Patents

Literature

222 results about "Ring doughnut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ring doughnuts are formed by one of two methods: by joining the ends of a long, skinny piece of dough into a ring, or by using a doughnut cutter, which simultaneously cuts the outside and inside shape, leaving a doughnut-shaped piece of dough and a doughnut hole (from the dough removed from the center).

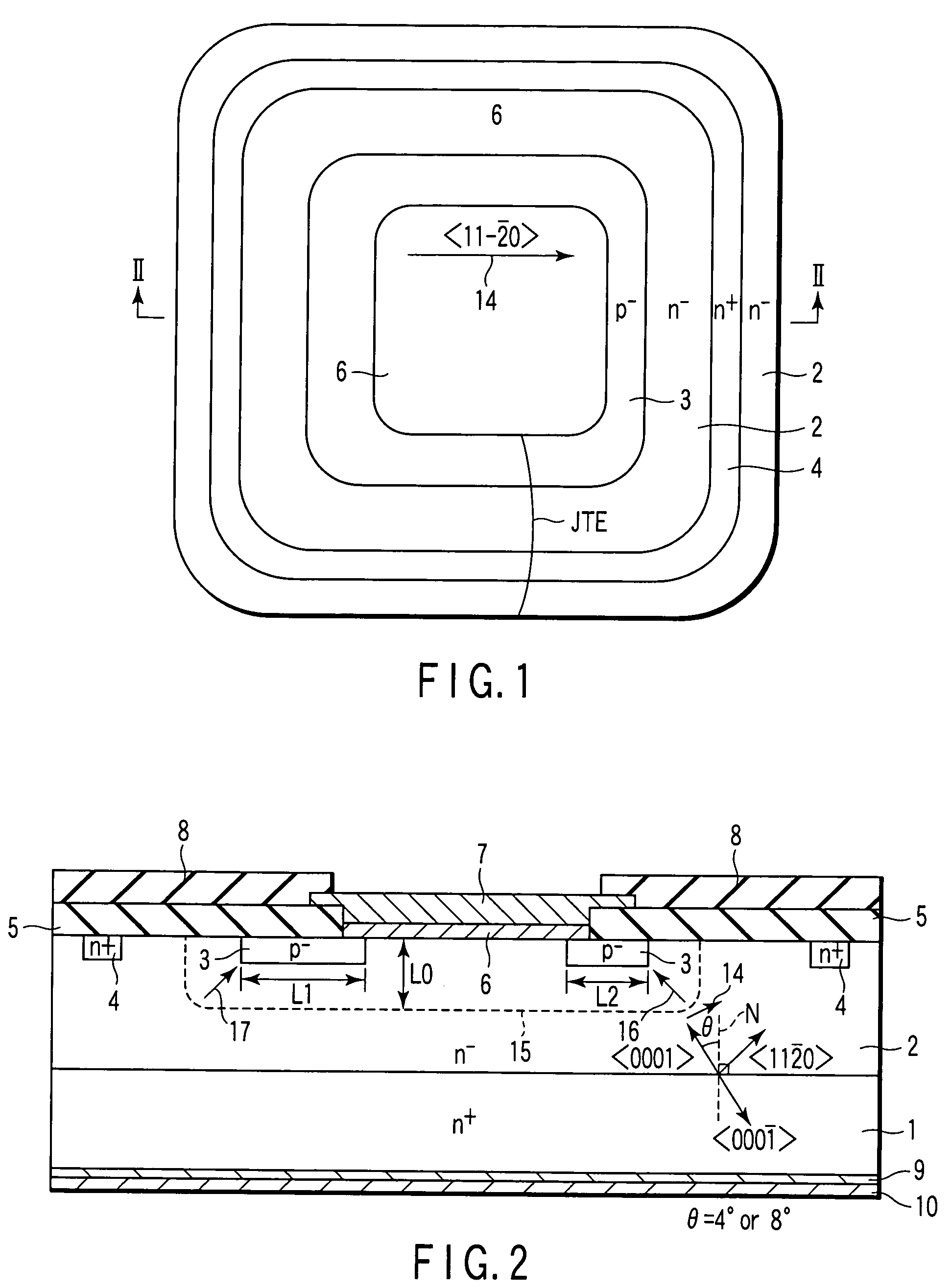

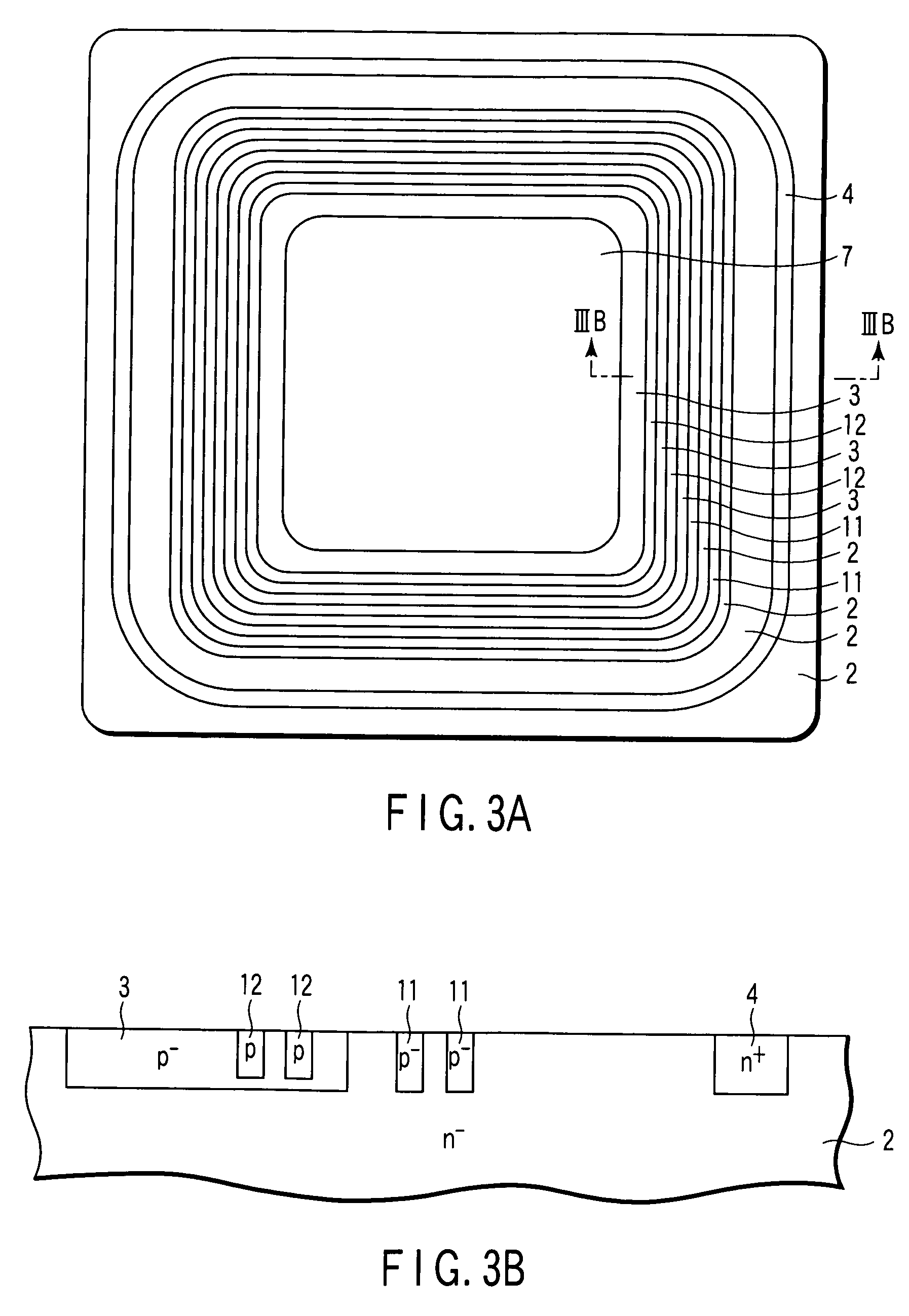

Semiconductor device

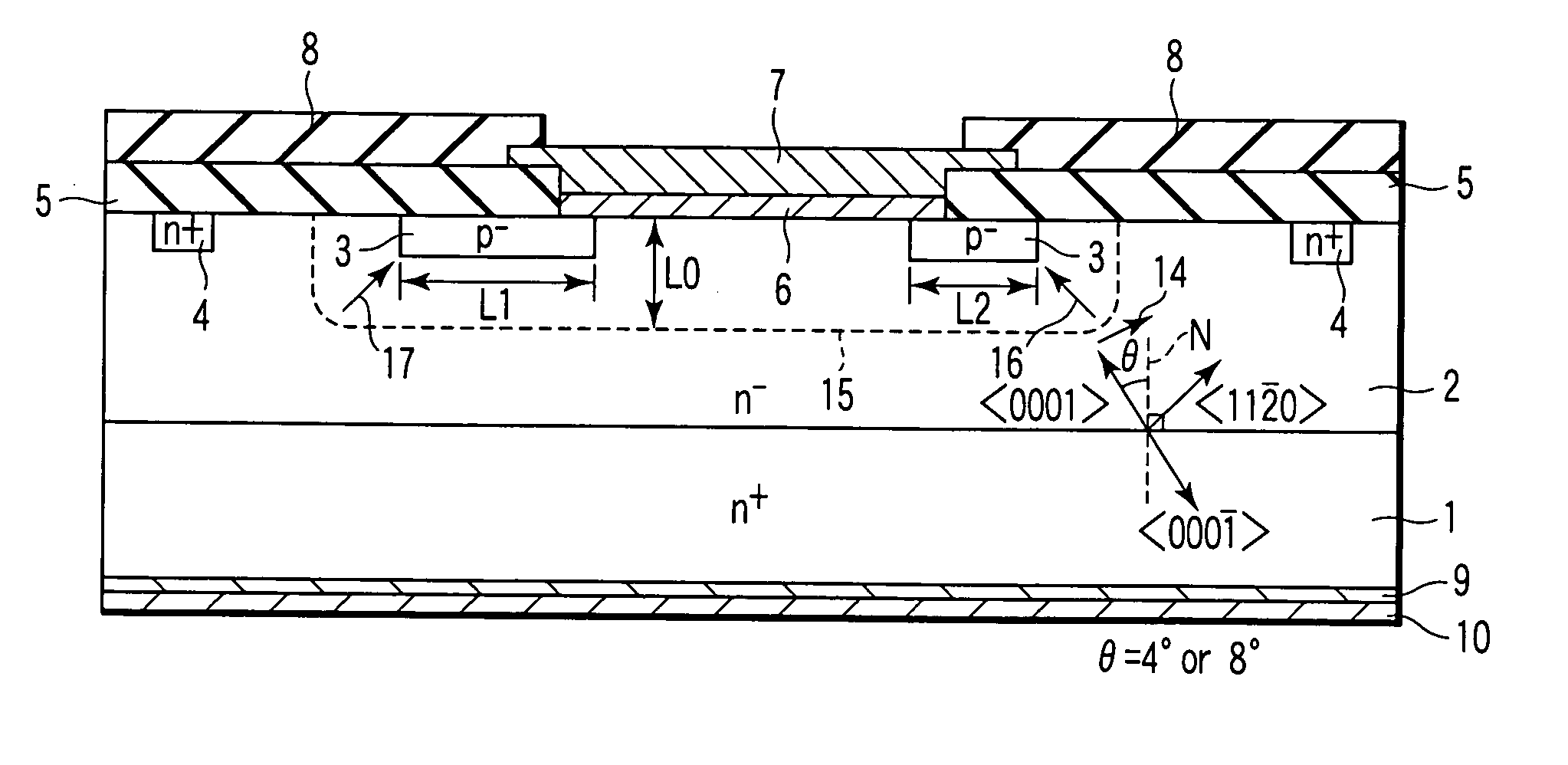

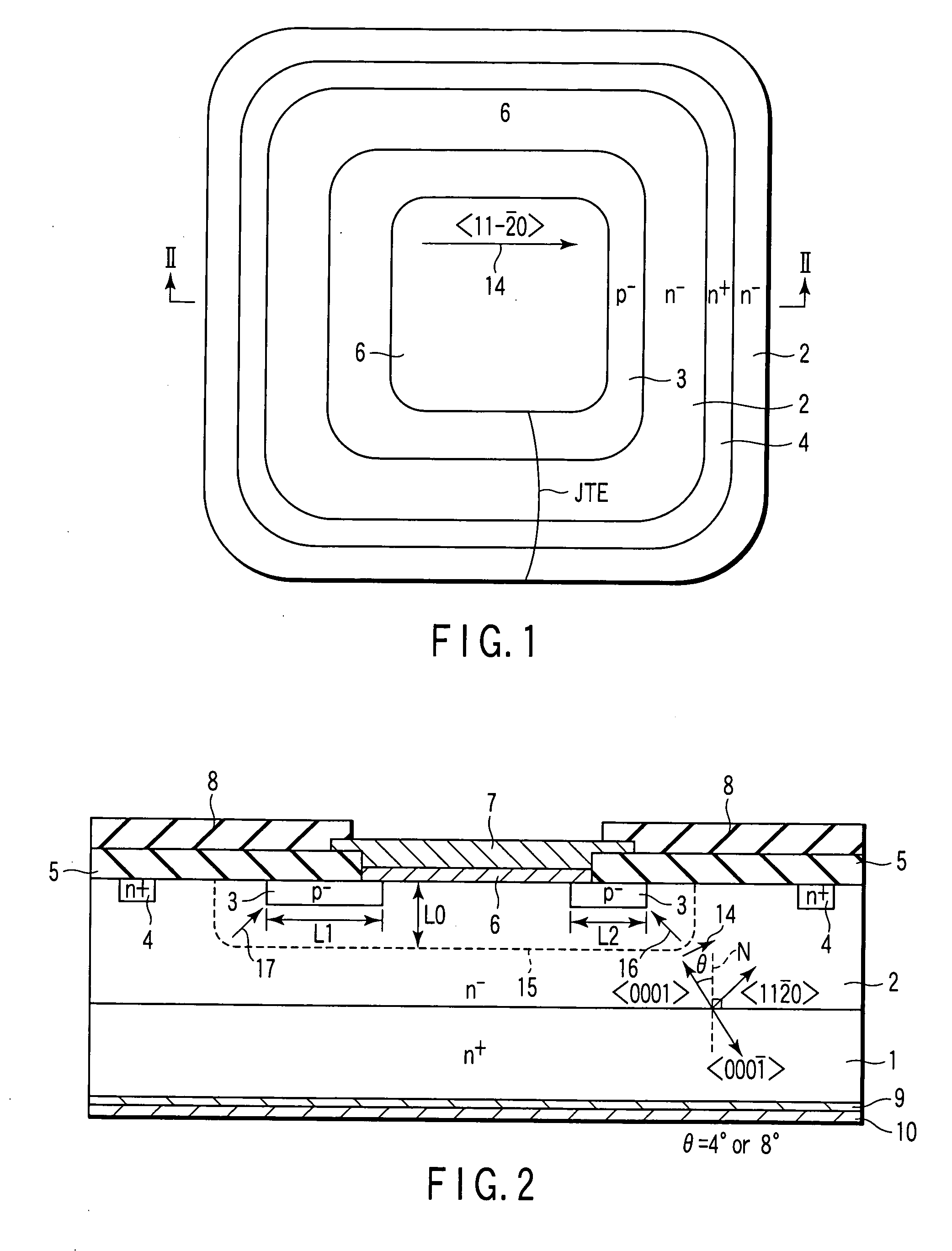

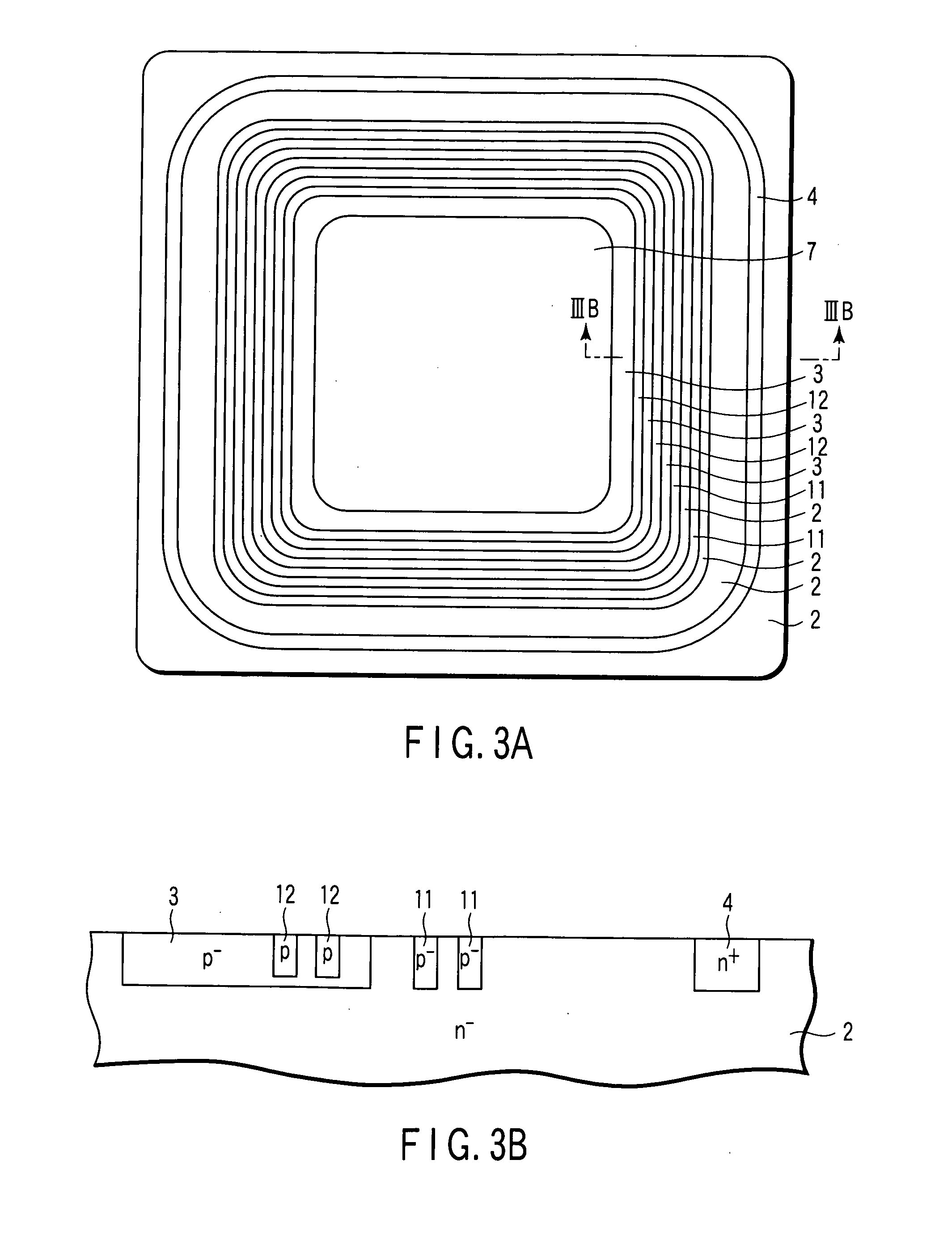

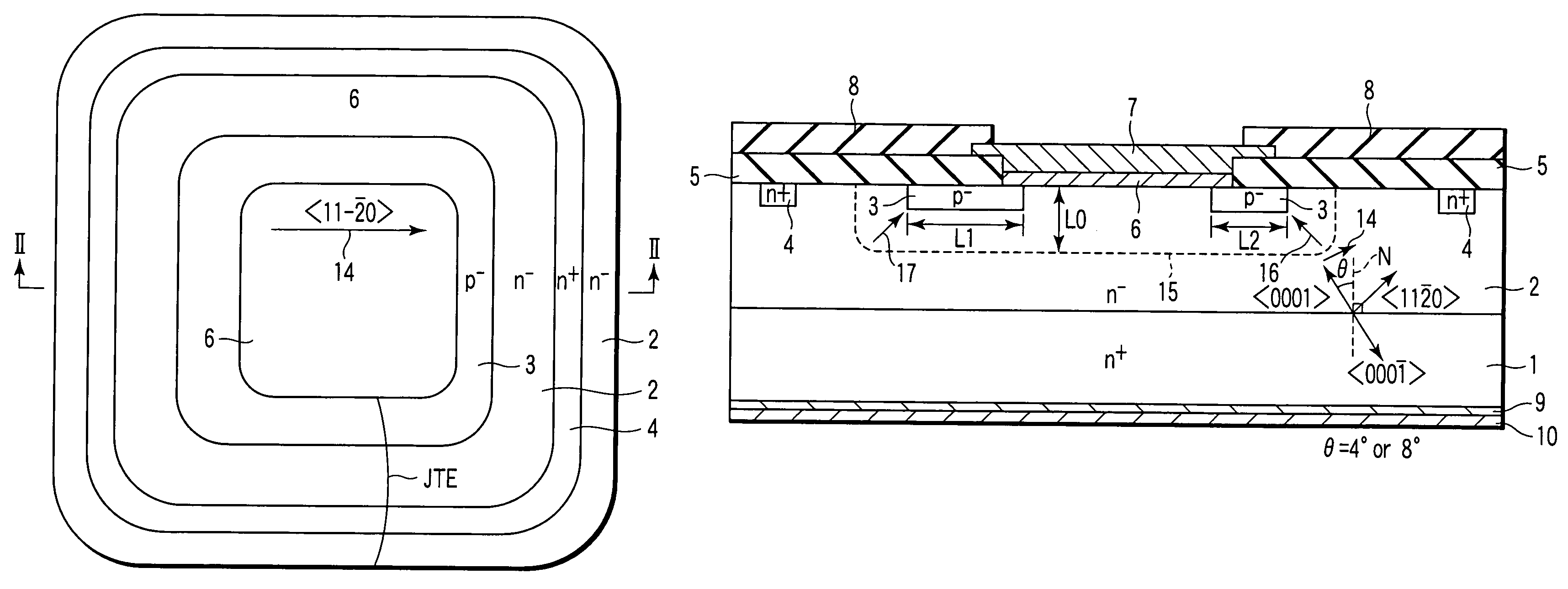

A semiconductor device includes an SiC substrate, a normal direction of the substrate surface being off from a <0001> or <000-1> direction in an off direction, an SiC layer formed on the SiC substrate, a junction forming region formed in a substantially central portion of the SiC layer, a junction termination region formed to surround the junction forming region, and including a semiconductor region of a conductivity type different from the SiC layer formed as a substantially quadrangular doughnut ring, having two edges facing each other, each crossing a projection direction, which is obtained when the off direction is projected on the upper surface of the SiC layer, at a right angle, wherein a width of one of the two edges on an upper stream side of the off direction is L1, that of the other edge on a down stream side is L2, and a relation L1>L2 is satisfied.

Owner:KK TOSHIBA

Semiconductor device

A semiconductor device includes an SiC substrate, a normal direction of the substrate surface being off from a <0001> or <000-1> direction in an off direction, an SiC layer formed on the SiC substrate, a junction forming region formed in a substantially central portion of the SiC layer, a junction termination region formed to surround the junction forming region, and including a semiconductor region of a conductivity type different from the SiC layer formed as a substantially quadrangular doughnut ring, having two edges facing each other, each crossing a projection direction, which is obtained when the off direction is projected on the upper surface of the SiC layer, at a right angle, wherein a width of one of the two edges on an upper stream side of the off direction is L1, that of the other edge on a down stream side is L2, and a relation L1>L2 is satisfied.

Owner:KK TOSHIBA

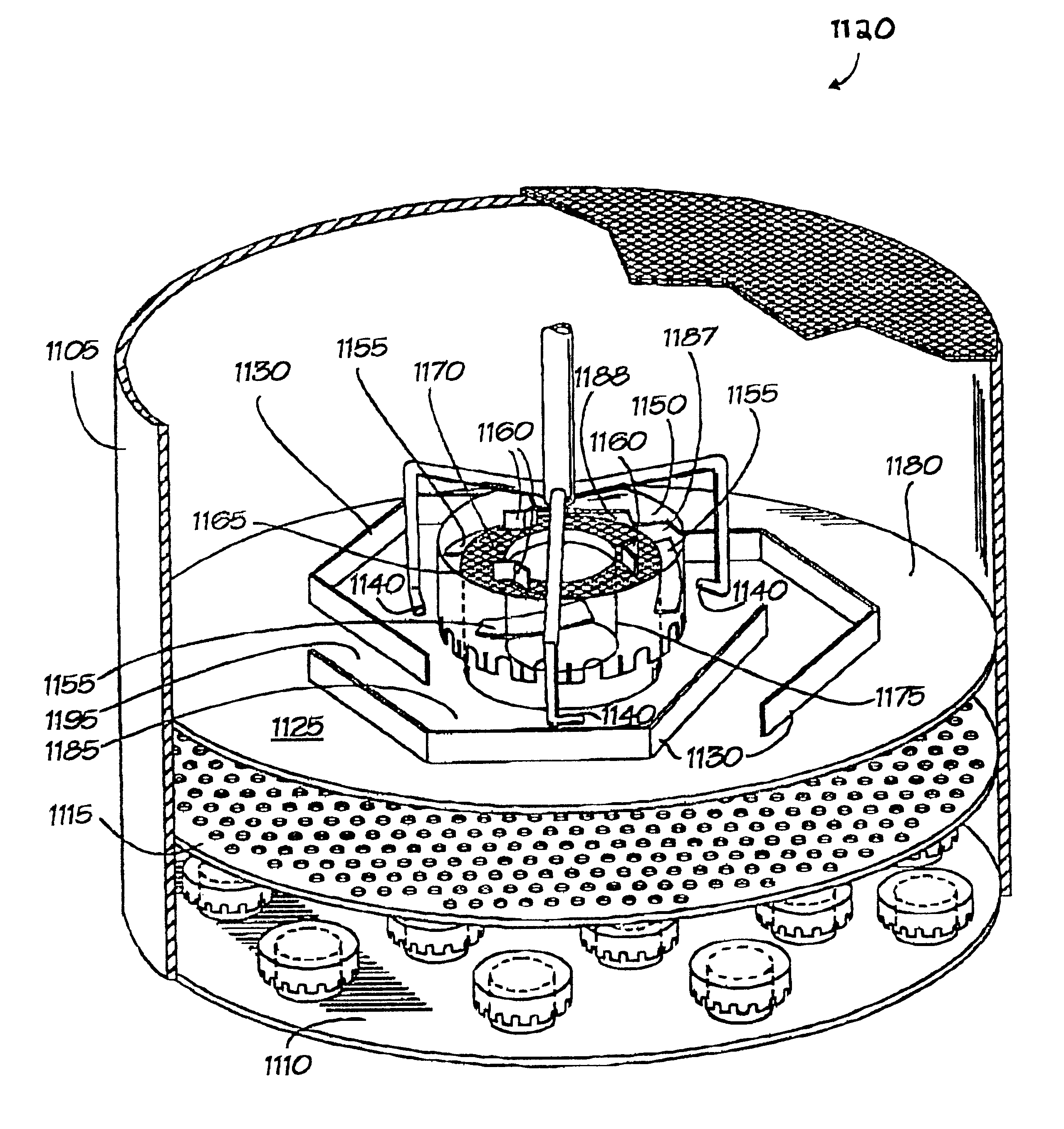

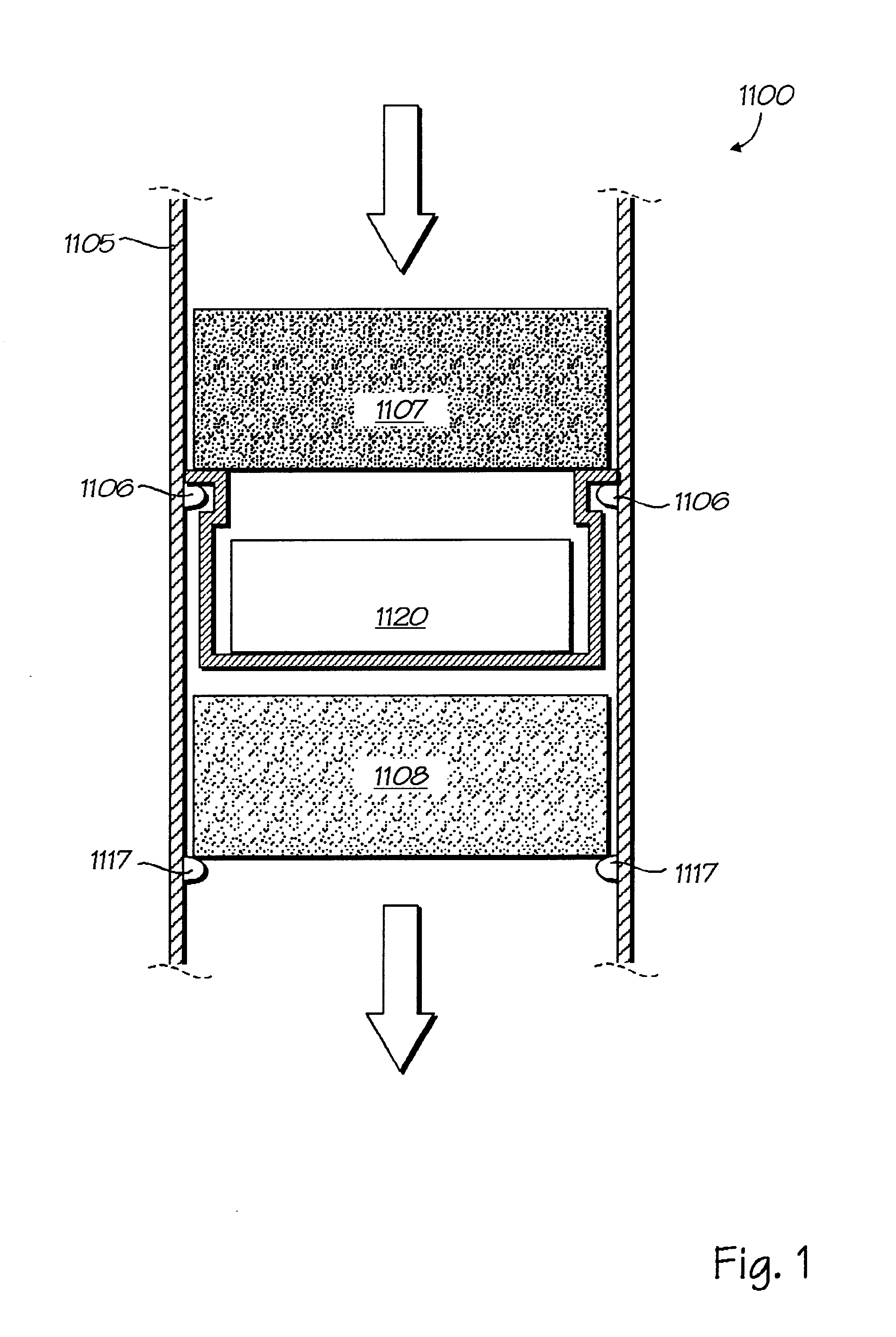

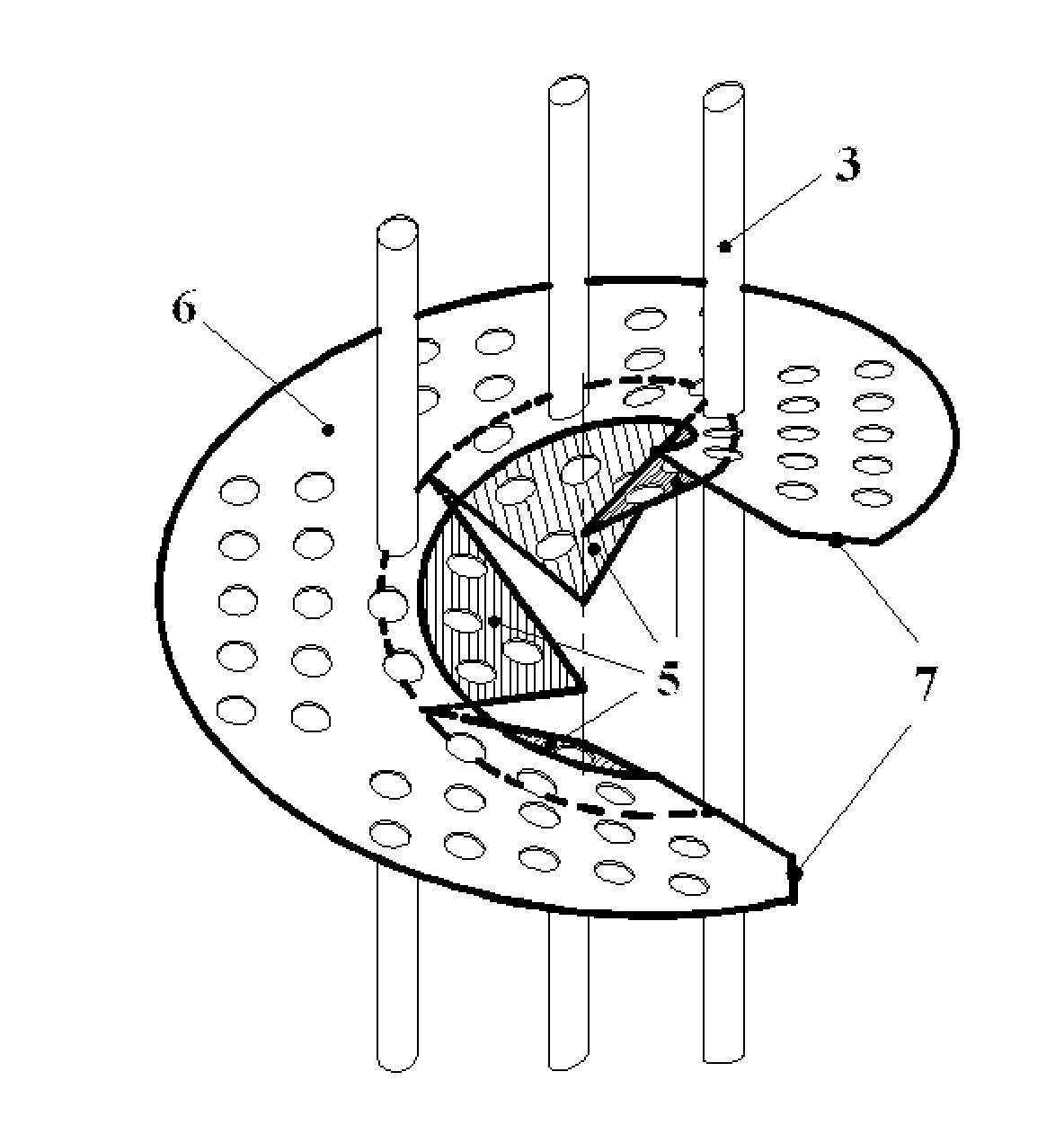

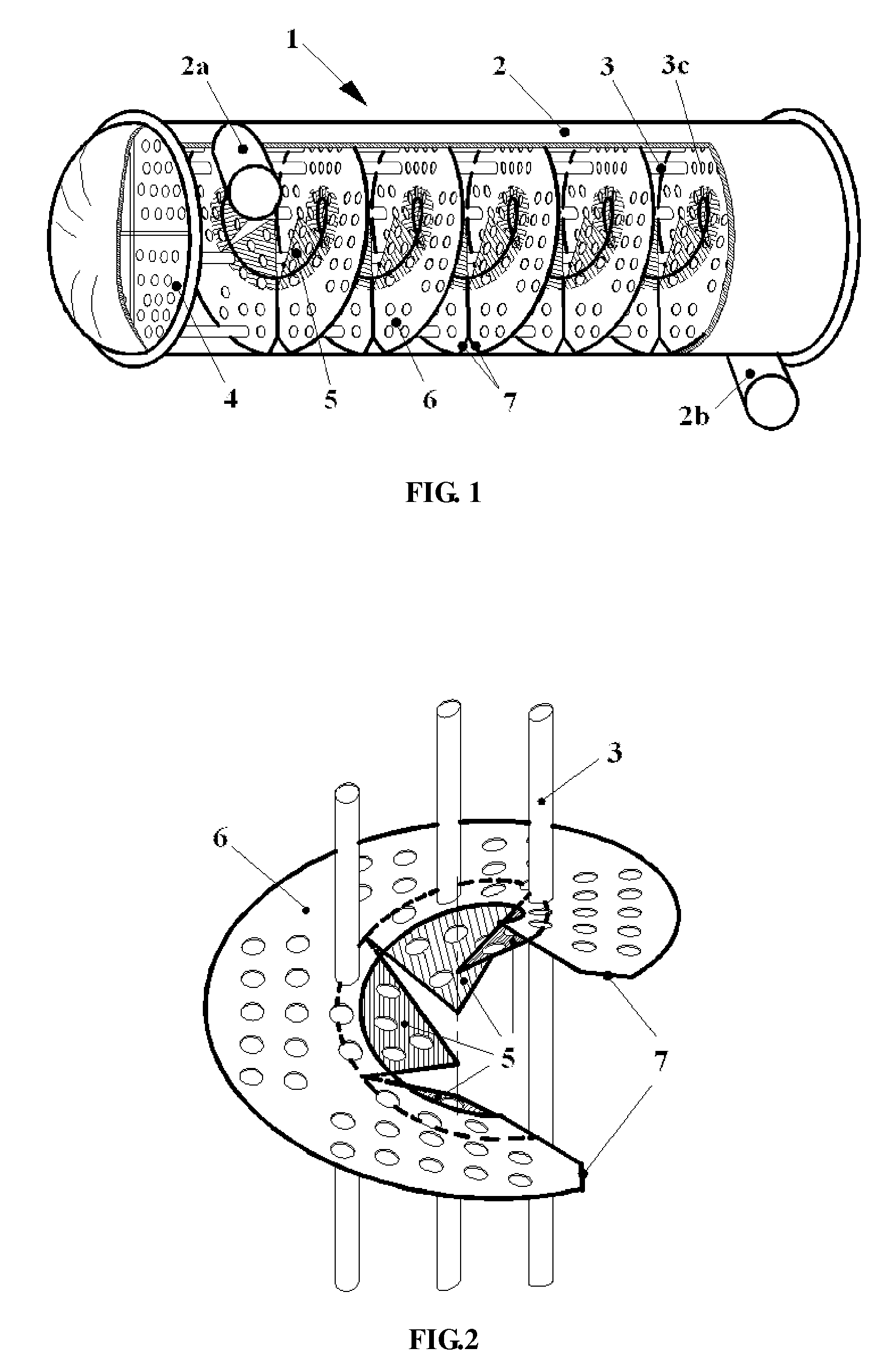

Fluid distributor assembly for a multi-bed, downflow catalytic reactor

InactiveUS6183702B1Low liquid holdupWell mixedPhysical/chemical process catalystsFuel re-atomisation/homogenisationProduct gasEngineering

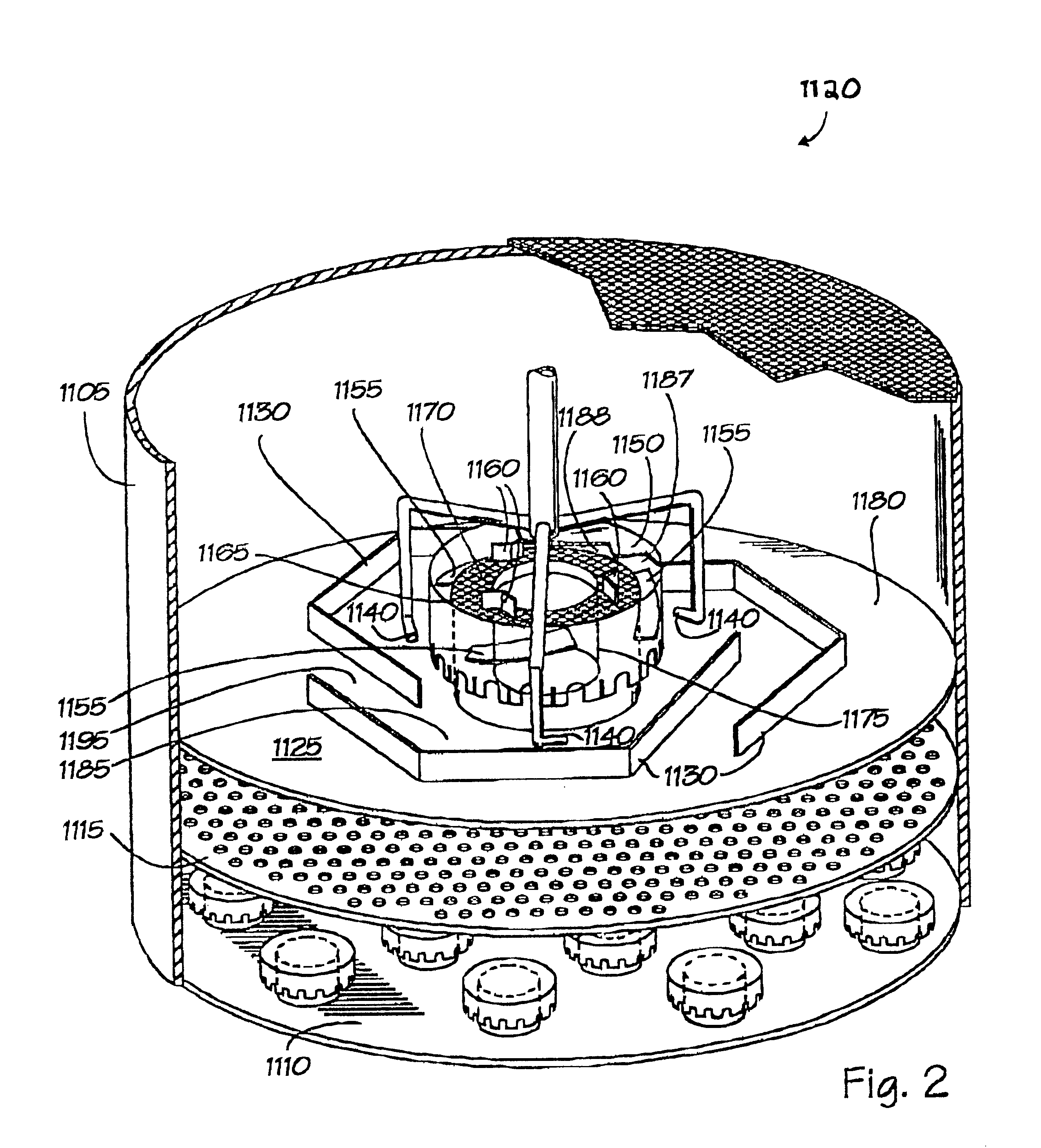

A distributor assembly for a multi-bed, downflow catalytic reactor is disclosed. The distributor assembly is configured for disposal and fixable attachment between the inner surfaces of the walls of a multi-bed downflow cylindrical reactor wall and for disposal between vertically stacked catalyst beds within the reactor. The assembly includes:(a) a collection plate configured for substantially horizontal disposal between the walls of a cylindrical reactor;(b) a plurality of generally arc-shaped elongated baffles disposed in a staggered, substantially symmetrical pattern about the collection plate;(c) a first mixing zone configured to be bounded on the bottom by the collection plate, on one side by a wall of a cylindrical reactor, and on the opposite side by the outer surface of the elongated baffles;(d) a cylindrical weir fixably attached to the collection plate about the outlet;(e) a second mixing zone bounded on the bottom by the collection plate, on one side by the outer surface of the cap and the first cylindrical weir, and on the opposite side by the inner surface of the elongated baffles;(f) a cap disposed over and about the first cylindrical weir, thereby forming a third mixing zone, plurality of semi-spiral-shaped baffles disposed in the third mixing zone, the semi-spiral-shape;(g) baffles having an elongated shape, having one lateral edge fixed to an inner surface of the cap or an opposite lateral edge fixed to an outer surface of the first cylindrical weir;(h) a substantially doughnut-shaped screen member disposed over a top portion of the cylindrical weir;(i) a plurality of fourth-mixing-zone baffles fixably attached to a top surface of the doughnut-shaped screen member; and(j) a plurality of quench gas ports disposed in the second mixing zone.

