Patents

Literature

131results about How to "Width is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of biodegradable polymer foamed sheet product

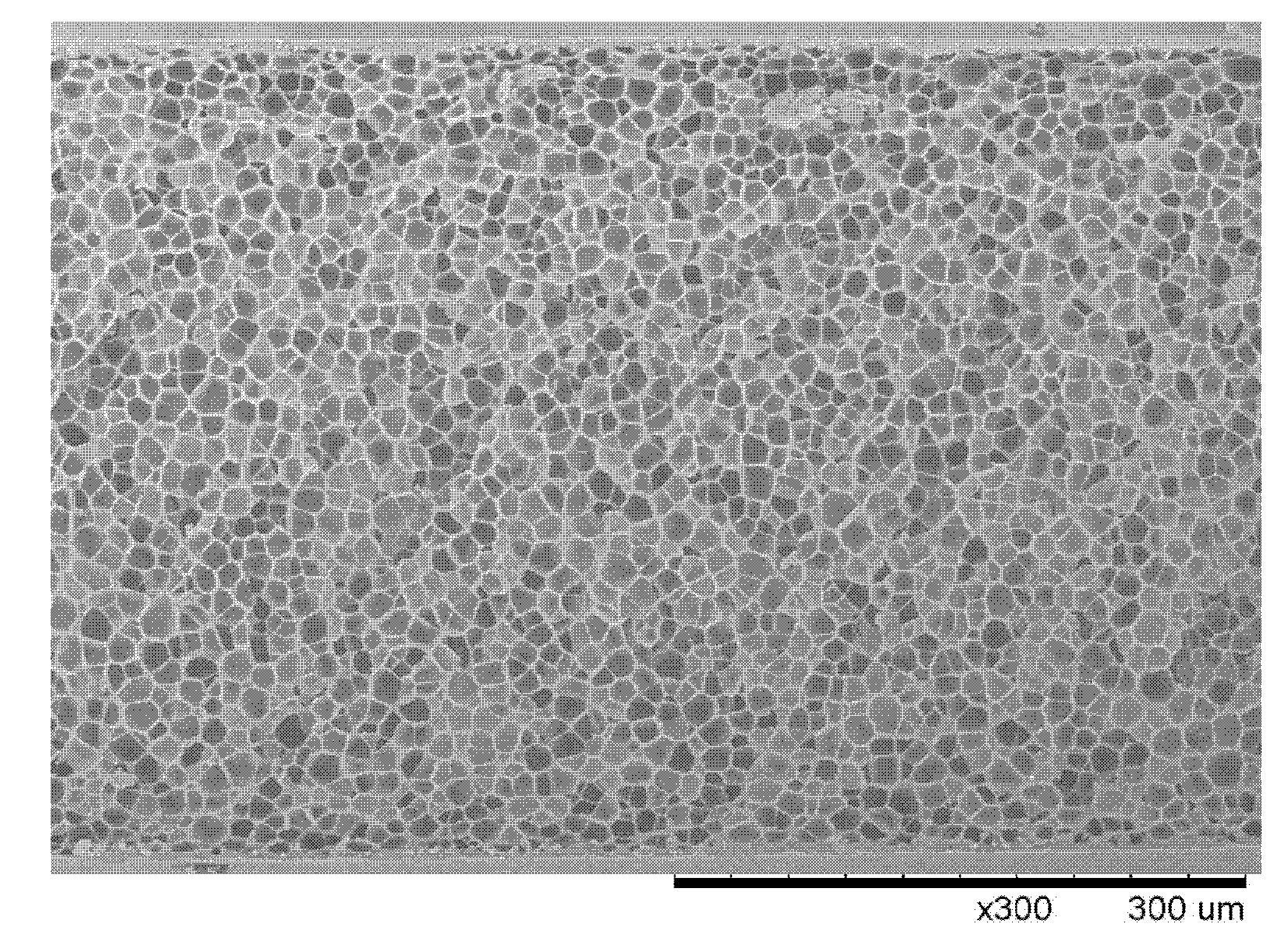

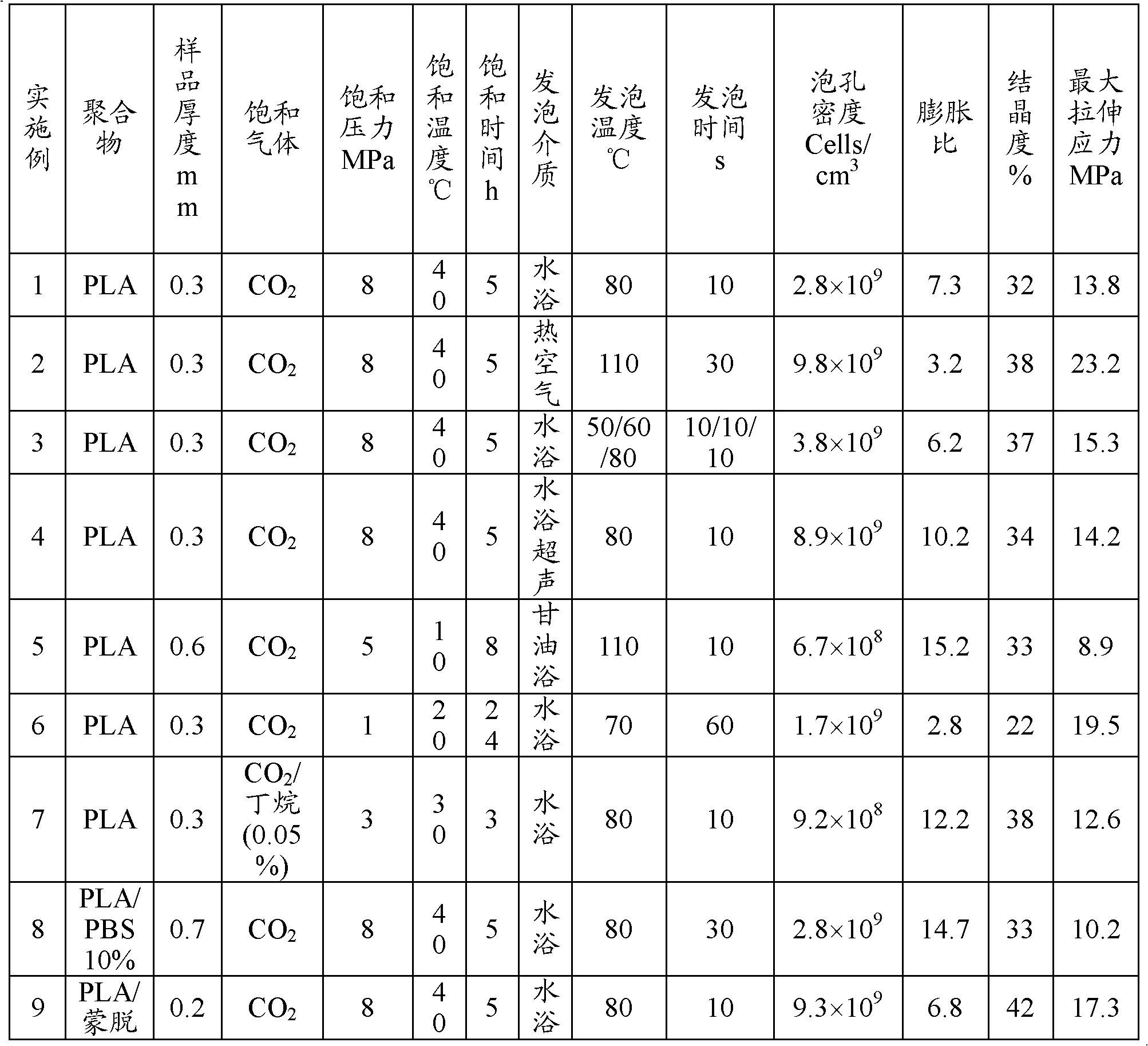

The invention discloses a preparation method of a biodegradable polymer foamed sheet product, comprising the following steps of: putting a polymer sheet into high-pressure fluid with the pressure of 0.5-10MPa to saturate the polymer sheet; then putting the saturated polymer sheet into a hot medium with the temperature of 40-140 DEG C for foaming for 2-300 seconds to obtain a polymer foamed sheet; and forming the polymer foamed sheet by heat treatment to obtain the biodegradable polymer foamed sheet product, wherein the polymer sheet is made of polylactic acid or the blend of polylactic acid and a polymer with an ester group or ether bond, and the thickness of the sheet is 0.1-2.0mm. The process disclosed by the invention is simple to operate, easy to control and favorable for industrial implementation, and the product has the advantages of bright and clean surface, light weight, uniform closed pore structure with the pore size of 5-50 micrometers, high tensile modulus and strength, excellent temperature tolerance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

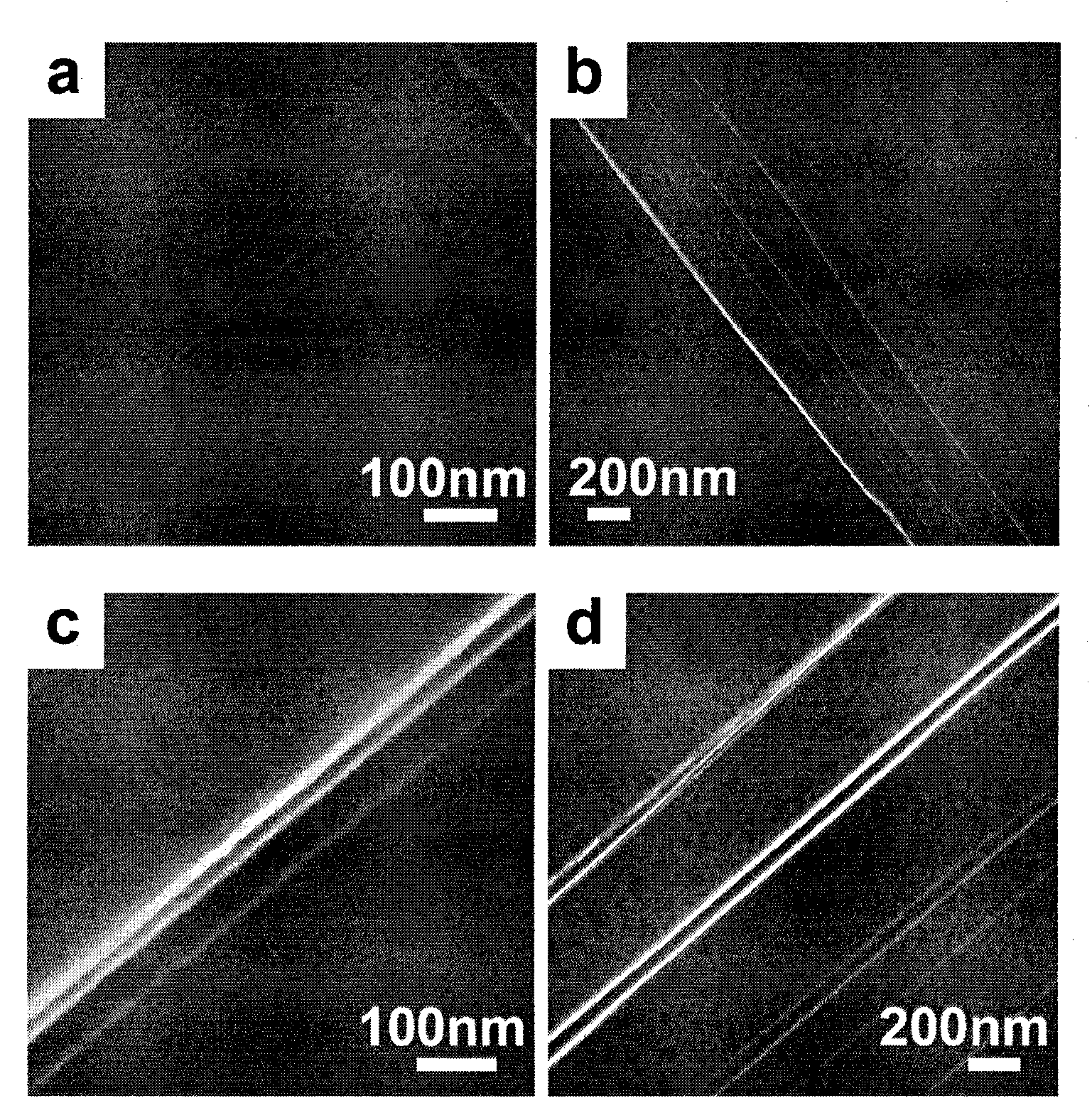

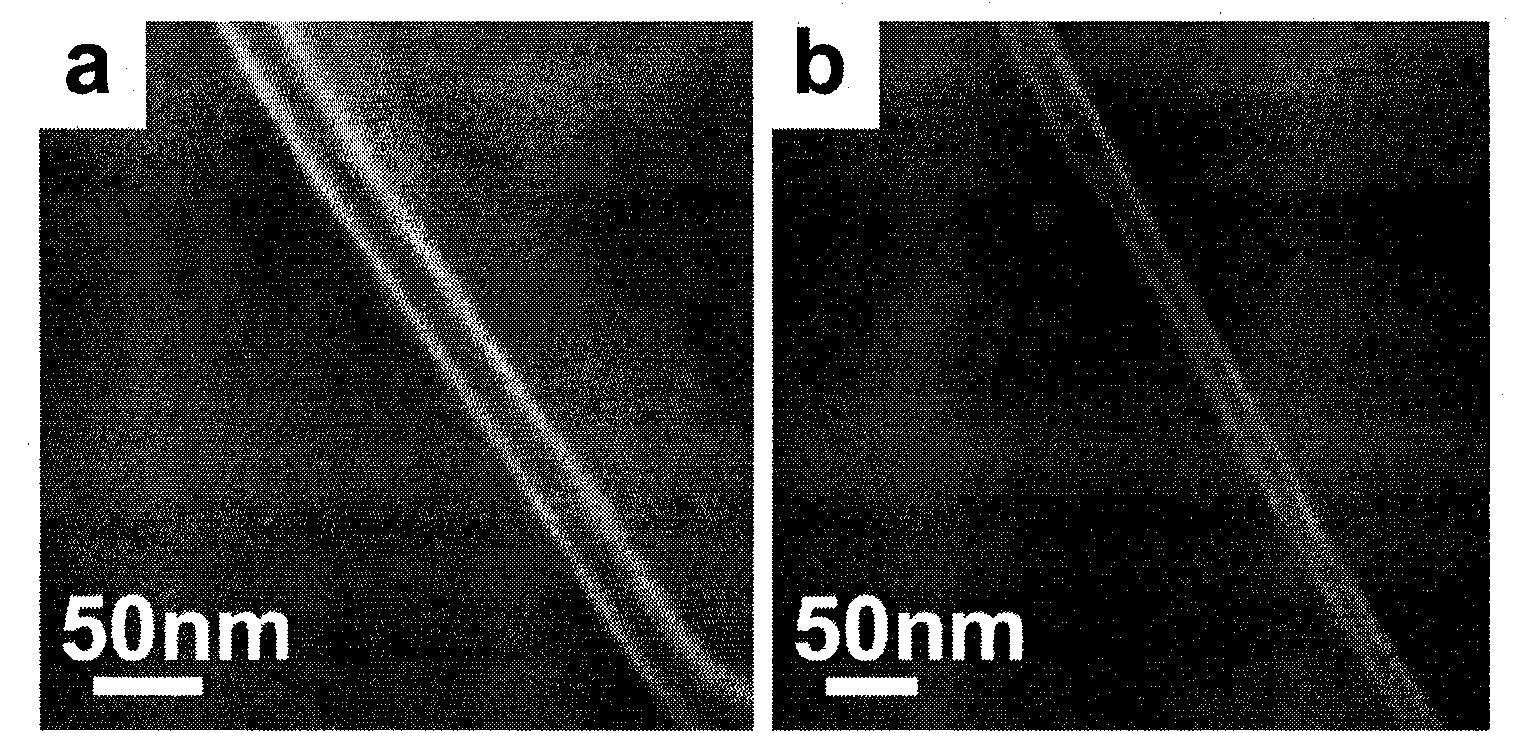

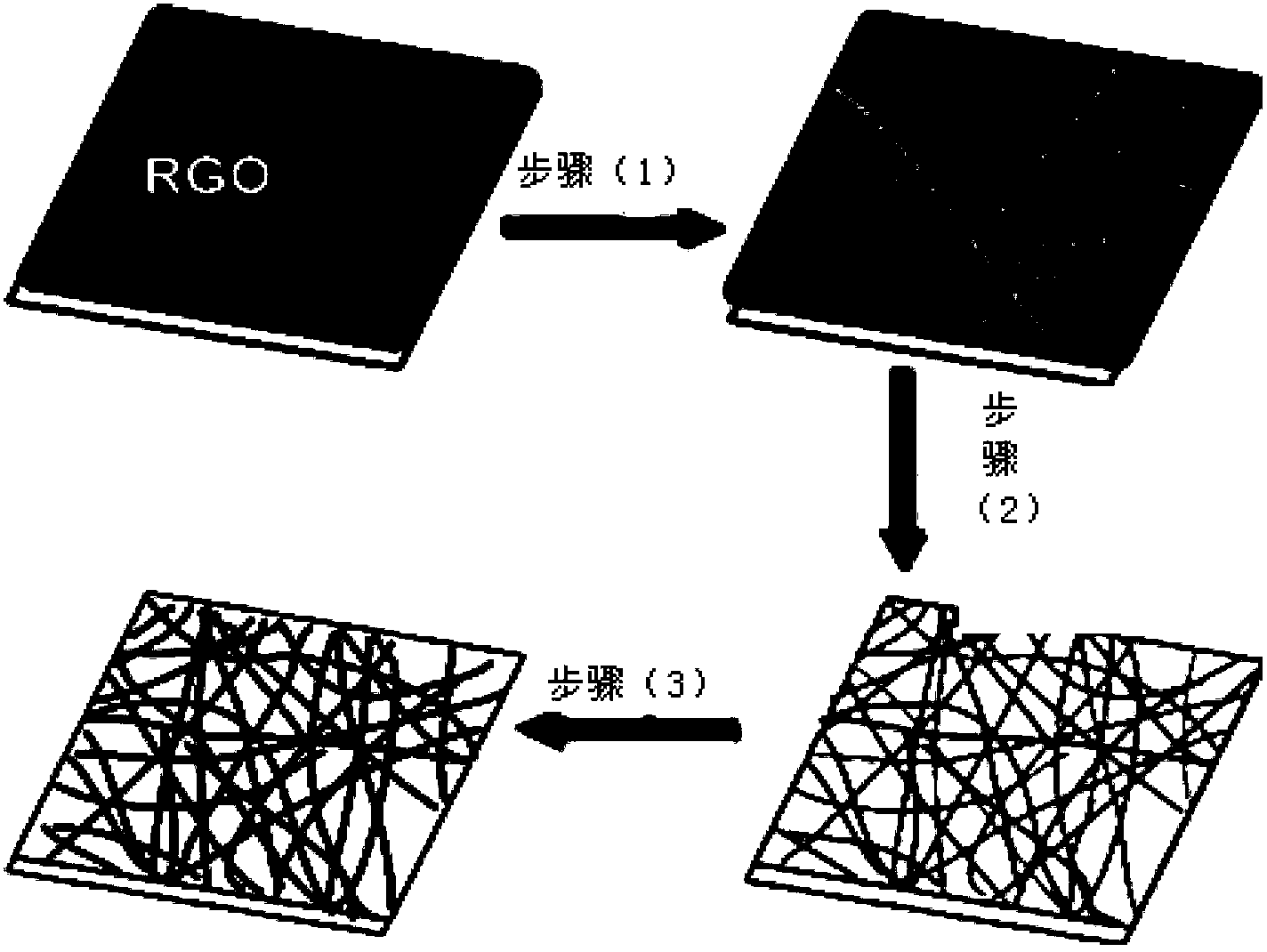

Method for producing graphene belts in controllable macroscopic quantity by chemically cutting grapheme

The invention relates to a technology for producing graphene belts, in particular to a method for producing graphene belts in controllable macroscopic quantity by chemically cutting grapheme. The method comprises the following steps of: firstly obtaining oxidized graphite in a Hummers method, selectively finishing line defects on the surface of the oxidized graphite by utilizing the oxygen-containing functional group in the process of oxidizing the graphite, and producing grapheme with surface line defects by combining high-temperature rapid expansion and peeling, thermal reduction, solvent dispersion and centrifugal separation; then cutting the graphene and recovering the structure of the graphene by utilizing ultrasonic shearing and chemical reduction; and finally removing large pieces of incompletely cut grapheme in a high-speed centrifuging method to further produce the graphene belt with controllable layer number and width. The method can be used for producing the graphene belt with controllable layer number, width and boundary by controlling the key cutting process parameters, such as graphite raw material variety, oxidization process, peeling process, reduction process, dispersion process and centrifugal treatment process, and the method is easy to operate and has low cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

