Patents

Literature

357 results about "Piezoelectric membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drive circuit having improved energy efficiency for implantable beneficial agent infusion or delivery device

InactiveUS7070577B1Valve arrangementsPiezoelectric/electrostriction/magnetostriction machinesElectricityEnergy recovery

An implantable beneficial agent infusion device featuring a unique energy recovery circuit and a deflectable energy storing member such as a piezo-electric membrane is disclosed. The circuit and deflectable energy storing member cooperate to permit electrical energy employed to activate the member to be at least partially recovered. In a preferred embodiment, the deflectable energy storing member is connected to a seal which is opened to permit the delivery or infusion of a pre-determined amount of a beneficial agent to a patient when the member is deflected or actuated through the application of a sufficiently high voltage thereacross. Charge stored on or in the deflectable energy storing member as a result of the voltage being applied thereacross is recovered by a novel circuit when the deflectable energy storing membrane is permitted to return to its non-actuated state or position.

Owner:MEDTRONIC INC

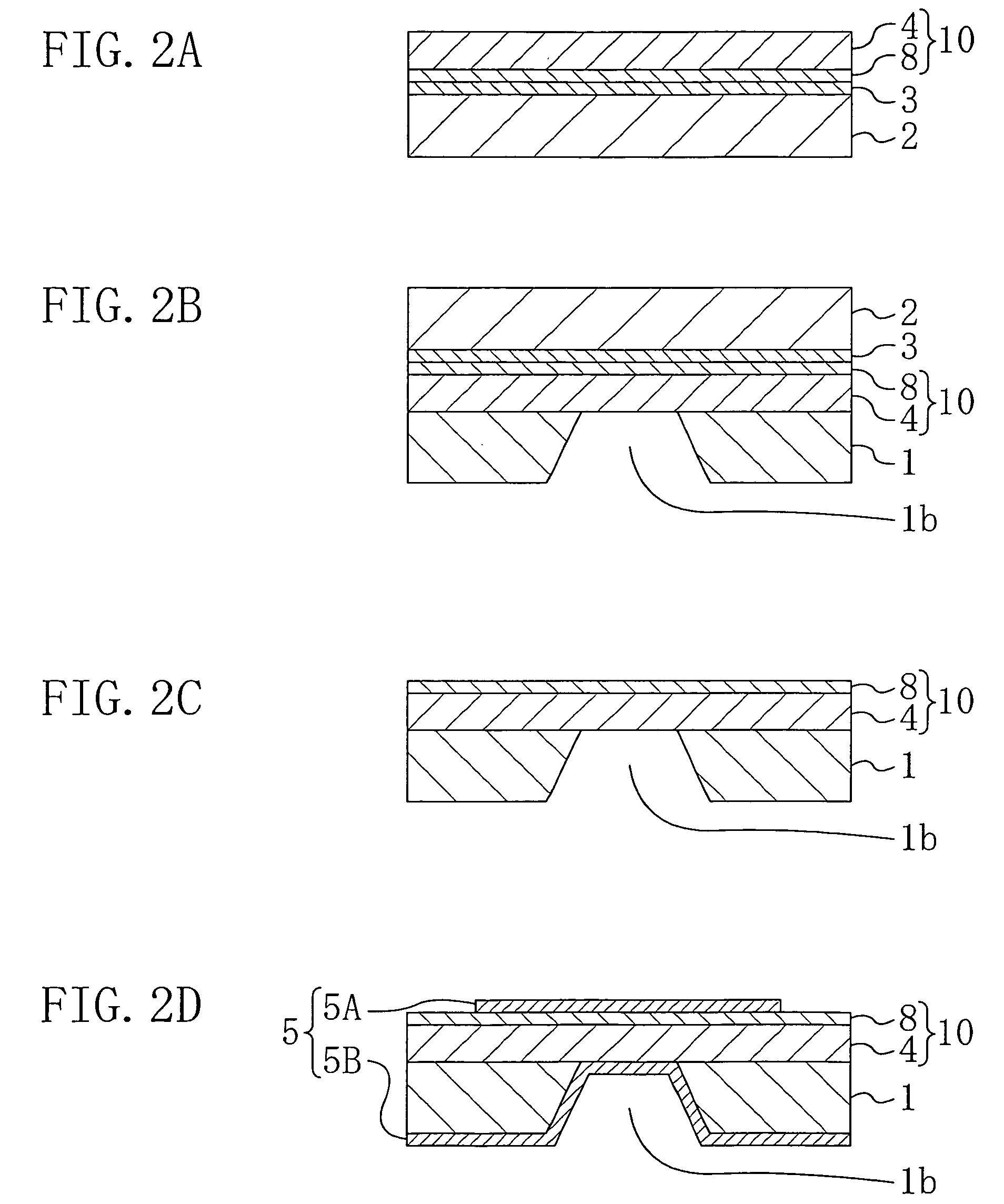

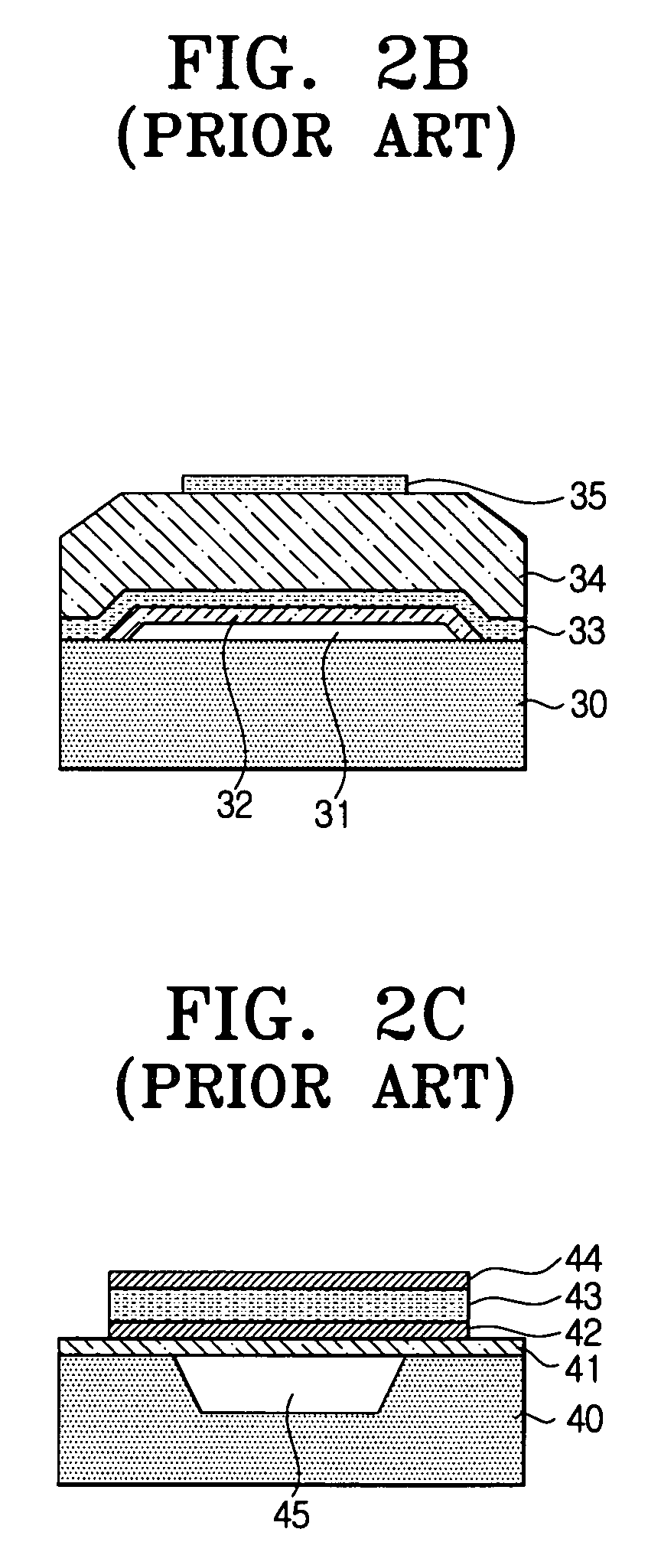

Method for manufacturing resonator

InactiveUS20050255234A1Uniform crystallinityUniform thicknessPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksResonatorFilm making

A method for manufacturing a resonator of the present invention includes the steps of (a) forming a resonator film including a piezoelectric film made of piezoelectric material and (b) preparing a resonator substrate for supporting the resonator film. The method further comprises the step of (c) bonding the resonator film formed in the step (a) and the resonator substrate prepared in the step (b).

Owner:PANASONIC CORP

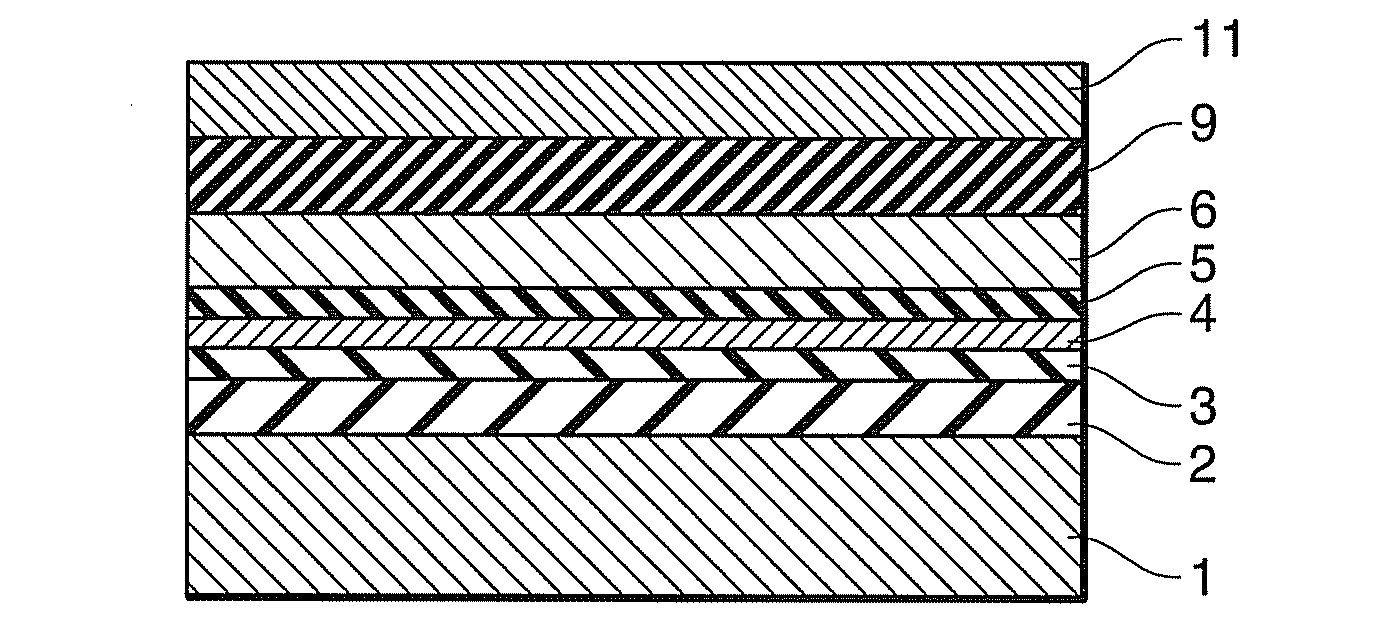

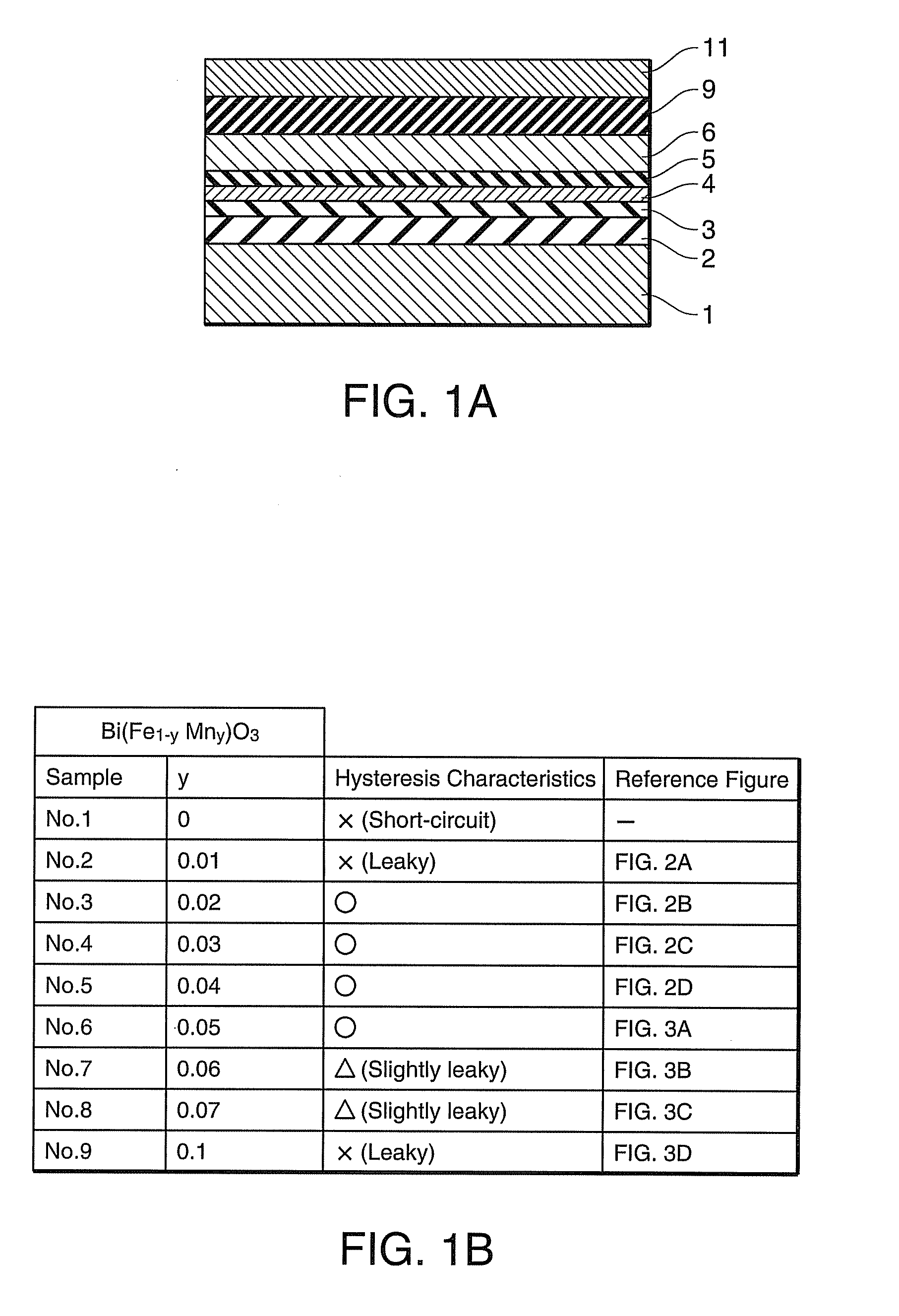

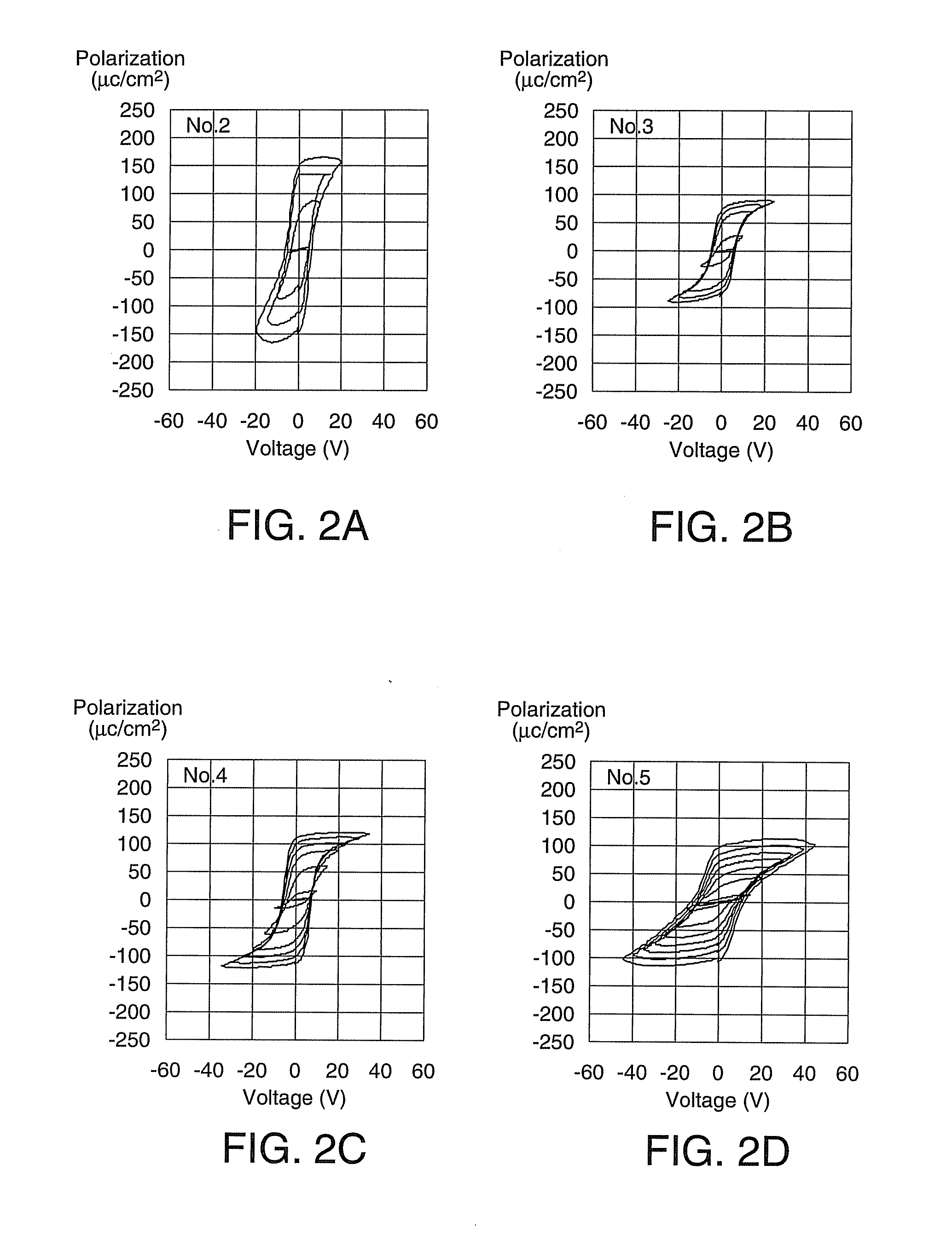

Piezoelectric material and piezoelectric element

ActiveUS20090243438A1Large piezoelectric constantHigh Curie temperaturePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesComposite materialSpontaneous polarization

A piezoelectric element includes a first electrode, a piezoelectric film disposed on the first electrode, and a second electrode disposed on the piezoelectric film. The piezoelectric film is composed of piezoelectric material that is lead free and formed by mixing 100(1−x)% of material A having a spontaneous polarization of 0.5 C / m2 or greater at 25° C. and 100 x % of material B having piezoelectric characteristics and a dielectric constant of 1000 or greater at 25° C., wherein (1−x)Tc(A)+xTc(B)≧300° C., where Tc(A) is the Curie temperature of the material A and Tc(B) is the Curie temperature of the material B.

Owner:SEIKO EPSON CORP

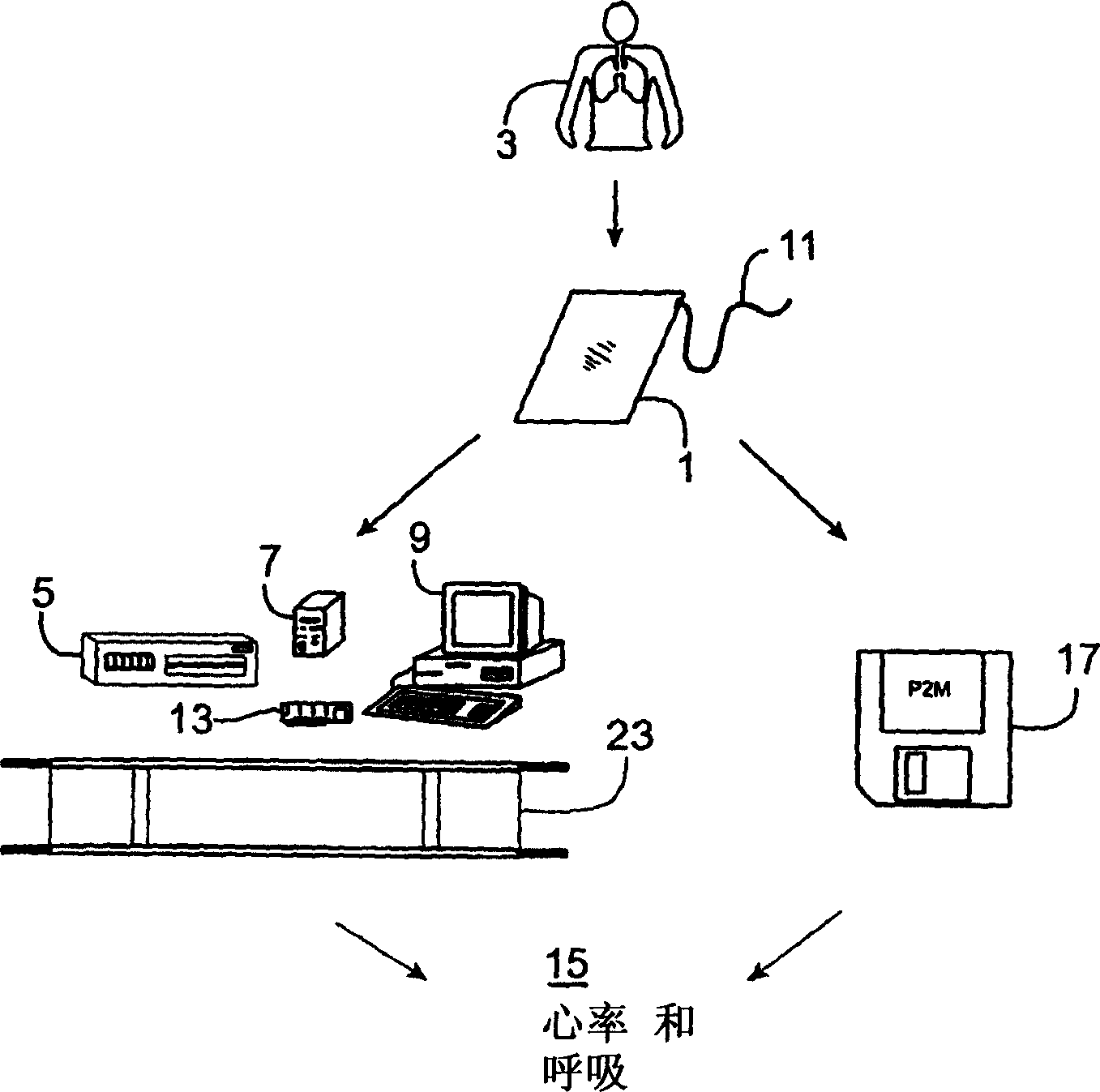

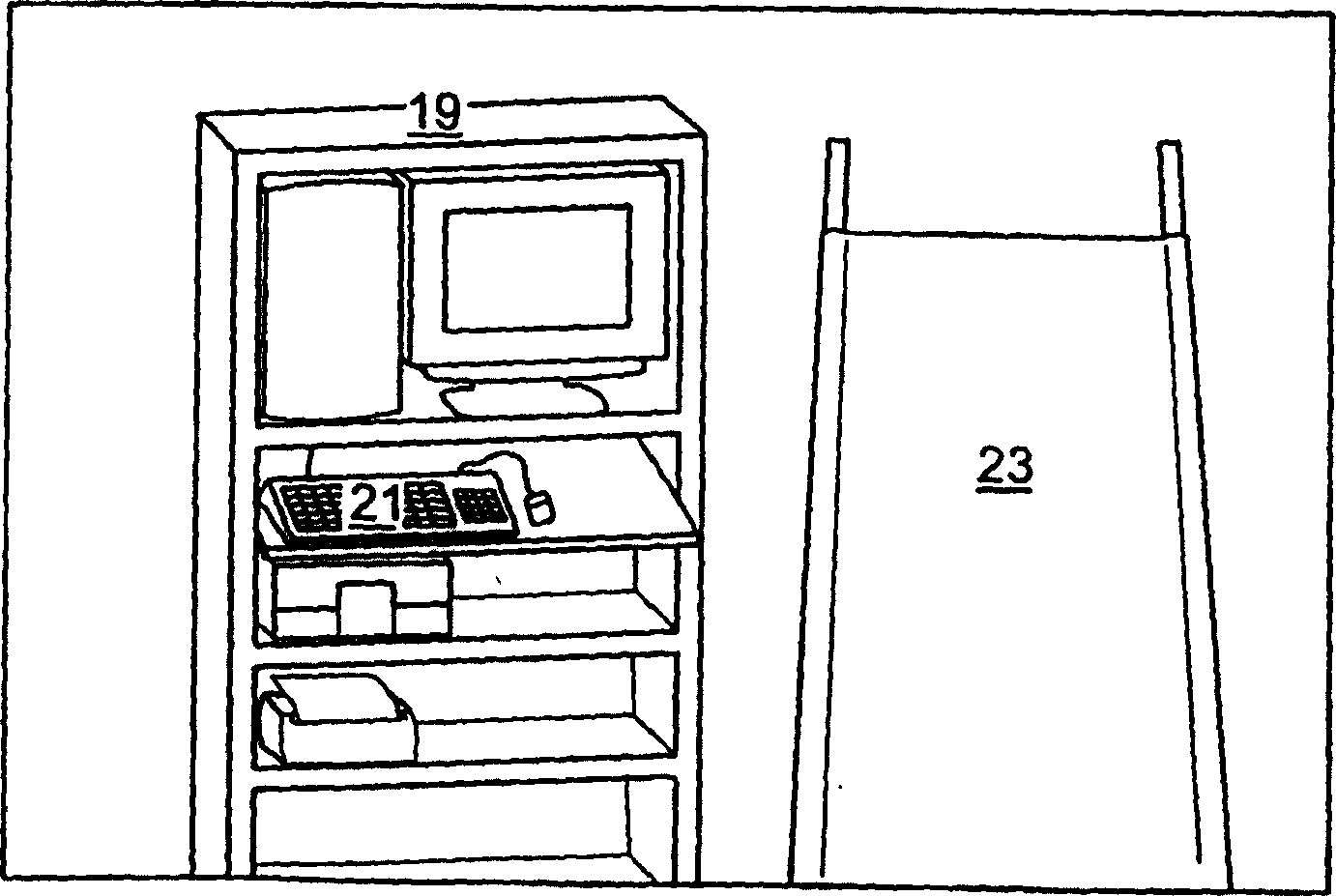

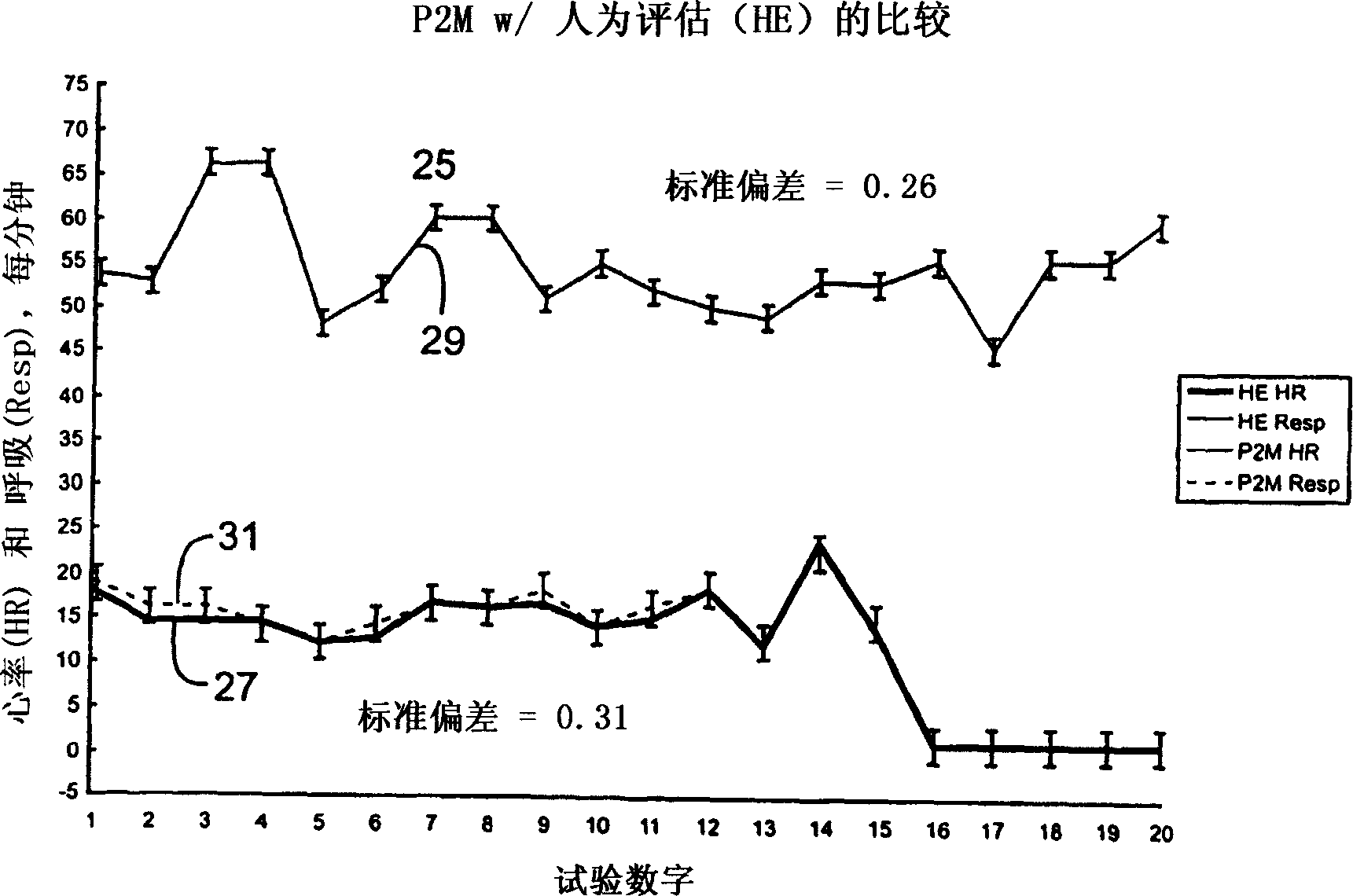

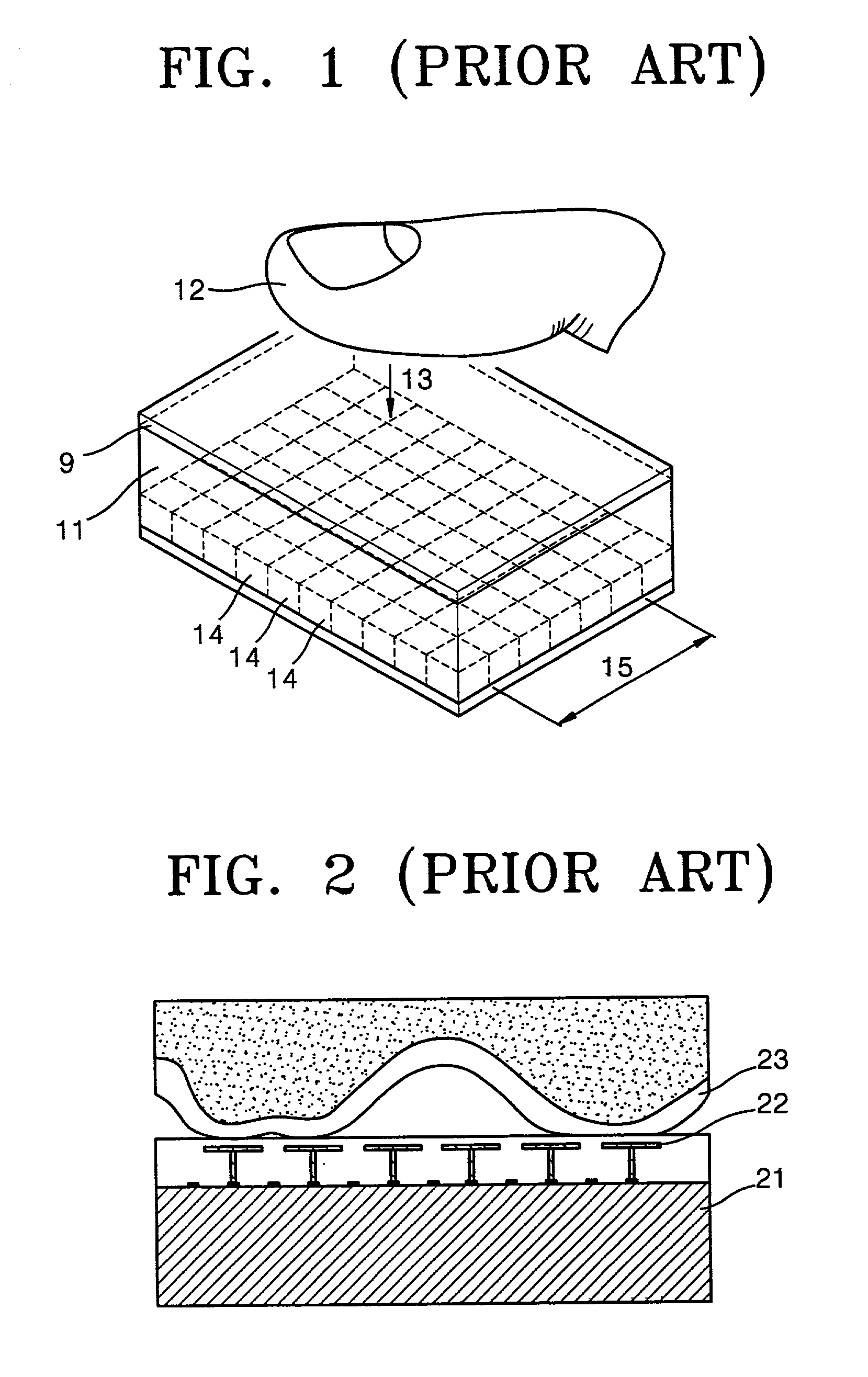

Passive physiological monitoring (P2M) system

Passive physiological monitoring apparatus has a sensor for sensing physiological phenomenon and method converter converts sensed data into electrical signals and a computer receives and computes the signals and output computed data for real-time interactive display. The sensor is a piezoelectric film of polyvinylidene fluoride. Signals detected include mechanical, thermal and acoustic signatures reflecting cardiac output, cardiac function, internal bleeding, respiratory, pulse, apnea and temperature. The sensor may be an array provided in a MEDEVAC litter or other device for measuring acoustic and hydraulic signals from the body of a patient for field monitoring, hospital monitoring, transport monitoring, home, remote monitoring.

