Motor rotor, molded motor, air conditioner, and method for producing molded motor

A manufacturing method and motor technology, which is applied in the field of air conditioners, molded motor manufacturing, and molded motors. It can solve the problems of rotor installation and inability to cope with specification changes, and achieve the effect of easy specification changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0090] (summary)

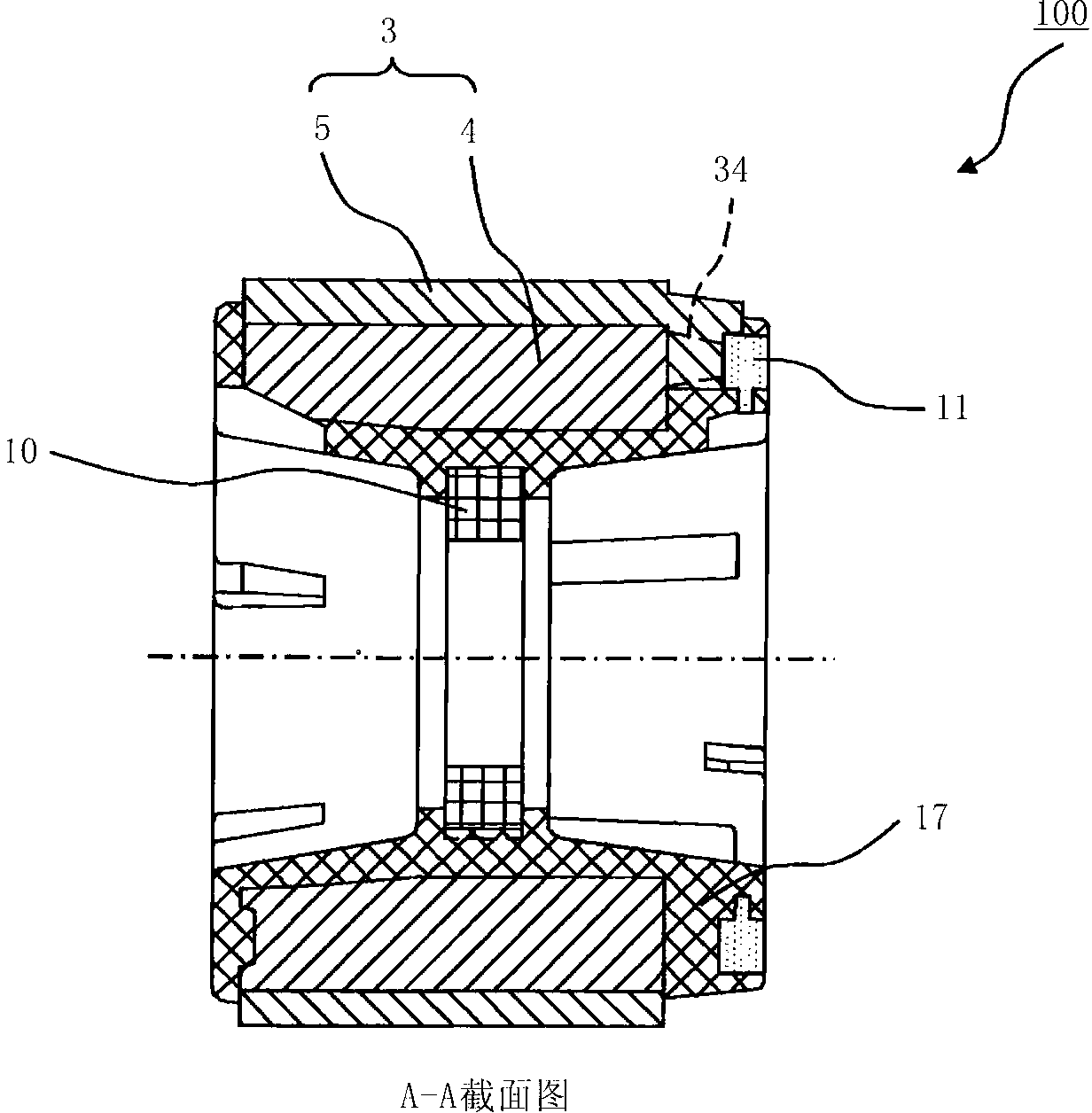

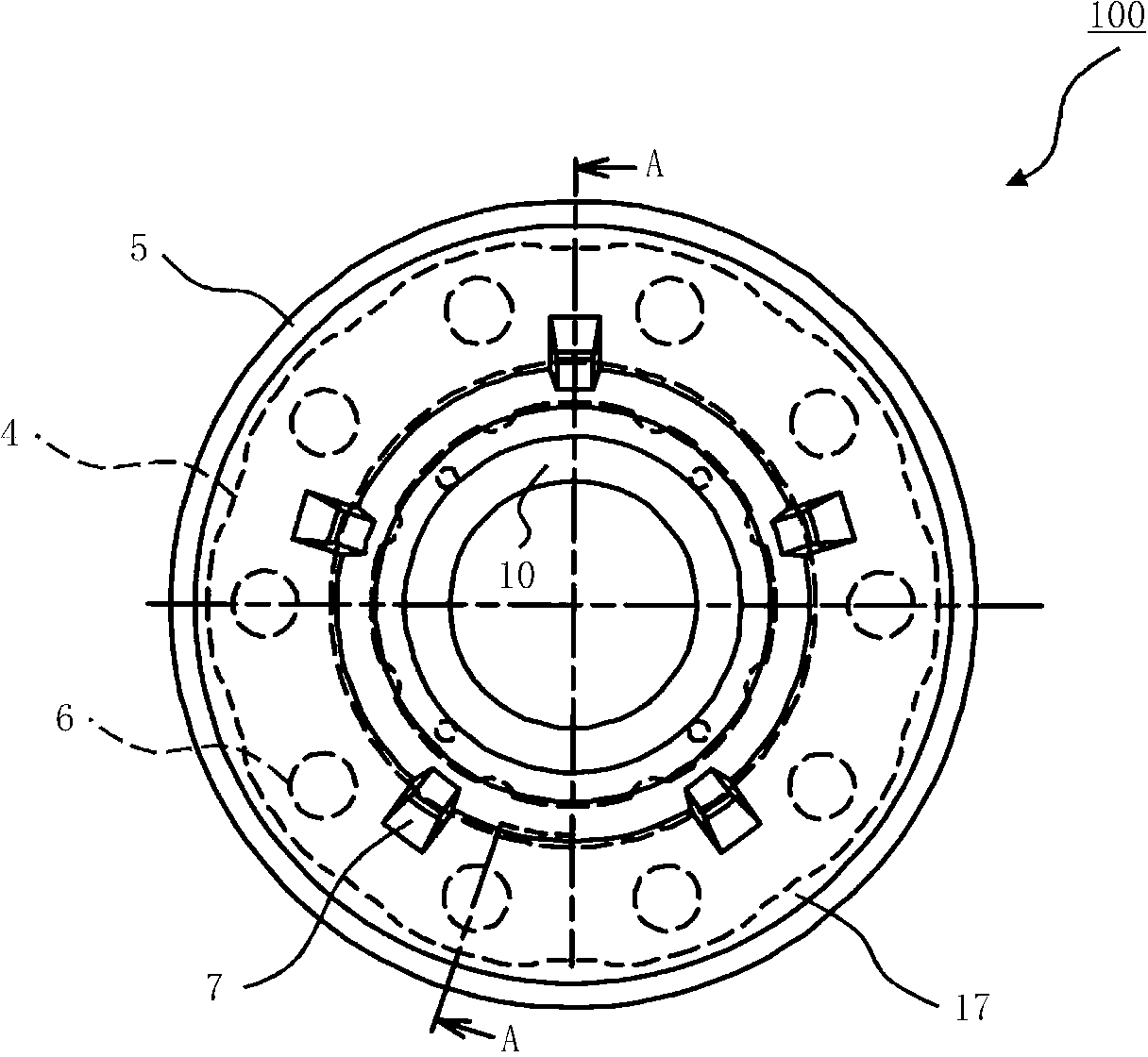