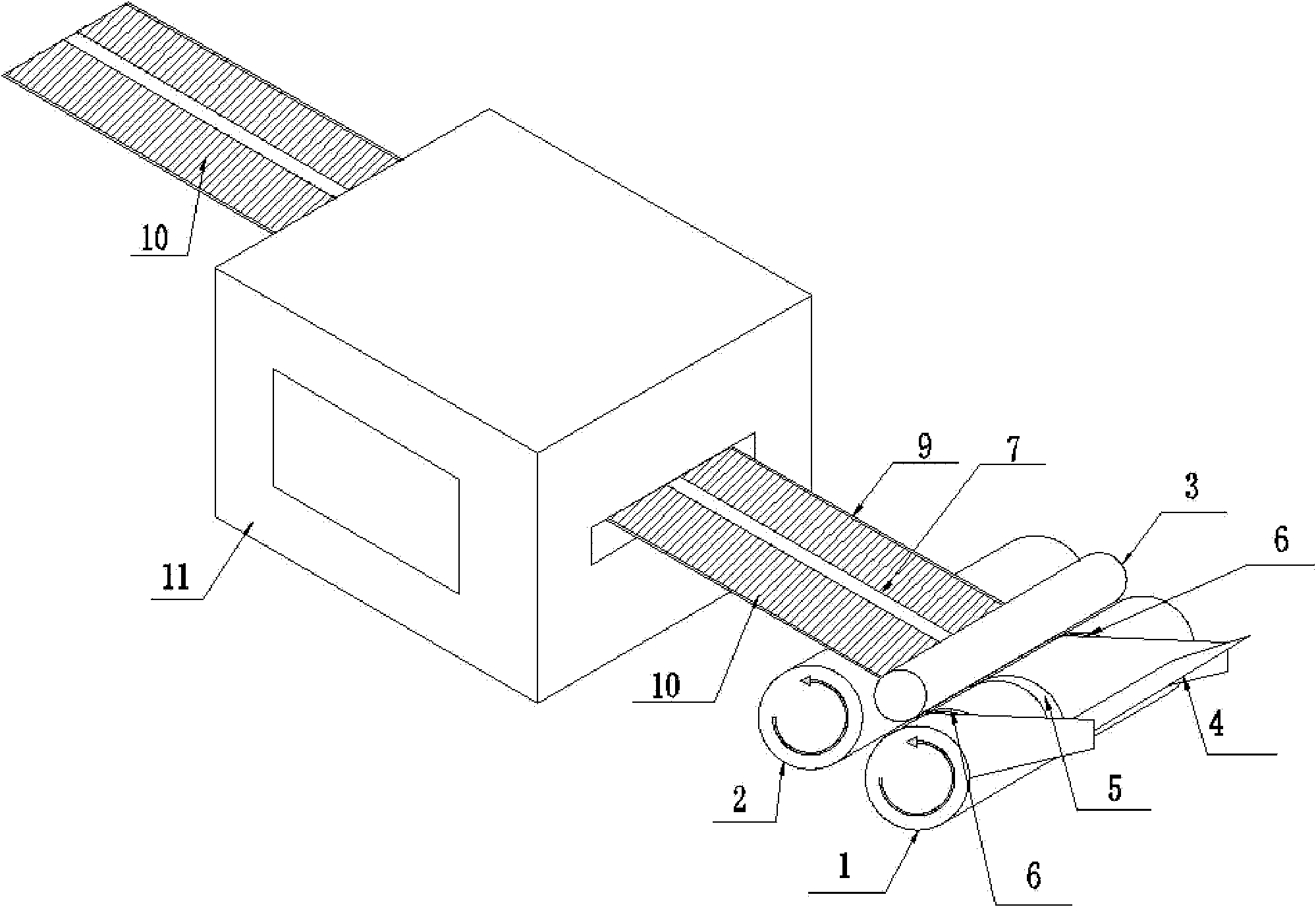

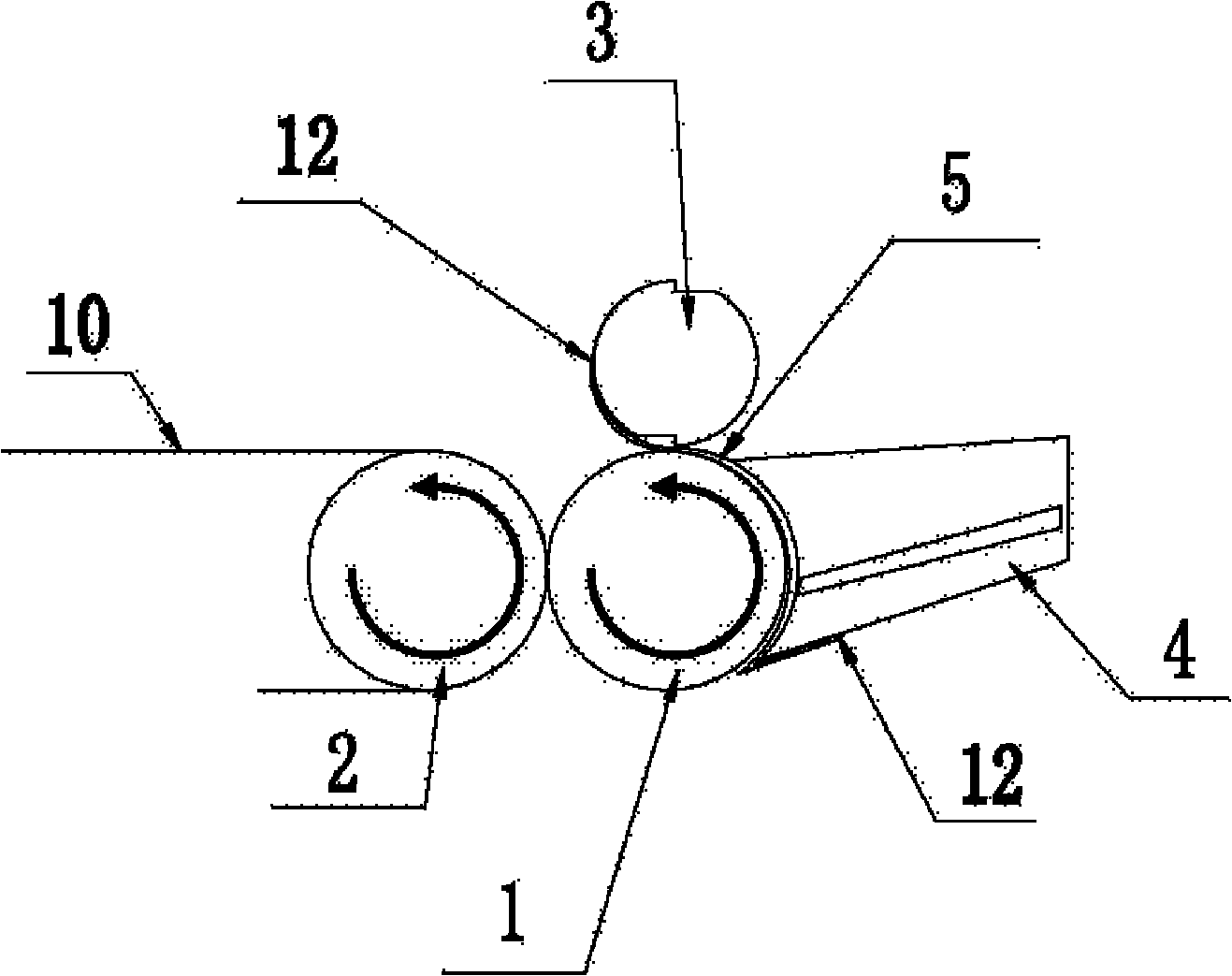

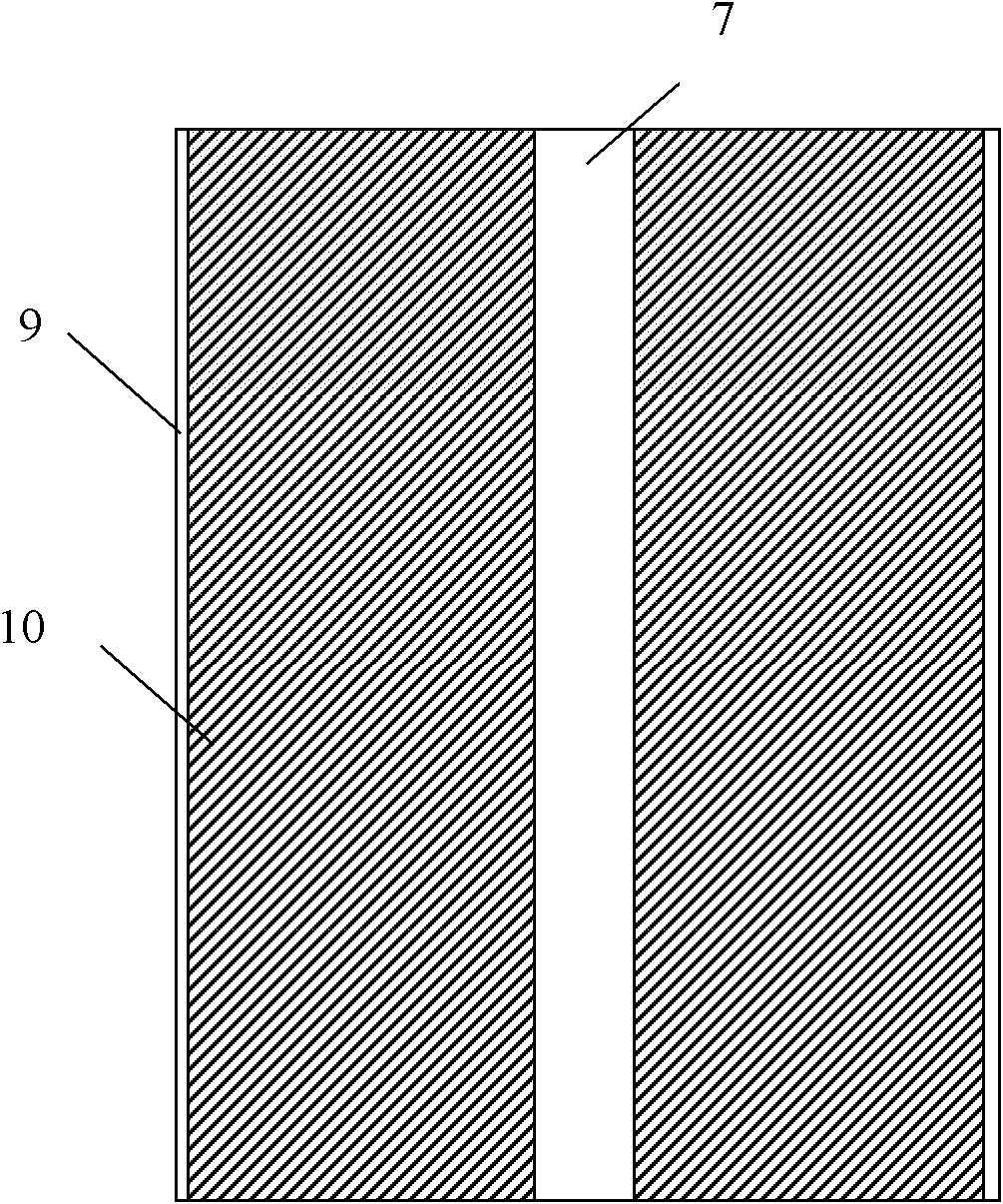

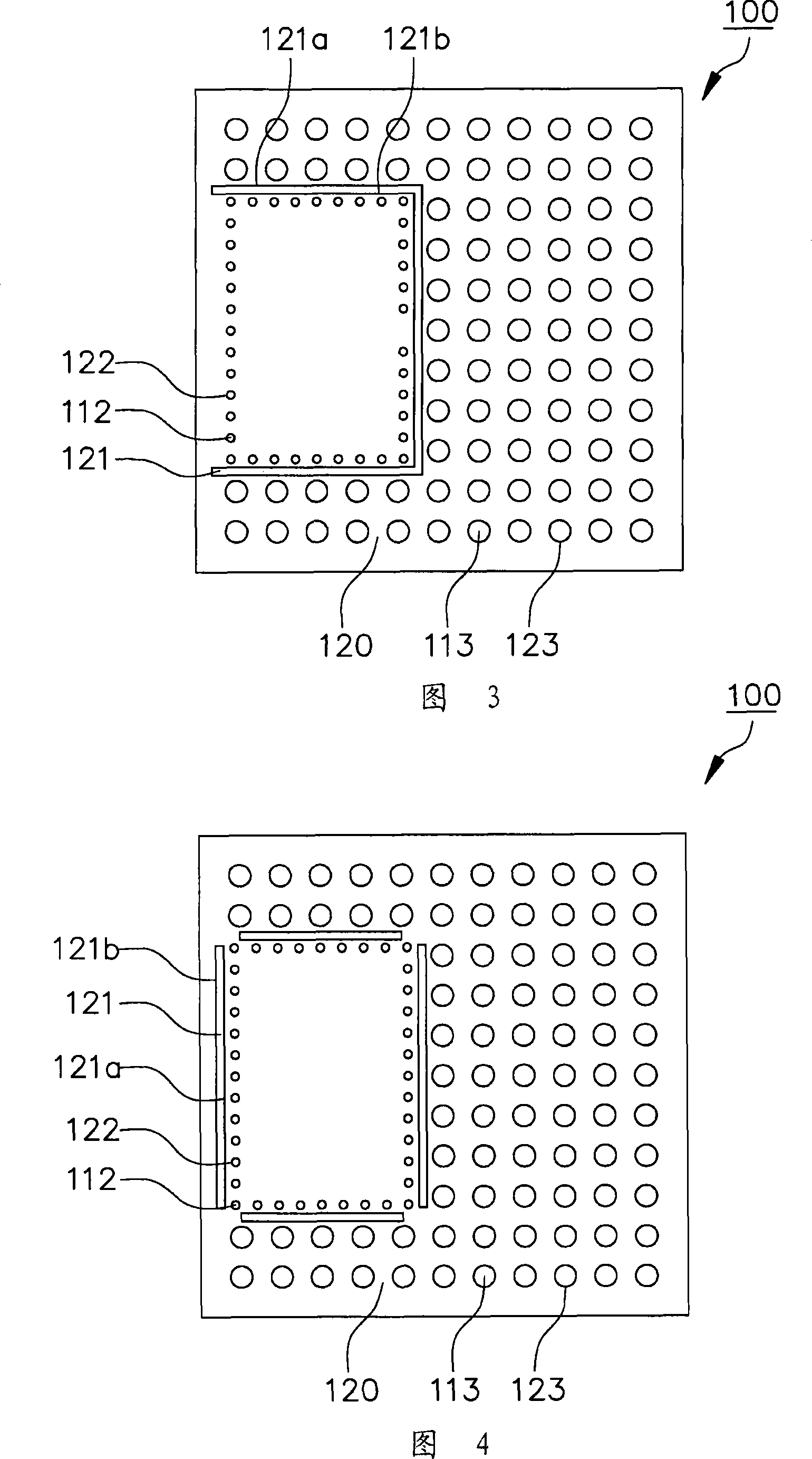

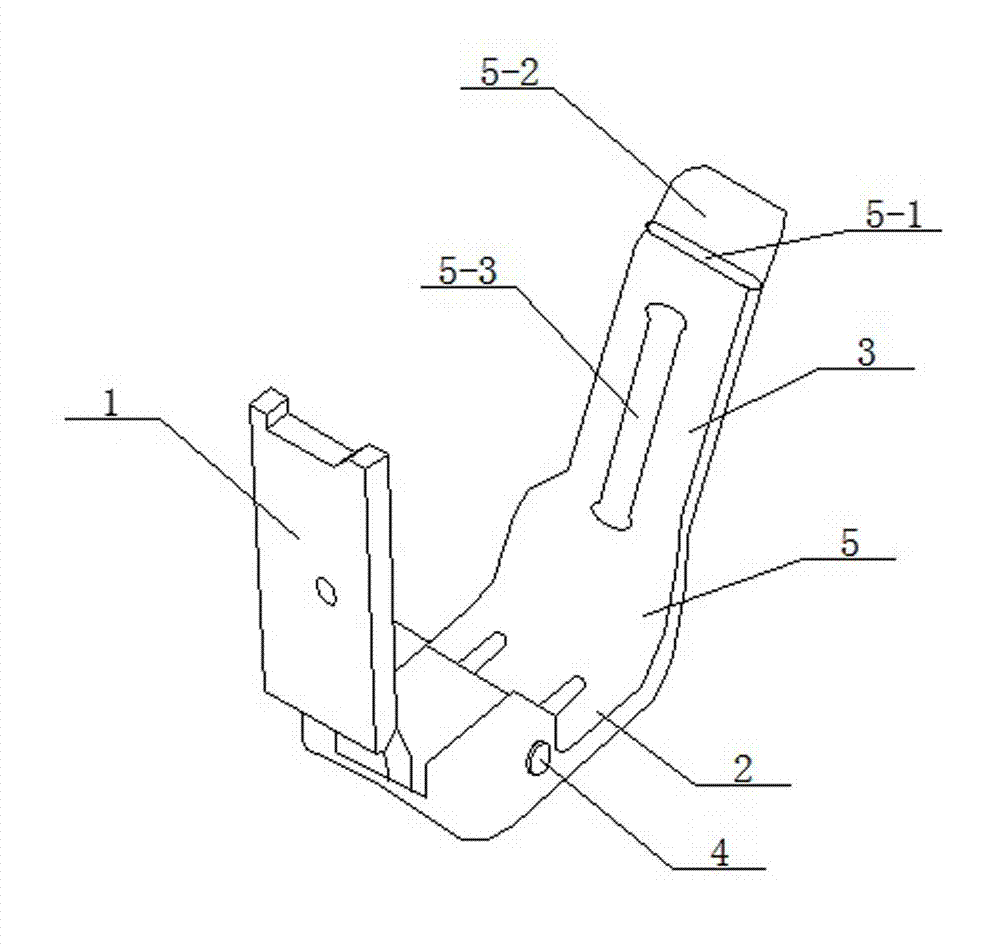

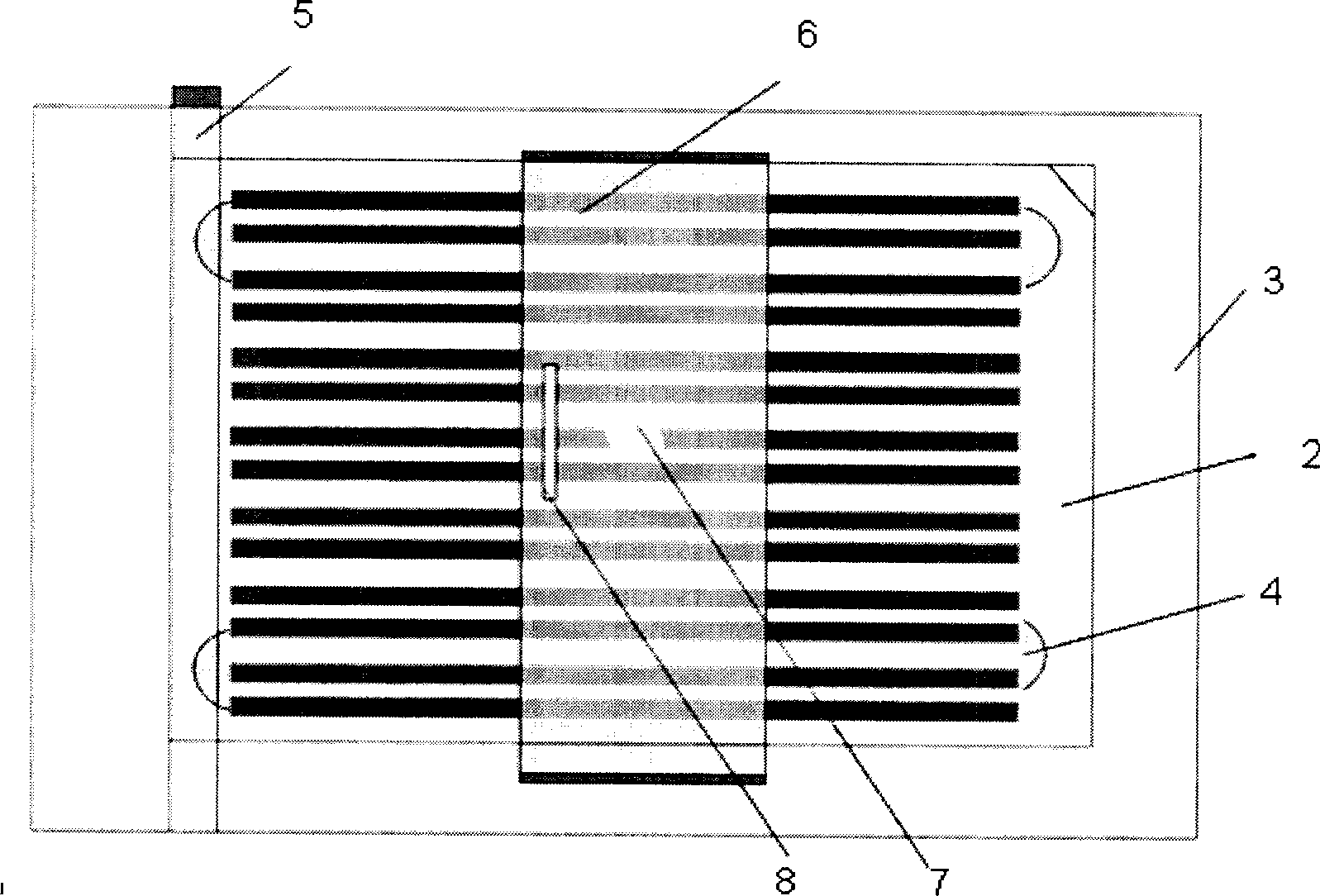

Device for manufacturing lithium ion secondary battery pole piece and manufacturing method thereof

InactiveCN102198437AIncrease profitReduce manufacturing costLiquid surface applicatorsCoatingsMaterial transferEngineering

The invention discloses a device for manufacturing a lithium ion secondary battery pole piece and a manufacturing method thereof. The device comprises a coating roller an a base material transfer roller arranged on one side of the coating roller, a scraping knife is arranged above the coating roller, and the other side of the coating roller is provided with a slurry tank; and a trapezoidal material blocking foil is arranged between the scraping knife and the coating roller, one end of the trapezoidal material blocking foil is fixed on the scraping knife, and the other end penetrates through a gap between the scraping knife and the coating roller and is fixed on the slurry tank. Both sides of the trapezoidal material blocking foil are provided with rectangular material blocking foils, one side of each rectangular material blocking foil is fixed on the scraping knife, and the other end penetrates through a gap between the scraping knife and the coating roller and is fixed on the slurry tank. During coating, the middle is left blank, the middle blank is used for manufacturing lugs, adjacent lugs are located in middle relative positions, so that the base material utilization rate is increased, and the production cost is reduced. During coating, the width of the blank has strict requirements, and the trapezoidal material blocking foil can be adjusted up and down, which is convenient to control the width of the middle blank.

