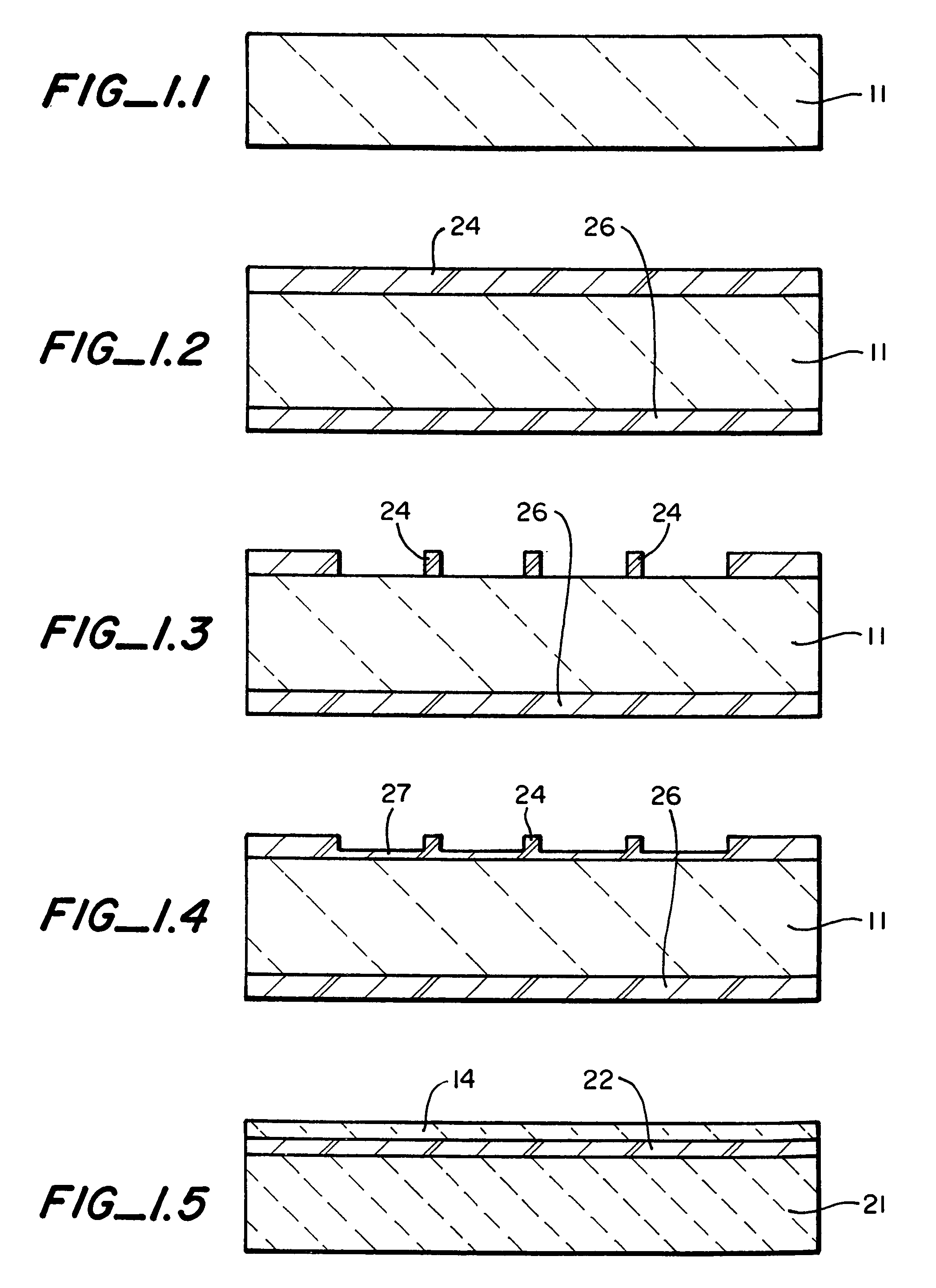

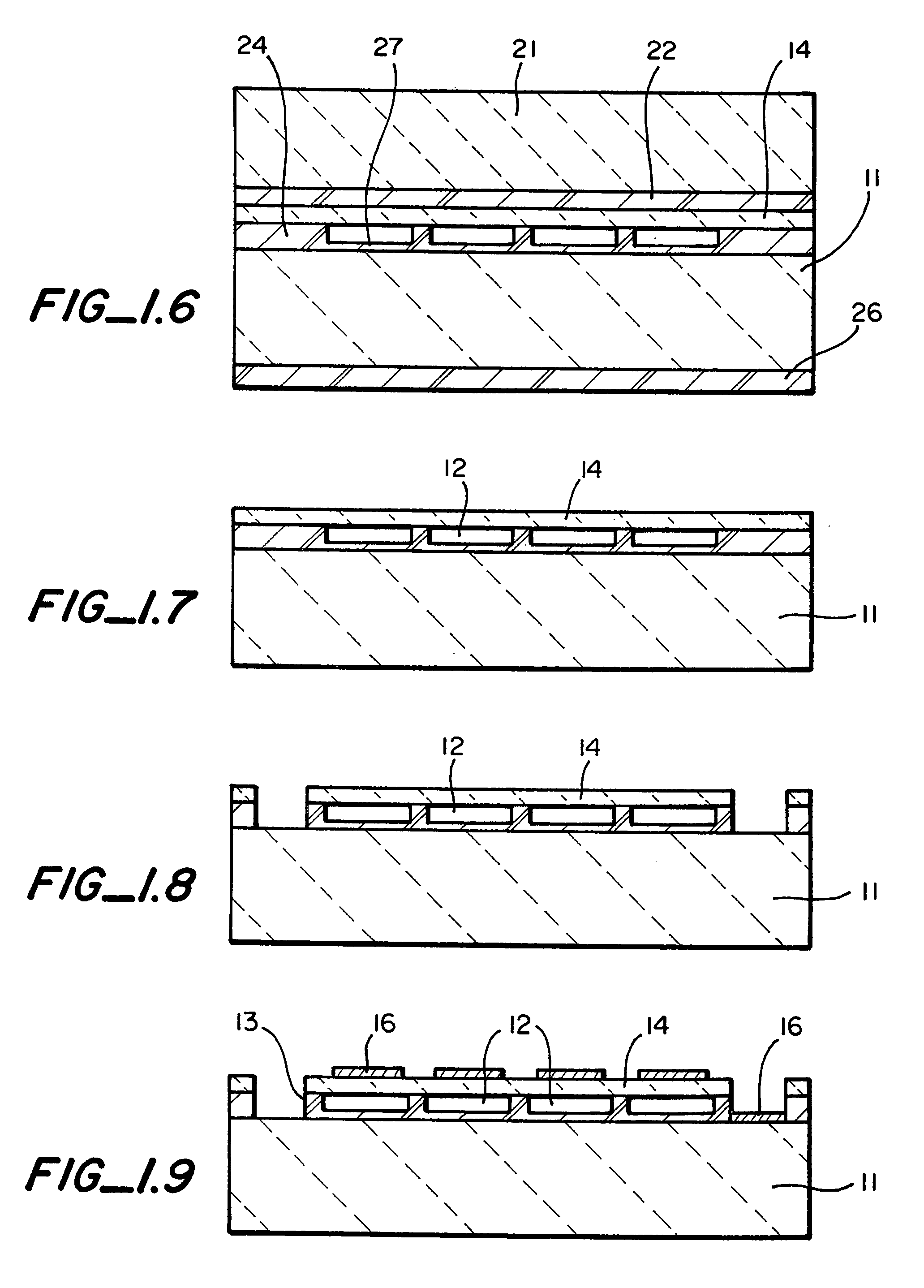

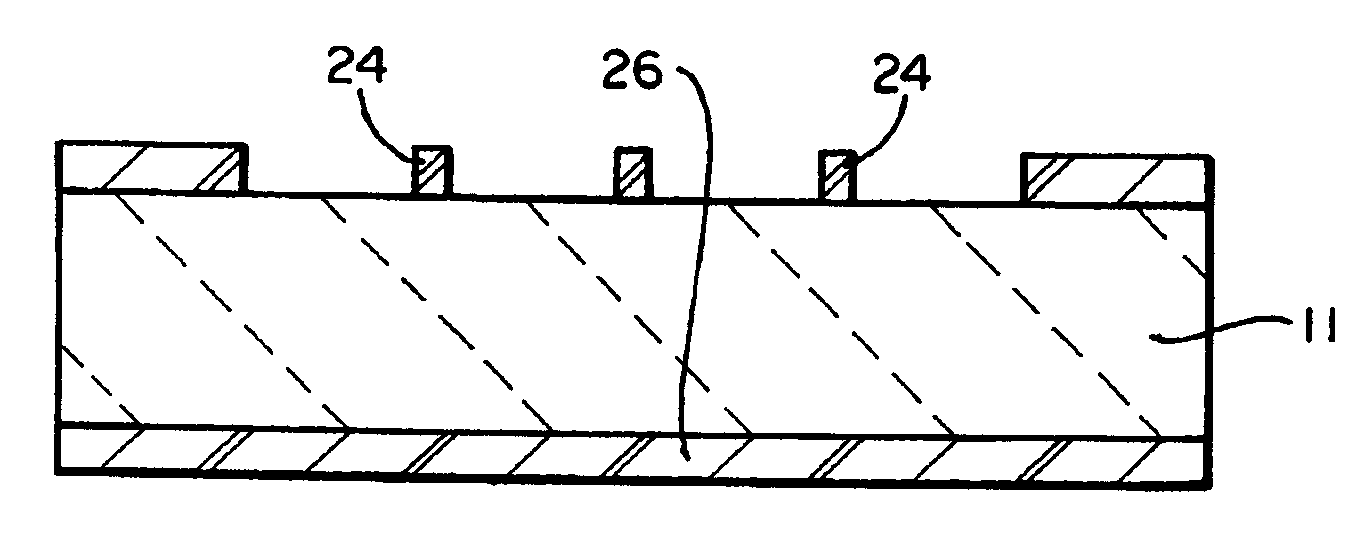

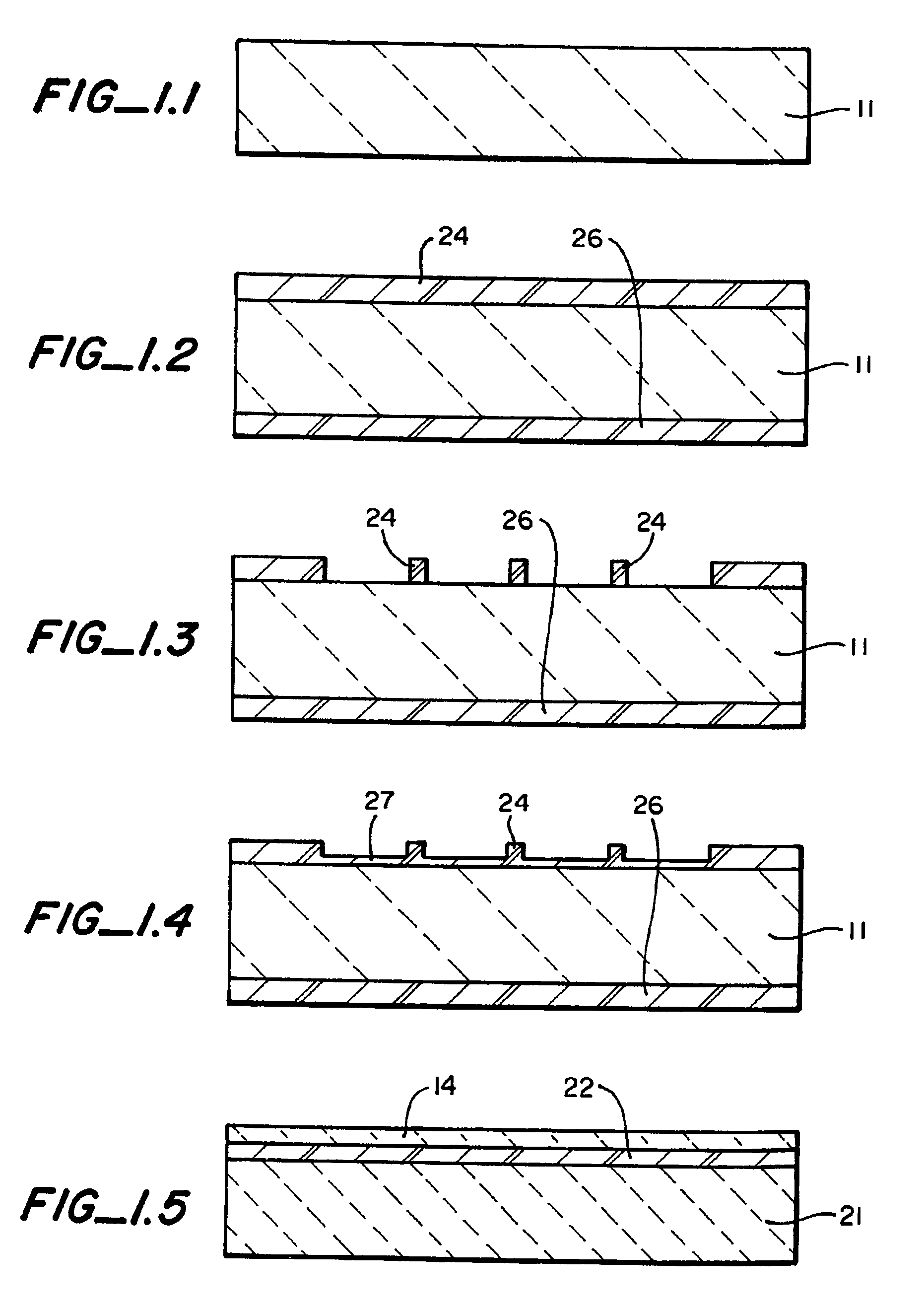

There is described a micromachined ultrasonic transducers (MUTS) and a method of fabrication. The membranes of the transducers are fusion bonded to cavities to form cells. The membranes are formed on a wafer of sacrificial material. This permits handling for fusions bonding. The sacrificial material is then removed to leave the membrane. Membranes of silicon, silicon nitride, etc. can be formed on the sacrificial material. Also described are cMUTs, pMUTs and mMUTs.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Micromachined ultrasonic transducers and method of fabrication

InactiveUS6958255B2Piezoelectric/electrostrictive device manufacture/assemblySubsonic/sonic/ultrasonic wave measurementPMUTSilicon nitride

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

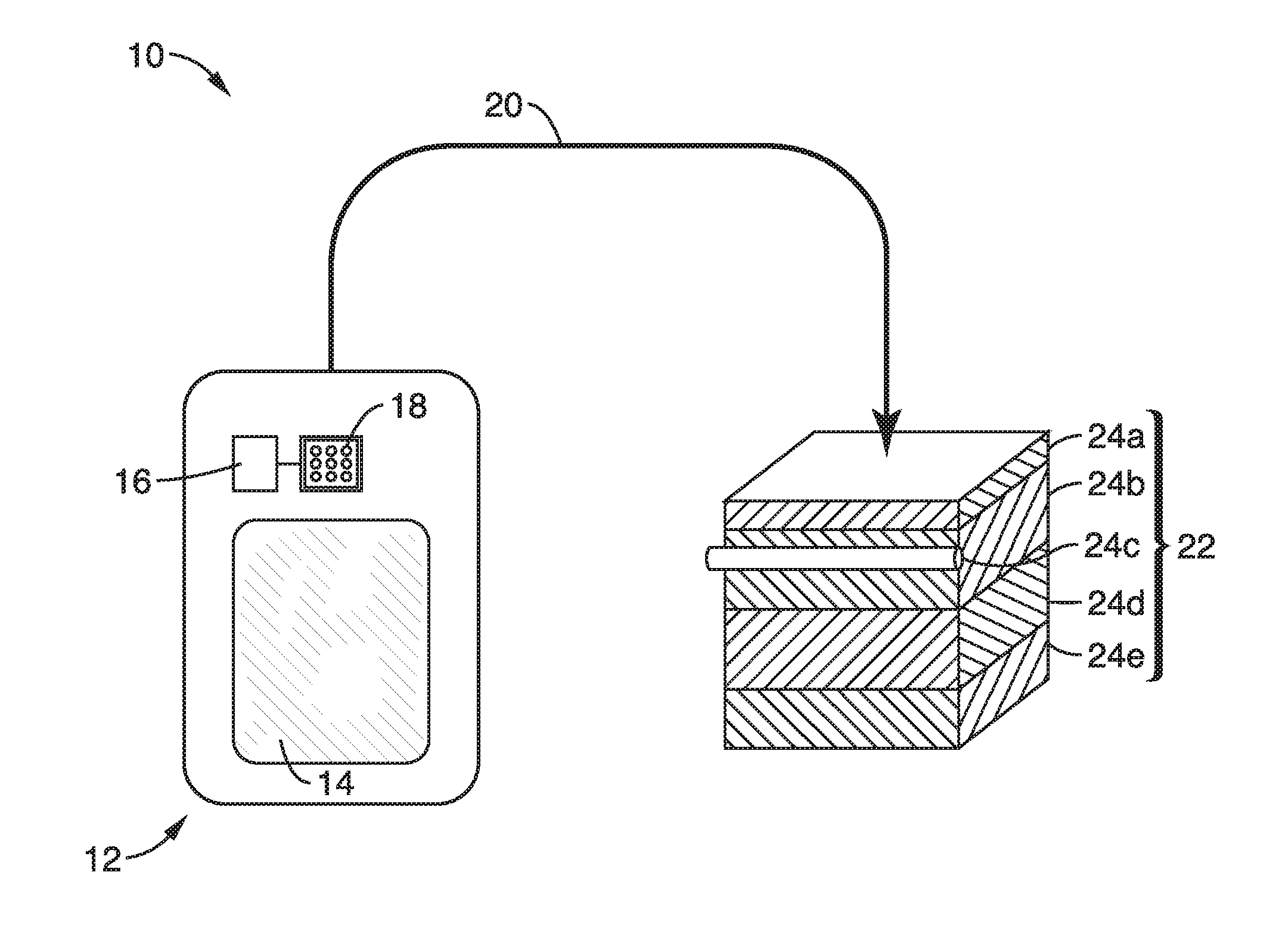

Curved micromachined ultrasonic transducer arrays and related methods of manufacture

ActiveUS20050146247A1Ultrasonic/sonic/infrasonic diagnosticsFixed microstructural devicesPMUTEngineering