Owner:CHEVROU USA INC

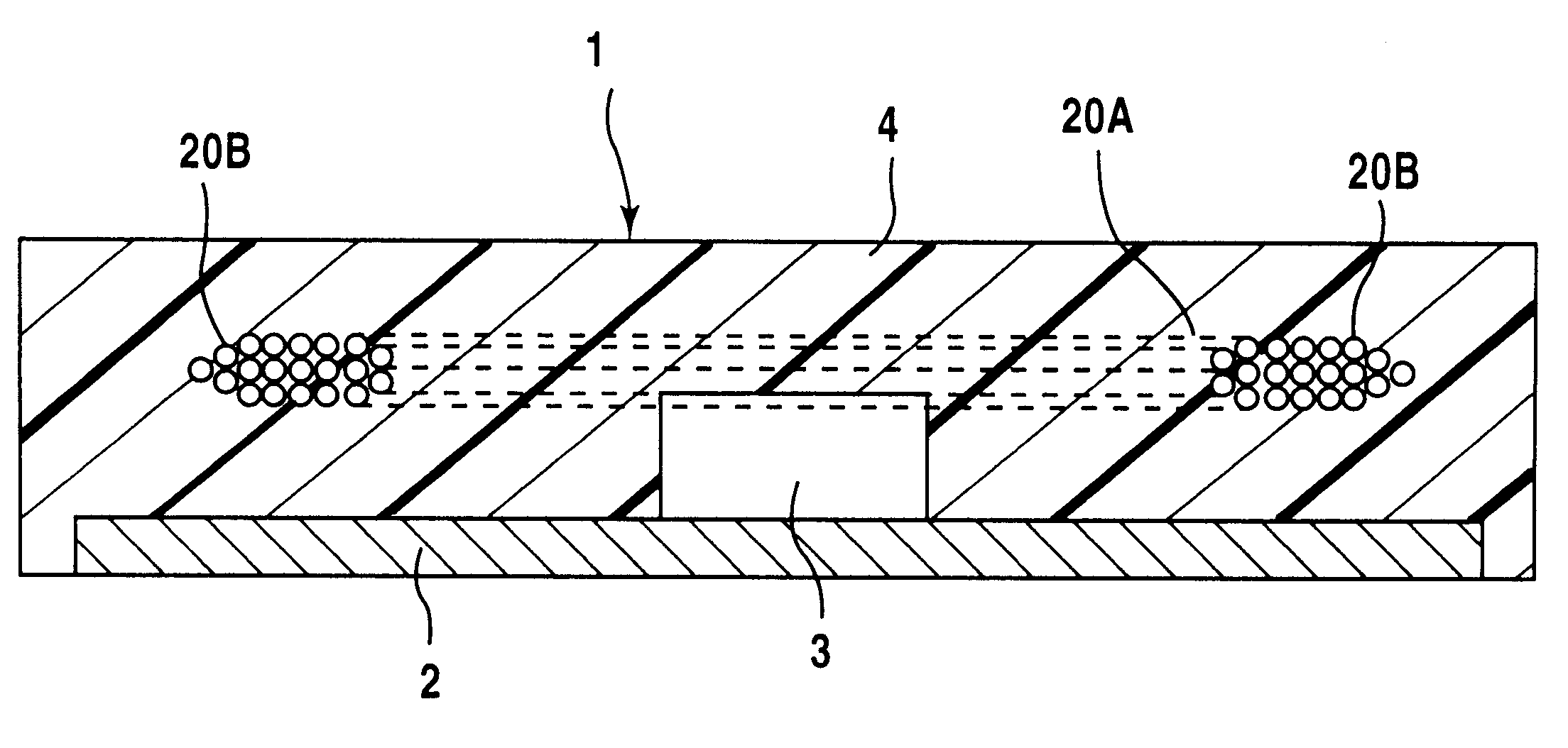

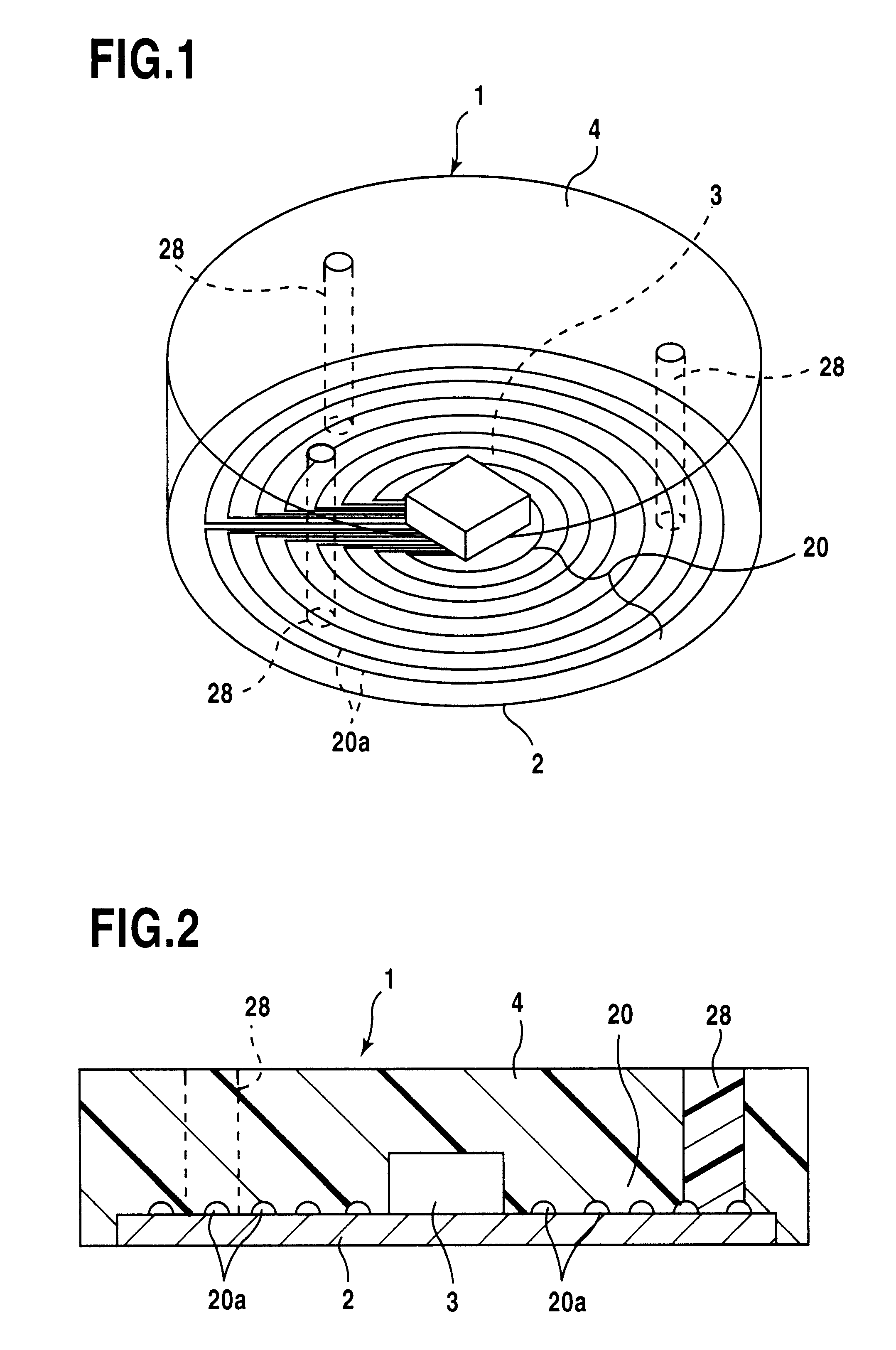

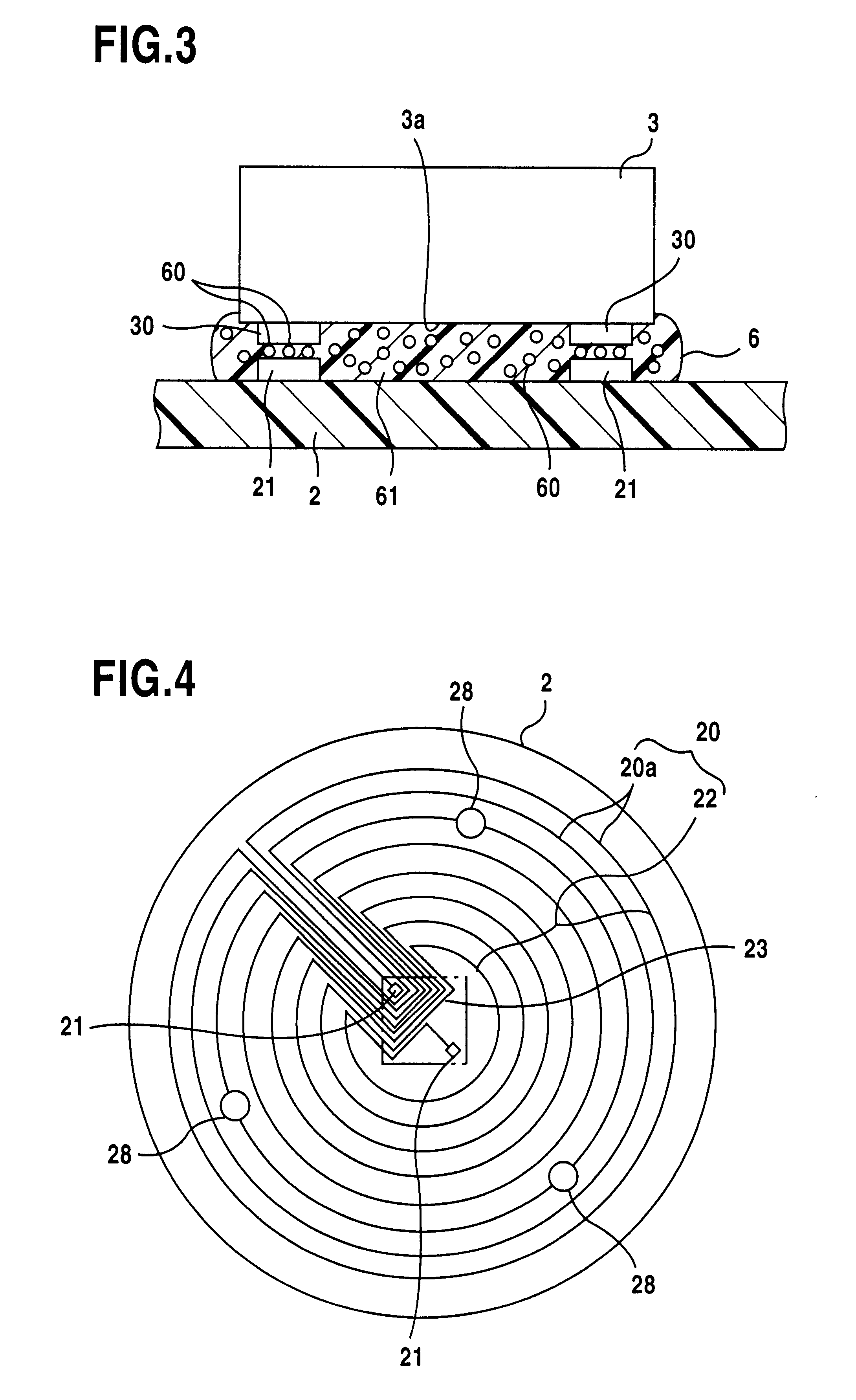

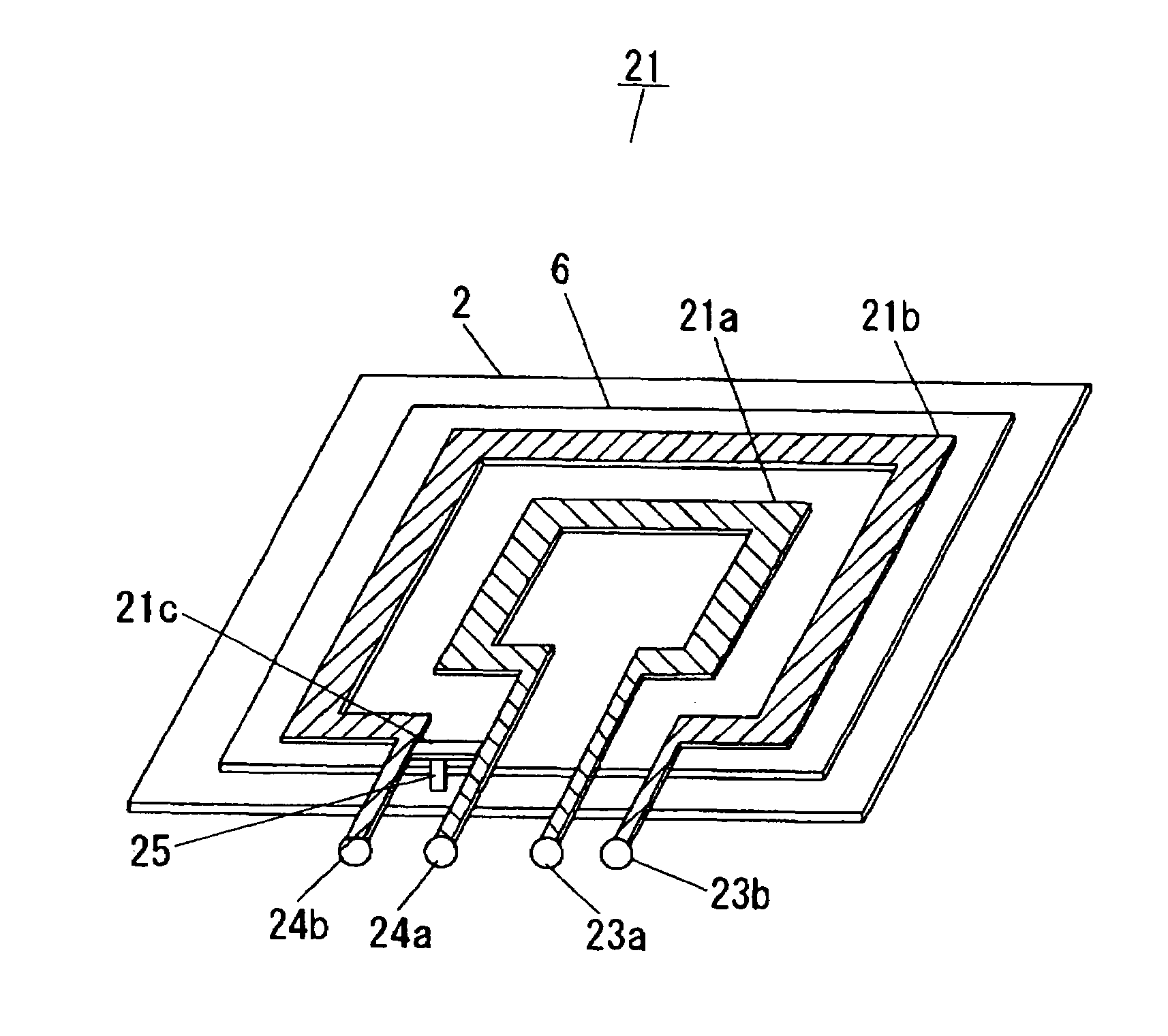

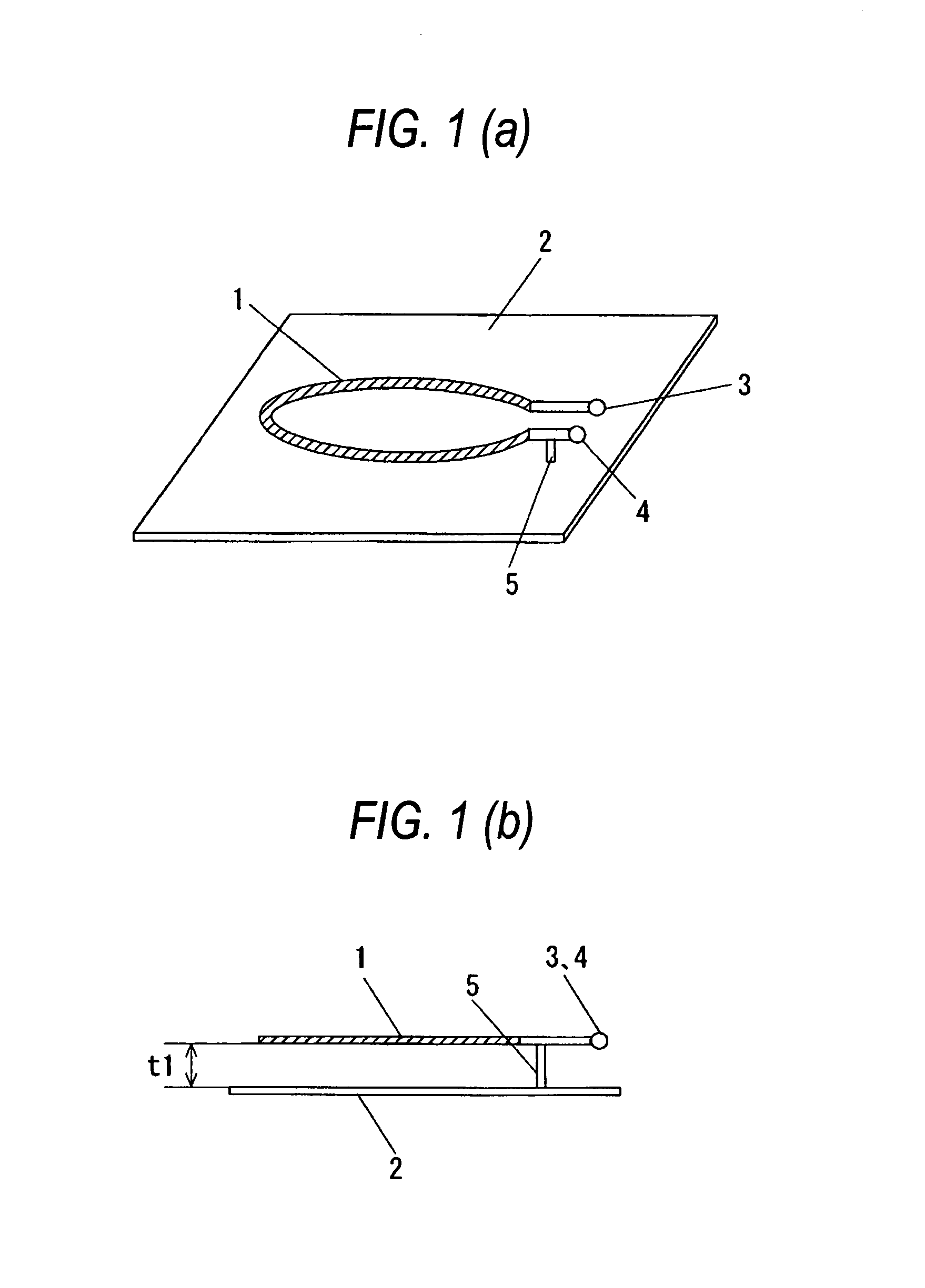

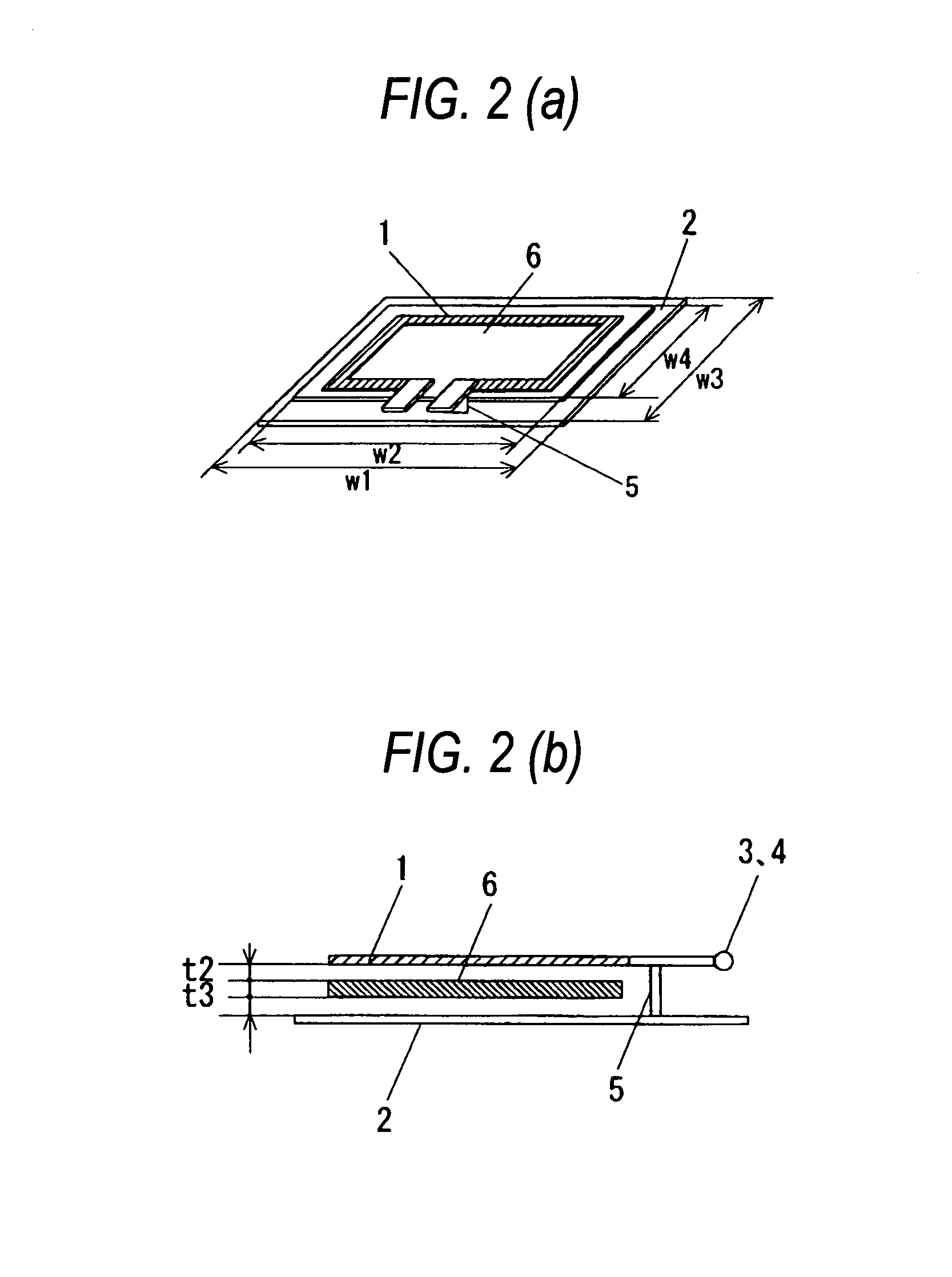

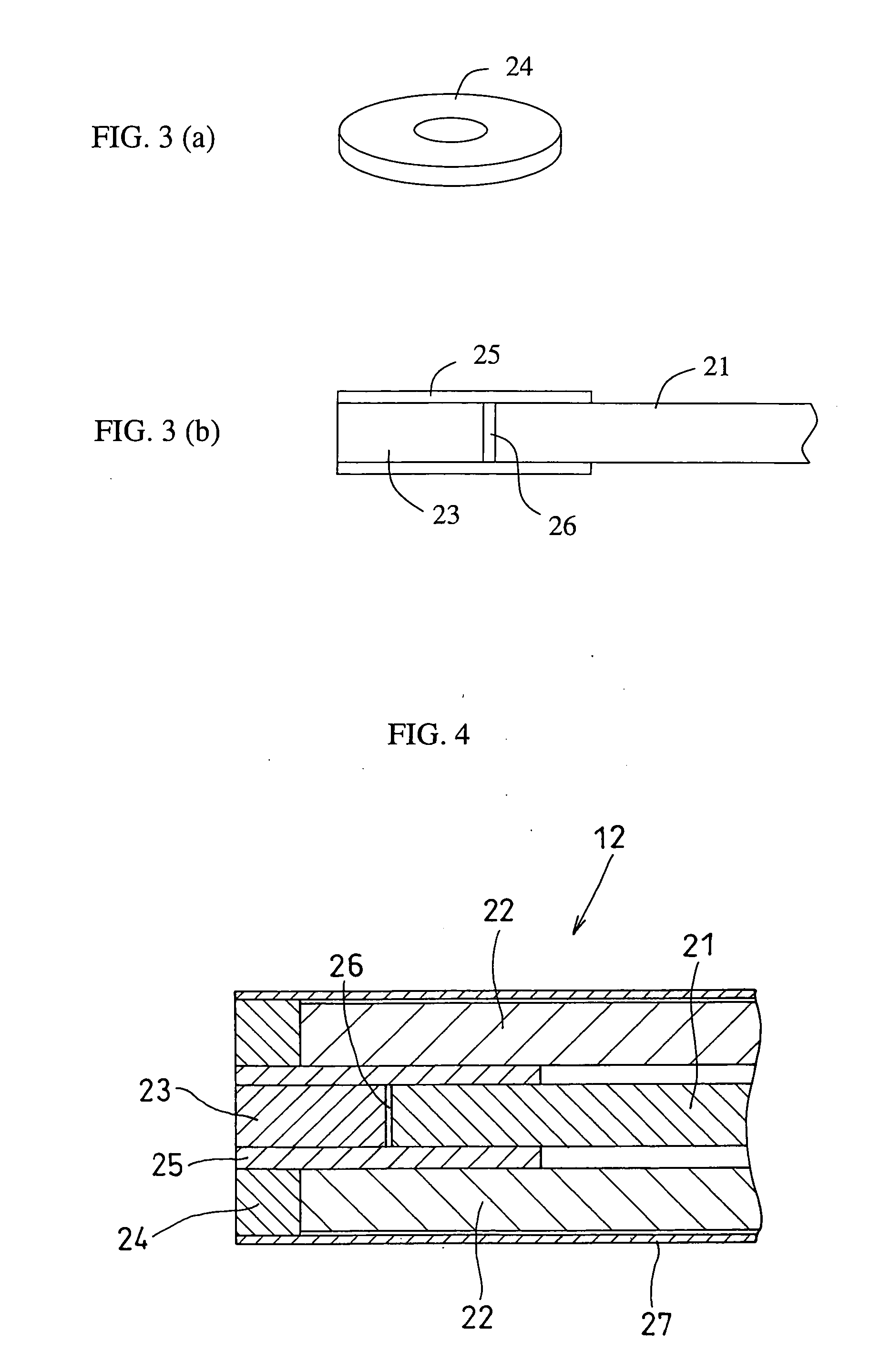

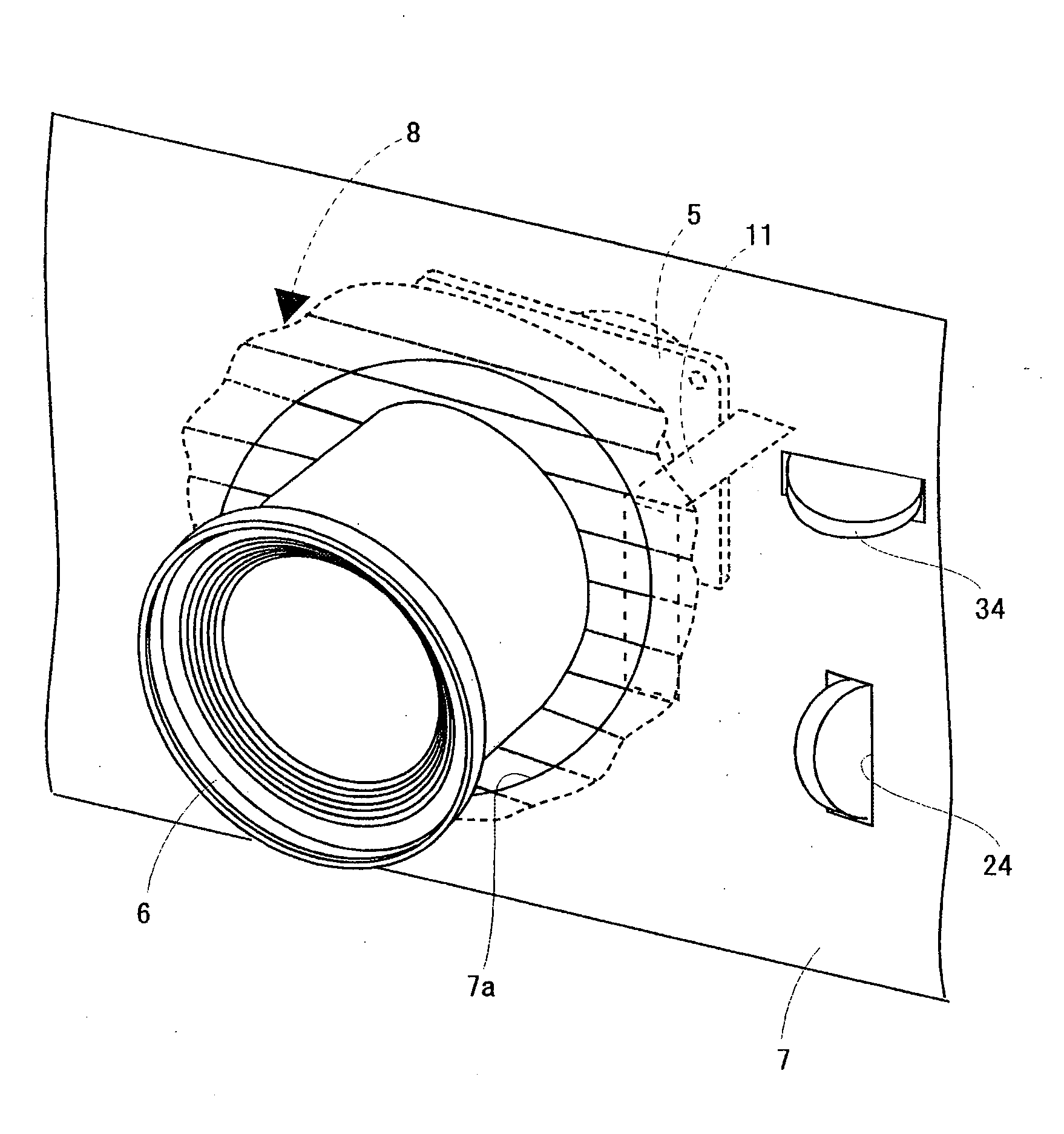

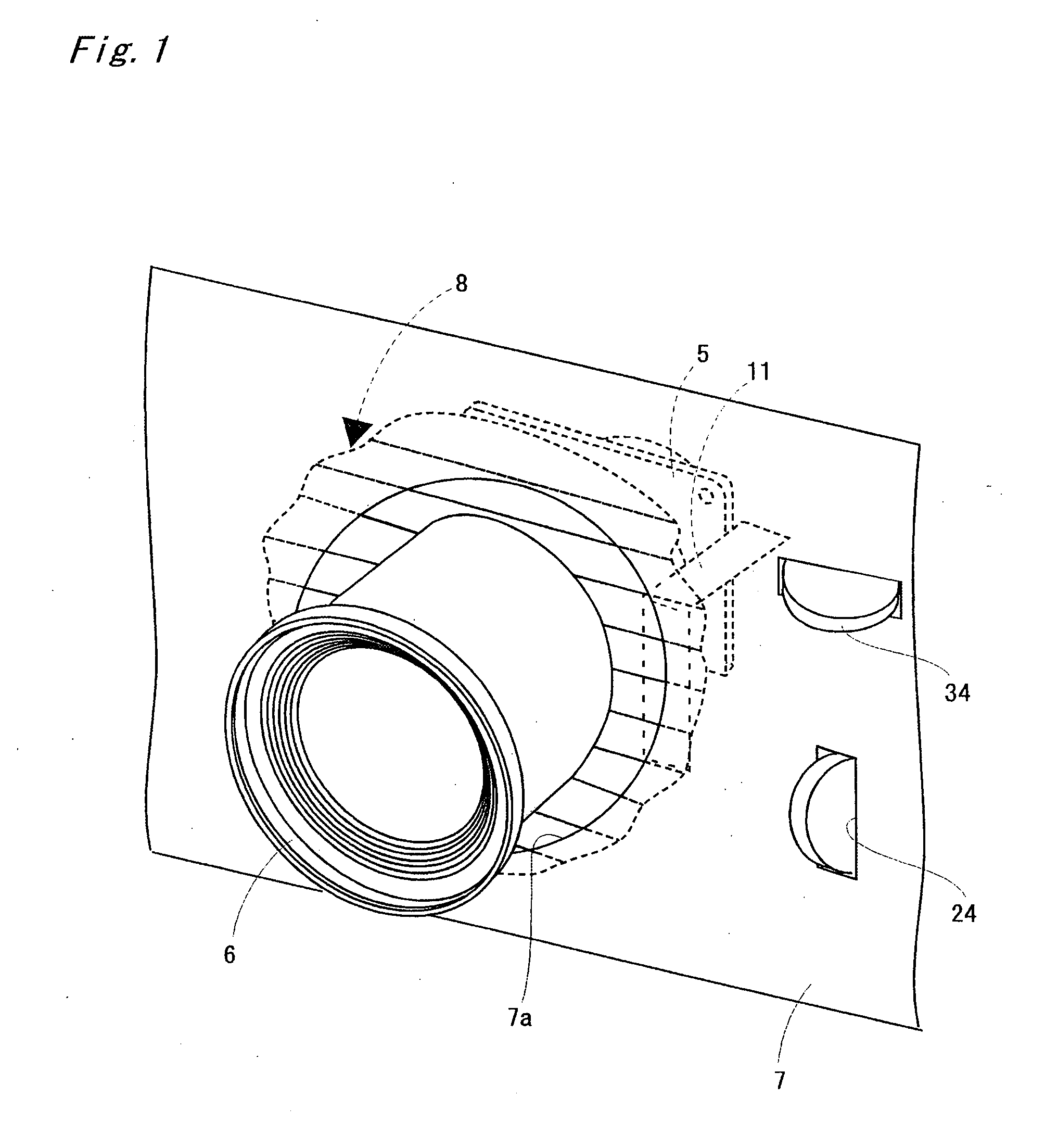

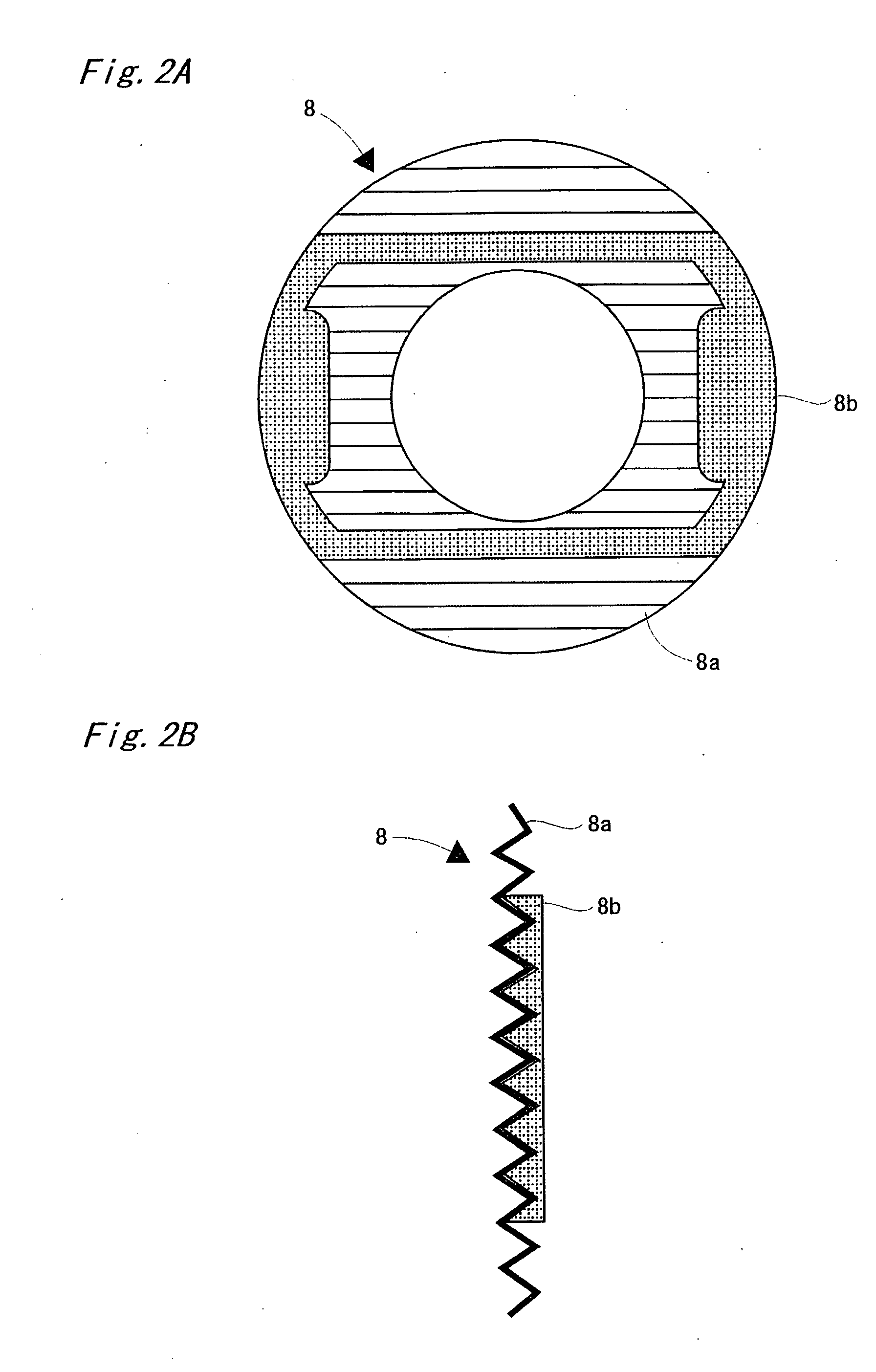

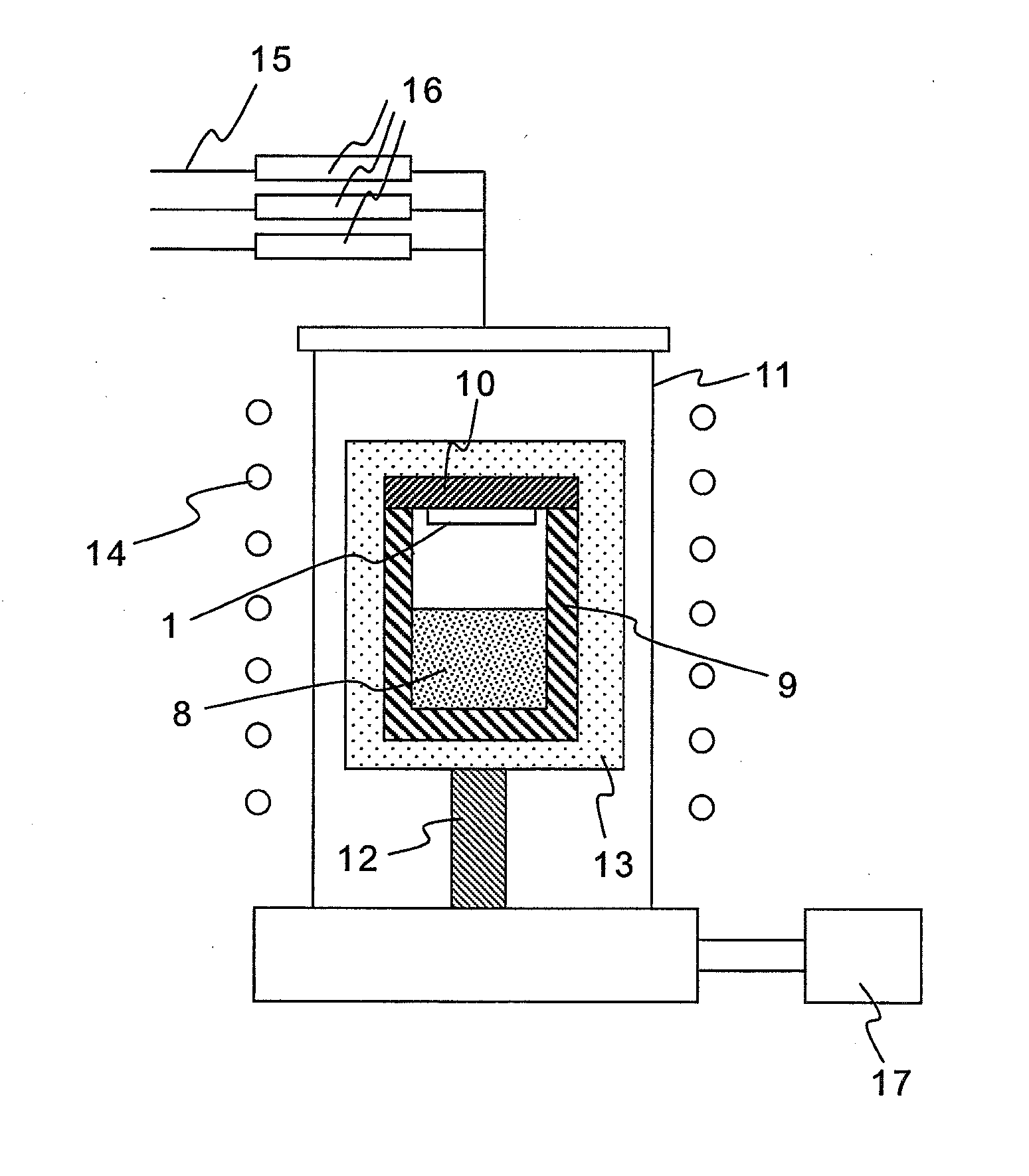

IC module, method of manufacturing the same and IC card provided with IC module

InactiveUS6308894B1Improve protectionSpeed up the flowOther printing matterSolid-state devicesEngineeringRing doughnut

In the method of manufacturing an IC module (1) including a resin packaging process using upper and lower dies (5) for forming a cavity (50) while the dies are clamped, the resin packaging process is carried out by introducing a melted resin while a substrate (2) on which an IC chip (3) is placed and a coil (20A) which has a doughnut shape when observed from above and is flattened as a whole are housed in the cavity (50). When a substrate (2) on which an antenna coil (20) is patterned is to be packaged with a resin, the resin packaging process is carried out by forming a spacer (28) having an equal and almost equal height to the height of the cavity (50) on the substrate (2), housing it in the cavity (50), and introducing a melted resin. Instead of forming the spacer (28) on the substrate (2), a substrate (2) housed in a cavity (50) may be sucked. The manufacturing method can provide good protection of an IC chip and an antenna coil.