Owner:CHERY AUTOMOBILE CO LTD

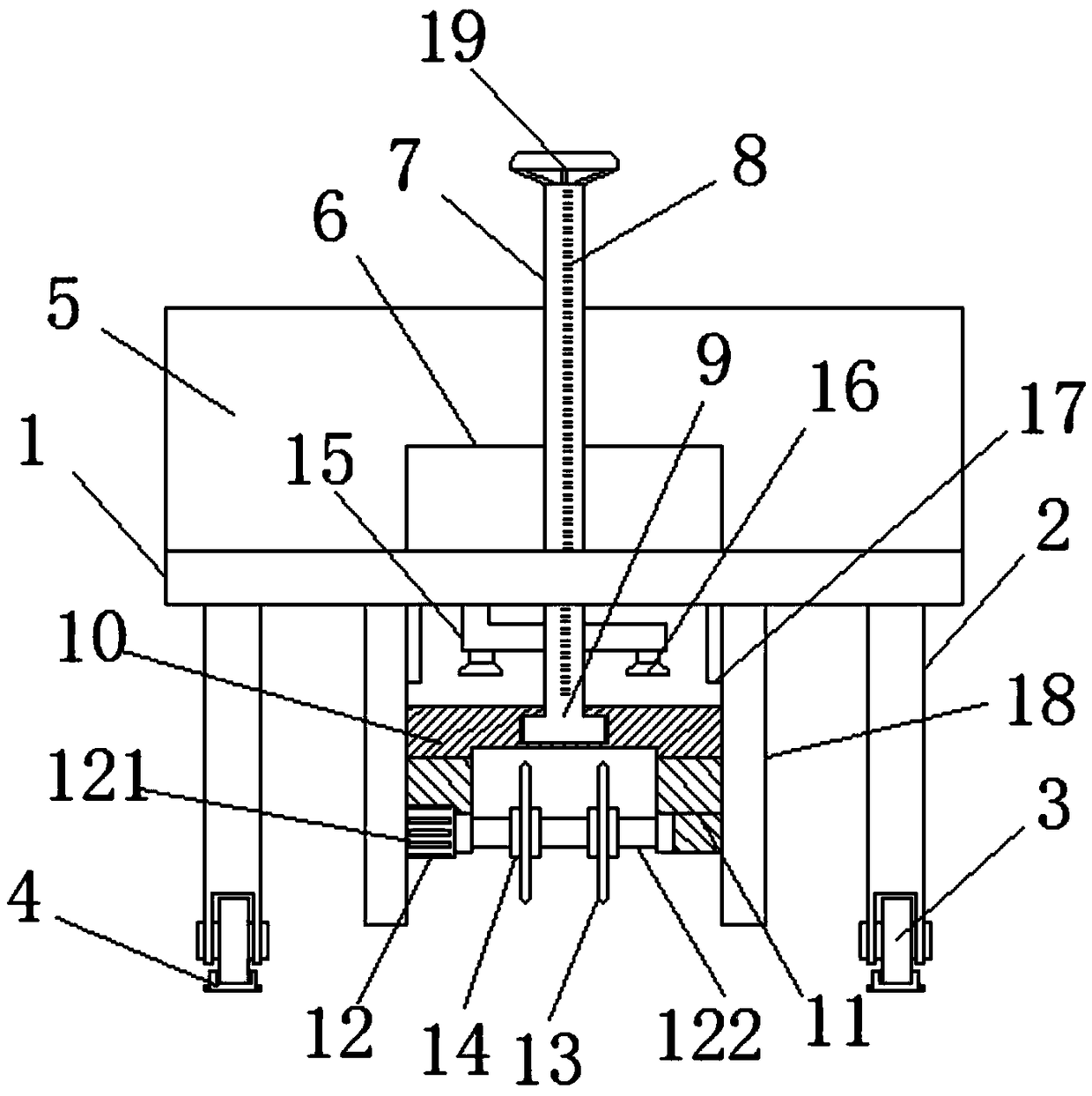

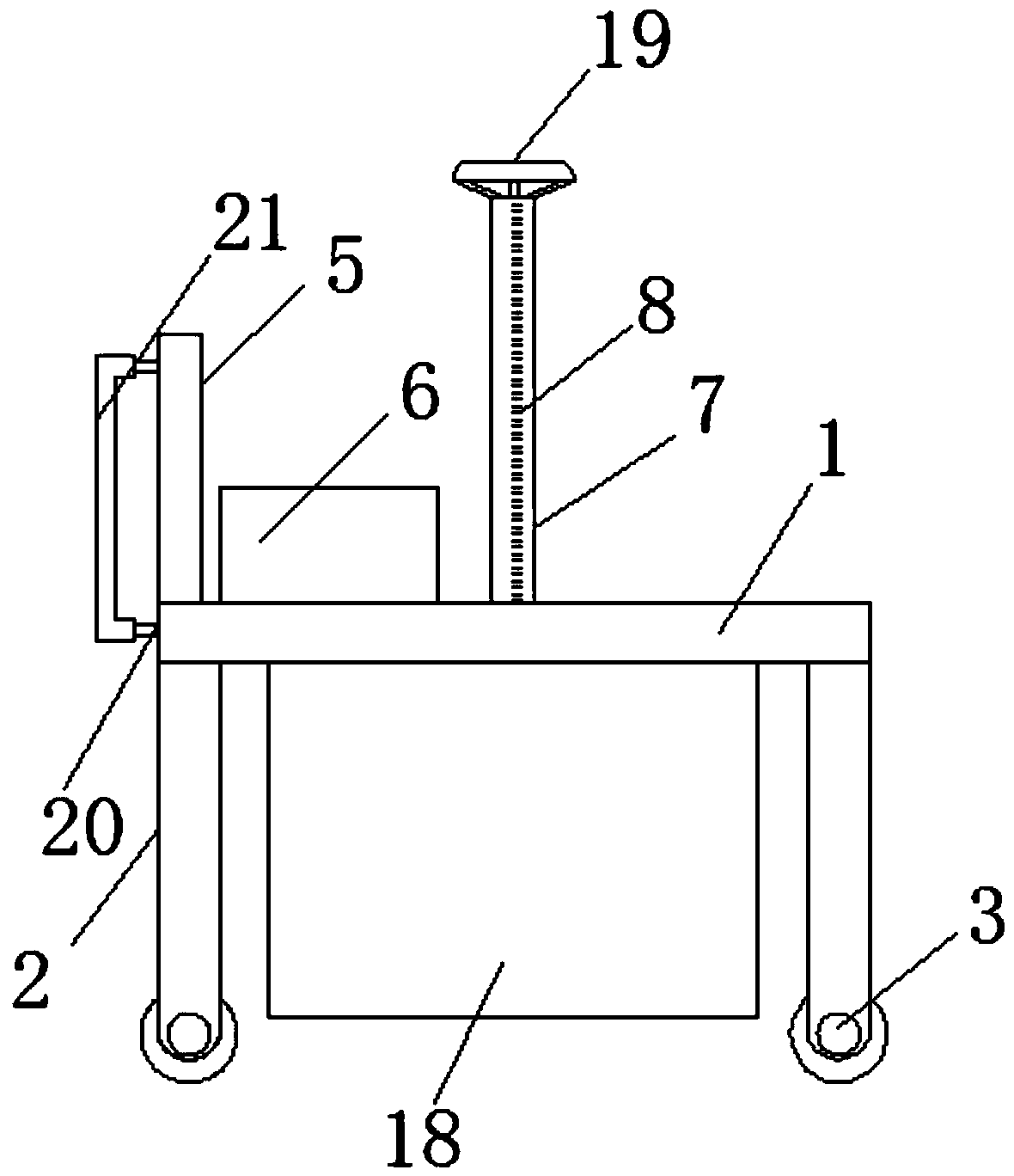

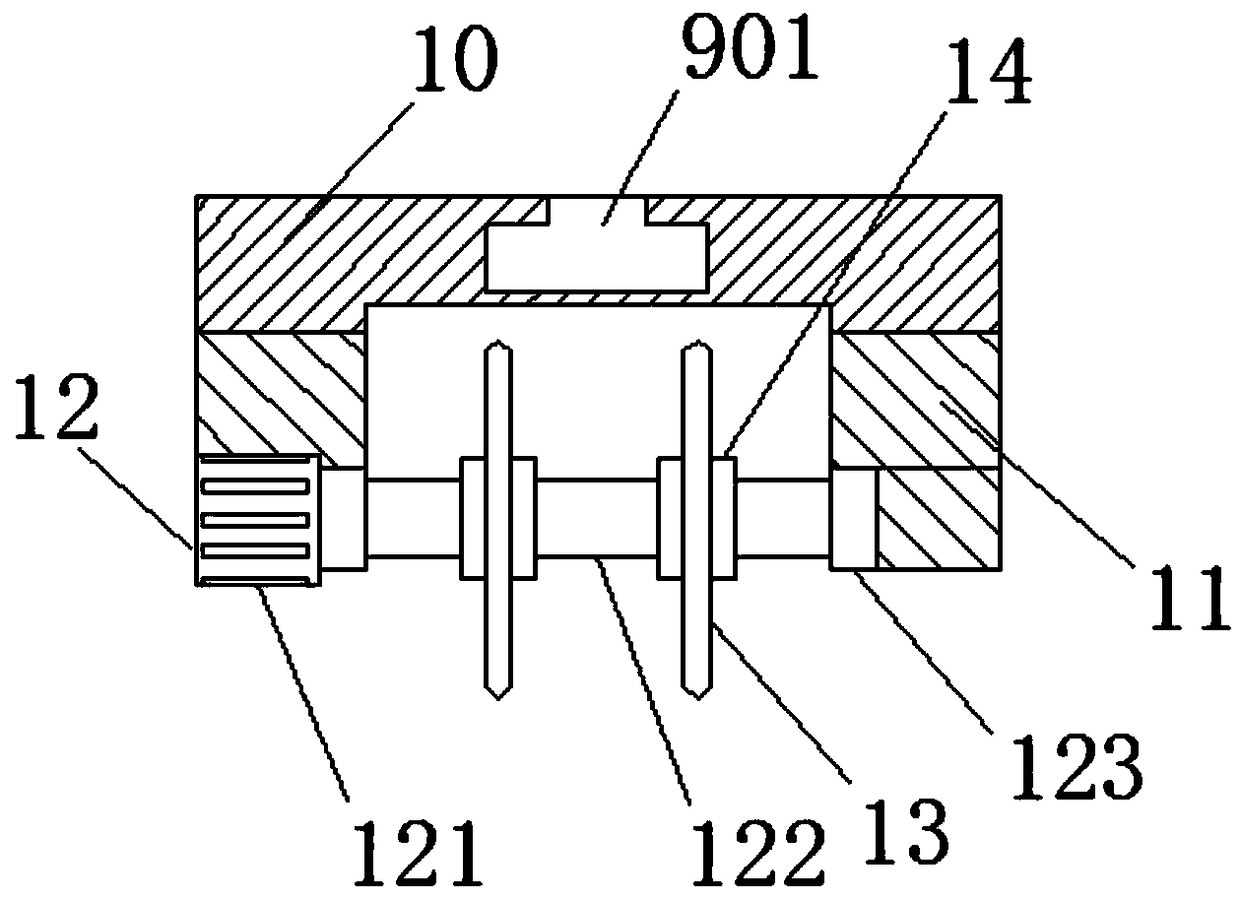

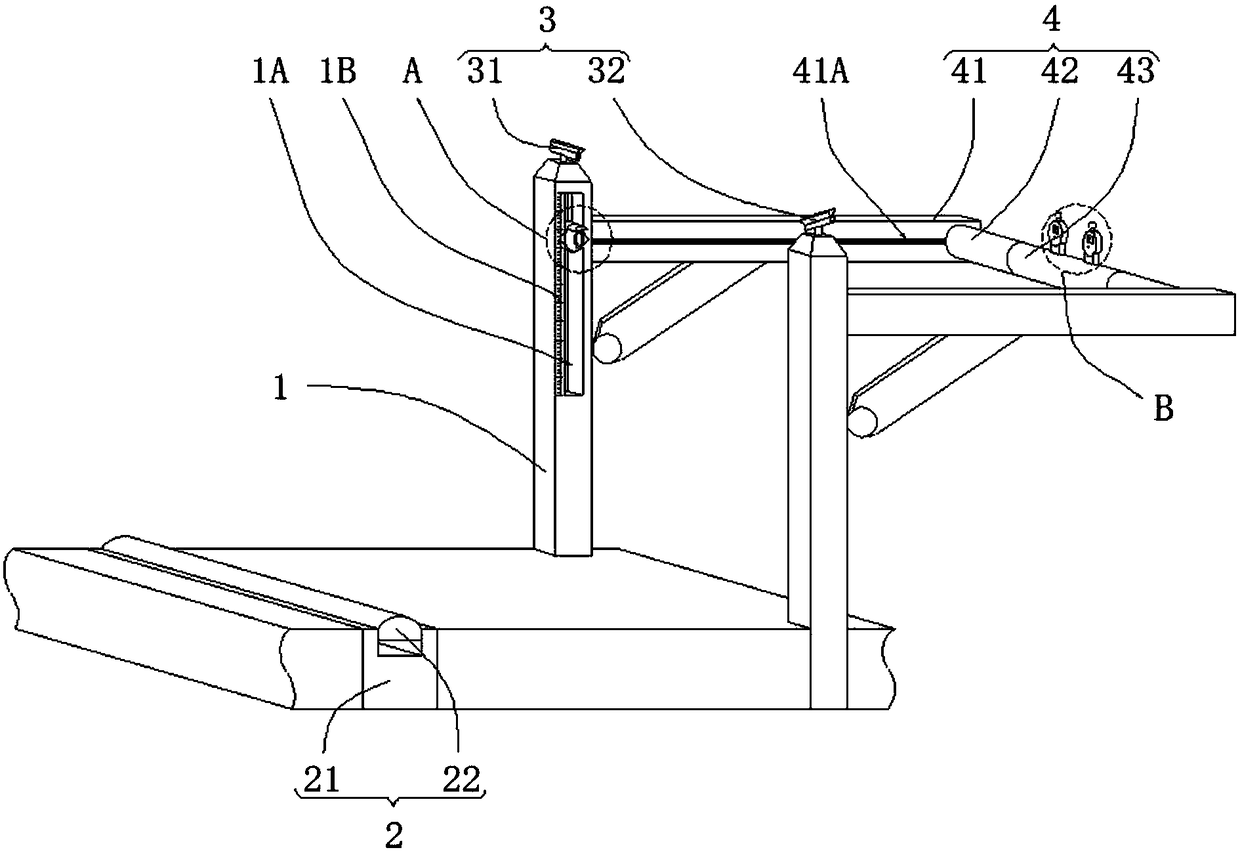

Dustproof construction base plane slotting device

InactiveCN108656370AAdd depthIncrease widthWorking accessoriesBuilding material handlingArchitectural engineeringScrew joint

The invention discloses a dustproof construction base plane slotting device. The dustproof construction base plane slotting device comprises a base plate and supporting legs arranged on the bottom ofthe base plate; a dust collector and a screw are arranged at the position, on one side of a vertical plate, of the base plate, the screw is evenly marked with scale marks, the screw penetrates the plane of the base plate, the bottom is rotatably connected with a supporting plate through a convex block, the bottom of the supporting plate is provided with a rotation mechanism through a guide block,limiting rods are arranged on the inner sides of limiting plates, two sets of cutting blades are fixedly arranged on the rotation mechanism through locking nuts in screw joint, a dust collection pipeon the dust collector penetrates the plane of the base plate, and the bottom communicates with two sets of dust collection covers through guide pipes, and cover opening directions of the dust collection covers are arranged in a manner of facing the cutting blades. The slotting depth and the width control can be achieved, operation is convenient, in the slotting process, generated dust is absorbed, air pollution is reduced, the device can be subject to linear movement, and linear slotting work can be facilitated.

Owner:潘艳婷

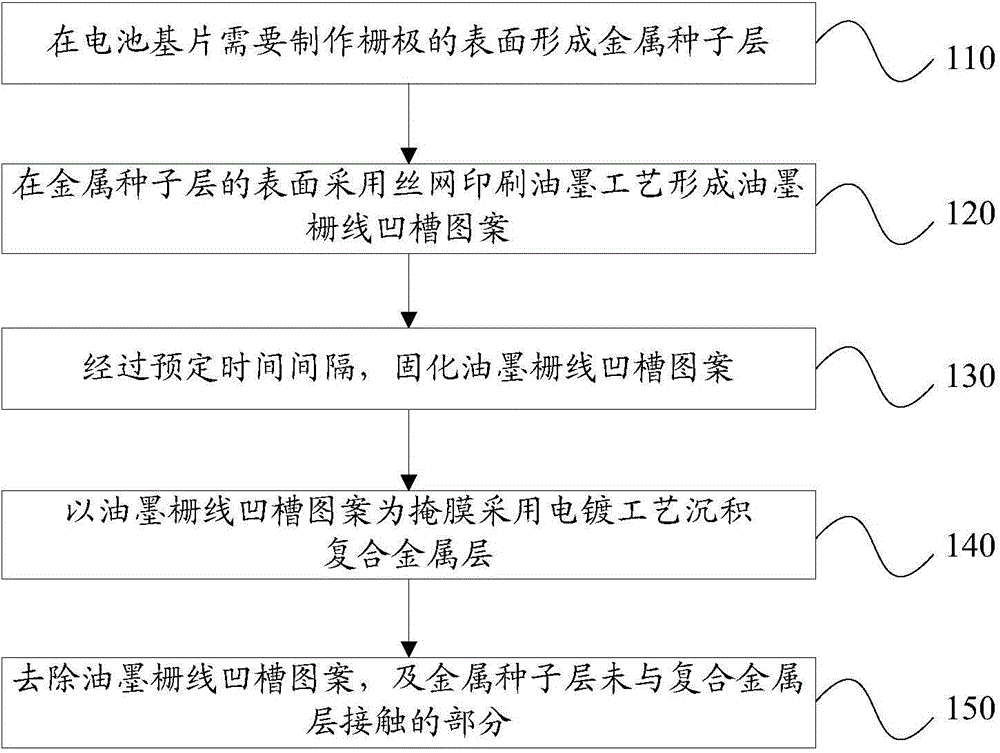

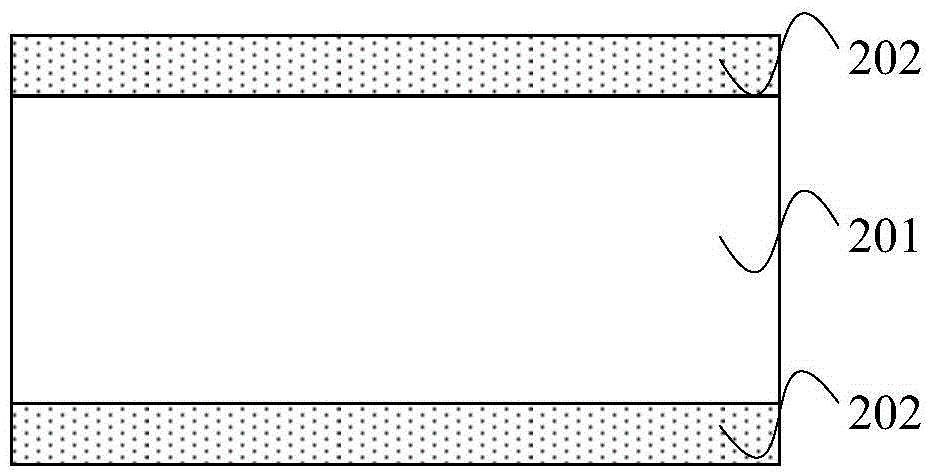

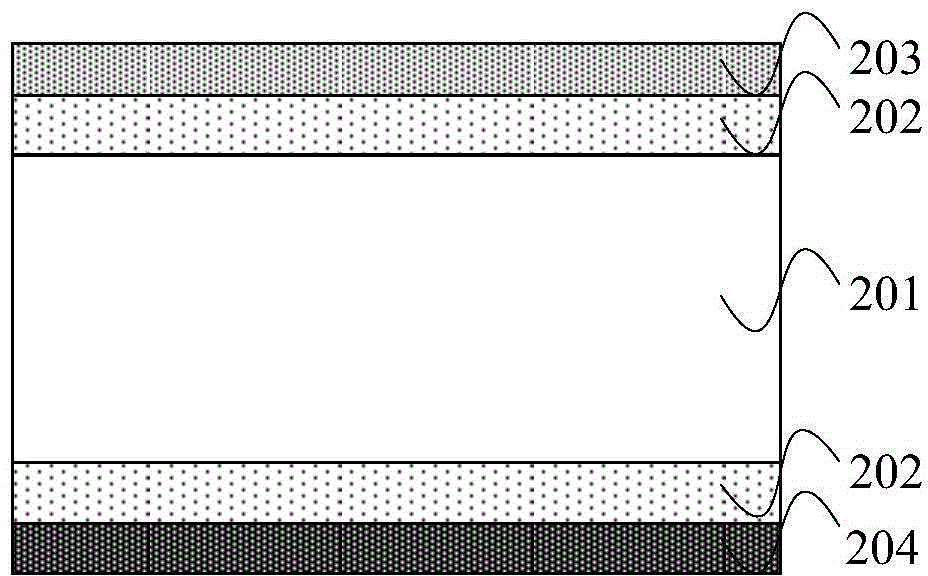

Silicon heterojunction solar cell with electroplating electrode and manufacturing method thereof

InactiveCN104538495AGood removal effectUniform expansion deformationPhotovoltaic energy generationSemiconductor devicesScreen printingManufacturing technology

The embodiment of the invention discloses a silicon heterojunction solar cell with an electroplating electrode and a manufacturing method thereof. The method comprises the steps that a metal seed layer is formed on the surface, where a grid needs to be manufactured, of a cell substrate; a silk-screen printing ink process is used for forming an ink grid line groove pattern on the surface of the metal seed layer; after a preset time interval, the ink grid line groove pattern is cured; the ink grid line groove pattern is used as a mask film, an electroplating process is used for depositing a composite metal layer; the ink grid line groove pattern and the part, which is not in contact with the composite metal layer, of the metal seed layer is removed. The implementation mode for forming the ink grid line groove pattern by the silk-screen printing ink process is simple and controllable, moreover, ink can be removed easily, and the manufacturing technology is simple. In the curing process, the ink can be evenly expanded and deformed, the width of an opening of the obtained ink grid line groove pattern is small, the depth-width ratio of a formed metal grid line is large, the light shading area is small, and the efficiency of the silicon heterojunction solar cell with the electroplating electrode is improved.

Owner:ENN SOLAR ENERGY

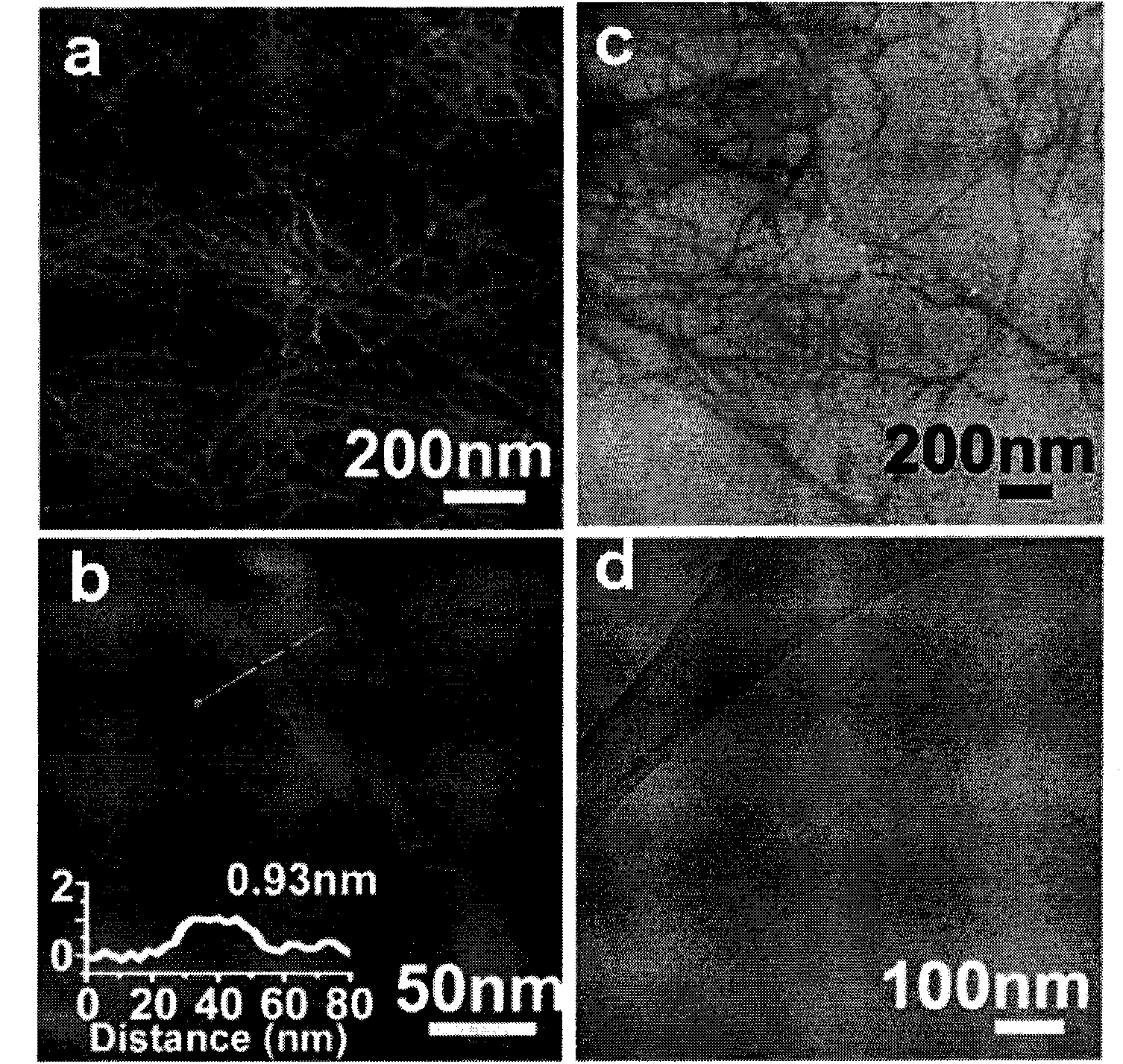

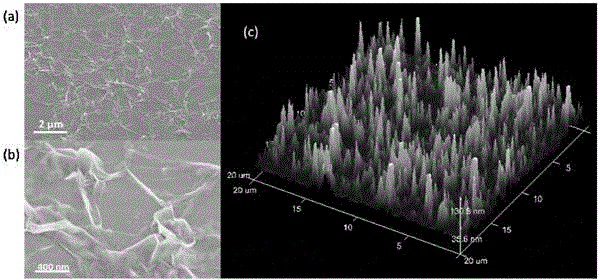

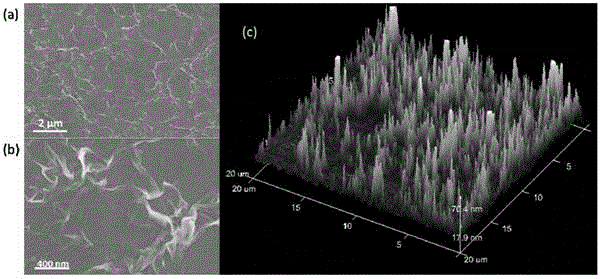

Folded graphene and controllable preparation method thereof

The invention discloses graphene with a folded structure. The structure of the graphene is formed by shrinking the graphene in a liquid phase environment to form ups and downs on the surface, wherein the folded parts are cone-shaped, and the height, width and distribution density of the folded parts are uniform and controllable. The folded parts can be formed in the processes of preparing the graphene and transferring the graphene to a target substrate, and are formed randomly and uncontrollably, but the folded structure formed controllably in a liquid phase, disclosed by the invention, can solve the problems. The invention realizes a novel graphene folded structure and provides a method for preparing the structure simply, conveniently and quickly on a large scale, and the graphene folded structure can be used in the fields of new energy resources, sensors, flexible electronic devices and the like.

Owner:SUN YAT SEN UNIV

Graphene nano-belts, preparation method of graphene nano-belts, and application of graphene nano-belts in transparent electrodes

InactiveCN103848415AEasy to control the lengthThickness is easy to controlCarbon compoundsNanotechnologyGraphene nanoribbonsElectrospinning

The present invention provides a graphene nano-belt preparation method, which comprises: (1) depositing a spinnable polymer-containing solution or melt on a graphene film through electrostatic spinning to form a mask; (2) etching away the graphene being not covered with the mask; and (3) removing the mask to form the graphene nano-belts. The present invention further provides the graphene nano-belts prepared through the preparation method, and an application of the graphene nano-belts in transparent electrodes. According to the present invention, the method has advantages of simple process, low cost, easy large-scale preparation and the like, and the graphene nano-belts prepared through the preparation method has characteristics of controllable length, controllable width, controllable thickness and controllable shape.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

