Patents

Literature

34results about How to "Reduce transmission structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

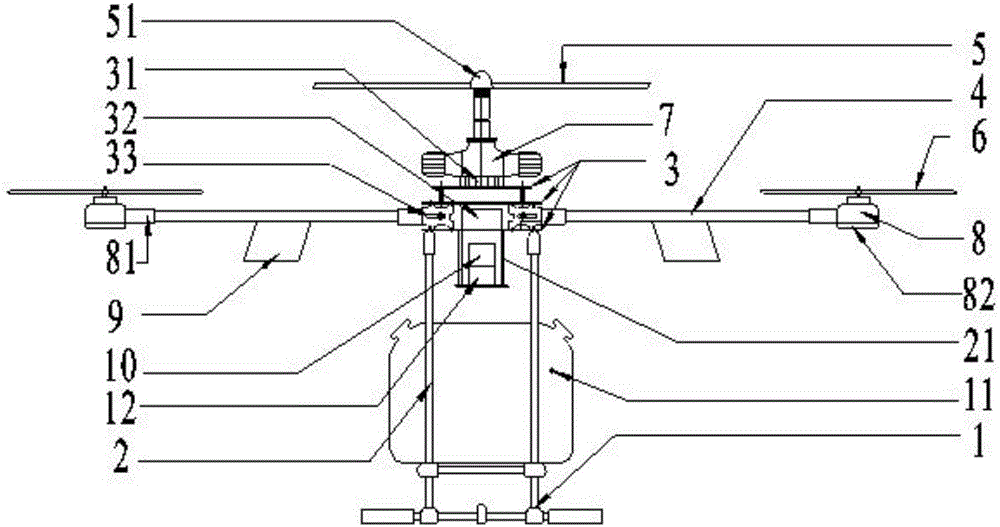

Multi-rotor plant protection unmanned aerial vehicle

The invention discloses a multi-rotor plant protection unmanned aerial vehicle, belonging to the technical field of unmanned aerial vehicles. The multi-rotor plant protection unmanned aerial vehicle comprises an undercarriage, a body, a rack, arms, a main rotor, an auxiliary rotor, a spray system and a control system, wherein the body is arranged above the undercarriage and connected with the undercarriage; the rack is arranged above the body and connected with the body; the arms are mounted on the rack; even number of arms are provided and symmetrically distributed on the rack; an engine is arranged at the upper part of the rack; the main rotor is connected with an output shaft of the engine; an motor is arranged on each arm; an output shaft of each motor is connected with the corresponding auxiliary rotor; a spoiler is arranged on each arm; the spoilers are used for offsetting the anti-torque effect generated by the rotation of the main rotor; the control system, the engine and the motors are all connected with a power supply; and the control system controls the working states of the main rotor, the auxiliary rotors and the spray system. In the invention, gasoline-electric hybrid power is adopted, the whole structure is simplified, the structure is simple, and the time of endurance is long.

Owner:BEIHANG UNIV +1

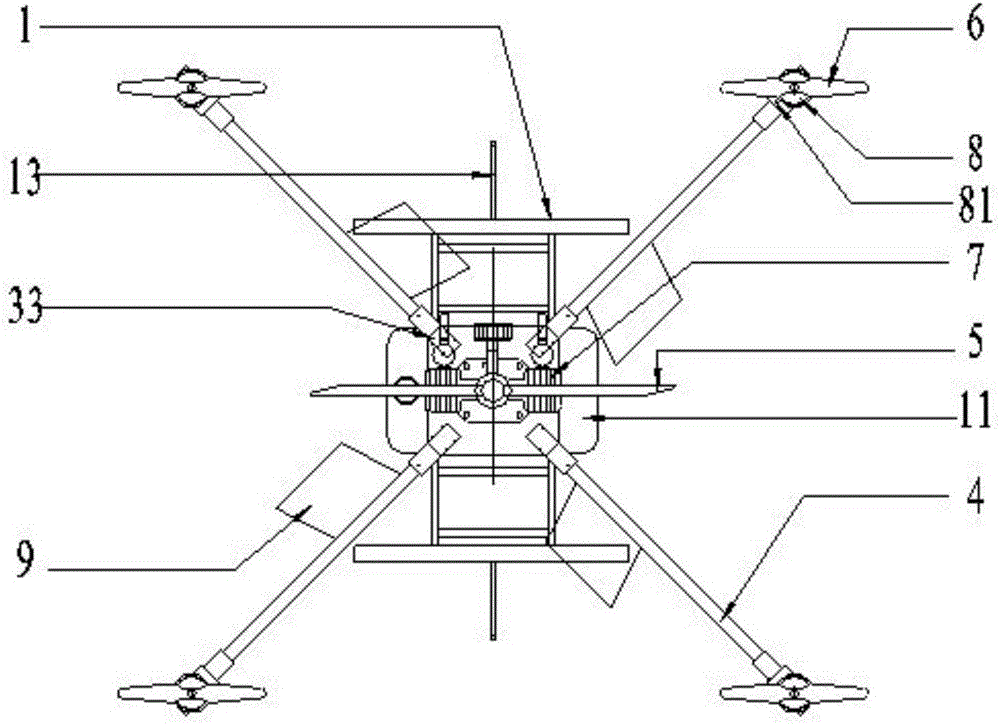

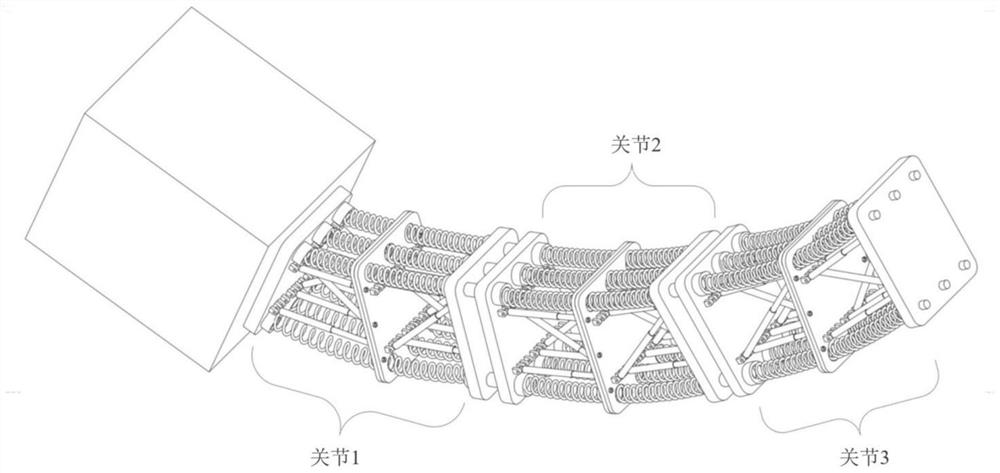

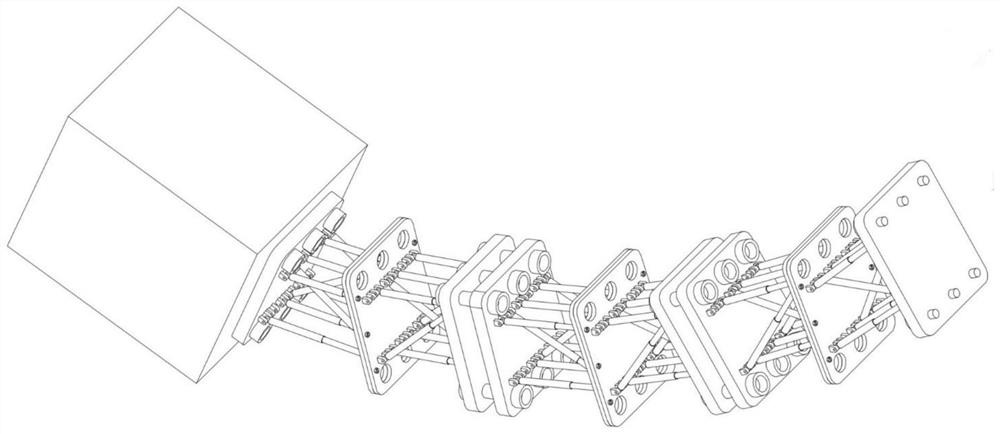

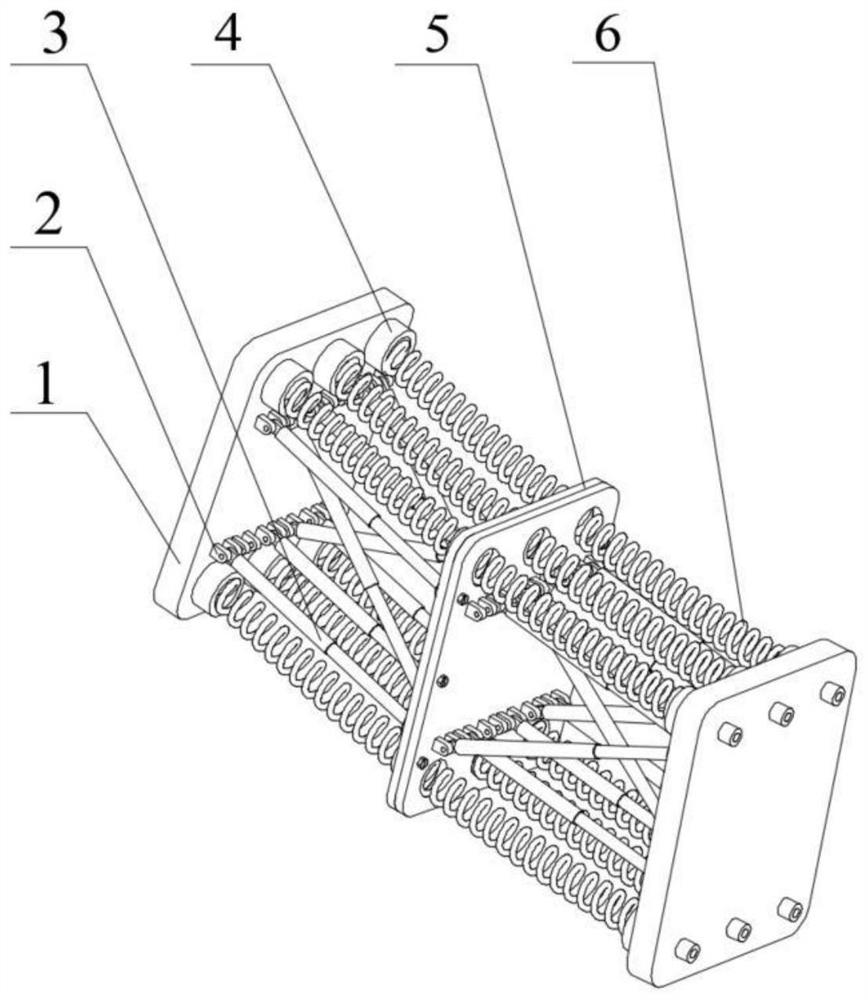

Hyper-redundant continuum robot driven by shape memory alloy

ActiveCN112091957AProminent substantive naturePrecise Feedback ControlProgramme-controlled manipulatorControl engineeringShape-memory alloy

The invention relates to a hyper-redundant continuum robot driven by a shape memory alloy. The hyper-redundant continuum robot is formed by connecting a control box and three joints which are arrangedon one side of the control box and are of the same structure through connecting pieces end to end in series, and each joint consists of two groups of deformable truss units with three degrees of freedom of a plane. Each joint is provided with a shape memory alloy spring as a driver; through arrangement of a circuit board in a proper size between every two joints, and by utilizing the characteristic that the shape memory alloy spring is powered on and heated to generate phase change shrinkage, the bending deformation of three different joints can be controlled separately; and the movement of the continuum robot is achieved through coupled motion between different joints. According to the hyper-redundant continuum robot, the shape memory alloy spring can be directly driven through current heating, the robot has the advantages of simple structure, light weight and easy control, and the degree of freedom of each joint can be independently controlled through the shape memory alloy spring.

Owner:SHANGHAI UNIV

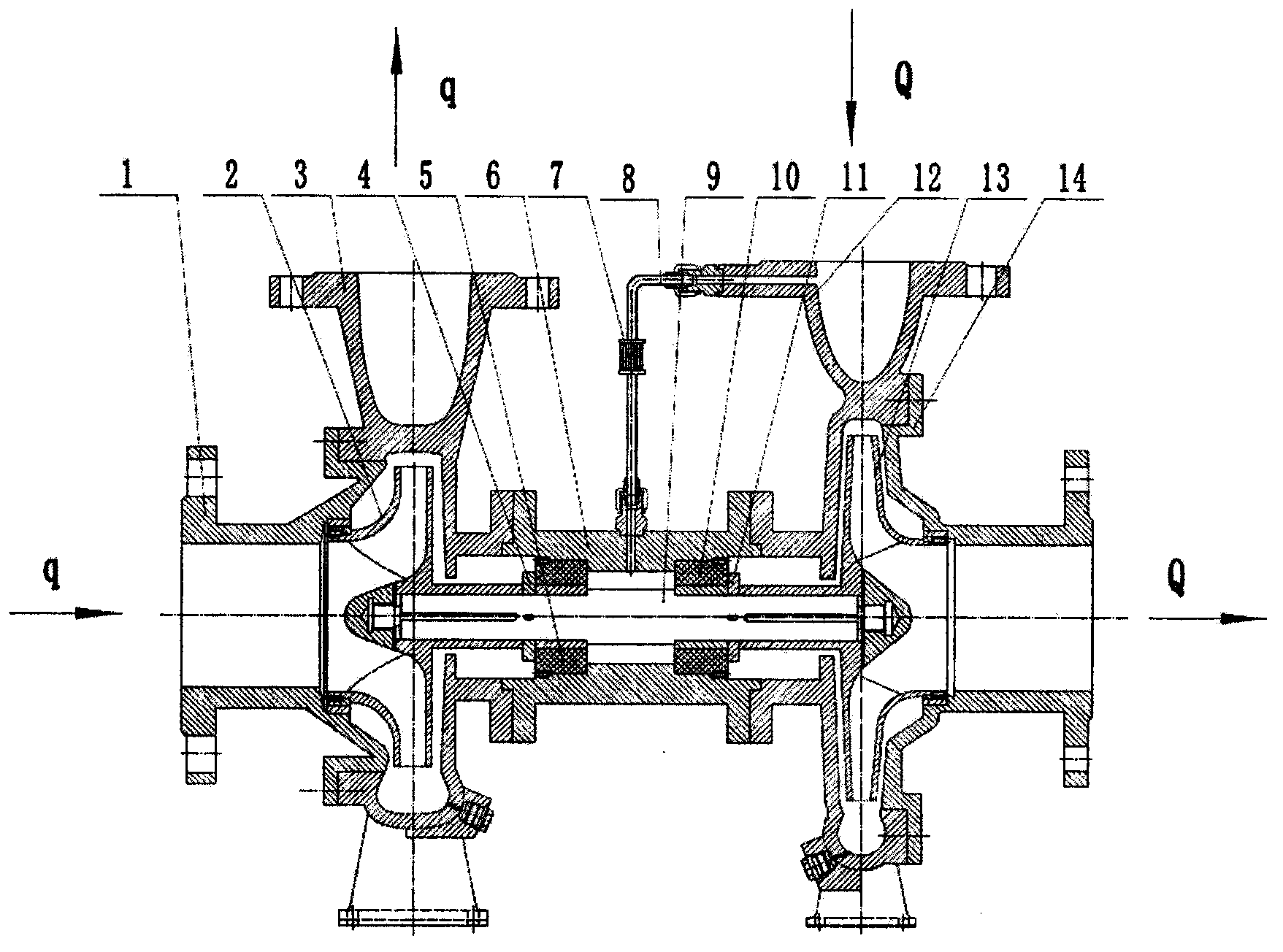

Novel hydrodynamic turbine pump free of shaft seal structure

InactiveCN103352855AAvoid shaft seal leakage problemsCompact structurePump componentsPump installationsLubricationImpeller

The invention relates to a novel hydrodynamic turbine pump free of a shaft seal structure. A hydraulic turbine and a pump are coaxial, sliding bearing support shafts and axial positioning are adopted, and a transmission mechanism and a shaft seal are omitted. The working principle of the novel hydrodynamic turbine pump is as follows: a liquid flows into the hydrodynamic turbine pump from an inlet of the hydraulic turbine, rotating wheels are impacted and rotate, and impellers are driven by the shaft to rotate. In a working process, right and left sliding bearings of the hydraulic turbine support the shafts and the axial positioning, a high pressure liquid introduced from a turbine casing enters cavities of the sliding bearings through a liquid flushing pipe and a filter, one part of the liquid enters a lower pressure area of a left end pump cavity through the left sliding bearing, the other part of the liquid enters a lower pressure area of a right end pump cavity through the right sliding bearing, and the introduced liquid cools and lubricates the right and left sliding bearings respectively. The turbine and the pump are coaxial, and the sliding bearing support shafts, the axial positioning, medium own circulation, cooling and lubrication structures and the like are used, and the shaft seal (a mechanical seal, framework seal and the like) is not required to be arranged, so that the hydrodynamic turbine pump is free of the shaft seal and compact in structure.

Owner:JIANGSU UNIV

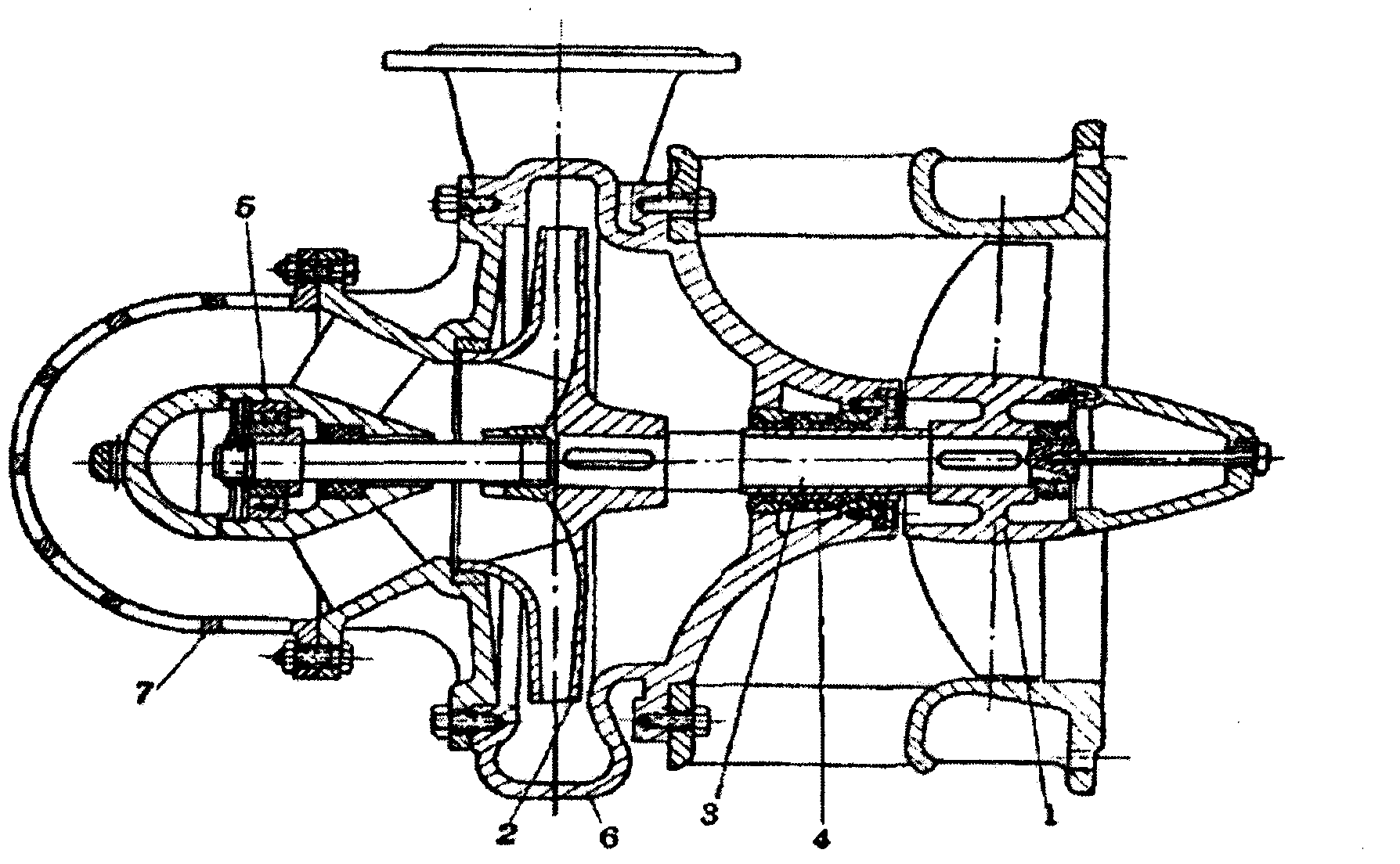

Shaftless propeller

InactiveCN107719613AReduce volumeSmall footprintRotary propellersPropulsion power plantsPropellerCooling effect

The invention discloses a shaftless propeller which comprises a shell, a rotor and two end caps. A stator and Hall sensors are fixedly mounted inside the shell, the rotor comprises blades, permanent magnets and a ring, the blades are fixedly mounted inside the ring, the permanent magnets are embedded inside the ring, the stator comprises a silicon steel sheet combination and a coil uniformly and compactly wound on the silicon steel sheet combination, circuits of the Hall sensors and the coil are gathered and connected together through a wiring port, an embedding groove is formed in each of twosides of the ring, a bearing is arranged inside each embedding groove, and a sealing groove corresponding to the corresponding embedding groove is formed in the inner side of each of the two end caps. Therefore, occupied space is small, and space utilization rate is increased; the shaftless propeller is compact in structure, high in energy utilization rate and good in lubricating effect and cooling effect, wear in the process of transmission is reduced, and structural complexity of the shaftless propeller is lowered, so that actual using cost is lowered.

