Patents

Literature

893results about "Fertiliser equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

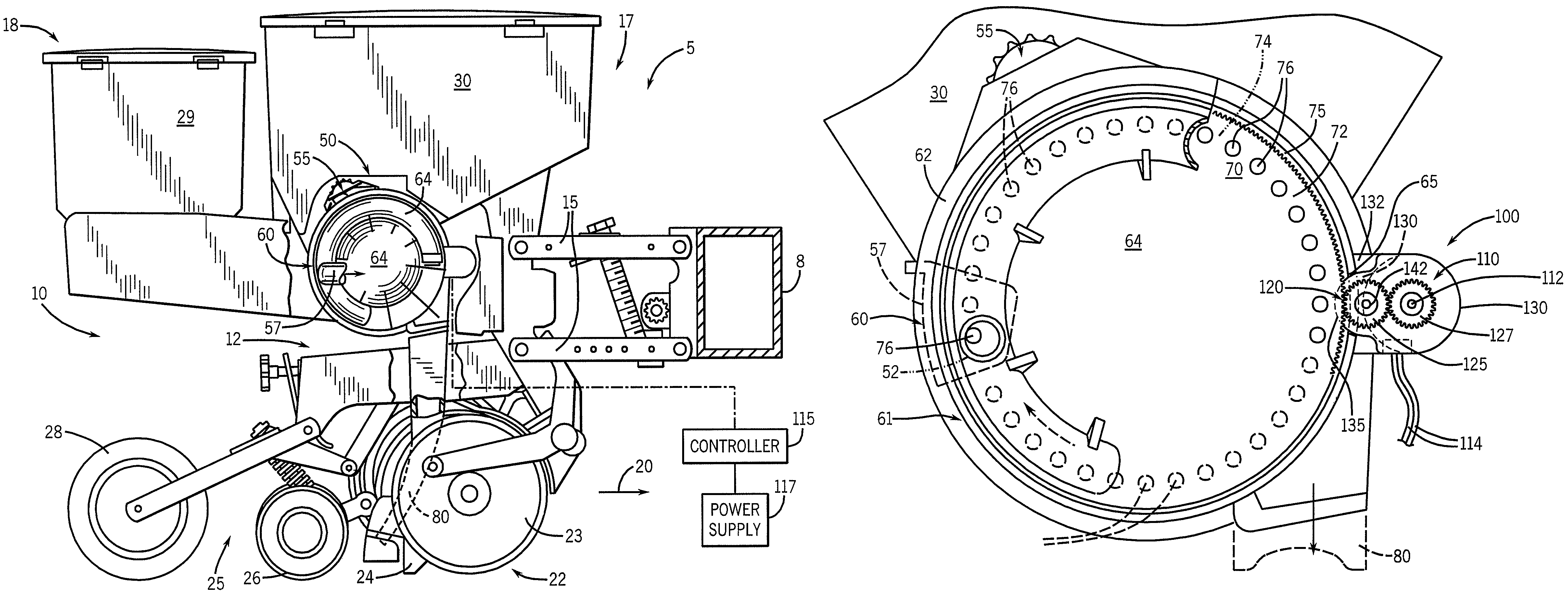

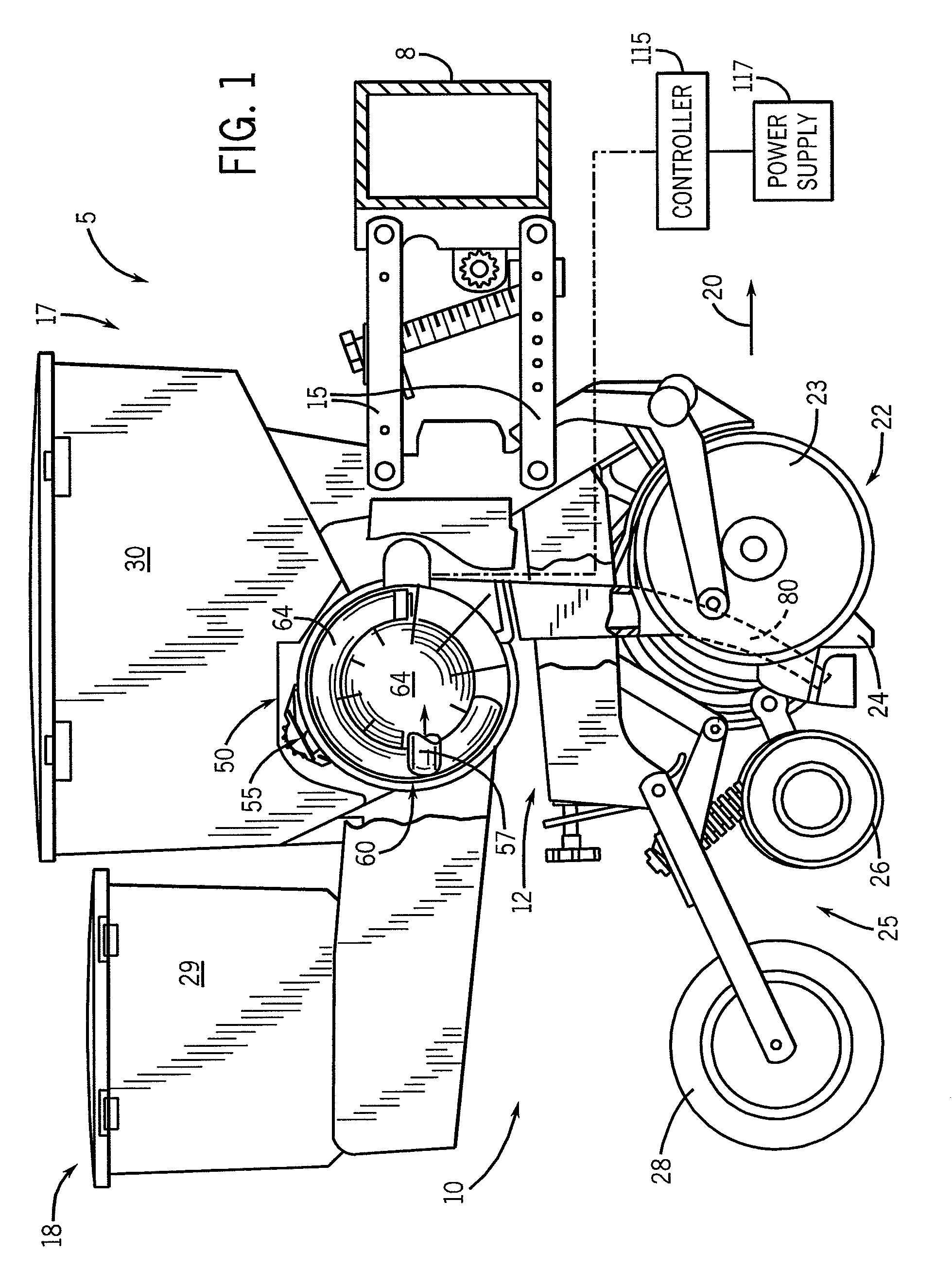

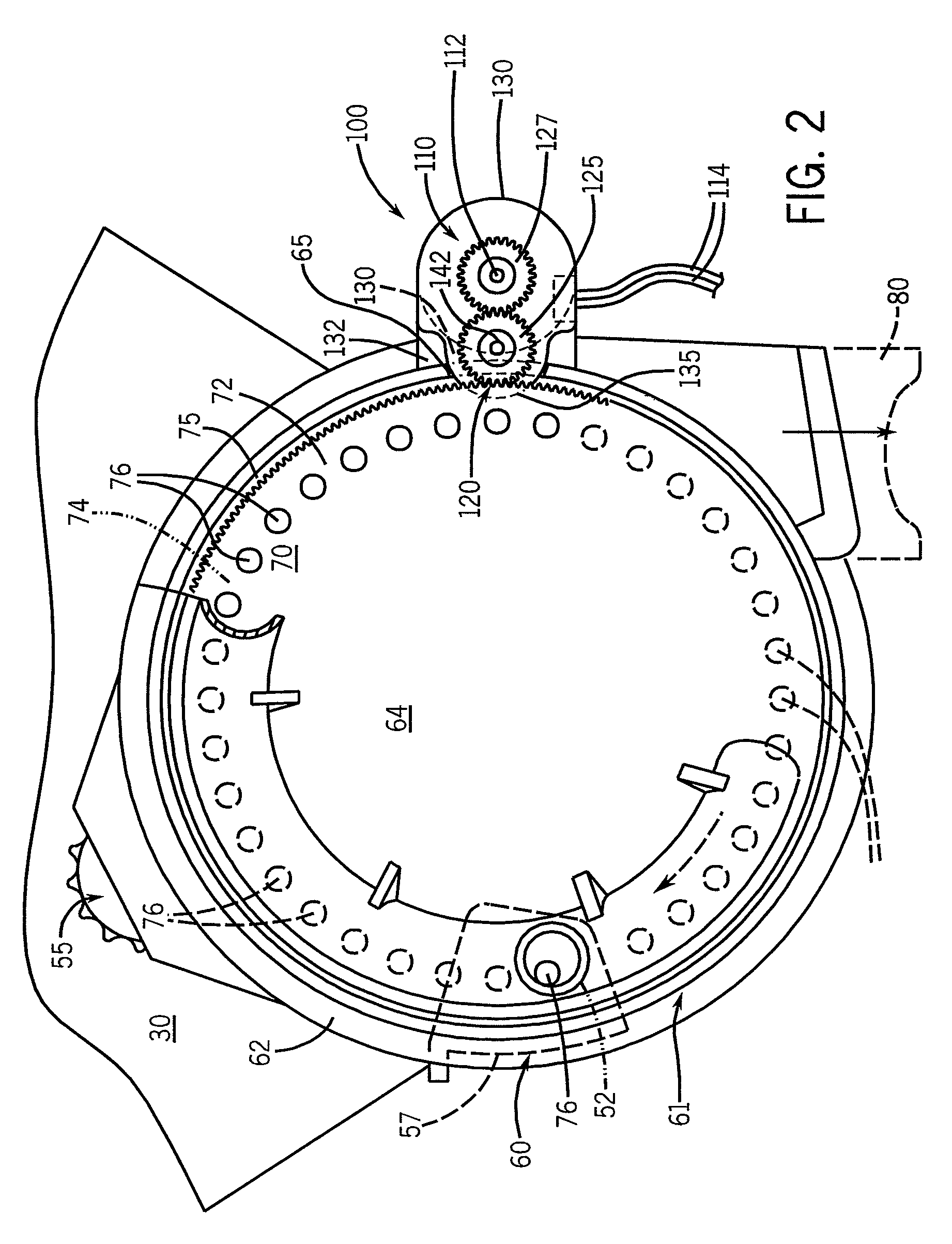

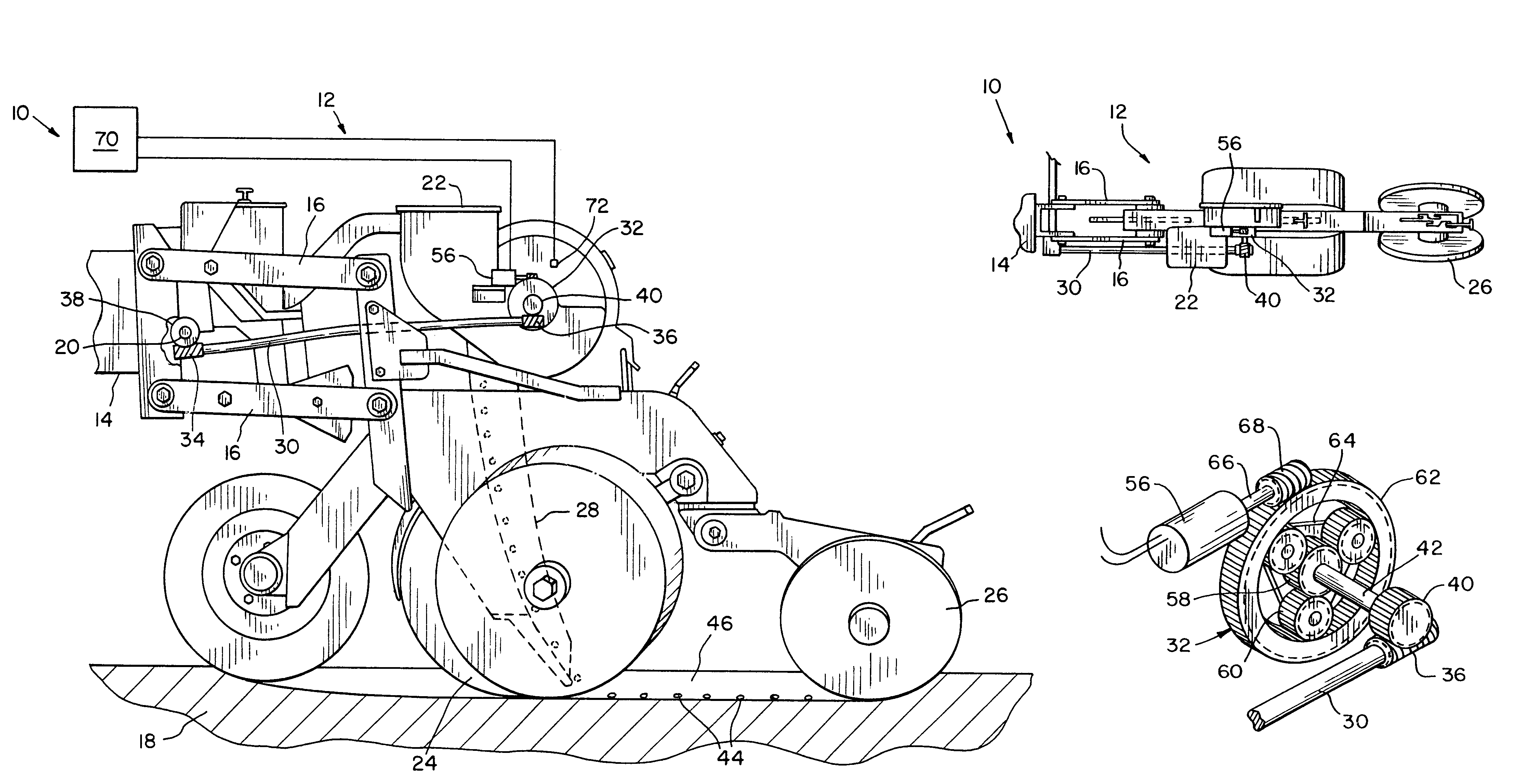

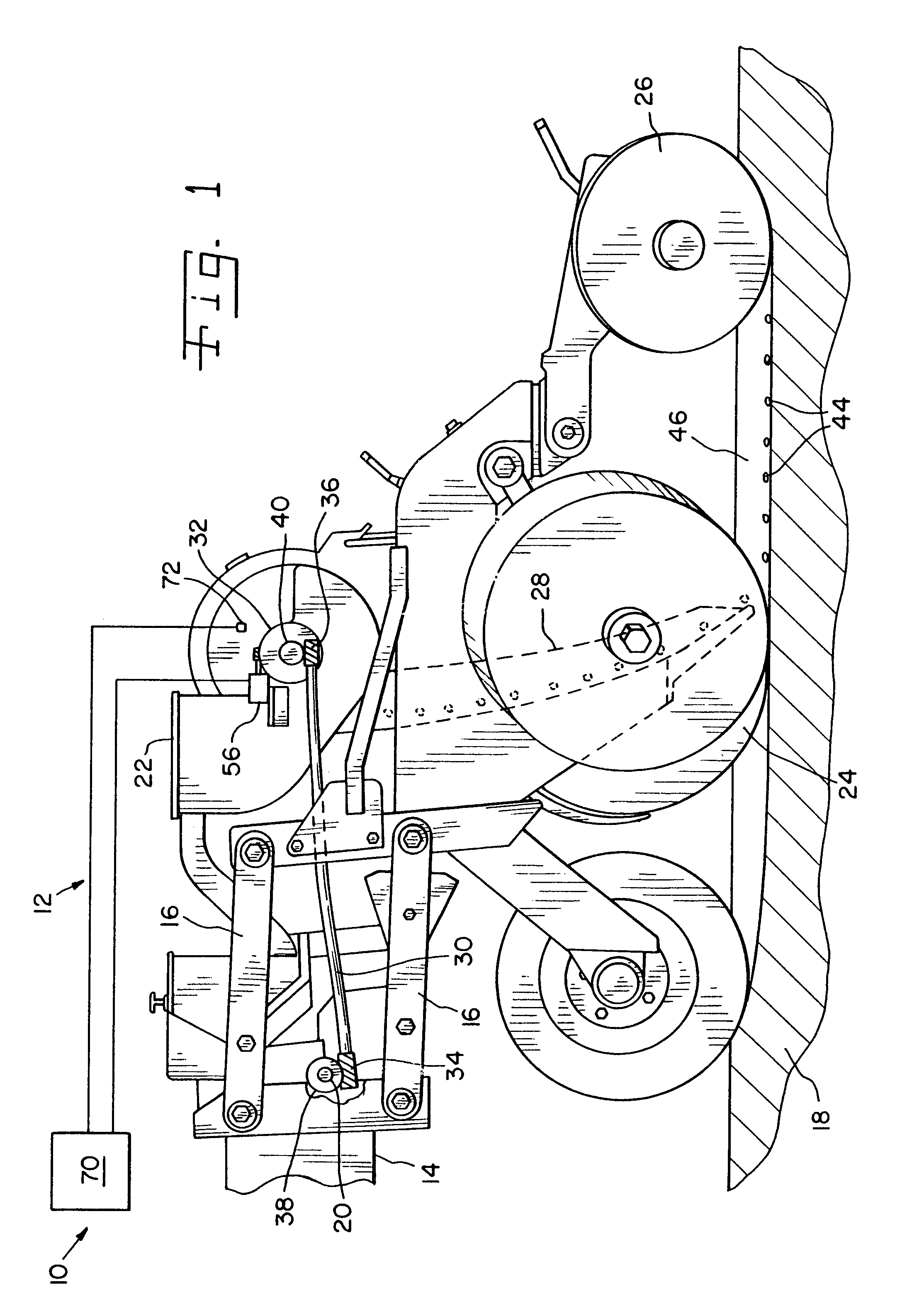

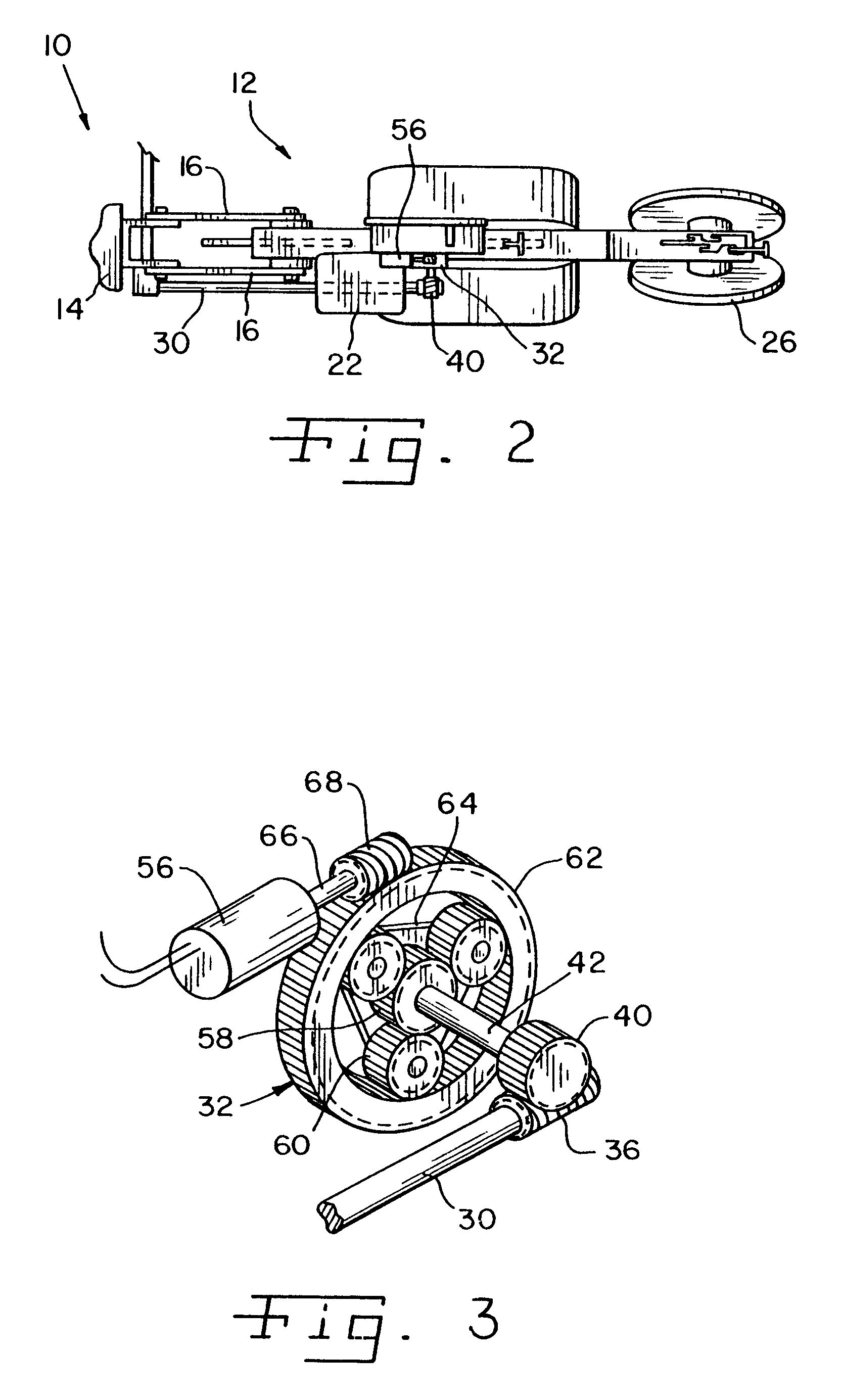

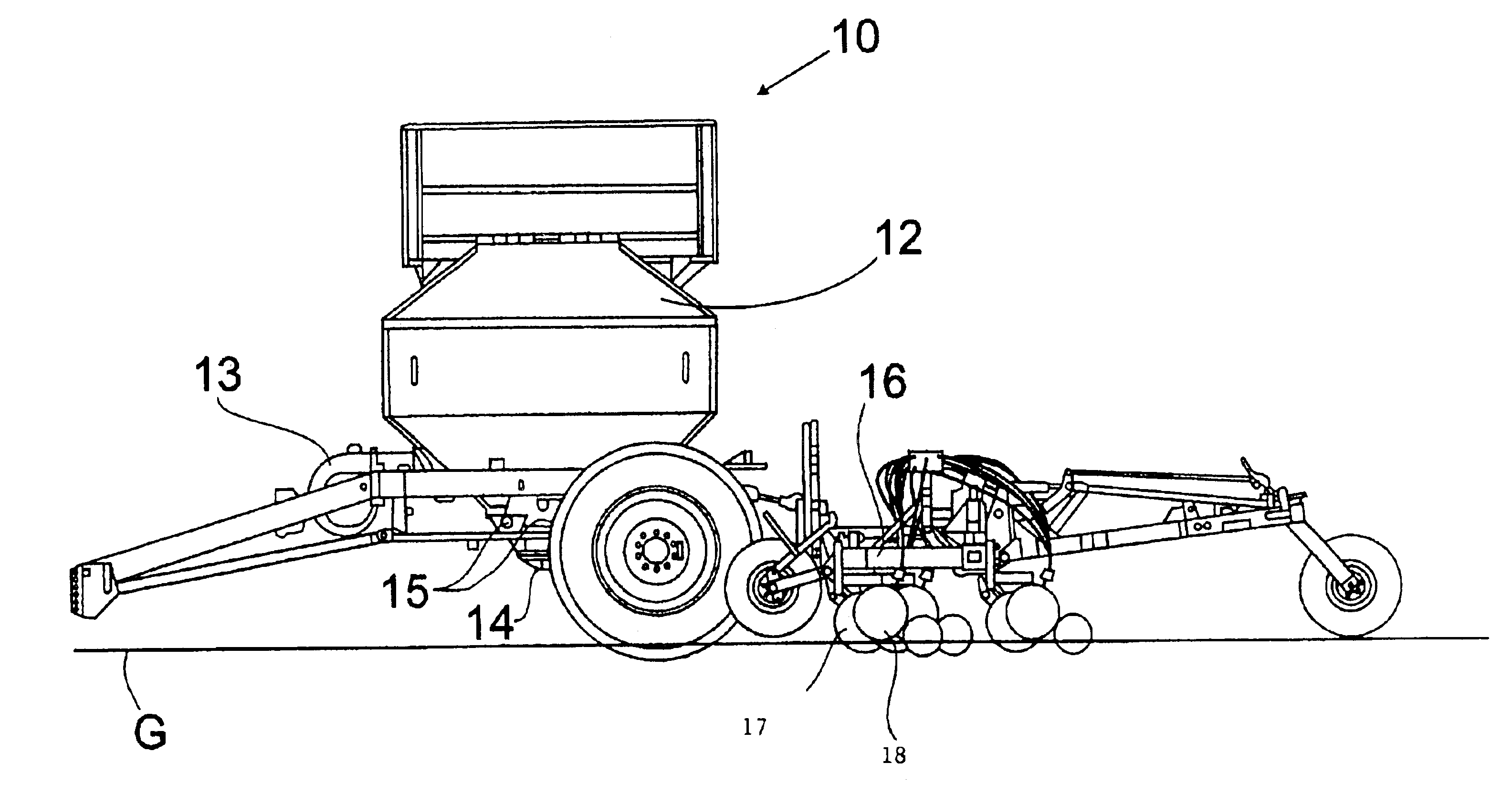

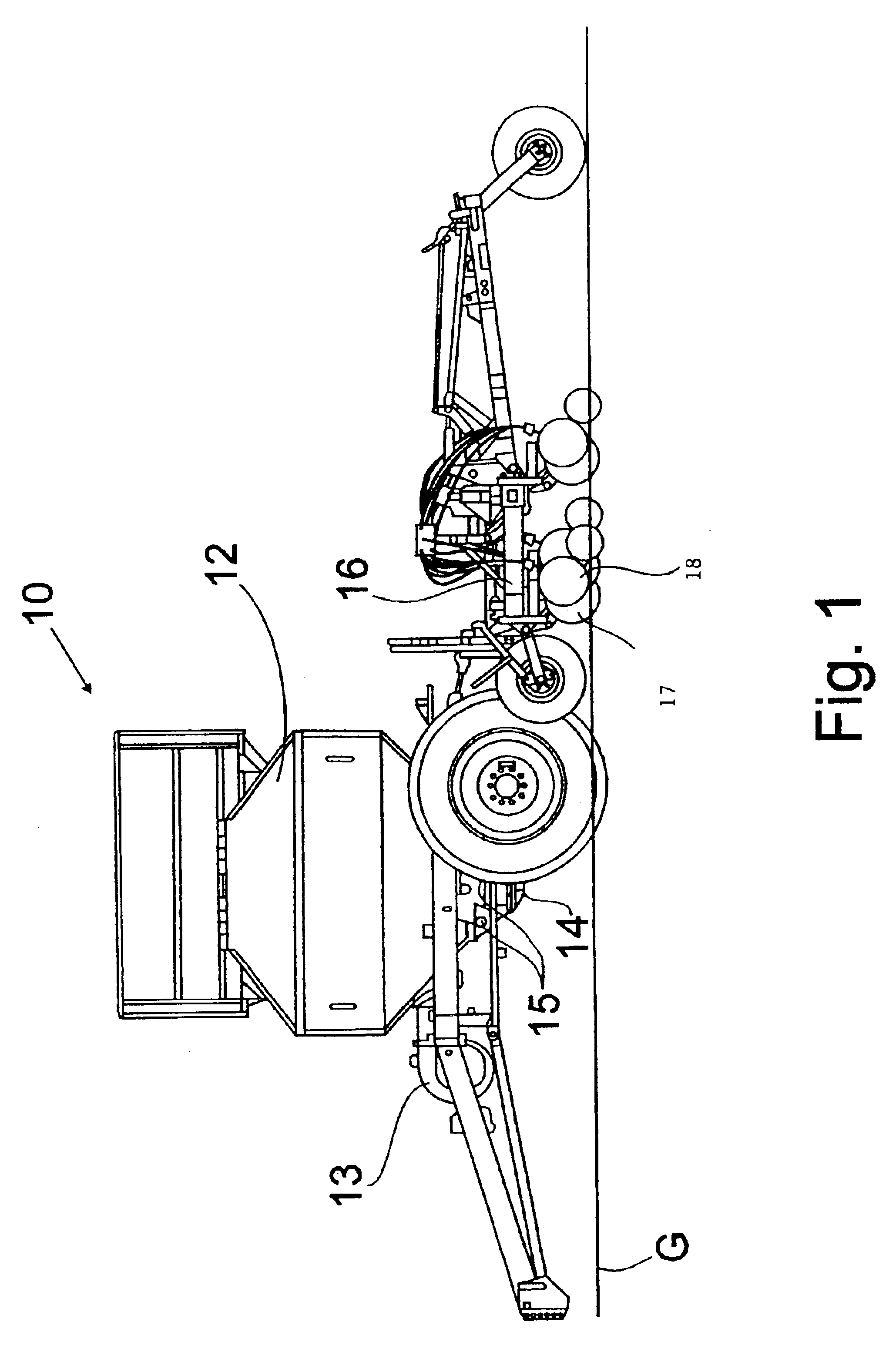

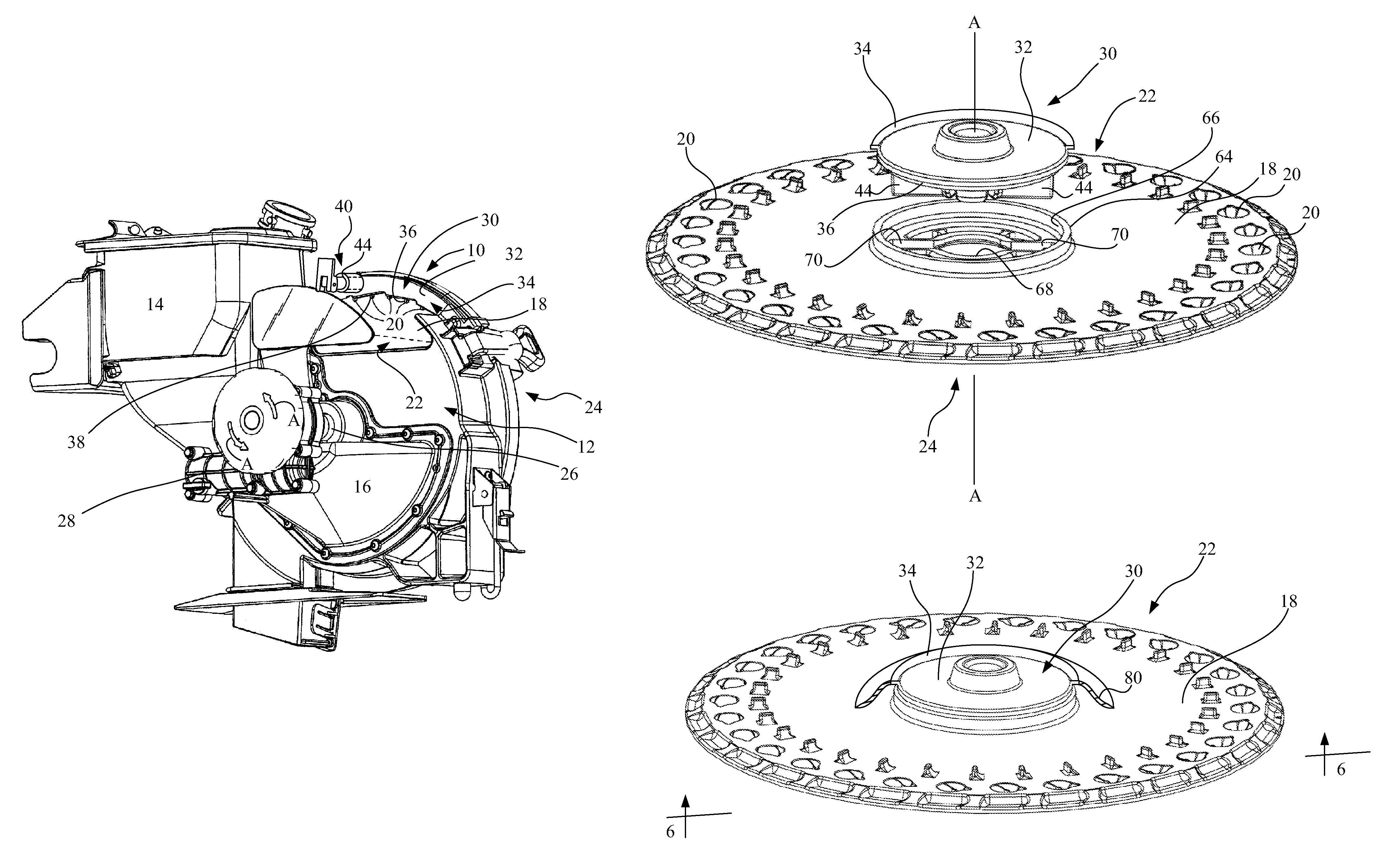

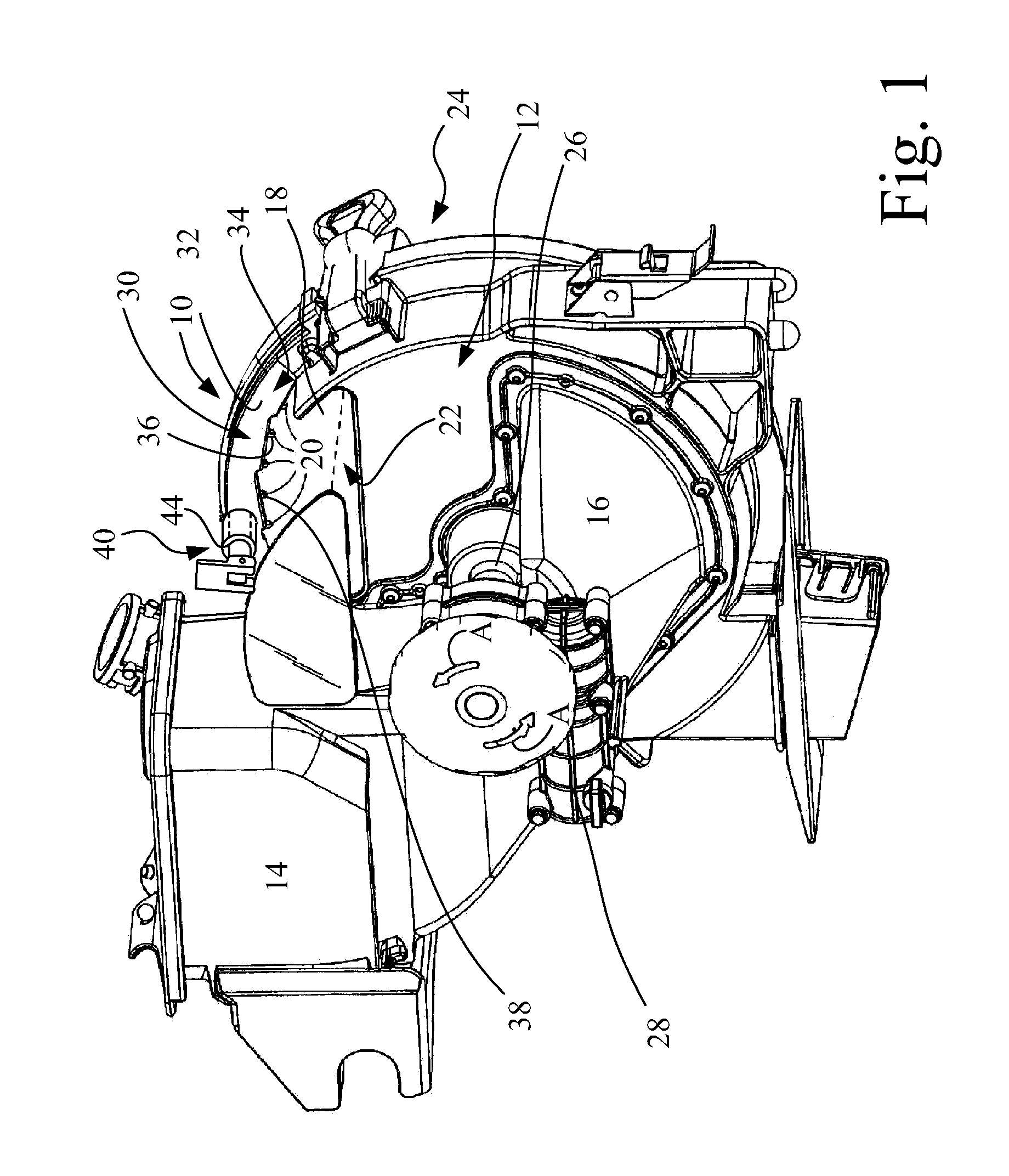

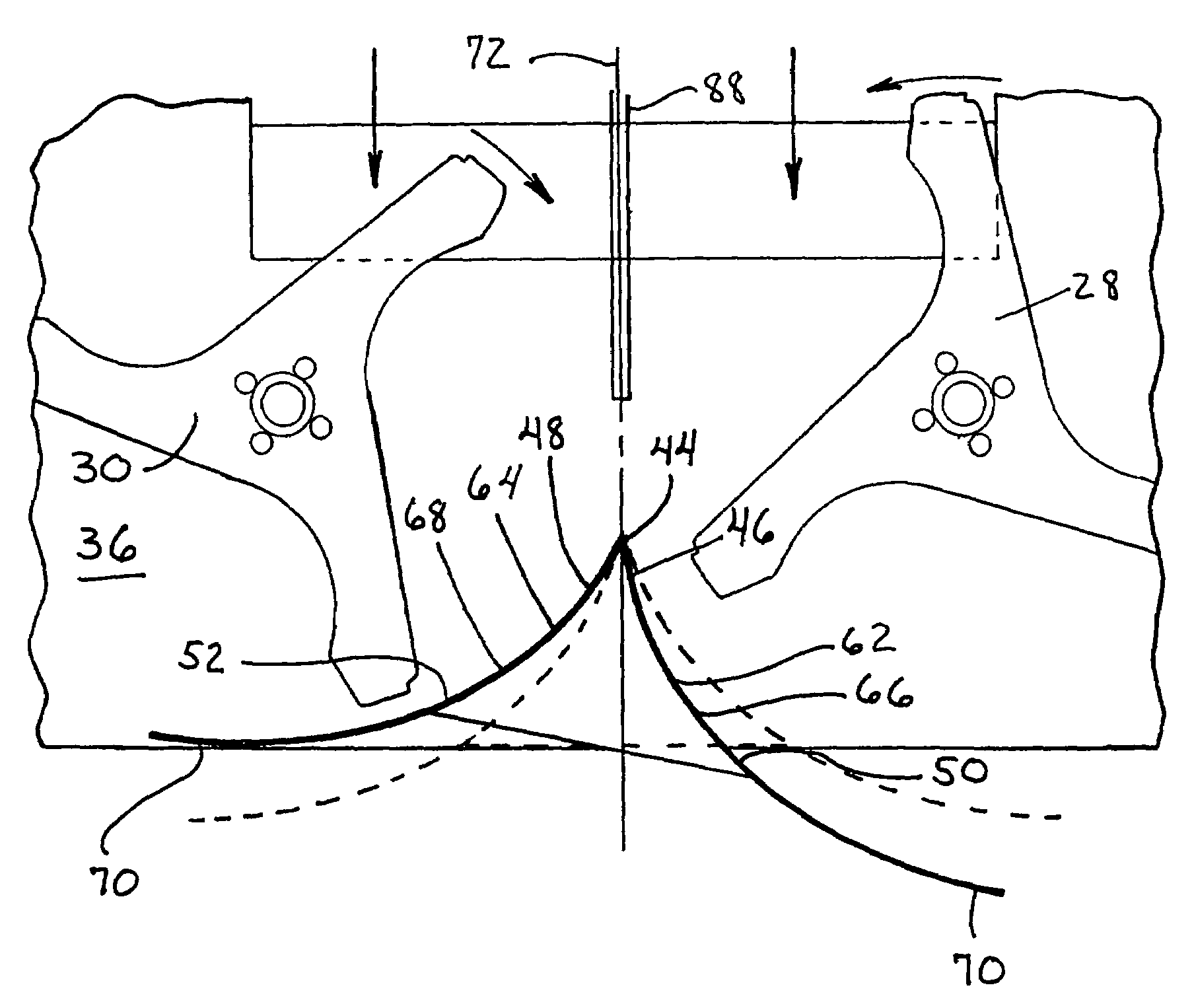

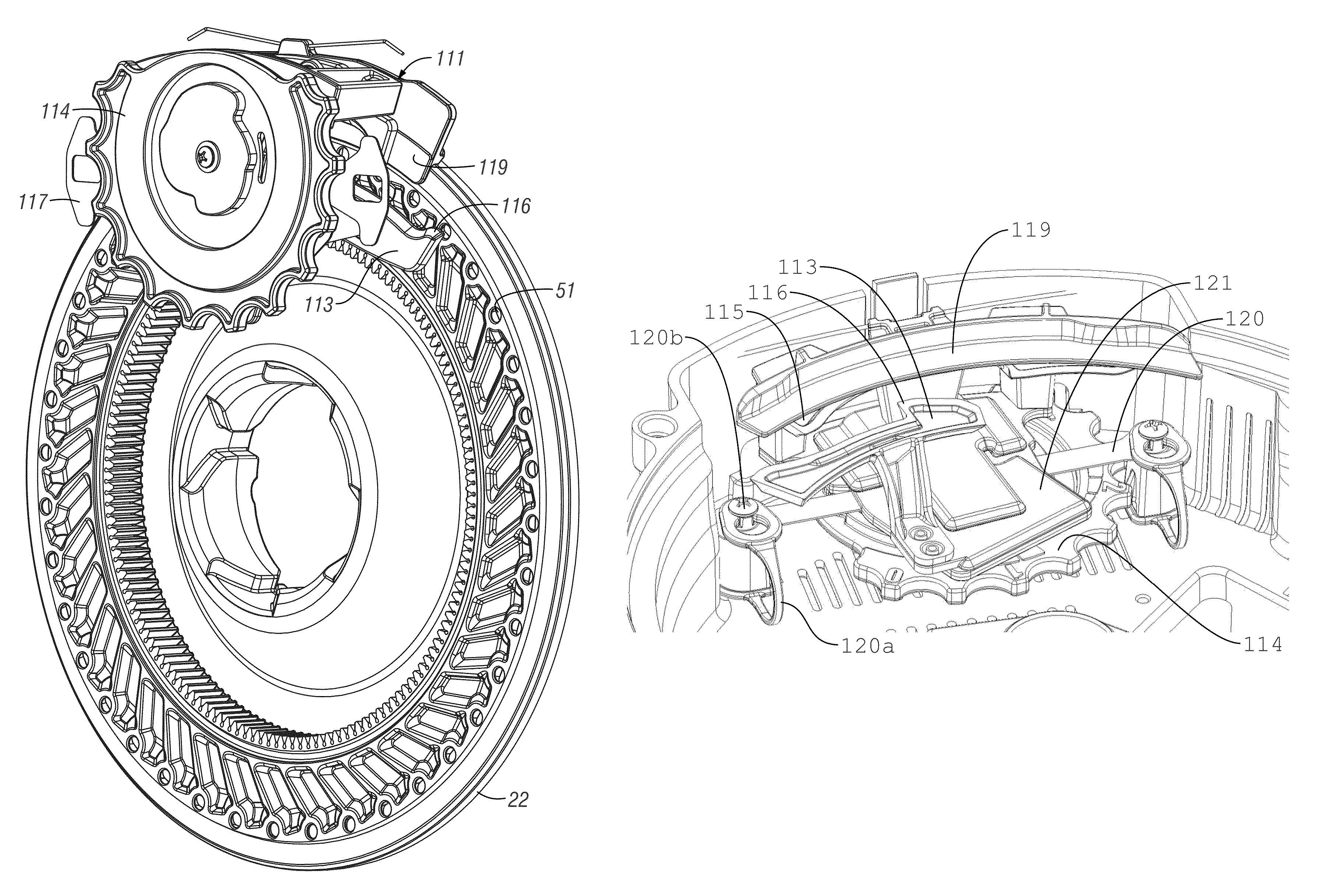

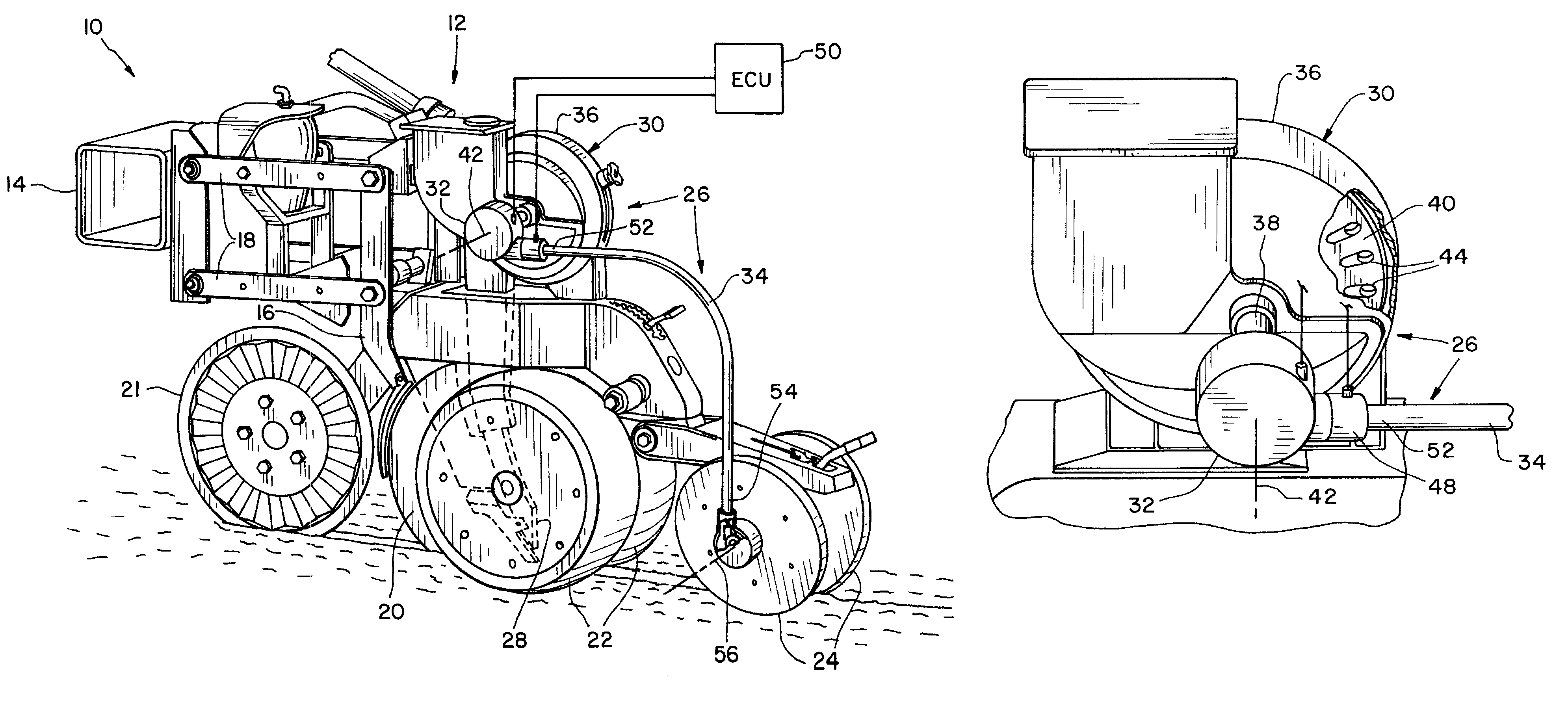

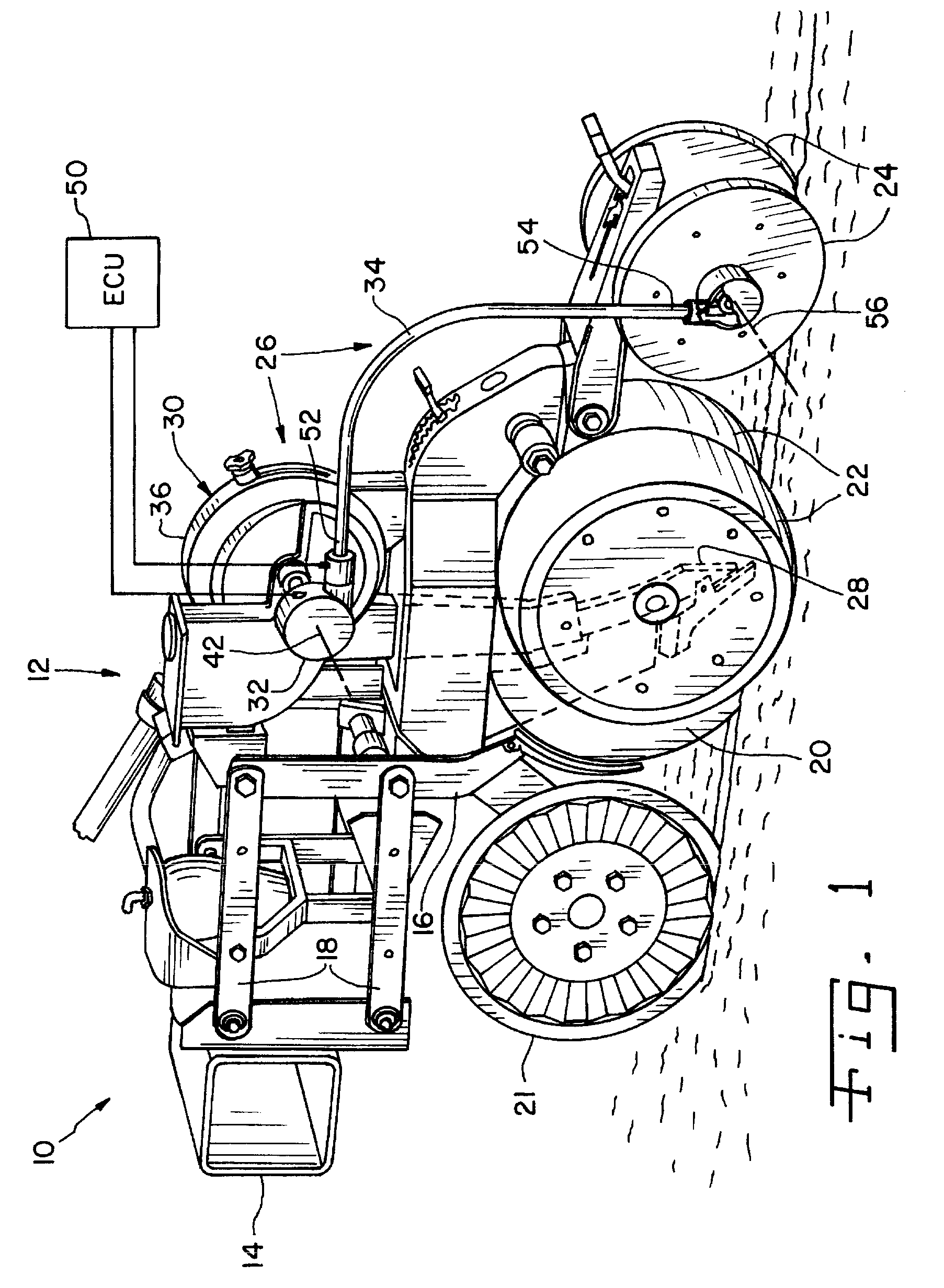

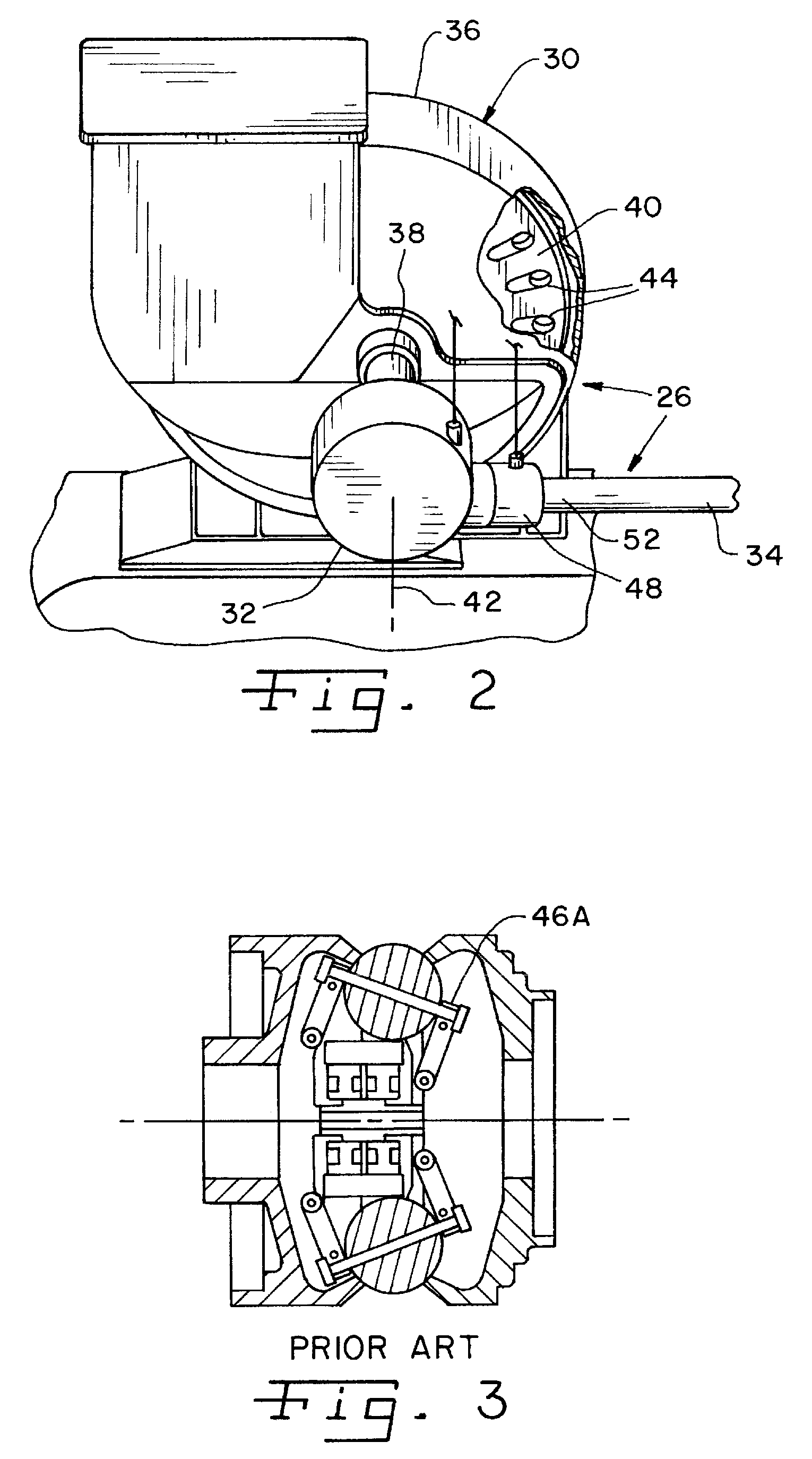

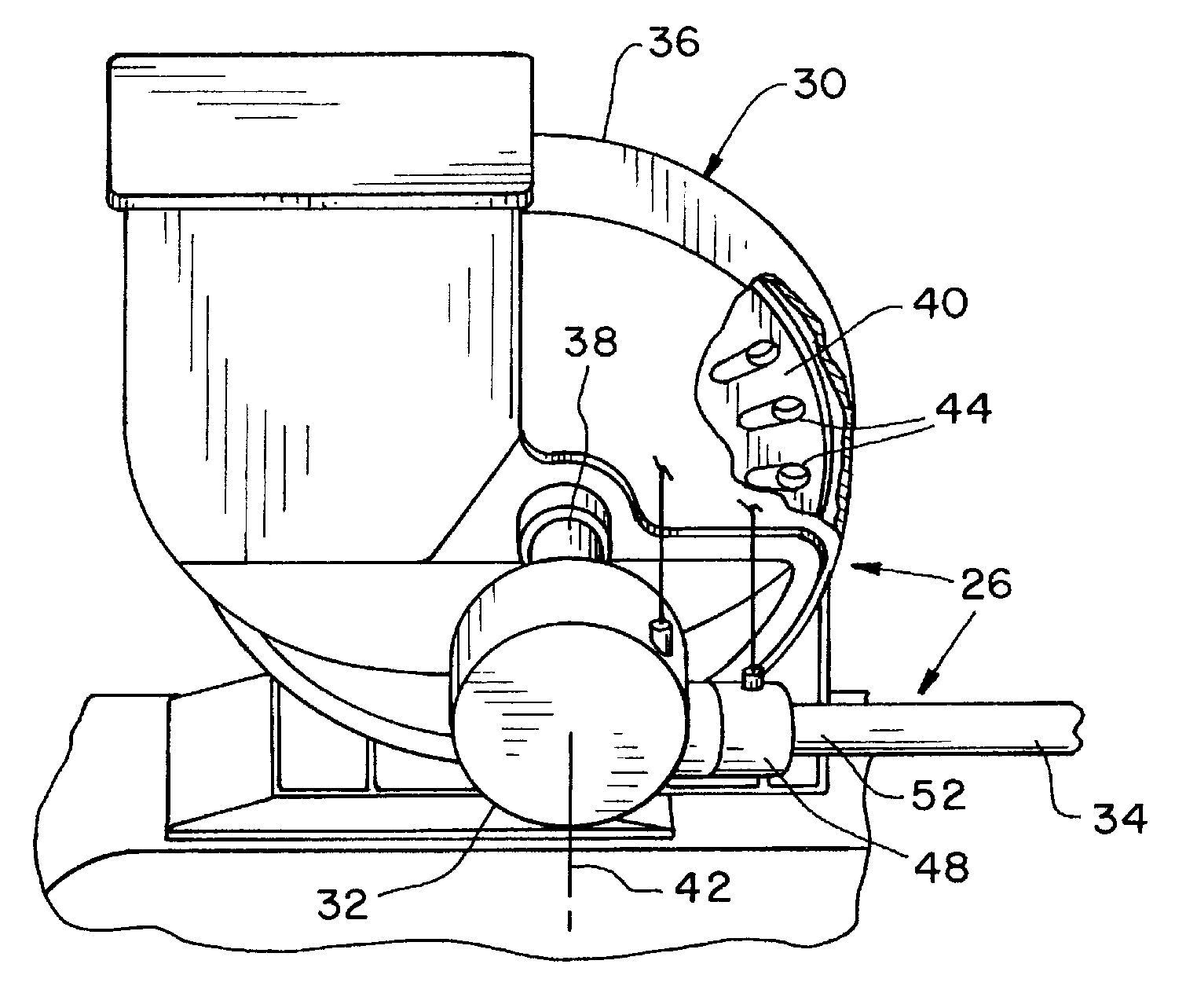