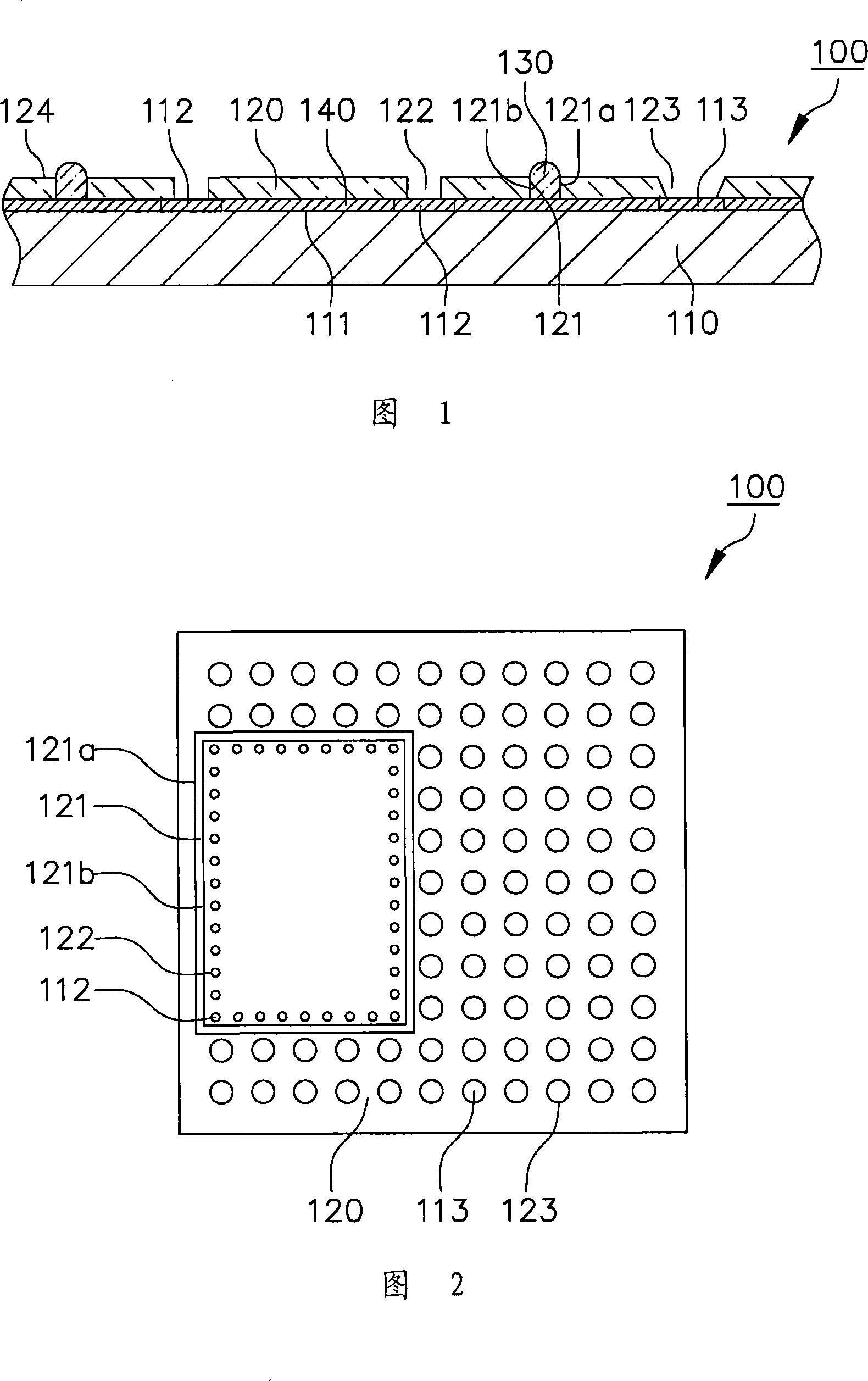

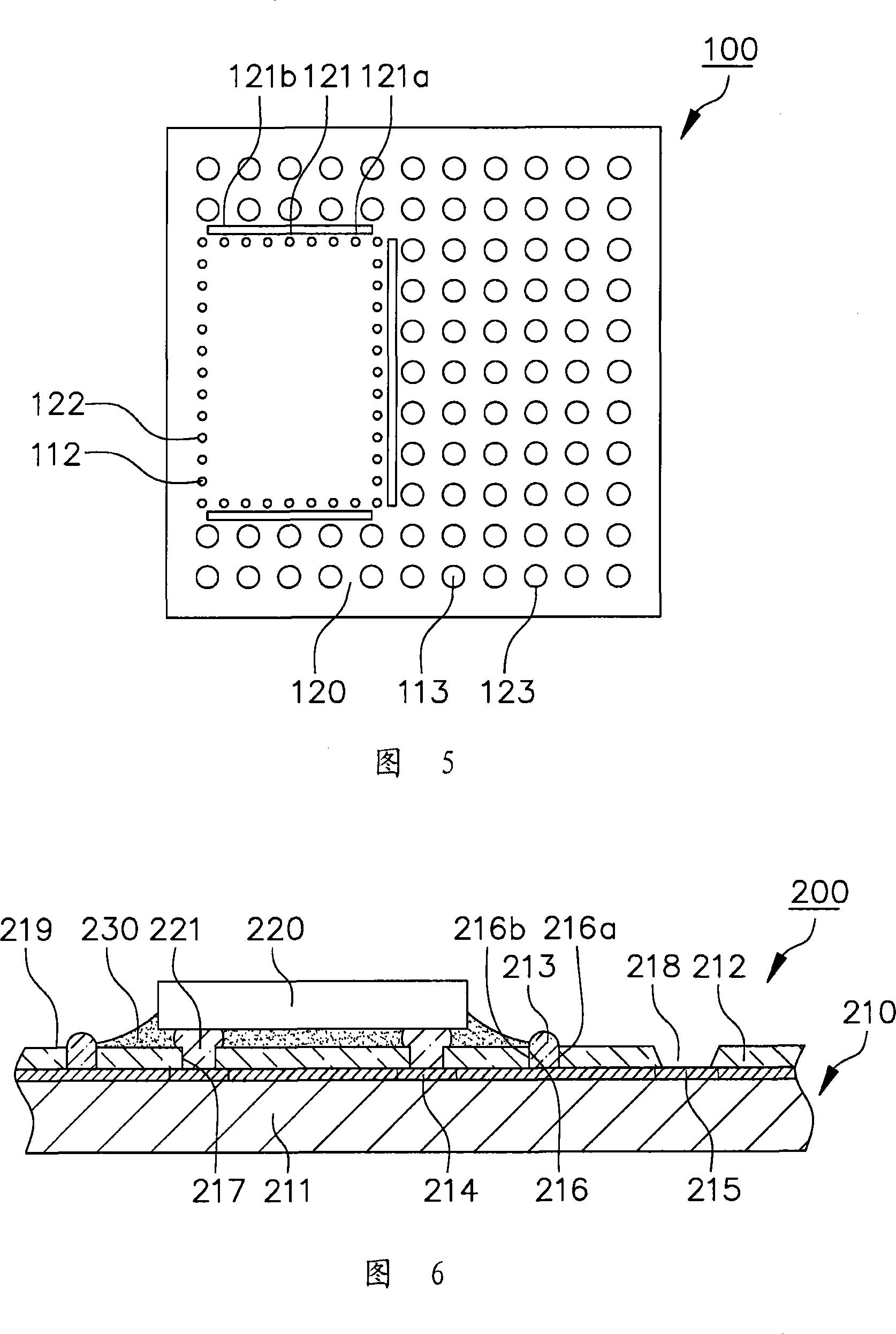

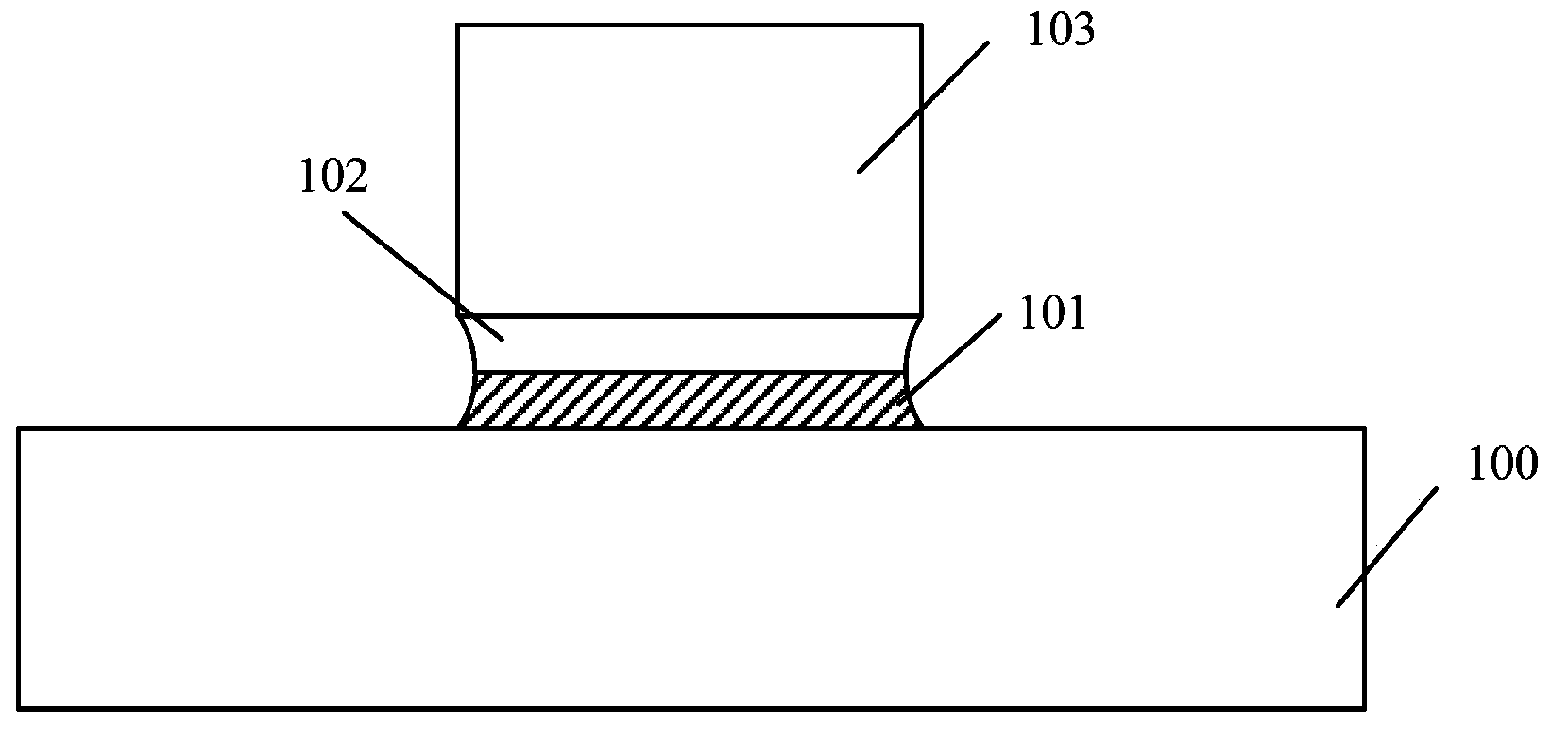

Chip carrier with dams

InactiveCN101226906AAvoid pollutionIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

The invention discloses a chip carrier with a barrage, which mainly comprises a base material, a protective layer and a barrage. The base material is equipped with a plurality of first connecting pads and second connecting pads, the protective layer is formed on the surface of the base material and is equipped with a dent, a plurality of first openings and second openings, wherein the dent is equipped with a first lateral wall and a second lateral wall, the first openings and the second openings respectively expose the first connecting pads and the second connecting pads. The barrage is formed between the first lateral wall and the second lateral wall of the dent, and projects out of the protective layer. The barrage has the function of preventing the overflow of under fill polluting chip carrier. The barrage is formed in the dent of the protective layer, thereby the width and height of the barrage can be controlled, and the touching area and bond strength of the barrage and the protective layer can be increased to avoid the peeling of the barrage and the protective layer. The invention also discloses a semi-conductor structure.

Owner:ADVANCED SEMICON ENG INC

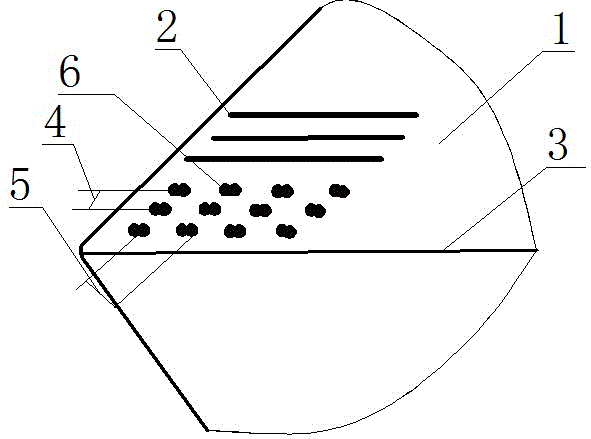

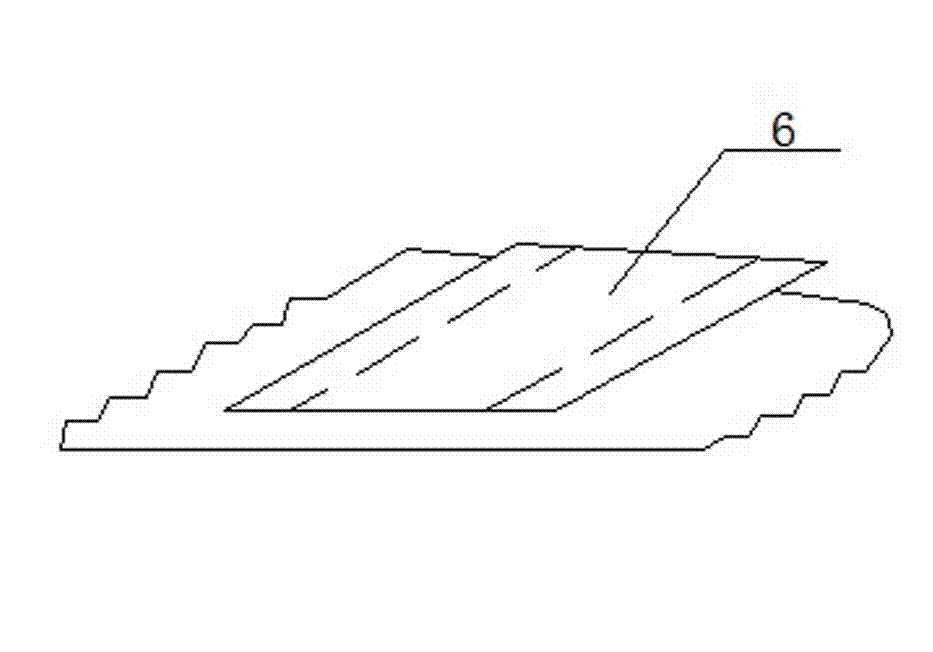

Tool provided with cutting chip flow guiding capillaries and functions and machining method of tool

InactiveCN106270582AExtend your lifeQuality improvementCutting insertsTurning toolsCapillary TubingEngineering

The invention discloses a tool provided with cutting chip flow guiding capillaries and functions and a machining method of the tool, relates to the tool in which the flow guiding capillaries are formed initiatively at the bottoms of cutting chips, and belongs to the field of mechanical manufacturing. The tool is characterized in that a texture array is arranged on the surface (1), on one side of the flowing direction of the cutting chips, of the tool; the texture array is formed by combination of micro-bulge (6) arrays and micro-groove (2) arrays; and the micro-bulge (6) arrays and the micro-groove (2) arrays are sequentially arranged along the flowing direction of the cutting chips. According to the tool, when a wet cutting machining mode is adopted, the direction of pouring or spraying is aligned with the direction of the capillaries or micro-grooves. Friction between the tool and the cutting chips is reduced; and cutting fluid reaches a bonding zone and a sliding zone, so that cutting force and cutting heat are lowered, and the service life of the tool is prolonged.

Owner:JIANGSU UNIV

Field cultivation method for toadstools

InactiveCN105724053AWidth is easy to controlIncrease widthCultivating equipmentsMushroom cultivationFisheryMorchella esculenta

The invention discloses a field cultivation method for toadstools. The method comprises the steps of flat tent construction, ridging and sowing, interplanting, irrigation and permeation, field management and harvesting. According to the step of field management, when toadstool primordial grow on ridge faces in spring in the second year and the temperature of the ridge faces reaches 10 DEG C, a second layer of sunshade net is pulled up to be 45-55 cm above the ridge faces; when the temperature is increased to 15-20 DEG C, the second layer of sunshade net is gradually pulled up to be 195-205 cm above the ridge faces, and in the process, a distance is kept between the second layer of sunshade net and a black sunshade net arranged at the top end. According to the step of harvesting, when growth of toadstool entities is finished, the toadstools are harvested according to specifications. The cultivation method can effectively control the toadstool product quality, and improve the toadstool yield.

Owner:BEICHUAN SHENNONG AGRI DEV CO LTD

Anti-collision type road height limiting frame

ActiveCN108265640AEfficient Response to ParkingAvoid hittingMeasurement devicesTraffic signalsAgricultural engineeringTruck

The invention relates to the technical field of road height limitation, in particular to an anti-collision type road height limiting frame. The anti-collision type road height limiting frame comprisessupporting boards, a weight control mechanism, a monitoring mechanism, a height limiting mechanism, a height measuring mechanism, a transmission mechanism and a reminding mechanism. An active infrared intrusion detector is installed in a first fixing seat, buzzer alarms are installed in a second fixing seat and a third fixing seat, once a truck exceeds the height, the buzzer alarms can be startedas soon as possible to remind a driver of the truck that the truck exceeds the height, meanwhile, a buffering distance exists between the height measuring mechanism and the height limiting mechanism,the driver can effectively make a response to stop the truck, and the truck is prevented from hitting a height limiting rod. The height is limited, meanwhile, a speed reduction lever can be effectively used for limiting the speed and the weight, once the truck is overweight, an alarm can be given as soon as possible, a camera function is started, and illegal and irregular actions can be conveniently traced to take evidence. The height of the height measuring mechanism and the height of the height limiting mechanism can be adjusted and can be accurately kept identical all the time, the width of the height limiting mechanism is controllable, and autonomous integrated control is fully achieved.

Owner:平邑经发科技服务有限公司

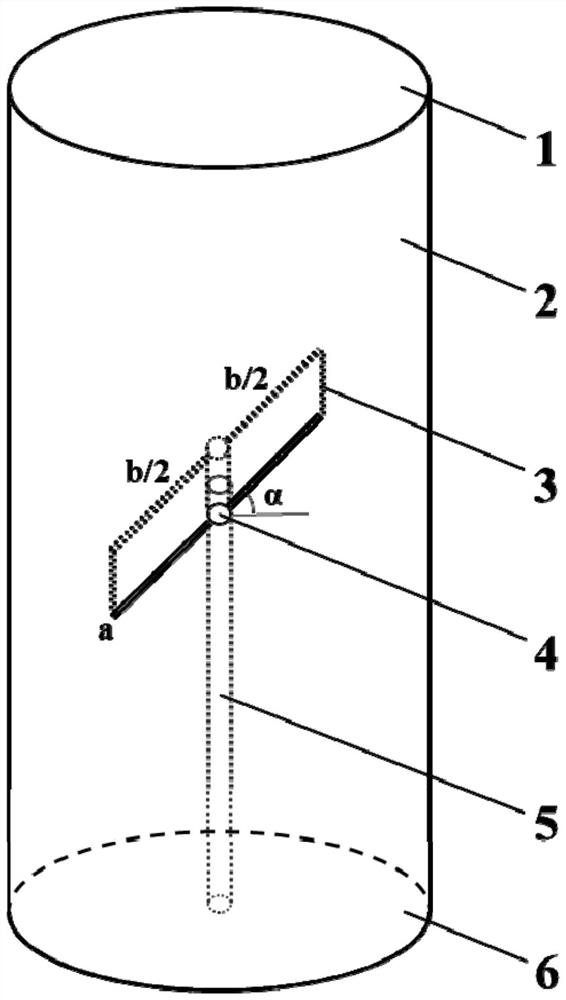

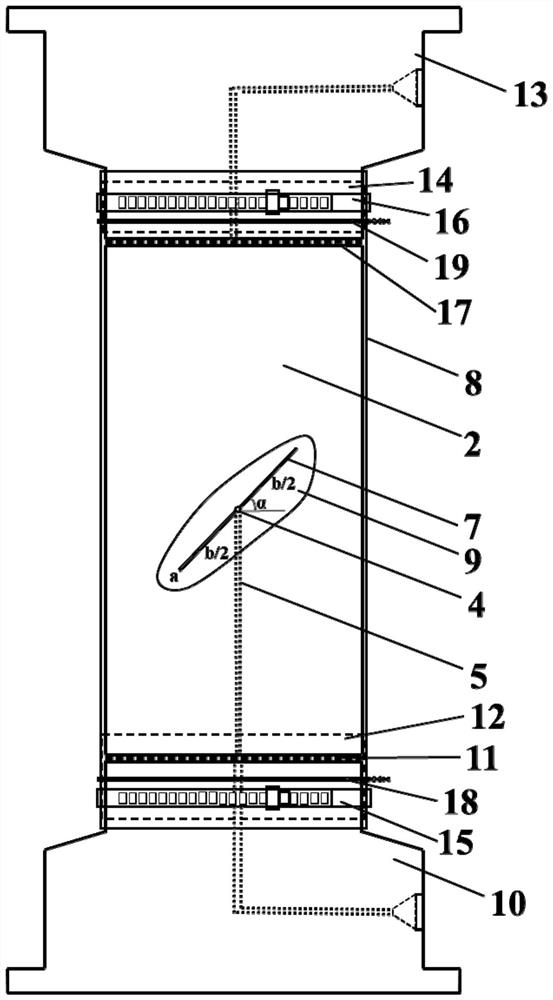

Preparation and sealing method of crack-containing rock sample for multi-field coupling triaxial test

PendingCN112557135ALittle rock damageGuarantee the success rate of triaxial testEngine sealsPreparing sample for investigationThermal hydraulicsWater saturation

The invention discloses a preparation and sealing method of a crack-containing rock sample suitable for a multi-field coupling triaxial test. The method comprises the following steps: preparing a complete rock sample; processing rock sample cracks; carrying out water saturation treatment on the crack-containing rock sample; sealing the crack-containing rock sample. By applying the method, cracks can be prefabricated on natural rock, the lengths, the widths and the angles of the cracks are controllable, meanwhile, the problem that confining pressure oil and high-pressure water break through a heat shrink tube at the prefabricated cracks in a multi-field coupling triaxial test to cause sealing failure is also solved, in addition, water pressure can directly act on the cracks in the rock sample, technical support is provided for researching the influence of high-pressure water seepage on crack propagation, and it is possible to simulate the hydraulic mechanical property of crack-containing rock under the condition of real geological environment complex condition thermal hydraulic multi-field coupling through experiments.

Owner:BEIJING RES INST OF URANIUM GEOLOGY +1

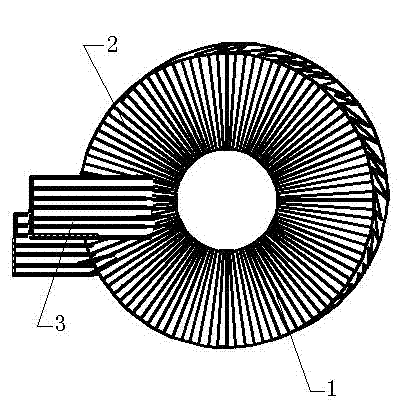

Residual cable winding device

ActiveCN111517169AWide range of applicationsEvenly distributedBinding material applicationBundling machine detailsElectric machineryControl theory

Owner:WUHU JINYI MACHINERY

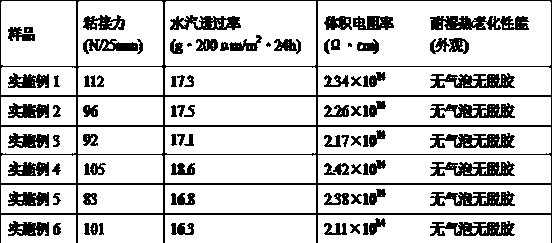

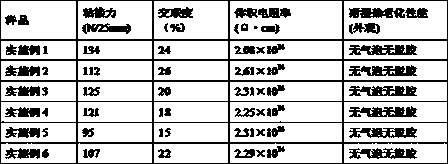

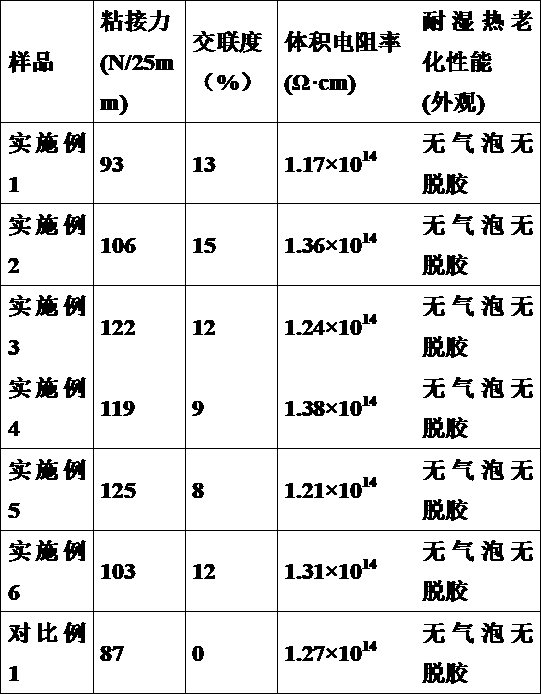

EVA hot melt adhesive film for wall covering and preparation method thereof

PendingCN108949046AImprove water vapor transmission rateImprove water resistanceMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesSolventMaleic anhydride

The invention discloses an EVA hot melt adhesive film for wall covering and a preparation method thereof. The EVA hot melt adhesive film for wall covering is prepared from 40-70 parts by weight of ethylene-vinyl acetate copolymer, 15-30 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 10-25 parts of ethylene-acrylic acid copolymer, 5-20 parts of polyolefin copolymer, 5-30 partsof tackifier, and 0.2-1 part of antioxidant by premixing and tape casting. The EVA hot melt adhesive film prepared by the invention can quickly bond the wall covering to a wall body, has the characteristics of high adhesion, moisture resistance, mildew resistance and no perishability, and does not contain harmful solvents such as benzene, toluene and xylene; the EVA hot melt adhesive film meets environmental requirements and can replace liquid glue applied to the wall covering bonding. The invention also discloses the preparation method of the EVA hot melt adhesive film for wall covering, andthe method has the advantages of simple process, convenient processing and easy operation.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

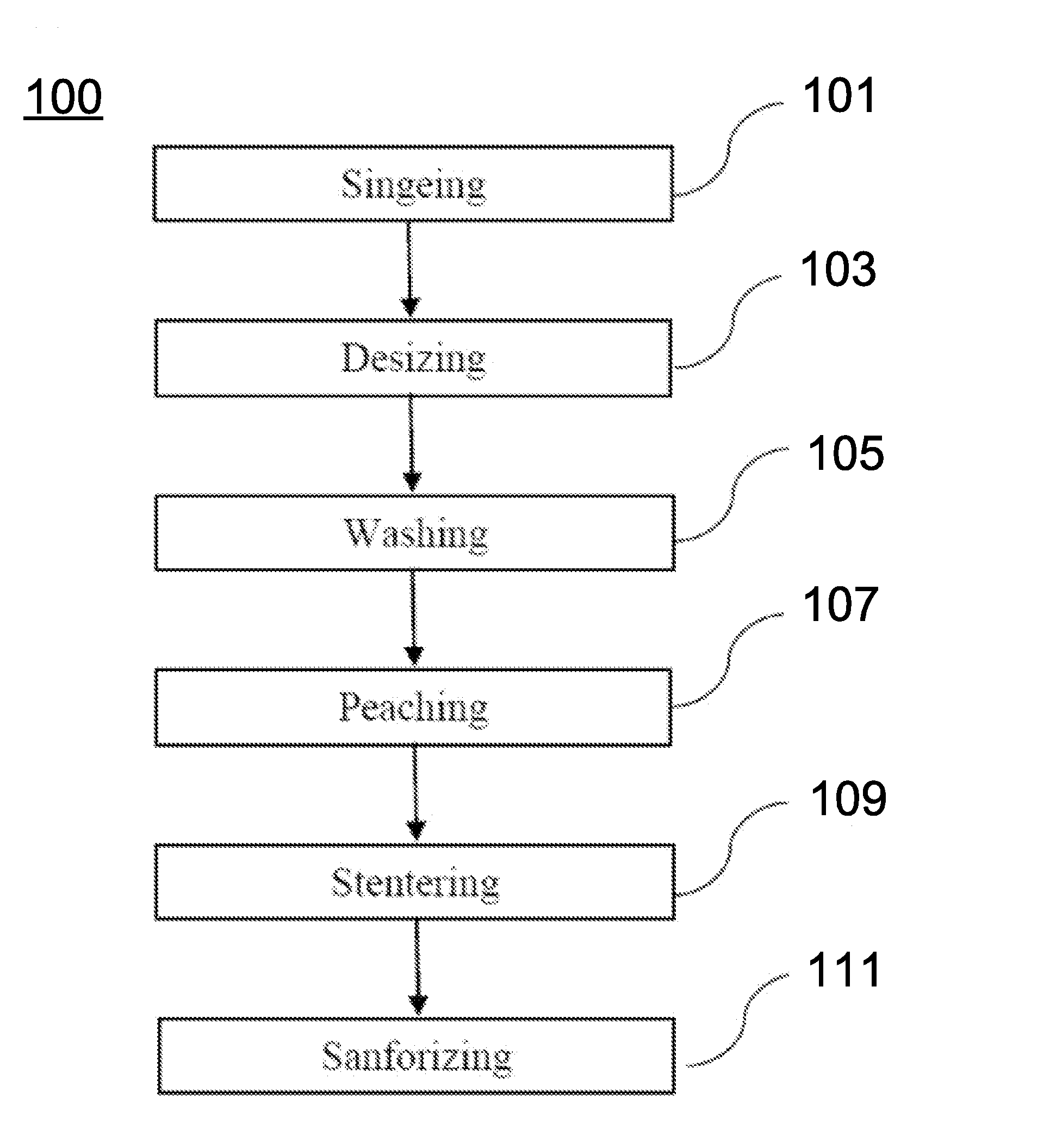

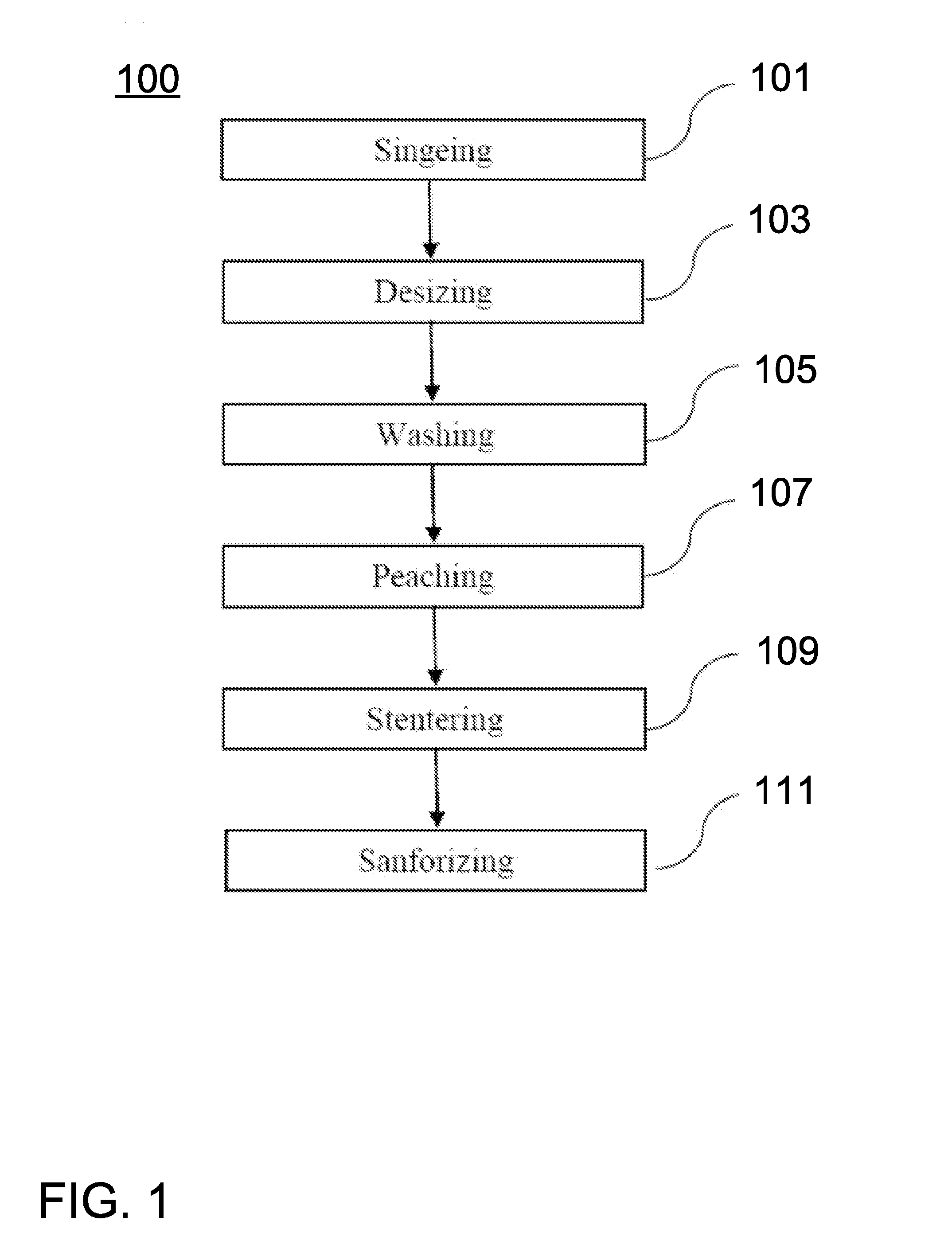

Natural finish fabric

ActiveUS20150259843A1Reduce consumptionWidth is easy to controlShrinkingSucessive textile treatmentsWater vaporEngineering

