Patents

Literature

70results about How to "Prevent sound leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

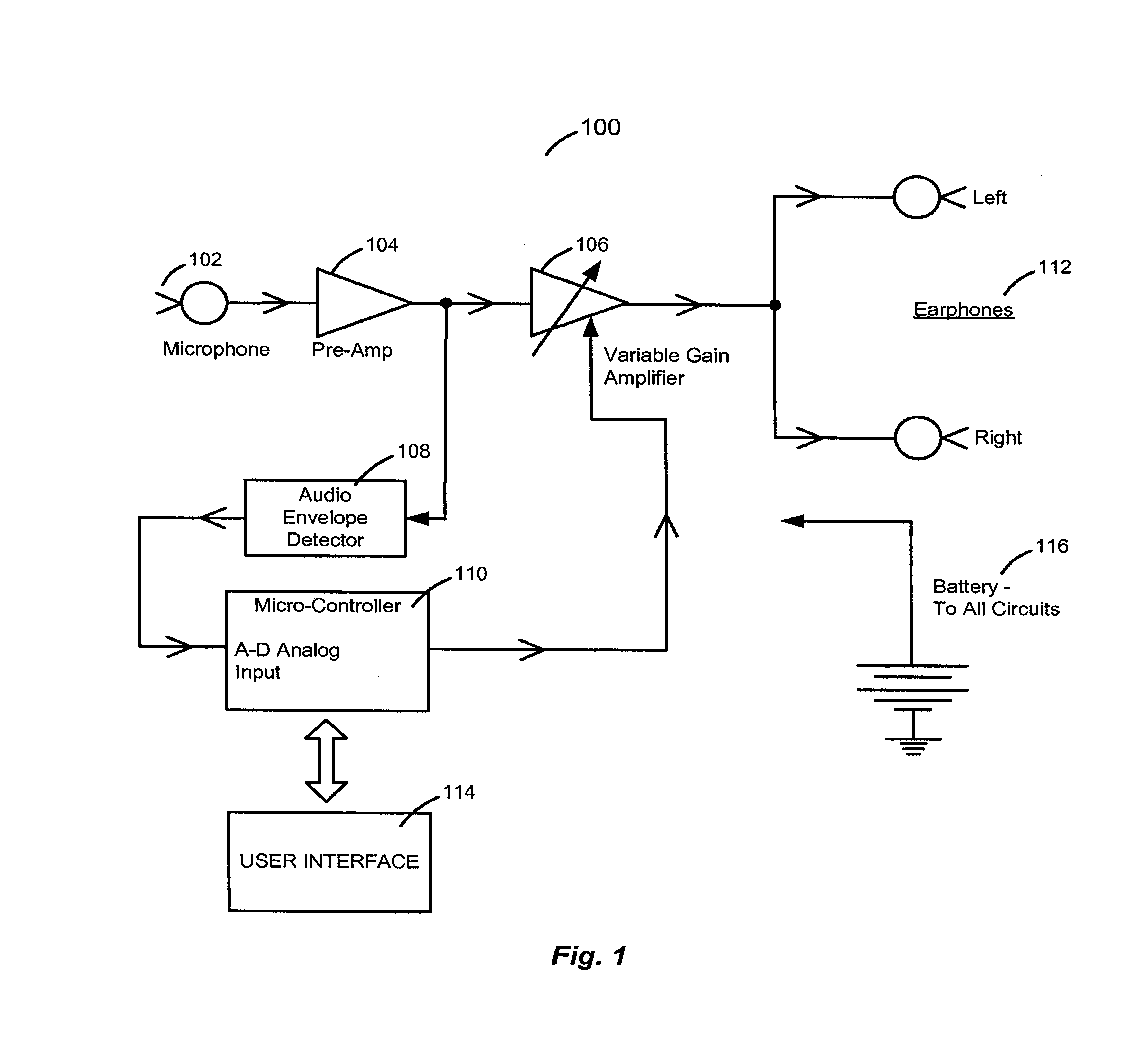

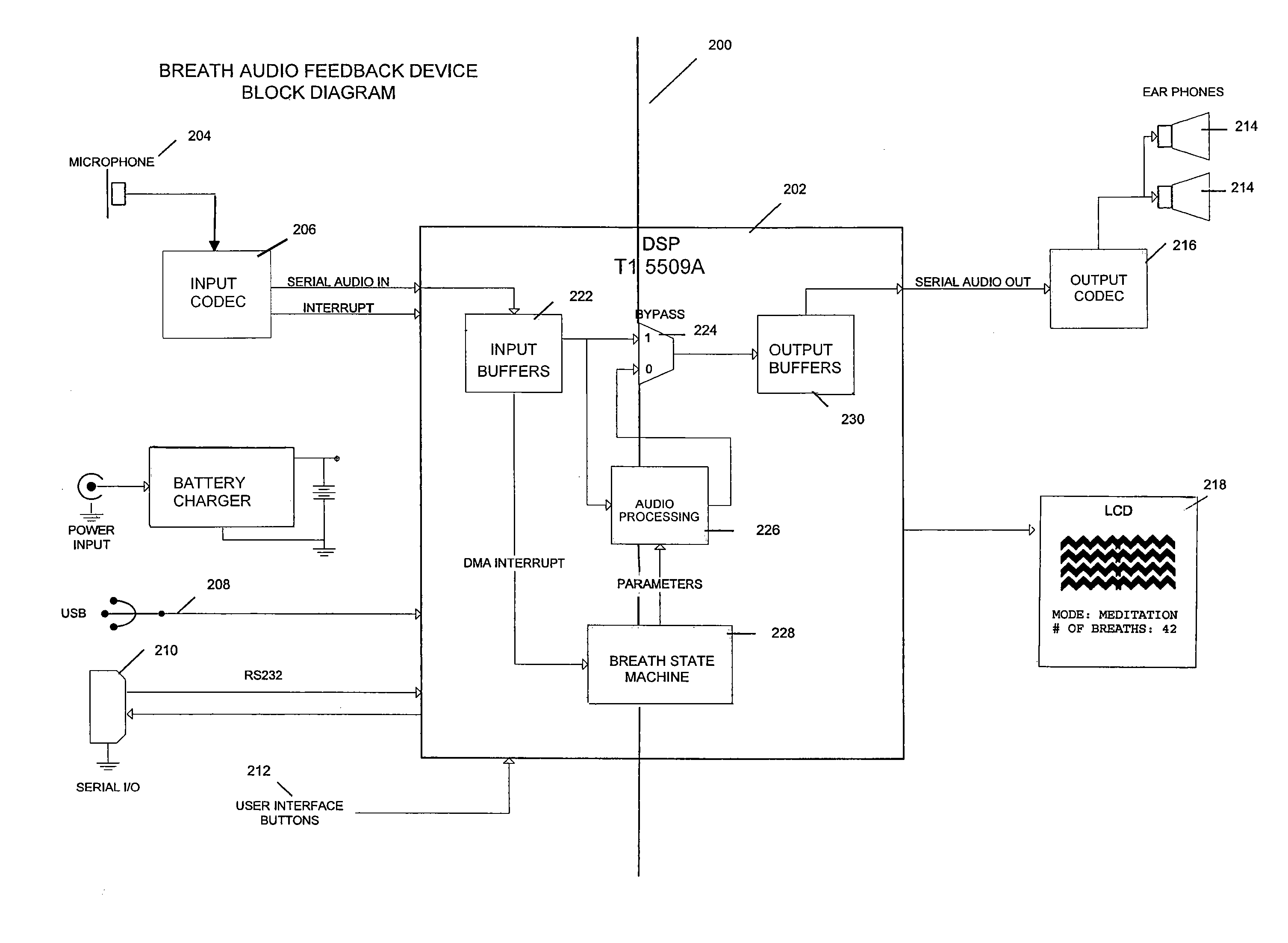

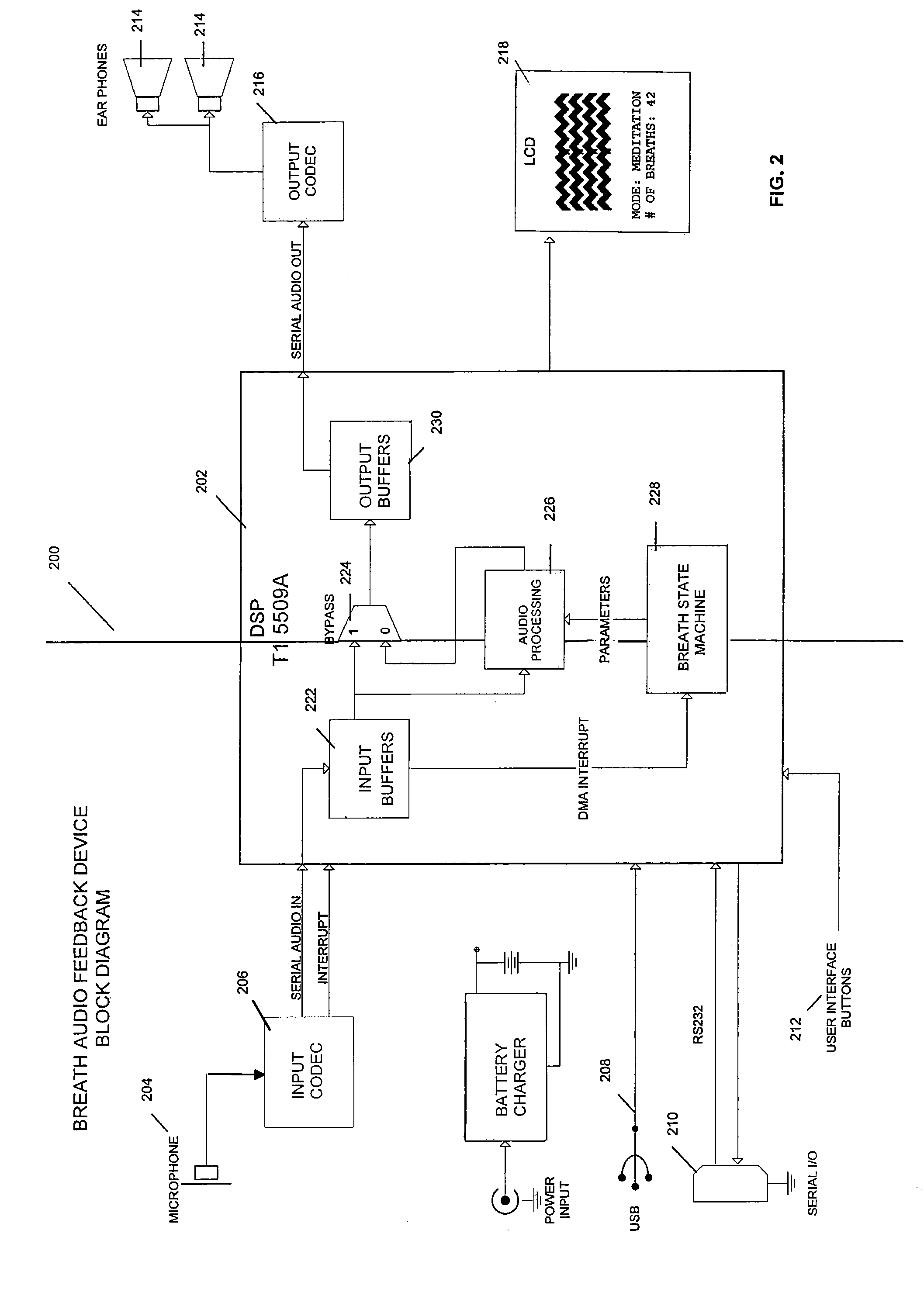

Respiratory biofeedback devices, systems, and methods

ActiveUS20100240945A1Improve respiratory activityImprove sleep qualityRespiratory organ evaluationAngiographyTime responseSound wave

Respiratory-based biofeedback devices, systems, and methods are provided. A respiratory biofeedback method includes producing a respiratory signal in response to a user's respiratory activity, generating an audio output signal that includes a modified version of the respiratory signal, and converting the audio output signal into sound waves output to the user to provide biofeedback. The sound waves can be output to the user in real time response to the user's respiratory activity. A microphone can be used to generate the respiratory signal. The generated audio output signal can includes the respiratory signal modified to increase a volume level of a portion of the respiratory signal where the volume level exceeds a specified volume level.

