Enhanced ultrasonic imaging probe using flexural-mode piezoelectric transducer

A technology of ultrasonic imaging and piezoelectric ultrasound, which is applied in the direction of vibrating fluids, surgery, catheters, etc., can solve the problems of large array elements and high-density integration that are not feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0103] The method of generating an enhanced received signal from an ultrasonic piezoelectric transducer is further described with reference to the following examples.

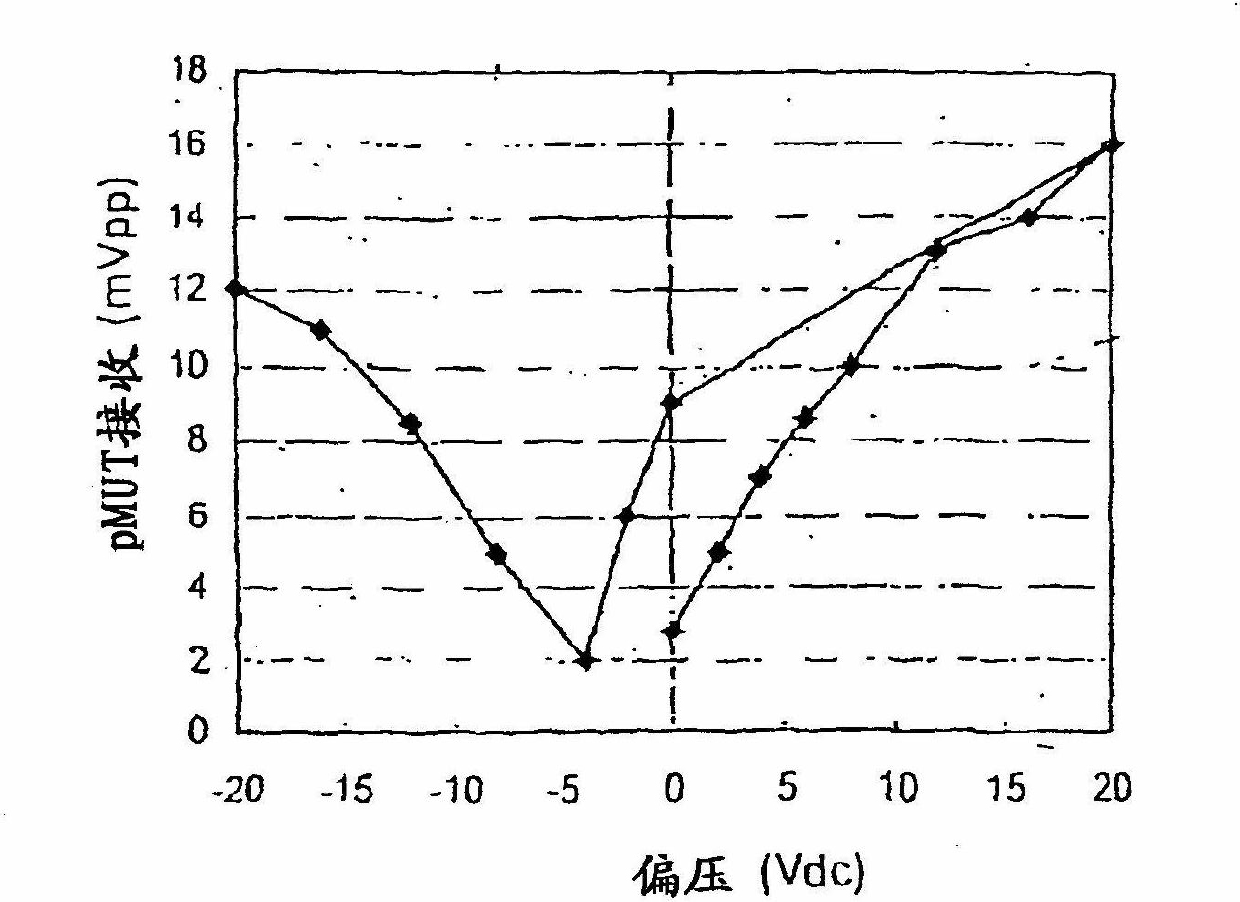

[0104] A single pMUT element experiences a DC bias from -20Vdc to +20Vdc. The acoustic signal provided by a separate piston transducer is directed towards the pMUT element. The signal received by the pMUT element is measured as a function of the applied DC bias. refer to figure 1 , which shows a graph depicting the peak-to-peak received signal (in mV) versus bias voltage. figure 1 The data for , represent the output response of the pMUT element for different levels of DC bias. The DC bias goes from 0V to +20V, back to 0V, and then from 0V to -20V. The received signal (mV) was recorded at each DC bias increment. figure 1 It is shown that, in this particular piezoelectric film, the optimal DC bias for the coercive field level increases the receiver sensitivity. When the DC bias voltage is close to the coerc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com