Owner:HOANA MEDICAL

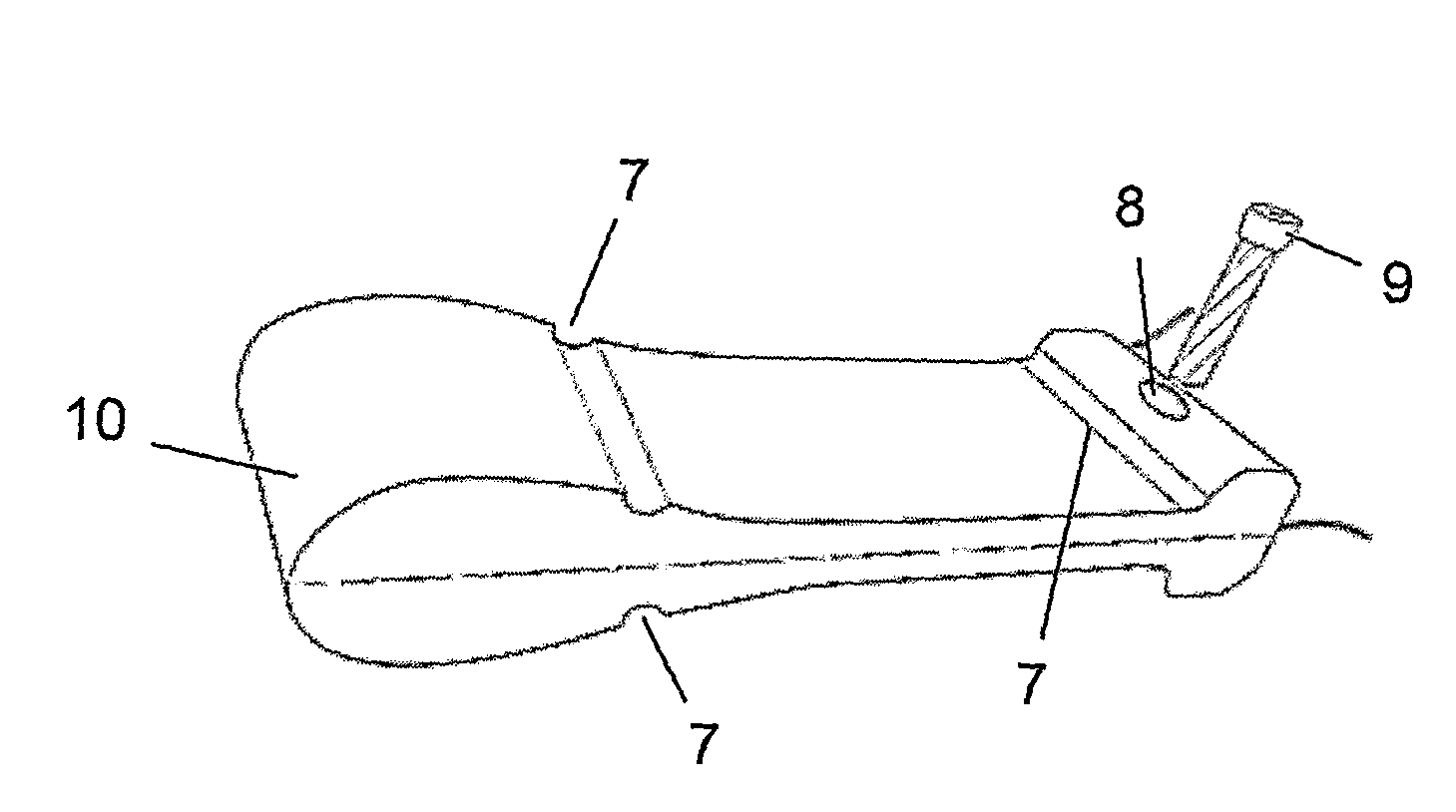

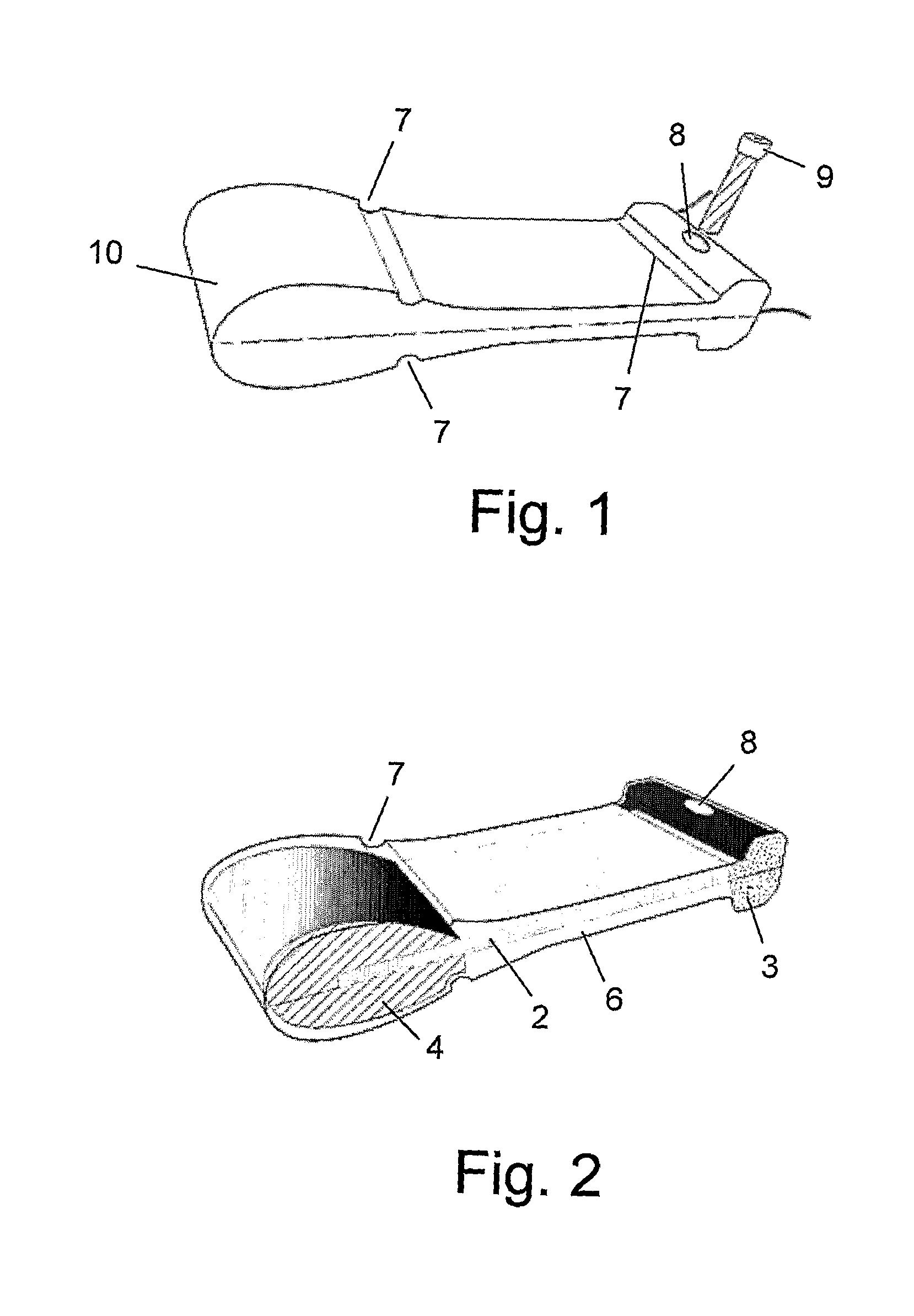

Miniature Bio-Compatible Piezoelectric Transducer Apparatus

InactiveUS20090220115A1Efficient sound transferEfficient transferBone conduction transducer hearing devicesDeaf-aid setsTransducerEngineering

Vibration transmitting apparatus comprises a vibrating element utilizing a piezoelectric membrane element installed within a bio-compatible sealed case, wherein one end of the piezoelectric element is in static positioned relationship with respect to its casing and the other end is free to move and to vibrate.

Owner:AUDIODENT ISRAEL

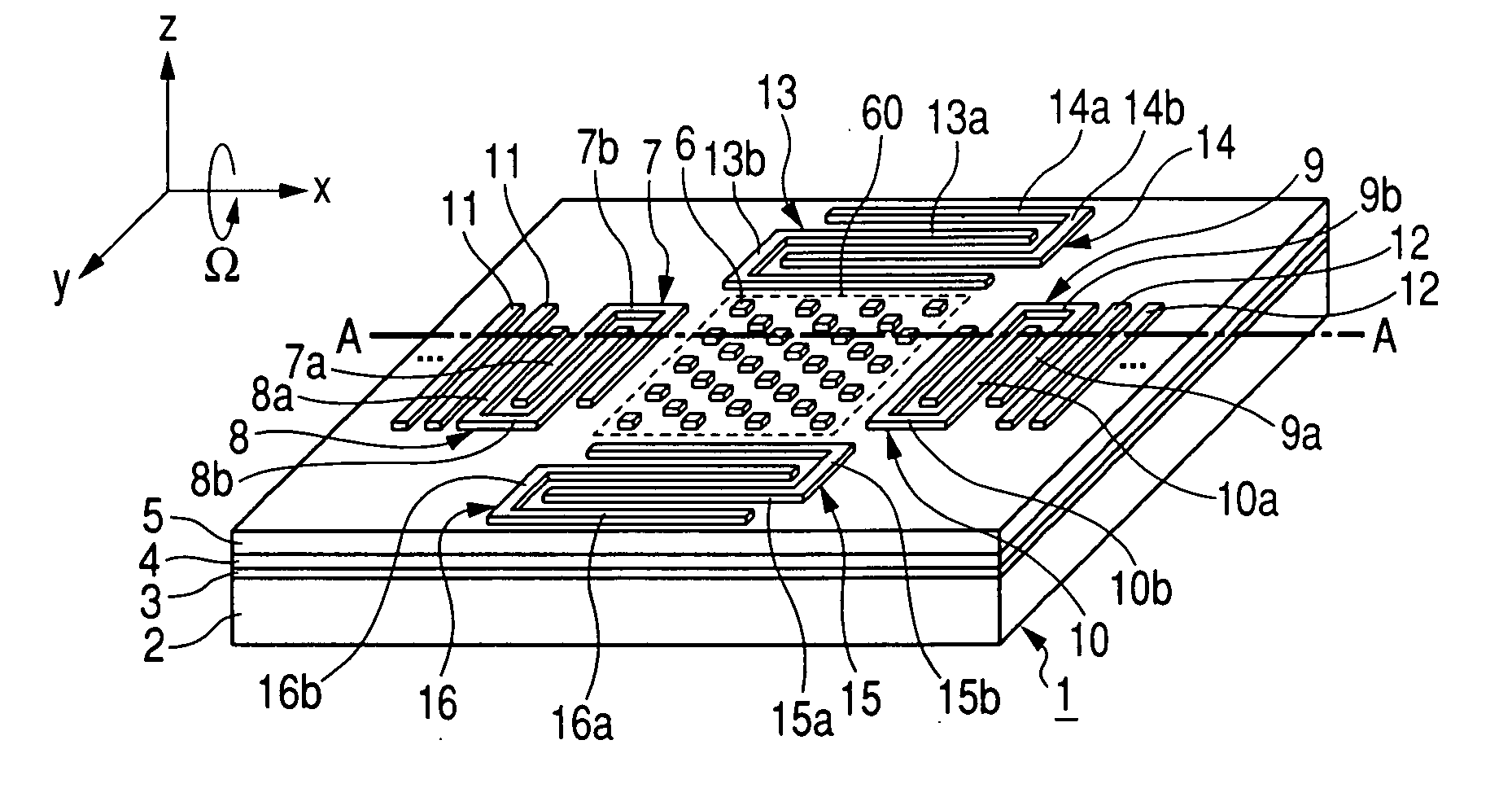

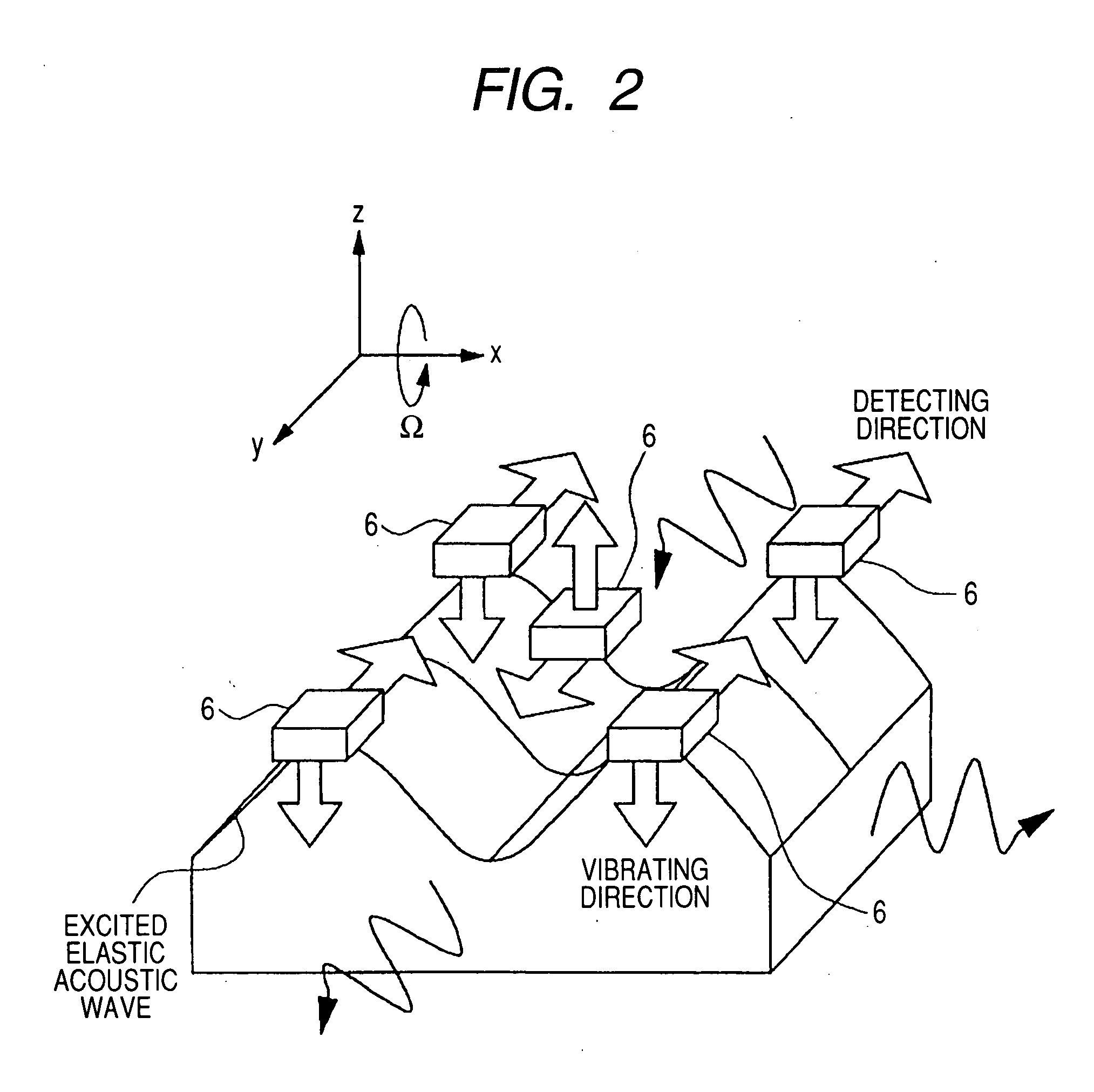

Angular rate sensor

ActiveUS20080028855A1High sensitivityImprove reliabilityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsElectricityAngular rate sensor

An angular rate sensor comprises a piezoelectric film having a first and a second surfaces forming an x-y plane and utilizes a perturbation mass coherently vibrating elastic acoustic waves on which a Coriolis force acts when the angular rate sensor undergoes a rotary motion about an x-direction. A first elastic acoustic wave is excited in the piezoelectric film by a driving transducer and a second elastic acoustic wave generated by the Coriolis force proportional to an angular rate of the rotary motion of the angular rate sensor itself is detected by the detecting transducer. The angular rate sensor further comprises at least a first electrode disposed on the first surface of the piezoelectric film for discharging a surface charge caused due to piezoelectric effect at the lower surface of the film in which the first elastic acoustic wave is excited.

Owner:DENSO CORP

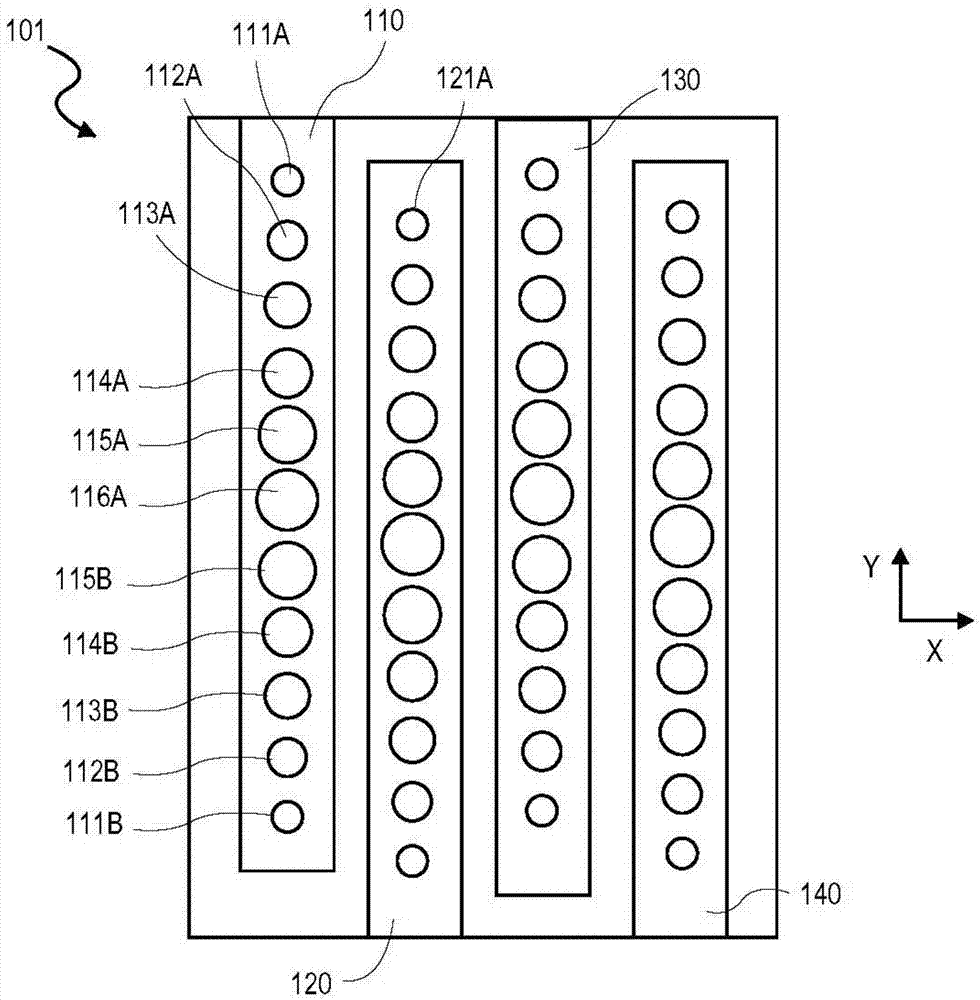

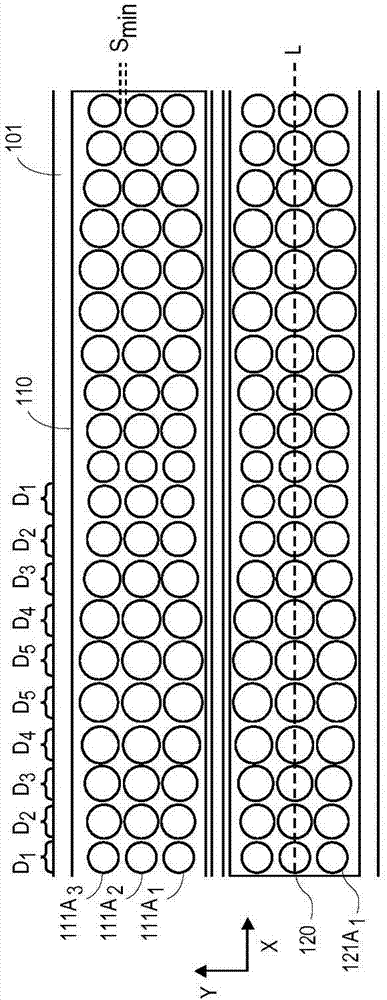

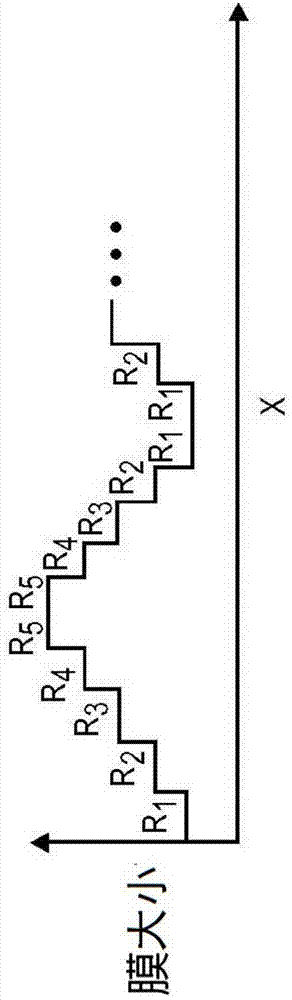

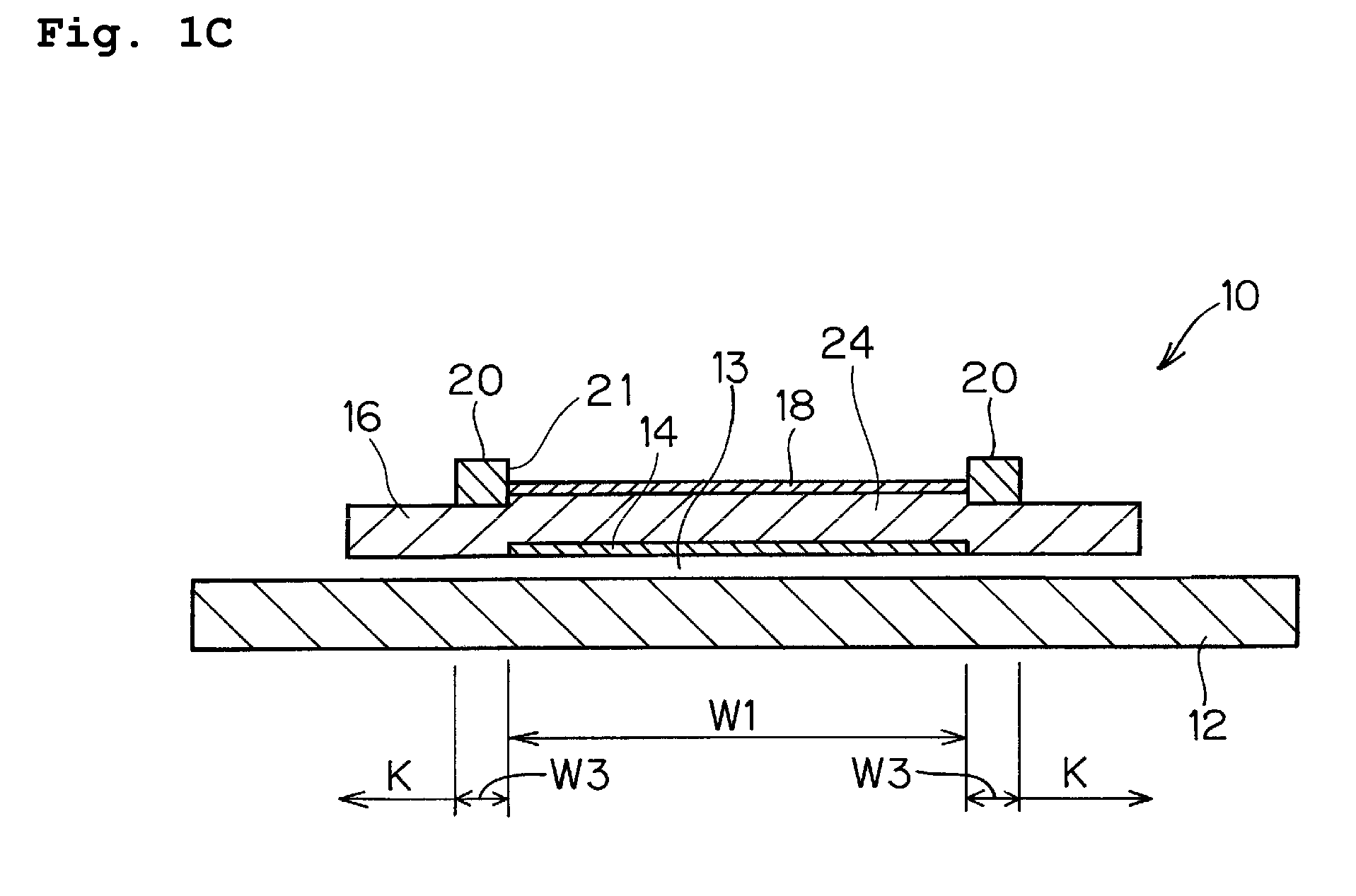

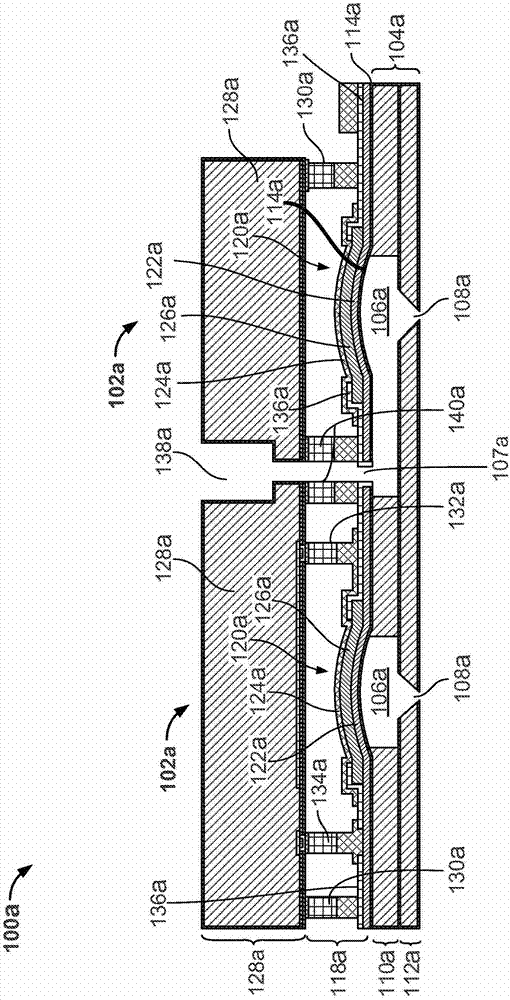

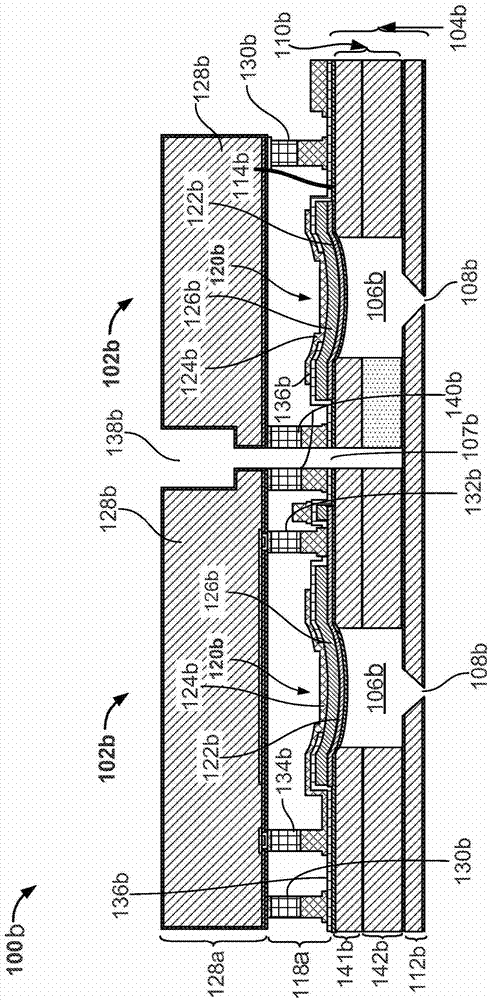

Micromachined ultrasonic transducer arrays with multiple harmonic modes

Micromachined ultrasonic transducer (MUT) arrays capable of multiple resonant modes and techniques for operating them are described, for example to achieve both high frequency and low frequency operation in a same device. In embodiments, various sizes of piezoelectric membranes are fabricated for tuning resonance frequency across the membranes. The variously sized piezoelectric membranes are gradually transitioned across a length of the substrate to mitigate destructive interference between membranes oscillating in different modes and frequencies.

Owner:FUJIFILM DIMATIX

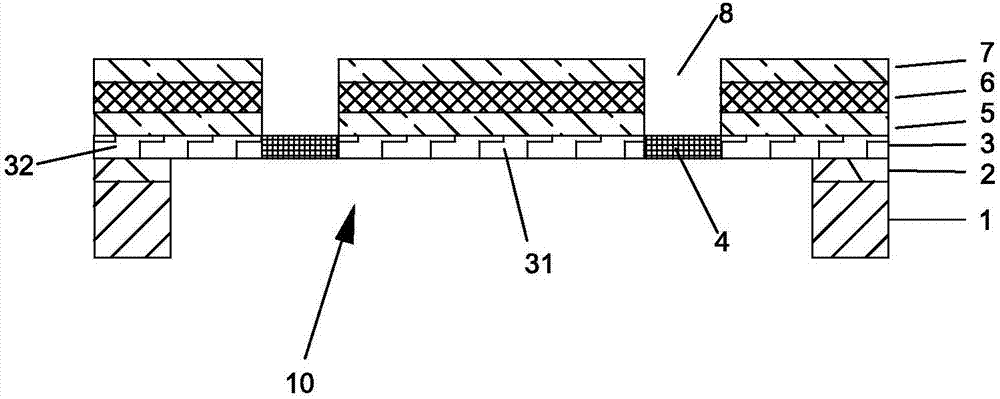

Piezoelectric ultrasonic transducer and manufacturing method thereof

ActiveCN107511318AIncreased sound pressure outputReduce the modulus of elasticityMechanical vibrations separationVibrating membraneUltrasonic sensor

The invention provides a piezoelectric ultrasonic transducer and a manufacturing method thereof. The piezoelectric ultrasonic transducer comprises a base, a vibrating membrane, a first electrode, a piezoelectric membrane and a second electrode, wherein the center of the base is provided with a cavity; the vibrating membrane is fixed to the base; the first electrode, the piezoelectric membrane and the second electrode are sequentially deposited on the vibrating membrane along a direction from the base to the vibrating membrane; the piezoelectric ultrasonic transducer is characterized in that the vibrating membrane comprises a first vibrating membrane and a second vibrating membrane, wherein the first vibrating membrane is positioned at the center; the second vibrating membrane is positioned at the outer side of the first vibrating membrane; the first vibrating membrane and the second vibrating membrane are arranged in a spaced manner and are connected with each other through an elastic structure layer; and the piezoelectric ultrasonic transducer is also provided with a through hole at a position corresponding to the elastic structure layer, wherein the through hole penetrates through the second electrode, the piezoelectric membrane and the first electrode. The piezoelectric ultrasonic transducer provided by the invention can improve output of sound pressure.