Owner:BREATH RES

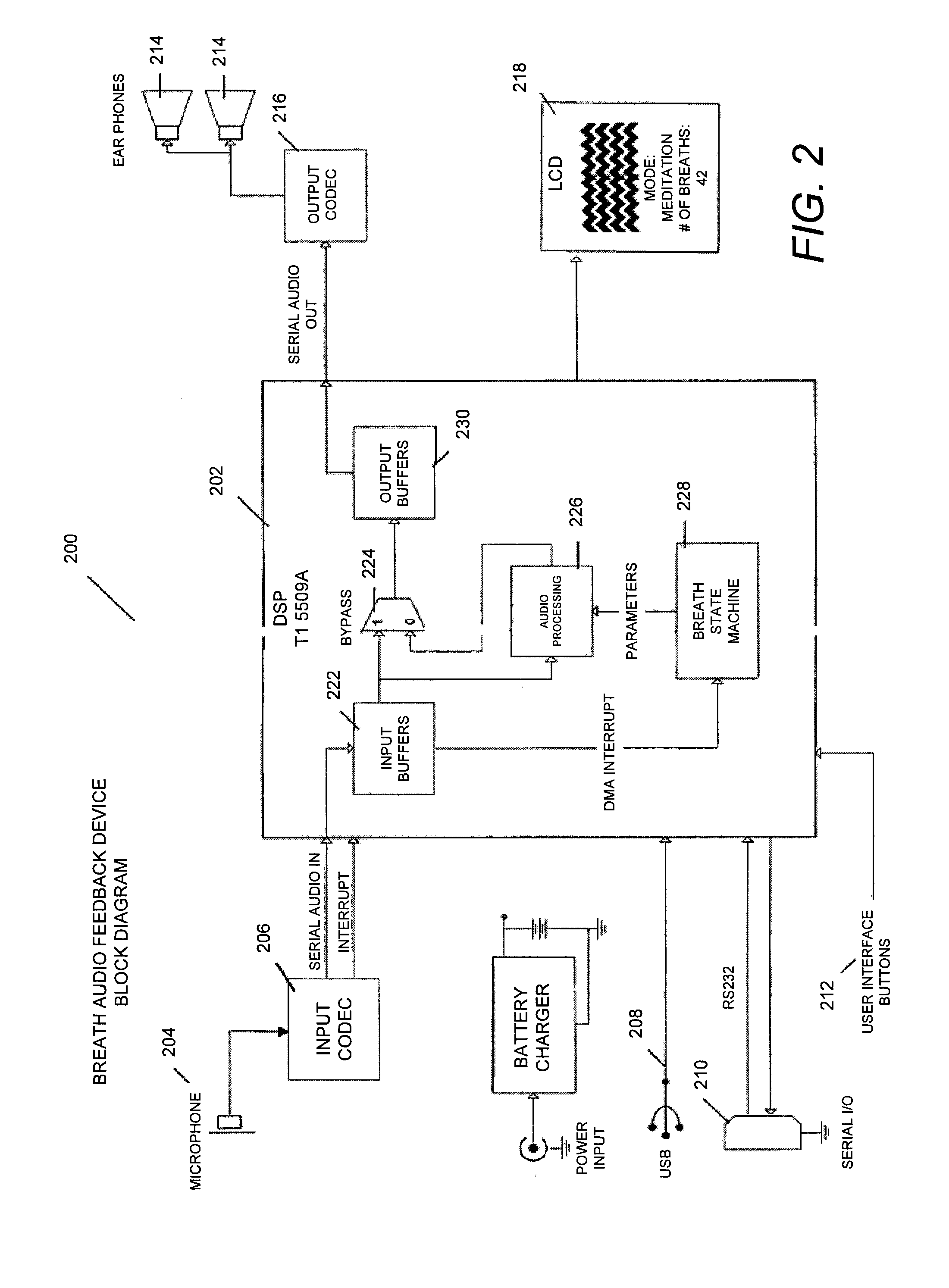

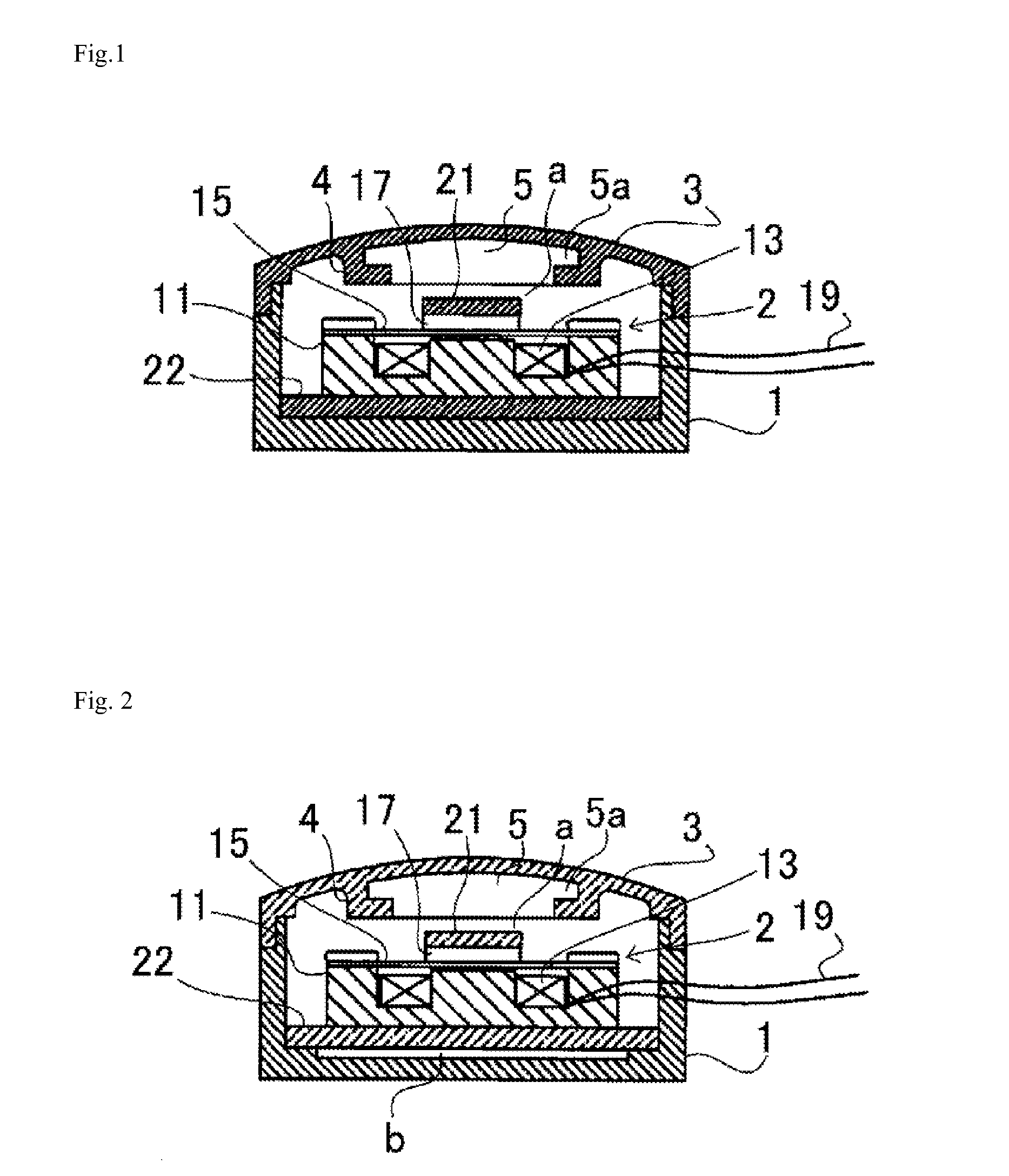

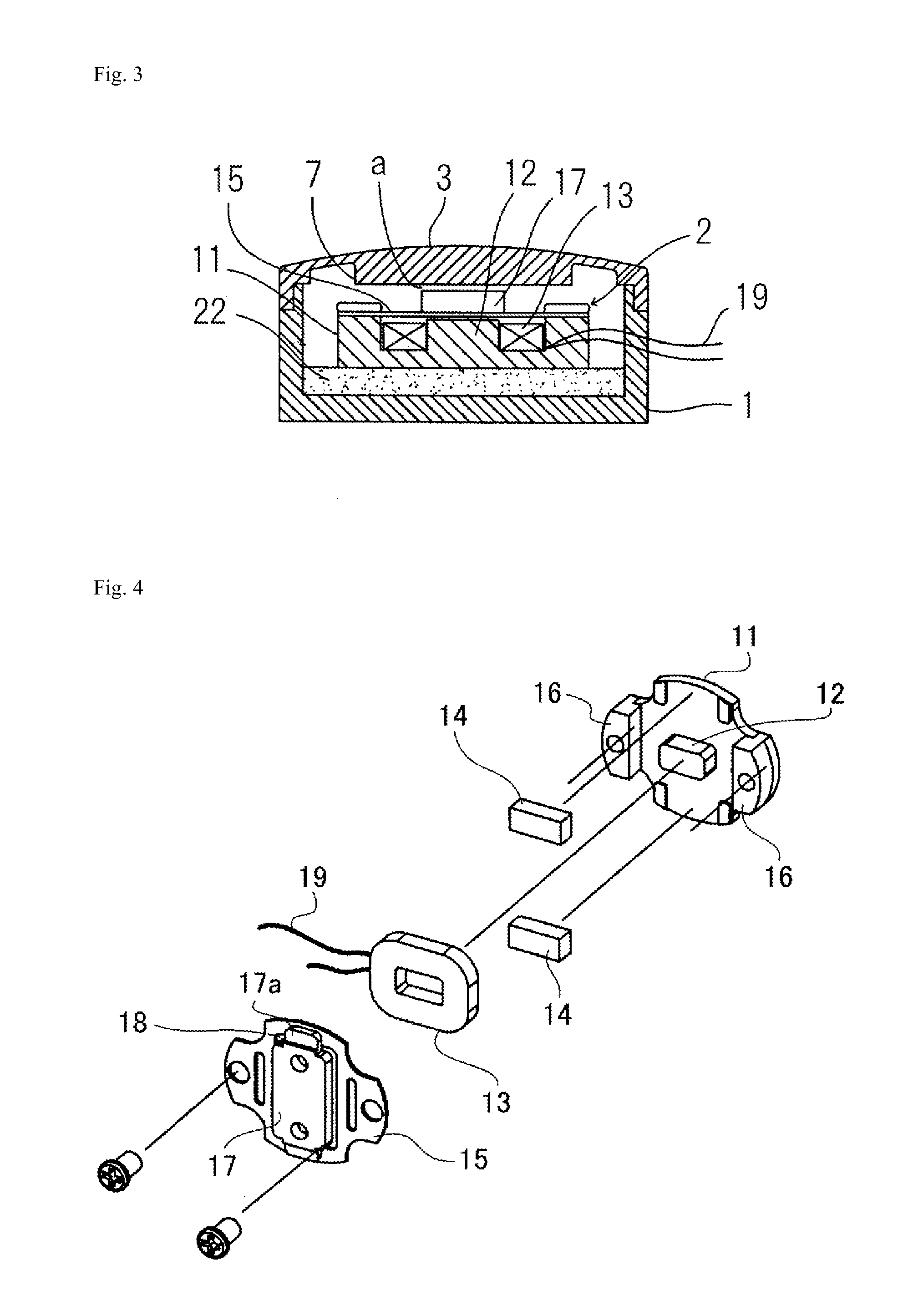

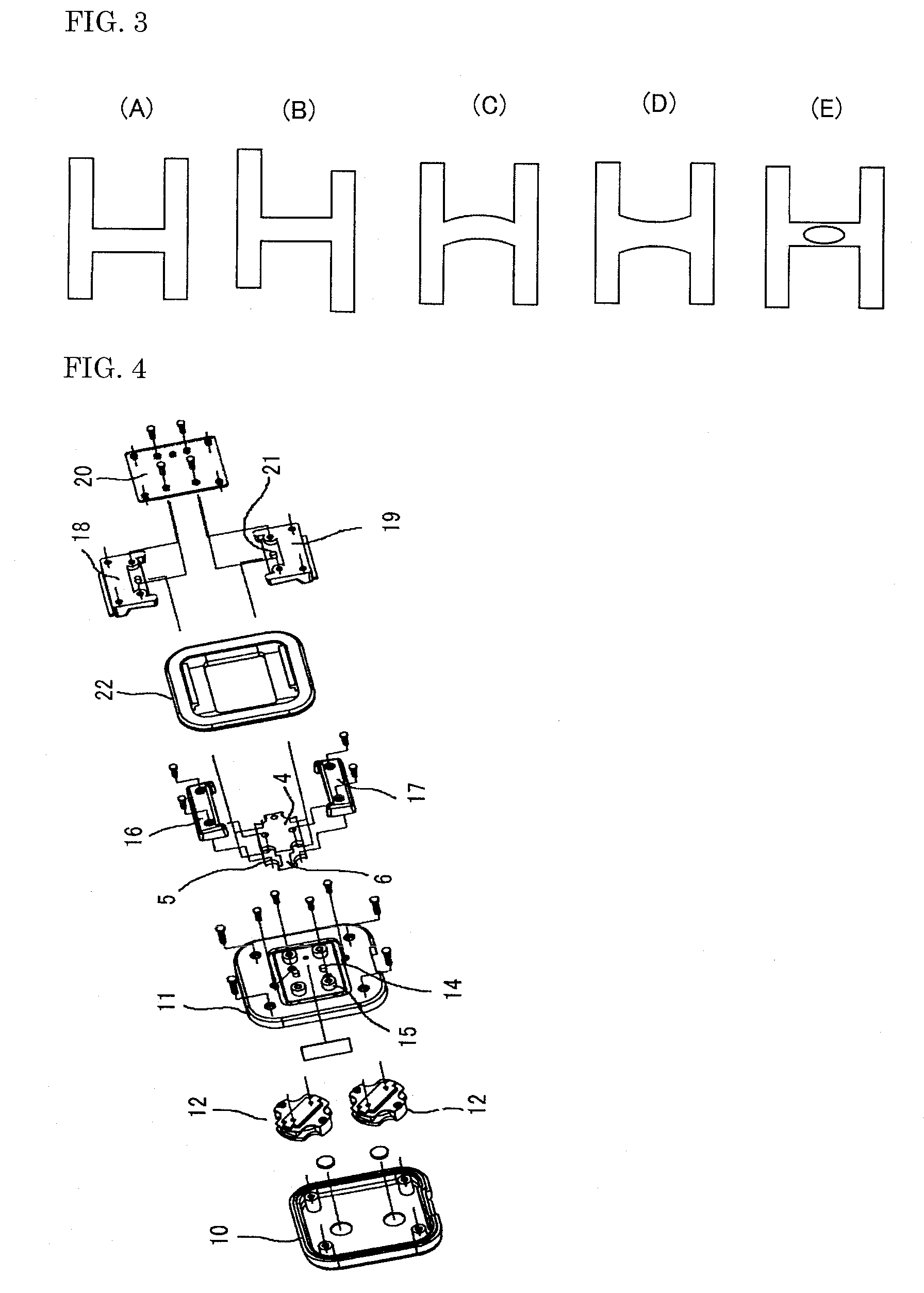

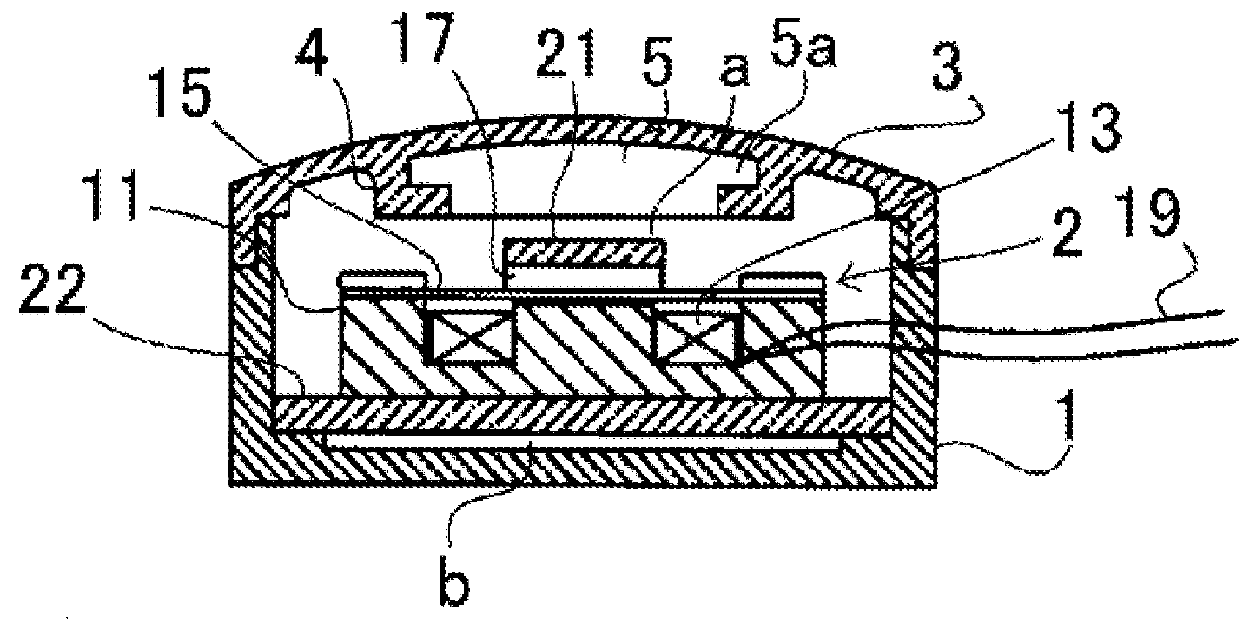

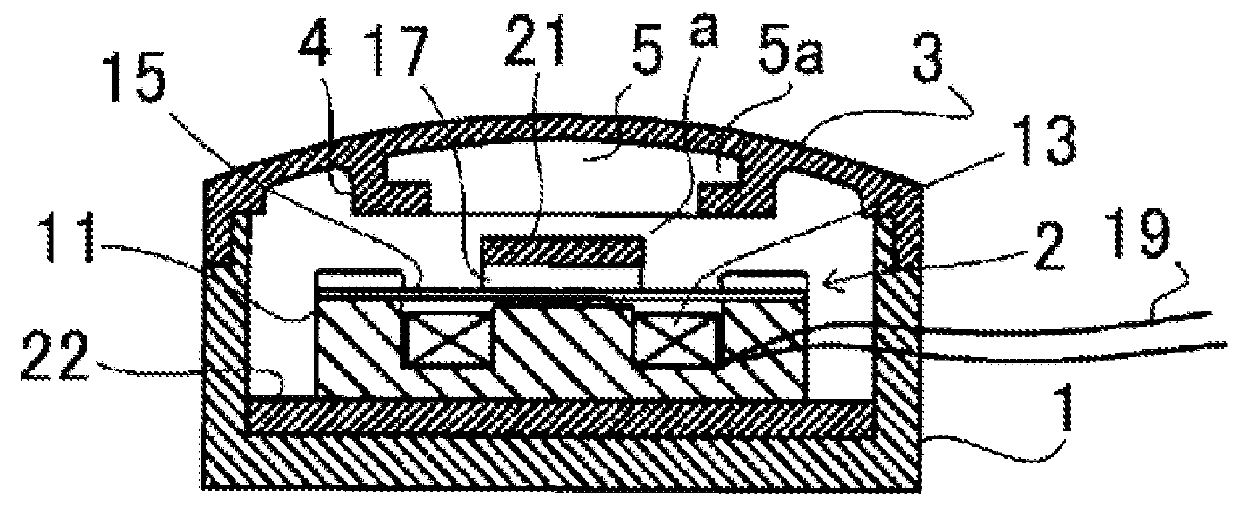

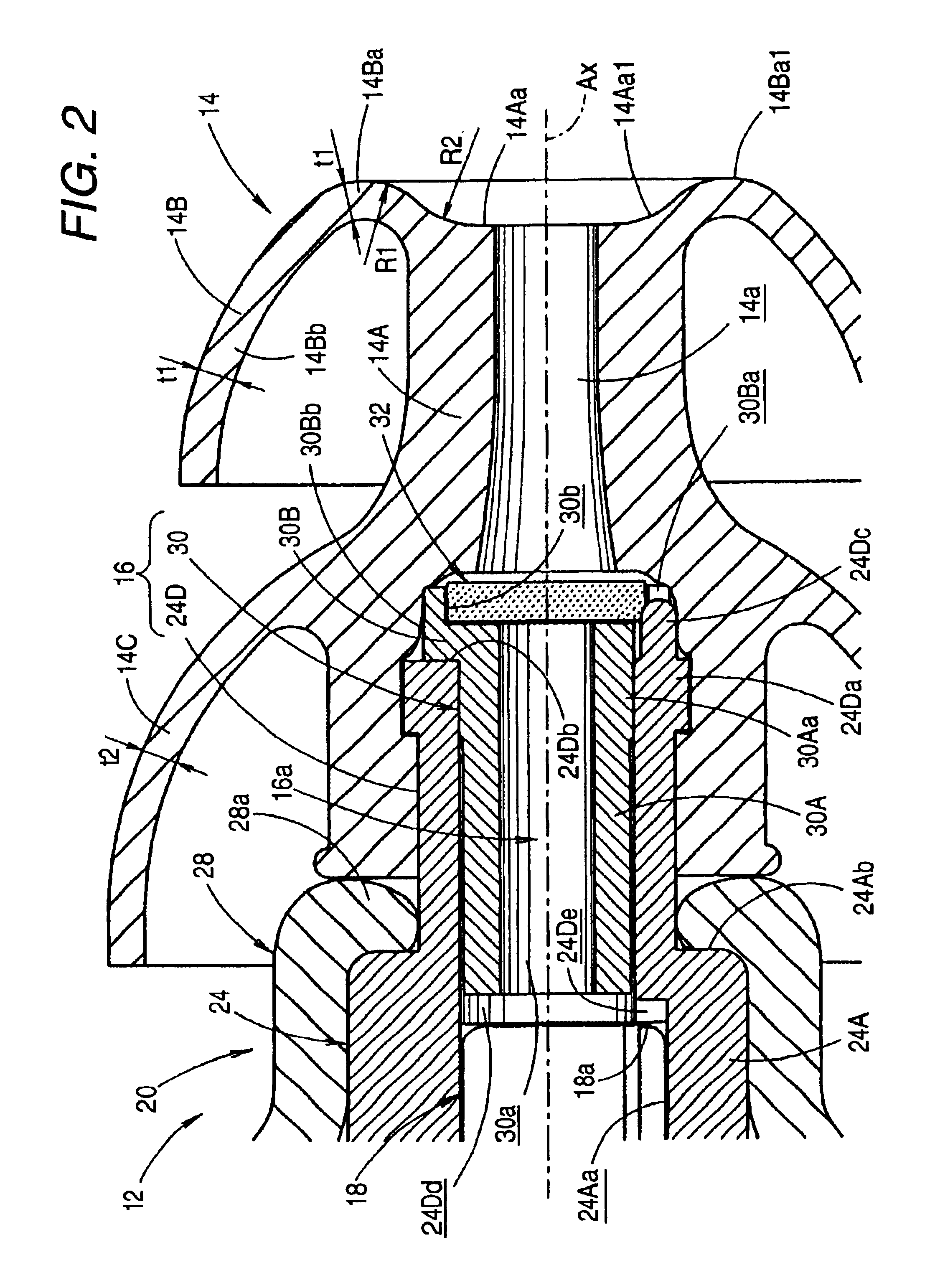

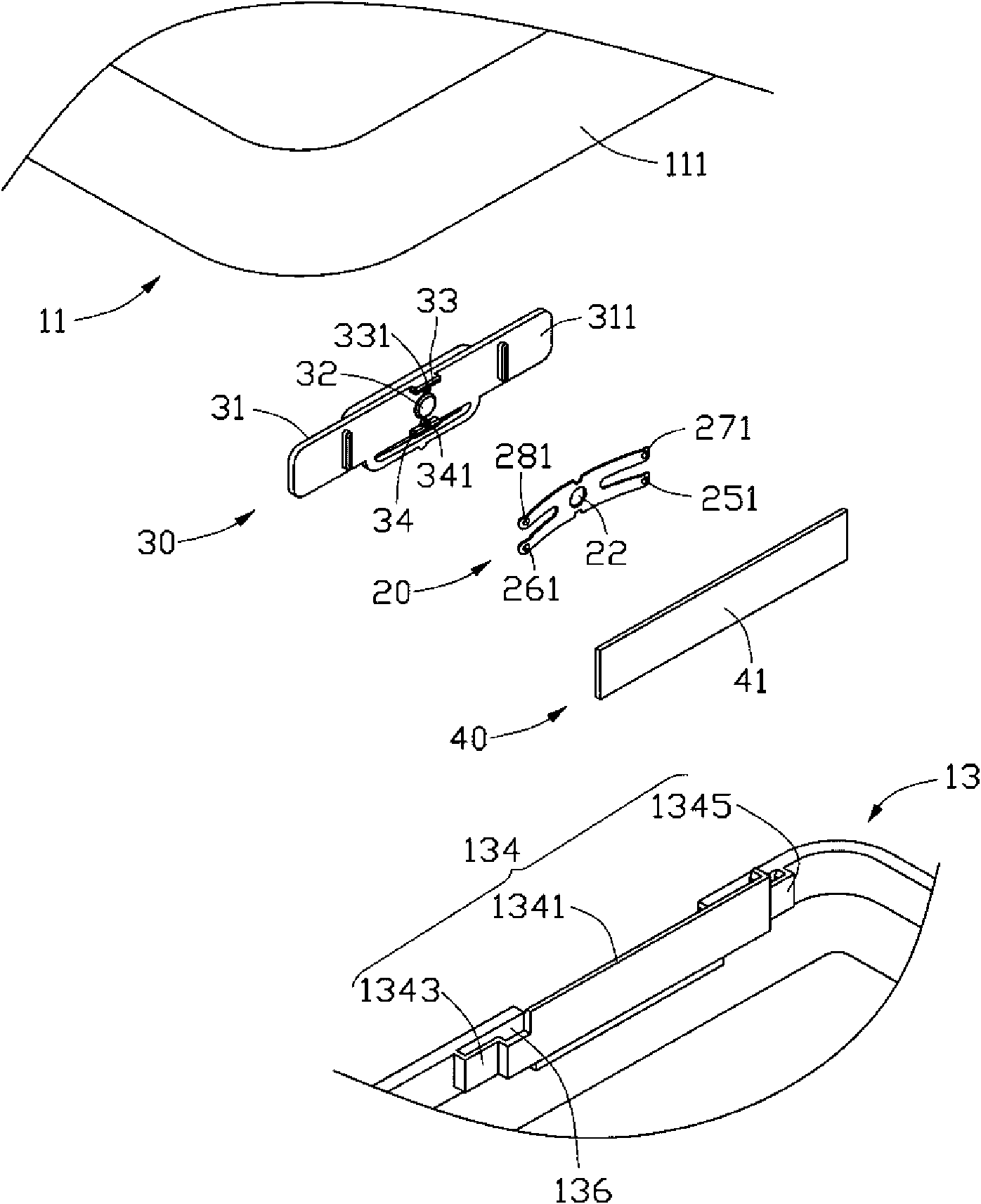

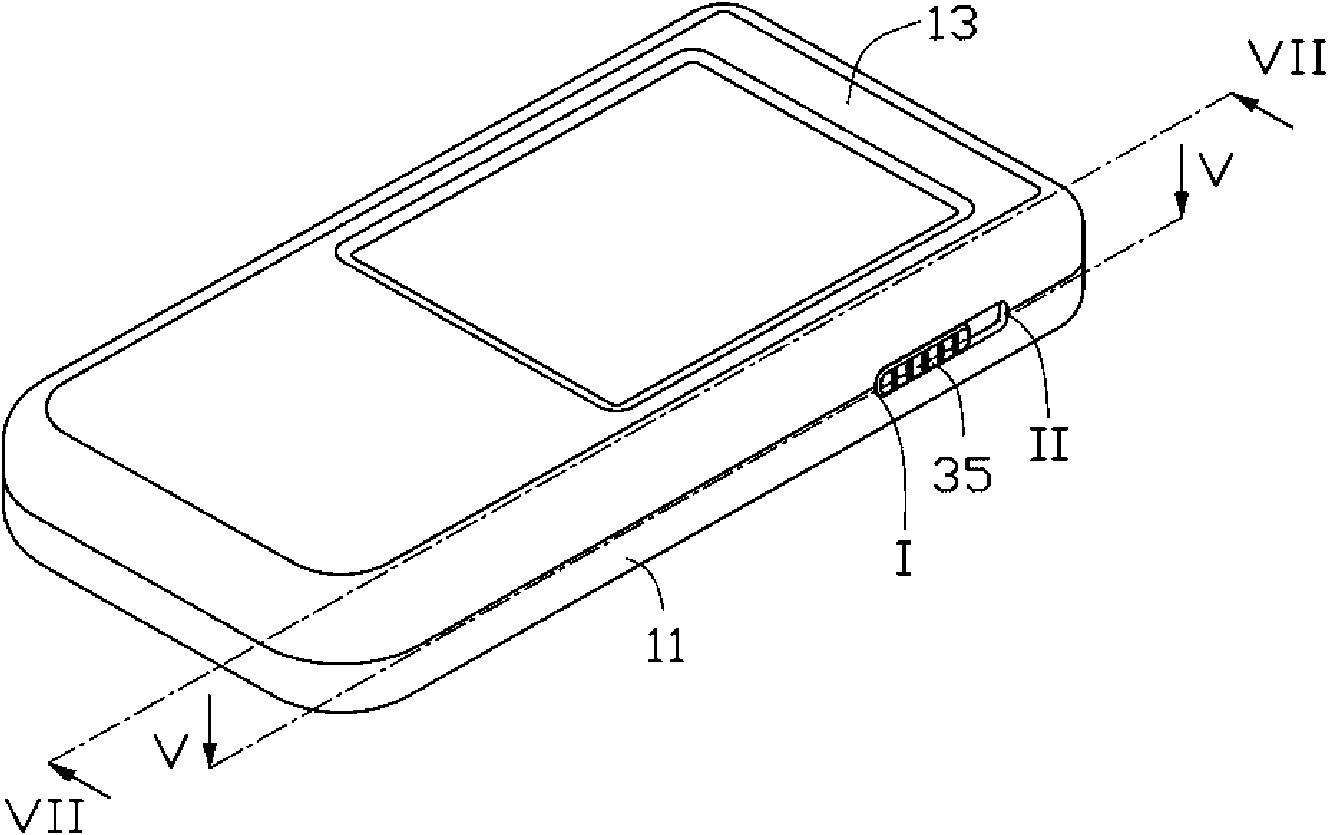

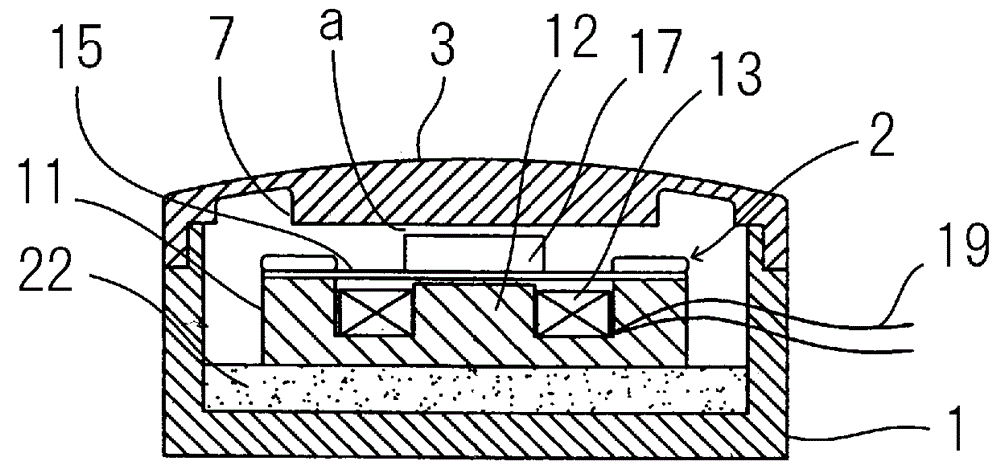

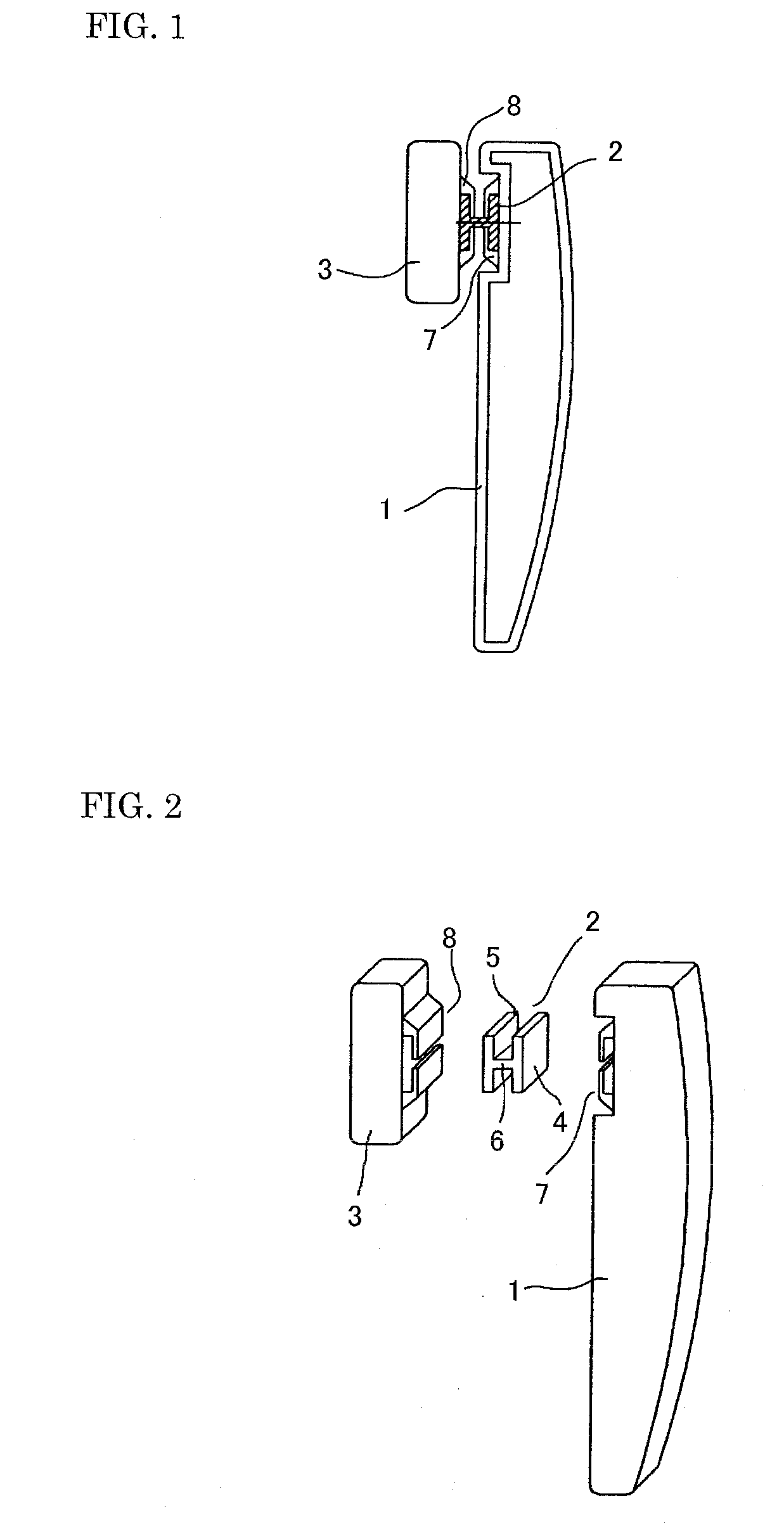

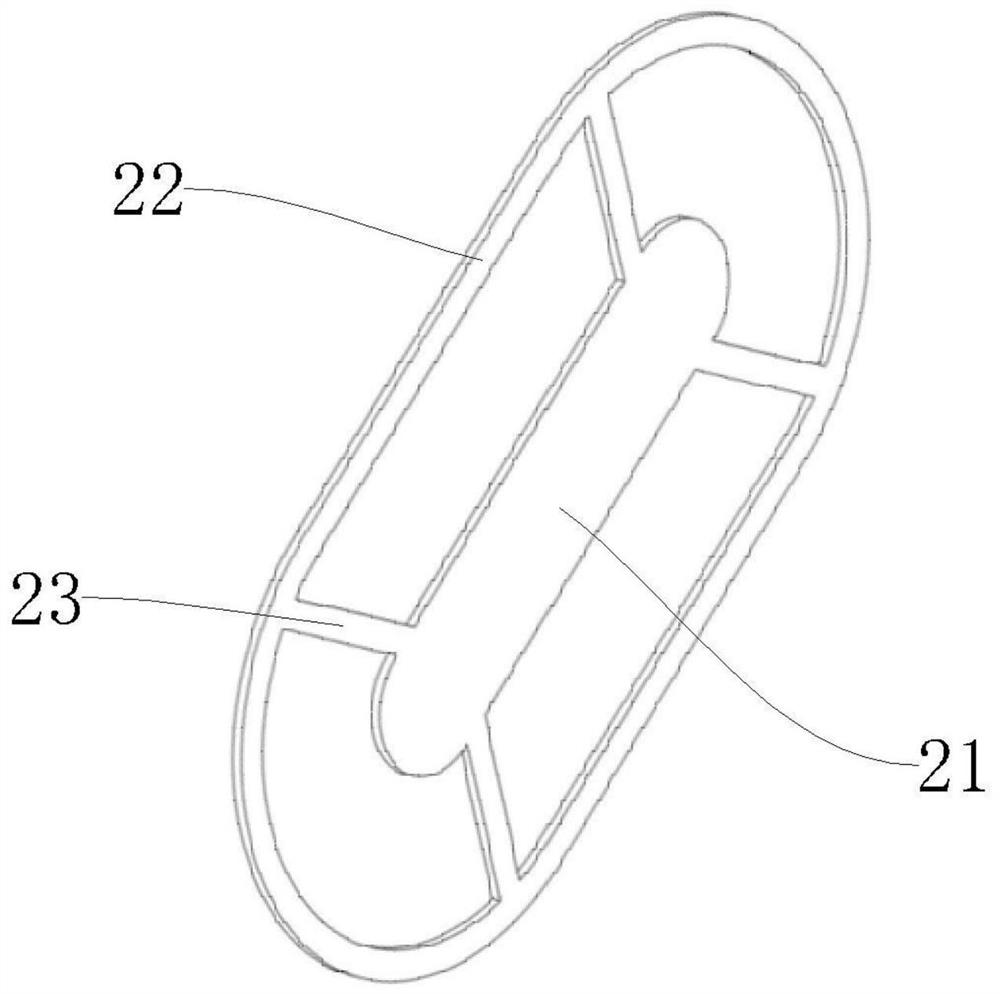

Bone conduction speaker unit

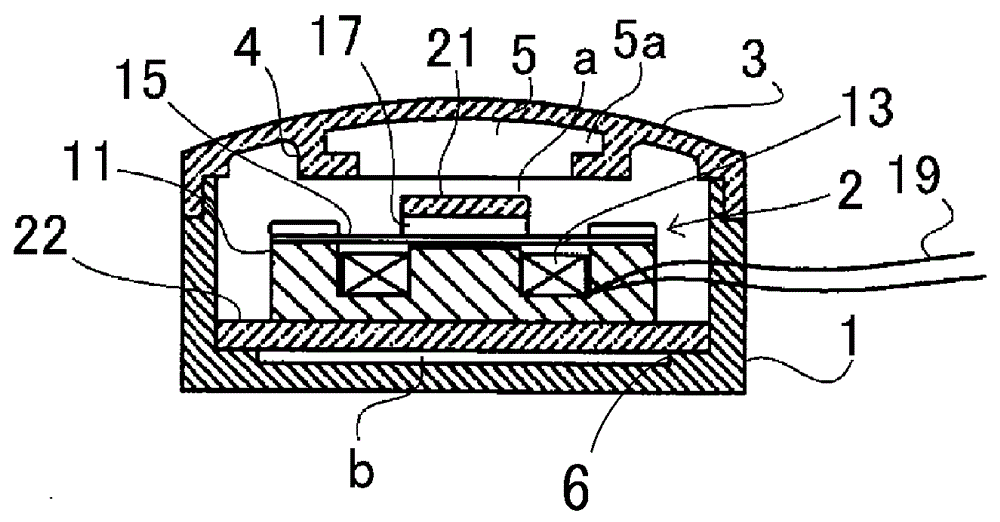

InactiveUS20150264473A1Easy constructionMinimized sound leakageLoudspeaker transducer fixingBone conduction transducer hearing devicesEngineeringBone conduction hearing

Problem: To provide a bone conduction speaker unit which can sufficiently prevent generation of sound leakage at the time of non-calling, and can be easily incorporated in a main body casing of mobile phones, and the like.Solution: A bone conduction speaker unit, being configured by incorporating a bone conduction speaker main body 2 in a housing 1, wherein an elastic plate 21 is fixed on a top face of a plate yoke 17 of the bone conduction speaker main body 2; an elastic base 22 is disposed on a rear face of a yoke 11; and an elastic cover 3 for holding a contact 5 which, upon a pressing force having been applied thereto in use, is abutted against the plate yoke 17 through the elastic plate 21 is loaded on the housing 1 with a gap “a” being held between a bottom face of the contact 5 and a top face of the elastic plate 21.

Owner:TEMCO JAPAN

Earphone Testing Device

ActiveUS20150264501A1Guaranteed tightnessThe test result is accurateTransducer detailsHeadphonesBiomedical engineering

The present invention discloses an earphone testing device. An earphone testing device provided by the embodiments of the present invention comprises an fixation base, a standard microphone attached to the fixation base, and a fixation scaffold for attaching and fixing the fixation base and the standard microphone; the fixation base is supported and fixed on the fixation scaffold by several supporting elements; a sealer is located on the position on the fixation base in contact with the outer shell of an earphone, the sealer forms an earphone storage portion for placing the earphone; a sealer is located on the position on the fixation base in contact with the outer shell of the standard microphone, the sealer forms a microphone attachment portion for attaching to the standard microphone; the earphone placed in the earphone storage portion and the standard microphone attached onto the microphone attachment portion are communicated with each other in the fixation base. The present invention provides a stable and highly precise testing solution of earphone, which can guarantee the precision and stability of earphone testing.

Owner:GOERTEK INC

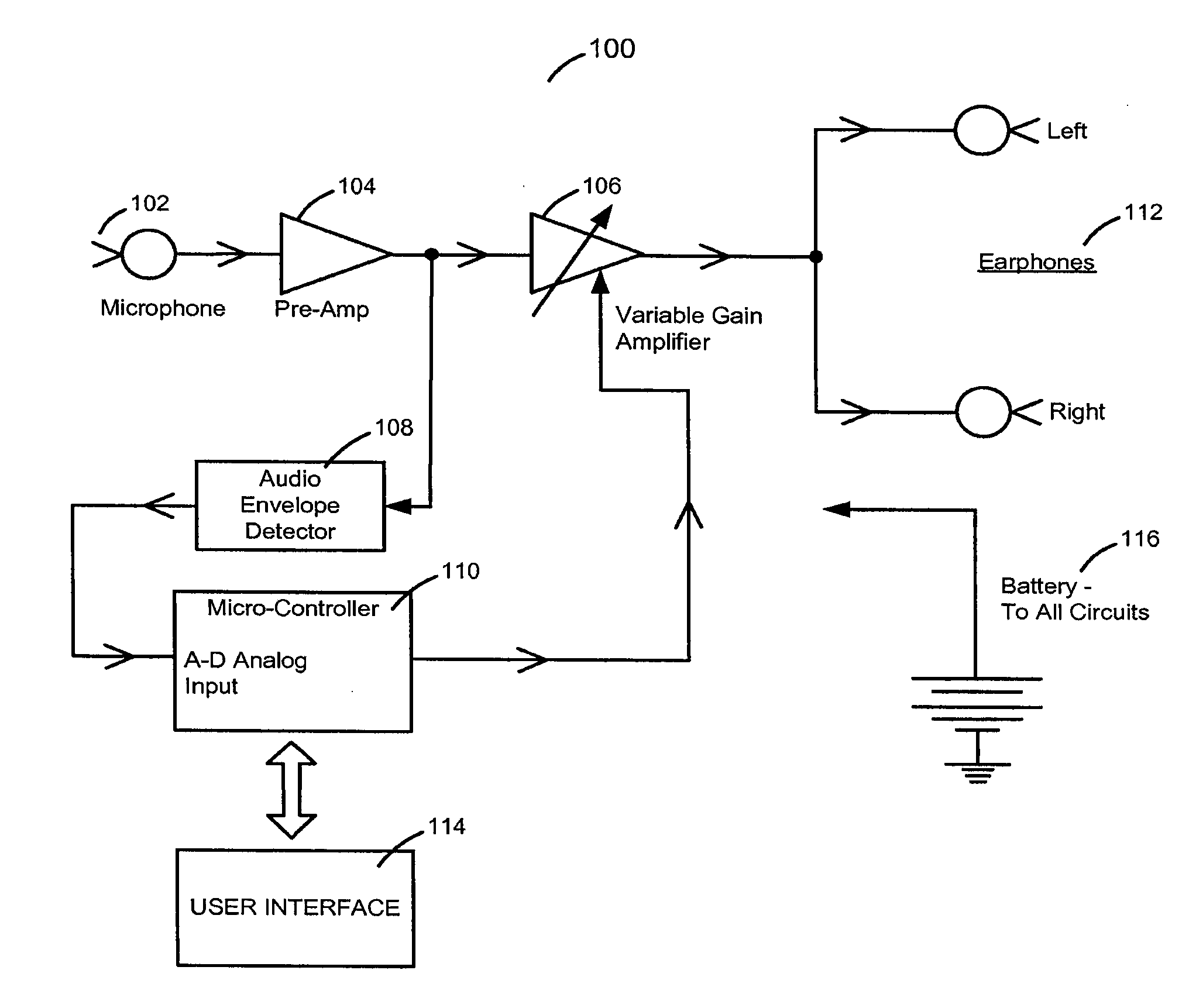

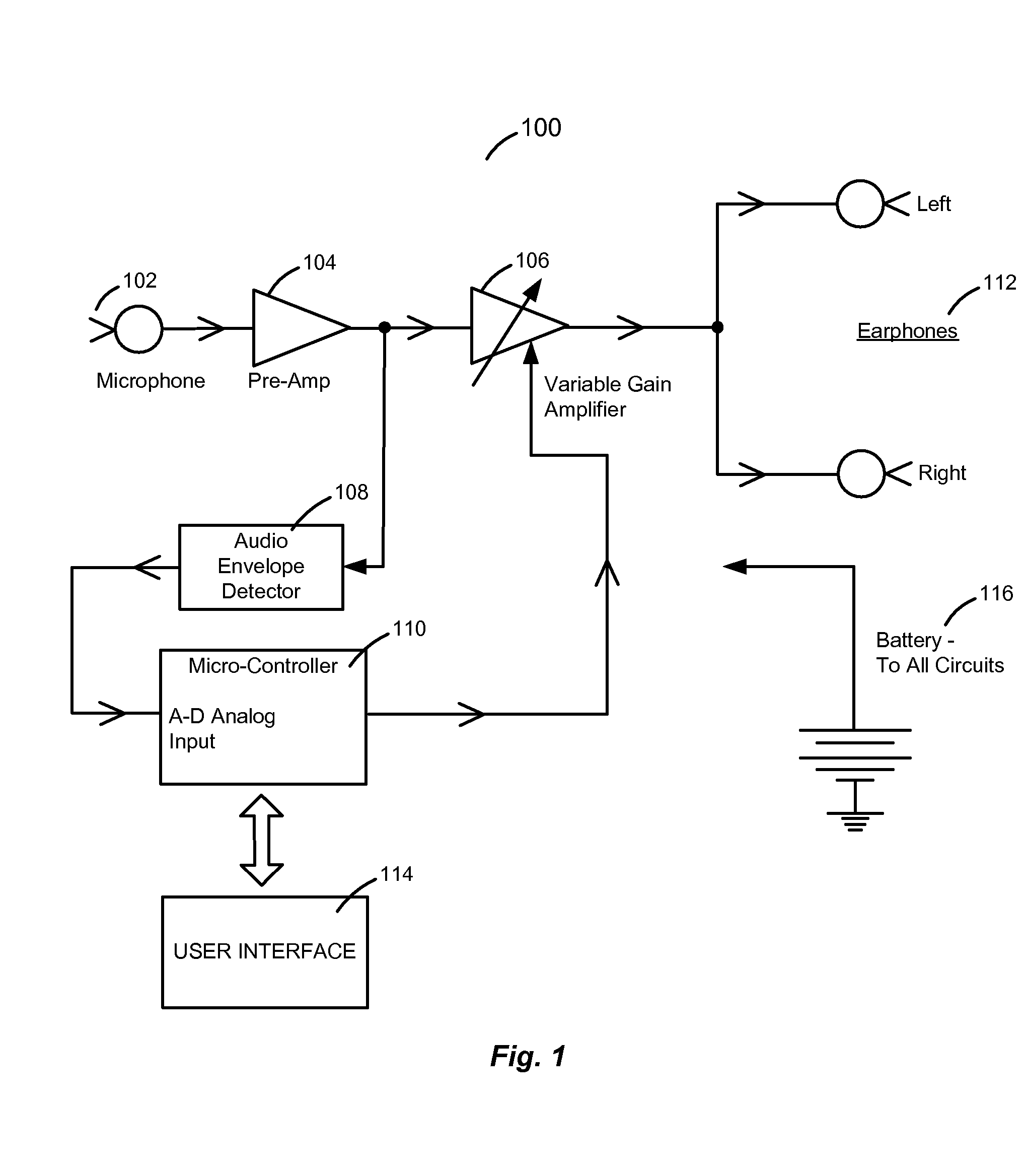

Breathing biofeedback device

ActiveUS20070173730A1Prevent sound leakagePhysical therapyAuscultation instrumentsAudio power amplifierVariable-gain amplifier

A breathing biofeedback device, having a microphone configured to acquire sounds of a user's breathing; a controller communicatively connected with the microphone, the controller processing the signals acquired by the microphone to produce an output signal, the controller processing the signal whereby the microphone signal is first pre-amplified to a voltage level that can be processed by an audio envelope detector circuit, the envelope detector signal is then fed into the analog-to-digital converter input of the controller allowing it to constantly sample the input volume level, the controller then controlling the output volume level fed to the headphones utilizing a digitally controlled variable-gain amplifier, wherein the output signal is not modified in any manner from the original input, except in volume; and a pair of earphones connected with the controller and configured to convey the output signal to the user.