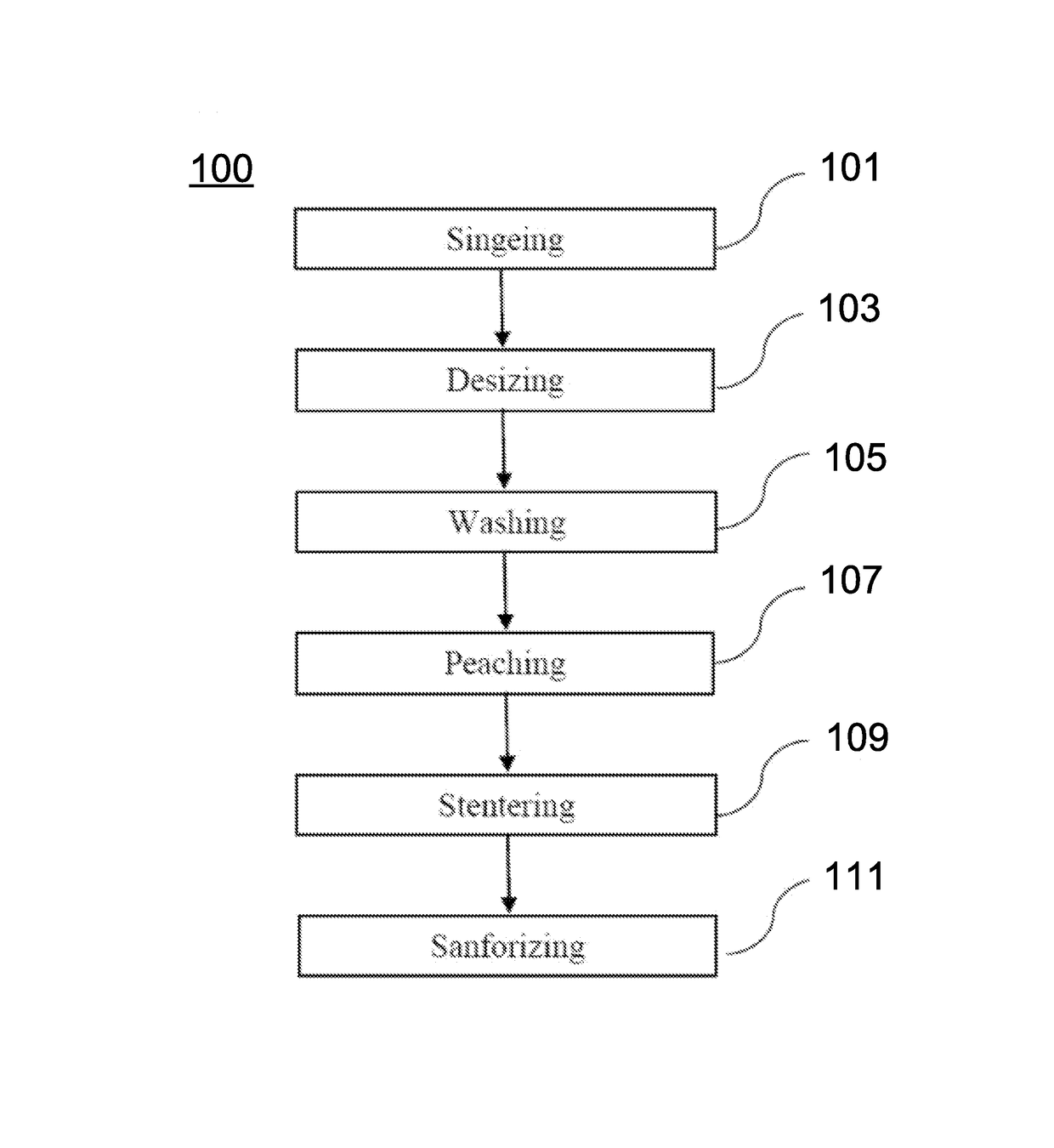

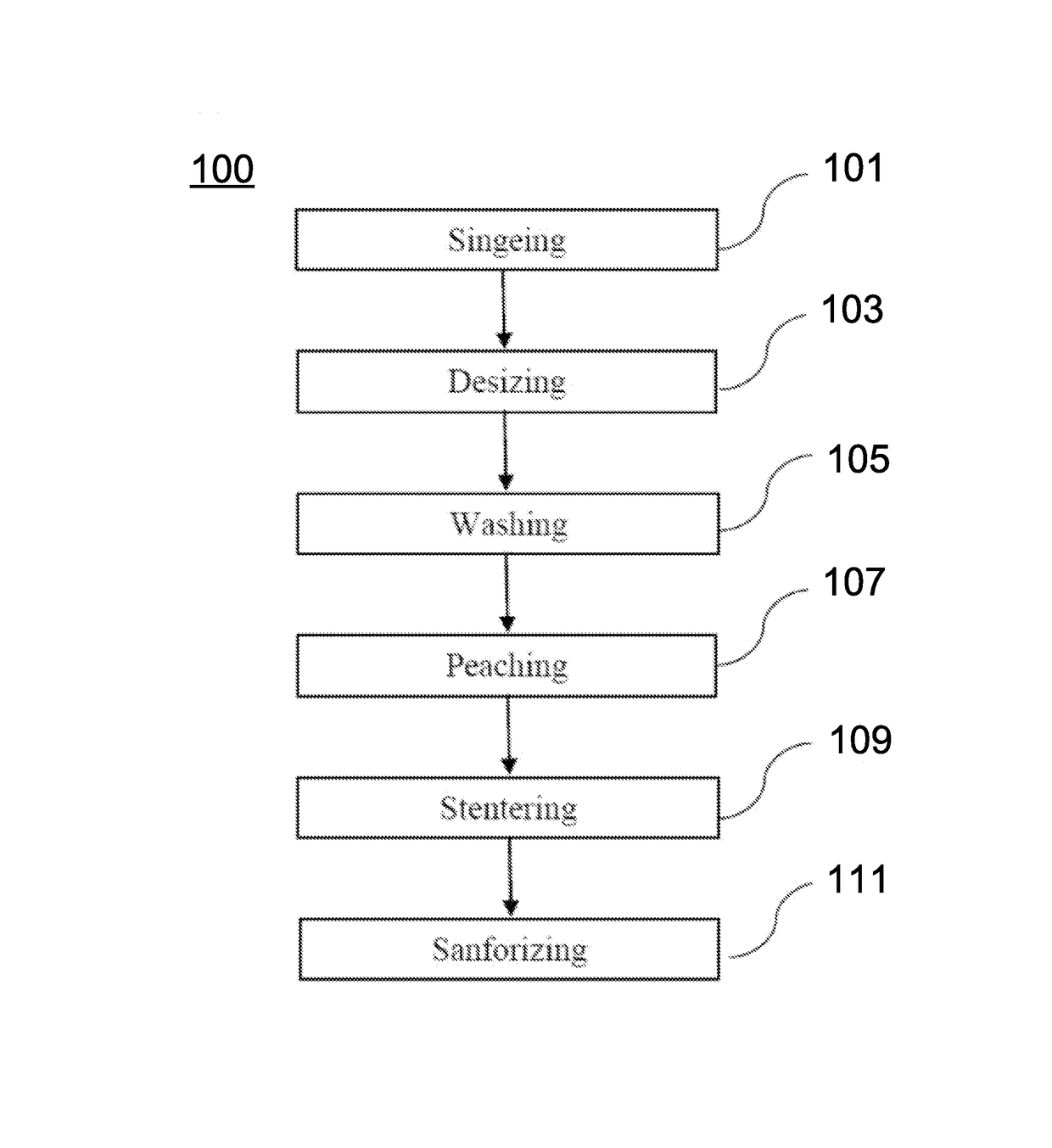

A method for producing environmentally friendly fabric and textile products without use of chemicals comprises a finishing process including the steps of: singeing, enzyme desizing; water washing, peaching, stentering, and sanforizing. The steps of the finishing process are purely physical and preferably uses only water, water vapor (steam), and enzymes, and not chemicals including chemical agents. As such, the finishing process is believed to be environmentally friendly.

Owner:WELSPUN INDIA LTD

Method for forming gate electrode

A method for forming a gate electrode includes the following steps: a semiconductor substrate is provided, the surface of the semiconductor substrate has a gate medium material layer, a protection material layer is arranged on the gate medium material layer, and a pseudo gate material layer is arranged on the protection material layer; the pseudo gate material layer is etched, and a pseudo gate is formed on the protection material layer; a first side wall is epitaxially formed on a side wall surface of the pseudo gate; the protection material layer is etched using the pseudo gate and the first side wall as a mask, so as to form a protective layer, and the width of the protective layer is larger than that of the pseudo gate; a second side wall is epitaxially formed on a side wall surface of the first side wall; and the gate medium material layer is etched using the pseudo gate and the second side wall as a mask, so as to form a gate medium layer, and the width of the gate medium layer is larger than that of the protective layer. In the gate electrode formed in the invention, the gate medium layer, the protective layer and the pseudo gate are in a stepped structure, and the gate electrode has good performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

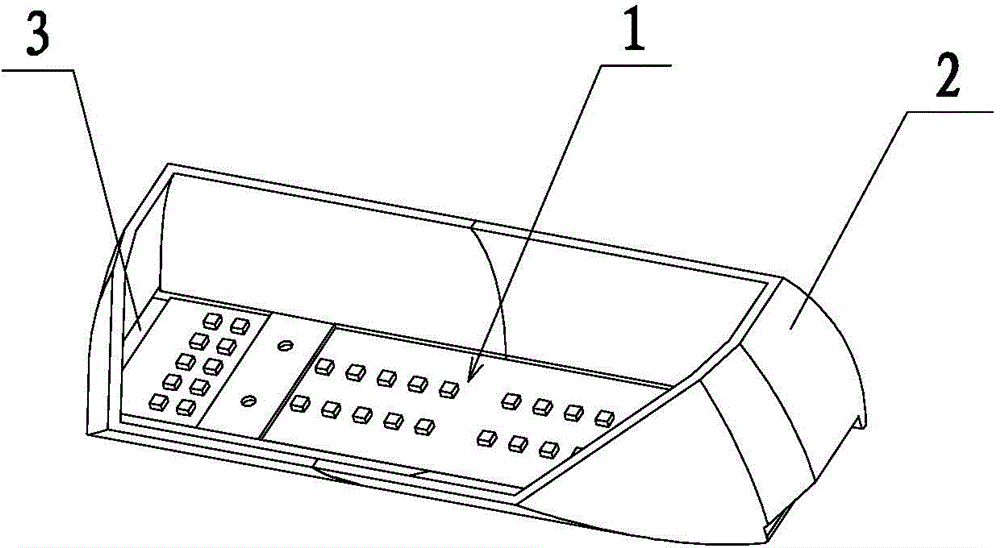

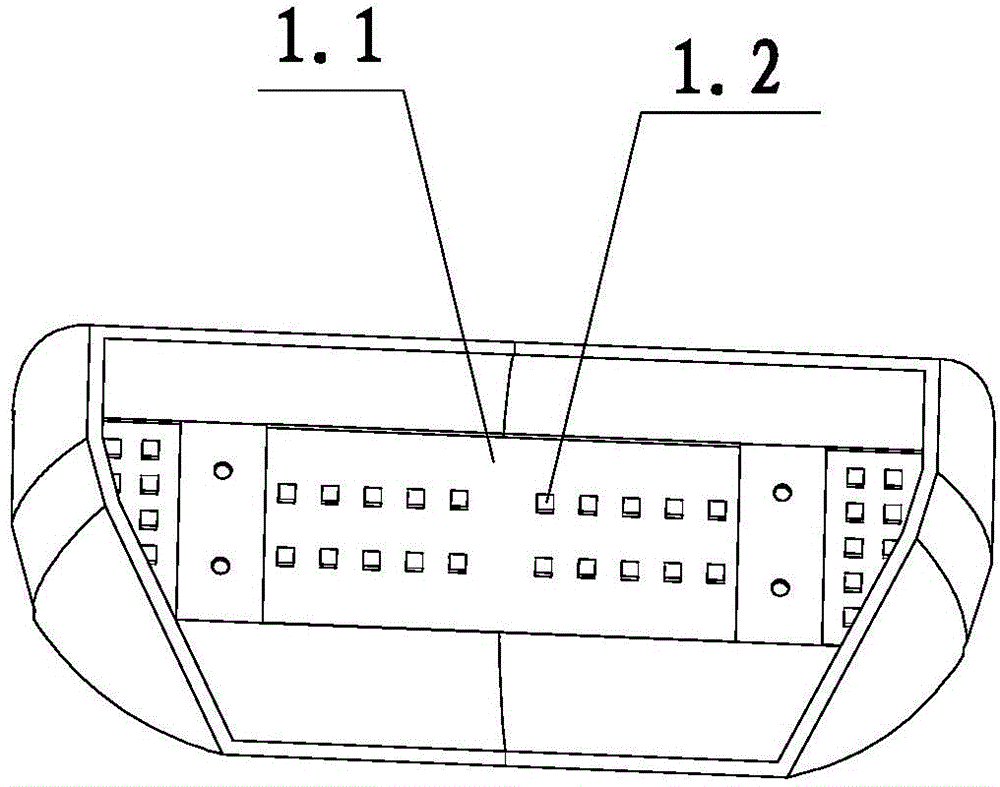

LED lighting source module group

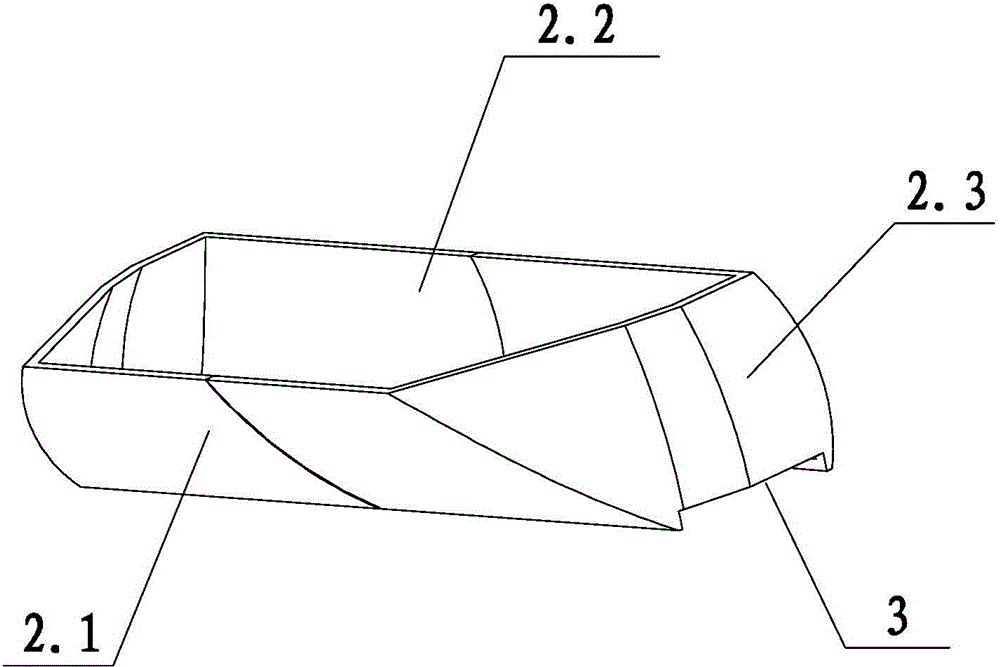

ActiveCN104930385AUniform brightnessAvoid safety accidentsMechanical apparatusPoint-like light sourceLight sourceEngineering

The present invention discloses an LED lighting source module group. The LED lighting source module group comprises an LED light source (1) and a reflection cup (2) with the bottom open-ended; the LED light source (1) comprises a circuit board (1.1) and a plurality of LEDs (1.2); the plurality of LEDs (1.2) are distributed on the circuit board (1.1); the circuit board (1.1) is disposed at the top of the reflection cup (2); the LEDs (1.2) are disposed in the reflection cup (2); the reflection cup (2) is long strip shaped; the reflection cup (2) comprises a front wall (2.1), a rear wall (2.2) and two side walls (2.3); the two side walls (2.3) are symmetrically disposed at two sides of the front wall (2.1) and the rear wall (2.2); the front wall (2.1) is an inclined surface; the rear wall (2.2) and the two side walls (2.3) are all convex arc-shaped surfaces; and the density of the LEDs distributed at two side portions of the circuit board (1.1) is larger than that of the LEDs distributed in the middle of the circuit board (1.1). The LED lighting source module group has uniform brightness, the glare phenomenon is prevented, reflection angles of the light source by a reflection cavity are relatively large, and formed light spots are relatively ideal.

