Quenching apparatus for glass toughening production line

A glass tempering and production line technology, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increasing energy consumption cost, glass plate deformation, wind spot on the surface of glass plate, etc., to improve cooling strength and reduce stress. Deformation, cooling effect uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

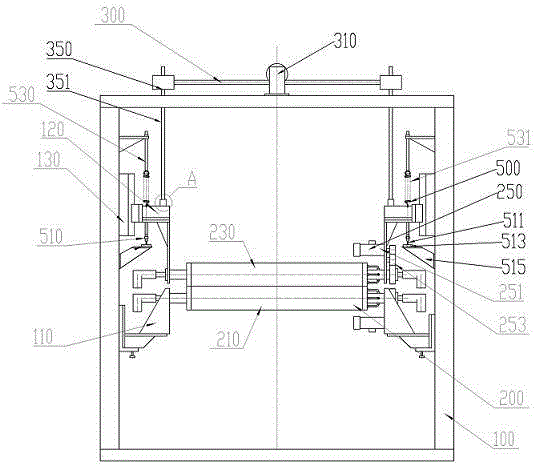

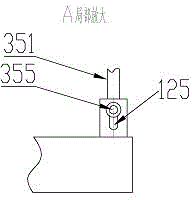

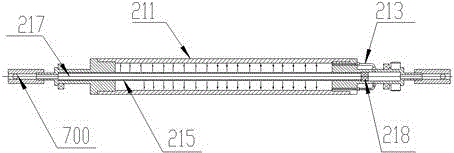

[0029] like figure 1 As shown, a quenching device for a glass tempering production line of the present invention includes a frame 100 on which a cooling mechanism 200 and a lifting mechanism 300 are arranged; the cooling mechanism 200 includes an upper cooling roller table 230, a lower cooling roller table 210, a drive mechanism 250 and a cooling liquid circulation system (not shown); the lifting mechanism 300 adjusts the gap between the upper cooling roller table 230 and the lower cooling roller table 210 by raising and lowering the upper cooling roller table 230; the drive The mechanism 250 includes a motor 251 and a transmission gear 253, which are used to rotate the upper and lower cooling rollers so as to convey the glass plate to be quenched after heating; when the to-be-quenched glass plate passes between the upper and lower cooling rollers, the upper and lower cooling rollers The cooling roller table is in contact with the glass plate to be quenched, and relies on the ...

Embodiment 2

[0044] like Figure 5 As shown in the figure, the difference between this embodiment and Embodiment 1 is that the quenching device for glass tempering production line also includes a plurality of quenching devices arranged on the frame for spraying cooling air on the opposite surfaces of the glass plate to be quenched to A blowing cooling unit 800 for quenching the glass plate, the blowing cooling unit is symmetrically arranged on the upper and lower surfaces of the glass plate to be quenched. Several blowing cooling units are arranged behind the cooling mechanism along the moving direction of the glass plate; after the glass plate is quenched by the cooling mechanism, it is slowly cooled by the blowing cooling unit, so as to avoid serious wind spots on the glass surface and glass damage. stress deformation.

[0045] In addition, if Image 6 As shown in the figure, the air blowing cooling unit can also be arranged at intervals with the upper and lower cooling rollers of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com