Patents

Literature

542 results about "Seed drill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A seed drill is a device that sows the seeds for crops by positioning them in the soil and burying them to a specific depth. This ensures that seeds will be distributed evenly. The seed drill sows the seeds at the proper seeding rate and depth, ensuring that the seeds are covered by soil. This saves them from being eaten by birds and animals, or being dried up due to exposure to sun. With seed drill machines, seeds are distributed in rows, however the distance between seeds along the row cannot be adjusted by the user as in the case of vacuum precision planters. The distance between rows is typically set by the manufacturer. This allows plants to get sufficient sunlight, nutrients, and water from the soil. Before the introduction of the seed drill, most seeds were planted by hand broadcasting, an imprecise and wasteful process with a poor distribution of seeds and low productivity. Use of a seed drill can improve the ratio of crop yield (seeds harvested per seed planted) by as much as nine times.The use of seed drill saves time and labor...

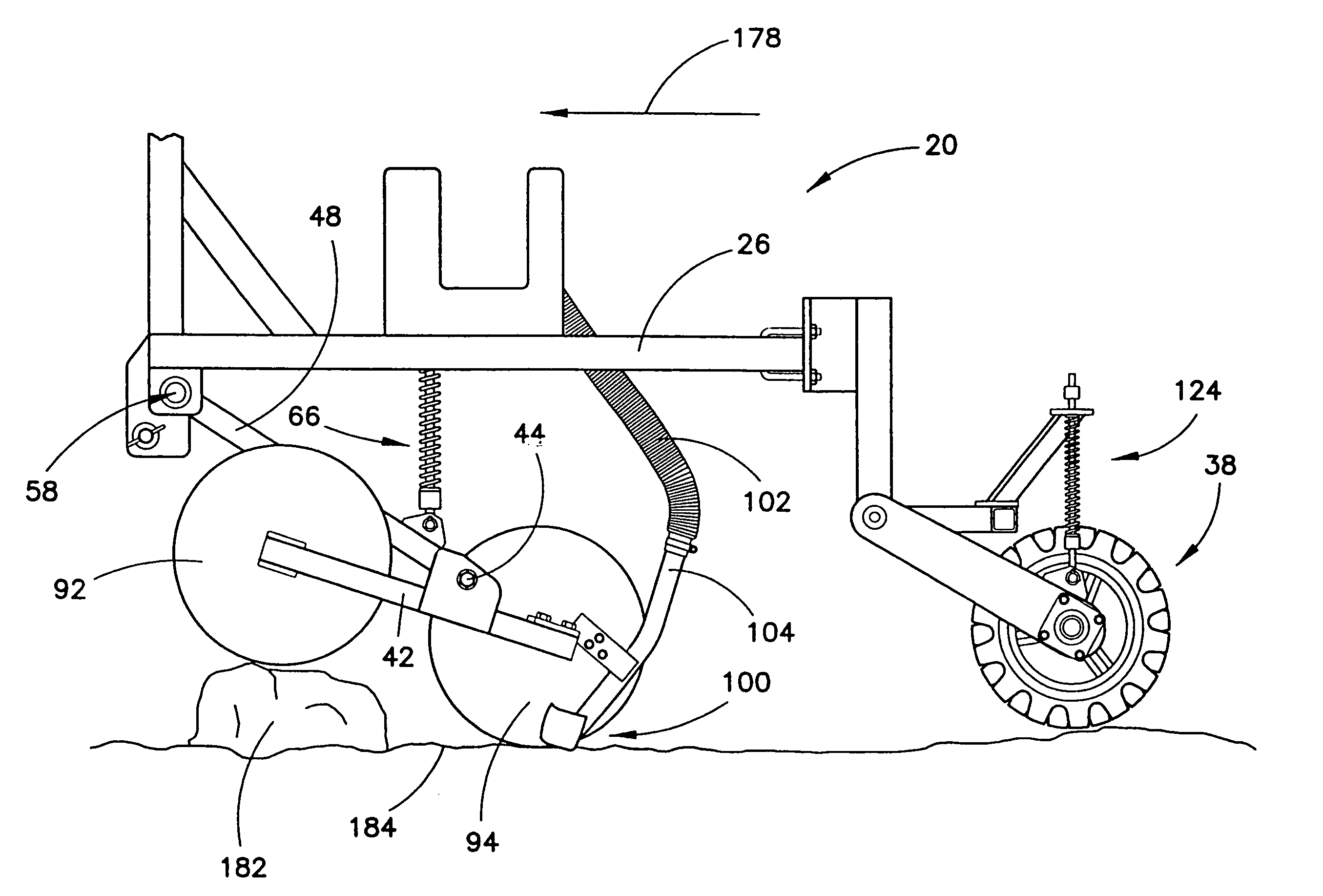

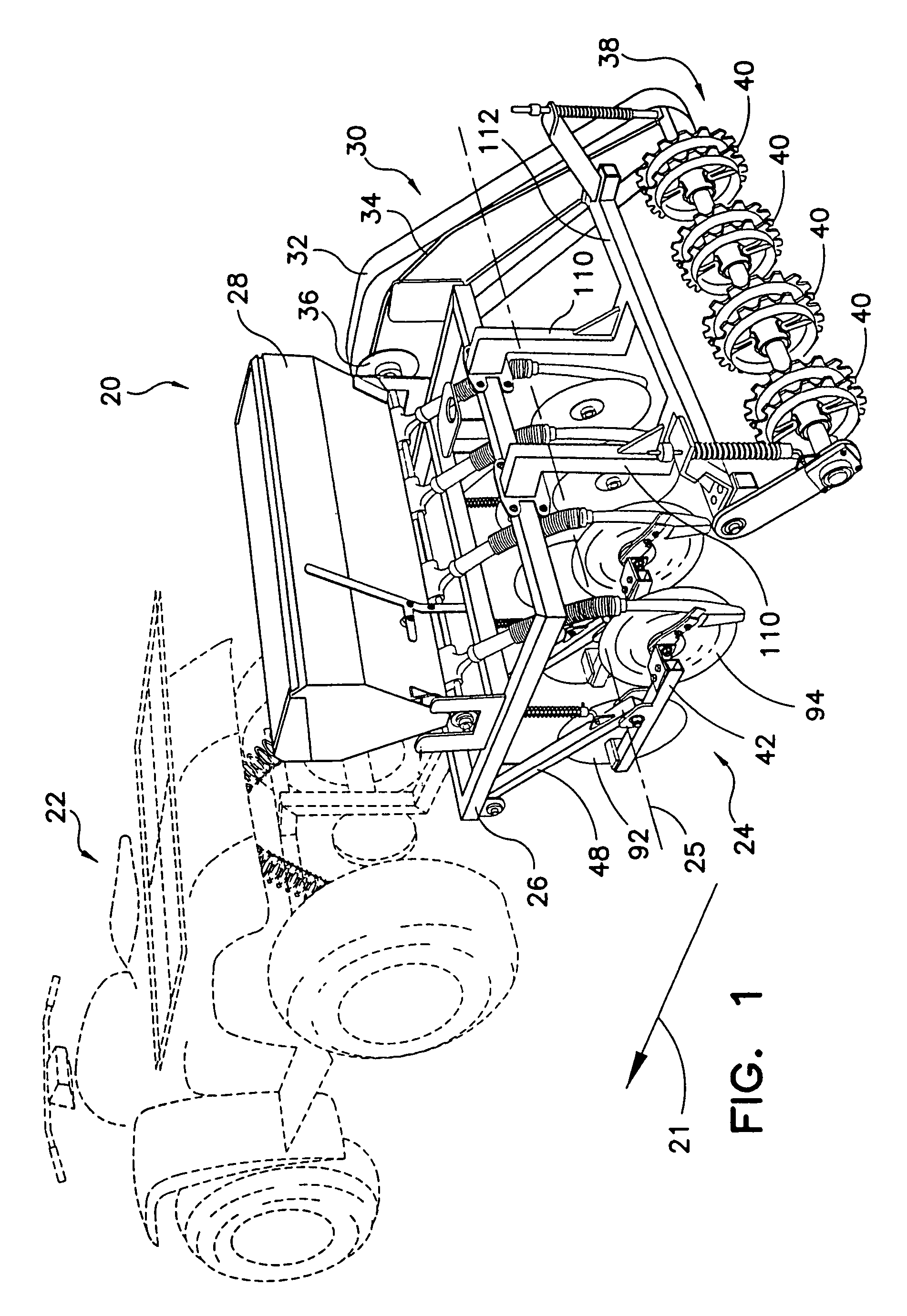

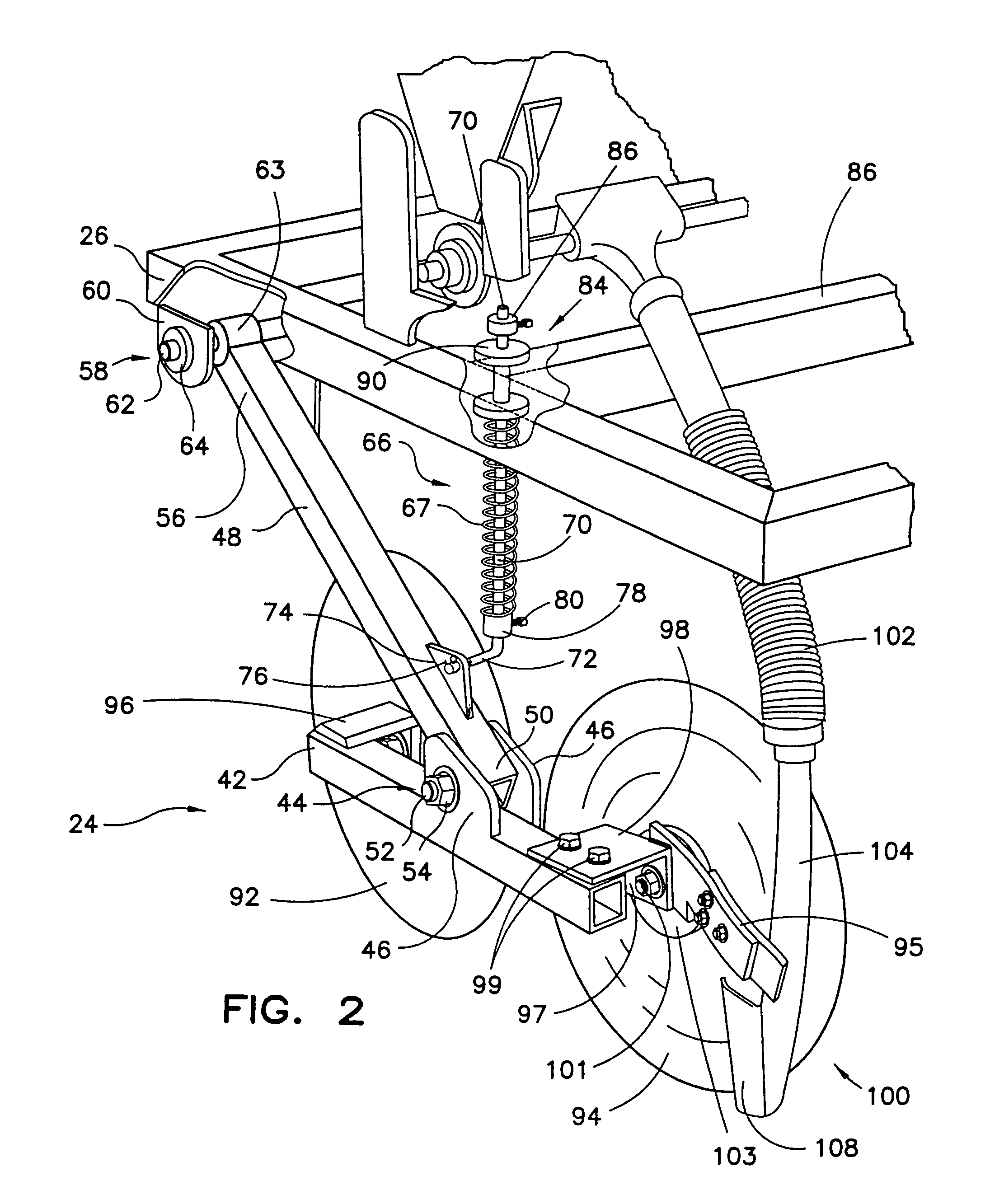

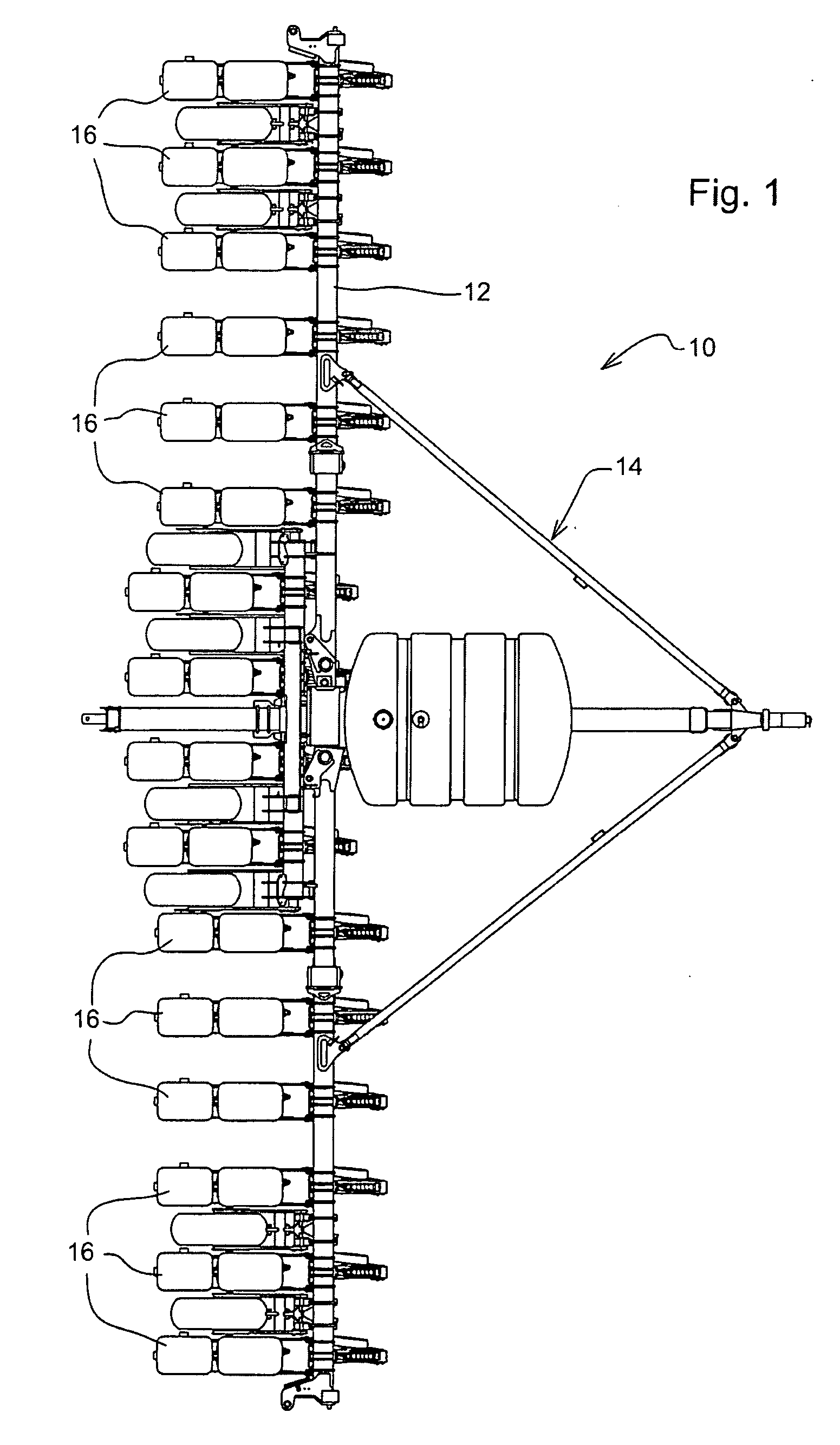

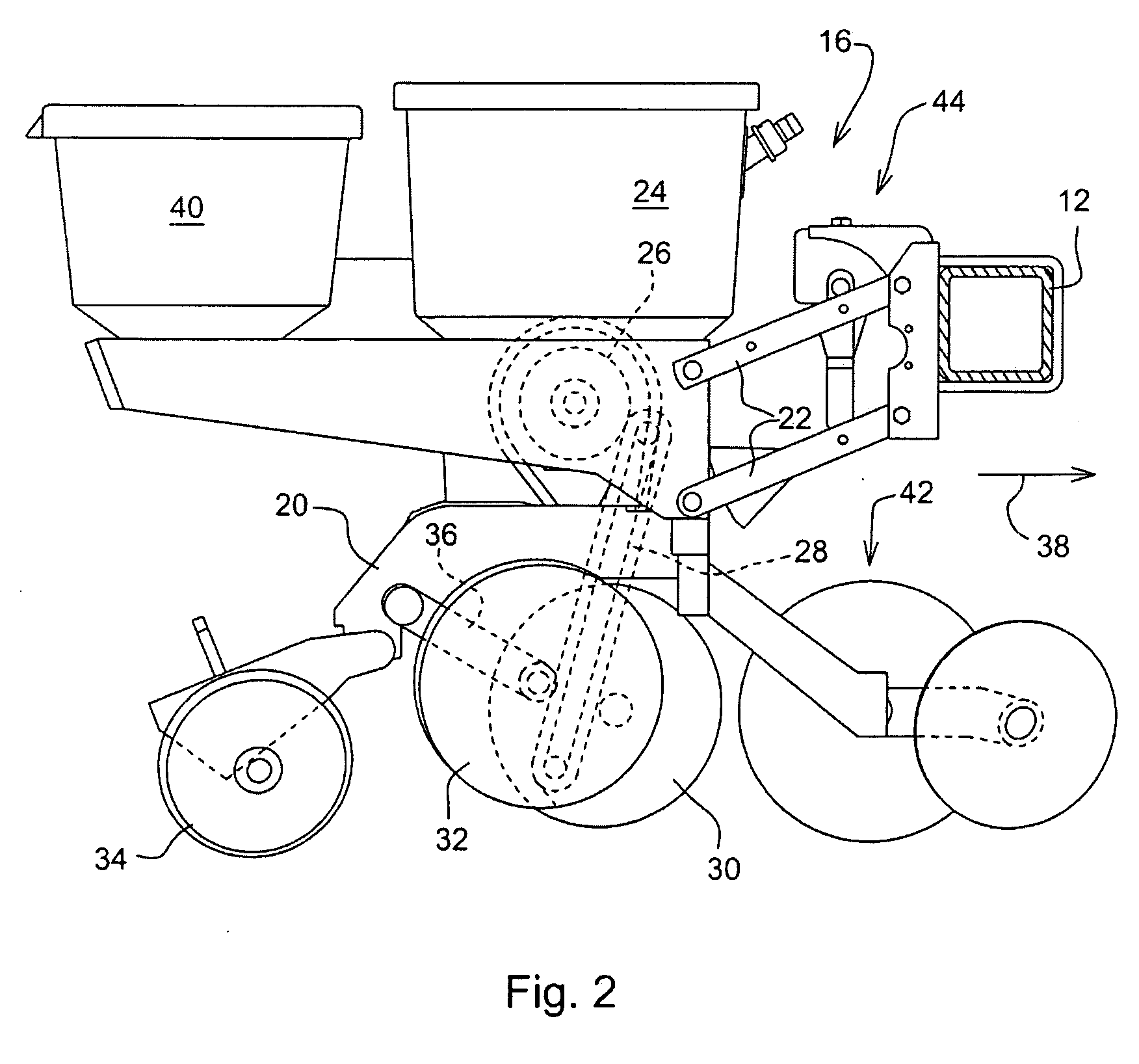

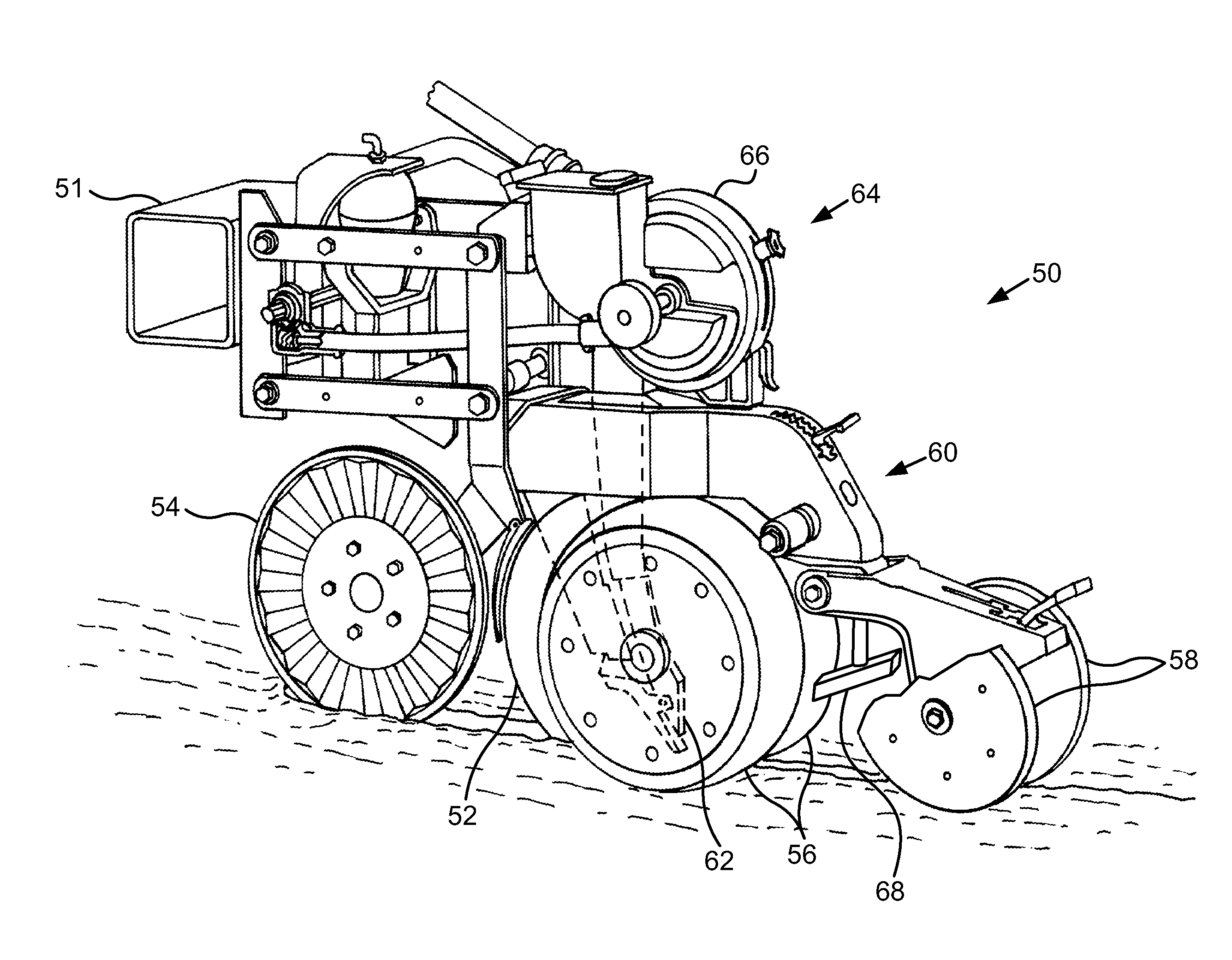

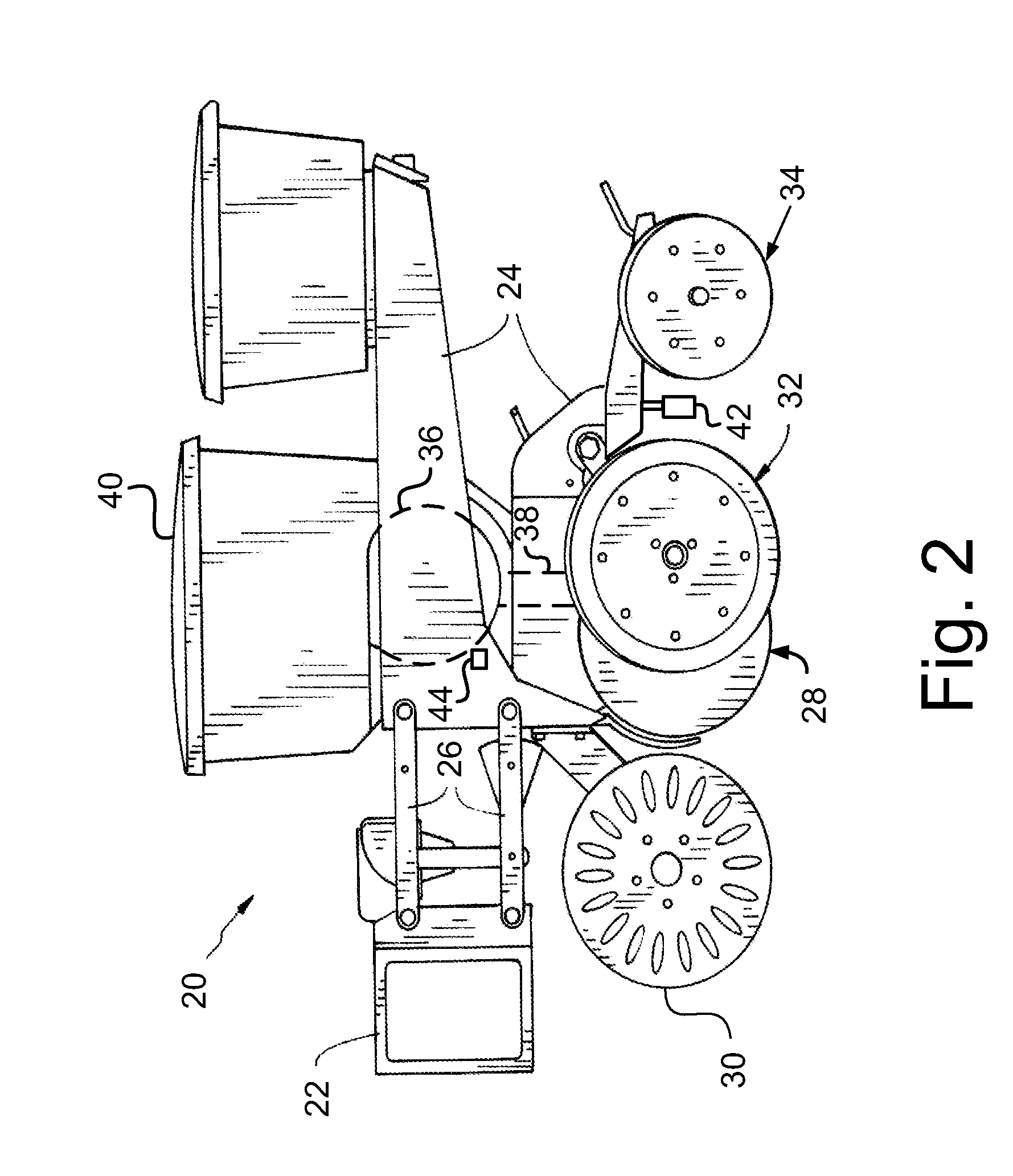

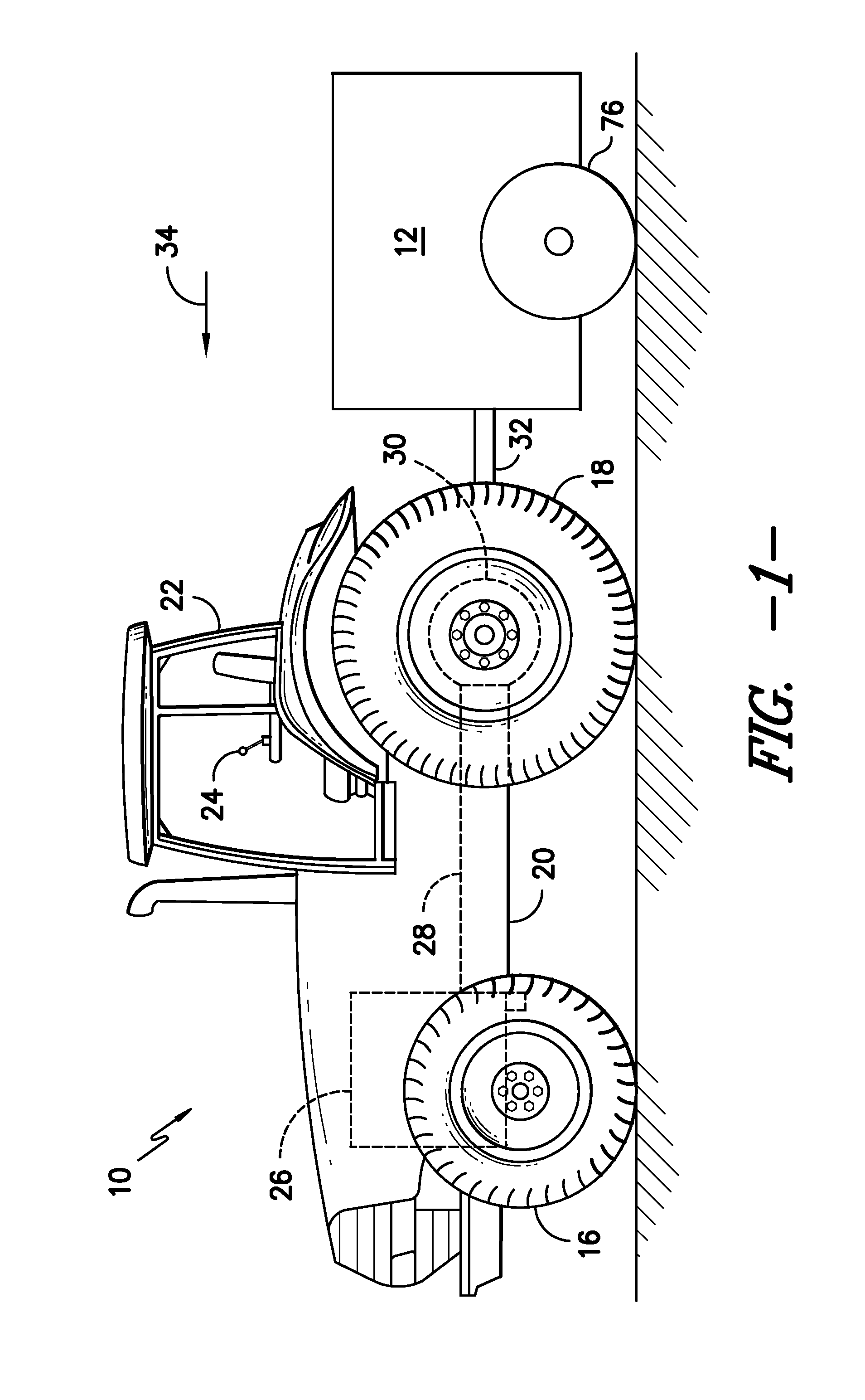

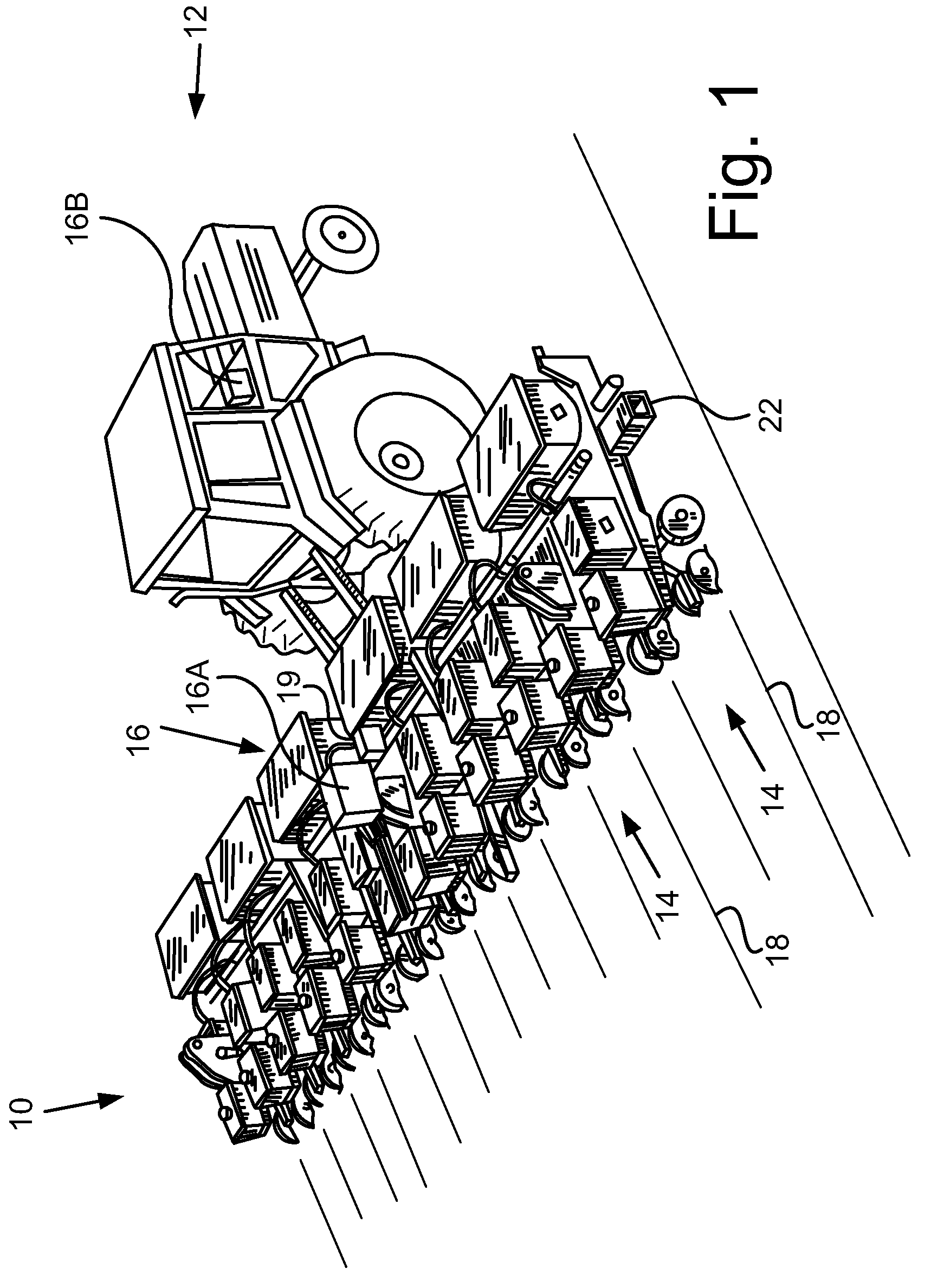

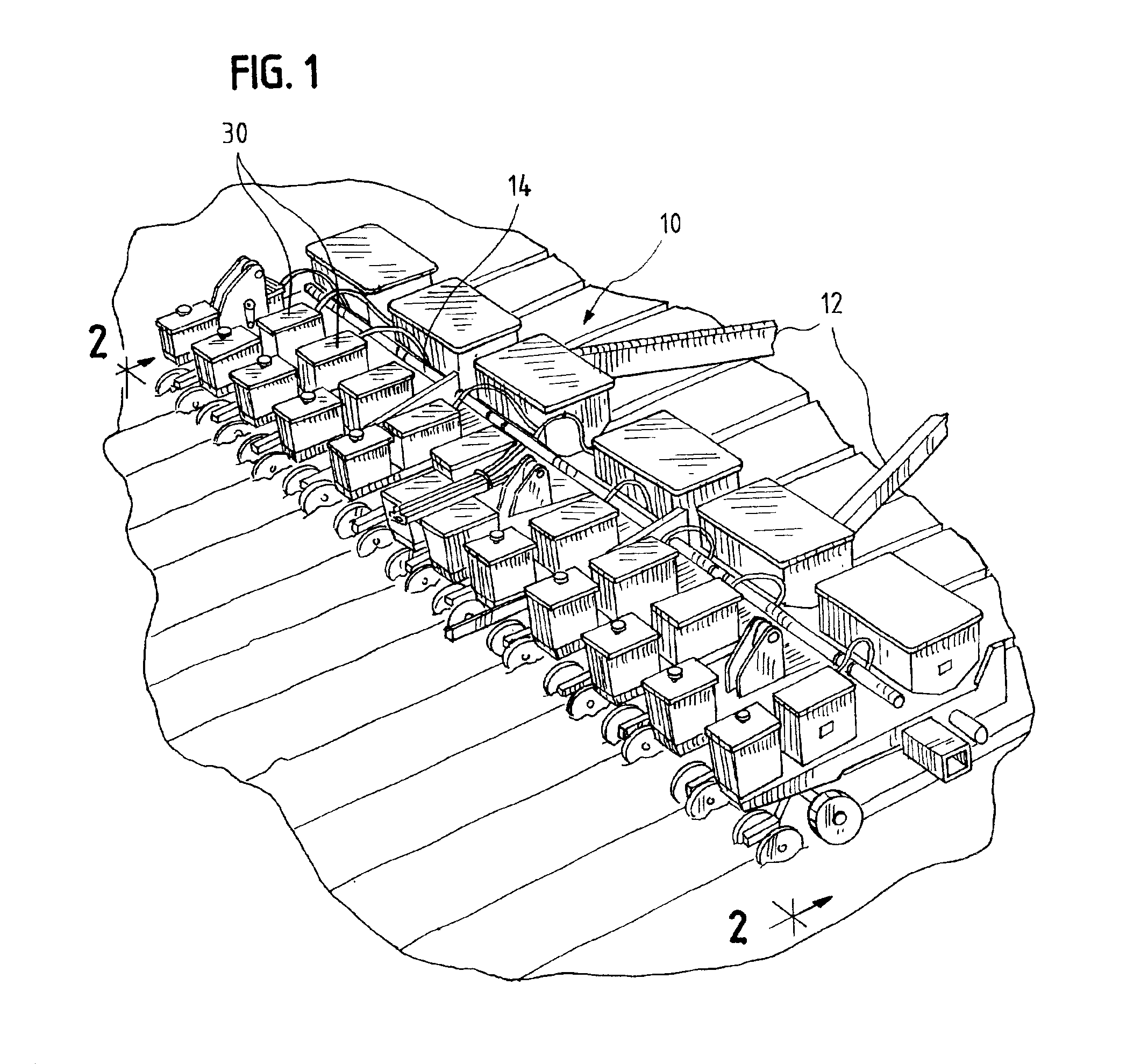

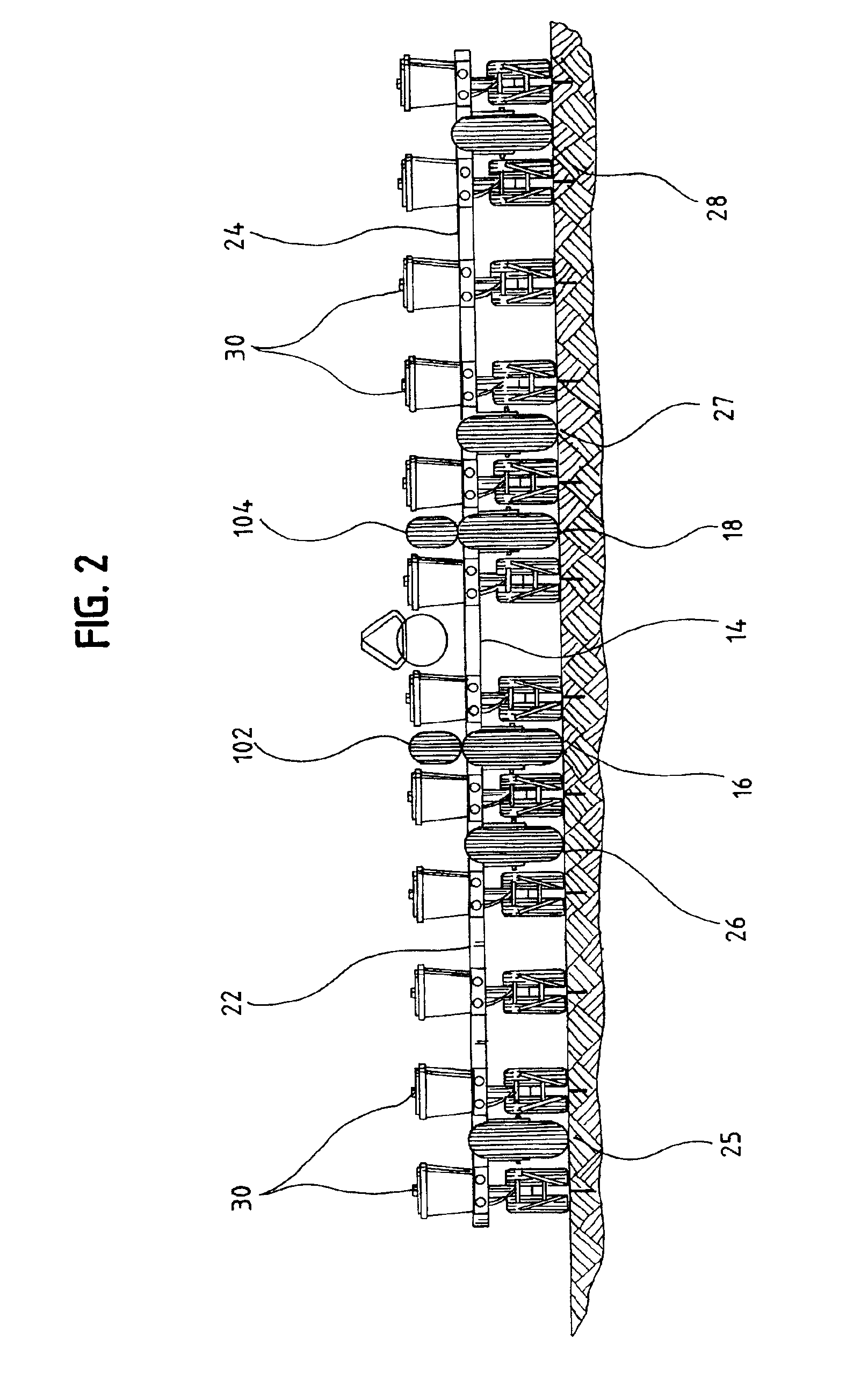

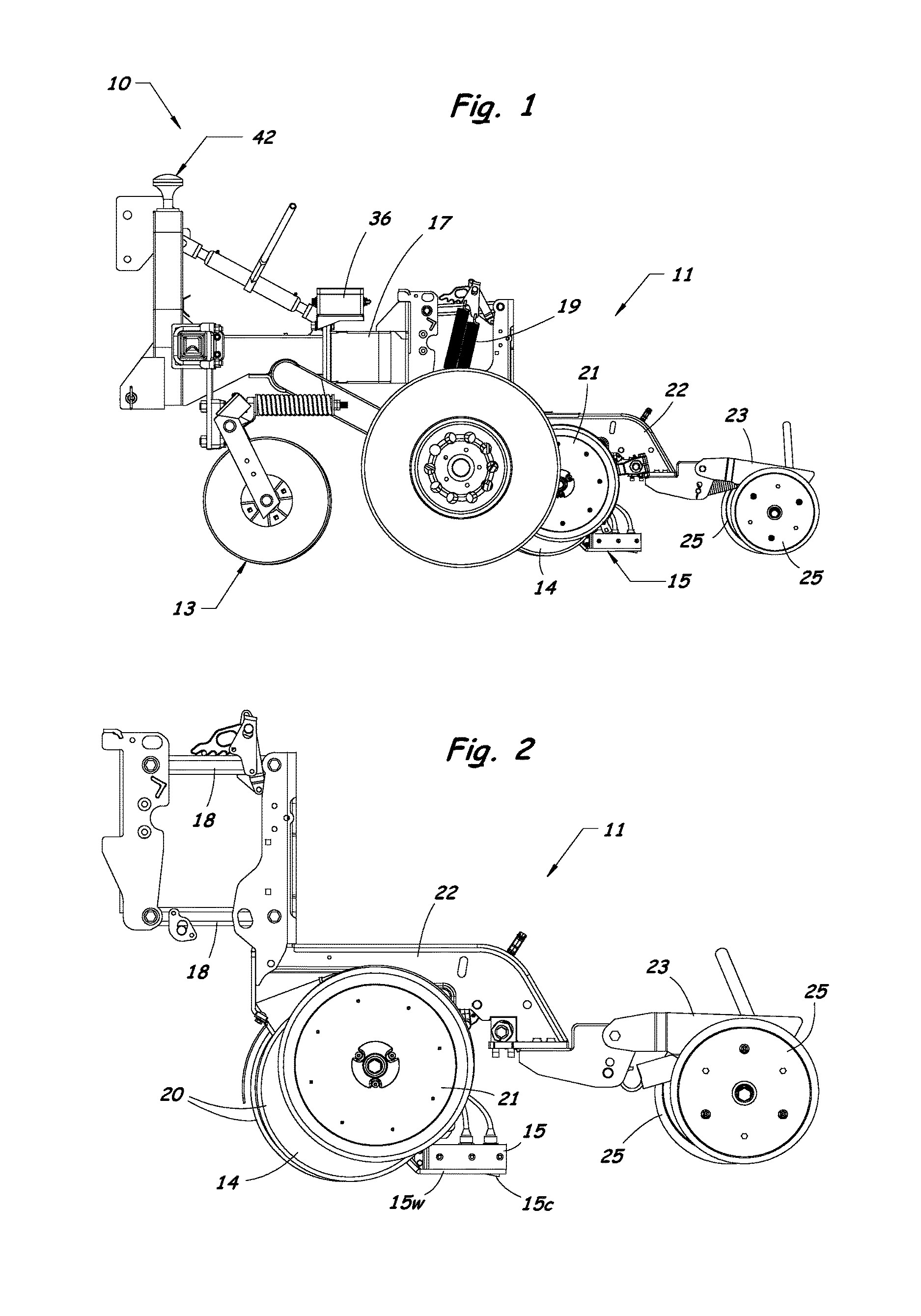

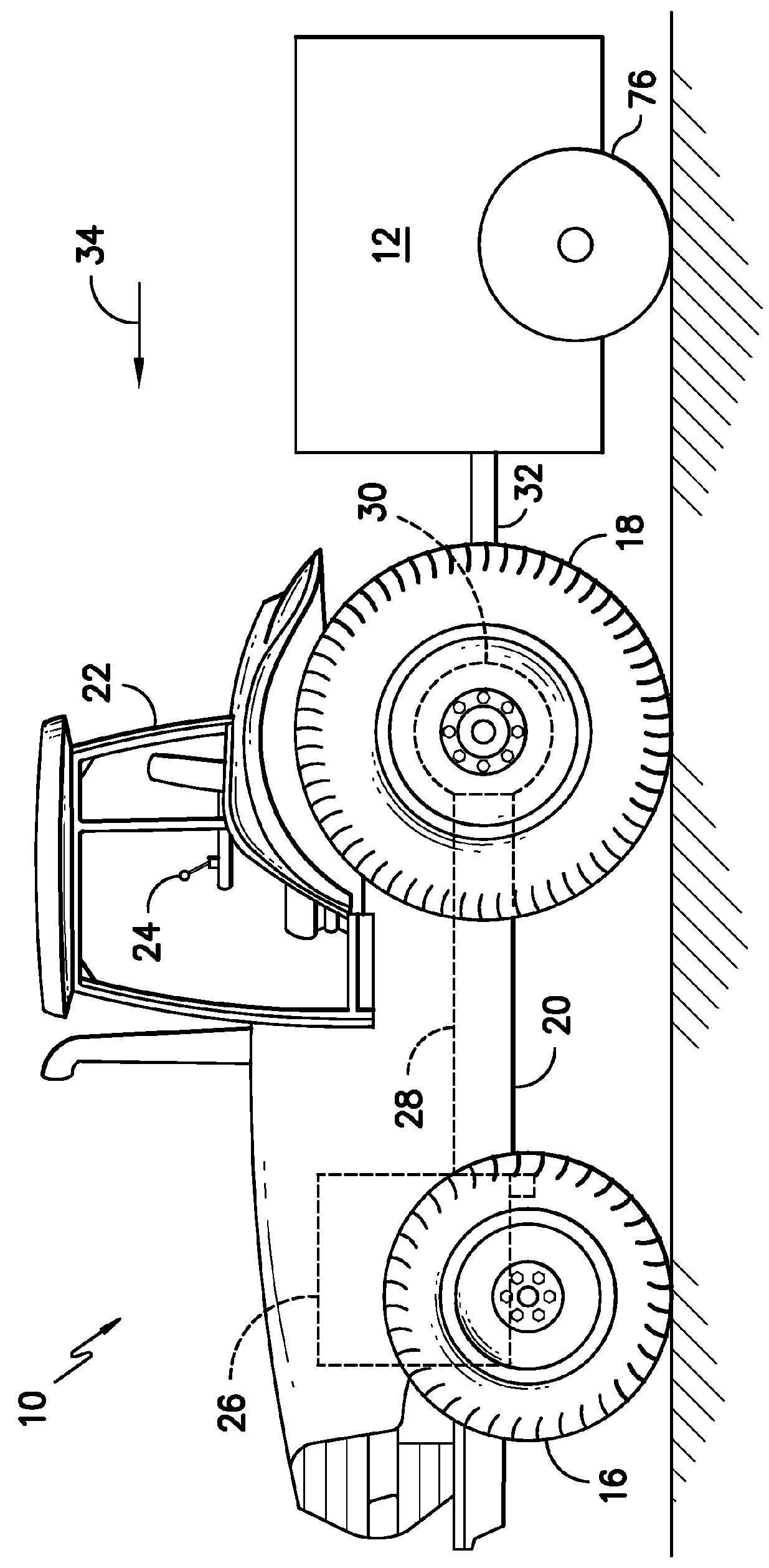

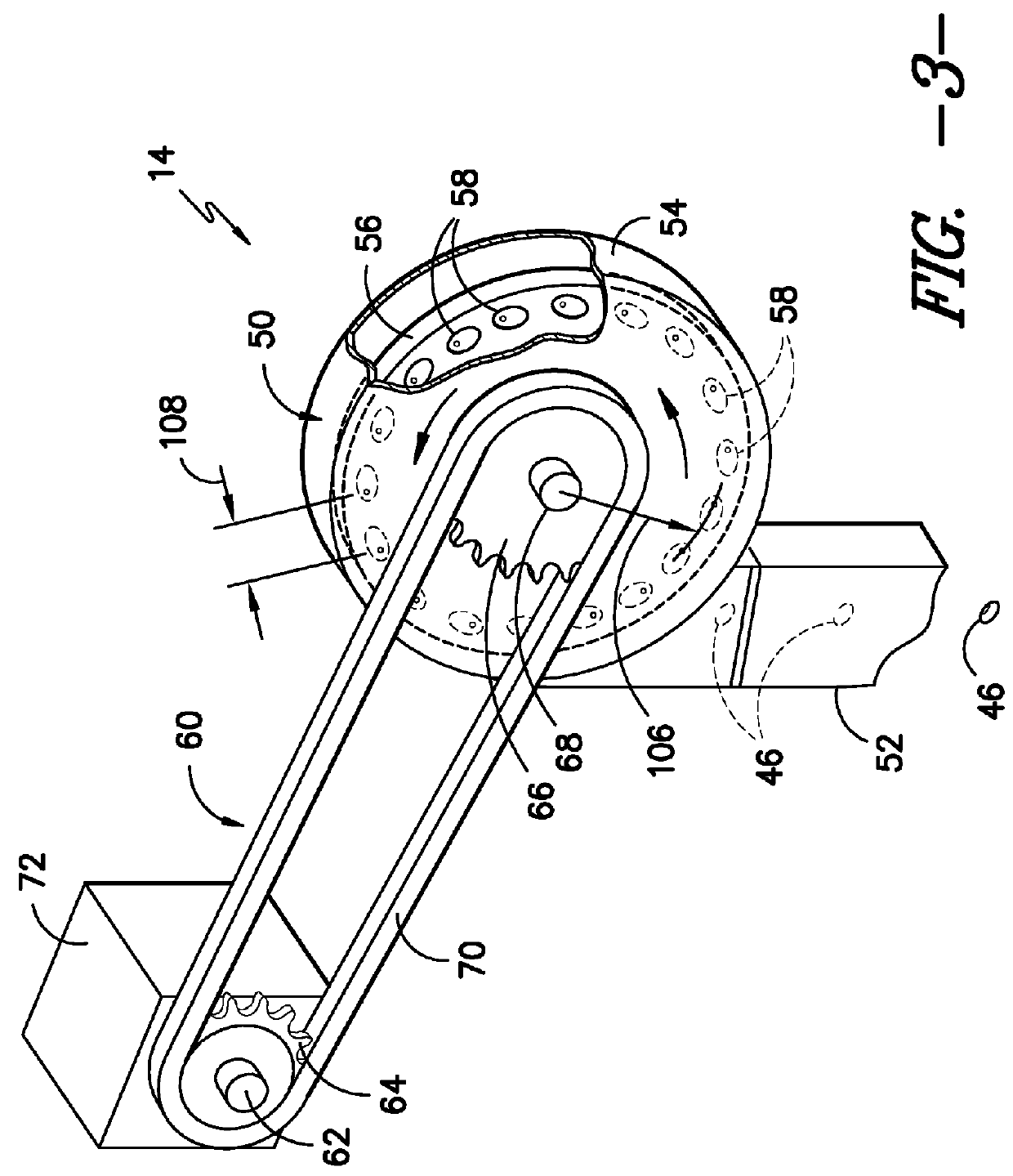

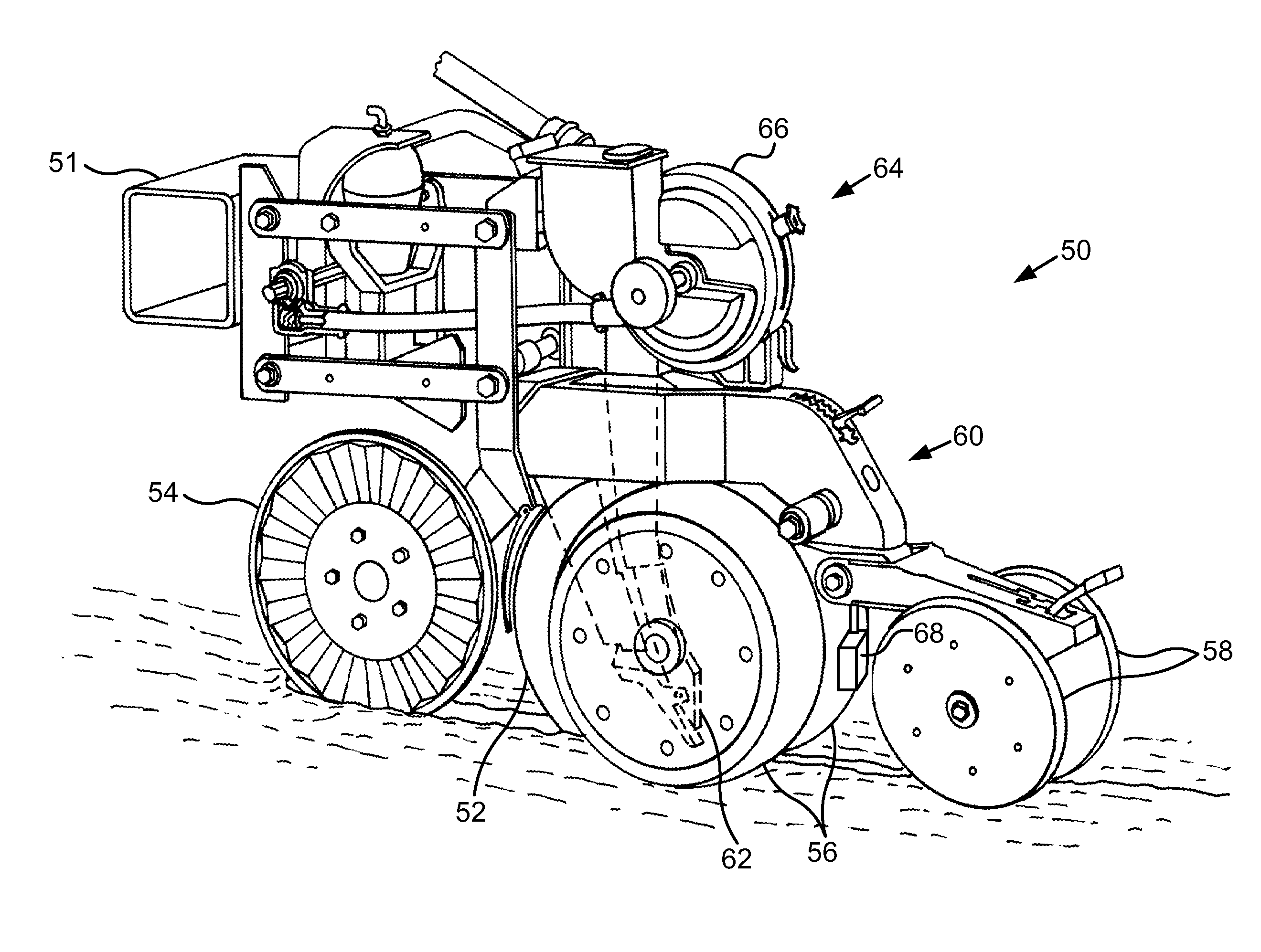

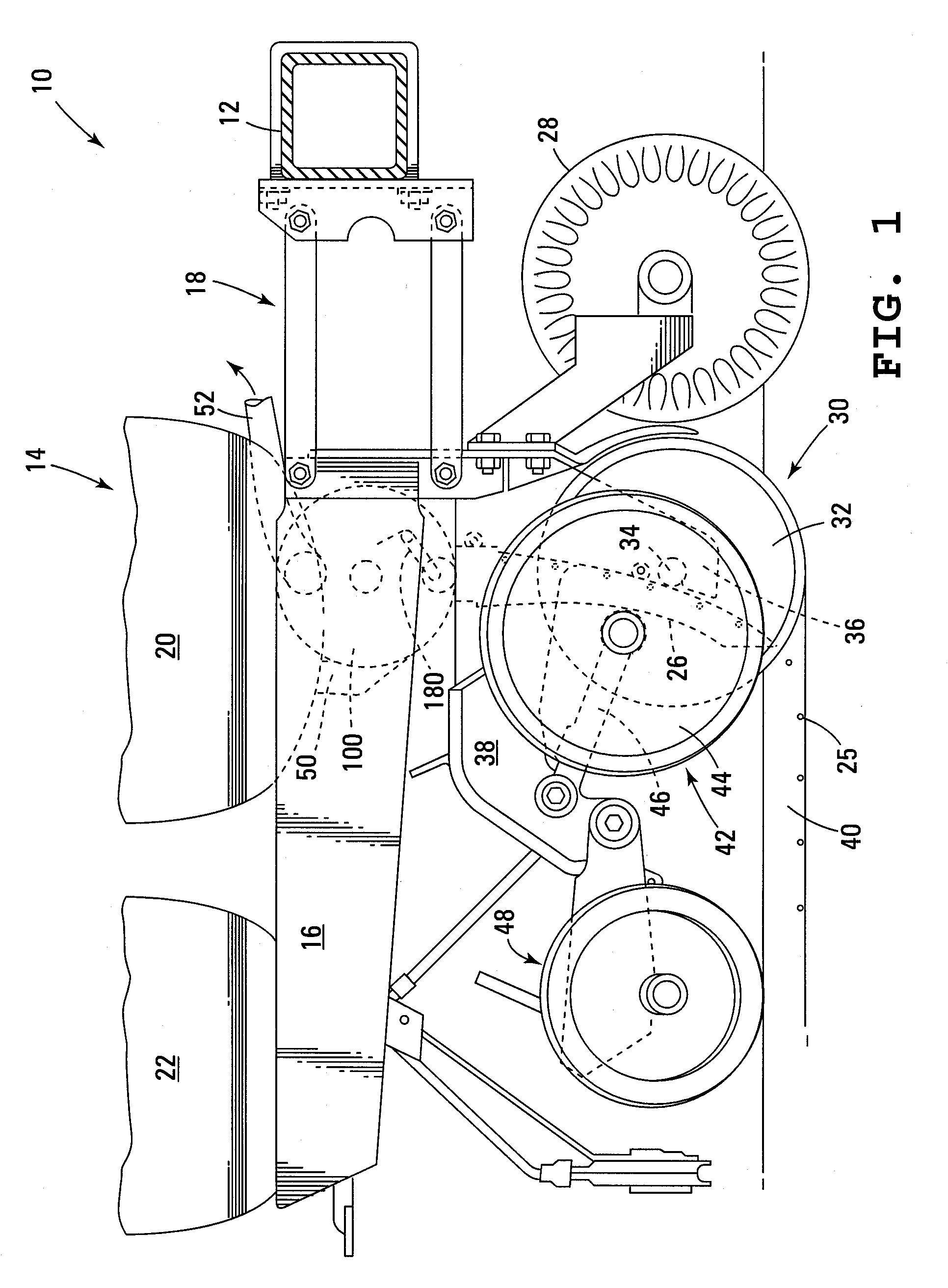

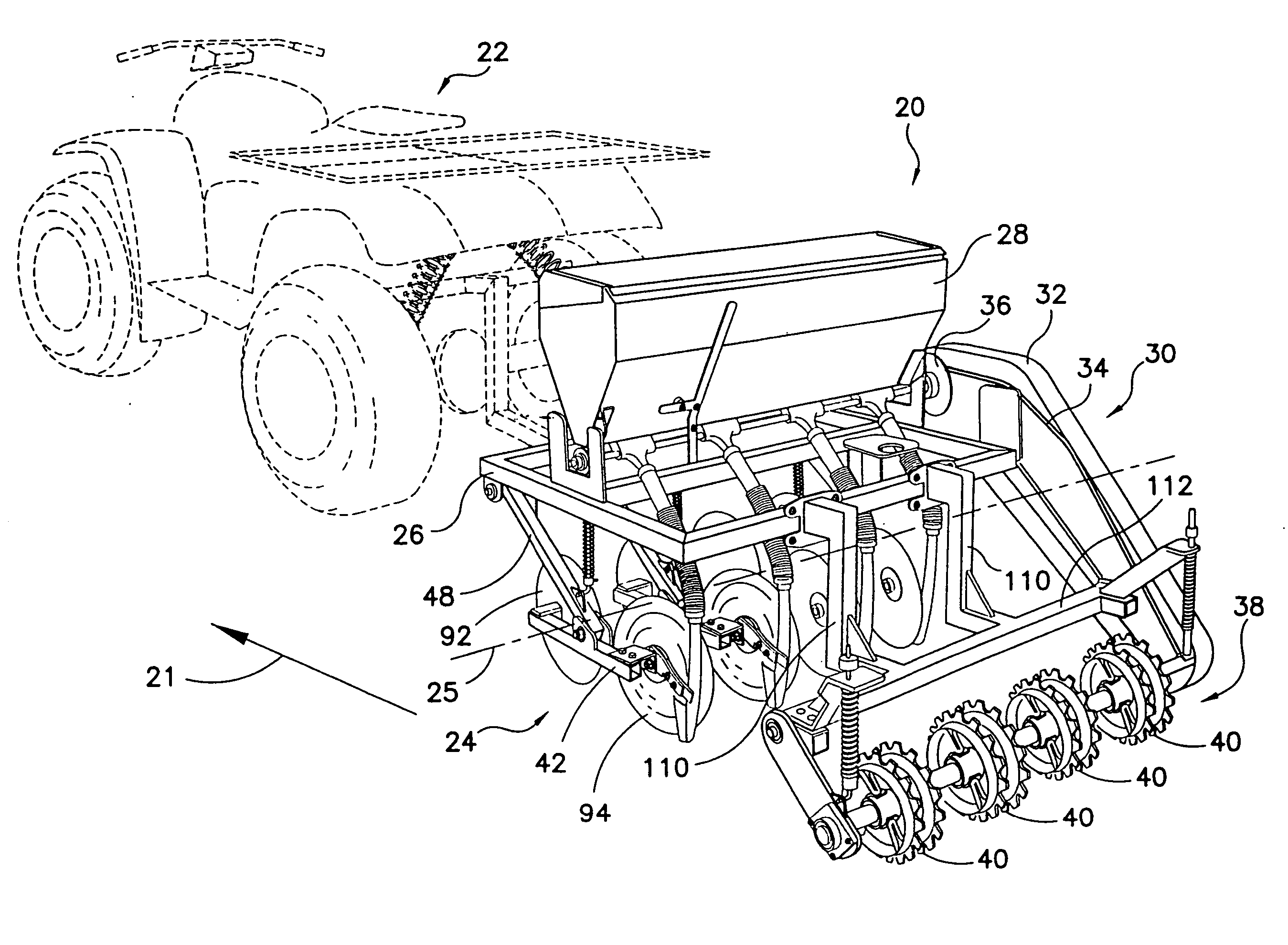

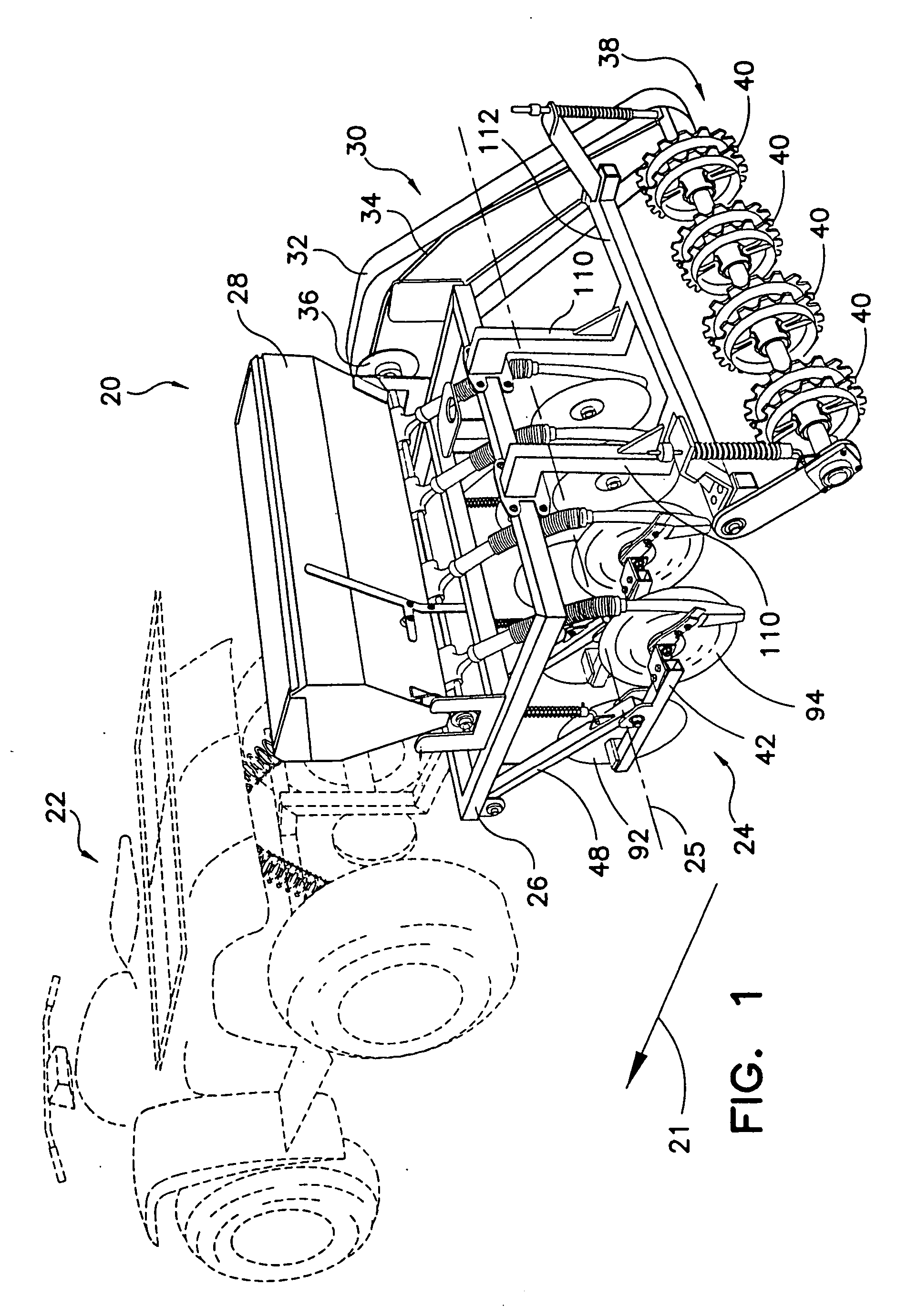

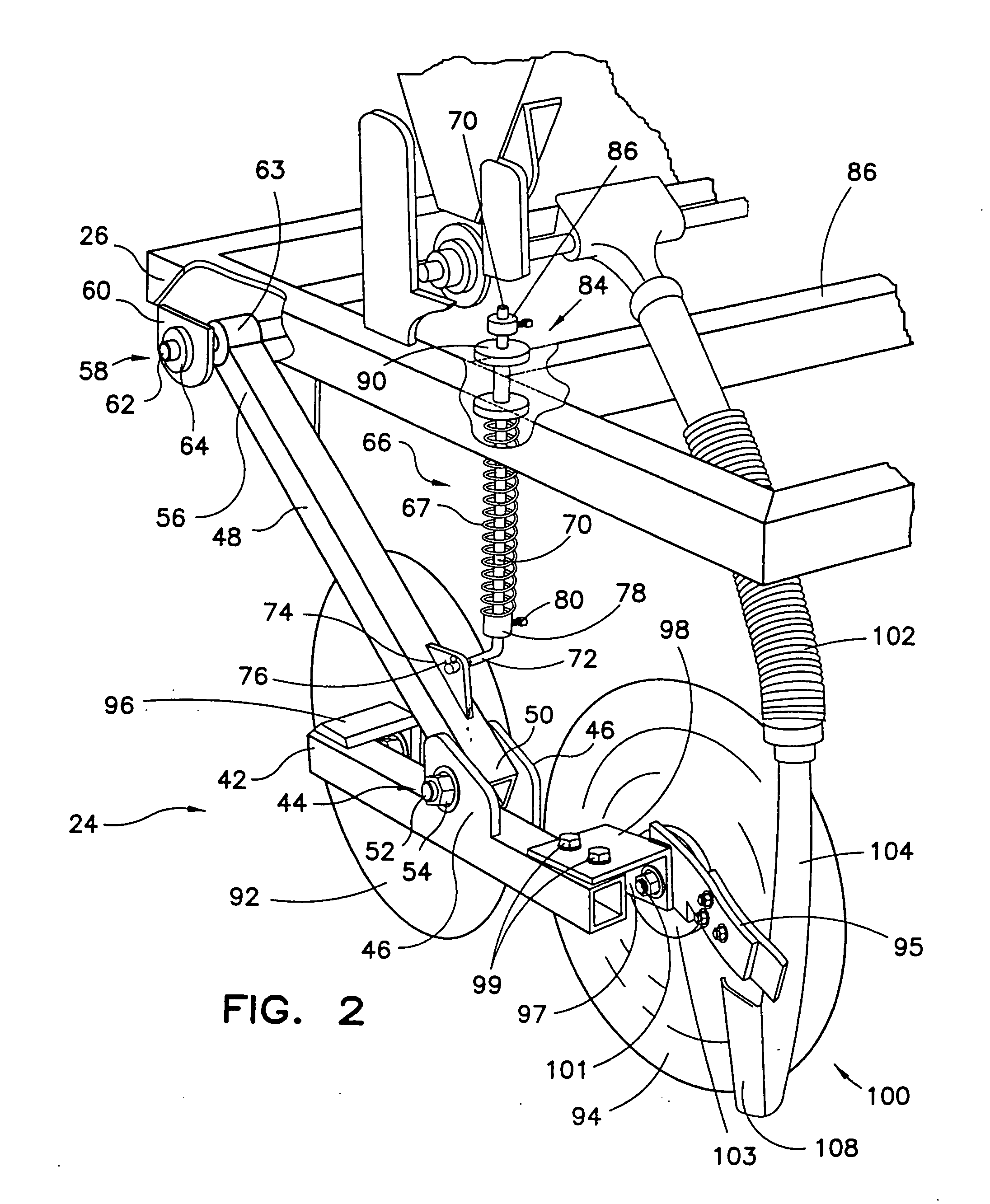

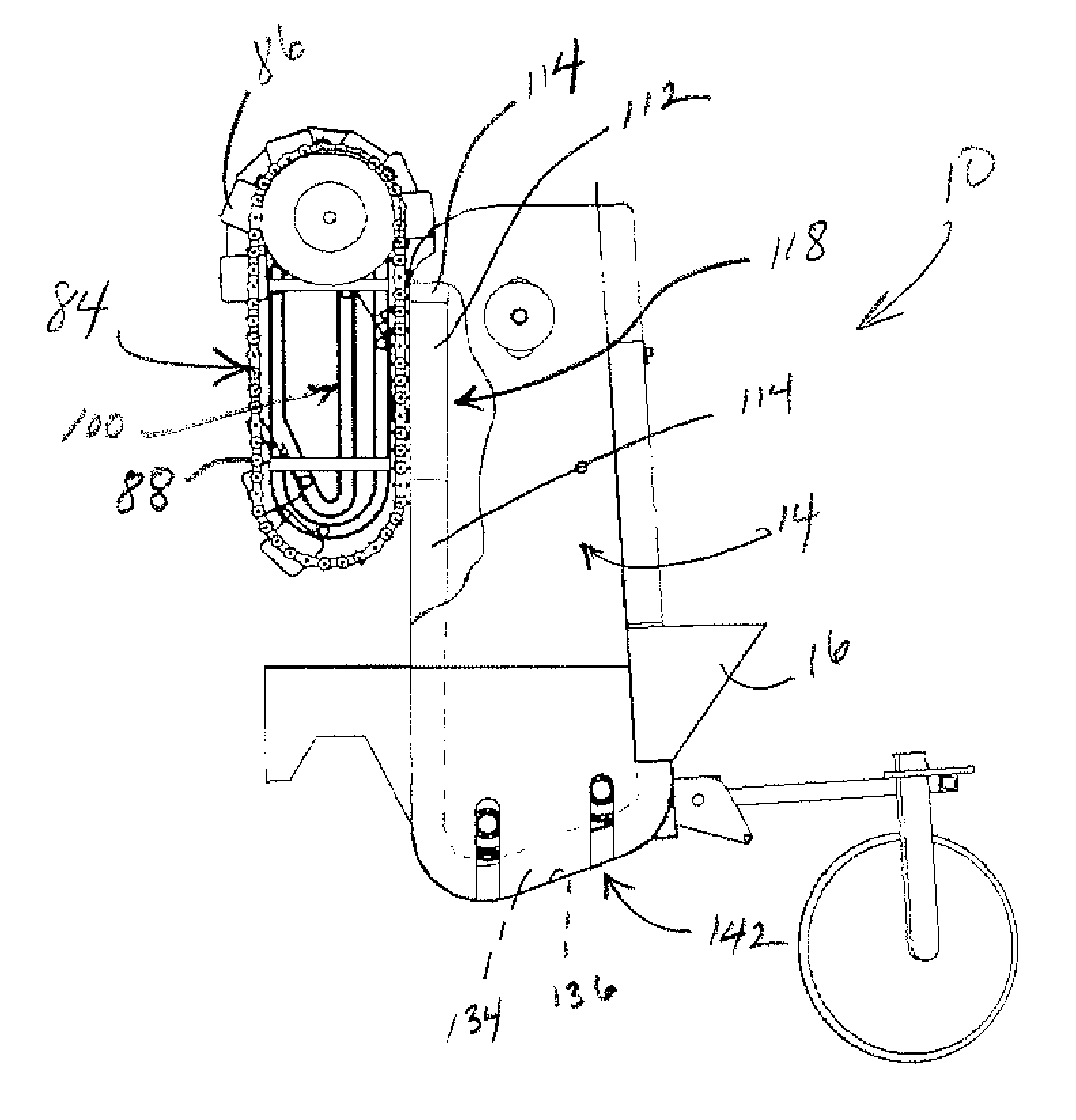

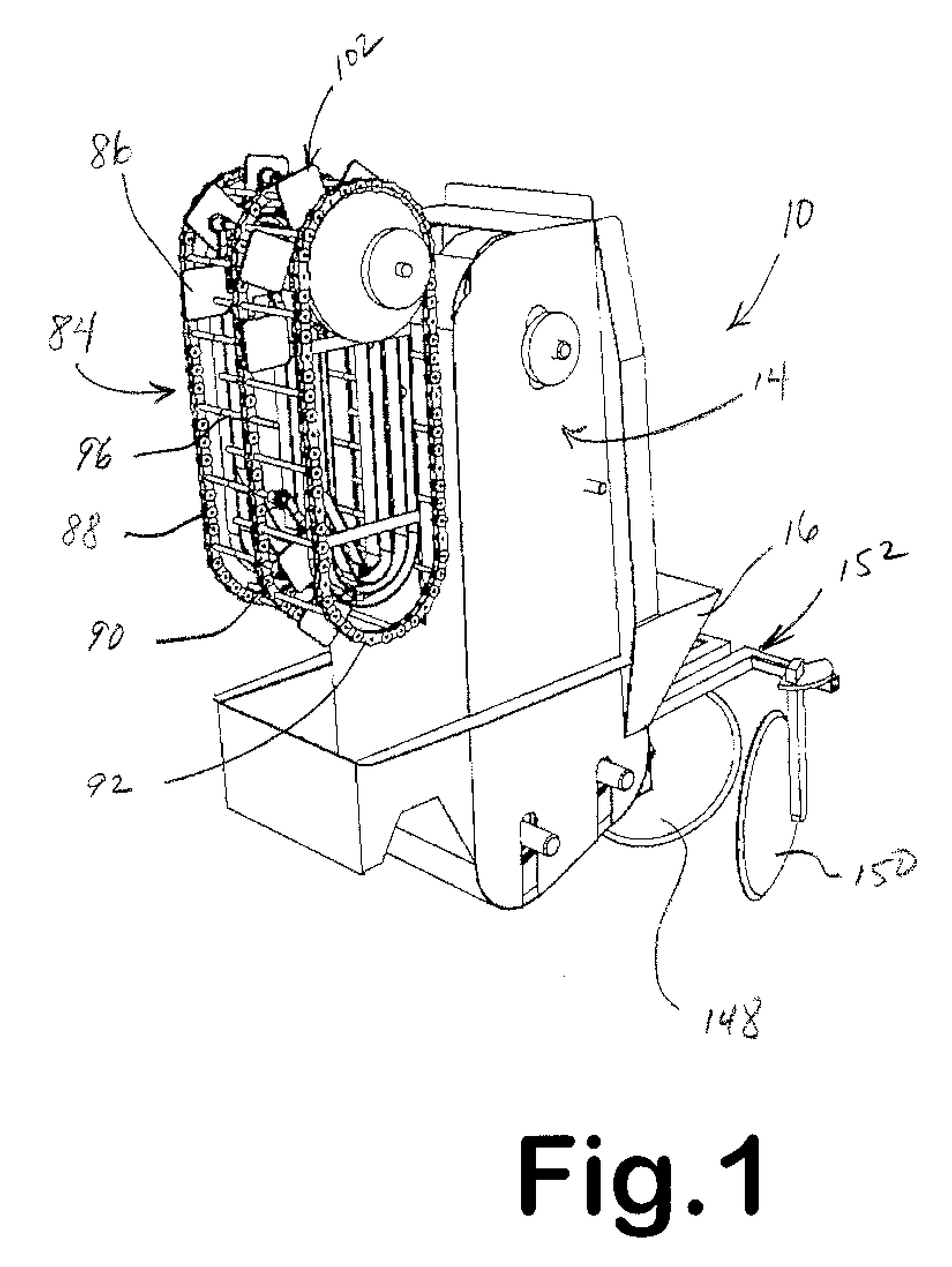

