Laser fabrication of continuous nanofibers

a technology of nanofibers and lasers, applied in the direction of fibre chemical treatment, carbonsing rags, textiles and paper, etc., can solve the problems of insufficient length and quantity of nanotubes, insufficient length and quantity to be useful in most industrial applications, and inability to meet the needs of continuous process, process is not continuous and must be stopped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

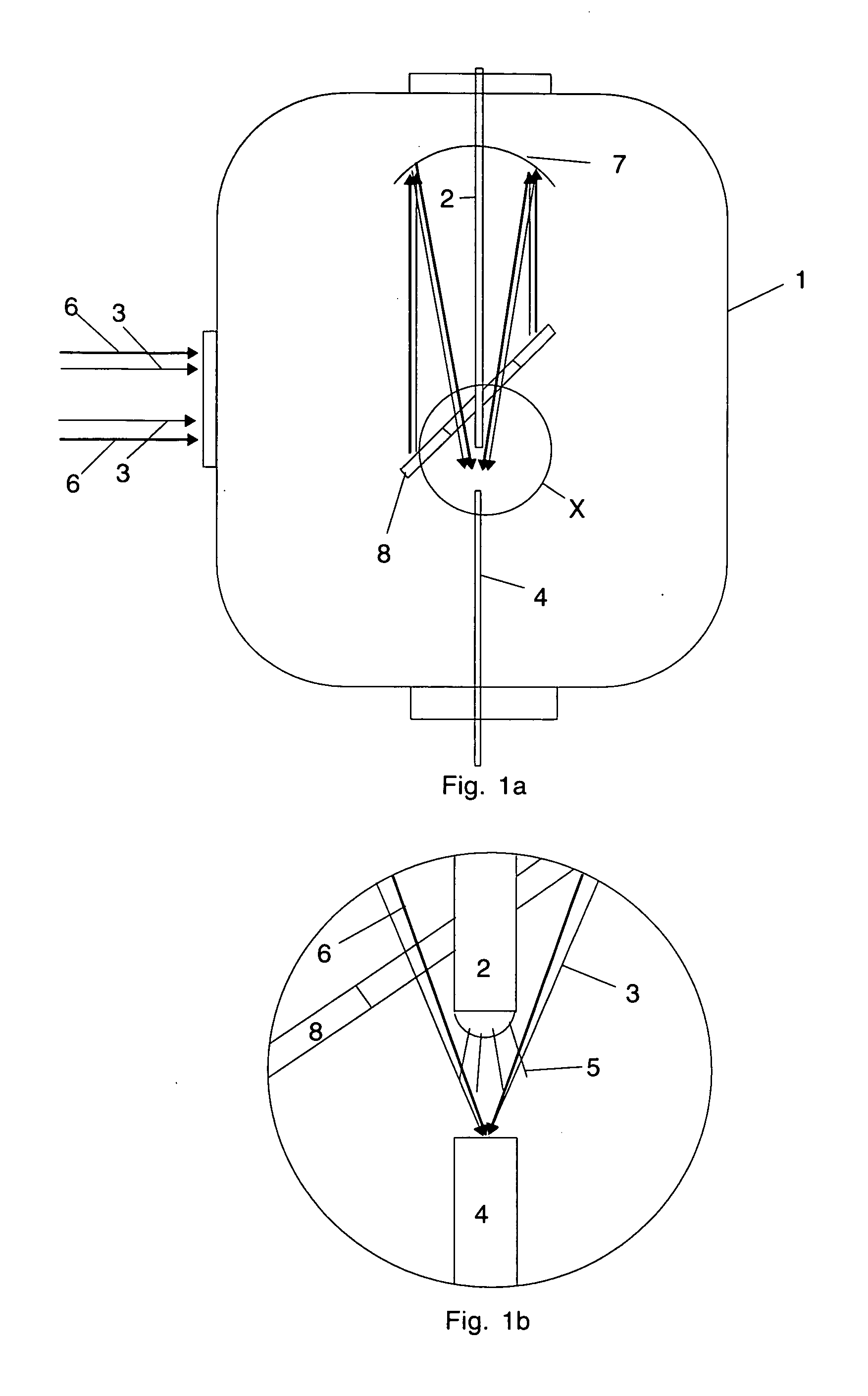

[0010] In a first embodiment seed-nanostructures are placed in a reactor 1 shown in FIG. 1a, which is capable of sustaining pressure. The pressure in the reactor 1 depends on the type of nanofibers to be built and controls their rate of growth to a manageable rate. The seed-nanostructures comprise nanotubes of any type and chemical composition including fullerenes and nanotube ropes together with catalyst nanoparticles, such as a mixture of Co and Ni. The catalyst nanoparticles are, alternatively, any of the transition elements or combinations thereof. In another example, seed-nanostructures comprise elements from which nanofibers are built. Nanostructures are defined to be structures less than 1 micron in thickness. An electric charge is imparted to an assembly of these seed-nanostructures relative to a filament 2 in the reactor 1 by means of a static charge generator until they become aligned relative to each other. Oxygen and water vapor are evacuated and inert gas is injected in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com