Patents

Literature

56results about How to "Uniform distribution density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

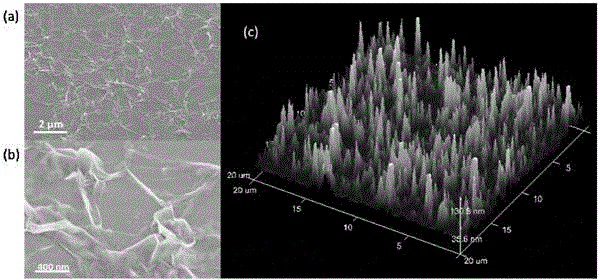

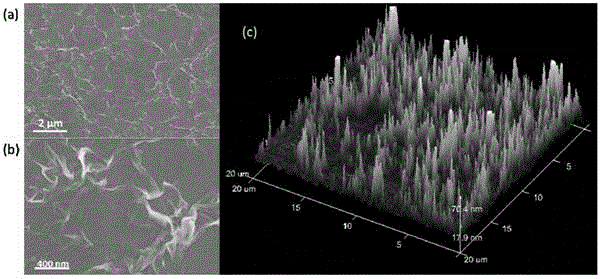

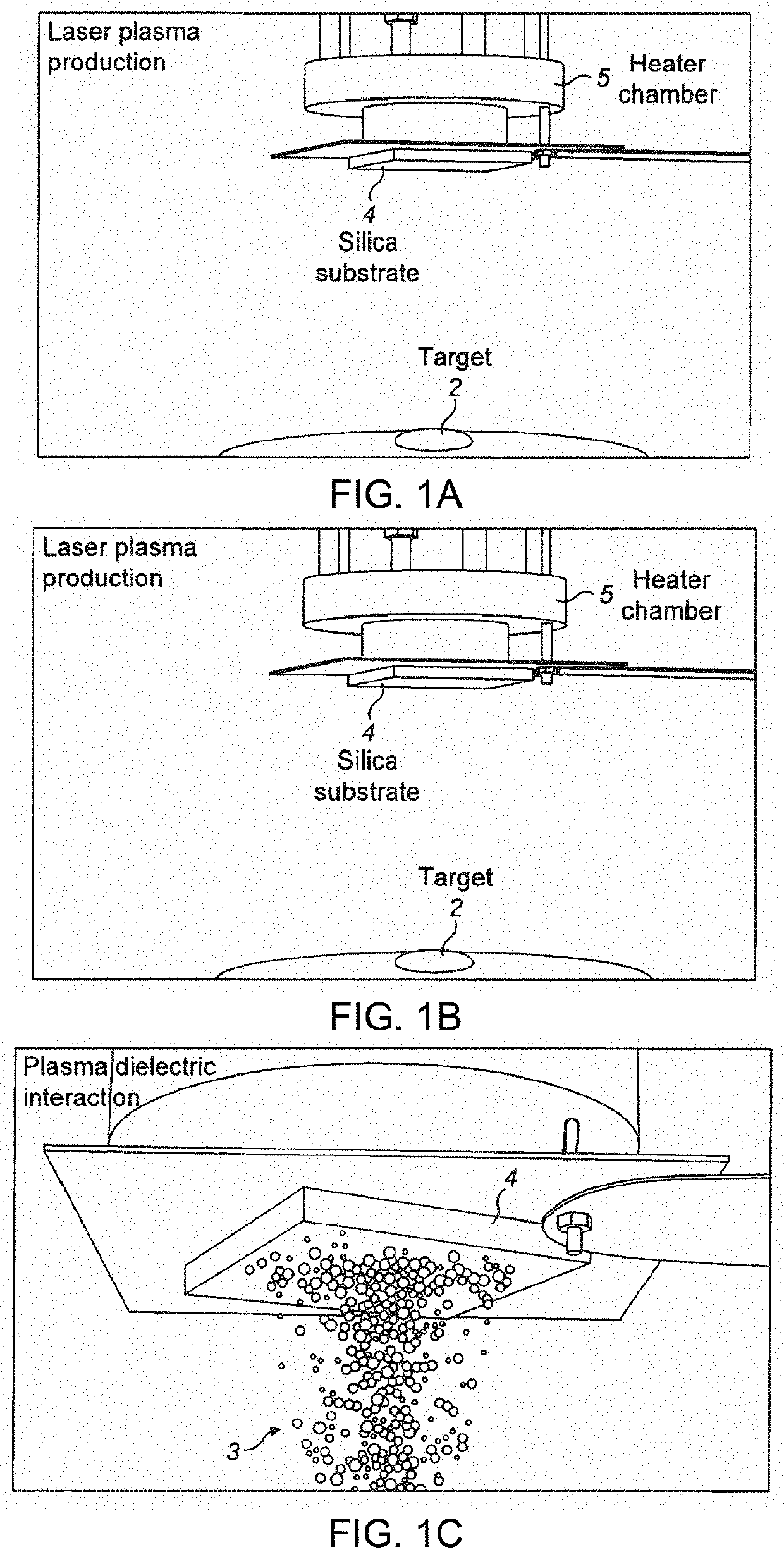

Folded graphene and controllable preparation method thereof

The invention discloses graphene with a folded structure. The structure of the graphene is formed by shrinking the graphene in a liquid phase environment to form ups and downs on the surface, wherein the folded parts are cone-shaped, and the height, width and distribution density of the folded parts are uniform and controllable. The folded parts can be formed in the processes of preparing the graphene and transferring the graphene to a target substrate, and are formed randomly and uncontrollably, but the folded structure formed controllably in a liquid phase, disclosed by the invention, can solve the problems. The invention realizes a novel graphene folded structure and provides a method for preparing the structure simply, conveniently and quickly on a large scale, and the graphene folded structure can be used in the fields of new energy resources, sensors, flexible electronic devices and the like.

Owner:SUN YAT SEN UNIV

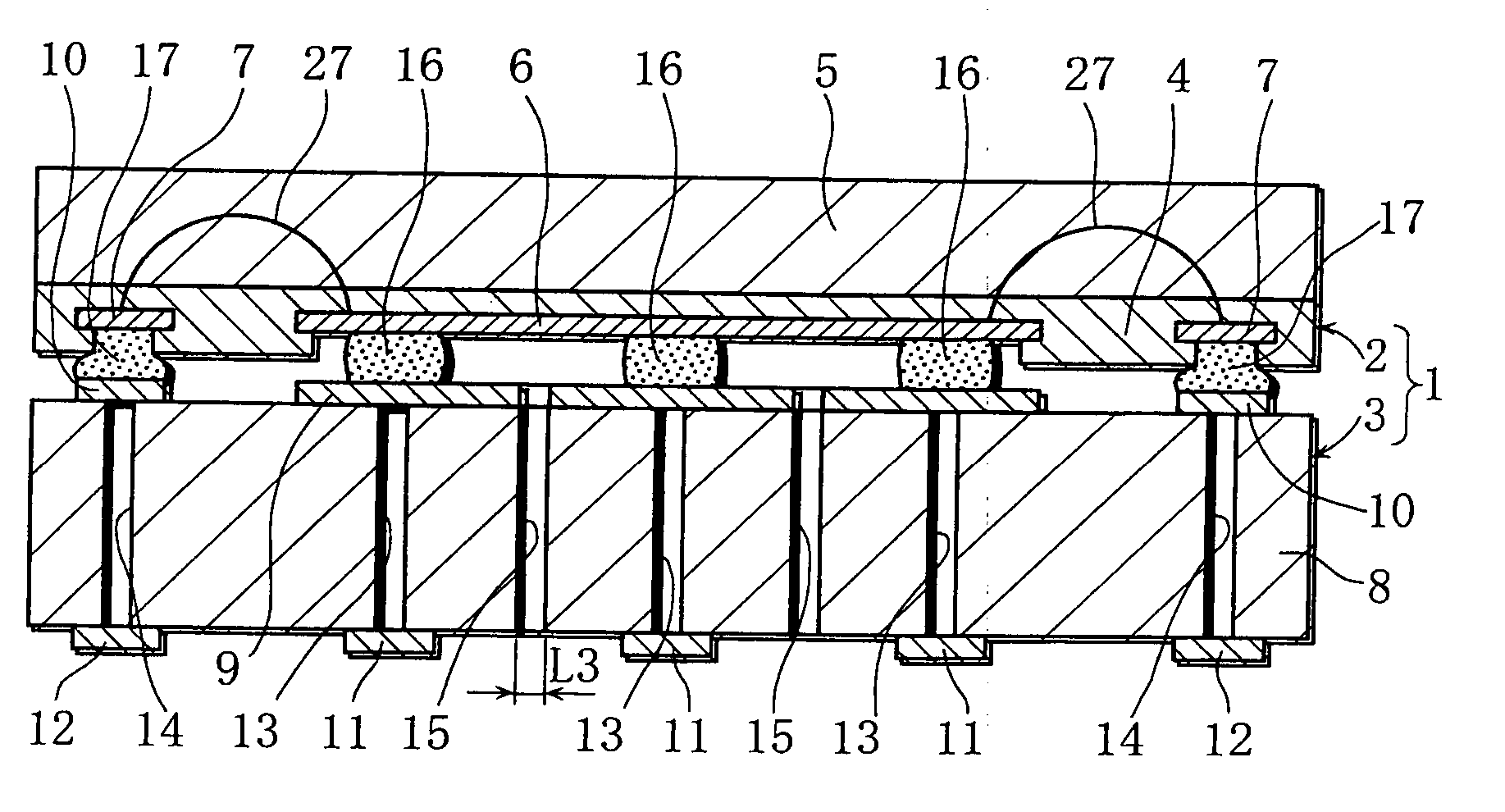

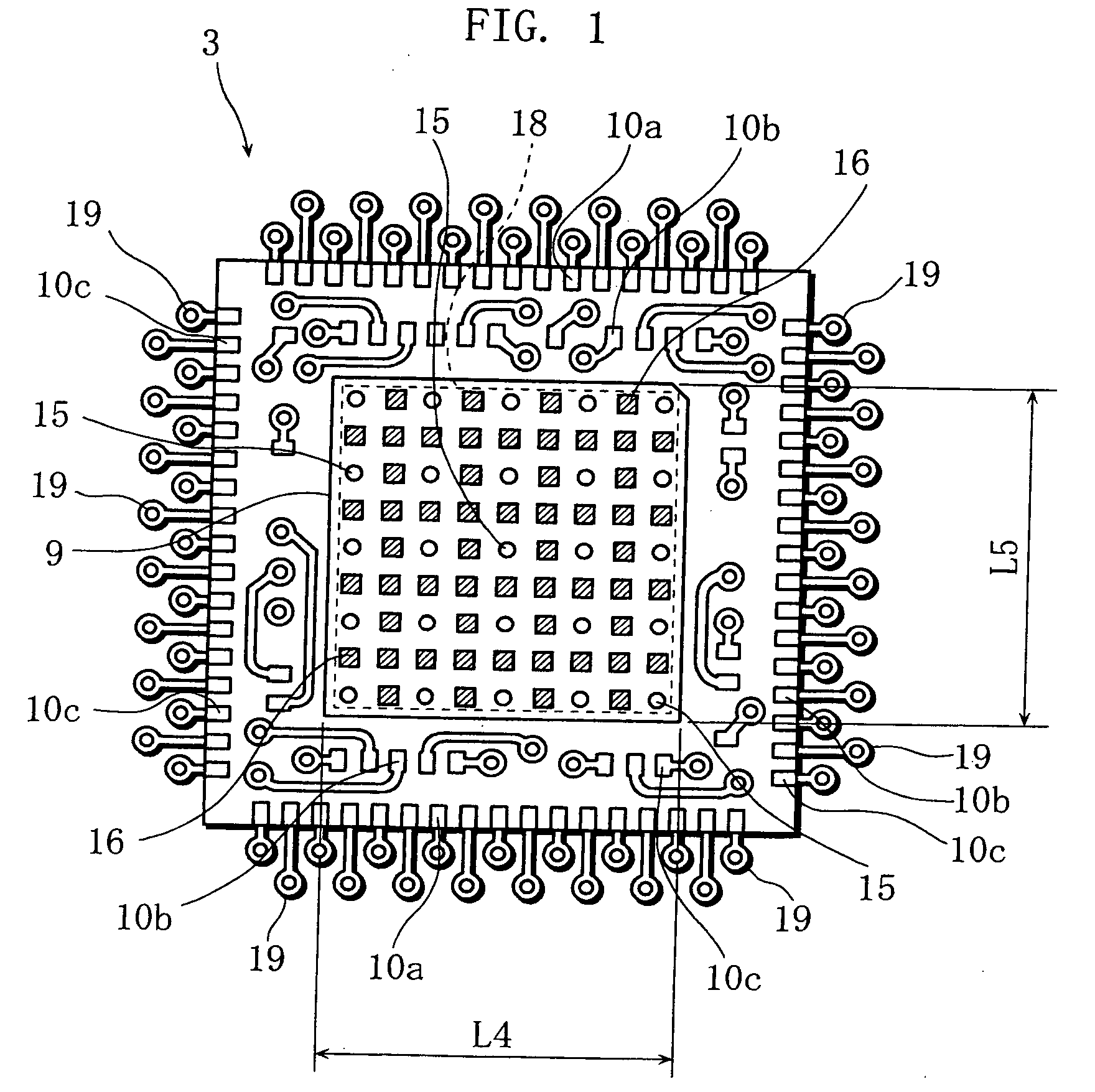

Land grid array package

InactiveUS20060186538A1Exhibit effectExhibit operationPrinted circuit assemblingFinal product manufactureEngineeringLand grid array

A land grid array package has a construction in which a device-side ground electrode 6 and a substrate-side ground electrode 9, as well as device-side peripheral electrodes 7 and substrate-side peripheral electrodes 10 are soldered by eutectic solder 16. The land grid array package is characterized in that one or more gas-vent through holes 15 passing through a package substrate 3 are formed within a soldering region 18 of the device-side ground electrode 6. Thus, a land grid array package that can prevent short circuits or disconnections is provided.

Owner:SANYO ELECTRIC CO LTD +1

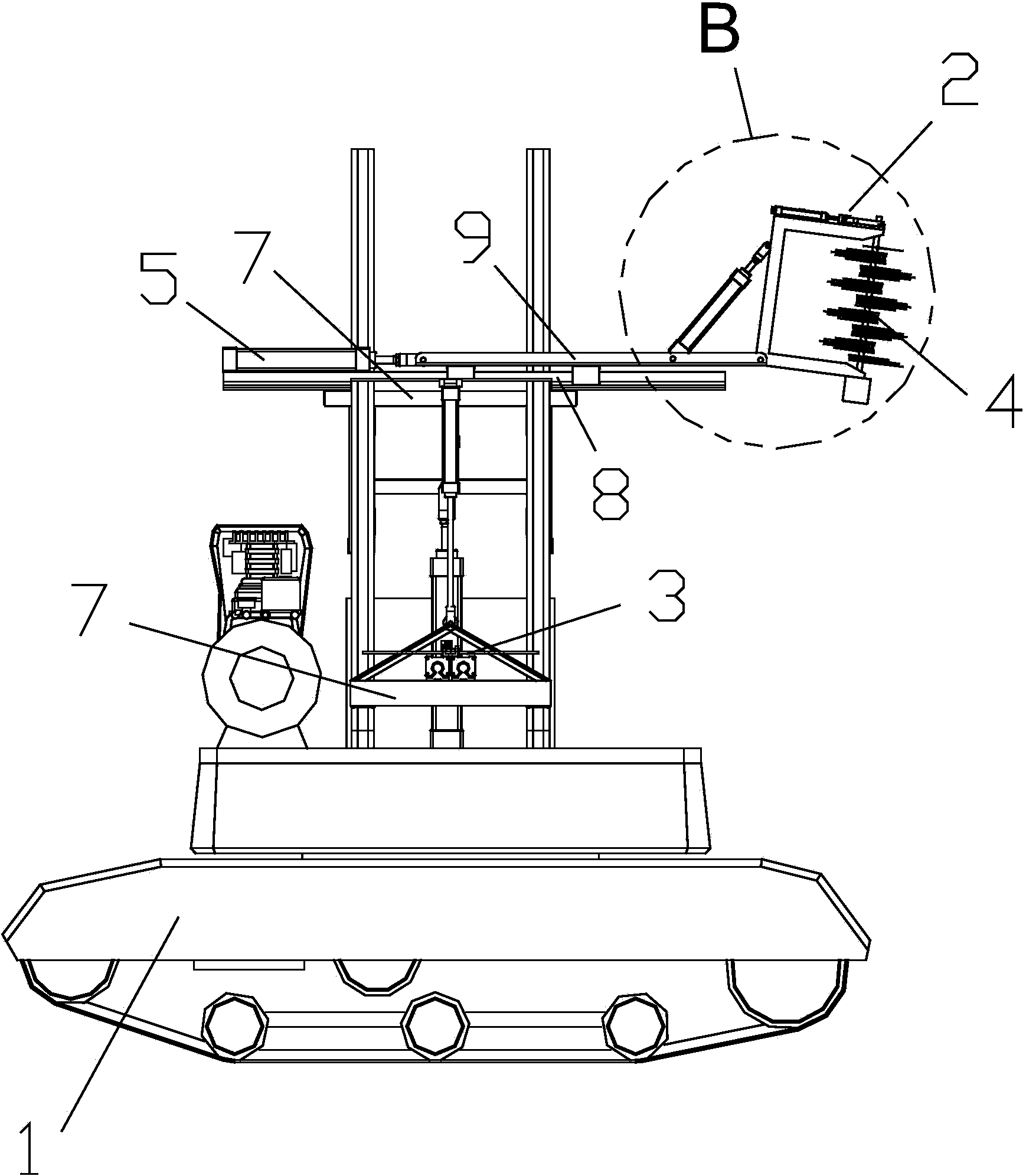

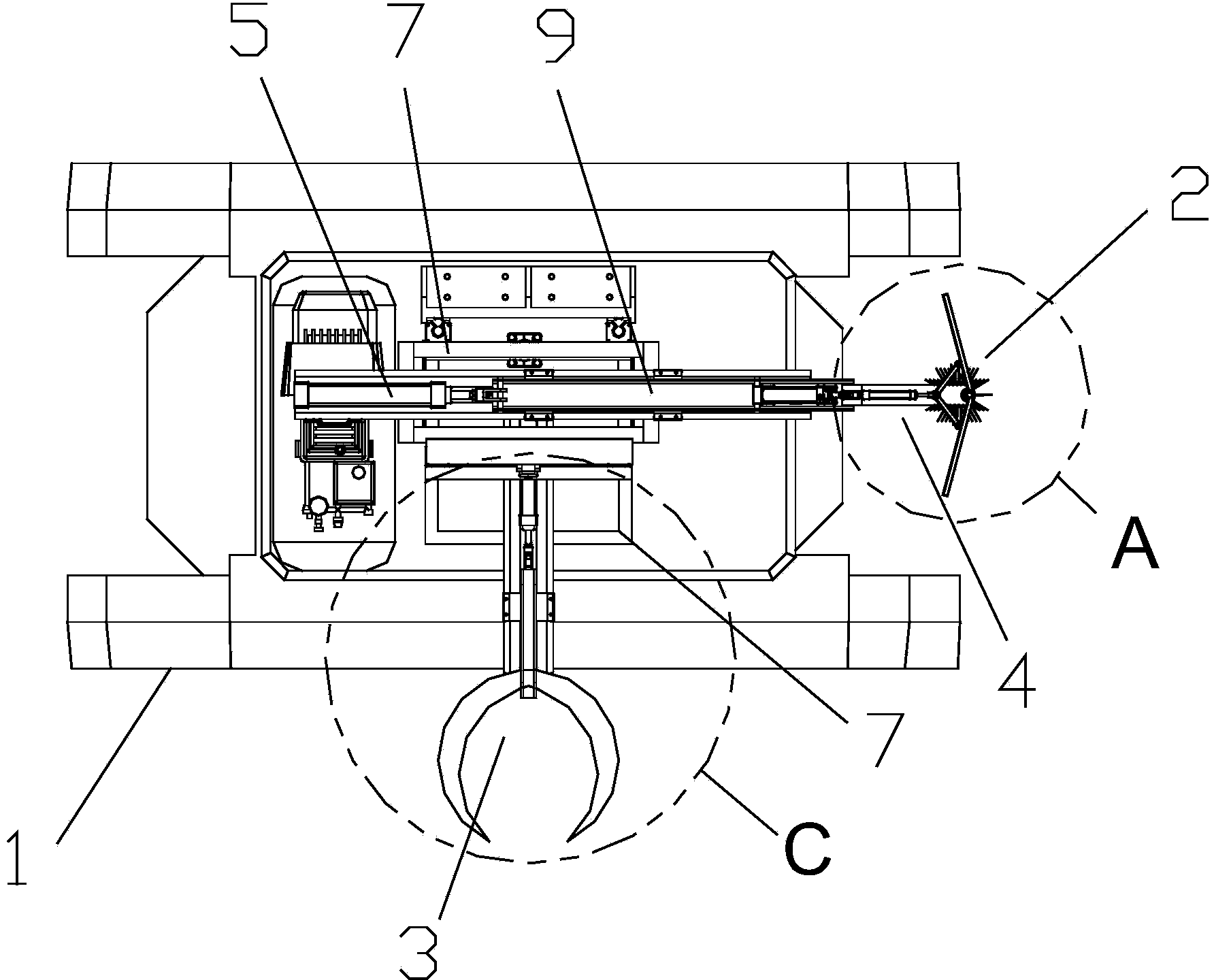

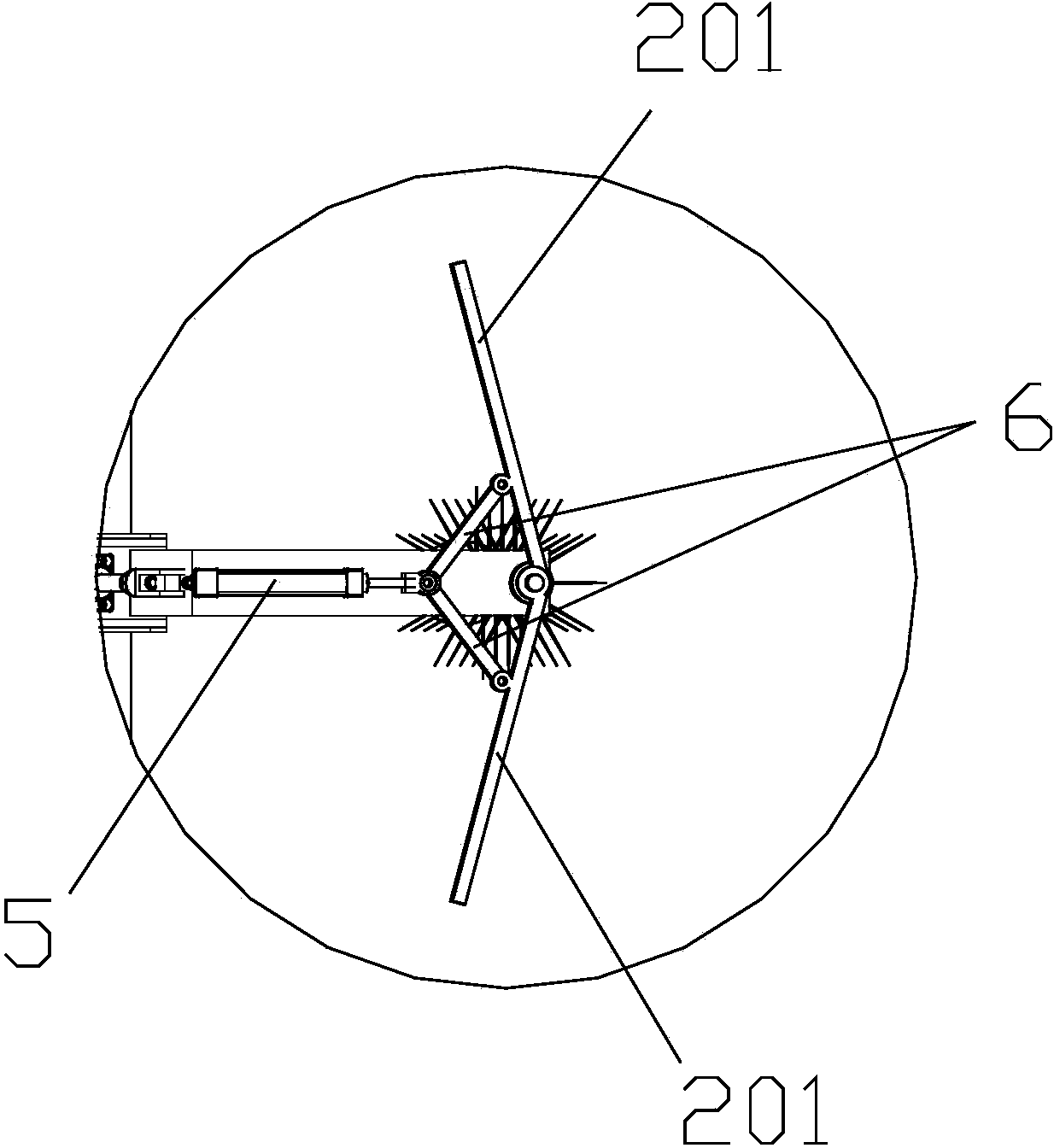

Multifunctional operation machine for orchard

ActiveCN103828785AVersatileRealize semi-automatic operationCultivating equipmentsHorticulture methodsFruit treeSemi automatic

A multifunctional operation machine for an orchard comprises a traveling mechanism, a pesticide spraying device, a whitening device and a flower thinning device. By using the multifunctional operation machine for the orchard, functions of pesticide spraying, whitening and flower thinning can be fulfilled in an integrated manner, semi-automatic operation of flower thinning, whitening and pesticide spraying on fruit trees in the orchard can be realized, flower thinning, whitening and pesticide spraying can be performed on the fruit trees by workers conveniently, the labor intensity of the workers is reduced, the production efficiency is improved, the single operation machine has a plurality of functions, the whole purchasing cost of equipment is reduced, and the output-input ratio is low.