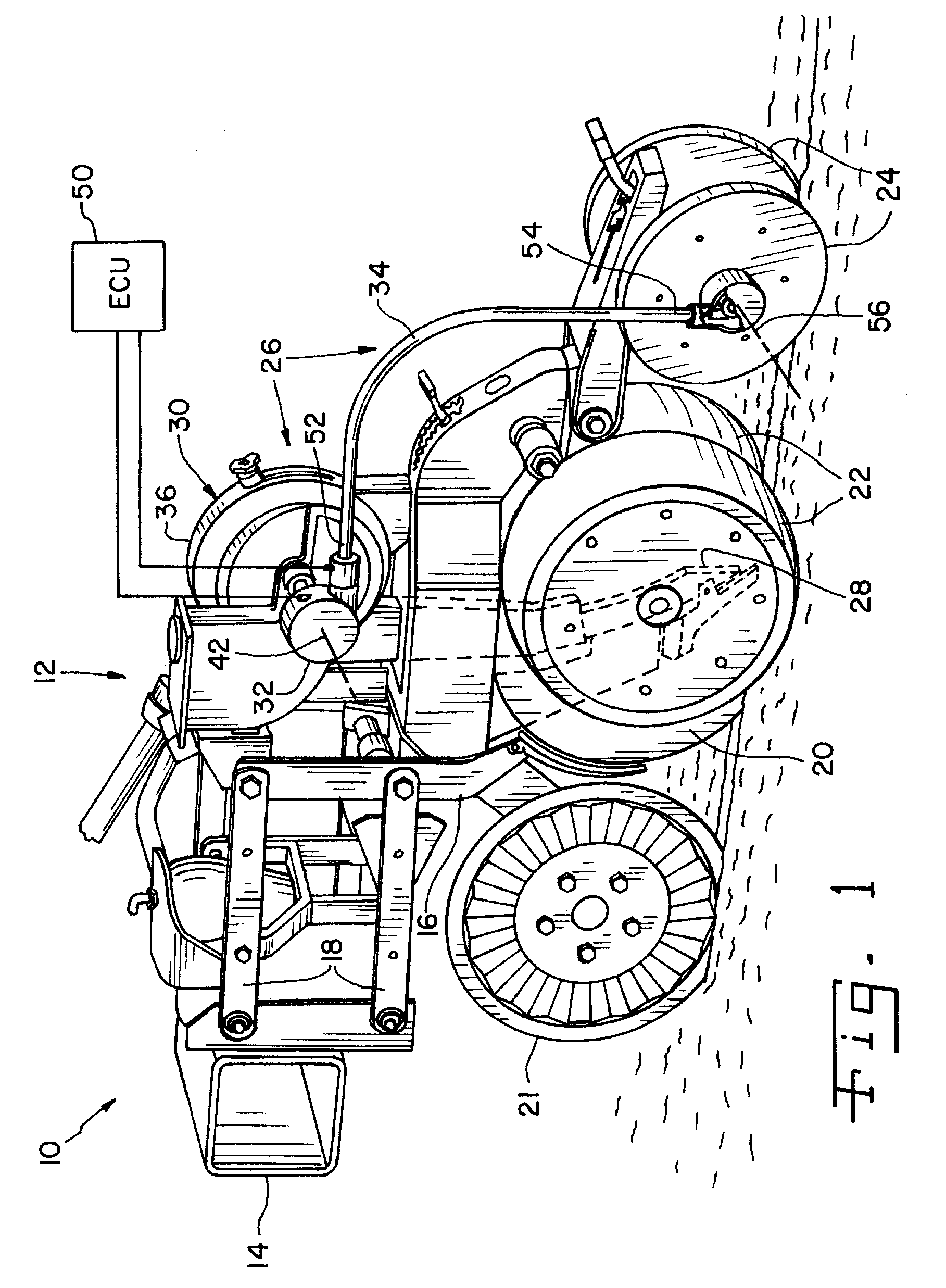

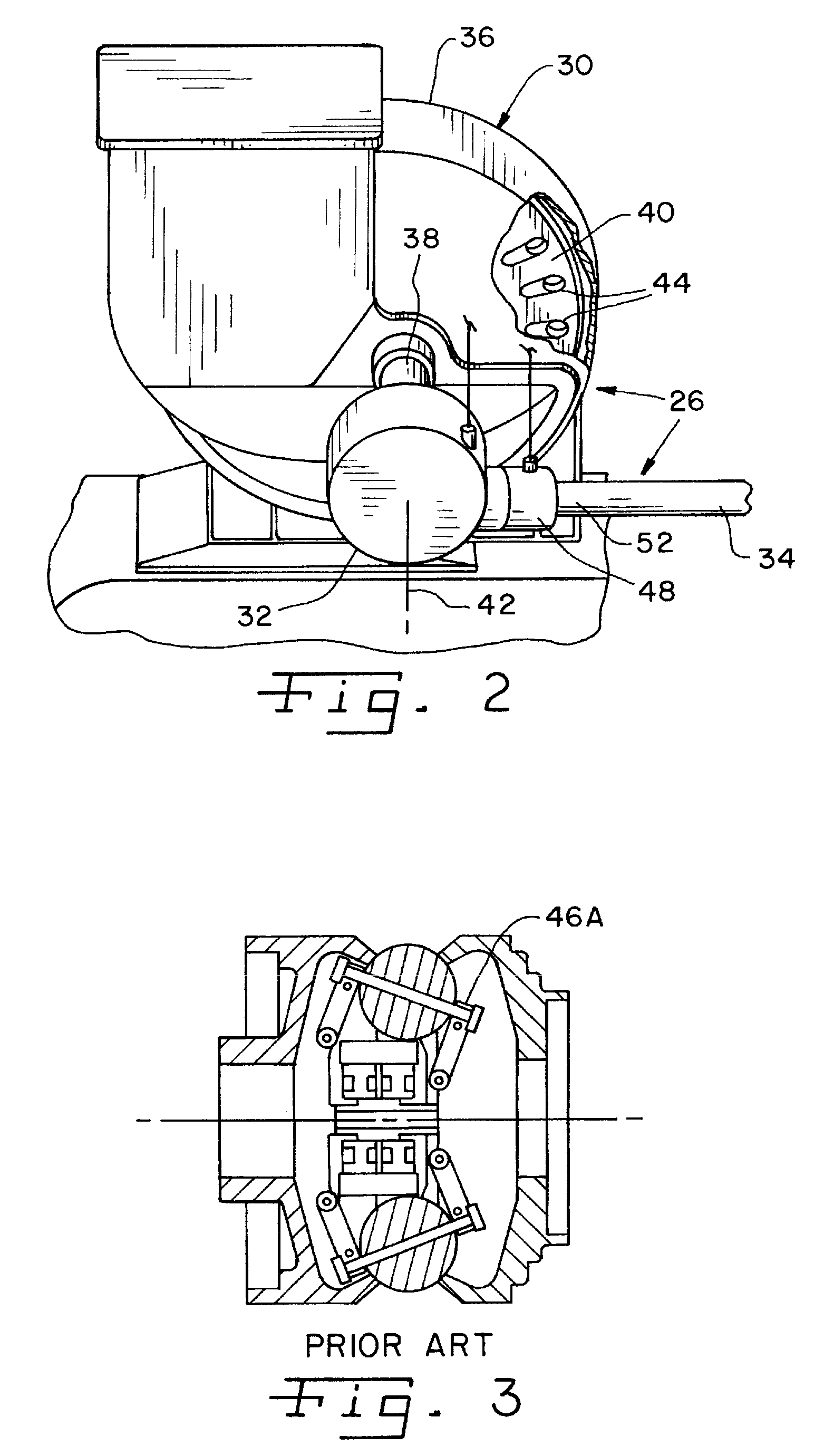

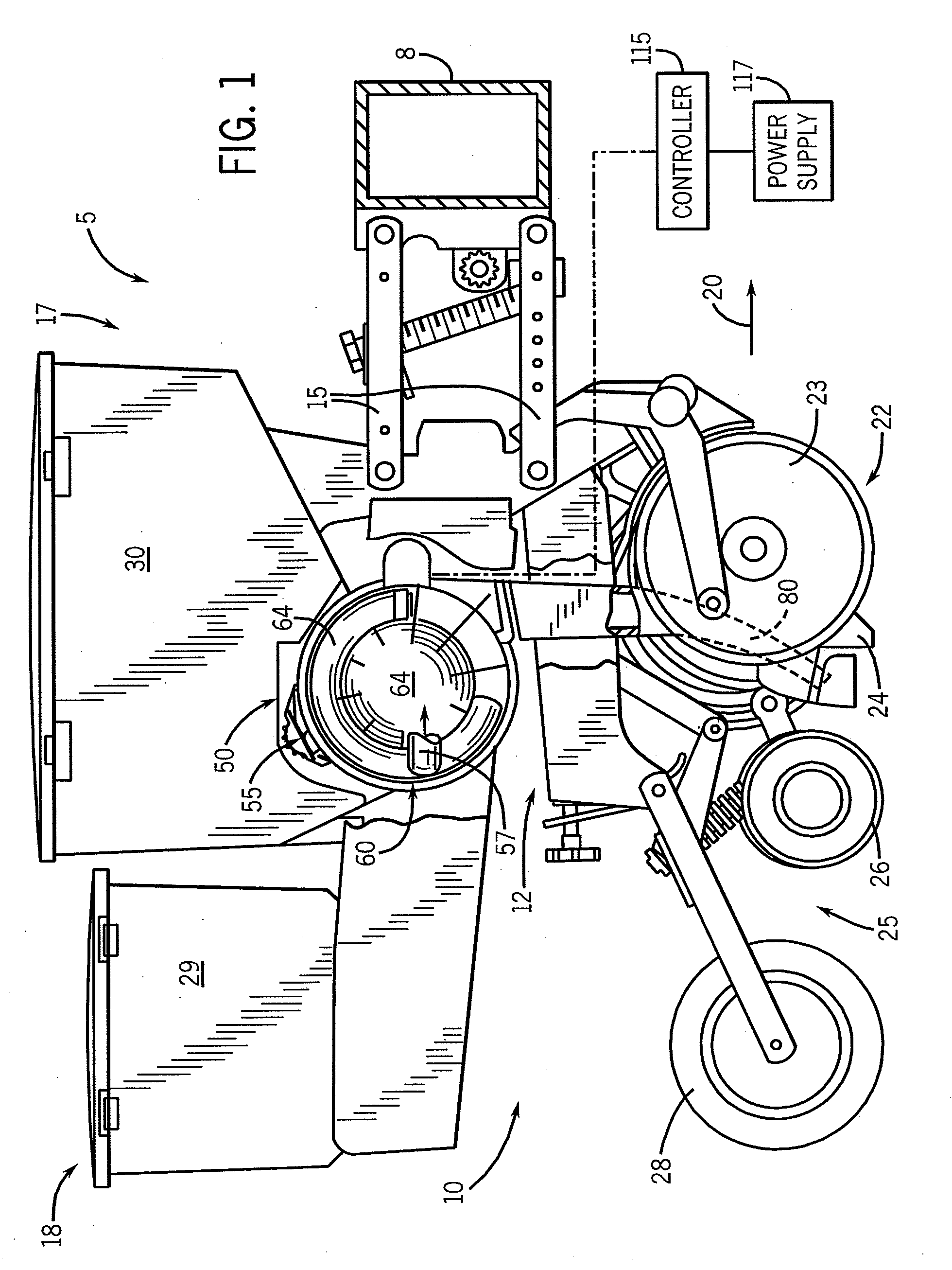

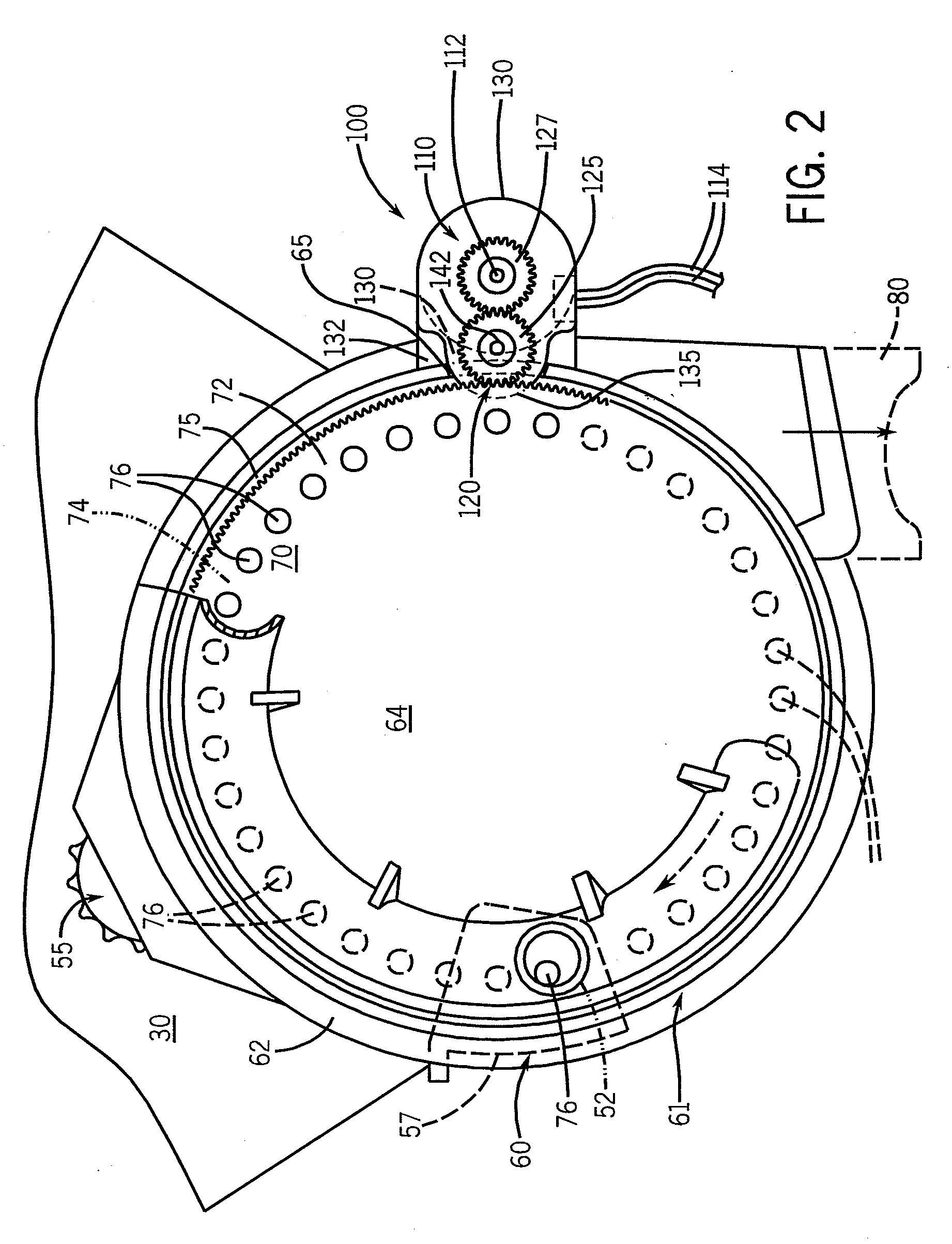

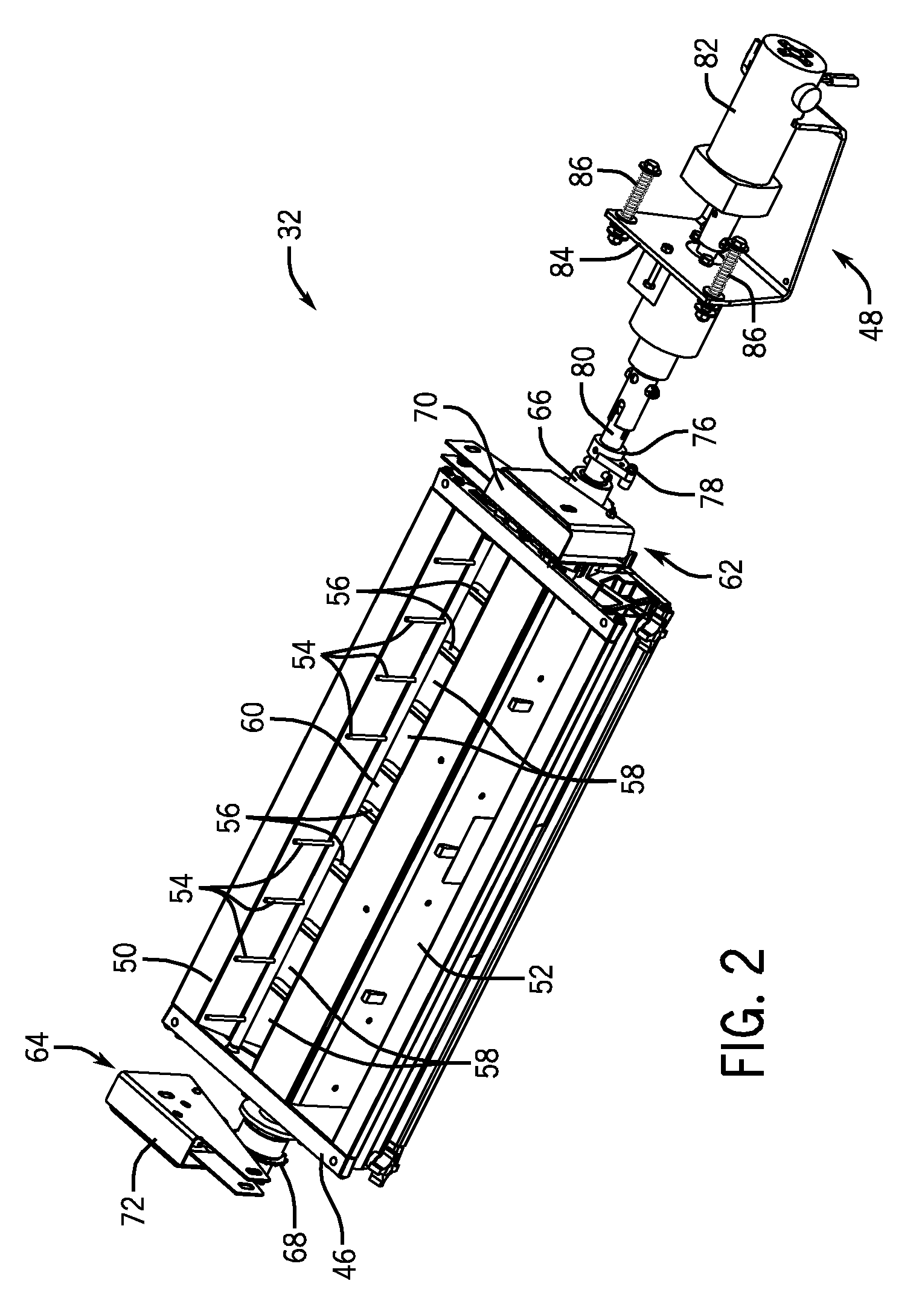

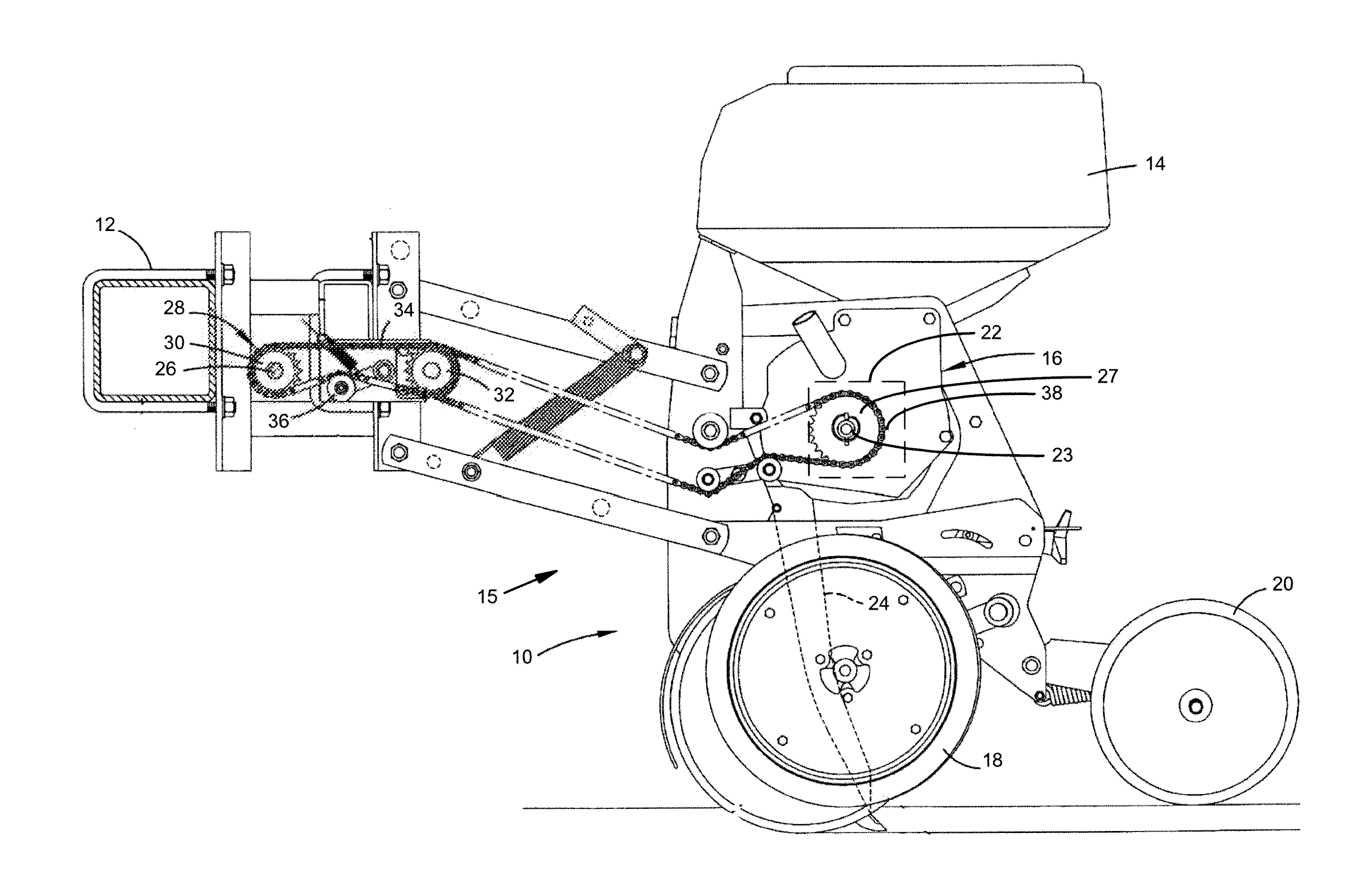

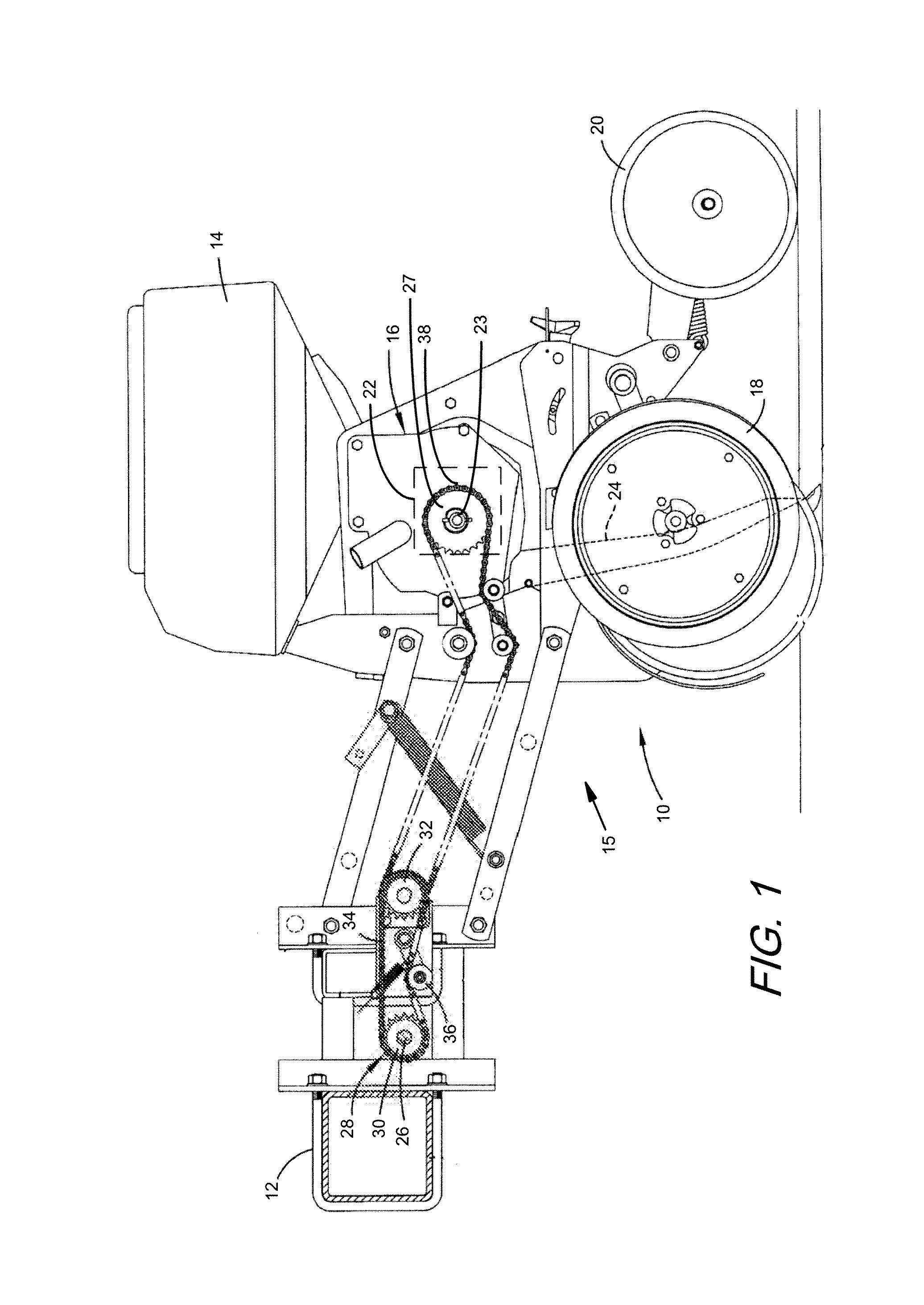

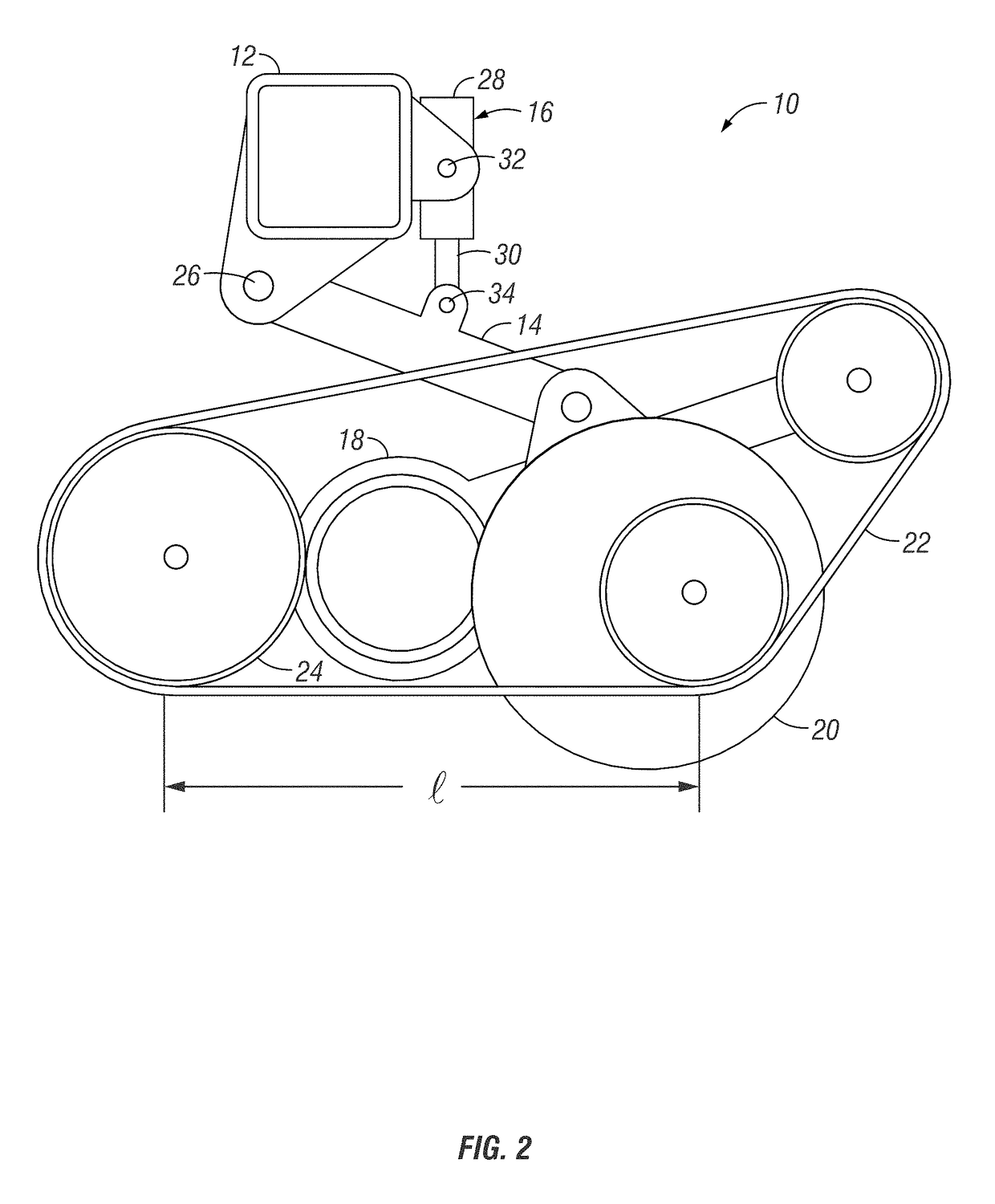

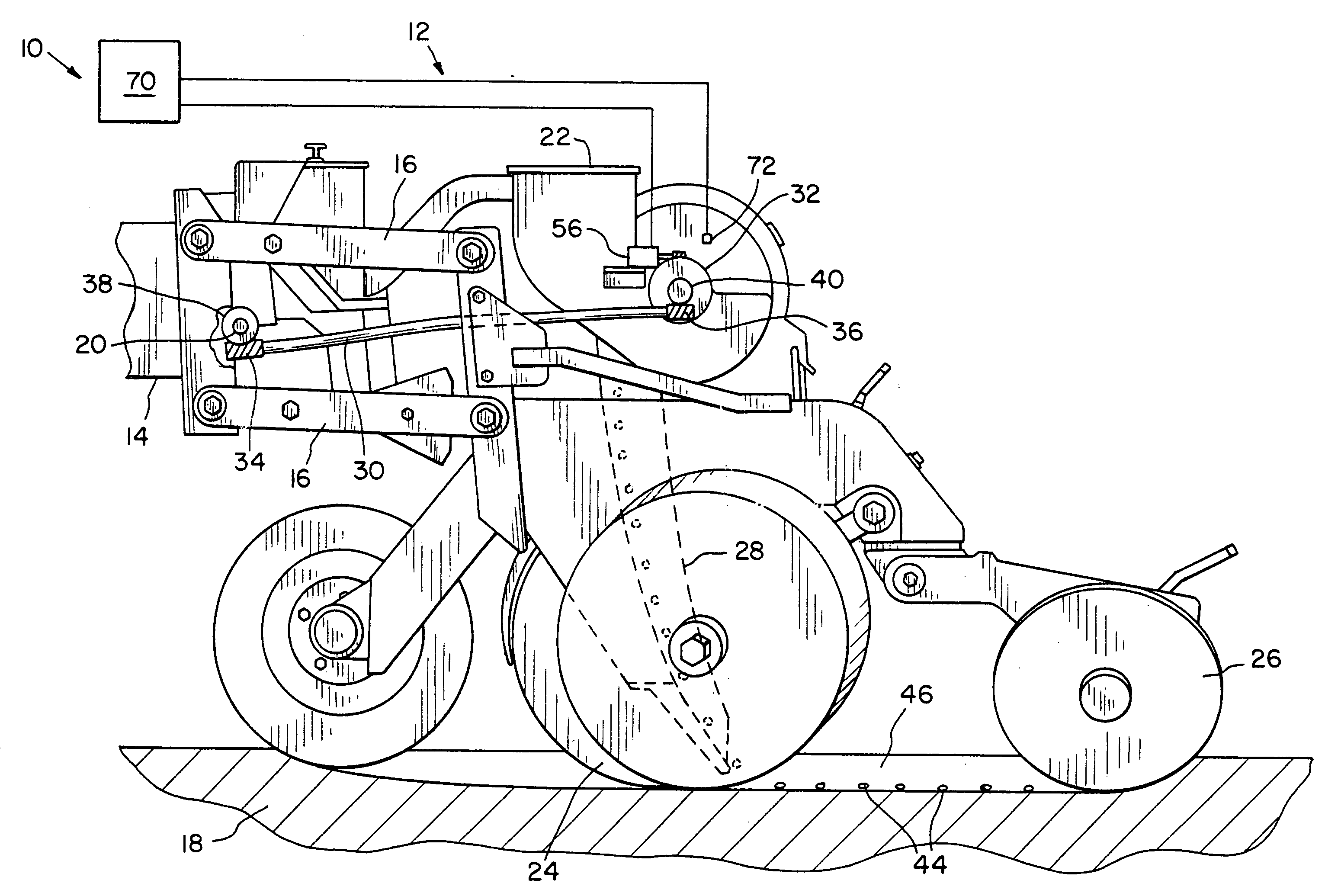

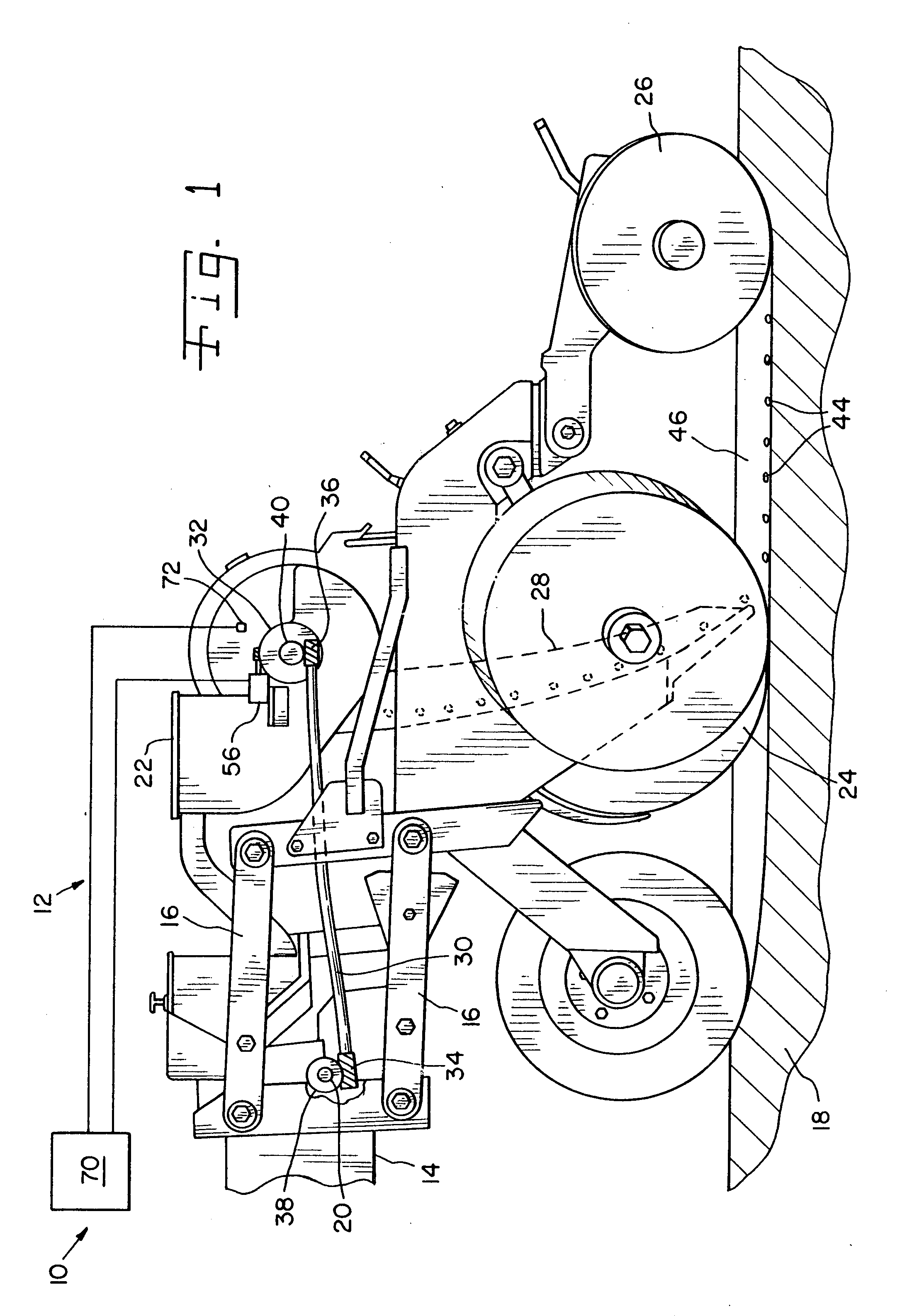

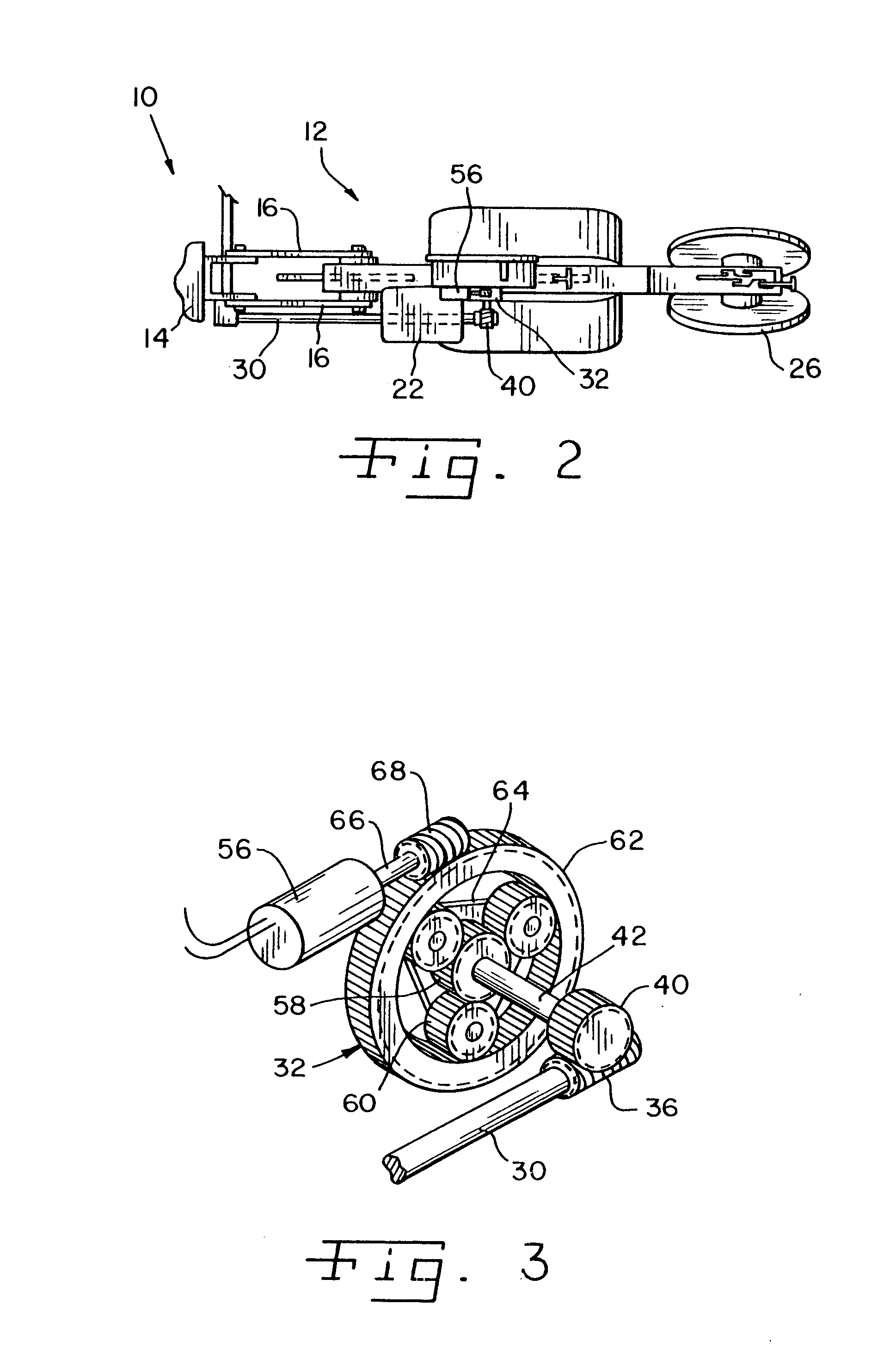

Direct drive electric seed metering system

ActiveUS7617785B2Improve uniformityReduce in quantitySowingPotato plantersElectricityAngular velocity

A direct drive electric seed metering system is provided for use with a row crop planter or seed planter that intakes a volume of multiple seeds from a seed hopper, draws individual seeds from the volume of multiple seeds and discharges them into a seed furrow formed in an agricultural field. The direct drive electric seed metering system includes a meter assembly having a meter housing and a seed plate rotatably mounted concentrically in the housing for singulating the seeds. A direct drive mechanism is mounted to the meter assembly for interfacing and driving the seed plate at an angular velocity which corresponds to the travel velocity of the seed planter. A single seed planter can have multiple direct drive electric seed metering systems, and each of the multiple direct drive electric seed metering systems preferably has its own prime mover to effectuate driving the seed plate.