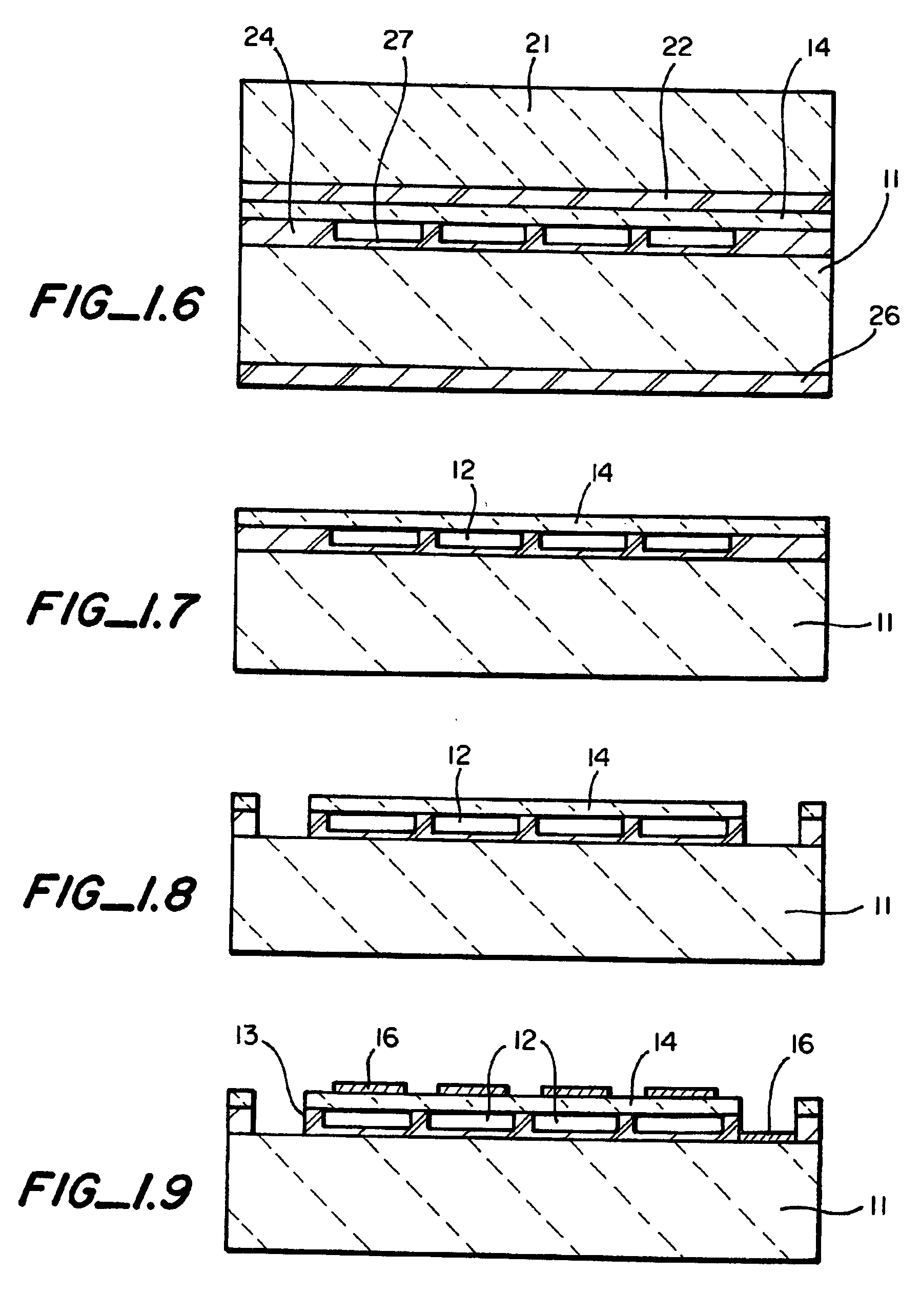

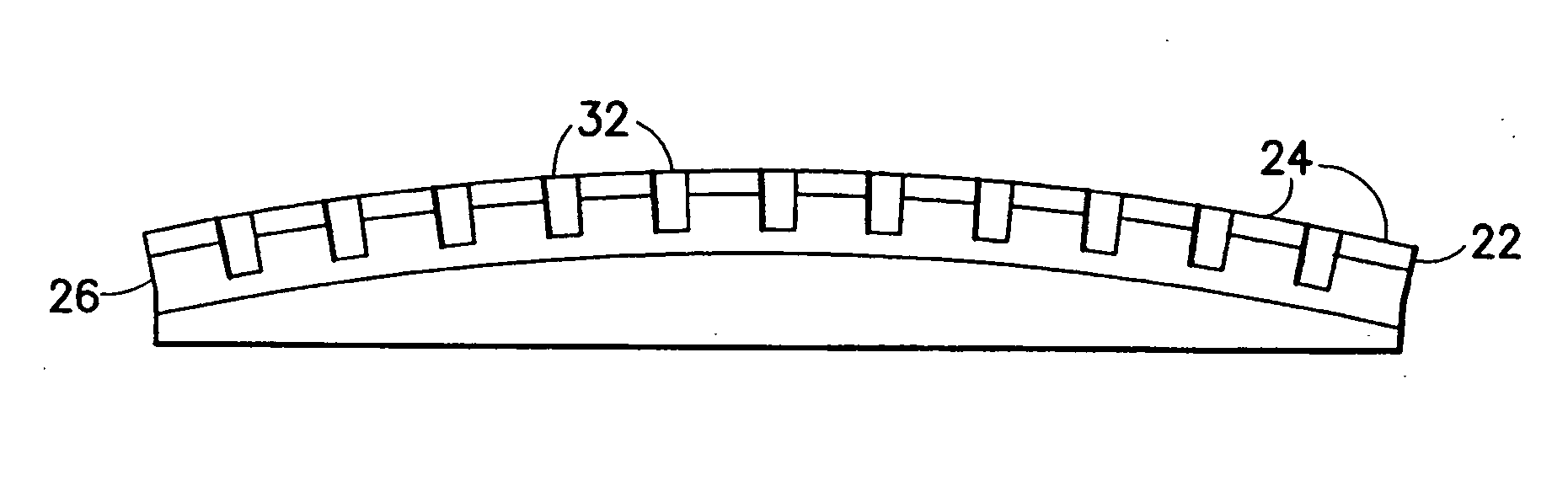

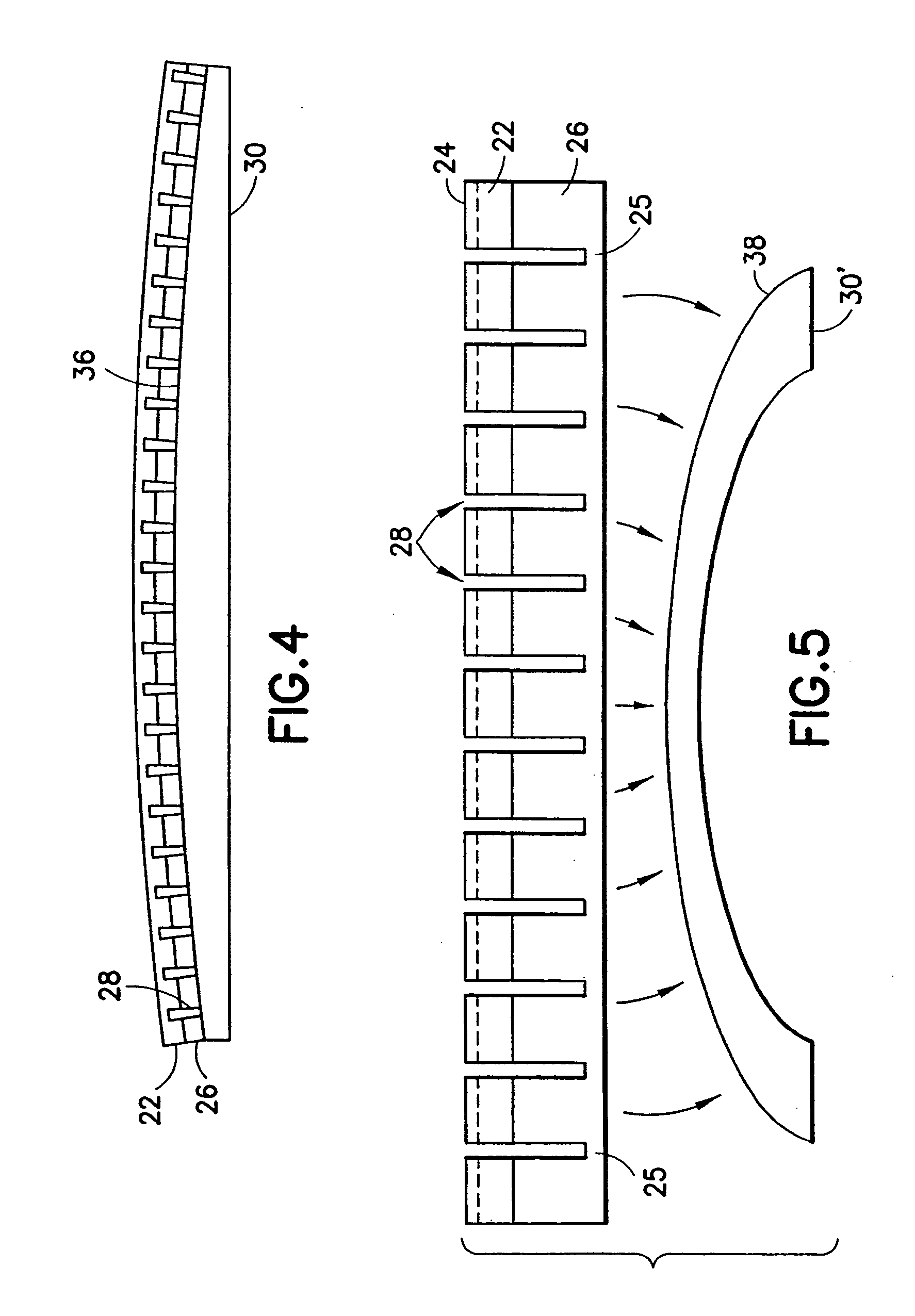

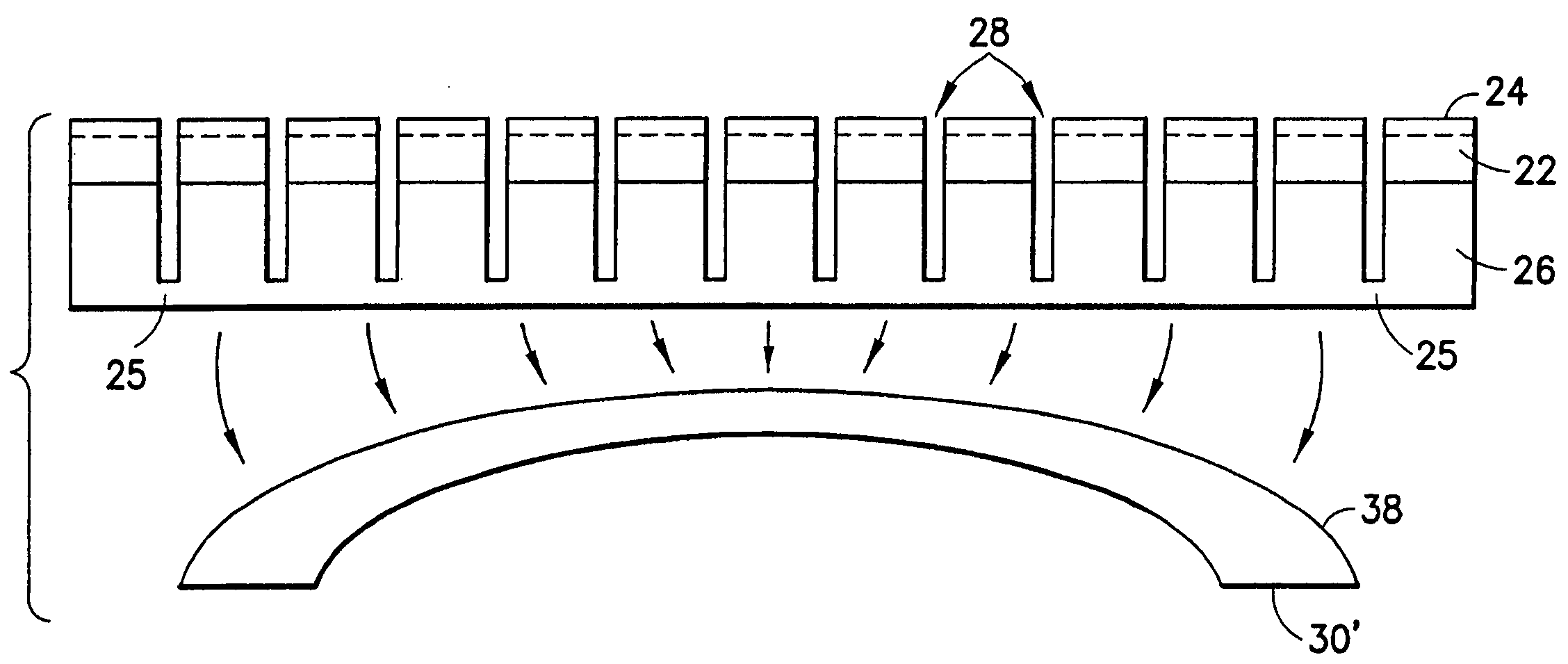

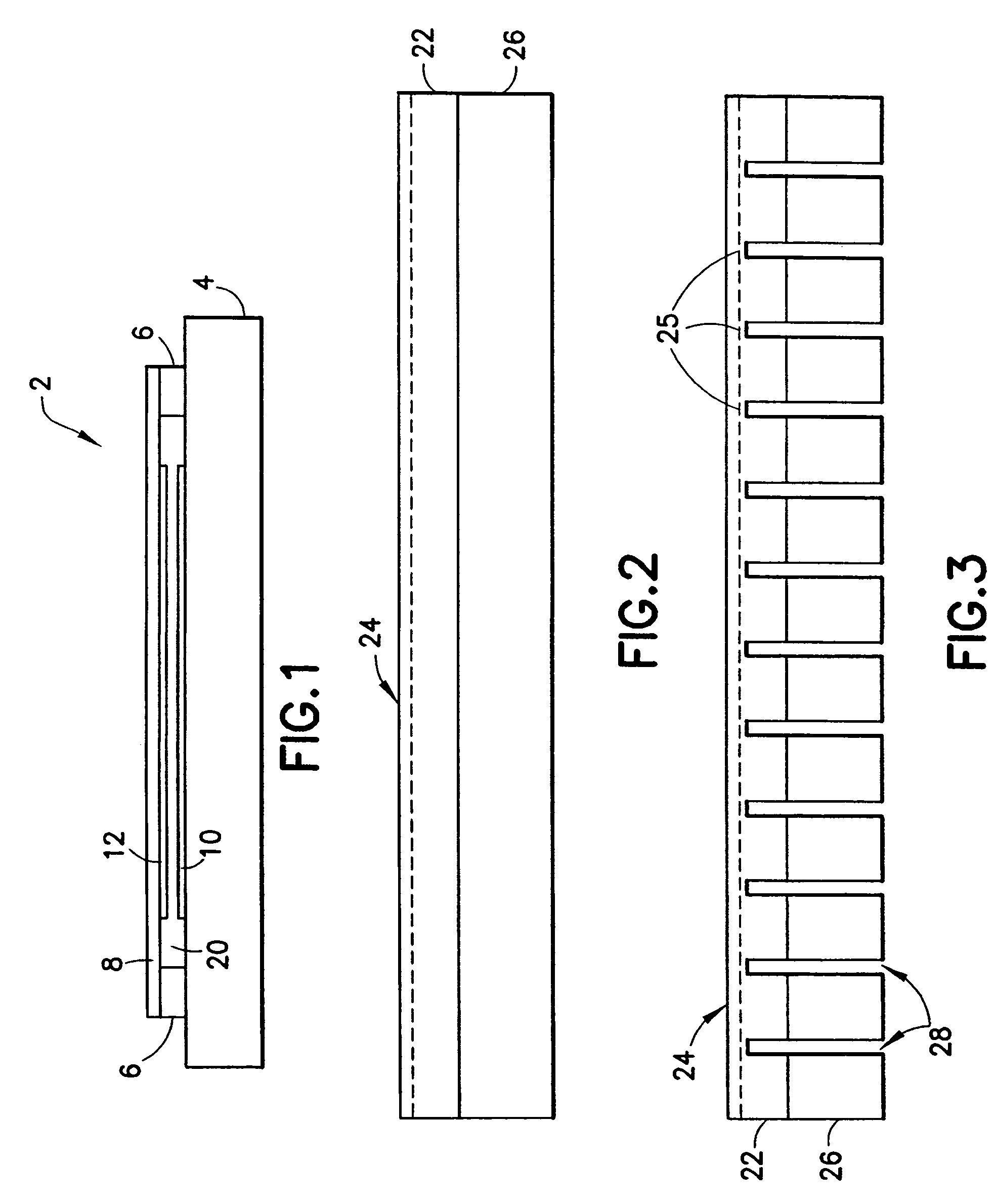

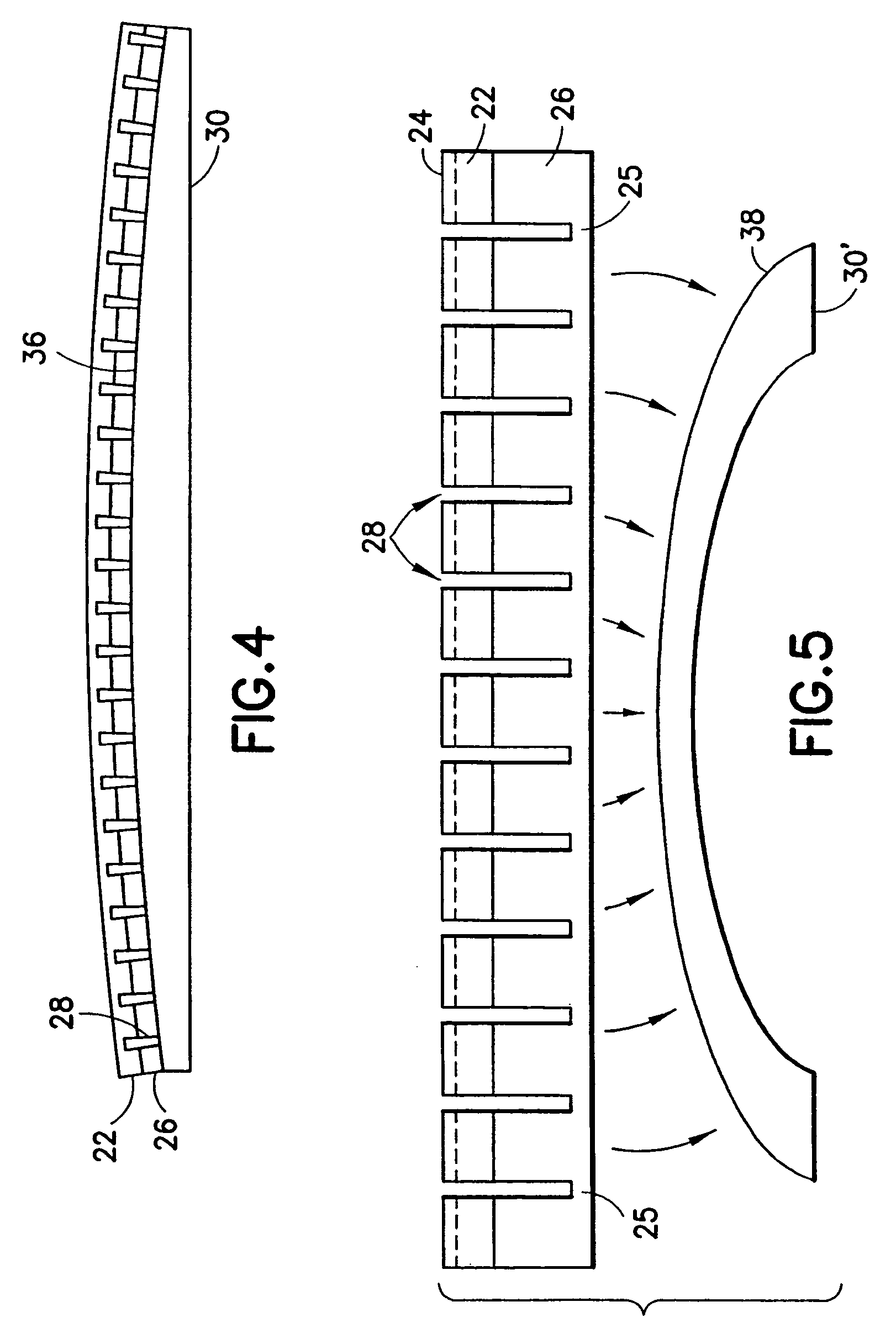

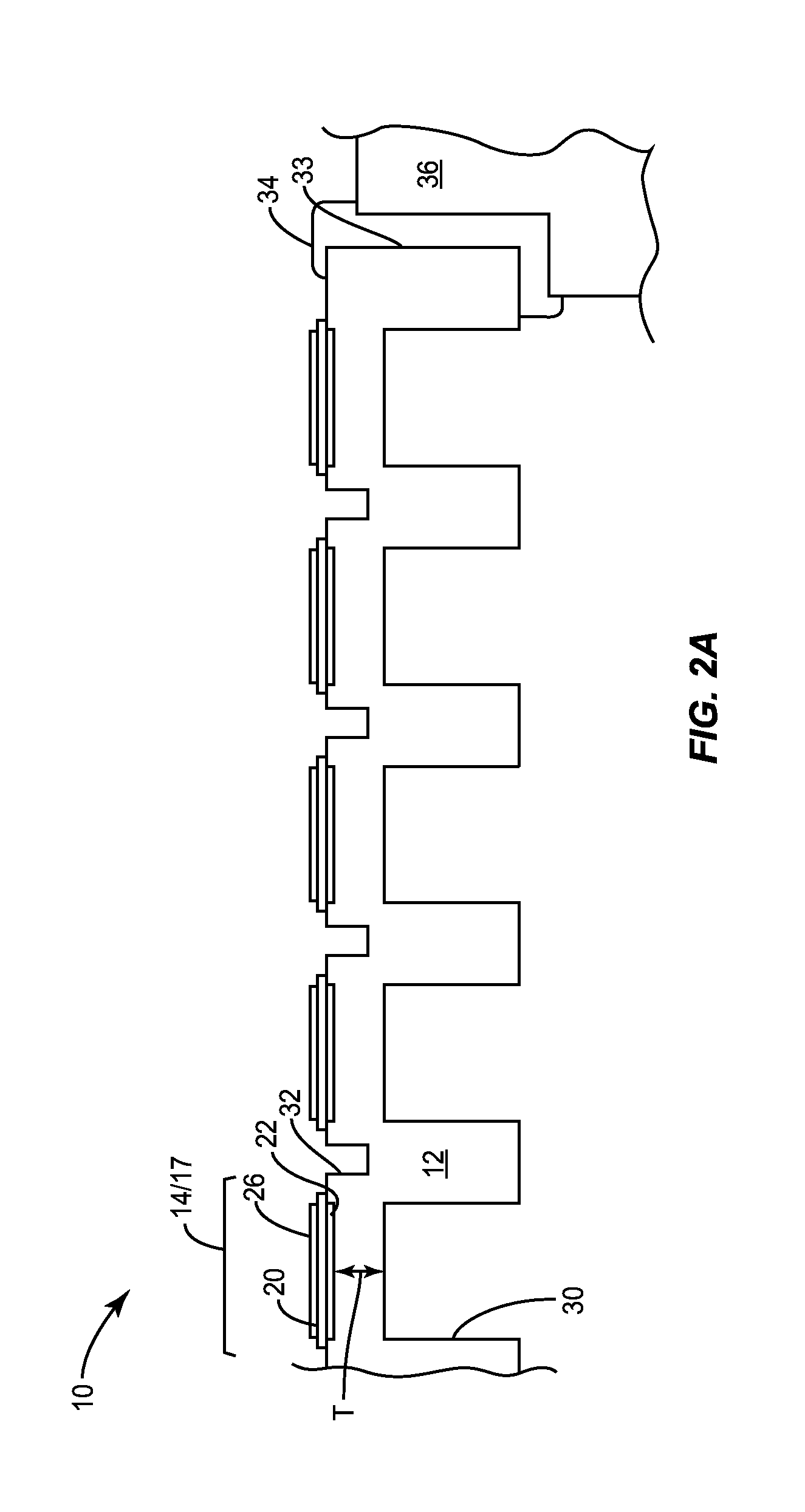

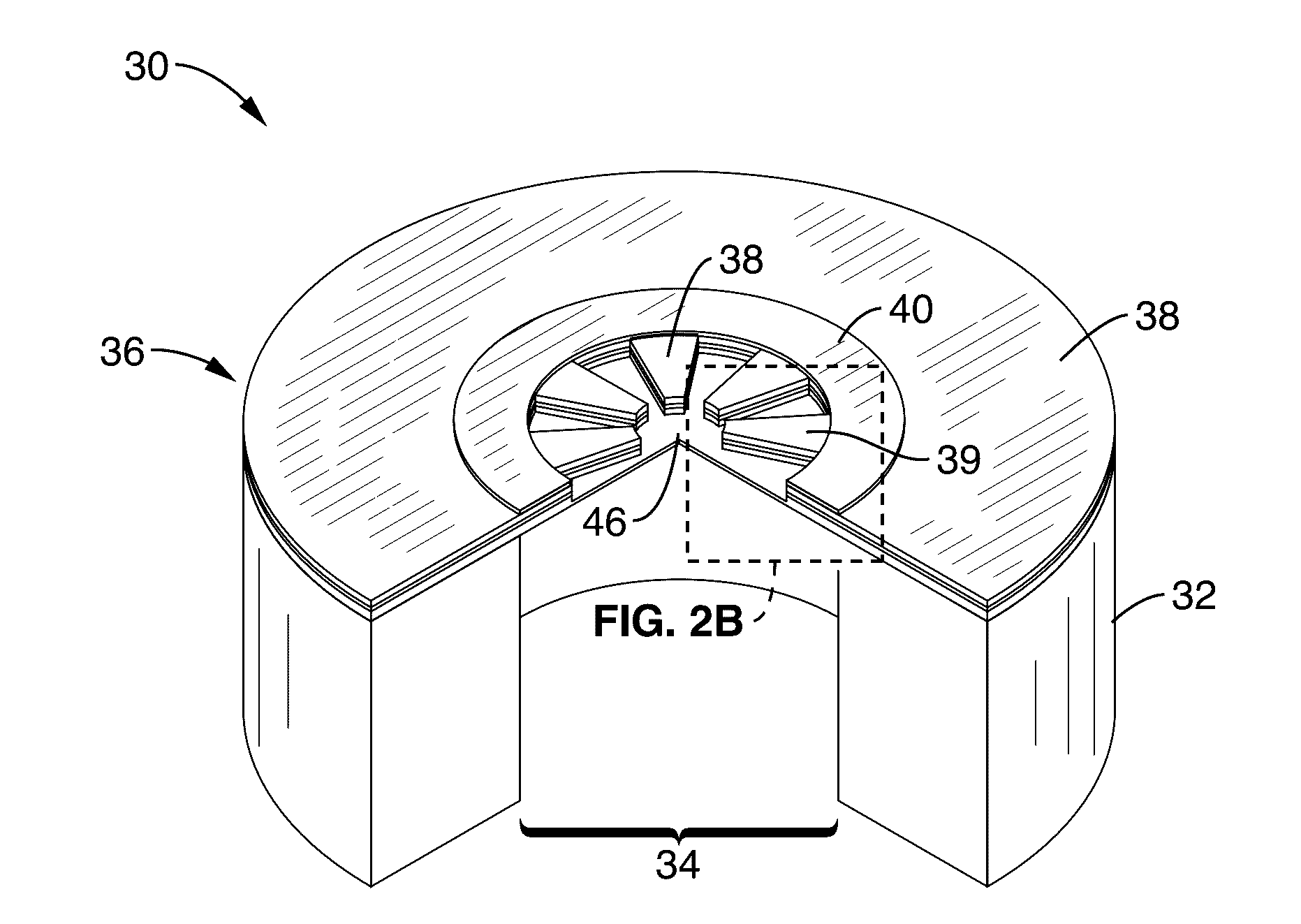

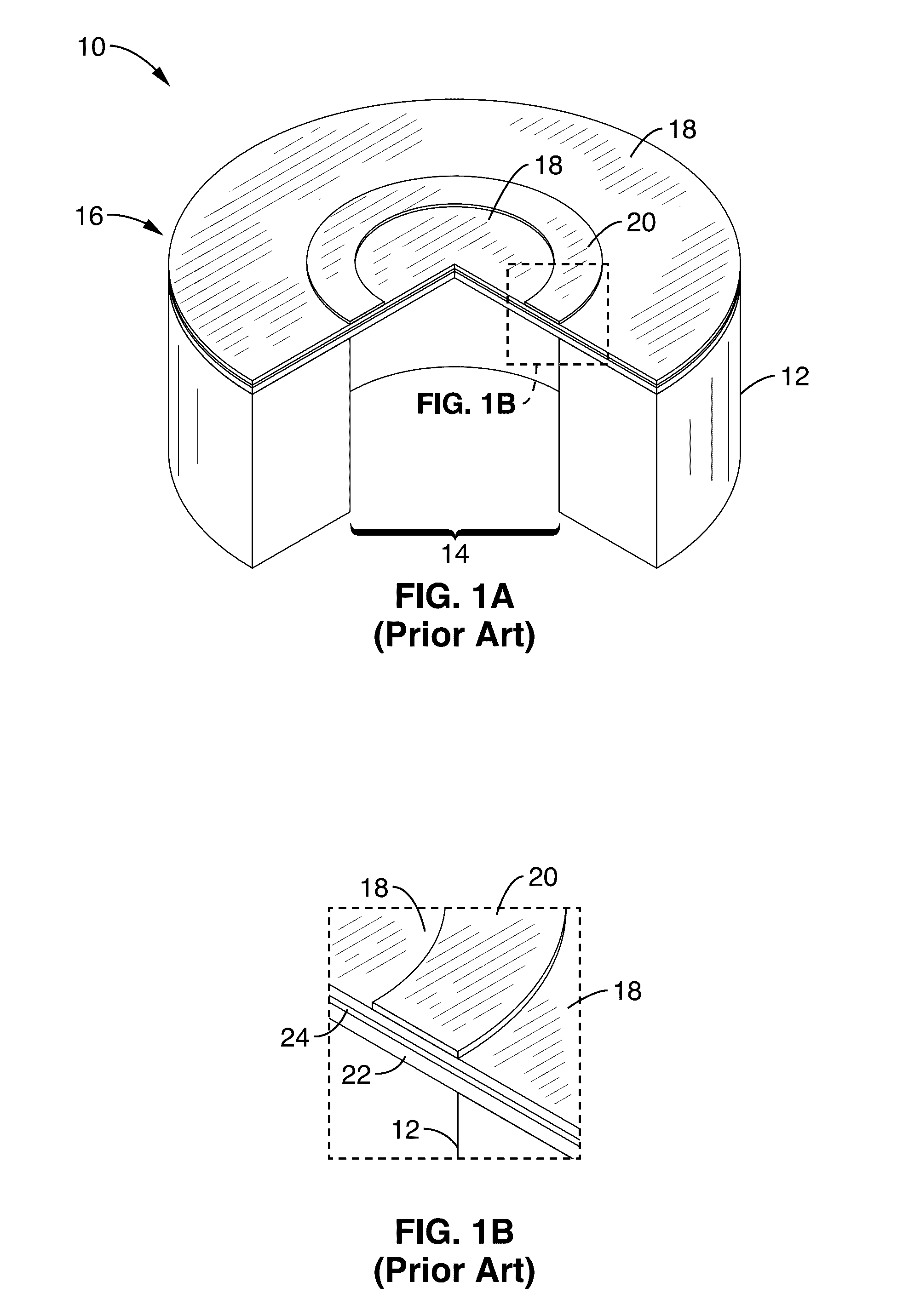

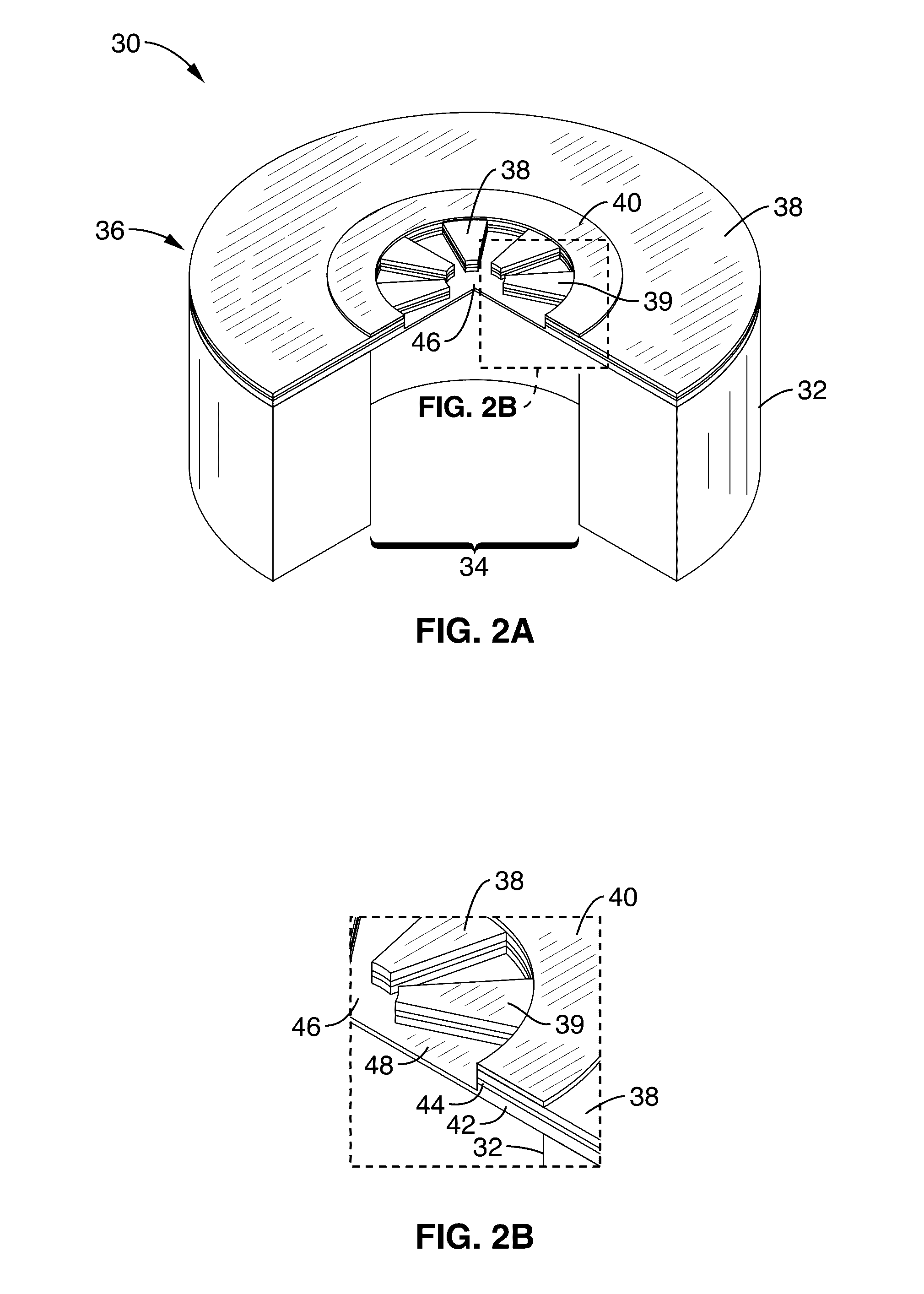

A curved sensor device, such as an ultrasonic transducer array, is fabricated from a flat micromachined sensor (such as cMUT or pMUT) array constructed using micromachined electromechanical systems (MEMS) techniques. The device comprises: a support structure comprising a spine having a profile that is generally curved and a multiplicity of teeth extending from one side of the curved spine; and a multiplicity of sensors built on the support structure. The spine can be bent forward or backward and attached to a curved front face of a support member, thereby causing the sensors to adopt a curved array.

Owner:GENERAL ELECTRIC CO

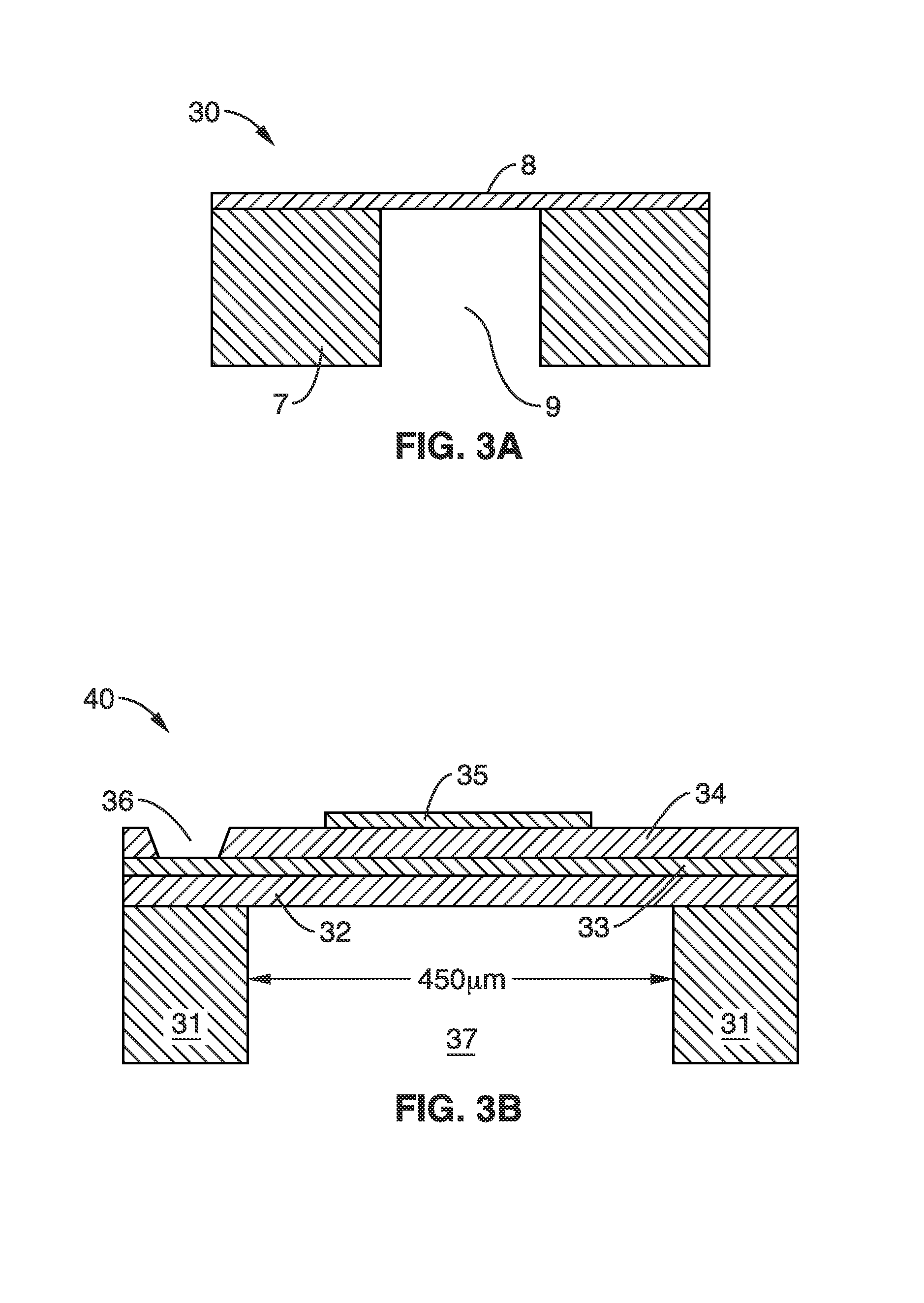

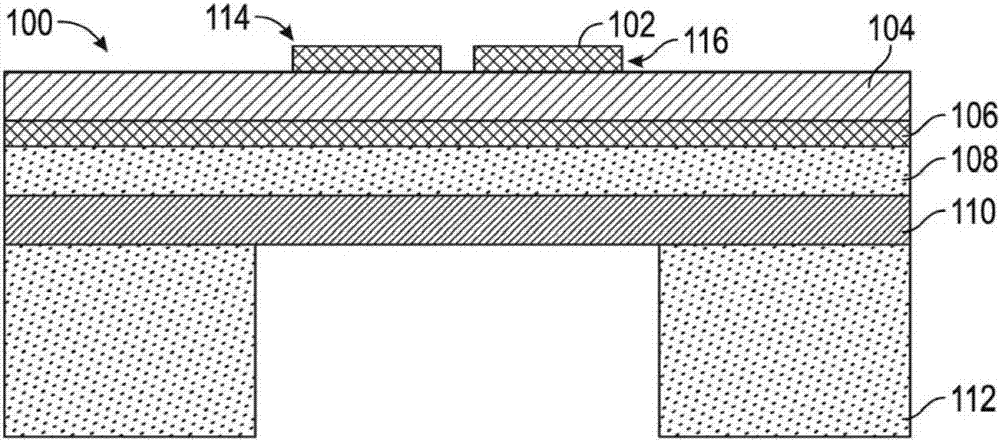

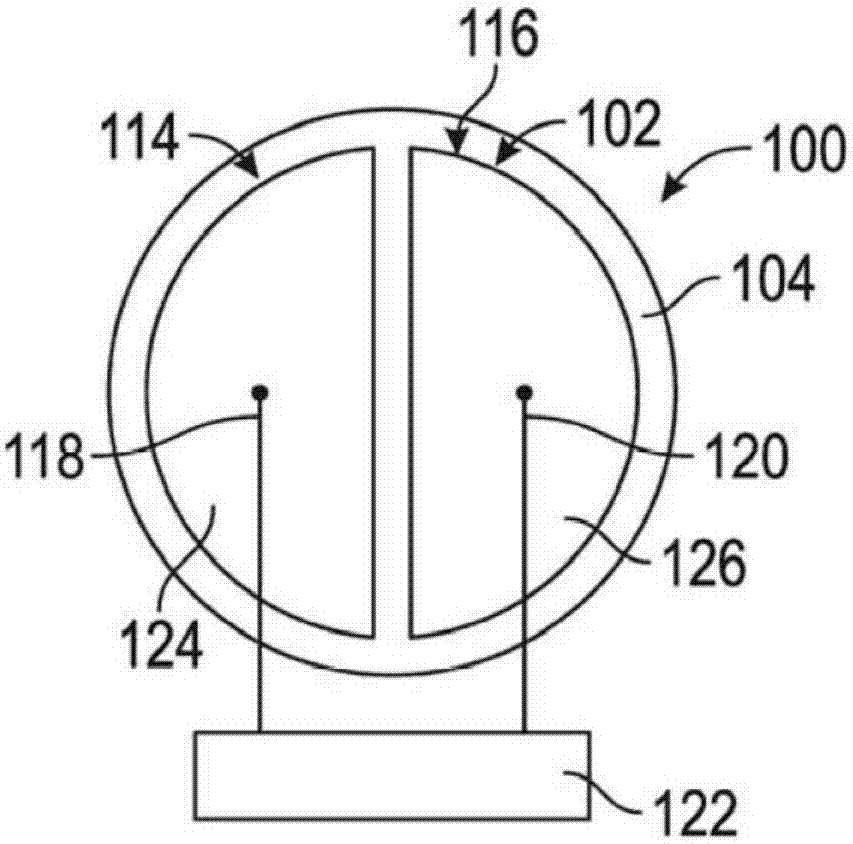

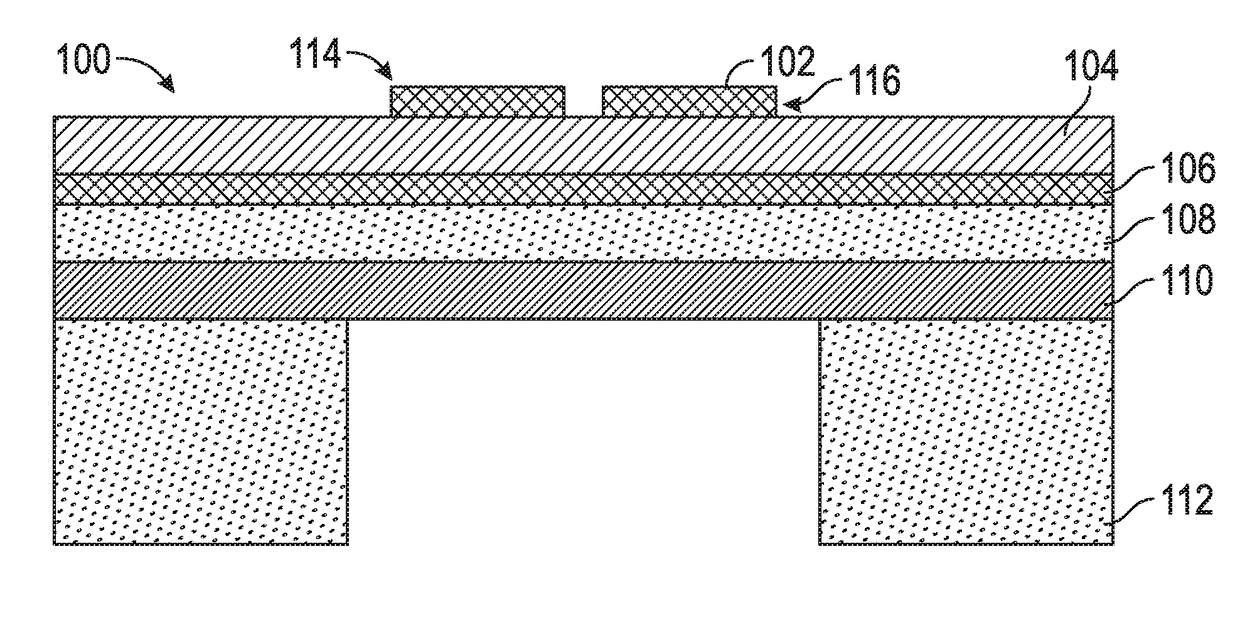

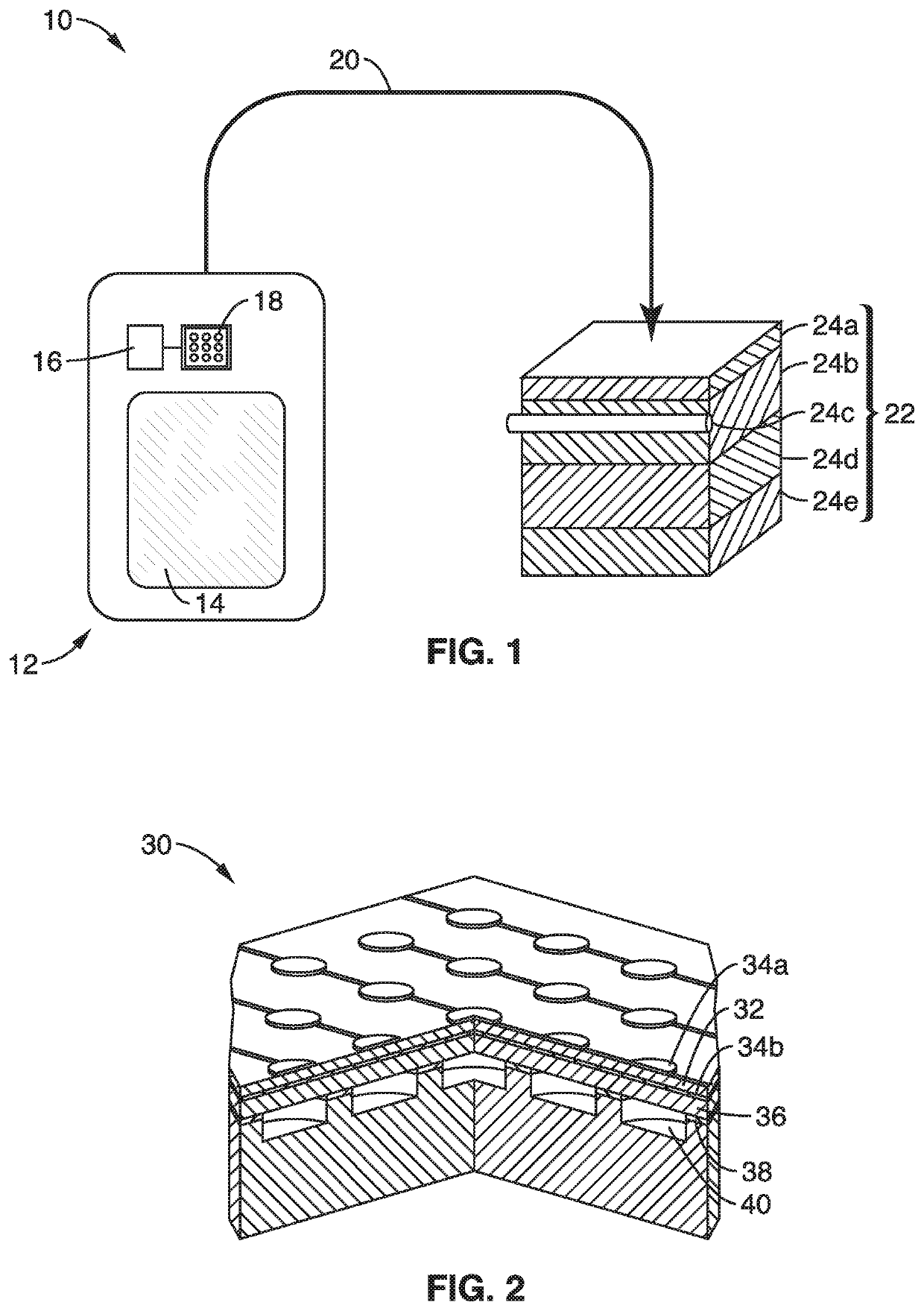

Methods for forming piezoelectric ultrasonic transducers, and associated apparatuses

ActiveUS20120319535A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPMUTElectrically conductive

