Large flux polyvinyl chlorid doughnut film, and its mfg. method

A technology of polyvinyl chloride and fiber membranes, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as difficult to achieve advanced treatment and reuse of wastewater, achieve membrane water permeability improvement, cost reduction, Good spinnability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

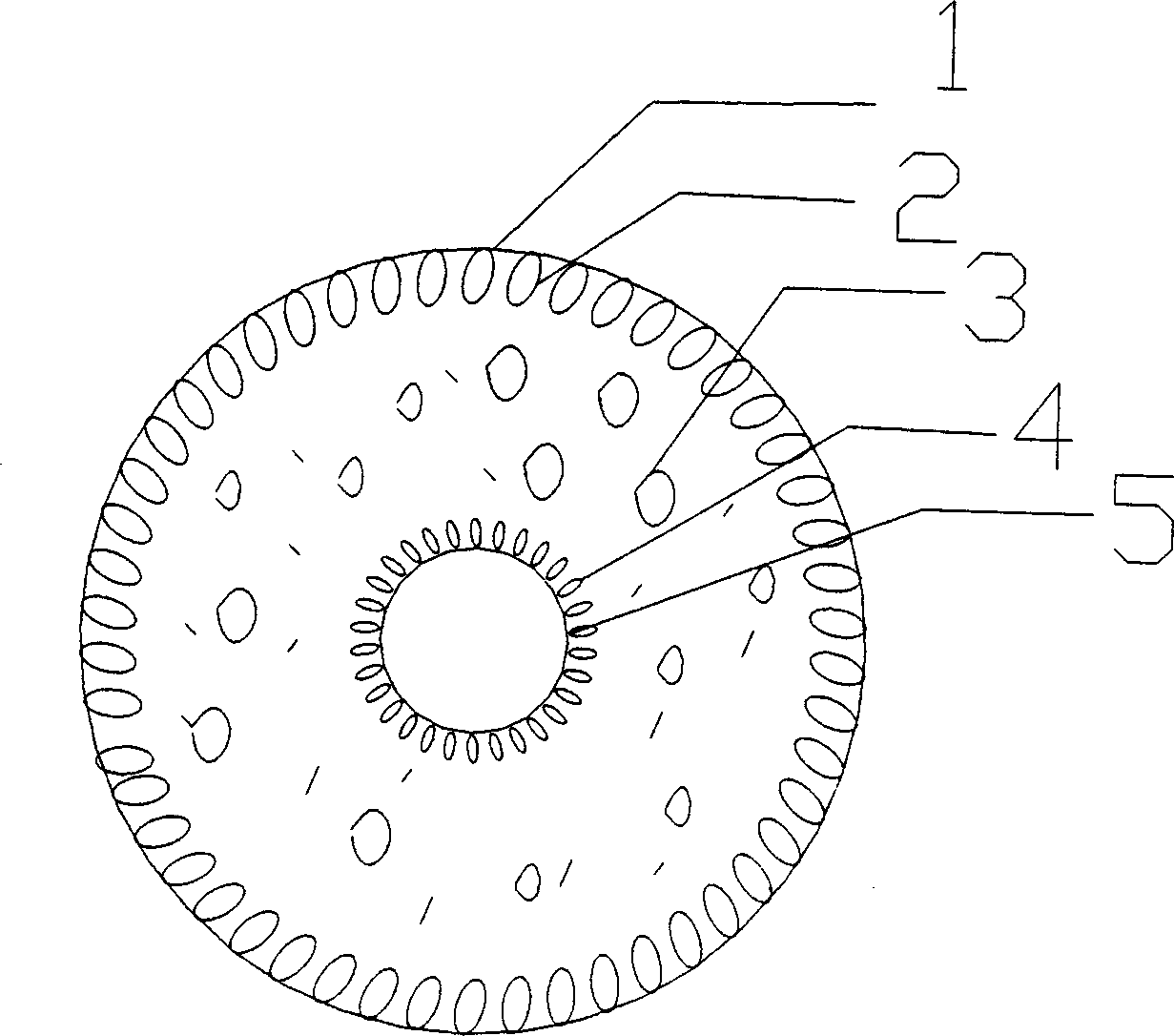

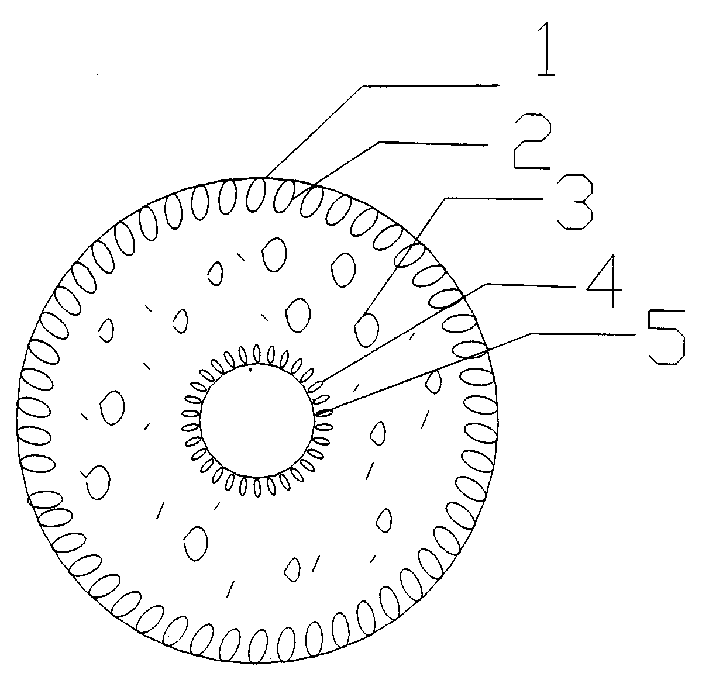

[0009] An embodiment of the present invention is a large flux polyvinyl chloride hollow fiber membrane suitable for advanced treatment of wastewater. General-purpose, low-cost polyvinyl chloride is used as a raw material, 1-methyl-2-pyrrolidone is used as a solvent, and polyethylene glycol with better porogenic properties is used as an additive, and the mass ratio of the solvent to the additive is controlled to 50 ~58:50~42. Dissolve various raw materials at a temperature of 60-95°C, and then prepare large-flux polyvinyl chloride hollow fiber membranes by dry-wet spinning method: the dry spinning length is 30-80cm, and the extrusion volume flow rate is 3-20ml / min, the temperature of the spinning solution is 25-85°C. The obtained hollow fiber membrane has a five-layer bidirectional asymmetric structure, which is an outer dense layer 1 , a finger-like hole support layer 2 , a sponge layer 3 , a finger-like hole layer 4 and an inner dense layer 5 . There are abundant pores in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com