Owner:宁波永望电子科技有限公司

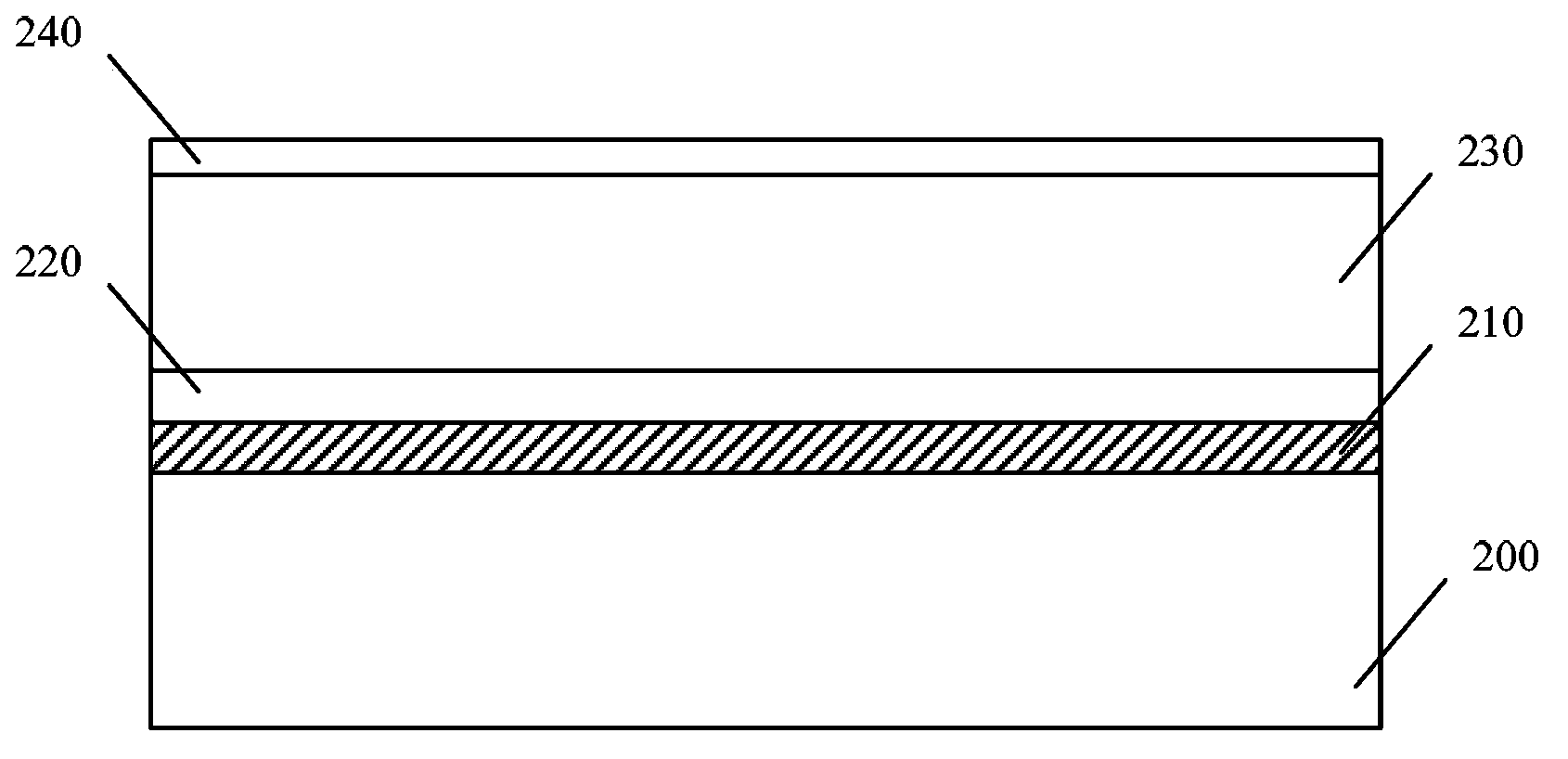

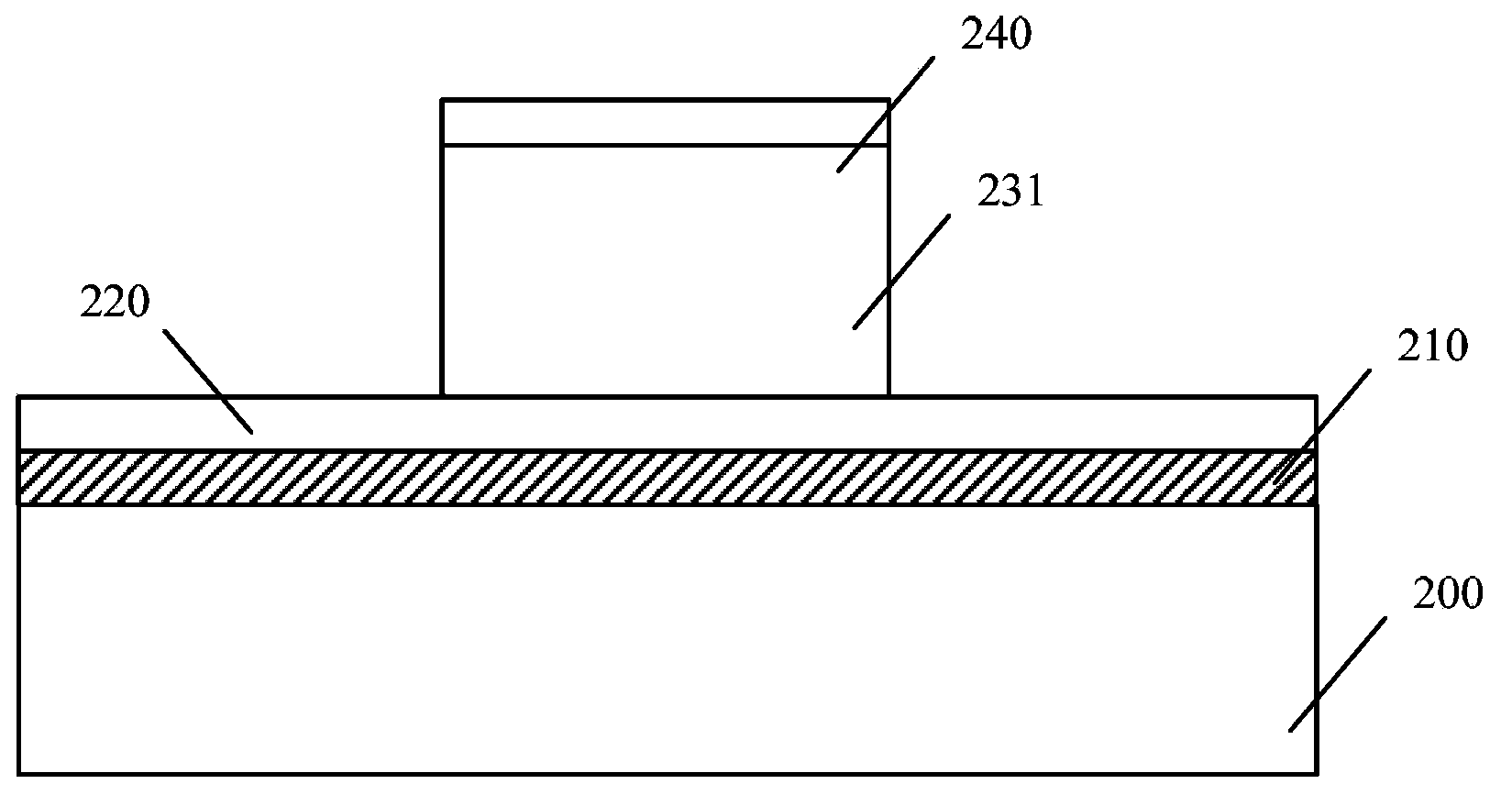

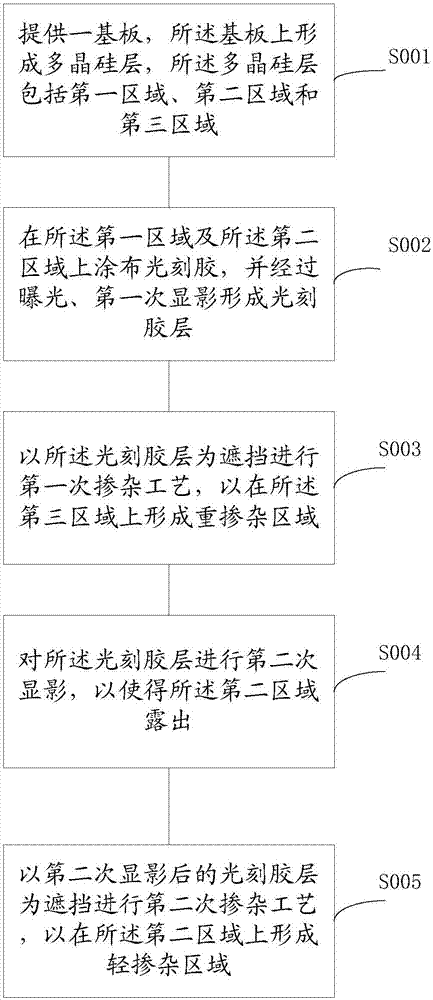

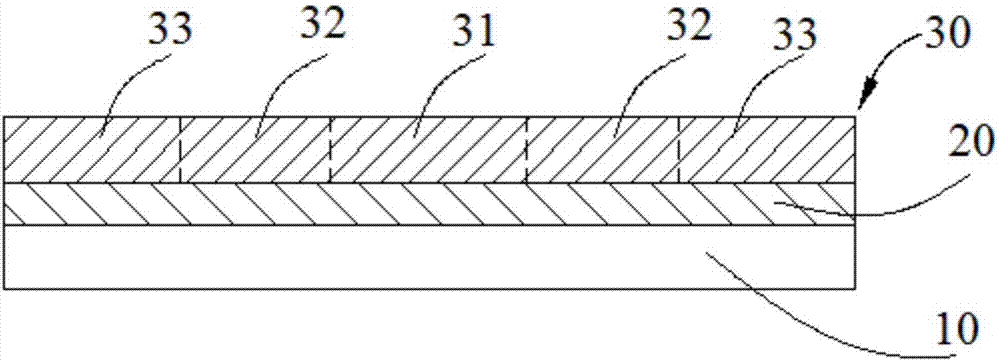

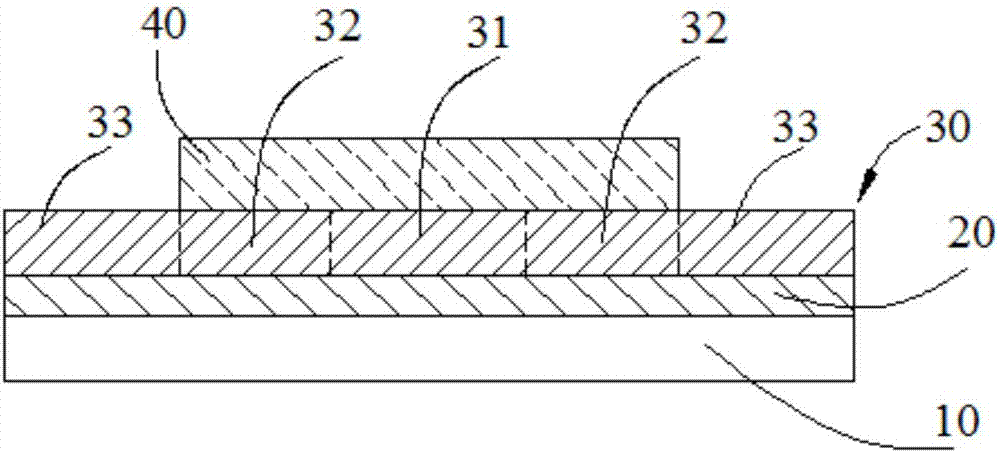

Fabrication method of low-temperature poly-silicon thin film transistor

InactiveCN106952824ASave stripping processReduce process costTransistorSemiconductor/solid-state device manufacturingPhotoresistEngineering

The embodiment of the invention provides a fabrication method of a low-temperature poly-silicon thin film transistor. The fabrication method comprises the steps of providing a substrate, wherein a poly-silicon layer is formed on the substrate and comprises a first region, a second region and a third region; coating photoresist on the first region and the second region, and performing exposure and first developing to form a photoresist layer; performing a first doping process by taking the photoresist layer as shading so as to form a heavy-doping region on the third region; performing second developing on the photoresist layer so that the second region is exposed; and performing a second doping process by taking the photoresist layer after the second developing as shading so as to form a light doping region on the second region. By the method, a process of yellow light and photoresist stripping can be omitted, and the process cost is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Hot melt adhesive membrane for reaction type wall cloth and preparation method thereof

InactiveCN108676507AIncrease polarityBonding is durable and stableNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesion forceAntioxidant

The invention discloses a hot melt adhesive membrane for reaction type wall cloth and a preparation method thereof. The hot melt adhesive membrane is prepared from the following components in parts byweight: 20 to 40 parts of a maleic anhydride grafted ethylene-vinyl acetate copolymer, 40 to 60 parts of an ethylene-vinyl acetate copolymer, 20 to 40 parts of an ethylene-acrylic acid copolymer, 0.2to 1.1 parts of a free radical thermal initiator, 0.5 to 1.5 parts of a crosslinking agent, 0.2 to 0.8 part of maleic anhydride and 0.2 to 1 part of an antioxidant; the components are extruded and granulated and then is further subjected to tape casting. After the hot melt adhesive membrane for the reaction type wall cloth, disclosed by the invention, is heated, gel is melted and is subjected tocrosslinking reaction; on the basis of original physical adhesion, an adhesion force is further improved, so that the adhesion between the wall cloth and a wall body is lasting and stable; the hot melt adhesive membrane for the reaction type wall cloth has the advantages of uniform thickness, simple adhesion technology, greenness and environment protection, no pollution and the like.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

Hot melt adhesive membrane for cross-linking polyolefin wall cloth and preparation method of hot melt adhesive membrane

ActiveCN108624258AImprove heat resistanceAvoid the risk of melt flowNon-macromolecular adhesive additivesFilm/foil adhesives without carriersCross-linkPolymer science

The invention discloses a hot melt adhesive membrane for cross-linking polyolefin wall cloth, and a preparation method of the hot melt adhesive membrane. The hot melt adhesive membrane comprises the following raw materials in parts by weight: 20-40 parts of maleic anhydride grafted polyolefin copolymer, 50-70 parts of polyolefin copolymer, 10-25 parts of ethylene-acrylic acid copolymer, 0.3-1 partof peroxide initiator, 0.5-1.5 parts of cross-linking agent, 0.3-1 part of maleic anhydride, and 0.2-1 part of antioxidant. The method comprises the steps of extrusion, granulation, and flow castingforming. The hot melt adhesive membrane for the cross-linking polyolefin wall cloth has physical and chemical bonding effects, and is high in bonding strength and excellent in thermal resistance at the same time; a risk of melting and flowing of the adhesive membrane caused by high temperature is avoided; and the problem in temperature adaptability of the hot melt adhesive membrane for the wall cloth is solved.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

Sewing machine pressing foot with cloth feeding sleeve body

InactiveCN102965855AWidth is easy to controlImprove aestheticsWork-feeding meansPressersFoot supportsEngineering

The invention discloses a sewing machine pressing foot with a cloth feeding sleeve body, and relates to the field of sewing machine parts. The sewing machine pressing foot comprises pressing foot supporting columns, a pressing foot plate and the cloth feeding sleeve body, wherein the bottoms of the pressing foot supporting columns are hinged through a pin shaft; an obliquely upward raised plate is arranged at the front end of the pressing foot plate; the top of the raised plate is connected with the cloth feeding sleeve body; the raised plate and the cloth feeding sleeve body are positioned on the same plane; the cloth feeding sleeve body is a hollow sleeve body; the top end of the cloth feeding sleeve body is a cloth inlet end; and a cloth guide plate is arranged at the cloth inlet end. The sewing machine pressing foot can easily control the width of a cloth strip, improves the sewing quality and the overall beautiful effect of clothing, is convenient to use and operate, is time-saving and labor-saving, and improves the working efficiency.

Owner:NANTONG GEMENGDE INT TRADE

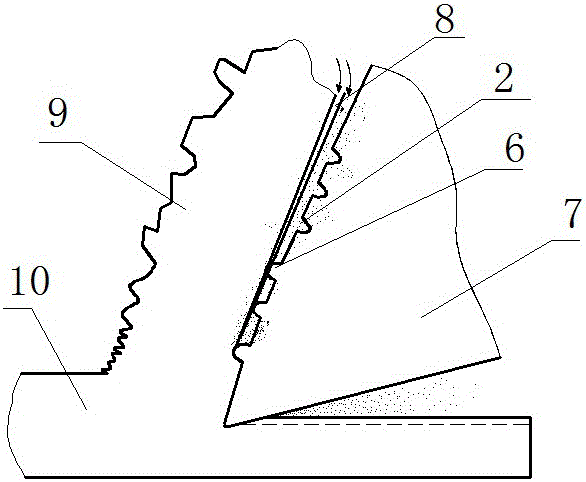

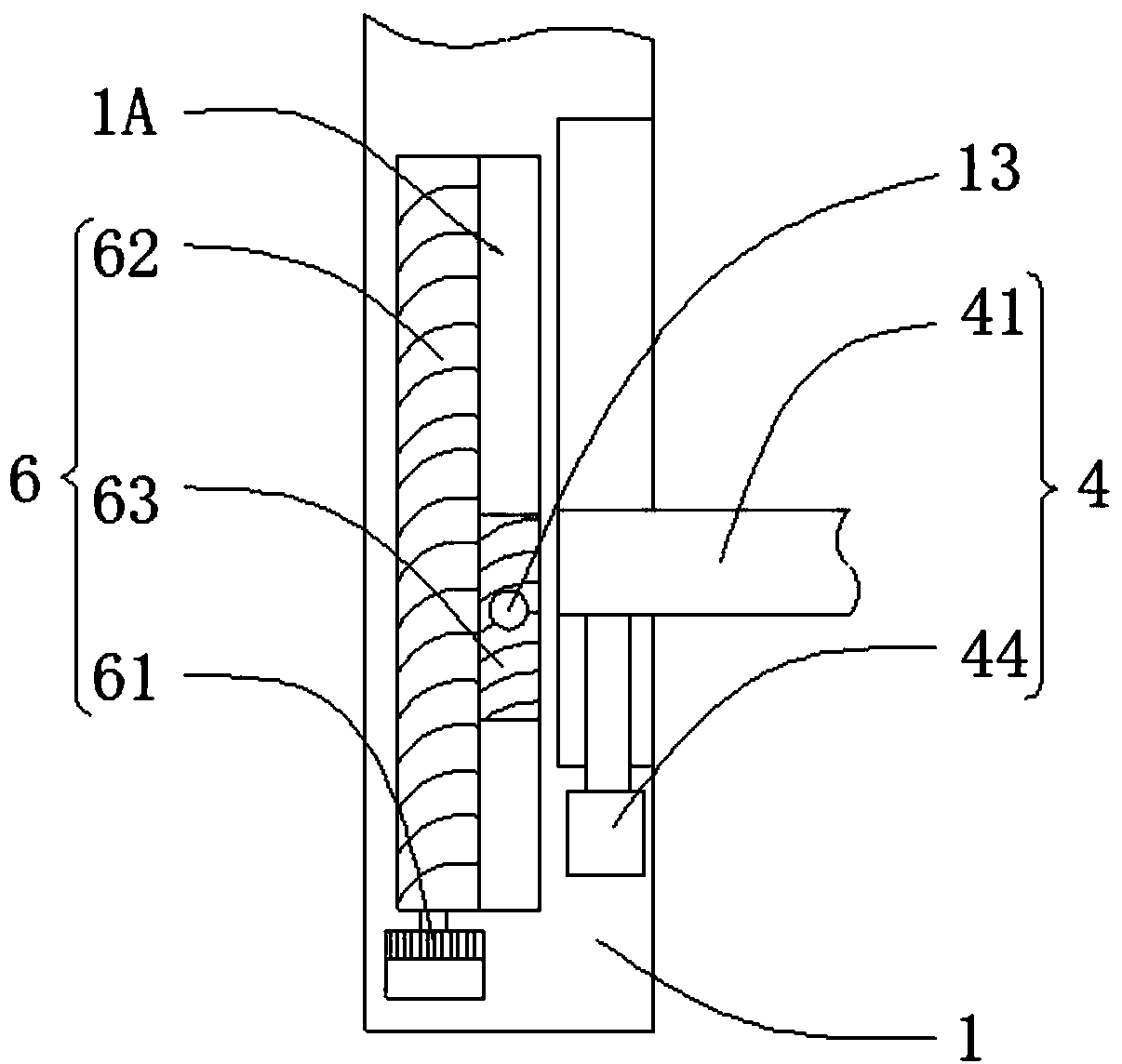

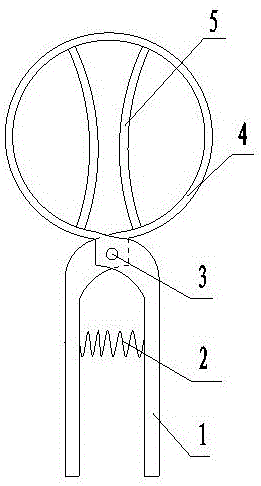

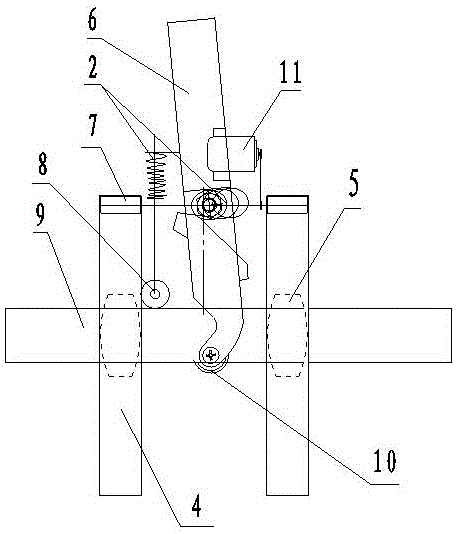

Artificial auxiliary handheld power-driven pomelo tree girdling machine capable of clamping branch in variable-diameter manner by using spring plates

The invention provides an artificial auxiliary handheld power-driven pomelo tree girdling machine capable of clamping a branch in a variable-diameter manner by using spring plates. The machine comprises a handle, a spring, a rotation shaft, the spring plates, a fixed ring and a miniature direct current motor, wherein the spring which is a tension spring is fixedly installed on the handle; when in operation, the spring plates clamp a branch of a pomelo tree to be prevented from rotating along with a girdling knife; the handle is divided into two parts; the fixed ring is installed on the handle; two parts of the fixed ring are buckled to form a whole ring; the fixed ring and the spring plates are opened and closed along with the opening and closing of the handle; a groove is arranged on the fixed ring; an idler wheel is embedded into the groove and rolls in the same; a link rod penetrates through the center hole of the idler wheel; the idler wheel rotates circumferentially; the two pomelo tree girdling machines are connected together by the link rod; a girdling handle is fixed on the link rod; the girdling knife is arranged at one end of the girdling handle while a link plate is arranged on the other end; and under artificial auxiliary, the girdling knife rotates circumferentially by taking the fixed point of the handle and the link rod as a circle center and the distance between the fixed point and the knife point of the girdling knife as a radius to girdle the pomelo tree.