Owner:ROHM CO LTD

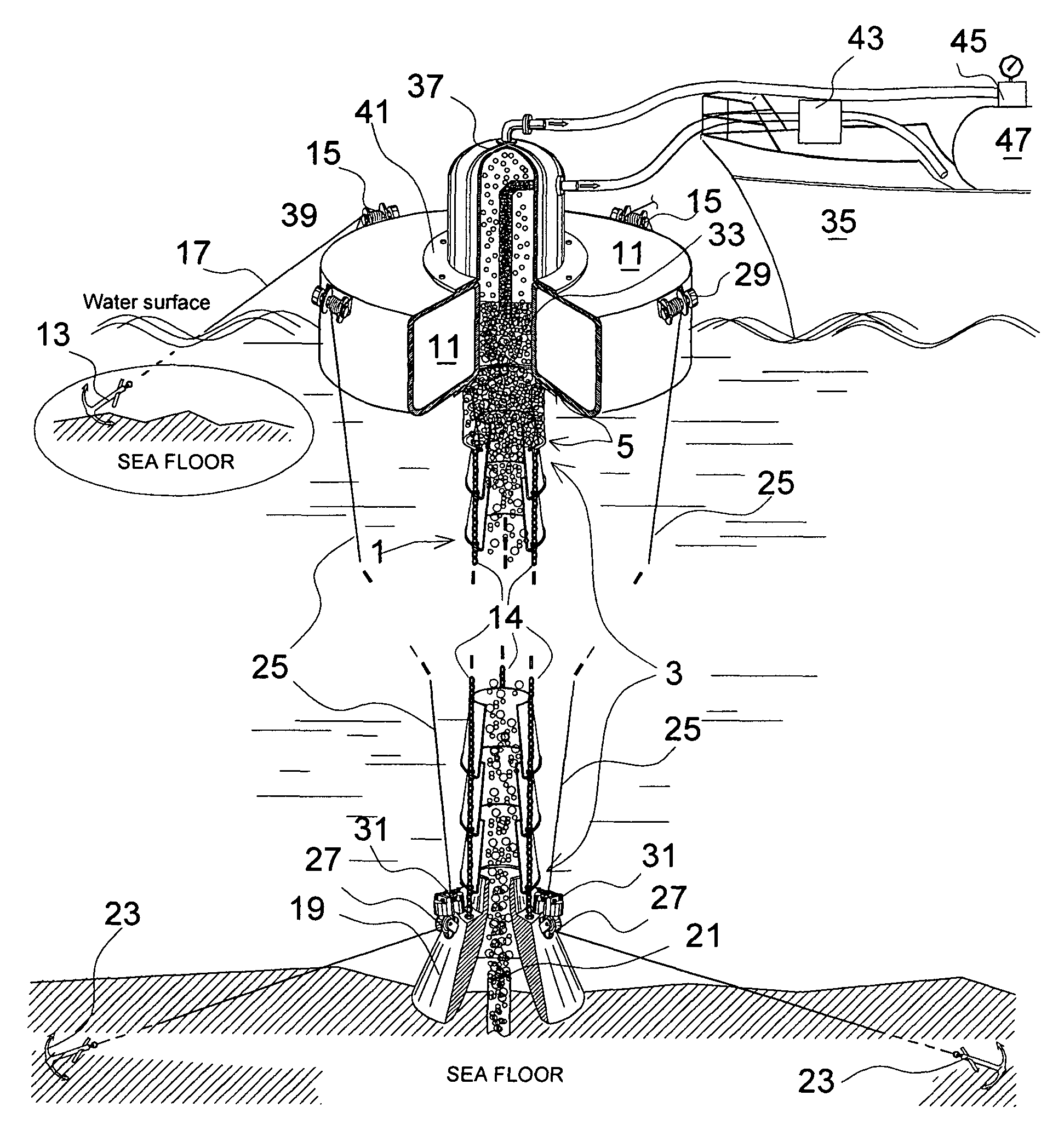

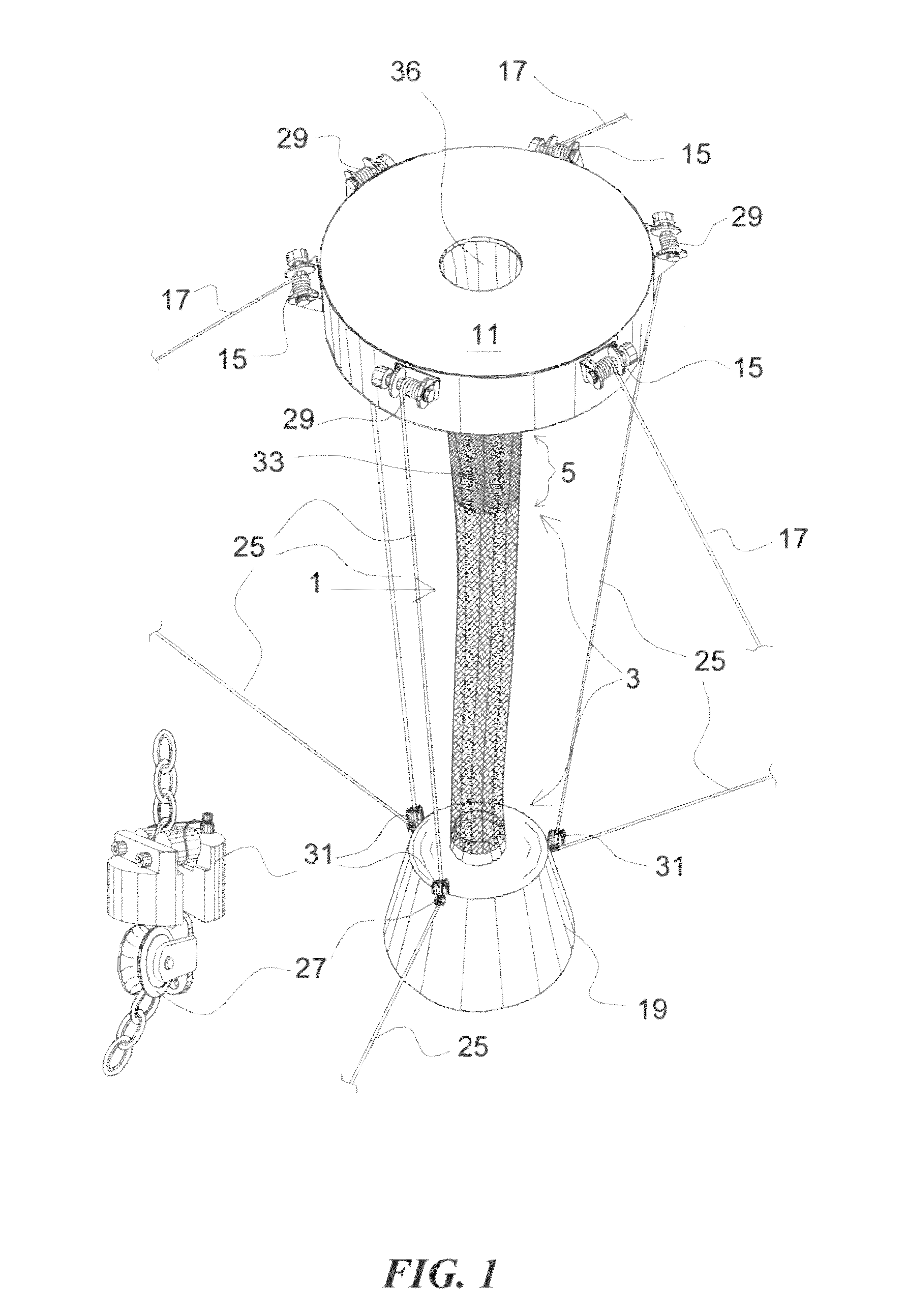

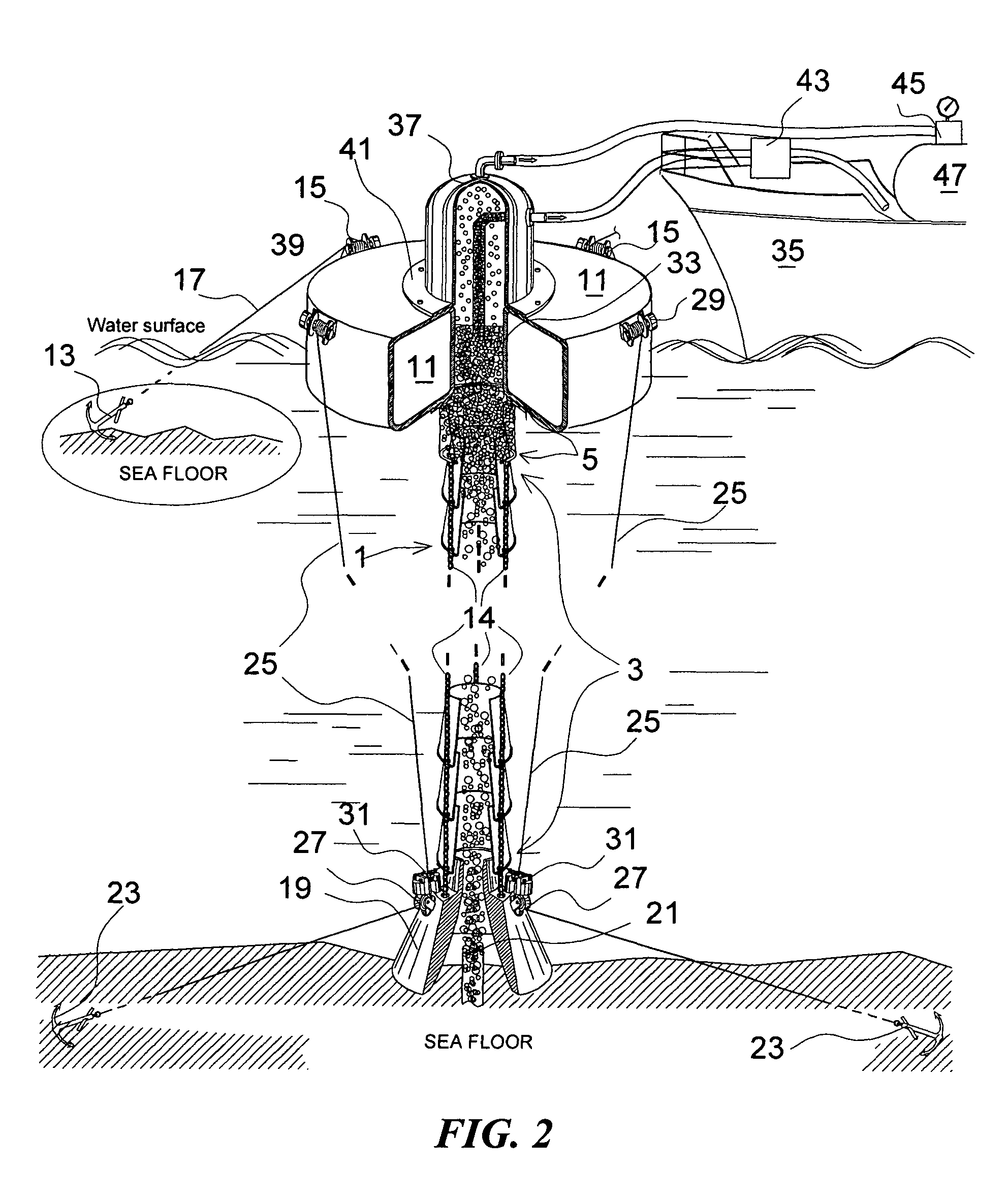

Marine oil leak recovery and marine petroleum mining method

A vertical flexible oil flow director hose is used to recover, to guide, and to filter the spilled oil from its source beneath the sea floor to the surface of water and to accumulate the floating oil therein for being ready to be pumped into an oil tanker. The said hose extends in the sea all the way from the sea floor to the surface of water by connecting its lower end to a circular sinking weight block and its upper end to a hollow doughnut-shaped floating device. The said hose includes two main portions abutting each other, the lower portion is for guiding and displacing water out through the gaps or meshes. The upper portion is for continued guiding and accumulating the oil in its upper section. A gas-tight dome cap having an opening at its bottom may be used to cap the upper opening of the oil accumulator well in the floating object, for holding the gas as necessary. A gas-compressor and gas tank or tanks will be equipped on the oil tanker ready to take and to store the gas.

Owner:CHE HUE NGUYEN

Food composition and method of making same

Owner:SLILATY GEORGE E

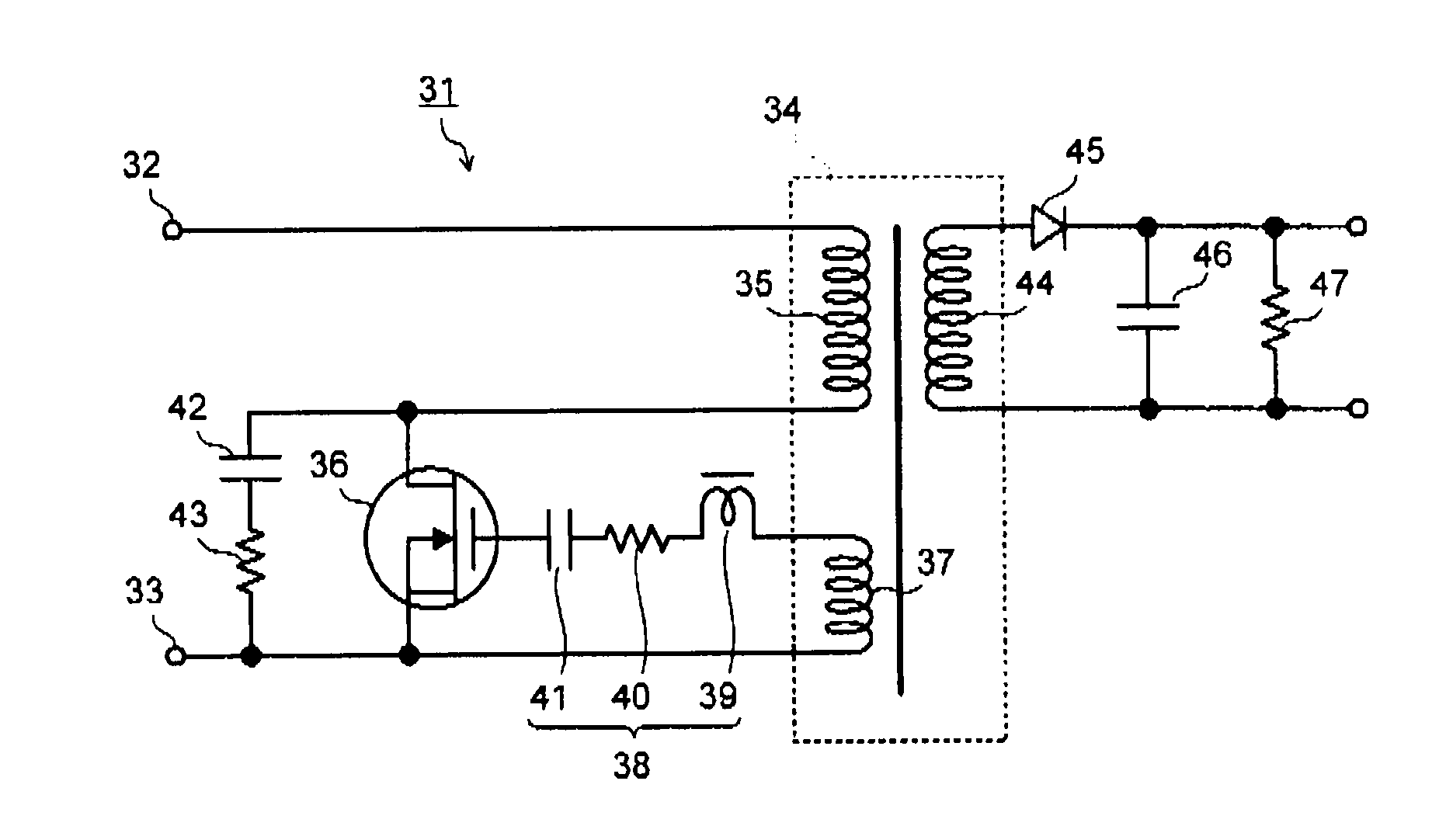

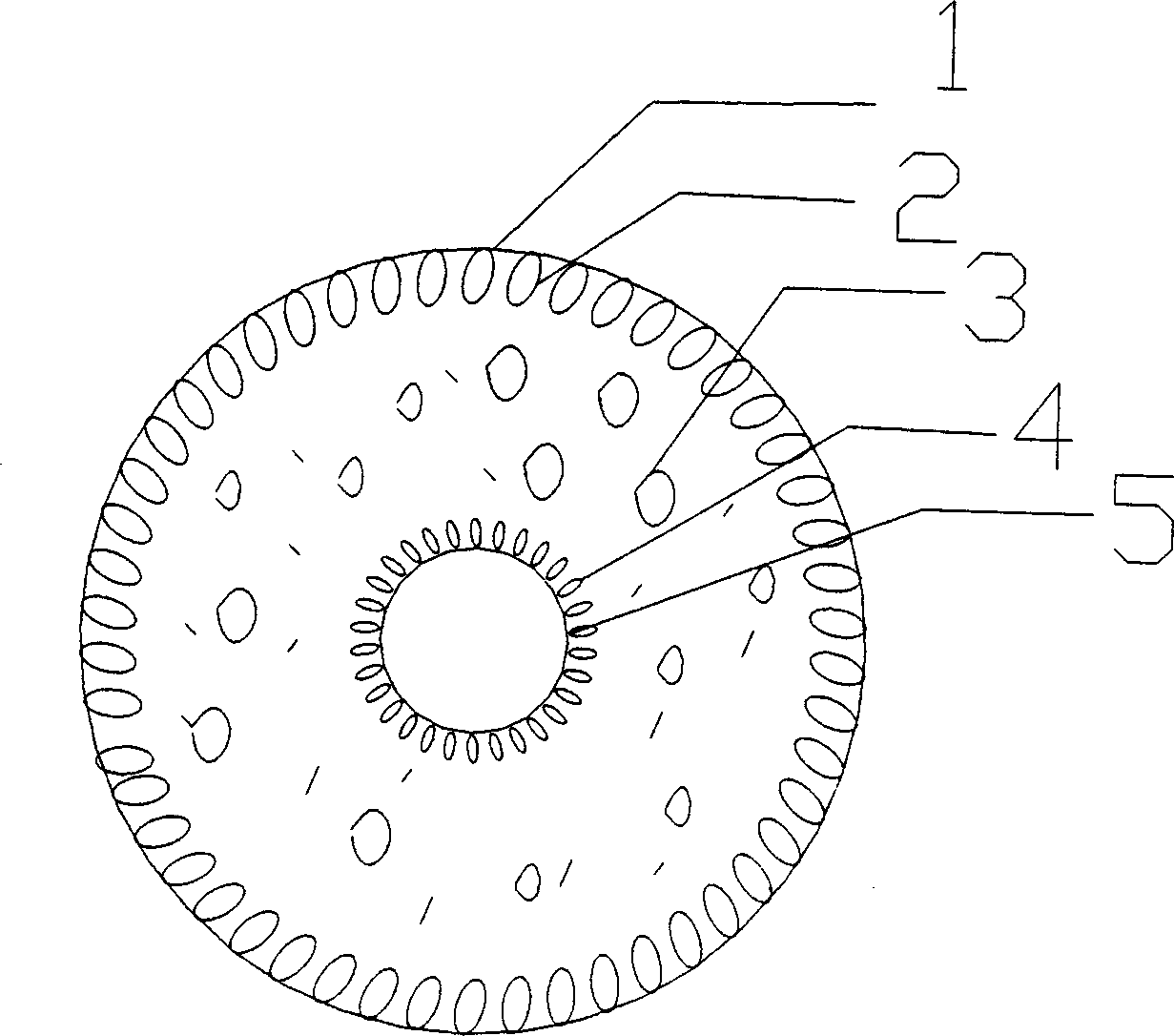

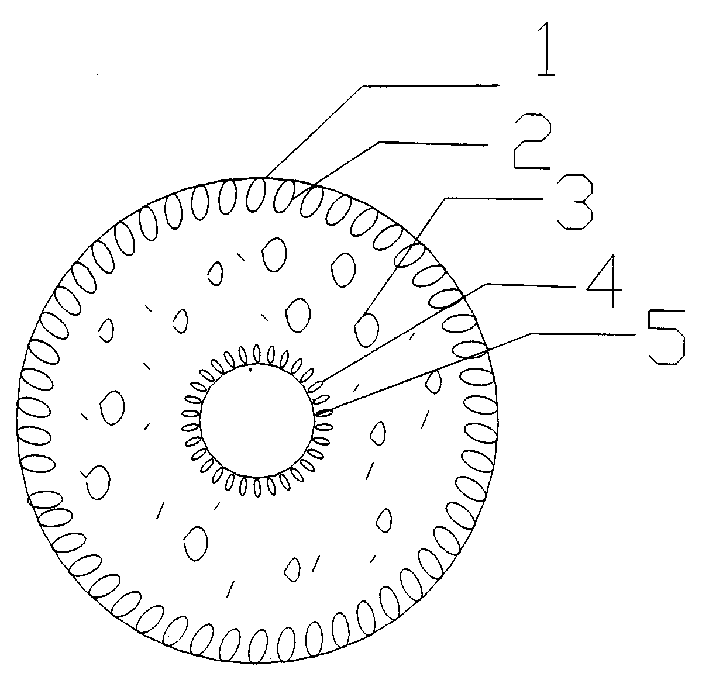

Loop antenna unit and radio communication medium processor

InactiveUS7446729B2Variation of the resonance frequency of the first loop antenna can be suppressedVariation in resonance frequencyResonant long antennasIndividually energised antenna arraysResonanceEngineering

It is an object of the present invention to provide a radio communication medium processor having a stable performance that does not receive a limitation for an installed place, especially, the influence of a metallic structure, does not need to adjust the resonance frequency of an antenna or an impedance, is excellent in its convenience and extensibility upon installation and strong for unnecessary noise from a periphery.In electric current fed loop antenna units, non-electric current fed loop antenna are arranged in doughnut shapes outside the substantially same planes of electric current fed loop antennas so as to surround the electric current fed loop antennas. Thus, when non-electric current fed loop antenna units are installed linearly, in radial directions and in arrays adjacently to electric current fed loop antenna units, the influence of the non-electric current fed loop antenna units to the antenna characteristics of the electric current fed loop antenna units can be suppressed. When the non-electric current fed loop antenna units are extended and increased, the antennas of the electric current fed loop antenna units do not need to be adjusted.

Owner:PANASONIC CORP

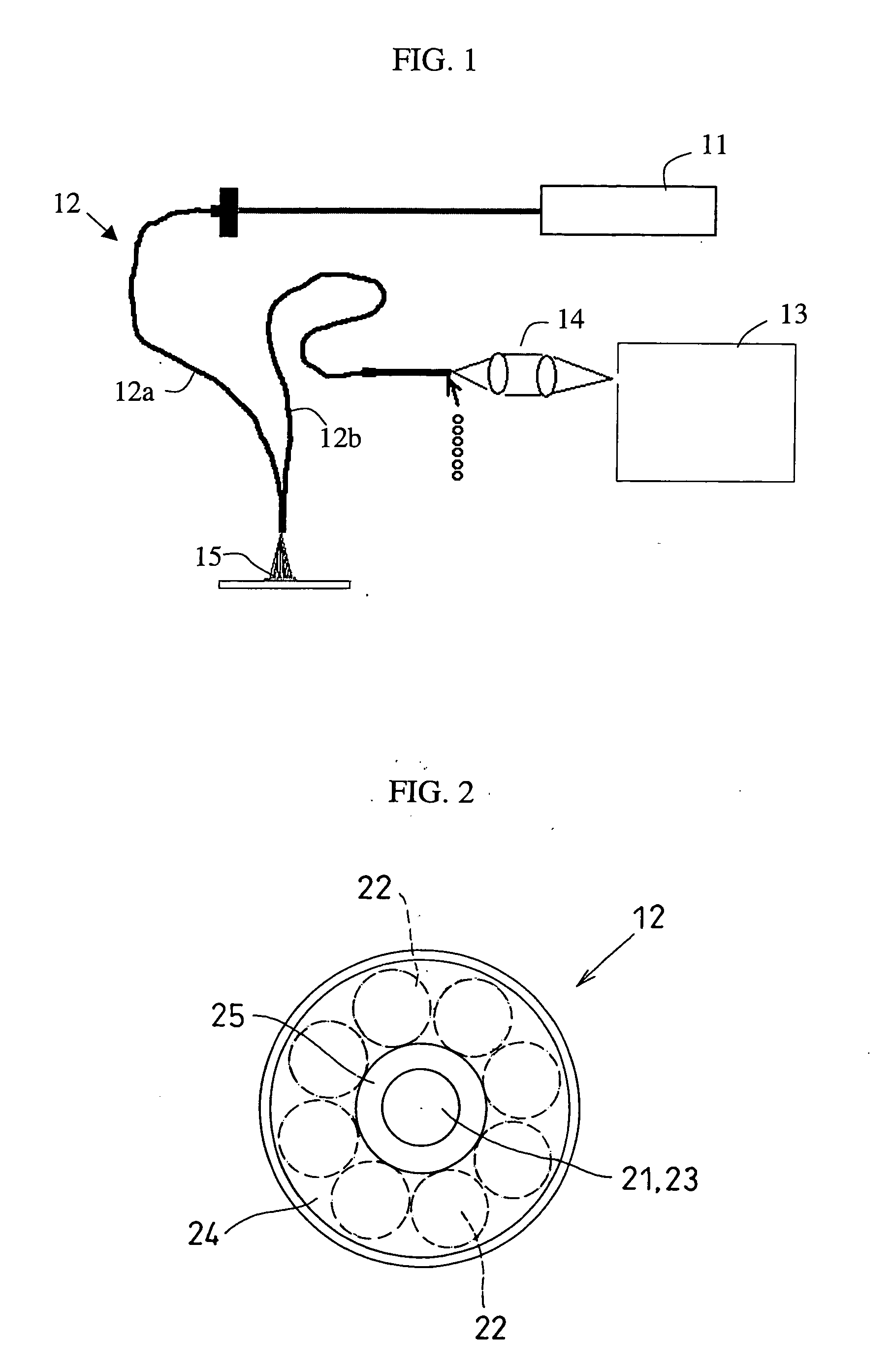

Raman probe and Raman spectrum measuring apparatus utilizing the same

InactiveUS20060146322A1Coupling lossRadiation pyrometryDiagnostics using spectroscopyHigh intensityRing doughnut

Owner:RIKEN +1

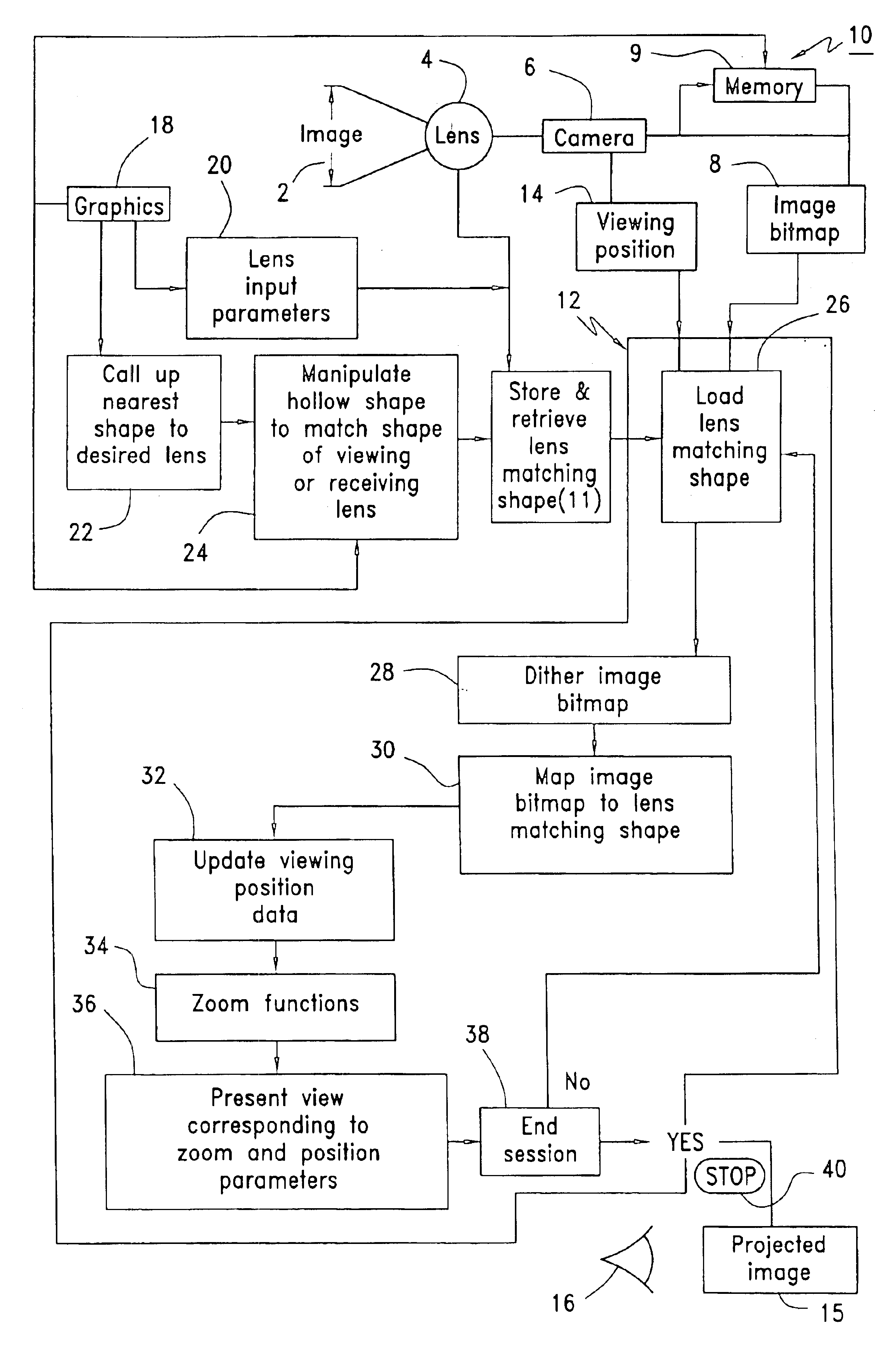

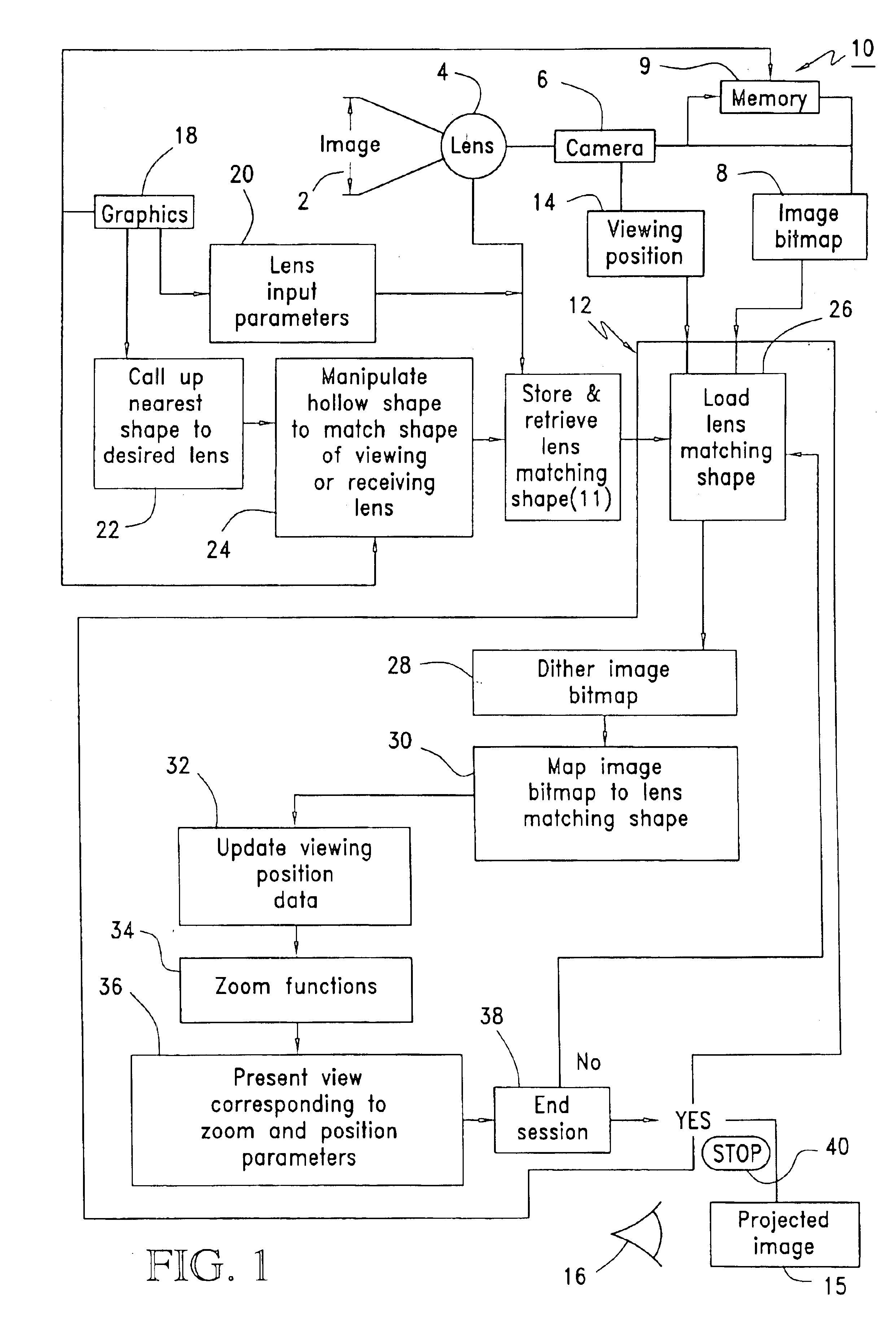

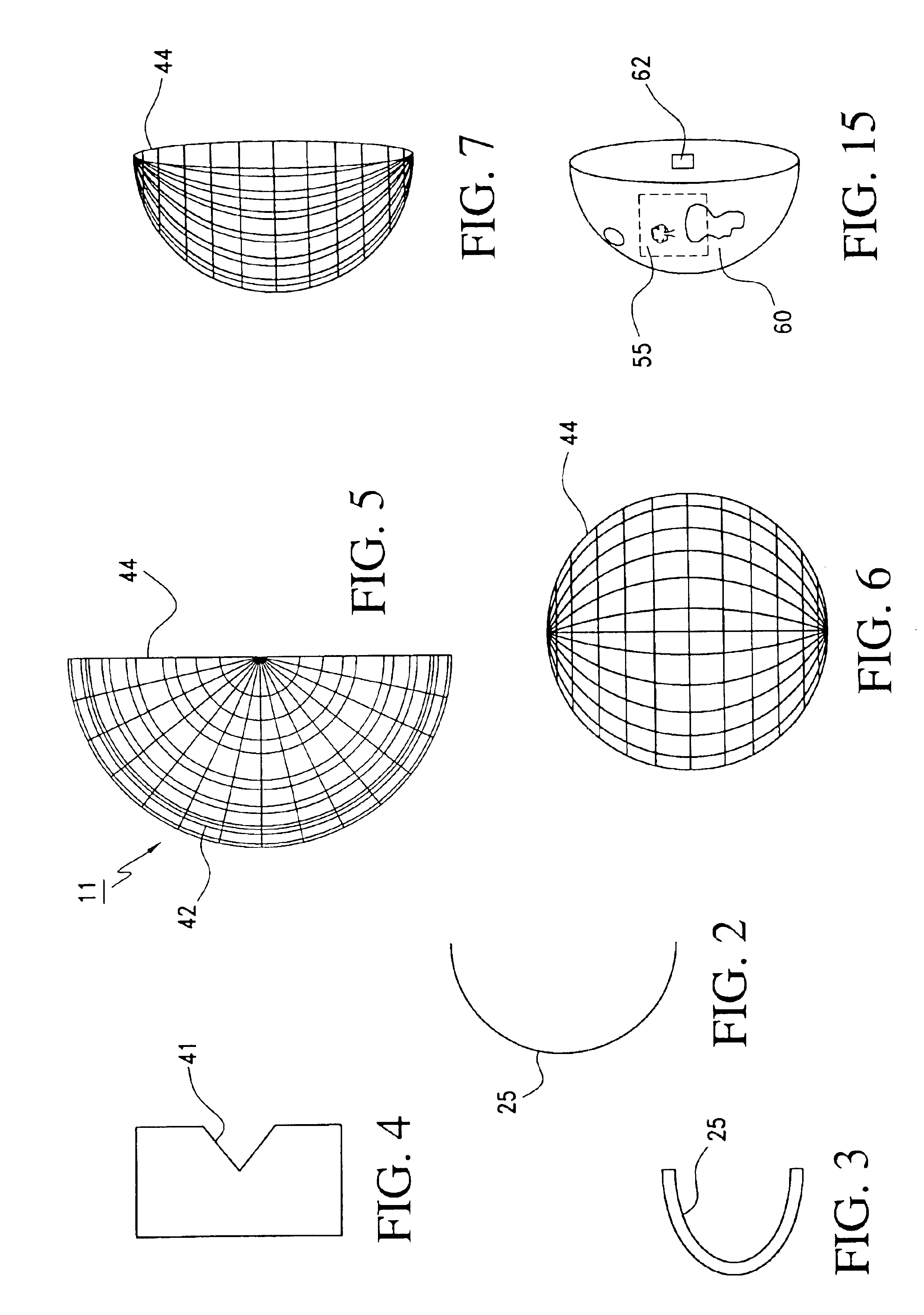

Image display

InactiveUS6870532B2Increase frame rateCorrect distortionTelevision system detailsGeometric image transformationCamera lensGraphics

The present invention converts a wide-angle lens image into a two dimensional view with reduced distortion and warping. The present invention uses a graphics engine which accepts a shape, an image, and a viewing position. An effective lens shape, corresponding to the recording lens, an image as well as a image-related viewing position is supplied to the graphics engine. The graphic engine projects the image on the effective shape and displays a portion of the image from the viewing position. The recording lens is often a wide-angle lens. The graphics rendering engine maps the wide-angle lens image onto an effective lens shape and displays sections of the mapped image on the shape in a full screen view. Portions of or the entire image are viewable at any one time. Use of acceleration hardware permits frame per second rates of display of up to 60 and greater frames per second. Typical wide-angle recording lenses include “fisheye” lenses and torus shaped (doughnut) lenses.