Owner:QINGDAO AGRI UNIV

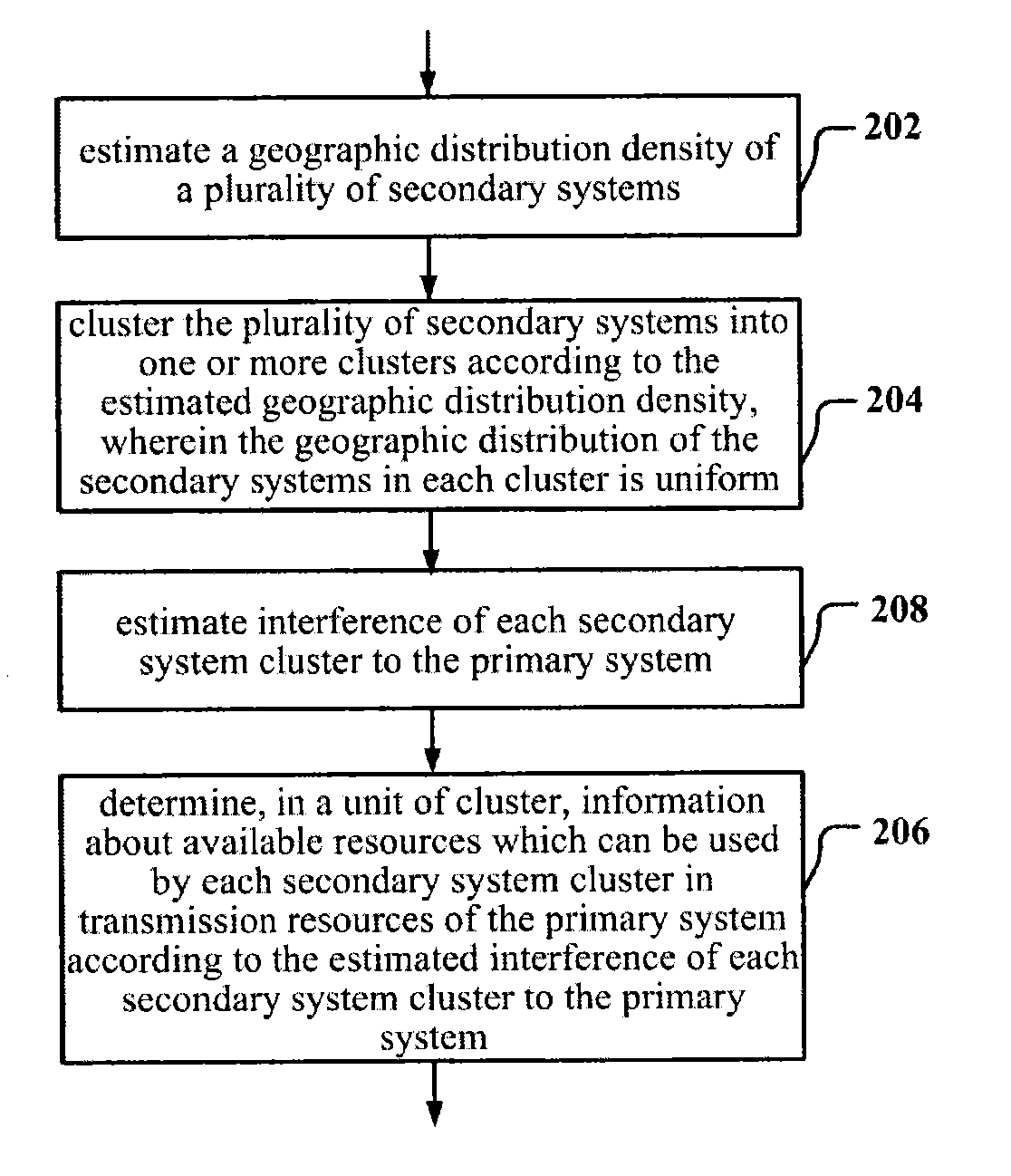

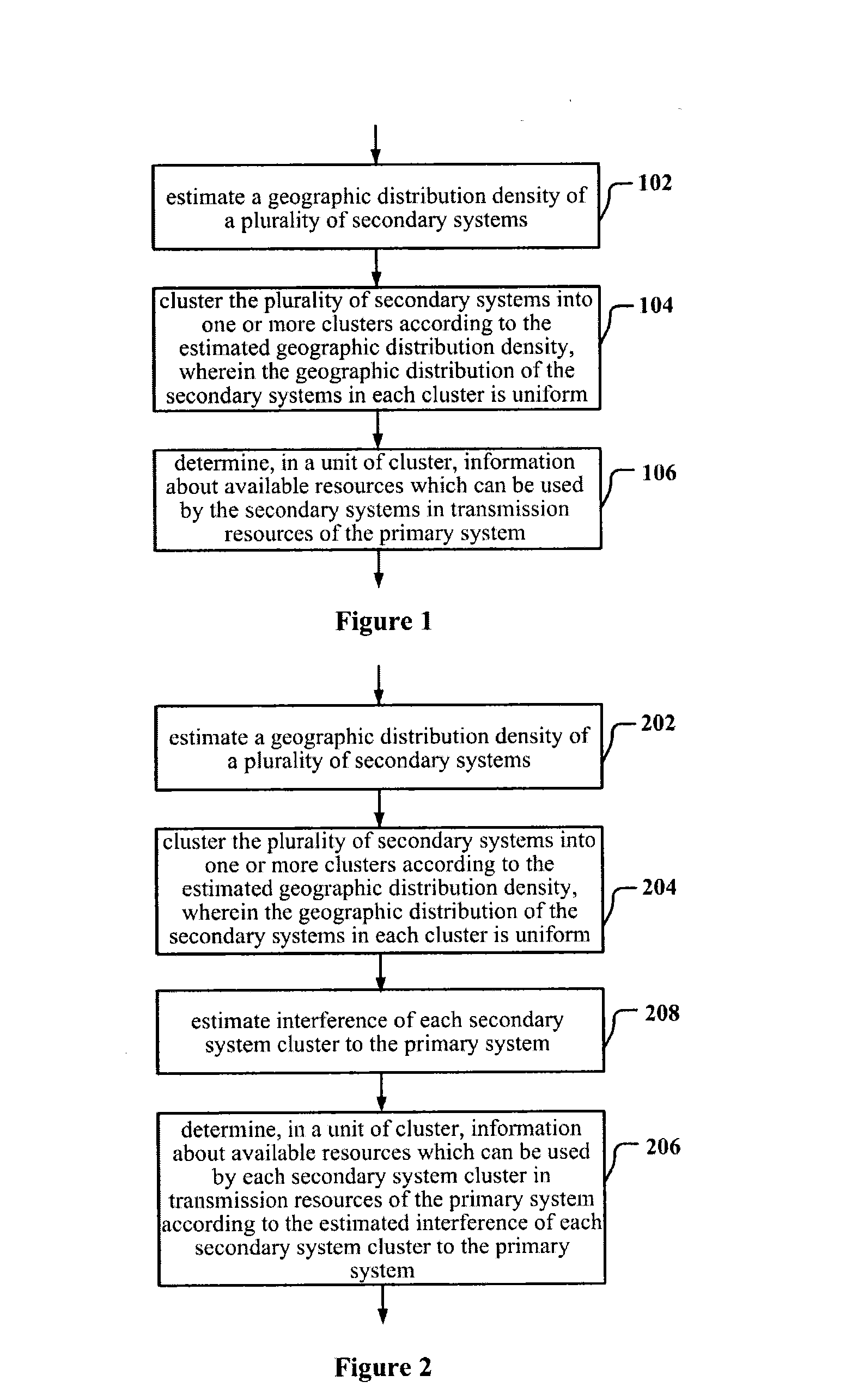

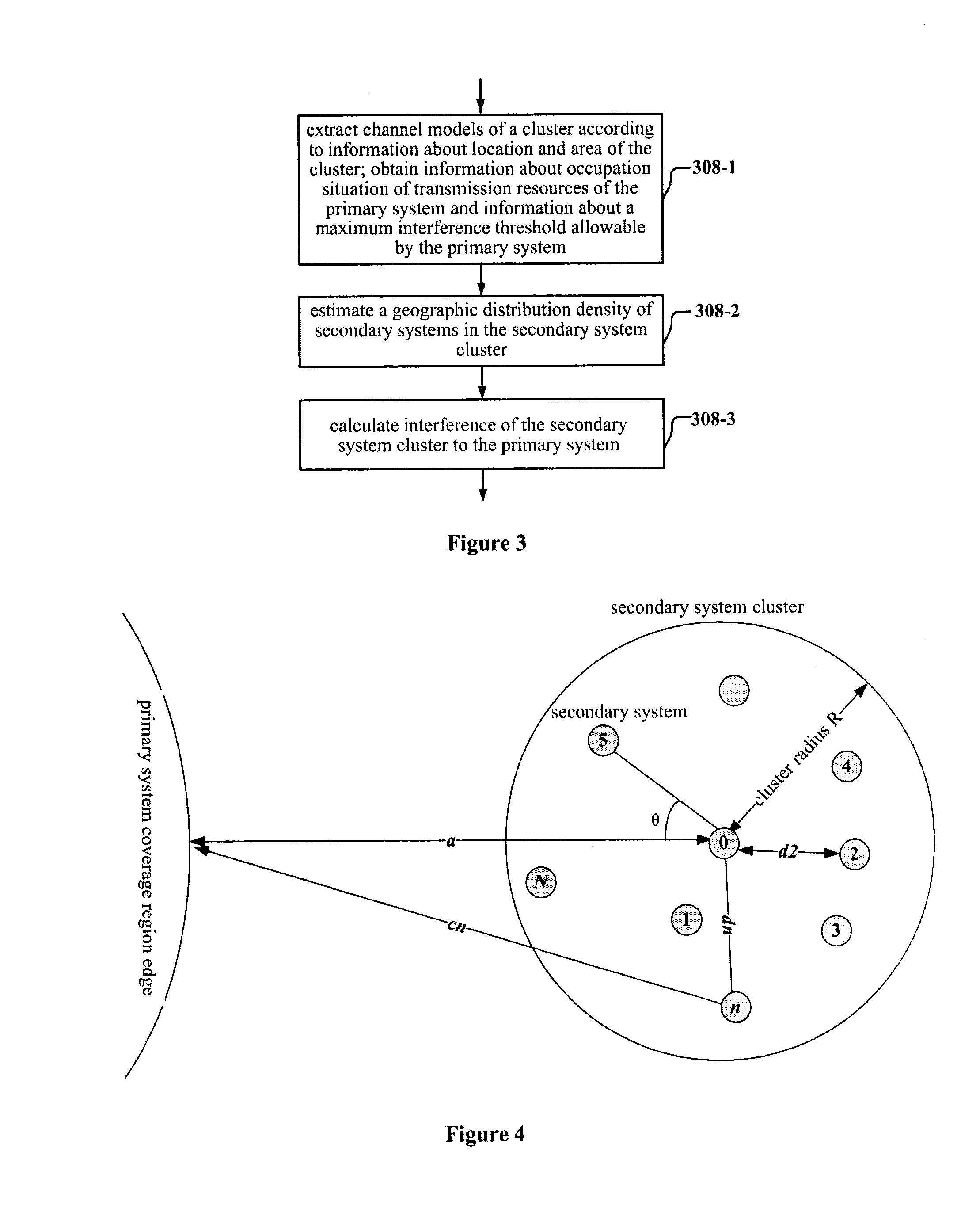

Apparatus and method for wireless communication system

ActiveUS20150319622A1Effectively allocate transmission resourceConfigure available resources for the secondary systemsNetwork planningCommunications systemAuxiliary system

A system that identifies a number of secondary systems located in a first geographical area; identifies a primary resource available to be assigned to the secondary systems, the primary resource being a resource to which a primary system has a priority usage right; determines whether the number of secondary systems located in the first geographical area exceeds a predetermined threshold value; and limits a number of secondary systems to which the primary resource is assigned when it is determined that the number of secondary systems located in the first geographical area exceeds the predetermined threshold value.

Owner:SONY CORP

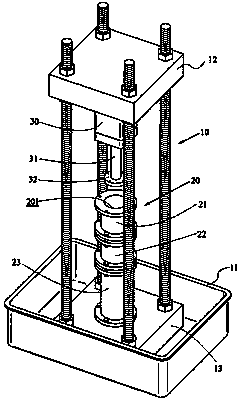

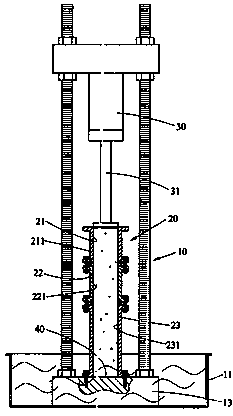

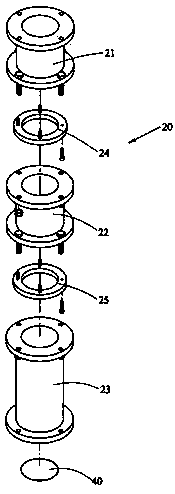

Method and equipment for preparing remolded soil specimen

InactiveCN103674643AImprove quality controlIntegrityPreparing sample for investigationWater storageEngineering

The invention discloses a method and equipment for preparing a remolded soil specimen. According to the equipment and the method, a lower adjusting disc containing a reaction frame is provided with a specimen mold group, the bottom of an upper adjusting disc on the reaction frame is provided with a piston pneumatic cylinder; the reaction frame is put in a water storage barrel filled with water; the specimen mold group comprises three specimen molds, and the interfaces of the three specimen molds are respectively provided with an annular water-permeable pad; gas-removed water is introduced into a thorough inner hole of the specimen mold group for fully being blended with soil, the pressure-shaft push rod of the piston pneumatic cylinder and a pressurization cover plate are moved to the thorough inner hole of the specimen mold group by pressurization, the pressure gas drives the pressure-shaft push rod and the pressurization cover plate to pressurize the soil; and after the specimen is compacted tightly, a jack is utilized to push out the specimen, and the specimen can be utilized to perform various tests. The beneficial effects comprise that the operation is simple and convenient; the specimen has complete integrality, is uniform in compactness distribution, does not generate phenomena of layers and discontinuous interfaces; and the subsequent saturation-state finishing process is accelerated.

