Once-firing multi-density composite foaming through-body decorative board and preparation method thereof

A technology for composite foaming and decorative plates, applied in the field of building decoration materials, can solve problems such as poor adhesion of surface decorative layers, and achieve the effects of improving flatness, reducing production costs and weakening density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] A method for preparing a single-firing multi-density composite foam whole-body decorative board, comprising the following steps S1-S7:

[0067]S1. Put the green body raw materials of the first and second foam layers into a ball mill according to the formula for ball milling. The ball milling process parameters of the green body raw material of the foam layer are: fineness 1.8-2.0%, slurry moisture in weight percentage 35-40%, flow rate 55-65", and the mud passes through 16 mesh and 100 mesh standard sieves after passing .

[0068] Fineness test method: 1 specific gravity cup with 325 mesh water washing, and the rest of the sieve is the fineness. The slurry flow rate was tested with a Tusi Viscometer.

[0069] Refer to the above ball milling process parameters to obtain a better uniformity of the slurry. The slurry passes through a 16-mesh and 100-mesh standard sieve, which can sieve out the oversized mud and fine powder, which is convenient for molding and improves th...

Embodiment 1

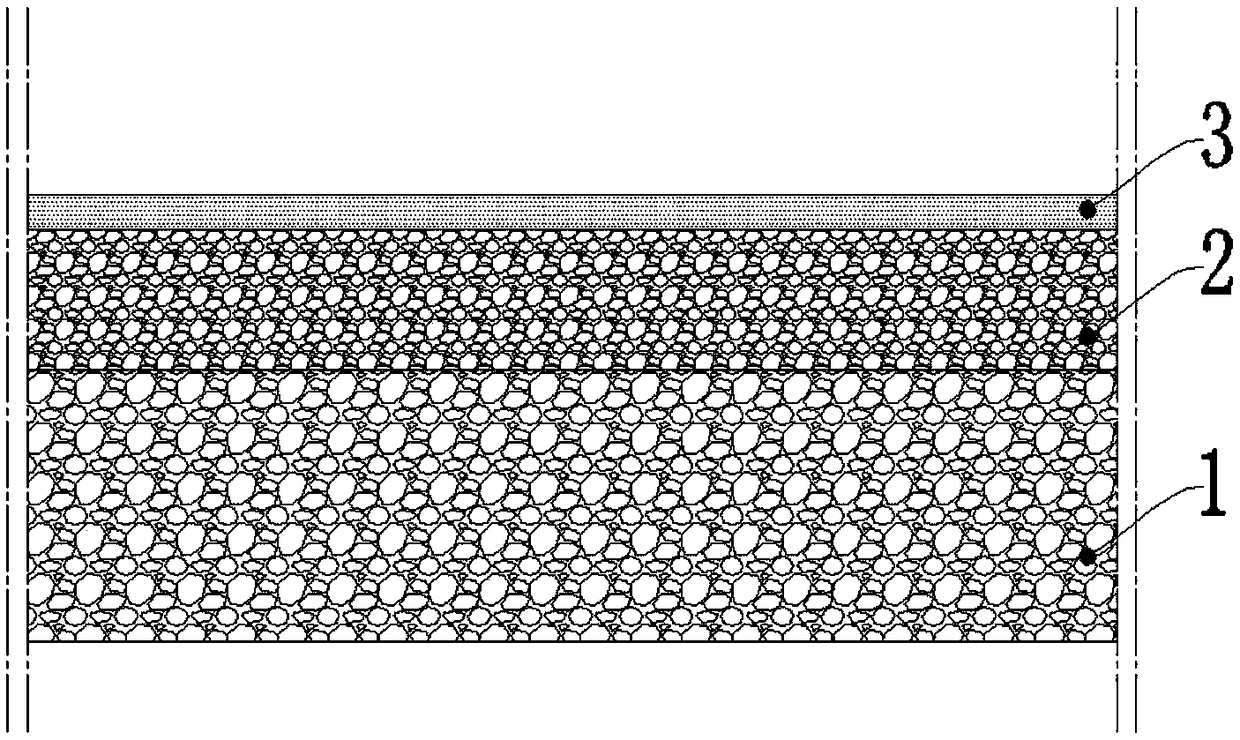

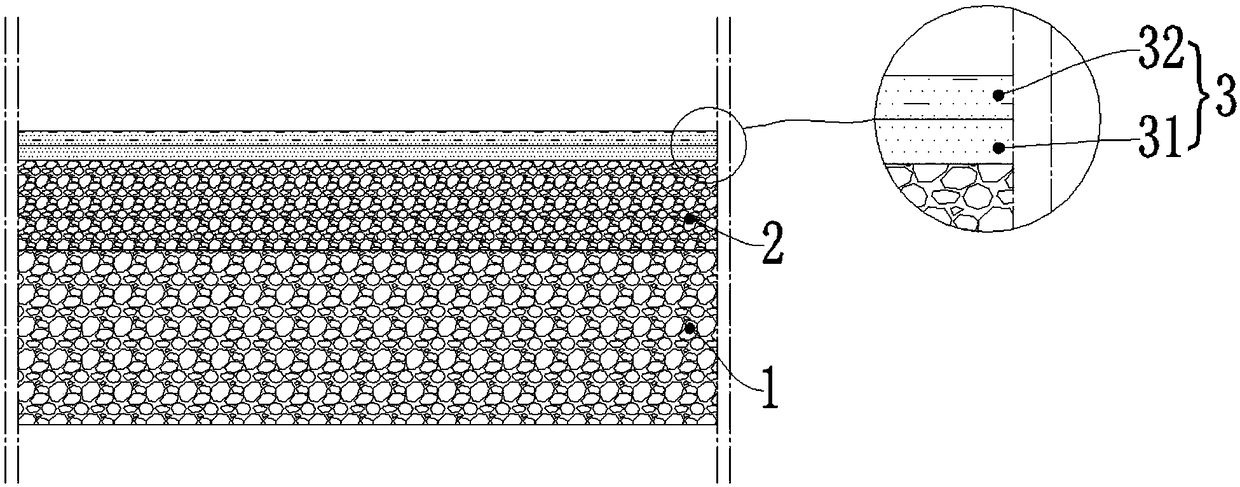

[0084] like figure 1 As shown, the single-firing multi-density composite foam whole-body decorative board of this embodiment includes a first foam layer 1, a second foam layer 2, and a surface hole for closing the second foam layer 2 arranged in sequence from bottom to