Hyper-redundant continuum robot driven by shape memory alloy

A memory alloy and memory alloy spring technology, applied in the field of super-redundant continuum robots, can solve the problems of large driving weight, low carrying capacity of continuum robots, and difficulty in miniaturization, and achieve small space occupation rate, light weight, controllable easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

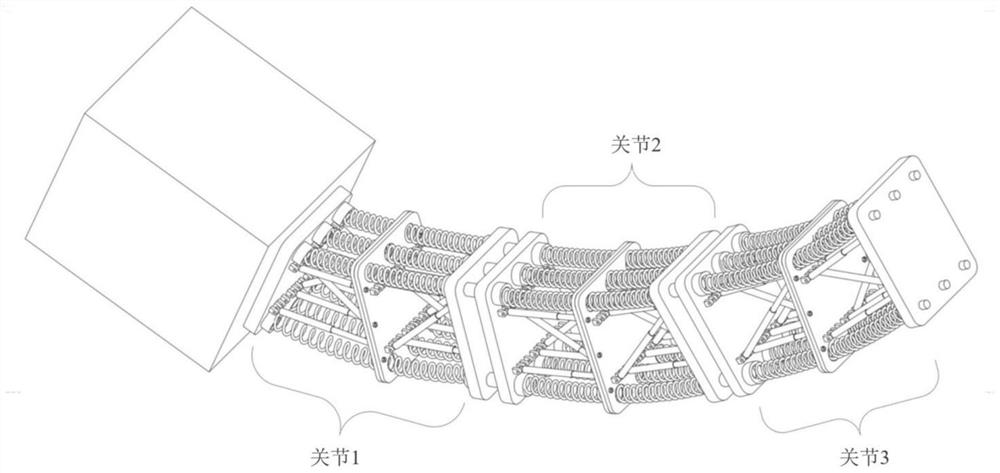

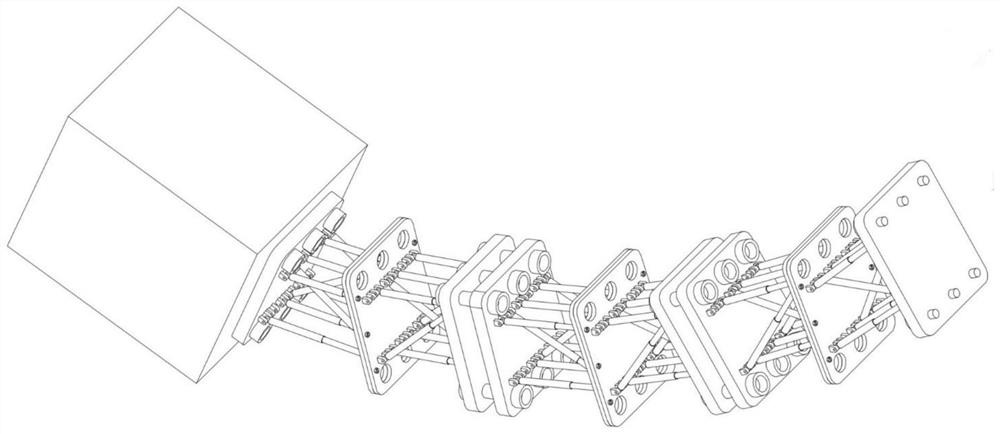

[0034]SeeFigure 1~Figure 10 , A super-redundant continuum robot driven by a shape memory alloy. The robot is formed by a control box and three or more joints with the same structure installed on one side of the control box through connecting pieces in series. A super-redundant continuum robot in which each joint is composed of two groups of deformable truss units with plane three degrees of freedom; each joint has a shape memory alloy spring as a driver, and each joint The platform is equipped with a circuit board of a suitable size; the shape memory alloy spring is energized and heated to cause thermal deformation to achieve independent control of the bending deformation of three different joints, and the movement of the continuum robot is realized through the coupling movement between the different joints; each; The joint has a passive deformable truss unit as the support of the robot, and the unlocked deformable truss rod is driven by the shape memory alloy spring to realize the...