Owner:BLUE LEAF I P INC

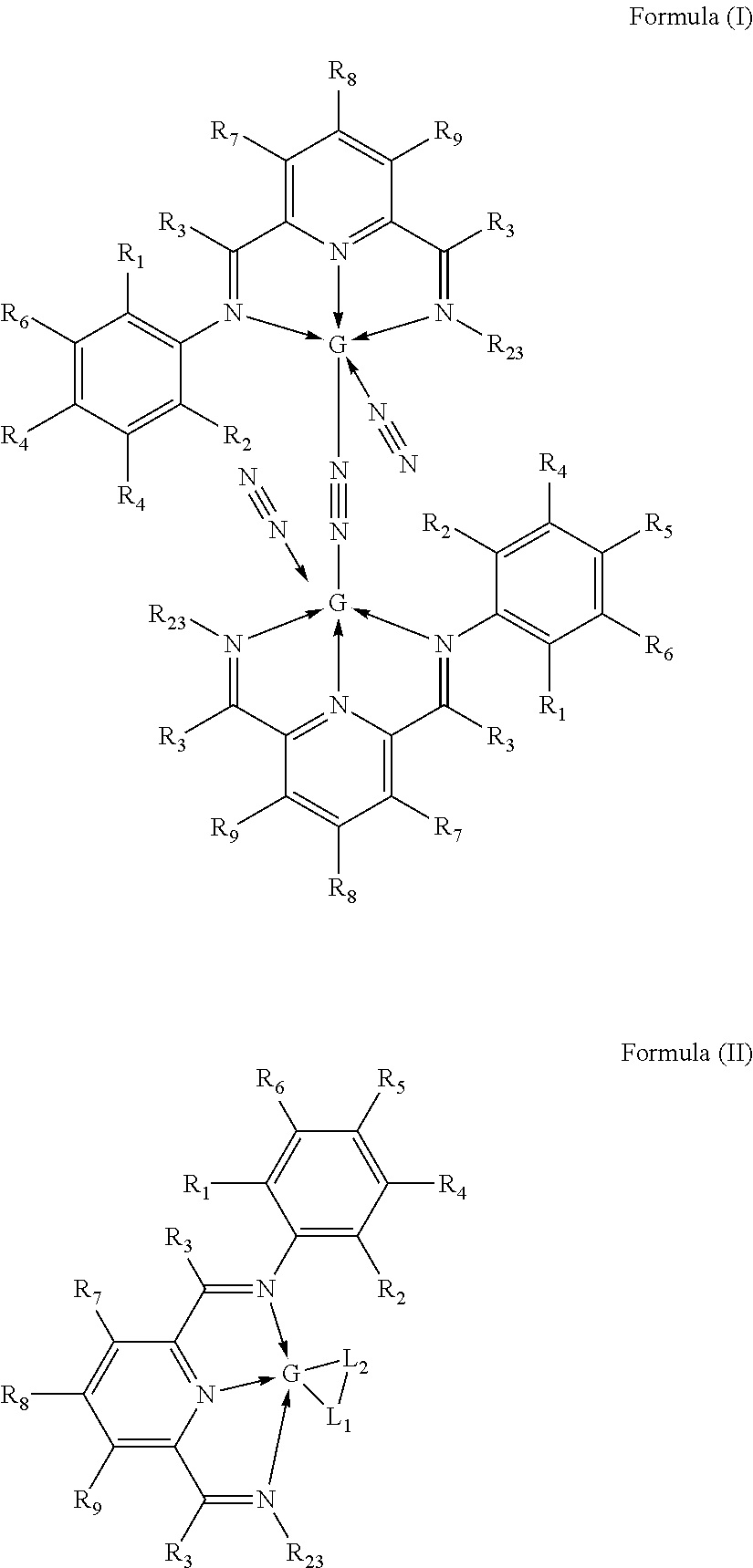

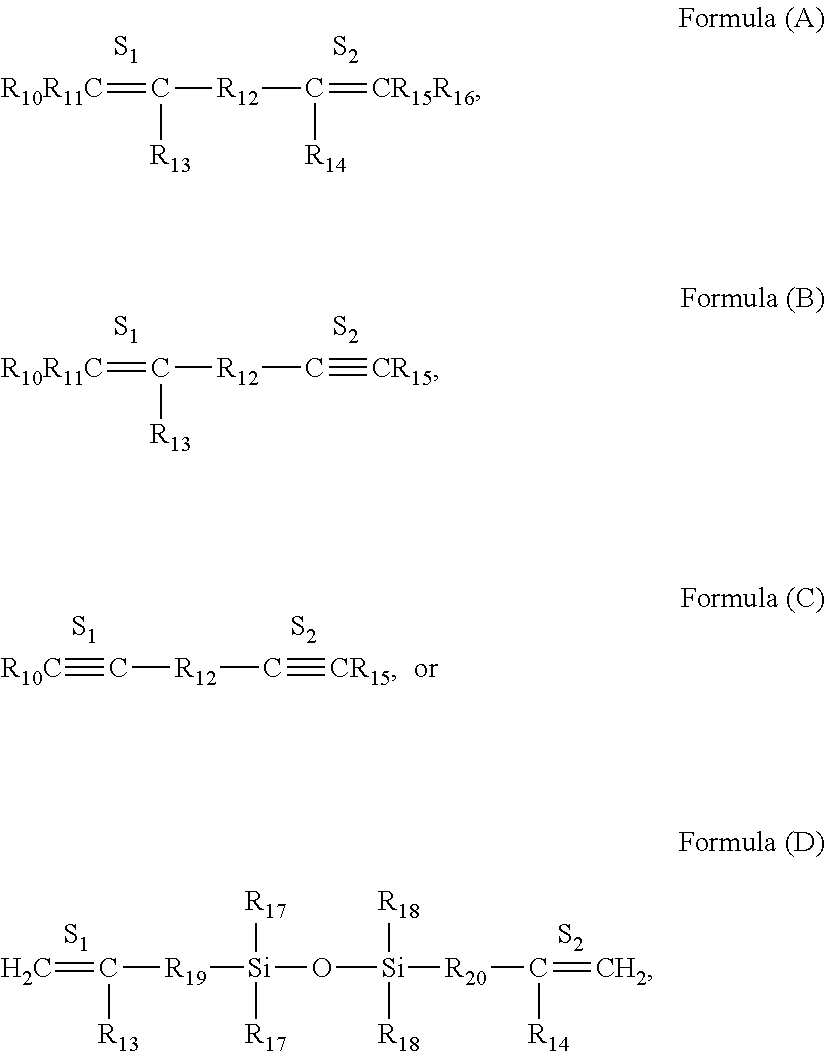

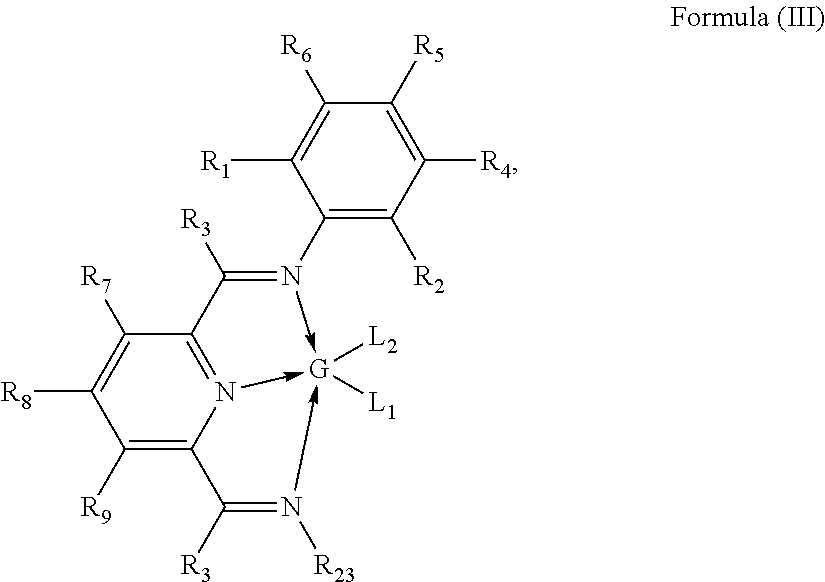

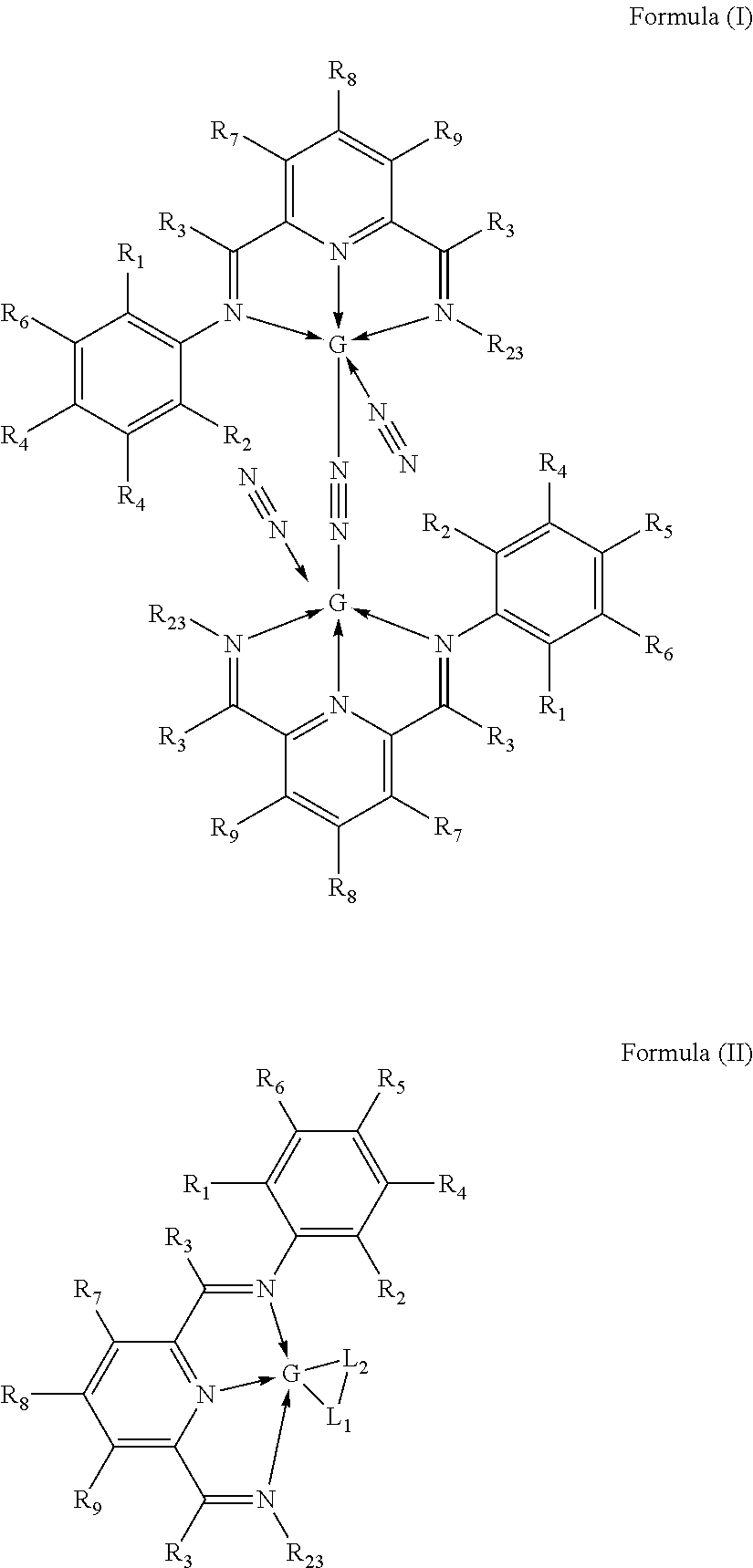

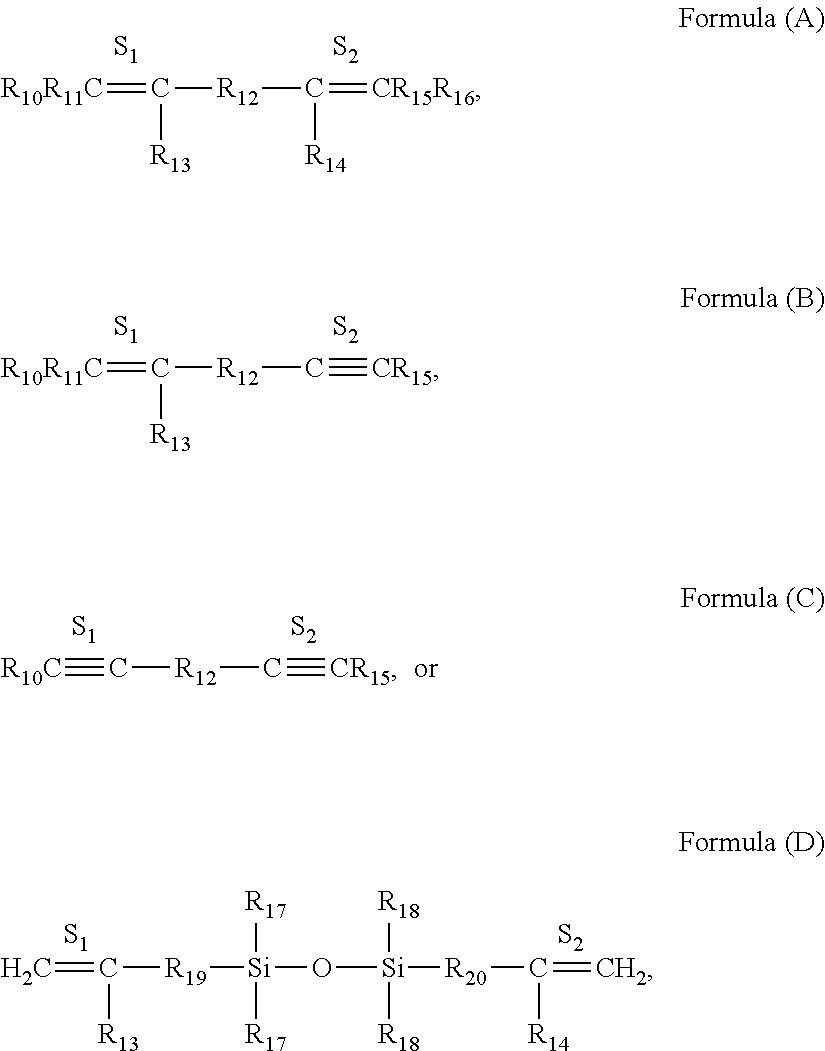

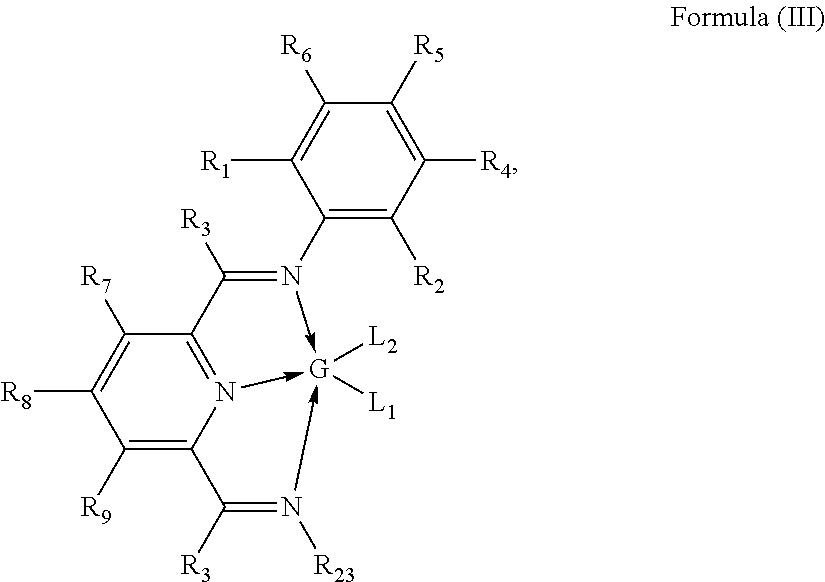

Hydrosilylation catalysts

ActiveUS8236915B2Group 4/14 element organic compoundsOther chemical processesManganeseHydrosilylation

Owner:CORNELL UNIVERSITY +1

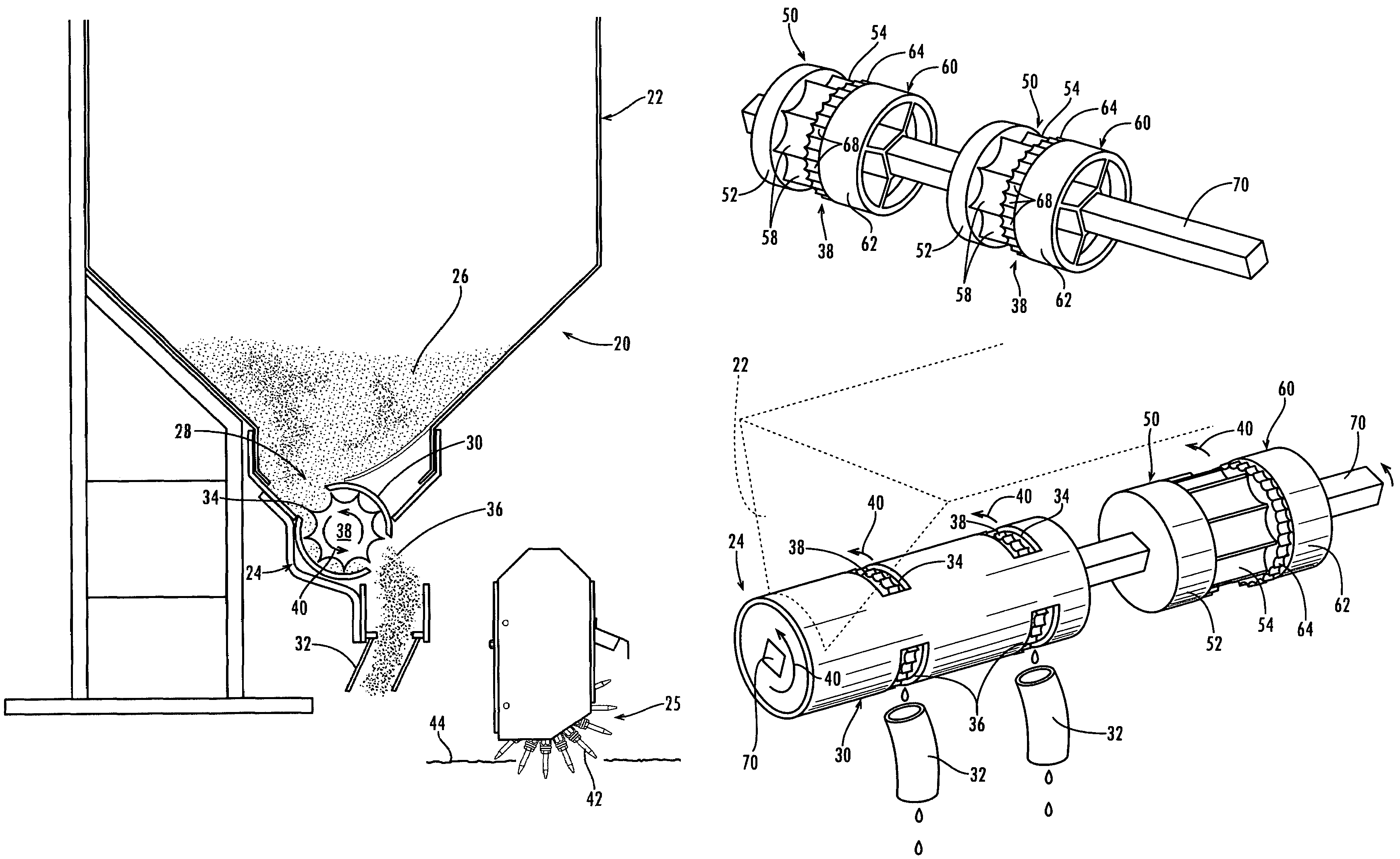

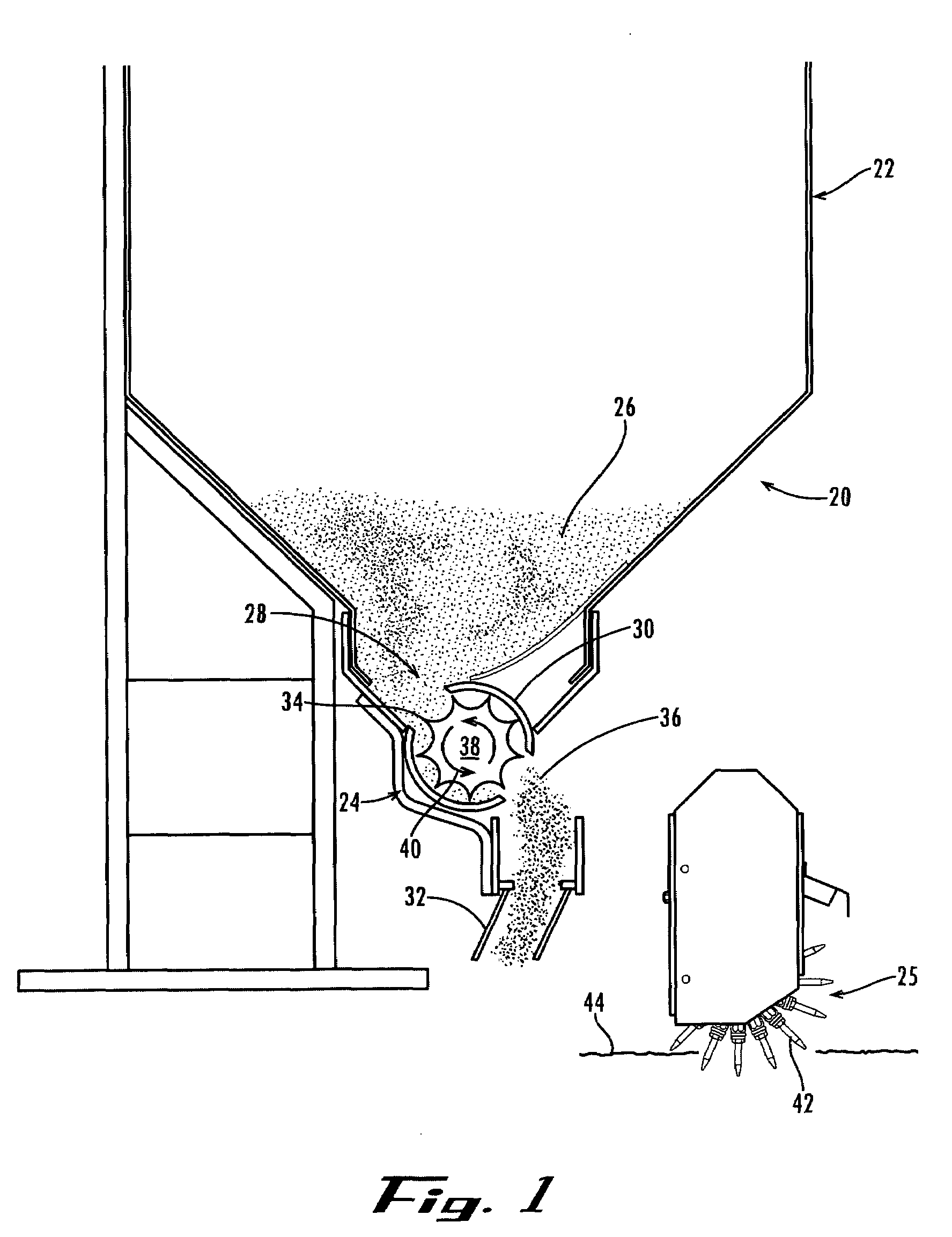

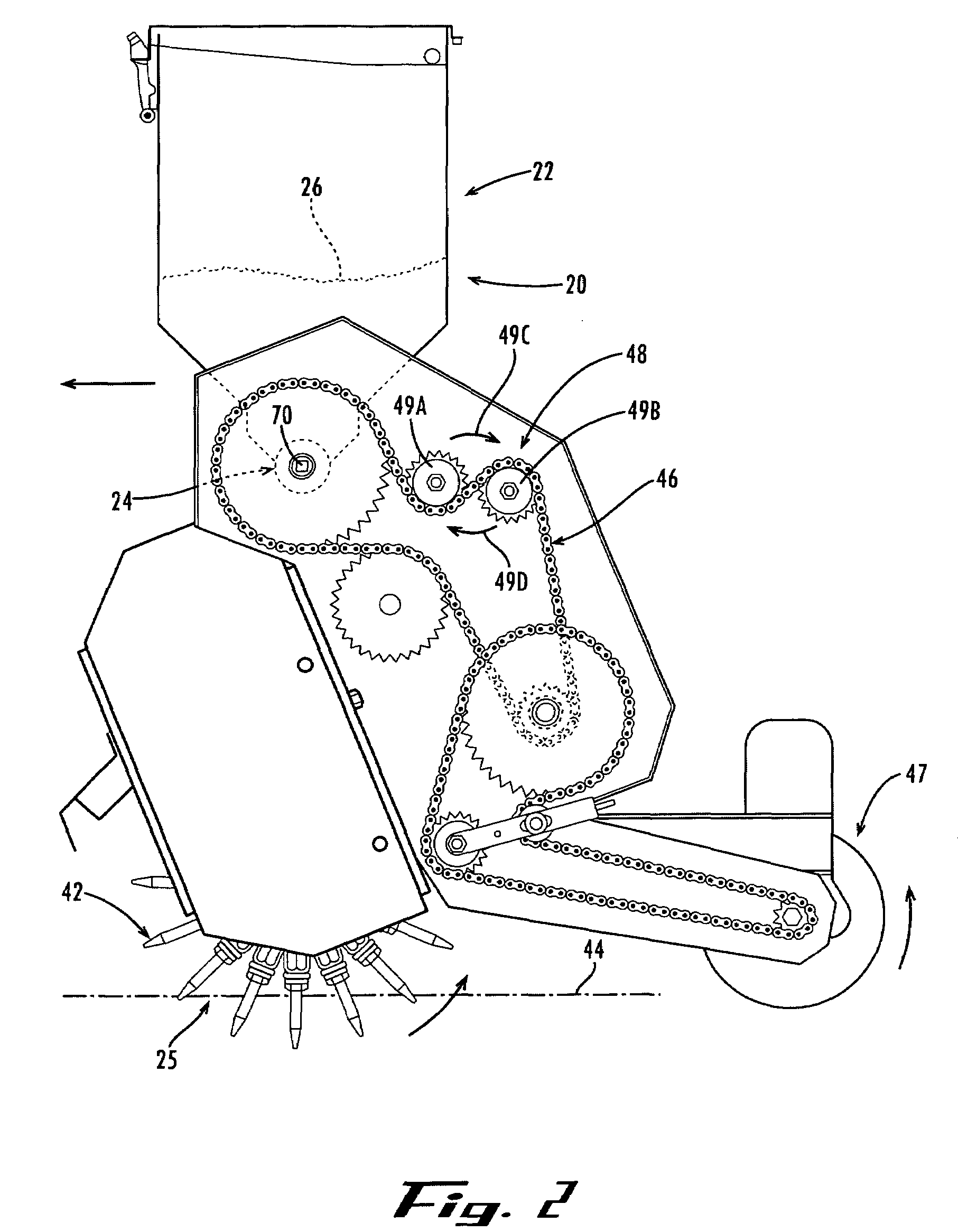

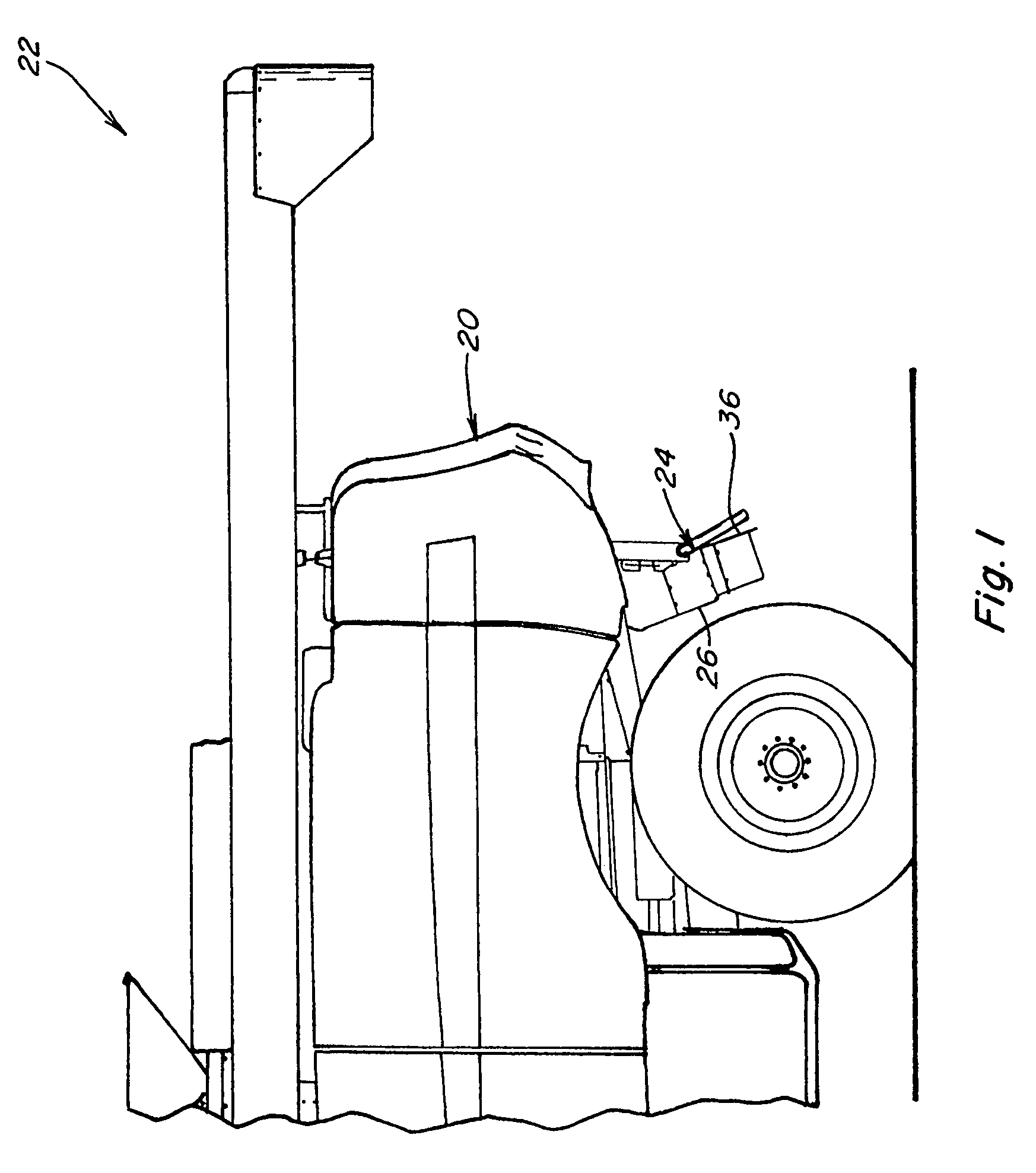

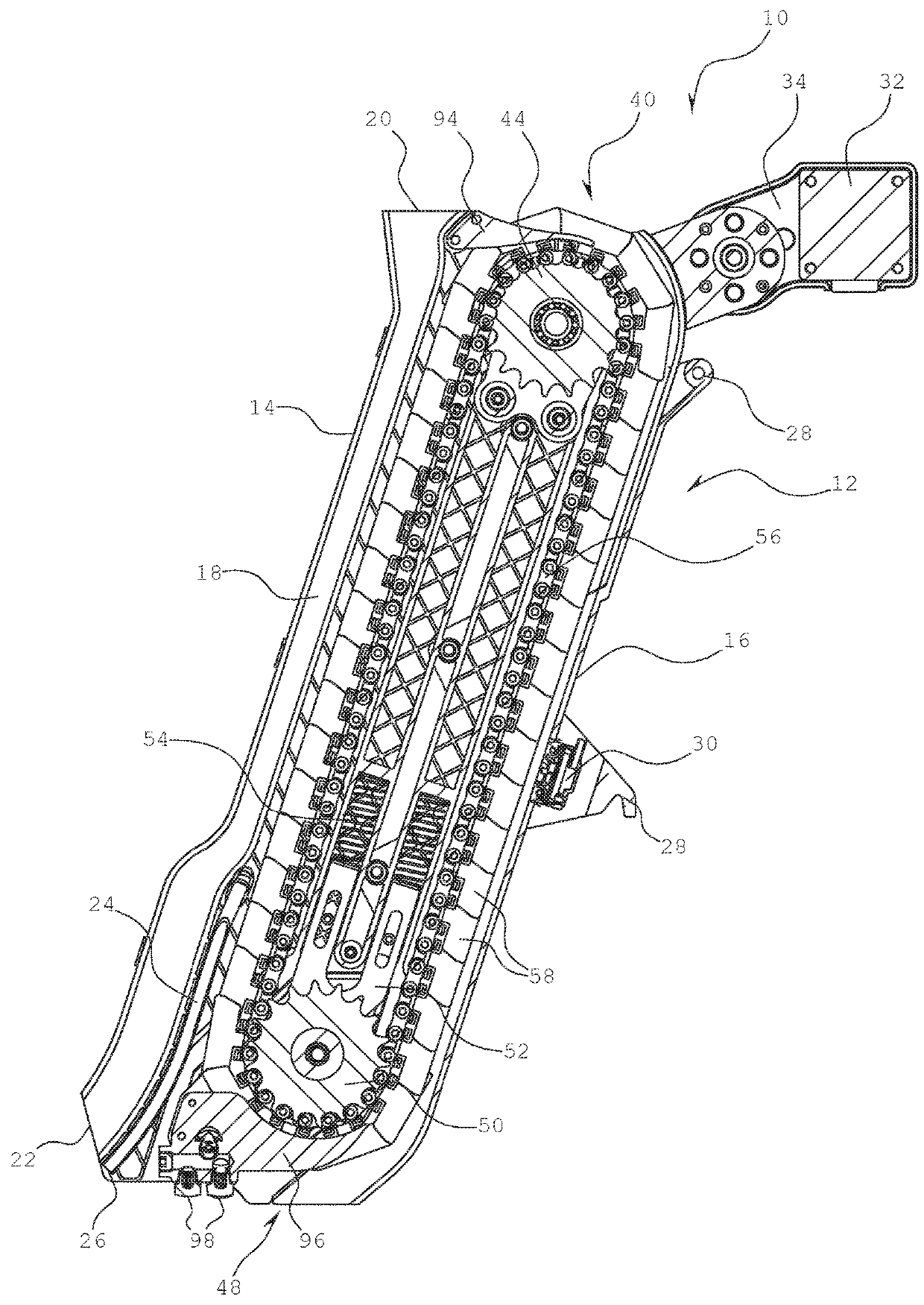

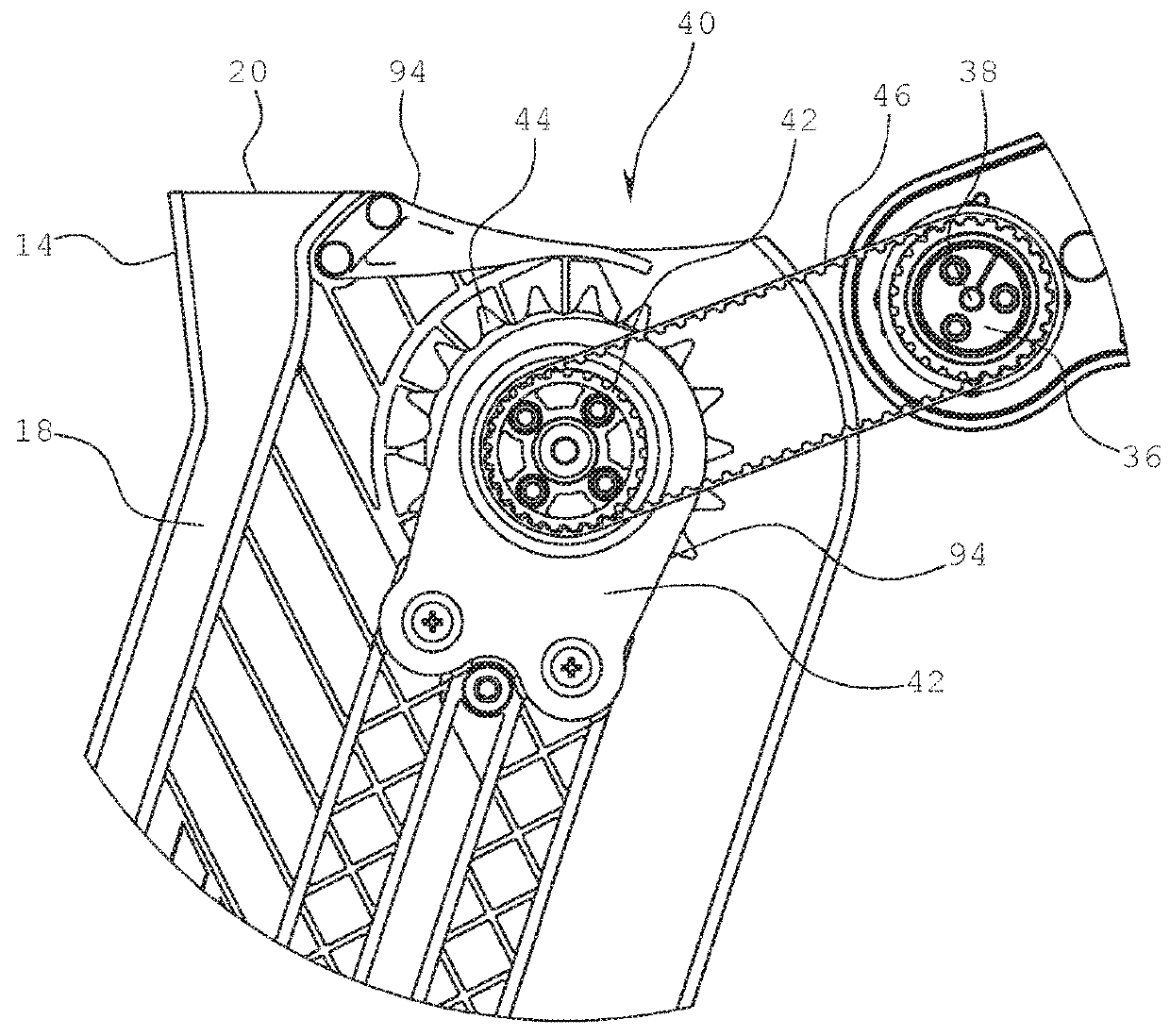

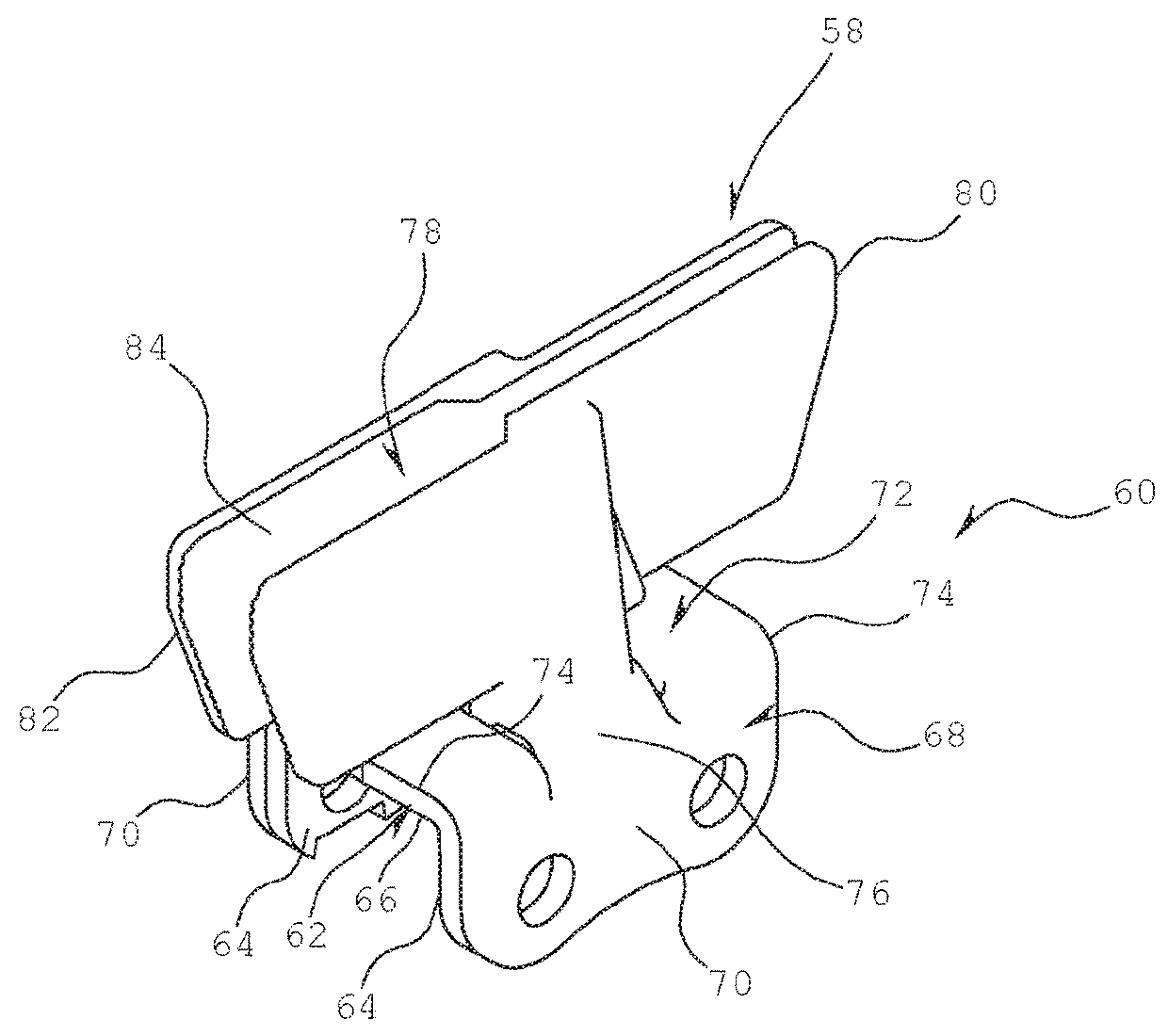

Multiple sized seed dispenser and turf aerator

A seeder (20) includes a seed hopper (22) that feeds seed by gravity to a seed dispenser (24). The seed feed wheels (38) of the seeder are mounted in a seed metering tube (30) so that rotation of the seed feed wheels meters the output of the seeds. The seed feed wheels can be formed in segments (50 and 60) so that by matching different segments, different sizes of seed receiving detents can be used for dispensing the seeds. An adjustment bracket (72) shifts the seed feed wheels so that different sizes of detents can register with the openings of the seed metering tube (30), thereby achieving the desired matching of sizes of detents with the sizes of the seeds.

