Combined lamination embedded mould

A mosaic and lamination technology, applied in the field of molds, can solve the problems of steam exhaust and hot pressing conflicts, difficult mold cleaning, and high processing costs, and achieve the effects of extending service life, flexible and diverse processing methods, and reducing processing requirements and difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

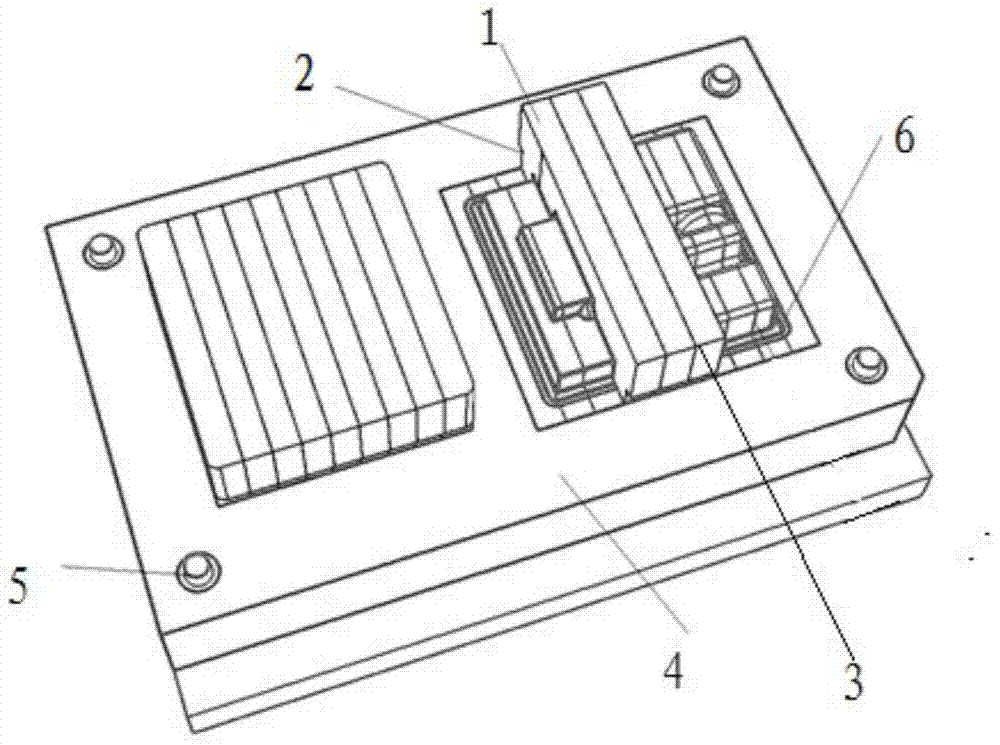

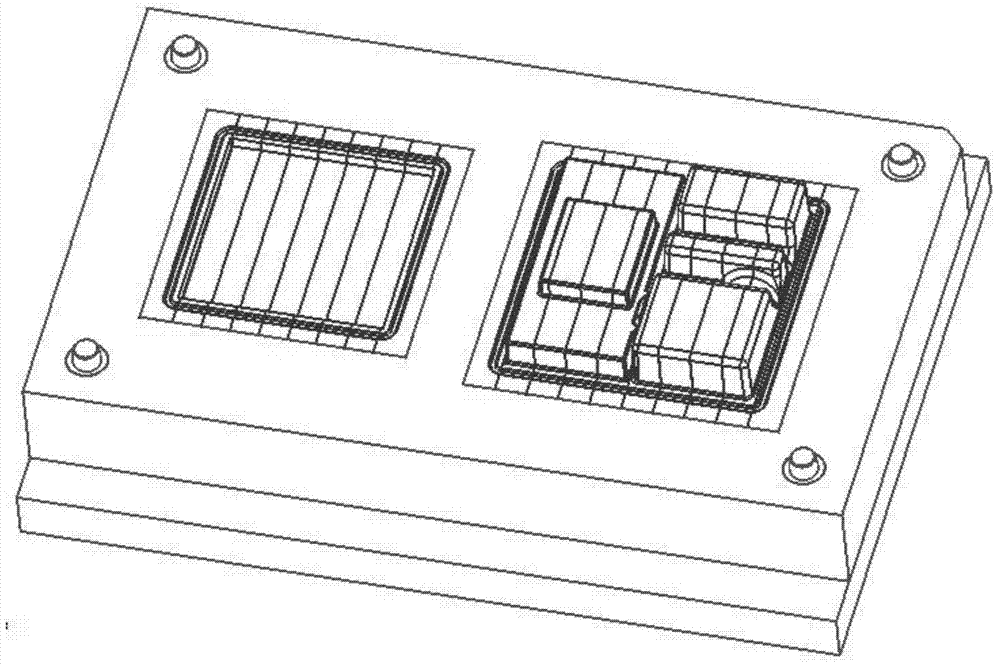

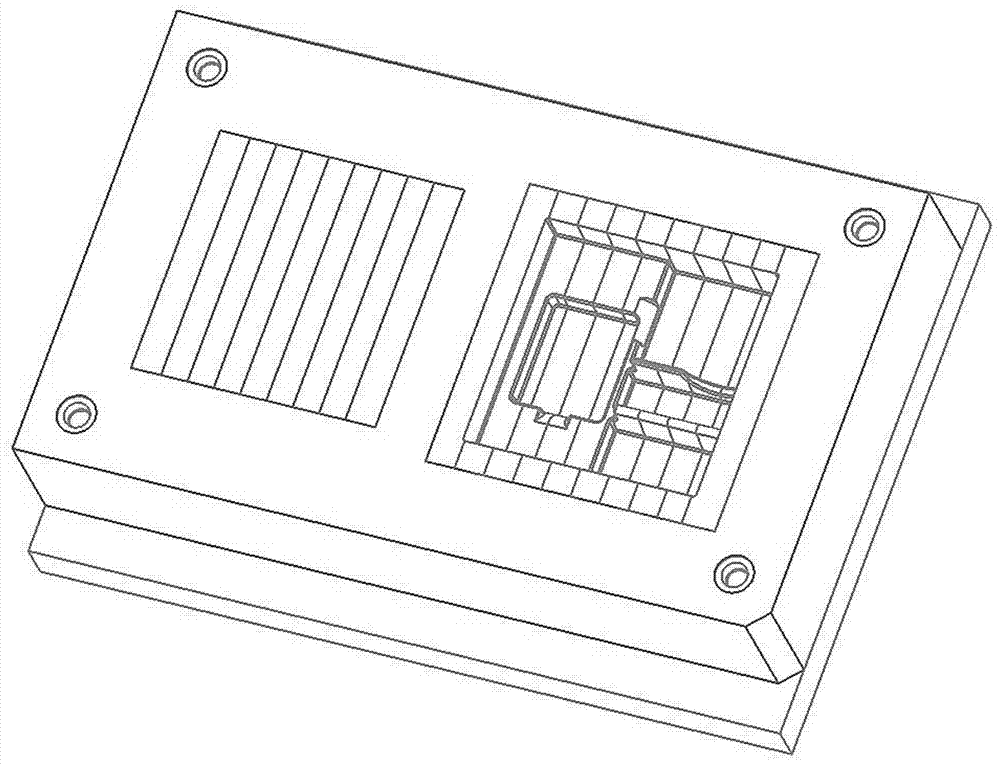

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

[0033] Such as Figure 1-3 As shown, a combined laminated mosaic mold includes a punch and a die. The punch and the die adopt a combined laminated mosaic device. Laminations form a number of steam lines 3 by stacking, and the steam lines 3 of the die and punch correspond to each other. There is an excess material groove 6 on the parting surface between the punch and the die. The lamination mosaic device includes several laminations 1, The lamination 1 is set in the mold seat 4 through the mosaic fit 2; the four corners of the mold seat 4 are respectively provided with a conical column positioning system 5, and the material of the mold seat 4 is cold-worked mold steel, and the structure of the lamination mosaic device corresponding to the processed product.

[0034] The number and spacing of the steam lines 3 can be set as required, and the width of the steam lines 3 is 0.05-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com