Garlic seeder

A seeder and garlic technology, which is applied to single seed seeders, seeder parts, fertilization devices, etc., can solve the problems of the garlic scale bud upright control mechanism is not very effective, the quality cannot be guaranteed, and the upright rate is not high, etc., to achieve benefits The effect of garlic growth and implementation of mechanical harvesting, stable control, and uniform sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

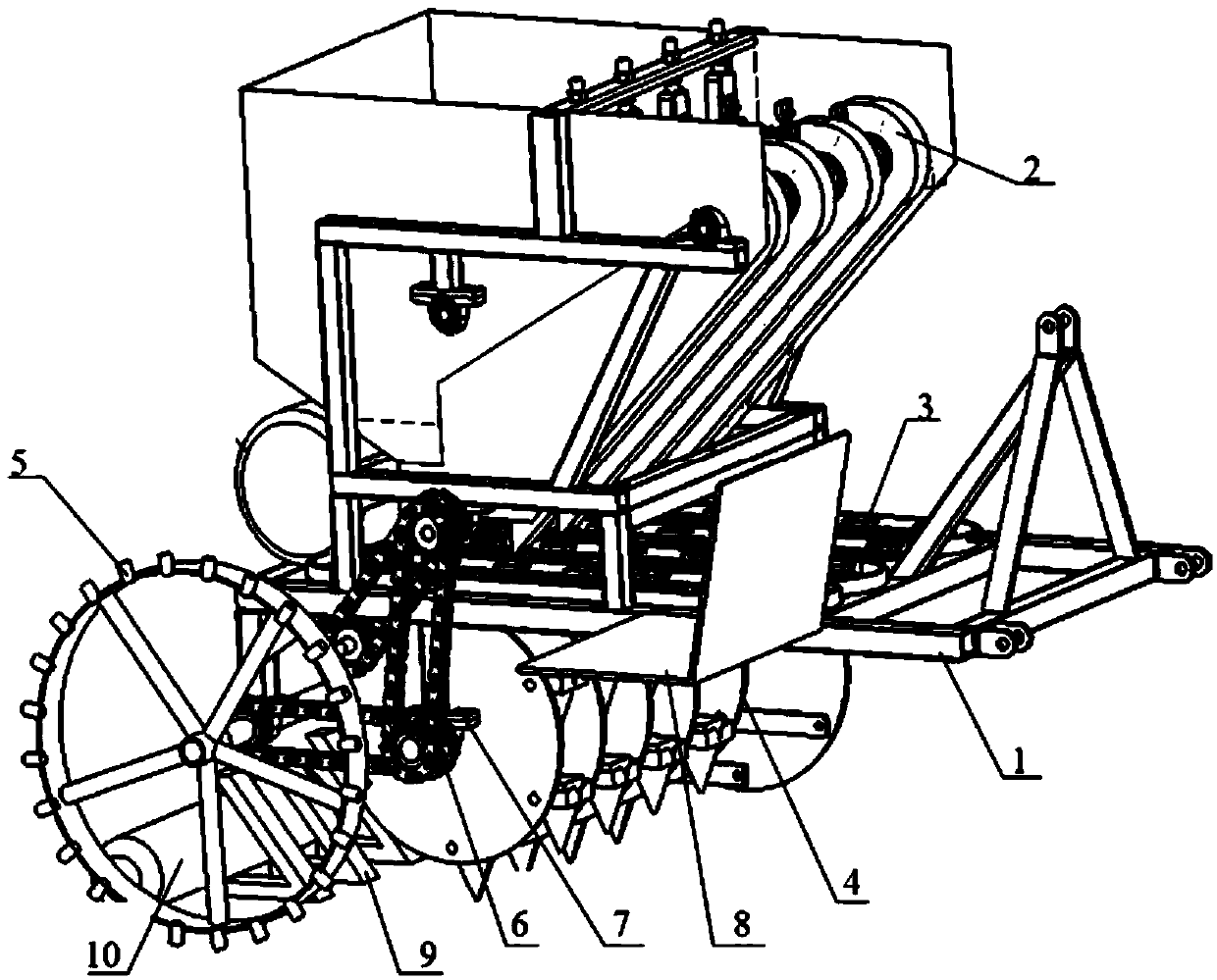