Owner:OCEAN UNIV OF CHINA

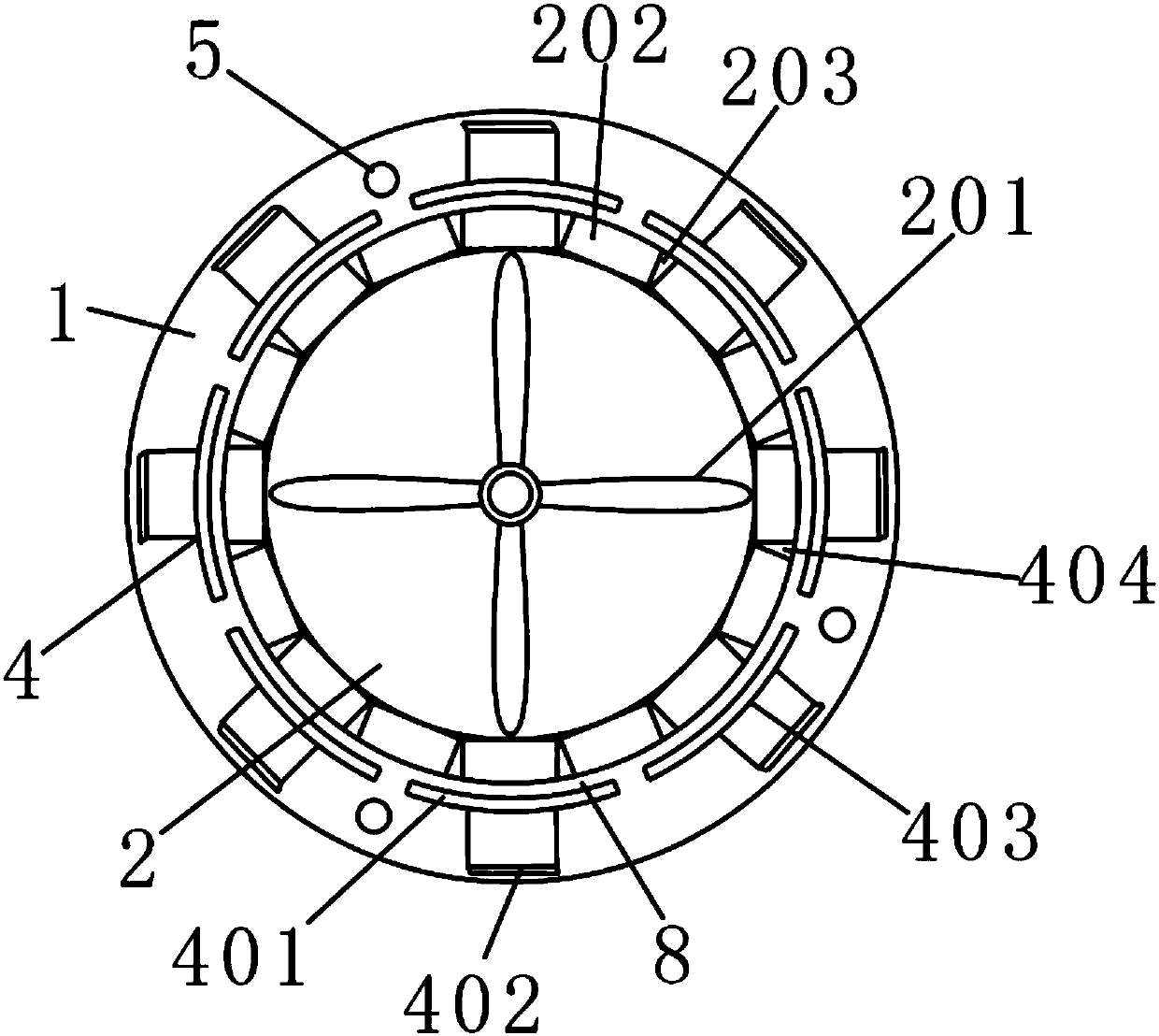

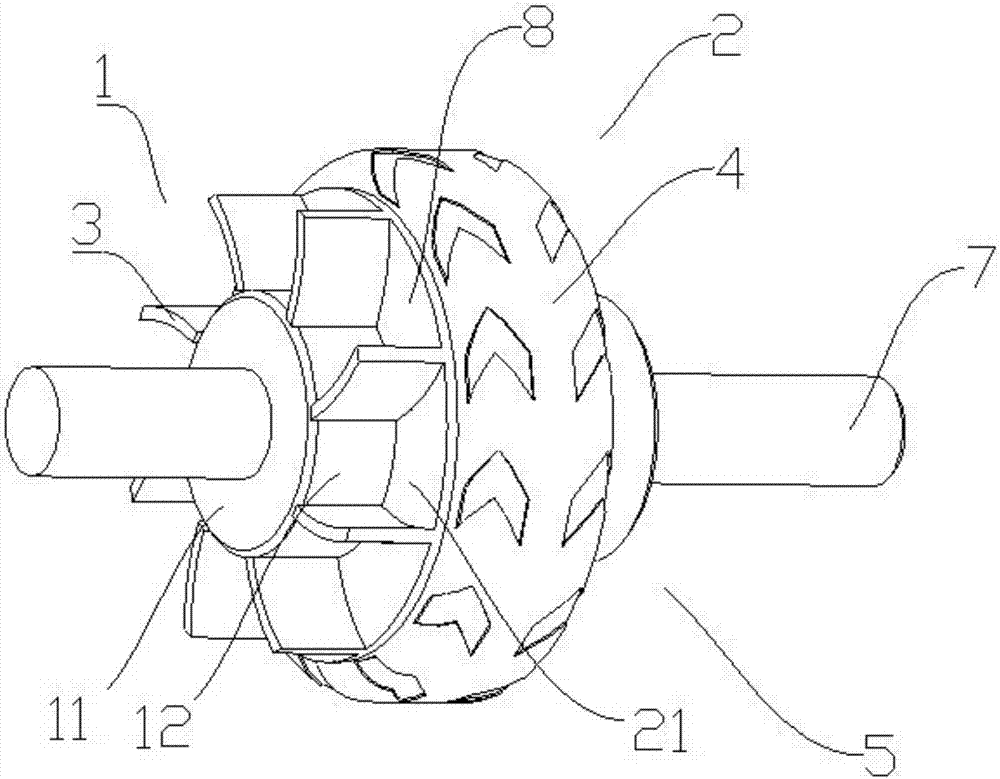

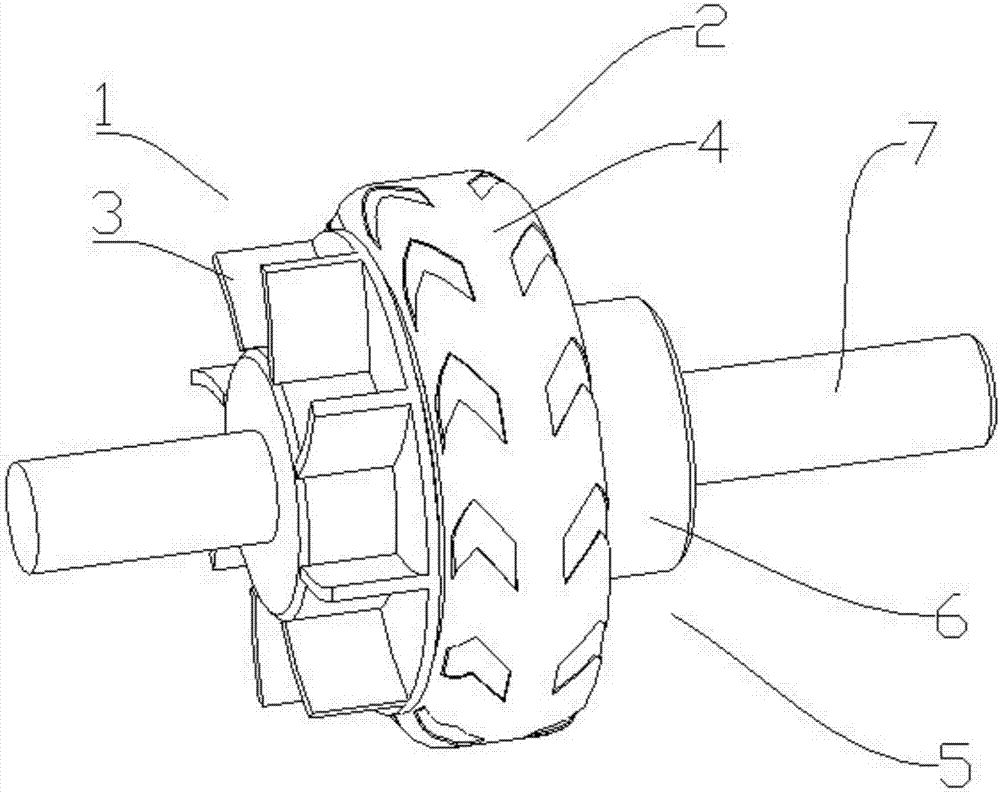

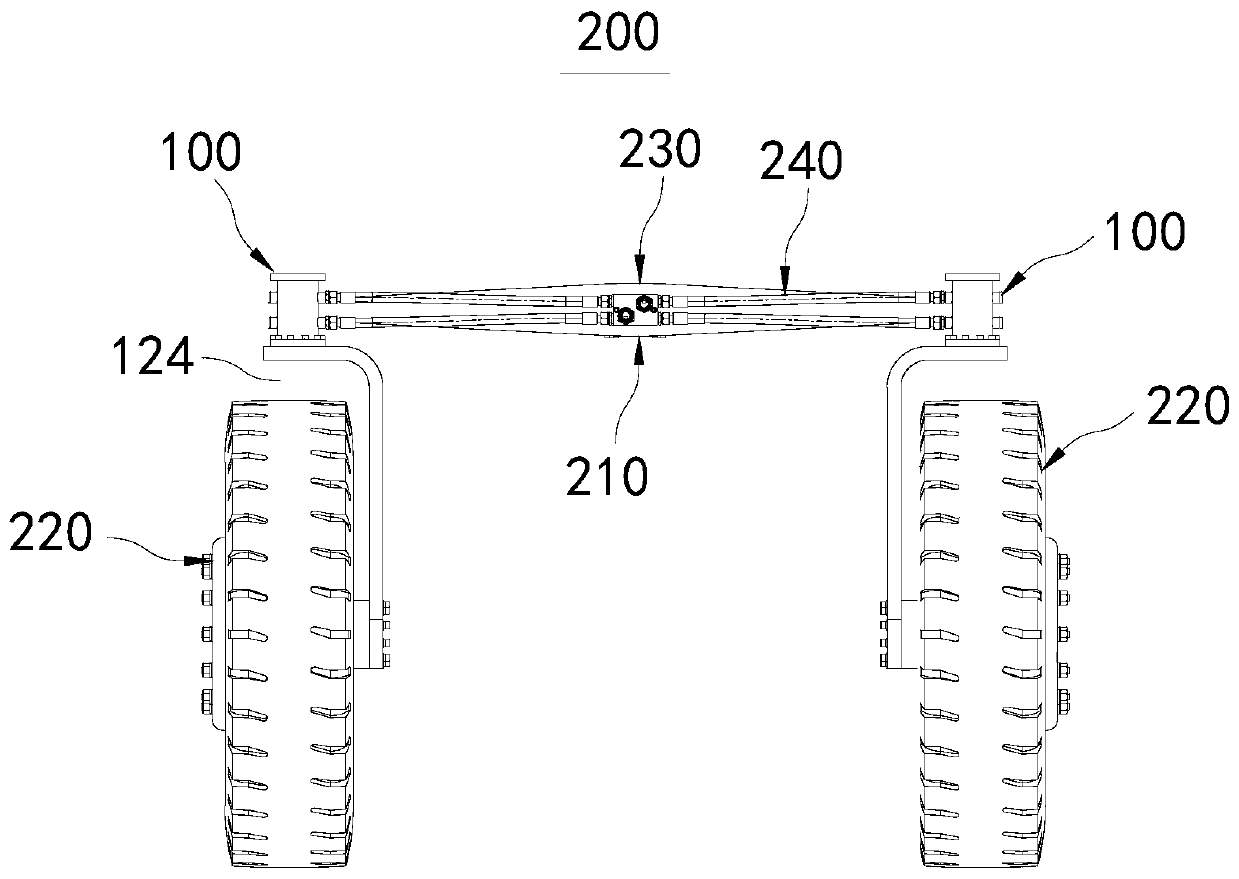

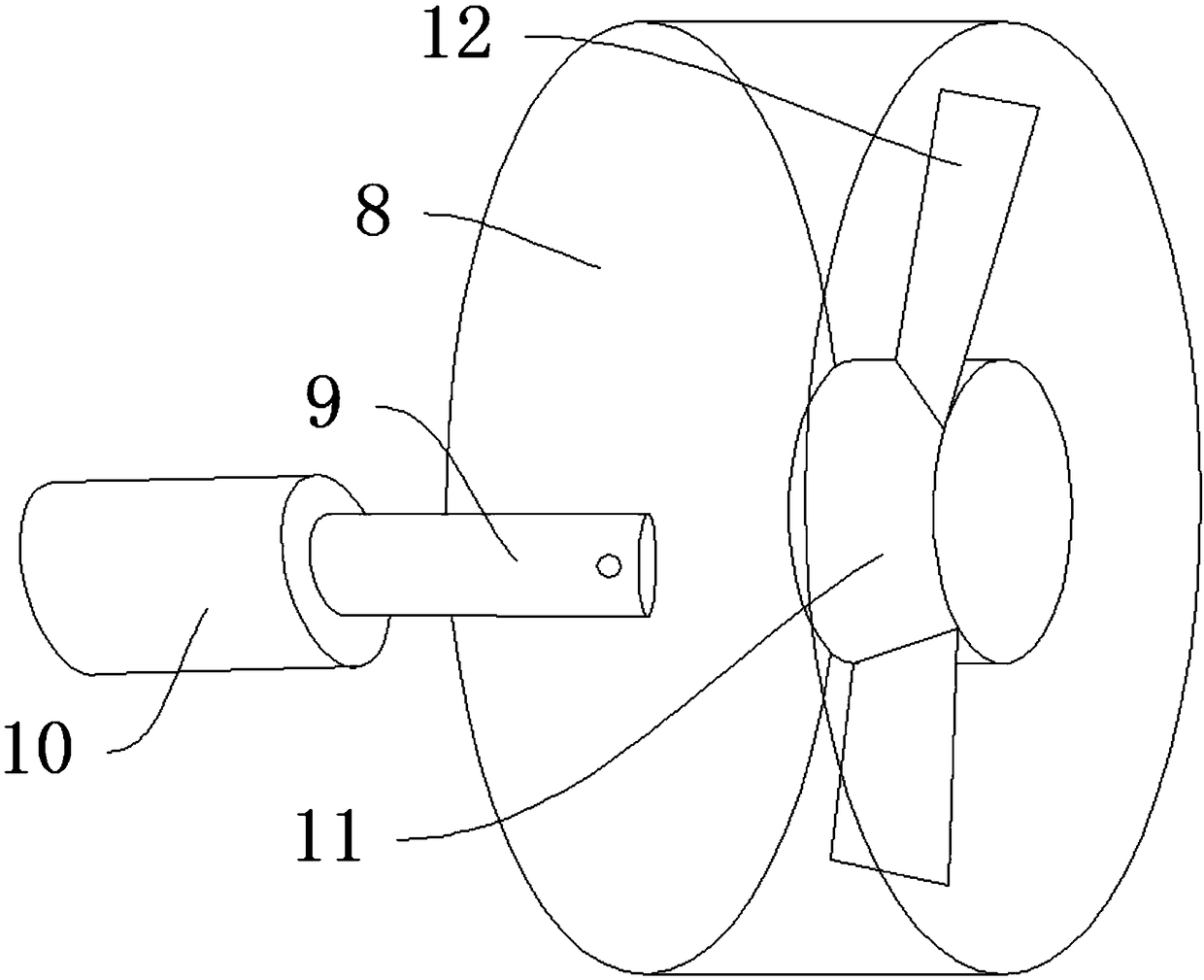

Amphibious propeller

InactiveCN107128137AImprove driving abilityReduce transmission structureAmphibious vehiclesMotor depositionEngineeringHigh lift

The invention provides an amphibious propeller which comprises a wading wheel and a land wheel, wherein the wading wheel and the land wheel are coaxially mounted and both can be driven by a driving device to rotate; the peripheral diameter of the wading wheel is less than that of the land wheel; the wading wheel comprises blades; the land wheel comprises a hub and a tire arranged at the periphery of the hub; the blades are fixedly connected with the hub; the wading wheel and the land wheel are combined, so that the propeller has the amphibious driving capacity, and the running capacity of a ship driven by the propeller is expanded; meanwhile, the propeller and a motor are directly connected to form a whole, so that a complicated transmission structure in the prior art is eliminated; therefore, the rotating speed of the wading wheel is increased, and the driving efficiency is improved; a ship body can obtain higher lifting force and thrust, so that the running speed of the ship body driven by the propeller is greatly increased.

