New-structure railway sound barrier

A new type of structure and sound barrier technology, applied in buildings, noise absorption devices, etc., can solve the problems of sound leakage, loss of noise reduction effect of sound barriers, and failure of sound absorbing materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] An embodiment of the present invention will be further described in conjunction with the accompanying drawings.

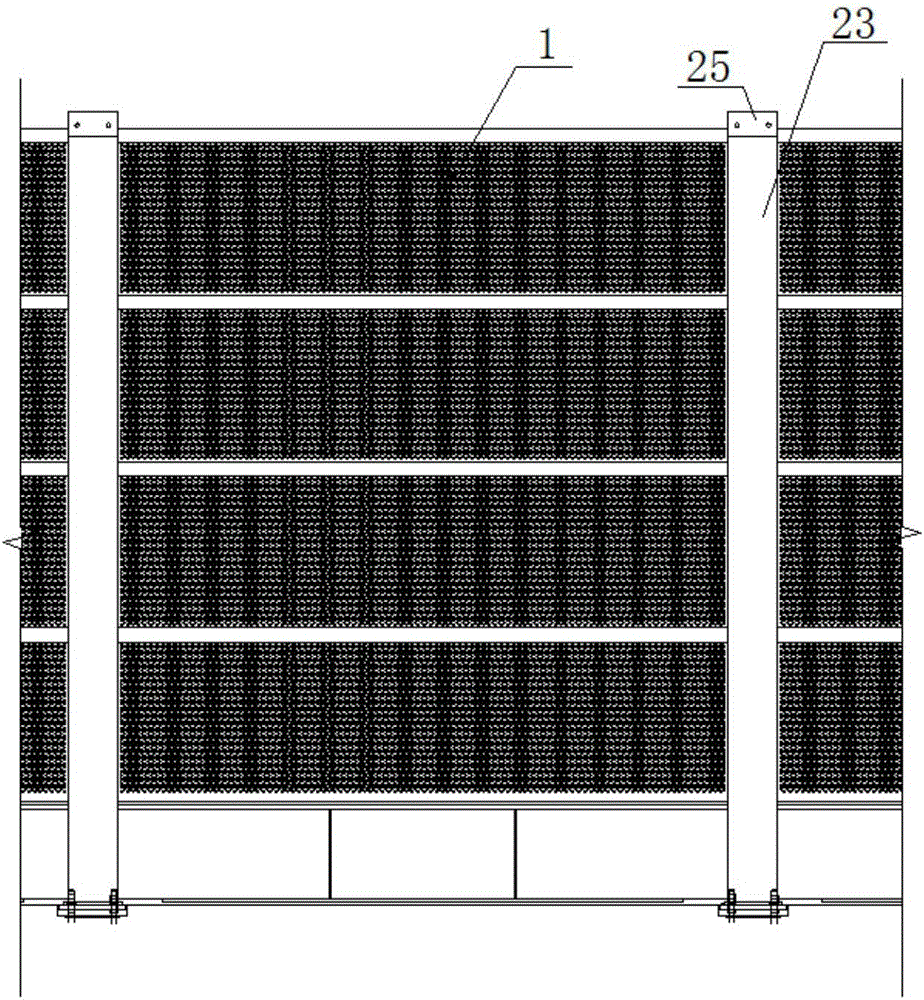

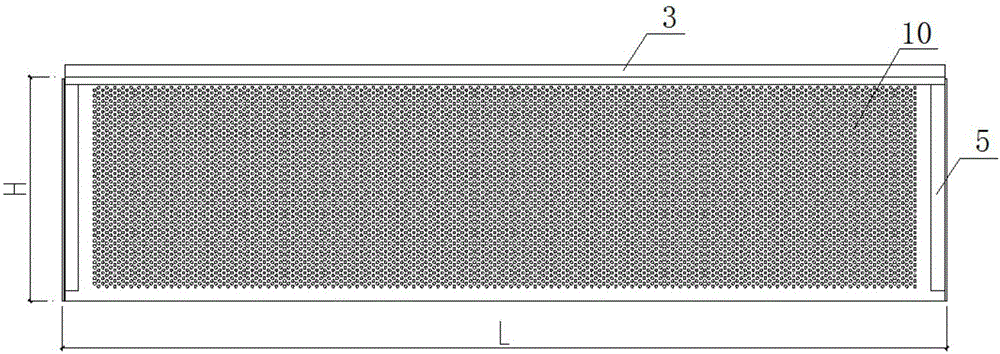

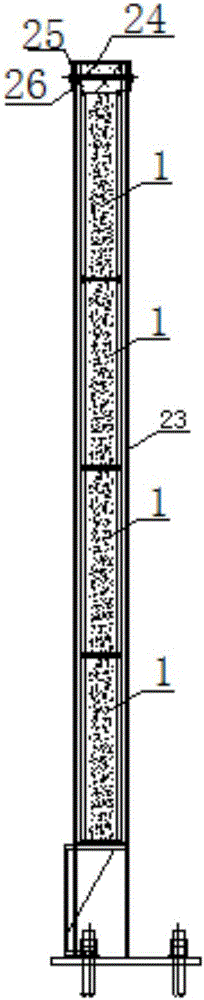

[0041] combine figure 1 and image 3 As can be seen. The new-type railway sound barrier has multiple H-shaped steels 23 for fixing unit plates, and the H-shaped steels 23 are connected to the foundation through embedded bolts. The new structure railway sound barrier unit plate (hereinafter referred to as the unit plate) 1 is sequentially inserted between the flanges of the H-shaped steel 23, and a vibration-damping rubber plate is arranged between the bottom unit plate and the foundation. After the uppermost unit plate is inserted, the C-shaped top cover plate 25 is fixed by bolts 26, and an elastic top rubber block 24 is placed between the C-shaped top cover plate 25 and the unit plate.

[0042] In the implementation example, the sound barrier is composed of four unit panels 1 , and other numbers of unit panels 1 also meet the requirements. The required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com