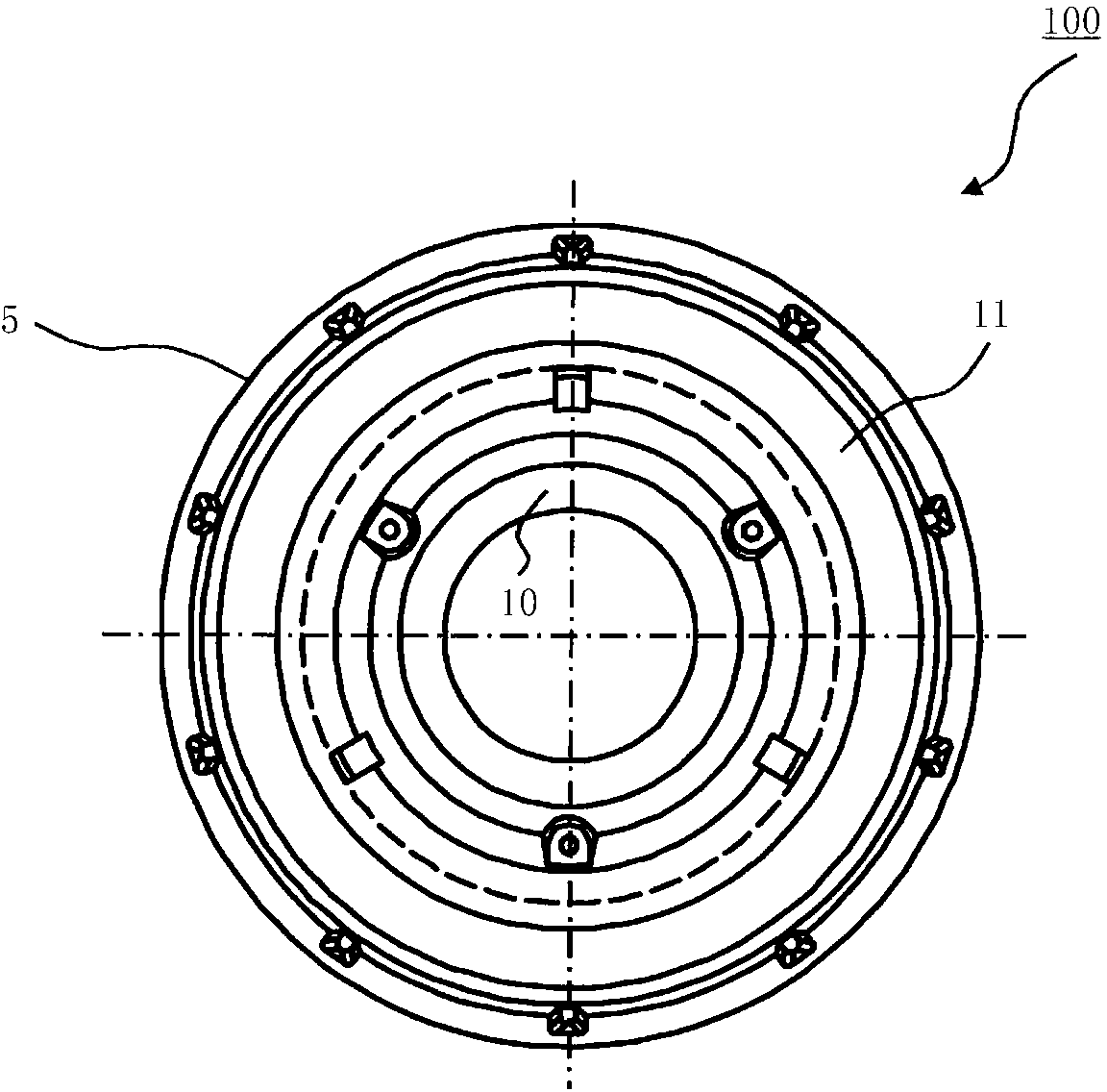

[0091] The rotor of the electric motor according to this embodiment is characterized in that the length (or diameter) of the shaft and the position of the rotor on the shaft can be arbitrarily selected. For example, the rotor of a motor with a load (fan, etc.) attached to only one end of the shaft, since the shaft is short and the position of the rotor on the shaft is determined, the rotor magnet, the magnet for position detection, and the shaft can be integrally molded with resin .

[0092] However, when the shaft is long, when the rotor magnet, the position detection magnet, and the shaft are integrally molded with resin, the length of the shaft is limited by the amount of mold opening during resin molding and cannot be of any length.

[0093] Therefore, different molds are required in case the position of the rotor on the shaft varies.

[0094] Therefore, in this embodiment, in addition to the rotor magnet and the magnet for position detection, a short ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com