Owner:AAC TECH PTE LTD

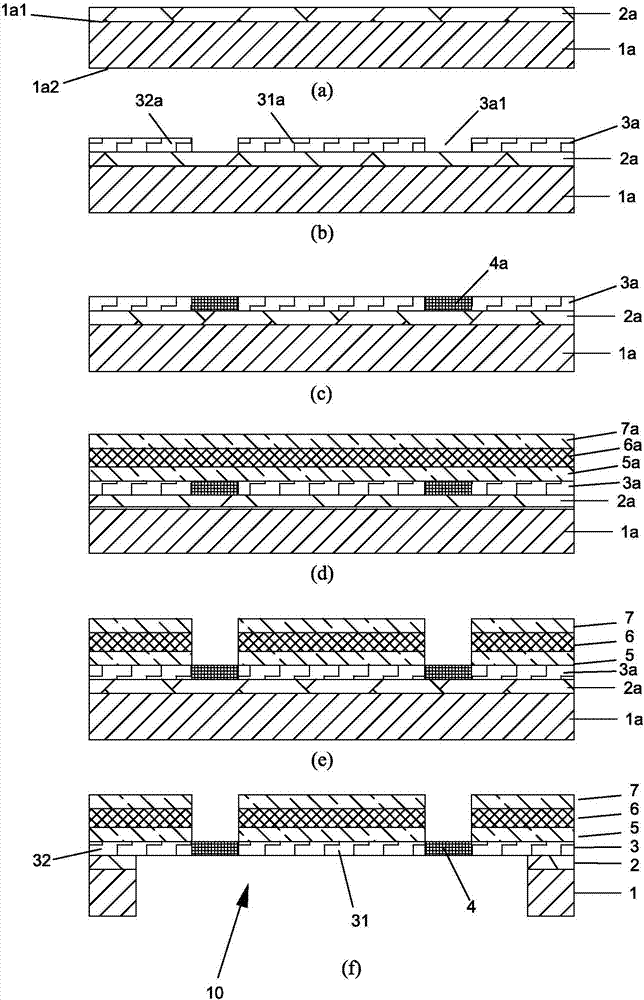

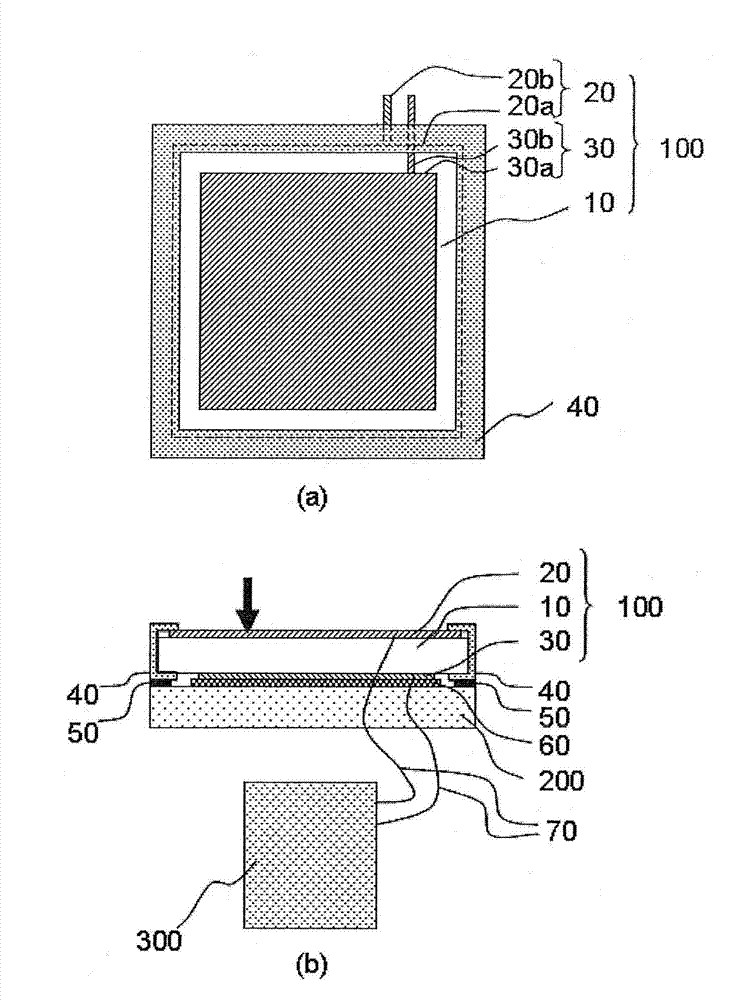

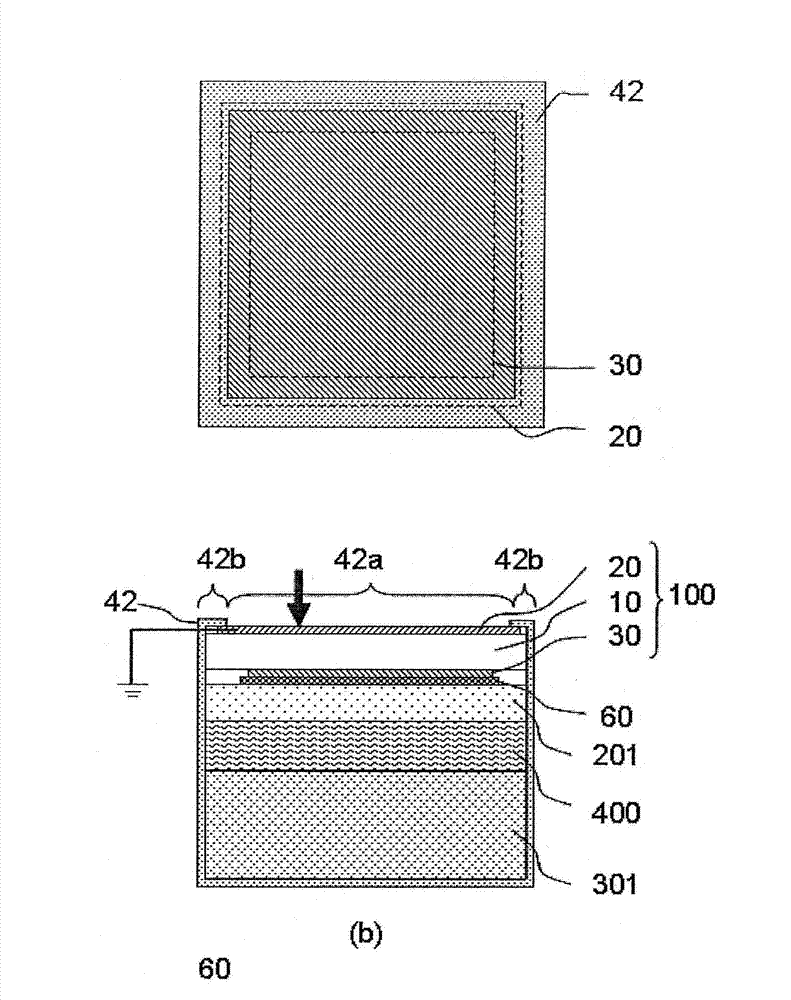

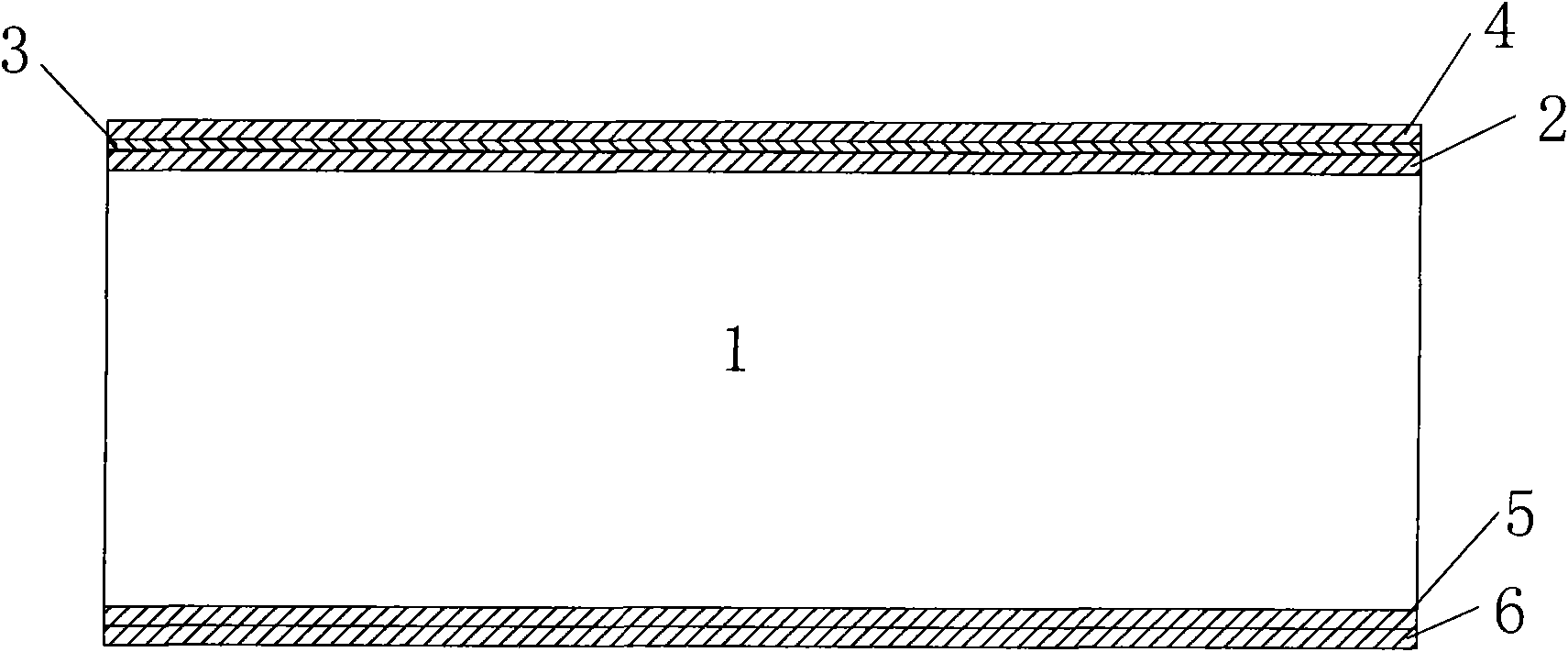

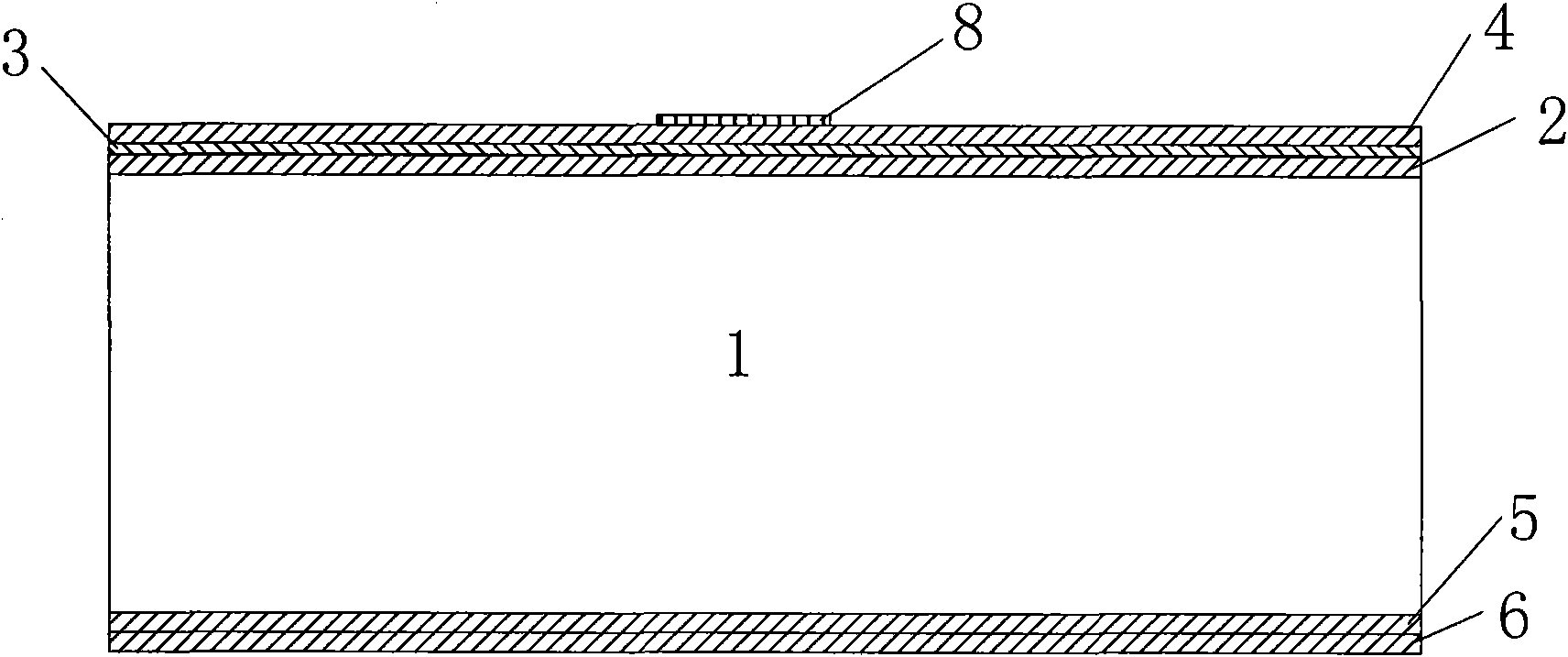

Transparent piezoelectric sheet with frame containing transparent piezoelectric sheet, touch panel containing transparent piezoelectric sheet, and electronic device

InactiveCN102822779AIncrease the effective areaHigh-precision detectionForce measurement using piezo-electric devicesInput/output processes for data processingEngineeringPiezoelectric membrane

Disclosed is a transparent piezoelectric sheet with a frame, which has a wider effective area, is capable of more accurate touch pressure recognition, and has low manufacturing cost and a pleasing appearance. The piezoelectric sheet with a frame comprises one transparent piezoelectric membrane containing an organic polymer, one first transparent flat-plate electrode disposed to a first principal surface of the transparent piezoelectric membrane, and one second transparent flat-plate electrode disposed to a second principal surface of the transparent piezoelectric membrane. The first transparent flat-plate electrode includes a first transparent flat-plate electrode section, and the second transparent flat-plate electrode includes a second transparent flat-plate electrode section. The outline of the second transparent electrode section includes a transparent piezoelectric sheet, which when seen in plan view is positioned inside the outline of the first transparent flat-plate electrode section, and a frame covering the periphery of the transparent piezoelectric sheet. The outline of the first transparent flat-plate electrode section when seen in plan view overlaps the whole of the frame, and the outline of the second transparent flat-plate electrode section does not overlap the frame at all.

Owner:DAIKIN IND LTD +1

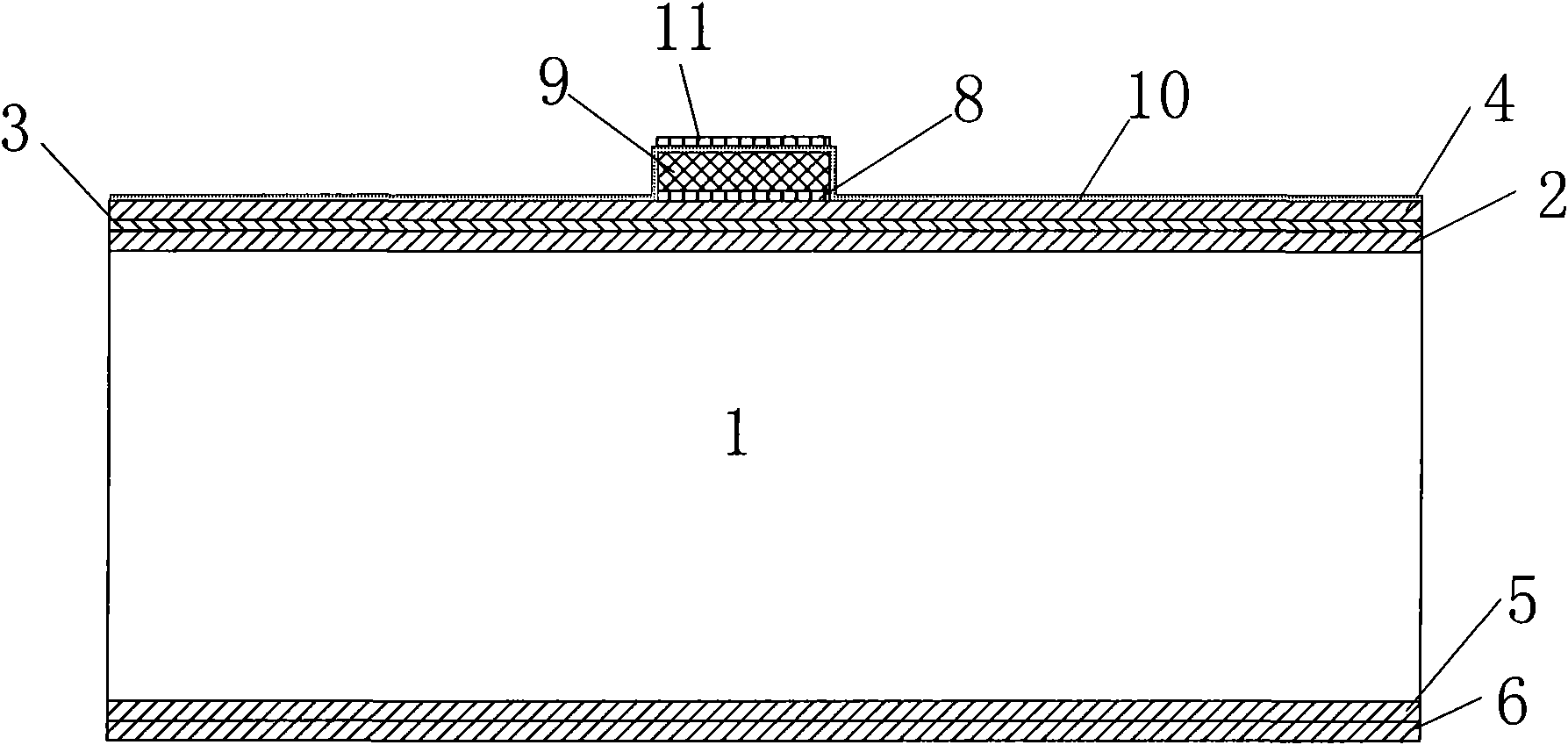

Muscle tension sensor and muscle tension detecting method

InactiveCN102247151AAccurately reflectHigh measurement accuracyMuscle exercising devicesEngineeringPiezoelectric membrane

The invention discloses a muscle tension sensor and a muscle tension detecting method. The muscle tension sensor is characterized in that: a box body and a bottom end cover form a cylindrical shell; in the cylindrical shell, a pressure sensor is adhered with the top plate of the box body, a 'T'-shaped probe is pressed against the bottom end face of the pressure sensor by the top end face, a raisecylinder on the 'T'-shaped probe runs through a central hole in the bottom end cover and protrudes to the outside of the cylindrical shell; outside the cylindrical shell, a piezoelectric membrane resistor serving as a piezoelectric device is adhered with the top plate of the box body; above the box body, another 'T'-shaped top cover is pressed against the piezoelectric membrane resistor by the bottom end face; and above the top cover, a pressure plate and a top cover form a clamp plate, and a band is clamped in the clamp plate formed by the pressure plate and the top cover. When the sensor and the method are used, muscle tension parameters can be acquired stably and used for evaluating the recovery state of muscle after rehabilitation of a human body.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Soft support bridge type silicon micro-piezoelectric ultrasonic transducer chip and prepration method thereof

InactiveCN101645484AHigh sensitivityGood process compatibilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionVertical projectionUltrasonic sensor

The invention relates to a soft support bridge type silicon micro-piezoelectric ultrasonic transducer chip which comprises a silicon substrate with a square conical hole which is small at the top andbig at the bottom in the center; a silicon layer and a first oxidation layer are sequentially covered on the front surface of the silicon substrate, and a second oxidation layer is covered on the backsurface; the corresponding silicon layer and the first oxidation layer above the square hole of the front surface of the silicon substrate constitute a square vibration membrane, one pair of oppositesides of the square vibration membrane respectively etch a vertical narrow slot, and the vertical projection of each narrow slot is positioned on the inner side of the hole edge above the front surface of the silicon substrate; a lower electrode, a piezoelectric membrane and an upper electrode are sequentially deposited on the square vibration membrane; a polyimide membrane is deposited on various parts on the front surface of the silicon substrate; and the square vibration membrane which is etched with the vertical narrow slots and the polyimide membrane commonly constitute a soft support anti-sound leakage bridge type vibration membrane. The anti-sound leakage bridge type structure is used on the vibration membrane of the transducer; in order to avoid sound leakage through the narrow slots, the soft polyimide membrane is deposited on the narrow slots, which has little effect on vibration of the vibration membrane and can still keep high sensitivity.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

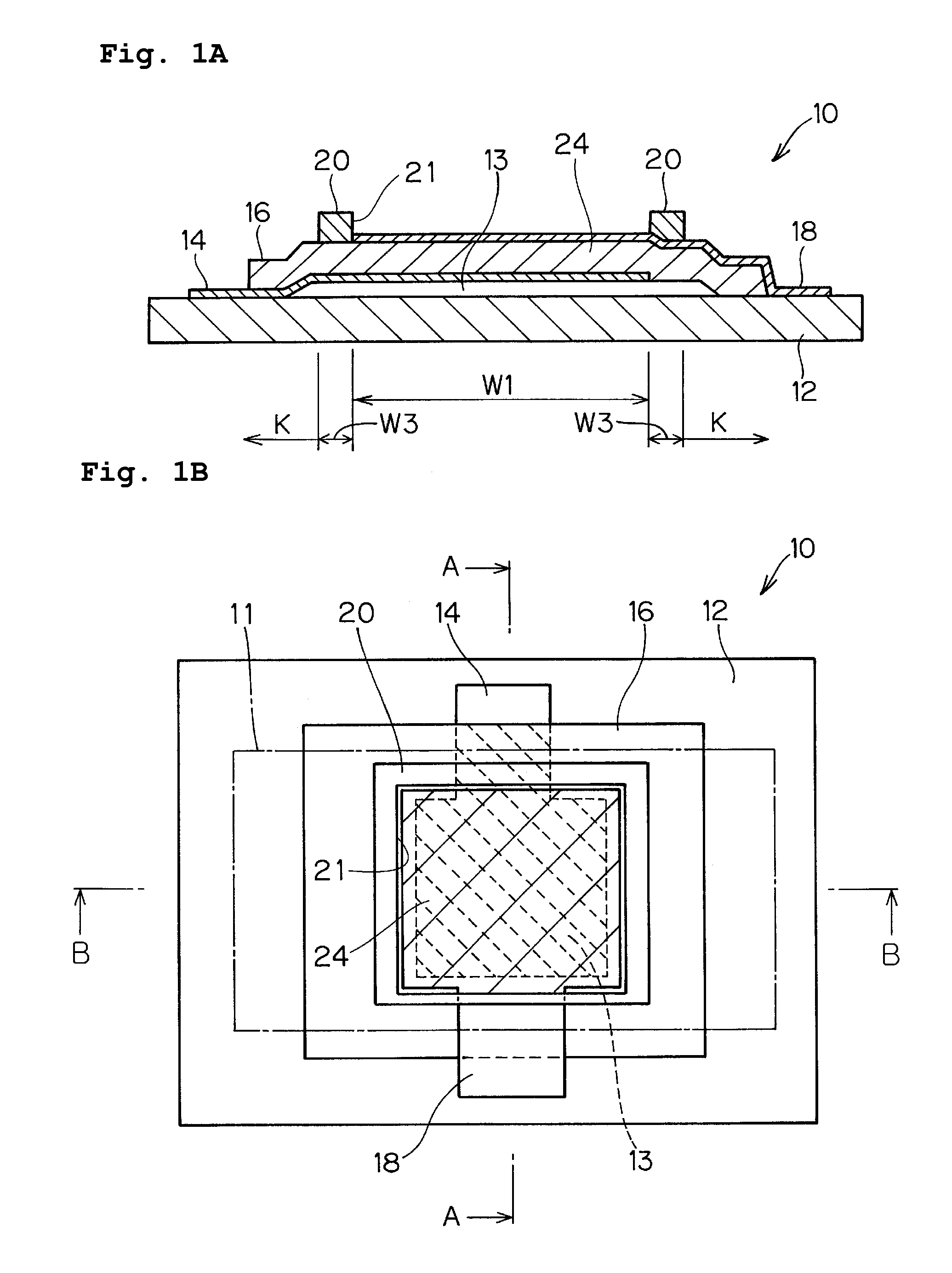

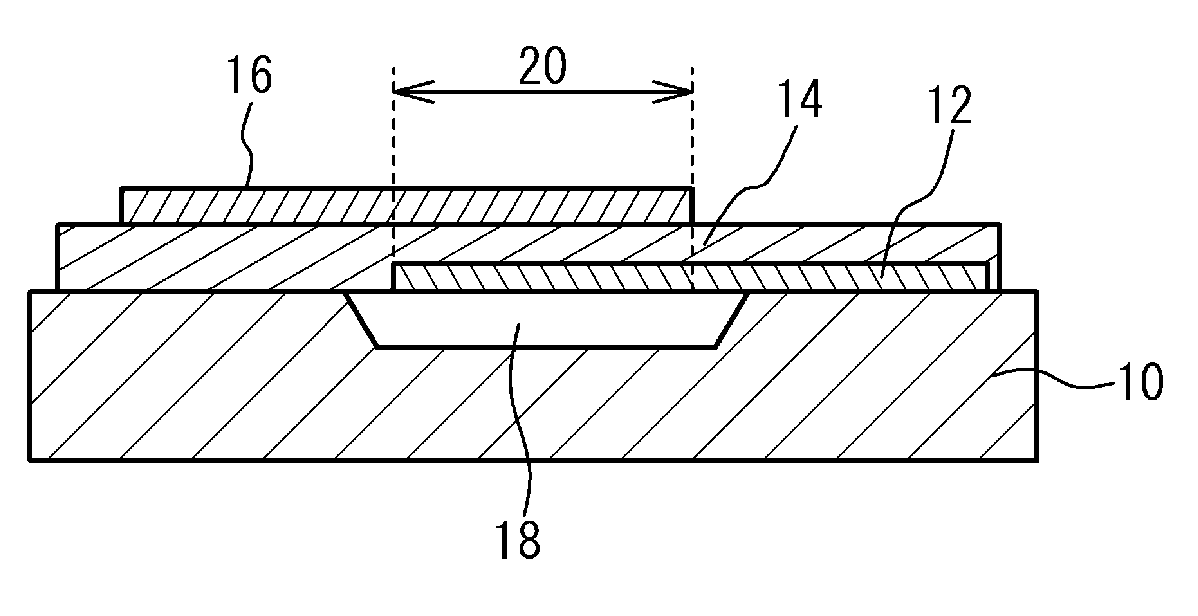

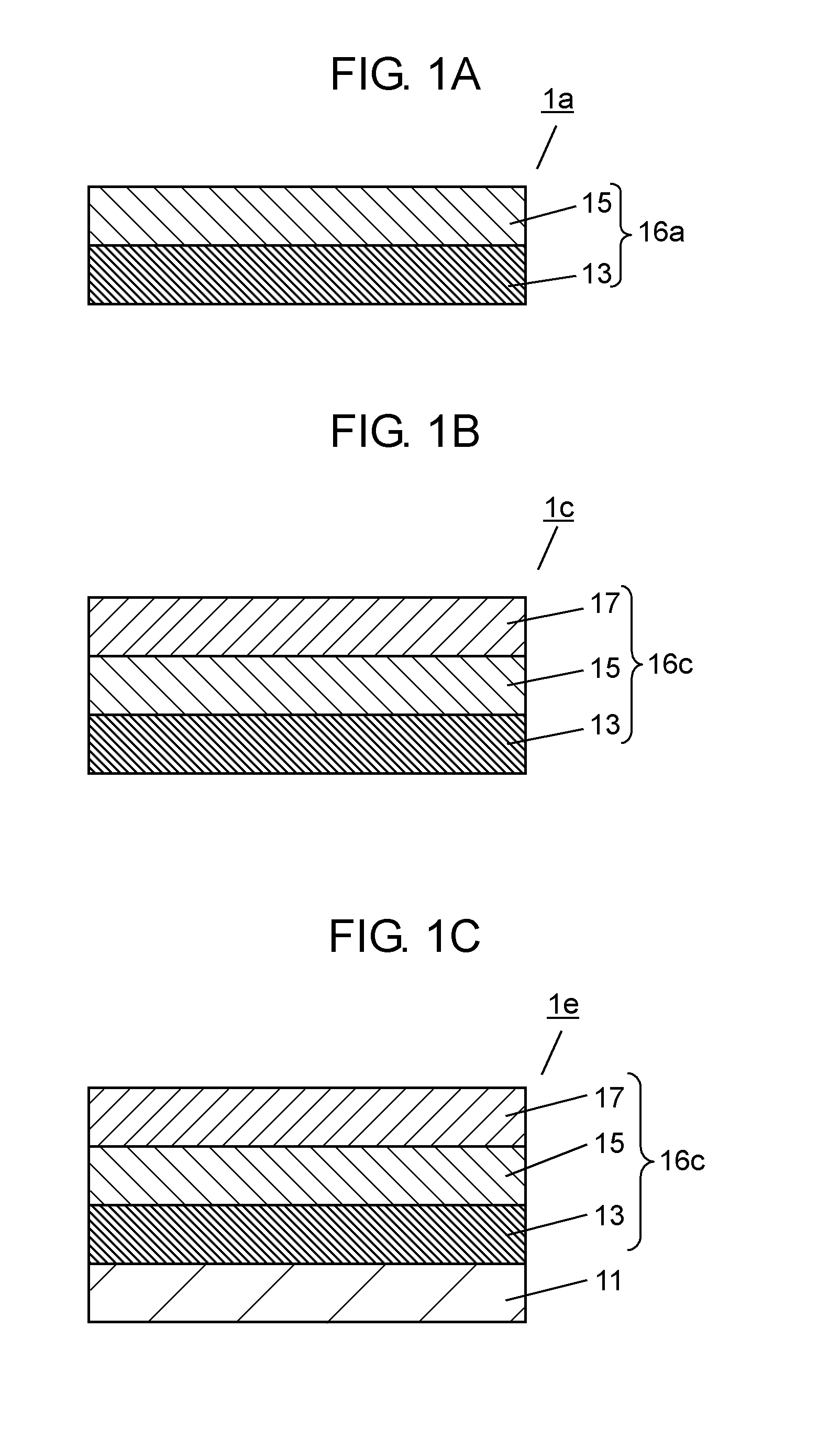

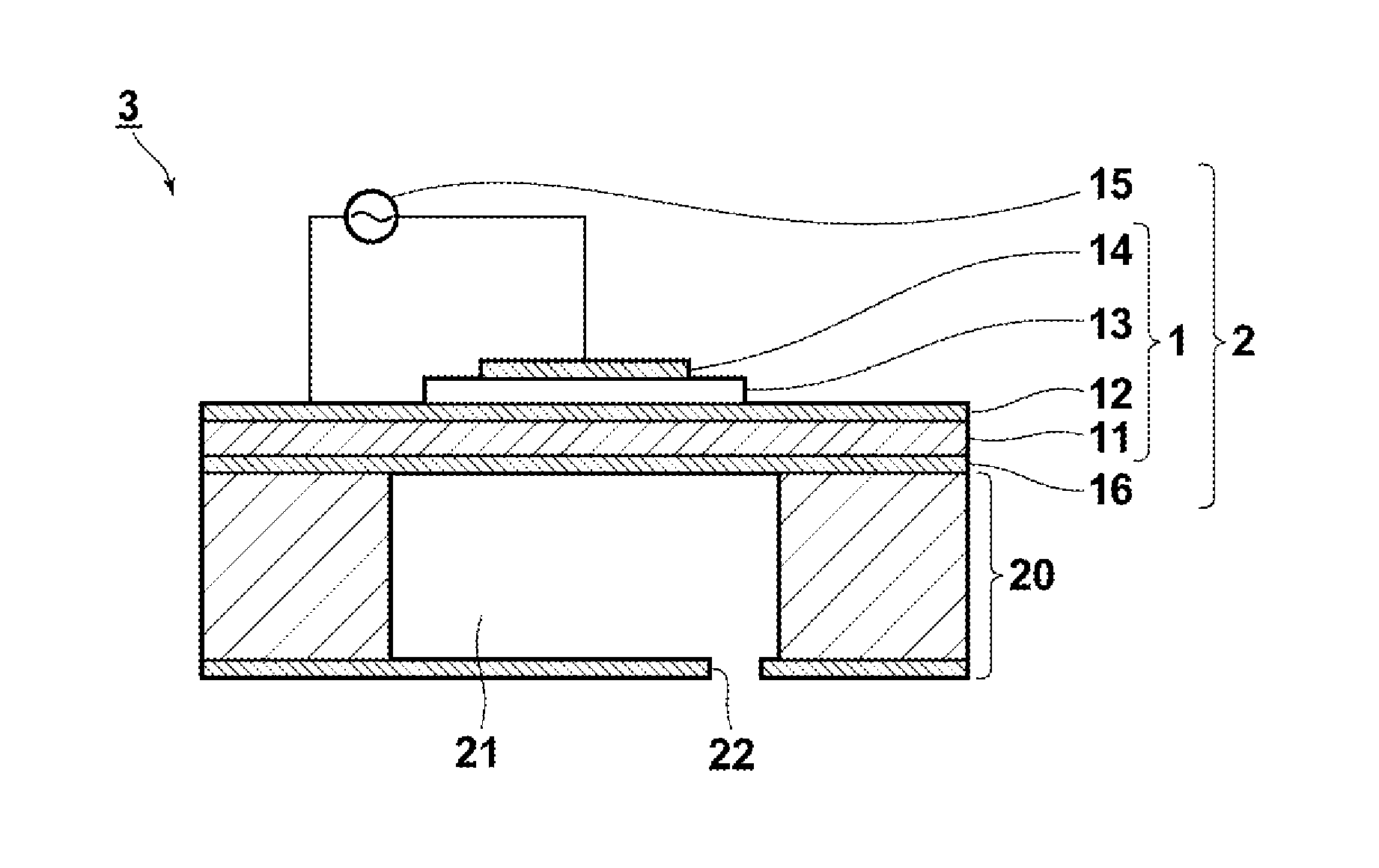

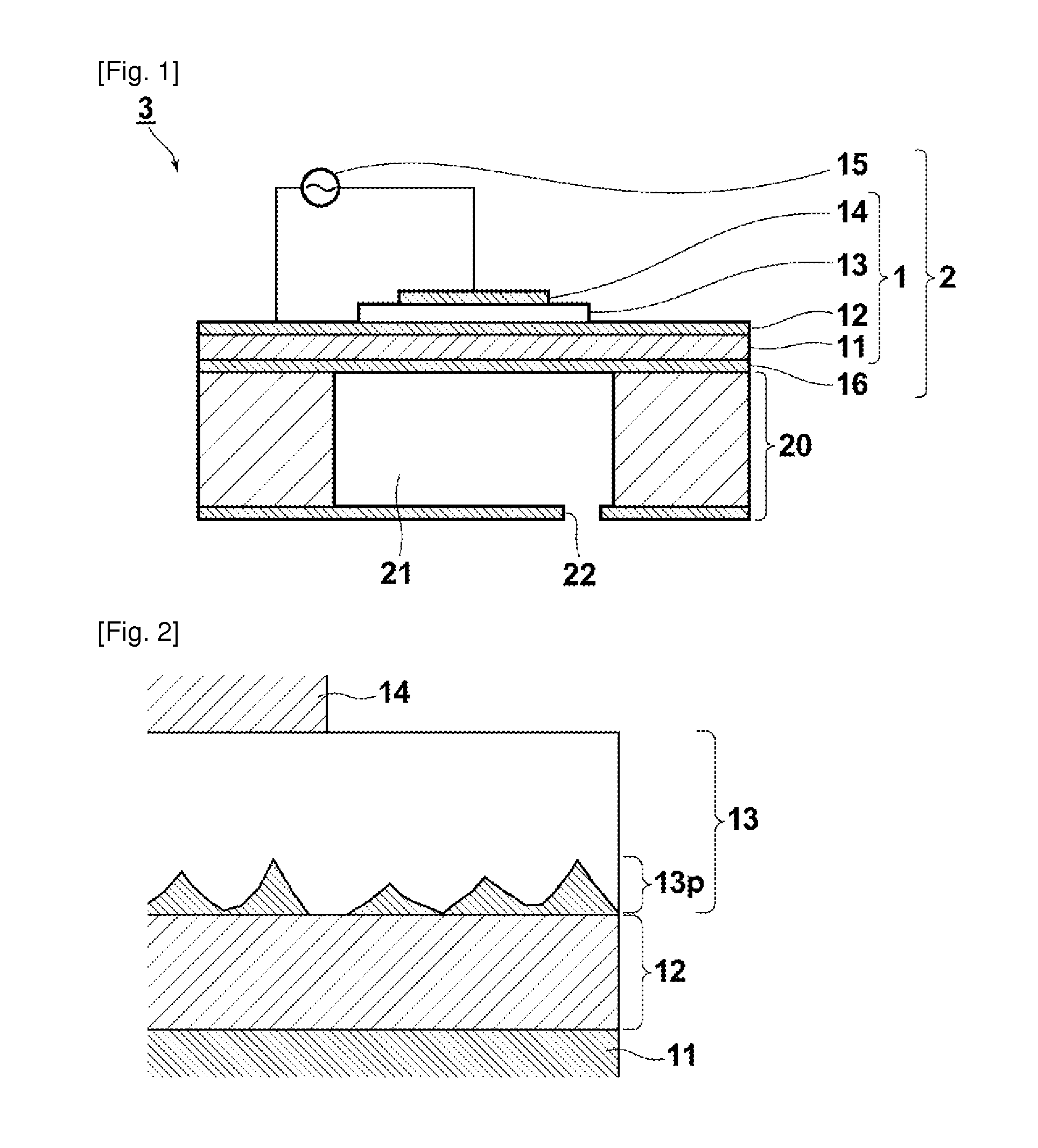

Piezoelectric thin-film resonator

ActiveUS7535154B2Suppress spursPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksConditional expressionYoung's modulus

Owner:MURATA MFG CO LTD

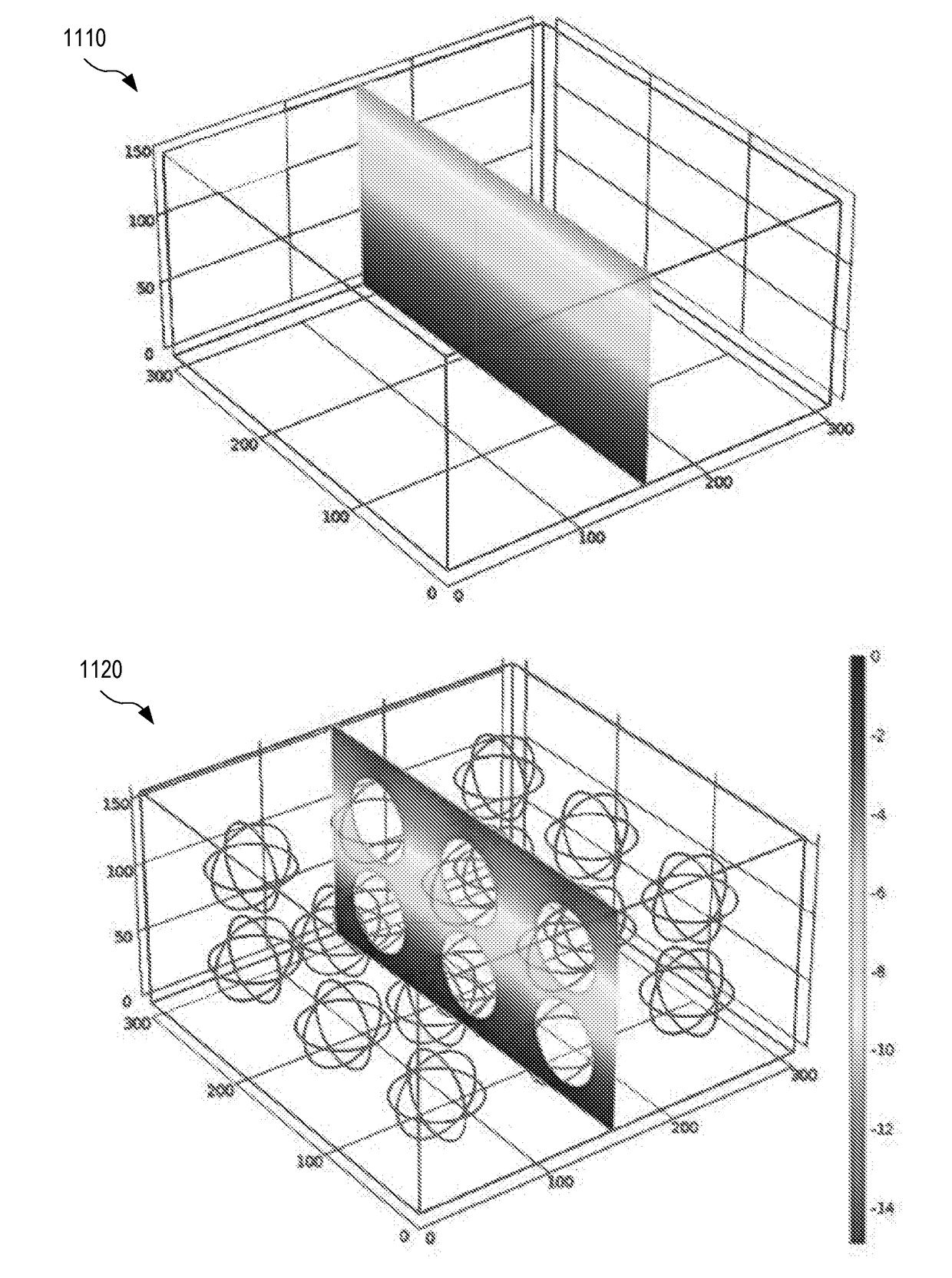

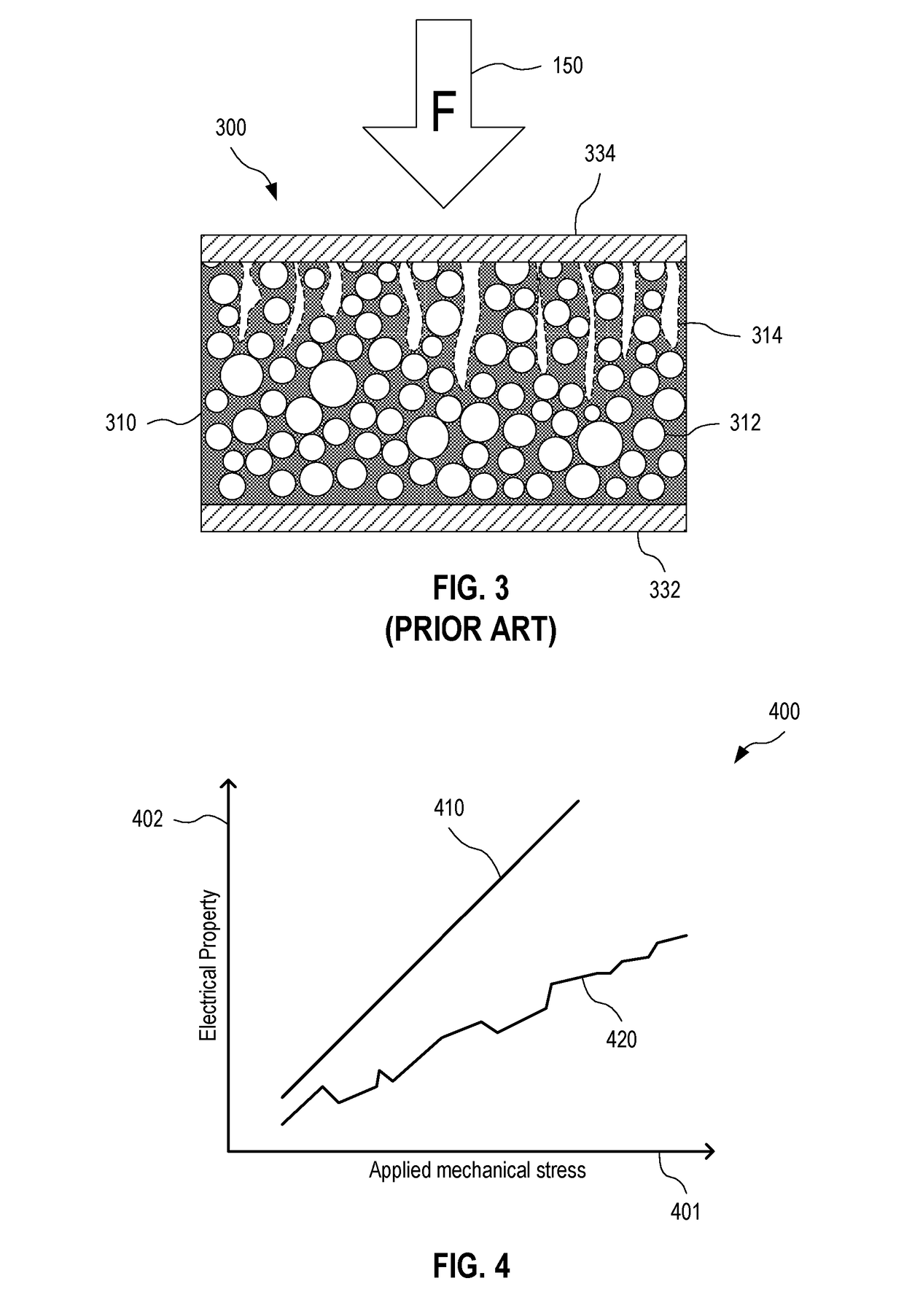

Porous piezoelectric material with dense surface, and associated methods and devices