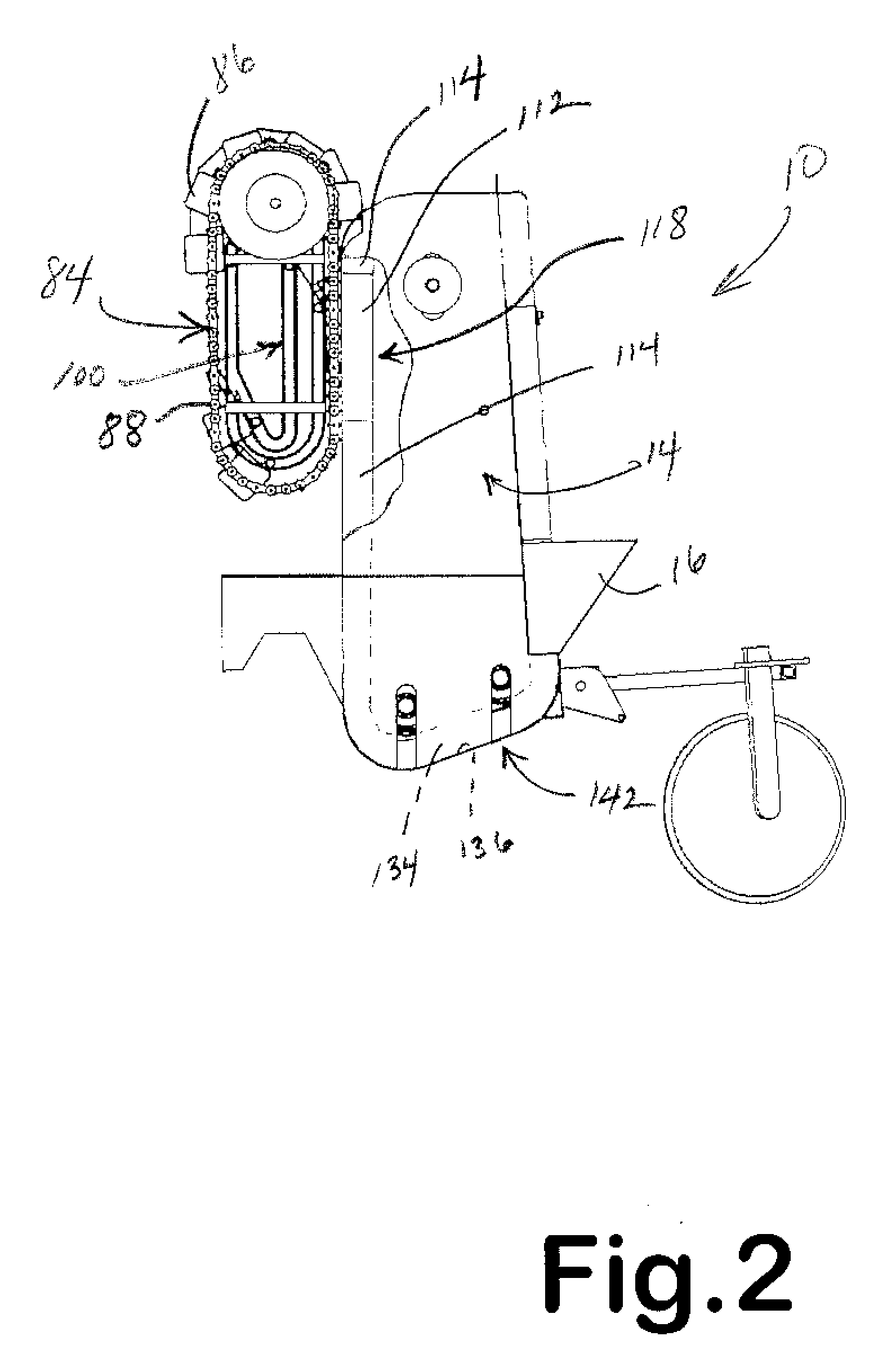

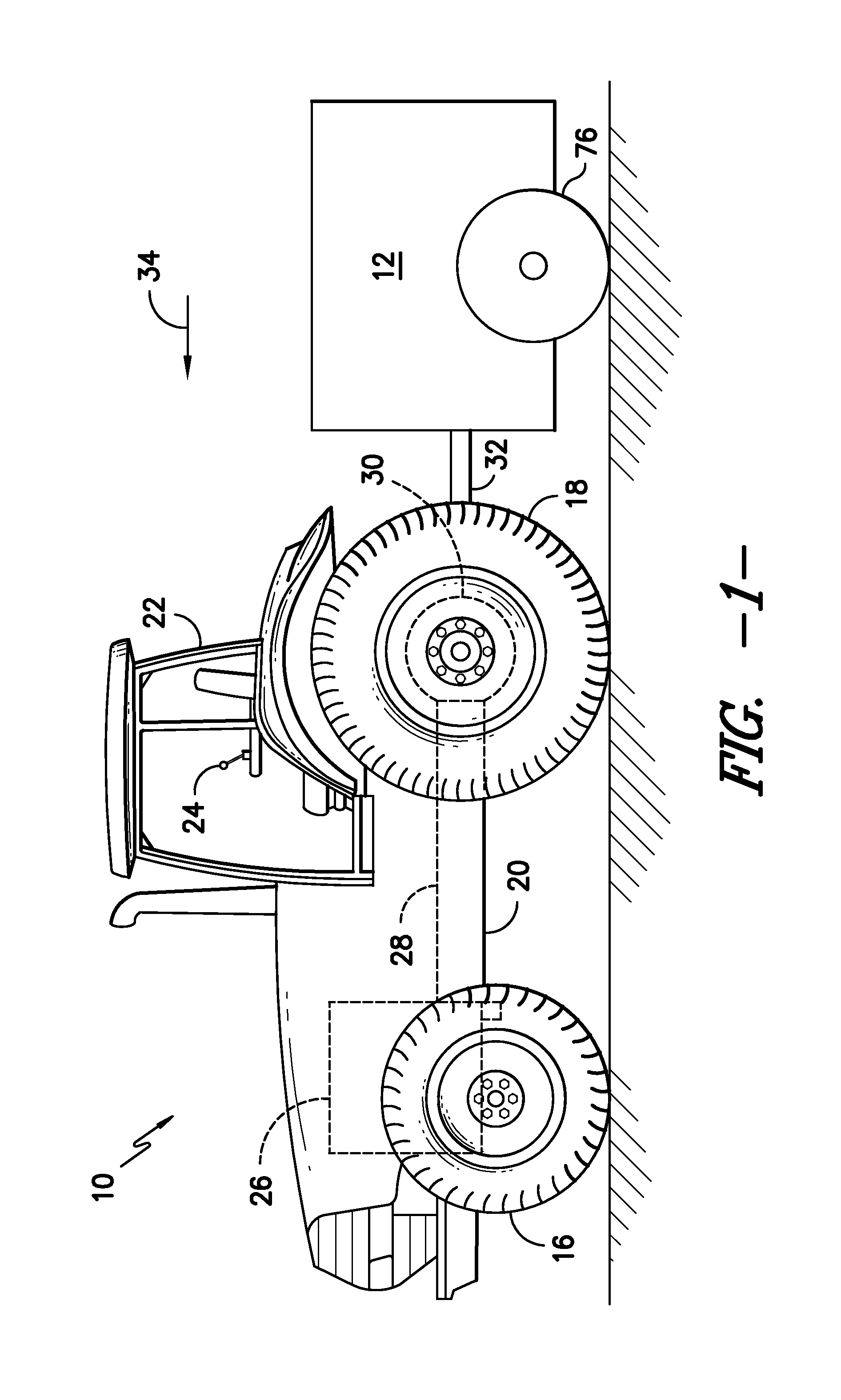

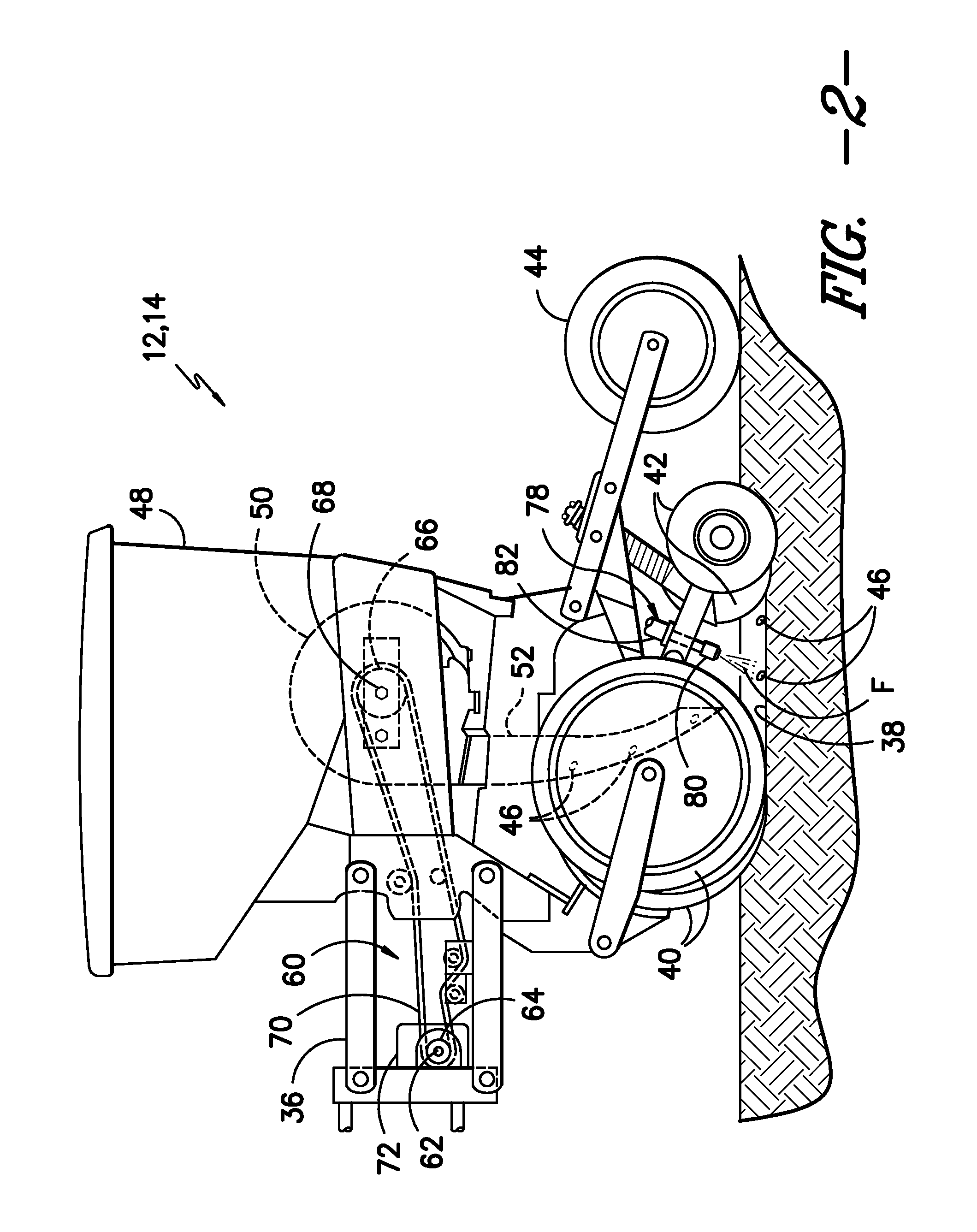

Seed drill with walking beam assembly

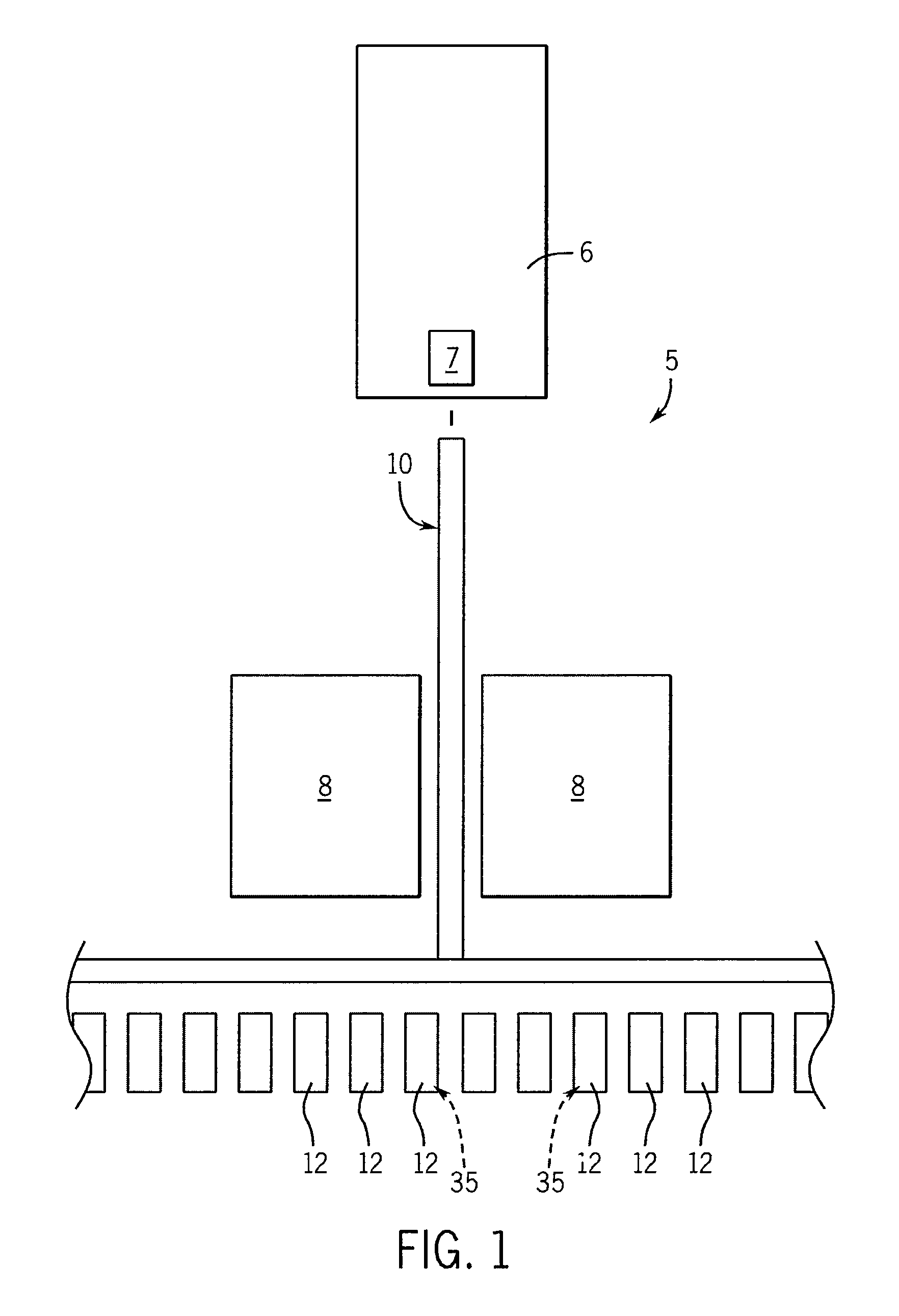

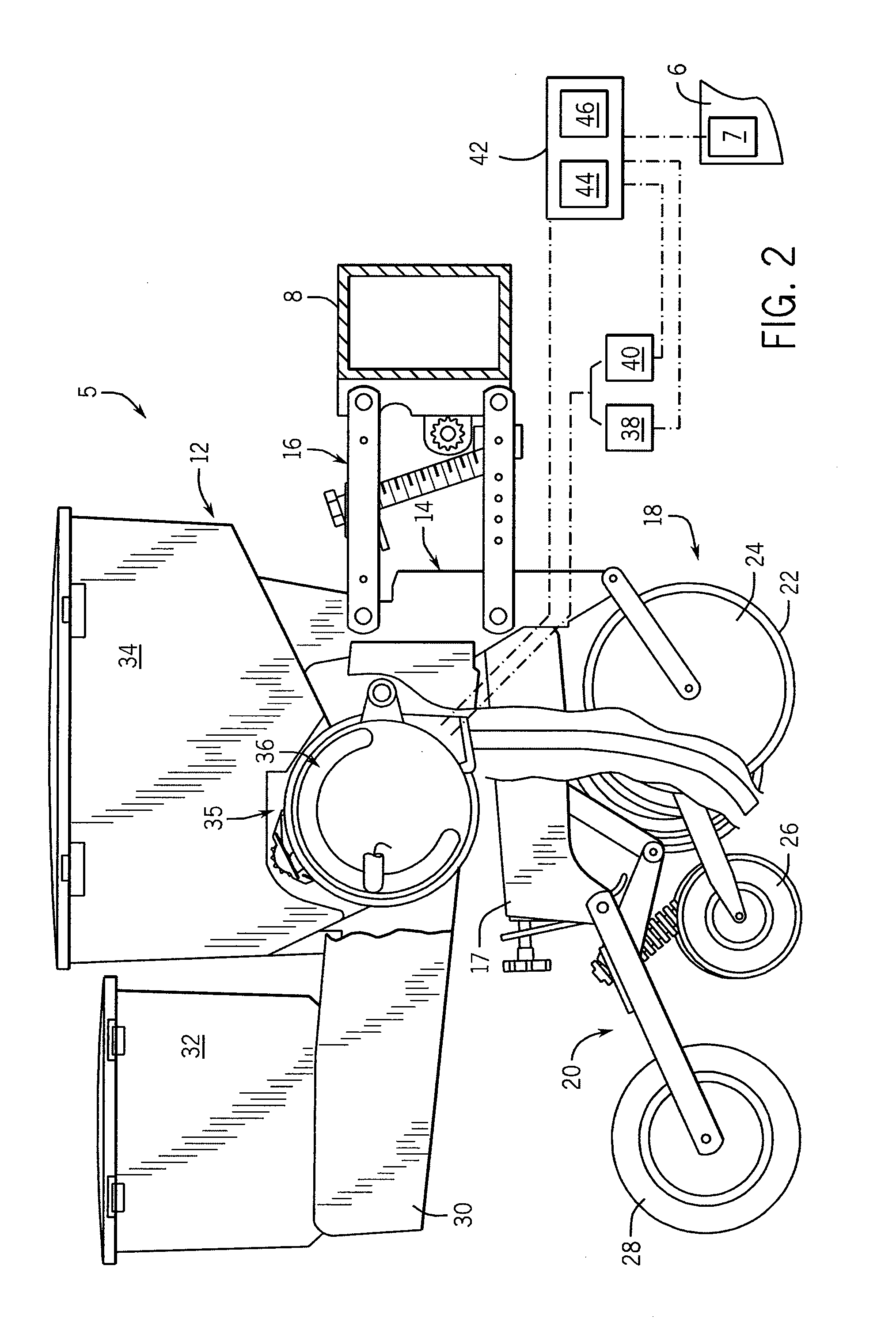

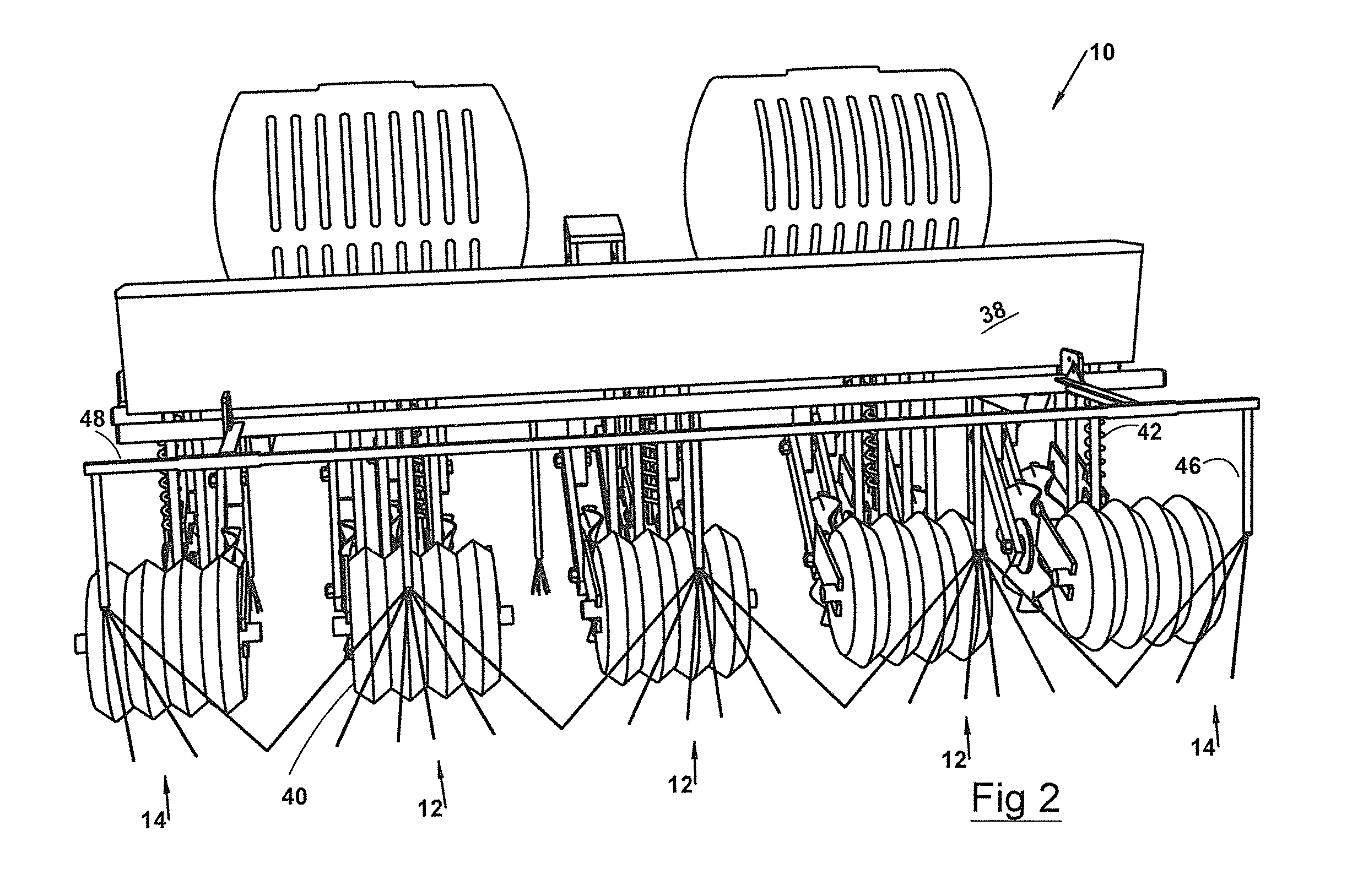

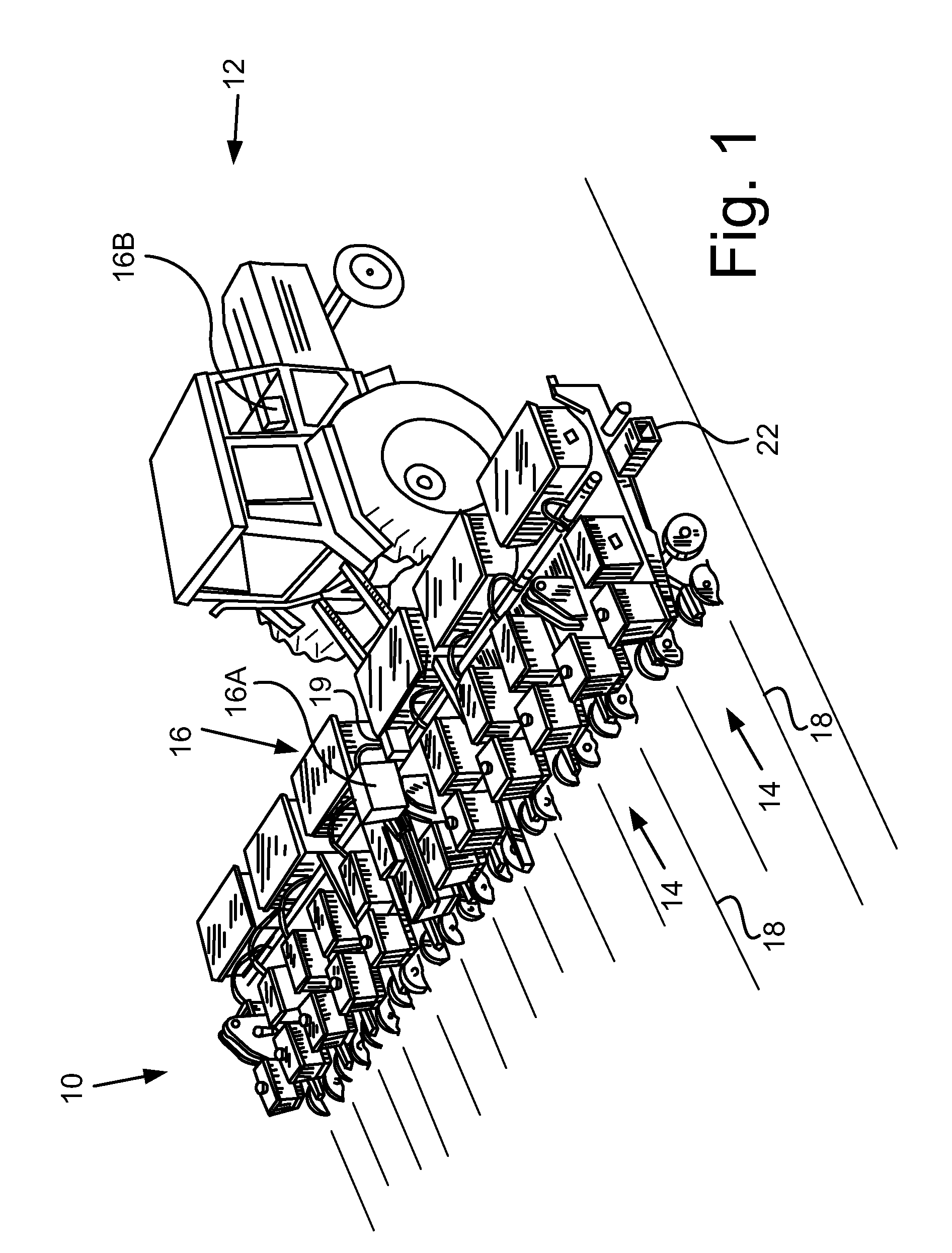

A no-till drill with a novel walking beam assembly that allows the drill to be pulled over severe terrain conditions that include large rocks, fallen limbs and other large obstructions. The inventive walking beam assembly includes two independent pivot points that allow the cutting and opening disks to maintain substantially constant or continuous contact with the ground, such that the length of the furrow formed and seed deposited therein are maximized. A closing disk assembly is suspended from the rear of the drill independently from the walking beam assembly. This independent suspension allows the walking beam assembly to function without interference from the closing disks.

