Stamp Hole Package Module Test Fixture

A technology for packaging modules and test fixtures, applied in manufacturing tools, measuring device casings, workpiece clamping devices, etc., can solve problems such as decreased work efficiency and unfavorable product debugging, and achieve the effects of low cost, high reliability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

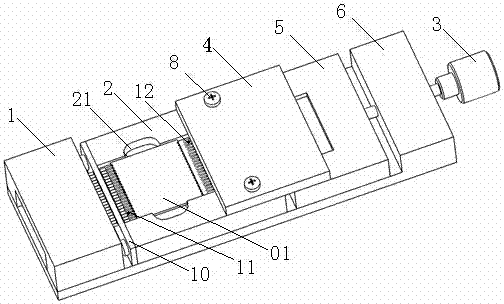

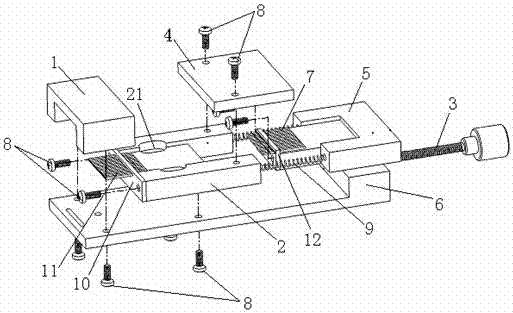

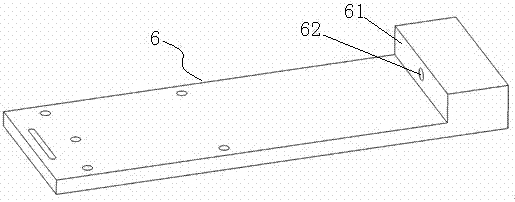

[0032] Embodiment: The following takes the clock transfer module as an example to introduce a preferred embodiment of the present invention. The tested module 01 is a clock transmission module, which uses double rows of 20-core "stamp holes" as the module signal lead-out and input pins. The diameter of the "stamp holes" is 0.66mm, and the center point distance between two adjacent "stamp holes" is 1.27mm, the spacing between two rows of pins is 25mm, and the thickness of the printed board is 1mm.

[0033] According to the appearance characteristics of the tested module 01, the entire test fixture is designed to use a spring-retractable test needle with a needle head, which is crimped from both sides to the middle, so as to achieve the purpose of clamping the module and leading out and inputting signals. Through the cooperation of various parts, the problems such as the arrangement and fixing of the test pins at 1.27mm pitch, and how to freely clamp and loosen the test pins to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com