Owner:AIREHEALTH INC

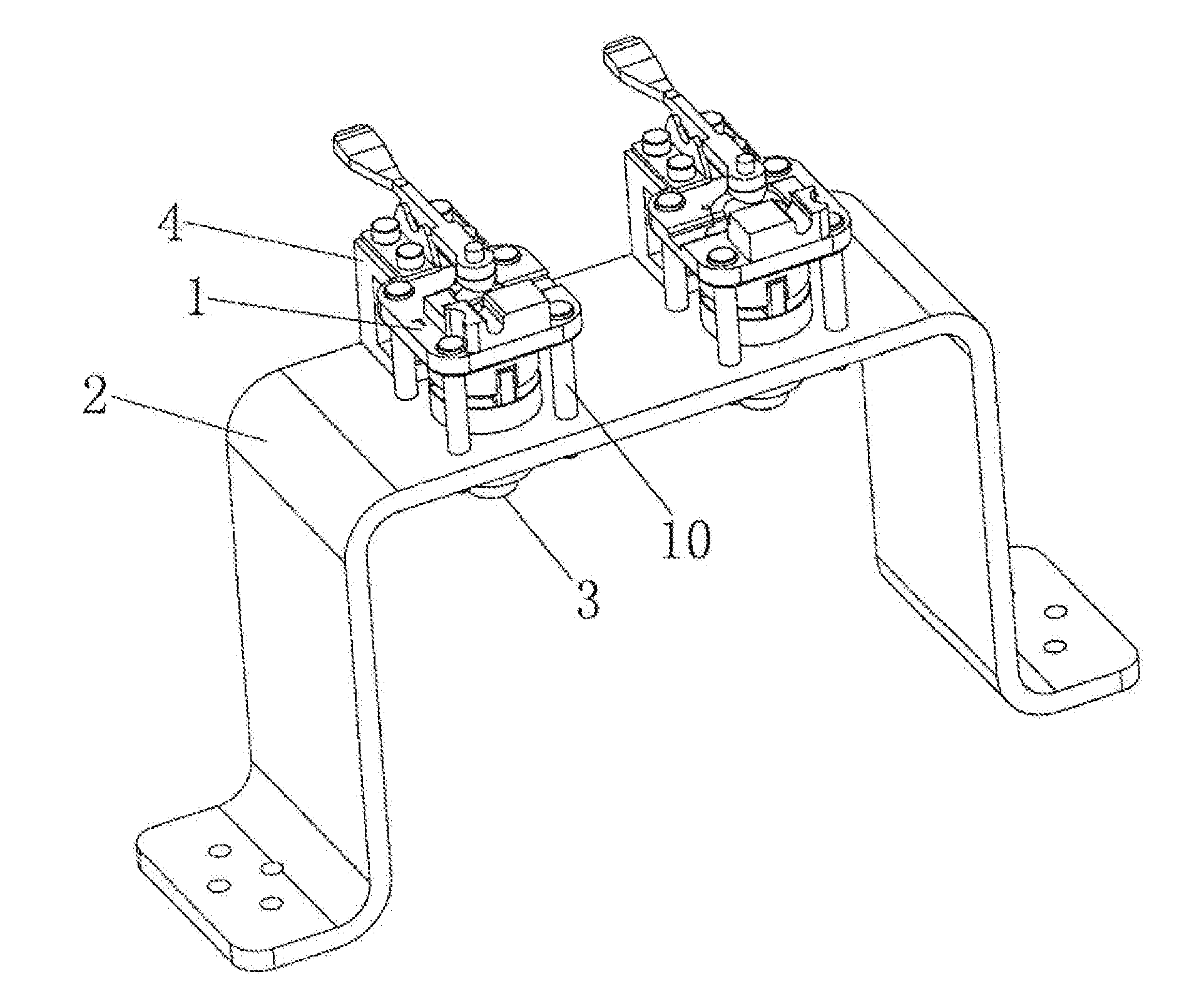

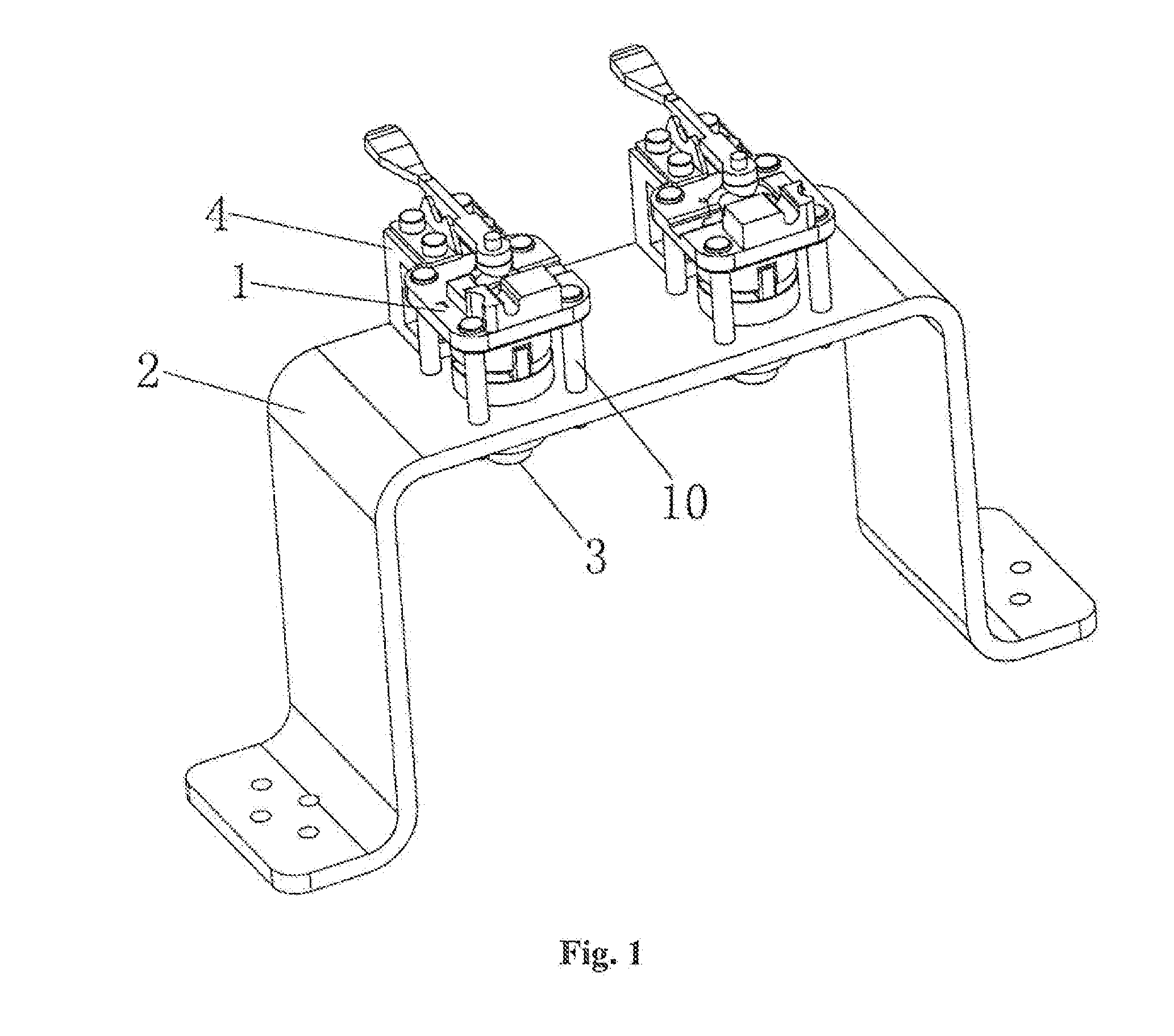

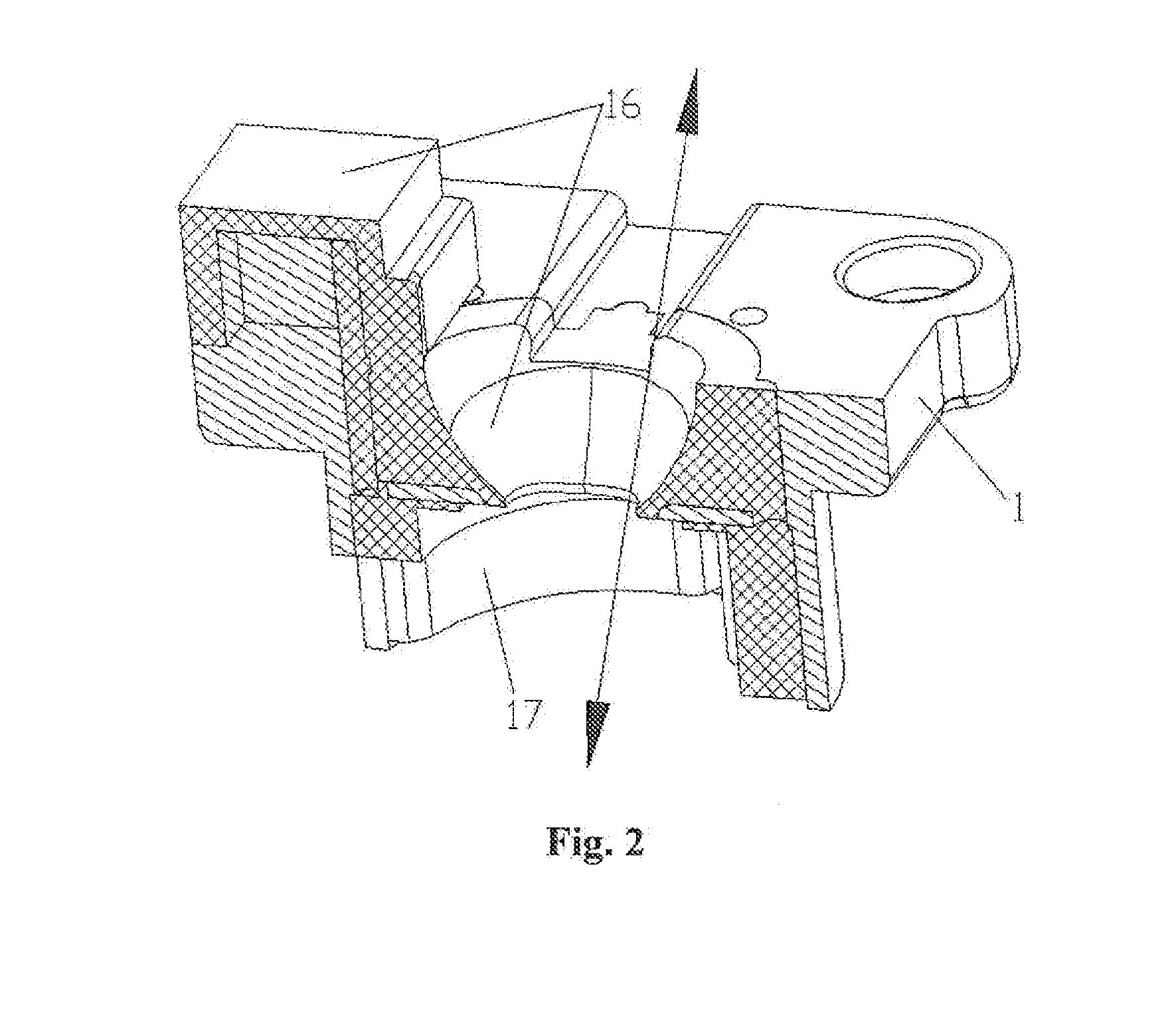

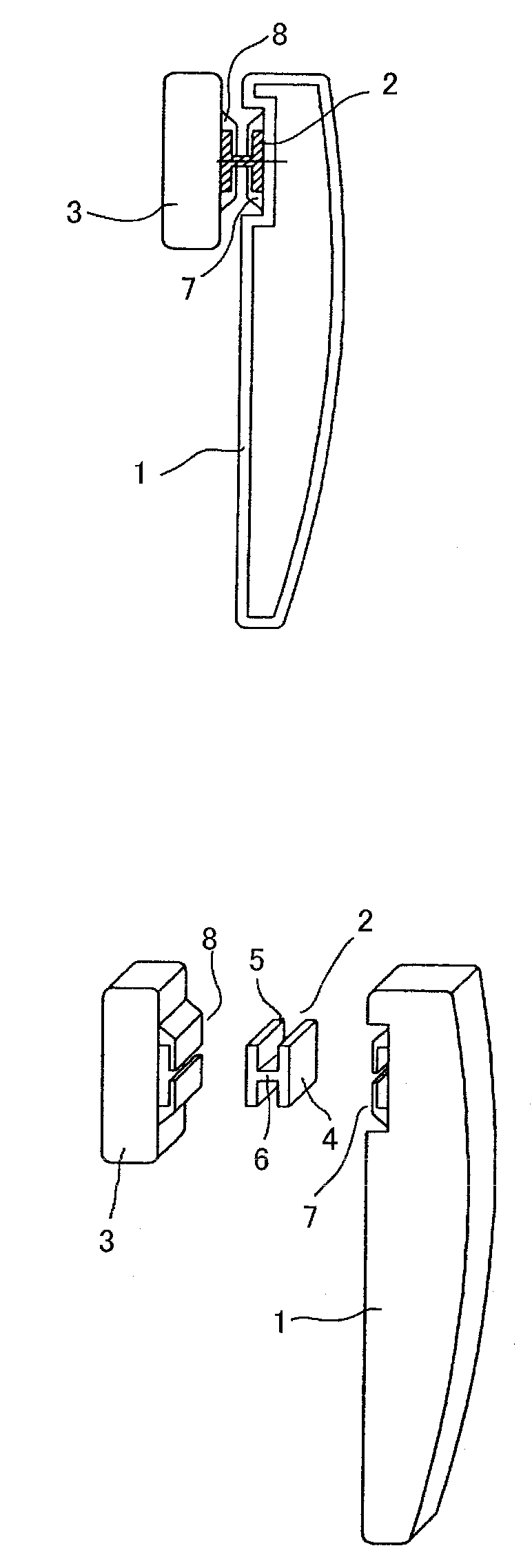

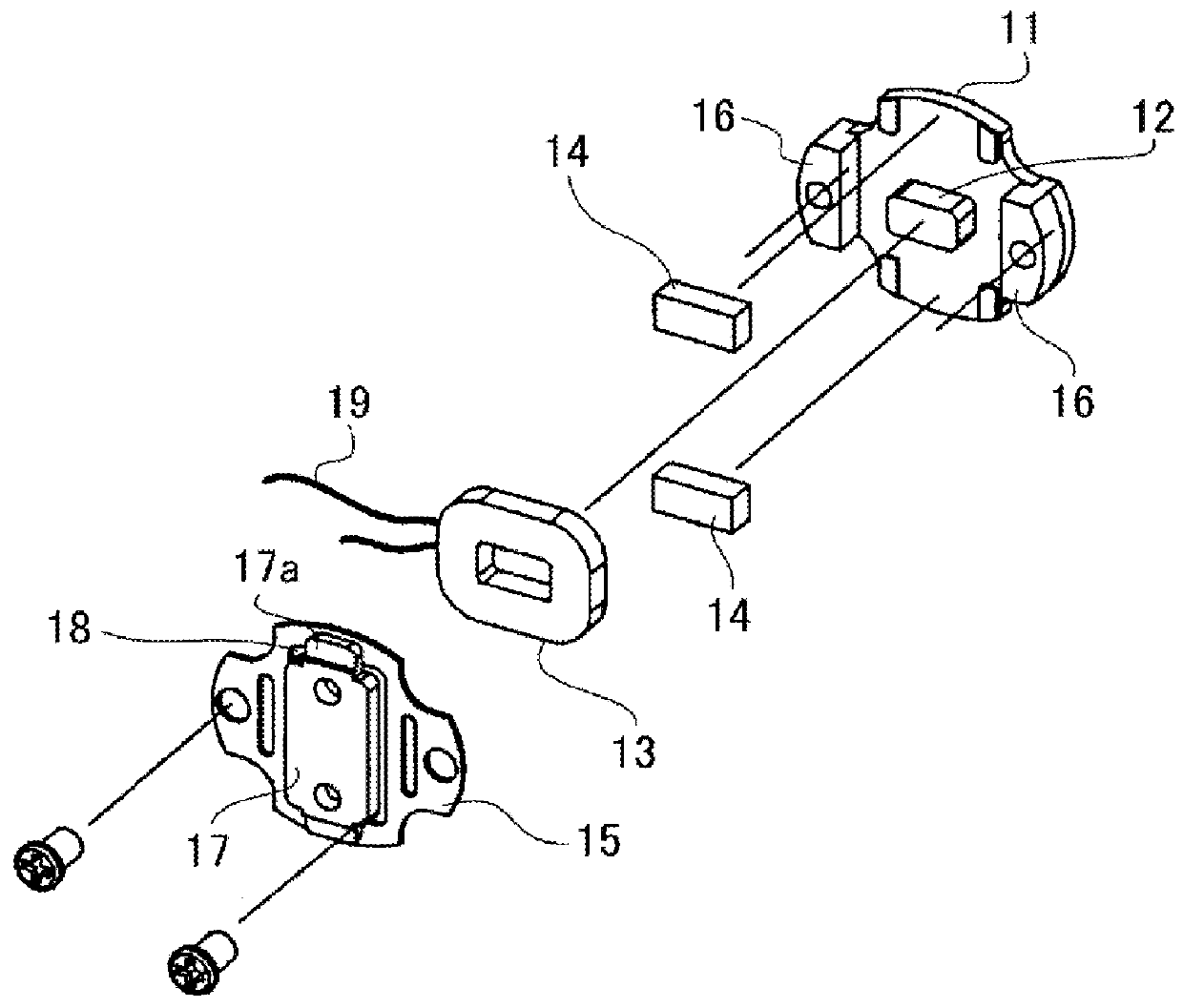

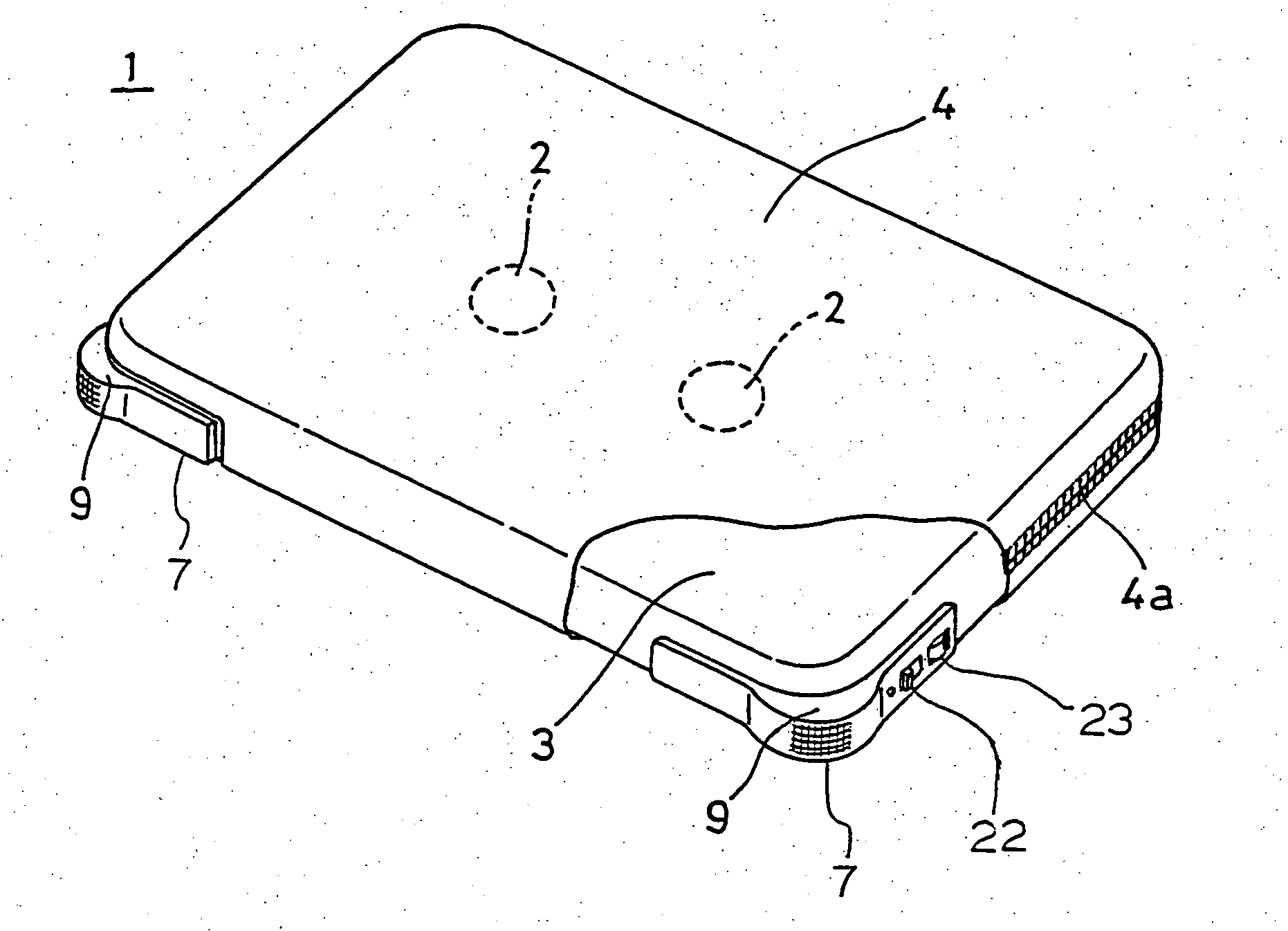

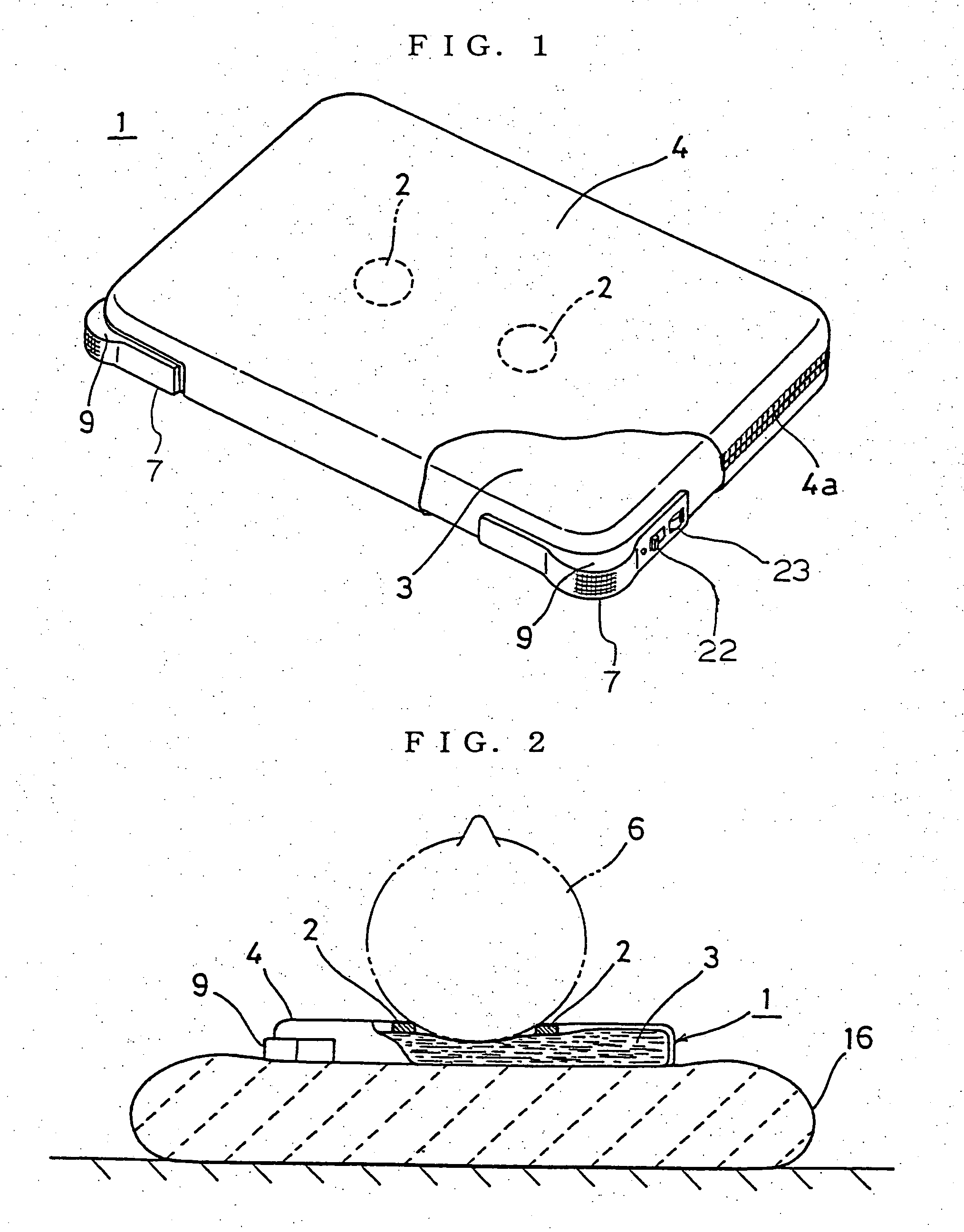

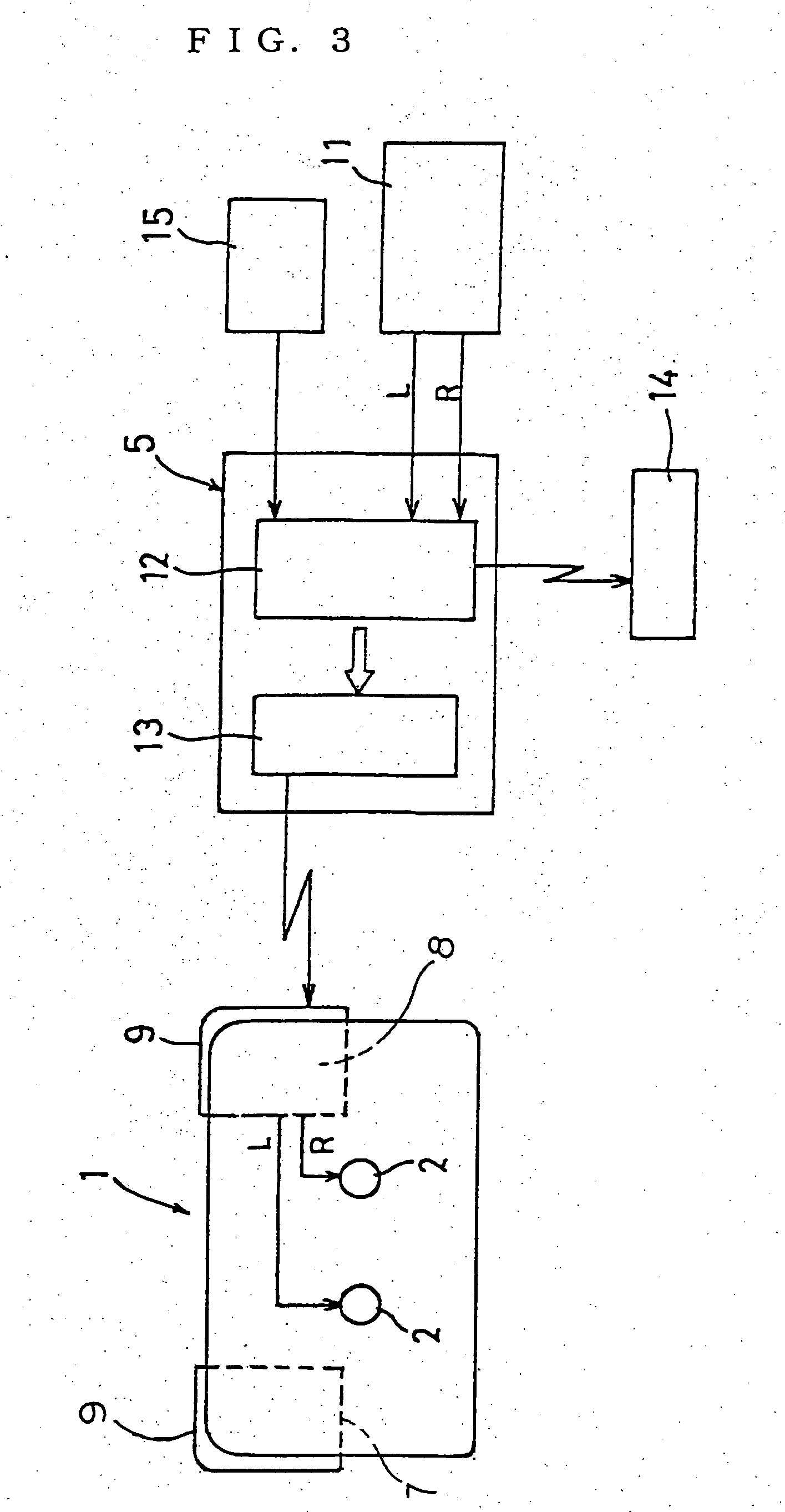

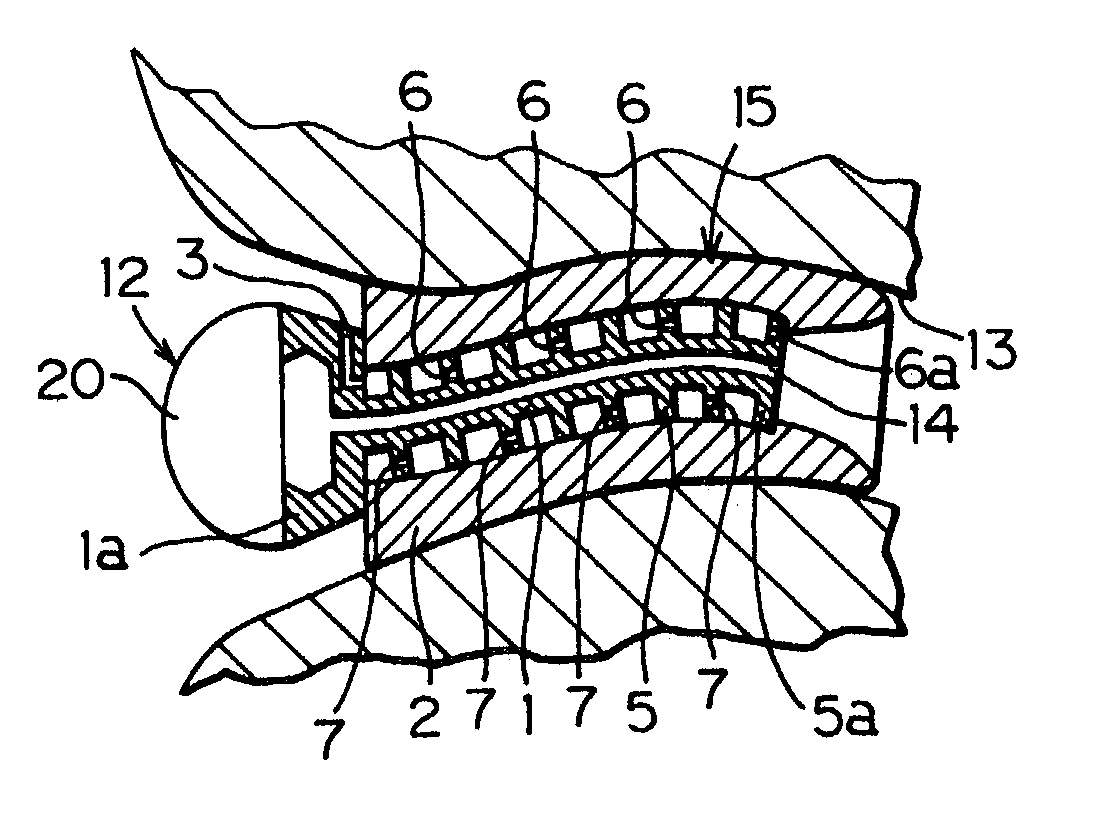

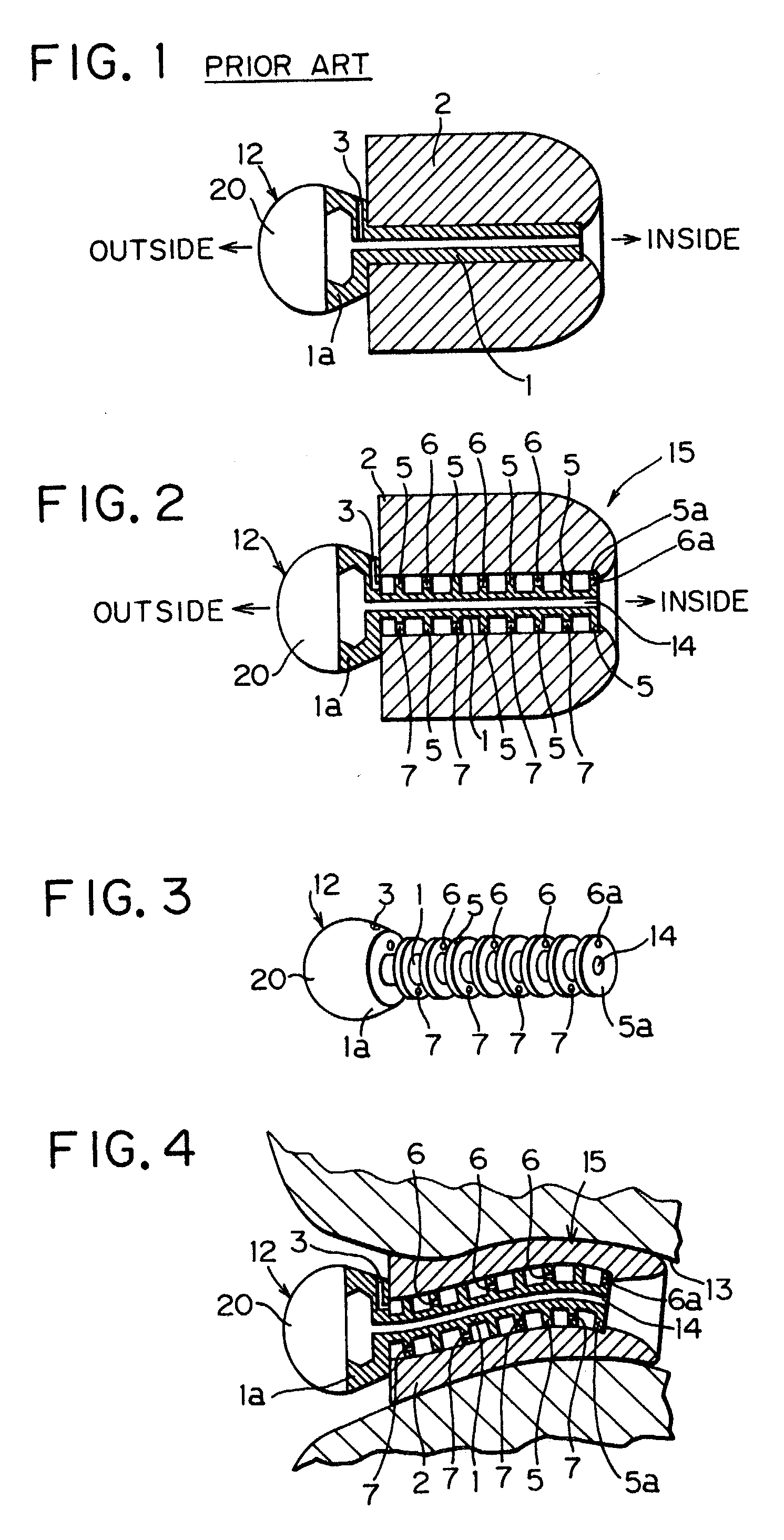

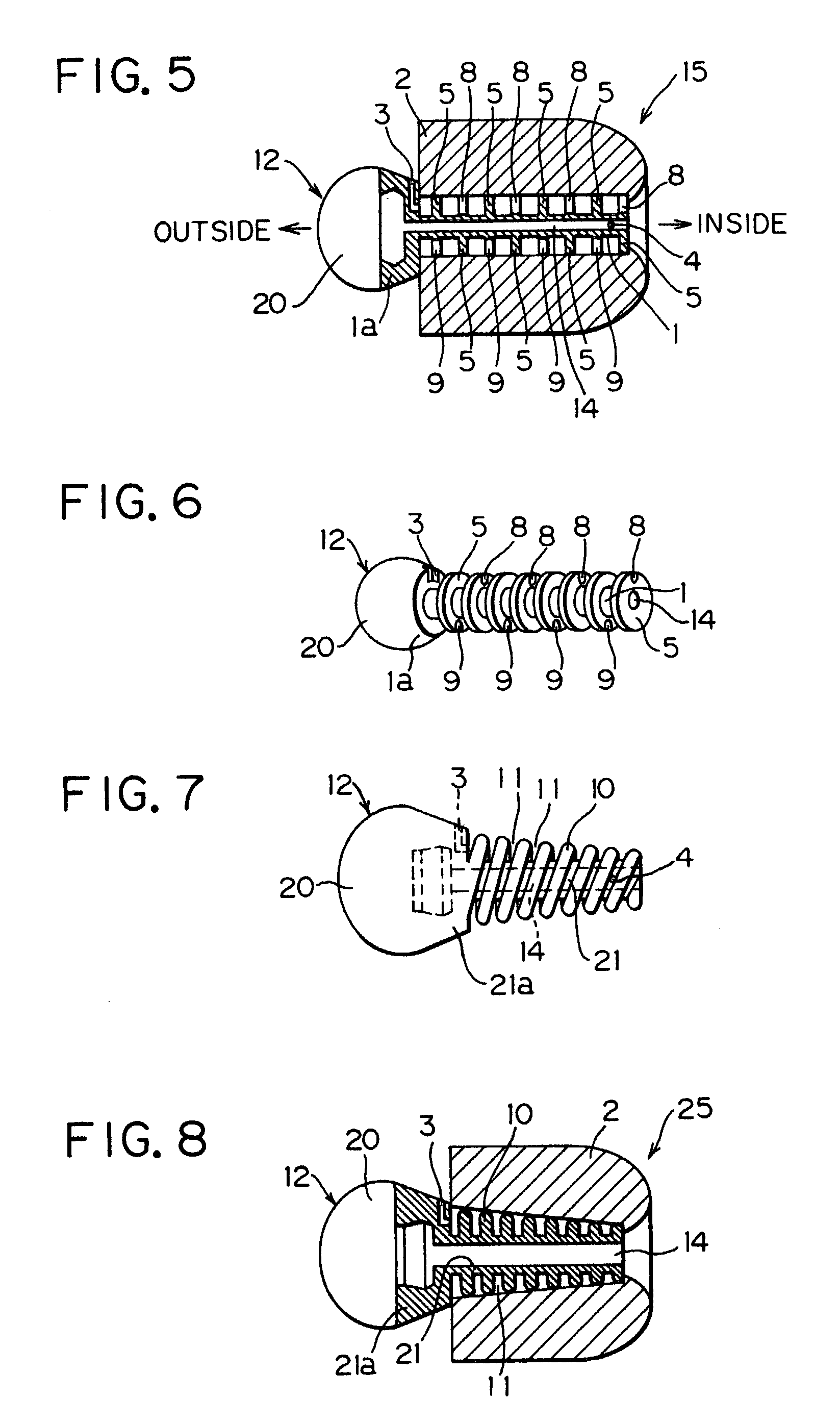

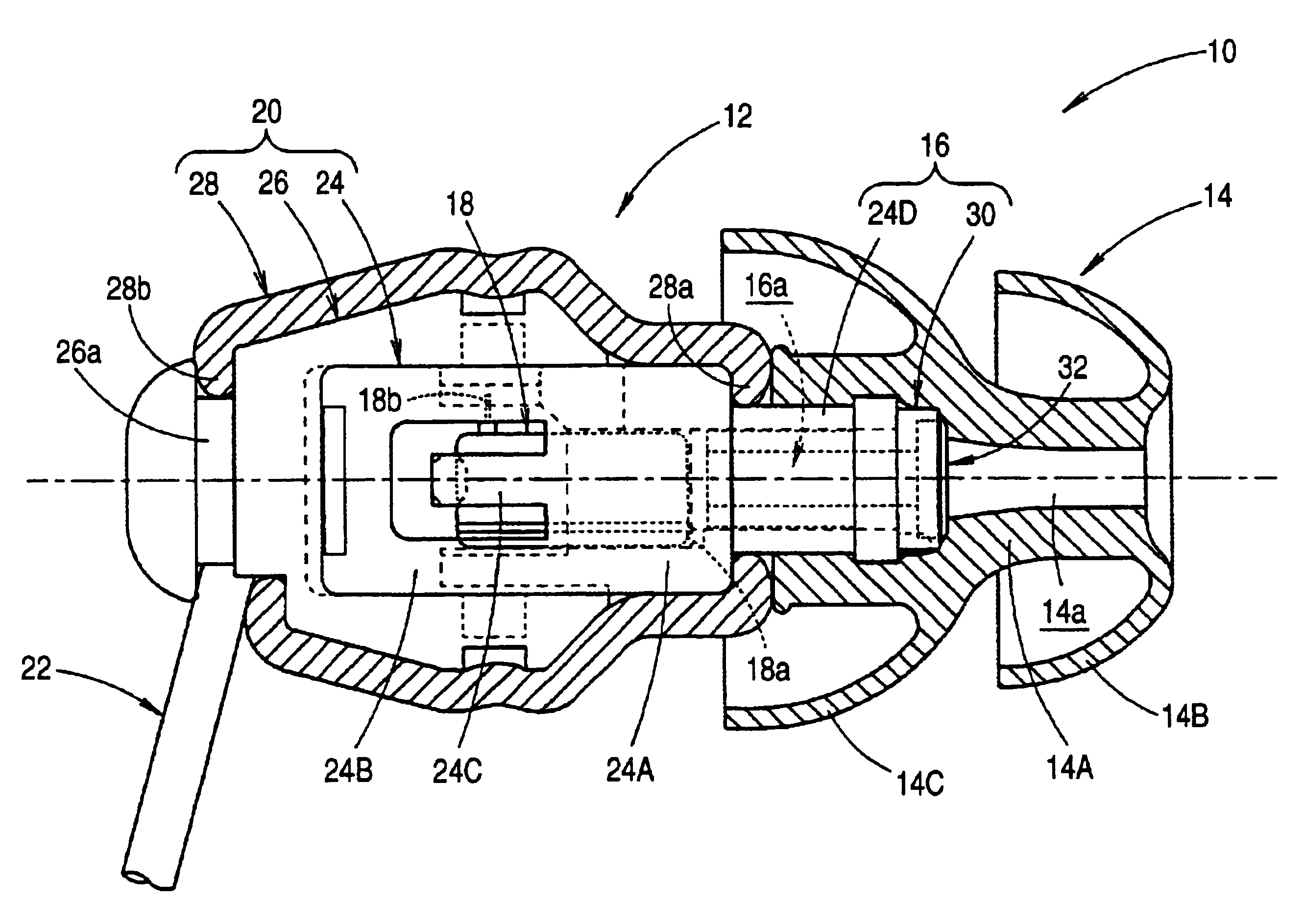

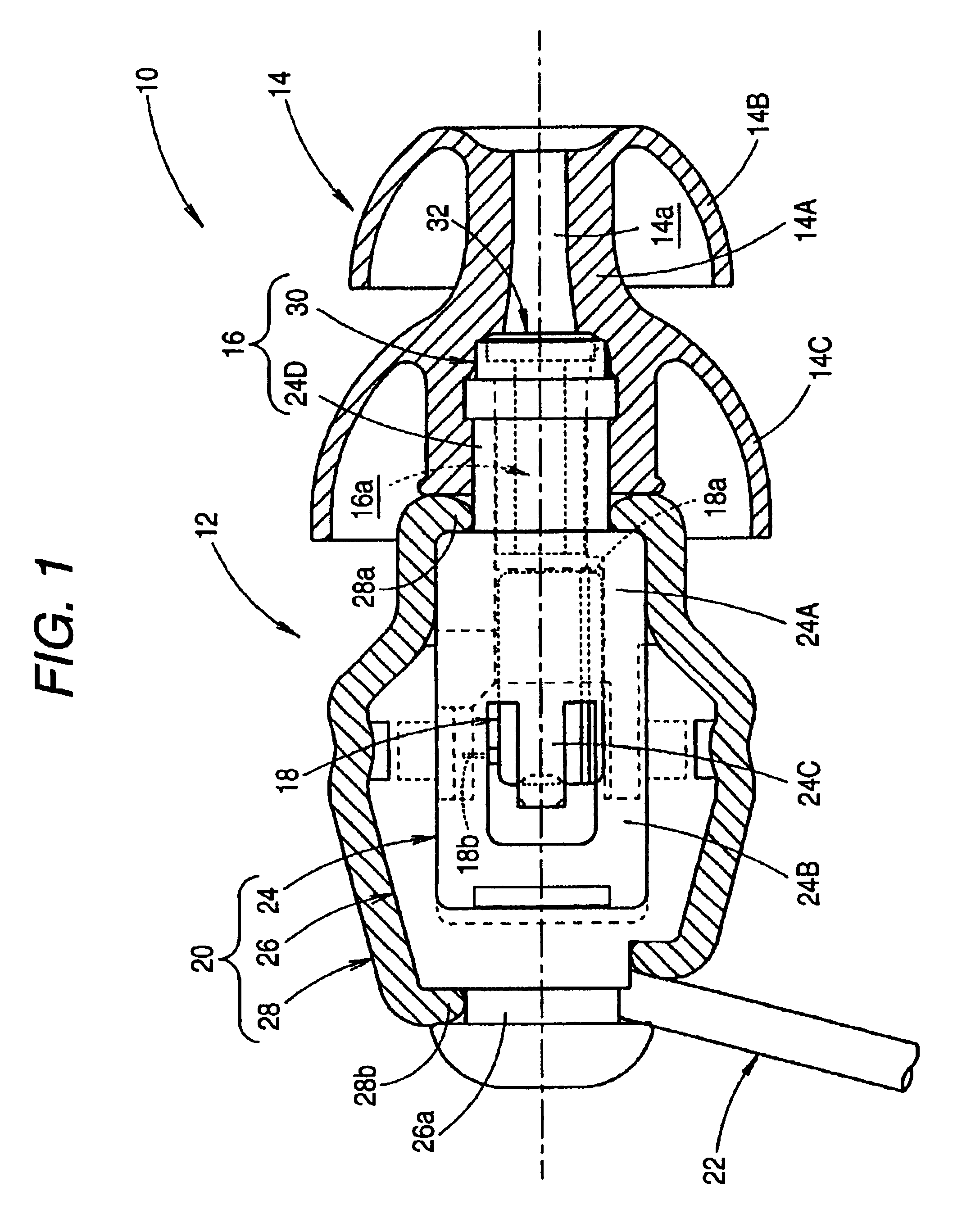

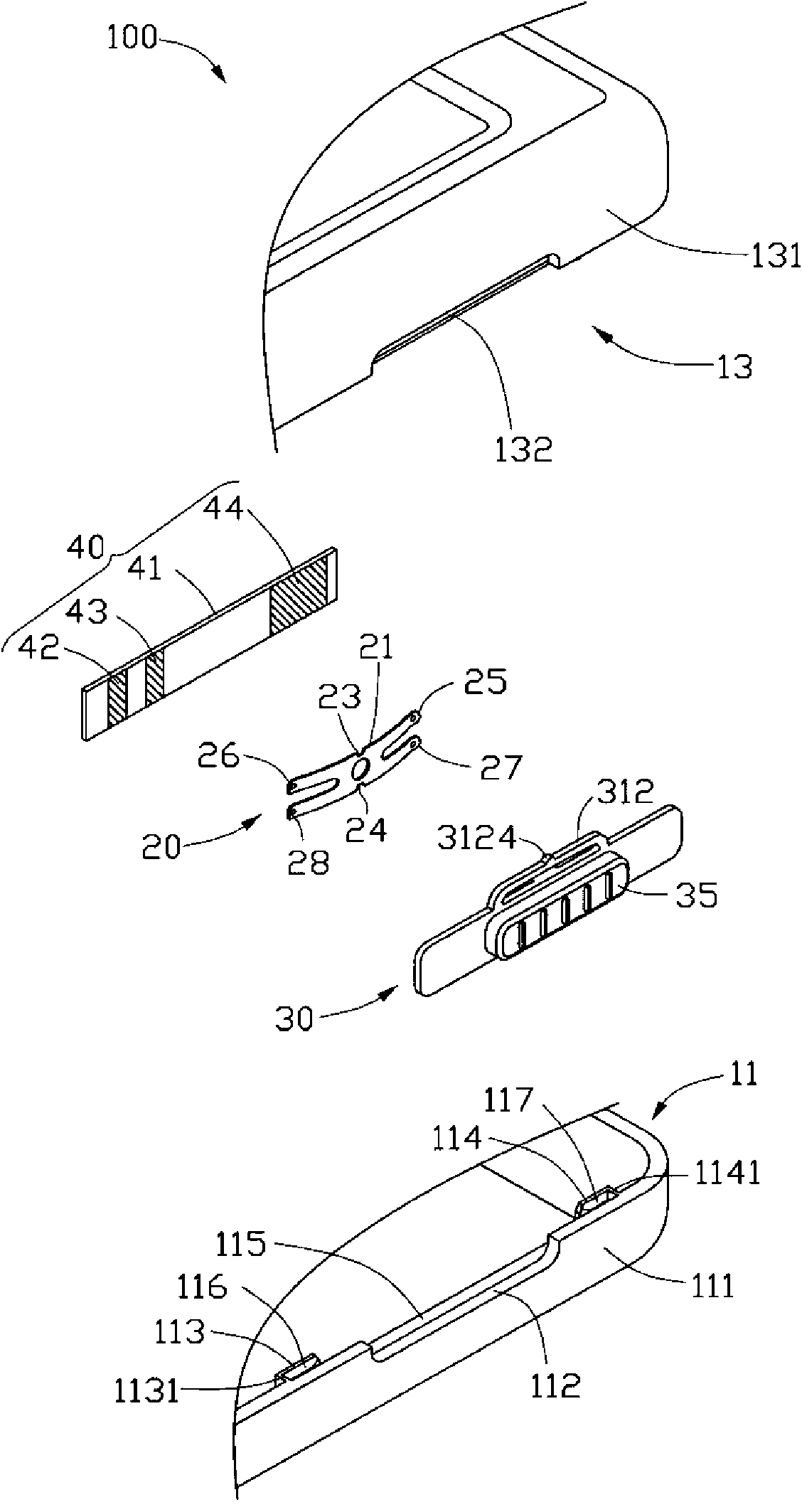

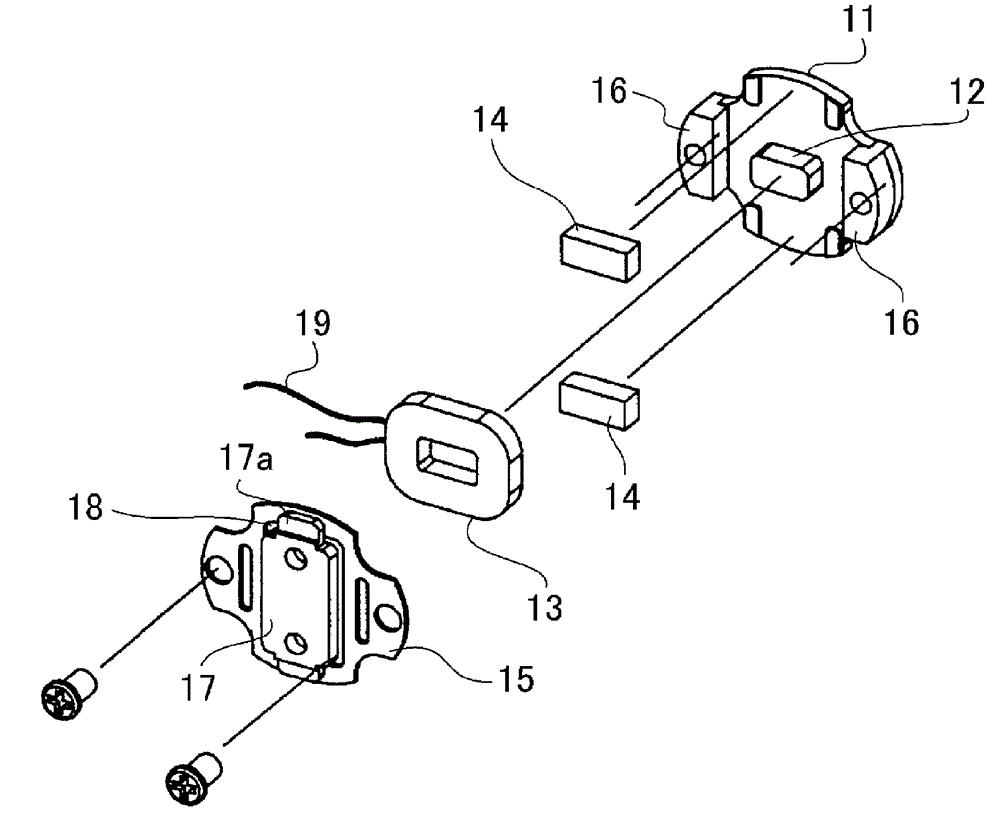

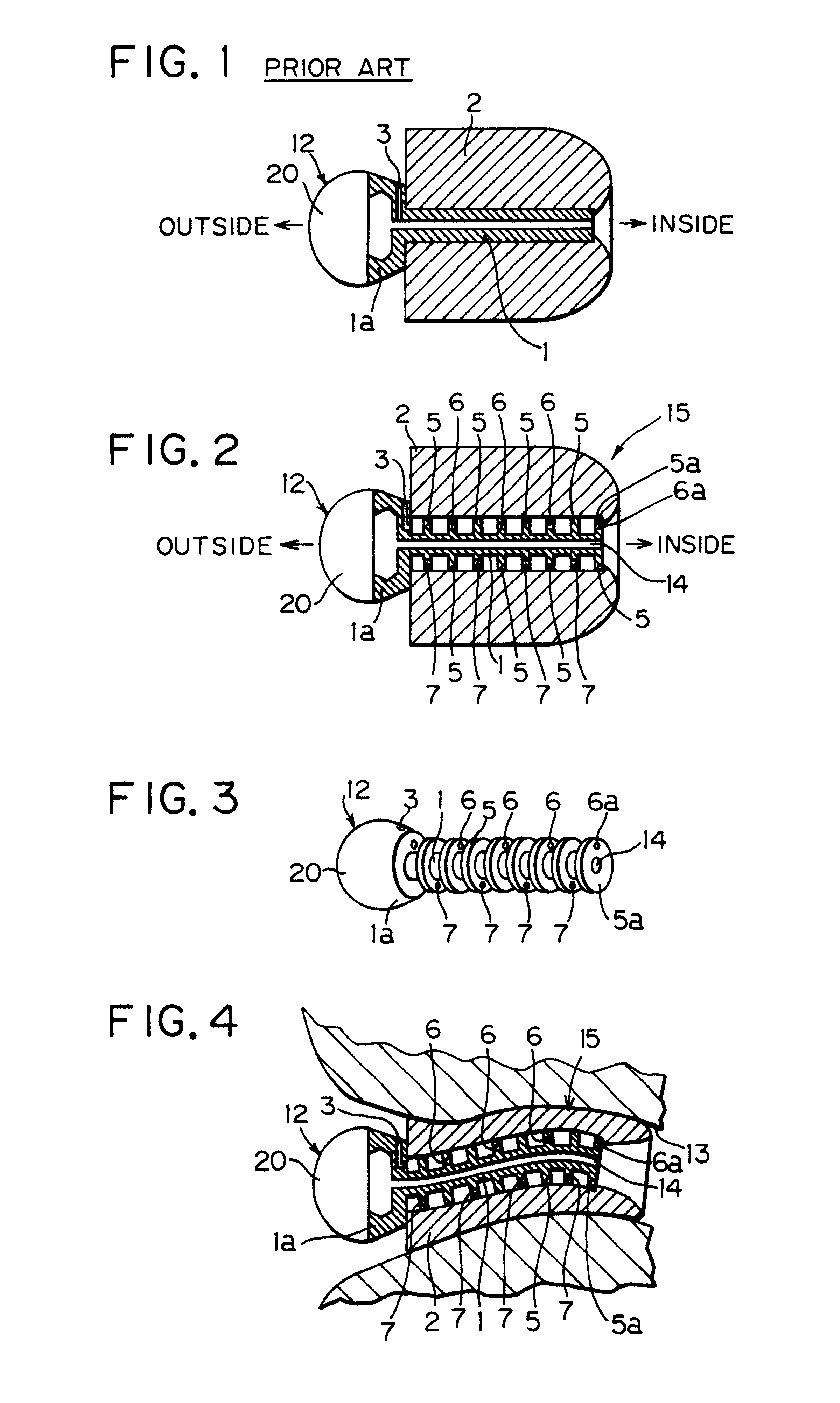

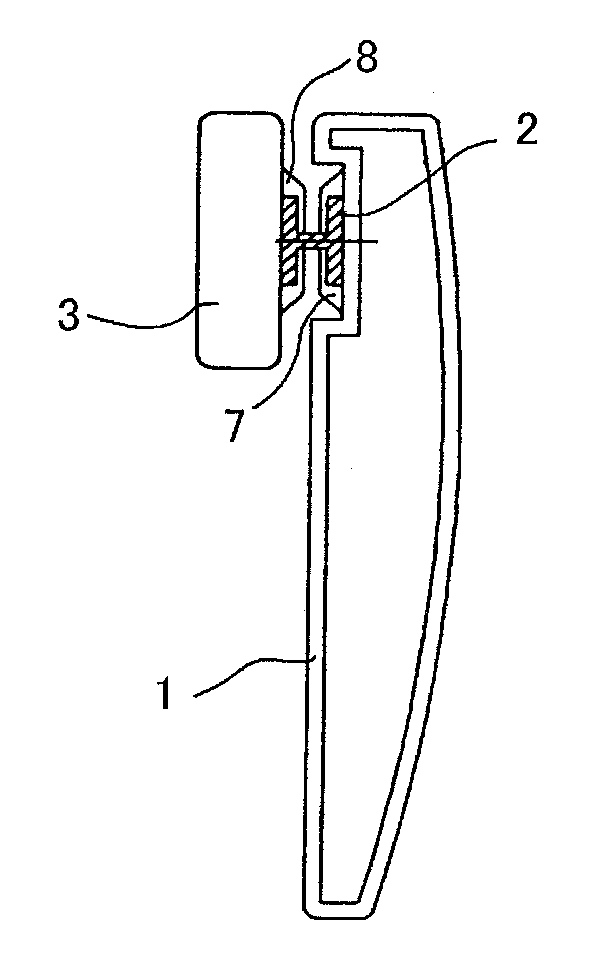

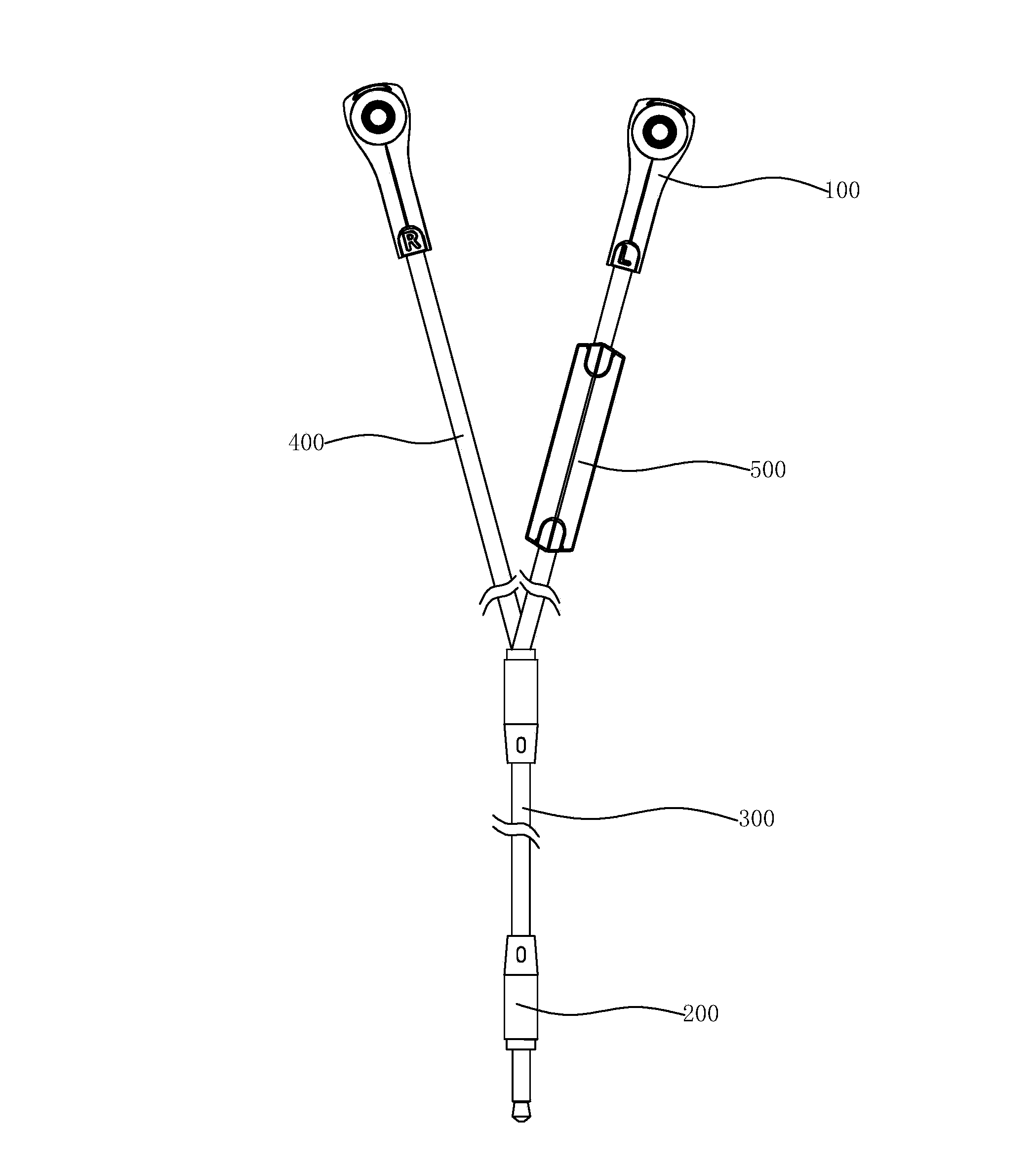

Bone-conduction handset

InactiveUS7639825B2Avoid howlingSolve easy vibrationBone conduction transducer hearing devicesTelephone set constructionsEngineeringBone conduction hearing

The object is to provide a bone-conduction handset, which has its main body (1) sufficiently isolated from a bone-conduction speaker unit (3) so that: the chances that howling and sound leaking may occur are reduced; and, the handset is improved in easiness in use. In the handset, the speaker unit (3) is mounted on the main body (1) through a speaker mounting member (2) made of a vibration-proof material. The mounting member (2) is characterized by comprising a connection portion (6), which is disposed perpendicularly to both the handset body (1) and the speaker unit (3) in a manner such that the main body (1) and the speaker unit (3) have their opposed inner surfaces disposed adjacent to opposite sides of the connection portion (6), whereby the main body (1) is isolated from the speaker unit (3).

Owner:TEMCO JAPAN

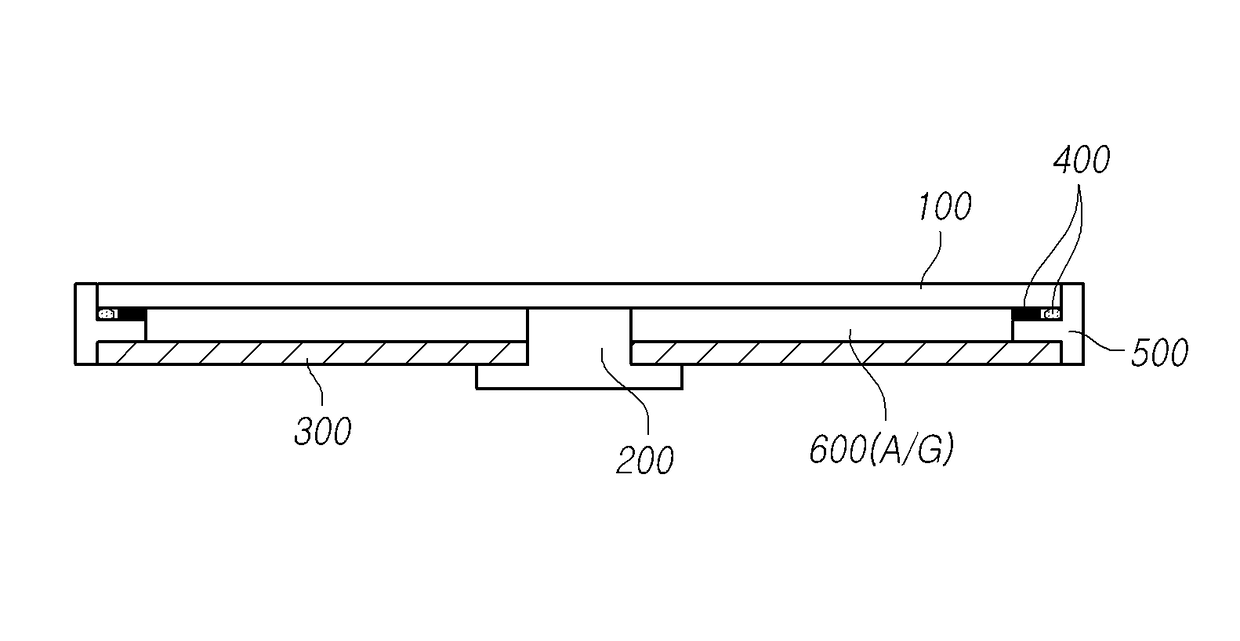

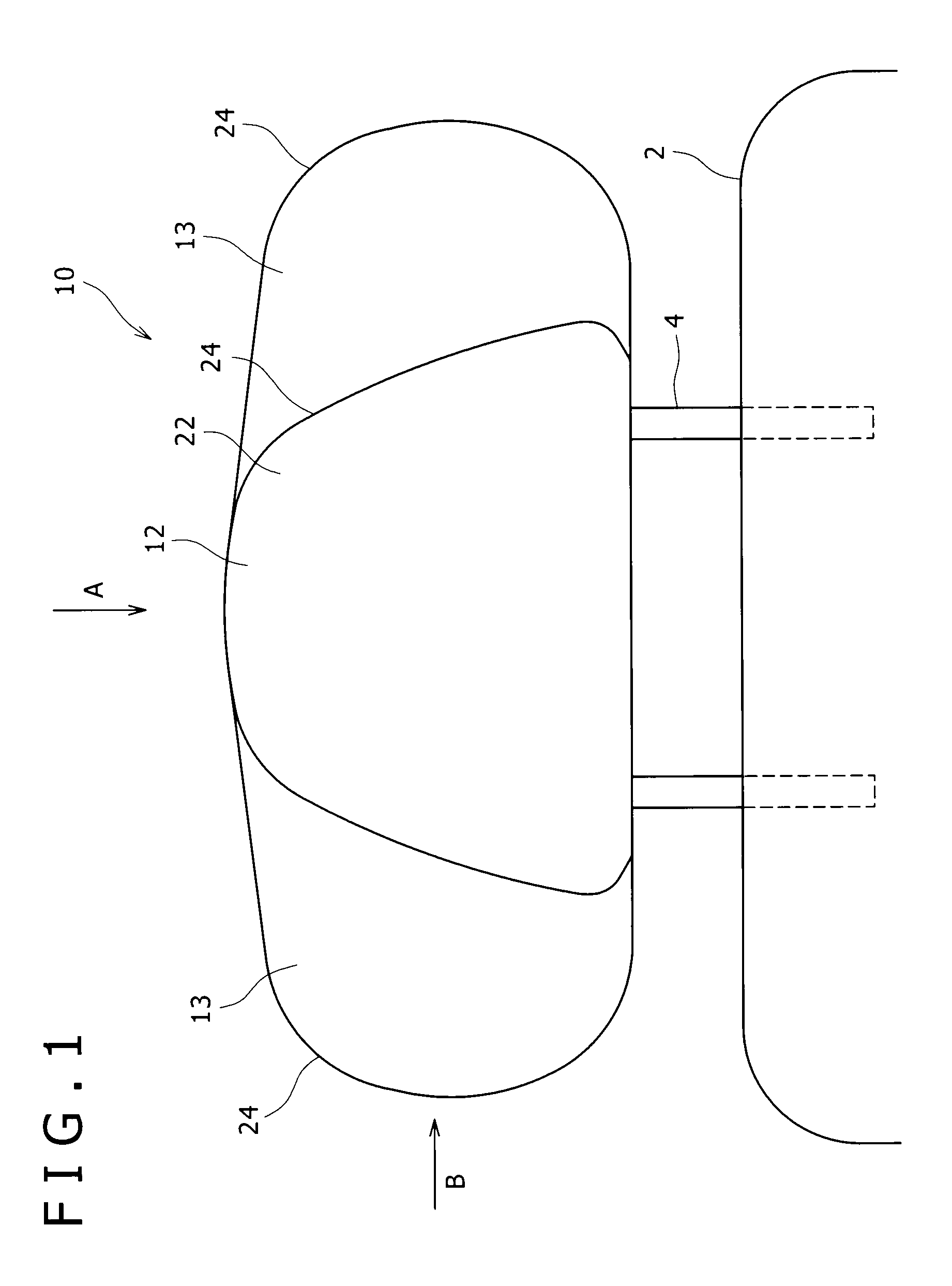

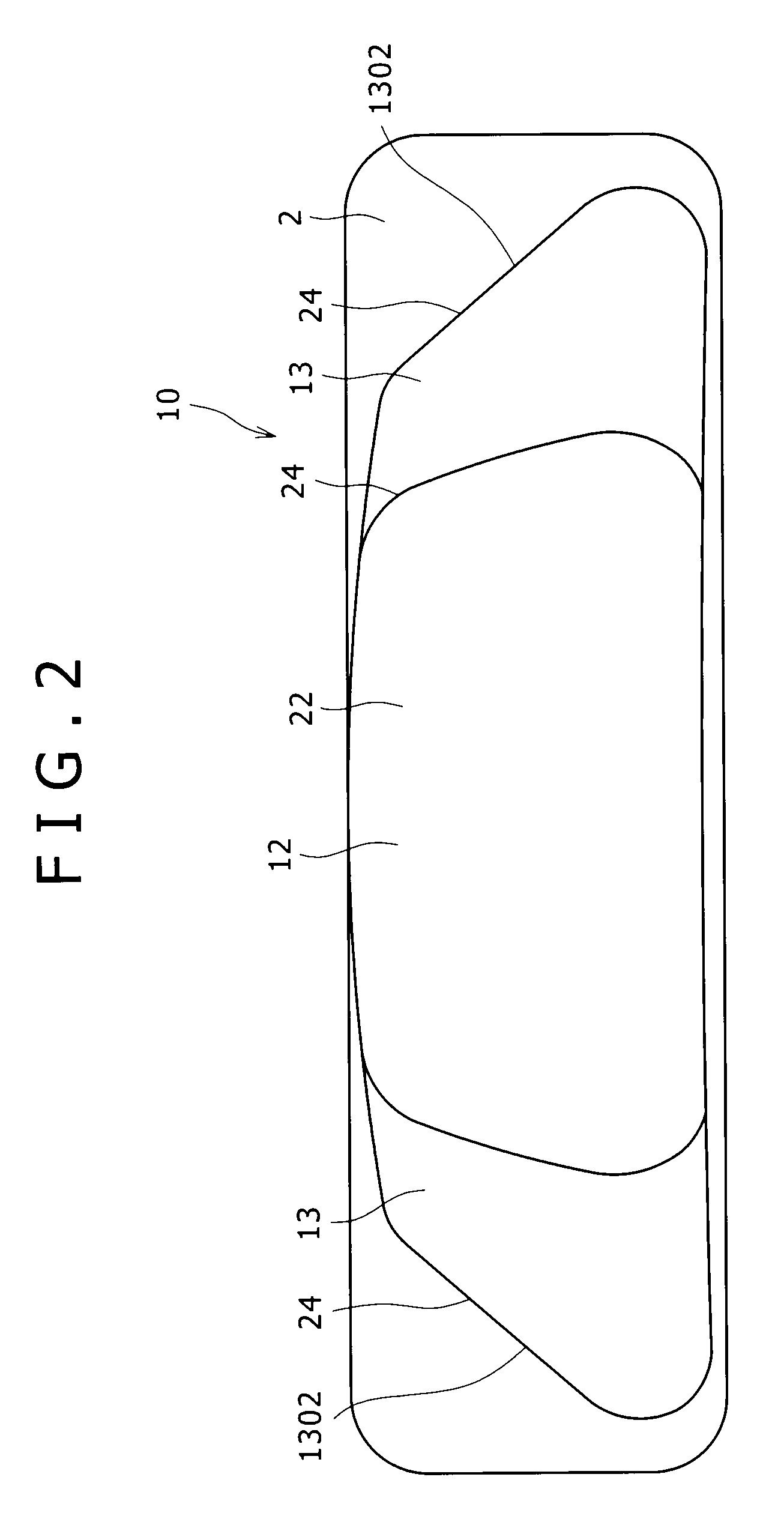

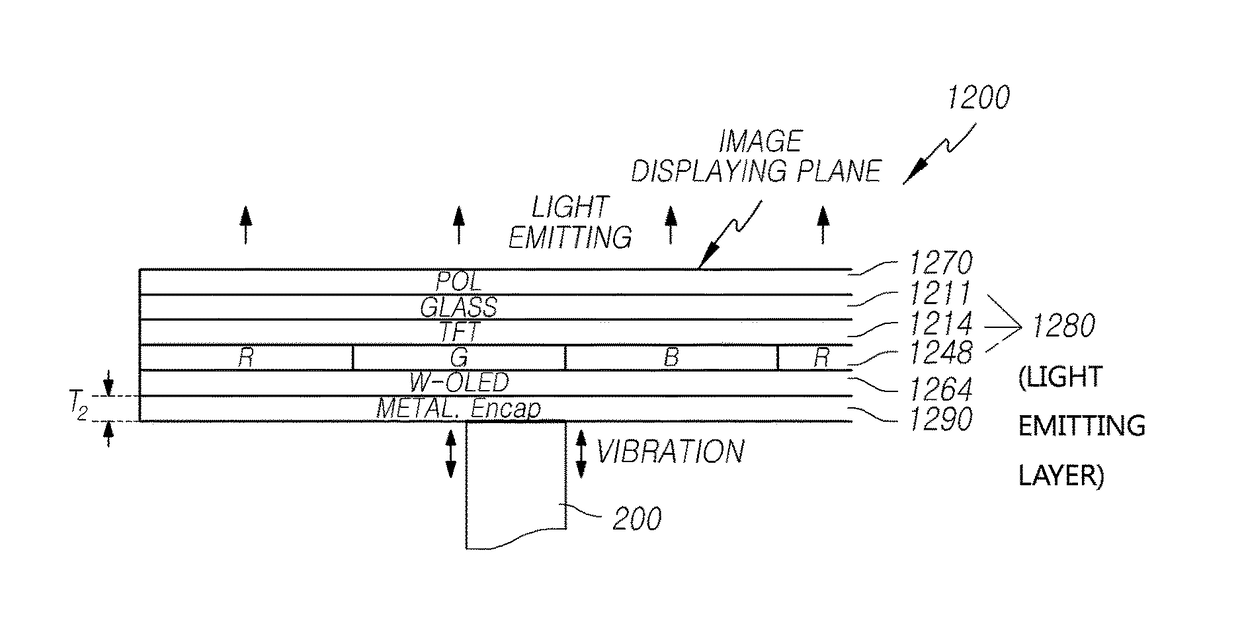

Organic light emitting display device including a sound generating apparatus

ActiveUS9818805B2Convenient ArrangementImprove sealingBending wave transducersSolid-state devicesSound generationDisplay device

Embodiments of the present disclosure relate to an organic light emitting display device which directly vibrates an organic light emitting display panel to generate sound, and includes: an organic light emitting display panel including a light emitting layer including an organic light emitting material layer and an encapsulation layer disposed at one side of the light emitting layer; and a sound generating actuator in direct contact with the organic light emitting display panel to vibrate the organic light emitting display panel to generate sound. Especially, the organic light emitting display panel is a bottom emission type device, and thus can prevent generation of a weighted color mixing phenomenon in a wide viewing angle at the time of panel vibration and reduce the thickness or weight of the panel to thereby enhance the sound generation characteristic.

Owner:LG DISPLAY CO LTD

Bone conduction speaker unit

InactiveUS9253563B2Prevent sound leakageSimple structureLoudspeaker transducer fixingBone conduction transducer hearing devicesEngineeringBone conduction hearing

Owner:TEMCO JAPAN

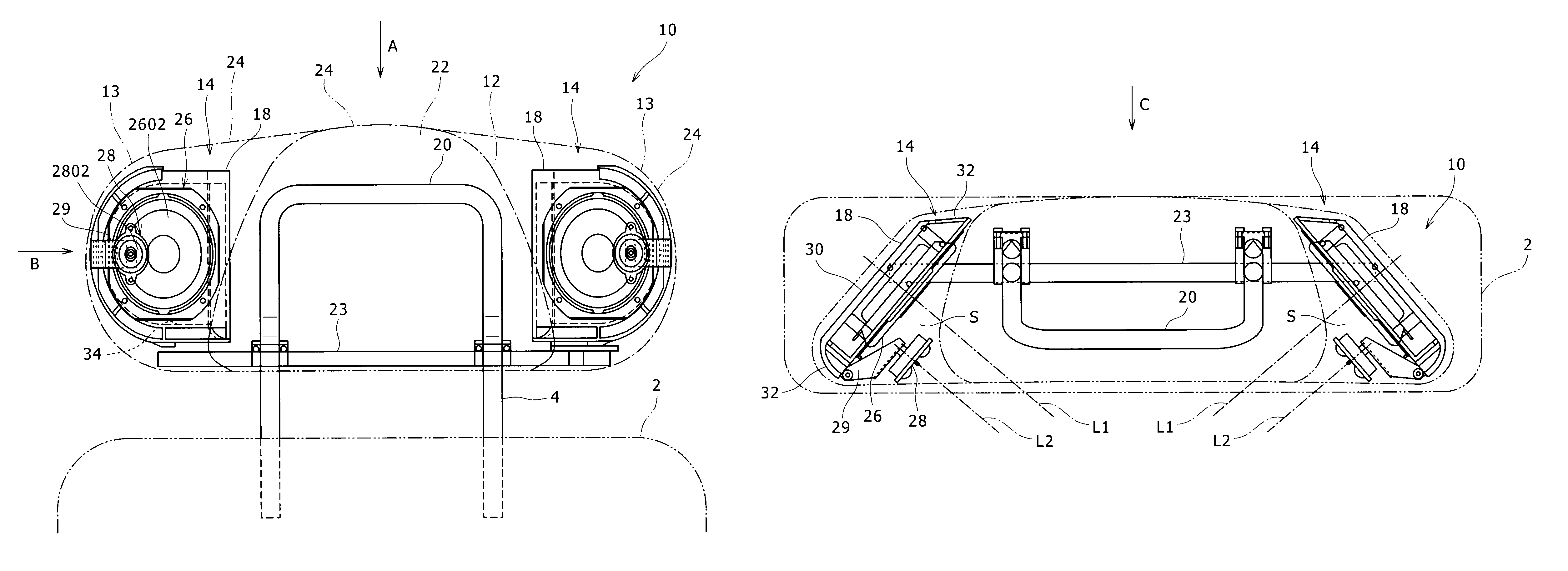

