Projection type video display

a projection lens and video display technology, applied in the direction of printers, instruments, cameras focusing arrangements, etc., can solve the problems of large clearance between the projection lens and the aperture of the front cover, which not only loses design, but also allows dust to easily enter the frame of the projector, so as to achieve the effect of wide lens shift width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

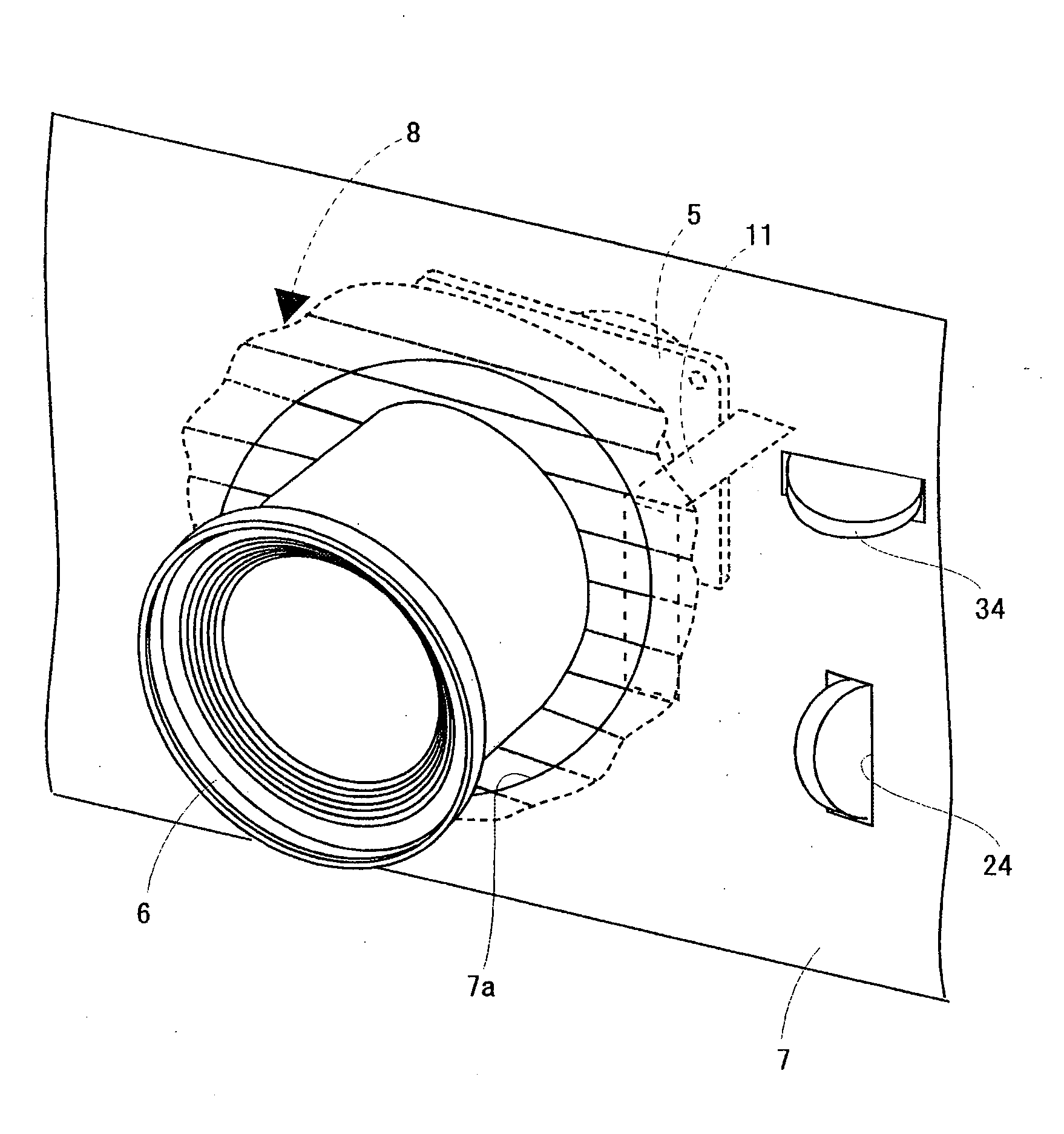

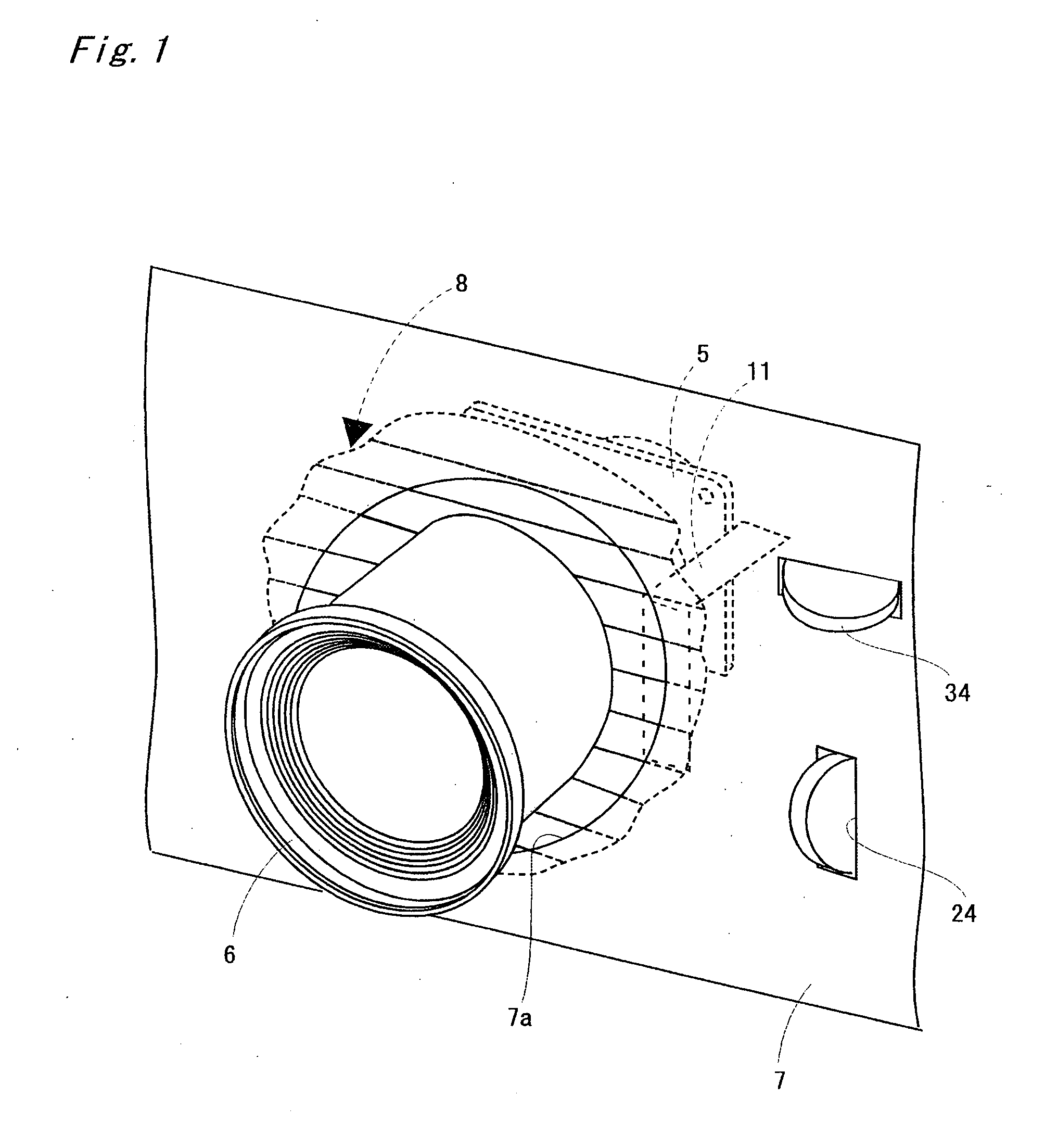