Owner:VUZIX

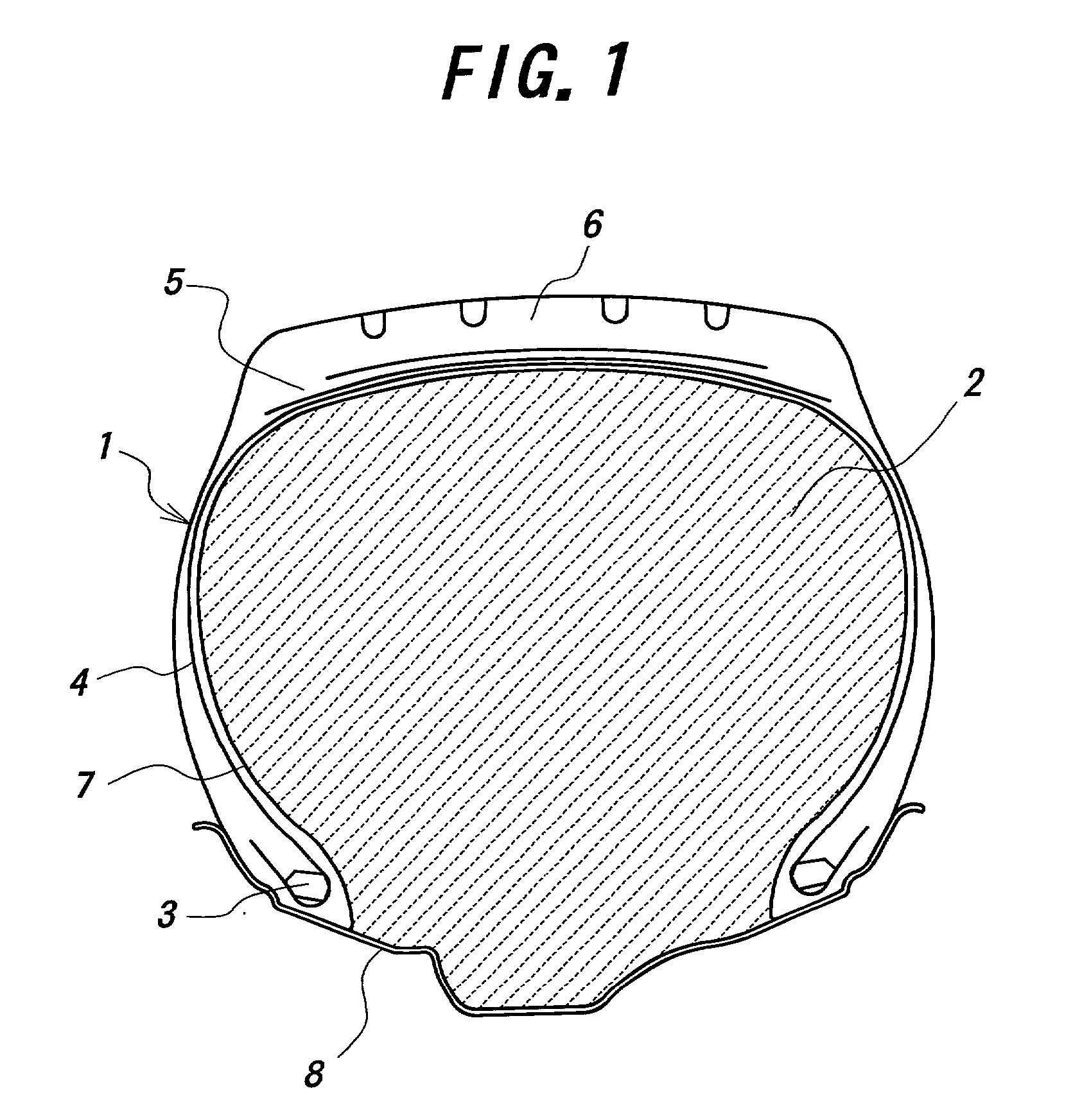

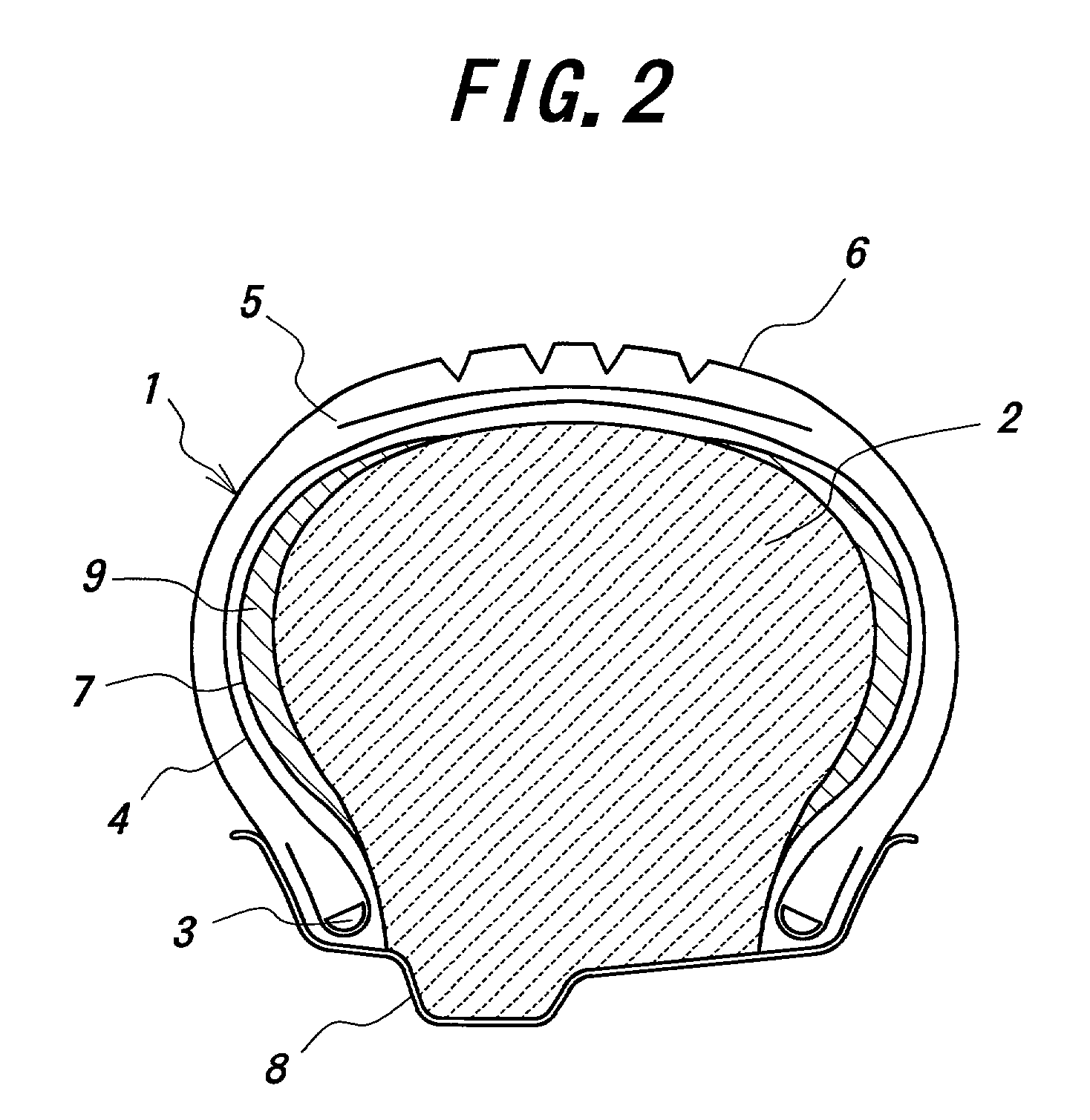

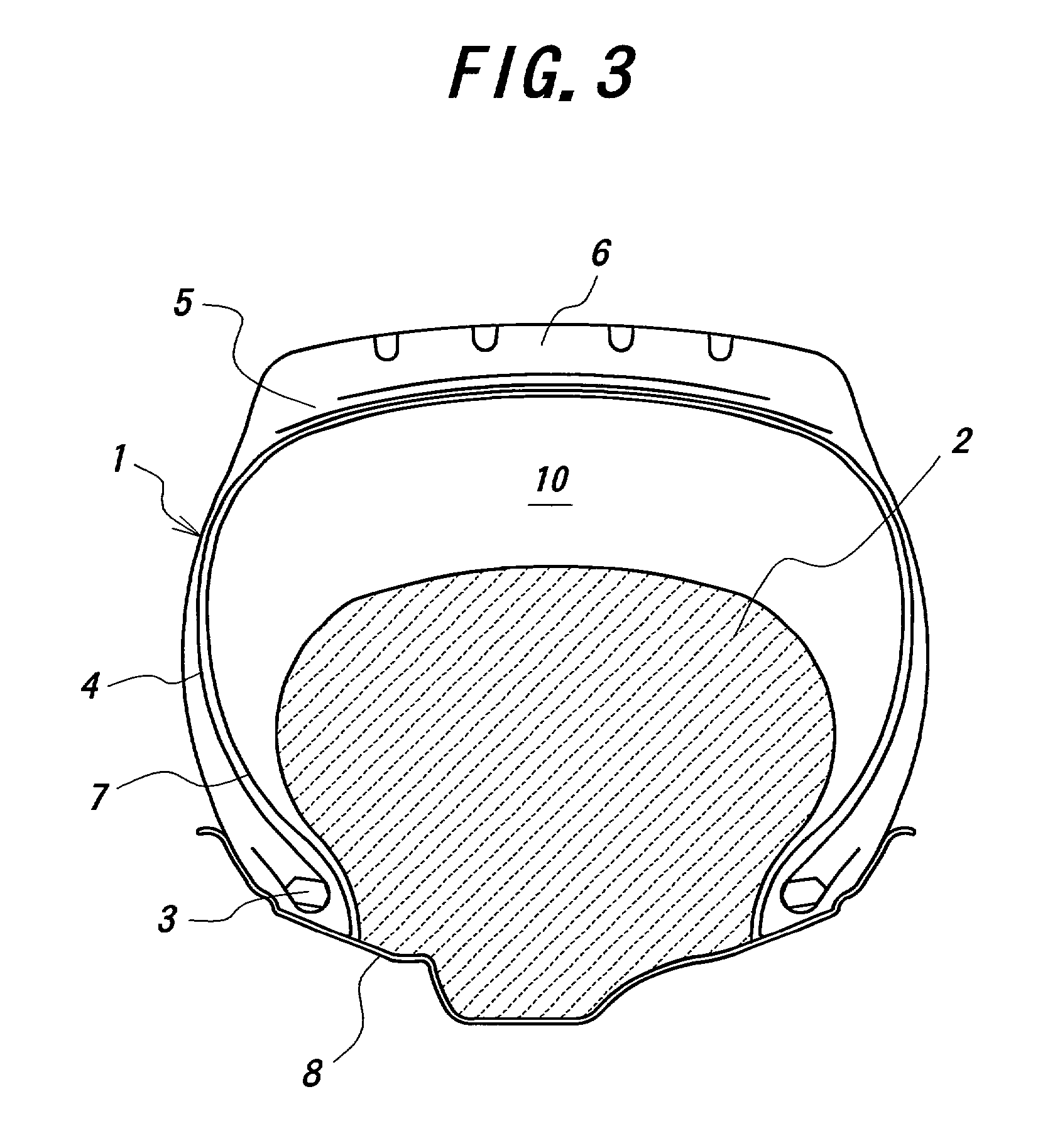

Insert earphone

InactiveUS6931142B2Prevent sound leakageImprove comfortEar supported setsIntra aural earpiecesEngineeringRing doughnut

An insert earphone which prevents a sound leakage and improves wearing comfort. An ear chip has a barrel portion and first and second annular flange portions having the shape of a parabola spreading from the top toward the middle and from the middle toward the base of the barrel portion respectively. The first annular flange portion has a smaller outer diameter than the second annular flange portion. The first annular flange portion has almost even thickness from the inner circumference to the outer circumference, and has the inner circumference neighborhood substantially formed in the shape of a sliced doughnut.

Owner:STAR MICRONICS

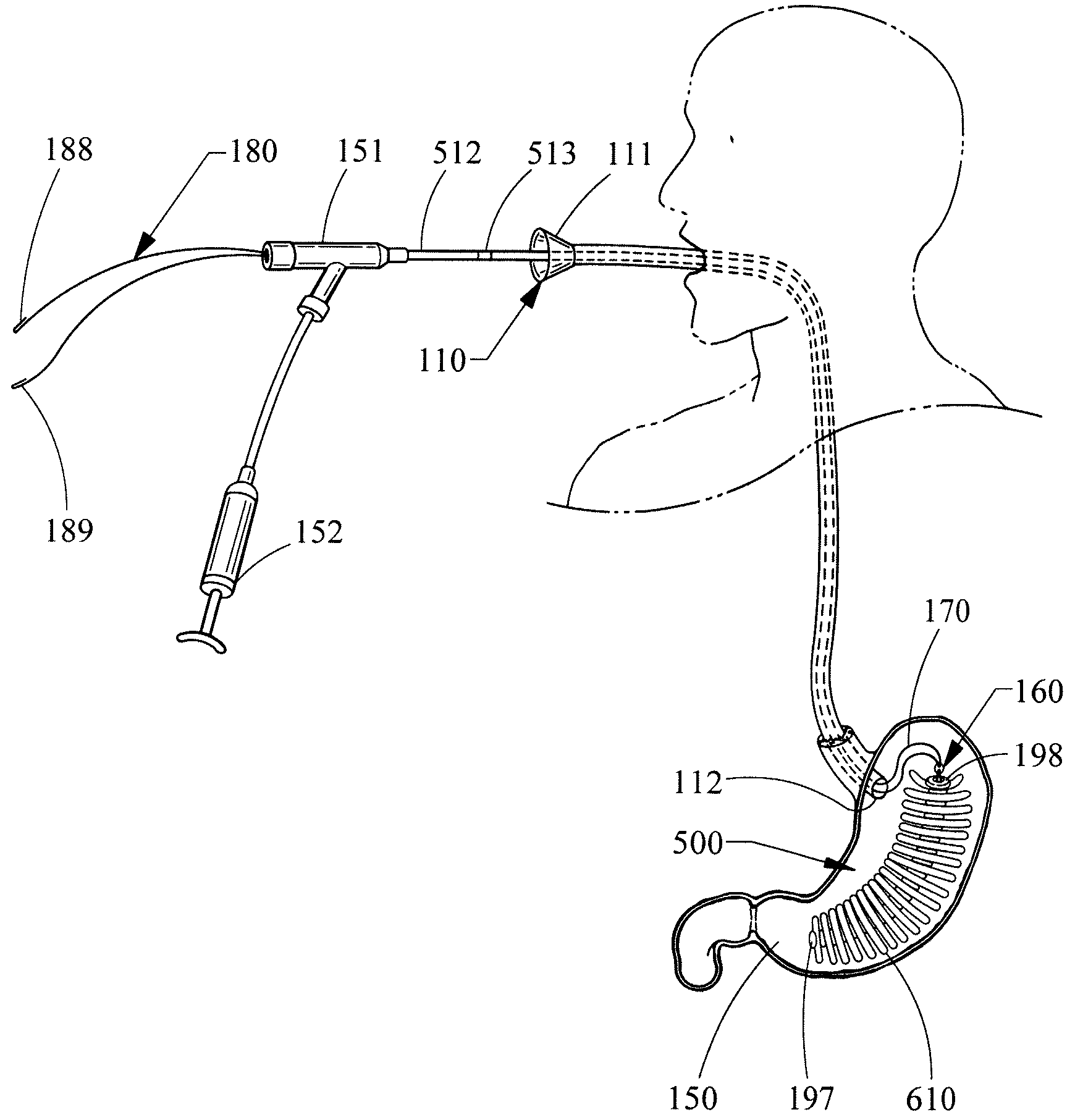

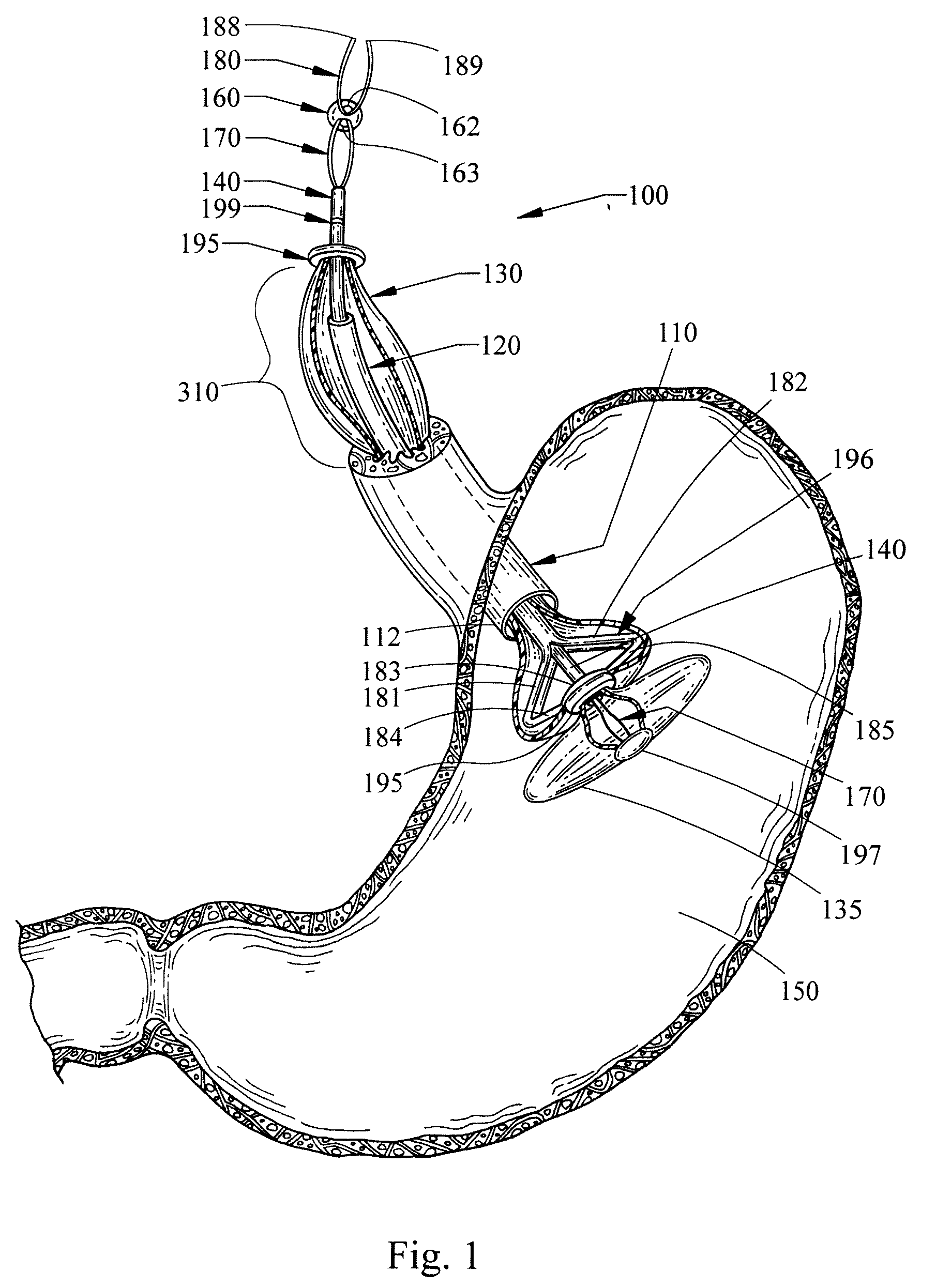

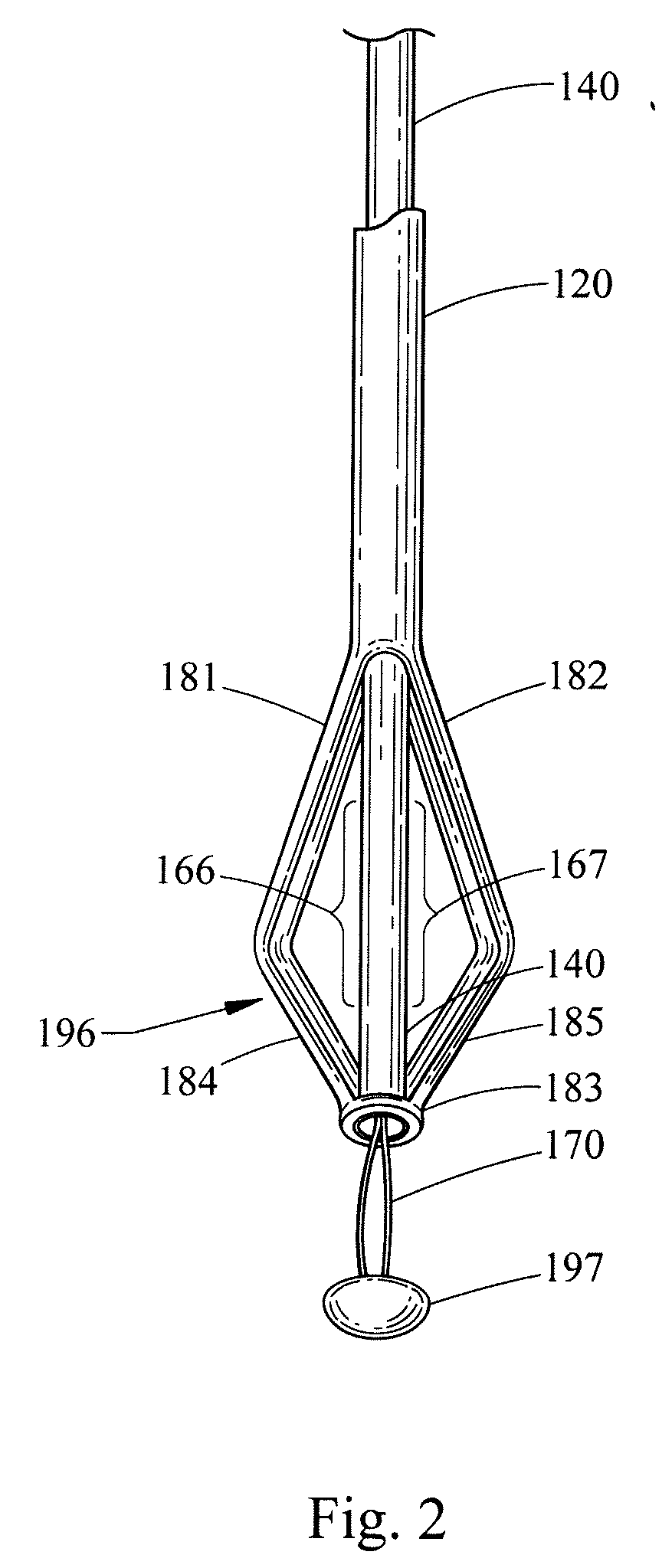

Delivery system and method of delivery for treating obesity

A delivery system and method of use thereof for introducing a bundled intragastric bag into a gastric lumen are described. The delivery system includes a pushing mechanism movable between an unexpanded and expanded configuration. The pushing mechanism in its expanded configuration pushes each of the bundles of the bag into the gastric lumen. A suture strand is periodically pulled during the procedure to help create doughnut-shaped bundles. Another suture strand extends between a proximal button and distal button of the deployed assembly to maintain the doughnut-shaped bundle structure.

Owner:COOK MEDICAL TECH LLC

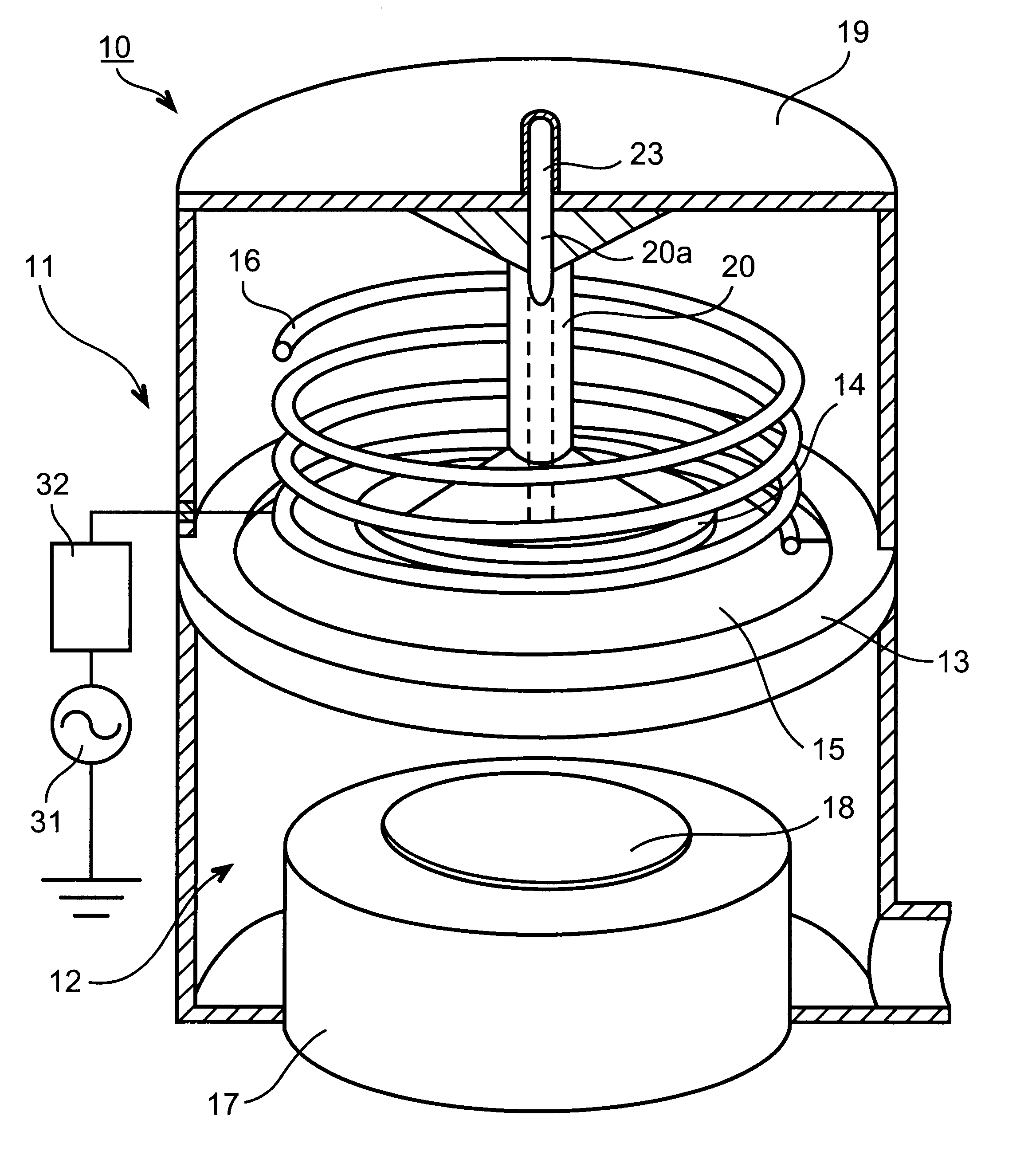

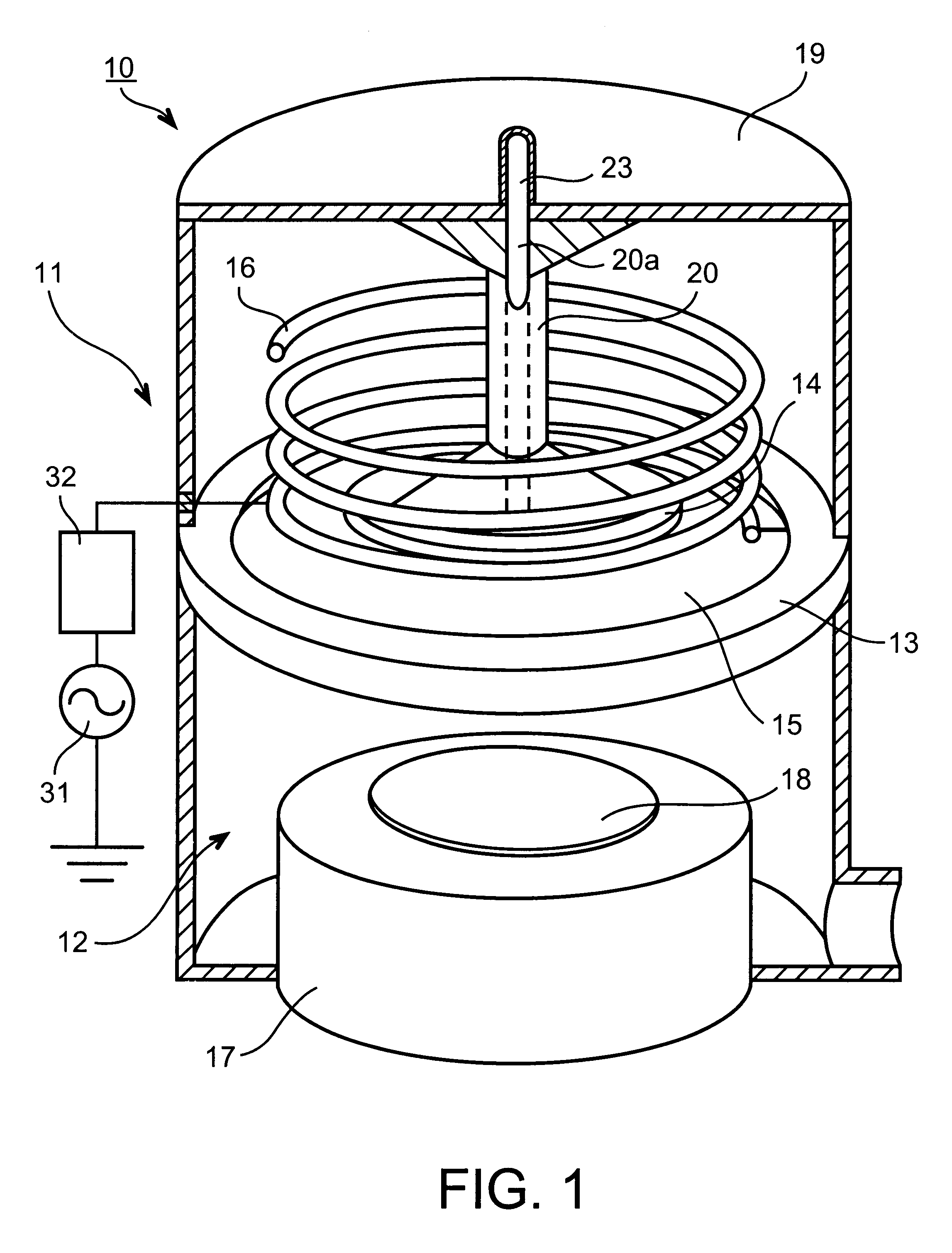

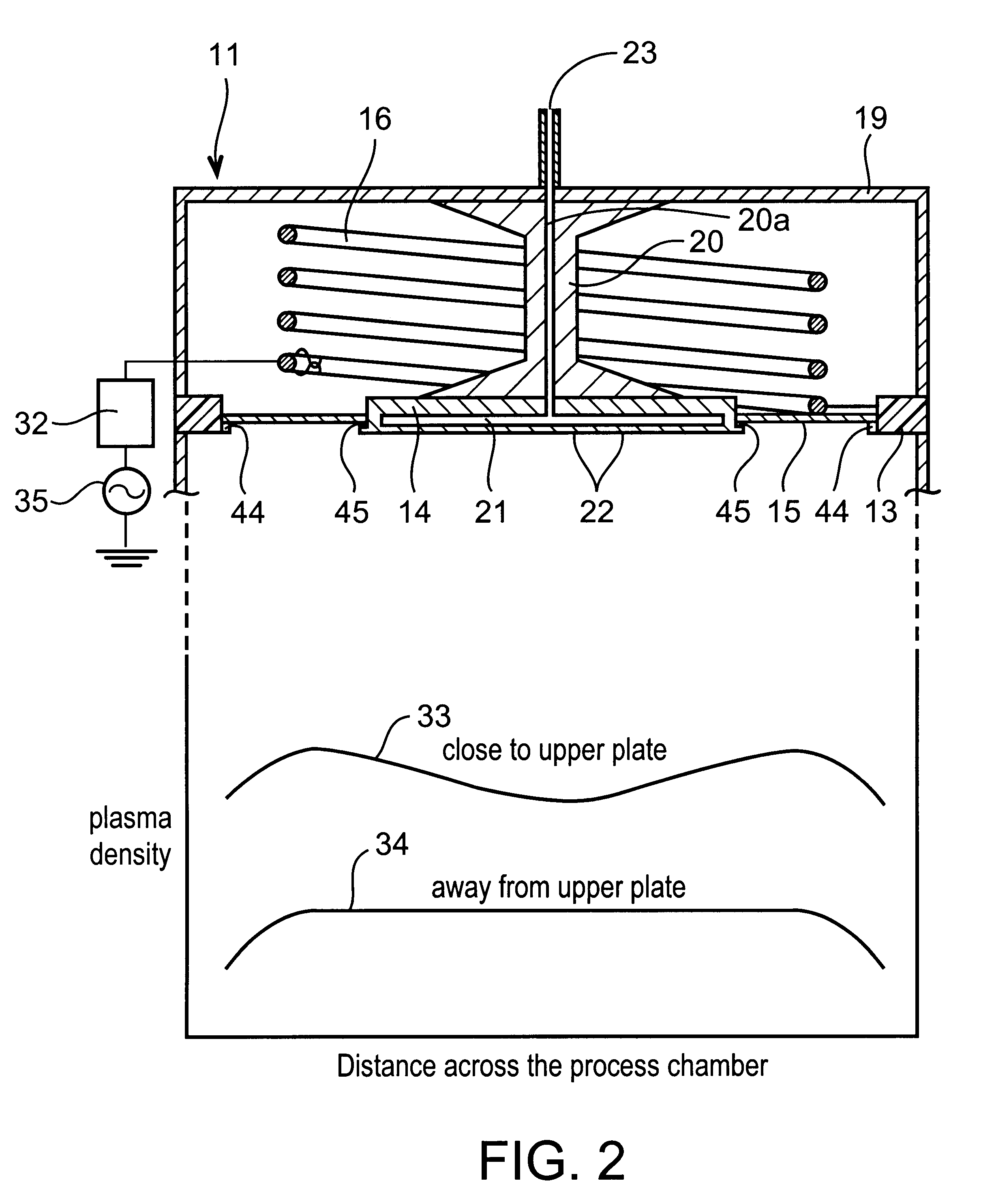

Plasma processing system

InactiveUS6225746B1High densityElectric discharge tubesElectric arc lampsVertical barDielectric plate

A plasma processing reactor includes a helical resonator including a top plate and a helical coil, the helical coil is made of a metal with a length of lambd / 4, wherein n is an integer and lambd is a wavelength of rf frequency applied to the helical coil. The reactor also includes a plasma process chamber including a wafer holder arranged at a lower position therein and a wafer to be processed is loaded on the wafer holder. The helical resonator has a vertical bar for introducing a gas, the vertical bar is fixed to the top plate of the helical resonator and is connected to a gas inlet port. A partition wall separates the helical resonator and the plasma process chamber. The partition wall includes an outer metal ring, a circular central metal plate, and a doughnut-shaped dielectric plate between the outer metal ring and the central metal plate, the doughnut-shaped dielectric plate having an inner diameter and an outer diameter. The central metal plate is fixed to the top plate using the vertical bar and includes a gas reservoir and a plurality of gas inlet ports. The helical coil is placed around the vertical bar, and the helical coil has a diameter that is greater than the inner diameter of the doughnut-shaped dielectric plate and is smaller than the outer diameter of the doughnut-shaped dielectric plate.

Owner:ANELVA CORP

Projection type video display

ActiveUS20050030492A1Large lens shift widthBig gapTelevision system detailsProjector focusing arrangementCamera lensEngineering

A doughnut-shaped dust-proof plate is externally fitted in the body of the projection lens. The dust-proof plate comprises a first member which is flexible like rubber and a second member made of plastic which is uneasy to deform. The second member is made lower in a vertical direction (lengthwise) than the first member, thereby making it possible to allow deformation at an upper end and a lower end of the first member. On the other hand, the second member is made long in a horizontal direction (crosswise). A longitudinal portion of the second member is set to have such a length that it can come into contact with a lower wall of the frame of the liquid crystal projector even if the projection lens is positioned at the uppermost position and can come into contact with an upper wall of the frame even if the projection lens is positioned at the lowermost position in a state where the dust-proof plate is obliquely turned. Therefore, the dust-proof plate is prevented from being turned at an angle of 90 degrees.

Owner:SANYO ELECTRIC CO LTD

Insert earphone

An insert earphone which prevents a sound leakage and improves wearing comfort. An ear chip has a barrel portion and first and second annular flange portions having the shape of a parabola spreading from the top toward the middle and from the middle toward the base of the barrel portion respectively. The first annular flange portion has a smaller outer diameter than the second annular flange portion. The first annular flange portion has almost even thickness from the inner circumference to the outer circumference, and has the inner circumference neighborhood substantially formed in the shape of a sliced doughnut.

