Soft support bridge type silicon micro-piezoelectric microphone chip and prepration method thereof

An electric microphone and soft support bridge technology, applied in piezoelectric/electrostrictive transducer microphones, piezoelectric/electrostrictive/magnetostrictive devices, sensors, etc., can solve the problems of low sensitivity and low sensitivity of microphones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

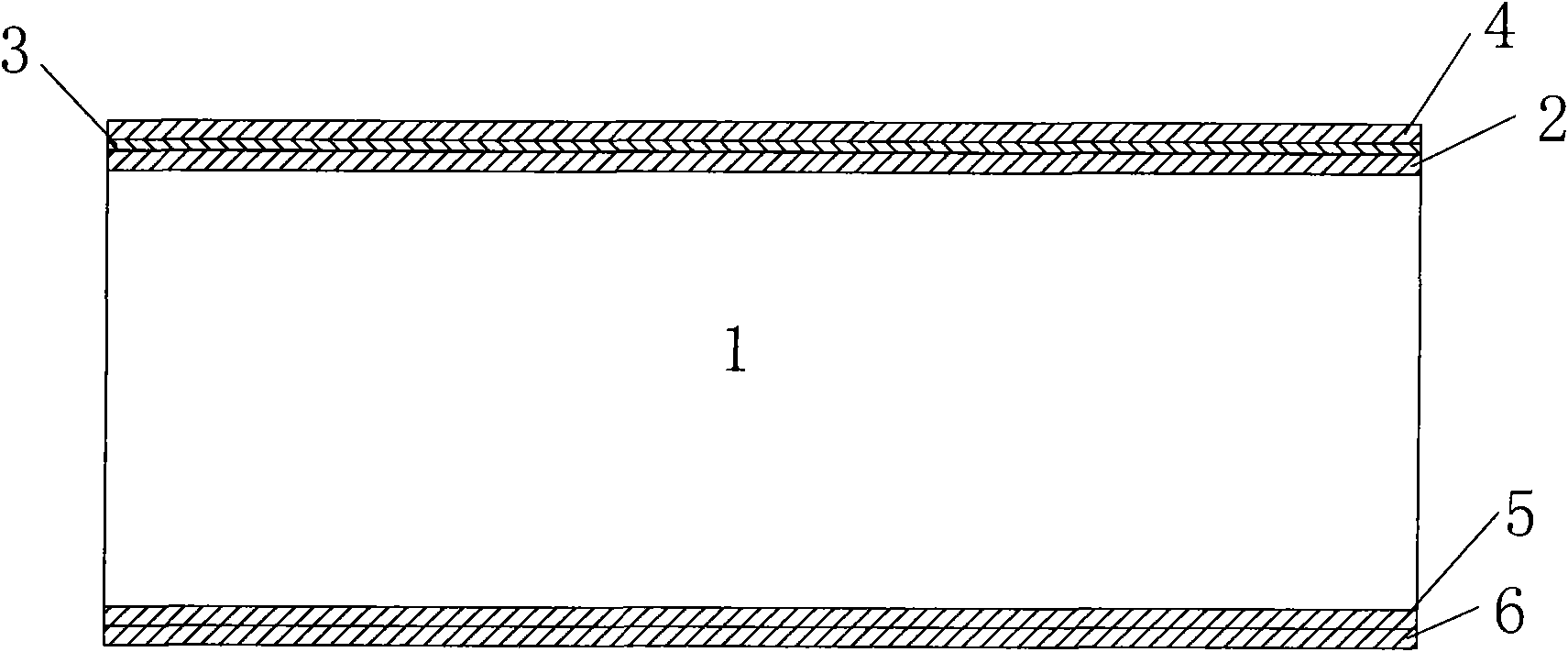

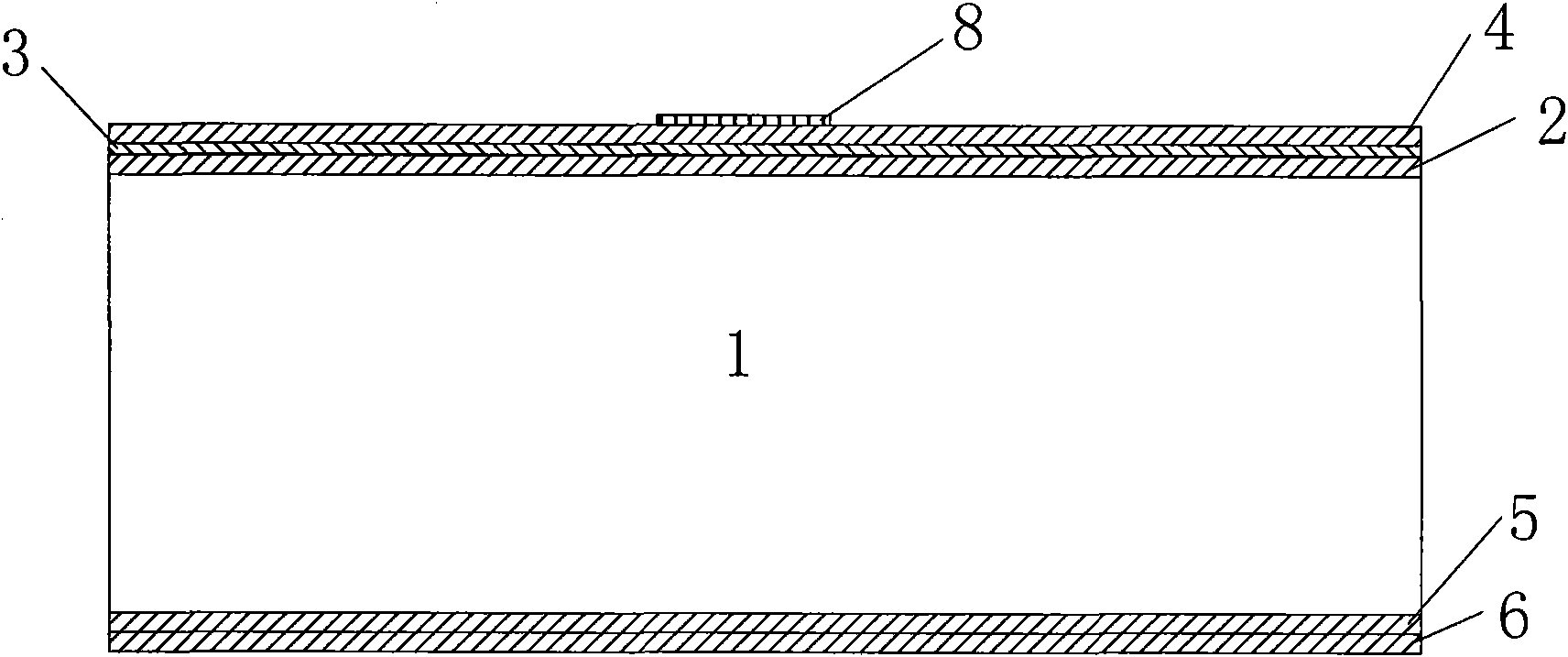

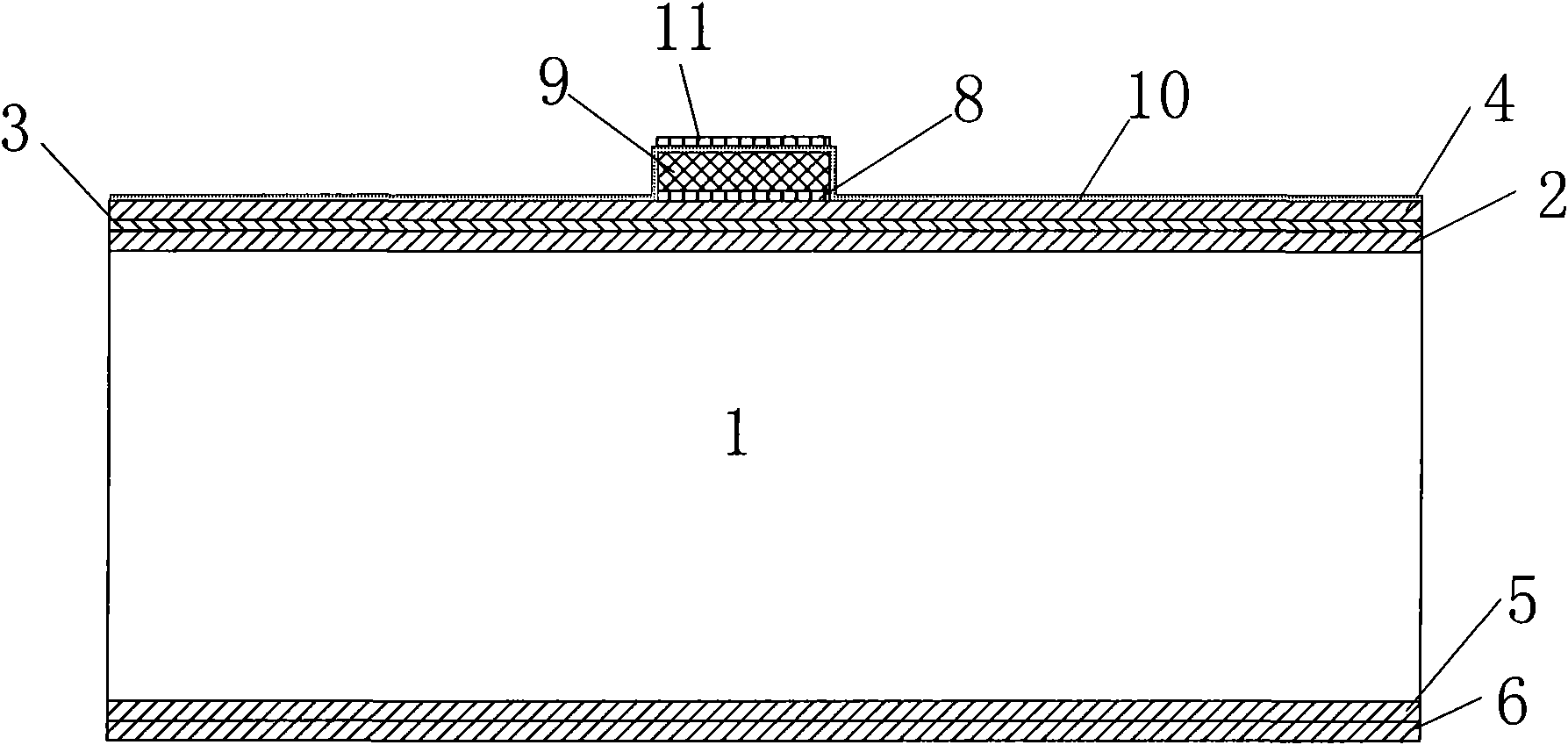

[0061] Embodiment 1, adopt preparation method of the present invention to prepare a soft support bridge type silicon micro piezoelectric microphone chip, its steps are as follows:

[0062] 1) Clean the silicon substrate 1

[0063] Cleaning the silicon substrate 1 with an acid cleaning solution and an alkaline cleaning solution respectively, and then rinsing it with deionized water;

[0064] 2) depositing the first silicon nitride film layer 2

[0065] Depositing a first silicon nitride film layer 2 with a thickness of 0.5 μm on the front side of the silicon substrate 1 and a silicon nitride mask layer 5 with a thickness of 0.5 μm on the back surface of the silicon substrate 1 by using low-pressure chemical vapor deposition equipment;

