Forming a device having a curved piezoelectric membrane

A piezoelectric layer, curved surface technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., and can solve the problem of inapplicability to small droplets , to achieve the effect of shortening effective life, long life and improving deflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

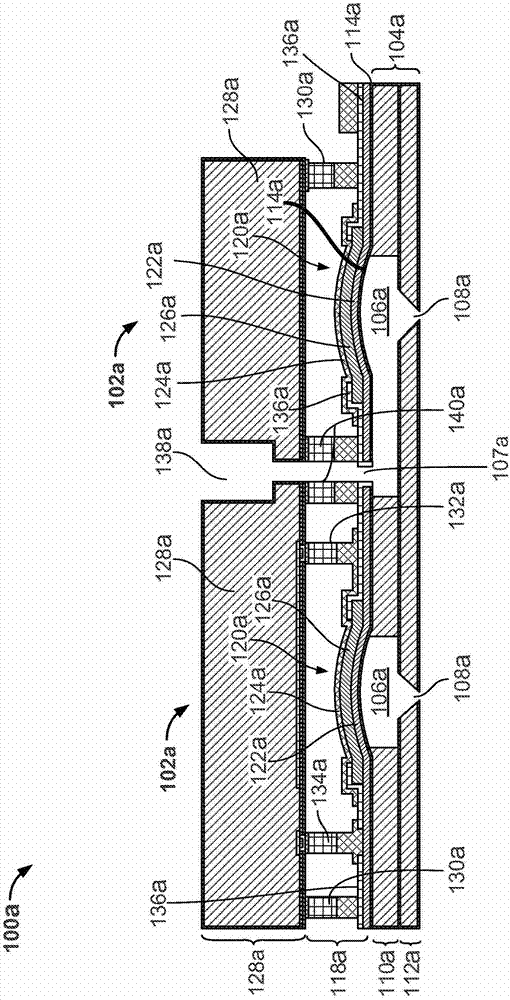

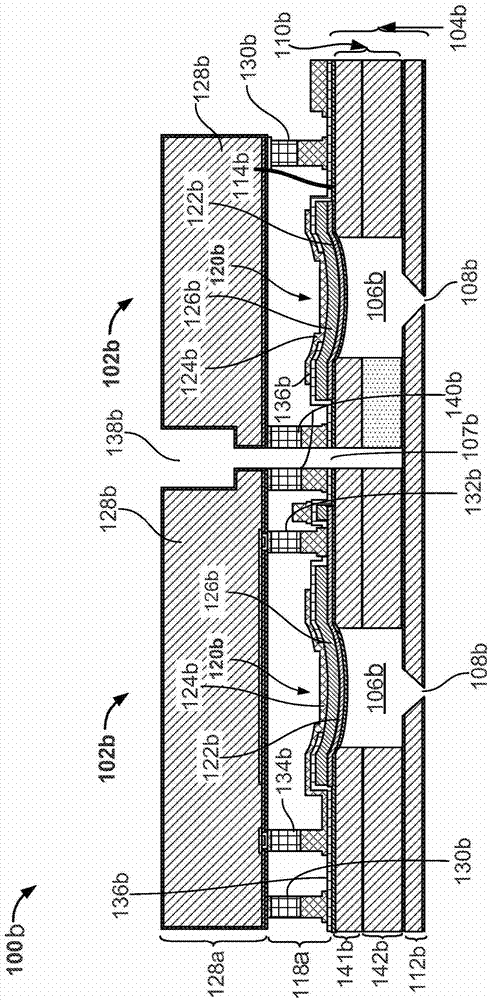

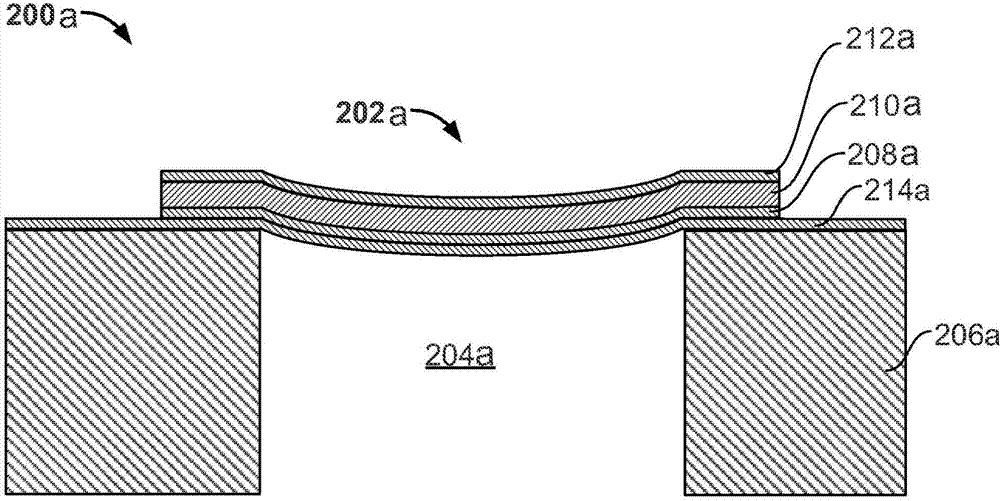

[0068] A MEMS actuator with a curved piezoelectric membrane can be formed using a profile-transferring substrate with a curved surface surrounded by a flat surface. The piezoelectric material for the piezoelectric actuator is deposited on at least the curved surface of the profile-transferring substrate before the profile-transferring substrate is removed from the underside of the curved piezoelectric film. The final curved piezoelectric film includes columnar and aligned grain structures, and all or substantially all of the columnar grains are locally perpendicular to the curved surface of the piezoelectric film. A variety of methods can be used to form curved features on profile-transferring substrates. Actuators with curved piezoelectric membranes are used, for example, for fluid droplet ejection.

[0069] Fluid droplet ejection can be performed by a printhead module that includes a die fabricated using semiconductor processing techniques. The printhead die includes a sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com