Owner:宁波市鄞州科启动漫工业技术有限公司

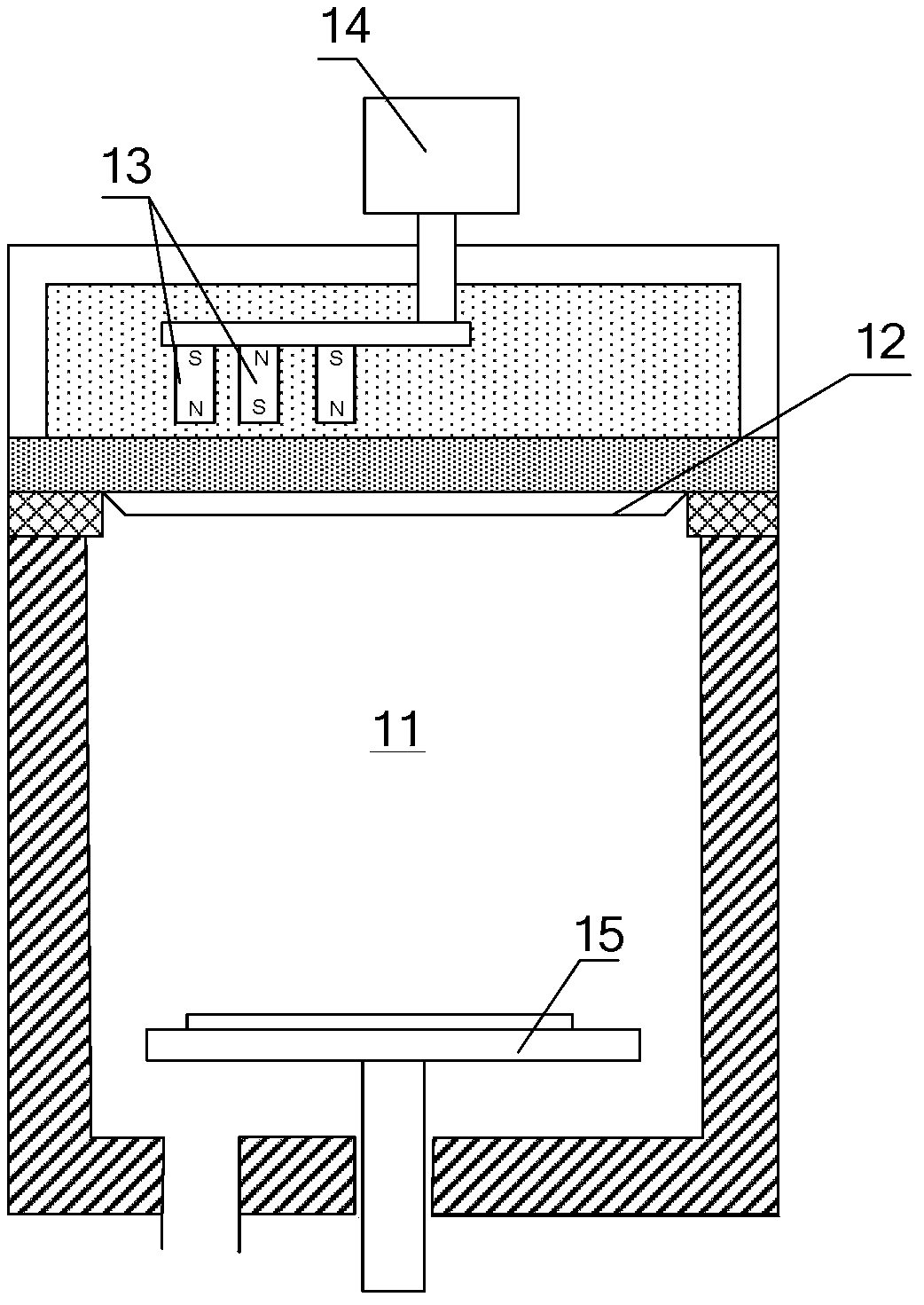

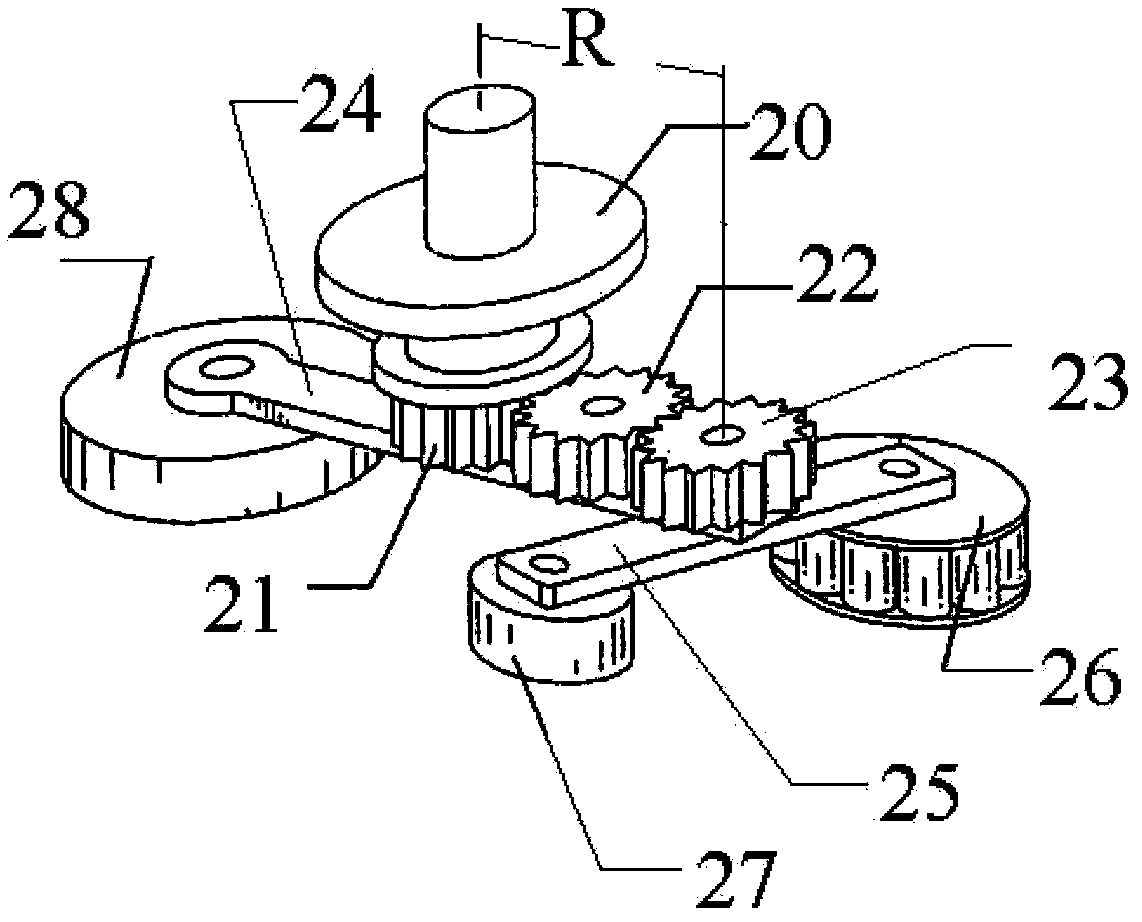

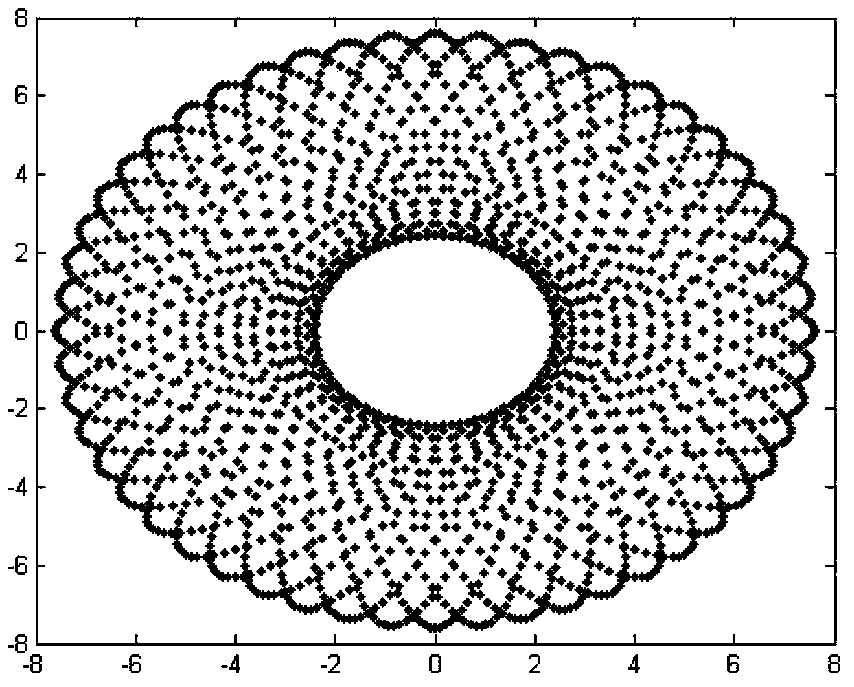

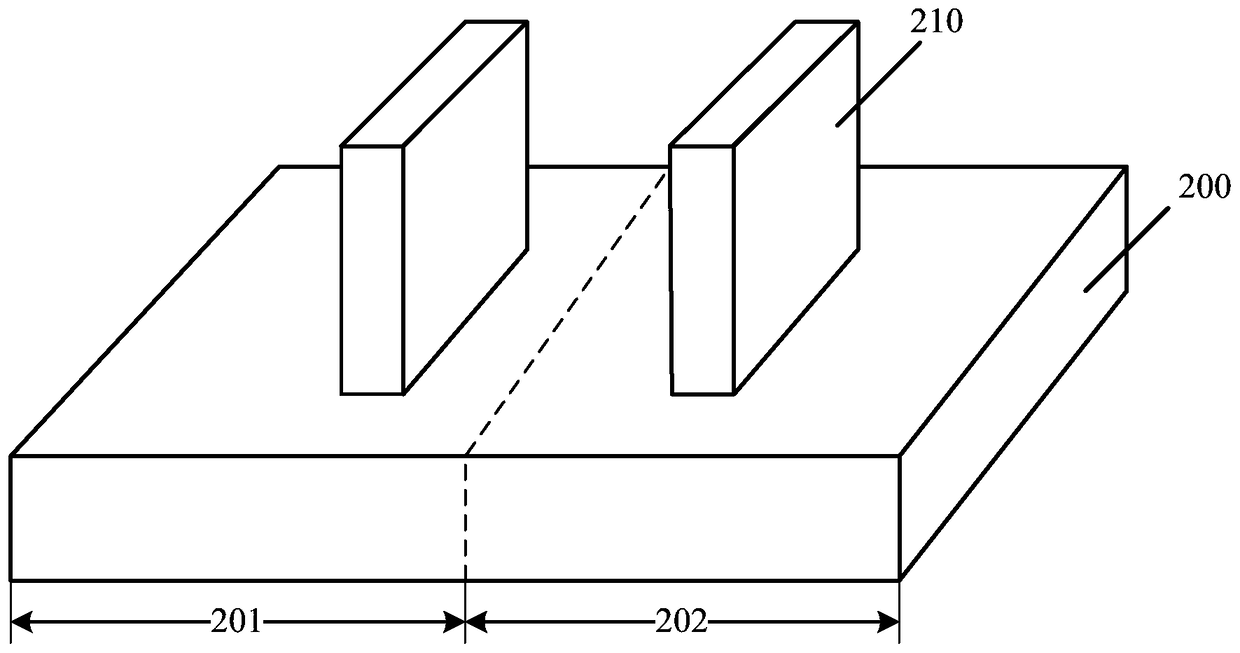

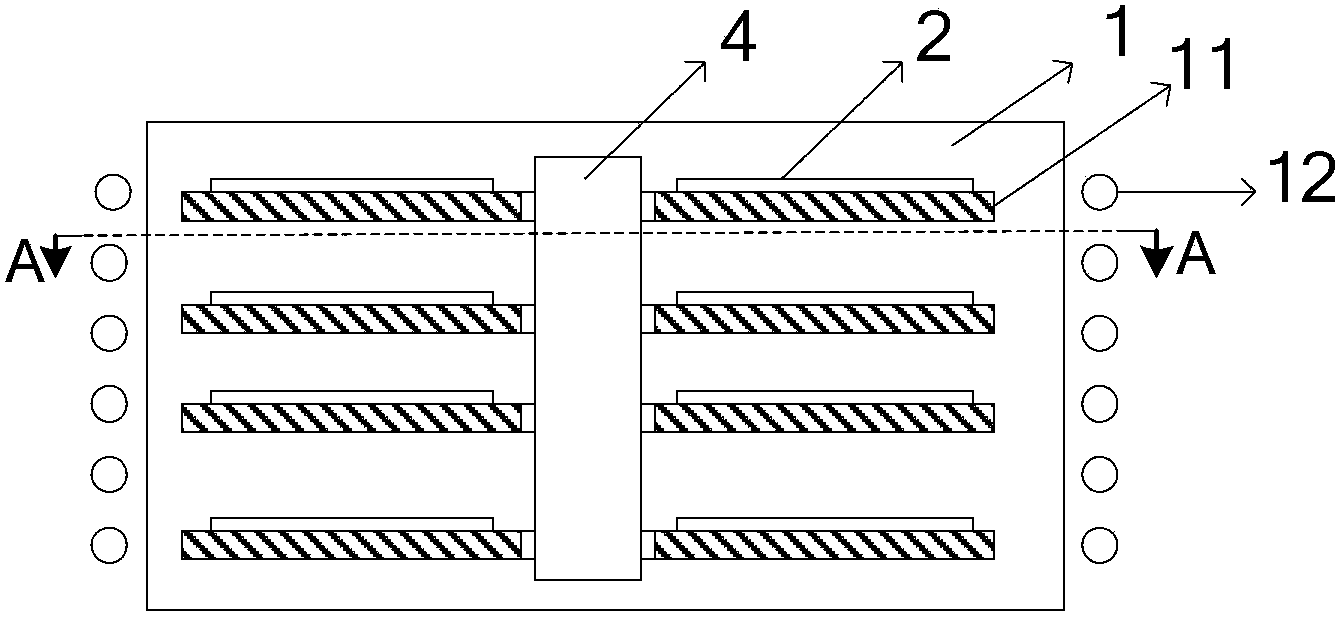

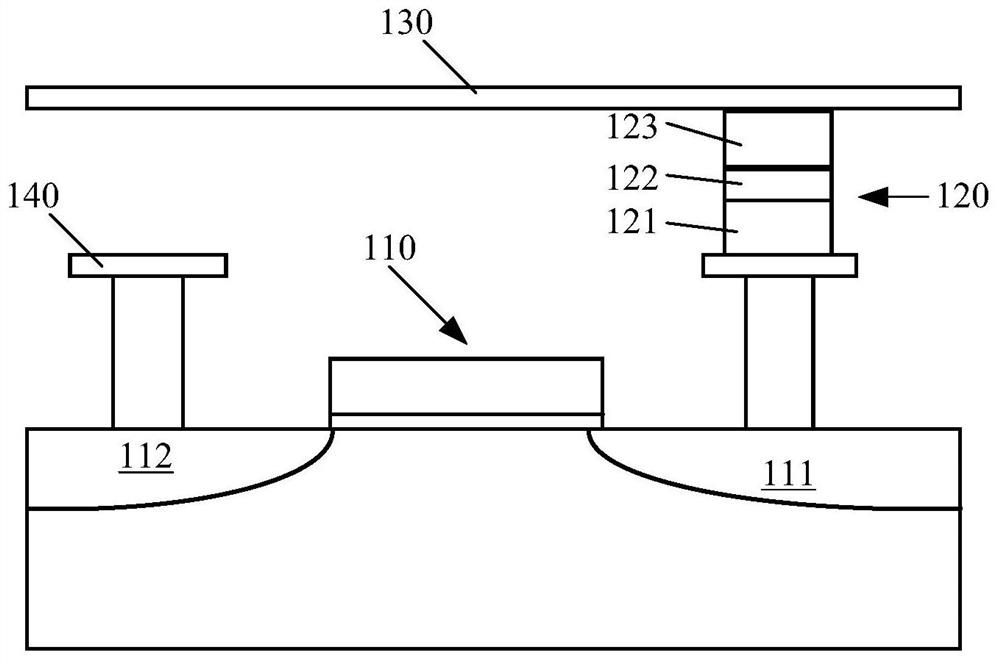

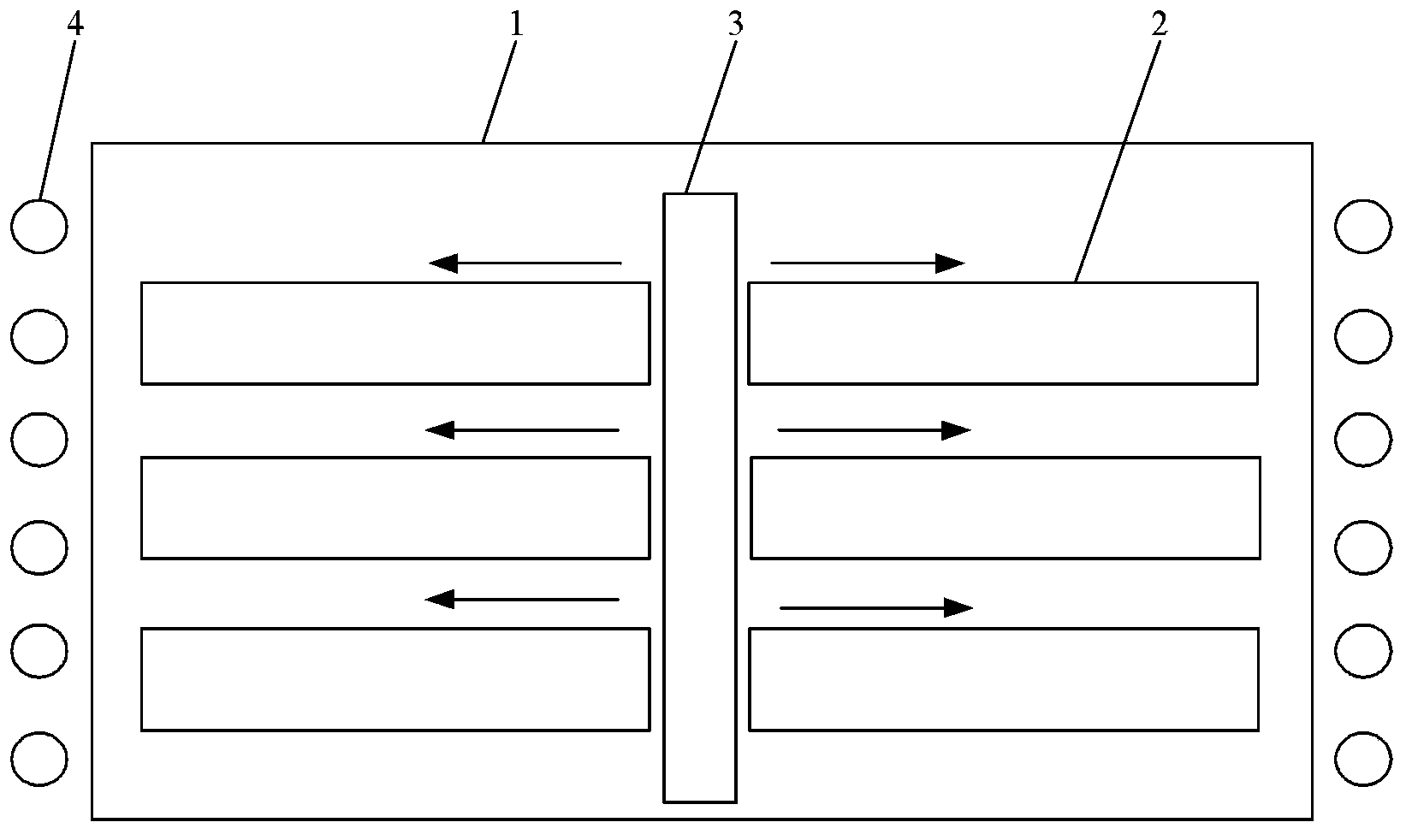

Driving mechanism used for driving magnetron, and magnetron sputtering processing apparatus

InactiveCN104120390AUniform distribution densityIncrease profitElectric discharge tubesVacuum evaporation coatingReciprocating motionDrive shaft

The invention provides a driving mechanism used for driving a magnetron, and a magnetron sputtering processing apparatus. The driving mechanism comprises a rotary driving source, a transmission shaft and a linear driving source, wherein the linear driving source is used for driving the magnetron to linearly move back and forth along a direction perpendicular to the transmission shaft in a hydraulic driving mode; and the driving shaft of the rotary driving source is fixedly connected with the linear driving source by means of the transmission shaft, and is also used for driving the magnetron to move around the transmission shaft in a rotary manner during the linear reciprocating movement of the magnetron. The driving mechanism used for driving the magnetron allows the running locus of the magnetron completely cover a whole target material and the distribution density of the running locus of the magnetron tend to uniformity, and is also suitable for target materials with many dimensions in order to enlarge the application range of the driving mechanism.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

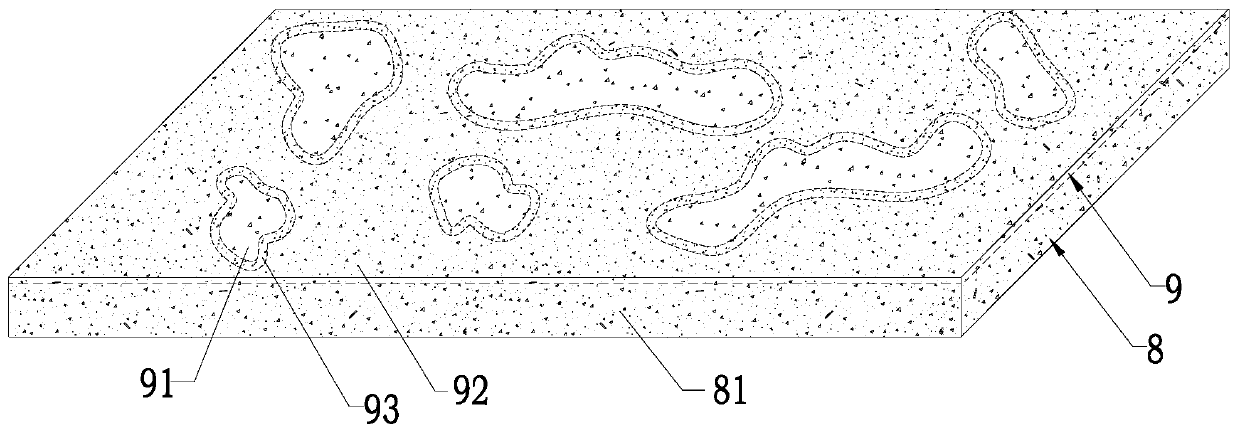

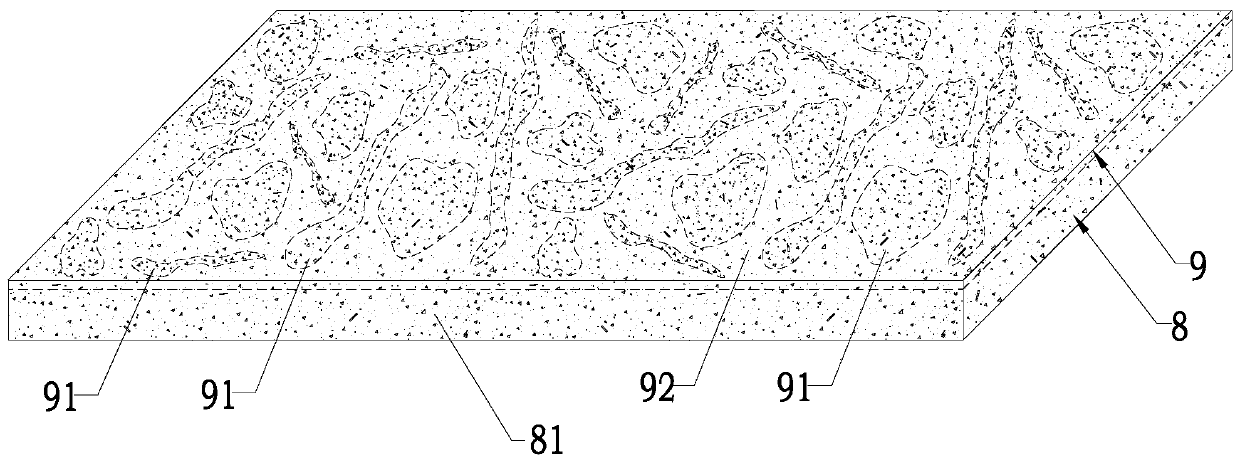

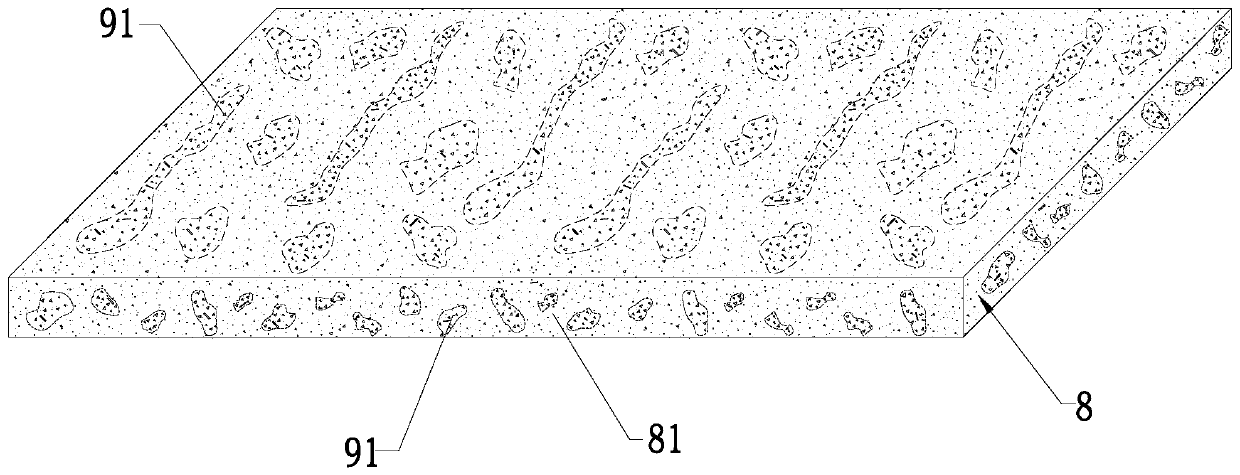

Porcelain plate containing green body texture and manufacturing method of porcelain plate

InactiveCN110103319AGood consistencyMore consistent colorsCovering/liningsFeeding arrangmentsControllabilityGreen body

The invention discloses a porcelain plate containing green body texture and a manufacturing method of the porcelain plate. The porcelain plate comprises a main body layer and a texture layer; the manufacturing method comprises the steps of material preparing, main body layer material distributing, texture layer material distributing, raw material uniform distributing, pressing, drying, sintering,edging or polishing; during texture layer material distributing, texture molding of a green body can be completed fast and efficiently through a carving type roller or a carving belt, or a special-shaped guiding material distributing device provided with a guiding material distributing plate is used, under the action of the guiding material distributing plate, the fluidity is different due to thefact that the particle sizes of flaky materials, granular materials and powdery raw materials are different, so that texture raw materials in a texture color zone form a texture layout with differentand changed accumulation forms. The method is suitable for large plate production, and compared with a traditional material distributing mode, the method has the advantages of being small in occupiedspace, simple in equipment structure and high in controllability.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

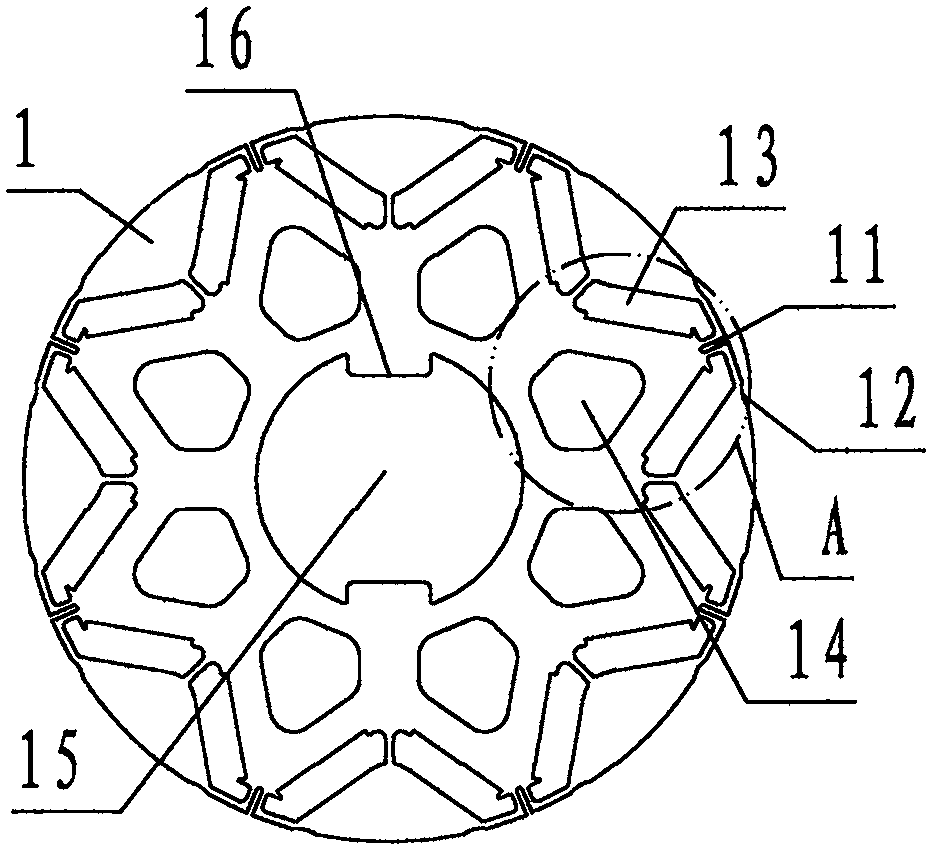

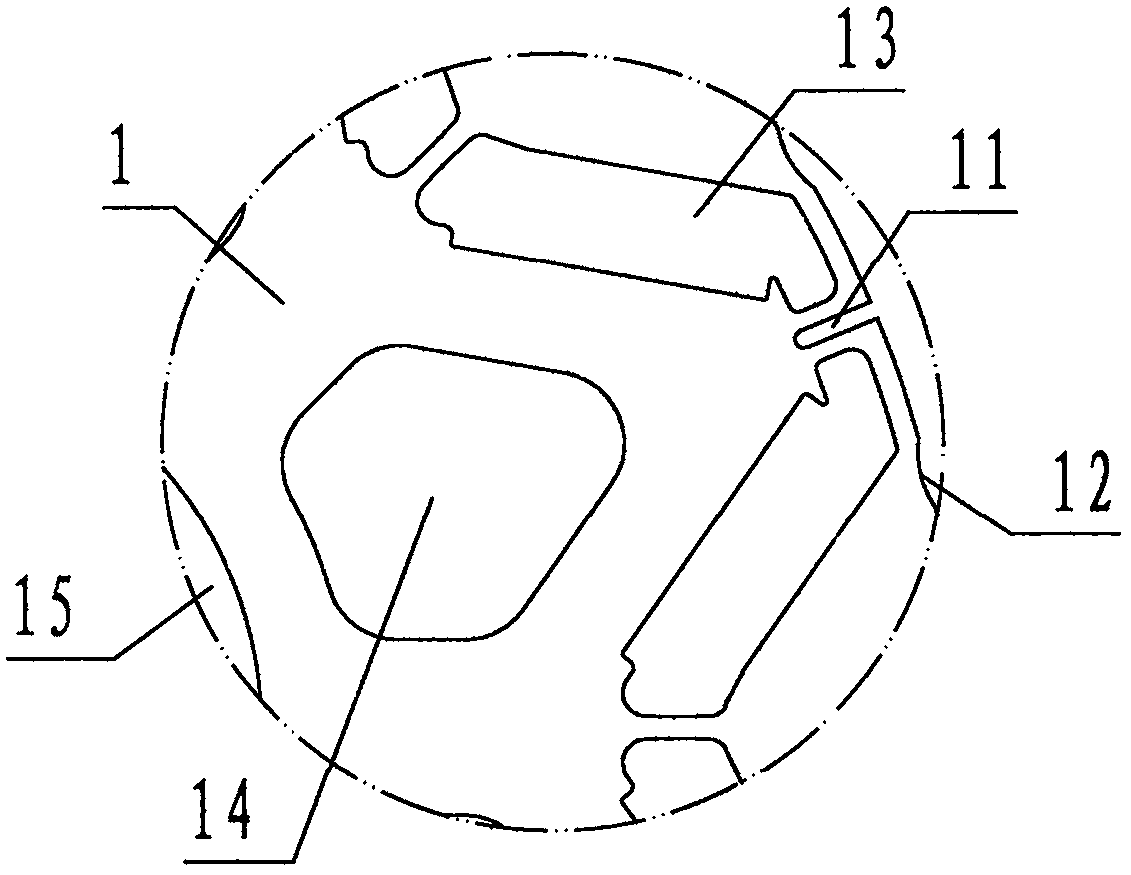

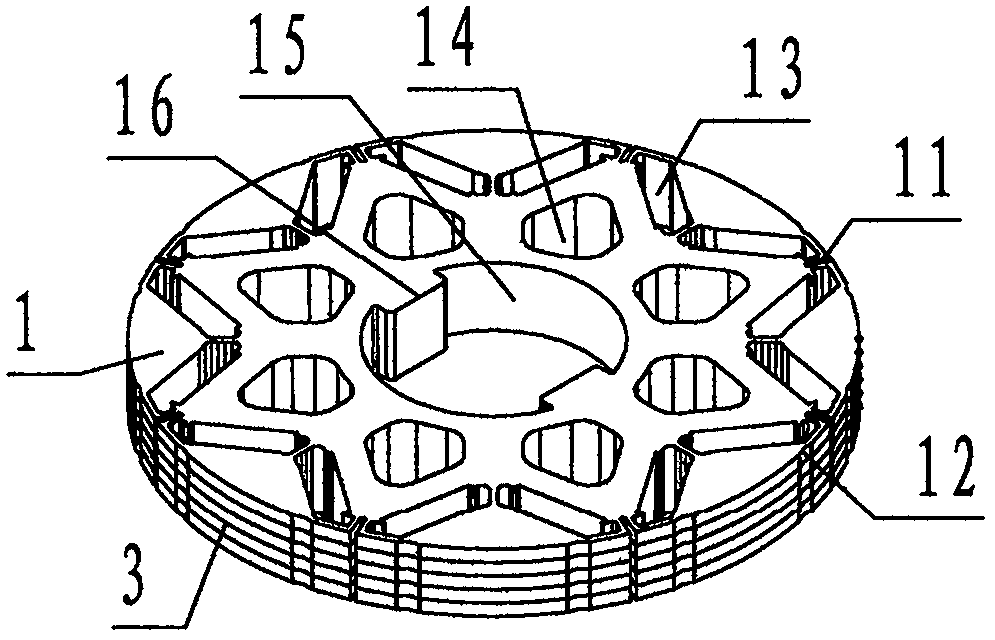

Rotor punching sheet for permanent-magnet motor of electric vehicle

PendingCN108110927AHarmonic reductionReduce torque rippleMagnetic circuit rotating partsElectric machinesPunchingMagnetic reluctance

The invention discloses a rotor punching sheet for a permanent-magnet motor of an electric vehicle. The rotor punching sheet comprises a sheet base (1), wherein the sheet base (1) is provided with magnetic isolation grooves (11), magnetic gap notches (12), permanent-magnet holes (13), weight reduction holes (14), a rotation shaft hole (15) and tenon keys (16). During application, a plurality of sheet bases are correspondingly superposed to form a rotor core, the rotation shaft hole is used for fixedly connecting a rotor shaft, the permanent-magnet holes are used for fixedly bearing permanent magnets, and thus, a permanent-magnet motor rotor is formed; during working and on the basis of a principle that air reluctance larger than iron core reluctance, the magnetic isolation grooves are usedfor improving reluctance, magnetic short-circuit is reduced, and the output power of the permanent-magnet motor rotor is improved; the magnetic gap notches are used for balancing distribution densityof a magnetic line, local enrichment of the magnetic line is suppressed, the torque pulse amplitude of the permanent-magnet motor rotor is reduced, and the torque fluctuation is smoothed; and the weight reduction holes are used for reducing weight and material cost, the technical scheme of an air-cooling passage of a cooling rotor is formed, so that the permanent-magnet motor of the electric vehicle achieves the purposes of reducing harmonic, torque pulse and cost and improving efficiency.