ActiveUS20170317269A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesPolymer scienceThin membrane

A method for producing a porous piezoelectric polymer film with a dense surface, includes depositing a polymer solution onto a substrate to form a polymer film including a solvent; evaporating a portion of the solvent to form the dense surface away from the substrate; forming water droplets in interior of the polymer film; and substantially evaporating the water droplets and remaining solvent to form porous interior. A piezoelectric composition includes a piezoelectric material with a porous interior and a dense surface for interfacing with an electrode. A piezoelectric device includes a first electrode; a porous piezoelectric film with a dense surface and porous interior, wherein the porous piezoelectric film is deposited on the first electrode and the dense surface is away from the first electrode; and a second electrode deposited on the dense surface for, together with the first electrode, providing an electrical interface for the porous piezoelectric film.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

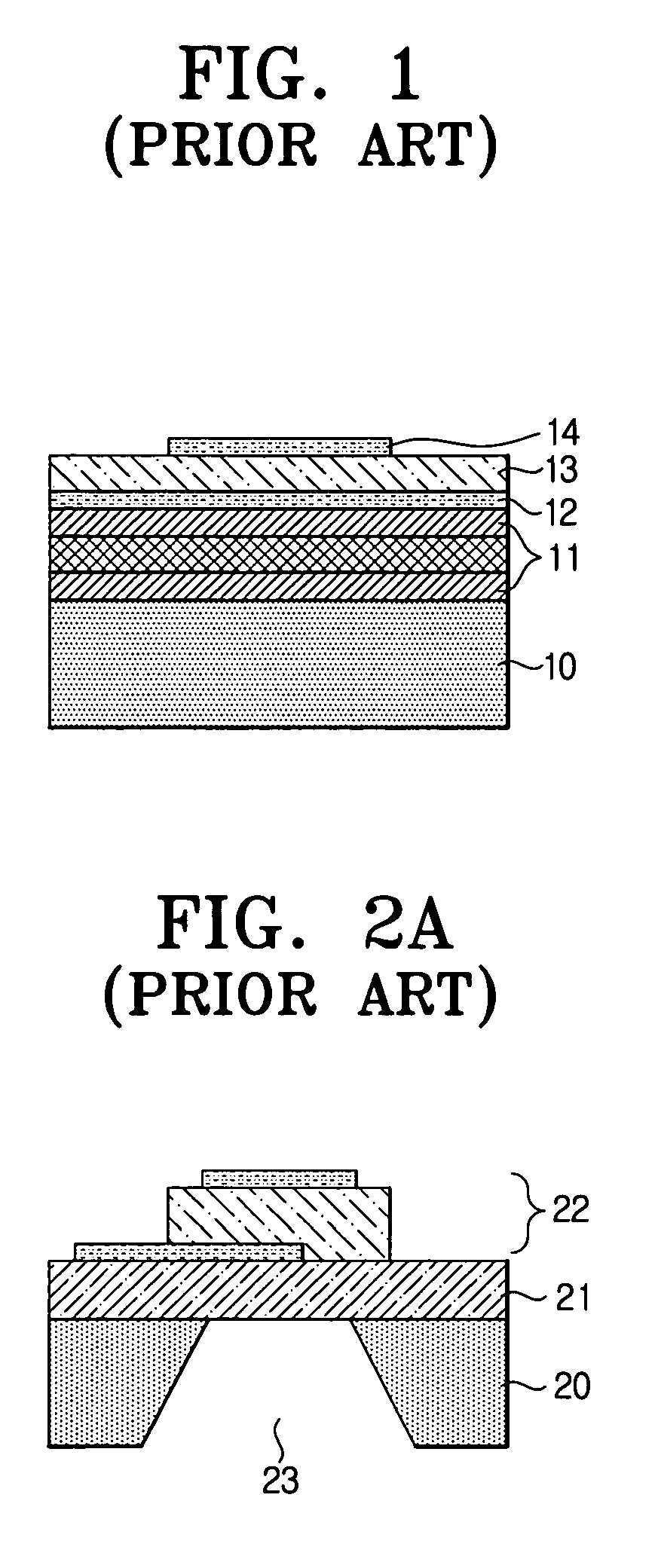

Piezoelectric element, fabrication method for the same, and inkjet head, inkjet recording apparatus and angular velocity sensor including the same

ActiveUS20050127795A1Easy to mass produceMinimize changesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCrystal orientationPiezoelectric membrane

A piezoelectric element includes a first electrode; a piezoelectric layered film composed of a first piezoelectric film formed on the first electrode film and a second piezoelectric film that is formed on the first piezoelectric film and is controlled in crystal orientation thereof by the first piezoelectric film; and a second electrode film formed on the second piezoelectric film. Each of the first and second piezoelectric films is an aggregate of columnar grains grown unidirectionally along a thickness direction of the piezoelectric layered film. A columnar grain of the second piezoelectric film has a larger cross-sectional diameter than a columnar grain of the first piezoelectric film. A ratio l / d of the thickness l of the piezoelectric layered film to the cross-sectional diameter d of the second piezoelectric film is not less than 20 and not more than 60.

Owner:PANASONIC CORP

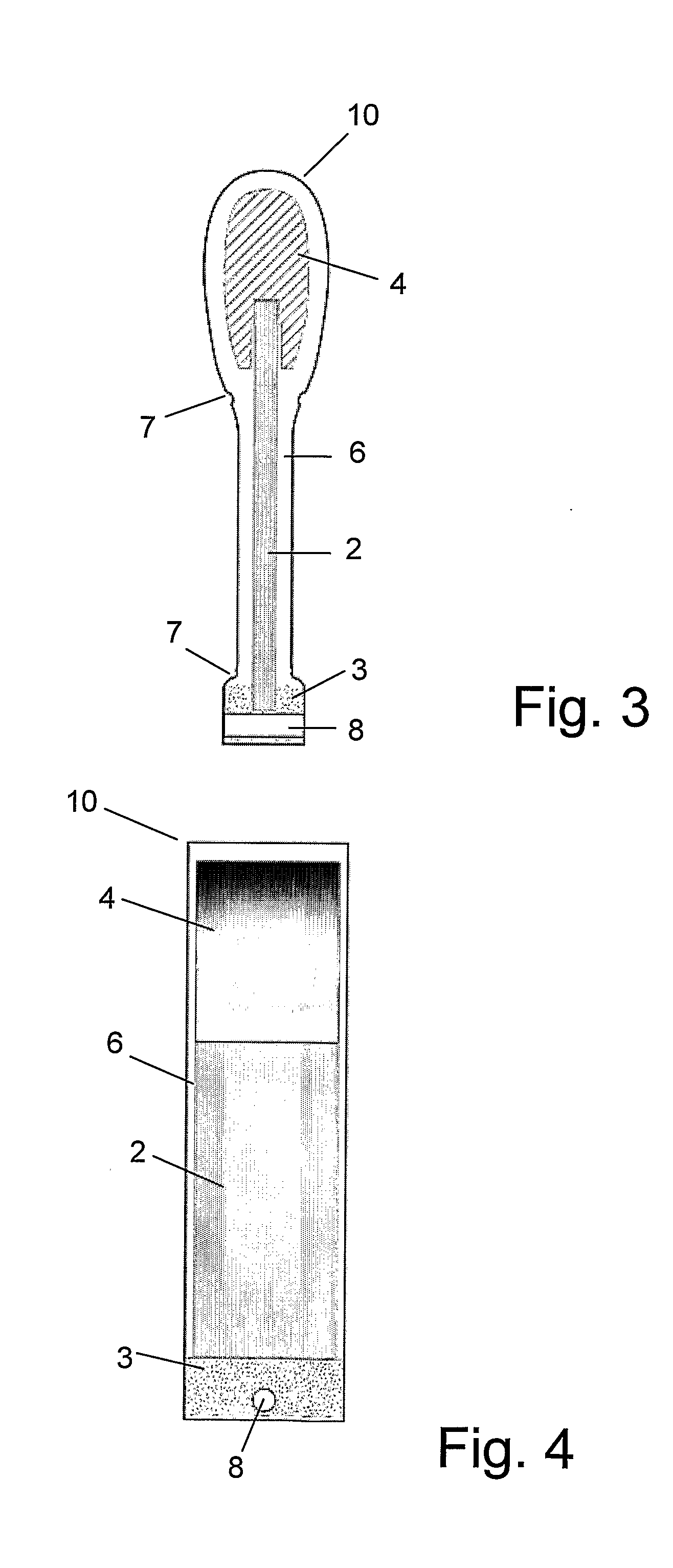

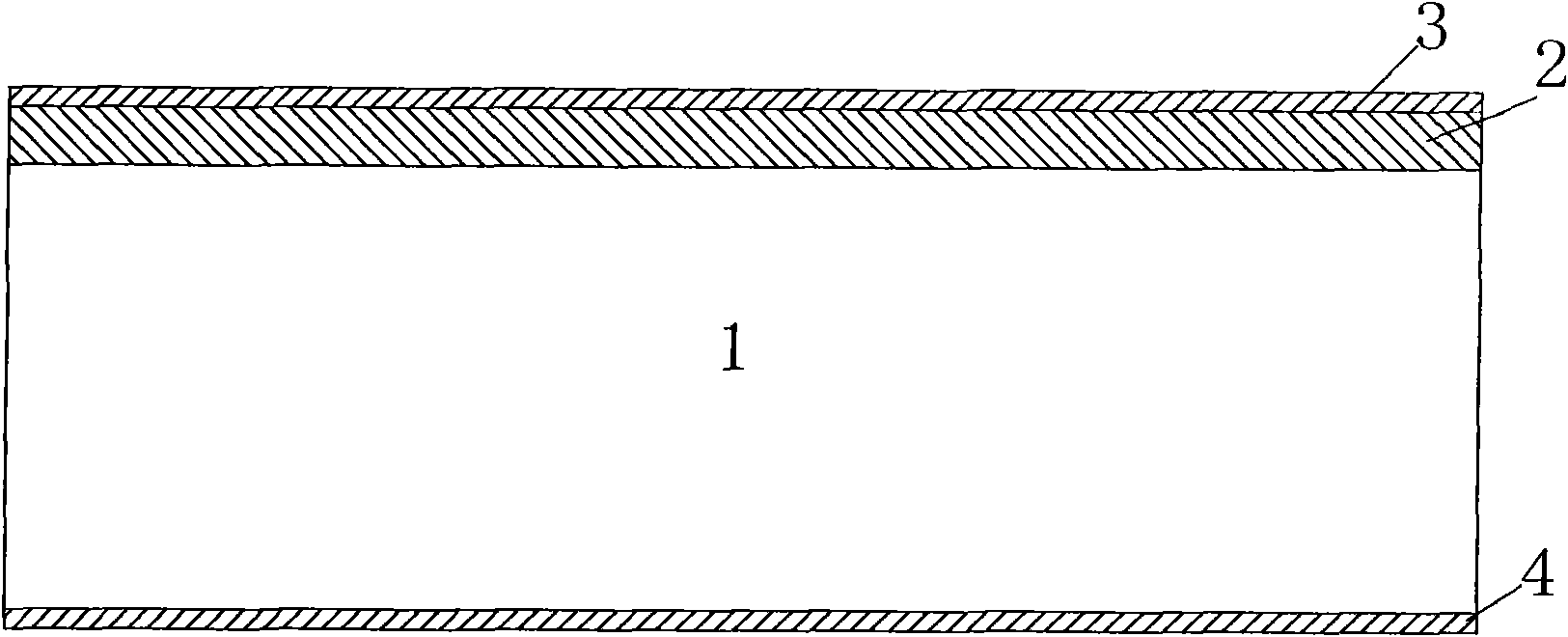

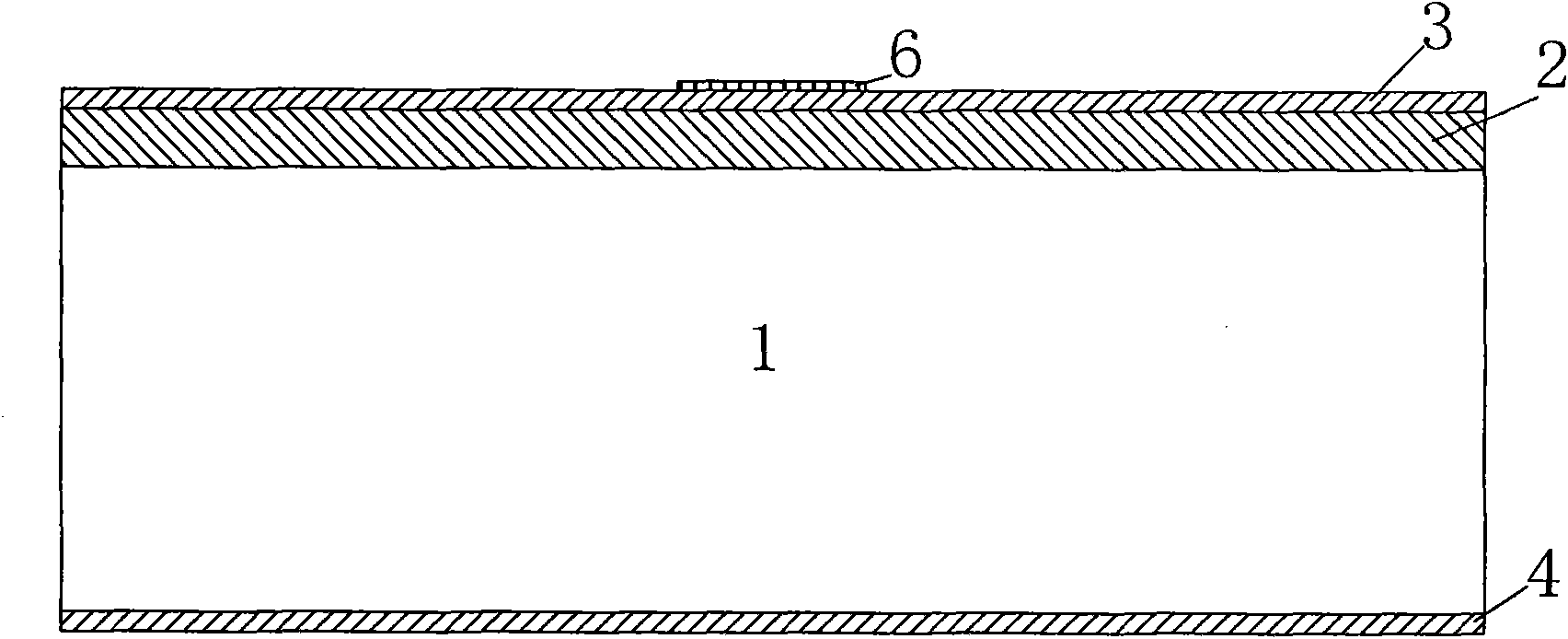

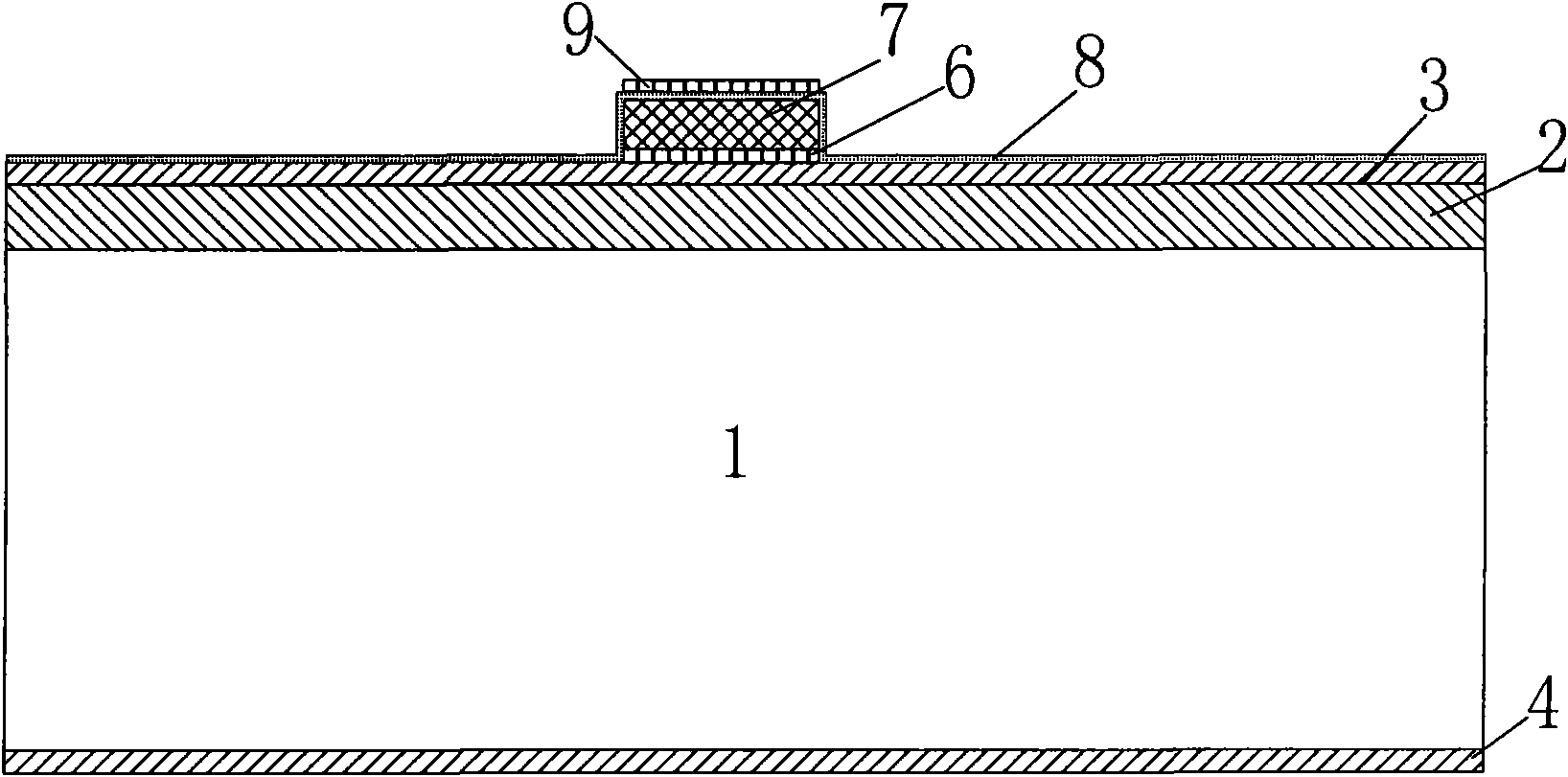

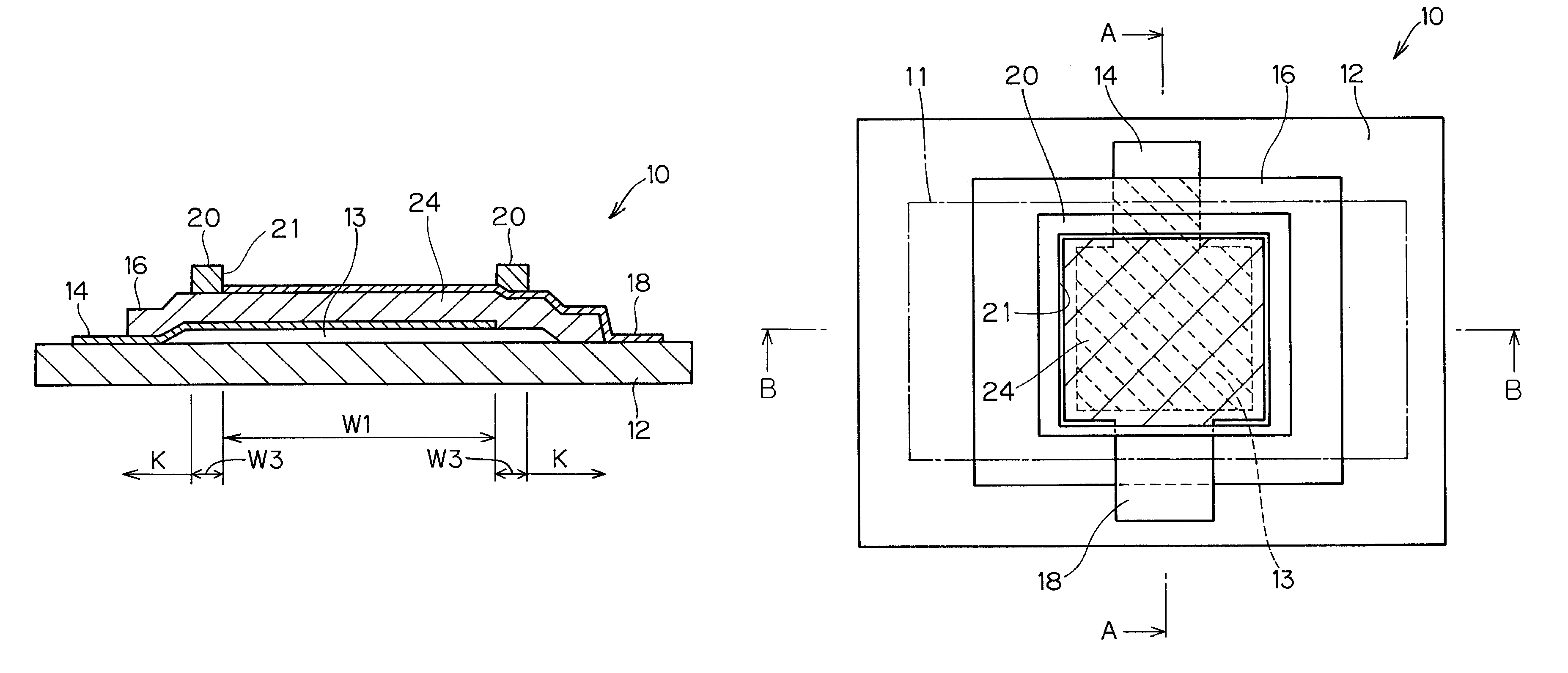

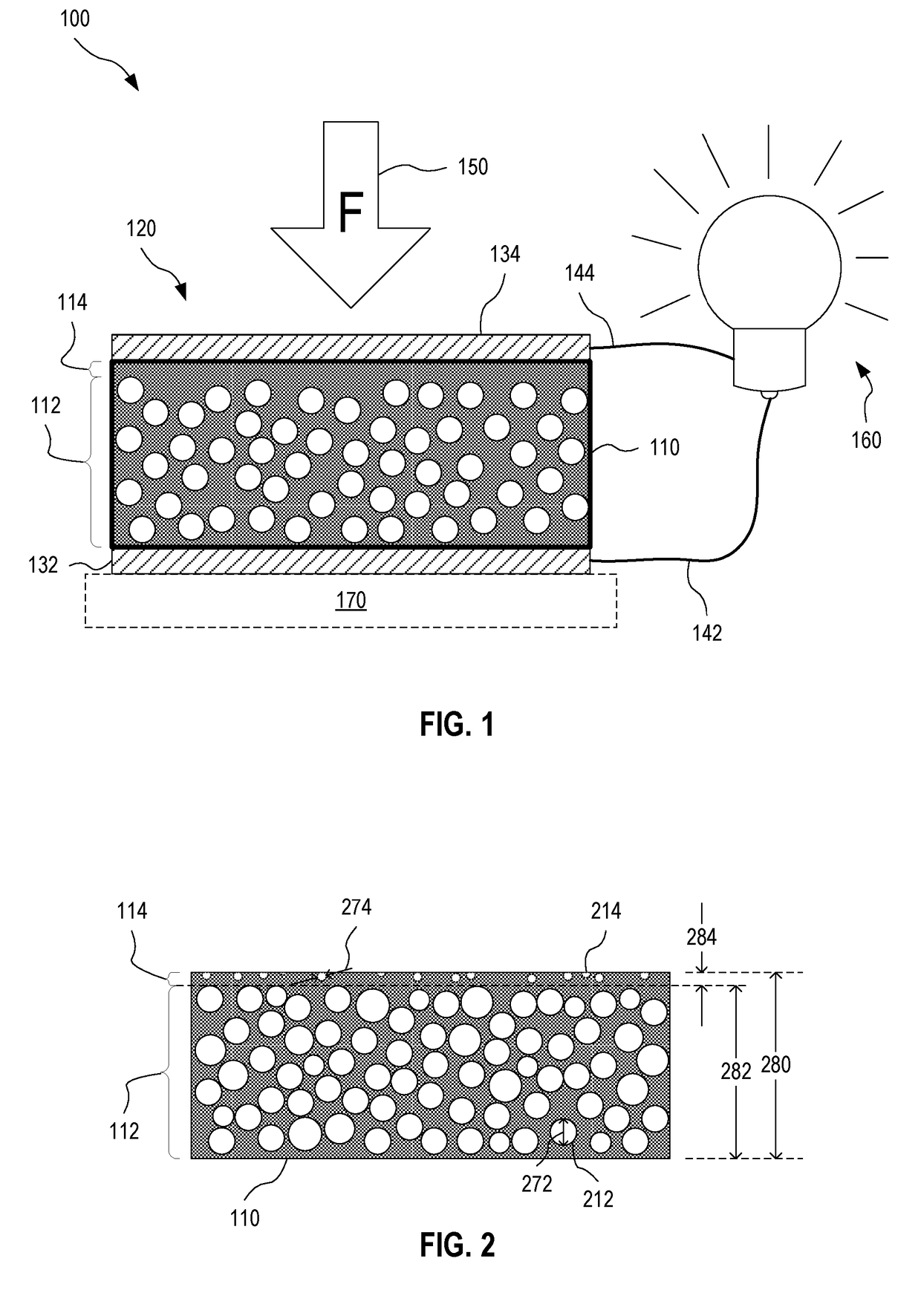

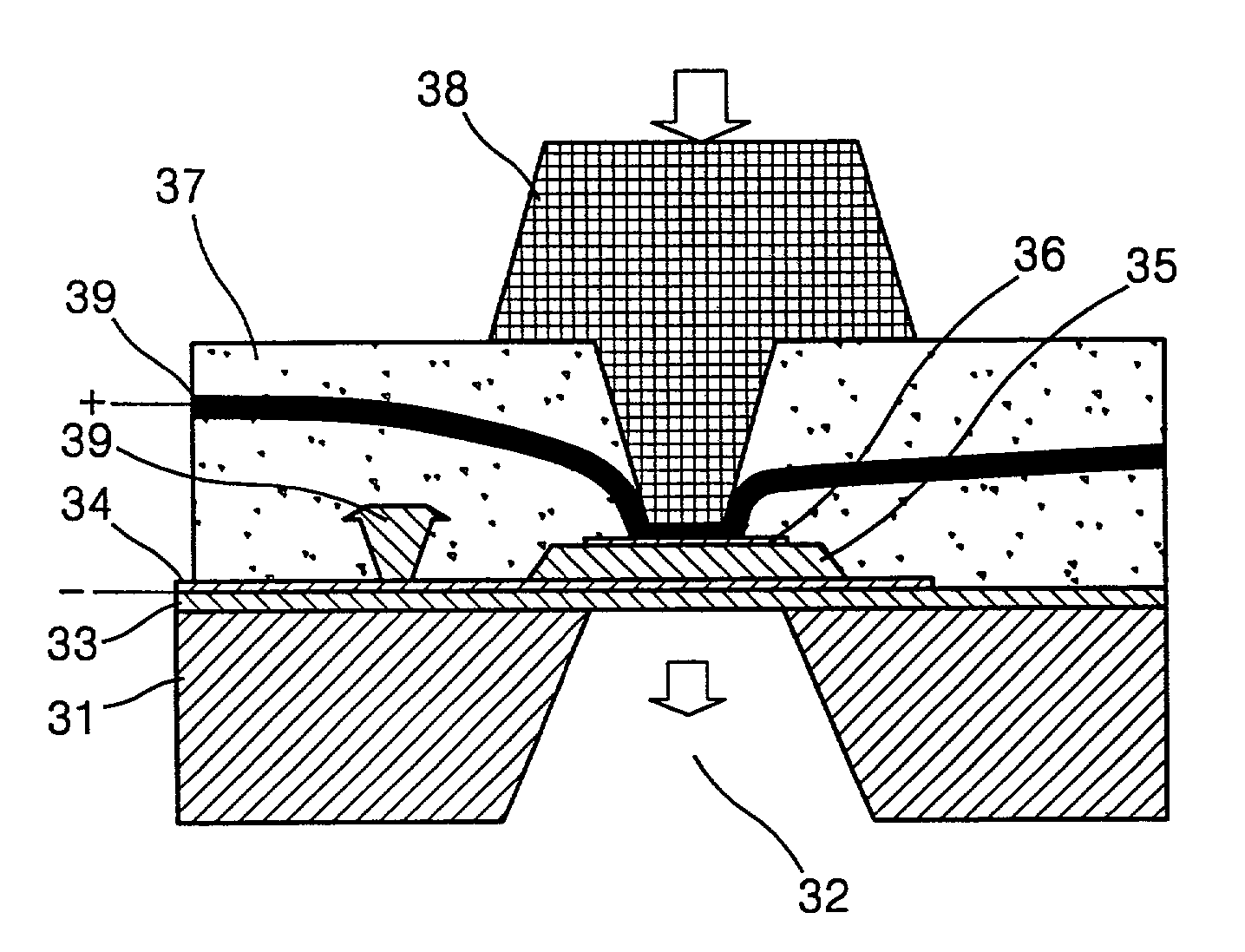

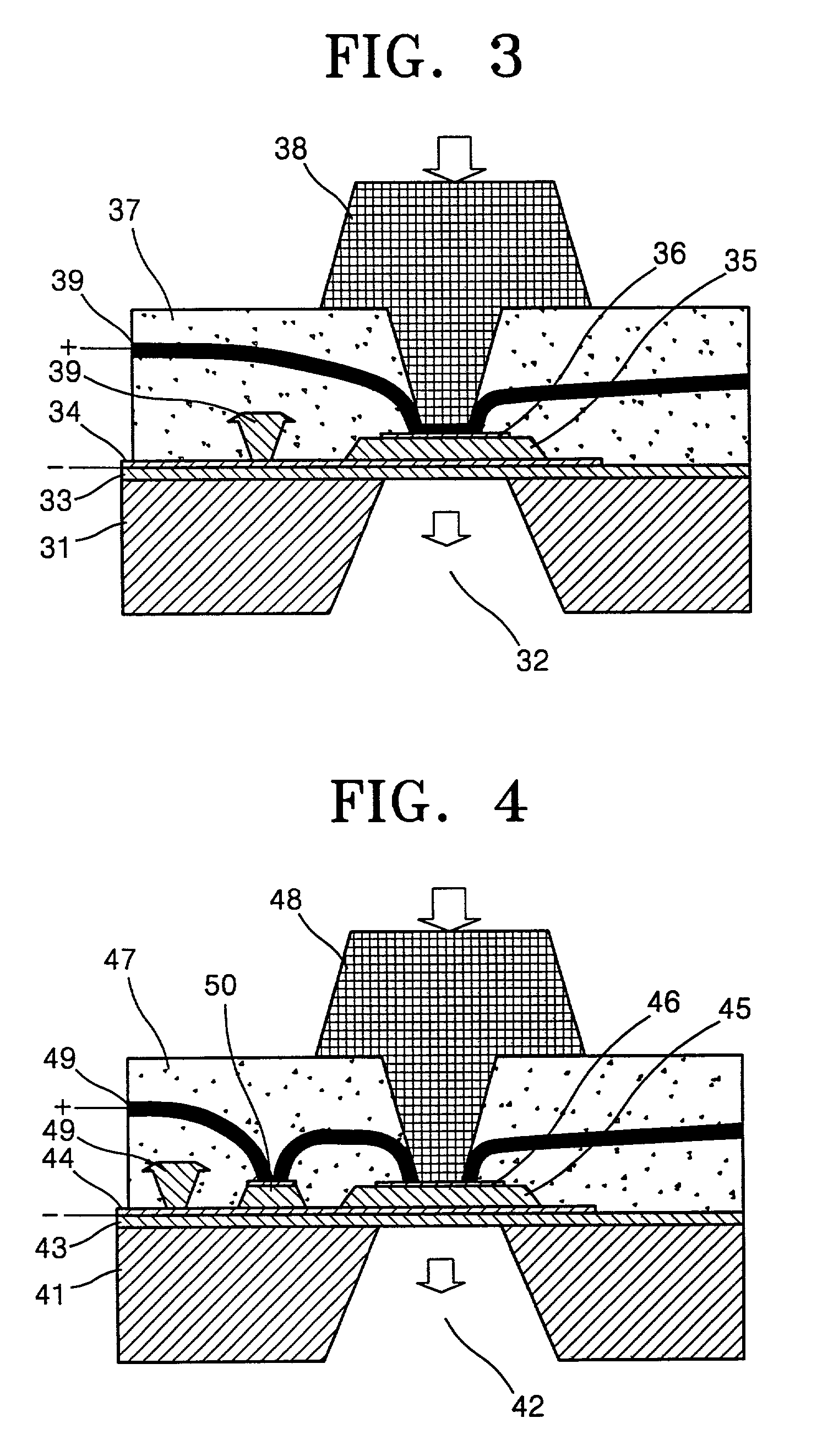

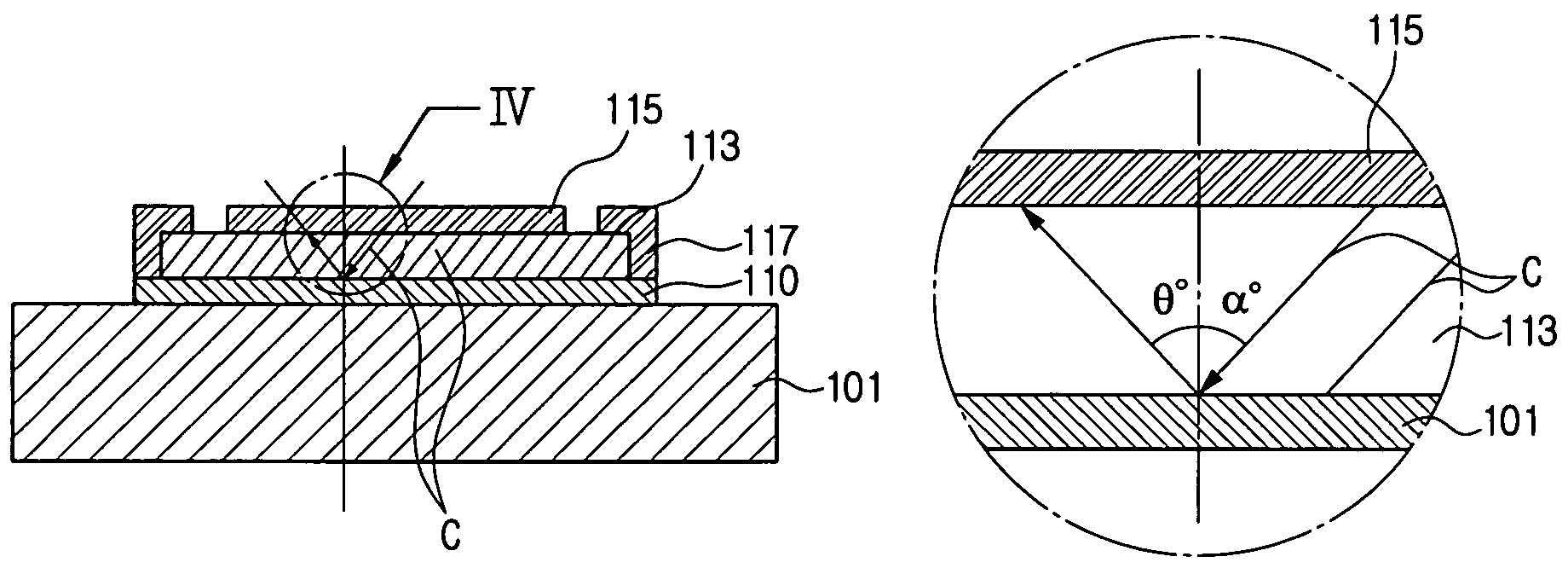

Fingerprint sensor using a piezoelectric membrane

ActiveUS7013031B2Accurate inductionPiezoelectric/electrostriction/magnetostriction machinesFluid pressure measurement by electric/magnetic elementsElectricityPiezoelectric membrane

A fingerprint sensor for sensing a fingerprint by converting pressure applied to a piezoelectric membrane into an electrical signal is provided, wherein the fingerprint sensor having an aggregate of piezoelectric devices includes: a substrate; a lower electrode formed on the substrate; a piezoelectric membrane formed on the lower electrode; an upper electrode formed on the piezoelectric membrane; a pressuring portion formed on the upper electrode for changing a quantity of charge on the piezoelectric membrane due to pressure exerted by contact of a fingerprint; and a non-conductive layer formed on the lower electrode for supporting and exposing the pressuring portion. Thus, a fingerprint sensor having a simple structure is provided, which is able to precisely sense fingerprint information utilizing a piezoelectric phenomenon. The fingerprint sensor may be applied to systems for identifying persons' identities in public institutions and private enterprises, and in individuals' portable systems.