Owner:KASCO MFG

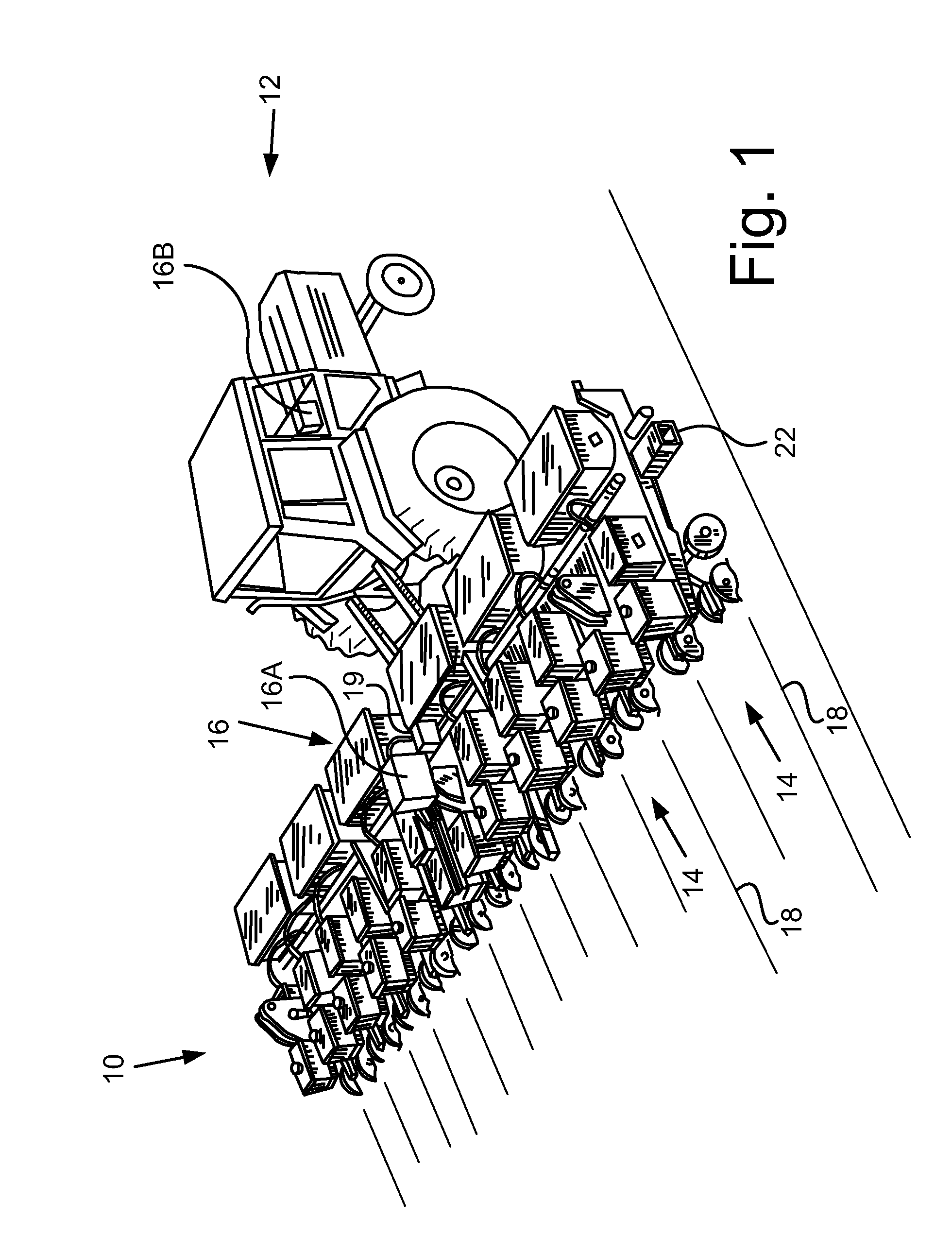

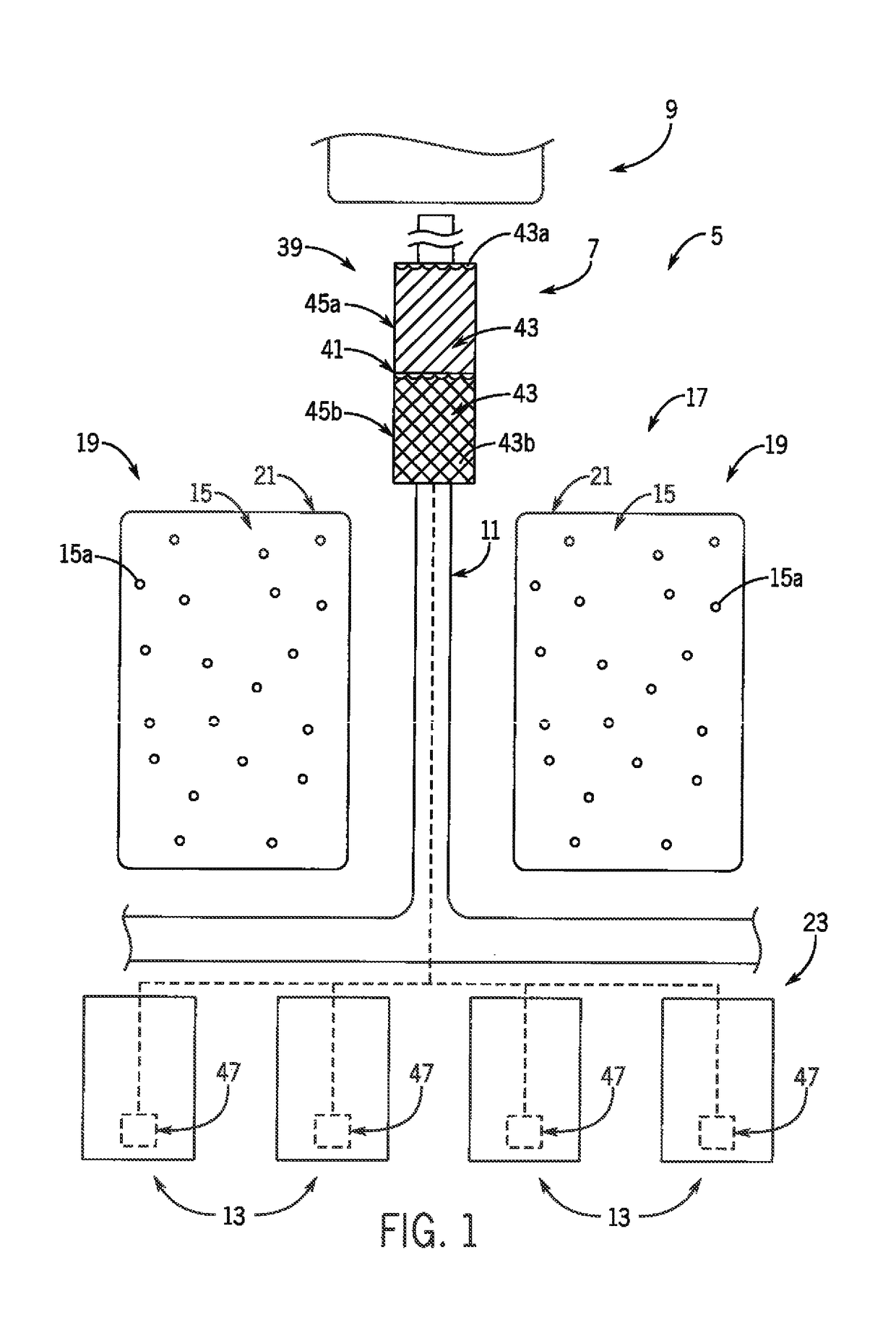

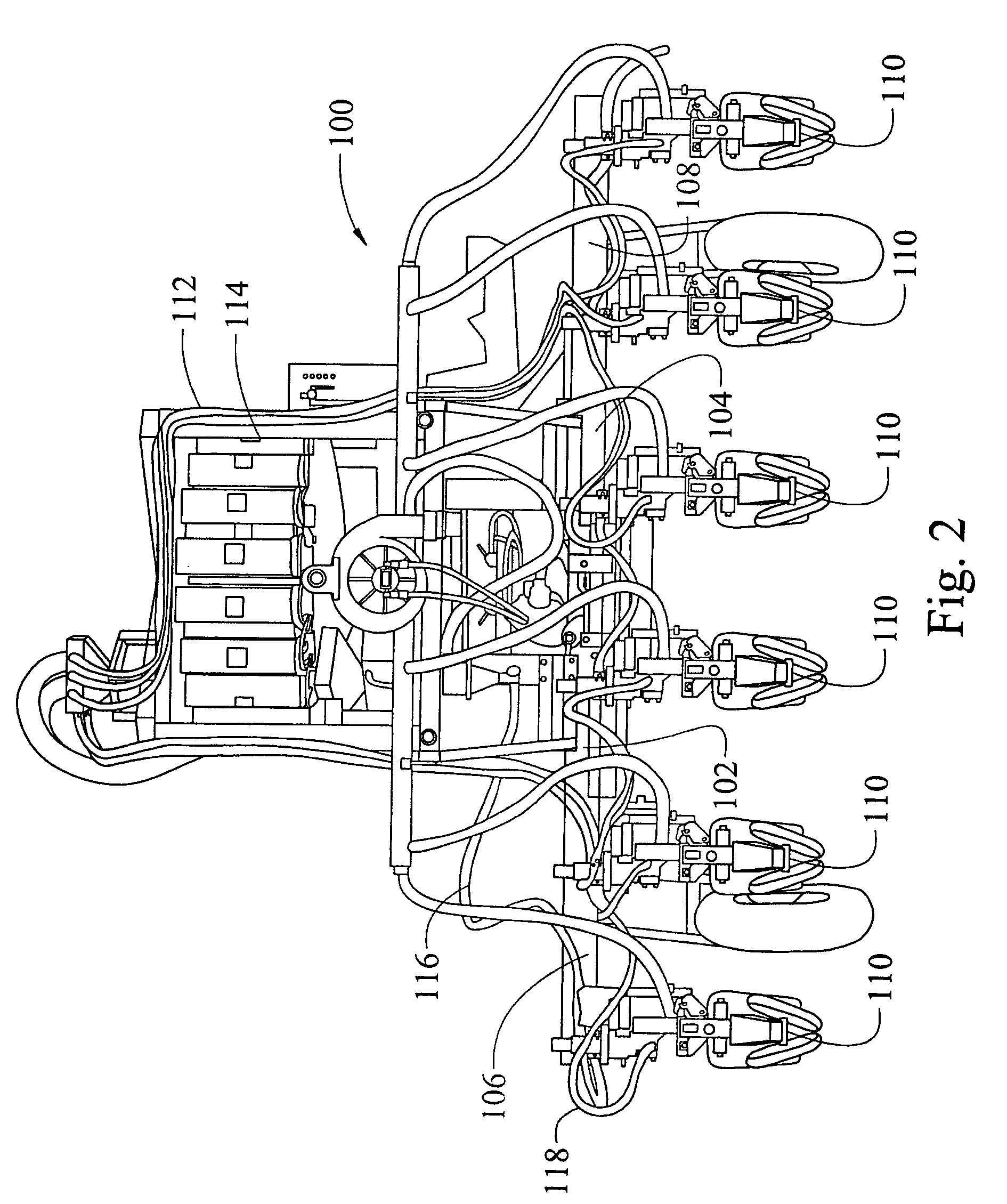

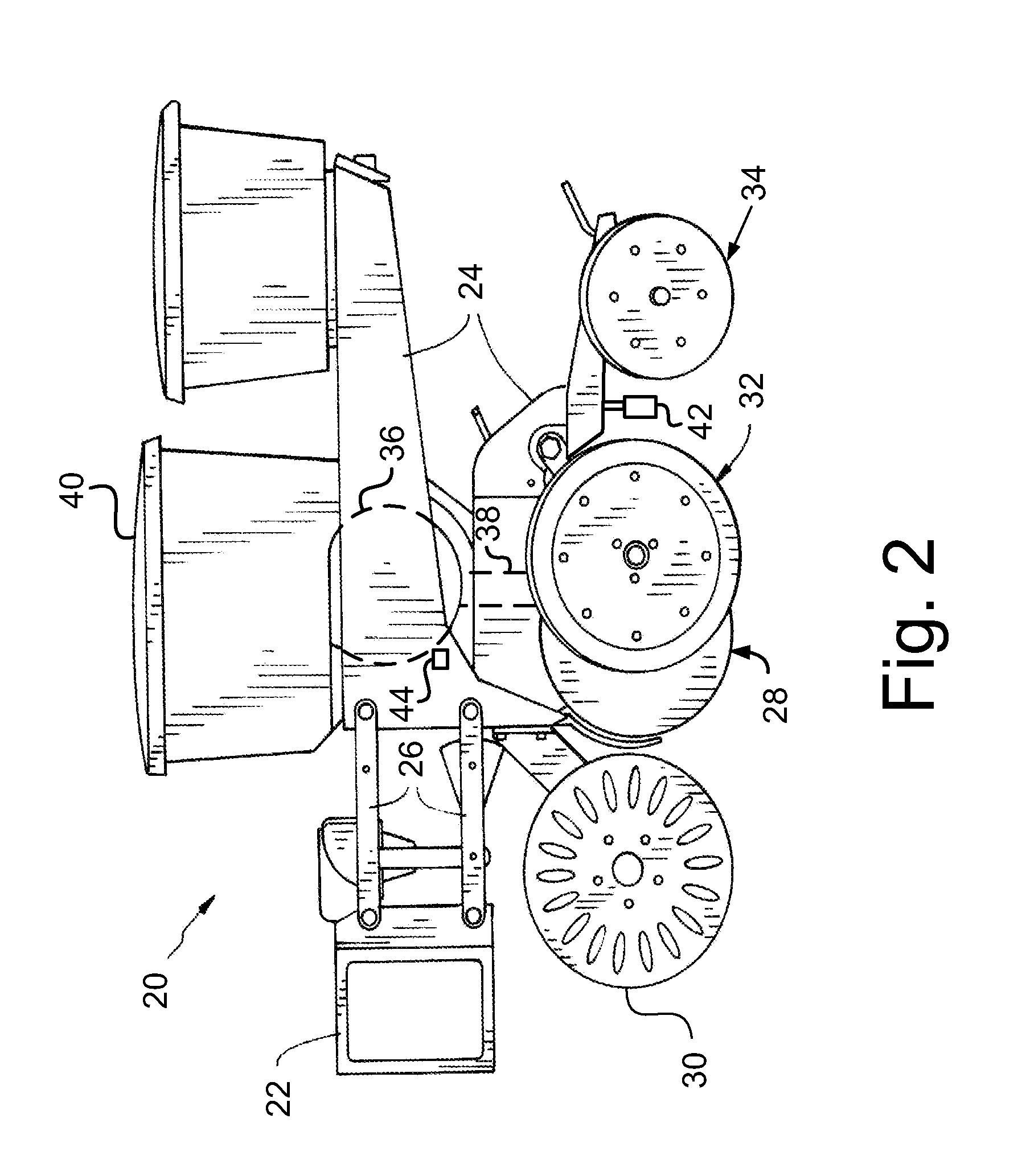

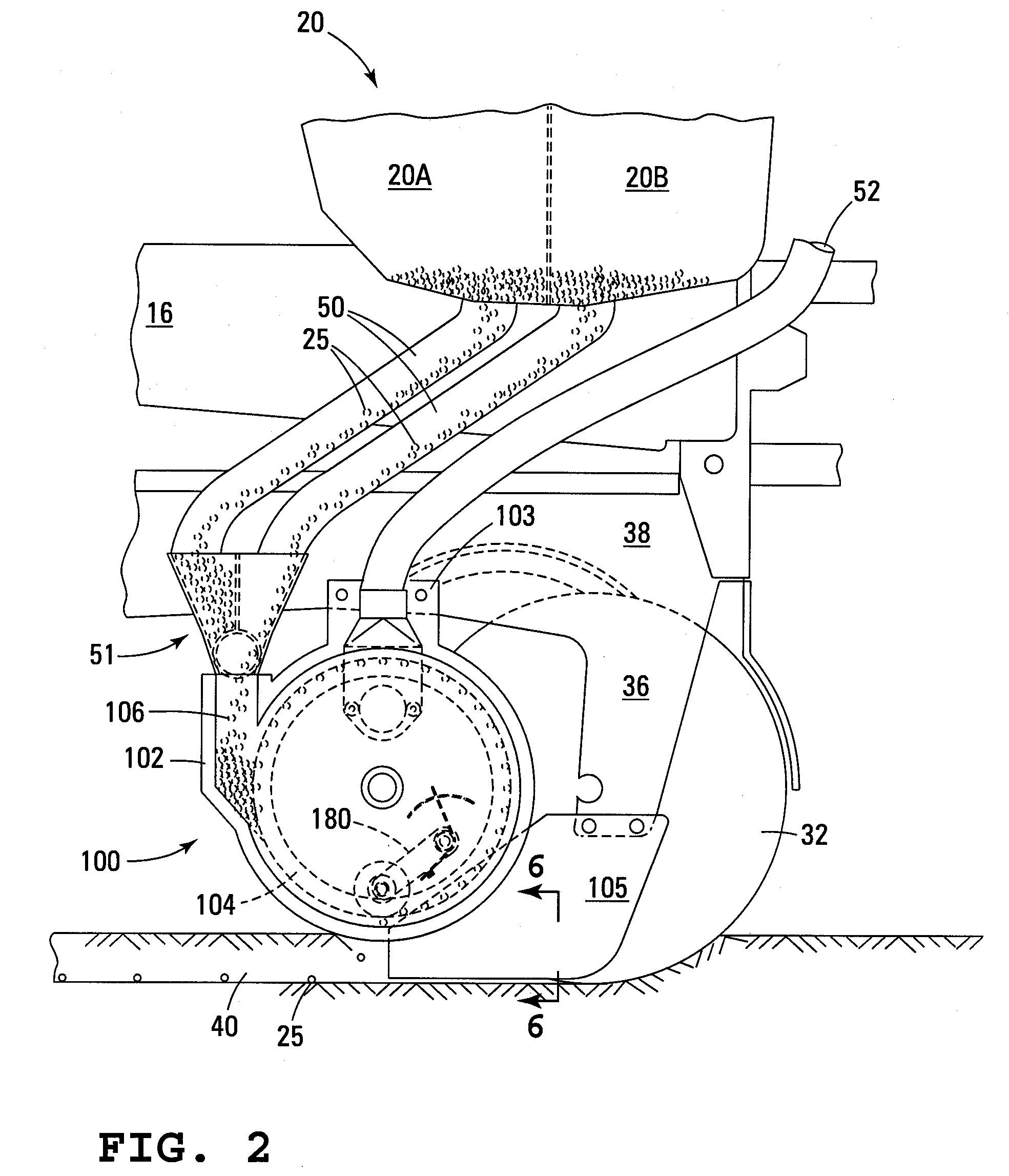

Seeding Machine With Seed Delivery System

ActiveUS20100192819A1Reduces seed spacing variabilityReduce scrollingFertiliser distributersCentrifugal wheel fertilisersEngineeringDelivery system

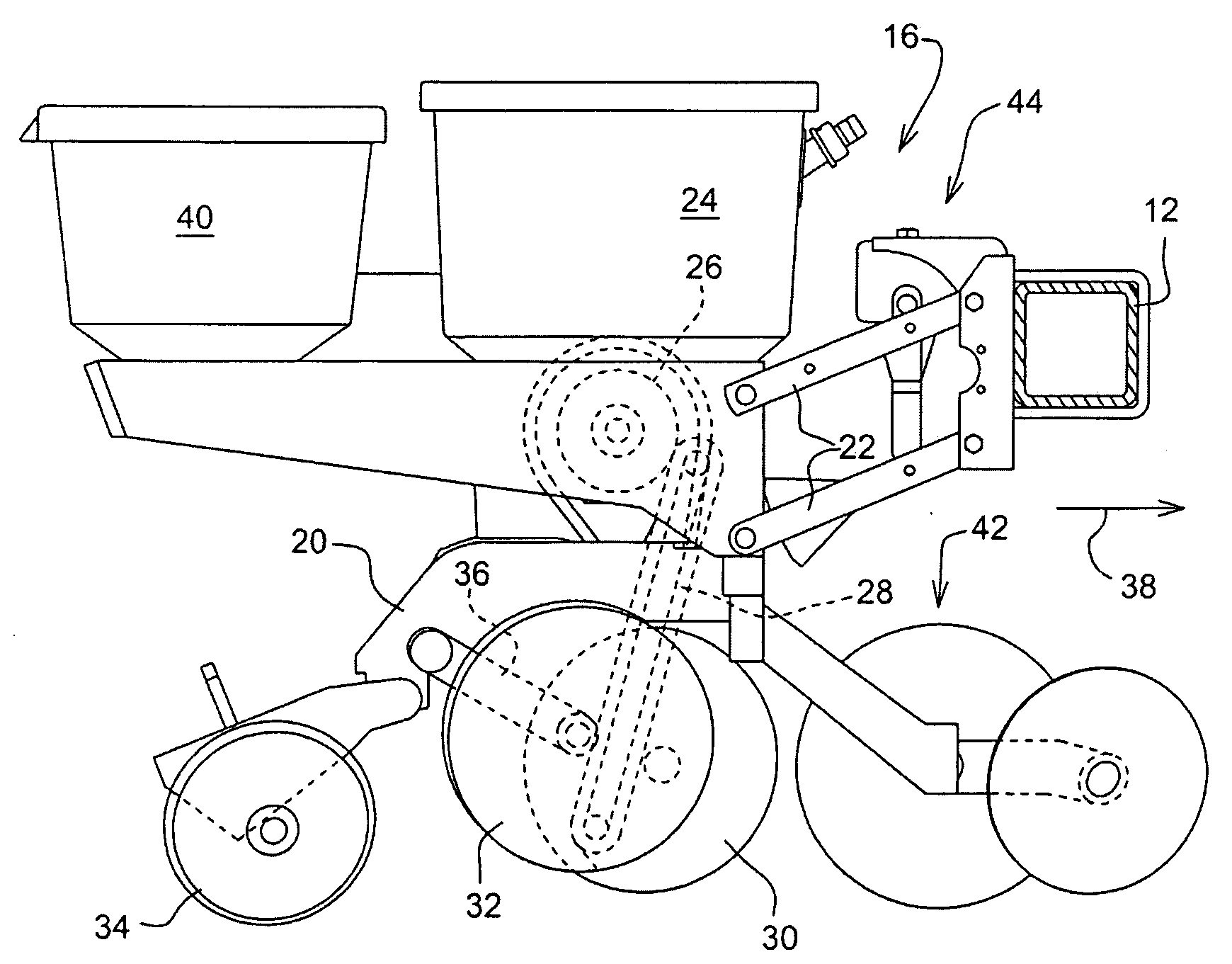

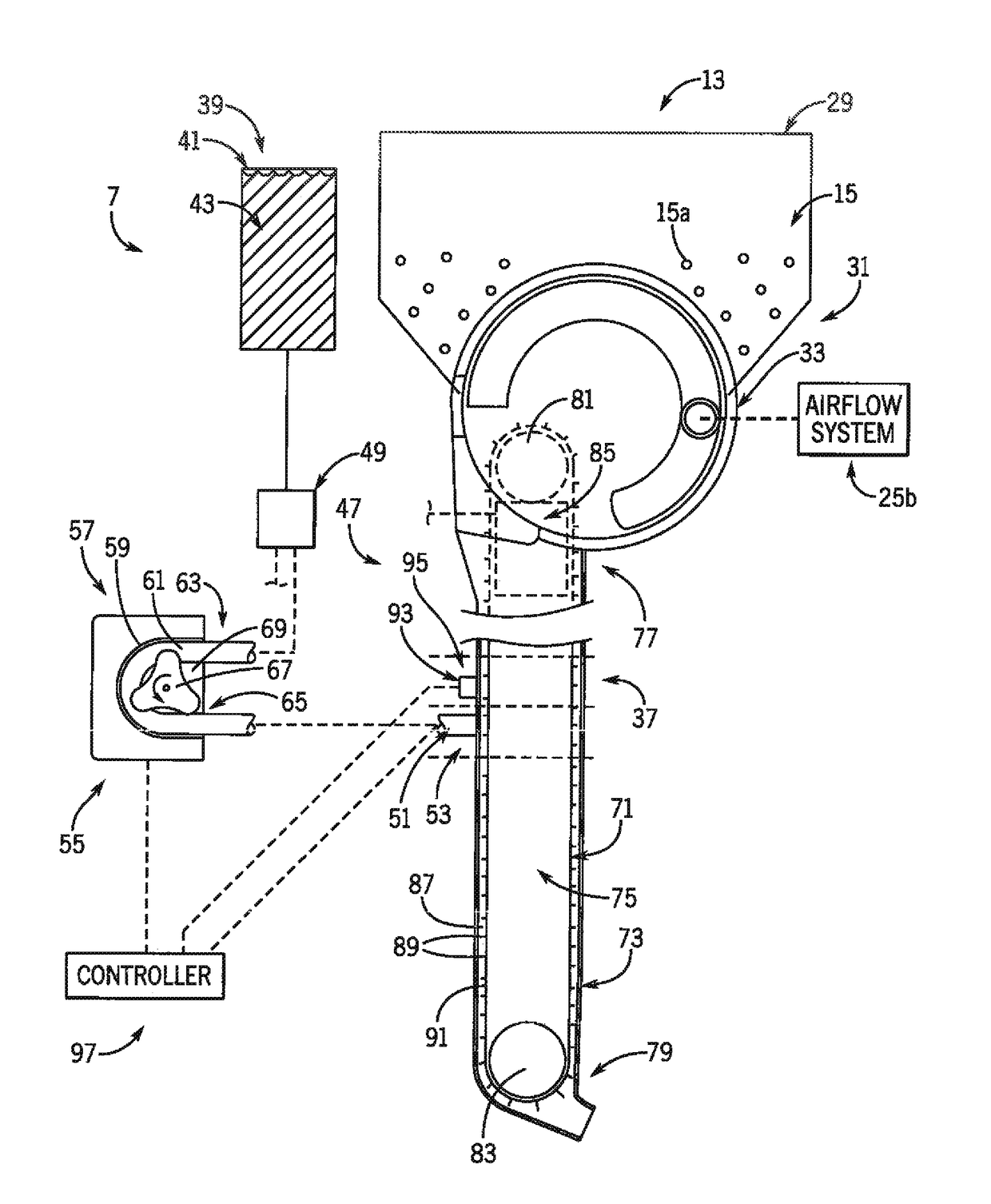

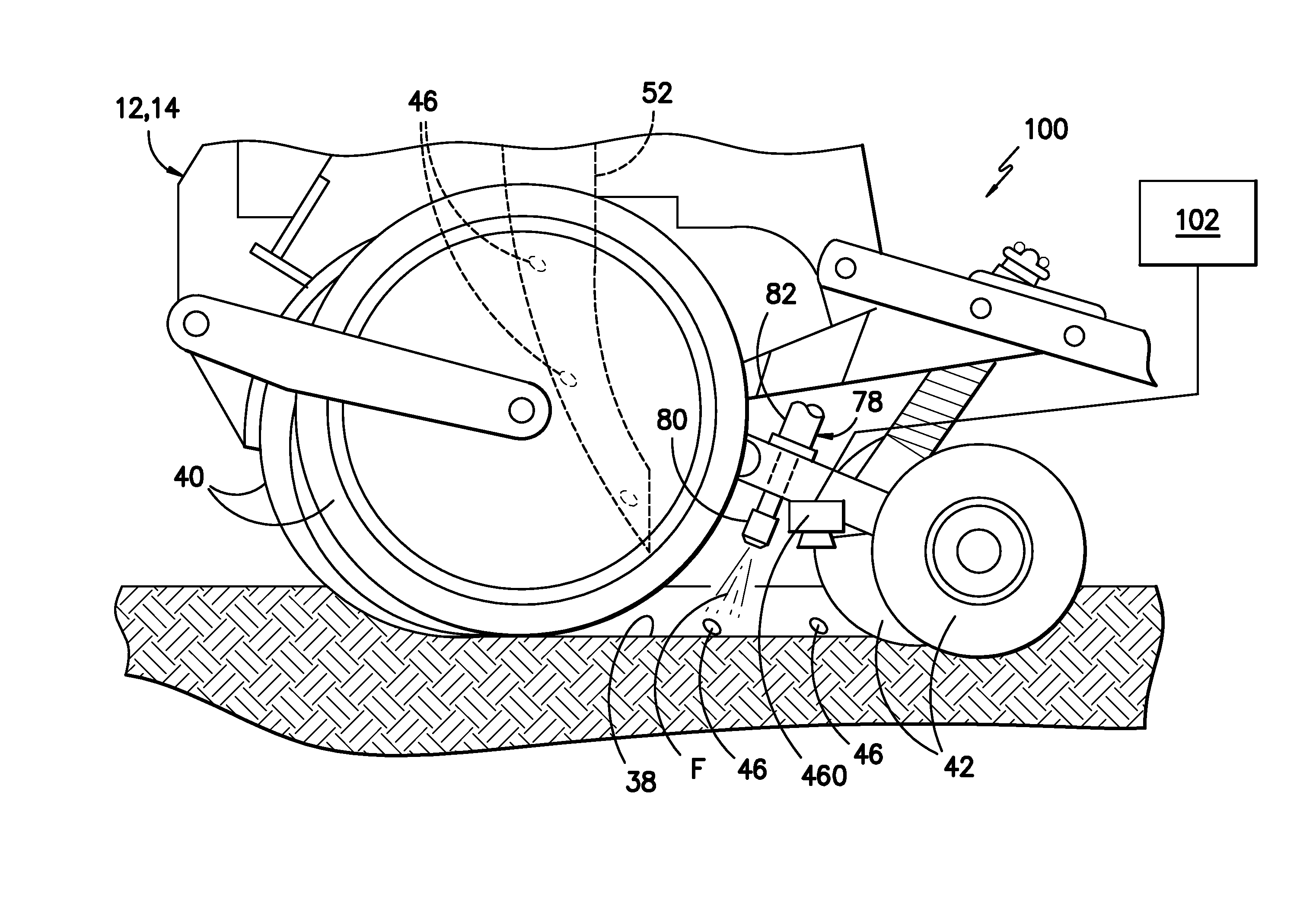

A seed delivery system for use in a seeding or planting machine that removes the seed from a seed meter by capturing the seed therefrom. The delivery system then moves the seed down to a lower discharge point and accelerates the seed horizontally rearward to a speed approximately equal to the forward travel speed of the seeding machine such that the seed, when discharged has a low or zero horizontal velocity relative to the ground. Rolling of the seed in the trench is thus reduced. Furthermore, as the seed only has a short drop from the outlet to the bottom of the seed trench, the seed has little vertical speed to induce bounce. The delivery system uses a brush belt to capture, move and accelerate the seed. By capturing the seed and moving it from the meter to the discharge, the seed is held in place relative to other seeds and the planter row unit. As a result, the seeds are isolated from row unit dynamics thereby maintaining seed spacing.