Owner:WUXI RUIFENG MARINE PROPULSION CO

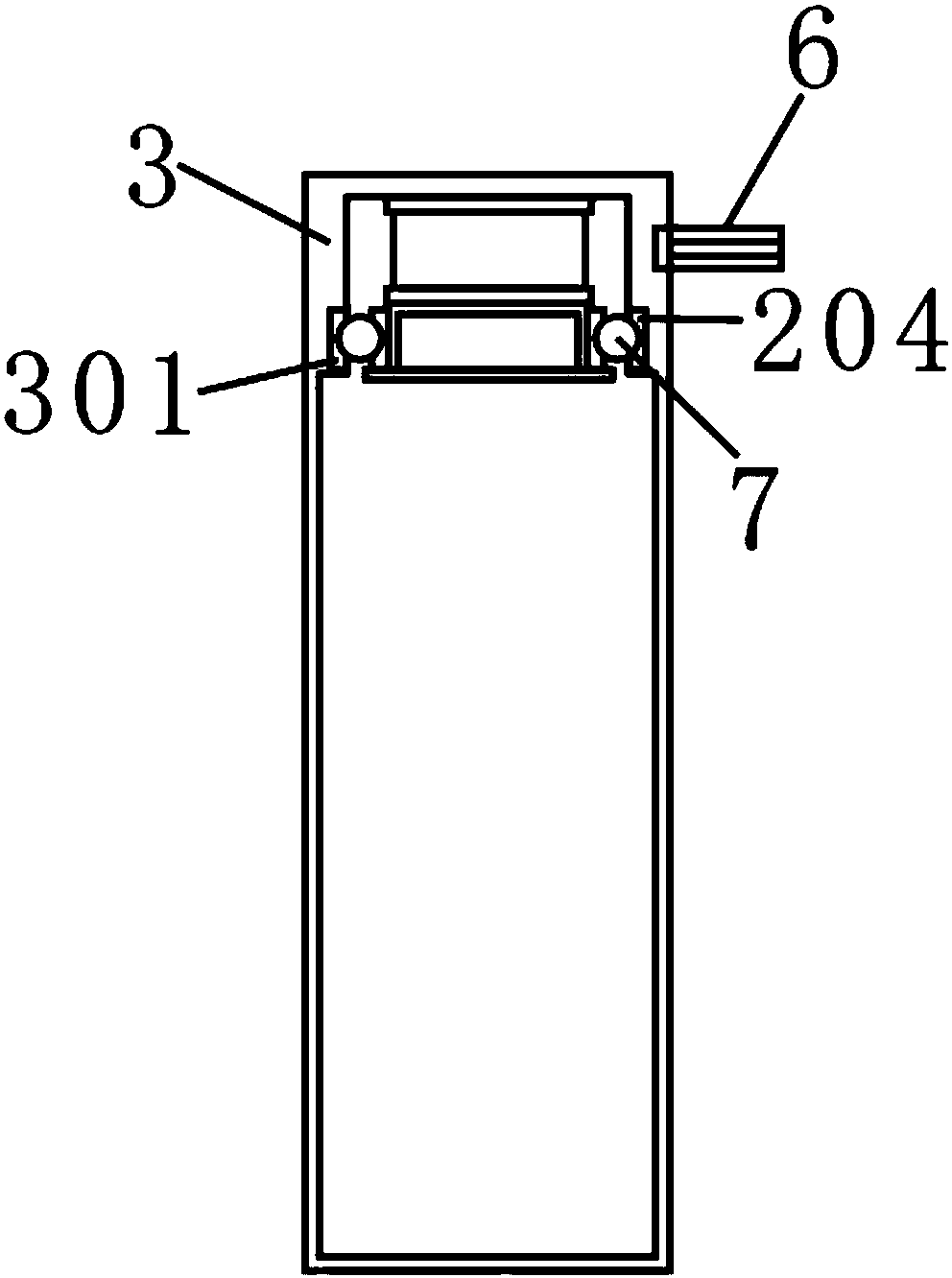

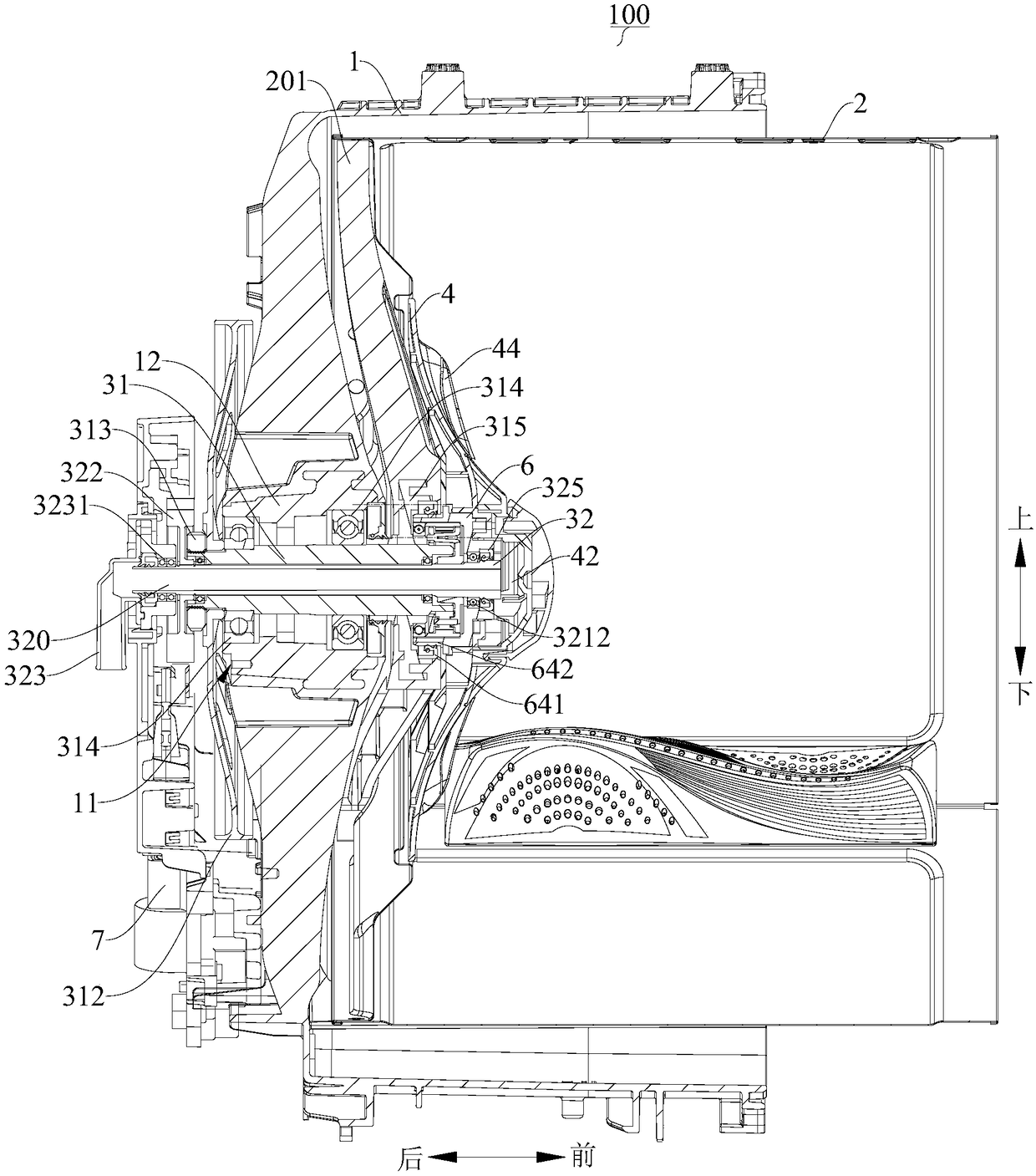

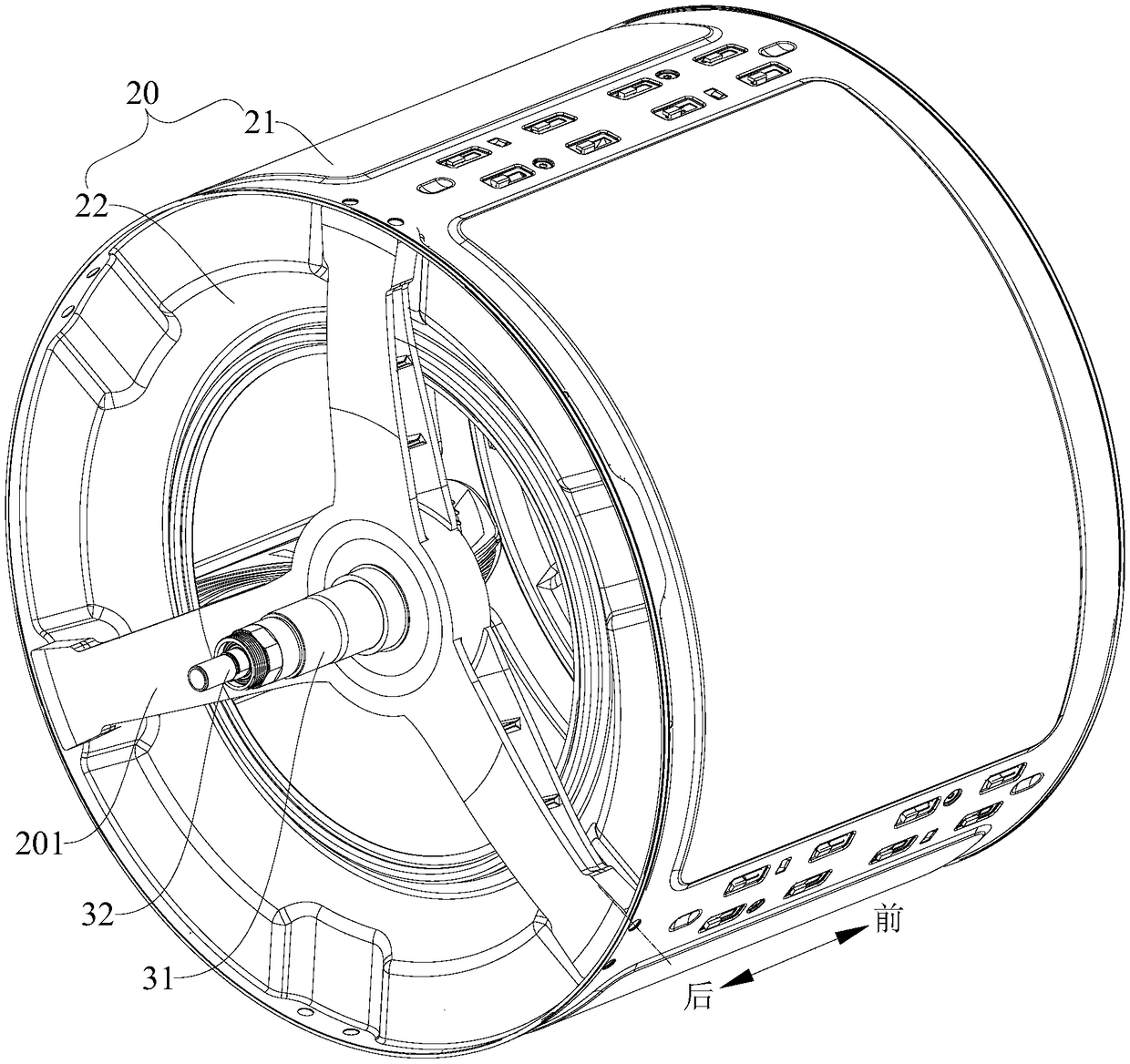

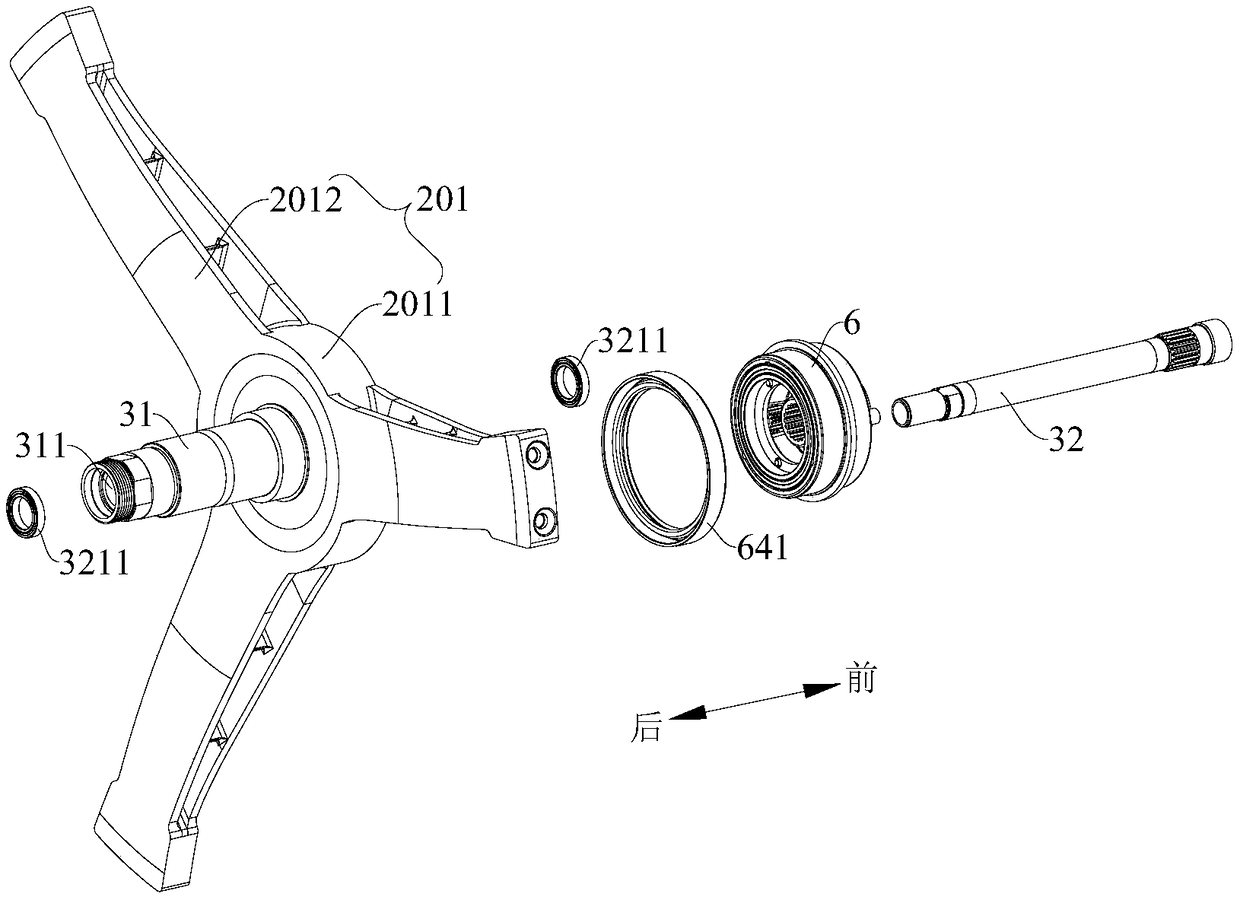

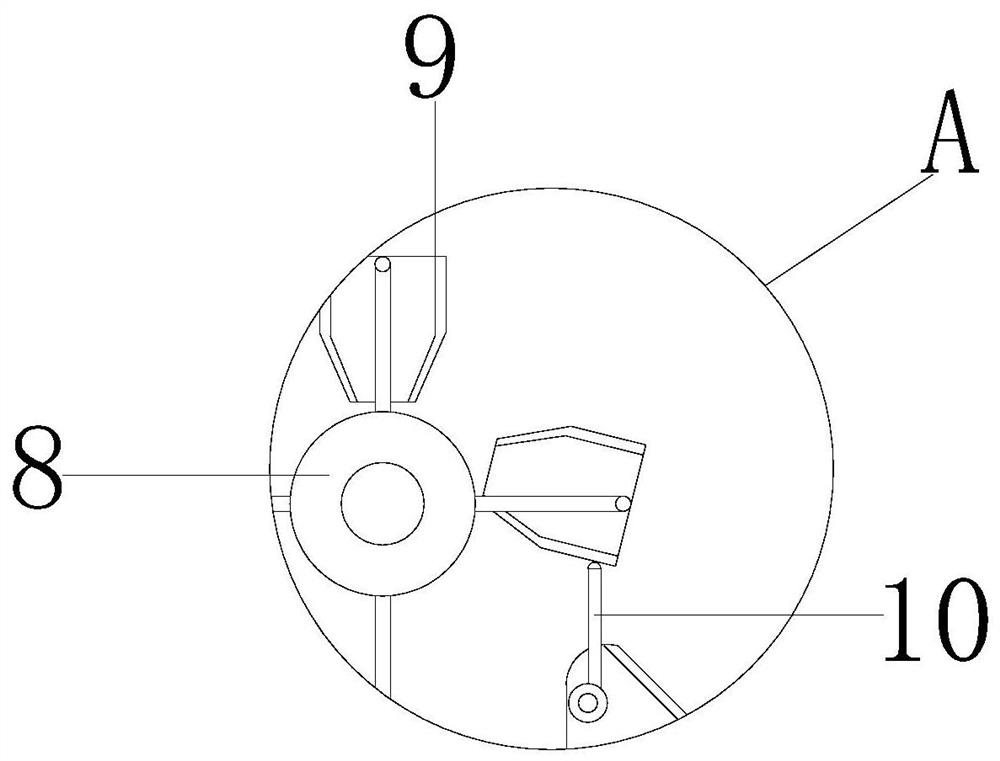

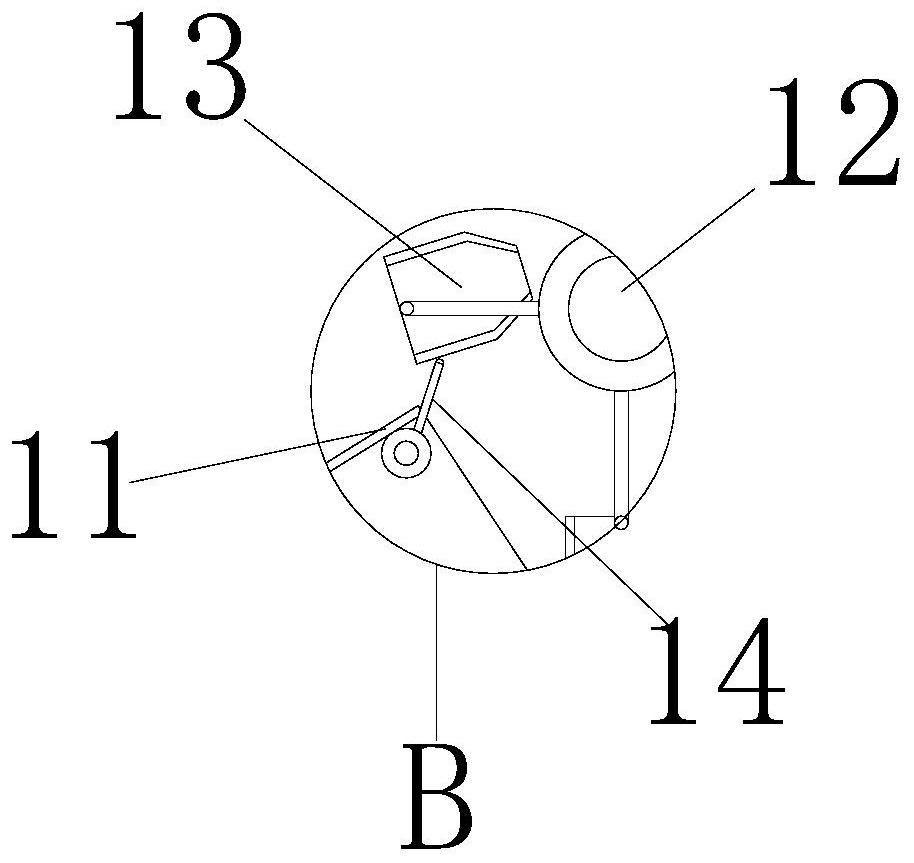

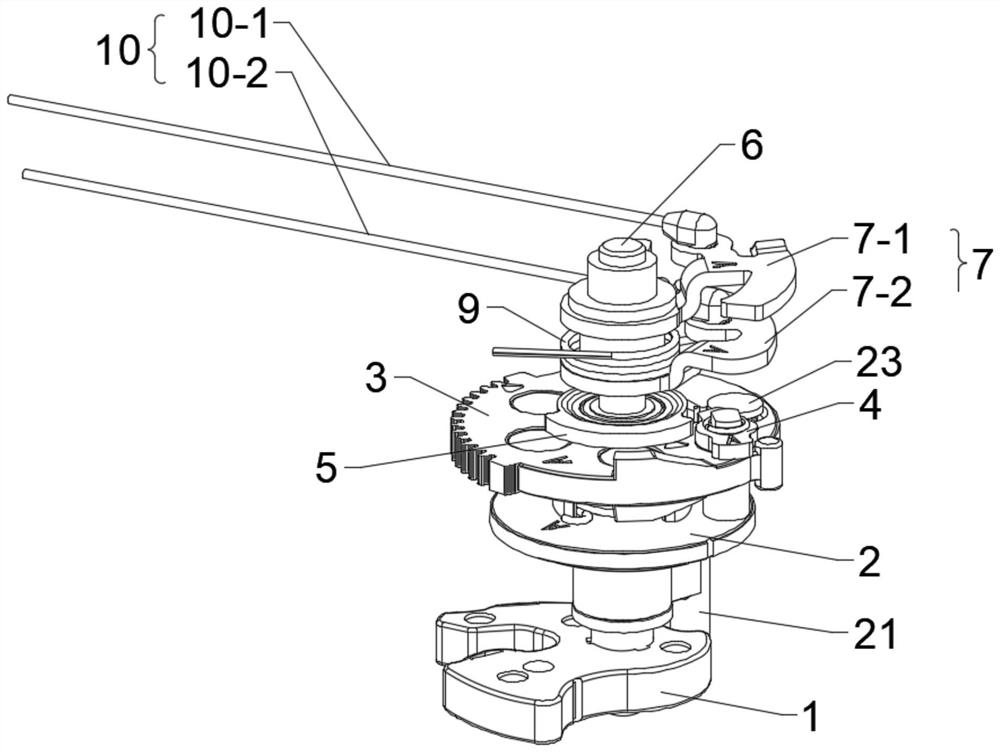

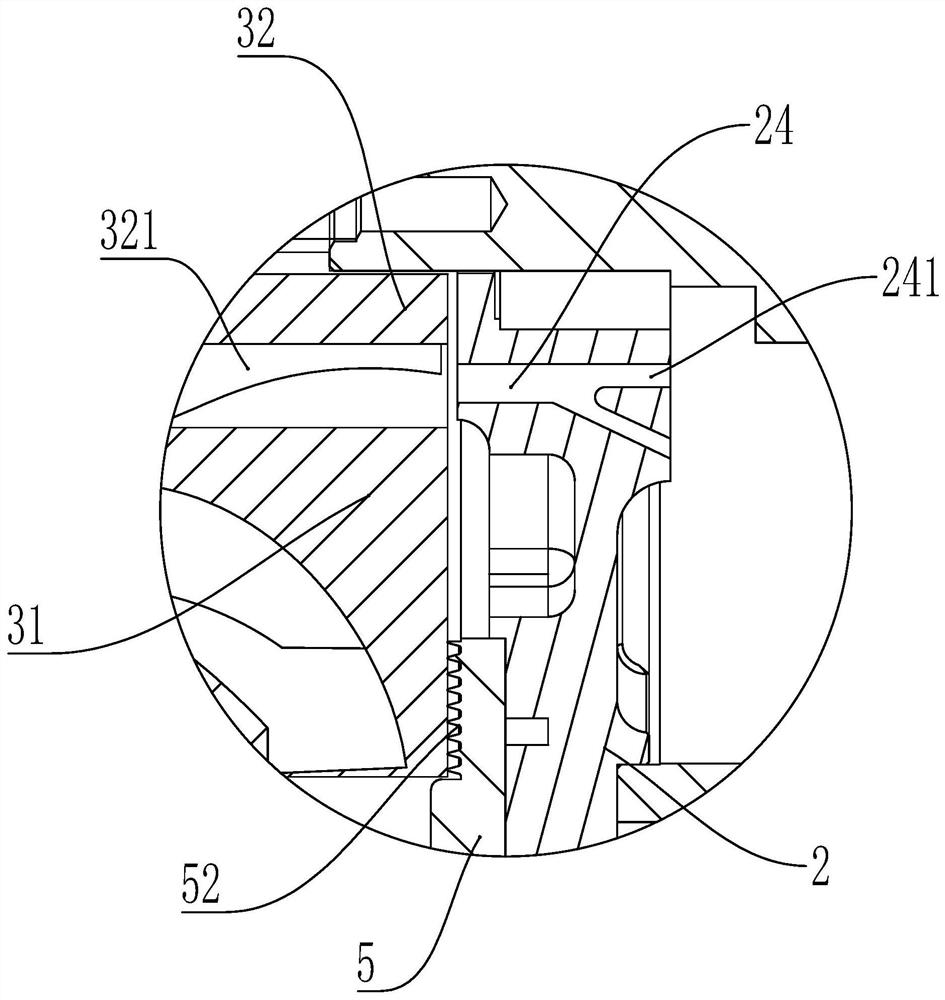

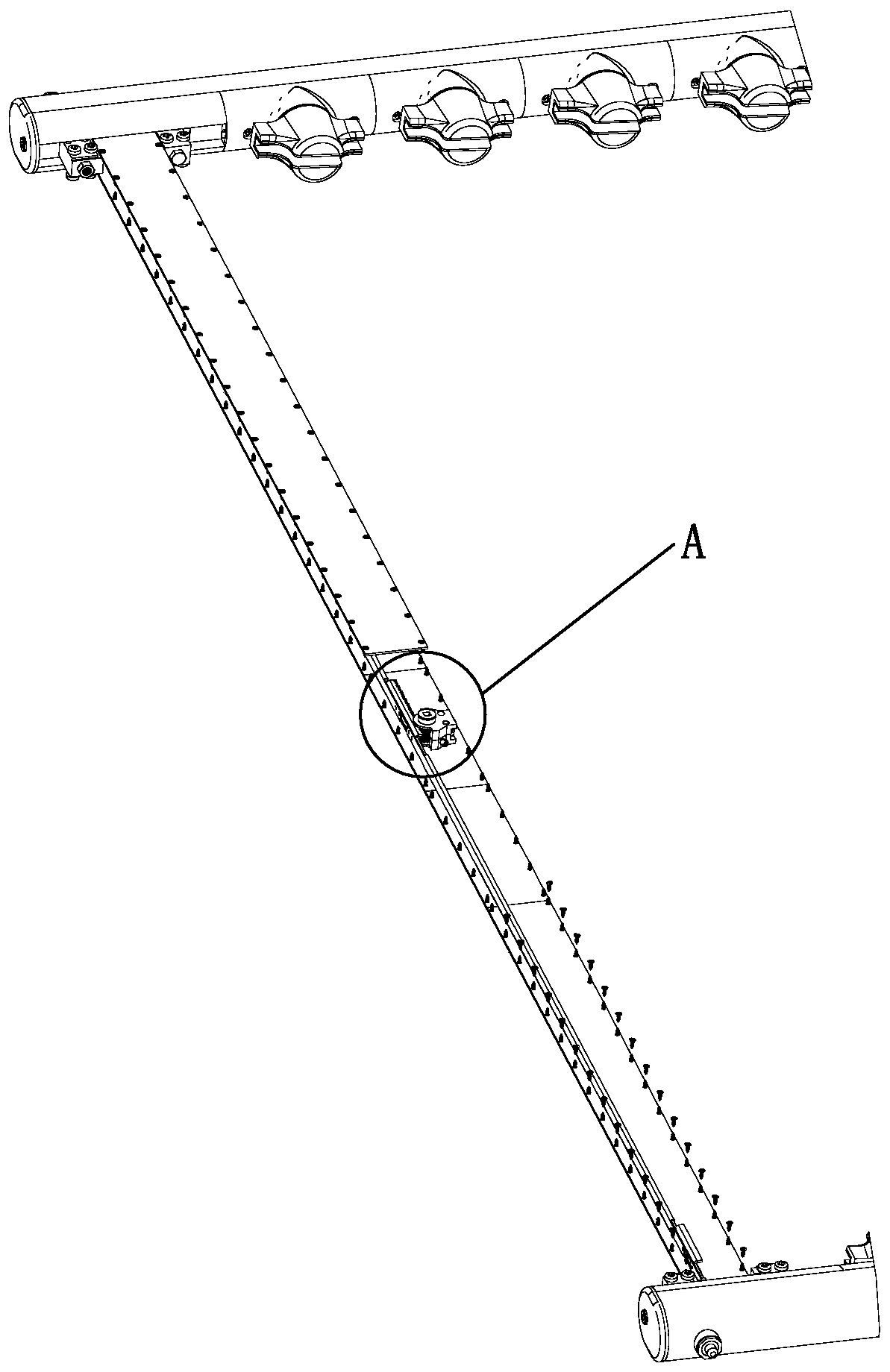

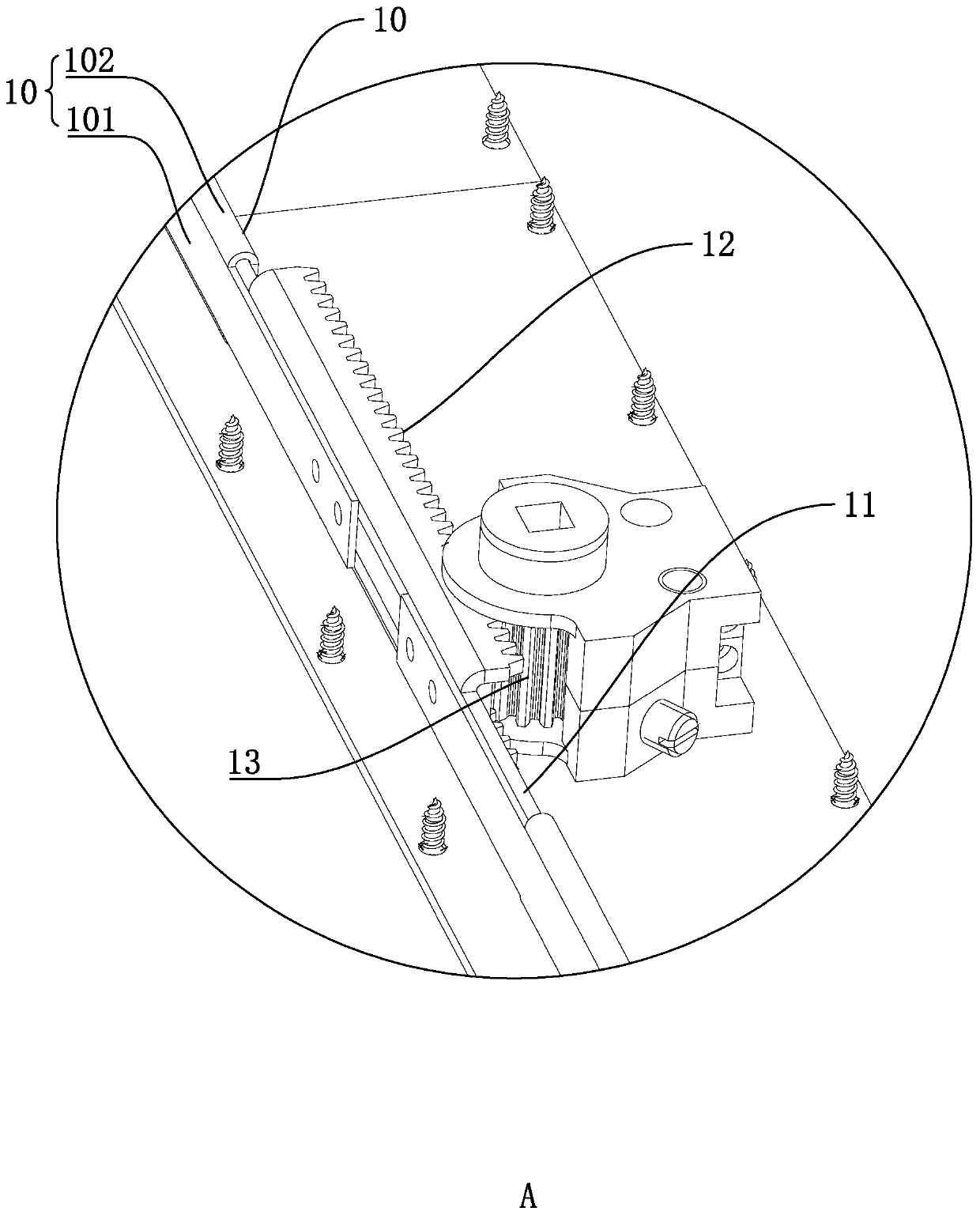

Brake for roller washing machine and roller washing machine

ActiveCN108866948AVarious washing methodsSimple structureOther washing machinesTextiles and paperCooperative workMode switch

The invention discloses a brake for a roller washing machine and the roller washing machine. The brake comprises a brake disc, a brake base, a brake pawl, a brake rod and a brake driver, wherein the brake disc is arranged on a second shaft; the brake base is provided with a sliding rail; the brake pawl is arranged on the brake base in a switchable manner between the tightening state of tightly holding the brake disc and the unfolding state of releasing the brake disc; the brake rod is slidingly matched to the sliding rail between an extending position and a retraction position, the brake pawlis switched to the tightening state when the brake rod is located at the extending position, and the brake pawl is switched to the unfolding position when the brake rod is located at the retraction position; the brake driver is installed on the brake base and in transmission connection with the brake rod, and drives the brake rod to move between the extending position and the retraction position.By means of the brake for the roller washing machine in the embodiment, mode switching for cooperative work between a stirrer and an inner drum can be achieved, and the brake has the advantages of being simple in structure, convenient to control, stable and the like.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

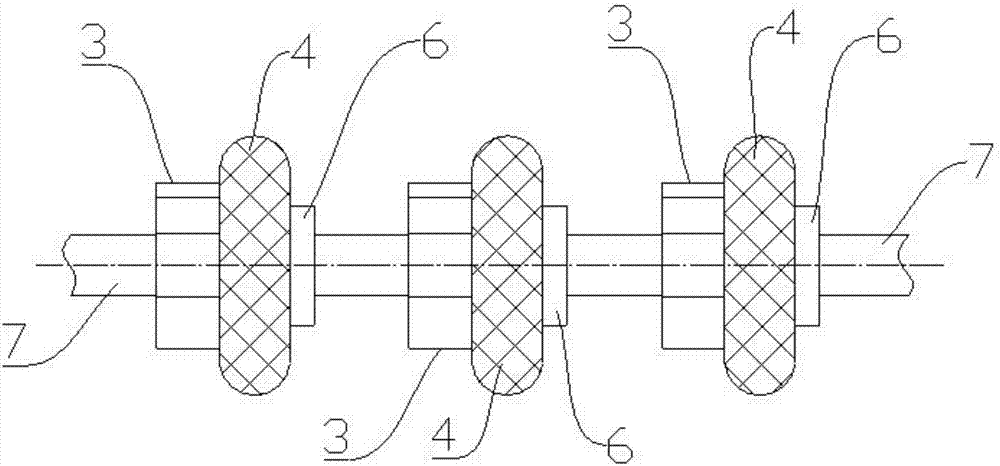

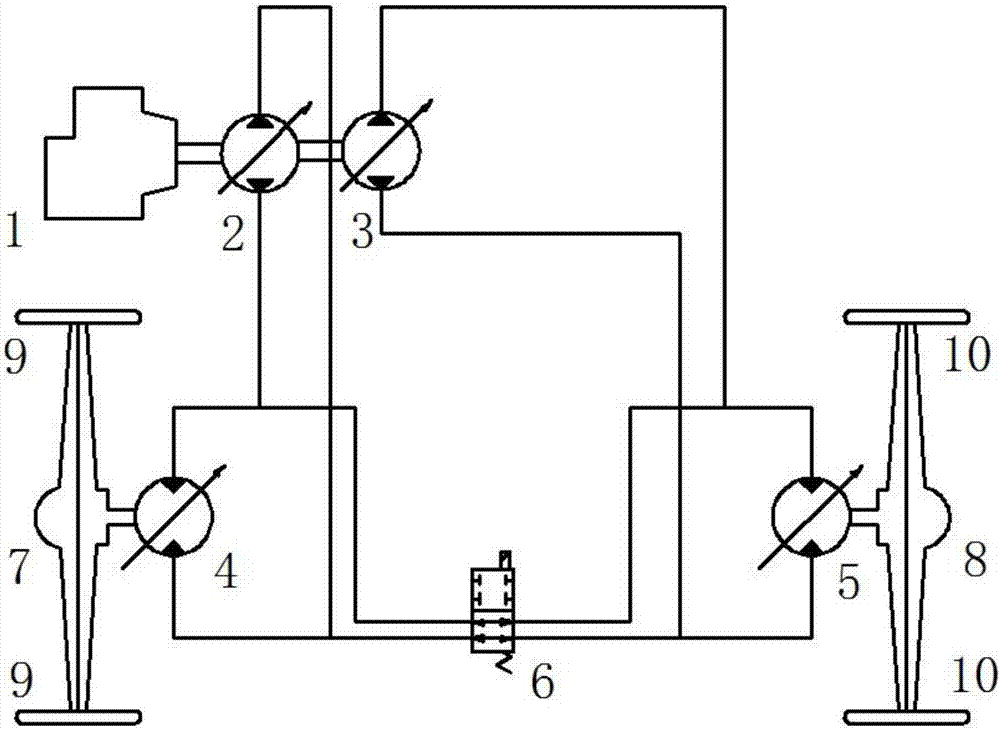

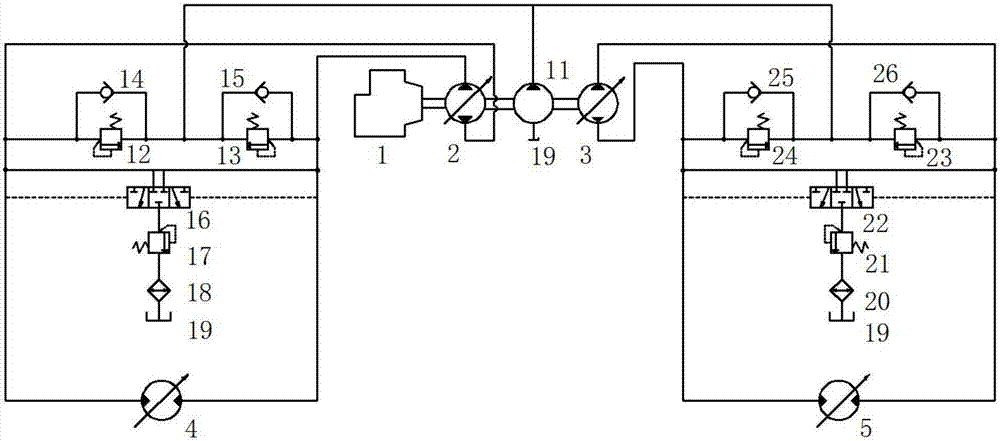

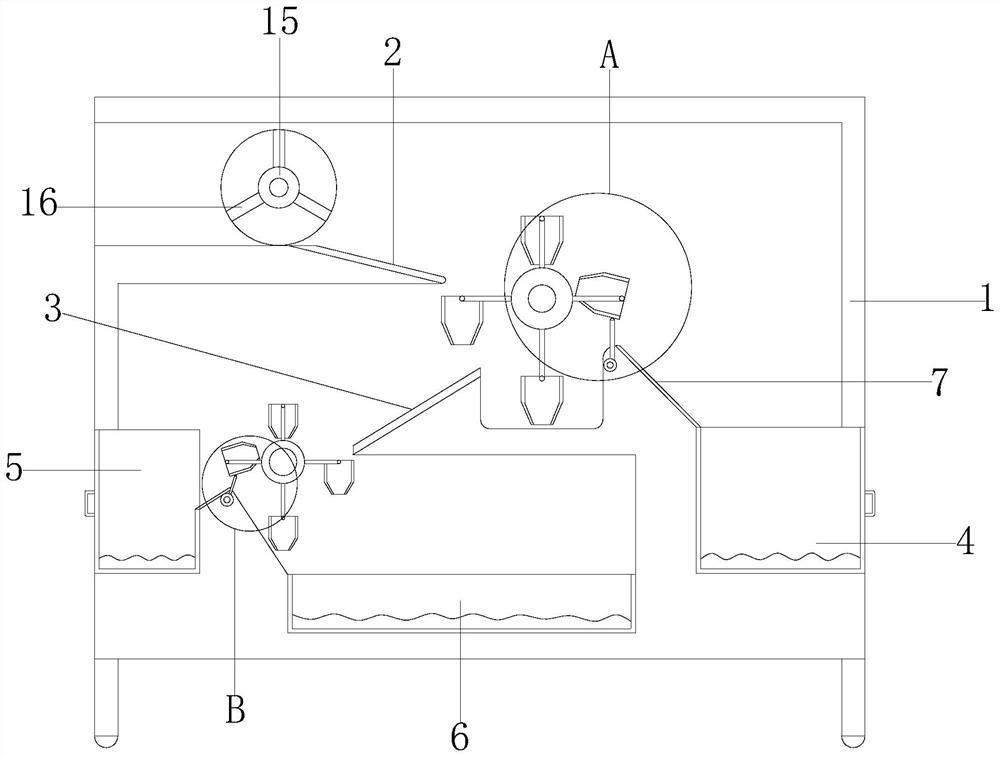

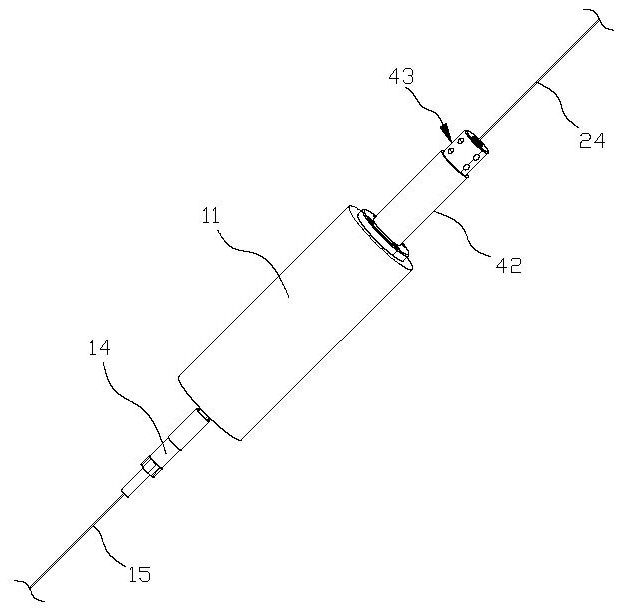

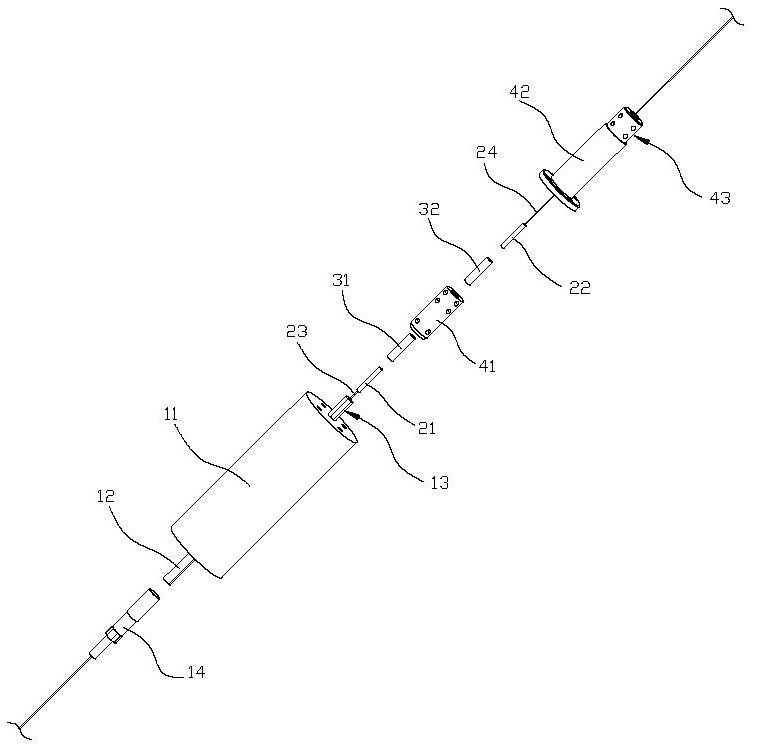

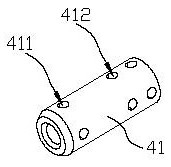

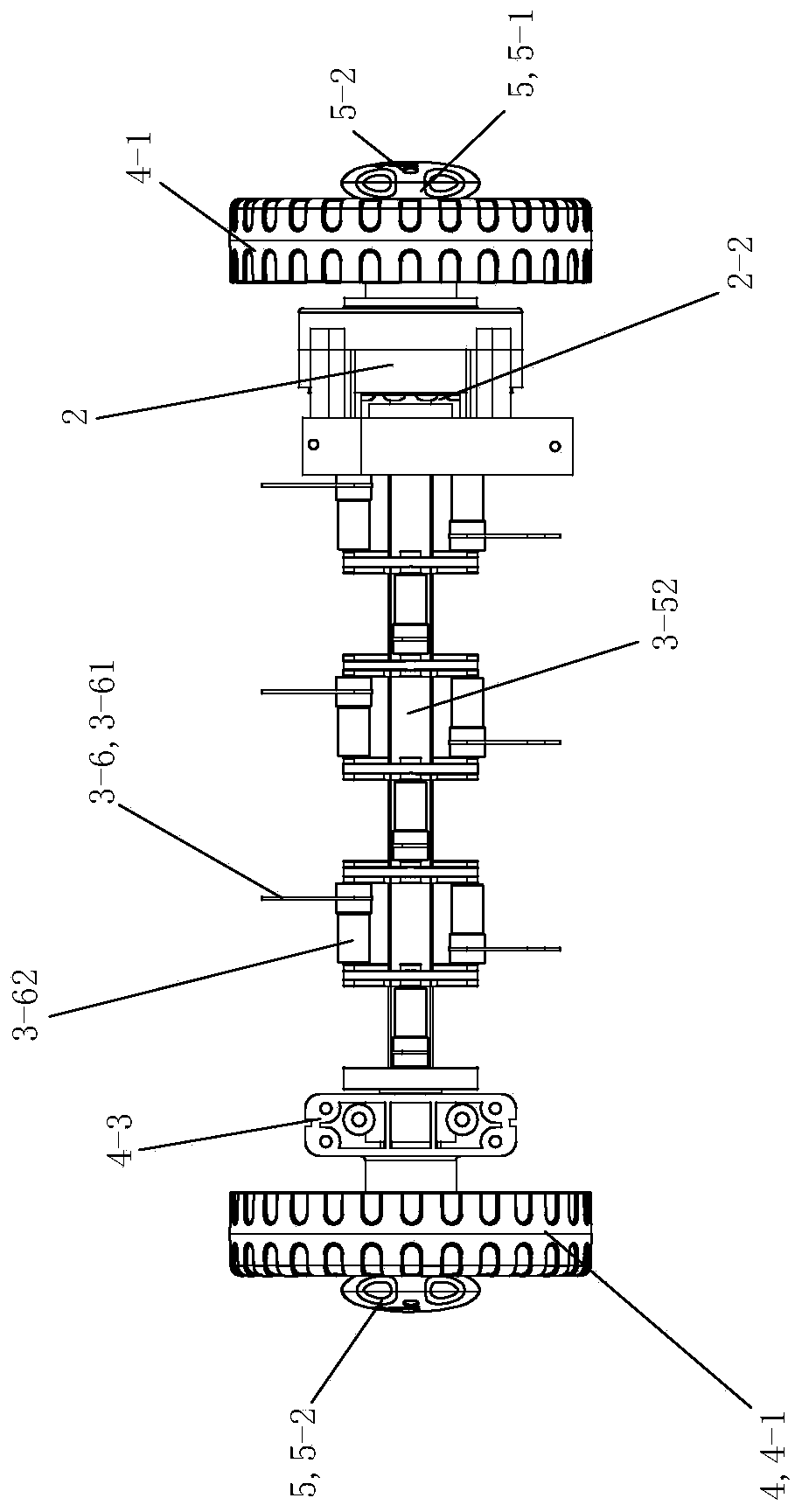

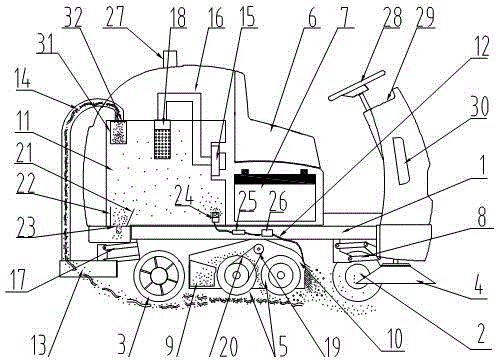

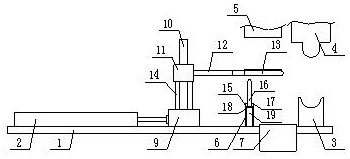

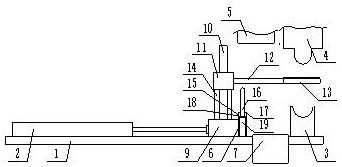

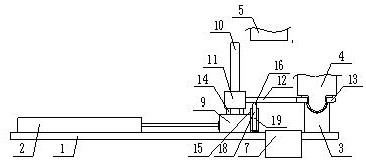

Driving system of seedling transplanter

ActiveCN106900234AGuaranteed passabilityOptimizing Layout FlexibilityTransplantingFertiliser equipmentsGear pumpControl engineering