Owner:FIRST PRODS A MINNESOTA CORP

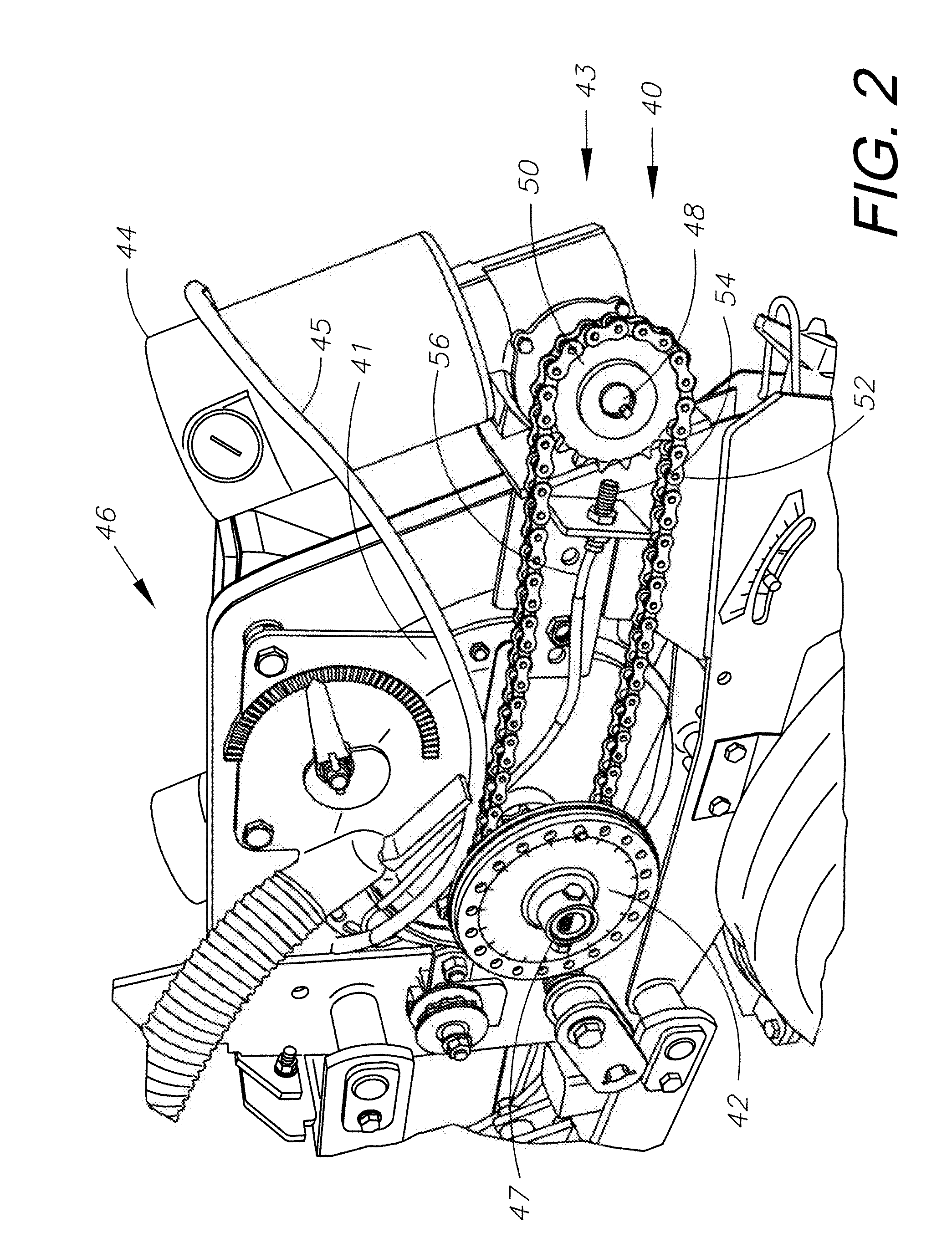

Variable speed drive for agricultural seeding machines

An agricultural seeding machine includes a mechanical drive; a seed meter including a driven shaft; and a planetary gear set. The planetary gear set includes an input shaft connected with the drive, an output shaft connected with the driven shaft, a ring gear, and a motor coupled with a ring gear.

Owner:DEERE & CO

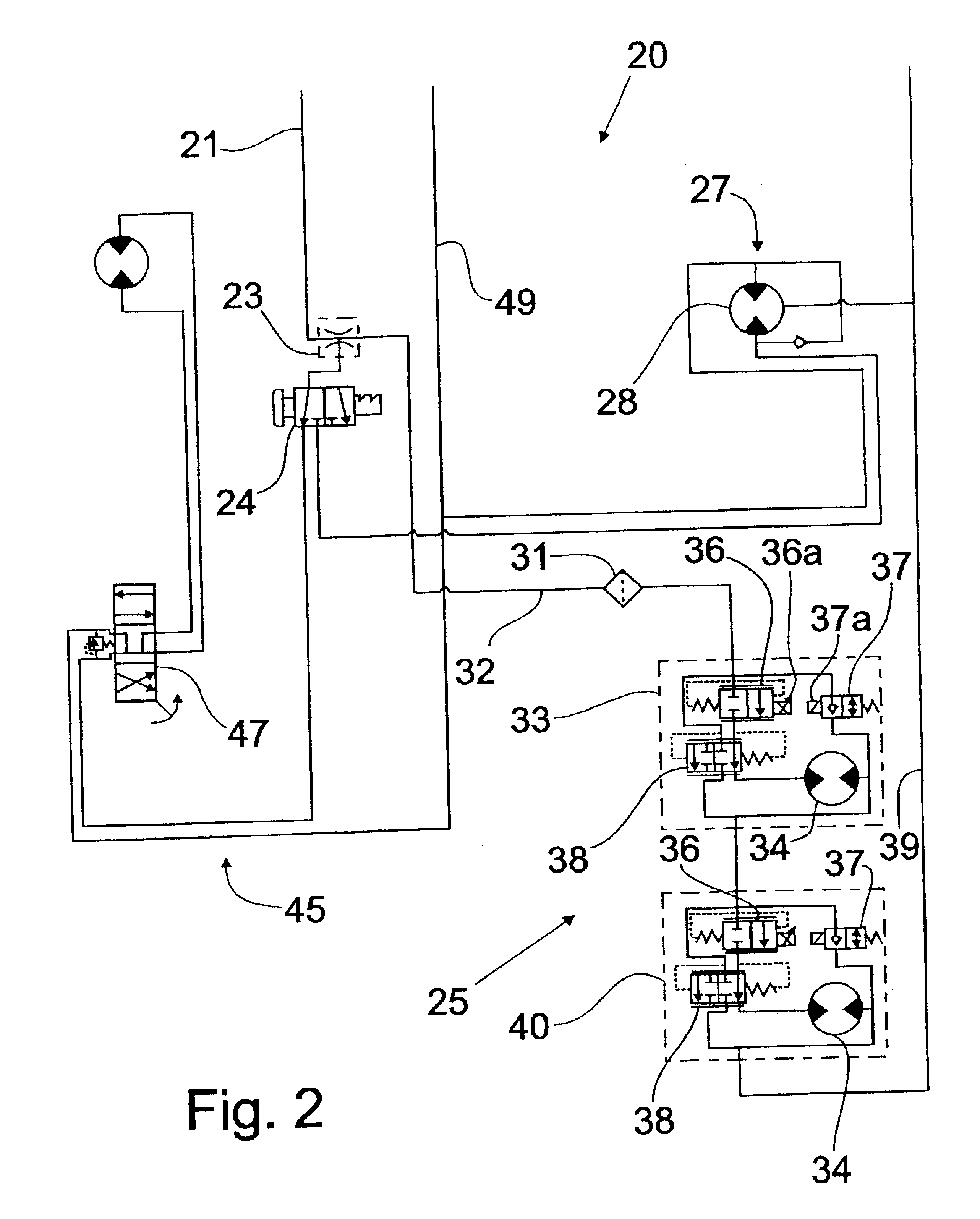

Variable rate meter drive system

InactiveUS6851377B2Efficiently usReduce manufacturing costServomotorsServometer circuitsHydraulic fluidControl theory

A hydraulic drive system provides a priority flow of hydraulic fluid to a variable rate drive system for powering the operation of the metering mechanisms before hydraulic fluid is supplied to a secondary drive mechanism for powering the operation of secondary devices, such as the fan mechanism or the loading auger. The hydraulic drive system includes a priority flow divider valve that diverts a predetermined flow rate to the variable rate drive system. The variable rate drive system includes a drive mechanism arranged in series for a plurality of metering mechanisms. The secondary drive system includes a selector valve that permits a selection between the alternative secondary devices. An alternative embodiment of the hydraulic drive system includes a counter balance valve that operates to provide a priority flow to the variable rate drive system.

Owner:CNH IND CANADA

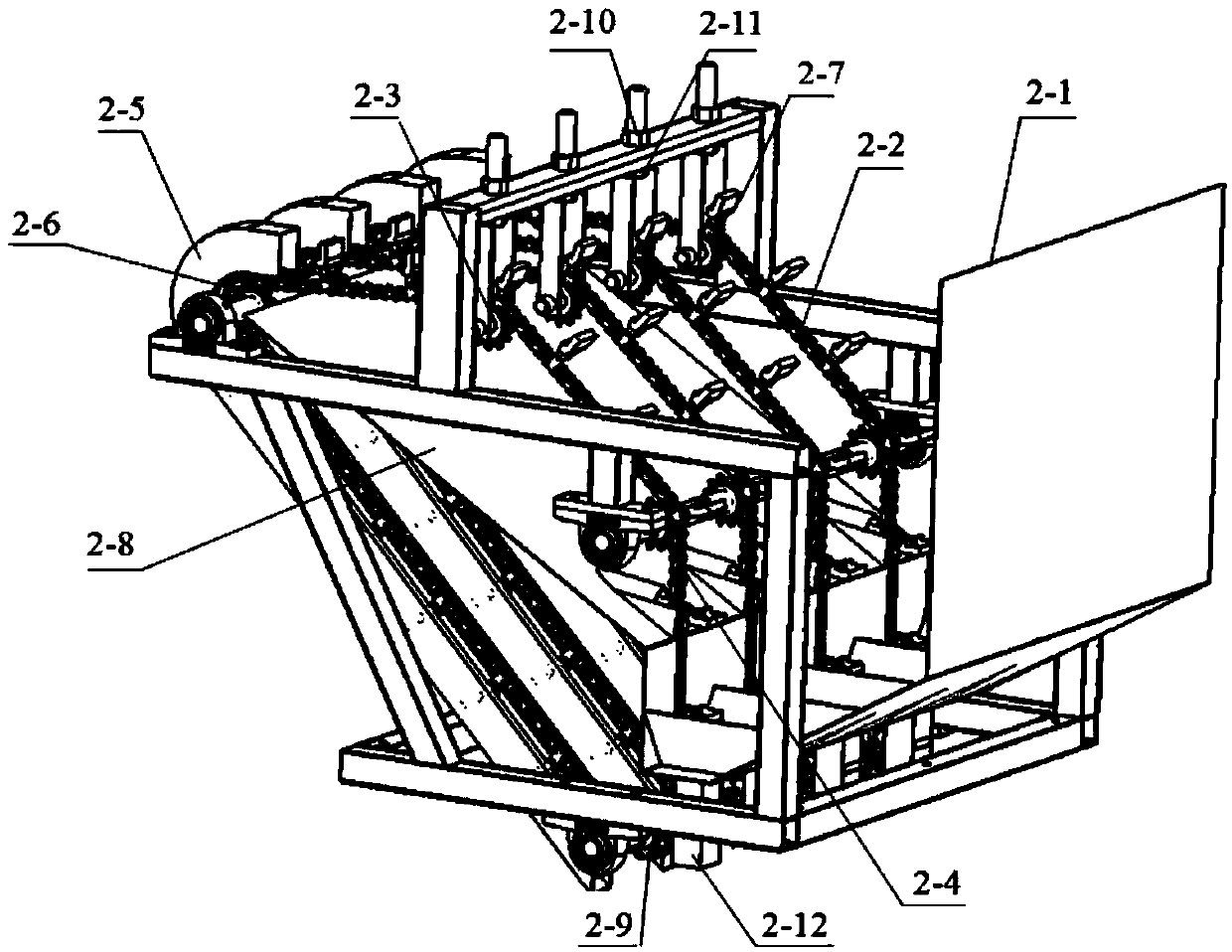

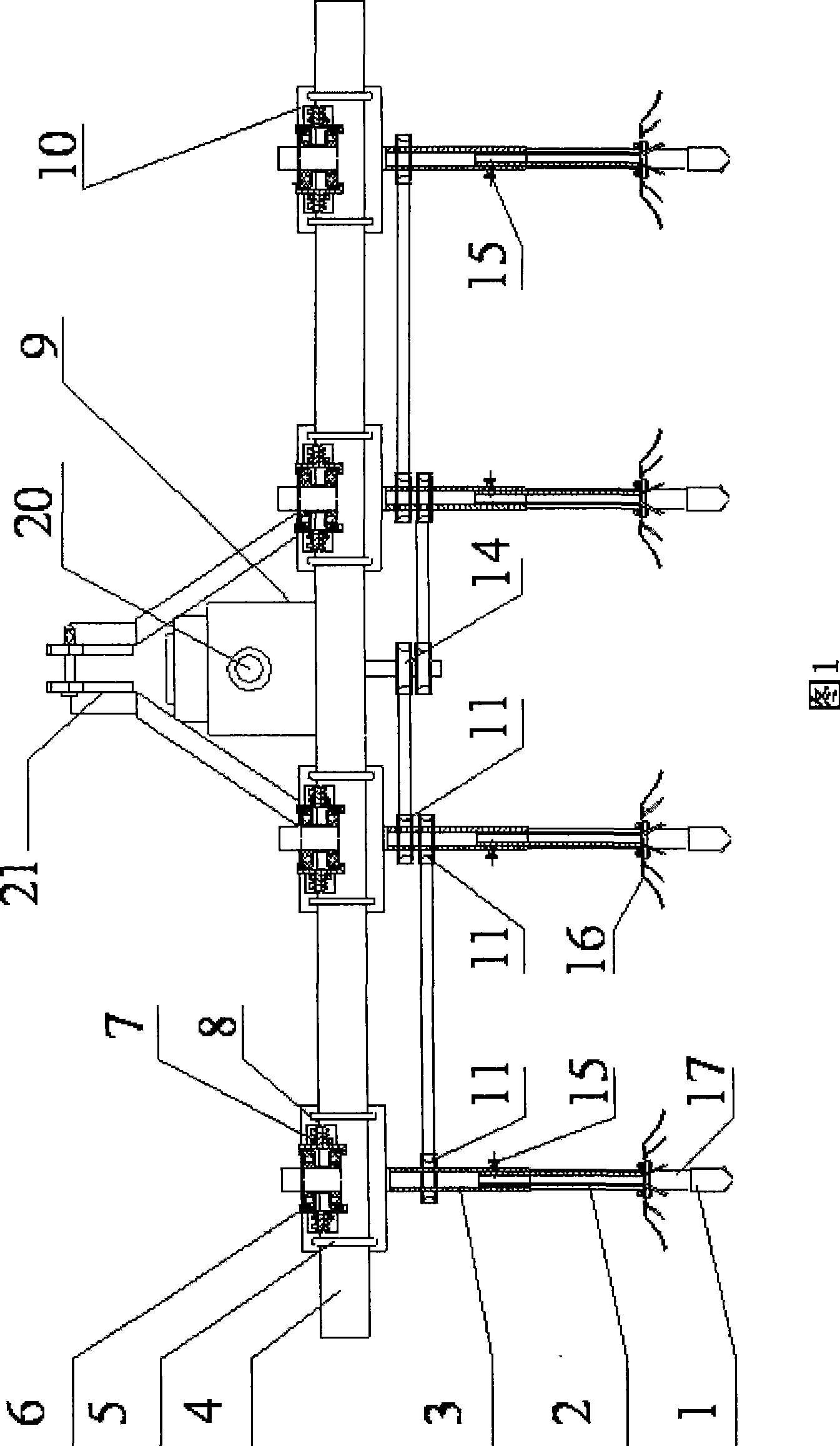

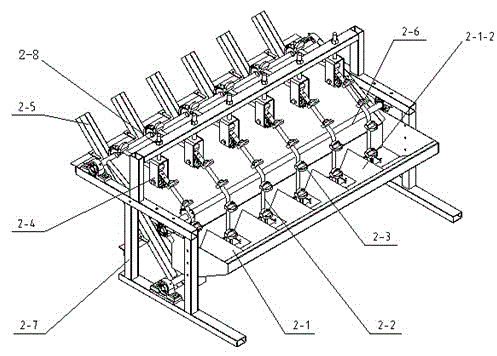

Garlic seeder

ActiveCN103733776AStable controlSow evenlySeed depositing seeder partsSingle grain seedersEngineeringAllium sativum

The invention discloses a garlic seeder which comprises a rack, a single seed grain taking device is arranged above the rack, a vertical planting device is arranged below the rack, a garlic bulbil direction control device matched with the two devices is arranged between the single seed grain taking device and the vertical planting device, and a drive assembly provides power for the single seed grain taking device, the vertical planting device and the garlic bulbil direction control device. By using the garlic seeder disclosed by the invention, seeding is uniform, the garlic bulbil direction is controlled stably, and the staggered upright sowing of seeds in adjacent rows can be realized, thereby facilitating the growth of garlics and the implementation of mechanized harvesting of garlics.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Environmentally compatible processes compositions and materials treated thereby

InactiveUS20040170742A1Cause and induce damageAvoid premature germinationBiocideInorganic active ingredientsEnvironmental resistanceWorkspace

Environmentally friendly processes for prevention of qualitative deterioration and quantitative loss of plant matter and foodstuffs, during all stages of storage and handling, including pre- and post-harvest, pre- and post-planting, distribution and marketing involves the use of H2O2 compositions including Ag and at least one of Cu and Zn ions. The processes can also be used to prevent sprouting and rooting, and to promote fecundity of certain plant matter, and can also be used to eliminate or reduce quantities of harmful organisms and substances from soil, other growth media and substrates, equipment, materials water, workspaces and surfaces.

Owner:PIMI AGRO CLEANTECH

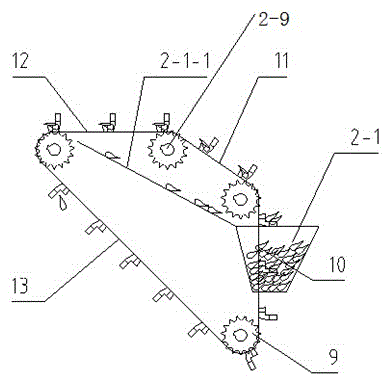

Accurate seed throwing mechanism and accurate seed throwing method of corn planter

InactiveCN104956815AGuaranteed spacing accuracyPrecision infusionSeed depositing seeder partsRegular seed deposition machinesAgricultural scienceSelf-gravitation

The invention relates to an accurate seed throwing mechanism and an accurate seed throwing method of a corn planter. The accurate seed throwing mechanism comprises a control part, a driving part and an executing part, wherein the executing part comprises a seed sowing device, a seed taking unit and a seed conveying unit; seeds can be adsorbed by profiled holes in a seed plate under the action of negative pressure, residual seeds are removed after the seeds adsorbed in the profiled holes in the seed plate pass through a seed scraping plate which is positioned above the left part of the seed sowing device, and only one seed is left in each profiled hole; pulling fingers of a seed taking wheel are used for pulling out the seeds which are about to drop in order and enabling the seeds to enter grilles formed by the pulling fingers and a seed guiding groove, the seeds are pushed to the left upper part of a conveyor belt by the pulling fingers and are thrown out, the seeds fall into separating grooves of the conveyor belt under the action of gravitation and move to the bottom part of the seed conveying unit along with the conveyor belt, and the seeds can fall onto a seedbed under the action of a pushing force of separating plates of the conveyor belt and the self gravitation of the seeds. The electrically-driven accurate seed throwing mechanism disclosed by the invention is capable of initiatively taking the seeds, accurately conveying the seeds, realizing real-time zero-speed seed throwing and maintaining the spacing accuracy of the seeds and has the characteristics that the structure is simple, the adjustment is convenient, and the like.

Owner:CHINA AGRI UNIV

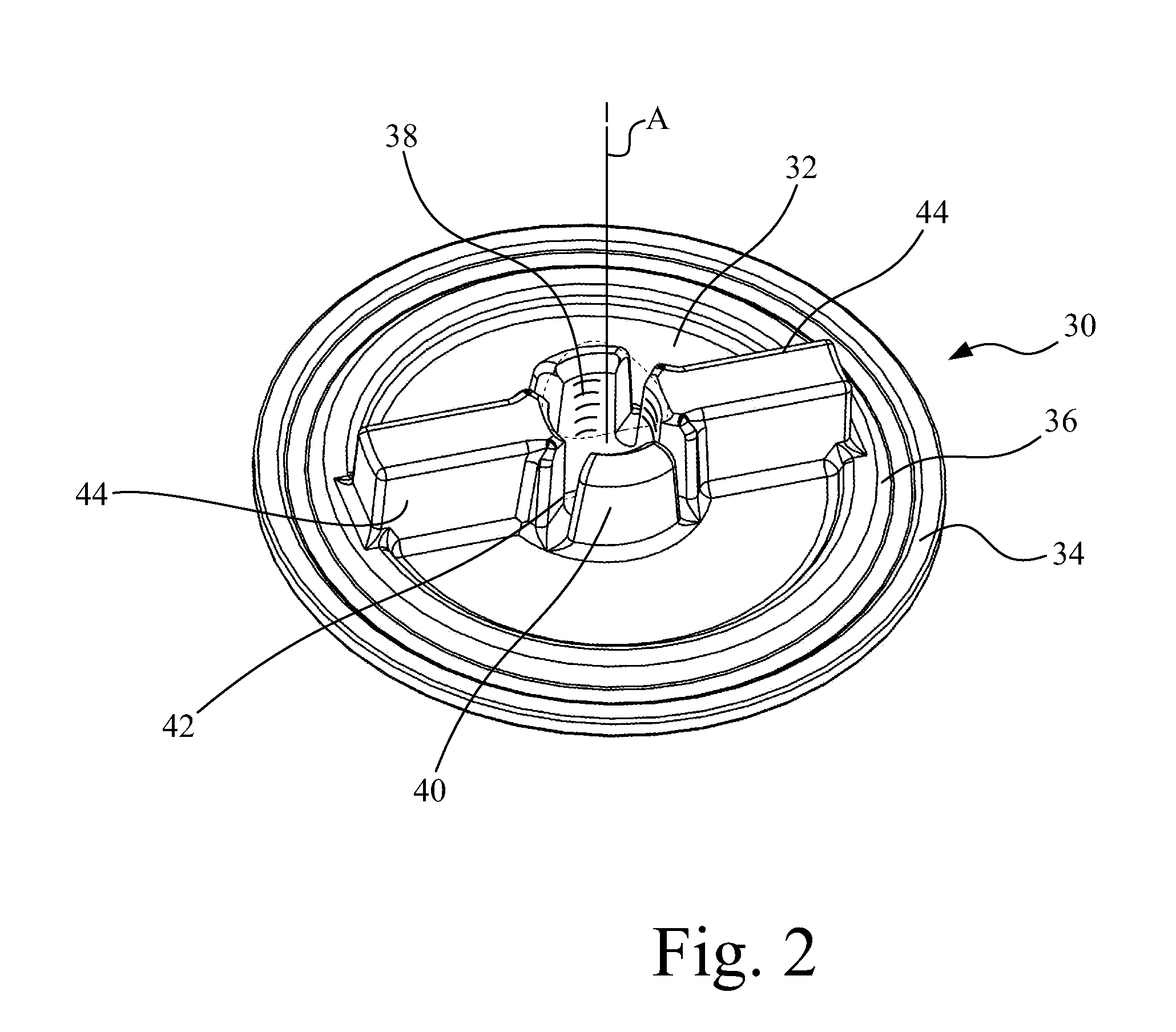

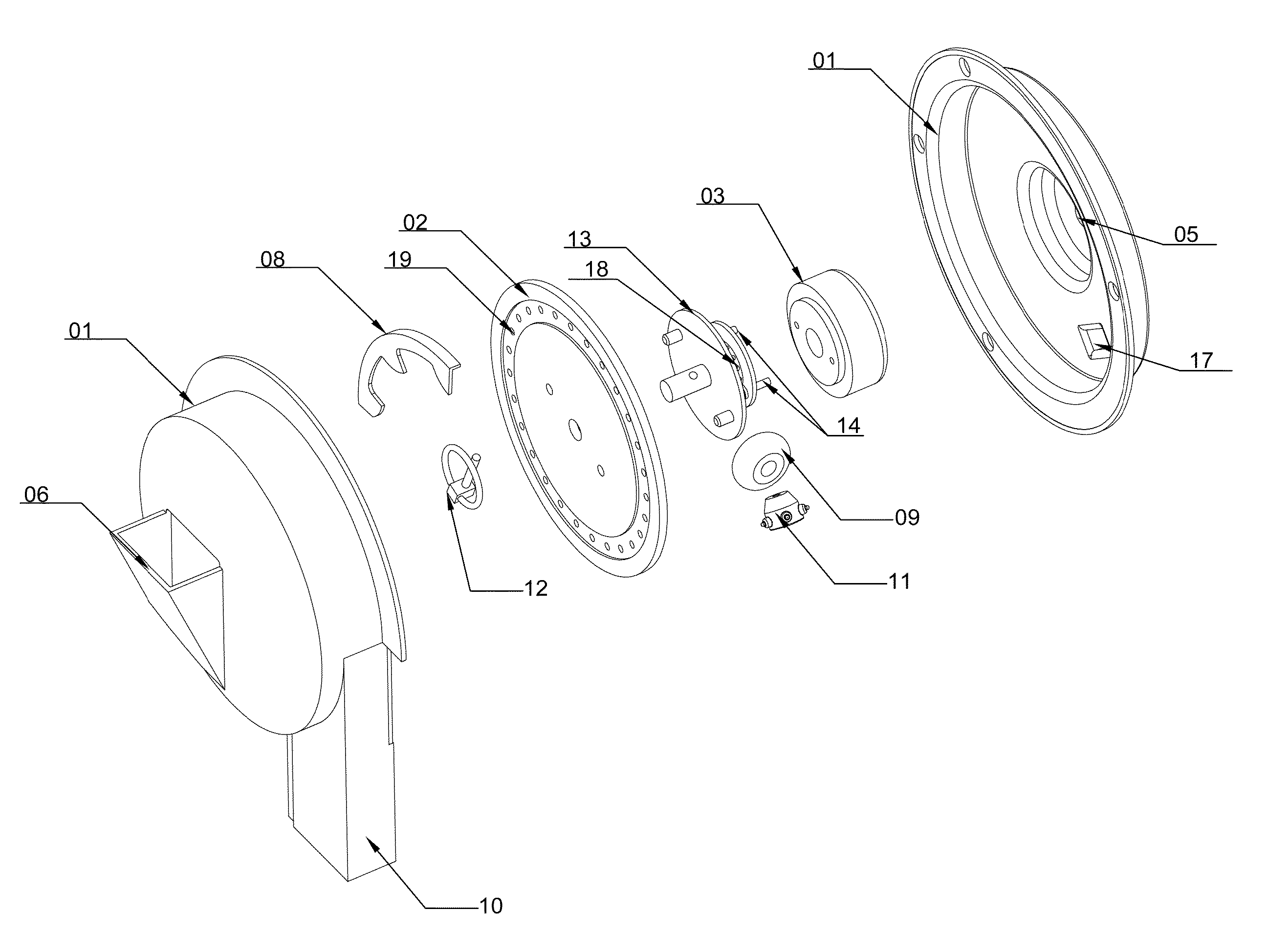

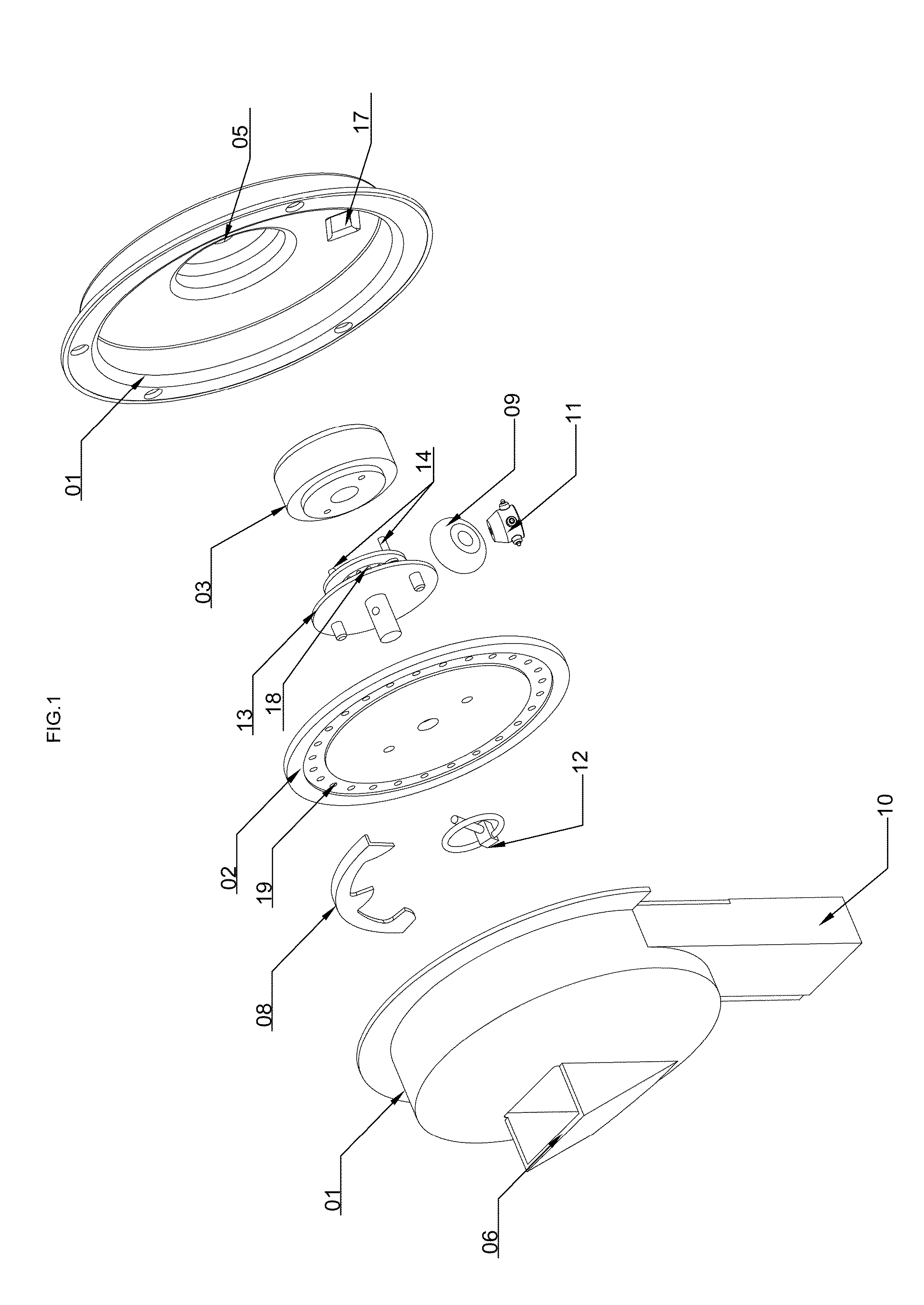

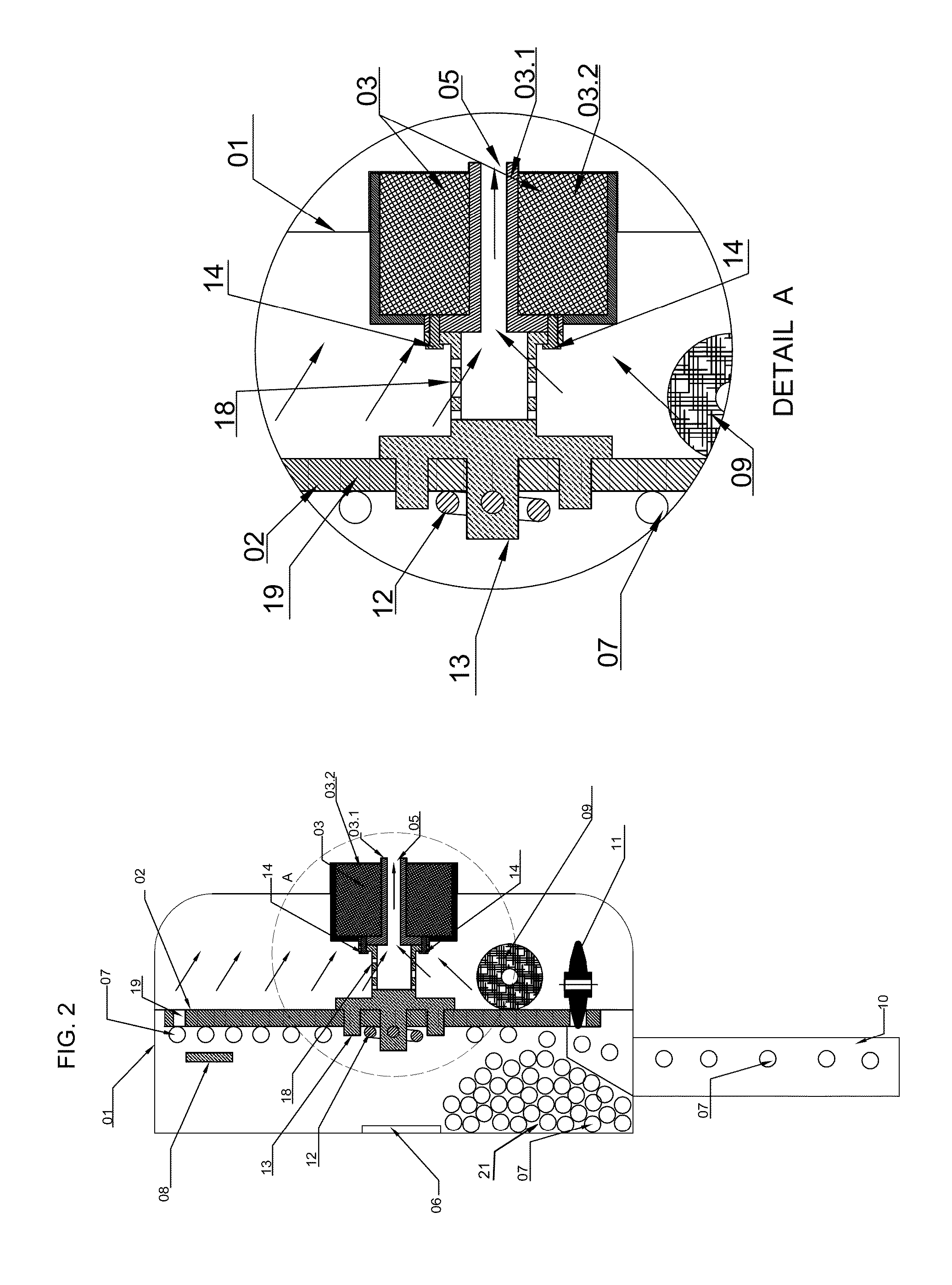

Seed disk drive hub

A hub assembly for a seed disk has a conical surface that mates with a cylindrical edge on a hub portion of a seed disk to establish the concentricity of the two components. A pair of paddles on the hub are received in, and inter-fit with corresponding recesses on the seed disk to provide torque transmission. A retention element holds the two components together.

