Accurate seed throwing mechanism and accurate seed throwing method of corn planter

A corn seeder and seed technology, which is applied to the parts of the seeder, the machine for interval quantitative sowing, and the fertilization device, etc., can solve the problems of reduced friction between the seed and the seeding plate, increased power consumption of the seeding system, and complex structure. , to achieve the effect of maintaining spacing accuracy, simple structure and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention is further described below in conjunction with embodiment.

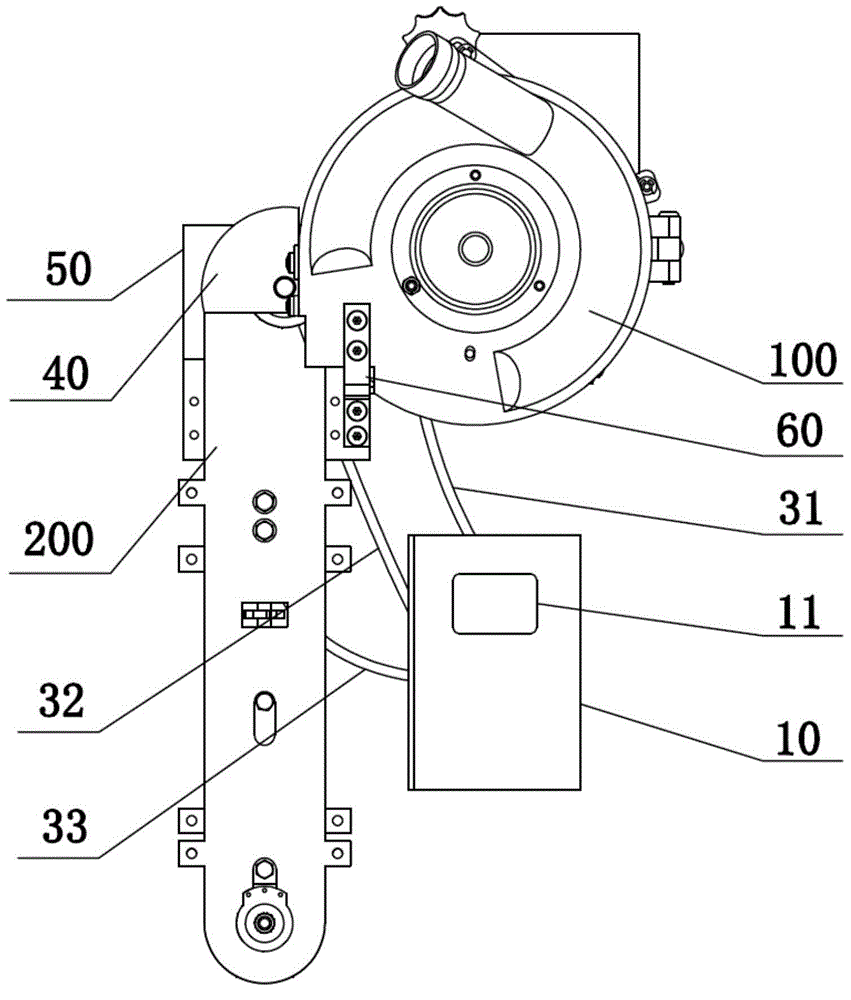

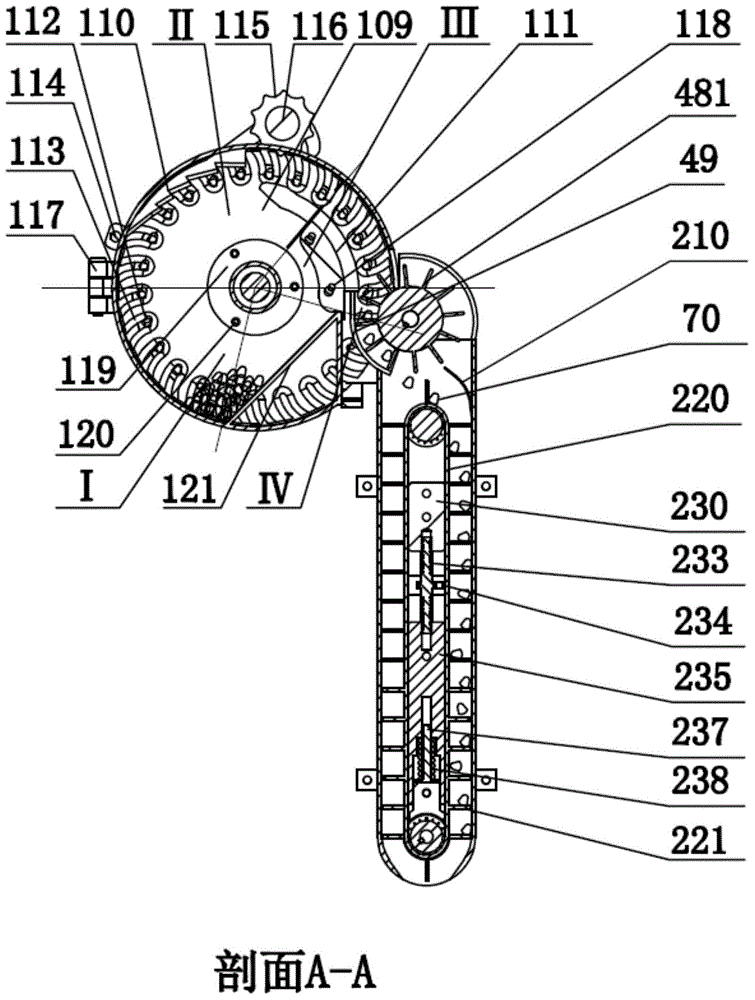

[0093] The present invention provides a precise seed delivery mechanism for a corn planter, which includes a control unit 10, a drive unit and an execution unit.

