An energy-saving degreasing machine for disk parts

A technology for disc parts and degreasers, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using gas flow, etc., can solve the problems that cannot be solved such as the thickness of the oil film on the surface of the workpiece, the oil in the inner hole of the workpiece, and the working environment. Poor and other problems, to achieve the effect of reducing the consumption of anti-rust oil, reducing oil loss and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

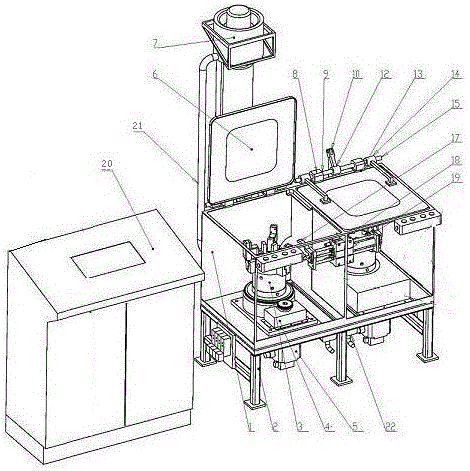

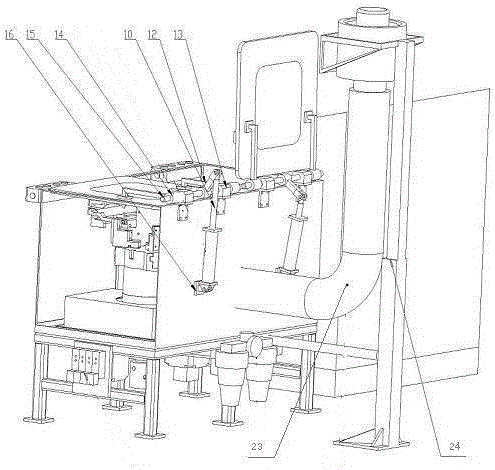

[0018] From figure 1 , figure 2 It can be seen that the present invention provides an energy-saving degreasing machine for disk parts, which includes a degreasing device, an oil mist recovery device and an electrical control cabinet 20 .

[0019] The degreasing device is provided with a main box body 1, a box body support 2, a visible protective door 6, and the like. The box support 2 supports the main box 1 and the visible protective door 6 to form a closed processing space. The main box 1 of the present invention is divided into left and right dual station boxes, which can carry out automatic degreasing processing of discs at the same time, and the anti-rust oil after degreasing is stored in the oil return through the oil return tank 22, and through the early warning device, Remind the staff to recycle anti-rust oil in time to save fuel consumption.

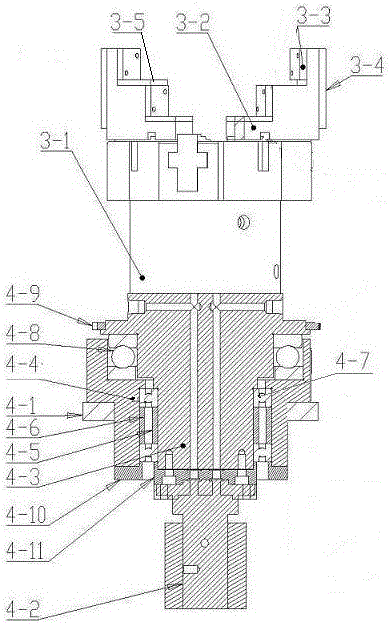

[0020] A self-centering clamping mechanism 3 , a rotating mechanism 4 , a servo drive mechanism 5 , and an air knife 17 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com