Sewing machine pressing foot with cloth feeding sleeve body

A technology of sewing machine presser feet and cloth covers, which is applied in the field of sewing machine presser feet, can solve the problems of not being easy to control the width of cloth strips, affecting the aesthetic effect of clothing, and affecting sewing quality, so as to achieve easy control, convenient use and operation, and improve sewing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

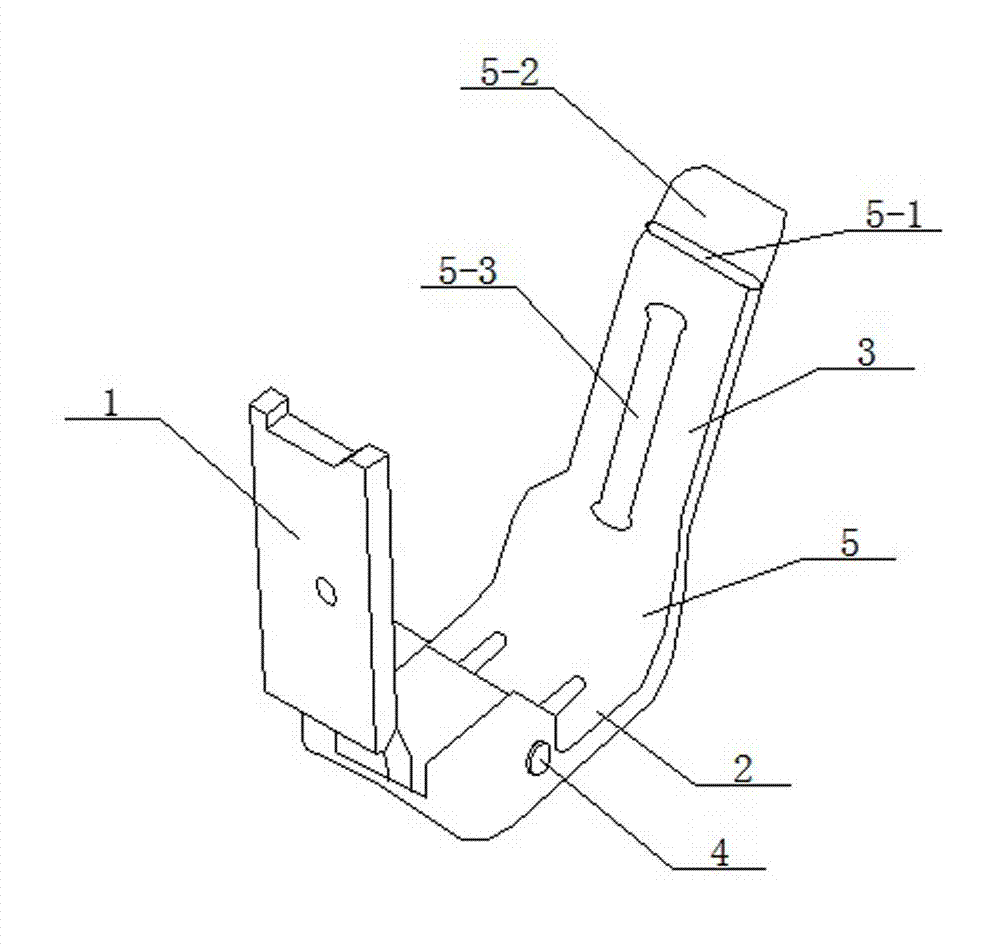

[0009] refer to figure 1 , figure 2 , the specific embodiment adopts the following technical solutions: a sewing machine presser foot that is brought into the cloth cover body, including a presser foot support 1, a presser foot plate 2 and a cloth cover body 3, and the bottom of the presser foot support 1 passes through a pin shaft 4 Hinged with the presser foot plate 2, the front end of the presser foot plate 2 is provided with an obliquely upward seesaw 5, the top of the seesaw 5 is connected with the cloth feeding cover body 3 by welding, the seesaw 5 and The cloth-feeding cover body 3 is on the same plane, which facilitates the smooth introduction of cloth strips into the cloth cover body 3 and extends to the seesaw 5 and then to the presser foot plate 2 for direct sewing by a sewing machine. The cloth-feeding cover body 3 is hollow cover body, and the top of the cloth cover body 3 is a cloth inlet port 5-1, and the cloth inlet port 5-1 is provided with a cloth guide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com