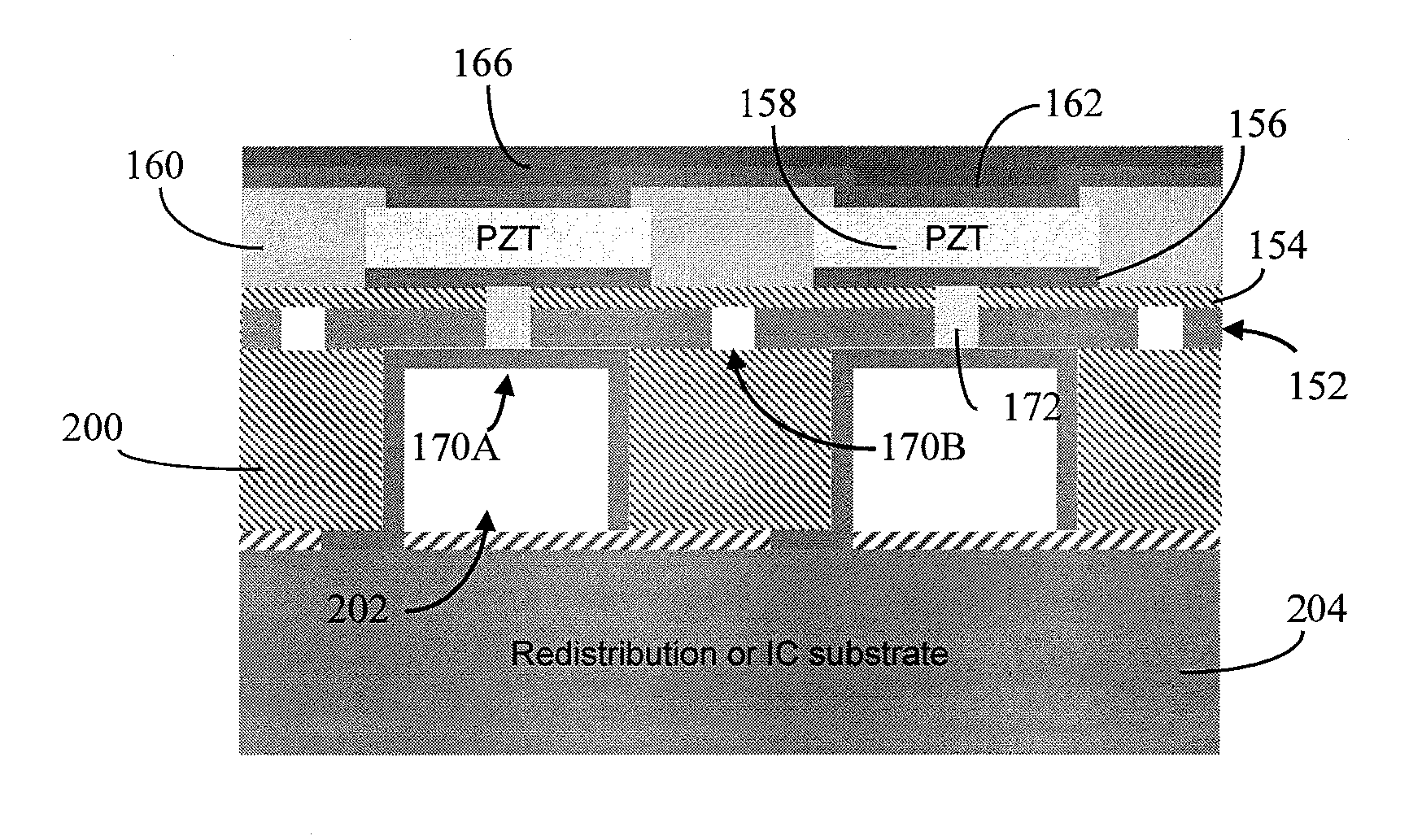

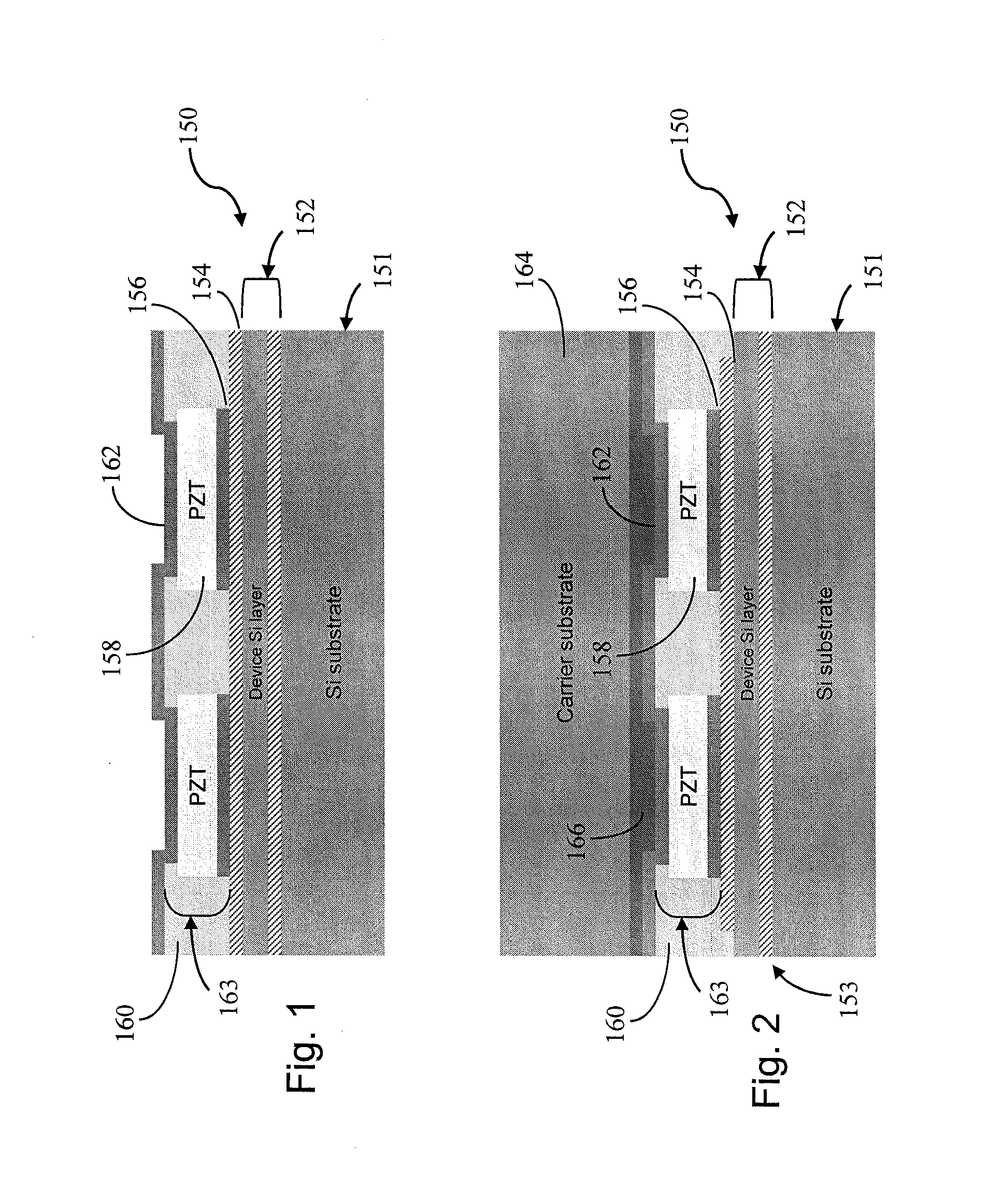

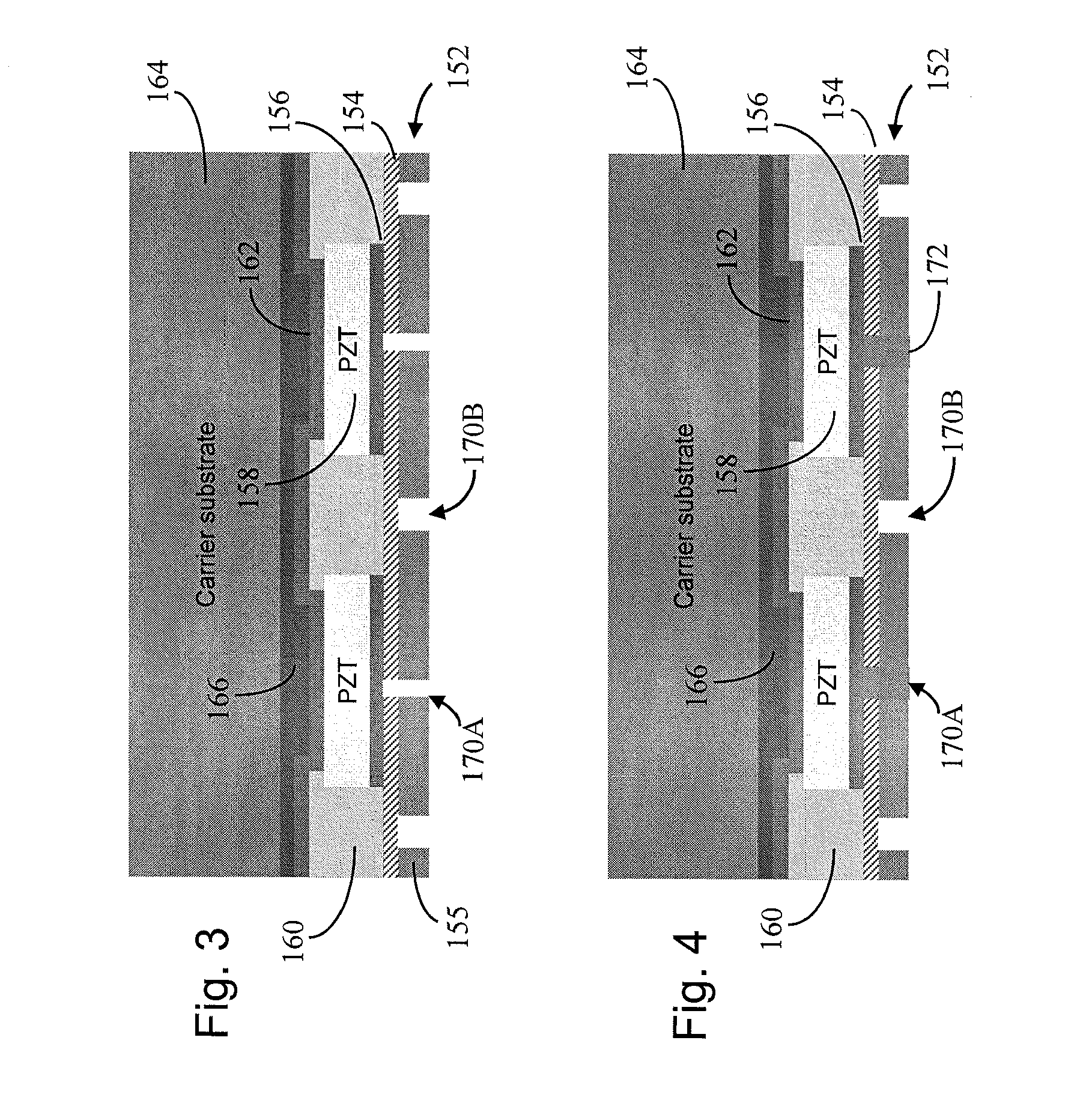

Methods are provided for creating a metal or other electrically-conductive member extending from an air-backed cavity of a piezoelectric ultrasonic transducer (pMUT) apparatus defining such an air-backed cavity, through a substrate layer disposed adjacent to the transducer device of the pMUT device, and into electrically-conductive engagement with a first electrode of the pMUT device, such that the electrically-conductive member provides an electrically-conductive engagement between the first electrode and a conformal electrically-conductive layer deposited in the air-backed cavity of the pMUT device. Associated apparatuses are also provided.

Owner:RES TRIANGLE INST

Curved micromachined ultrasonic transducer arrays and related methods of manufacture

ActiveUS7285897B2Ultrasonic/sonic/infrasonic diagnosticsFixed microstructural devicesPMUTEngineering

A curved sensor device, such as an ultrasonic transducer array, is fabricated from a flat micromachined sensor (such as cMUT or pMUT) array constructed using micromachined electro-mechanical systems (MEMS) techniques. The device comprises: a support structure comprising a spine having a profile that is generally curved and a multiplicity of teeth extending from one side of the curved spine; and a multiplicity of sensors built on the support structure. The spine can be bent forward or backward and attached to a curved front face of a support member, thereby causing the sensors to adopt a curved array.

Owner:GENERAL ELECTRIC CO

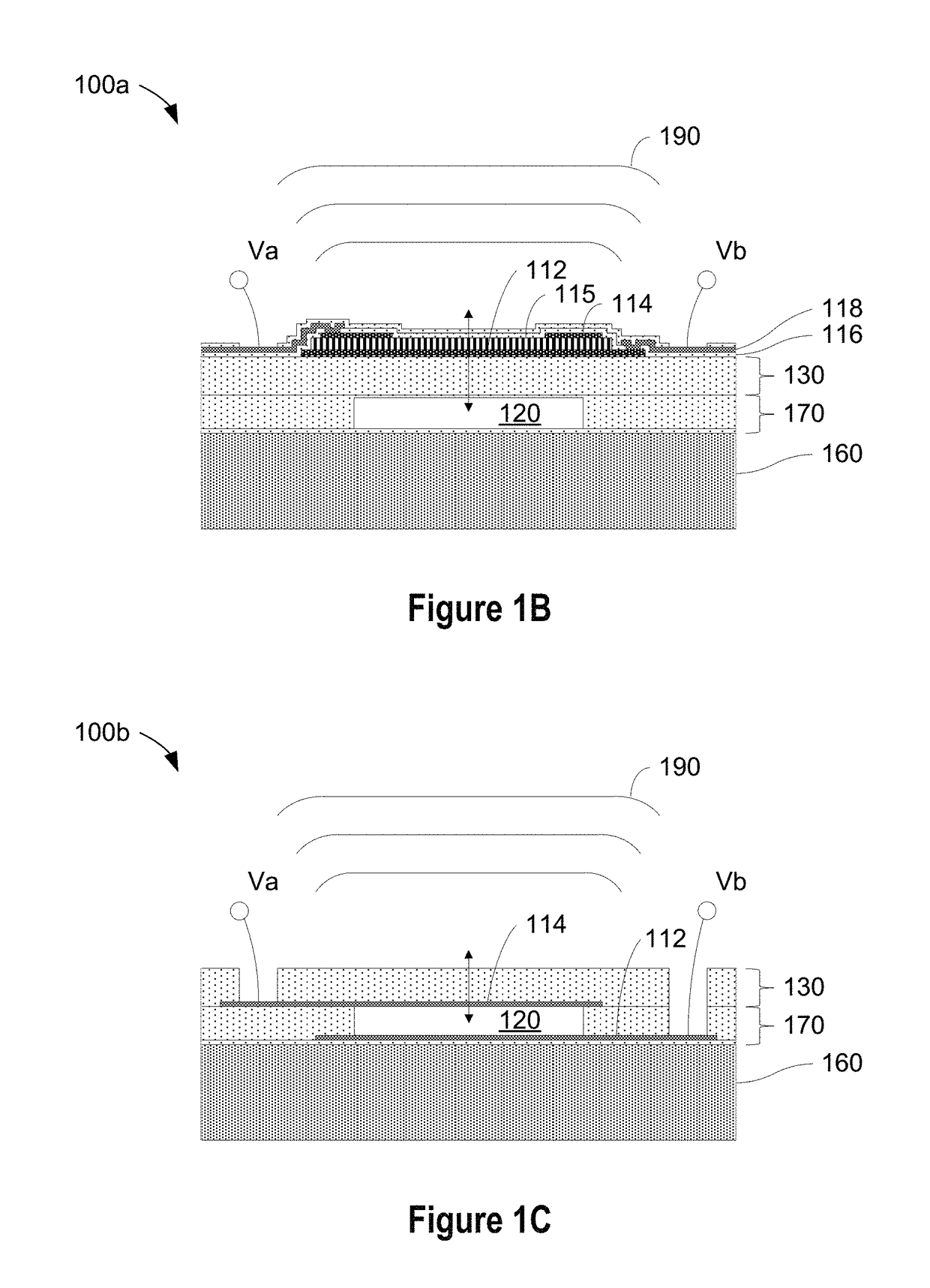

Micromechanical ultrasonic transducers and display

ActiveUS9815087B2Piezoelectric/electrostrictive device manufacture/assemblyMechanical vibrations separationCapacitanceDisplay device

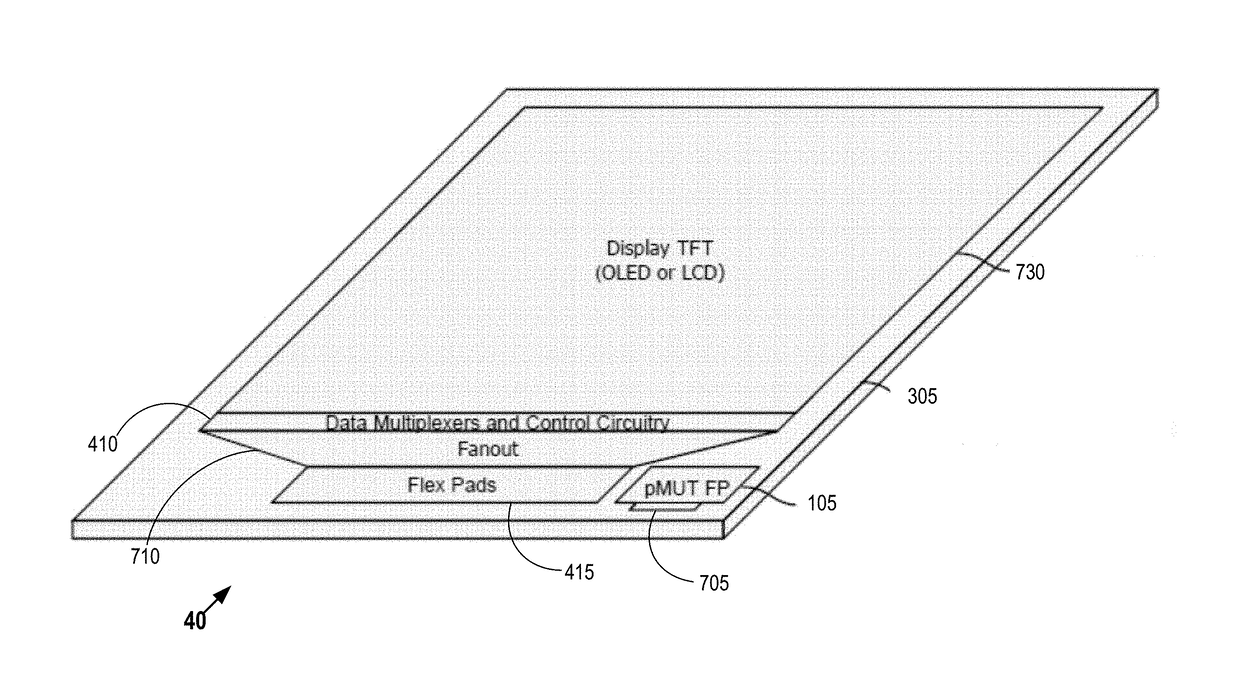

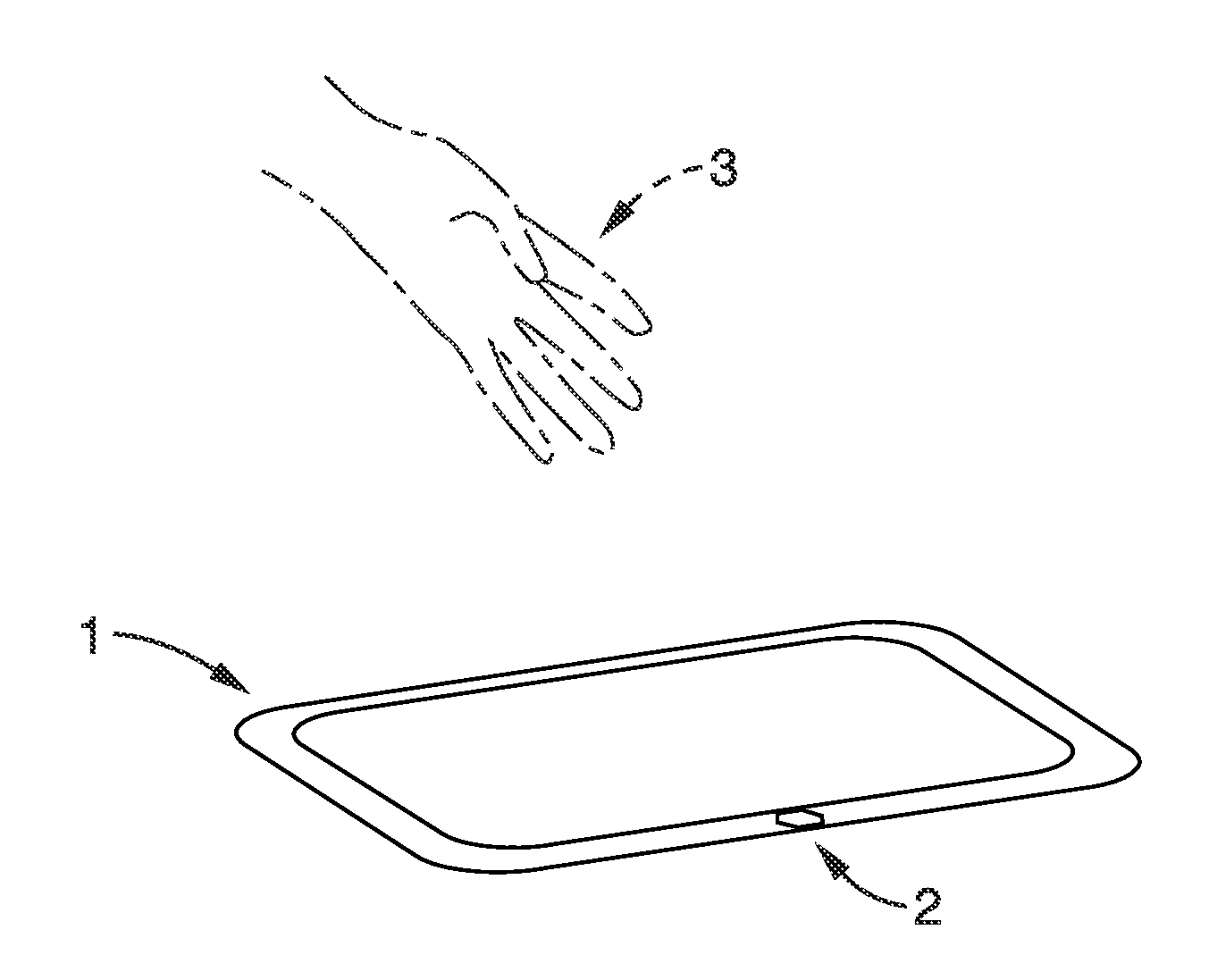

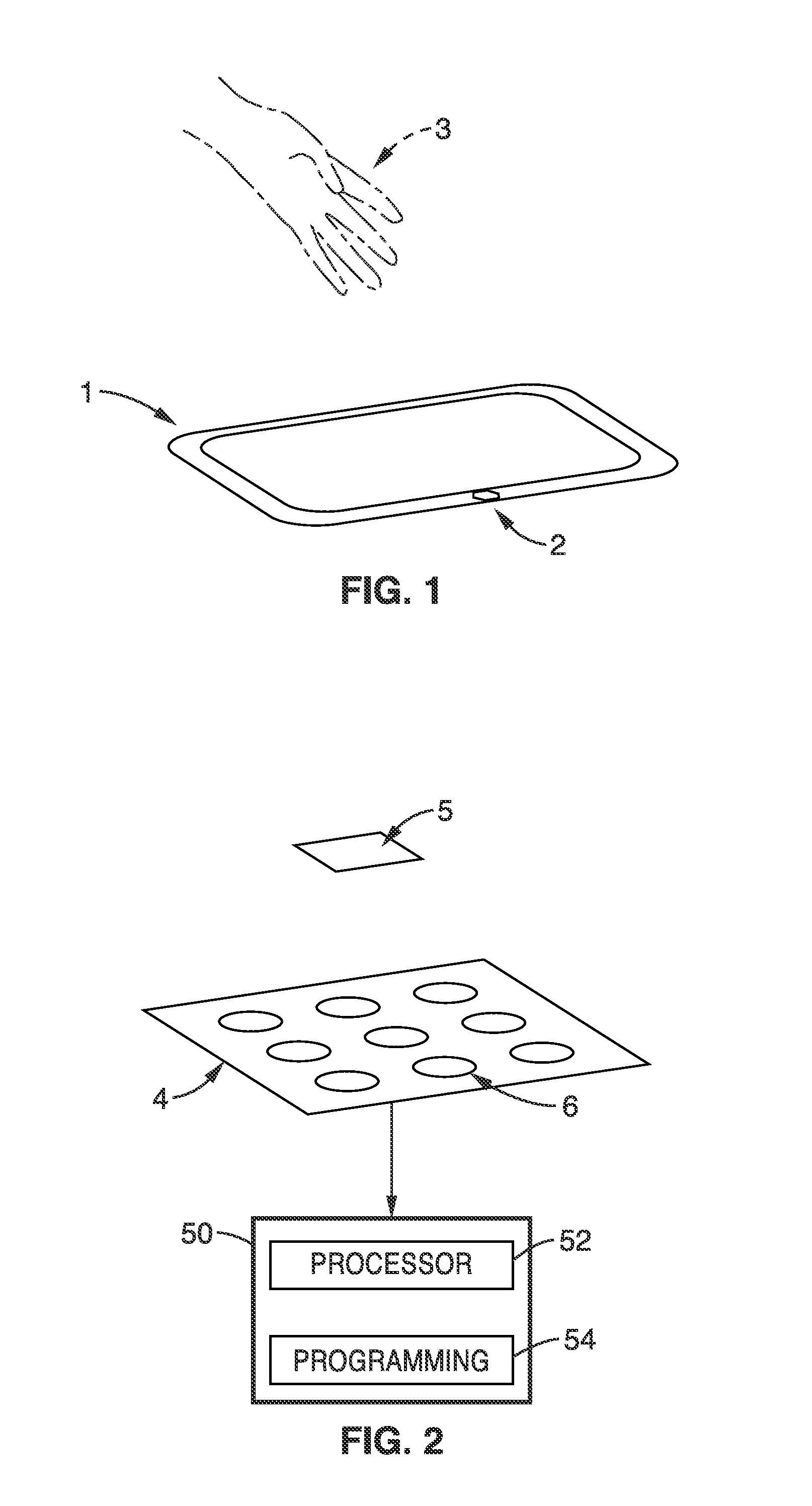

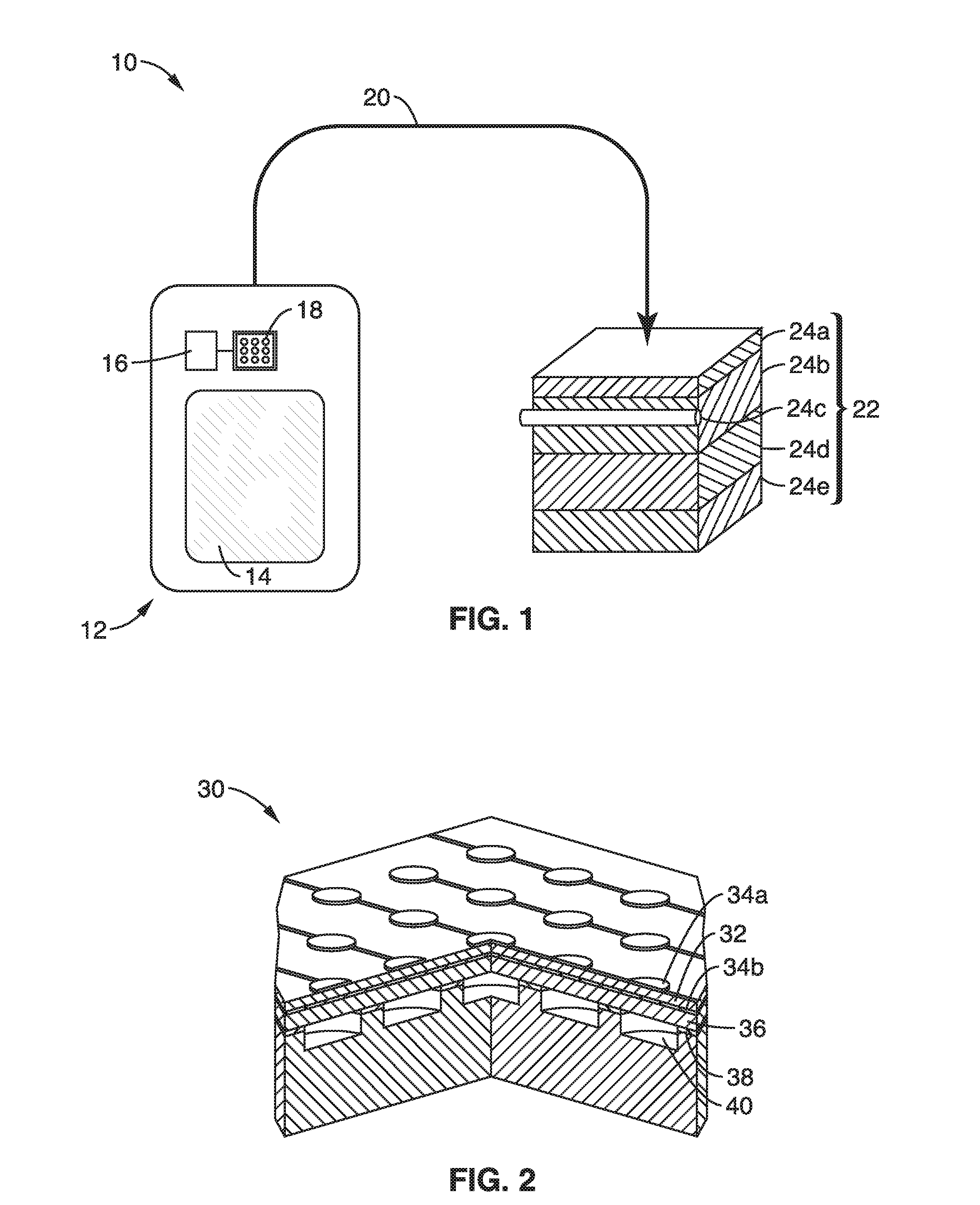

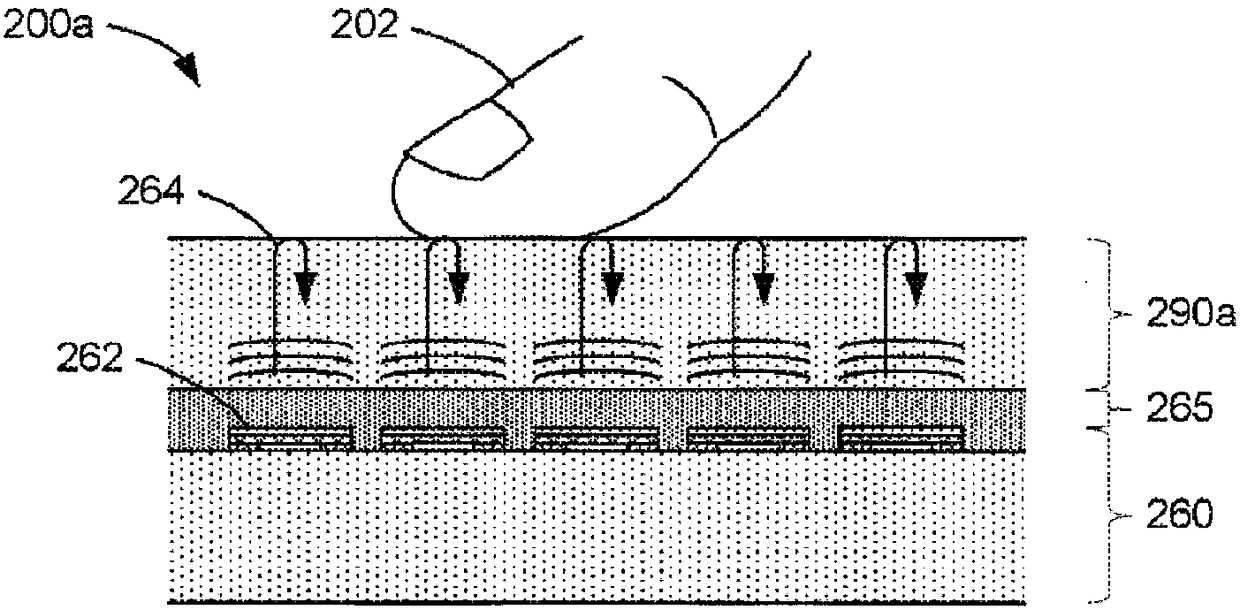

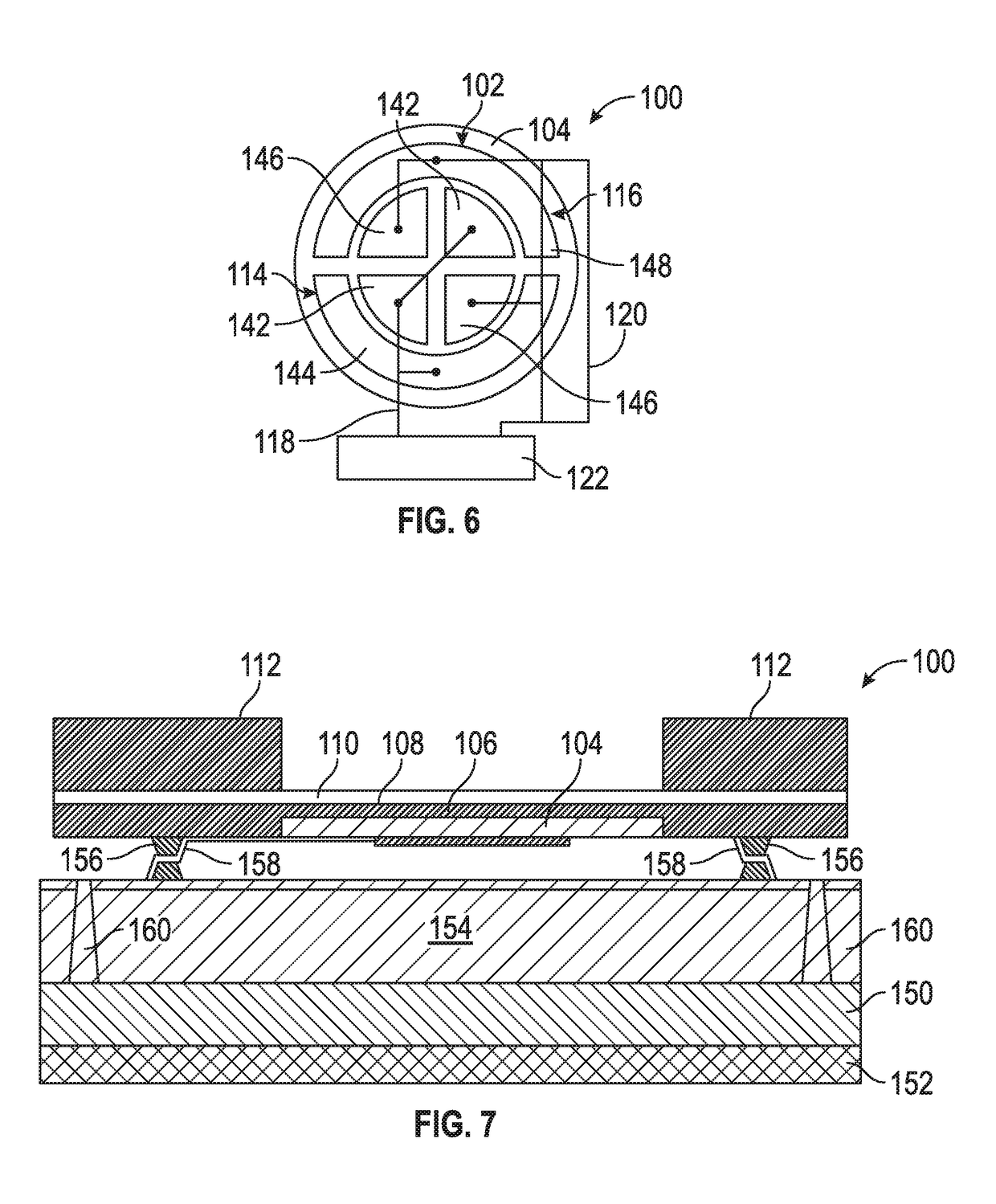

An apparatus may include a one- or two-dimensional array of micromechanical ultrasonic transducer (PMUT) elements positioned below, beside, with, on, or above a backplane of a visual display. The backplane may be a thin-film transistor (TFT) backplane. The array of PMUT elements may be a piezoelectric micromechanical ultrasonic transducer (PMUT) array or a capacitive micromechanical ultrasonic transducer (CMUT) array. The PMUT array may be configurable to operate in modes corresponding to multiple frequency ranges. When operating in the low-frequency mode, the apparatus may be capable of gesture detection. A high-frequency mode may include a fingerprint sensor mode or a stylus detection mode.