top. The sealing layer 3, the density of the second foaming layer 2 is less than the first foaming layer 1, and the formula of the first foaming layer 1, the second foaming layer 2 and the sealing layer 3 all contains colorant, and the sealing layer 3 is Make-up soil layer. The thickness of the second foam layer 2 is 1.5 times that of the first foam layer 1 .

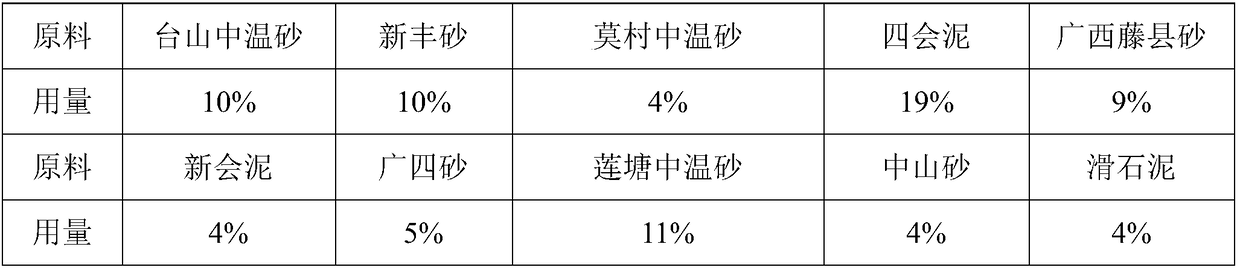

[0085] The green body formula of the first foam layer 1 includes a green body basic formula and a green body colorant, and the weight ratio of the green body colorant to the green body basic formula is 10:100, and the basic formula raw materials in weight percentage are shown in the following table :

[0086] raw material

Taishan moderate ...

Embodiment 2

[0101] The single-firing multi-density composite foam whole-body decorative board of this embodiment includes a first foam layer, a second foam layer, and a sealing layer for sealing the surface holes of the second foam layer arranged in sequence from bottom to top. The density of the foaming layer is smaller than that of the first foaming layer, and the formulations of the first foaming layer, the second foaming layer and the sealing layer all contain pigments, and the sealing layer is a make-up soil layer. The thickness of the first foam layer is 2.5 times that of the second foam layer.

[0102] The green body formula of the first foaming layer includes a green body basic formula and a green body colorant, and the weight ratio of the green body colorant to the green body basic formula is 5:100, and the basic formula raw materials in weight percentage are shown in the following table:

[0103] raw material

Taishan moderate temperature sand

Xinfengsha

Warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com