Owner:SAMSUNG ELECTRONICS CO LTD

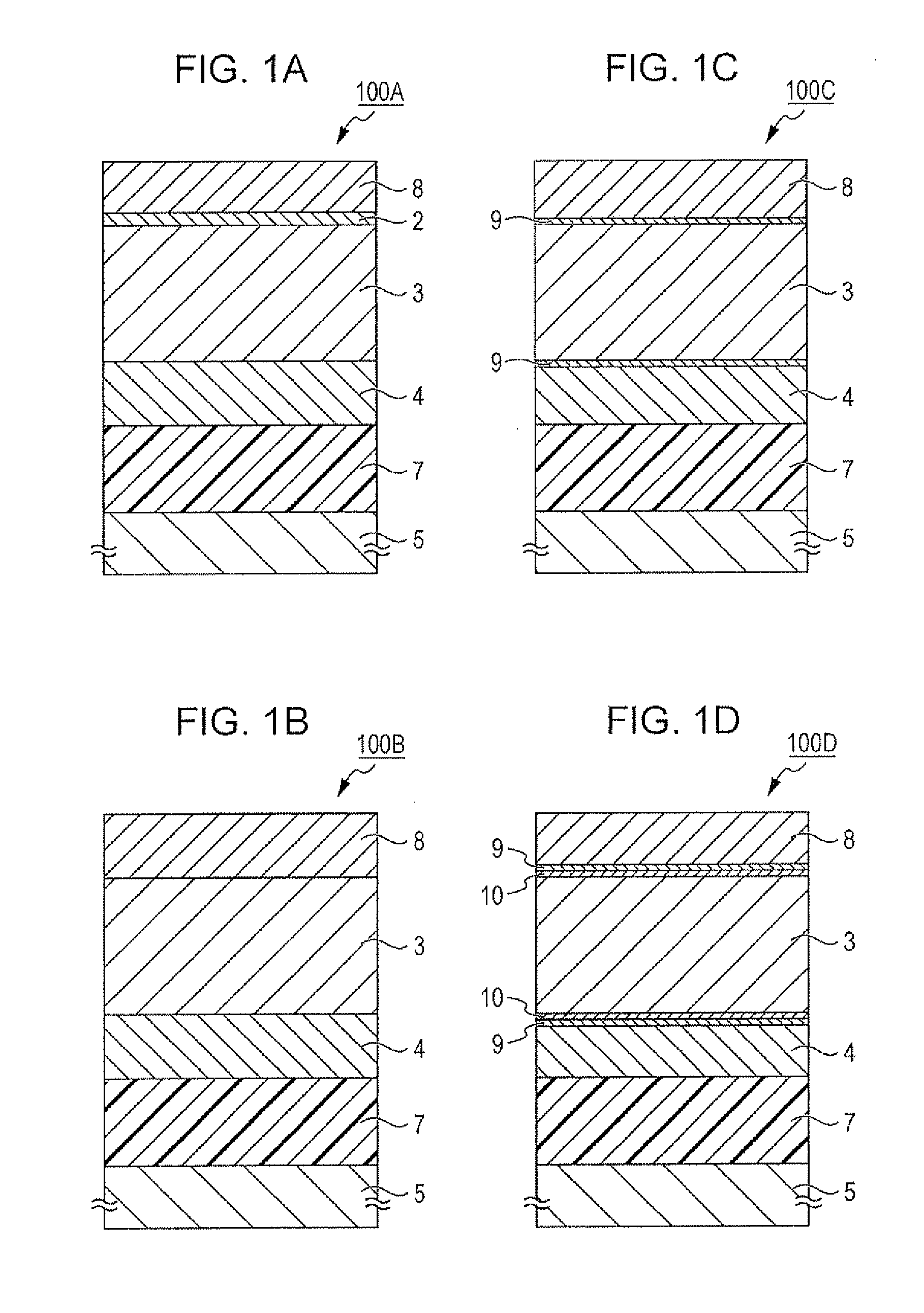

Piezoelectric device

ActiveUS20140339962A1Large displacementImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesThin membraneAlloy

A piezoelectric device includes a first electrode film, a piezoelectric film disposed on the first electrode film, and a second electrode film disposed on the piezoelectric film. At least one of the first and second electrode films is composed of an alloy, and a main component of the alloy is a metal selected from the group consisting of Ti, Al, Mg, and Zn. The piezoelectric film has a main composition represented by (K1-x-y-w-vNaxLiyBawSrv)m(Nb1-z-uTazZru)O3 (1), where x, y, z, w, v, u, and m in formula (1) satisfy 0.4<x≦0.7, 0.02≦y≦0.11, 0.5≦x+y<0.75, 0<z≦0.28, 0<w≦0.02, 0.02≦v≦0.11, 0.02≦u≦0.11, and 0.95≦m<1.2, and contains 1% by mass or less of MnO relative to the main composition.

Owner:TDK CORPARATION

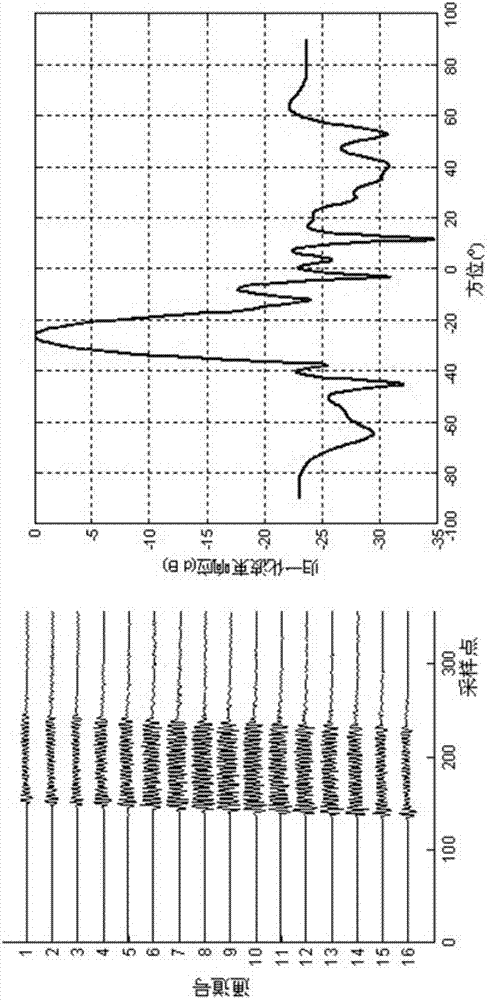

High-frequency closely-spaced piezoelectric film hydrophone array and production method thereof

ActiveCN103175601AImproved detection resolutionImprove electromagnetic compatibilityVibration measurement in fluidTransducerEngineering

The invention relates to the technical field of underwater sound transducers, in particular to a high-frequency hydrophone array applicable to underwater phased array camera and a production method thereof, and solves the technical problems that a large cardinal number of high-frequency hydrophone array elements need to be accurately located and disposed in a limited array area and charge sensed by efficient coupling array elements is required to pick up and receive high-frequency weak underwater sound signals. A piezoelectric device PVDF (polyvinylidene fluoride) film, a rigid backing and PCBs (printed circuit board) are jointed; the high-frequency PVDF hydrophone backing is made of copper to increase sensitivity; multiple layers of PCBs are used as a substrate; a large number of array element backings are integrally pre-processed; the array element backing clusters are positioned and fitted to the PCB substrate; the backing units are separated by secondary processing; decoupling bars are added among the separated units; the piezoelectric film is adhered to form an array; finally, watertight sealing is performed to form the high-frequency piezoelectric film hydrophone array. The high-frequency hydrophone array is applicable to high-frequency sonar receiving arrays for imaging sonar, multi-beam sonar, side-scan sonar and the like.

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP

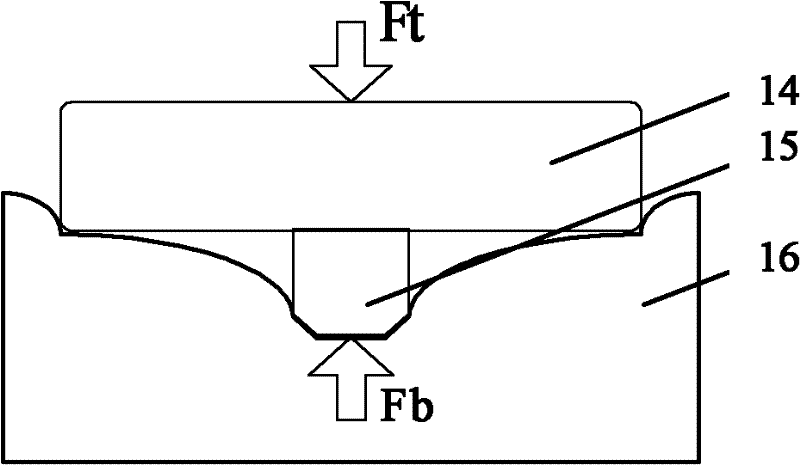

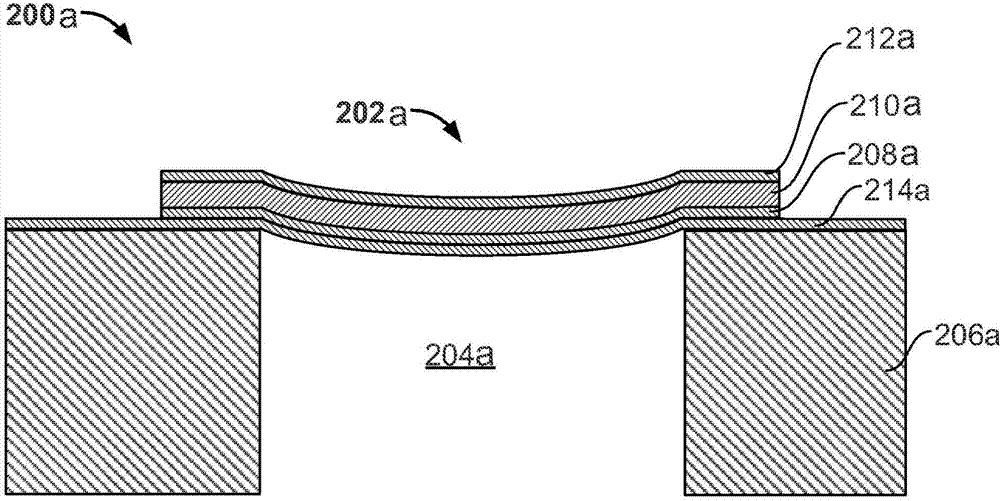

Forming a device having a curved piezoelectric membrane

ActiveCN103026520APiezoelectric/electrostrictive device manufacture/assemblyPrintingPiezoelectric actuatorsEngineering

Processes for forming an actuator having a curved piezoelectric membrane are disclosed. The processes utilize a profile-transferring substrate having a curved surface surrounded by a planar surface to form the curved piezoelectric membrane. The piezoelectric material used for the piezoelectric actuator is deposited on at least the curved surface of the profile-transferring substrate before the profile-transferring substrate is removed from the underside of the curved piezoelectric membrane. The resulting curved piezoelectric membrane includes grain structures that are columnar and aligned, and all or substantially all of the columnar grains are locally perpendicular to the curved surface of the piezoelectric membrane.

Owner:FUJIFILM CORP

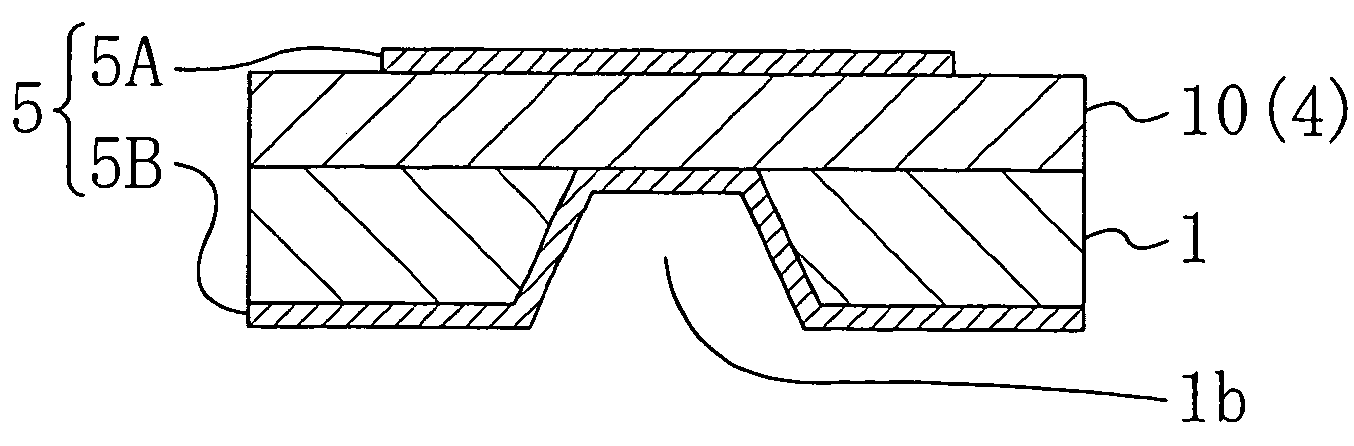

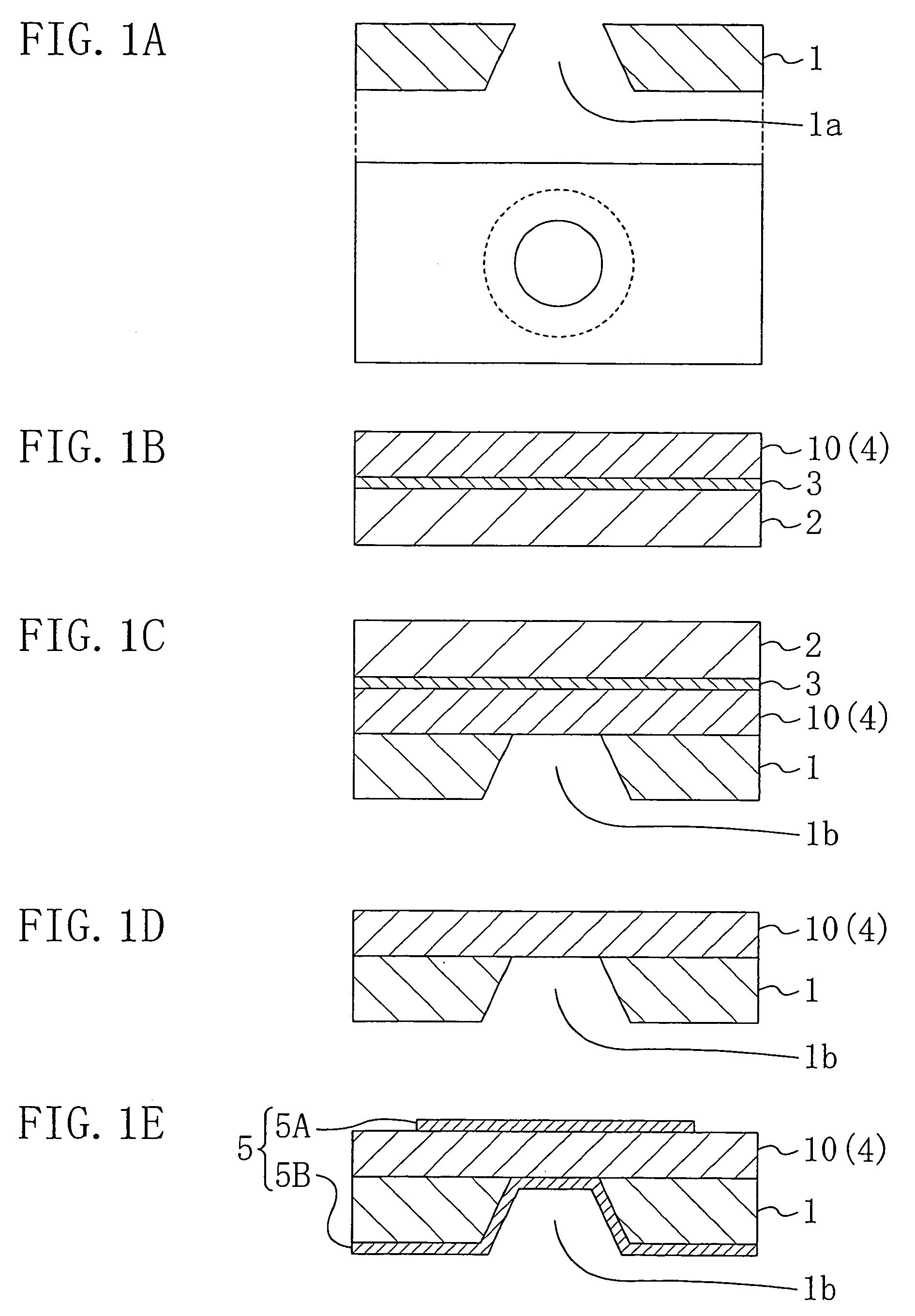

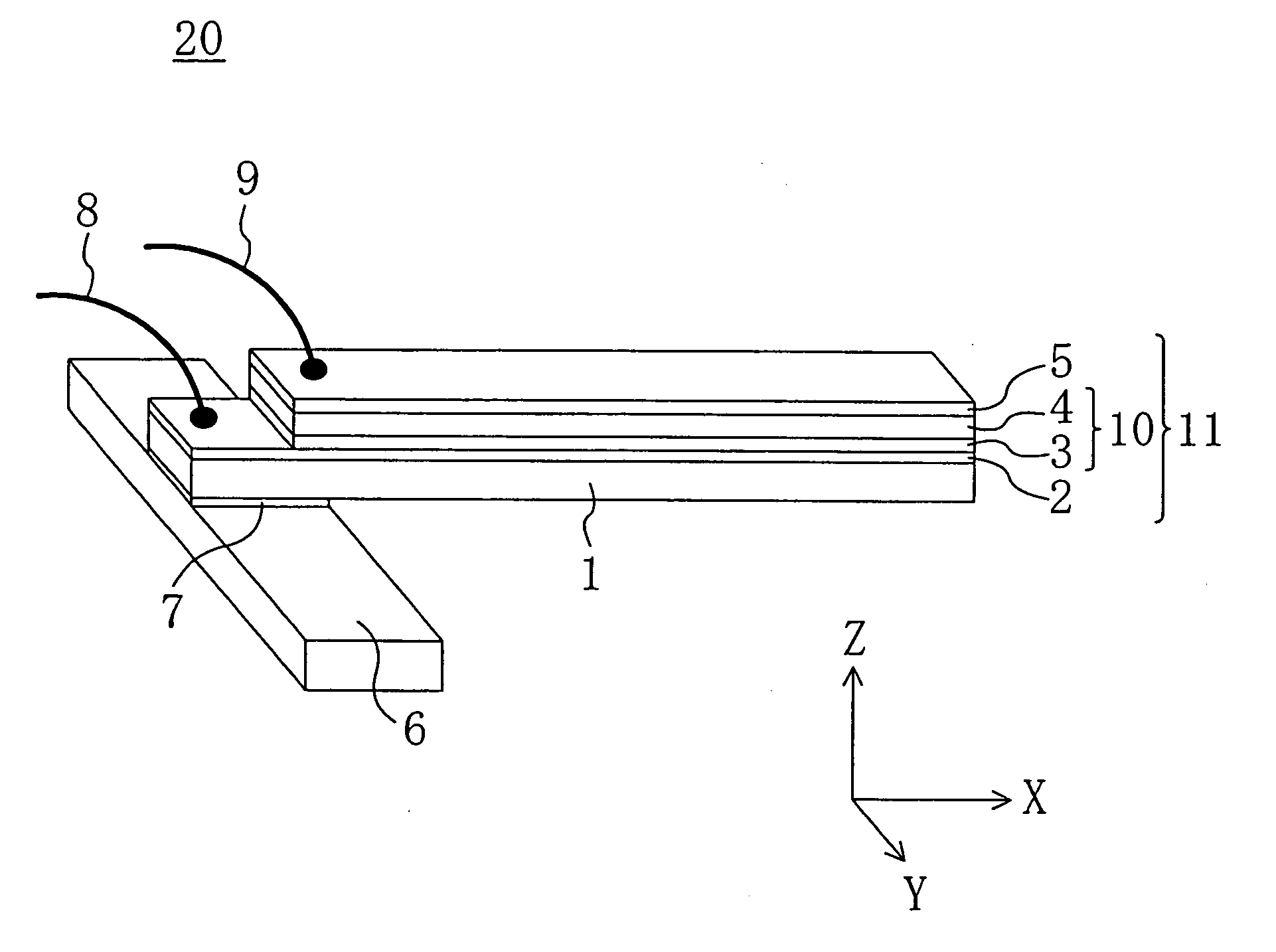

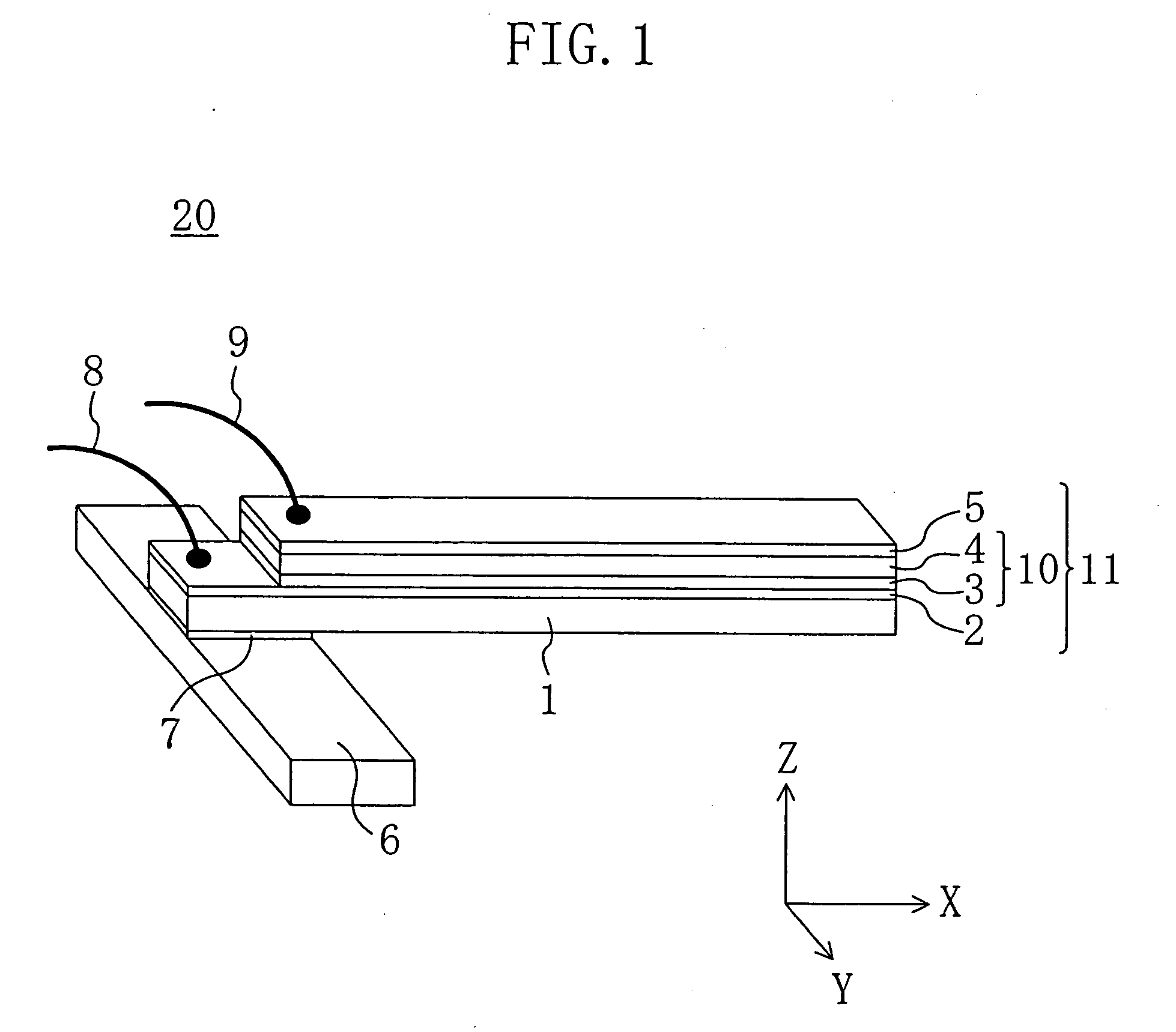

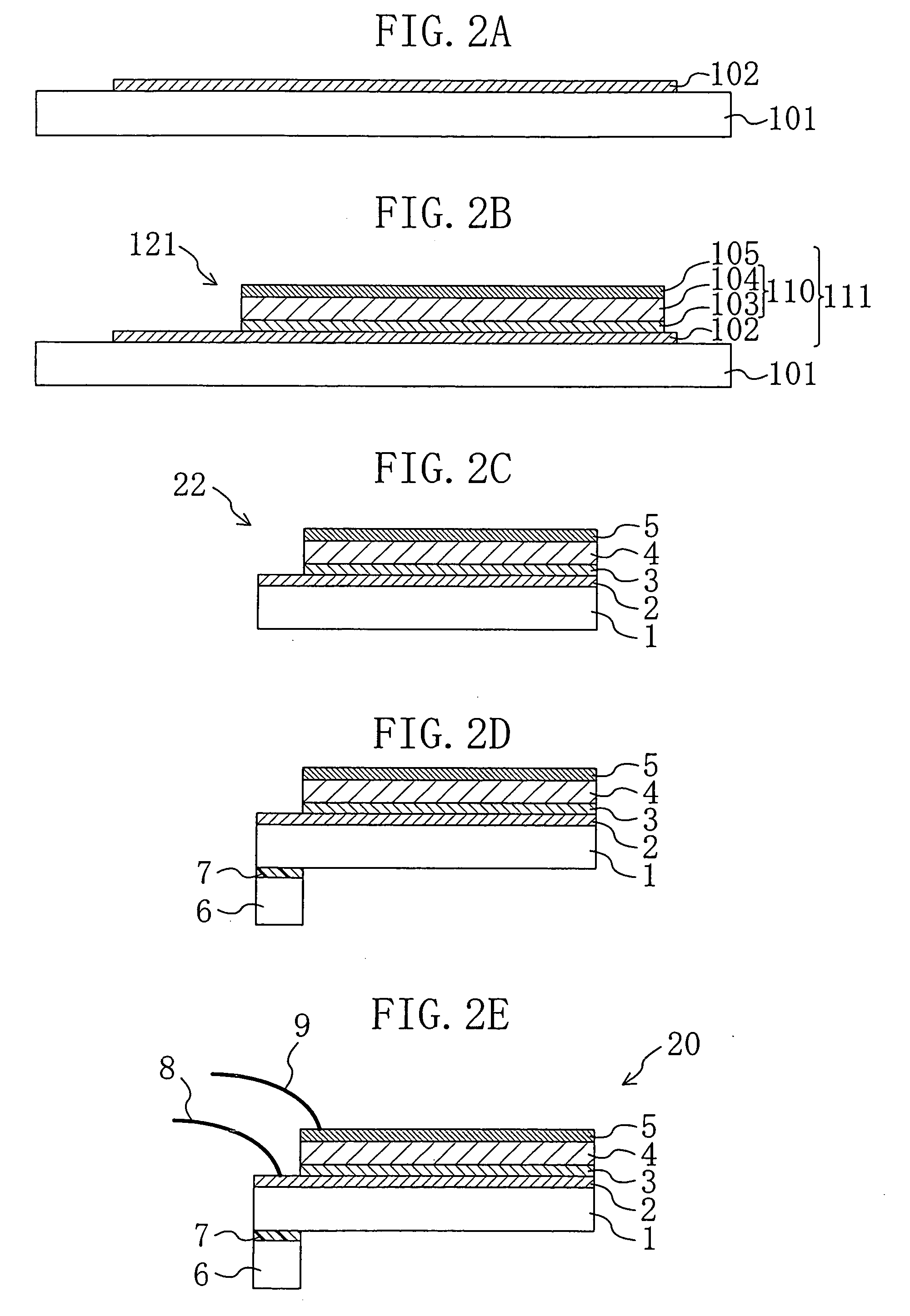

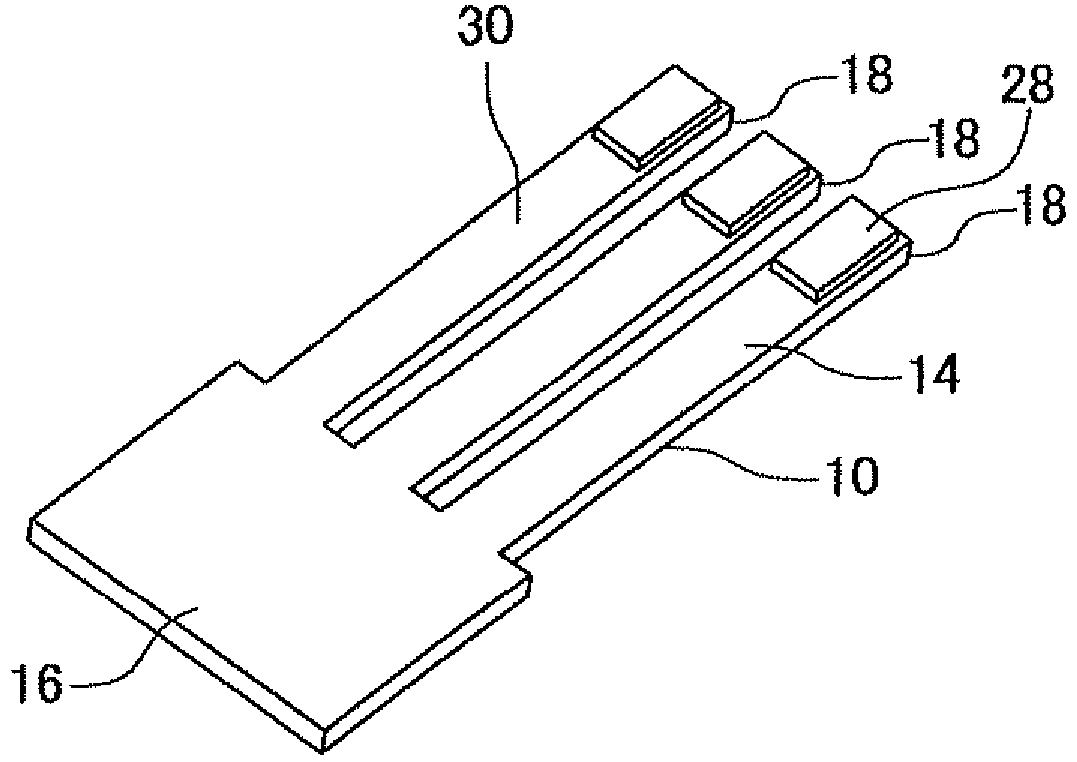

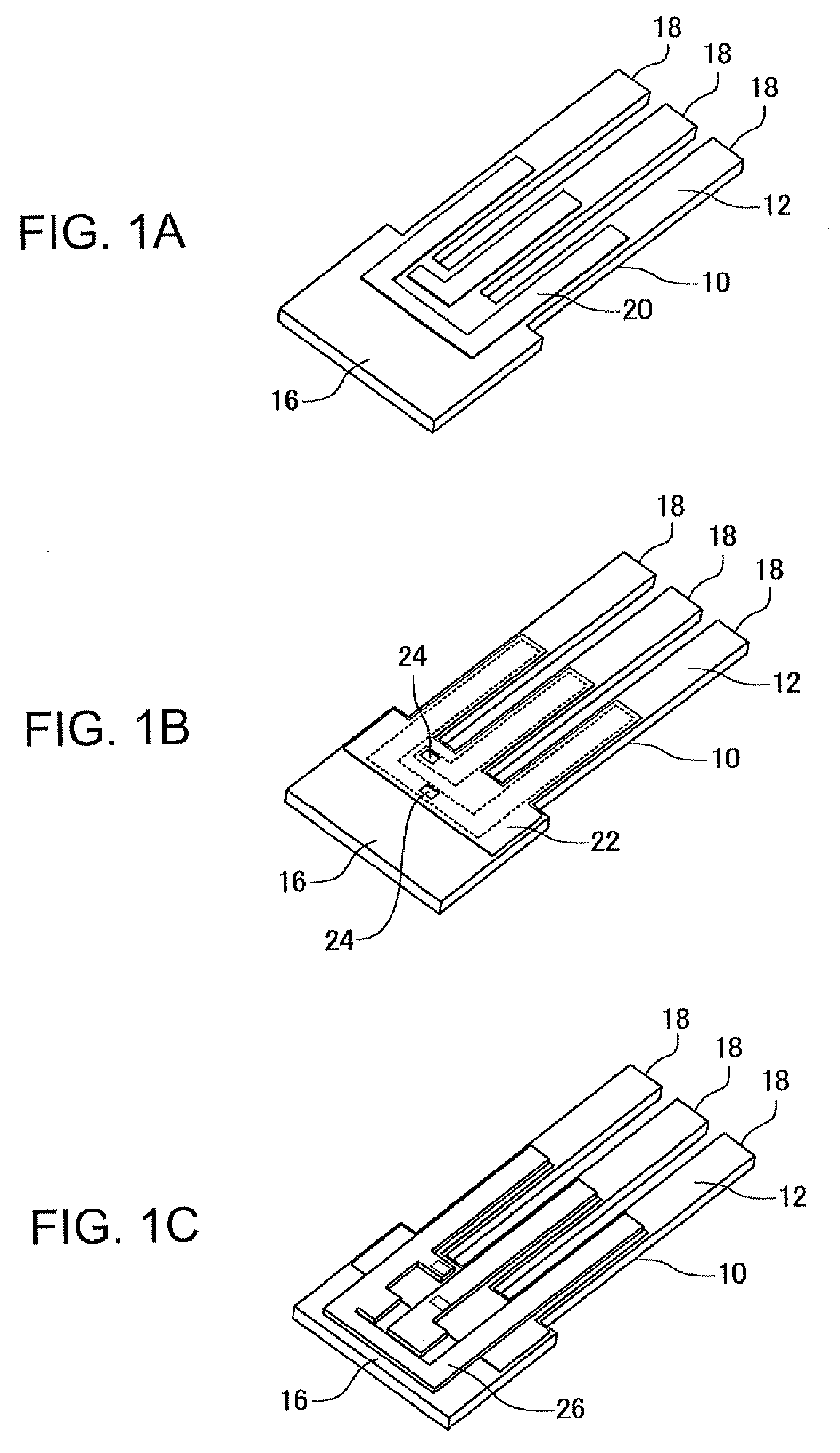

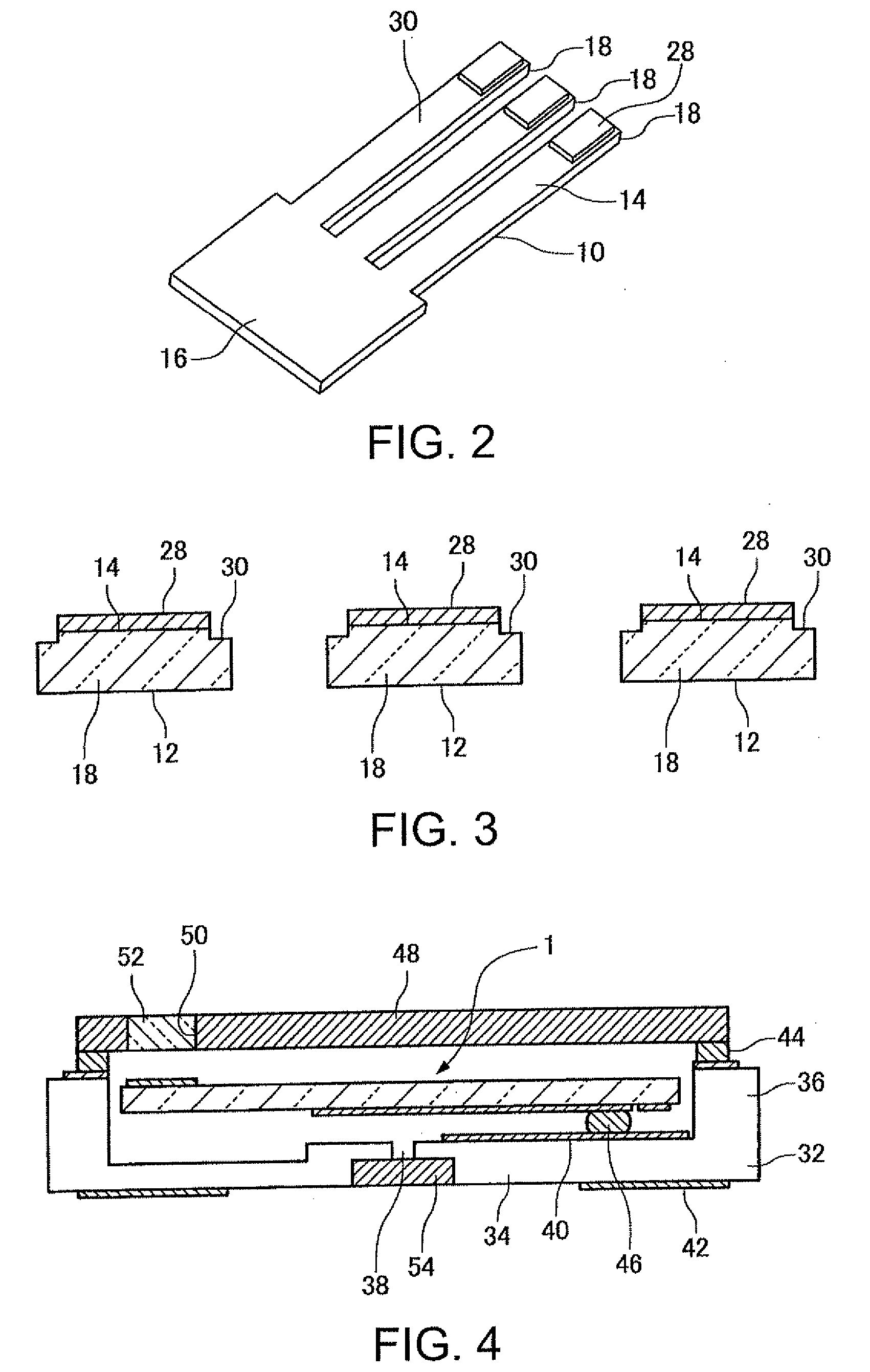

Vibrating piece manufacturing method and vibrator manufacturing method

InactiveUS20090178260A1Extend the scope of controlReduce thicknessPiezoelectric/electrostrictive device manufacture/assemblyRecord carriersEngineeringFlexural rigidity

A vibrating piece manufacturing method includes: (a) preparing a supporting body having first and second surfaces, the first and second surfaces defining a thickness while being directed toward opposite directions, the supporting body including a base and a plurality of arms, the arms extending side-by-side in a direction orthogonal to a direction of the thickness from the base, a lower electrode film being disposed on the first surface of each of the arms, a piezoelectric film being disposed on the lower electrode films, at least one upper electrode film being disposed on the piezoelectric film, at least a part of the second surface of each of the arms being an exposed area; and (b) etching the exposed area of the second surface so as to reduce the thickness to reduce flexural rigidity of the arms with respect to the thickness direction.