[0066] 3) Deposit silicon dioxide film layer 3

[0067] Depositing a silicon dioxide film layer 3 with a thickness of 0.2 μm on the first silicon nitride film layer 2 by using plasma-assisted chemical vapor deposition equipment;

[0068] 4) D...

Embodiment 2

[0087] Embodiment 2, adopting the preparation method of the present invention to prepare a soft support bridge type silicon micro piezoelectric microphone chip, its steps are as follows:

[0088] 1) Clean the silicon substrate 1

[0089] Cleaning the silicon substrate 1 with an acid cleaning solution and an alkaline cleaning solution respectively, and then rinsing it with deionized water;

[0090] 2) depositing the first silicon nitride film layer 2

[0091] Deposit the first silicon nitride film layer 2 with a thickness of 0.5 μm on the front side of the silicon substrate 1 and the third silicon nitride mask layer 5 with a thickness of 0.5 μm on the back surface of the silicon substrate 1 by using low-pressure chemical vapor deposition equipment ;

[0092] 3) Deposit silicon dioxide film layer 3

[0093] Depositing a silicon dioxide film layer 3 with a thickness of 0.5 μm on the first silicon nitride film layer 2 by using plasma-assisted chemical vapor deposition equipment...

Embodiment 3

[0113] Embodiment 3, adopting the preparation method of the present invention to prepare a soft support bridge type silicon micro piezoelectric microphone chip, its steps are as follows:

[0114] 1) Clean the silicon substrate 1

[0115] Cleaning the silicon substrate 1 with an acid cleaning solution and an alkaline cleaning solution respectively, and then rinsing it with deionized water;

[0116] 2) depositing the first silicon nitride film layer 2

[0117] Deposit the first silicon nitride film layer 2 with a thickness of 0.5 μm on the front side of the silicon substrate 1 and the third silicon nitride mask layer 5 with a thickness of 0.5 μm on the back surface of the silicon substrate 1 by using low-pressure chemical vapor deposition equipment ;

[0118] 3) Deposit silicon dioxide film layer 3

[0119] Depositing a silicon dioxide film layer 3 with a thickness of 0.8 μm on the first silicon nitride film layer 2 by using plasma-assisted chemical vapor deposition equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com