Speaker system with a plurality of openings in side walls of each of two speaker boxes

InactiveUS8130987B2Prevent sound leakageImprove sound qualityTransmissionFrequency/directions obtaining arrangementsEngineeringLoudspeaker

Owner:SONY CORP

Bone-conduction speaker device

InactiveUS20070053530A1Improve reliabilityPrevent sound leakagePillowsLoudspeaker transducer fixingLoudspeakerEngineering

It is aimed to provide a bone-conduction speaker device which makes no leakage of sound annoying the other and does not restrict posture and rolling-over motion of the user when lying on a bed or sitting on a sofa, and which makes highly reliable and excellent transmission and receiving of sound signal as to enable enjoying of music or the like with almost no locational restrictions. The speaker device comprises: a transmitter converting the inputted sound signal into output of infrared signal and then transmitting it; a receiver demodulating the inputted infrared signal into the sound signal; a bone-conduction speaker amplifying the sound signal and outputting it as sound vibration; and a pad-shaped elastic cushioning body holding on its surface the bone-conduction speaker, thereby forming a pad embedded with the bone-conduction speaker(s). Photo-acceptors for the receiver are arranged on fringe of the cushioning body as spaced apart to each other.

Owner:TOSHIBA HA PROD

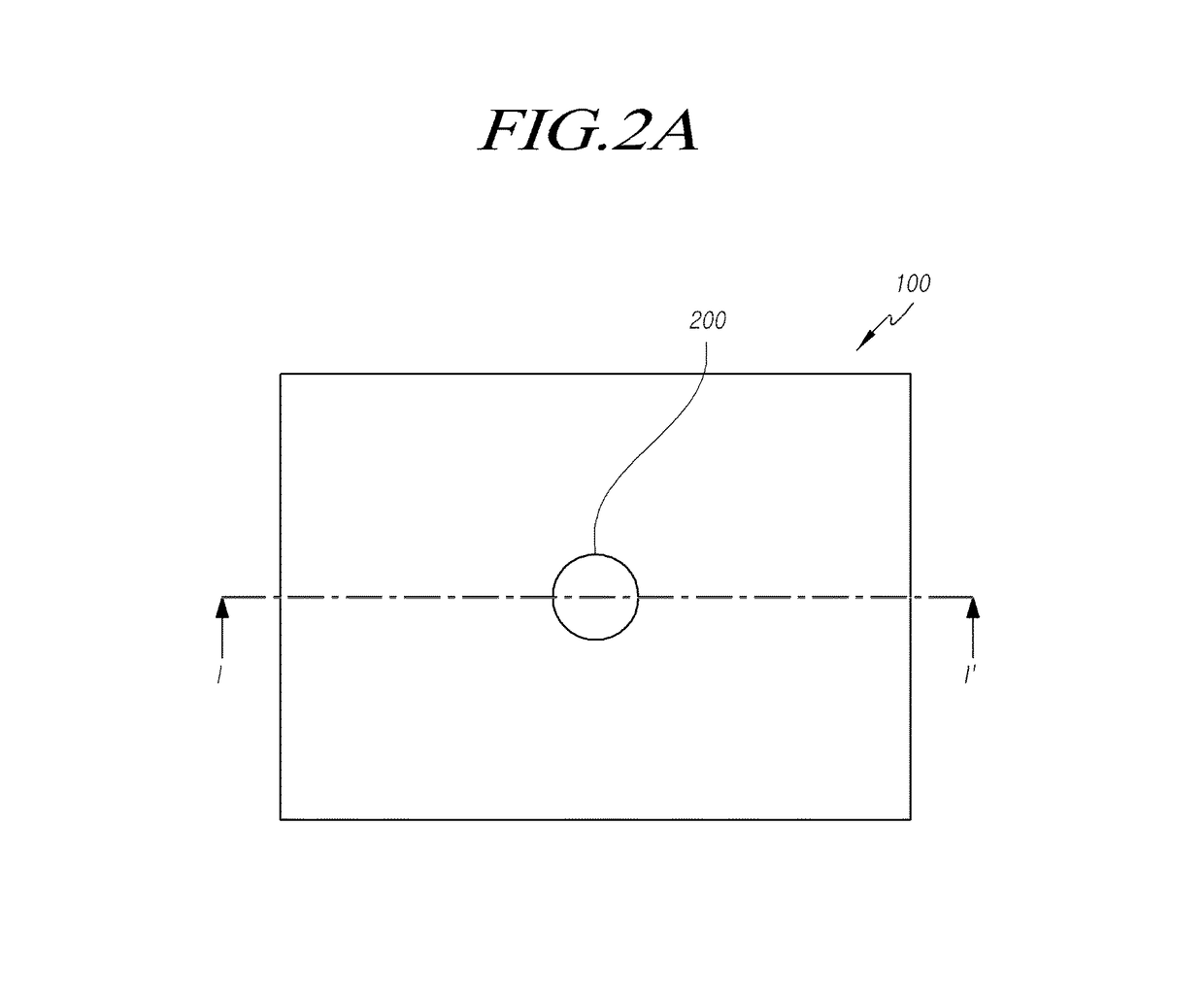

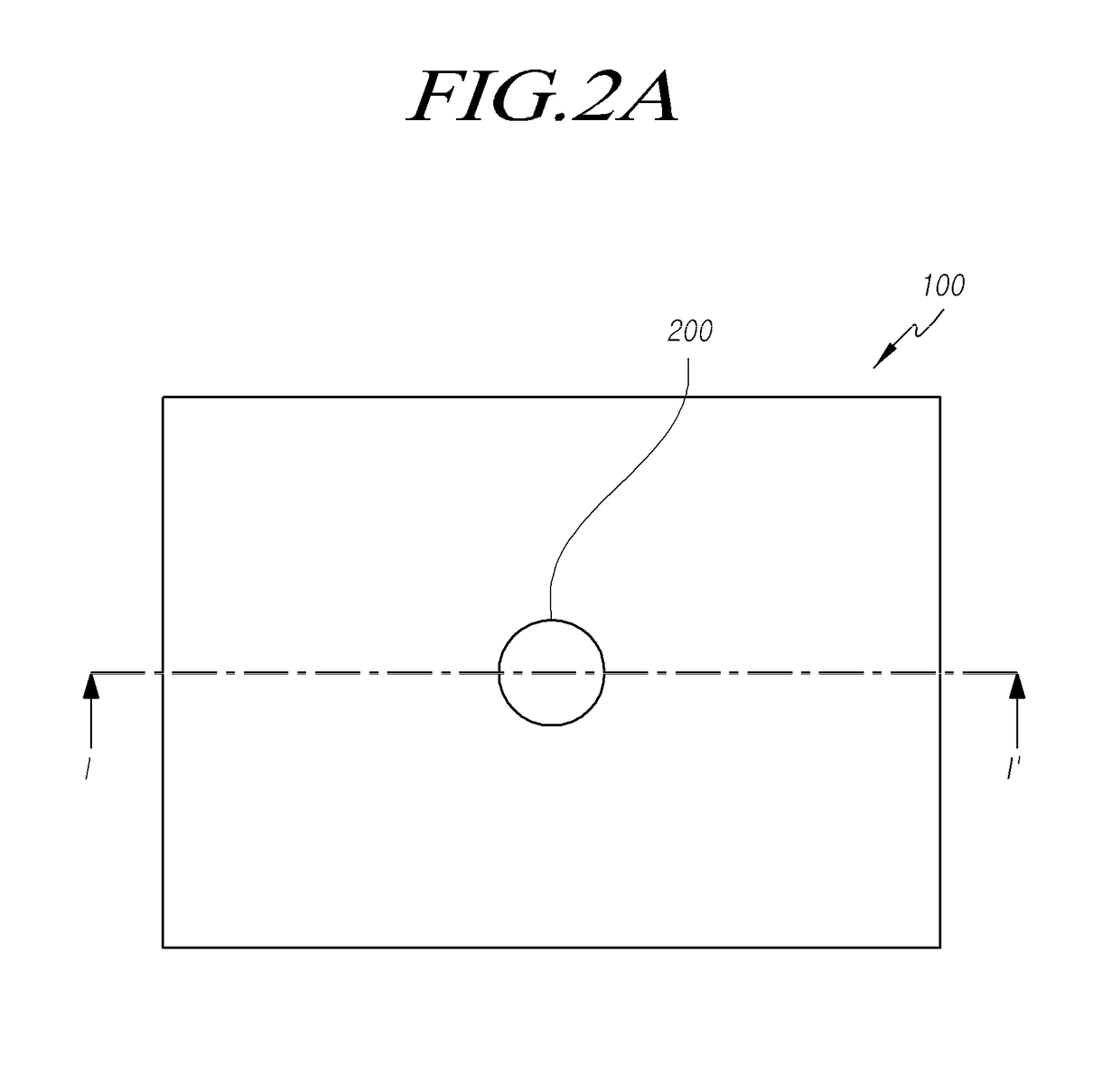

Organic light emitting display device including a sound generating apparatus

ActiveUS20170287990A1Convenient ArrangementImprove sealingPolymeric diaphragmsLoudspeakersSound generationDisplay device

Embodiments of the present disclosure relate to an organic light emitting display device which directly vibrates an organic light emitting display panel to generate sound, and includes: an organic light emitting display panel including a light emitting layer including an organic light emitting material layer and an encapsulation layer disposed at one side of the light emitting layer; and a sound generating actuator in direct contact with the organic light emitting display panel to vibrate the organic light emitting display panel to generate sound. Especially, the organic light emitting display panel is a bottom emission type device, and thus can prevent generation of a weighted color mixing phenomenon in a wide viewing angle at the time of panel vibration and reduce the thickness or weight of the panel to thereby enhance the sound generation characteristic.

Owner:LG DISPLAY CO LTD

Ear plug to be inserted into the external auditory canal

An ear plug to be inserted into the external auditory canal, having a compressible sleeve member and a core member attached therein, the improvement in which plural projections or a single projection are formed intermittently or continuously on an exterior of the core member, and vent is formed through or along the projection to make the external auditory canal communicate with the external atmosphere when inserted into the external auditory canal. A communicating passage or vent to an effective degree for remarkably decreasing the pressure difference between the inside of the external auditory canal and the external atmosphere as well as preventing leakage of sound causing so-called howling.