Owner:SEIKO EPSON CORP

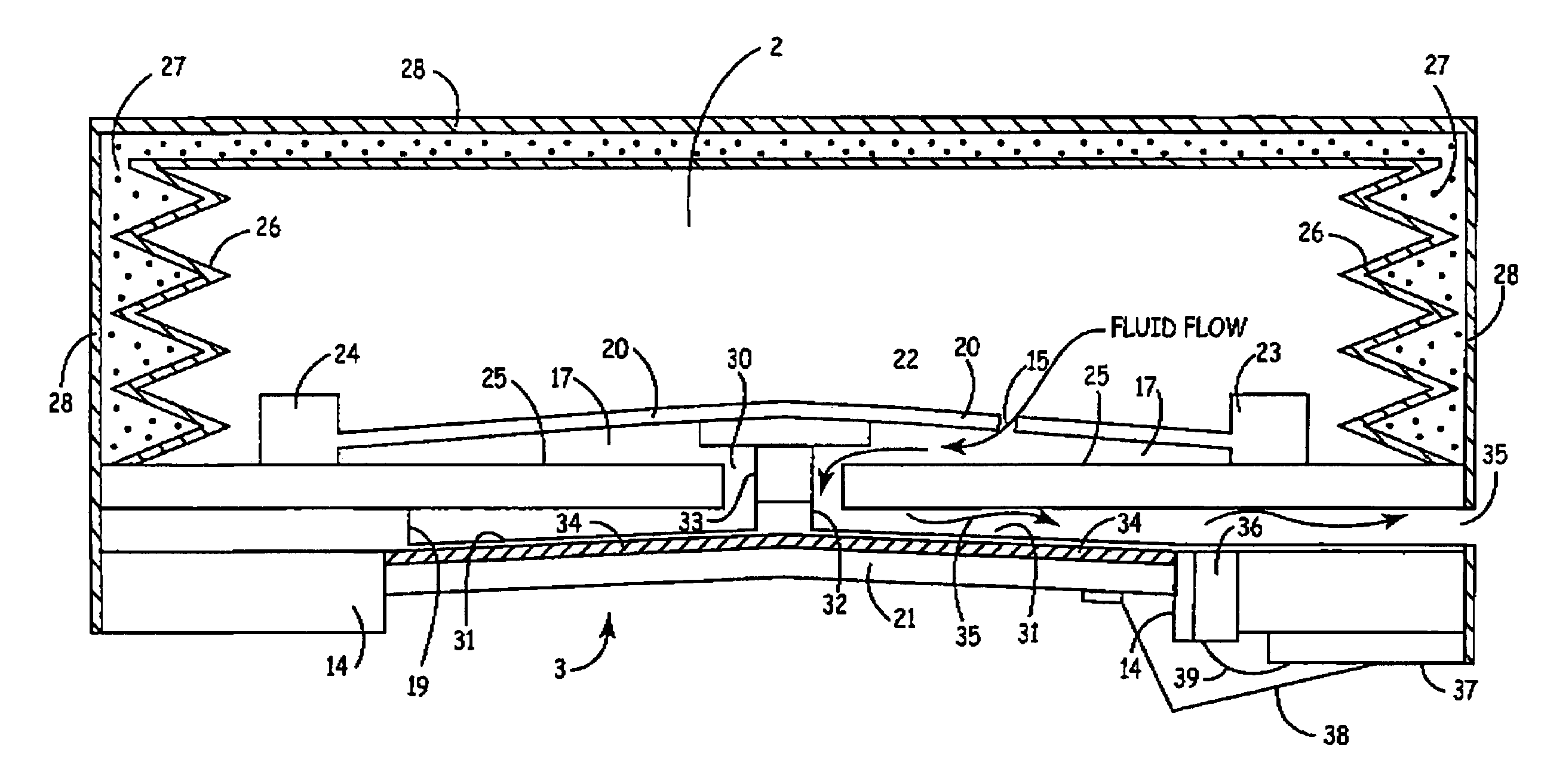

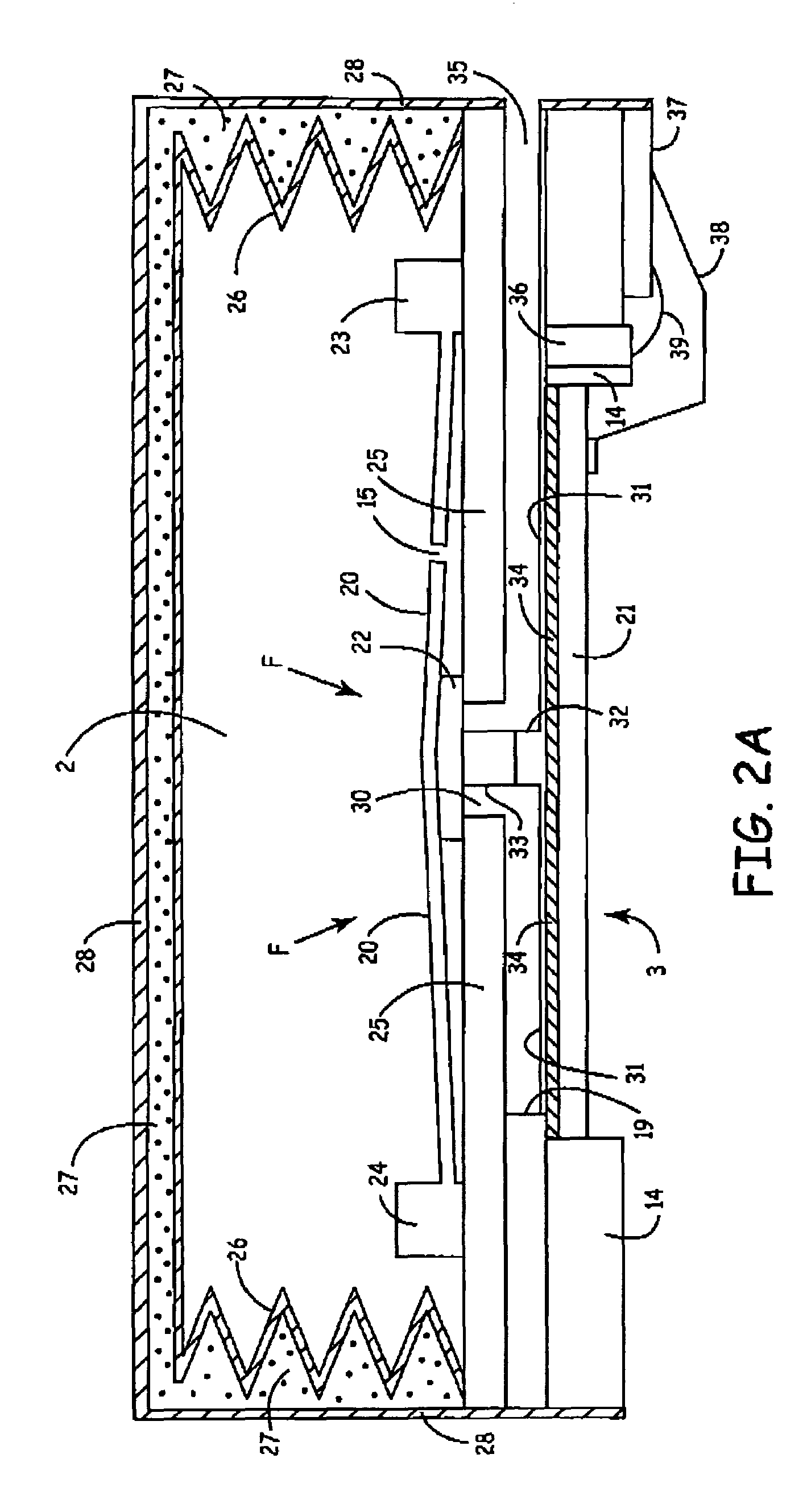

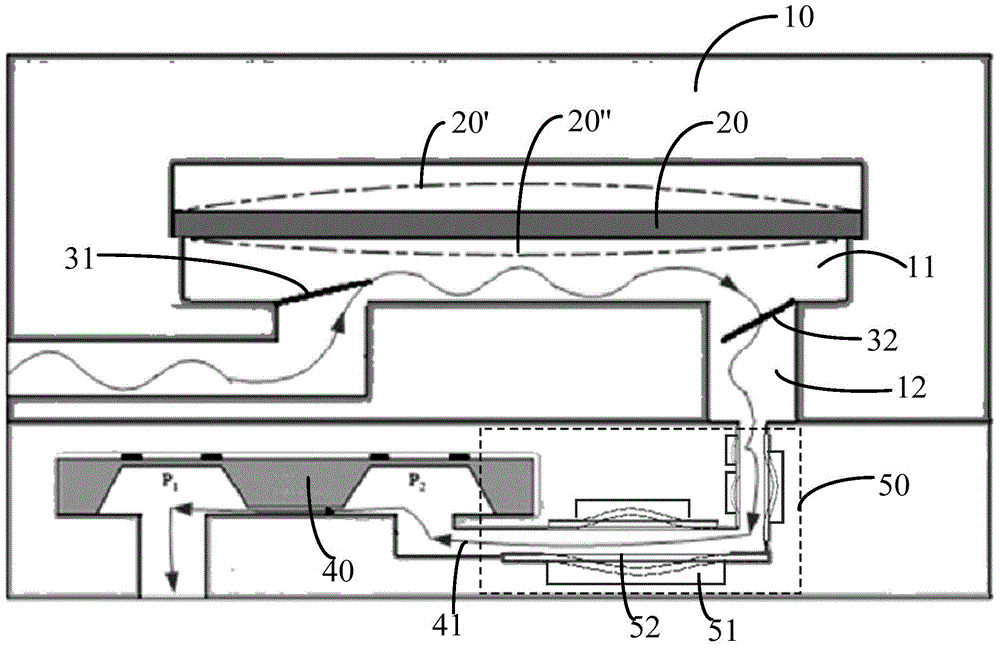

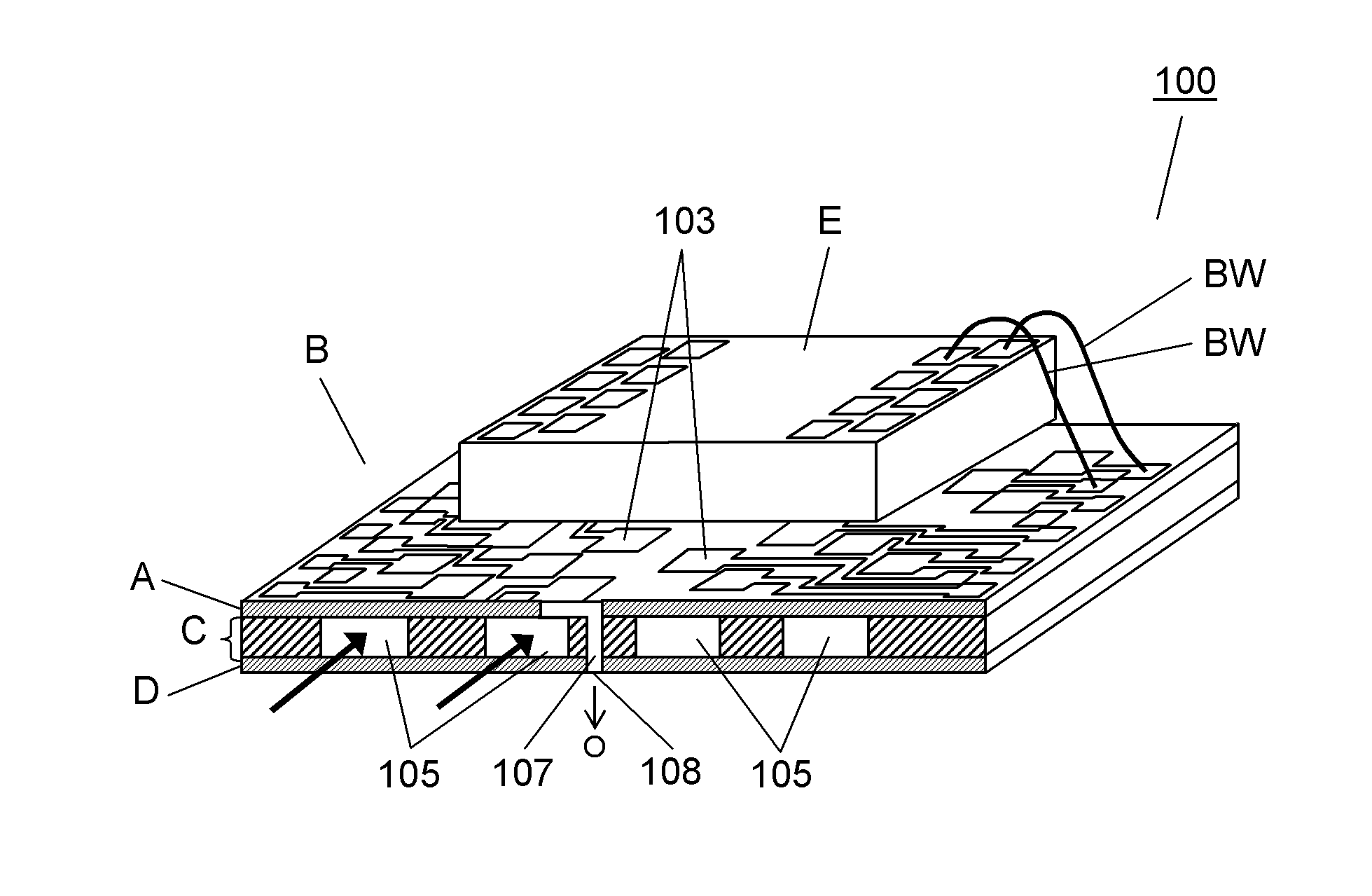

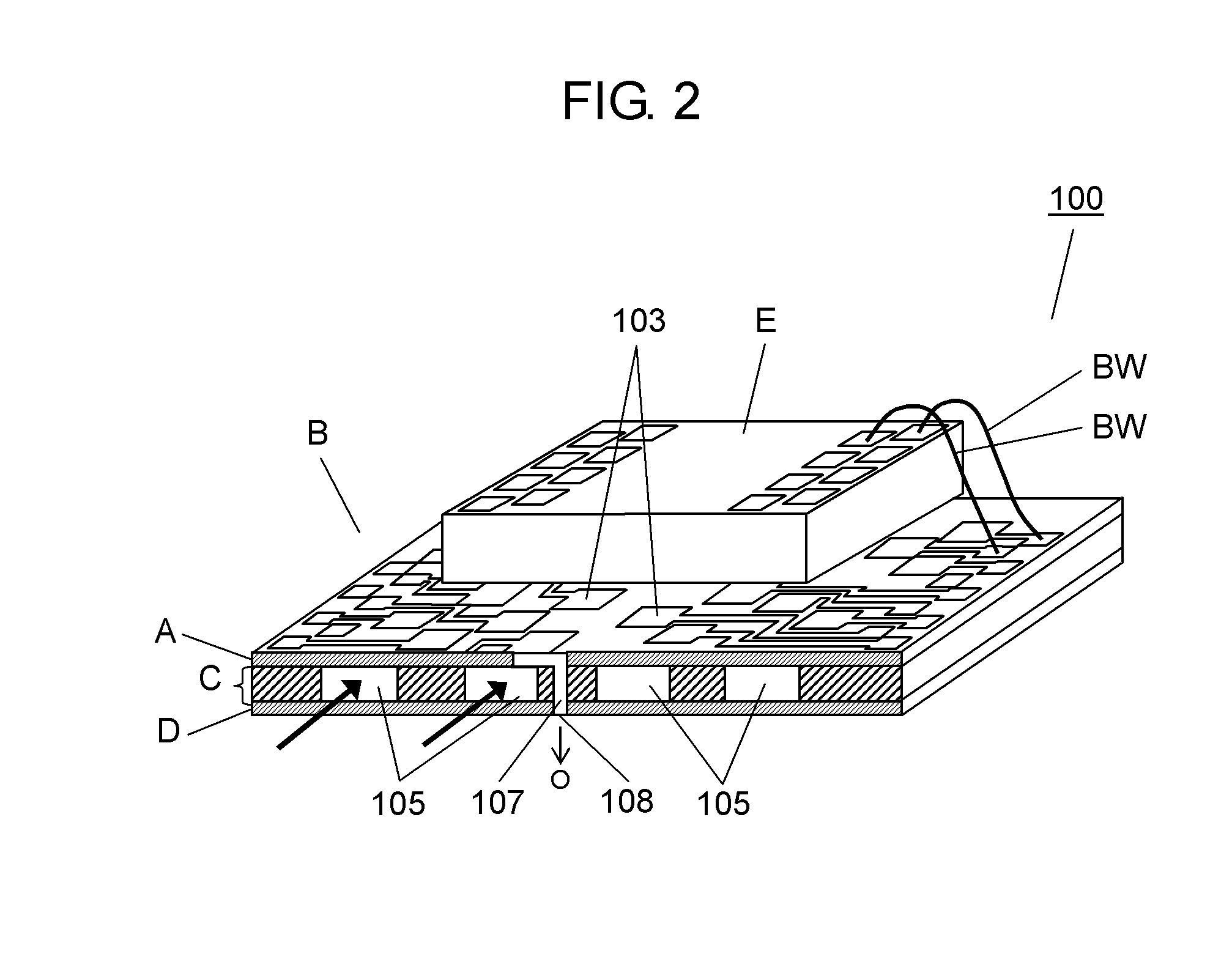

Closed loop piezoelectric membrane pump and flow control method thereof

ActiveCN103557143AReduce volumeSimple structureFlexible member pumpsPump controlElectricityPiezoelectric actuators

The invention discloses a closed loop piezoelectric membrane pump and a flow control method thereof. The closed loop piezoelectric membrane pump comprises a piezoelectric vibrator, a flow sensor, a piezoelectric pump basal body, a circuit control module, a liquid inlet valve and a liquid outlet valve, wherein the liquid inlet valve and the liquid outlet valve are used for controlling the motion direction of fluid; the piezoelectric pump basal body is provided with a pipeline and a pump cavity formed in the piezoelectric pump basal body; the piezoelectric vibrator, the liquid inlet valve and the liquid outlet valve are all mounted on the piezoelectric pump basal body; the flow sensor and the piezoelectric pump basal body are integrated into a whole structure; a flow filter is arranged between a microchannel and the liquid outlet valve; the fluid uniformly flows into the flow sensor through controlling the pressure of the fluid by the flow filter. The closed loop piezoelectric membrane pump is small in size, high in precision of driving the fluid, and good in machinability and consistency.

Owner:SUZHOU SUXIANG ROBOT INTELLIGENT EQUIP CO LTD

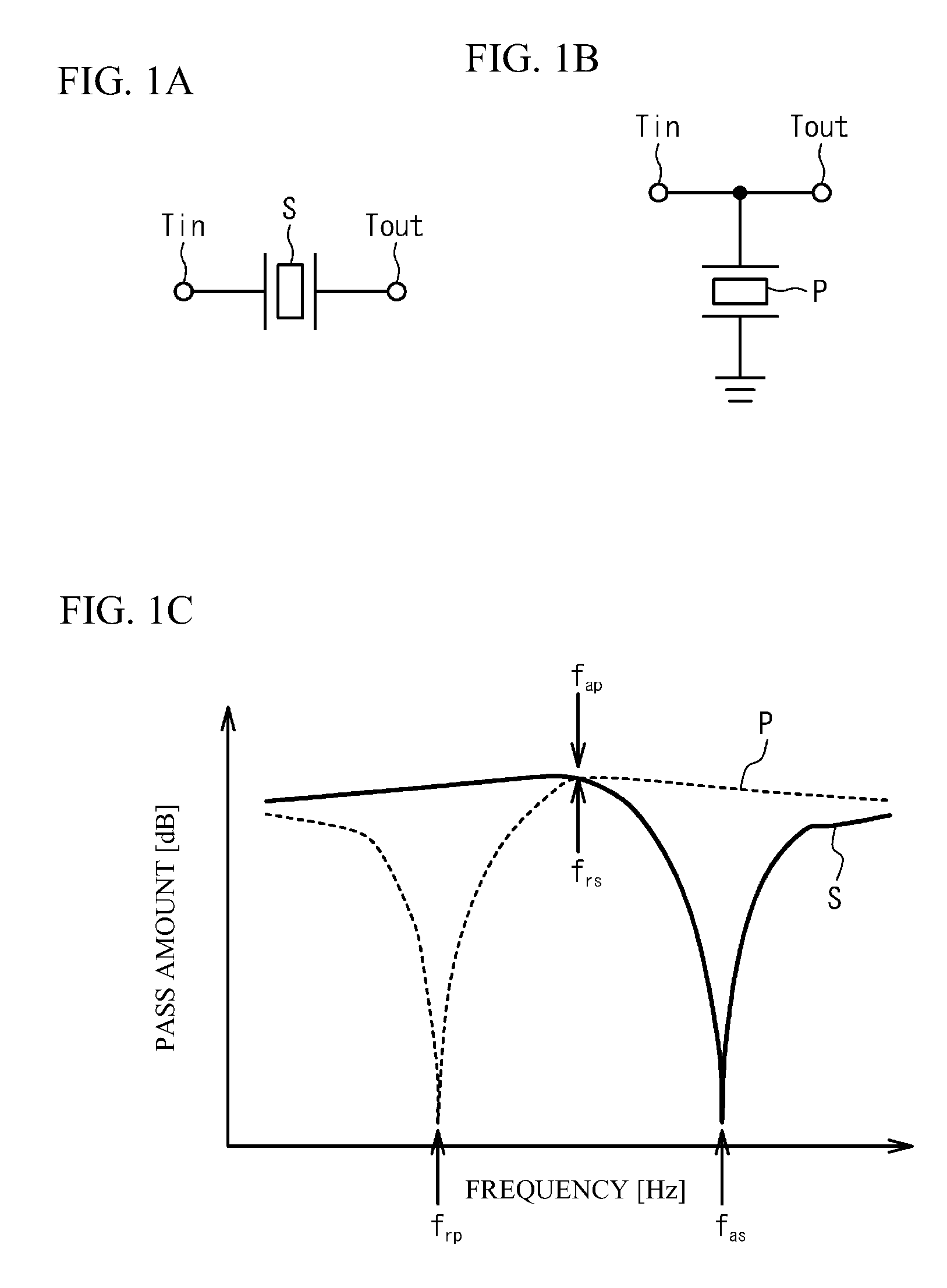

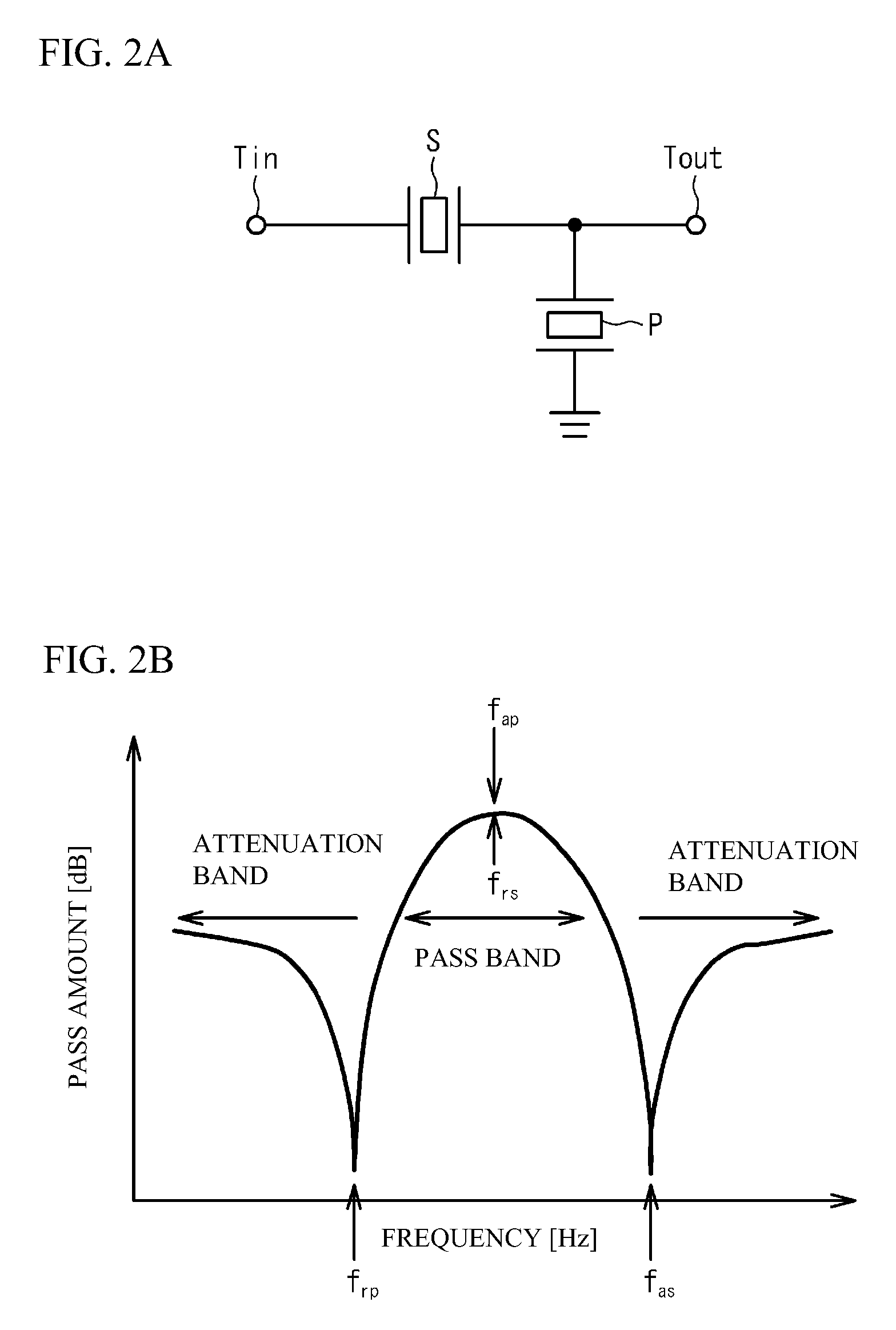

Filter and duplexer

ActiveUS20120299664A1Large thicknessImpedence networksPiezoelectric/electrostrictive/magnetostrictive devicesResonanceAcoustic wave

A filter includes one or a plurality of parallel resonators coupled in parallel and one or a plurality of a film bulk acoustic resonators coupled in series, the film bulk acoustic resonator having a substrate, a lower electrode, a piezoelectric membrane, and an upper electrode, wherein: at least one of the lower electrode and the upper electrode has a thick membrane region having a thickness larger than that of a center portion of a resonance region at an edge of the resonance region, the resonance region being a region where the lower electrode and the upper electrode face with each other through the piezoelectric membrane; and a width of the thick membrane region is smaller than a wavelength of an acoustic wave propagating in a direction crossing a thickness direction of the piezoelectric membrane.

Owner:TAIYO YUDEN KK

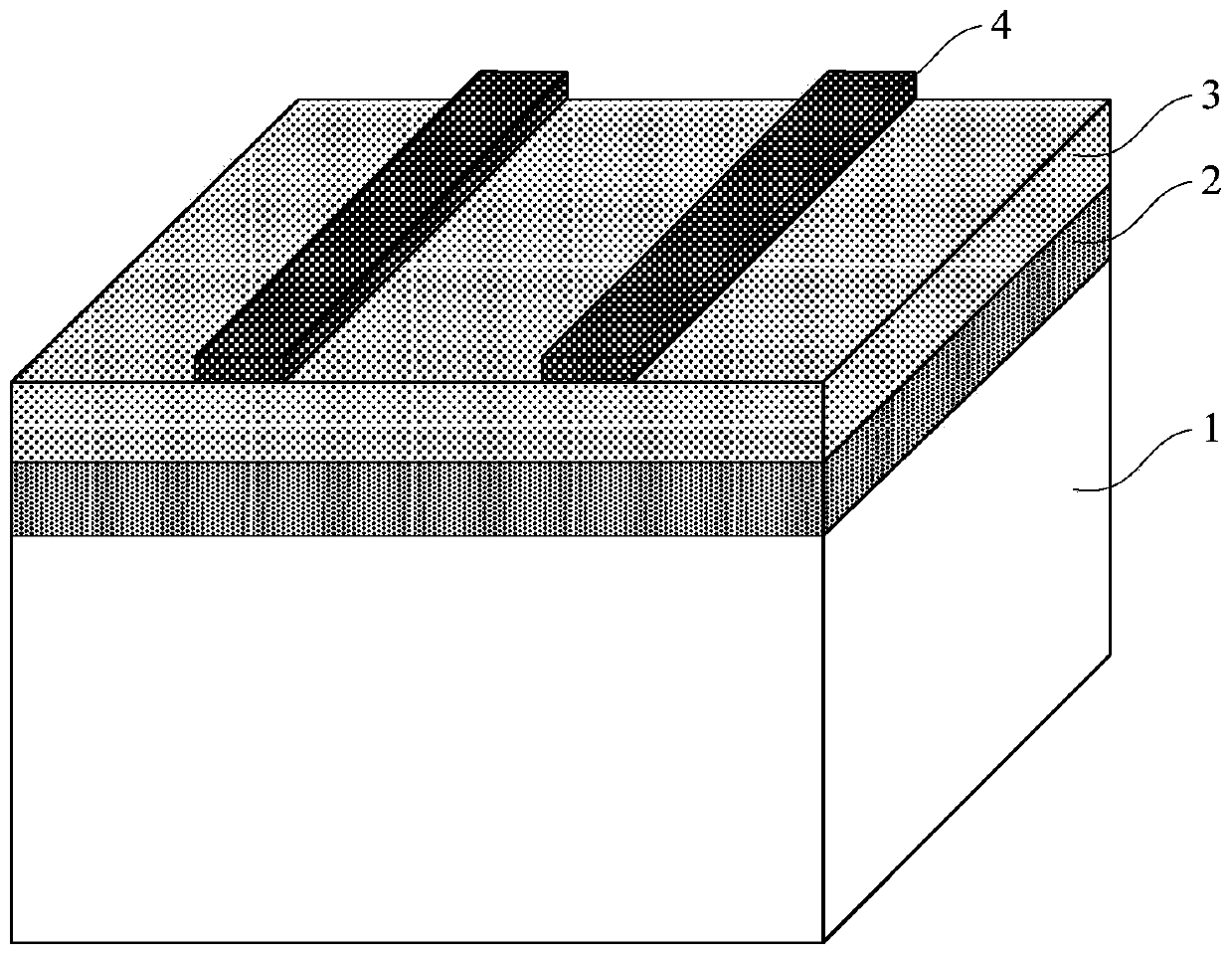

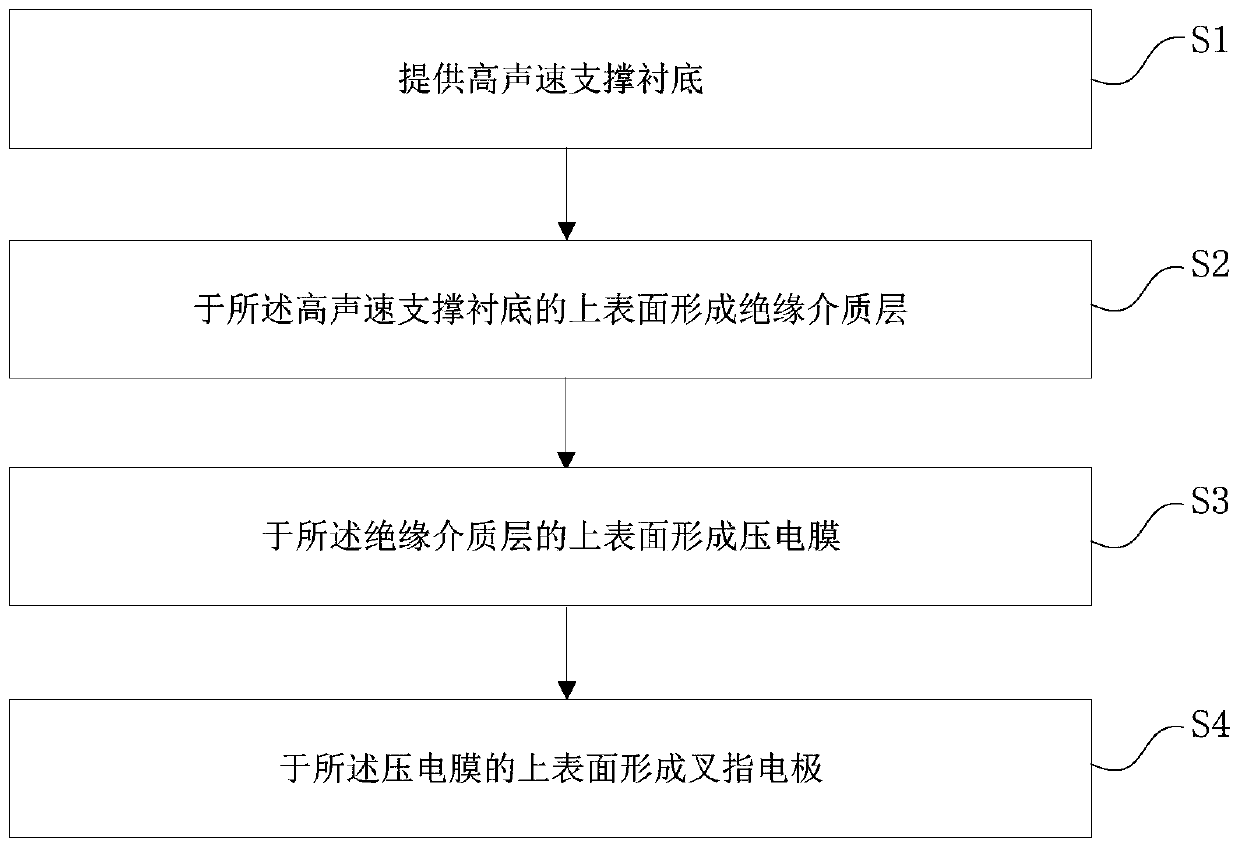

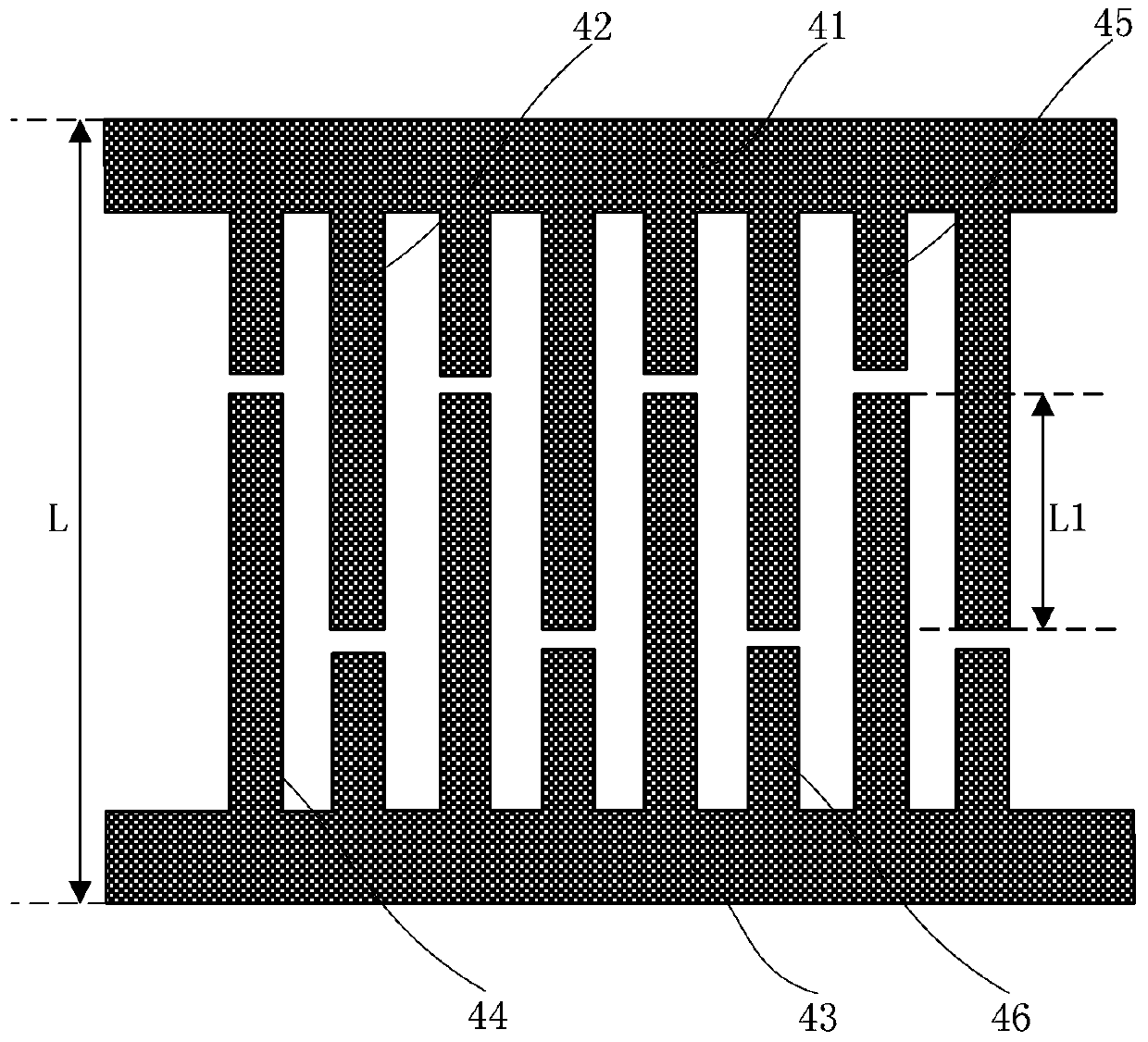

High-frequency acoustic wave resonator and preparation method thereof

ActiveCN111416590ARaise the resonant frequencyHigh electromechanical coupling coefficientImpedence networksHigh level techniquesElectromechanical coupling coefficientAcoustic wave