Embodiment 2

[0037]This embodiment is basically the same as the first embodiment, and the special features are:

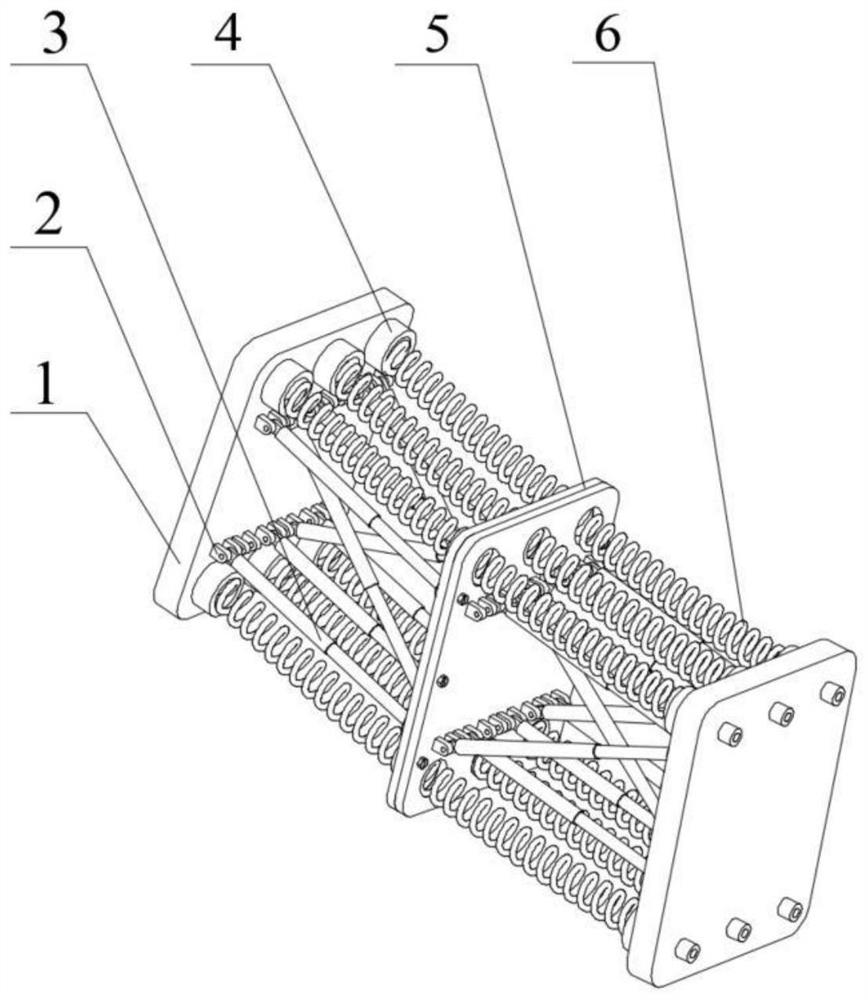

[0038]SeeFigure 1~Figure 10 Each joint is composed of two groups of deformable truss units with three degrees of freedom in the plane, including a bottom plate 1, a deformable truss unit 3, a circuit board 4 of appropriate size, a support plate 5, a shape memory alloy spring 6, and Both ends of the deformed truss unit 3 are hinged to the bottom plate 1 and the supporting plate 5 through hinges 2, and the two supporting plates 5 in the middle of each joint are connected by bolts and nuts. A circuit board 4 of a suitable size is arranged on the bottom plate 1, shape memory The alloy spring 6 passes through the support plate 5 and is fixed on the two circuit boards 4 to form a set of drive units. Each joint has three or more drive units arranged in parallel on the upper and lower planes, and the shape memory alloy spring energized wire connects each circuit. All the driving units of the u...

Embodiment 3

[0048]This embodiment is basically the same as the above embodiment, and the special features are:

[0049]Such asimage 3 The structure diagram of a single joint of the super-redundant continuum robot driven by the shape memory alloy of this embodiment includes a base plate 1, a deformable truss unit 3, a circuit board 4 of a suitable size, a support plate 5, a shape memory alloy spring 6, and Both ends of the deformed truss unit 3 are hinged to the bottom plate 1 and the supporting plate 5 through hinges 2, and the two supporting plates 5 in the middle of each joint are connected by bolts and nuts. A circuit board 4 of a suitable size is arranged on the bottom plate 1, shape memory The alloy spring 6 passes through the support plate 5 and is fixed on two circuit boards to form a group of driving units. The upper and lower planes of each joint are arranged in parallel with three groups of driving units. The shape memory alloy spring energizing wire is connected to each circuit board. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com