Owner:QUALCOMM INC

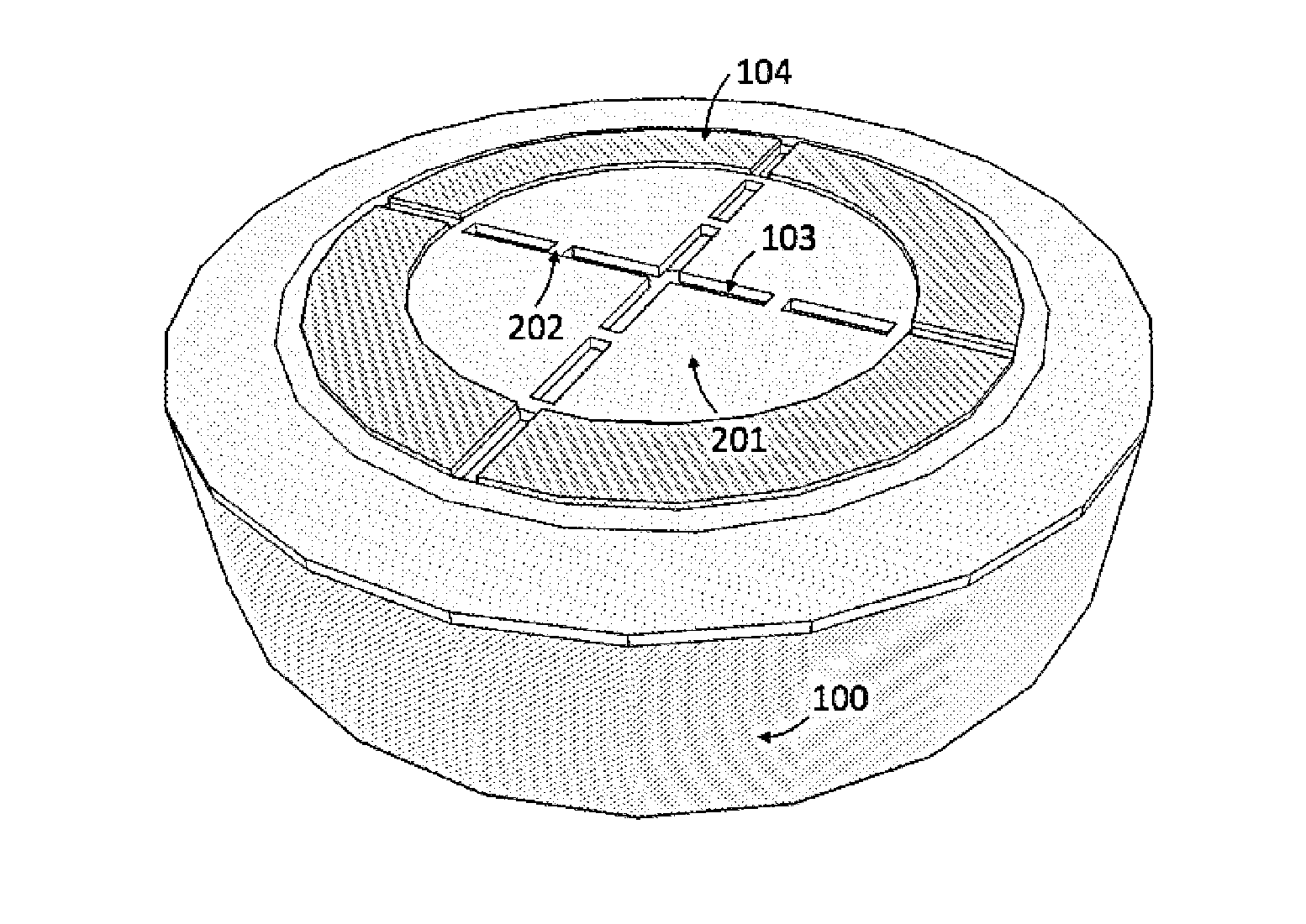

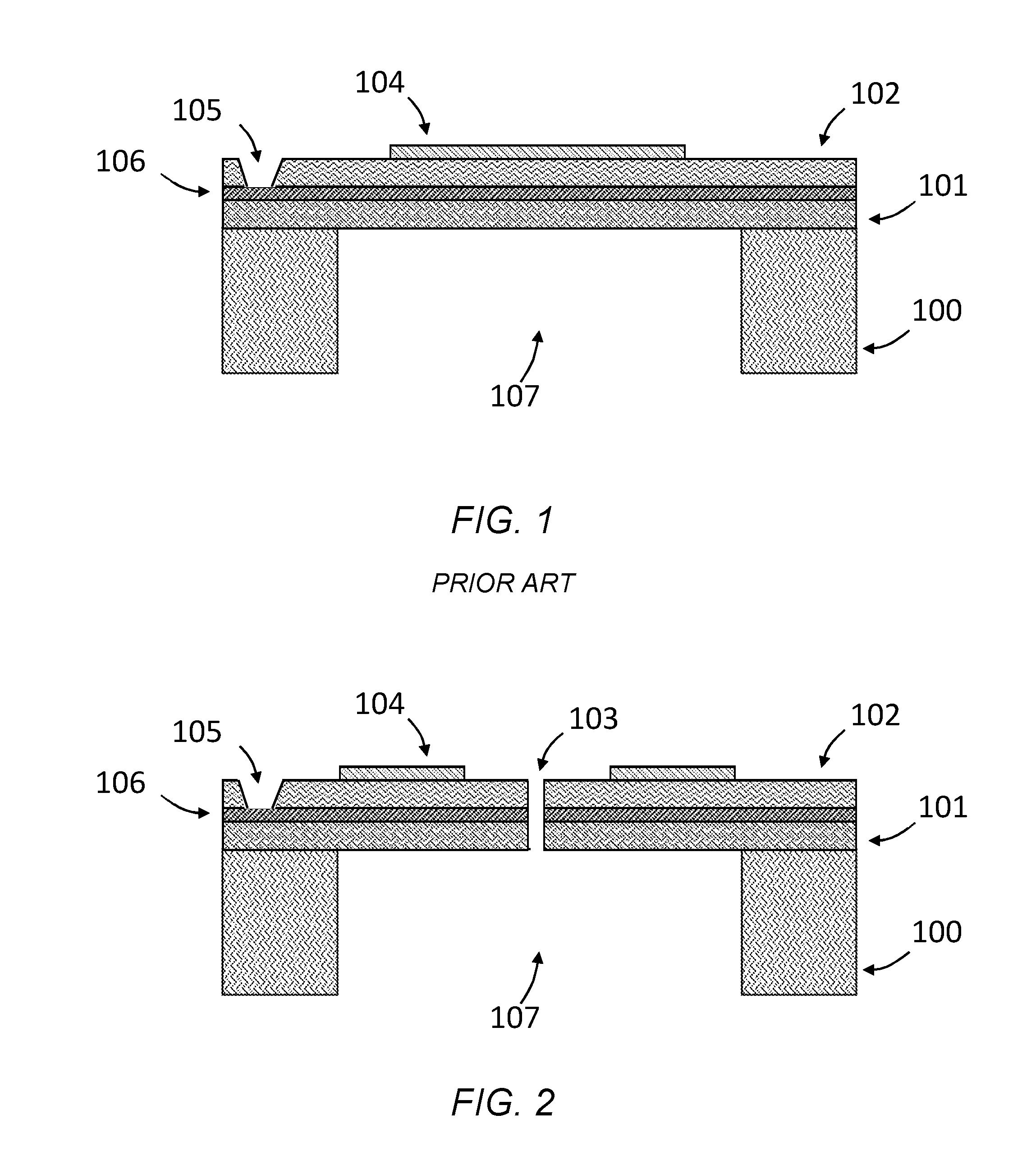

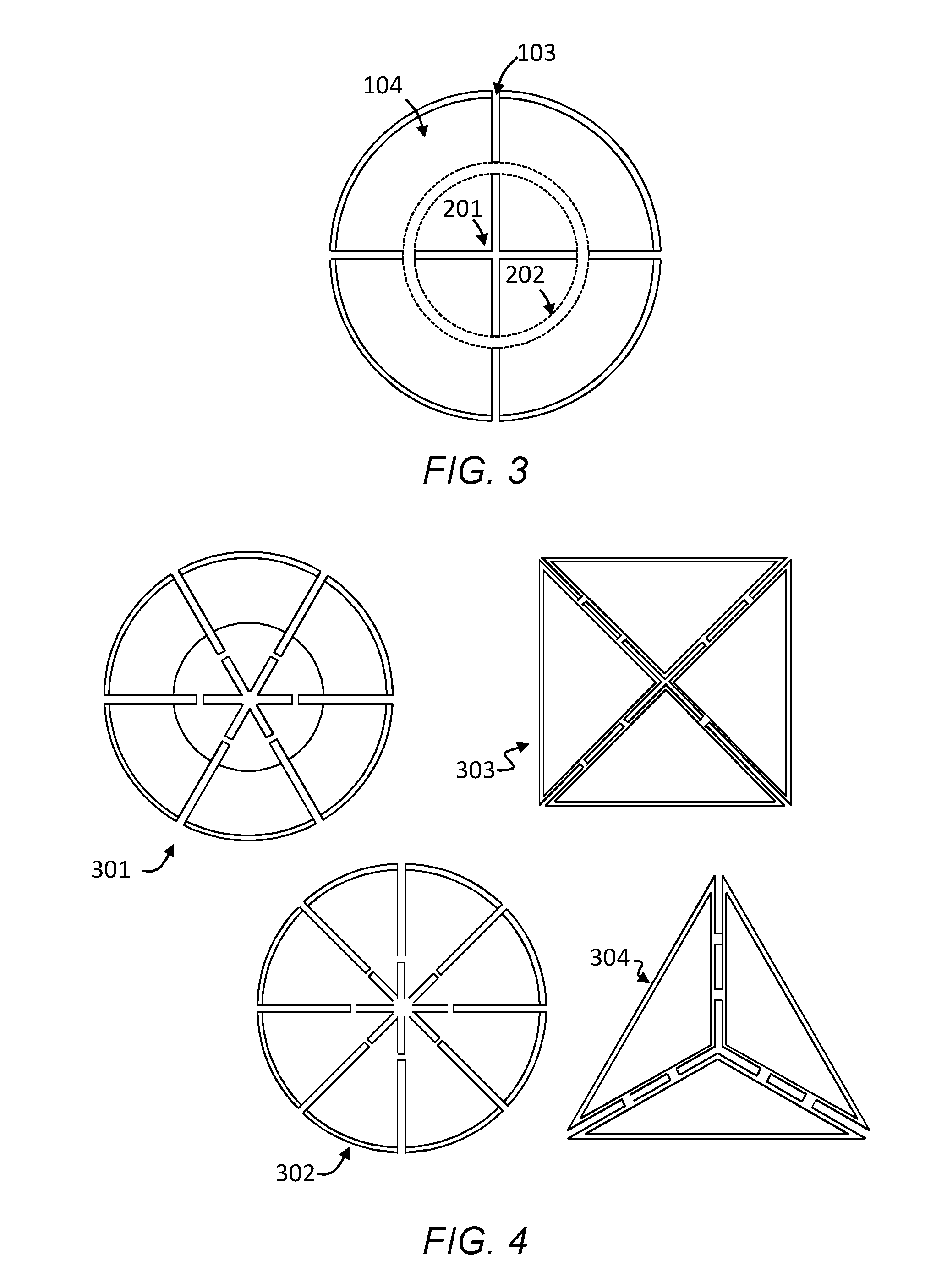

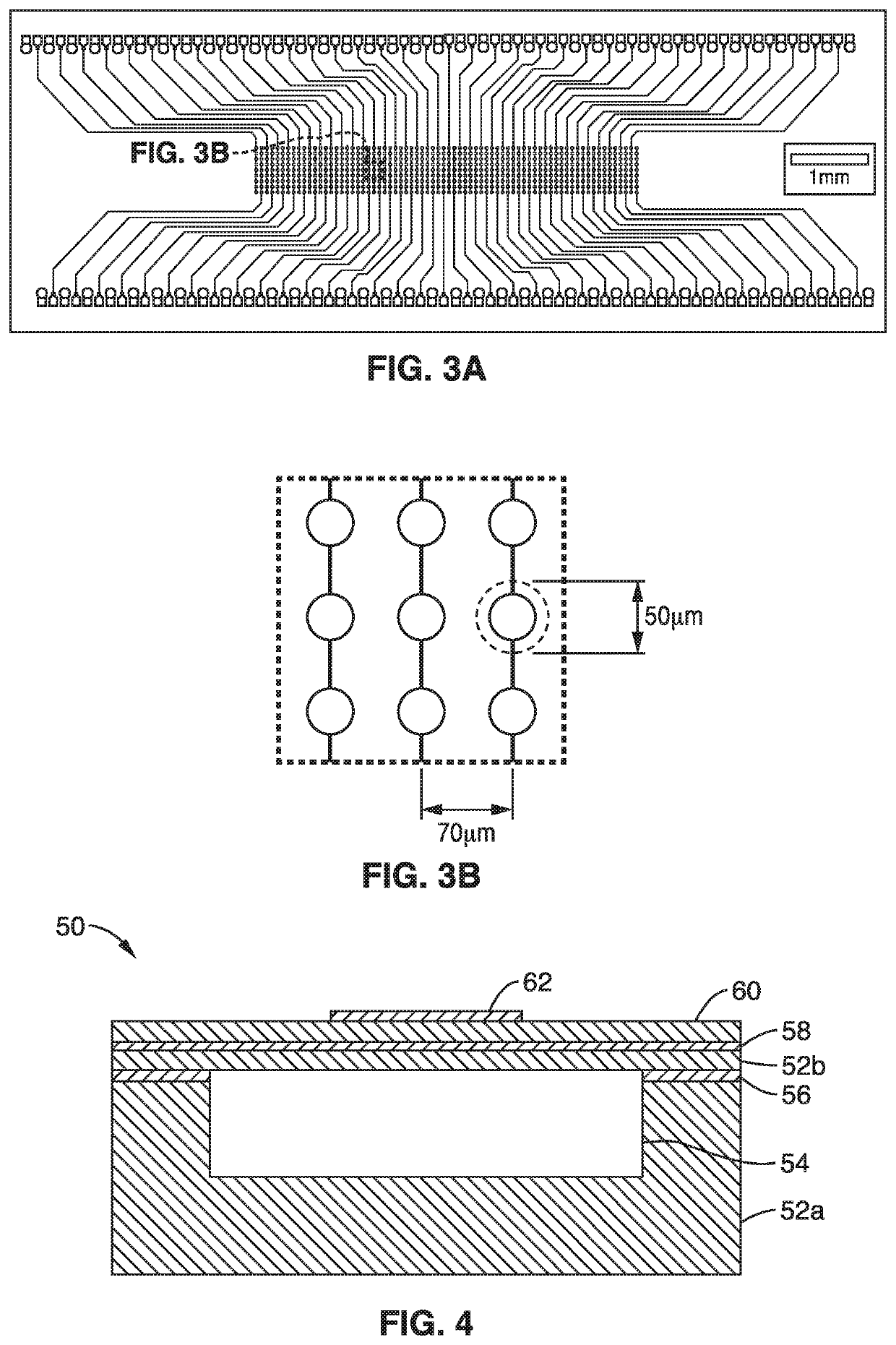

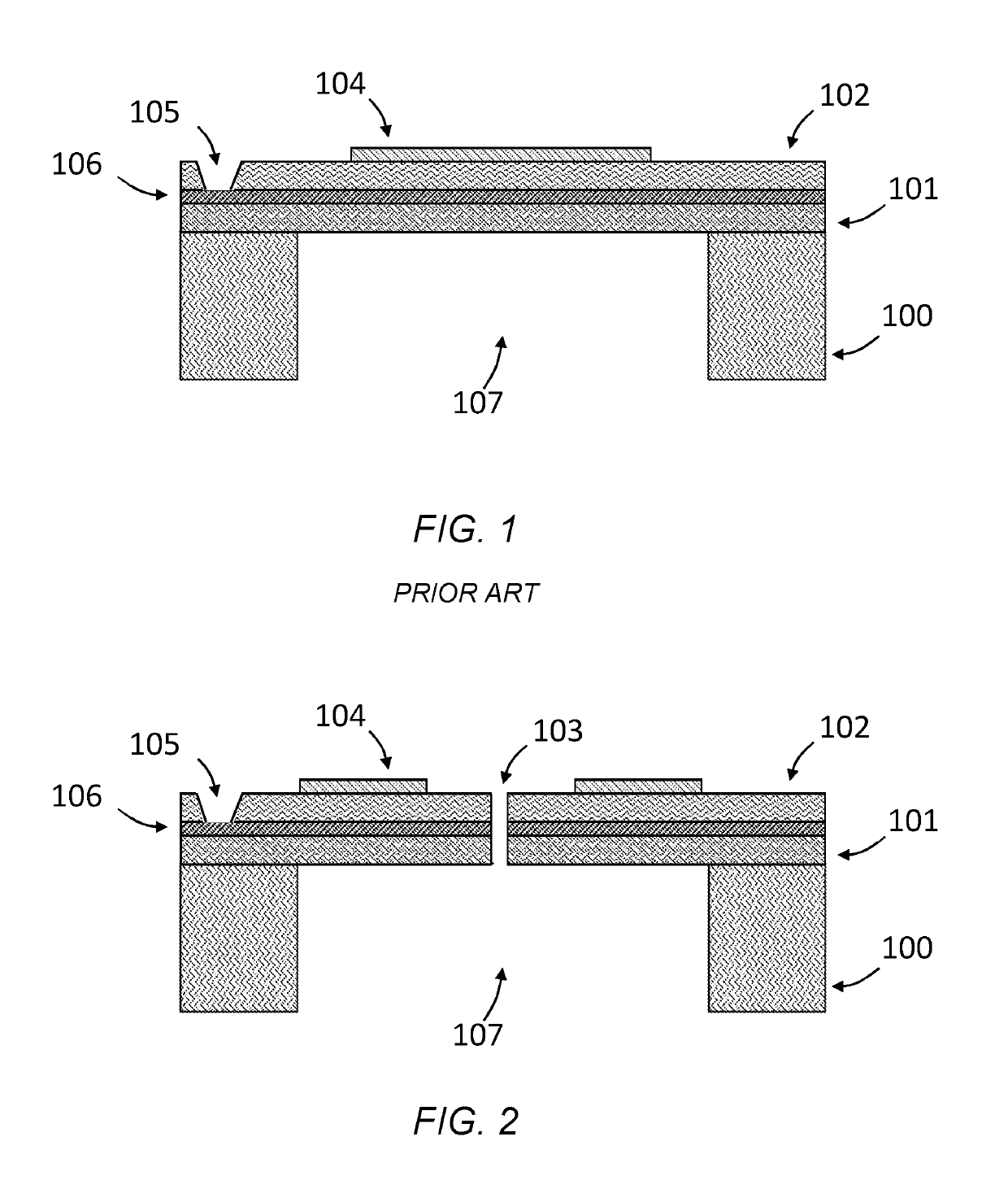

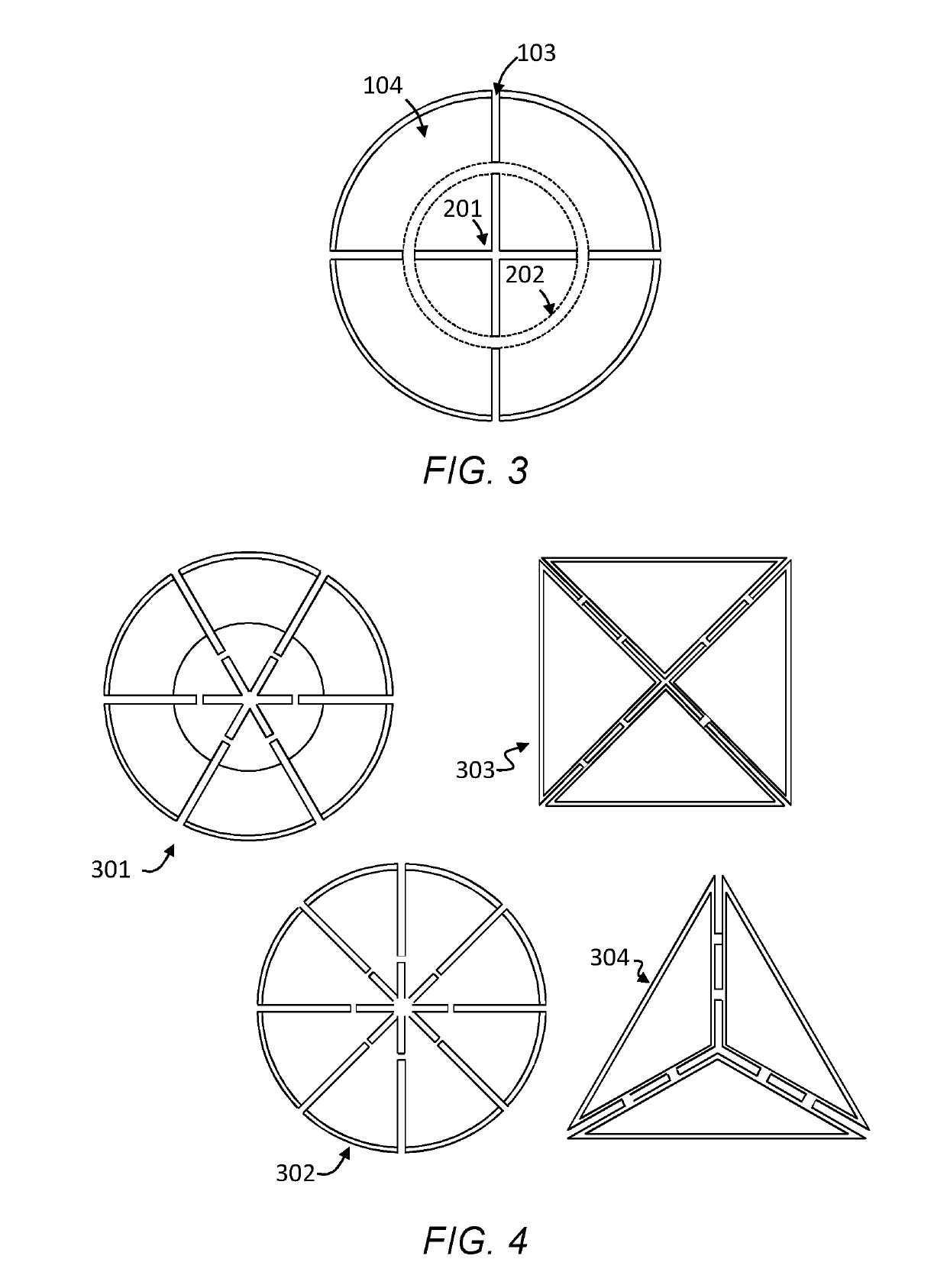

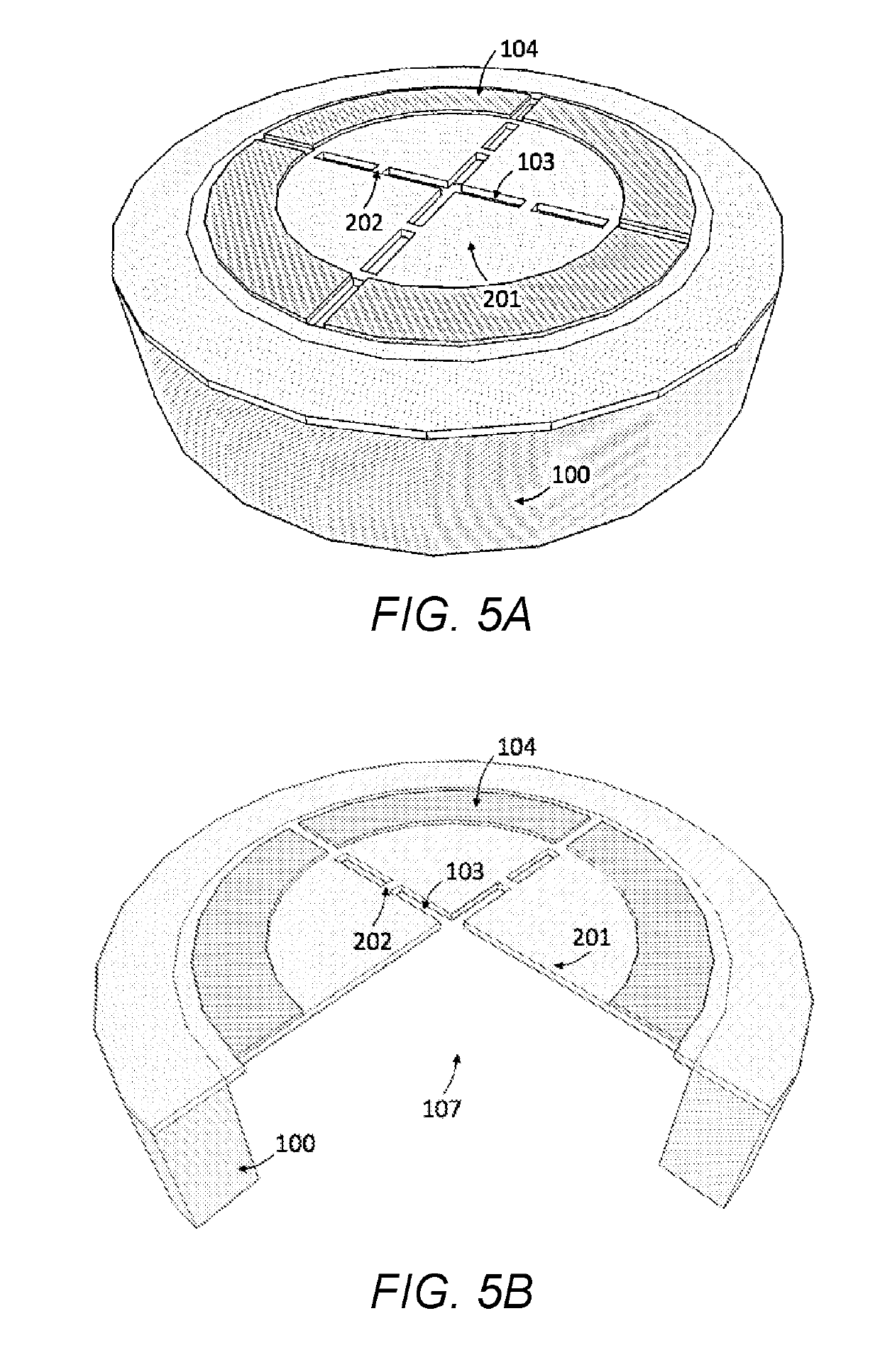

Micromachined ultrasonic transducers with a slotted membrane structure

ActiveUS20170021391A1Large displacementEasy to adjustPiezoelectric/electrostrictive device manufacture/assemblyMaterial analysis using sonic/ultrasonic/infrasonic wavesPMUTEngineering

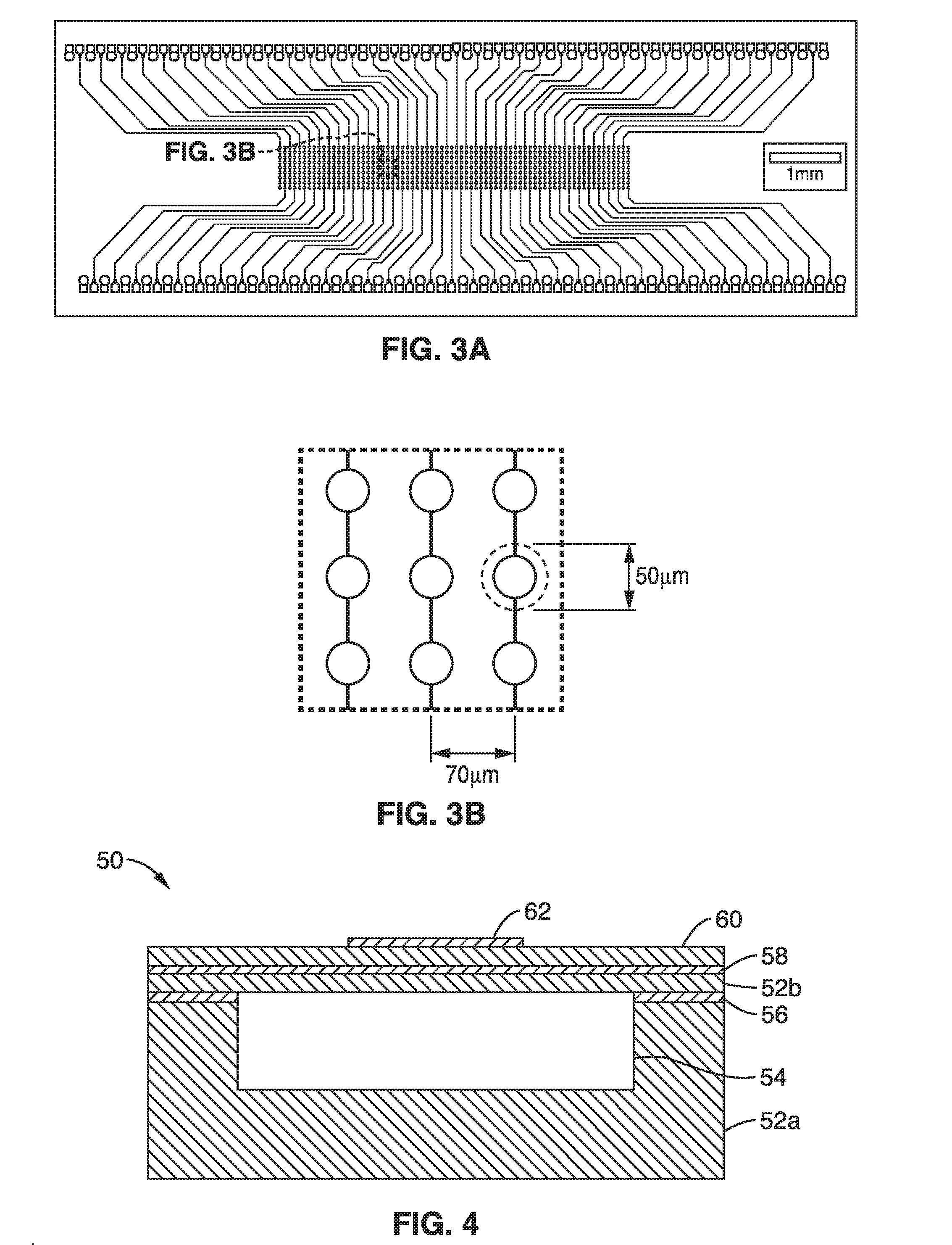

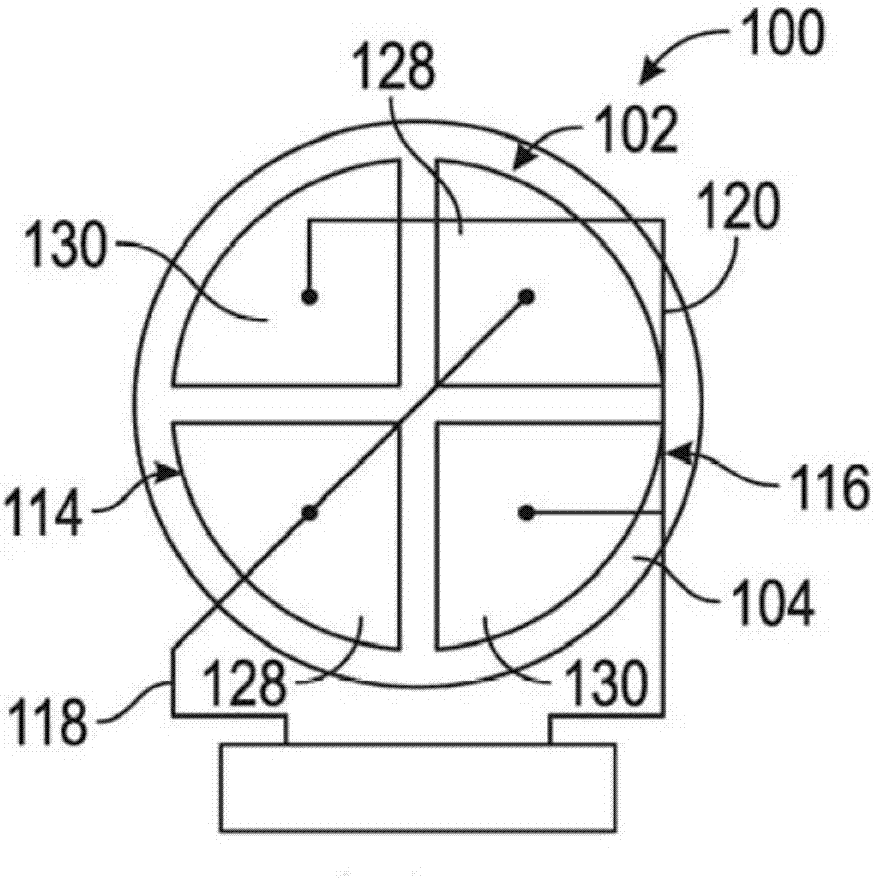

A piezoelectric micromachined ultrasonic transducer (PMUT) device includes a substrate having an opening therethrough and a membrane attached to the substrate over the opening. A portion of the membrane that overlies the opening is divided into a plurality of cantilevers that are mechanically coupled so that the cantilevers resonate at a common frequency.

Owner:INVENSENSE

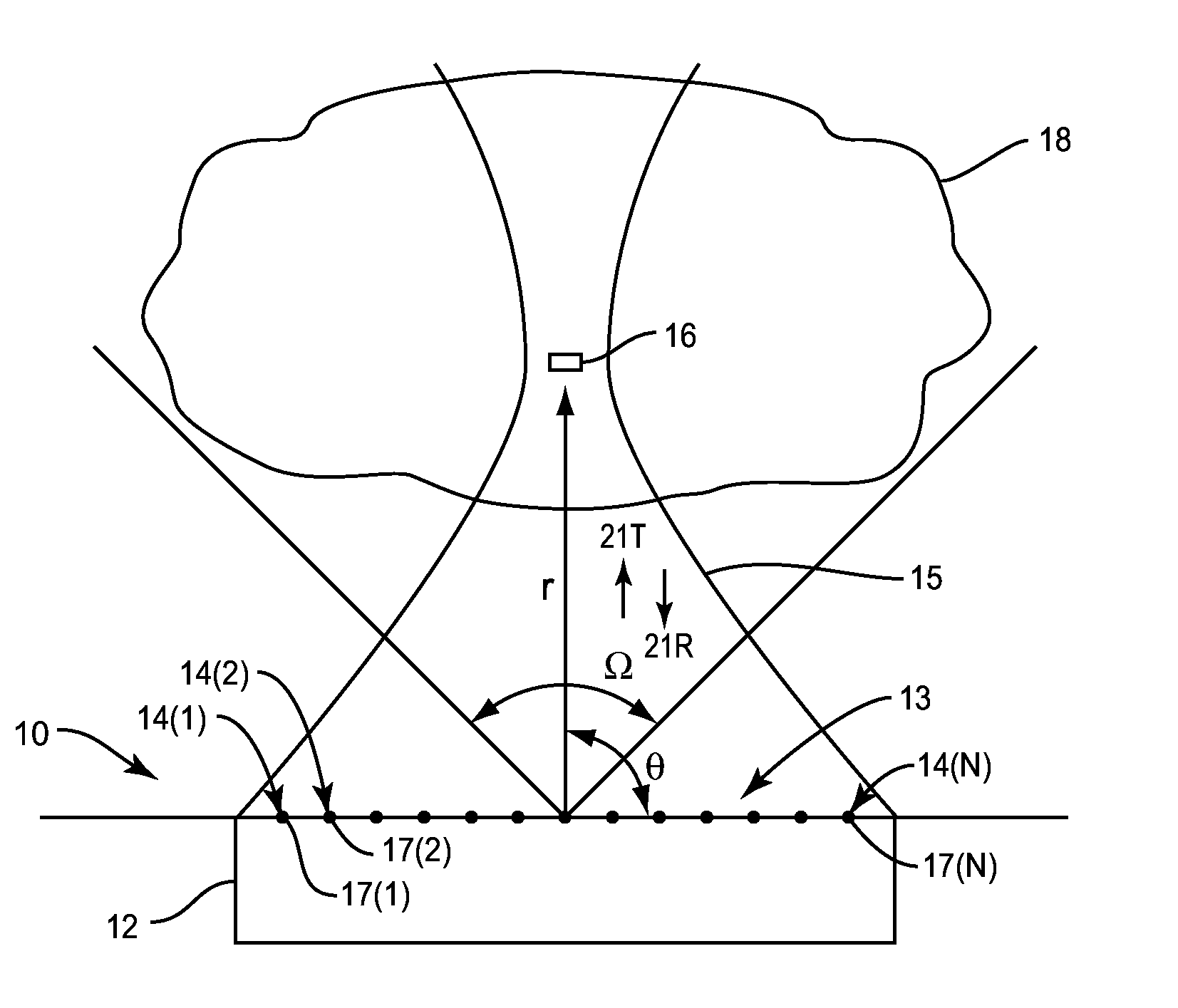

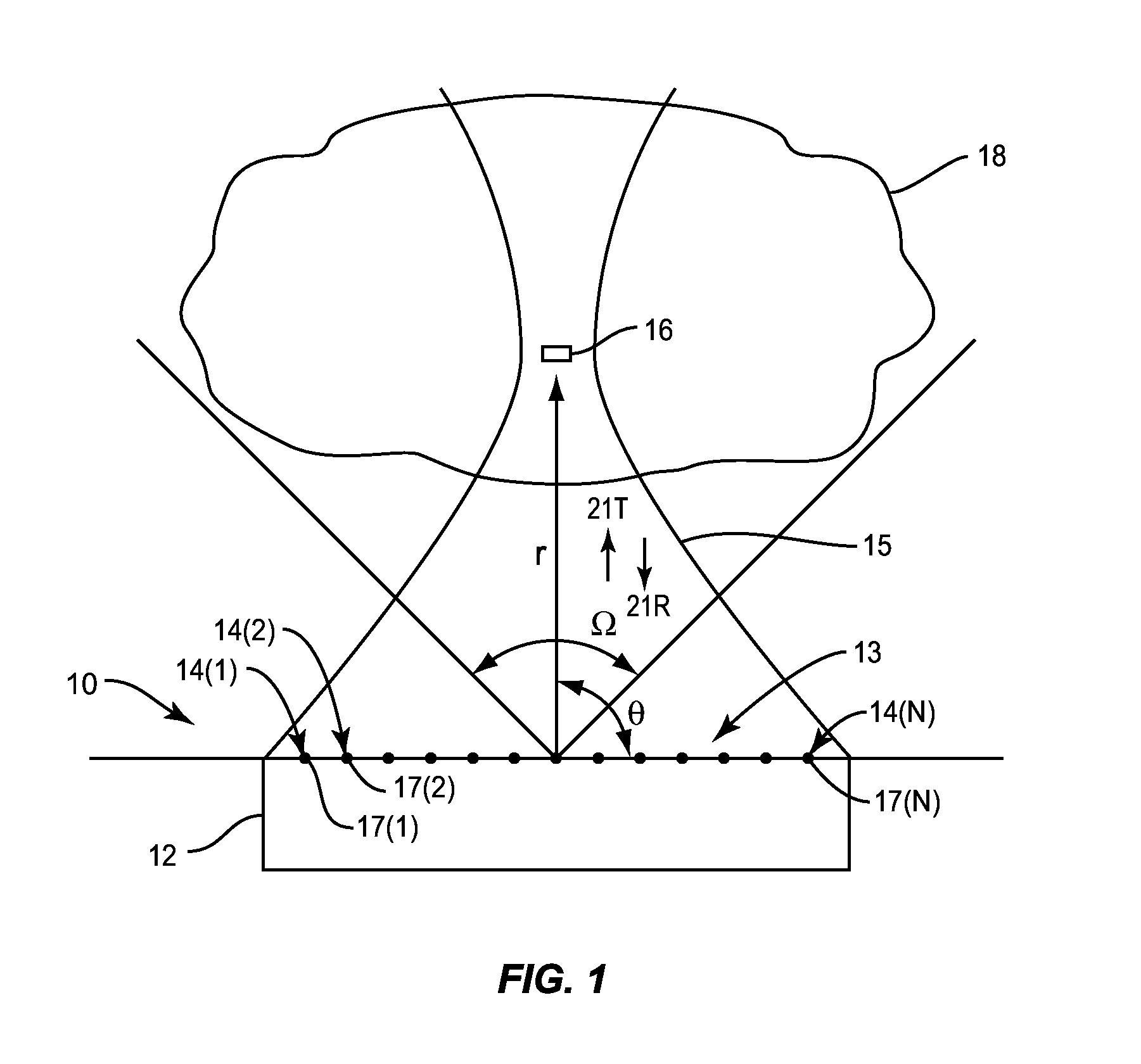

In-air ultrasonic rangefinding and angle estimation

ActiveUS20140253435A1Less powerInput/output for user-computer interactionCathode-ray tube indicatorsSonificationPMUT

An apparatus for determining location of a moveable object in relation to an input device includes an array of one or more piezoelectric micromachined ultrasonic transducer (pMUT) elements and a processor. The array is formed from a common substrate. The one or more pMUT elements include one or more transmitters and one or more receivers. The processor configured to determine a location of a moveable object in relation to an input device using sound waves that are emitted from the one or more transmitters, reflected from the moveable object, and received by the one or more receivers.