Owner:DEERE & CO

Flow distributor apparatus for controlling spread width of a straw spreader

A flow distributor apparatus for a vertical spreader operable for discharging a flow of straw or other crop residue in a sideward direction over a field, the flow distributor apparatus including a flow guide element, an adjusting mechanism, and a coupling connector connecting the flow guide element to the adjusting mechanism for controllable repositioning of the flow guide element relative to the spreader paddles. The flow guide element is disposed generally adjacent to the back plate of the spreader and intermediate the spreader paddles with an apex portion, laterally extending arm portions, and longitudinally extending crop residue flow surfaces, at least portions of which crop residue flow surfaces extend beneath the spreader paddles. The adjusting mechanism is operable to effect at least either vertical, horizontal, or rotational movement of the flow guide element relative to the spreader paddles to adjustably vary the clearances between the outer swept diameters of the spreader paddles and the crop residue flow surfaces to control the sidewardly outwardly discharge of crop residue from the spreader.

Owner:BLUE LEAF I P INC

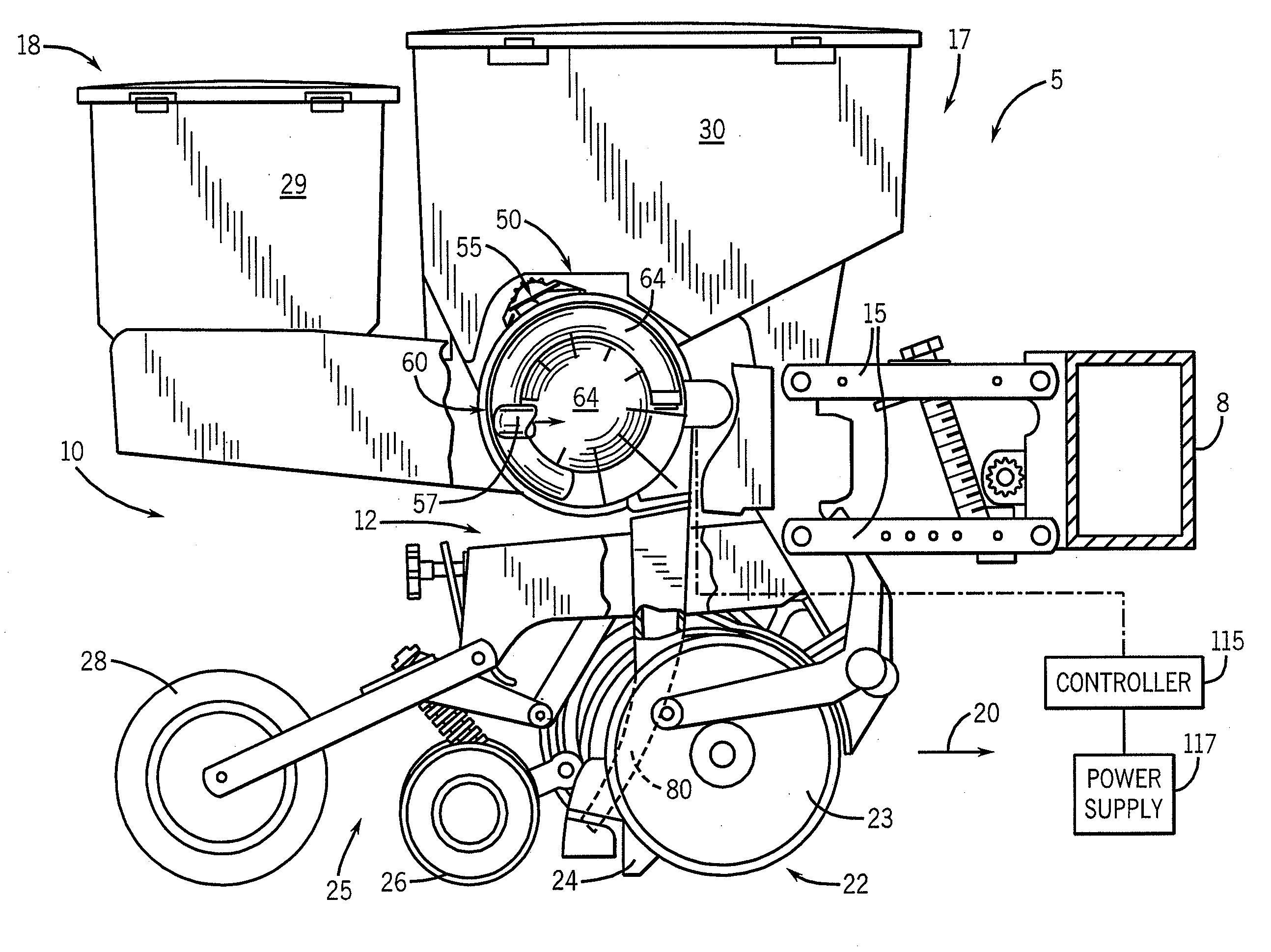

Air seed meter with adjustable singulator

ActiveUS9277688B2Improve on and overcomeReduce frequencyAgriculture and animal husbandary industryBroadcast seedersDrive motorEngineering

Owner:KINZE MFG INC

Ground driven seed metering system with a continuously variable transmission

An agricultural seeding machine includes at least one tool bar, and a plurality of row crop units, with each row crop unit coupled with a respective tool bar. Each row crop unit includes a seed meter; a ground engaging wheel; a continuously variable transmission (CVT) driven by the wheel; and a rotatable drive element coupled between the CVT and the seed meter.

Owner:DEERE & CO

Ground driven seed metering system with a continuously variable transmission

An agricultural seeding machine includes at least one tool bar, and a plurality of row crop units, with each row crop unit coupled with a respective tool bar. Each row crop unit includes a seed meter; a ground engaging wheel; a continuously variable transmission (CVT) driven by the wheel; and a rotatable drive element coupled between the CVT and the seed meter.

Owner:DEERE & CO

Direct drive electric seed metering system

ActiveUS20090000533A1Improve uniformityReduce in quantityPotato plantersFurrow making/coveringElectricityAngular velocity

A direct drive electric seed metering system is provided for use with a row crop planter or seed planter that intakes a volume of multiple seeds from a seed hopper, draws individual seeds from the volume of multiple seeds and discharges them into a seed furrow formed in an agricultural field. The direct drive electric seed metering system includes a meter assembly having a meter housing and a seed plate rotatably mounted concentrically in the housing for singulating the seeds. A direct drive mechanism is mounted to the meter assembly for interfacing and driving the seed plate at an angular velocity which corresponds to the travel velocity of the seed planter. A single seed planter can have multiple direct drive electric seed metering systems, and each of the multiple direct drive electric seed metering systems preferably has its own prime mover to effectuate driving the seed plate.

Owner:BLUE LEAF I P

Sectioned metering system and method

ActiveUS20120325131A1Agriculture tools and machinesMetal-working apparatusEngineeringMechanical engineering

A sectioned metering system and method is provided. One metering system for distributing an agricultural product in a field includes a drive input and a rotary shaft assembly coupled to the drive input and configured to be driven in rotation by the drive input. The metering system also includes a first metering section driven by the rotary shaft assembly and at least two additional metering sections. Each additional metering section is selectively engageable to drive the respective additional metering section by the rotary shaft assembly. Each additional metering section is also selectively disengageable to interrupt driving of the respective additional metering section by the rotary shaft assembly while the first metering section remains driven.

Owner:CNH IND CANADA

Horizontal initiative grass-poking wheel anti-blocking device

InactiveCN101379905ASolve the problem of anti-blocking lagStable trench widthPlantingFurrow making/coveringAgricultural engineeringAgricultural machinery

The invention discloses a horizontal active weeding wheel anti-blocking device used in a no-tillage seeding machine, and belongs to the technical field of agricultural machinery. The whole structure of the device consists of a frame and 2-8 horizontal active weeding wheel anti-blocking elements. The horizontal active weeding wheel anti-blocking elements are arranged in parallel on the square beam of the frame, with the same space from the left side and the right side of a gear box. The power output by a rear shaft of a tractor is transferred to all active square shafts of the horizontal active weeding wheel anti-blocking elements by the gear box through a belt gear, which causes the horizontal weeding wheels to rotate horizontally on the ground surface to push the met straws to the area between two seeding zones. The weeding wheels are arranged right ahead a furrow opener to prevent the straws from blocking the furrow opener during furrowing operation. The anti-blocking device solves the problem of anti-blocking delay resulting from clearing only after the blockage of the traditional anti-blocking device, ensures the furrow opener finishes the furrowing operation on the straw-free seeding zone, and is particularly suitable for no-tillage corn seeding machines.

Owner:CHINA AGRI UNIV

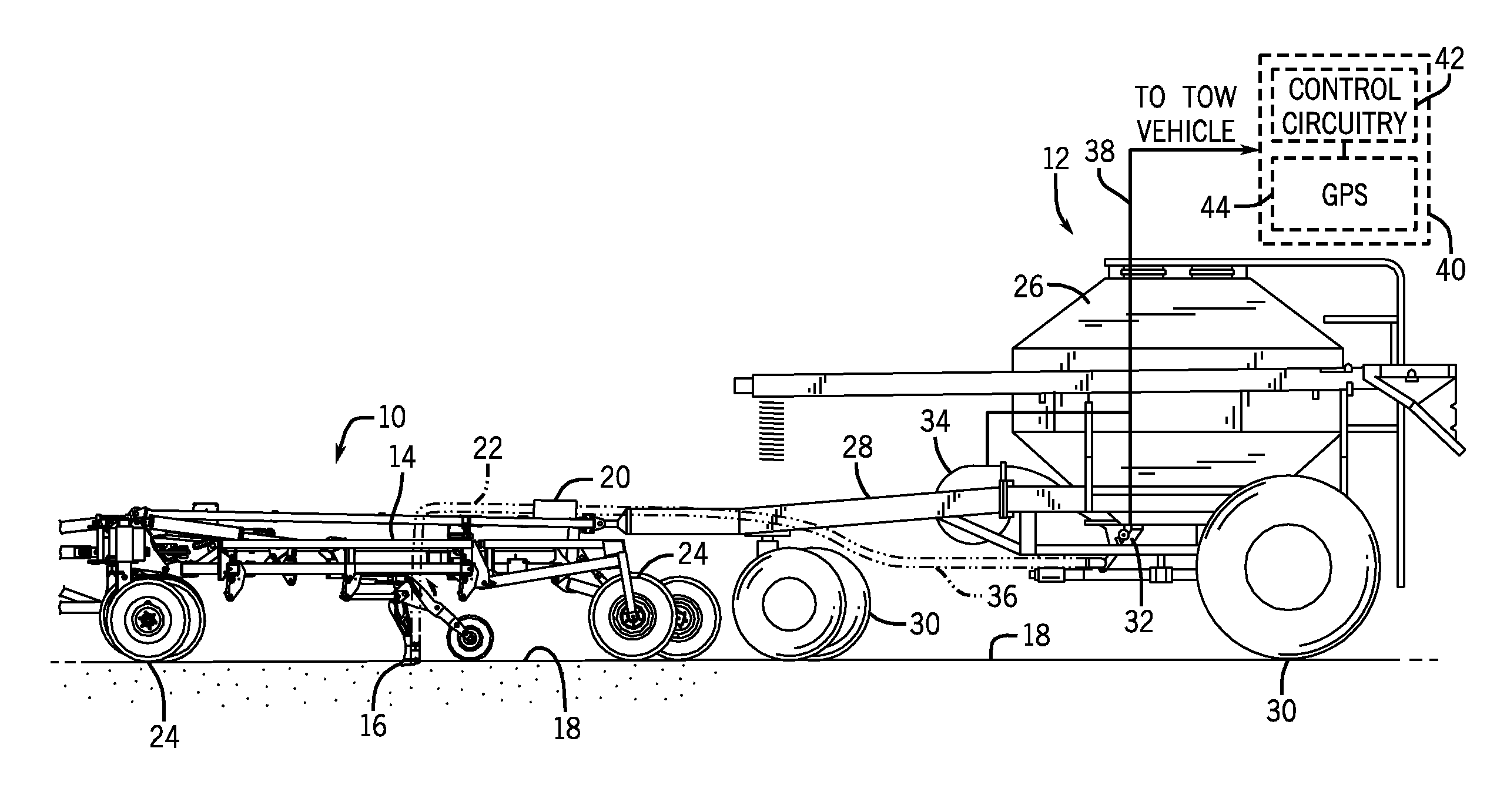

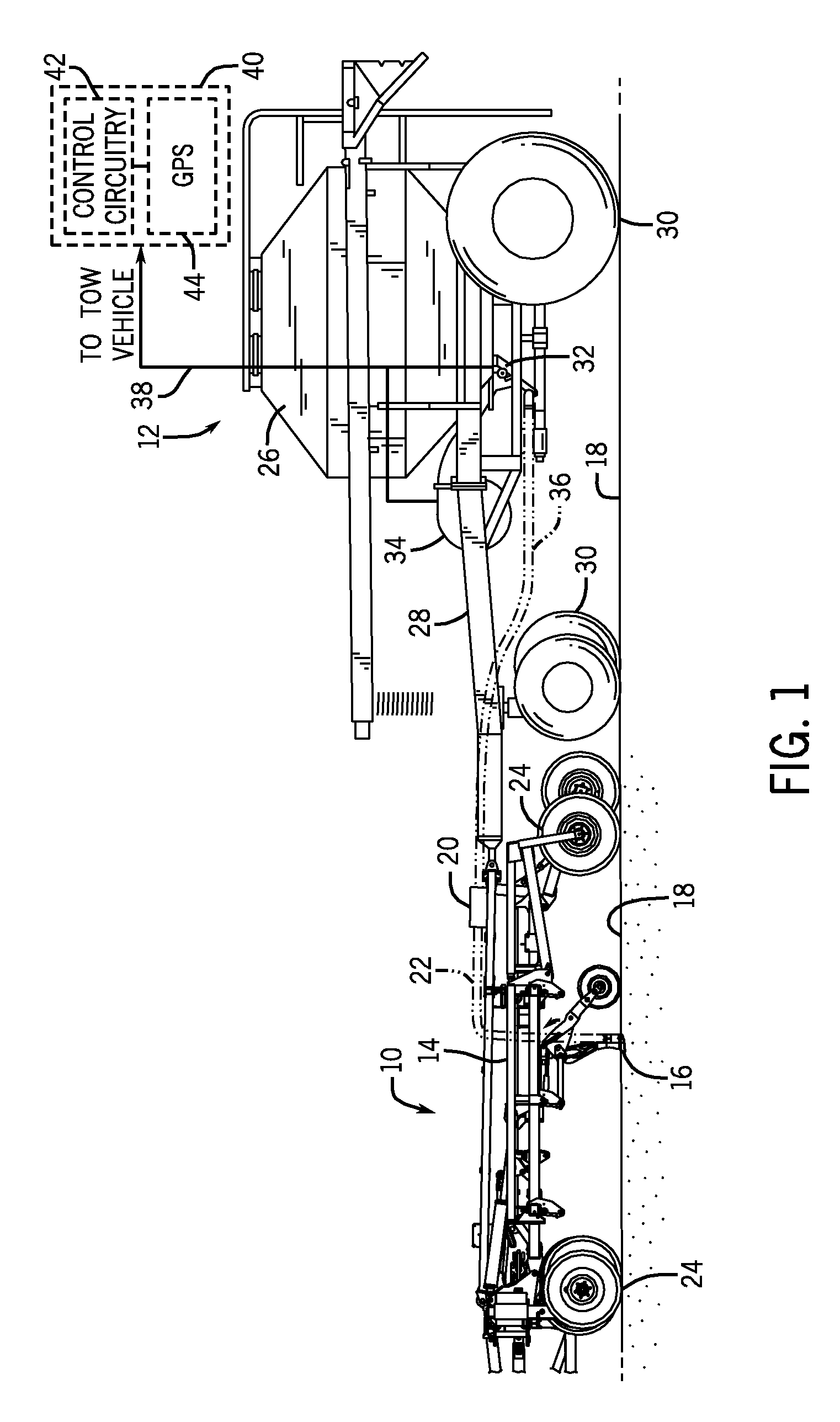

Method and apparatus for controlling seed population

Provided is an apparatus and method for controlling seed population for a conventional row crop planter utilizing a microprocessor, information from a seed population controller provided with the conventional row crop planter, a GPS or other locating or positioning device and motors for driving the conventional seed metering system of the planter. The microprocessor further feedback from the motors and compares the actual seed population data with the desired density and adjusts the output of the motors to compensate for variations in seed population densities.

Owner:GRAHAM TOBY E +1

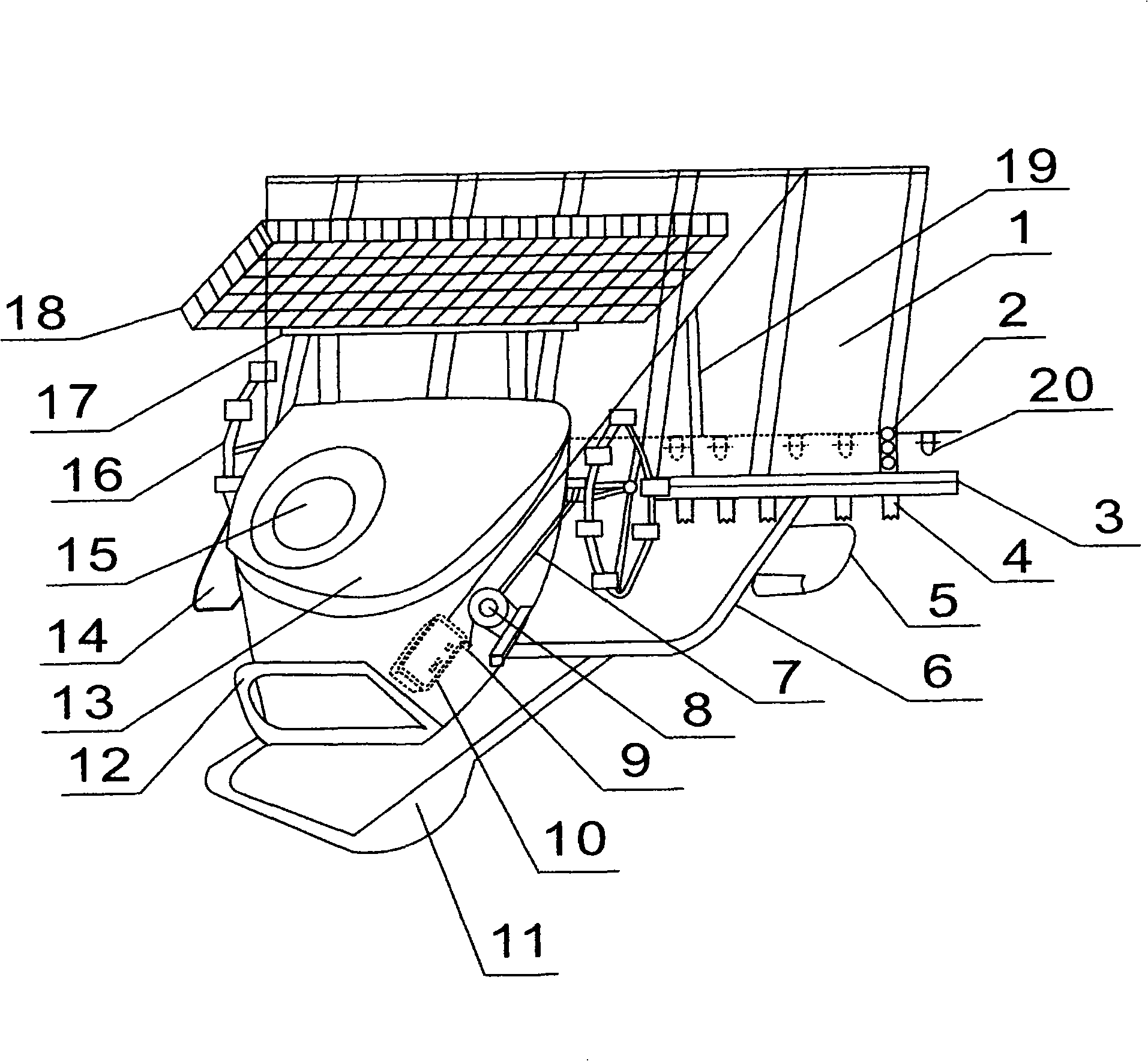

Wide- and narrow-row handheld rice transplanter with wide partition in seedling box

InactiveCN101796905ARealize wide and narrow row transplanting operationReduce design costTransplantingFertiliser equipmentsDrive wheelAgricultural science

The invention discloses a wide- and narrow-row handheld rice transplanter with a wide partition in a seedling box, which comprises an engine, a ground profiling mechanism, two driving wheel systems, a seedling claw movement mechanism, a seedling box movement mechanism and a handheld operating system. The seedling box with the wide partition of the invention can ensure that only a set of spiral shaft for feeding seedlings transversely is required when the ratio of wide rows to narrow rows of the rice transplanter is not an integral multiple, so the seedling feeding mechanism is greatly simplified. The principle and the structure of the spiral shaft mechanism for feeding seedlings transversely of the wide- and narrow-row hand-held rice transplanter are the same as those of the spiral shaft mechanism for feeding the seedlings transversely of an equal-row rice transplanter, so the design and manufacturing cost of the wide- and narrow-row hand-held rice transplanter is greatly reduced.

Owner:南通富来威农业装备有限公司

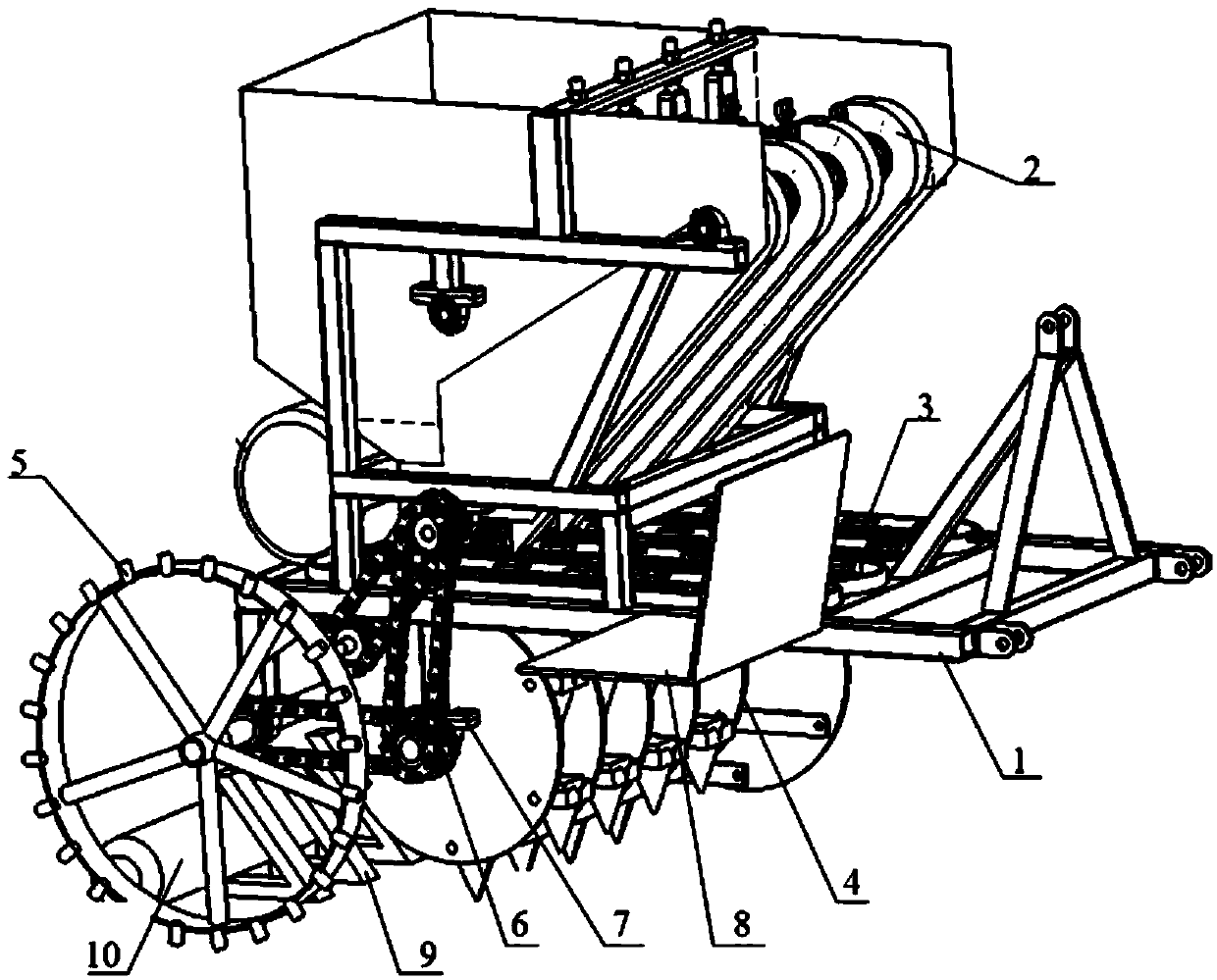

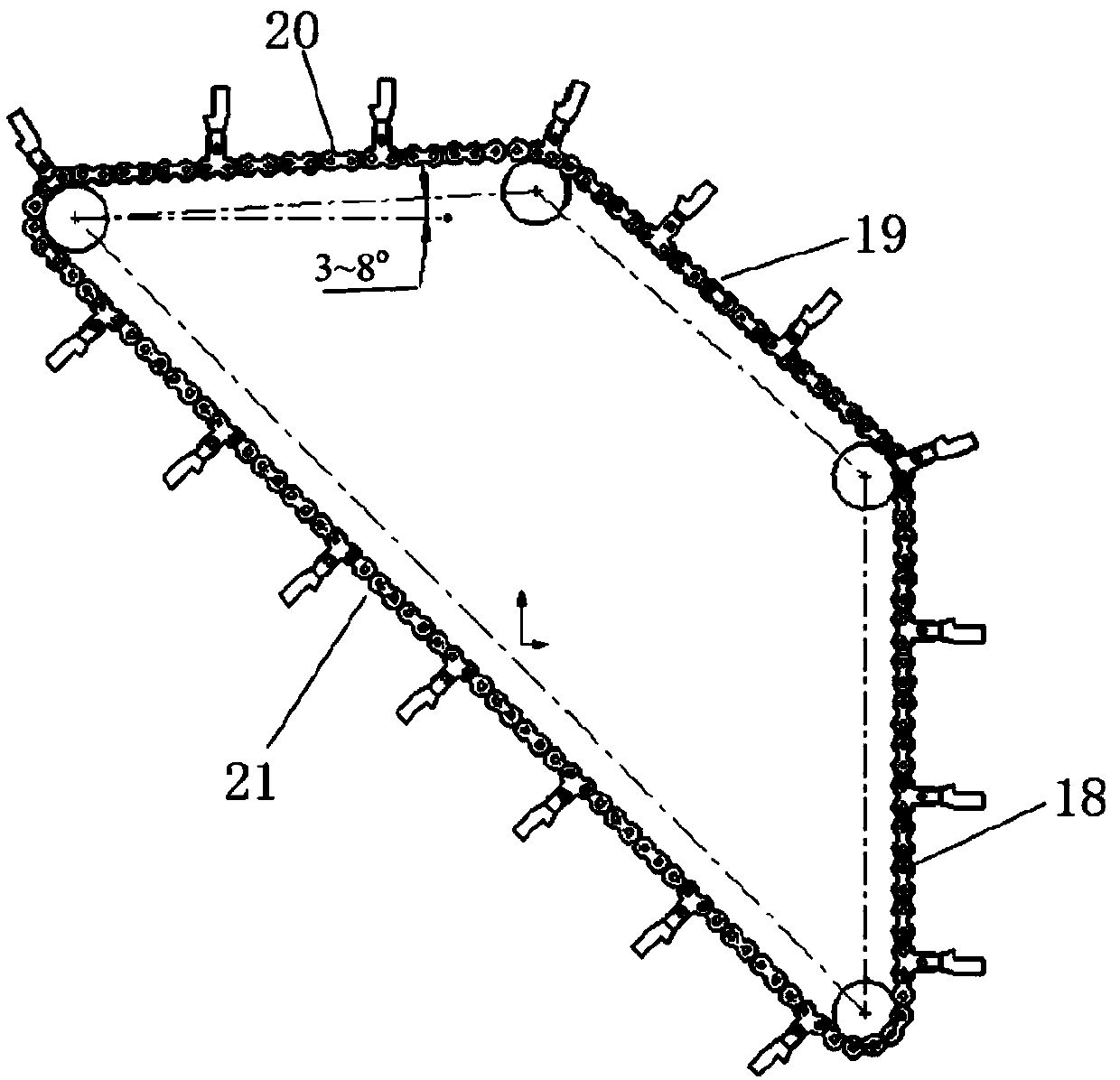

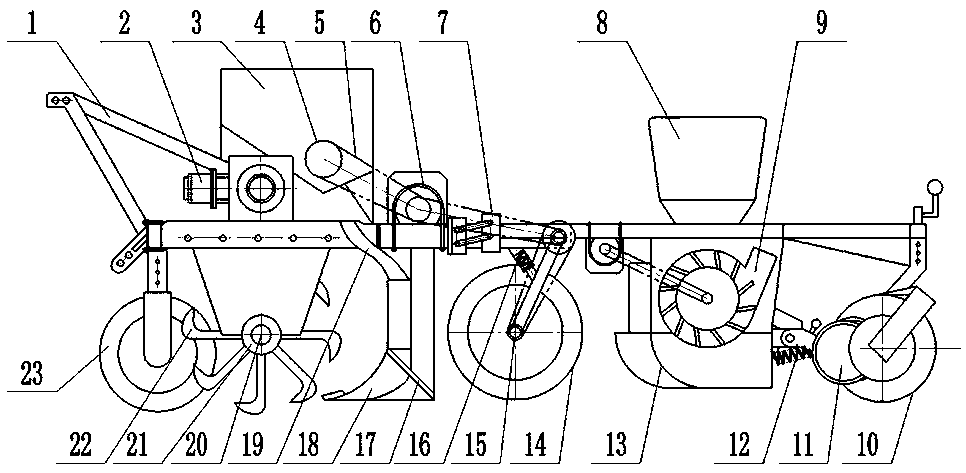

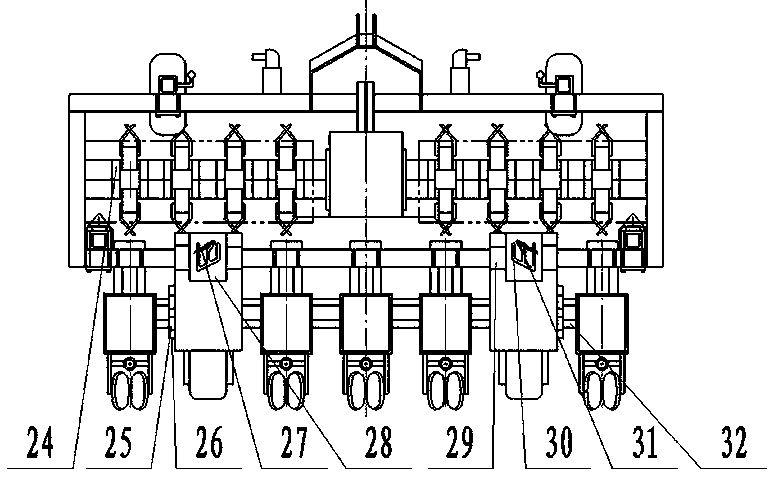

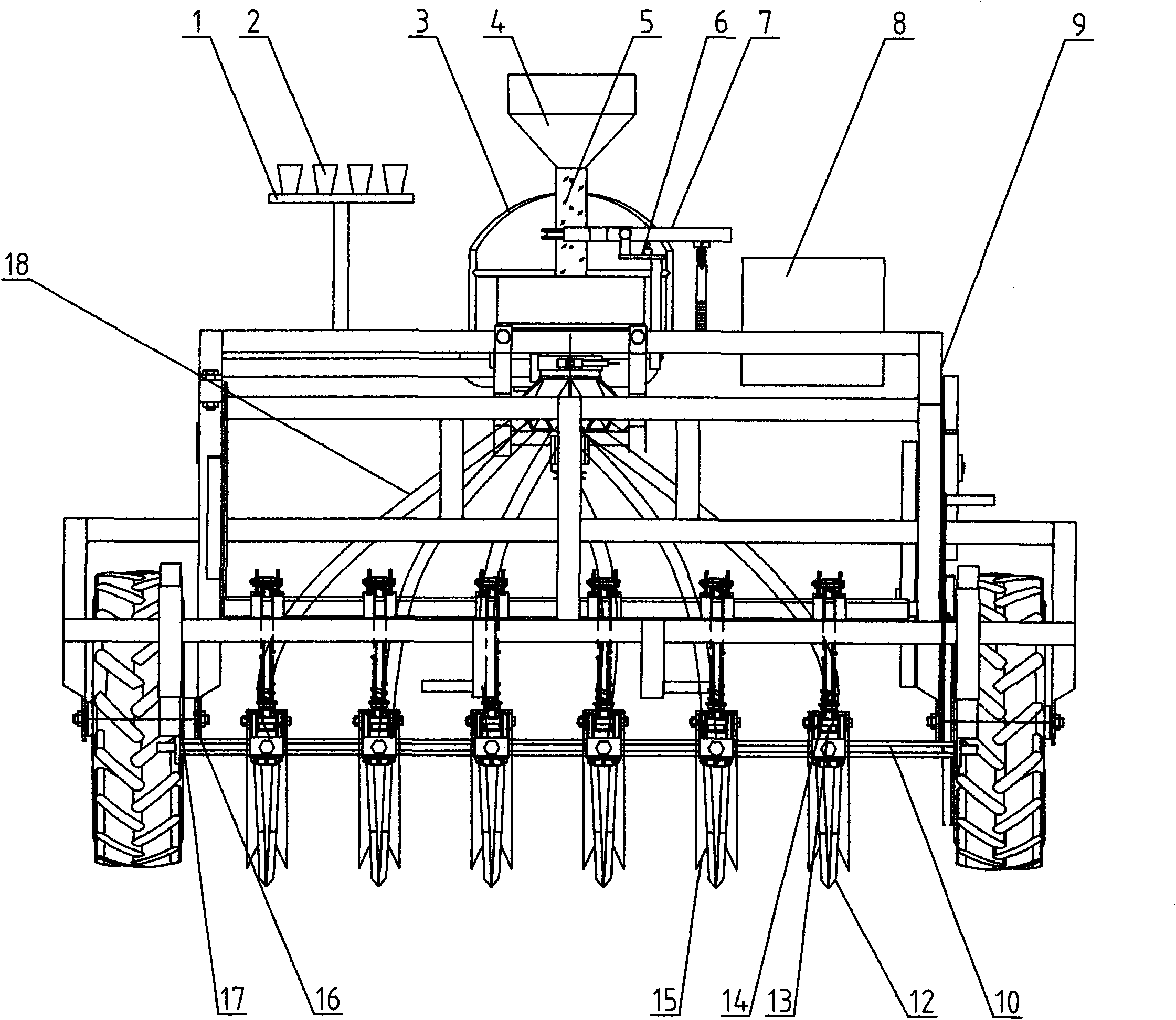

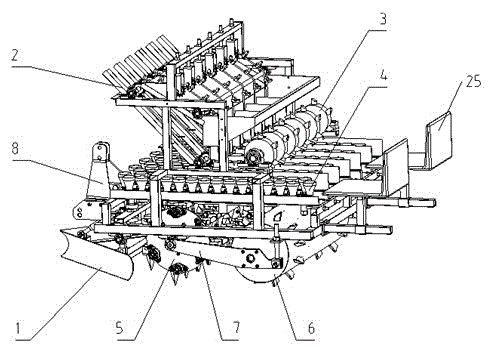

Corn-soybean strip-shaped compound planting no-tillage fertilization precision seeder

The invention discloses a corn-soybean strip-shaped compound planting no-tillage fertilization precision seeder and belongs to the technical field of farm machines. The machine includes a suspension machine frame, a rotary tillage system, a power transmission system, a fertilization and ditching system and a sowing and soil covering system. Through an installation mode that reverse-rotation rotarytillage and the inclined and forward arrangement of a drive land wheel is combined, blades thus can cut stubbles forward, the stubble cleaning and soil breaking effects are ensured, the drive wheel thus can always walk on the ground, the occurrence of seedling missing and ridge breaking is avoided, and the seeder has the advantages of being simple in structure, precise in sowing, uniform in quality and the like, Under various kinds of parameters, the plant distance is adjusted and changed, and the minimum plant distance can be adjusted to 6 cm, the application range is wider, and smooth implementation of a high-yield close-planting mode is ensured. The seeder has high adaptability to crops, and is suitable for simultaneous sowing operation of corn, soybeans and other seeds with the shapesimilar to the shape of core or soybeans.