Owner:MIMY ELECTRONICS

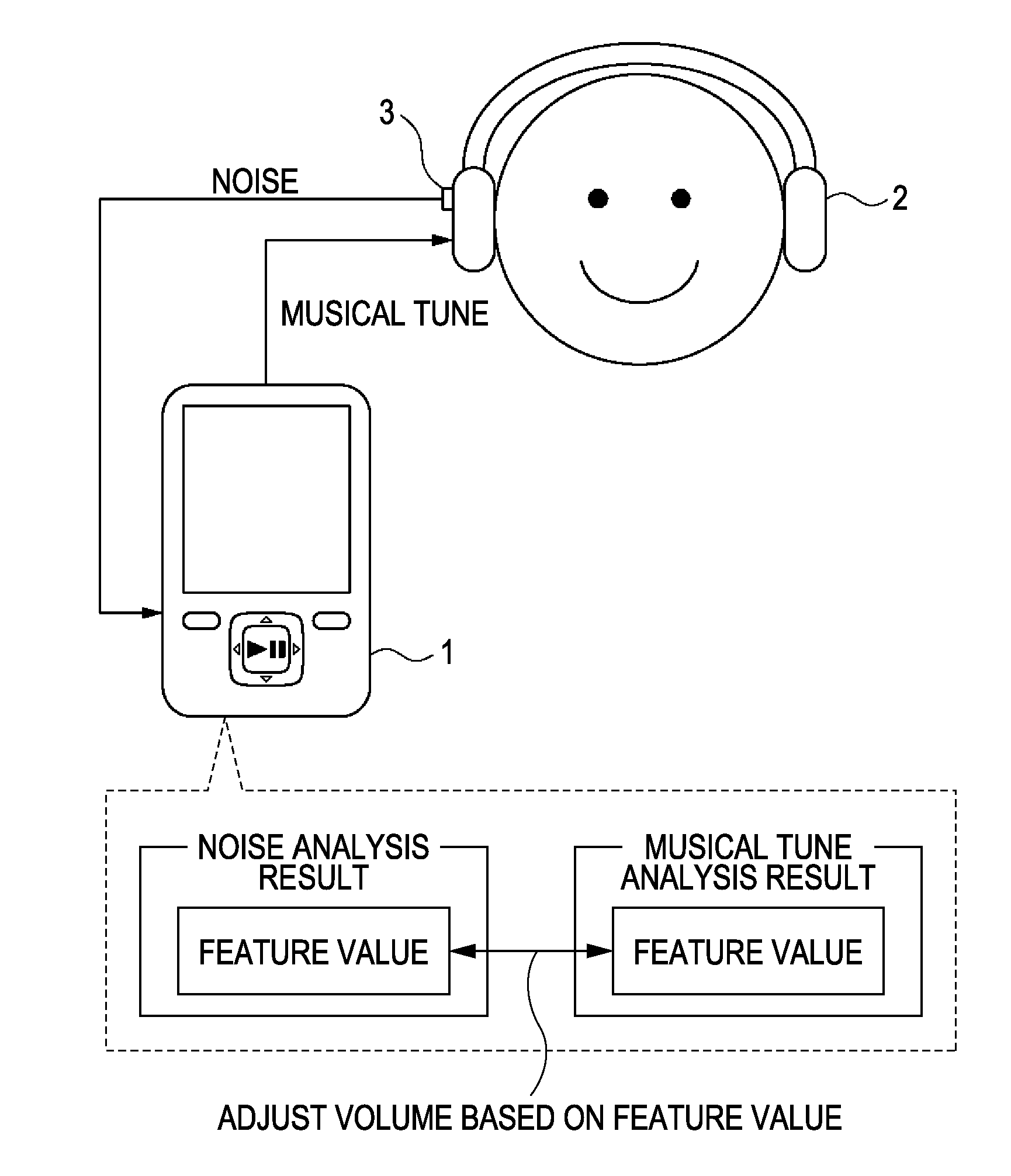

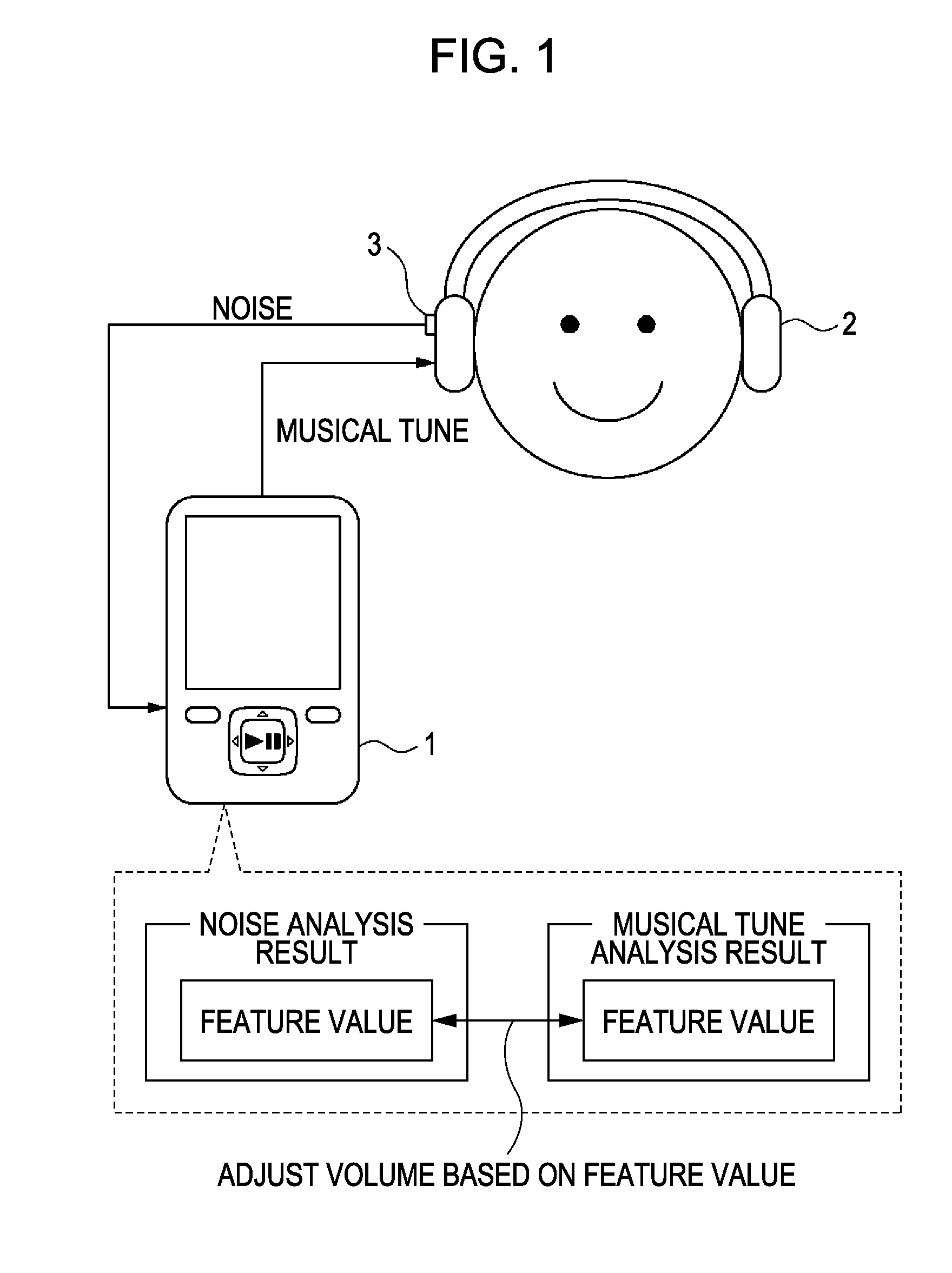

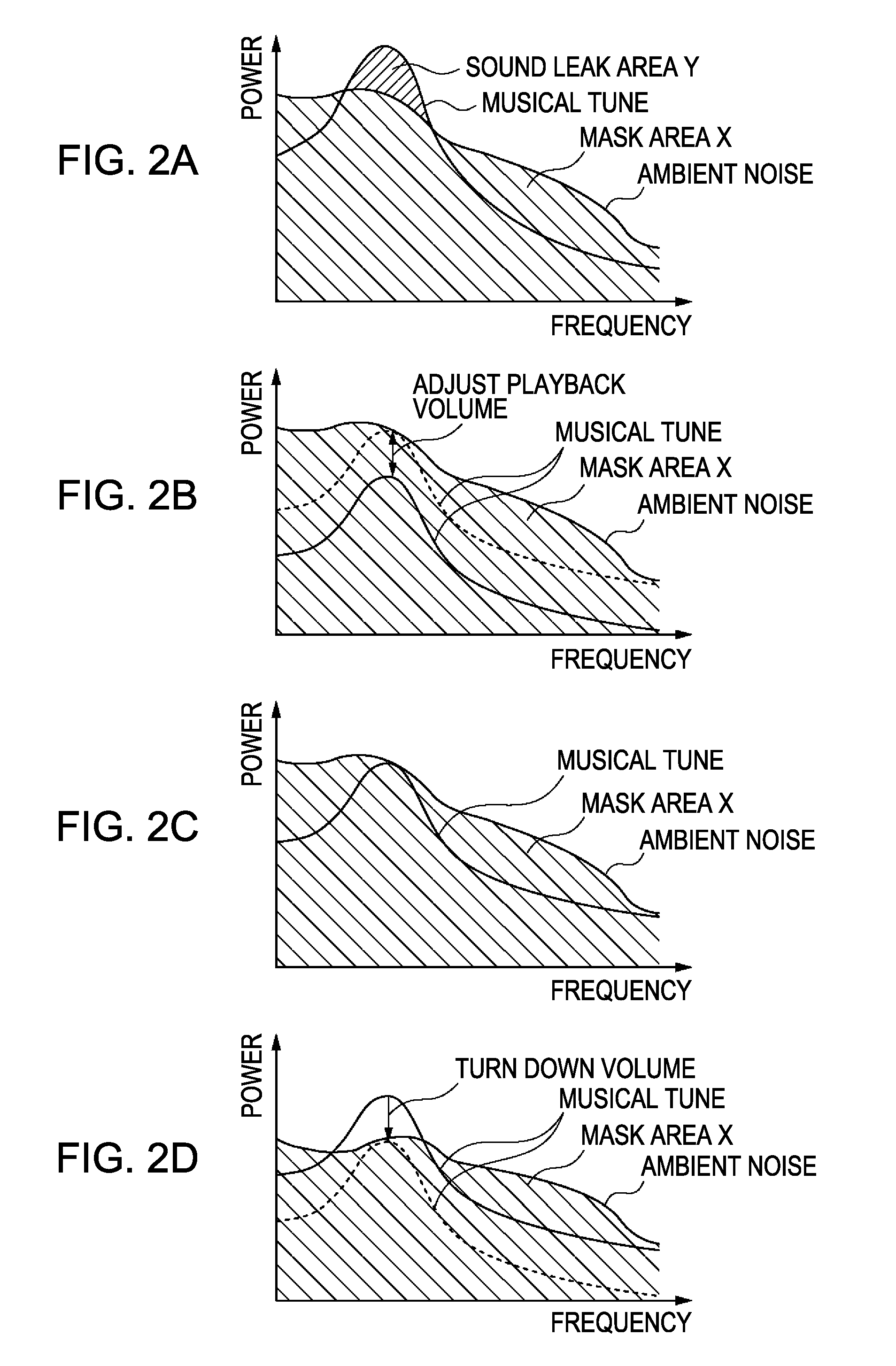

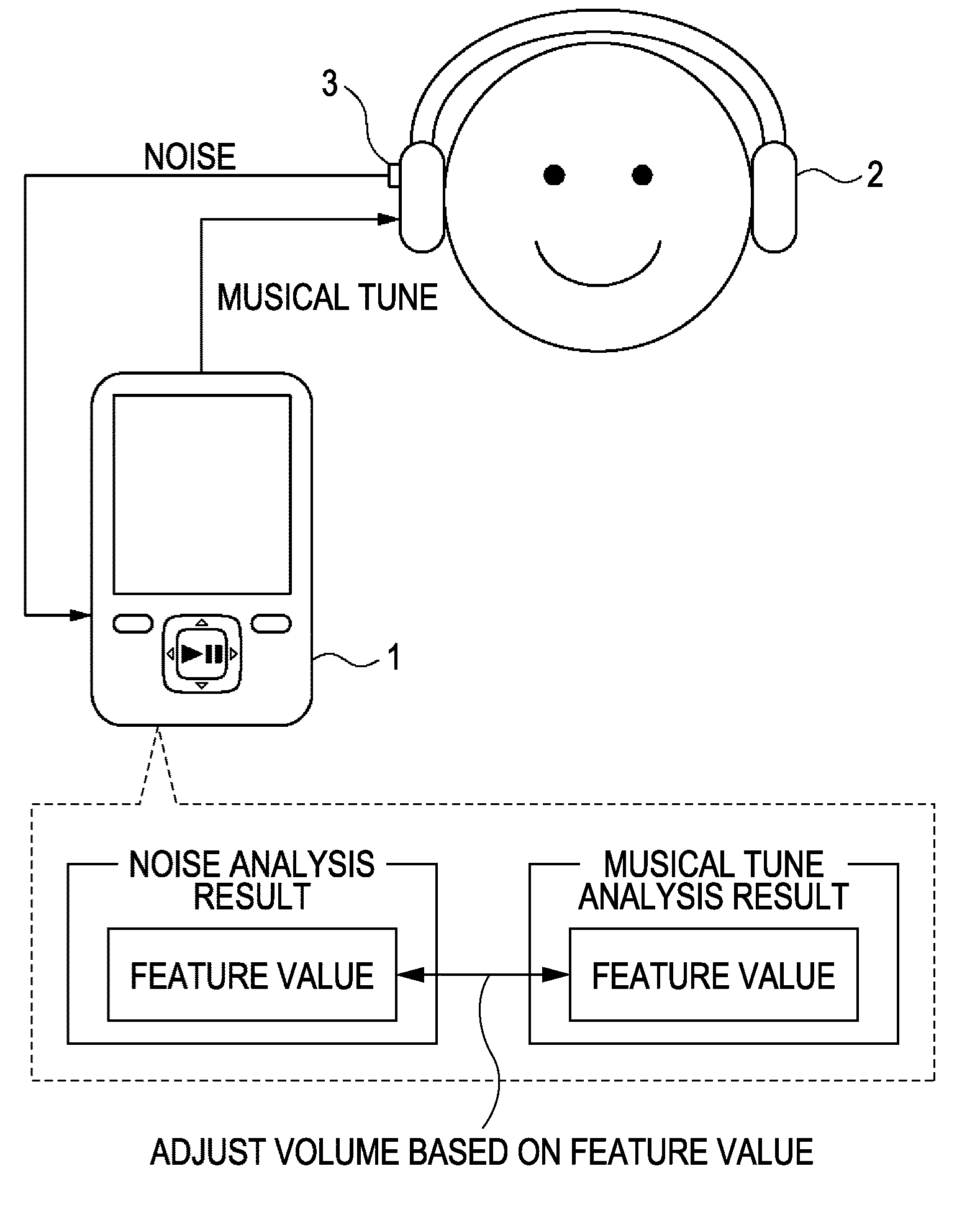

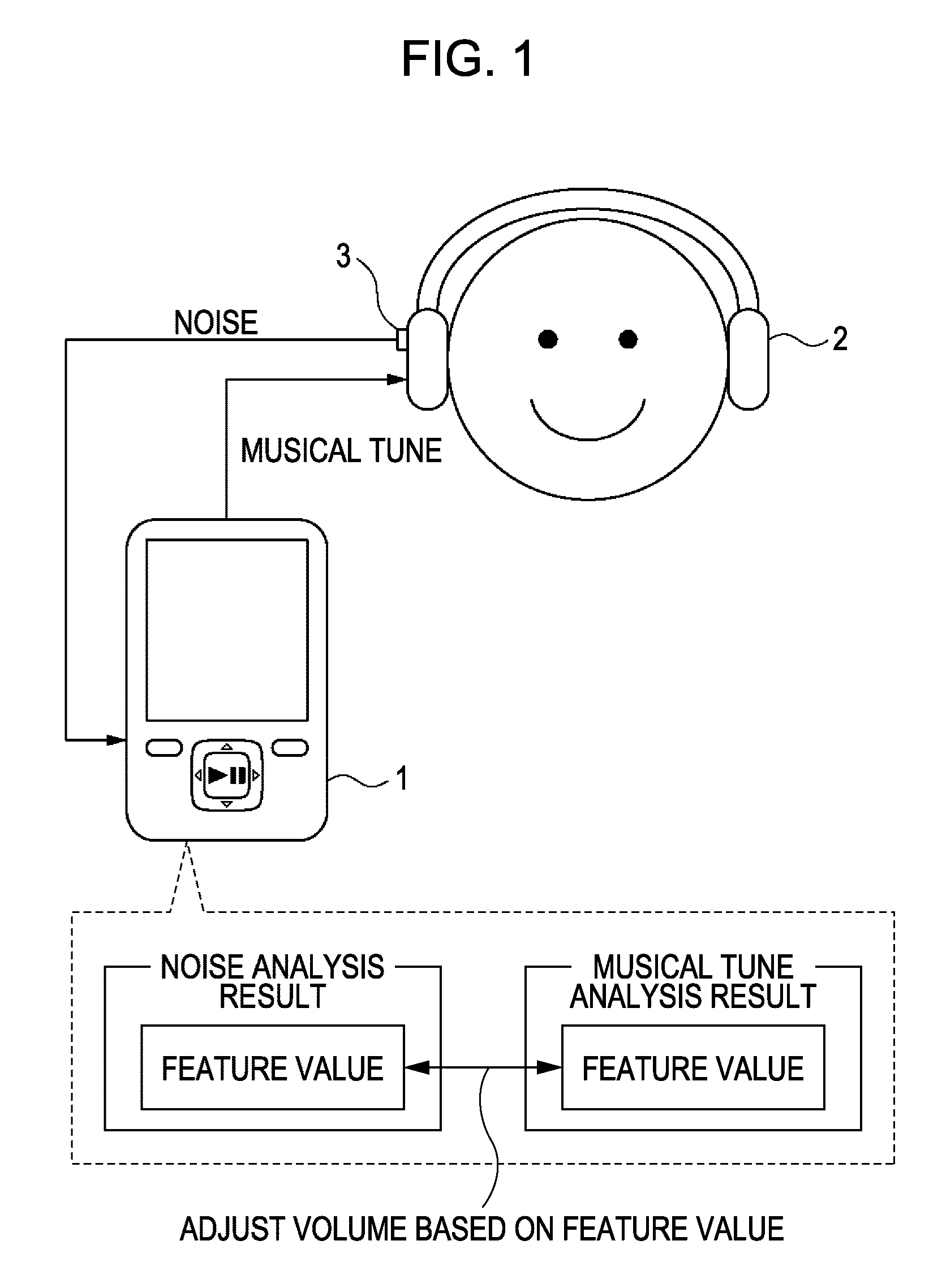

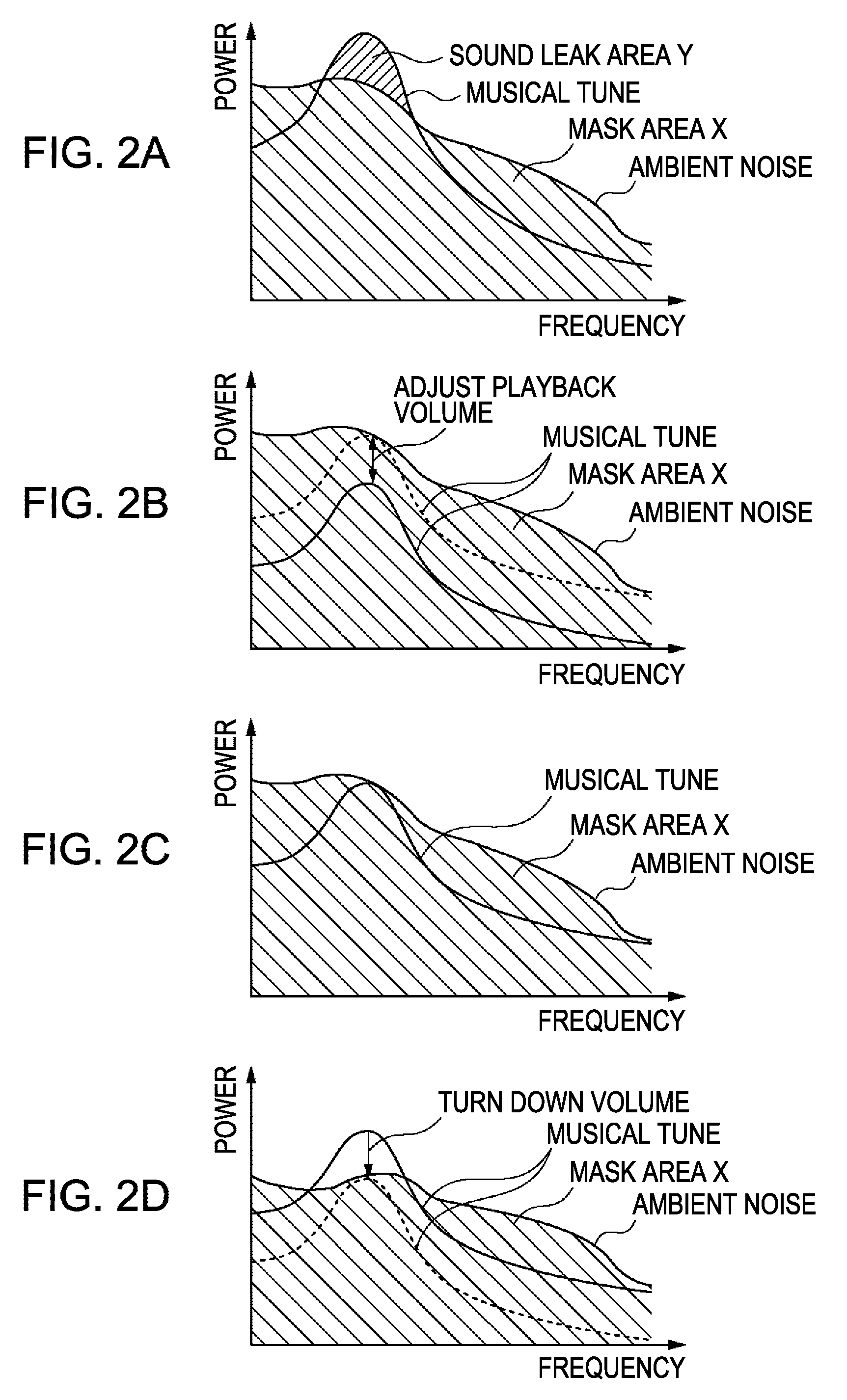

Volume adjusting apparatus and volume adjusting method

InactiveUS20100005953A1Easy to solvePrevent sound leakageElectrophonic musical instrumentsSignal processingComputer scienceControl unit

A volume adjusting apparatus includes a sound collecting unit configured to collect noise data of a surrounding environment, an analyzing unit configured to extract a feature value indicating a feature of the noise data collected by the sound collecting unit and a feature value indicating a feature of supplied musical tune data, and a control unit configured to generate volume adjustment information for adjusting playback volume of the musical tune data based on the feature value of the noise data and the feature value of the musical tune data and adjusts the playback volume of the musical tune data based on the volume adjustment information.

Owner:SONY CORP

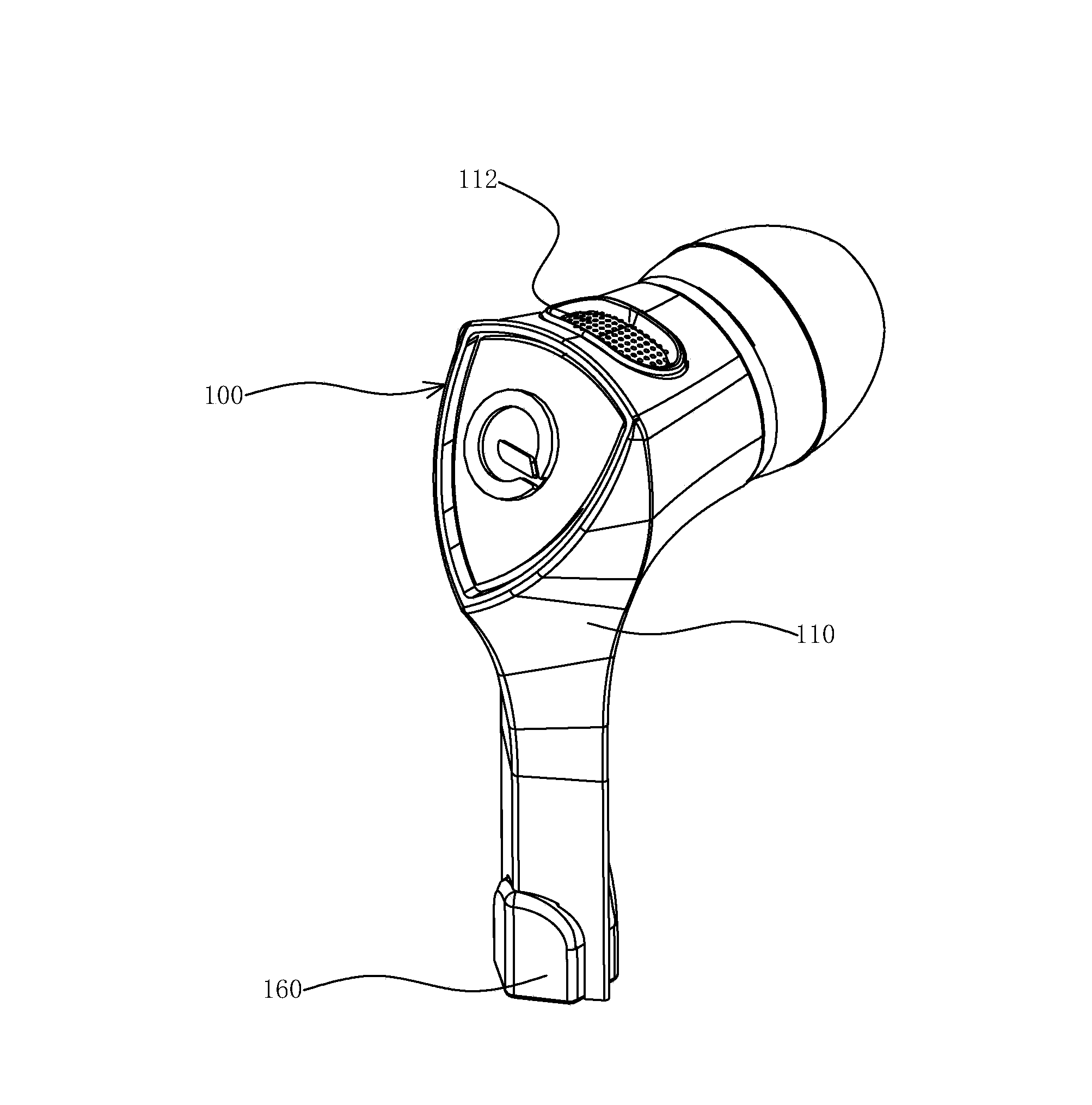

Insert earphone

InactiveUS6931142B2Prevent sound leakageImprove comfortEar supported setsIntra aural earpiecesEngineeringRing doughnut

An insert earphone which prevents a sound leakage and improves wearing comfort. An ear chip has a barrel portion and first and second annular flange portions having the shape of a parabola spreading from the top toward the middle and from the middle toward the base of the barrel portion respectively. The first annular flange portion has a smaller outer diameter than the second annular flange portion. The first annular flange portion has almost even thickness from the inner circumference to the outer circumference, and has the inner circumference neighborhood substantially formed in the shape of a sliced doughnut.

Owner:STAR MICRONICS

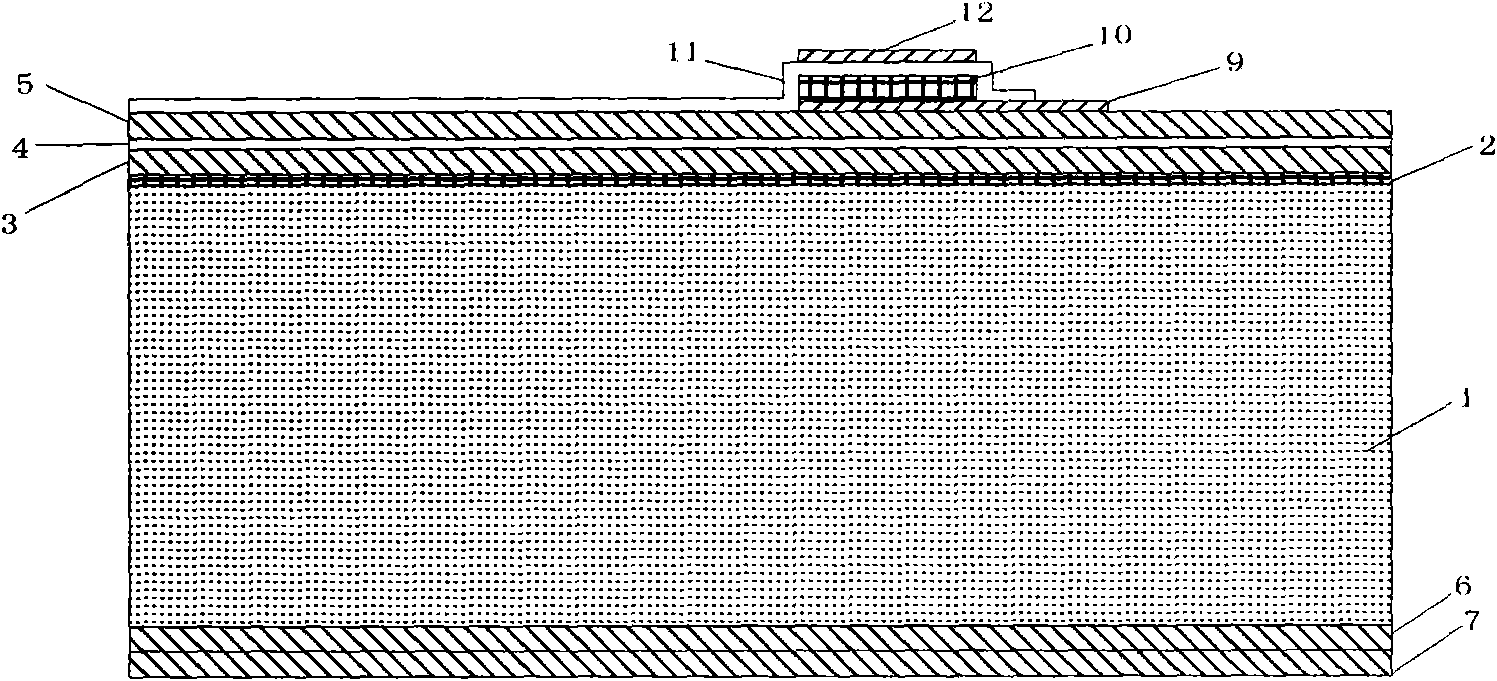

Soft support bridge type silicon micro-piezoelectric ultrasonic transducer chip and prepration method thereof

InactiveCN101645484AHigh sensitivityGood process compatibilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionVertical projectionUltrasonic sensor

The invention relates to a soft support bridge type silicon micro-piezoelectric ultrasonic transducer chip which comprises a silicon substrate with a square conical hole which is small at the top andbig at the bottom in the center; a silicon layer and a first oxidation layer are sequentially covered on the front surface of the silicon substrate, and a second oxidation layer is covered on the backsurface; the corresponding silicon layer and the first oxidation layer above the square hole of the front surface of the silicon substrate constitute a square vibration membrane, one pair of oppositesides of the square vibration membrane respectively etch a vertical narrow slot, and the vertical projection of each narrow slot is positioned on the inner side of the hole edge above the front surface of the silicon substrate; a lower electrode, a piezoelectric membrane and an upper electrode are sequentially deposited on the square vibration membrane; a polyimide membrane is deposited on various parts on the front surface of the silicon substrate; and the square vibration membrane which is etched with the vertical narrow slots and the polyimide membrane commonly constitute a soft support anti-sound leakage bridge type vibration membrane. The anti-sound leakage bridge type structure is used on the vibration membrane of the transducer; in order to avoid sound leakage through the narrow slots, the soft polyimide membrane is deposited on the narrow slots, which has little effect on vibration of the vibration membrane and can still keep high sensitivity.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

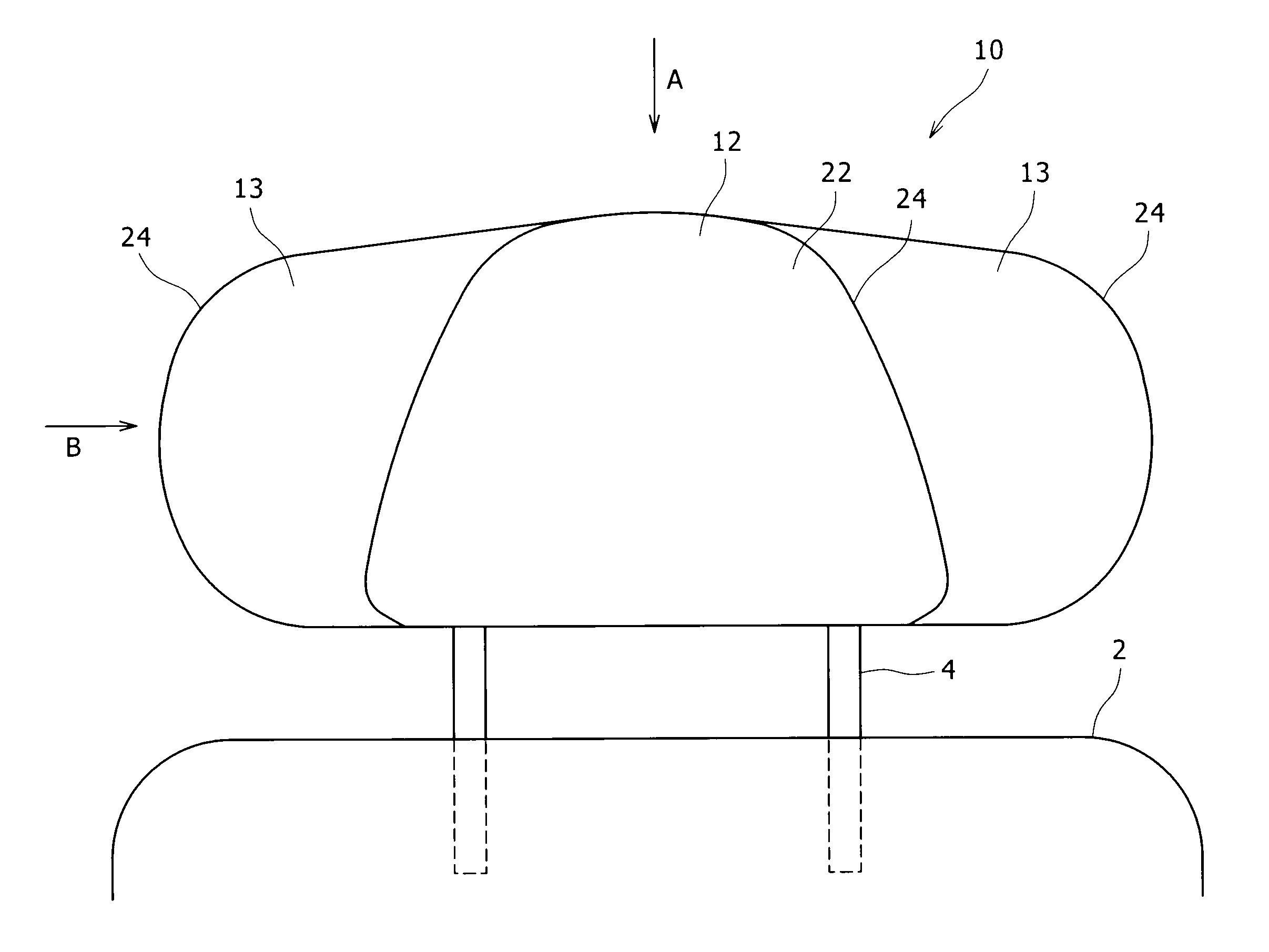

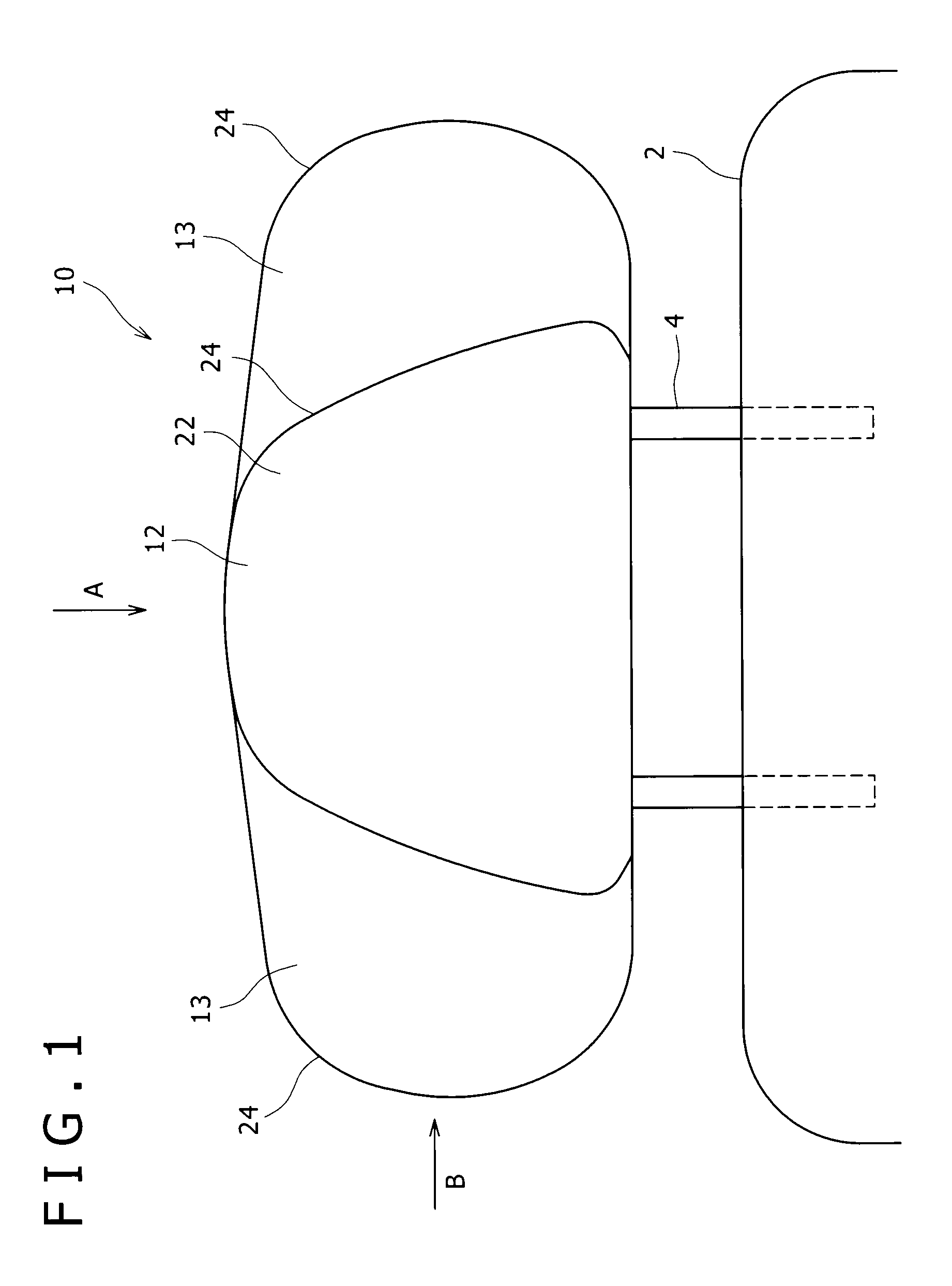

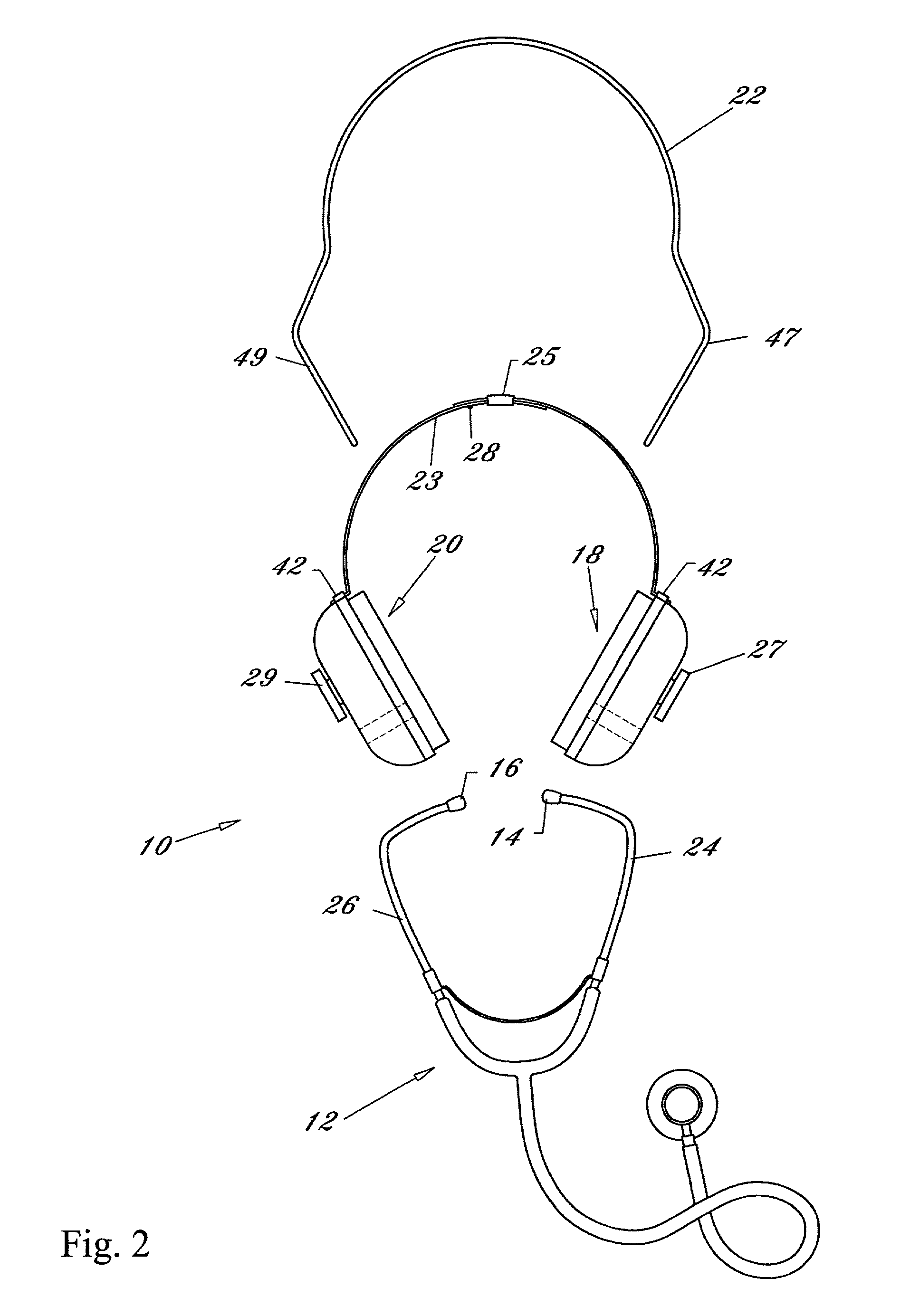

Speaker system

InactiveUS20090257616A1Prevent sound leakageImprove sound qualityTransmissionFrequency/directions obtaining arrangementsEngineeringLoudspeaker

Disclosed herein is a speaker system including: a laterally extending body portion for supporting the back of the head of a user; and a pair of right and left side portions respectively connected to the right and left ends of the body portion.