Owner:STAR MICRONICS

Single shell-pass or multiple shell-pass shell-and-tube heat exchanger with helical baffles

InactiveUS7740057B2Flow pressure dropIncrease heat transfer rateHeat exchanger casingsStationary tubular conduit assembliesInterior spaceShell and tube heat exchanger

Owner:XI AN JIAOTONG UNIV

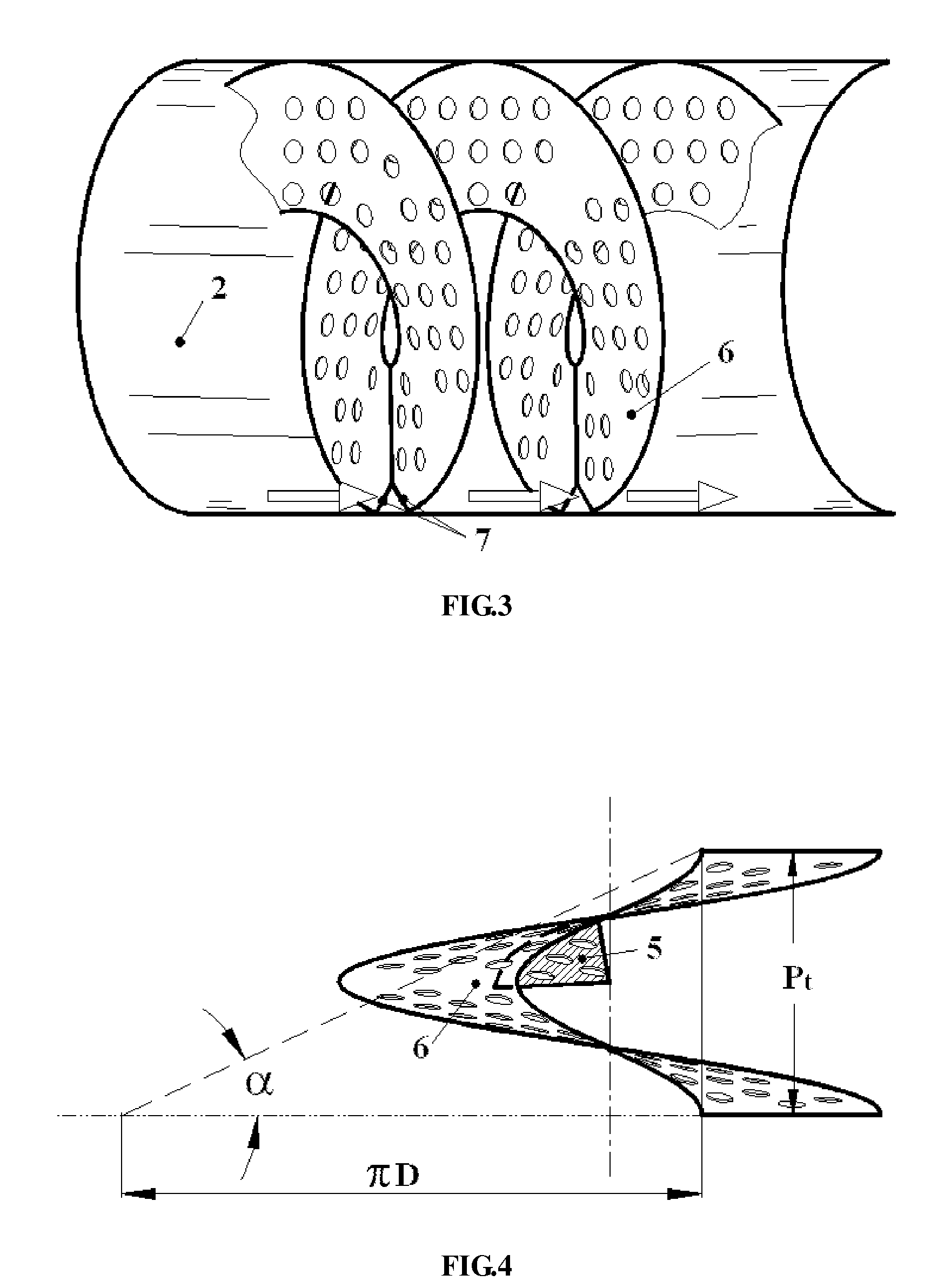

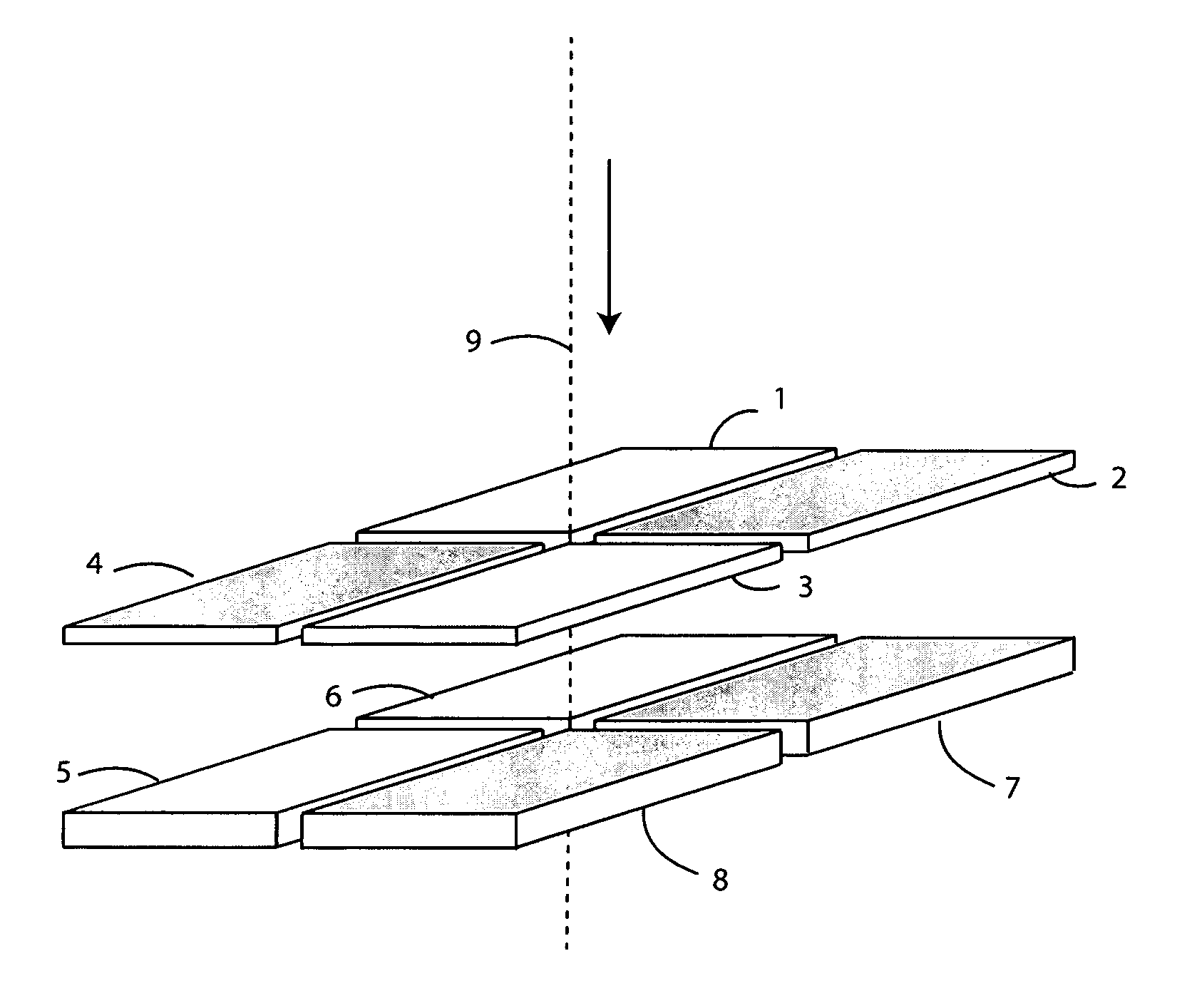

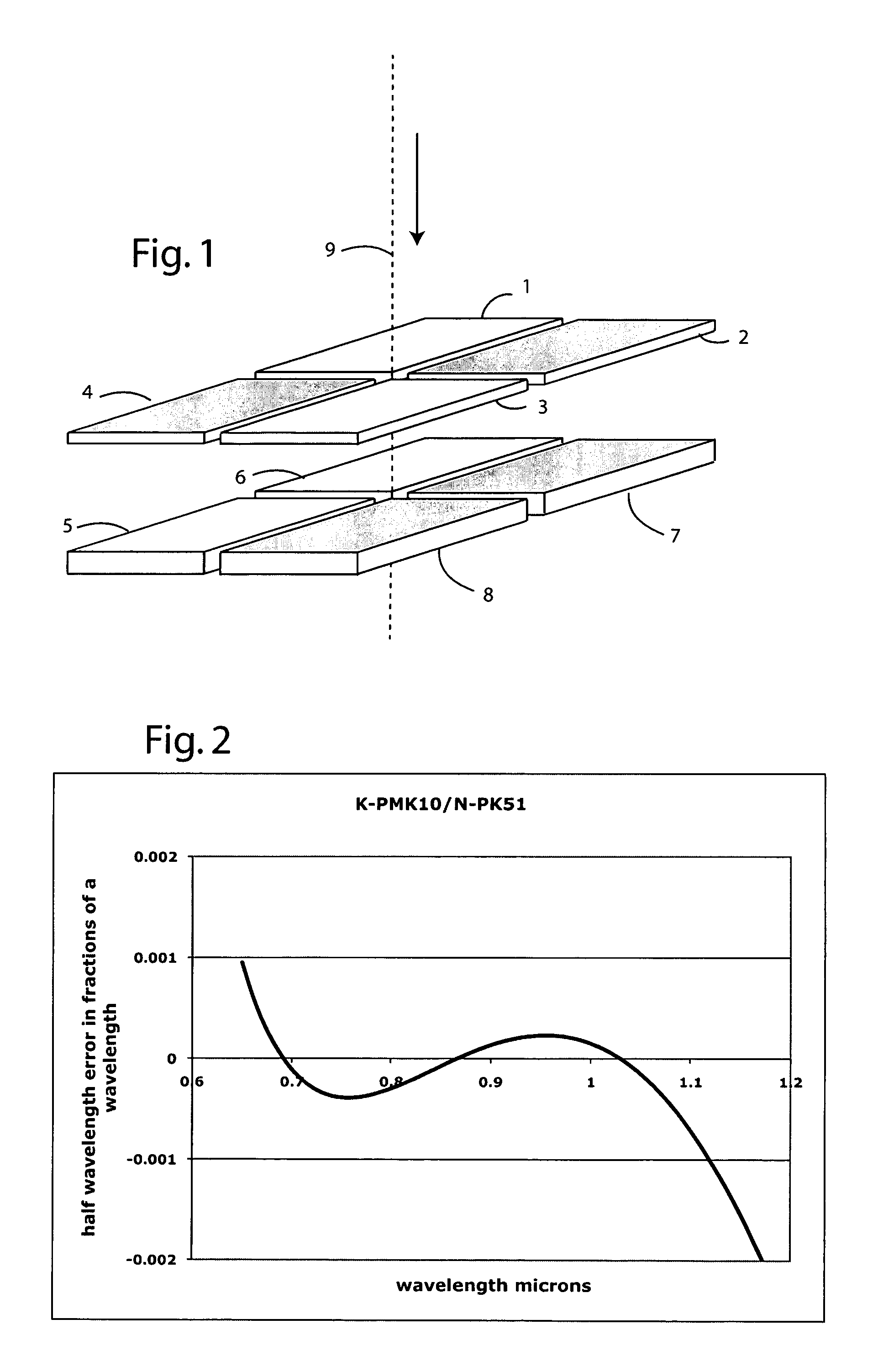

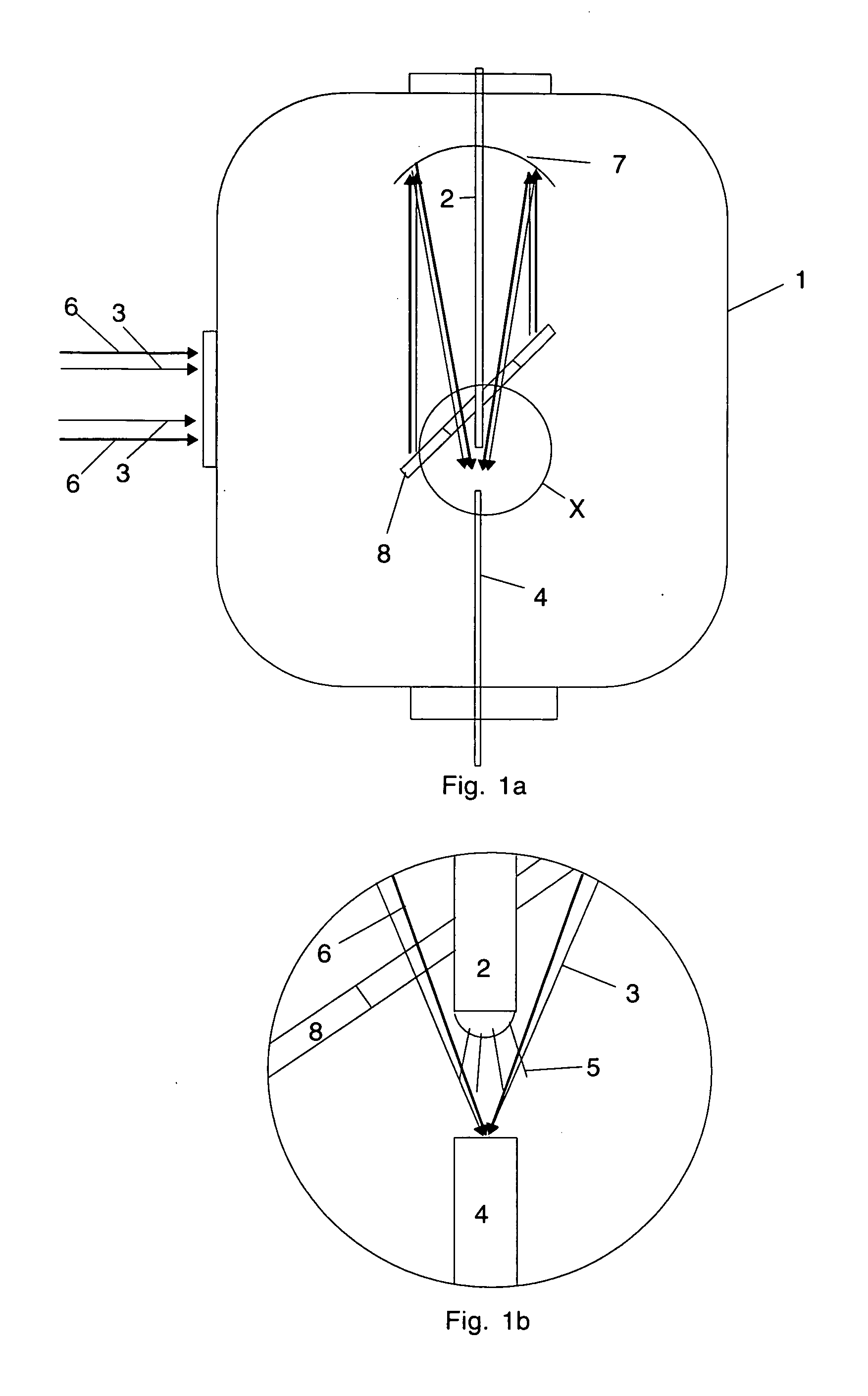

Forming light beams and patterns with zero intensity central points

In order to produce a beam with a zero intensity axial ray or to produce a beam that when focused will produce an image of a doughnut shaped pattern with a zero intensity central point, a beam with a uniform or Gaussian profile is directed to a plurality of transparent plates, arranged in pairs on opposite sides of the beam axis, such that for at least one pair, the plates have a composition and thickness different from each other, and chosen so that the transmitted light has a has a phase difference of half a wavelength for at least three different wavelengths. An additional plate with a center on the perpendicular of the line connecting the first two plates has a composition and thickness such that the light transmitted through that additional plate has a phase difference of a quarter wavelength with respect to the light transmitted through one of the plates of said first pair of plates, at at least one wavelength.

Owner:BAER

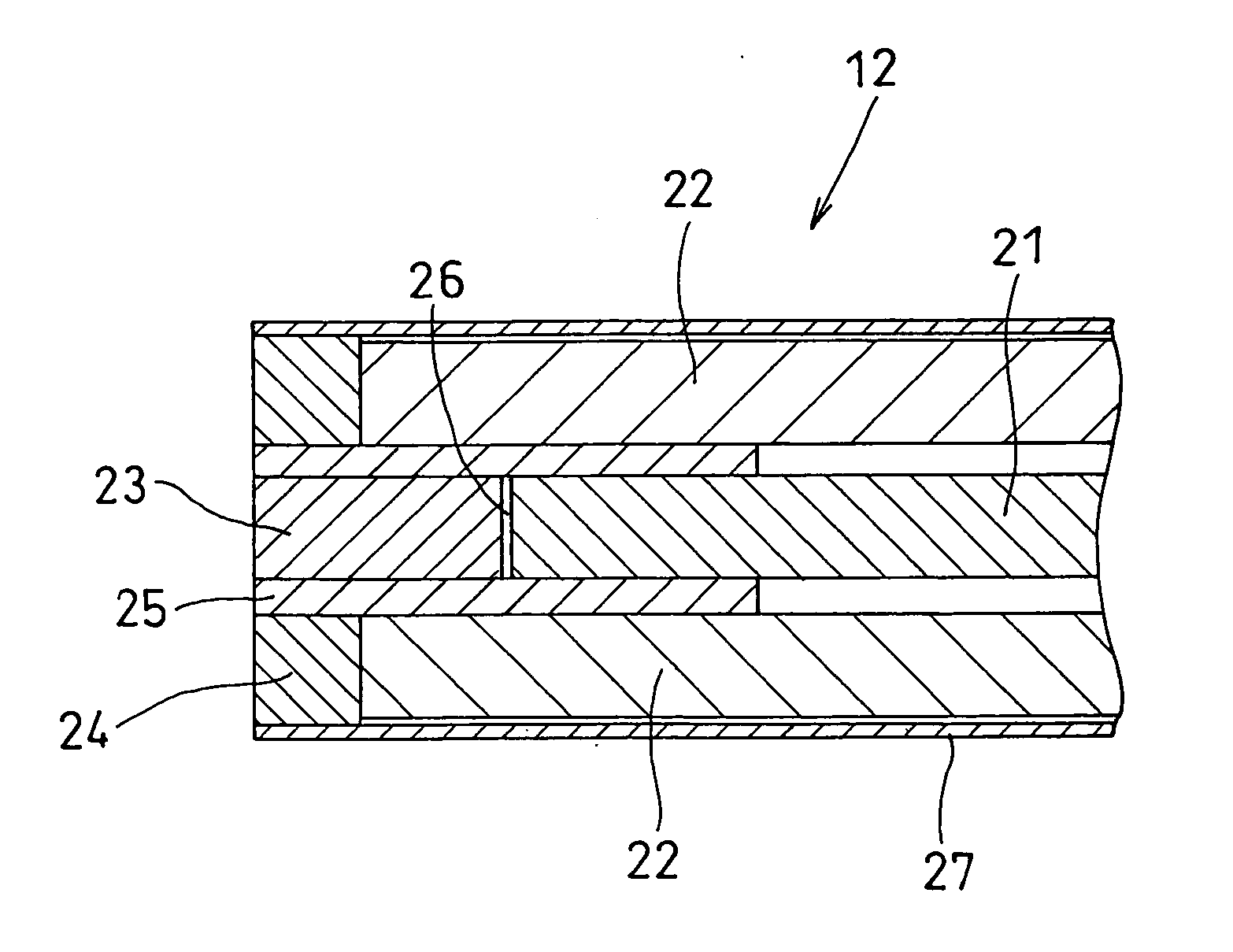

Soft-magnetic, amorphous alloy ribbon and its production method, and magnetic core constituted thereby

ActiveUS20120154084A1Low iron-lossHigh lamination factorLayered productsArc welding apparatusAlloyRing doughnut

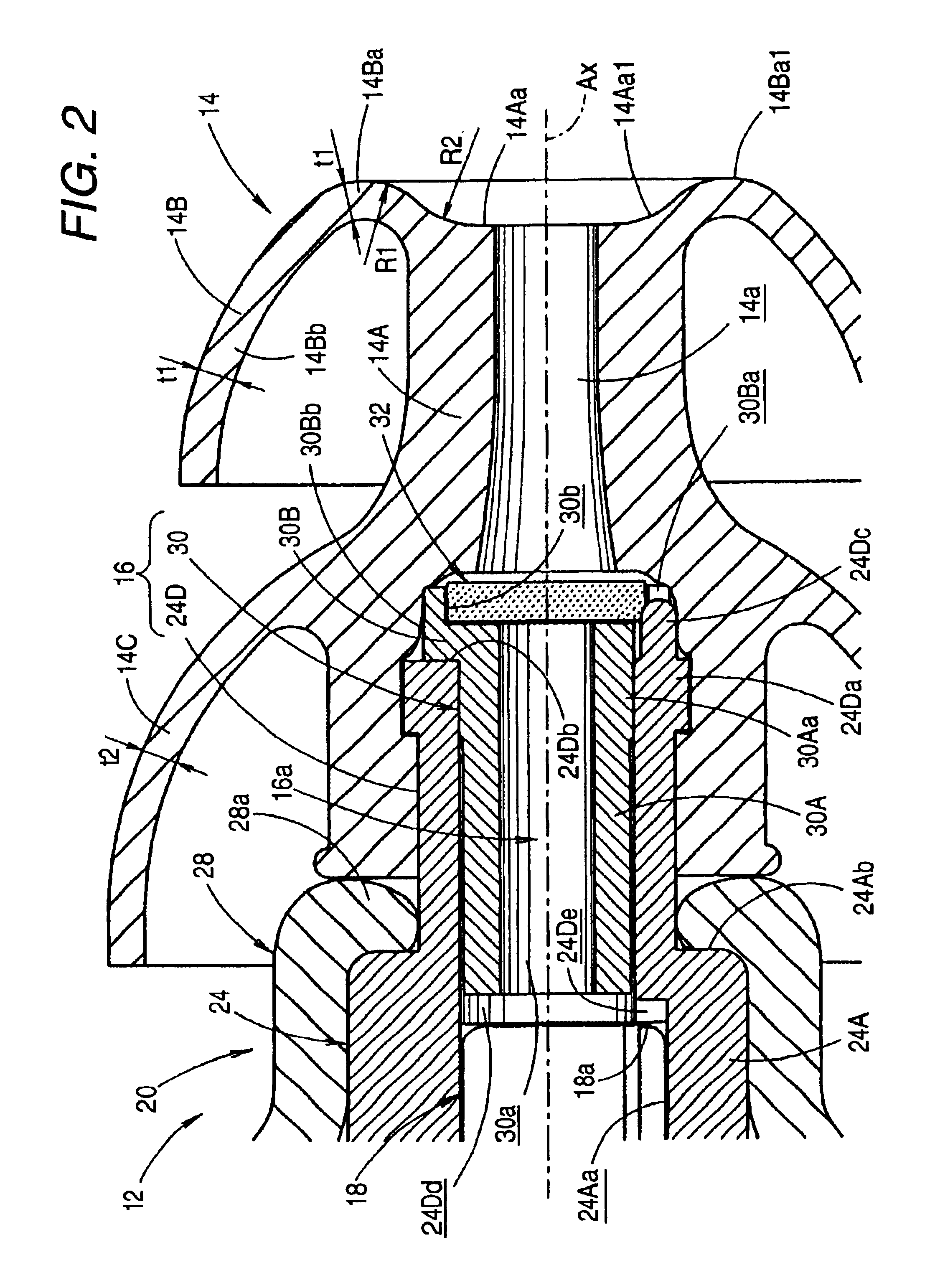

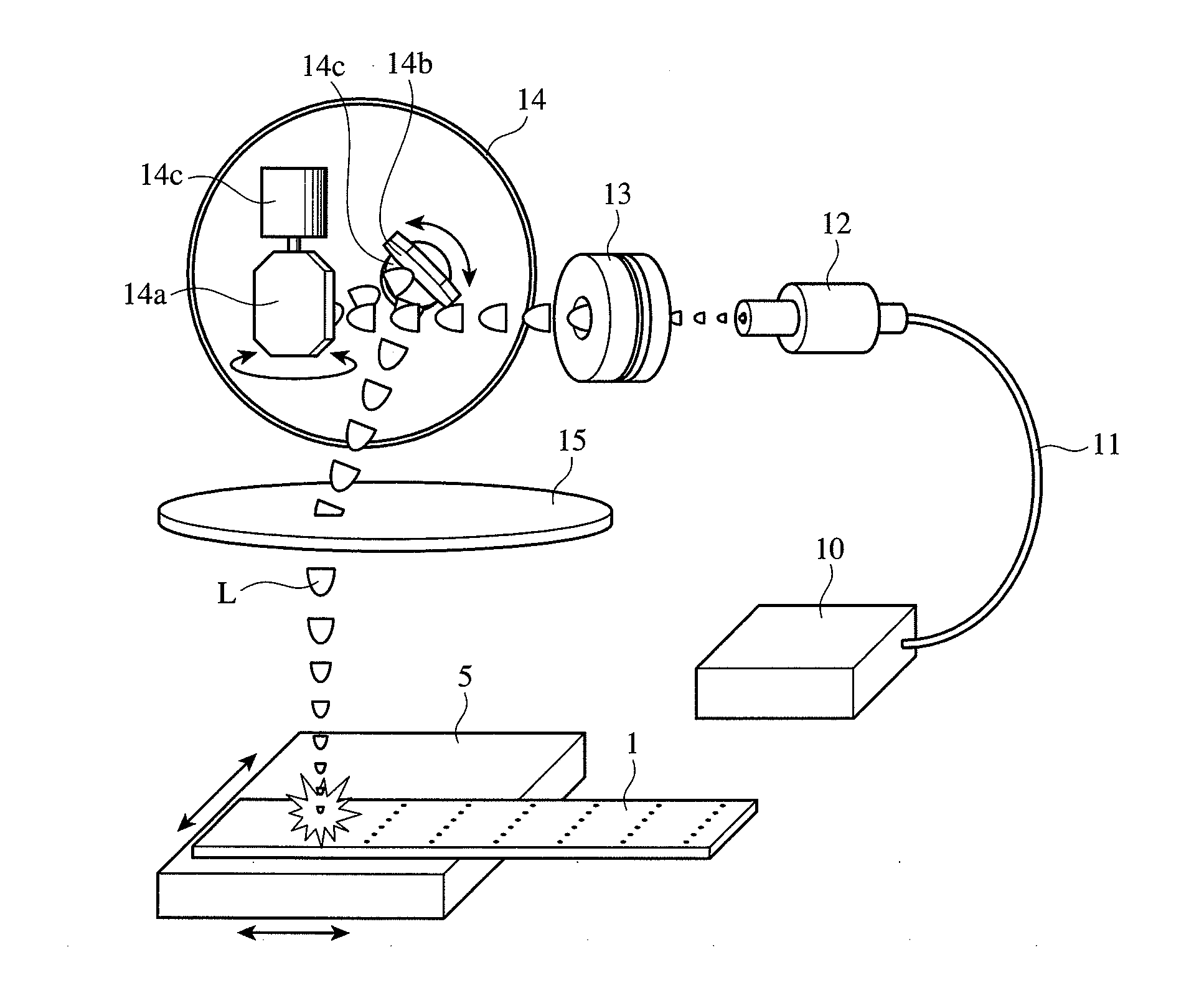

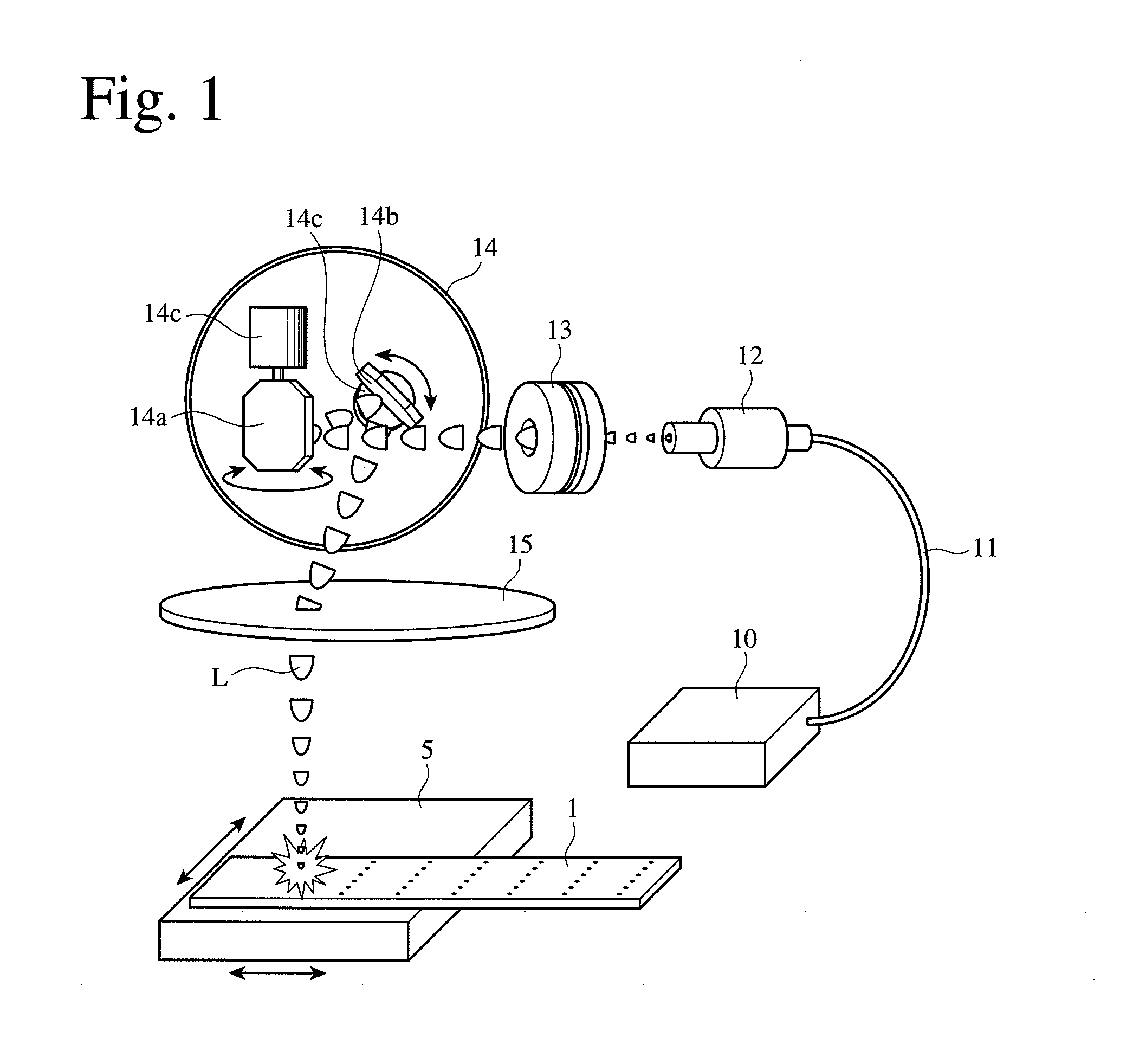

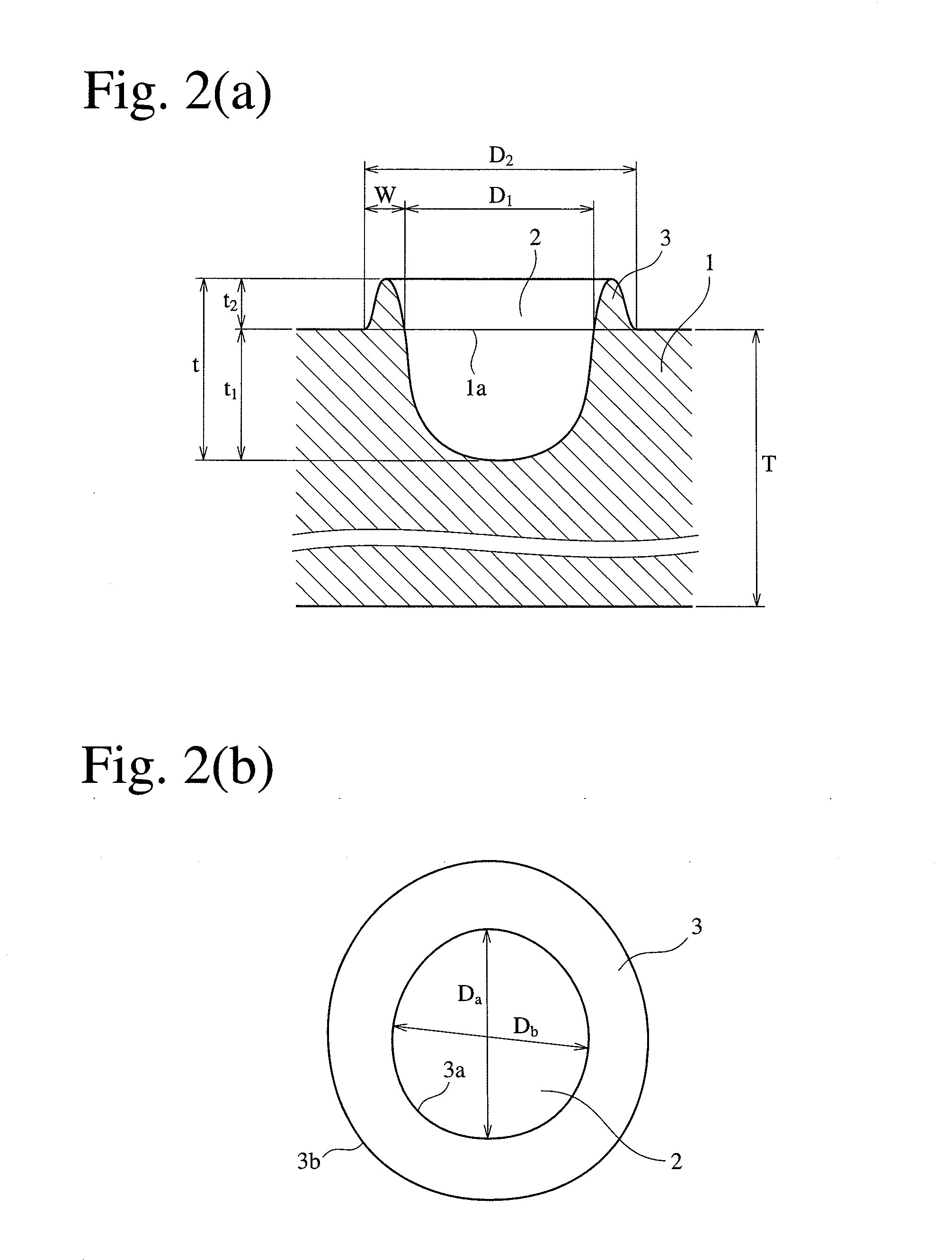

A soft-magnetic, amorphous alloy ribbon produced by a rapid quenching method, having transverse lines of recesses formed on its surface by laser beams with predetermined longitudinal intervals, with a doughnut-shaped projection formed around each recess; doughnut-shaped projections having smooth surfaces substantially free from splashes of the alloy melted by the irradiation of laser beams, and a height t2 of 2 μm or less; and a ratio t1 / T of the depth t1 of the recesses to the thickness T of the ribbon being in a range of 0.025-0.18, thereby having low iron loss and low apparent power.