Owner:RGT UNIV OF CALIFORNIA

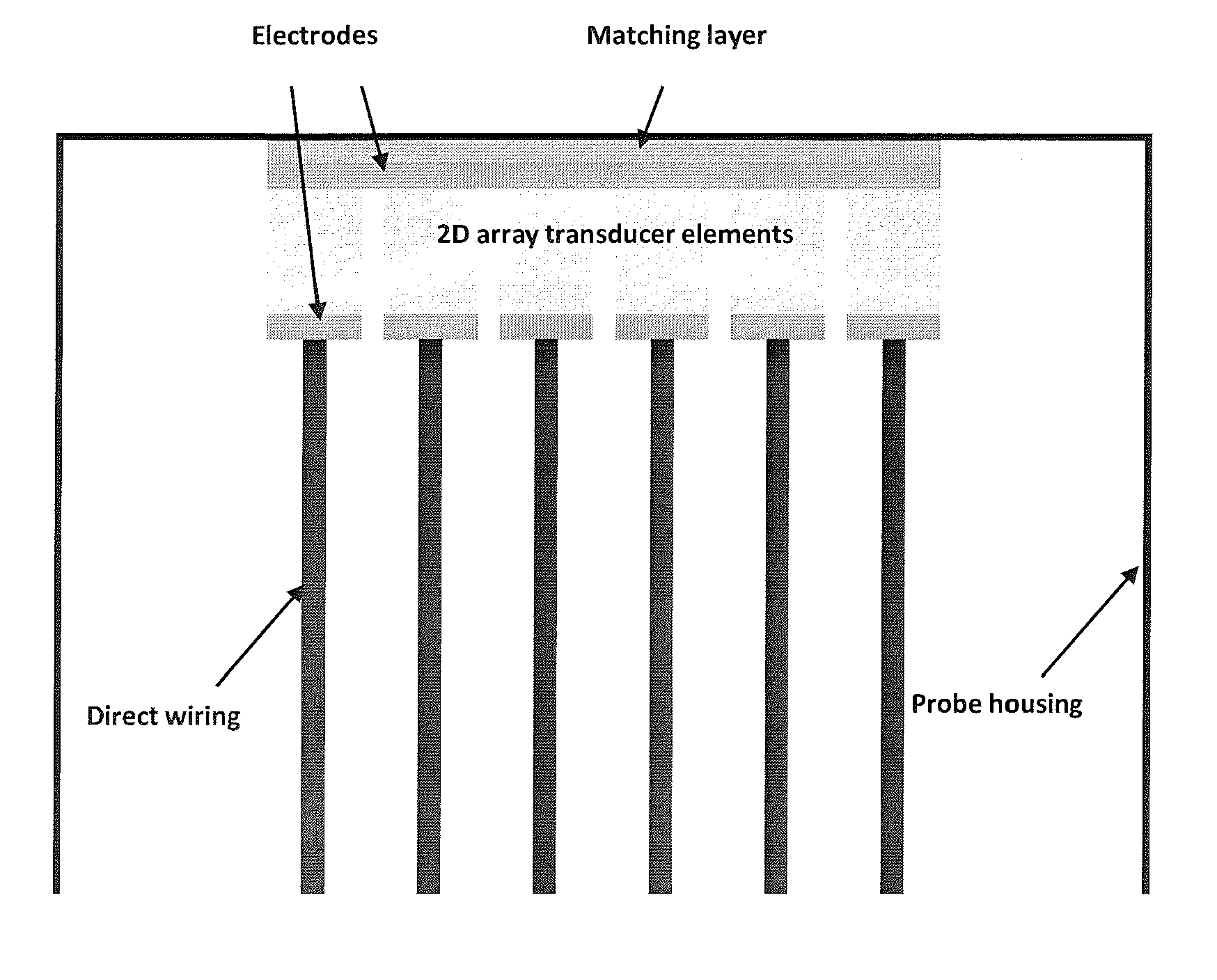

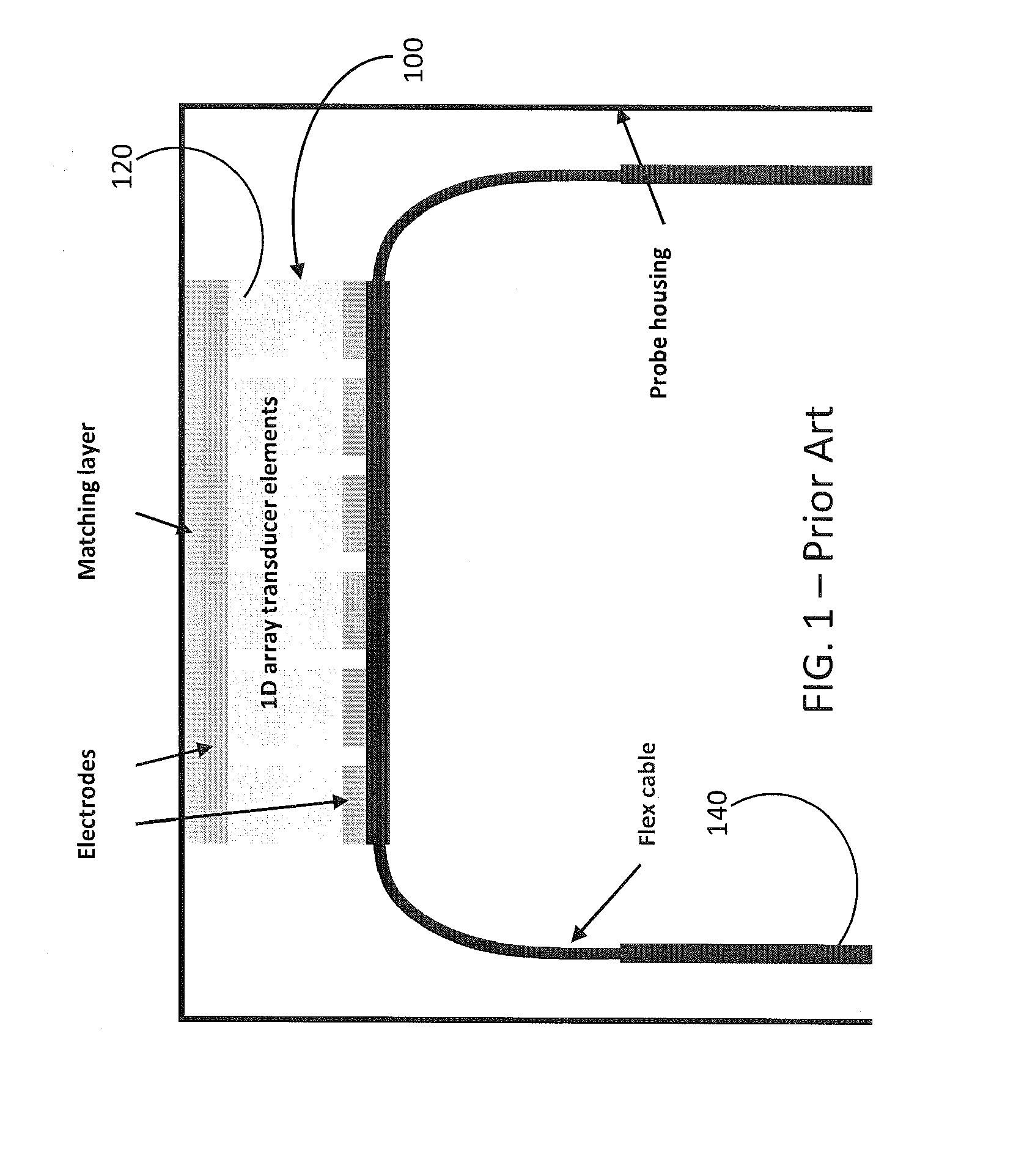

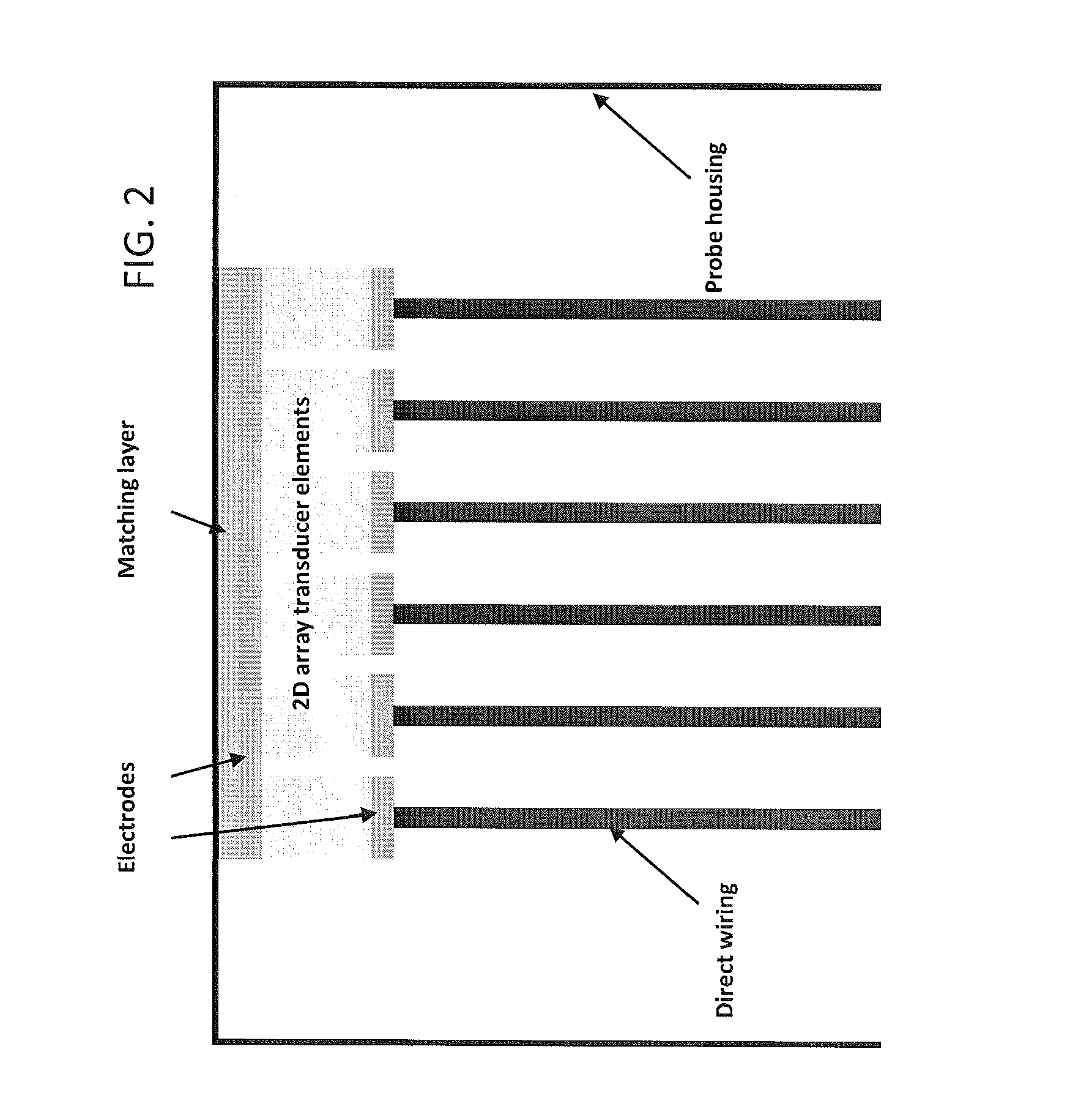

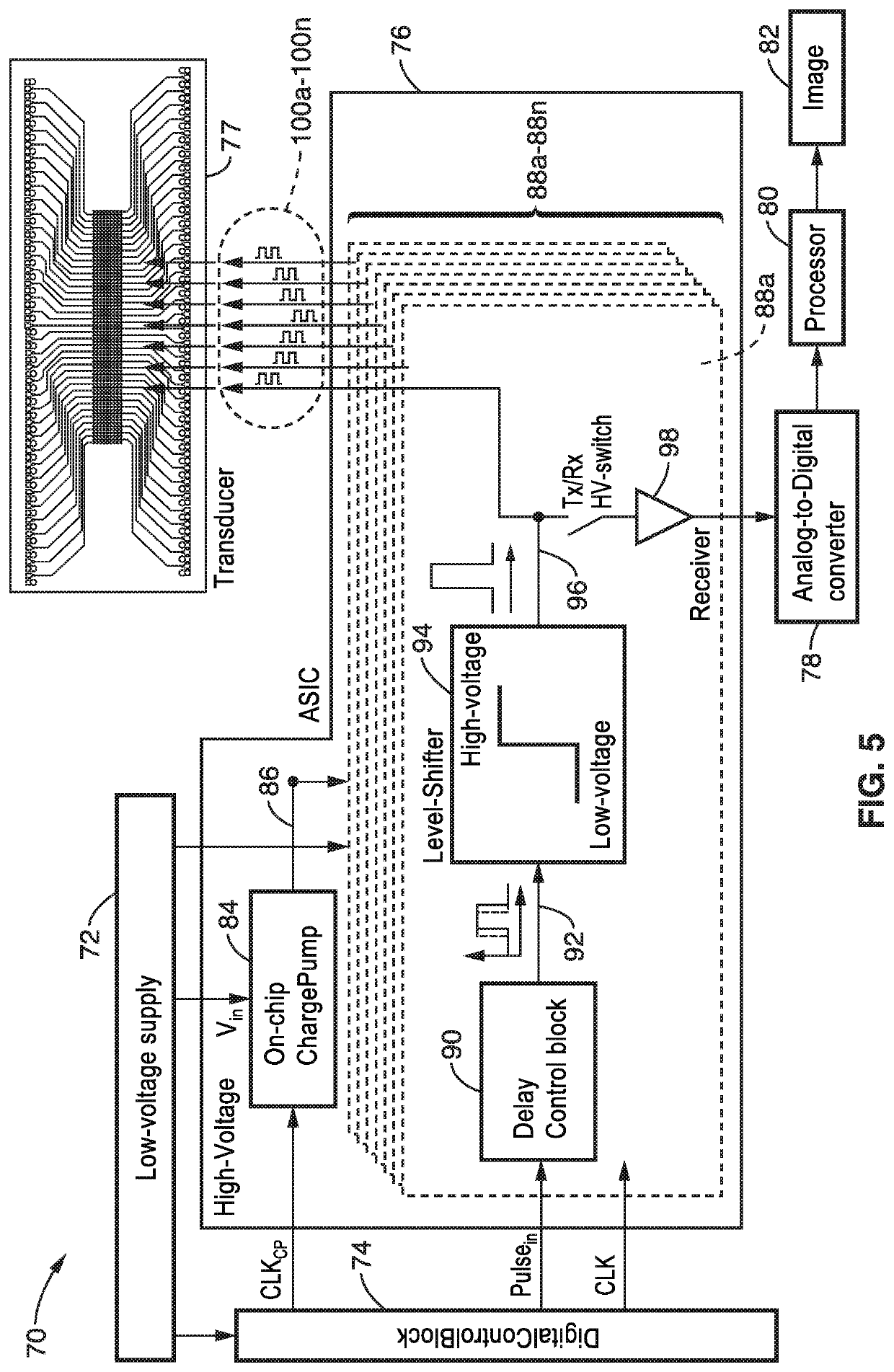

Low voltage, low power MEMS transducer with direct interconnect capability

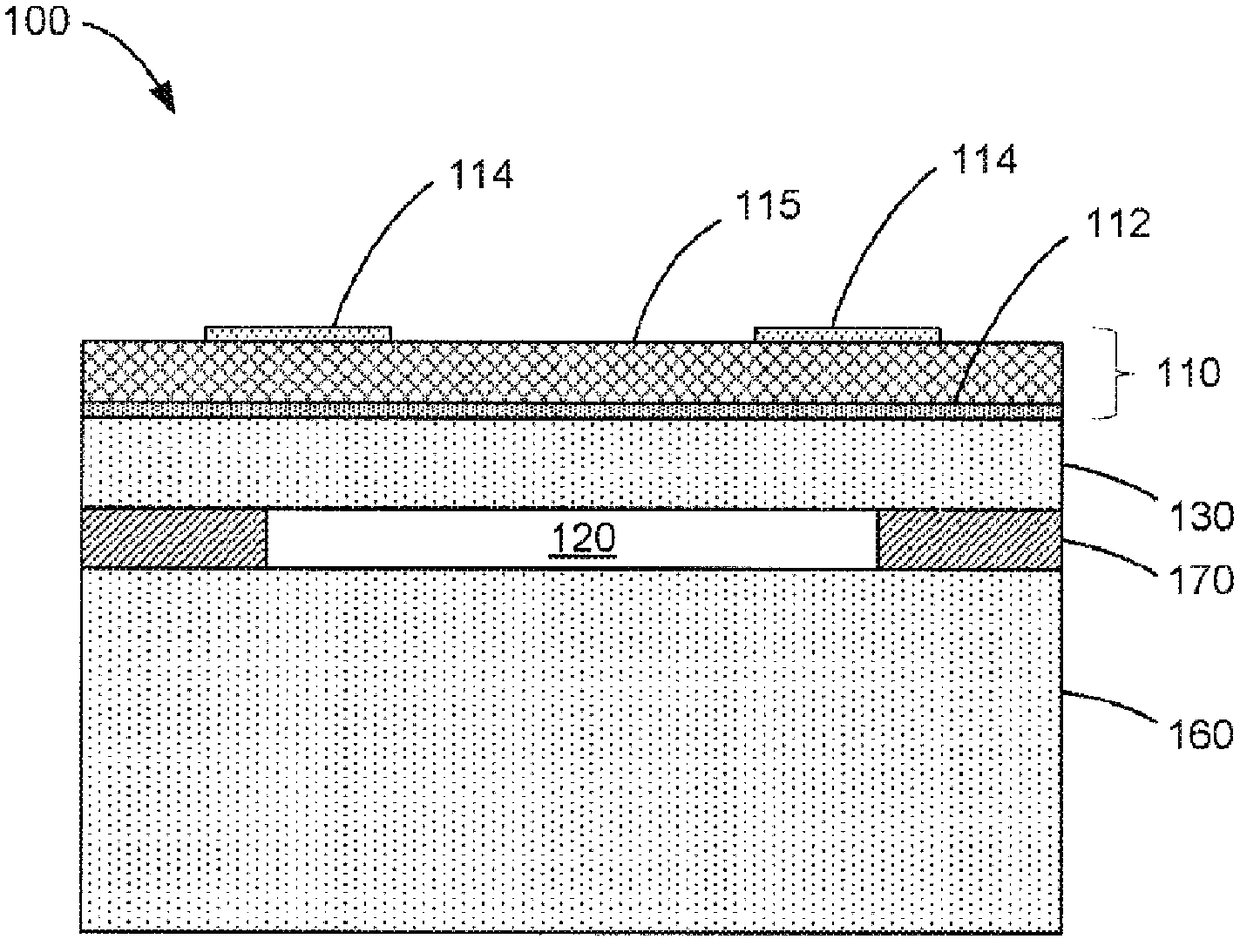

A transceiver includes an array of pMUT elements, where each pMUT element includes: a substrate; a membrane suspending from the substrate; a bottom electrode disposed on the membrane; a piezoelectric layer disposed on the bottom electrode; and a first electrode disposed on the piezoelectric layer. Each pMUT element exhibits one or more modes of vibration.

Owner:EXO IMAGING INC

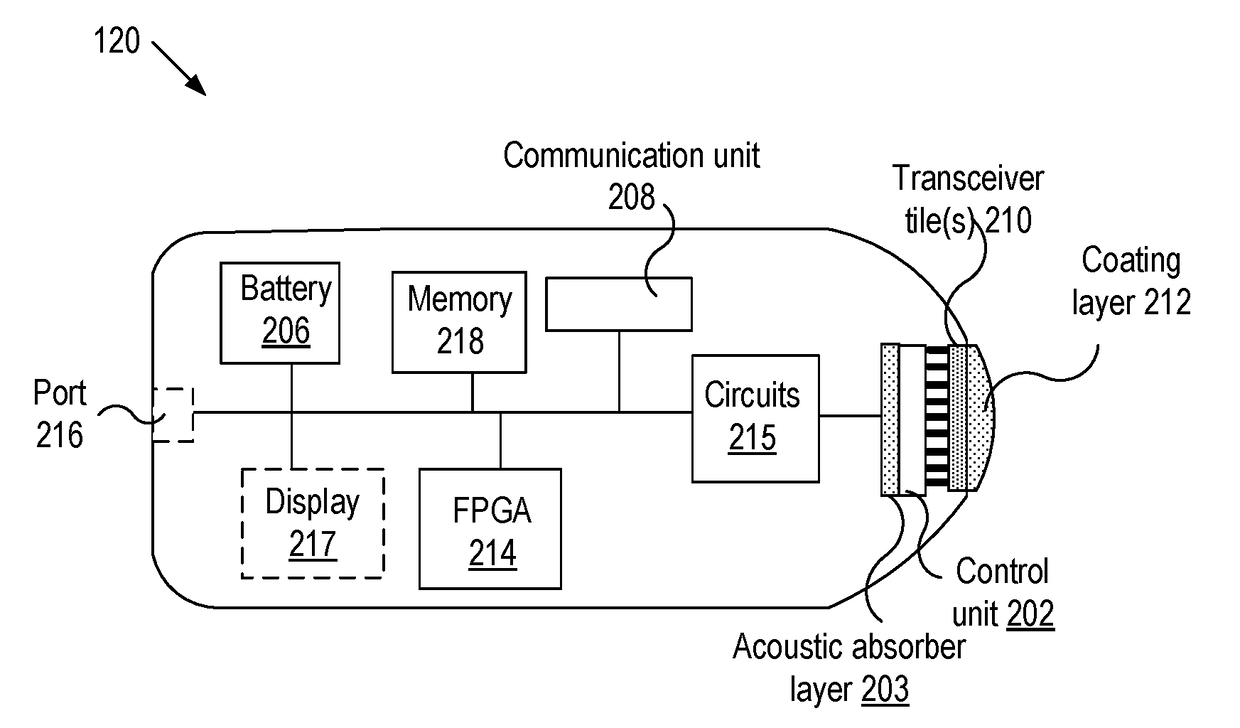

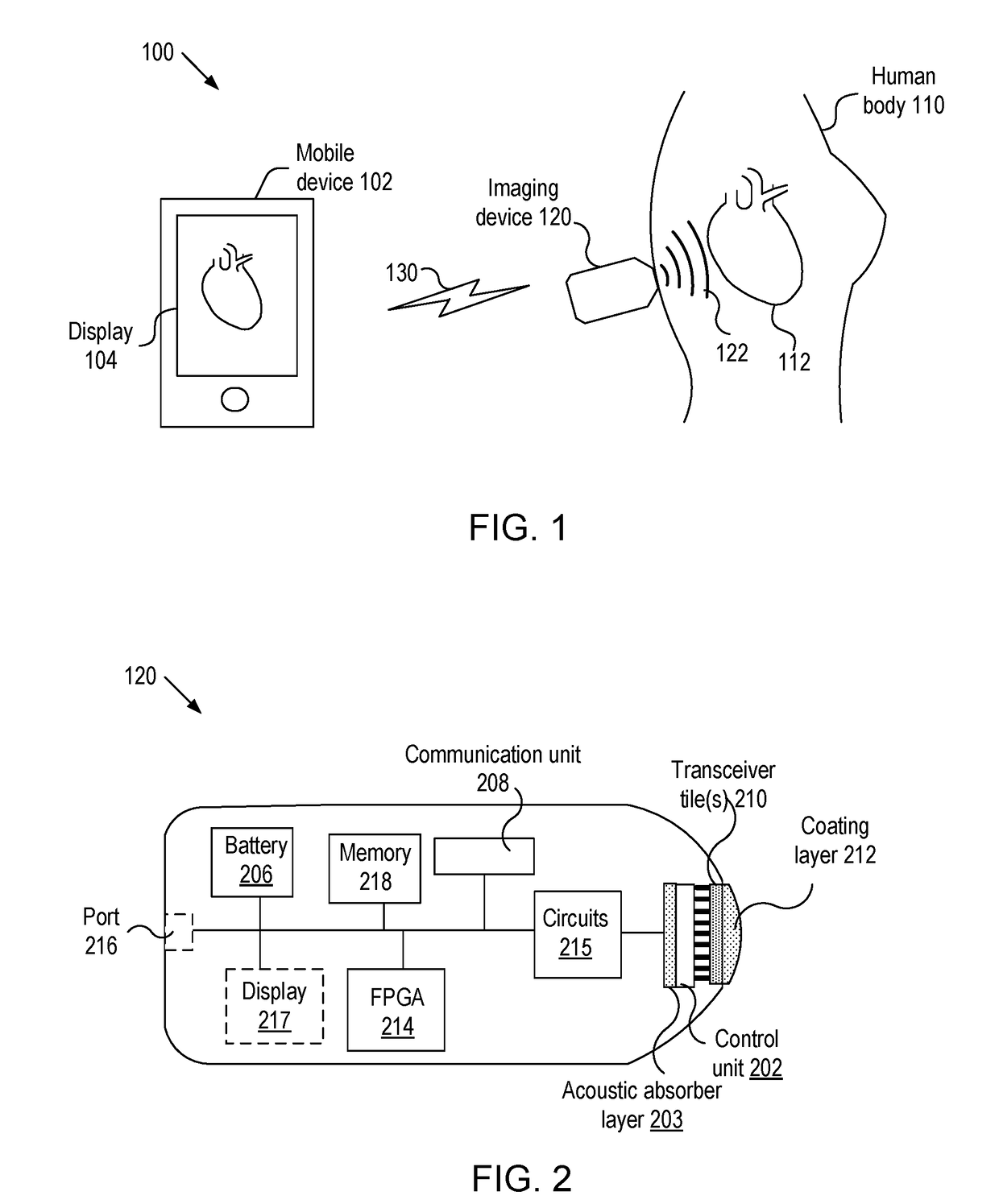

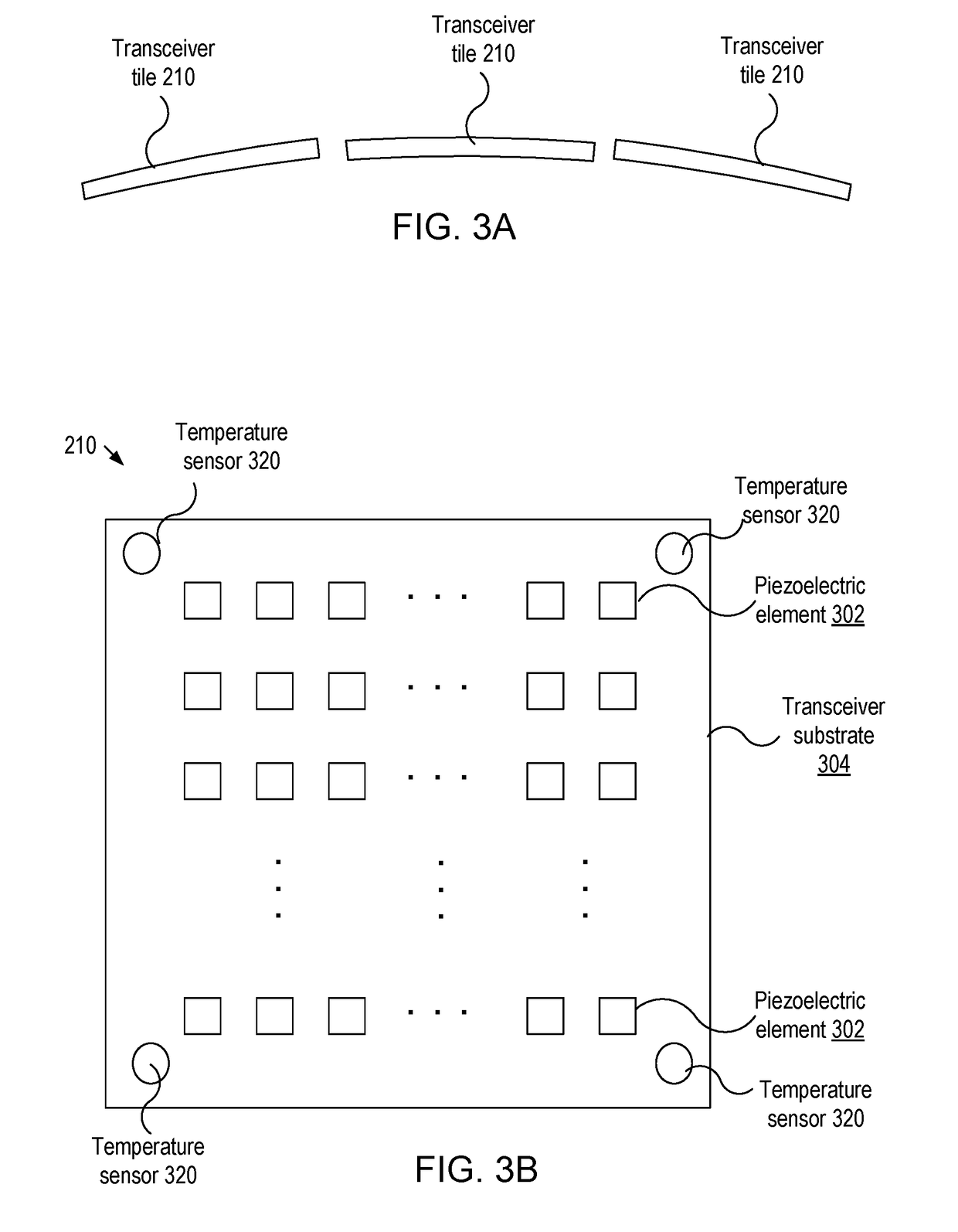

Miniature ultrasonic imaging system

ActiveUS20160262725A1Easy to superviseEasy compatibilityBlood flow measurement devicesOrgan movement/changes detectionUltrasonic imagingPMUT

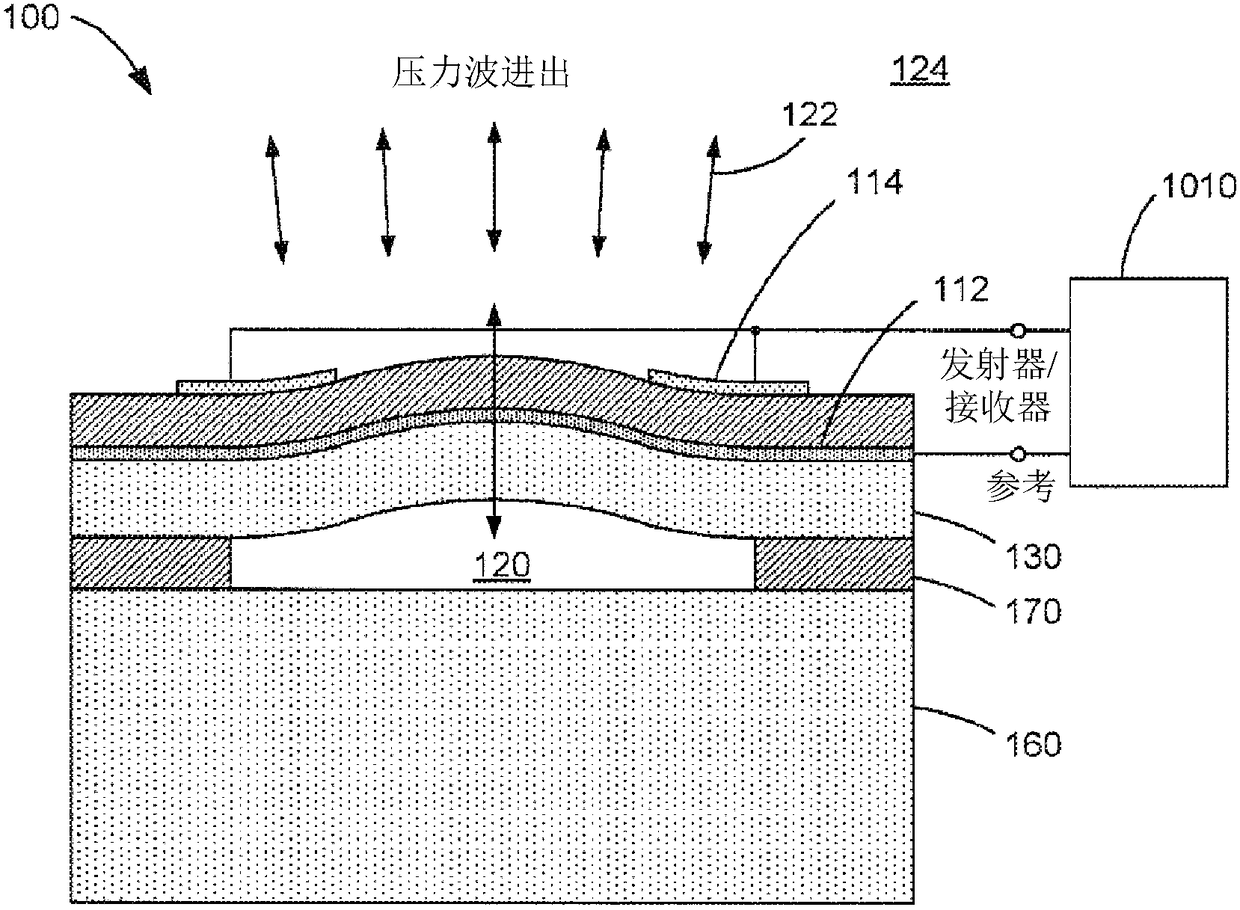

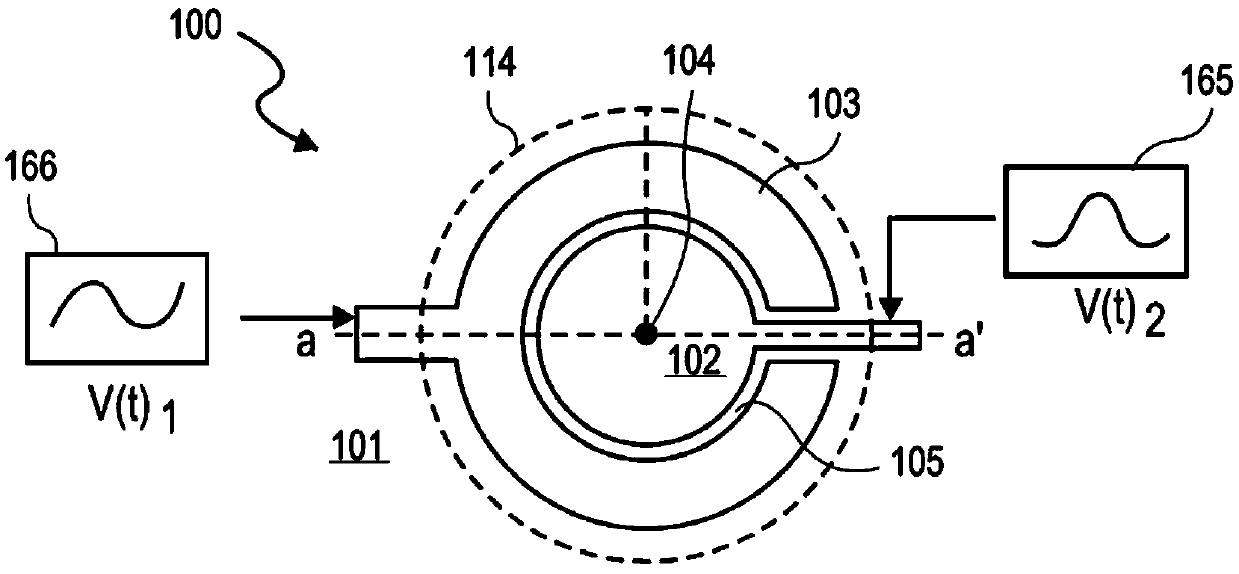

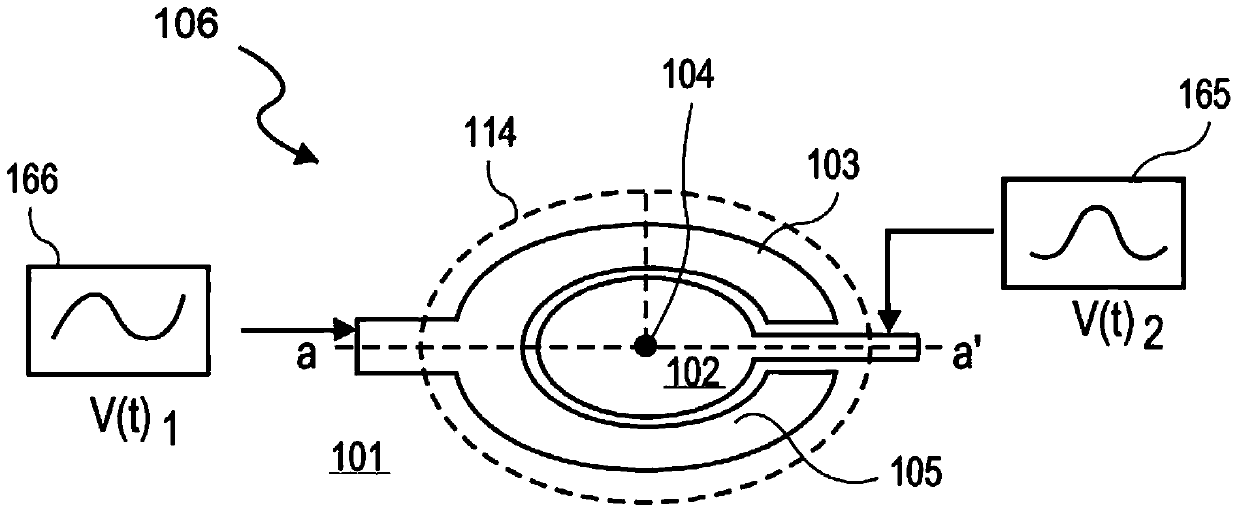

An ultrasonic imaging apparatus having a Micro-machined Ultrasonic Transducer (MUT), such as a Piezoelectric MUT (PMUT) or Capacitive MUT (CMUT), with a transmitting mode and a receiving mode for generating and sensing acoustic pressure in imaging applications. During transmission in a PMUT the inverse piezoelectric effect on the piezo layer causes transverse stress, which causes a bending moment in the PMUT structure leading to out-of-plane deflection. Different applied signs of voltage generates different signs of stress inside the piezo that in turn cause oscillating motion generating an acoustic pressure wave. During signal reception, incident pressure waves deflect the PMUT creating transverse stress, resulting in a charge determined through measuring voltage between electrodes. The apparatus is particularly well-suited for use in health care, such as measuring fat / muscle thickness, blood-flow, and blood pressure.