Owner:DEERE & CO

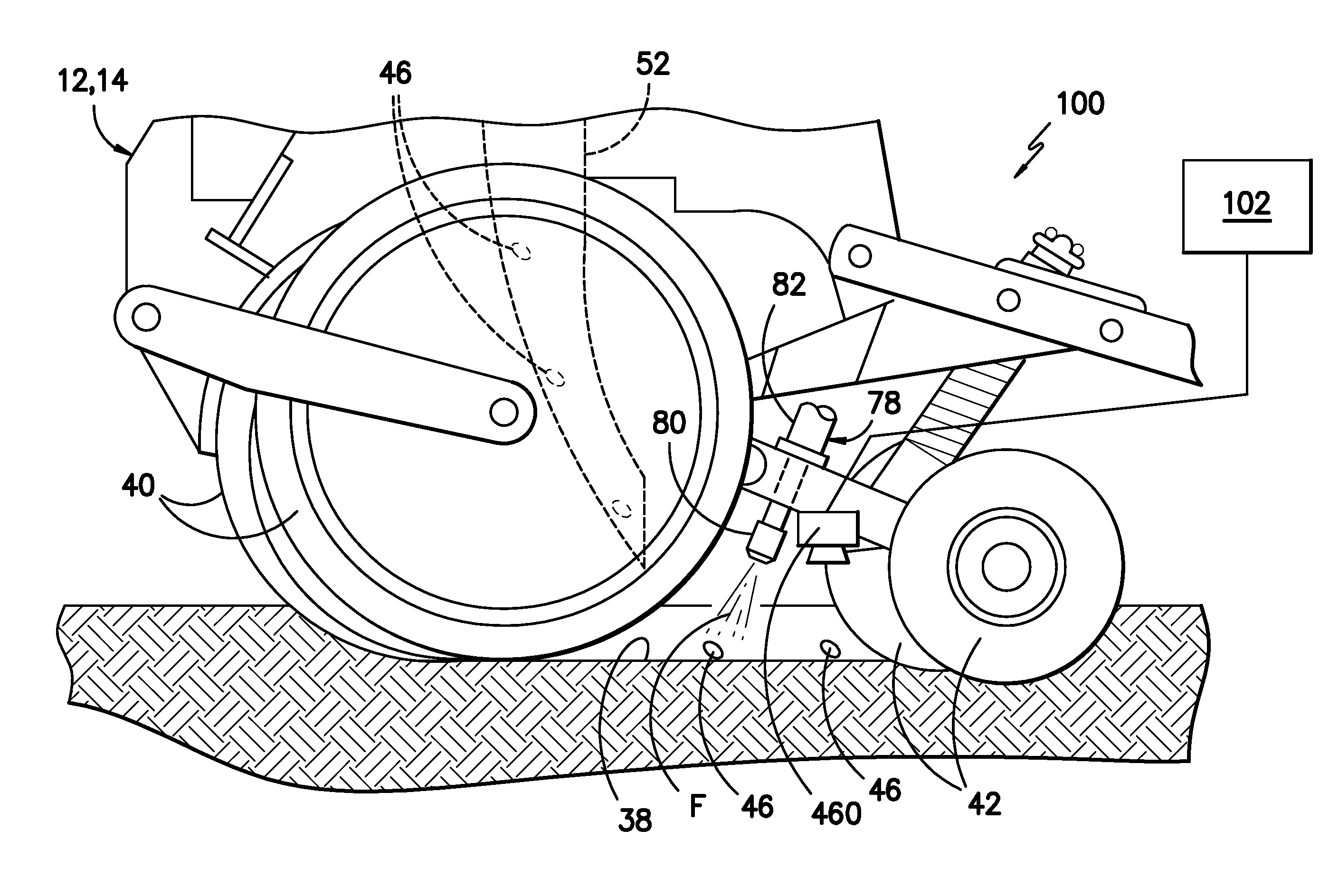

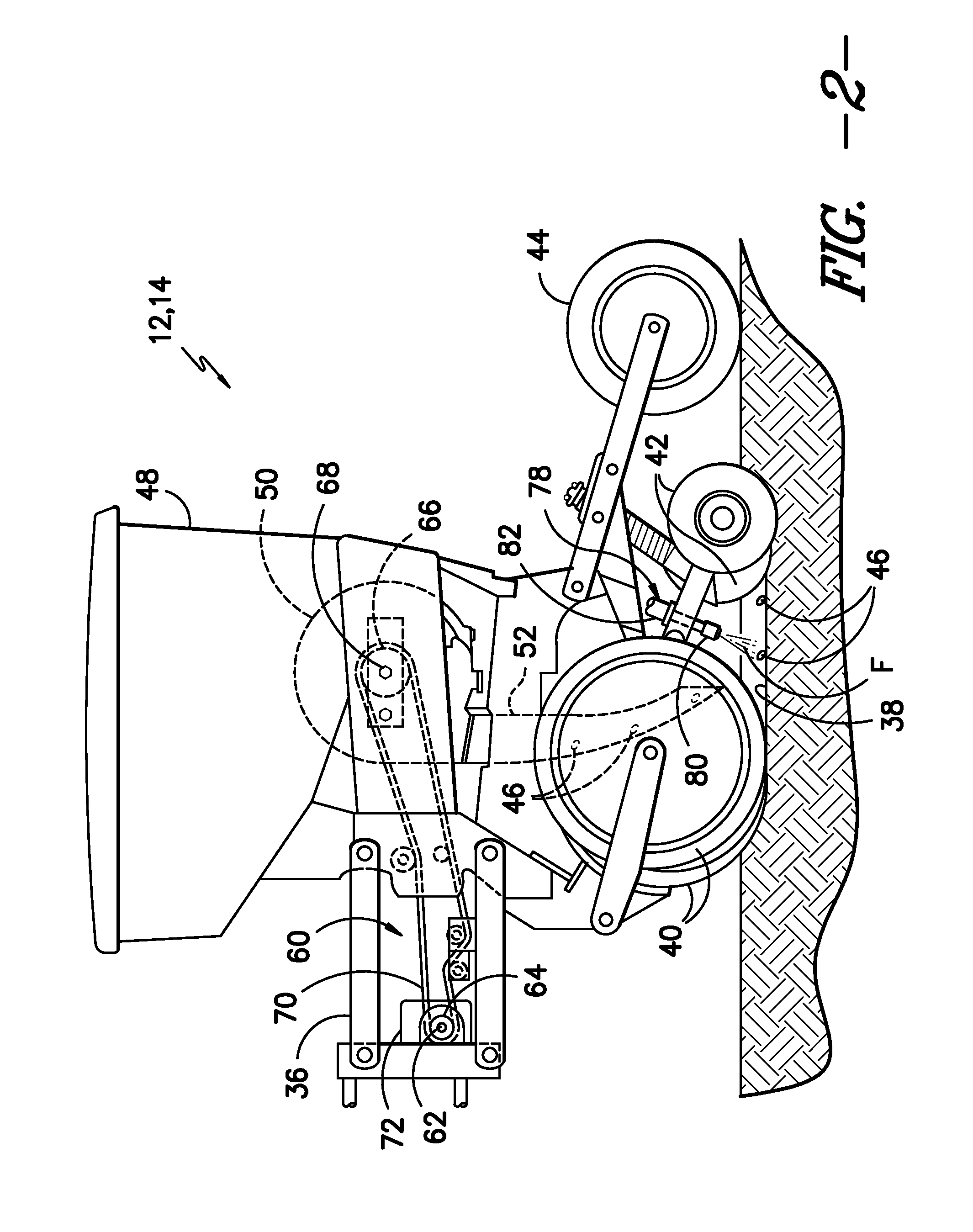

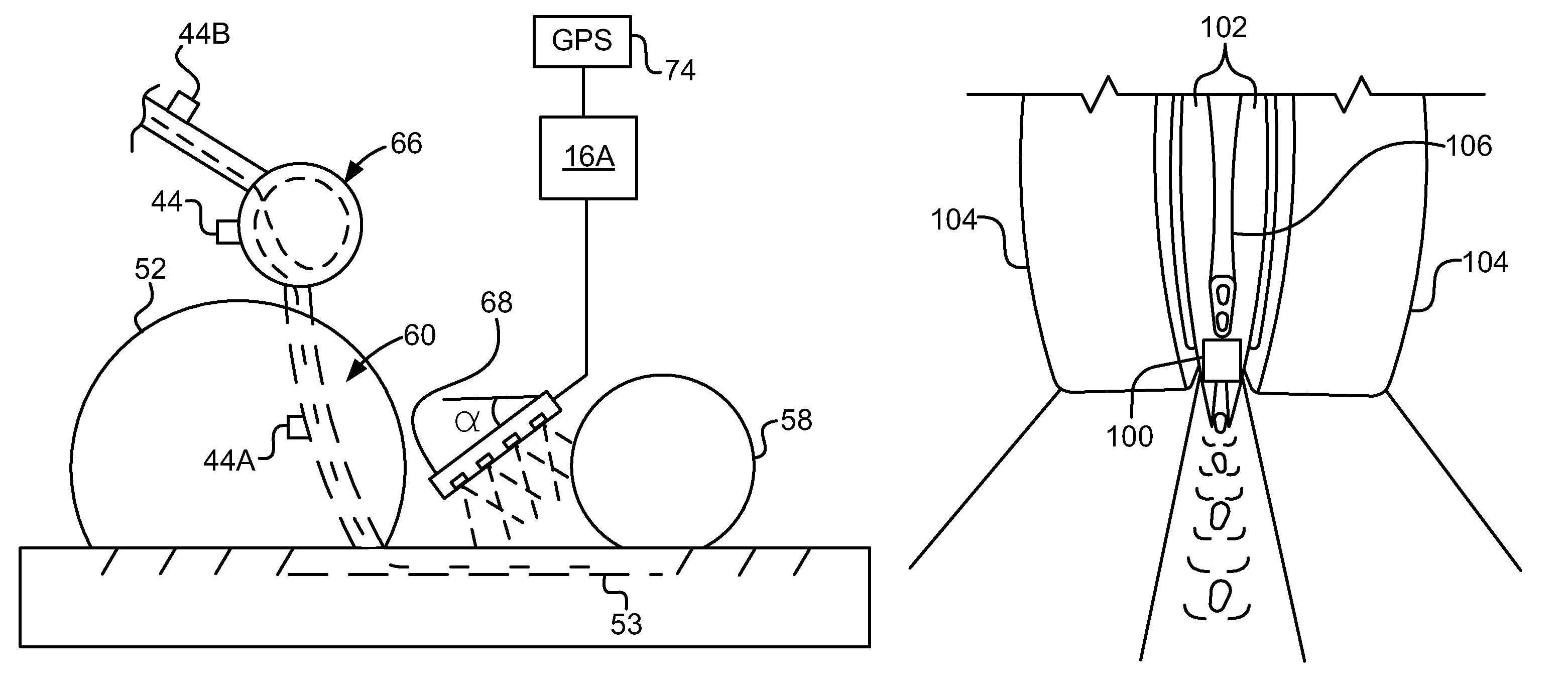

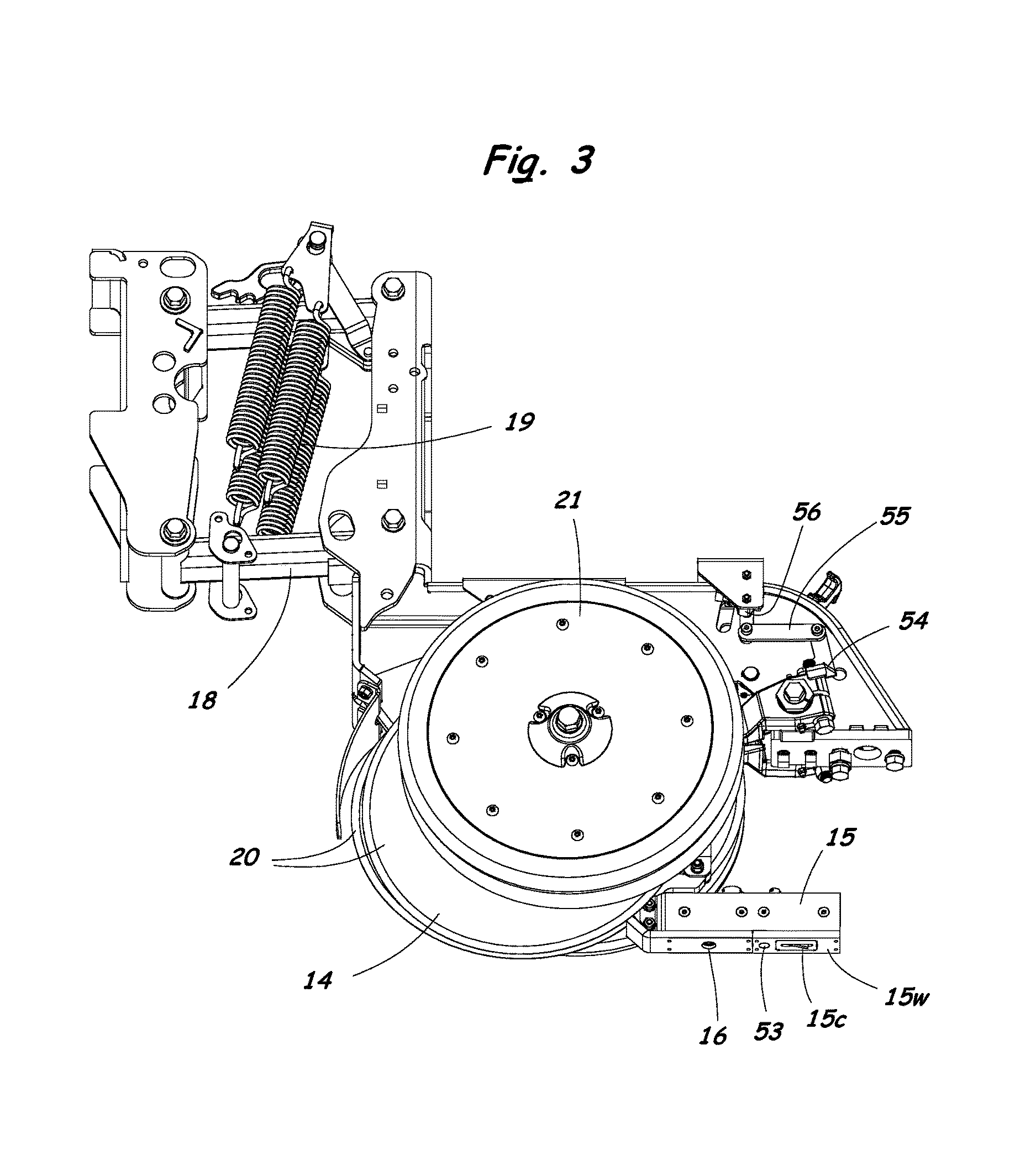

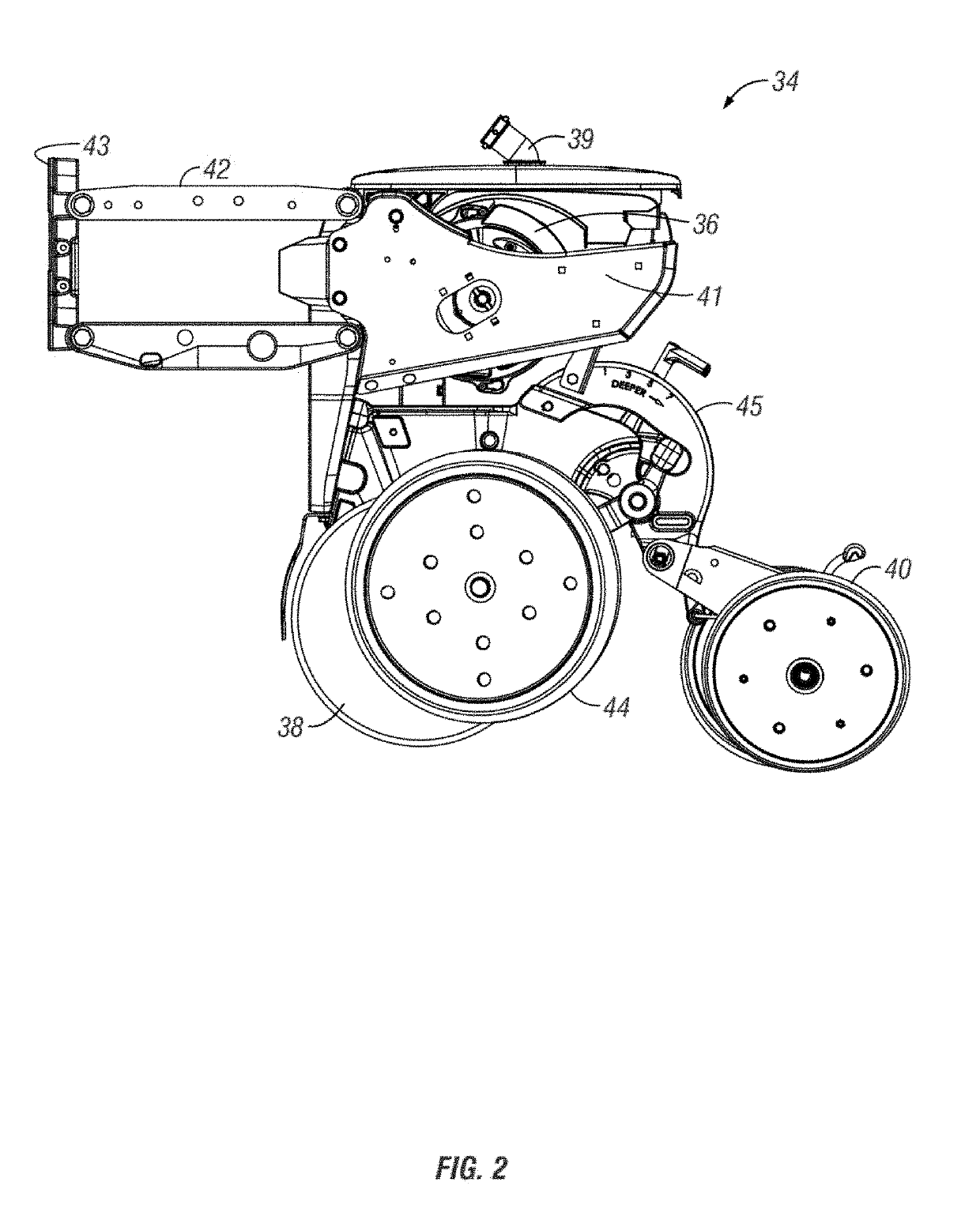

In-ground seed spacing monitoring system for use in an agricultural seeder

ActiveUS20120042813A1Reduce viewing angleHigh sensitivityRadiation pyrometryPlantingSensor arrayPositive pressure

A row crop unit for use in an agricultural seeder includes a furrow opener for opening a furrow in the soil, a seed metering system for metering seed to be placed in the furrow, and a seed placement system for placing seeds in the furrow. The seed placement system and the seed metering system are in communication with each other and at least in part define a seed travel path associated with the furrow. A furrow closer covers the seed in the furrow with soil. A seed temperature conditioner is associated with the seed travel path for varying a temperature of seed traveling through the seed travel path. A temperature sensitive sensor is positioned to sense seed which has been deposited in the furrow between the furrow opener and the furrow closer. An optional packaging tube holds a temperature sensor or sensor array. A lens is mounted with the same tube. A larger diameter tube may be positioned around the sensor packaging tube. A positive air pressure / air flow may be introduced between the two tubes. This positive air-flow forms a positive pressure and / or air flow barrier to push dust away from the sensor lens or sensor surface.

Owner:DEERE & CO

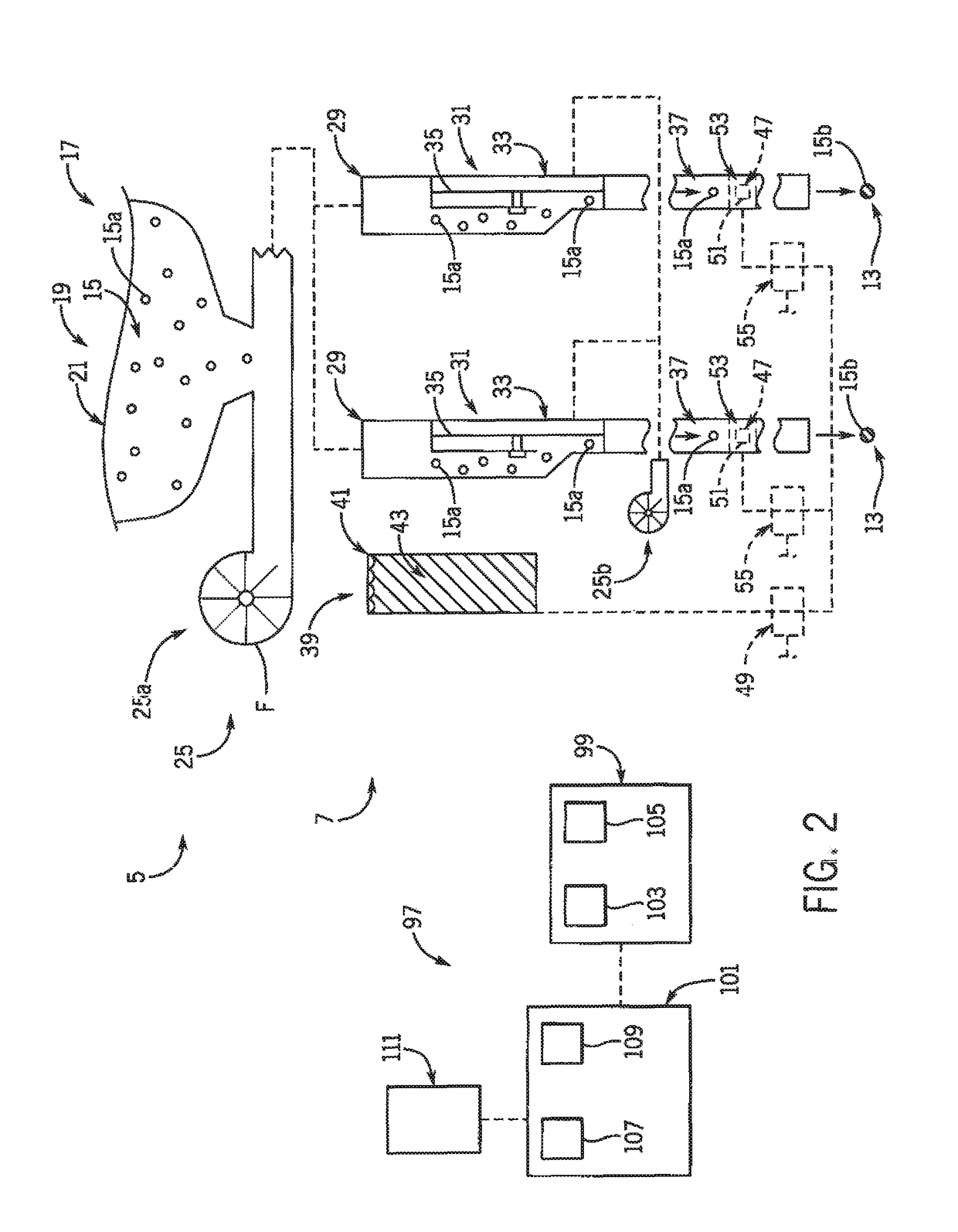

System and Method for Spraying Seeds Dispensed from a Planter

ActiveUS20140048002A1Liquid fertiliser regulation systemsFertilising methodsEngineeringControl valves

In one aspect, a system for providing seed-specific placement of fluid as seeds are planted by a planter is disclosed. The system may generally include a seed meter configured to dispense seeds into a furrow at a seed frequency and a nozzle assembly configured to spray the seeds dispensed into the furrow. The nozzle assembly may include a valve. In addition, the system may include a controller communicatively coupled to the valve. The controller may be configured to determine the seed frequency of the seed meter based on a speed-related parameter of the planter. The controller may also be configured to control the operation of the valve based on the seed frequency such that a metered amount of fluid is sprayed at least one of on or adjacent to each seed.

Owner:CAPSTAN

Seed Delivery System

ActiveUS20140182495A1Minimize seed tumble of seedImprove Spatial ConsistencyPotato plantersFurrow making/coveringPositive pressureDelivery system

A seed delivery system is provided that includes a row crop seed planter having a seed meter that can pneumatically deliver seeds to the agricultural field at a rearward velocity that matches a forward velocity of the planter. The seed meter may include a positive pressure source that pressurizes the seed meter and creates an airflow out of a seed tube of the seed meter that carries the individual seeds out of the seed tube at a rearward velocity that is automatically adjusted to match a forward velocity of the seed planter and tractor.

Owner:BLUE LEAF I P INC

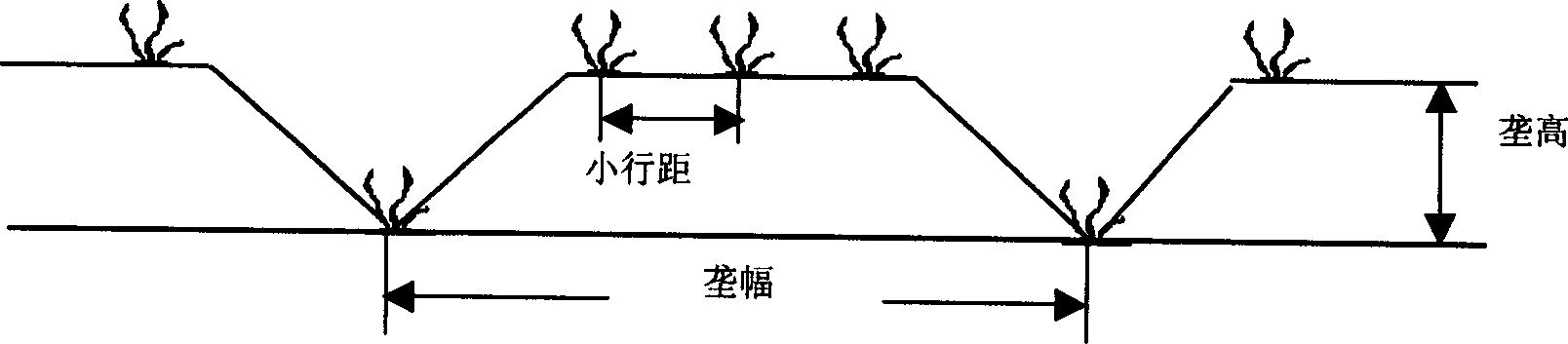

Wheat-corn ridge-culture zero-tillage direct-sowing cultivating method

InactiveCN1774983AEfficient use ofAchieving new breakthroughs in productionHorticulture methodsEarth surfaceDrill

The present invention relates to a wheat-maize ridge-planting non-tillage cultivation method by direct seeding. Said method uses special-purpose ridge drill for wheat to making ridge forming and ridge sowing, after the wheat is harvested, the straw can be covered with surface layer, and the special-purpose sowing machine for maize can be used for sowing on the ridge, so that it is favorable for high-yield of maize.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

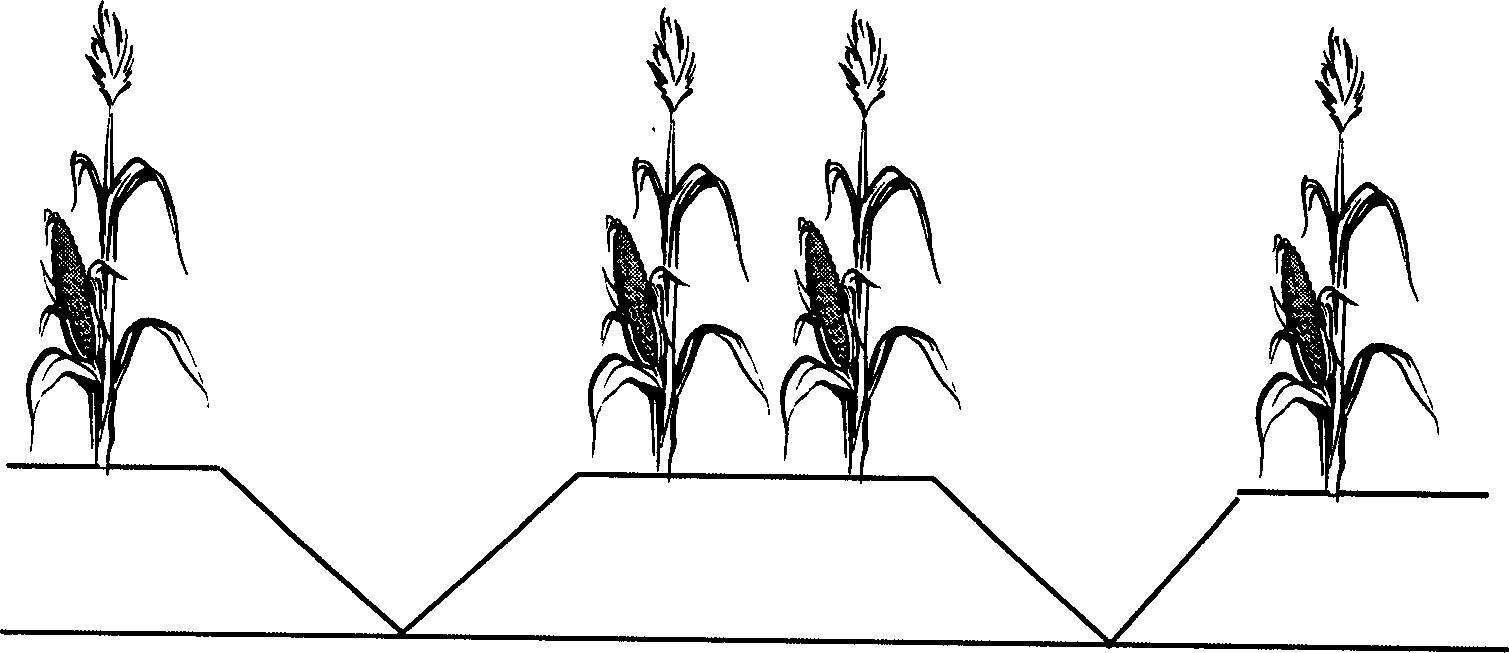

Corn planting and cultivating method

The invention discloses a corn planting and cultivating method. The corn planting and cultivating method includes the following steps of selecting a corn variety and conducting soil preparation before planting, arranging wide rows and narrow rows at intervals, sowing corn, completing sowing, pipe paving, film paving and soil covering through an air suction type precision seeder, and conducting field management in the seedling stage, the ear stage and the flower stage, wherein the width of each wide row ranges from 85cm to 95cm, the width of each narrow row ranges from 25cm to 35cm, a drip irrigation zone is paved in the middle of each narrow row. According to the corn planting and cultivating method, due to the fact that the method that the wide rows and the narrow rows are arranged at intervals is adopted, the number of drip lines which are used can be lowered. Modifiers are sprayed in the early period of the field management in the seedling stage to control the plant height and the ear position, and the defect that through a conventional planting method, the corn easily falls over due to the fact that the plant height is large and the ear position is high is overcome. Pesticide is sprayed through a self-propelled high-stalk crop boom sprayer in the middle and later period of management to control pests, the influences of natural disasters on corn growth are reduced, and the influences on productivity caused by a large number of European corn borers, cotton bollworms, aphids, leafhoppers and red spiders appearing after corn jointing are eliminated.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Method and apparatus for improving the efficiency of a John Deere vacuum planter

The efficiency of a John Deere planter to plant corn seed is improved where the planter is of the type having a vacuum operated metering unit enclosing a seed disk and a double eliminator. To improve the efficiency a kit is provided including an improved seed disk, an improved double eliminator, and an alignment tool for properly aligning the double eliminator with respect to the seed disk. When the parts are installed and properly aligned the planter can accept corn seed in the range of 1200 seeds per pound to 2800 seeds per pound without requiring readjustment of the vacuum setting or replacing the seed disk.

Owner:VEN HUIZEN DALE A

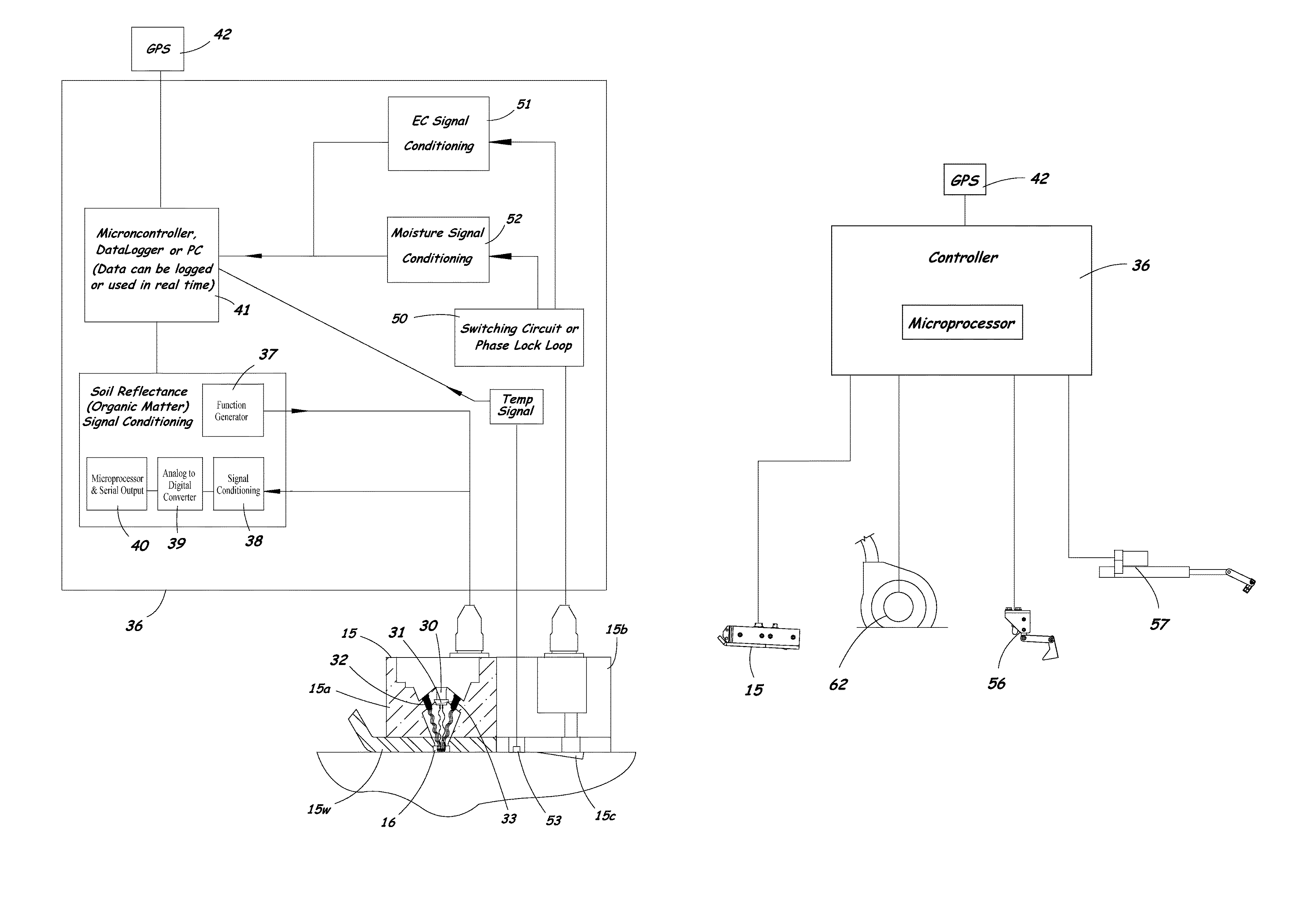

Agricultural planter with automatic depth and seeding rate control

An agricultural planter having sensors for measuring multiple soil properties adjusts planting depth and seeding rate in real time based on the measured soil properties. An optical module is carried by the planter for collecting soil reflectance data. A pair of soil contact blades protrude from or are embedded in the optical module for collecting soil EC data and soil moisture data. A switching circuit or phase lock loop allows the same soil contact blades to feed signals to both a soil EC signal conditioning circuit and a soil moisture signal conditioning circuit. The soil moisture data can be used to calibrate the soil EC data and the soil reflectance data to compensate for effects of changing soil moisture conditions across a field. The sensor module can be positioned behind a seed tube and used as a seed firmer, or incorporated into a seed tube guard.

Owner:VERIS TECH

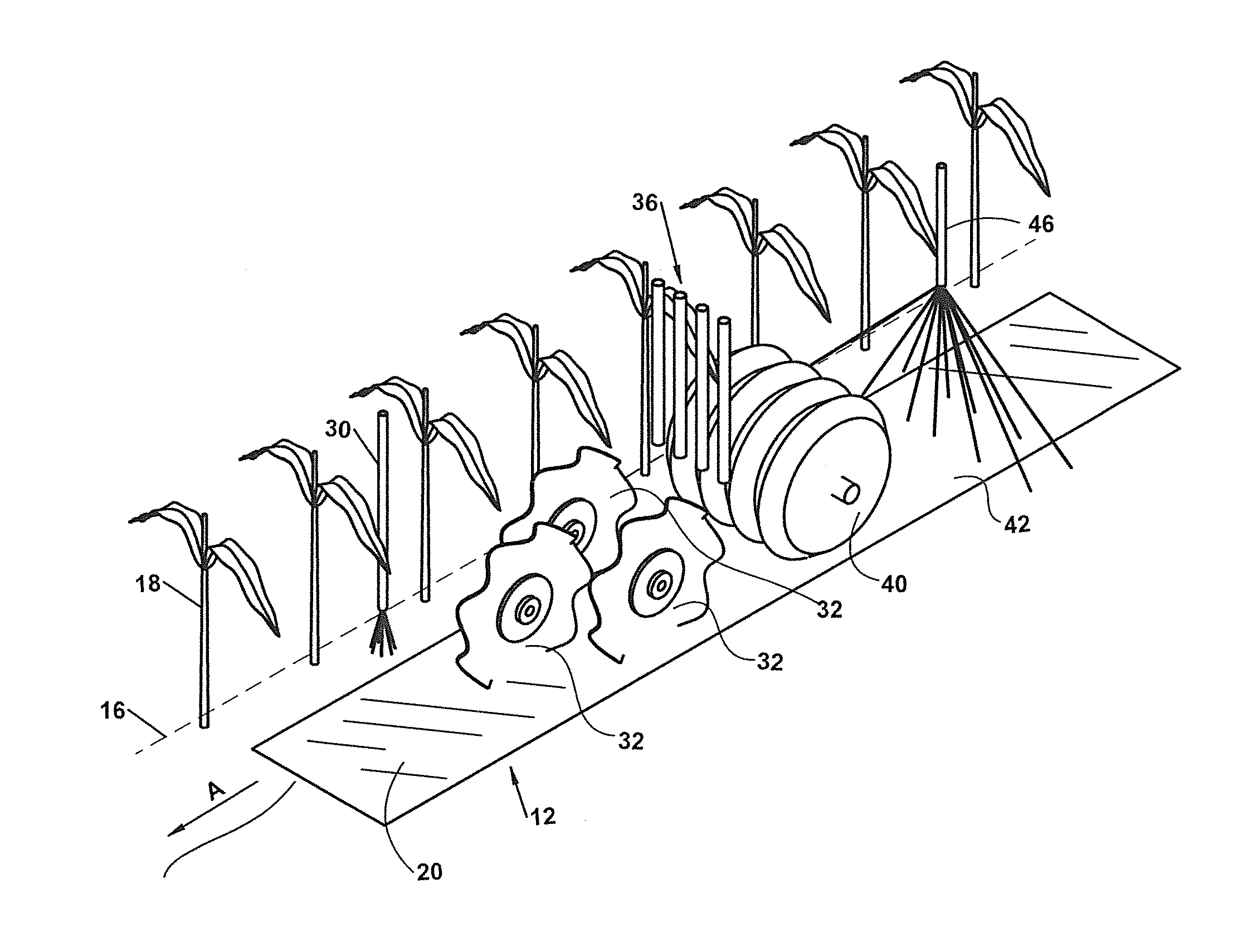

Apparatus and method for no-till inter-row simultaneous application of herbicide and fertilizer, soil preparation, and seeding of a cover crop in a standing crop

A no-till apparatus for application of herbicide and fertilizer, soil preparation, and seeding of a cover crop in a standing crop has inter-row assemblies configured to pass along inter-row areas between adjacent row lines of standing crop plants. Each assembly includes a fertilizer applicator, a no-till soil preparation element, a cover crop seed applicator, and a post-seeding element. The apparatus may include movable auxiliary seeding units such that the apparatus may operate as a grain drill.

Owner:PENN STATE RES FOUND

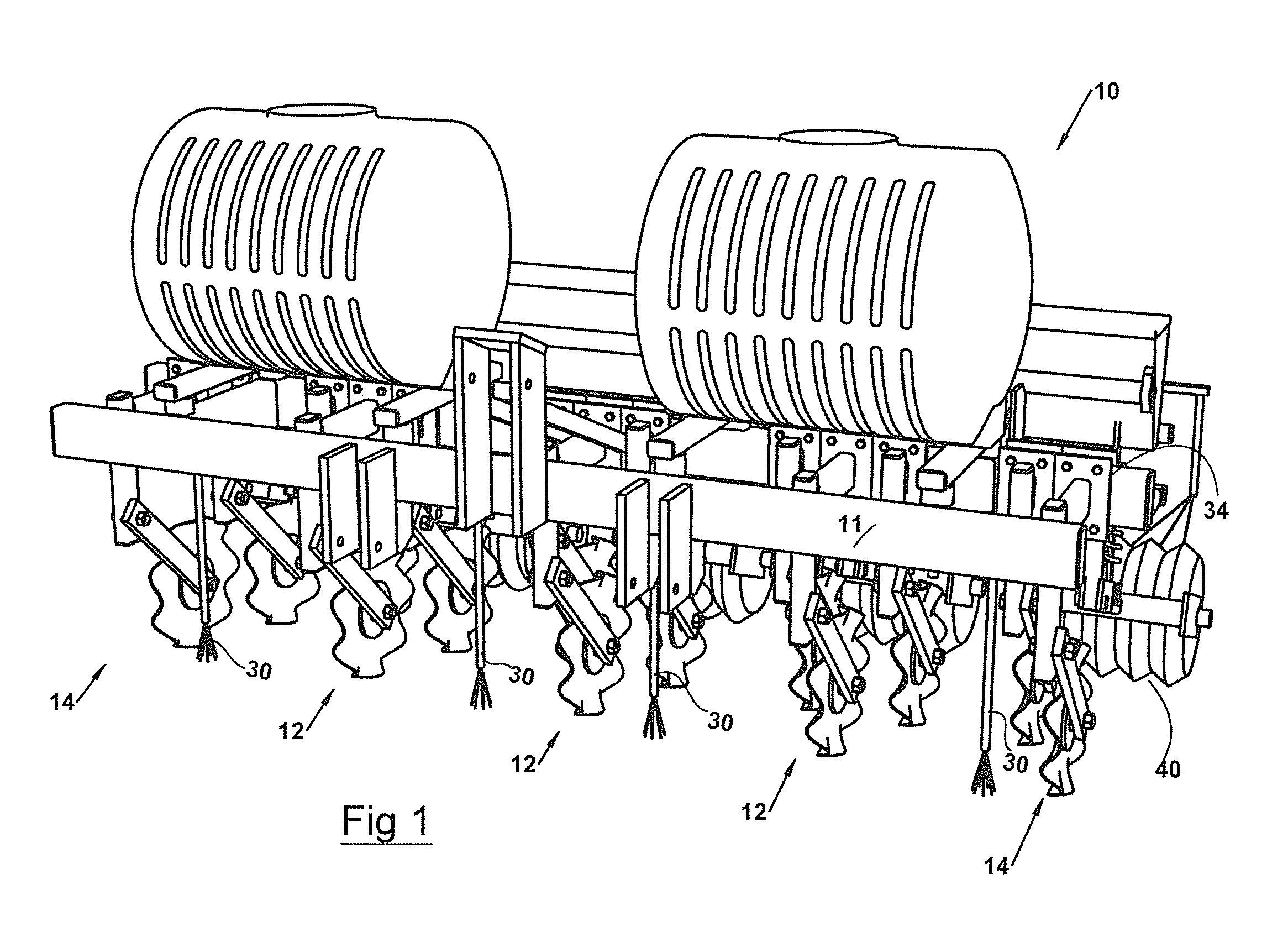

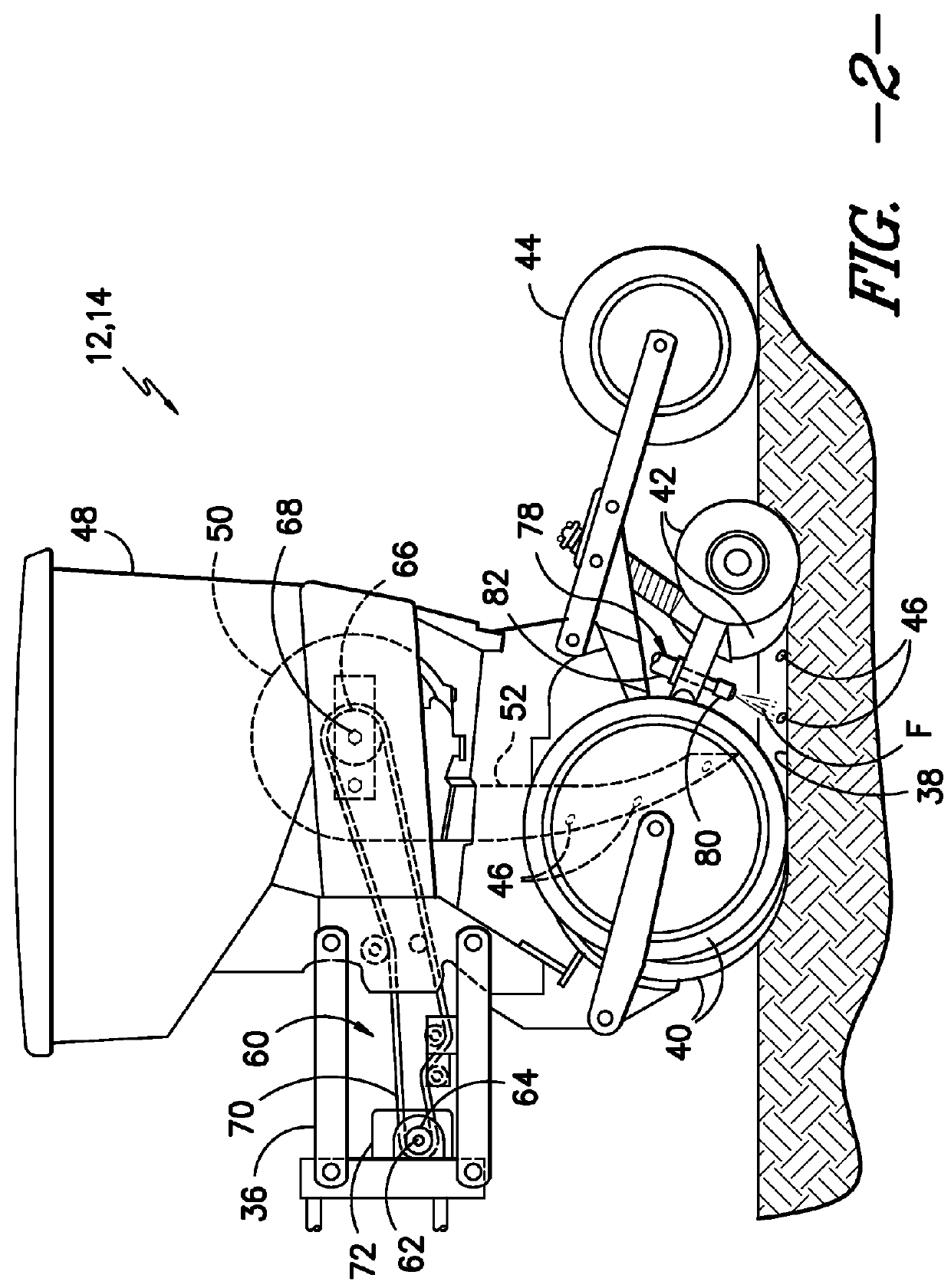

Enhanced minimum tillage planter/renovator system

InactiveUS6425445B1Enhanced seed bedEnhanced clean furrowSpadesAgricultural machinesMinimum tillageEngineering

