Double-layer fabric containing polytetrafluoroethylene fiber and application of double-layer fabric

一种聚四氟乙烯、双层织物的技术,应用在织物、多股织物、纺织等方向,能够解决复合材料与金属表面剥离、很难粘贴、自润滑轴承失效等问题,达到受力变形小、生产成本低、摩擦系数小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

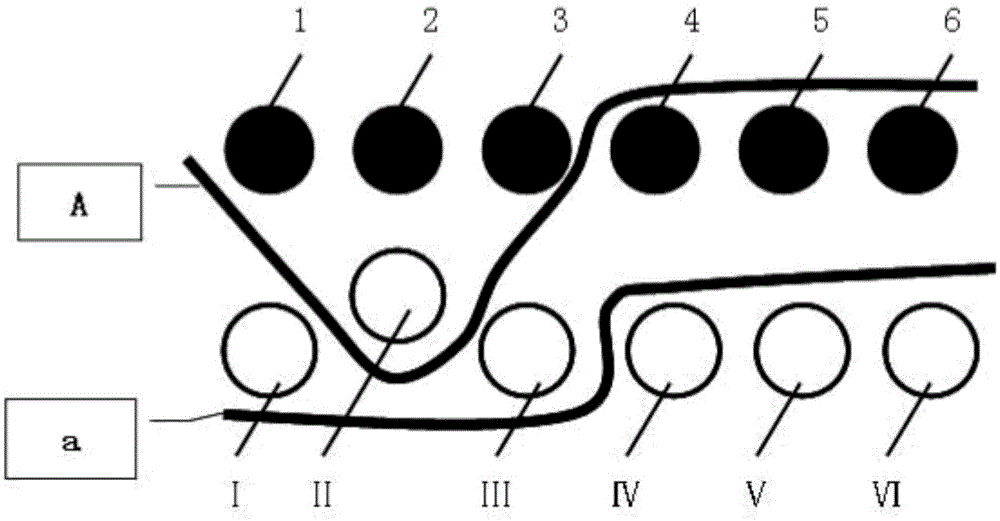

Method used

Image

Examples

Embodiment 1

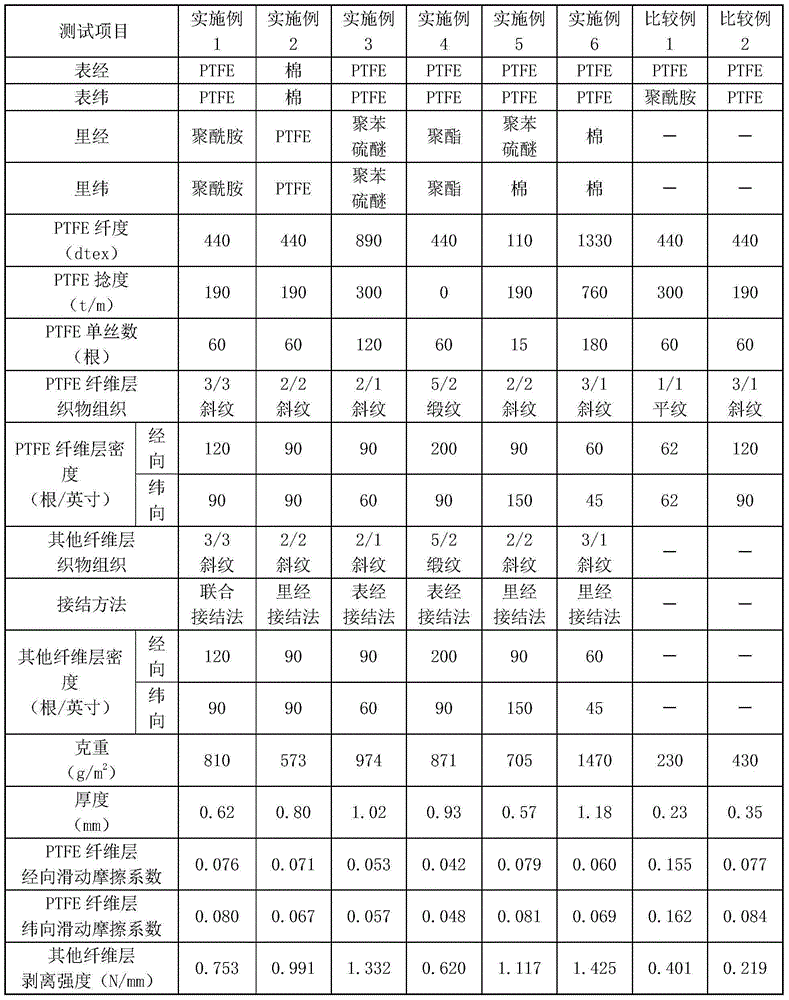

[0045] The surface warp and surface weft yarns are made of polytetrafluoroethylene filaments with a denier of 440dtex, a twist of 190t / m, and 60 filaments. , the tensile strength is 39.8N, and the polyamide full-drawn yarn with the elongation at break of 23.3%, the surface layer and the inner layer are set to adopt 3 / 3 twill weave, and the above-mentioned polytetrafluoroethylene fiber layer is bonded by joint bonding method It is integrated with the polyamide fiber layer, and then woven by a rapier loom to obtain a surface layer with a warp density of 120 threads / inch and a weft density of 90 threads / inch, and an inner layer with a warp density of 120 threads / inch and a weft density of 120 threads / inch. 90 threads / inch double layer fabric. The prepared double-layer fabric is placed under the conditions of a temperature of 20±2°C and a humidity of 65±4% for humidity conditioning treatment. The properties of the fabric were evaluated and are shown in Table 1. When the double-l...

Embodiment 2

[0047] The surface warp and surface weft yarns are all made of 40S / 2 cotton yarn, and the inside warp and inside weft yarns are all made of polytetrafluoroethylene filaments with a denier of 440dtex, a twist of 190t / m, and a number of 60 single filaments. The layers are all made of 2 / 2 twill weave, and the above-mentioned cotton fiber layer and the polytetrafluoroethylene fiber layer are bonded into one through the inner warp bonding method, and then weaved by a rapier loom to obtain a surface warp density of 90 / Inch, weft yarn density is 90 / inch, inner warp yarn density is 90 / inch, weft density is 90 / inch double layer fabric. The prepared double-layer fabric is placed under the conditions of a temperature of 20±2°C and a humidity of 65±4% for humidity conditioning treatment. The properties of the fabric were evaluated and are shown in Table 1. When the double-layer fabric is applied to the bearing, the polytetrafluoroethylene fiber layer as the inner layer is used as the f...

Embodiment 3

[0049] The surface warp and surface weft yarns are all made of polytetrafluoroethylene filaments with a denier of 890dtex, a twist of 300t / m, and 120 single filaments. The inner warp and inner weft yarns are all made of 20S / 2 polyphenylene sulfide yarns. The surface layer and the inner layer are set to adopt 2 / 1 twill weave, and the above-mentioned polytetrafluoroethylene fiber layer and polyphenylene sulfide fiber layer are bonded into one body through the surface warp bonding method, and then weaved by a rapier loom. Obtain the double layer fabric that surface layer warp density is 90 / inch, weft density is 60 / inch, inner layer warp density is 90 / inch, weft density is 60 / inch. The prepared double-layer fabric is placed under the conditions of a temperature of 20±2°C and a humidity of 65±4% for humidity conditioning treatment. The properties of the fabric were evaluated and are shown in Table 1. When the double-layer fabric is applied to a bearing, the polytetrafluoroethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com