Owner:山东双林新能源科技有限公司

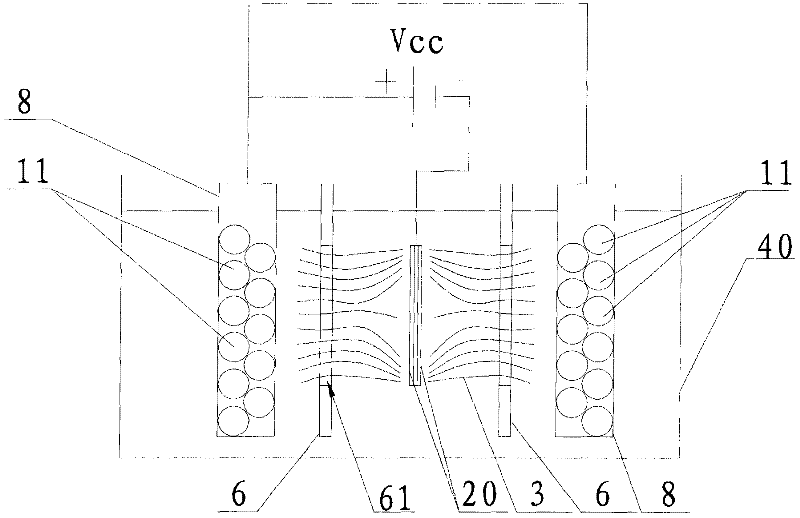

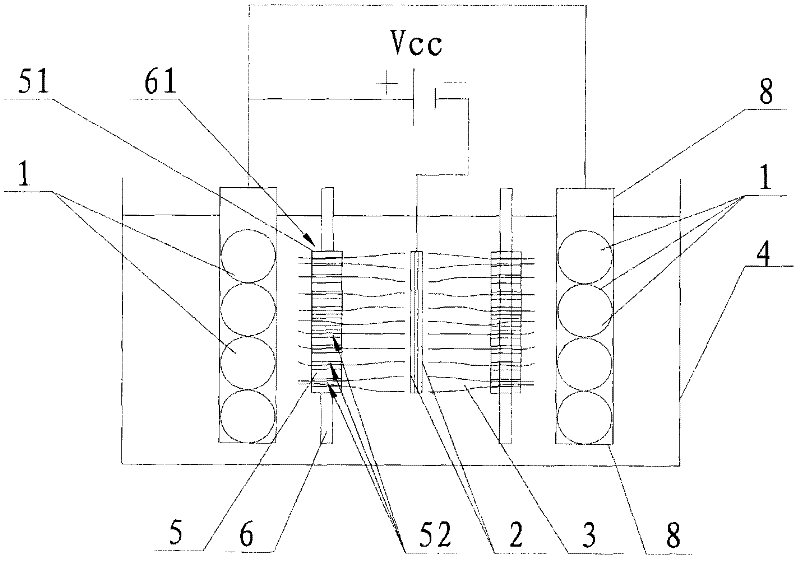

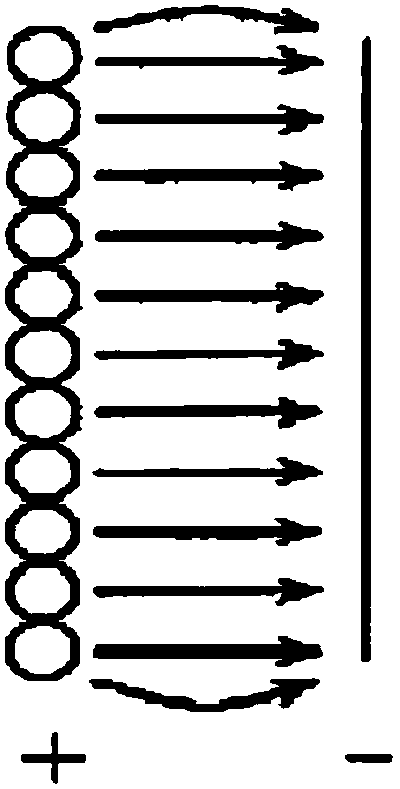

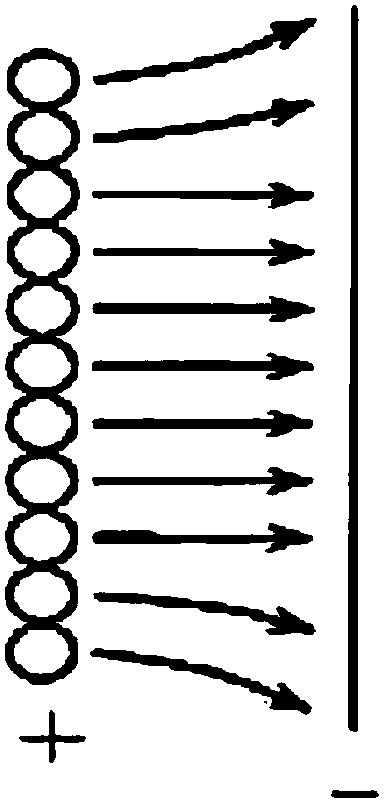

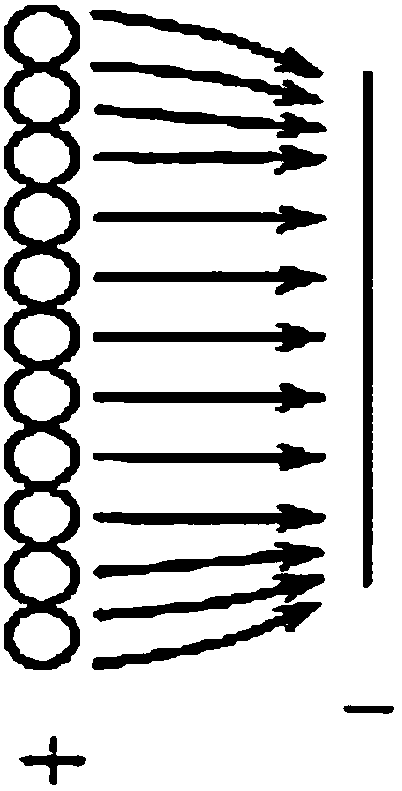

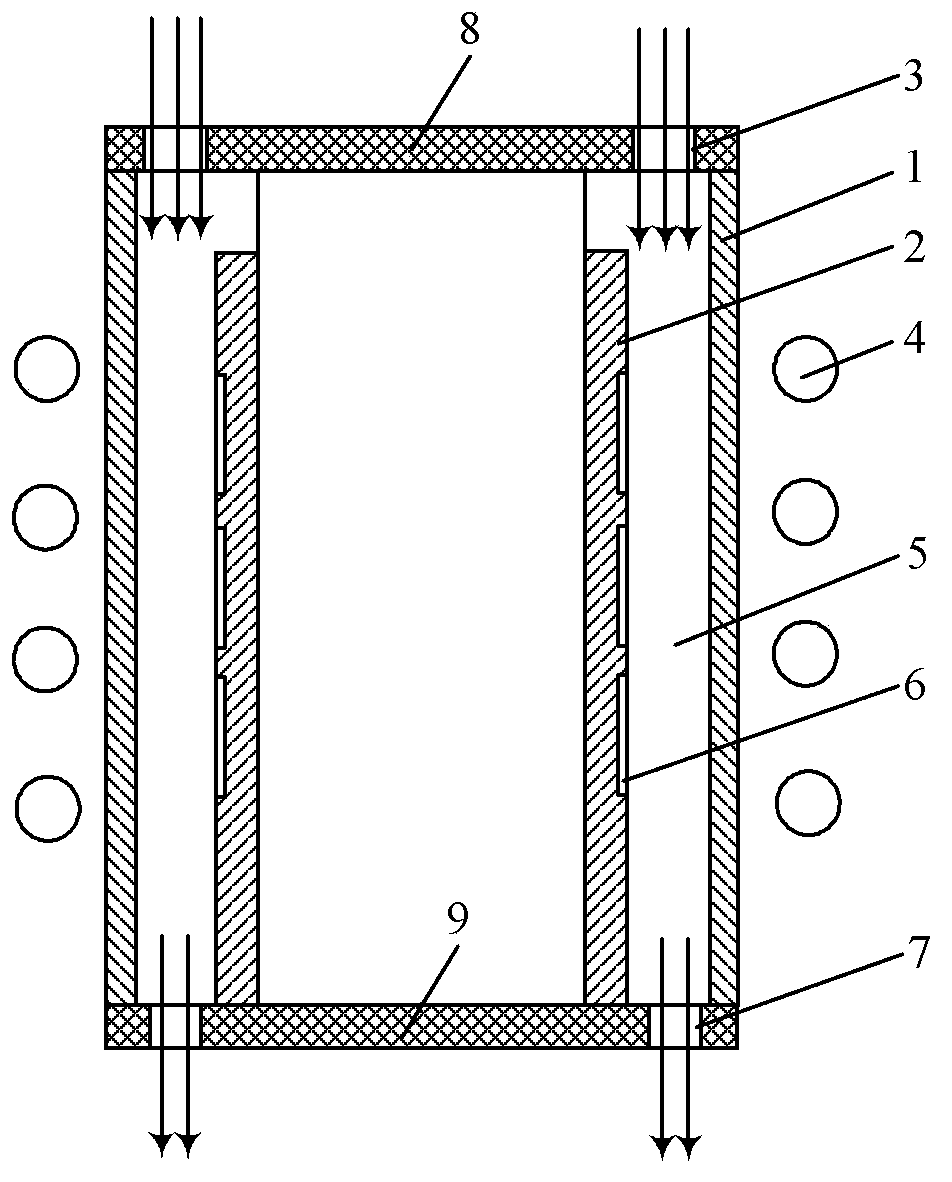

Electroplating device and electroplating method

ActiveCN102534733AUniform distribution densitySolve technical problems with low yieldCellsEngineeringElectroplating

The invention discloses an electroplating device and an electroplating method, relating to the technical field of electroplating and solving the technical problem that the yield of products is lower due to larger thickness differences on different areas of a plating formed through electroplating by using the traditional electroplating method. The electroplating device comprises a power supply, a container storing an electroplating solution and a power wire regulating device, wherein a metal ion source article as an anode is immersed in the electroplating solution, an article to be plated, as a cathode, is immersed in the electroplating solution, metal ions are attached onto the article to be plated under the action of power wires between the metal ion source article and the article to be plated, and the power wire regulating device is used for regulating the distribution of the power wires from the metal ion source article to the article to be plated. The electroplating method comprises the step of: regulating the distribution of the power wires from the metal ion source article to the article to be plated by using the power wire regulating device so as to attach the metal ions ionized from the metal ion source article to a metal layer of the article to be plated along the power wires to form the plating. The invention is applicable to plating electroplating.

Owner:NEW FOUNDER HLDG DEV LLC

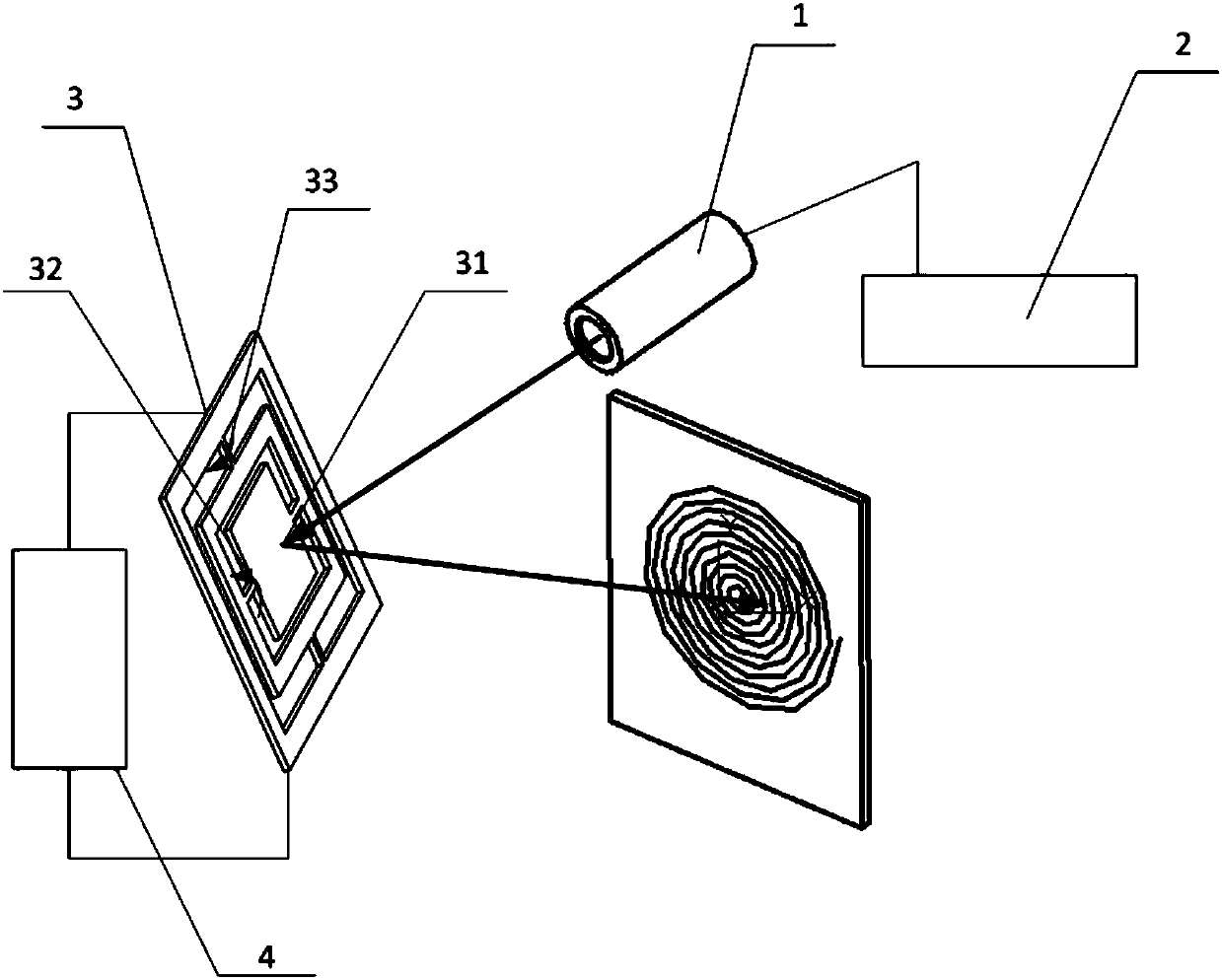

Vibrating mirror-based spiral scanning laser projection method and system

ActiveCN108398779ASmall driving forceThe projection screen is uniformProjectorsOptical elementsResonance oscillationHelical line

The invention belongs to the field of laser projection display and relates to a vibrating mirror-based laser projection display method and specifically relates to a vibrating mirror-based spiral scanning laser projection method and system. A vibrating mirror is enabled to perform resonance oscillation around two axes, a scanning trajectory is spirally scanned, and the scanning trajectory is used to realize projection. The vibrating mirror-based spiral scanning laser projection method and system can be used for solving problems of complex algorithms, low projection resolution, excessively low resonant frequency of the vibrating mirror, low vibration resistance vibration resistance and the like of conventional MEMS vibrating mirror-based laser projection display which is performed via a Lissajous Scanning and grating scanning method.

Owner:XI AN ZHISENSOR TECH CO LTD

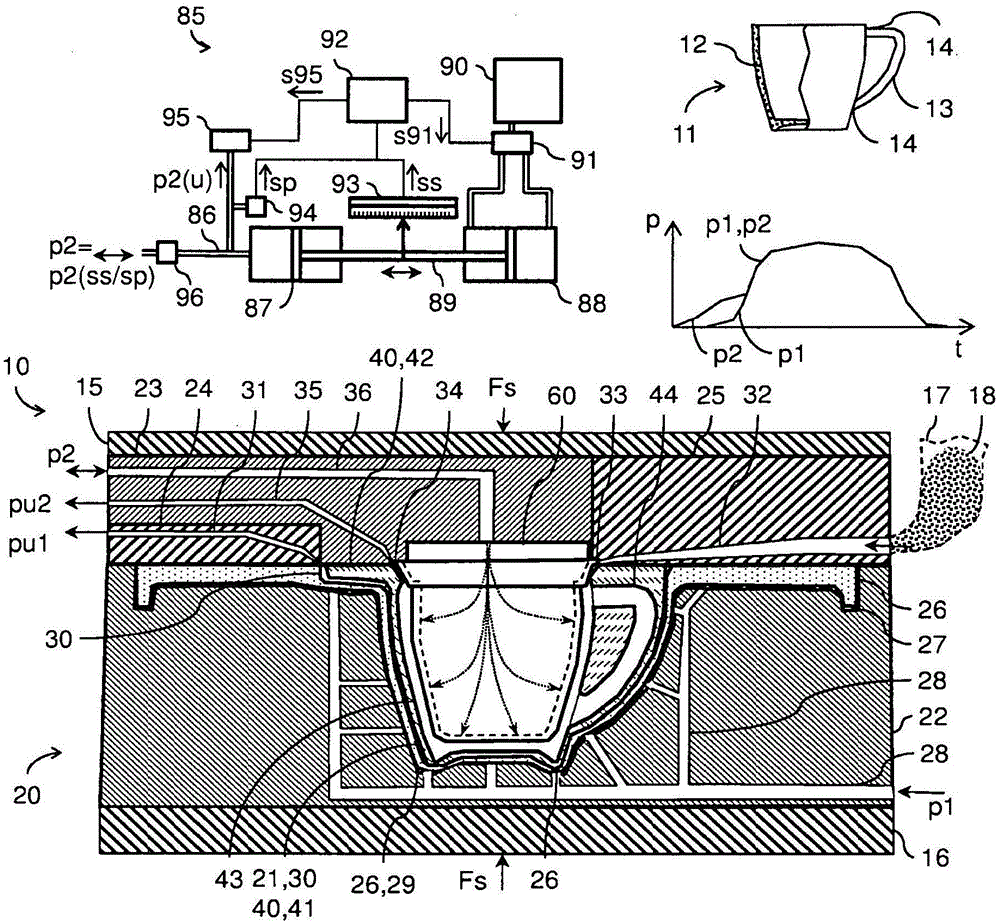

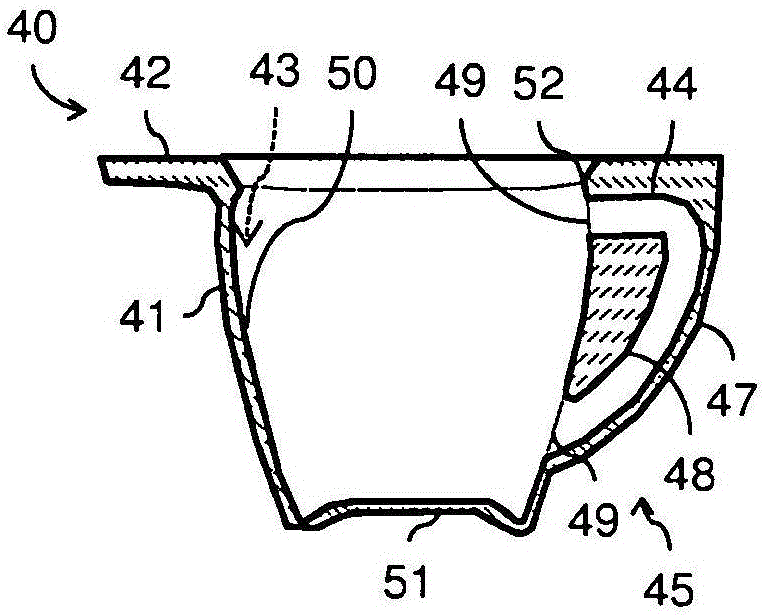

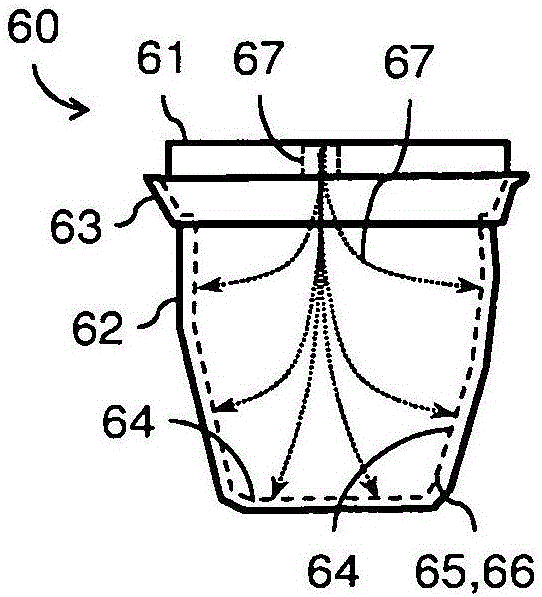

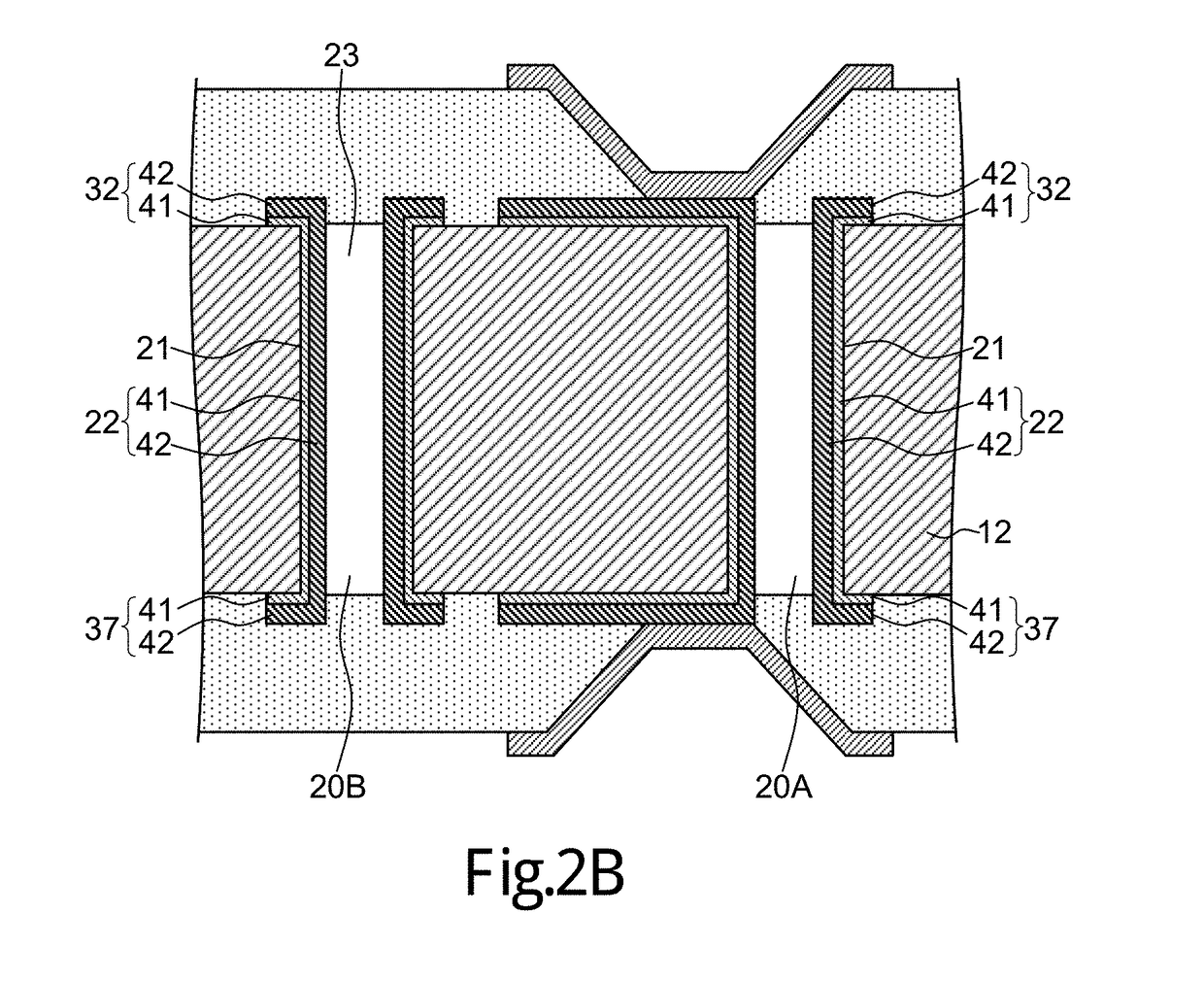

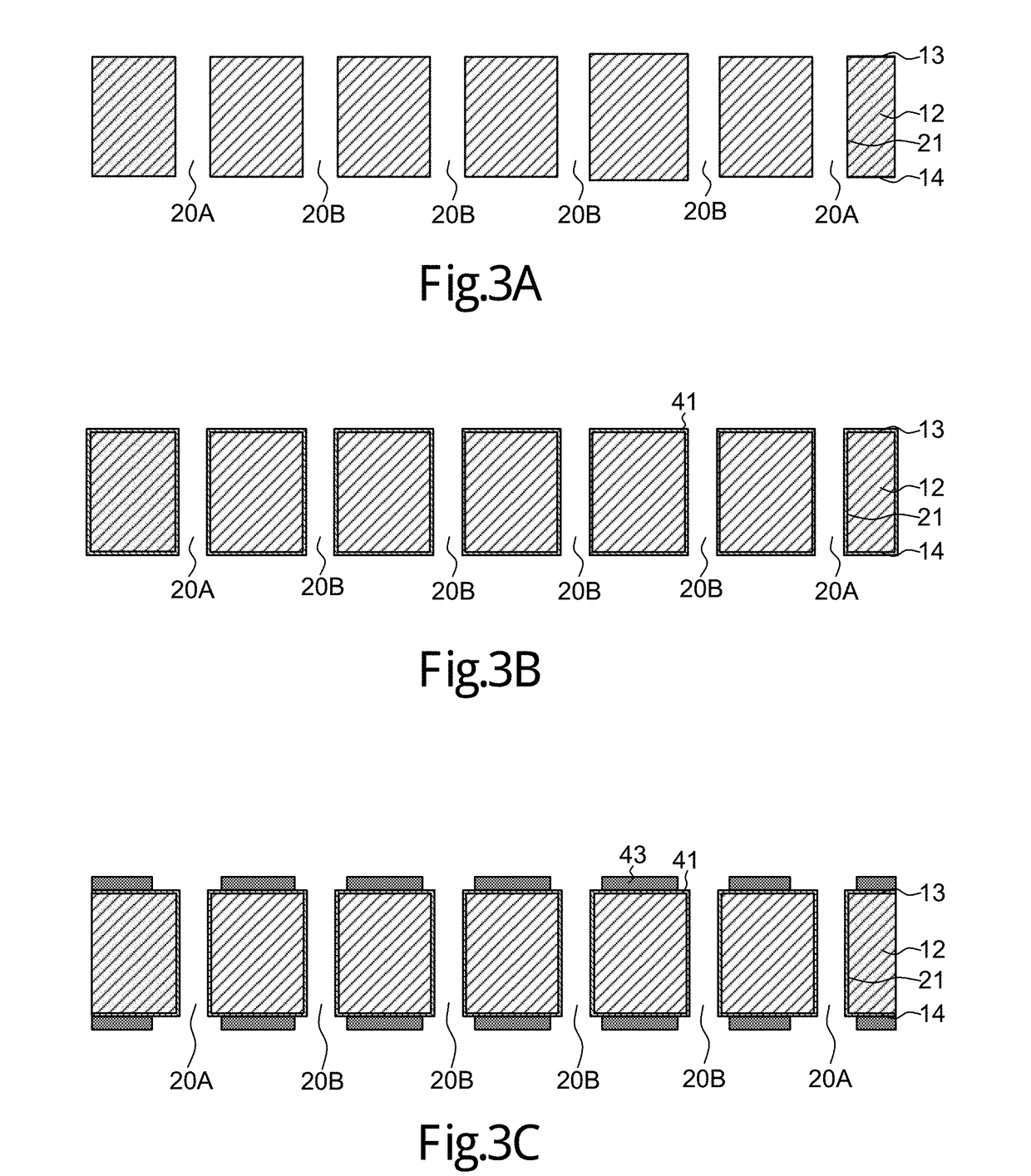

Press arrangement and method for pressing pressed parts

ActiveCN106536141APrevent pull outPreventer from peeling offCeramic shaping apparatusShaping pressMechanical engineeringCompression pressure

The invention relates to a method and an in particular container press arrangement (10) for pressing a pressed part, in particular a container (11) having at least one handle (13) made from a powdered and / or granulated ceramic material to be pressed (18). The press arrangement has a first compression mould component (22), which has a membrane (26) at which compression pressure (p1) can be applied on the back side, an outer mould (40) which is elastic at least in sections, and which is inserted or can be inserted in the first compression mould component (22), and a second compression mould component (23; 60) which can be arranged as a counter element for forming a moulding cavity (43) between itself on the one side and an interior mould section, in particular a cup moulding section (50) of the outer mould (40), on the other side. In addition, an outer mould of this type, a method, and a device for the production of the same are also provided.