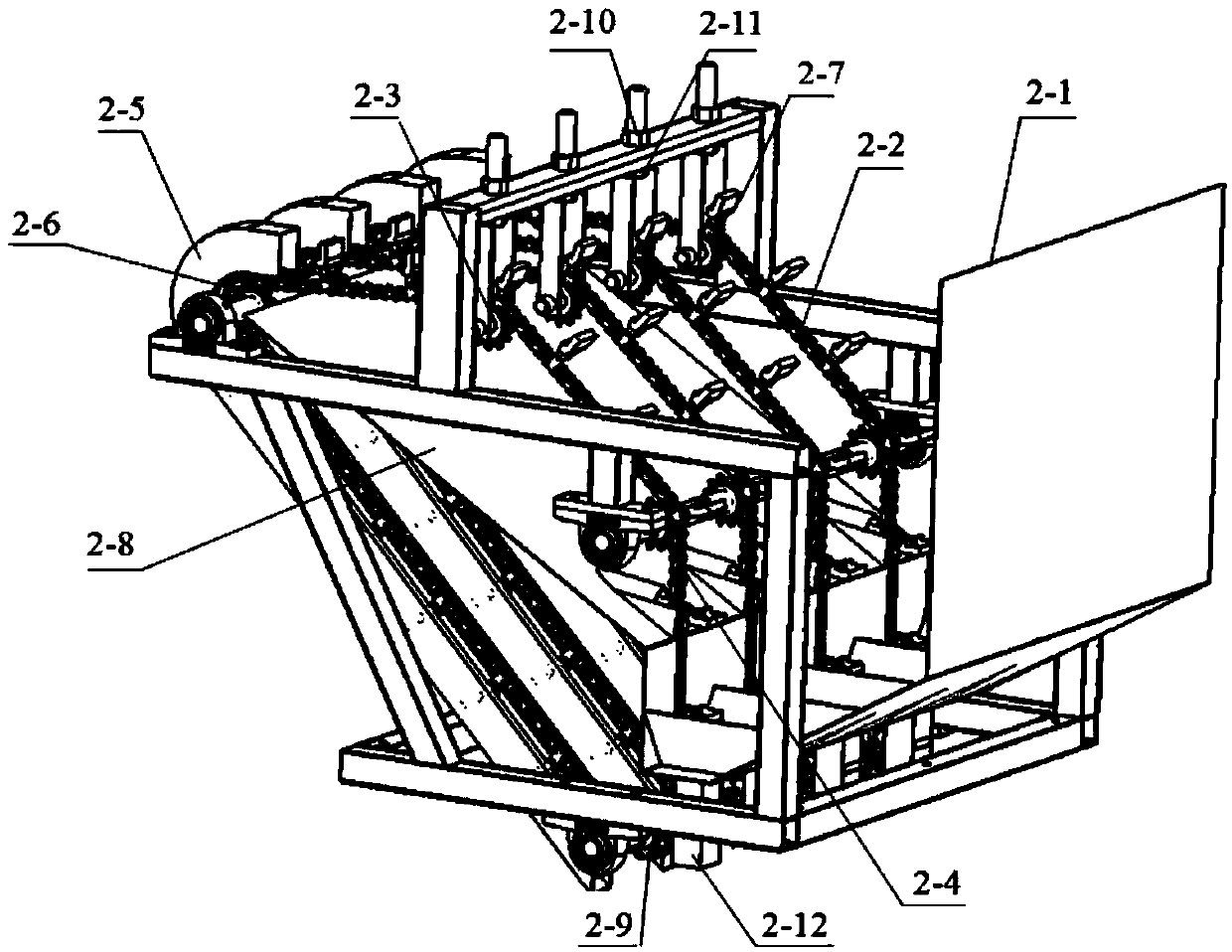

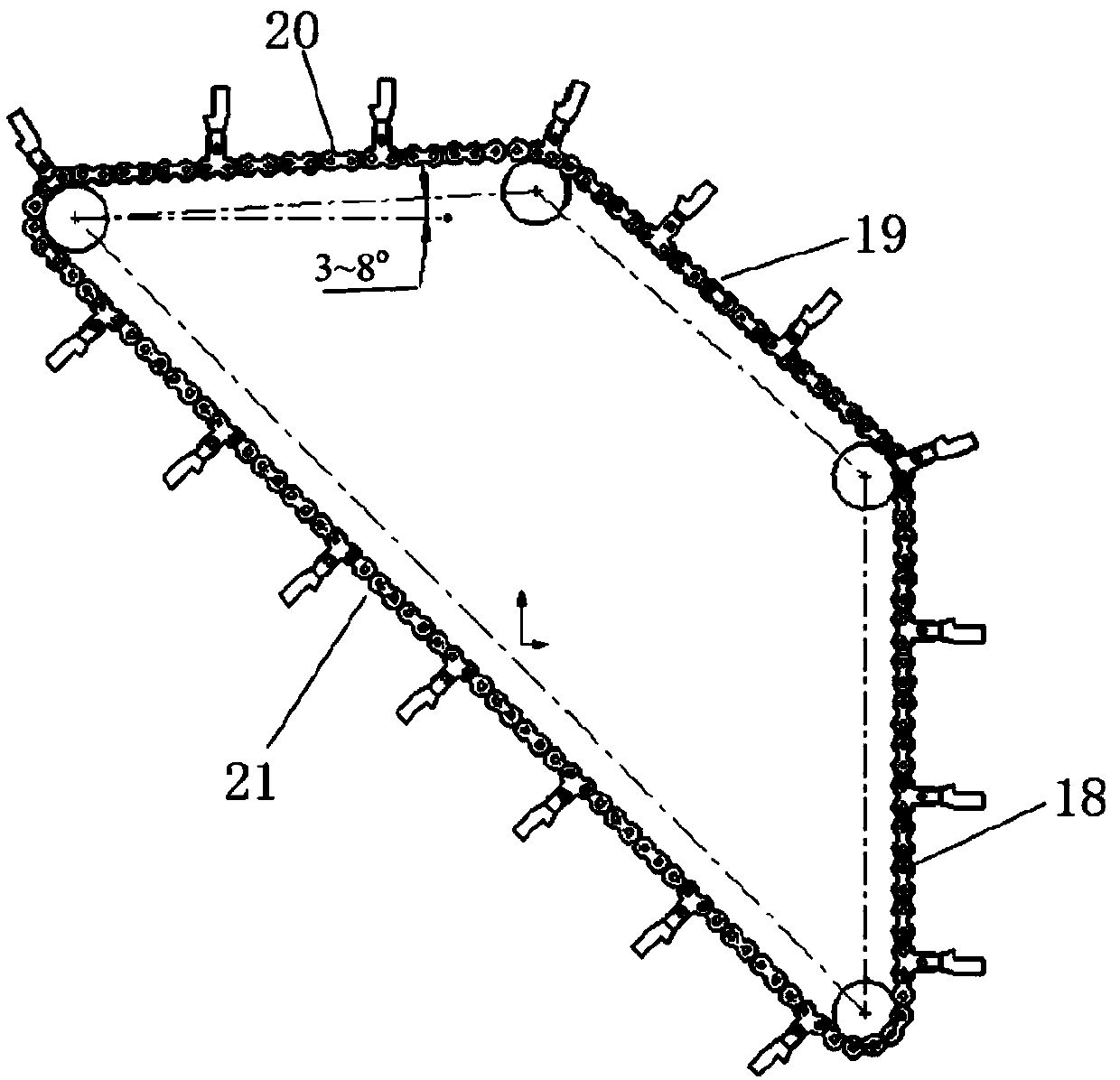

[0055] Such as figure 1 , Figure 8 with Figure 17 As shown, the planter consists of a frame 1, a single seed picking device 2, a garlic scale bud direction control device 3, an upright planting device 4, a ground wheel 5, a transmission assembly 6, an artificial seat 8, a soil covering device 9 and a suppressor Composed of device 10, wherein the single grain seeding device 2 is installed above the frame 1, the vertical planting device 4 is mounted on the bottom of the frame through the bearing seat 7, and garlic scale buds are arranged between the single grain seeding device 2 and the vertical planting device 4 The direction control device 3, the ground wheel 5 provides power for the upright planting device 4 through the driving sprocket 6-1 and the first transmission chain 6-2, and provides power for the single seed picking device 2 through the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com