The invention relates to a driving system of a seedling transplanter, the driving system includes a travelling driving hydraulic system and a seedling box lifting energy recovery hydraulic system, the travelling driving hydraulic system includes a driving main loop, an oil compensating loop and a cooling loop; a front wheel plunger pump and a rear wheel plunger pump are driven to work by an engine via a belt, the front wheel plunger pump and the rear wheel plunger pump are swashplate type, the size and the direction of the dip angle of a swash plate can be regulated by change of displacement, oil-suction direction and oil pressing direction of the pumps, the front wheel plunger pump and the rear wheel plunger pump have dual functions of change of flow rate and direction, a power element of the seedling box lifting energy recovery hydraulic system is gear pump driven by the engine, the oil outlet of the gear pump is connected with a three-position four-way directional control valve, the three-position four-way directional control valve is used to control the flow direction of hydraulic oil so as to control lifting and descending of a seedling box, a reversing valve is O-type meso-position function, and is used to lock the position of an oil cylinder, an oil outlet of a rodless cavity of a lifting oil cylinder is equipped with a two-position solenoid directional valve which is used to change the direction of the hydraulic oil, and an energy accumulator is mounted on one oil outlet of the reversing valve to store and release energy.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

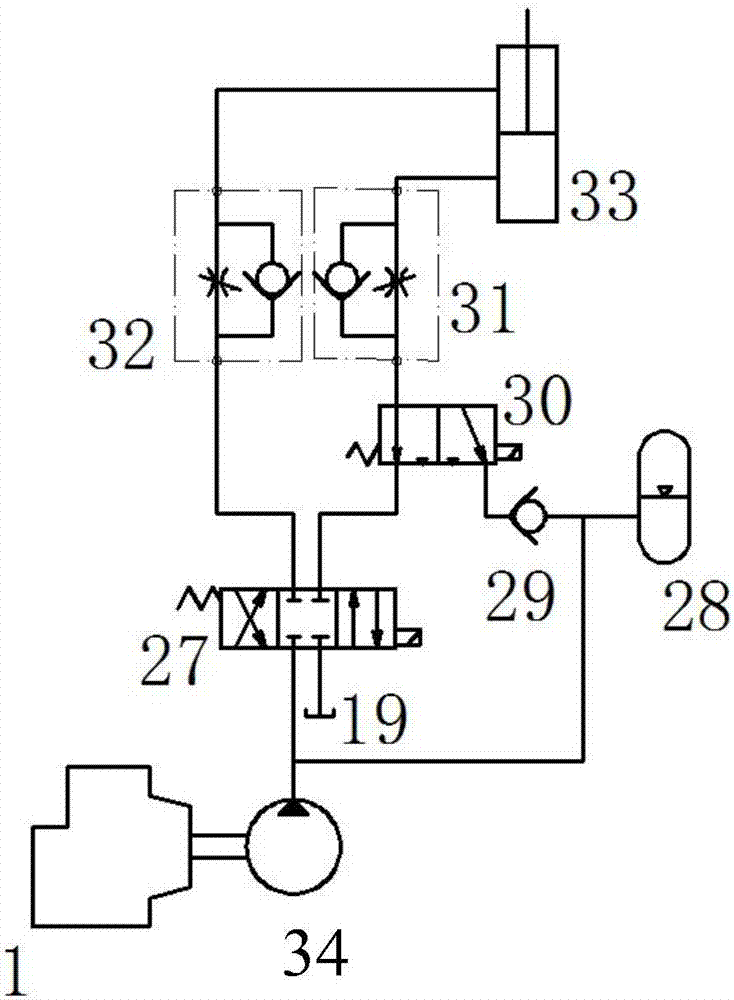

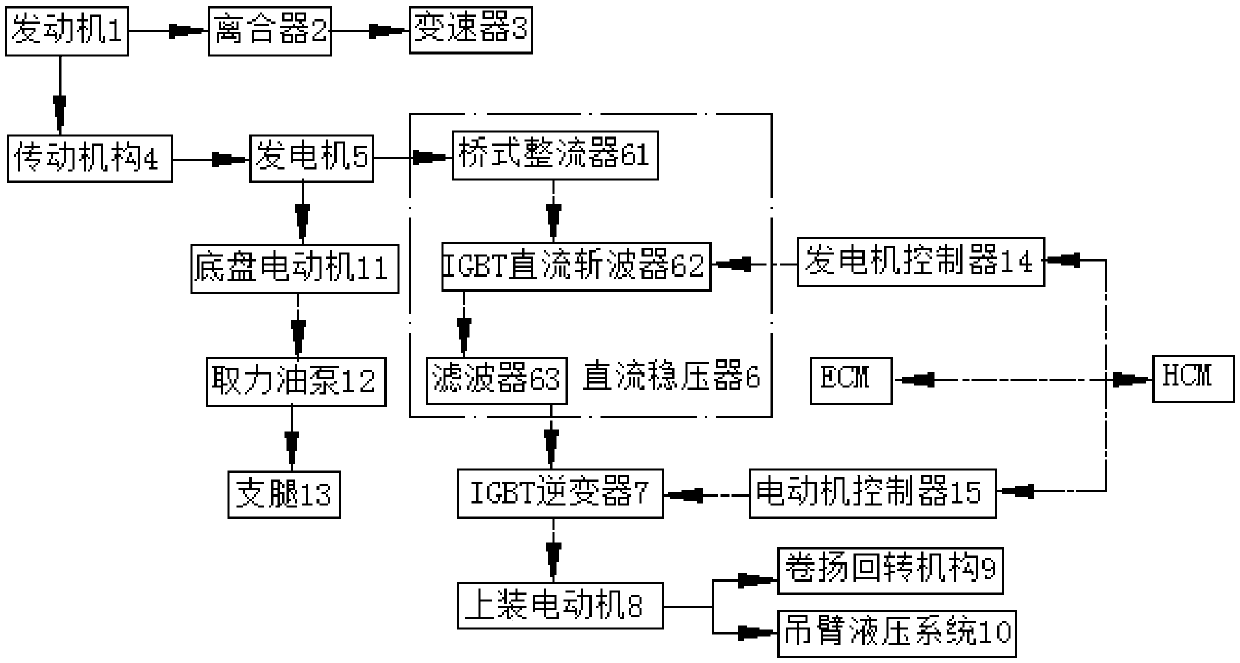

Automobile crane top-mounted electrification control system

The invention discloses an automobile crane top-mounted electrification control system. The system comprises an engine arranged on an automobile chassis and a gearbox connected with an output shaft ofan engine through a clutch, the output shaft of the engine is connected with an input shaft of a generator through a transmission mechanism, the output end of the generator is connected with a top-mounted motor through a direct-current voltage stabilizer and an inverter sequentially, the top-mounted motor is used for performing power supply driving on a winch rotating mechanism and a lifting armhydraulic system, the output end of the generator is connected with the input end of a chassis motor, and the output end of the chassis motor is in driving connection with a force taking oil pump of asupporting leg. According to the system, a top-mounted engine structure is cancelled, so that the weight of the whole crane is reduced, moreover, the generator is used for supplying power to the motors, so that electrification driving of the crane is realized.

Owner:ANHUI LIUGONG CRANE

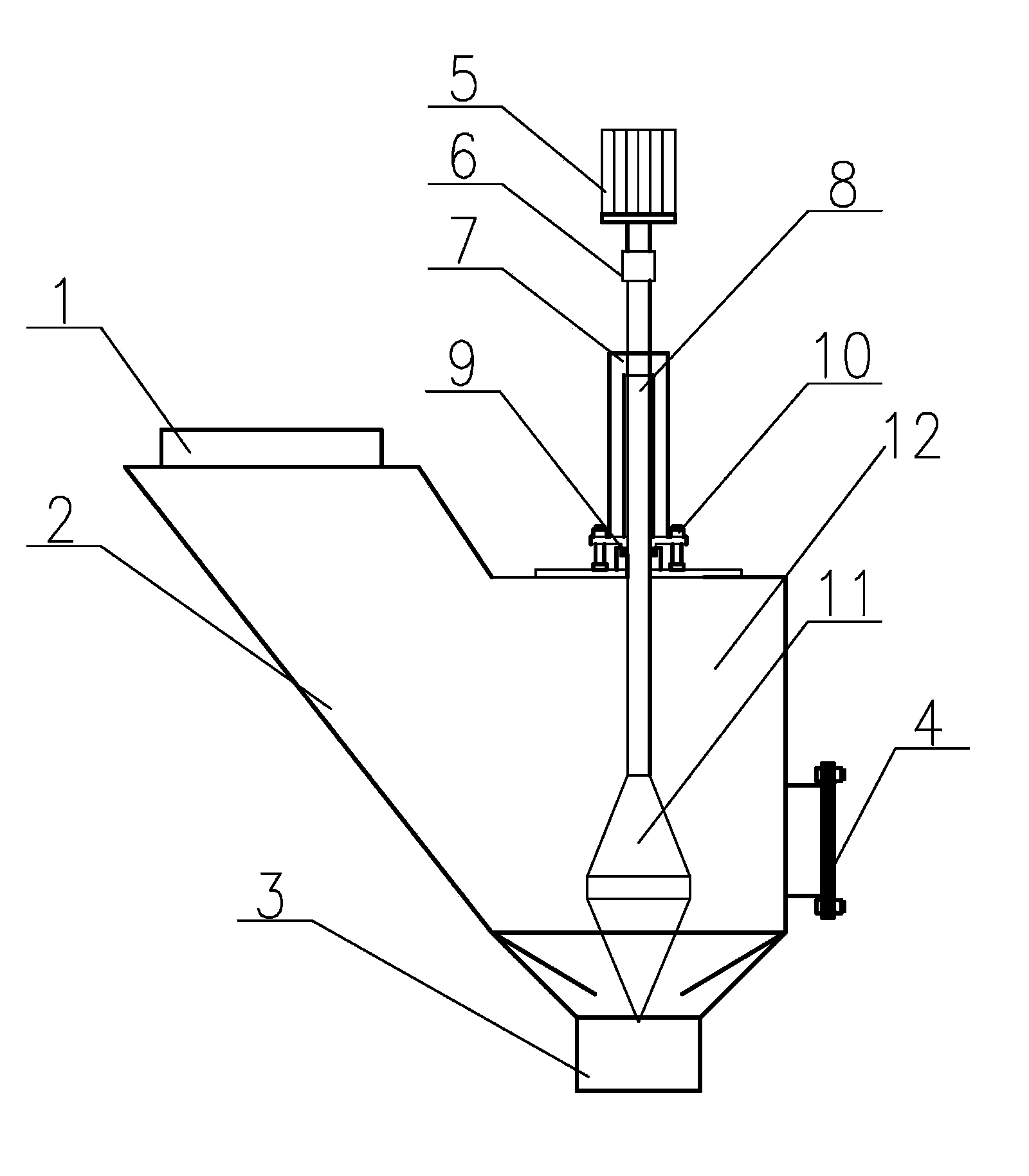

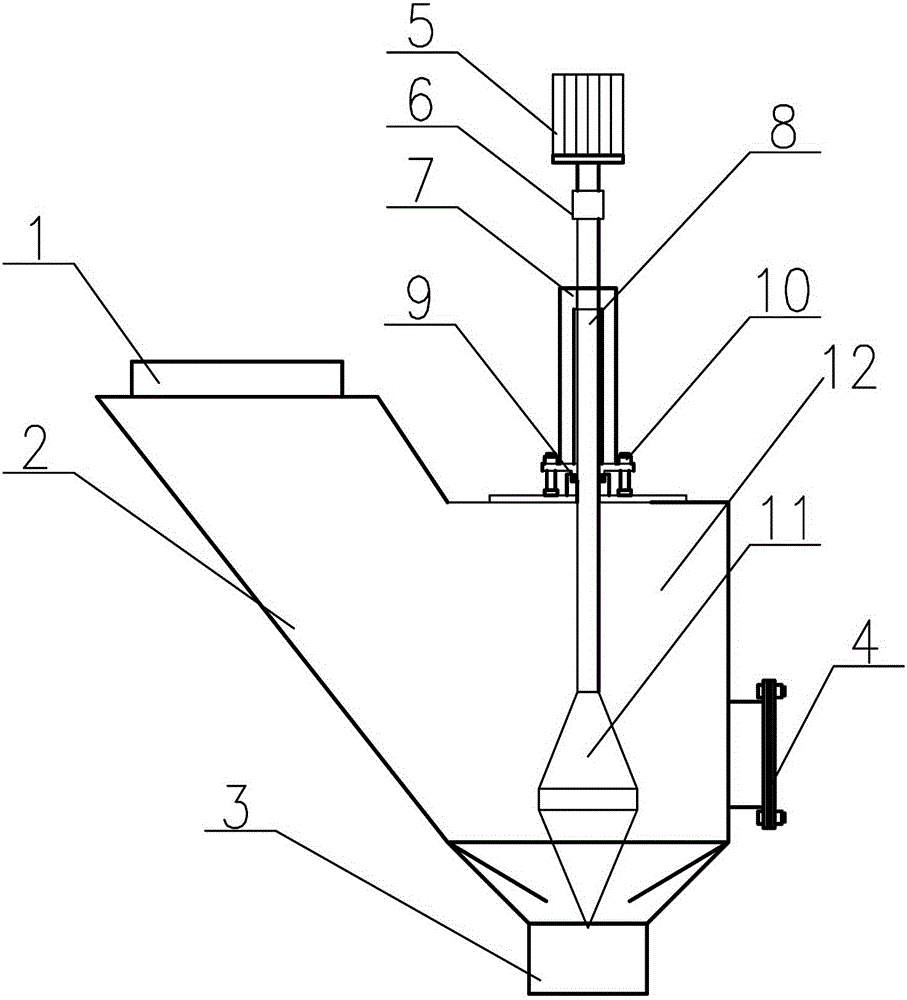

Blanking adjusting device of powder fixed hole and adjusting method of blanking adjusting device

The invention relates to a blanking adjusting device of a powder fixed hole and an adjusting method of the blanking adjusting device. The blanking adjusting device is structurally formed as follows: an inclined feeding channel is arranged; a feeding opening is formed in the top of the inclined feeding channel; a discharging opening of the inclined feeding channel is communicated with a feeding opening of a discharging cavity; a blanking opening is formed in the bottom of the discharging cavity; an adjusting hammer head for controlling a blanking flow is arranged in the discharging cavity; the lower part of the adjusting hammer head is conical and the discharging opening is a cylinder; the upper part of the adjusting hammer head is fixedly connected with one end of an adjusting rod; the other end of the adjusting rod is connected with a power device. The blanking adjusting device of the powder fixed hole has the advantages that the quantitative and uniform blanking of powder materials is realized by a method of linearly changing a blanking hole of the powder materials according to the properties of the powder materials, so as to realize the continuous adjustment of a flow. The blanking adjusting device of the powder fixed hole is simple in structure, practical and few in maintenance amount, is not influenced by powder impurities, and has a high application value. The blanking adjusting device of the powder fixed hole is good in sealing performance, few in transmission structures, easy to operate and few in maintenance times, and is applicable to adjusting the flow of aluminum oxide of an electrolytic aluminum factory.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

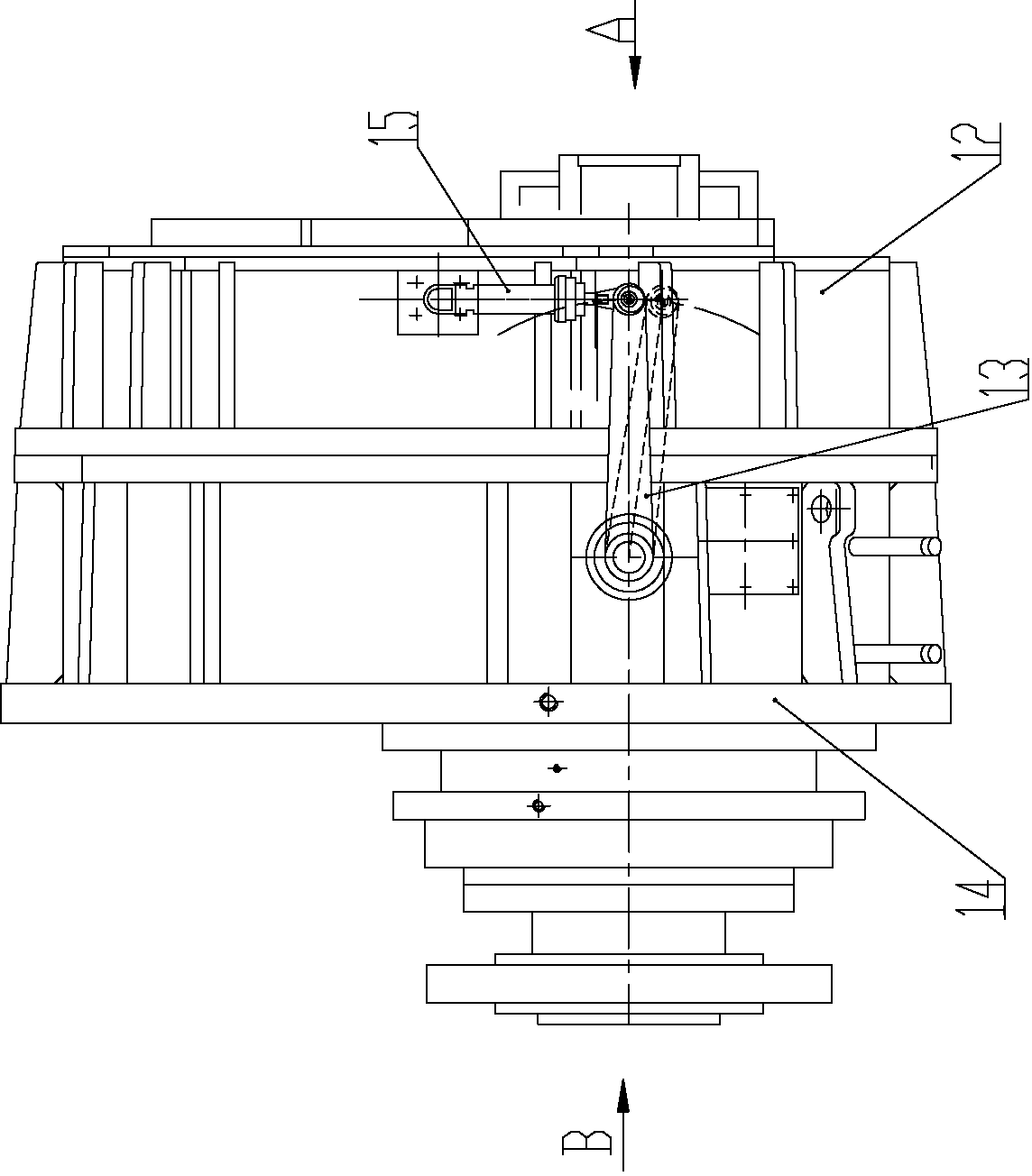

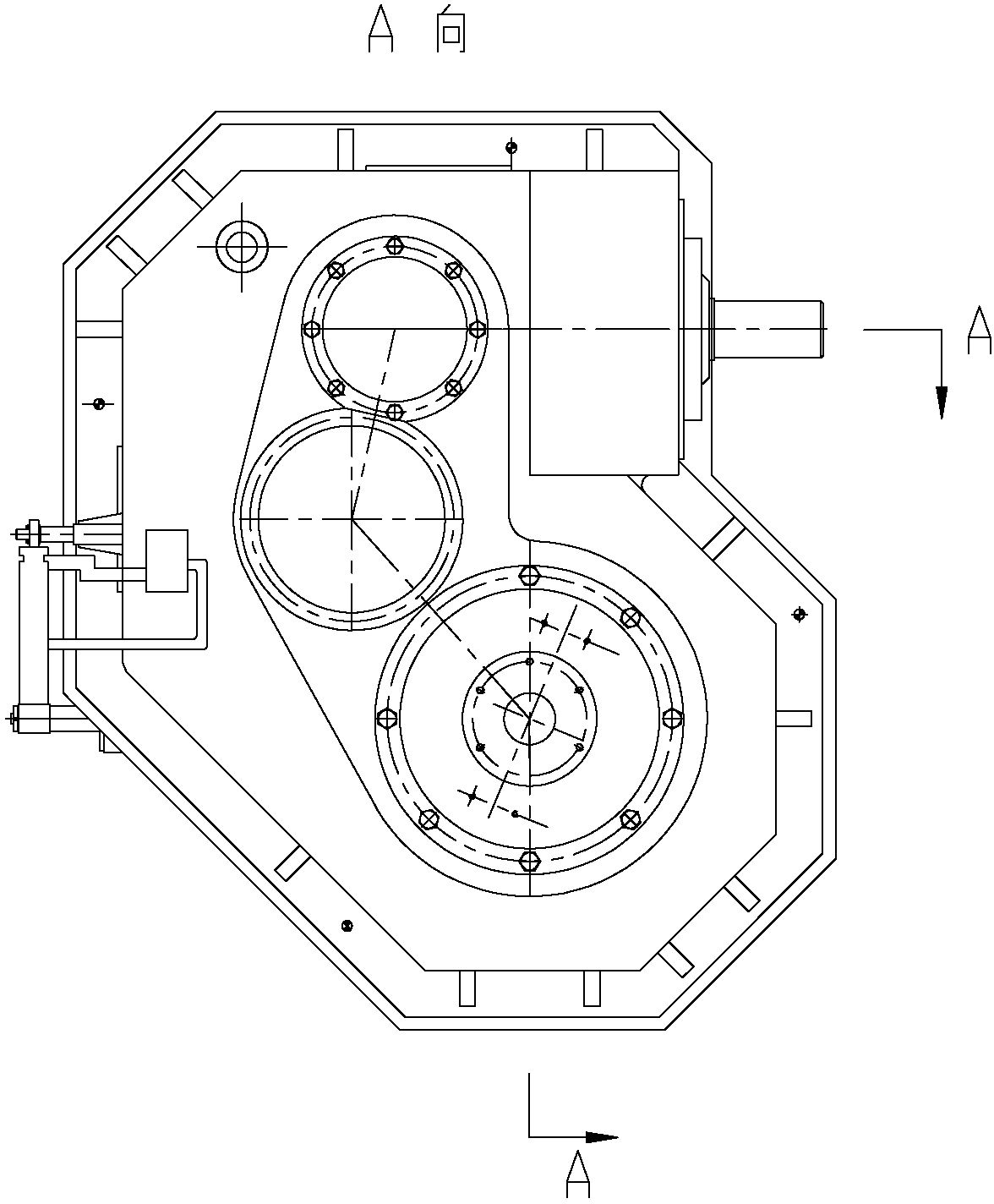

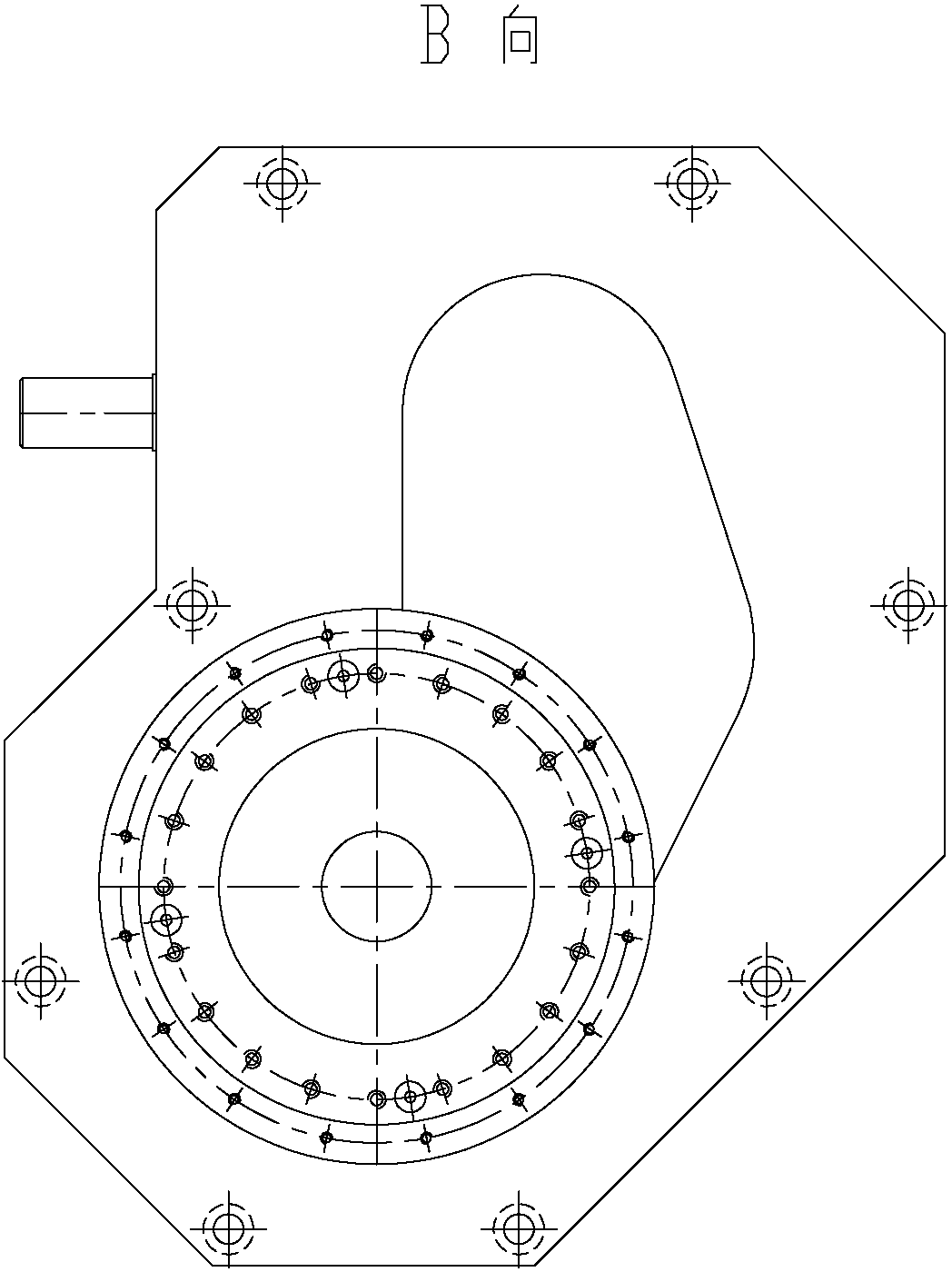

Gear speed reducer for combined type copper pipe coil drawing machine

InactiveCN103234009AImprove transmission efficiencyReduce energy consumptionControlled membersToothed gearingsEngineeringReducer

The invention discloses a gear speed reducer for a combined type copper pipe coiling drawing machine. The gear speed reducer comprises a box body, an input bevel gear shaft (1) and a coiling and drawing flange shaft (5), wherein the input bevel gear shaft (1) is engaged with a big bevel gear on a first gear shaft (3) through a small bevel gear on the input bevel gear shaft (1); a shaft gear (17) and a gear (11) are respectively engaged with a first shifting gear (10) and a second shifting gear (7) both installed on a second gear shaft (4); the first shifting gear (10) and the second shifting gear (7) are controlled by an inner spline gear (9); the inner spline gear (9) is sleeved on an outer spline gear (8); the inner spline gear (9) is provided with a shifting fork (16) which is connected to a shifting deflector rod (13); a coaxial gear (18) installed on the second gear shaft (4) is engaged with a big gear (6) on the coiling and drawing flange shaft (5) to drive the coiling and drawing flange shaft (5) to rotate; and the coiling and drawing flange shaft (5) is connected to the coiling drawing machine through a connecting flange. The gear speed reducer for the combined type copper pipe coiling drawing machine has a simple structure, high transmission efficiency and small volume.