Owner:HITACHI METALS LTD

Condenser microphone

ActiveUS20060045302A1Improve reliabilityWithstanding stressPiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesCapacitanceEngineering

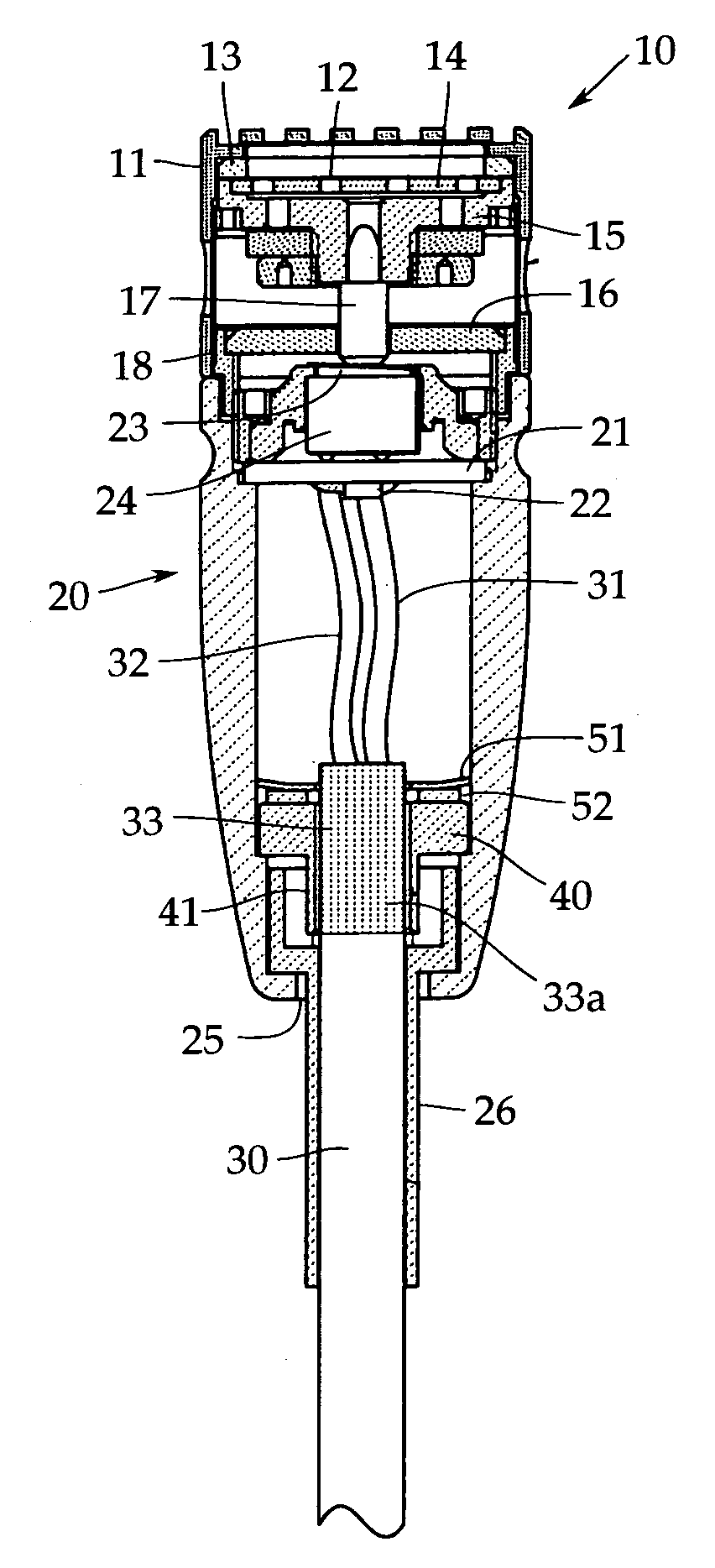

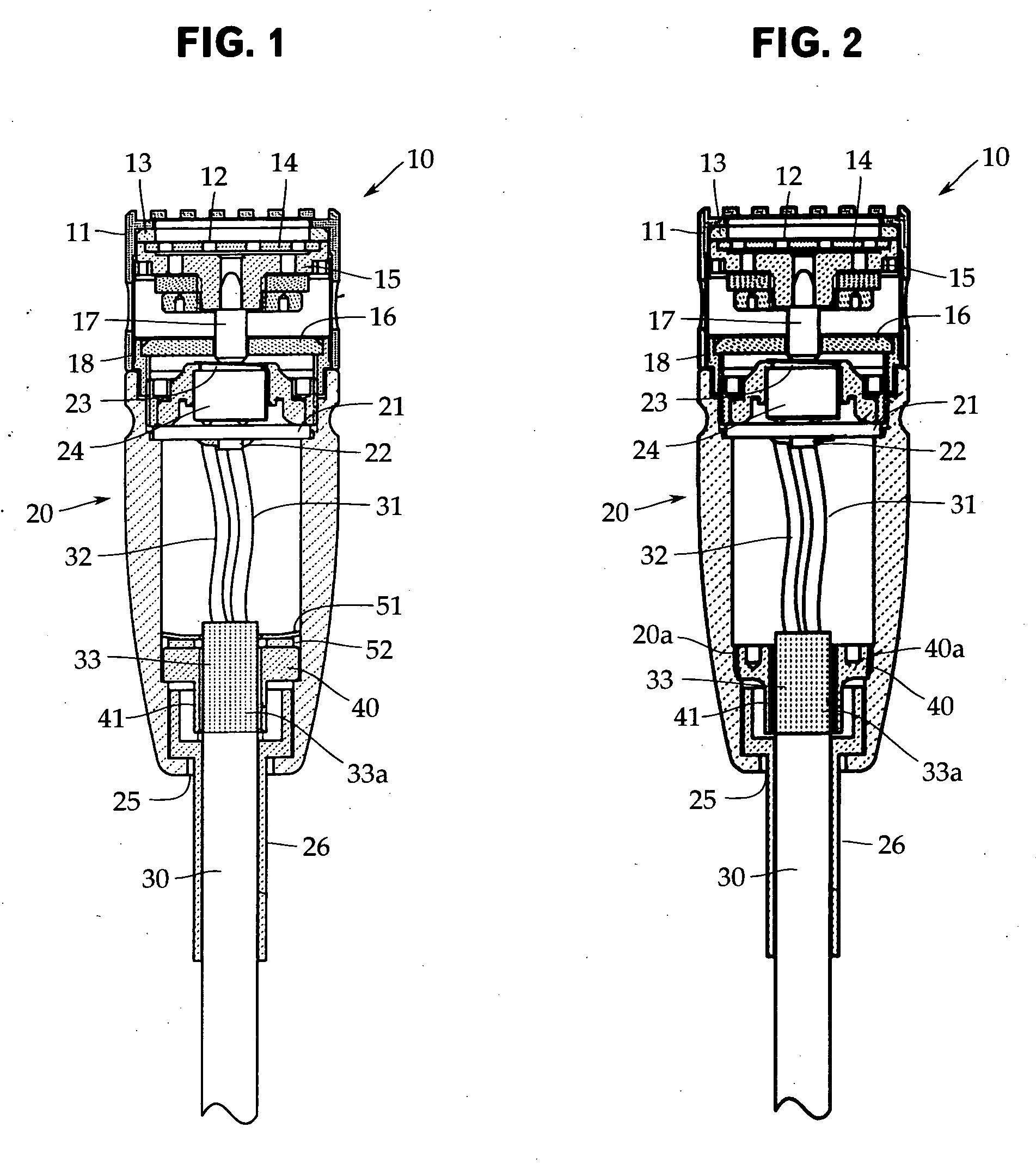

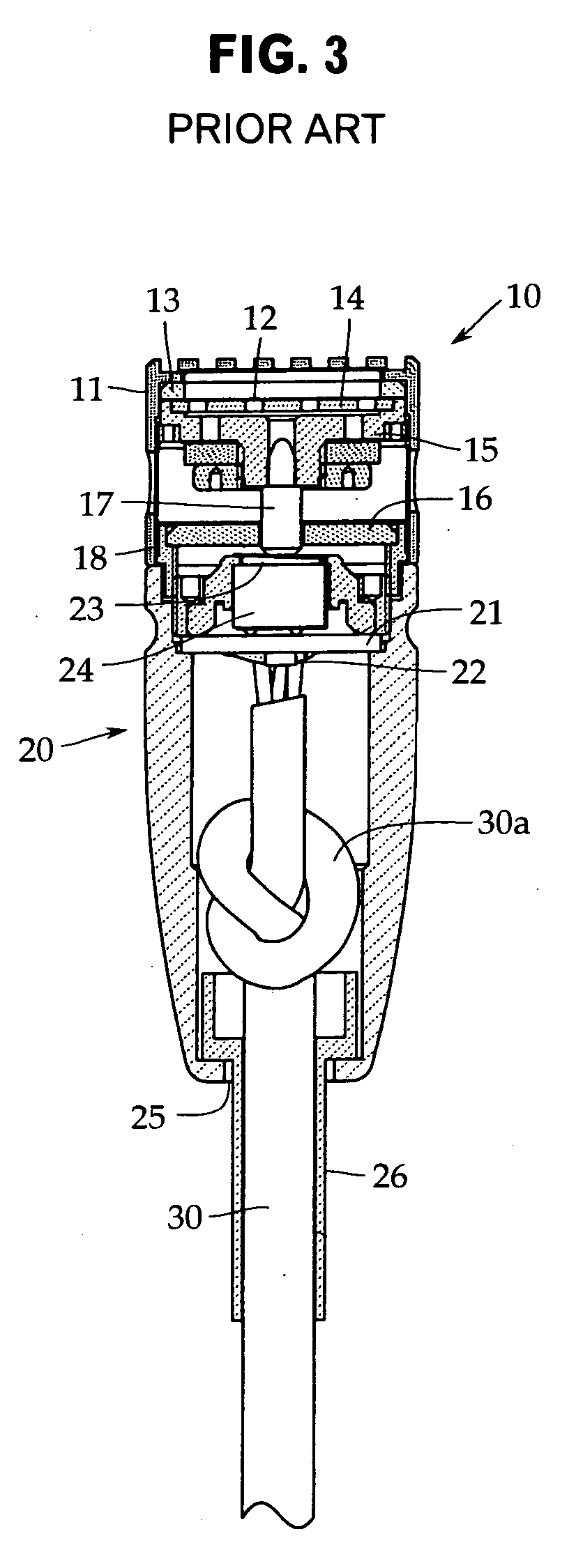

In a condenser microphone unit connected to an output module section via a dedicated microphone cord, the generation of noise caused by strong electromagnetic waves sent from a cellular phone etc. is effectively prevented by a simple configuration. In the condenser microphone unit in which a microphone capsule 10 is supported, for example, exchangeably on a support enclosure 20 and a microphone cord 30 consisting of a two-core shield covering line for connecting the condenser microphone unit to the output module section is pulled into the support enclosure 20, a shield covering line exposure portion 33a, in which a shield covering line 33 is stripped off, is provided in a portion in which the microphone cord 30 is pulled into the support enclosure 20, and a fixing member 40 formed into a doughnut shape is fixed to the shield covering line exposure portion 33a by staking, by which the shield covering line 33 is connected to the support enclosure 20 via the fixing member 40.

Owner:AUDIO-TECHNICA

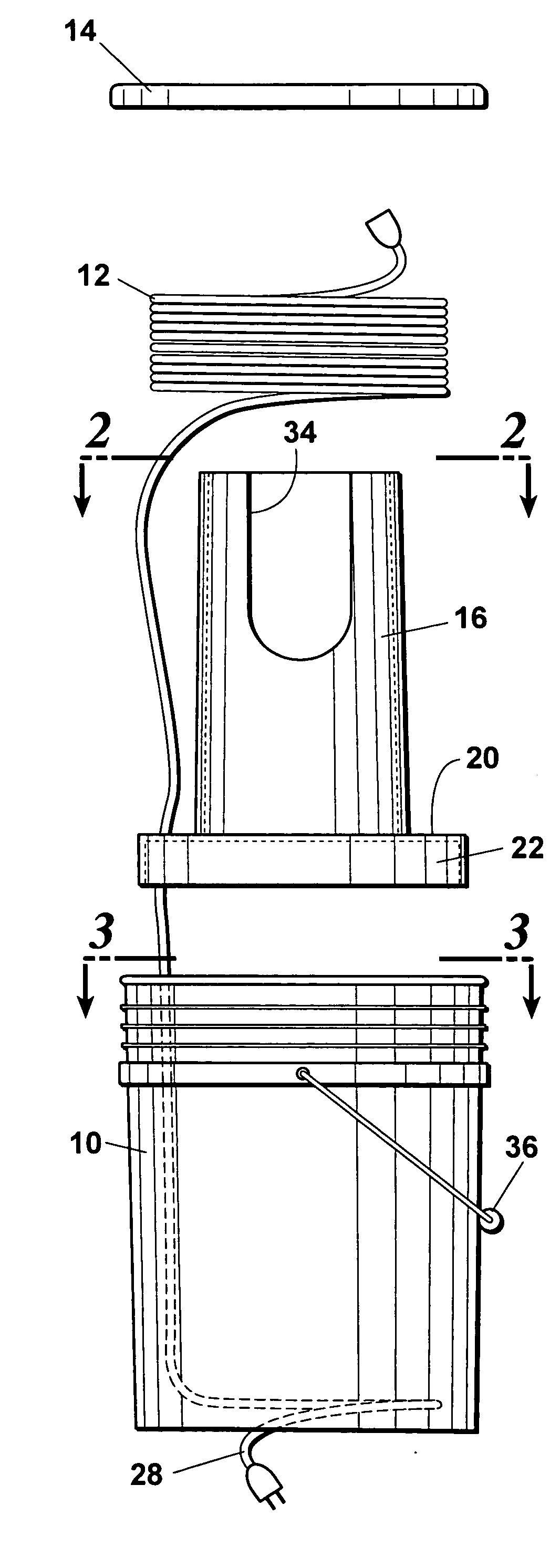

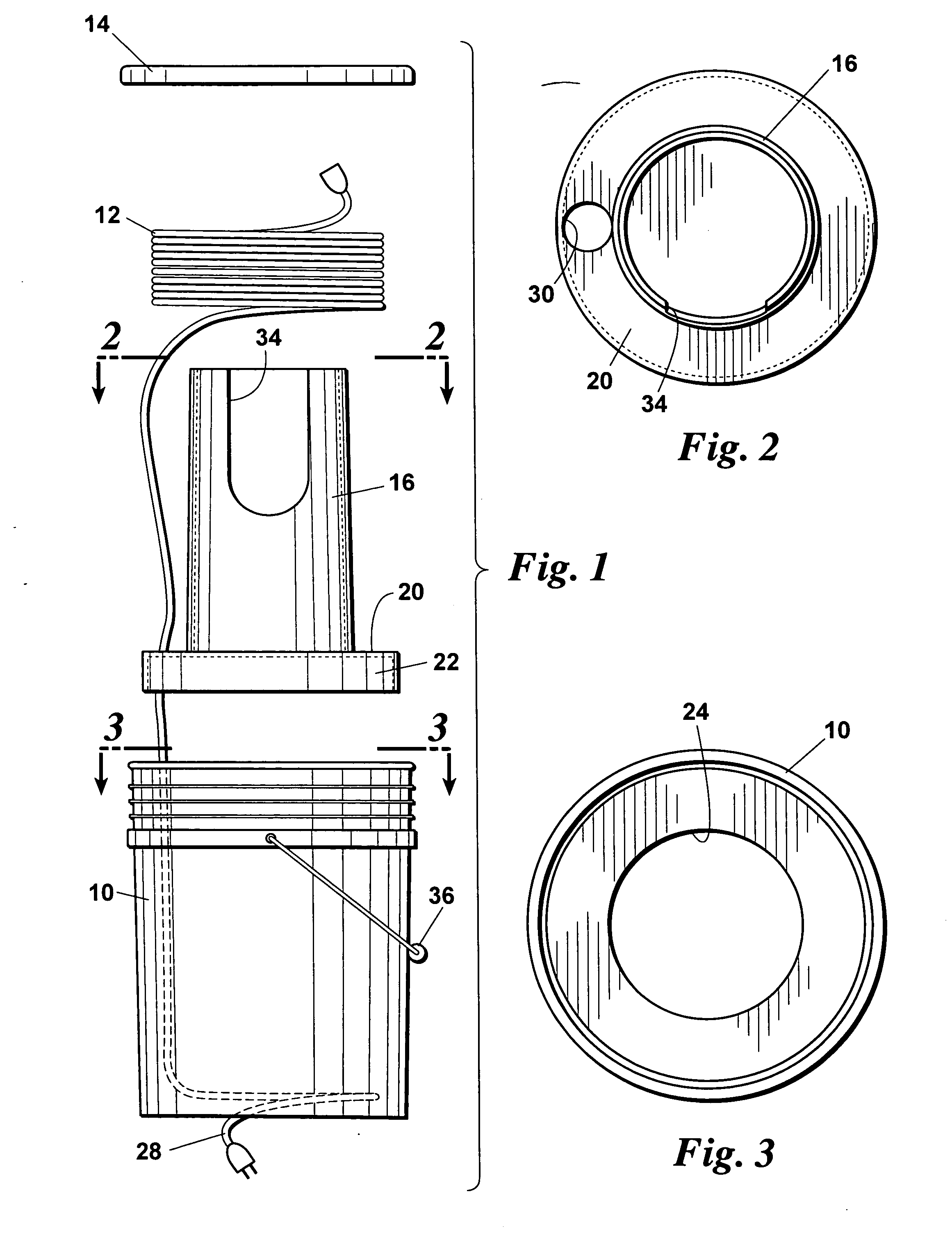

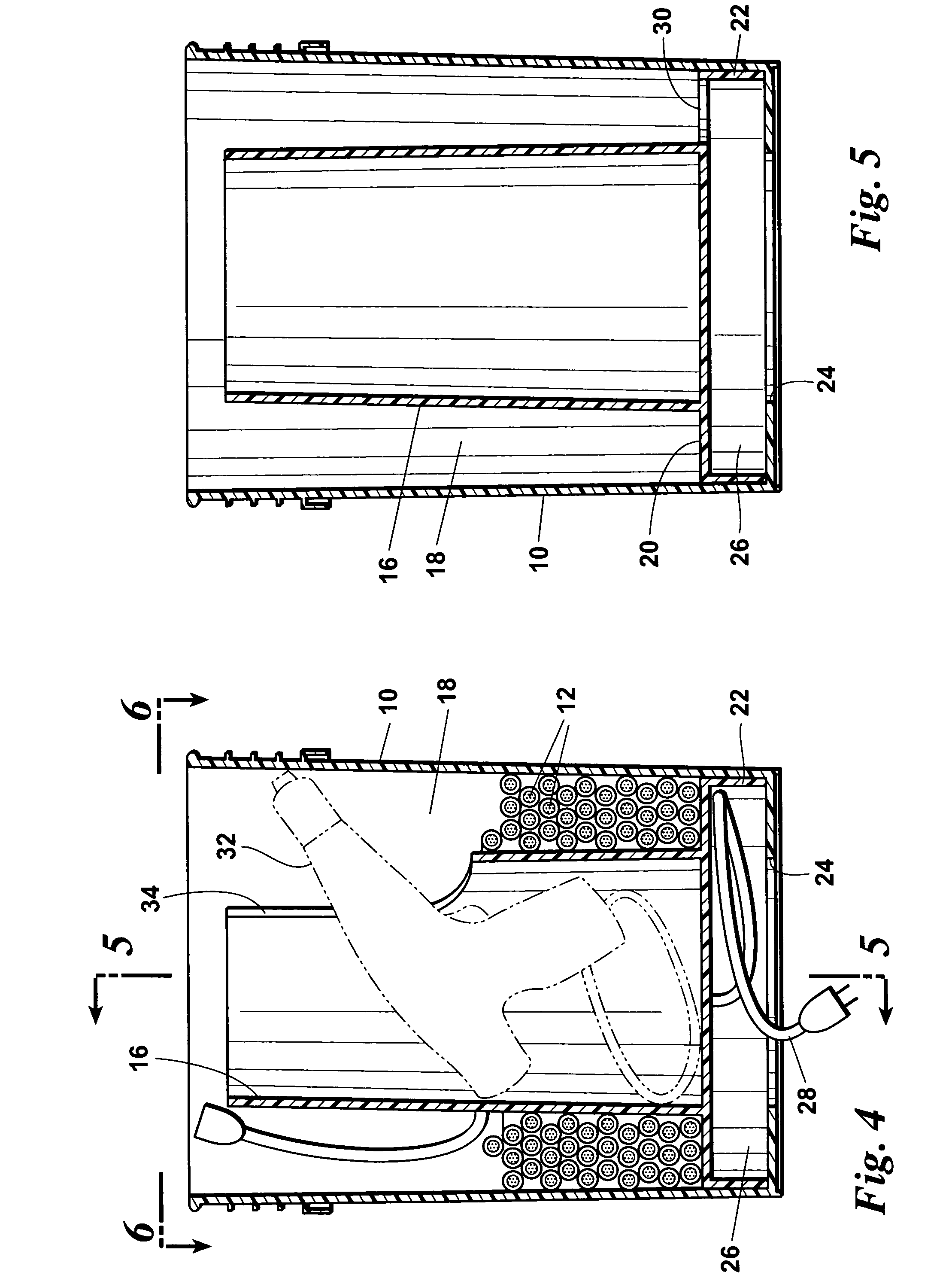

Bucket and cord

A bucket and cord combination comprising a cylindrical bucket having a predetermined diameter and height for storing an elongated flexible cord therein between an inner cylindrical surface of the bucket and an outer curved surface of an axial insert received in the bucket and forming therewith an annular space for the storage of the cord, the insert having a vertical height equal to or less than the height of the bucket and having a diameter less than the diameter of the bucket, the bucket having a substantially flat circular bottom with a hole therein whose diameter is less than the diameter of the bucket, the bottom of the insert being provided with a flat shoulder extending horizontally outward from the periphery of the insert to the inner periphery of the bucket and spaced from the bottom of the bucket so as to form therewith a doughnut shaped space for storage therein of one terminal end of the cord, the other end of the cord extending from the lower terminal end thereof through a hole in the flat horizontal circular member up into the annular area between the insert and the bucket for storage of the majority of the length of the cord therein.

Owner:OTTO GARY D

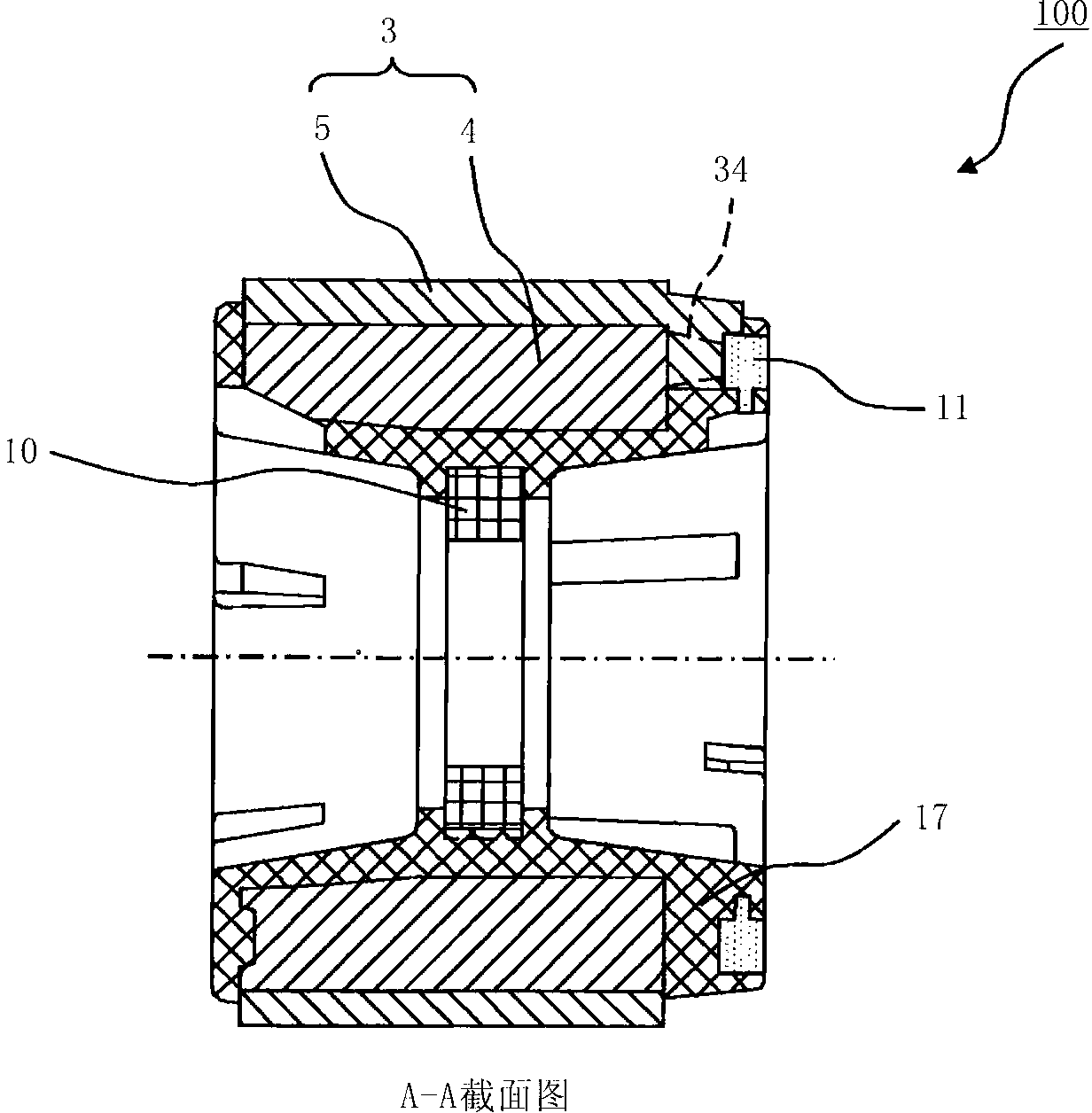

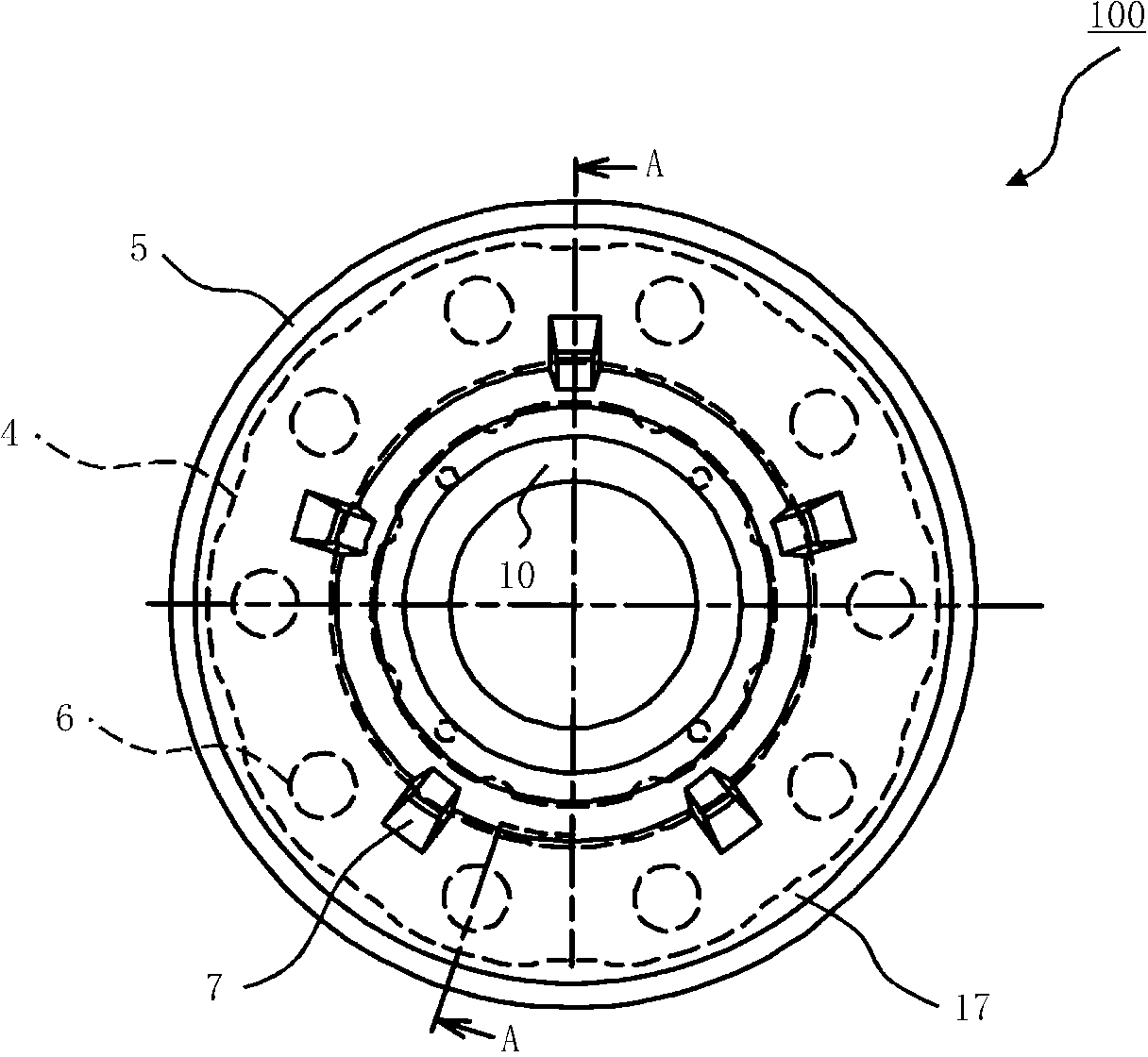

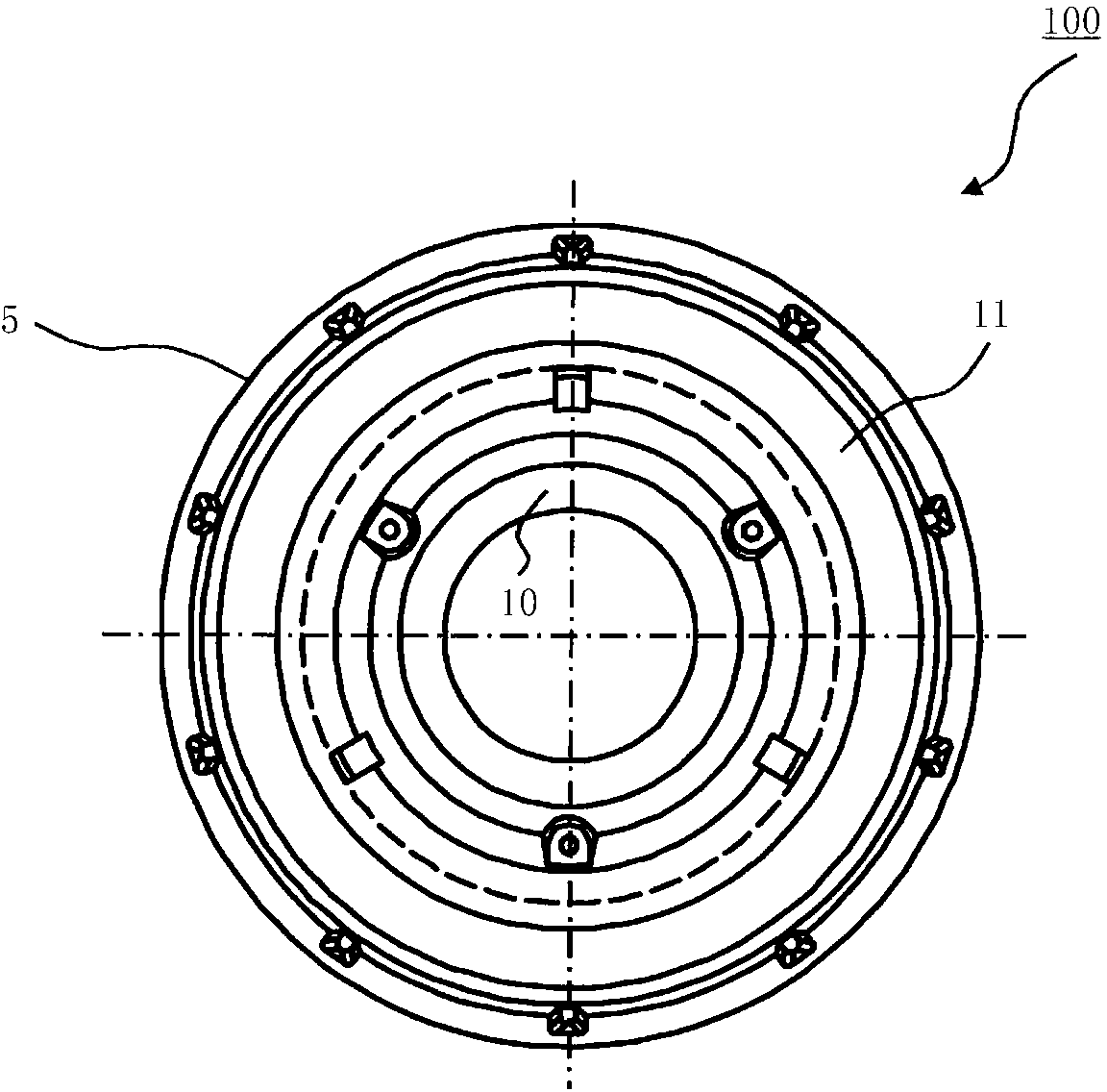

Motor rotor, molded motor, air conditioner, and method for producing molded motor

InactiveCN103329402AMagnetic circuit rotating partsManufacturing stator/rotor bodiesRotor magnetsEngineering

In the present invention, a rotor resin assembly (100) of a motor rotor (200) is provided with: a rotor magnet having an approximately cylindrical yoke, which is formed from a thermoplastic resin containing ferrite or a soft magnetic body, and a resin magnet, which is formed integrally to the outer periphery of the yoke; a position detection magnet disposed at one end in the axial direction of the rotor magnet; and an approximately doughnut-shaped rotor core disposed at the inner periphery of the rotor magnet and formed by layering a predetermined number of electromagnetic steel sheets. The rotor magnet, the position detection magnet, and the rotor core are formed integrally from resin, and the rotor resin assembly (100) is attached to a jig by inserting a shaft (1) into the inner diameter of the rotor core and caulking at the jig in a manner so as to form depression in the vicinity of the inner diameter of both end surfaces of the rotor core.

Owner:MITSUBISHI ELECTRIC CORP

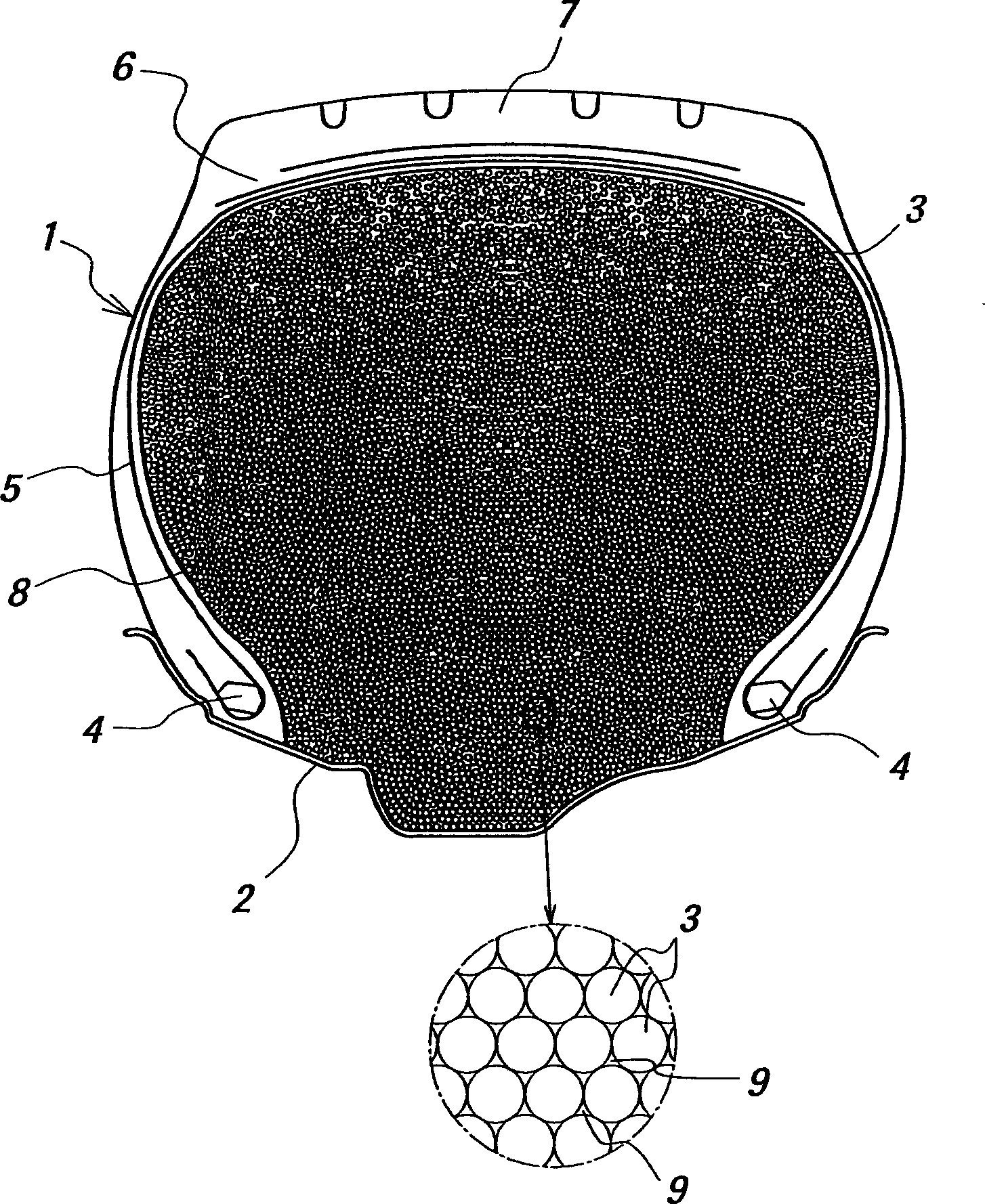

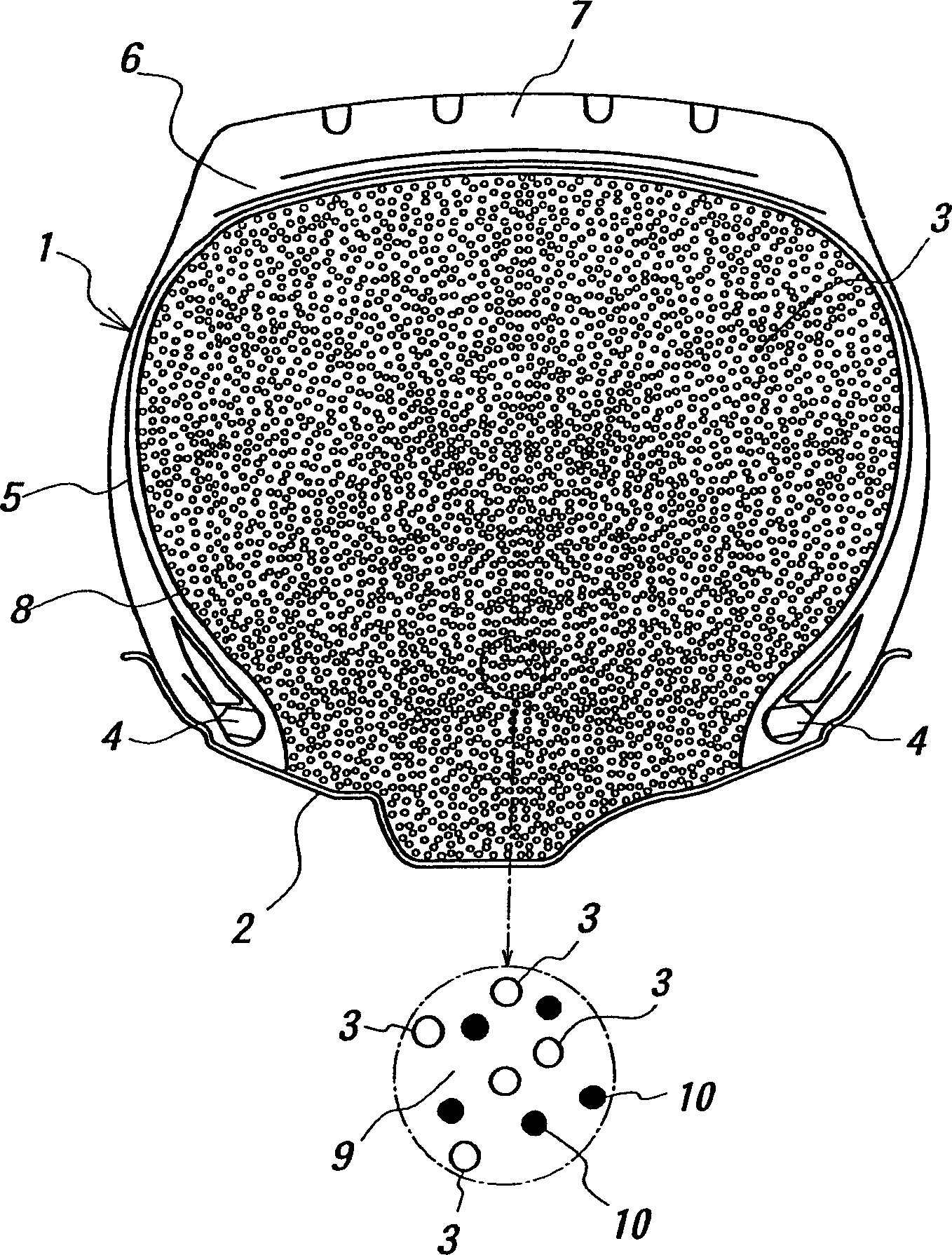

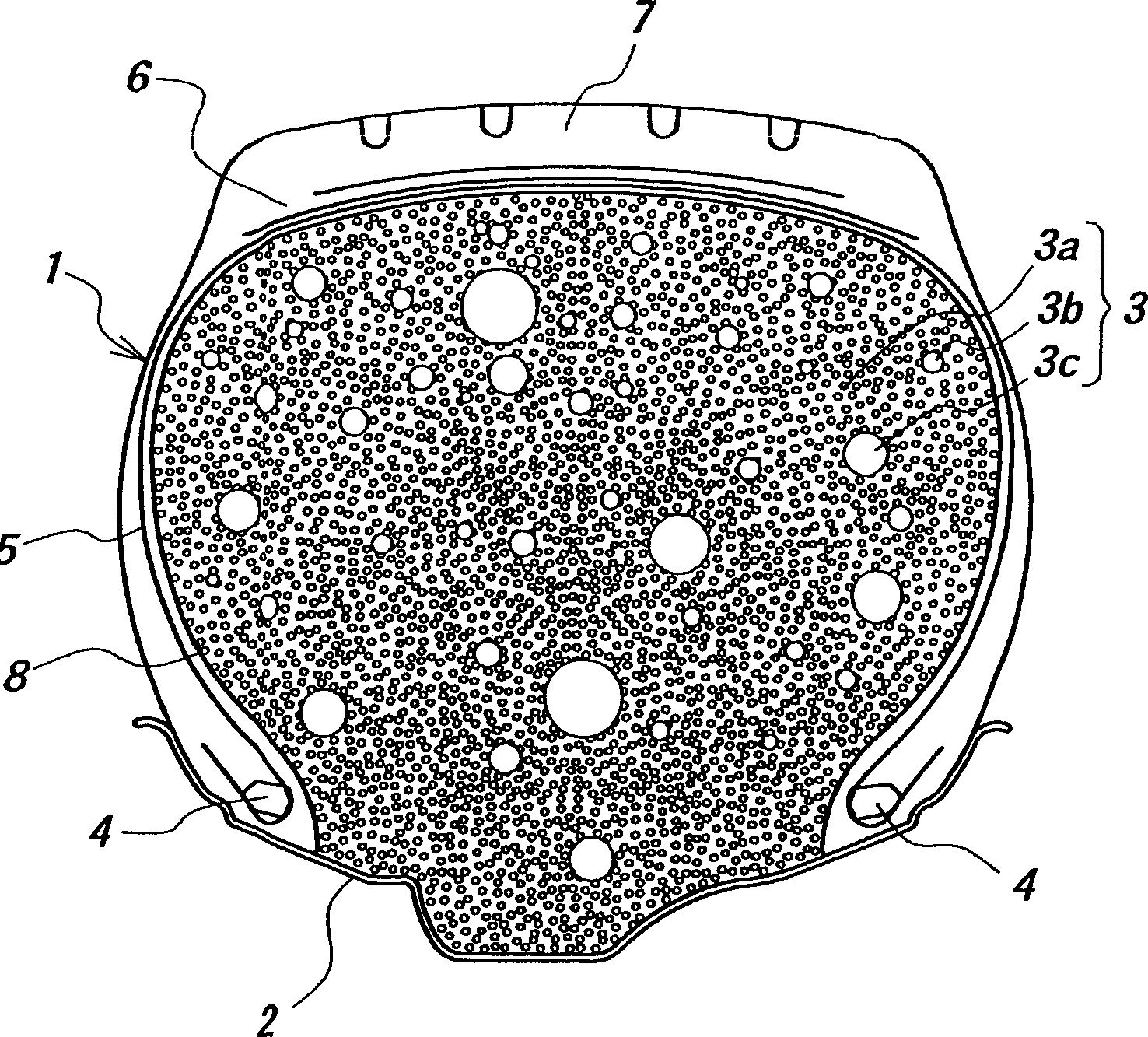

Assembly of tire and rim

InactiveCN1458881AReduce the alarm functionWithout separate inflatable insertsNon-inflatable tyresInternal pressureRolling resistance

There is provided a tire-rim assembly capable of stably running over a distance required even in the dropping of the tire internal pressure after the injuring of the tire without sacrificing rolling resistance and ride comfort in the usual running before the injuring of the tire, wherein a great number of substantially sphere-shaped particles each consisting of a continuous phase of a resin and a closed cell(s) and having a mean bulk specific gravity of not more than 0.1 are disposed in an interior defined by assembling a hollow doughnut-shaped tire onto an approved rim, and a pressure at 25 DEG C in the interior of the tire is not less than 150 kPa as an absolute pressure.