The invention provides a high-frequency acoustic wave resonator and a preparation method thereof. The high-frequency acoustic wave resonator comprises a high-acoustic-velocity support substrate, an insulating dielectric layer which is located on the upper surface of the high-sound-velocity supporting substrate, a piezoelectric film which is located on the upper surface of the insulating dielectriclayer, and an interdigital electrode which is located on the upper surface of the piezoelectric film. By arranging the high-sound-velocity supporting substrate below the piezoelectric film, the soundvelocity of target elastic waves excited and propagated in the piezoelectric film can be increased, propagation of the target elastic waves can be effectively restrained, and the resonant frequency of the high-frequency sound wave resonator is improved; the insulating dielectric layer is arranged between the piezoelectric film and the high-sound-velocity supporting substrate, the leakage of electric field energy in the piezoelectric film can be effectively reduced, and the electromechanical coupling coefficient of the high-frequency sound wave resonator can be enhanced; by selecting the appropriate insulating dielectric layer, temperature compensation can be carried out on the high-frequency acoustic wave resonator, temperature drift of the high-frequency acoustic wave resonator is reduced, and temperature stability of the high-frequency acoustic wave resonator is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

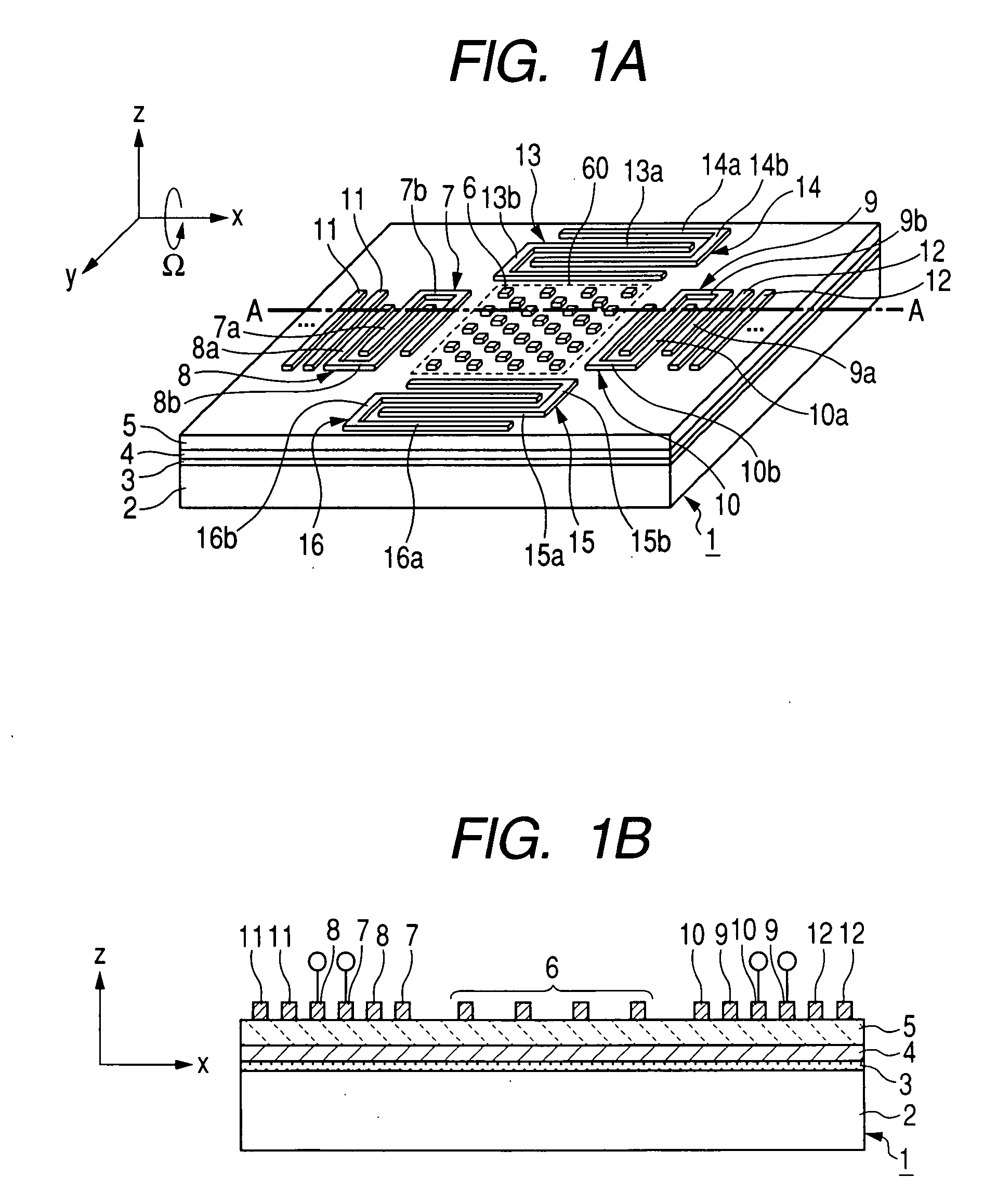

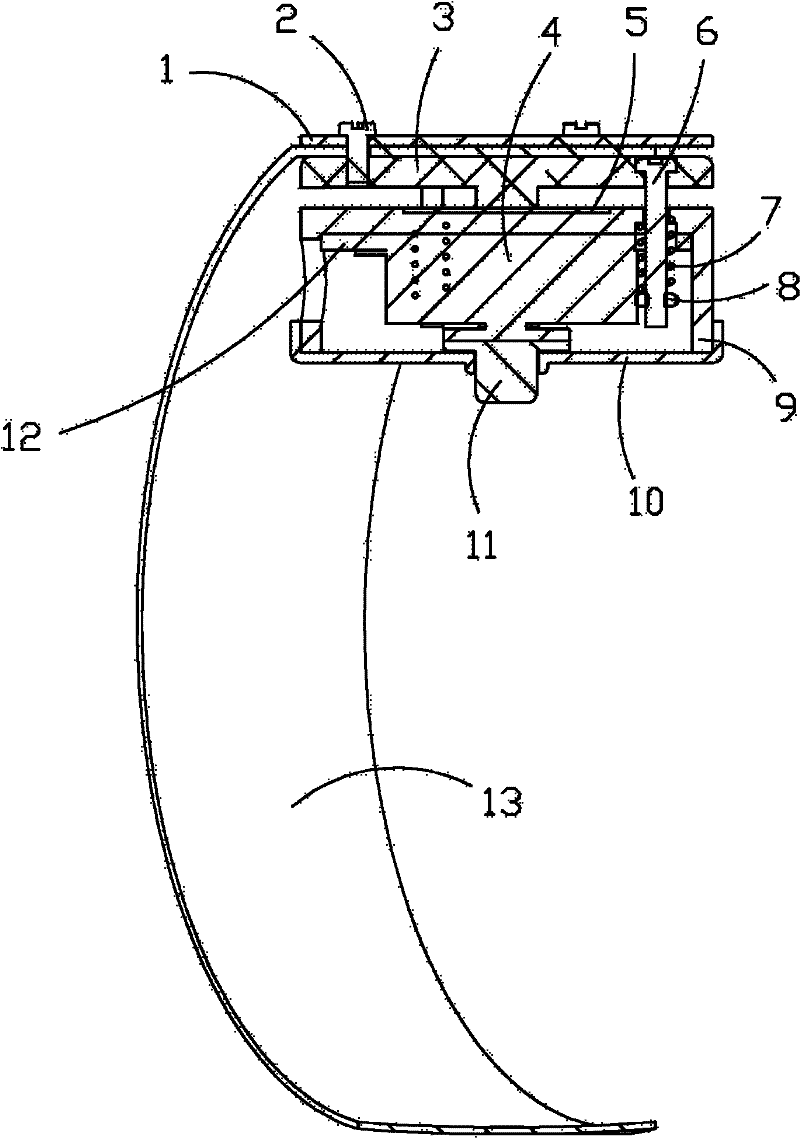

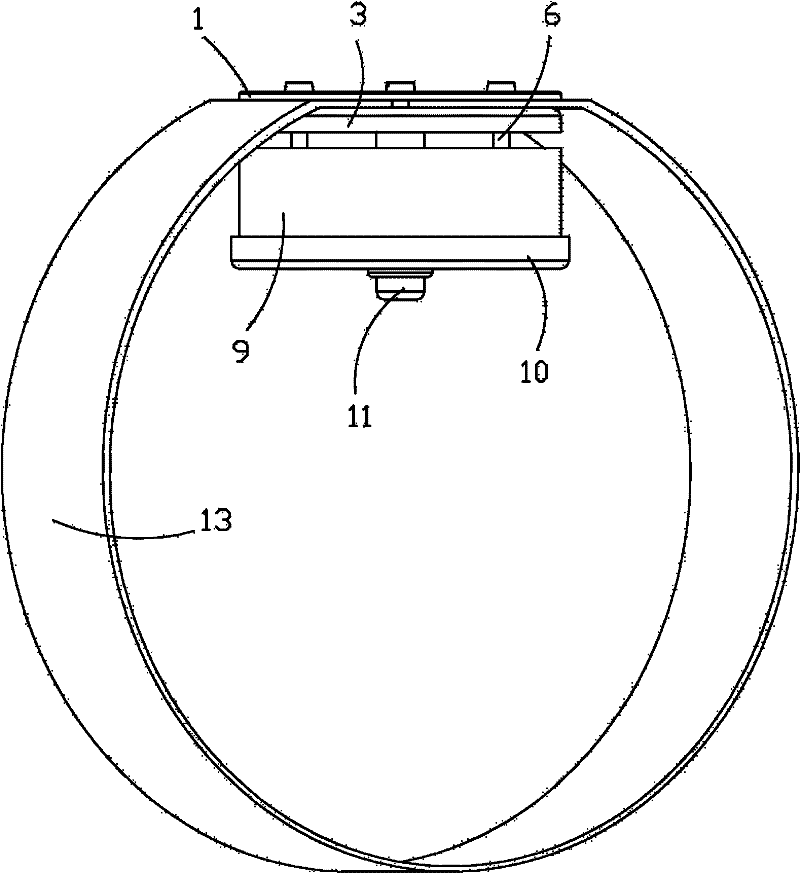

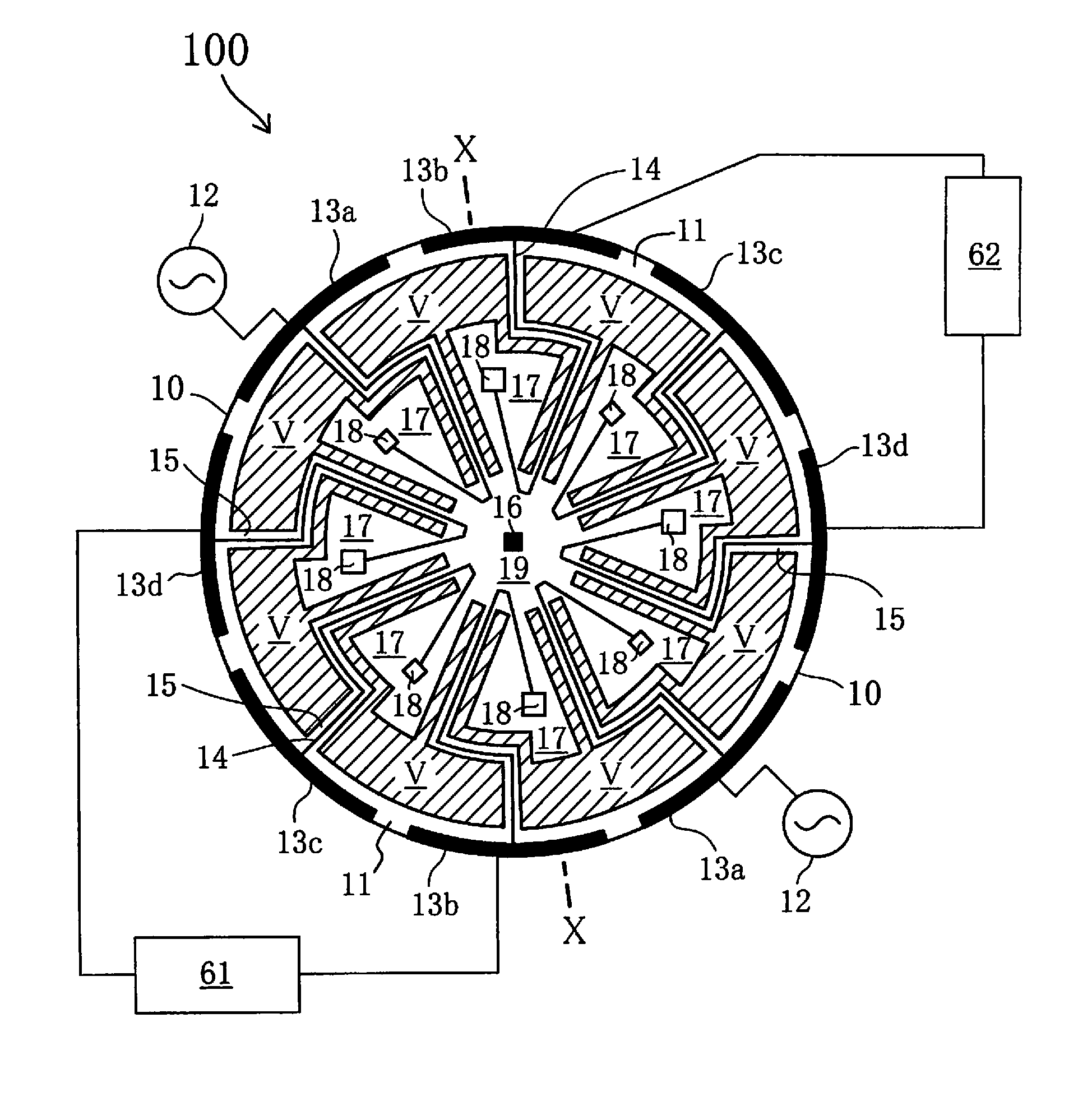

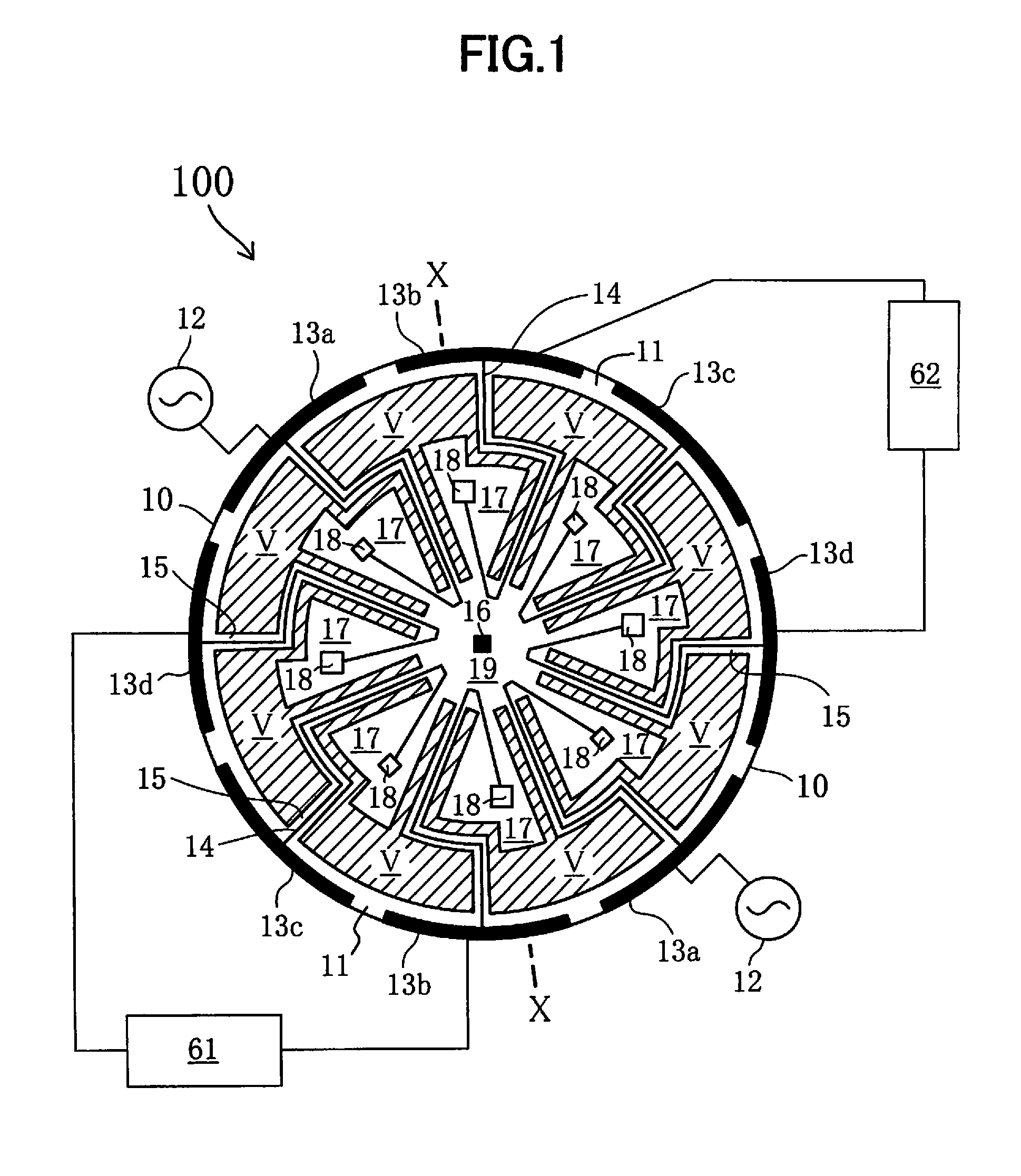

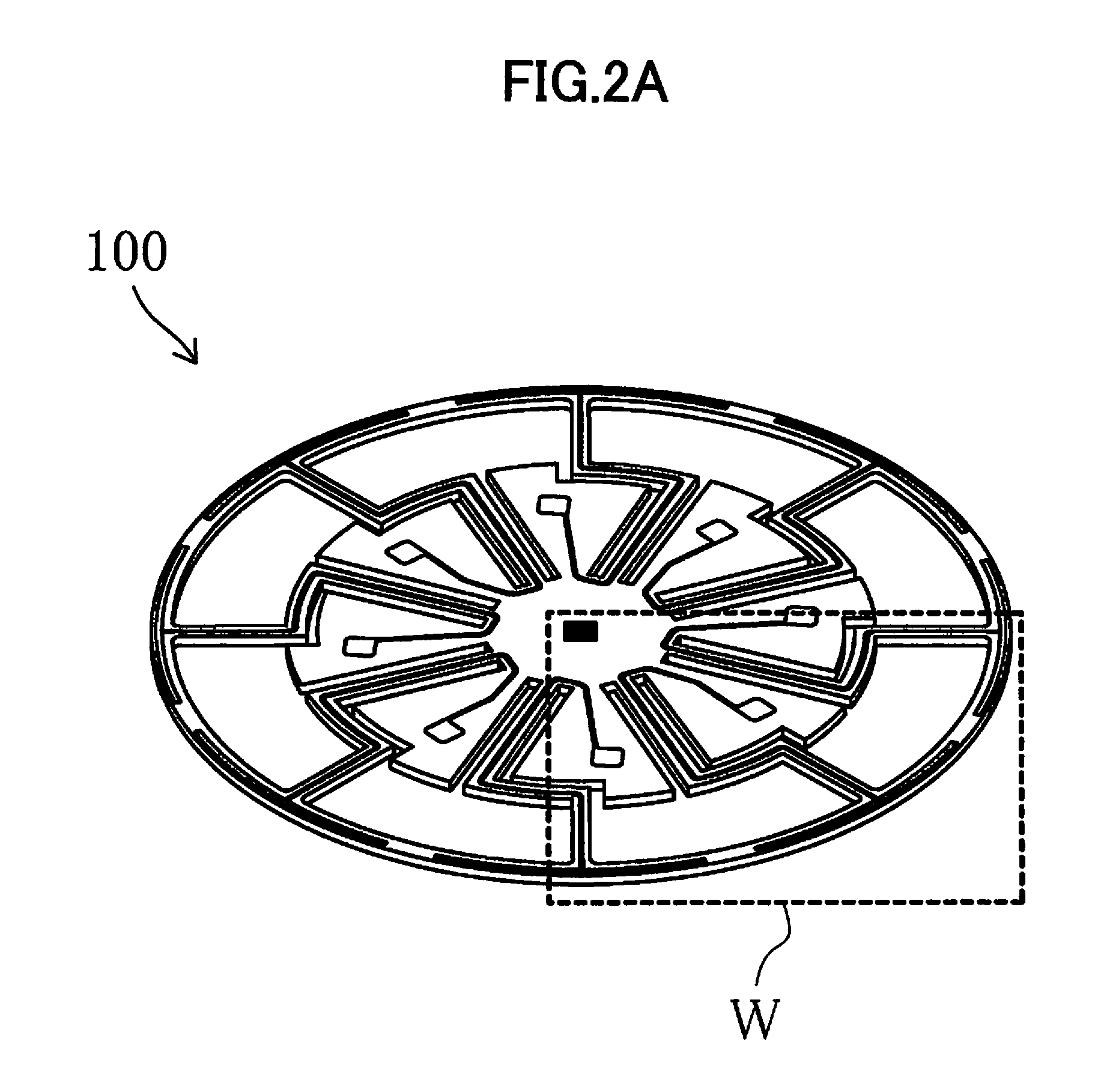

Vibrating gyroscope including piezoelectric film and method for manufacturing same

ActiveUS20110308315A1High precisionDegree of flexibilityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopeThin membrane

A vibratory gyro which is provided with a ring-shaped vibrating body, leg portions flexibly supporting the ring-shaped vibrating body, a plurality of electrodes formed by having a piezoelectric film sandwiched between an upper-layer metallic film and a lower-layer metallic film in the thickness direction, and a fixed potential electrode. The plurality of electrodes include a bank of driving electrodes for exciting primary vibration, detection electrodes for detecting secondary vibration, and suppression electrodes for suppressing the secondary vibration on the basis of a voltage signal from the detection electrodes. The driving electrodes, the detection electrodes and the suppression electrodes are disposed in the region from an outer peripheral edge of the ring-shaped vibrating body to a vicinity of the outer peripheral edge and / or a region from an inner peripheral edge thereof to a vicinity of the inner peripheral edge.

Owner:SUMITOMO PRECISION PROD CO LTD

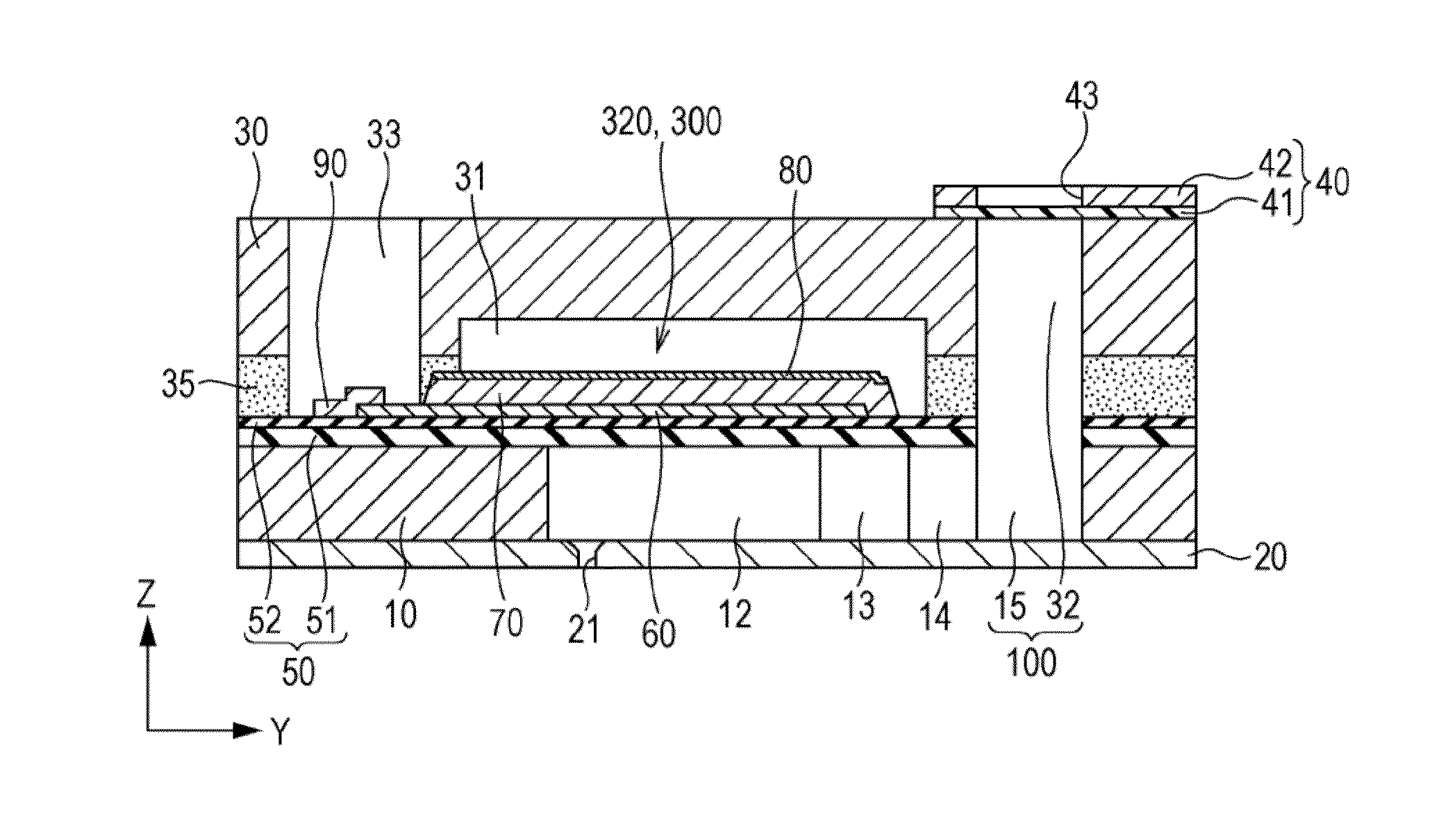

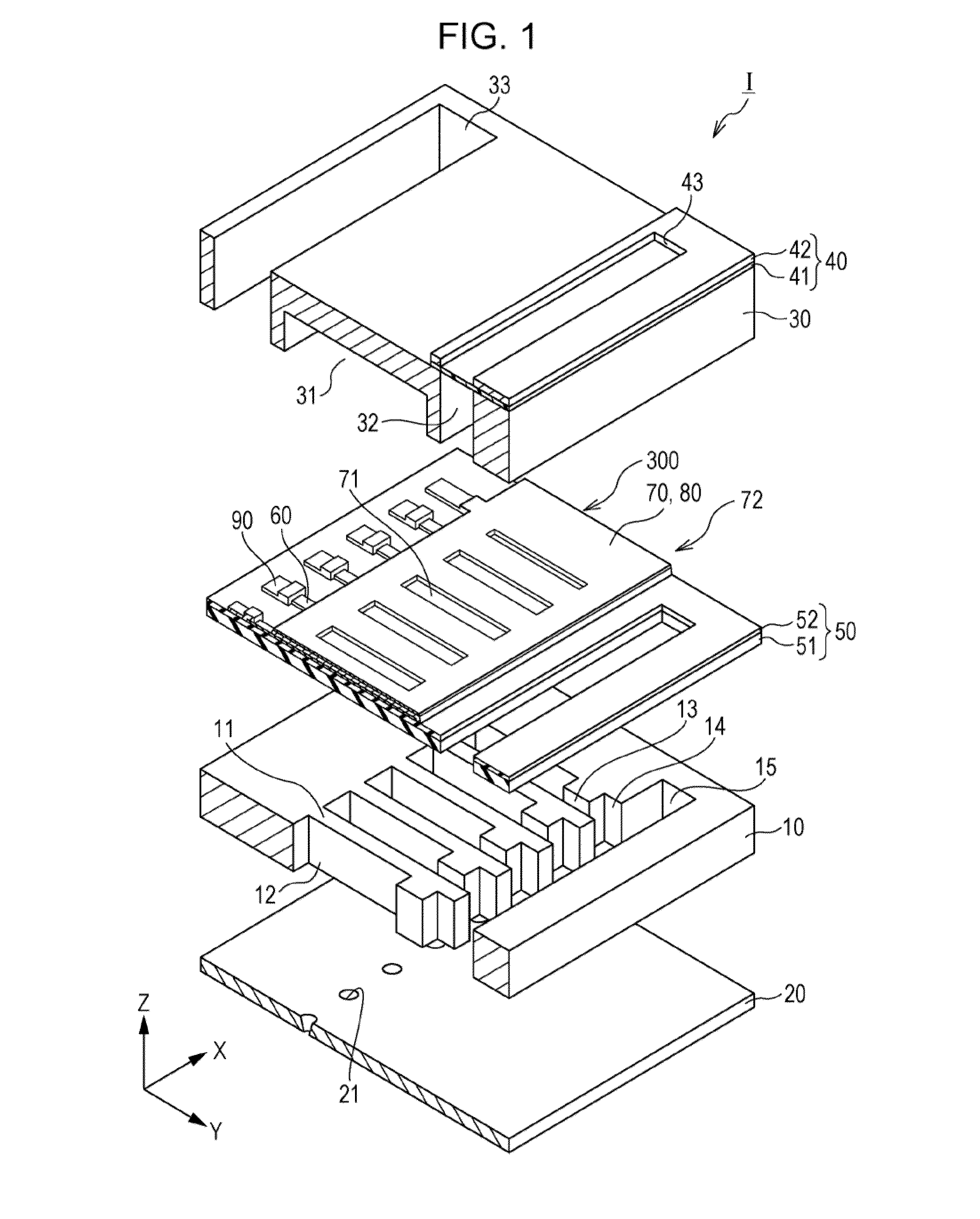

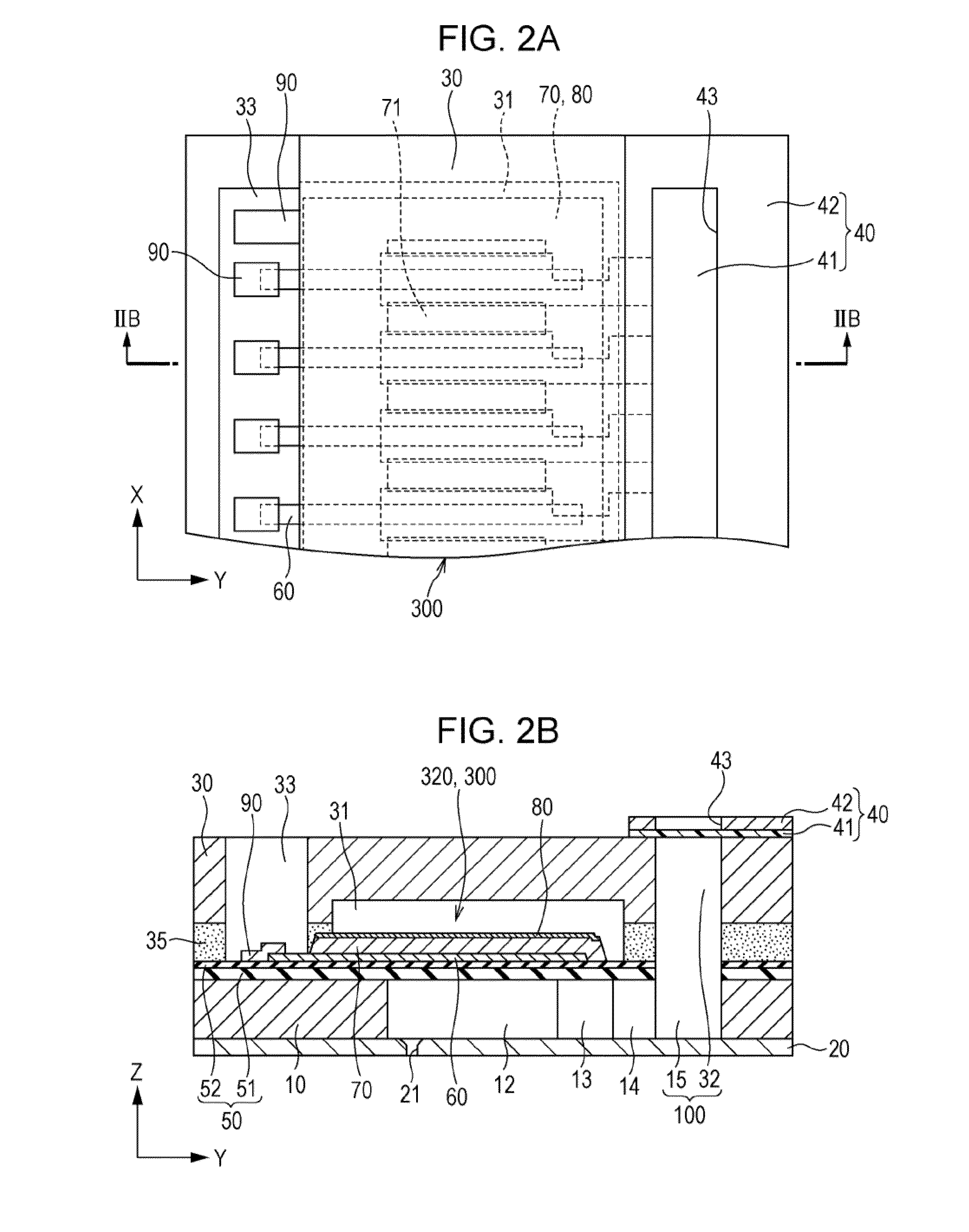

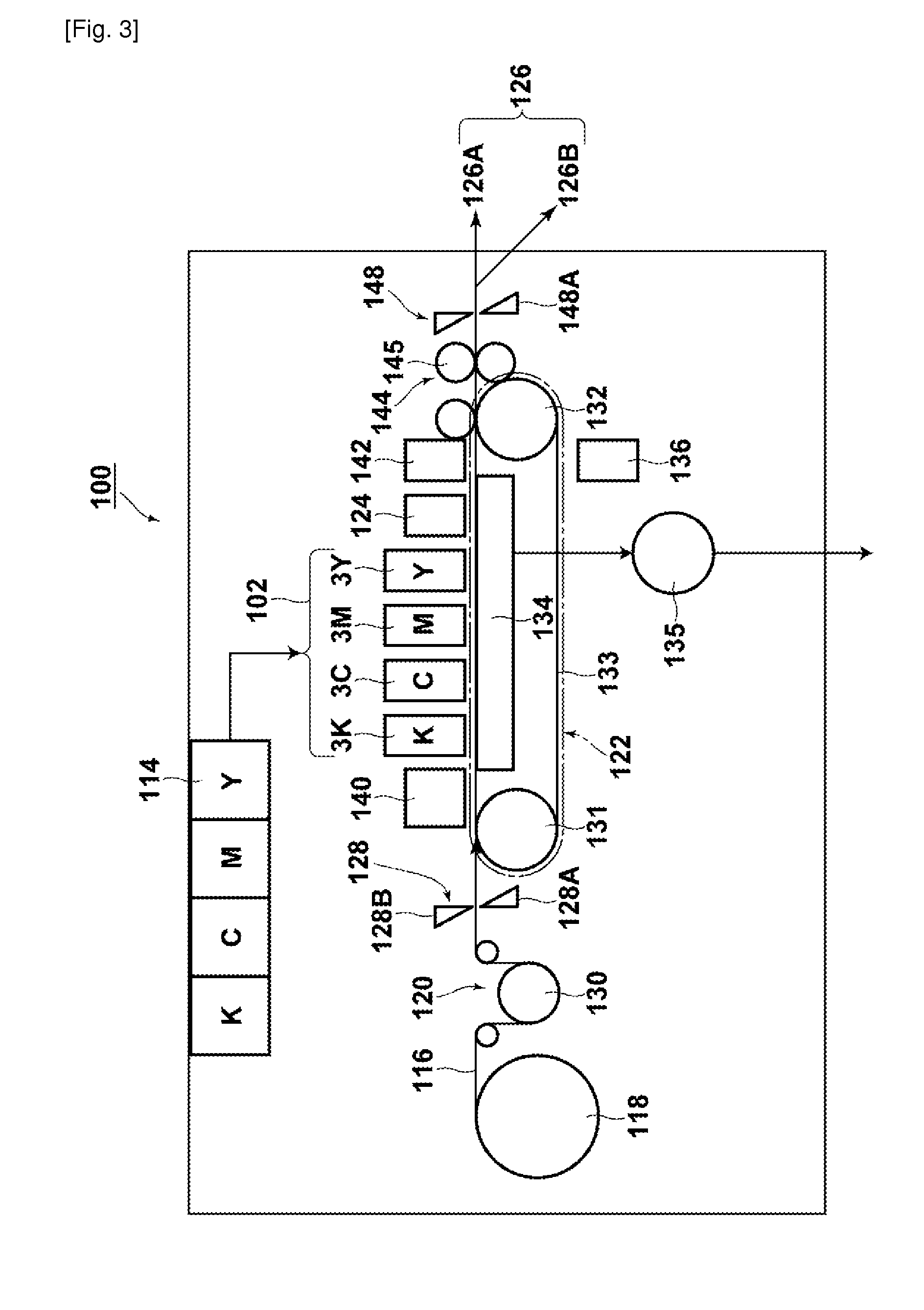

Liquid ejecting head, liquid ejecting apparatus, piezoelectric element, and ultrasonic sensor