Owner:SONY CORP

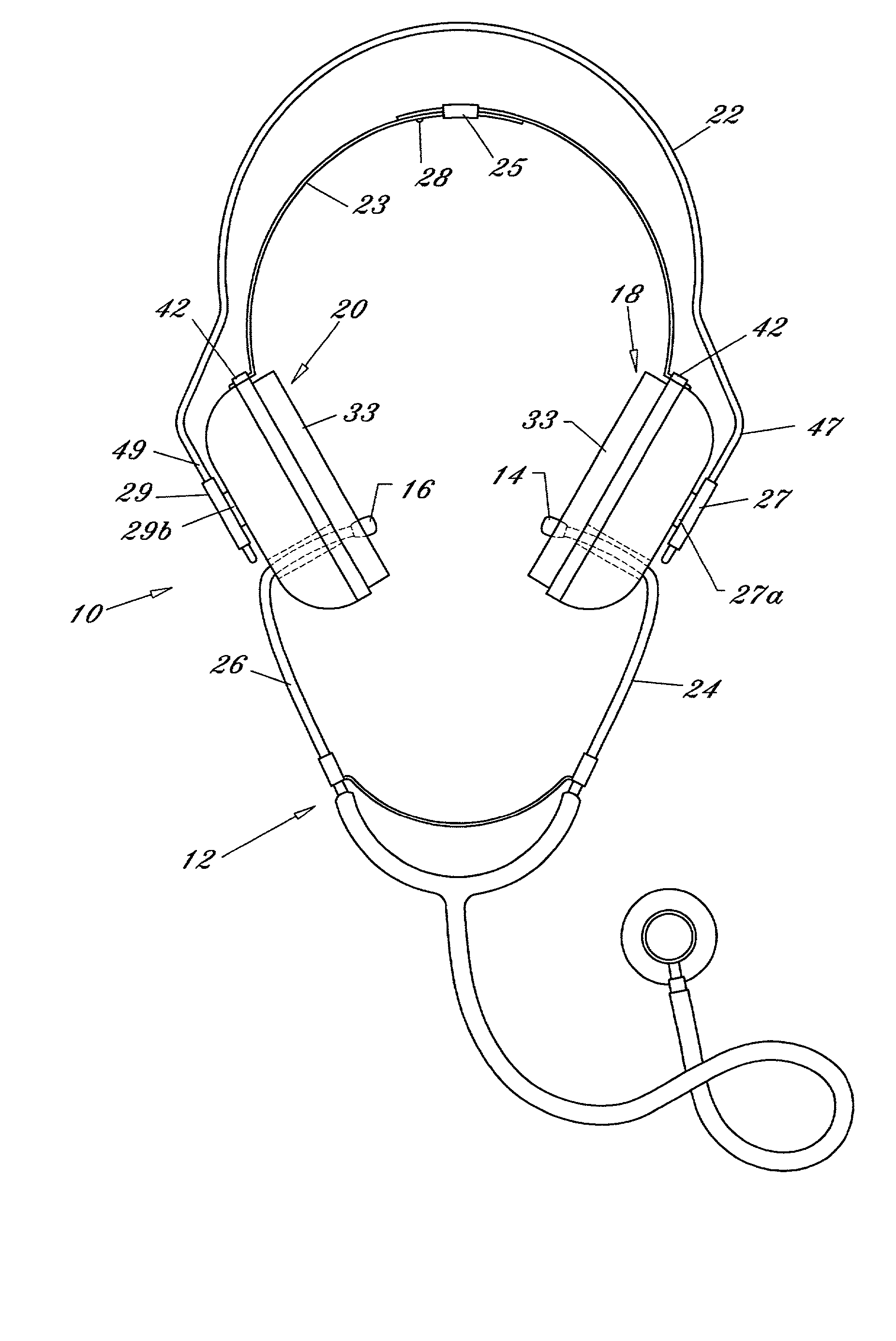

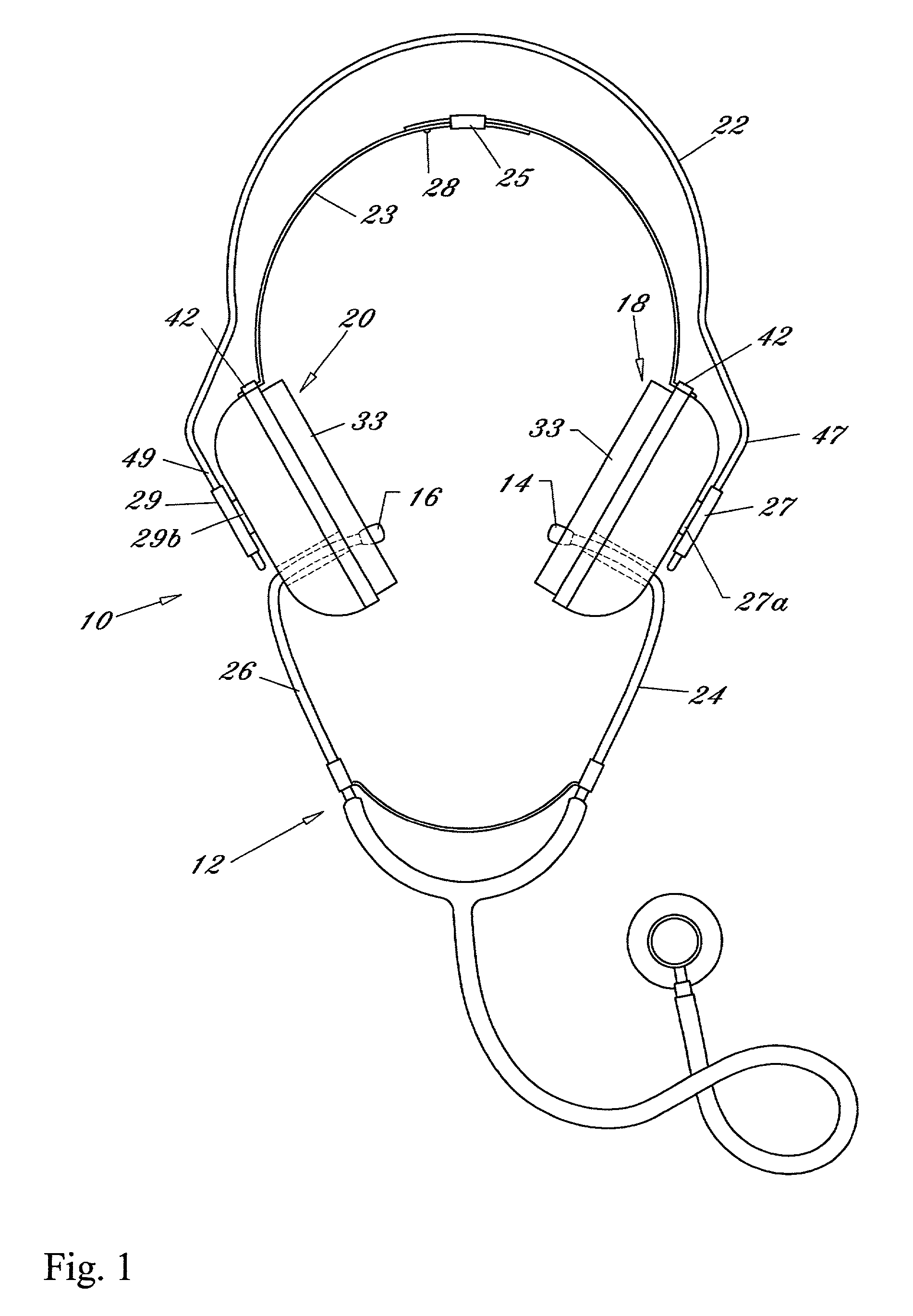

Stethoscope sound isolation headset

A stethoscope amplifier headset for receiving, isolating and transferring sound received from a stethoscope to a user's ears, the stethoscope sound isolation headset including left and right ear assemblies connected by an adjustable length headband, ear receiving cavities, stethoscope receiving apertures, and acoustic insulators. Each of the left and right ear assemblies may also include an amplifier assembly including an adjustable volume control.

Owner:PARSONS MARK

Switching device

InactiveCN101677039AStable resistanceClosely resistEmergency actuatorsEmergency casingsPrinted circuit boardMechanical engineering

The invention discloses a switching device, mounted in an electronic apparatus. The switching device comprises a housing, an accommodating chamber formed in the housing, a slide button disposed in theaccommodating chamber and a spring provided on the slide button. The accommodating chamber is used for accommodating a printed circuit board in the accommodating chamber, the printed circuit board isprovided with a plurality of metal regions for connecting to other circuits of the electronic apparatus, the slide button is supported at the inner side of the housing under the spring action of thespring, one end of the spring slides under the drive of the slide button and can slide on one of the metal regions, while the other end can slide between other metal regions, and can be selectively supported to one of the other metal regions, so that the electronic apparatus is located at different function states.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

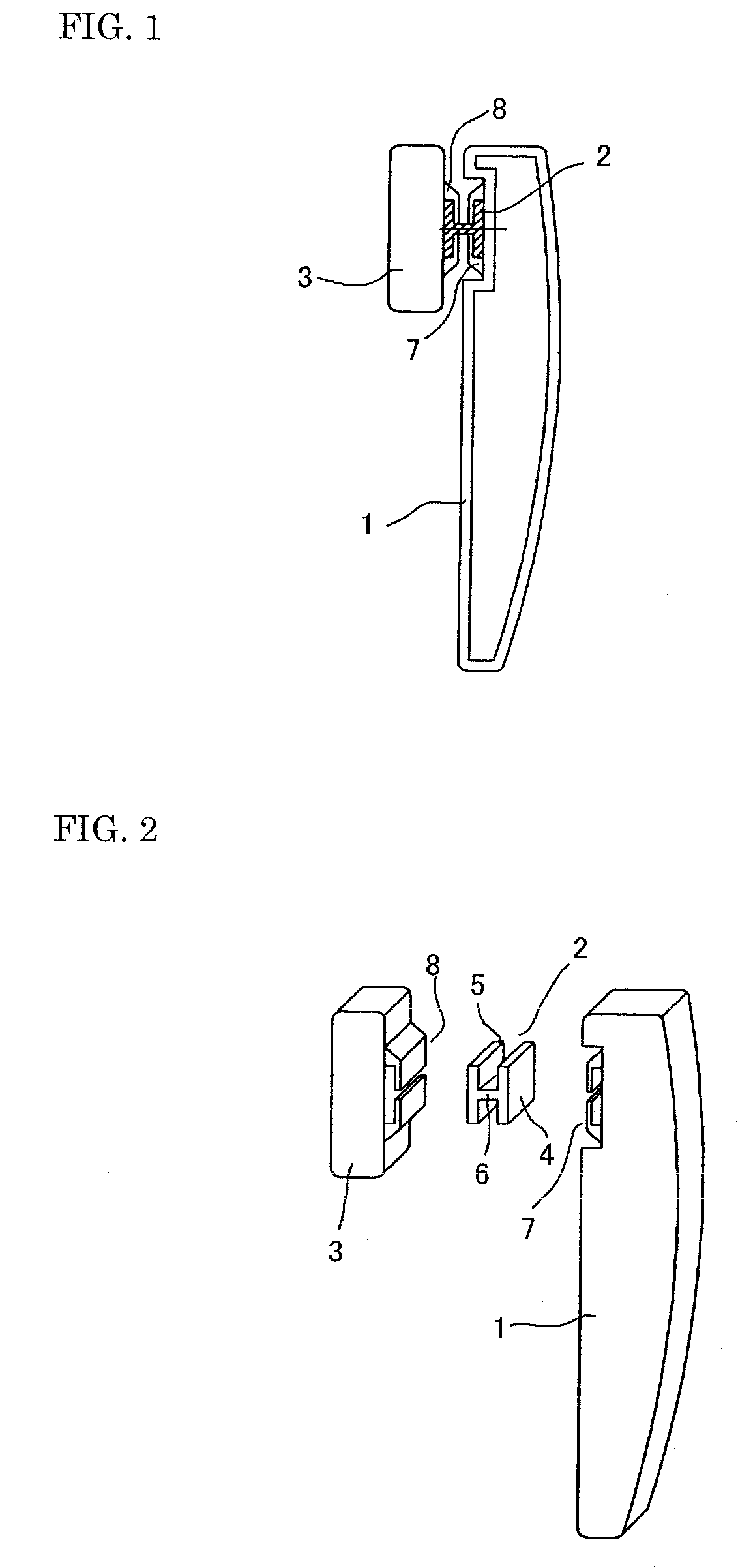

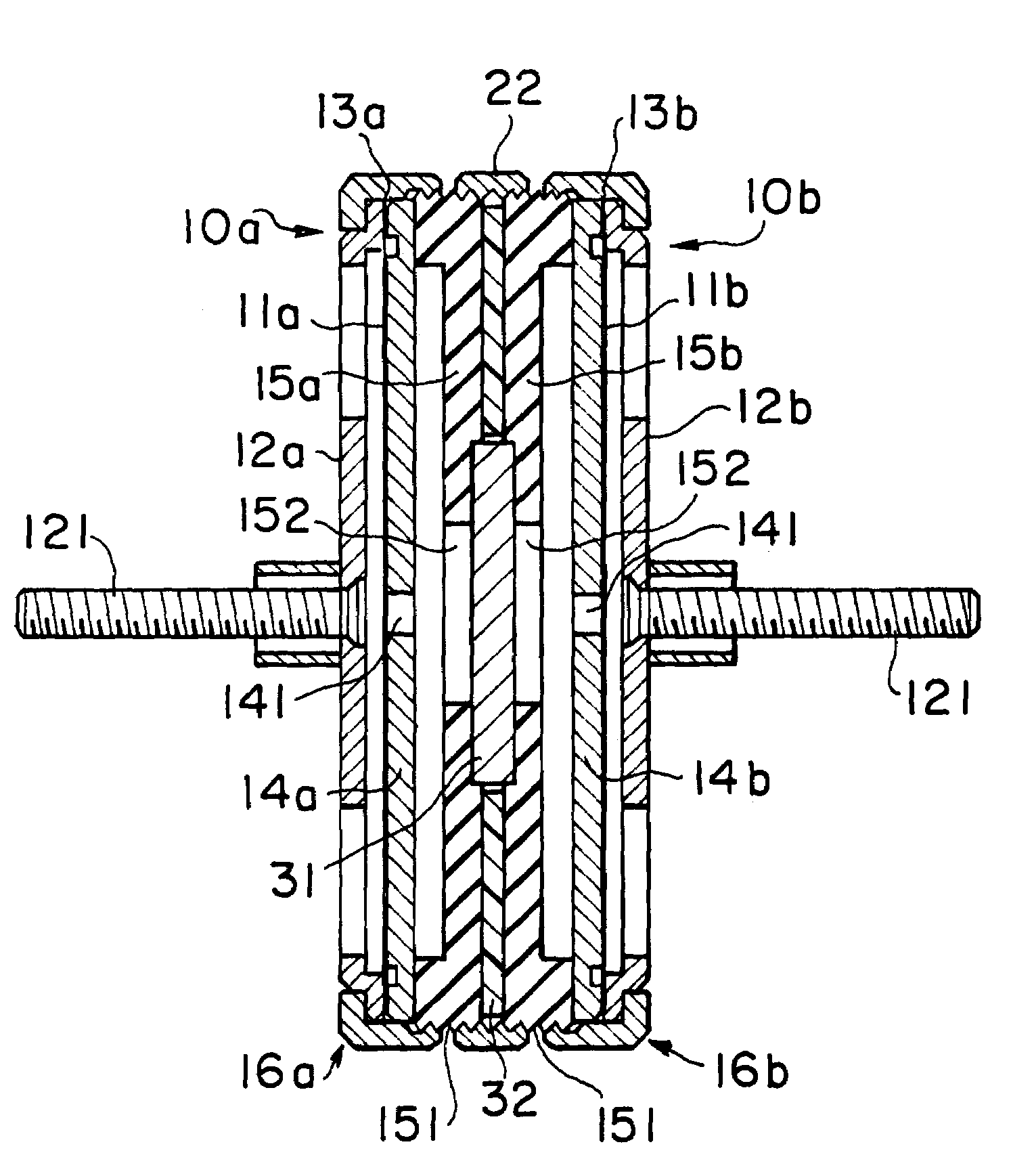

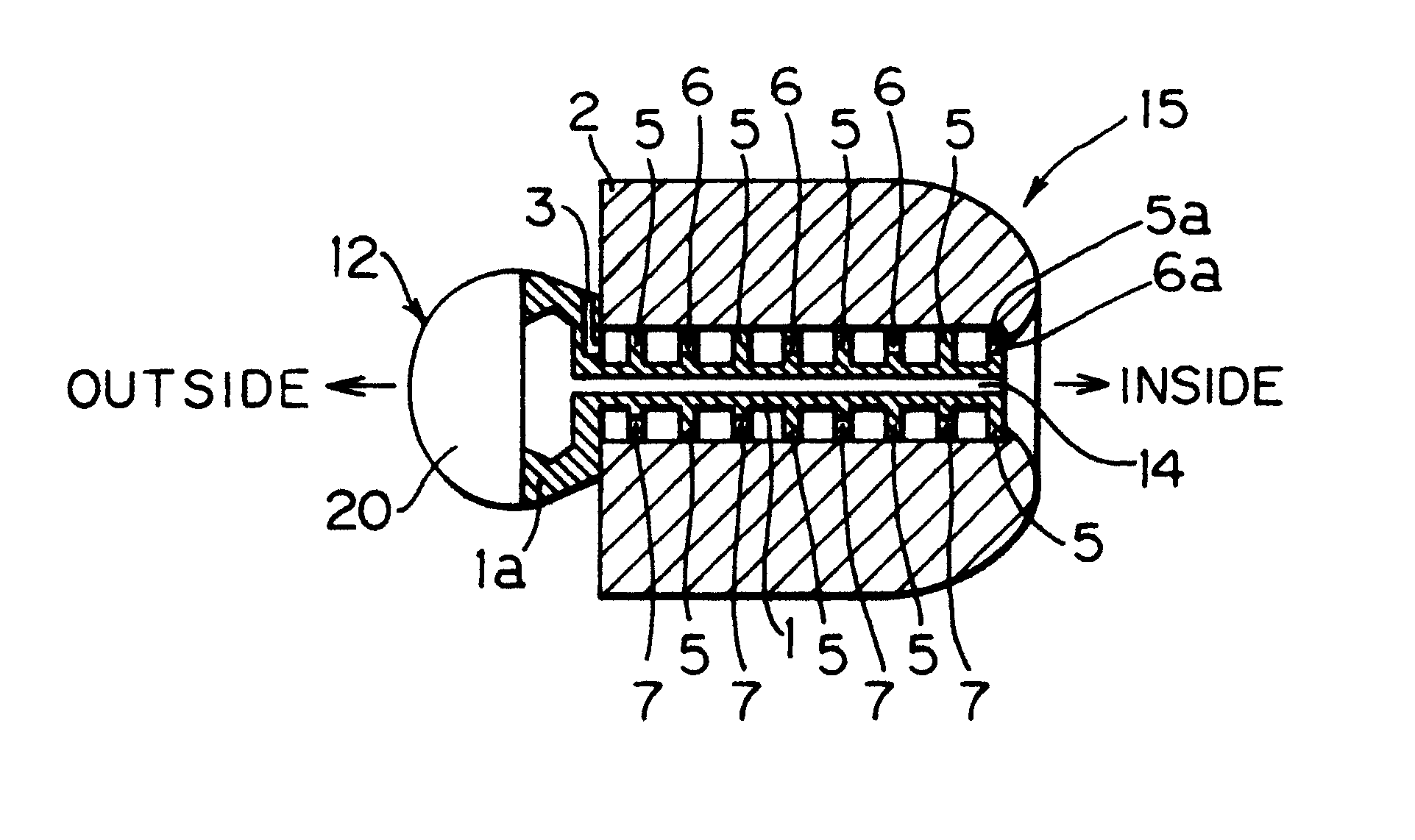

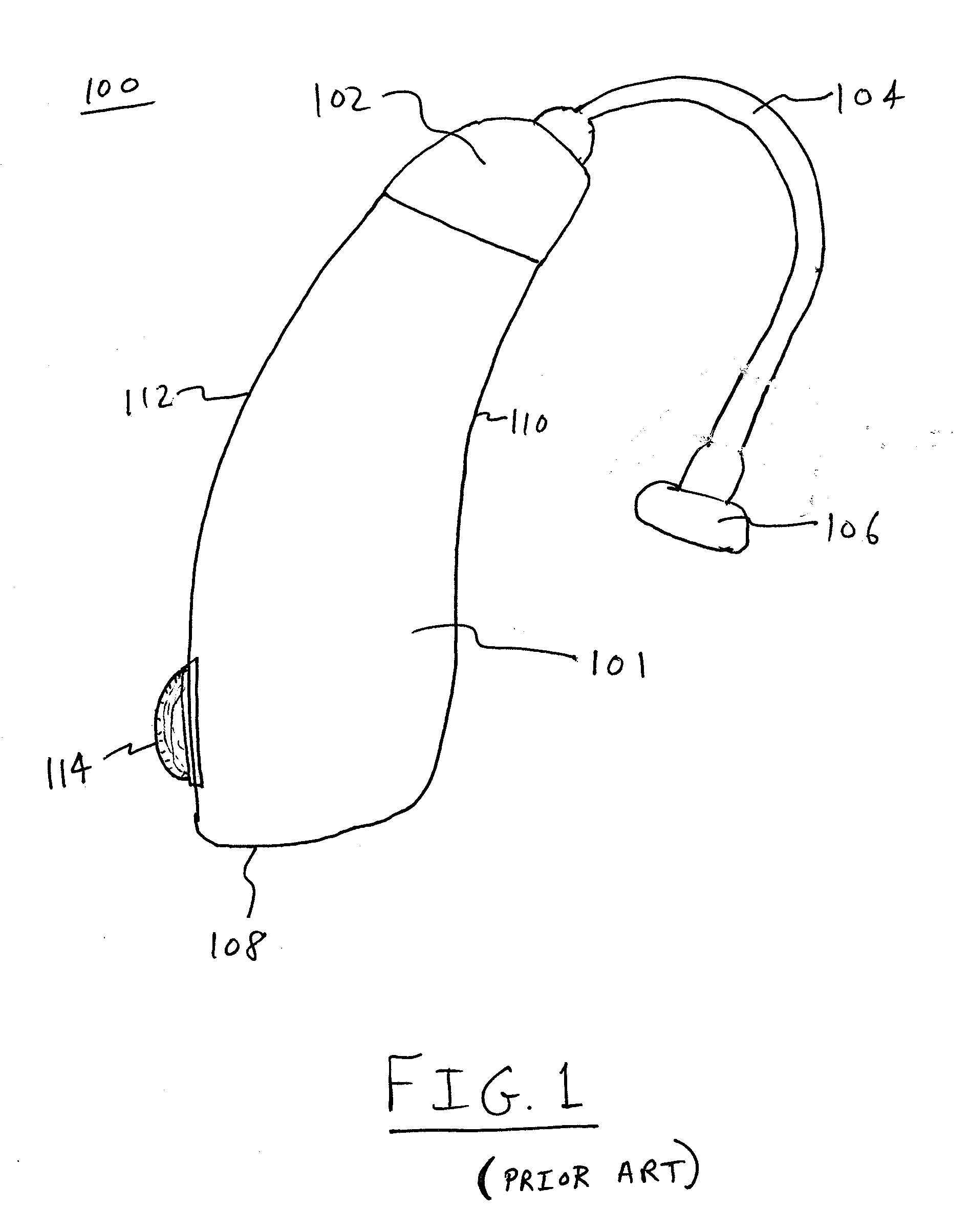

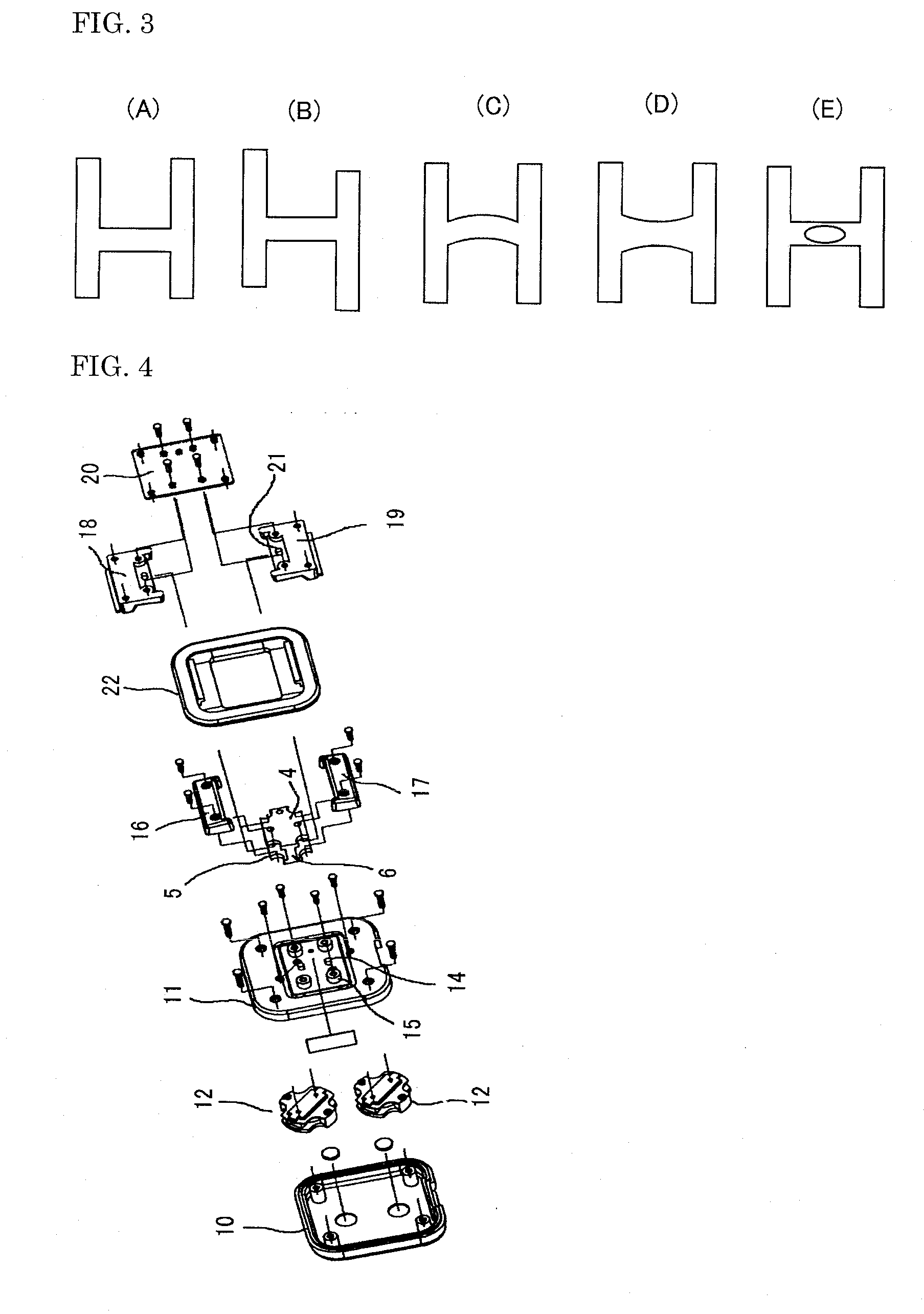

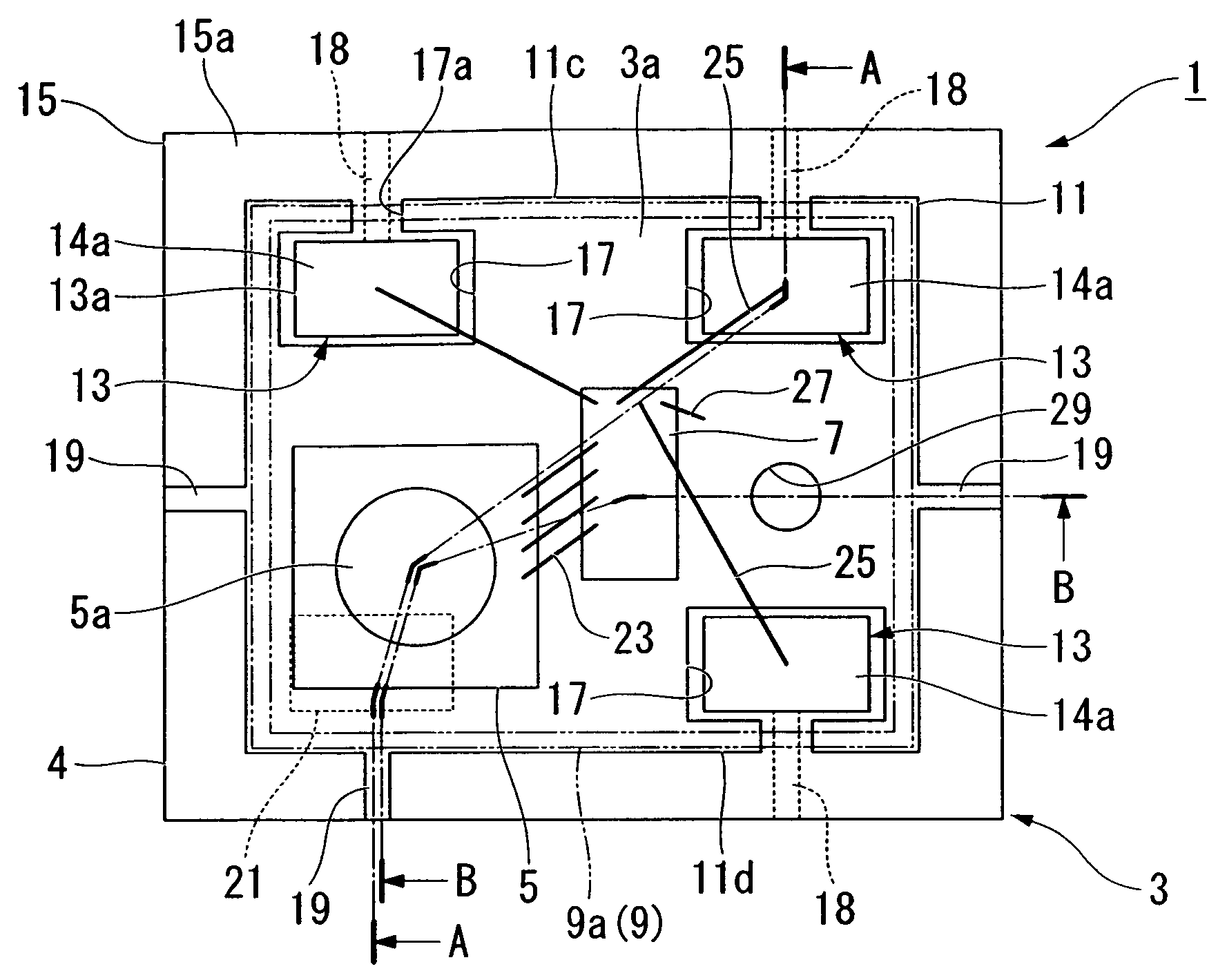

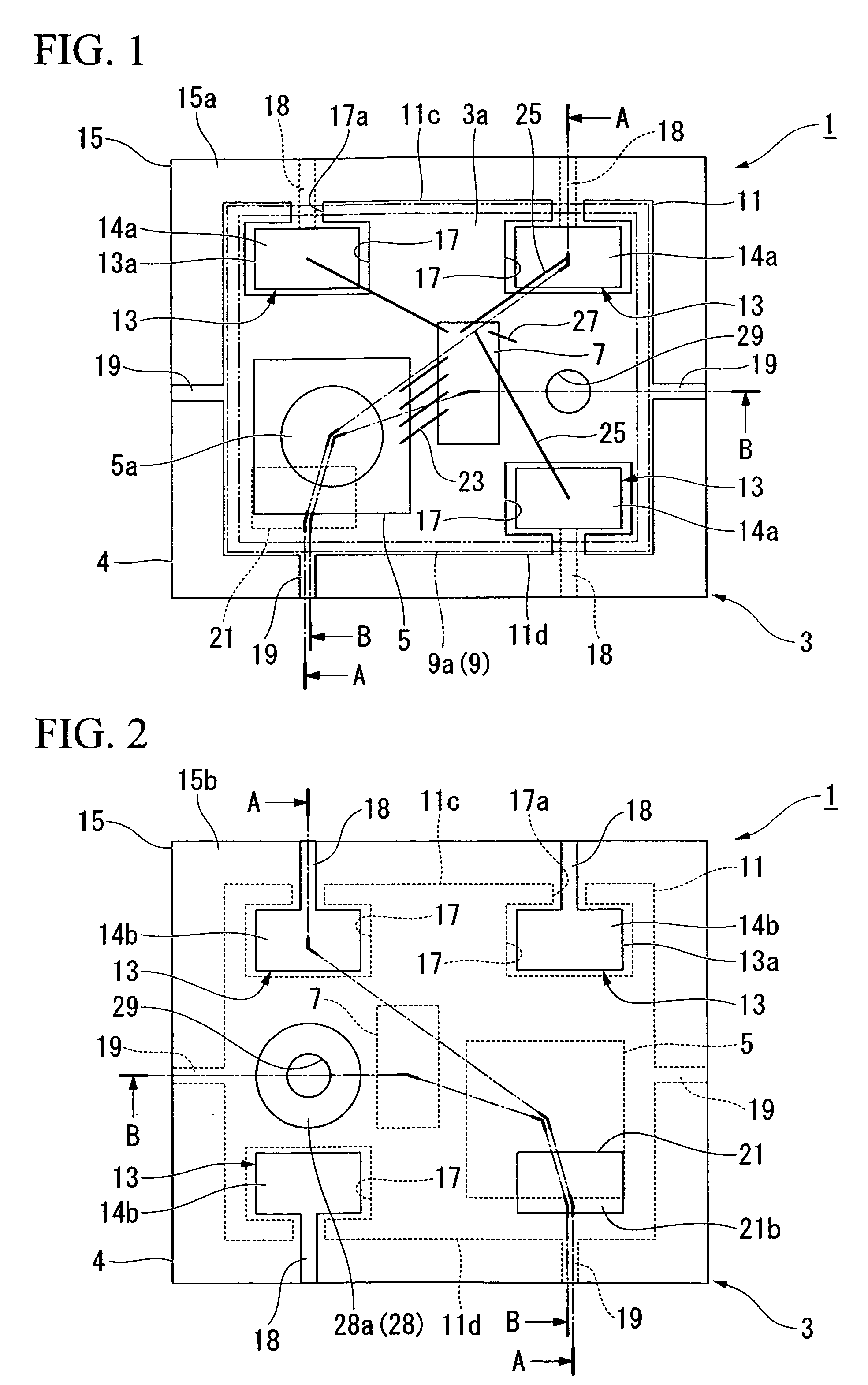

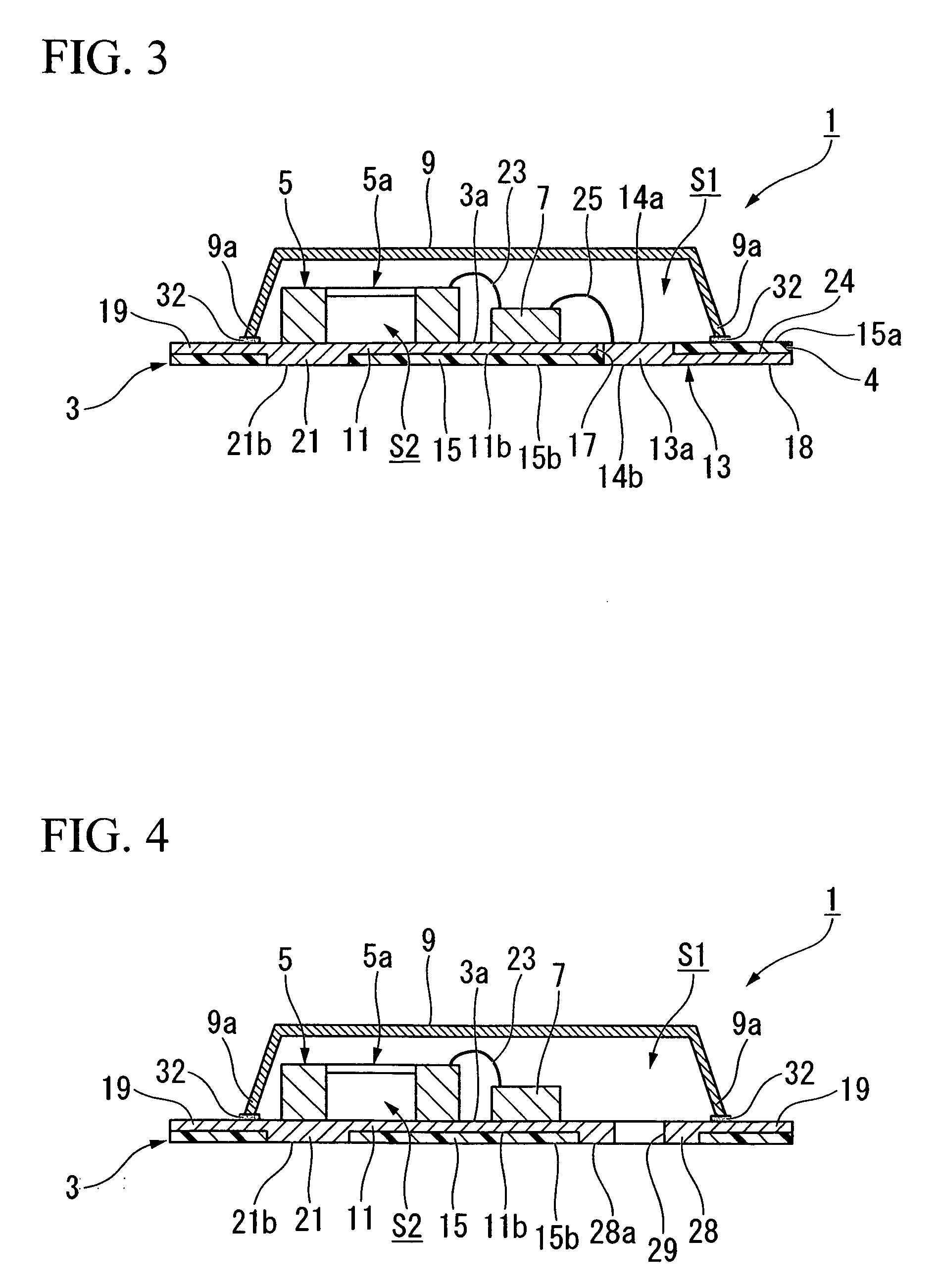

Variable directional capacitor microphone comprising elastic acoustic resisting member

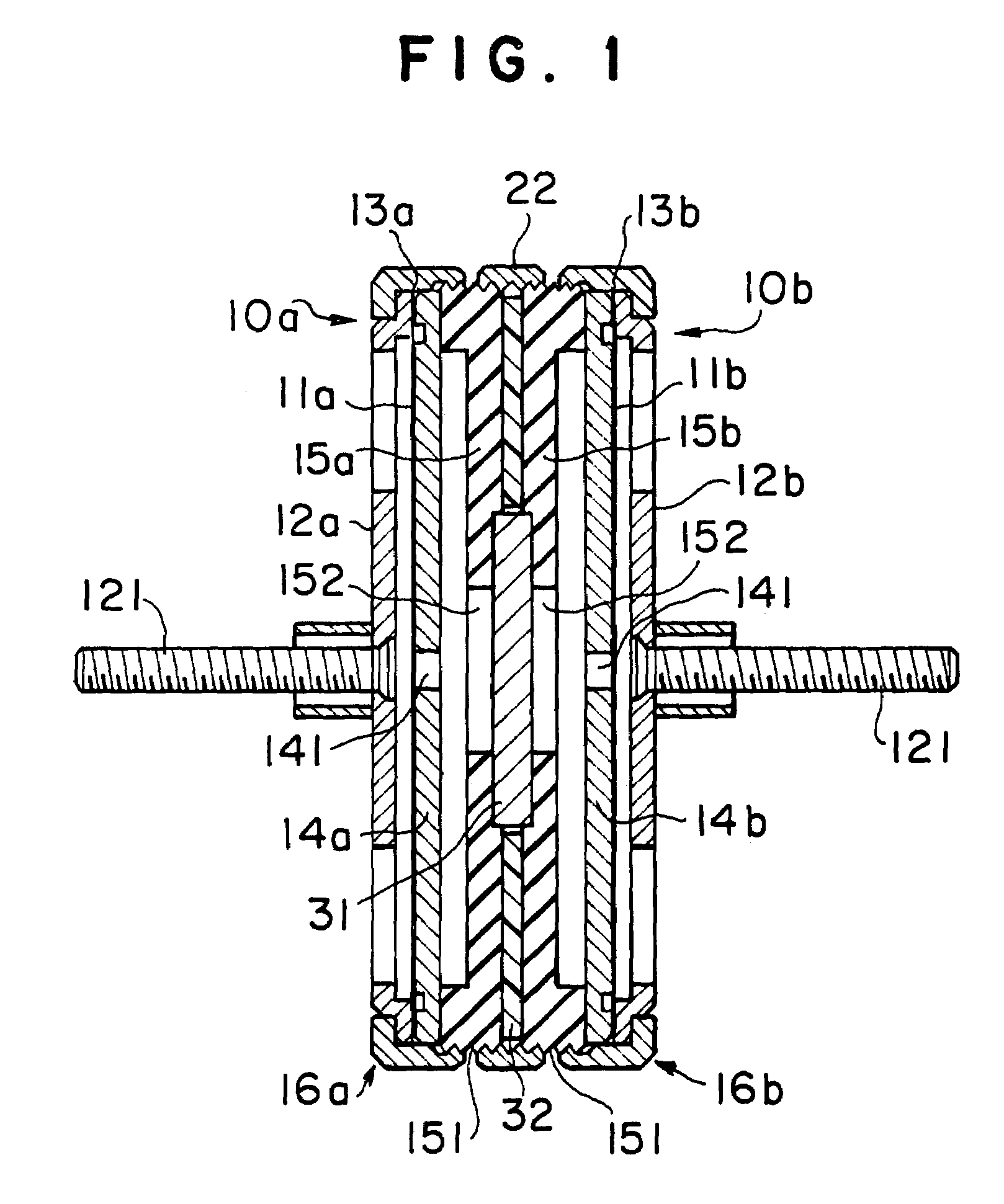

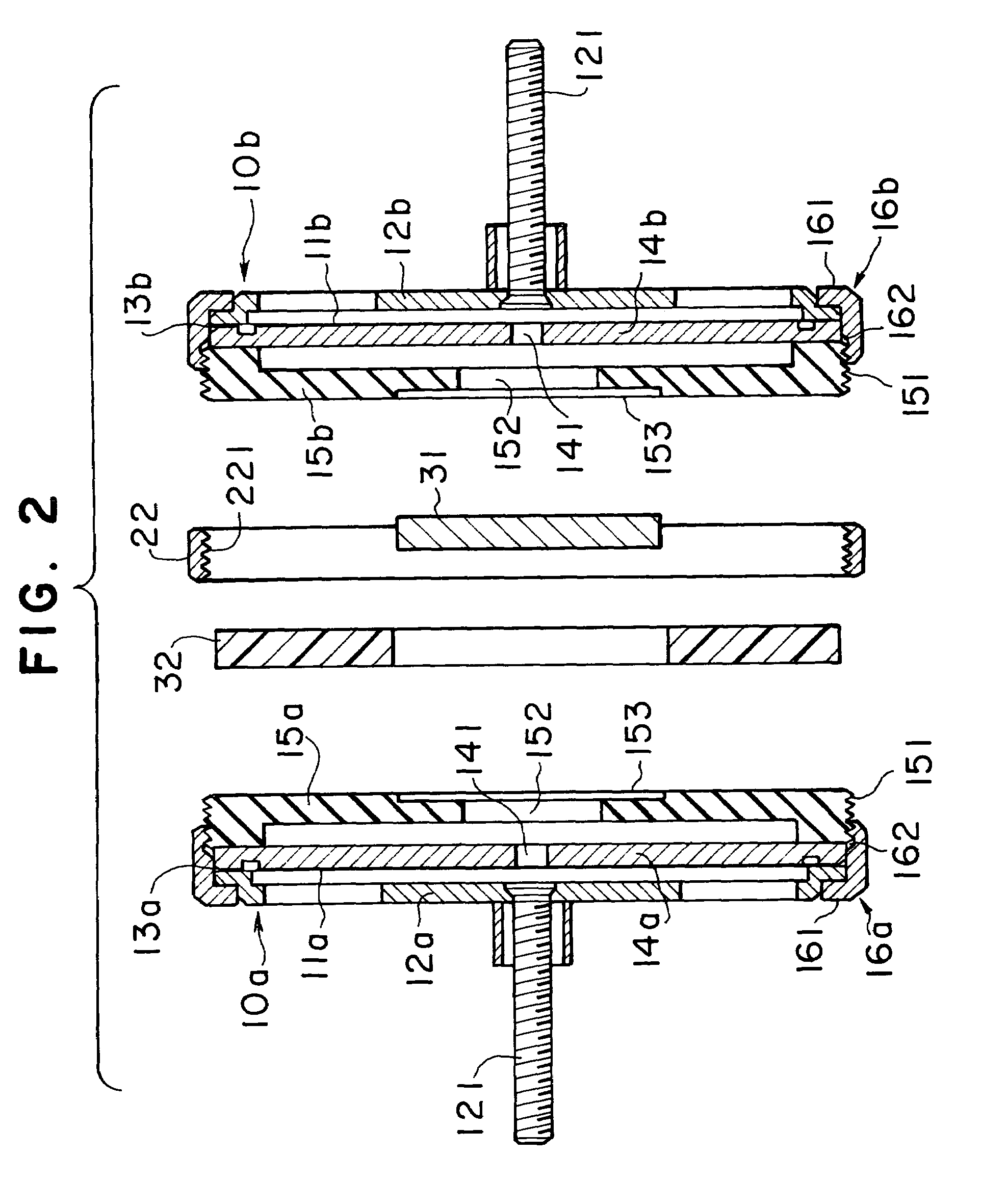

InactiveUS6985597B2Prevent sound leakagePiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesEngineeringCapacitor

The present invention includes a variable directional capacitor microphone in which two capacitor elements are combined. Each of the capacitor elements includes a vibrating plate and a fixed electrode, and an acoustic resistance can be adjusted in the state that the microphone has been assembled. The variable directional capacitor microphone of this invention includes capacitor elements 10a, 10b. In each of the capacitor elements 10a, 10b, each of vibrating plate supporting members 12a, 12b, each of spacer rings 13a, 13b, each of fixed electrodes 14a, 14b having through holes 141 and each of pedestals 15a, 15b having a through hole in each center of the pedestals are assembled in this order, respectively, in each of ring-shaped cases 16a, 16b. Each of vibrating plates 11a, 11b is strained and fixed on each of vibrating plate supporting members 12a, 12b, respectively. The capacitor elements 10a, 10b are combined through a connecting ring 22 having female screw threads 221 with the pedestal 15a, 15b facing back-to-back. An elastic acoustic resisting member 31 is disposed between the pedestals 15a, 15b. The acoustic resistance of the acoustic resisting member 31 can be adjusted with the lengths of thread engagement of the pedestals 15a, 15b with the connecting ring 22.

