A frequency conversion induction heating and cooling device

A cooling device and induction heating technology, applied in design optimization/simulation, computer-aided design, improvement of process efficiency, etc., can solve the problems of grain production shape and composition distribution, inability to study the influence of magnetic field, low space application rate, etc. , to achieve the effect of improving space utilization, improving experimental accuracy and reducing volume

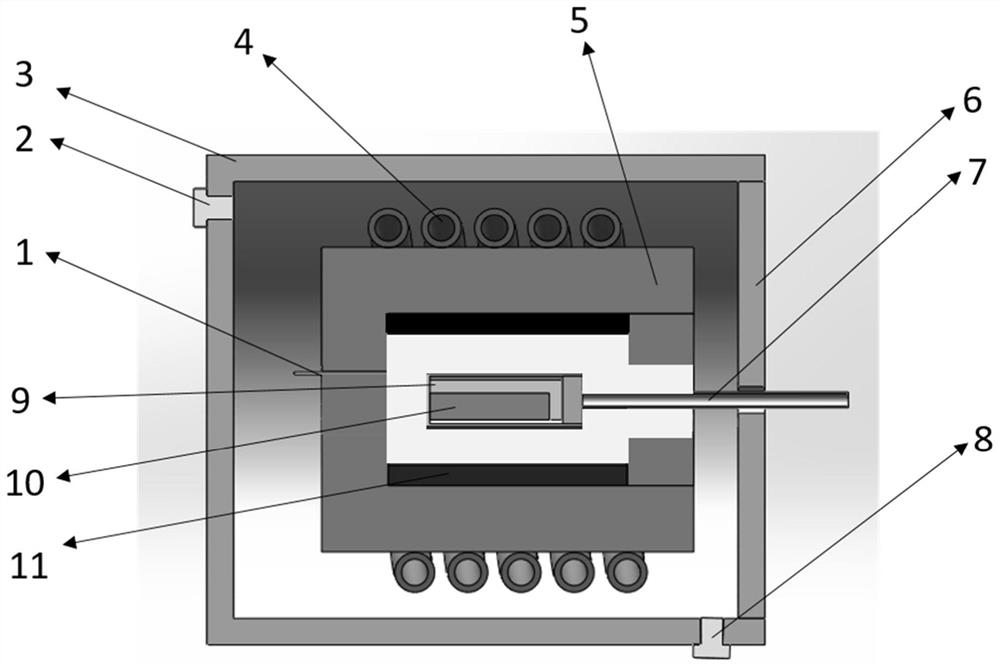

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, duplex stainless steel is used as the experimental material, that is, the metal sample is a duplex stainless steel sample, to illustrate the sample preparation process without magnetic field disturbance treatment.

[0053] (1) Wash the Al2O3 crucible and metal sample with absolute ethanol and blow dry;

[0054] (2) Open the furnace door and install the sample, crucible and water-cooled chuck according to the diagram to ensure the coaxial relationship between the three;

[0055] (3) vacuum is drawn in the body of furnace;

[0056] (4) Switch the switchable frequency conversion power supply to the high-frequency current mode, and start the experiment. After the temperature of the chamber reaches 1500°C, keep it warm for 5 minutes to fully melt the metal sample;

[0057] (5) Disconnect the power supply after processing;

[0058] (6) Open the gas valve, the low-temperature inert gas is charged from the lower end gas valve, and flows out from the upper ...

Embodiment 2

[0061] In this embodiment, GCr15 bearing steel is used as the experimental material, that is, the metal sample is a GCr15 bearing steel sample, to illustrate the sample production process subjected to the disturbance treatment of the intermediate frequency pulsed magnetic field.

[0062] (1) Wash the Al2O3 crucible and metal sample with absolute ethanol and blow dry;

[0063] (2) Open the furnace door and install the sample, crucible and water-cooled chuck according to the diagram to ensure the coaxial relationship between the three;

[0064] (3) vacuum is drawn in the body of furnace;

[0065] (4) Switch the switchable frequency conversion power supply to the high-frequency alternating current mode, turn on the power supply and start the experiment. After the chamber temperature reaches 1600°C, keep it warm for 5 minutes to fully melt the metal sample;

[0066] (5) Switch the power output of the switchable variable frequency power supply to the intermediate frequency pulsed ...

Embodiment 3

[0071] In this embodiment, GCr15 bearing steel is used as the experimental material, that is, the metal sample is a GCr15 bearing steel sample, to illustrate the thermal simulation process of continuous casting slabs with pulsed magnetic field interference.

[0072] (1) Wash the Al2O3 crucible and metal sample with absolute ethanol and blow dry;

[0073] (2) Open the furnace door and install the sample, crucible and water-cooled chuck according to the diagram to ensure the coaxial relationship between the three;

[0074] (3) vacuum is drawn in the body of furnace;

[0075](4) Switch the switchable frequency conversion power supply to the high-frequency alternating current mode, turn on the power supply and start the experiment. After the chamber temperature reaches 1600°C, keep it warm for 5 minutes to fully melt the metal sample;

[0076] (5) Switch the power output of the switchable frequency conversion power supply to the pulsed magnetic field mode to disturb the molten me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com