Owner:BRIDGESTONE CORP

Laser fabrication of continuous nanofibers

This invention provides a continuous process of making continuous nanofibers of all kinds, such as SiC, BN, AlN, and C. Laser heating a vapor of feed-material made of all atomic elements needed to grow chosen nanofibers results in growth of nanofibers onto seed-nanostructures attached to a filament, which is then pulled up continuously at a rate controlled by a rate of growth of the nanofibers. More feed-material is supplied at a rate sufficient to enable the nanofibers to grow longer continuously without limit. Laser light focused into a doughnut shape provides a photon density gradient, which constrains the nanofibers to grow parallel to each other and in the form of cylinders, so that industrially useful structures like cables and cylinders can be made in one low cost operation and in large quantities.

Owner:SHIMOJI YUTAKA +1

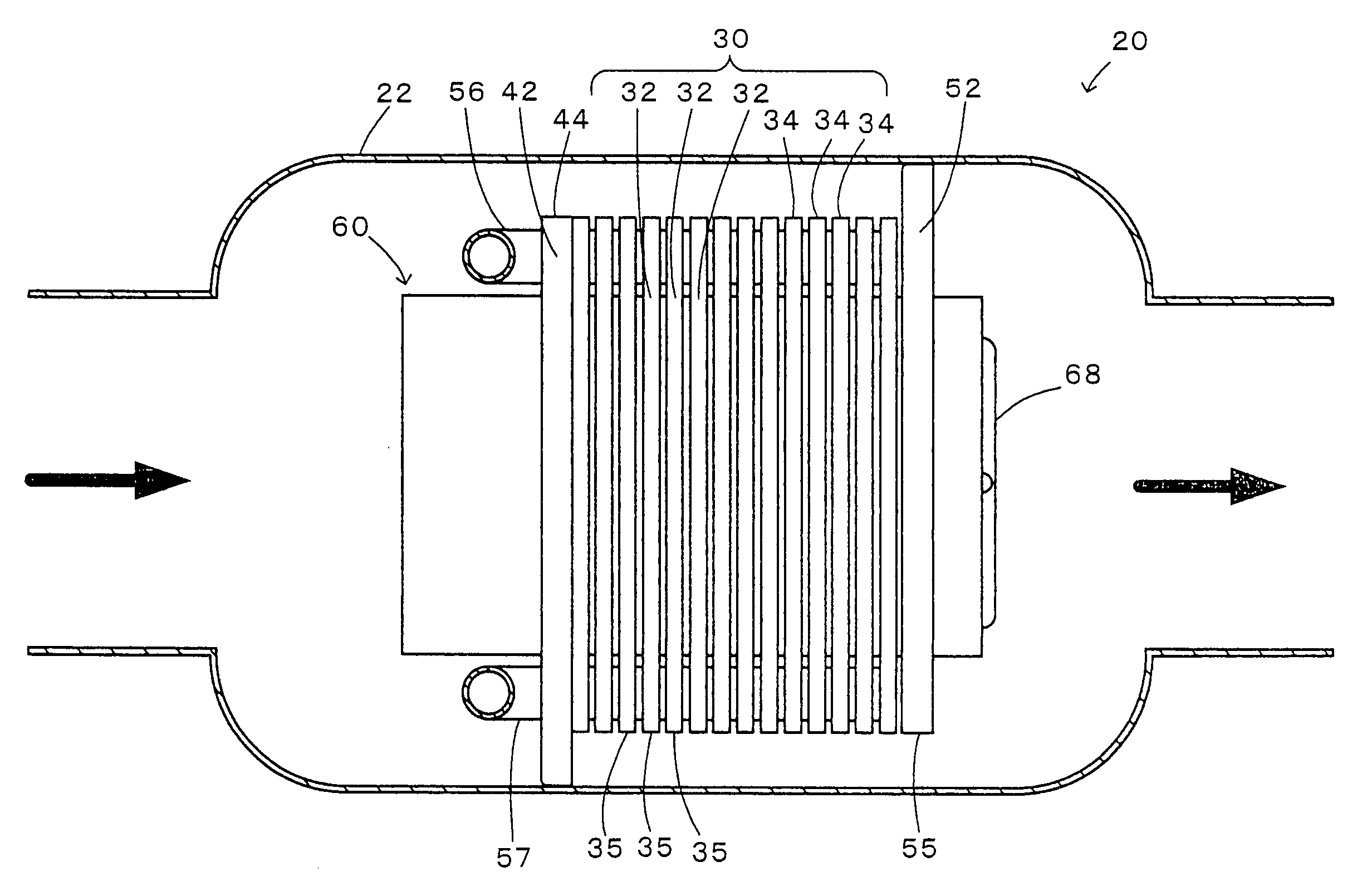

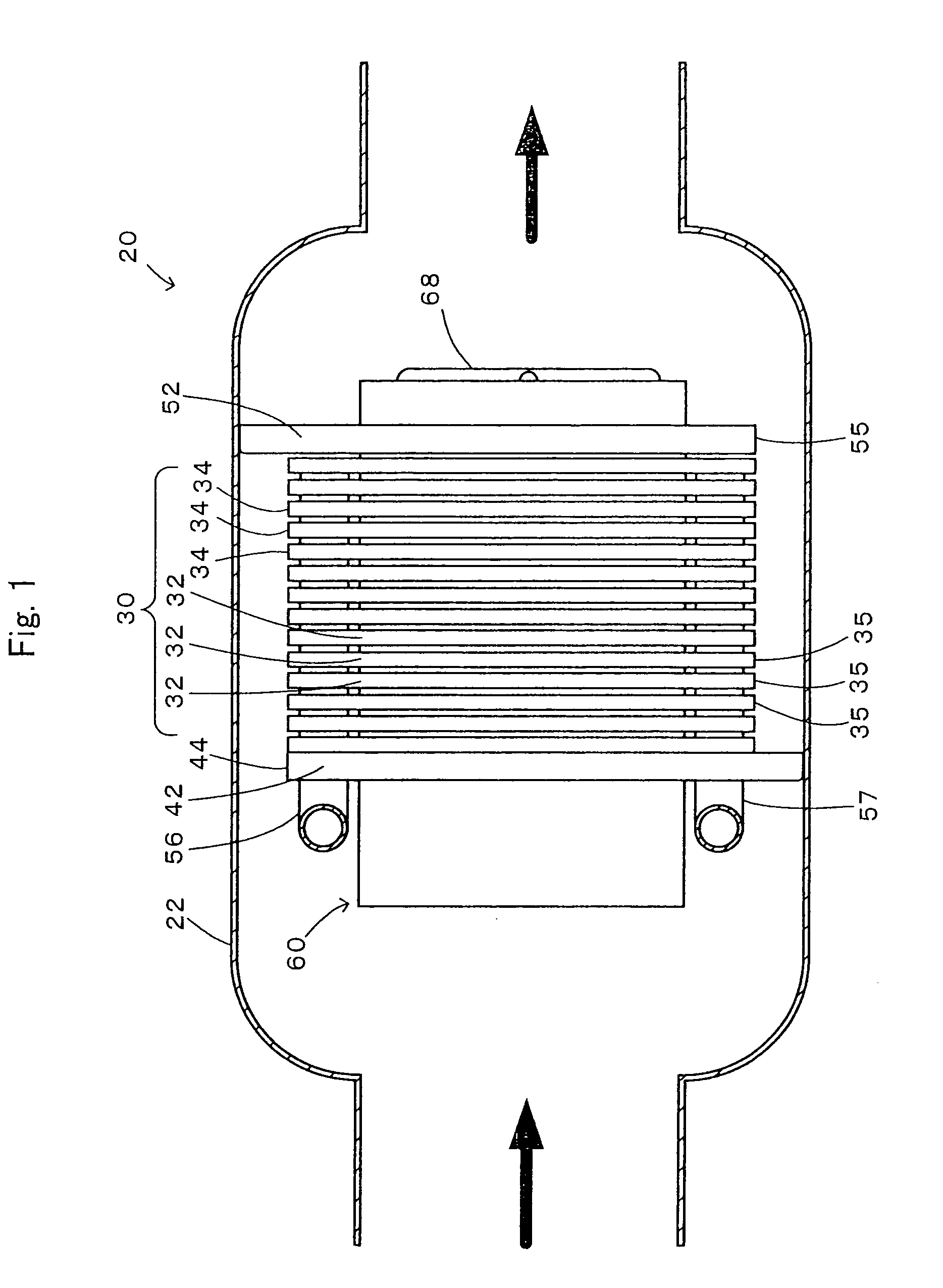

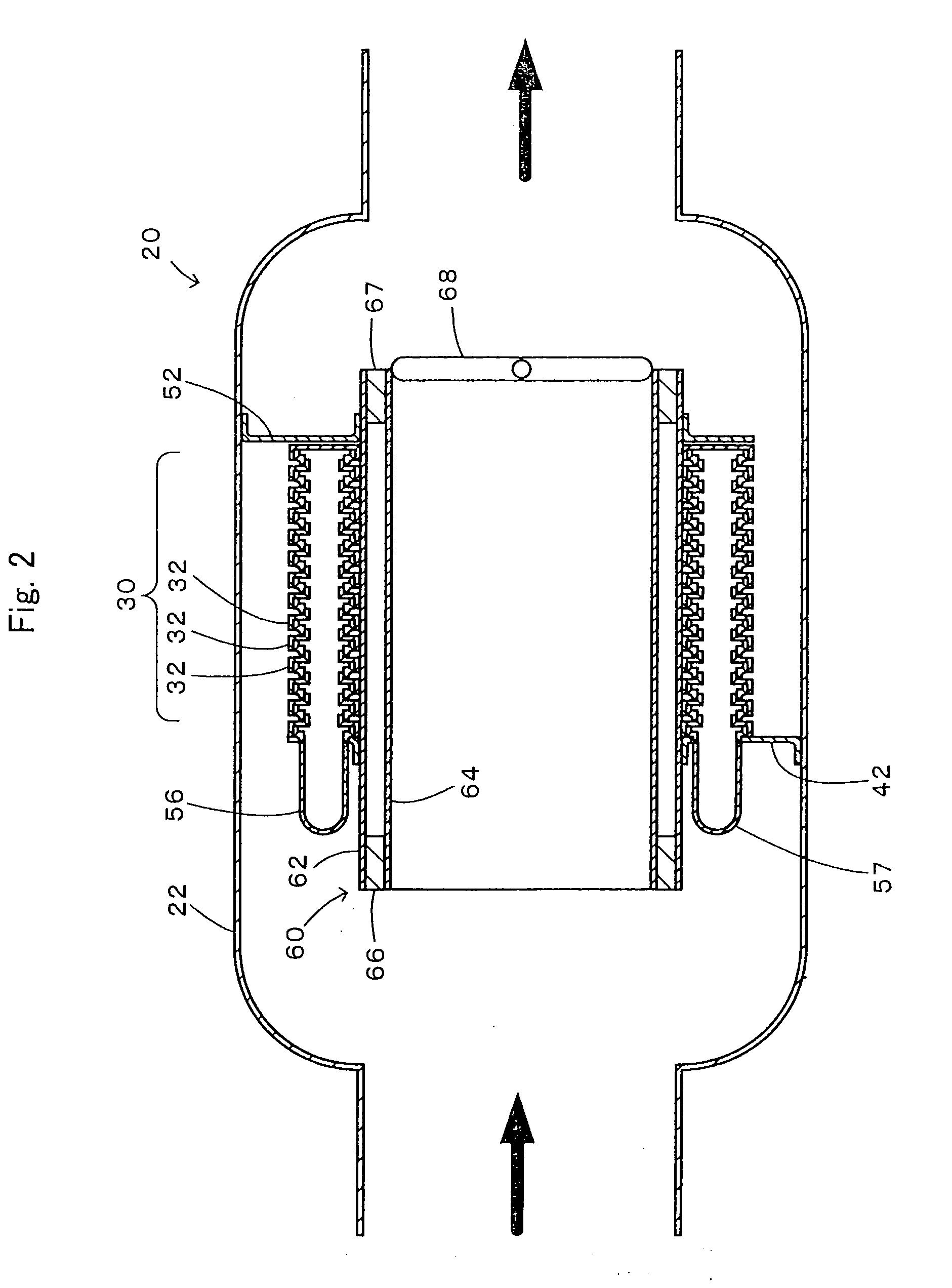

Heat Recovery System

InactiveUS20100251702A1Improve warm-upEfficient heat recoveryInternal combustion piston enginesRecuperative heat exchangersEngineeringInternal combustion engine

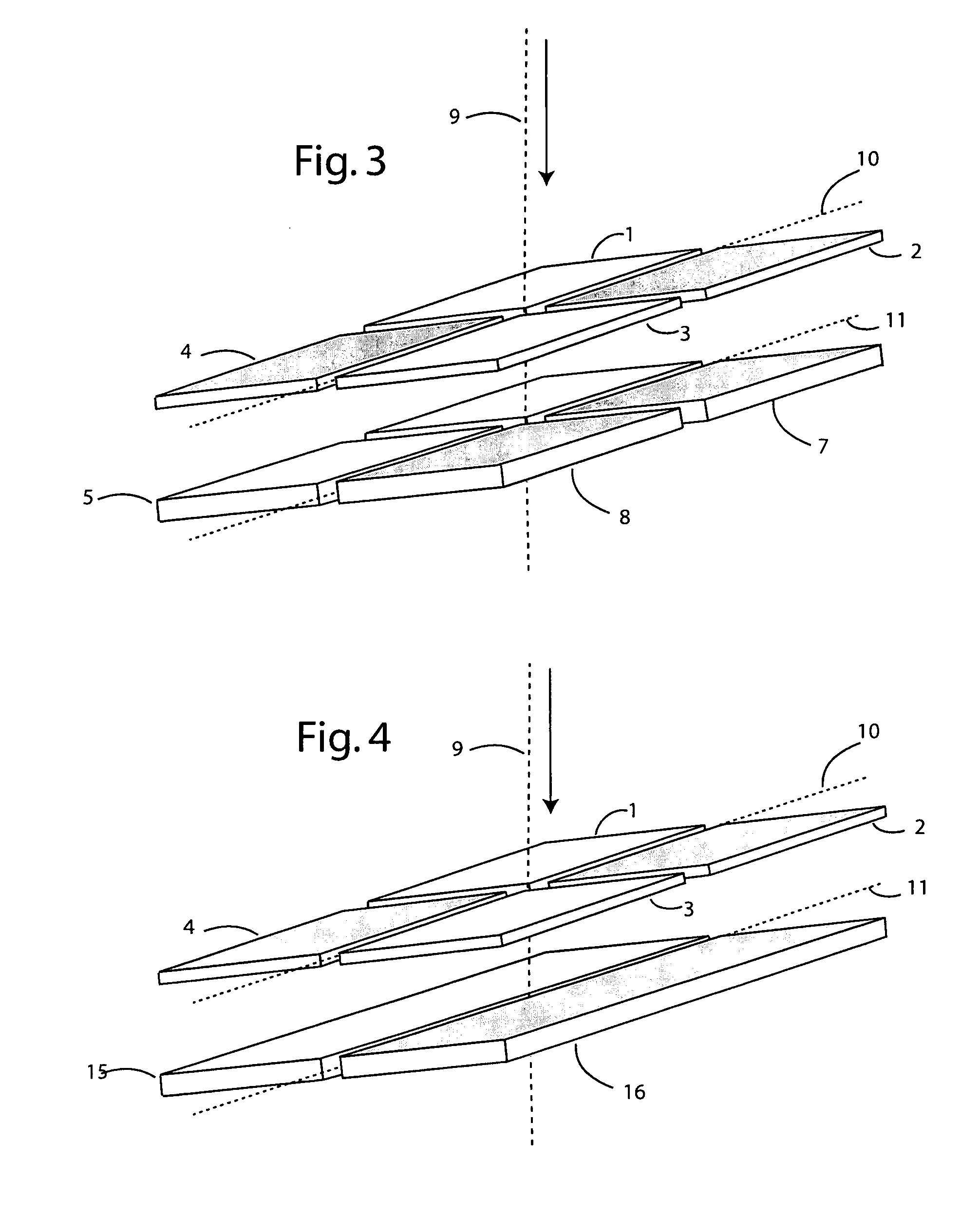

A plurality of flat tubes formed as a tube having notches by linearly cutting upper and lower parts from a hollow flat circular doughnut shape are stacked to structure a tube laminate. It is attached to a case so that a notch aligns with the notch and faces upward by an exhaust inflow end plate and that a notch aligns with the notch and faces downward by an exhaust outflow end plate. A cutoff valve is provided at an exhaust outflow end of an exhaust communication tube passing through the center of the tube laminate by heat insulation. While an internal combustion engine is warming up, the cutoff valve is closed to cause the exhaust to flow in gaps of the respective flat tubes from upward to downward as a whole and also a heat exchange medium is caused to flow in the respective flat tubes from downward to upward as a whole to have heat exchanged between the exhaust and the heat exchange medium to recover the exhaust heat.

Owner:THE UNIV OF TOKYO +3

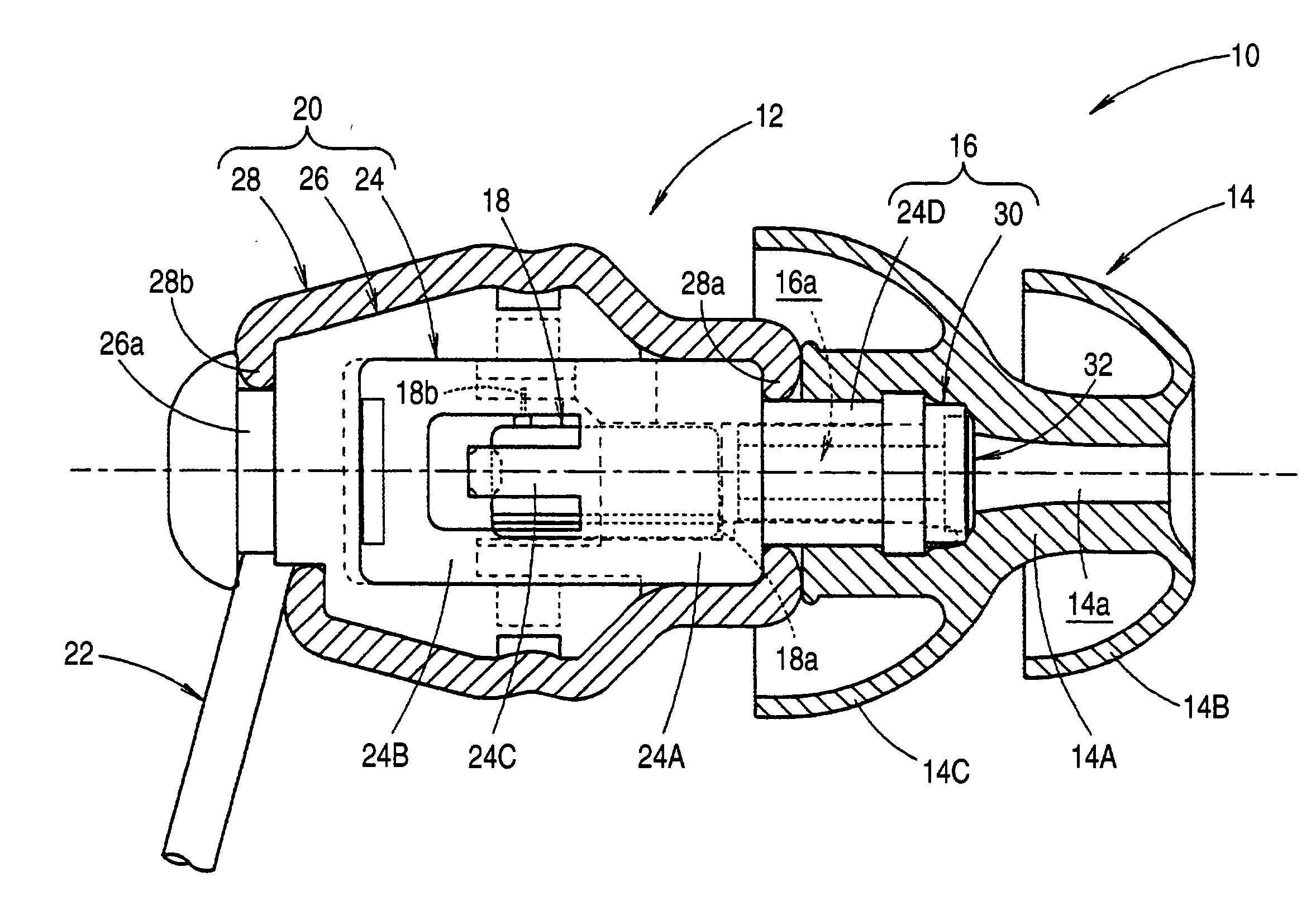

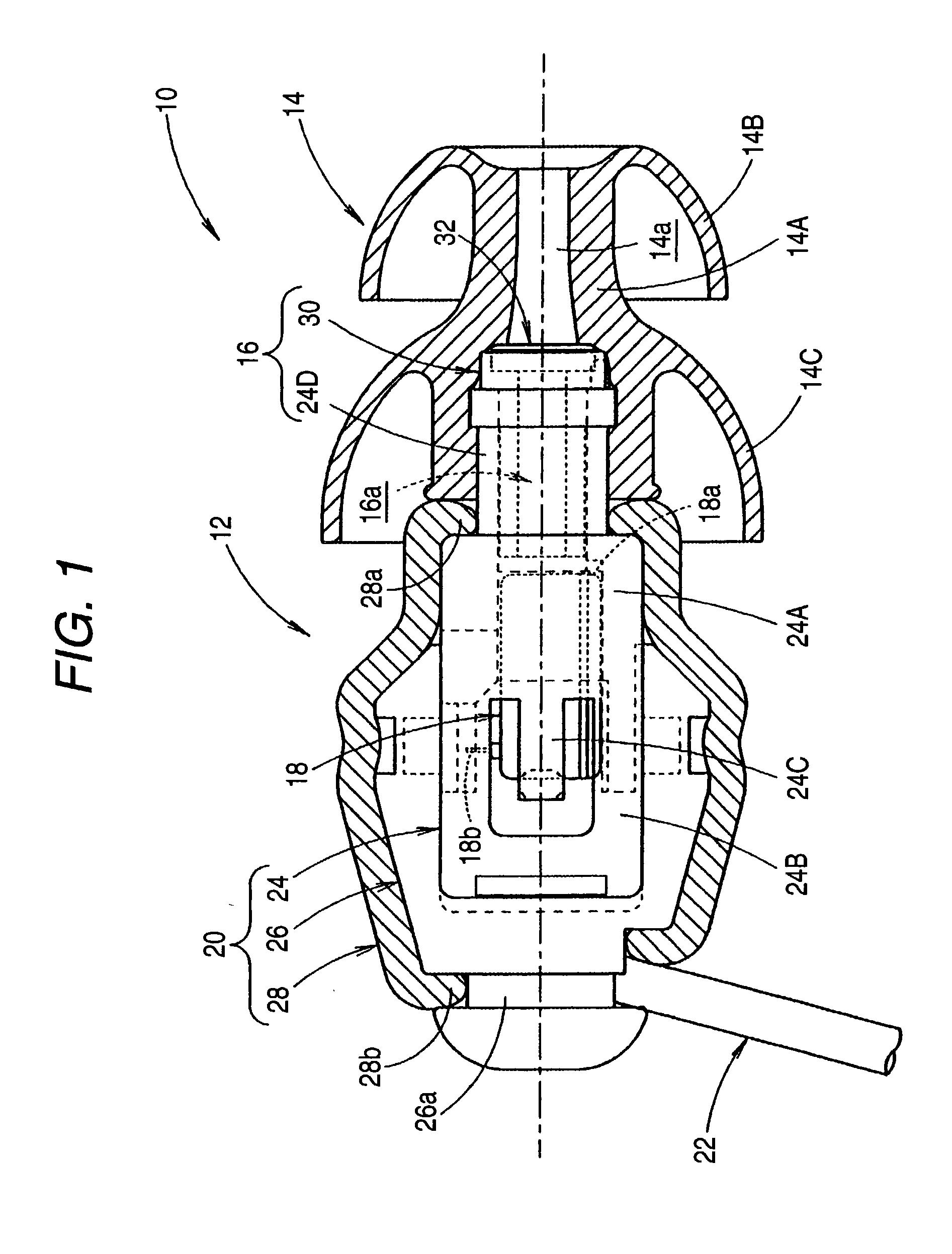

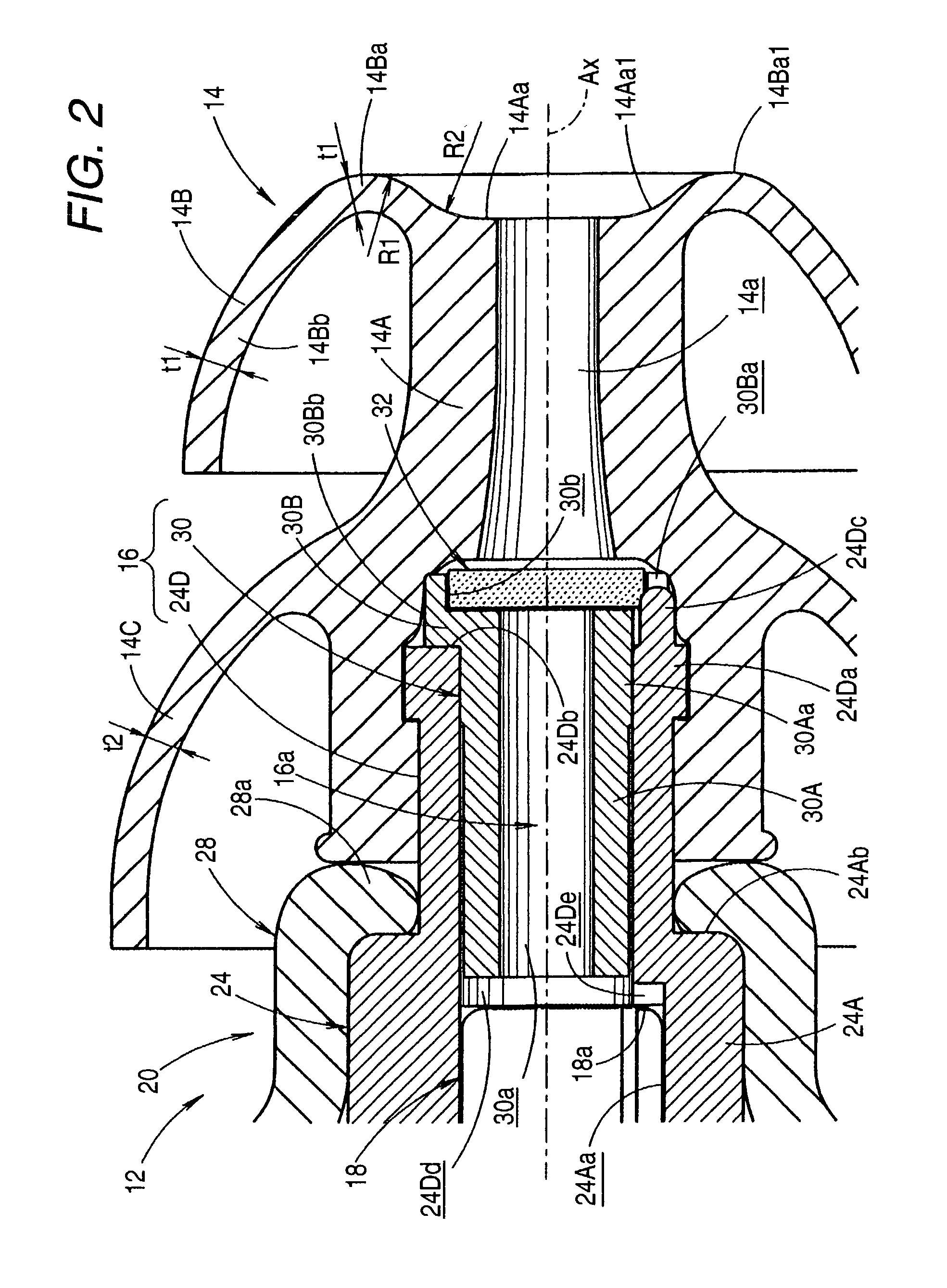

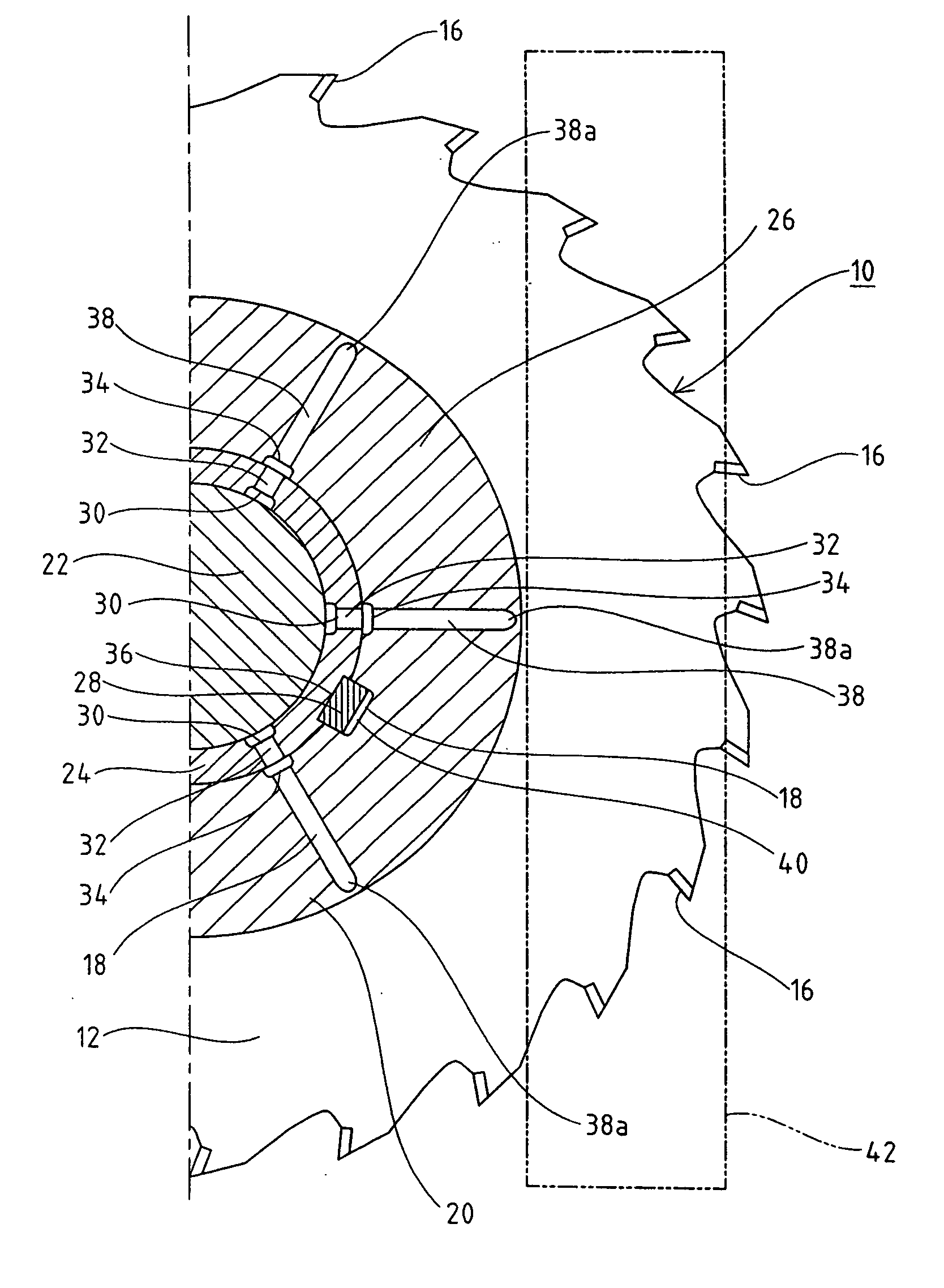

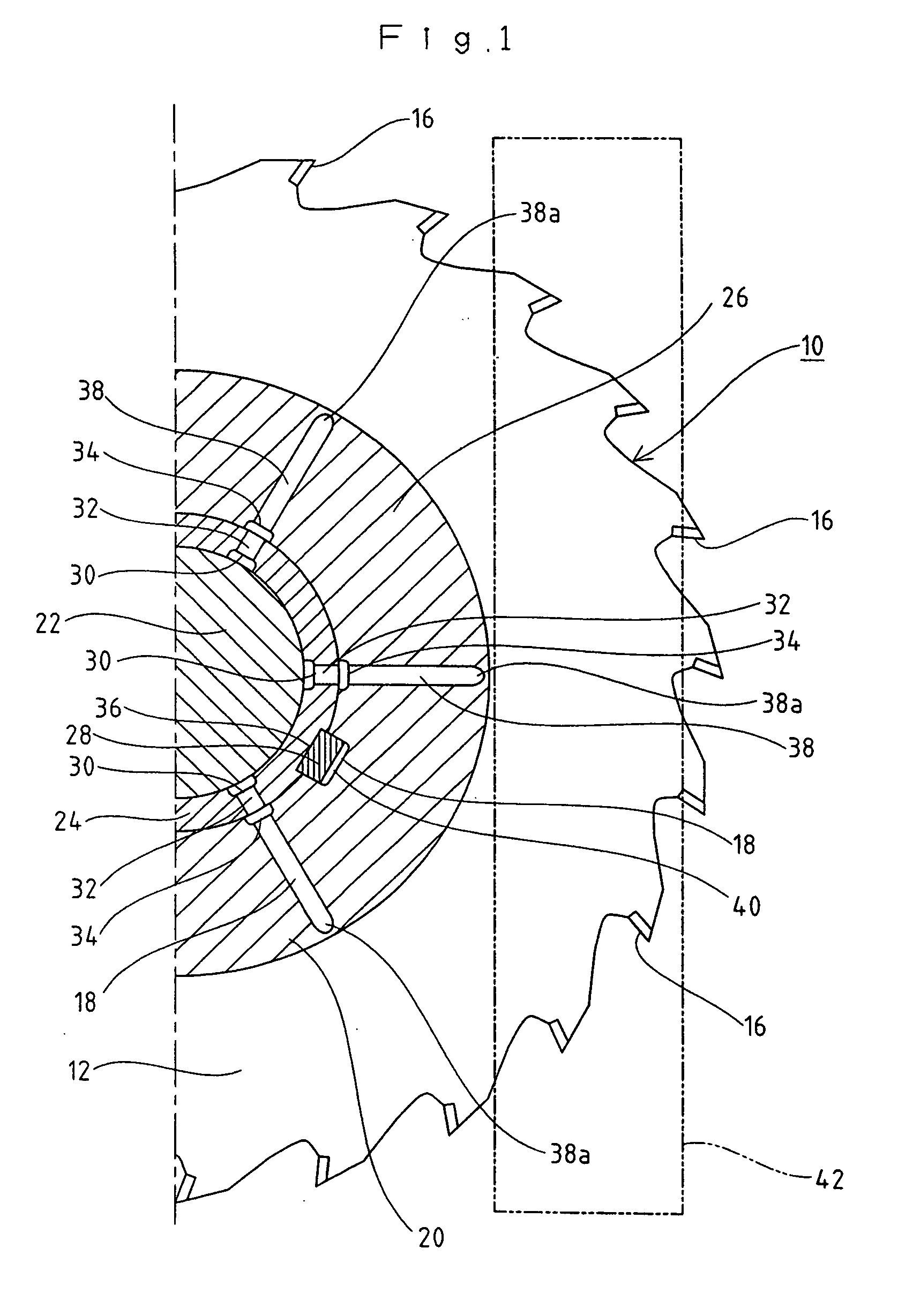

Fluid supply mechanism for rotary tool

InactiveUS20110048200A1Avoid influence costAvoid work environmentMetal sawing accessoriesMetal working apparatusCircular sawEngineering

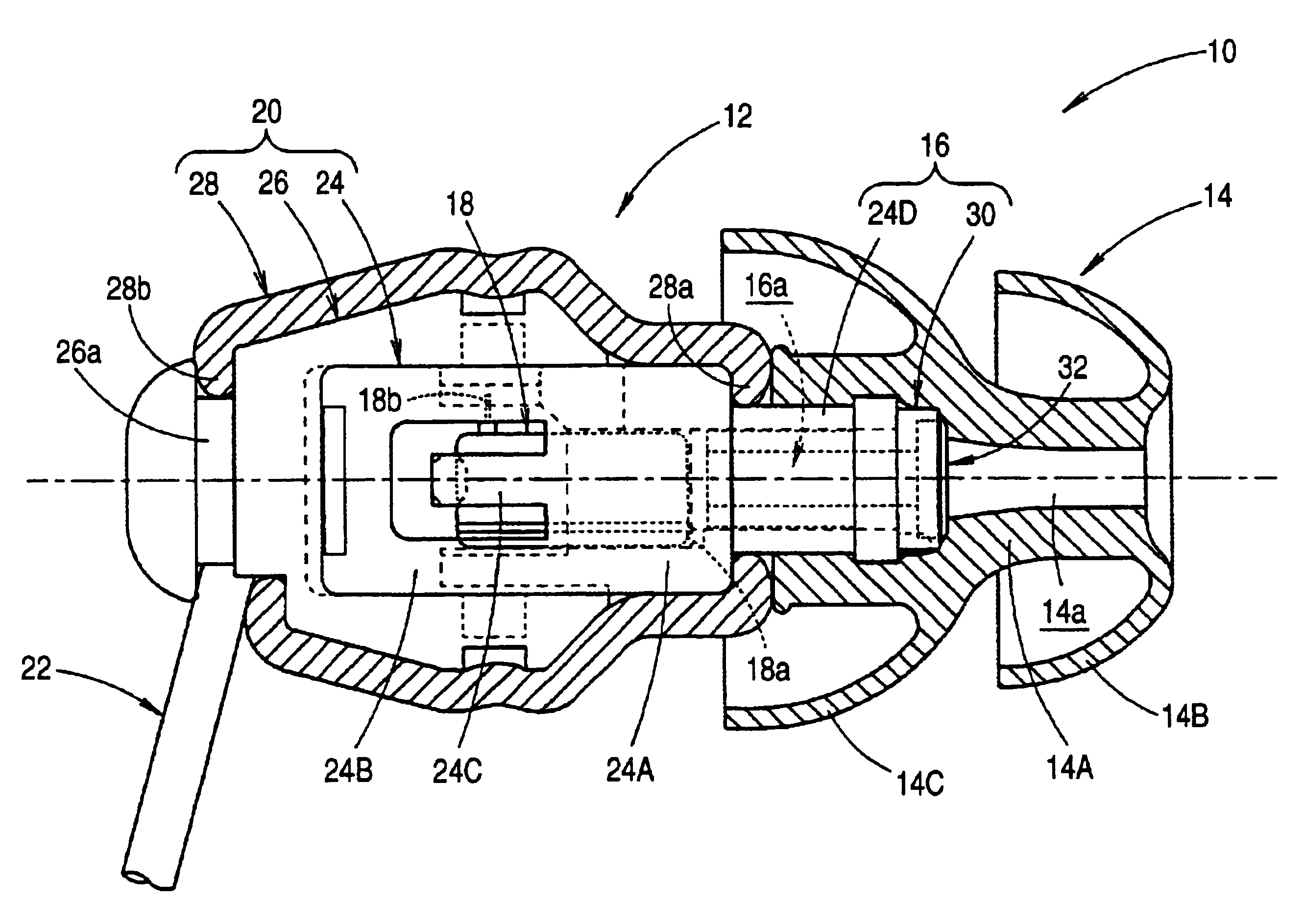

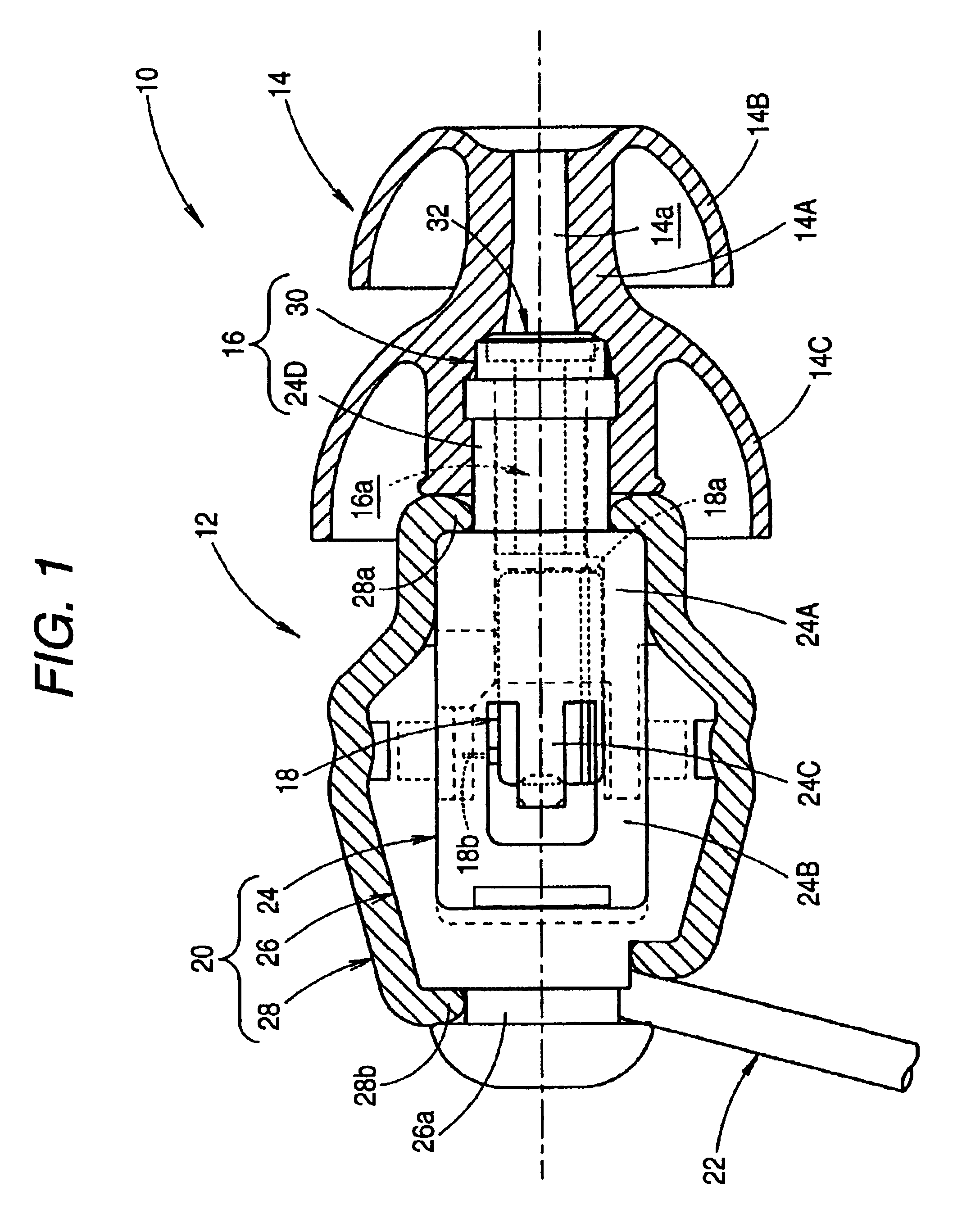

There is provided a fluid supply mechanism that, when a circular saw blade having a thick boss type base is used, can achieve lubrication and / or cooling of the circular saw blade by performing excellent mist supply.The fluid supply mechanism includes a sleeve 24 with a required length that is attached to a rotary shaft 22, a required number of doughnut-like shims 26 attached to the sleeve 24 and a rotary tool 10 which is attached to the sleeve 24 and is clamped and fixed by the shims 26 from both sides. A fluid is transferred by pressure from gutter-like passages 30 formed on an inner periphery of the sleeve 24 via through holes 32 formed in the sleeve 24 in the radial direction, the fluid is transferred by pressure to passages 34 provided on inner peripheral faces of the shims 26 and gutters 38 formed to extend in the radial direction on both sides or one sides of the shims 26, and the fluid is supplied to the rotary tool 10 to lubricate and / or cool the rotary tool 10 during machining a work.