Owner:DORST TECH

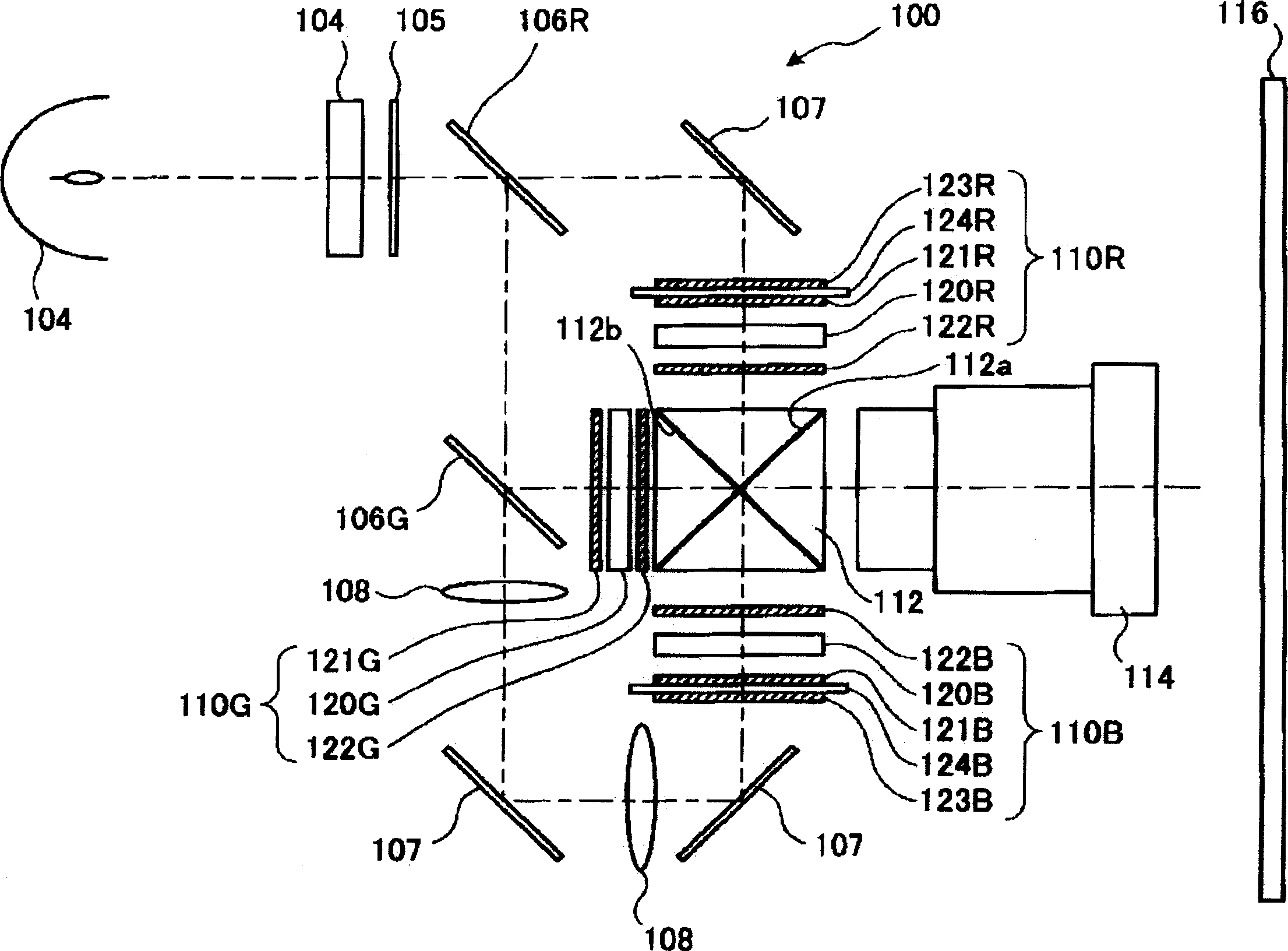

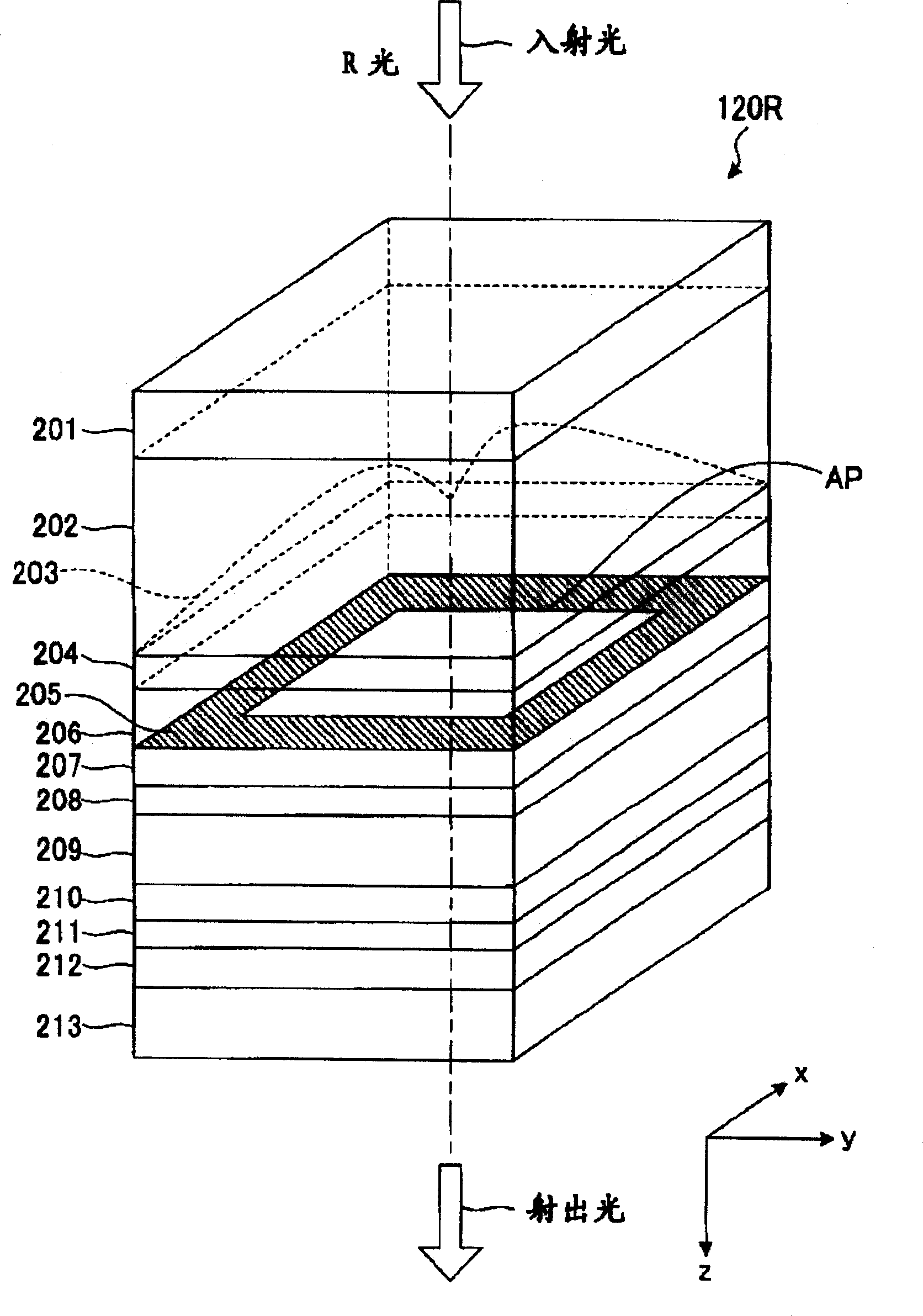

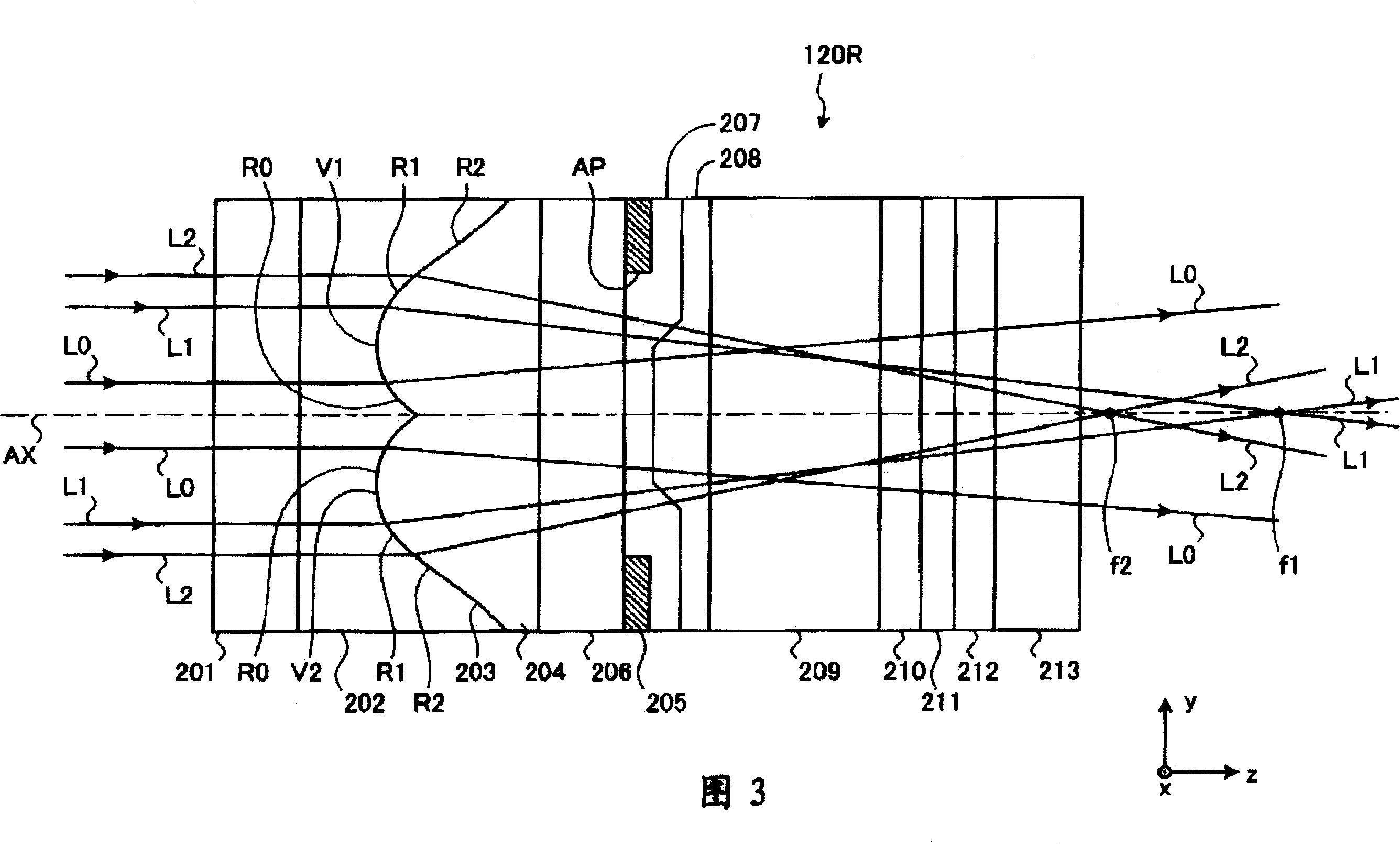

Spatial light modulator and projector

InactiveCN1652015AUniform distribution densityIncrease contrastTelevision system detailsProjectorsOptical axisBand pattern

The invention provides a spatial light modulator and projector with low cost and long service life for obtaining a high contrast image with a high light utilization efficiency. The spatial light modulator comprises a plurality of pixel opening areas (AP), a liquid crystal layer (209) for modulating and transmitting lights according to the image signal, and a plurality of micro lens components (203) capable of condensing the incident light and passing through the opening area (AP) on the incident side of the liquid crystal layer (209) and the opening area AP counterpart arrangement. Moreover, the micro lens components (203) have a plurality of focus positions (f1) and (f2) for each different roughly wheel shaped parts (R1) and (R2) corresponding to the optical axis as a center; the focus position (f2) of every wheel shaped part (R2) in a plurality of wheel shaped parts is positioned at a position closer to the micro lens component (203) based on the wheel shaped part (R2) and closed to one side of the optical axis (AX); every focus position of a plurality of focus positions (f1) and (f2) is closer to the ejaculating side compared with the liquid crystal layer (209).

Owner:SEIKO EPSON CORP

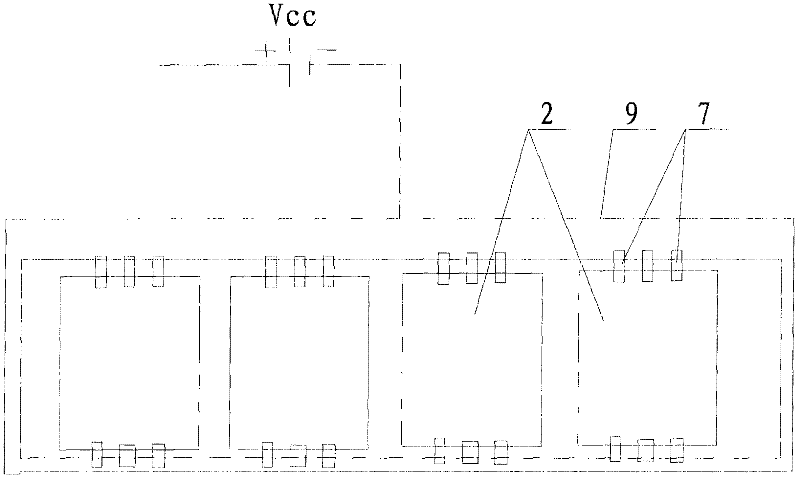

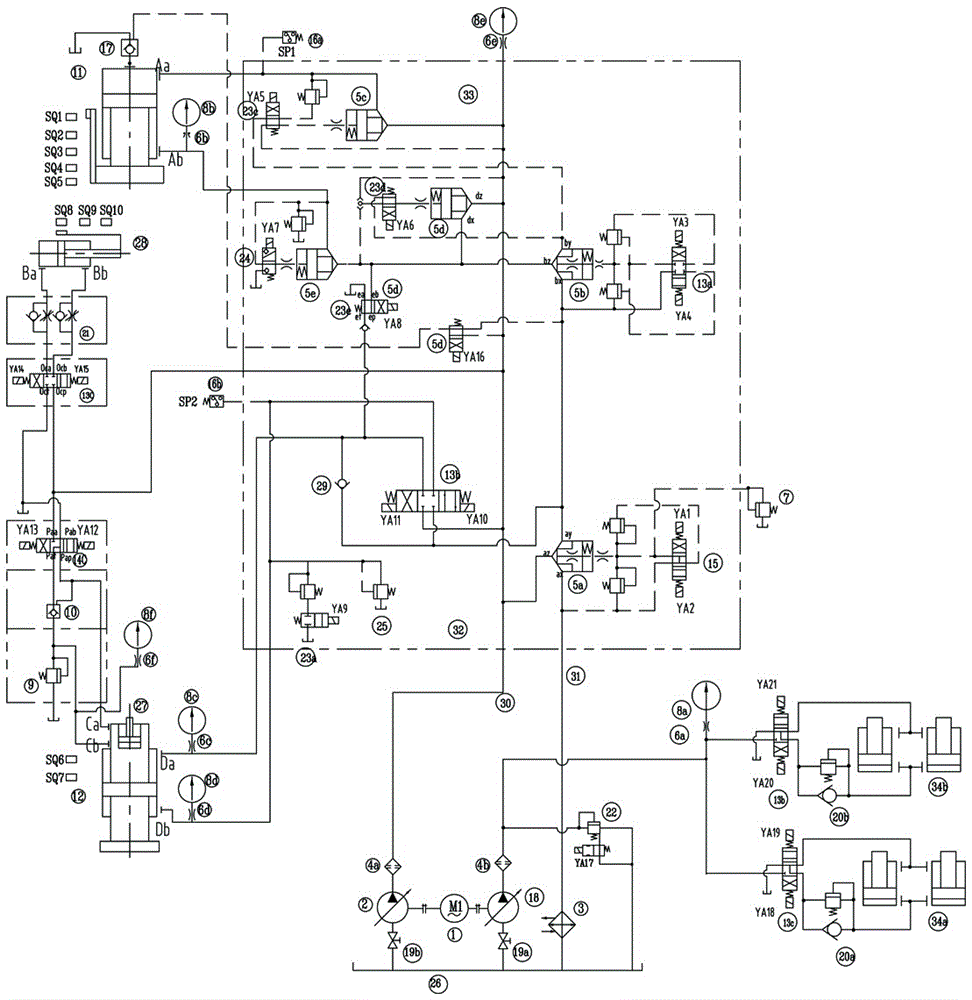

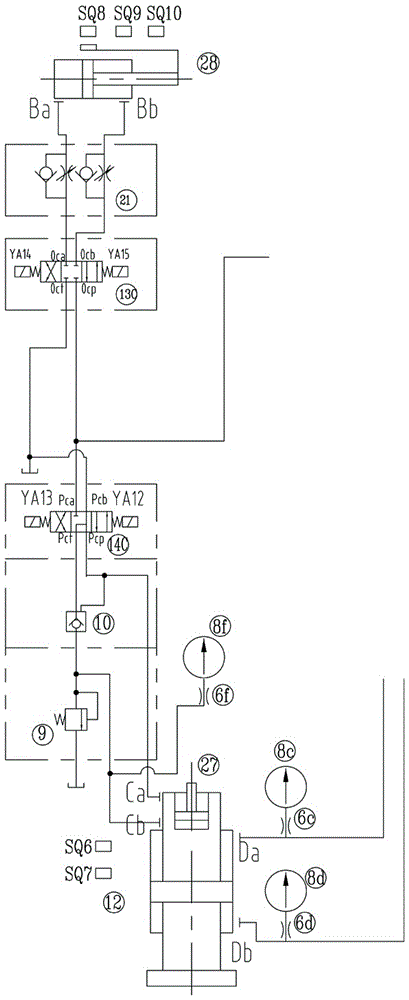

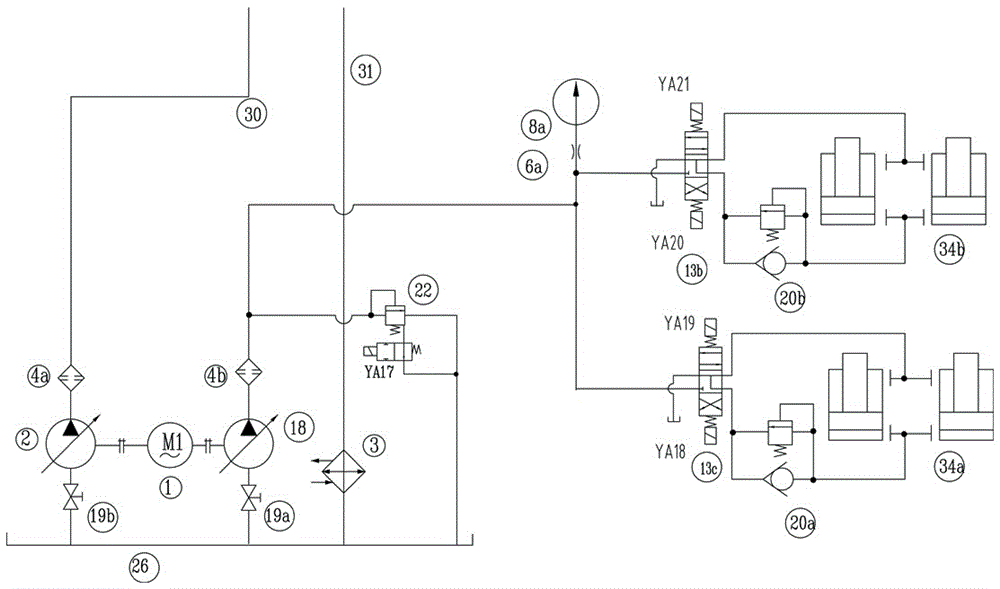

Hydraulic system of tear bomb powder hydraulic machine

ActiveCN106402064AGuaranteed densityGuaranteed even distributionServomotor componentsServomotorsVolume fillingControl system

The invention relates to a hydraulic system of a tear bomb powder hydraulic machine. The hydraulic system is characterized in that the hydraulic system of the tear bomb powder hydraulic machine comprises a control system, a cartridge valve system, an auxiliary system and an execution system; the control system is connected with the cartridge valve system and the auxiliary system; and the execution system is connected with the cartridge valve system. According to the hydraulic system of the tear bomb powder hydraulic machine, automatic circulation of a series of process actions such as constant-volume filling, pre-pressing, floating pressing, post-pressing, core pulling, demolding and piece taking is achieved, the pressing force, the filling amount, the pressing stroke and the like of the hydraulic system can be accurately adjusted, the repeated locating precision of key positions is smaller than + / -0.05 mm, the size and density consistency and uniformity of products are ensured, and the efficiency is eighteen times that of an original universal hydraulic machine.

Owner:江苏金泽重机集团有限公司 +1

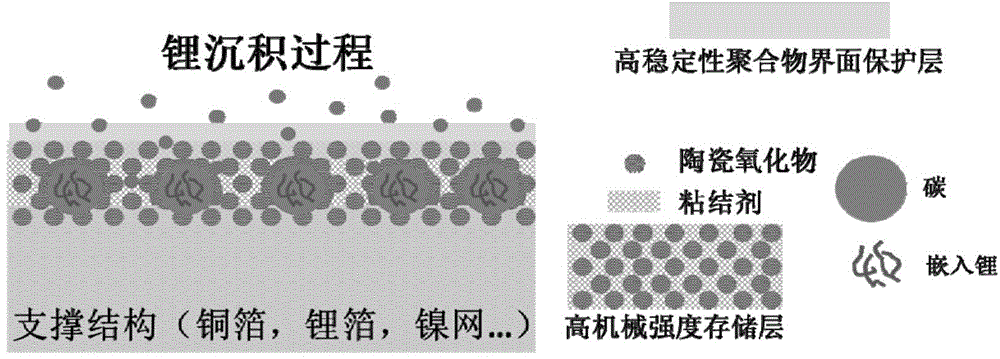

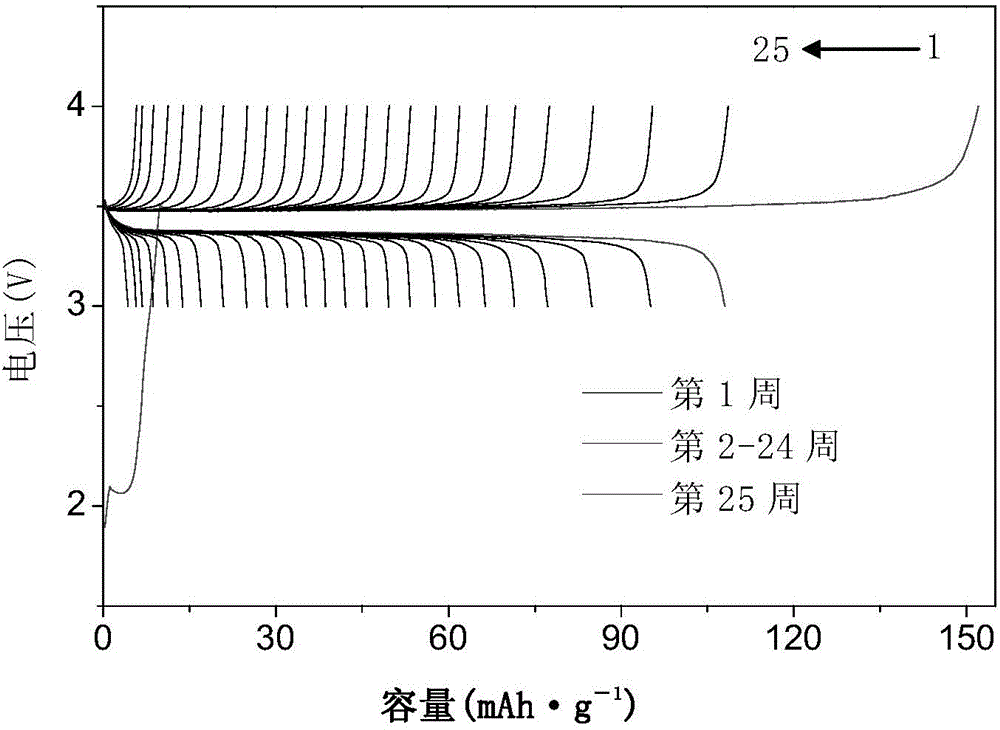

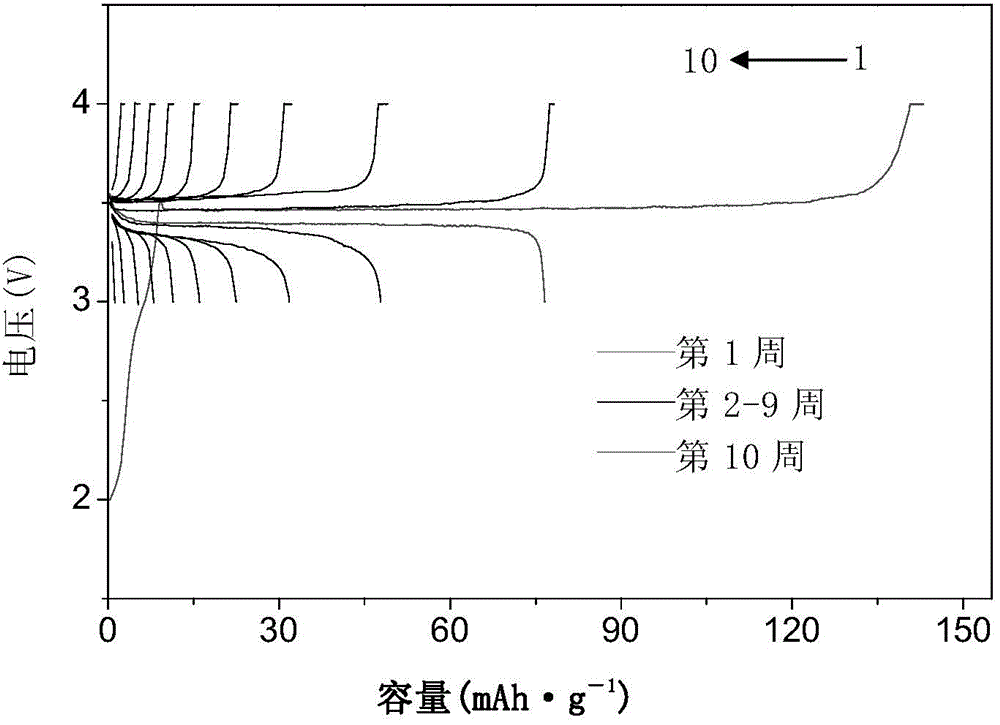

Lithium battery and preparation method thereof

InactiveCN105762326AImproved storageGrowth inhibitionFinal product manufactureCell electrodesInterface impedanceLithium metal

The present invention relates to a lithium battery and a preparation method thereof, and specifically discloses a lithium battery, the lithium battery includes a positive electrode, a negative electrode, a separator, an electrolyte and a housing, the negative electrode contains a negative electrode material or comprises the following negative electrode material, the negative electrode material comprises a support structure and a lithium-ion / lithium metal storage layer coating one side of the support structure, the electrolyte contains a film-forming additive, and a polymer interface protective layer is formed by the film-forming additive on the lithium-ion / lithium metal storage layer. The present invention also discloses the preparation method of the lithium battery. The lithium battery prepared by the preparation method has excellent lithium metal storage function, can inhibit lithium metal dendritic growth, make electrode interface current density uniform in distribution, maintain electrodes surface low interface impedance and other series characteristics for optimization of electrode cycle efficiency and service life.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Measuring device and method for improving plating uniformity analysis efficiency

InactiveCN107560533ASteps to reduce markupImprove analysis and detection efficiencyElectrical/magnetic thickness measurementsCopperElectroplating

The invention discloses a measuring device and method for improving the plating uniformity analysis efficiency. The measuring device is a flat plate which is of the same size as a plate to be measured. Through holes are arranged in the flat plate along the long side direction of the flat plate and in length positions as follows: 1 / 64, 1 / 32, 1 / 16, 1 / 8, 1 / 4, 1 / 2, 3 / 4, 7 / 8, 15 / 16, 31 / 32, and 63 / 64. The through holes of the measuring device are set according to the electric field distribution during whole-plating of the plate to be measured. By using the measuring device, the analysis efficiency of the electroplating uniformity of a circuit board can be improved, and the accuracy of the electroplating copper thickness uniformity analysis result can be greatly improved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

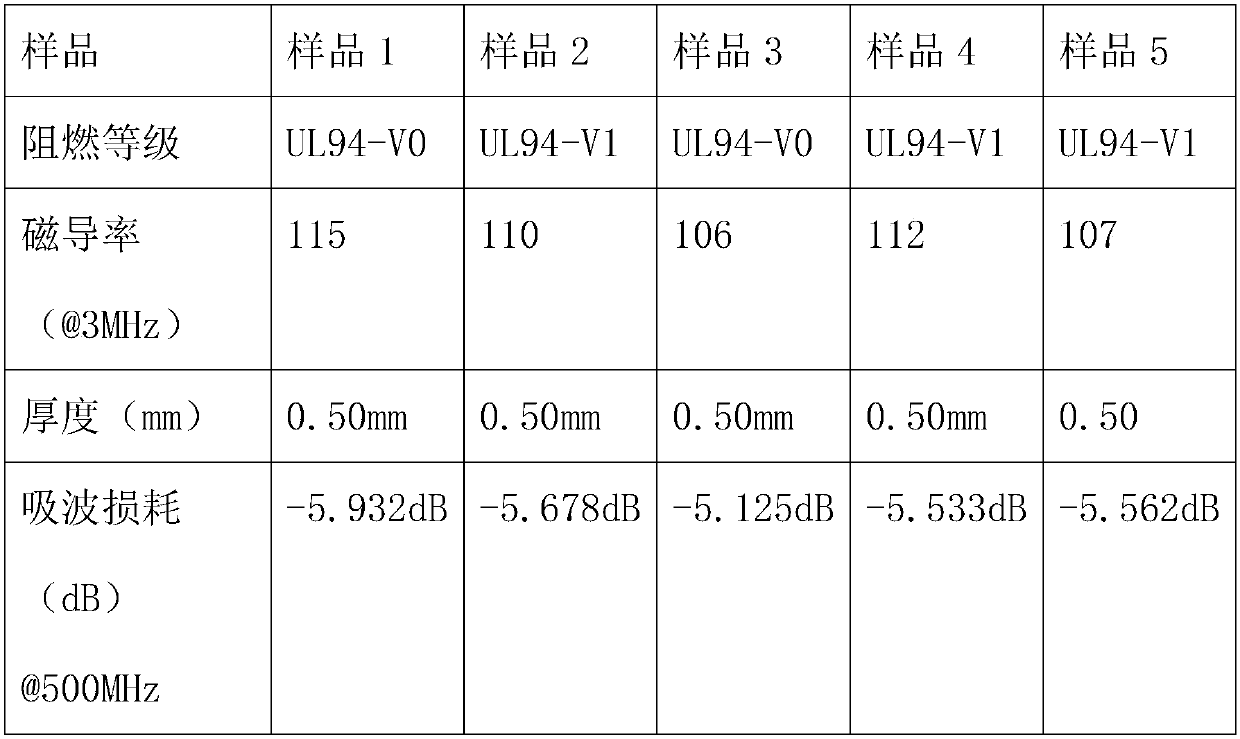

Rubber with excellent flame retardant and wave absorbing performance and preparation method thereof

The invention relates to rubber with excellent flame retardant and wave absorbing performance. The rubber with the excellent flame retardant and wave absorbing performance comprises the following components: a rubber matrix, an electromagnetic wave absorbent, dimethyl silicone oil, talcum powder, a flame retardant, a carbon fiber material, a stripping agent, a silane coupling agent and a vulcanizing agent. The rubber with the excellent flame retardant and wave absorbing performance disclosed by the invention has reasonable components. The electromagnetic wave absorbent can absorb most of electromagnetic waves radiating on the surface of the electromagnetic wave absorbent by virtue of polarization mechanisms such as hysteresis loss, eddy current loss and residual loss, and consumes the electromagnetic energy by converting the electromagnetic energy into heat energy or other forms of energy by virtue of electric or magnetic loss of the material. The electromagnetic wave absorbent is combined with the rubber to prepare the composite functional material with low reflectivity, scattering and transmittance. When applied to an electronic device, the product of the rubber with the excellent flame retardant and wave absorbing performance can absorb the additional electromagnetic waves, thereby reducing the influence of electromagnetic wave radiation for the device and human body.

