Display screen line protection device and method

A line protection and display technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor product quality, consistency, and inability to guarantee film thickness, etc., to improve work efficiency, plasma Evenly spread effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

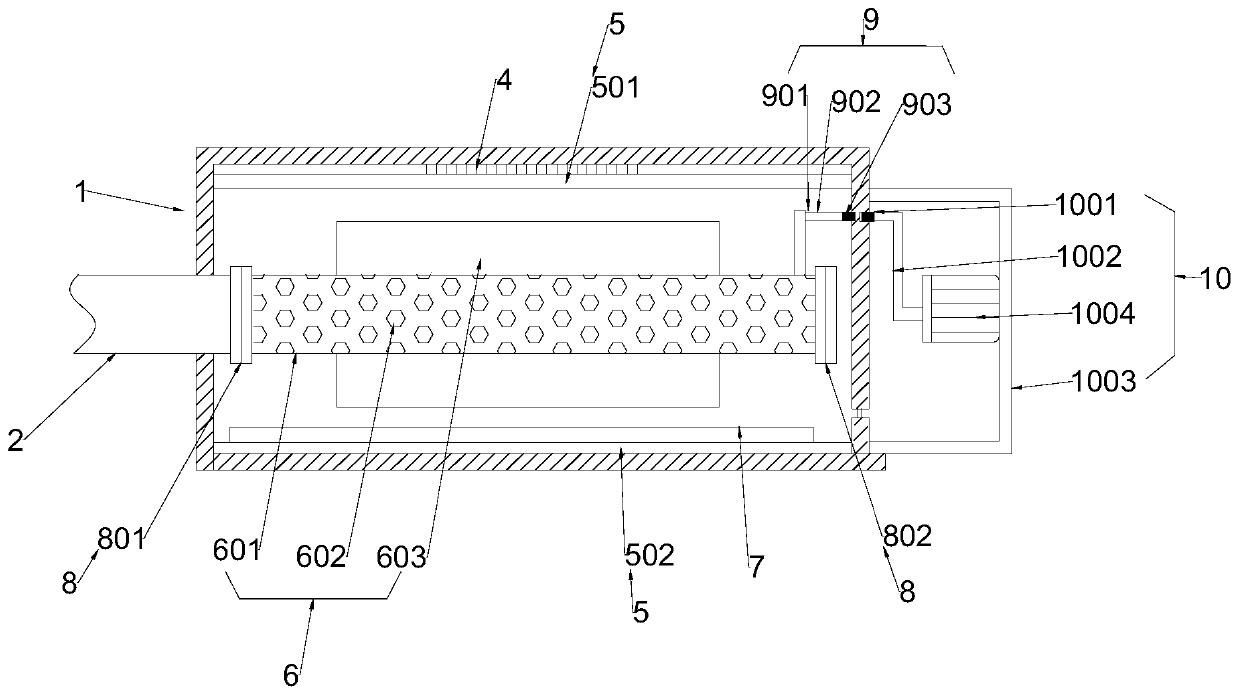

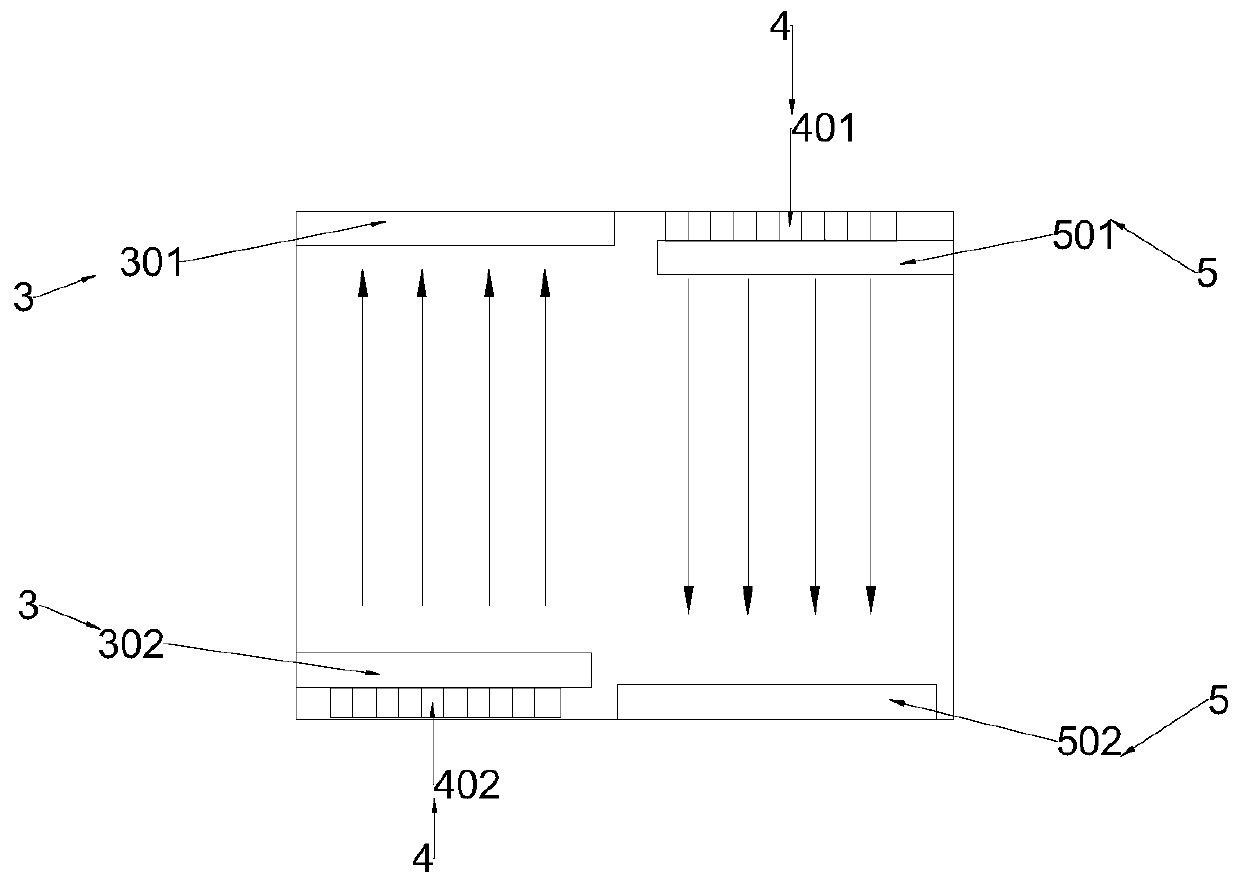

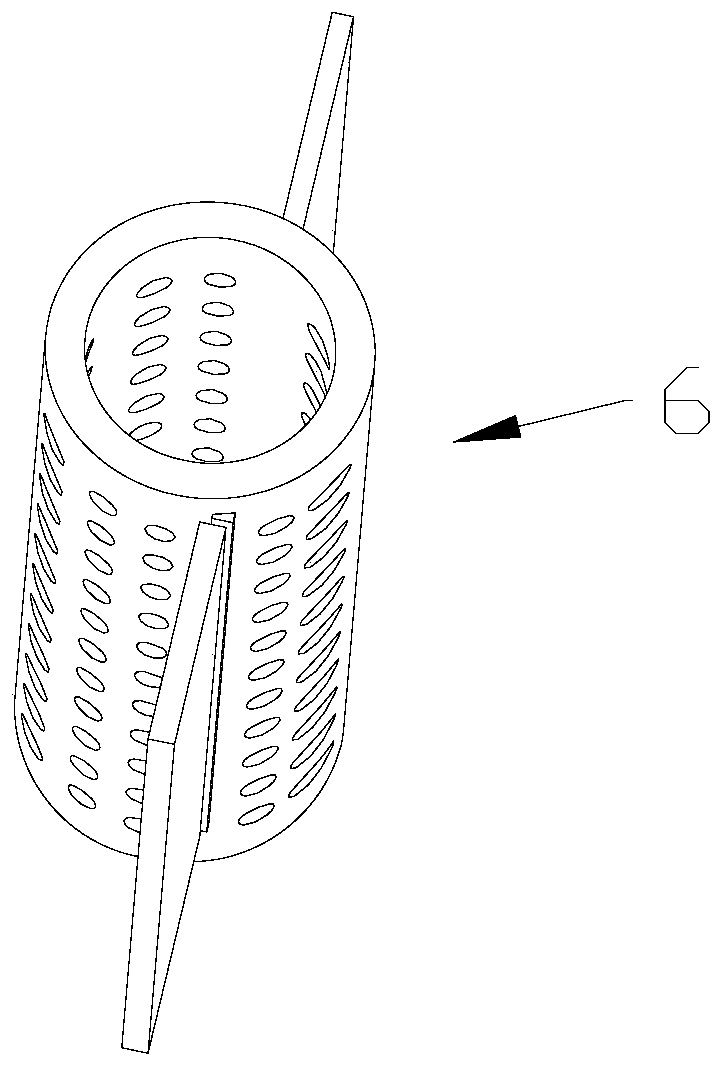

[0029] by figure 1 The direction shown in is the setting direction of the device. figure 1 A schematic structural diagram of a display screen line protection device provided in Embodiment 1 of the present invention; figure 1 , a display screen line protection device, including a vapor deposition device 1, a pipeline 2, a first electrode 3, a coil 4, a second electrode 5, a rotating mechanism 6, a connector 8, a rotating auxiliary mechanism 9 and a first driving mechanism 10, The middle part of the vapor-phase precipitation device 1 is provided with a pipeline 2 through which the pipeline 2 and the rotating mechanism 6 are rotationally connected through a joint 8, and the end of the rotating mechanism 6 away