Owner:NANJING KINGDOM HEAVY DUTY GEAR BOX

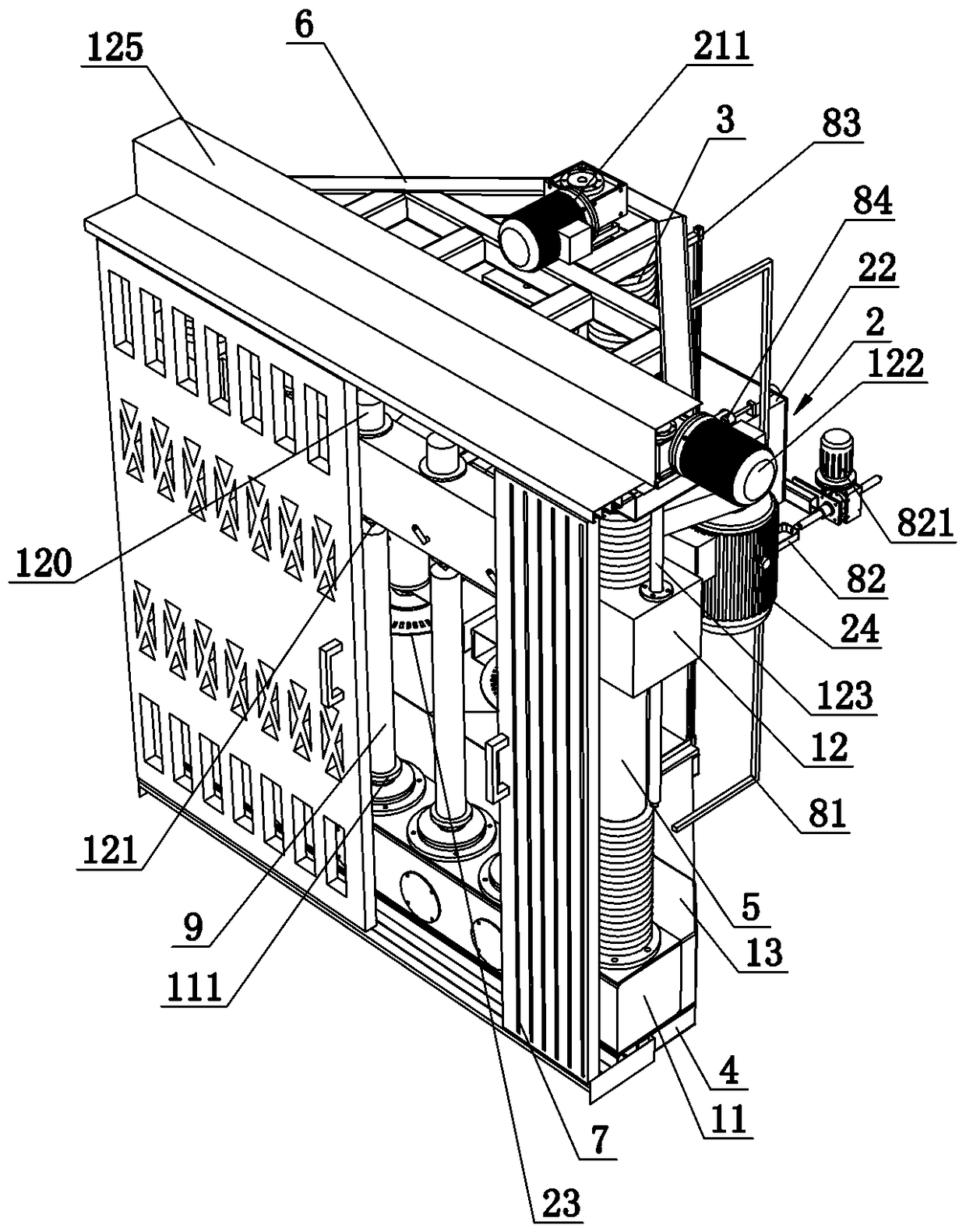

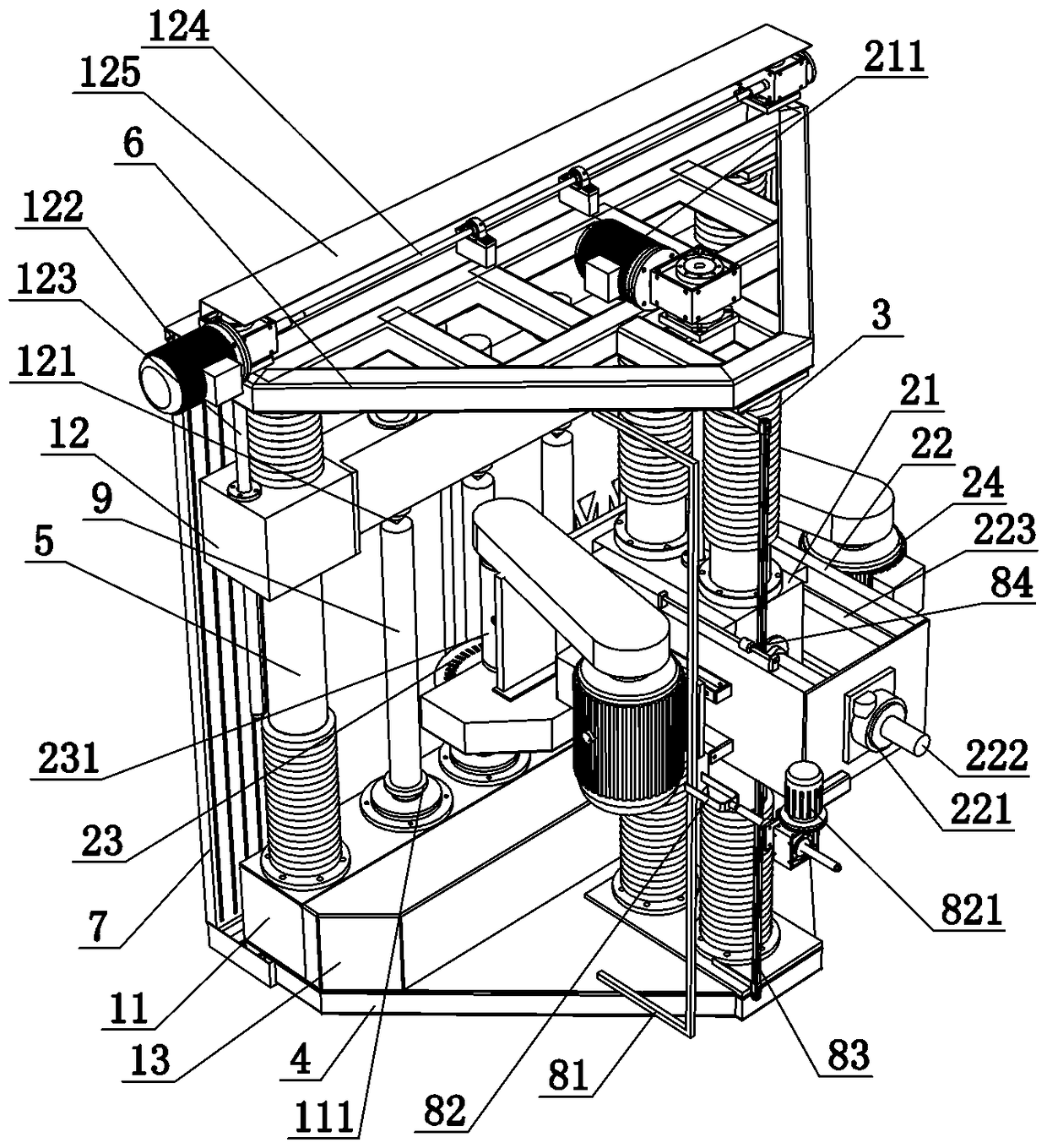

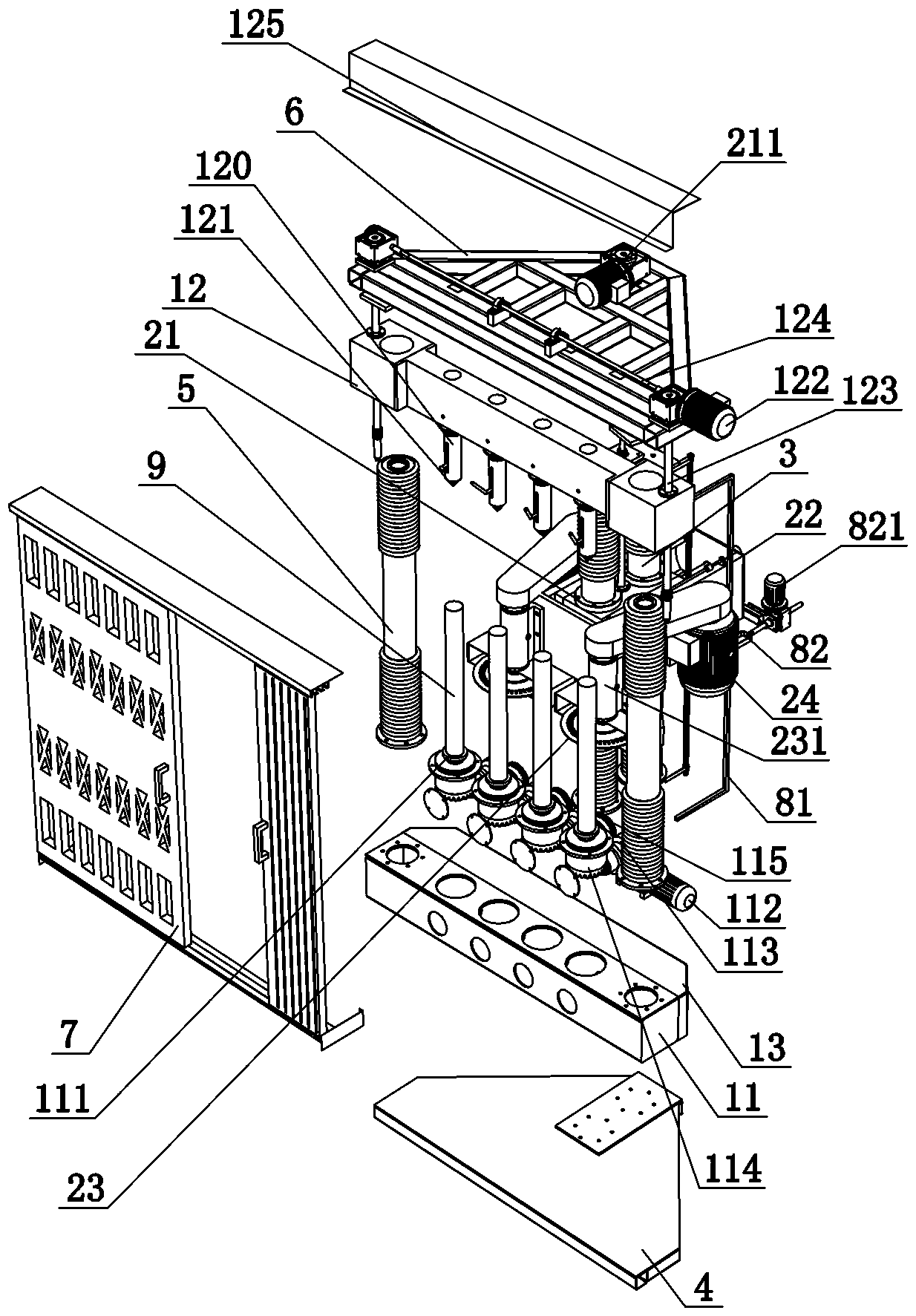

A rack with sorting function

ActiveCN113287910BEasy to sort and take outConvenient fully automatic operationShow shelvesGradingIndustrial engineeringPallet

The invention relates to the technical field of shelves, and discloses a shelf with sorting function, comprising a mounting frame, a first pallet, a second pallet, a delivery mechanism, a first collection box, a second collection box and a third a collection box, the first and second pallets are mounted on the mounting rack, the delivery mechanism is mounted on the mounting rack and used to deliver goods to the first pallet; the first sorting mechanism is mounted on the mounting rack The first sorting mechanism receives and sorts the goods conveyed by the first pallet, and the first sorting mechanism transfers the sorted goods to the second pallet or the first collection box; the second sorting mechanism is installed in the On the installation rack, the second sorting mechanism receives and sorts the goods conveyed by the second pallet. The shelf with sorting function of the present invention can not only uniformly feed the goods, but also can classify the goods for many times according to their size, and sort the goods of different sizes into different collection boxes. fast and convenient.

Owner:滁州优力恩物流设备制造有限公司

Automobile door lock and automobile

InactiveCN111677386ALess transmission partsSimple transmission structurePower transmission/actuator featuresElectrical locking circuitsClutchManufacturing engineering

The invention relates to an automobile door lock and an automobile, and belongs to the technical field of automobile door locks. The automobile door lock comprises a coaxial and laminated locking structure with a spring bolt and a rotating piece, a clutch piece arranged on the locking structure and used for driving the rotating piece and the spring bolt to coaxially rotate or be separated in a matched mode, a brake part used for clamping the spring bolt to realize locking, and a first unlocking part used for driving the brake part and the spring bolt to be unlocked. The invention further provides the automobile comprising the automobile door lock. According to the automobile door lock, the internal structure of the automobile door lock is simplified, so that the size of the automobile doorlock is greatly reduced, and the manufacturing cost is reduced.

Owner:QINGDAO TIANCHENJIACHUANG AUTO PARTS CO LTD

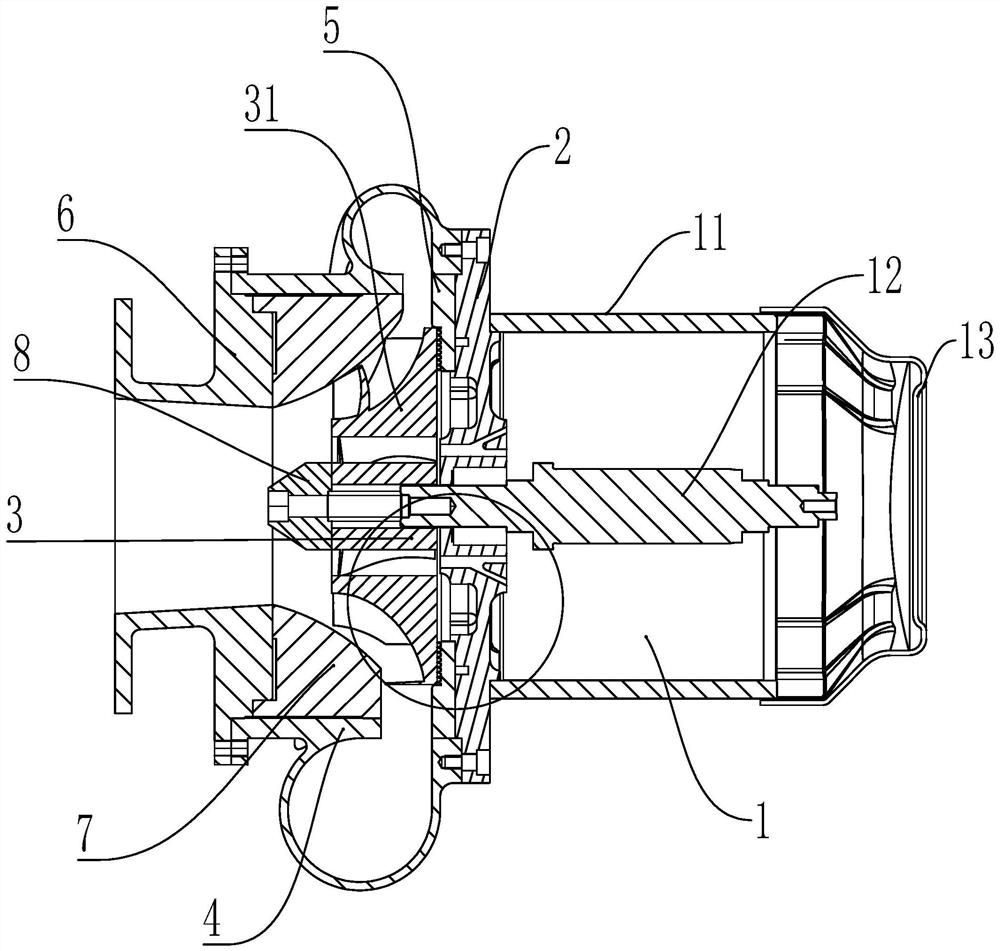

Motor with optical fiber communication

PendingCN114499031AExtended service lifeReduce transmission structureMechanical energy handlingStructural associationElectric machineDrive shaft

The invention relates to a motor with optical fiber communication, which comprises a slip ring part and a driving part, the driving part is provided with a rotatably mounted driving shaft, the slip ring part is provided with a stator unit and a rotor unit, and the driving shaft and the rotor unit are arranged along the central line of the driving shaft and are fixedly connected. According to the scheme provided by the invention, the driving shaft and the rotor unit are sequentially and fixedly connected, so that a transmission structure between the driving shaft and the rotor unit is reduced, the production cost is saved, the noise during operation is reduced, the service life of the motor with optical fiber communication is prolonged, and the application range is widened.

Owner:ANHUI LANXUAN PHOTOELECTRIC TECH CO LTD

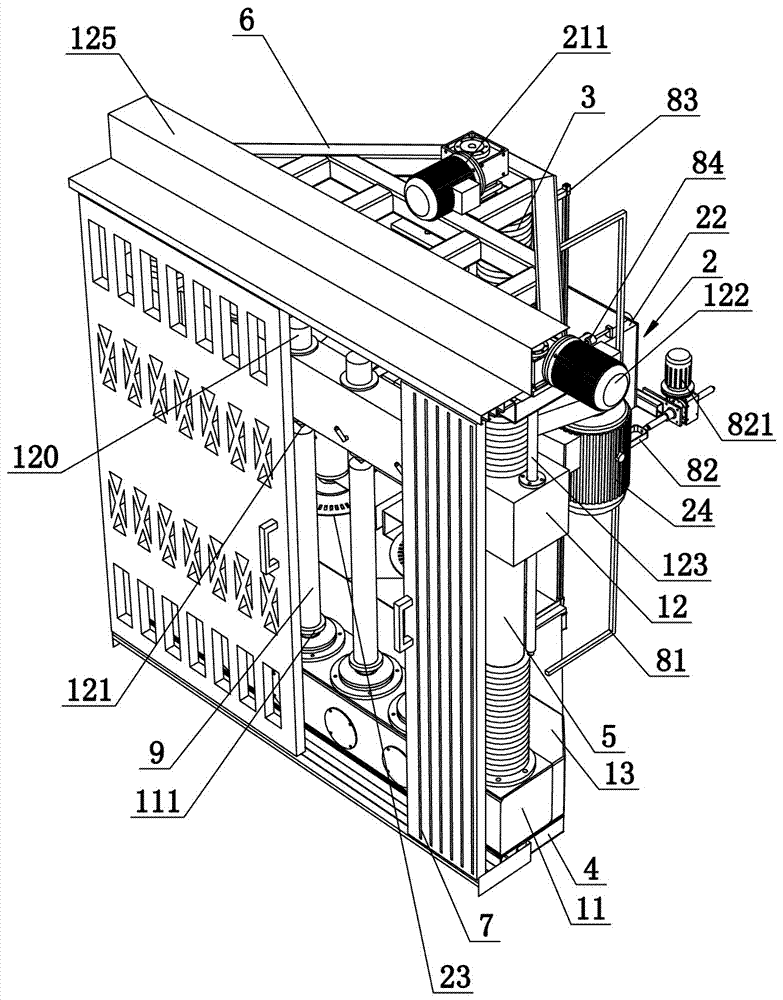

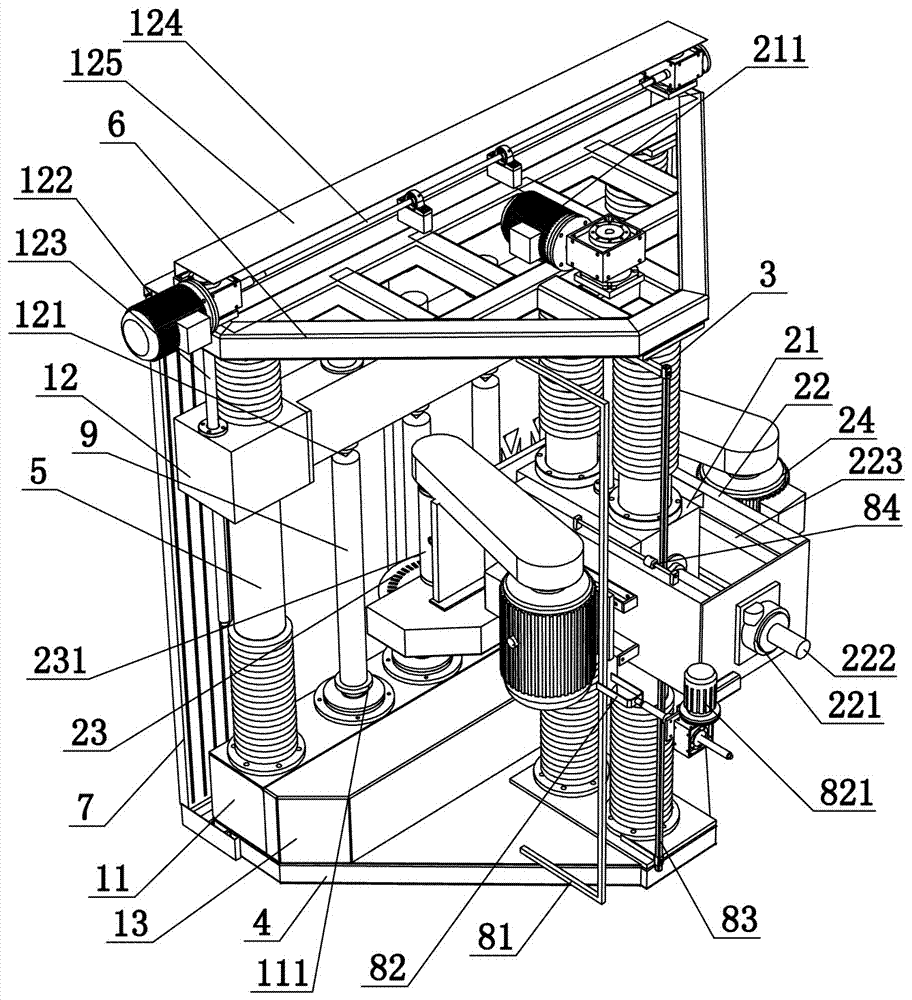

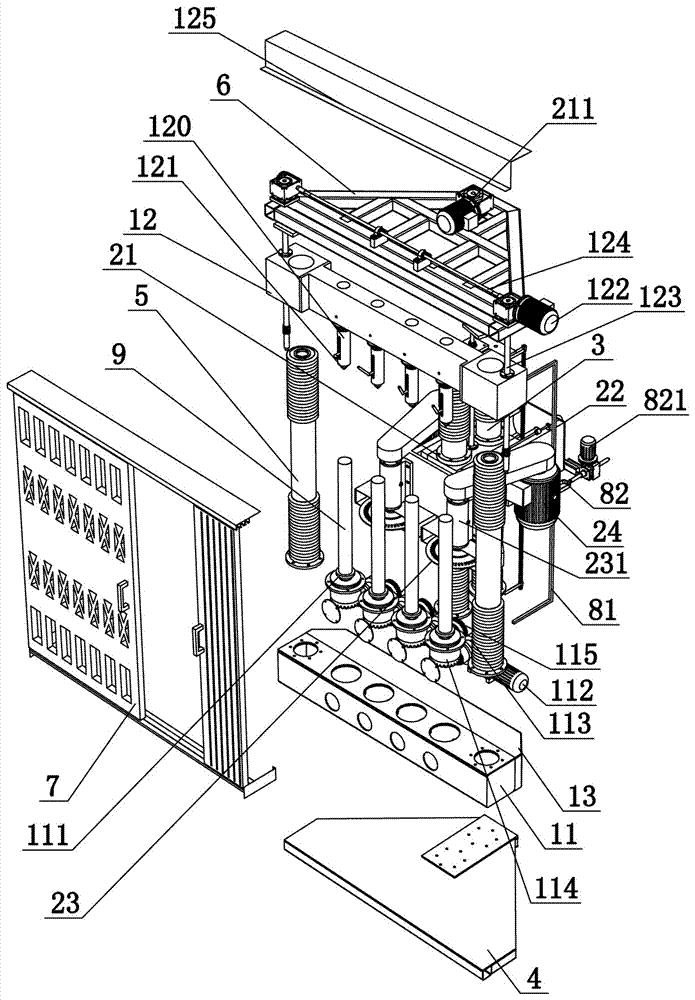

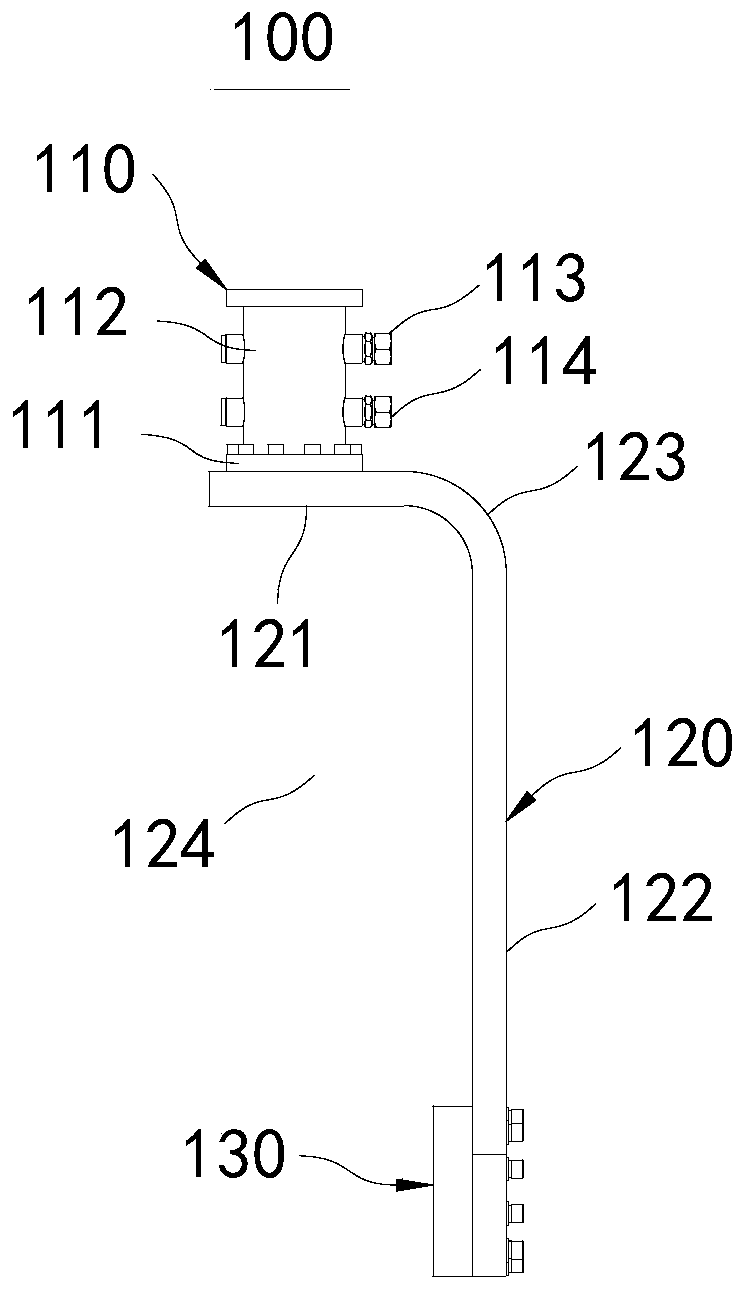

Multi-head vertical stone processing equipment

ActiveCN107379288AReduce shockGood product identityWorking accessoriesStone-like material working toolsEngineering

The invention relates to multi-head vertical stone processing equipment which comprises a worktable, a cutting mechanism and cutting upright columns. The worktable is used for vertically arranging a plurality of stone workpieces, the stone workpieces are positioned on the same plane, the cutting mechanism is used for simultaneously processing the stone workpieces and is assembled on the cutting upright columns in such a manner that the cutting mechanism can move along the cutting upright columns, and the stone workpieces and the cutting upright columns can extend along the vertical directions. The cutting upright columns are arranged on the plane where the stone workpieces are positioned, the projection of the cutting upright columns on the plane where the stone workpieces are positioned is positioned in the middles of the arrangement distances of the stone workpieces. The multi-head vertical stone processing equipment has the advantages that the multi-head vertical stone processing equipment is stable in structure and comprises few transmission structures (such as lifting driving mechanisms of lifting sliders) of various inner driving mechanisms, accordingly, the running stability of the multi-head vertical stone processing equipment can be improved, the durability of the multi-head vertical stone processing equipment can be enhanced, and the market competitiveness of the multi-head vertical stone processing equipment can be enhanced.