Owner:苏州铂韬新材料科技有限公司

Pressureless sintering preparation method of boron carbide composite material

The invention discloses a pressureless sintering preparation method of a boron carbide composite material. Preparation raw materials comprise 83-94.9% of boron carbide, 1-6% of hafnium boride, 1-5% oftitanium dioxide, 0.1-6% of carbon, 2-20% of a binder, 0.5-5% of polyimide and 0.5-2% of a dispersing agent. The pressureless sintering preparation method comprises the following steps: ball milling,spray drying, sieving and drying, mixing, compression molding, biscuit vacuum sintering and the like. The boron carbide ceramic composite material is reasonable in compatibility; on the basis of boron carbide powder, a certain amount of hafnium boride and titanium dioxide are added as toughening phases, and optimized preparation process conditions are controlled, so that the prepared boron carbide composite material has the characteristics of high hardness, small specific gravity, high temperature resistance, good chemical stability, small thermal expansion coefficient, good thermal conductivity and the like, and meanwhile, the toughness is improved.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

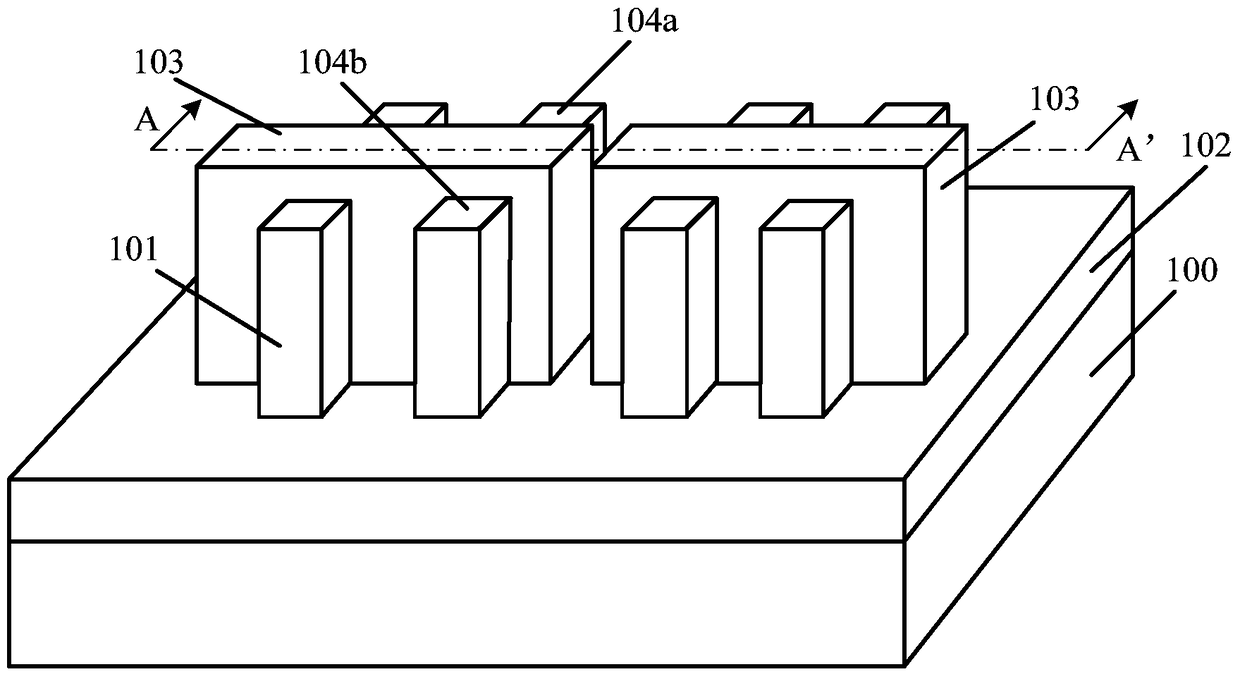

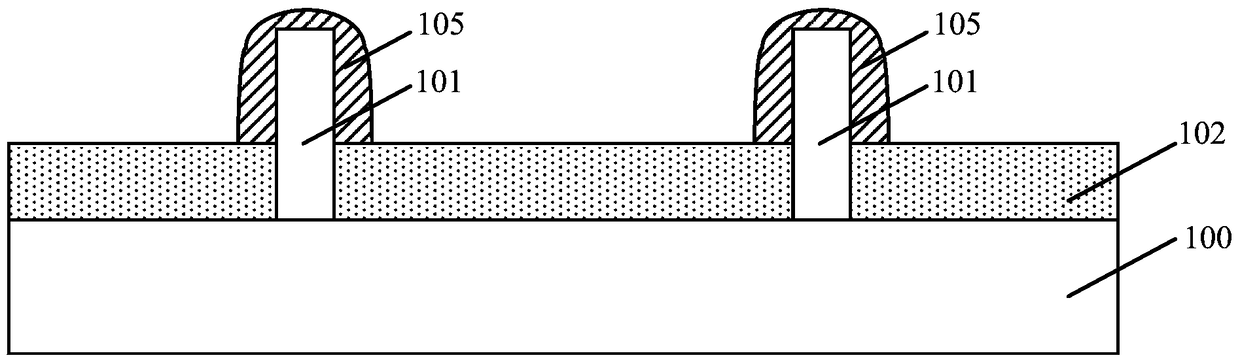

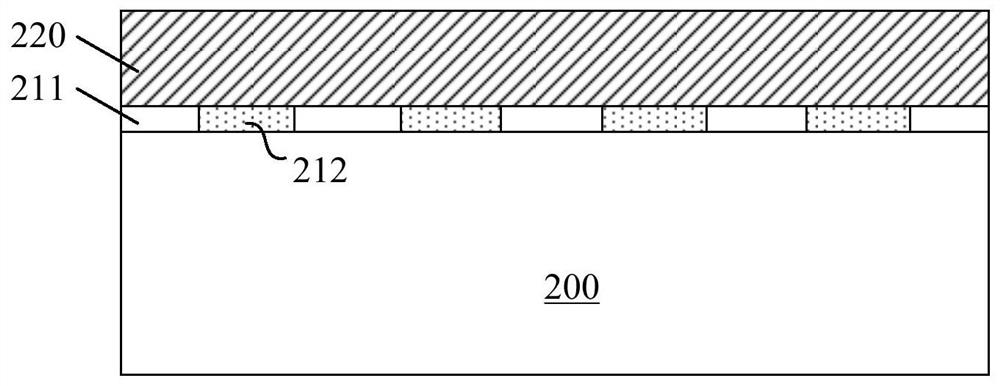

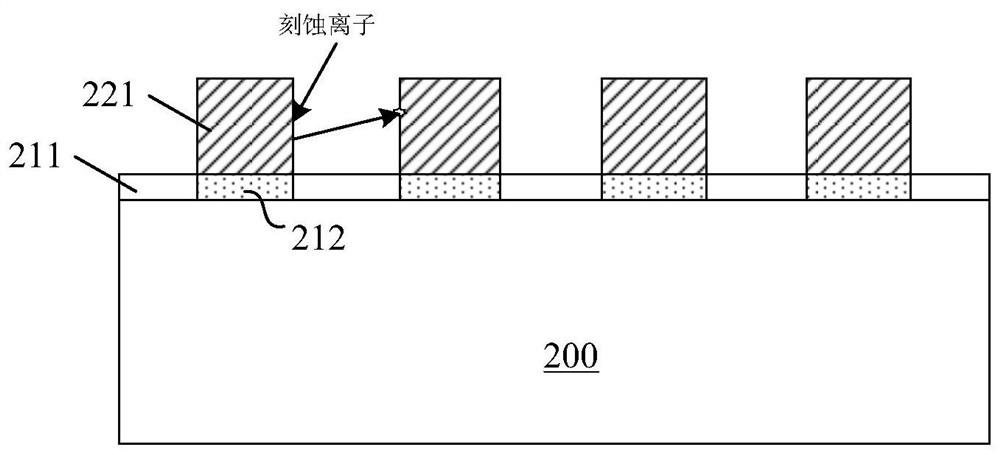

Formation method of semiconductor structure

ActiveCN105261566BUniform distribution densityUniform thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureEngineering

Owner:SEMICON MFG SOUTH CHINA CORP

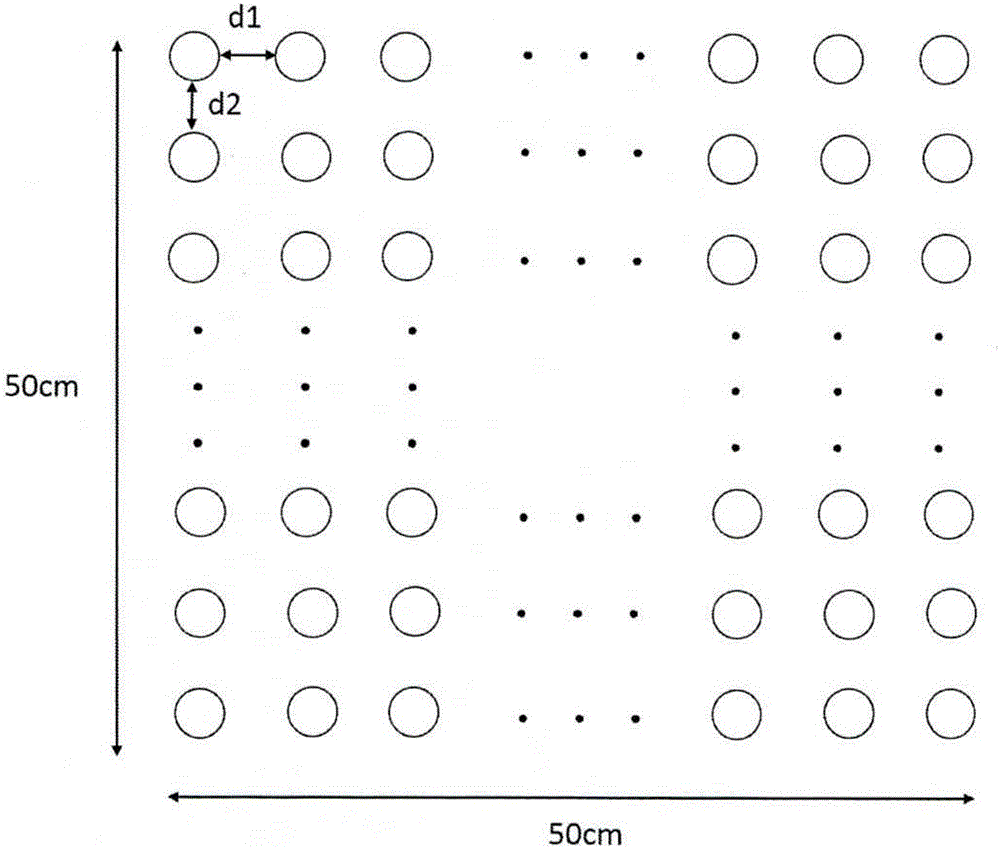

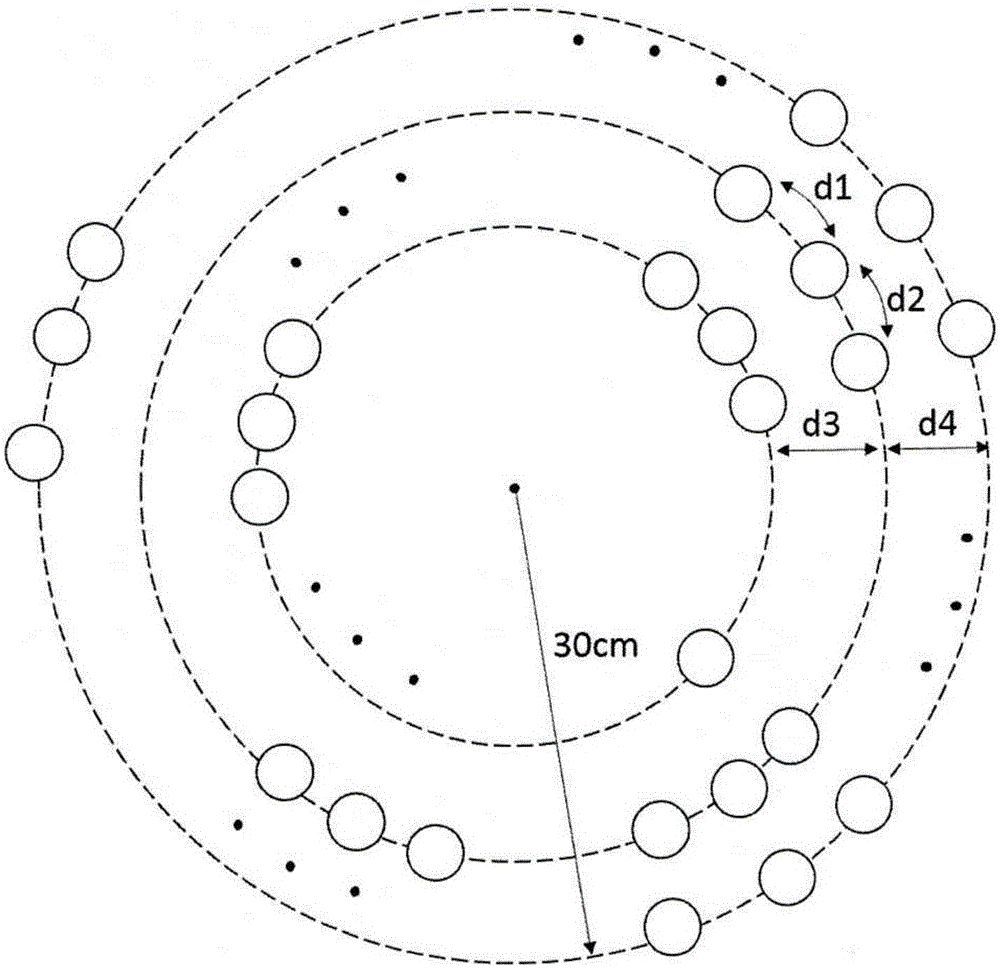

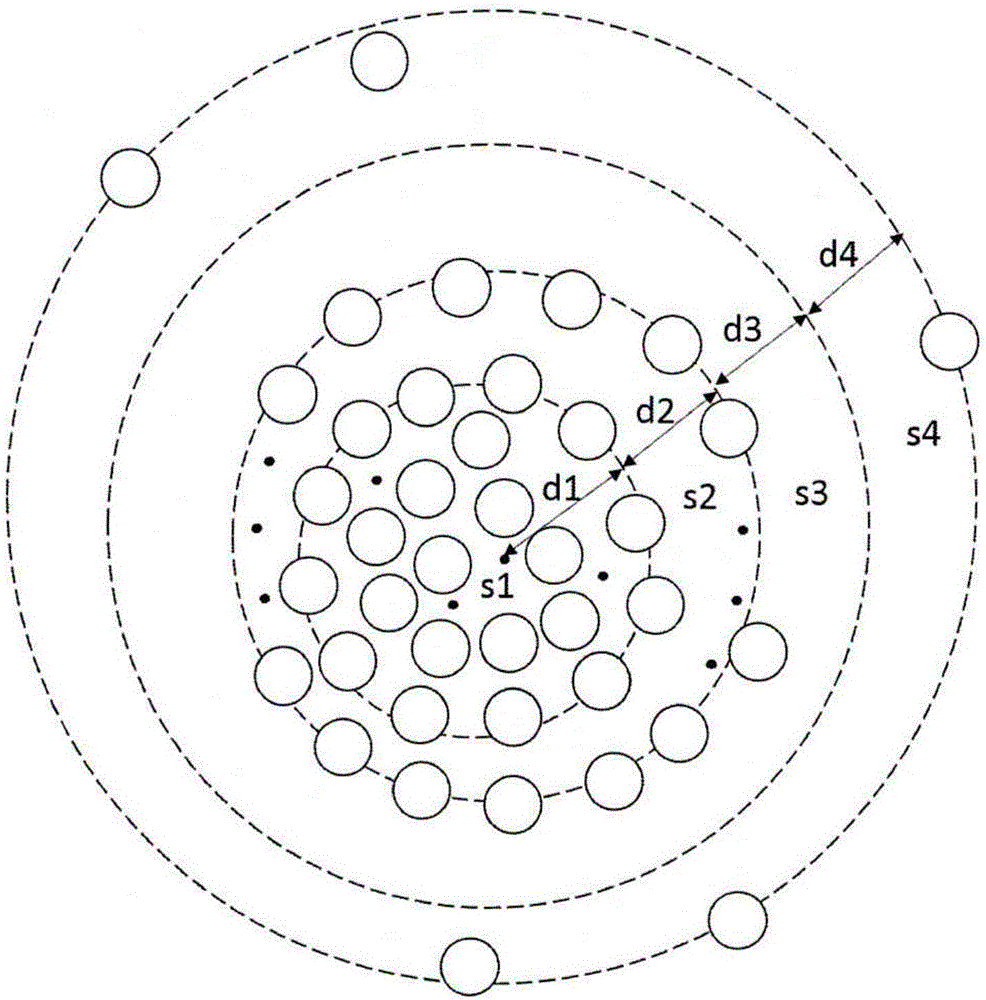

Arrangement structure of pressure sensor

ActiveCN105844086AHigh measurement accuracyReduce usageSpecial data processing applicationsInformaticsSensing dataData acquisition

The invention discloses an arrangement structure of a pressure sensor. The arrangement structure comprises pressure sensors which are subjected to Gaussian distribution arrangement and form a plurality of concentric circle structures, and the density arrangement of each pressure sensor is subjected to the Gaussian distribution arrangement. The pressure sensors are subjected to the Gaussian distribution arrangement, so that the measurement precision of the sensors can be effectively improved, the use amount of the sensors is reduced, crosstalk among the sensors and the complexity of sensing data acquisition are reduced, the certainty of sensor node position selection is improved, and the influence of a random arrangement error is lightened.

Owner:ENG UNIV OF THE CHINESE PEOPLES ARMED POLICE FORCE

High-flame-retardant organic silicon foam sheet and preparation method thereof

ActiveCN112795198AImprove buffering effectHigh tear strengthCell component detailsPower batteryPtru catalyst

The invention discloses a high-flame-retardant organic silicon foam sheet. The foam sheet is prepared from the following raw materials: a halogen-free flame retardant, vinyl-terminated polysiloxane, a polysiloxane coupling agent with a side chain containing a silicon-hydrogen group, a catalyst, an inhibitor, polysiloxane with a side chain containing a silicon-hydrogen group, a foaming agent and a reinforcing filler. In the high-flame-retardant organic silicon foam sheet, inorganic flame retardant particles are uniformly dispersed and serve as physical cross-linking points, so that the cross-linking density of organic silicon foam is greatly improved; and the inorganic flame retardant particles serve as bubble nucleation centers during foaming at the same time, so that generated foam pores are more uniform in size and distribution, and the buffering performance, the tearing strength, the pressure change performance and the elongation of the organic silicon foam are greatly improved. The organic silicon foam has the advantages of being excellent in buffering performance, high in tearing strength, large in elongation, good in pressure change performance and excellent in flame retardant performance, the flame retardant performance reaches the UL942.5mm V0 grade, and the organic silicon foam is quite suitable for vibration buffering and sealing of a lithium ion power battery pack of a new energy automobile.

Owner:广德祥源新材科技有限公司

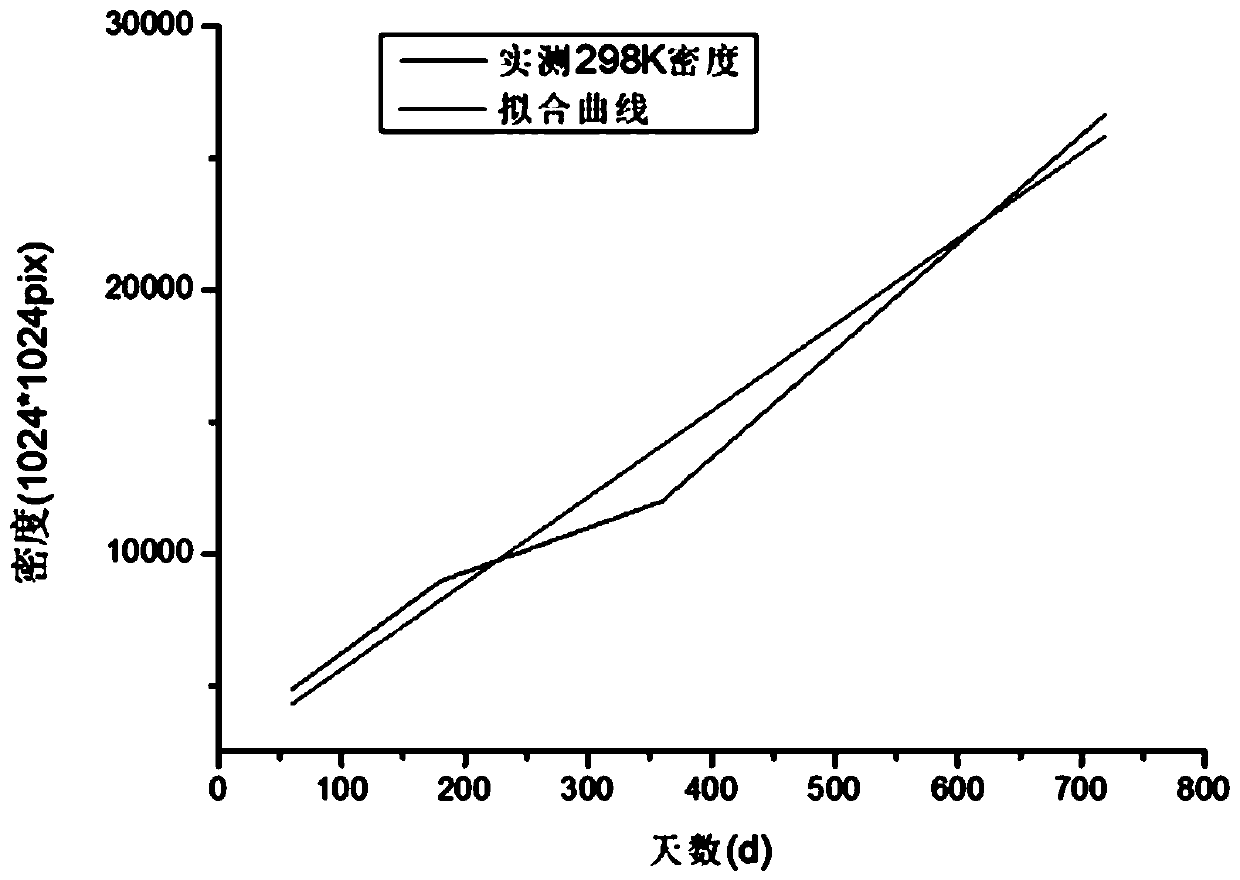

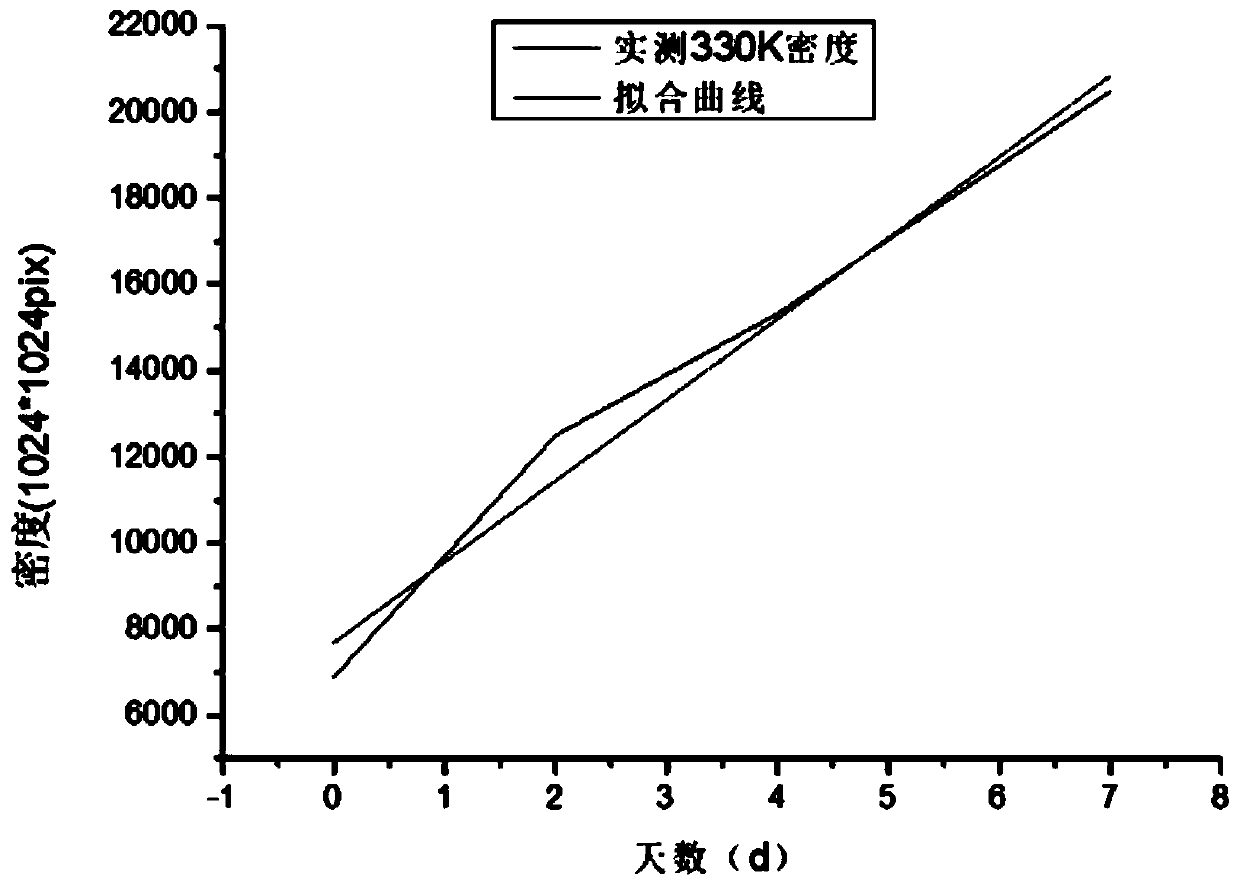

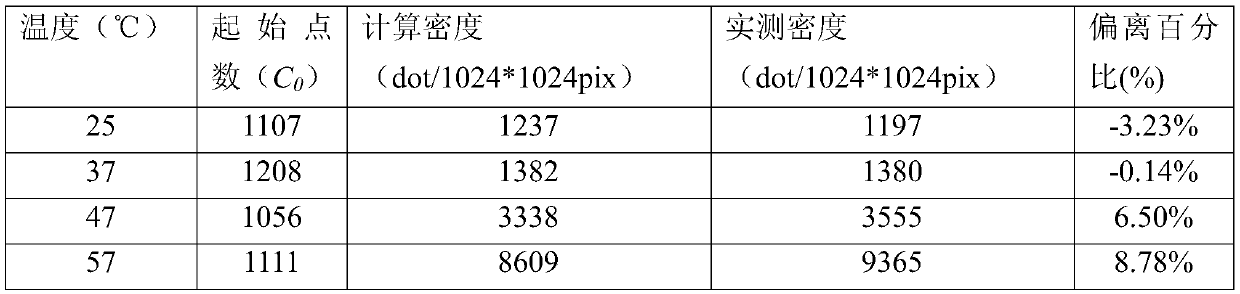

Solid phase substrate, processing method thereof, and method for determining processing conditions