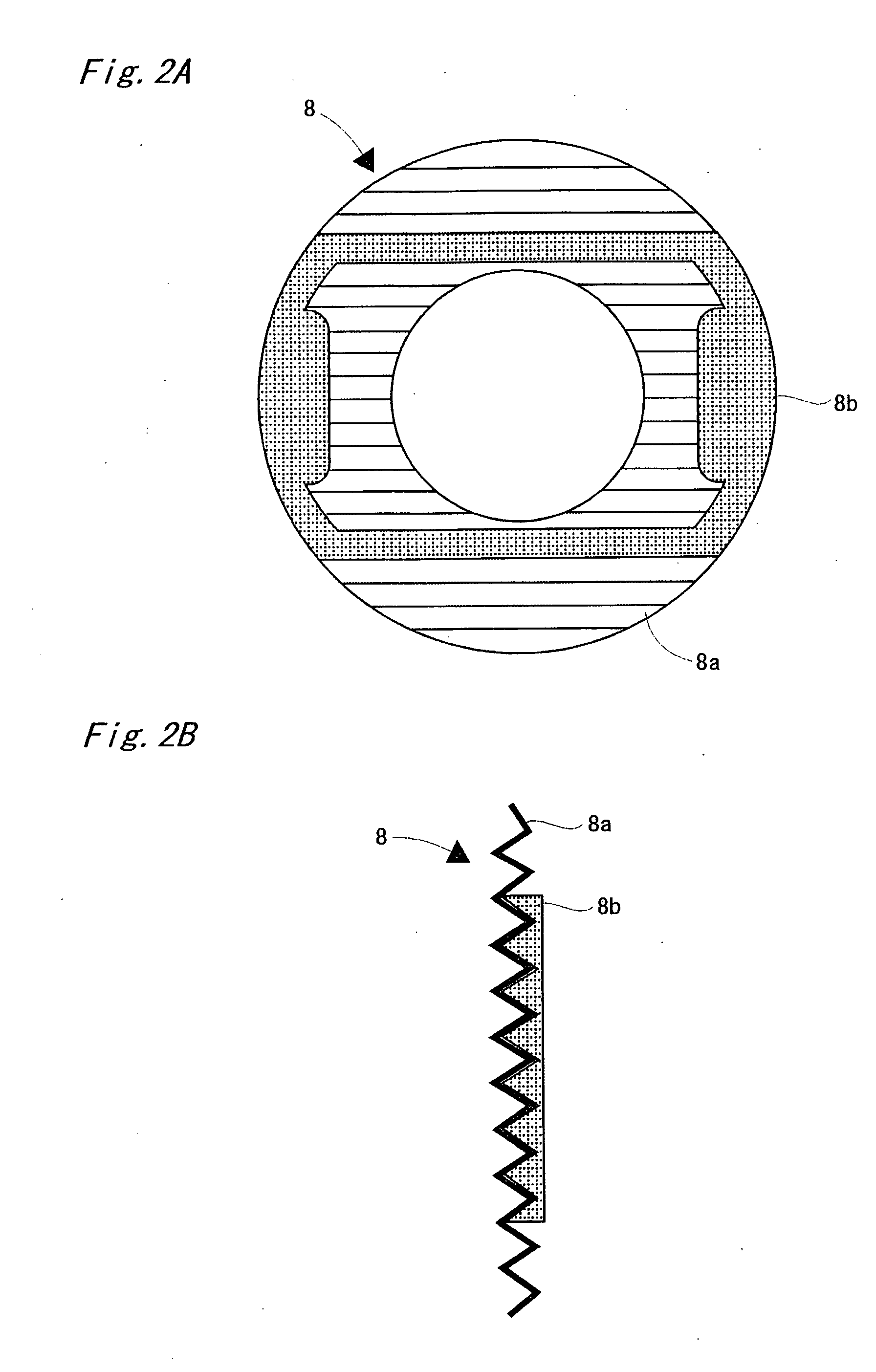

[0023] A projection type video display according to an embodiment of the present invention will be described on the basis of FIGS. 1 to 8. First, an optical system for a liquid crystal projector is illustrated. FIG. 8 is a diagram illustrating an optical system for a three-panel color liquid crystal projector. A light emitter in a light source 101 is composed of a ultra-high pressure mercury lamp, a metal halide lamp, a xenon lamp, or the like, and its irradiated light is emitted after being changed into parallel lights by a parabolic reflector, and is introduced into an integrator lens 102

[0024] The integrator lens 102 is composed of pairs of groups of lenses, and each of the pairs of lenses introduces the light emitted from the light source 101 into the whole surface of liquid crystal light valves 111, 112, and 113. The light which has passed through the integrator lens 102 is introduced into a first dichroic mirror 103.

[0025] The first dichroic mirror 103 transmits light in a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com