Owner:RGT UNIV OF CALIFORNIA

Integrated piezoelectric micromechanical ultrasonic transducer pixel and array

An ultrasonic sensor pixel includes a substrate, a piezoelectric micromechanical ultrasonic transducer (PMUT) and a sensor pixel circuit. The PMUT includes a piezoelectric layer stack including a piezoelectric layer disposed over a cavity, the cavity being disposed between the piezoelectric layer stack and the substrate, a reference electrode disposed between the piezoelectric layer and the cavity, and one or both of a receive electrode and a transmit electrode disposed on or proximate to a first surface of the piezoelectric layer, the first surface being opposite from the cavity. The sensor pixel circuit is electrically coupled with one or more of the reference electrode, the receive electrode and the transmit electrode and the PMUT and the sensor pixel circuit are integrated with the sensor pixel circuit on the substrate.

Owner:QUALCOMM INC

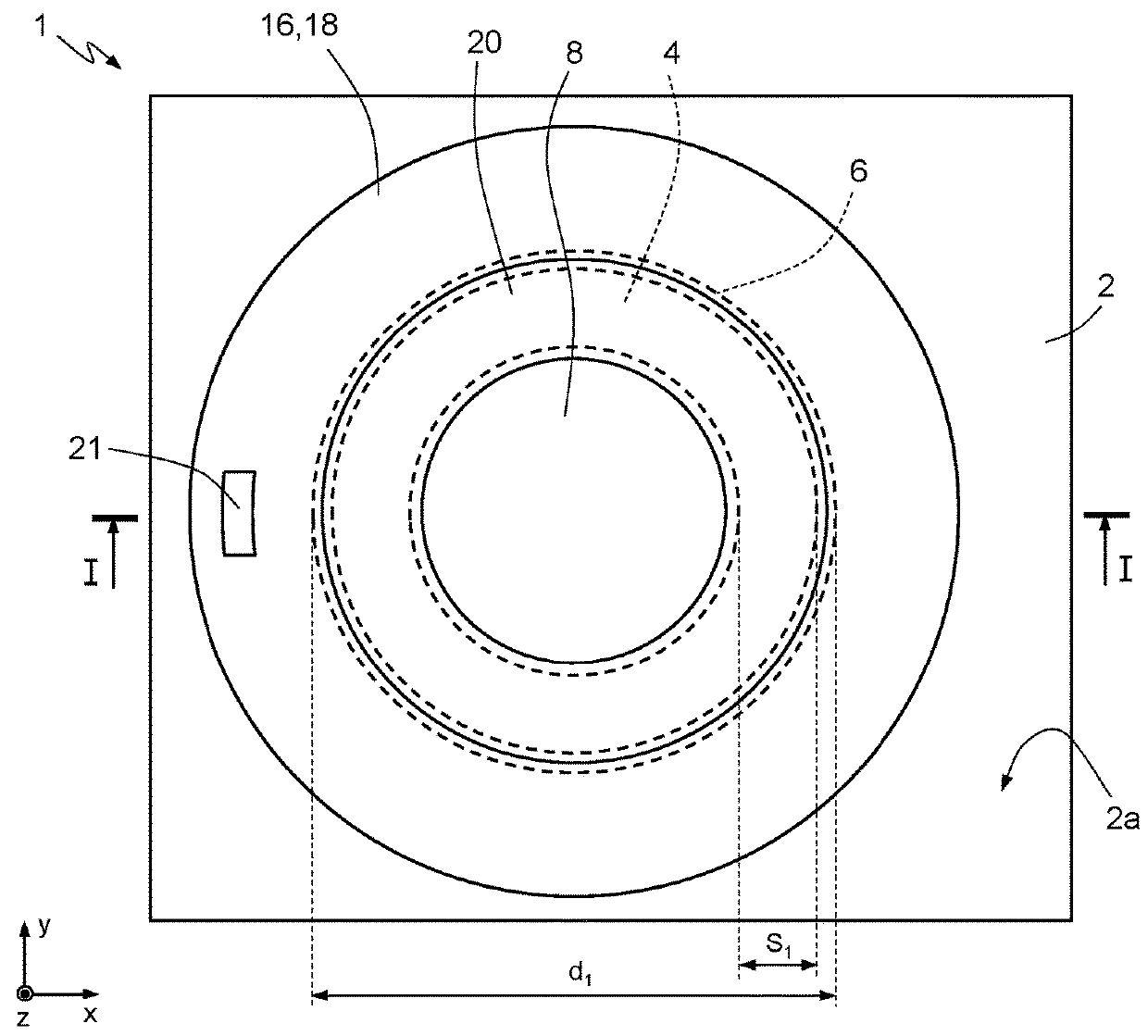

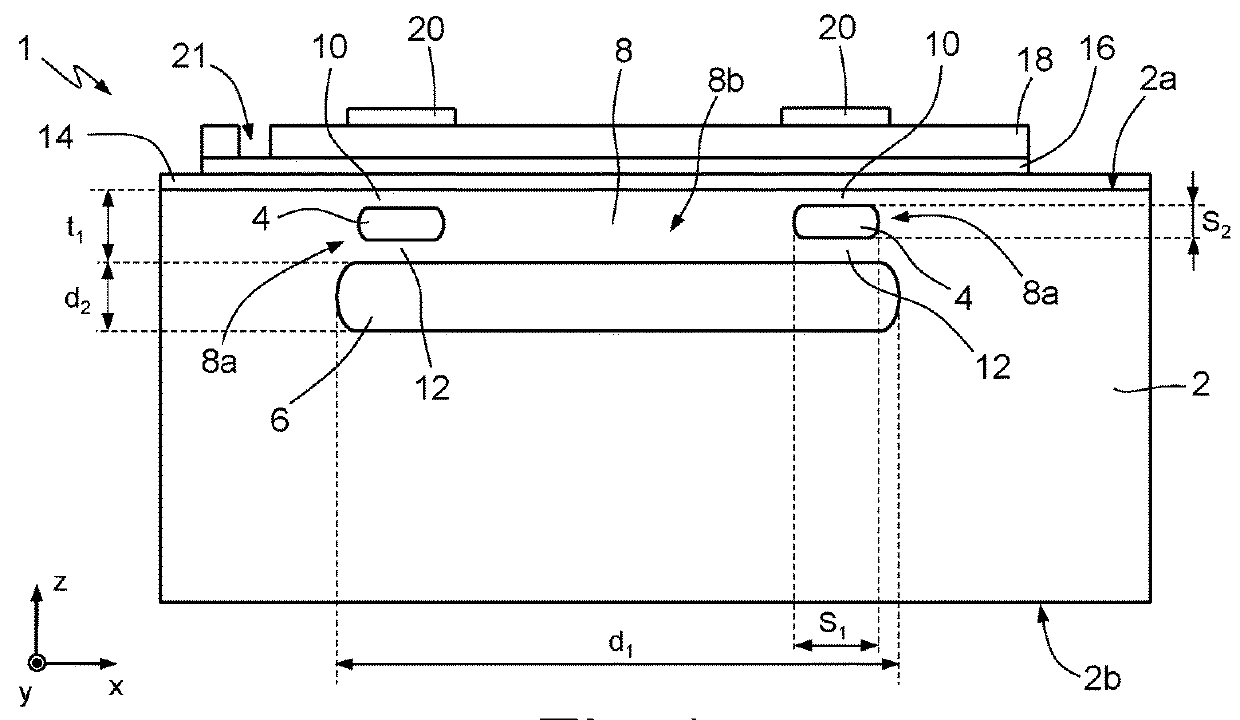

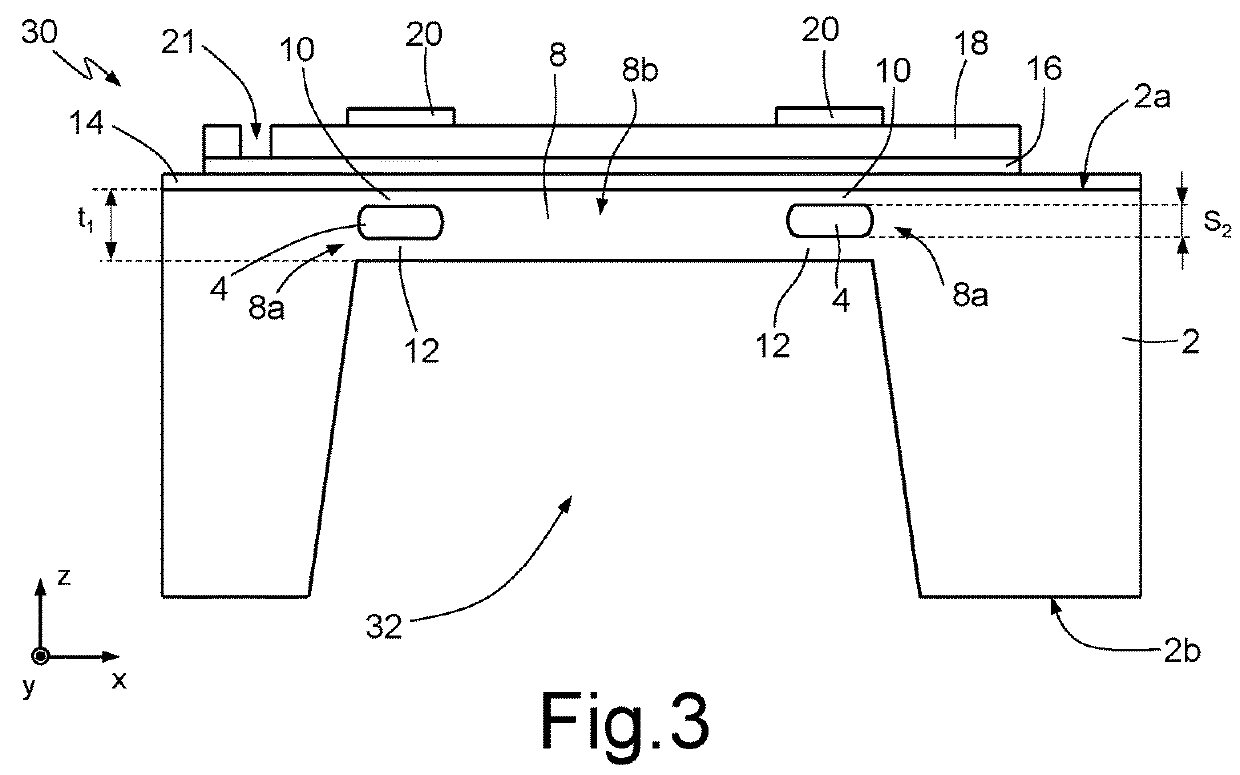

Piezoelectric micro-machined ultrasonic transducer (PMUT) and method for manufacturing the pmut

ActiveUS20180178251A1Subsonic/sonic/ultrasonic wave measurementUsing electrical meansPMUTSemiconductor

A piezoelectric micro-machined ultrasonic transducer (PMUT) comprising: a semiconductor body having a first cavity and a membrane, which is suspended over the first cavity and faces a front side of the semiconductor body; and a piezoelectric transducer assembly extending at least in part on the membrane, which may be actuated for generating a deflection of the membrane. A second cavity extends buried in a peripheral region of the membrane and delimits a central region of the membrane. Moreover, the peripheral portion has a stiffness lower than the stiffness of the central portion.

Owner:STMICROELECTRONICS SRL

Micromechanical ultrasonic transducers and display

An apparatus may include a one- or two-dimensional array of micromechanical ultrasonic transducer (PMUT) elements positioned below, beside, with, on, or above a backplane of a visual display. The backplane may be a thin-film transistor (TFT) backplane. The array of PMUT elements may be a piezoelectric micromechanical ultrasonic transducer (PMUT) array or a capacitive micromechanical ultrasonic transducer (CMUT) array. The PMUT array may be configurable to operate in modes corresponding to multiple frequency ranges. When operating in the low-frequency mode, the apparatus may be capable of gesture detection. A high-frequency mode may include a fingerprint sensor mode or a stylus detection mode.

Owner:QUALCOMM INC

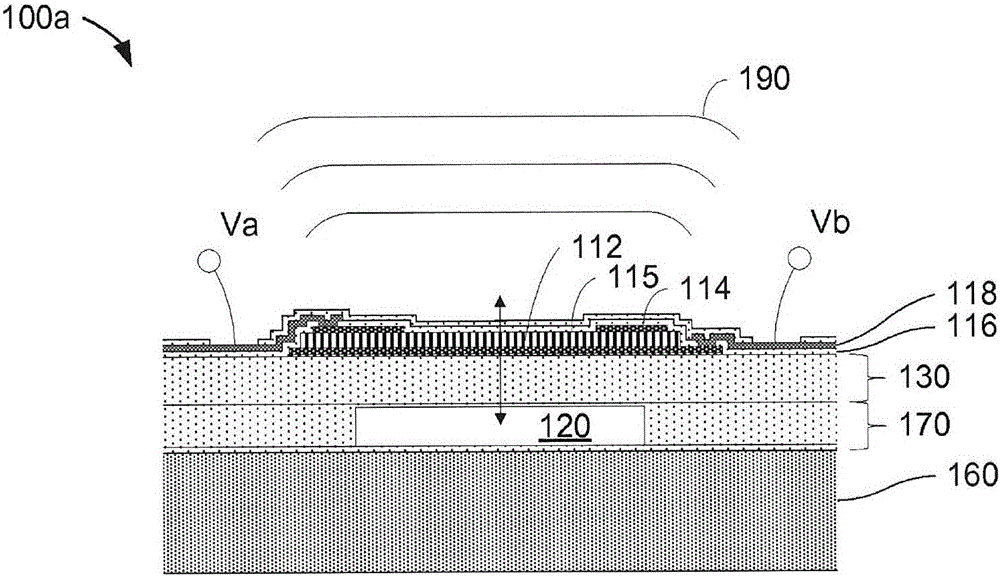

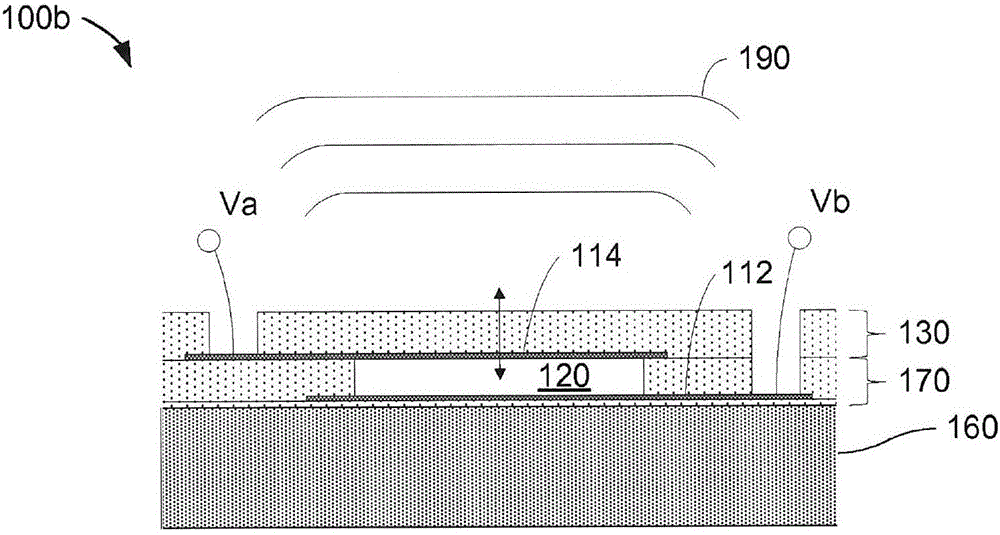

Piezoelectric micromachined ultrasonic transducers using two bonded substrates

ActiveUS20170128983A1Reducing mechanical cross-talkIncrease acoustic output pressurePiezoelectric/electrostrictive device material selectionMechanical vibrations separationPMUTUltrasound

A piezoelectric micromachined ultrasound transducer (PMUT) is disclosed. The PMUT consists of a flexural membrane that is piezoelectrically actuated. These membranes are formed on a first substrate that is bonded to a second substrate. The two substrates are separated by an air gap to allow the PMUT to vibrate. Several methods for joining the two substrates are described.

Owner:INVENSENSE

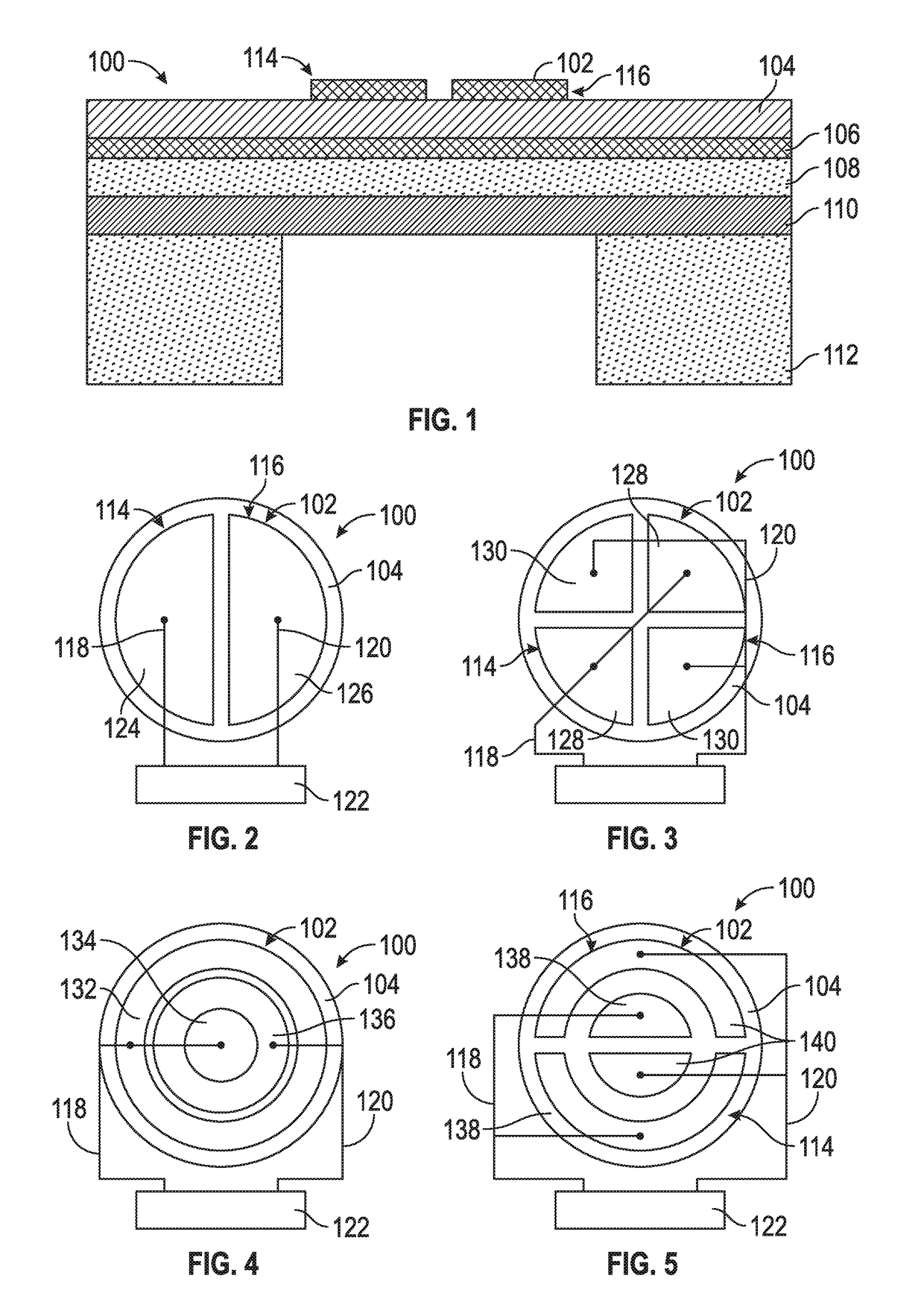

ELECTRODE ARRANGEMENT FOR A pMUT and pMUT TRANSDUCER ARRAY

Provided in accordance with the herein described exemplary embodiments are piezo micro-machined ultrasonic transducers (pMUTs) each having a first electrode that includes a first electrode portion and a second electrode portion. The second electrode portion is separately operable from the first electrode portion. A second electrode is spaced apart from the first electrode and defines a space between the first electrode and the second electrode. A piezoelectric material is disposed in the space. Also provided are arrays of pMUTs wherein individual pMUTs have first electrode portions operably associated with array rows and second electrode portions operably associated with array columns.

Owner:VANGUARD INT SEMICON SINGAPORE PTE LTD

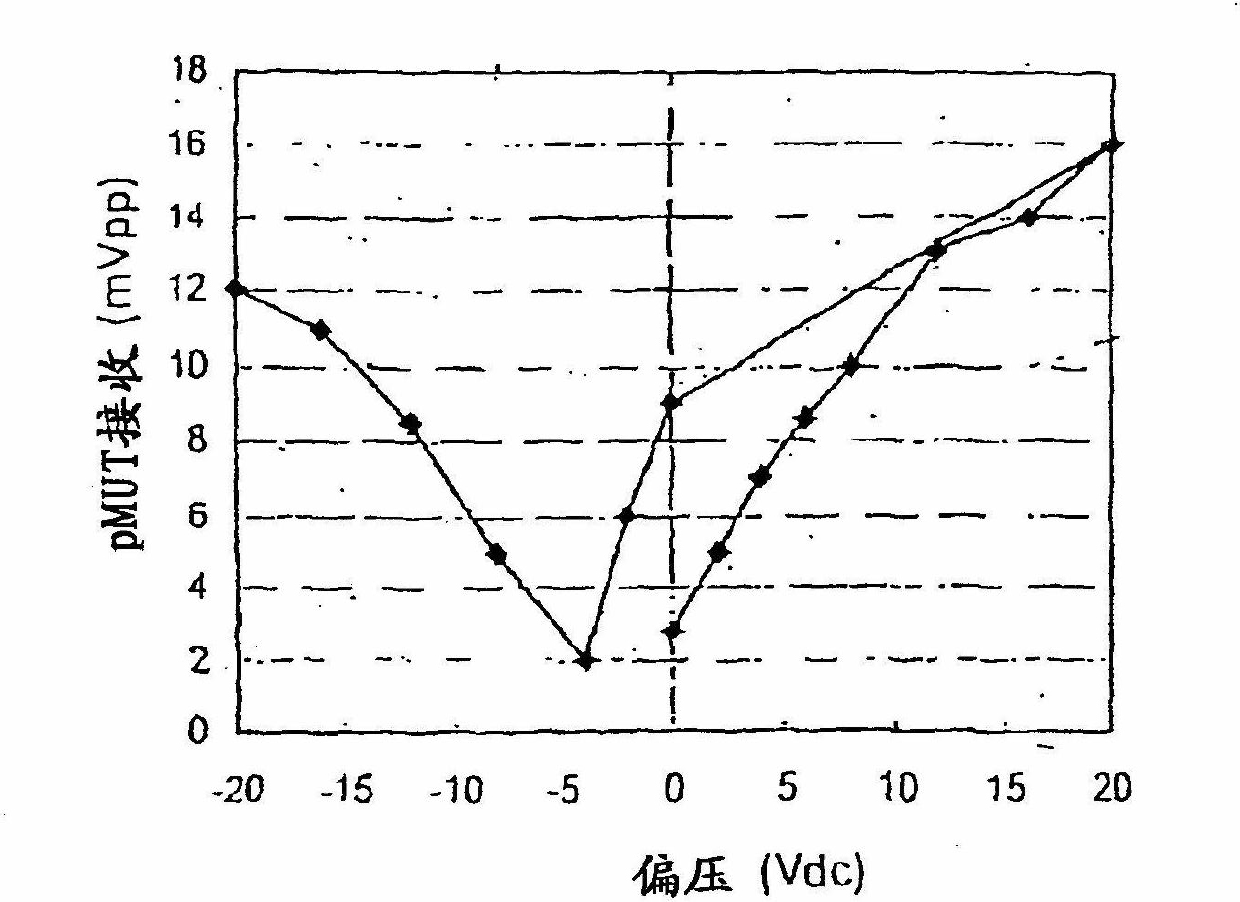

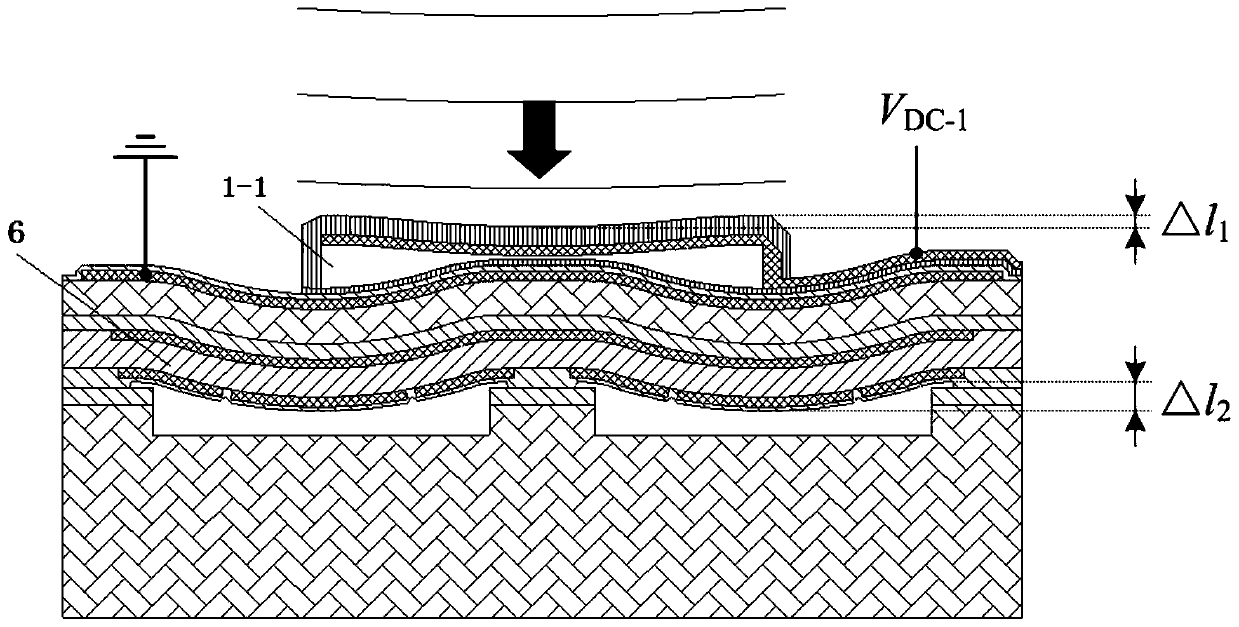

Enhanced ultrasonic imaging probe using flexural-mode piezoelectric transducer

The invention relates to an enhanced ultrasonic imaging probe using a flexural-mode piezoelectric transducer and discloses a method for generating an enhanced receiving signal by the piezoelectric ultrasonic transducer. The method comprises the following steps of: supplying the piezoelectric ultrasonic transducer, wherein the piezoelectric ultrasonic transducer comprises a piezoelectric element which can work under a flexural mode; receiving an acoustic signal by the piezoelectric element; applying DC (Direct Current) bias voltage to the piezoelectric element before receiving the acoustic signal and / or while receiving the acoustic signal; and generating the enhanced receiving signal by the piezoelectric element, and using the enhanced receiving signal as a result of receiving the acoustic signal by the piezoelectric element. The invention also discloses an imaging probe based on a pMUT (Piezoelectric Micro-processing Ultrasonic Transducer) using the method.

Owner:RES TRIANGLE INST +1

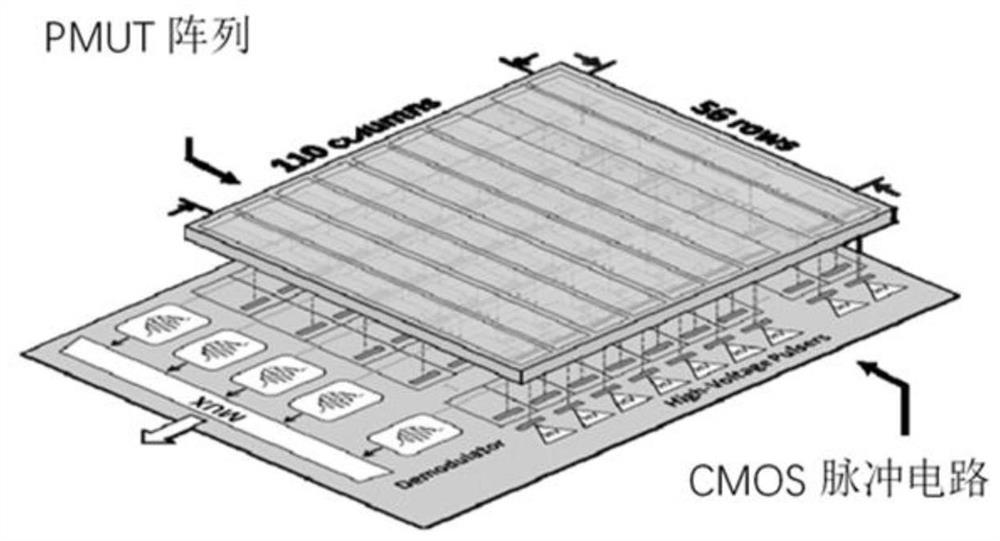

Monolithic integration of PMUT on CMOS

ActiveUS10322929B2Reduce distanceImprove fill factorMaterial analysis using sonic/ultrasonic/infrasonic wavesSolid-state devicesCMOSDielectric

This disclosure describes a monolithic integrated device that comprises a substrate layer being the base of the device, an inter-layer dielectric disposed on top of the substrate layer and below a passivation layer, an electronic circuitry formed within the inter-layer dielectric and supported by the substrate layer, the electronic circuitry comprises a plurality of metal layers formed by one or more spaced apart metals; and at least one micromachined ultrasonic transducer. Each micromachined ultrasonic transducer comprises a bottom electrode disposed on top of the passivation layer and connected to the electronic circuitry, a piezoelectric disposed on top of the bottom electrode, a top electrode disposed on top of the piezoelectric, and an elastic layer positioned on top of the top electrode. There is a cavity formed below the bottom electrode that extends from the passivation layer to a portion of the inter-layer dielectric.