Owner:SHANDONG UNIV OF TECH

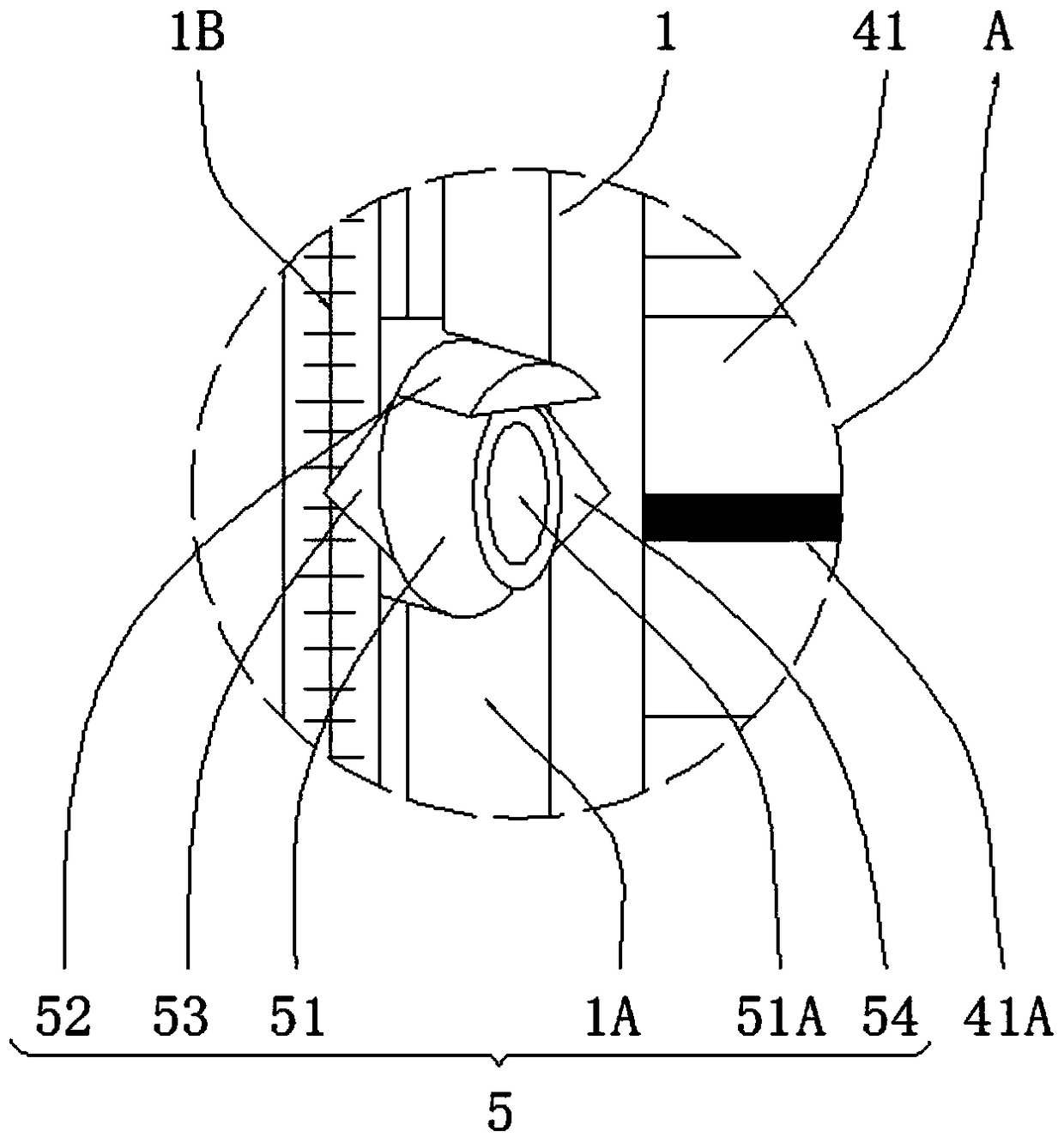

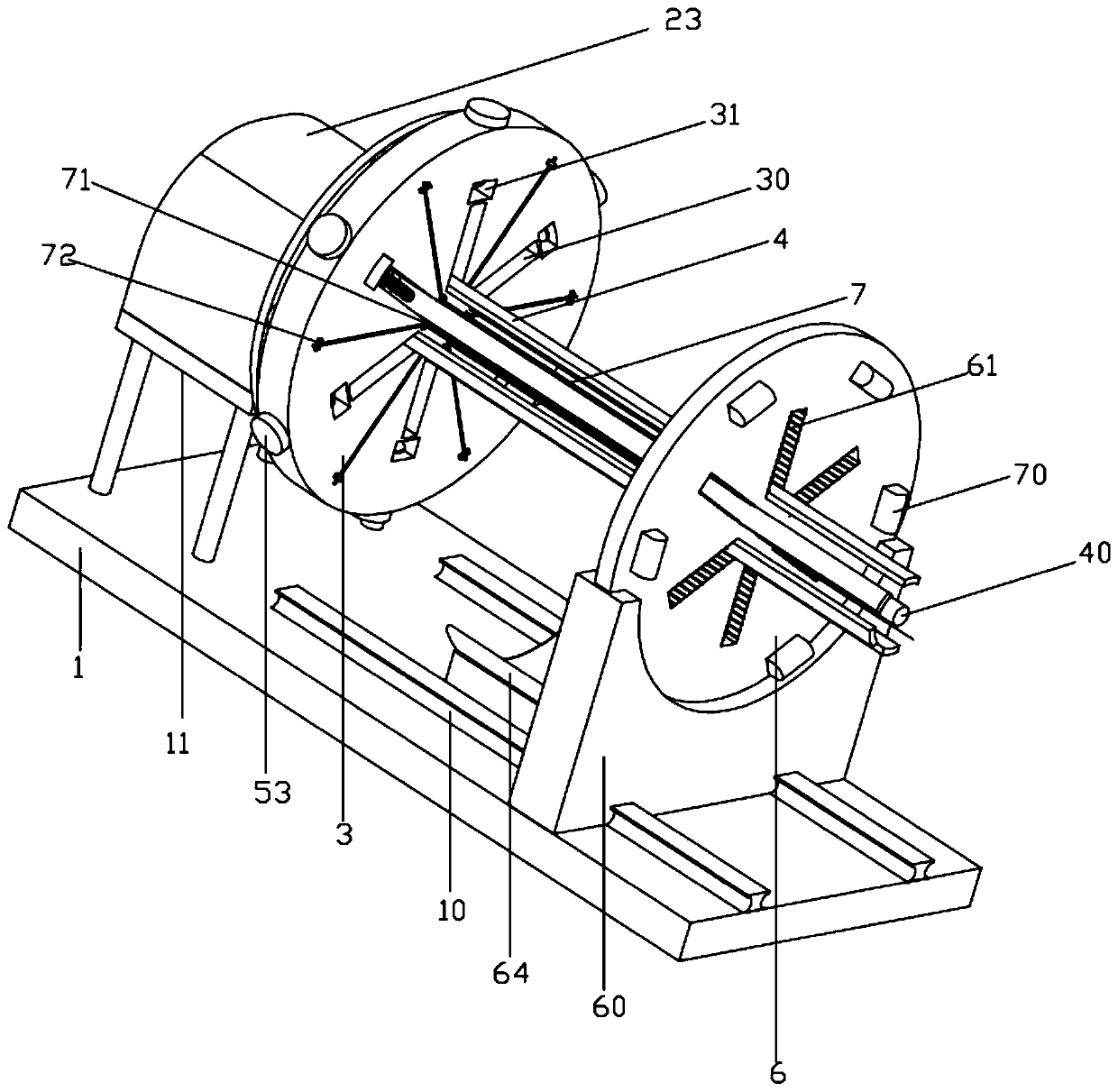

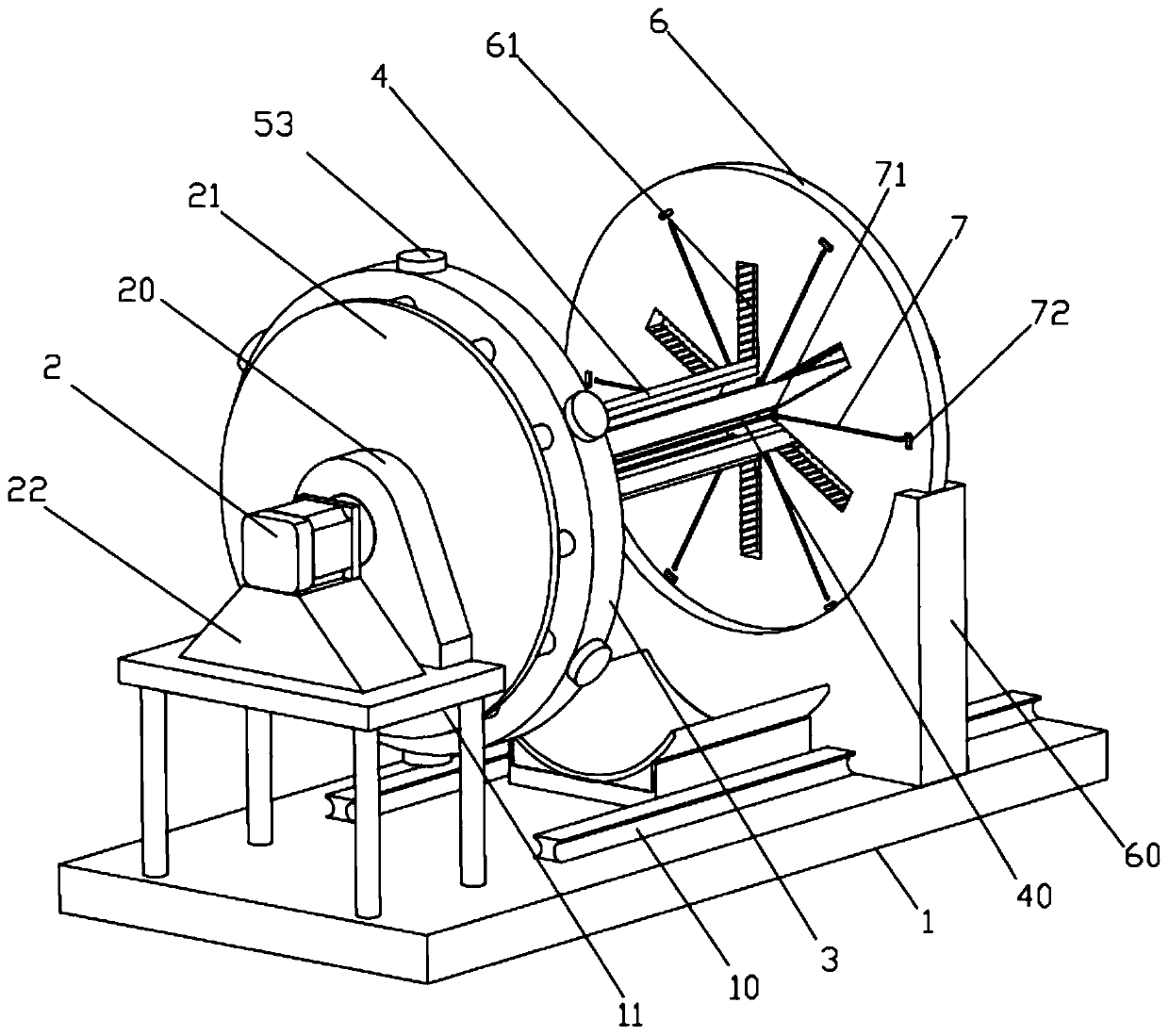

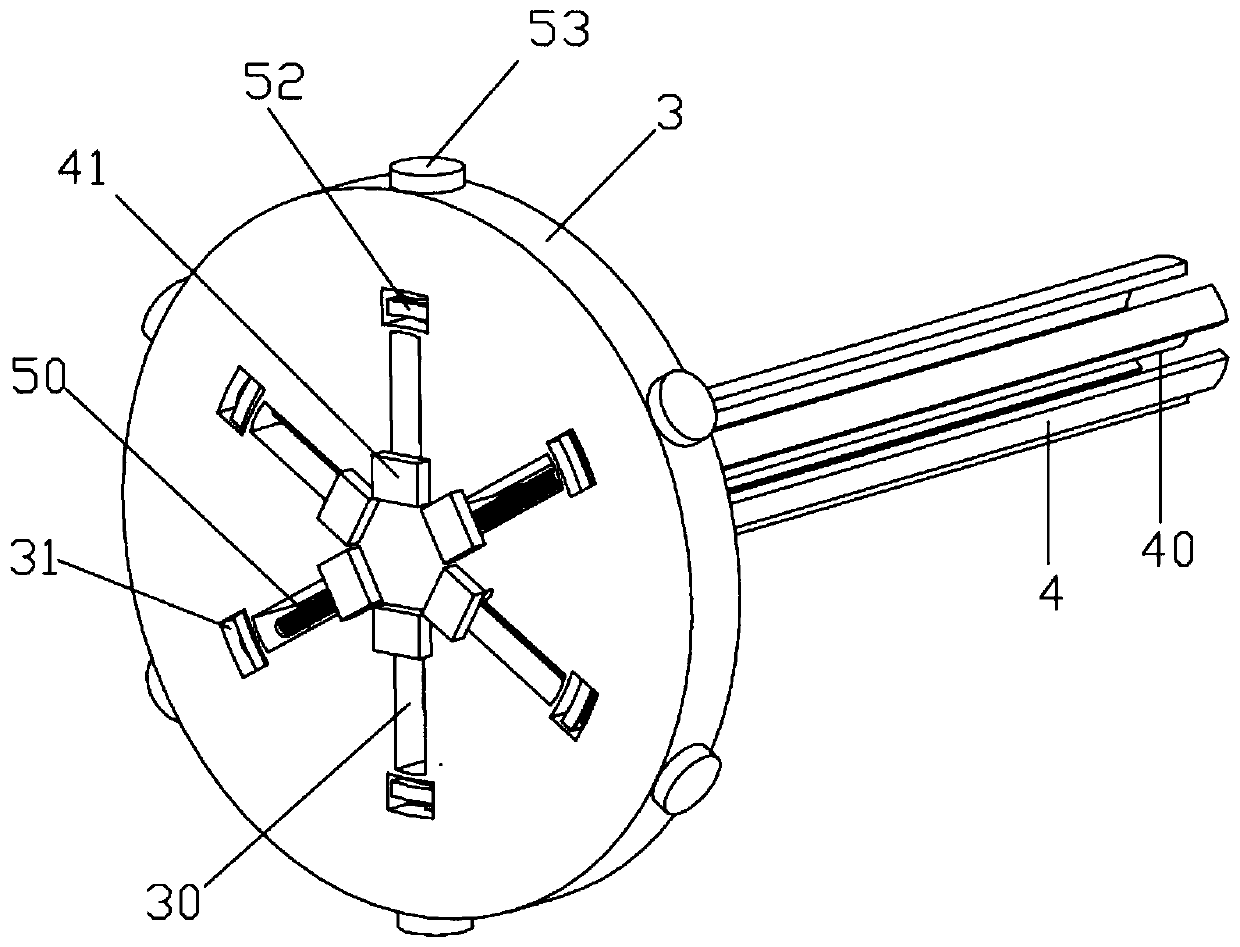

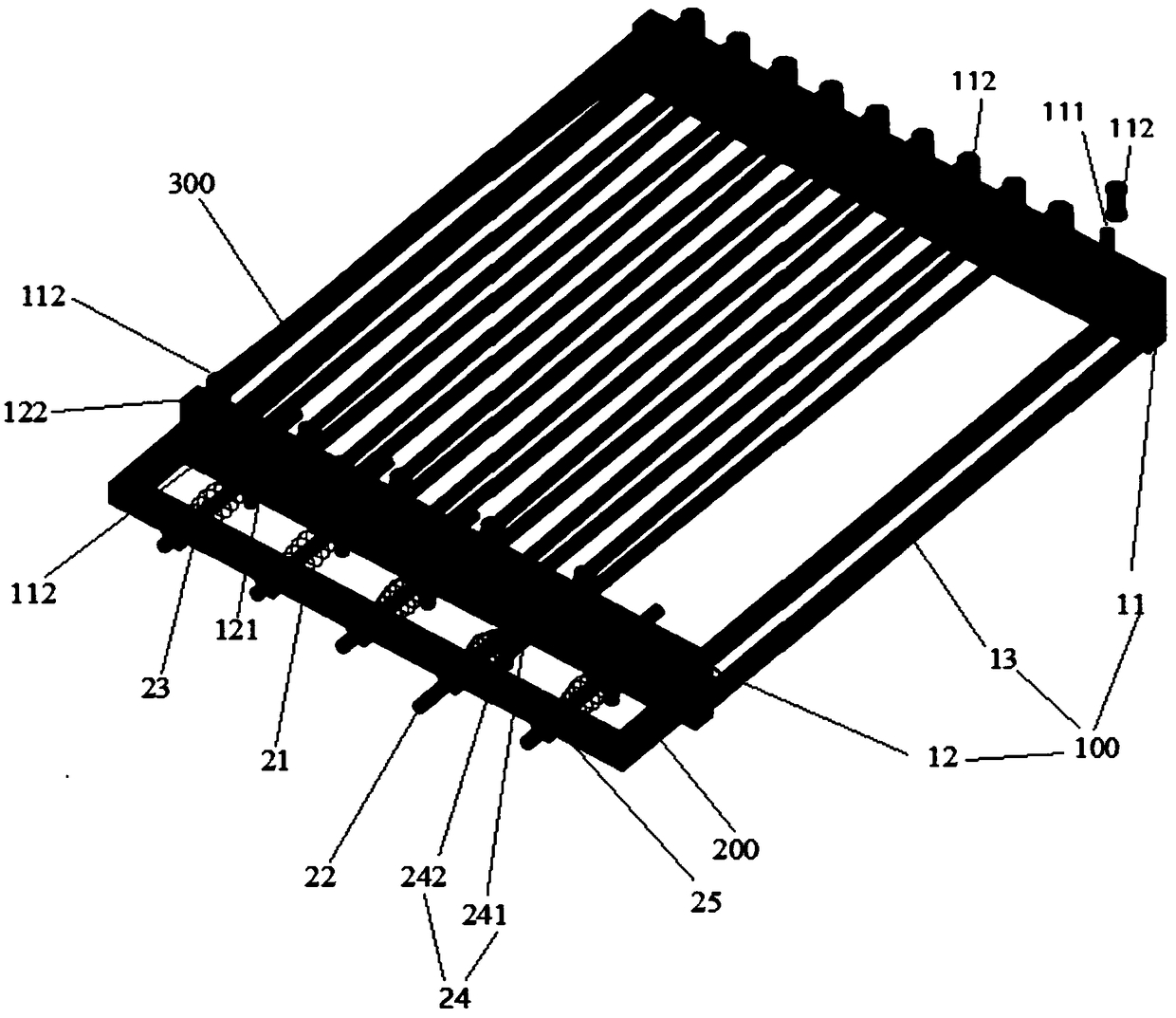

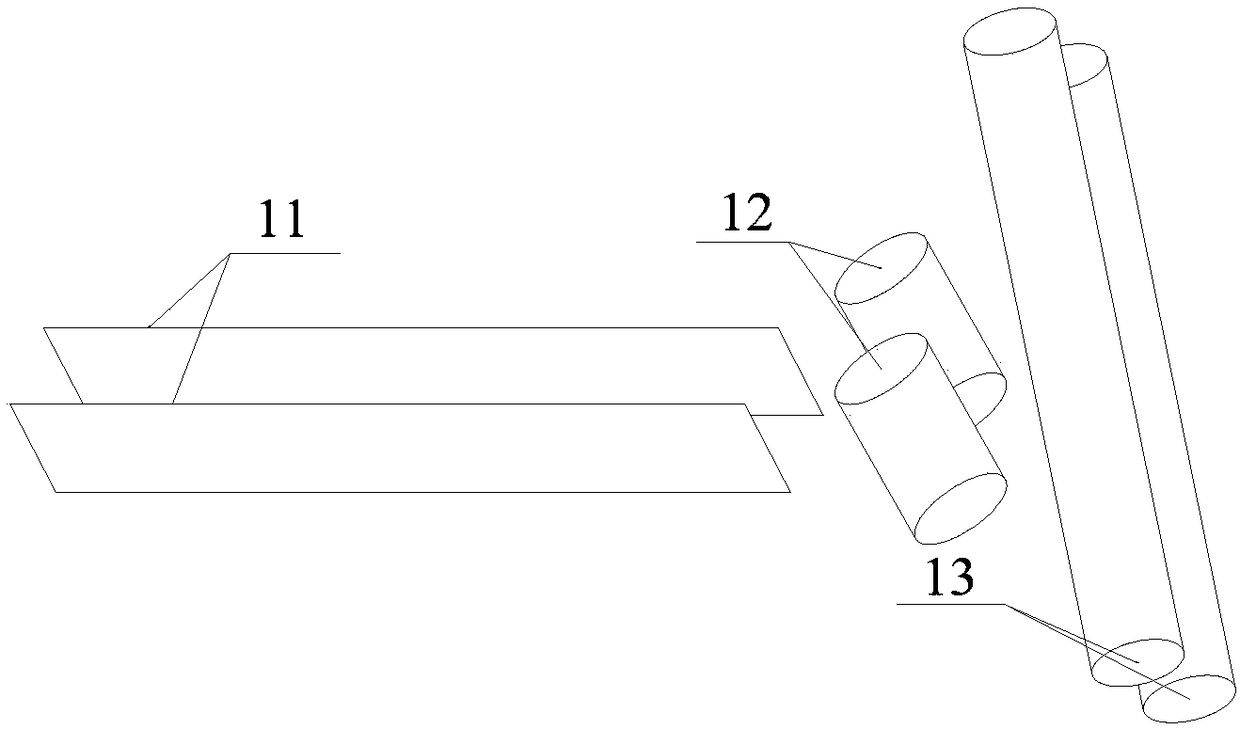

Large-tow carbon fiber multifilament tensile sample and preparation device and method thereof

PendingCN109406234AGuaranteed tensionGuaranteed straightnessPreparing sample for investigationEngineeringFilament winding

The invention discloses a large-tow carbon fiber multifilament tensile sample and a preparation device and method thereof. The device comprises a main body support and a tensioning mechanism; the mainbody support comprises a first cross beam and a second cross beam which are arranged at an interval; the two ends of the first cross beam and the two ends of the second cross beam are connected through supporting frames; the first cross beam is provided with first fixed filament winding rods, and the first fixed filament winding rods are detachably sleeved with filament winding rings; the tensioning mechanism comprises a force bearing rod, screws, elastic parts, movable filament winding rods and nuts; the force bearing rod is arranged at one end, far away from the first cross beam, of the second cross beam; the movable filament winding rods are detachably sleeved with filament winding rings; each movable filament winding rod comprises a positioning rod and a filament winding rod; the positioning rods are perpendicular to the filament winding rods; the end surface, close to the force bearing rod, of the second cross beam is provided with positioning holes; the positioning rods are movably arranged in the positioning holes in the direction perpendicular to the second cross beam; the screws penetrate through the force bearing rod and are connected with the movable filament winding rods; the nuts are arranged on one side, far away from the second cross beam, of the screws; and the screws penetrate through the elastic parts and abut against the elastic parts, the force bearing rodand the movable filament winding rods.

Owner:BEIJING UNIV OF CHEM TECH

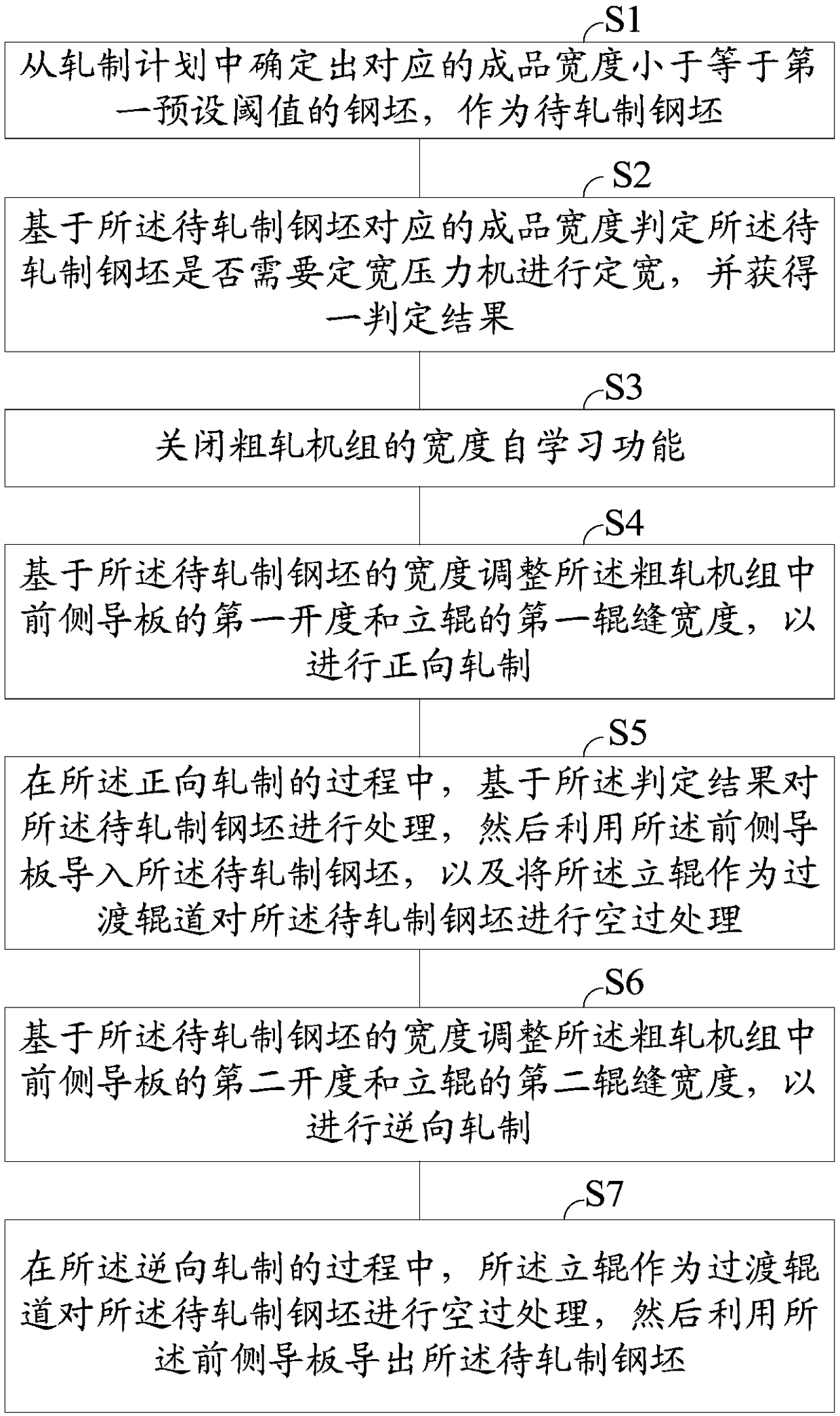

Rough rolling vertical roll shallow pass treatment method

ActiveCN108838213ASave process investmentAvoid productivity lossRoll mill control devicesMetal rolling arrangementsMachine pressEngineering

The invention discloses a rough rolling vertical roll shallow pass treatment method. The method comprises the steps that a to-be-rolled steel blank is determined from a rolling plan; whether width fixing needs to be conducted on the to-be-rolled steel blank through a width-fixed pressure machine or not is judged, and a judgment result is obtained; the width self-learning function of a rough rolling unit is closed; the first opening degree of a front guide board and the width of a first roll seam of a vertical roll are adjusted, and forward rolling is conducted; in the forward rolling process,the to-be-rolled steel blank is processed according to the judgment result and guided in through the front guide board, and the vertical roll serves as a transition roller way to conduct shallow passtreatment on the to-be-rolled steel blank; the second opening degree of the front guide board and the width of a second roll seam of the vertical roll are adjusted, and inverse rolling is conducted; and in the inverse rolling process, the vertical roll serves as a transition roller way to conduct shallow pass treatment on the to-be-rolled steel blank, and the to-be-rolled steel blank is guided outthrough the front guide board. The rough rolling vertical roll shallow pass treatment method provided by the invention can avoid capacity loss caused by halt production and ensure controllability ofthe width of finished products.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Natural finish fabric

ActiveUS9732455B2Reduce consumptionWidth is easy to controlShrinkingSucessive textile treatmentsWater vaporEngineering

A method for producing environmentally friendly fabric and textile products without use of chemicals comprises a finishing process including the steps of: singeing, enzyme desizing; water washing, peaching, stentering, and sanforizing. The steps of the finishing process are purely physical and preferably uses only water, water vapor (steam), and enzymes, and not chemicals including chemical agents. As such, the finishing process is believed to be environmentally friendly.

Owner:WELSPUN INDIA LTD

Method for repairing plasma display screen wire break electrode

InactiveCN1801434ASolve the problem of adding a very small amount of electrode slurryImprove yieldManufacture testing/measurementsElectronic waste recyclingScreen printingSlurry

The invention provides a repair method for broken electrode of plasma screen. Wherein, lying flat the glass base plate to be repaired on table top fit to fix or vacuum sorption to make two sides of missing printed plate parallel to right-angle sides of said glass base plate; labeling on the missing printed plate with small electrode slurry according to found defect coordinate; using screen printing method of small area to coat the slurry on area contained broken wire; sintering and repairing the broken wire with slurry by laser repair machine. This invention needs no costly feeding device, and has well repair effect.

Owner:四川世纪双虹显示器件份有限公司

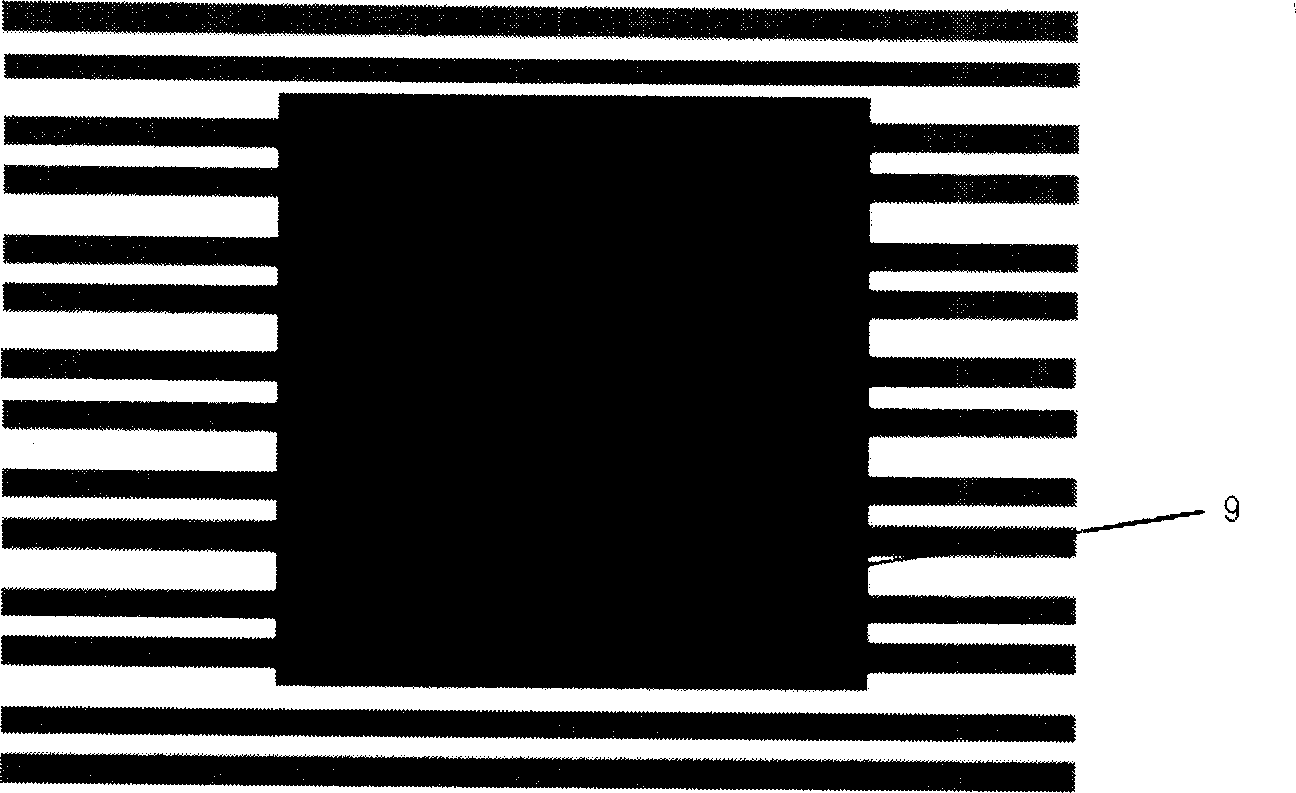

High-power high-current choking winding

InactiveCN102737812AEasy to cutEasy to insertTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringConductor Coil

The invention discloses a high-power high-current choking winding which comprises an annular magnetizer and a coil winding which is wound around the annular magnetizer, and is characterized in that the coil winding is formed by stranding more than three strands of enameled wires; and the lead-out part of the coil winding has a flat plate shape formed by arranging and connecting each strand of enameled wires one by one. According to the high-power high-current choking winding, the lead-out part of the coil winding is of a flat plate shape formed by arranging and connecting each strand of enameled wires one by one, so that the choking winding is easily cut off during shearing, the pin has controllable height and width, a reserved hole on a power board is arranged to have a rectangular shape close to the diameter of the enameled wires, and the high-power high-current choking winding is easily inserted and welded, easy in through welding and firm in welding.