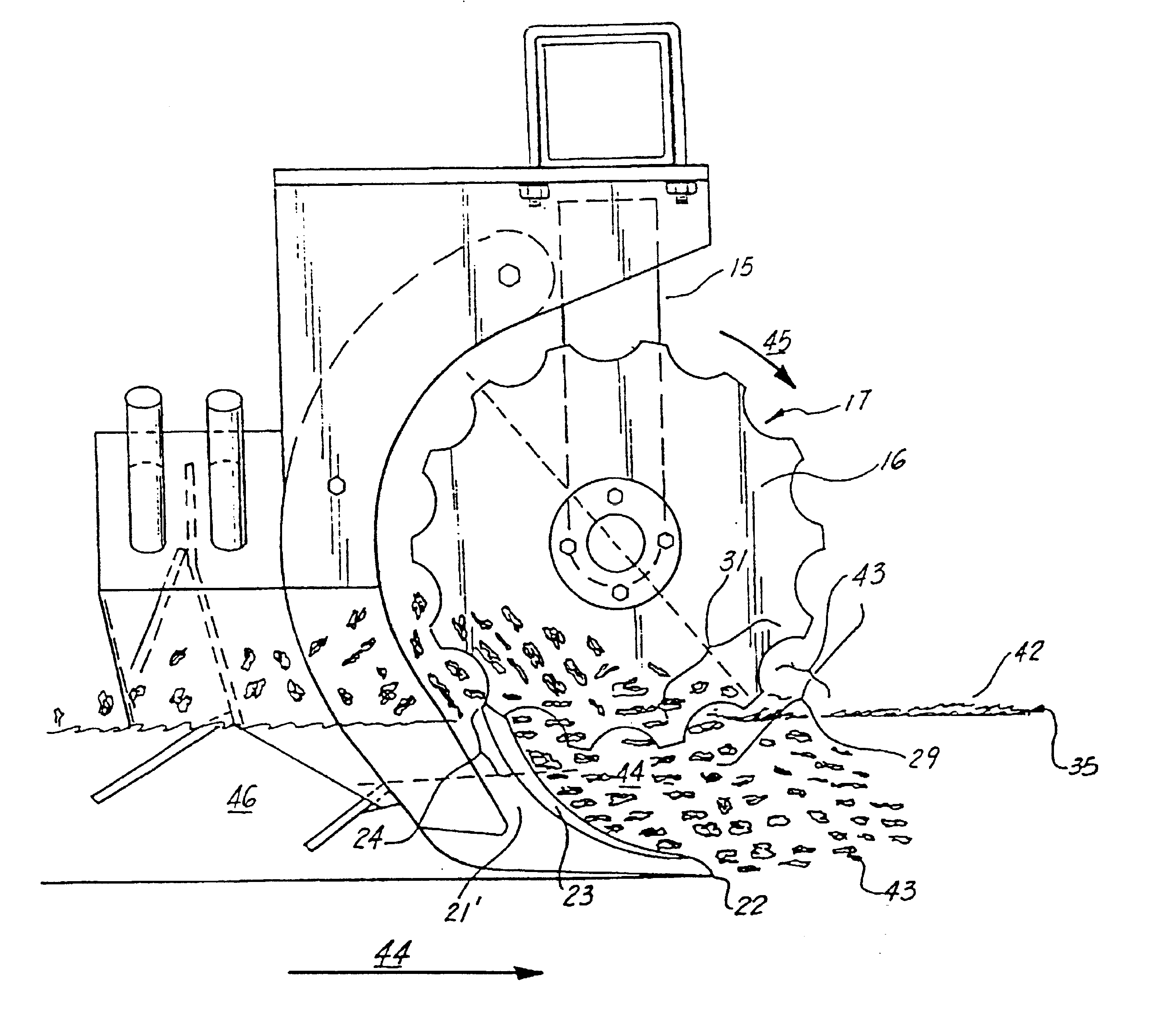

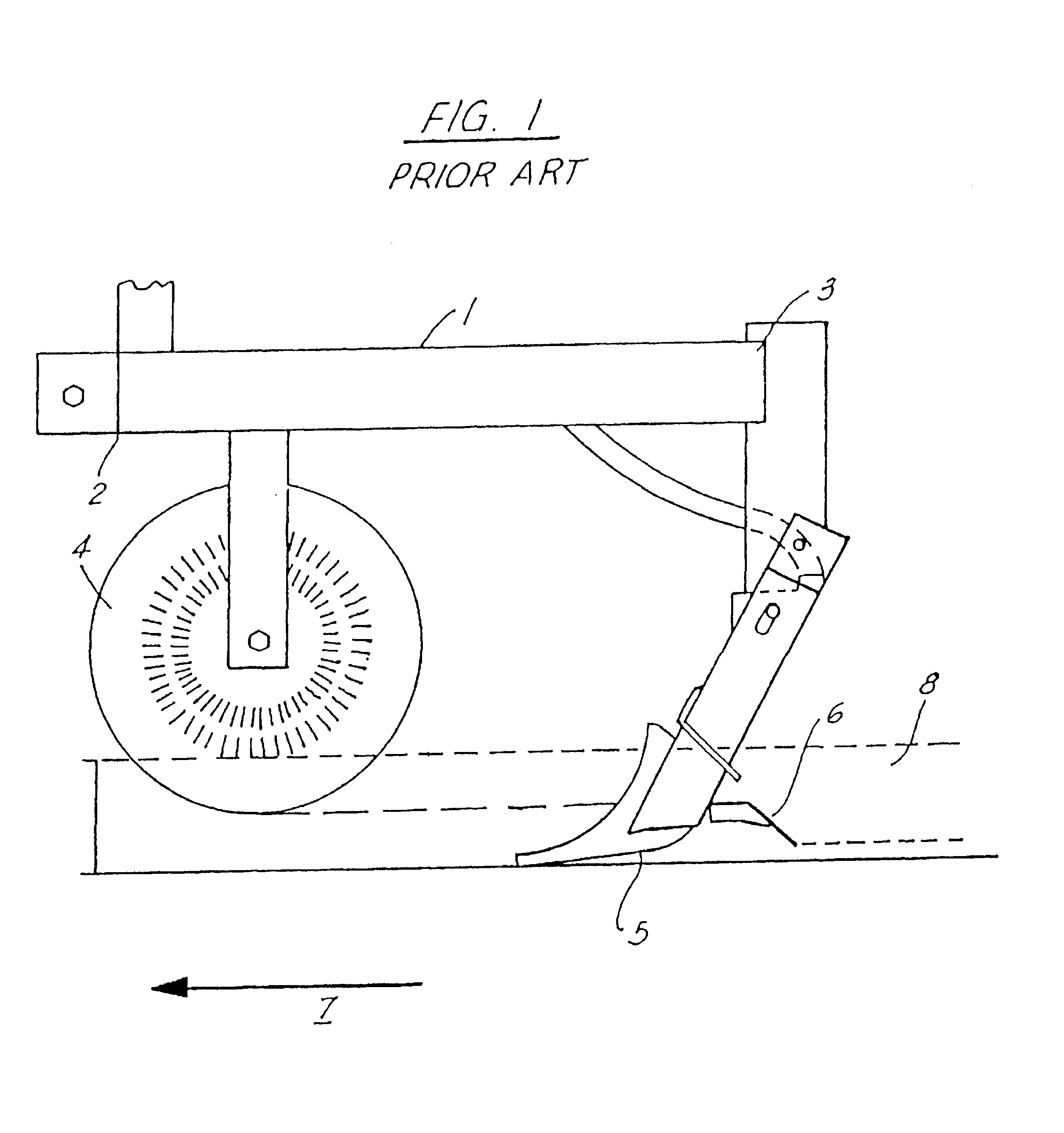

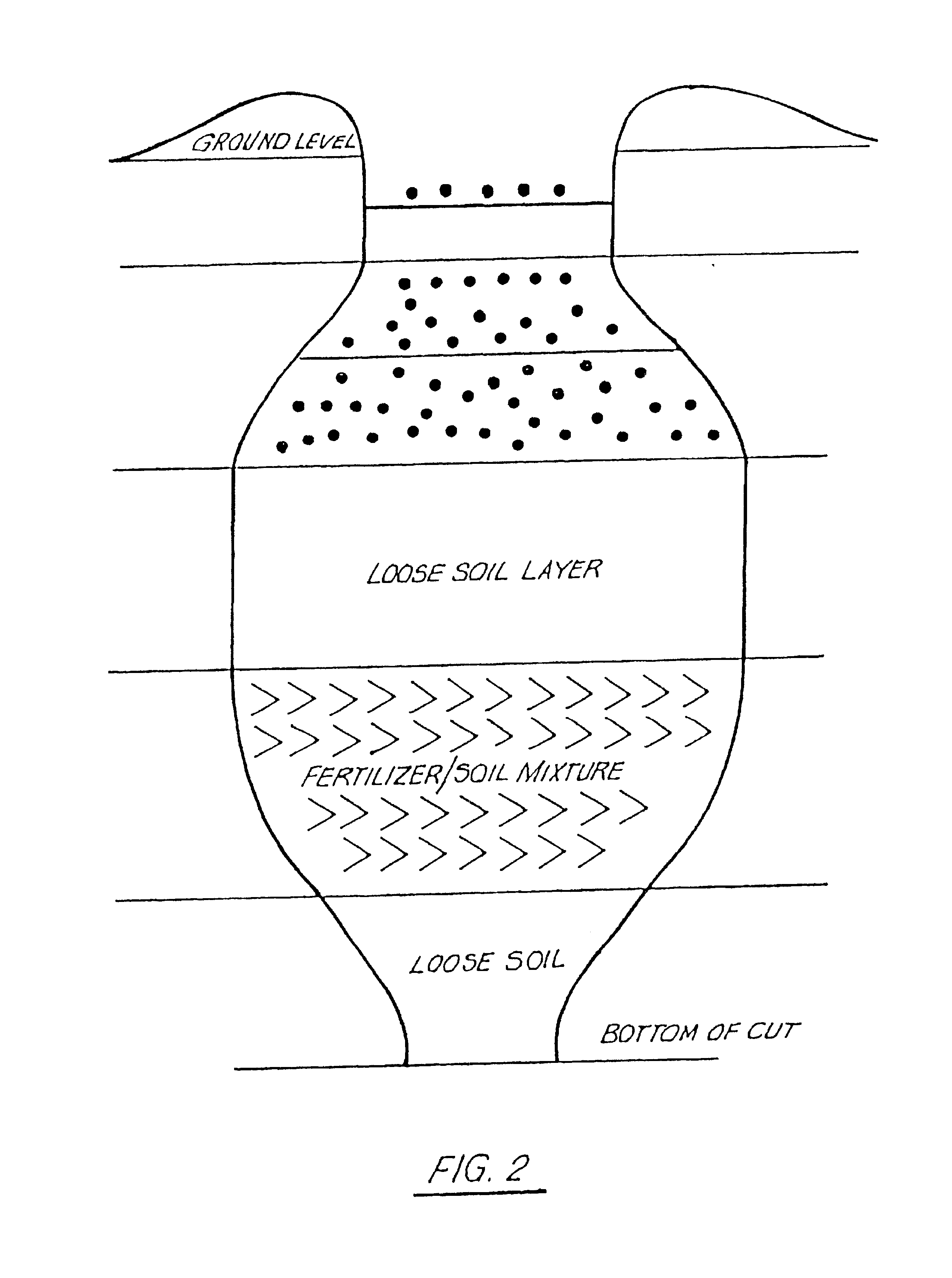

A planter / fertilizer wherein there is provided a ripping point configured to penetrate a predetermined depth into the soil or sod, the ripping point designed to facilitate a splitting and lifting of the soil, forming a seed bed void, while cutting any organic ground cover, which might comprise, for example, sod, widening the ground cover, and lifting same to a prominent head, wherein first and second coulters, situated above and about the ripping point, are configured to independently engage and cut first and second sides of the lifted ground cover, trash and the like, respectively, then cutting the lifted ground cover, etc., as the coulters rotate, the coulters cooperatively grinding at least a portion of the lifted ground cover, forming tilth, and redepositing the tilth into the seedbed void, providing an enhanced seedbed region with nominal surface disturbance, and a clean furrow. Situated behind the first and second mole plows and fertilizer and seed chutes are opposing first and second wheels, the first wheel a larger diameter furrow trimming wheel, having outwardly emanating therefrom a depth ring or drum for controlling the depth and covering of the seed for the first side of the furrow, the second wheel being smaller in diameter than the first and situated to trim the furrow and assist further in covering the seed for the second side of the furrow, the first and second wheels having different diameters so that they cooperatively rotate at different speeds to prevent clogging, and are situated at opposing angles on horizontal and vertical planes so as to be self cleaning in a variety of soil conditions. Following the first and second wheels is a pressure wheel about the width of the furrow, which is directed over the furrow so as to apply pressure to the furrow, flattening so as to complete the furrow forming process.

Owner:TARVER III SAM A

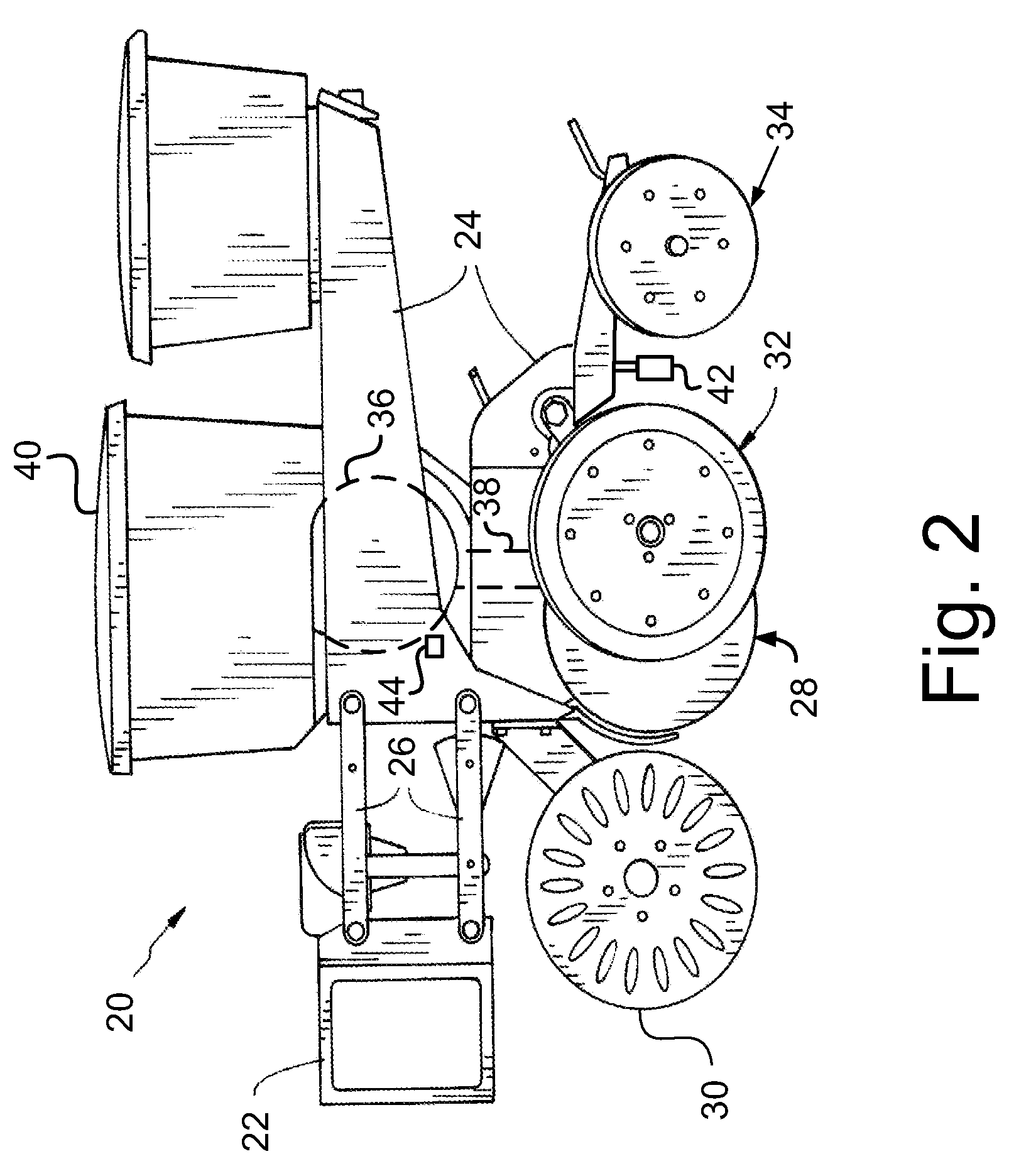

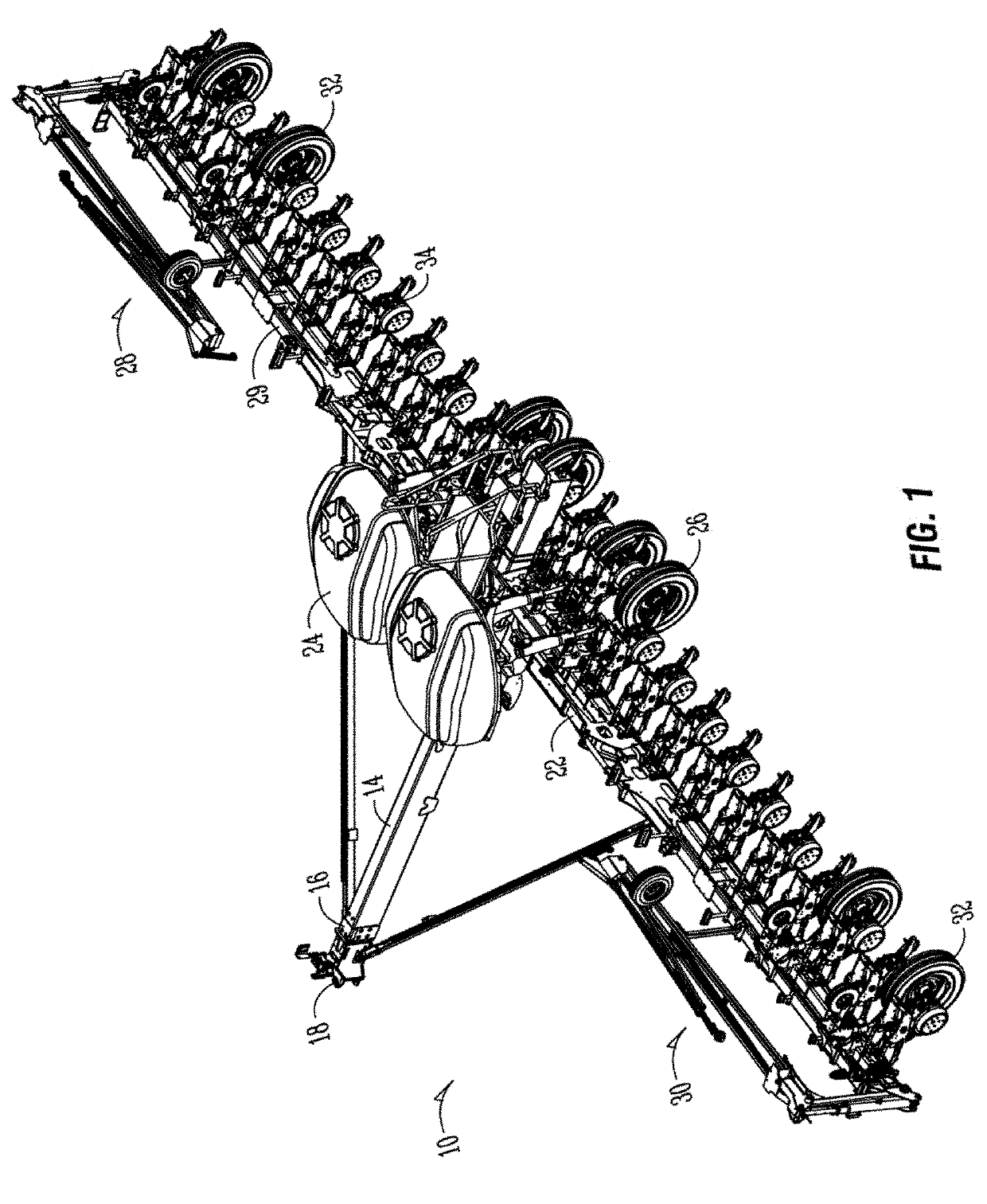

Seed spacing monitoring system for use in an agricultural seeder

ActiveUS20120046838A1Accurate inductionSpadesAgricultural machinesAgricultural engineeringMonitoring system

A seed spacing monitoring system is used In an agricultural seeder for planting seeds. The agricultural seeder has a furrow opener, a seed meter for metering seed to be dispensed in the furrow, and a furrow closer to cover the seed in the furrow. The seed spacing monitoring system includes a detector supported to detect seeds in the furrow prior to the seeds being covered. The detector provides a plurality of seed presence signals, with each seed presence signal being indicative of a respective seed present in the furrow. A speed sensor is associated with the seeder and provides a speed signal indicating a ground speed of the seeder. An electrical processor receives the plurality of seed presence signals and the speed signal. The electrical processor determines a seed spacing, dependent upon the seed presence signals and the speed signal.

Owner:DEERE & CO

Rice direct-seeding drip irrigation under mulch-film dry-farming cultivation method

ActiveCN101422120AIncrease profitImprove drought resistanceClimate change adaptationWatering devicesPunchingPesticide pollution

The invention discloses a drip irrigation dry-farming planting method under a rice direct seeding film, which belongs to a crop planting agriculture method. A timely seeding operation is carried out after the preparation before seeding is finished; the seeding operation is as follows: the operations of drip irrigation zone paving, film covering, punching, hole seeding and soil covering on a hole are accomplished by one time by a drip irrigation tube-paving film-paving fine seeder under the film; the drip irrigation zone is arranged on the lower surface of a plastic film and is connected with a water-carriage system; and timely and proper water dripping and fertilizing are carried out according to the growing demand of the crops. The drip irrigation dry farming planting method can be applied to save water by 60 to 70 percent, save the fertilizers by 30 percent, have high degree of mechanization, save labor, reduce the field management and reduce the pesticide pollution.

Owner:XINJIANG TIANYE GRP +1

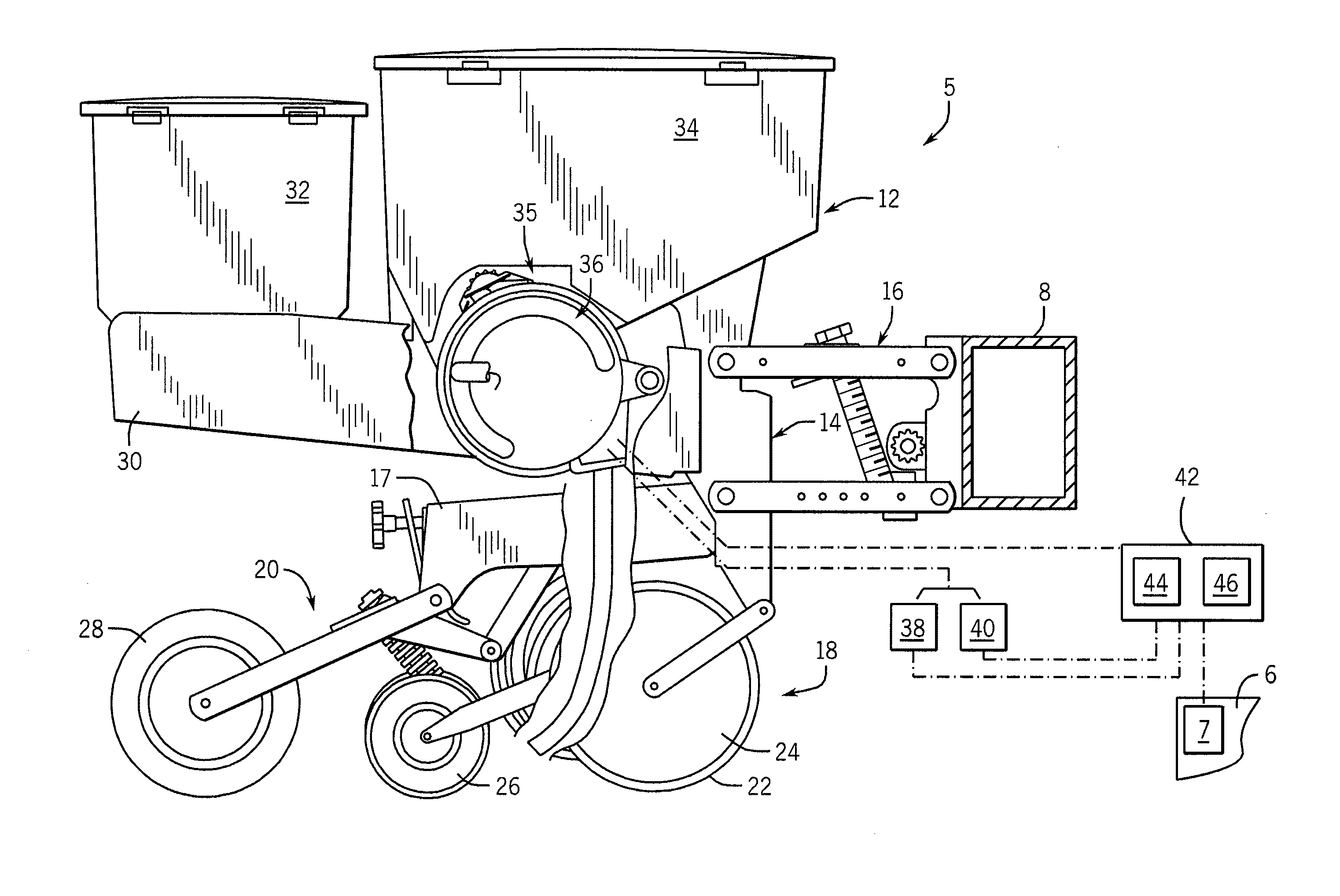

Planter with on-board seed treatment

ActiveUS9730377B2Reduce exposureGood choiceFertilising methodsSeed depositing seeder partsOn boardSpray nozzle

A planter is provided with onboard seed treatment for treating seeds on the go during row-crop planting of an agricultural field. The seed treatment system of the planter allows for selective planting of specific zones of a field with treated seed, which may include planting different zones of the field with seeds having different treatments. The planter may store untreated seed in bulk and include a seed treatment system that selectively and precisely treat the untreated seeds during treatment events by way of an injection or spray nozzle system that applies liquid treatment to the seeds traveling along a tightly defined travel path, such as within pockets of a belt that carries the seeds through a seed tube.

Owner:CNH IND CANADA

System and method for spraying seeds dispensed from a planter

In one aspect, a system for providing seed-specific placement of fluid as seeds are planted by a planter is disclosed. The system may generally include a seed meter configured to dispense seeds into a furrow at a seed frequency and a nozzle assembly configured to spray the seeds dispensed into the furrow. The nozzle assembly may include a valve. In addition, the system may include a controller communicatively coupled to the valve. The controller may be configured to determine the seed frequency of the seed meter based on a speed-related parameter of the planter. The controller may also be configured to control the operation of the valve based on the seed frequency such that a metered amount of fluid is sprayed at least one of on or adjacent to each seed.

Owner:CAPSTAN

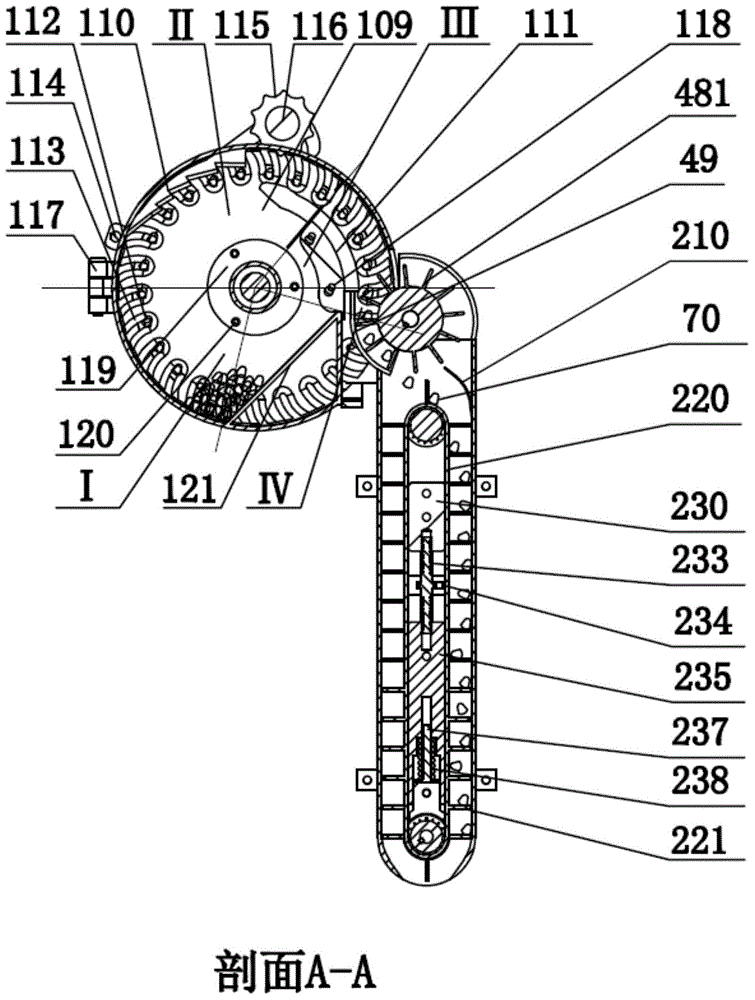

Accurate seed throwing mechanism and accurate seed throwing method of corn planter

InactiveCN104956815AGuaranteed spacing accuracyPrecision infusionSeed depositing seeder partsRegular seed deposition machinesAgricultural scienceSelf-gravitation

The invention relates to an accurate seed throwing mechanism and an accurate seed throwing method of a corn planter. The accurate seed throwing mechanism comprises a control part, a driving part and an executing part, wherein the executing part comprises a seed sowing device, a seed taking unit and a seed conveying unit; seeds can be adsorbed by profiled holes in a seed plate under the action of negative pressure, residual seeds are removed after the seeds adsorbed in the profiled holes in the seed plate pass through a seed scraping plate which is positioned above the left part of the seed sowing device, and only one seed is left in each profiled hole; pulling fingers of a seed taking wheel are used for pulling out the seeds which are about to drop in order and enabling the seeds to enter grilles formed by the pulling fingers and a seed guiding groove, the seeds are pushed to the left upper part of a conveyor belt by the pulling fingers and are thrown out, the seeds fall into separating grooves of the conveyor belt under the action of gravitation and move to the bottom part of the seed conveying unit along with the conveyor belt, and the seeds can fall onto a seedbed under the action of a pushing force of separating plates of the conveyor belt and the self gravitation of the seeds. The electrically-driven accurate seed throwing mechanism disclosed by the invention is capable of initiatively taking the seeds, accurately conveying the seeds, realizing real-time zero-speed seed throwing and maintaining the spacing accuracy of the seeds and has the characteristics that the structure is simple, the adjustment is convenient, and the like.

Owner:CHINA AGRI UNIV

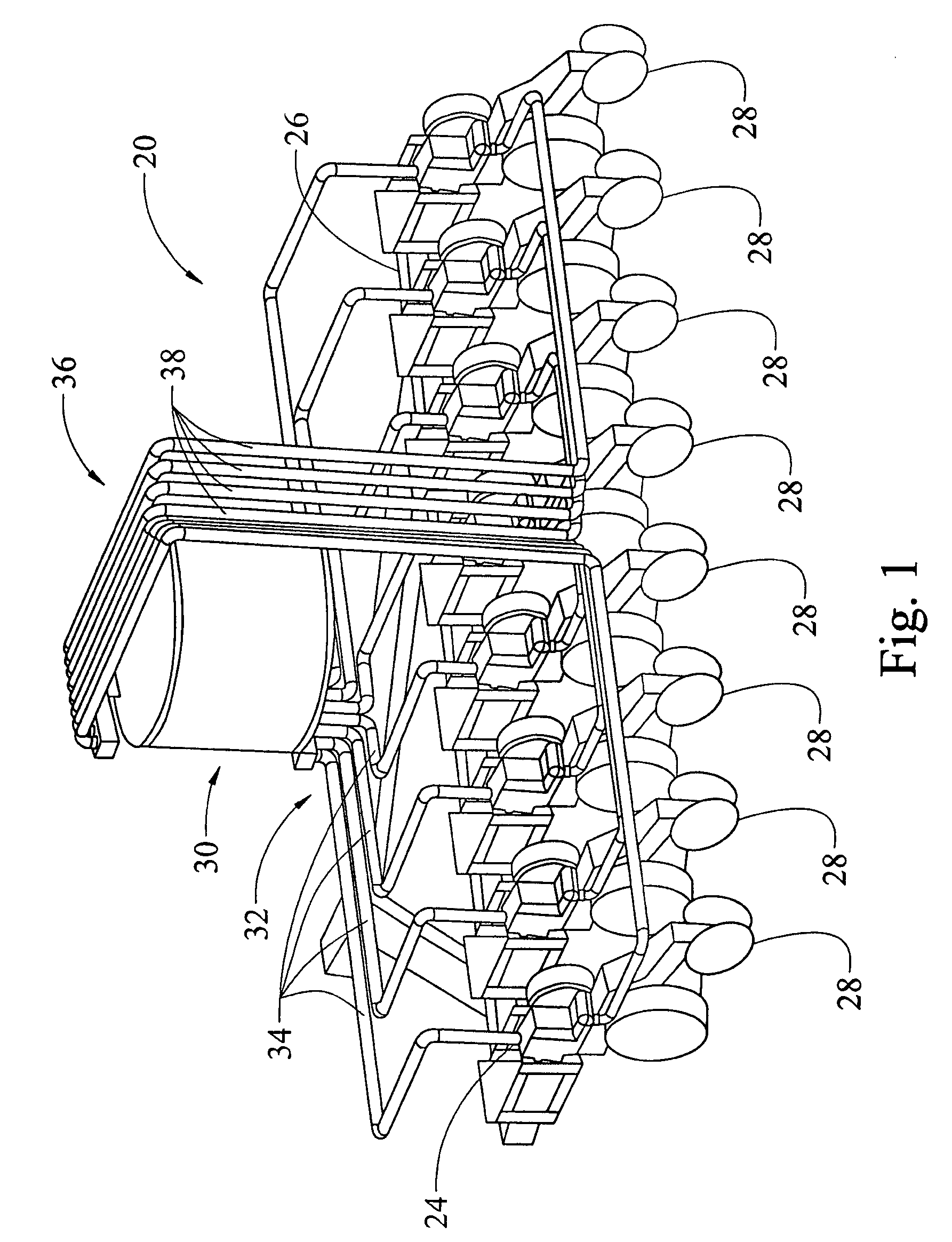

Custom planter and method of custom planting

A method of planting test plots of different seeds in a field includes loading a multi-row planter with a first seed, and traversing the field and planting a test plot of the test plot of the first seed in a portion of the test field; automatically removing the first seed from the multi-row planter and loading a second seed into the multi-row planter, and traversing the field and planting a test plot of the test plot of the second seed in the field.

Owner:MONSANTO TECH LLC

Seed spacing monitoring system for use in an agricultural seeder

ActiveUS8365679B2Accurate inductionSpadesAgricultural machinesAgricultural engineeringMonitoring system

A seed spacing monitoring system is used In an agricultural seeder for planting seeds. The agricultural seeder has a furrow opener, a seed meter for metering seed to be dispensed in the furrow, and a furrow closer to cover the seed in the furrow. The seed spacing monitoring system includes a detector supported to detect seeds in the furrow prior to the seeds being covered. The detector provides a plurality of seed presence signals, with each seed presence signal being indicative of a respective seed present in the furrow. A speed sensor is associated with the seeder and provides a speed signal indicating a ground speed of the seeder. An electrical processor receives the plurality of seed presence signals and the speed signal. The electrical processor determines a seed spacing, dependent upon the seed presence signals and the speed signal.

Owner:DEERE & CO

Planter with high speed seed delivery apparatus

Owner:KINZE MFG INC

Seed drill element having improved topsoiling means

InactiveUS6895876B2Easily and accuratelyGood repeatabilitySpadesAgricultural machinesLocking mechanismEngineering

The seed drill element comprises a frame, a seed tank, a seed dispenser, and a member for opening a furrow in the ground. The seed drill element further comprises mechanism for bearing against the ground, having a rear block and / or a front block, with each block having at least one wheel and an arm hinged to the frame, and also topsoiling mechanism including a rear link, two front links, and an intermediate link. The topsoiling mechanism also comprise a mechanism for moving the rear link relative to a reference part connected to the frame. In addition, the seed drill element includes a locking mechanism so that the topsoiling mechanism can be configured for front topsoiling, for rear topsoiling, and / or for rocker topsoiling.

Owner:RIBOULEUA MONOSEM

Wheat rotary tillage combined seed and fertilizer drill

InactiveCN102687611ACompact structureImprove fertilizer efficiencySpadesPloughsAgricultural engineeringMoisture

The invention discloses a wheat rotary tillage combined seed and fertilizer drill which comprises a rack, a rotary blade, a fertilizing mechanism, a sowing mechanism and a land wheel suppression mechanism, wherein the fertilizing mechanism comprises a fertilizer box and a fertilizer discharge pipe; the sowing mechanism comprises a seed box, a seeding mechanism and a sowing boot; the fertilizer box is located right above the rotary blade and fixed on the rack; the fertilizer discharge pipe is arranged in front of the rotary blade; the sowing boot is arranged behind the rotary blade; an adjustable soil guide plate is arranged behind the sowing boot; and the soil guide plate is fixed on the rack. According to the wheat rotary tillage combined seed and fertilizer drill disclosed by the invention, the overall structure is relatively compact; a sowing sequence of fertilizing, rotary tillaging, sowing, earthing and pressing is formed by improving the agricultural technology; chemical fertilizer and soil can be uniformly mixed to improve the fertilizer efficiency; the rotary blade backwards throws a mixture of crushed straws and the soil at a high speed; and when meeting the soil guide plate, the back-thrown mixture falls back to the land surface along the soil guide plate and covers wheat seeds to realize the aim of soil moisture conservation and water conservation.