Owner:QUANZHOU MINYAN STONE MACHINERY CO LTD

Steering mechanism, steering system and vehicle

PendingCN110641548ASmall turning radiusFlexible steeringSteering linkagesFluid steeringCylinder blockMechanical engineering

The invention relates to the technical field of steering, in particular to a steering mechanism, a steering system and a vehicle. The steering mechanism comprises a spiral swinging oil cylinder, a connecting rod and a steering knuckle. The two ends of the connecting rod are correspondingly connected with an output shaft and the steering knuckle of the spiral swinging oil cylinder so as to drive the steering knuckle to rotate relative to a cylinder body of the spiral swinging oil cylinder through the spiral swinging oil cylinder. The invention aims to provide a steering mechanism, a steering system and a vehicle, which can reduce the steering radius of the steering mechanism.

Owner:SANY MARINE HEAVY IND

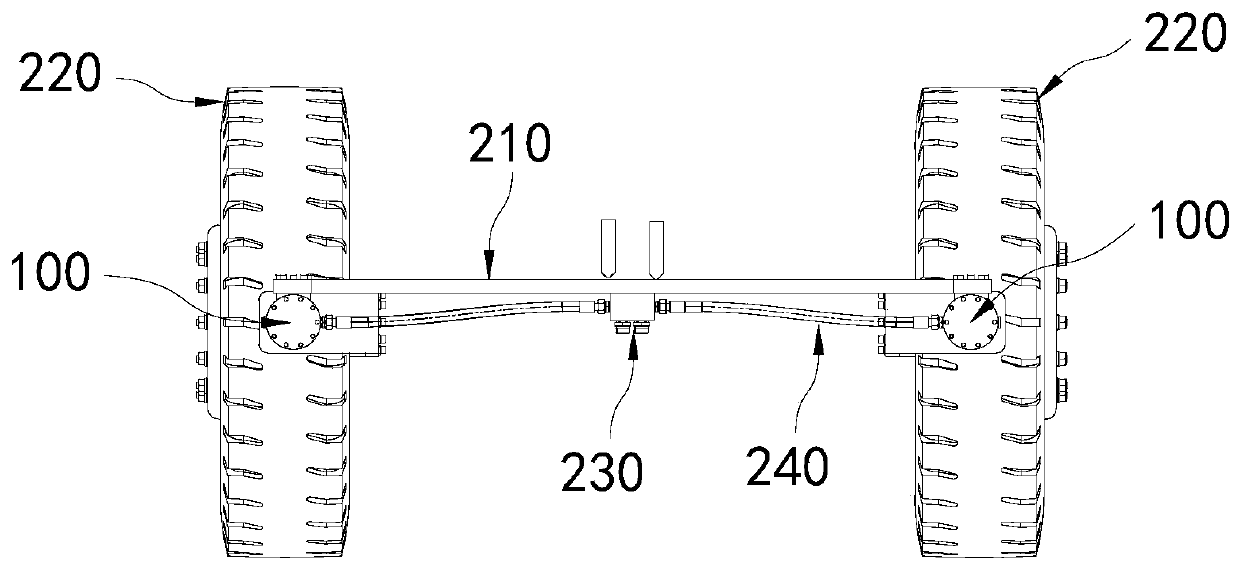

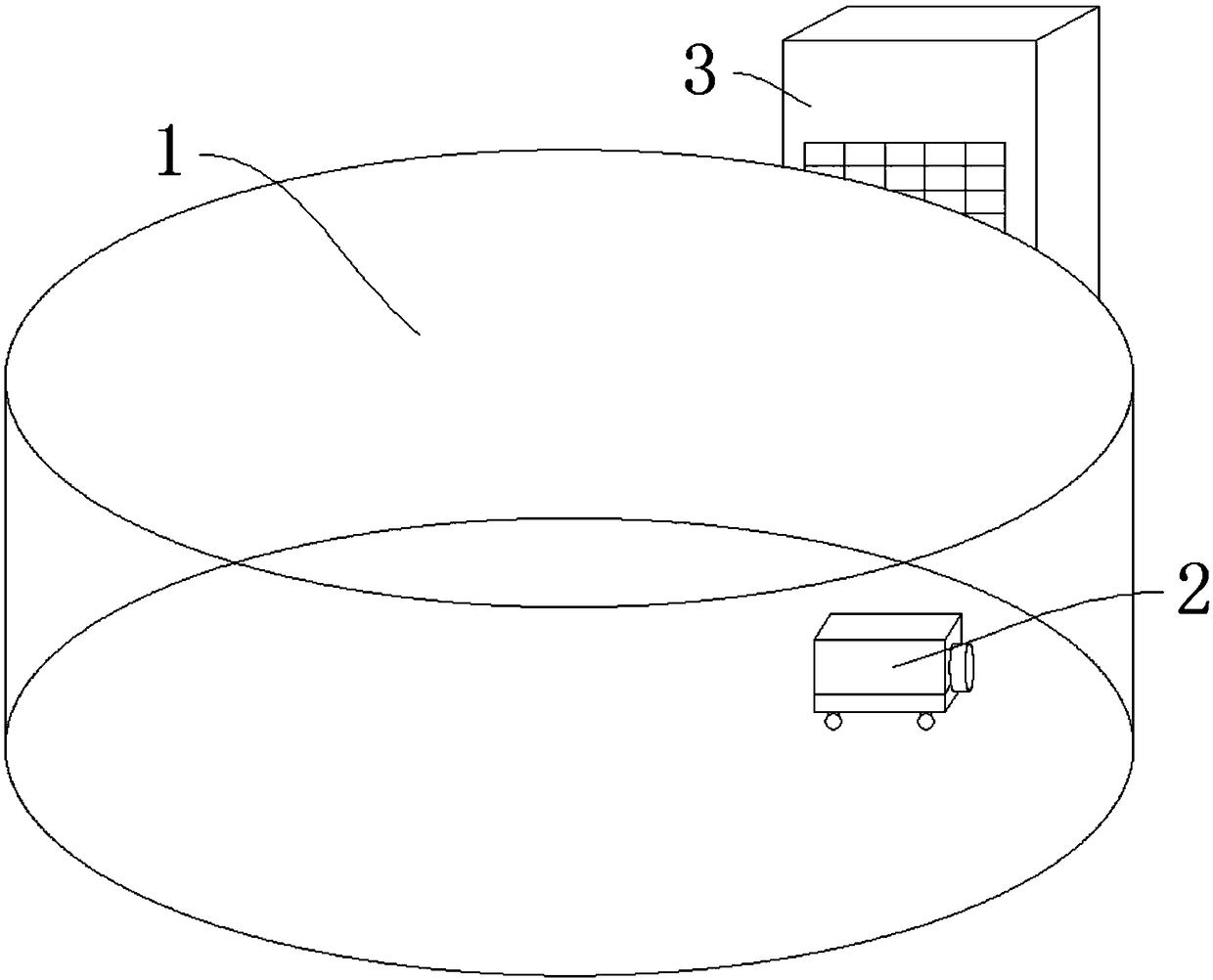

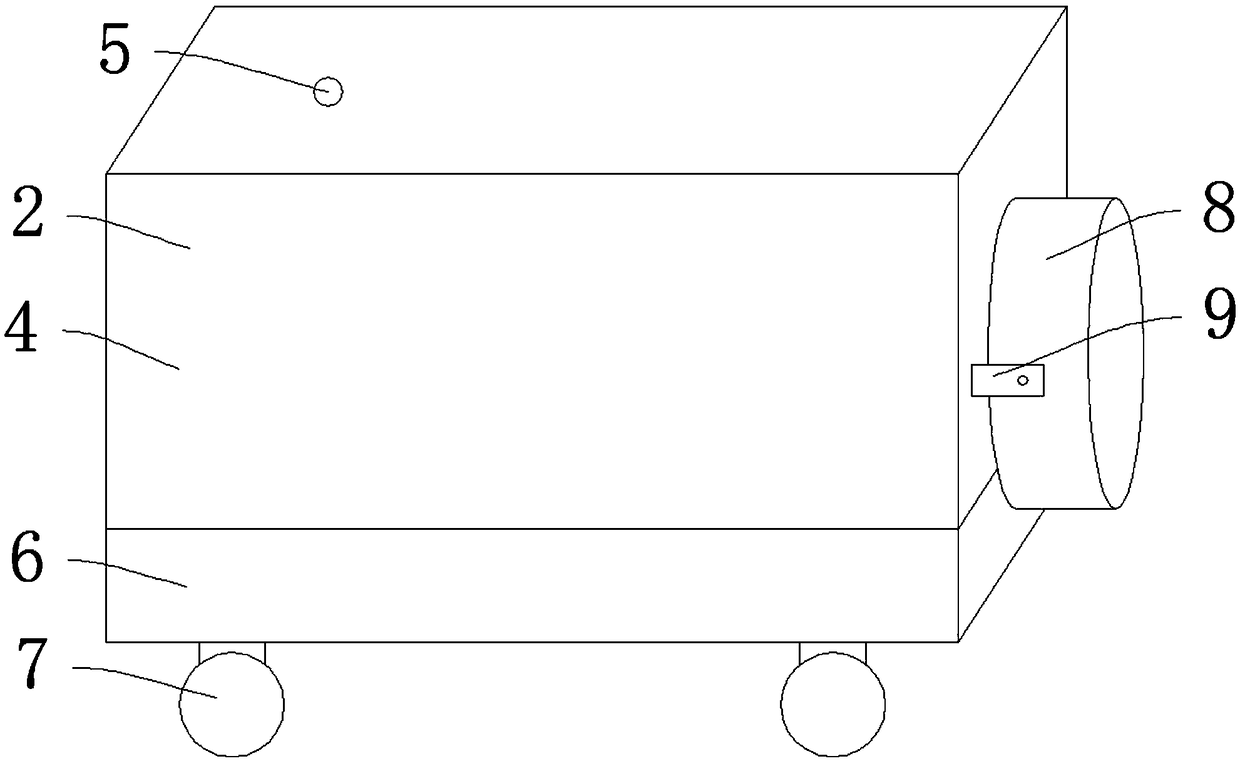

Water quality monitoring device for organic chlorella culture, and use method of device

InactiveCN109239288AIncrease diversityReduce transmission structureUnicellular algaeMicroorganism based processesWater flowWater quality

The invention discloses a water quality monitoring device for organic chlorella culture. The water quality monitoring device comprises a culture pond, a walking vehicle and a control table, wherein the walking vehicle is arranged in the culture pond; the walking vehicle comprises a supporting plate; a protective cover is arranged above the supporting plate; a camera is arranged at the top of the protective cover; a filter screen is arranged on the supporting plate; a flow velocity sensor is arranged on one side of the filter screen; a temperature sensor is arranged on one side of the flow velocity sensor; a water quality sensor is arranged on one side of the temperature sensor; and a lithium battery is arranged in the supporting plate. The device has the beneficial effects that the walkingvehicle is used for moving and transferring the device in the culture pond, and the water quality conditions of different areas are collected, so that the comprehensive performance of monitoring is improved; meanwhile, the water flow is controlled to be changed through a flow guide cover, and the walking vehicle is pushed to move forwards and make a turn, so that a transmission structure is reduced, and manufacturing is facilitated; and a manual and automatic combined mode is adopted for performing control, so that the combination of key monitoring and automatic monitoring is facilitated.

Owner:福清市新大泽螺旋藻有限公司

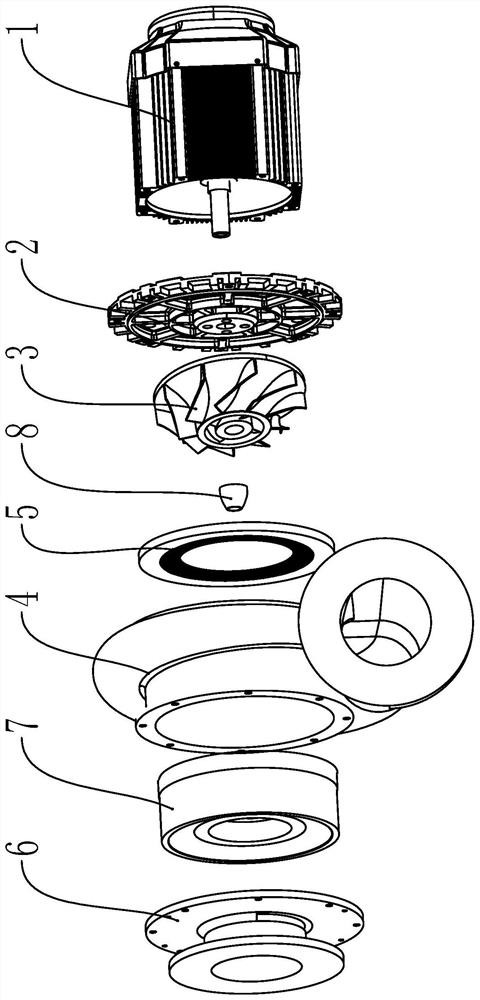

Combined impeller air compressor

ActiveCN114370426ARealize heat dissipationImprove cooling efficiencyPump componentsPumpsImpellerElectric machinery

The invention discloses a combined impeller air compressor, and aims to solve the problems that the heat dissipation effect of an air compressor in the prior art is poor, and the rotating speed of a motor is limited along with the increase of the rotating speed of the air compressor. According to the technical scheme, a motor assembly provides power for the air compressor; the motor assembly comprises a shell and a rotating shaft, and the rotating shaft is arranged in the shell in a penetrating mode. A first end cover and a second end cover are respectively arranged at two ends of the rotating shaft; the impeller comprises a centrifugal impeller and an axis impeller, a through hole is formed in the centrifugal impeller in the axis direction, the centrifugal impeller is arranged in the through hole, axis blades are arranged in the circumferential direction of the axis impeller, and the axis blades are connected with the inner wall of the through hole; the centrifugal impeller is connected with the rotating shaft; the centrifugal impeller and the axis impeller are driven by the motor to rotate at the same time, and the motor assembly is cooled through the axis impeller.

Owner:XINLEI COMPRESSOR CO LTD

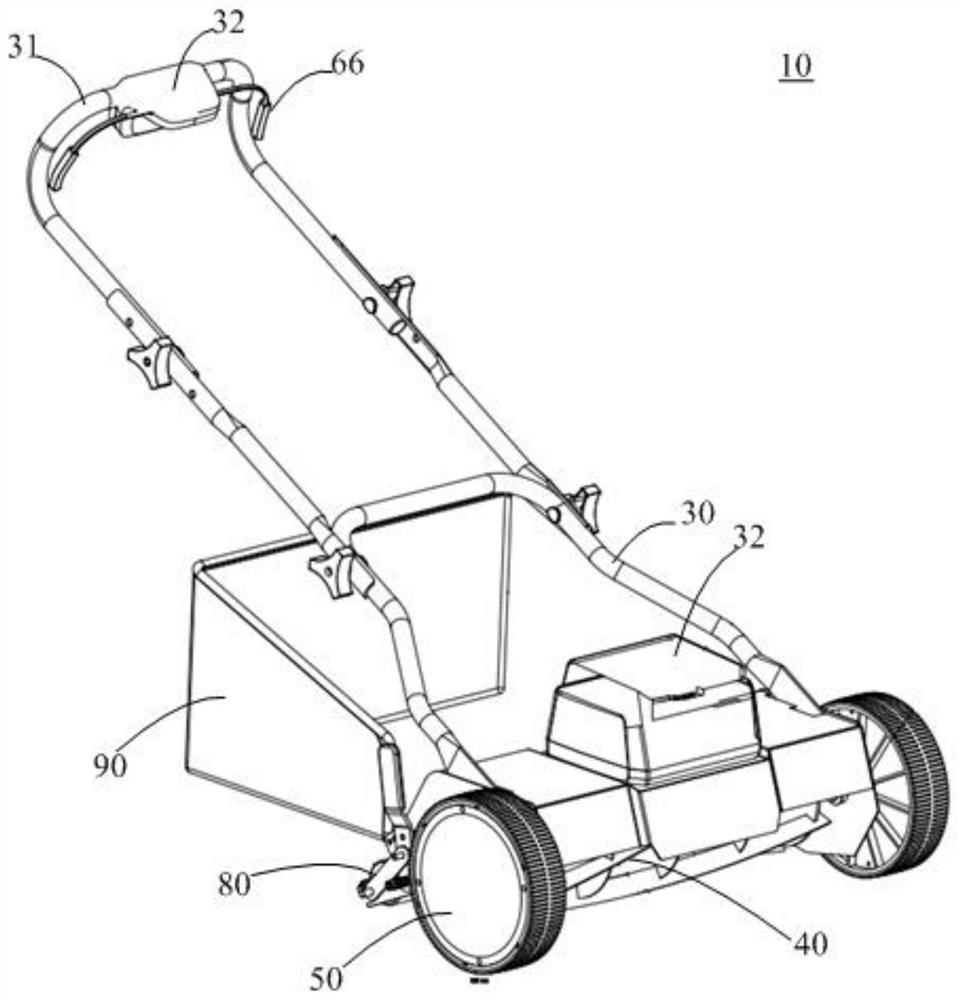

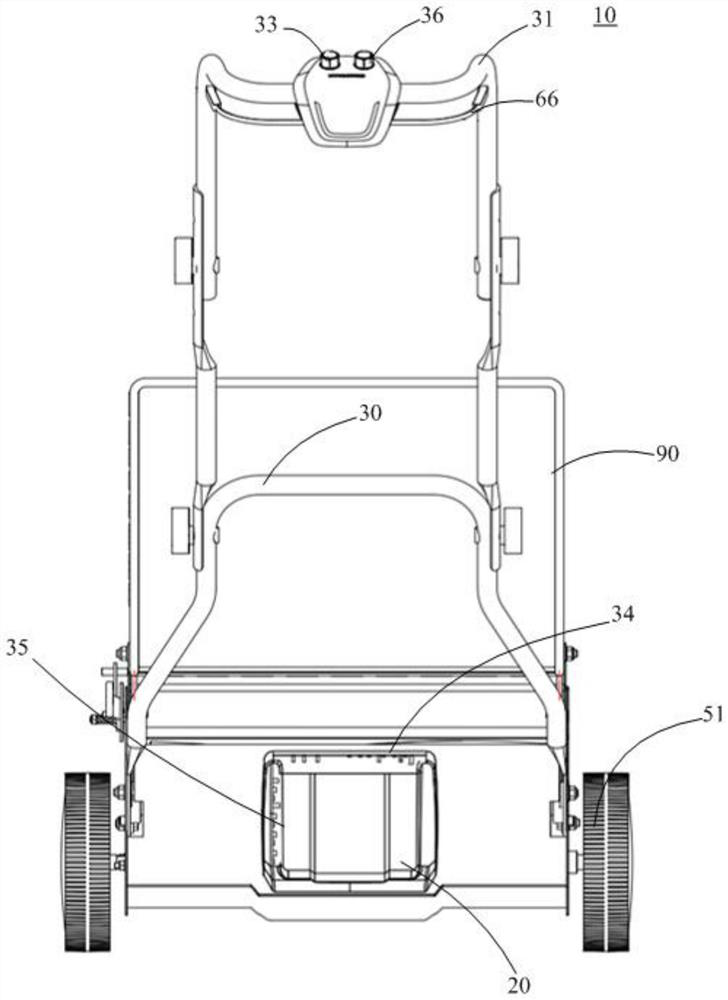

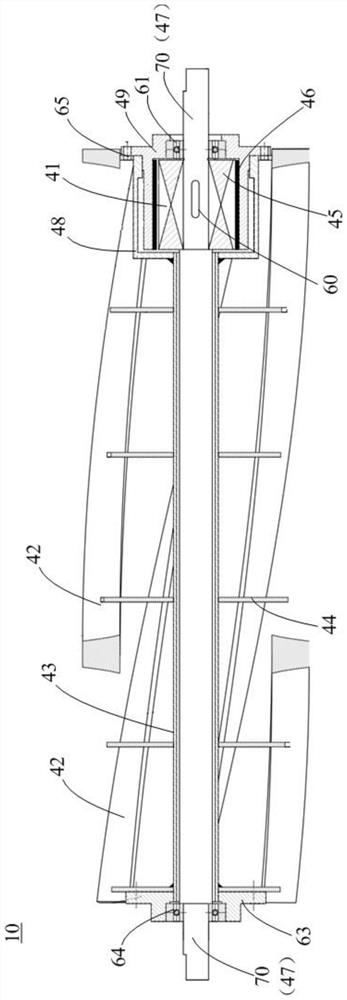

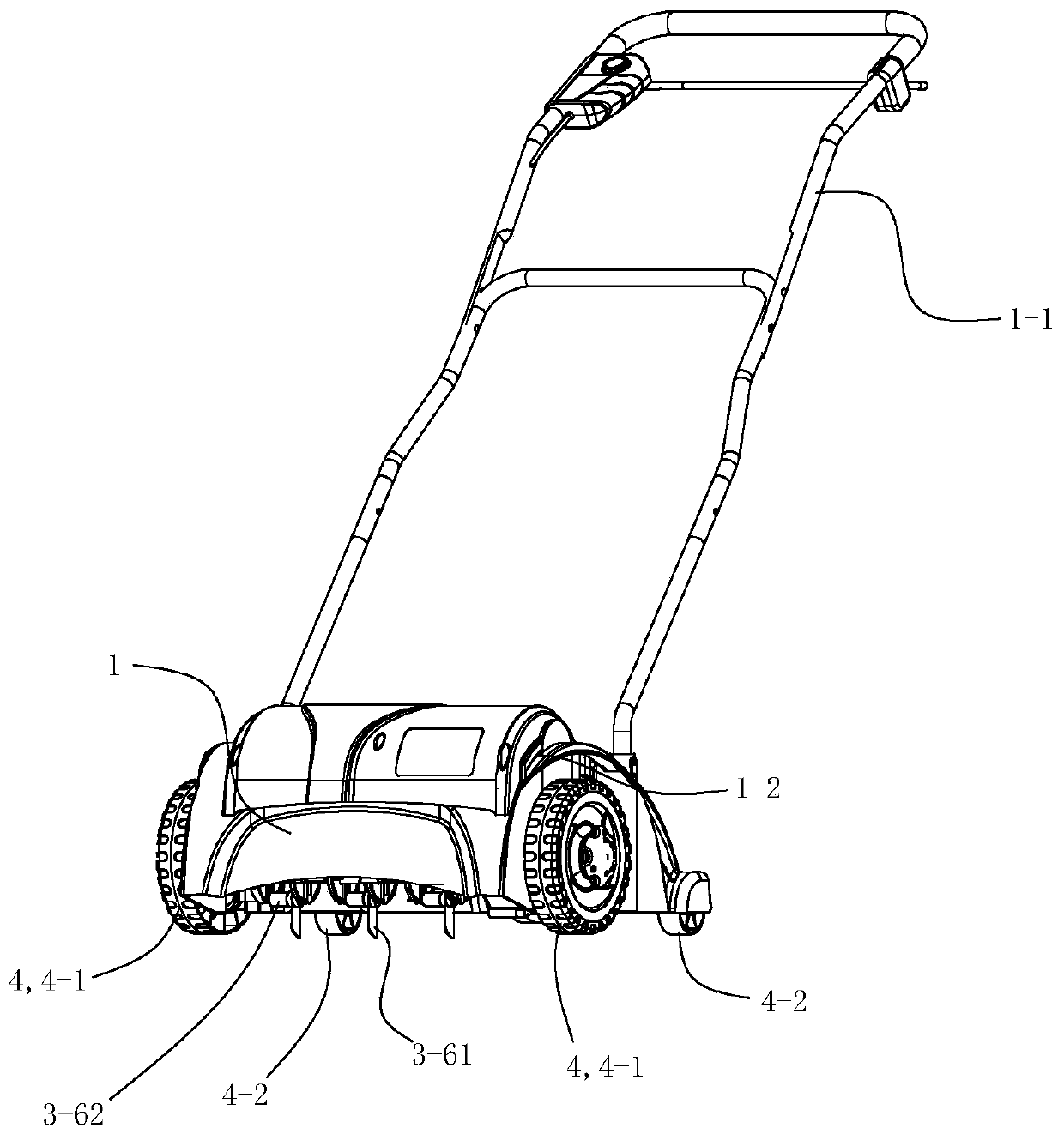

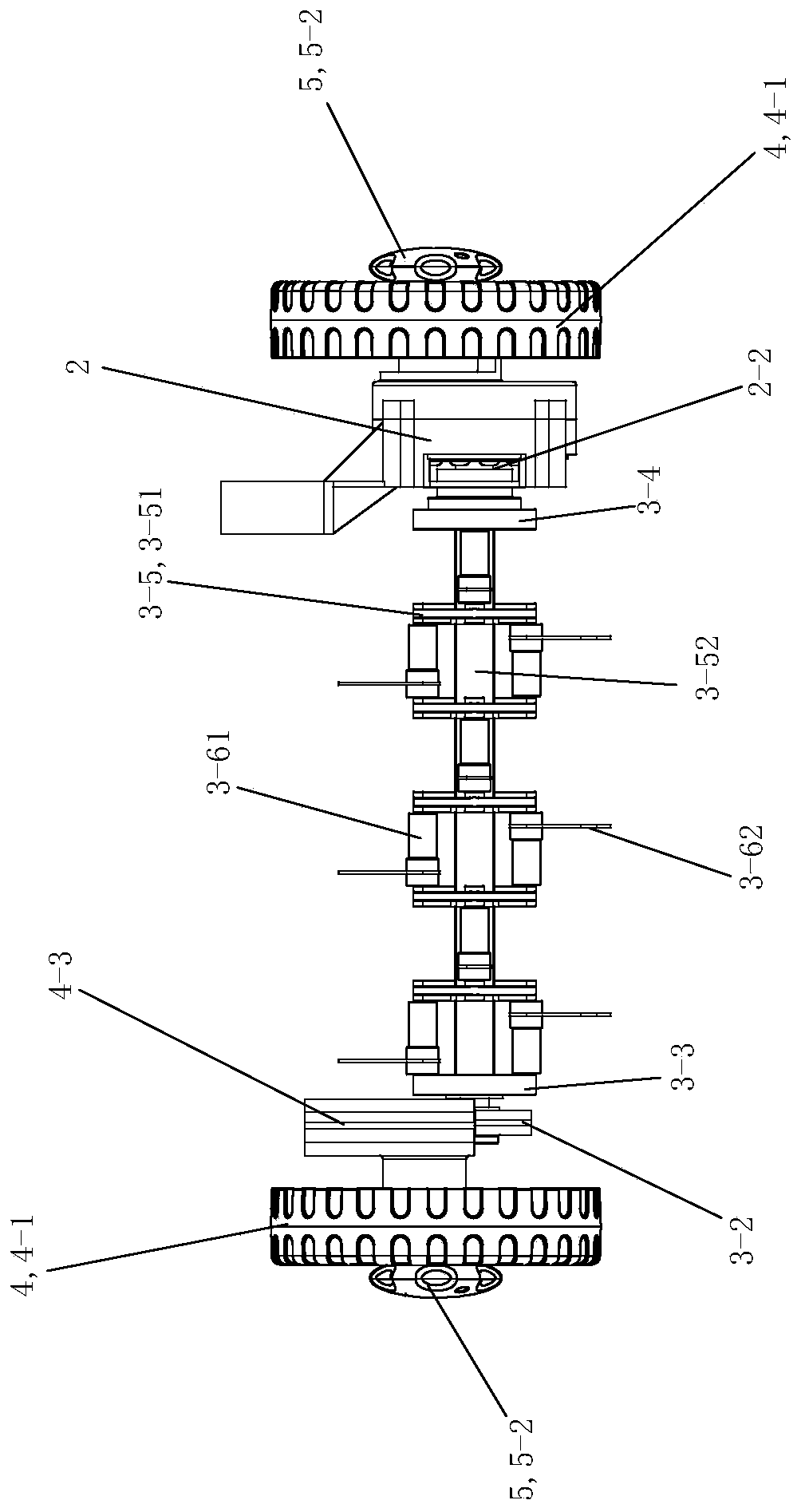

Self-propelled light hob grass mower

InactiveCN112690083AReduce transmission structureSimple transmission structureMowersClassical mechanicsElectric machinery