Owner:AUDIO-TECHNICA

Bone-conduction speaker unit

InactiveCN104823458APrevent sound leakageFully functionalLoudspeaker transducer fixingBone conduction transducer hearing devicesEngineeringBone conduction hearing

Problem: To provide a bone conduction speaker unit which can sufficiently prevent generation of sound leakage at the time of non-calling, and can be easily incorporated in a main body casing of mobile phones, and the like. Solution: A bone conduction speaker unit, being configured by incorporating a bone conduction speaker main body 2 in a housing 1, wherein an elastic plate 21 is fixed on a top face of a plate yoke 17 of the bone conduction speaker main body 2; an elastic base 22 is disposed on a rear face of a yoke 11; and an elastic cover 3 for holding a contact 5 which, upon a pressing force having been applied thereto in use, is abutted against the plate yoke 17 through the elastic plate 21 is loaded on the housing 1 with a gap "a" being held between a bottom face of the contact 5 and a top face of the elastic plate 21.

Owner:TEMCO JAPAN

Soft support bridge type silicon micro-piezoelectric microphone chip and prepration method thereof

InactiveCN101646117ALarge strainPrevent sound leakagePiezoelectric/electrostrictive microphonesTelevision system detailsVibrating membraneThin membrane

The invention relates to a soft support bridge type silicon micro-piezoelectric microphone chip which comprises a silicon substrate with a square conical hole which is small at the top and big at thebottom, a square compound vibration membrane which consists of a first silicon nitride membrane layer, a silicon dioxide membrane layer and a second silicon nitride membrane layer is covered on the front surface of the silicon substrate, and a third silicon nitride membrane layer and a fourth silicon nitride membrane layer are sequentially covered on the back surface of the silicon substrate; thethird and the fourth silicon nitride membrane layers both have central square holes; one pair of opposite sides of the vibration membrane respectively etch a vertical narrow slot penetrating the vibration membrane, and the vertical projection of each narrow slot is positioned on the inner side of the edge of the square hole in the front surface of the silicon substrate; a lower electrode, a piezoelectric membrane and an upper electrode are sequentially deposited on the vibration membrane; a polyimide membrane is deposited on various parts on the front surface of the silicon substrate; the compound vibration membrane which is etched with the vertical narrow slots and the polyimide membrane commonly constitute a soft support anti-sound leakage bridge type vibration membrane; two sides of thevibration membrane are fixedly supported, and strain can be produced during the vibration process; in order to prevent the microphone from producing sound leakage through the narrow slots, the soft polyimide membrane is deposited on the narrow slots, thereby being capable of effectively preventing sound leakage phenomenon.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

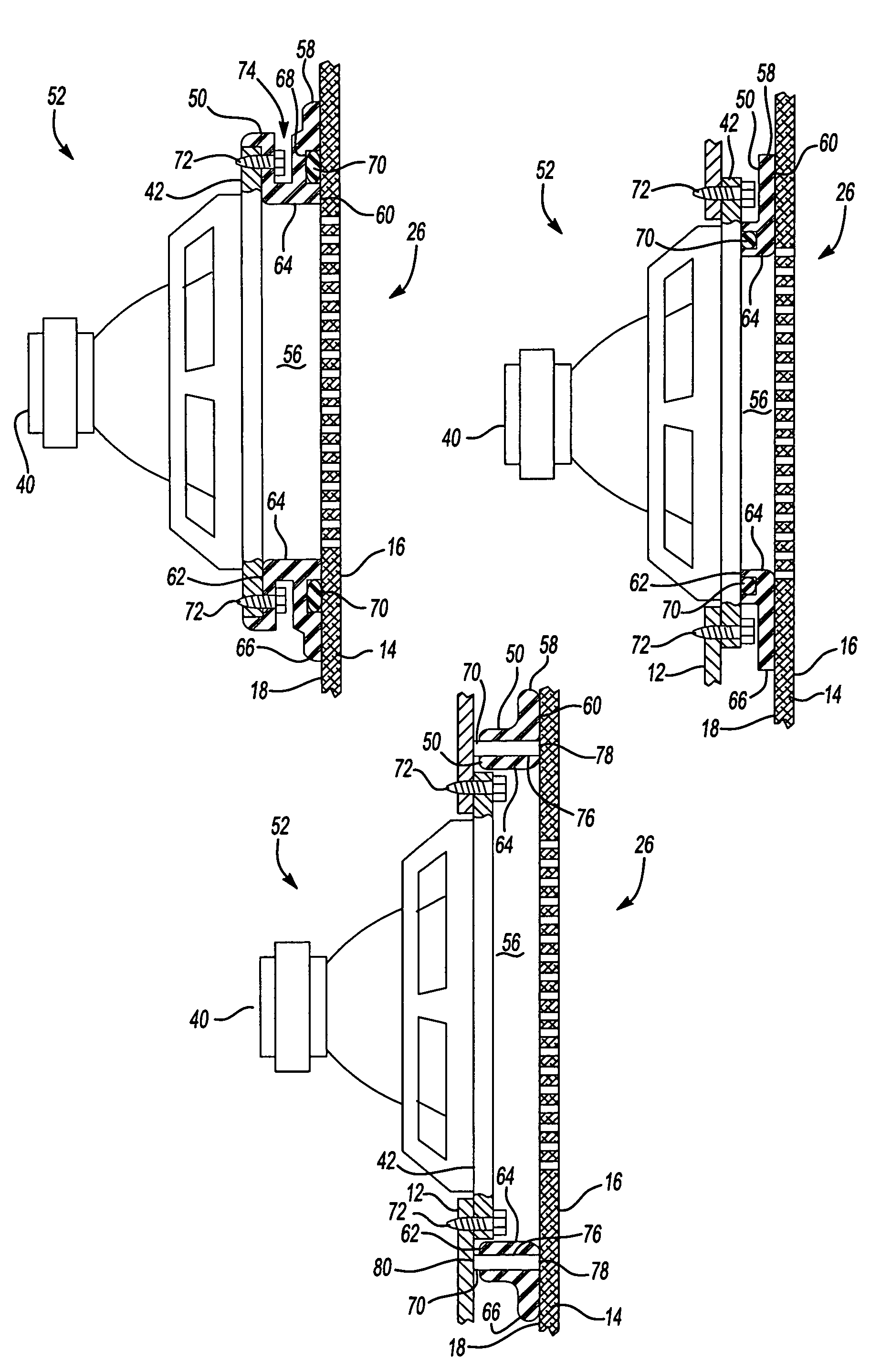

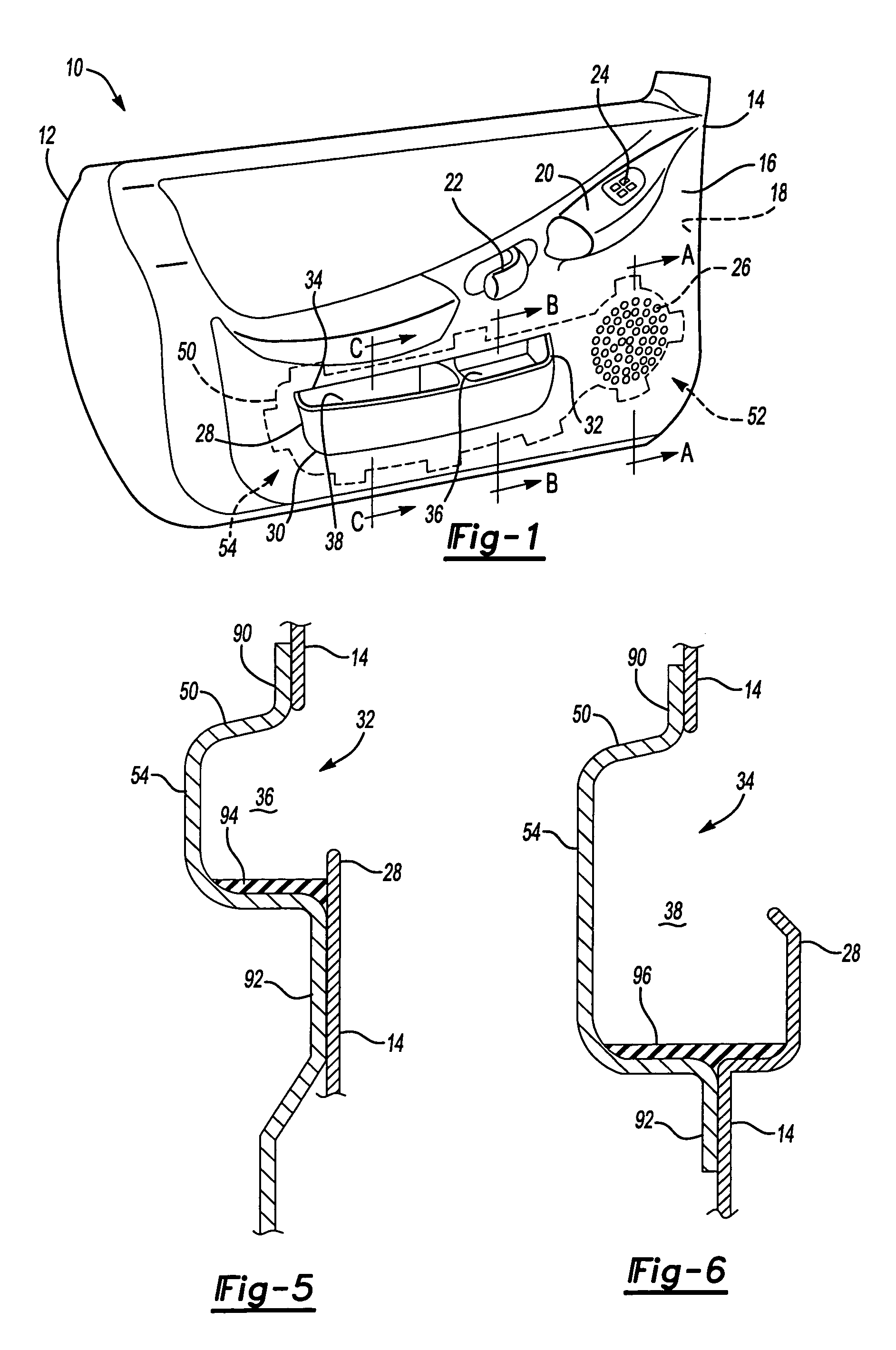

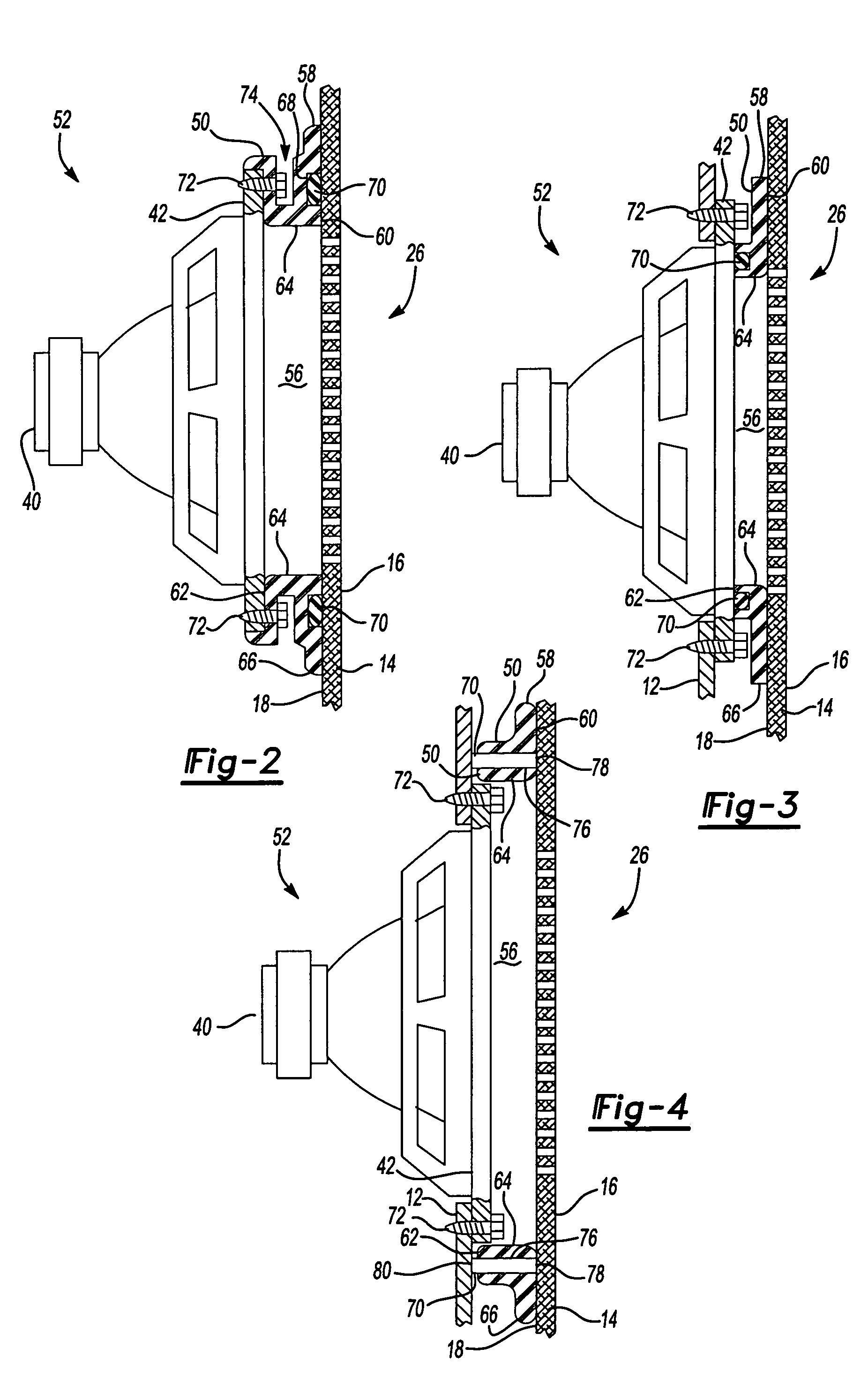

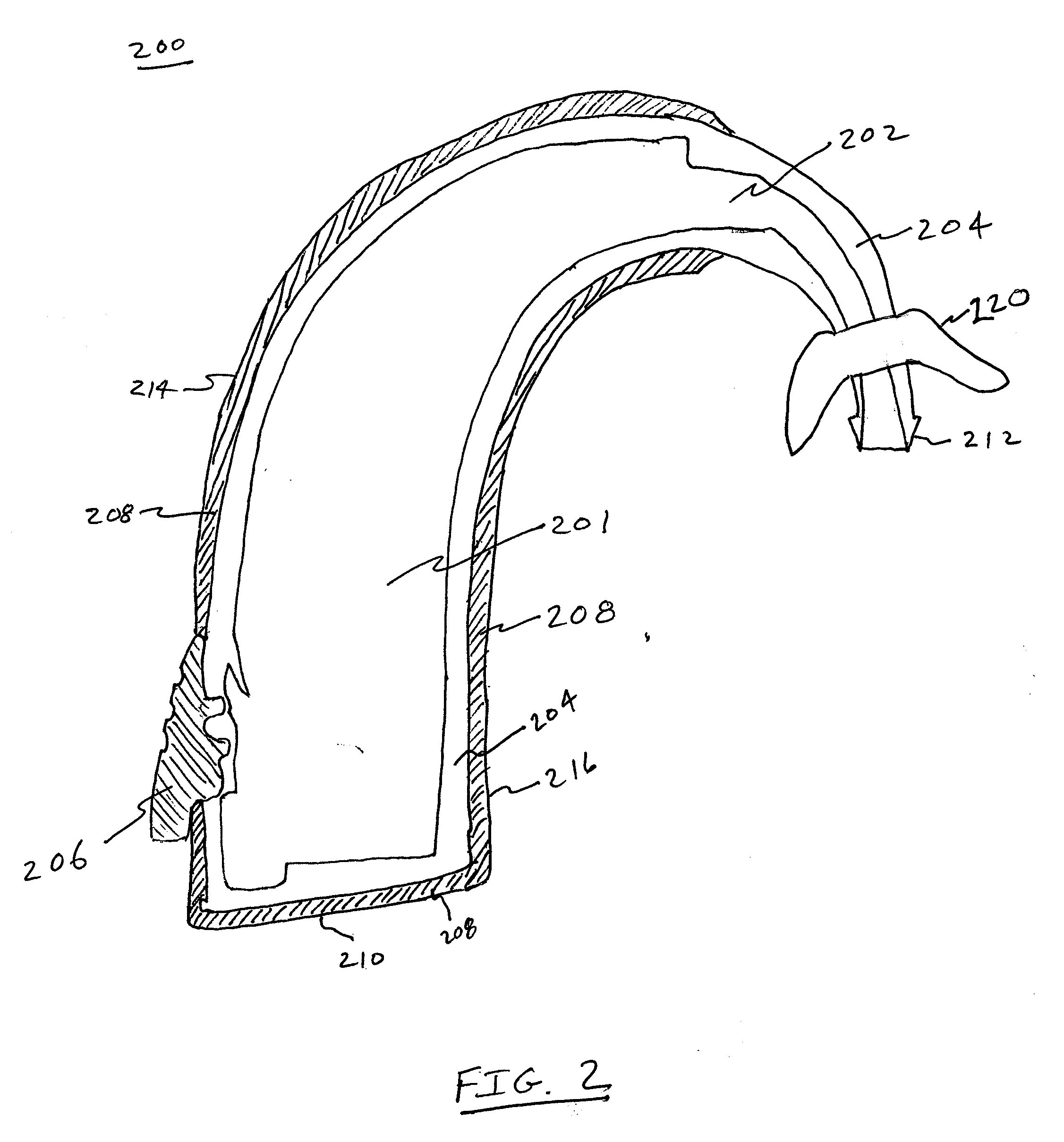

Trim panel assembly and method of manufacture

InactiveUS7073843B2Prevent sound leakagePassenger spaceLoudspeaker transducer fixingEngineeringLoudspeaker

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Ear plug to be inserted into the external auditory canal

InactiveUS6761173B1Prevent sound leakageReduce differential pressureEarplugsExternal Auditory CanalsPressure difference

An ear plug to be inserted into the external auditory canal, having a compressible sleeve member and a core member attached therein, the improvement in which plural projections or a single projection are formed intermittently or continuously on an exterior of the core member, and vent is formed through or along the projection to make the external auditory canal communicate with the external atmosphere when inserted into the external auditory canal. A communicating passage or vent to an effective degree for remarkably decreasing the pressure difference between the inside of the external auditory canal and the external atmosphere as well as preventing leakage of sound causing so-called howling.

Owner:MIMY ELECTRONICS

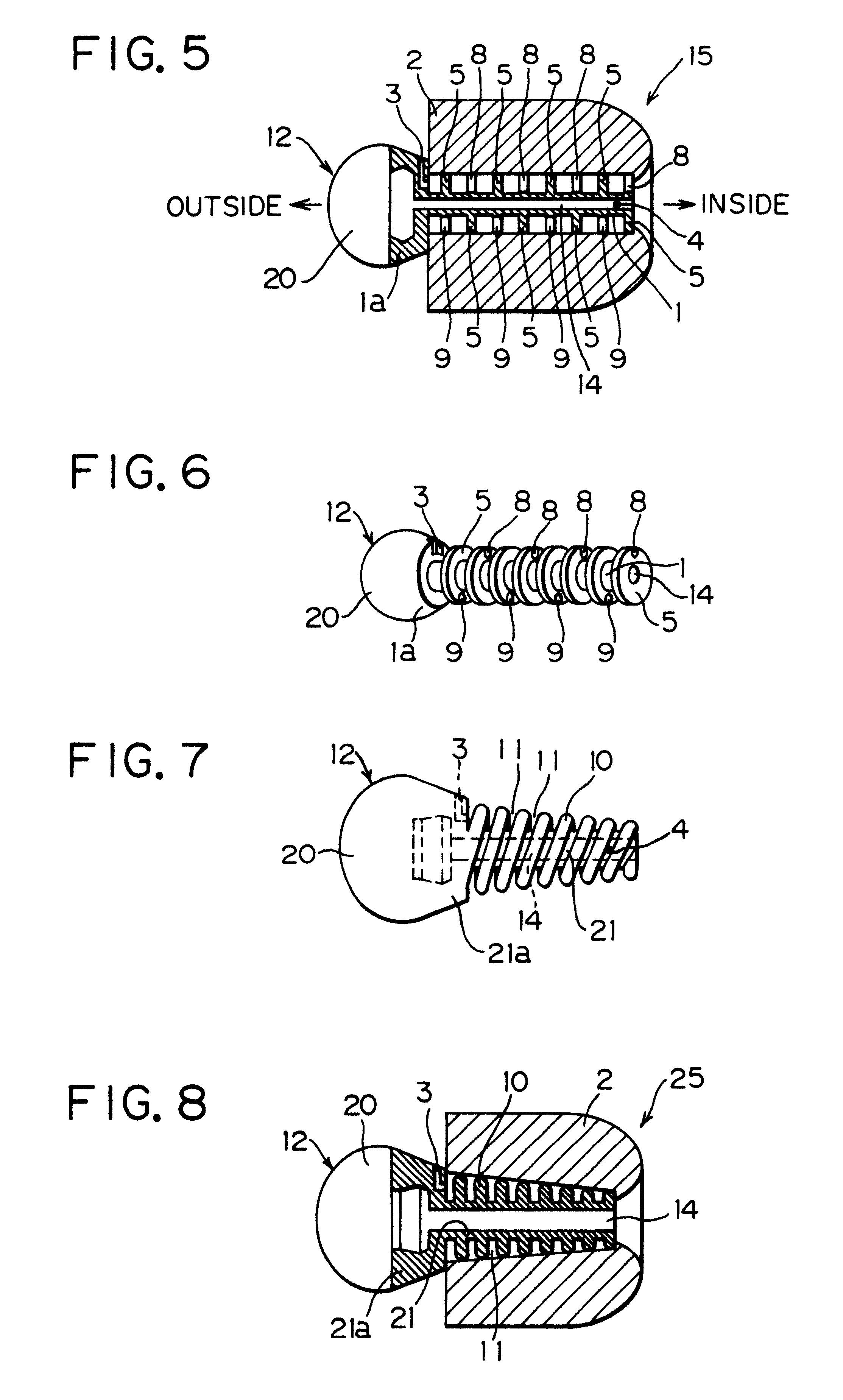

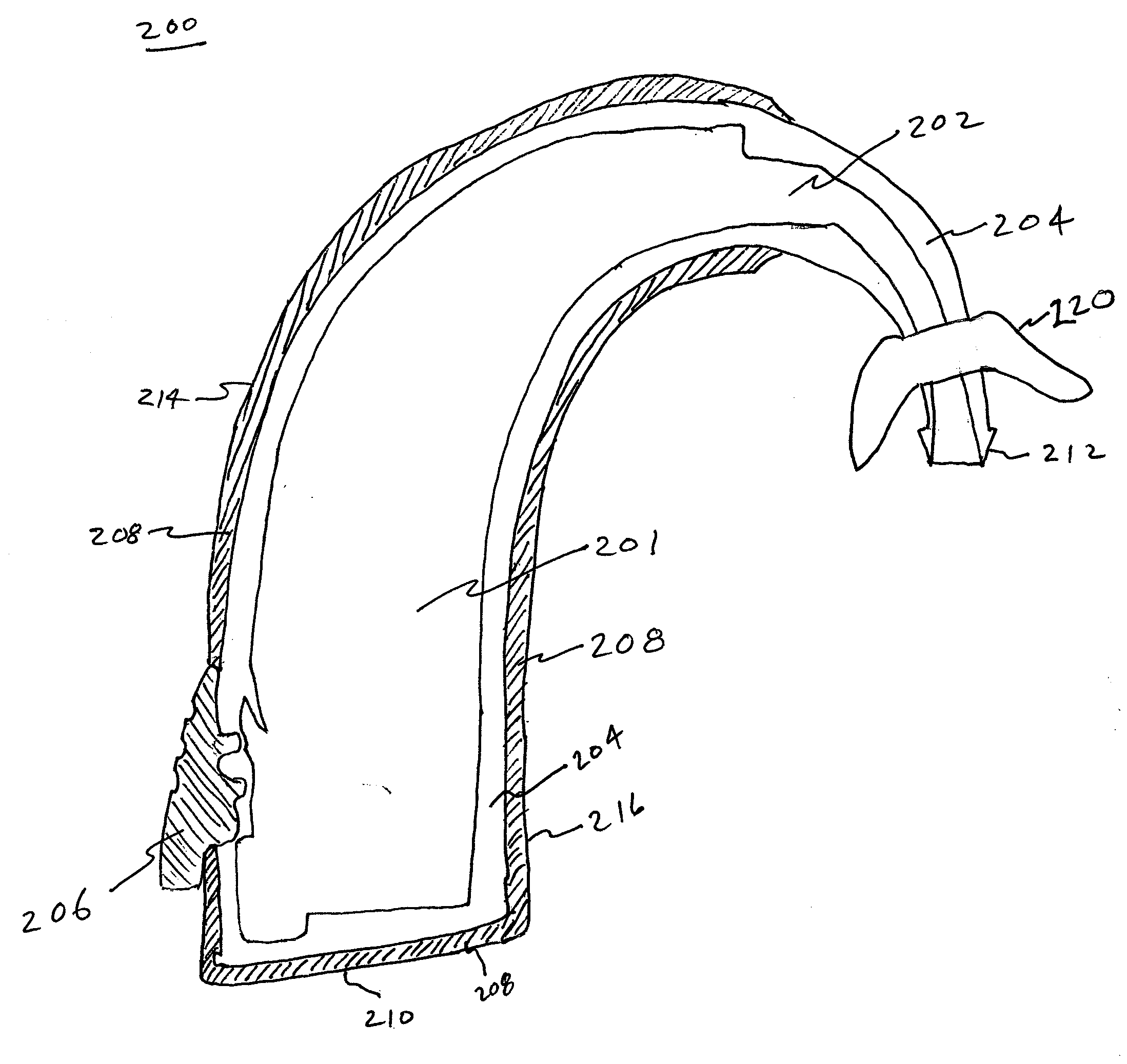

Shielding of Behind-The-Ear Hearing Aids

InactiveUS20100166239A1Prevent leakagePrevent sound leakageHearing aids housingEngineeringElectromagnetic radiation

Provided is a method and shield for shielding a behind-the-ear hearing aid. A Mu metal shielding material is bonded to the external or internal surface of the behind-the-ear hearing aid, the shielding providing effective shielding of electromagnetic radiation in the frequency range of 20 Hz to MHz and effective sound shielding in the audio frequency range of 20 Hz to 20,000 Hz. A hearing canal mold comprised of a rubber-like compound, shaped to encompass and seal an outer portion of a hearing tube of a hearing aid and a user's hearing canal entrance is also provided.

Owner:BRUNDA DANIEL D

Volume adjusting apparatus and volume adjusting method

InactiveUS7968786B2Prevent sound leakageReduce environmental noiseElectrophonic musical instrumentsSignal processingComputer scienceControl unit

A volume adjusting apparatus includes a sound collecting unit configured to collect noise data of a surrounding environment, an analyzing unit configured to extract a feature value indicating a feature of the noise data collected by the sound collecting unit and a feature value indicating a feature of supplied musical tune data, and a control unit configured to generate volume adjustment information for adjusting playback volume of the musical tune data based on the feature value of the noise data and the feature value of the musical tune data and adjusts the playback volume of the musical tune data based on the volume adjustment information.

Owner:SONY CORP

Bone-conduction handset

InactiveUS20090190781A1Harder for vibrationPrevent leakageBone conduction transducer hearing devicesTelephone set constructionsHandsetLoudspeaker

The object is to provide a bone-conduction handset, which has its main body (1) sufficiently isolated from a bone-conduction speaker unit (3) so that: the chances that howling and sound leaking may occur are reduced; and, the handset is improved in easiness in use. In the handset, the speaker unit (3) is mounted on the main body (1) through a speaker mounting member (2) made of a vibration-proof material. The mounting member (2) is characterized by comprising a connection portion (6), which is disposed perpendicularly to both the handset body (1) and the speaker unit (3) in a manner such that the main body (1) and the speaker unit (3) have their opposed inner surfaces disposed adjacent to opposite sides of the connection portion (6), whereby the main body (1) is isolated from the speaker unit (3).