ActiveUS20140240405A1Performance deteriorationAvoid feverPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesPressure generationEngineering

A liquid ejecting head which includes a piezoelectric element which includes a first electrode, a piezoelectric layer which is provided on the first electrode, and on which a plurality of piezoelectric films are laminated, a second electrode which is provided on the piezoelectric layer, and a plurality of active units which are interposed between the first electrode and the second electrode, and a pressure generating chamber which communicates with nozzle openings which eject liquid, and in which a pressure fluctuation is generated by the piezoelectric element, in which a plurality of grooves with inner faces facing the first electrode side are formed on a side surface of the piezoelectric layer on each interface of each of the piezoelectric films along a first direction and a second direction which cross a third direction which goes from the first electrode to the second electrode.

Owner:SEIKO EPSON CORP

Piezoelectric thin film, method for manufacturing same, inkjet head, method for forming image using inkjet head, angular velocity sensor, method for measuring angular velocity using angular velocity sensor, piezoelectric power generation element, and method for generating power using piezoelectric power generation element

ActiveUS20130136951A1Polycrystalline material growthInking apparatusAngular velocityPiezoelectric thin films

Provided is a piezoelectric thin film including a non-lead-containing (that is, lead-free) ferroelectric material and having high piezoelectric performance comparable to that of PZT, and a method of manufacturing the piezoelectric thin film. The piezoelectric film according to the present invention comprises a laminate structure. The laminate structure comprises an electric film and a (1-x)(Na,Bi)TiO3-xBaTiO3 film. x represents a value of not less than 0.03 and not more than 0.15. The (1-x)(Na,Bi)TiO3-xBaTiO3 film has a (110) surface orientation only. The (1-x)(Na,Bi)TiO3-xBaTiO3 film has an orthorhombic crystal structure only.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Soft support bridge type silicon micro-piezoelectric microphone chip and prepration method thereof

InactiveCN101646117ALarge strainPrevent sound leakagePiezoelectric/electrostrictive microphonesTelevision system detailsVibrating membraneThin membrane

The invention relates to a soft support bridge type silicon micro-piezoelectric microphone chip which comprises a silicon substrate with a square conical hole which is small at the top and big at thebottom, a square compound vibration membrane which consists of a first silicon nitride membrane layer, a silicon dioxide membrane layer and a second silicon nitride membrane layer is covered on the front surface of the silicon substrate, and a third silicon nitride membrane layer and a fourth silicon nitride membrane layer are sequentially covered on the back surface of the silicon substrate; thethird and the fourth silicon nitride membrane layers both have central square holes; one pair of opposite sides of the vibration membrane respectively etch a vertical narrow slot penetrating the vibration membrane, and the vertical projection of each narrow slot is positioned on the inner side of the edge of the square hole in the front surface of the silicon substrate; a lower electrode, a piezoelectric membrane and an upper electrode are sequentially deposited on the vibration membrane; a polyimide membrane is deposited on various parts on the front surface of the silicon substrate; the compound vibration membrane which is etched with the vertical narrow slots and the polyimide membrane commonly constitute a soft support anti-sound leakage bridge type vibration membrane; two sides of thevibration membrane are fixedly supported, and strain can be produced during the vibration process; in order to prevent the microphone from producing sound leakage through the narrow slots, the soft polyimide membrane is deposited on the narrow slots, thereby being capable of effectively preventing sound leakage phenomenon.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Film bulk acoustic wave resonator and manufacturing method thererof

ActiveUS7423501B2Simple structureReduce production processPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThin-film bulk acoustic resonatorAcoustic wave

A film bulk acoustic resonator includes a substrate; a lower electrode formed on top of the substrate; a piezoelectric membrane formed on top of the lower electrode and having a crystallographic axis so inclined as to generate a total reflection when an acoustic wave advances toward the lower electrode; and an upper electrode formed on top of the piezoelectric membrane.

Owner:SAMSUNG ELECTRONICS CO LTD

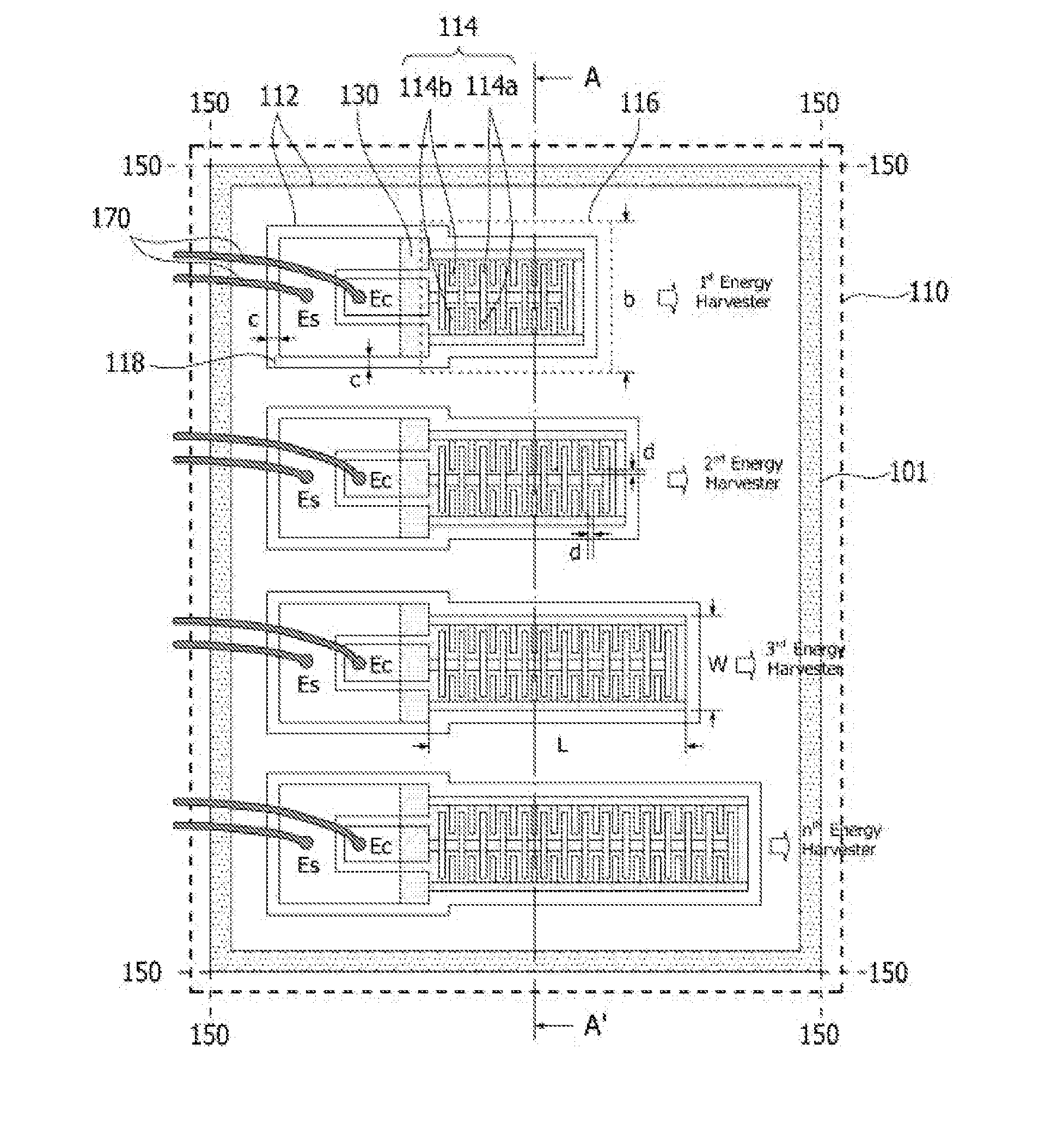

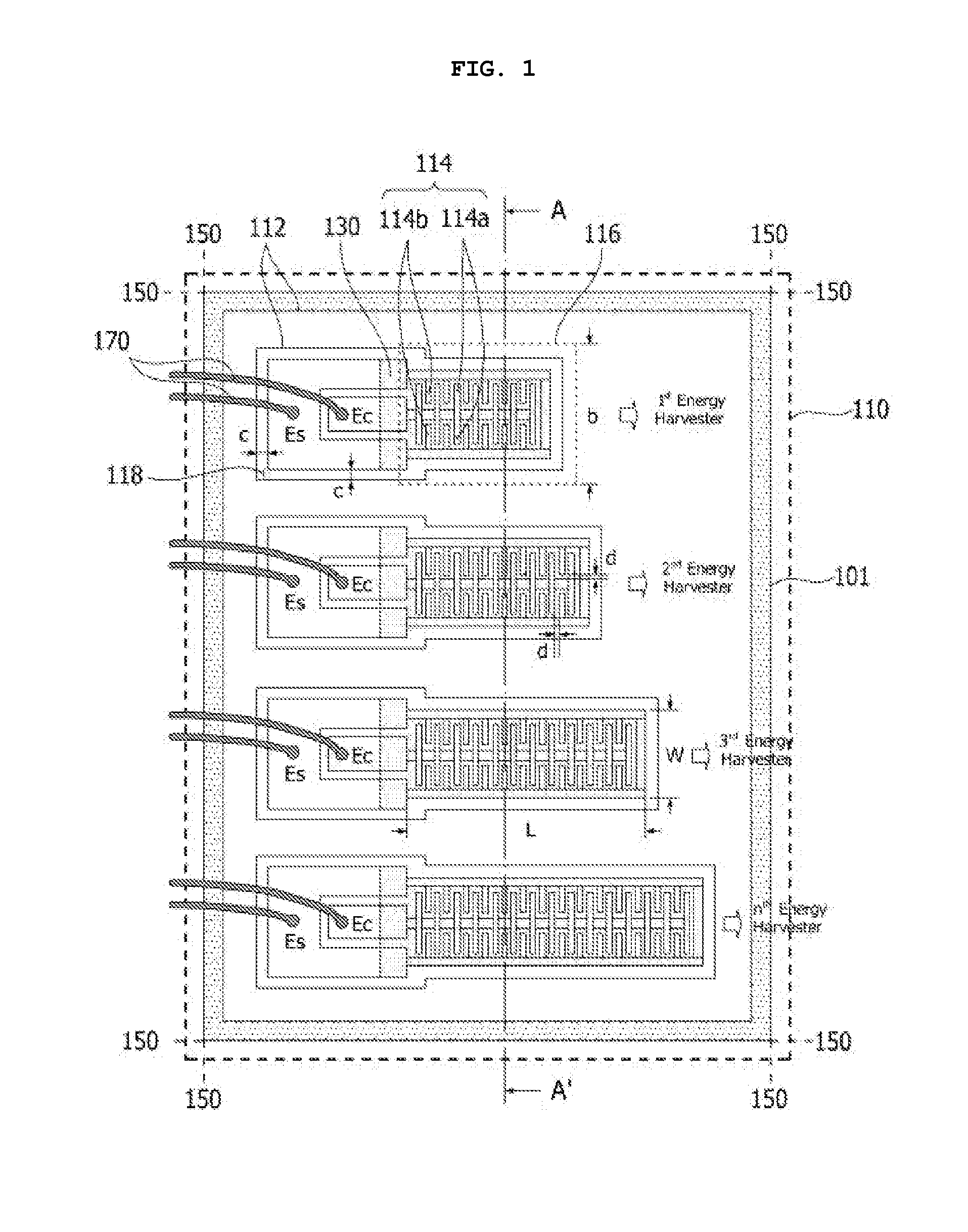

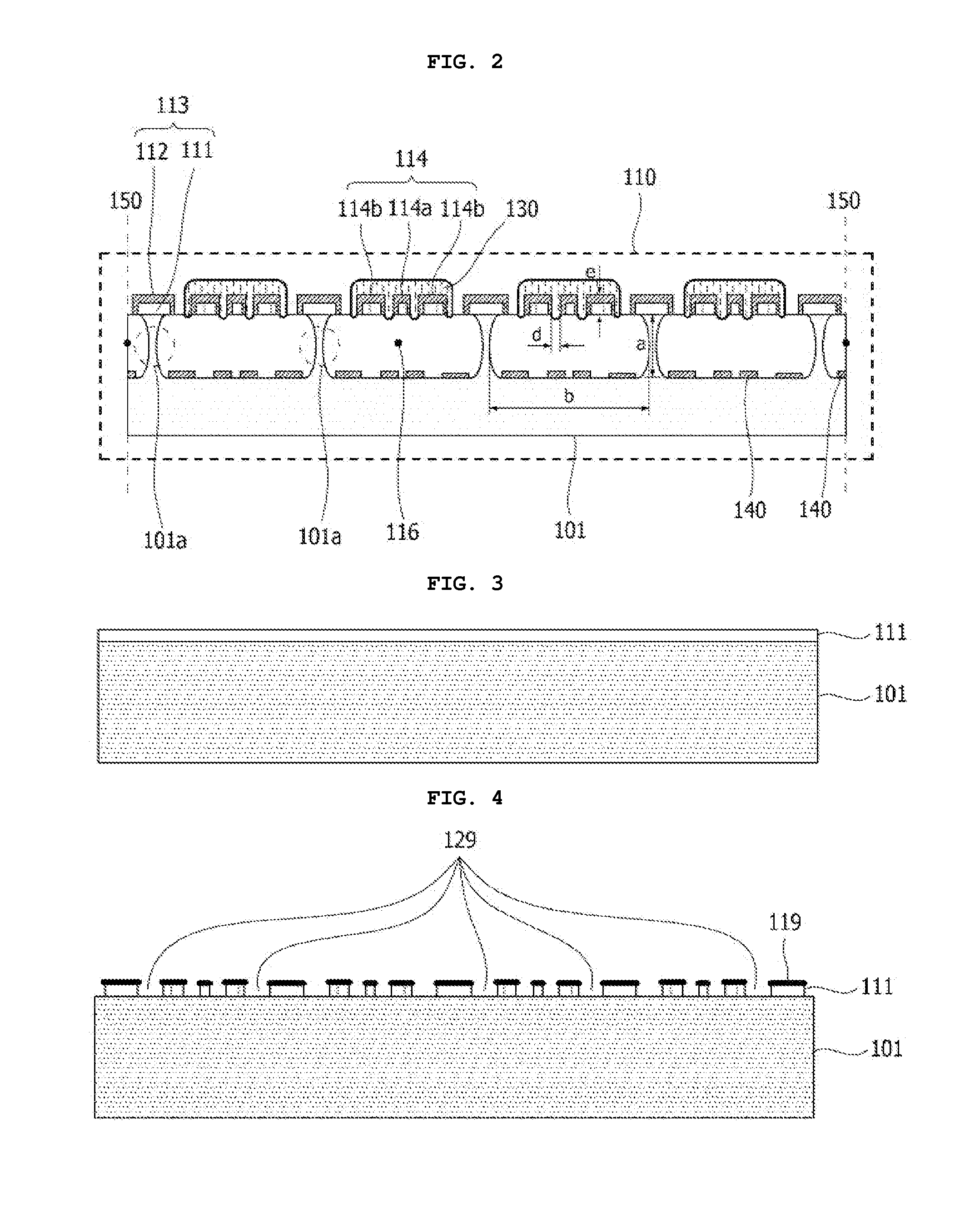

Piezoelectric micro energy harvester and manufacturing method thereof

InactiveUS20120153778A1Easy to useEasy to mass producePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEnergy harvesterThin membrane

Disclosed is a piezoelectric micro energy harvester and manufacturing method thereof, the method including: forming an insulation film on a substrate; patterning the insulation film and forming an electrode pad pattern, a center electrode pattern, and a side electrode pattern; forming an open cavity at an inside of the substrate for suspension of the center electrode pattern and the side electrode pattern; disposing a conductive film on the electrode pad pattern, the center electrode pattern, and the side electrode pattern and forming electrode pads, a center electrode, and a side electrode; and forming a piezoelectric film so as to cover a space between the center electrode and the side electrode and upper surfaces of the center electrode and the side electrode.

Owner:ELECTRONICS & TELECOMM RES INST

Piezoelectric device, piezoelectric device manufacturing method, and liquid discharge apparatus

ActiveUS20110121096A1Improve moisture resistanceIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPyrochloreOxygen

A piezoelectric device, including the following on a substrate in the order listed below: a lower electrode, a piezoelectric film which contains a Pb containing perovskite oxide represented by a general expression (P) below, and an upper electrode, in which the piezoelectric film has a layer of pyrochlore oxide on the surface facing the lower electrode, and the average layer thickness of the pyrochlore oxide layer is not greater than 20 nm.AaBbO3 (P)where, A: at least one type of A-site element containing Pb as a major component, B: at least one type of B-site element selected from the group consisting of Ti, Zr, V, Nb, Ta, Cr, Mo, W, Mn, Sc, Co, Cu, In, Sn, Ga, Zn, Cd, Fe, and Ni, and O: an oxygen element.

Owner:FUJIFILM CORP

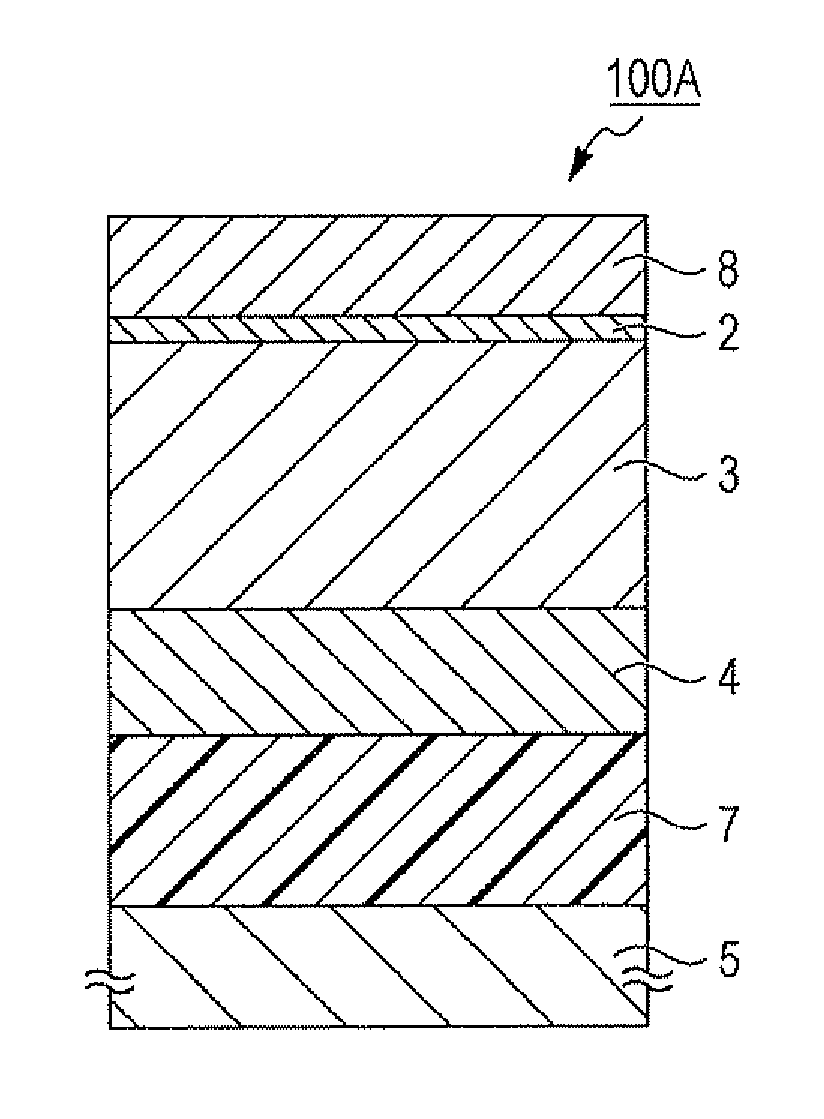

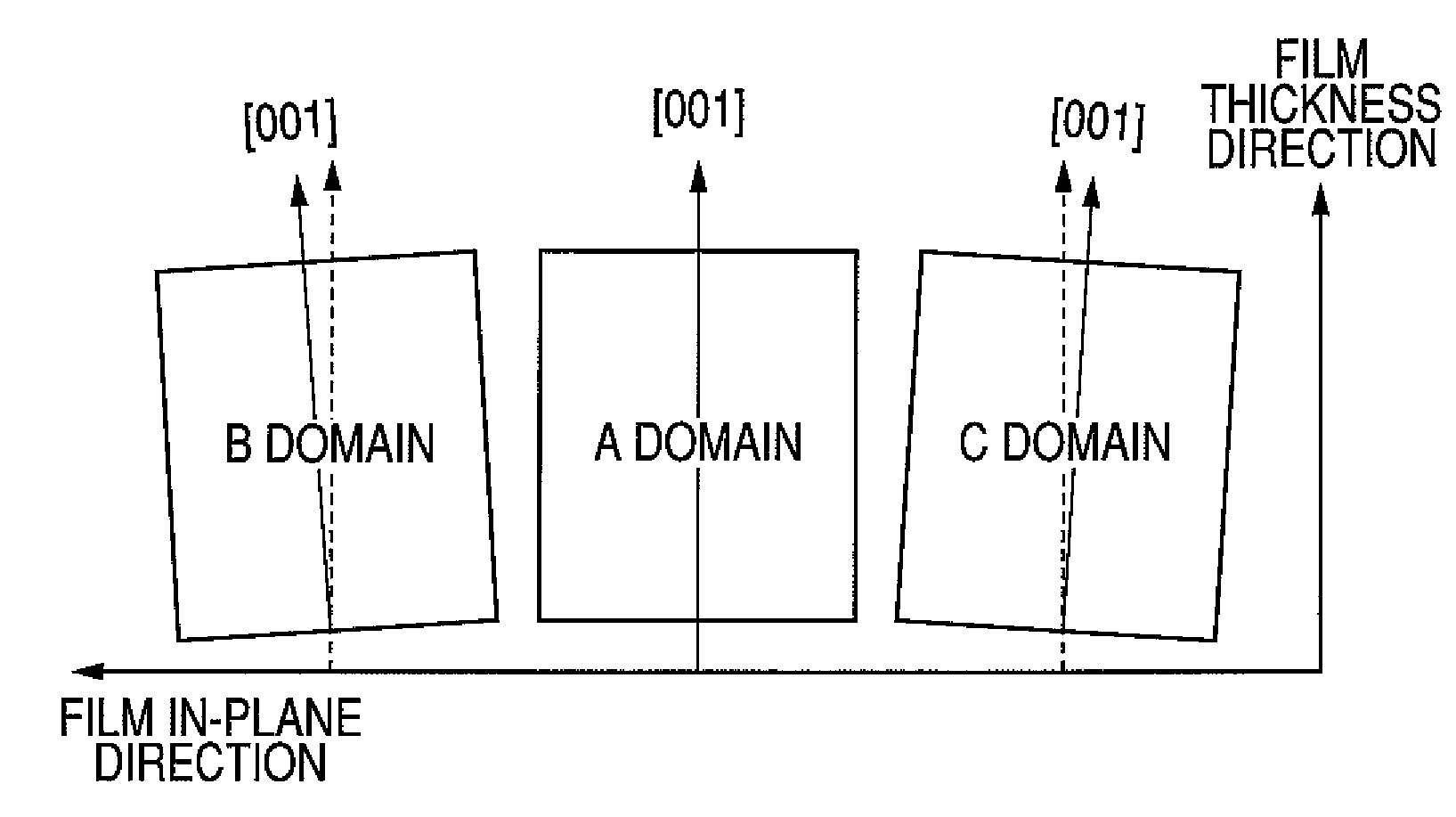

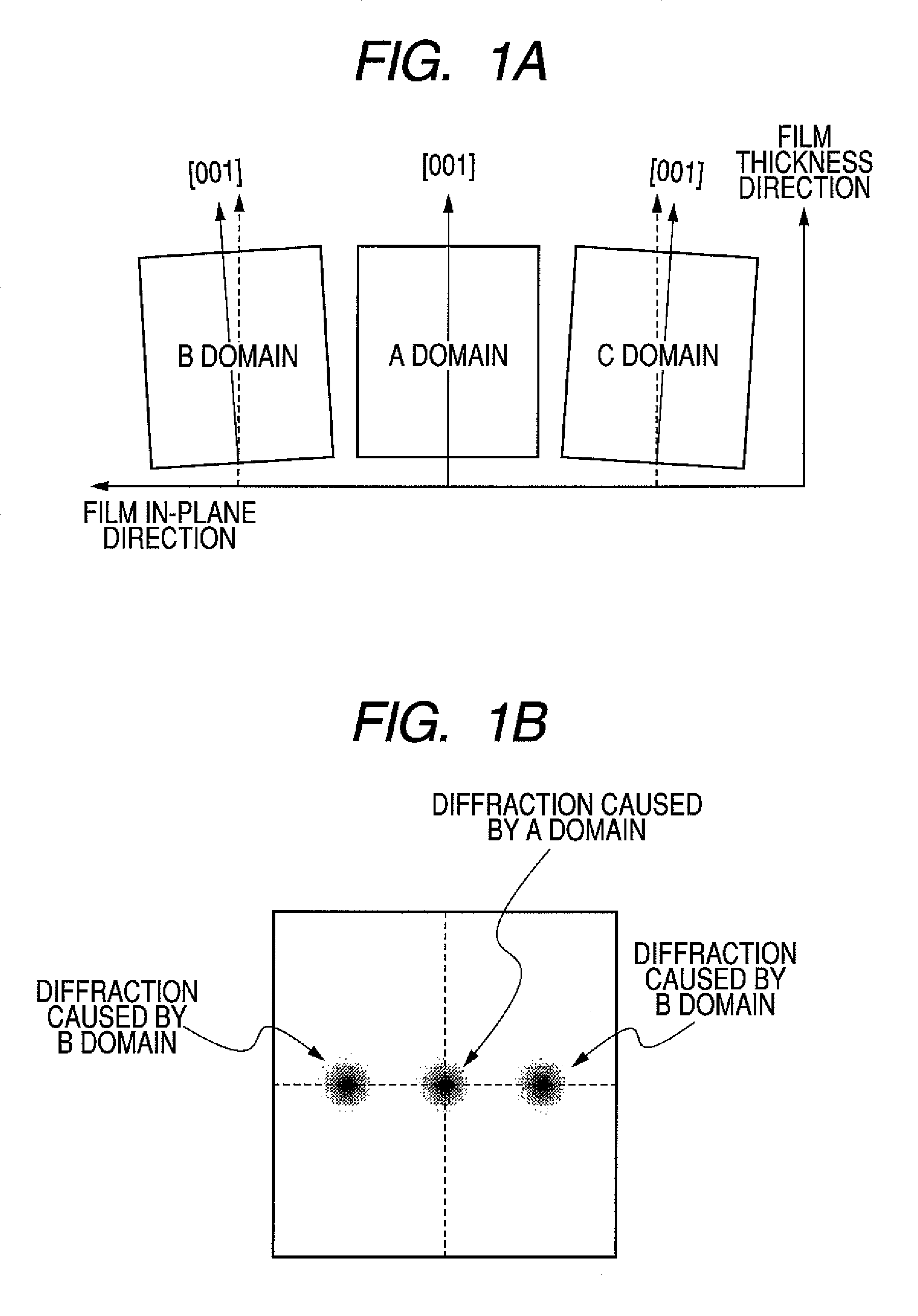

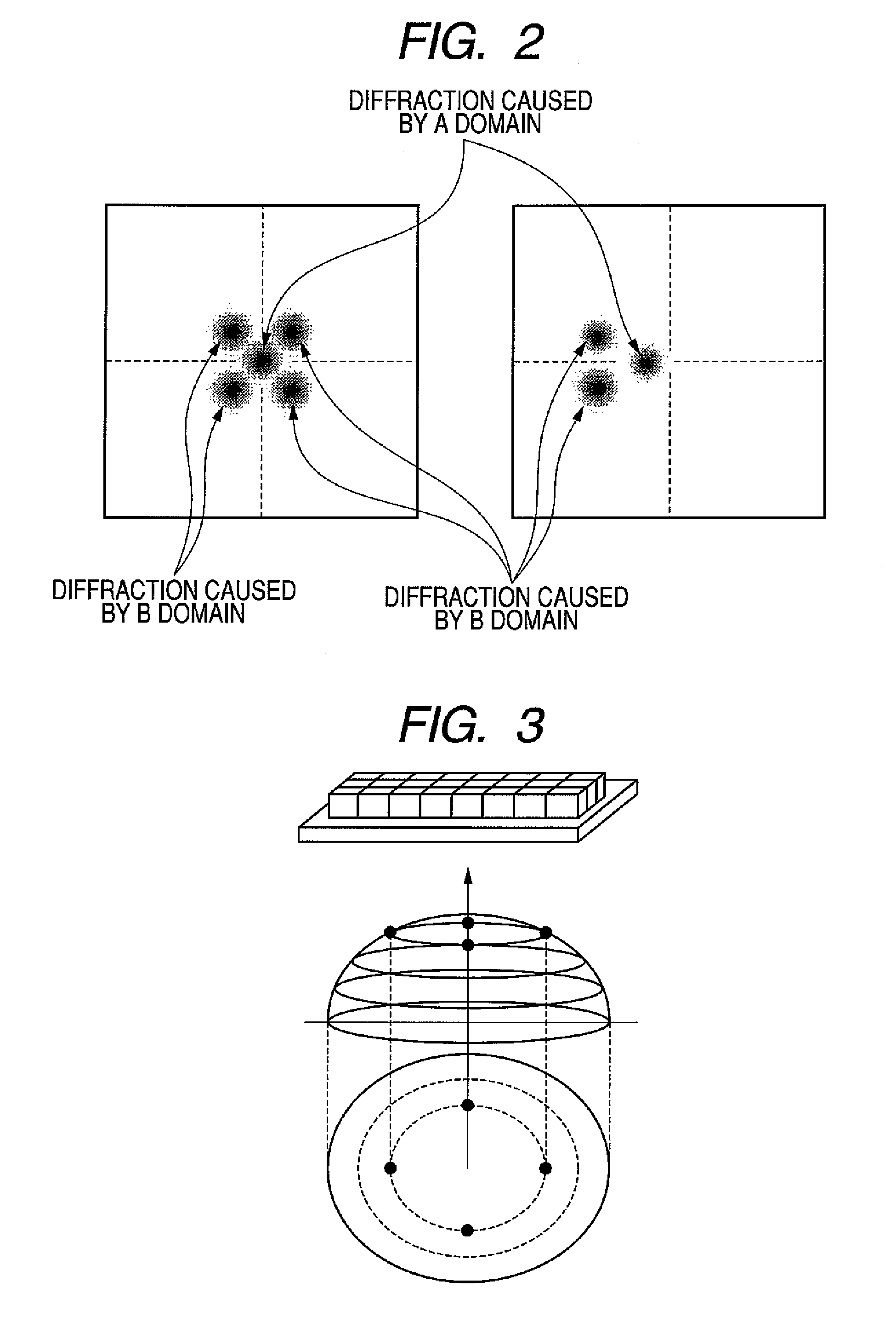

Epitaxial oxide film, piezoelectric film, piezoelectric film element, liquid discharge head using the piezoelectric film element, and liquid discharge apparatus

ActiveUS7804231B2Large piezoelectricityImprove discharge performancePolycrystalline material growthInking apparatusCrystal orientationDischarge pressure

Provided are a piezoelectric film, a piezoelectric film element, a liquid discharge head using the piezoelectric film element, and a liquid discharge apparatus. A piezoelectric film element that can be suitably used for a discharge pressure-generating element of a liquid discharge head is obtained by using an epitaxial oxide film composed of a perovskite composite oxide constituted according to a general formula ABO3 as a piezoelectric film. The epitaxial oxide film has at least an A domain and a B domain having a crystal orientation deviation with respect to each other. The crystal orientation deviation between the A domain and the B domain is less than 2°.

Owner:CANON KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com