Owner:SILTERRA MALAYSIA

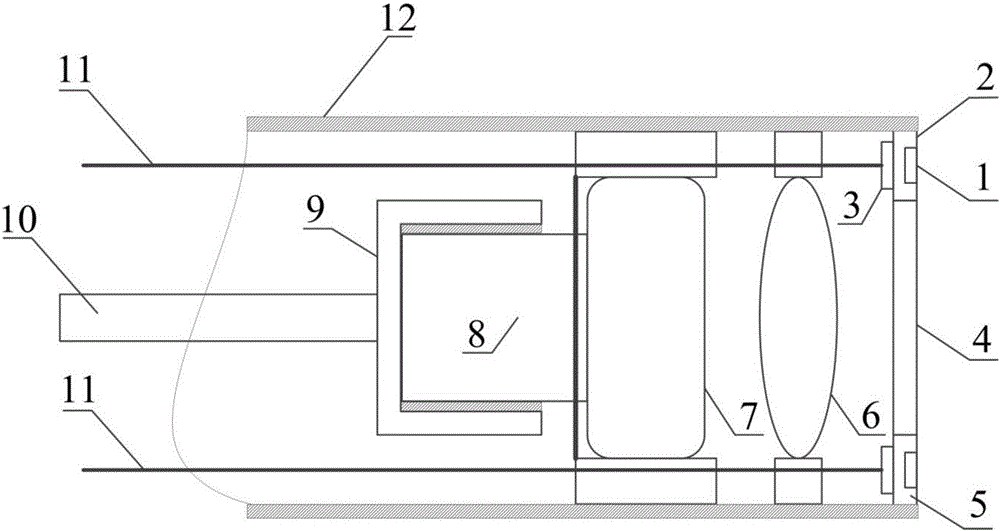

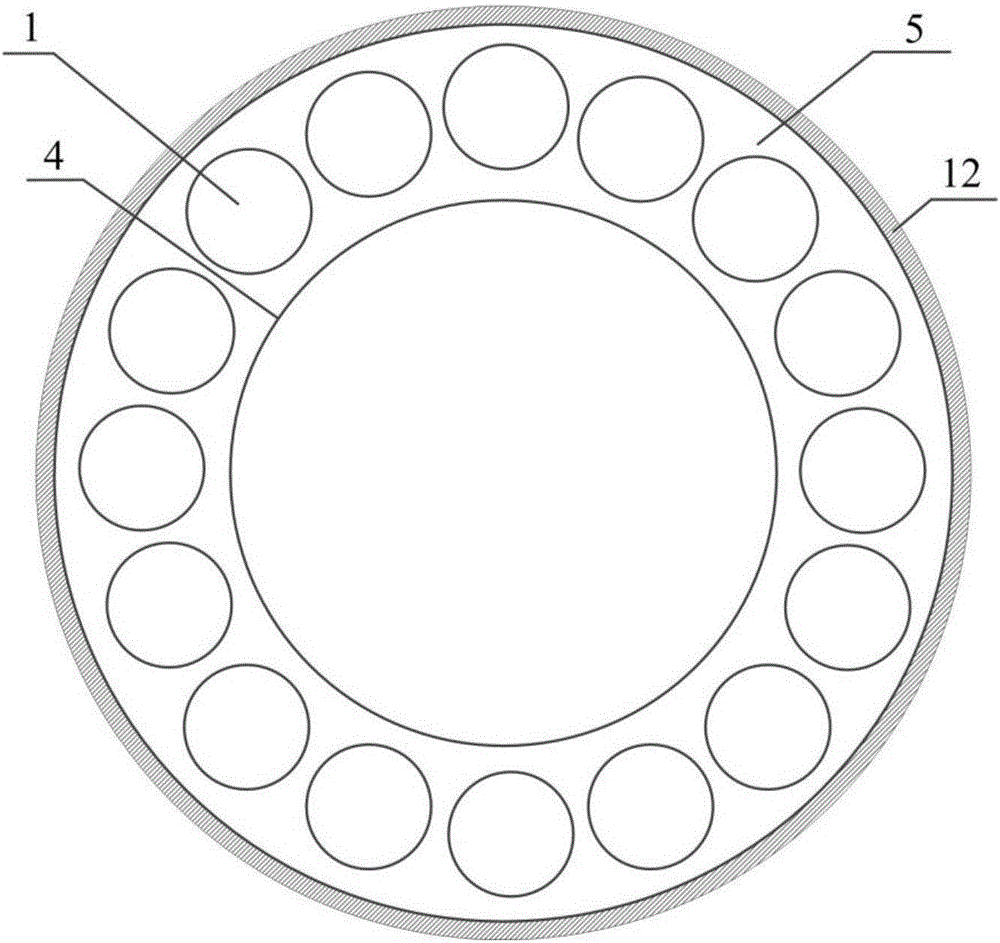

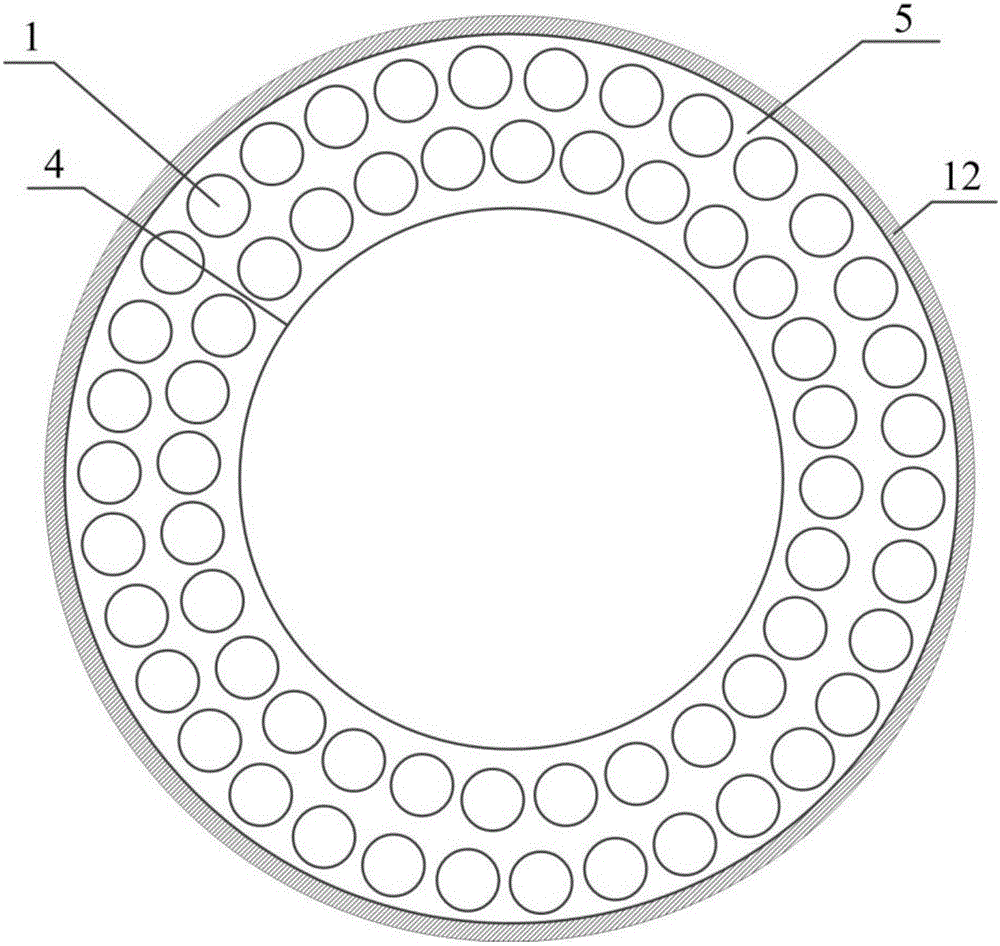

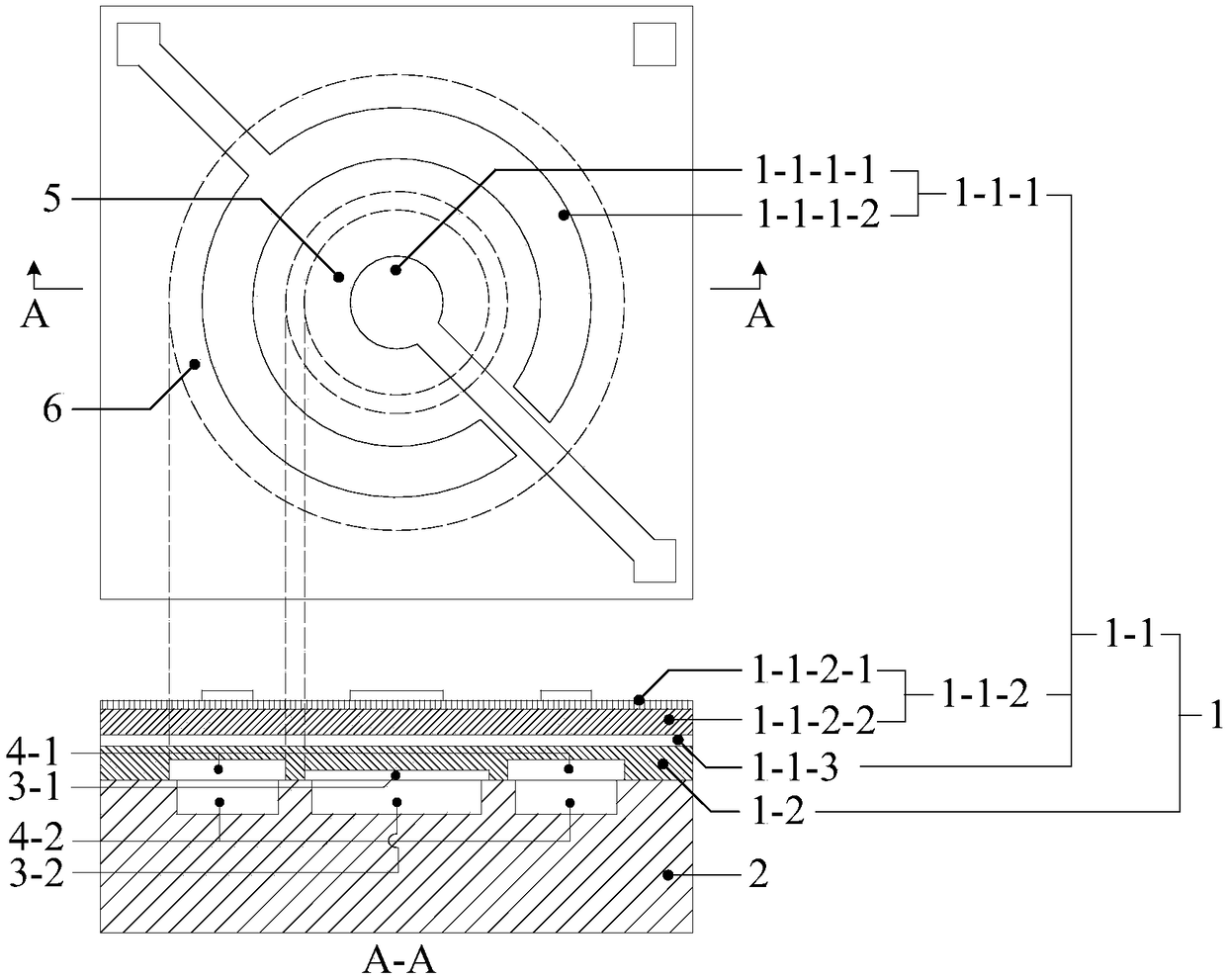

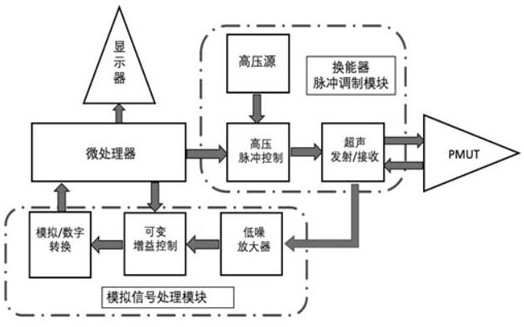

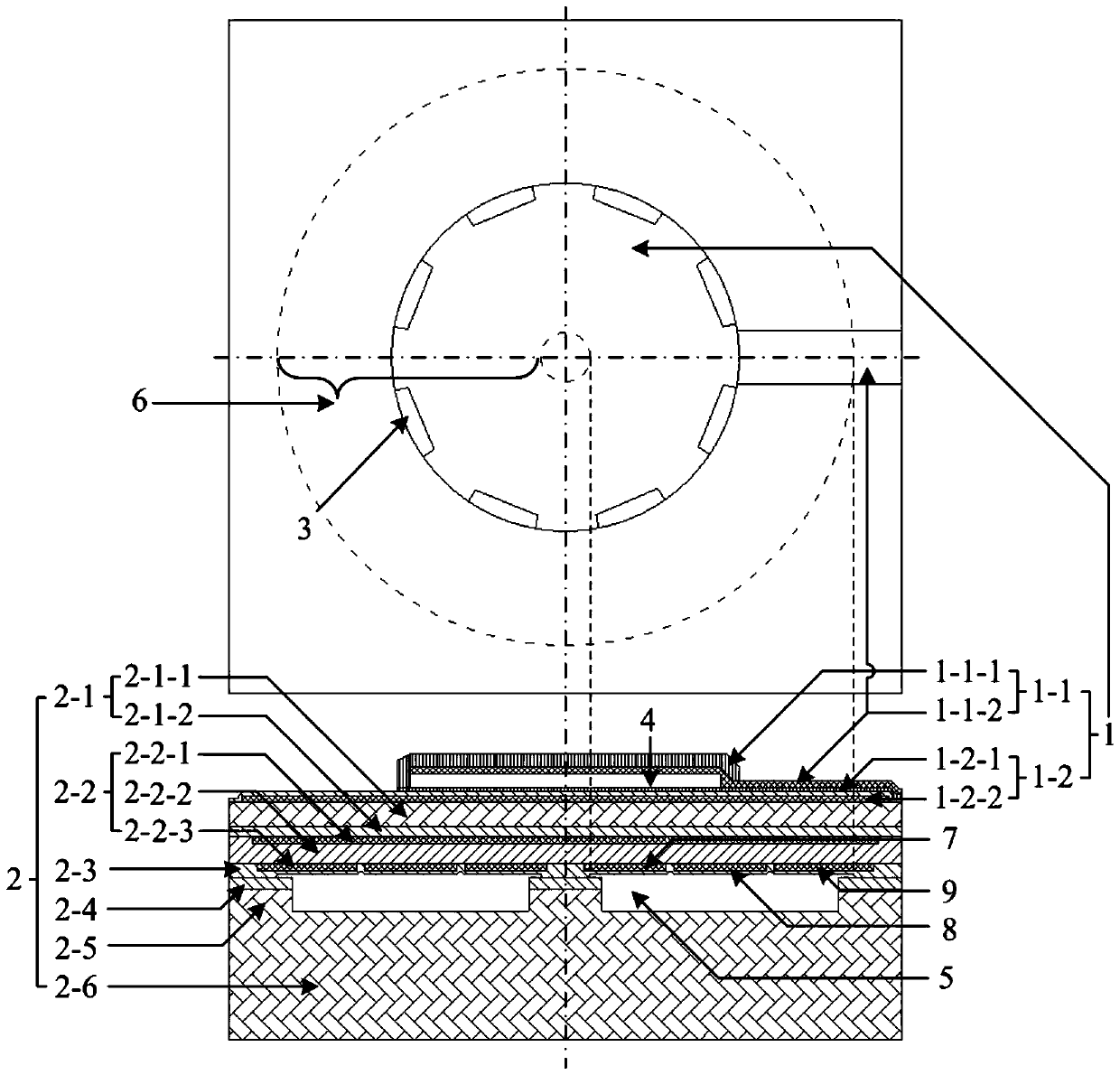

Optoacoustic/ultrasonic dual mode endoscope based on miniature piezoelectric ultrasonic transducer arrays

The invention discloses an optoacoustic / ultrasonic dual mode endoscope based on piezoelectric micromachined ultrasonic transducer arrays. The optoacoustic / ultrasonic dual mode endoscope includes a piezoelectric micromachined ultrasonic transducer (PMUT) array probe (2), a PMUT array element (1), an integrated circuit (3), a plane lens (4), a condenser lens (6), an optical fiber coupling collimator (7), a single-mode fiber (8), an optical fiber FC / APC connector (9), an optical fiber (10), a signal line (11) and an housing (12). The optoacoustic / ultrasonic dual mode endoscope is characterized in that, the piezoelectric micromachined ultrasonic transducers are adopted, the transducers and the integrated circuit are good in compatibility during manufacturing process, and the transducers are easy to form an array; transducer arrays are adopted, the endoscope does not need to rotate, the imaging speed is raised, real time imaging is achieved; and the multiple transducer arrays can effectively raise the signal to noise ratio of a signal, deep imaging through focusing and scanning is achieved. The optoacousitc / ultrasonic dual mode endoscope can be widely applied to fields of medical endoscopes and industrial flaw detection, and particularly has great application value in in-vivo scar tissue identification, assessment of damage of ablation of tissue, atherosclerotic degree assessment and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

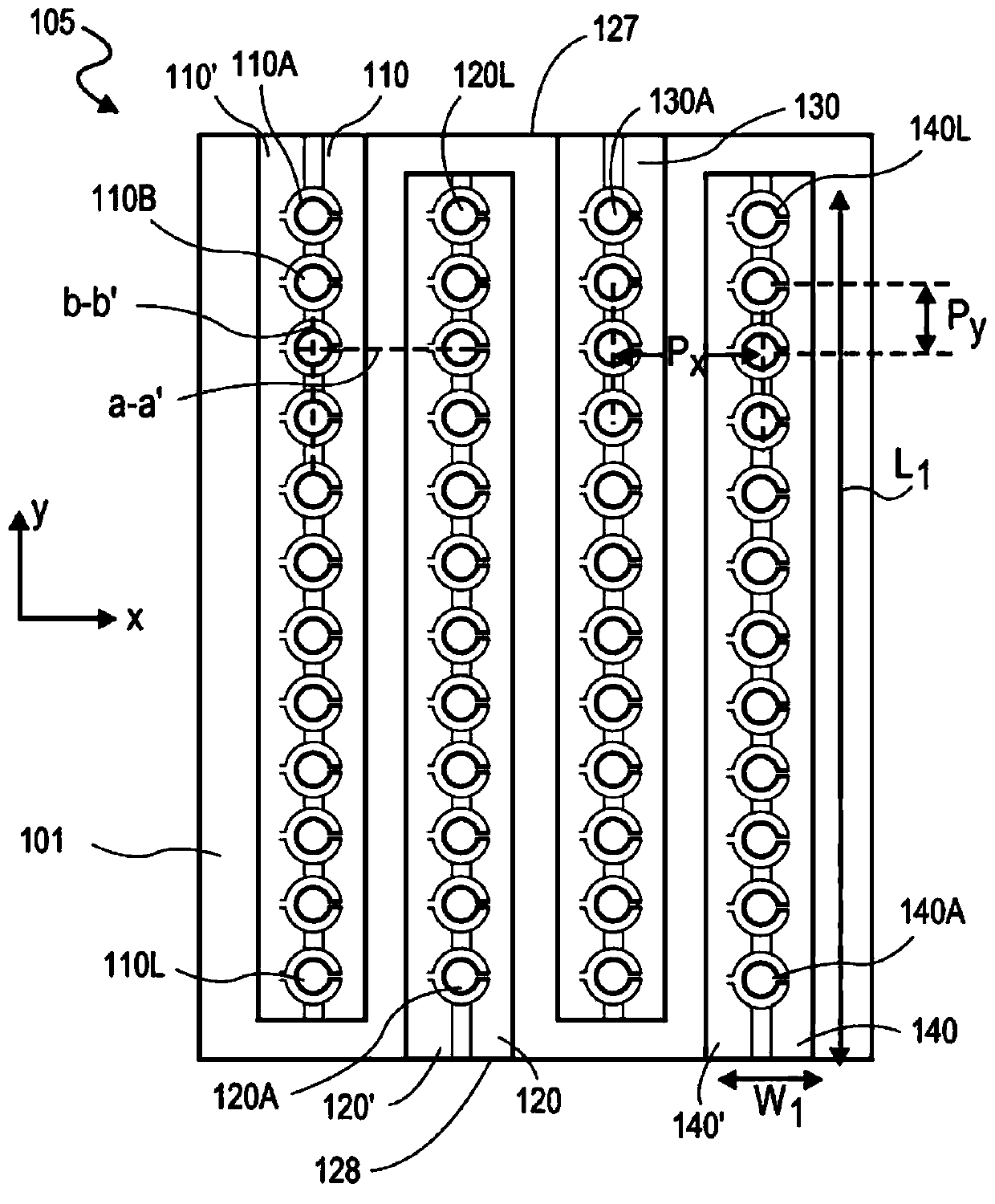

pMUT ARRAY FOR ULTRASONIC IMAGING, AND RELATED APPARATUSES, SYSTEMS, AND METHODS

ActiveUS20150265245A1Efficient executionImprove performanceWave based measurement systemsOrgan movement/changes detectionUltrasonic imagingPMUT

Owner:DUKE UNIV

Flexible micro piezoelectric ultrasonic transducer, array and formation methods of flexible micro piezoelectric ultrasonic transducer and flexible micro piezoelectric ultrasonic transducer array

InactiveCN109301061AWith flexible baseGood flexibilityPiezoelectric/electrostrictive device manufacture/assemblyMechanical vibrations separationPMUTUltrasonic transducer array

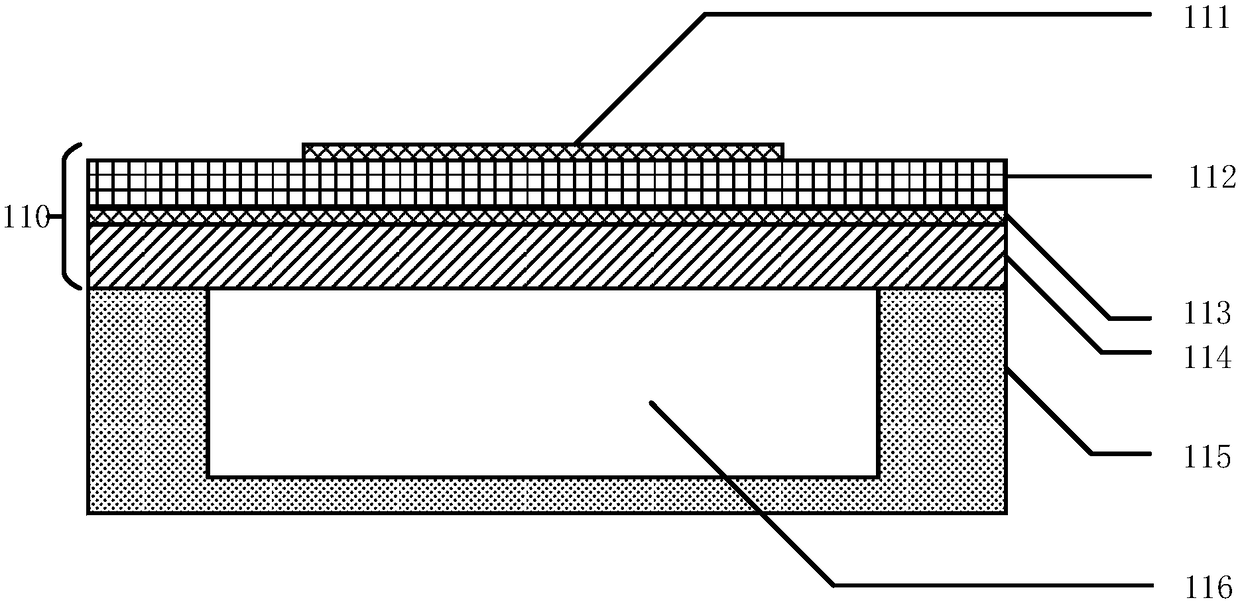

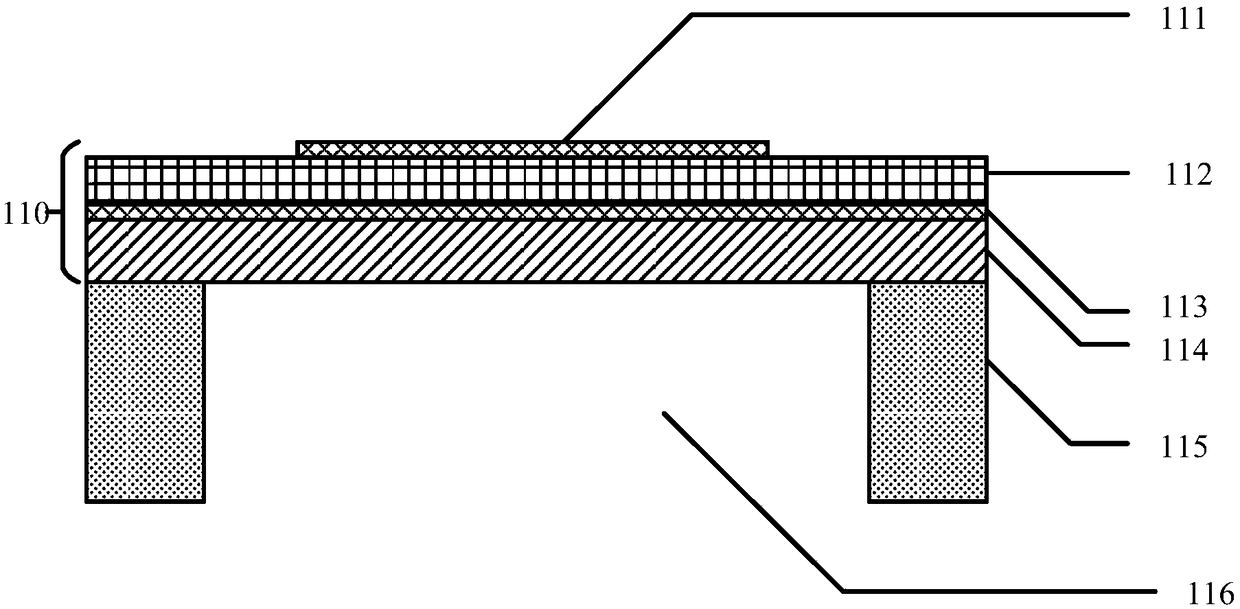

The invention provides a flexible micro piezoelectric ultrasonic transducer, a flexible micro piezoelectric ultrasonic transducer array and formation methods of the flexible micro piezoelectric ultrasonic transducer and the flexible micro piezoelectric ultrasonic transducer array. The flexible micro piezoelectric ultrasonic transducer is provided with a flexible substrate and has high flexibility.The flexible micro piezoelectric ultrasonic transducer of the invention includes a flexible substrate and PMUT structures; a first cavity is defined in the top of the flexible substrate; the depth ofthe first cavity is less than or equal to the thickness of the flexible substrate; the PMUT structures are located on the flexible substrate; and the PMUT structure comprises at least a lower electrode, a piezoelectric layer, and an upper electrode.

Owner:TIANJIN UNIV

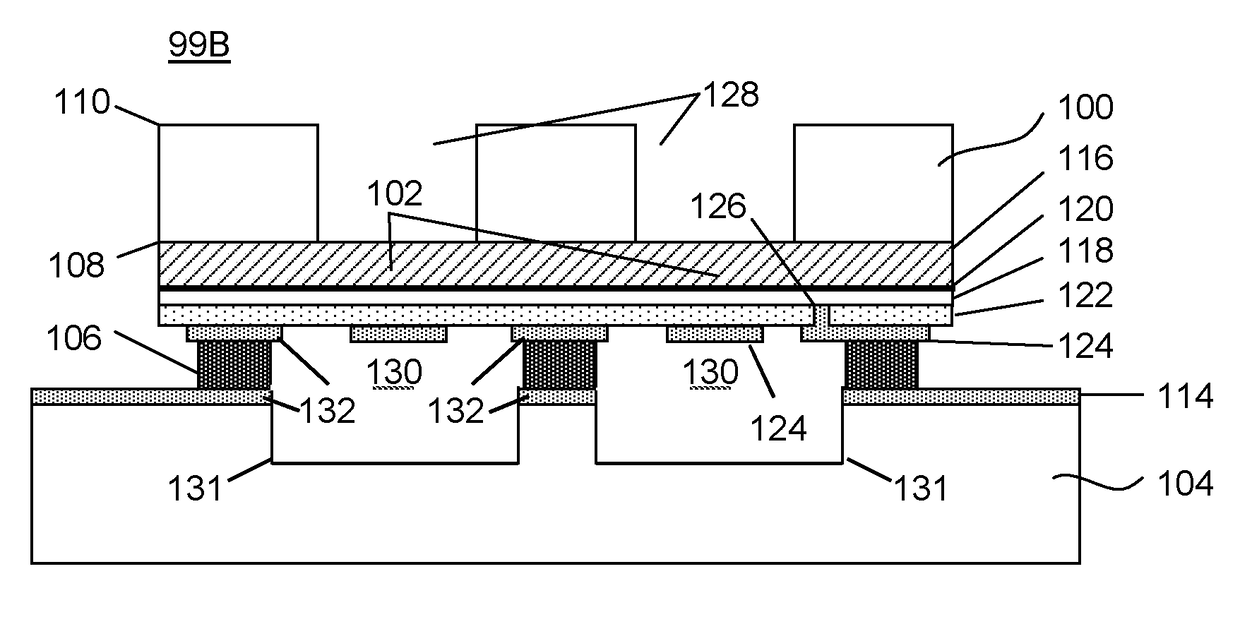

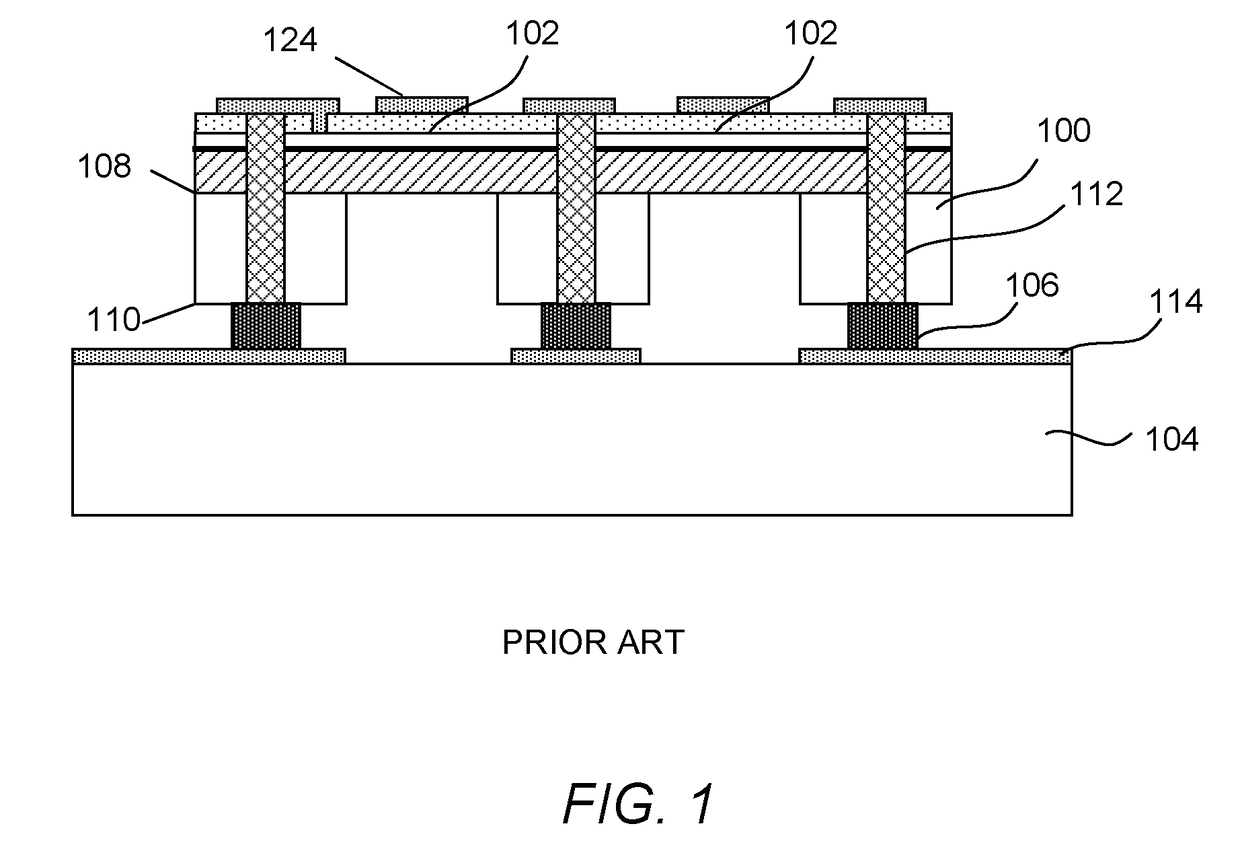

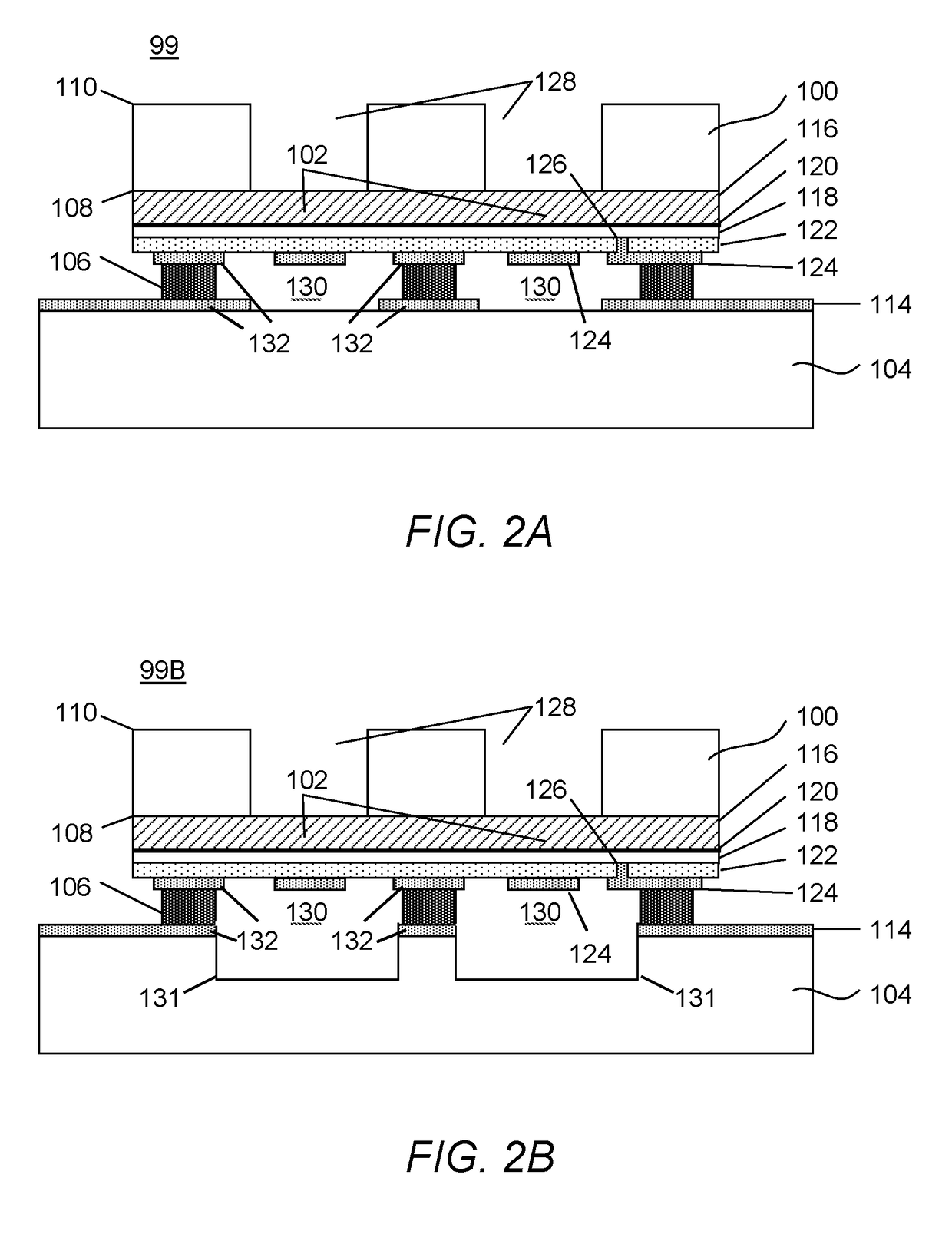

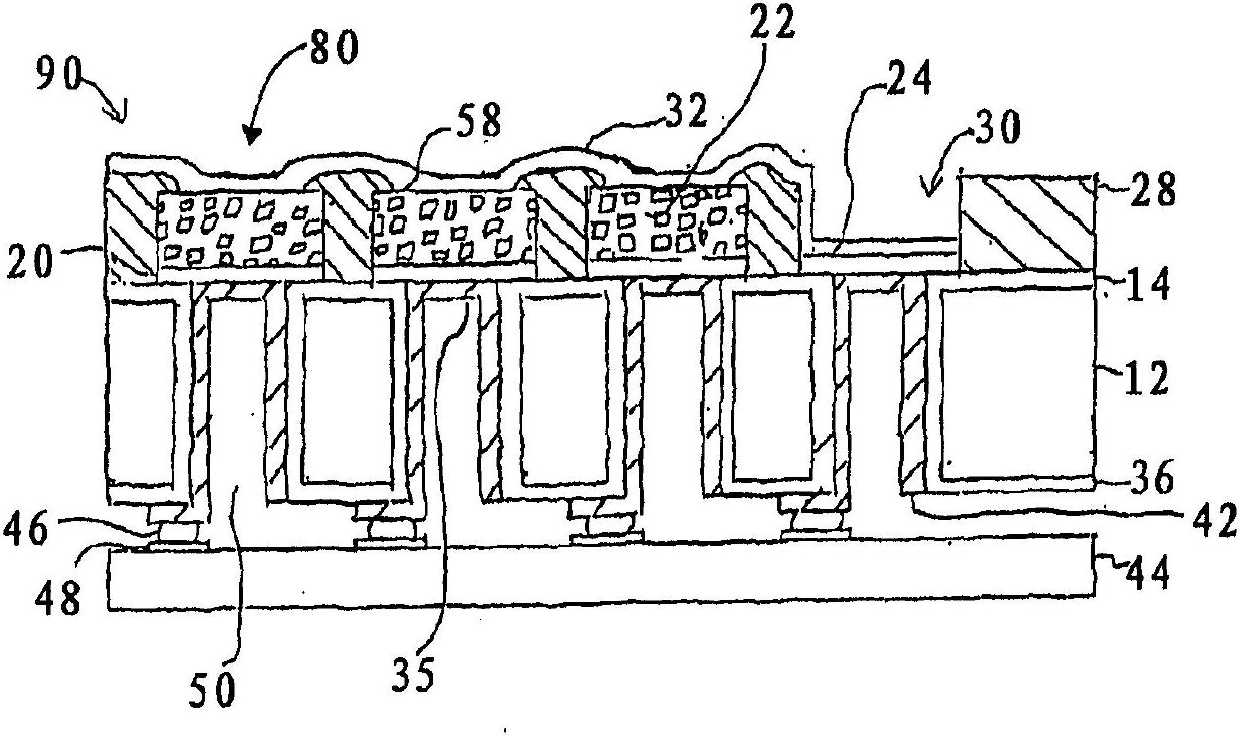

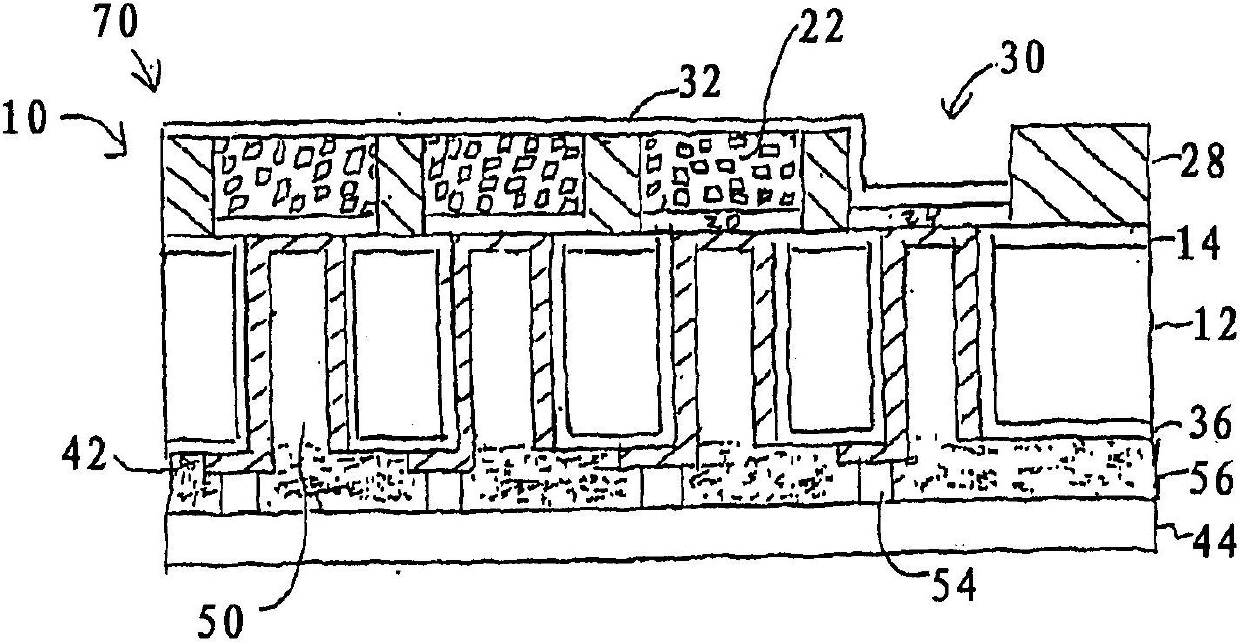

Methods for forming a connection with a micromachined ultrasonic transducer, and associated apparatuses

ActiveUS20130200753A1Ultrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive device manufacture/assemblyPMUTEngineering

A method and associated apparatus directed to a piezoelectric micromachined ultrasonic transducer (pMUT) defining an air-backed cavity are provided. A first via defined by a device substrate and associated dielectric layer, and extending to the first electrode, is substantially filled with a first conductive material. A support member engaged with the device substrate defines a second via extending to the first conductive material. The second via has a second conductive material disposed thereon, forms an electrically-conductive engagement with the first conductive material, and extends outwardly of the second via to be accessible externally to the support member. A connective element extends through a third via defined by a connection support substrate and is in electrically-conductive engagement with the second conductive material, wherein one of the connective element and connection support substrate is bonded to one of the support member and second conductive material by a bonding material engaged therebetween.