ActiveCN111100785AStable distribution densityUniform distribution densityBioreactor/fermenter combinationsBiological substance pretreatmentsPhysical chemistryAnalytical chemistry

The invention relates to a solid phase substrate, a processing method thereof, and a method for determining processing conditions. The solid phase substrate is provided with at least one silanized surface; the surface is exposed in specific environment for a certain time and can realize that the amount of nucleic acid molecules fixed on the surface achieves an expected value; the specific environment is inert gas environment, and the temperature of the specific environment is selected from 37 DEG C to 60 DEG C; and the certain time meets a preset relation, and the preset relation is the relation between the duration that the surface is exposed in the specific environment and the amount of the nucleic acid molecules fixed by the surface. Thus, the accuracy of chip aging experiments can be enhanced; and the solid phase substrate can be accurately used for guiding the production or research and development of chips, especially for application scenes with high requirements for the chips.

Owner:GENEMIND BIOSCIENCES CO LTD

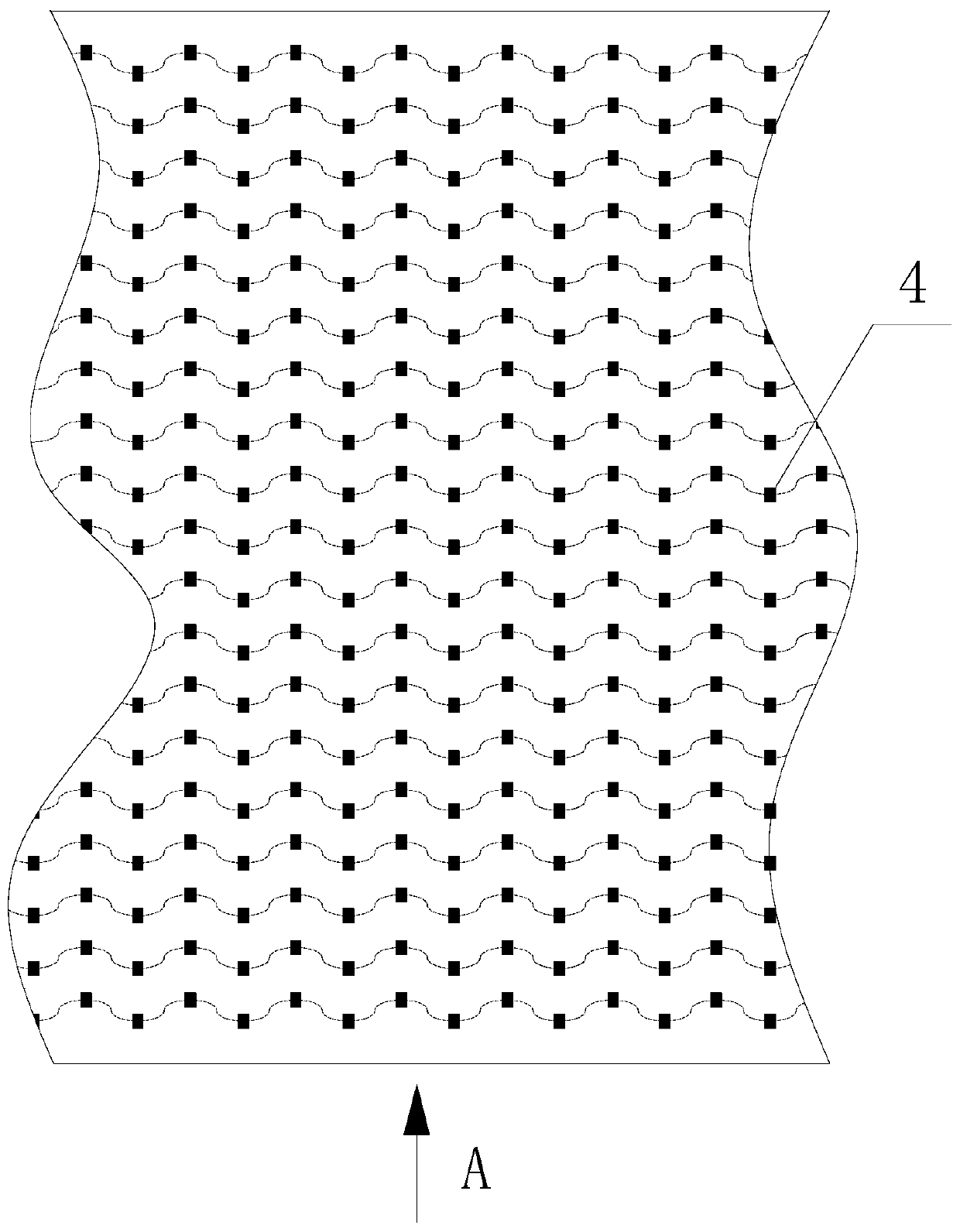

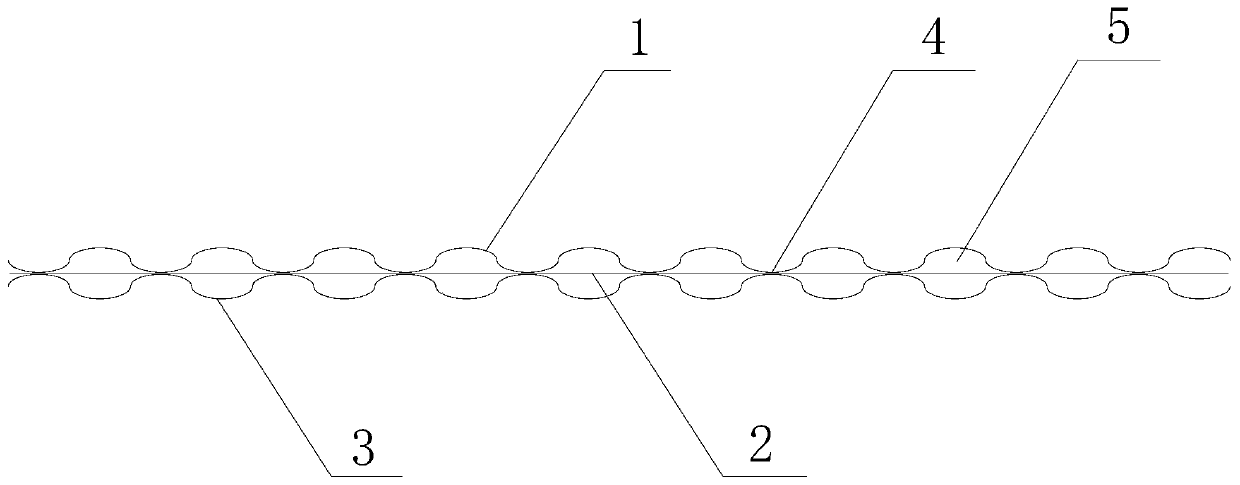

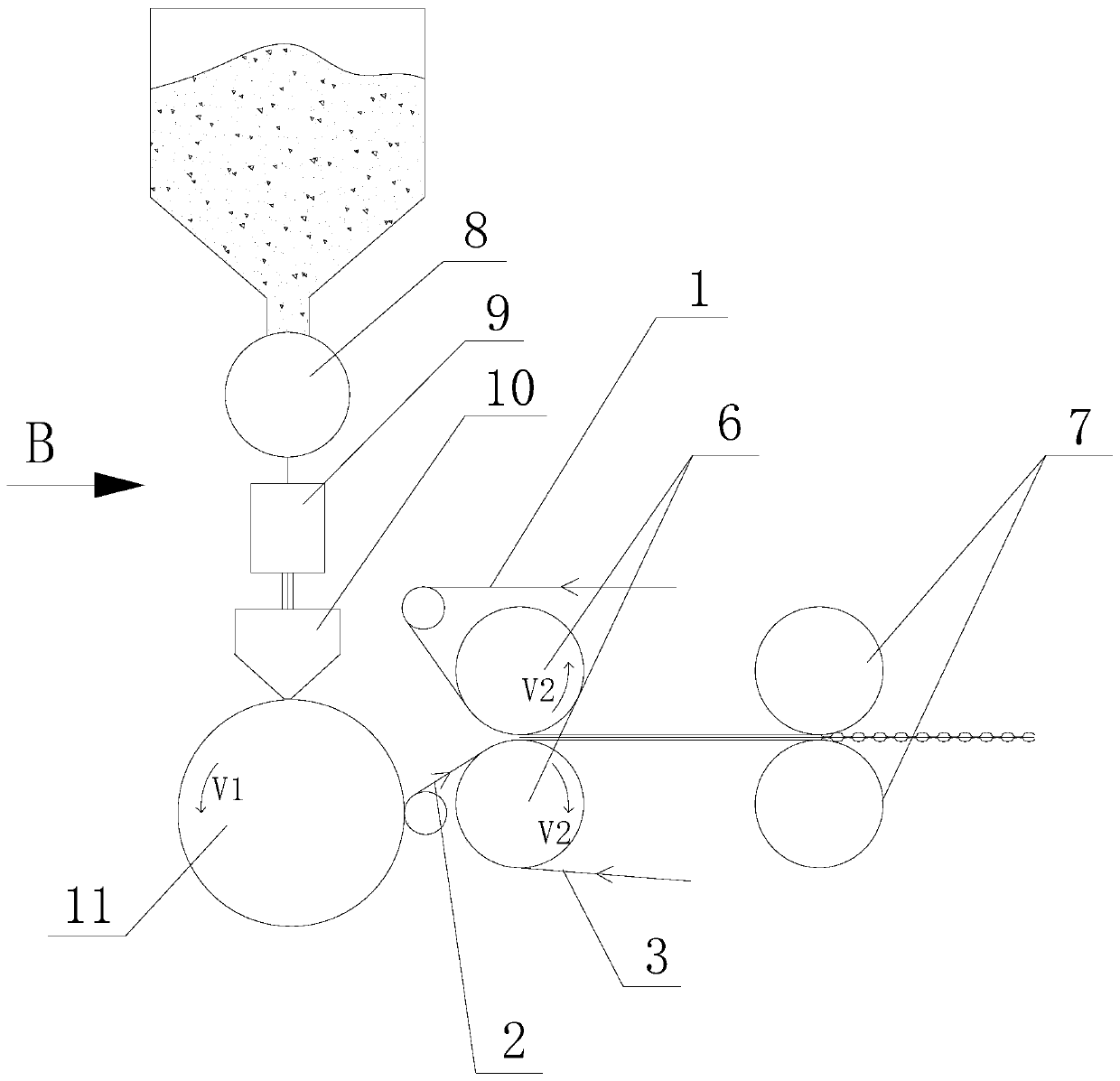

Composite elastic sheet and manufacturing method and manufacturing equipment thereof

InactiveCN111590983AImprove breathabilityReduce manufacturing costPersonal careSynthetic resin layered productsFiberMechanical engineering

The invention discloses a composite elastic sheet as well as a manufacturing method and manufacturing equipment thereof. The composite elastic sheet comprises a first surface layer, a middle elastic layer and a second surface layer which are sequentially compounded, wherein the middle elastic layer is of a layered structure formed by distributing a plurality of continuous elastic fiber filaments or strip-shaped fiber layers side by side, and the middle elastic layer is compounded with the first surface layer and the second surface layer in an intermittent mode. According to the manufacturing method and the manufacturing equipment of the composite elastic sheet, the middle elastic layer is formed on line through an extruder and a wire extruding plate and is intermittently compounded with the first surface layer and the second surface layer in a stretching state, and finally the composite elastic sheet is formed. The manufacturing principle is simple, the formed composite elastic sheet has higher air permeability, the production cost is lower, the stretching ratio can be adjusted in the production process according to the product requirements of practical application, and the composite elastic sheet is suitable for a wider range of applicable disposable hygienic products.

Owner:GUANGZHOU XINGSHI EQUIPS

Pallet and plasma processing equipment for induction heating

InactiveCN103422073AHeating evenlyReduce temperature differenceChemical vapor deposition coatingInduction heating apparatusEddy currentEngineering

The invention provides a pallet for induction heating. The pallet comprises a pallet body made of a magnetic conductive material, and is characterized in that a plurality of adjusting parts are arranged at the circumferential direction of the pallet body at intervals; and the adjusting parts are used for guiding eddy current in the edge area of the pallet body and generated by electromagnetic induction to a central area of the pallet body. The pallet for induction heating provided by the invention can uniformly heat the workpiece to be processed, thereby increasing technical uniformity of the workpiece to be processed.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

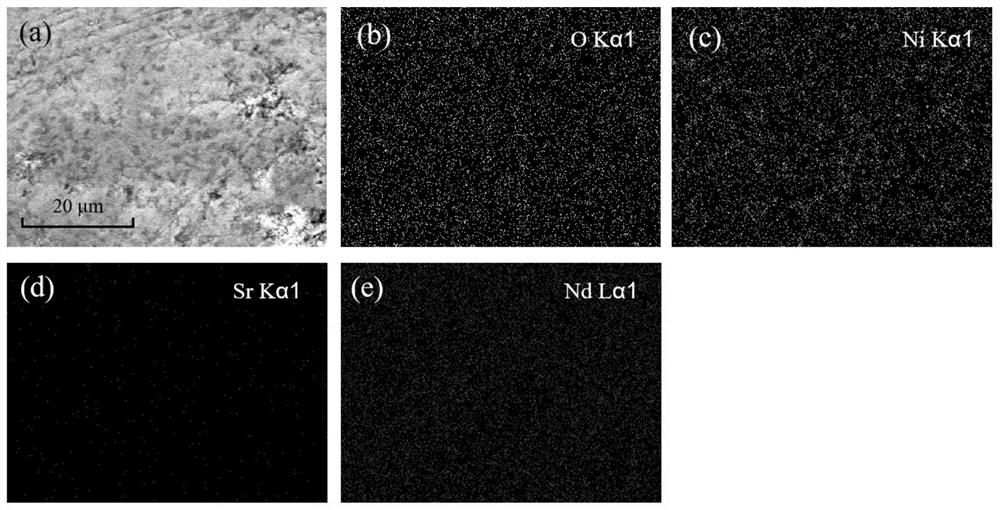

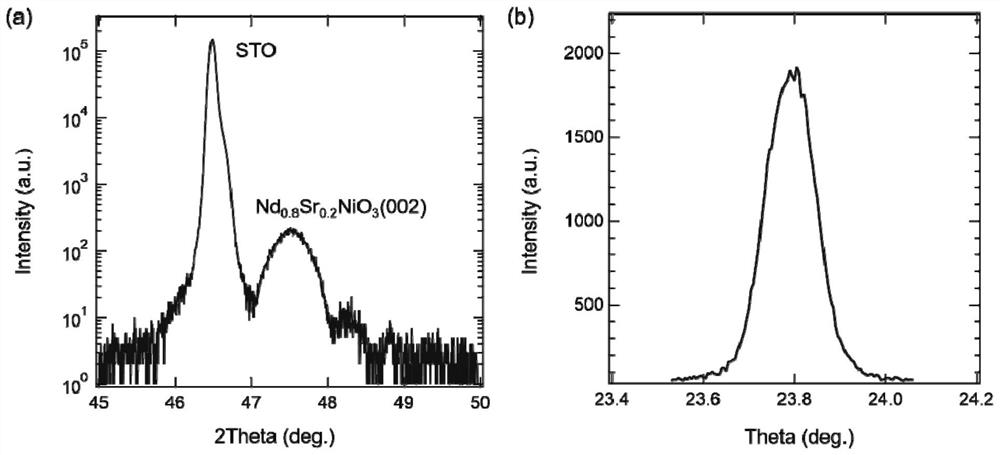

Nickel-based target material and preparation method and application thereof

ActiveCN112479710AWell mixedHigh mechanical strengthVacuum evaporation coatingSputtering coatingThin membraneSingle crystal

The invention relates to the field of ceramic target materials, and particularly relates to a nickel-based target material and a preparation method and application thereof. The Nd<1-x>AxNiO3 ceramic target material which is pure in component, uniform in element and density distribution and good in mechanical strength, hardness and density is prepared through a production process of ball-milling, presintering, secondary ball-milling, granulation, blank making, rubber discharging, programmed temperature rising and sintering and programmed cooling, a Nd<1-x>AxNiO3 film can be obtained through magnetron sputtering growth of the Nd<1-x>AxNiO3 ceramic target material, and the film has good crystallinity and high-quality single crystal epitaxy property. In addition, the invention further providesthe Nd<1-x>AxNiO2 film, and the Nd<1-x>AxNiO2 film has excellent superconducting characteristics and electrical transport properties.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

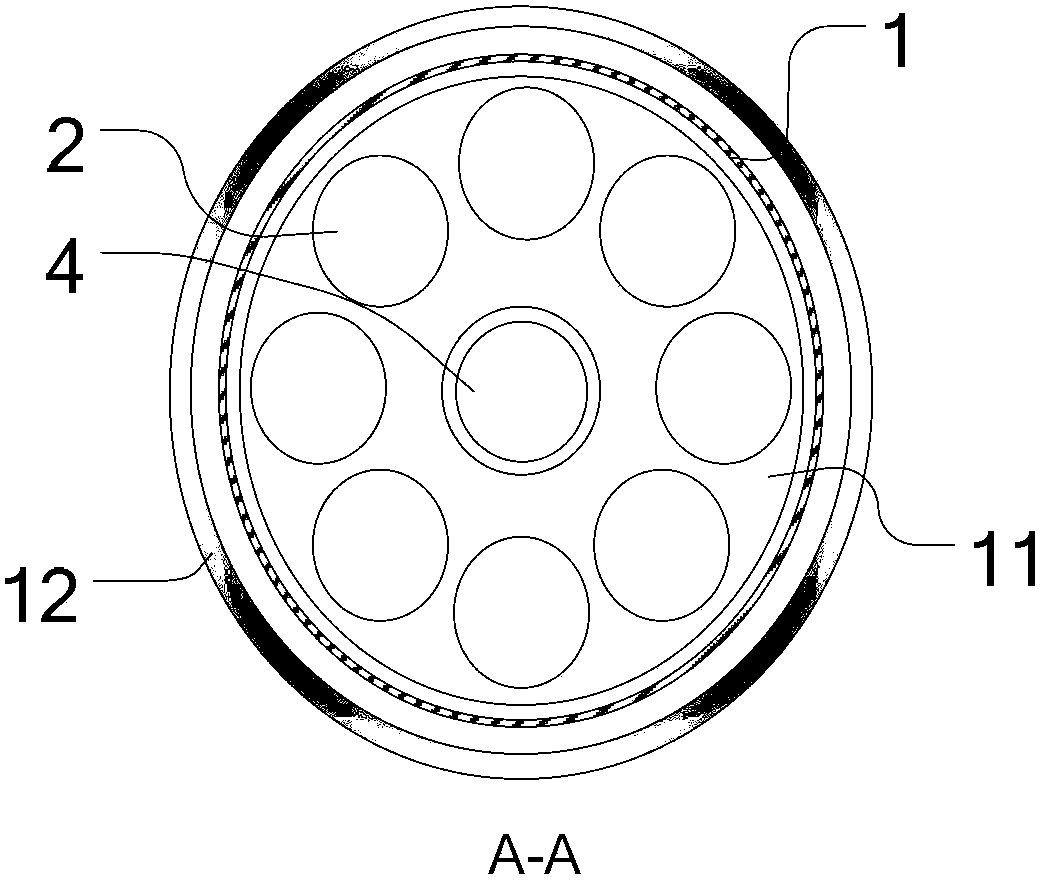

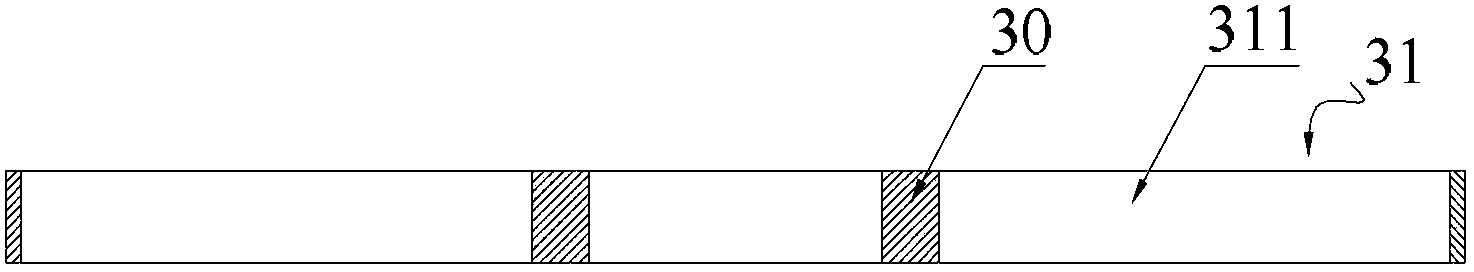

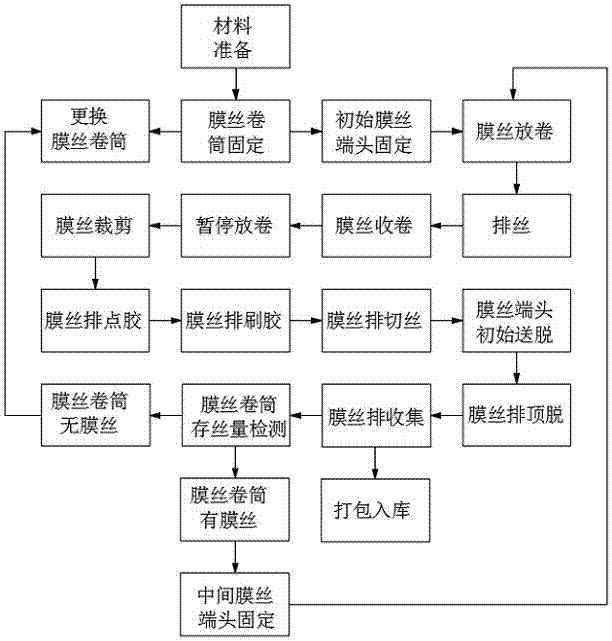

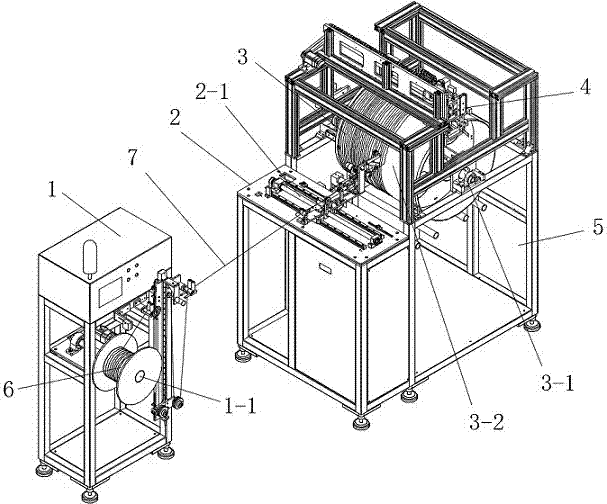

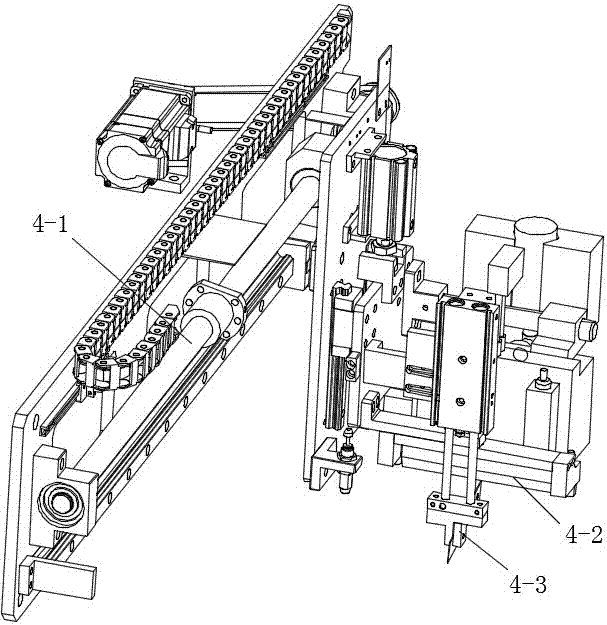

Membrane filament array production technology based on membrane filament array filament dispenser

ActiveCN107265569AUniform distribution densityOrderly rowsSemi-permeable membranesLiquid surface applicatorsVolumetric Mass DensityEngineering

The invention discloses a membrane filament array production technology based on a membrane filament array filament dispenser. The membrane filament array filament dispenser comprises an unreeling work station, a filament arraying work station, a rolling work station, a dispensing filament cutting work station, and a collecting work station. The membrane filament array production technology based on the membrane filament array filament dispenser comprises following steps: fixing of membrane filament terminal, unreeling of membrane filament, filament arraying, rolling, cutting, membrane filament array dispensing, brush coating, filament cutting, removing, collecting, and detection of membrane filament coiling block filament storage amount. Membrane filament array produced using the membrane filament array filament dispenser and the membrane filament array production technology possesses following advantages: membrane filament arrangement density is uniform, dispensing thickness is uniform, production efficiency is high, quality is ensured, labor cost is reduced effectively, and market competitiveness of enterprise is increased.