The invention discloses a self-propelled light hob grass mower which comprises a power module and a rack. A handrail and a control module are arranged on the rack, and a hob assembly and a walking mechanism are arranged at the front end of the rack; the power module supplies power to the grass mower; the control module is used for controlling the working states of the hob assembly and the walking mechanism; the walking mechanism comprises at least one pair of walking wheels which are symmetrically arranged at the two sides of the front end of the rack, and the at least one pair of walking wheels comprise at least one unilateral shaft hub motor; the hob assembly comprises hob blades and a hob shaft, the hob blades are fixedly connected with the hob shaft through a plurality of supporting plates, and at least one end of the hob shaft is provided with an outer rotor motor; and each outer rotor motor comprises a stator assembly and an outer rotor, each stator assembly is connected with the rack through a connecting piece, and each outer rotor is fixedly connected with the corresponding supporting plate. By means of the self-propelled light hob grass mower, the working efficiency is high, and the whole machine structure is more compact.

Owner:GREENMAN MACHINERY

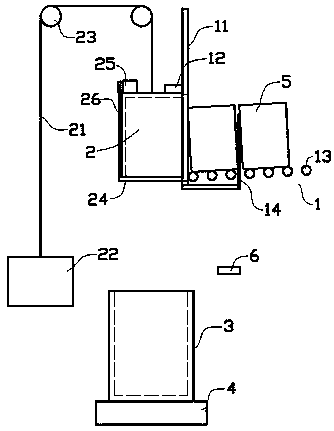

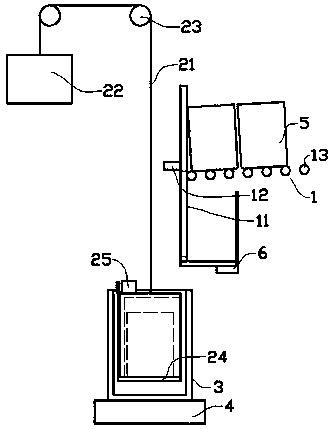

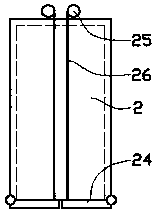

High automatic feeding device

The invention provides a high-order automatic feeding device. The high-order automatic feeding device comprises a charging rail, a feeding box, a discharging box and a discharging rail, wherein an element to be arranged in the discharging box is arranged on the charging rail; the feeding box is connected with a counter weight through a rope; rotary wheels are fixedly assembled at the upper parts of the feeding box and the counter weight; the element on the charging rail can slide and penetrate through a charging frame of a material stopping block to enter the feeding box, so that the feeding box carries the element to slide off downward; when the feeding box containing the element moves into the discharging box, a rope spinning module is used for opening a discharging bottom plate at the lower part of the feeding box through two stranded wires, so that the element slides into the discharging box and a discharging process is finished. A working process of the device is automatically finished through gravity so that a transmission structure is greatly reduced and a structure design is simpler; meanwhile, energy are saved.

Owner:新沂市恒利玻璃有限公司

Lawn ventilator

PendingCN109845431ASimple structureReduce transmission structureAgricultural machinesAdjusting devicesEngineeringCentrifugal force

The invention discloses a lawn ventilator which comprises an enclosure, a motor, a soil loosening tool and a walking mechanism. The walking mechanism is arranged on the enclosure; a hand rail is arranged on the enclosure; an operation switch is arranged on the upper portion of the hand rail; the technical scheme includes that the soil loosening tool includes a rotating shaft rotatably arranged onthe enclosure and blades movably arranged on the rotating shaft. The motor shaft of the motor is in direct transmission connection with the rotating shaft of the soil loosening tool to drive the rotating shaft of the soil loosening tool to rotate to enable the blades on the rotating shaft to be swung out under the action of centrifugal force to conduct lawn loosening and aeration.

Owner:CHANGZHOU CREATE ELECTRIC APPLIANCE

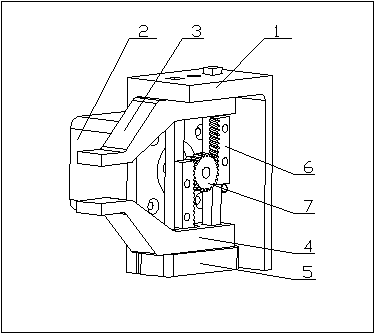

Manipulator capable of parallel clamping

The invention discloses a manipulator capable of parallel clamping. The manipulator comprises a manipulator fixing seat, a motor, a manipulator upper claw, a manipulator lower claw, a manipulator limiting block, a rack and a gear, wherein the motor is used as a power output component, the gear and the rack form a transmission pair to convert the motor rotating motion into linear motion, and the manipulator fixing seat, the manipulator upper claw, the manipulator lower claw and the manipulator limiting block serve as limiting and guiding structures, so that the parallel clamping stability and precision are guaranteed. The manipulator capable of parallel clamping is simple in structure, low in manufacturing cost, convenient to control and high in precision, can clamp a thin article and can be applied to various scenes.

Owner:武汉医尔特科技有限公司

Powder fixed hole blanking adjustment device and adjustment method

The invention relates to a blanking adjusting device of a powder fixed hole and an adjusting method of the blanking adjusting device. The blanking adjusting device is structurally formed as follows: an inclined feeding channel is arranged; a feeding opening is formed in the top of the inclined feeding channel; a discharging opening of the inclined feeding channel is communicated with a feeding opening of a discharging cavity; a blanking opening is formed in the bottom of the discharging cavity; an adjusting hammer head for controlling a blanking flow is arranged in the discharging cavity; the lower part of the adjusting hammer head is conical and the discharging opening is a cylinder; the upper part of the adjusting hammer head is fixedly connected with one end of an adjusting rod; the other end of the adjusting rod is connected with a power device. The blanking adjusting device of the powder fixed hole has the advantages that the quantitative and uniform blanking of powder materials is realized by a method of linearly changing a blanking hole of the powder materials according to the properties of the powder materials, so as to realize the continuous adjustment of a flow. The blanking adjusting device of the powder fixed hole is simple in structure, practical and few in maintenance amount, is not influenced by powder impurities, and has a high application value. The blanking adjusting device of the powder fixed hole is good in sealing performance, few in transmission structures, easy to operate and few in maintenance times, and is applicable to adjusting the flow of aluminum oxide of an electrolytic aluminum factory.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

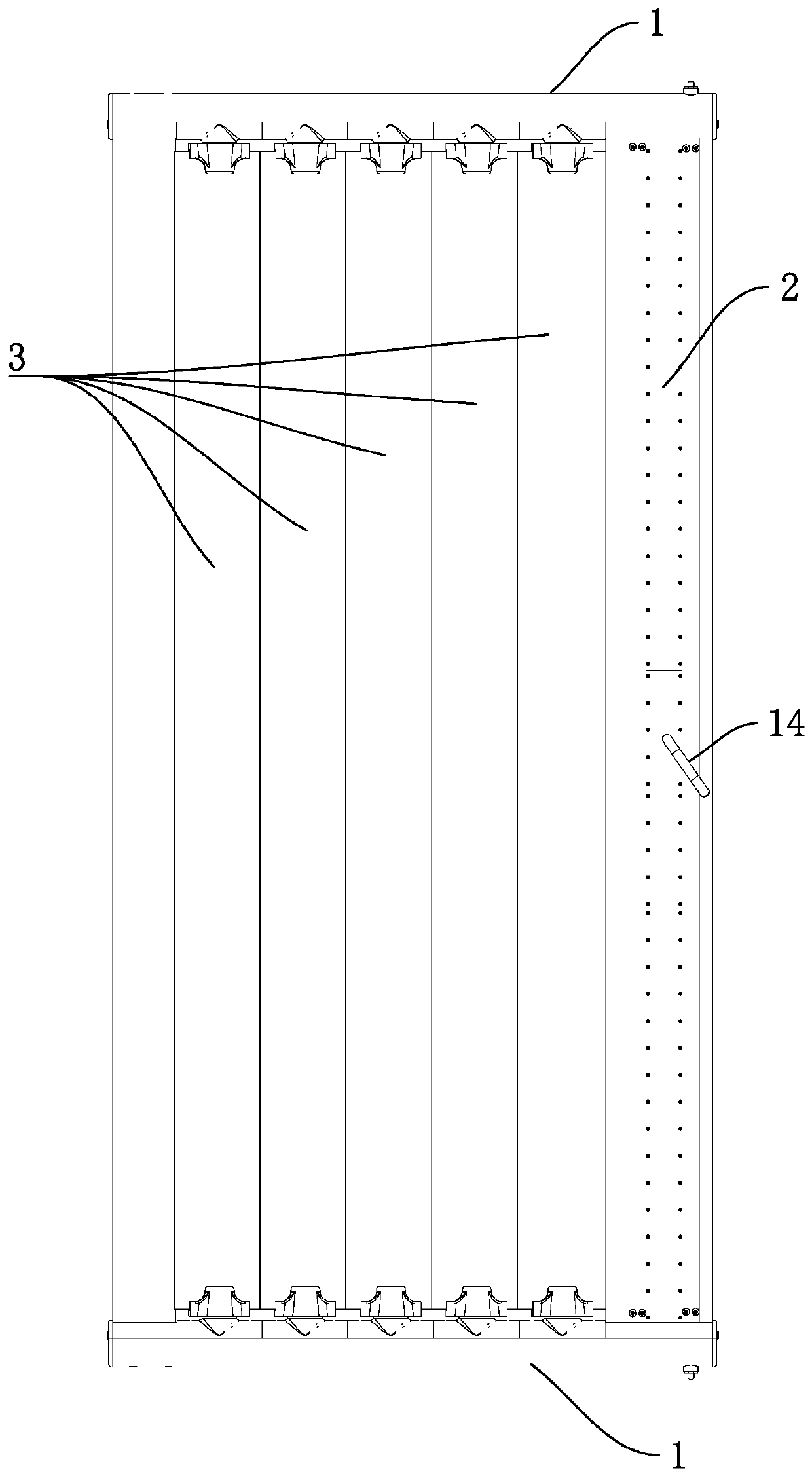

Long-leaf torsion-resistant shutters

InactiveCN109113543BReduced torque gapSmall amount of deformationSpecial door/window arrangementsWindow shutterClassical mechanics

Owner:江阴市誉闻节能科技有限公司

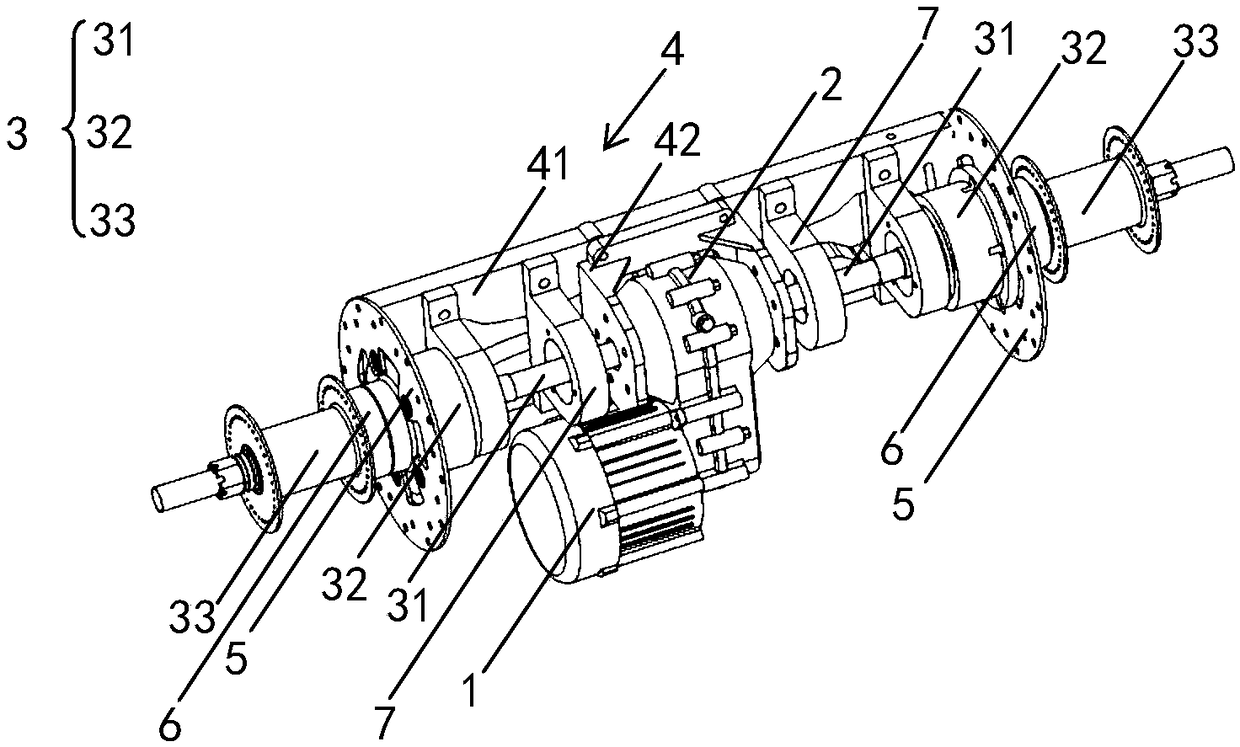

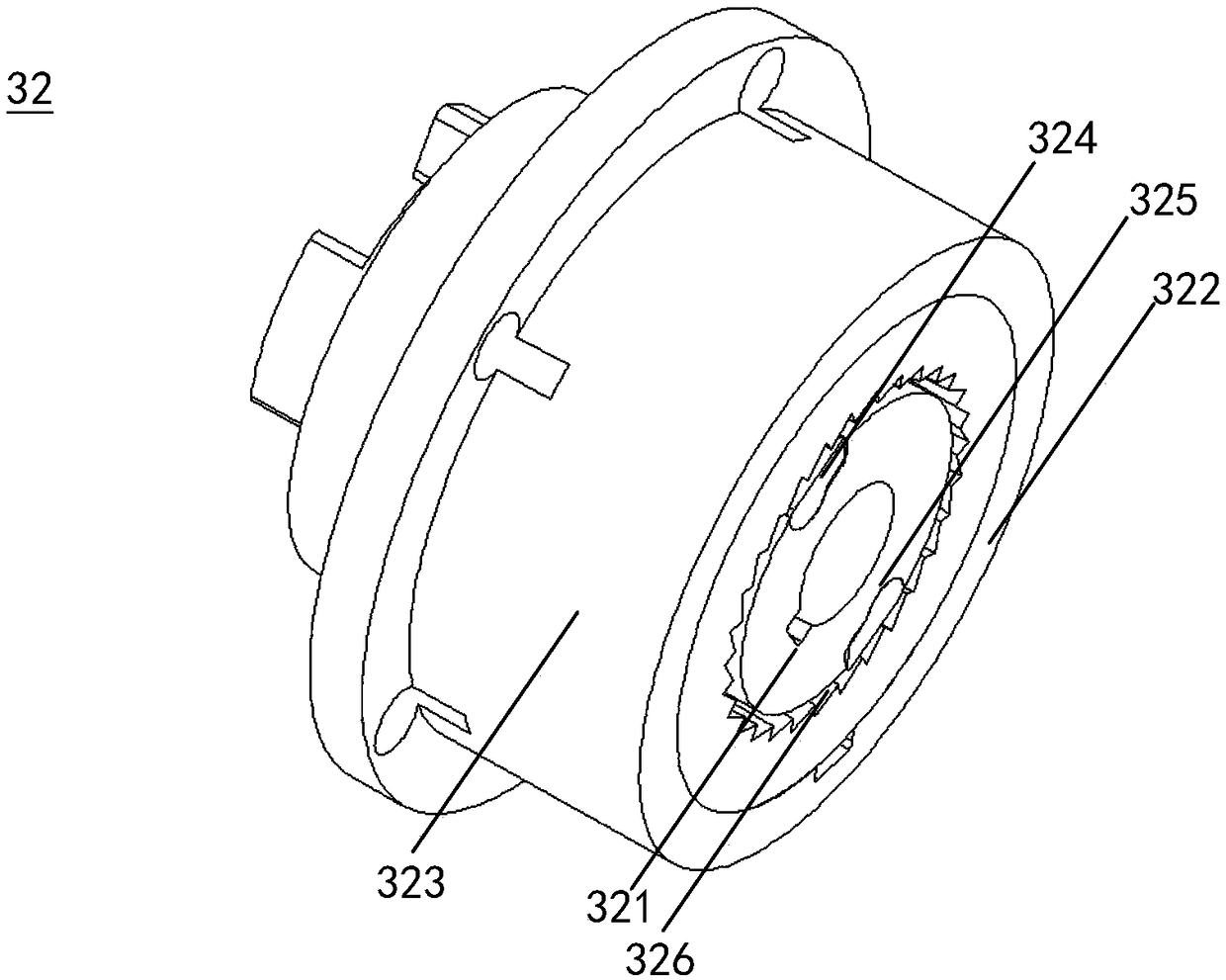

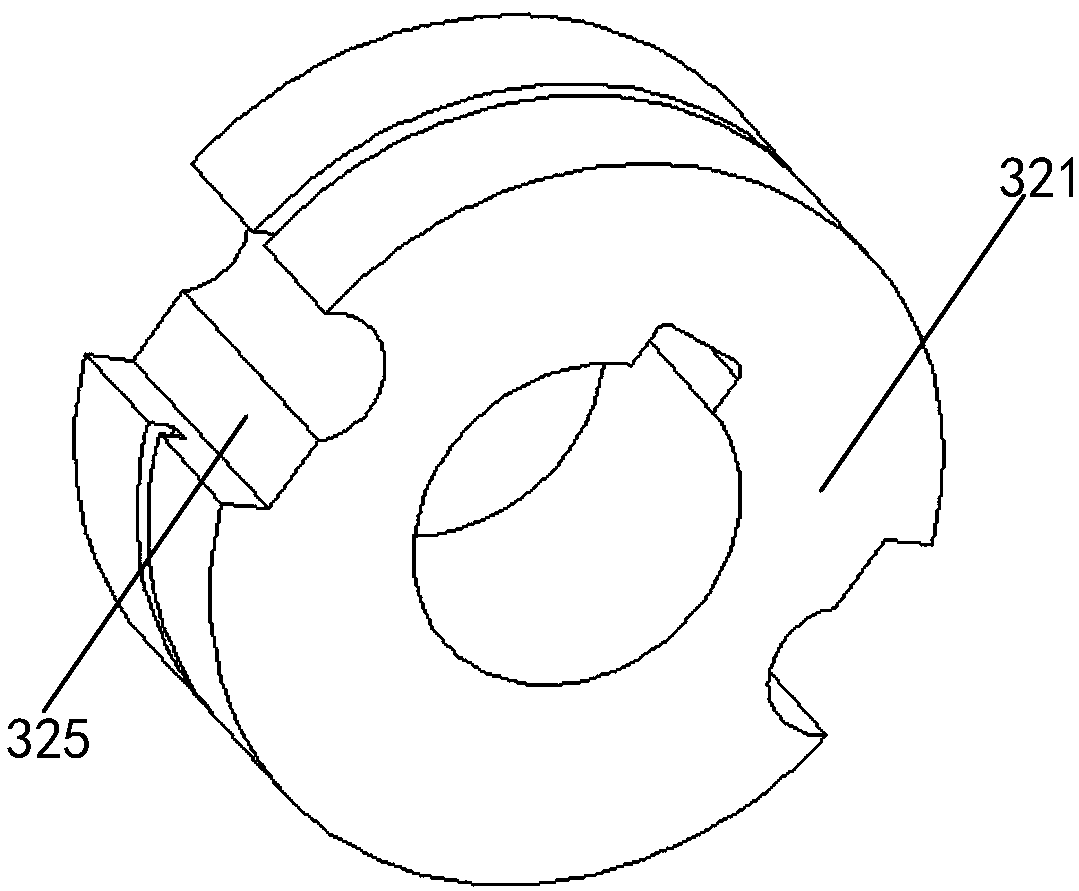

Transmission mechanism used for electric vehicle

PendingCN108790805ARealize energy savingReduce the difficulty of assemblyControl devicesCouplingDrive shaft

The invention provides a transmission mechanism used for an electric vehicle. The transmission mechanism comprises a power device and a speed reducer. The power device is connected with the speed reducer. The two sides of the speed reducer are connected with transmission components. Each transmission component comprises a transmission shaft, a tower footing assembly and a hub. The two transmissionshafts are inserted in the two sides of the speed reducer. The tower footing assemblies and the hubs are arranged on the transmission shafts. The tower footing assemblies are arranged between a transmission and the hubs. Each tower footing assembly comprises a first tower footing, a second tower footing and a third tower footing. The transmission shafts are inserted in the first tower footings. Multiple ratchet annular groove parts are arranged in the circumferential direction of each first tower footing and connected with ratchet blocks. Ratchet grooves are formed in the second tower footings. The first tower footings and the second tower footings are connected through engagement of the ratchet blocks and the ratchet grooves. The second tower footings are inserted in the third tower footings. The third tower footings are connected with the hubs through couplers.