Owner:SICHUAN AGRI UNIV

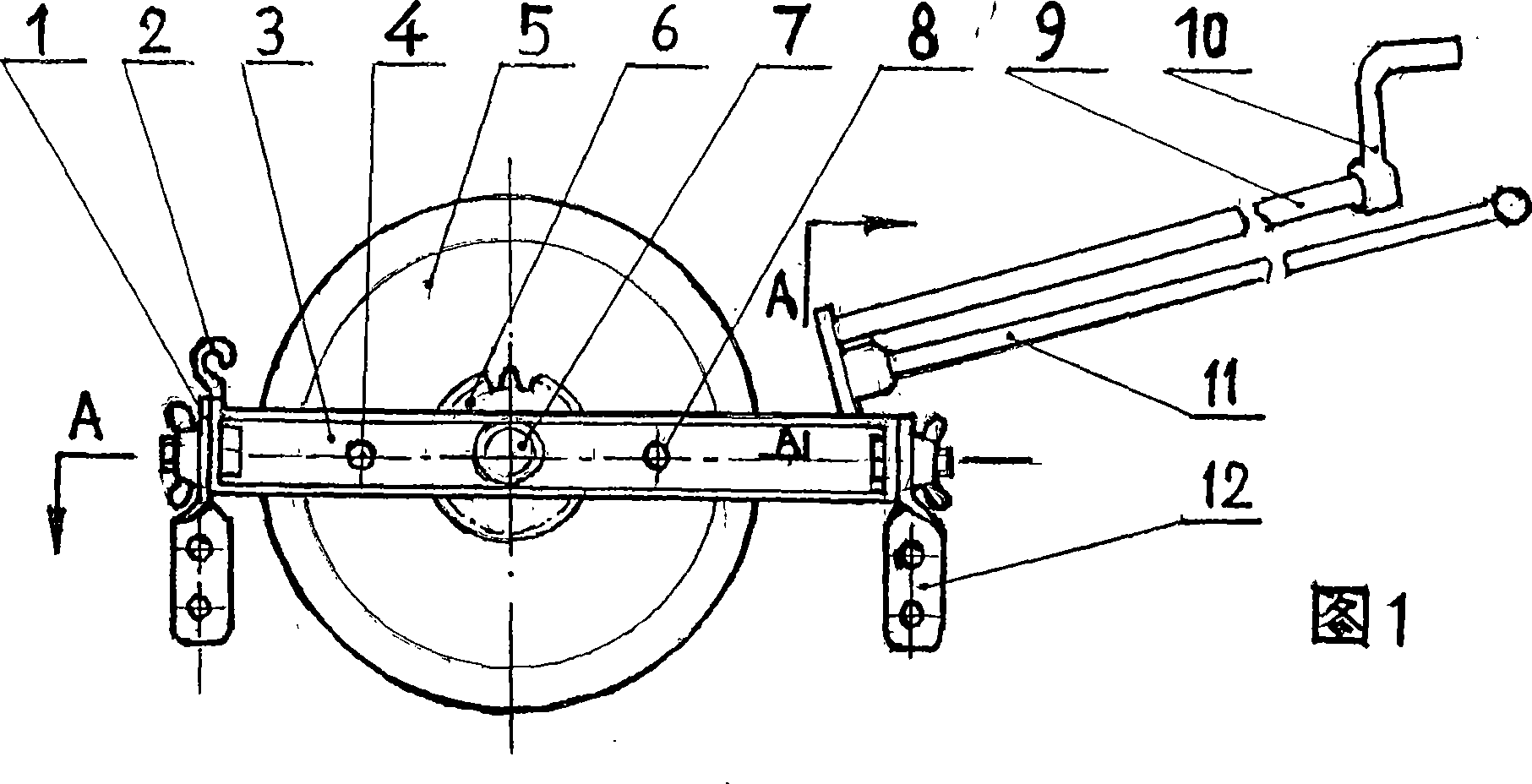

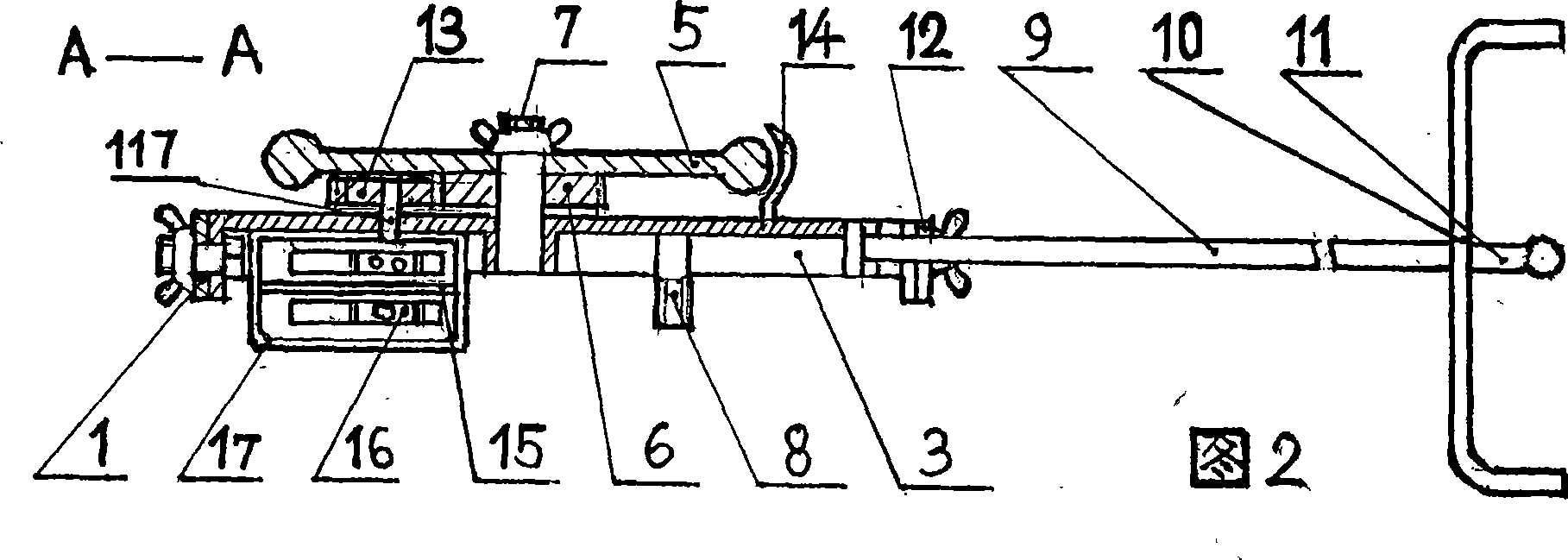

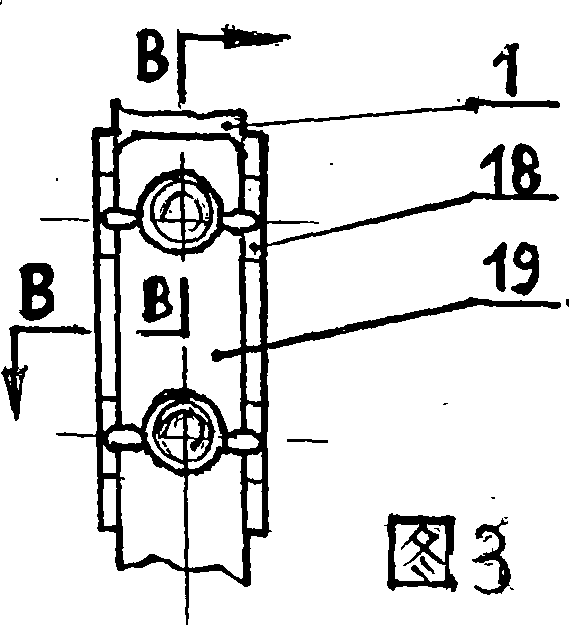

Multipurpose manpower agricultural machinery base part, thrust rod and push-pull belt, and matching component thereof

InactiveCN101434251AEasy loading and unloadingIncrease walking resistanceLoadersSoil-working equipmentsPull forcePush pull

The invention relates to a multifunctional manpower machine basic part, a thrust rod, a pushing and pulling belt and accessories thereof. The basic part comprises a running wheel axle (2) arranged on a single frame (3), a running wheel (5) provided with a driving gear (6) at the end part, an armrest cross-rod (10) fixed tightly on an armrest straight rod (9), a thrust straight rod (11), a front-movable vertical rod (1), a back-movable vertical rod (12), a frame hook (2), a front suspension arm shaft (4), a back suspension arm shaft (8), etc. More than ten kinds of various functional mechanisms, tools and work parts are arranged on the suspension arm shafts and movable vertical rod in a module manner and each kind is provided with different specifications, functions and capabilities so as to lead a user to select parts individually for the mutual coordination without interruption. Particularly, the cooperation between the thrust rod and pushing belt changes the prior manner that hands and arms generate thrust so as to lead the abdomen to get thrust; and the shoulders generate pulling force so as to lead the waist to get pulling force, thereby saving force under the same work load. With a support connecting part, an operator can hold the machine with one hand and also can push the machine to move forward.

Owner:汪新民

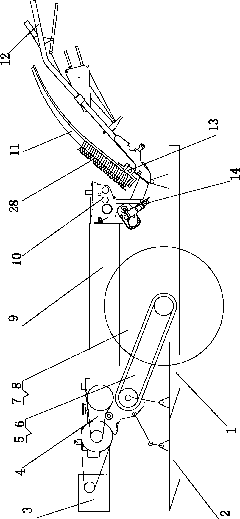

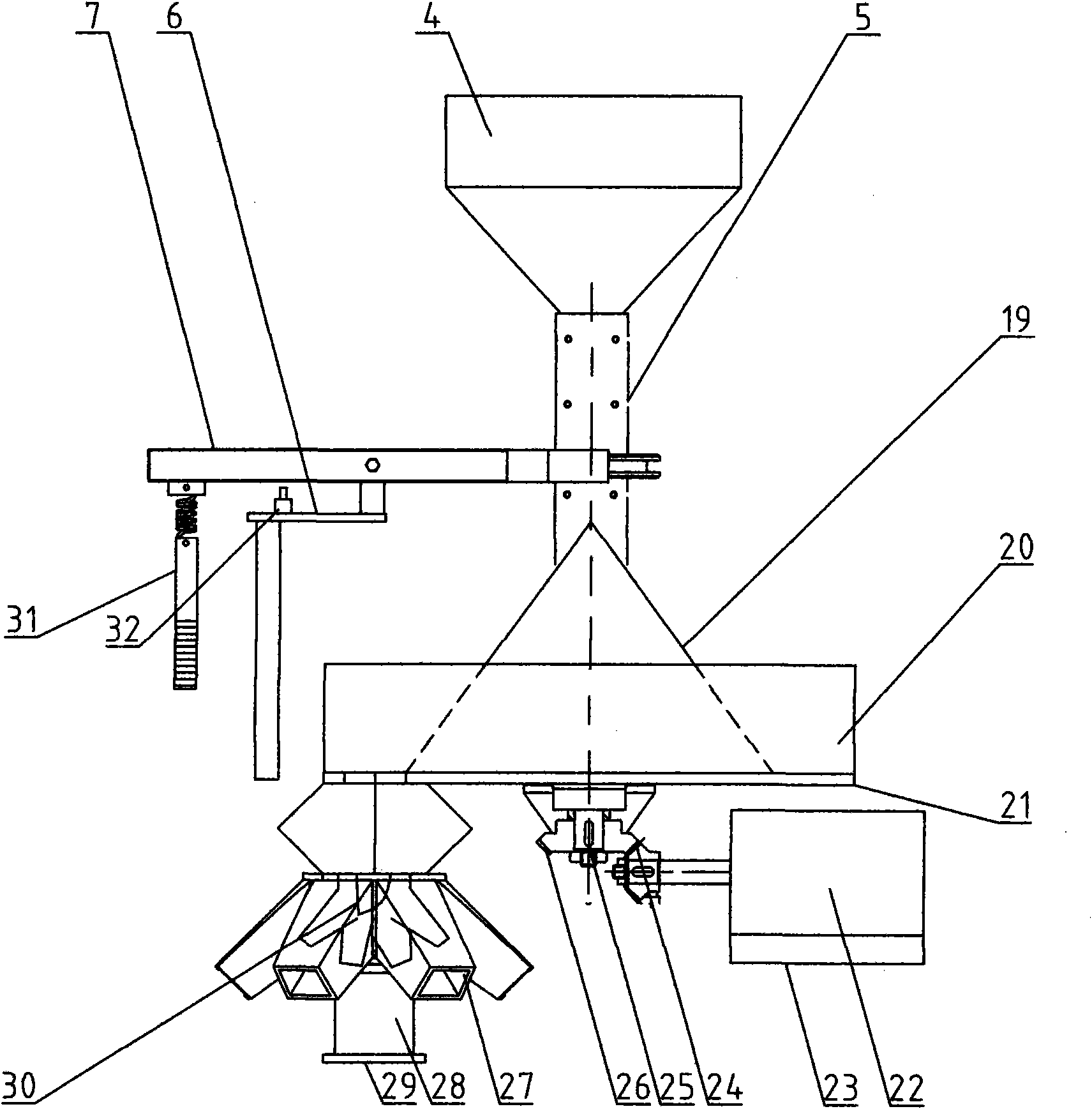

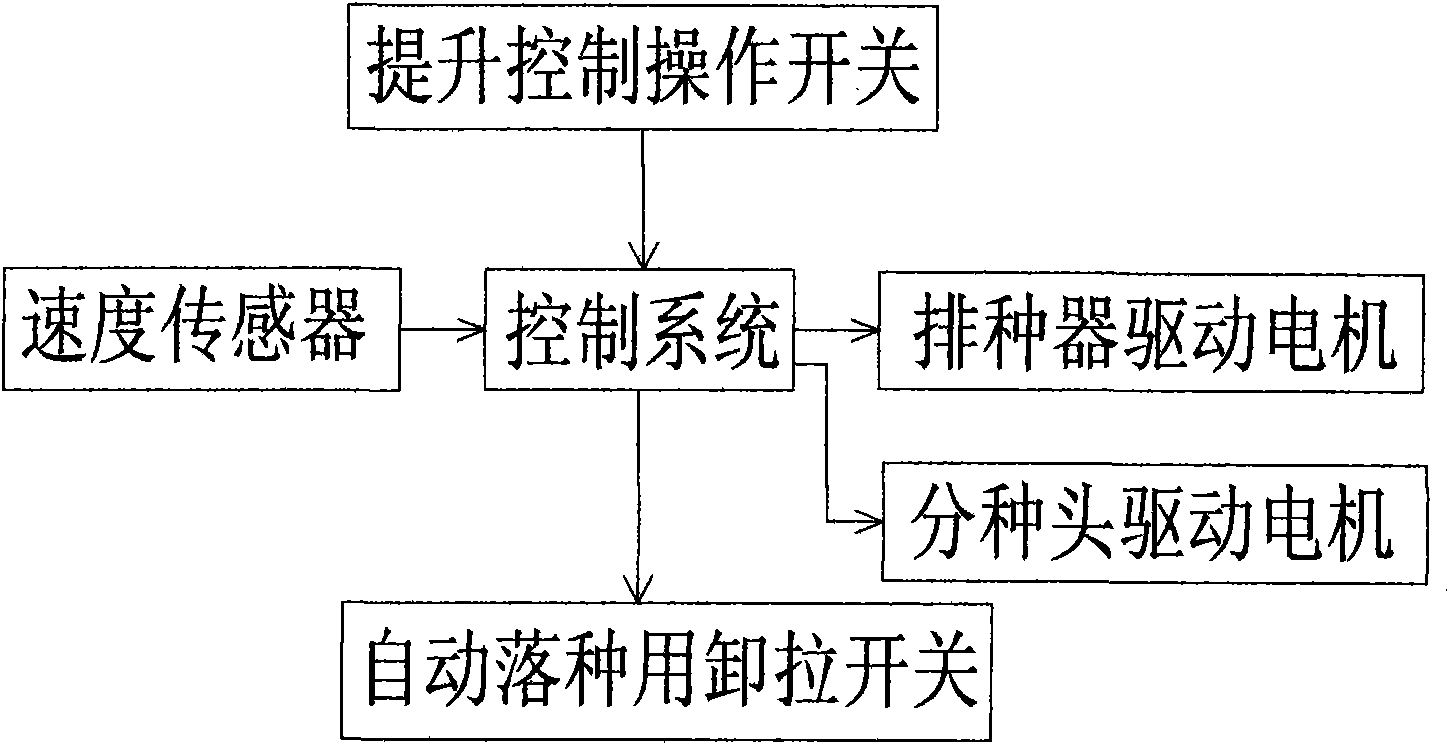

Small field sower

InactiveCN101953247AReduce instabilityImprove accuracySeed depositing seeder partsFertiliser equipmentsSeederAgricultural science

The invention relates to a small field sower, which comprises a frame, and a seed supply device, a seed dropping device, a seed dropping control device and a ditching and covering device which are positioned on the frame. The rear of the frame is provided with a seed supply operating platform; one side of the seed supply operating platform is provided with the seed supply device, while the other side is provided with a seed dropping control operating platform; the front of the seed supply operating platform is provided with the seed dropping device; the ditching and covering device is arranged under the frame; and the seed dropping device is connected with the ditching and covering device through a grain tube. The small field sower eliminates instability of power supply of a ground wheel in mechanical seed dropping, reduces power loss caused by a plurality of mechanical transmission links, improves mechanical transmission efficiency, adopts motor control to replace the conventional mechanical control mode, has a simple structure, improves the sowing accuracy due to constant power output, greatly reduces adverse effect caused by a seed dropping control transmission system, improves the accuracy, scientificity and universality of small field contrast test study, and meets the current development requirement of small field sowers in China.

Owner:QINGDAO AGRI UNIV

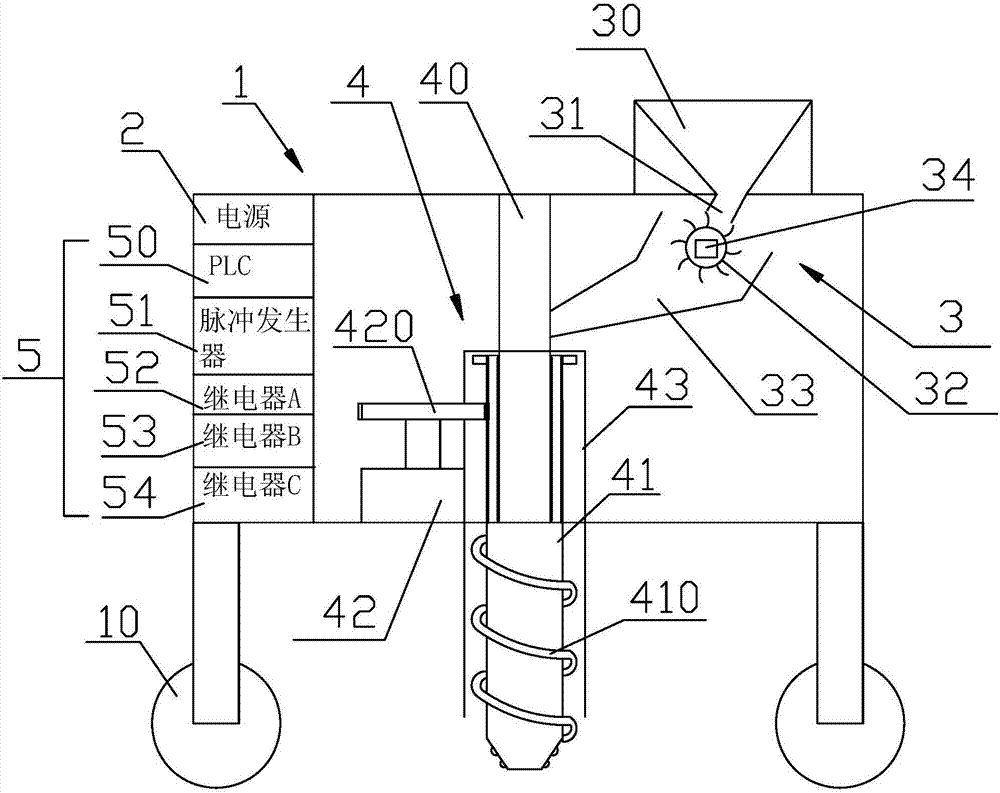

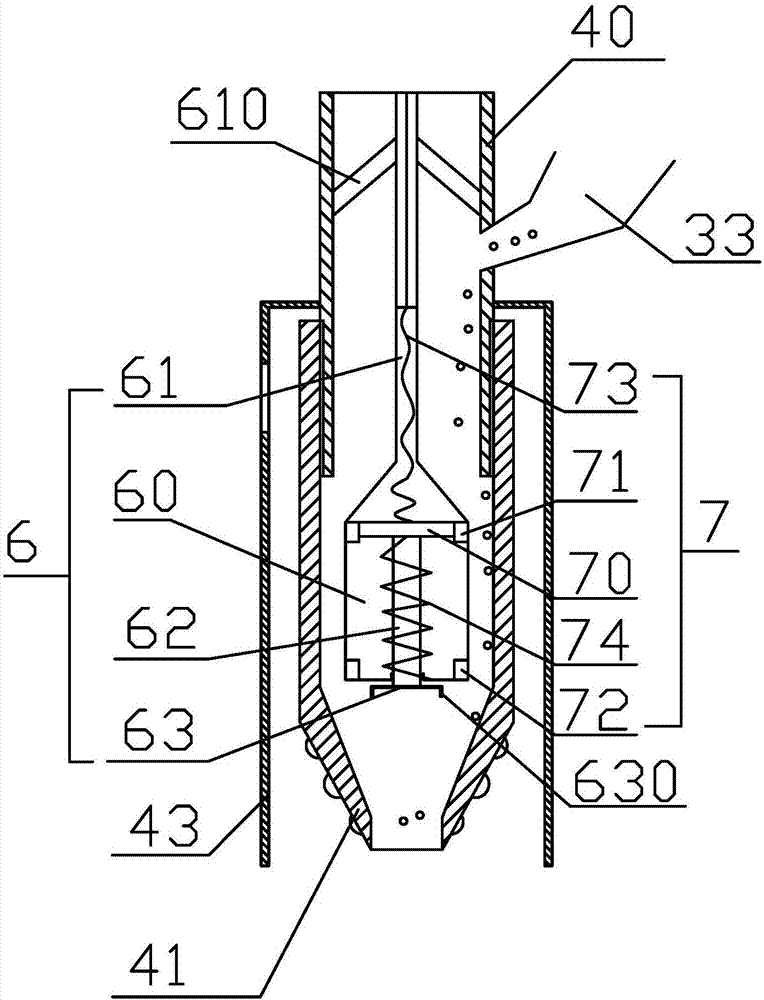

One-piece drilling and seeding machine

PendingCN107124939ASimple mechanical structureReduce manufacturing costPlantingDibble seedersSeederThermodynamics

The invention discloses a one-piece drilling and seeding machine which comprises a cart, a power source, a seed flow control mechanism, a drilling device and a control device. The drilling device comprises a fixing shaft and a rotational drilling pipe which are vertically and downwardly arranged and a drilling pipe machine capable of driving the rotational drilling pipe to rotate, the rotational drilling pipe is sleeved in the lower end of the fixing shaft, both the fixing shaft and the rotational drilling pipe are hollow structures, and the bottom of the rotational drilling pipe is opened; a sleeve is sleeved outside the rotational drilling pipe, a spiral blade is arranged on the side wall of the lower end of the rotational drilling pipe, and a gap is reserved between the inner wall of the sleeve and the spiral blade; seeds can be quantitatively sent to the interior of the rotational drilling pipe through the seed flow control mechanism. Three processes of digging, seeding and earthing can be realized through a common rotational drilling pipe structure, unnecessary processes of ripping and ploughing are avoided, the mechanical structure of the seeding machine is simplified, and manufacturing cost is low; meanwhile, the one-piece drilling and seeding machine is high in quality and efficiency, novel in concept and high in practical value.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Lithium ion battery new energy source applied on power mechanism of rice-transplanting machine

InactiveCN101406121AQuality improvementExtended working hours in the fieldTransplantingFertiliser equipmentsNew energyMechanical energy

The invention relates to a power unit applying new energy of lithium ion batteries to a transplanter and belongs to the technical field of agricultural machinery. A transplanter is formed by connecting a lithium ion battery power system and a seed planting device. The lithium ion battery power system charges a lithium ion battery with a power supply for storing electric energy. When a power switch of the lithium ion battery is turned on, the lithium ion battery begins to supply power which is then converted to mechanical energy to be transmitted to the seed planting device through a transmission belt. Through the motion of parts of the seed planting device, the seed planting device walks in a paddy field to convey seedlings, grasps seedlings and plants seedlings. The transplanter has an LED for illumination behind a seedling box plate to find missed seedling planting and clear fault timely, so the quality of mechanical seedling planting is improved and the operation time for mechanical seedling planting in field is prolonged.

Owner:缪同春

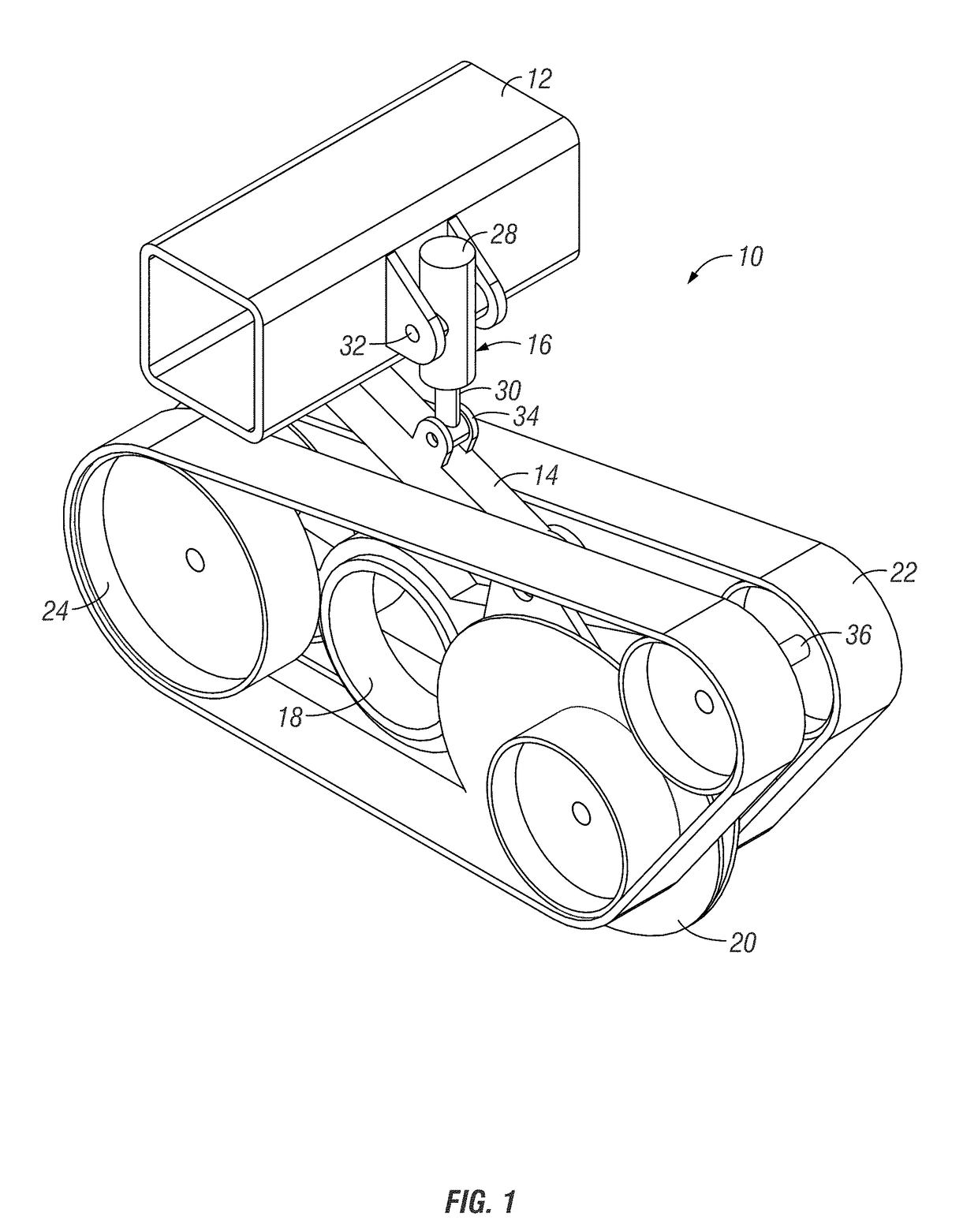

Seed delivery system

ActiveUS20180263177A1Reduce the overall heightAgriculture gas emission reductionSeed depositing seeder partsEngineeringMechanical engineering

A seed delivery system having a housing with an input opening at a first end and discharge opening at a second end. The input opening is adjacent a seed meter and is adapted to receive an or transport seeds from the seed meter to a first of a plurality of seed transport rollers disposed within the housing.

