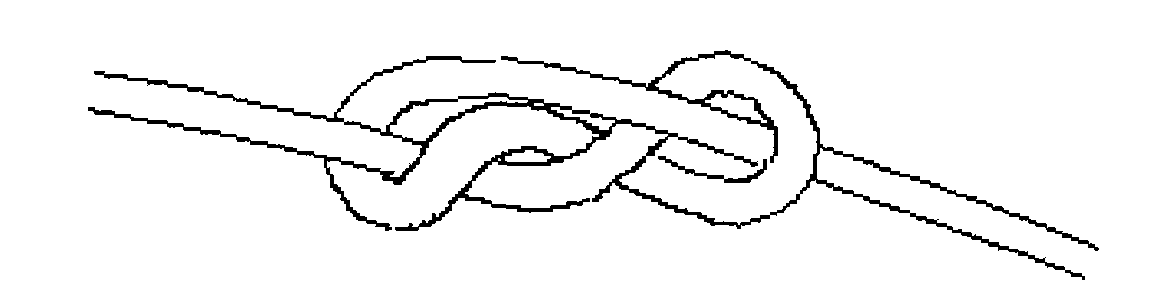

Mechanical knot formation method of heterogenous 8-shaped knot

A figure-8 knot and special-shaped technology, which is used in the parts of bundling machinery, knotting, textiles and papermaking, etc., can solve the problem of reducing the mechanical knotting rate and stability of rope half-knots, small rope twist joint area, and easy creep. Change the pre-tension requirements and other issues to achieve the effect of increasing the hinge area, not easy to slip off, and improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The invention provides a mechanical knotting method for special-shaped figure-eight knots with complicated twist structures and knots that can be knotted by a mechanical device. It can effectively reduce the slippage of the knot under the tension state of the rope, and improve the reliability and stability of the knot.

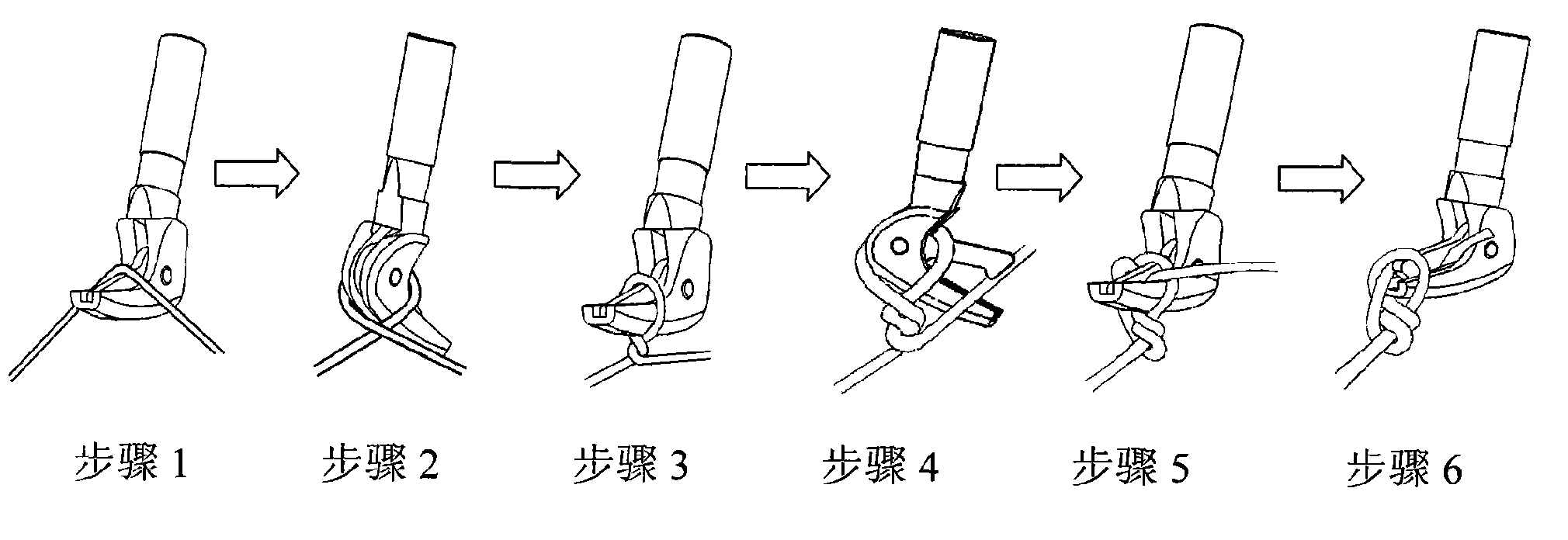

[0010] Shaped figure 8 knots can be knotted mechanically by such as figure 2 The steps shown are completed: first, the tensioned rope is placed on the inner arc of the knotting mouth; then, the knotting mouth hooks the rope and rotates 720° to form an α-shaped rope loop surrounding the knotting mouth and a twist-shaped braid at the end , and at the same time the knotting tongue opens and bites one end of the rope, and the end of the rope bitten by the knotting tongue is released immediately; after that, the α-shaped rope loop breaks away from the knotting mouth, and at the same time the end of the rope bitten by the knotting tongue is released. The α-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com