Owner:KUNSHAN DAGONG ELECTRONICS

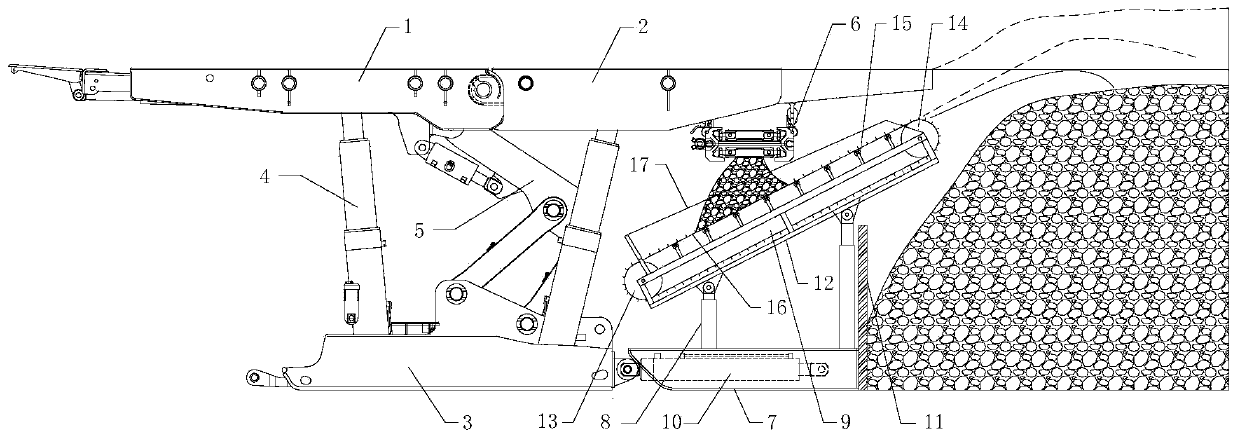

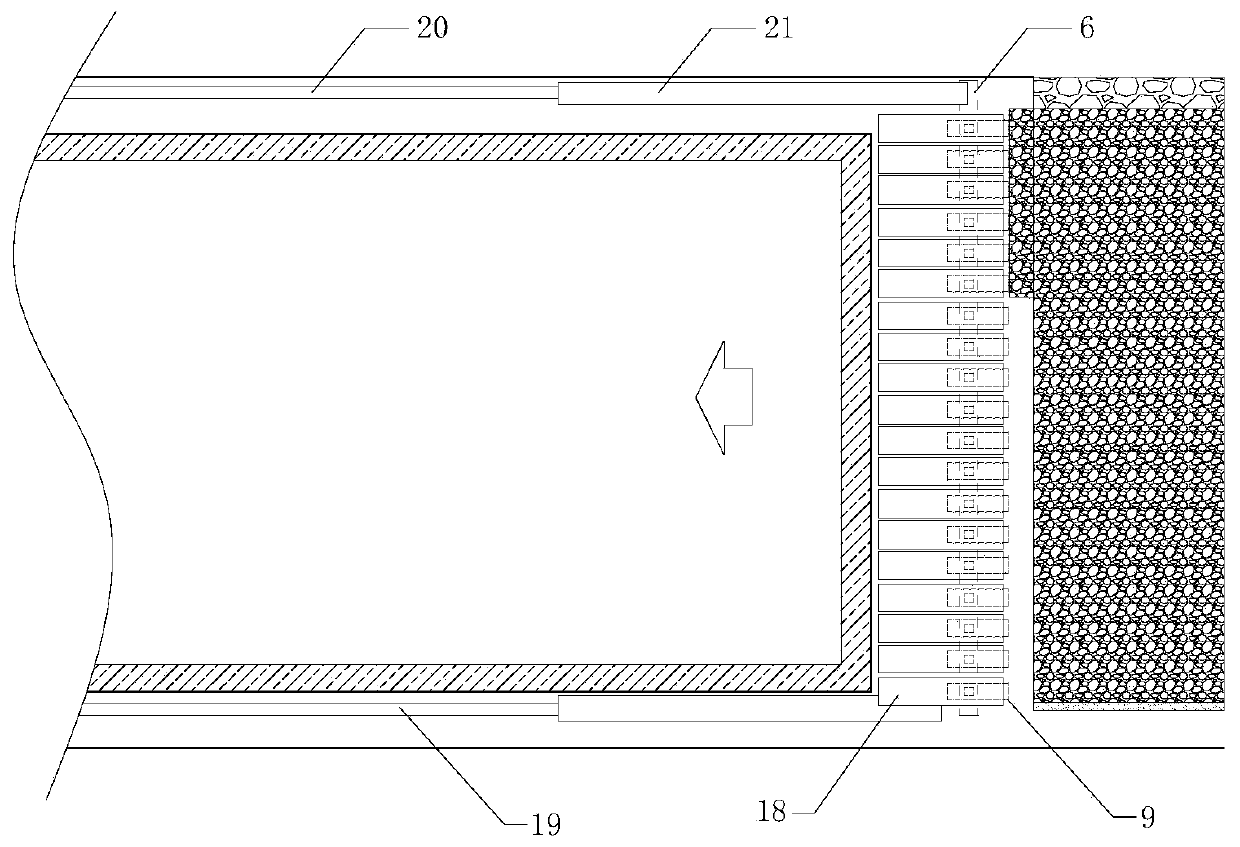

Fully-mechanized mining gangue-throwing filling hydraulic support and filling method thereof

PendingCN111485929AImprove filling efficiencyImprove fill rateConveyorsUnderground miningMining engineeringStructural engineering

The invention provides a fully-mechanized mining gangue-throwing filling hydraulic support and a filling method thereof. The hydraulic support comprises a gangue filling hydraulic support body withouta tamping mechanism, and a gangue-throwing belt mechanism on the rear portion of the gangue filling hydraulic support body without the tamping mechanism. The gangue filling hydraulic support body without the tamping mechanism is composed of a front top beam, a rear tail beam, a base, four stand columns, four connecting rods and a porous bottom-discharge scraper conveyor, wherein the four stand columns and the four connecting rods are used for connecting the front top beam, the rear tail beam and the base; and the porous bottom-discharge scraper conveyor is hung on the rear tail beam. The gangue-throwing belt mechanism consists of a rear seat, a vertical lifting oil cylinder, a belt conveyor, a horizontal pulling and moving oil cylinder and a rear baffle plate, wherein the inclination angle of the belt conveyor is 10-45 degrees. The filling method comprises the following steps that when coal is cut, a rear scraper gangue leakage hole of the filling hydraulic support is opened, the beltconveyor which is arranged behind the rear scraper gangue leakage hole is started, gangue falls onto the belt conveyor from the gangue leakage hole, and a conveying belt rotates at a high speed to throw the gangue into a goaf for filling. According to the fully-mechanized mining gangue-throwing filling hydraulic support and the filling method thereof, tamping is replaced by throwing, the throwingdistance is long, the throwing height is high, the filling efficiency is high, and the fully-mechanized mining gangue-throwing filling hydraulic support and the filling method thereof are widely applied to the fields of coal mine filling mining, gob-side entry retaining and the like.

Owner:中煤能源研究院有限责任公司 +1

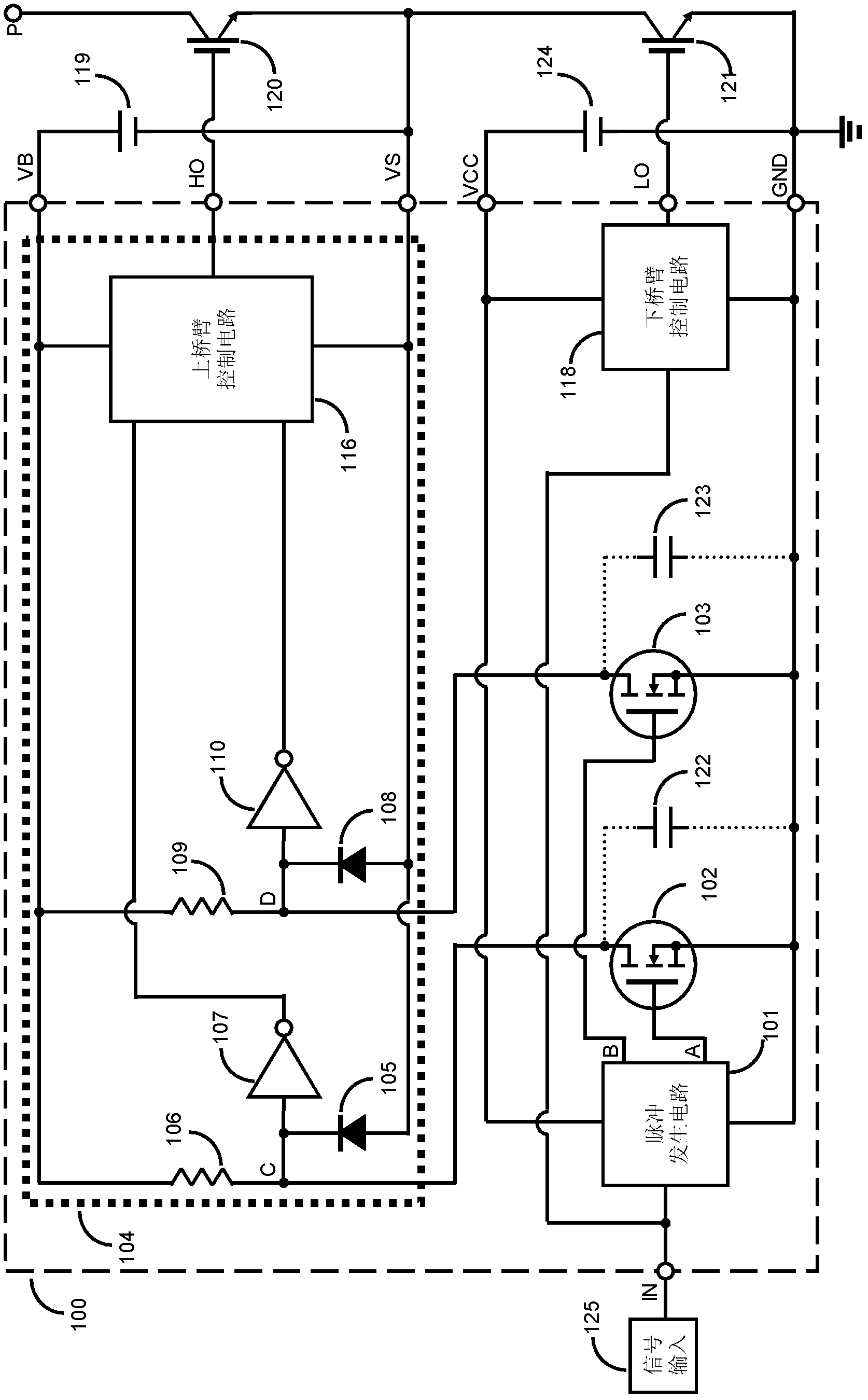

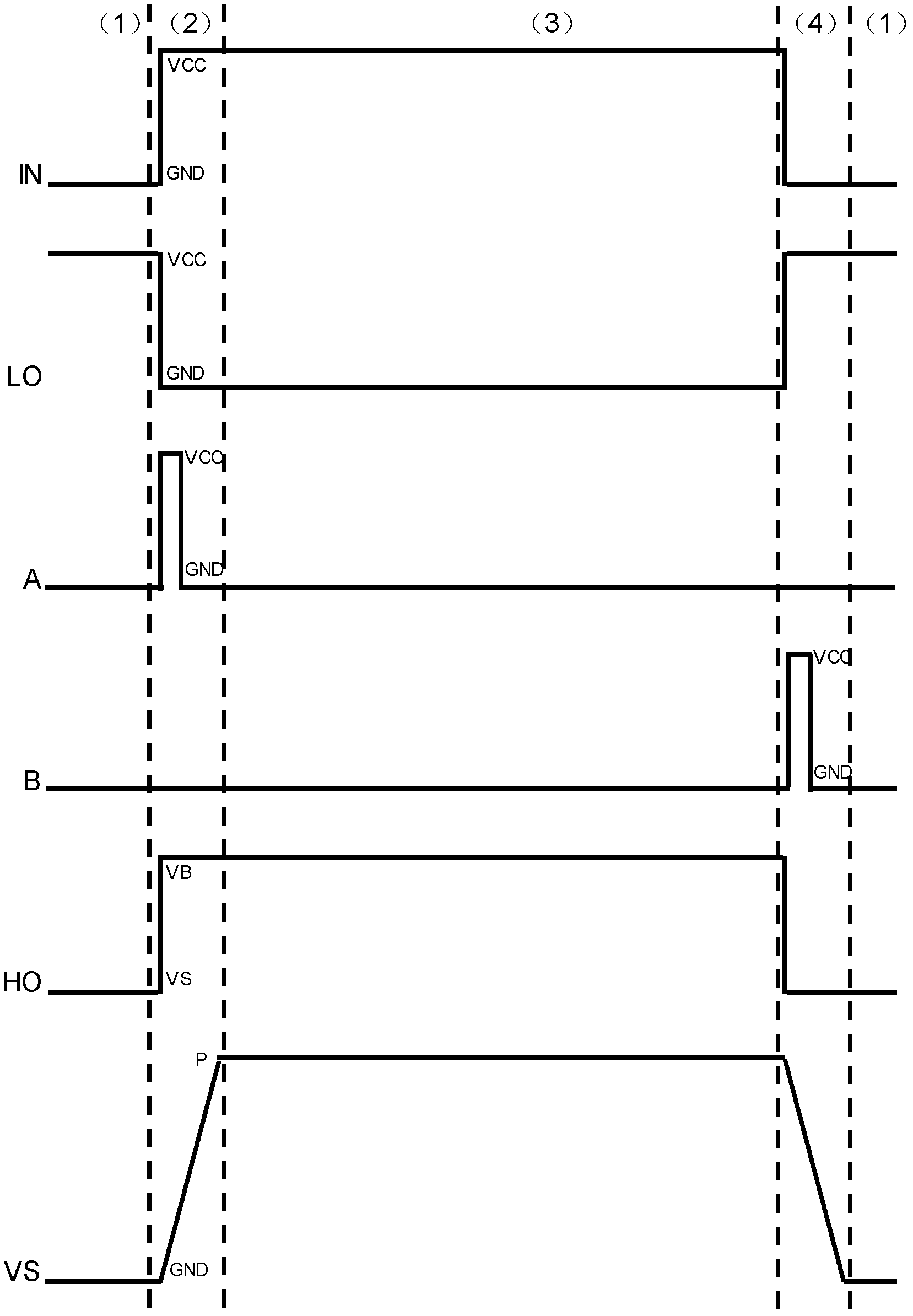

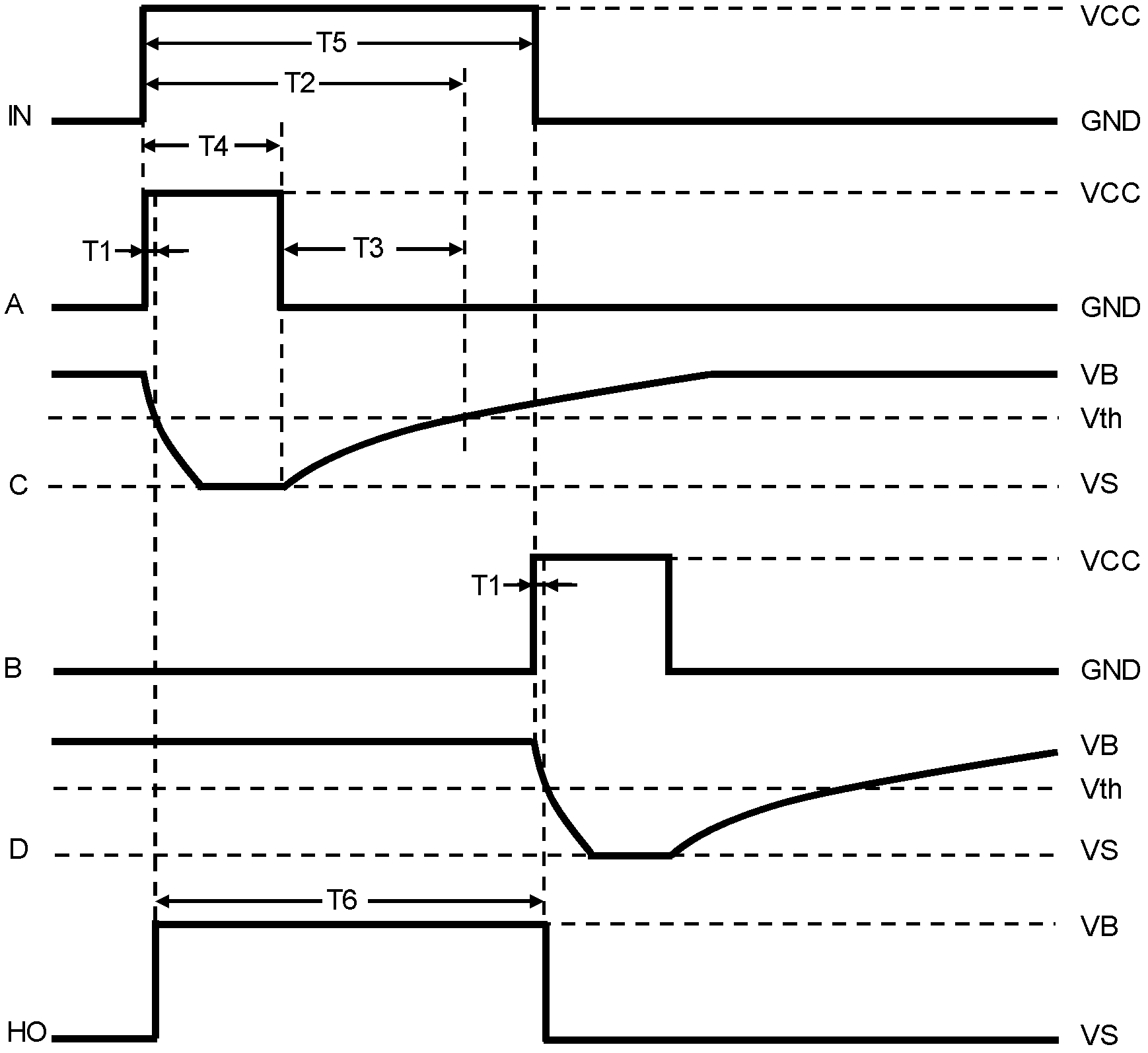

Level switching circuit for high-voltage integrated circuit

ActiveCN102324925AImprove stabilityExtended service lifeLogic circuits coupling/interface using field-effect transistorsDouble diffusionLow voltage

The invention relates to a level switching circuit for a high-voltage integrated circuit, which comprises a pulse generating circuit 601, a high-voltage DMOS (double-diffusion metal oxide semiconductor) transistor 602, a high-voltage DMOS transistor 603, a lower bridge arm control circuit 618, a high-voltage region 604, a quick charge level switching circuit 611 positioned in a low-voltage regionand a quick charge level switching circuit 606 positioned in the high-voltage region, wherein a capacitor 622 is a parasitic capacitor of the high-voltage DMOS transistor 602, a capacitor 623 is a parasitic capacitor of the high-voltage DMOS transistor 603, an input signal 625 enters the pulse generating circuit 601 and the lower bridge control circuit 618 from an IN end of the high-voltage integrated circuit 600, and the first output end A of the pulse generating circuit 601 is connected with a grid electrode of the high-voltage DMOS transistor 602 and the input end of the rapid quick level switching circuit 611. The level switching circuit for the high-voltage integrated circuit has the characteristics that the operation is flexible, and the situation that the output pulse width is changeless when the input pulse width is little is avoided.

Owner:MIDEA GRP CO LTD

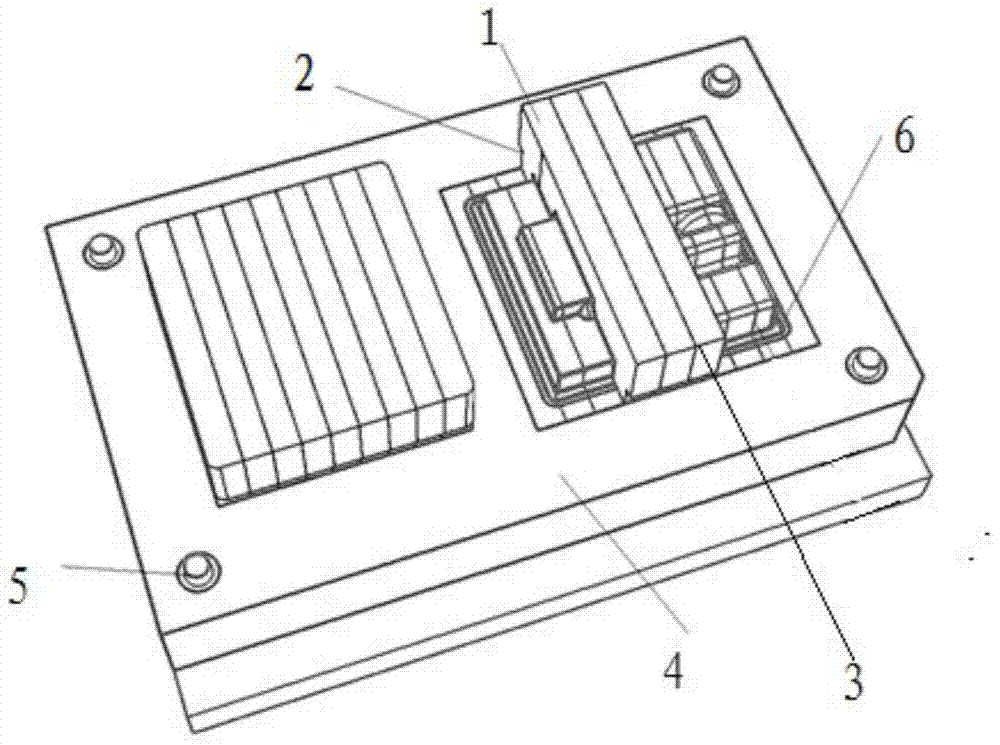

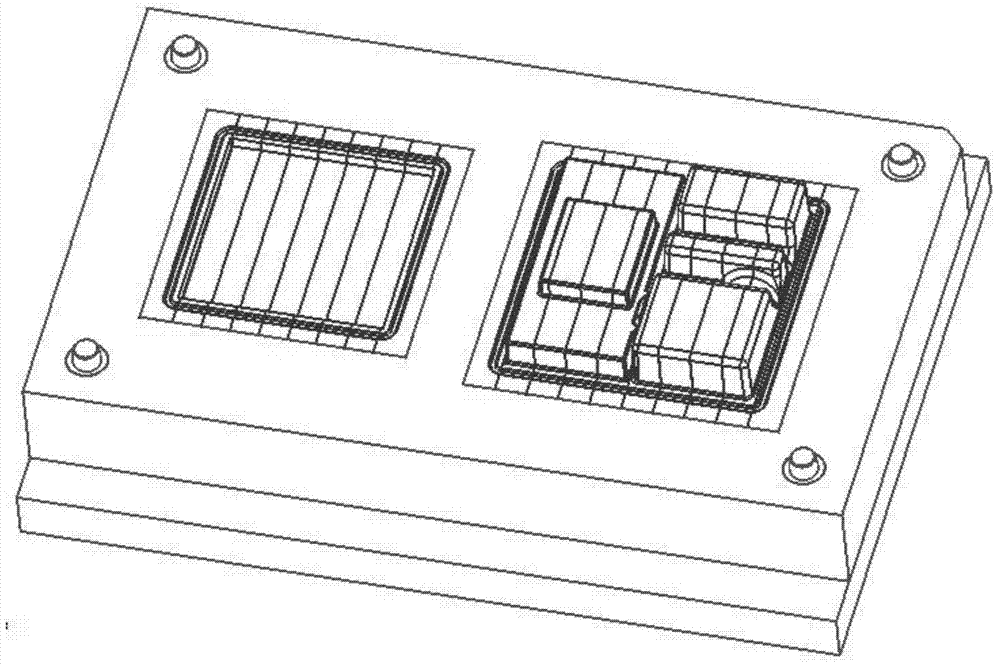

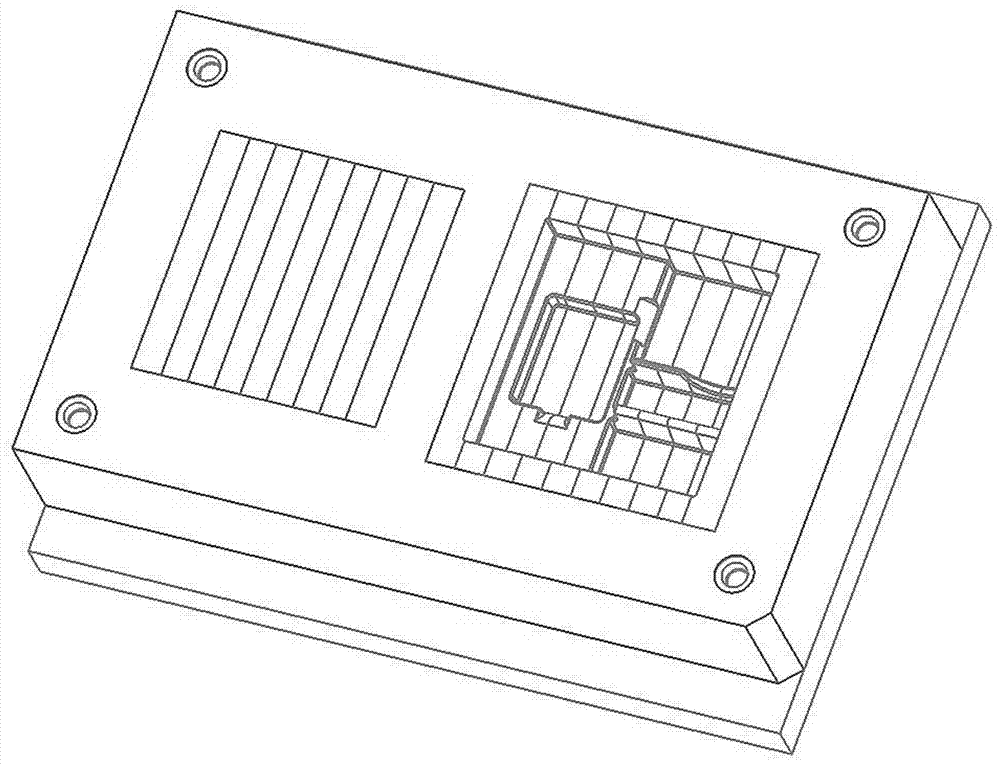

Combined lamination embedded mould

The invention discloses a combined lamination embedded mould which comprises a convex mould and a concave mould, wherein the convex mould and the concave mould adopt combined lamination embedded devices. The combined lamination embedded devices comprise a plurality of laminations, wherein the laminations are overlapped to form a plurality of steam lines, the combined lamination embedded devices of the concave mould and the convex mould are matched to form a structure cavity, the steam lines of the concave mould and the convex mould mutually correspond, an excessive material trough is formed in a parting surface between the convex surface and the concave surface, the plurality of laminations are matched and arranged in a mould base through embedding, and conical cylinder positioning systems are respectively arranged on four corner surfaces of the mould base. The mould cavity can be subjected to finish machining by blocks, thus the machining requirement and difficulty are reduced, the restriction to the machining width and a machining method of the steam lines is relieved, and a detachable structure also brings the great convenience to cleaning and maintaining; the excessive material trough is formed in the parting surface between the convex mould and the concave mould, thus the problem of material spraying is effectively solved, and the effect is remarkable; and the conical cylinder combined positioning system integrates multiple advantages.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com