Owner:TOPCON POSITIONING SYST INC

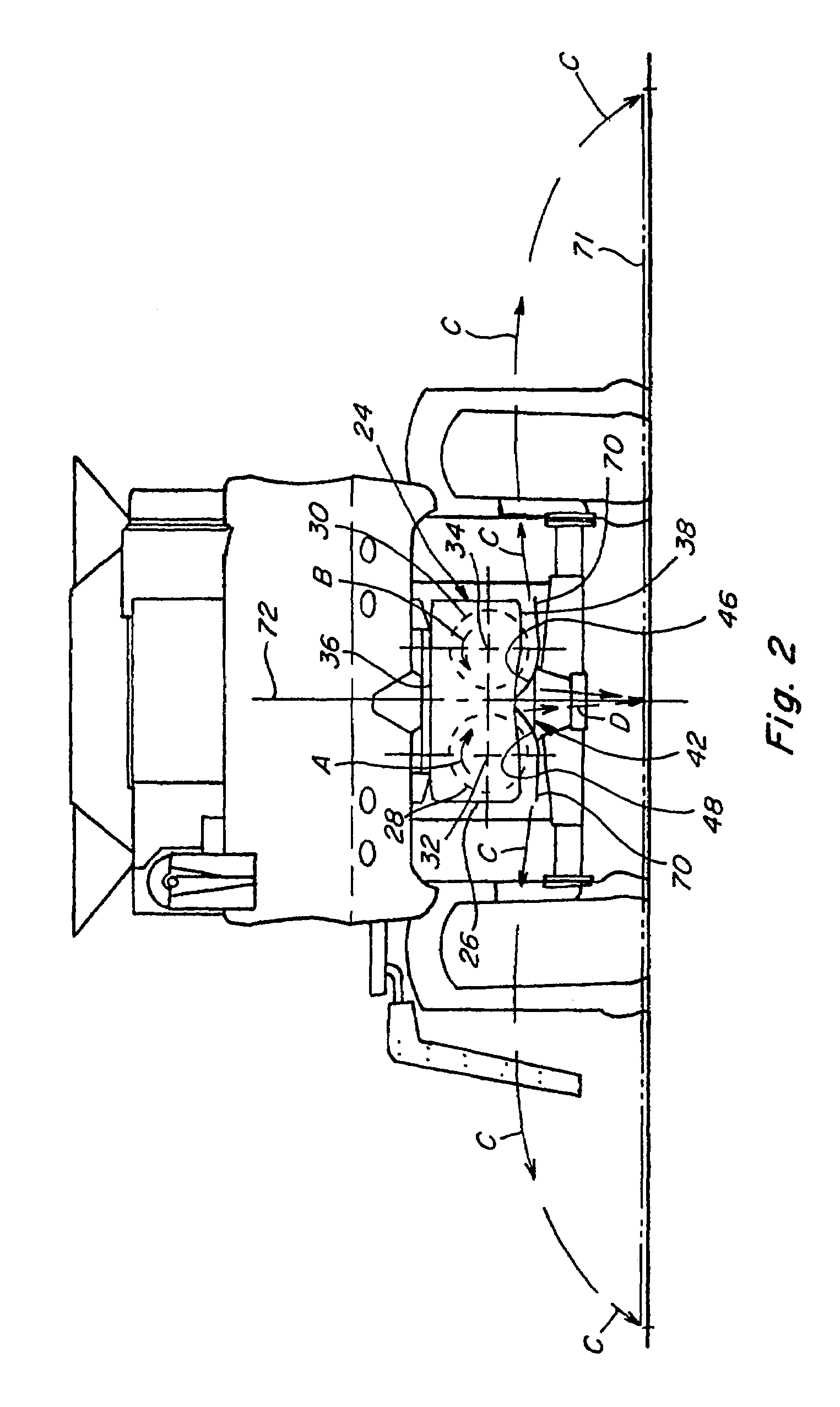

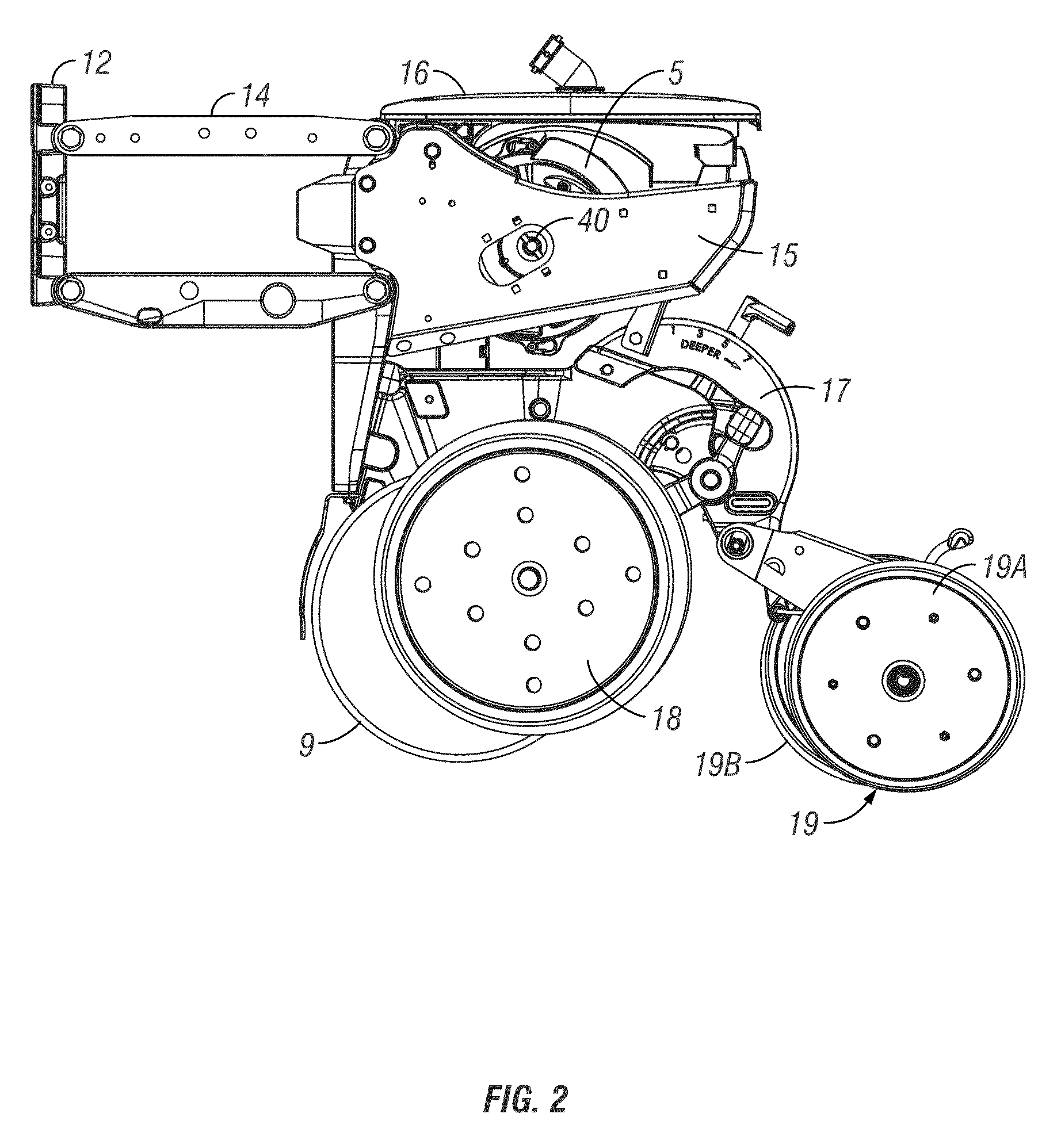

Direct drive seed metering device

ActiveUS20150334913A1SimplerReduced Power RequirementsPotato plantersFurrow making/coveringControl mannerEngineering

A direct drive seed metering device for sowing machines operated by vacuum or high pressure and driven by a coaxial electric motor, comprising a seed metering disc for capturing seeds from a reservoir and laying them in a controlled manner in a furrow in the soil, where in the coaxial electrical motor couples directly and coaxially to the metering disc without the need for intermediate transmission elements, redactors, gears or timing belts, and where said coaxial electrical motor is a toroidal electric motor with a hollow rotor shaft, which fluidly connects said seed capturing means with a vacuum or high pressure generating means.

Owner:PLANTIUM SA

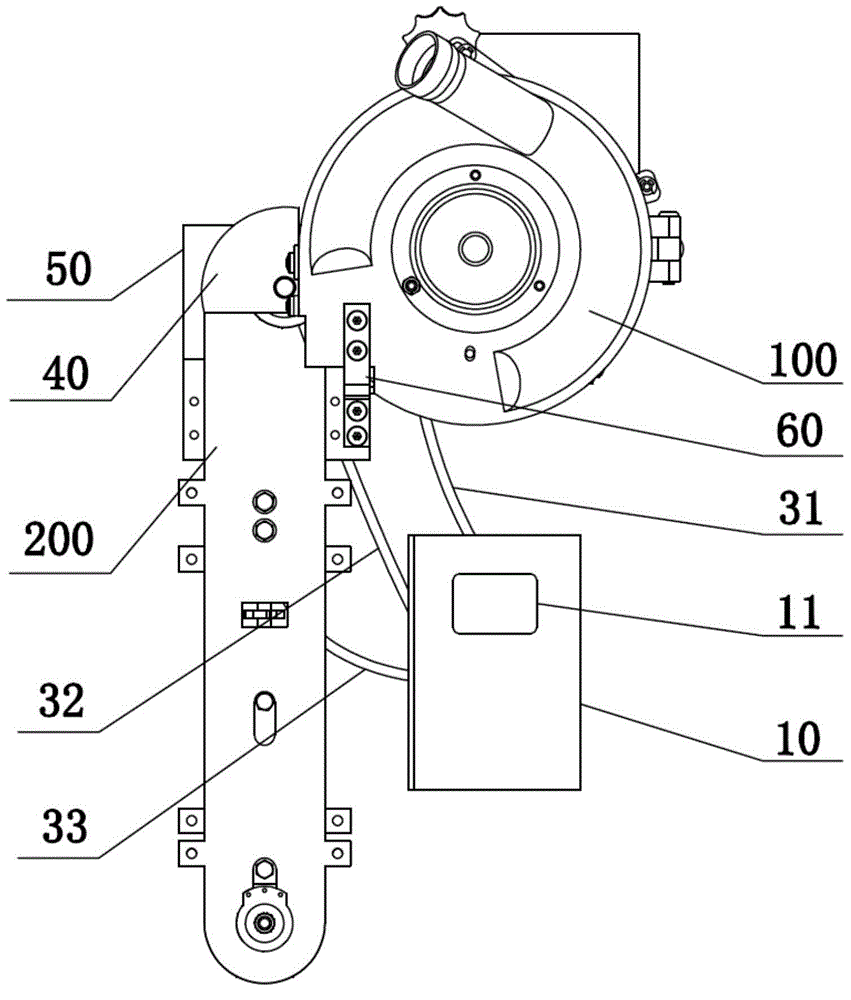

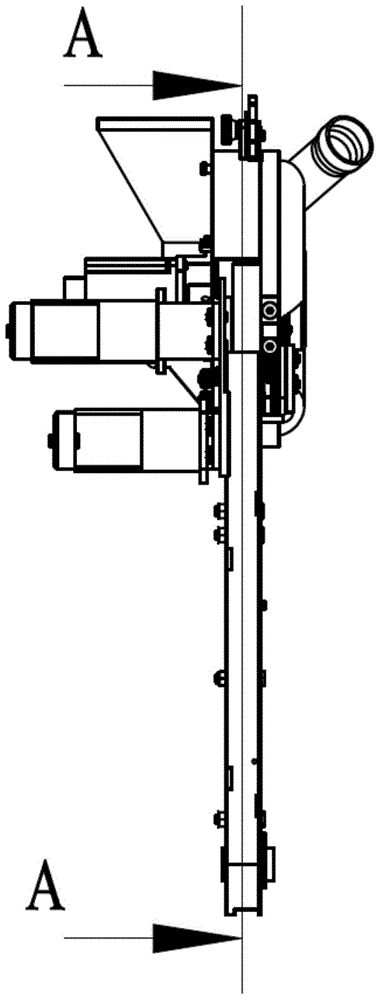

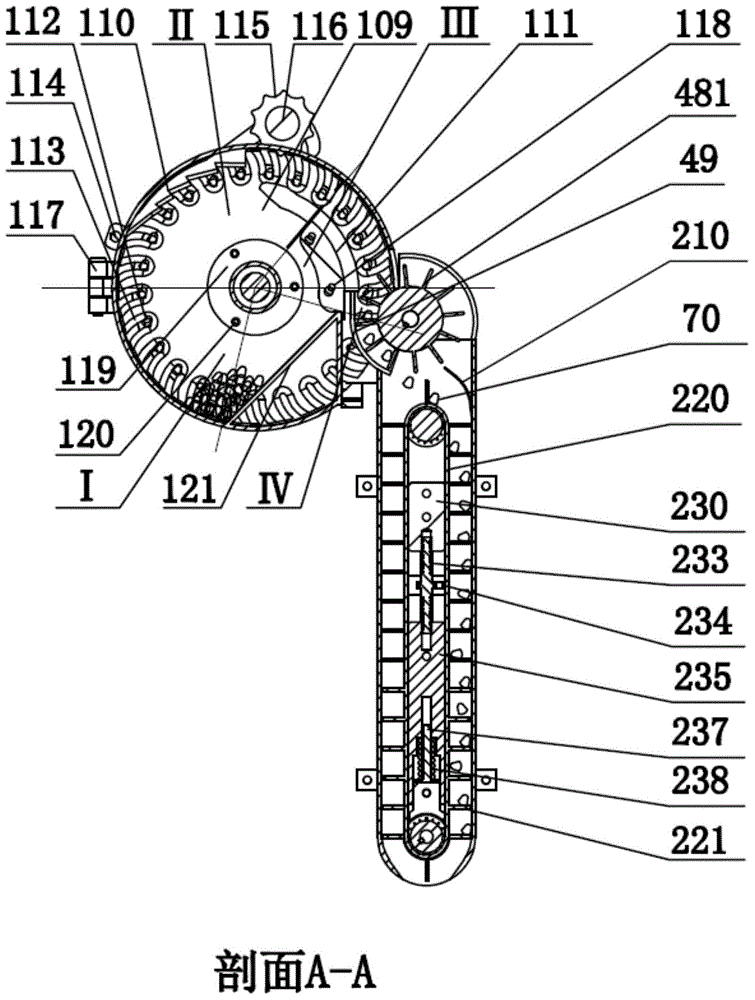

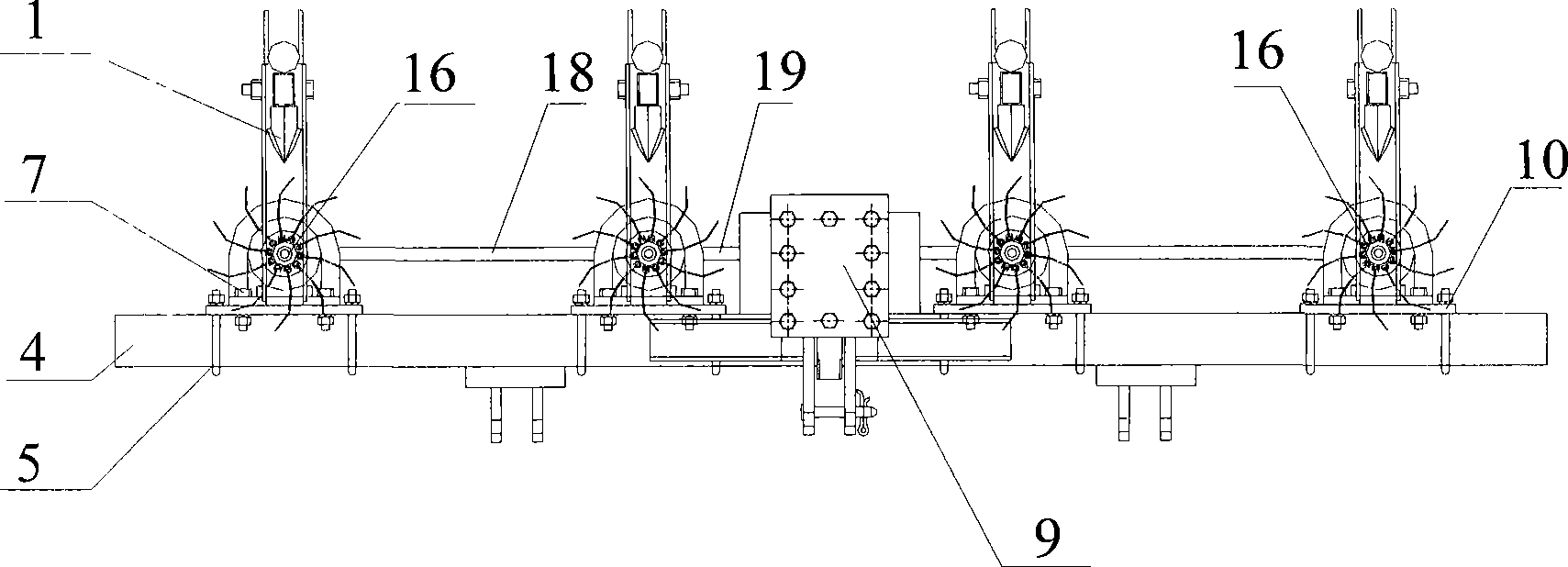

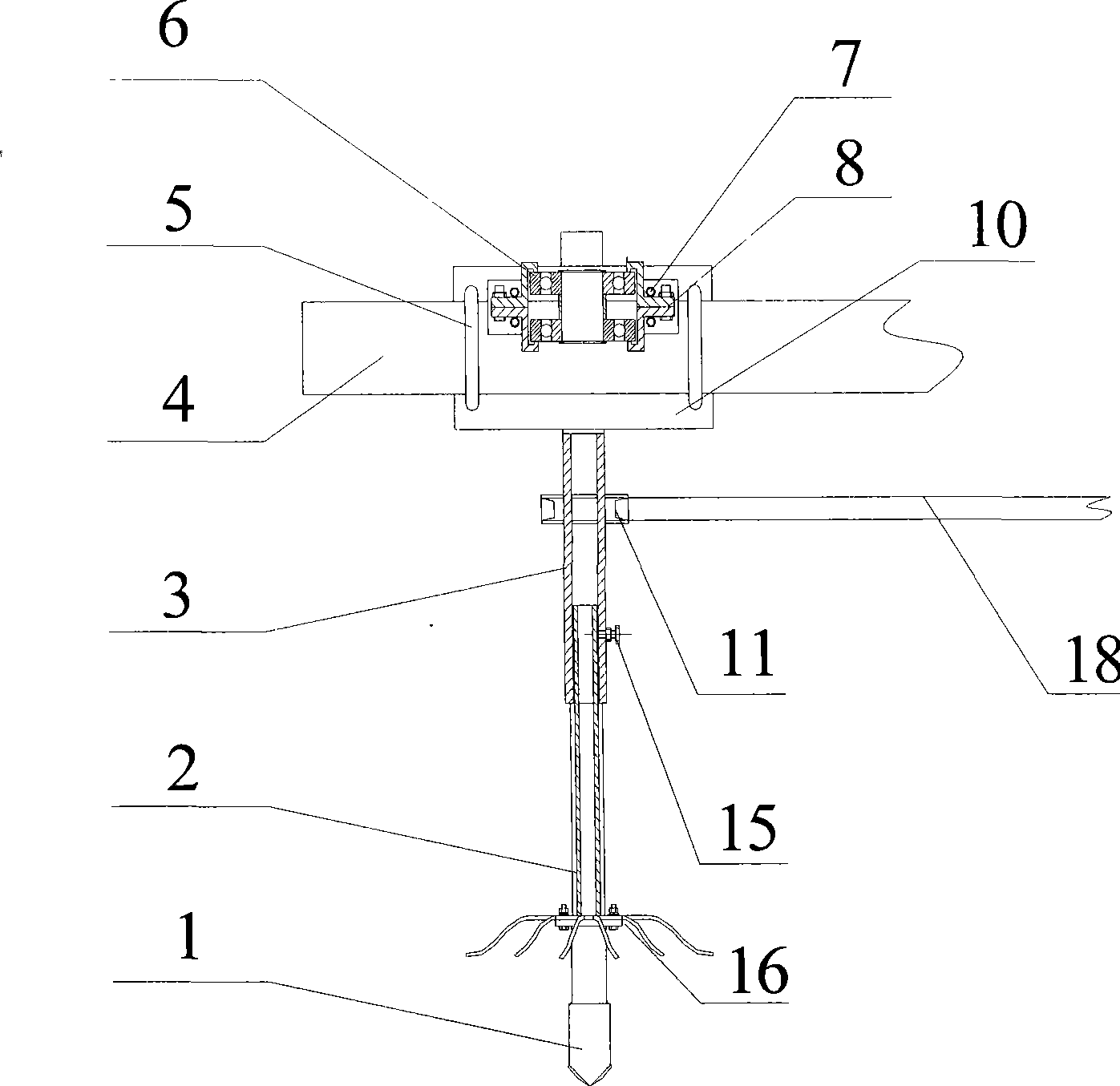

Erect-planting seed sowing machine for garlic

ActiveCN105103723ATowards stabilityAchieve targeted plantingSeed depositing seeder partsSingle grain seedersPlanting seedAgricultural engineering

The invention provides an erect-planting seed sowing machine for garlic. According to the erect-planting seed sowing machine for the garlic, the garlic can be buried erectly, and the scaly bud direction is stable to control. The erect-planting seed sowing machine comprises a machine frame, a seed fetching device, an erect planting device, a soil leveling device, a scaly bud direction control device, a quantitative water injection device, a transmission device and a land wheel device, wherein the machine frame is a carrier of the entire seed sowing machine; the seed fetching device is located at the front part of the entire seed sowing machine; the erect planting device is located at the front part of the entire seed sowing machine; the soil leveling device is located in front of the erect planting device; the scaly bud direction control device is arranged between the seed fetching device and the erect planting device and is matched with the seed fetching device and the erect planting device; the quantitative water injection device is located at the rear part of the seed fetching device, is located above the scaly bud direction control device and is matched with the scaly bud direction control device; the transmission device is used for supplying power to all functional components; and the entire seed sowing machine achieves power by friction between the land wheel device and the ground, and the land wheel device is used for pressing the sown garlic.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

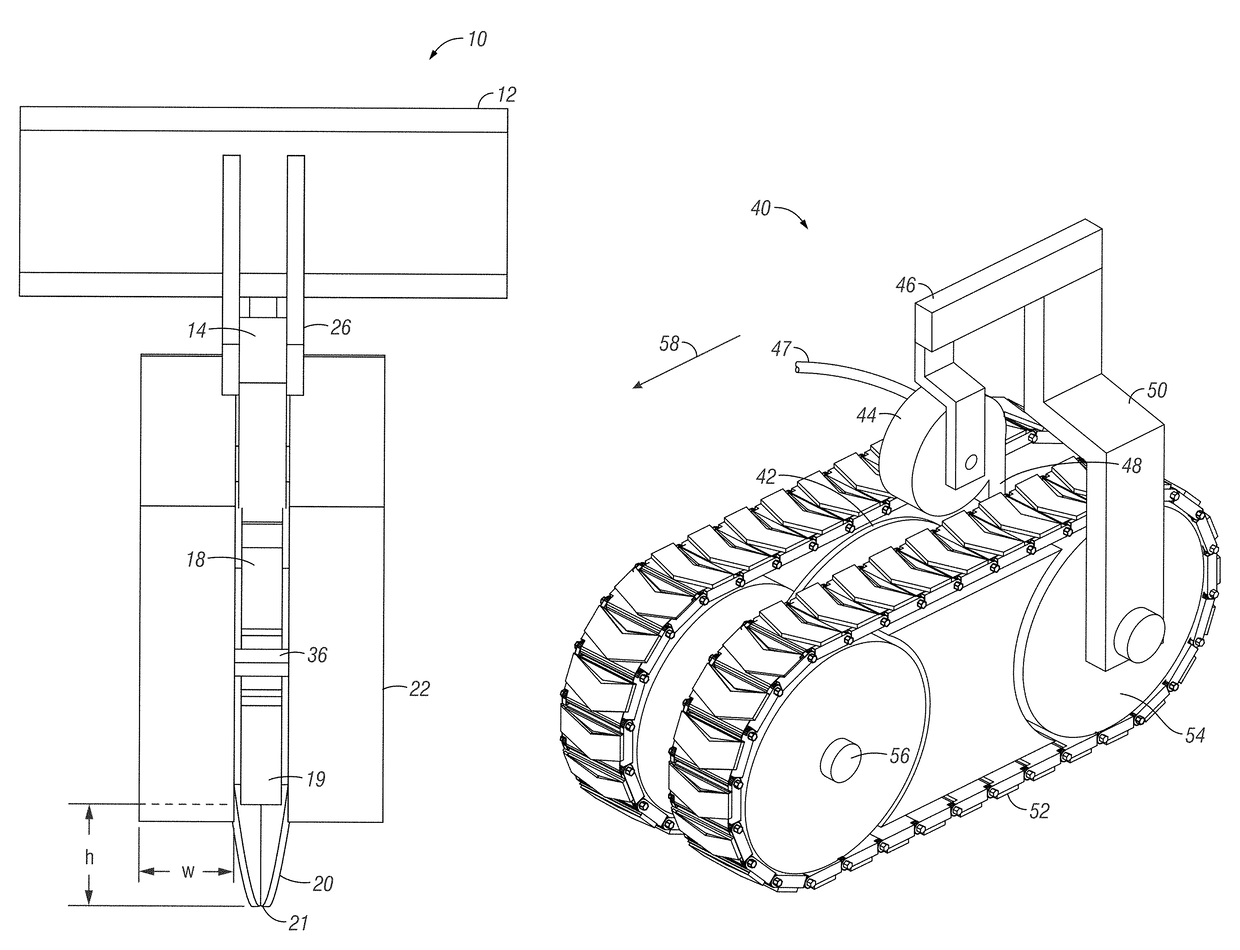

Row unit with tracks

ActiveUS9795077B2Overcome and improveReduce forcePlantingFurrow making/coveringPlanting seedEngineering

An agricultural planter includes a plurality of row units attached thereto for planting seed in a field. The row units include a seed meter for singulating and dispensing seed. Opening wheels or discs are included to create an opening in the field, such as a furrow. The row unit can include one or more continuous tracks for supporting the row unit as it moves through the field. The tracks reduce compaction around the created furrow and provide better control of seed depth placement. Furthermore, one or more cylinders may be provided that control the depth of furrow being created to also control the depth at which the seed is deposited.

Owner:KINZE MFG INC

Variable speed drive for agricultural seeding machines

ActiveUS20050257725A1Not affecting overall sizeSowingCoin-freed apparatus detailsGear wheelDrive shaft

An agricultural seeding machine includes a mechanical drive; a seed meter including a driven shaft; and a planetary gear set. The planetary gear set includes an input shaft connected with the drive, an output shaft connected with the driven shaft, a ring gear, and a motor coupled with a ring gear.

Owner:DEERE & CO

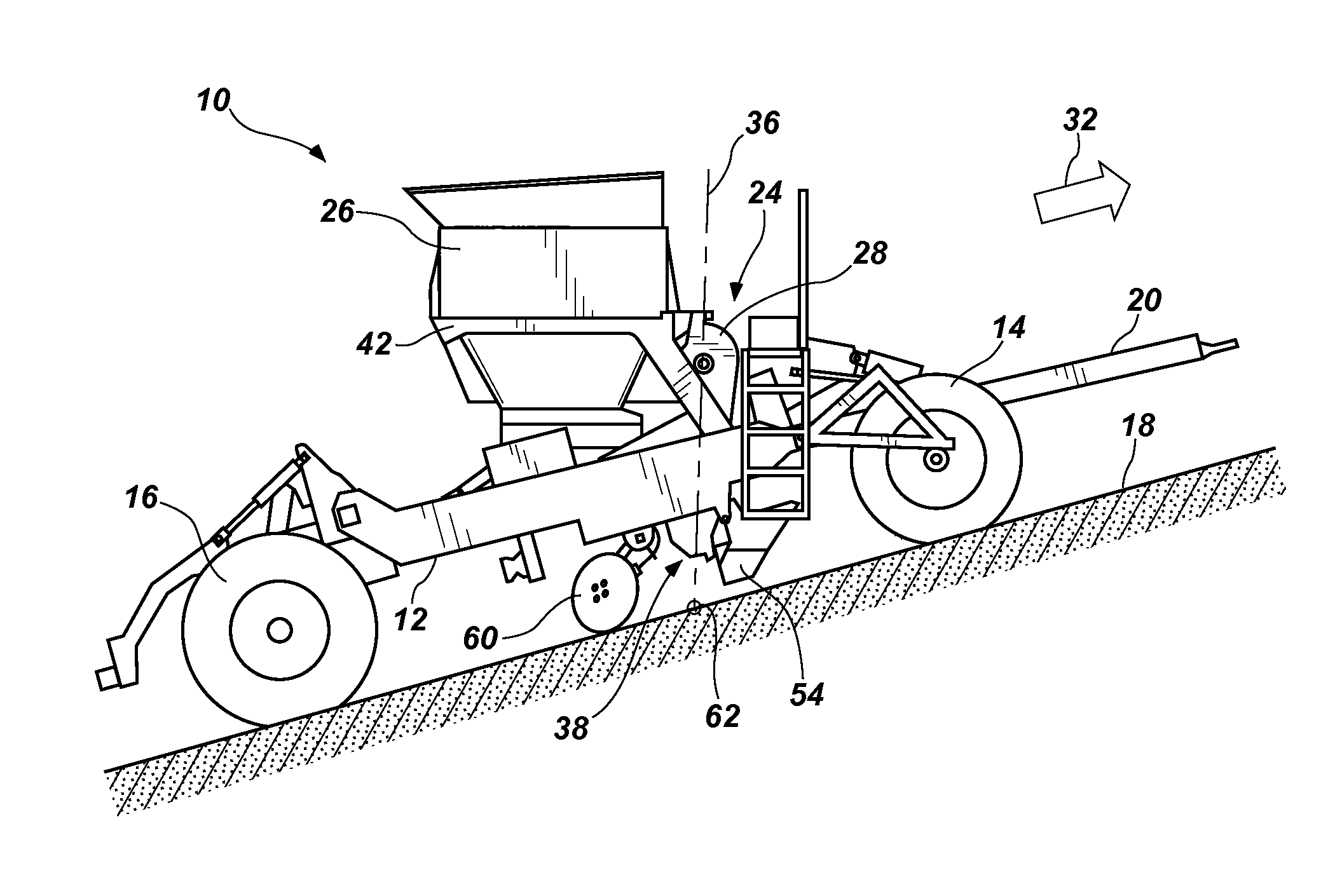

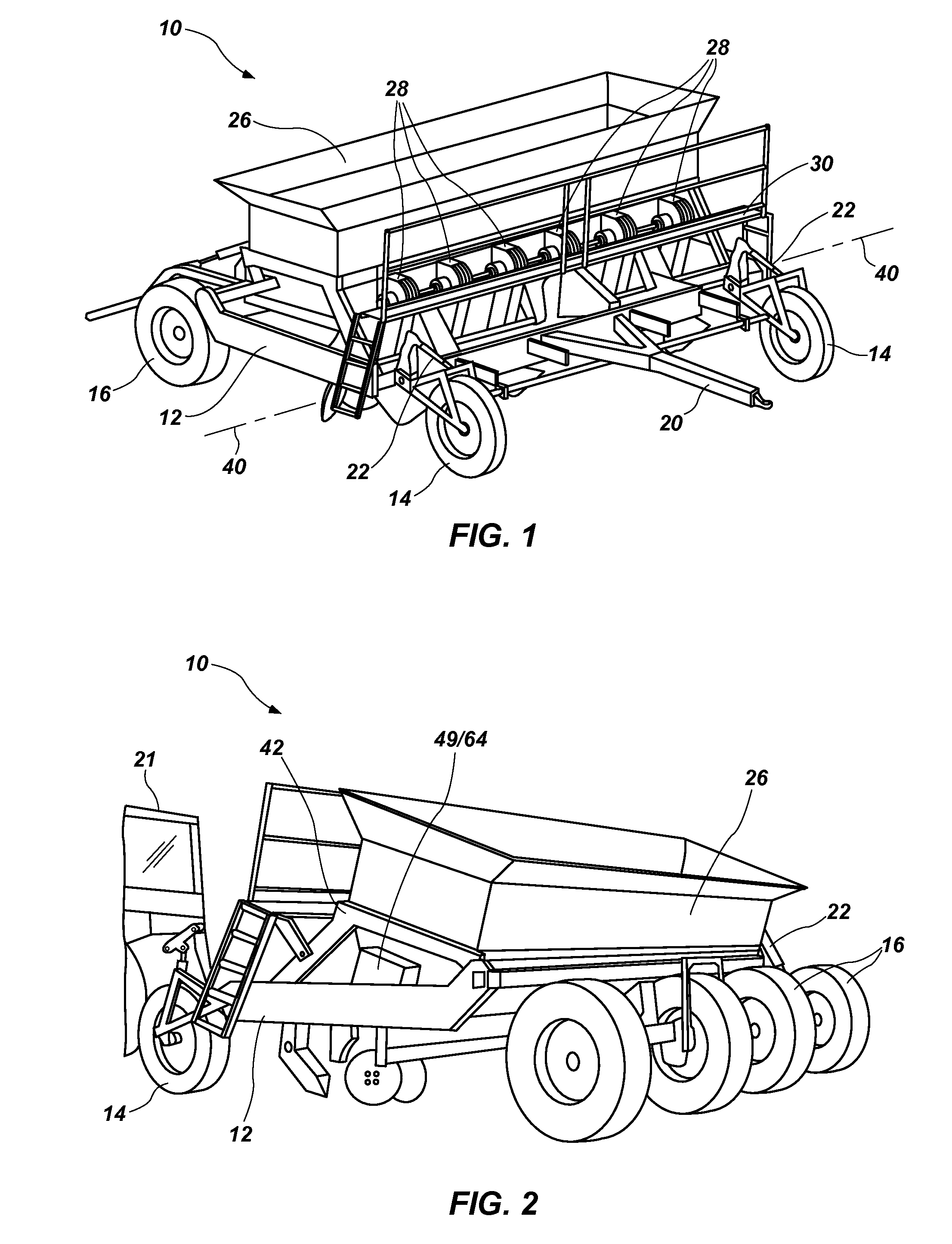

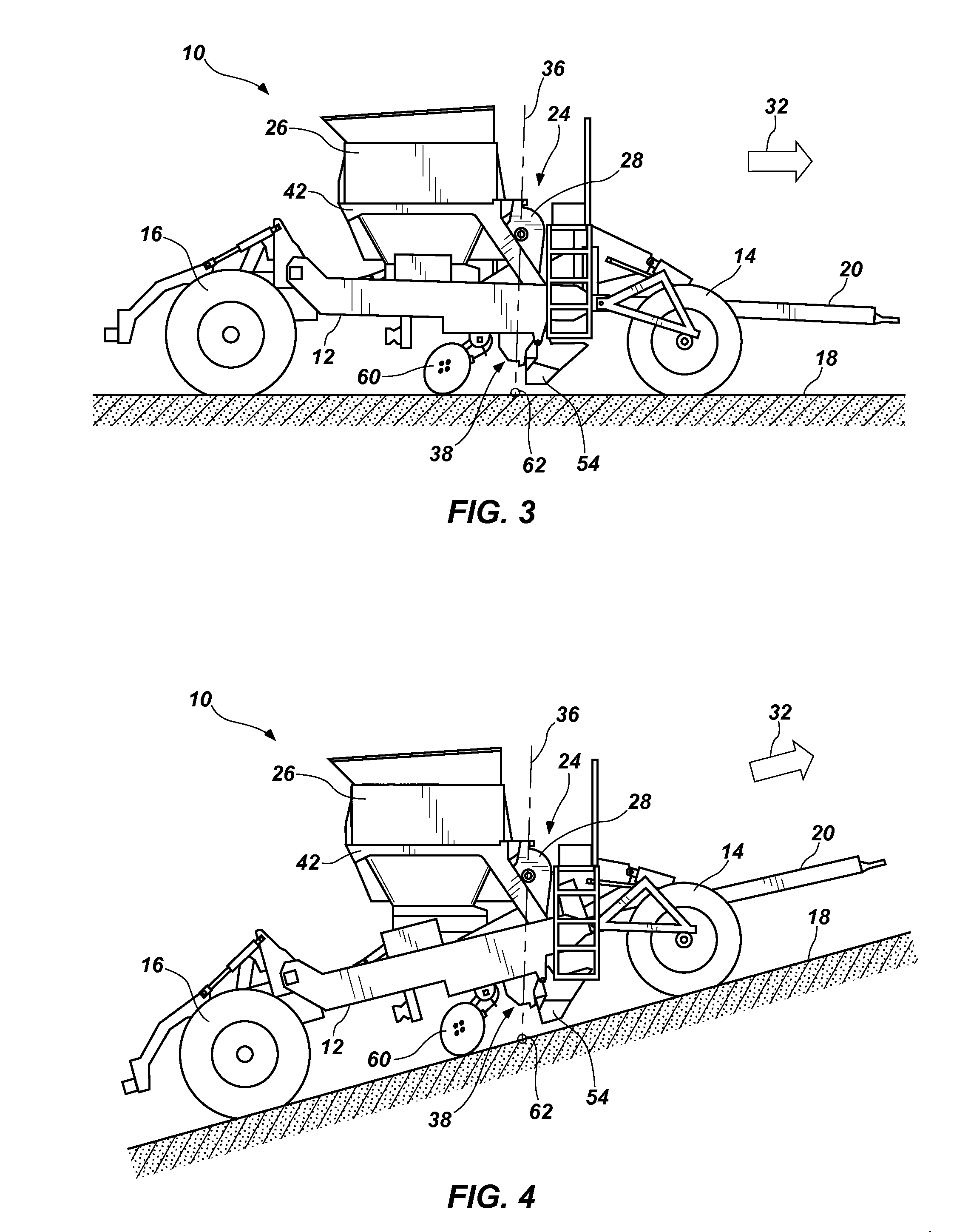

Hill-compensating planter and method

A seed planting device operable on ground includes a main frame, having wheels, configured to be moved in a planting direction on the ground, a seed hopper, attached to the frame, having a discharge, and a cup-type seed dispenser, having a dispenser axis, disposed adjacent to the discharge of the hopper. The seed dispenser is configured to controllably receive and dispense individual seeds from the hopper and drop the seeds from a seed discharge below the frame. The seed hopper and seed dispenser are pivotally attached to the main frame and configured to rotate about a generally horizontal axis to maintain the dispenser axis in a substantially upright orientation relative to an uphill or downhill planting direction.

Owner:SPUDNIK EQUIP

Popular searches

Iron group organic compounds without C-metal linkages Nickel organic compounds Cobalt organic compounds Metal/metal-oxides/metal-hydroxide catalysts Group 7/17 element organic compounds Organic-compounds/hydrides/coordination-complexes catalysts Lawn machines De-stacking articles Apparatus for dispensing discrete articles Article separation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com