Owner:河北省农林科学院粮油作物研究所 +1

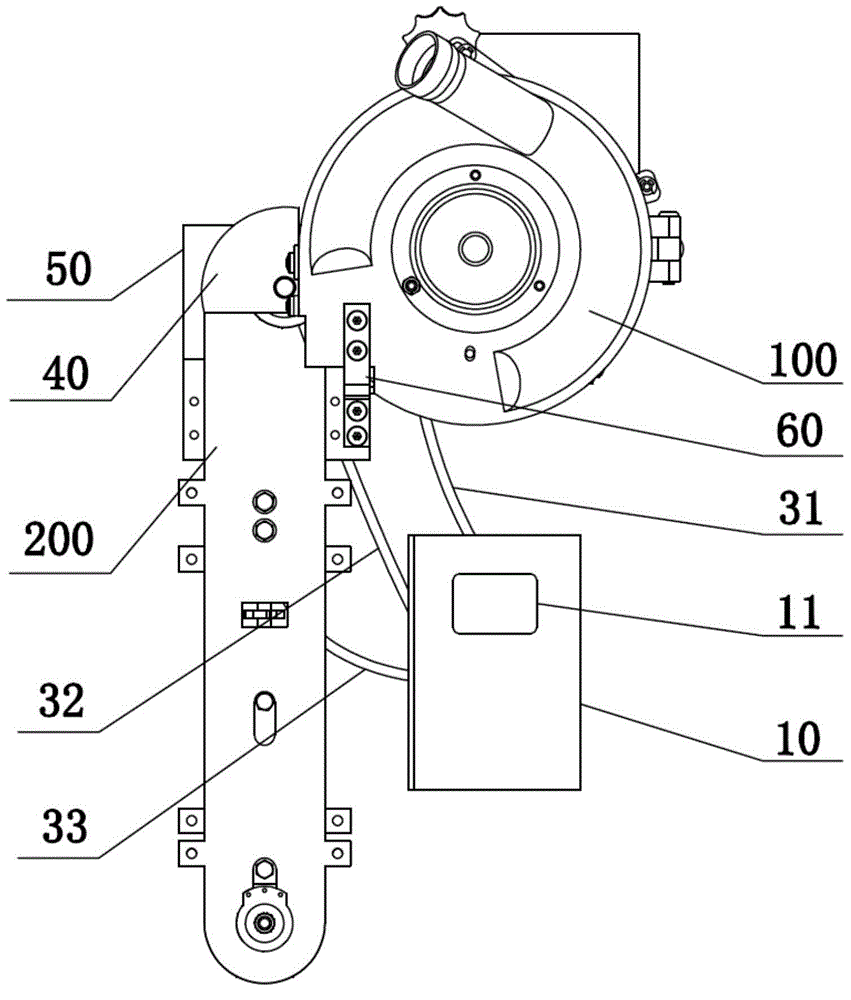

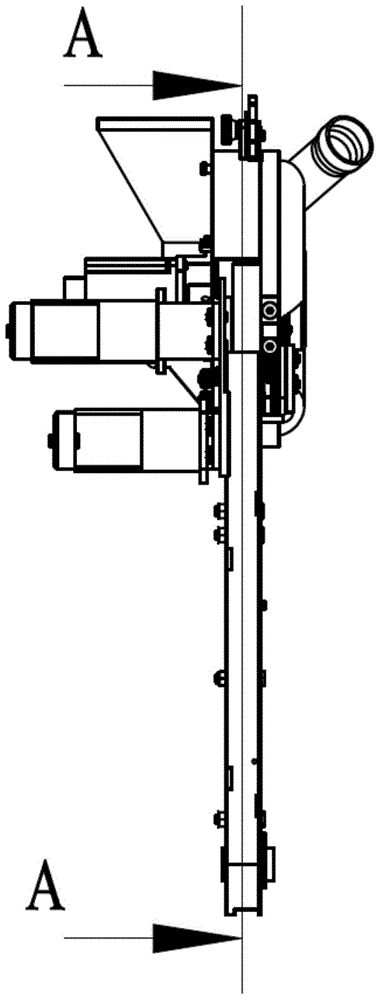

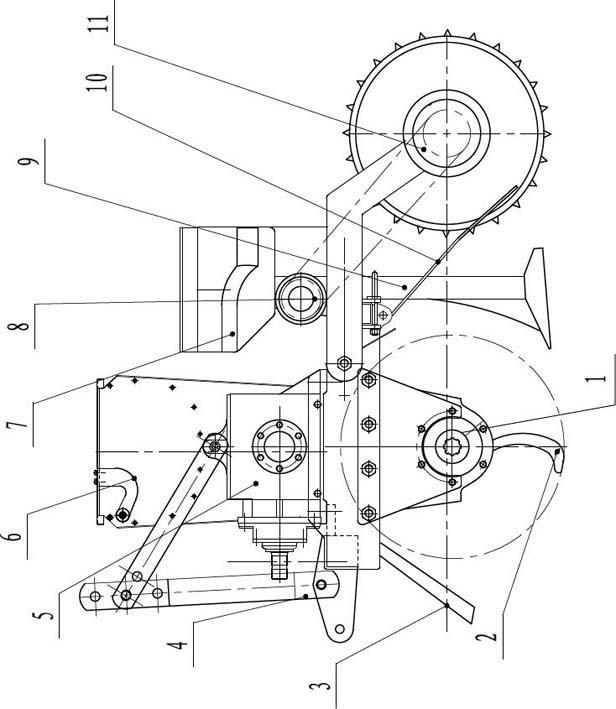

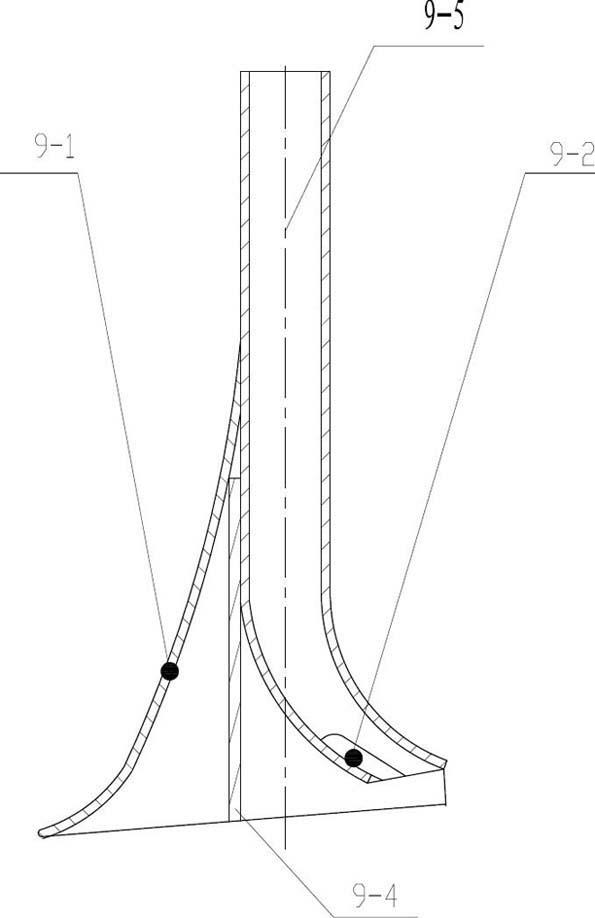

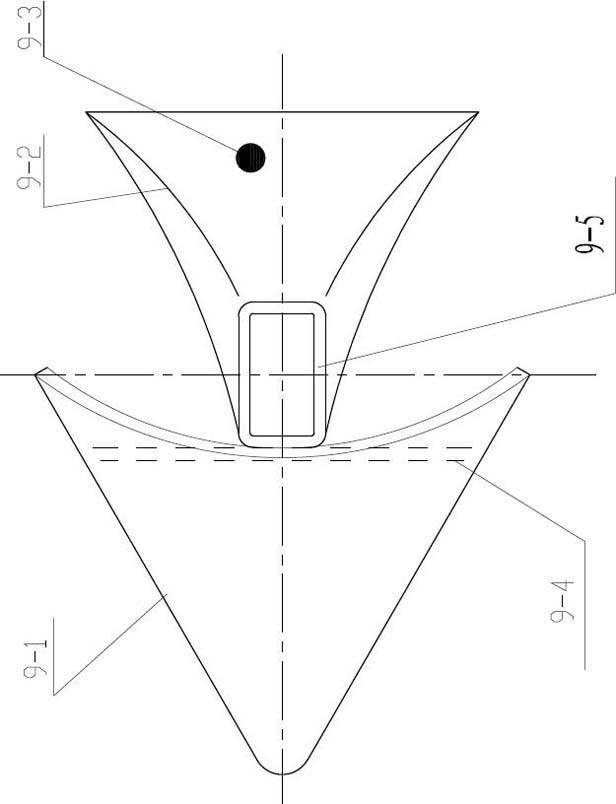

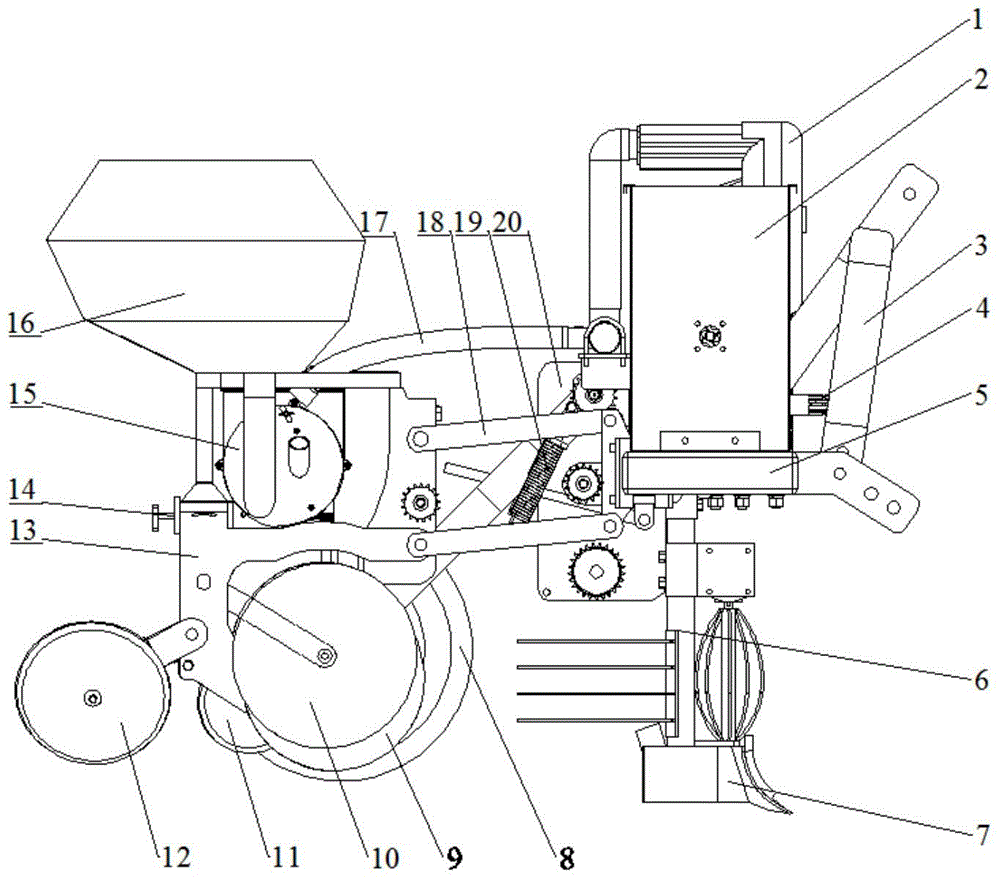

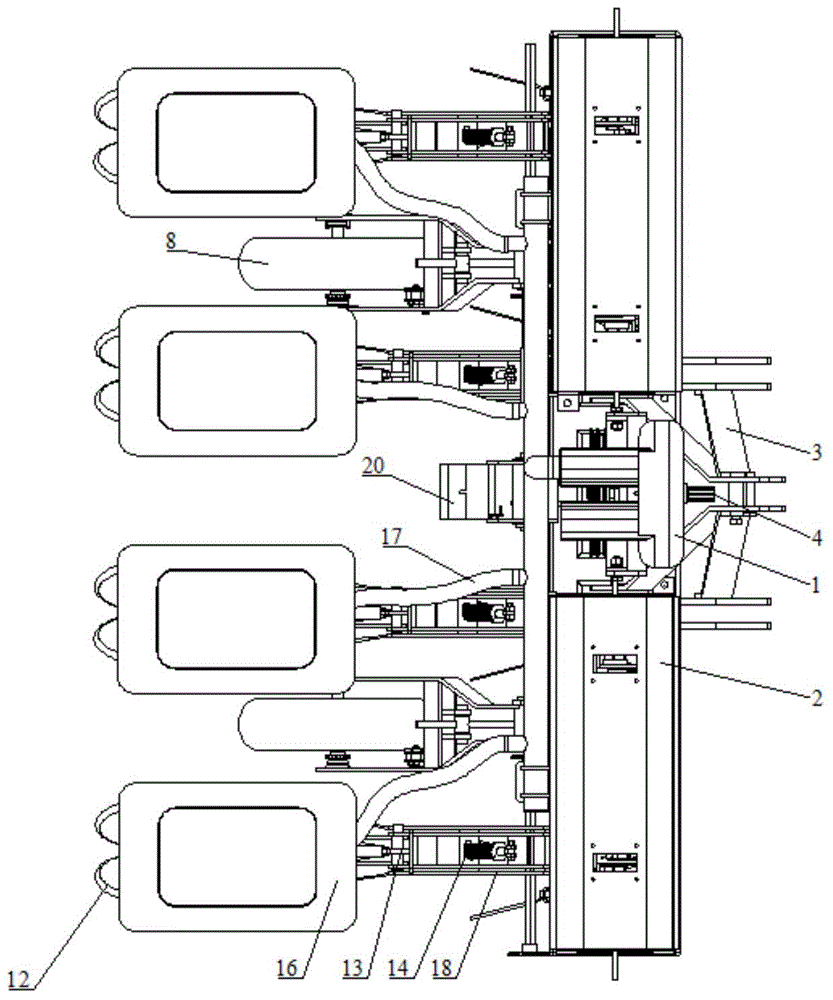

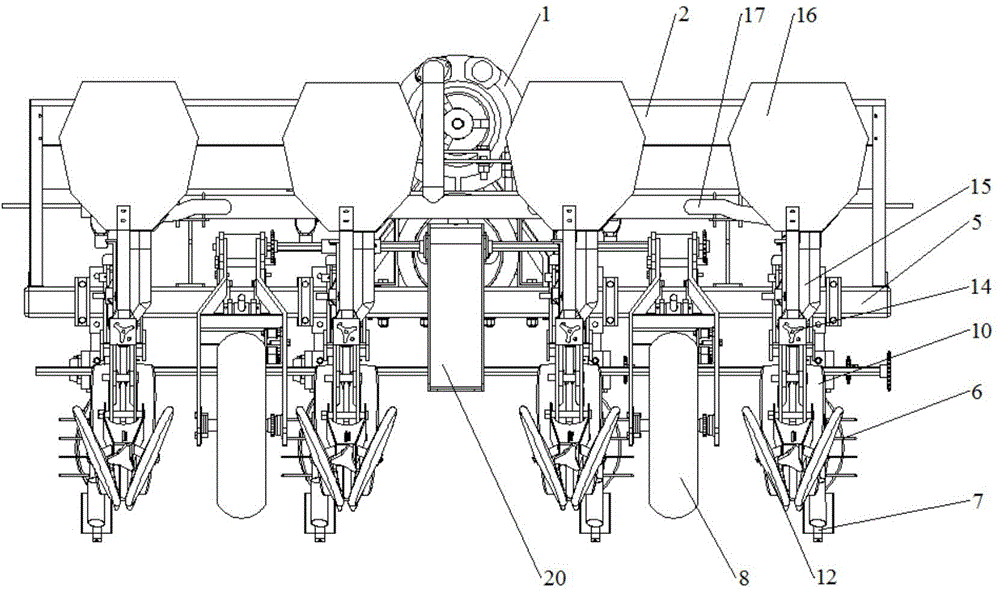

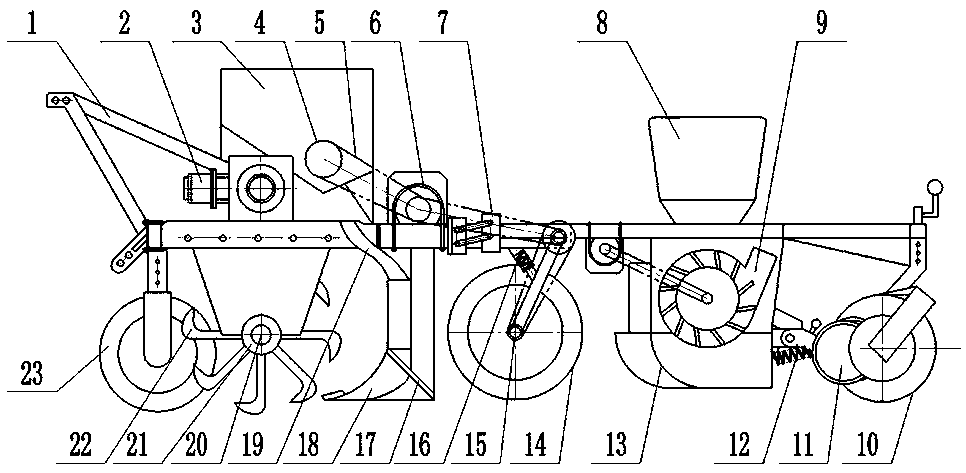

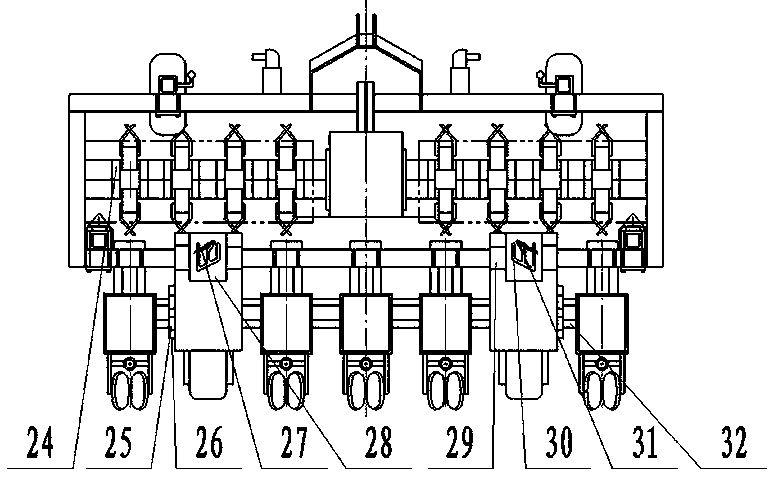

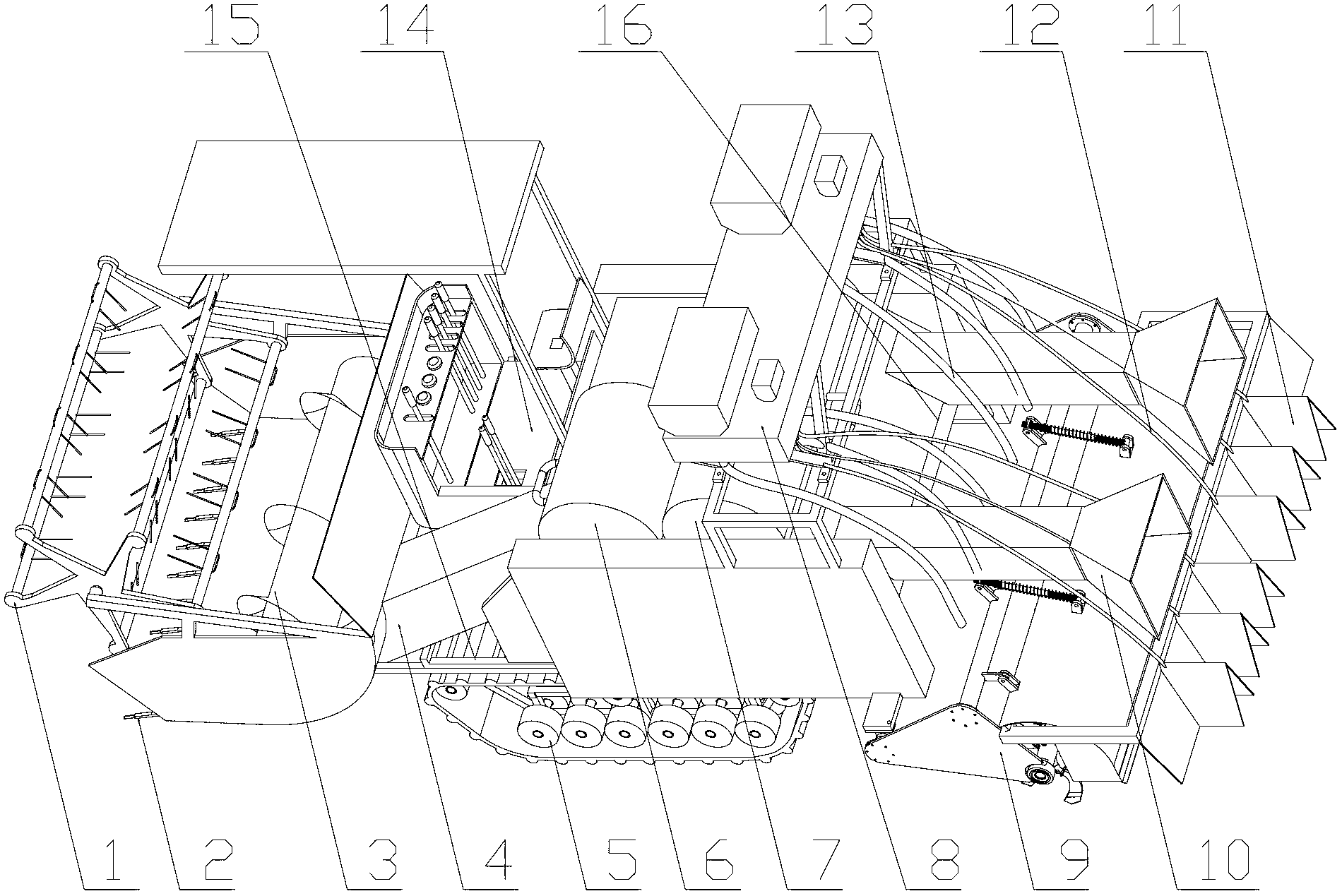

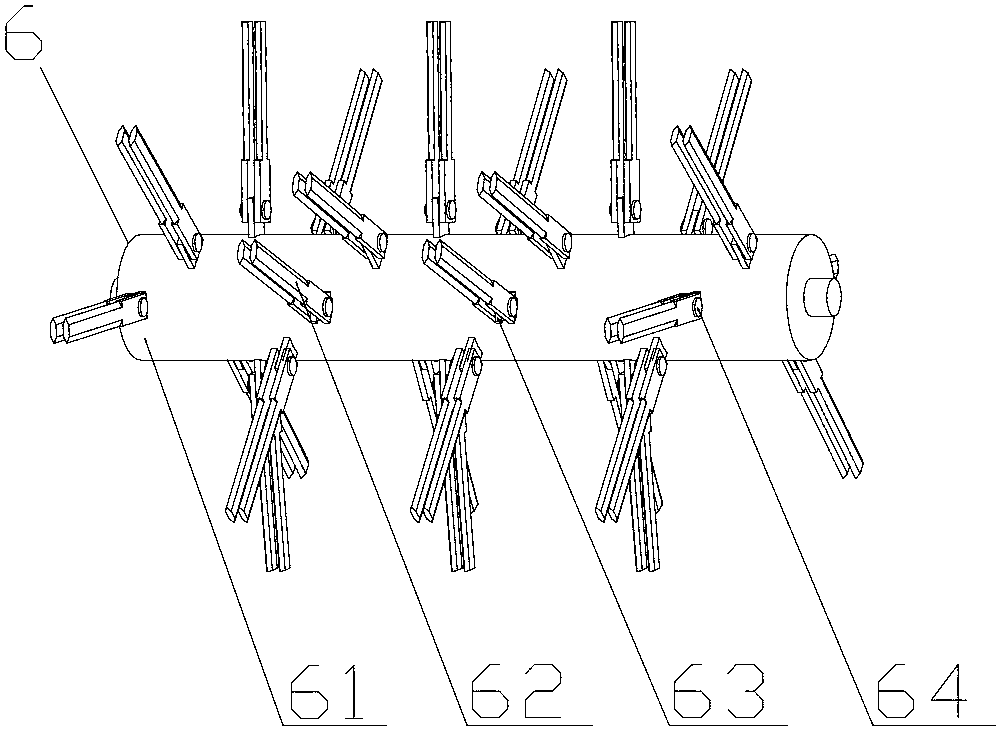

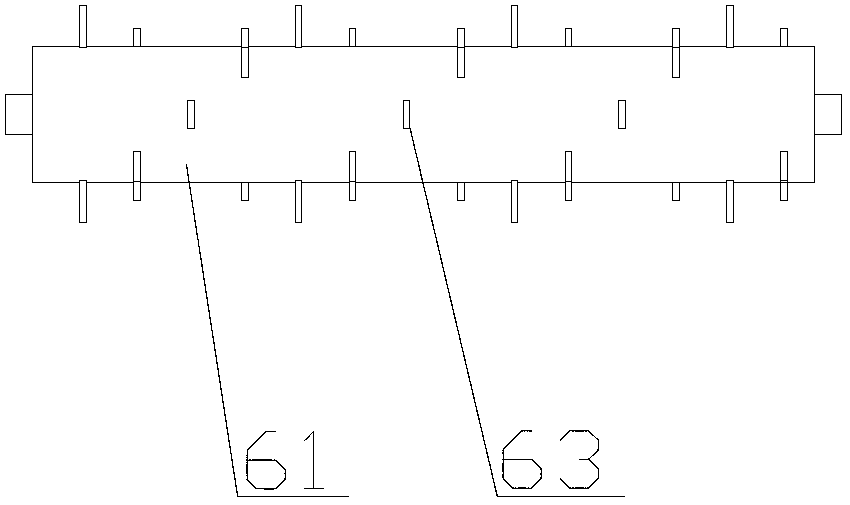

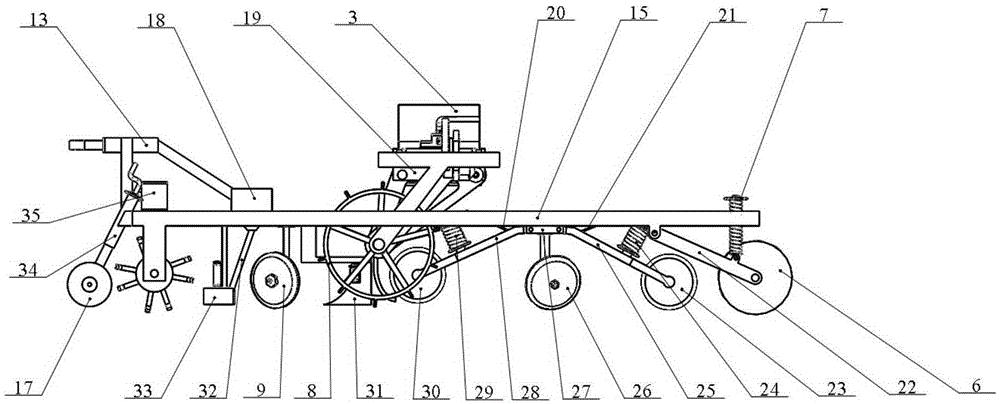

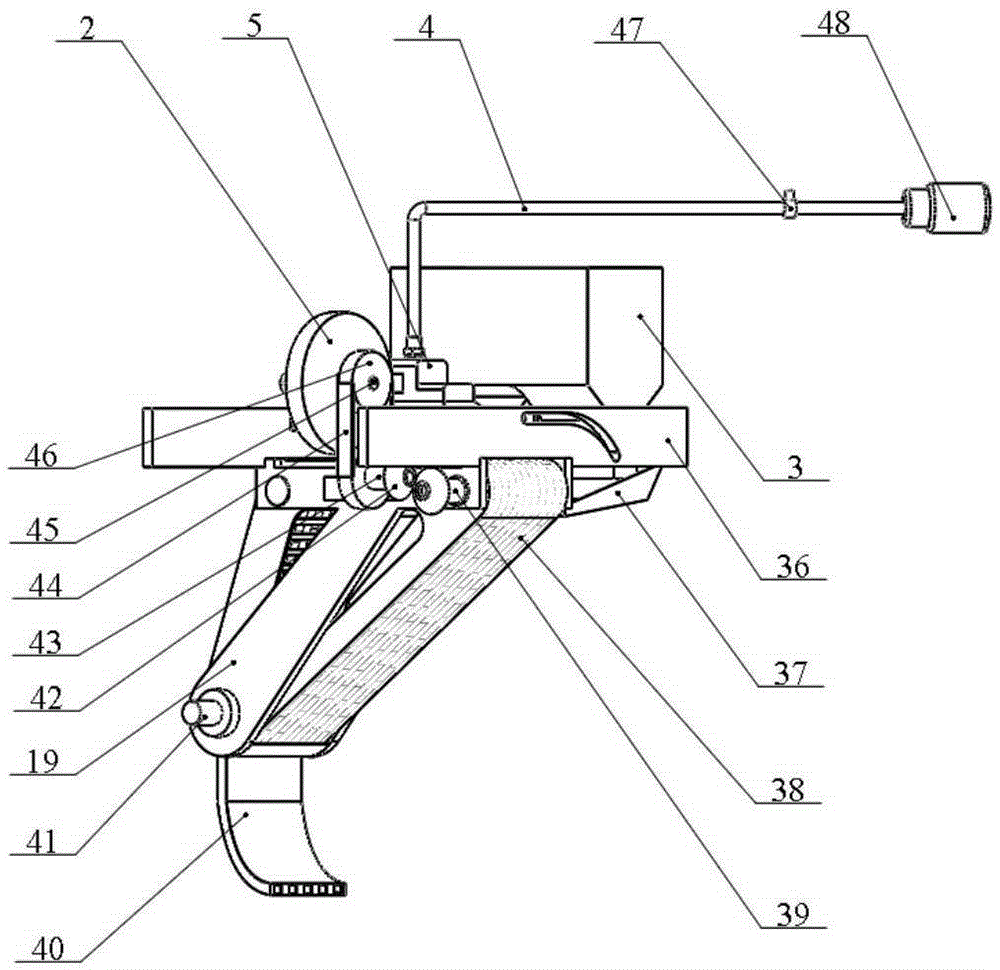

Collocated-copying no-tillage and precision corn sowing machine

InactiveCN104081917AIncrease productionImprove work efficiencyFertiliser and seeding apparatusAgricultural engineeringSeedling

The invention relates to the technical field of agricultural sowing equipment, in particular relates to a collocated-copying no-tillage and precision corn sowing machine, and aims to provide the collocated-copying no-tillage precision corn sowing machine which can precisely control the corn sowing depth and adjust the corn sowing depth in real time. The collocated-copying no-tillage precision corn sowing machine is high in passing property and compact in structure, and is suitable for no-tillage sowing of corns in the Huang-Huai-Hai area. The collocated-copying no-tillage precision corn sowing machine can implement the combined work of clearing of wheat straws, no-tillage ditching and fertilizer application, precision no-tillage sowing, earth covering and pressing in one-step work, so that the working efficiency is greatly improved; meanwhile, the sowing depth stability can be precisely guaranteed, and the sowing depth can be effectively adjusted in real time; therefore, the collocated-copying no-tillage precision corn sowing machine can meet requirements on the sowing depth under different sowing environments; the consistency of seedlings is guaranteed, and the crop yield is increased; the collocated-copying no-tillage and precision corn sowing machine is high in sowing stability and can meet a requirement on high-speed sowing.

Owner:CHINA AGRI UNIV

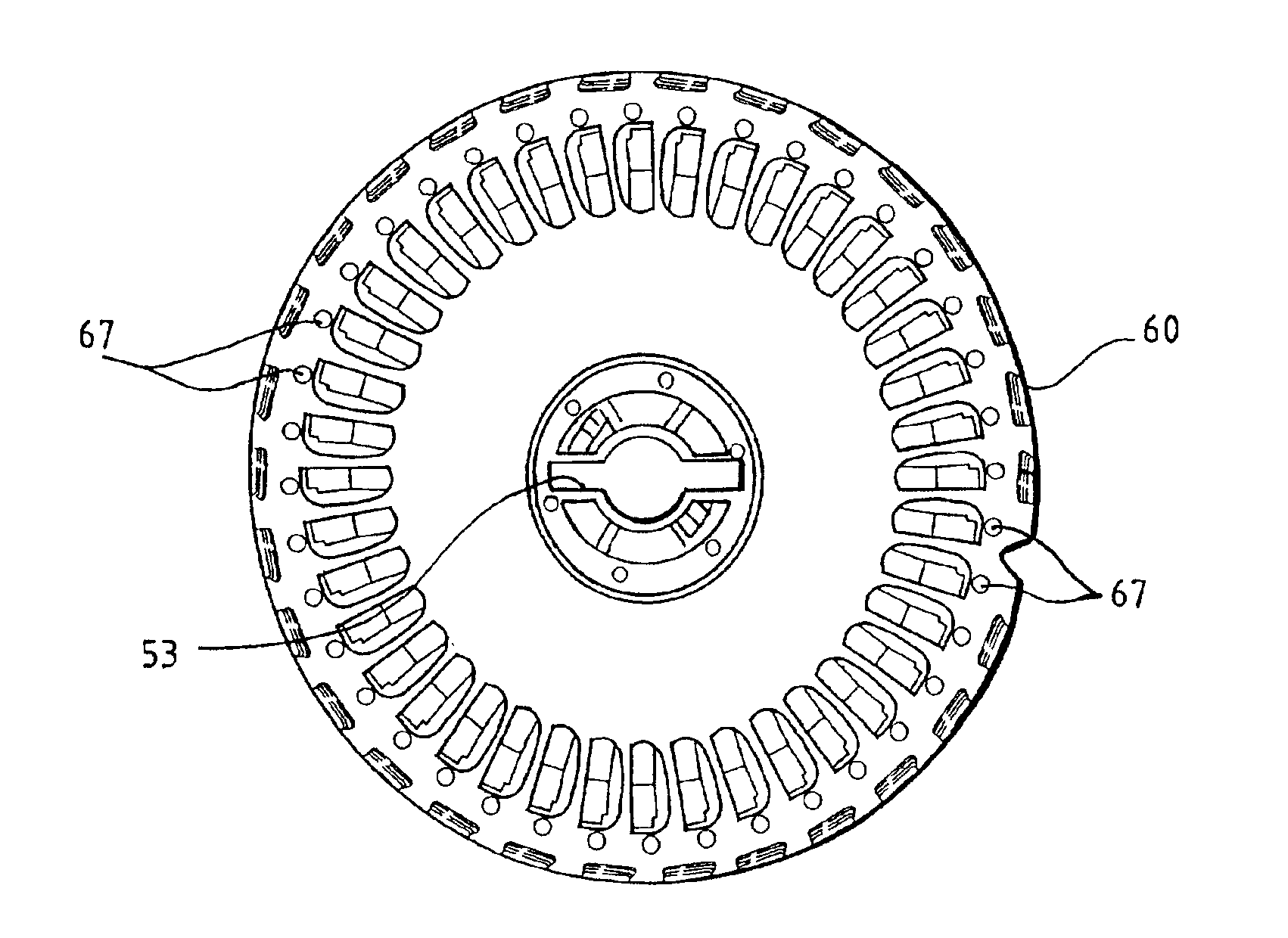

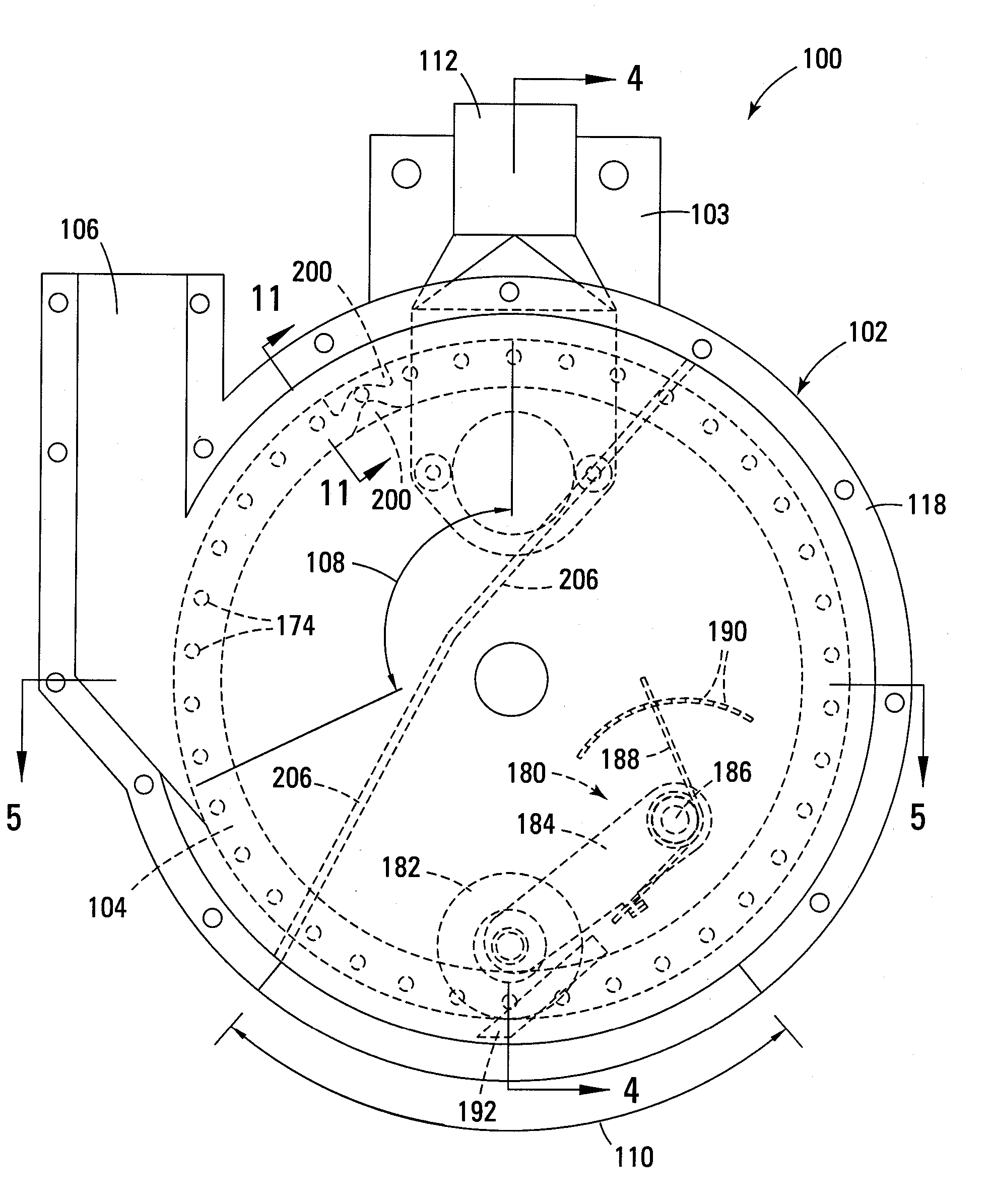

Vacuum seed meter and dispensing apparatus

InactiveUS20030116068A1Uniformity of seed placementEliminate needCoin-freed apparatus detailsFertilising methodsEngineeringSoil surface

Abstract of Disclosure An agricultural seed planter and seed meter therefore, wherein the seed meter includes a rotary vacuum drum disposed within a stationary housing to entrain individual seeds on an annular circumferential periphery of the drum. As the entrained seeds rotate with the drum the seeds are singulated before being released from said vacuum drum. The seed metering and dispensing device is adapted to be mounted below the seed hopper to discharge the seeds into a seed tube as is conventional, or alternatively the seed metering and dispensing device is preferably adapted for mounting just above the soil surface and between the furrow opening assembly and furrow closing wheel assembly of a conventional agricultural planter such that the seeds are deposited directly into the seed furrow.