from the pipeline 2 is connected with an end of the rotating auxiliary mechanism 9, so that The other end of the rotation auxiliary mechanism 9 is slidingly connected to the groove provided on the side wall of the vapor deposition device 1, and the side wall of the gas pha...

Embodiment 2

[0046] Figure 4 A schematic structural diagram of a display screen line protection device provided in Embodiment 2 of the present invention, as shown in Figure 4 The difference between Embodiment 2 and Embodiment 1 is that the rotation assist mechanism 9 and the first rotation mechanism 10 are replaced by a second drive mechanism 11, and the second drive mechanism 11 includes a drive rod 1101, a second motor 1102, The support plate 1103, the support plate 1103 is fixedly arranged on the right side wall of the meteorological precipitation device 1, the top of the support plate 1103 is connected with the second motor 1102 by bolts, the second motor 1102 is a servo motor, and the first The output shaft of the second motor 1102 is fixedly connected with 802, and the rotation of the second motor 1102 drives 6 to rotate; the rest are the same as in Embodiment 1.

[0047] Working principle: when the second motor 1102 is working, the rotation of the second motor 1102 drives the rot...

Embodiment 3

[0049] A display screen line protection method, comprising the following steps:

[0050] S1, making metal wires, on the existing display screen, the metal wires are sputtered on the glass substrate by sputtering method;

[0051] S2. Using a coating method, apply a photoresist on the metal circuit of the substrate. The photoresist can be purchased in the market, and the type can be selected according to actual needs;

[0052] S3, perform exposure, and use a mask to perform exposure according to the design requirements of the display screen product;

[0053] S4, the display screen after exposure is placed in the display screen line protection device described in embodiment 1, a layer of shading cloth is pasted, only the metal line is leaked, and then the display screen line protection device is started to generate a thin film on the metal line, Then, a protective layer is formed on the circuit by means of a photomask mask.

[0054] In this embodiment, the protective layer is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com