Owner:GUANGZHOU COLLEGE OF SOUTH CHINA UNIV OF TECH

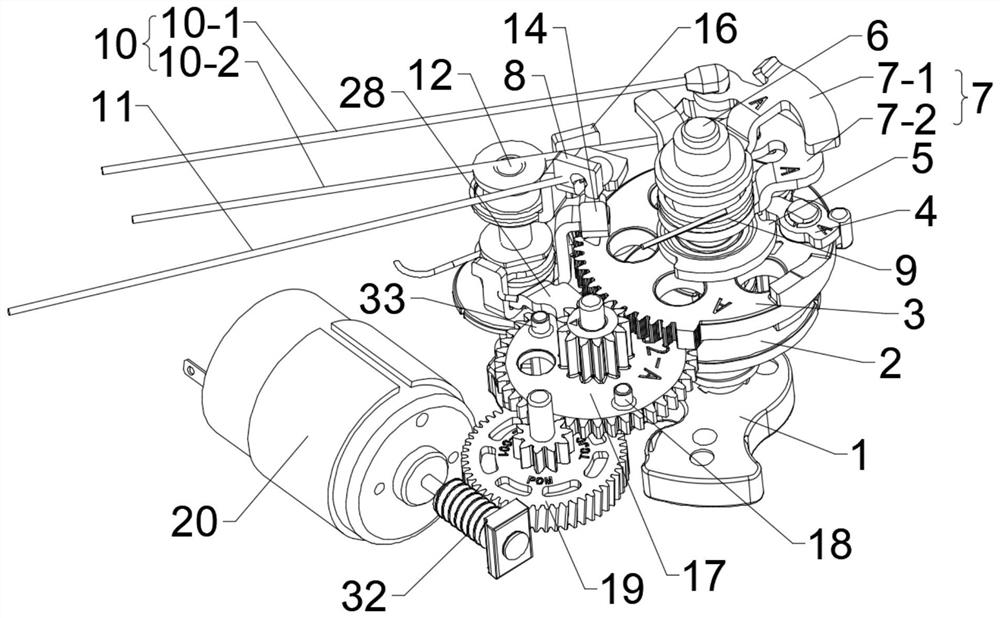

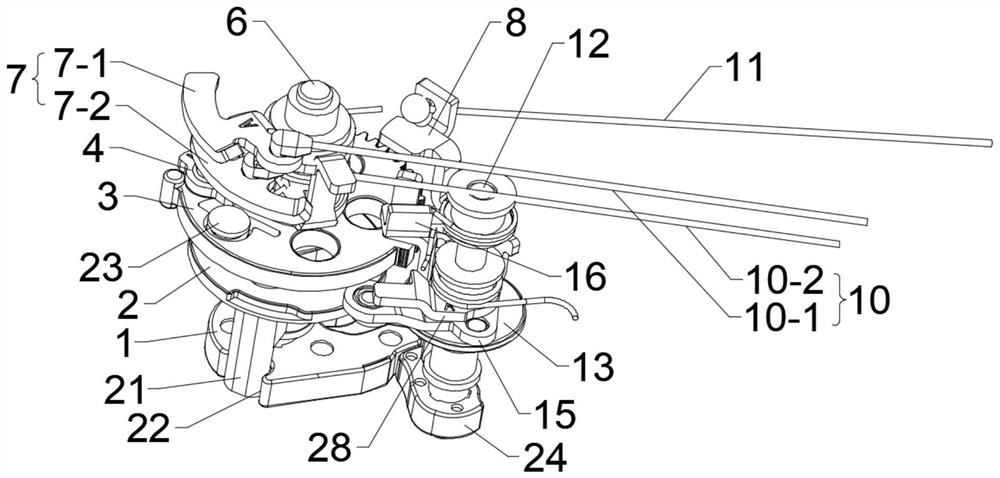

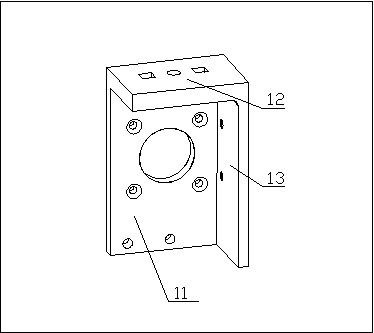

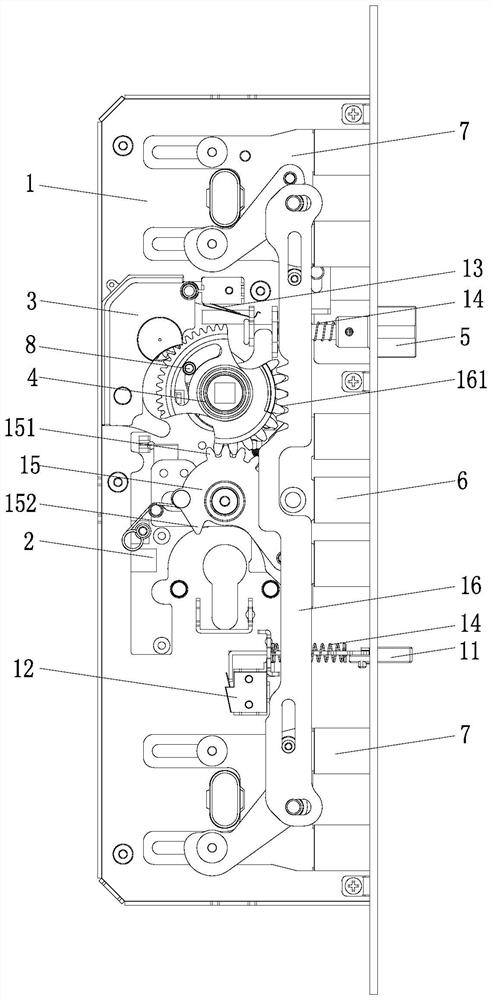

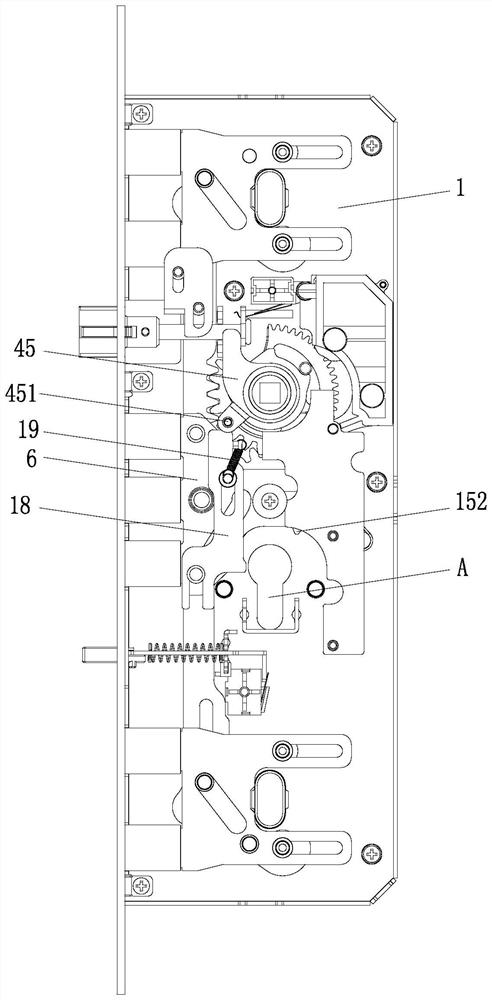

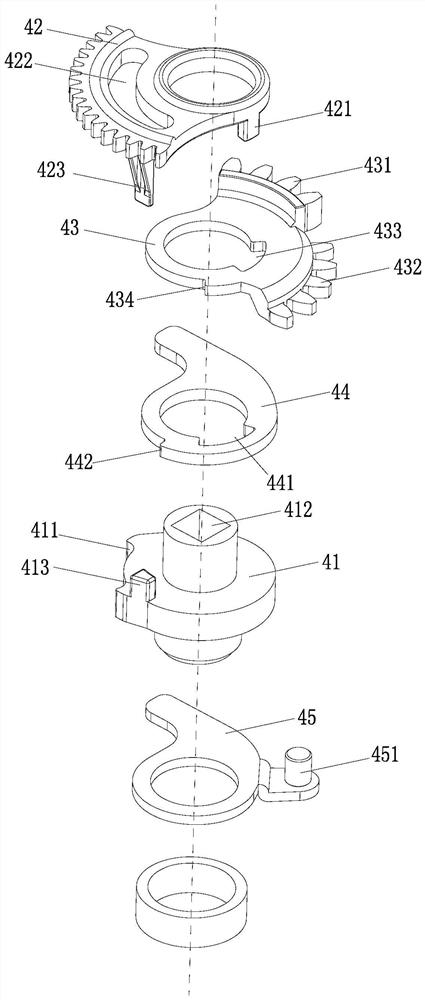

Full-automatic heavy electronic door lock

The invention relates to a full-automatic heavy electronic door lock which comprises a shell, an electric control board, a driving controller, an unlocking shifting fork assembly, a latch bolt, a main spring bolt assembly and an auxiliary spring bolt assembly are arranged in the shell, and the driving controller is electrically connected with the electric control board and drives the main spring bolt assembly and the auxiliary spring bolt assembly to move through the unlocking shifting fork assembly. The unlocking shifting fork assembly comprises a shifting wheel, a driving gear, a linkage gear and a front latch bolt shifting fork, the driving gear, the linkage gear and the front latch bolt shifting fork are rotationally arranged on the shifting wheel, the driving gear is in transmission connection with the output end of the driving controller, the linkage gear and the front latch bolt shifting fork, and the front latch bolt shifting fork is in transmission connection with the latch bolt. The linkage gear is provided with a first tooth surface and a second tooth surface, the first tooth surface and the second tooth surface are in transmission connection with the auxiliary spring bolt assembly and the main spring bolt assembly respectively, according to the structure, the auxiliary spring bolt assembly and the main spring bolt assembly can be driven through the first tooth surface and the second tooth surface at different angles, the door lock structure is simplified, and operation is easy and convenient.

Owner:ZHONGSHAN ROYALWAND HARDWARE

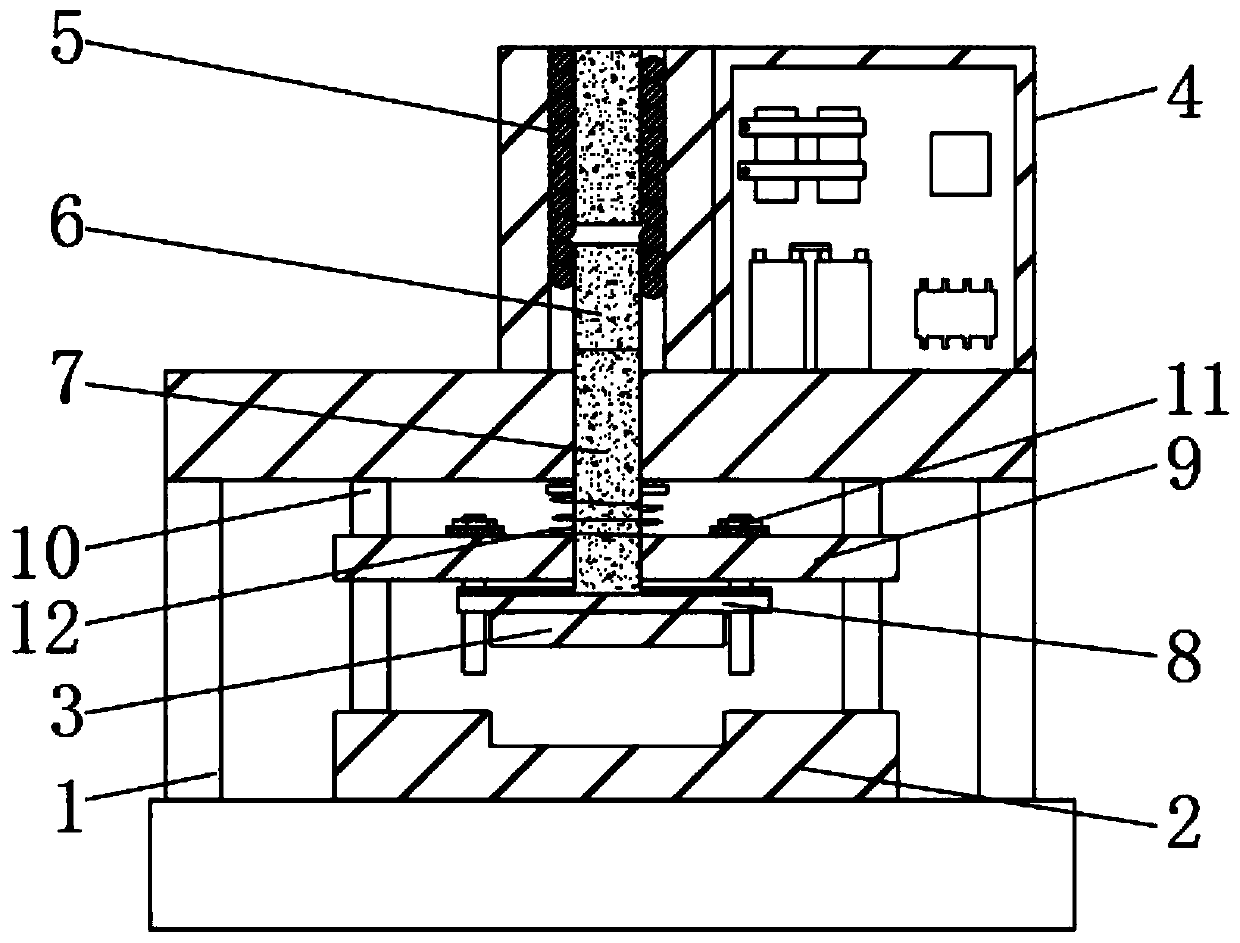

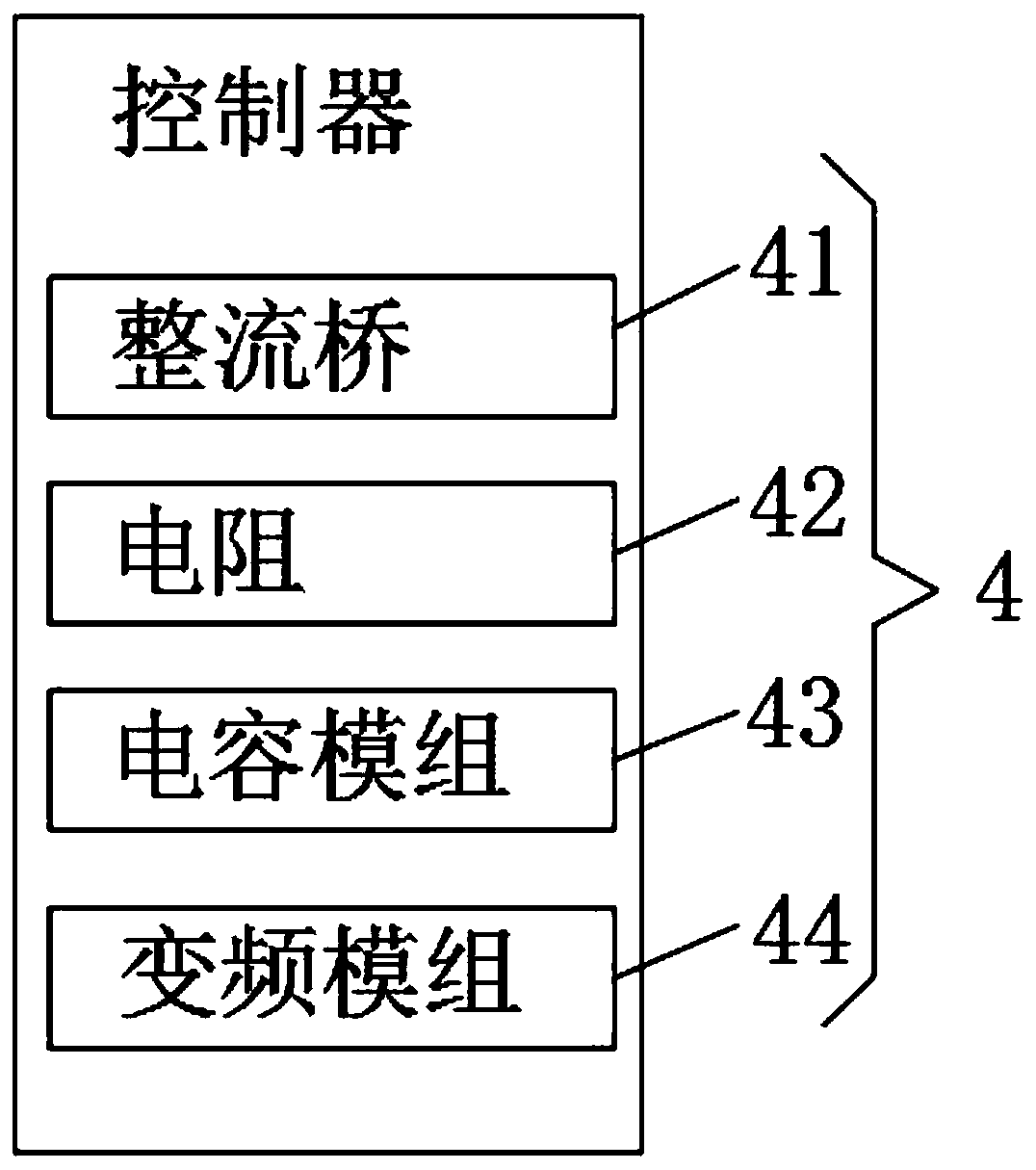

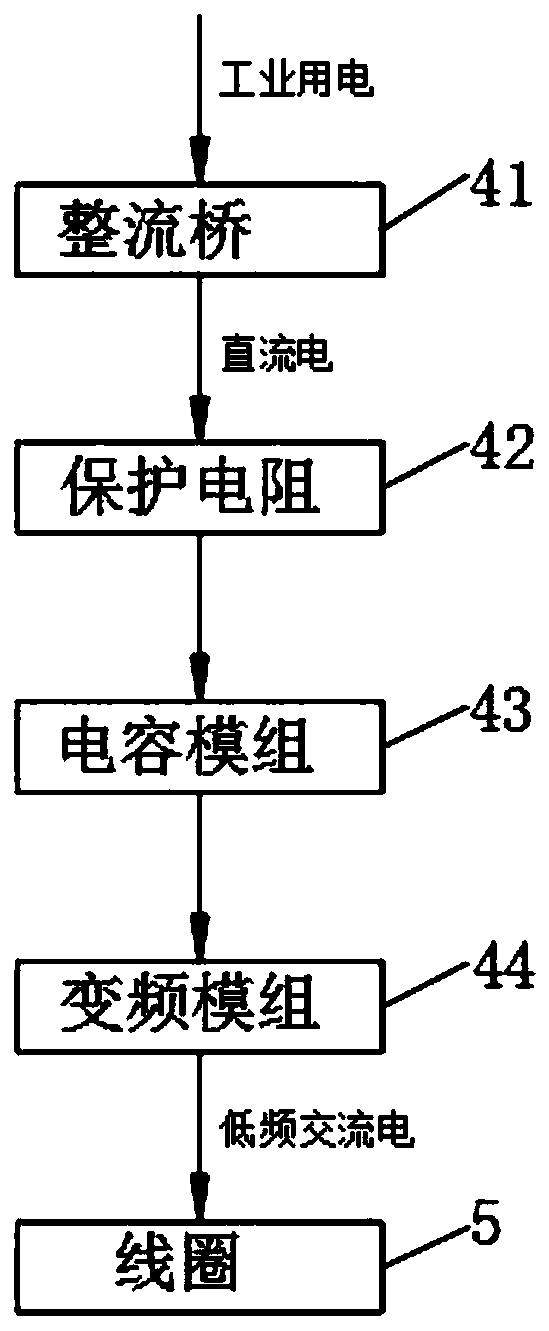

Battery pole piece forming device

InactiveCN110181601AImprove machining accuracyImprove the holding time of machining accuracyMetal working apparatusRetention timePole piece

The invention relates to the technical field of battery processing equipment, and discloses a battery pole piece forming device which comprises a rack. A lower die is arranged at the lower end of therack, a cutter die is arranged at the upper end of the lower die, a controller is arranged on the outer surface of the rack, and a coil with an iron core is mounted on the upper end surface of the rack. According to the battery pole piece forming device, a connecting rod is driven by the coil to drive a cutter die to punch a battery pole piece, only the connecting rod bears the vertical driving force and the reaction force when the pole piece is punched, the abrasion of the outer side wall of the battery pole piece forming device is far less than that of a conventional device, the retention time of the processing precision of the battery pole piece forming device is prolonged, the redundant driving force generated when the battery pole piece is punched is borne by a positioning block, theservice life of the cutter die is prolonged, besides, when the thickness of the cutter die is abraded to a certain degree, the displacement of the cutter die can be adjusted through an inner positioning rod to enable the cutter die to continue to be used, the connecting rod and the cutter die are directly driven to move through the coil, and the control precision of the processing time of the device is improved.

Owner:谢敬群

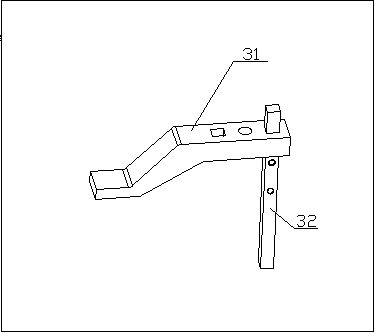

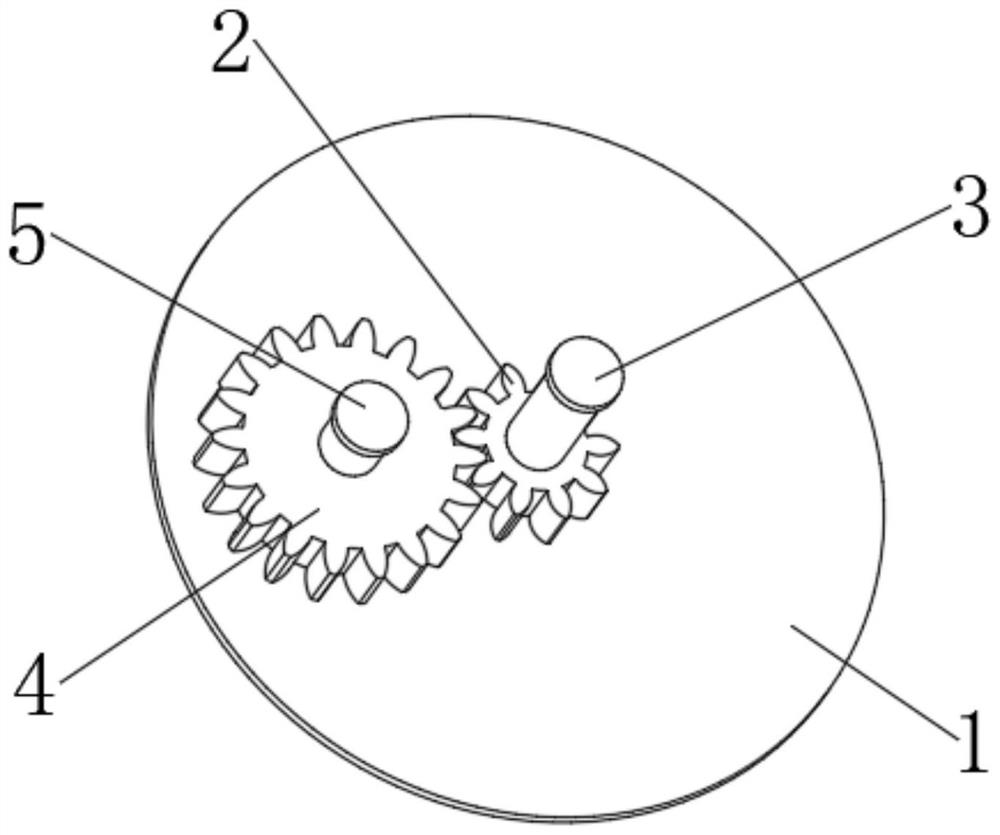

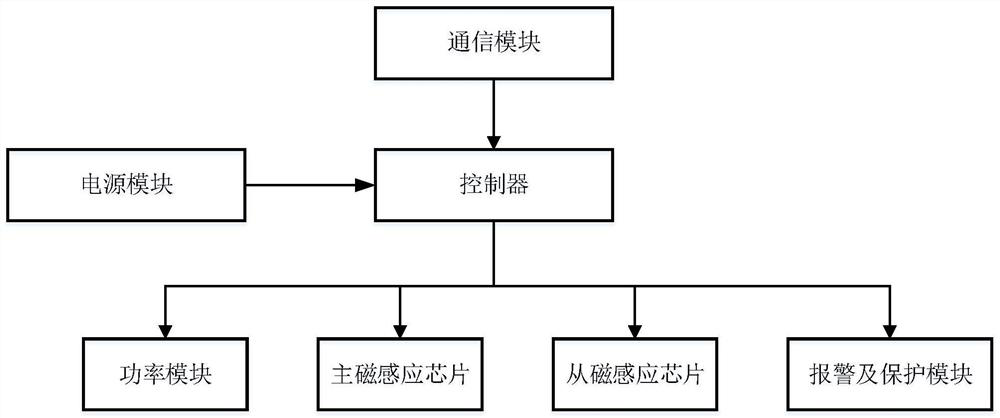

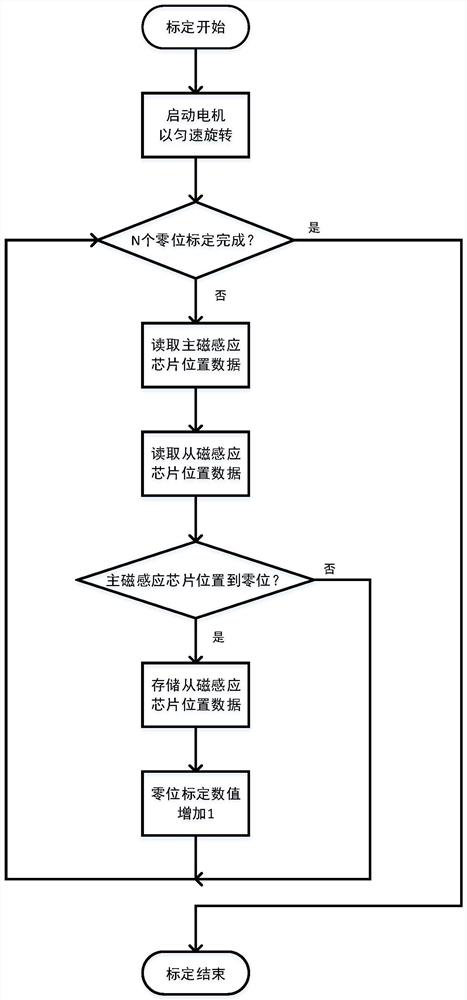

Mechanical multi-turn encoder for joint of foot-type robot

The invention provides a mechanical multi-turn encoder for a foot type robot joint, the mechanical multi-turn encoder comprises a driving gear, a master magnet, a driven gear, a slave magnet, a master magnetic induction chip and a slave magnetic induction chip, the driving gear is coaxially connected with a motor shaft, the master magnet is installed at the end of the motor shaft and is coaxially arranged with the driving gear, and the slave magnet is installed at the end of the motor shaft and is coaxially arranged with the driven gear. The driving gear and the main magnet rotate together with the motor shaft; the driven gear is installed on the motor rear end cover, and the driven magnet and the driven gear are coaxially arranged. The driving gear is meshed with the driven gear and drives the driven gear and the driven magnet to rotate; the master magnetic induction chip and the slave magnetic induction chip are connected with a controller in the motor driver, and the master magnetic induction chip and the slave magnetic induction chip are arranged right opposite to the master magnet and the slave magnet respectively. The gear of the encoder is directly installed on the motor, and the magnetic induction chip is integrated on the motor driving board, so that the cost and the size of the encoder are greatly reduced.

Owner:南京蔚蓝智能科技有限公司

Electric driving sweeper

The invention discloses an electric driving sweeping and washing machine, which comprises a chassis, a driving system, a sweeping and washing system, a wiper system and a central control system. The driving system includes a driving motor and a steering wheel, and the driving motor drives the rear wheel to rotate. The sweeping system includes side brushes installed on both sides of the front bottom of the chassis and a roller brush installed under the middle of the chassis; the wiper system includes a wiper rake, a water suction pipe, a fan and a fan connection pipe. The all-in-one electric driving type sweeping and washing machine of the present invention is a battery-driven driving type floor washing machine, which can efficiently clean and clean various types of ground, is simple to operate, safe and comfortable, has no secondary pollution, and has a large cleaning width. The volume of the water tank is large, and it can work for half an hour at a time, and the continuous working time is about 4 hours, which greatly solves the problem that the workers clean the floor slowly and the cleaning effect is not ideal. Water absorption efficiency.

Owner:WUHU AIRUITE ENVIRONMENTAL TECH

A multi-head vertical stone processing equipment

ActiveCN107379288BReduce shockImprove identityWorking accessoriesStone-like material working toolsEngineeringWorkbench

The invention relates to multi-head vertical stone processing equipment which comprises a worktable, a cutting mechanism and cutting upright columns. The worktable is used for vertically arranging a plurality of stone workpieces, the stone workpieces are positioned on the same plane, the cutting mechanism is used for simultaneously processing the stone workpieces and is assembled on the cutting upright columns in such a manner that the cutting mechanism can move along the cutting upright columns, and the stone workpieces and the cutting upright columns can extend along the vertical directions. The cutting upright columns are arranged on the plane where the stone workpieces are positioned, the projection of the cutting upright columns on the plane where the stone workpieces are positioned is positioned in the middles of the arrangement distances of the stone workpieces. The multi-head vertical stone processing equipment has the advantages that the multi-head vertical stone processing equipment is stable in structure and comprises few transmission structures (such as lifting driving mechanisms of lifting sliders) of various inner driving mechanisms, accordingly, the running stability of the multi-head vertical stone processing equipment can be improved, the durability of the multi-head vertical stone processing equipment can be enhanced, and the market competitiveness of the multi-head vertical stone processing equipment can be enhanced.

Owner:QUANZHOU MINYAN STONE MACHINERY CO LTD

Intelligent stamping mechanism capable of achieving automatic feeding and discharging

The invention discloses an intelligent stamping mechanism capable of achieving automatic feeding and discharging. The intelligent stamping mechanism comprises a base, wherein an air cylinder is fixedly installed at one end of the base, a fixed die is fixedly installed at the other end of the base, a movable die is arranged above the fixed die, a discharging guide groove frame is arranged above thebase, a workpiece withdrawing rod is fixedly installed at the position, between the air cylinder and the fixed die, of the base, a finished product box is installed on the position, between the workpiece withdrawing rod and the fixed die, of the base, a guide rail is arranged on the position, between the workpiece withdrawing rod and the air cylinder, of the base, the guide rail is parallel to aconnecting line between the workpiece withdrawing rod and a telescopic rod of the air cylinder, a sliding seat is installed on the guide rail, and the sliding seat is fixedly connected with the telescopic rod of the air cylinder through a flange and is driven by the telescopic rod to slide along the guide rail. The mechanism has the beneficial effects that the automatic workpiece feeding and withdrawing functions are achieved through the simple mechanical structure design, and the production cost and the maintenance cost are effectively reduced while the working efficiency is guaranteed.

Owner:深圳市领拓实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com