Owner:PRECISION PLANTING LLC

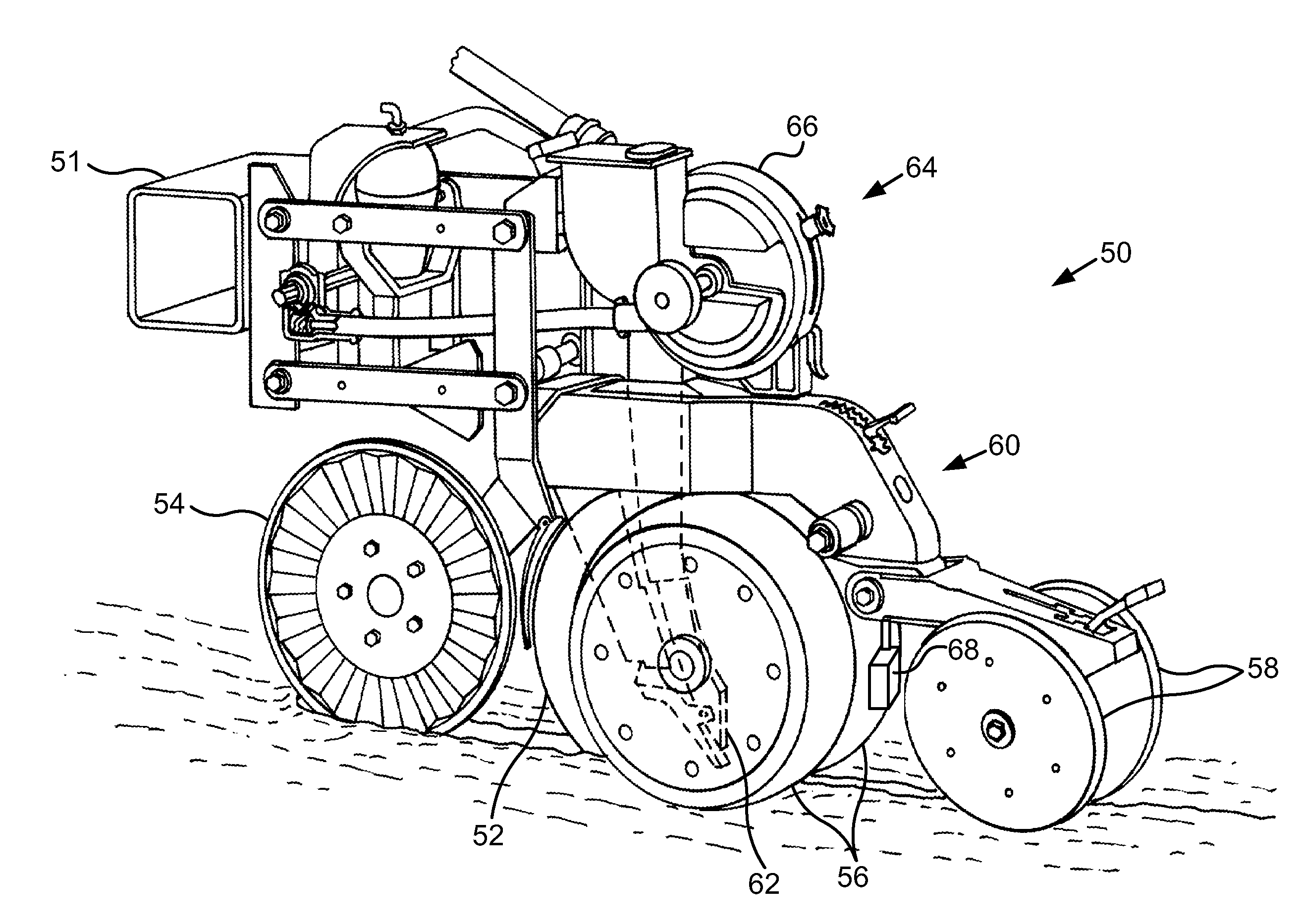

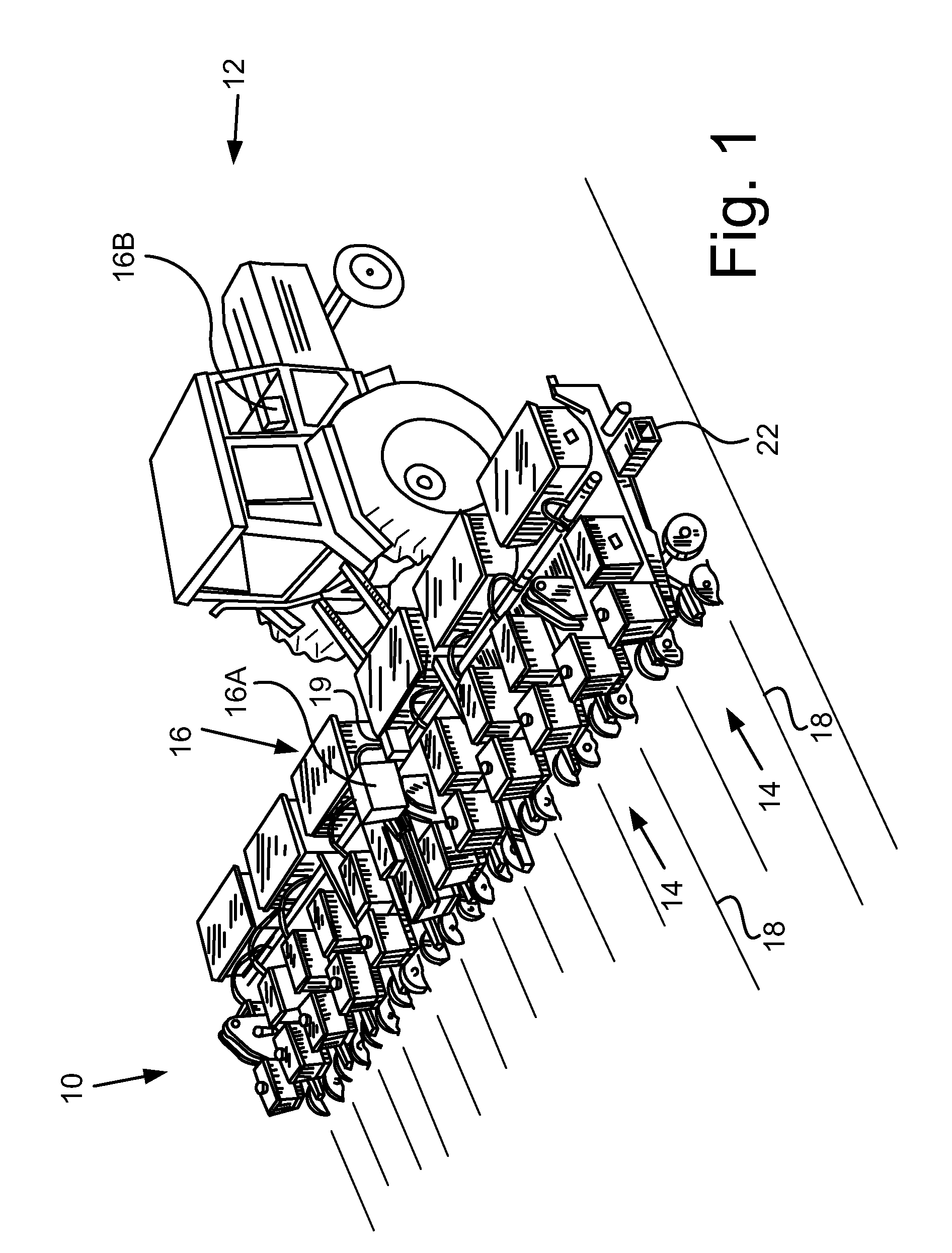

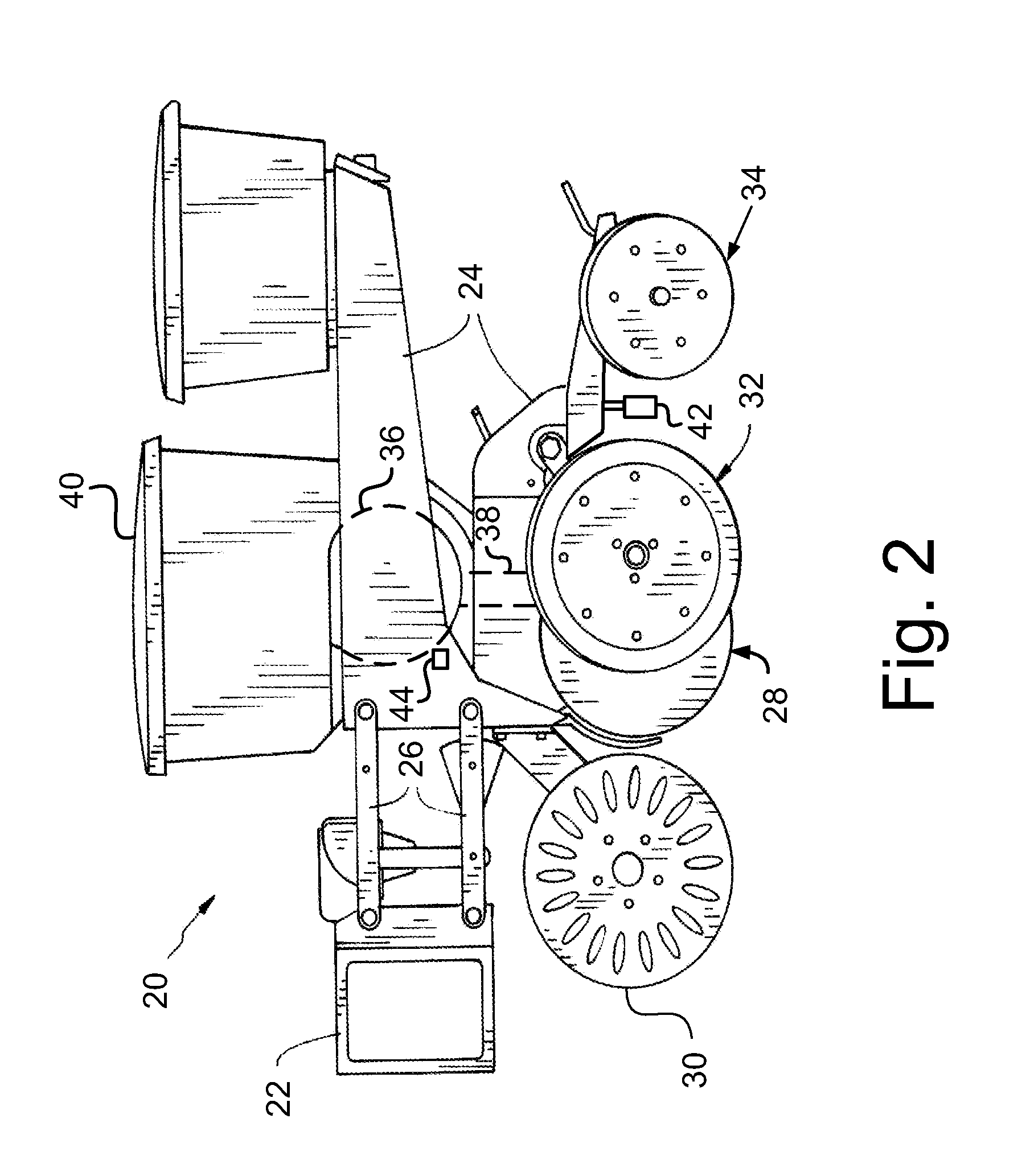

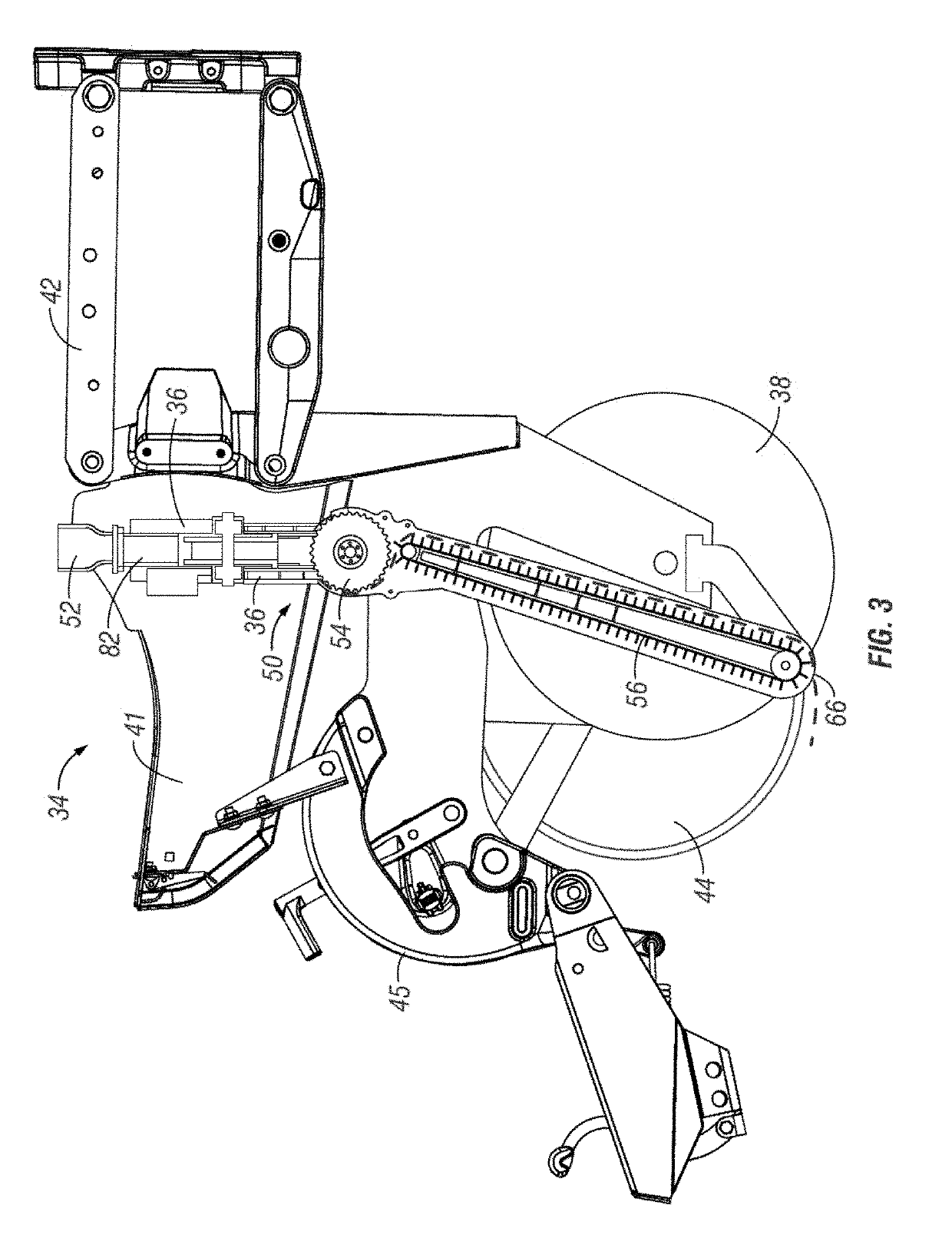

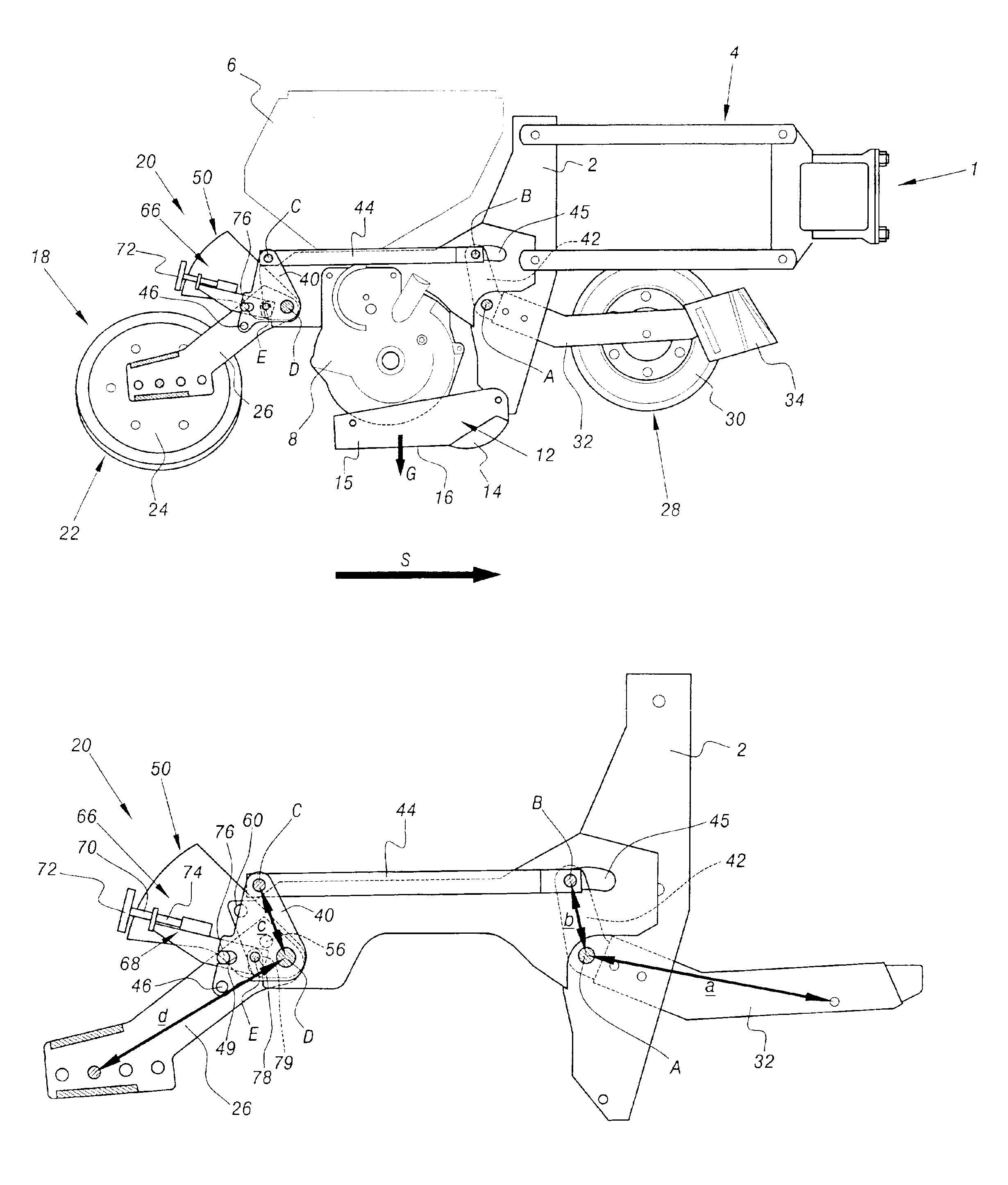

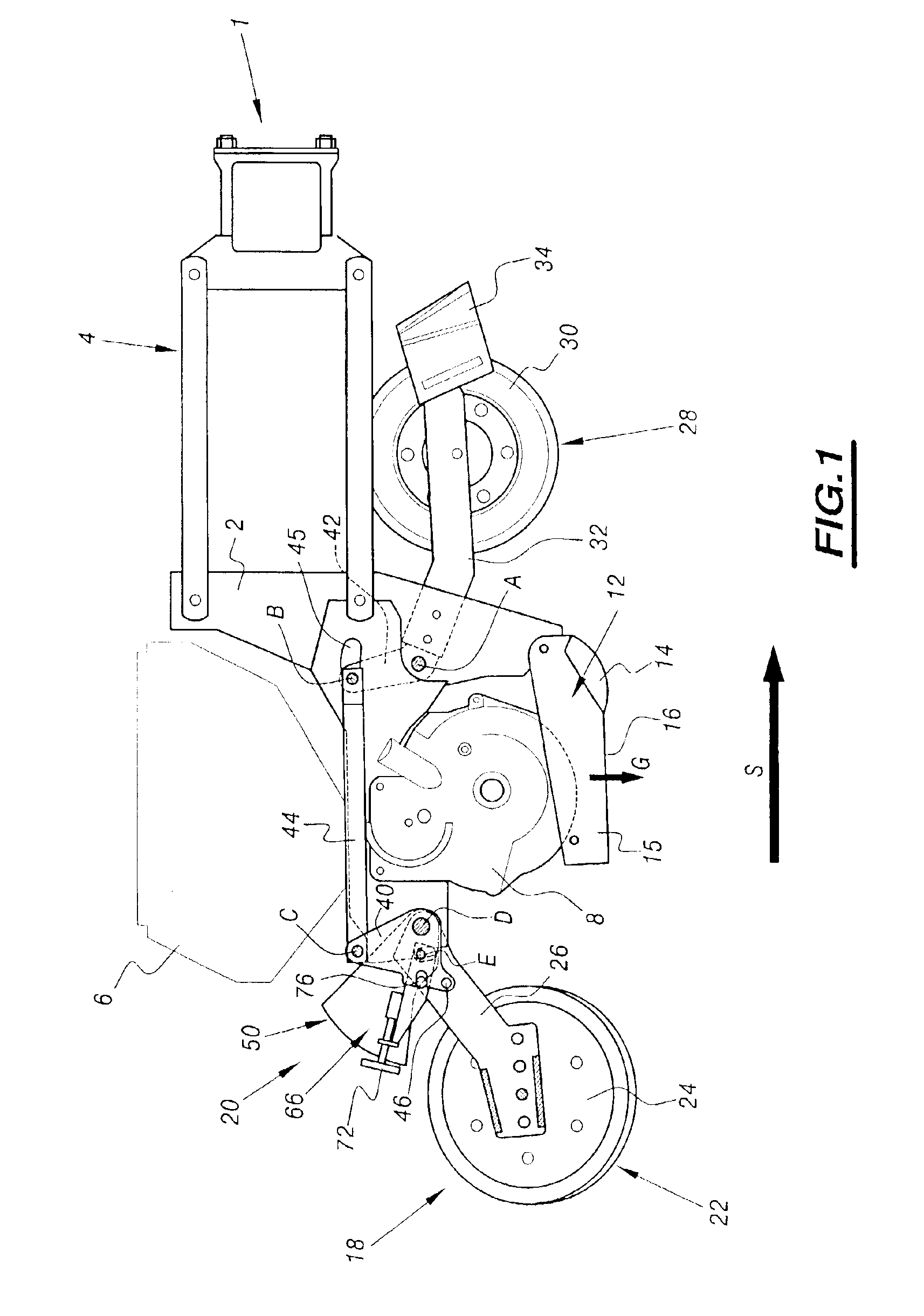

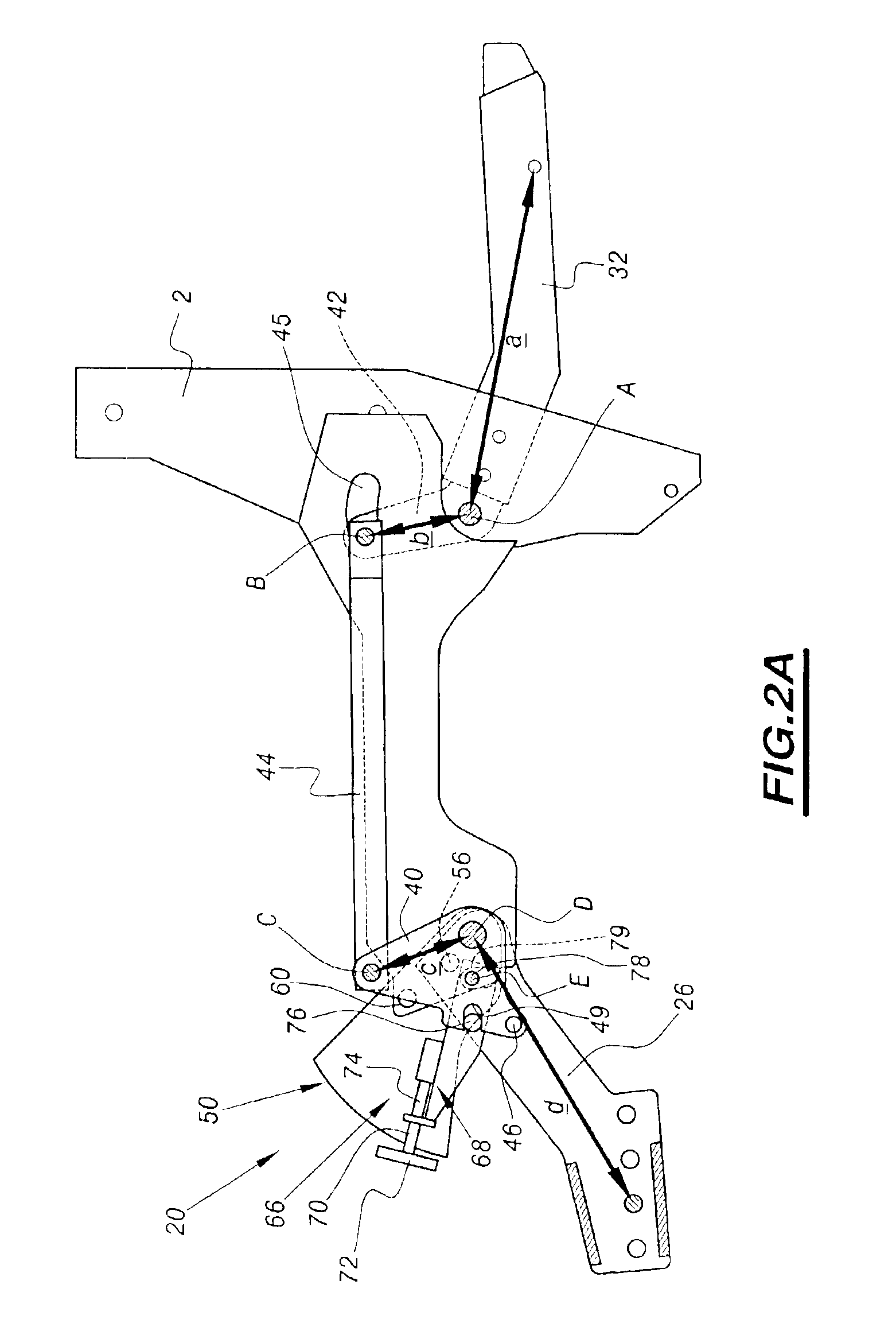

Seed drill with walking beam assembly

A no-till drill with a novel walking beam assembly that allows the drill to be pulled over severe terrain conditions that include large rocks, fallen limbs and other large obstructions. The inventive walking beam assembly includes two independent pivot points that allow the cutting and opening disks to maintain substantially constant or continuous contact with the ground, such that the length of the furrow formed and seed deposited therein are maximized. A closing disk assembly is suspended from the rear of the drill independently from the walking beam assembly. This independent suspension allows the walking beam assembly to function without interference from the closing disks.

Owner:KASCO MFG

Potato Planter Improvement to Reduce Skips and Rolling

InactiveUS20060283363A1Same dynamic changeSlow velocityPotato plantersFurrow making/coveringEngineeringSolanum tuberosum

An improved cup-style potato planter that corrects seed “skips.” Cups on a continuous belt conveyor sometimes fail to pick up potato seeds from a bin, or the seeds drop from the cup due to vibration. The design disclosed here puts replacement seeds in empty cups before the conveyor reaches a point in conveyor travel where the seed is supposed to be dropped into the ground.

Owner:WOLLMAN ALBERT E +1

System and method for spraying seeds dispensed from a twin row planter

ActiveUS20160073576A1Liquid fertiliser regulation systemsFertilising methodsEngineeringControl valves

A system for providing seed-specific placement of fluid as seeds are planted by a twin row planter includes a planter row unit, at least one nozzle assembly, and a controller. The planter row unit includes a first seed meter configured to dispense seeds into a first furrow at a seed frequency and a second seed meter configured to dispense seeds into a second furrow at the seed frequency. The nozzle assembly is configured to spray the seeds dispensed into the first and second furrows, and includes a valve. The controller is communicatively coupled to the valve, and is configured to determine the seed frequency of the first and second seed meters based on a speed-related parameter of the planter. The controller is further configured to control operation of the valve based on the seed frequency such that fluid is sprayed at least one of on or adjacent to each seed.

Owner:CAPSTAN

Corn-soybean strip-shaped compound planting no-tillage fertilization precision seeder

The invention discloses a corn-soybean strip-shaped compound planting no-tillage fertilization precision seeder and belongs to the technical field of farm machines. The machine includes a suspension machine frame, a rotary tillage system, a power transmission system, a fertilization and ditching system and a sowing and soil covering system. Through an installation mode that reverse-rotation rotarytillage and the inclined and forward arrangement of a drive land wheel is combined, blades thus can cut stubbles forward, the stubble cleaning and soil breaking effects are ensured, the drive wheel thus can always walk on the ground, the occurrence of seedling missing and ridge breaking is avoided, and the seeder has the advantages of being simple in structure, precise in sowing, uniform in quality and the like, Under various kinds of parameters, the plant distance is adjusted and changed, and the minimum plant distance can be adjusted to 6 cm, the application range is wider, and smooth implementation of a high-yield close-planting mode is ensured. The seeder has high adaptability to crops, and is suitable for simultaneous sowing operation of corn, soybeans and other seeds with the shapesimilar to the shape of core or soybeans.

Owner:SICHUAN AGRI UNIV

Multifunctional direct seed sowing machine for coating grass on rape

ActiveCN103299734ATo achieve moisture conservationAchieve heat preservationSpadesCrop conditionersVehicle frameAgricultural engineering

The invention discloses a multifunctional direct seed sowing machine for coating grass on rape. The multifunctional direct seed sowing machine comprises a walking system, a vehicle frame, a towing bracket, a sowing and fertilizing system, and a rotary tillage ditching system, wherein the vehicle frame is arranged on the walking system; the towing bracket is connected with the vehicle frame and arranged behind the walking system; a horizontal header, a straw chopping and conveying system and a throwing about mechanism, which are connected with each other in sequence, are arranged on the vehicle frame from front to back; the rotary tillage ditching system is arranged on the towing bracket below the throwing about mechanism; the sowing and fertilizing system is arranged on the vehicle frame; and the sowing ports and the fertilizing ports of the sowing and fertilizing system are arranged before and behind shallow winter breaking and ditching formed ridges respectively. According to the multifunctional direct seed sowing machine, six processes such as shallow ploughing, stubble cleaning, sowing, fertilizing, ridge forming ditching, and grass coating between sowed rows can be fulfilled simultaneously, so as to effectively solve the problems of complex processes, low efficiency, and grass winding and mud hilling on soil operation components, greatly improve the working performance, efficiently realize soil moisture conservation and heat insulation on rape ridges due to secondary utilization of former plant stubble, and improve the operation quality of sowing.

Owner:HUNAN AGRICULTURAL UNIV

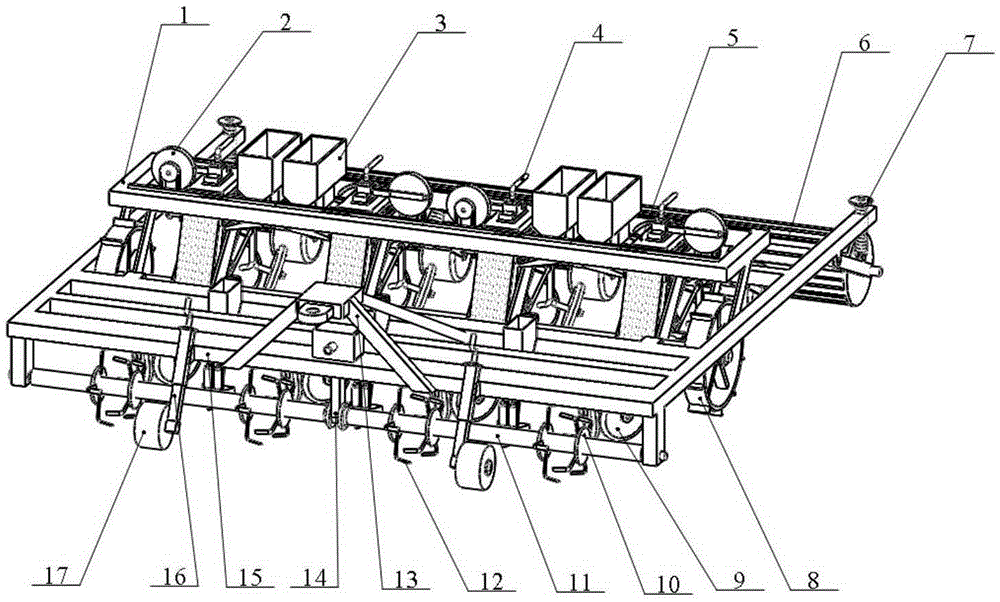

Wide-seedling-strip wheat precision planter achieving both minimal tillage and fertilizer and work method thereof

InactiveCN105247998AUniform distribution densityPromote growth and developmentSpadesTilling equipmentsDrive shaftAgricultural engineering

The invention relates to a wide-seedling-strip wheat precision planter achieving both minimal tillage and fertilizer and a work method thereof. The wide-seedling-strip wheat precision planter comprises a rack, a traction beam, seed discharging devices, rotary cultivators, openers, fertilizer applying mechanisms, pressing mechanisms, earthing mechanisms, compacting mechanisms, soil flattening mechanisms, ground wheels, seed boxes and seed discs. The seed discharging devices are mounted at the position, behind the traction beam, of the rack. The traction beam is fixedly mounted at the front end of the rack. The earthing mechanisms are mounted below the position, behind pressing wheels, of a connecting frame. Soil flattening wheels are mounted at the rearmost end of the rack. The ground wheels are mounted on the two sides of a rack of the seed discharging devices and connected with a driving shaft. An air suction device is adopted for seed taking and falling, the seed hole conveying belt seed discharging devices are used for wide-seedling-strip precision seed discharging, the whole seed taking and arranging process is controllable, meanwhile, a series of functions of seedling strip rotary tillage, ditching, fertilizer applying, pressing, earthing, compacting, soil flattening and the like are achieved, the workload of sowing wheat is reduced, and the precision and work efficiency of wheat sowing are improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com