Owner:TEMCO JAPAN

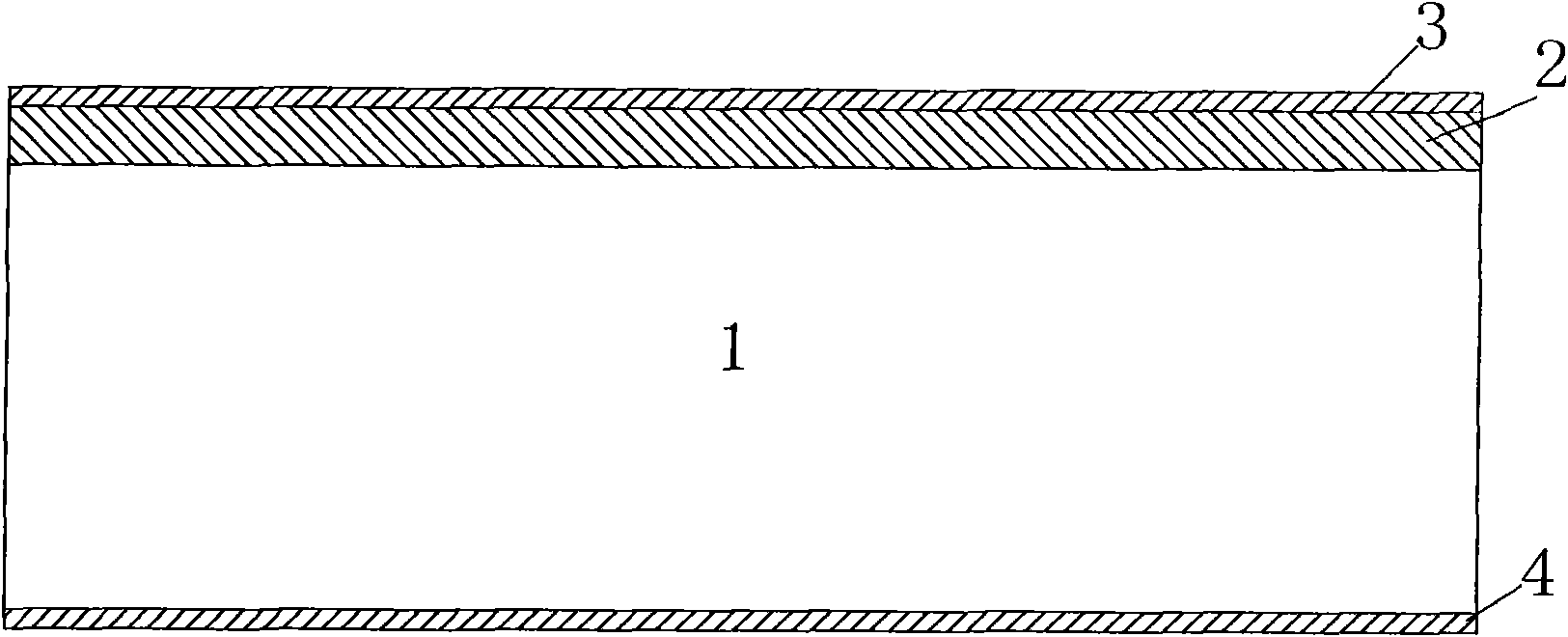

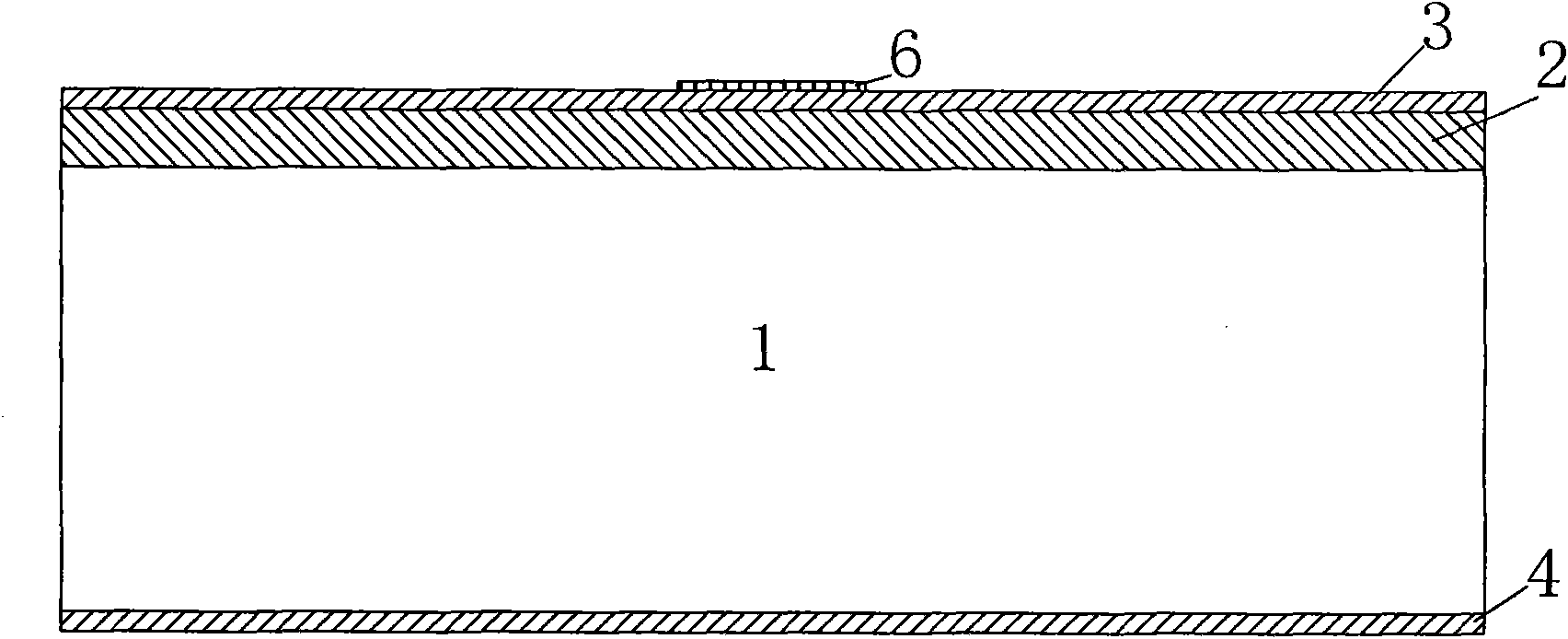

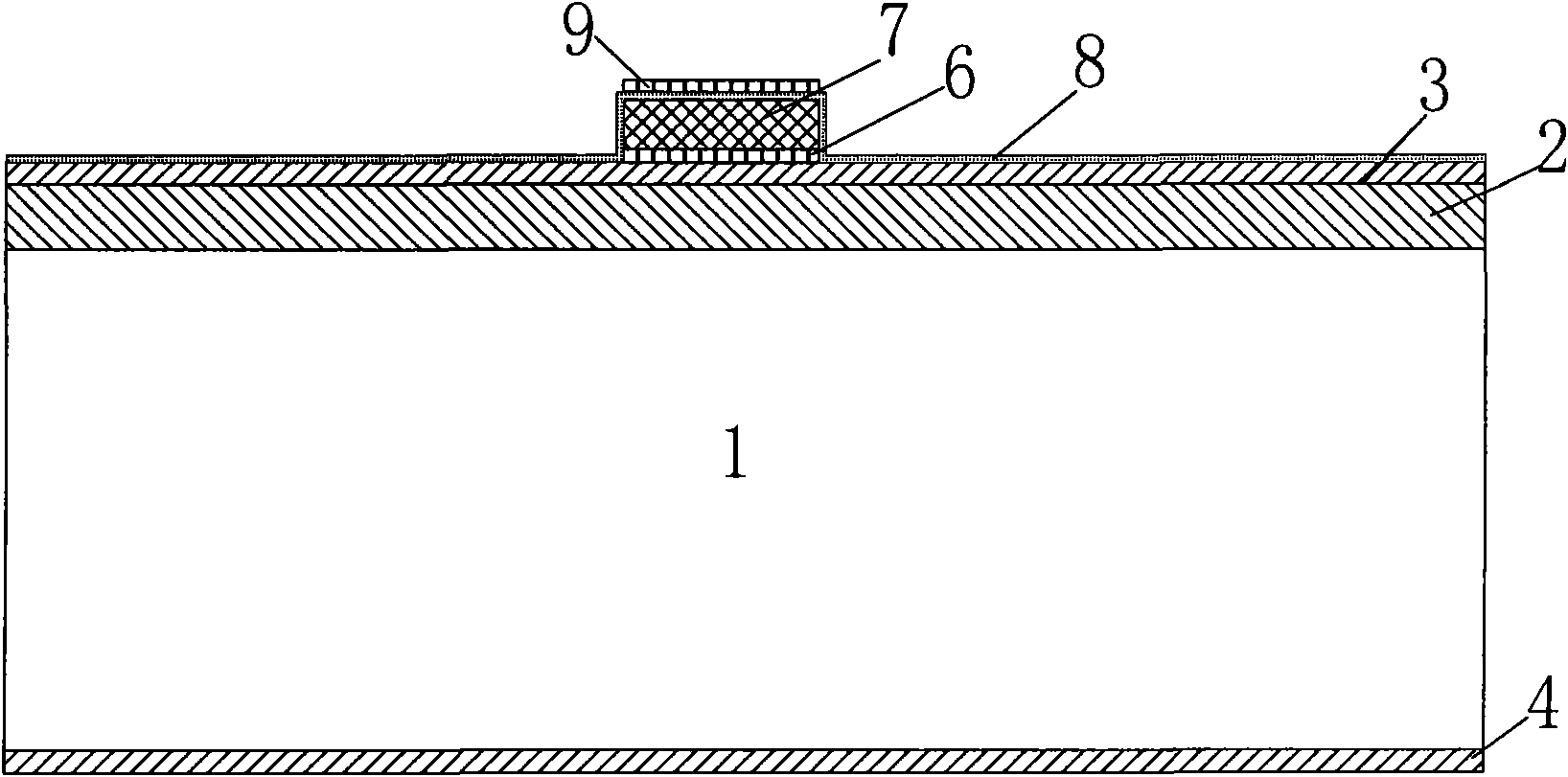

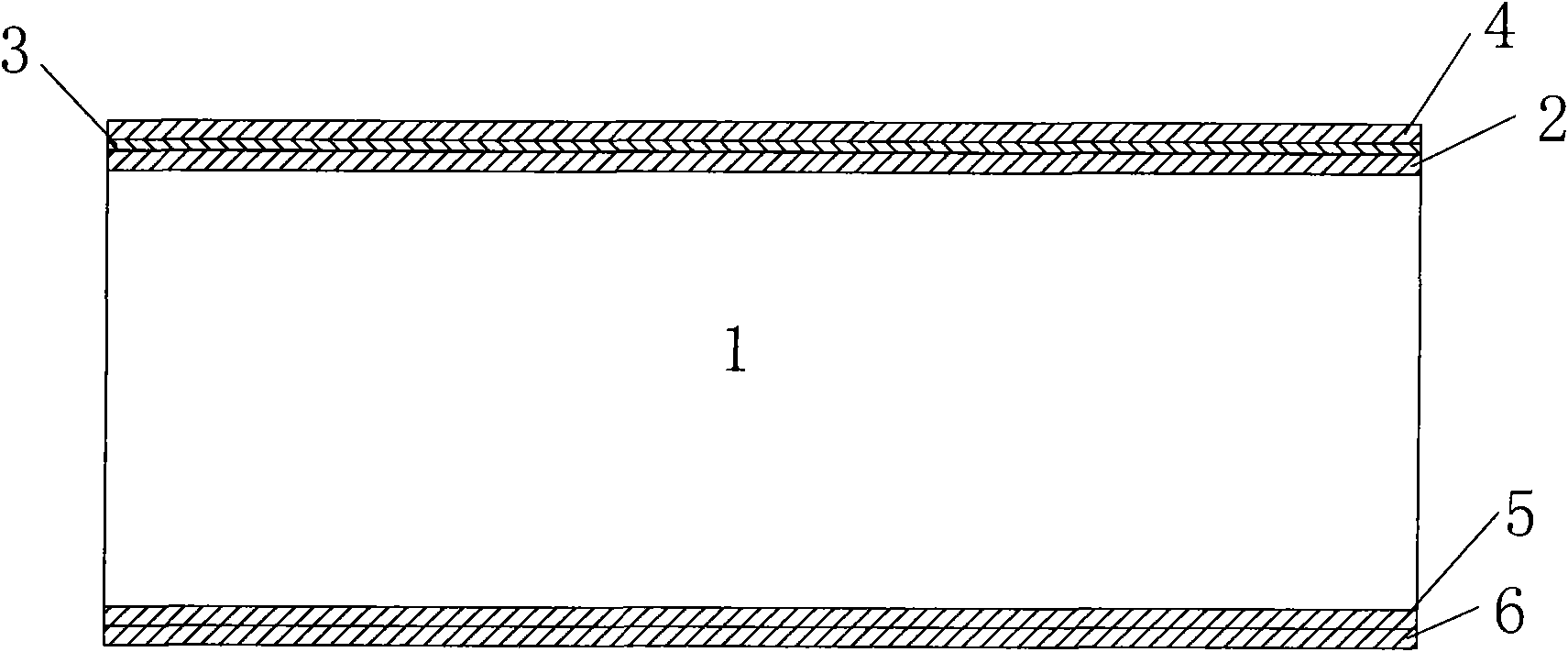

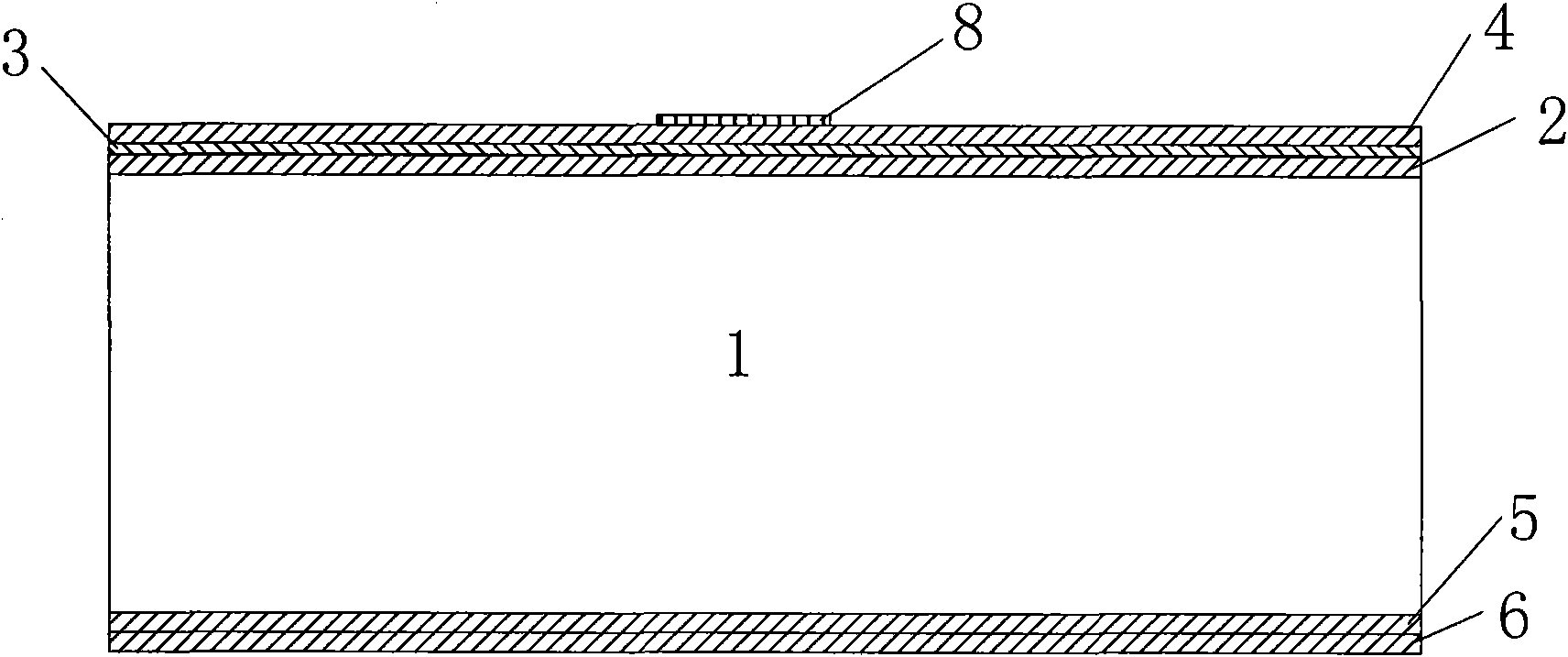

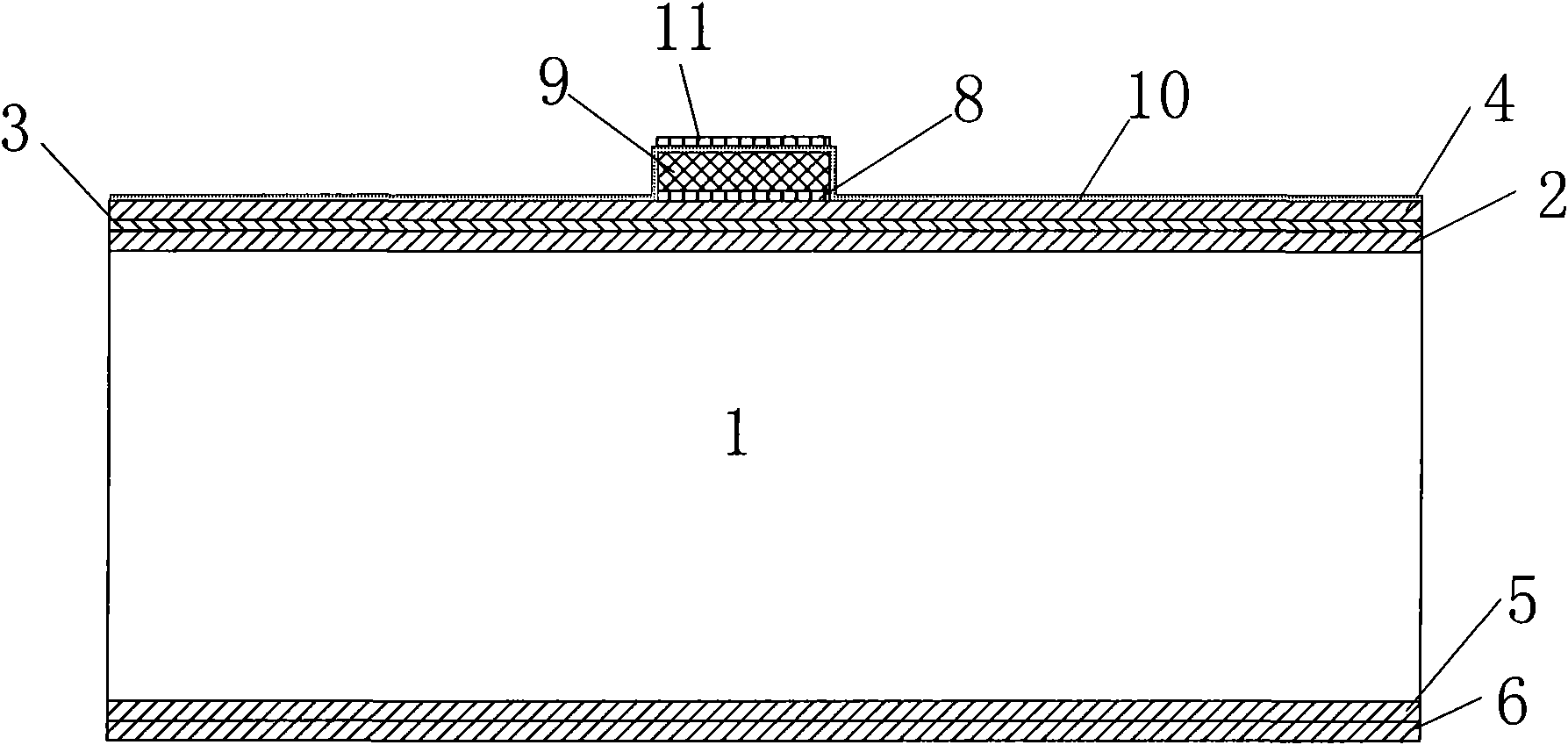

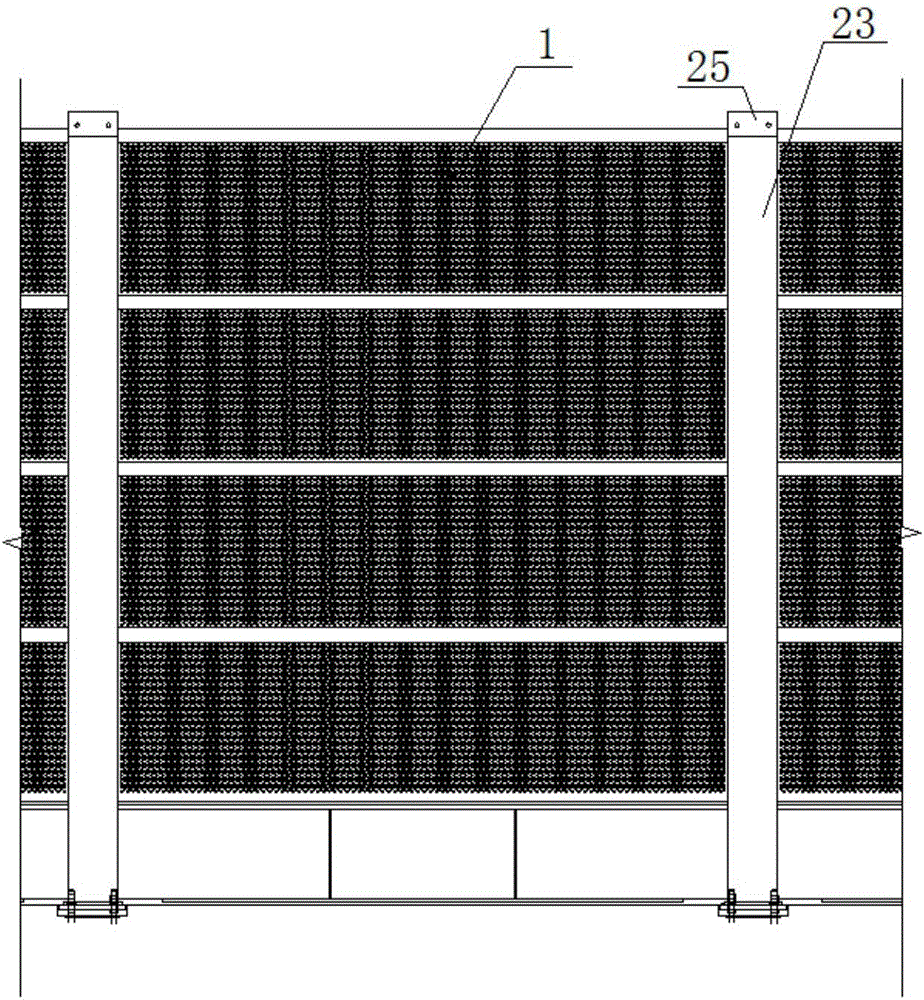

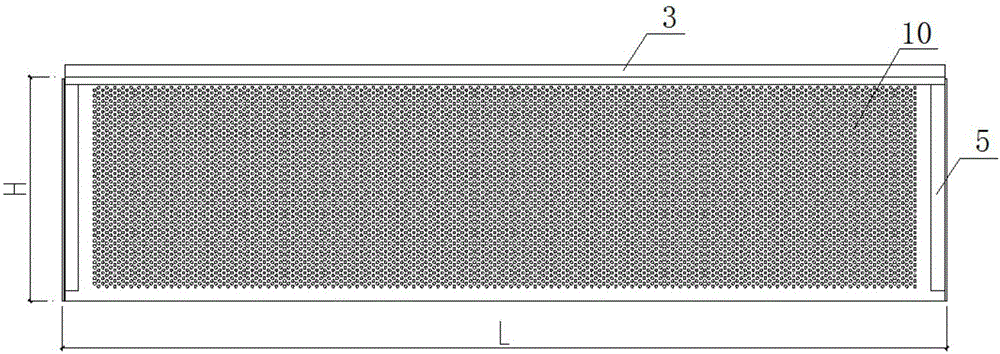

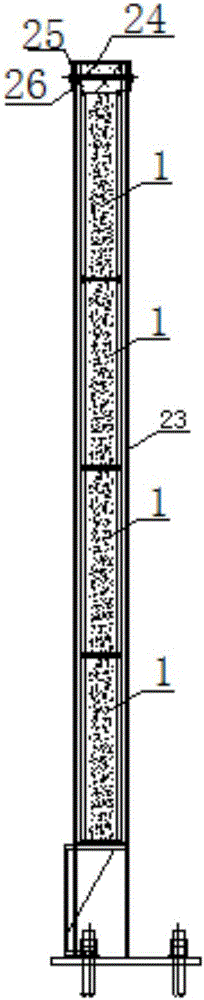

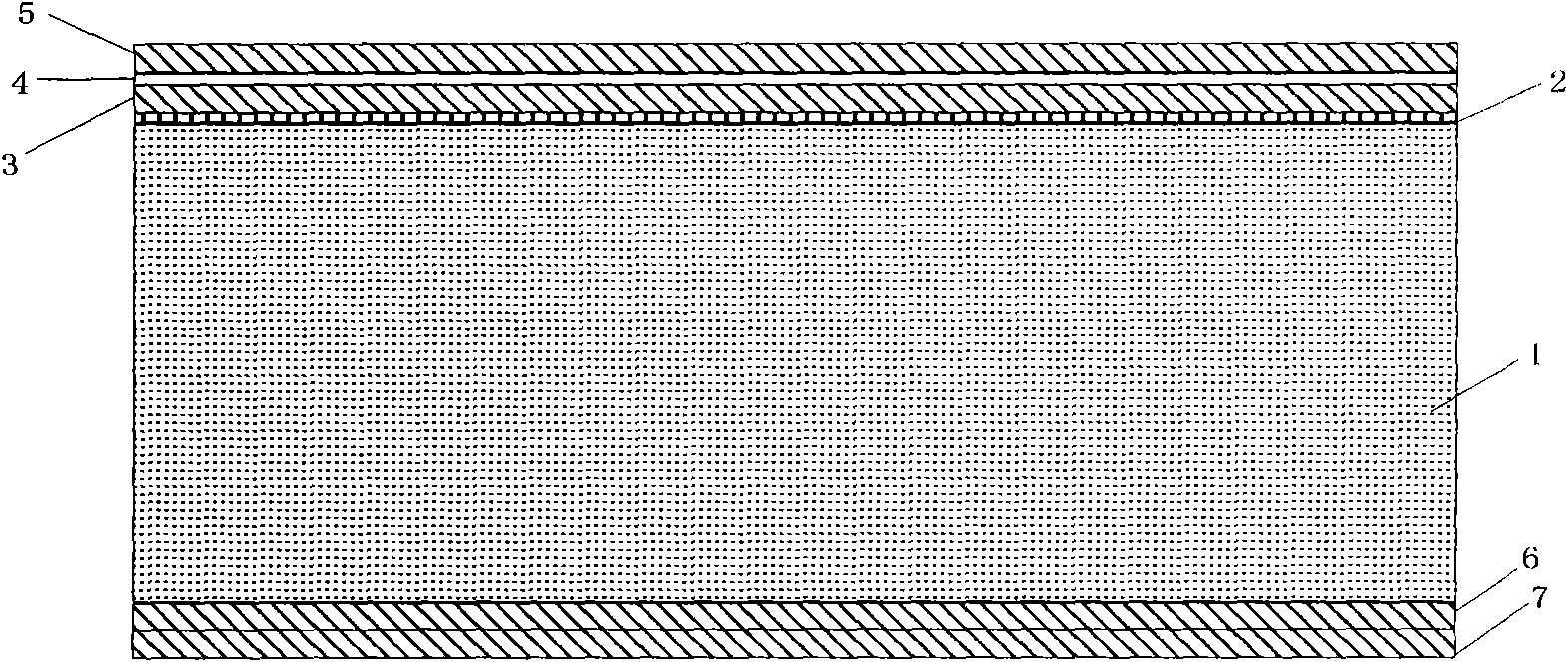

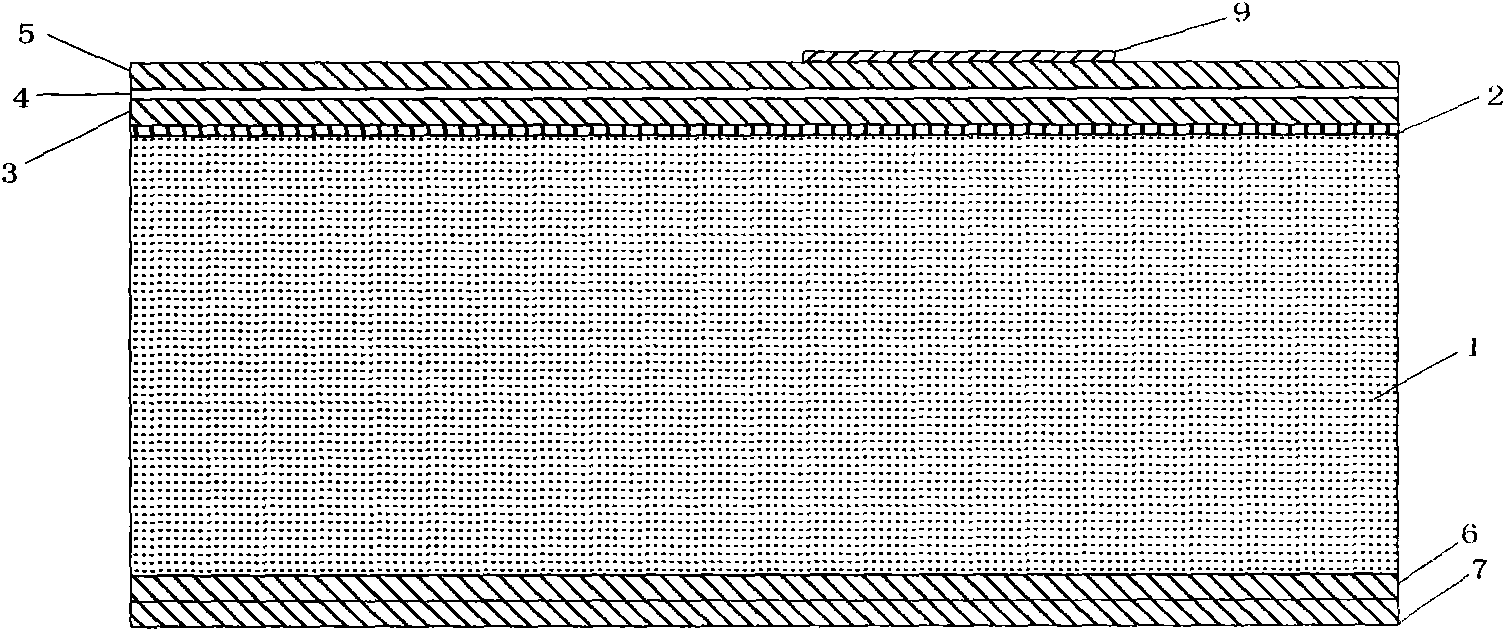

New-structure railway sound barrier

ActiveCN105803966AEliminate gapsPrevent sound leakageNoise reduction constructionSound barrierWeather resistance

The invention relates to a new-structure railway sound barrier which is mainly formed by combining a plurality of new-structure railway sound barrier unit plates (1). Each new-structure railway sound barrier unit plate (1) is composed of an aluminum alloy housing and a light sound absorbing plate (6), wherein the aluminum alloy housing consists of a bottom aluminum section bar (4), a top aluminum section bar (3), end aluminum section bars (5) at the two ends and a U-shaped panel (2). The two sides of each U-shaped panel (2) are restrained in insertion slots of the aluminum section bars (5) at the two ends; each bottom aluminum section bar (4) and each top aluminum section bar (3) are respectively fixed to the top and the bottom of each U-shaped panel (2) through rivets. Each light sound absorbing plate (6) is fixedly arranged in the aluminum alloy housing through upper and lower aluminum section bar clamping slots; each light sound absorbing plate is made of a light sound absorbing material with high strength, good weather resistance and good sound absorption; and a light receiving surface of each light sound absorbing plate (6) is provided with concave and convex slots (22) with special dimension so as to achieve a better noise reduction effect.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Soft support cantilever beam type silicon micro-piezoelectric microphone chip and preparation method thereof

InactiveCN101645485AReduce stressPrevent sound leakagePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksVertical projectionPolyimide membrane

The invention relates to a soft support cantilever beam type silicon micro-piezoelectric microphone chip which comprises a silicon substrate with a square conical hole which is small at the top and big at the bottom in the center, a square compound vibration membrane which consists of a thermal oxidation membrane layer, a first silicon nitride membrane layer, a silicon dioxide membrane layer and asecond silicon nitride membrane layer is covered on the front surface of the silicon substrate, and a first silicon nitride mask layer and a second silicon nitride mask layer with square holes in thecenters thereof are sequentially covered on the back surface; three of four sides of the square compound vibration membrane respectively are etched to form a vertical narrow slot penetrating the square compound vibration membrane, and the vertical projection of each vertical narrow slot is positioned on the inner side of the edge of the square hole in the front surface of the silicon substrate; alower electrode, a piezoelectric membrane and an upper electrode are sequentially deposited on the square compound vibration membrane; one side of the upper electrode is coincided with or near to theside without the narrow slot of the square vibration membrane; and a polyimide membrane which is patterned is deposited on various parts positioned on the front surface of the silicon substrate. Thecantilever beam structure can prevent sound leakage phenomenon and has the advantages of high sensitivity, anti-sound leakage and the like.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Microphone package, lead frame, mold substrate, and mounting structure therefor

InactiveUS20090175479A1Low costPrevent sound leakagePiezoelectric/electrostrictive microphonesPrinted circuit detailsEngineeringLead frame

A microphone package is constituted of a cover and a mold substrate that is formed in accordance with the resin mold technology so as to form a cavity for embracing a microphone chip. The mold substrate is constituted of a stage having conductivity and a rectangular shape for mounting a microphone chip thereon, a plurality of lead terminals having conductivity and electrically connected to the microphone chip, and a resin mold for electrically insulating the stage from the lead terminals. A sound hole is formed in the mold substrate by use of a cylindrical projection which projects from the backside of the stage and whose distal surface is exposed from the backside of the mold substrate. When the microphone package is mounted on the mounting surface of an external substrate, it is possible to prevent sound from being leaked via gaps therebetween.

Owner:YAMAHA CORP

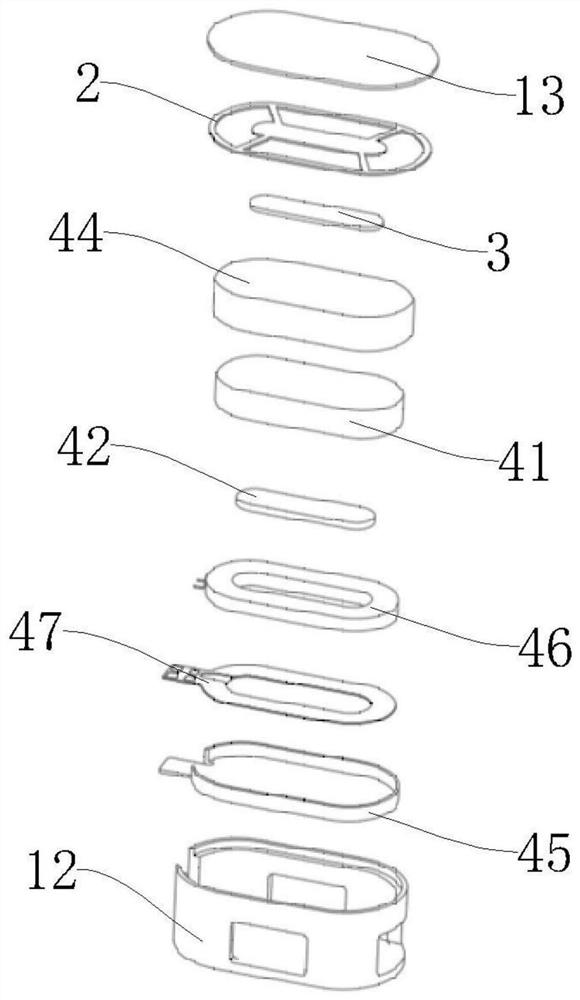

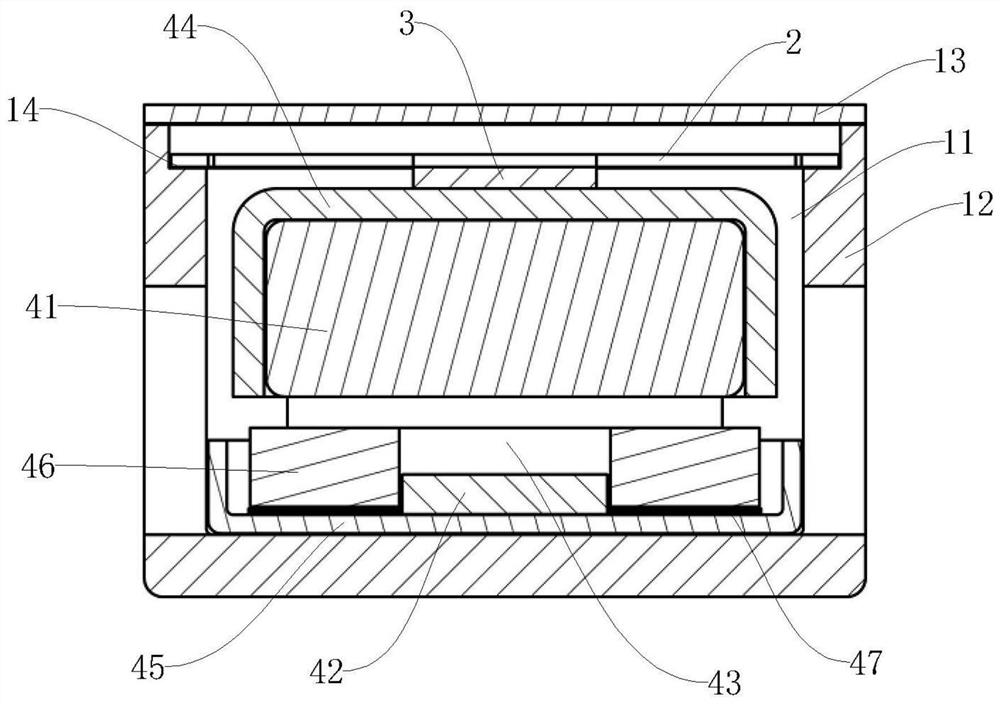

Bone conduction sound production device and wearable equipment

PendingCN112887870AImprove experienceModerate rangeBone conduction transducer hearing devicesFrequency/directions obtaining arrangementsVibration amplitudeTransmission amplitude

The invention discloses a bone conduction sound production device and wearable equipment, wherein the bone conduction sound production device comprises an external packaging structure, the external packaging structure is internally provided with a hollow cavity, and the hollow cavity is internally provided with: a hollow elastic sheet; an exciter, which comprises an upper magnetic piece and a lower magnetic piece, wherein the upper magnetic piece and the lower magnetic piece are oppositely arranged in parallel in the Z-axis direction, and a gap exists between the upper magnetic piece and the lower magnetic piece to form an isolation area; a space low-frequency adjusting plate, which is arranged between the hollowed-out elastic piece and the exciter, wherein the space low-frequency adjusting plate is used for adjusting the framework stacking of the hollowed-out elastic piece and the exciter in the Z-axis direction and adjusting the gap of the isolation area; the hollowed-out elastic piece is matched with the space low-frequency adjusting plate to adjust the effective vibration area of the hollowed-out elastic piece so as to adjust the resonant frequency point of the device. The wearable equipment provided with the bone conduction sound production device can transmit low-frequency signals, wherein the transmission amplitude is moderate, the whole sound frequency band is balanced, the good acoustic effect is achieved, and the user experience and the product sound quality are remarkably improved.

Owner:SUZHOU THOR ELECTRONIC TECH CO LTD

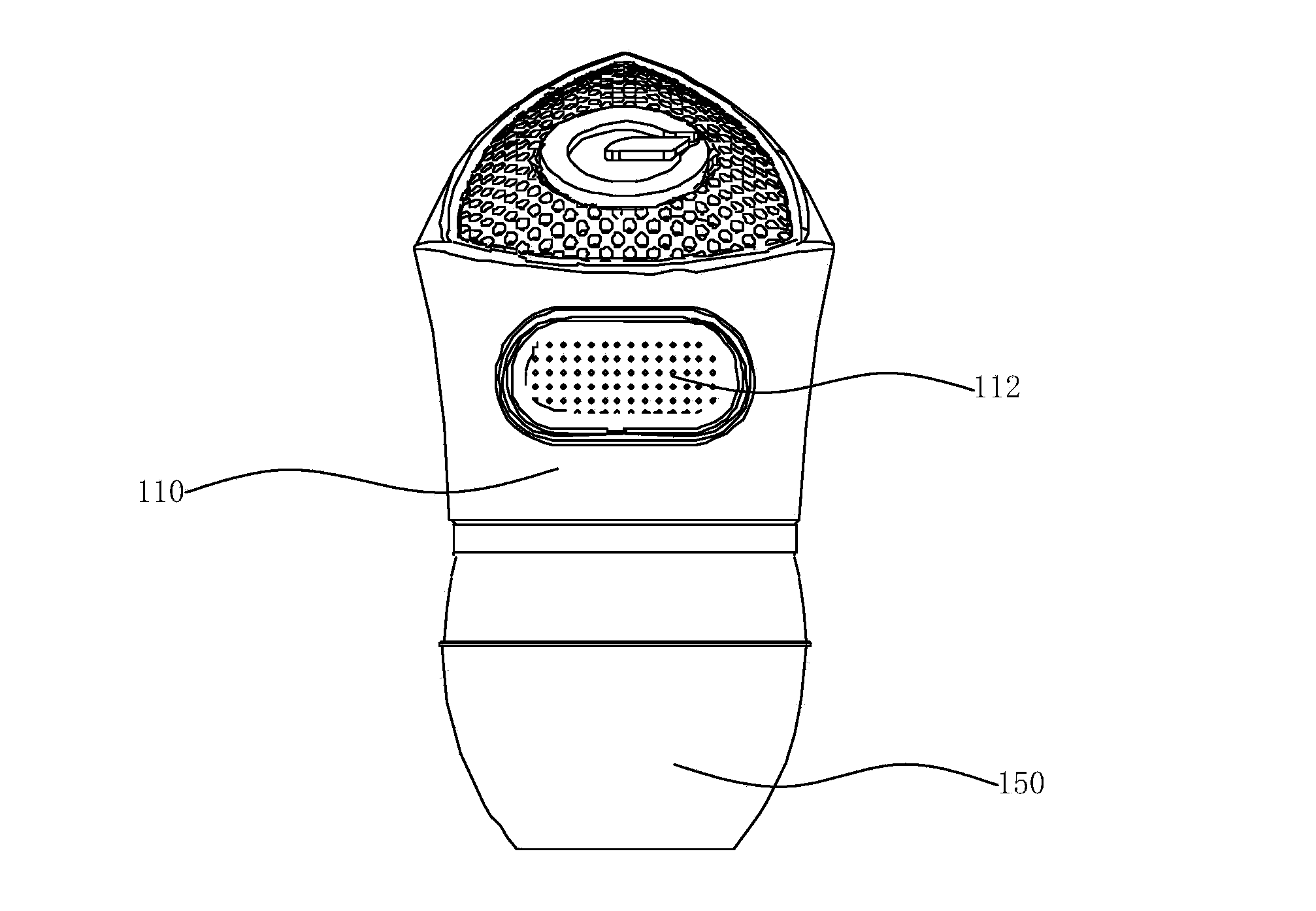

In-ear earphone

InactiveCN103533470AEnhanced low frequency reproducibilityImprove sound qualityEarpiece/earphone attachmentsEngineeringHeadphones

The invention provides an in-ear earphone, and belongs to the technical field of earphones. The problems of poor low-frequency reproducibility, poor sealing performance and more serious sound leakage of a conventional in-ear earphone are solved. The in-ear earphone comprises earphone bodies, wherein each earphone body comprises a main shell with an accommodation cavity and a loudspeaker arranged in the main shell; a front cover is arranged at the front end of each main shell; a sound guide tube axially extends from the middle part of each front cover; the front end of each loudspeaker is in sealing connection with the inner wall of the corresponding front cover; the inner wall of each front cover is gradually reduced from the rear end to the front end; a bucket-shaped sound guide hole is formed in each front cover and the corresponding sound guide tube; a toning hole is vertically formed in the top of each main shell, and is positioned in the rear end of the corresponding loudspeaker; a net cover is arranged on each toning hole; the rear wall of each accommodation wall is parallel to the rear end face of the corresponding loudspeaker; the loudspeakers and the toning holes are perpendicular to the bucket-shaped sound guide holes. According to the in-ear earphone, the low-frequency reproducibility of the earphone is enhanced, ear canals of a user can be prevented from being completely isolated from the outside, potential threats are avoided, and the occurrence of a sound leakage phenomenon is prevented.

Owner:NINGBO VICTORY ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com