Corn-soybean strip-shaped compound planting no-tillage fertilization precision seeder

A compound planting and seeding machine technology, which is applied in the field of farmland machinery and tools, can solve problems such as the minimum adjustment range of plant spacing and large row spacing, the inability to meet the density scale, and the impact of seed metering, so as to eliminate dragging, lack of seedlings and ridges, Guarantee the effect of stubble removal and broken soil, and ensure the effect of smooth implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

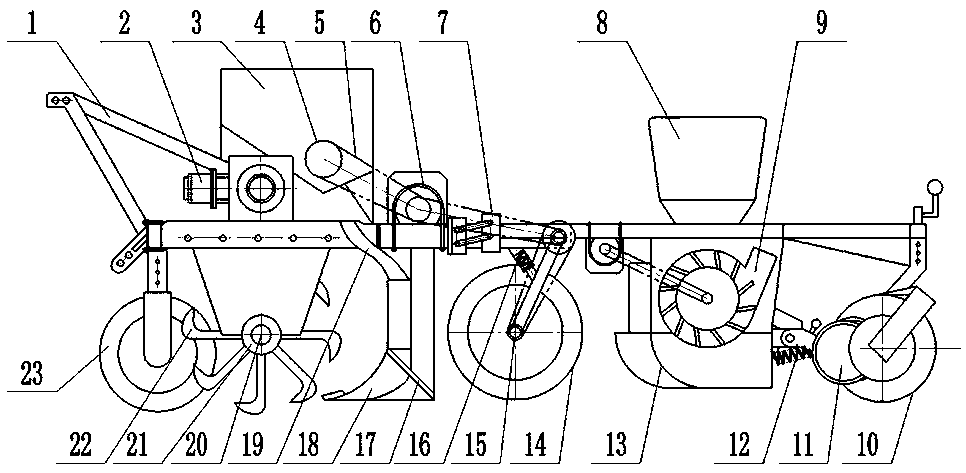

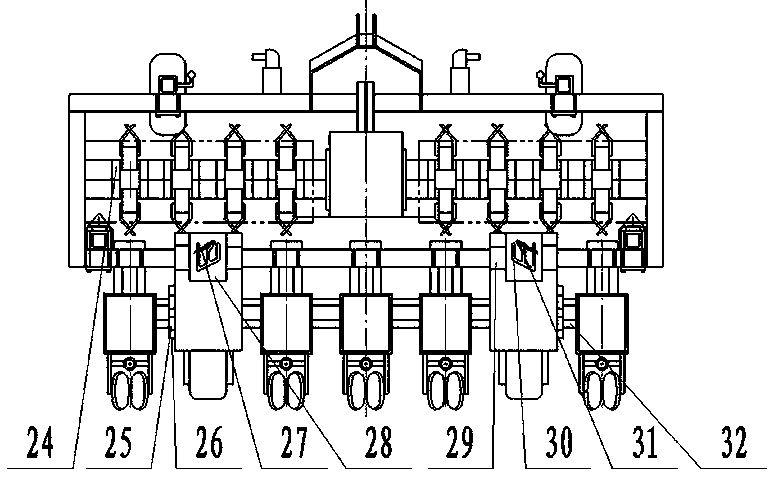

[0021] figure 1 and figure 2 Shown are the structural front view and structural top view of the present invention respectively, the corn-soybean strip compound planting no-tillage and fertilization precision seeder consists of a suspension frame, a rotary tillage system, a power transmission system, a fertilization ditching system and a sowing and soil covering system .

[0022] When the seeder is working, the driving wheel is tilted forward and kept in contact with the ground by the pressure of the spring, so as to provide continuous power for the seeding tray and fertilizer box, and avoid the situation of lack of seedlings and broken ridges. The rotary tiller roller is connected with the power output of the tractor through the gearbox to realize reverse rotary tillage, and finally throw the broken stubble stems forward, so as to prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com