[0094] Such as Figure 7 As shown, the control unit 10 includes a chip 407, a vehicle-mounted 12V DC power supply 401, a voltage stabilizing device 402, a speed measuring radar 403, a signal processing circuit 404, a reset button 405, a first switch 408, a second switch 406, a man-machine interface 11, a second A stepping motor encoder 106 , a second stepping motor encoder 41 and a third stepping motor encoder 203 . The chip is preferably an STC90C51 chip.

[0095] The drive unit includes a first stepping motor 105 , a first stepping motor driver 71 , a second stepping motor 42 , a second stepping motor driver 72 , a third stepping motor 202 and a third stepping motor driver 73 .

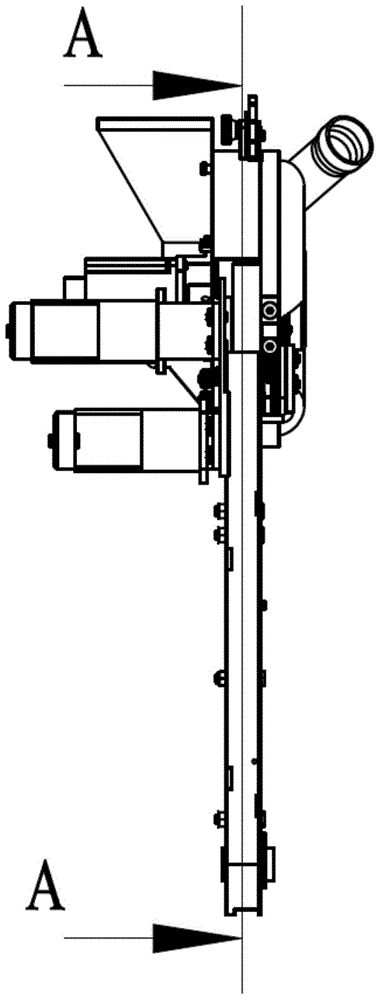

[0096] Such as figure 1 , image 3 , Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com