Owner:ZHEJIANG AET INTELLIGENT TECH

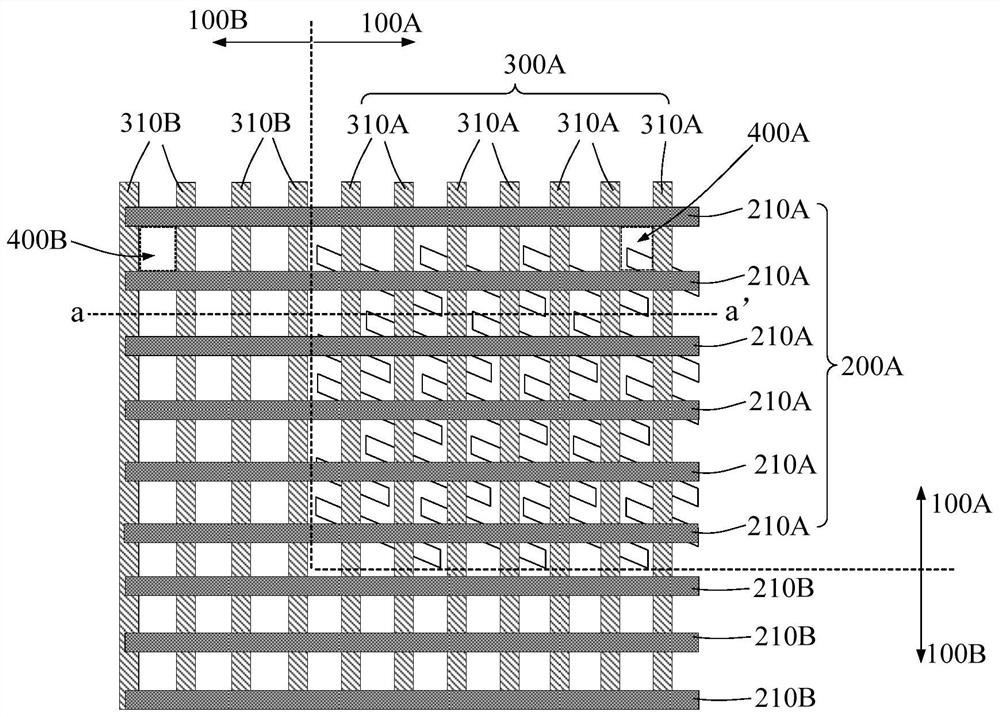

Magnetic random access memory and forming method thereof

PendingCN111816671AImprove performanceIncrease spacingMagnetic-field-controlled resistorsSolid-state devicesContact padRandom access memory

The invention discloses a magnetic random access memory and a forming method thereof, and the magnetic random access memory comprises: a substrate, wherein a conductive contact pad is formed on the surface of the substrate; and a magnetic storage layer which is positioned on the surface of the substrate, wherein the magnetic storage layer comprises at least two sub-storage layers stacked on the surface of the substrate, the magnetic storage layer comprises a plurality of magnetic storage units which vertically penetrate through each sub-storage layer and are connected with the conductive contact pad, the plurality of magnetic storage units are arranged according to an array form of rhombus array units, each magnetic storage unit comprises a magnetic tunnel junction, and each sub-storage layer comprises at least one magnetic tunnel junction. The magnetic random access memory has relatively high performance.

Owner:CHANGXIN MEMORY TECH INC

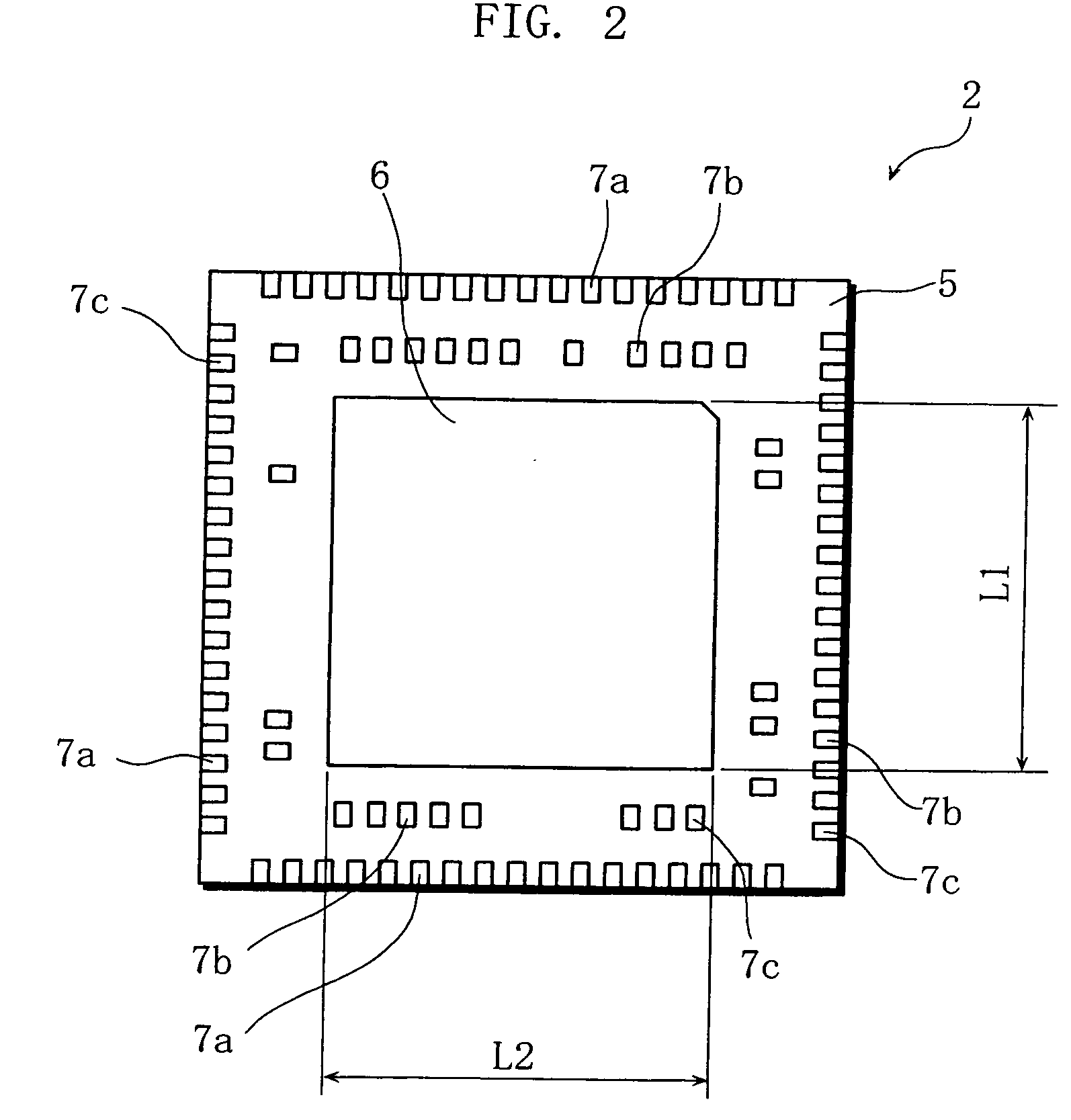

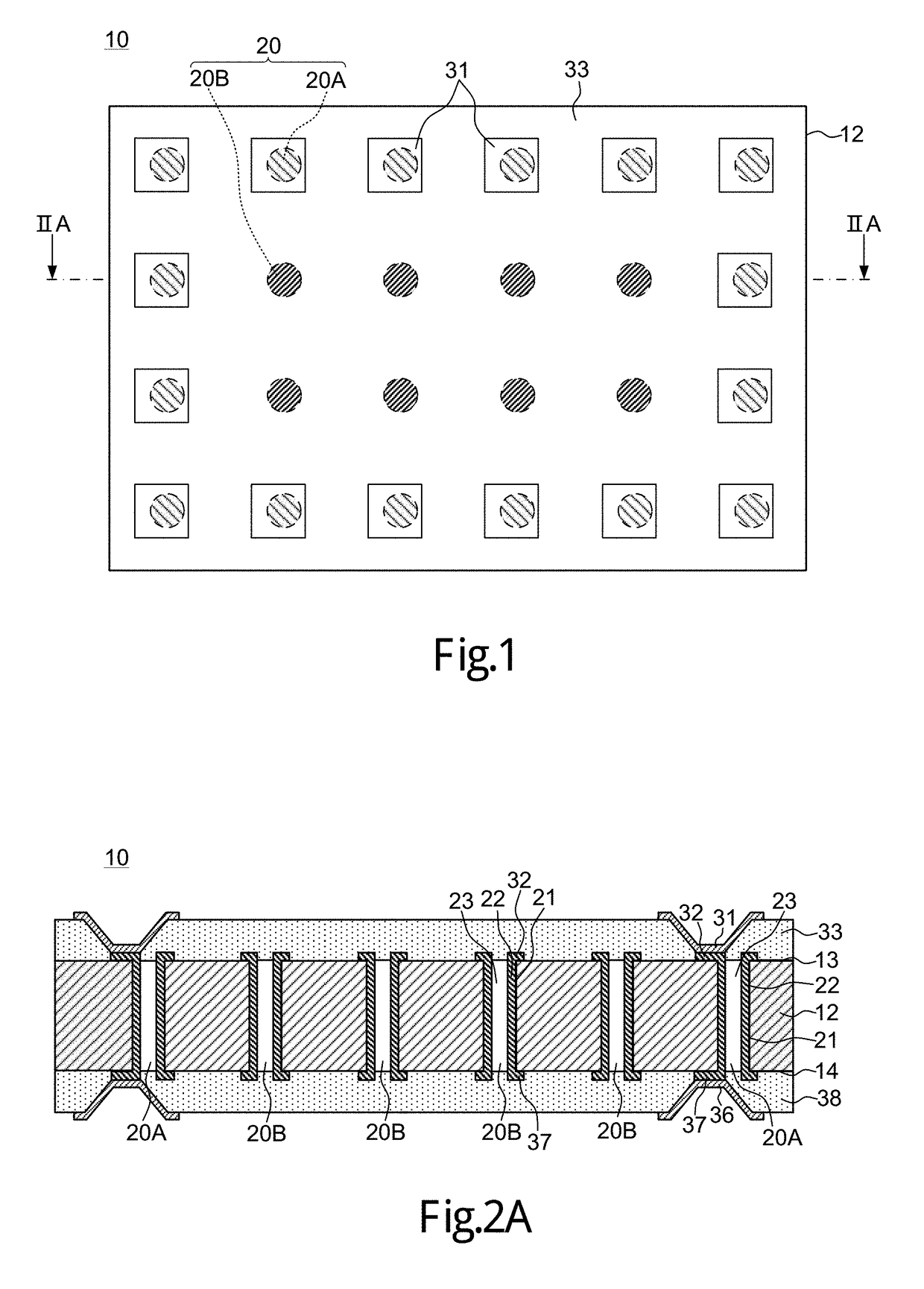

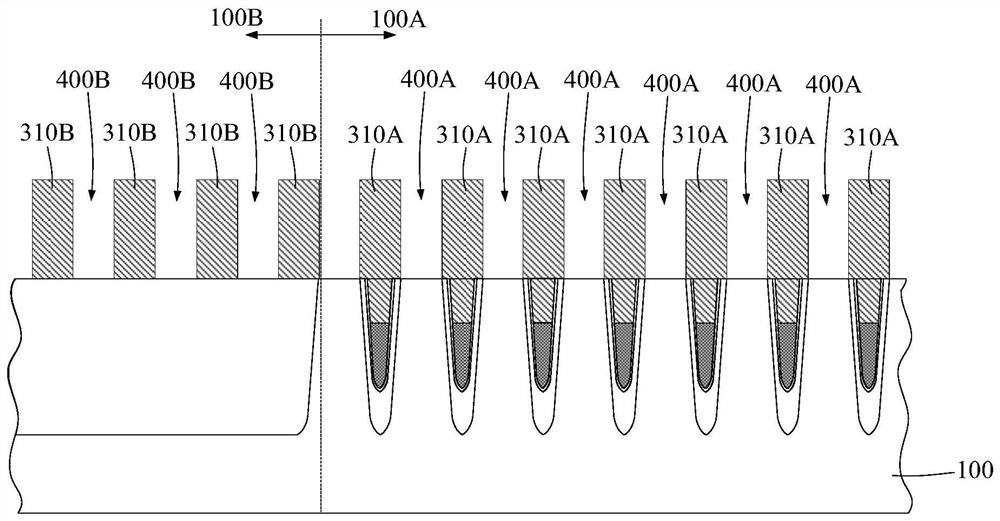

Through electrode substrate and manufacturing method thereof

ActiveUS20190080977A1Avoid it happening againEasy to transformSemiconductor/solid-state device detailsPrinted circuit aspectsBiomedical engineeringElectrode

A through electrode substrate includes: a substrate; a first electrode part provided on a first surface side of the substrate; and a second electrode part provided on a second surface side of the substrate. The plurality of holes includes a plurality of first holes and a plurality of second holes. The hole electrode part of each first hole is electrically connected to the first electrode part on the first surface side of the substrate, and the hole electrode part thereof is electrically connected to the second electrode part on the second surface side of the substrate. The electrode part of each second hole is electrically insulated from the first electrode part on the first surface side of the substrate, or the hole electrode part thereof is electrically insulated from the second electrode part on the second surface side of the substrate.

Owner:DAI NIPPON PRINTING CO LTD

Process reaction chamber and process equipment

InactiveCN103898473AAvoid problems with uneven induction heatingImprove uniformityChemical vapor deposition coatingProcess equipmentVolumetric Mass Density

The invention discloses a process reaction chamber and process equipment. The process reaction chamber comprises a chamber body, a bearing device, a gas inlet device and induction coils, wherein the induction coils are located out of the chamber body and used for generating a magnetic field, the bearing device is arranged in the chamber body and is coaxial with the chamber body, a gas channel is formed between the bearing device and the chamber body, substrates are disposed on the outer peripheral surface of the bearing device and located in the gas channel, and the gas inlet device is used for introducing process gas into the gas channel. According to a technical scheme in the invention, density of magnetic lines passing through the bearing device is uniformly distributed, so the induction coils have a uniform heating temperature in heating of the bearing device, and thus, process uniformity is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

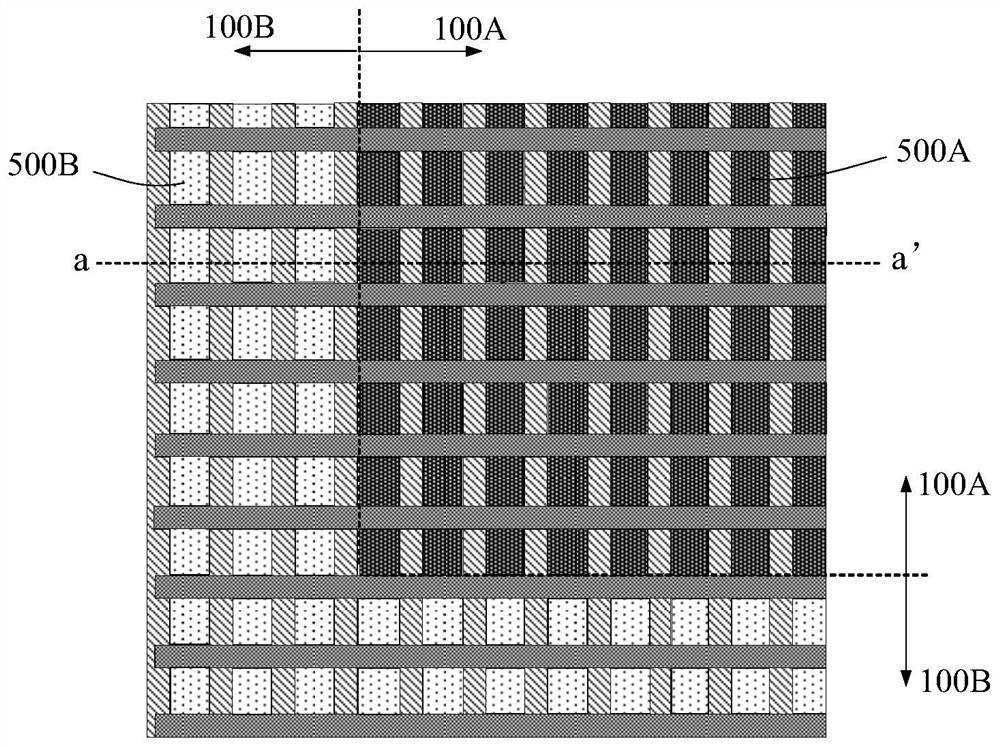

Semiconductor device and forming method thereof

PendingCN111640751AUniform distribution densityReduce the packing densityTransistorSemiconductor/solid-state device detailsBit lineDevice material

The invention provides a semiconductor device and a forming method thereof. A node contact window array is defined by using a bit line group and an isolation line group, an auxiliary line is further arranged, and an auxiliary contact window is defined at the periphery of the node contact window array by utilizing the auxiliary line, at this time, the auxiliary contact window is used, so that the arrangement density of the node contact windows in the edge area and the middle area in the node contact window array can be effectively balanced, the morphology precision of the node contact windows in the edge area is improved, and the morphology uniformity of the node contact windows in the edge area and the node contact windows in the middle area can be further improved.

Owner:FUJIAN JINHUA INTEGRATED CIRCUIT CO LTD

Novel material

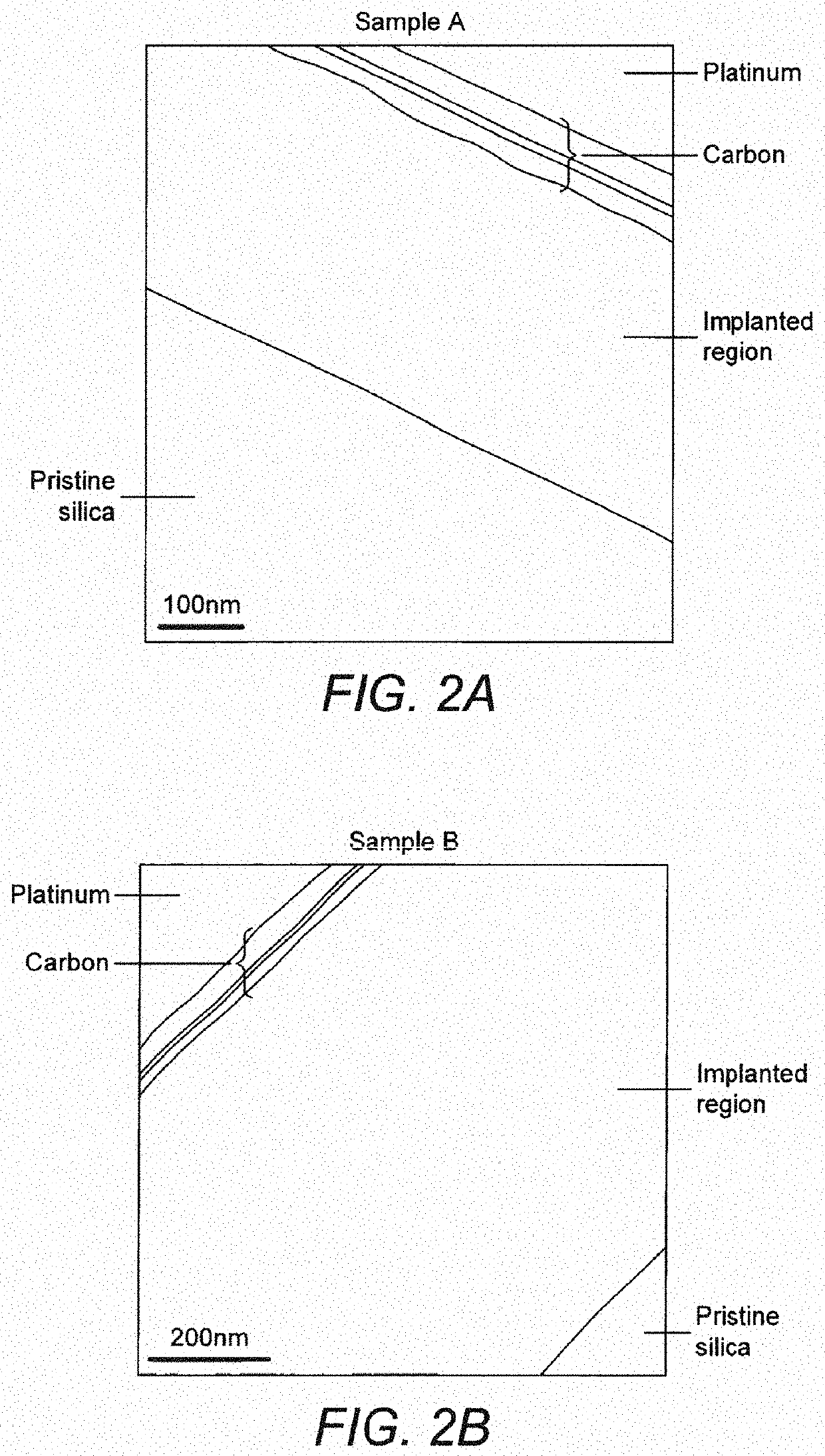

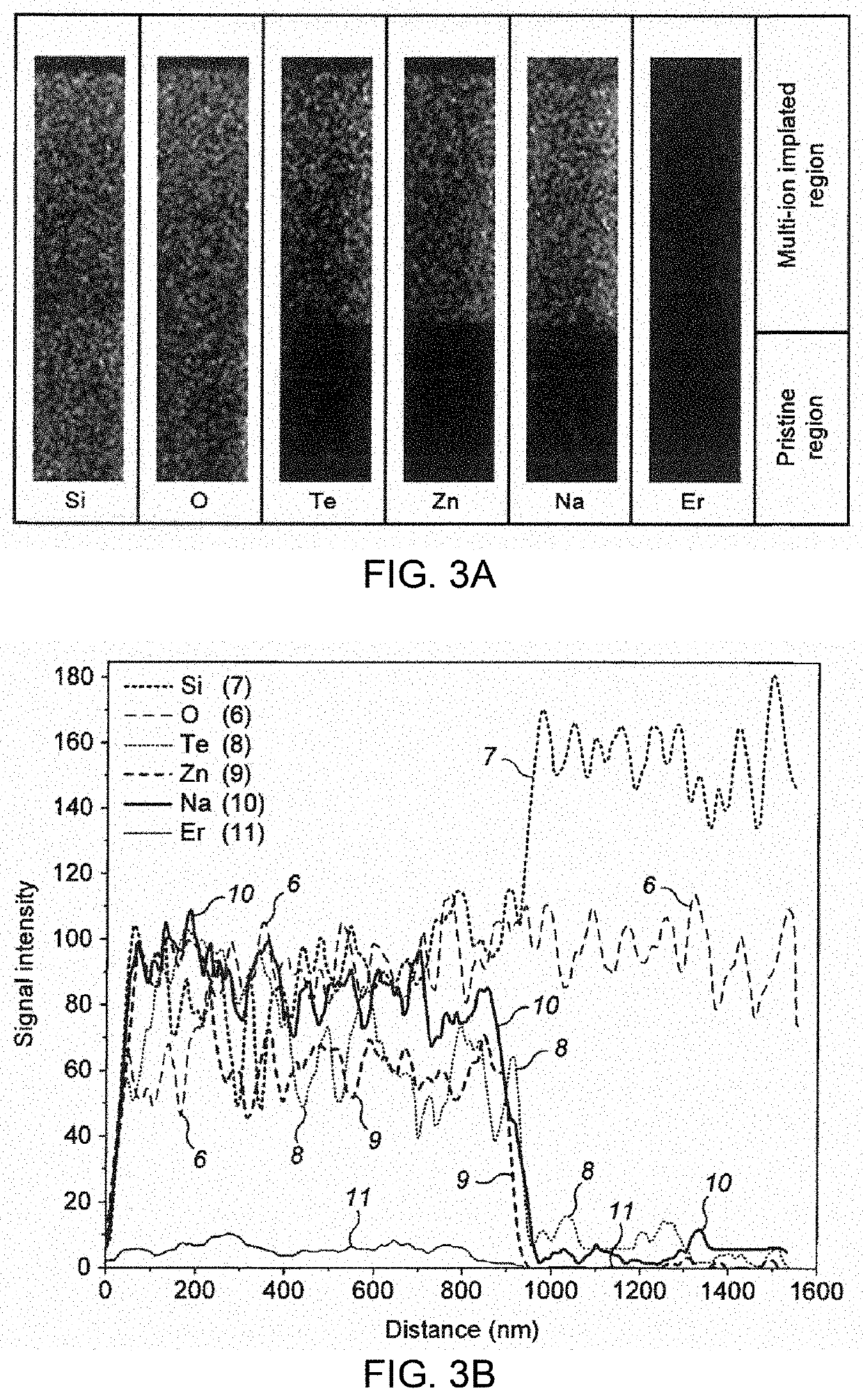

InactiveUS20200239362A1Uniform distribution densityGood light transmissionVacuum evaporation coatingSputtering coatingEngineeringWaveguide

The present invention relates to a substrate comprising an ion-implanted layer, for example a cation, wherein the ion implanted layer has a substantially uniform distribution of the implanted ions at a significantly greater depth than previously possible, to a well-defined and sharp boundary within the substrate. The invention further comprises said substrate wherein the substrate is a silicon based substrate, such as glass. The invention also comprises the use of said material as a waveguide and the use of said material in measurement devices.

Owner:UNIV OF LEEDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com