Owner:RES TRIANGLE INST

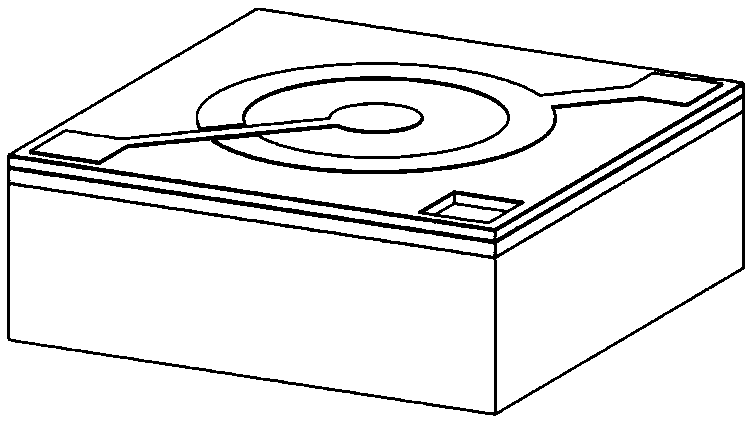

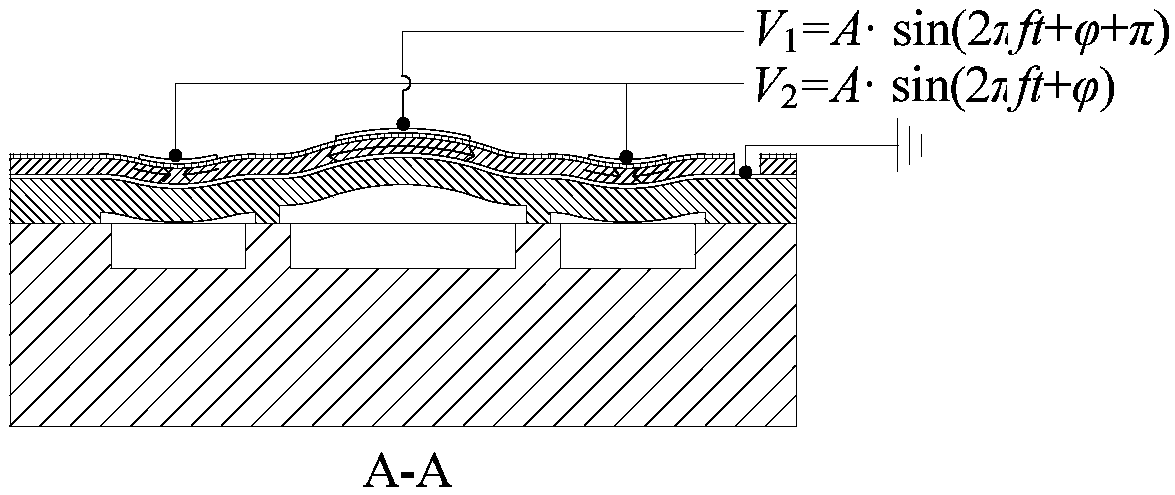

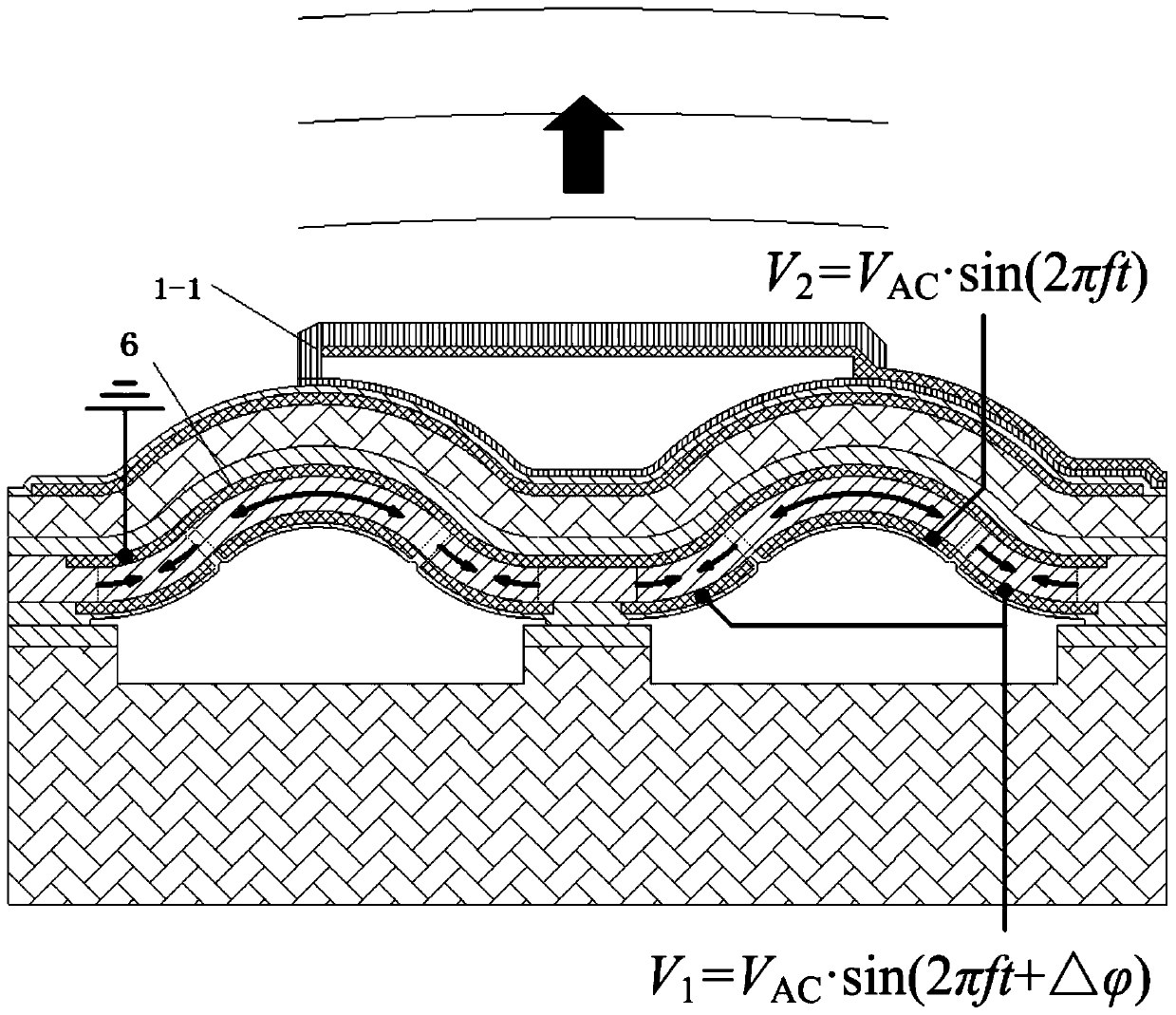

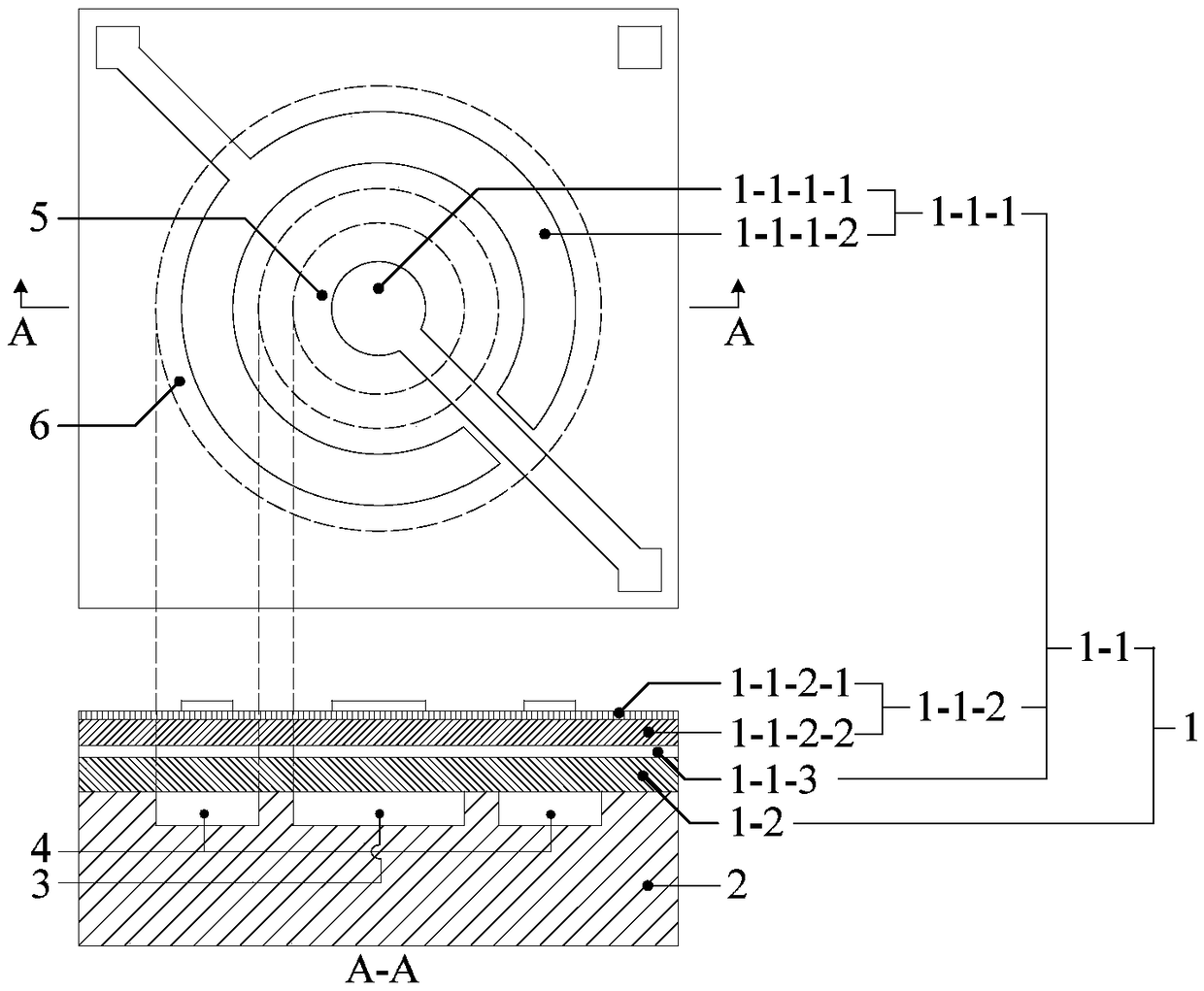

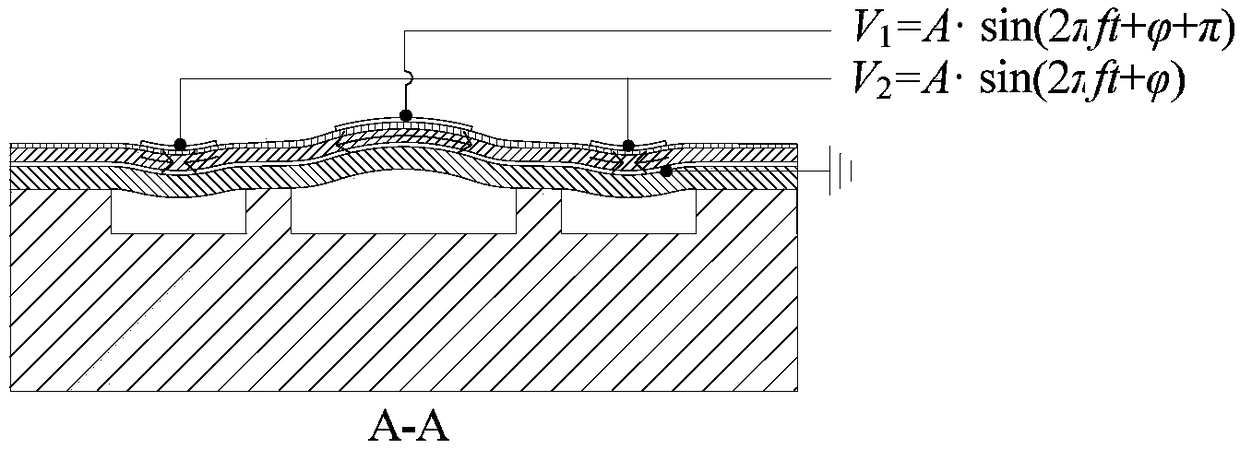

Combined stiffness-variable thin film pMUTs and preparation method thereof

ActiveCN109225789AIncrease the ultrasonic transmission powerImplementation of ultrasonic receptionMechanical vibrations separationResonancePhase difference

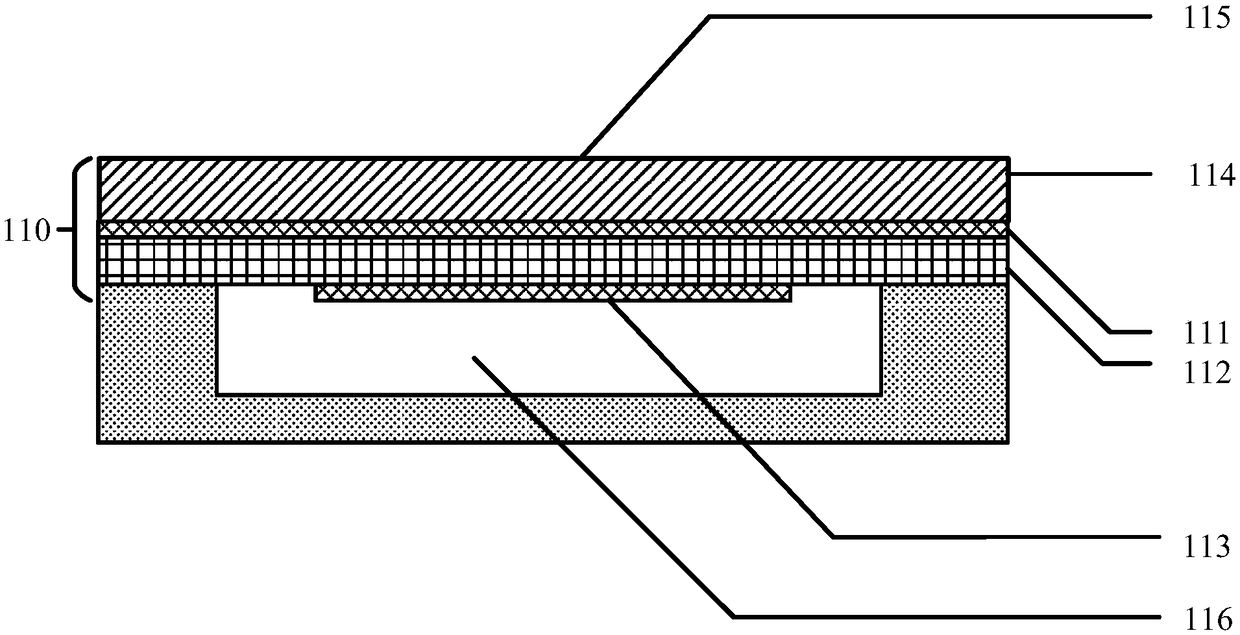

The invention provides combined stiffness-variable thin film pMUTs and a preparation method thereof. A combined stiffness-variable thin film structure is composed of circular thin film and annular thin film which surrounds the circular thin film in the circumferential direction and is concentric with the circular thin film; according to different working condition demands, the thickness of the circular thin film and the thickness of the annular thin film are adjusted separately to achieve combined stiffness-variable thin film; the overall structure of the combined stiffness-variable thin filmpMUTs sequentially comprises an upper electrode, a vibration thin film piezoelectric driving layer, a lower electrode, a vibration thin film structural layer, a thin film supporting structure and a base structure from top to bottom; when the combined stiffness-variable thin film pMUTs are used in a mode of emitting ultrasonic waves, the circular thin film and the annular thin film are excited according to a certain phase difference, the coupling effect among the circular thin film, a fluid medium and the annular thin film is achieved, and the unit ultrasonic wave emitting power is greatly increased; when the combined stiffness-variable thin film pMUTs are used for receiving the ultrasonic waves, the ultrasonic wide bandwidth receiving performance is achieved through the resonance frequencydeviation of the circular thin film and the annular thin film in the fluid medium. The combined stiffness-variable thin film pMUTs have the high emitting power and wide bandwidth receiving performance.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

ELECTRODE ARRANGEMENT FOR A pMUT and pMUT TRANSDUCER ARRAY

PendingUS20170320093A1Subsonic/sonic/ultrasonic wave measurementUsing electrical meansSensor arrayPMUT

Provided in accordance with the herein described exemplary embodiments are piezo micro-machined ultrasonic transducers (pMUTs) each having a first electrode that includes a first electrode portion and a second electrode portion. The second electrode portion is separately operable from the first electrode portion. A second electrode is spaced apart from the first electrode and defines a space between the first electrode and the second electrode. A piezoelectric material is disposed in the space. Also provided are arrays of pMUTs wherein individual pMUTs have first electrode portions operably associated with array rows and second electrode portions operably associated with array columns.

Owner:VANGUARD INT SEMICON SINGAPORE PTE LTD

Variable thickness diaphragm for a wideband robust piezoelectric micromachined ultrasonic transducer (PMUT)

ActiveUS20160315247A1Simple designMechanical vibrations separationSound producing devicesVariable thicknessResonance

A diaphragm for a piezoelectric micromachined ultrasonic transducer (PMUT) is presented having resonance frequency and bandwidth characteristics which are decoupled from one another into independent variables. Portions of at least the piezoelectric material layer and backside electrode layer are removed in a selected pattern to form structures, such as ribs, in the diaphragm which retains stiffness while reducing overall mass. The patterned structure can be formed by additive, or subtractive, fabrication processes.

Owner:RGT UNIV OF CALIFORNIA

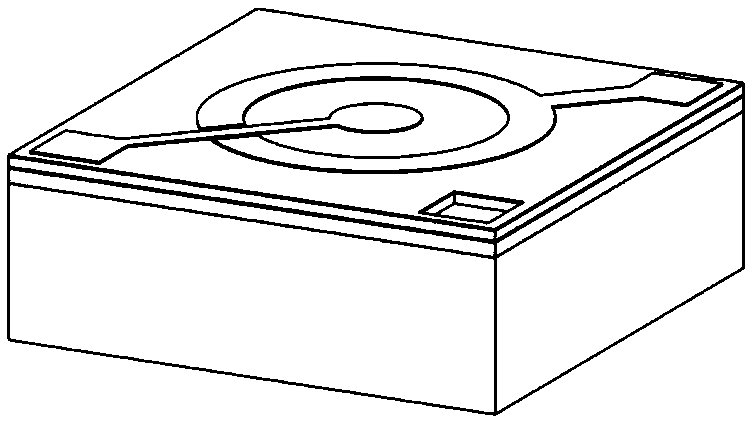

Ultra wide bandwidth transducer with dual electrode

ActiveCN104271264AMaterial analysis using sonic/ultrasonic/infrasonic wavesMechanical vibrations separationPMUTPiezoelectric membrane

Wide bandwidth piezoelectric micromachined ultrasonic transducers (pMUTs), pMUT arrays and systems having wide bandwidth pMUT arrays are described herein. For example, a piezoelectric micromachined ultrasonic transducer (pMUT) includes a piezoelectric membrane disposed on a substrate. A reference electrode is coupled to the membrane. First and second drive / sense electrodes are coupled to the membrane to drive or sense a first and second mode of vibration in the membrane.

Owner:FUJIFILM DIMATIX

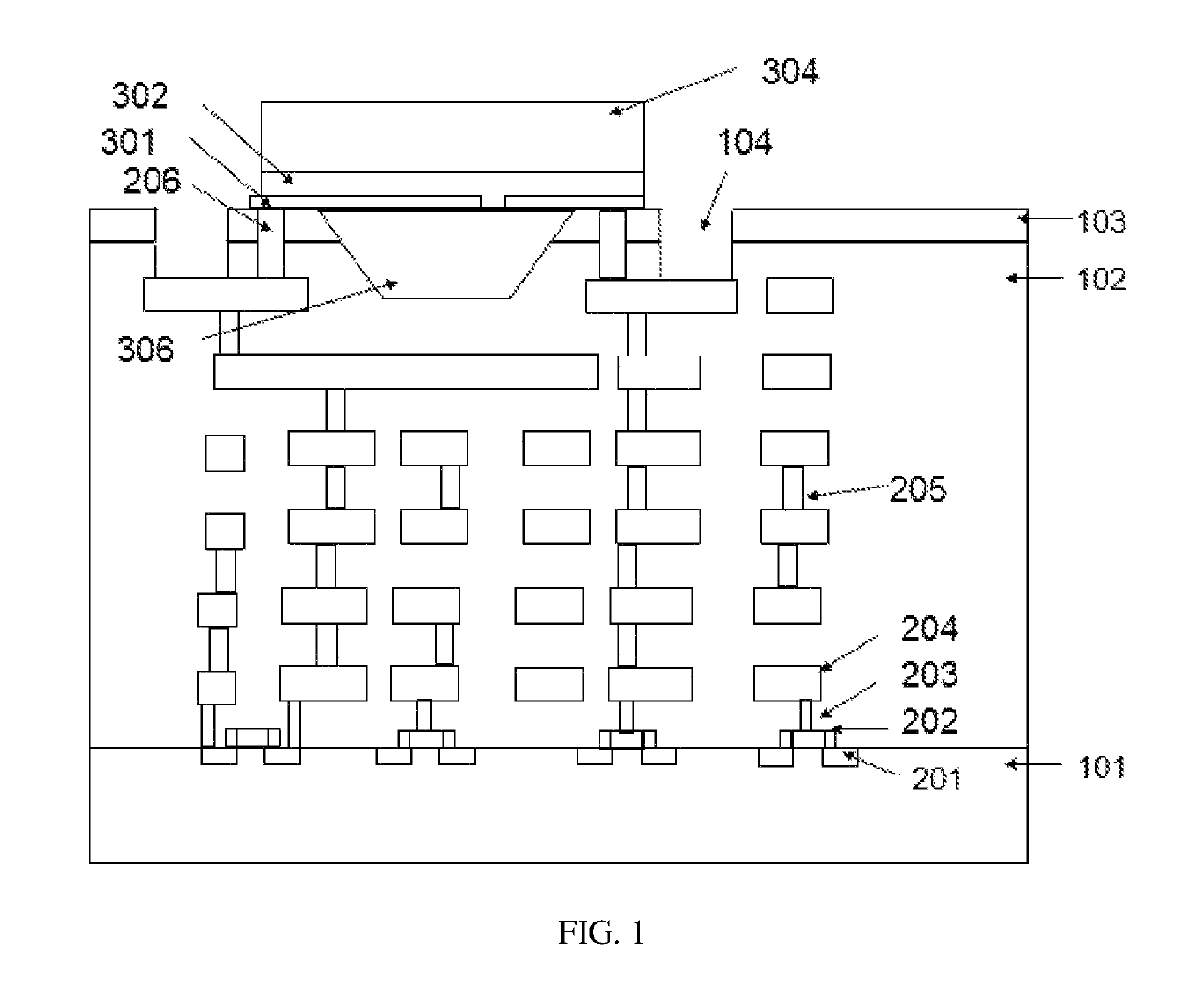

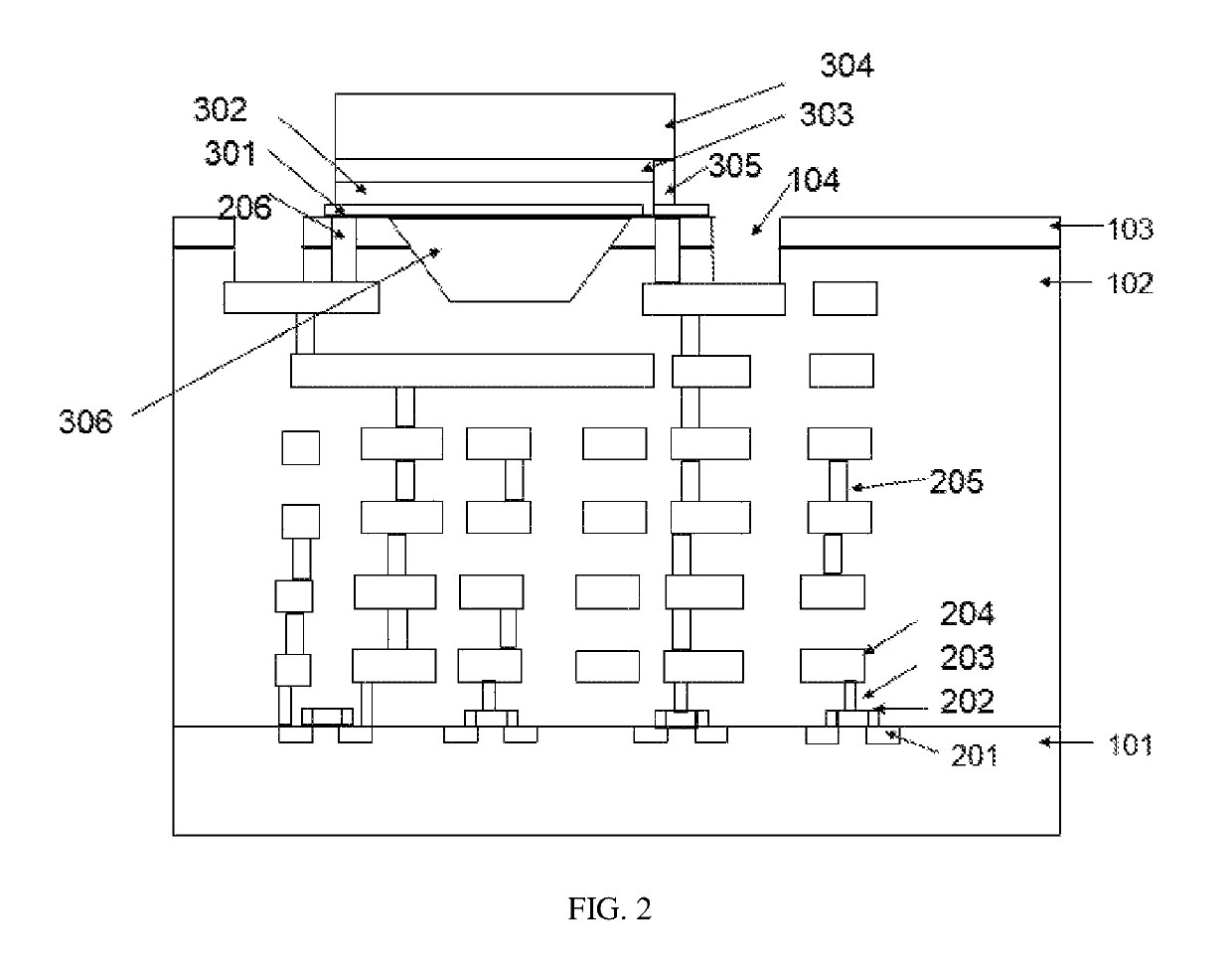

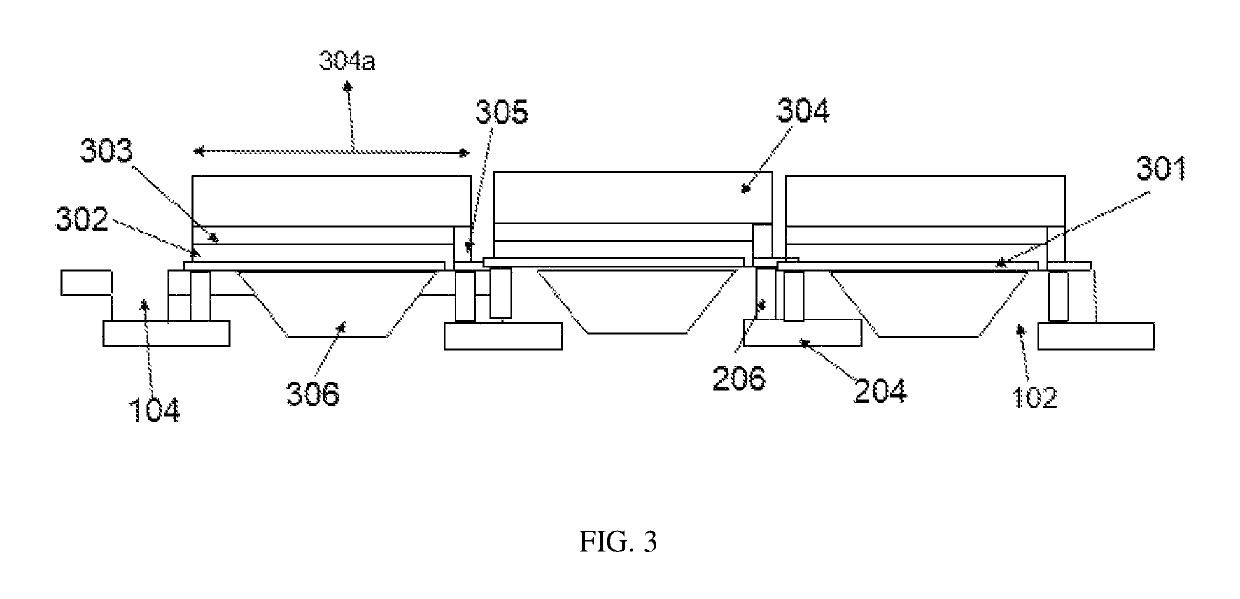

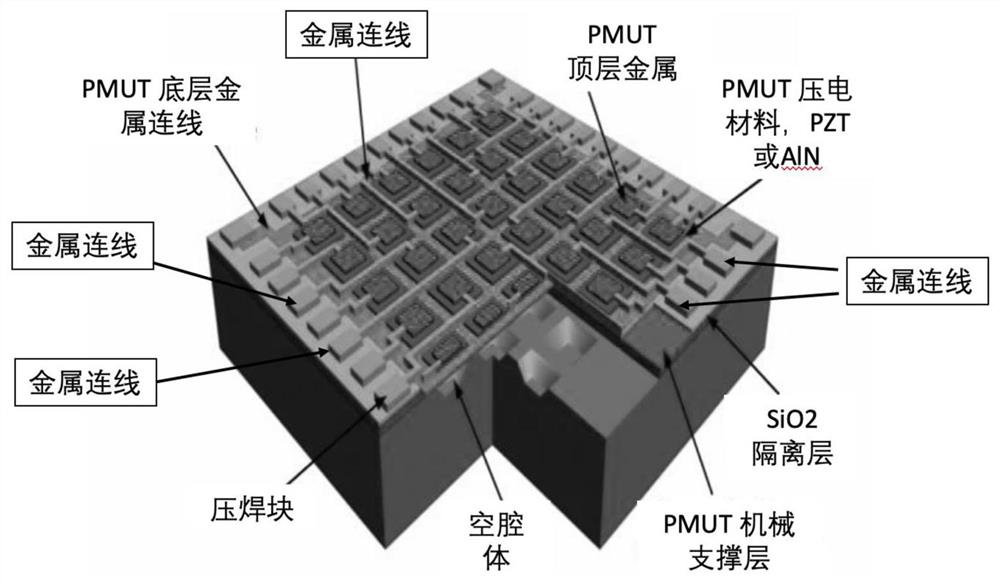

SOC PMUT suitable for high-density system integration, array chip and manufacturing method

ActiveCN113666327AFully consider compatibilityDebottlenecking the interconnectionUltrasonic/sonic/infrasonic diagnosticsTelevision system detailsCMOSMetal interconnect

The invention discloses an SOC PMUT suitable for high-density system integration, an array chip and a manufacturing method. The SOC PMUT suitable for high-density system integration realizes vertical stacking and monolithic integration of an SOC PMUT array and a CMOS auxiliary circuit thereof through direct bonding of an active wafer and a multi-channel metal wire structure in the vertical direction, and extends to a packaging layer through a TSV, so that the SOC PMUT does not need to be communicated with a CMOS through pressure welding blocks on the periphery of the array, the bottleneck of traditional ultrasonic transducer metal interconnection is relieved, the chip area occupied by the ultrasonic transducer metal interconnection is greatly reduced, meanwhile, the length of metal wiring is reduced, and the bad influence of the electrical parasitic effect caused by the length on the performance of an ultrasonic transducer array is reduced.

Owner:NANJING SHENGXI XINYING TECH CO LTD

Miniature ultrasonic imaging system

ActiveUS10820888B2Easy compatibilityEasy to superviseBlood flow measurement devicesOrgan movement/changes detectionUltrasonic imagingPMUT

An ultrasonic imaging apparatus having a Micro-machined Ultrasonic Transducer (MUT), such as a Piezoelectric MUT (PMUT) or Capacitive MUT (CMUT), with a transmitting mode and a receiving mode for generating and sensing acoustic pressure in imaging applications. During transmission in a PMUT the inverse piezoelectric effect on the piezo layer causes transverse stress, which causes a bending moment in the PMUT structure leading to out-of-plane deflection. Different applied signs of voltage generates different signs of stress inside the piezo that in turn cause oscillating motion generating an acoustic pressure wave. During signal reception, incident pressure waves deflect the PMUT creating transverse stress, resulting in a charge determined through measuring voltage between electrodes. The apparatus is particularly well-suited for use in health care, such as measuring fat / muscle thickness, blood-flow, and blood pressure.

Owner:RGT UNIV OF CALIFORNIA

Piezoelectric emission capacitor sensing high-performance MUT unit and preparation method thereof

ActiveCN110523607AIncrease the effective vibration areaIncrease displacementSubsonic/sonic/ultrasonic wave measurementUsing electrical meansCapacitanceElectricity

The invention discloses a piezoelectric emission capacitor sensing high-performance MUT unit and a preparation method thereof. An ultrasonic transmitting working mode of the PMUT unit and an ultrasonic receiving working mode of the CMUT unit are combined with each other. The MUT unit is composed of a piezoelectric driving annular thin film and a circular capacitance sensing thin film stacked on the upper surface of the annular thin film. In the ultrasonic transmitting working mode, the annular thin film is driven based on the inverse piezoelectric effect, meanwhile, the circular thin film stacked on the annular thin film is driven to generate piston type vibration, and therefore the ultrasonic emission directivity and ultrasonic output are improved. In the ultrasonic receiving working mode, the annular thin film and the circular thin film are simultaneously subjected to an incident ultrasonic action to generate deflection. Due to the superposition of the deflection of the circular thinfilm and the annular thin film, the stroke variation between the capacitor upper polar plate and the capacitor lower polar plate is increased, so that the unit ultrasonic receiving sensitivity is improved; and meanwhile, the unit can work in a collapse mode by adopting lower bias voltage in an ultrasonic receiving mode, so that the ultrasonic receiving sensitivity of the unit is further improved.

Owner:XI AN JIAOTONG UNIV

Micromachined ultrasonic transducers with a slotted membrane structure

ActiveUS10293377B2Large displacementEasy to adjustPiezoelectric/electrostrictive device manufacture/assemblyMaterial analysis using sonic/ultrasonic/infrasonic wavesPMUTEngineering

A piezoelectric micromachined ultrasonic transducer (PMUT) device includes a substrate having an opening therethrough and a membrane attached to the substrate over the opening. A portion of the membrane that overlies the opening is divided into a plurality of cantilevers that are mechanically coupled so that the cantilevers resonate at a common frequency.

Owner:INVENSENSE

A composite thin film pMUTs and a preparation method thereof

ActiveCN109231150AEnhanced Mutual CouplingIncrease the ultrasonic transmission powerTelevision system detailsImpedence networksComposite filmPhase difference

The invention provides a combined thin film pMUTs and a preparation method thereof. The composite membrane structure is composed of a circular membrane and an annular membrane surrounding the circumferential direction of the circular membrane and concentric with the circular membrane. The integral structure comprises an upper electrode, a vibration membrane piezoelectric driving layer, a lower electrode, a vibration membrane structure layer, a membrane support structure and a substrate structure from top to bottom in this order. When used in ultrasonic emission mode, circular thin film and annular thin film are excited with a certain phase difference, resulting in a coupling effect between a circular thin film-fluid medium-annular thin film, which can greatly increase the ultrasonic emission power of the cell. For an ultrasonic receiving mode, both circular and annular thin films vibrate to generate detectable electrical signals, and the wide-band ultrasonic receiving performance is realized by the resonant frequency deviation between circular and annular thin films in fluid medium. The combined thin film structure pMUTs provided by the invention have high emission power and wide bandwidth reception performance.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com