Owner:KANEFUSA HAMONO KOUGIYOU KK

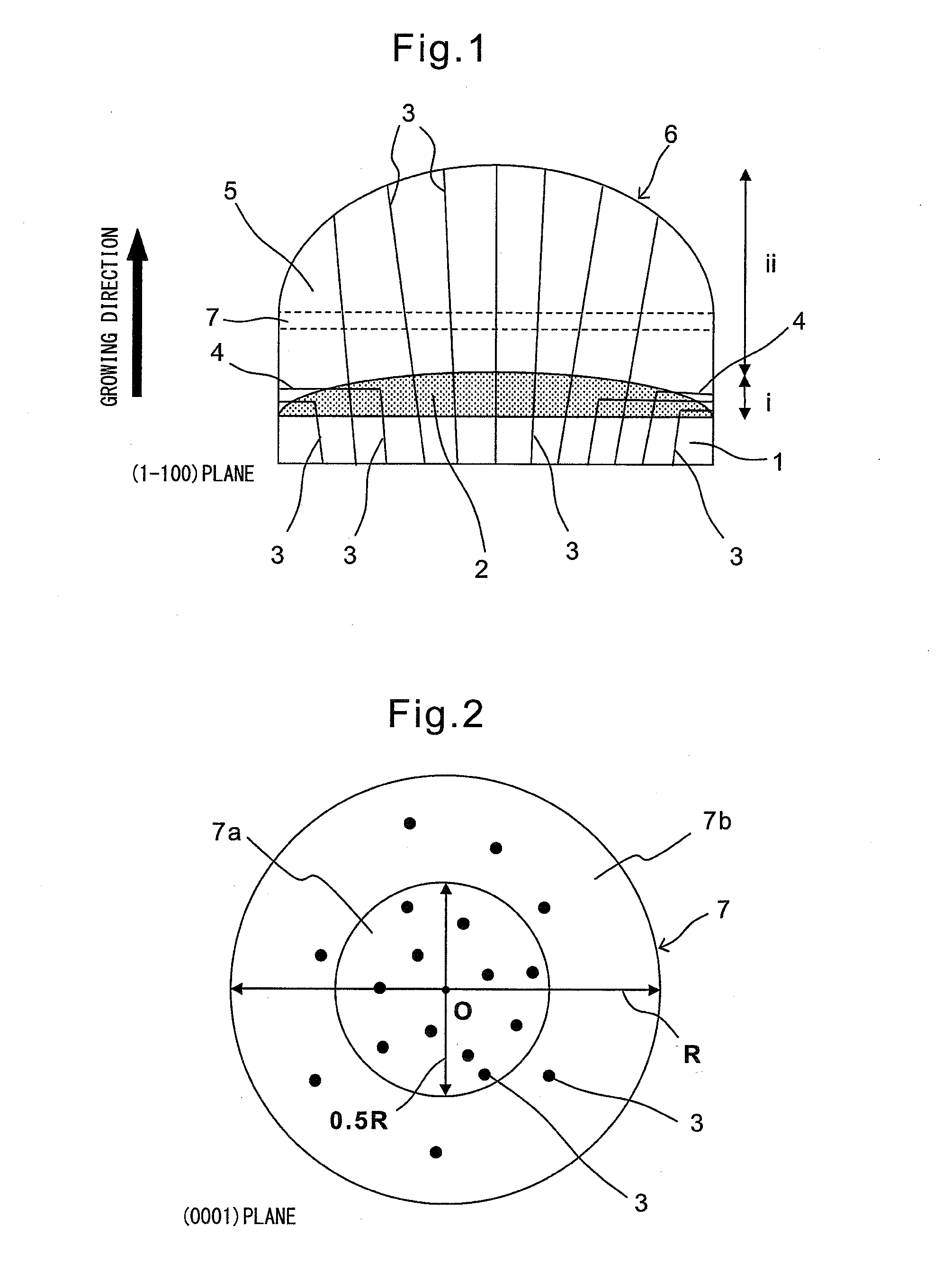

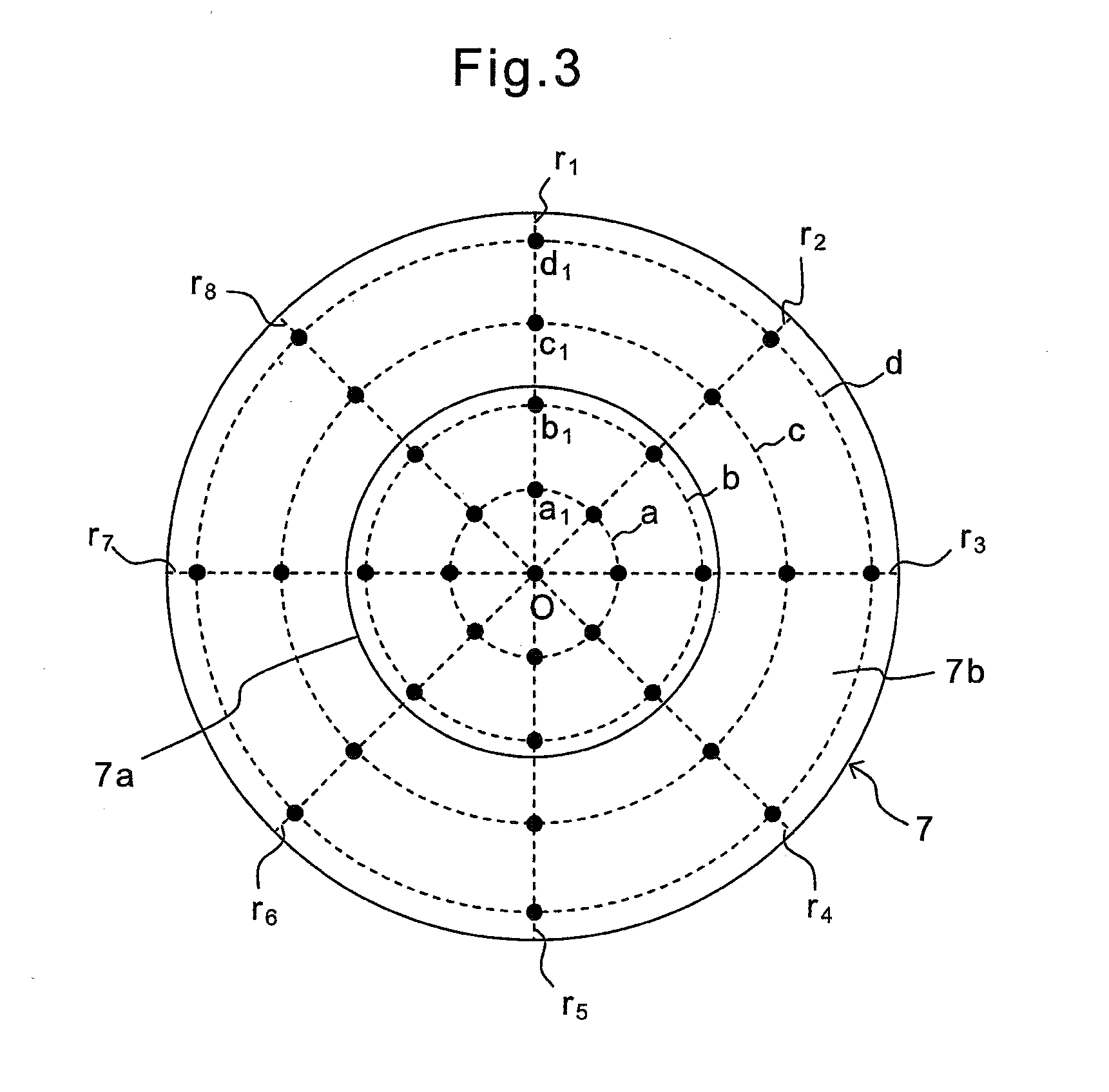

Silicon carbide single crystal wafer and manufacturing method for same

ActiveUS20140363607A1Reduce pressureReduce the temperaturePolycrystalline material growthLayered productsSingle crystal substrateOptoelectronics

Provided are a method for manufacturing a SiC single crystal having high crystal quality and, in particular, extremely low screw dislocation density and a SiC single crystal ingot obtained by the method. In particular, provided is a silicon carbide single crystal substrate that is a substrate cut from a bulk silicon carbide single crystal grown by the Physical Vapior Transport (PVT) method, in which the screw dislocation density is smaller in the peripheral region than in the center region, so that screw dislocations are partially reduced.The method is a method for manufacturing a SiC single crystal by the PVT method using a seed crystal and the ingot is a SiC single crystal ingot obtained by the method. Particularly, the silicon carbide single crystal substrate is a silicon carbide single crystal substrate in which when, by representing the diameter of the substrate as R, a center circle region having a diameter of 0.5×R centered around a center point O of the substrate and a doughnut-shaped peripheral region remaining by excluding the center circle region are defined, the average value of screw dislocation densities observed in the doughnut-shaped peripheral region is 80% or less of the average value of screw dislocation densities observed in the center circle region.

Owner:RESONAC CORP

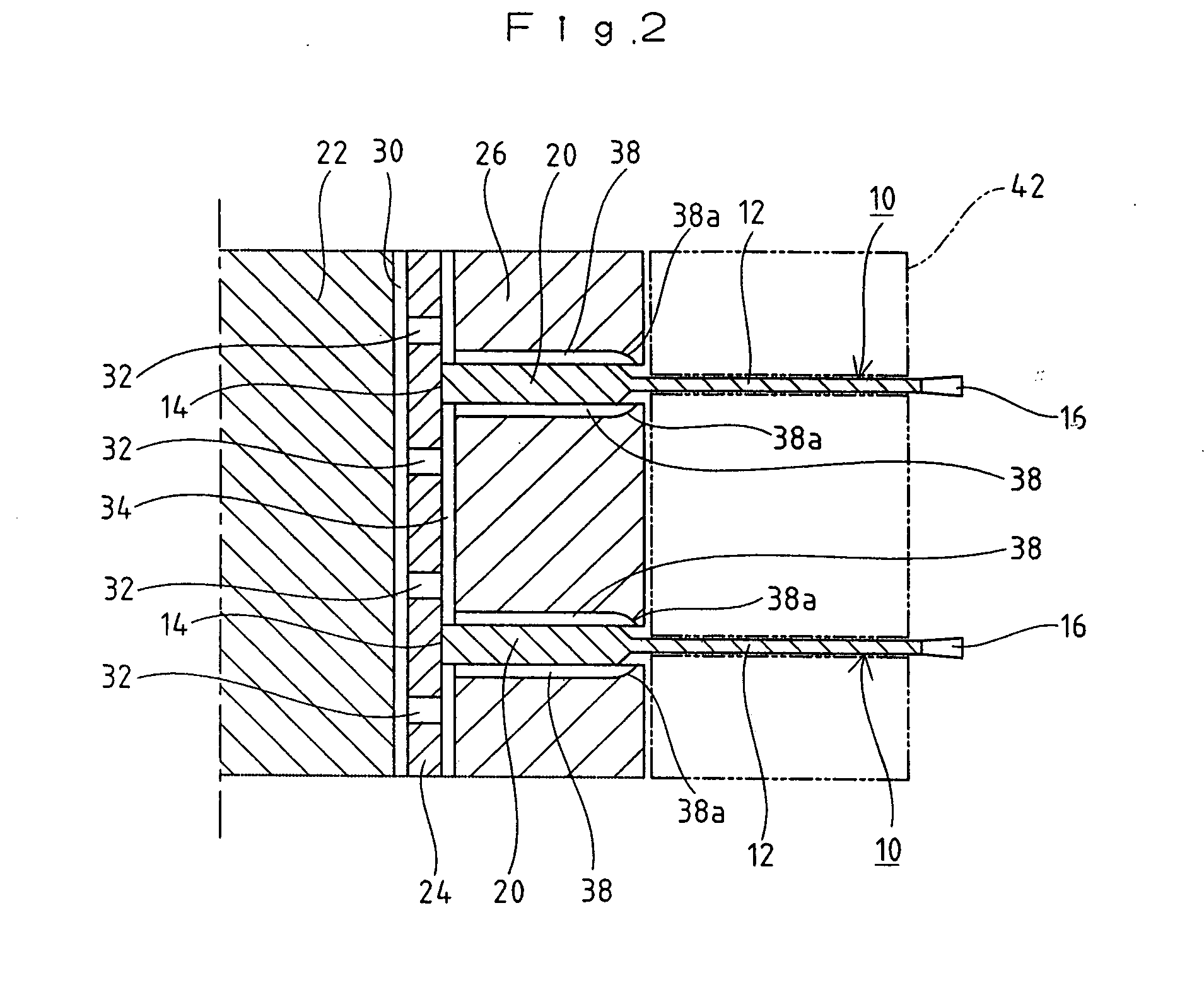

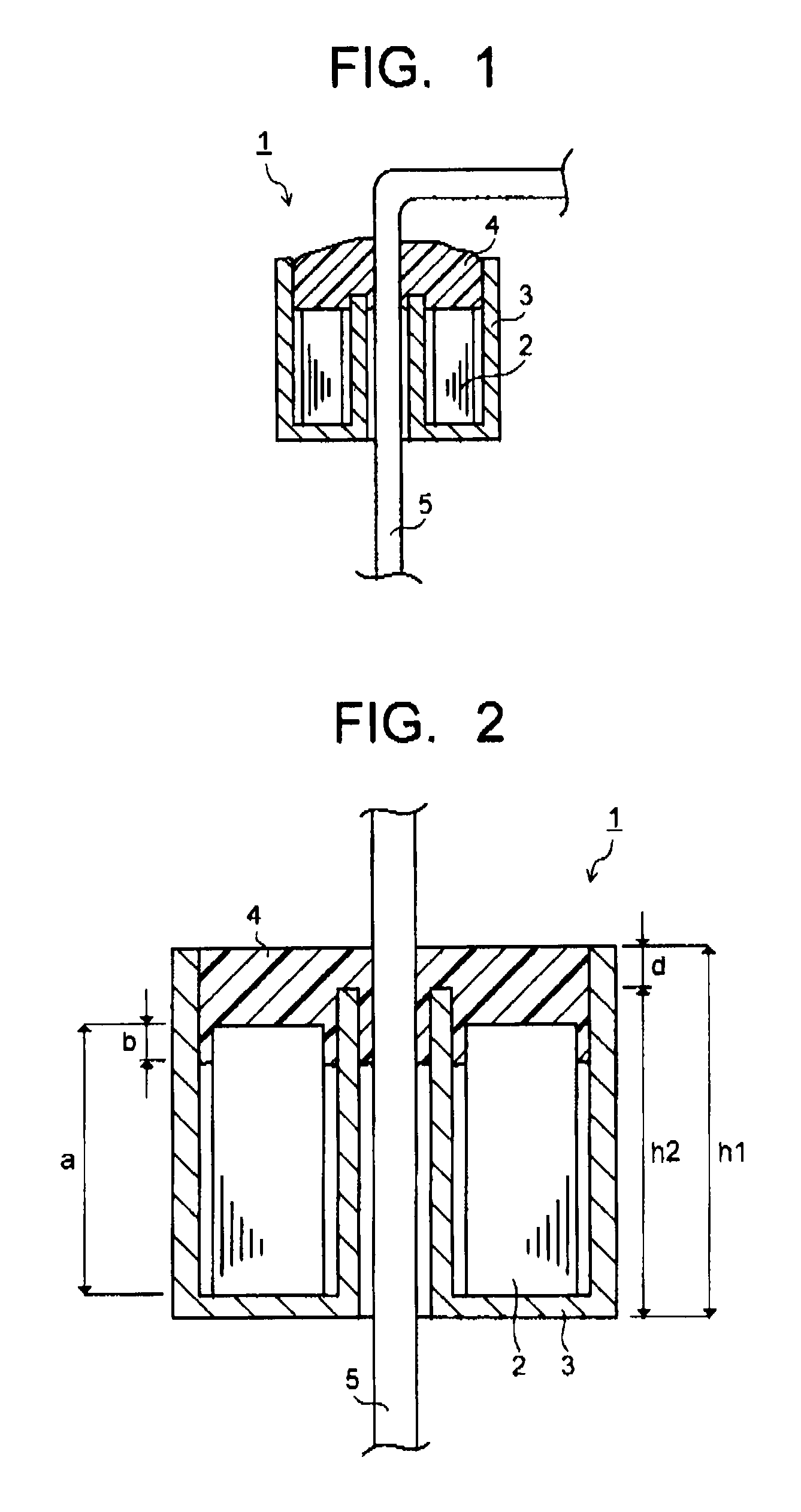

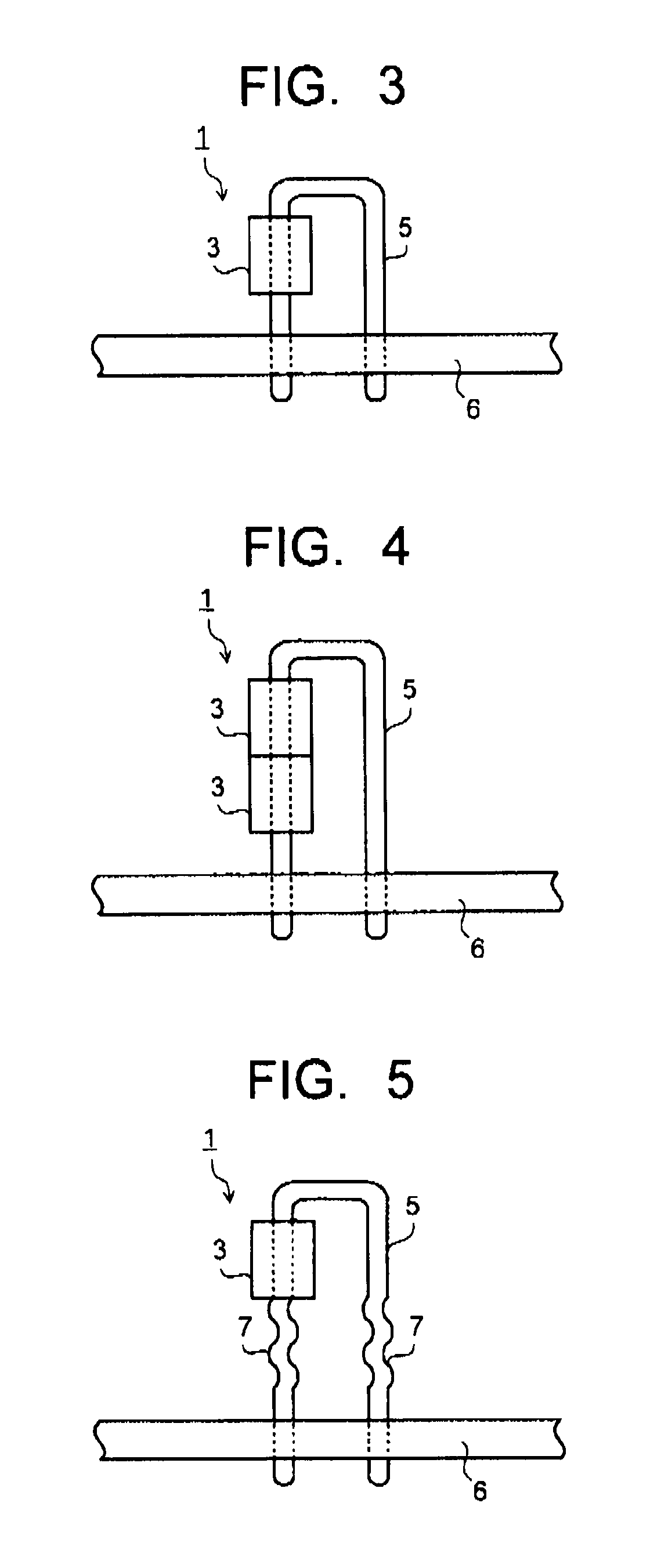

Inductance element, method for manufacturing the same, and switching power supply using the same

ActiveUS20100085778A1Ease of mass productionSuppresses deterioration of magnetic propertiesTransformers/reacts mounting/support/suspensionTransformers/inductances casingsMagnetic tapeInductor

An inductance element (1) includes a doughnut-shaped magnetic core (2) having a wound body or a stacked body of a magnetic ribbon, a bottomed container (3) in which the doughnut-shaped magnetic core (2) is housed, and a conductive lead portion (5) inserted into a hollow section of the doughnut-shaped magnetic core (2) housed in the bottomed container (3). An open section of the bottomed container (3) is covered with an adhesive portion (4) which integrally fixes the doughnut-shaped magnetic core (2), the bottomed container (3) and the conductive lead portion (5). The adhesive portion (4) is entered into a gap between the doughnut-shaped magnetic core (2) and the bottomed container (3) and a gap between the bottomed container (3) and the conductive lead portion (5) in a range of 5 to 50% in average to a thickness of the doughnut-shaped magnetic core (2).

Owner:KK TOSHIBA +1

Large flux polyvinyl chlorid doughnut film, and its mfg. method

InactiveCN1418723AGood water permeabilityHigh mechanical strengthSemi-permeable membranesFiberPolyethylene glycol

The present invention relates to a large-flux polyvinyl chloride hollow fibre membrane and its preparation method. It uses polyvinyl chloride as raw material, uses I-methyl-2-pyrrolidone as solvent and uses polyethylene glycol as additive, and adopts dry-wet spinning process to implement said invention. The above-mentioned materials are dissolved at 60-95 deg.C, its dry spinning path is 30-80 cm,extrusion volume flow rate is 3-20 ml / min, and spinning solution temp. is 25-85 deg.C. Said hollow fibre membrane is made into five-layer bidirectional asymmetrical structure including outer compact layer, finger pore support layer, sponge layer, finger pore layer and inner compact layer, its water permeability is 500-900 L / sq.m.h, and its trapping molecular weight is 8-15 tea thousand.

Owner:DONGHUA UNIV

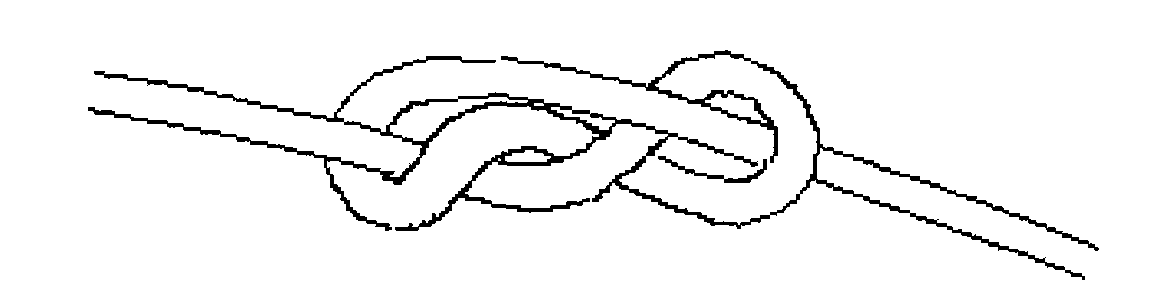

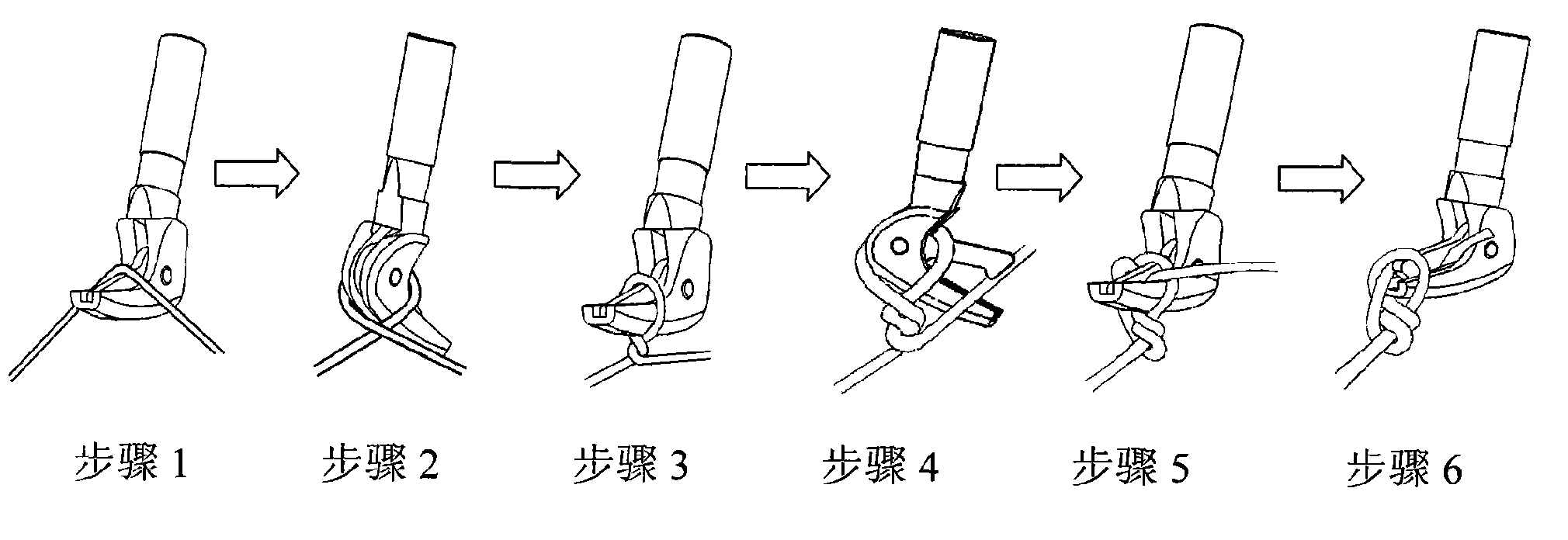

Mechanical knot formation method of heterogenous 8-shaped knot

InactiveCN101597837AReduce slippageImprove reliabilityKnottingBundling machine detailsAlpha shapeEngineering

The invention discloses a mechanical knot formation method of a heterogenous 8-shaped knot, which belongs to the technical field of strapping. The heterogenous 8-shaped knot is formed by changing one of two X-shaped cross structures at the middle part of the standardized 8-shaped knot into Chinese doughnut-shaped twisted structure. The heterogenous 8-shaped knot is formed by the following steps: hawk-mouth-shaped knotter jaw hooks the rope to finish two circles of twisting so that one end head of the rope crosses an alpha-shaped rope ring encircling the knotter jaw, thus forming the heterogenous 8-shaped knot. The heterogenous 8-shaped knot has more complex twisting relation and increased twisting area than half-knot, thus effectively reducing slipping of buckles at the tensioning state of the rope and improving reliability and stability of buckles.

Owner:CHINA AGRI UNIV

Tires

There is a tire capable of stably running even if the tire is subjected to external injury without sacrificing rolling resistance and ride comfort in the usual running before being subjected to external injury, wherein a composite body consisting of a continuous phase of a resin and closed cells is arranged in an inside of a hollow doughnut-shaped tire and the composite body has a cell content of 80.00 vol % to 98.75 vol % and an internal pressure at 25° C. in the closed cell included therein is not less than 150 kPa as an absolute pressure.

Owner:BRIDGESTONE CORP

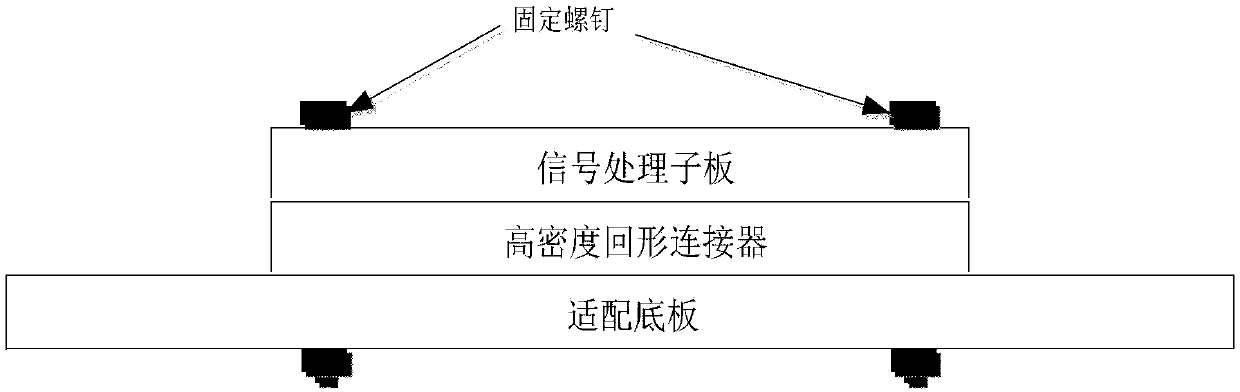

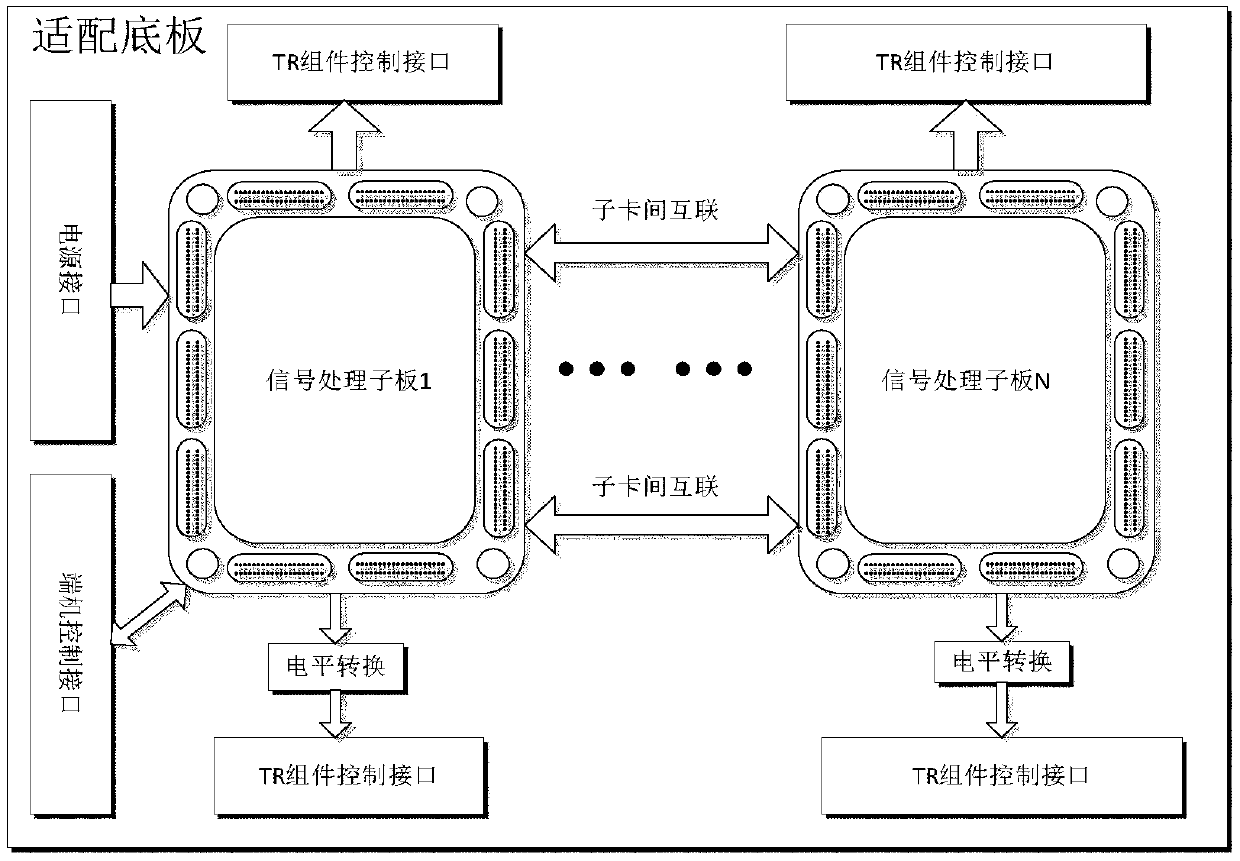

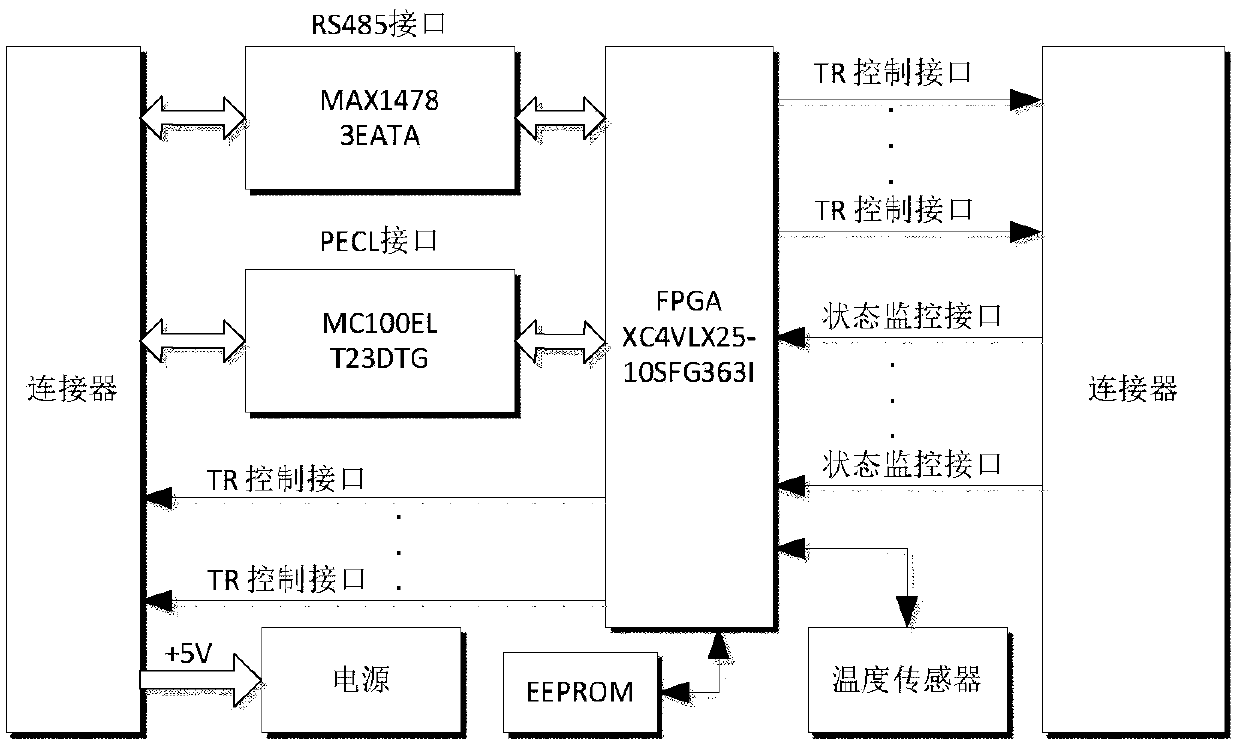

Phased array antenna beam control device

ActiveCN109541993ALow profileNon-destructive disassemblyProgramme controlWave based measurement systemsMachine controlControl signal

The invention discloses a phased array antenna beam control device and aims to provide a phased array antenna beam control device which is low in power consumption, small in size, high in reliability,good in expandability and strong in universality. According to the technical scheme, the beam control device is realized through the following technical scheme: n doughnut shape-like connectors are interconnected through sub-cards, fixedly connected onto an adaptive bottom plate and connected with a TR module control interface, a power interface and an end machine control interface; 1-n signal processing sub-boards are respectively fixed inside the doughnut shape-like hollow-out areas of 1-n doughnut shape-like connectors so as to form a signal processing sub-board embedded doughnut shape-like connector; the adaptive bottom plate is matched with the phased array antennas of different platforms through the TR module control interface; a selected signal processing sub-board receives a communication instruction from a beam control system end computer by means of the TR module control interface and the state monitoring interface; the communication instruction is analyzed and a wave position code is calculated; a control time sequence is outputted to the doughnut shape-like connector; the doughnut shape-like connector fans out the control signal pin of the signal processing sub-board to a TR module which needs to be controlled through the adaptive bottom plate.

Owner:10TH RES INST OF CETC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com